Patents

Literature

495 results about "Conversion coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Conversion coatings are coatings for metals where the part‘s surface is subjected to a chemical or electro-chemical process by the coating material which converts it into a decorative or protective substance. Examples include chromate conversion coatings, phosphate conversion coatings, parkerizing, bluing, black oxide coatings on steel, and anodizing. They are used for corrosion protection, to add decorative color and as paint primers.

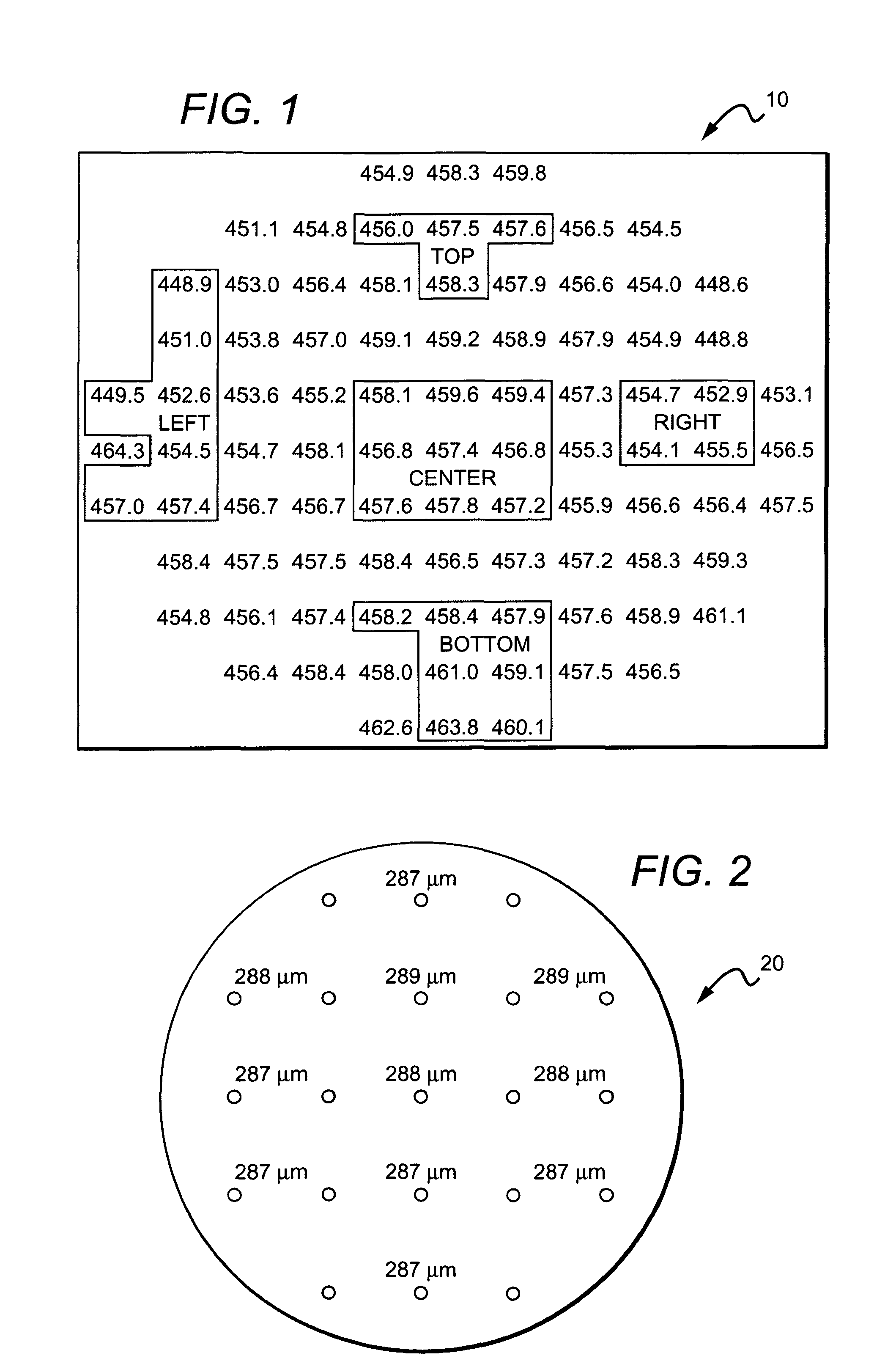

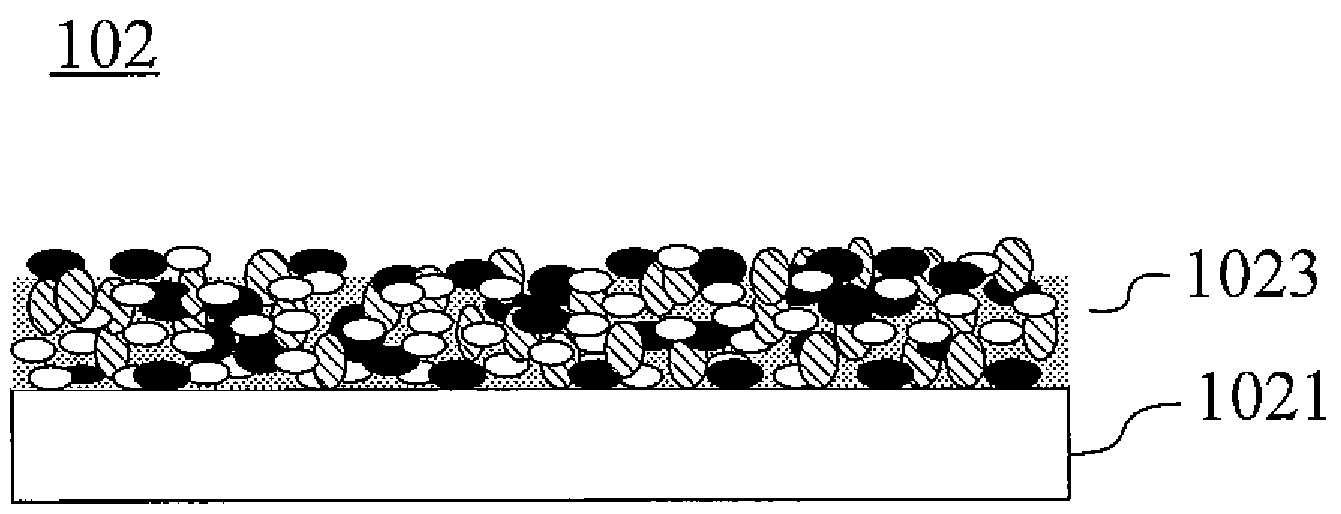

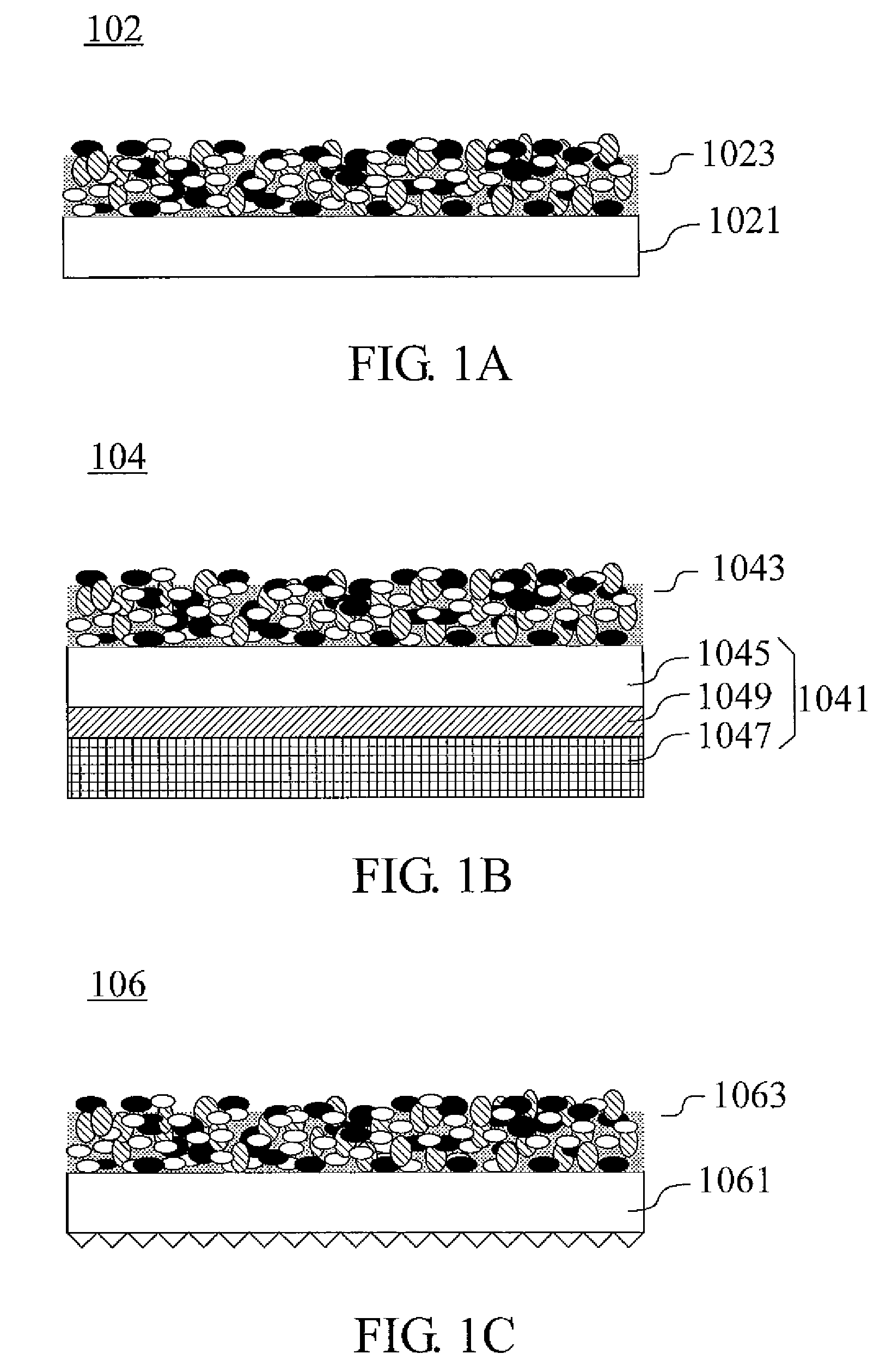

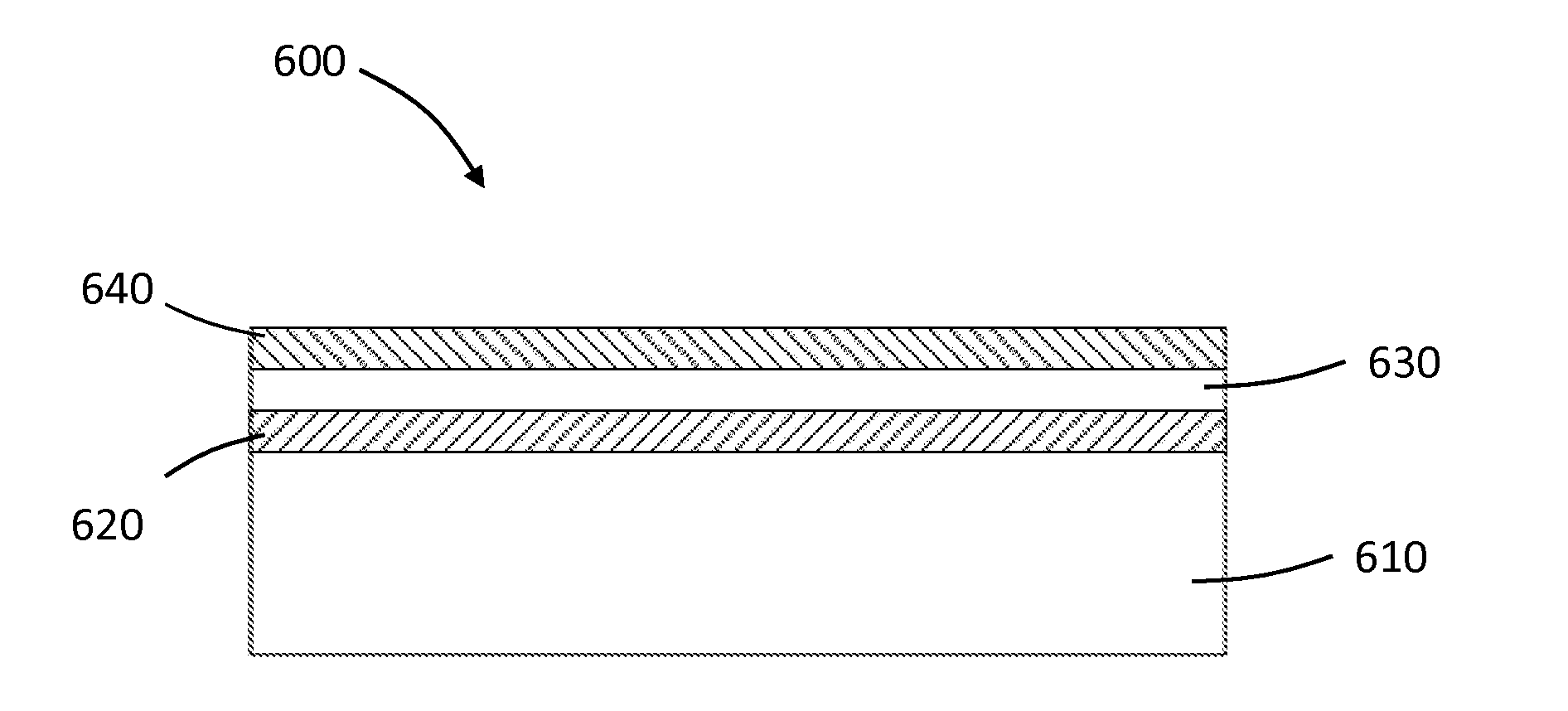

Wafer level phosphor coating technique for warm light emitting diodes

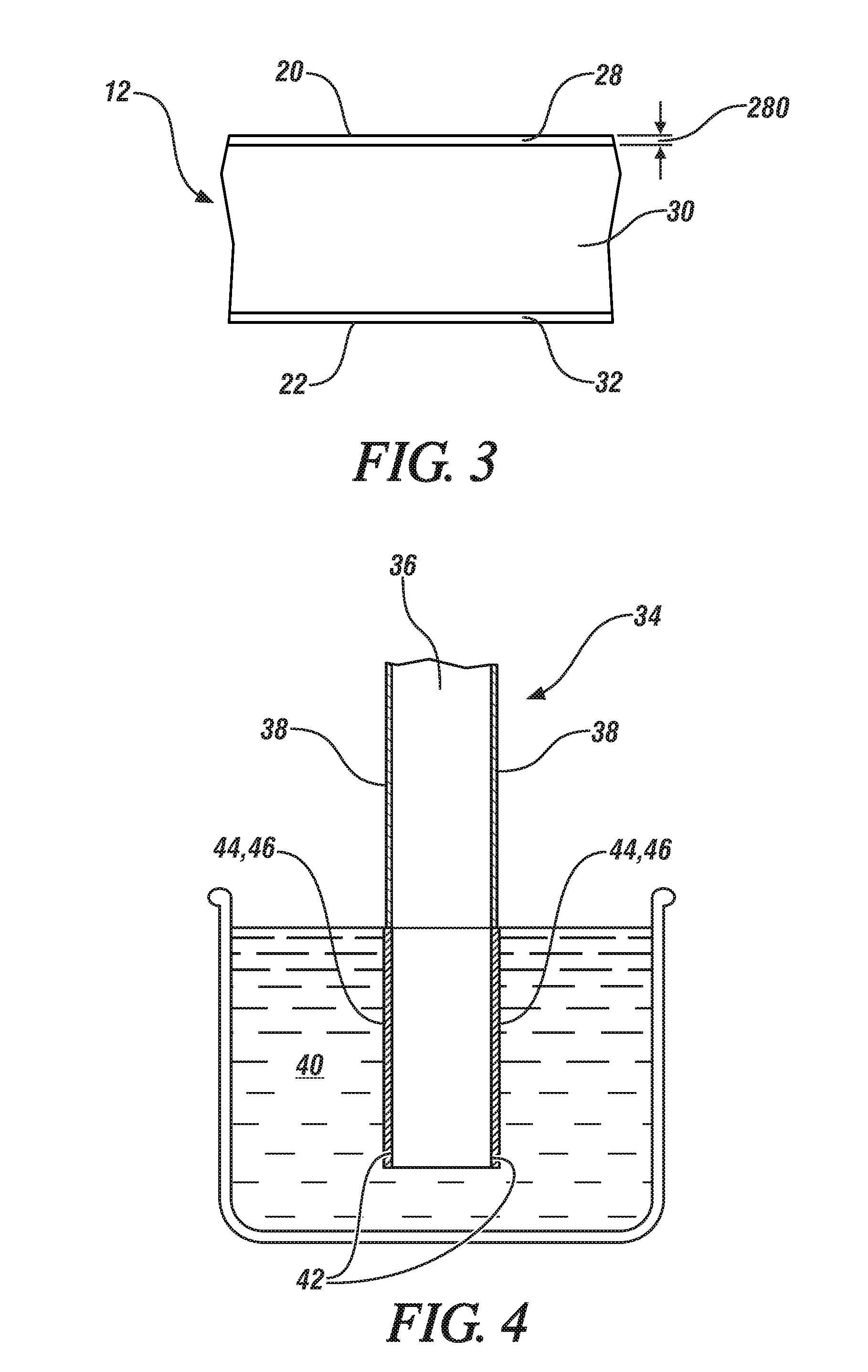

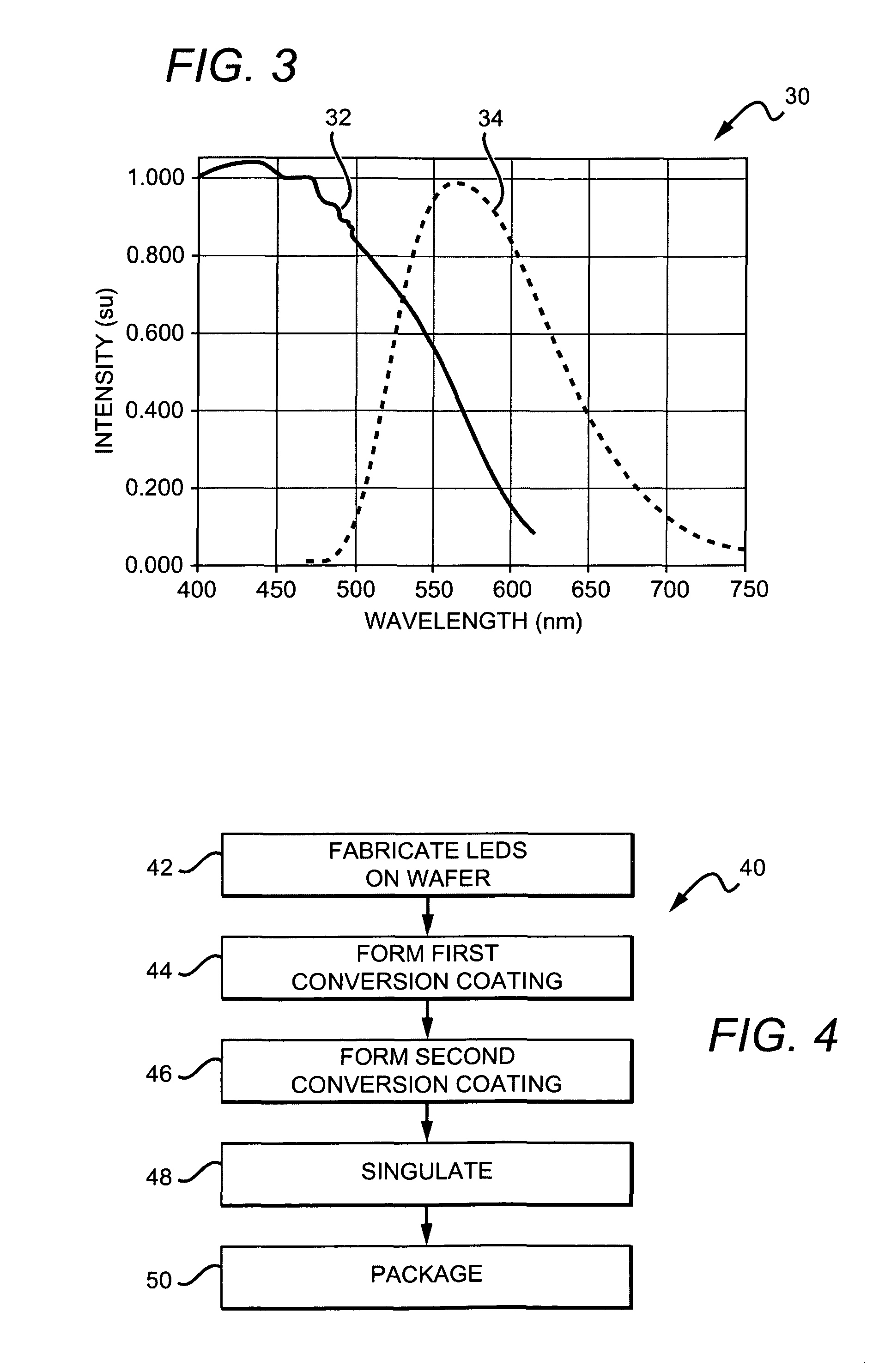

Methods for wafer level fabricating of light emitting diode (LED) chips are disclosed with one embodiment of a method according to the present invention comprising providing a plurality of LEDs and then coating of the LEDs with a layer of first conversion material so that at least some light from the LEDs passes through the first conversion material. The light is converted to different wavelengths of light having a first conversion material emission spectrum. The LEDs are then coated with a layer of second conversion material arranged on the first layer of conversion. The second conversion material has a wavelength excitation spectrum, and at least some light from the LEDs passes through the second conversion material and is converted. The first conversion material emission spectrum does not substantially overlap with the second conversion material excitation spectrum. Methods according to the present invention can also be used in wafer level fabrication of LED chips and LED packages with pedestals for electrically contacting the LEDs through the conversion coatings.

