Patents

Literature

125results about How to "Fast corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metallographic etchant and metallographic etching method for pure titanium and beta titanium alloy

InactiveCN102808179AAccelerated corrosionFast corrosionPreparing sample for investigationHydrofluoric acidEtching

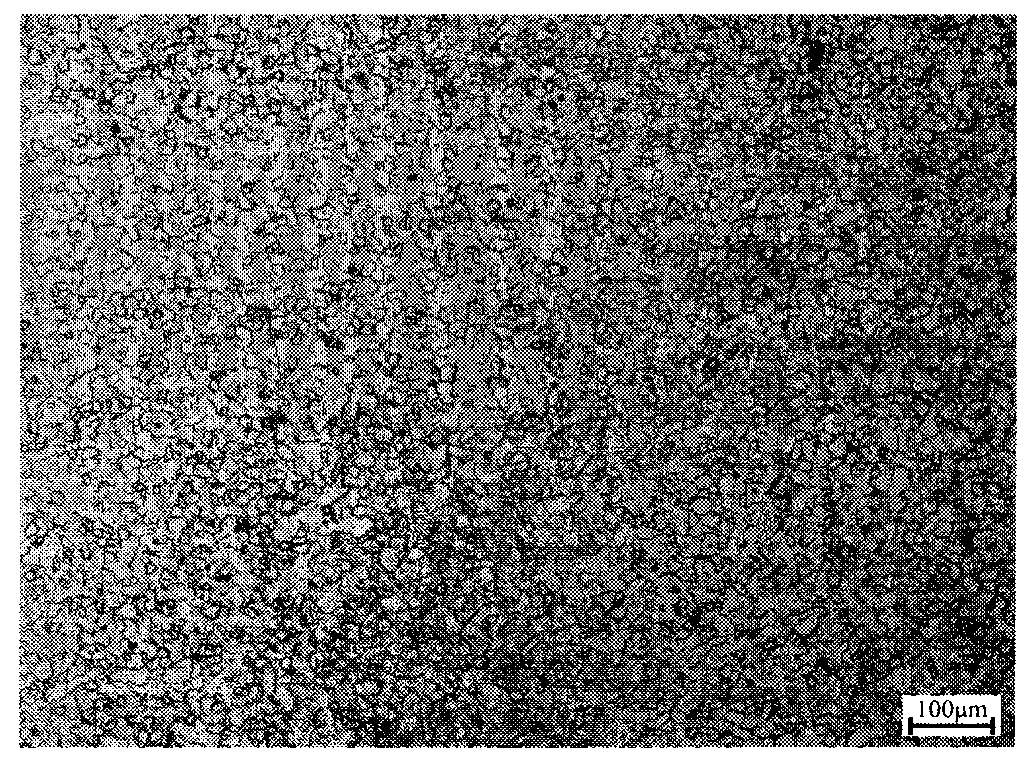

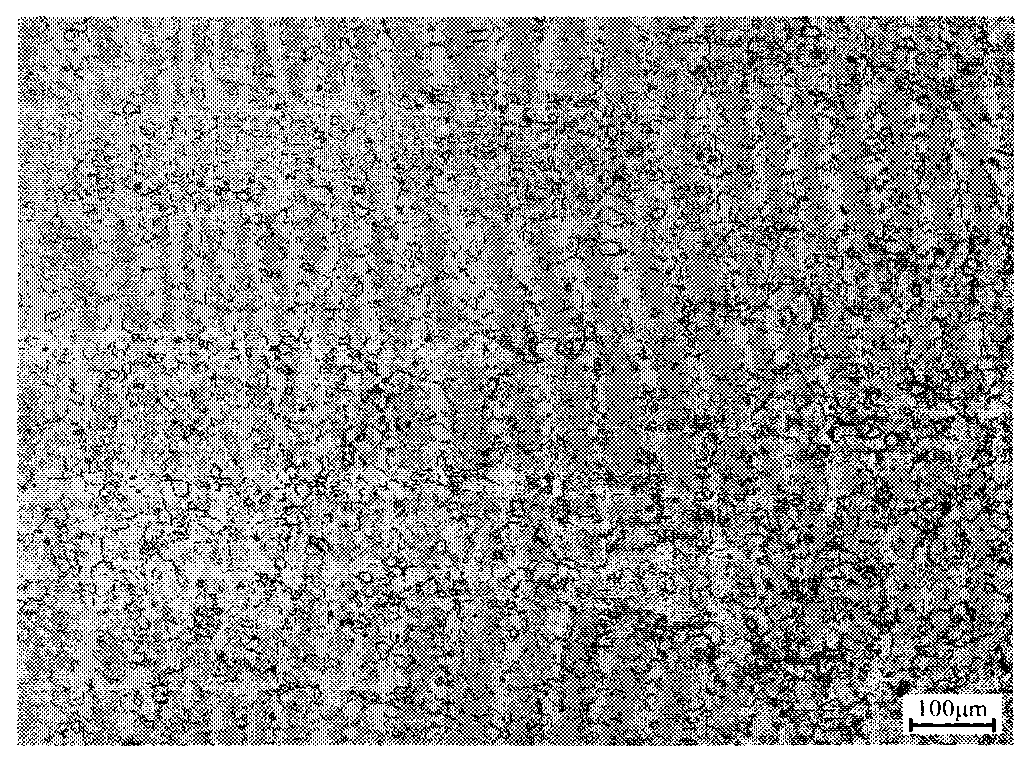

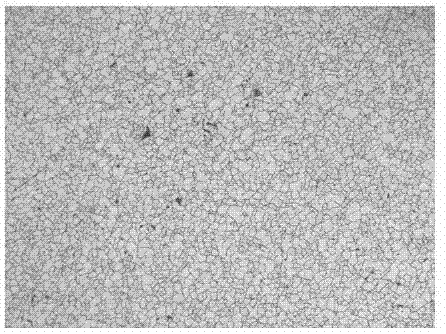

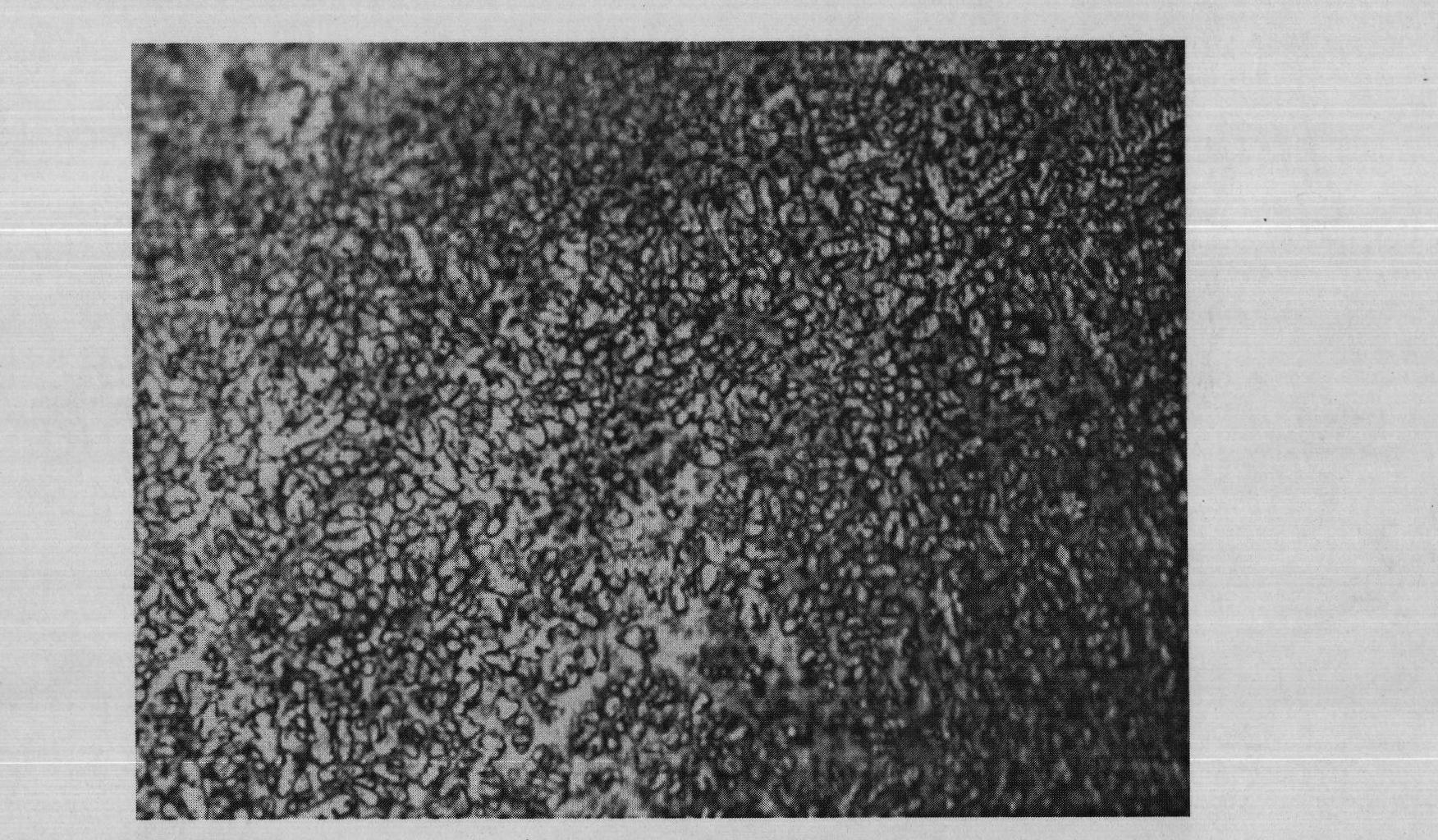

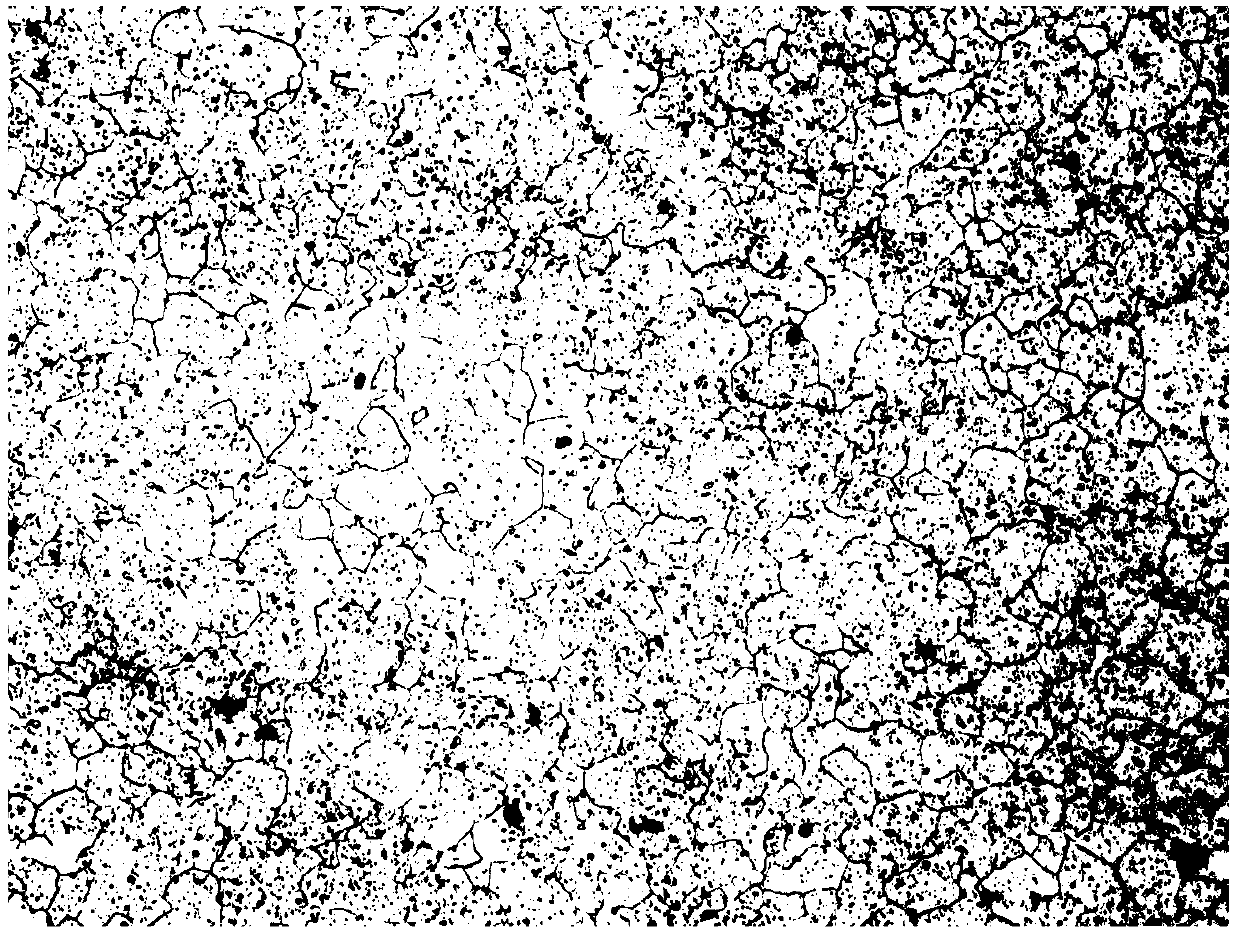

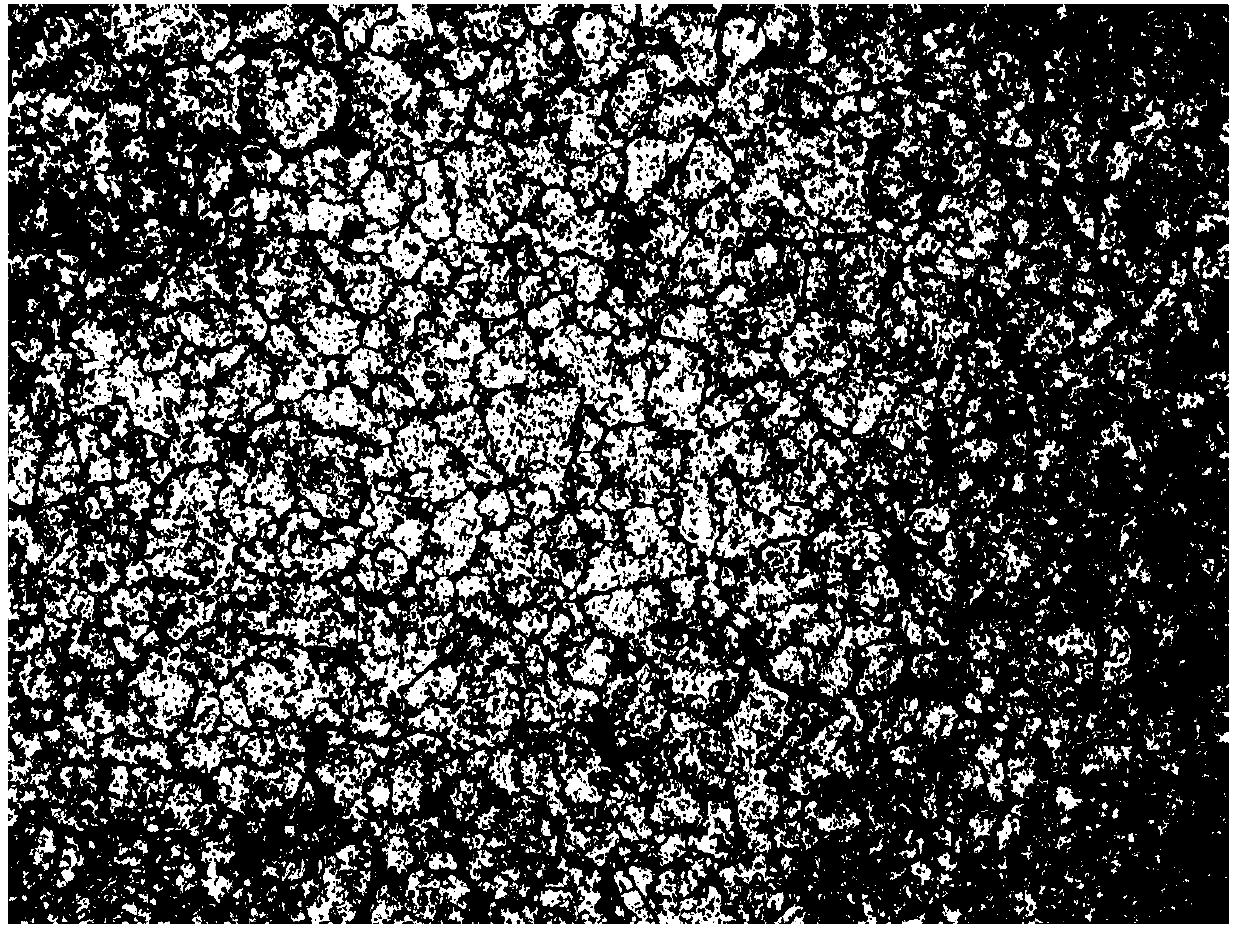

The invention relates to the field of metallographic etching of titanium and titanium alloy and discloses metallographic etchant and a metallographic etching method for pure titanium and beta titanium alloy. The metallographic etchant and the metallographic etching method are mainly used for metallographic etching of the pure titanium and the beta titanium alloy. The etchant consists of 10 to 40 volume parts of nitric acid, 5 to 10 volume parts of hydrofluoric acid, and 30 to 100 volume parts of water. The method comprises the following steps of: soaking a ground and polished metallographic specimen in the etchant for a certain period of time, then placing the metallographic specimen in warm absolute ethanol at the temperature of between 30 and 50 DEG C for a moment, polishing again to ensure that the etching layer is polished completely, and etching the metallographic specimen for the second time by using etchant which is similar to the etchant used in the first-time etching to obtain a single-phase metallographic structure. By the method, processing-state and annealing-state pure titanium and beta titanium alloy bars, wires and plates are subjected to metallographic etching, and the obtained single-phase metallographic structure is clear and complete in crystal boundary, and abnormal etching pits or plaques in a single crystal grain can be avoided.

Owner:西安赛特新材料科技股份有限公司

Chemical etching solution for titanium and titanium alloy

A chemical etching solution used in Ti and Ti alloys characterizes that it is composed of H2F2, HNO3 and water, their volume percentage is: H2F2 5-15% HNO3 8-35%, water 50-85%, which can be used under normal temperature having the advantages of quick corrosion, small side corrosion, long life time of the solution and low process cost.

Owner:OCEAN UNIV OF CHINA

Nickel-chromium alloy metallographic corrosion solution and corrosion method

InactiveCN104513985AGrain contrast is obviousFast corrosionPreparing sample for investigationAcetic acidAlcohol

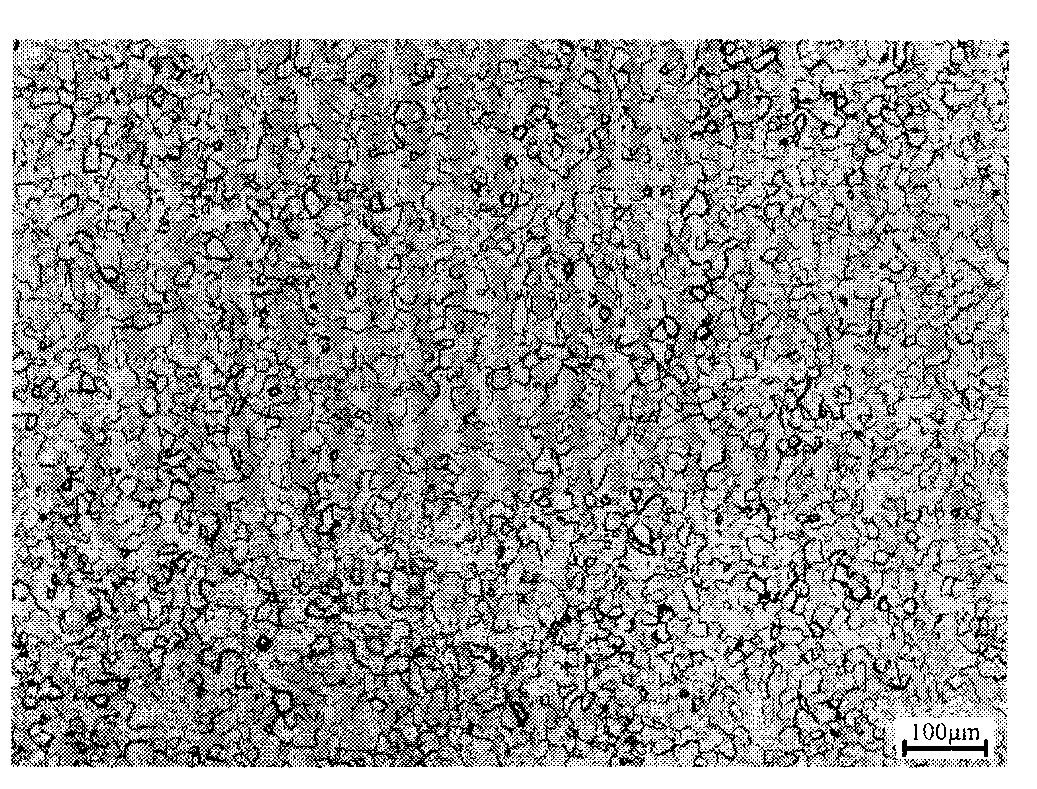

The invention relates to a nickel-chromium alloy metallographic corrosion solution and a corrosion method. The corrosion solution is a mixed solution of concentrated nitric acid, concentrated hydrochloric acid, glacial acetic acid and water in a volume ratio of 1:1:1:1. The concrete steps include: (1) preparing the corrosion solution, firstly adding water into a container, then adding concentrated nitric acid, concentrated hydrochloric acid and glacial acetic acid respectively, conducting stirring and then performing standing for 10-20min; (2) dripping the corrosion solution on the corrosion surface of a ground and polished nickel-chromium alloy metallographic sample, immersing the sample into the corrosion solution to a depth of 1-2mm, and controlling the corrosion time at 10s-10min; (3) flushing the sample surface with distilled water for more than 2min; and (4) flushing the sample surface with alcohol, and then wiping the sample surface with alcohol-carrying absorbent cotton. According to the invention, the corroded metallographic sample has obvious grain contrast and clear grain boundary line, and at the same time, the defects of under-corrosion and over-corrosion can be avoided. The corrosion solution can rapidly and efficiently corrode the metallographic structure of the sample.

