Zirconium and zirconium alloy zinc-manganese composite phosphating solution and phosphating method thereof

A technology of zirconium alloy and phosphating liquid, applied in the direction of metal material coating process, etc., can solve the problems of poor corrosion resistance and wear resistance, coarse phosphating film crystals, low phosphating film thickness, etc., to achieve both wear resistance. Excellent, low cost, stable process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

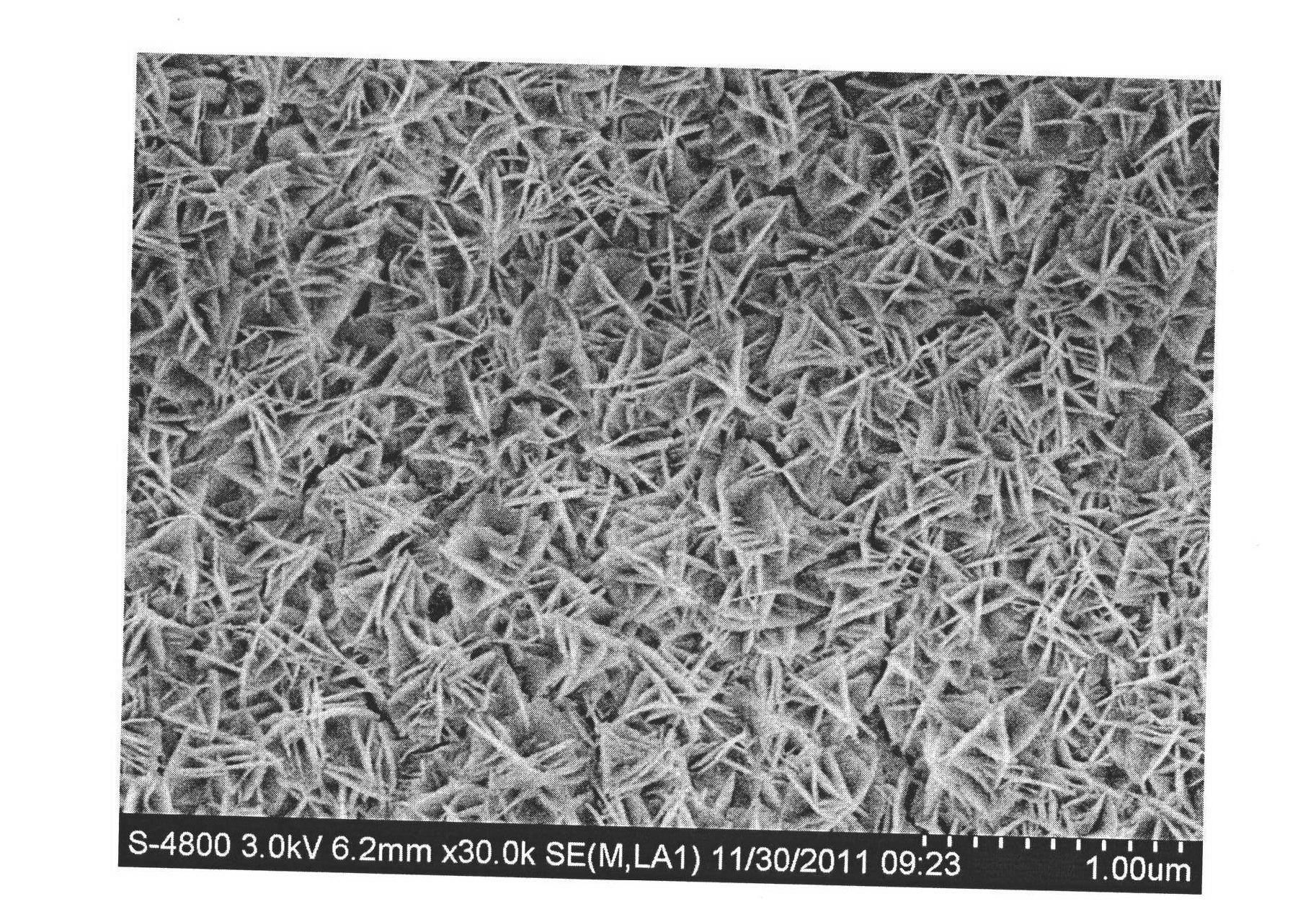

[0028] The zirconium alloy material is a Zr-Al binary alloy with an aluminum content of 8.5% (mass percentage, the same below), which is cut into a 15×25×5mm rectangular sample by wire cutting, and passed through sandpaper of 240, 500, 1000, and 1500 in sequence polished. The composition and process parameters of the zinc-manganese composite phosphating solution involved in the present embodiment are as follows:

[0029] The composition of the pickling solution is as follows: water is used as a solvent, and each liter of pickling solution contains:

[0030] 350ml nitric acid (68%); 50ml hydrofluoric acid (40%).

