Patents

Literature

247 results about "State structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The structure of state governments is defined by state constitutions. These state constitutions must not contradict the federal Constitution. Most state governments are organized, like the federal government, with executive, legislative, and judicial branches.

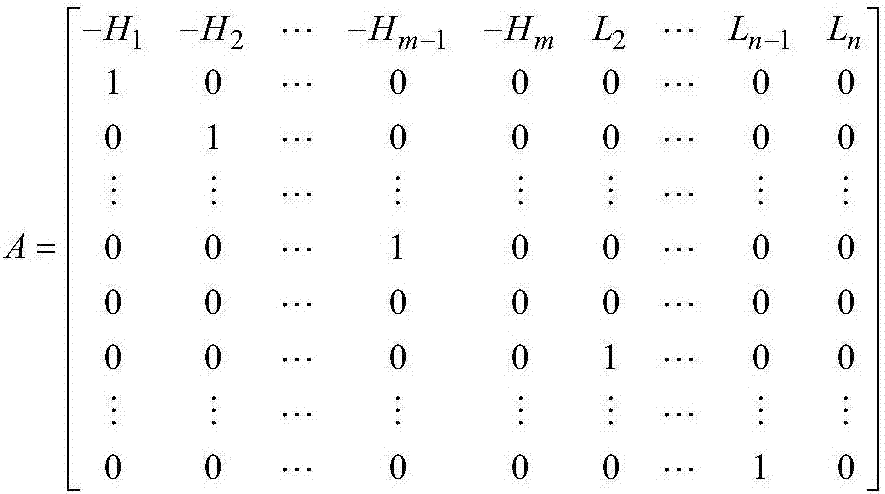

Apparatus and method of CTCM encoding and decoding for a digital communication system

InactiveUS7010052B2Improve energy efficiencyData representation error detection/correctionOther decoding techniquesCommunications systemMulti dimensional

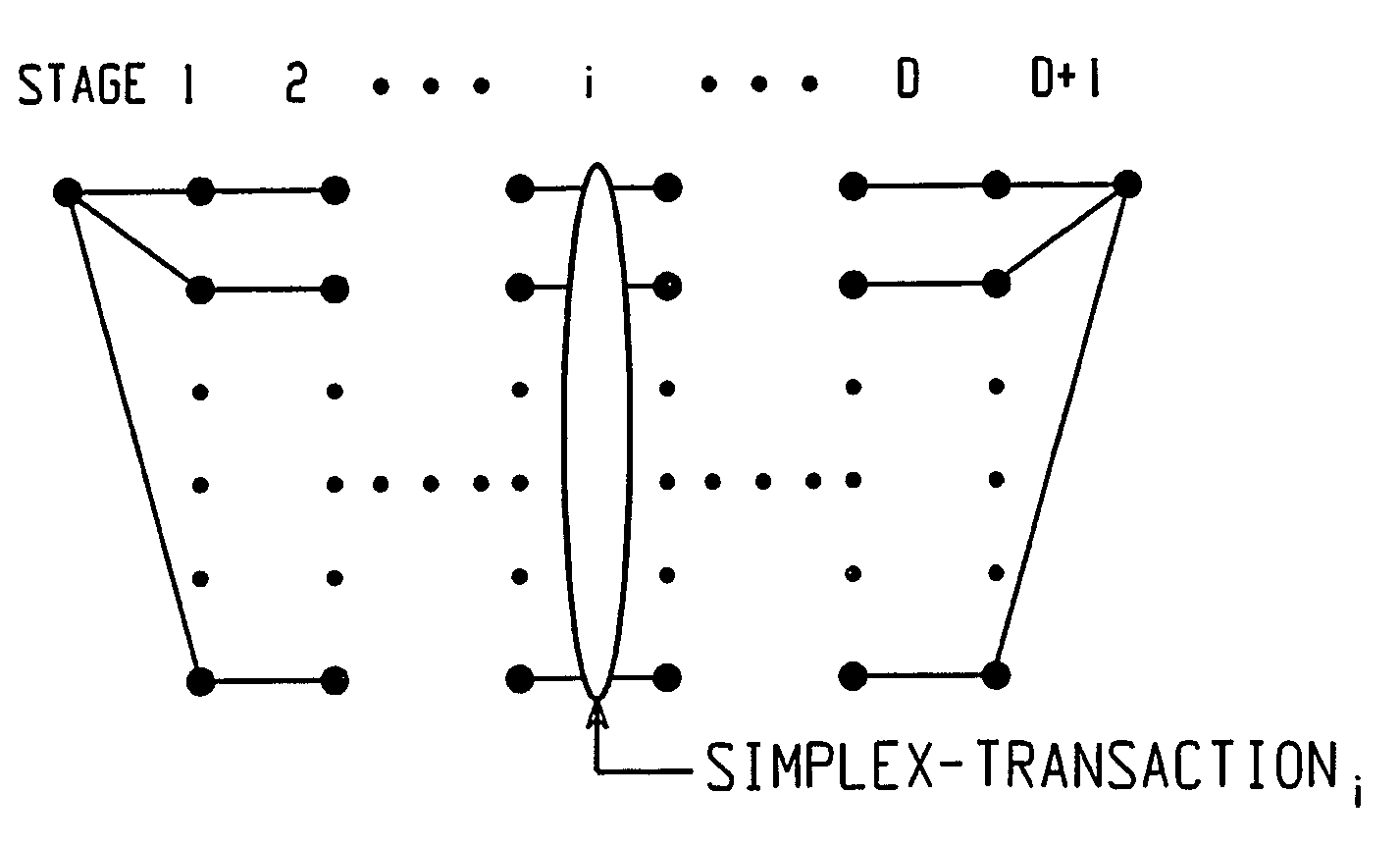

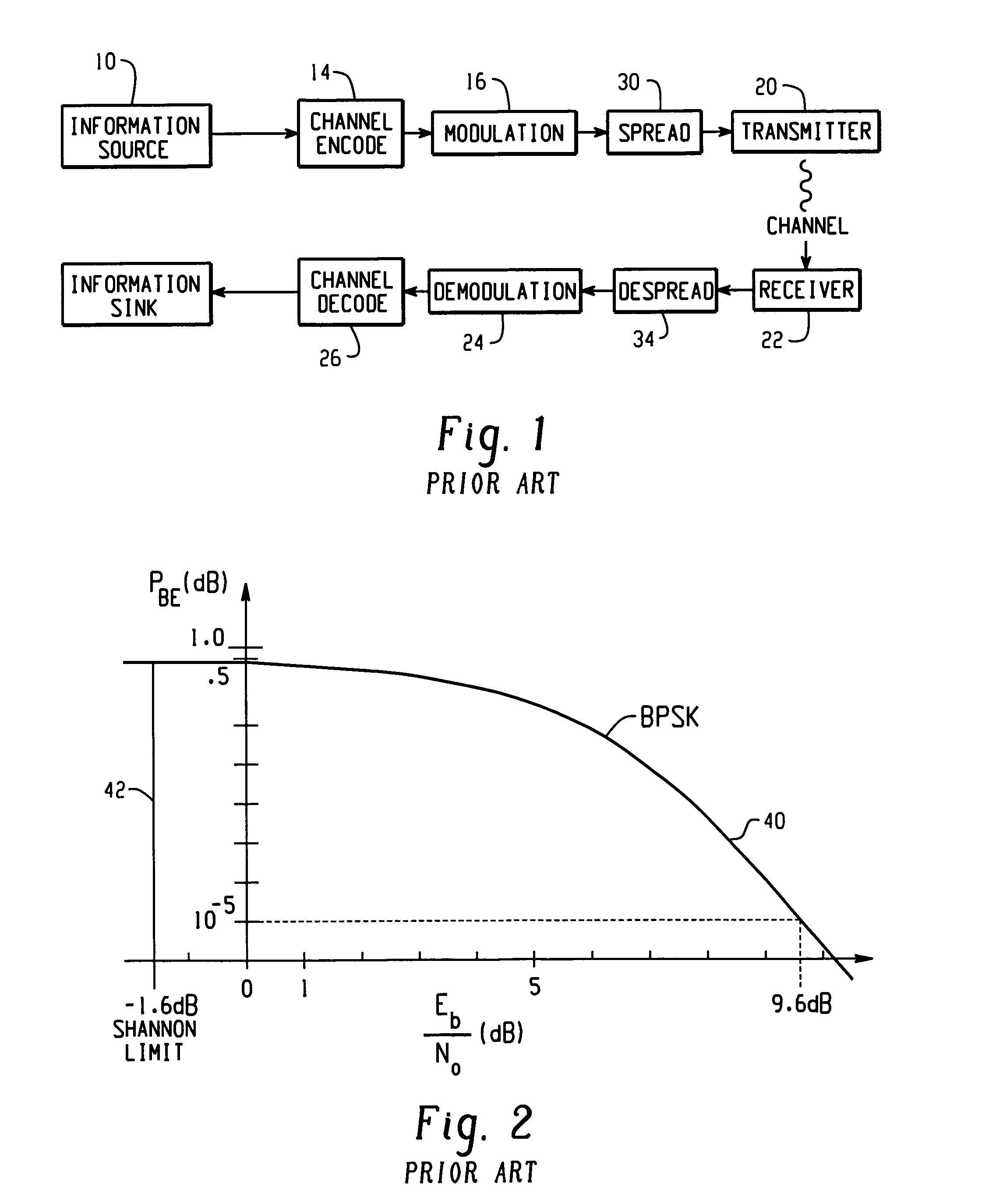

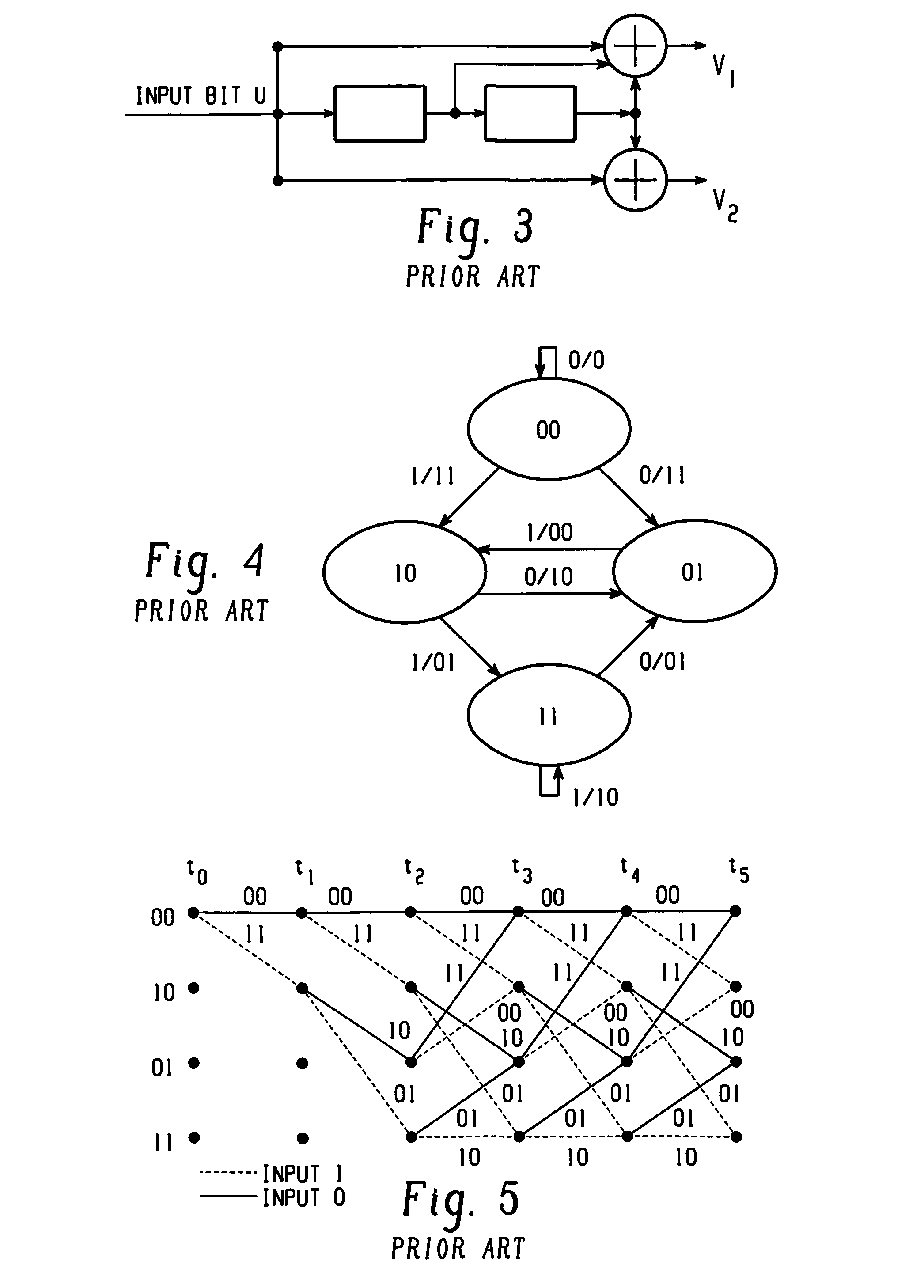

A method of building systematically a multi-dimensional (n, D, L) circular trellis coded modulation (CTCM) encoder with properties of optimal energy efficiency, strong tail biting and maximum minimum distance (dmin) of trellis paths is disclosed. In addition, a communication system for use in a power limited channel application is disclosed comprising a circular trellis coded modulation (CTCM) encoder with permuted state structure for encoding based on a circular trellis path associated with a sequence of digital information bits and a set of simplexes identified for the path from a multi-dimensional signal constellation; a transmitter coupled to said CTCM encoder for transmitting said sequence of channel symbols over said channel; a receiver for receiving a transmission from said transmitter including said sequence of channel symbols and any noise induced therein; and a CTCM decoder coupled to said receiver for decoding the received transmission without knowledge of the starting state of the circular trellis path of the CTCM encoder to recover the sequence of information bits. Apparatus and methods of encoding and decoding are also disclosed utilizing a combination of circular trellis-coded modulation with permuted state structure and simplex signal constellation techniques for use in the digital communication system.

