Dendritic crystal corrosive liquid for precipitated reinforced martensitic stainless steel and use method thereof

A martensitic stainless steel, precipitation strengthening technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problem of inability to corrode dendritic structure, precipitation strengthening martensitic stainless steel seed dendritic corrosion effect is not good , heating and insulation problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

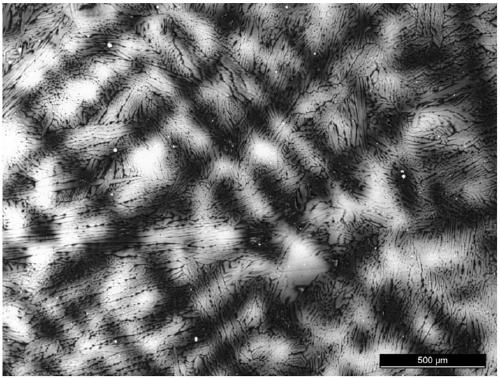

[0036] This embodiment is used to precipitate and strengthen the dendrite corrosion solution of martensitic stainless steel as cast. The composition and proportion are: 2.5 g of sodium metabisulfite, 5 ml of analytically pure hydrochloric acid, 3 ml of analytically pure nitric acid, and 75 ml of water; the mass fraction of hydrochloric acid is 36 ~38%, the mass fraction of nitric acid is 65~68%.

[0037] The precipitation strengthened martensitic stainless steel in this example is 15-5PH steel.

[0038] This embodiment is used to precipitate and strengthen the method for using the dendrite corrosion solution in the as-cast state of martensitic stainless steel, comprising the following steps:

[0039] (1) Prepare the detection sample of precipitation strengthening martensitic stainless steel as-cast state: carry out coarse grinding, fine grinding, polishing, cleaning (water or alcohol) and drying of the detection sample;

[0040] (2) Preparation of dendrite corrosion solution:...

Embodiment 1-2

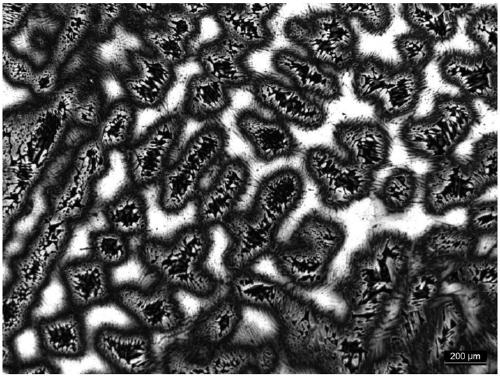

[0045] This embodiment is used to precipitate and strengthen the dendritic corrosion solution of martensitic stainless steel as cast. The composition and proportion are: 2.8 g of sodium metabisulfite, 6 ml of analytically pure hydrochloric acid, 4 ml of analytically pure nitric acid, and 75 ml of water; the mass fraction of hydrochloric acid is 36 ~38%, the mass fraction of nitric acid is 65~68%.

[0046] The precipitation strengthened martensitic stainless steel in this example is 15-5PH steel.

[0047] This embodiment is used to precipitate and strengthen the method for using the dendrite corrosion solution in the as-cast state of martensitic stainless steel, comprising the following steps:

[0048](1) Prepare the detection sample of precipitation strengthening martensitic stainless steel as-cast state: carry out coarse grinding, fine grinding, polishing, cleaning (water or alcohol) and drying of the detection sample;

[0049] (2) Preparation of dendrite corrosion solution ...

Embodiment 1-3

[0053] This embodiment is used to precipitate and strengthen the dendritic corrosion solution of martensitic stainless steel as cast. The composition and proportion are: 2.8 g of sodium metabisulfite, 6 ml of analytically pure hydrochloric acid, 4 ml of analytically pure nitric acid, and 75 ml of water; the mass fraction of hydrochloric acid is 36 ~38%, the mass fraction of nitric acid is 65~68%.

[0054] The precipitation strengthened martensitic stainless steel in this example is 15-5PH steel.

[0055] This embodiment is used to precipitate and strengthen the method for using the dendrite corrosion solution in the as-cast state of martensitic stainless steel, comprising the following steps:

[0056] (1) Prepare the detection sample of precipitation strengthening martensitic stainless steel as-cast state: carry out coarse grinding, fine grinding, polishing, cleaning (water or alcohol) and drying of the detection sample;

[0057] (2) Preparation of dendrite corrosion solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com