Patents

Literature

95 results about "Phosphate conversion coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphate coatings are used on steel parts for corrosion resistance, lubricity, or as a foundation for subsequent coatings or painting. It serves as a conversion coating in which a dilute solution of phosphoric acid and phosphate salts is applied via spraying or immersion and chemically reacts with the surface of the part being coated to form a layer of insoluble, crystalline phosphates. Phosphate conversion coatings can also be used on aluminium, zinc, cadmium, silver and tin.

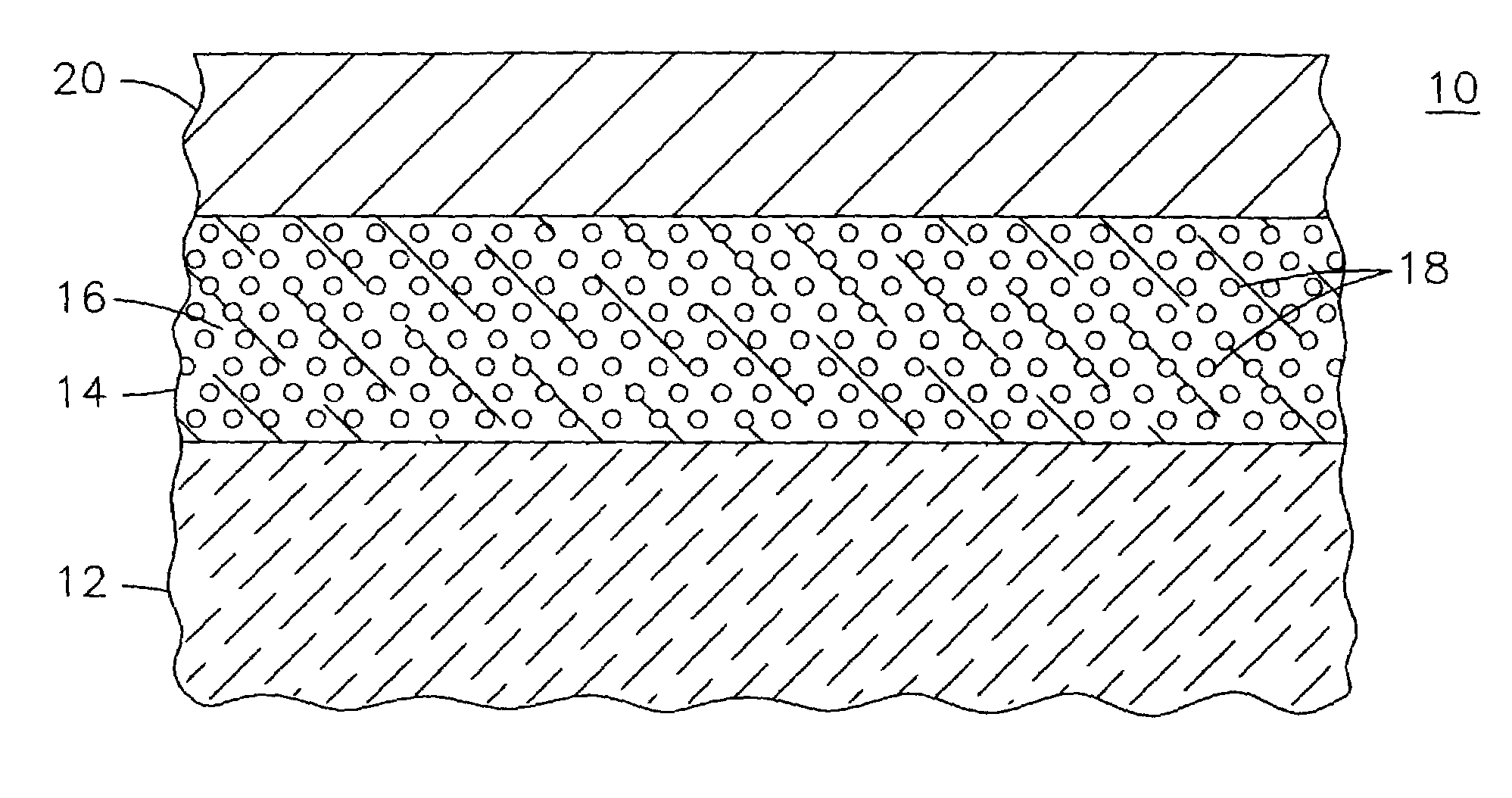

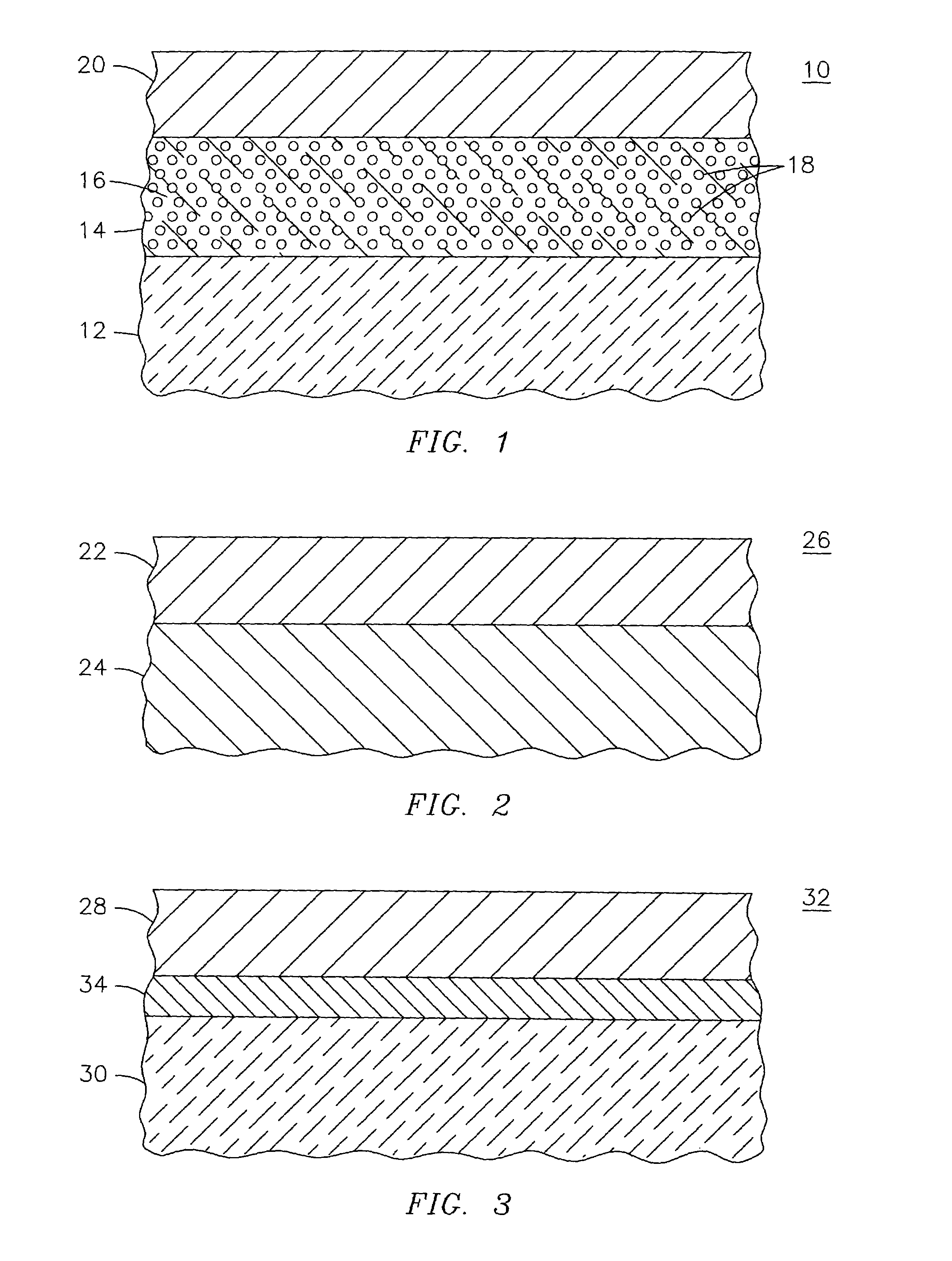

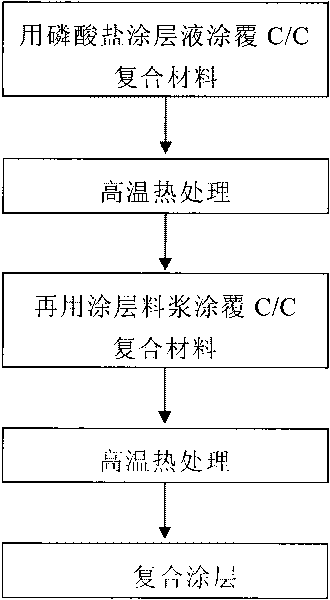

Protective overlayer for ceramics

A xenotime phosphate protective overlayer (22) for protecting a ceramic material (24) from a high temperature, moisture-containing environment. Yttrium phosphate may be used as a protective overlayer to protect an underlying mullite layer to temperatures in excess of 1,500° C. The coating may have porosity of greater than 15% for improved thermal shock protection. To prevent the ingress of oxygen to an underlying ceramic non-oxide material, such as silicon carbide or silicon nitride, an oxygen barrier layer (34) is disposed between the xenotime phosphate coating and the non-oxide material. Such a protective overlayer may be used for an article having a ceramic matrix composite substrate.

Owner:SIEMENS ENERGY INC

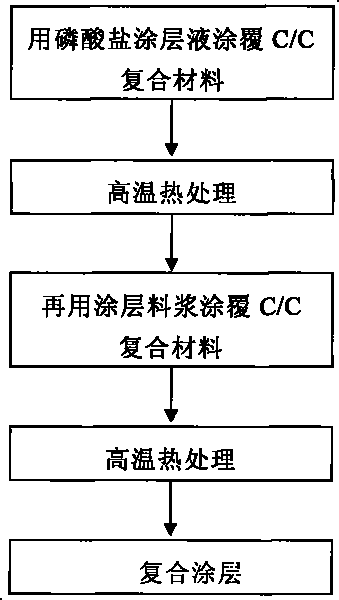

Surface anti-oxidation processing method for aircraft carbon brake disc

The invention discloses a surface anti-oxidation processing method for an aircraft carbon brake disc, which comprises the following steps: firstly, coating a layer of phosphate coating solution on the surface of a material needing to be processed, and forming a bottom phosphate coating through high temperature heat treatment; secondly, coating a layer of slurry coating which uses refractory ceramic powders as the main raw material and uses the phosphate coating solution as solution on the surface of the bottom phosphate coating; and finally forming a composite coating through the high temperature heat treatment. The composite coating of the invention has anticatalytic effect, and can improve the high temperature anti-oxidation capacity of C / C composite materials, such as the aircraft carbon brake disc and the like, under the condition of sea or salt spray pollution; and the ceramic component in the composite coating is melted and flows at high temperature so as to effectively heal the crackles in the coating, delay the time that oxygen is contacted with C / C materials, and improve the oxidation resistance of the composite coating.

