Original state sampling method for constructed fractured rock mass

A rock mass and undisturbed technology, applied in the field of undisturbed sampling of structurally broken rock masses, can solve problems such as poor structural stability, difficulty in obtaining representative samples, and damage to the undisturbed structure of geological bodies, so as to enhance the sealing effect, expand the scope of application, and enhance the overall The effect of the consolidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

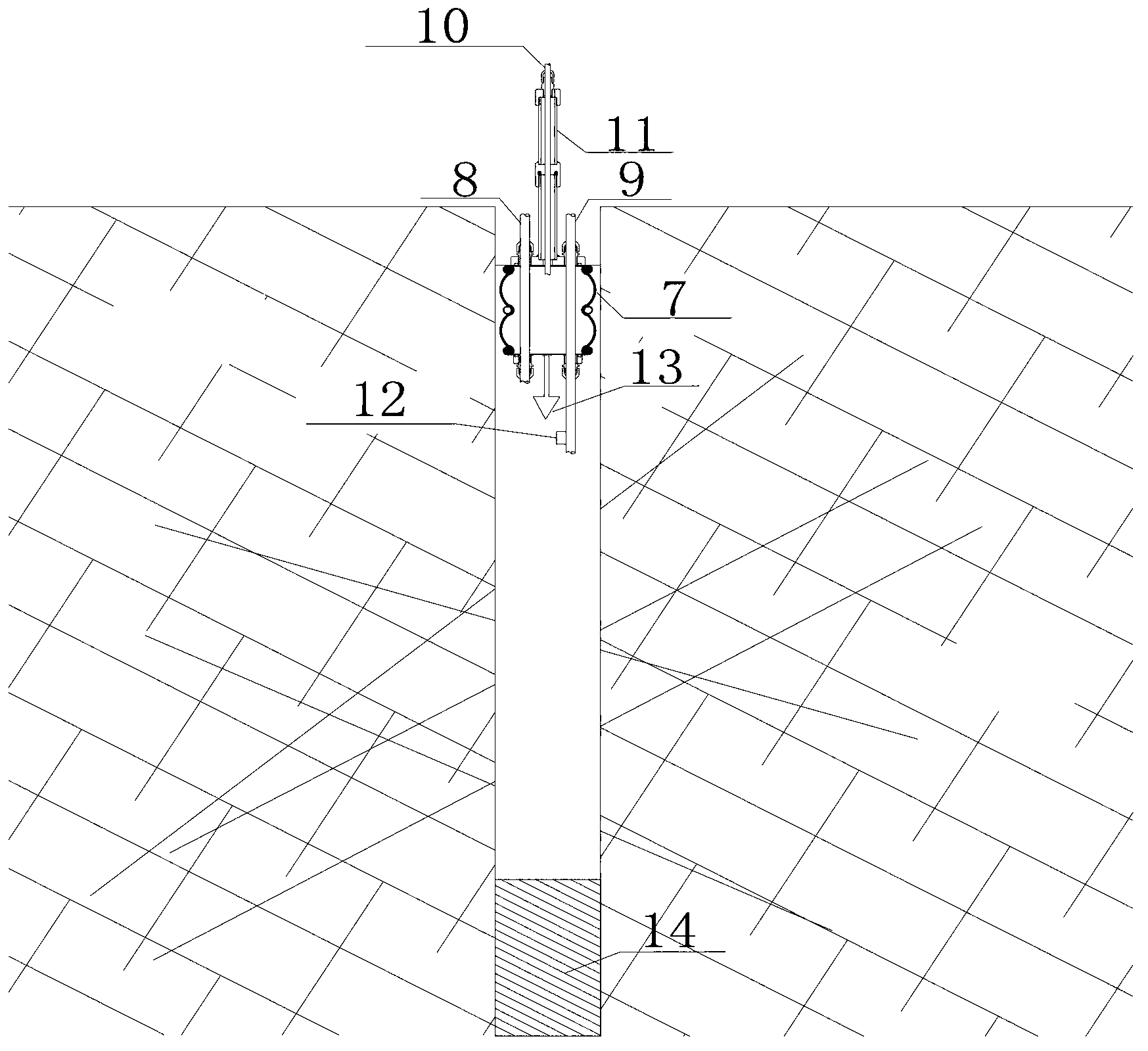

