Patents

Literature

234results about How to "Uniform corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fused cast refractory block with high zirconia content

ActiveUS20100068492A1Increase contentEasy to useGlass furnace apparatusSynthetic resin layered productsZirconium oxideOxide

The present invention provides a fused cast refractory block comprising a mean zirconia (ZrO2+HfO2) content of more than 85% as a percentage by weight based on the oxides, and with a standard deviation σ of the local zirconia content divided by the volume of the block of less than 7.5.

Owner:SAINT GOBAIN CENT DE RES & DEVS & DETUD EUROEN

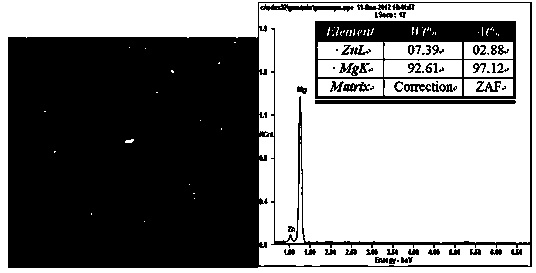

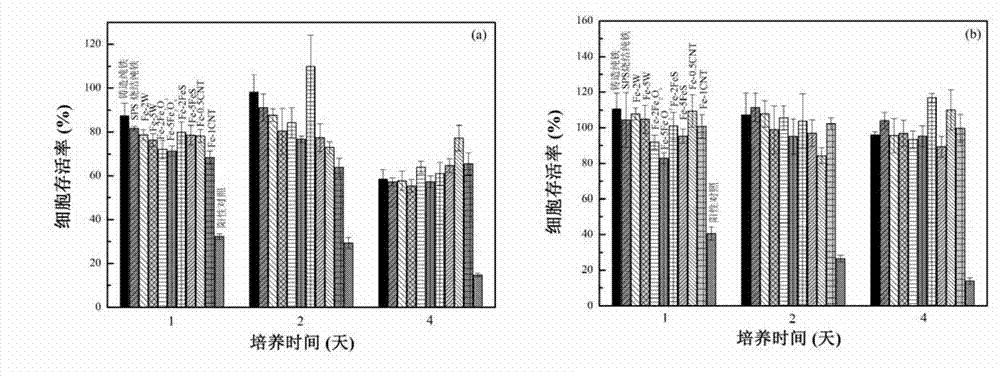

Biodegradable medical magnesium alloy as well as preparation method thereof

ActiveCN103526091AImprove biocompatibilityReduce the segregation of elementsRare-earth elementCorrosion resistant

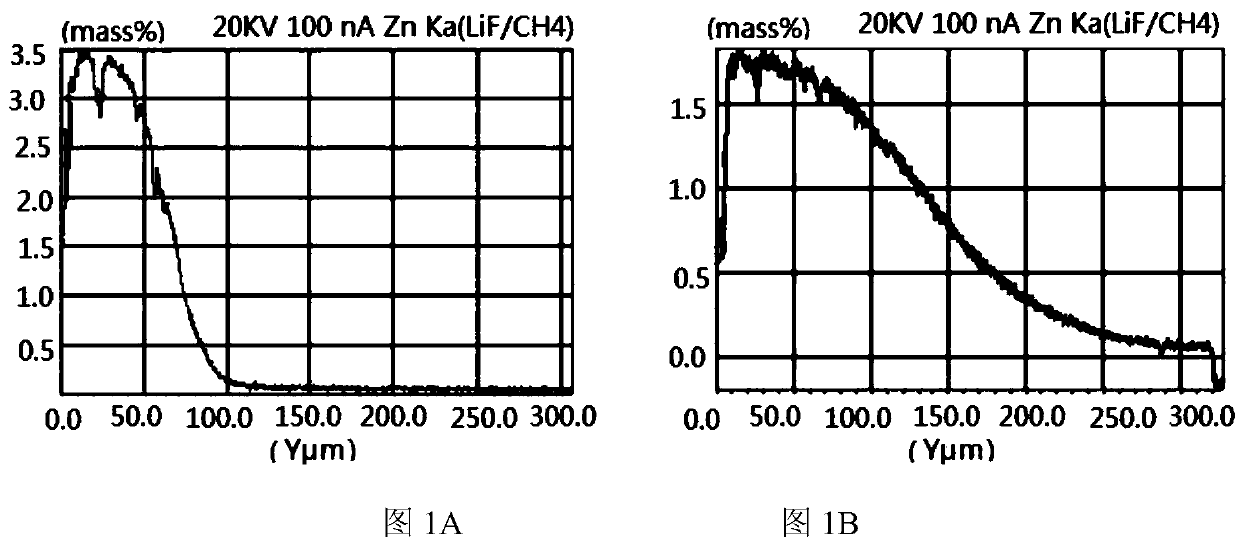

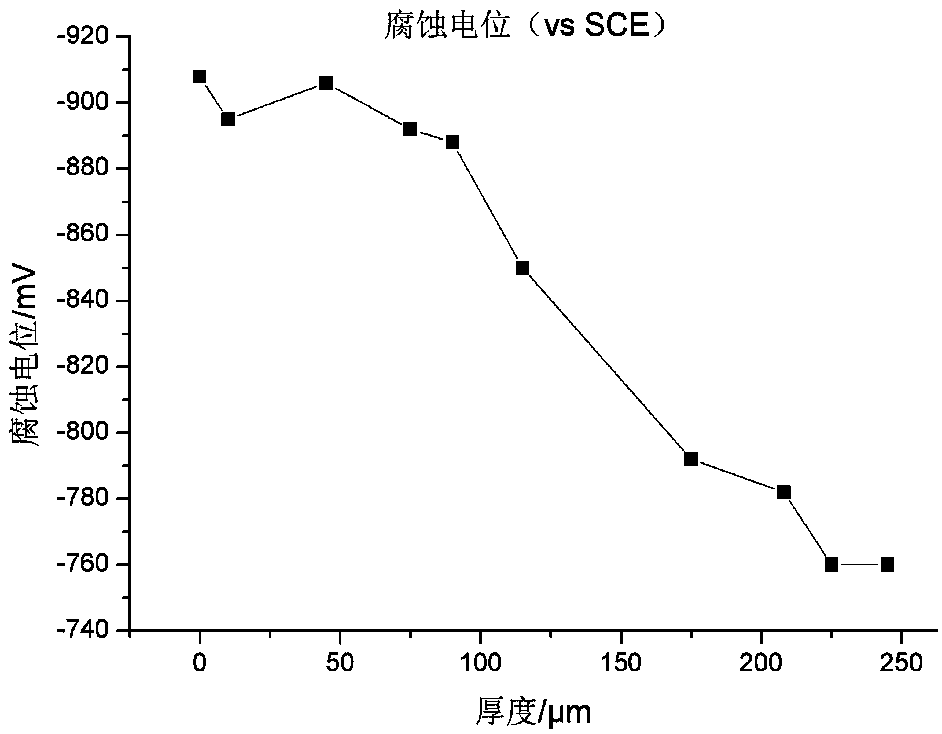

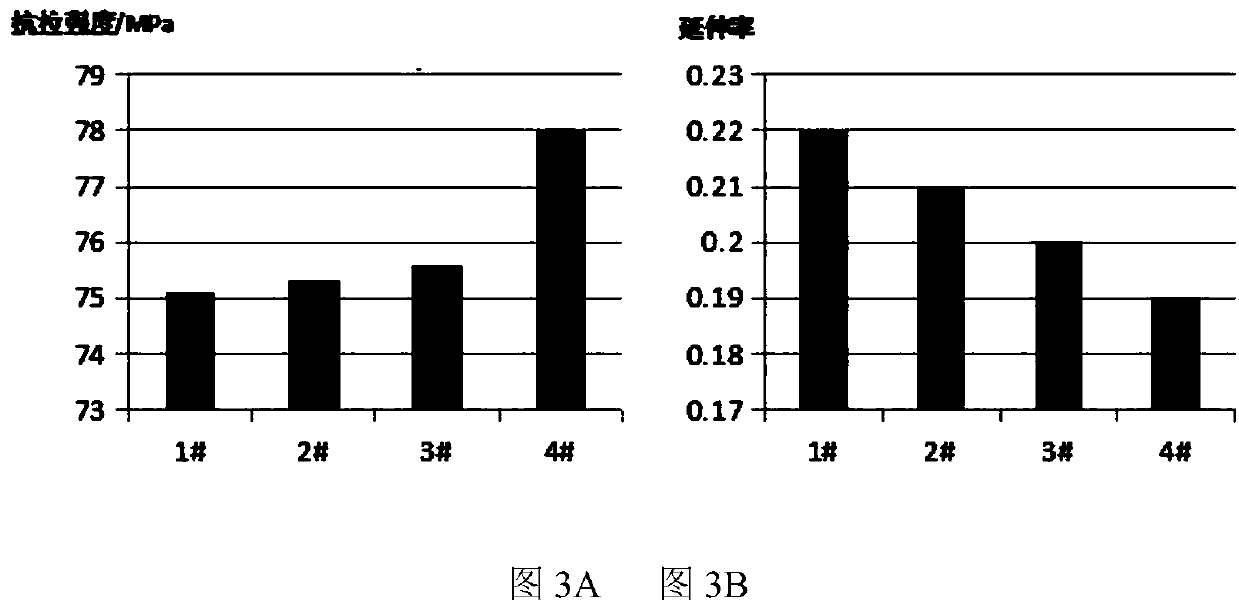

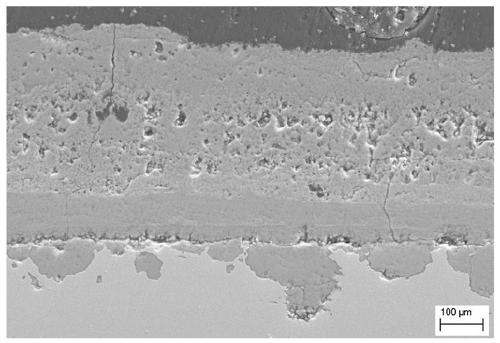

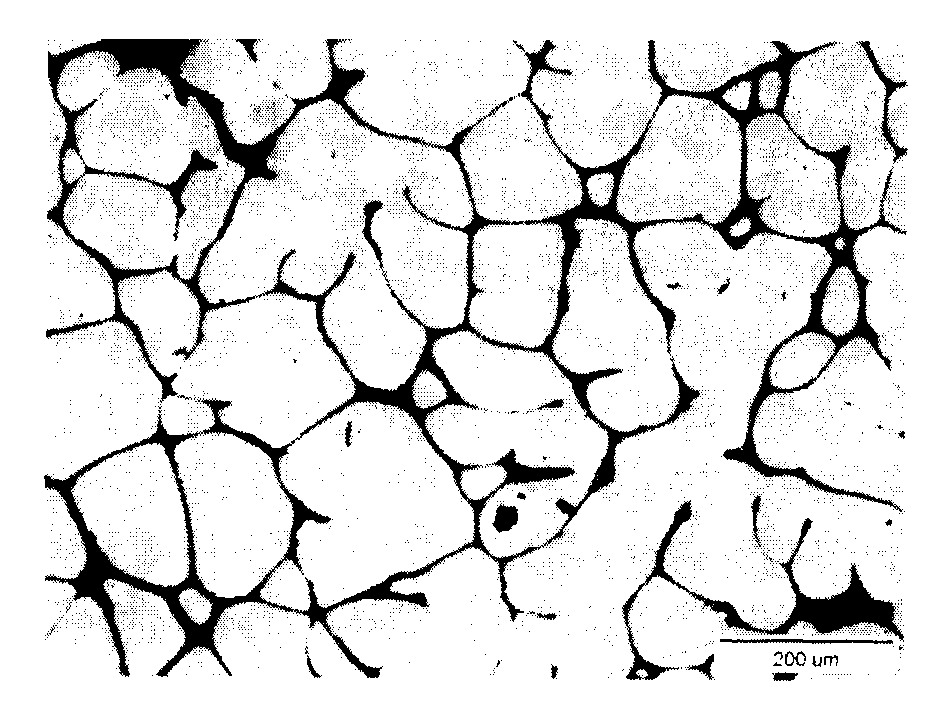

The invention discloses a biodegradable medical magnesium alloy which consists of the following matters in percentage by weight: 1.0-3.0% of Zn, 0.20-1.50% of Y, 0.40-1.50% of Nd, 0.30-0.50% of Zr and the balance of Mg and inevitable impurity elements. Meanwhile, the invention discloses a preparation method of the alloy. The magnesium alloy is smelted to prepare common magnesium alloy. The use level of Zn, Y and Nd in furnace burden is 1.2-1.4 times the content of Zn, Y and Nd in the magnesium alloy, and the use level of Zr is 2-2.5 times the content of Zr in the magnesium alloy. According to the invention, the magnesium alloy overcomes the problems of cytotoxicity, excessively high corrosion rate and the like by adding rare earth elements Y, Nd and Zr into a magnesium-zinc alloy, and the potential difference with a matrix is reduced due to a lot of uniformly dispersed and distributed nano MgZn particle phases in the matrix by extrusion and processing, so that the corrosion resistance of the alloy is greatly improved, and the alloy has better mechanical properties.

Owner:ZHENGZHOU UNIV

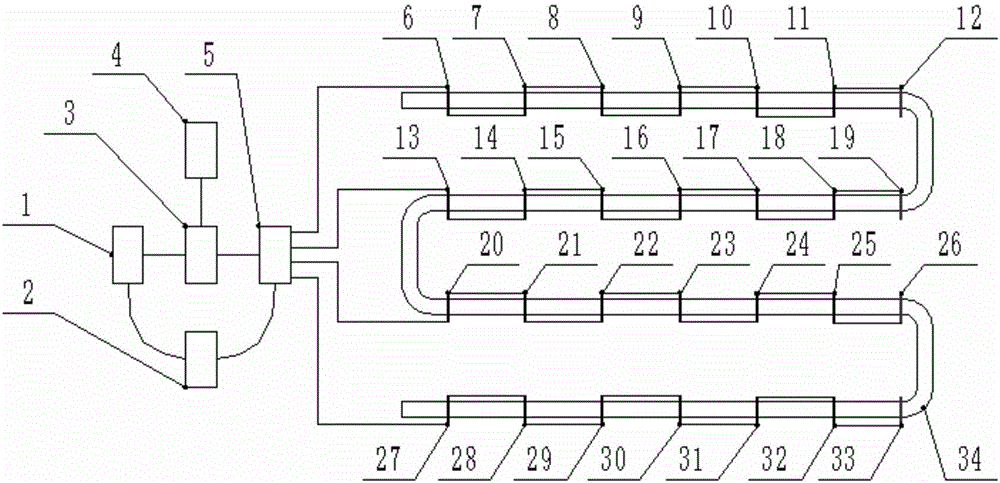

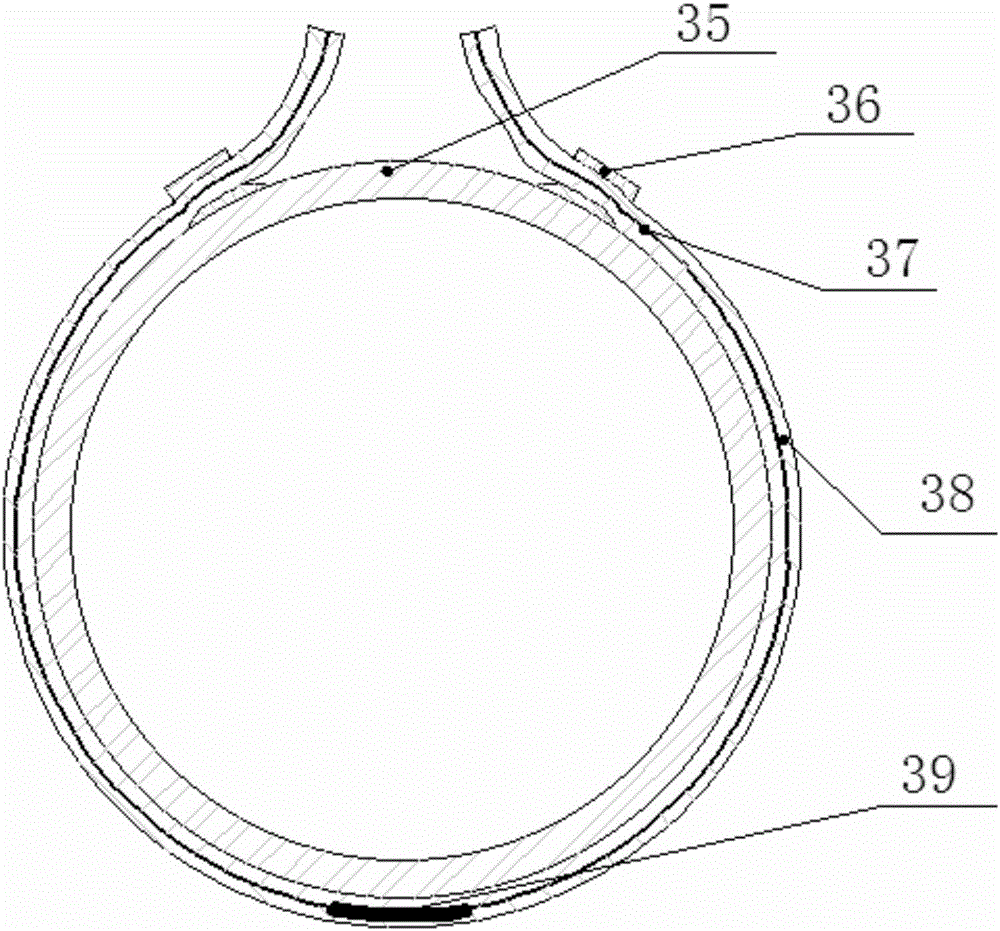

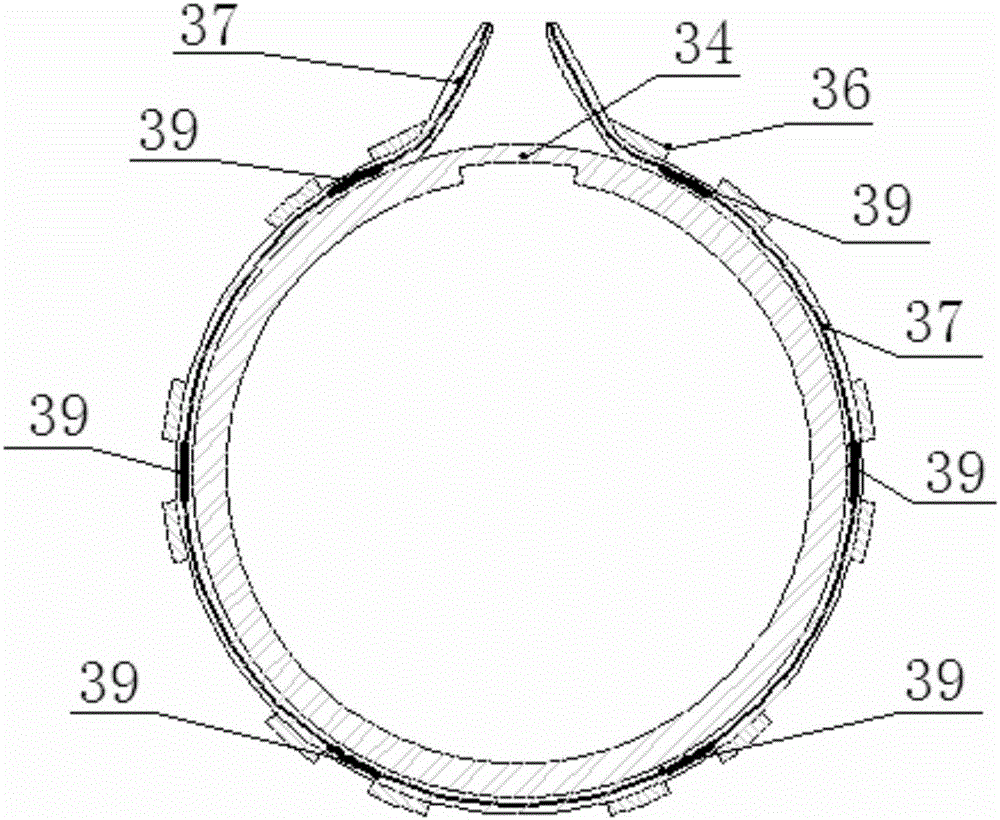

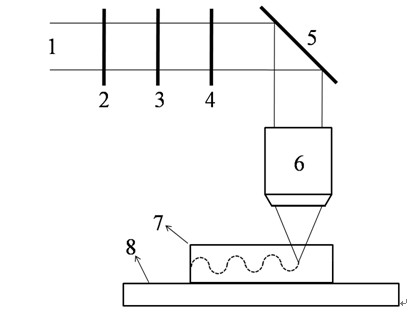

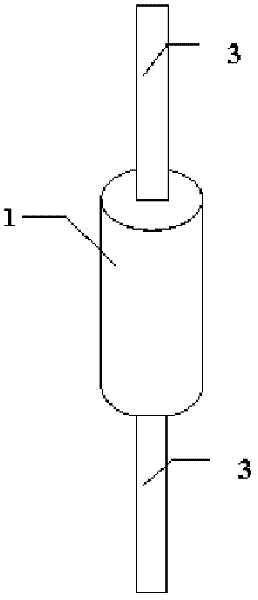

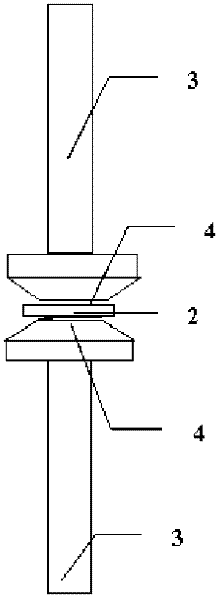

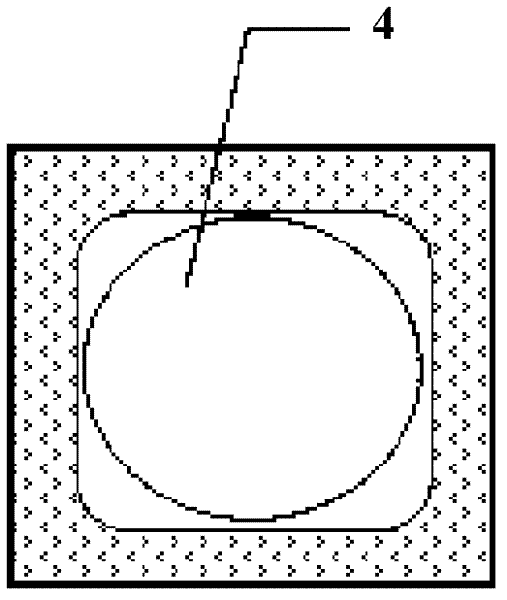

Pipeline leakage and corrosion online monitoring device and method based on optical fiber grating sensing

ActiveCN106764463ALeak real-time monitoringReal-time monitoring of leakagePipeline systemsGratingBeam splitting

The invention relates to a pipeline leakage and corrosion online monitoring device and method based on optical fiber grating sensing. The device comprises a beam splitting system, a demodulating system, a control system and optical fiber grating sensors which are fixed on the outer wall of a long straight pipeline and the outer wall of a bent pipe. The optical fiber grating sensors fixed on the outer wall of the long straight pipeline only have one optical fiber grating and are arranged axially at equal intervals, and judge whether the long straight pipeline leaks or not according to a change condition of detected hoop strain of the pipeline, find out the leak position and acquire uniform corrosion condition; and the optical fiber grating sensors fixed on the outer wall of the long straight pipeline are provided with a plurality of optical fiber gratings and the optical fiber gratings on the same optical fiber grating sensor are uniformly arranged along the circumference, and the optical fiber grating sensors judge non-uniform corrosion condition at the bent pipe according to a change condition of detected local hoop strain. The device is simple in structure, low in cost, convenient to mount and high in monitoring precision.