Owner:XIAN CHAOMA SCI TECH

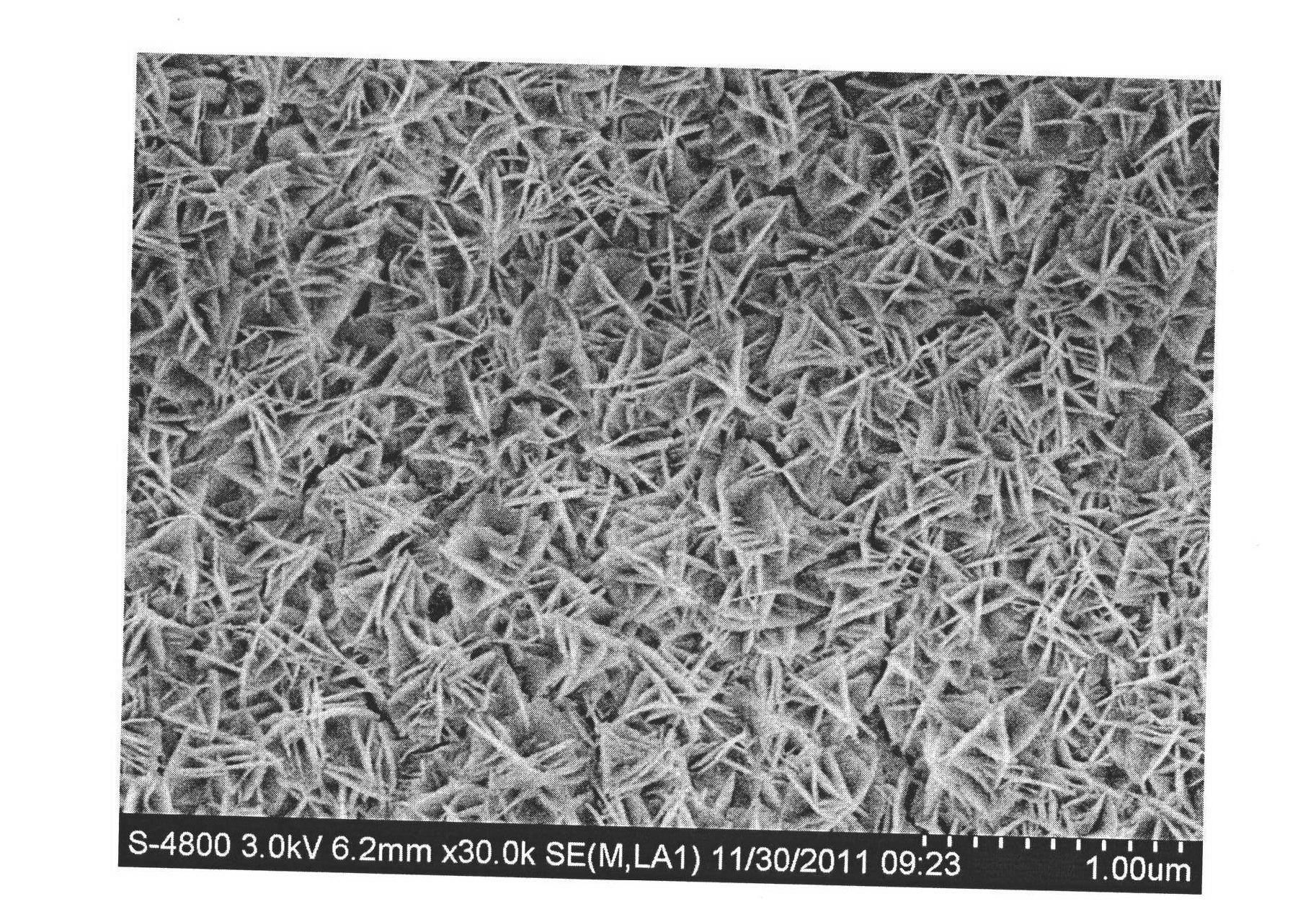

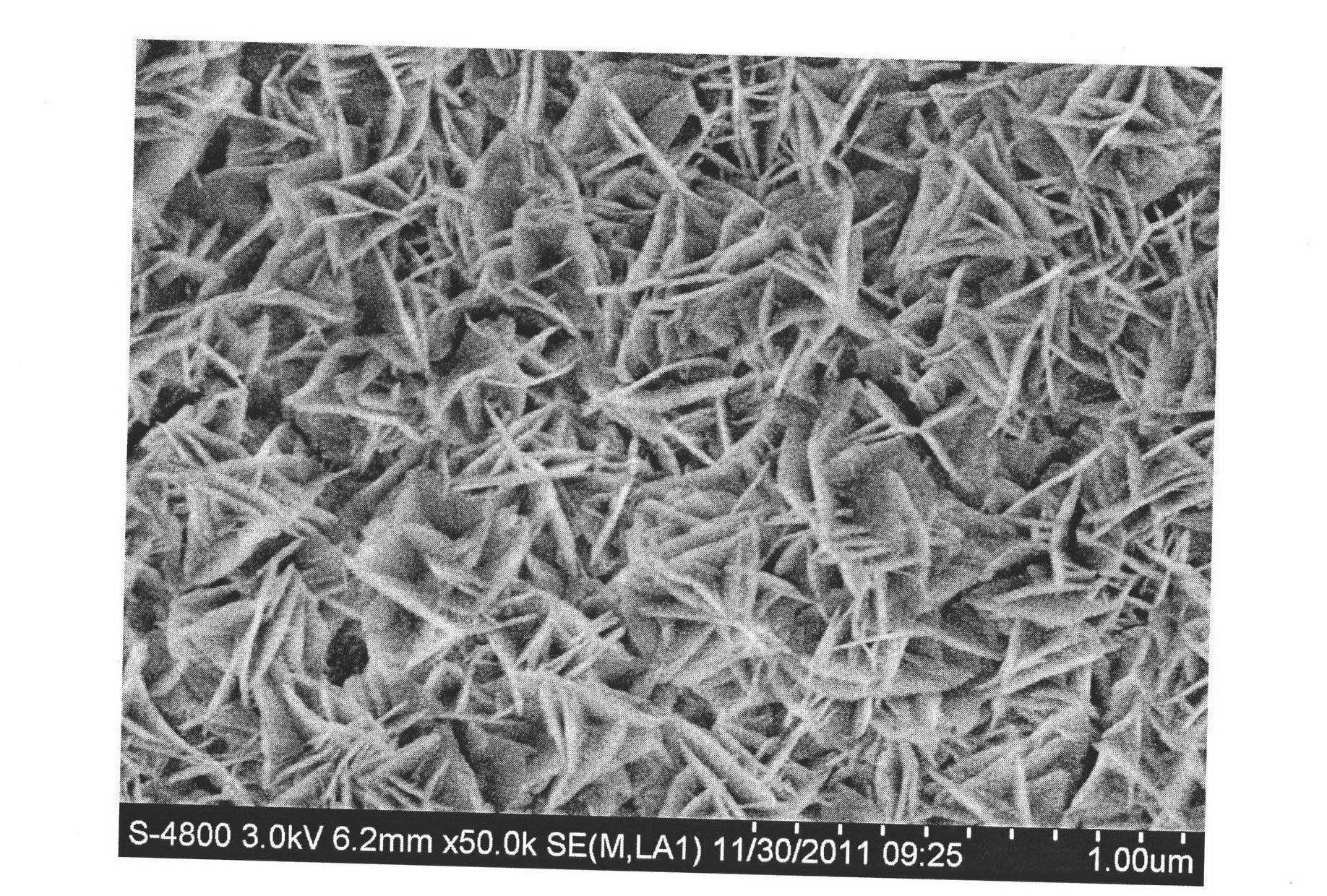

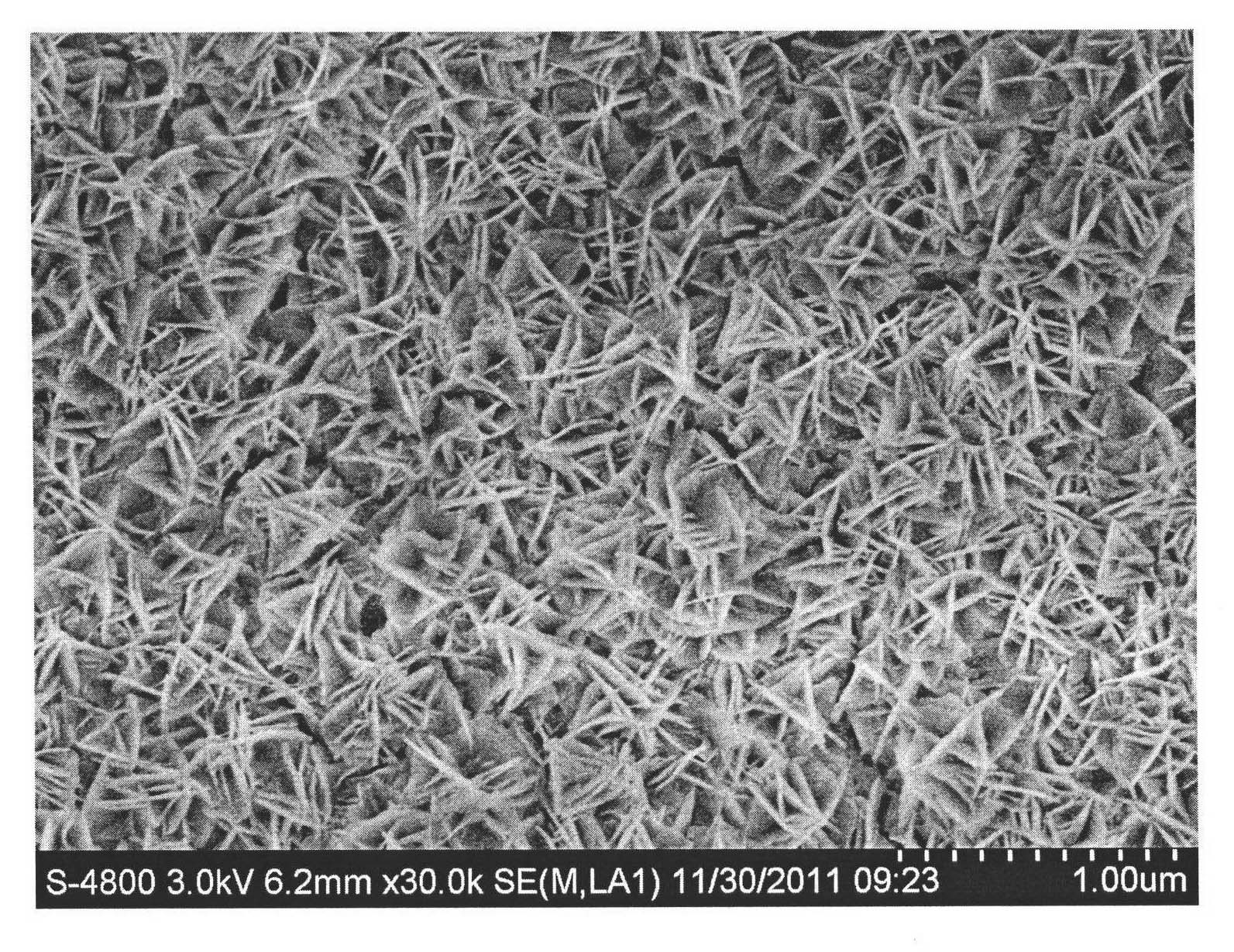

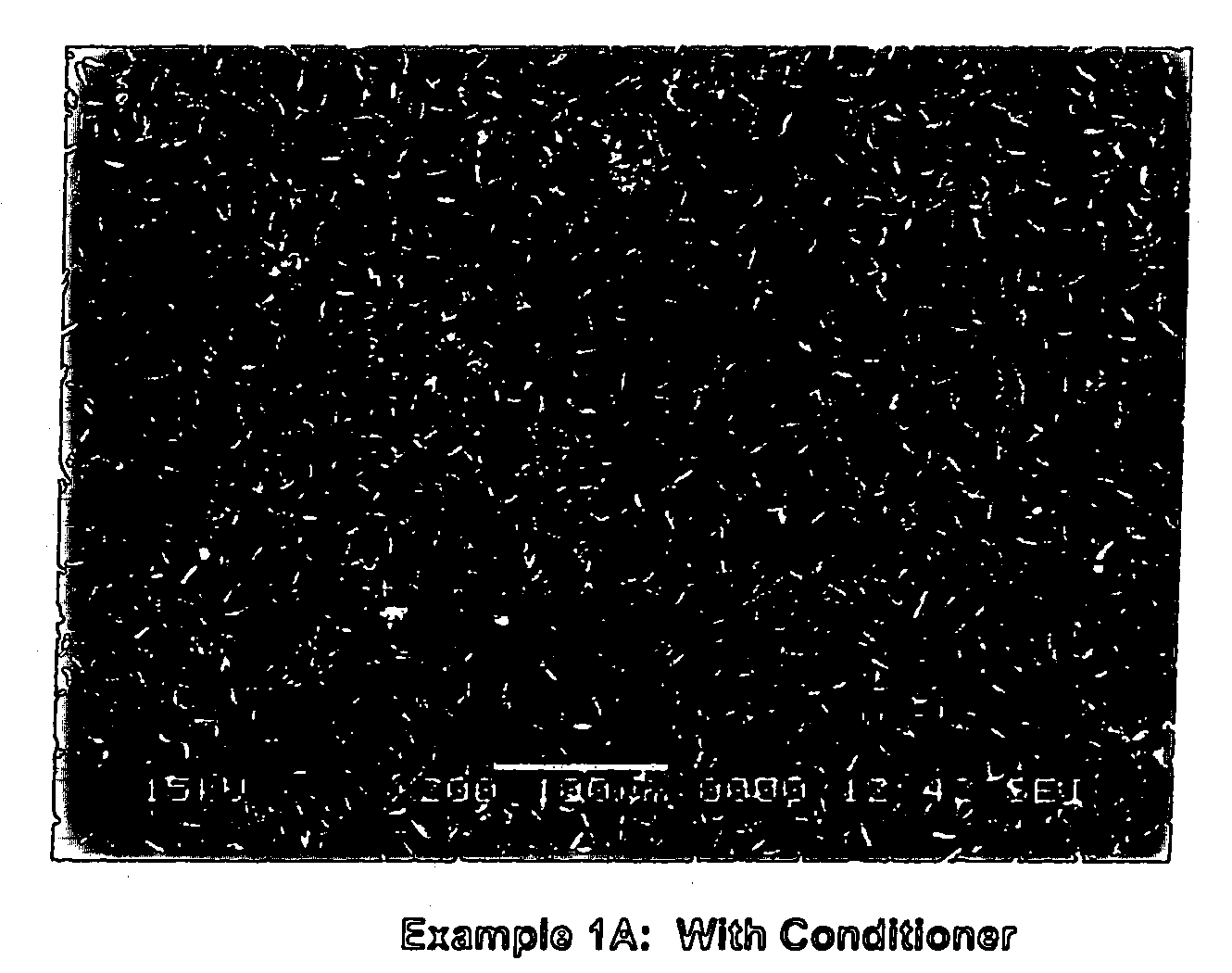

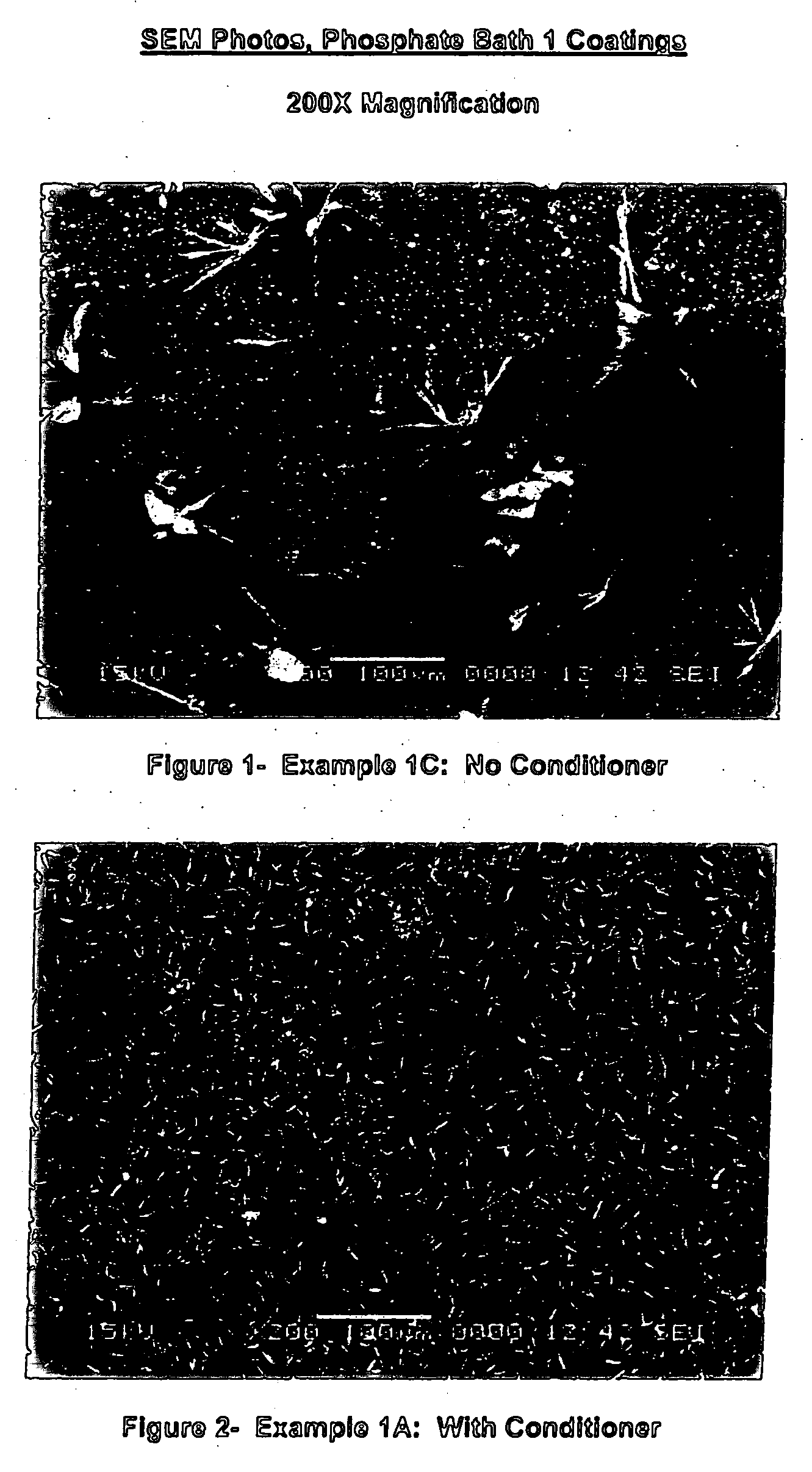

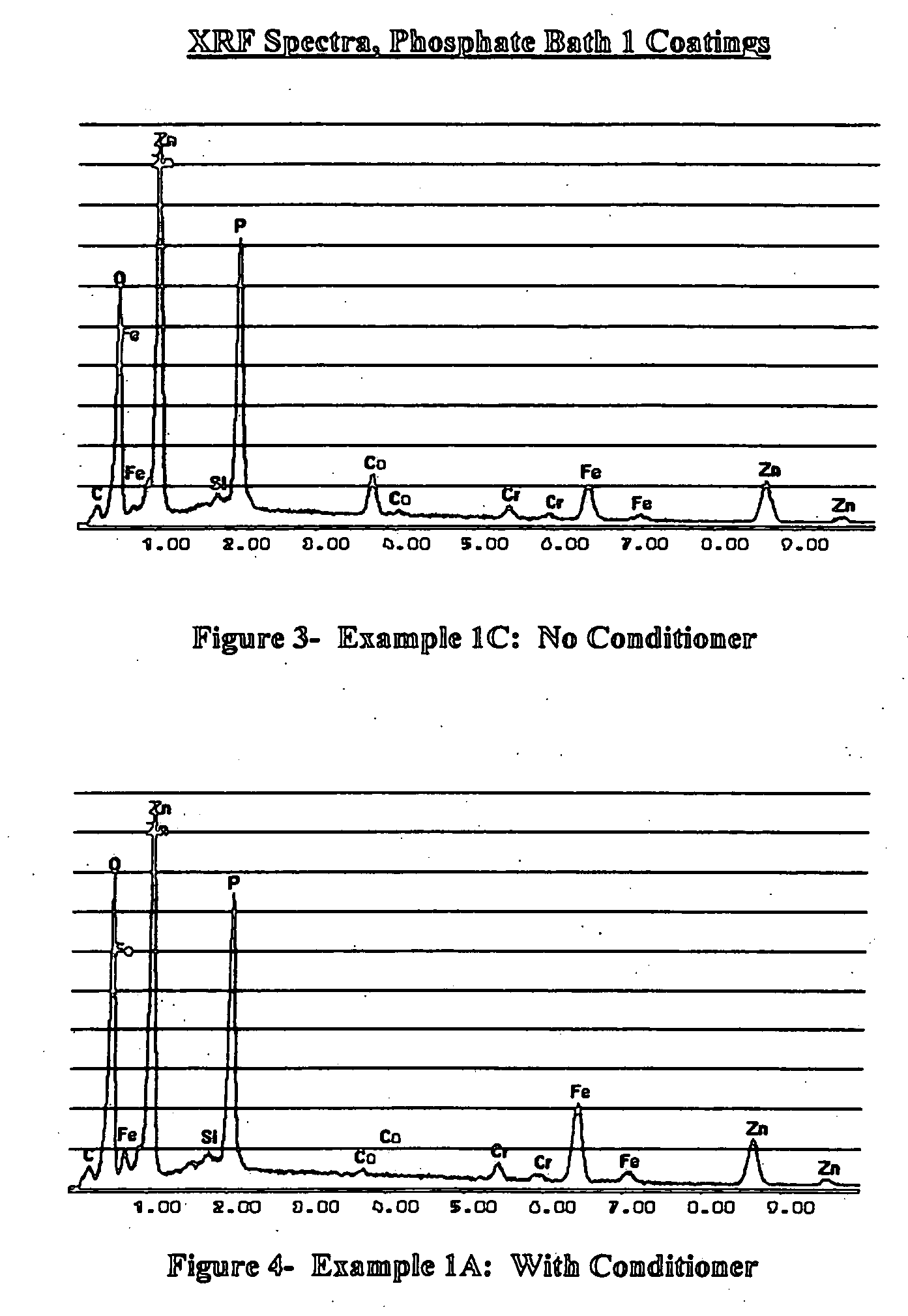

Conditioning metal surfaces prior to phosphate conversion coating

InactiveUS6214132B1Increase concentrationSmall sizeMetallic material coating processesChromate conversion coatingPhosphate

A pretreatment before phosphating conversion coating is effected by contacting a metal substrate to be coated with a pretreatment composition that has a pH from 4 to 13 and contains dispersed fine particle size alkali metal or ammonium salts and divalent or trivalent metal phosphates. The conditioning achieved is as good as with conventional Jernstedt salts and the pretreatment compositions according to the invention are more storage stable.

Owner:HENKEL CORP

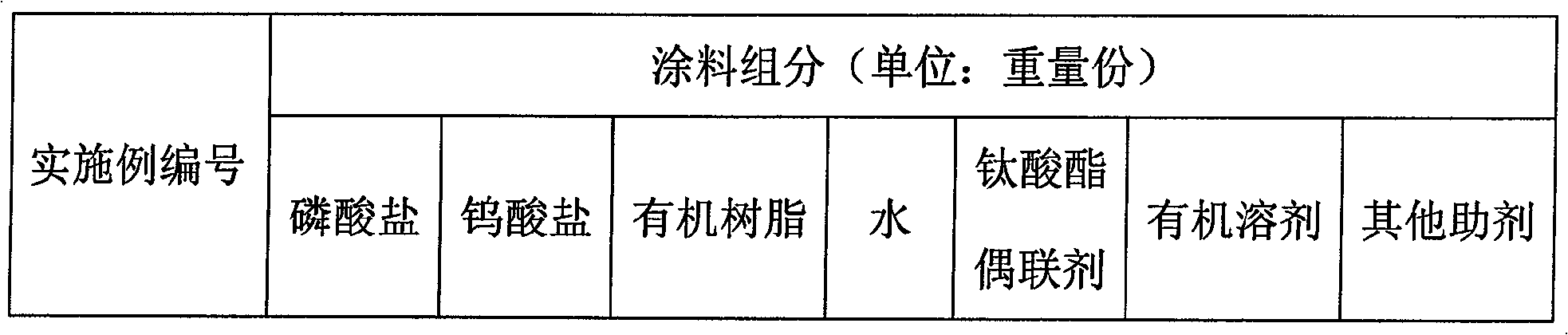

Non-oriented electric steel semi-organic phosphate insulating paint with good corrosion resistance

ActiveCN101560342AImprove corrosion resistanceImprove coating appearanceAnti-corrosive paintsPolyurea/polyurethane coatingsTungstateOrganic phosphates

The invention discloses a non-oriented electric steel semi-organic phosphate insulating paint with good corrosion resistance. The semi-organic phosphate insulating paint comprises the following main components: water-soluble phosphate, tungstate, organic resin, water, a titanate coupling agent, an organic solvent and the like; and contents of the components of the insulating paint (parts by weight) based on 100 parts of the water-soluble phosphate by weight are as follows: 1-15 parts of the tungstate, 20-200 parts of the organic resin, 500-2000 parts of the water, 0.1-3 parts of the titanate coupling agent, 10-50 parts of the organic solvent and 0.1-3 parts of other paint addictives. The semi-organic phosphate insulating paint contains no harmful ingredients restricted by an EU directive RoHS, which can meet the requirements for environmental protection; and compared with the common phosphate coating, the coating of the semi-organic phosphate insulating paint has better corrosion resistance, good insulating property, good adhesiveness, good blanking property, good welding property, good heat resistance and the like, which can meet the requirements of electric motor and transformermanufacturers for application to the electric steel coating.

Owner:MAANSHAN IRON & STEEL CO LTD

Inorganic phosphate corrosion resistant coatings

ActiveCN102770583AAnti-corrosive paintsMetallic material coating processesInorganic phosphateAlkali metal oxide

This disclosure relates to phosphate coatings that inhibit corrosion of metals, specifically coatings comprising acidic phosphate and alkaline metal oxide / hydroxide components. In one particular embodiment, phosphate-based coating formulations that reduce or eliminate corrosion of steel and other metals are disclosed. In other embodiments, methods for coating steel surfaces with acidic phosphate and alkaline metal oxide / hydroxide components to reduce or eliminate corrosion of the metal surfaces are disclosed.