Owner:OHIO UNIV

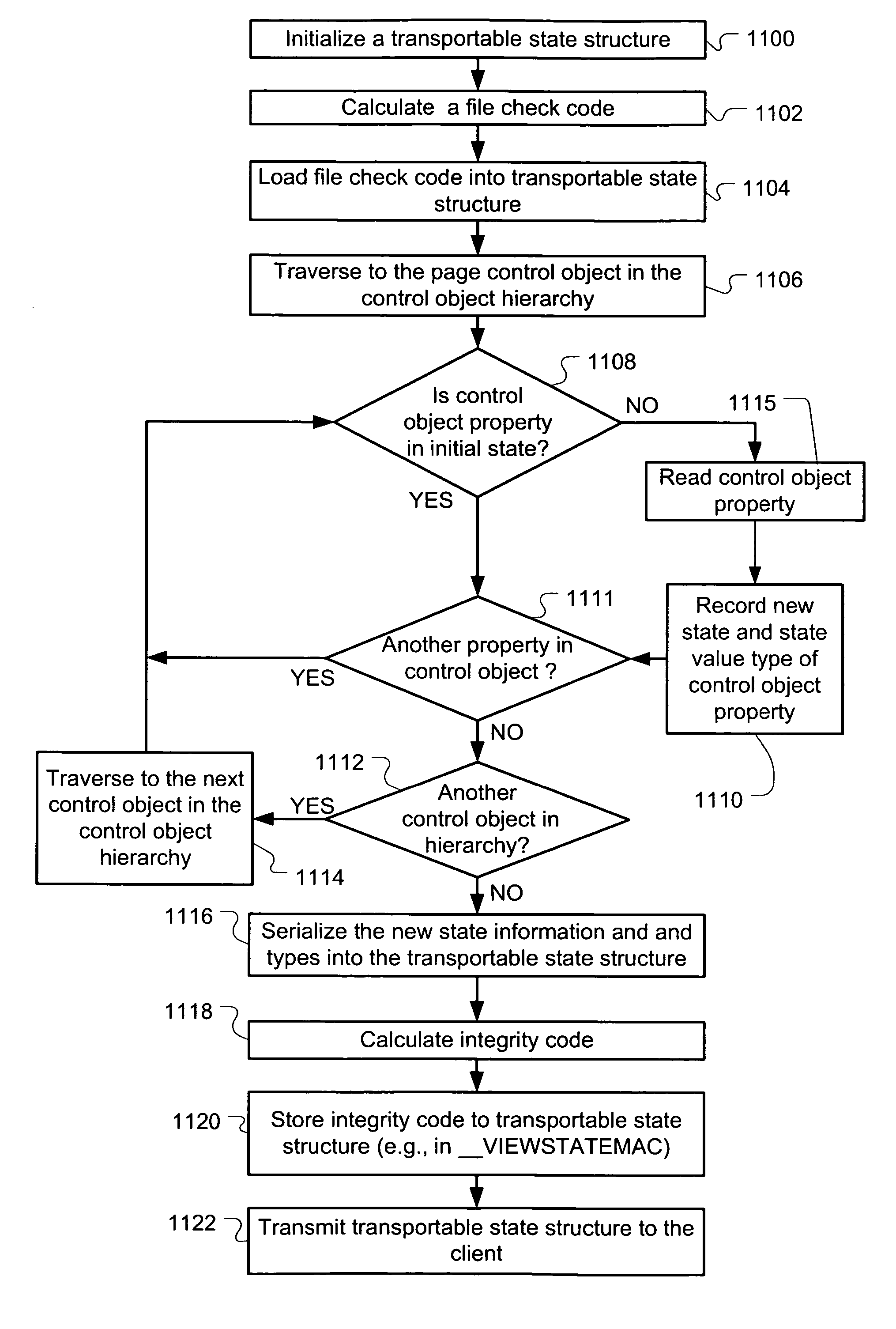

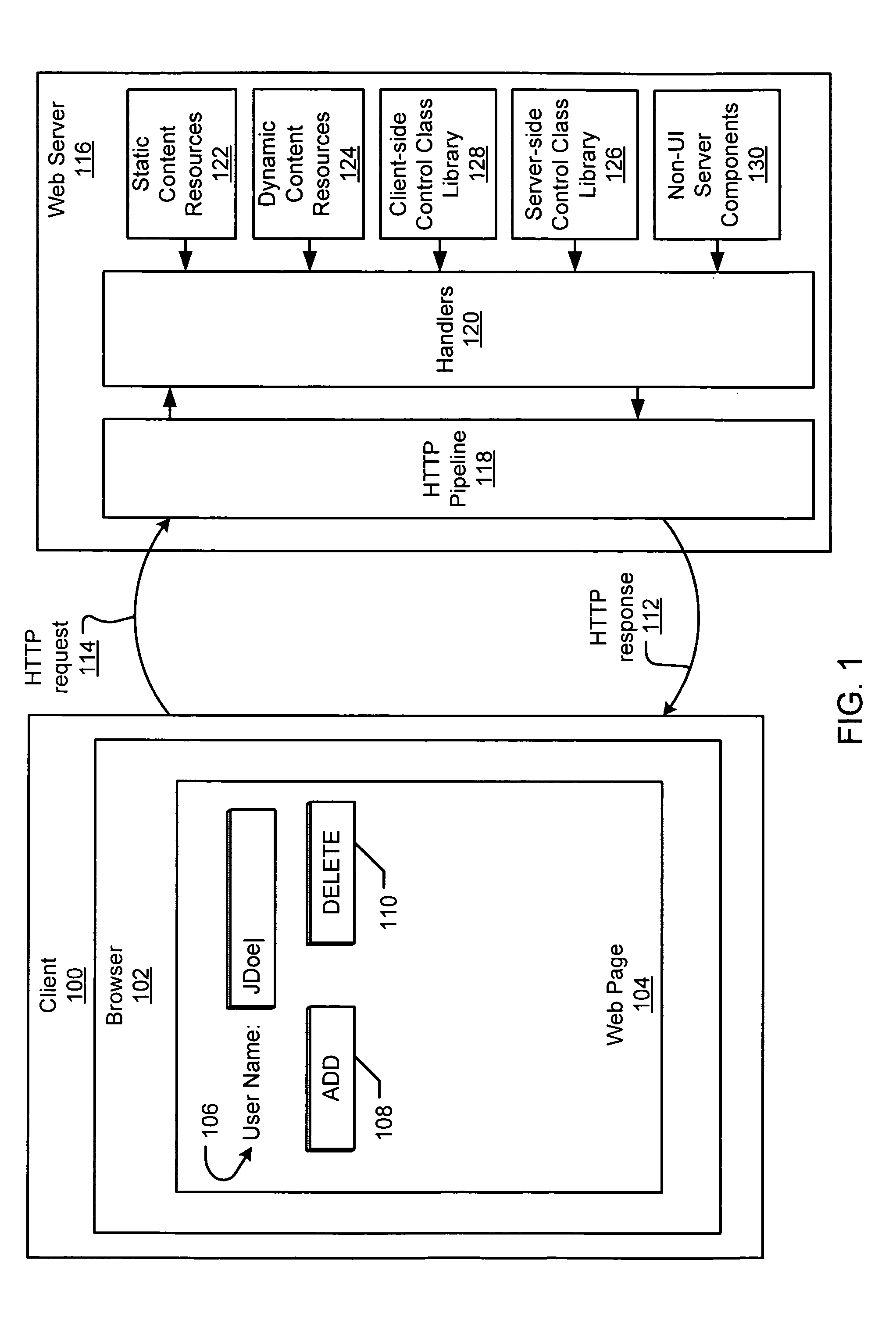

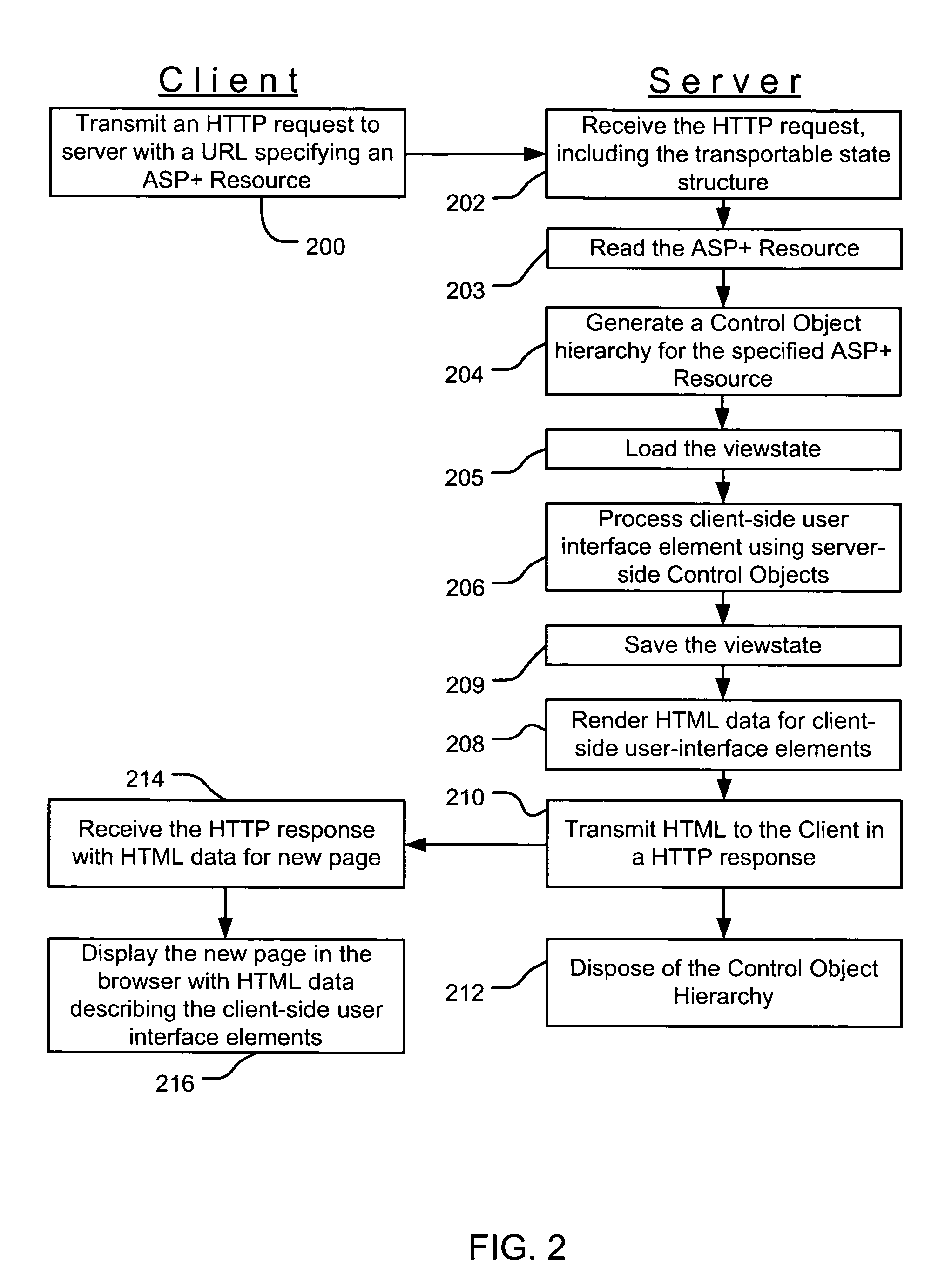

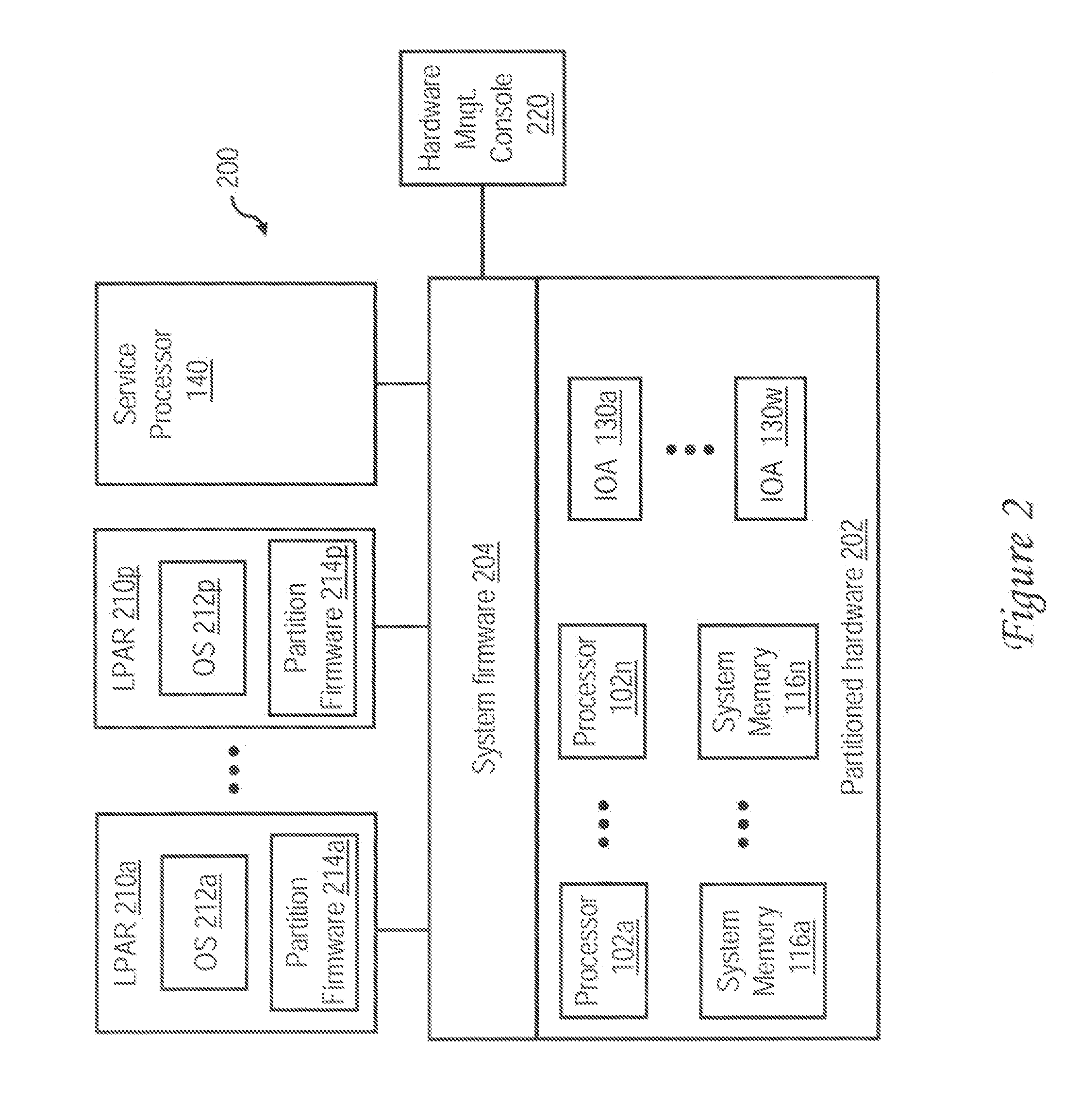

State management of server-side control objects

The state of one or more server-side control objects is managed using a transportable state structure that is communicated between a web server and a client. The transportable state structure may include state information, hierarchical information, and an integrity code. Prior to a response to the client, the state information of one or more server-side control objects is recorded into the transportable state structure for transmission to the client in the response. The transportable state structure is then returned to the server and loaded into the server-side control objects to restore the hierarchy to its previous state.

Owner:MICROSOFT TECH LICENSING LLC

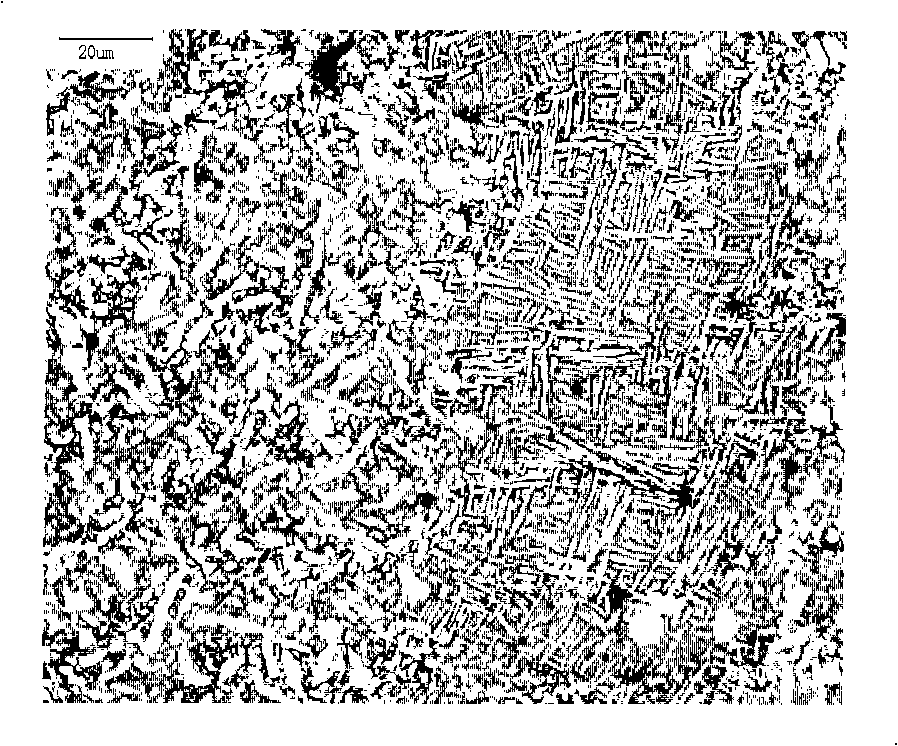

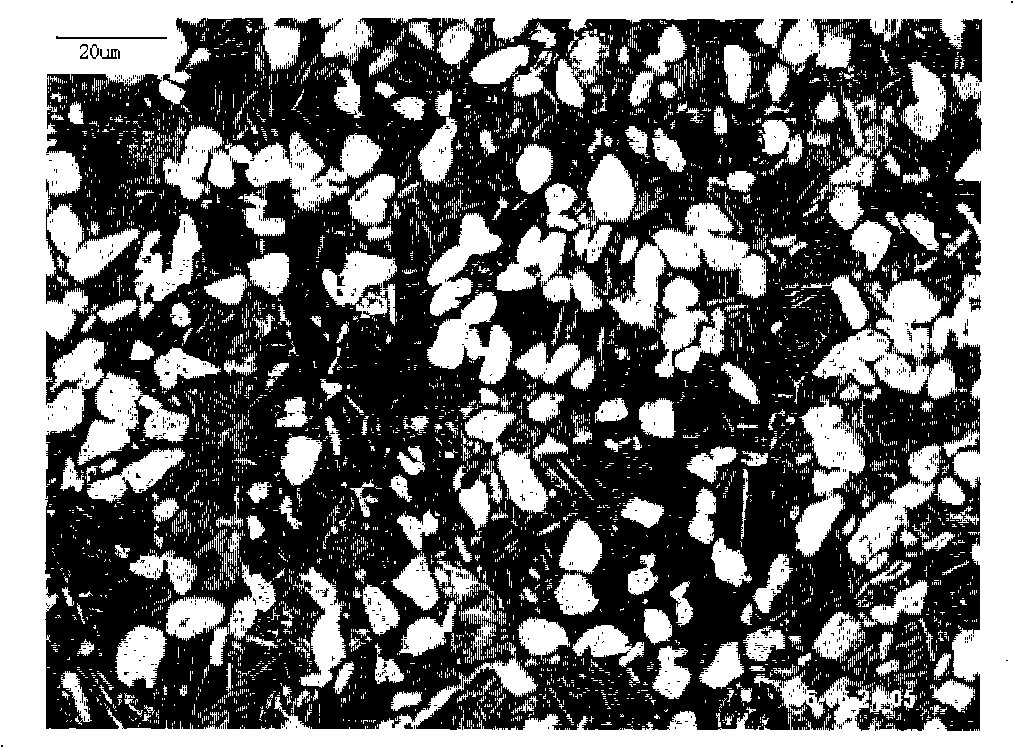

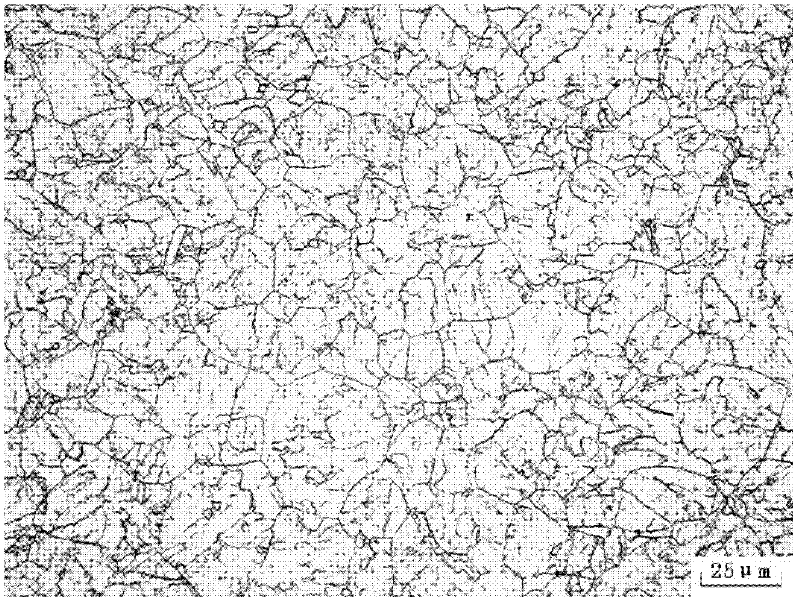

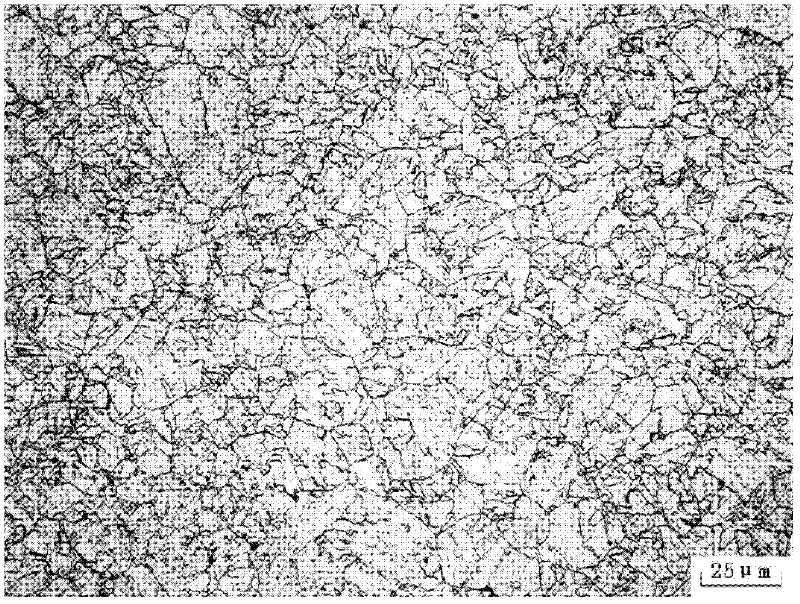

Process for manufacturing type alpha+beta titanium alloy rod bar for rotor impeller vane

InactiveCN101294264AEliminate surface oxidationPrevent surface oxidationTemperature control deviceBlade accessoriesImpellerIngot

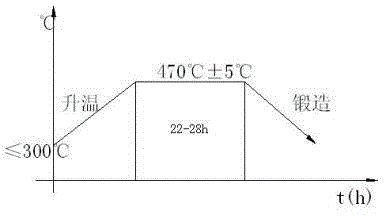

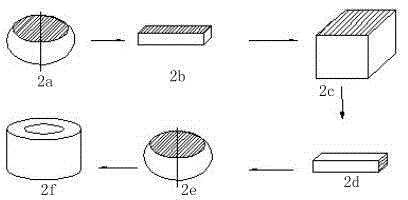

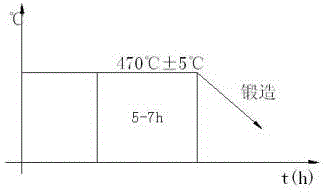

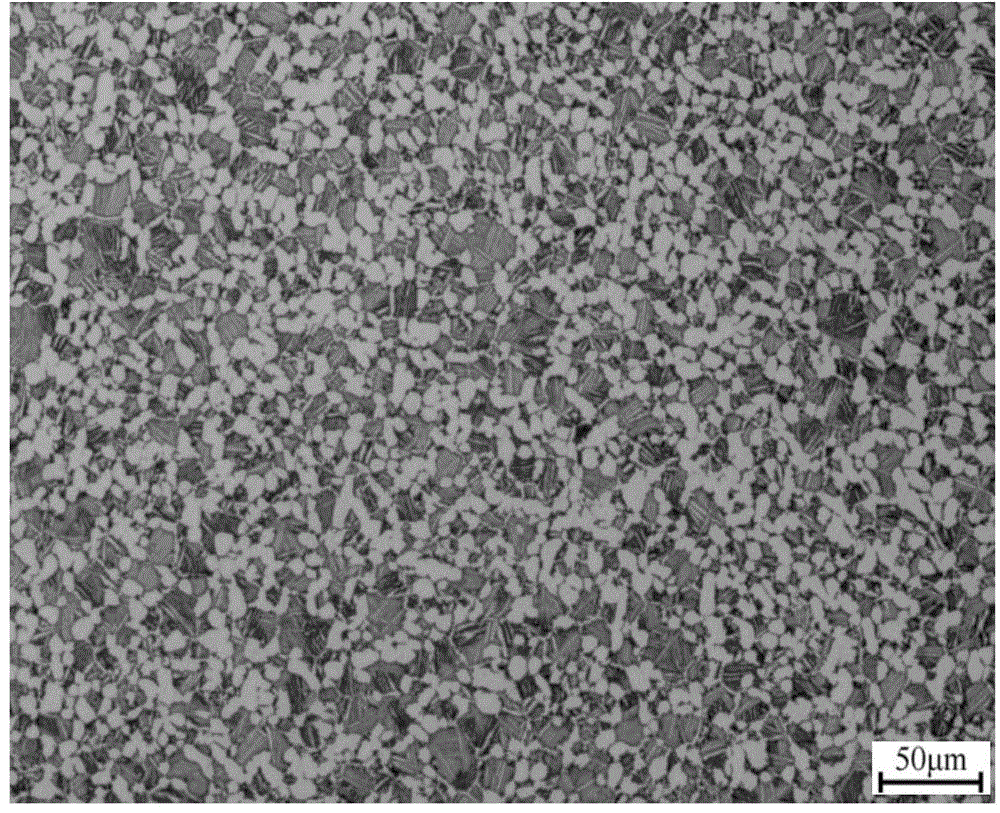

The invention relates to an Alpha+Beta type titanium alloy steel bar fabrication technology used on a rotor vane, which comprises the following steps: (1) a cast ingot is heated, and the temperature is risen to 40 to 60 DEG C above a Beta transformation point after entering in a furnace, and the temperature is kept for 10 to 20 hours; (2) the cast ingot is processed through cogging and smithing, each pier drawing deformation amount is controlled between 30 percent to 40 percent; the smithing is performed in a two phase region after the pier drawing, and the total deformation amount is more than or equals to 90 percent; (3) the cast ingot is heated until the temperature reaches 20 to 40 DEG C above the transformation point after returning to the furnace, the temperature is preserved, and then the water quench is performed; (4) after the water quench, stocks are returned to the furnace and heated, and then are heat-preserved in the two phase region; the two phase region smithing is performed in a radial forging machine after the stocks reach a certain temperature, and the lengthening coefficient is controlled between 1.2 to 1.3; (5) after the radial smithing, the stocks is returned to the furnace and heat continuously and then is heat-preserved in the two phase region, then the stocks is rolled on a rolling mill, and the rolling temperature ranges from 910 to 940 DEG C. The Alpha+Beta type titanium alloy steel bar fabrication technology eliminates the figures on a macrostructure and the Beta spots on a microstructure of the heat strong two-phase titanium alloy caused by the hot work, and obtains a small-size two-phase titanium alloy steel bar with a fine and uniform equiaxed two-state structure.

Owner:BAOSHAN IRON & STEEL CO LTD

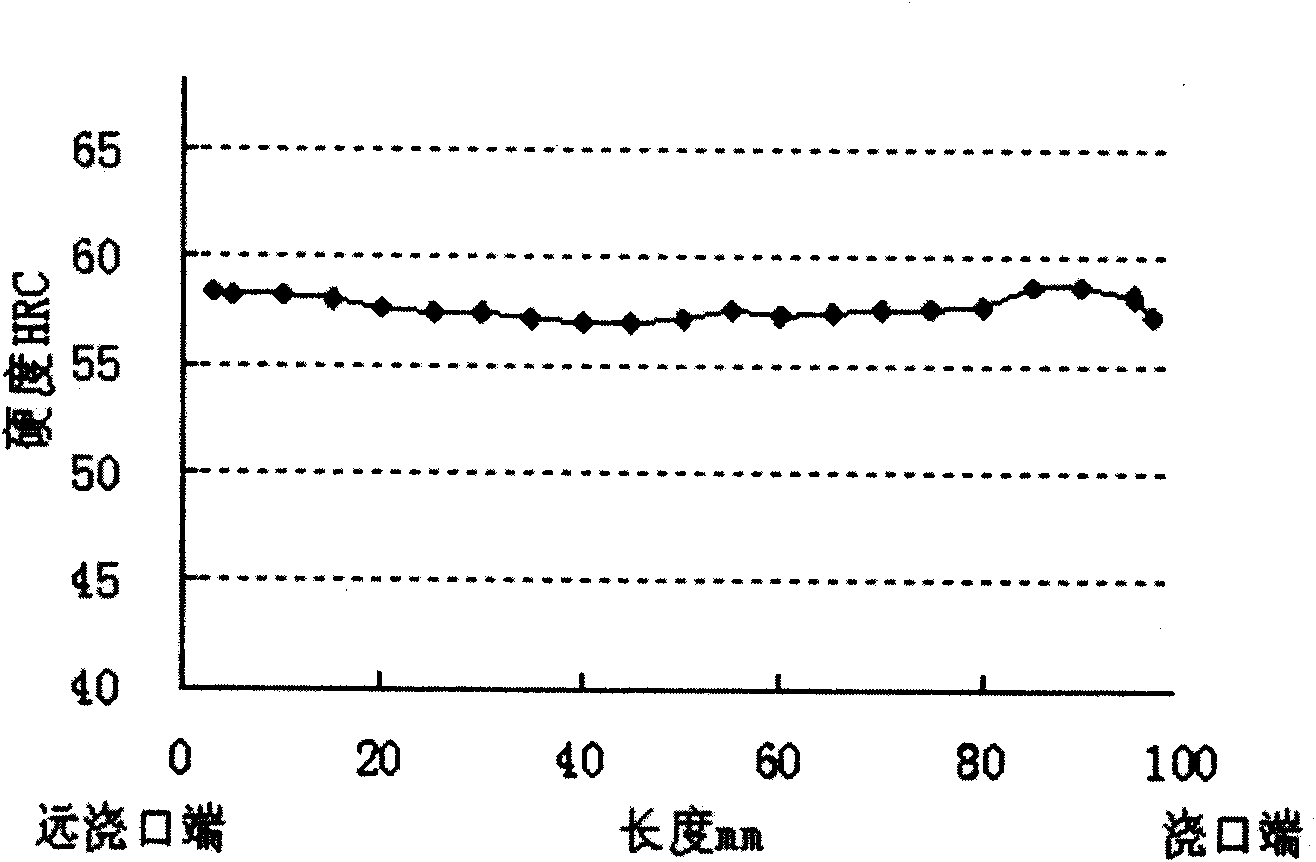

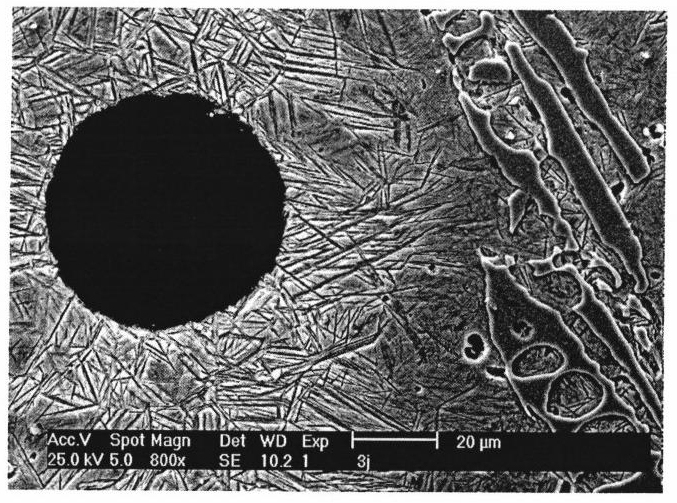

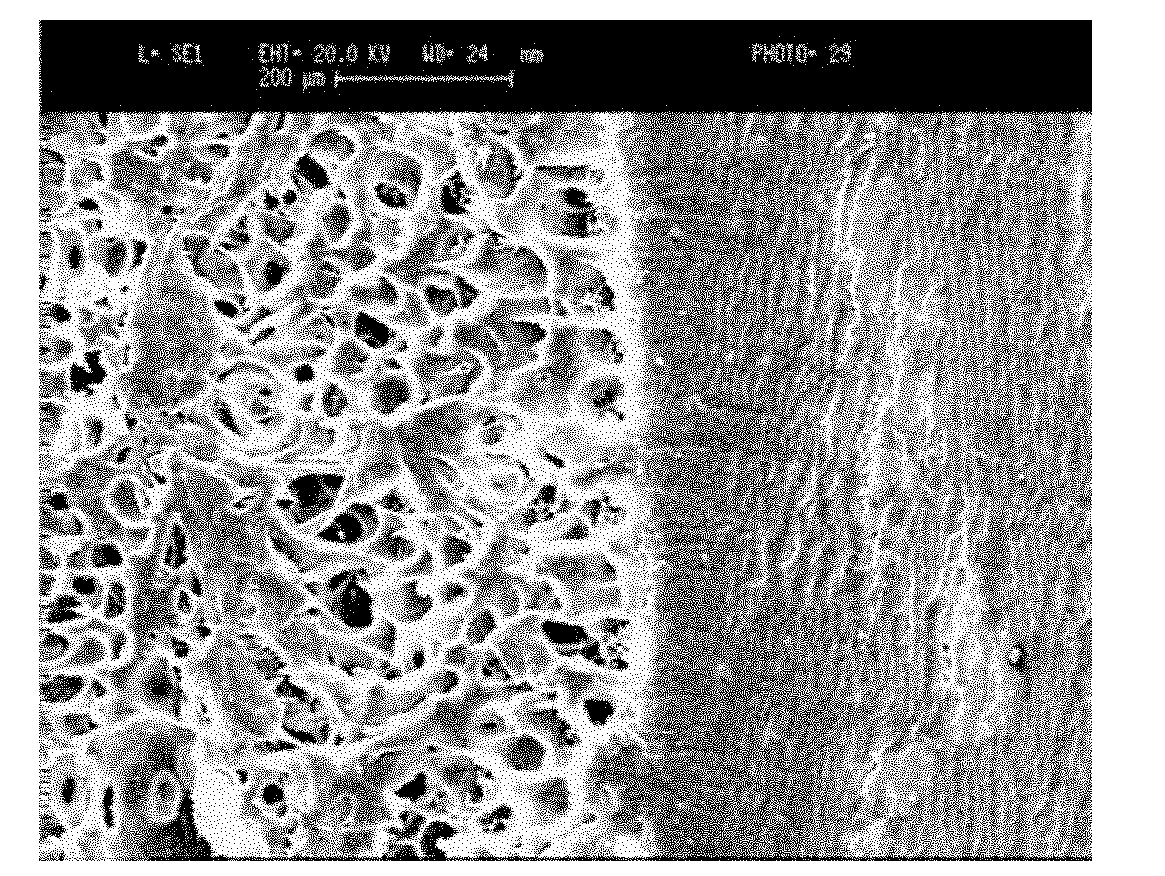

Carbide-containing ausferrite spheroidal graphite cast iron grinding ball and manufacturing method thereof