Owner:WUHAN UNIV OF TECH

Anti-explosion material and manufacturing method thereof

The invention relates to an anti-explosion material, which is made of a cut and extended aluminum alloy foil mesh and has mesh-like or beehive-like porous structure, and is characterized in that: an aluminum alloy foil comprises the following chemical components in percentage by weight: 0.05 to 0.15 percent of silicon, 1.0 to 1.6 percent of copper, 0.2 to 0.5 percent of manganese, 1.0 to 3.0 percent of magnesium, 3.0 to 6.0 percent of zinc, 0.02 to 0.06 percent of titanium, 0.05 to 0.15 percent of zirconium, 0.1 to 0.3 percent of scandium and the balance of aluminum. Meanwhile, the invention also discloses a manufacturing method of the anti-explosion material. The material obtained by the method has the advantages of high electric and heat conductivities and large specific area and has the characteristics of corrosion resistance and high strength. When used as an anti-explosion material, the material is free from scraps and deformation. The material is particularly suitable for safe protection of containers for flammable and combustible liquid containers with high corrosivity as well as skid-mounted gasoline and gas filling station containers.

Owner:北京福吉长安防爆材料有限责任公司 +1

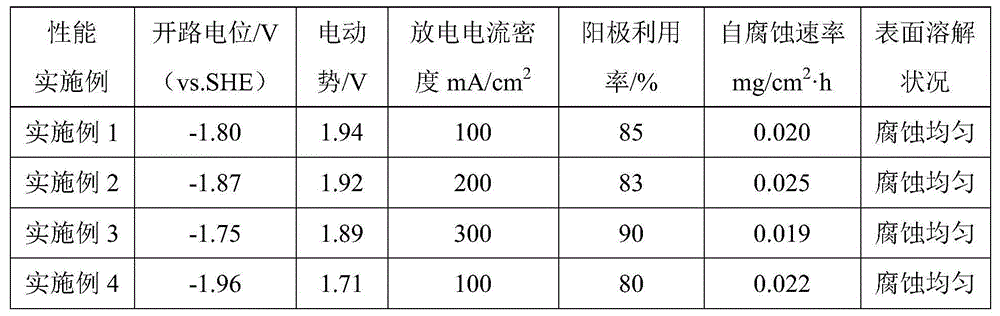

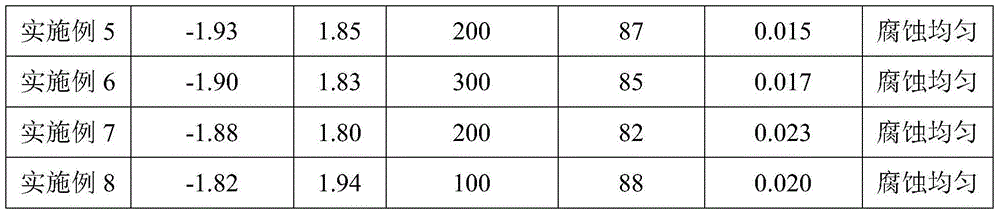

Aluminum alloy electrode material and preparation method and application of aluminum alloy electrode material

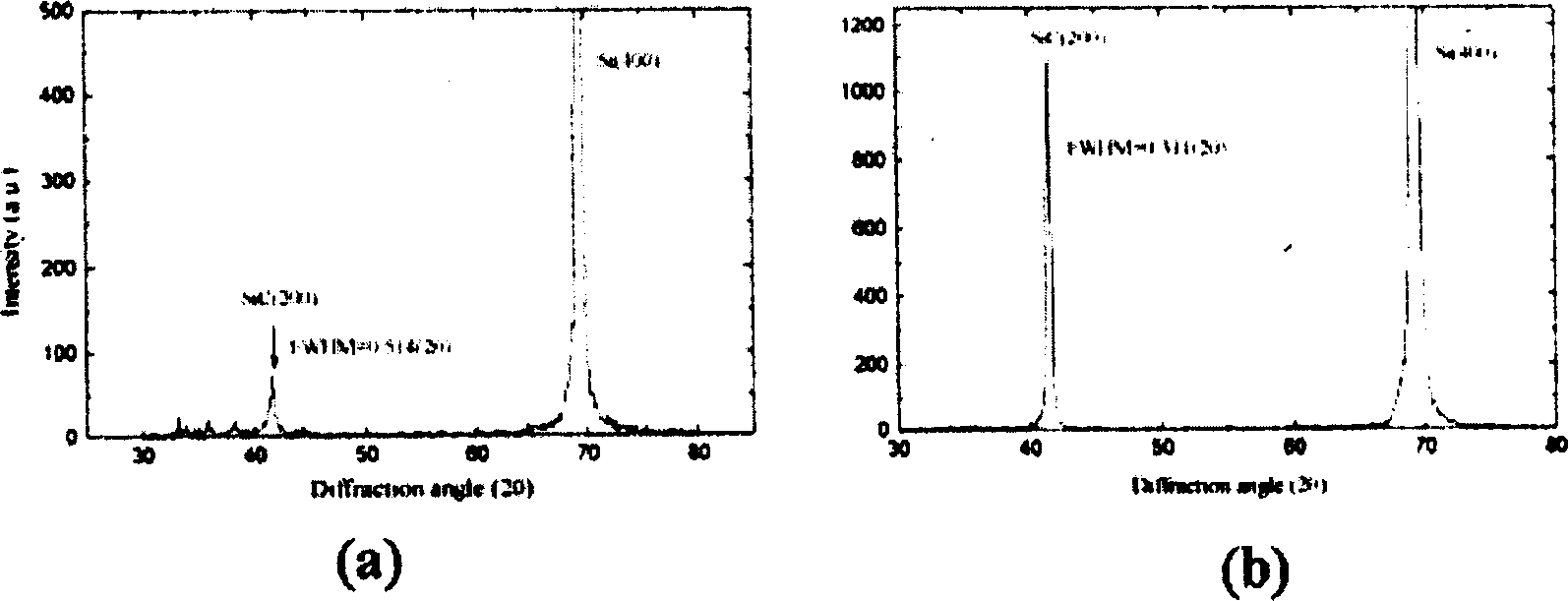

ActiveCN106191571AUniform corrosionReduce corrosion rateFuel and primary cellsCell electrodesRare-earth elementCrystallite

The invention provides an aluminum alloy electrode material. The aluminum alloy electrode material comprises 0.1-3 wt% of Mg, 0.05-1 wt% of Sn, 0.01-0.5 wt% of Ga, 0.02-0.1 wt% of RE and the balance Al. According to the aluminum alloy electrode material, an aluminum substrate is doped with a certain amount of magnesium, stannum, gallium and the rare earth element, on the basis of improving the activity of an aluminum anode, through the refining function of the rear earth element on grains, corrosion of the aluminum anode is evener, and the corrosion rate is lowered; meanwhile on the one hand, due to addition of the elements, the electrochemical performance of the aluminum alloy is good; on the other hand, the added elements are free of contamination; and the rare earth element is added in the form of an aluminum rare earth master alloy, and the price is low. The invention further provides a preparation method of the aluminum alloy electrode material and application of the aluminum alloy electrode material in air batteries.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Anticorrosive and antiwear cast cobalt-base alloy

The present invention relates to Co-base alloy, especially, an anticorrosive and antiwear cast Co-base alloy. The alloy consists of C 1.0-2.5 wt%, Cr 20-35 wt%, W 5-20 wt%, Mo 1-6 wt%, Nb 1-8 wt%, Cu0.5-2.0 wt%, Si 0.5-3.0 wt%, Ni 2-15 wt% and Co 35-65 wt%. It has excellent anticorrosive performance and average hardness of about 48 HRC, and may be used in making cutter of water flow type chemical fiber cutting machine. Substituting partial Co with Ni can reduce the cost of the alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Rare earth-containing amorphous/nanocrystal aluminum anode composite material, preparation method and aluminum air battery

InactiveCN104372206AImprove electrochemical performanceAbundant resourcesFuel and primary cellsCell electrodesRare-earth elementDissolution

The present invention discloses a rare earth-containing amorphous / nanocrystal aluminum anode composite material, a preparation method and an aluminum air battery, and belongs to the techncial field of air batteries. The aluminum anode composite material comprises, by weight, 0.5-5% of Mg, 0.02-2% of Sn, 0.02-2% of Ga, 0.1-5% of La or Ce, and the balance of Al. According to the present invention, aluminum with the purity of more than or equal to 99.8% is adopted as the base, the trae amounts of Mg, Sn, Ga and the rare earth element La or Ce are added so as to reduce the self-corrosion rate and improve the electrochemical property and the surface dissolution uniformity of the alloy, especially the trae amount of the rare earth element is added to the aluminum alloy, and the addition of the rare earth element to the aluminum has effects of oxygen removing, hydrogen removing, desulfuration, melting rate accelerating, metal burning loss reducing, change of species distribution and refinement modification of iron and other harmful impurities, and the like so as to slow down the self-corrosion of the aluminum alloy, such that the anode utilization rate is improved.

Owner:HENAN UNIV OF SCI & TECH

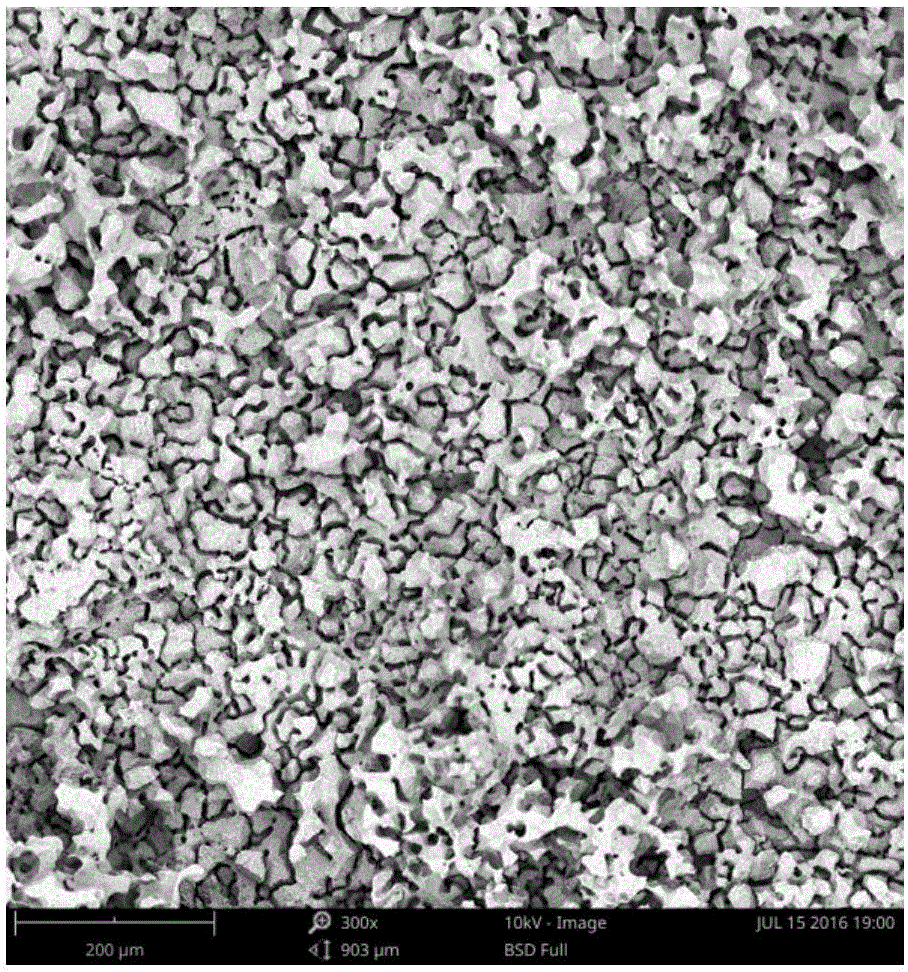

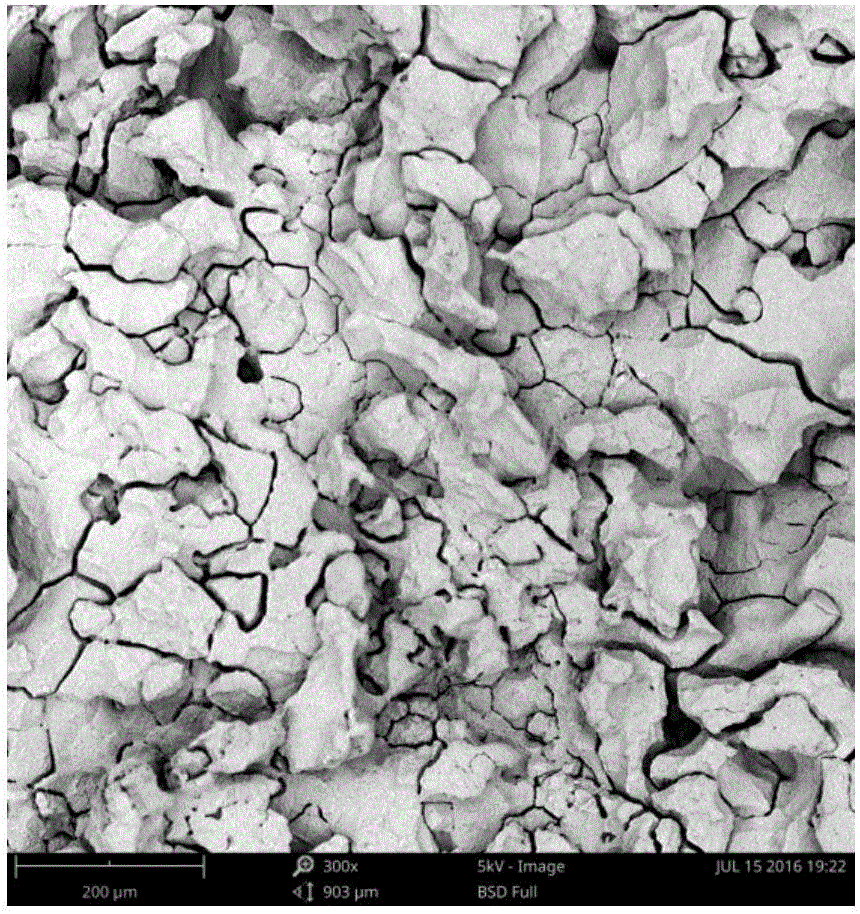

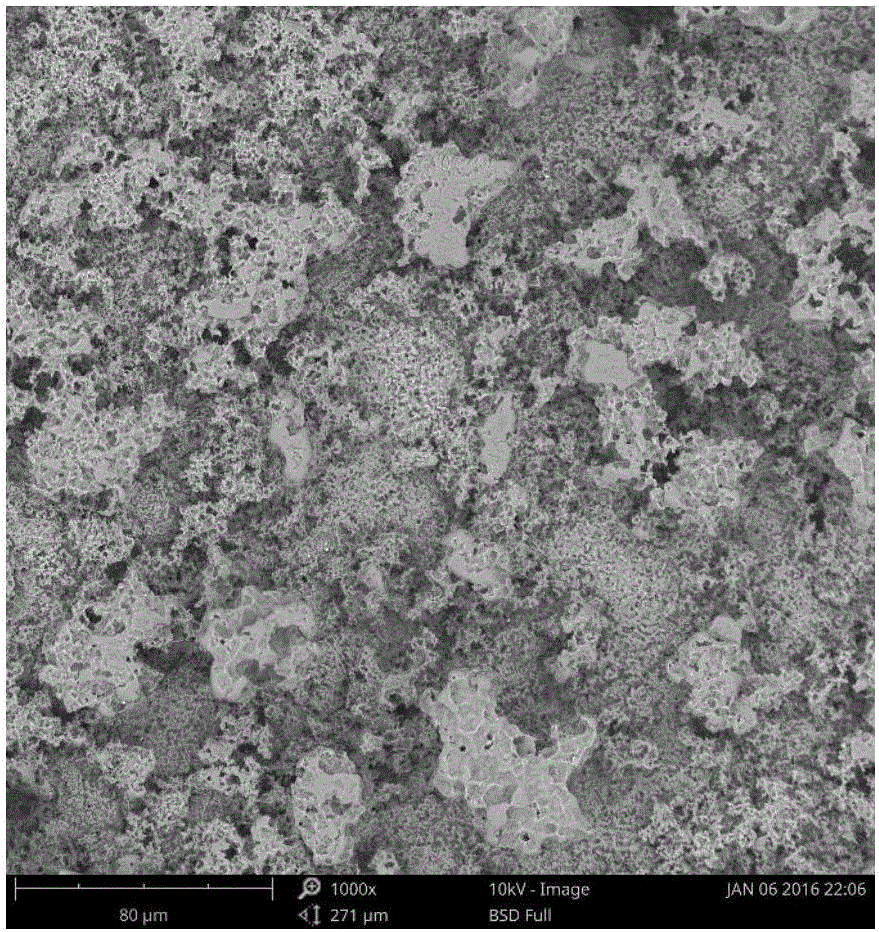

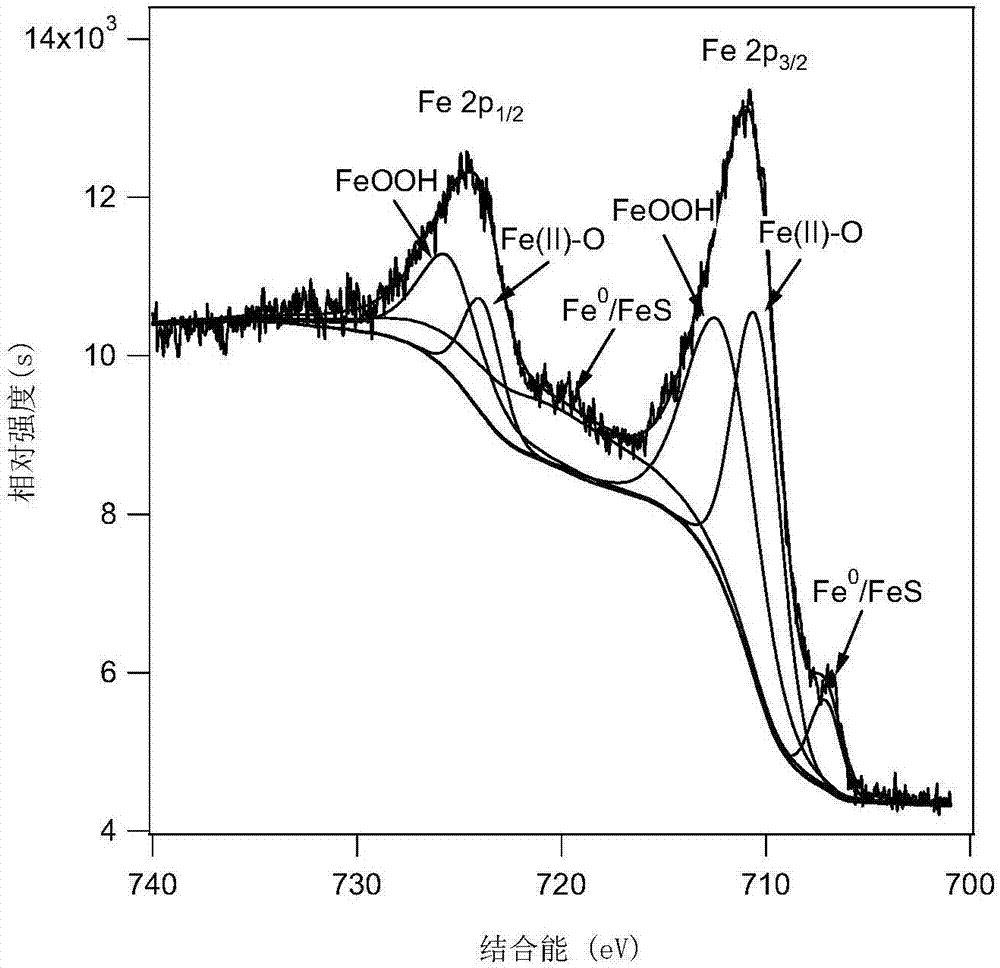

Bentonite-loaded sulfurized nanoscale zero-valent iron composite material and preparation method and application thereof