Owner:LATITUDE 18

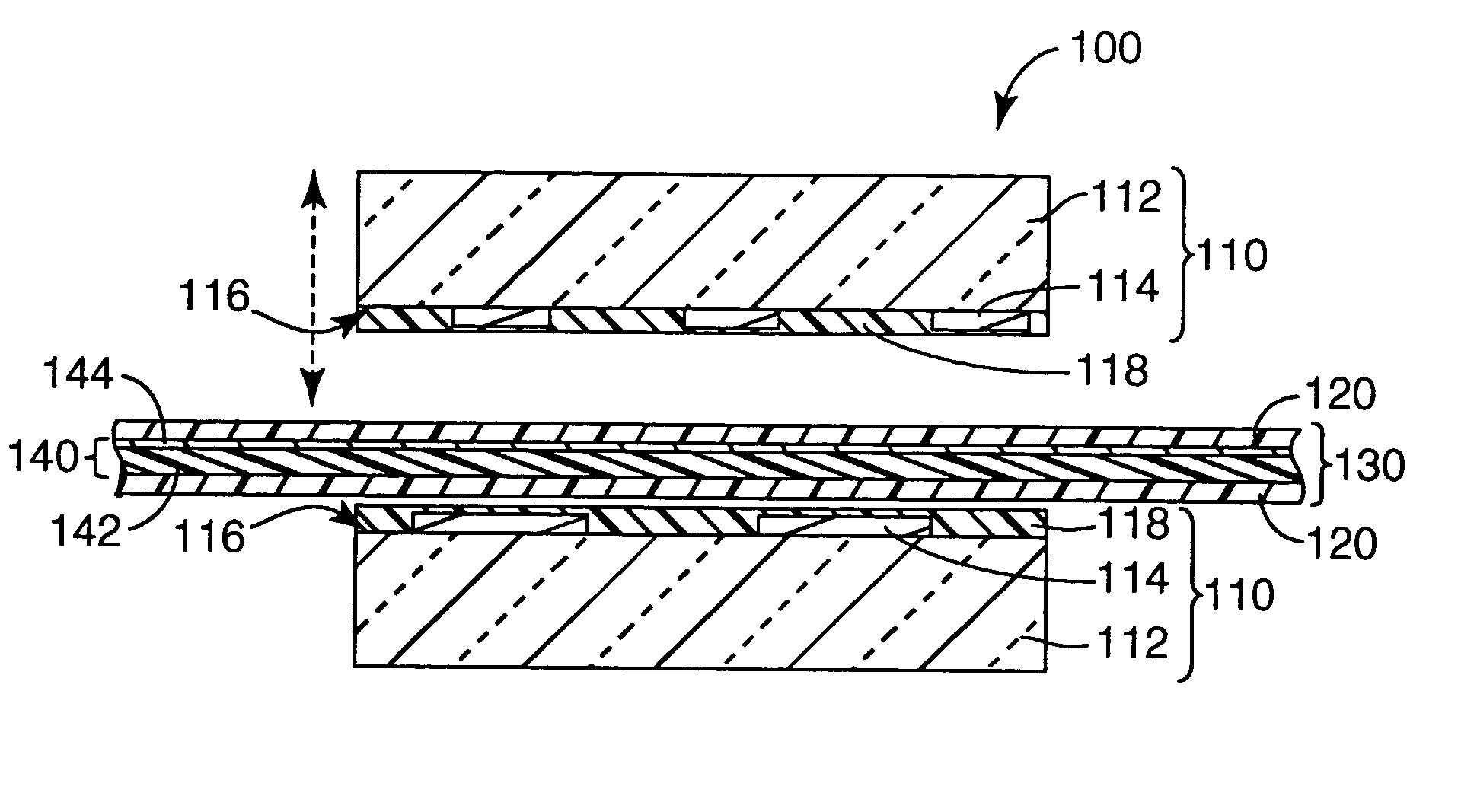

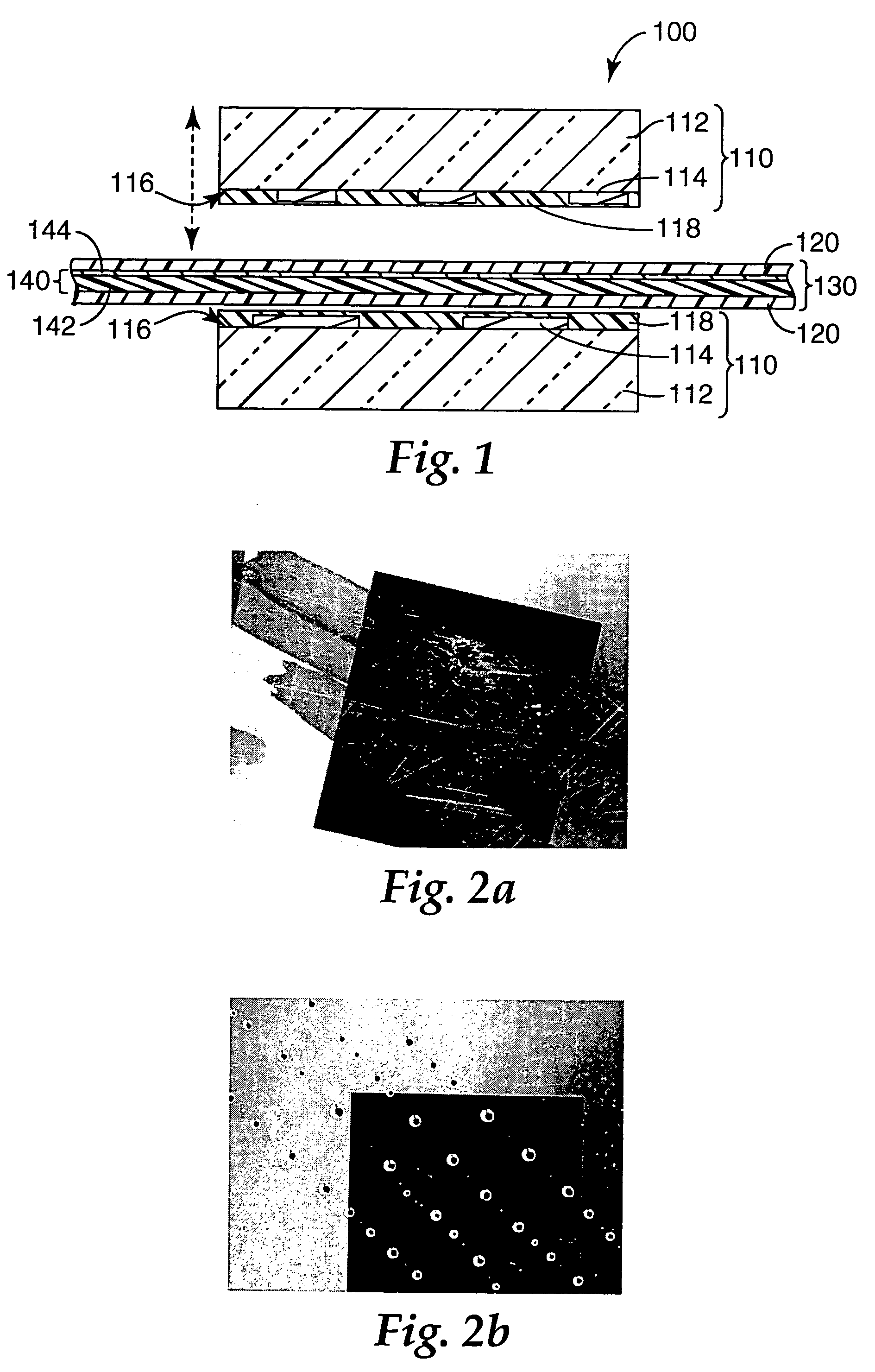

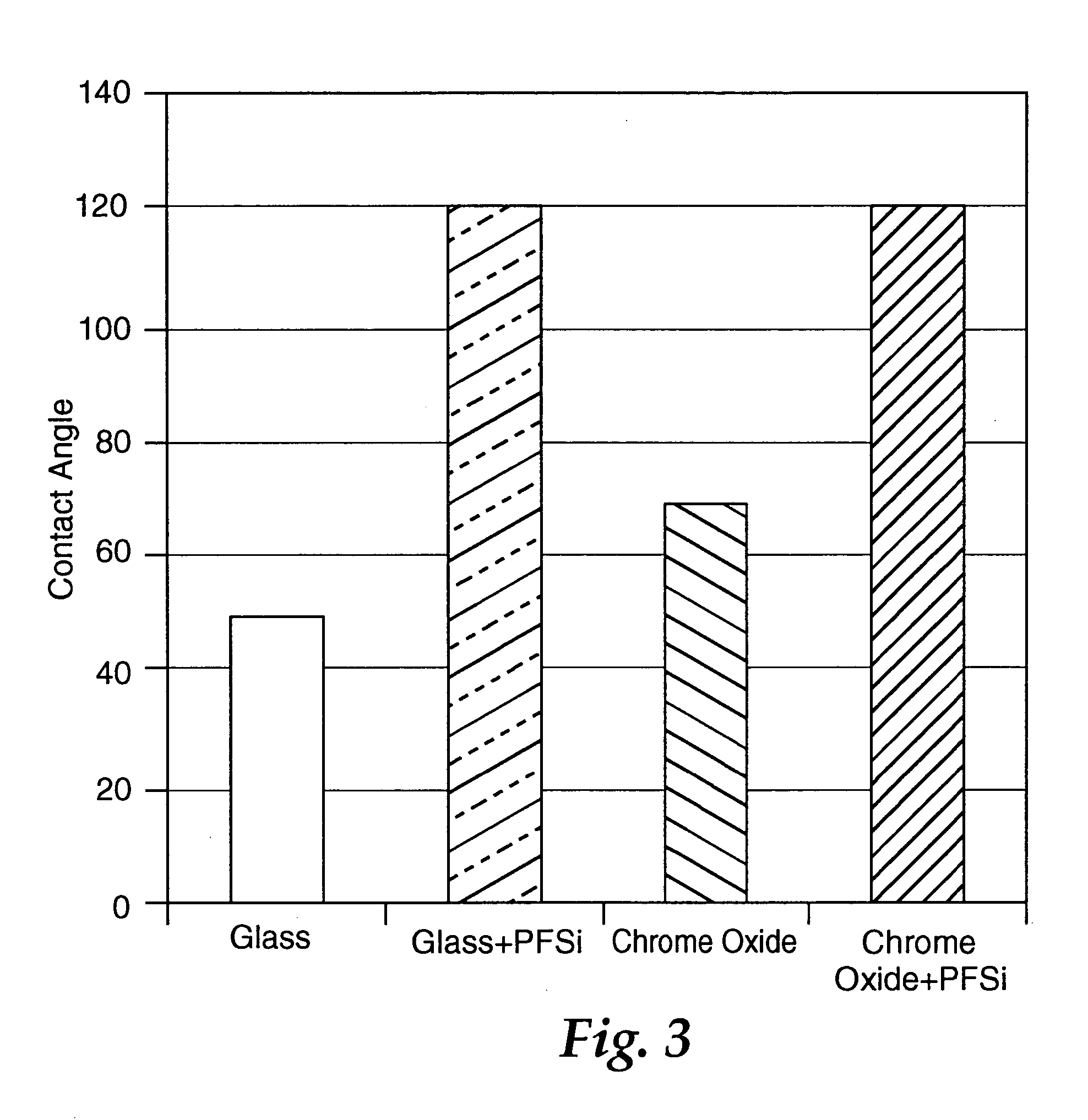

Phototool coating

InactiveUS20050042553A1Reliable coatingSurface energy is lowMaterial nanotechnologyPhotosensitive materialsChemistryCoating

Owner:3M INNOVATIVE PROPERTIES CO

Zirconium and zirconium alloy zinc-manganese composite phosphating solution and phosphating method thereof

InactiveCN102560461AImprove protectionRealize environmental friendlinessMetallic material coating processesPhosphatePhosphoric acid

The invention discloses a zirconium and zirconium alloy zinc-manganese composite phosphating solution and a phosphating method thereof. The zirconium and zirconium alloy zinc-manganese composite phosphating solution is an aqueous solution comprising the following components of: 0.001-10g of zinc salts, 0.001-5g of manganese salts, 5-30g of phosphoric acid, 1-8g of accelerator, 0.001-15g of complexing agent, 0.001-10g of anionic surface agent and 0.001-5g of corrosion inhibitor in each liter of phosphating treatment solution. The phosphating method of the zirconium and zirconium alloy zinc-manganese composite phosphating solution comprises the steps of preliminary grinding, water washing, chemical degreasing, water washing, acid pickling, water washing, phosphating, water washing and drying, wherein the phosphating treatment temperature is 50-90DEG C, the pH value is 1.5-3.5 and the treatment time is 1-30 minutes. According to the zirconium and zirconium alloy zinc-manganese composite phosphating solution and the phosphating method thereof disclosed by the invention, a phosphate conversion coating with favorable protective performance, favorable wear resistance, fineness and uniformity can be obtained from the surfaces of zirconium and zirconium alloy workpieces. The phosphate conversion coating is stable and strong in a binding force and can be used for improving the service performances of zirconium and zirconium alloy and prolonging the service life of the zirconium and zirconium alloy. The phosphating method disclosed by the invention is stable in process, easy to control and is environment-friendly.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