The invention discloses a carbide-containing ausferrite spheroidal graphite cast iron grinding ball and a manufacturing method thereof, relating to a cast iron alloy containing spheroidal graphite. The grinding ball comprises the following chemical elements in percentage by mass: 3.3 to 3.7 percent of C, 2.4 to 3.3 percent of Si, 2.5 to 3.6 percent of Mn, 0.6 to 1.5 percent of Cr, less than 0.08 percent of P, less than 0.025 percent of S, 0.03 to 0.05 percent of Mg, 0.02 to 0.04 percent of Re and the balance of Fe. The preparation method of the grinding ball comprises the following steps of: (1) raw material preparation and smelting; (2) spheroidization and inoculation; and (3) isothermal quenching heat treatment. In the invention, a certain quantity of carbides and graphite balls are formed in a grinding ball casting-state structure by utilizing a sand lined metal casting technology; and an ausferrite base body with excellent comprehensive mechanical property is obtained by adopting an isothermal quenching technology; and as a certain quantity of carbides are distributed in the ausferrite base body, the carbide-containing ausferrite spheroidal graphite cast iron grinding ball has high wear resistance and toughness.

Owner:HEBEI UNIV OF TECH +1

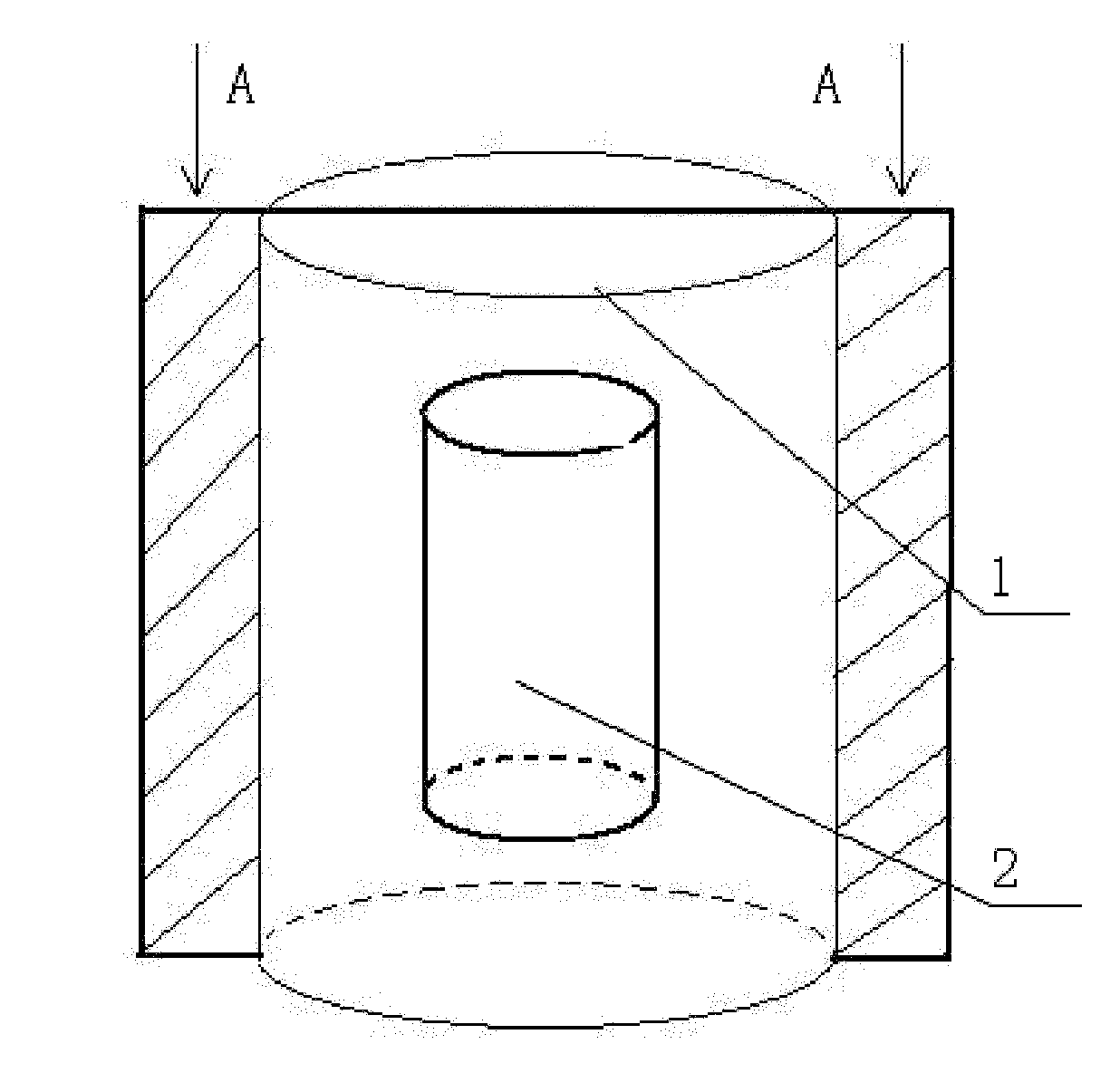

Forging forming process of high barrel-shaped aluminum alloy forged piece

ActiveCN104438419AReduce anisotropyIncrease radial elongationMetal rollingMachining deformationBarrel Shaped

The invention relates to a forging forming process of a high barrel-shaped aluminum alloy forged piece. A cross upsetting and rolling method is adopted in a forging process, so that on one hand, an aluminum alloy blank can be fully deformed, and a casting-state structure is enabled to be changed into a forged structure, on the other hand, by use of the cross upsetting and rolling method, the anisotropy of an aluminum alloy ring piece can be reduced and the radial elongation of the aluminum alloy ring piece can be improved. The feeding rate of a ring rolling machine during ring rolling is changed in a forging process, so that the aluminum alloy forged piece is prevented from being overheated on one hand, and the end surface of the aluminum alloy forged piece can be prevented from peeling and sinking; and besides, the aluminum alloy forged piece is subjected to heat treatment, so that the intensity of the forged piece can be improved, hardening constituents precipitated out from the aluminum alloy forged piece at the heat treatment temperature can be finely dispersed and distributed, the participating stress of the aluminum alloy forged piece can be reduced and the follow-up machining deformation can be prevented.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

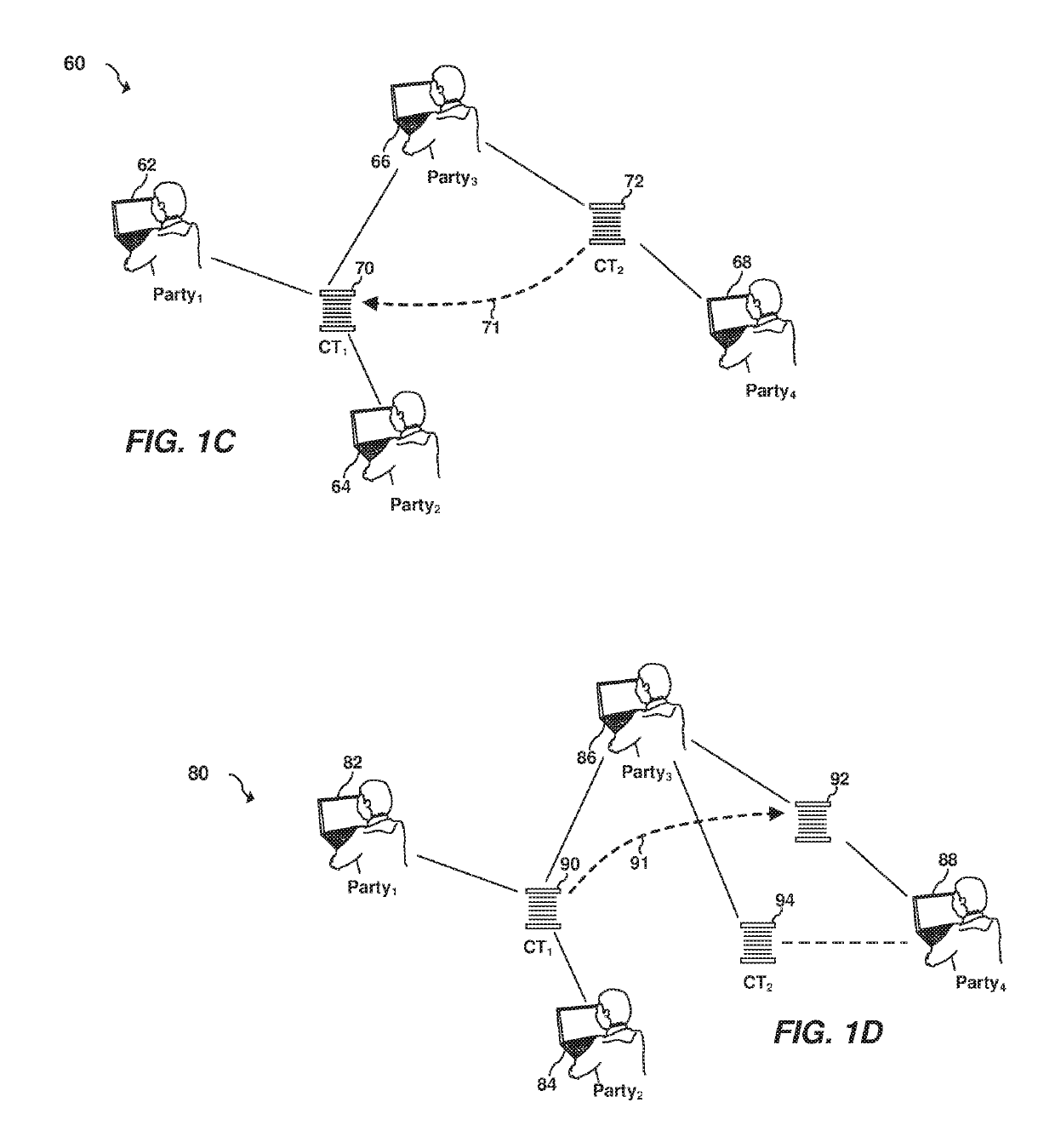

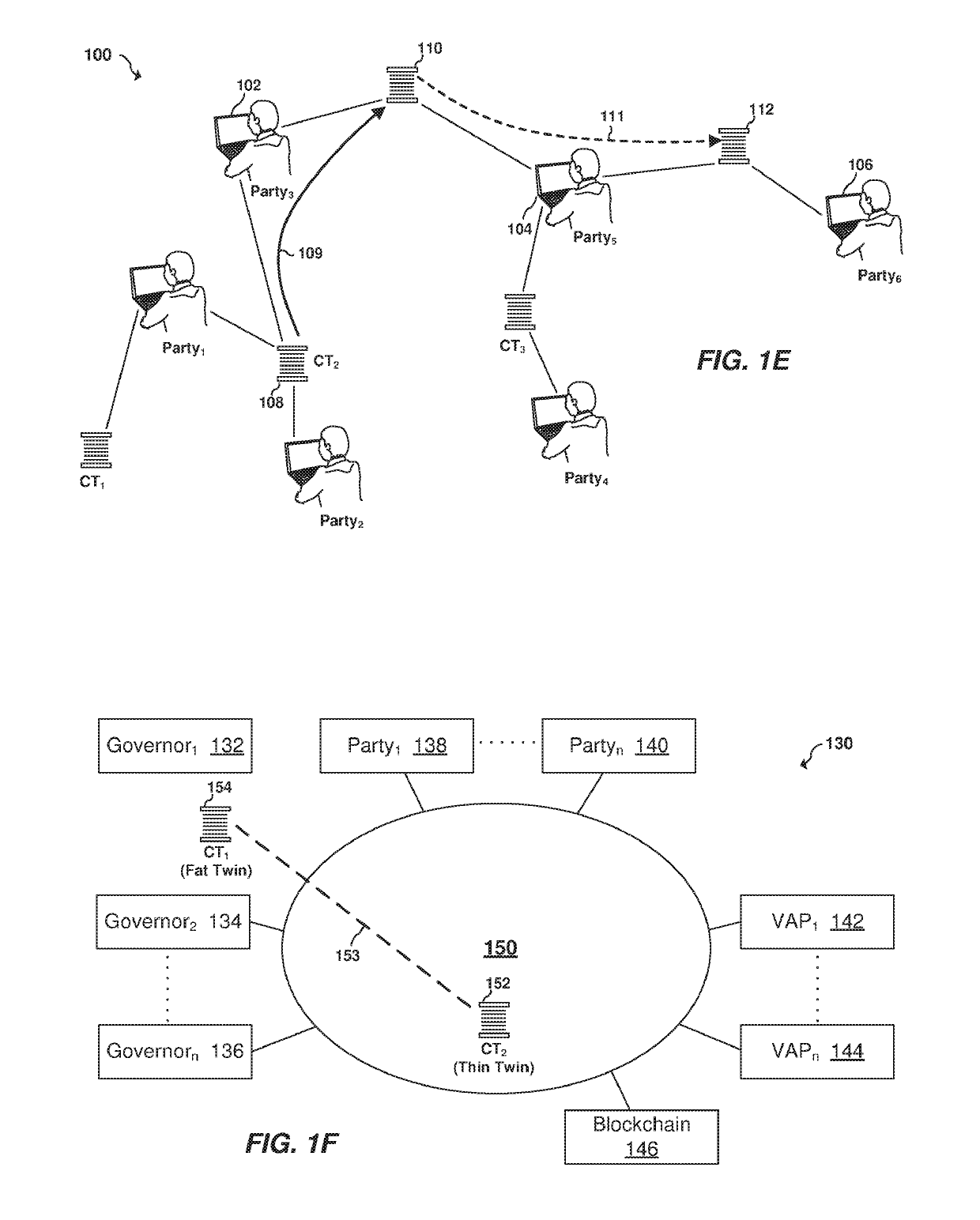

System and computer program product for certified confidential data collaboration using blockchains

ActiveUS20190215159A1Key distribution for secure communicationEncryption apparatus with shift registers/memoriesTimestampData collaboration

A system and computer program product for providing certified confidential data collaboration between two or more of a plurality of parties where an established trust relationship is not required between the plurality of parties. The method includes creating, by a first party, a changeset proposal, the changeset proposal having a comment, a list of attachments, a list of parties, and a list of versioned and typed data sections, remotely performing, by the first party, a certified operation on a computer associated with a semi-trusted governor party and passing the changeset proposal to the certified operation, creating, by the semi-trusted governor party, a globally unique changeset reference in a certified thread having a globally unique thread tracking number and a sequential changeset number, validating, by the semi-trusted governor party, the changeset proposal and creating, by the semi-trusted governor party, a state-at-changeset structure including the validated changeset proposal and a timestamp, extracting, by the semi-trusted governor party, a section-state-at-changeset structure from the changeset proposal, performing, by the semi-trusted governor party, a cryptographic hash of the state-at-changeset structure, performing, by the semi-trusted governor party, a cryptographic hash of the section-state-at-changeset structure, writing, by the semi-trusted governor party, to a local transactional database a changeset fat twin record including the changeset reference and its associated state-at-changeset structure and section-state-at-changeset structure, communicating, by the semi-trusted governor party, a changeset reference notification for each fat twin record to each of the one or more parties, performing, by the semi-trusted governor party, a certified operation in a blockchain a certified thin twin smart contract and passing the changeset reference, the cryptographically hashed state-at-changeset structure and the cryptographically hashed section-state-at-changeset structure, validating, by the certified thin twin smart contract, that there does not exist a previous certified operation with the same changeset reference, and writing by the thin twin smart contract to the blockchain a new thin twin record containing the changeset reference, the cryptographically hashed state-at-changeset structure and the cryptographically hashed section-state-at-changeset structure. The section-state-at-changeset structure is a subset of a total state of the list of versioned and typed data sections. A certified operation is expressed by the changeset reference, the state-at-changeset structure and the section-state-at-changeset structure occurred may be proved by each of the list of parties by cryptographically hashing the state-at-changeset structure and the section-state-at-changeset structure associated with the certified operation, and performing a proof-of-certified-operation on the thin twin smart contract and passing the changeset reference, the cryptographically hashed state-at-changeset structure and cryptographically hashed state-at-changeset structure. The proof may be determined even where the semi-trusted governor party is unresponsive after performance of the certified operation.

Owner:NOTANI RANJIT

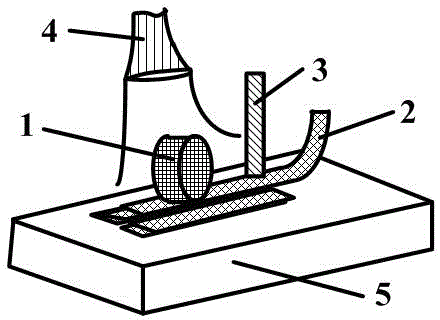

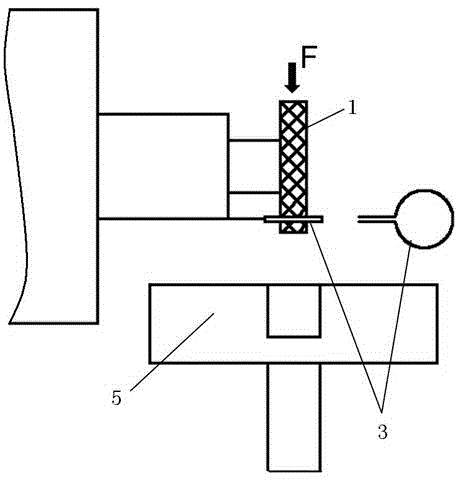

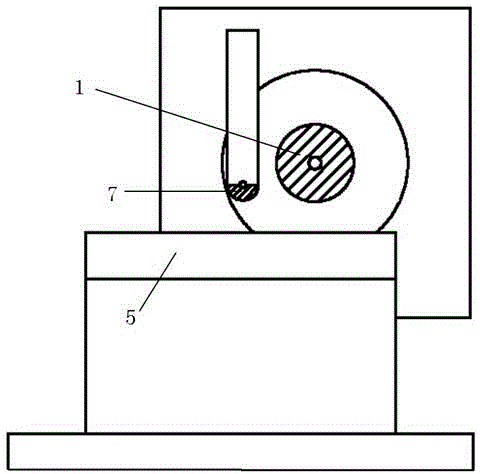

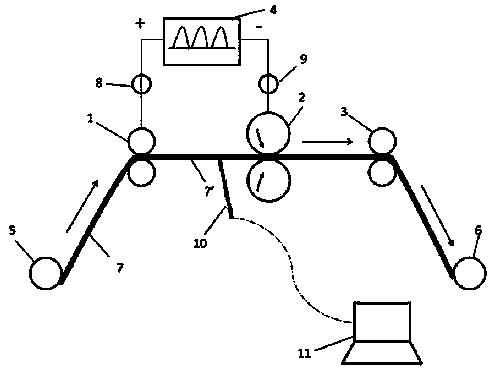

Method and device for auxiliary heating type ultrasound rapid forming

ActiveCN103600166AAvoid formingGuaranteed solid phase junction propertiesNon-electric welding apparatusNumerical controlMetal foil

The invention belongs to the technical field of rapid forming, and particularly relates to a method for achieving multilayer bead welding of metal foil strips through combination of extra auxiliary heating and ultrasonic welding. According to the method, preheating is conducted on metal foil or a base body material in rapid forming, the metal foil or the base body material is softened through preheating conducted by an external heating field, good gas protection is provided, and the welding thickness and width of a metal foil sheet are increased under the condition that the ultrasonic welding power is limited, so that multilayer one-time ultrasonic bead welding or multilayer multi-time ultrasonic bead welding of the metal foil is achieved and a three-dimensional solid block is formed in the solid-phase connection mode. Finally, a machining platform controlled by a numerical control program is applied, so that geometrical characteristic machining of a needed part is achieved. A metal piece obtained according to the method has the advantages of being low in cost, high in efficiency, compact in organization, free of casting-state structure, capable of achieving rapid forming of a functionally gradient material and the like.

Owner:WEIHAI WANFENG MAGNESIUM IND DEV

Manufacturing technology of novel hobbing cutter with laser cladding WC wear-resistant coating

ActiveCN103737273AImprove wear performanceInhibit sheddingMetallic material coating processesNumerical controlHobbing

The invention relates to a manufacturing technology of a novel hobbing cutter with a laser cladding WC wear-resistant coating. The manufacturing technology comprises the following steps: (1) manufacturing the hobbing cutter with a forging method, wherein the hobbing cutter is made of alloy steel; (2) carrying out peel removal cleaning treatment on surfaces to be machined of the intertooth space of an alloy cutter; (3) using a transverse flow CO2 laser, taking a numerical control machine tool as a workbench, and carrying out cladding wear-resistant strengthening treatment on the intertooth space of a cutter ring cutter, wherein the thickness of the WC cladding layer is 1.5-2.5mm; (4) carrying out performance detection on a composite coating. A laser surface cladding technology is adopted, and the tissues of a cladding coating mainly consist of carbides and a supersaturated solid solution superfine casting-state structure, wherein spherical tungsten carbide ceramics are of ultra-high hardness and uniformly distributed on a binding phase with extremely high hardness level, and also achieves an inhibition effect on abrasion, and the grinding resistance between hobbing cutter edges can be effectively improved; the binding phase is good in tenacity and high in strength, the formation of cracks can be effectively reduced, and the wear resistance and corrosive resistance of the hobbing cutter is improved, and the service life of the hobbing cutter is prolonged.