Owner:CREELED INC

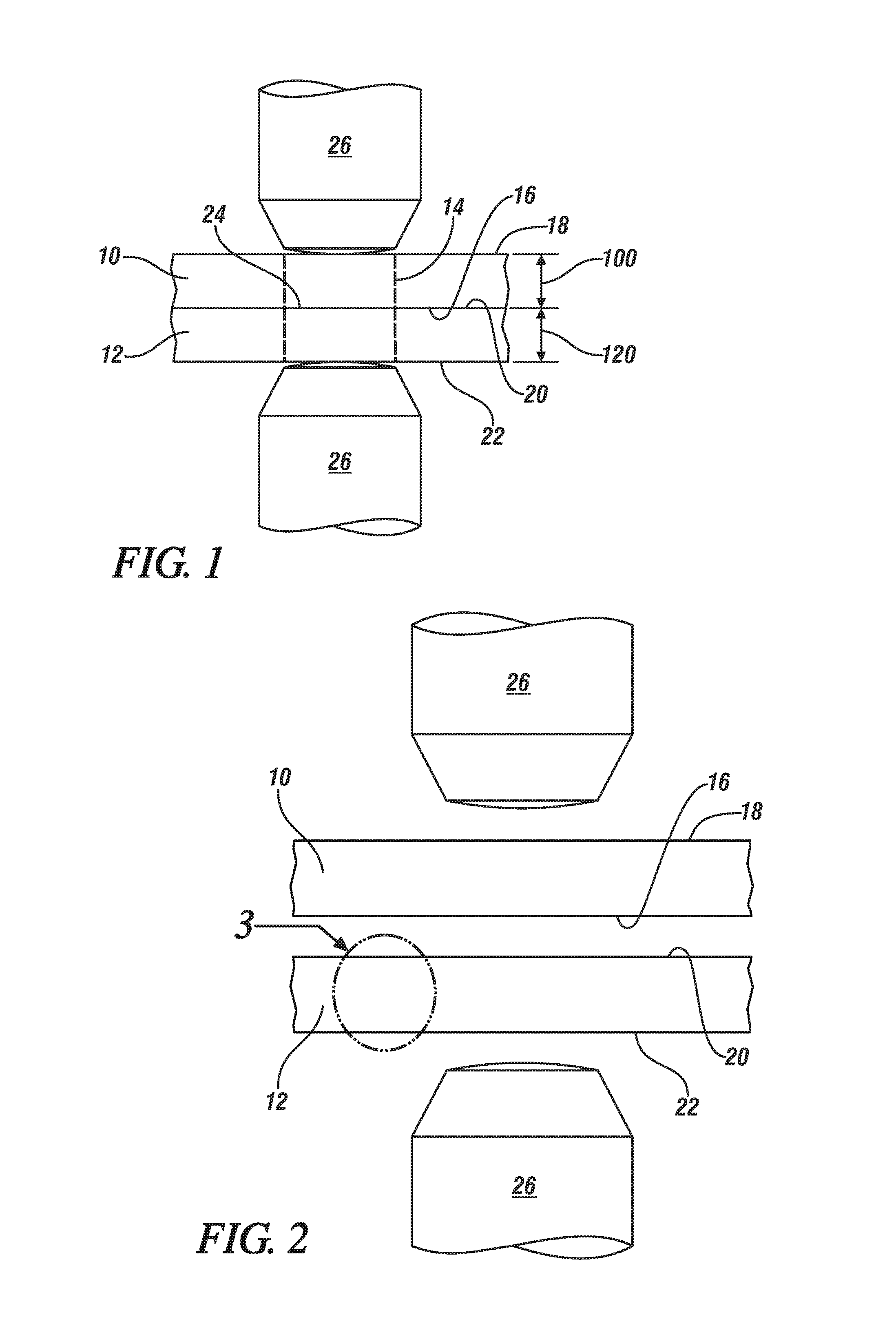

Resistance spot welding of steel to pre-coated aluminum

ActiveUS20140360986A1Low melting pointImprove the immunityWelding/soldering/cutting articlesResistance welding apparatusTitanium zirconiumConversion coating

Resistance spot welding of a steel workpiece to an aluminum or an aluminum alloy workpiece can be facilitated by replacing the refractory aluminum oxide-based layer(s) on at least the faying surface of the aluminum or aluminum alloy workpiece with a protective coating that is more conducive to the spot welding process. The protective coating may be a metallic coating or a metal oxide conversion coating. In a preferred embodiment, the protective coating is a coating of zinc, tin, or an oxide of titanium, zirconium, chromium, or silicon.

Owner:GM GLOBAL TECH OPERATIONS LLC

Environment-friendly metal surface treating agent and using method thereof

InactiveCN101701336ALarge specific surface areaStrong corrosion resistanceMetallic material coating processesStrong acidsFluoride

The invention discloses an environment-friendly metal surface treating agent and a using method thereof. The treating agent comprises fluoride, zircon salt, silane, silicon dioxide, accelerating agent, dispersing agent and stabilizing agent. A conversion coating having the advantages of being compact and even, strong in corrosion resistance and excellent in adhesive force of the coating is respectively formed on the metal surface of steel and zinc; a treatment method of the metal surface treating agent is simple and is operated at the normal temperature; the original phosphating treatment equipment can be used without any change; and strong acid and strong base are not used as the treating agent; therefore, the environment-friendly metal surface treating agent is safe in production without emission, and is the best substitute product of the phosphating treatment technique and an energy-saving type environment-friendly product.

Owner:芜湖市瑞杰环保材料科技有限公司

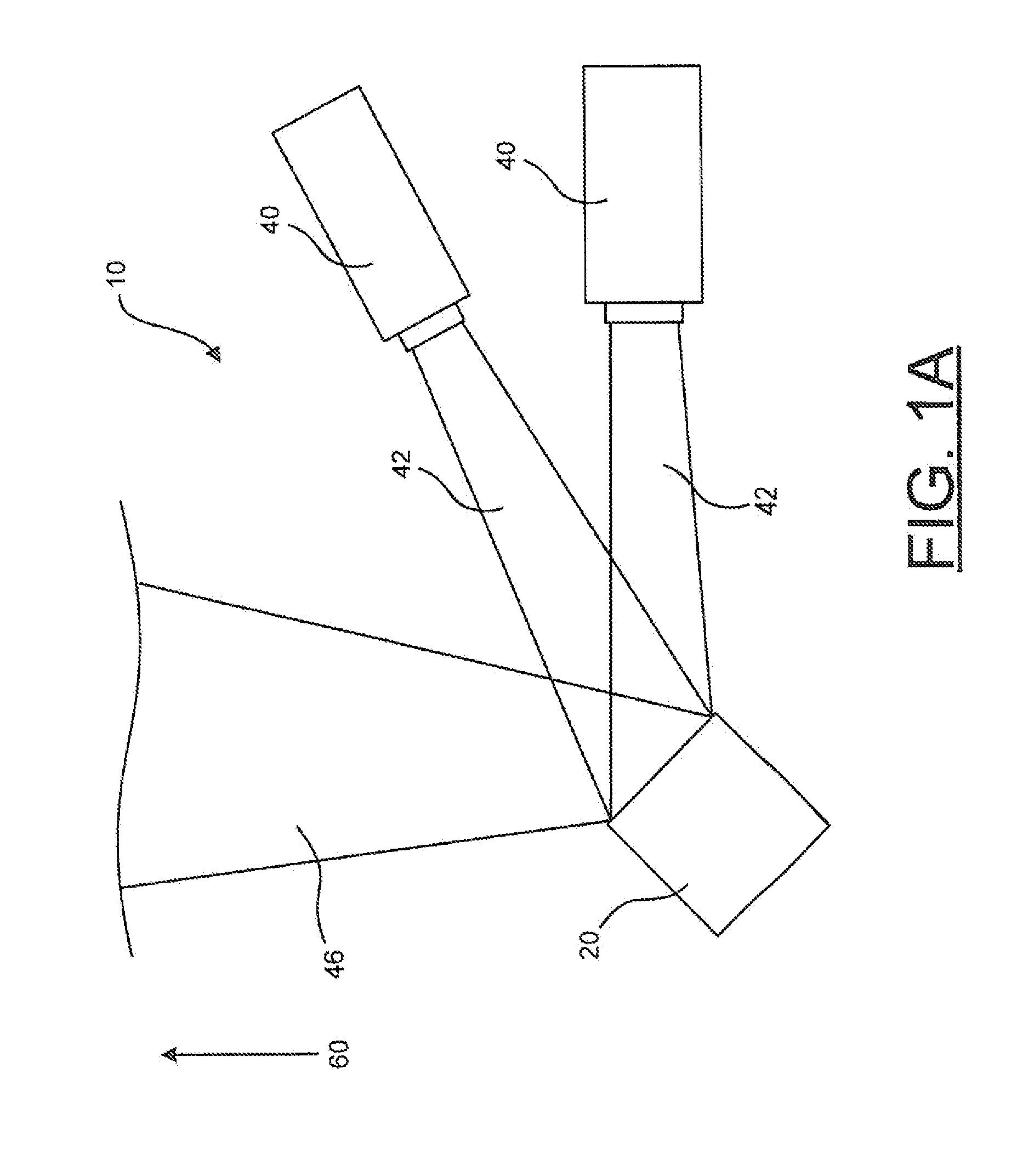

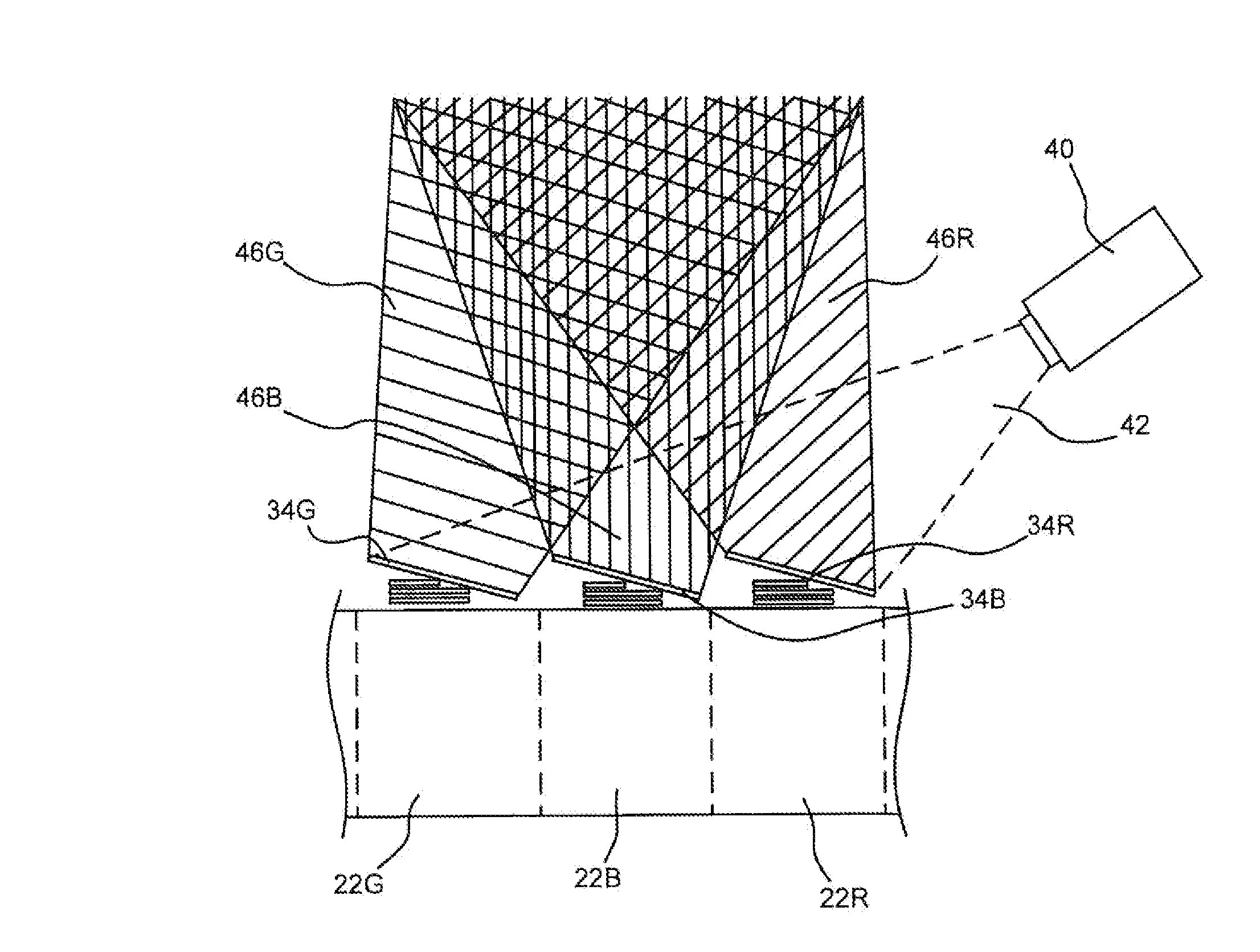

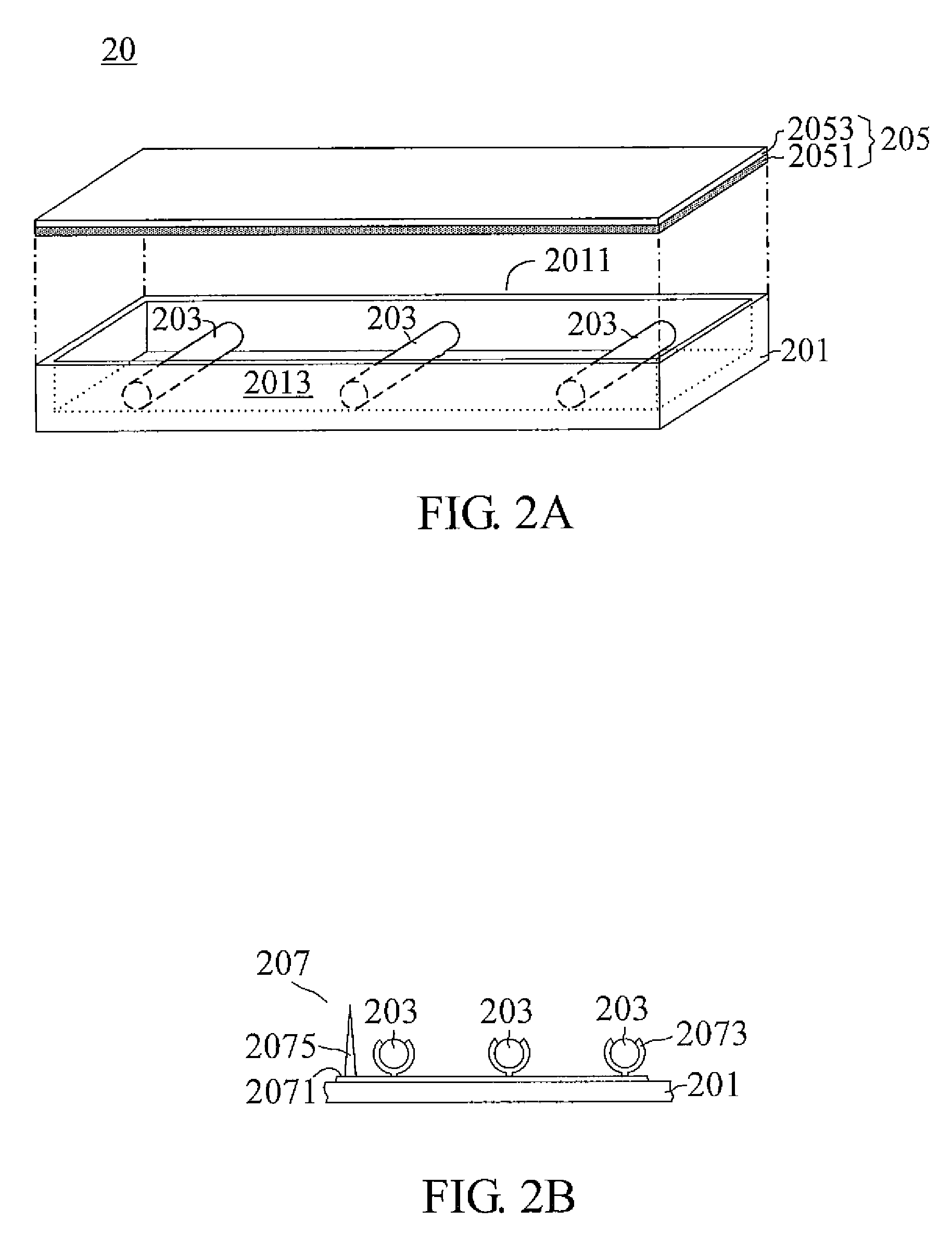

MEMS wavelength converting lighting device and associated methods

ActiveUS20120250137A1Reduce complexitySmall sizeColor television detailsOptical elementsLight equipmentEffect light