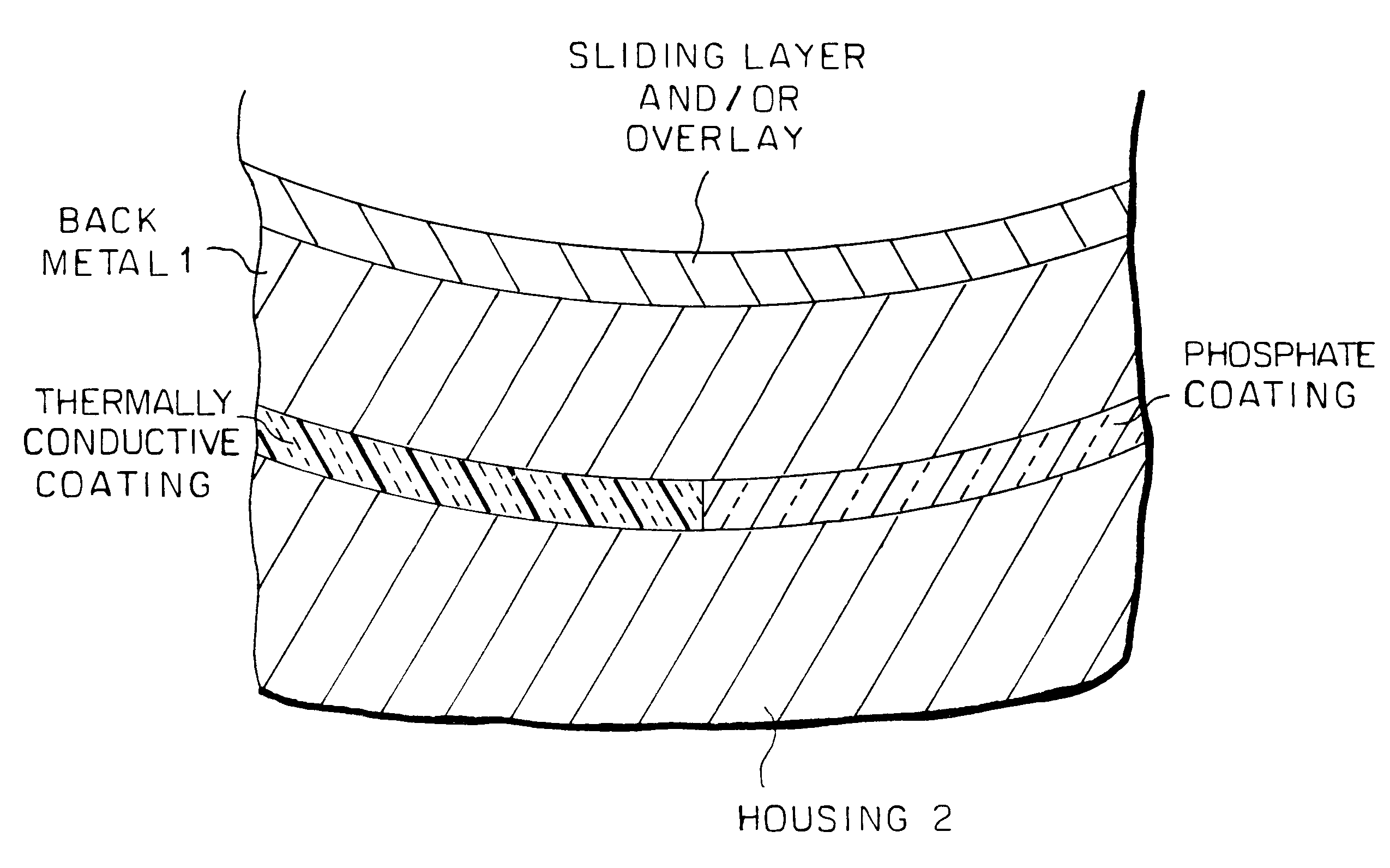

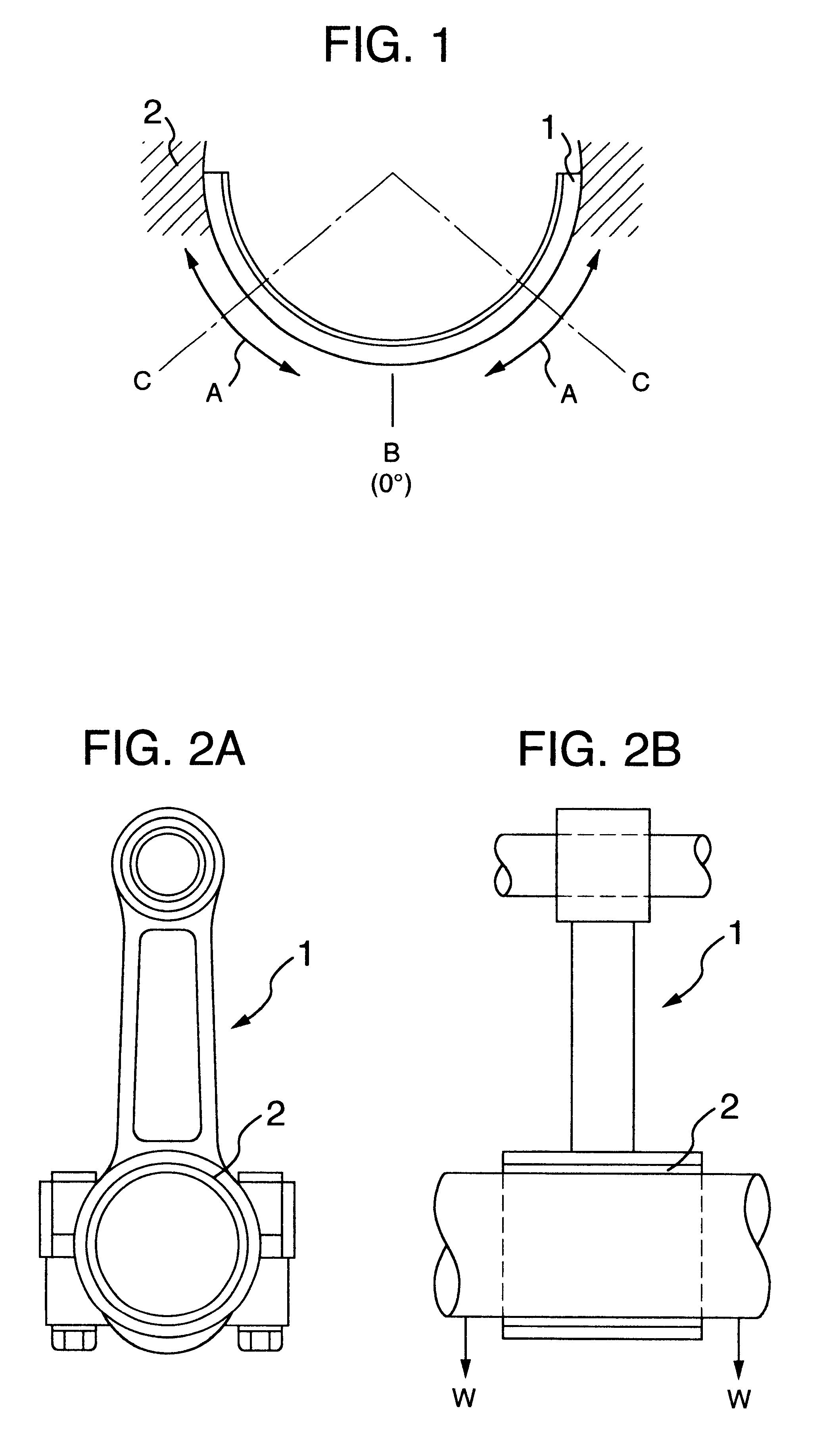

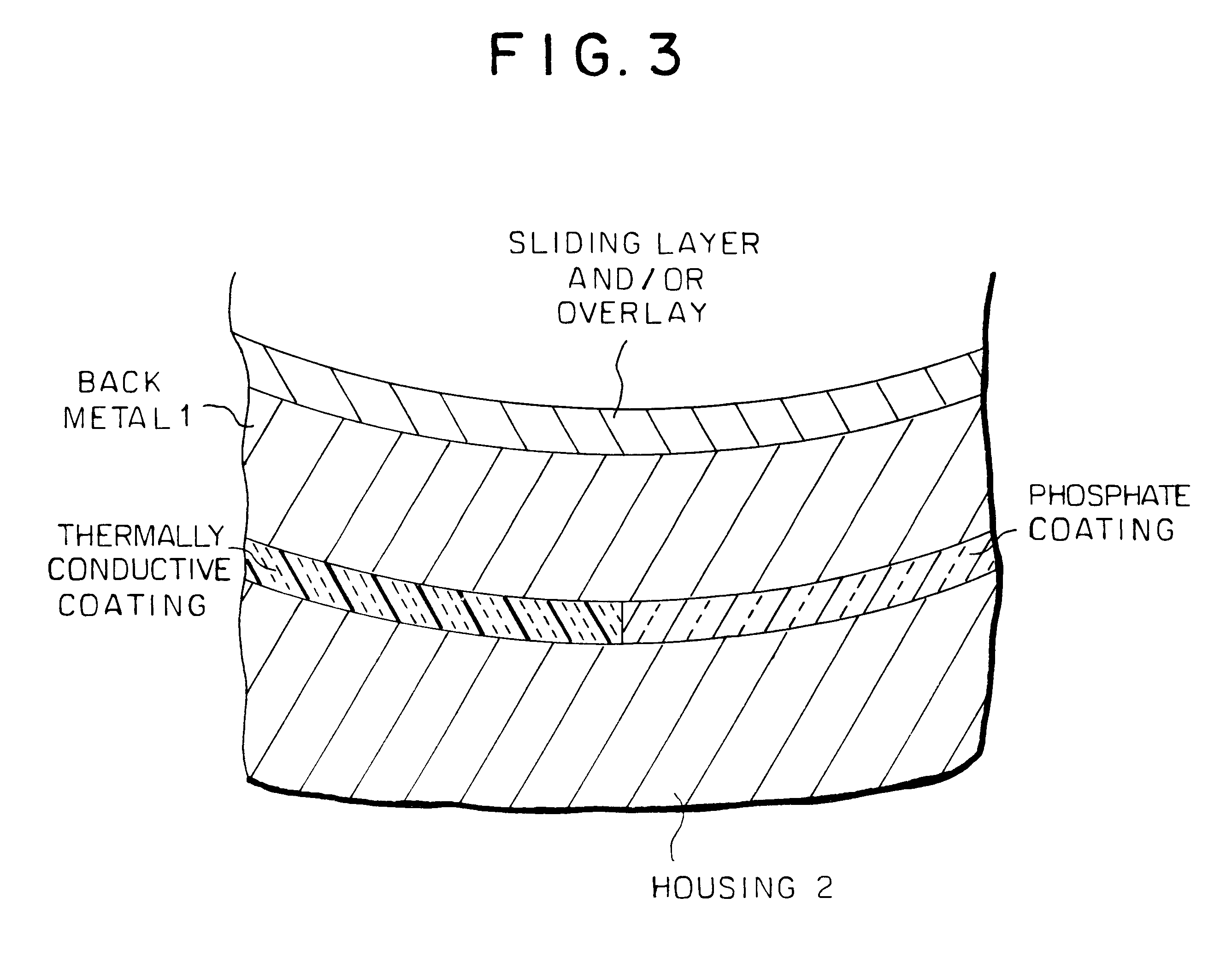

Sliding bearing and sliding bearing structure

InactiveUS6357918B1Improve the immunityGood anti-occlusion performanceConnecting rod bearingsCrankshaft bearingsElectrical conductorFretting wear

There is disclosed a sliding bearing provided with a sliding bearing layer and a back metal layer bonded to the outer face of the sliding bearing layer, the back face of which back metal layer being coated with a phosphate coating at a portion where fretting wear is apt to occur while coated with a coating of a thermally good conductor at another portion where no phosphate coating is provided, whereby seizure resistance as well as fretting resistance is improved because the dispersing of heat can be improved by the coating of the thermally good conductor.

Owner:DAIDO METAL CO LTD

Phosphate conversion coating process and composition

By including nitric acid and hydroxylamine in a manganese phosphating composition and controlling the ratio of nitric to phosphoric acids and the ratio of Total Acid to Free Acid within a specified range, satisfactory manganese phosphate conversion coatings can be obtained within a reasonable time at temperatures much lower than has previously been thought necessary for operating a manganese phosphating composition with no other metal cations (except possibly for iron).

Owner:HENKEL KGAA

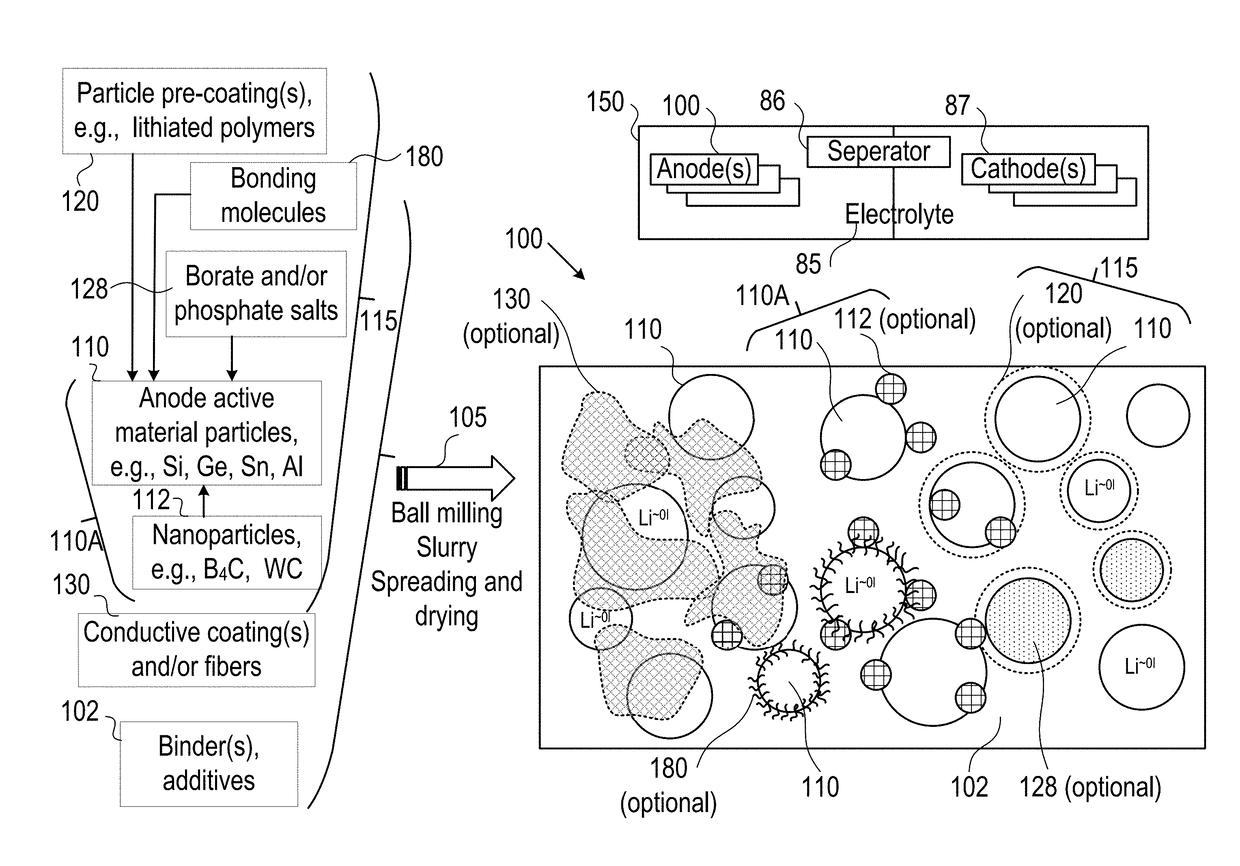

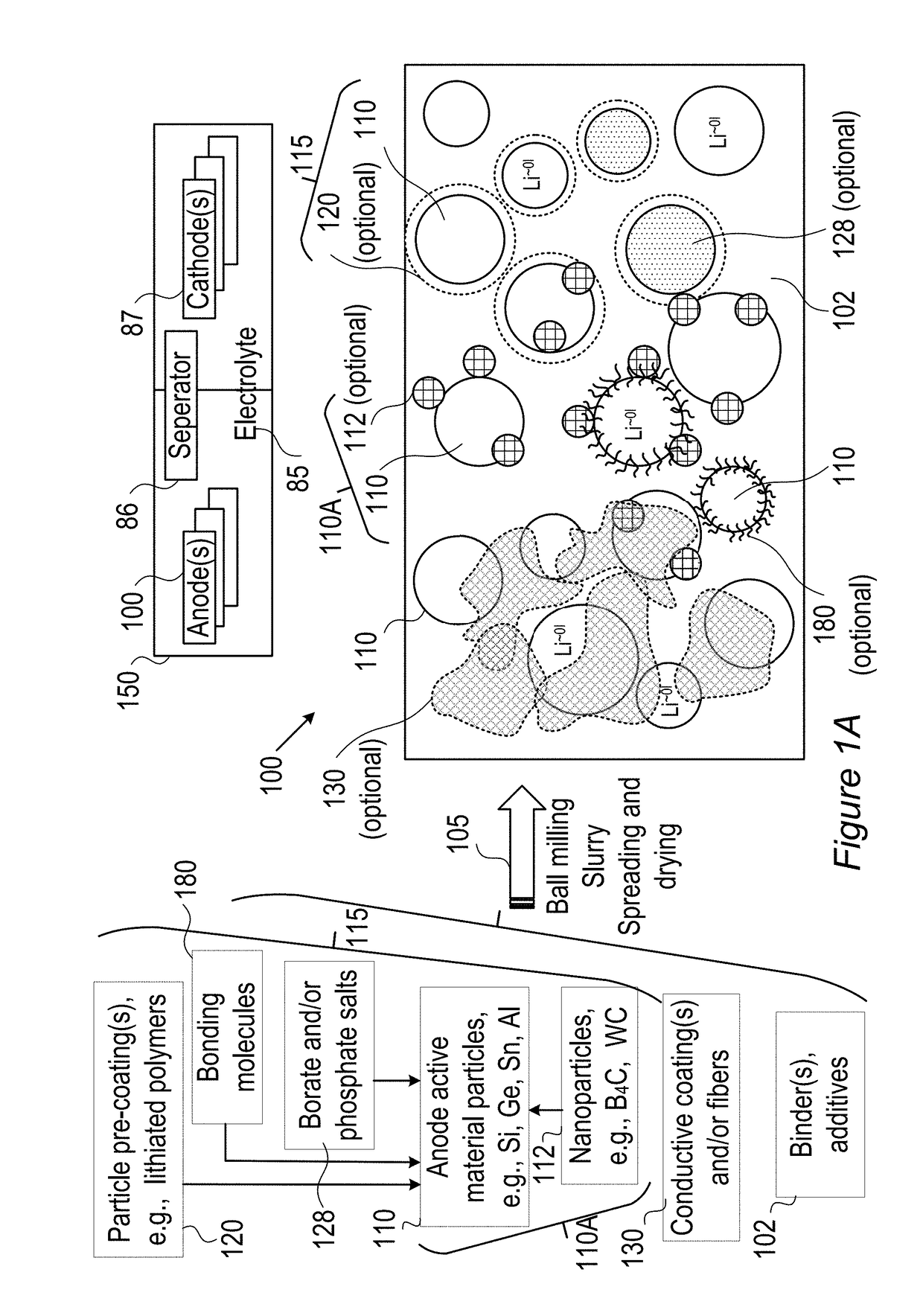

Lithium borates and phosphates coatings

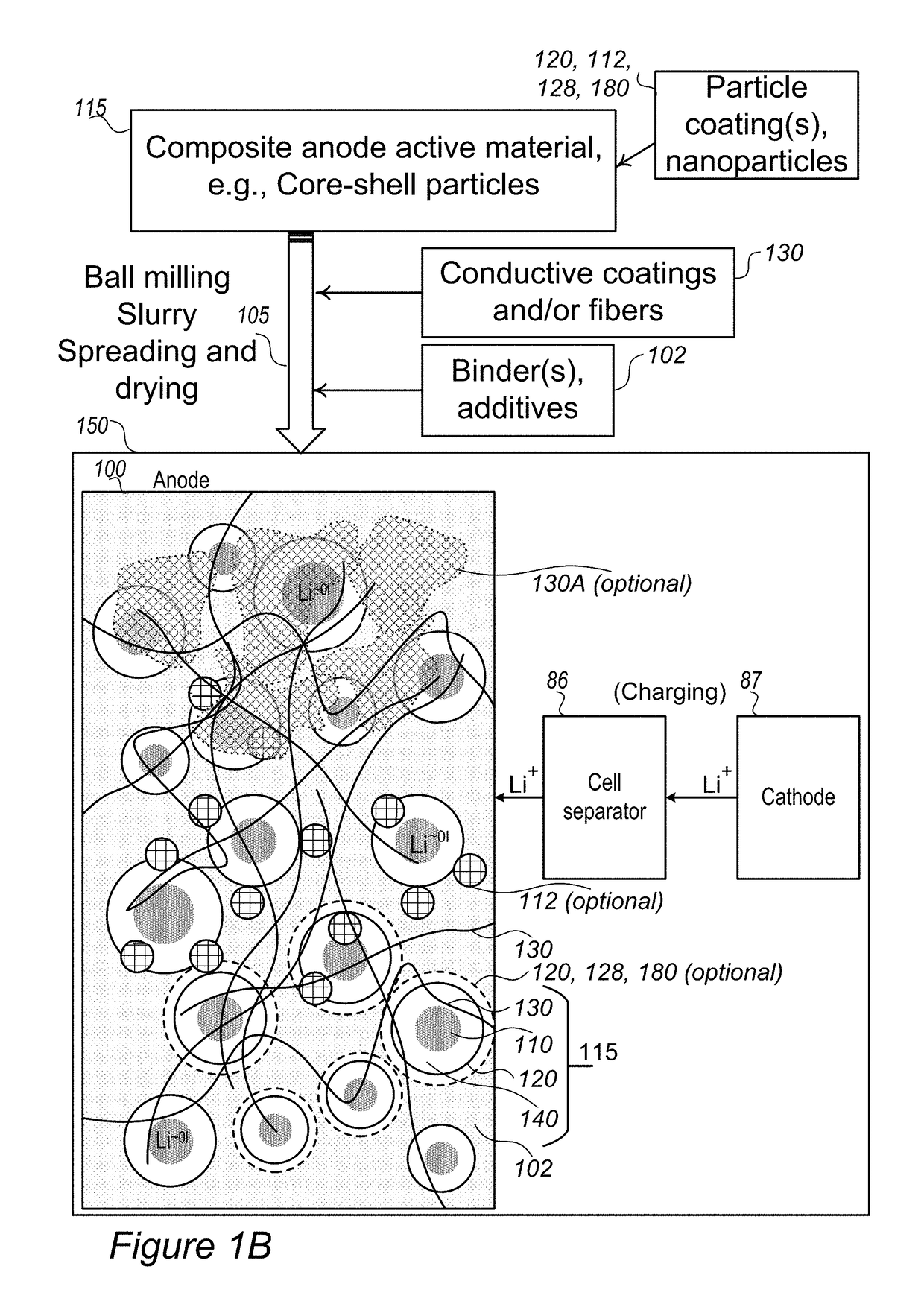

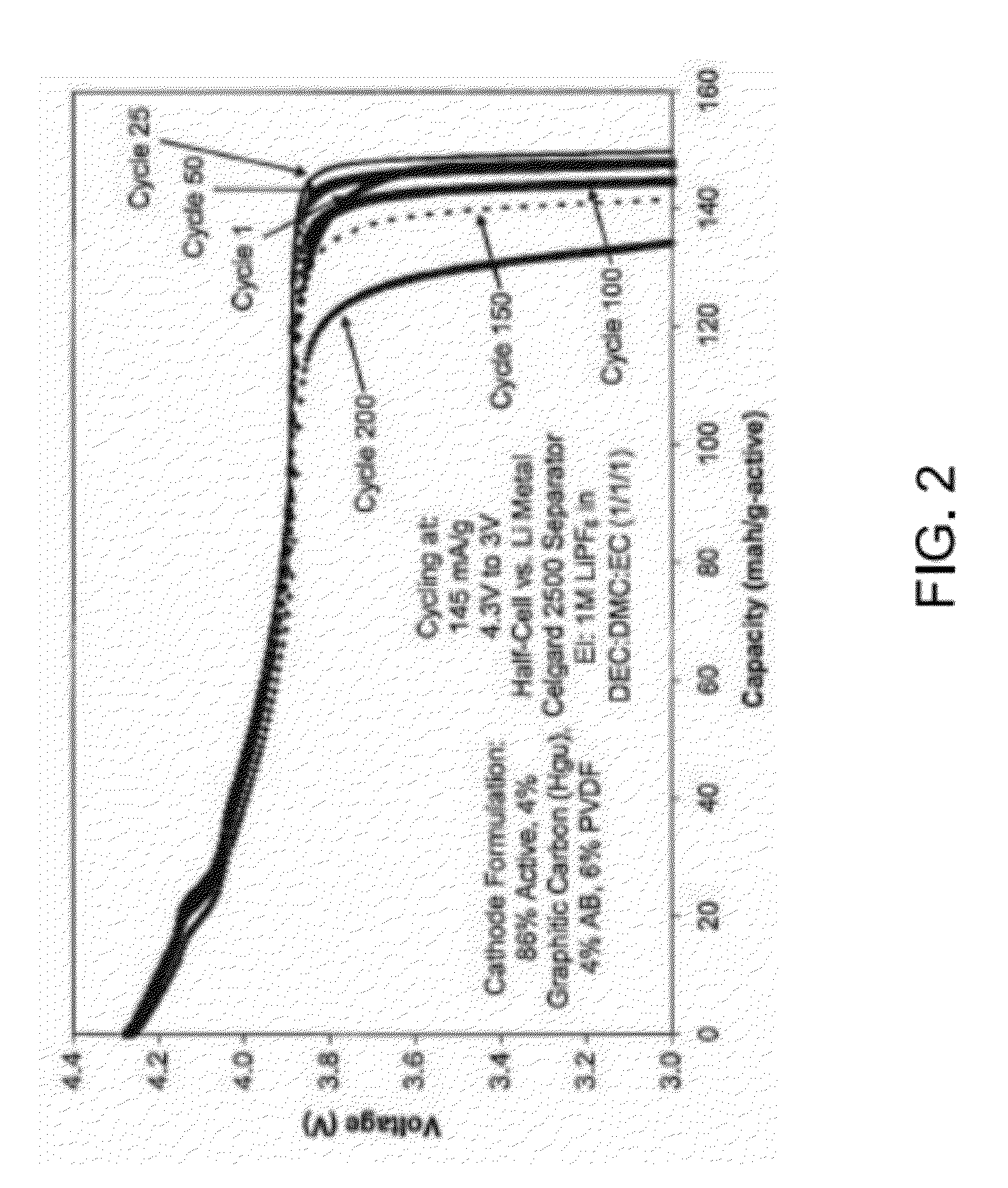

Improved anodes and cells are provided, which enable fast charging rates with enhanced safety due to much reduced probability of metallization of lithium on the anode, preventing dendrite growth and related risks of fire or explosion. Anodes and / or electrolytes have buffering zones for partly reducing and gradually introducing lithium ions into the anode for lithiation, to prevent lithium ion accumulation at the anode electrolyte interface and consequent metallization and dendrite growth. Various anode active materials and combinations, modifications through nanoparticles and a range of coatings which implement the improved anodes are provided.