Owner:JINCHUAN GROUP LIMITED

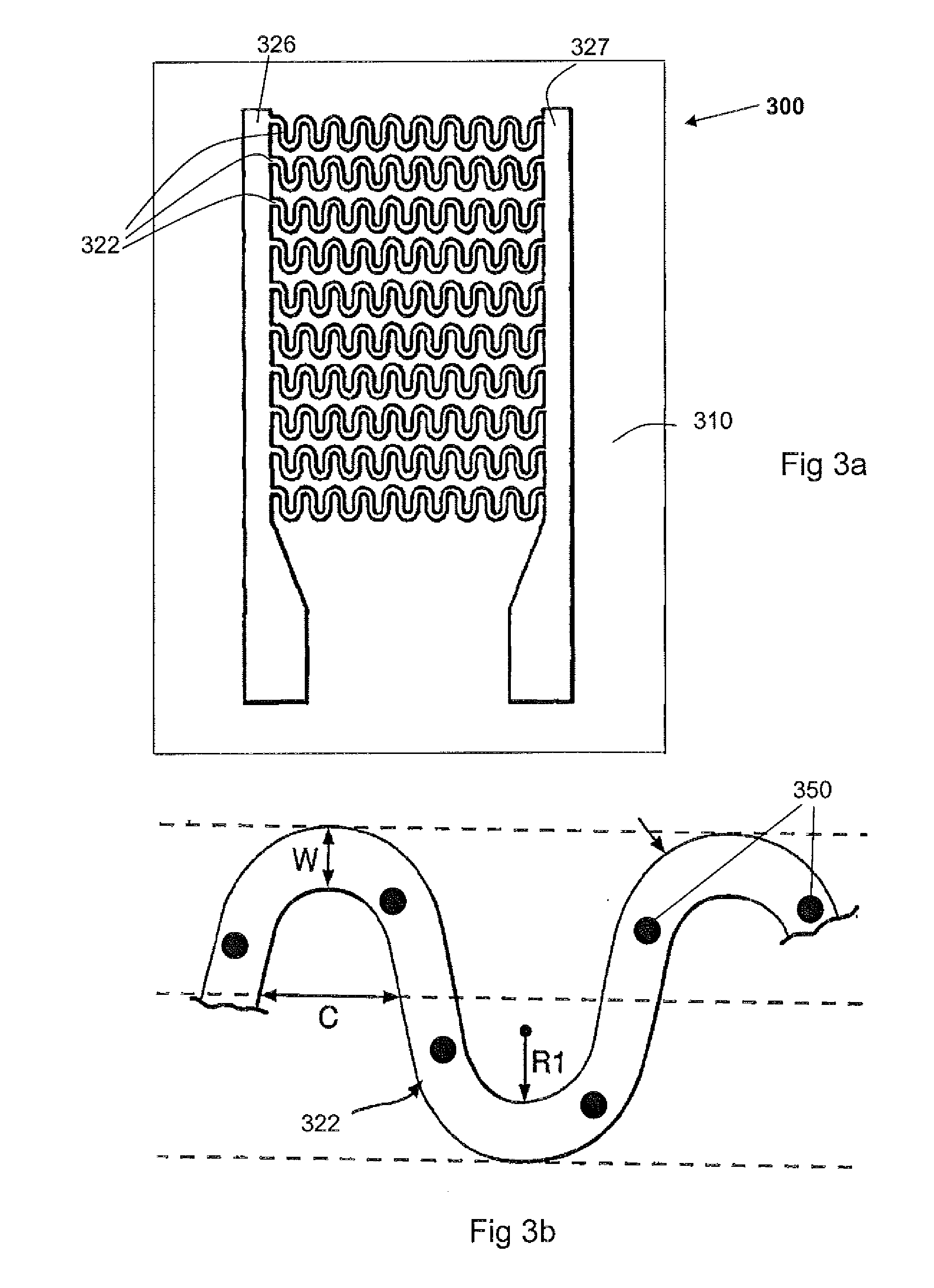

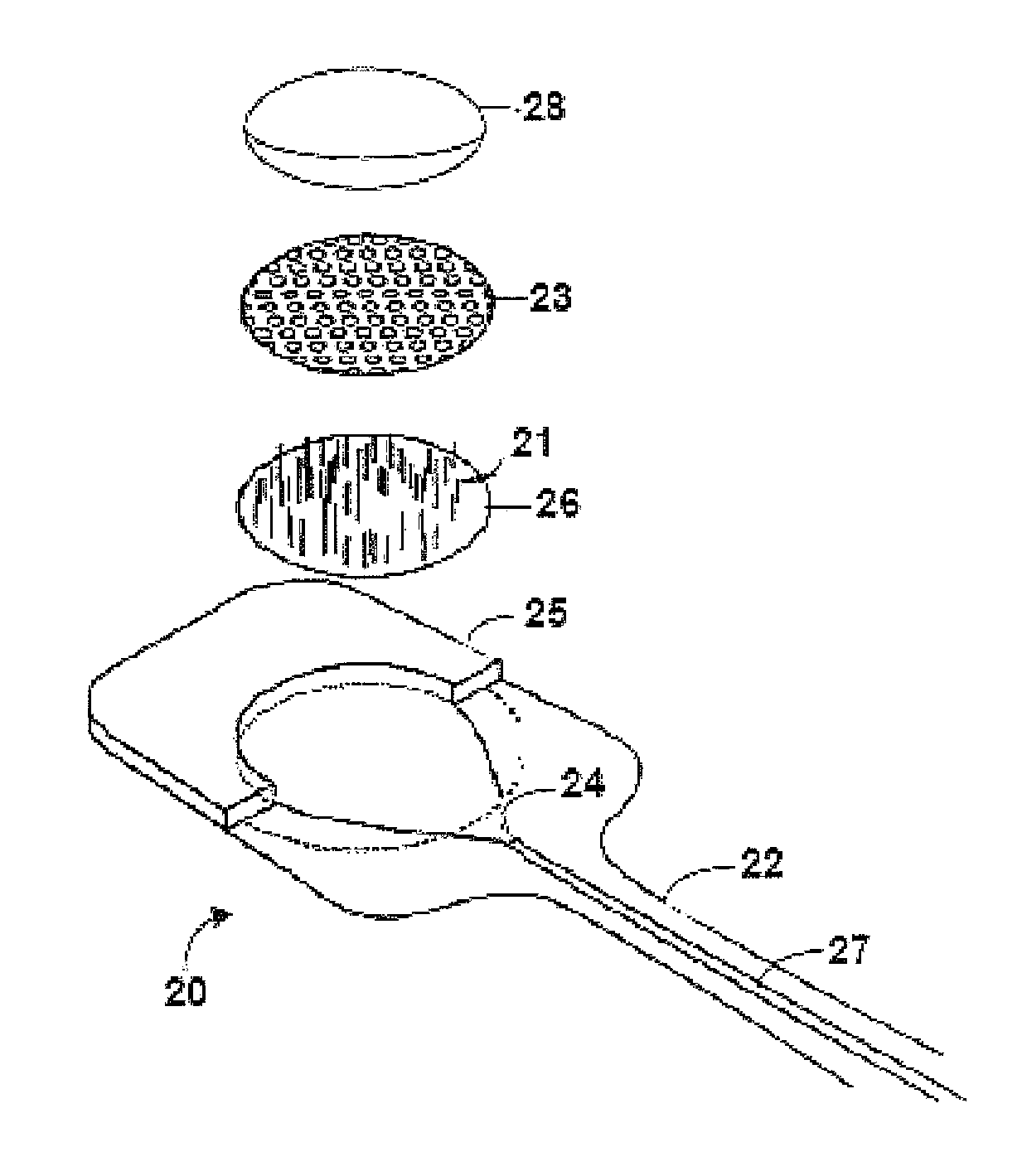

Corrosion sensors

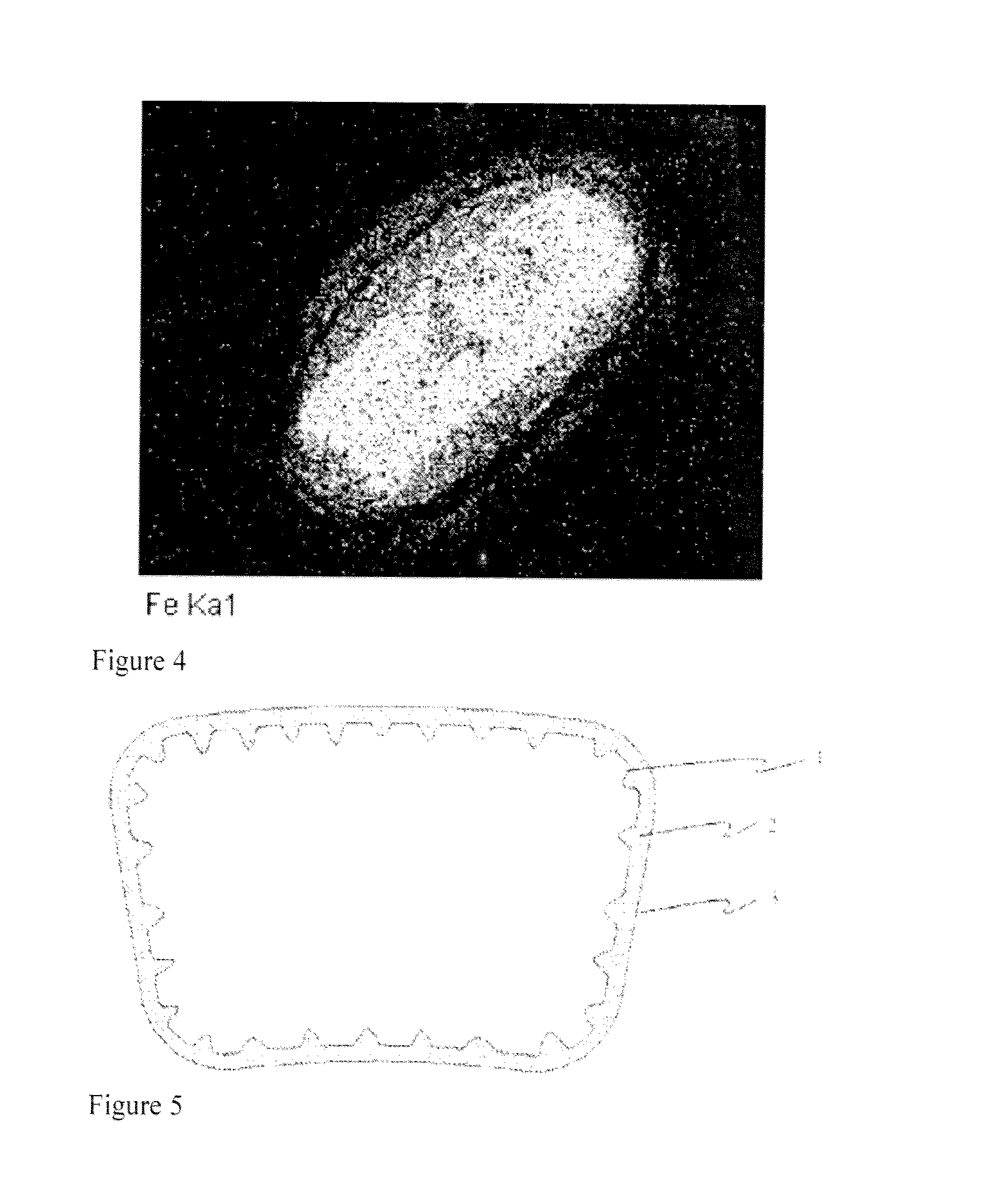

ActiveUS20110187395A1Fast corrosionEliminate needWeather/light/corrosion resistanceResistance/reactance/impedenceCorrosionMetallic materials

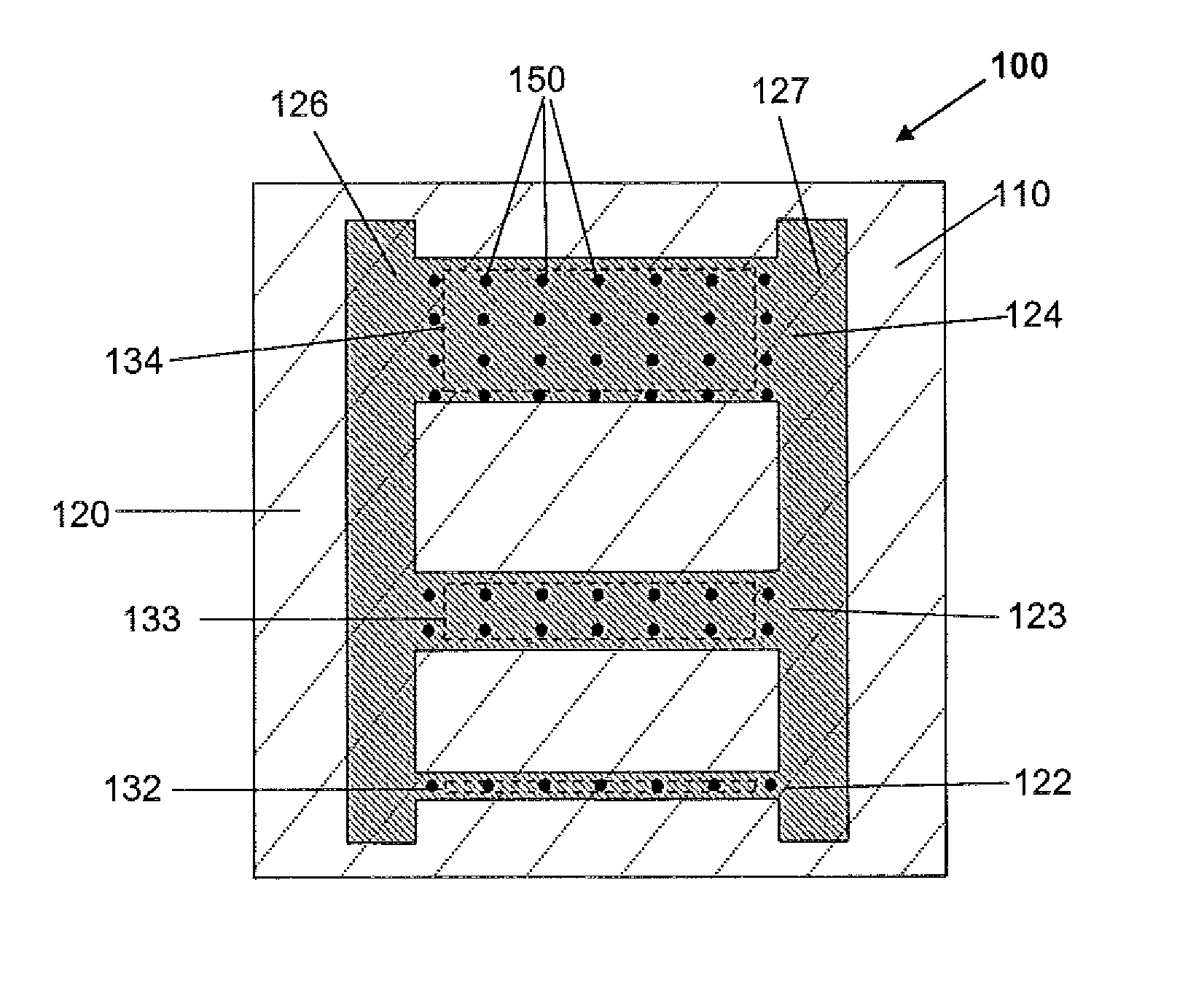

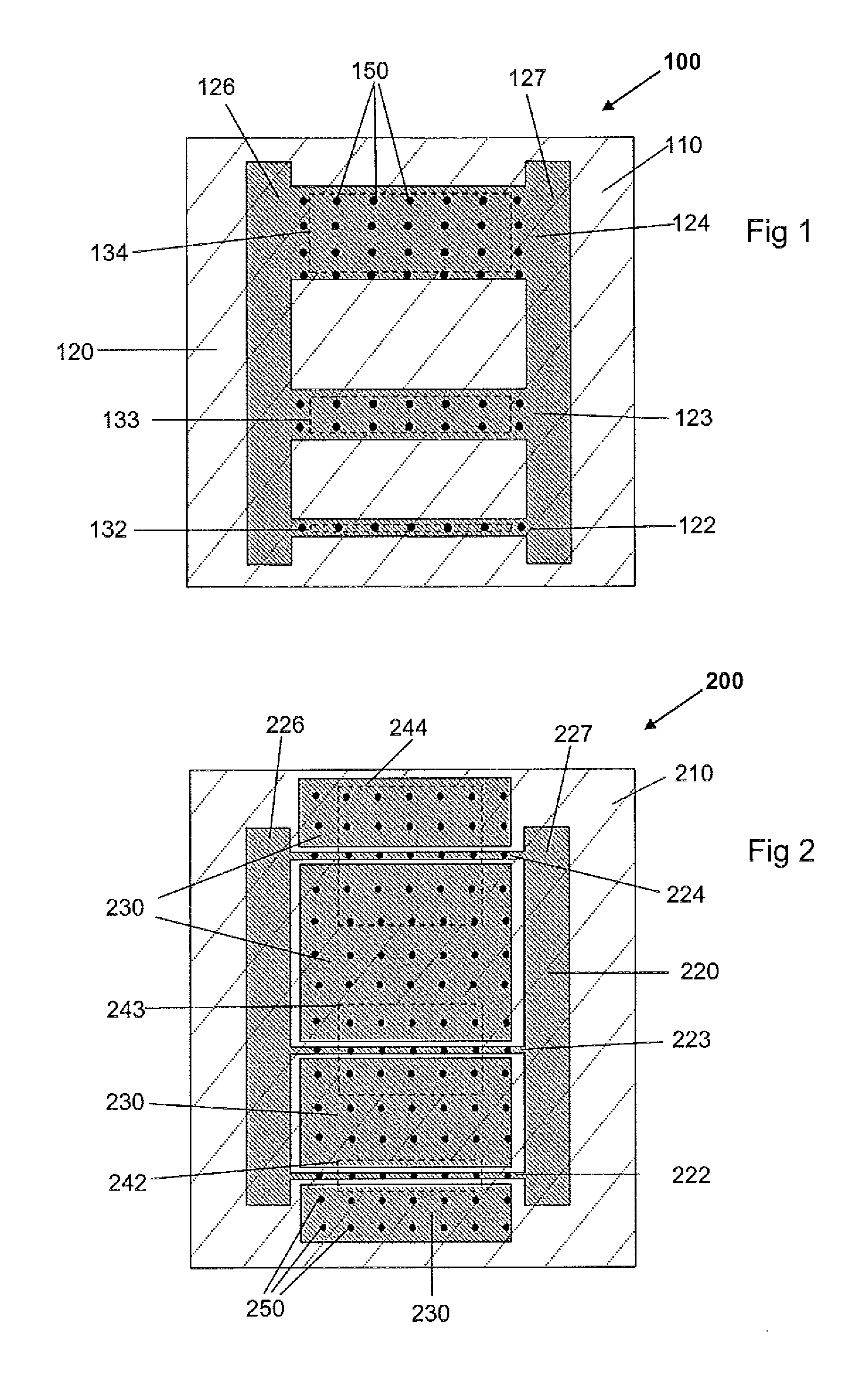

A corrosion sensor includes an insulating substrate, a thin film of a first metallic material formed on the substrate; and an array of areas what includes a second metallic material provided at the surface of the thin film. A method for manufacturing such a sensor is also disclosed. An exemplary embodiment is disclosed in which the thin film is patterned to define a number of tracks, the resistance of which can be monitored in order to determine the degree to which the thin film has corroded.