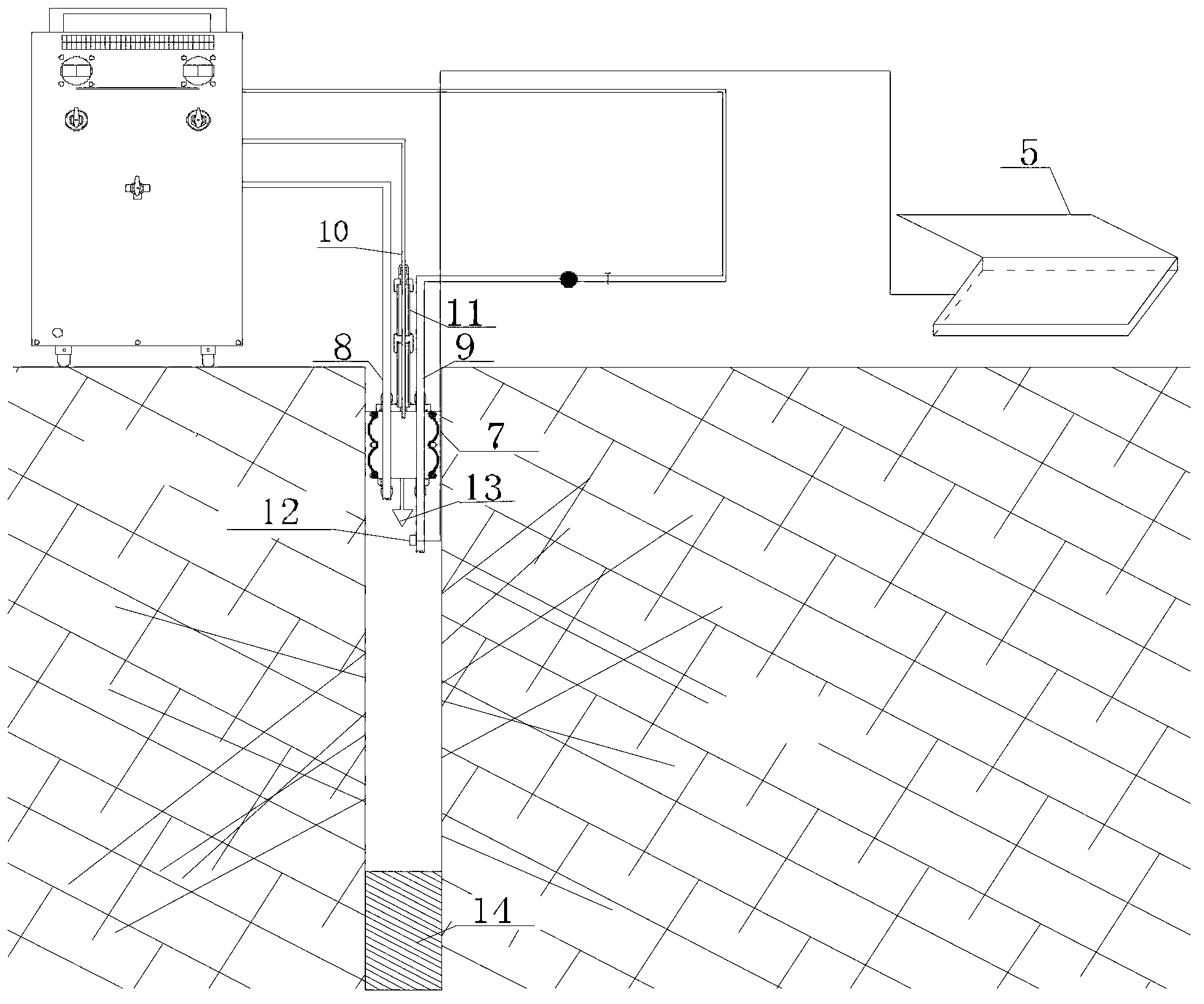

[0048] When the cracks at the bottom of the observation hole are sparsely distributed and tightly closed, rubber pads are used to block the bottom of the hole, and expansion and contraction air bags are used to block the opening of the observation hole.

[0049] The specific operation steps are to block the opening of the observation hole with the expansion and contraction air bag in the hole, seal the bottom of the observation hole with a rubber pad, inject glue on the high-pressure side wall, expand the hole and drill.