Owner:STOREDOT

Method of Forming a Metal Phosphate Coated Cathode for Improved Cathode Material Safety

InactiveUS20120164319A1Decrease and substantially eliminate precipitationLimited amountCell electrodesSpecial surfacesPhosphateSolvent

The invention features a method of forming a metal phosphate coated cathode. Either a metal salt or a phosphate salt is dissolved in a nonaqueous solvent to form a first solution. The other of the metal salt or the phosphate salt (e.g., whichever compound is not dissolved in the nonaqueous solvent) is dissolved in a second solvent to form a second solution. The first solution and the second solution are mixed to form a precursor solution. A cathode material is added to the precursor solution to form a cathode-precursor solution. The cathode-precursor solution is dried to form the metal phosphate coated cathode.

Owner:PHYSICAL SCI

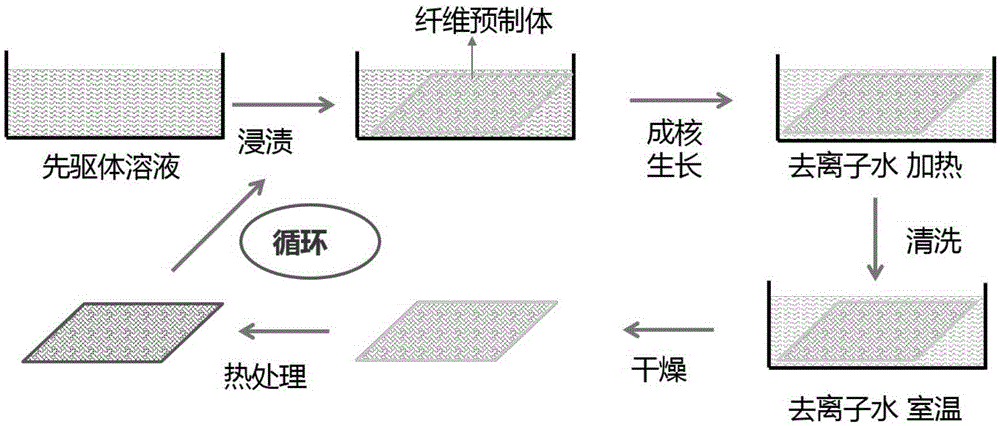

Preparation method of continuous oxide fabric surface coating

The invention belongs to the preparation technology of continuous fiber enhanced ceramic base composite materials, and relates to a preparation method of a coating interface between fiber and a base body in the continuous oxide fiber enhanced oxide ceramic base composite material. The method includes the steps of preparing a coating phase phosphate precursor solution, soaking an oxide fiber prefabricated part in the precursor solution, taking out the prefabricated part after soaking, conducting desizing on the prefabricated part at an appropriate temperature, and obtaining a phosphate coating on the fiber surface through a repeated soaking and thermal processing process. The coating can protect fiber against mechanical and heat damage in the base body densification process and provide an appropriate weak interface combination for fiber and the base body, thereby improving strength and toughness of the material. In addition, the phosphate coating has the advantage of high temperature oxidation resistance, thereby greatly prolonging the service life of the composite material and improving high temperature reliability.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST +1

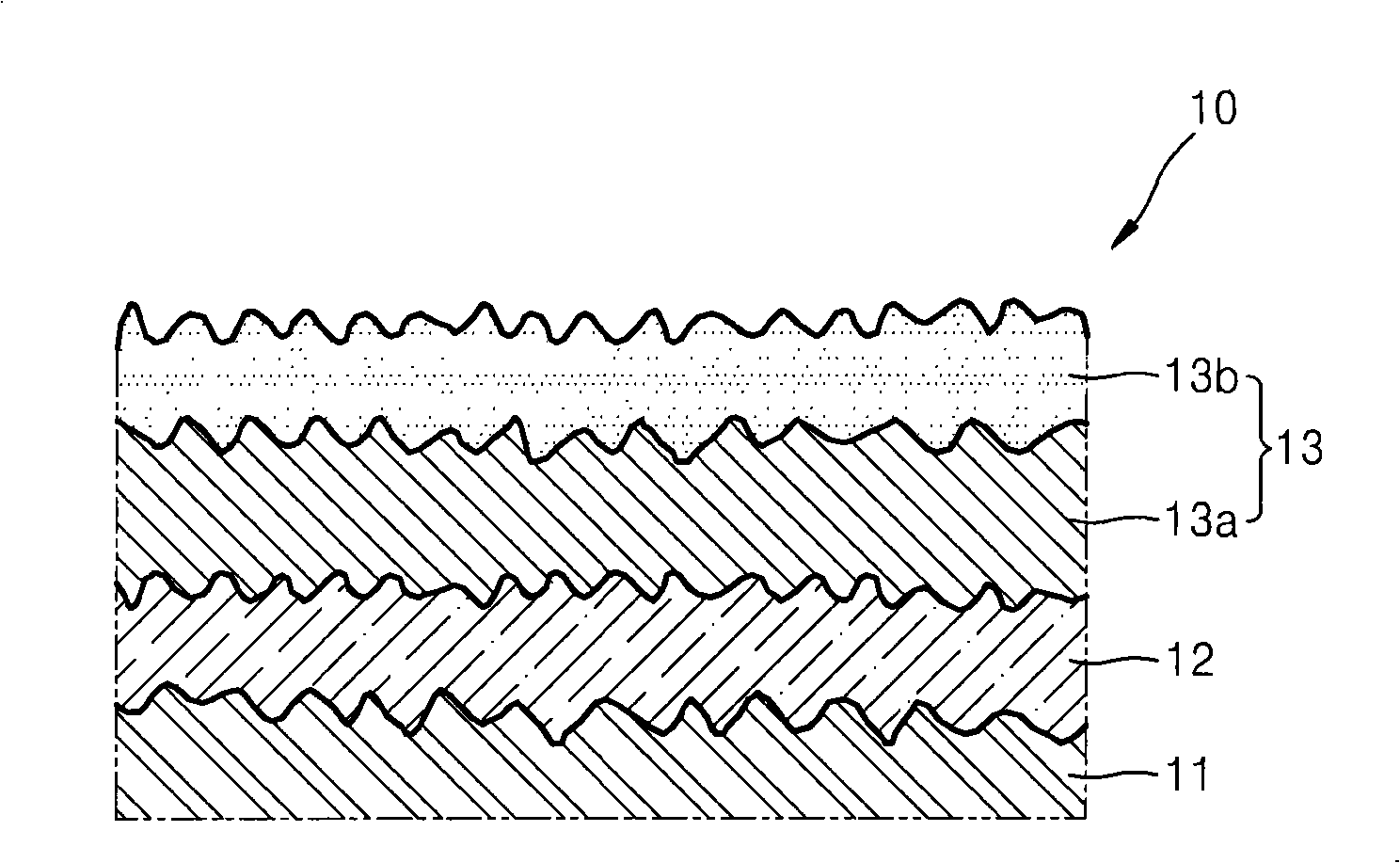

Iron-based soft magnetic powder for dust core, production method thereof, and dust core

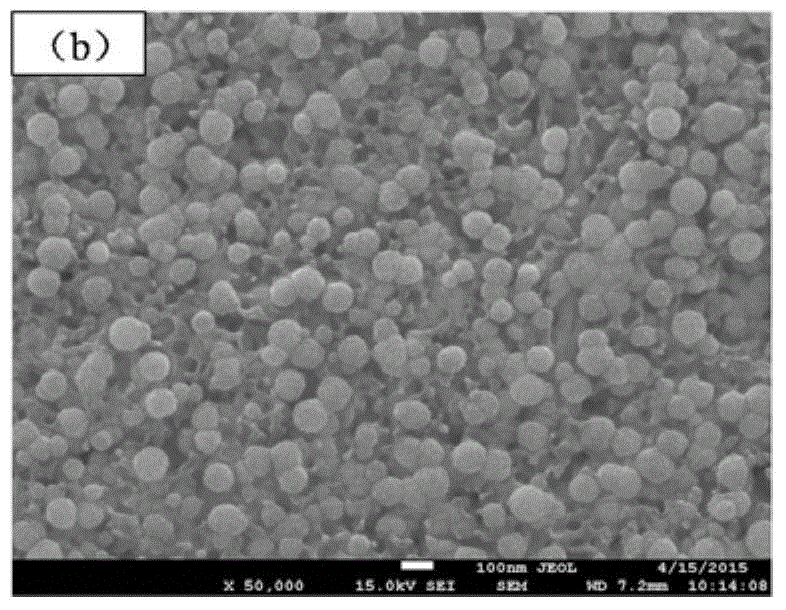

InactiveUS20090242825A1Improve thermal stabilityImprove insulation performanceTransportation and packagingMetal-working apparatusPhosphateHeat treated

An iron-based soft magnetic powder for dust core includes an iron-based soft magnetic matrix powder, and arranged thereon in the following order, a phosphate coating and a silicone resin coating. The phosphate coating contains P, Co, Na, and S in combination with at least one of Al and Cs. This iron powder for dust core has superior mechanical strength, in which effective insulation is achieved between iron powdery particles even when the amount of an insulating material is reduced for realizing high-density molding. The iron powder for dust core is also superior in thermal stability, so that electrical insulation is maintained even after a heat treatment at high temperatures.

Owner:KOBE STEEL LTD

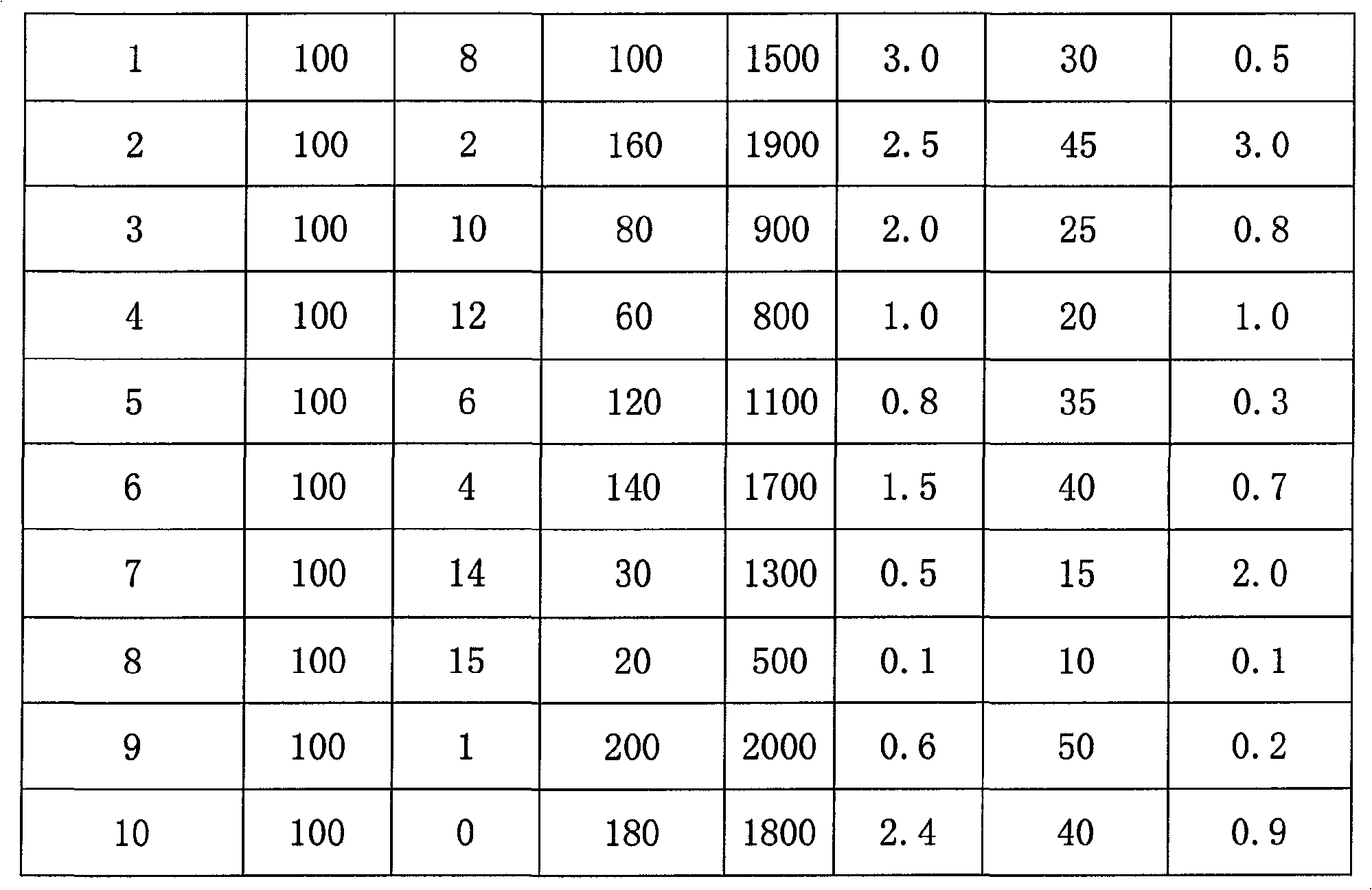

Magnesium alloy chromium-free fluorine-free phosphorization solution and phosphorization method

InactiveCN101851755AProcess stabilityFew ingredientsMetallic material coating processesChromium freeSal ammoniac

The invention relates to magnesium alloy chromium-free fluorine-free phosphorization solution and a phosphorization method. Each liter of the magnesium alloy chromium-free fluorine-free phosphorization solution comprises 1 to 50 g of dihydric phosphate, 0 to 30 g of nitrate and 0.1 to 5 g of additive. The processed magnesium alloy workpiece is soaked and stood in the phosphorization solution of which the pH value is adjusted to be 2.0 to 5.0 by using phosphoric acid and ammonia water and is subjected to phosphating treatment at the temperature of between 30 and 100 DEG C for 1 to 60 minutes to form a phosphate coating. The magnesium alloy is phosphated by the phosphorization solution and the process, a uniform phosphate conversion coating with high corrosion resistance can be obtained on the surface of the magnesium alloy and the phosphate coating can effectively improve the adhesion and the protective property of the subsequent coatings. The phosphorization solution on the surface ofthe magnesium alloy has the advantages of few components and simple preparation. The phosphorization method of the phosphorization solution has the advantages of easy control, stable process, low cost and little sediment.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

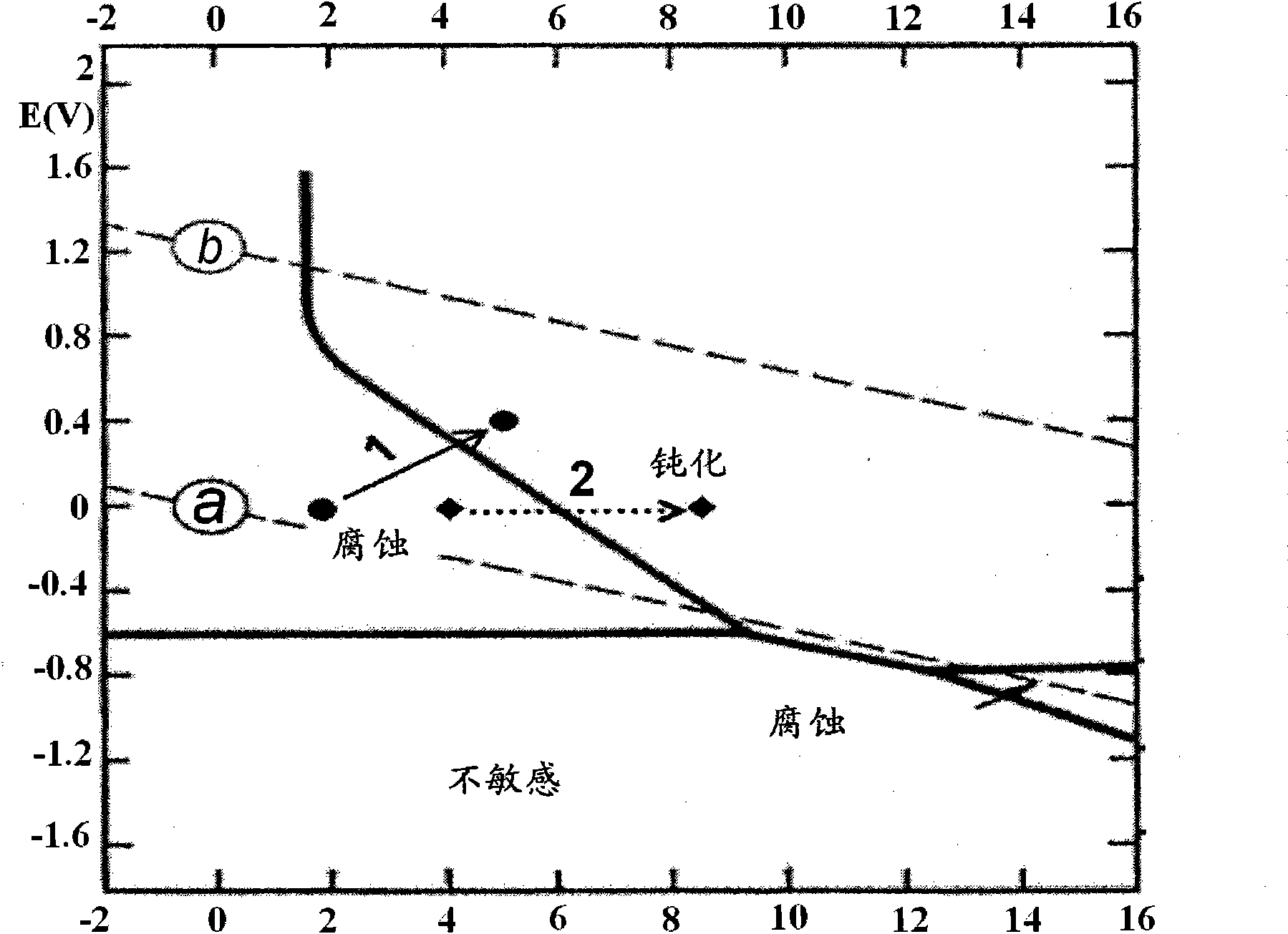

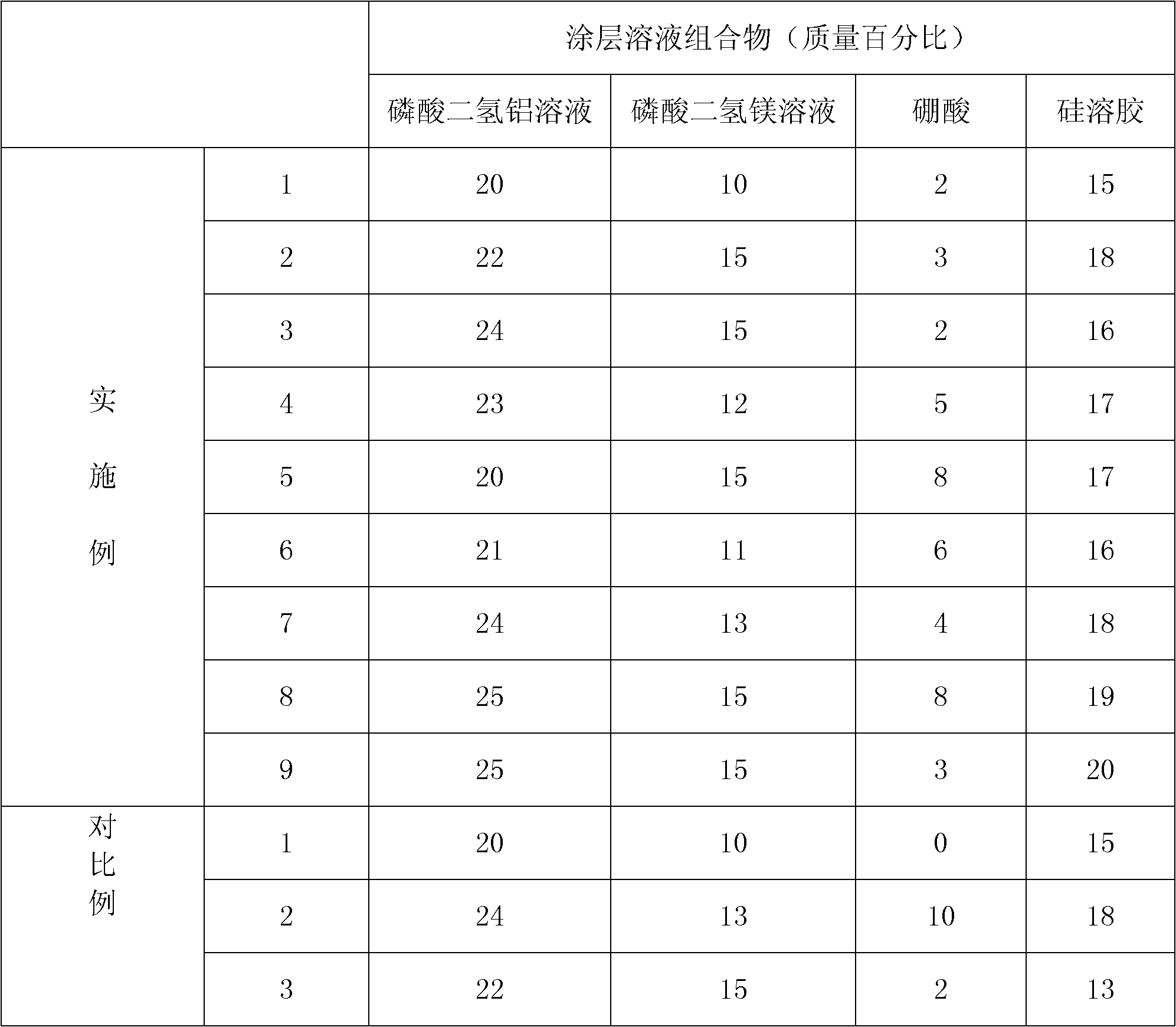

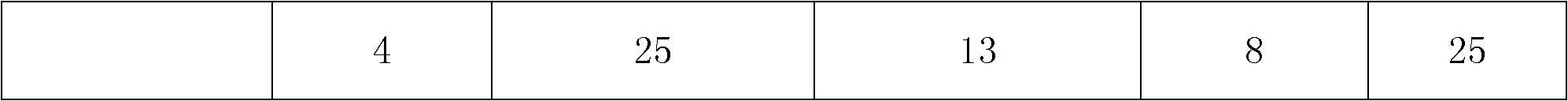

Environment-friendly insulating coating solution used for non-oriented silicon steel and preparation and application thereof

