Nickel-chromium alloy metallographic corrosion solution and corrosion method

A nickel-chromium alloy and corrosion solution technology, which is applied in the field of metallographic analysis of nickel-chromium alloys, can solve the problems of insignificant secondary corrosion effects, black grain boundaries and grains, and no visible metallographic structure, so as to avoid corrosion Insufficient and over-corrosion defects, grain contrast is obvious, and the effect of grain boundary lines is clear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

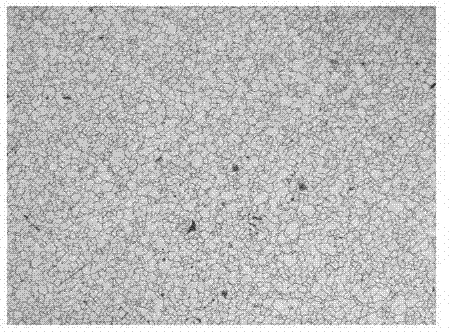

[0033] According to the volume ratio of concentrated nitric acid, concentrated hydrochloric acid, glacial acetic acid and water as 1:1:1:1, first add 50ml of water to the container, then add 50ml of concentrated nitric acid, 50ml of concentrated hydrochloric acid and 50ml of glacial acetic acid, stir and let stand 10 minutes, wherein the mass percent concentration of concentrated nitric acid was 65%, the mass percent concentration of concentrated hydrochloric acid was 36%, and the mass percent concentration of glacial acetic acid was 99.6%. Then take 2080 nickel-chromium alloy rods (the composition is shown in Table 1 below), and then use wire cutting to sample metallographic samples to make metallographic samples of 20mm*20mm*15mm, and use water sandpaper of different thicknesses for grinding , Such as 400 mesh, 600 mesh, 800 mesh, 1000 mesh, 1500 mesh, 2000 mesh water abrasive paper for grinding samples. The grinding and polishing quality of metallographic samples directly a...

Embodiment 2

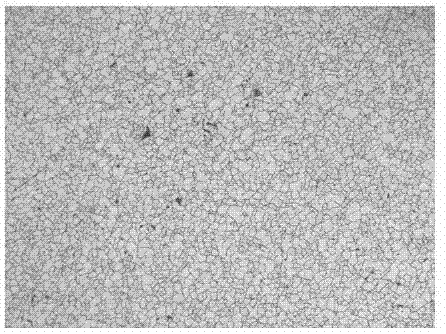

[0039] According to the volume ratio of concentrated nitric acid, concentrated hydrochloric acid, glacial acetic acid and water as 1:1:1:1, first add 55ml of water to the container, then add 55ml of concentrated nitric acid, 55ml of concentrated hydrochloric acid and 55ml of glacial acetic acid, stir and let stand For 20 minutes, the mass percentage concentration of concentrated nitric acid was 68%, the mass percentage concentration of concentrated hydrochloric acid was 38%, and the mass percentage concentration of glacial acetic acid was 99.9%. The nickel-chromium alloy sample was taken for corrosion, and the depth of immersion of the corrosion solution into the sample was 2mm. , the corrosion time is 60 seconds, and then rinse the surface of the sample with distilled water or alcohol, and use a metallographic microscope for metallographic observation.

Embodiment 3

[0041] According to the volume ratio of concentrated nitric acid, concentrated hydrochloric acid, glacial acetic acid and water as 1:1:1:1, first add 50ml of water to the container, then add 50ml of concentrated nitric acid, 50ml of concentrated hydrochloric acid and 50ml of glacial acetic acid, stir and let stand For 15 minutes, the mass percentage concentration of concentrated nitric acid was 67%, the mass percentage concentration of concentrated hydrochloric acid was 37%, and the mass percentage concentration of glacial acetic acid was 99.8%. The nickel-chromium alloy sample was taken for corrosion, and the depth of immersion of the corrosion solution into the sample was 2mm. , the corrosion time is 5min, and then rinse the surface of the sample with distilled water or alcohol for 2.5min, and use a metallographic microscope for metallographic observation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com