InactiveCN107081125AHigh reactivityFacilitates electron transferOther chemical processesWater contaminantsSodium BentoniteMass ratio

The invention relates to a bentonite-loaded sulfurized nanoscale zero-valent iron composite material and a preparation method and application thereof. According to the composite material, sulfurized modified nanoscale zero-valent iron is loaded on bentonite; the mass ratio of bentonite to total iron is (0.85-1.2):1, and the molar ratio of a sulfur element to total iron is (0.05-0.065):1. The bentonite-loaded sulfurized nanoscale zero-valent iron composite material is more stable and efficient, and is suitable for treatment of multiple pollutants; electron transfer on the surface of the nanoscale zero-valent iron can be accelerated through sulfurized modification and corrosion is promoted, thereby greatly improving the reaction activity of the material; furthermore, the sulfuration process is simple and is free of pollution; and the material is not easy to reunite when loaded on bentonite and the activity can be kept for a long period of time. The removal rate of the material on 4-nitrophenol within 2min reaches over 97.5%, and the removal rate on orange I is close to 100%.

Owner:山东大学深圳研究院 +1

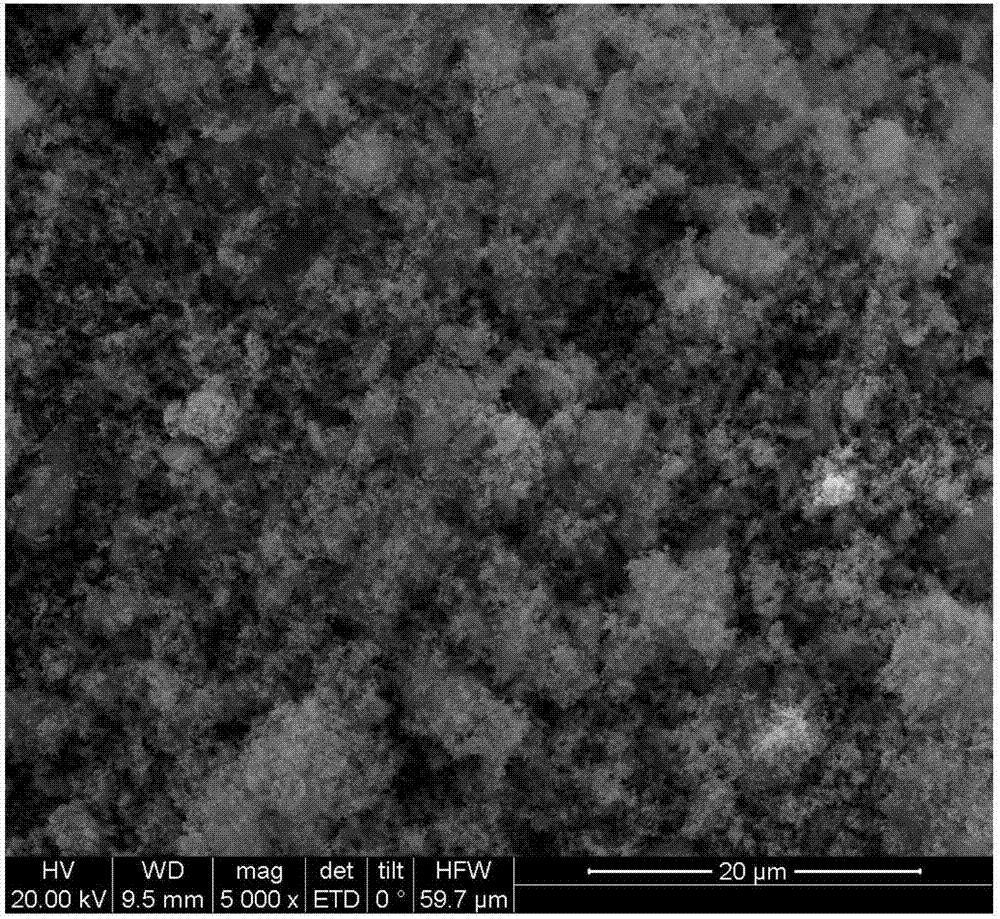

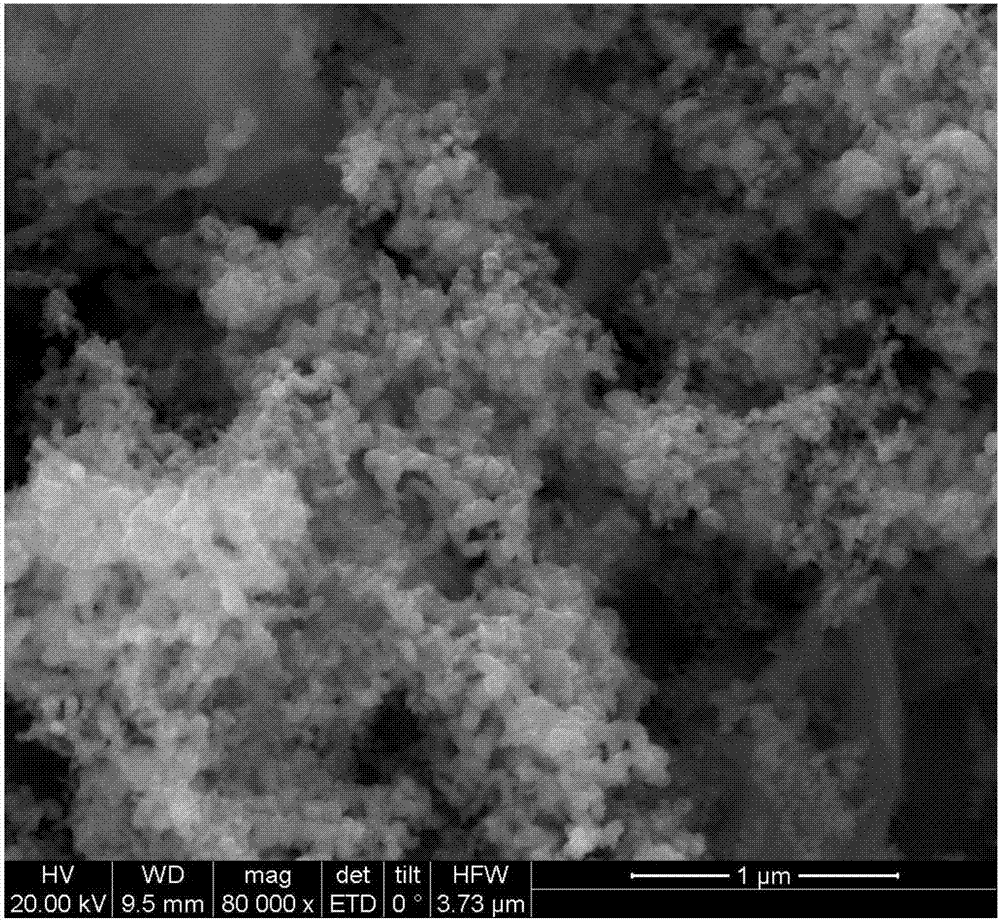

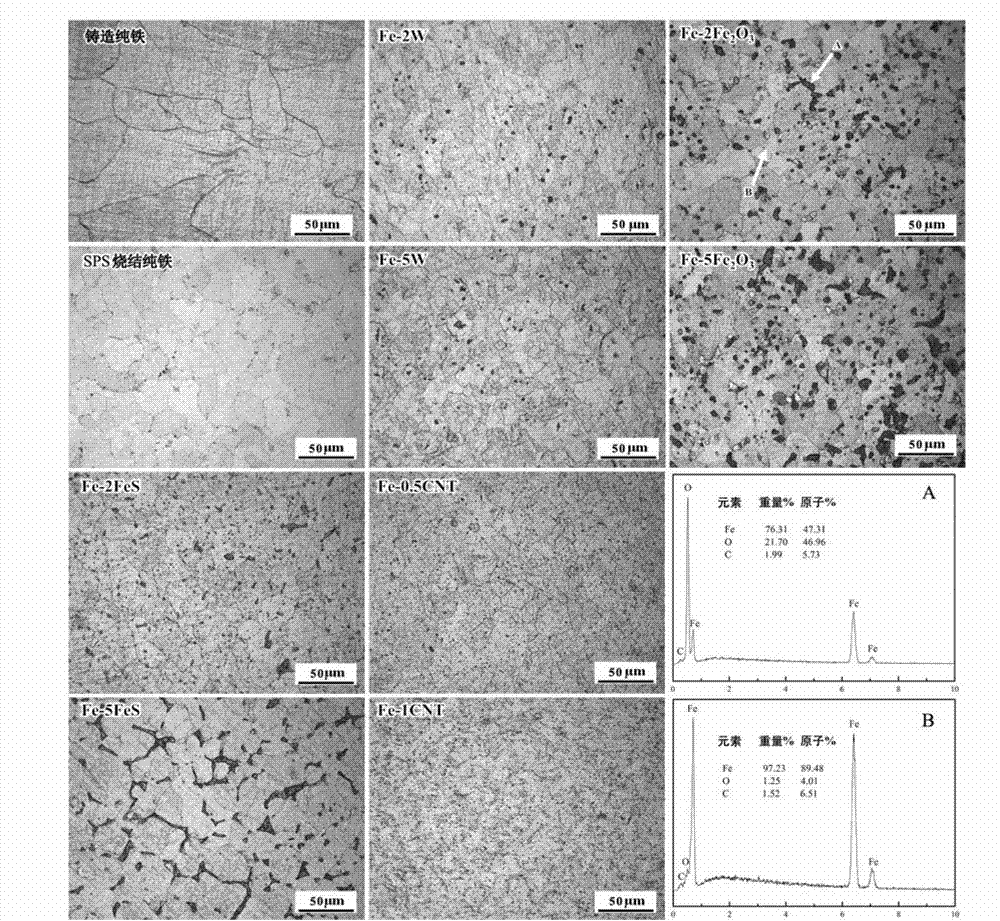

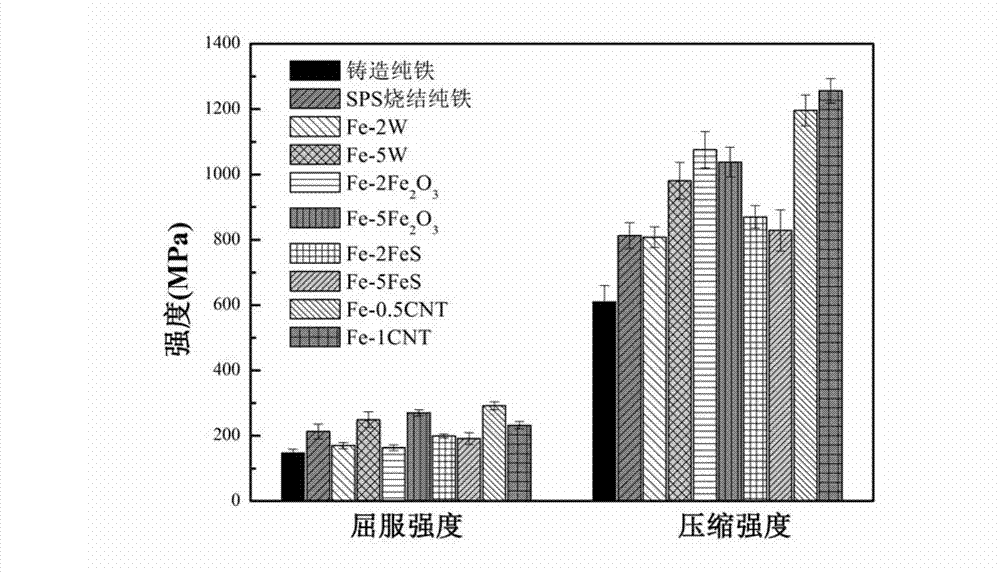

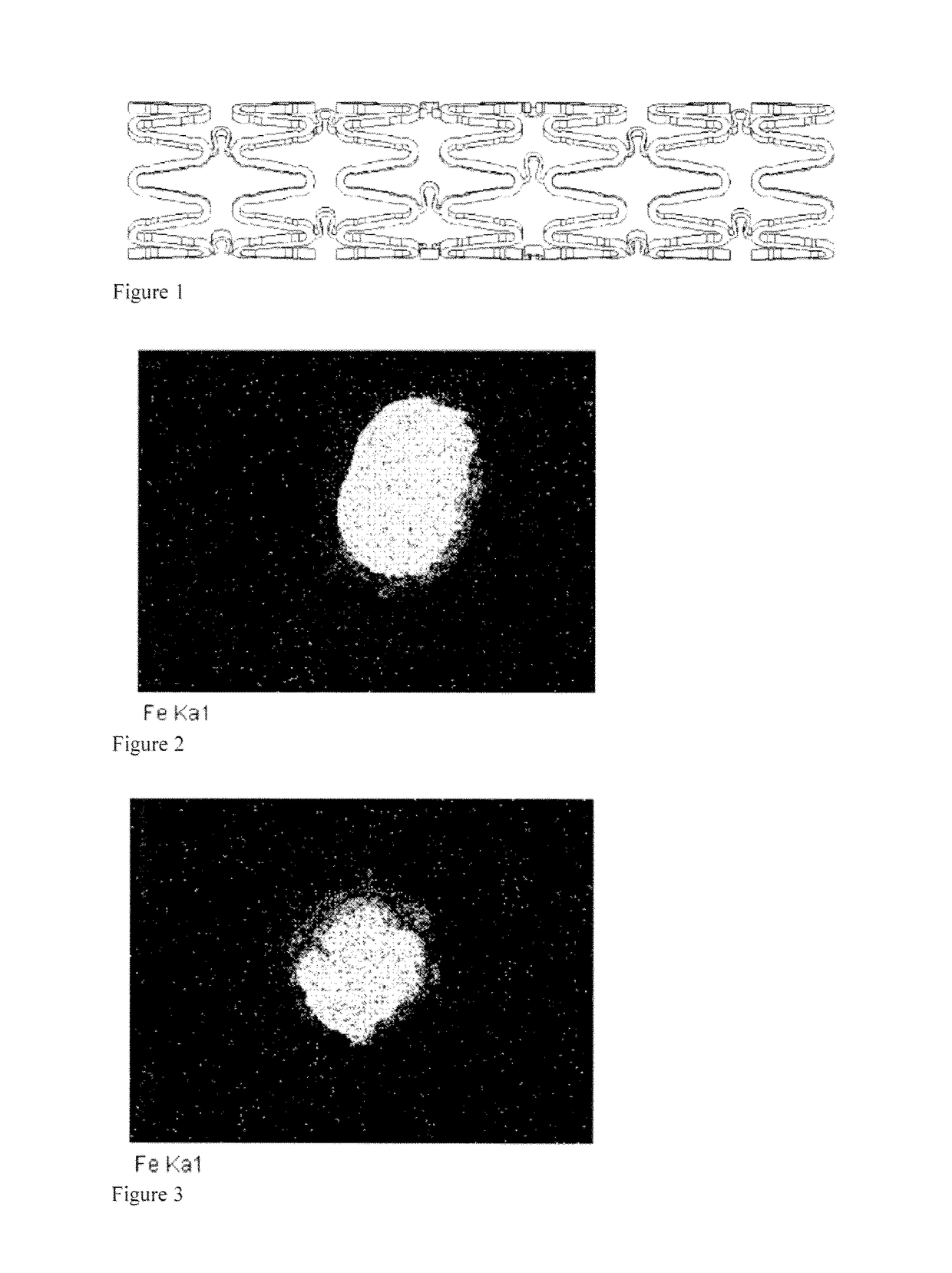

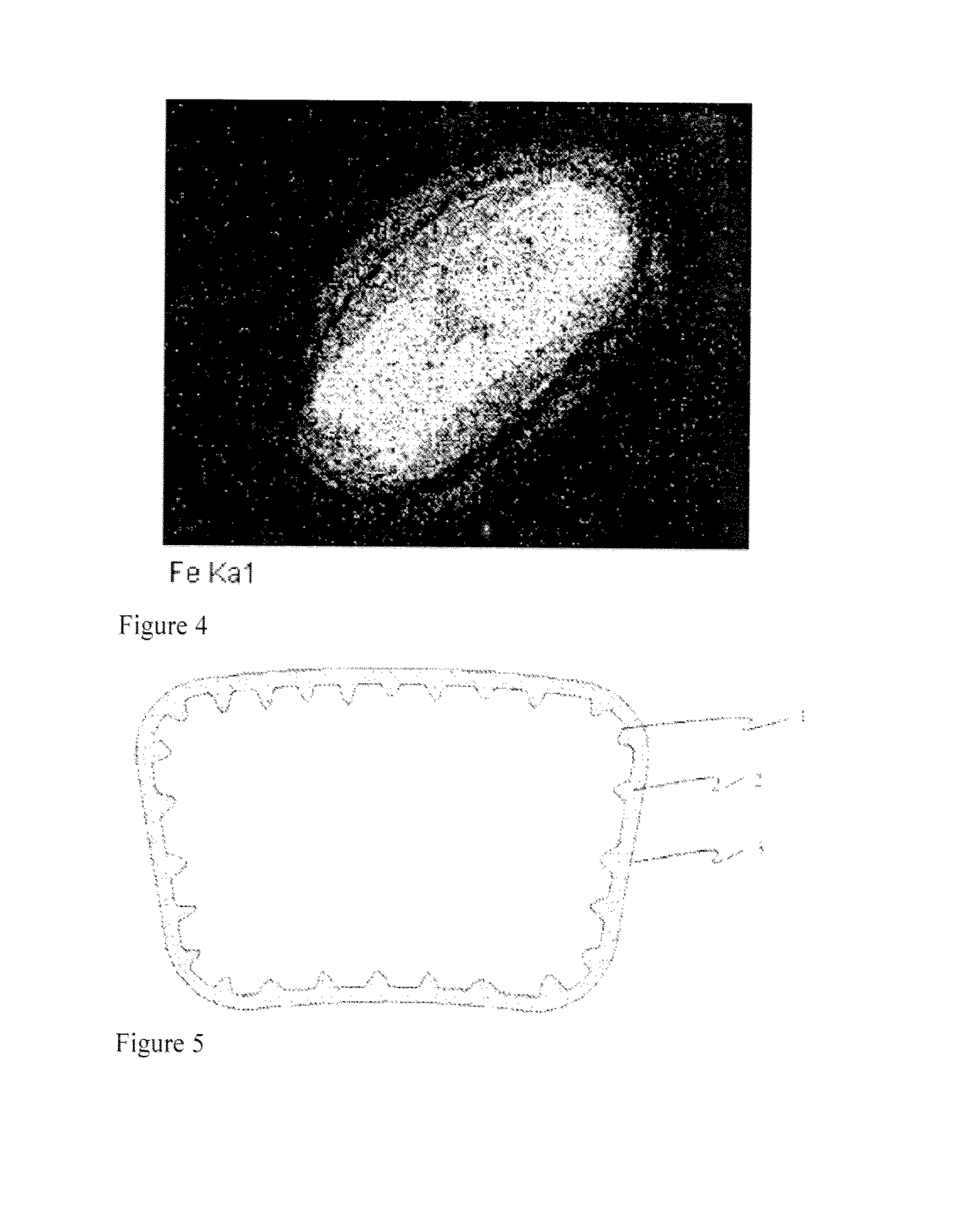

Iron-based composite material used for full-degradation cardiovascular support and preparation method thereof

InactiveCN102961787AFulfil requirementsIncrease corrosion rateSurgeryCoatingsCardiovascular stentCarbon nanotube

The invention discloses an iron-based composite material used for a full-degradation cardiovascular support and a preparation method thereof. The iron-based composite material comprises Fe and any one of W, Fe2O3, FeS and carbon nano tube, wherein the content of any one of W, Fe2O3, FeS and carbon nano tube is 0-10% and more than 0% in the iron-based composite material in percent by weight. The preparation method of the iron-based composite material comprises the following steps of: mixing iron powder with any one of tungsten powder, Fe2O3 powder, FeS powder and carbon nano tube powder, then carrying out spark plasma sintering or sintering by virtue of powder metallurgy, and cooling, so that the iron-based composite material is obtained. The iron-based composite material used for full-degradation cardiovascular support disclosed by the invention overcomes the defects of the traditional inert metal support such as late thrombosis and restenosis; and a secondary phase harmless to a human body is selected as a strengthening phase of the composite material, so that corrosion rate of an iron base in a body fluid environment is increased, and corrosion of the iron base is more uniform.