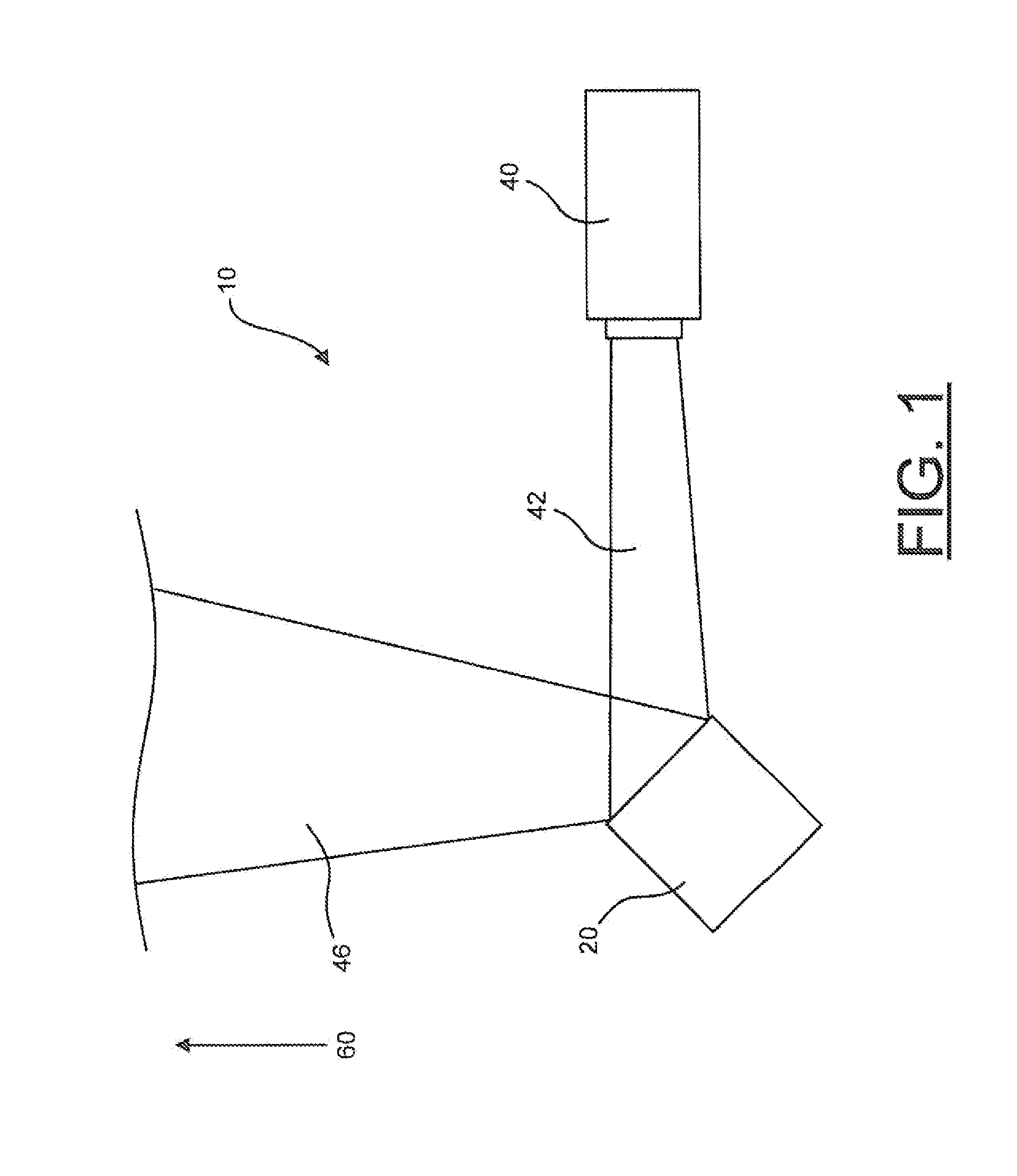

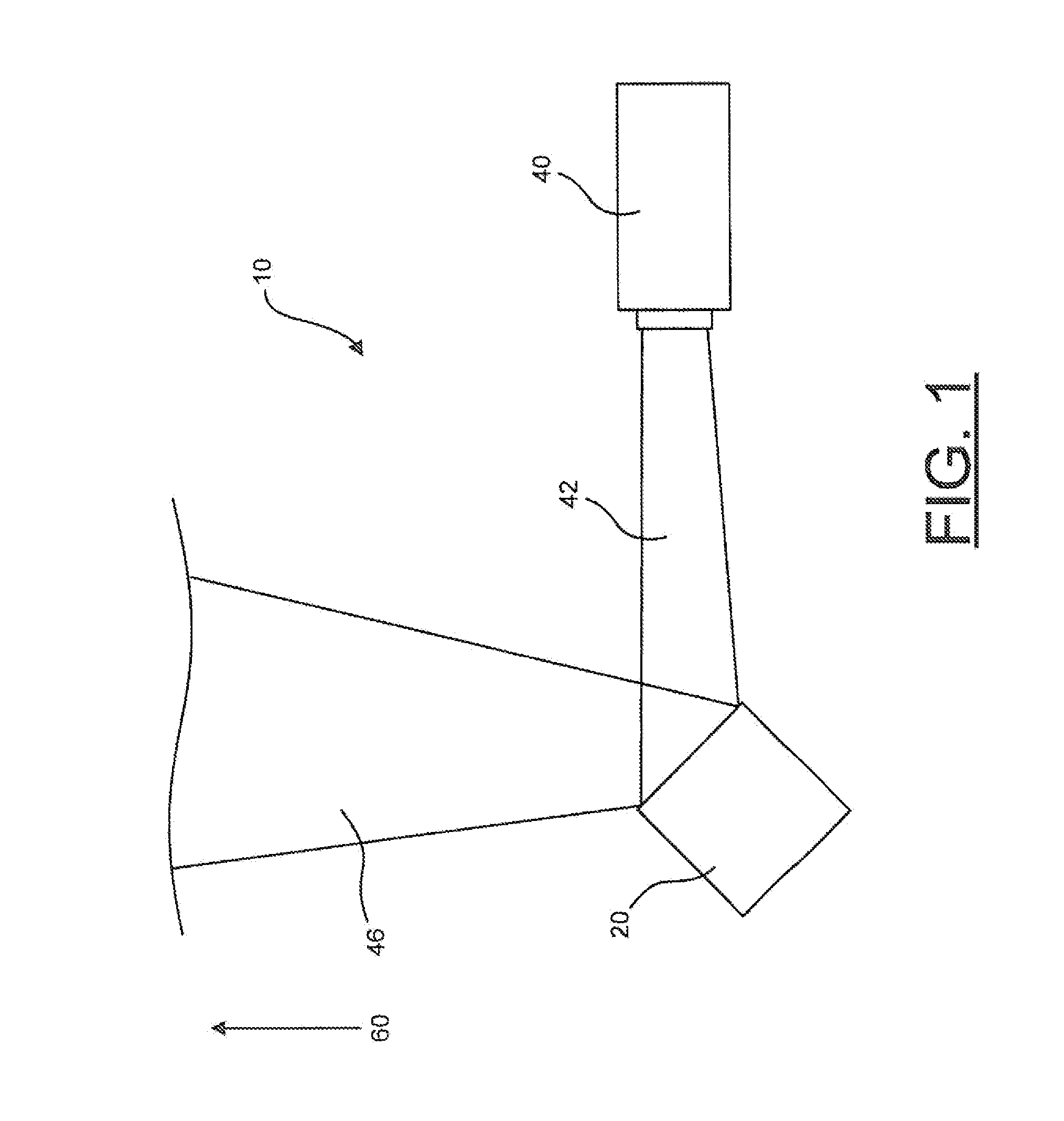

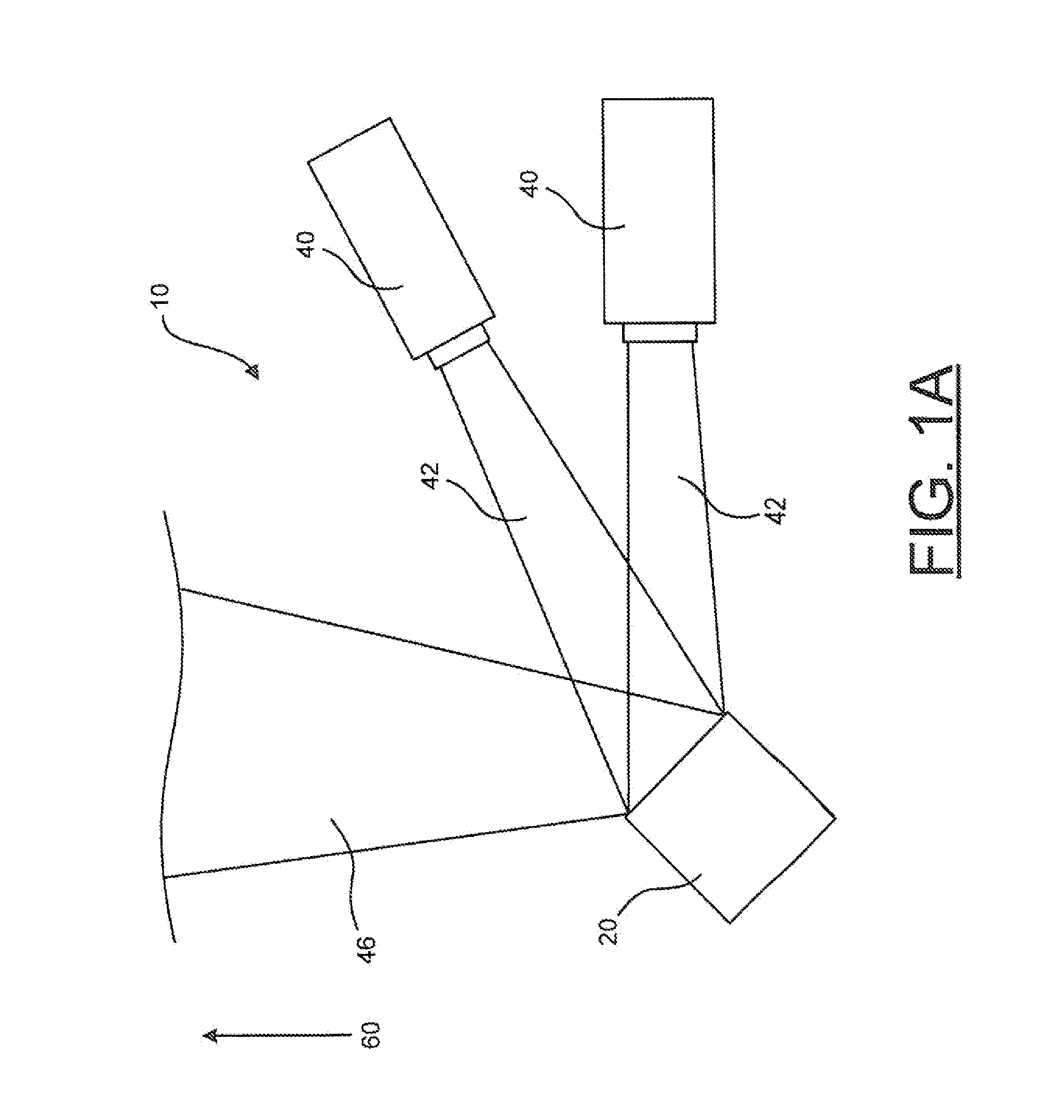

A lighting device is described for receiving source light within a predetermined source wavelength range, converting the source light into a converted light, and reflecting the converted light to a desired output direction. The lighting device may use a micro electromechanical system (MEMS) device to receive and redirect the source light to the desired output direction. A conversion coating may be applied to the operative surface of the MEMS device to convert the source light into a converted light.