Owner:江苏点金激光科技有限公司

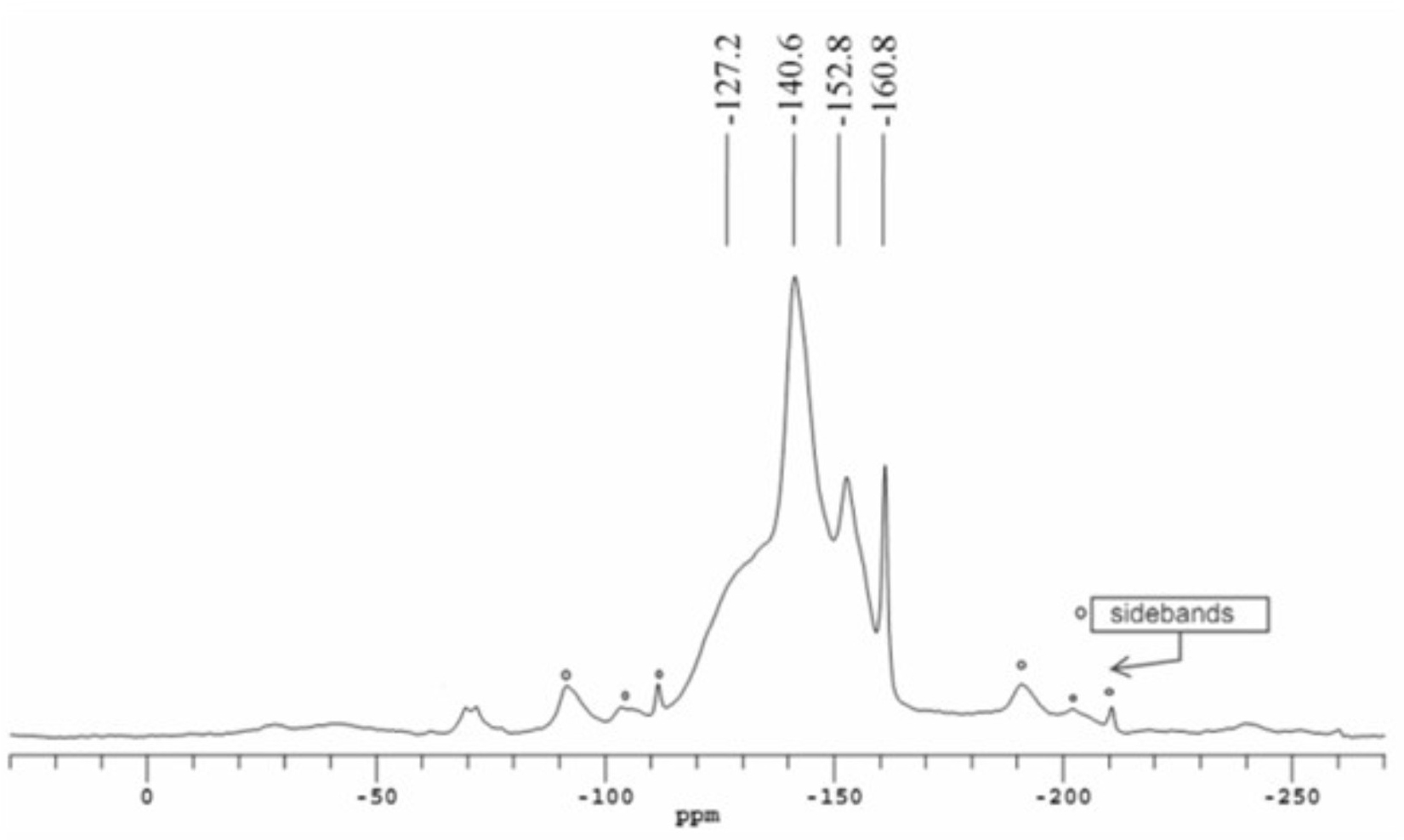

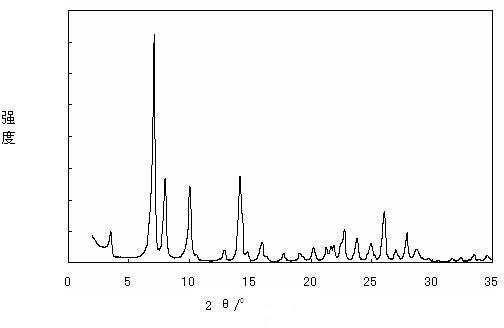

Fluorine-containing titanium-silicon molecular sieve with MWW (Manual Wire Wrap) structure and preparation method and application thereof

ActiveCN102627291AComplete crystalline structureImprove catalytic oxidation performanceMolecular sieve catalystsEther/acetal/ketal group formation/introductionX-rayCatalytic oxidation

The invention discloses a fluorine-containing titanium-silicon molecular sieve with a MWW (Manual Wire Wrap) structure and a preparation method and an application thereof. In the molecular sieve, a fluorine atom is connected with a framework silicon atom in the form of a chemical bond, an XRD (X-Ray Diffraction) spectrogram contains a characteristic spectral line of the molecular sieve with the MWW structure, and characteristic peaks of -150+ / -5ppm and -143+ / -5ppm appear in a 19FMAS-NMR (19 File Management Assistant For Server-Nuclear Magnetic Resonance) spectrogram; the preparation method comprises the following steps of: synthesizing a boron-containing parent body, post-treating, baking and the like; and the molecular sieve serving as a catalyst is applied to catalytic oxidation reactions of compounds containing carbon-carbon double bonds and at least one other functional group as well as reactions for catalytically synthesizing oxime. The molecular sieve has a complete crystalline state structure; according to the electronic effect of framework fluorine, the molecular sieve and higher catalytic oxidation capability; a preparation process is simple, and is easy for industrial production; synthesis of corresponding epoxides or catalytic synthesis of oxime from compounds containing carbon-carbon double bonds and at least one other functional group can be catalyzed at higher activity and high selectivity; and a reaction process is environmentally-friendly.

Owner:EAST CHINA NORMAL UNIV

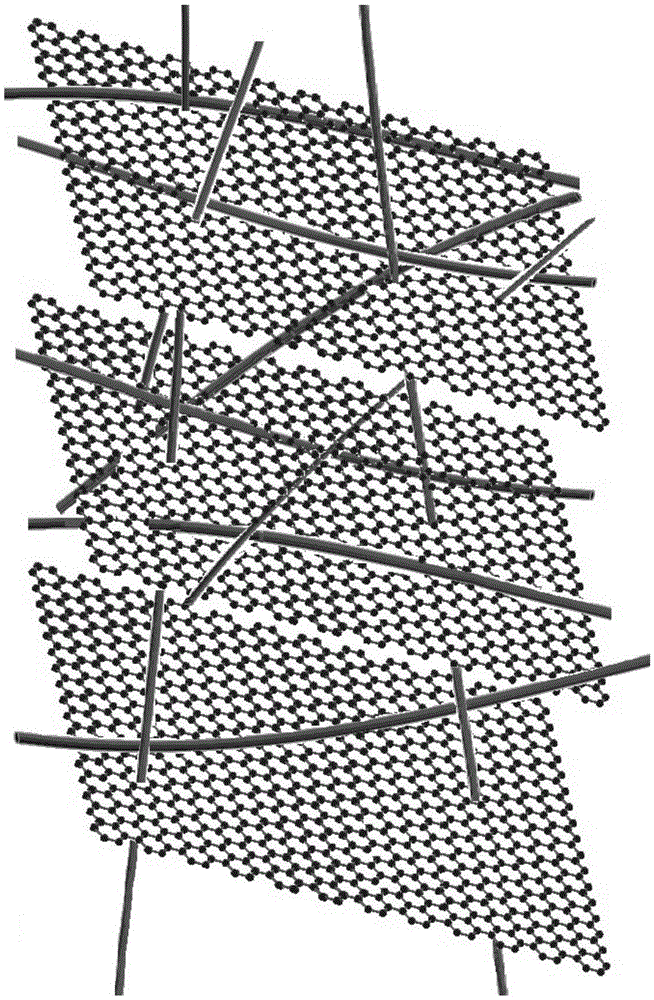

Polyamide6-graphene quantum dot/carbon nanotube anti-static fiber and preparation

InactiveCN105463613AHigh transparencyImprove conductivityElectroconductive/antistatic filament manufactureMonocomponent polyamides artificial filamentElectronic transmissionPolyamide

The invention provides polyamide6-graphene quantum dot / carbon nanotube anti-static fiber and preparation. According to the method, the molecular template effect of graphene quantum dots is utilized for being compounded with a carbon nanotube to form a self-assembled three-dimensional network structure first and then combined with a PA6 knitting state structure to form a dislocation effect to construct a conductive path, conductivity is improved on the condition of not losing a mechanical property of PA6 fiber, and meanwhile conductivity and the mechanical property of the PA fiber are promoted. Moreover, by means of compounding of the graphene quantum dots and the carbon nano tube and the self-assembled three-dimensional network structure, electronic transmission efficiency in the carbon nano tube is improved, a small quantity of GQD / CNT is added, conductivity of the fiber can be improved, and transparency is improved at the same time, which is beneficial for treatment technologies like dyeing in the fiber preparing process. By means of the traditional mature PA6 melt spinning technology, the high-strength and high-conductivity PA6-GQD / CNT composite fiber with tensile strength being 0.52-0.81 GPa and line resistance being magnitude 106 is prepared and can be applied to anti-static clothes, needle-punched carpet, filter felt, industrial non-woven fabric, medical supplies and the like.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

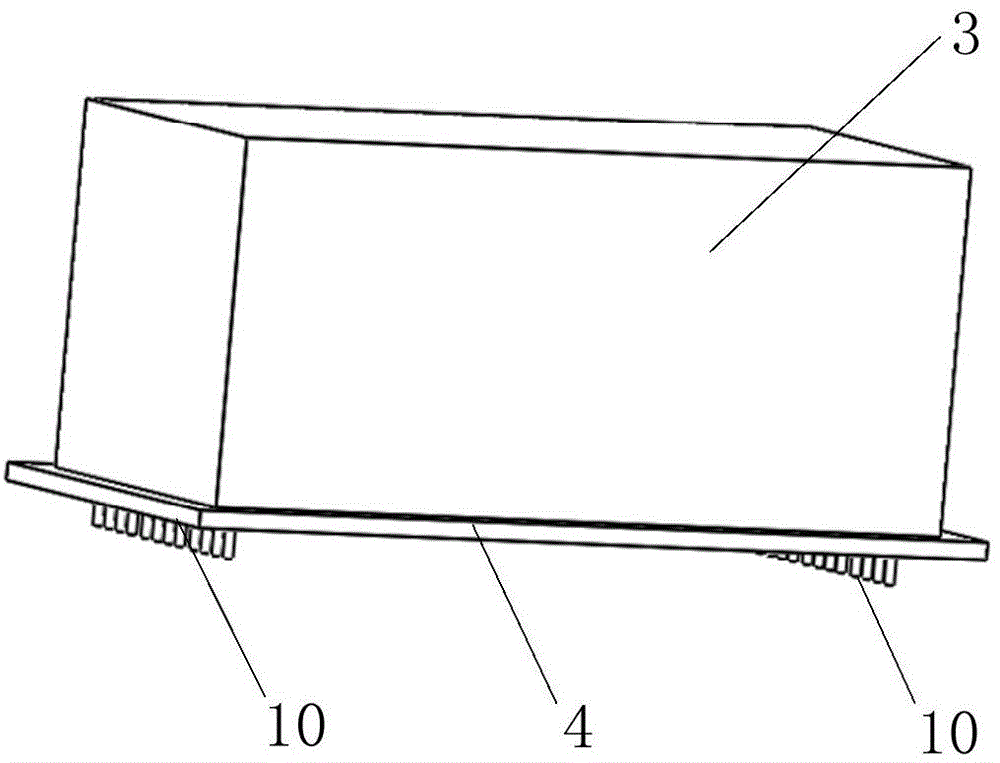

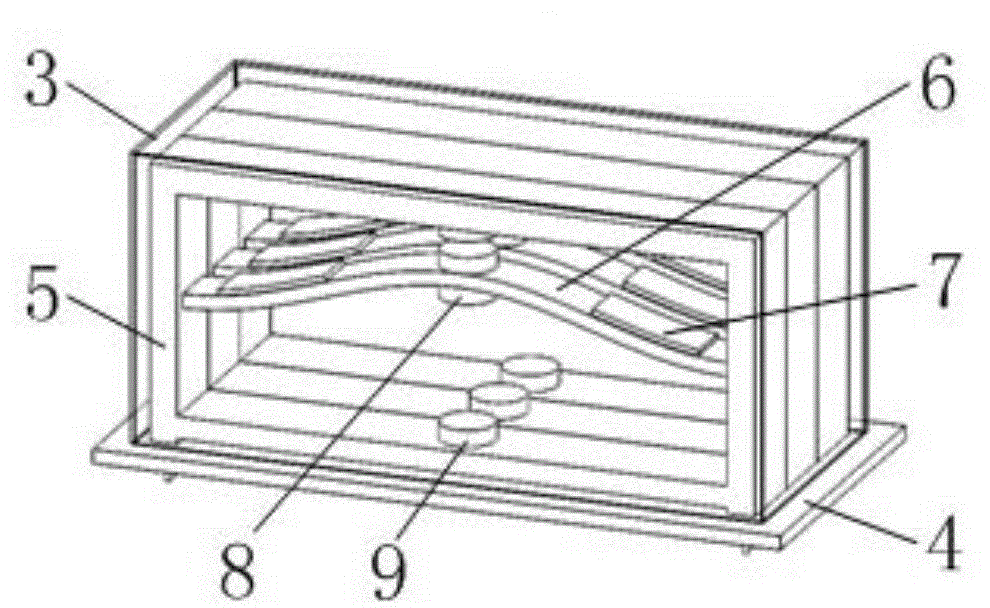

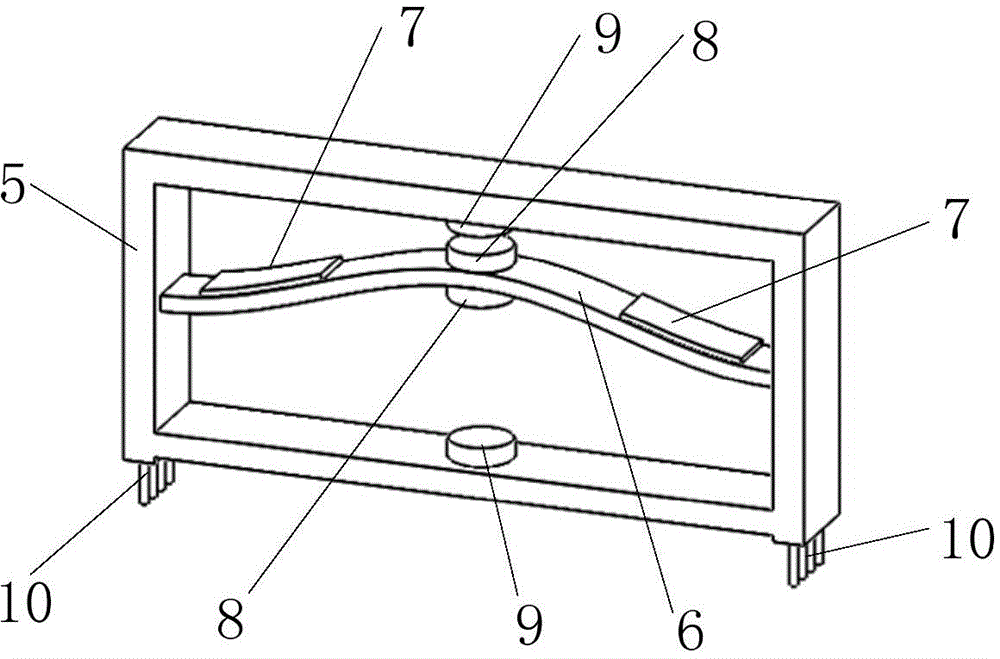

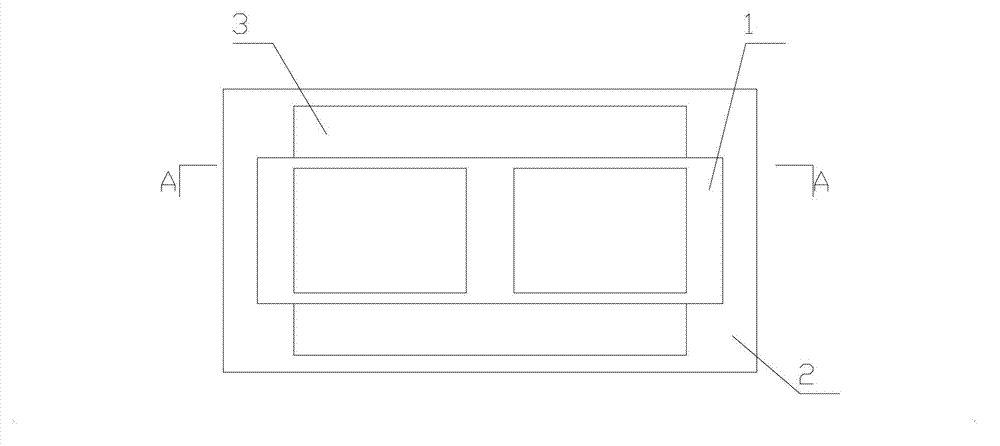

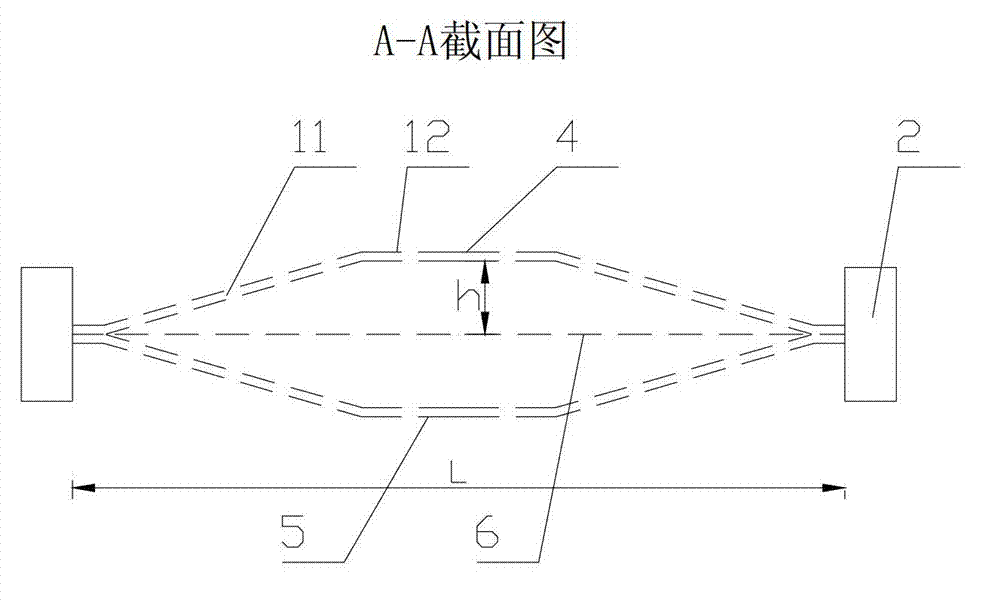

Electronic device posture adjustment device based on bistable-state structure

InactiveCN104536534ANovel structureSimple structurePiezoelectric/electrostriction/magnetostriction machinesDigital data processing detailsElectricityEngineering

The invention relates to an electronic device posture adjustment device based on a bistable-state structure. The electronic device posture adjustment device comprises a shielding cover (3) and a PCB bottom plate (4), a posture adjustment unit is packaged in the shielding cover (3) and comprises a frame (5), bistable-state elastic beams (6) and piezoelectric units (7), the bistable-state elastic beams (6) are fixed to the inner side of the frame (5) and has the upwards-convex state and the downwards-concave state, the piezoelectric units (7) are symmetrically spliced to the left sides and the right sides of the bistable-state elastic beams (6), permanent magnets (8) are fixed to the middles of the bistable-state elastic beams (6), and electromagnets (9) are arranged above and below the permanent magnets (8) and fixed to the frame (5). By means of the electronic device posture adjustment device, the external vibration energy can be collected, the in-air posture of a portable electronic device in the falling process can be further adjusted, and an impacting resistant portion of the portable electronic device is in contact with the ground firstly so that the effect of protecting a fragile part can be achieved.

Owner:张文明 +2

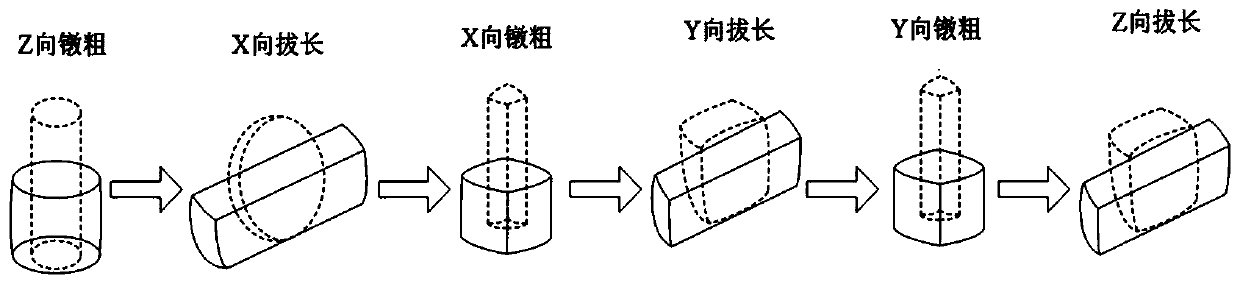

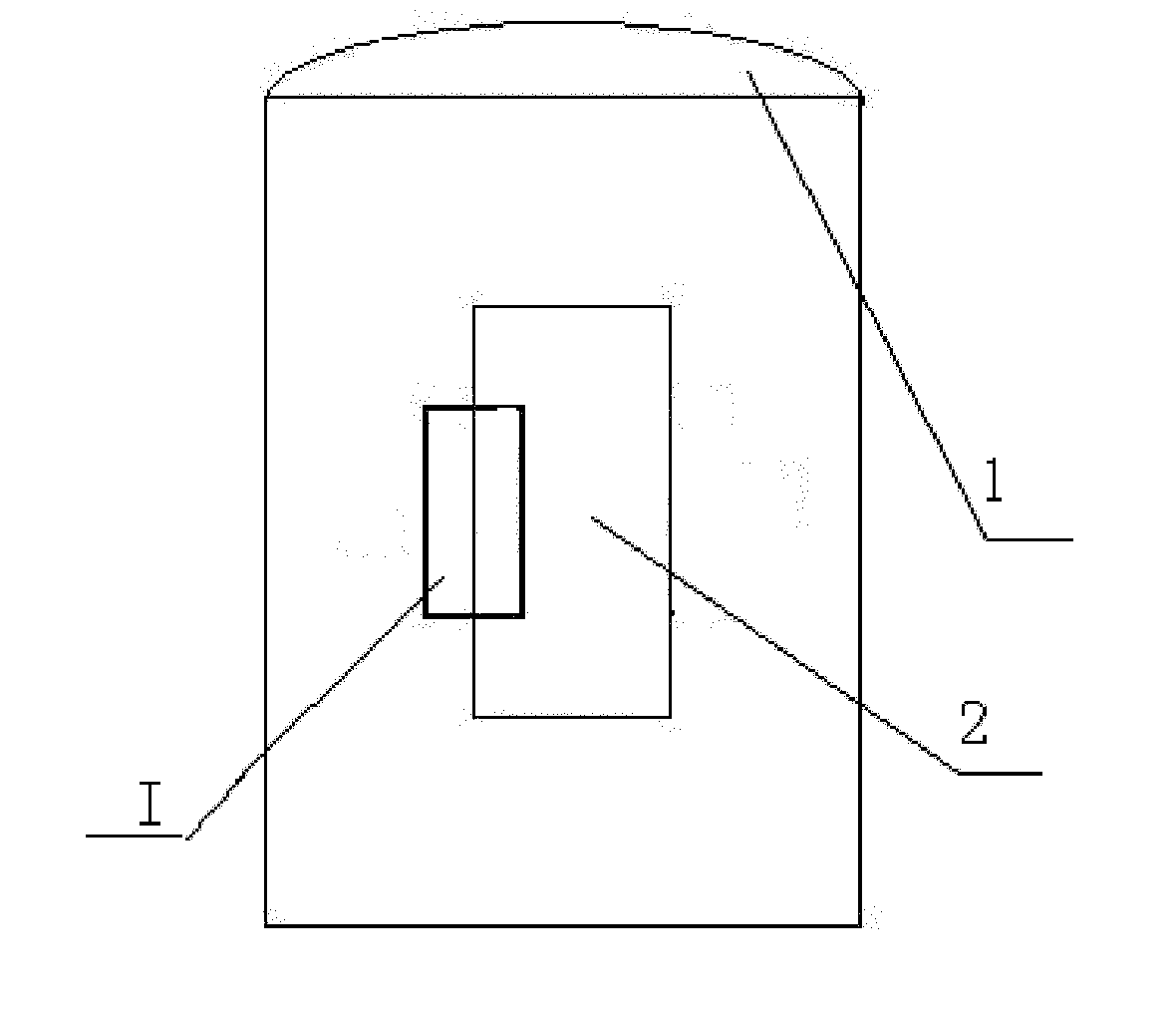

Three-directional near-isotropy high-performance aluminum alloy cylindrical forge piece manufacturing process

InactiveCN109759783AThree-way performance is nearly identicalImprove solubilityQuenchingHeat treated

The invention provides a three-directional near-isotropy high-performance aluminum alloy cylindrical forge piece manufacturing process. The manufacturing process specifically comprises the following steps of raw material size design, cast ingot quality detection, heating before ingot casting, multi-directional forging, return to a furnace for heating, Z-direction upsetting and punching, return toa furnace for heating, core shaft drawing out, return to a furnace for heating, saddle forging, machining, heating before rolling, ring rolling, solution treatment, aging treatment and quality detection. According to the manufacturing process, an aluminum alloy cylindrical forge piece is subjected to nearly equal deformation in three directions, so that the three-direction performance of a productis nearly isotropic; a thick residual crystalline phase in cast-state structure is fully crushed so as to provide structure preparation for second phase uniform dispersion distribution in the heat treatment process; a second phase in the structure is fully dissolved, the degree of supersaturation is improved, the material potential is excavated to the maximum extent, and the performance limit ofa material is exerted; and the small reduction rate is adopted, the quenching water temperature is increased, the stress in the product manufacturing process is reduced, so that the residual stress ofthe forge piece is controlled within a certain range.

