Minimizing corrosion and build-up in a flue-gas system including a desulfurizer

a technology of desulfurizer and flue gas system, which is applied in the direction of separation process, dispersed particle separation, chemistry apparatus and processes, etc., to achieve the effect of minimizing corrosion or deposit build-up, rapid corrosion of steel metal strips, and high initial ph

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

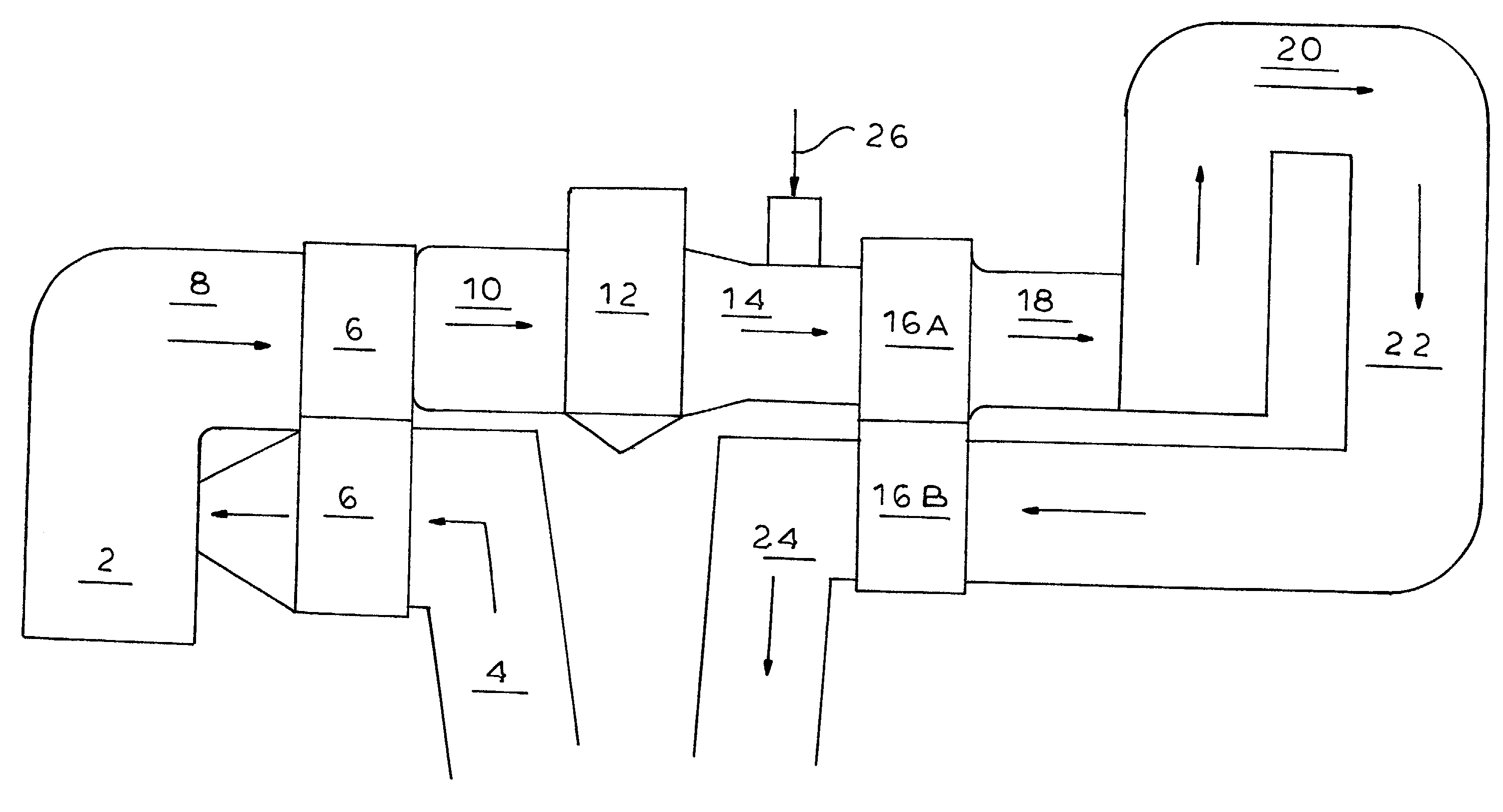

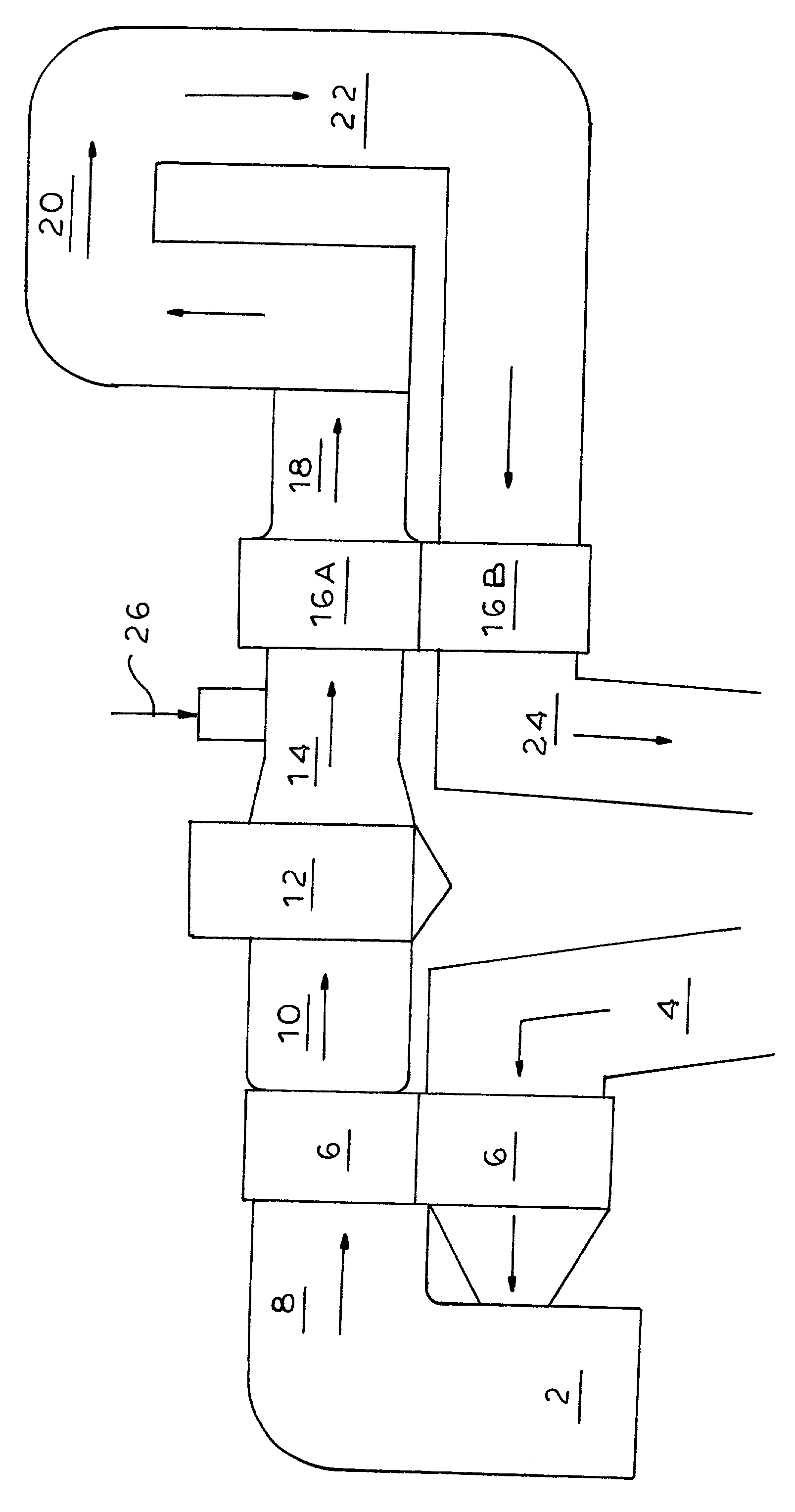

[0009] A typical flue-gas system such as is shown in FIG. 1 comprises a furnace or boiler 2 where steam is generated. Ambient air enters the system at 4 and passes through a primary air heater 6 in which it is heated to perhaps 150.degree. F. and it then enters the furnace 2 to combine with fuel for combustion purposes. A waste product from the combustion in the furnace 2 is the flue-gas which exits the furnace at 8 at a temperature of perhaps 800.degree. F. The flue-gas passes through the air heater 6, providing the means for the initial heating of the ambient air, and the flue-gas which leaves the air heater 6, at 10, will have lost a great deal of its heat and be at a temperature of about 350.degree. F. to 400.degree. F. It then passes into an electrostatic precipitator 12 in which certain impurities are removed, and it escapes from the precipitator 12 at 14 at a further reduced temperature of about 275.degree. to 300.degree. F. Because of its reduced temperature the flue-gas may...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pH | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com