Owner:HEALTHE INC

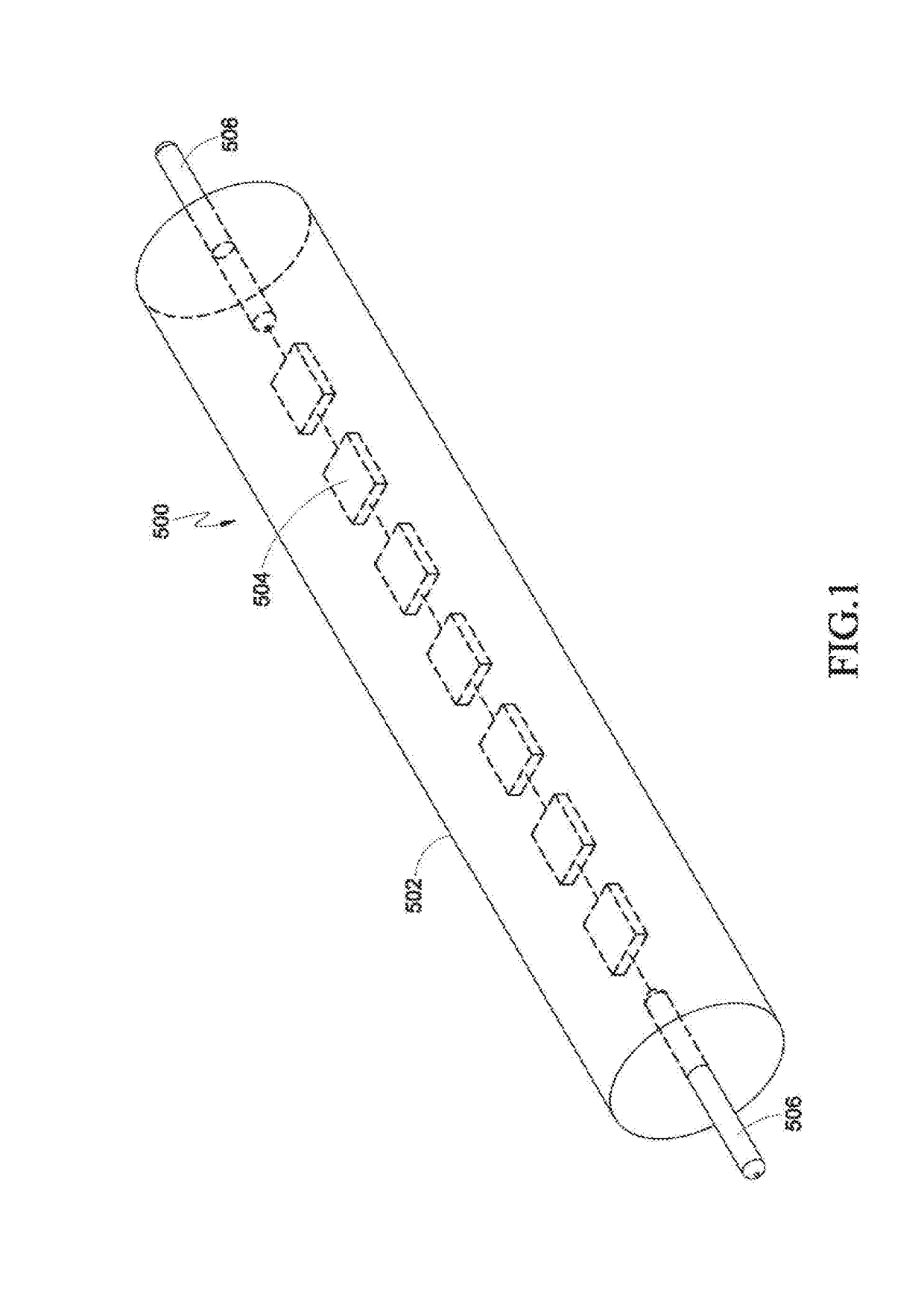

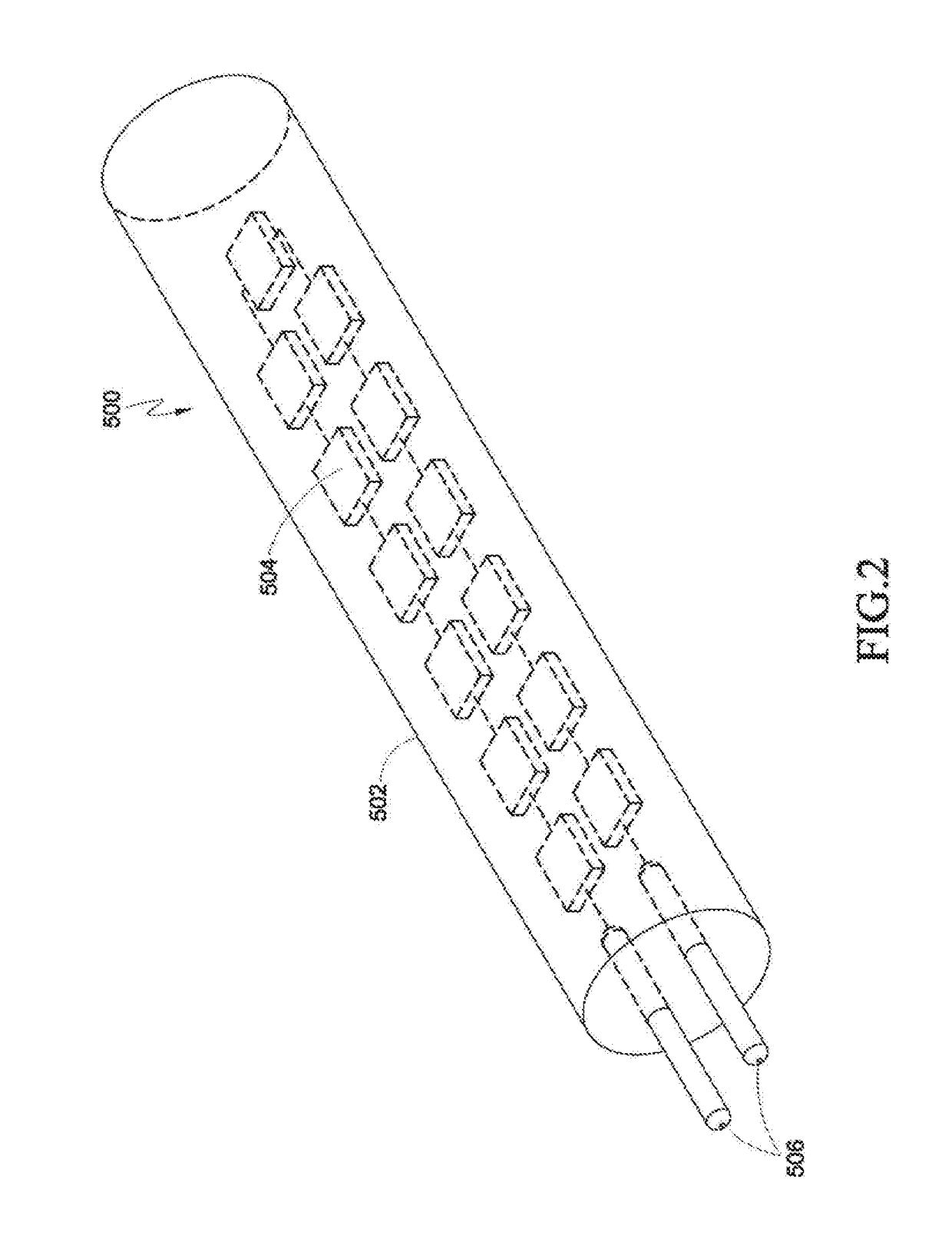

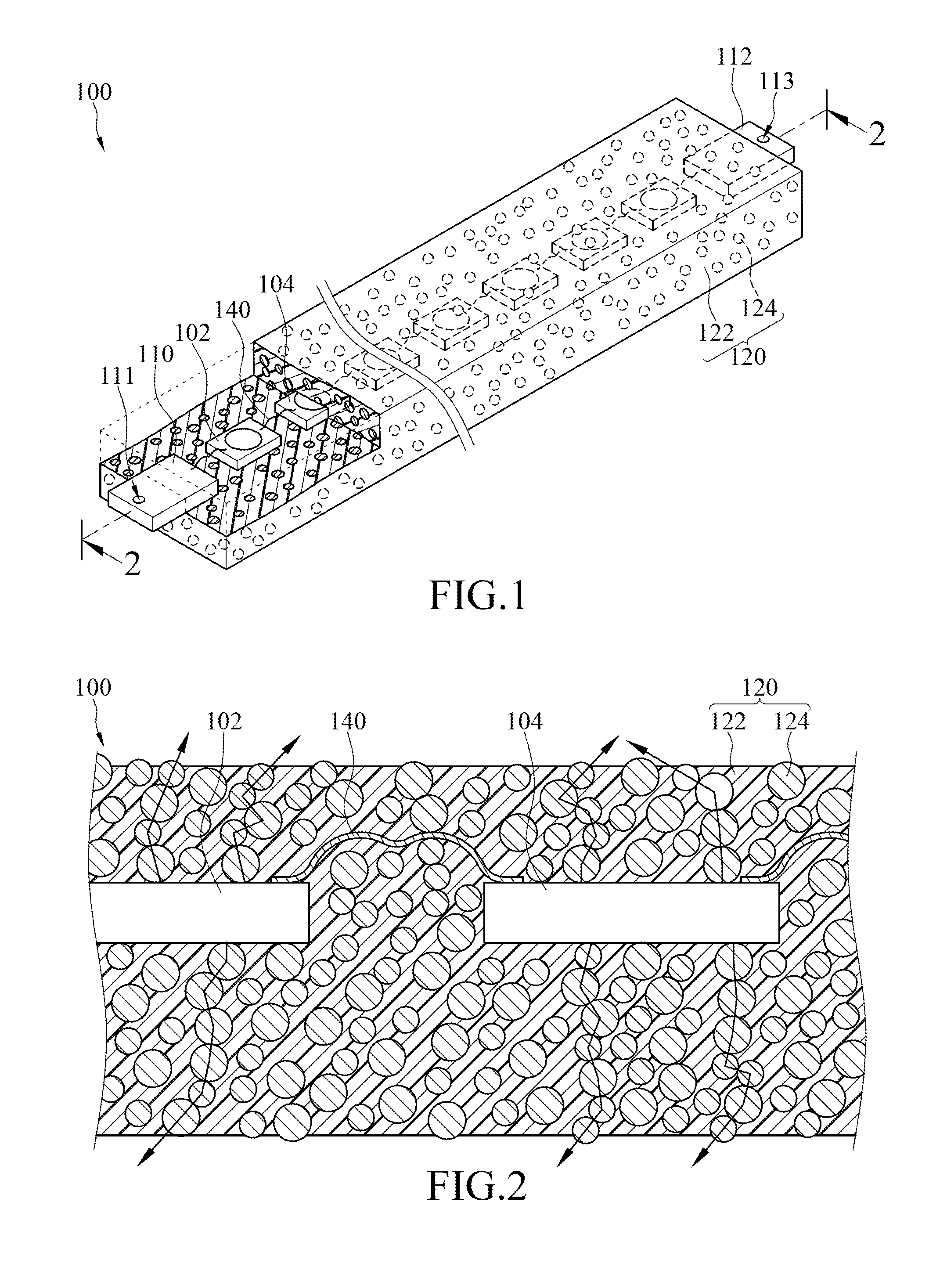

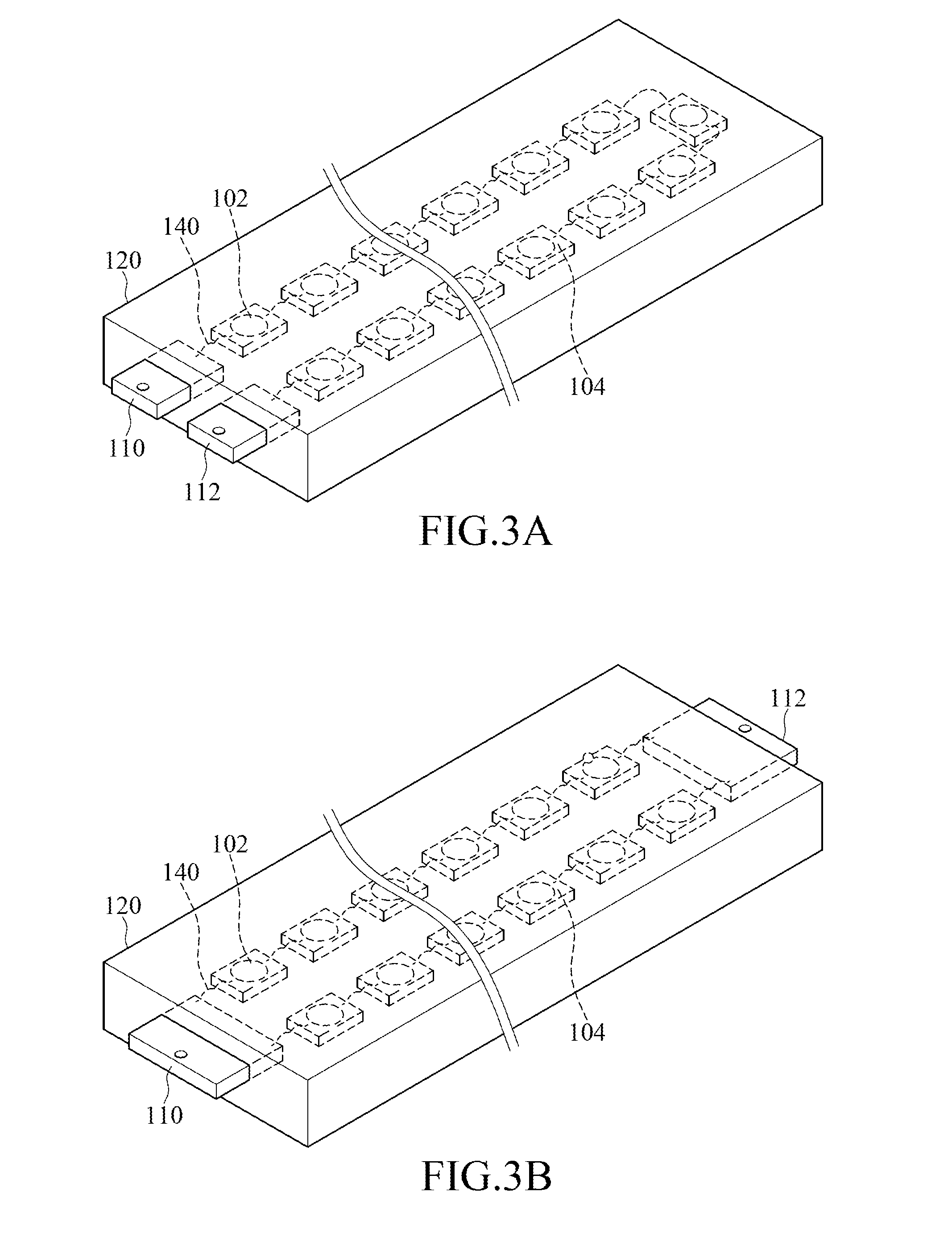

LED filament

ActiveUS20170130906A1Improve energy efficiencyEasy to useElongate light sourcesElectric circuit arrangementsEngineeringLED filament

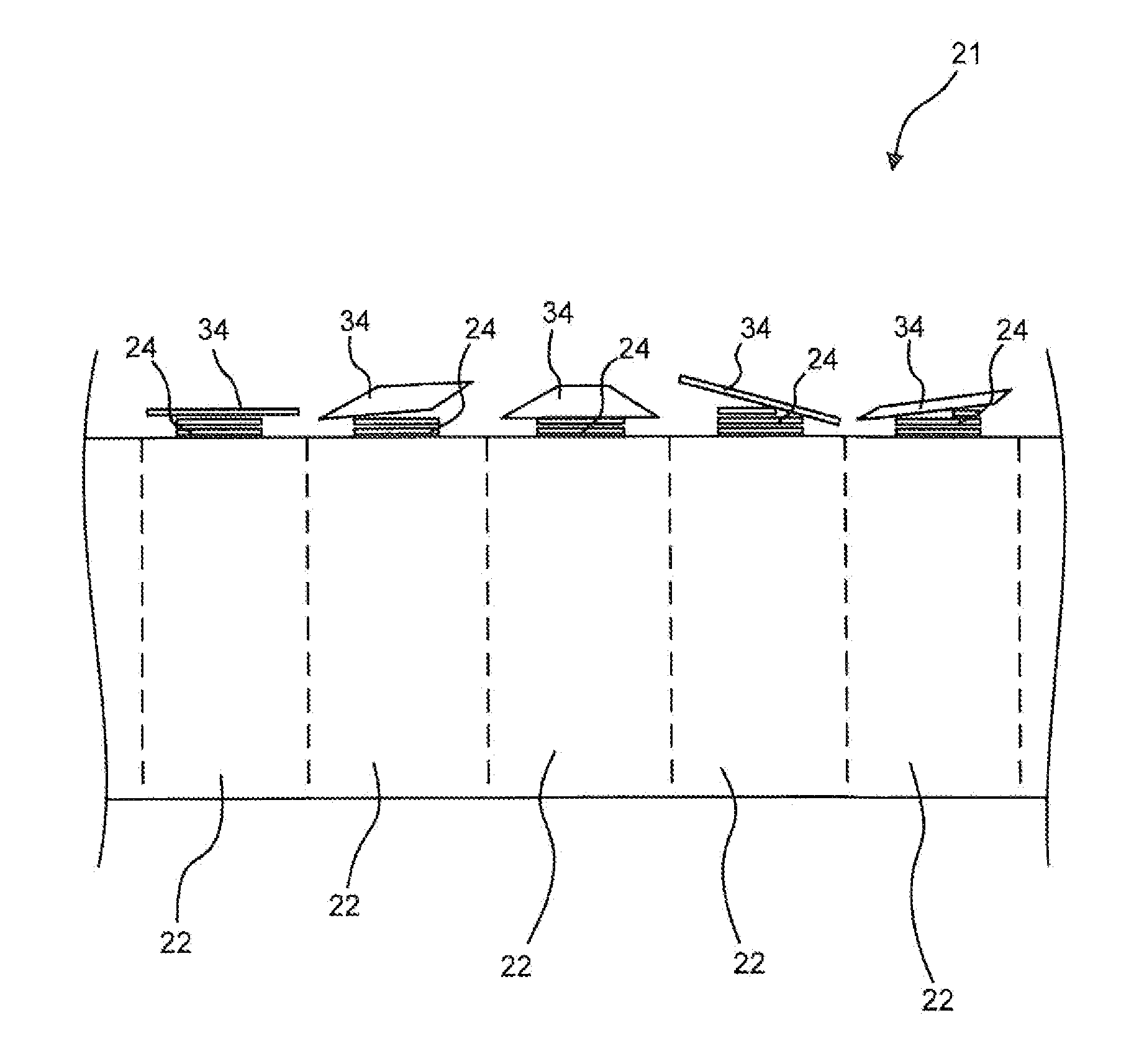

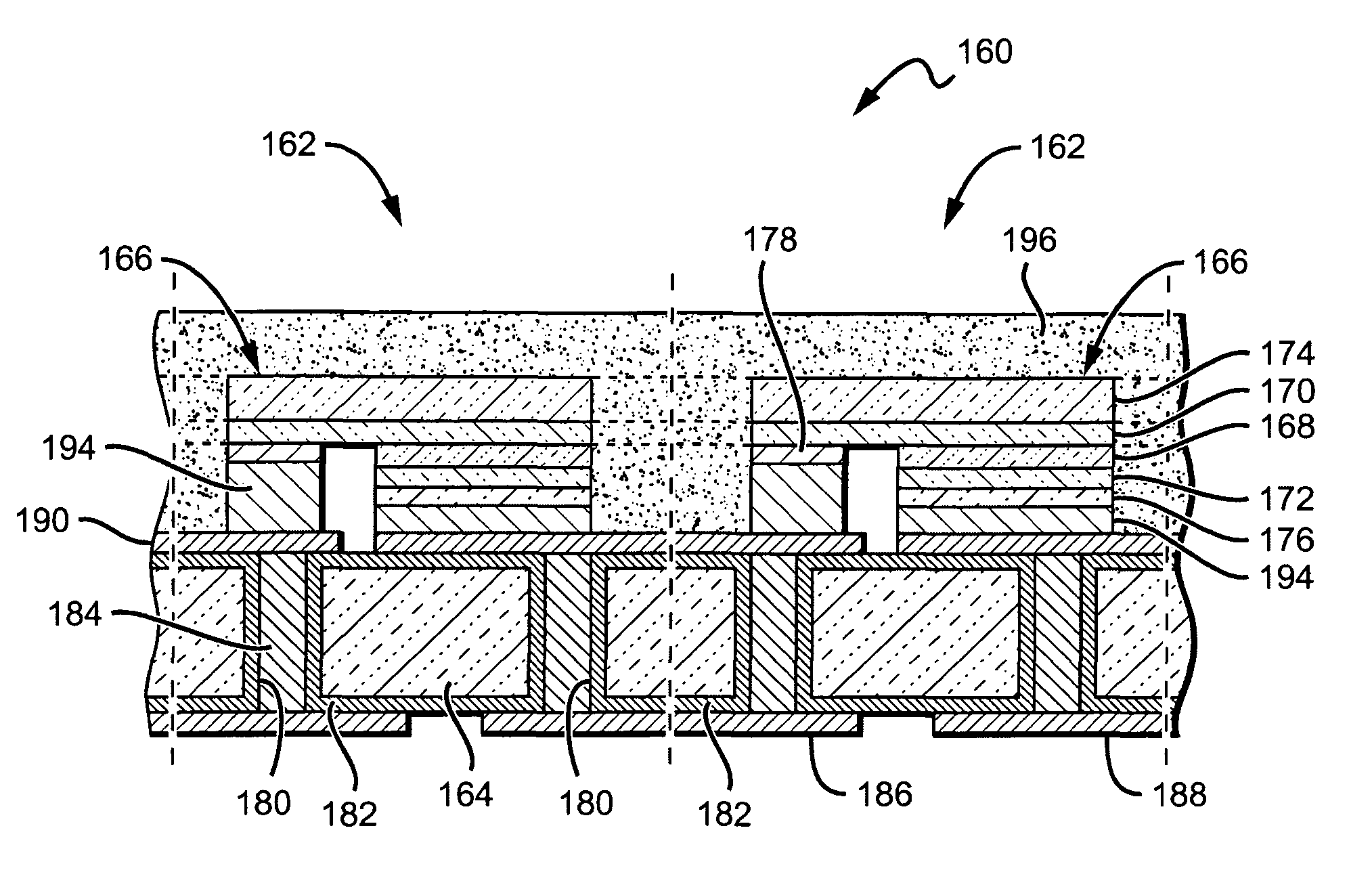

An LED filament configured to emit omnidirectional light includes a linear array of LED chips operably interconnected to emit light upon energization and a conductive electrode. The linear array of LED chips is electrically connected with the conductive electrode. A light conversion coating encloses the linear array of the LED chip and the conductive electrode. The light conversion layer includes a top layer and a base layer conformally interconnected to form a unitary enclosure. The top layer is coated on a first side of the linear array of LED chips and the conductive electrode. The base layer is coated on a second side of the linear array of LED chips and the conductive electrode.

Owner:ZHEJIANG SUPER LIGHTING ELECTRIC APPLIANCE

Use of Cathodic Protection Compounds on Treated Metal Articles

A cathodic protection coating is disclosed that unexpectedly protects a treated metal substrate, notwithstanding the presence of a phosphate-containing conversion coating between the metal substrate and the cathodic protection compound. The cathodic protection coating includes sacrificial metallic particles less noble than metal in the metal substrate to be protected. The coating also includes inherently conductive polymer.

Owner:AVIENT CORP

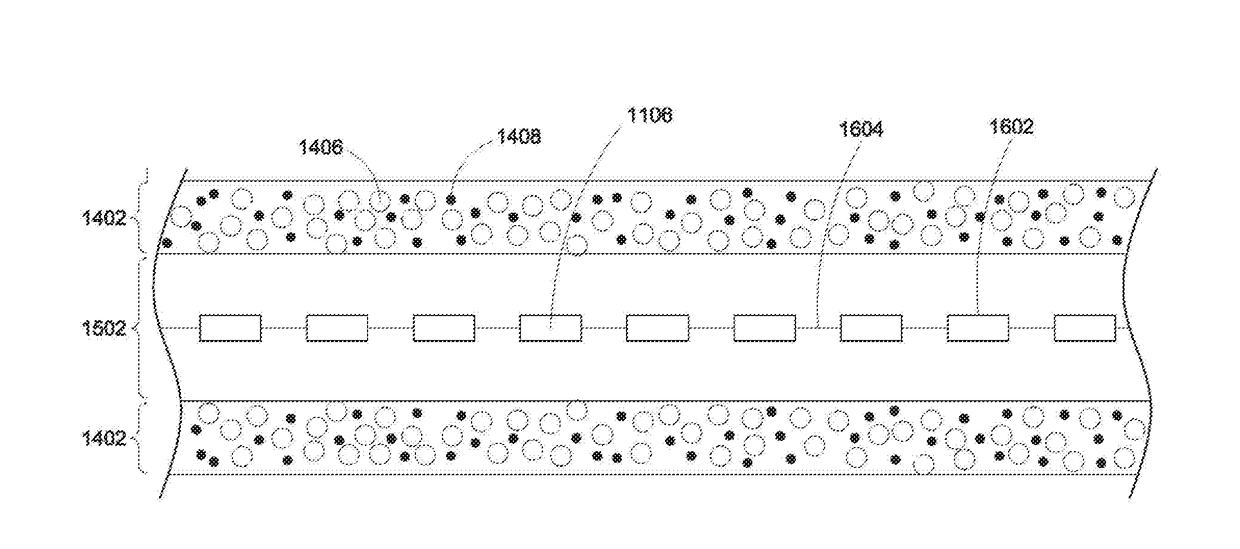

Quantum dot/acrylate polymer nanocrystal complex, preparation method of quantum dot/acrylate polymer nanocrystal complex, and colored conversion coating

ActiveCN103772872AGood dispersionEvenly dispersedPhotomechanical coating apparatusPhotosensitive materials for photomechanical apparatusPhotoluminescenceResin matrix

The invention discloses a quantum dot / acrylate polymer nanocrystal complex, a preparation method of the quantum dot / acrylate polymer nanocrystal complex, and a colored conversion coating, wherein the quantum dot / acrylate polymer nanocrystal complex is prepared by virtue of electrostatic interaction between an annion acrylate polymer and quantum dots with opposite charges. According to the invention, the quantum dots are pre-dispersed into the acrylate polymer, so as to prepare quantum dot / acrylate polymer nanocrystal complex. By virtue of similar composition of an acrylate polymer protection layer and acrylics as well as an acrylics modified photoresist resin matrix, the quantum dots can be easily dispersed into photoresist, are not easy to separate and are uniformly dispersed without aggregation, and thus the photoluminescent characteristic of the quantum dots is ensured. After the colored conversion coating prepared from the quantum dot / acrylate polymer nanocrystal complex is applied to a display, the colors of sub-pixel units of R / G / B colors corresponding to the colored conversion coating are relatively pure and have the relatively high saturability, energy of a backlight is sufficiently utilized, and the luminous efficiency is relatively high.