Owner:BAE SYSTEMS PLC

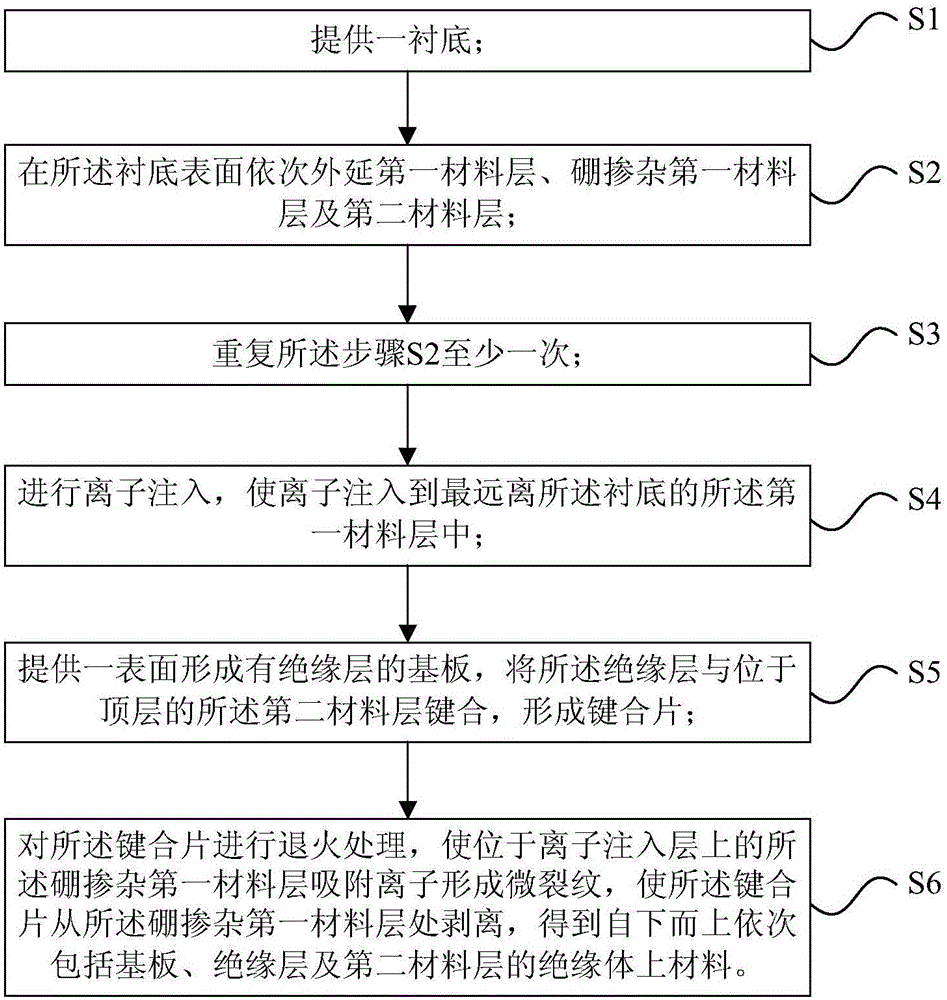

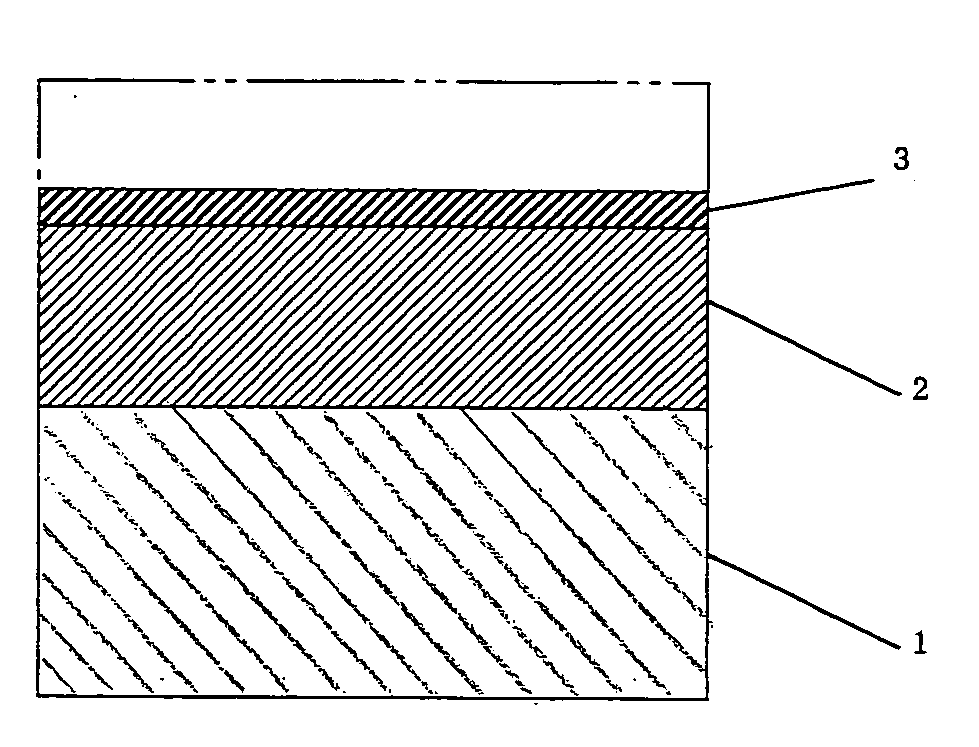

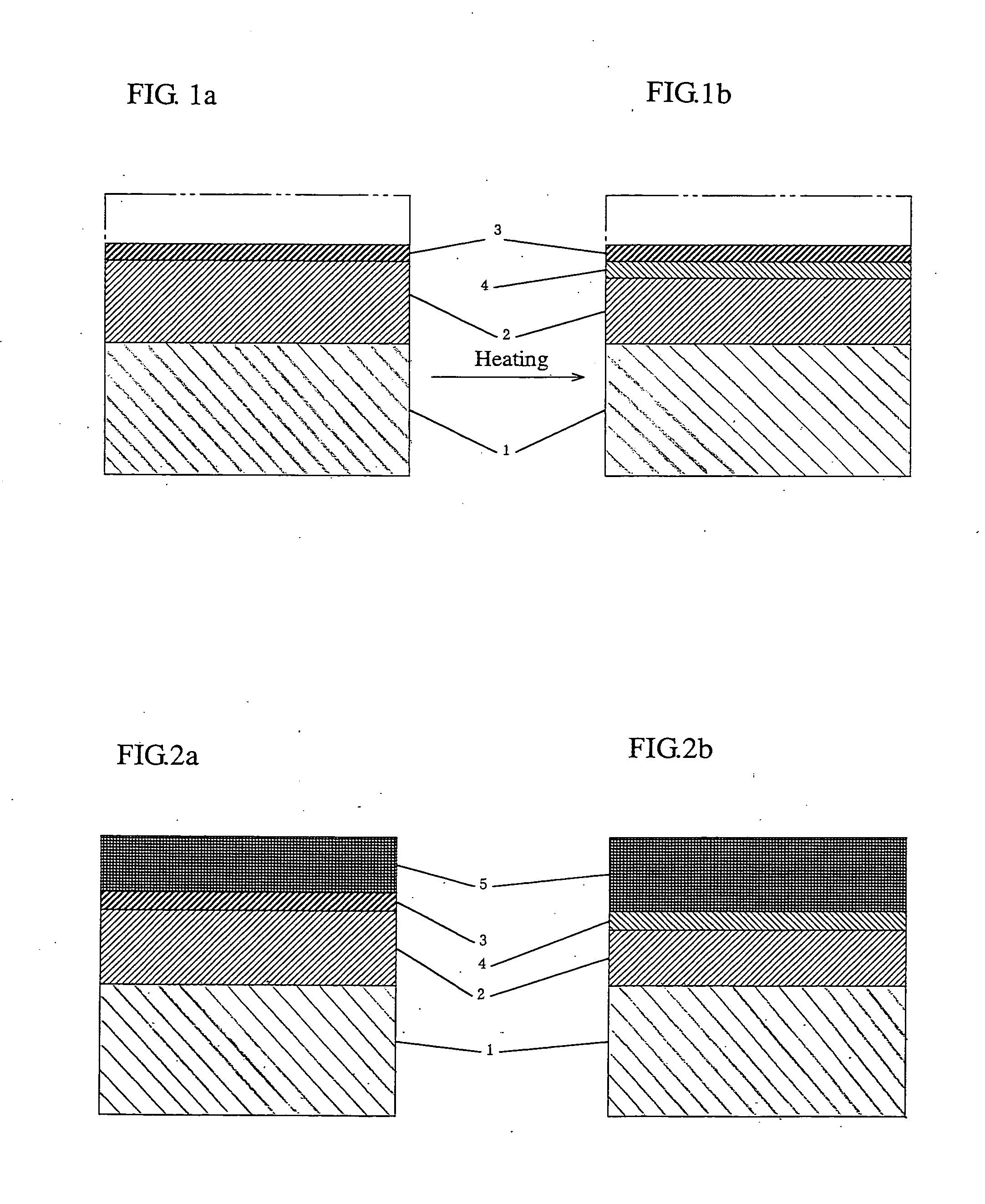

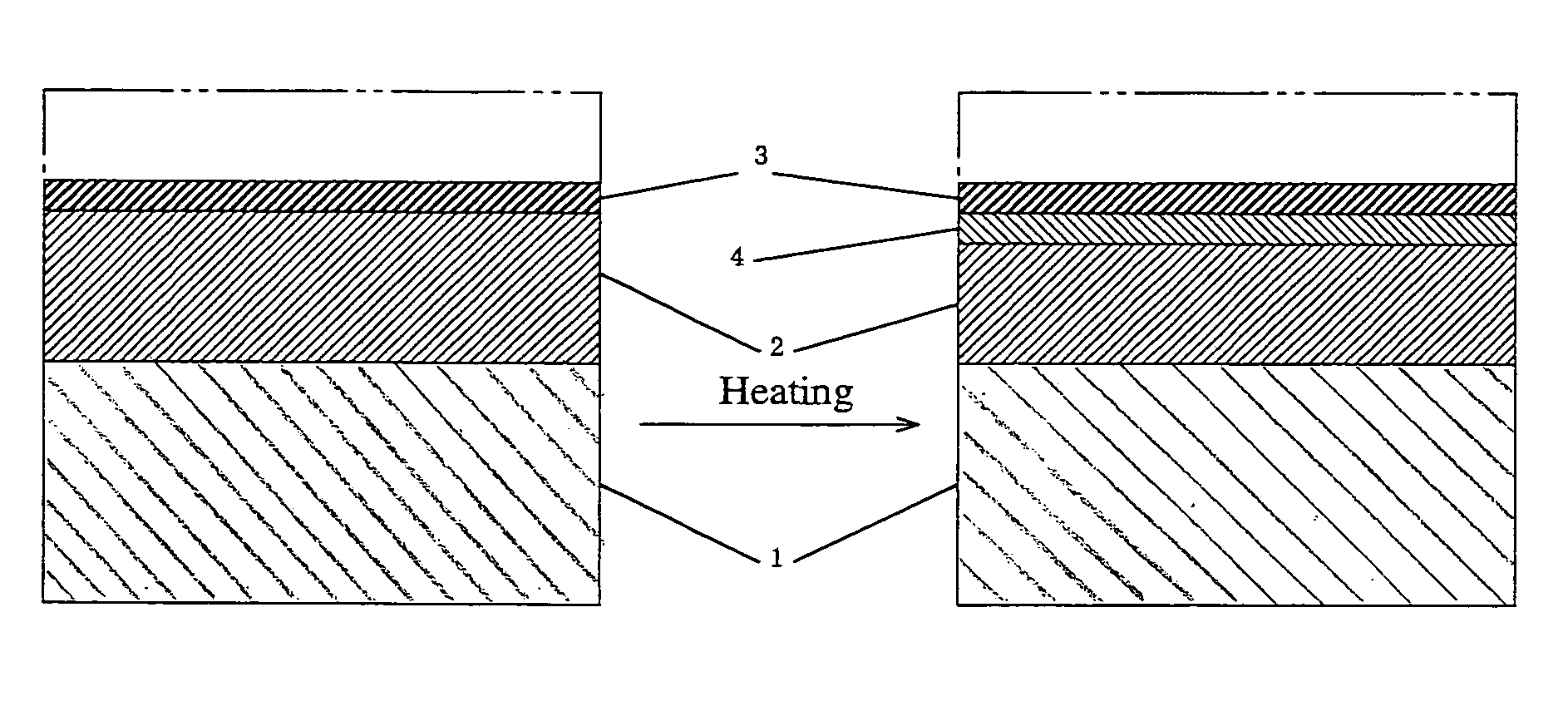

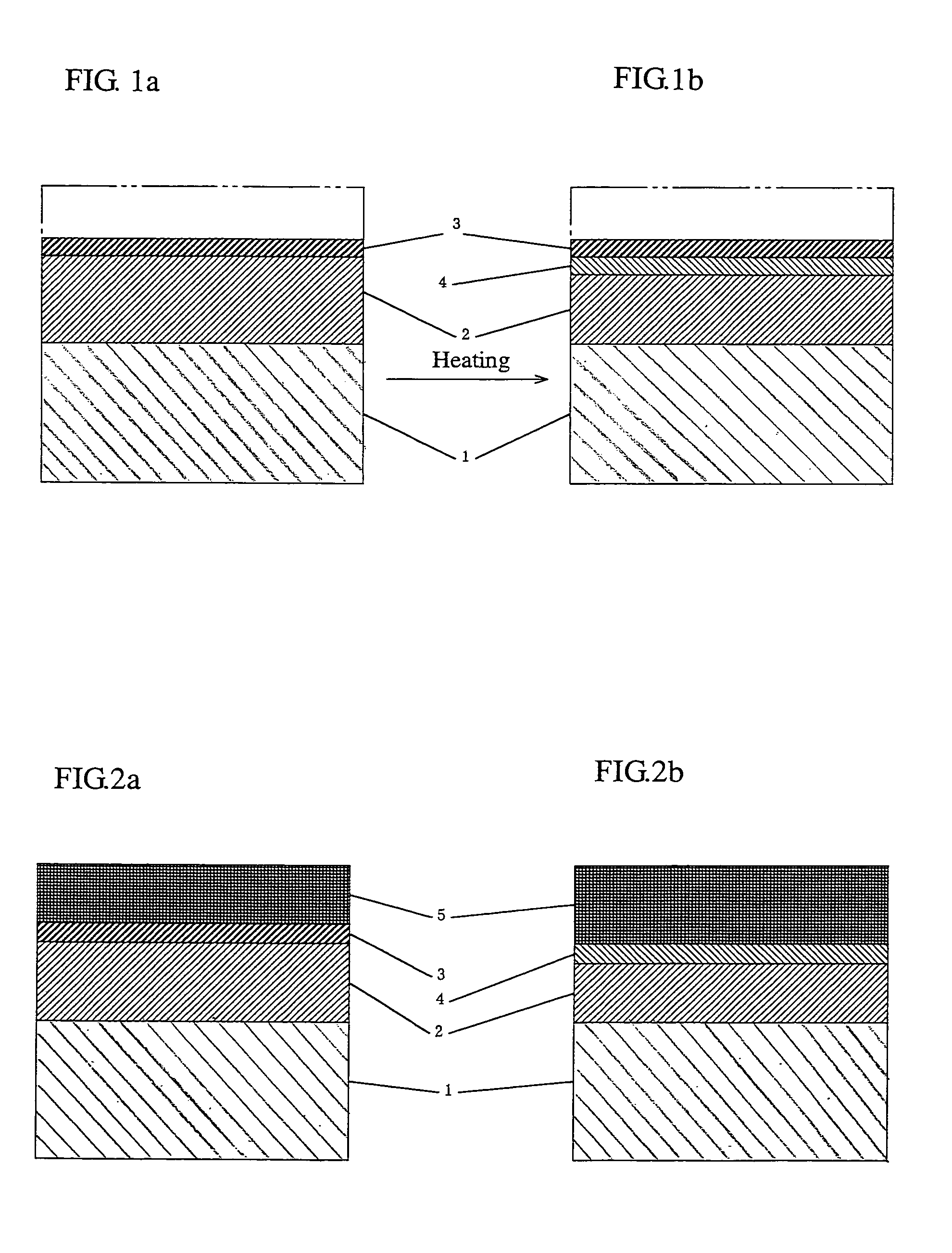

Preparation method of material-on-insulator

ActiveCN105140171ALow costQuality improvementSemiconductor/solid-state device manufacturingBoronIon implantation

The invention provides a preparation method of a material-on-insulator. The method comprises the following steps: (S1) a substrate is provided; (S2) a first material layer, a boron-doped first material layer and a second material layer sequentially extend on the surface of the substrate; (S3) the step (S2) is repeated at least once; (S4) ion implantation is carried out, so that the ions are injected into the first material layer which is the furthest to the substrate; (S5) a base plate formed with an insulating layer on the surface is provided; and the insulating layer and the second material layer on the top layer are bonded to form a bonding wafer; and (S6) annealing treatment is carried out on the bonding wafer; and the boron-doped first material layer on an ion implantation layer absorbs the ions to form microcracks for stripping, so as to obtain the material-on-insulator. According to the preparation method, the substrate can be repeatedly utilized, so that the cost of the production material is reduced; the technological process is simplified; the ion implantation dosage is relatively low; improvement of the crystal quality is facilitated; the implantation cost is reduced; and the obtained material-on-insulator is very smooth in surface and does not need to be polished.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Metallographic corrosive agent for amorphous alloys and observation method for metallographic structures of amorphous alloys

InactiveCN102383130AFast corrosionSimple preparation processPreparing sample for investigationMaterial analysis by optical meansOxalateHydrofluoric acid

The invention provides a metallographic corrosive agent for amorphous alloys, which comprises a primary corrosive agent and a secondary corrosive agent, wherein the primary corrosive agent is mixed liquor of hydrofluoric acid, phosphoric acid and oxalic acid, and the secondary corrosive agent is water liquor of FeCl3 (ferric trichloride) and KCl (potassium chloride). The invention further relates to an observation method for metallographic structures of the amorphous alloys, which includes the steps of placing the amorphous alloys under a metallographic microscope after rough grinding, fine grinding and polishing for the surfaces of the amorphous alloys and after corroding the amorphous alloys with the metallographic corrosive agent. The steps of corroding the amorphous alloys with the metallographic corrosive agent include: a etching the surfaces of the amorphous alloys with the mixed liquor of the hydrofluoric acid, the phosphoric acid and the oxalic acid, and b wiping the surfaces of the amorphous alloys with the water liquor of the FeCl3 and the KCl. The metallographic corrosive agent is beneficial to observation of the metallographic structures of the amorphous alloys and evaluation of the quality of the amorphous alloys.

Owner:SUZHOU SHIHAO BUILDING MATERIAL NEW TECH ENG

Rapid metallographic determination method for grain size of GCr15 steel bearing assembly

InactiveCN103344532AEasy to operateAccelerated corrosionPreparing sample for investigationParticle size analysisMetallurgyImaging analysis

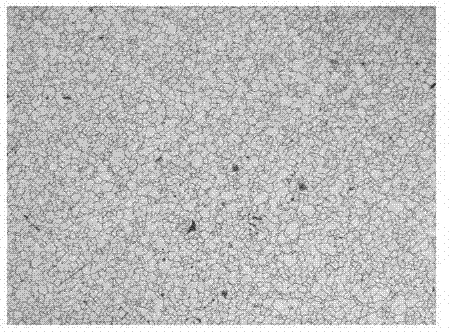

The invention belongs to the technical field of bearing detection. The invention relates to a rapid metallographic determination method for of grain size of a GCr15 steel bearing assembly. The rapid metallographic determination method comprises the following steps of 1), preparing an etching solution; 2), etching a sample of the bearing assembly; 3), determining the grain size: shooting a metallograph of a grain boundary profile by using an optical microscope, then determining the grain size of the metallograph by using image analysis software and in reference to steel size determination standards of an average grain size of the steel by an intercept method. The clear grain boundary profile can be obtained by using a rapid and easily operational chemical etching method; and efficient and accurate determination for the GCr15 steel bearing assembly can be realized by combining the metallographic determination method for the grain size.