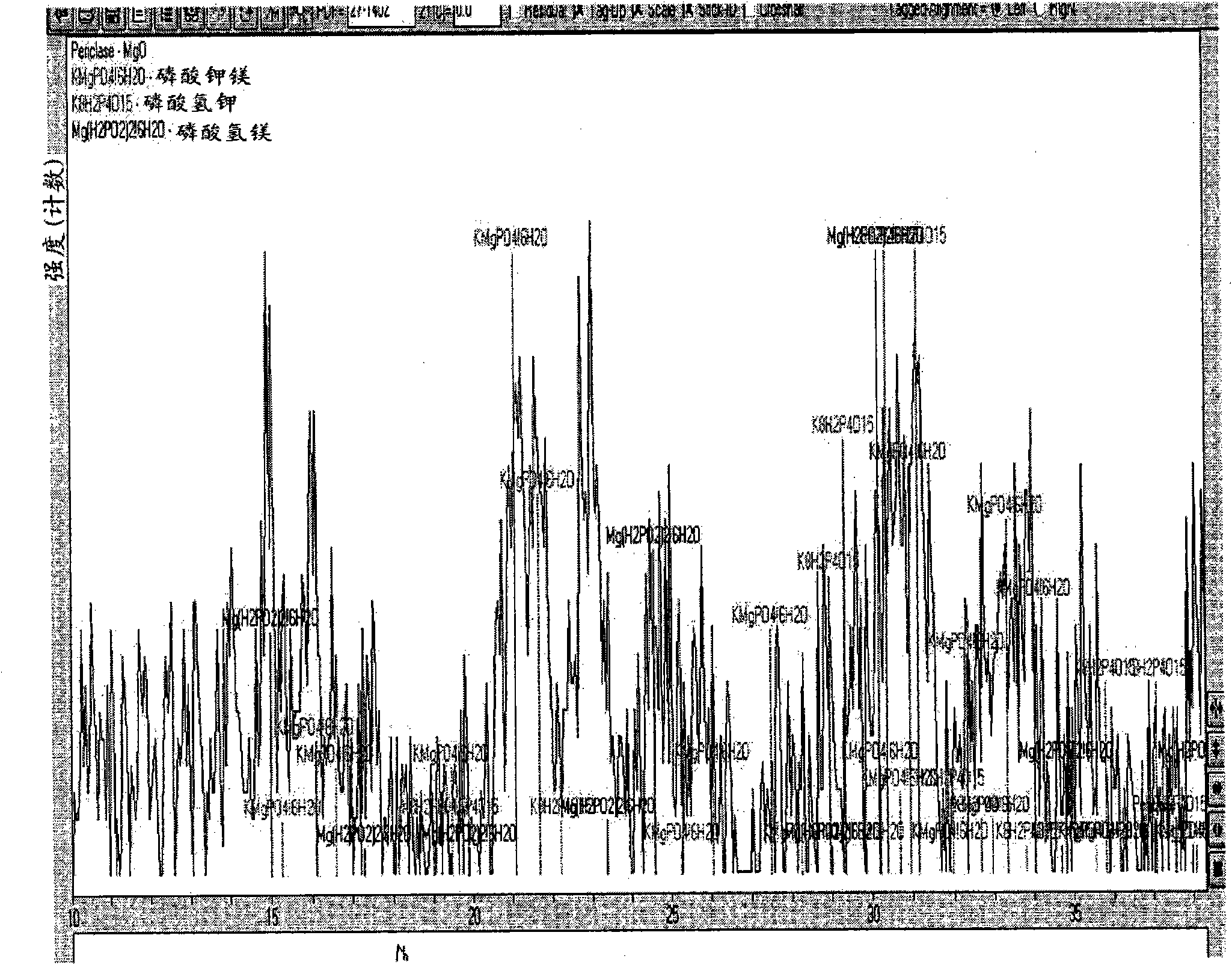

ActiveCN102115881AReduce wearEliminate environmental concernsMetallic material coating processesMonomagnesium phosphatePhosphate

The invention relates to an environment-friendly insulating coating solution used for non-oriented silicon steel and preparation and application thereof, in particular to a phosphate coating solution and preparation and application thereof, belonging to the technical field of preparation of a silicon steel insulating coating. Based on the total mass of the coating solution, the environment-friendly insulating coating solution used for non-oriented silicon steel comprises the components by the mass percentage of: 20 to 25 percent of aluminum dihydric phosphate solution, 10 to 15 percent of magnesium dihydrogen phosphate solution, 15 to 20 percent of ludox, 2 to 8 percent of boric acid and the balance of deionized water. The insulating coating prepared by using the environment-friendly insulating coating solution used for non-oriented silicon steel not only can guarantee that all the performances such as uniformity, insulating performance, adhesiveness, corrosion resistance, heat resistance, weldability and the like are excellent, but also totally solves the problem in environment protection caused by chromium.

Owner:上海迪升防腐新材料科技有限公司

Non-toxic corrosion-protection rinses and seals based on cobalt

InactiveUS7235142B2Optimized formulaAvoid corrosionSurface reaction electrolytic coatingSolid state diffusion coatingSolubilityPhosphate

Rinsing or sealing solutions based on cobalt are described for barrier films such as anodic coatings, phosphate coatings, or “black oxide” coatings. The treated films contain a trivalent or tetravalent cobalt / valence stabilizer complex. The rinsing or sealing bath may also contain an optional preparative agent or an optional solubility control agent. The oxidized cobalt is present in the coating in a “sparingly soluble” form. The valence stabilizers can be either inorganic or organic in nature. Cobalt / valence stabilizer combinations are chosen based on the well-founded principles of cobalt coordination chemistry. A number of cobalt / valence stabilizer combinations that match the performance of conventional hexavalent chromium systems are presented.

Owner:UNIV OF DAYTON

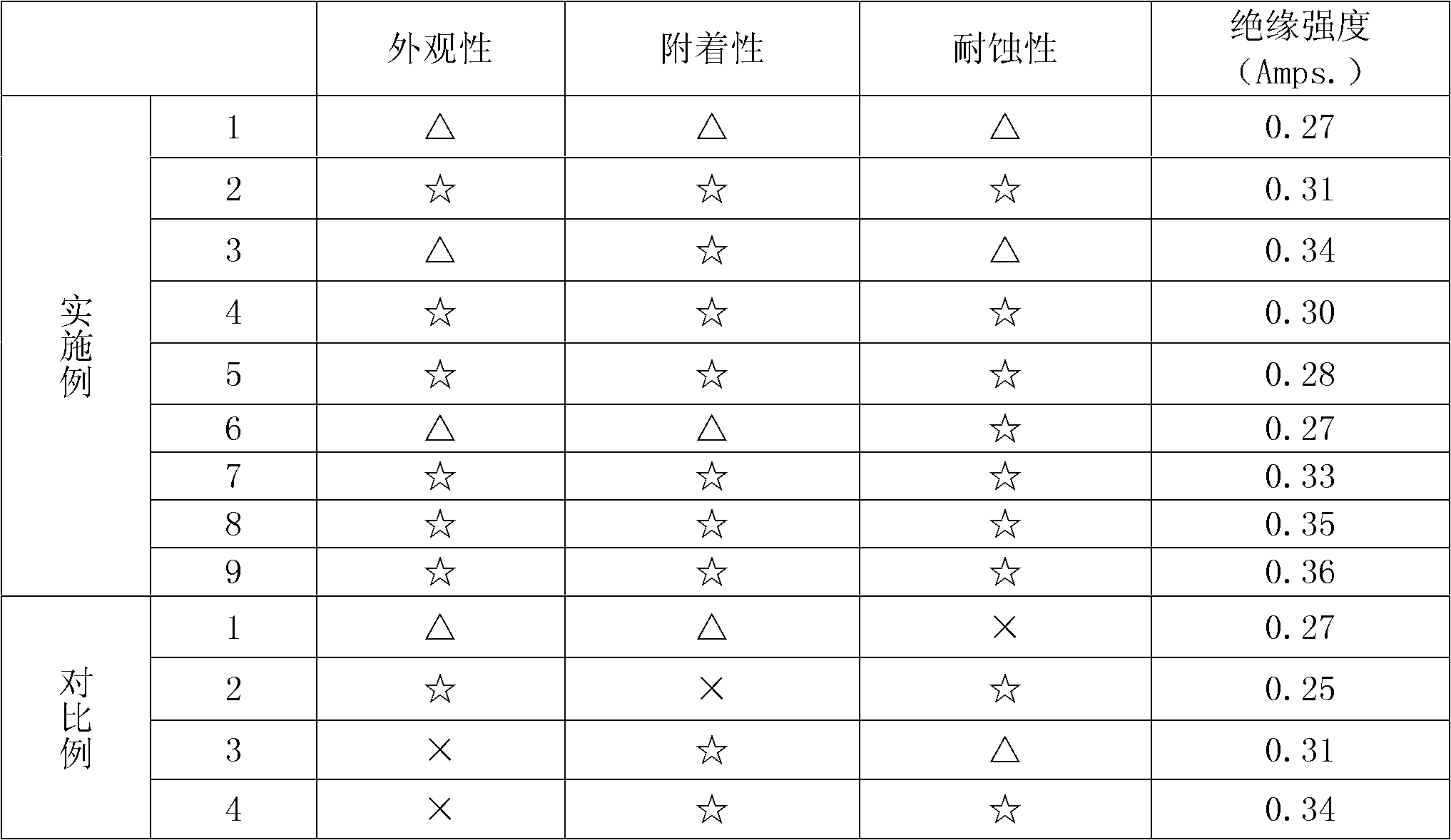

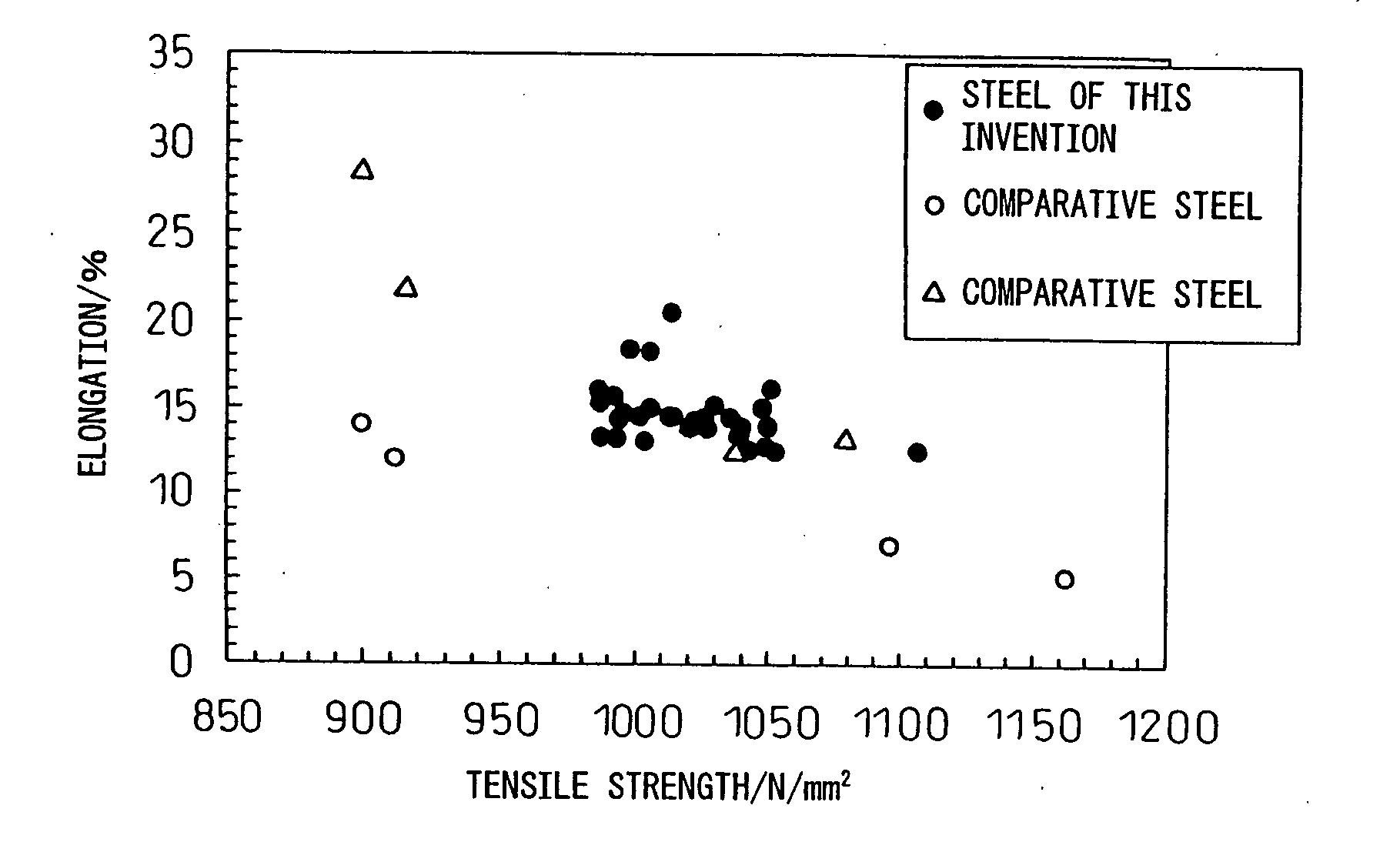

High strength thin steel excellent in hole expansibility, ductility and chemical treatment characteristics, and method for production thereof

ActiveUS20060113012A1High strengthImprove abilitiesFurnace typesHeat treatment furnacesChemical treatmentHigh intensity

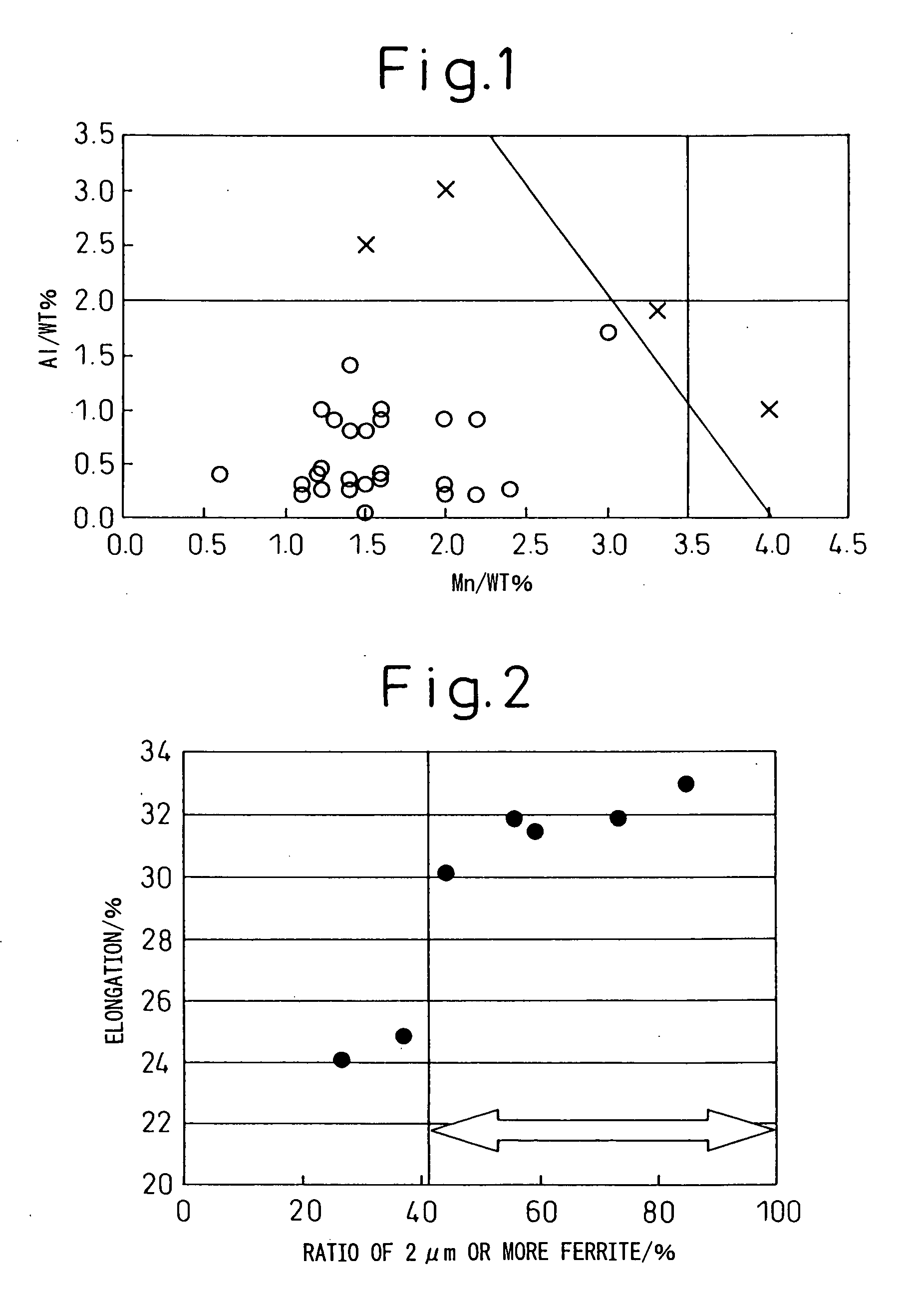

High strength hot rolled steel sheet having at least a 590 N / mm2 tensile strength and excellent in elongation and ability of phosphate coating, that is, high strength hot rolled steel sheet excellent in burring, elongation, and ability of phosphate coating having a tensile strength of 590 N / mm2 or more comprising a steel composition containing, by mass %, C: 0.02 to 0.08%, Si: 0.50% or less, Mn: 0.50 to 3.50%, P: 0.03% or less, S: 0.01% or less, Al: 0.15 to 2.0%, and the balance of iron and unavoidable impurities, satisfying Mn+0.5×Al<4, having a microstructure of the steel sheet having a ratio of ferrite having a grain size of 2 μm or more of 40% or more.