Owner:TCL CORPORATION

Metal surface vitrification agent and application method thereof

ActiveCN102747355AImprove corrosion resistanceStrong impact resistanceMetallic material coating processesSilanesConversion coating

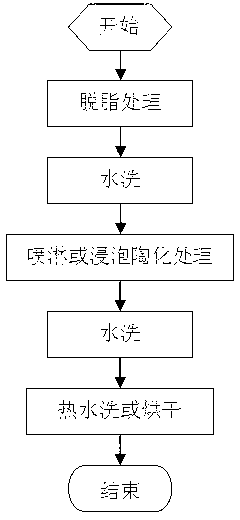

The invention provides a metal surface vitrification agent and an application method thereof, aiming for solving the problem of possibility of environmental pollution caused by waste water discharge in a treatment process or after treatment in the existing metal surface phosphating treatment technology. According to the invention, the metal surface vitrification agent comprises 2.0-38.0% of zirconium titanium salt, 0.1-8.0% of silane, 0.5-18.0% of a buffer agent, 0.01-5.00% of film forming assistant, 0.1-6.1% of an anti-rust agent and 0.2-7.0% of a complexing agent, wherein the surface appearance is clear transparent liquid and no suspended matter exists; pH value is 1-2, and the specific gravity is 1.05+ / -0.02 g / cm<3>. The metal surface vitrification agent has the advantages that an embedded hybrid indissolvable nanometer ceramic conversion coating is formed on the metal surface at normal temperature and is excellent in impact resistance, the adhesion force of the coating is improved, and the corrosion resistance of the metal surface is enhanced. In addition, the metal surface vitrification agent, provided by the invention, contains no component capable of causing environmental pollution, and can be directly discharged without environmental pollution.

Owner:CHOGNQING CHANGYU METAL SURFACE TREATMENT TECH

Process for treating metal surfaces

ActiveUS20080280046A1Pretreated surfacesMetallic material coating processesHydrofluoric acidAqueous solution

The corrosion resistance of a metal substrate surface treated with an acidic aqueous composition to form a conversion coating is improved by first contacting the surface with an oxidizing acidic pre-rinse, such as an aqueous solution of nitric acid and hydrogen peroxide, or nitric acid and hydrofluoric acid, or Fe+3 cations and hydrofluoric acid.

Owner:HENKEL KGAA

Treating fluid and method for preparing vanadium-zirconium composite conversion coatings with self-repairing performance on aluminum alloy surfaces through same

ActiveCN102766862AImprove corrosion resistanceGuaranteed stabilityMetallic material coating processesMetallic bondingSodium fluoride

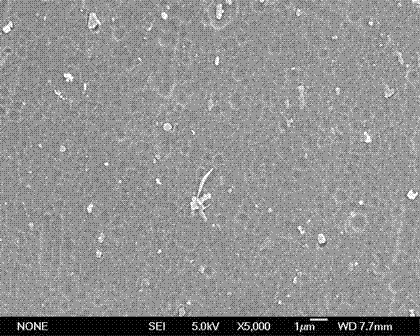

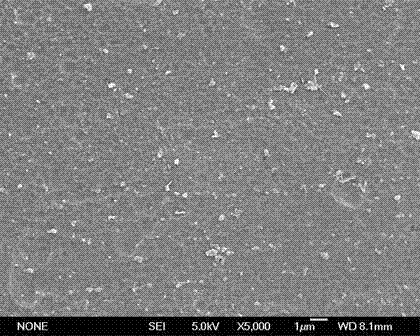

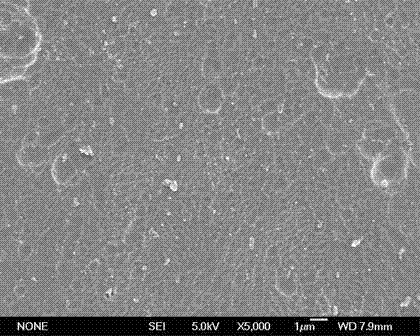

The invention belongs to the technical field of chemical materials, and relates to a treating fluid and a method for preparing vanadium-zirconium composite conversion coatings with self-repairing performance on aluminum alloy surfaces through the same. The method includes the steps of firstly preparing the treating fluid containing fluorozirconate, metavanadate, sodium fluoride, nitrate, an accelerate and an additive; then putting an aluminum alloy after surface pretreatment into a working fluid made of the diluted treating fluid for 2min-10min; and finally subjecting the aluminum alloy to washing, drying and cooling to obtain the vanadium-zirconium composite conversion coatings. The preparation process is simple, heavy metals such as hexavalent chromium and nickel are not contained, the environment is friendly, the conversion coatings of the aluminum alloy after a conversion coating treatment are dense and high in binding force, metal ions in the conversion coatings can bond with base metal under a corrosion environment and provided with a certain self-repairing performance, and the treating technology of vanadium-zirconium conversion coatings can effectively replace chromate treatment on aluminum alloy surfaces.

Owner:湖南松井先进表面处理与功能涂层研究院有限公司

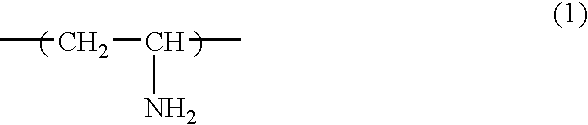

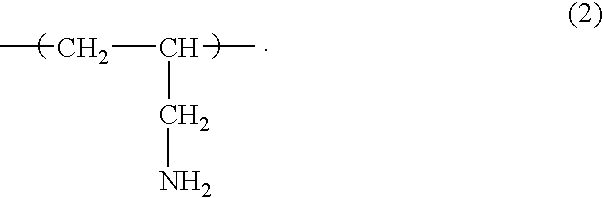

Chemical conversion coating agent and surface-treated metal

ActiveUS7510612B2Reduce environmental impactConvenient treatmentOther chemical processesSolid state diffusion coatingHafniumWater soluble

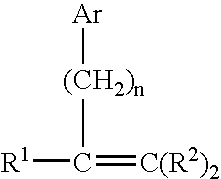

The present invention disclosure provides a chemical conversion coating agent which places a less burden on the environment and can apply good chemical conversion treatment to all metals such as iron, zinc and aluminum, and a surface-treated metal obtained using the same. The chemical conversion coating agent comprising: at least one kind selected from the group consisting of zirconium, titanium and hafnium; fluorine; and a water-soluble resin, wherein said water-soluble resin has, in at least a part thereof, a constituent unit expressed by the chemical formula (1):and / or the chemical formula (2):

Owner:NIPPON PAINT CO LTD

MEMS wavelength converting lighting device and associated methods

ActiveUS8384984B2Reduce complexityReduce expensesColor television detailsOptical elementsLight equipmentConversion coating

Owner:HEALTHE INC

Conversion coating compositions

InactiveUS6764553B2Reduce the smellExcellent characteristicsOther chemical processesSolid state diffusion coatingVanadium CompoundsHydrophilic coating

Owner:HENKEL KGAA

Process for treating steel-, zinc- and aluminum-based metals using a two-step coating system

InactiveUS6733896B2Effective treatmentPretreated surfacesSolid state diffusion coatingZinc phosphateCeramic composite

The present invention comprises a method for treating one or more multi-metal articles. The method comprises exposing the one or more articles to a first treatment composition capable of providing a conversion coating on steel- and zinc-based metal, and exposing the one or more articles to a second treatment coating composition suitable for providing a conversion coating on aluminum-based metal articles. Preferably, the first treatment composition comprises a zinc-phosphate conversion coating comprising, zinc ion, phosphate ion, manganese ion, and fluoride ion. Preferably, the second treatment composition comprises a ceramic composite treatment composition.

Owner:HENKEL KGAA

Water-based rust conversion paint and preparation method thereof

InactiveCN105062245AGood conversion effectImprove corrosion resistanceAnti-corrosive paintsWater basedEmulsion

The invention discloses a water-based rust conversion paint and a preparation method thereof. For an existing rust conversion coating, a commonly used rust converting agent is acidic, and an acidic condition is required for an iron rust conversion process. The acidic rust converting agent can damage the stability of a commonly used alkaline emulsion. The water-based rust conversion paint comprises the components of, by mass, 30-47 parts of an aqueous polymer emulsion, 2-12 parts of a rust converting agent, 3-17 parts of a coloring pigment, 3-20 parts of an anti-rust pigment, 4-8 parts of a filler, 0.1-0.5 part of a deforming agent, 0.1-1 part of a dispersing agent, 0.5-4 parts of a film coalescing aid, 0.1-2 parts of an emulsion stabilizer, 0.1-0.5 part of a thickeners, 0.1-0.5 part of a mildew preventive, and 10-35 parts of water. The paint has good stability, and excellent rust layer conversion effect. A coating formed with the paint has good corrosion resistance. The paint is suitable for steel rusty surface rust conversion and corrosion prevention, and is mainly used as a primer.