Owner:PEKING UNIV

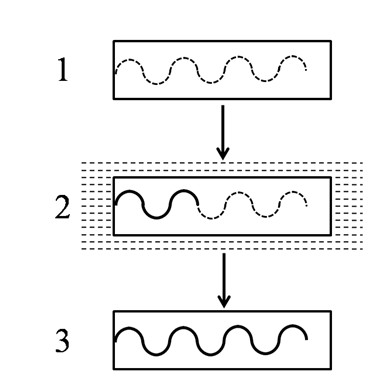

Method for preparing three-dimensional fluid channel in transparent material

InactiveCN102627257AUniform corrosionReduce corrosionMicrostructural devicesLaser beam welding apparatusPolymer chemistryCircular polarization

The invention discloses a method for preparing a three-dimensional fluid channel in a transparent material. The complex three-dimensional fluid channel is prepared inside the transparent material by utilizing femtosecond lasers of circular polarization. The three-dimensional fluid channel prepared by the method disclosed by the invention has the advantages of same anisotropic etch rate and faster etch rate for a complex structure.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Dissecting process for diode device

InactiveCN102646618ASlow corrosionUniform corrosionSemiconductor/solid-state device manufacturingSemiconductor devicesRetention timeCopper

The invention discloses a dissecting process for a diode device. The dissecting process comprises the steps of: 1) continuously heating concentrated sulfuric acid with concentration of 98 percent in a beaker to 95 DEG C; 2) putting the diode device in the concentrated sulfuric acid; 3) putting the diode device in clean water for ultrasonic oscillation cleaning; 4) putting the diode device treated in the step 3 in acetone solution; 5) forming first mixed solution in a beaker by using nitric acid and hydrogen peroxide according to a ratio of 5 to (0.8-1.2) and immersing the diode device in the first mixed solution; 6) forming second mixed solution in a beaker by using nitric acid and water according to a ratio of 5 to (1.8-2.2) and putting the diode device which is decoppered in the step 5) in the second mixed solution in a boiling state and keeping retention time to be 5-10 minutes; and 7) washing the diode device with water, immersing the diode device in acetone solution for oscillation dewatering and keeping washing time to be 20-40 seconds to obtain a diode chip. By adopting the dissecting process, when an epoxy layer is removed, the internal structure of the device is not influenced at all and the reliability of data analysis is greatly improved.

Owner:SUZHOU GOODARK ELECTRONICS CO LTD

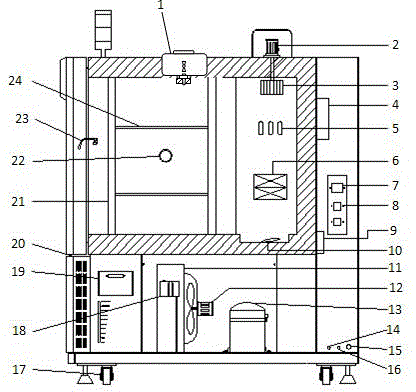

Salt spray test device with constant temperature and constant humidity

InactiveCN104535483AReasonable designUniform corrosionWeather/light/corrosion resistanceSalt spray testSoftware engineering

The invention provides a salt spray test device with constant temperature and constant humidity. The salt spray test device comprises a box body, a test cabinet, a humidifier, a cooling device, a heater, an evaporator, a water tank, a circumfluence device and a salt spray generator. The salt spray test device is reasonable in design; firstly the salt spray generator is matched with the circumfluence device, so that the salt spray can integrally and equably etch a solid-shaped object, and the whole device has a structure required by constant temperature and humidity, so that the corrosion test condition is set in a needed scene, and the test condition is more approximate to the real environment. In addition, the salt spray test device also has a favorable drainage and overflowing structure, the device use safety is ensured, and the salt spray test device has excellent capability of saving the salt spray.

Owner:陈东晓 +2

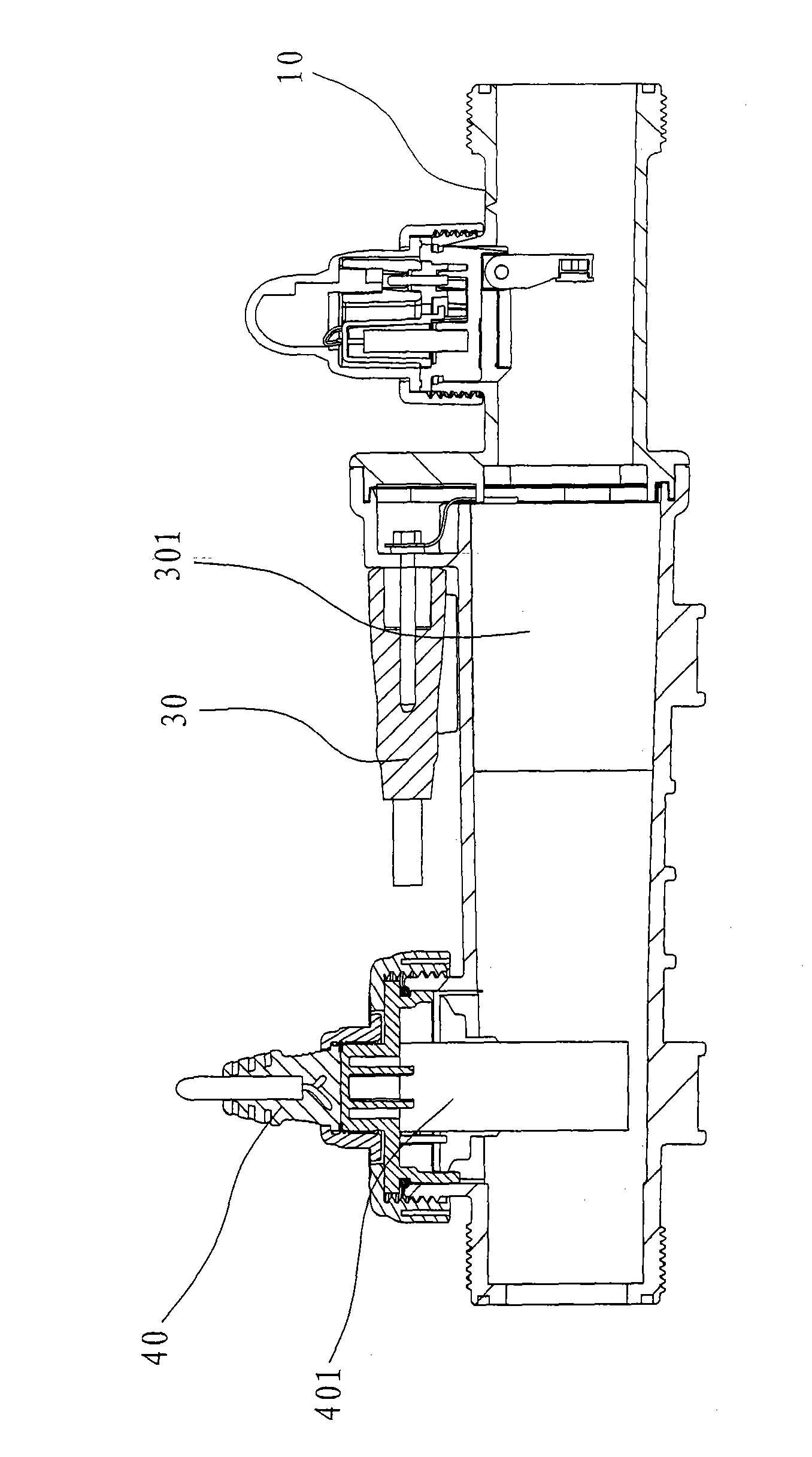

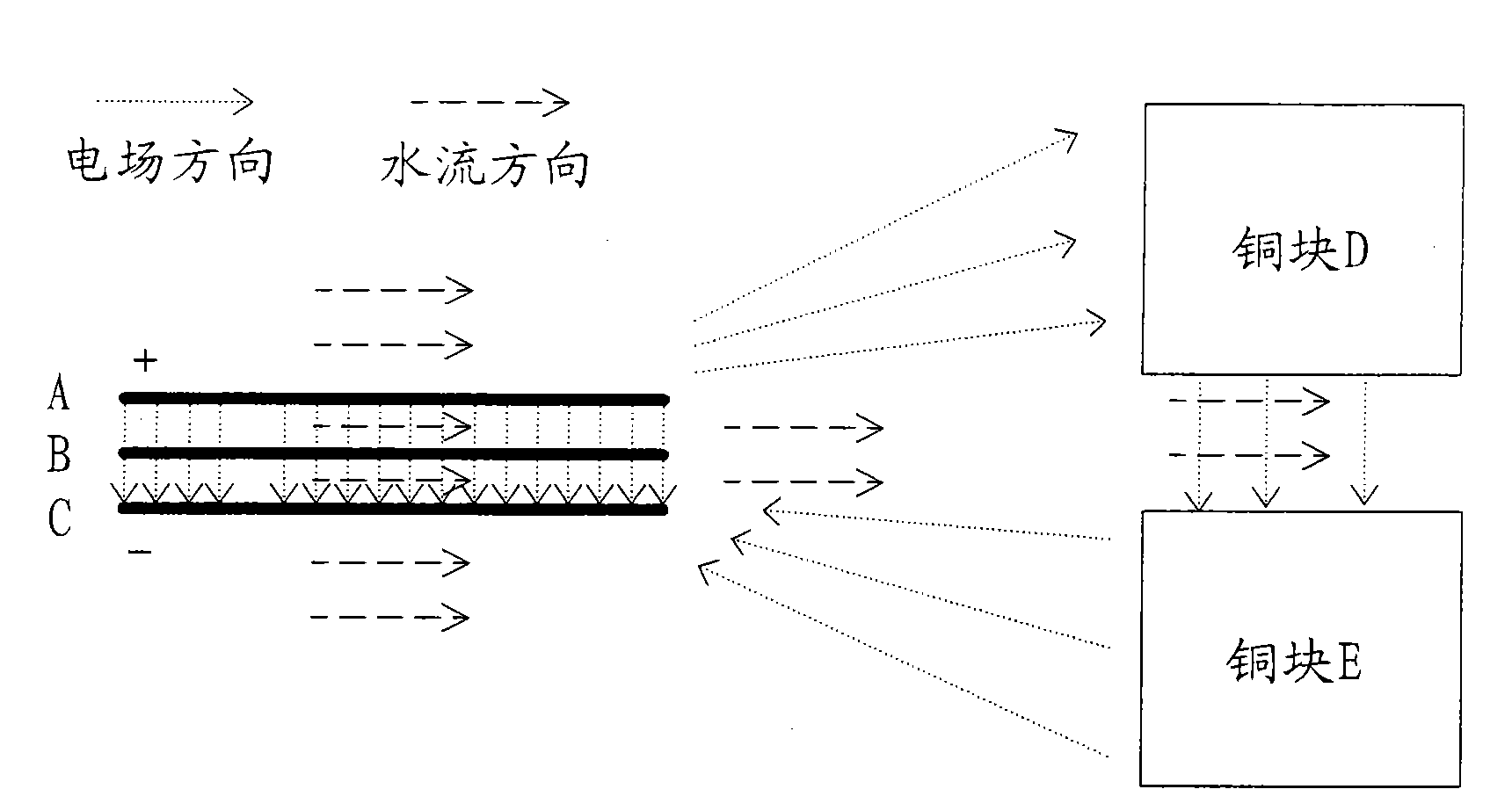

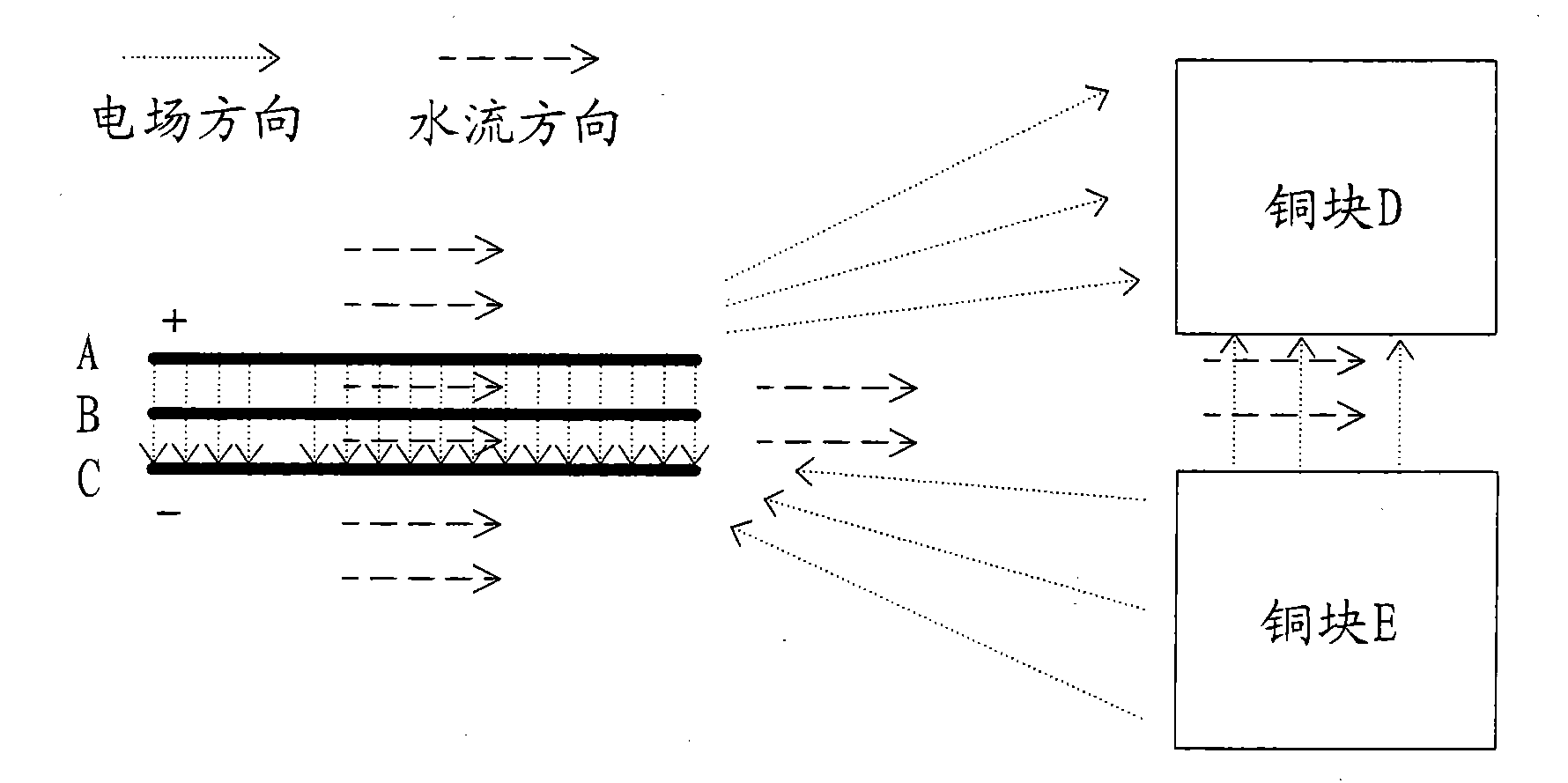

Two-in-one cupric chloride/cupric bromide disinfecting apparatus for swimming pool and control method thereof

ActiveCN101993135AInhibition releaseThe amount of release is controllableWaste water treatment from bathing facilitiesGymnasiumCupric bromideGraphite electrode

The invention discloses a control method of a two-in-one cupric chloride / cupric bromide disinfecting apparatus for a swimming pool, comprising the following steps of: when copper is released, periodically inverting an anode and a cathode of a copper block and allowing an anode and a cathode of titanium plate / graphite electrode plate to be in a suspending state simultaneously; and when chloride / bromide is released, periodically inverting the anode and the cathode of the titanium plate / graphite electrode plate and short connecting the anode and the cathode of the copper plate simultaneously and then connecting the copper block with the cathode of the titanium plate / graphite electrode plate or applying the voltage lower than the voltage of the titanium plate / graphite electrode plate. In the method, by short connecting the copper block when not in work with the cathode of the titanium plate / graphite electrode plate or applying the voltage lower than the voltage of the cathode, the release amount of copper ions can be controlled, the volume of the disinfecting apparatus can be reduced and the corrosion between the anode and the cathode of the copper block is balanced. The invention also discloses the two-in-one cupric chloride / cupric bromide disinfecting apparatus for the swimming pool.