Owner:天津航天长征技术装备有限公司

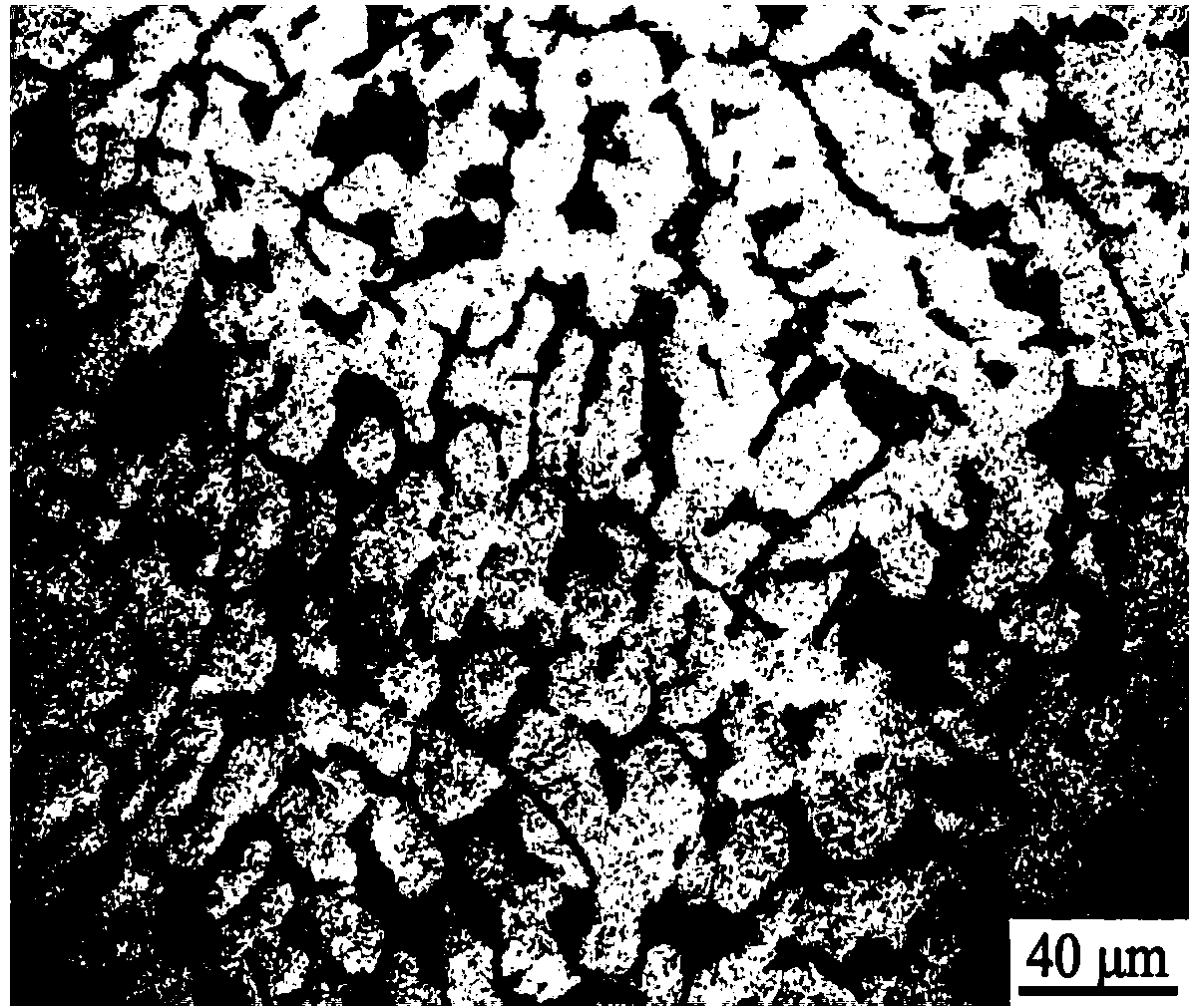

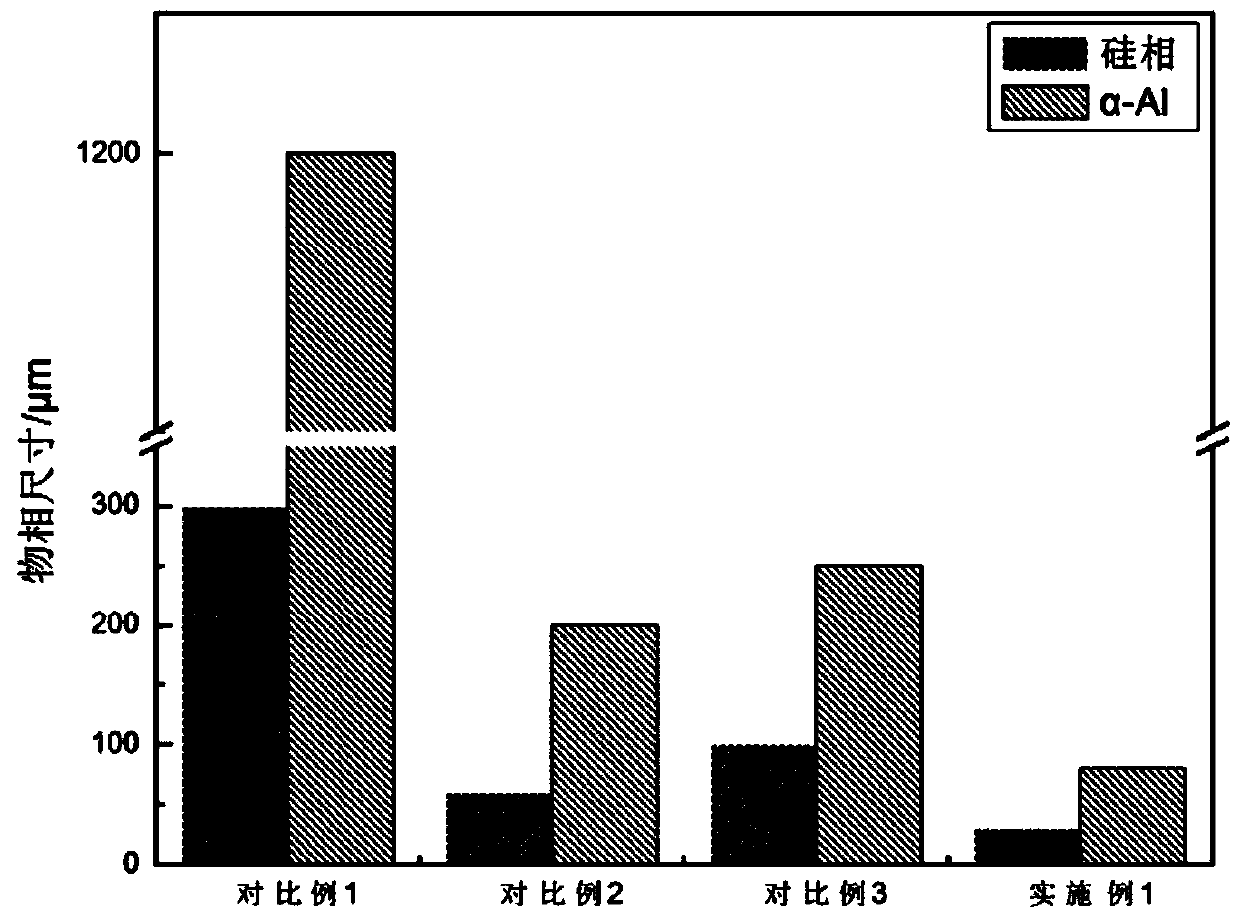

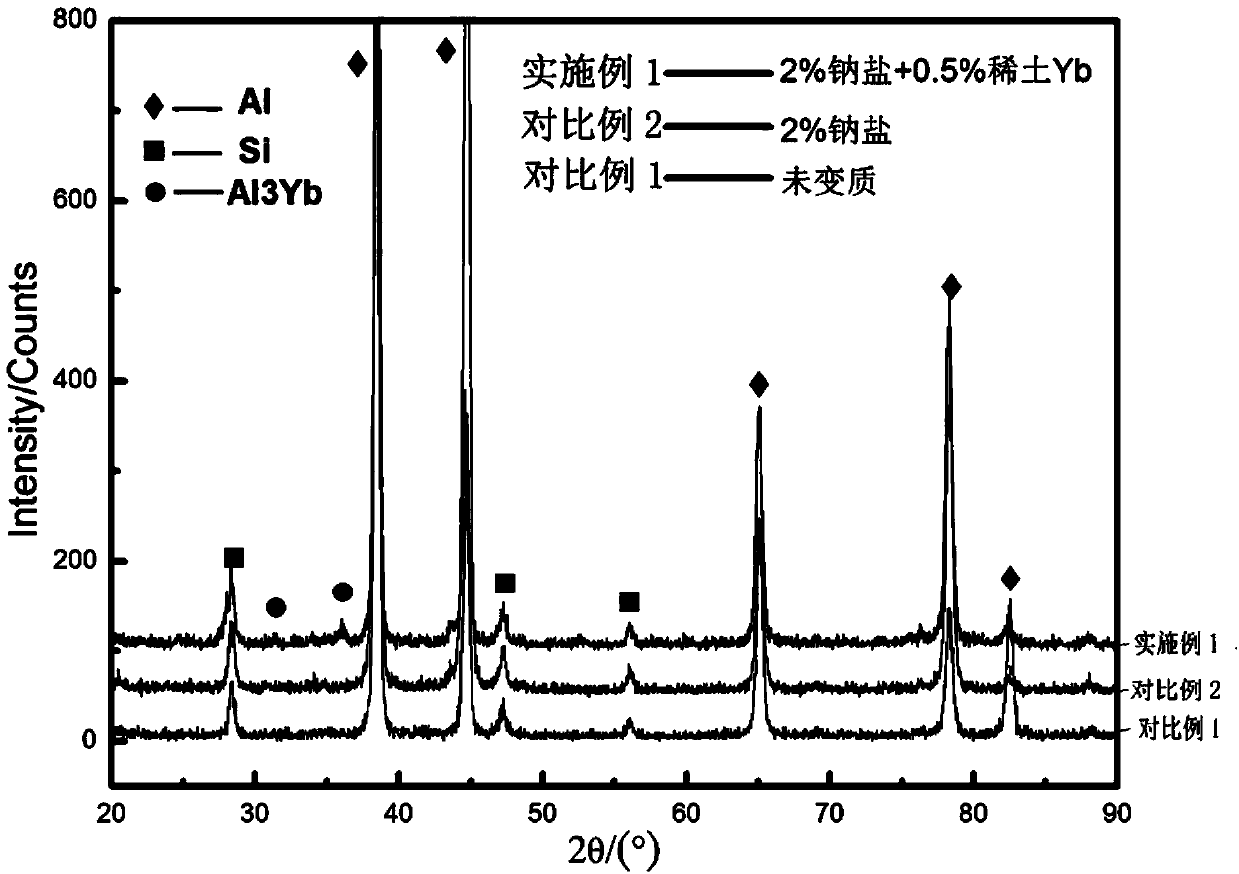

Composite metamorphic cast aluminum alloy and preparation method and application thereof

The invention provides a composite metamorphic cast aluminum alloy. The composite metamorphic cast aluminum alloy comprises, by weight, 8.0 % to 10.5 % of Si, 0.17 % to 0.3 % of Mg, 0.2 % to 0.5 % of Mn, 0.1 % to 1.0 % of Yb, 0.5 % to 3.0 % of sodium salt, less than 0.2 % of Fe, less than 0.1 % of Sn, less than 0.1 % of Cu and less than 0.05 % of Pb and the balance Al, wherein the Fe, the Sn, the Cu and the Pb are limited impurity elements. The invention further provides a preparation method and application of the composite metamorphic cast aluminum alloy. Due to metamorphism of the heavy rare earth element Yb and the alloying function, the casting-state structure of the alloy is significantly refined, strength and toughness of the alloy are improved, oxidation blending imported by the sodium salt metamorphism is reduced, and the compactness of a casting is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

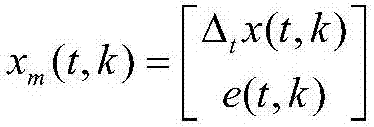

Model prediction tracking control method in batch chemical engineering

ActiveCN107168293AGood tracking effectImprove anti-interference abilityProgramme controlElectric testing/monitoringProcess stateDSPACE

The invention discloses a model prediction tracking control method in batch chemical engineering. According to the invention, the method introduces an improved state space model to the model prediction control and iterative learning control method so as to increase the control properties in batch manufacturing. Different from traditional state space models, the method herein, in the state model structure in the proposed method, introduces the dynamic combination between a process state variable and output tracking errors, and uses the improved process model. By using the improved technical solution, the method can obtain controllers which have more freedom to regulate control properties, and can achieve better controlling effects.

Owner:HANGZHOU DIANZI UNIV +2

Ti6242 titanium alloy and preparation method of small-size bar thereof

The invention discloses a Ti6242 titanium alloy consisting of the following components in percentage by mass: 5.5-6.5% of Al, 1.8-2.2% of Sn, 3.6-4.4% of Zr, 1.8-2.2% of Mo, 0.06-0.1% of Si, less than or equal to 0.1% of Fe, less than or equal to 0.15% of O, less than or equal to 0.05% of C, less than or equal to 0.05% of N, and the balance of titanium and inevitable impurity elements. A preparation method of a small-size bar of the Ti6242 titanium alloy comprises the following steps: performing billet forging to obtain a blank with a preliminarily broken as-cast state structure; then performing 7 fire forging to obtain a blank structure with fully broken and uniformly refined crystalline grains; then performing 2-3 fire forging to obtain a black skin bar; and finally, performing heat treatment to obtain a finished product bar. By adopting the Ti6242 titanium alloy and the preparation method disclosed by the invention, the problem that the structural uniformity of the edges and center of the bar is poor is solved, a small-size (phi 20-100mm) Ti6242 titanium alloy bar for vanes of aircraft engines is obtained, and the structure is highly homogenized and is good in flaw detection.

Owner:西部超导材料科技股份有限公司

Titanium alloyed aluminium copper magnesium silver series high strength heat resistant aluminium alloy

An AlCuMgAg-series high-strength refractory Al alloy with alloyed Ti contains Cu (4-8 wt.%), Mg (0.4-1.0), Ag (0.3-1.0), Mn (0.3-0.6), Zr (0.05-0.30), Ti (0.05-1.1) and Al (rest). It features that the Ti is contained for finding the original cast-state structure of alloy, so optimizing its performance.

Owner:SHANGHAI JIAO TONG UNIV

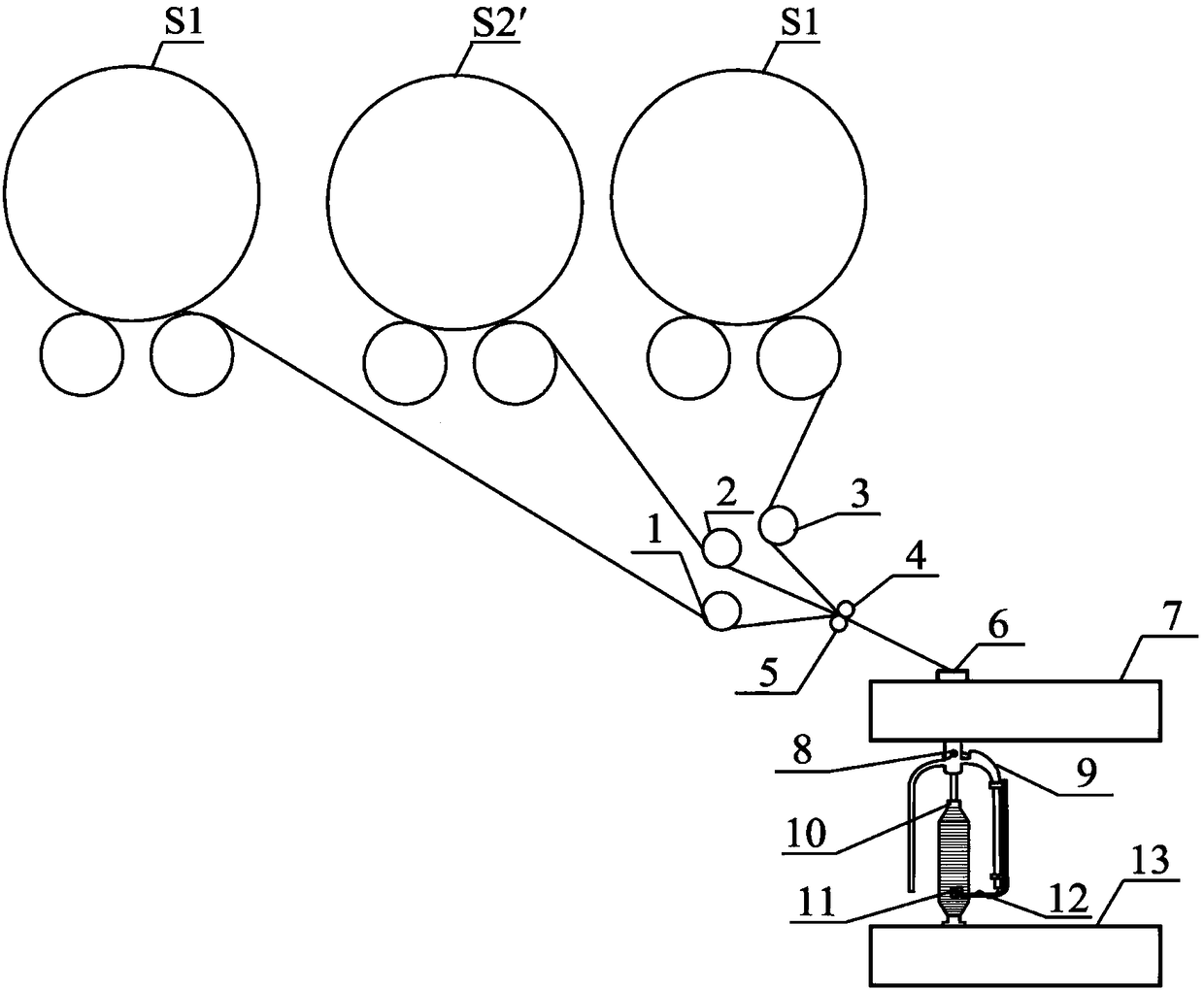

Composite yarn formation method of built-in powder materials

ActiveCN108286101AAchieve stabilityEnhancing wrapping and cohesionDrafting machinesYarnYarnTextile technology

The invention relates to a composite yarn formation method of built-in powder materials, and belongs to the technical field of textiles. The method comprises the steps that firstly, non-woven flexiblefabric materials are divided into fiber strips S1 and fiber strips S2; secondly, a padding method is adopted for conducting padding combination on the fiber strips S2 and powder to form powder stripsS2'; finally, each composite strip formed by sandwiching one powder strip S2' with two overlapping fiber strips S1 is subjected to composite twisting and yarn formation by adopting a flyer spindle twisting and winding mode, and the linear sheet-shaped composite strips are converted into linear cylindrical yarn. The sheet-shaped untwisted loose-state structures of the composite strips are changed,the technical bottleneck that it is difficult to comb and collect powder into strips by means of traditional methods is broken through, the built-in short-flow yarn formation of powder materials is achieved, the technical purpose of the composite yarn formation of the powder materials is achieved, and the quick and effective method is provided for preparing high-functionality high-quality yarn and apparel fabrics by using the powder materials. The method is short in process flow and easy to popularize and apply.

Owner:WUHAN TEXTILE UNIV

Production method of integral special-shaped heavy forging made of austenitic stainless steel

ActiveCN103350173AImprove surface qualityImprove hot workabilitySS - Stainless steelArgon oxygen decarburization

The invention discloses a production method of an integral special-shaped heavy forging made of austenitic stainless steel, and belongs to the technical field of stainless steel machining. The process comprises the following steps of smelting which combines an electric furnace, AOD (argon oxygen decarburization) and electroslag remelting, hammer cogging, upsetting, stretching, remelting heating and forging, heat treatment, machining, cold bending or hot bending machining, heat treatment and the like. Electroslag ingot surface quality is improved through surface grinding, and an electroslag ingot casting-state structure is broken through hammer cogging, so that the hot-working character of billet steel is improved, the electroslag ingot is restrained from hammer cogging, and conditions are provided for following large-deformation upsetting and stretching. The steel ingot crystal grain size is refined through repeated large-deformation upsetting and stretching processes, recrystallized grains are restrained from abnormal growth through controlling of last flame path remelting heating temperature, forging deformation and final heat treatment process, coarse crystals and mixed crystals are avoided, the forging structure is refined, and the crystal grain size reaches a 4.0 grade or high.