Owner:WUHAN UNIV OF TECH

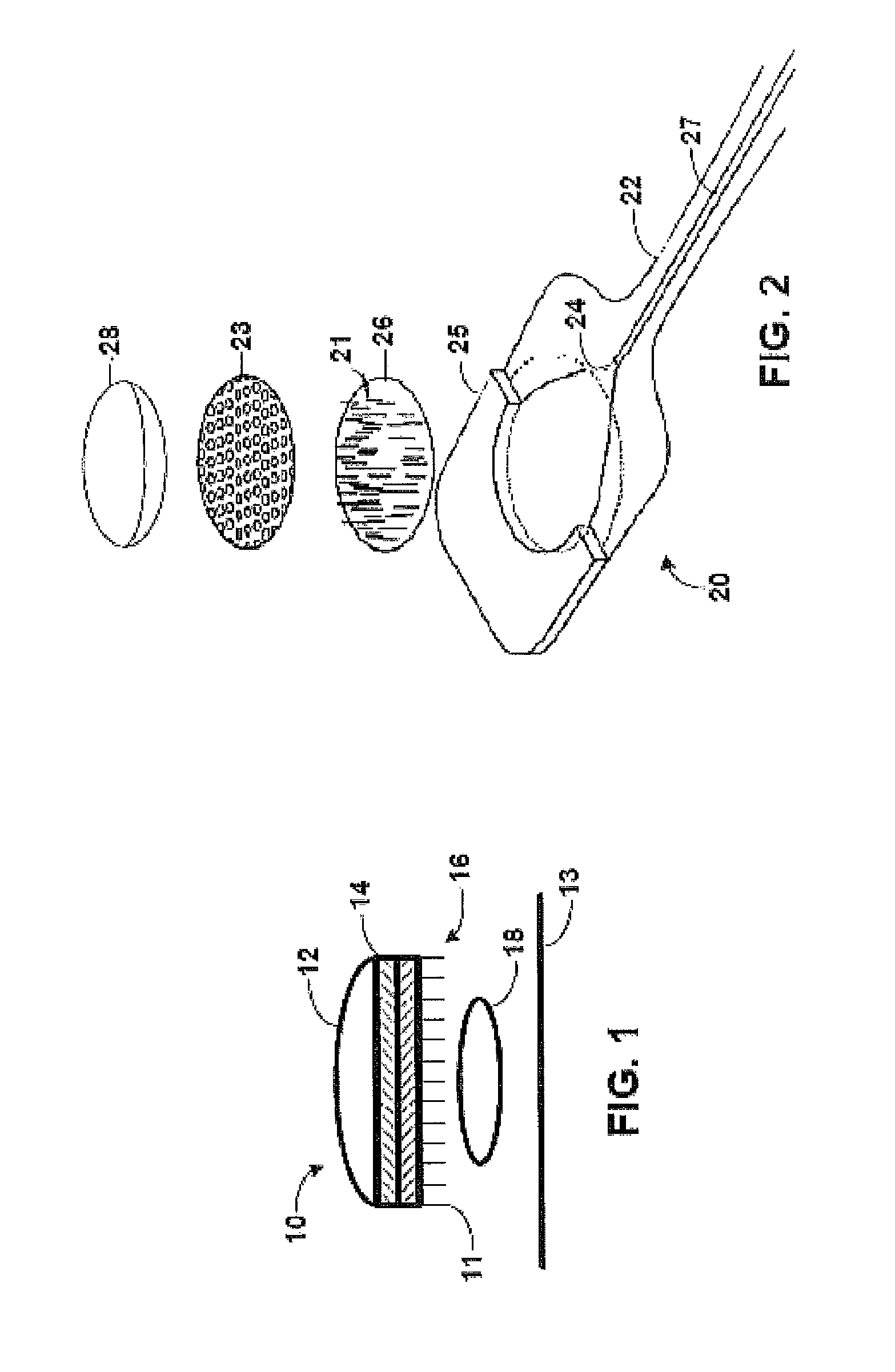

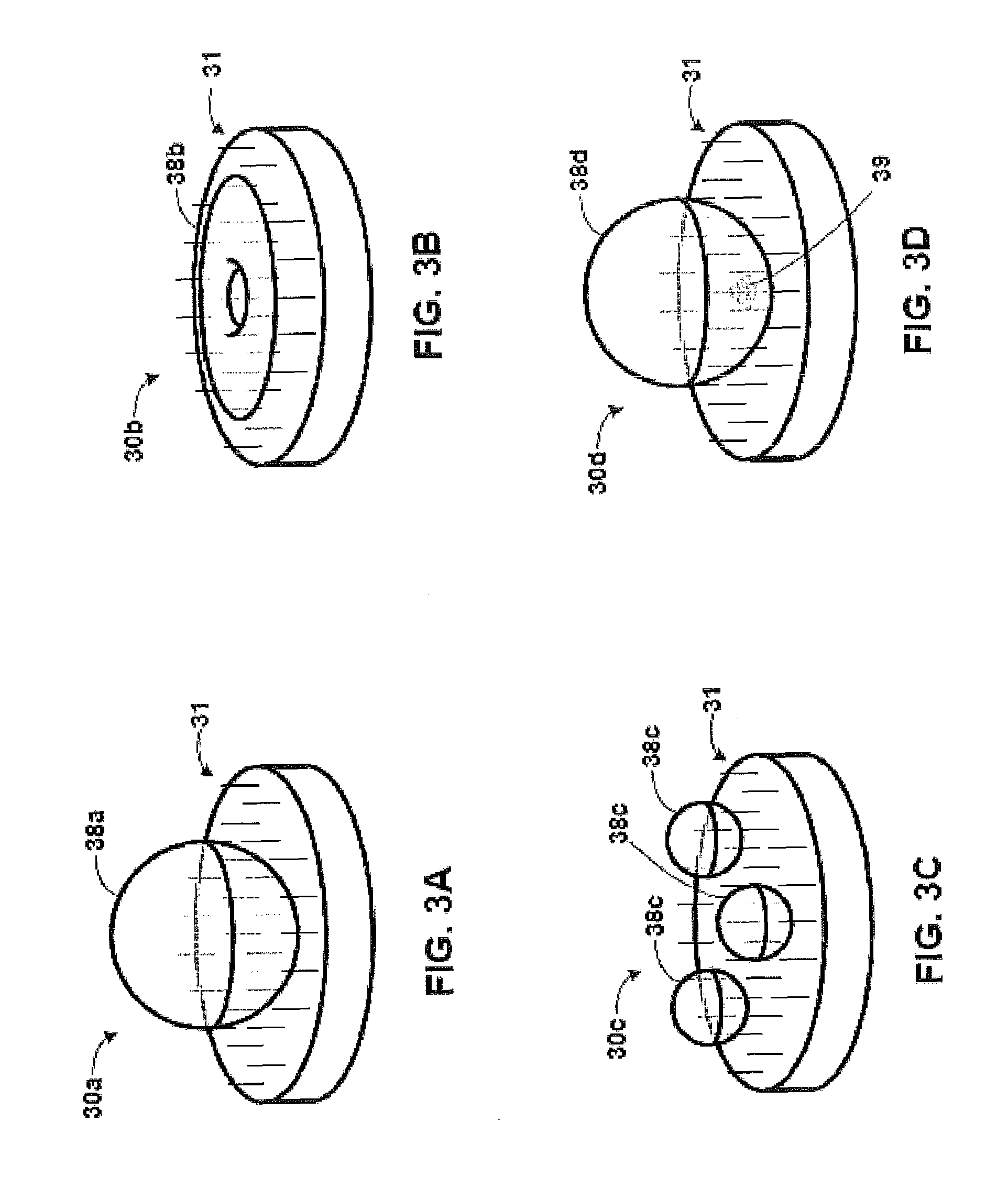

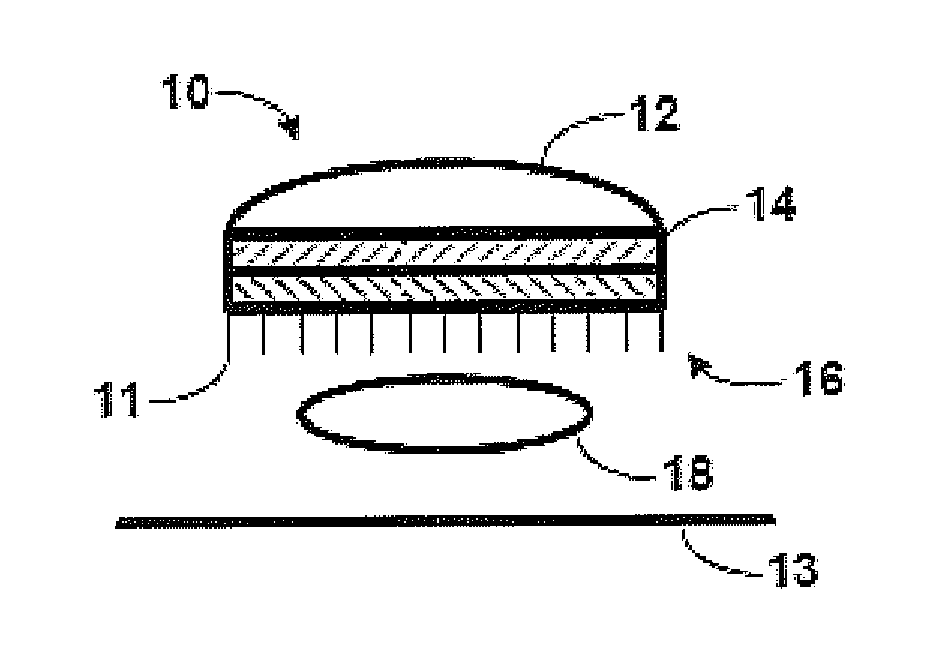

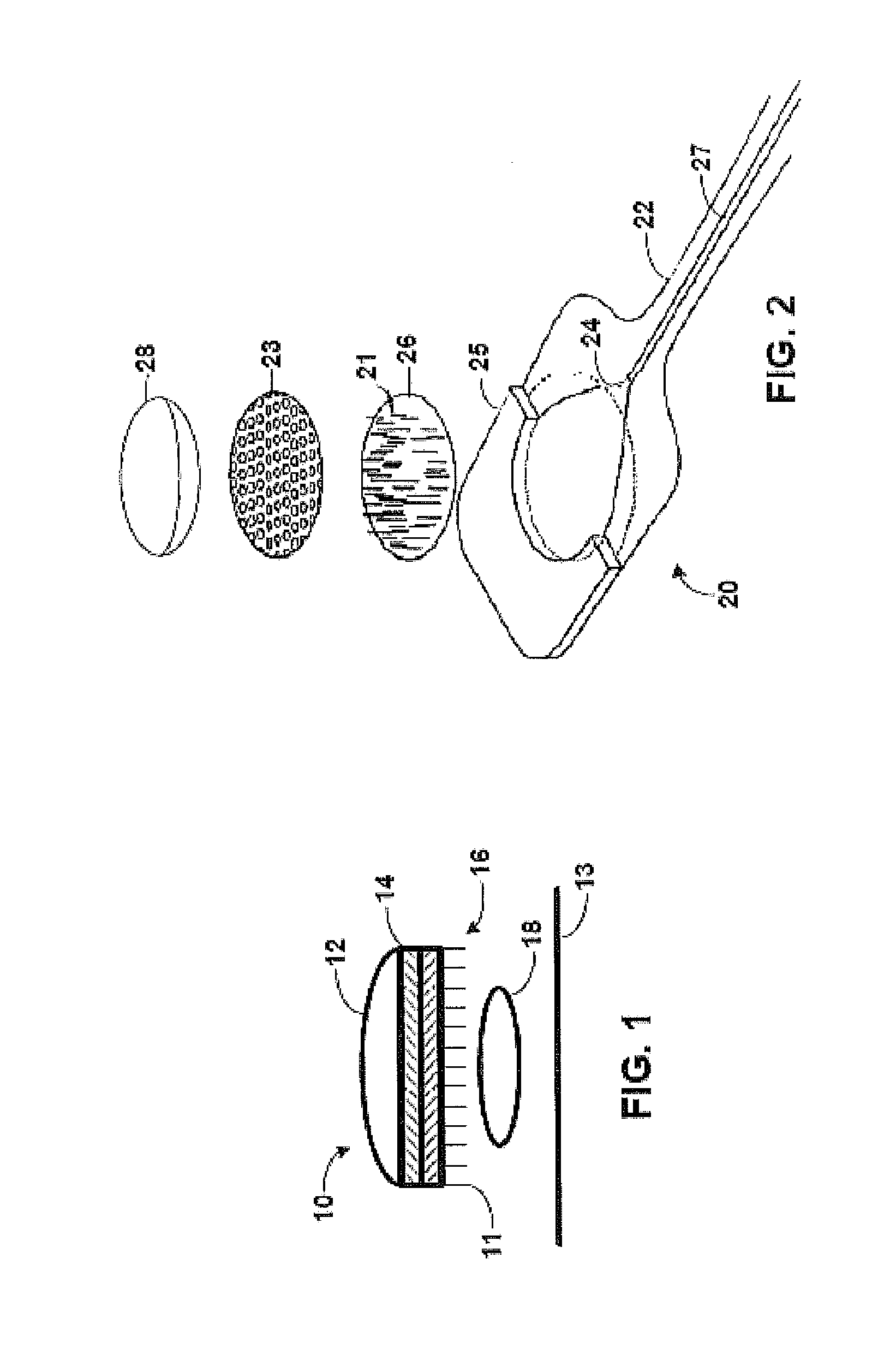

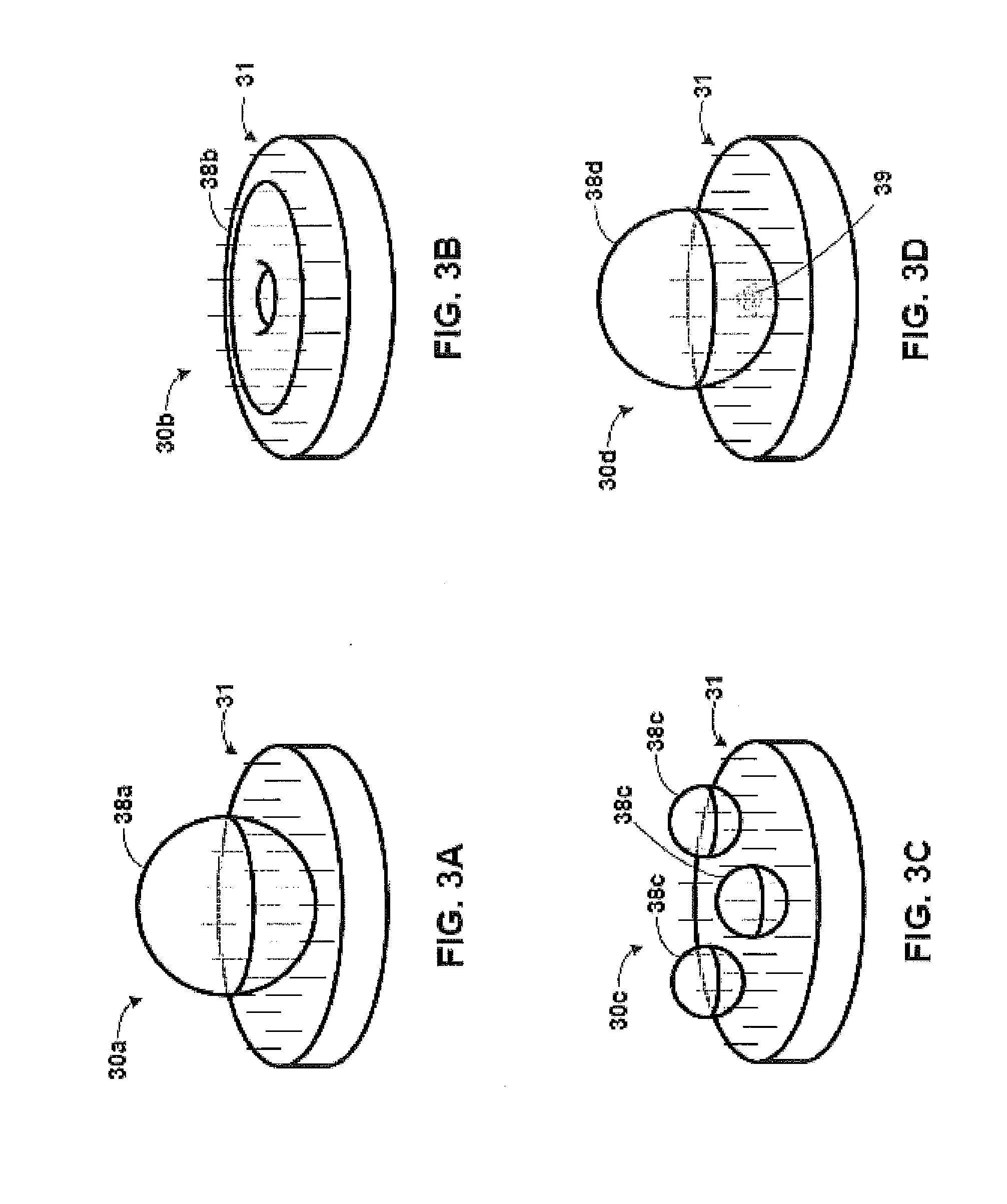

Device with encapsulated gel

ActiveUS8805470B2Simple interfaceReduce equipment capacityElectroencephalographySensorsBiomedical engineeringMedical treatment

Apparatus and techniques are provided for interfacing a device with a surface. The apparatus and techniques provide gel encapsulation and isolation mechanisms to extend the shelf-life of the preparation devices, allow for the use of more effective materials, and improve the quality of the contact between a device and an application surface. Particular embodiments of these apparatus and techniques suitable for use in medical contexts are also provided.

Owner:TYCO HEALTHCARE GRP LP

Coating material for thermal barrier coating having excellent corrosion resistance and heat resistance and method of producing the same

InactiveUS20080166548A1Reduce coatingReduce generationMolten spray coatingElectric discharge heatingInter layerHeat resistance

A coating material for a thermal barrier coating having excellent corrosion resistance and heat resistance comprises a substrate, an undercoat made of an aluminum-containing heat-resistant alloy, Cr2O3 layer as a middle layer on the undercoat, and a top coat made of ZrO2 based ceramic on the middle coat.

