Patents

Literature

1203results about "Embankments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Retaining wall block

InactiveUS7168892B1Reduced and zero predetermined setbackArtificial islandsCoastlines protectionVertical planeEngineering

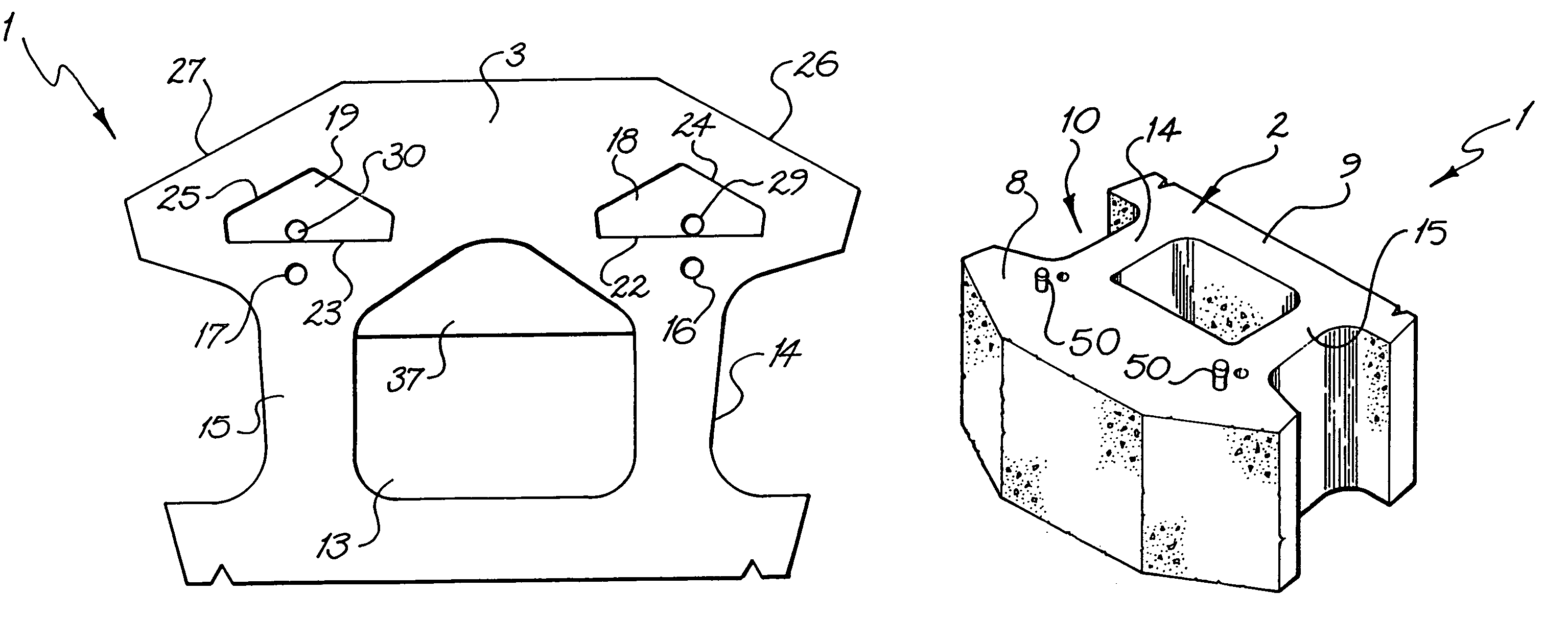

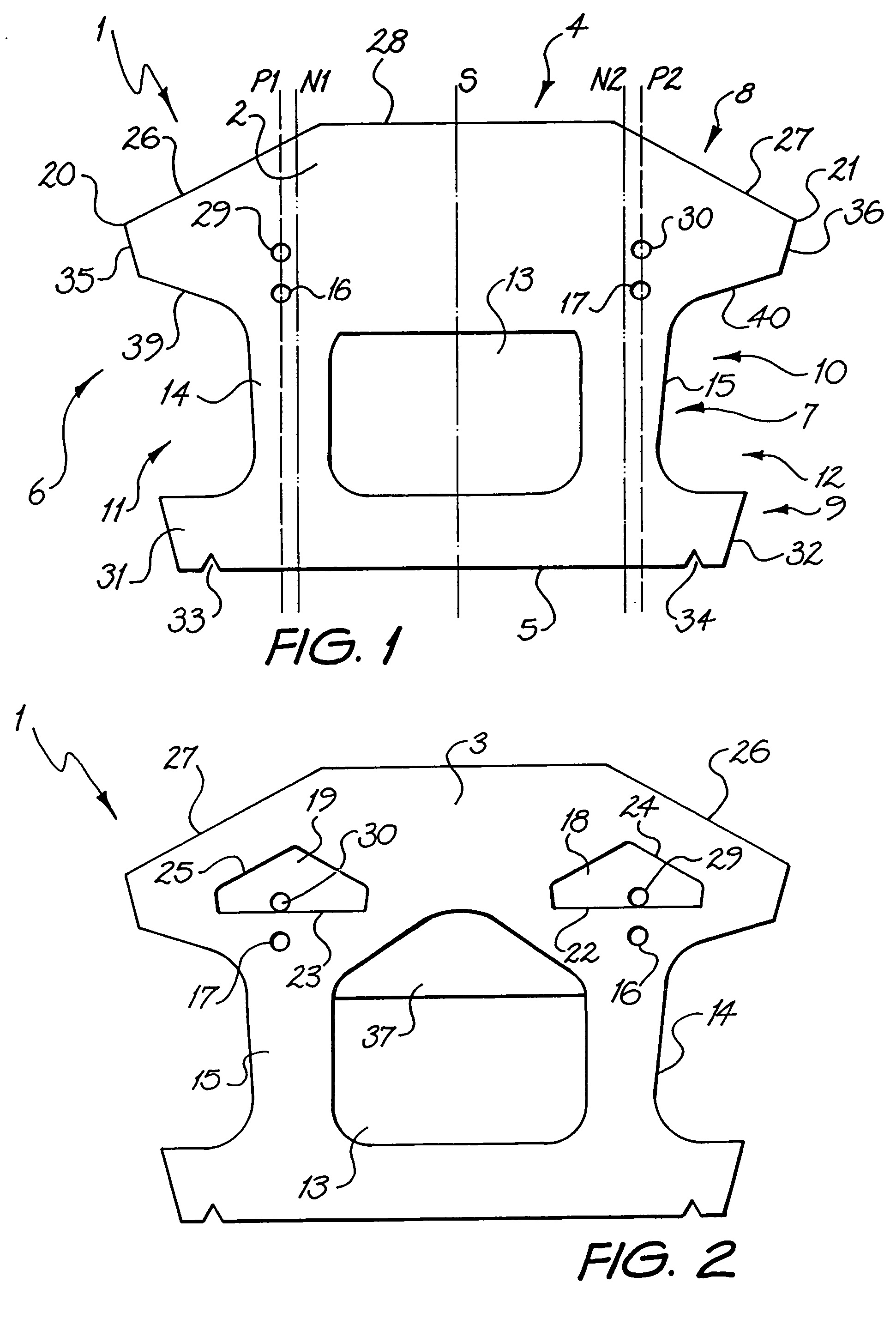

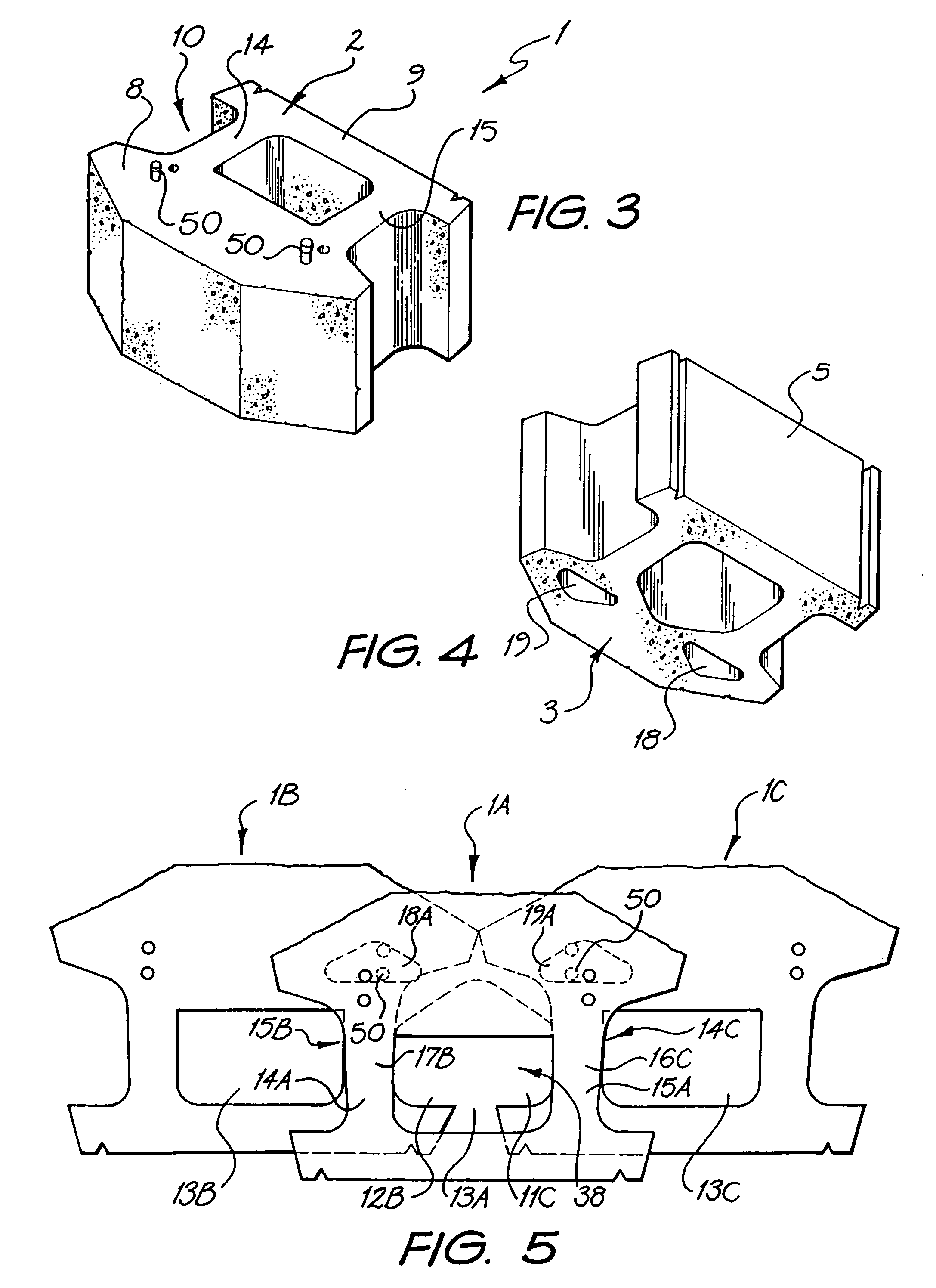

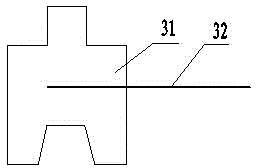

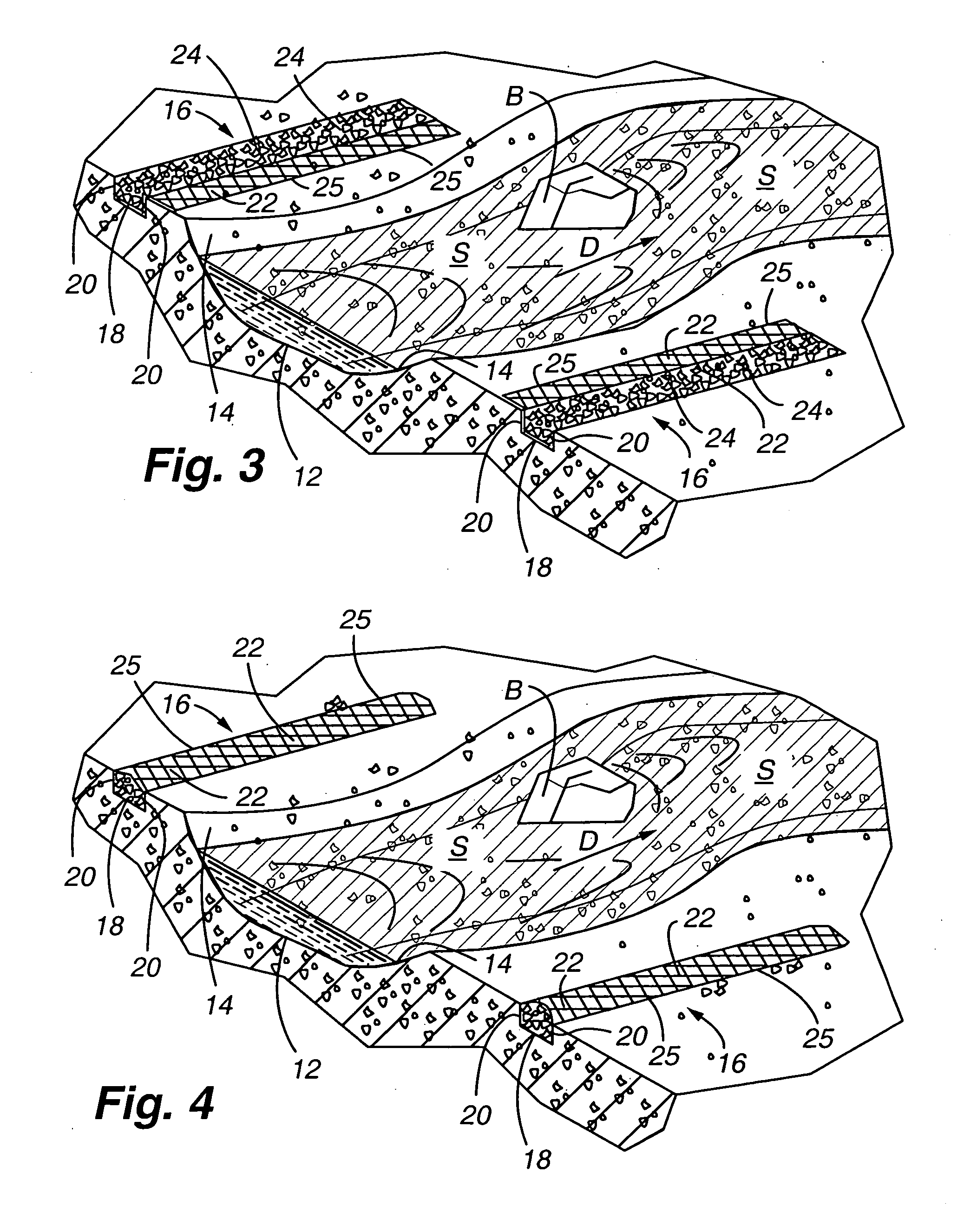

A retaining wall block (1) has parallel top and bottom faces (2, 3), a front face (4), a rear face (5), first and