Owner:CENT IRON & STEEL RES INST

Aluminum alloy anodizing coloring treatment method

InactiveCN105506706AAvoid concentrated heat-generating situationsReduce voltageAnodisationLow voltageMetallic materials

The invention relates to an aluminum alloy anodizing coloring treatment method, and belongs to the technical field of metal materials. In the mode of direct-current low-voltage power source loading, a sulfuric acid solution is used as a main ingredient of an electrolyte, and anodizing coloring is carried out with organic dyestuff as a dyeing agent through the method of organic dyestuff adsorption coloring. The method includes the concrete steps of anodizing treatment, wherein the sulfuric acid solution electrolyte is used, a low-voltage direct-current power source is used, and the treatment is carried out at normal temperature, and after treatment is finished, deionized water washing and airing are conducted to obtain an anodised aluminum film sample surface of a crystalline state structure; coloring treatment, wherein the organic dyestuff is dissolved fully, heated to 45 DEG C and kept warm, and a prepared anodised aluminum film sample is put in the organic dyestuff, and soaked for 30 min to form a dyed sample. Heat in the treatment process is small, and concentrated heat production is effectively avoided. The prepared anodised aluminum film is of the crystalline state structure, and surface hardness, abrasive resistance and corrosion resistance are greatly improved.

Owner:SHENYANG JIANZHU UNIVERSITY

Preparation method of biological function composite auxetic hydrogel with shell core structure

InactiveCN102107023APerformance is easy to controlFacilitate cross-linkingProsthesisCross-linkRadiation Dosages

The invention belongs to the field of biomedical material and relates to a preparation method of biological function composite auxetic hydrogel with shell core structure. In the method, the biological function composite auxetic hydrogel with shell core structure is prepared by the radiation cross-linking technology or freezing / unfreezing method, i.e. an inner core is of a dense structure with lowwater content, and an outer shell is of a communicated porous structure with relatively low modulus. Macroscopically, a negative Poisson's ratio effect of the material is realized, and the inner coreand outer shell are in firm combination. By controlling the core component and size as well as the shell composition and structure of the material, the auxetic hydrogel meeting various application requirements can be prepared; by controlling the radiation dosage in the radiation cross-linking as well as the parameters of the freezing / unfreezing process such as temperature, time, circulation timesand the like, the condensed state structure and crystallization degree of the polymer can be changed so as to prepare the biological function composite auxetic hydrogel with controllable performance.The biological function composite auxetic hydrogel is suitable for the bionic implantation repair material for the soft tissues such as blood vessels, nerves, cartilage, intervertebral disk, muscles,ligaments and the like.

Owner:UNIV OF SCI & TECH BEIJING

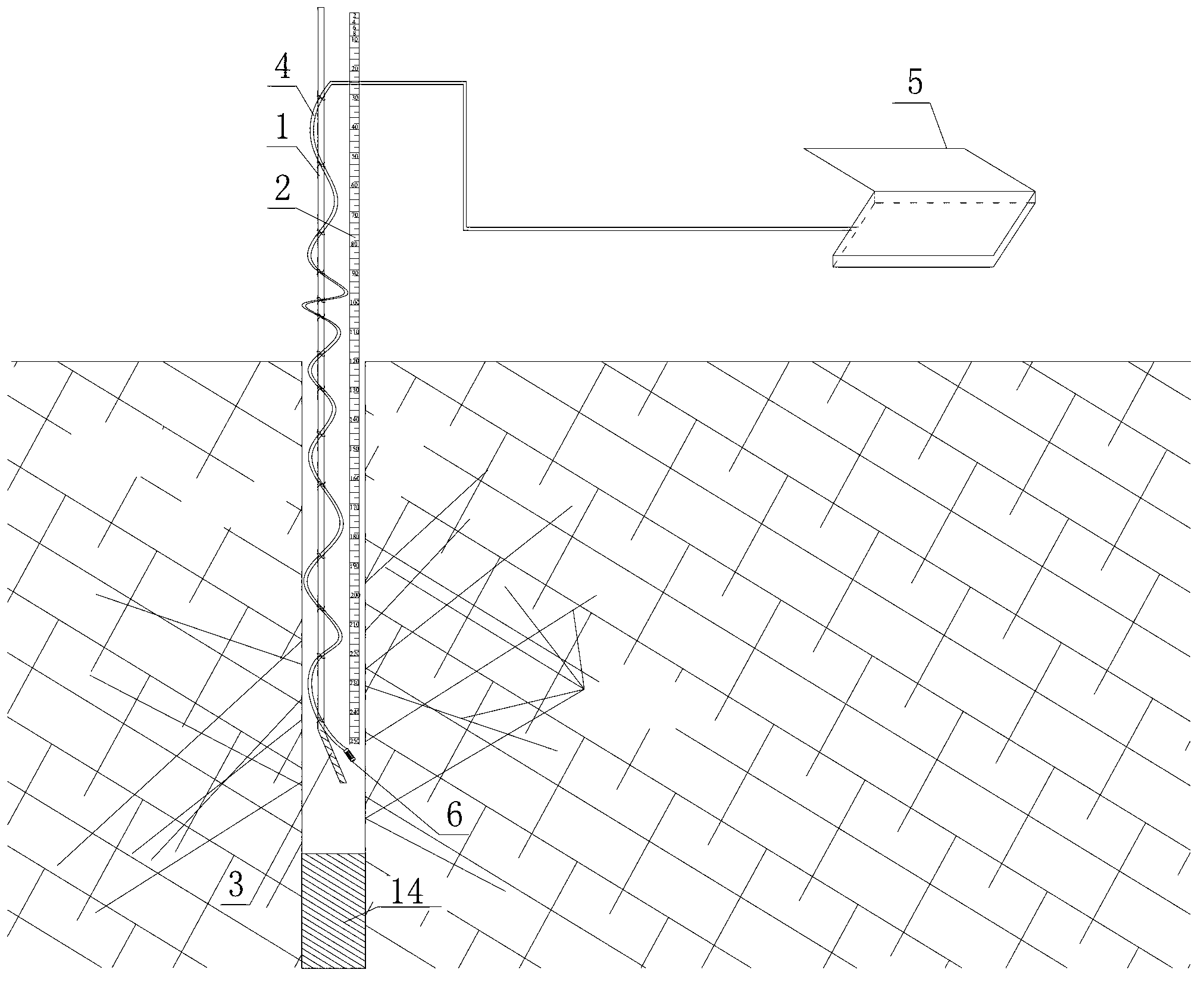

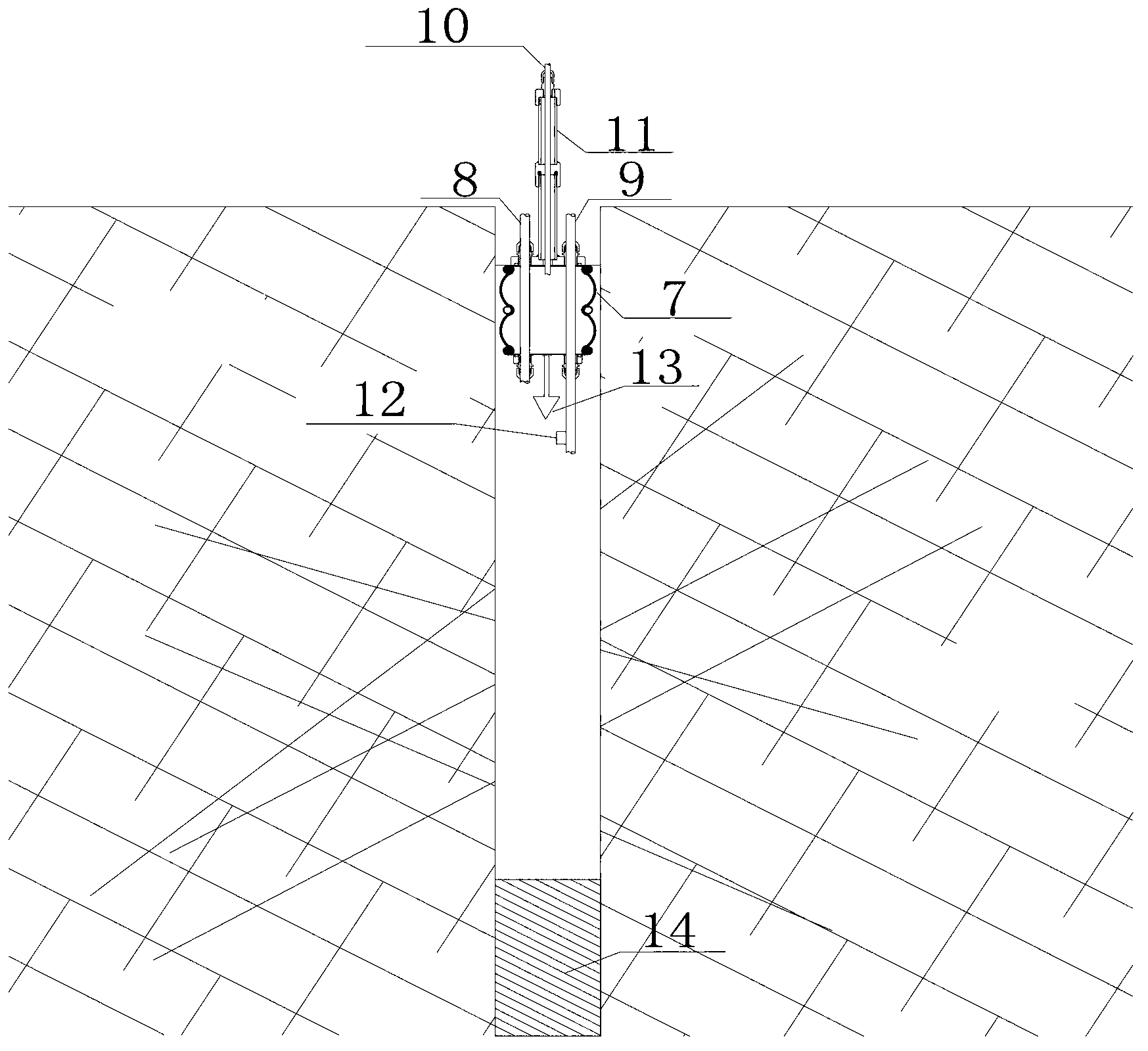

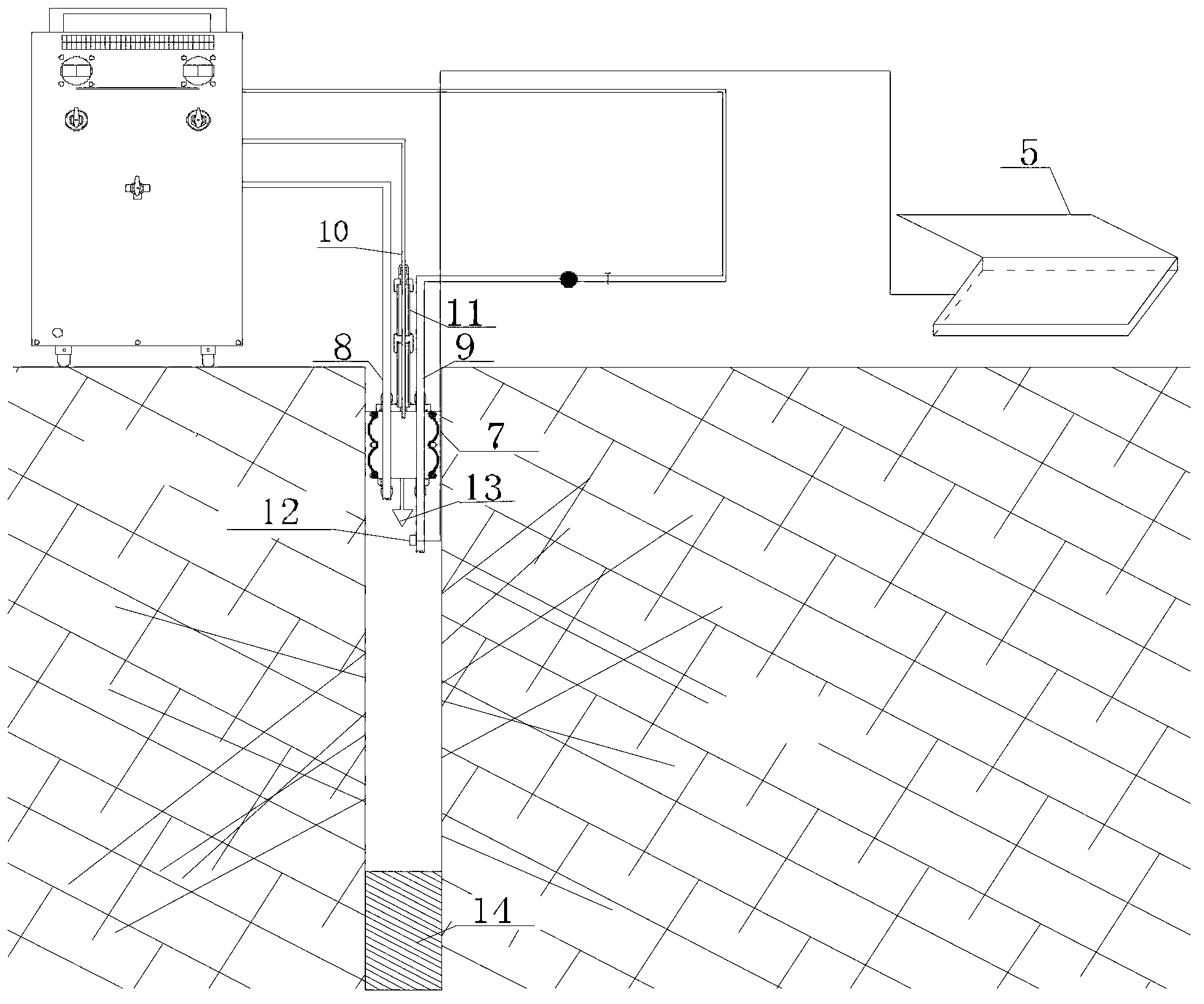

Original state sampling method for constructed fractured rock mass

ActiveCN103293023AImprove the consolidation effectTargetedWithdrawing sample devicesHigh pressureEarth surface

Owner:NANJING UNIV

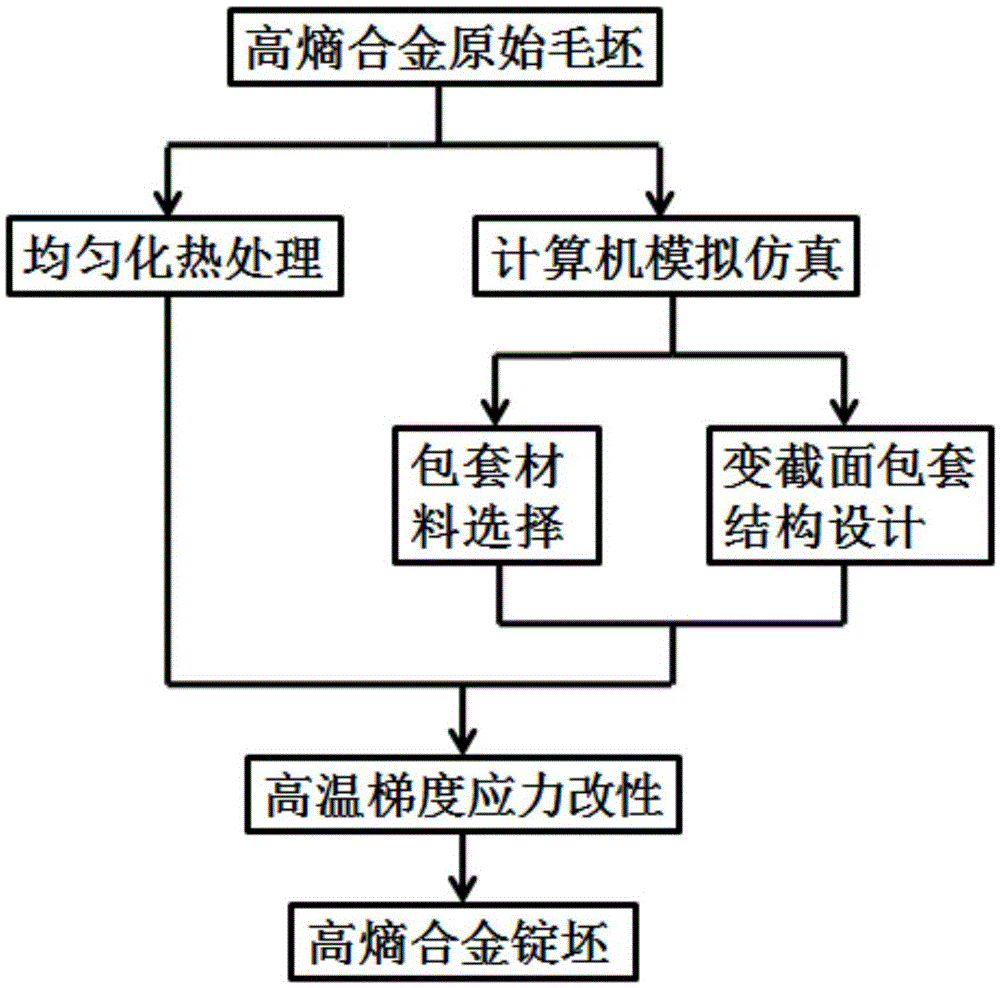

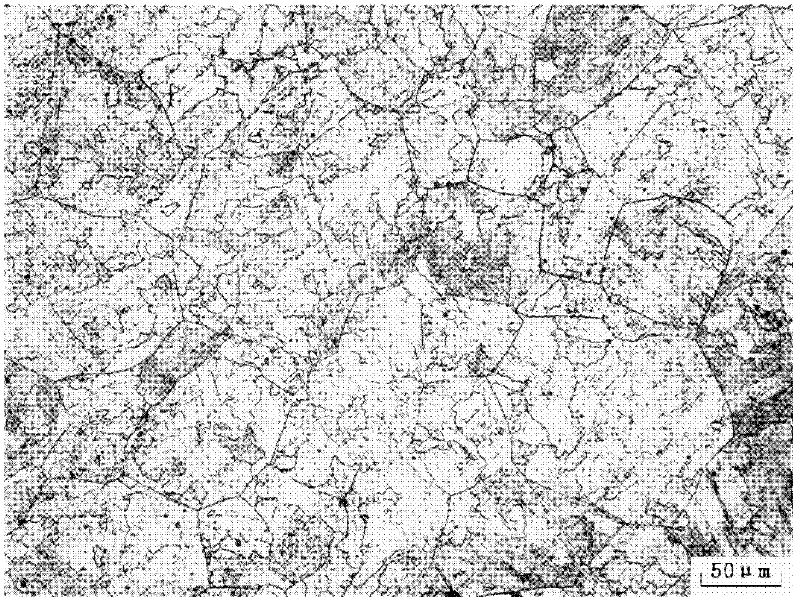

High-entropy alloy gradient stress modification technology

InactiveCN105543749AUniform and excellent tissue performanceEasy to useFine structureHigh entropy alloys

The invention relates to a gradient stress plasticity modification method which specially aims at damage control and fine structure regulation of high-entropy alloy material characteristics. The purpose of the method is to solve the problems that a high-entropy alloy casting state structure is mainly composed of bulky pine-tree crystals, and the comprehensive mechanical property of the high-entropy alloy casting state structure is poor. A preparation method mainly comprises the steps that a high-entropy alloy ingot is prepared; homogenization heat treatment, analogue simulation and canned forging are conducted; and a high-entropy alloy ingot blank is obtained. When the high-entropy alloy ingot is processed, preset variable cross-section canning is mainly adopted, the stress state of the interior of a high-entropy alloy material in the process is effectively controlled, and the gradient three-way compressive stress combined with deformation characteristics is formed. By means of the gradient stress plasticity modification method, initiation and propagation of microcracks induced by lattice distortion can be effectively inhibited finally, crystalline grains are refined, the comprehensive mechanical property is improved, and effective modification of the high-entropy alloy is achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for refining grains of heavy forging steel of nuclear reactor evaporator

ActiveCN102234706AImprove mechanical propertiesImprove toughnessProcess efficiency improvementElectric furnaceHeat treatedLadle furnace

The invention relates to a method for refining grains of heavy forging steel of a nuclear reactor evaporator, which belongs to the technical field of heat treatment of steel. The method comprises the following steps of: performing electric furnace smelting and ladle seconclary refining during steel production; performing vacuum pouring by an improved vacuum carbon deoxidation (VCD) process or a silicon killed deoxidation process and a subsequent multi-furnace pouring (MP) process to obtain 200 to 600 tons of steel ingots; accurately controlling the components of the steel in the smelting process, wherein the mass fraction of aluminum elements is between 0.02 and 0.04 percent, the mass fraction of nitrogen elements is between 0.005 and 0.015 percent, the mass fraction of silicon elements is less than 0.1 percent when the improved VCD process is used, and the mass fraction of the silicon elements is between 0.1 and 0.3 percent when the silicon killed deoxidation process is used; and homogenizing a forging state structure by a two-time normalizing preheating treatment process after the ingot is subjected to forging molding, and refining the grains. The method has the advantages that:the grains used for manufacturing the heavy forging steel of the nuclear reactor evaporator are obviously refined; and the level of the grain size is improved from a level 5 to a level 8.5.