Owner:TOCALO CO LTD

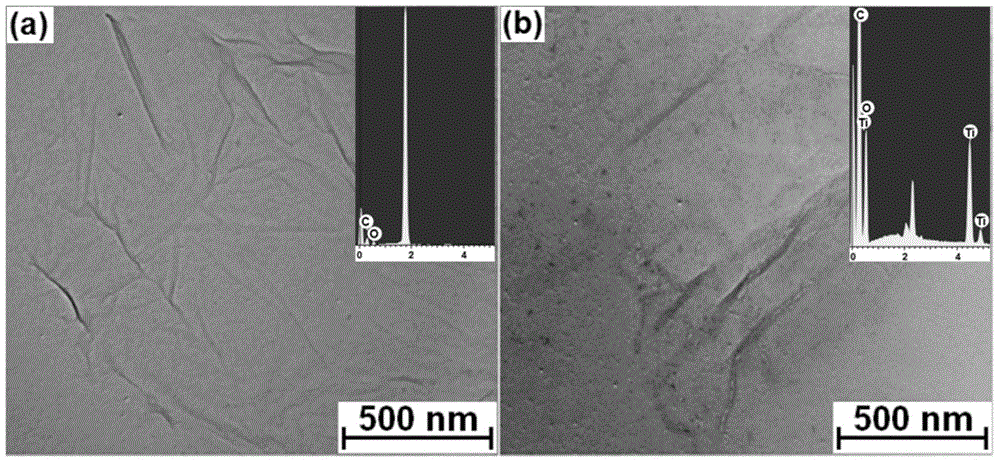

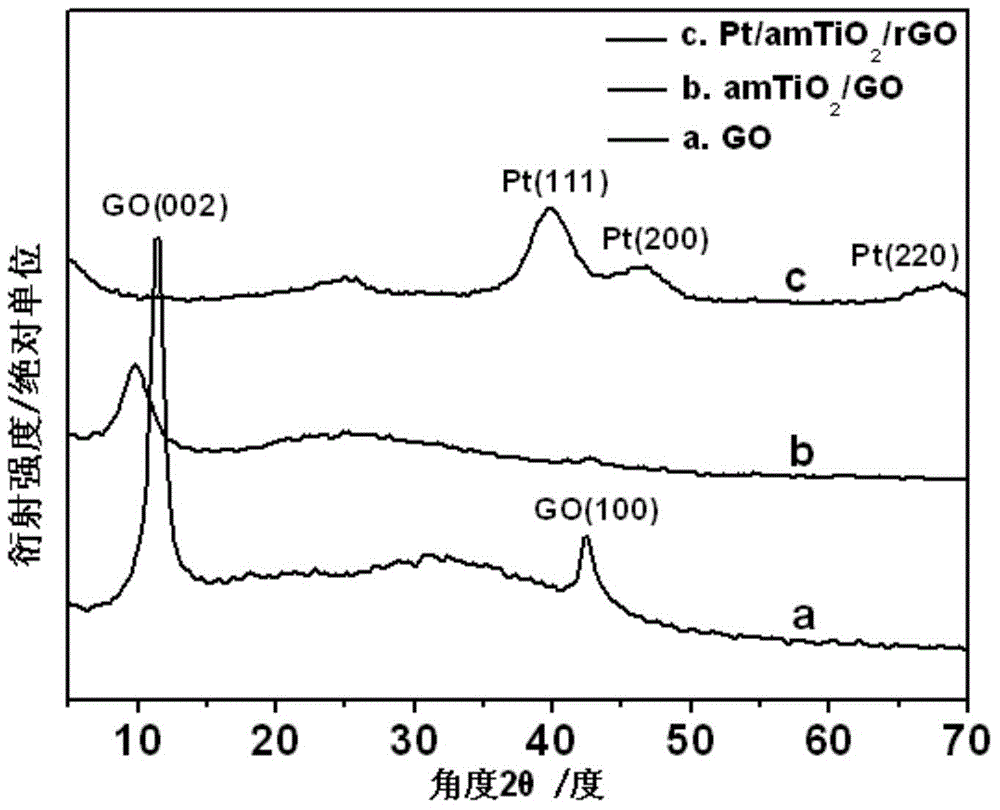

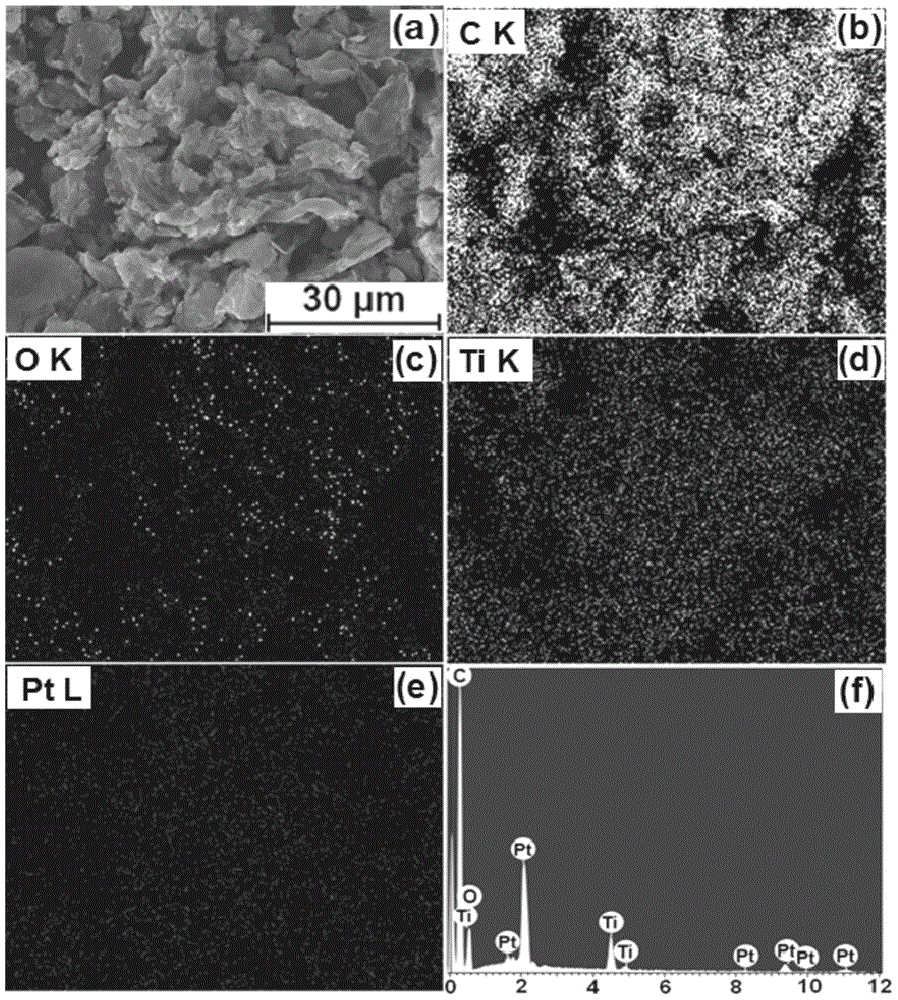

Electro-catalyst Pt/amTiO2/rGO and preparation method

InactiveCN104437475AEvenly dispersedIncrease layer spacingCell electrodesMetal/metal-oxides/metal-hydroxide catalystsWater bathsSolvent

The invention provides an electro-catalyst Pt / amTiO2 / rGO and a preparation method, and belongs to the technical field of fuel-cell catalysts. The preparation method comprises the following steps: firstly, an improved sol-gel method is adopted to prepare TiO2-GO (graphene oxide) sol, the sol is volatilized naturally in water bath at the temperature of 25 DEG C, and a GO complex amTiO2 / GO uniformly modified by amorphous TiO2 is obtained; and then chloroplatinic acid is taken as a platinum source, ethylene glycol is taken as a solvent and a reducing agent, Pt nanoparticles are loaded on amTiO2 / GO with an impregnation reduction method, meanwhile, GO is reduced to reduced GO rGO, and the electro-catalyst Pt / amTiO2 / rGO is obtained. For the catalyst, an amTiO2 modifier is uniformly dispersed on the surface of rGO, one function of the amTiO2 modifier is to solve the corrosion problem of rGO, another function is to increase the dispersion degree of the loaded Pt nanoparticles, meanwhile, the electrical conductivity of amTiO2 is improved by rGO, so that performance advantages of rGO and amTiO2 can be played sufficiently, the electrocatalytic activity and stability of the catalyst are improved, and the precious metal Pt is used efficiently. The electro-catalyst Pt / amTiO2 / rGO and the preparation method have the advantages of simple technology, easiness in operation and environmental protection.

Owner:BEIJING UNIV OF CHEM TECH

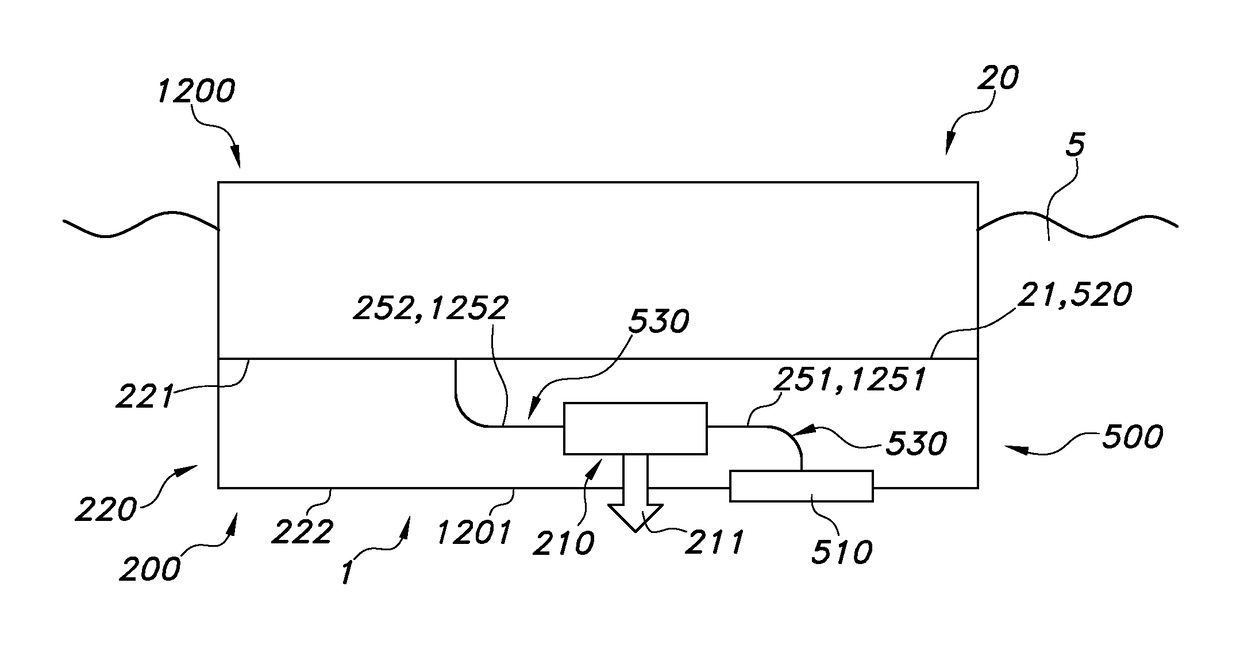

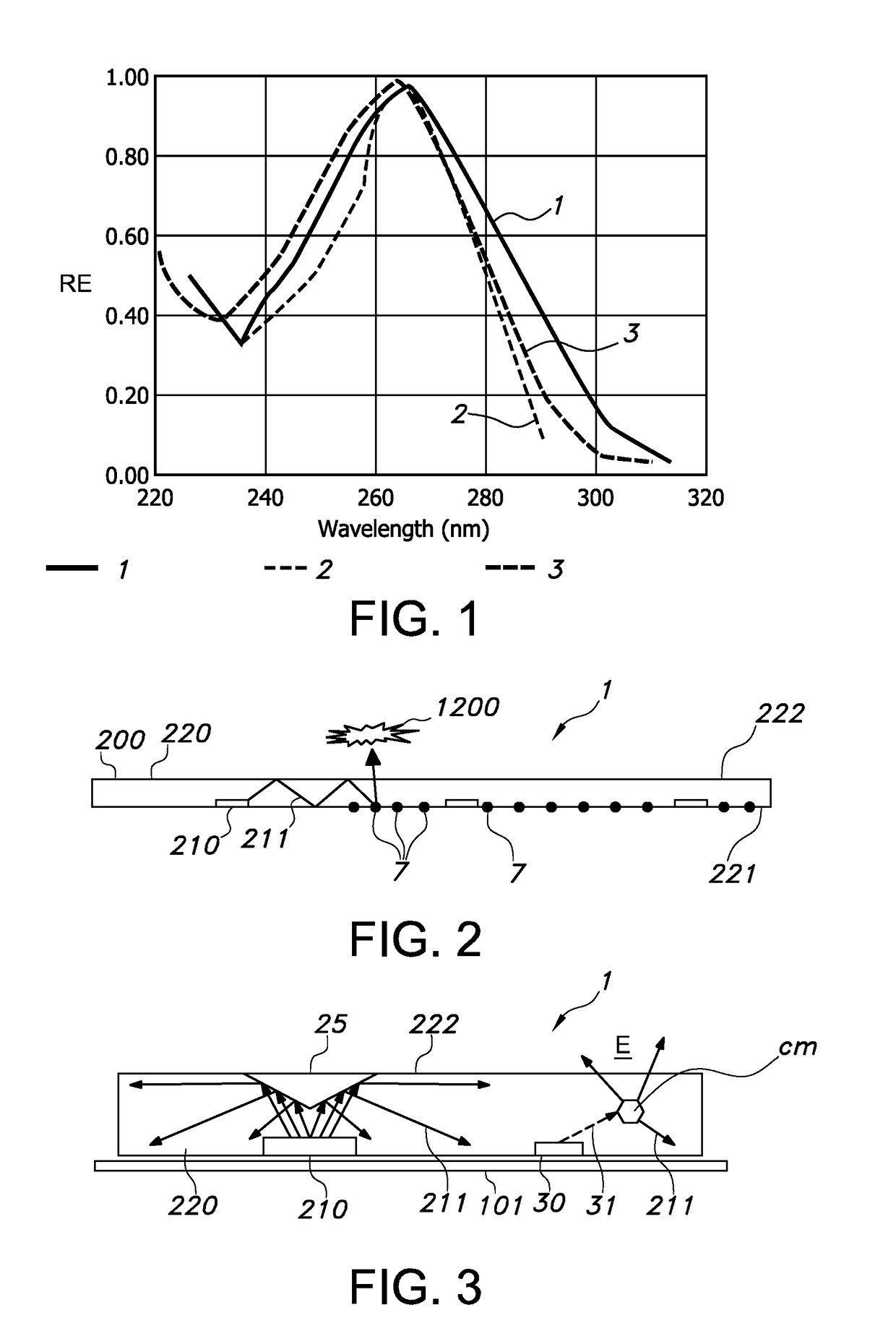

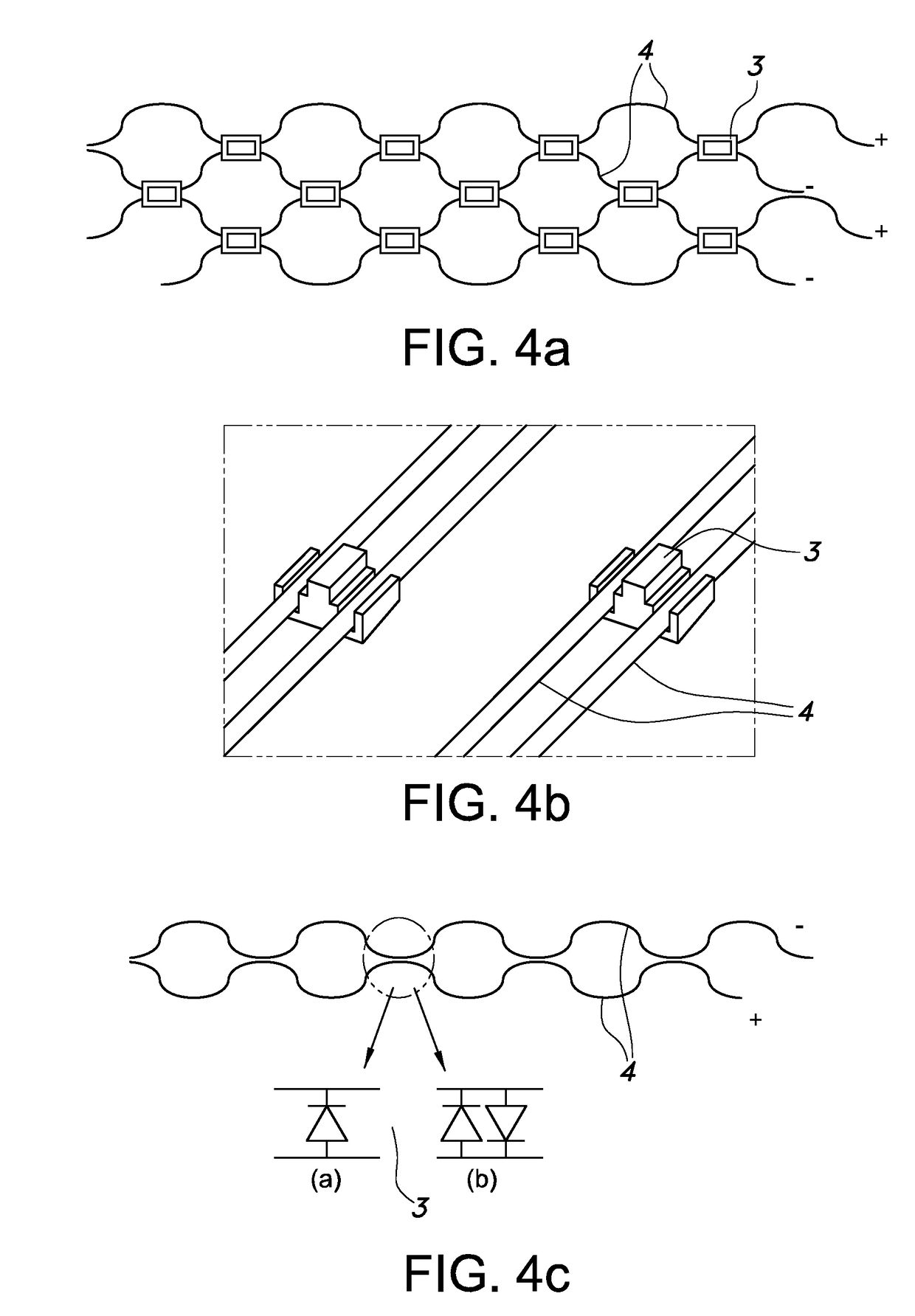

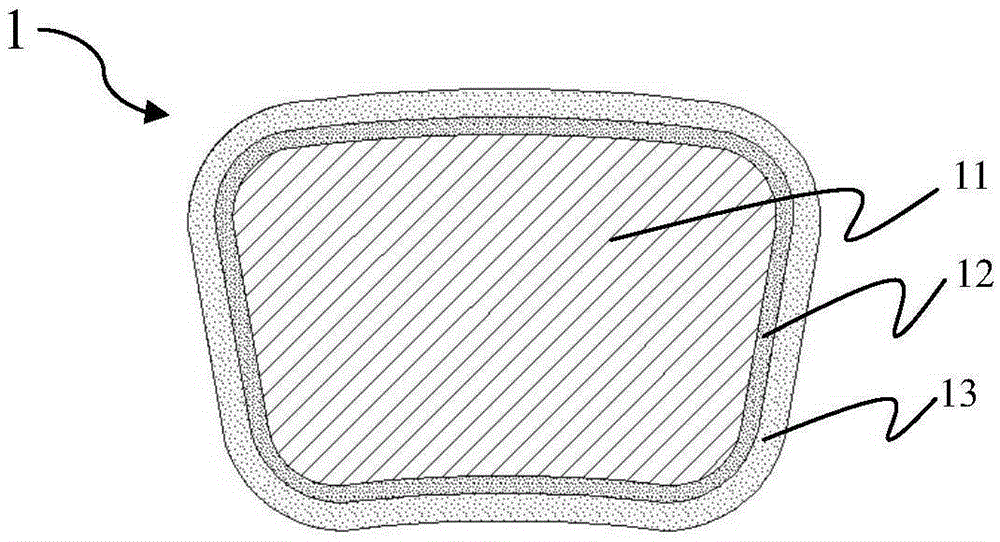

Anti-fouling system using energy harvested from salt water

InactiveUS20170190397A1Corrosion controlEasy to corrodeEnergy supplySeawater treatmentSaline waterSalt water

The invention provides an anti-fouling lighting system (1) configured for preventing or reducing biofouling on a fouling surface (1201) of an object (1200) that during use is at least temporarily exposed to a liquid, by providing an anti-fouling light (211) to said fouling surface (1201), the anti-fouling lighting system (1) comprising: —a lighting module (200) comprising a light source (210) configured to generate an anti-fouling light (211); and —an energy system (500) configured to locally harvest energy and configured to provide electrical power to said light lighting module (200), wherein the energy system (500) comprises (i) a sacrificial electrode (510), and (ii) a second energy system electrode (520), wherein the energy system (500) is configured to provide electrical power to the lighting module (200) when the sacrificial electrode (510) and the second energy system electrode (520) are in electrical contact with the liquid.