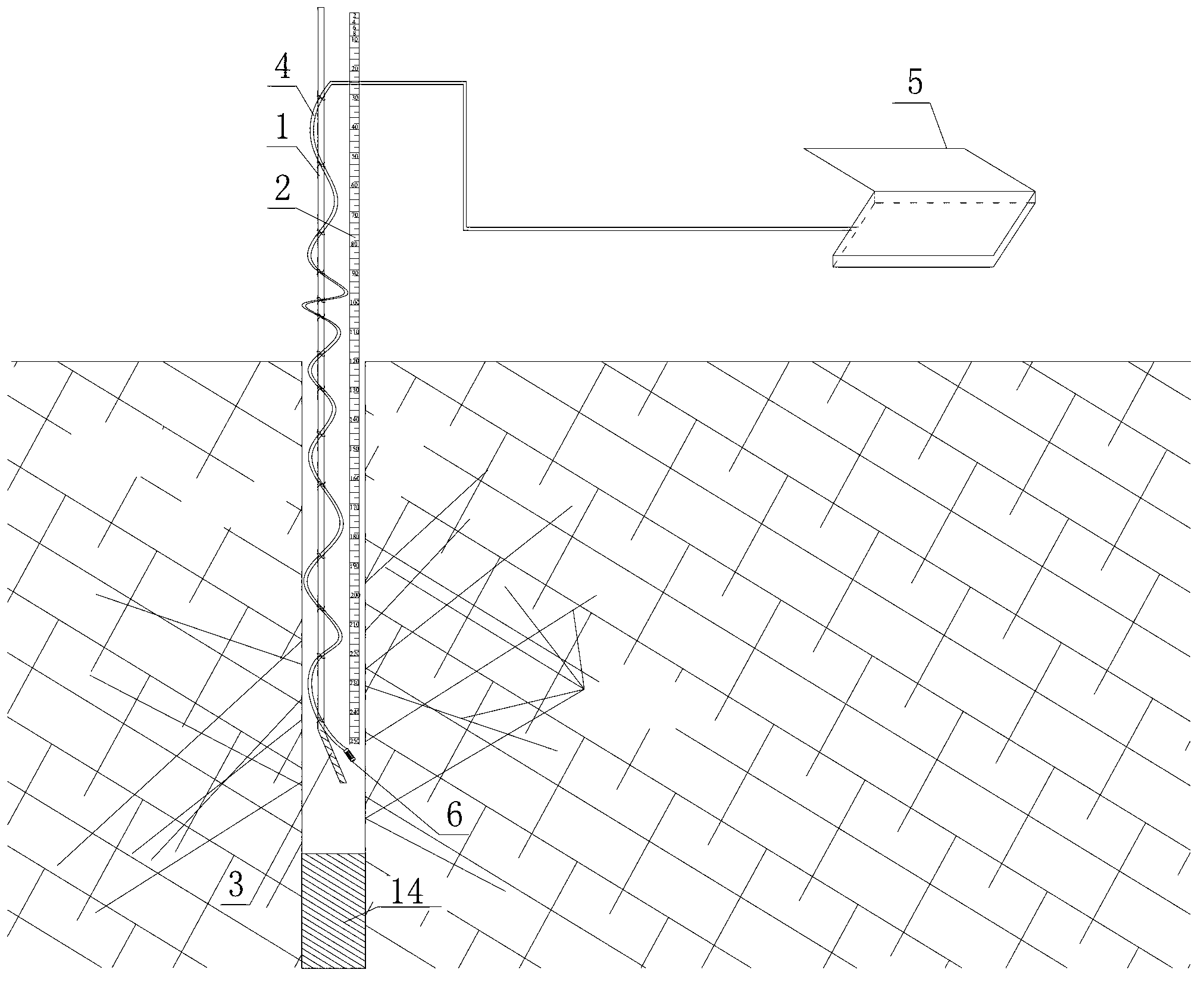

[0050] The first step is to select a suitable location containing enough feasible geological structures according to the degree of fragmentation of the rock mass to be taken and the geological terrain conditions, and use a drilling rig to drill a rock pillar with a diameter of about 6 cm and a height of 45 cm in the shallow layer of the surface, and take out the rock pillar. A small hole with a diameter of 6cm is reserved; the second step is to use the positi...

Embodiment 2

[0054] The distribution of fractures at the bottom of the observation hole is dense, and the geological structure is mostly concentrated at the bottom of the hole, while the distribution of fractures on the wall of the observation hole is relatively sparse. The plastic film is used to cling to the hole wall, and the expansion and contraction air bag is used to block the hole.

[0055] The specific operation steps are to use expansion and contraction air bags to block the hole, cover the hole wall with plastic film, inject glue at the bottom of the high-pressure hole and drill the hole.

[0056] The first step is to select a suitable location containing enough feasible geological structures according to the degree of fragmentation of the rock mass to be taken and the geological terrain conditions, and use a drilling rig to drill a rock pillar with a diameter of about 8 cm and a height of 45 cm in the shallow layer of the surface, and take out the rock pillar. Reserve an observa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com