Owner:CENT IRON & STEEL RES INST

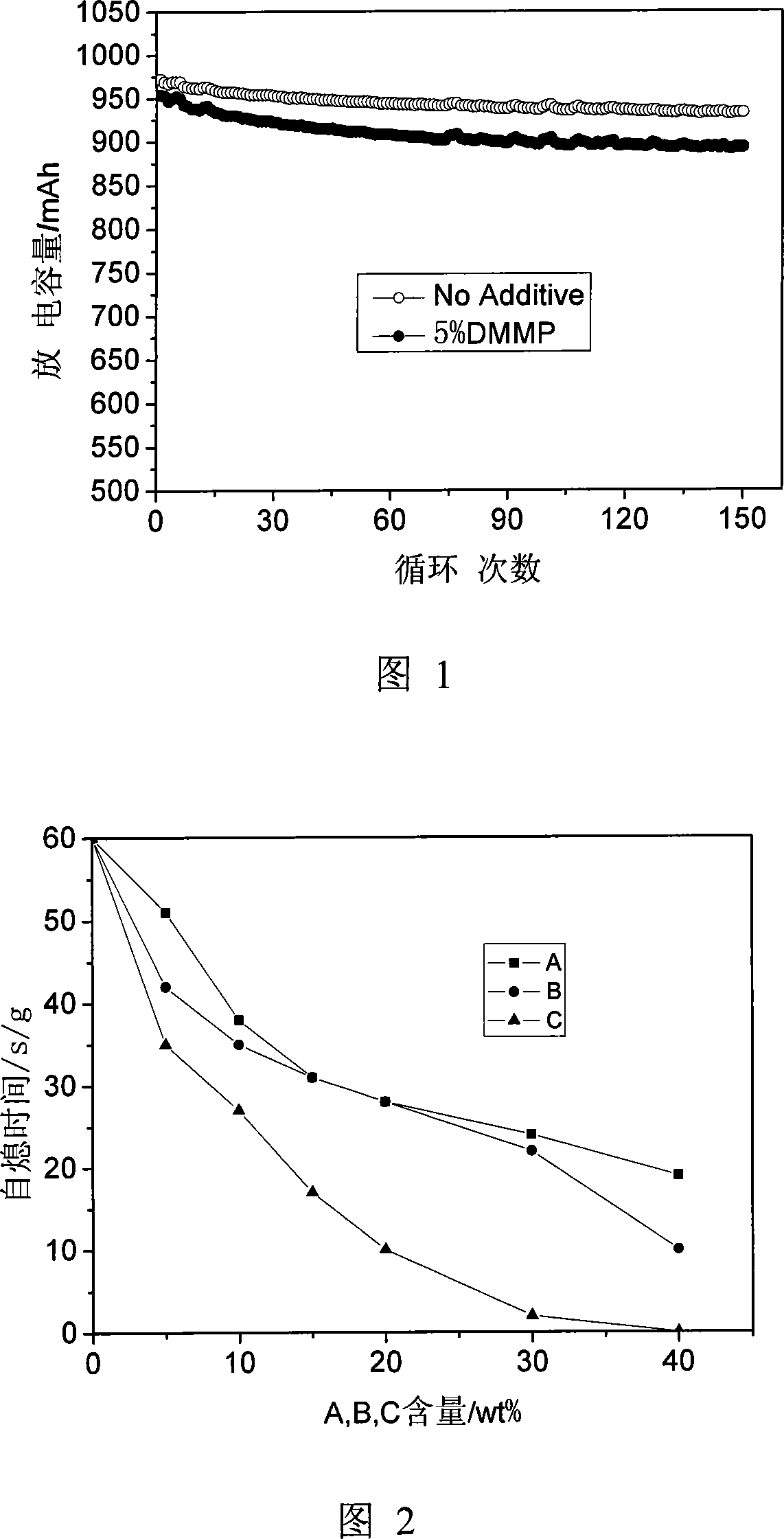

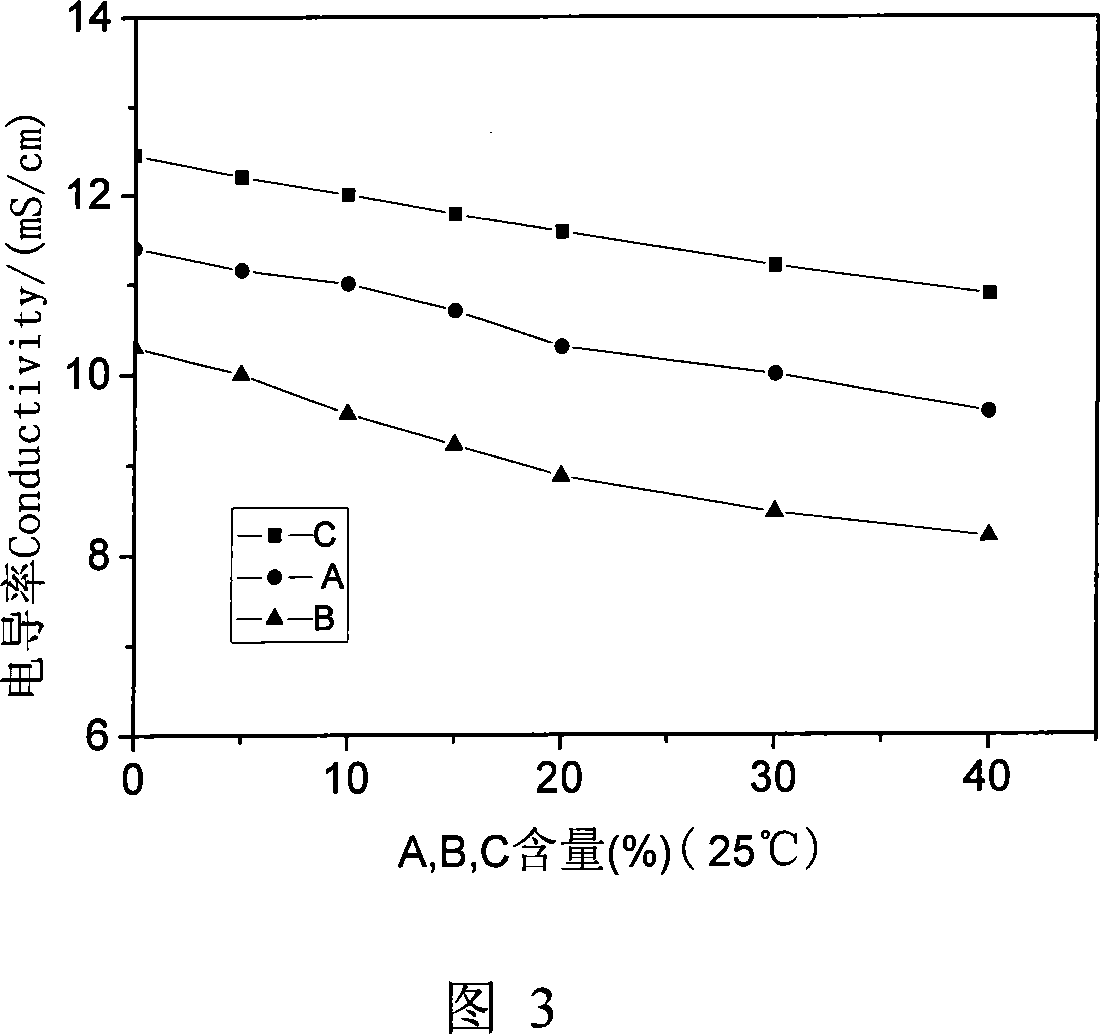

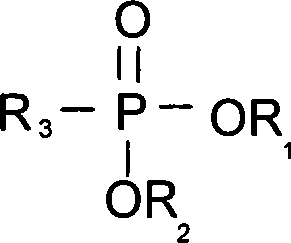

Phosphorus-contained flameproof additive agent for lithium ion cell electrolysing solution and method of use thereof

InactiveCN101083345AHigh in phosphorusImprove flame retardant performanceSecondary cellsHeat-exchange elementsPole pieceStructural formula

The invention publishes a phosphoric flame-resistant additive which is used in the solution of the lithium ion battery, which is a phosphoric organic compound, its basic structural formula likes right, or is the isometry body of the state structure; of which R1, R2, R3 are alkyl CnH2n+1 or alkene base CnH2n-1, and the carbon atom number of R1, R2, R3 is 1<=n<=4. The application method of the phosphoric flame-resistant additive is adding the phosphoric flame-resistant additive in the ordinary lithium ion battery solution; its quantity is the 5 to 40wt% of the lithium ion battery solution weight. The phosphoric flame-resistant additive has high phosphoric quantity, the good flame-resistant effect, and low viscosity, not only enables the electrolyte to have the good flame retardance, simultaneously has little influence of viscosity, conductivity of electrolyte, has good wettability with positive and negative pole piece and the membrane, and has good charging and discharging performance.

Owner:SOUTH CHINA NORMAL UNIVERSITY

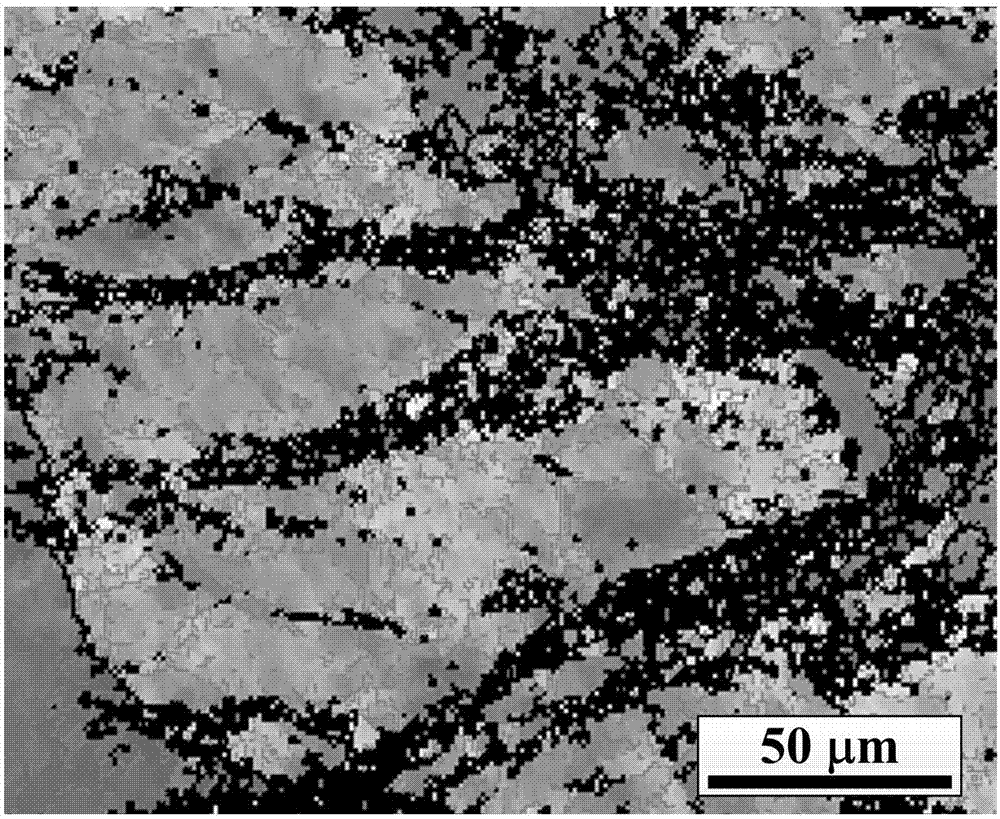

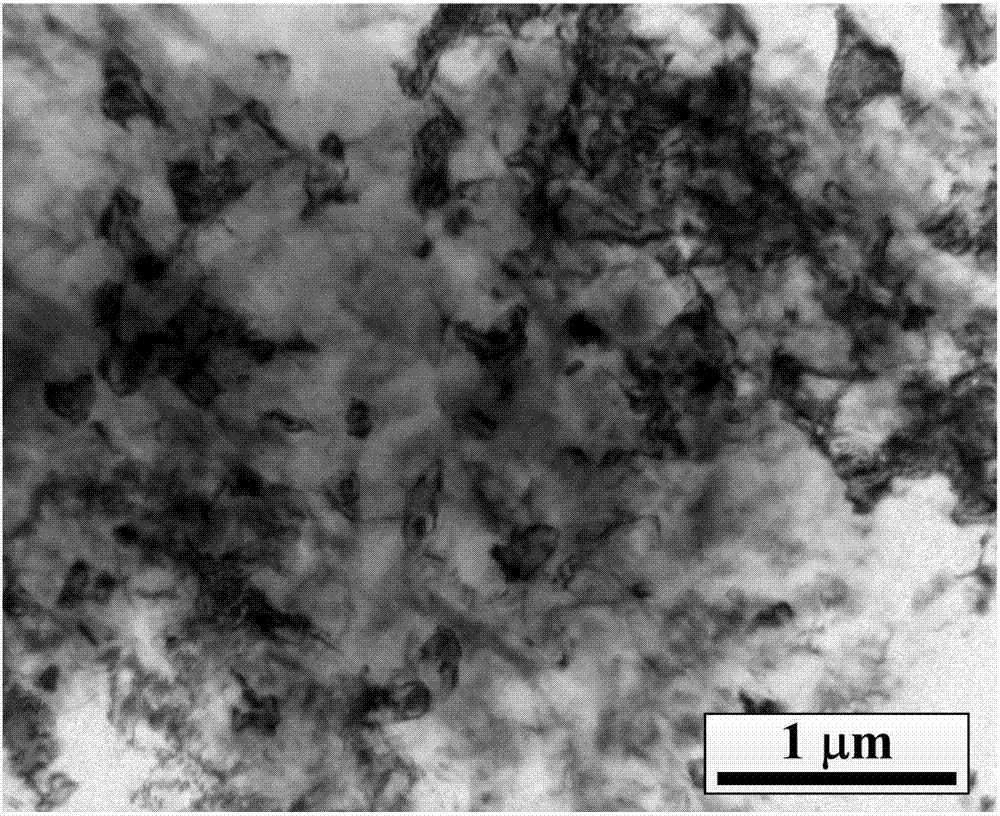

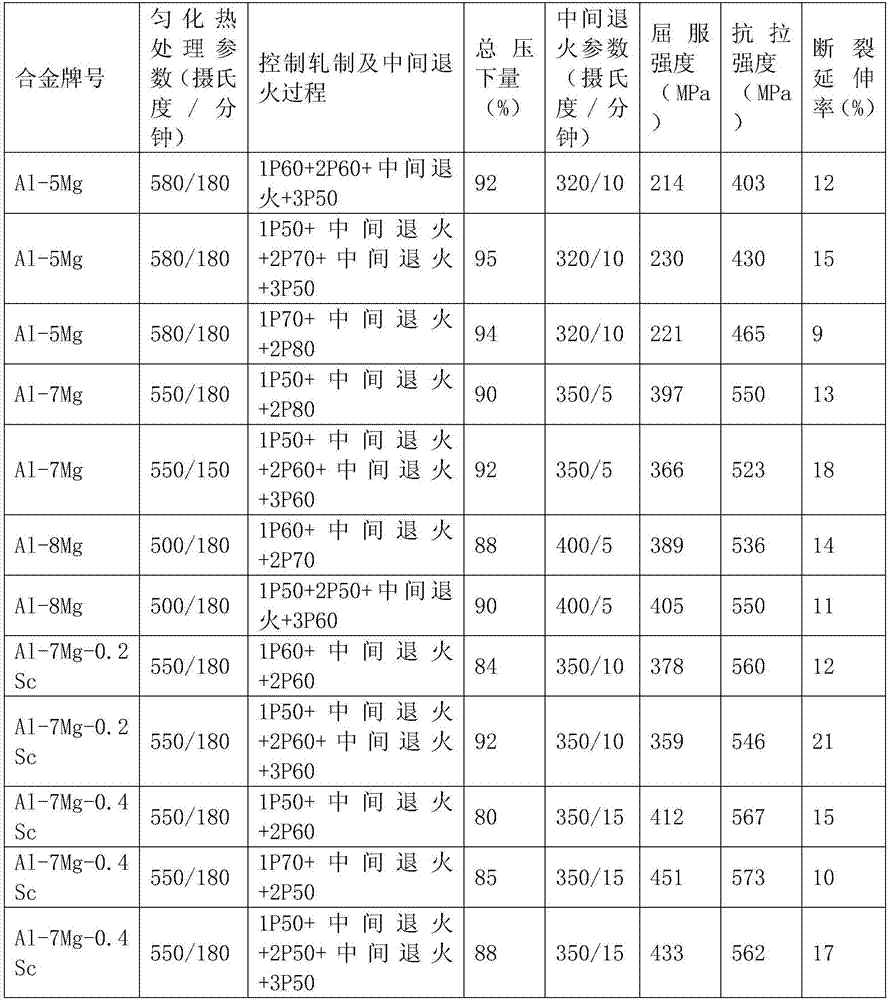

Method for preparing high strength and high plasticity aluminum-magnesium alloy of mixcrystal structure

The invention relates to a method for preparing high strength and high plasticity aluminum-magnesium alloy of a mixcrystal structure. The preparing method includes the two steps of homogenizing treatment and intermediate annealing-assisted large reduction controlled rolling. The method specially comprises the steps that element macro segregation in a cast-state structure is removed through high-temperature homogenizing treatment at first to achieve high alloying element solubility; and then controlled rolling deformation is combined with intermediate annealing treatment to introduce high-density dislocation, and recrystallization is promoted to refine crystal grains. Nano-grains, ultra-fine grains and micro-grains in the aluminum-magnesium alloy structure prepared through the method are mixed to coexist, and compared with a single nano-grain or ultra-fine grain structure, the mixcrystal structure aluminum-magnesium alloy has high strength and high plasticity. Dislocation motion, accumulation and storage in the plastic deformation process can be facilitated through the mixcrystal structure, plastic strain local concentration of a nano-grain metal material is effectively prevented, and work hardening and plastic deformability of the material can be improved obviously.

Owner:JILIN UNIV

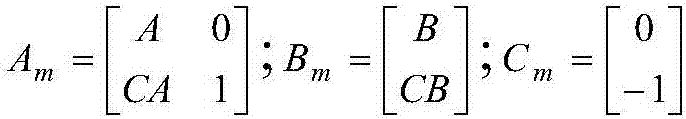

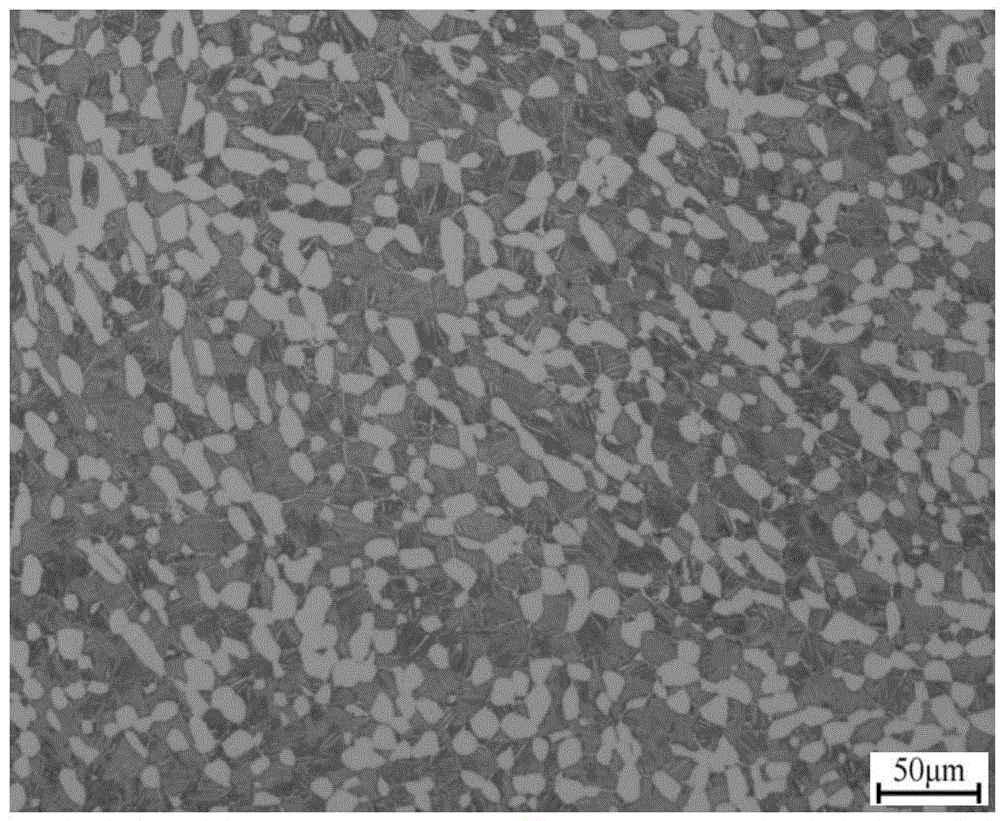

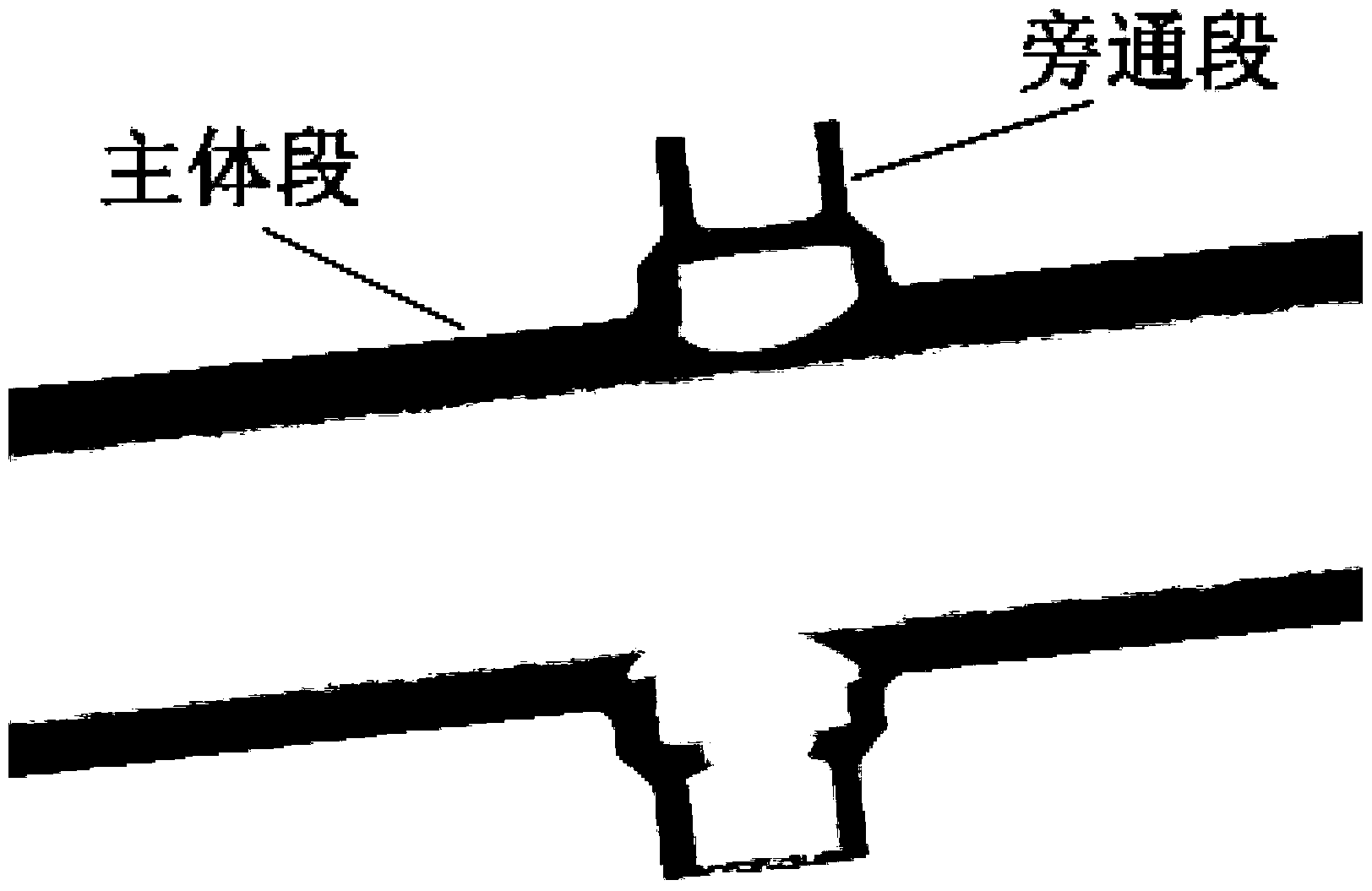

Method for promoting phase change strengthening and toughening of two-phase titanium alloy strip by using pulse current and strip

The invention discloses a method for promoting phase change strengthening and toughening of a two-phase titanium alloy strip by using pulse current. The method comprises the following steps: tensioning a TC4 titanium alloy strip through a decoiling device, a winding device, a roller and a support roller of a rolling mill, so that the strip is in tightly elastic contact with the roller; driving the strip to transmit at the speed of 150-800mm / min through friction force by virtue of the roller; inputting the pulse current into a power-up area section of the strip through the roller, the support roller and the like, wherein the pulse current generates a joule heating effect and a non-thermal effect in the power-up area section of the strip within 12-18 seconds, so that the internal microstructure of the strip turns into a two-phase long-axis structure or a two-phase dual-state structure from an original quasi-single phase thick equiaxed structure; and then cooling by natural air at room temperature. Through adjustment of parameters of the pulse current, the TC4 strip with the two-phase long-axis structure and the two-phase dual-state structure can be quickly obtained, thus the ductility is increased; the treatment temperature is far lower than 960 DEG C of a traditional thermal treatment process; the processing process of the titanium alloy strip can be finished without a short period of time at relatively low temperature without an oxidation phenomenon; and therefore, the method is energy-saving, environmentally friendly, safe and efficient.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