Owner:INTEX IND (XIAMEN) CO LTD

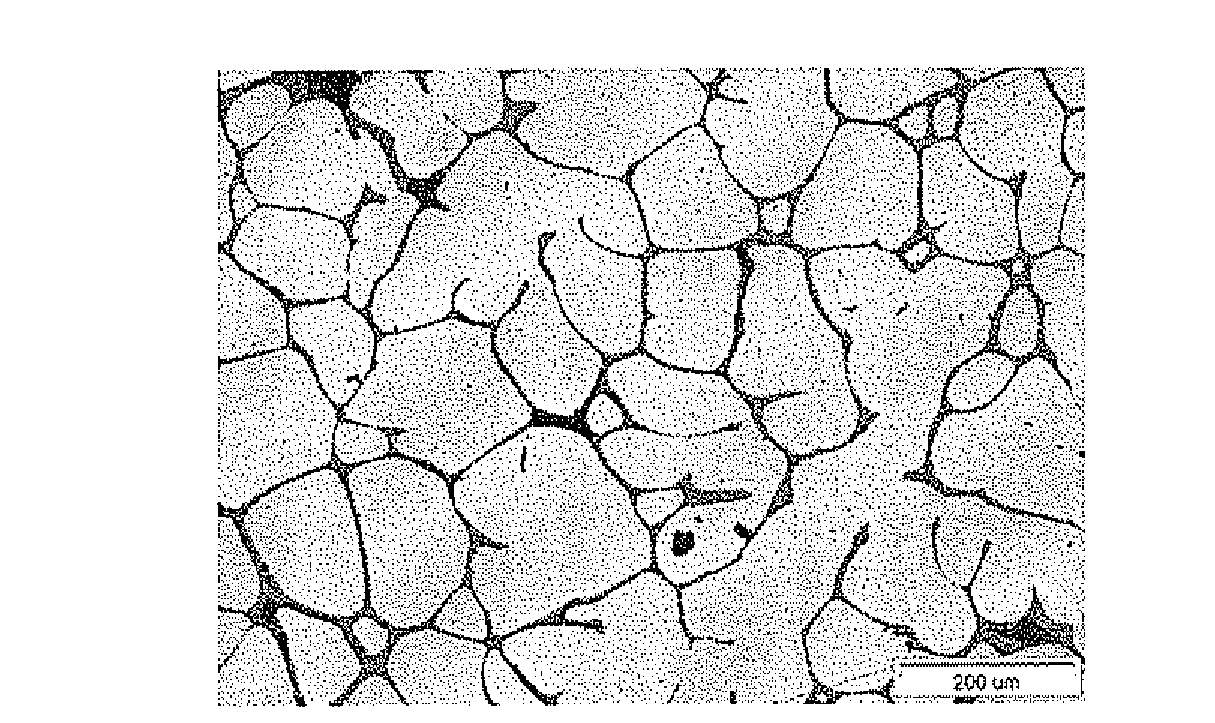

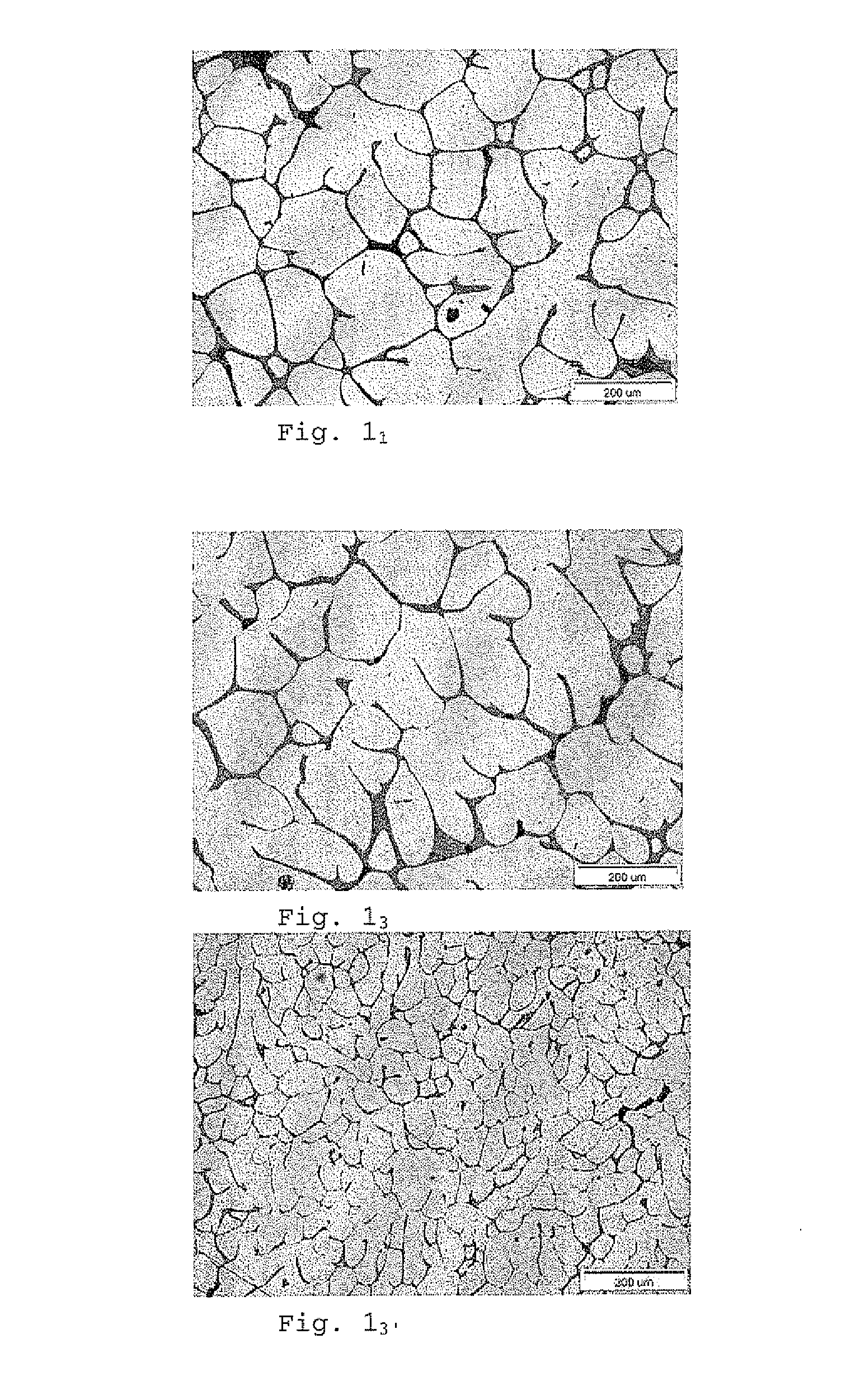

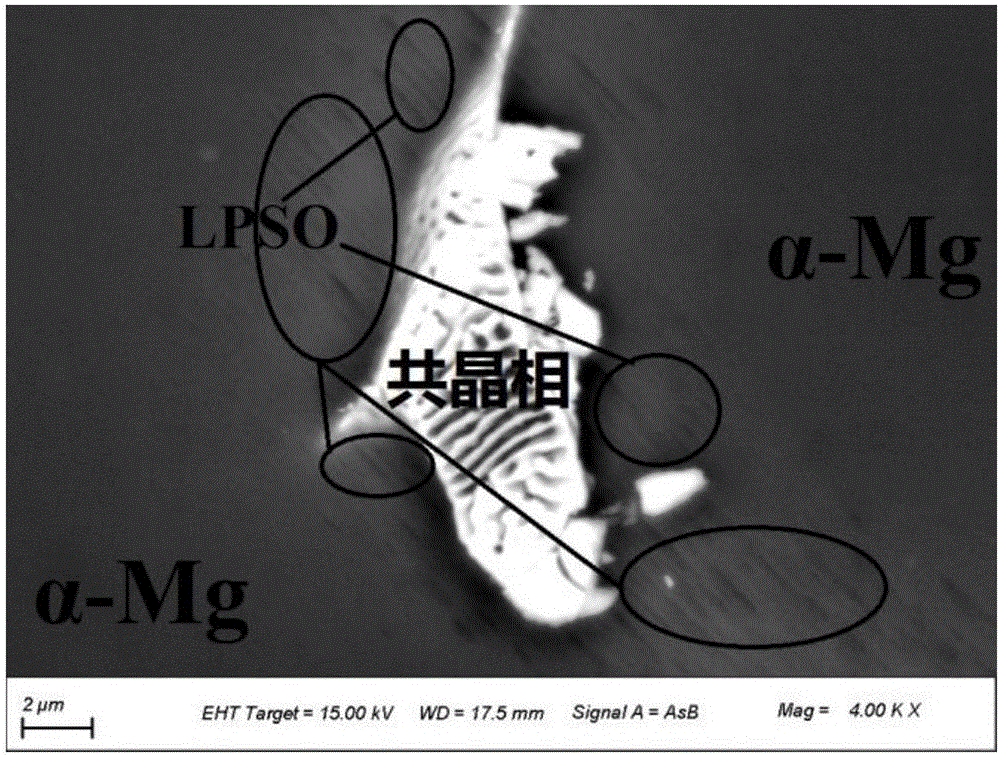

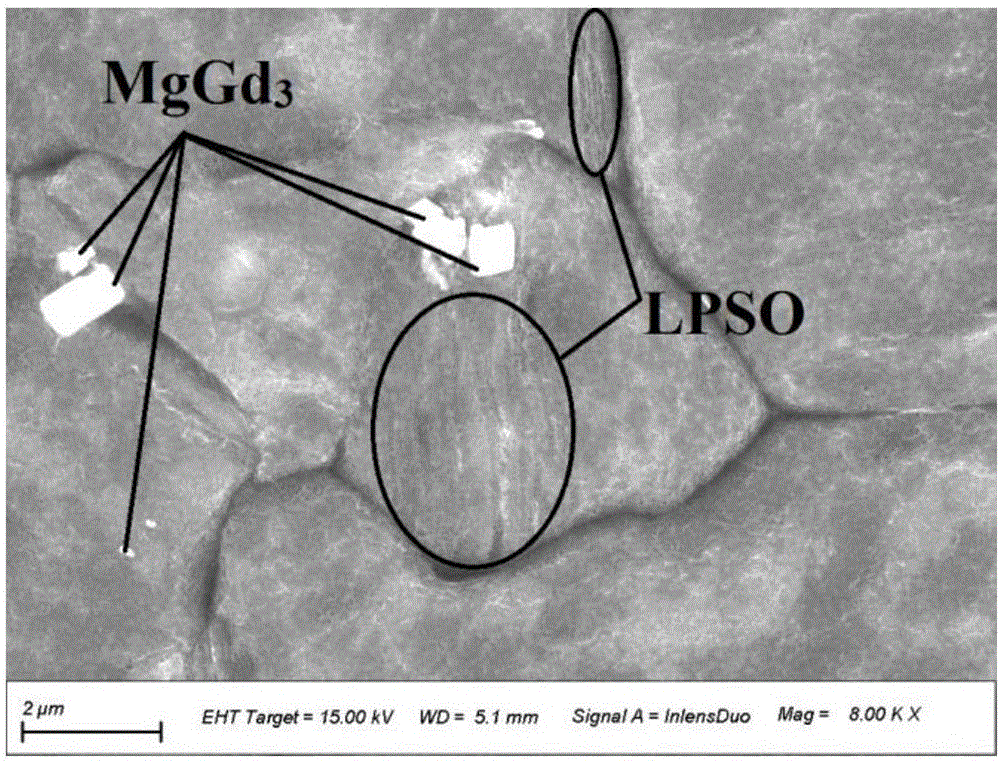

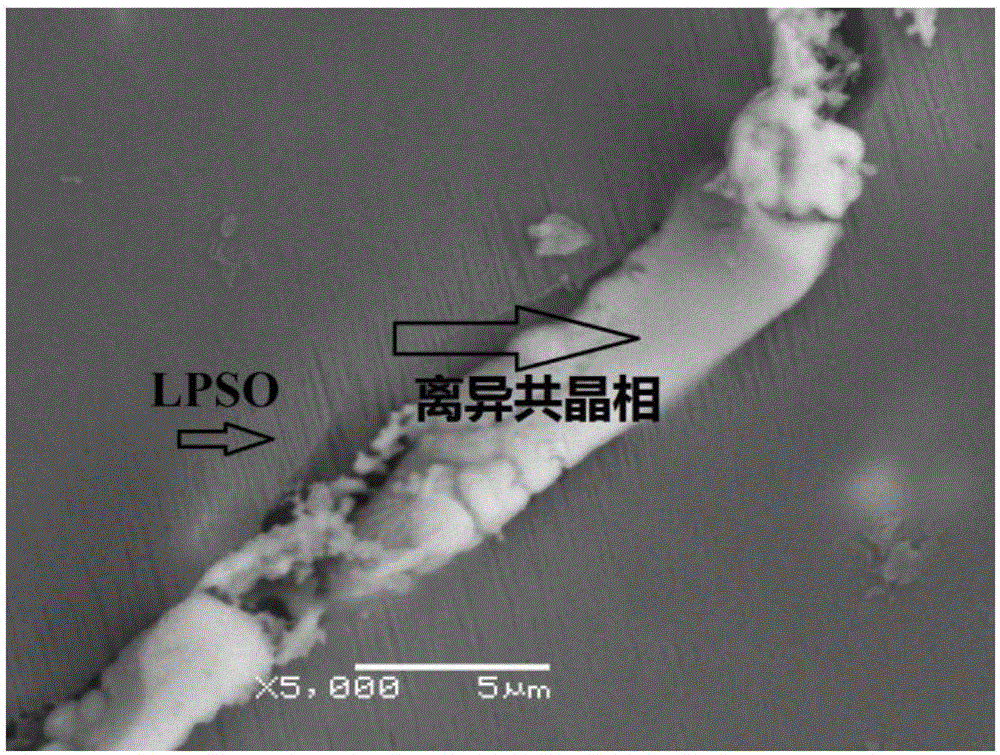

Medical Mg-Gd-Zn (-Ca) magnesium alloy with LPSO structure and preparation method thereof

The invention relates to a medical Mg-Gd-Zn (-Ca) magnesium alloy with an LPSO structure and a preparation method of the medical Mg-Gd-Zn (-Ca) magnesium alloy with the LPSO structure and belongs to the field of medical magnesium alloy preparation. The medical Mg-Gd-Zn (-Ca) magnesium alloy with the LPSO structure comprises, by mass, 1.0%-3.5% of Gd, 0.3%-1.2% of Zn and 0-1.0% of Ca. The preparation method of the medical Mg-Gd-Zn (-Ca) magnesium alloy with the LPSO structure comprises the steps that raw materials which are in an appropriate ratio are placed in a crucible containing mixed protective gases of CO2 and SF6 in sequence for melting, stirring, standing and casting, wherein during casting, the solidification rate is controlled; and a cast ingot is placed in a resistance furnace with a protective atmosphere for heat treatment, and then rod materials are formed through extrusion. The medical Mg-Gd-Zn (-Ca) magnesium alloy with the LPSO structure has the advantages that the contents of the Gd element and the Zn element are low, the biological safety is high, the cost is low, and the technology is simple. Cast alloy tissue and extrusion alloy tissue both have the LPSO structure. Besides, after Ca is added, a divorced eutectic (Mg, Zn, Ca) 3Gd phase is formed in the cast alloy and is beneficial for the abrasion resistance performance of the alloy, the microstructure is adjustable, and the corrosion resistance of a material can be effectively improved. The medical Mg-Gd-Zn (-Ca) magnesium alloy with the LPSO structure has broad application prospect in the biomedical fields of orthopedics and cardiovascular stent implantation.

Owner:NANJING INST OF TECH

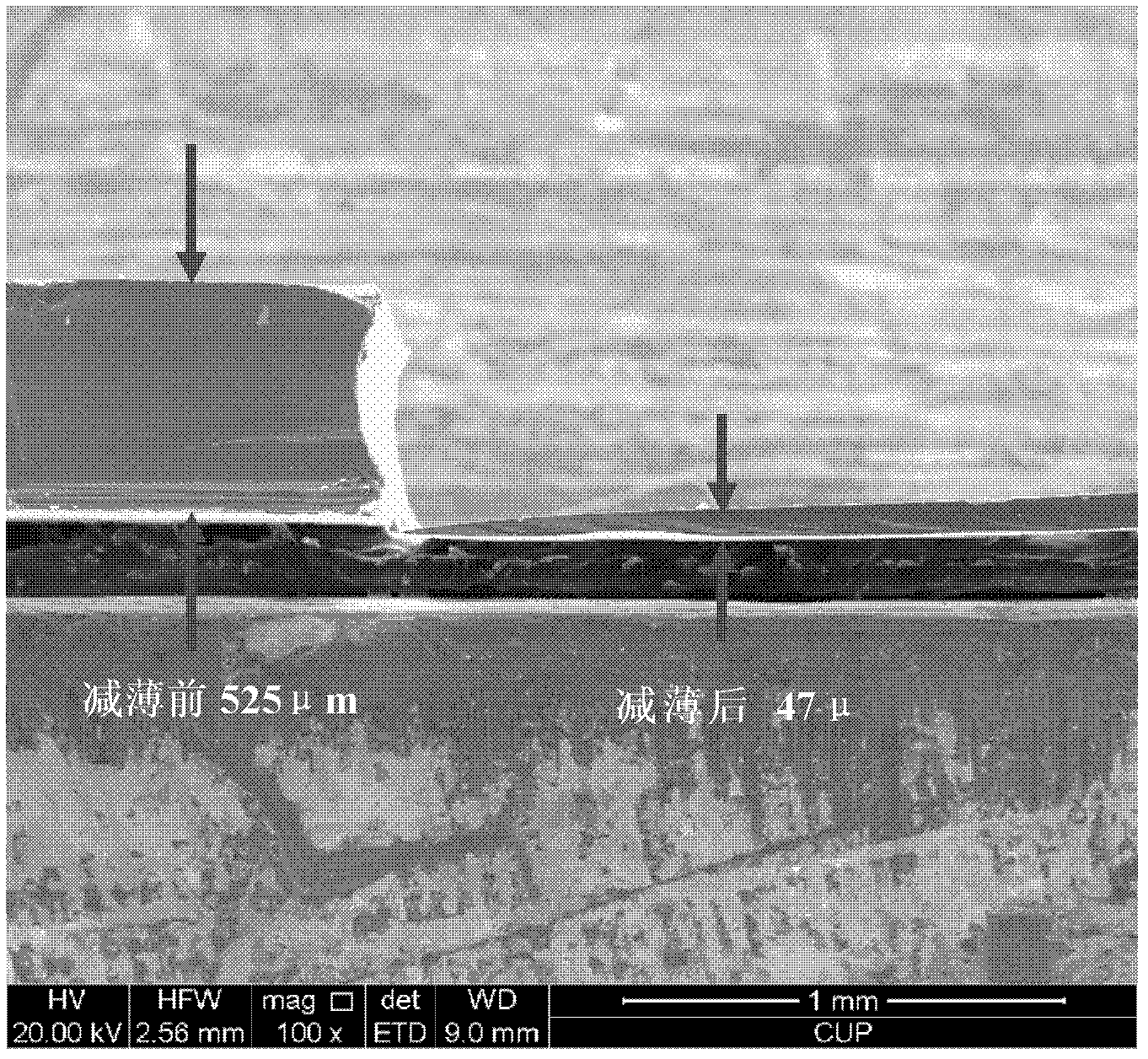

Silicon slice thinning method based on metal nano particle catalysis

ActiveCN102354661AUniform corrosionGood repeatabilitySemiconductor/solid-state device manufacturingWater bathsEtching

The invention discloses a silicon slice thinning method based on metal nano particle catalysis in the technical field of microelectronics. The method comprises the following steps of: pretreating a silicon slice (100) or (111) at normal temperature by using acetone, a CP4-A solution and hydrofluoric acid so as to obtain a clean silicon surface; and preparing a thinning solution which is formed byuniformly mixing silver nitrate, hydrogen peroxide and hydrofluoric acid, putting the thinning solution into a water bath for preheating, immersing the silicon slice into the thinning solution, and thus obtaining an ultrathin silicon slice with a required thickness by controlling reaction time, temperature and a solution ratio. In the method, the silicon slice can be uniformly etched by using a metal nano particle catalysis characteristic at the first time; a silicon slice thinning process is simplified by using a one-step method; characteristics of wet etching at near normal temperature and normal pressure can be retained, so the ultrathin silicon slice with the thickness of less than 50 microns can be obtained; furthermore, an application range of metal nano particle catalysis silicon etching is expanded; and a new idea and a new technical measure can be supplied to the silicon slice thinning process.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

High petential magnesium alloy sacrificial anode material and its manufacturing method

A high-potential Mg alloy used as consumable anode for the underground oil or gas pipeline, storage tank and water pipe is prepared through micro-alloying the Mg-Mn alloy by Mg-Ca and Mg-RE intermediate alloys, and refining by use of special refining agent to obtain Mg MnRECa alloy, which contains proportionally Mn, Ce, Ca, Si, Cu, Ni, Fe and Mg. Its advantages are high open-circuit potential 1.7-1.8 (-V) and high current efficiency (55-60%).

Owner:TAIYUAN UNIV OF TECH

Aluminum foil for plastic-aluminum film used for flexible package of lithium ion battery, and preparation method thereof

InactiveCN107901536AMeet the long-term requirements of corrosion resistanceImprove corrosion resistanceSecondary cellsJackets/cases materialsPower batteryAluminum foil

The invention discloses an aluminum foil for a plastic-aluminum film used for flexible package of a lithium ion battery, and a preparation method thereof. The aluminum foil is composed of a core layerand a protective layer which are compounded together. The core layer comprises, by weight, no less than 0.1% and no more than 1.0% of Si, no less than 0.1% and no more than 1.8% of Fe and no less than 0.1% and no more than 1.8% of Mn, with the balance being Al. The protective layer comprises, by weight, no less than 0.1% and no more than 1.0% of Mn, no less than 0.1% and no more than 1.0% of Si,no less than 0.1% and no more than 1.8% of Fe and no less than 0.1% and no more than 1.8% of Zn, with the balance being Al. According to the invention, the production process flow of the plastic-aluminum film is simplified, and the protective layer is allowed to directly contact with an antifreezing solution and performs protection effect as a sacrificial anode; and a special annealing process iscooperatively used to guarantee uniform corrosion of a material in the process of corrosion, so the high corrosion resistance of the plastic-aluminum film in the antifreezing solution is effectively ensured, local corrosion is prevented, and the requirement of a power battery for long-lasting corrosion resistance of the plastic-aluminum film is met.