second side wall faces (6, 7) and a vertical plane of symmetry (S) extending between the front and rear faces (4, 5). The block (1) is formed as a body portion (8) including the front face (4), a head portion (9) including the rear face (5) and a neck portion (10) connecting the body portion (8) and the head portion (9). The body, head and neck portions (8, 9, 10) each extend between the top and bottom faces (2, 3) and between the first and second side wall faces (6, 7). An opening (13)′ extends through the neck portion (10) from the top face (2) to the bottom face (3), dividing the neck portion (10) into first and second neck wall members (14, 15) extending rearwardly from the body portion (8) to the head portion (9). First and second pin holes (16 and 17) are each disposed in the body portion (8) and open onto the top face (2) for receiving a pin (50, 51) with a free end of the pin protruding beyond the top face. First and second pin receiving cavities (18, 19) are each disposed in the body portion (8) and open onto the bottom face (3) for receiving the free end of a pin (50, 51) received in a pin hole (16 and 17) of an adjacent block (1) disposed therebeneath so as to interlock the blocks (1) with a predetermined setback. The neck wall members (14, 15), pin holes (16 and 17) and pin receiving cavities (18, 19) are positioned such that a first plane (P1) extending parallel to the plane of symmetry (5) passes through the first pin receiving cavity (18), first pin hole (16) and first neck wall member (14) and a second plane (P2) extending parallel to the plane of symmetry (5) passes through the second pin receiving cavity (19), second pin hole (17) and second neck wall member (15).