Owner:NIPPON STEEL CORP

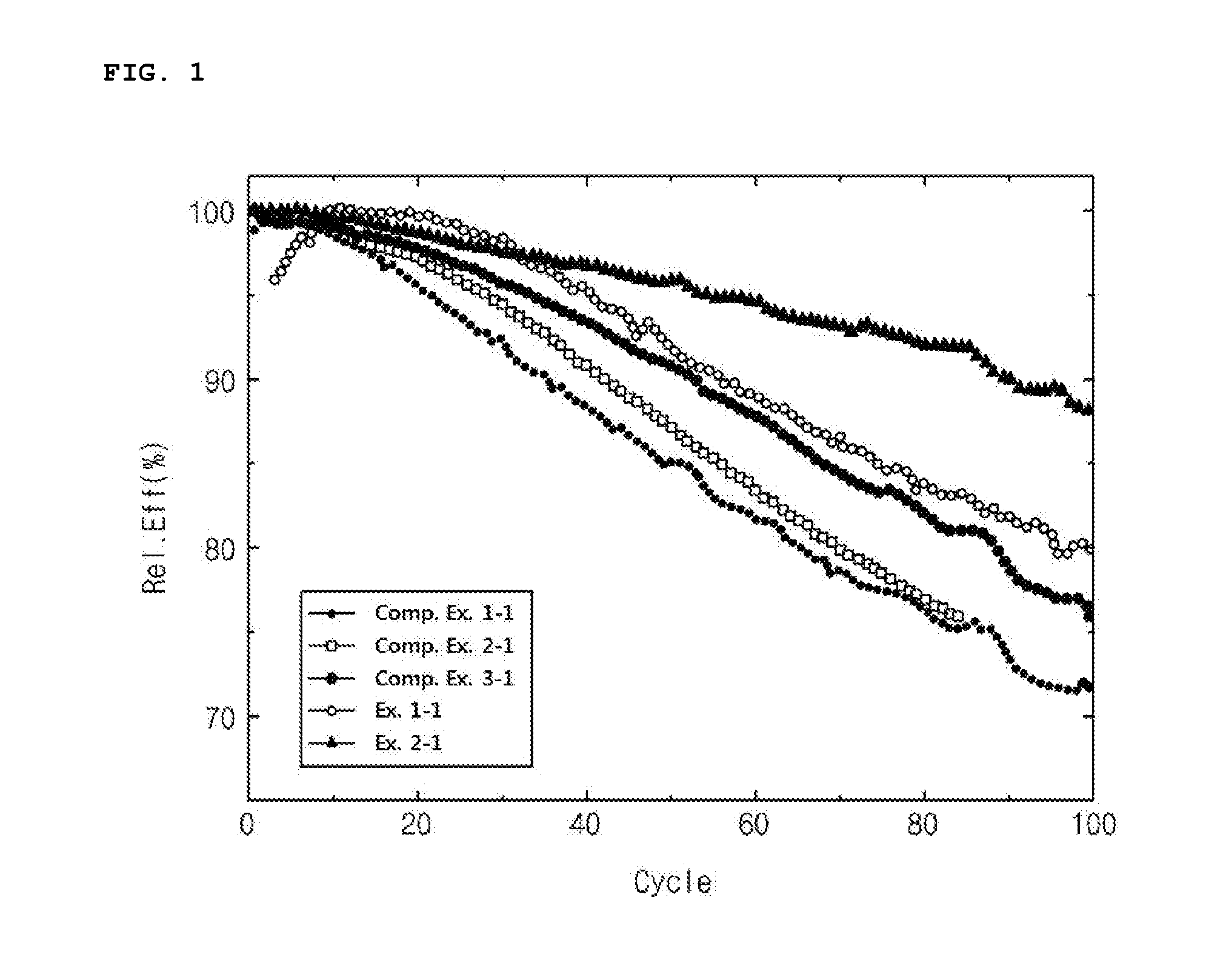

Lithium-nickel based positive electrode active material, method of preparing the same, and lithium secondary battery including the same

ActiveUS20160293951A1Improve structural stabilityInhibit swellingElectrode thermal treatmentFinal product manufactureAlkaline earth metalPhosphate

The present disclosure relates to a positive electrode active material which reduces lithium by-products and improves structural stability and includes a lithium-nickel based transition metal composite oxide in which an alkaline earth metal having oxidation number of +2 is doped and a phosphate coated layer formed on the outer surface of the composite oxide. Accordingly, a second battery including the positive electrode active material has excellent capacity characteristics, and also improves structural stability during charging / discharging and prevents swelling, thereby being capable of exhibiting excellent life characteristics. Therefore, the present invention may be easily applied to industry in need thereof, and particularly to electric vehicles industry requiring high capacity and long-term life characteristics.

Owner:LG ENERGY SOLUTION LTD

Protection of thermal barrier coating by a sacrificial coating

According to an embodiment of the invention, an article of manufacture for use in a gas turbine engine is disclosed. The article comprises a part having a surface covered with a ceramic thermal barrier coating. The thermal barrier coating has an outer surface covered with a sacrificial phosphate coating, wherein the sacrificial phosphate coating reacts with contaminant compositions to prevent contaminant infiltration into the thermal barrier coating.

Owner:GENERAL ELECTRIC CO

Phosphate conversion coating process and composition

Owner:HENKEL KGAA

Integrated hole sealing method for anodic oxide films of aluminum alloys

InactiveCN104831328AMore than corrosion resistanceOver wear resistanceSurface reaction electrolytic coatingPhosphateCerium

The invention discloses an integrated hole sealing method for anodic oxide films of aluminum alloys. The integrated hole sealing method is excellent in hole sealing effect and high in timeliness and includes the steps: firstly, preparing phosphate solution and cerium salt solution; secondly, putting the anodic oxide films of the aluminum alloy into the cerium salt solution to carry out cerium salt hole sealing; thirdly, uniformly brushing the phosphate solution onto the anodic oxide films subjected to cerium salt hole sealing, curing for a while in the air, and carrying out thermal treatment at the temperature ranging from 150 DEG C to 350 DEG C; finally, forming a compact phosphate coating on the surface of the anodic oxide films after the steps are repeated for 2-8 times. Corrosion resistance and abrasion resistance of the anodic oxide films subjected to integrated hole sealing are much higher than those of anodic oxide films subjected to single hole sealing, and effects of integrated hole sealing are much higher than additive effects of single cerium salt hole sealing and phosphate hole sealing. In addition, cerium salt and phosphate integrated hole sealing method is high in timeliness and suitable for popularization and application in the technical field of hole sealing.

Owner:SOUTHWEST JIAOTONG UNIV

Steel sheet for containers

ActiveUS20130209829A1Improve adhesionMaintain good propertiesElectrolytic inorganic material coatingPhosphatisationPhosphatePhosphoric acid

Disclosed is a steel sheet for containers that maintains excellent corrosion resistance even when a surface treatment that replaces a chromate treatment has been conducted, and that has excellent film adhesion qualities and appearance. This steel plate for containers has, on at least one surface thereof, a chemical conversion coating including at least two coatings selected from a zirconium coating that contains zirconium and has a metal zirconium content of 0.1-9 mg / m2, a phosphate coating that contains phosphoric acid and has a phosphorous content of 0.1-8 mg / m2, and a phenolic resin coating that contains phenolic resin in an amount of 0.5-8 mg / m2 in terms of carbon, the percentage of the area of the surface of the chemical conversion coating layer having particles Of a prescribed size being 0.1-50%.

Owner:JFE STEEL CORP

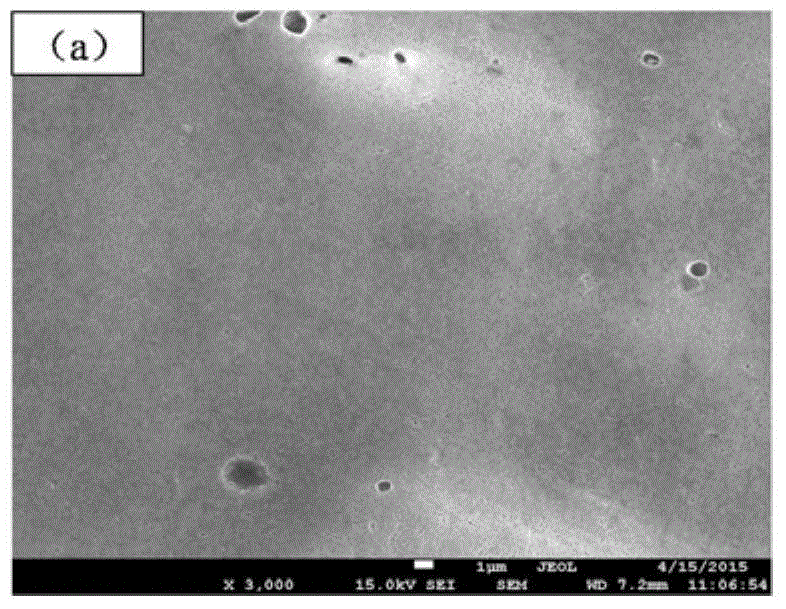

Iron-based soft magnetic powder for dust core, method for manufacturing the same, and dust core

InactiveUS20100212455A1High magnetic flux densityMechanical strengthMetal-working apparatusPretreated surfacesReflectance spectroscopyVolumetric Mass Density

An iron-based soft magnetic powder for dust core having a high magnetic flux density, maintaining high electric insulation even after annealing, and more excellent in the mechanical strength in which a coating film having a phosphate conversion coating film is formed on the surface thereof and the peak height for the absorption of hydroxyl groups formed at 3700 cm−1 to 2500 cm−1 is 0.04 or more being indicated by absorbance when the coating film is analyzed by infrared diffuse reflectance spectroscopy.

Owner:KOBE STEEL LTD

Aluminium basis material surface treatment method

InactiveCN1970844AExcellent adhesionImprove corrosion resistanceMetallic material coating processesPretreatment methodElectrolysis

PROBLEM TO BE SOLVED: To provide a pretreatment method which imparts a chromium-free chemical conversion coating adhesiveness to a paint film and corrosion resistance equivalent to or better than those of a chromating conversion coating containing hexavalent chromium ions, when an aluminum-based substrate is subjected to the chromium-free chemical conversion treatment as an alternative method for the chromate conversion treatment.SOLUTION: A surface treatment method for the aluminum-based substrate comprises the steps of: subjecting the aluminum-based substrate to a treatment process including the chemical conversion treatment; and then painting it. The method also includes treating the aluminum-based substrate with a strongly alkaline aqueous solution or electrolyzed alkaline water before the step prior to the painting step including the chemical conversion treatment to enhance a cleanliness degree of the surface of the aluminum-based substrate.

Owner:CENTRAL MOTOR WHEEL CO LTD

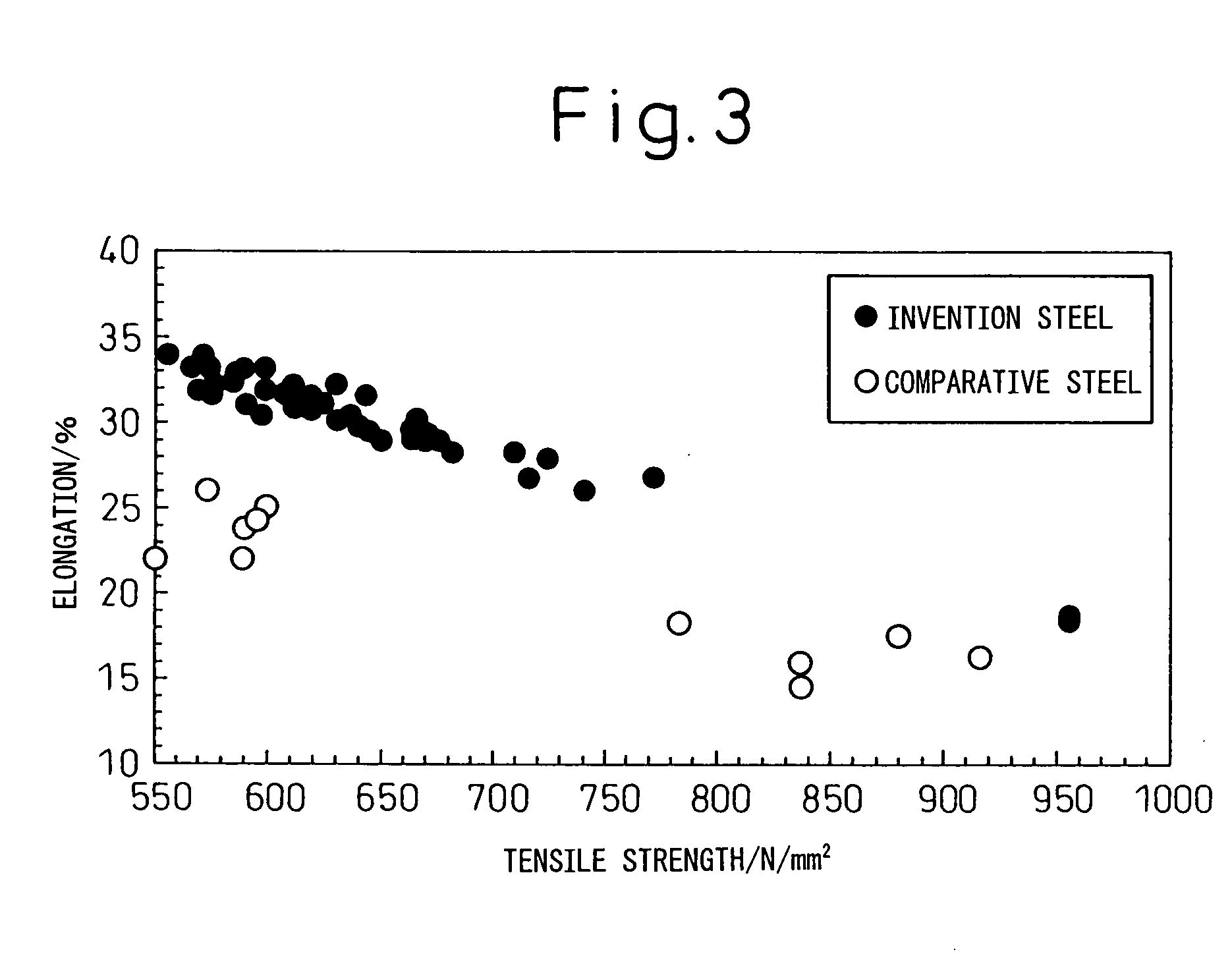

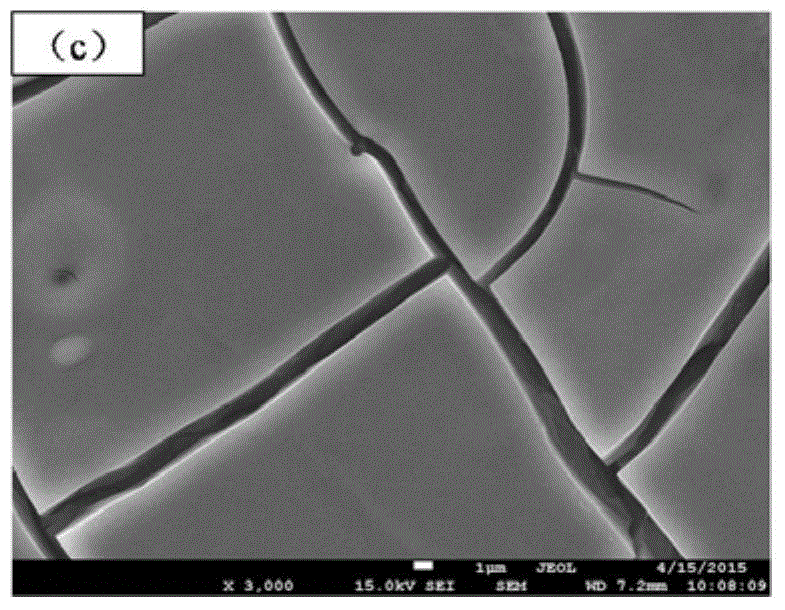

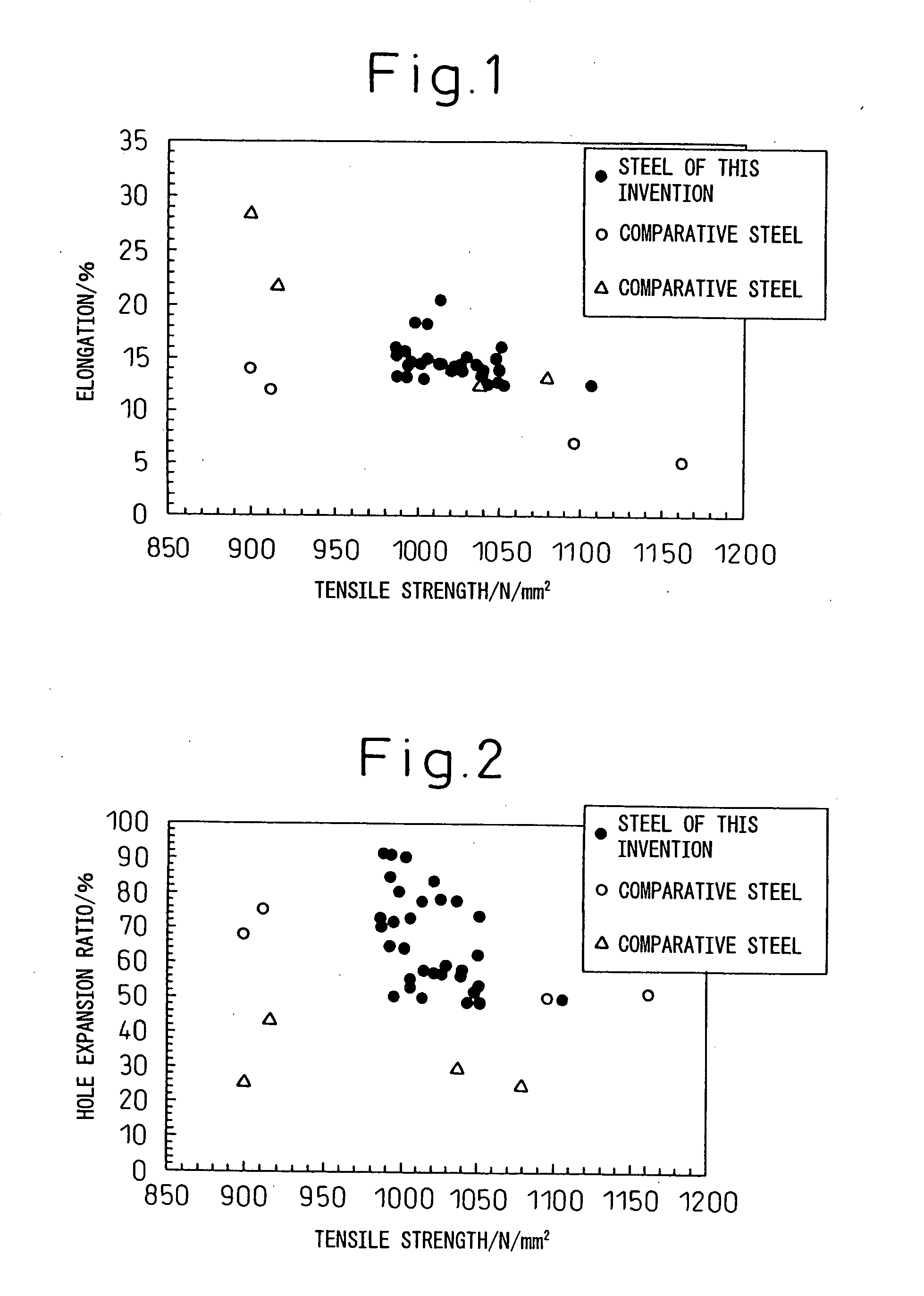

High-strength hot-rolled steel sheet excelling in bore expandability and ductility and process for producing the same

InactiveUS20060231166A1Inhibit deteriorationImprove hole reaming effectMetal rolling stand detailsSolid state diffusion coatingSectilityHigh intensity

This invention provides a high-strength hot-rolled steel sheet having strength of at least 980 N / mm2 at a sheet thickness of from about 1.0 to about 6.0 mm and excellent in hole expandability, ductility and ability of phosphate coating, which steel sheet is directed to automotive suspension components that are subjected to pressing. The high-strength hot-rolled steel sheet contains, in terms of a mass %, C: 0.01 to 0.09%, Si: 0.05 to 1.5%, Mn: 0.5 to 3.2%, Al: 0.003 to 1.5%, P: 0.03% or below, S: 0.005% or below, Ti: 0.10 to 0.25%, Nb: 0.01 to 0.05% and the balance consisting of iron and unavoidable impurities; satisfies all of the following formulas <1>to <3>: 0.9≦48 / 12×C / Ti<1.7 <1>50,227×C−4,479×Mn>−9,860 <2>811×C+135×Mn+602×Ti+794×Nb>465 <3>, and has strength of at least 980 N / mm2.