[0031] The composition of the phosphating solution is as follows: water is used as the solvent, and each liter of the phosphating solution contains:

[0032] 25g orthophosphoric acid, 2.5g zinc oxide, 1.5g manganese nitrate, 2g sodium nitrate, 5g sodium tartrate, 0.1g thiourea, 1.5g NaF, 1g sodium dodecylsulfonate, 10g sodium nitrobenzenesulfonate; The above reagen...

Embodiment 2

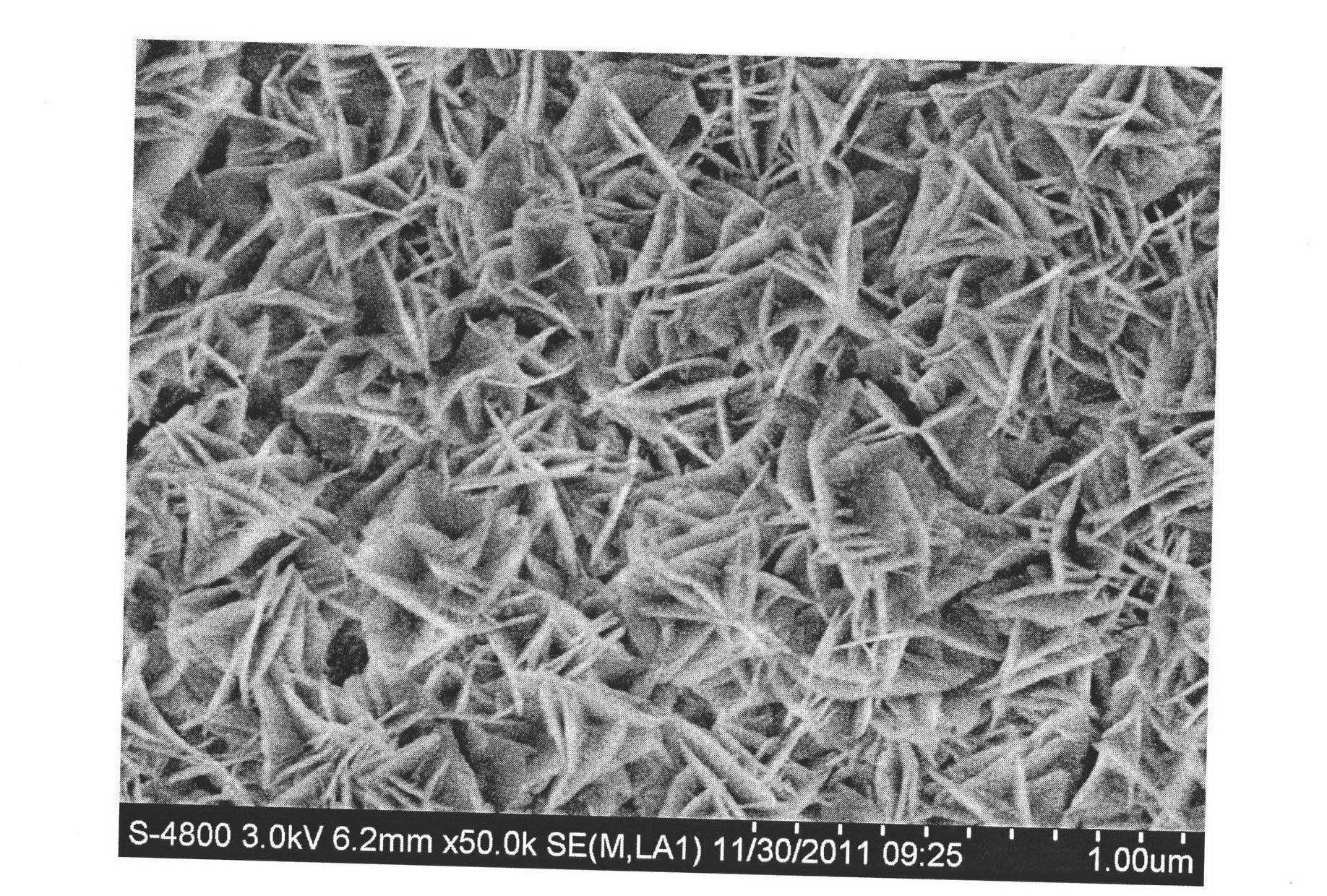

[0042] The zirconium alloy material is a Zr-Al binary alloy with an aluminum content of 8.5%, which is cut into a 15×25×5mm rectangular sample by wire, and polished with 240, 500, 1000, and 1500 sandpaper in sequence. The composition and process parameters of the zinc-manganese composite phosphating solution involved in the present embodiment are as follows:

[0043] The composition of the pickling solution is as follows: water is used as a solvent, and each liter of pickling solution contains:

[0044] 400ml nitric acid (68%, mass concentration, the same below); 100ml hydrofluoric acid (40%).

[0045] The composition of the phosphating solution is as follows: water is used as the solvent, and each liter of the phosphating solution contains:

[0046] 20g orthophosphoric acid, 3g zinc nitrate, 3g manganese dihydrogen phosphate, 4g sodium nitrate, 8g sodium citrate, 1g thiourea, 2g NaF, 5g sodium dodecylsulfonate; Mix and dilute to 1 liter.