Owner:KONINKLJIJKE PHILIPS NV

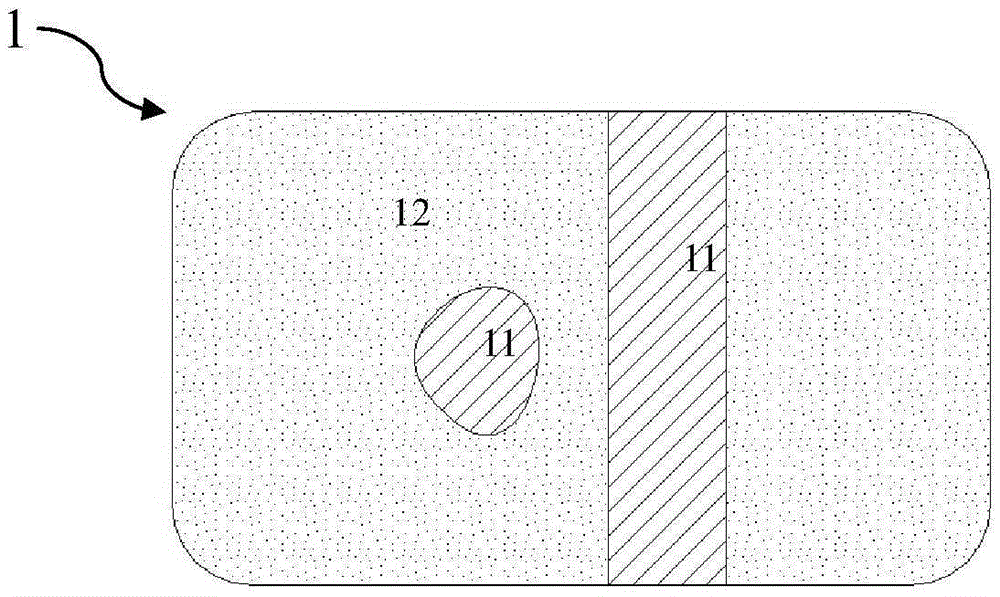

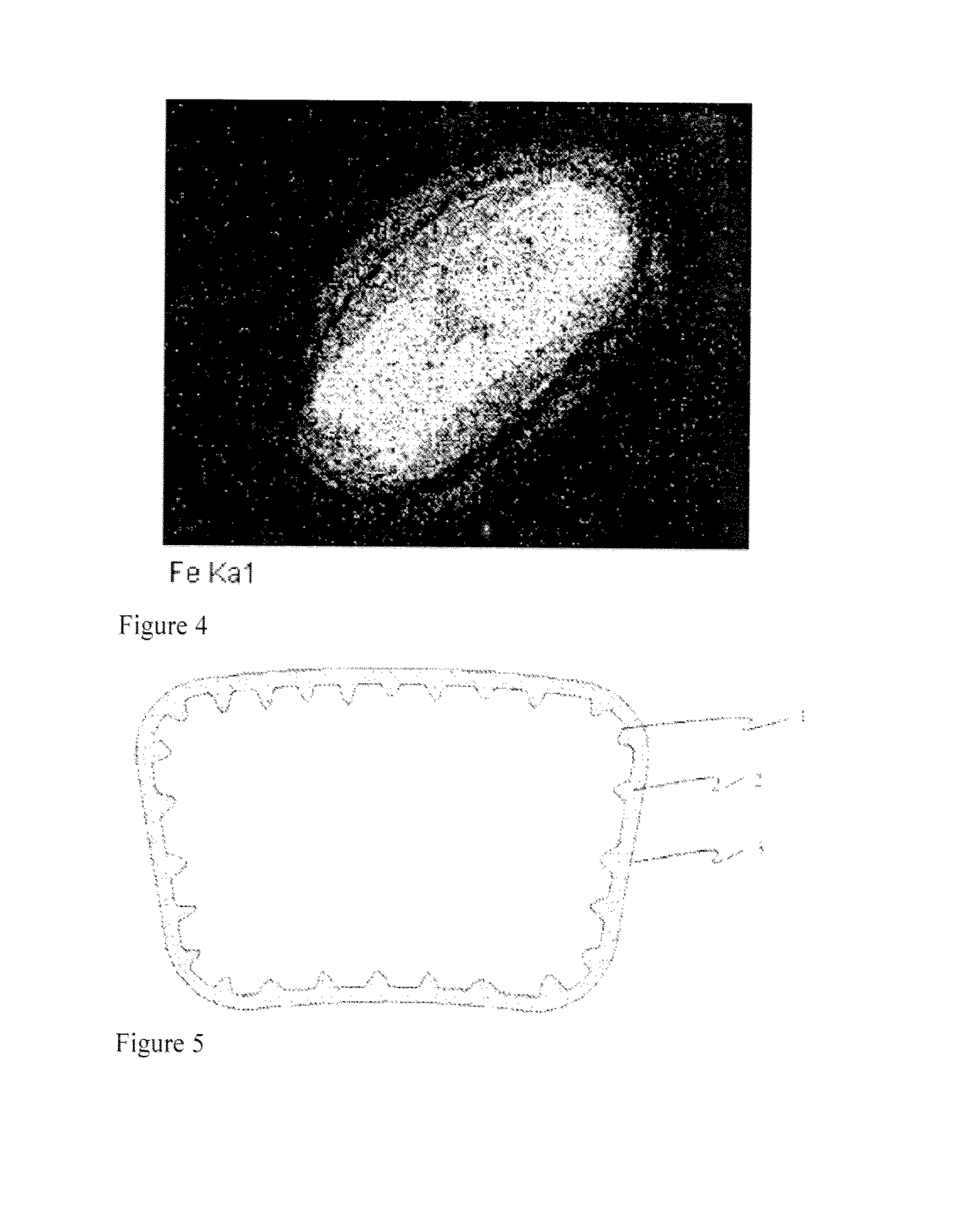

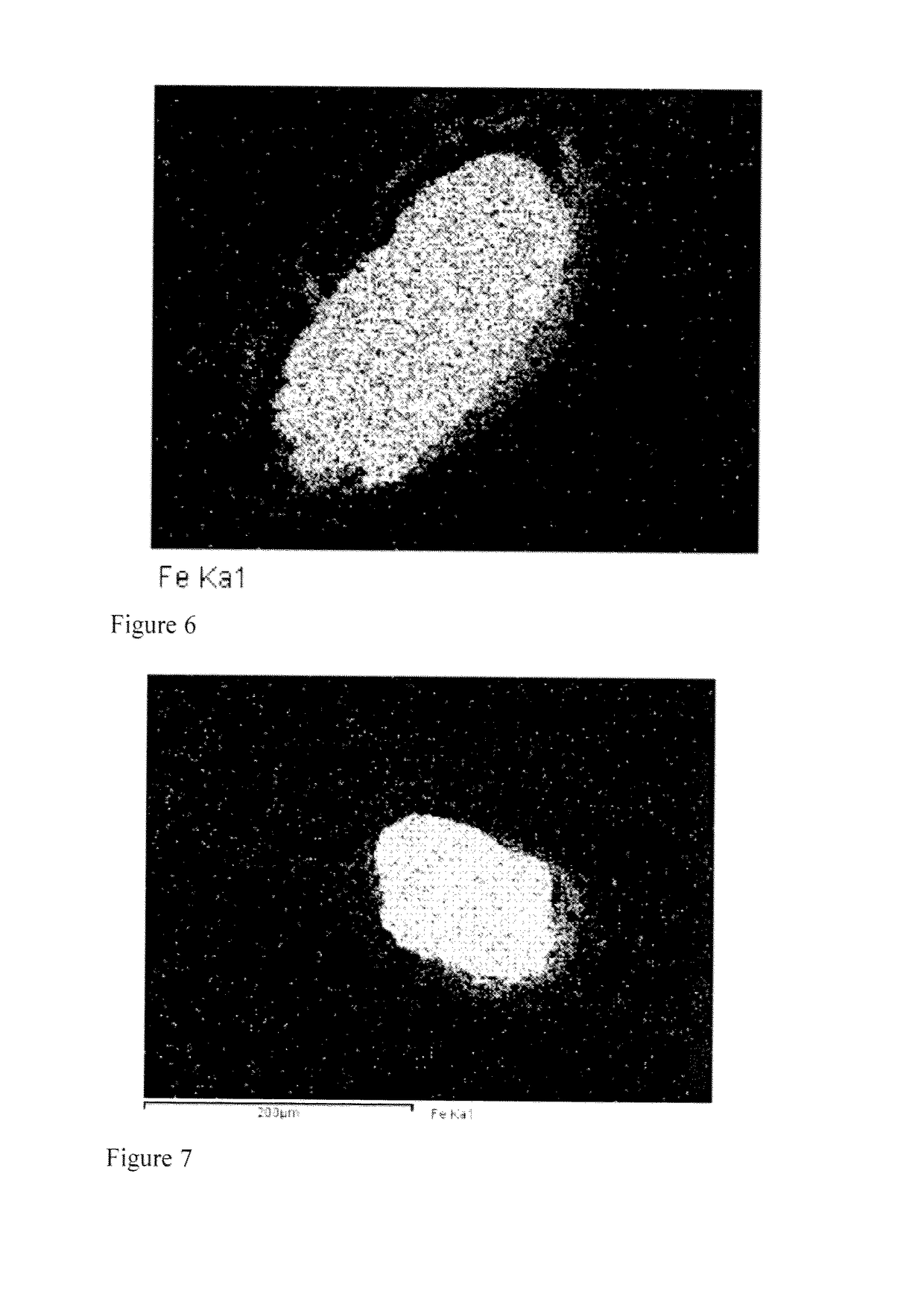

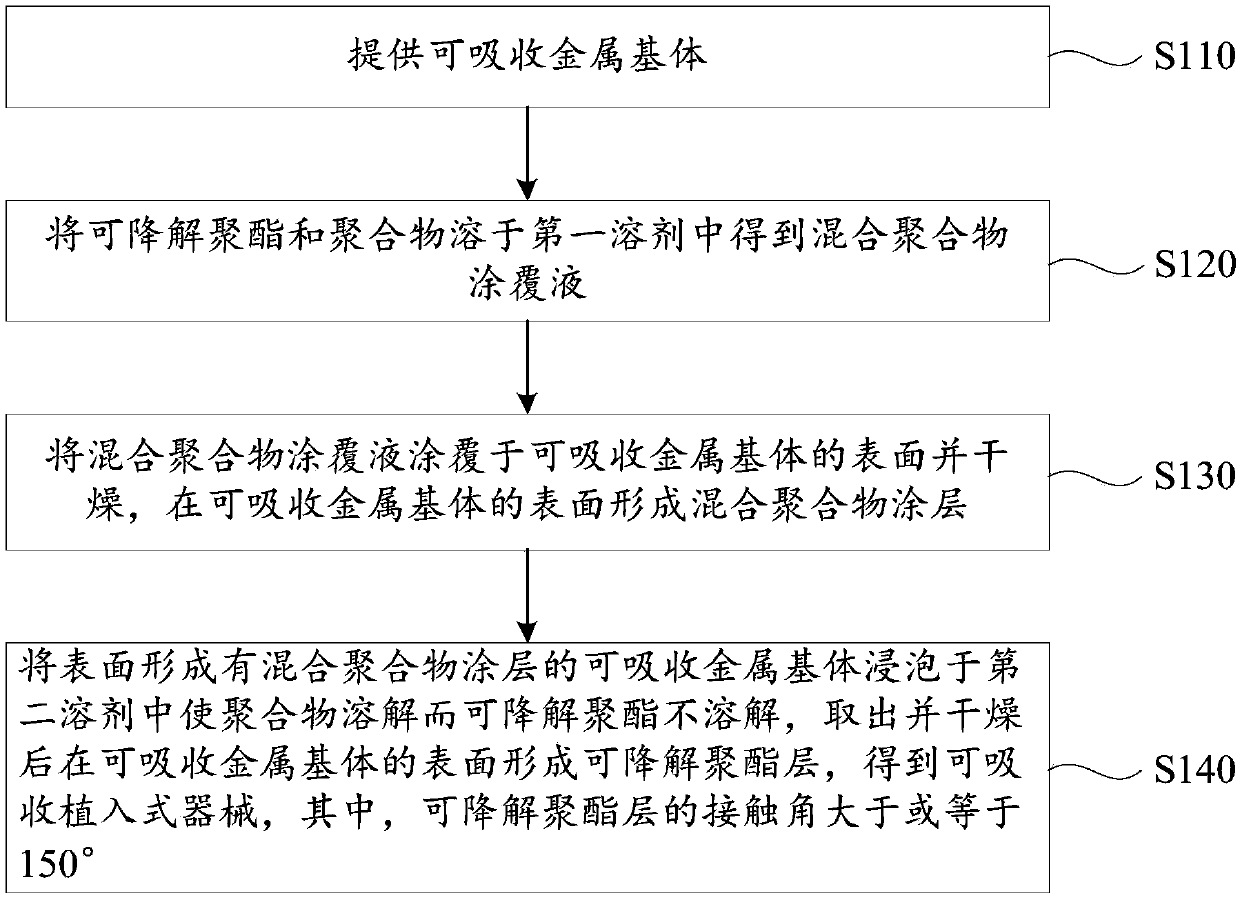

Absorbable iron-base alloy implantable medical device and preparation method thereof

ActiveCN106693043AMeet the degradation cycle requirementsMitigate early corrosionStentsSurgeryAcid substancesMechanical property

The invention discloses an absorbable iron-base alloy implantable medical device and a preparation method thereof. The absorbable iron-base alloy implantable medical device comprises an iron-base alloy matrix, a degradable polymer arranged at the surface of the iron-base alloy matrix and an alkaline protector arranged at the surface of the iron-base alloy matrix. The alkaline protector contains at least one alkaline substance; during the early stage of implantation of the device, the alkaline substance can be neutralized with an acidic substance generated by a polymer so as to retard corrosion of the iron-base alloy matrix at the early stage of implantation, so that the iron-base alloy matrix is basically non-corroding or slow in corrosion during the early stage of implantation, and meets the clinical requirements on mechanical properties of the device at the early stage of implantation. Furthermore, the alkaline protector is consumed by neutralizing to expose the matrix, the matrix still can be eroded more quickly in an acidic environment formed by polymers and thus clinically meets the requirement on the corrosion period of the device.

Owner:BIOTYX MEDICAL (SHENZHEN) CO LTD

Fire barrier protection comprising graphitized films

InactiveUS20110011601A1Superior fire barrier protectionImprove fire performanceSynthetic resin layered productsMedical devicesPolymerCivil engineering

Owner:KANEKA CORP

Coating material for thermal barrier coating having excellent corrosion resistance and heat resistance and method of producing the same

InactiveUS7445434B2Reduce coatingReduce generationMolten spray coatingVacuum evaporation coatingHeat resistanceAlloy

A coating material for a thermal barrier coating having excellent corrosion resistance and heat resistance comprises a substrate, an undercoat made of an aluminum-containing heat-resistant alloy, Cr2O3 layer as a middle layer on the undercoat, and a top coat made of ZrO2 based ceramic on the middle coat.

Owner:TOCALO CO LTD

Device with encapsulated gel

ActiveUS20130023748A1Simple interfaceReduce equipment capacityElectroencephalographySensorsMedicineBiomedical engineering

Apparatus and techniques are provided for interfacing a device with a surface. The apparatus and techniques provide gel encapsulation and isolation mechanisms to extend the shelf-life of the preparation devices, allow for the use of more effective materials, and improve the quality of the contact between a device and an application surface. Particular embodiments of these apparatus and techniques suitable for use in medical contexts are also provided.

Owner:TYCO HEALTHCARE GRP LP

Bioresorbable iron-based alloy stent

Owner:BIOTYX MEDICAL (SHENZHEN) CO LTD

Preparation method of sintered nd-fe-b magnet surface protective coating

InactiveCN107937875AImprove surface activityImprove bindingVacuum evaporation coatingSputtering coatingComposite filmElectrochemistry

The invention discloses a preparation method of a sintered nd-fe-b magnet surface protective coating. According to the method, the furnace pre-treatment is carried out on a magnet by adopting circulating argon ion bombardment and main arc bombardment, then, the magnetic control sputtering mode is carried out on the surface of a base body to prepare a layer of a metal film with relative low hardness and the electrochemical activity being higher than that of the iron element for bottoming, the bottoming thin film is further bombarded and compacted by adopting the main arc bombardment mode to ensure that the thin film and the base body is tightly combined, and a layer of diamond-like thin film is prepared on the surface of the bottoming layer by adopting a vacuum evaporation ion beam assisteddeposition technology; after the composite thin film is deposited and discharged out of the furnace, the composite coating is further mechanically compacted by adopting a shot blasting process, and the prepared bottoming metal / the diamond-like composite coating has high hardness and also has excellent wear resistance and corrosion resistance, and meanwhile, the binding force between the composite coating and the base body is extremely high by adopting the scheme and the method; and the preparation of high-hardness, high-binding force and corrosion-resistant coating on the surface of the sintered nd-fe-b magnet can be realized.

Owner:HEFEI UNIV OF TECH

A kind of saline solution etching method of suede ZNO base film

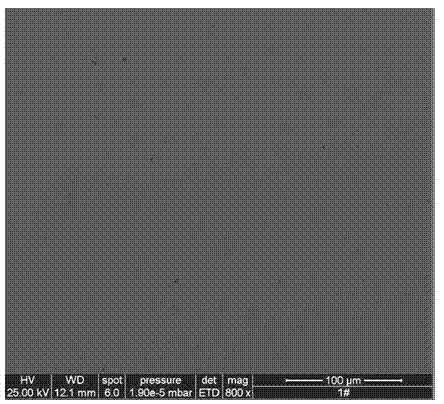

InactiveCN102270568AFast corrosionUniform structureFinal product manufactureSemiconductor/solid-state device manufacturingTrappingAmmonium nitrate

The invention discloses a saline solution corrosion method for a flocked ZnO-base thin film. A flocked structure is formed by corroding an intrinsic or doped ZnO, ZnMgO, ZnCdO, ZnBeO or ZnCaO thin film by adopting ammonium sulphate, ammonium nitrate or ammonium phosphate solution. The saline solution corrosion method has proper corrosion speed and is easy to operate; the texture process can be controlled well; and the prepared flocked ZnO-base thin film has high optical and electric characteristics and a remarkable light trapping effect.

Owner:ZHEJIANG UNIV

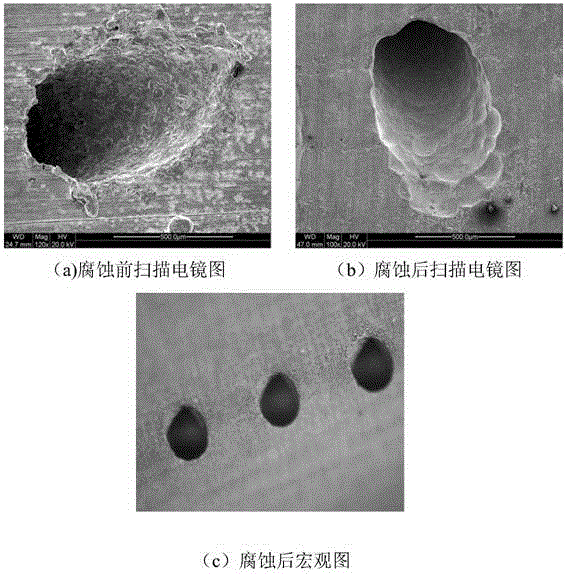

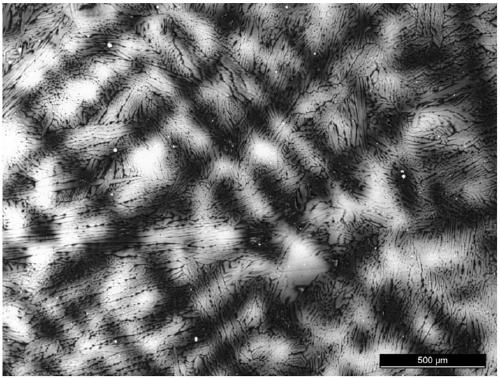

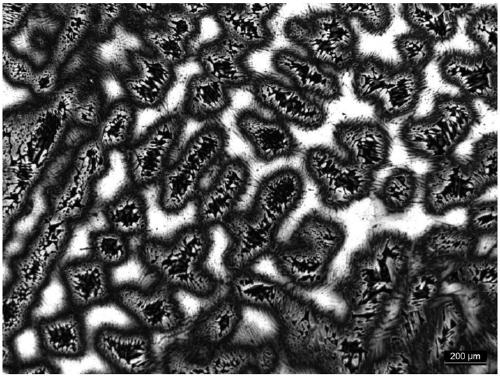

Bioresorbable Iron-Based Alloy Stent

The invention discloses an absorbable iron-based alloy stent, comprising an iron-based alloy substrate and a degradable polyester in contact with the surface of the substrate, in which the degradable polyester has a weight average molecular weight of between 20,000 and 1,000,000 and a polydispersity index of between 1.2 and 30. With the degradable polyester, the iron-based alloy is capable of corroding rapidly and controllably within a predetermined period. Following implantation into the human body, the degradable stent serves as a mechanical support at early stage, then gradually degrading and being metabolized and absorbed by the human body. During the process of degradation, minimal or no solid product is produced. Ultimately, the configuration of the lumen with an implanted stent as well as the systolic and diastolic functions thereof return to their natural states.