Owner:STATE GRID CORP OF CHINA +2

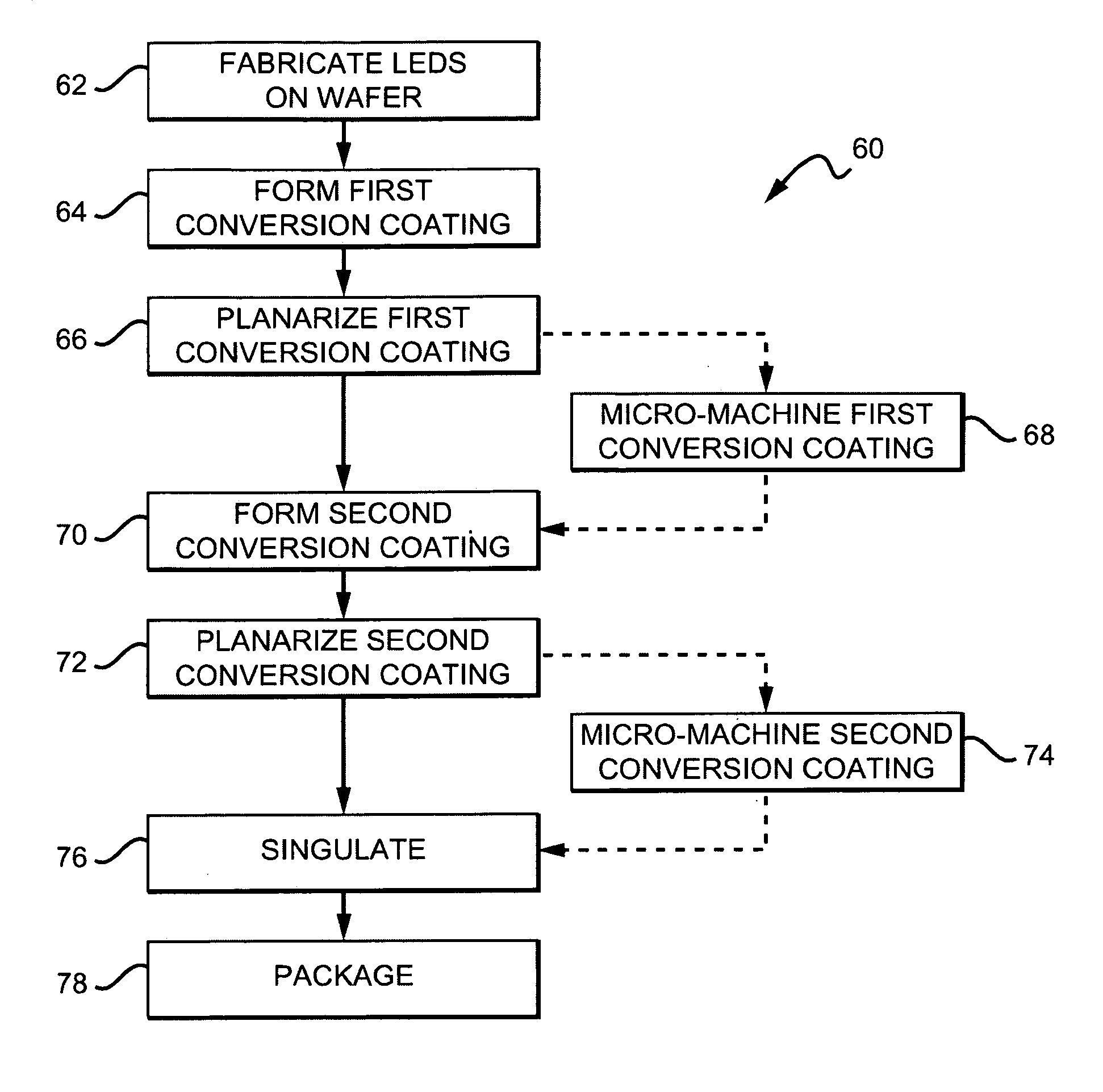

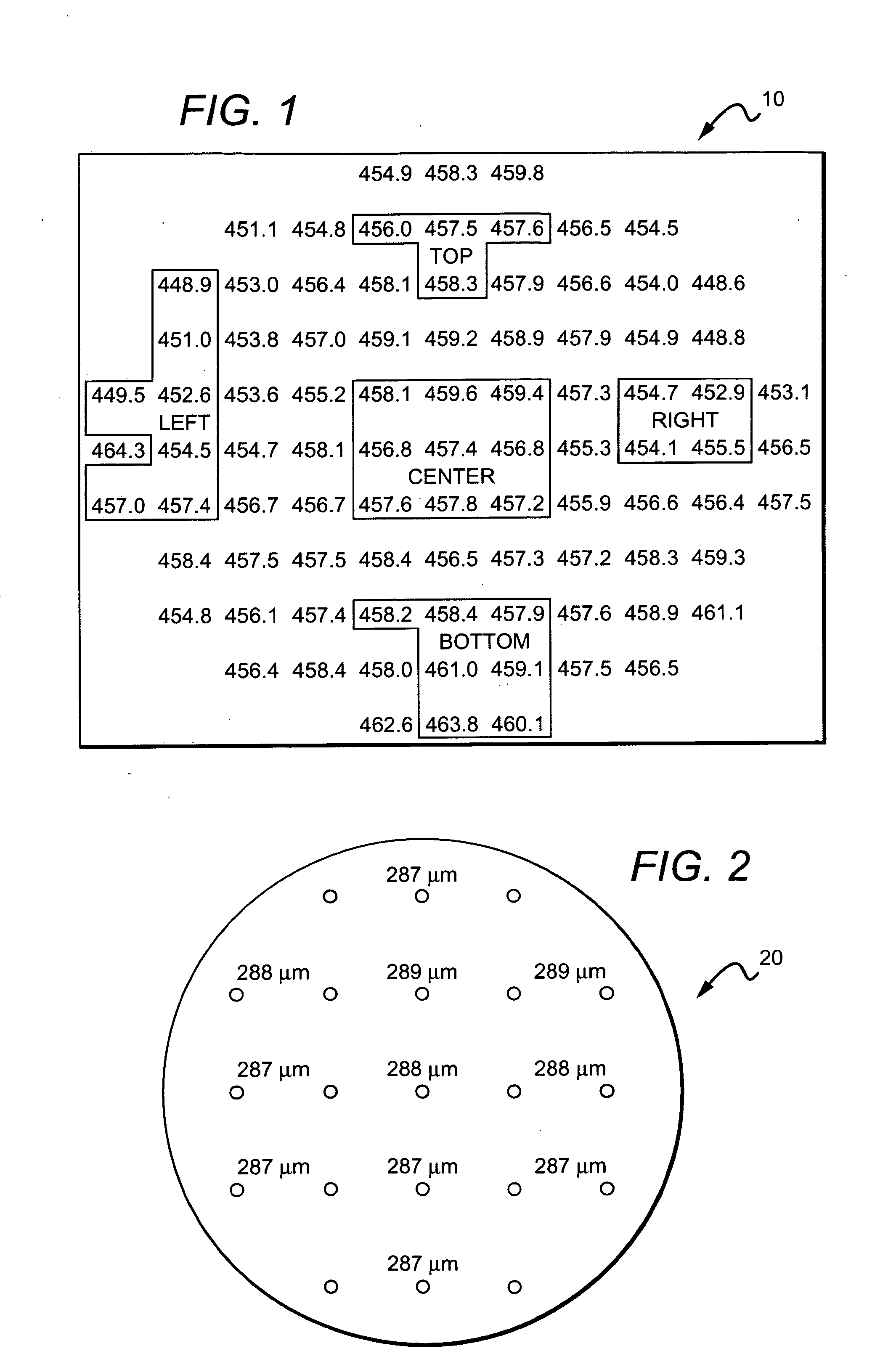

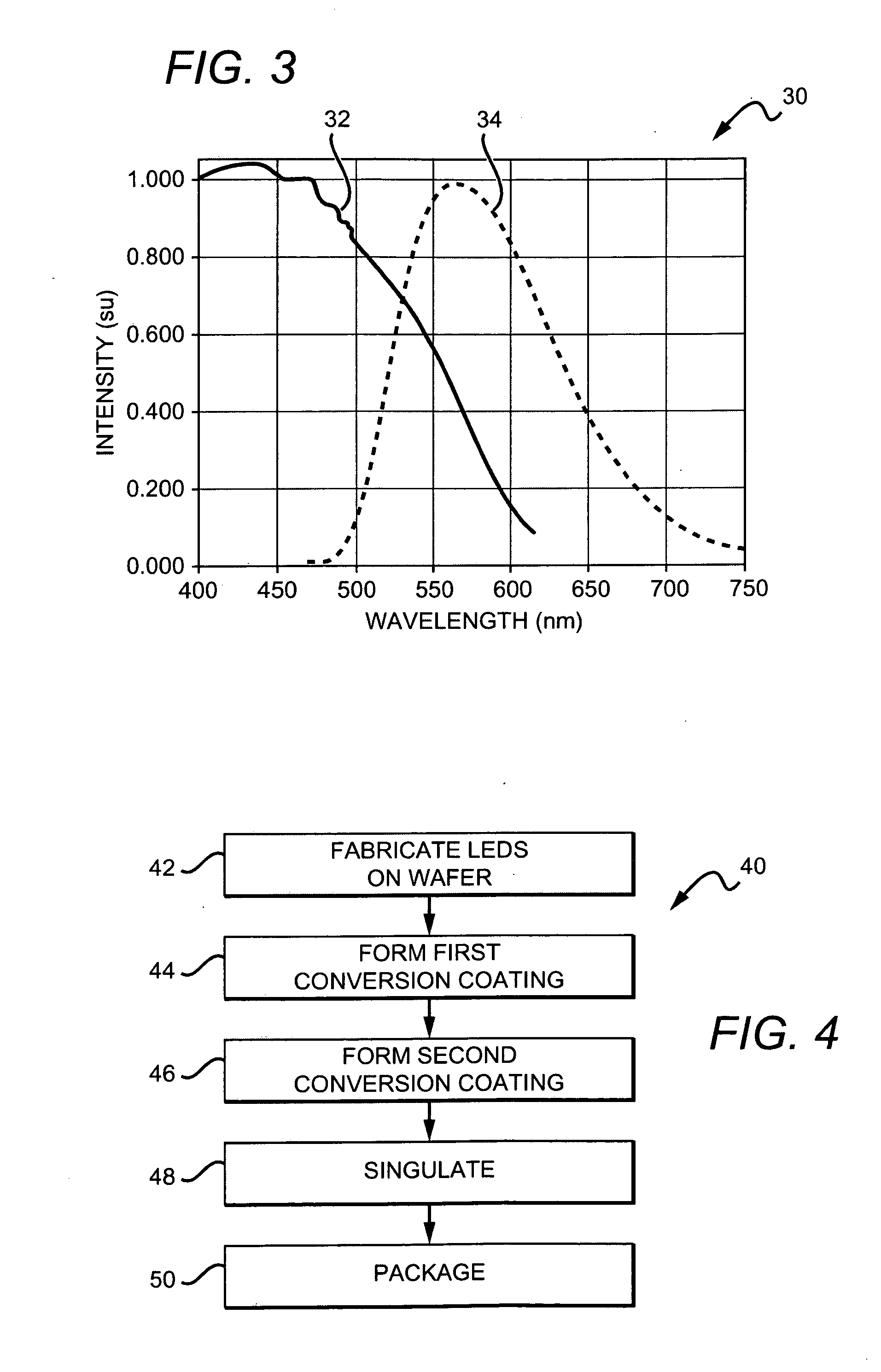

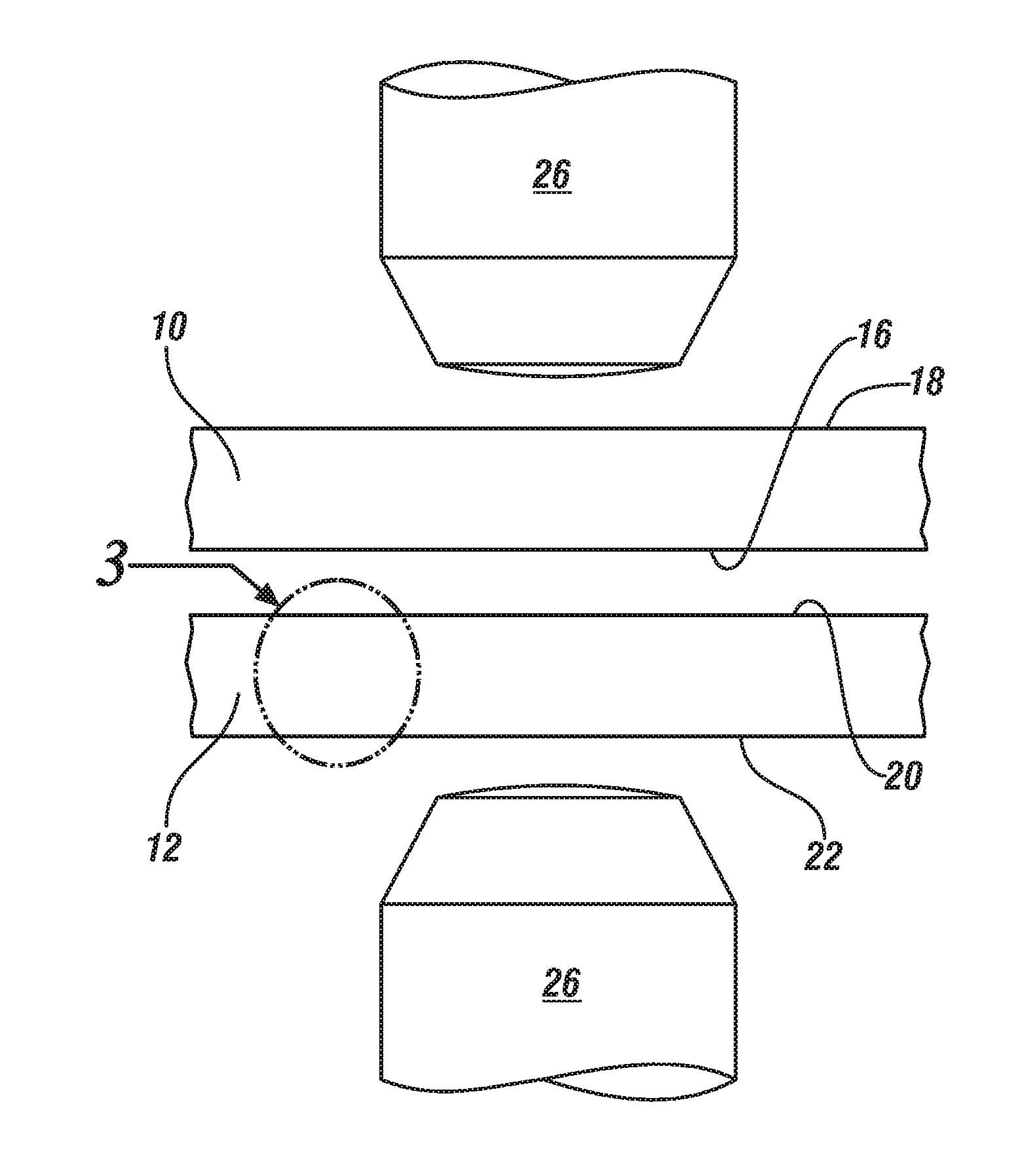

Wafer level phosphor coating technique for warm light emitting diodes

Methods for wafer level fabricating of light emitting diode (LED) chips are disclosed with one embodiment of a method according to the present invention comprising providing a plurality of LEDs and then coating of the LEDs with a layer of first conversion material so that at least some light from the LEDs passes through the first conversion material. The light is converted to different wavelengths of light having a first conversion material emission spectrum. The LEDs are then coated with a layer of second conversion material arranged on the first layer of conversion. The second conversion material has a wavelength excitation spectrum, and at least some light from the LEDs passes through the second conversion material and is converted. The first conversion material emission spectrum does not substantially overlap with the second conversion material excitation spectrum. Methods according to the present invention can also be used in wafer level fabrication of LED chips and LED packages with pedestals for electrically contacting the LEDs through the conversion coatings.

Owner:CREELED INC

Method for treating and/or coating a substrate with non-chrome materials

InactiveUS20100243108A1Solid state diffusion coatingSuperimposed coating processAluminum substrateConversion coating

The present invention is directed to a method for coating a substrate comprising: (a) applying a caustic cleaner onto at least a portion of the substrate; (b) rinsing at least a portion of the substrate that was subjected to step (a) with water; (c) applying an acid cleaner onto at least a portion of the caustically cleaned substrate; (d) rinsing at least a portion of the substrate that was subjected to step (c) with water; and (e) applying a conversion coating comprising zirconium onto at least a portion of the acid cleaned substrate; and wherein at least one of the materials used in steps (c) and (e) is substantially chrome free. The present invention is also directed to a substrate, such as an aluminum substrate, that has been coated using the aforementioned method.

Owner:PRC DE SOTO INT INC

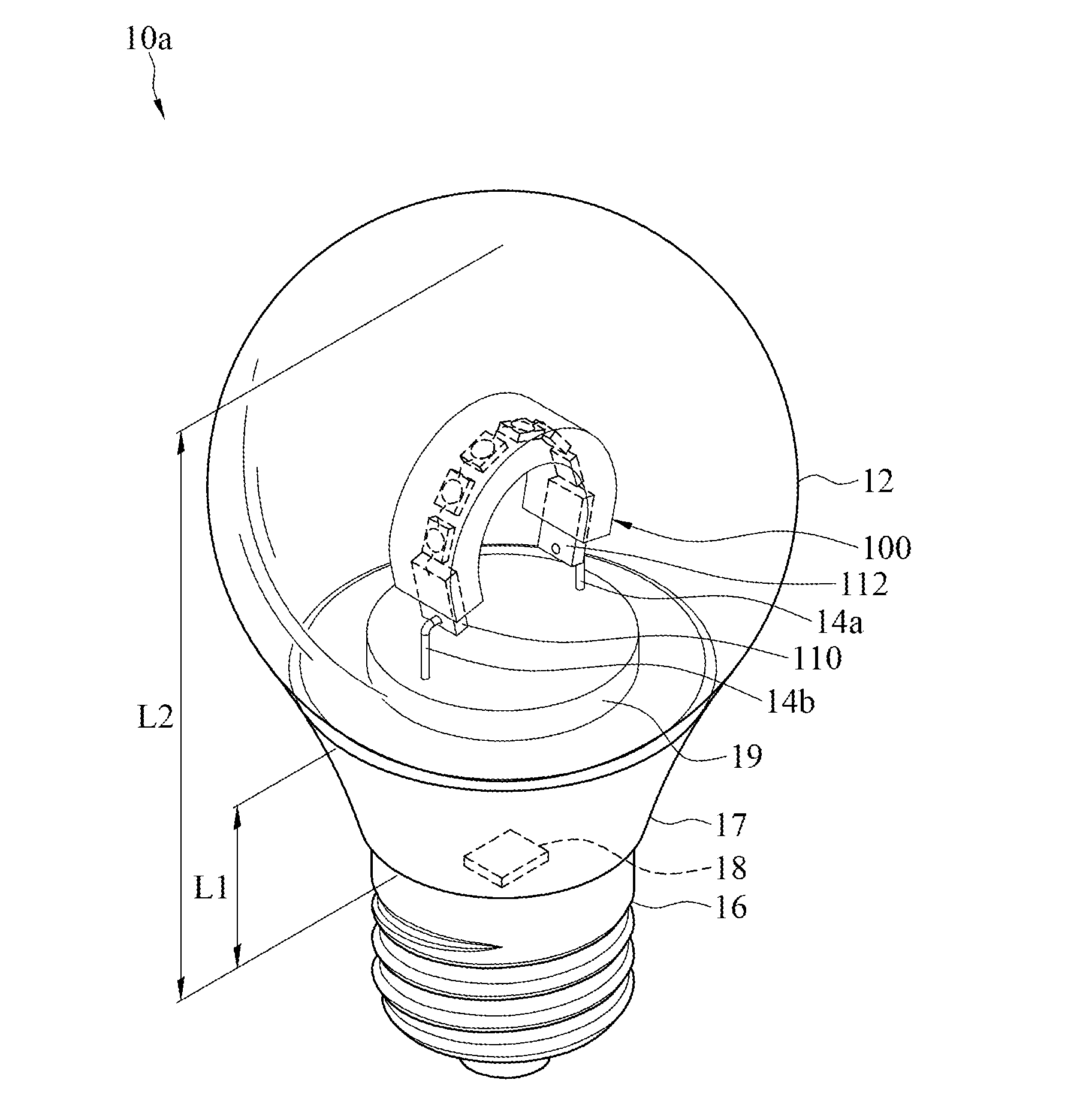

LED light bulb and LED filament thereof

ActiveUS20170051878A1Rigid enoughLong wavelengthElongate light sourcesElectric circuit arrangementsAdhesivePhosphor

An LED filament and an LED light bulb applying the same are disclosed. The LED filament includes LED chips, conductive electrodes disposed corresponding to the LED chips, and a light conversion coating. The LED chips are electrically connected together and the conductive electrodes are electrically connected with the LED chips. The light conversion coating includes an adhesive and a plurality of phosphors. The light conversion coating coats on at least two sides of the LED chips and the conductive electrodes. The light conversion coating exposes a portion of two of the conductive electrodes. Accordingly, the LED filament is capable of emitting light similar to that a point light source does and the LED light bulb may emit omnidirectional light.

Owner:JIAXING SUPER LIGHTING ELECTRIC APPLIANCE

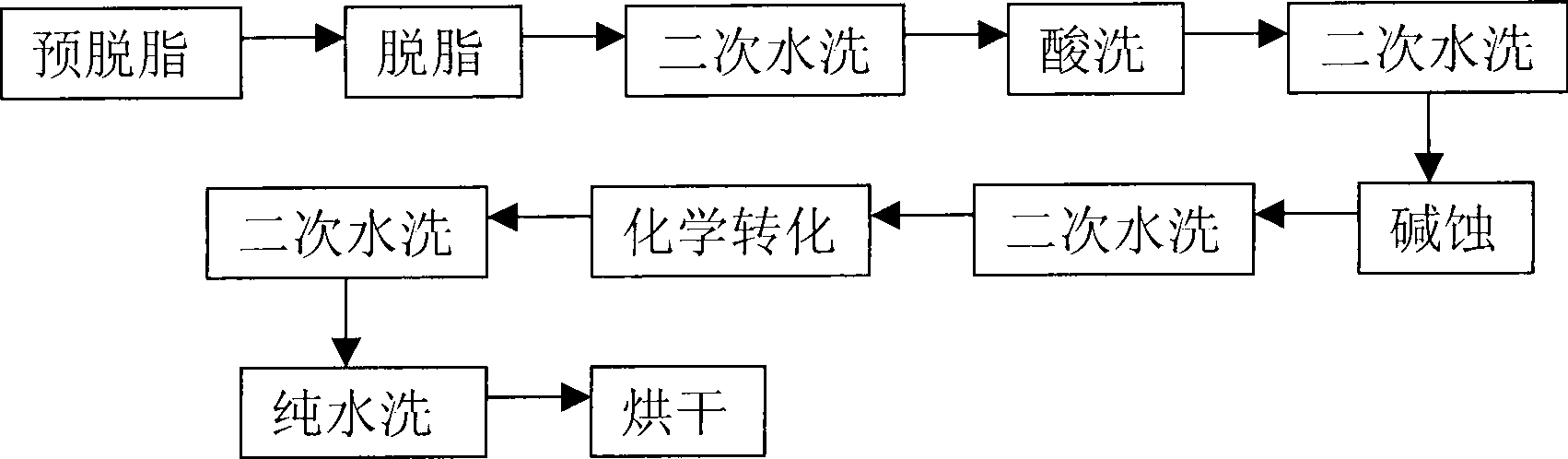

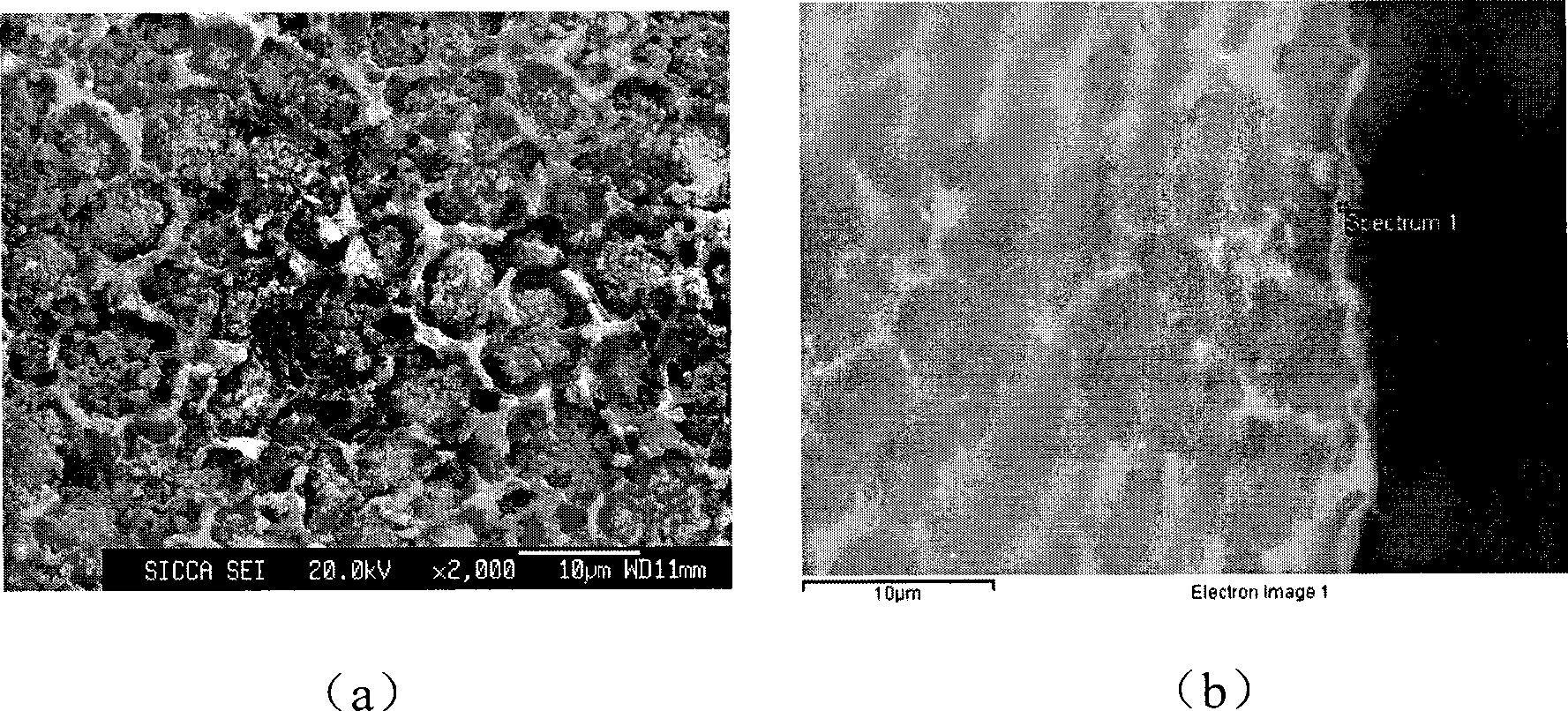

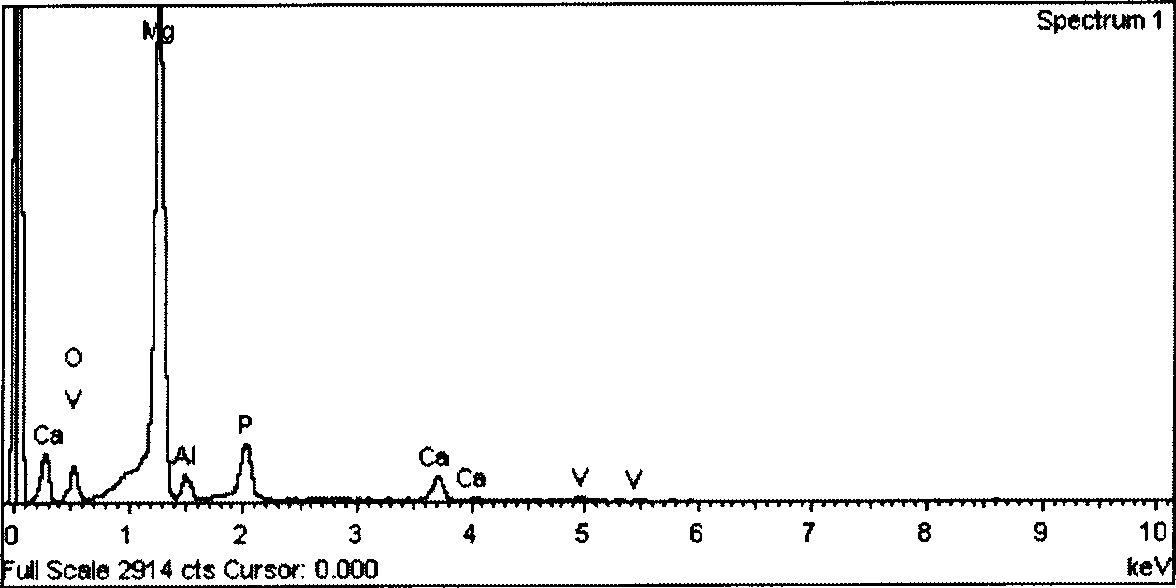

P-Ca-V composite phosphating solution on magnesium alloy surface and chemical conversion processing method

ActiveCN101418441AImprove corrosion resistanceLow resistivityMetallic material coating processesSalt spray testAcid washing

The invention relates to a composite phosphating solution of P-Ca-V on the surface of a magnesium alloy and a method for chemical conversion treatment. The solution is characterized in that each liter of the composite phosphating solution comprises the following compositions: 4 to 20 milliliters of 85 percent phosphoric acid of, 5 to 30 grams of sodium dihydrogen phosphate, 10 to 40 grams of calcium nitrate, 0.5 to 10 grams of benzene sulfonic acid sodium salt, 0.5 to 5 grams of ammonium metavanadate, and the balance being water. The method comprises the following steps: pre-degreasing, degreasing, secondary water washing, acid washing, secondary water washing, alkaline etching, secondary water washing, chemical transformation, secondary water washing, pure water washing, and drying. Taking an AZ91D magnesium alloy as an example, 48 hours after a corrosion resistance salt spray test after the treatment by the method of the invention, the corrosion area of the AZ91D magnesium alloy is less than 1 percent; the paint film adhesive force is at 0 level by a grid method and is obviously superior to the performance of a chromate conversion coating; and the formed chemical conversion coating does not contain crystal water. The composite phosphating solution has the synergistic reaction of Ca and V, as well as the functions of a corrosion inhibitor and a wetting agent of the benzene sulfonic acid sodium salt.