Owner:SHANGHAI HUAFON NEW MATERIAL R&D TECH CO LTD +1

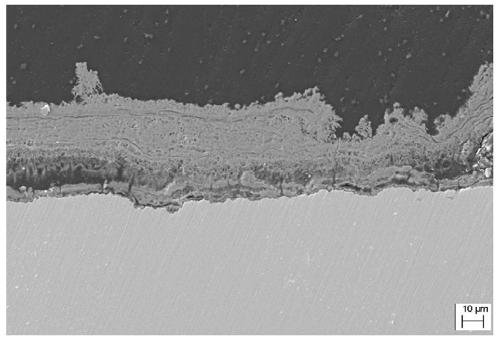

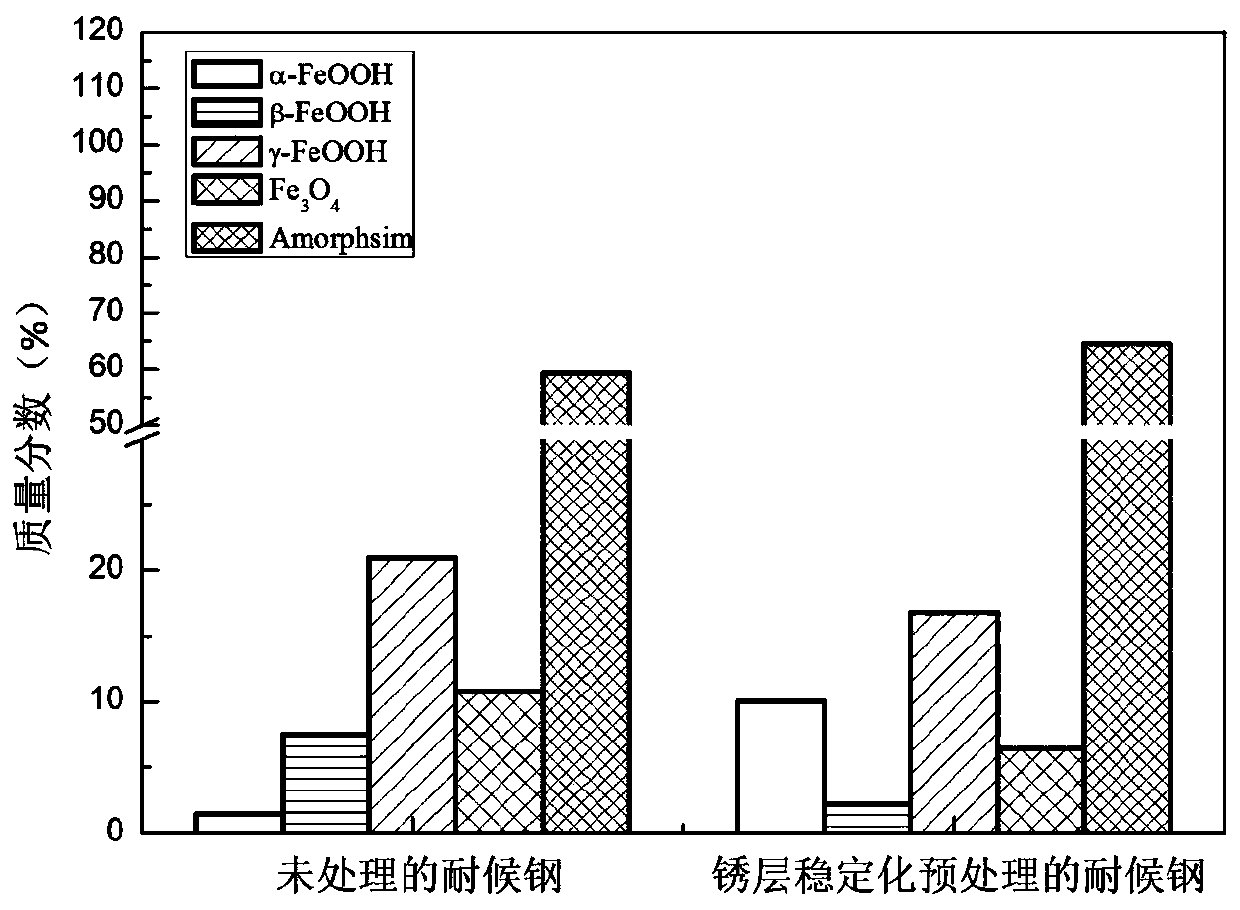

Stabilizer for promoting formation of weather-resistant steel rust layer and preparation method of weather-resistant steel rust layer

InactiveCN110093599AAdjust porosityUniform corrosionMetallic material coating processesWater basedAlpha-FeOOH

The invention belongs to the technical field of weather-resistant steel surface pretreatment, relates to corrosion of weathering steel materials in an atmospheric environment, in particular to a stabilizer for promoting the formation of a weather-resistant steel rust layer and a preparation method of the weather-resistant steel rust layer. The stabilizer comprises the following components of, nanoalpha-FeOOH, nano gamma-FeOOH, nano Fe3O4, CuSO4, Cr2(SO4)3, water-based acrylic acid and water; the nano alpha-FeOOH, the nano gamma-FeOOH, the nano Fe3O4, the CuSO4 and the Cr2(SO4)3 are uniformlydispersed in an aqueous acrylic acid aqueous solution; and the nano alpha-FeOOH, the nano gamma-FeOOH and the nano Fe3O4 can induce rust layer nucleation, meanwhile, the surface of the weather-resistant steel can be uniformly corroded in the service process through the characteristics of the water-permeable and oxygen-permeable stabilizer coating, and meanwhile, uniform corrosion causes uniform shedding of the rust layer stabilizer, so that the color of the weather-resistant steel structure is more uniform.

Owner:北京创氪材料科技有限公司

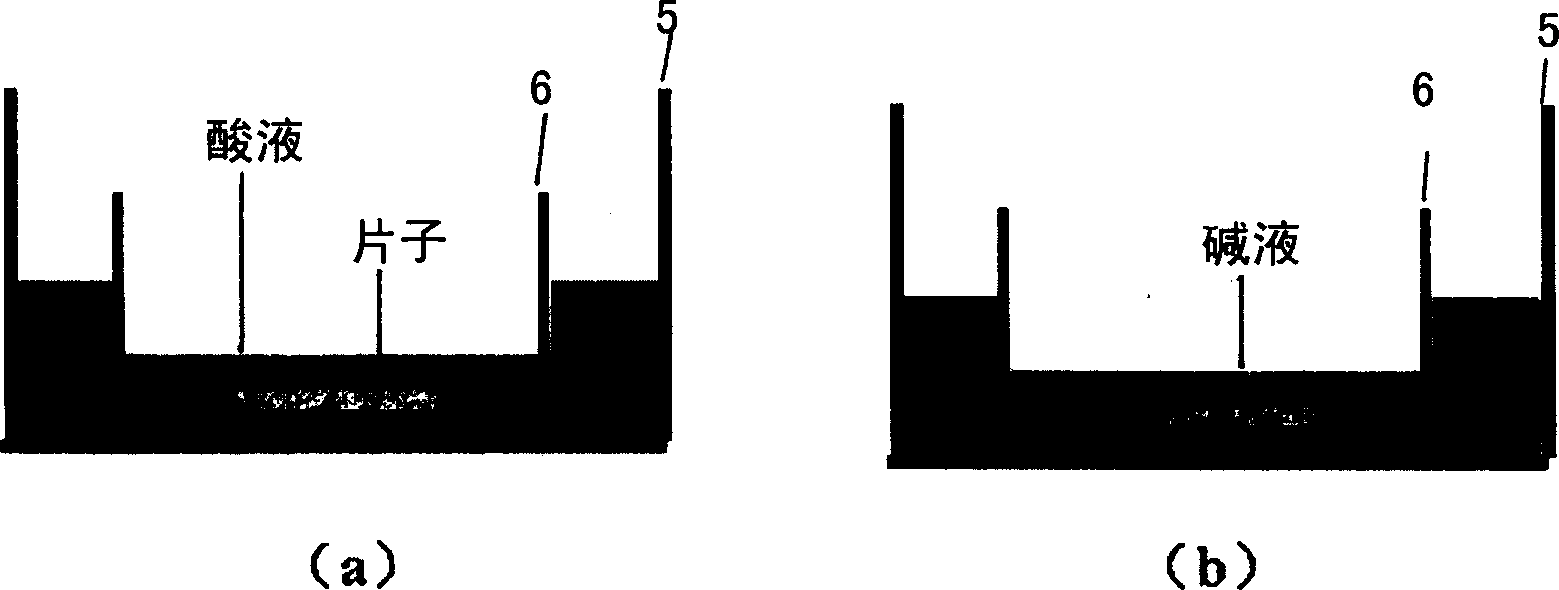

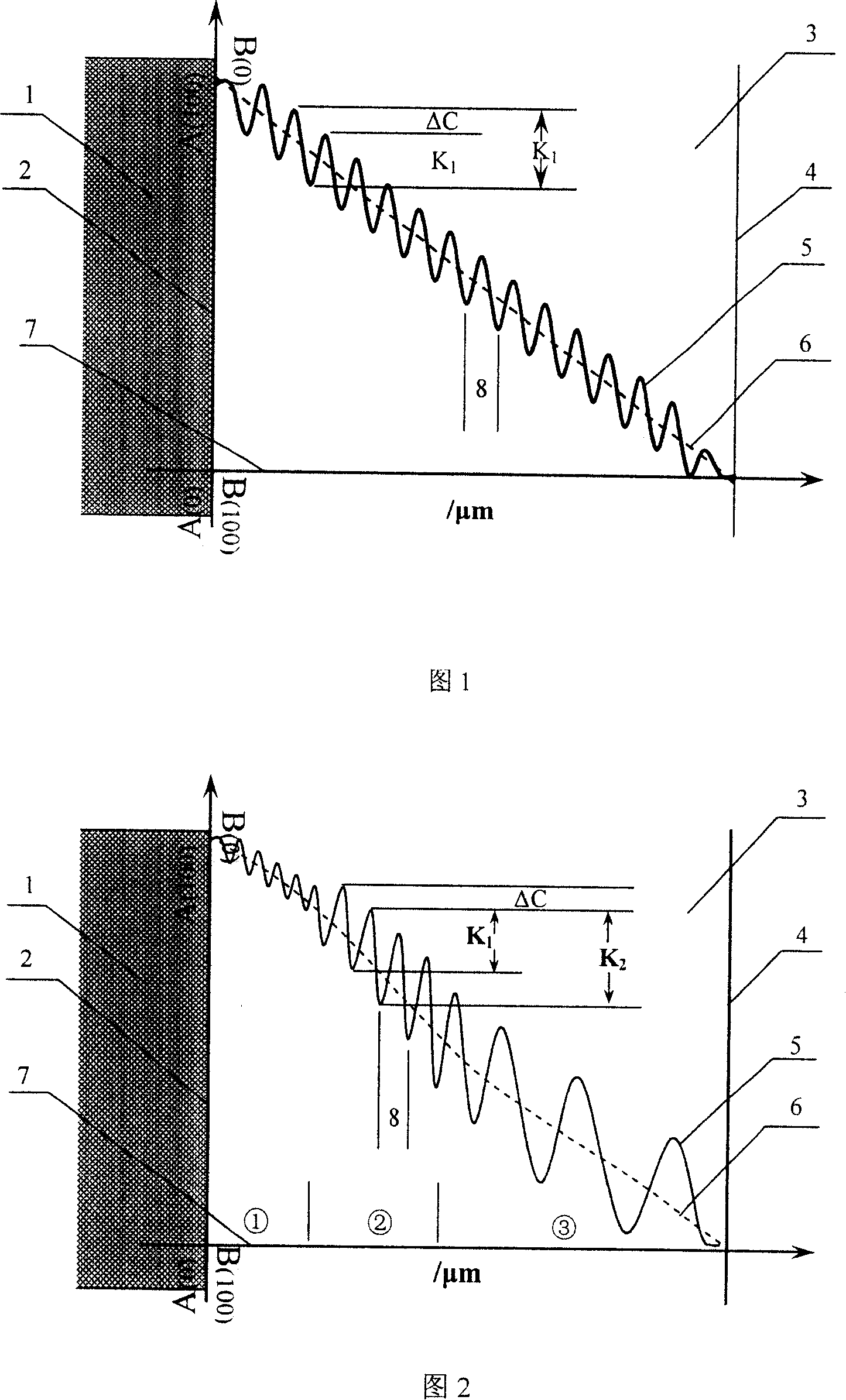

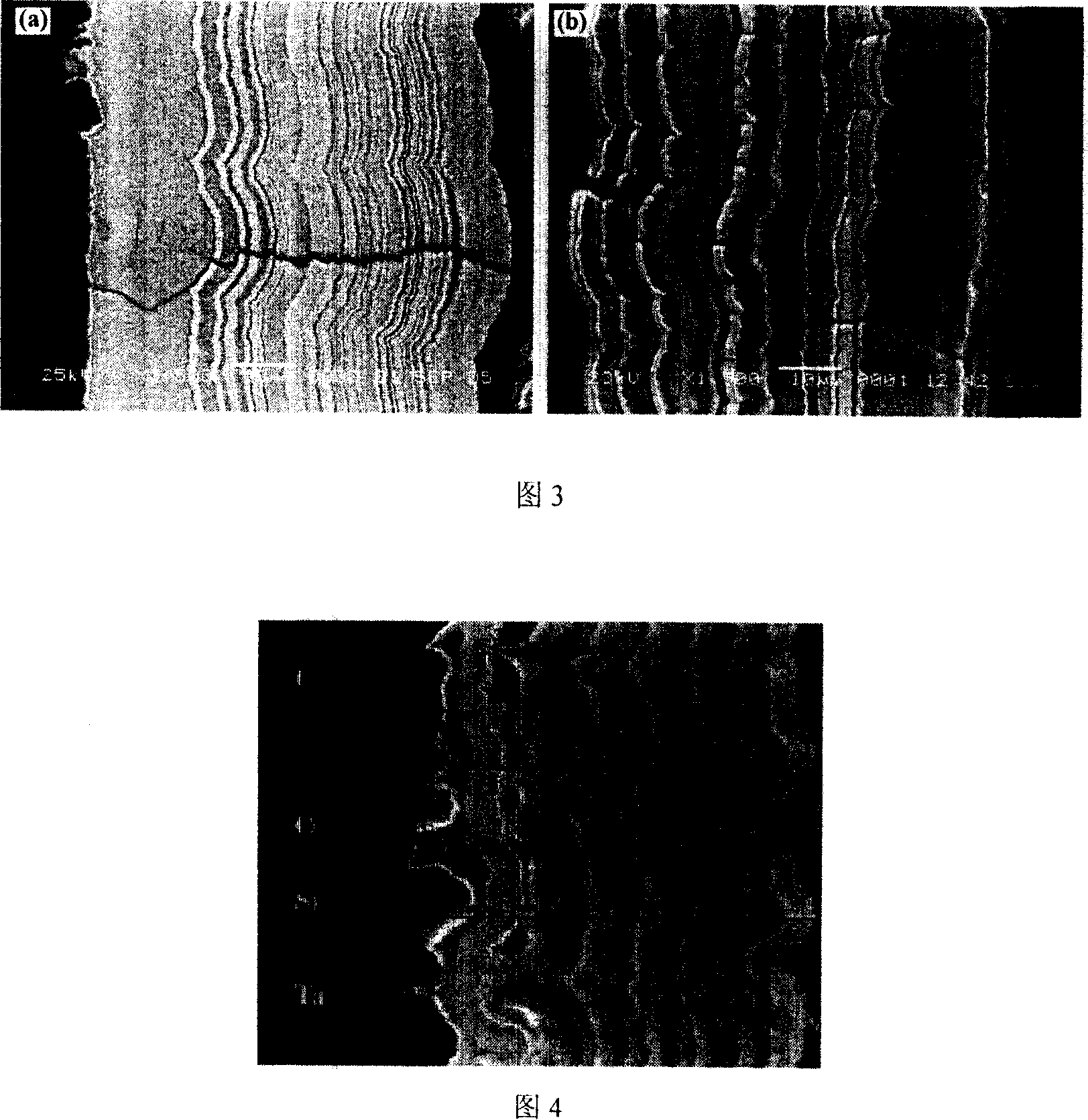

Etching technique for preparing ultrathin flexible silicon sustrate through two step method in wet-process etching

InactiveCN1697140ASolve the situation of uneven corrosionUniform corrosionSemiconductor/solid-state device manufacturingHydrofluoric acidAcid etching

The disclosed technique is applicable to thinning down silicon flexible substrate of having oxidation buried layer. Substrate material capable of coordinating mismatched strain is provided for epitaxial growth with large mismatch. The etching technique includes following steps: (1) carrying out degreasing treatment for chip with silicon flexible substrate, cleaning by deionized water, rinsing in diluent hydrofluoric acid, and carrying out ultrathin etching process; (2) first, carrying out acid etching; (3) then, carrying out alkali etching. The invention reaches purpose of uniform etching by using steps of first acid etching and then alkali etching.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Bioresorbable iron-based alloy stent