Owner:BIOTYX MEDICAL SHENZHEN CO LTD

Biofilter

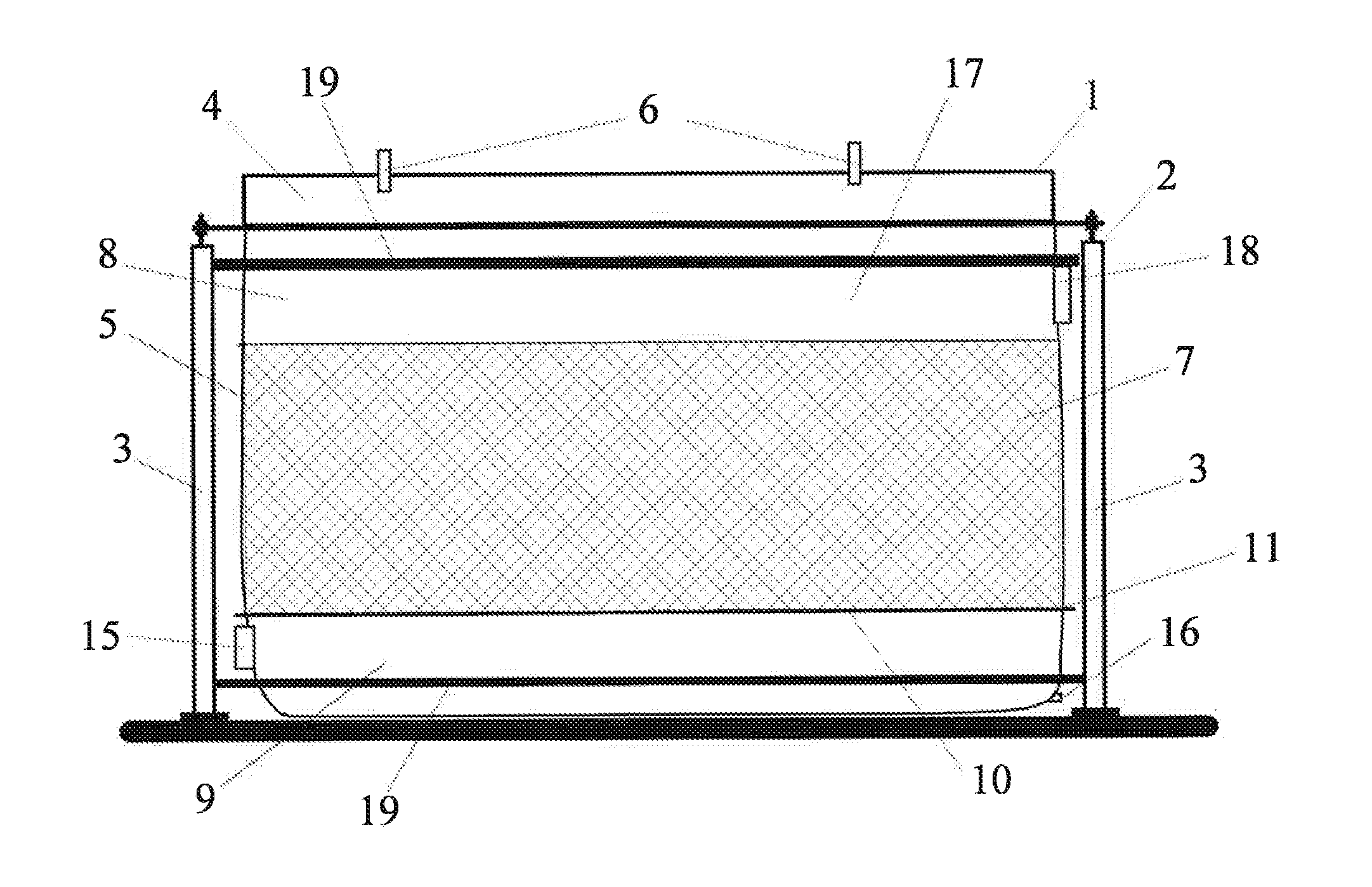

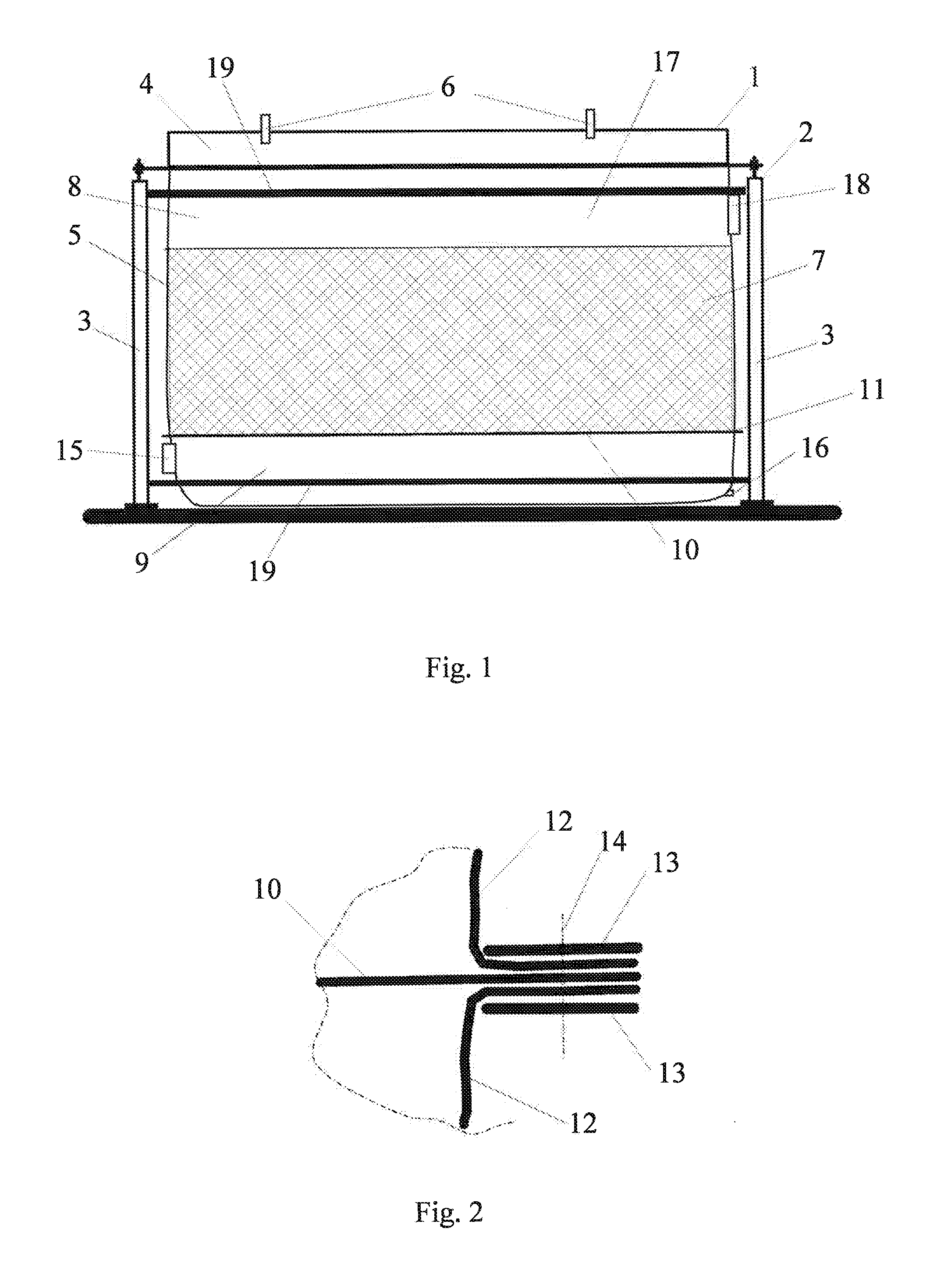

InactiveUS20130318935A1Cost-effective to buildEasy maintenanceCombination devicesGas treatmentFilter mediaBiological filter

A biofilter (1) having filter media (7) in a stowage space (5) having sidewalls and a bottom, inlet opening (15) for the unpurified gases / air and the stowage space (5) is made of flexible gas-tight material filled at least partly with the filter media (7). A biofilter system having two or more biofilters (1) is also described.

Owner:MALLINEN MATTI

Microphone chip and its preparation method

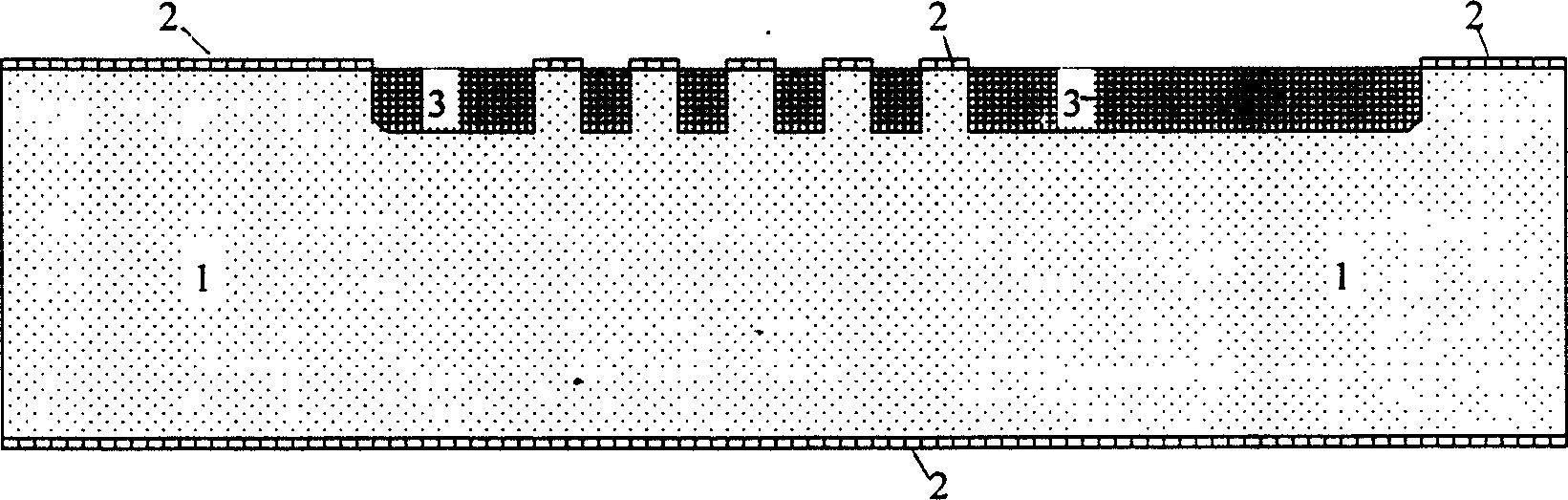

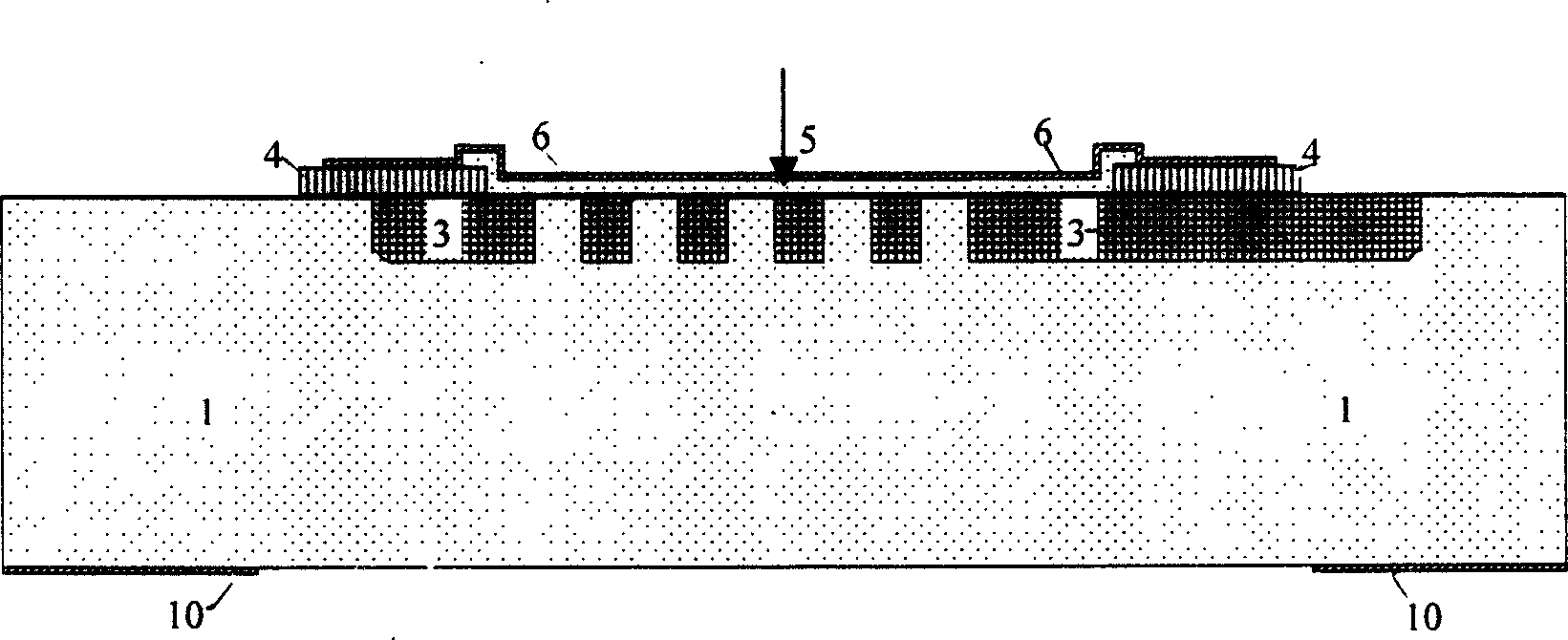

InactiveCN1582065AHigh sensitivityAchieve preparationElectrostatic transducer microphonesMetallic materialsIsolation layer

The method includes following steps: diffusing boron on front face of n- type silicon base plate to form p+ type doped layer; then depositing silicon dioxide on the said doped layer; then forming isolation layer through etching and eroding; attaching a diaphragm layer, depositing metal aluminum film on diaphragm layer and quadrate aluminum electrode; there is a layer of protective film made from silicon nitride on back face of silicon base plate; eroding a trape notch on underside of silicon base plate till p+ type doped layer, and eroding upwards to form acoustics hole perforated through back board; there is a air gap between the perforated back board and diaphragm layer made from silicon nitride. The method for fabricating chip of microphone is simple. The chip includes circular isolation layer and circular sacrificial layer made from different metal materials. Circular structure reduces stress of diaphragm, raises sensitivity of diaphragm so as to avoid aging cracking.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

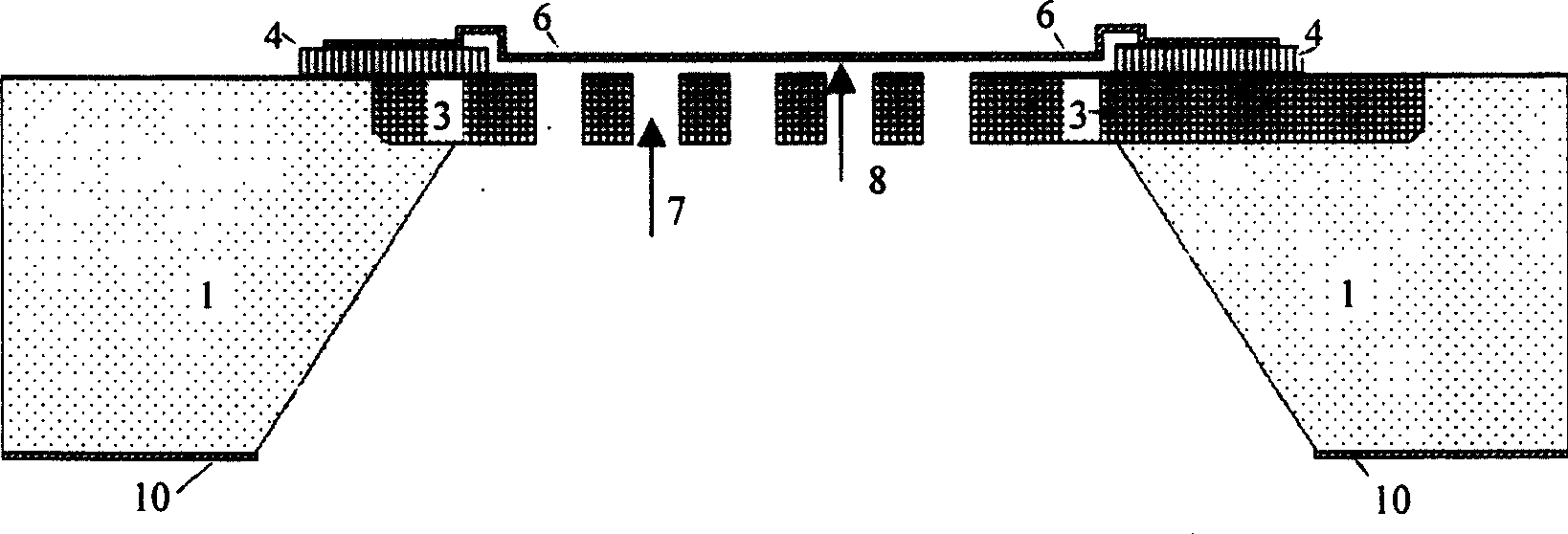

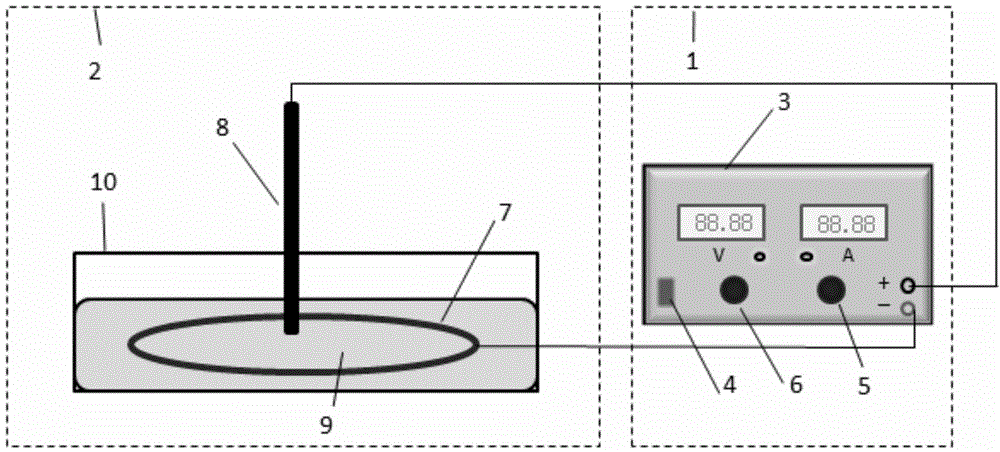

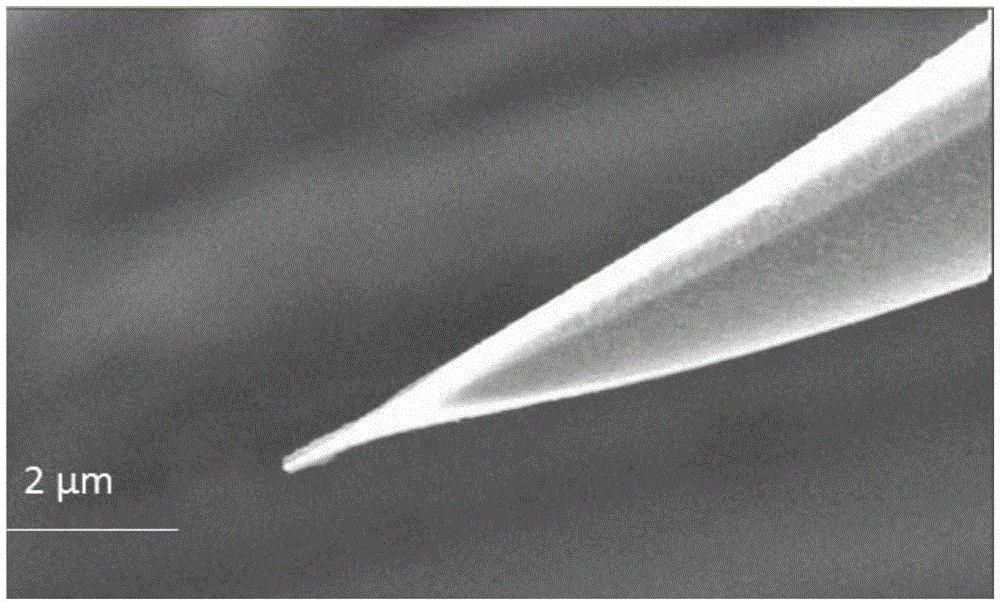

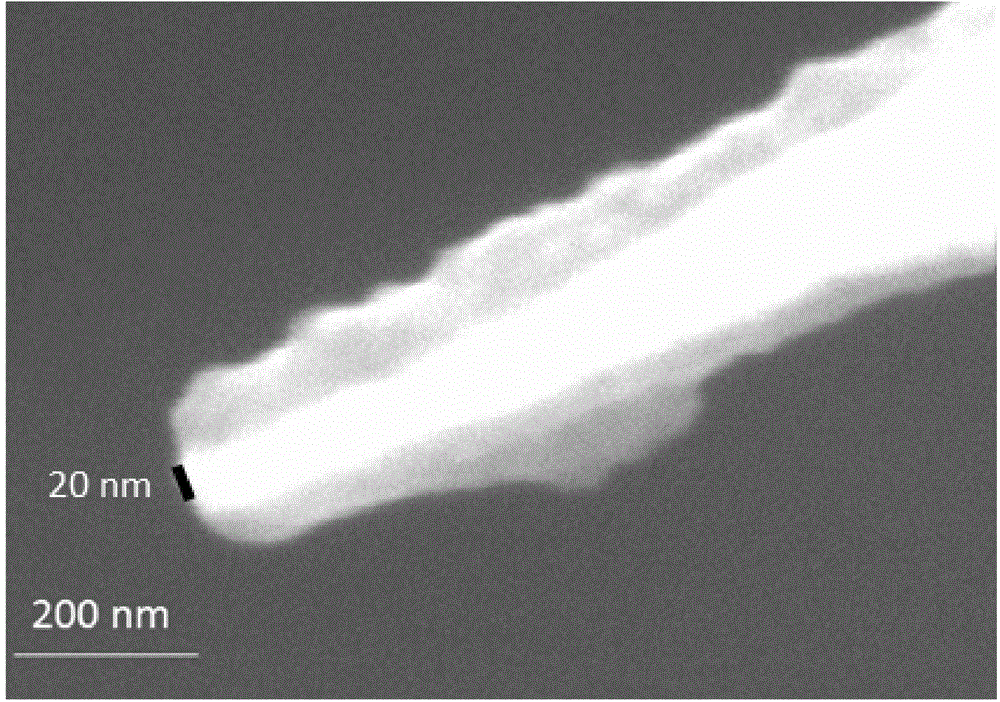

Apparatus and method for preparing metal probe tip

ActiveCN105301288AShort timeShorten the timeScanning probe microscopyConcentration ratioElectrolytes levels

The present invention discloses an apparatus and method for preparing a metal probe tip and controlling the curvature radius of the metal probe tip. The method includes the steps as follows: 1) a magnetic metal wire to be prepared is provided; 2) one end of the metal wire to be prepared is immersed under the electrolyte level of an electrochemical cell, and the other end of the metal wire to be prepared is connected with a positive electrode side of a control circuit; 3) a switch is closed, the constant current or constant voltage of the apparatus is maintained by a constant current and constant voltage source of the control circuit, and the electrochemical cell performs reaction until the metal wire to be prepared forms the metal probe tip under the electrolyte level. The method for preparing the magnetic probe tip has fast preparing speed and high efficiency, and can control the probe tip shape. The curvature radius of the probe tip is small, the probe tip surface is smooth, and the probe tip has stable quality. Additionally, the curvature radius of the probe tip can be controlled by the adjustment of the outputted constant current value and the concentration ratio of electrolyte. The prepared magnetic probe tip can realize spinning resolution in magnetic sample measurement.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Cement-based material reinforced basalt fiber special impregnating agent, and preparation method thereof

The invention discloses a cement-based material reinforced basalt fiber special impregnating agent, and a preparation method thereof. The cement-based material reinforced basalt fiber special impregnating agent comprises, by weight, 40 to 60 parts of a film forming agent, 5 to 15 parts of a coupling reagent, 1 to 5 parts of a lubricating agent, 10 to 20 parts of a modifying agent, and 30 to 50 parts of water; the modifying agent comprises a soluble phosphate, a strong base, and a dissoluble silicate at a mass ratio of 2-4:1-3:3-6. The cement-based material reinforced basalt fiber special impregnating agent is used for impregnating and fiber surface modifying at the same time, fiber surface roughness is increased, and a large amount of active site and active groups are formed on fiber surfaces, so that chemical bonding and mechanical riveting of basalt fiber with a cement-based material are realized, an integrated stable whole body is formed by basalt fiber and the cement matrix, reinforcing effect on the cement-based material is obvious, reinforcing effect is excellent, and popularization and application of basalt fiber in the cement-based material is promoted.