Owner:嘉兴中科亚美合金技术有限责任公司

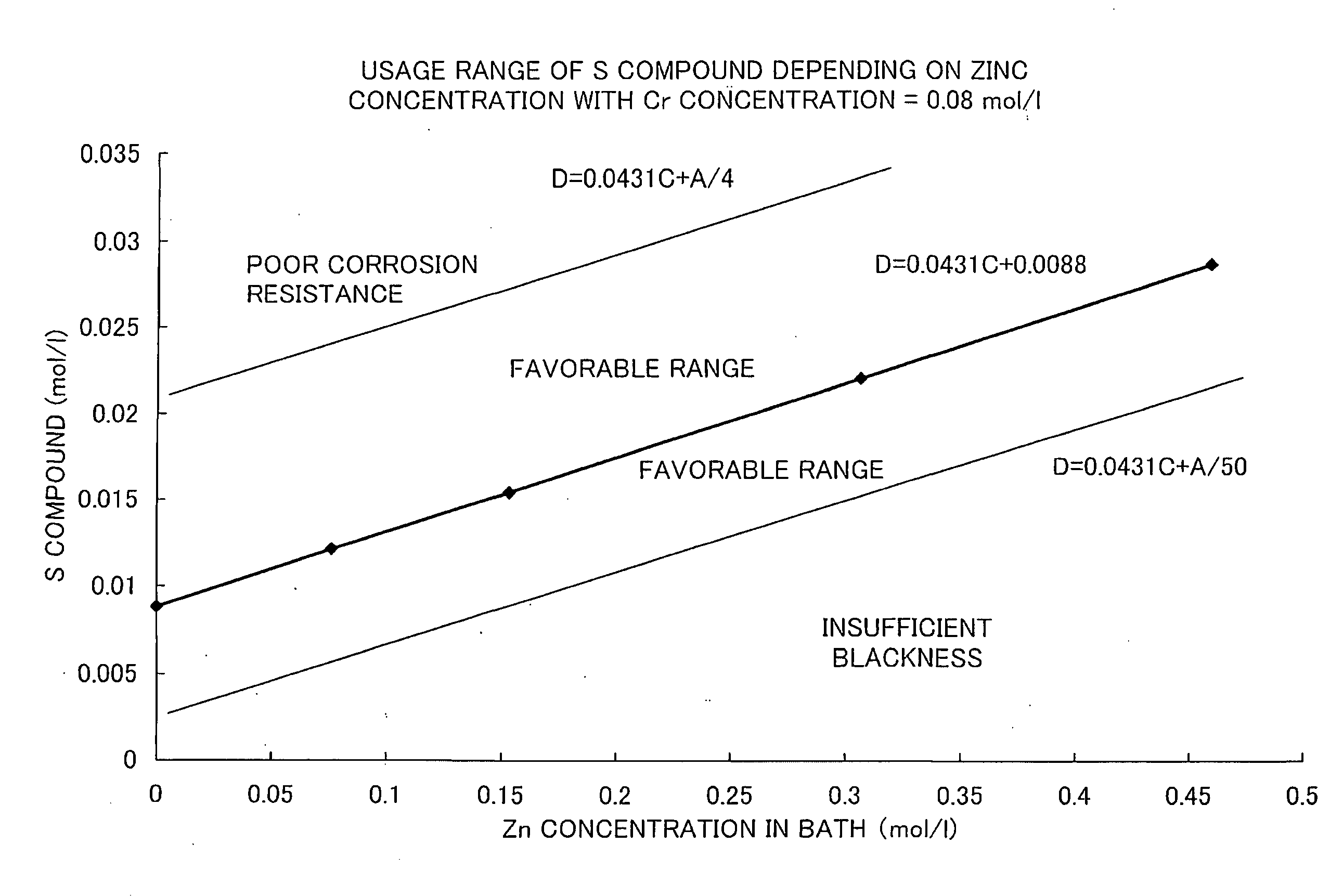

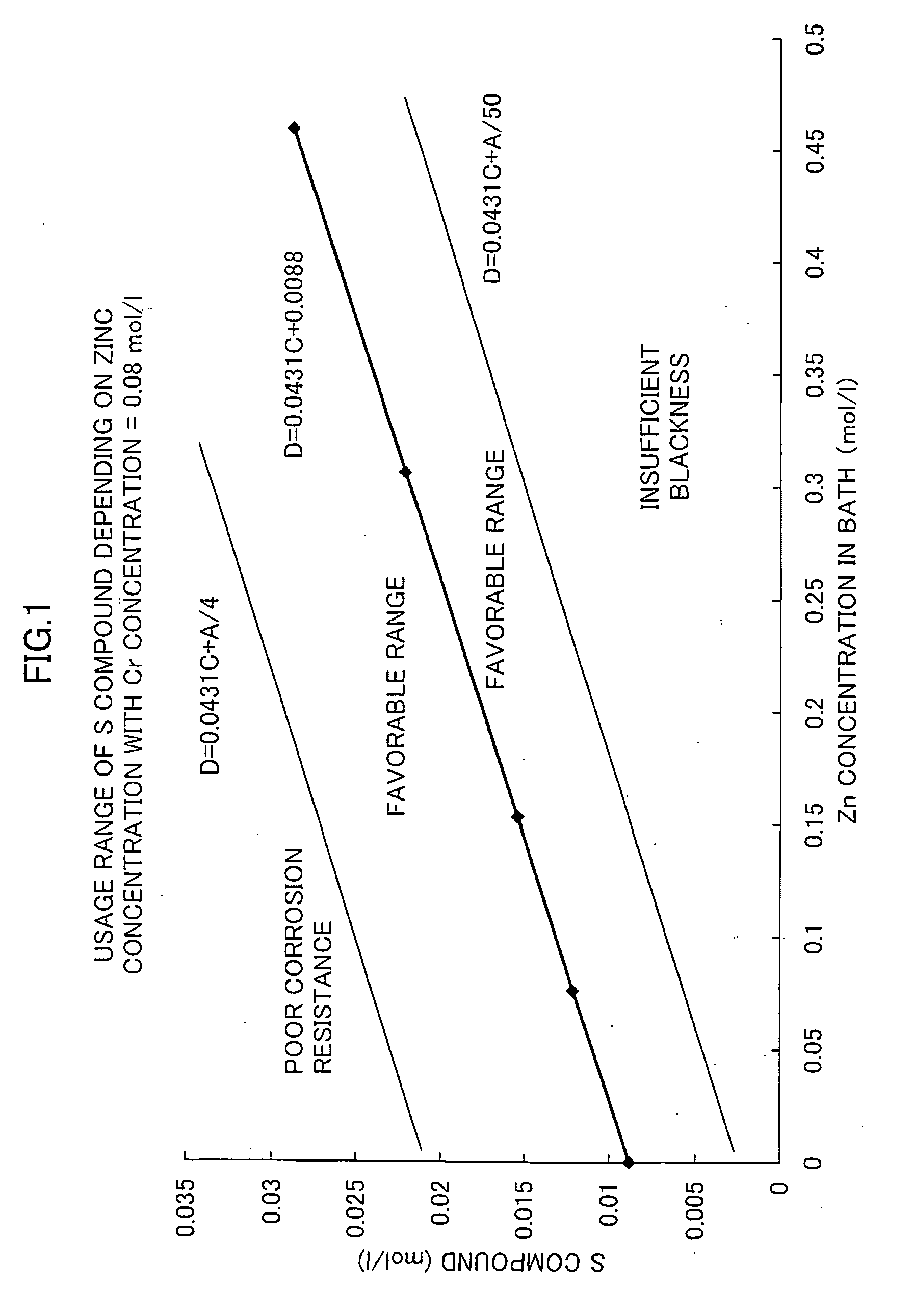

Aqueous treating solution for forming black trivalent-chromium chemical conversion coating on zinc or zinc alloy and method of forming black trivalent-chromium chemical conversion coating

ActiveUS20090020185A1Excellent black appearanceImprove corrosion resistanceMetallic material coating processesWelding/cutting media/materialsPhosphoric Acid EstersChemical treatment

A treating solution for forming on a surface of either zinc or a zinc alloy a hexavalent-chromium-free trivalent-chromium chemical conversion coating which has an even black appearance and satisfactory corrosion resistance. The treating solution has a long treating-bath life. Also provided is a method of forming a black trivalent-chromium chemical conversion coating. The aqueous treating solution, which is for forming a black trivalent-chromium chemical conversion coating on zinc or a zinc alloy, contains trivalent chromium ions, a phosphoric ester and / or phosphorous ester, and a sulfur compound. The method is a method of chemically treating zinc or a zinc alloy which comprises using the aqueous treating solution to chemically treat the zinc or zinc alloy at a solution temperature of 10-60° C., whereby a black trivalent-chromium chemical conversion coating is formed on the zinc or zinc alloy. Furthermore provided is a coated zinc or zinc alloy metal which comprises zinc or a zinc alloy and, formed thereon, a black trivalent-chromium chemical conversion coating formed by a chemical treatment with the aqueous treating solution.

Owner:DISPOL CHEMICALS CO LTD

Wavelength converting structure and manufacture and use of the same

InactiveUS20080176066A1Increase the areaDischarge tube luminescnet screensSynthetic resin layered productsPhosphorAdhesive

A wavelength converting structure is provided. The wavelength converting structure comprises the following:a substrate, anda wavelength converting coating which is deposited on the substrate and comprises:(a) a phosphor powder which can be excited by UVC; and(b) an anti-UVC adhesive,wherein the thickness of the wavelength converting coating is 2 to 10 times the average particle size of the phosphor powder and the amount of the phosphor powder in the wavelength converting coating conforms to at least one of the following requirements:(i) the phosphor powder should be about 30% to 85% by volume of the wavelength converting coating based on the total volume of the phosphor powder and the adhesive; and(ii) the weight ratio of the phosphor powder to the adhesive should range from 1:1 to 20:1.The wavelength converting coating can effectively convert UVC to visible light to provide a visible light source with a high surface area.

Owner:KISMART

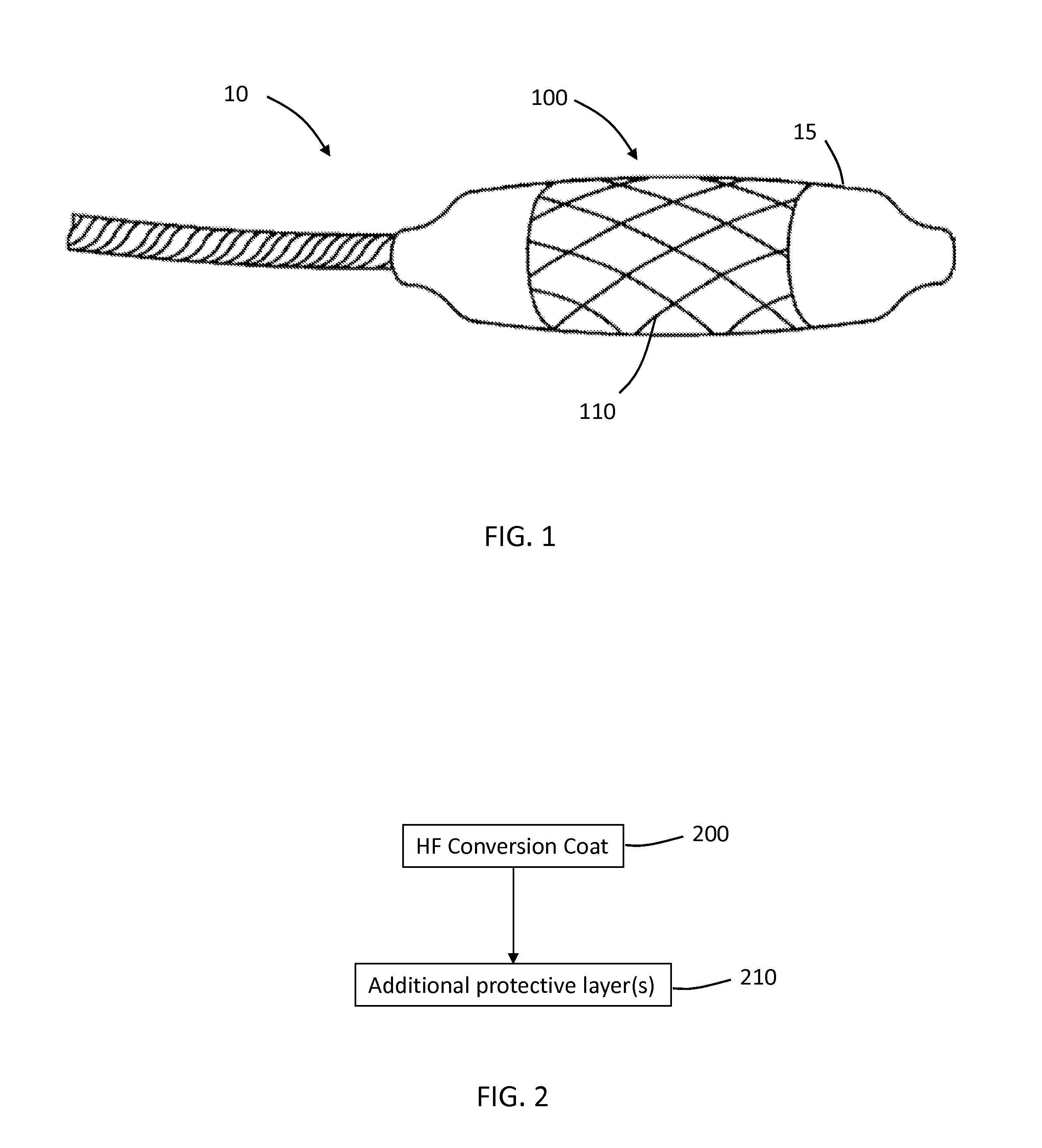

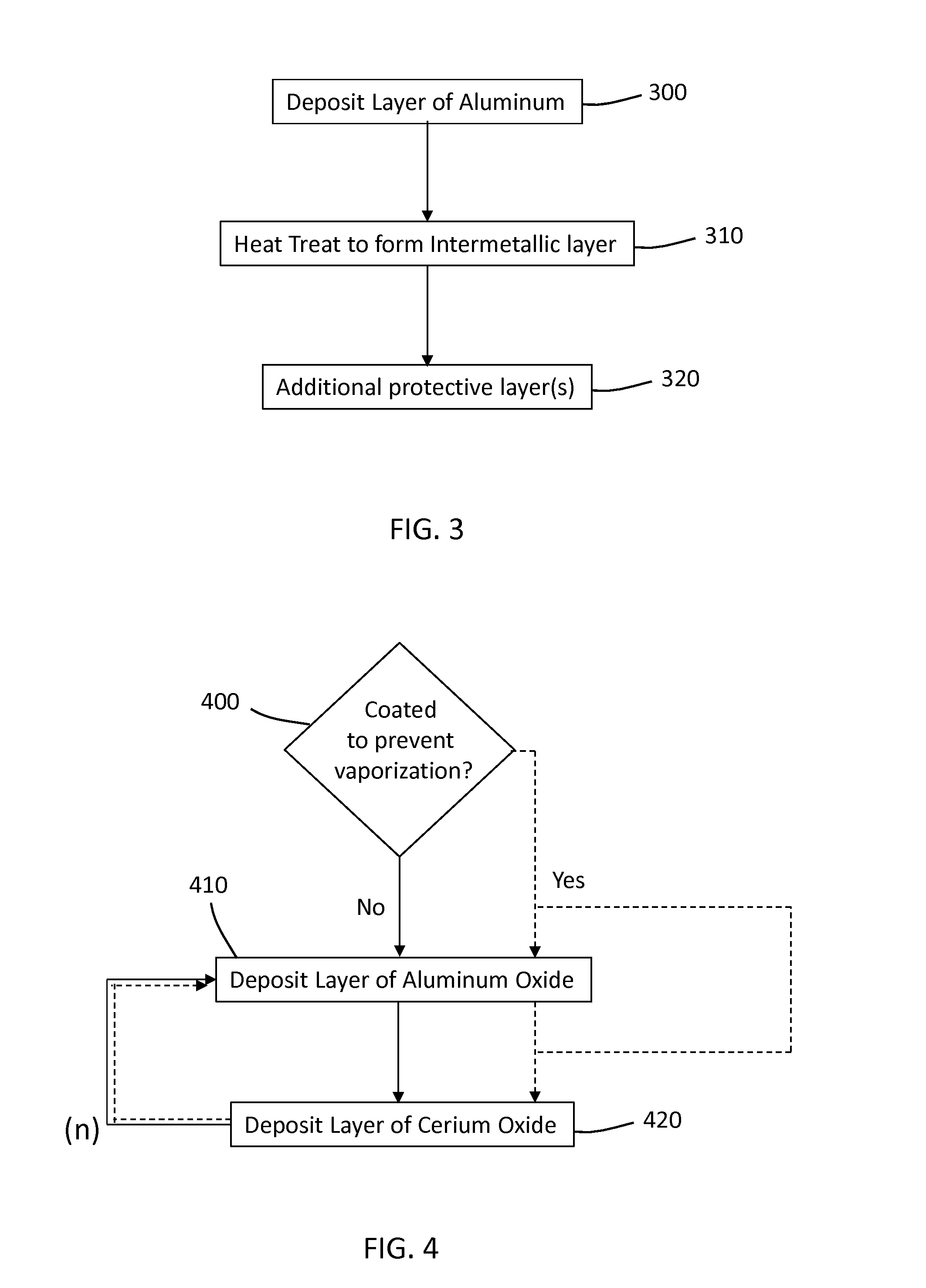

Protected Magnesium Alloys for Bioresorbable Stents

ActiveUS20160129162A1Uniform corrosionAvoid corrosionStentsSurgeryChromate conversion coatingInsertion stent

Biodegradable magnesium alloy implantable medical devices are protected to delay onset of corrosion, and thus biodegradability, or to corrode more uniformly. The protection allows for extended effective use of the devices while maintaining biodegradability. Examples of protective coatings include conversion coatings that at least partially remove exposed second phases from a surface of the magnesium alloy and coatings that provide a barrier between water and the surface of the magnesium alloy.

Owner:MEDTRONIC VASCULAR INC

Surface conditioner containing zinc phosphate, phosphate chemical conversion treatment steelboard, coating steelboard and zinc phosphate dispersion liquid

A zinc phosphate-containing surface conditioning agent to be used for surface conditioning as pretreatment for zinc phosphate conversion coating of a metallic material, which contains from 500 to 20,000 ppm of zinc phosphate and which has a pH of from 3 to 11, wherein said zinc phosphate has an average particle size of at most 3 mu m and D90 of at most 4 mum.