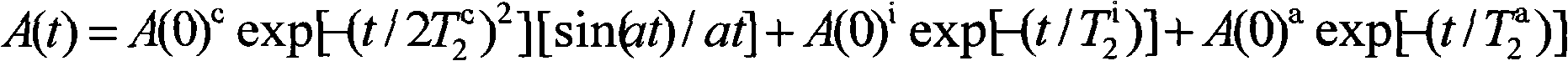

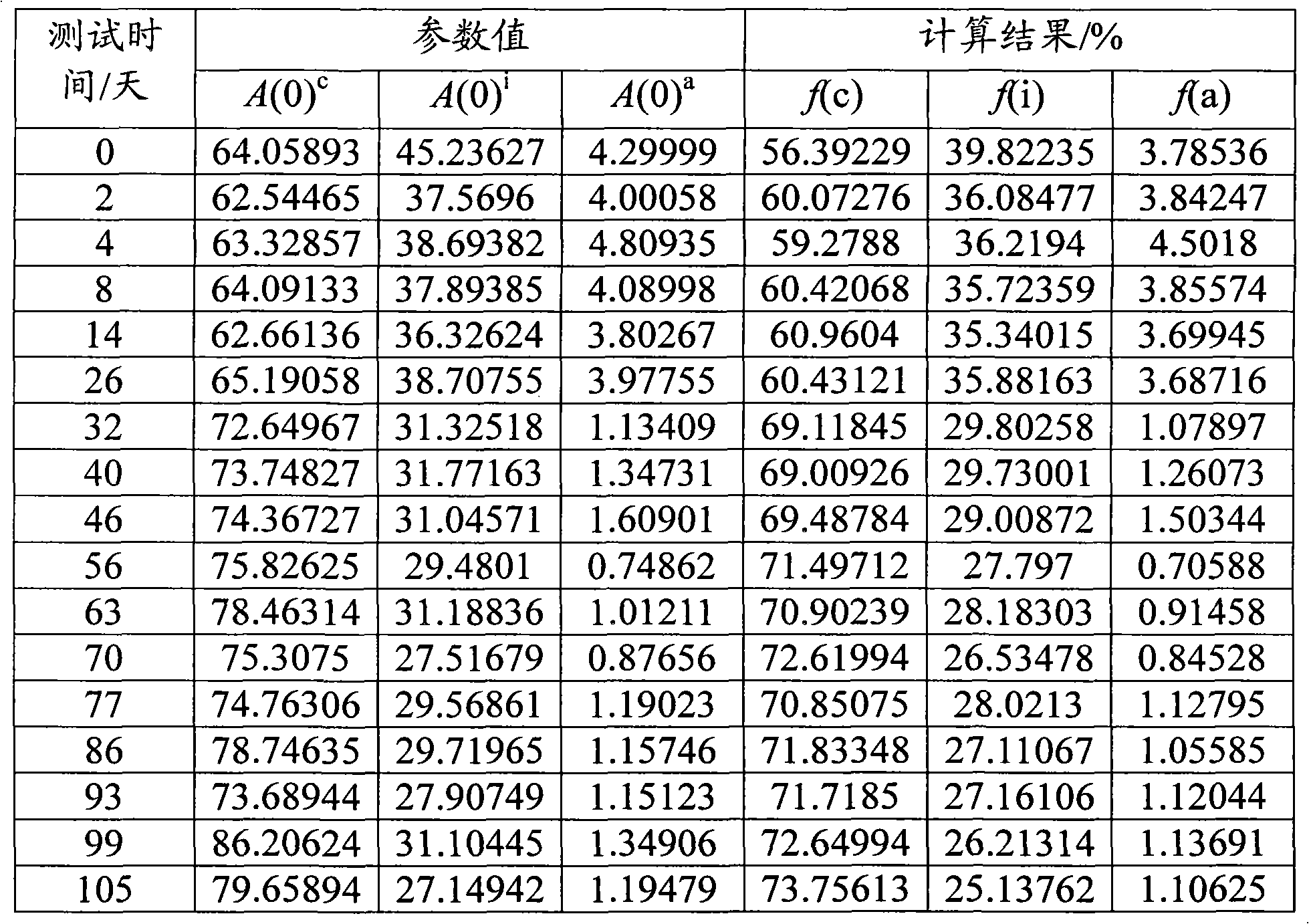

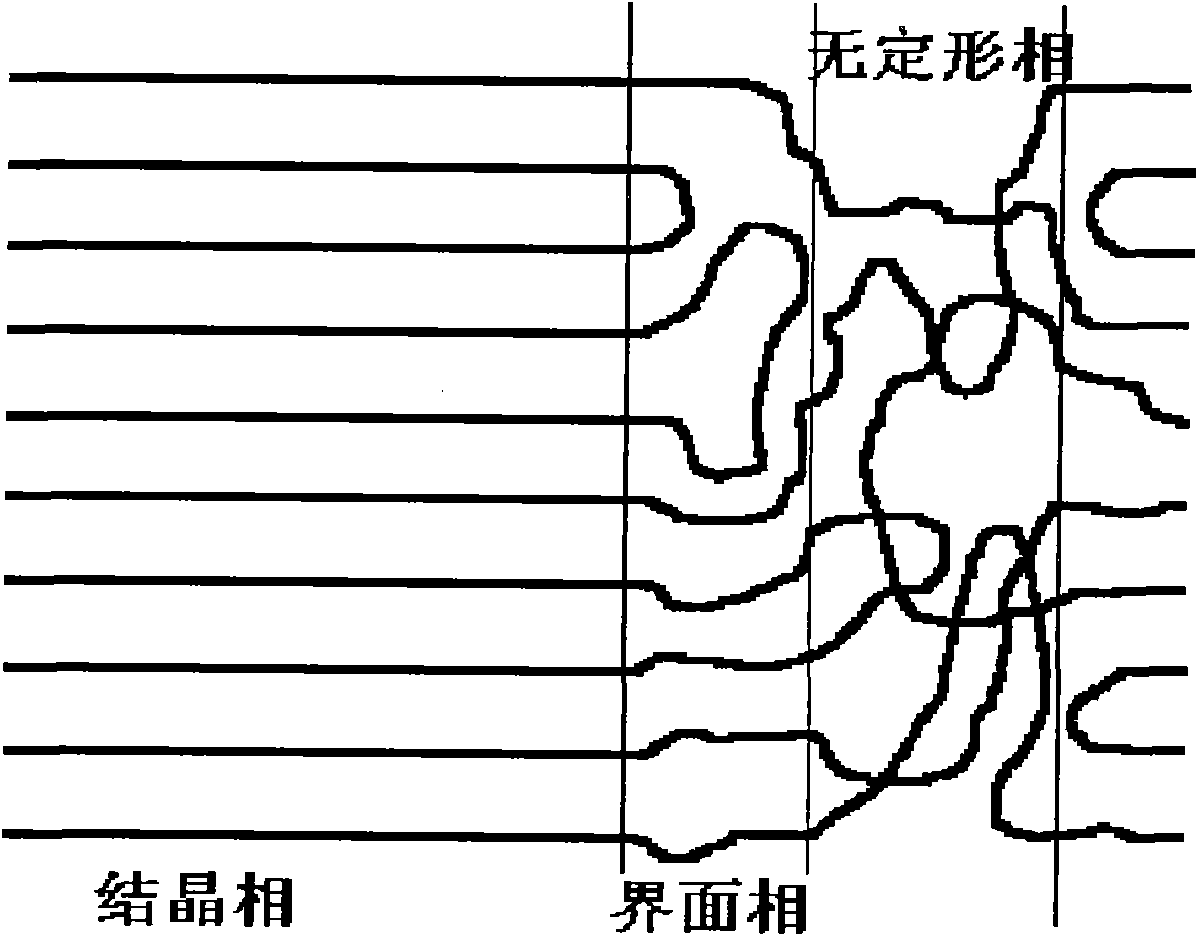

Method for testing thermo-oxidative ageing degree of polyethylene material

InactiveCN101813647ANon-destructiveSmall amount of sampleMaterial analysis by using resonanceSmall sampleAmorphous phase

The invention discloses a method for testing the thermo-oxidative ageing degree of a polyethylene material, which comprises: (1) testing the molecular motion performance and condensed-state structure distribution of the polyethylene material; (2) calculating an aging factor, crystal phase mass percent content, interface mass percent content and amorphous phase mass percent content according to the result of test of the step (1) ; and (3) determining the aging degree of the polyethylene material according to the result of the calculation of the step (2). Compared with the traditional test method, the method of the invention has the advantages of convenience, quickness, high accuracy, small sample number, no damages to materials in use and wide application range.

Owner:ZHEJIANG UNIV

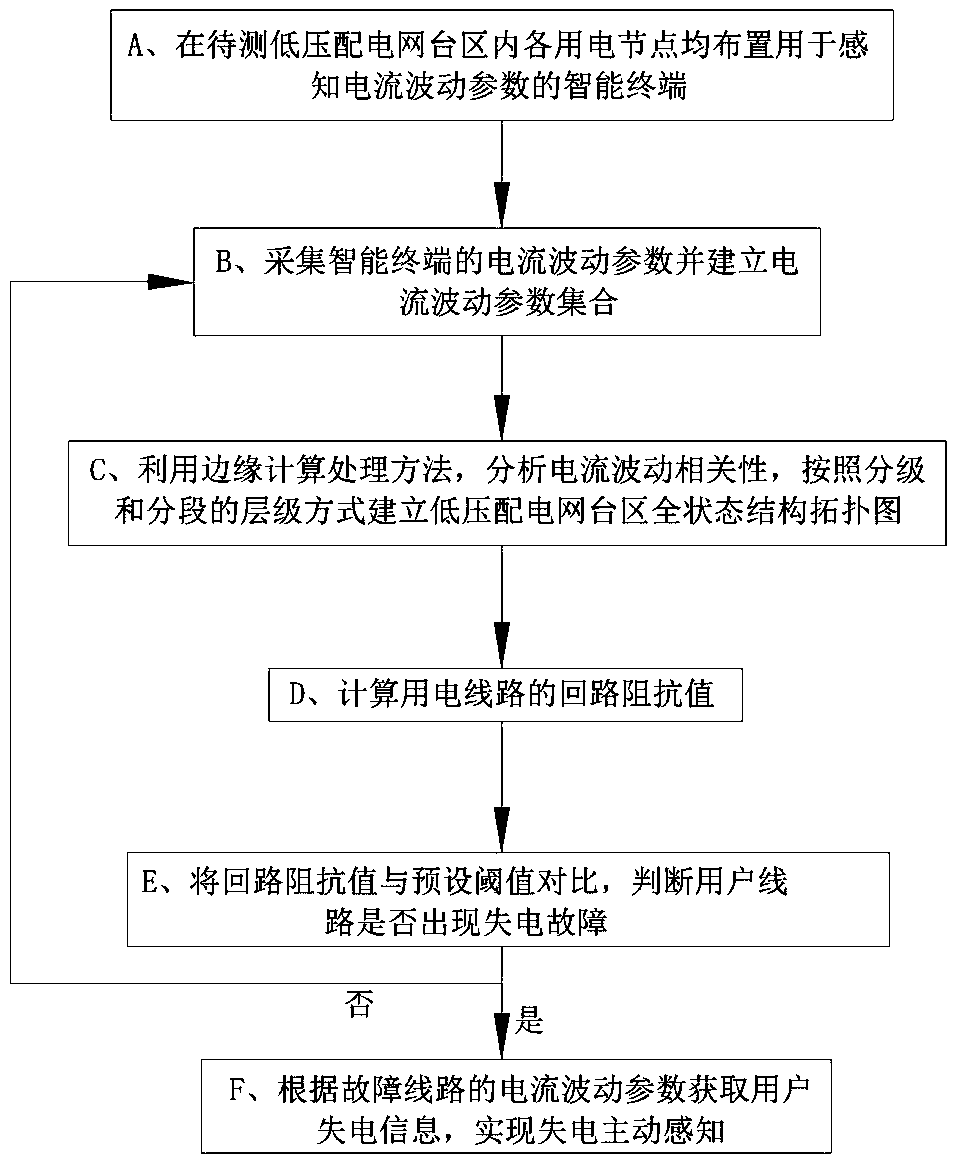

Court power loss active sensing method based on Internet of Things

PendingCN110609209AFull coverage from side to sideAchieve full coverageResistance/reactance/impedenceFault location by conductor typesElectricityLow voltage

The invention discloses a court power loss active sensing method based on an Internet of Things. According to the method, intelligent terminals used for sensing current fluctuation parameters are sequentially arranged in all electric nodes in a to-be-detected low-voltage distribution network court, the current fluctuation parameters of the intelligent terminals are collected, a current fluctuationparameter set is established, a total-state structural topological graph of the low-voltage distribution network court is established, a loop impedance value of an electric line is calculated, whether a user line has a power loss fault or not is judged by comparing the loop impedance value with a preset threshold, finally user power loss information is acquired according to the current fluctuation parameters of a fault line, and power loss active sensing is realized. Through the method, automatic early-warning of a low-voltage distribution network fault and fault research, judgment and positioning can be effectively realized, the research and judgment accuracy and rush-repair commanding efficiency of the distribution network fault are improved, and active rush-repair service of the low-voltage distribution network court fault is realized.

Owner:STATE GRID SICHUAN ELECTRIC POWER CO

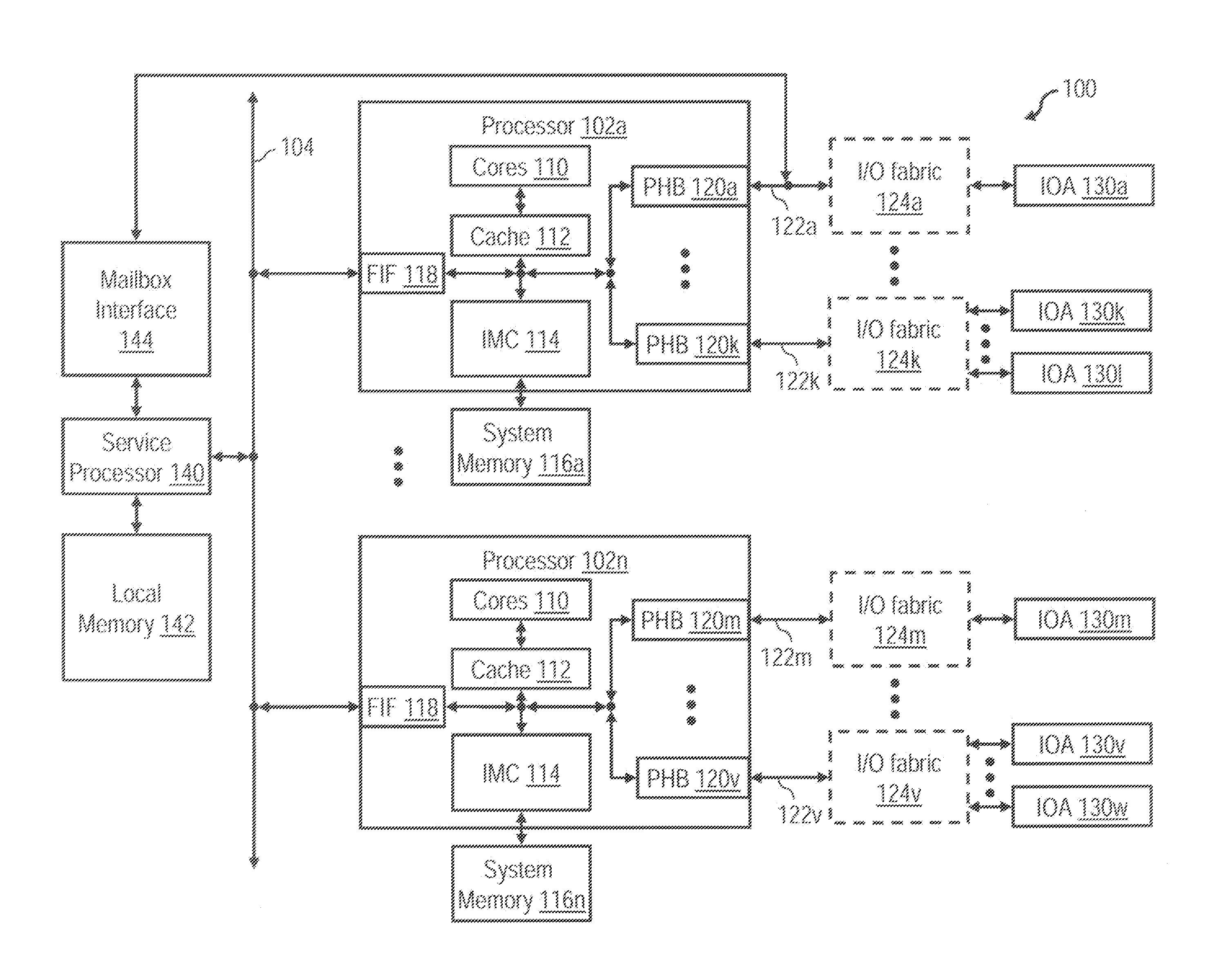

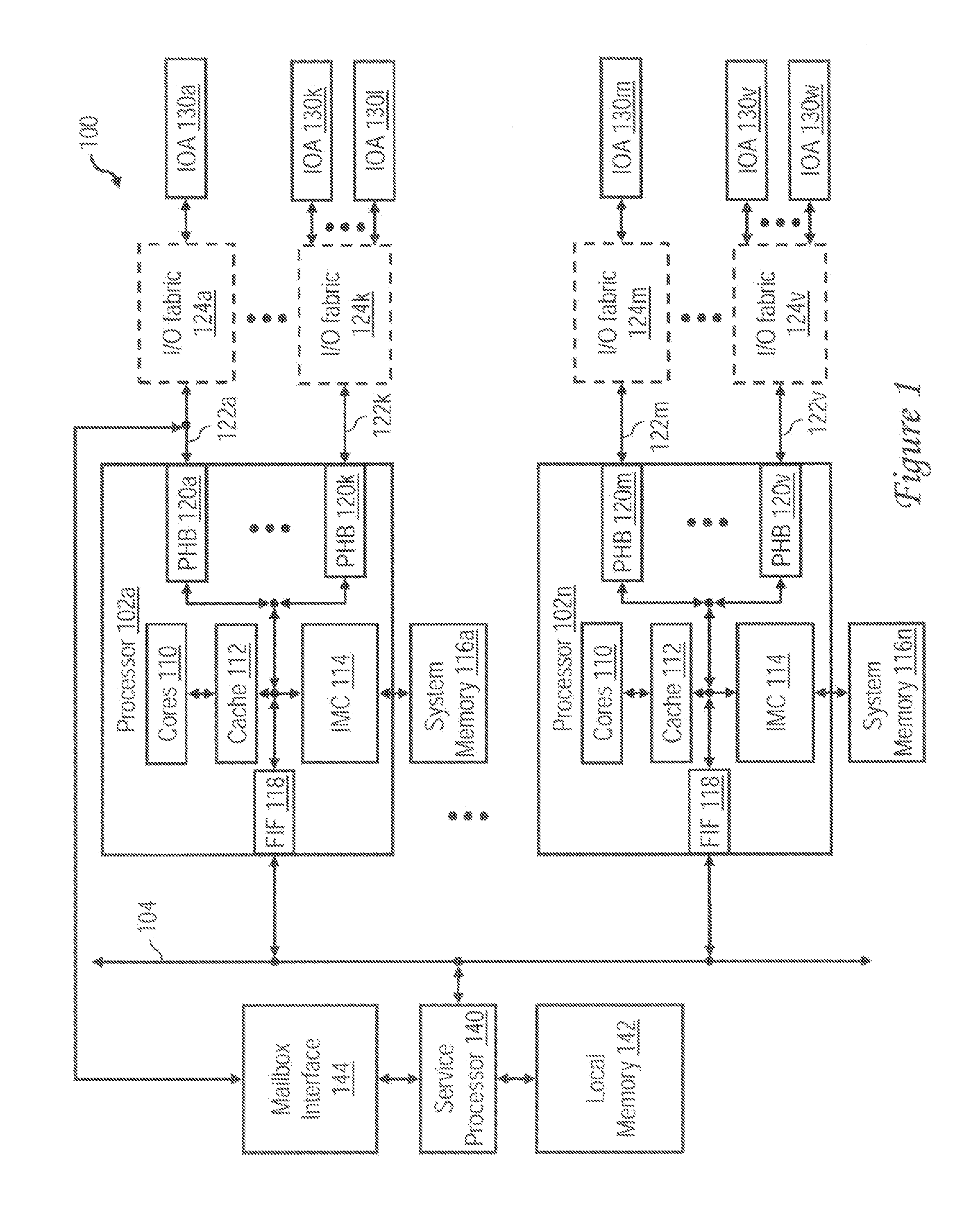

Interrupt source controller with scalable state structures

A data processing system includes a processor core, a system memory, coupled to the processor core, that includes an interrupt data structure including a plurality of entries each associated with a respective one of a plurality of interrupts. An input / output (I / O) subsystem including at least one I / O host bridge and a plurality of partitionable endpoints (PEs) each having an associated PE number. The I / O host bridge, responsive to receiving a message signaled interrupt (MSI) including at least a message address, determines from the message address a system memory address of a particular entry among the plurality of entries in the interrupt data structure, accesses the particular entry, and, based upon contents of the particular entry, validates authorization of an interrupt source to issue the MSI and presents an interrupt associated with the particular entry for service.

Owner:IBM CORP

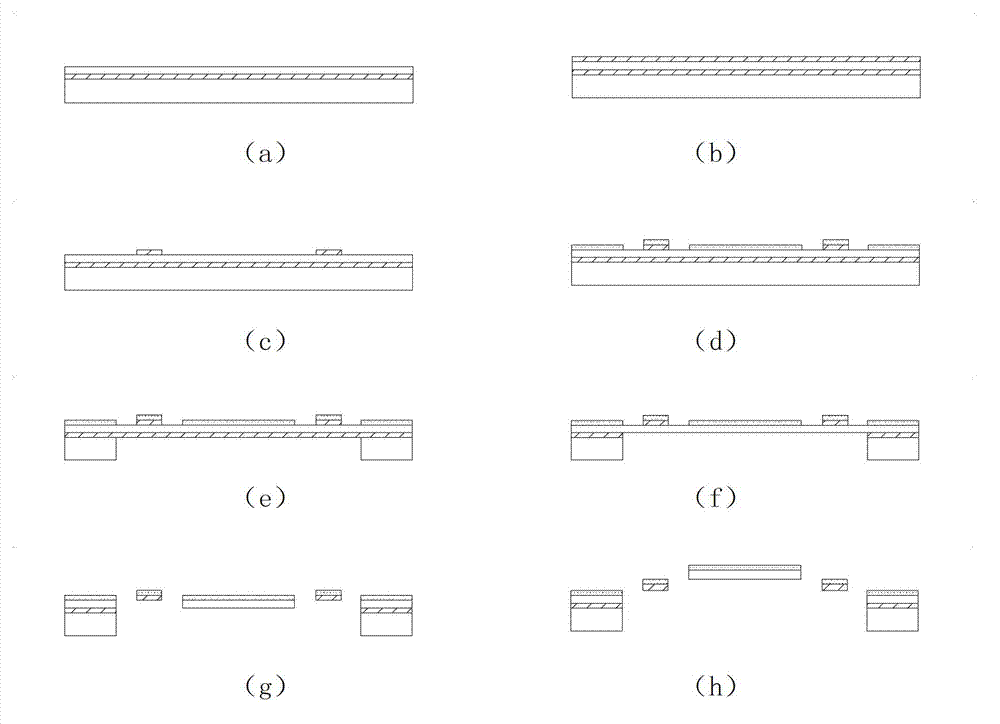

Manufacturing method for micro electro mechanical system (MEMS) micromirror bistable state structure and optical switch

ActiveCN102928977AImprove processing efficiencySimple and fast operationTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesElectricityRoom temperature

The invention discloses a manufacturing method for a micro electro mechanical system (MEMS) micromirror bistable state structure. The method comprises the following steps of: depositing a first-layer dielectric thin film material on the front of a high-impedance silicon slice and etching; evaporating a first-layer metal thin material and etching to form a metal layer; sputtering a second-layer metal film and etching to form a micromirror surface; performing deep silicon etching on the back of the silicon slice to form a cavity; performing deep silicon etching on the front of the high-impedance silicon slice; and after etching, cooling to room temperature to form the initial state of the bistable state structure. An optical switch which has the MEMS micromirror bistable state structure which is manufactured by the method comprises the bistable state structure and a drive structure; and the bistable state structure is arranged above the drive structure. The manufacturing process is simple and practicable; the micromirror surface, a straight beam drive arm, and a foundation are integrally formed; and high manufacturing accuracy can be guaranteed; and the optical switch is convenient to operate, high in response speed and reliability and low in energy consumption, and two states are switched by solenoid drive.

Owner:无锡微文半导体科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com