Owner:BIOTYX MEDICAL (SHENZHEN) CO LTD

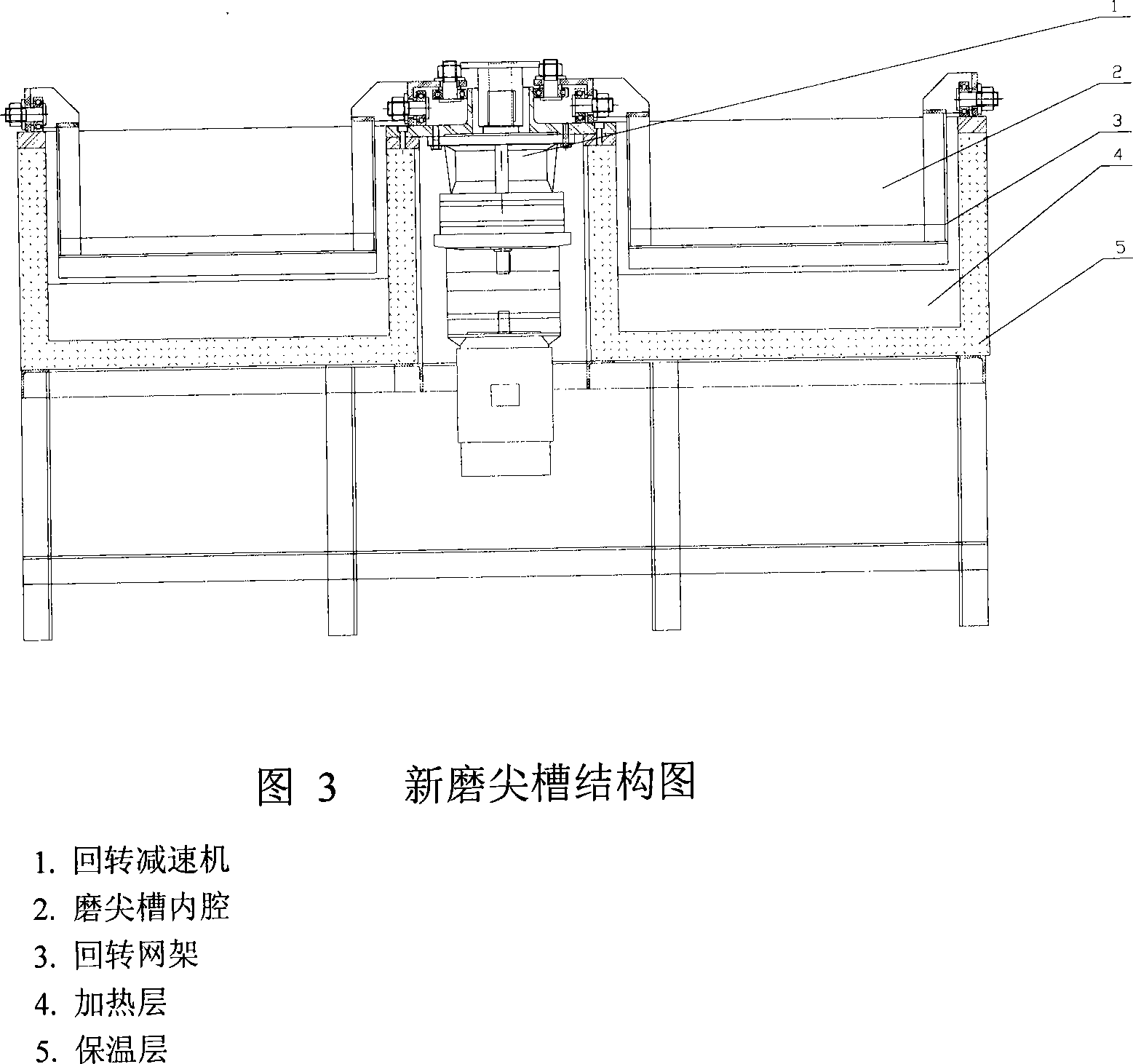

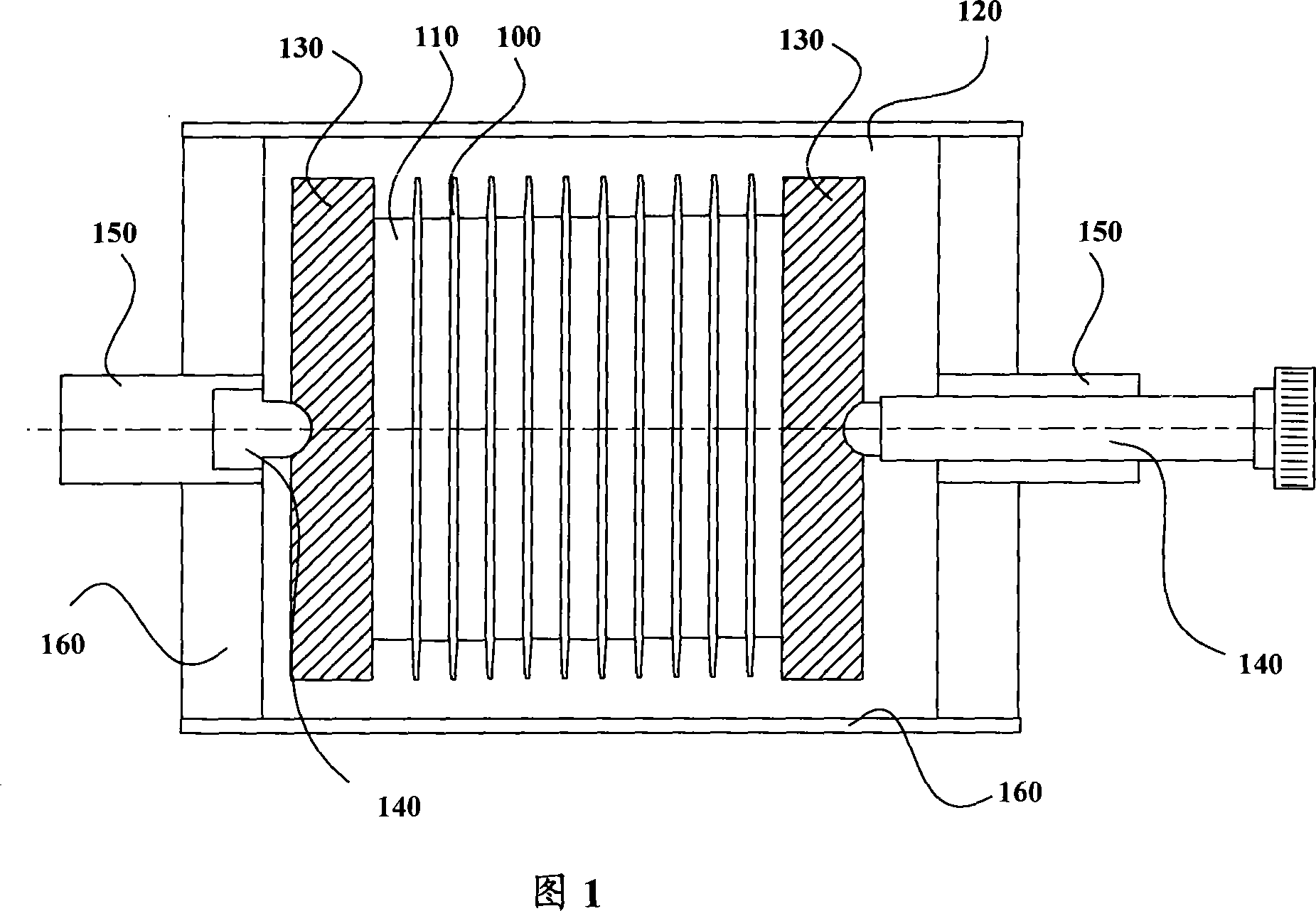

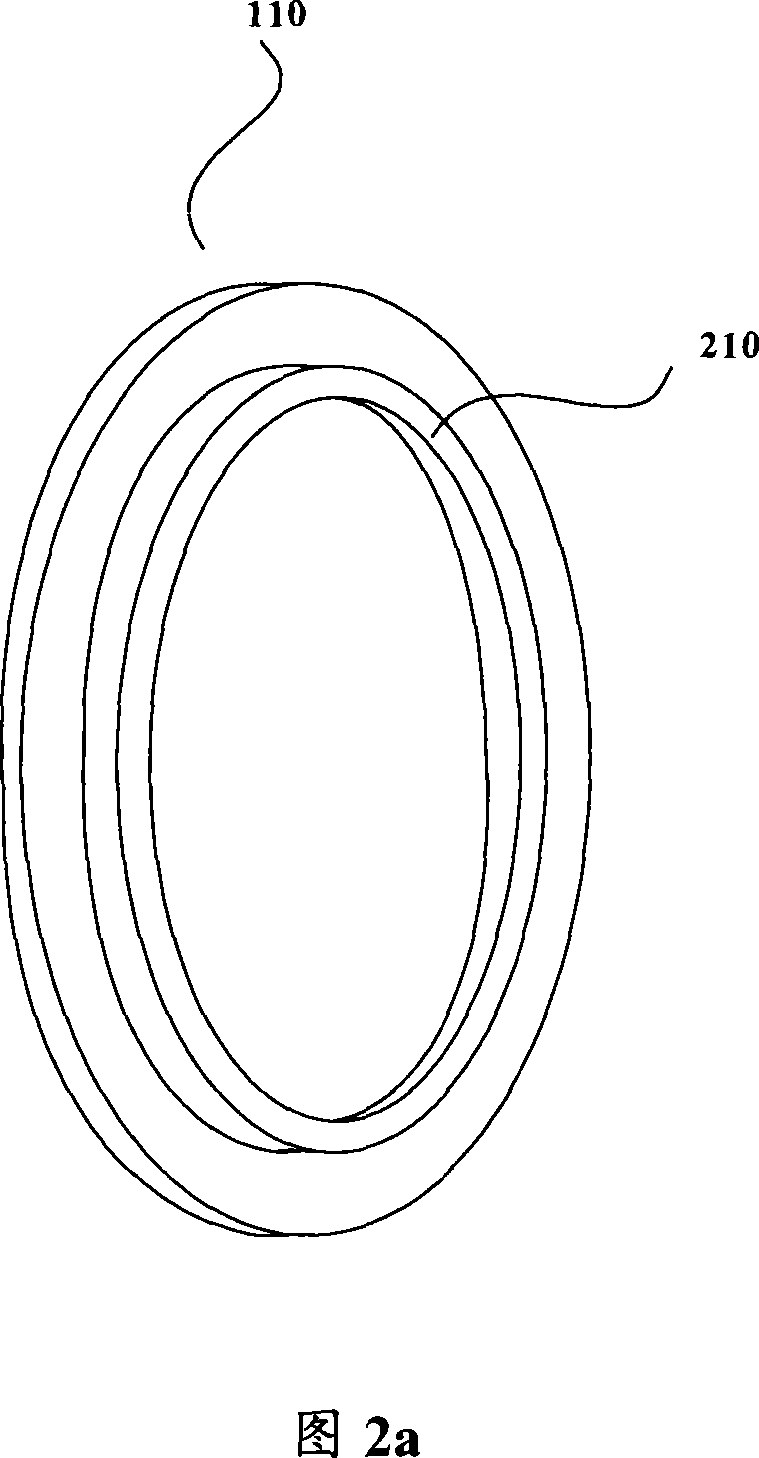

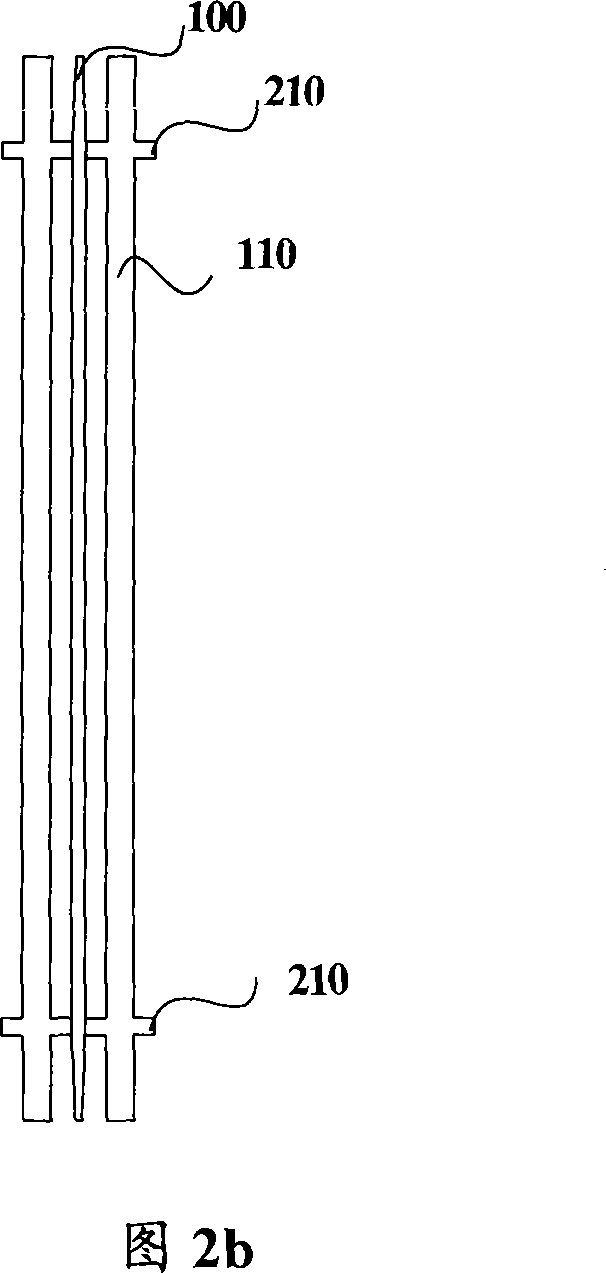

Sharp-point brush bristle forming apparatus

The sharp-point brush bristle forming apparatus includes one slewing motor, one sharpening cavity, one rotary net rack set inside the sharpening cavity, one heating layer in the bottom of the sharpening cavity, and one heat insulating layer around the heating layer and the inner wall of the sharpening cavity. After filament cake to be etched is fixed inside the rotary net rack vertically, the slewing motor drives the rotary net rack with filament cake to rotate inside the sharpening cavity. Compared with available technology, the present invention has the advantages of high work efficiency and high brush bristle product quality.

Owner:慈溪市洁达纳米复合材料有限公司

Fused cast refractory block with high zirconia content

ActiveUS8124554B2Increase contentEasy to useGlass furnace apparatusGlass productionMaterials scienceOxide

The present invention provides a fused cast refractory block comprising a mean zirconia (ZrO2+HfO2) content of more than 85% as a percentage by weight based on the oxides, and with a standard deviation σ of the local zirconia content divided by the volume of the block of less than 7.5.

Owner:SAINT GOBAIN CENT DE RES & DEVS & DETUD EUROEN

Biodegradable hydroxylapatite-magnesium and calcium metallic matrix composite

InactiveCN101524558AGood biocompatibilityImprove creep resistanceProsthesisPowder metallurgyBone tissue engineering

The invention relates to a biodegradable hydroxylapatite-magnesium and calcium metallic matrix composite, belonging to the field of biomedical materials. The material of the invention is composed of the composite of magnesium-calcium alloy and hydroxylapatite particles, the components and mass percent thereof are: 0.01-5% of Ca, 0-1% of Zn and Mg as the balance; the mass ratio of the hydroxylapatite to magnesium-calcium alloy is 0.01-50:100. In the invention, powder metallurgic method is adopted. The material matrix of the invention has close bonding with strengthened nano particles which areevenly distributed. The composite of the invention can be biologically degradable and has fine mechanical property and biological activity, and wide application prospect in medical material field such as repairing impairment of scaffold for bone tissue engineering, fixed fasteners within bones and weight-bearing parts of bones.

Owner:CHONGQING UNIV

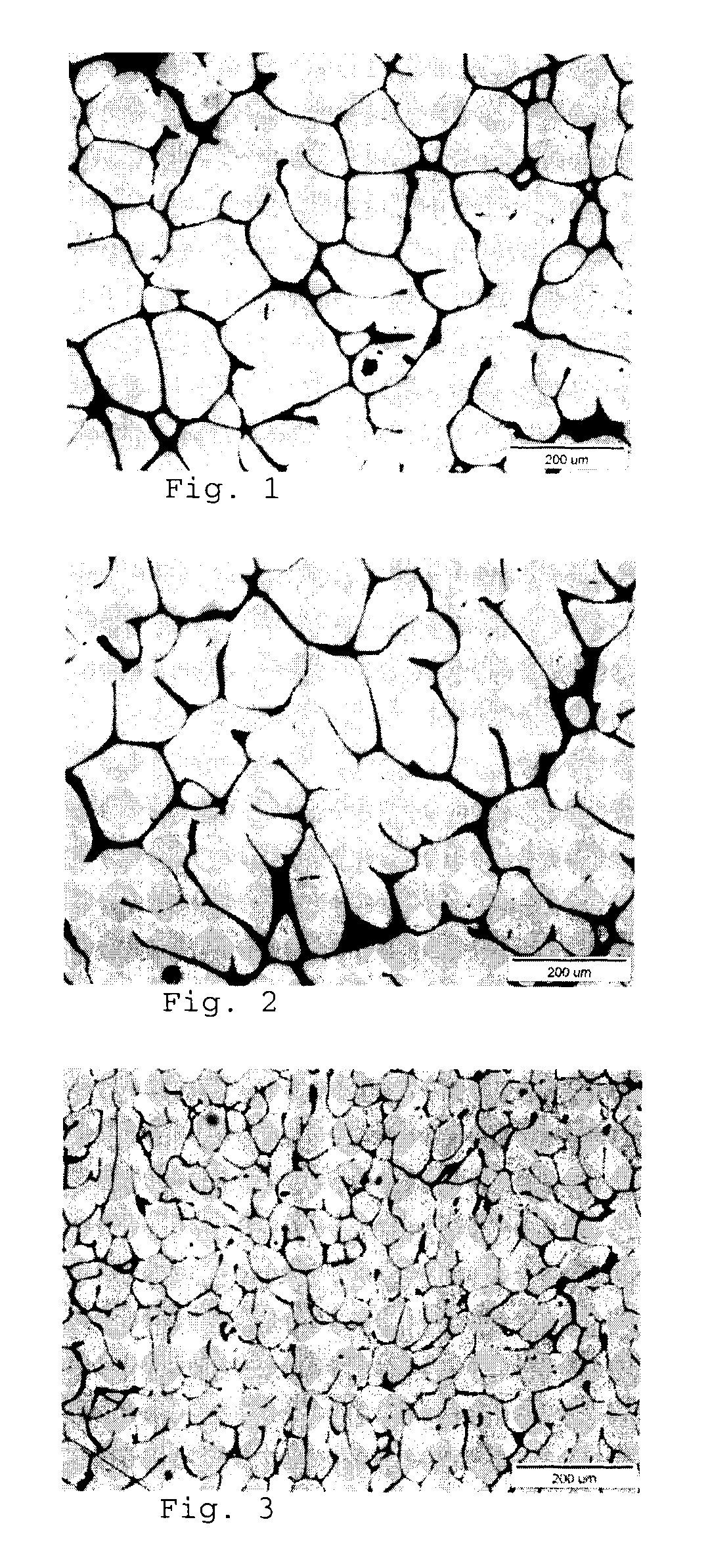

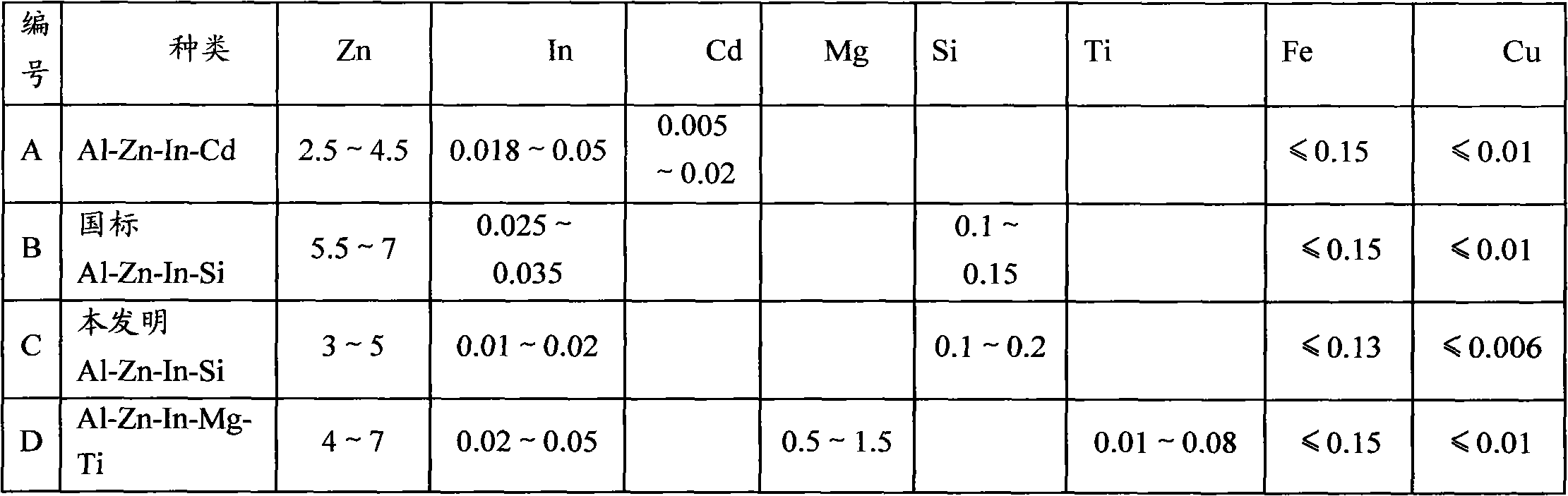

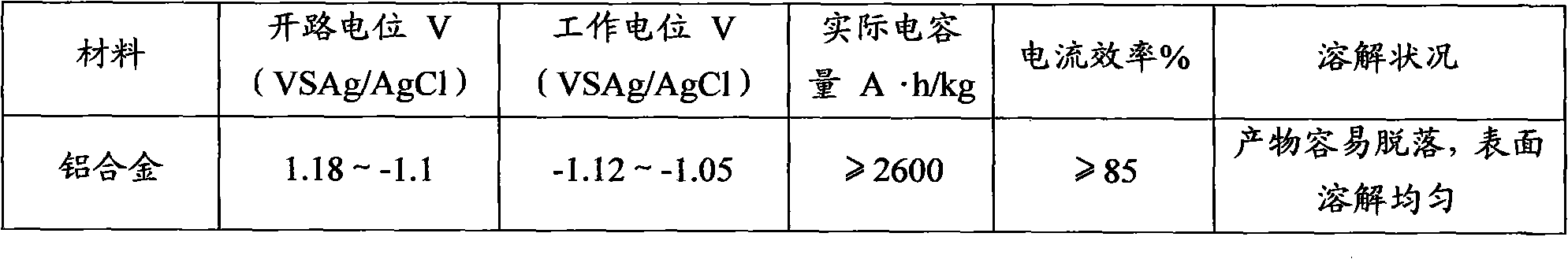

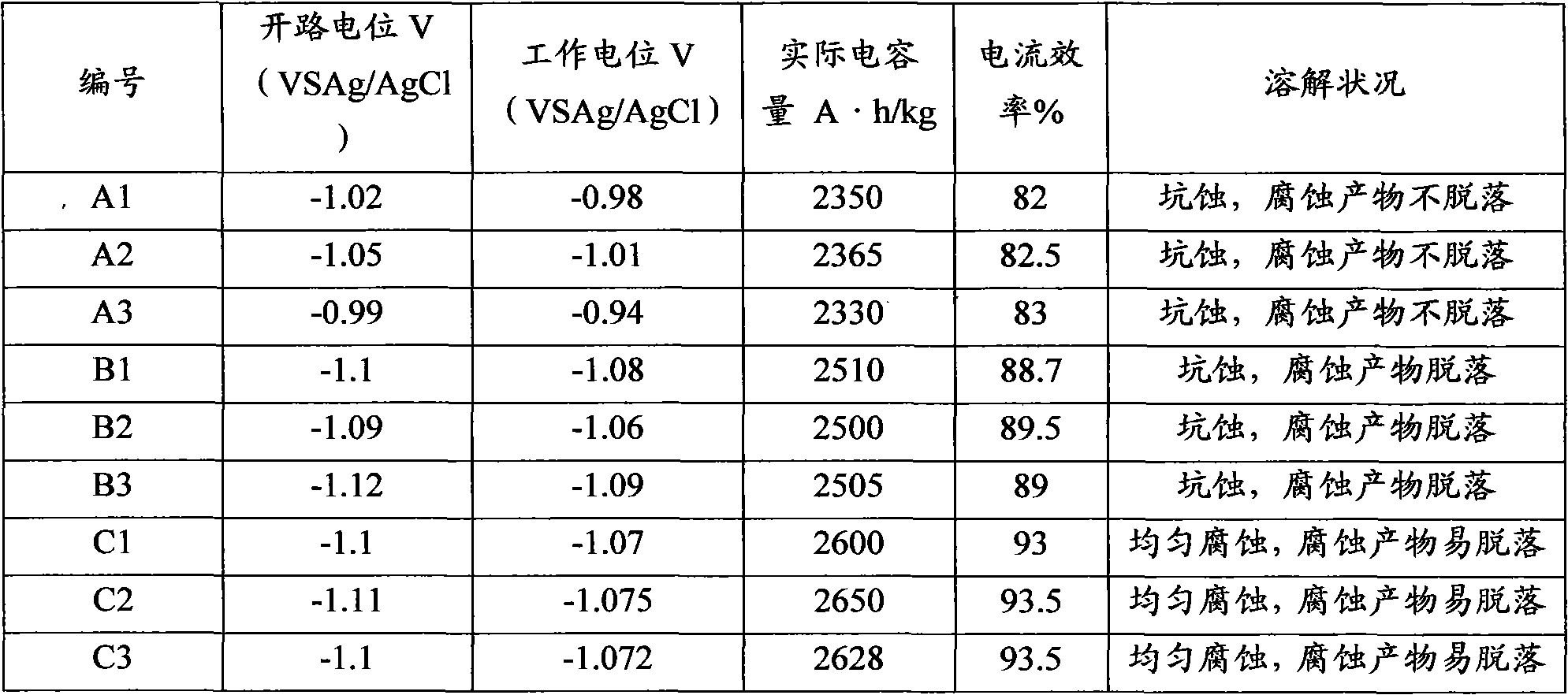

Sacrificial anode for deep sea environment and manufacturing method thereof

The invention discloses a sacrificial anode for deep sea environment. The sacrificial anode comprises main components by weight percent: 3.0-5.0% of zinc, 0.01-0.02% of indium, 0.10-0.20% of silicon and less than or equal to 0.16% of impurities, wherein the impurities comprise less than or equal to 0.13% of iron, less than or equal to 0.006% of copper and the balance of aluminum. The sacrificial anode has the working potential of -1.12 to -1.05V, the current efficiency of more than or equal to 93% and the capacitance of more than or equal to 2600 in the deep sea environment, and is even in corrosion, and corrosion products can easily fall off. The sacrificial anode has higher actual capacitance and current efficiency in the environment of low temperature and low dissolved oxygen, has the working potential of -1.12 to -1.05V, the current efficiency of more than or equal to 93% and the capacitance of more than or equal to 2600, and is even in corrosion. Furthermore, the sacrificial anode for the deep sea environment is low in indium content, effectively reduces the anode cost, and is especially suitable for cathode protection of ocean structure in the deep sea environment, thus the sacrificial anode has high performance.