Owner:NIPPON PAINT SURF CHEM +1

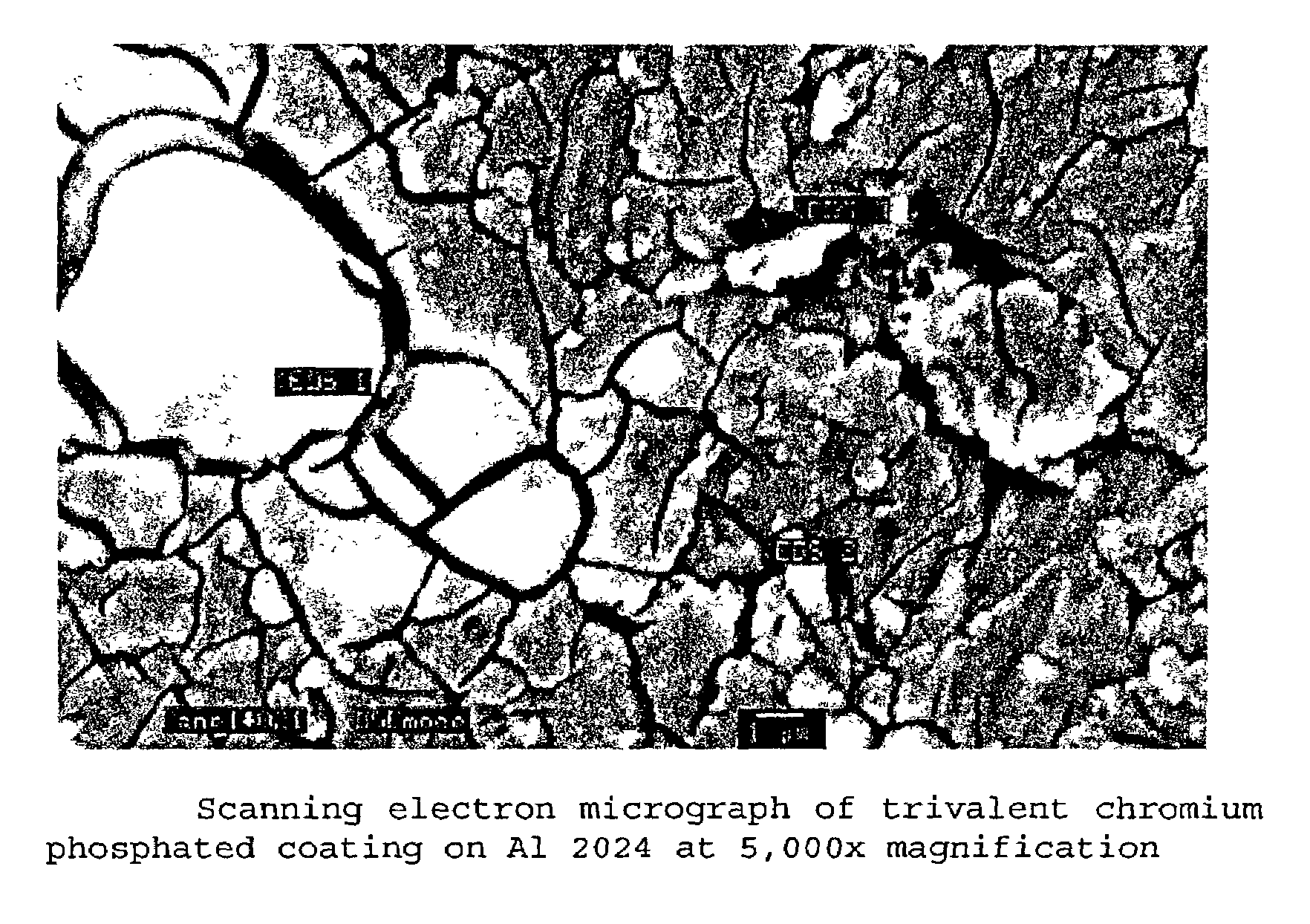

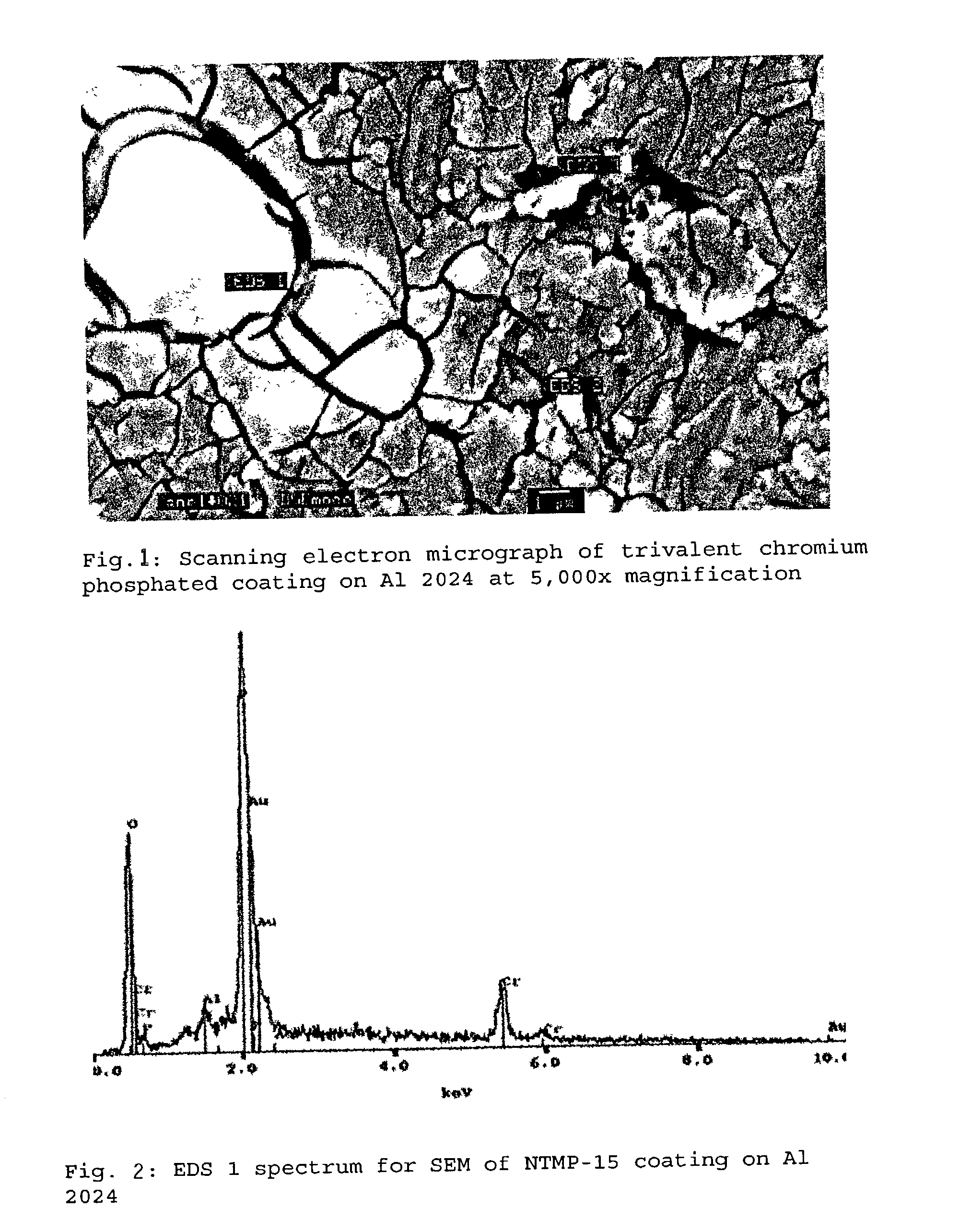

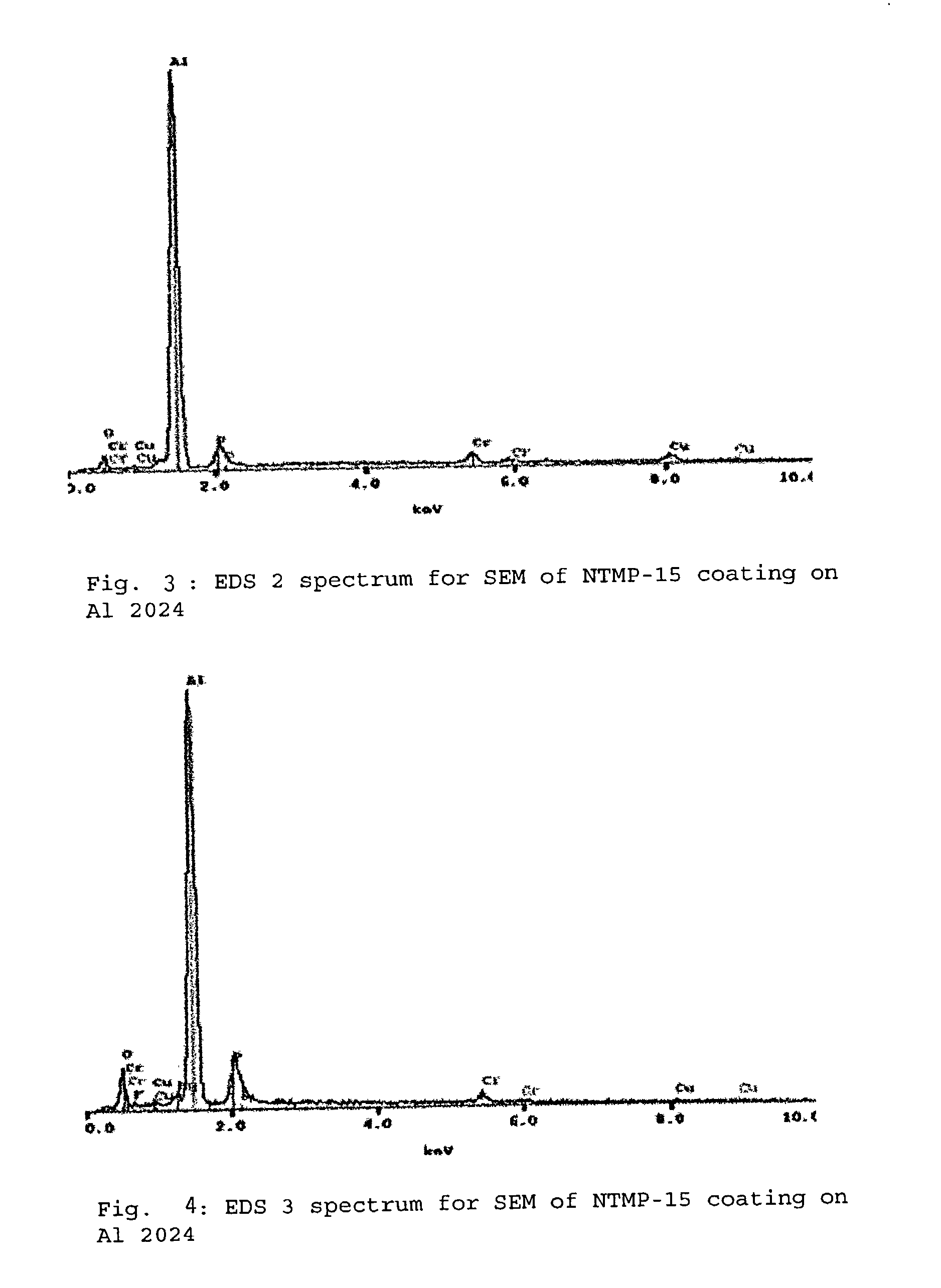

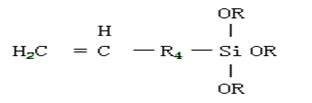

Corrosion resistant trivalent chromium phosphated chemical conversion coatings

InactiveUS7018486B2Reduce precipitationImprove protectionSurface reaction electrolytic coatingSolid state diffusion coatingChromium CompoundsChromate conversion coating

An acidic aqueous solution containing a water soluble trivalent chromium compound is provided with a additive for improving corrosion resistance and reducing precipitation of trivalent chromium over time. A suitable additive is nitrilotris (methylene) triphosphonic acid (NTMP).

Owner:RTX CORP

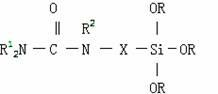

Phosphonic acid and polyvinyl alcohol conversion coating

Compositions for preparing coatings on metal substrates include a phosphonic acid, polyvinyl alcohol, an optional catalyst, and optionally an organo-functional silane. The catalyst may be a group IV-B compound, a boron compound, a vanadium compound, or a molybdenum compound. The compositions may be applied from an aqueous carrier to a metal surface and then dried to form a coating imparting good paint adhesion and corrosion resistance to the metal substrate.

Owner:BULK CHEM

Aqueous phosphating composition and process for metal surfaces

InactiveUS6179934B1High-quality coatingLess spaceSolid state diffusion coatingZinc phosphateHydroxylamine

An aqueous zinc phosphate conversion coating that contains 5 to 50 g / L of phosphate ions, 0.2 to 10 g / L of zinc ions, and 0.5 to 4.0 g / L as hydroxylamine of a hydroxylamine source, and also: (1) contains 0.01 to 5.0 g / L polycarboxylic acid or salt thereof and / or starch phosphate; or (2) has a zinc ions / phosphate ions weight ratio below 0.27 and a zinc ions concentration of at least 2.0 g / L forms high quality zinc phosphating coatings on metal surfaces even if the surfaces have not been previously conditioned by contact with a dispersion of colloidal titanium.

Owner:HENKEL CORP

Metal surface silanization treatment agent and surface silanization treatment method using the same

InactiveCN102181228AEasy to manageEasy to handleLiquid surface applicatorsCoatingsEpoxyEnvironmental resistance

The invention relates to a metal surface silanization treatment agent and a metal surface silanization treatment method using the same, and in particular relates to a non-phosphorus metal surface treatment method which replaces or partially replaces the traditional zinc phosphorization and iron phosphorization process. The metal surface silanization treatment agent comprises organosilane, organic acid, alcohol, a promoter and deionized water; and the mixed silanol solution can generate a surface protective film on a metal matrix. The surface silanization treatment agent has the advantages of no need of heating, no phosphorus and sediments and heavy metals, less energy consumption and simple management method, and the treatment agent can provide excellent adhesive force for combination between metal substrates and polyester, epoxy, acrylic and other types of coatings. The metal surface silanization treatment agent is particularly applicable to non-phosphorus environmentally-friendly conversion coating treatment on surfaces of cold rolled steel, zinc, iron, aluminum and aluminum alloys.

Owner:龚向光

Thermoplastic elastomer bonded directly to metal substrate

InactiveUS20050228157A1Metallic material coating processesMetal layered productsPolymer scienceThermoplastic elastomer

Disclosed is a bonded assembly comprising a thermoplastic elastomer and a conversion coated metal substrate, a method to produce a bonded assembly comprising a thermoplastic elastomer and a conversion coated metal substrate and articles produced therefrom.

Owner:PETERSON CURT E +1

Trivalent chromate conversion coating

InactiveUS7029541B2Other chemical processesSolid state diffusion coatingChromate conversion coatingCobalt

In a preferred embodiment of the present invention, a conversion coating composition comprising chromium (III) ions, cobalt (II) ions, and nitric acid is provided. The coating composition is substantially free of chromium (VI) ions and substantially free of an oxidizing agent. The present trivalent chromium based conversion coating provides corrosion protection equal to or greater than most hexavalent chromium conversion coatings.

Owner:PAVCO INC +1

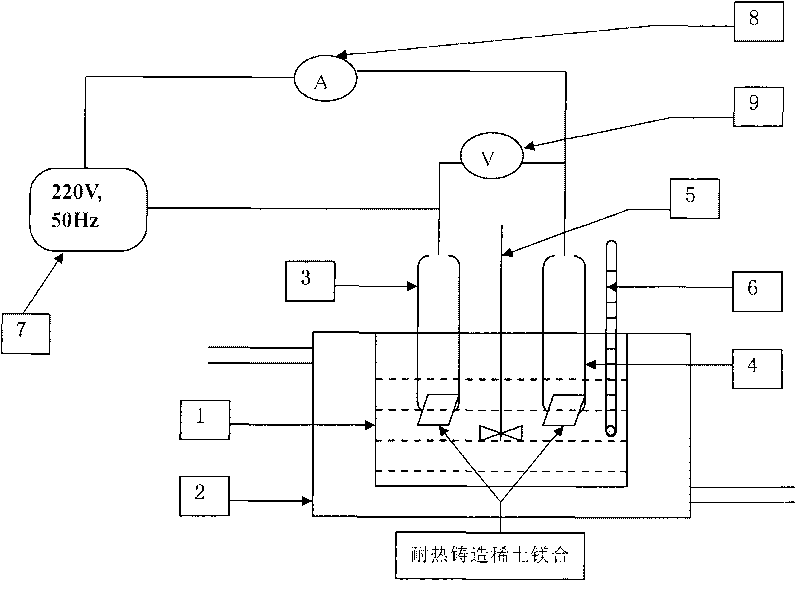

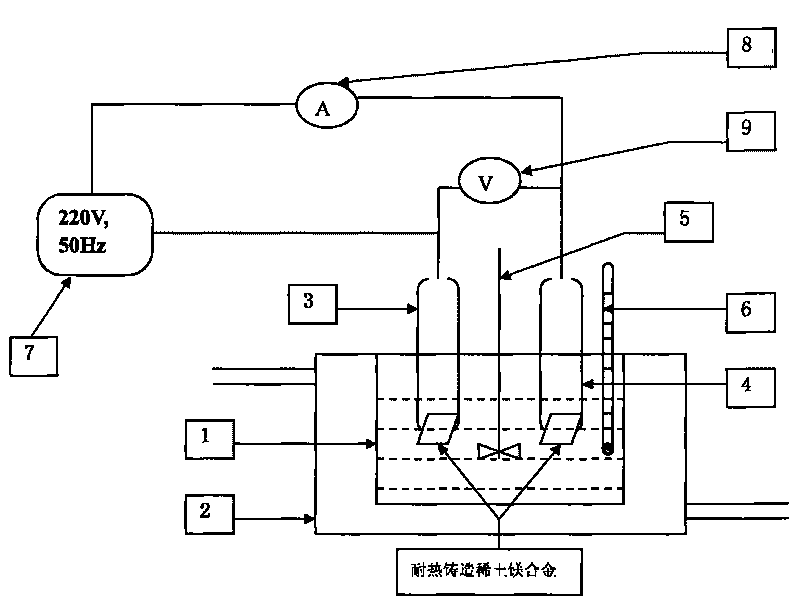

Micro-arc oxidation treatment method of heat-resistant cast rare earth magnesium alloy

InactiveCN101698957AImprove corrosion resistanceLow costAnodisationChemical treatmentMicro arc oxidation

The invention relates to a micro-arc oxidation treatment method of a heat-resistant cast rare earth magnesium alloy. The method has the advantages of simple equipment, low cost and no point discharge phenomenon. The heat-resistant cast rare earth magnesium alloy processed by the method has excellent corrosion resistance, when using the neutral salt spray (NSS) method in Corrosion-resistant testing method of the metal deposits and conversion coatings for the light industrial products of QB / T 3826-1999 for testing, taking sodium chloride solution with the weight percent of 5%, keeping the temperature constant at 35 DEG C plus or minus 1 DEG C and meeting the neutral salt spray-resistant test conditions, the heat-resistant cast rare earth magnesium alloy is rated nine grade according to Methods for corrosion testing of metallic and other inorganic coatings on metallic substrates-Rating of test specimens and manufactured articles subjected to corrosion tests of GB / T 6461-2002. The corrosion resistance is more than 96 hours.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com