[0047] The present embodiment zin...

Embodiment 3

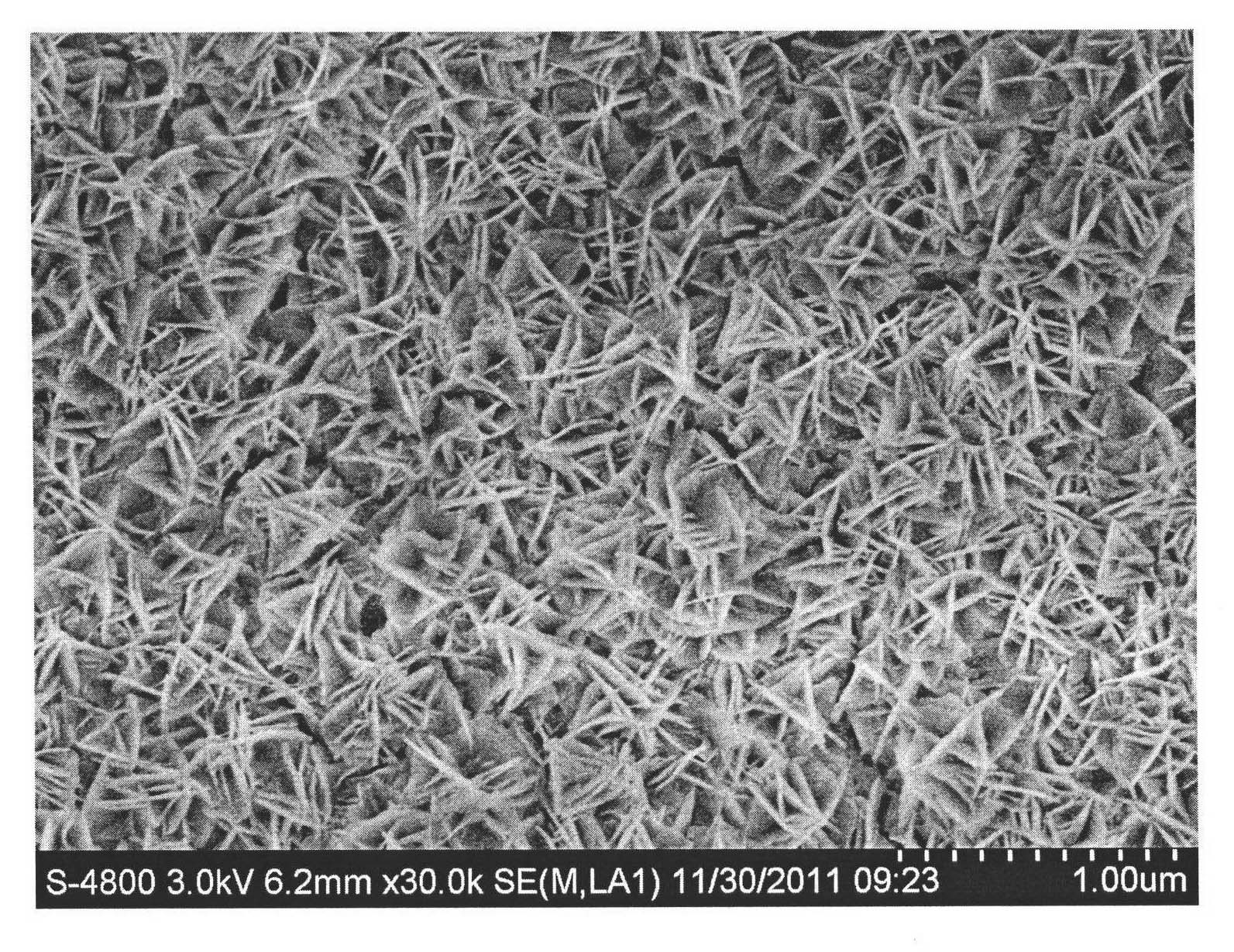

[0056]The zirconium alloy material is a Zr-Al binary alloy with an aluminum content of 8.5%, which is cut into a 15×25×5mm rectangular sample by wire, and polished with 240, 500, 1000, and 1500 sandpaper in sequence. The composition and process parameters of the zinc-manganese composite phosphating solution involved in the present embodiment are as follows:

[0057] The composition of the pickling solution is as follows: water is used as a solvent, and each liter of pickling solution contains:

[0058] 450ml nitric acid (68%); 150ml hydrofluoric acid (40%).

[0059] The composition of the phosphating solution is as follows: water is used as the solvent, and each liter of the phosphating solution contains:

[0060] 15g orthophosphoric acid, 5g zinc nitrate, 1g manganese dihydrogen phosphate, 6g sodium nitrate, 10g tartaric acid, 2g thiourea, 1.7g NaF, 1g sodium dodecyl sulfate, 6g sodium dodecylsulfonate; Dissolve each with a small amount of water, then mix and dilute to 1 li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com