Owner:李振国

Bioresorbable Iron-Based Alloy Stent

The invention discloses an absorbable iron-based alloy stent, comprising an iron-based alloy substrate and a degradable polyester in contact with the surface of the substrate, in which the degradable polyester has a weight average molecular weight of between 20,000 and 1,000,000 and a polydispersity index of between 1.2 and 30. With the degradable polyester, the iron-based alloy is capable of corroding rapidly and controllably within a predetermined period. Following implantation into the human body, the degradable stent serves as a mechanical support at early stage, then gradually degrading and being metabolized and absorbed by the human body. During the process of degradation, minimal or no solid product is produced. Ultimately, the configuration of the lumen with an implanted stent as well as the systolic and diastolic functions thereof return to their natural states.

Owner:BIOTYX MEDICAL SHENZHEN CO LTD

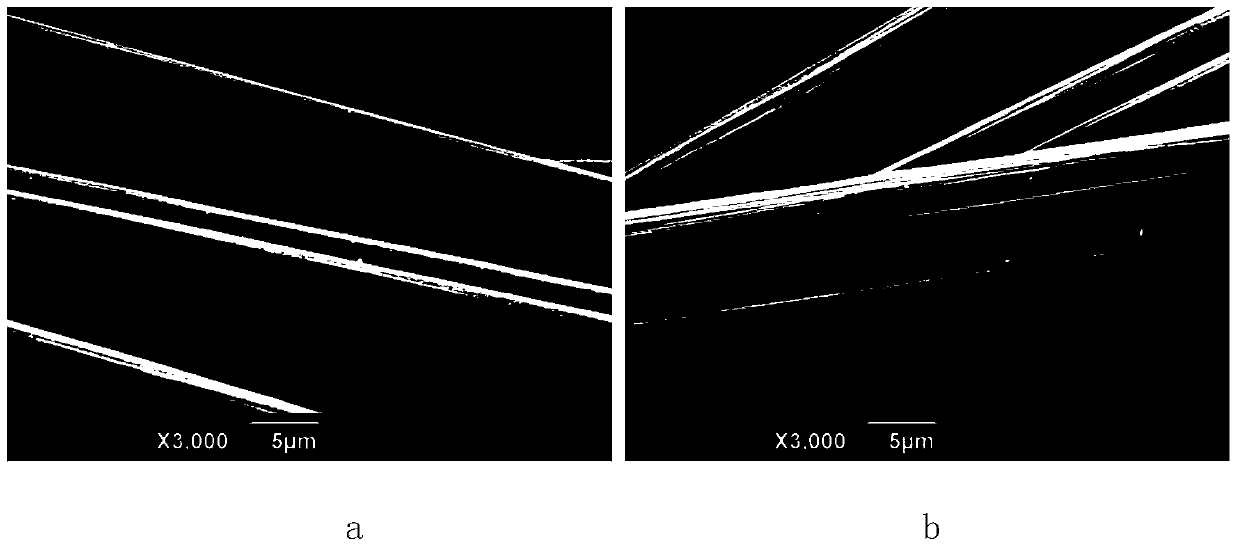

Preparation method of carbon cloth with wet chemical modified surface

InactiveCN104179001AUniform corrosionIncrease oxygen contentCarbon fibresOxygen contentOxidative treatment

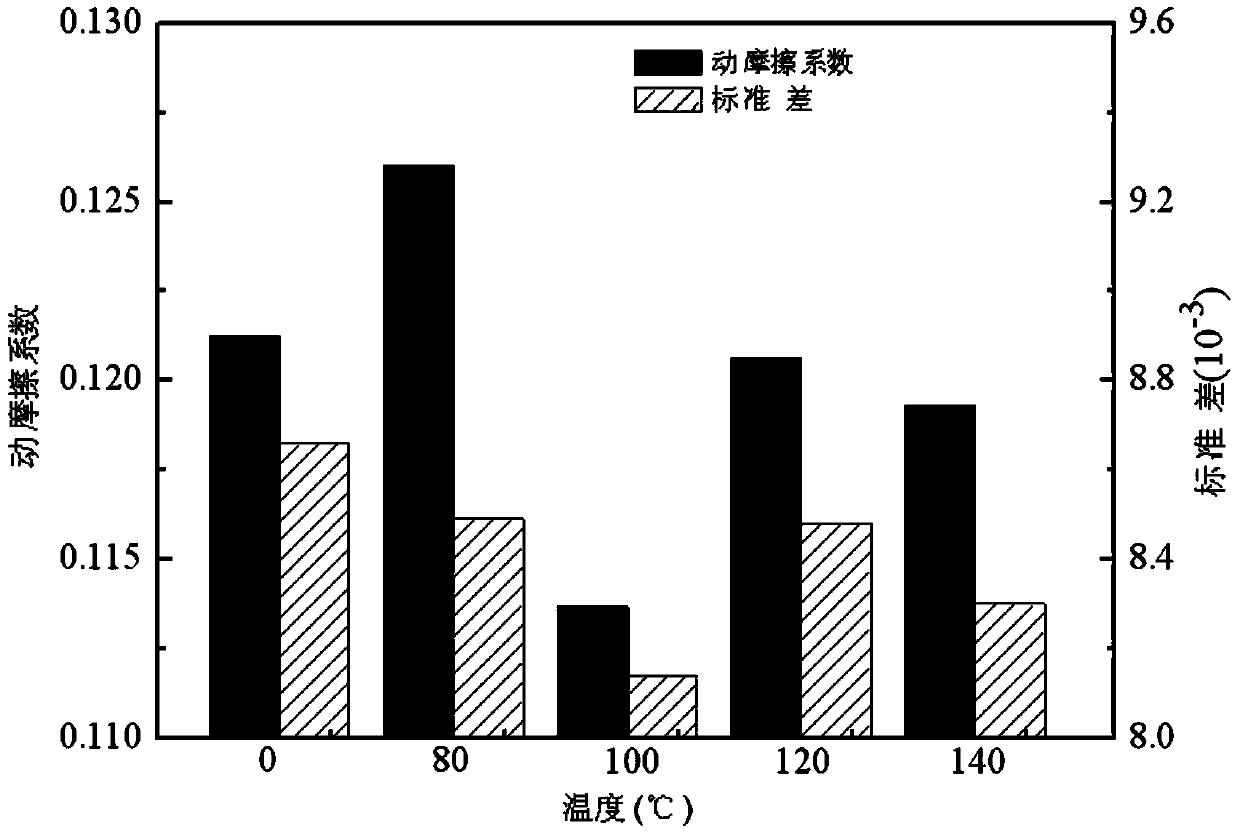

The invention relates to a preparation method of carbon cloth with the wet chemical modified surface. The method comprises the steps of putting cut carbon cloth into acetone, saturating, naturally drying the taken saturated carbon cloth in the air to obtain a sample A; putting the sample A and concentrated nitric acid into a hydrothermal reaction kettle; putting the hydrothermal reaction kettle into a homogeneous reactor, carrying out heat preservation at the temperature of 80-140 DEG C, and carrying out reaction for 1-4 hours; after the reaction, cleaning the taken carbon cloth by deionized water; finally, carrying out vacuum drying to obtain the carbon cloth with the wet chemical modified surface. According to the preparation method, the oxidation treatment is carried out on the surface of the carbon cloth under the hydrothermal condition; the preparation method has the advantages of being simple in equipment, efficient, even in corrosion, capable of effectively optimizing friction and wear properties of a carbon cloth reinforced resin-based friction material, and the like; the oxygen content of the surface of the prepared carbon cloth is high, and thus the method is a modification method which is low in cost and consumption, high in efficiency, simple to operate and controllable in conditions.

Owner:SHAANXI UNIV OF SCI & TECH

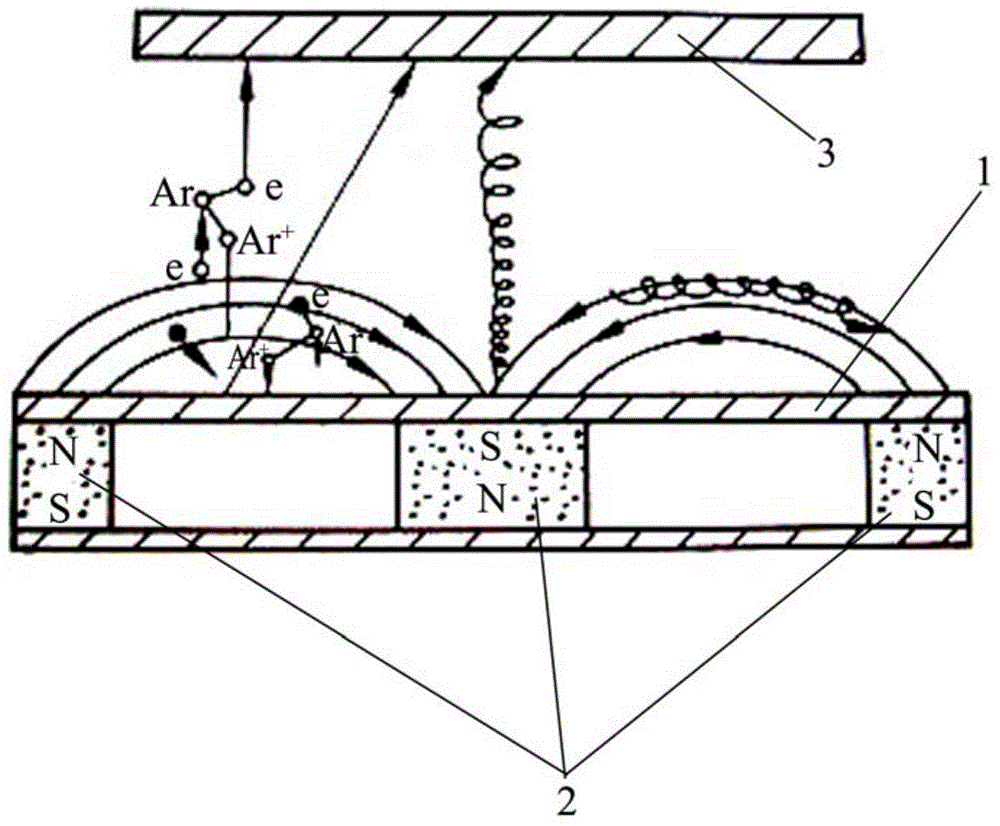

Adjustment method of magnetic field intensity of magnetron

ActiveCN104651786AThe strength of the magnetic field increases or decreasesUniform bombardmentVacuum evaporation coatingSputtering coatingSputter depositionUltimate tensile strength

The invention relates to an adjustment method of magnetic field intensity of a magnetron, wherein the magnetron comprises a plurality of magnet assemblies arranged successively. Each magnet assembly comprises a magnet, and an upper cover and a lower cover which are arranged respectively on upper end surface and lower end surface of the magnet. The adjustment method includes a step of, with maintenance of constant total height of each magnet assembly, changing the heights of the magnet, the upper cover and the lower cover of the each magnet assembly in a to-be-adjusted zone in the magnetron, or changing proportion of the heights of any two of the three heights in the total height of the total height of the magnet assembly, so that the magnetic field intensity in the to-be-adjusted zone in the magnetron is enhanced or weakened. By means of the adjustment method, a uniform magnetic field intensity in all zones in an upper surface of a target material can be obtained, and further particles can bombard the target material uniformly during a magnetron sputtering deposition technology process, so that the target material is uniformly corroded during the technology process, thereby increasing utilization rate of the target material and achieving a better uniformity of a thin film deposited onto a to-be-processed workpiece.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Double -gradient composite coating

The invention discloses a dual-gradient composite coating. A coating which is arranged on the surface of a basal body comprises a plurality of sub-coatings, which forms a shock wave moving gradient. The shock wave moving gradient is compounded by two simultaneously existing gradients--a composition gradient and a composition wave centre-value gradient. Every sub-coating consists of two composition gradients with opposite composition changing trends. The composition changing trends of adjacent sub-coatings are similar. From the basal body to the surface, the composition medium value which forms gradient composition in adjacent sub-coatings also changes in gradient, namely the composition wave centre-value gradient. The combined effect of multiple coatings and the designing ability of gradient coating are used, and the dual-gradient coating is arranged on the surface of metal, inorganic non-metallic, polymer and composite material and other solid materials. Compared with the ordinary gradient coating, the present invention has the advantage of smaller thermal stress, better thermal stability high thermal shock resistant ability, no significant macro cracks and good connection performance with the basal body.

Owner:CENT SOUTH UNIV

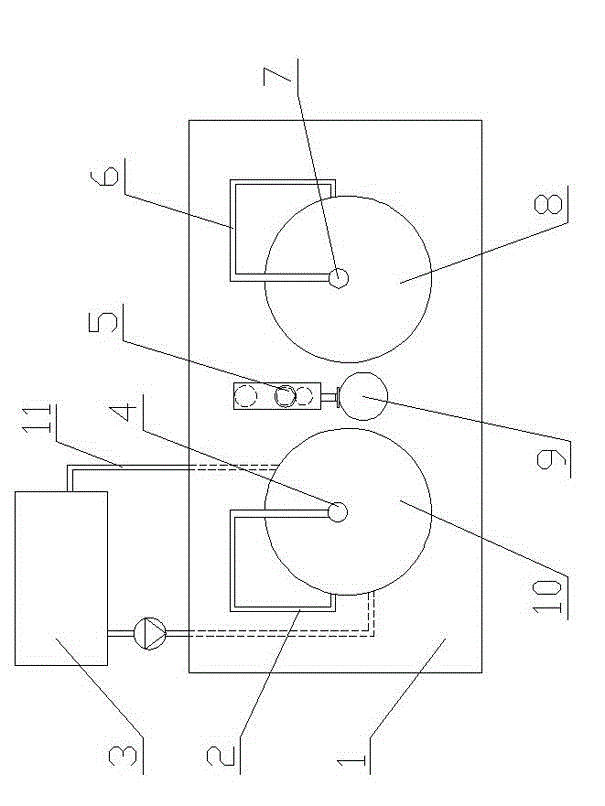

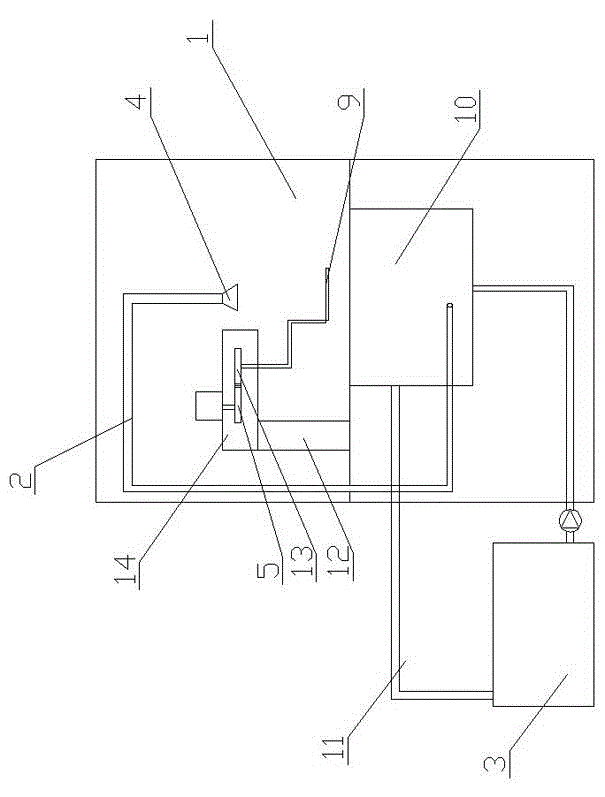

Quartz crystal wafer corrosion machine

The invention discloses a quartz crystal wafer corrosion machine which comprises a box body, wherein the box body is internally provided with a corrosion liquid pool and a cleaning pool; an automatic cleaning swing mechanism is arranged on a table board between the corrosion liquid pool and the cleaning pool; the upper end of a support arm of the automatic cleaning swing mechanism is connected with a crossbeam through a rotating shaft; the front end of the crossbeam is connected with a cleaning frame for placing a wafer basket; the crossbeam is internally provided with a driving gear and a driven gear which are meshed with each other; the driving gear is connected with a driving motor output shaft on the crossbeam; the driven gear is connected with the cleaning frame; and a corrosion liquid spray head which is connected with the corrosion liquid pool and a cleaning liquid spray head which is connected with the cleaning pool are respectively arranged above the corrosion liquid pool and the cleaning pool. According to the quartz crystal wafer corrosion machine, the automatic cleaning swing mechanism is arranged, so that the cleaning frame is capable of driving the wafer basket to alternate between the corrosion liquid pool and the cleaning pool and automatically rotates 360 DEG, the cleaning and the corrosion are more even, the manual operation is replaced, the work efficiency is improved and the labor intensity of the workers is reduced.

Owner:徐培炎

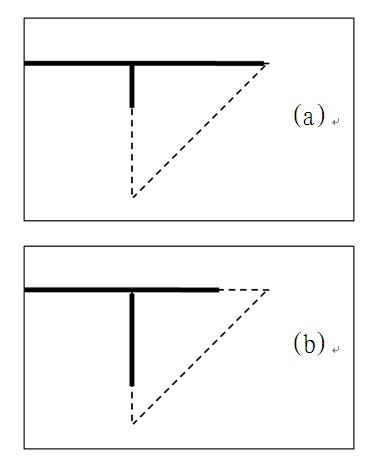

A chip table top etching device

ActiveCN101217108AEliminate the removal linkEasy to operateSemiconductor/solid-state device manufacturingFixed frameEngineering

The invention discloses a chip mesa etching device, which mainly includes a spacer and a chip frame; the spacer takes a shape of round slice; the chip frame includes baffles, a locking device, a rotation device and a fixed frame; the baffles are positioned at the both sides of the chip frame, the outsides of the baffles are connected with the locking device, the locking device can inwardly extrude the baffles, then the spacer and a chip which are arranged between the baffles can be clamped tightly by the baffles, the rotating device is sheathed at the outside of the locking device, the locking device is embedded and sheathed in the side surface of the fixed frame and is connected with the side surface, the locking device and the rotation device extend to the outside from both sides of the side surface of the fixed frame. The invention eliminates the coating of a chip protective coating layer and solves the problems of complicated process procedure and the long time of the traditional method. Furthermore, the invention has simple operation, can load dozens of chips at one time, as well as carry out the corrosion simultaneously and greatly improve the working efficiency.

Owner:ZHUZHOU CRRC TIMES SEMICON CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com