Owner:NIPPON STEEL CORP

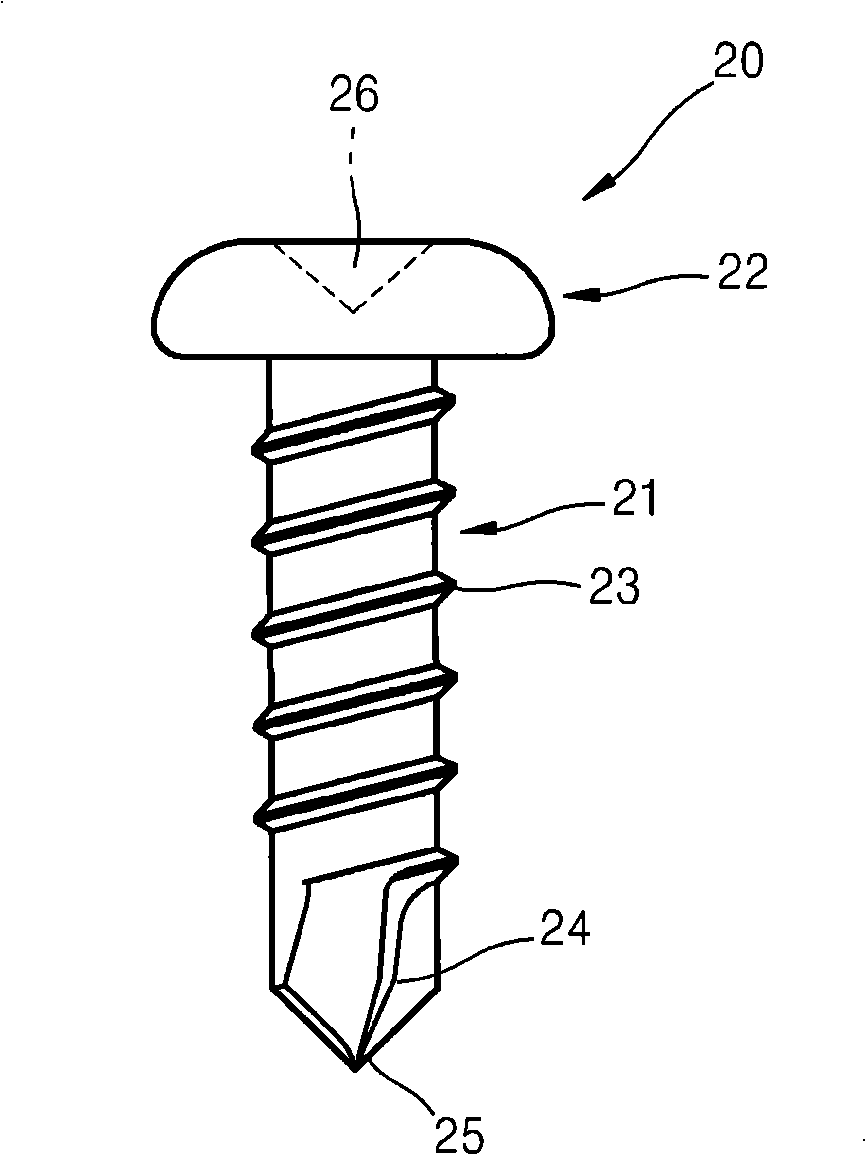

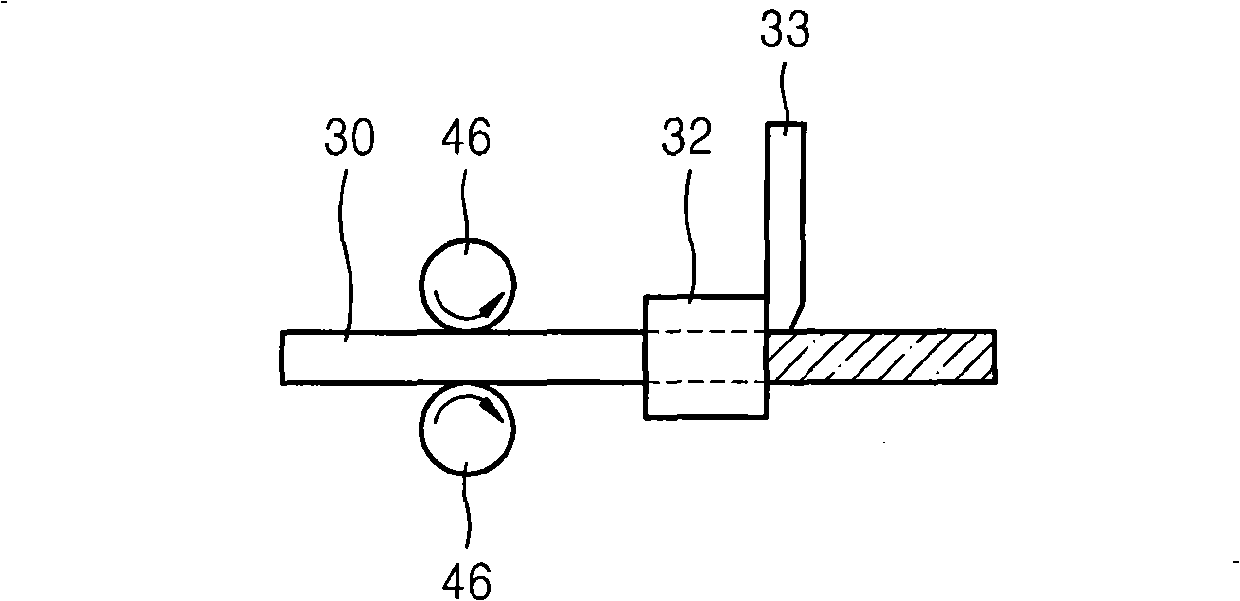

Phospahte coated stainless steel wire for cold heading and self-drilling screw using the stainless steel wire

Provided are a phosphate coated stainless steel wire for cold heading and a self-drilling screw using the stainless steel wire. Since a phosphate coating is formed on a surface of the stainless steel wire, cold headability and clamping force can be significantly improved, and since outer appearance is improved, a post-process after a heading is not required.

Owner:高丽特殊线材株式会社 +1

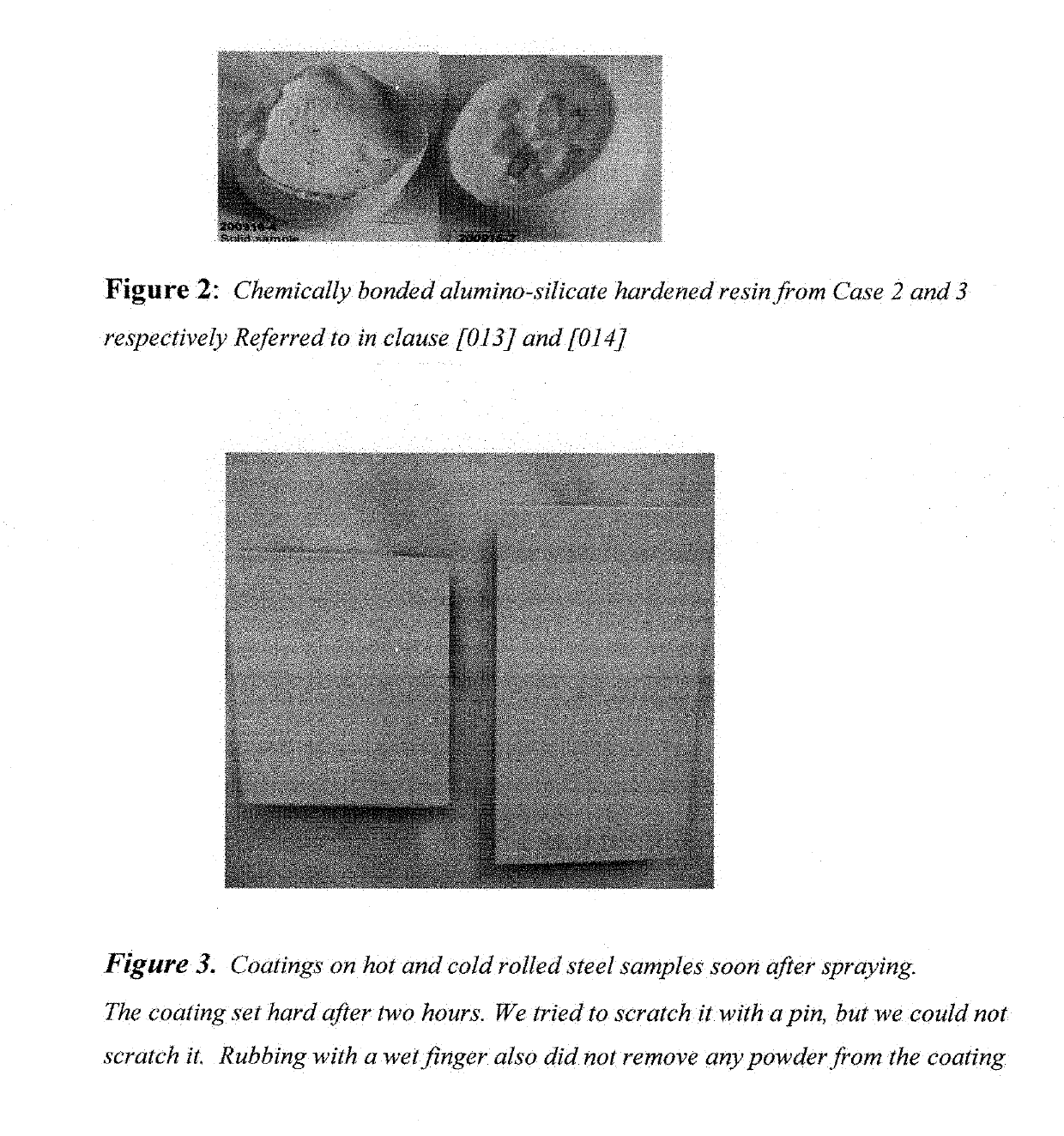

Sprayable alumino-silicate coatings, resins, their compositions and products

InactiveUS20190135681A1Safe disposalEasy to cleanFireproof paintsLiquid surface applicatorsFire protectionPhosphate

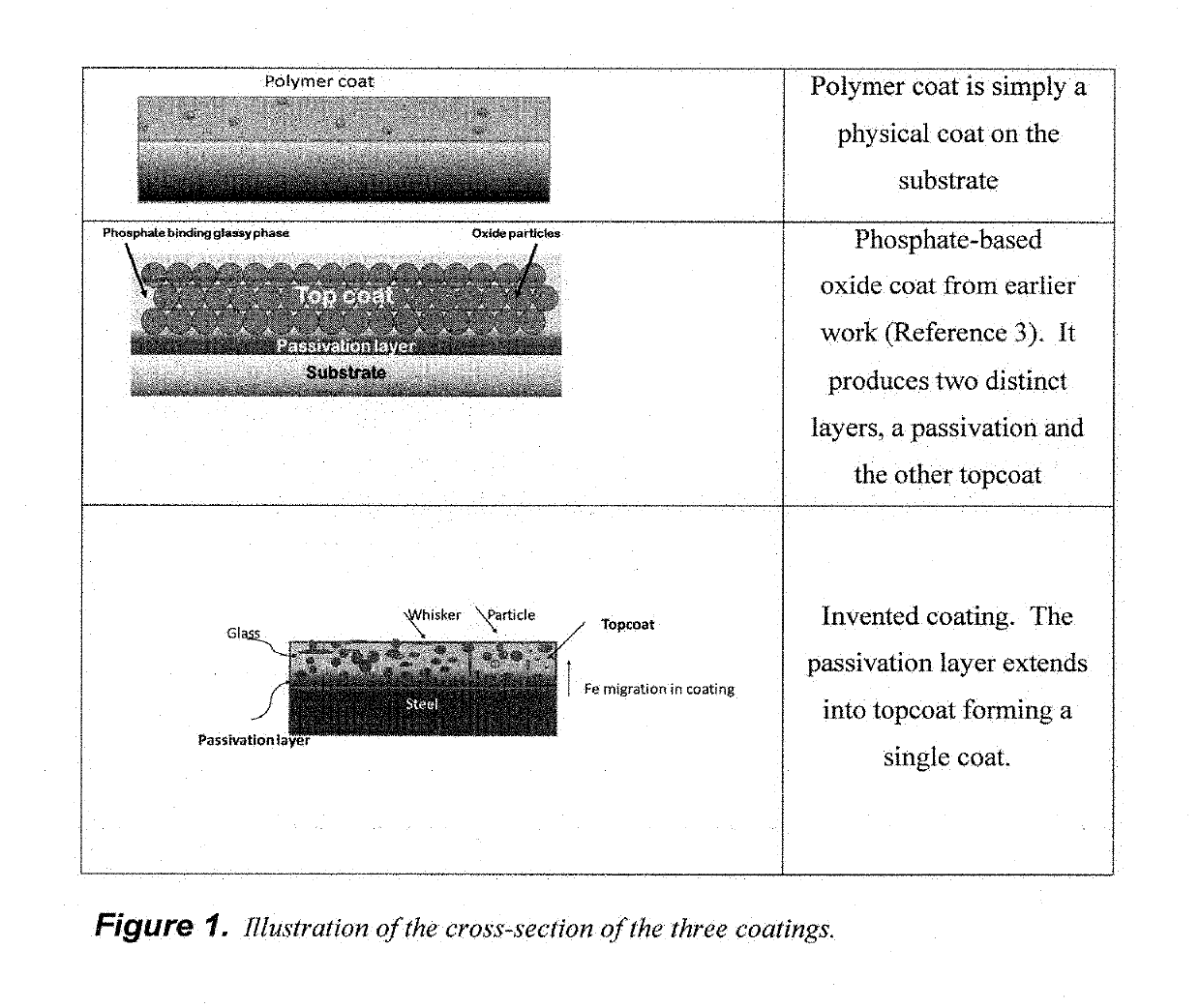

Novel formulations of inorganic, chemically bonded, phosphate alumino silicate sprayable coatings are disclosed. The disclosed coatings retain all the positive attributes of similar coatings disclosed in recent patents on corrosion and fire protection, and in addition, provide, superior surface toughness and smoothness, better abrasion and acid resistance, less erosion and longer durability with zero flame-spread coatings on wood surfaces. Being pore-free, water cannot penetrate into these coatings. Unlike the previous inorganic oxide-based phosphate coatings, the glassy phase in these coatings provides a translucent and dense surface. The component pastes are smoother to pump, do not settle or harden during storage and transport, and in addition, do not exhibit pozzalinic properties.

Owner:CERAMICOAT INT LTD

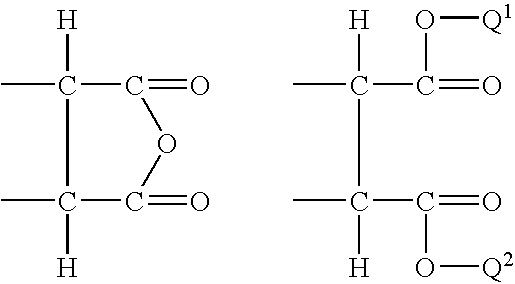

Lubricant system for cold forming, process and composition therefor

InactiveUS20060060265A1Solution to short lifeImprove adhesionMetallic material coating processesAdditivesHydroxylamineCold formed

The invention is directed to a combination of a conditioner bath and a calcium modified zinc phosphating solution optionally containing hydroxylamine which provide an improved phosphate coating on the surface of ferrous metal articles. In a preferred embodiment, the treatment process further comprises coating the workpiece with a second lubricant. The three treatments work together to provide finer grained phosphate coatings, longer life of the second lubricant bath and improved adherence of the second lubricant, as compared to a similar phosphating bath that is used alone or with a similar second lubricant.

Owner:HENKEL KGAA

Coating for cold working metals

The invention involves a composition for forming a combined conversion and lubricating coating on a metal substrate with which the composition is brought into contact. The composition comprises (a) an oxyethylated aliphatic alcohol whose aliphatic hydrocarbon moiety contains 18 or more carbon atoms and (b) dissolved phosphate anions. Preferably the composition also comprises inorganic boron, an alkali metal salt of a fatty acid, and an accelerator for phosphate coating.

Owner:HENKEL KGAA

Mg-Zn based alloy phosphating solution and surface phosphating method

InactiveCN101709465AImprove corrosion resistanceGood adhesionMetallic material coating processesPhosphateAlloy

The invention discloses an Mg-Zn based alloy phosphating solution, which is prepared by adding 110-130 g of monopotassium phosphate, 12-18 g of potassium permanganate and 6-10 g of citric acid per liter of water. When in phosphorization film forming treatment, pretreated Mg-Zn based alloy is soaked in the Mg-Zn based alloy phosphating solution at 15-40 DEG C for 6-10 minutes; during soaking, the solution pH value is adjusted within 4.5-6.5 by using an H3PO4 adjusting solution; and then water washing is carried out. The Mg-Zn based alloy phosphating solution can enable the Mg-Zn based alloy to form a layer of phosphate conversion coating on the surface of the Mg-Zn based alloy, wherein the phosphate conversion coating has the advantages of favorable corrosion resistance and film adhesiveness, firm attachment to matrix, even surface, uniform film layer, no poisonous elements like Chrome and the like, and pollution free; and the surface phosphating process is simple with high efficiency and low cost.

Owner:ZHENGZHOU UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com