Owner:浙江长兴市政建设有限公司

Semi-submerged etching laser plate making method

ActiveCN103522732AAvoid uneven corrosionEasy to controlPrinting pre-treatmentForme preparationEngineering

The invention relates to a semi-submerged etching laser plate making method. The method comprises the following steps: performing skim coating or spraying on the surface of a copper-plated plate base to form a surface protection glue layer on the surface; then engraving patterns on the glue layer through a laser engraving machine; putting the copper-plated plate base with the patterns into a cleaning tank to perform pre-etching; after pre-etching, putting the copper-plated plate base on a wheel of an etching groove, and turning on a rotating switch to ensure that the copper-plated plate base starts rotating; and then pressing a direction switch to ensure that one third of the surface of the copper-plated plate base is submerged into etching liquid to start etching, and finally obtaining a copper plated plate with required patterns. Compared with the prior art, the semi-submerged etching laser plate making method disclosed by the invention solves the problems that a laser plate has inconsistent mesh points and is non-uniform in etching, dappled etching of the plate surface is too deep or too shallow, and the like.

Owner:SHANGHAI YUNCHENG PLATE MAKING

Method for removing remelting layer in electric spark drilling for single crystal turbine blade

InactiveCN104451682AFast corrosionSurface does not affectAfter-treatment detailsTurbine bladeSingle crystal

The invention discloses a method for removing a remelting layer in electric spark drilling for a single crystal turbine blade. The method comprises the following steps: mixing hydrochloric acid, water and hydrogen peroxide according to the volume ratio of (91-100) to (40-44) to (20-25) to obtain a corrosive liquid; putting a blade which is subjected to electric spark drilling into the corrosive liquid, and corroding under ultrasonic waves for 20-40 minutes to remove the remelting layer. By adopting a chemical corrosion method, the method is simple, feasible, relatively good in removal effect, and high in efficiency; the corrosion test surface recrystallization procedure in the of manufacturing process of a DD6 single crystal turbine blade proves that the surface of the blade is not affected by chemical corrosion in the invention, and the method is a feasible method.

Owner:AECC AVIATION POWER CO LTD

Method for preparing light calcium carbonate from carbide slag as raw material

The invention provides a method for preparing light calcium carbonate from carbide slag as a raw material. The method comprises following steps: (1), performing slurrying to remove toxins and foul smell; (2), performing filtration and dissolution separation; (3), performing spraying carbonization; (4), performing drying and powder grinding, or performing washing, drying and powder grinding or performing spray drying to obtain the product. The method is simple to operate, free of secondary pollution, easy to implement and low in energy consumption, main raw materials only comprise industrial residue carbide slag and CO2 captured in carbon capture and emission reduction projects, the cost is low, and the method has market competitiveness; a large quantity of limestone resources can be savedindirectly, and therefore, environmental protection and blue sky and green water social engineering construction are facilitated.

Owner:长沙紫宸科技开发有限公司

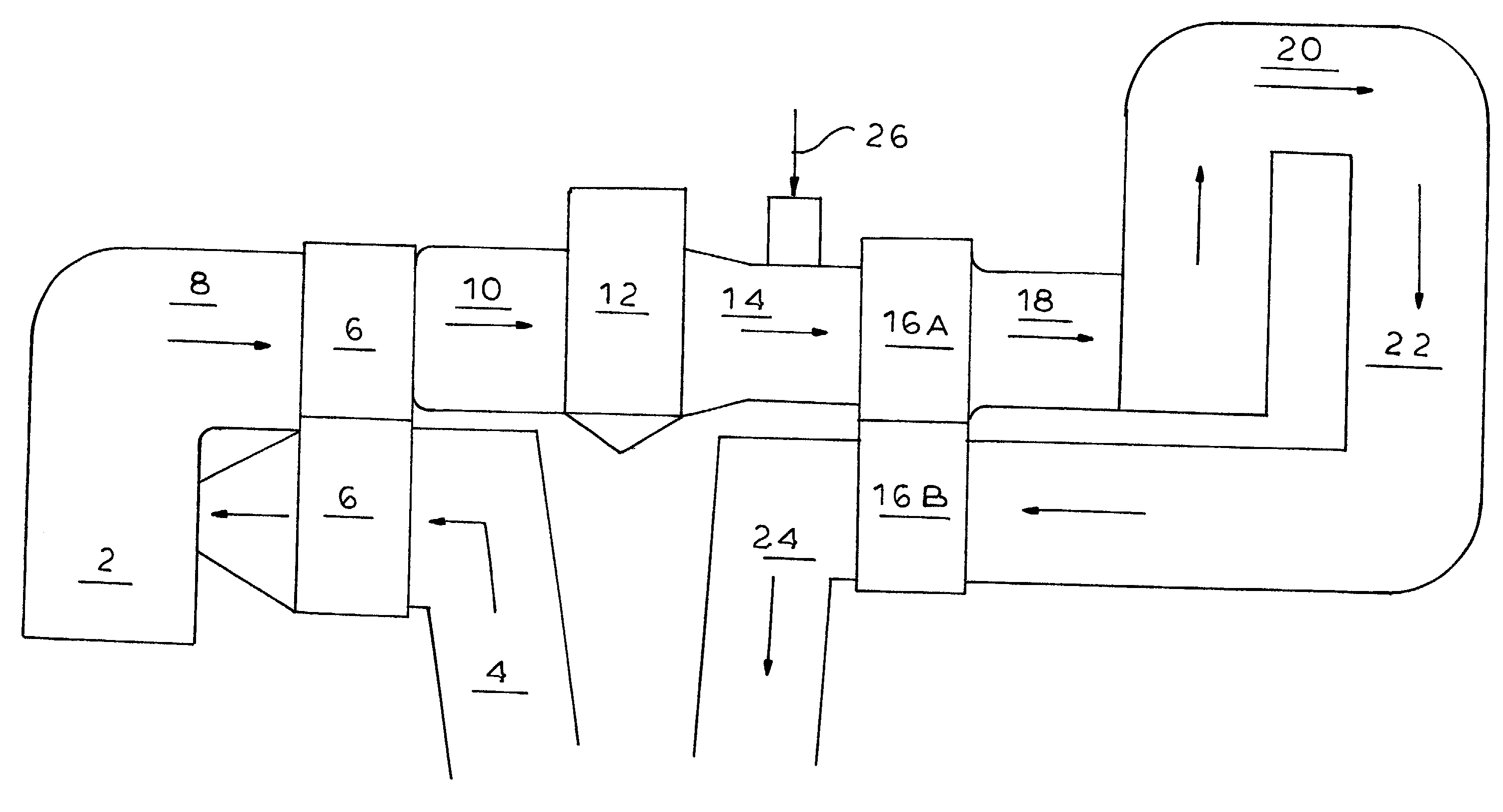

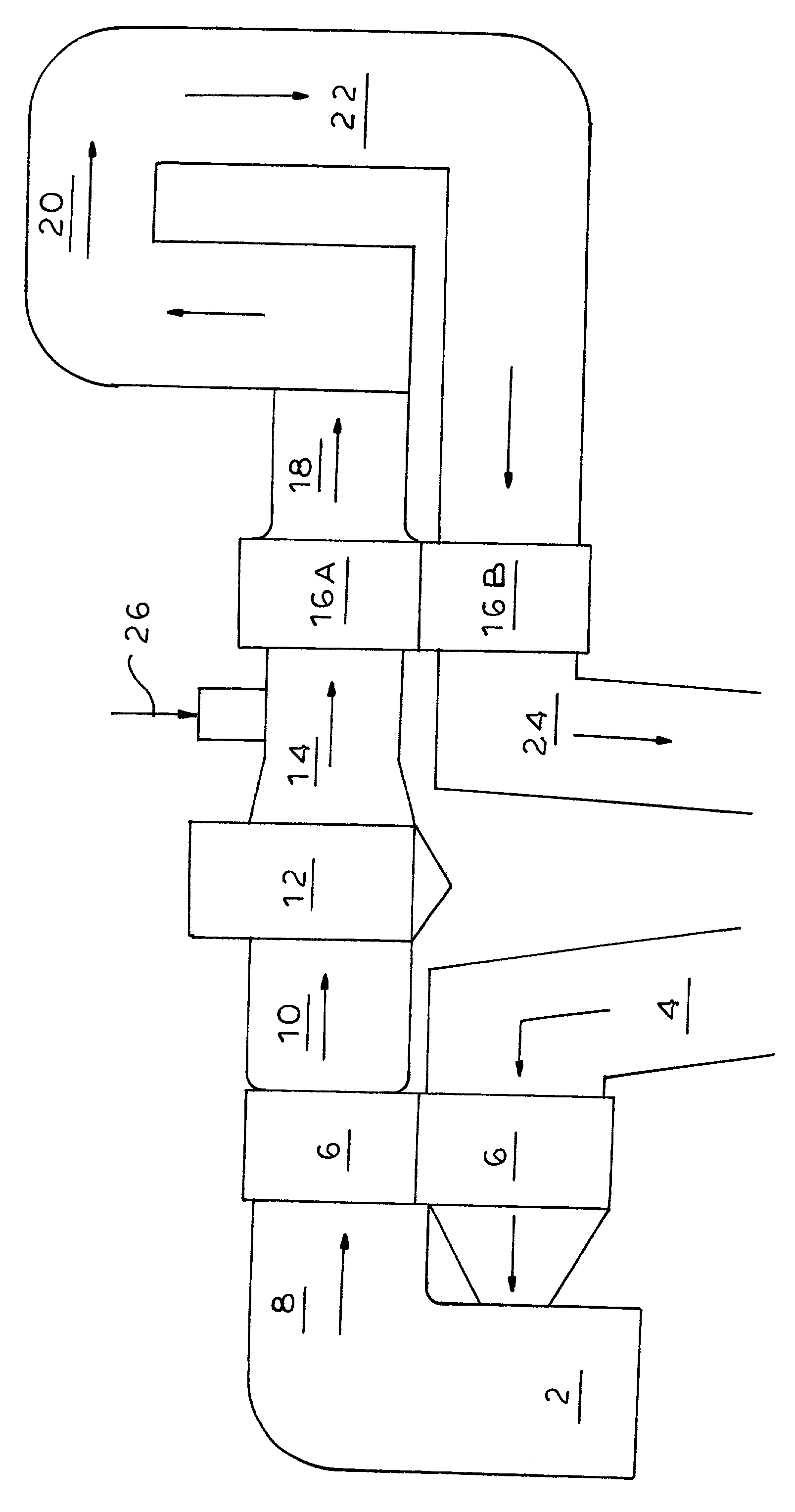

Minimizing corrosion and build-up in a flue-gas system including a desulfurizer

InactiveUS20030049160A1Corrosion minimizationMinimizing deposit build-upDispersed particle separationFlue gasWater soluble

A method for minimizing corrosion and the build-up of deposits on surfaces of a flue-gas system exposed to moist substances and elevated temperatures, and which includes a desulfurizer and heat transfer means communicating with the desulfurizer, said method involving adding to the system at the heat transfer means a readily water soluble alkaline substance such as sodium hydroxide in amounts sufficient to produce with said flue-gas in said heat transfer means a minimum pH of about 5, preferably 7 or higher.

Owner:APOLLO TECH INTL

Chemical etching preparation technology of titanium alloy and etching agent used in said technology

InactiveCN1757794ASolve the problem of processing through holesFast corrosionHydrofluoric acidEtching

A process for preparing pinholes, pattern, or holes on the surface of Ti-alloy by chemical etching includes such steps as washing the Ti-alloy workpiece for removing oil, spraying a plastic protecting layer, carving pinholes, preparing the etching liquid from nitric acid and hydrofluoric acid through proportional mixing, chemical etching to form the pinholes, and removing said plastic protecting layer.

Owner:BEIJING MONTAGNE MEDICAL DEVICE

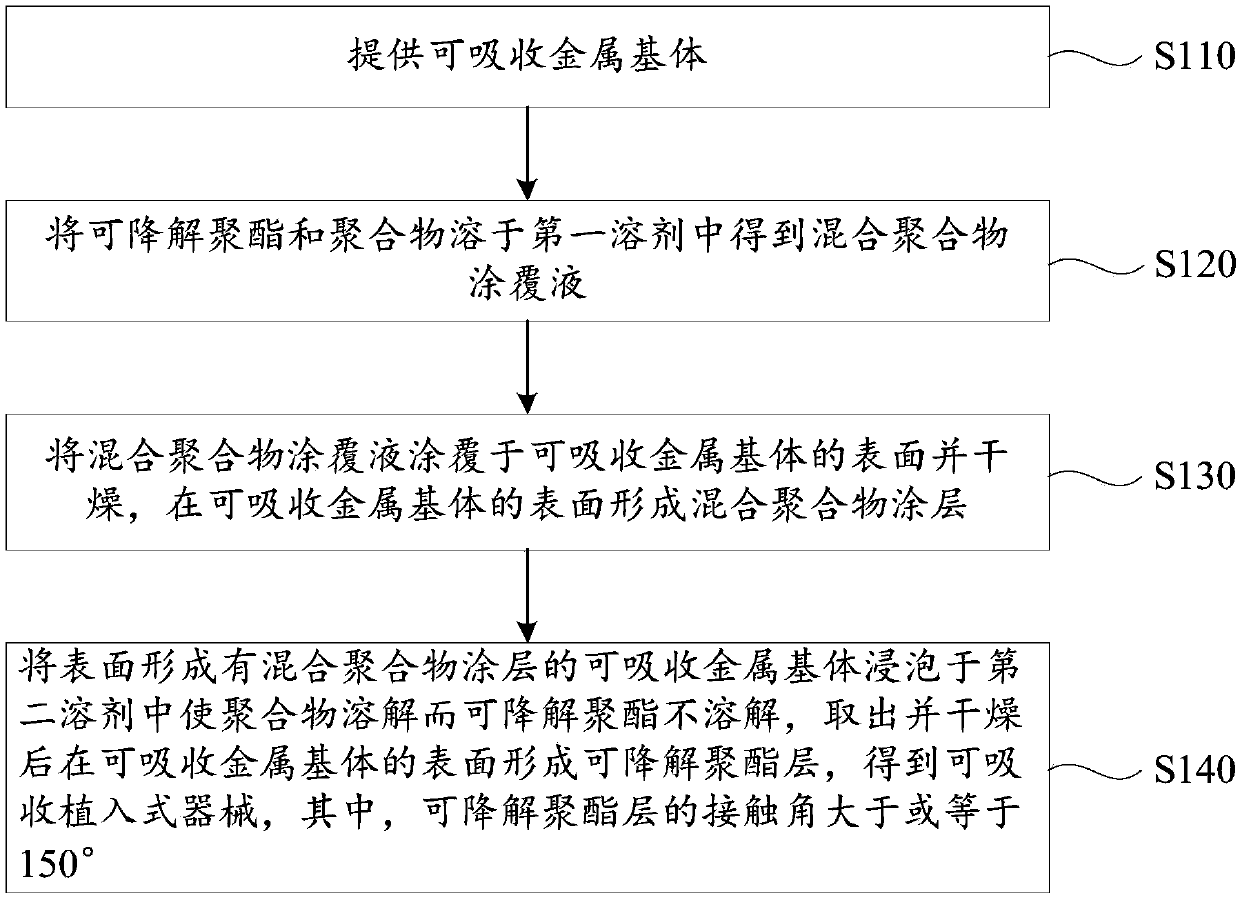

Absorbable implantable device

The invention relates to an absorbable implantable device comprising an absorbable metal matrix and a degradable polyester layer at least partially covering the surface of the absorbable metal matrix.The contact angle of the degradable polyester layer is more than or equal to 150 degrees. The degradable polyester layer has superhydrophobicity, and can form a hydrophobic barrier in body fluid to isolate the absorbable metal matrix from the body fluid, so as to protect the absorbable metal matrix from slow corrosion or even non-corrosion at the early stage of implantation; moreover, due to thesuperhydrophobicity of the degradable polyester layer, degradation of the degradable polyester layer in the aqueous body fluid environment can be delayed, and delaying or avoiding of the formation ofa local acidic environment at the early stage of implantation is facilitated. Therefore, adequate mechanical support can be provided in the repair period of lesion sites after implantation; while after the repair of the lesion sites is completed, the local micro-acid environment is produced by the degradation of the degradable polyester itself, and the absorbable metal matrix is allowed to be rapidly corroded.

Owner:BIOTYX MEDICAL SHENZHEN CO LTD

Dendritic crystal corrosive liquid for precipitated reinforced martensitic stainless steel and use method thereof

ActiveCN109295456AFast corrosionCorrosion clearWeather/light/corrosion resistanceDirect observationMartensitic stainless steel

The invention relates to dendritic crystal corrosive liquid for precipitated reinforced martensitic stainless steel and a use method thereof, and belongs to the technical field of continuous casting steel metallographic analysis. According to the formula, the dendritic crystal corrosive liquid comprises 2 to 4 g of sodium metabisulfite, 5 to 8 ml of hydrochloric acid, 2 to 4 ml of nitric acid, and75 ml of distilled water; the sodium metabisulfite, the distilled water, the hydrochloric acid, and the nitric acid are sequentially added into a container, and are evenly stirred; during use, a detection sample polishing face is immersed in the corrosive liquid upwards, standing is carried out, and after the dendritic structure is displayed out, the corroded precipitatted reinforced martensiticstainless steel detection face is subjected to detection observation through an optical microscope or scanning electron microscope. The corrosive liquid can simply, conveniently and rapidly corrode out the clear dendritic structure of the precipitated reinforced martensitic stainless steel, the dendritic structure can be directly observed, the dendrite spacing is measured, and the corrosive liquidis used for evaluating the casting state structure quality of the precipitated reinforced martensitic stainless steel and assisting in evaluating the removing effect of homogenization heat treatmenton the dendritic segregation.

Owner:TIANJIN HEAVY EQUIP ENG RES +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com