Owner:MELLON BANK N A

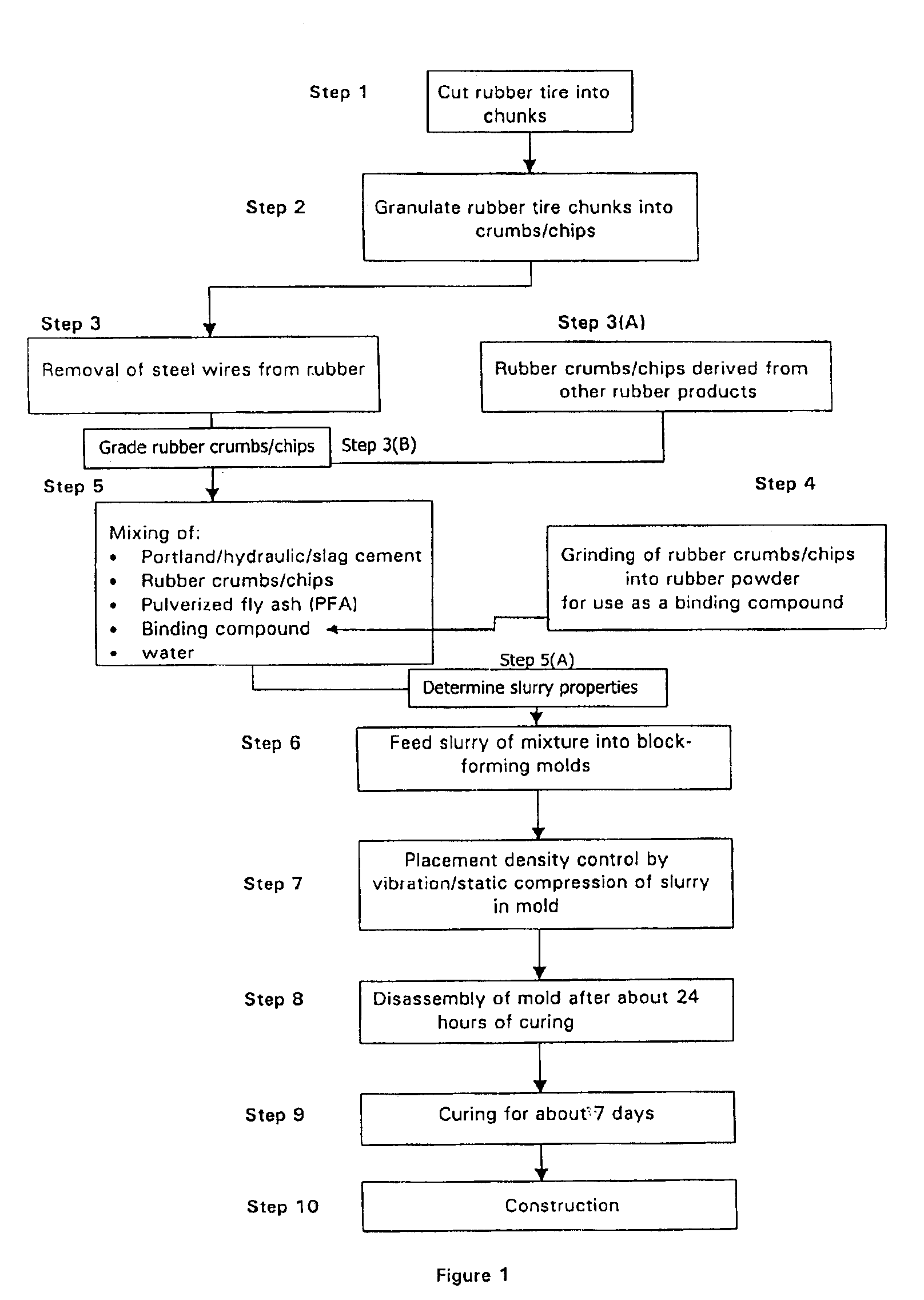

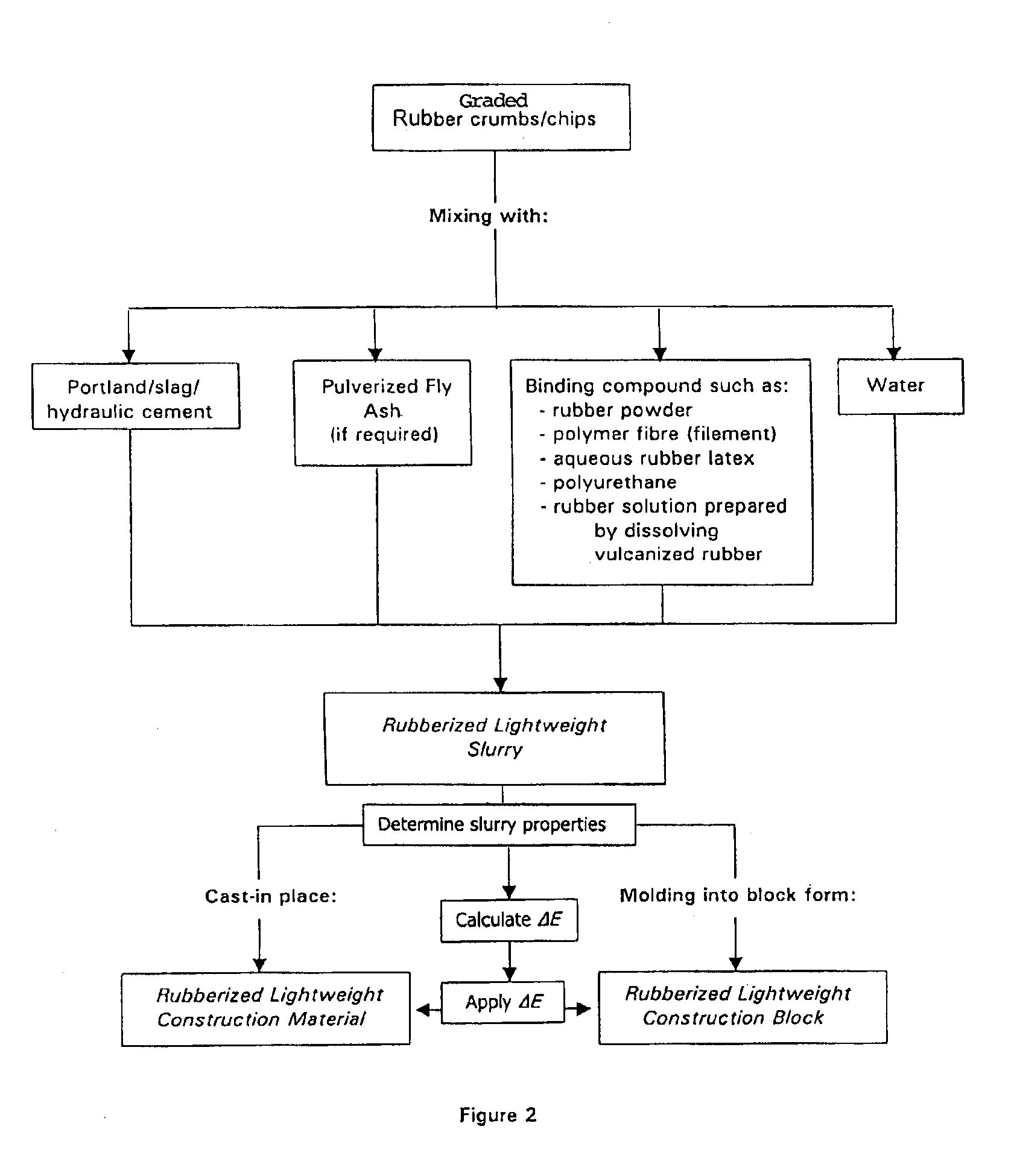

Lightweight and porous construction materials containing rubber

Owner:EARTH LINK TECH ENTERPRISES

Retaining wall block

Owner:KEYSTONE RETAINING WALL SYST

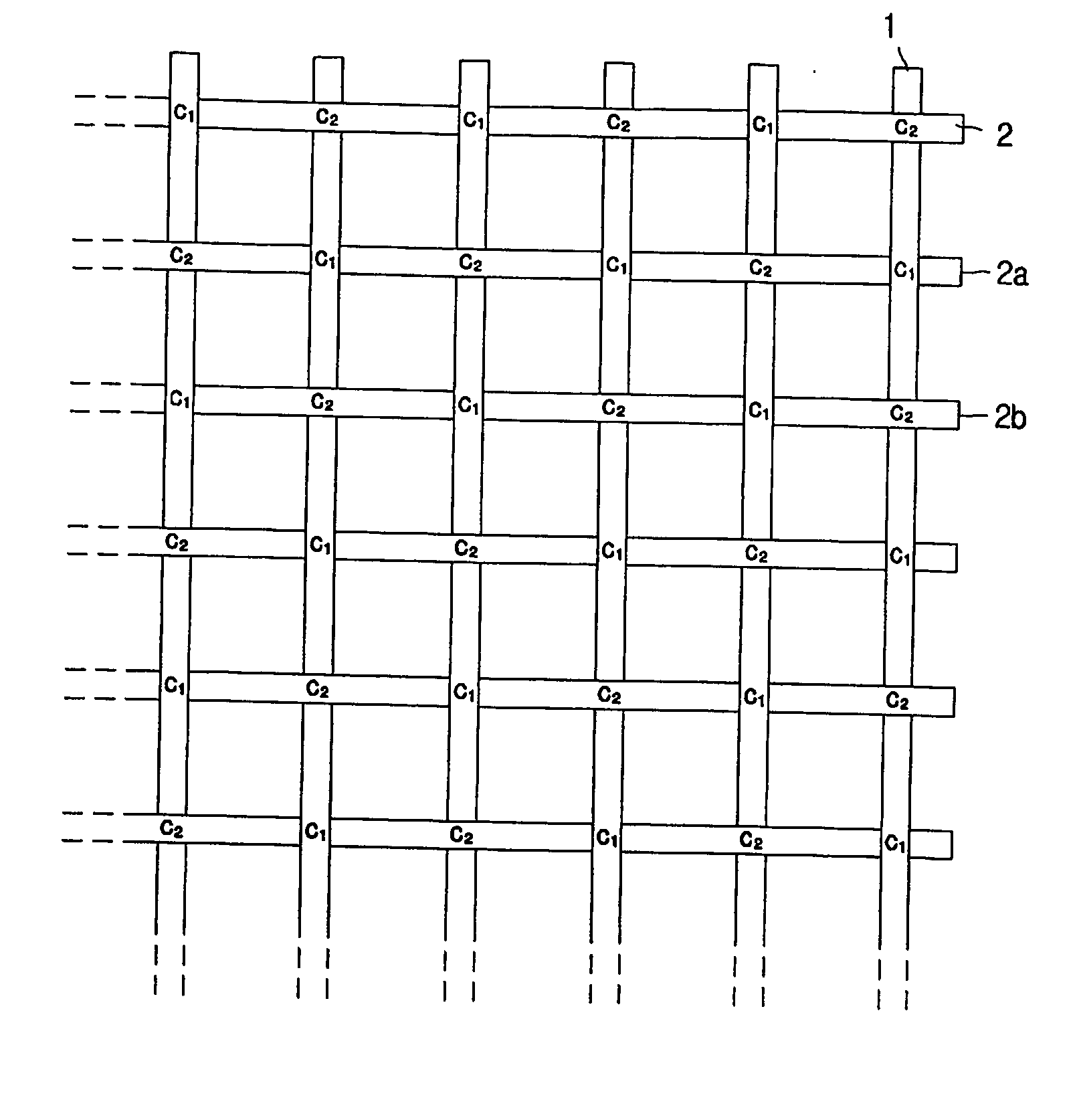

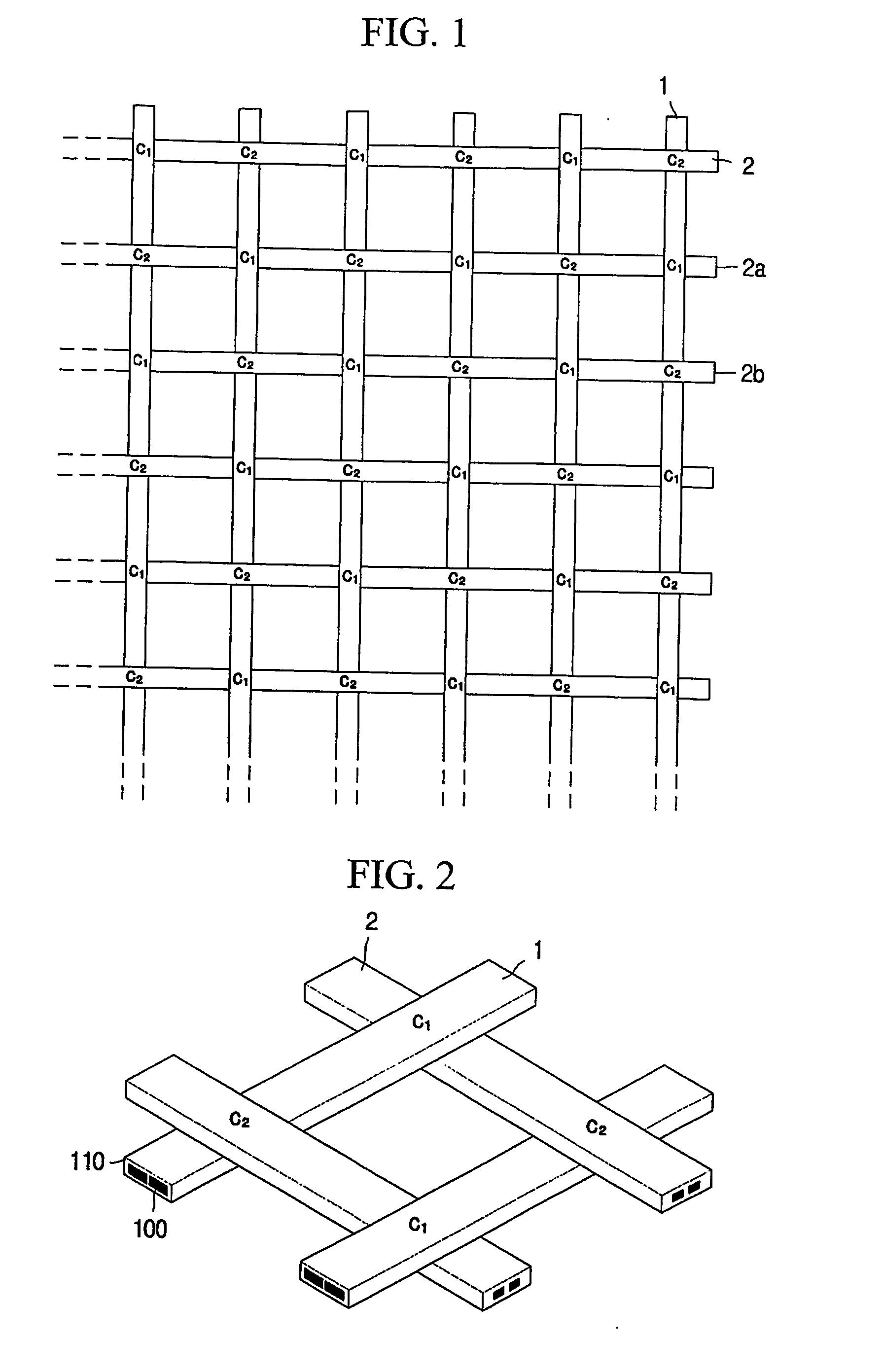

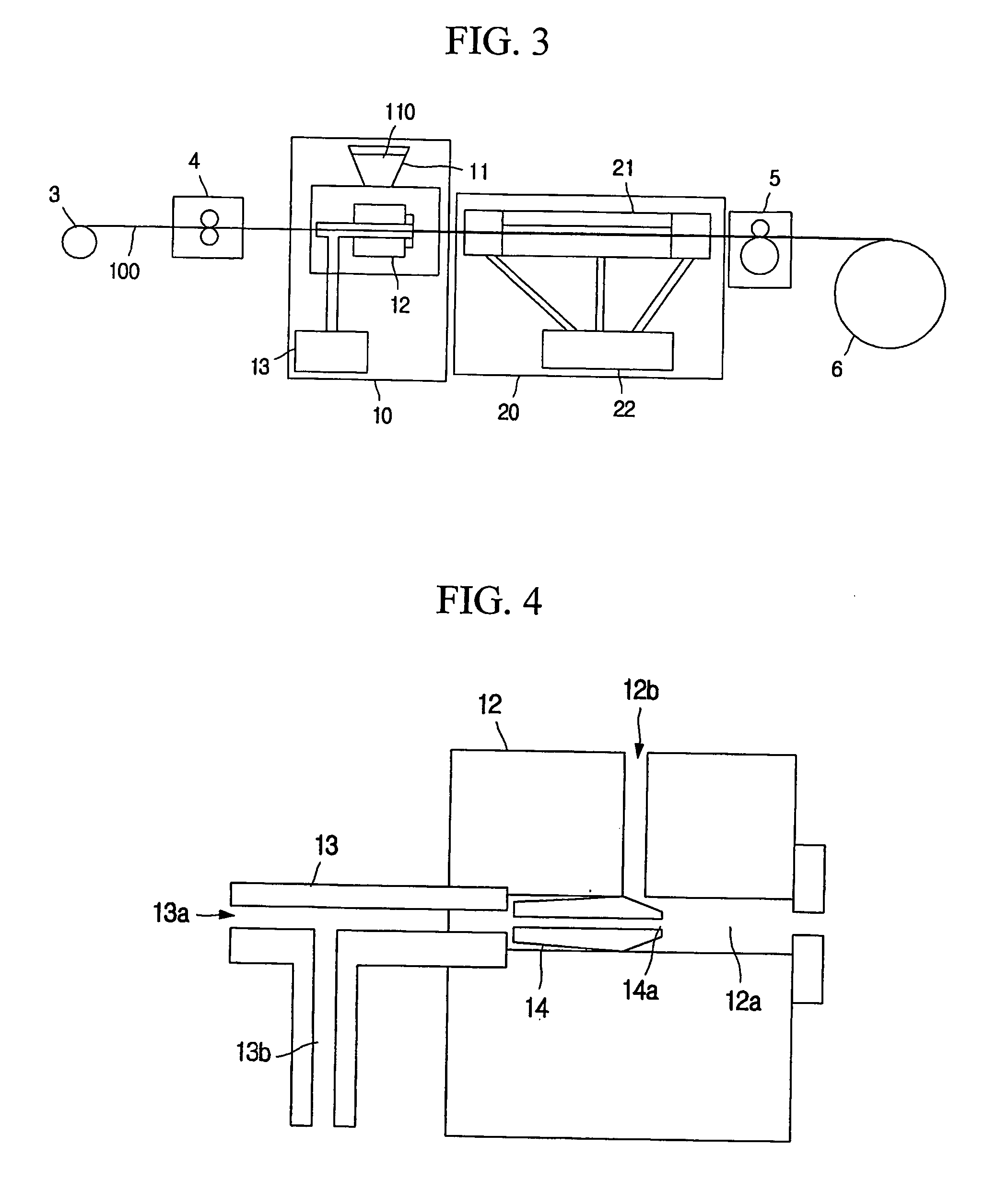

Geogrid composed of fiber-reinforced polymeric strip and method for producing the same

InactiveUS20060116040A1Increase resistance against vertical loadIncrease friction forceWarp knittingWelding/cutting auxillary devicesTensile strainGeogrid

A geogrid using fiber-reinforced polymeric strips and its producing method are disclosed. The geogrid of a lattice shape includes plural longitudinal fiber-reinforced polymeric strips longitudinally arranged in parallel at regular intervals and formed by reinforcing fiber in a thermoplastic polymer resin, and plural lateral fiber-reinforced polymer strip laterally arranged in parallel at regular intervals and formed by reinforcing fiber in a thermoplastic polymer resin. Each longitudinal fiber-reinforced polymer strip has at lease one first contact point crossed with the lateral fiber-reinforced polymer strip on the upper surface and at least one second contact point crossed with the lateral fiber-reinforced polymer strips on the lower surface. The contact points are fixed by welding the longitudinal and lateral fiber-reinforced polymer strips. The geogrid is excellent in installation capacity, frictional feature and shape stabilisation and shows high tensile strength and low tensile strain and low creep deformation.

Owner:SAMSANG CORP

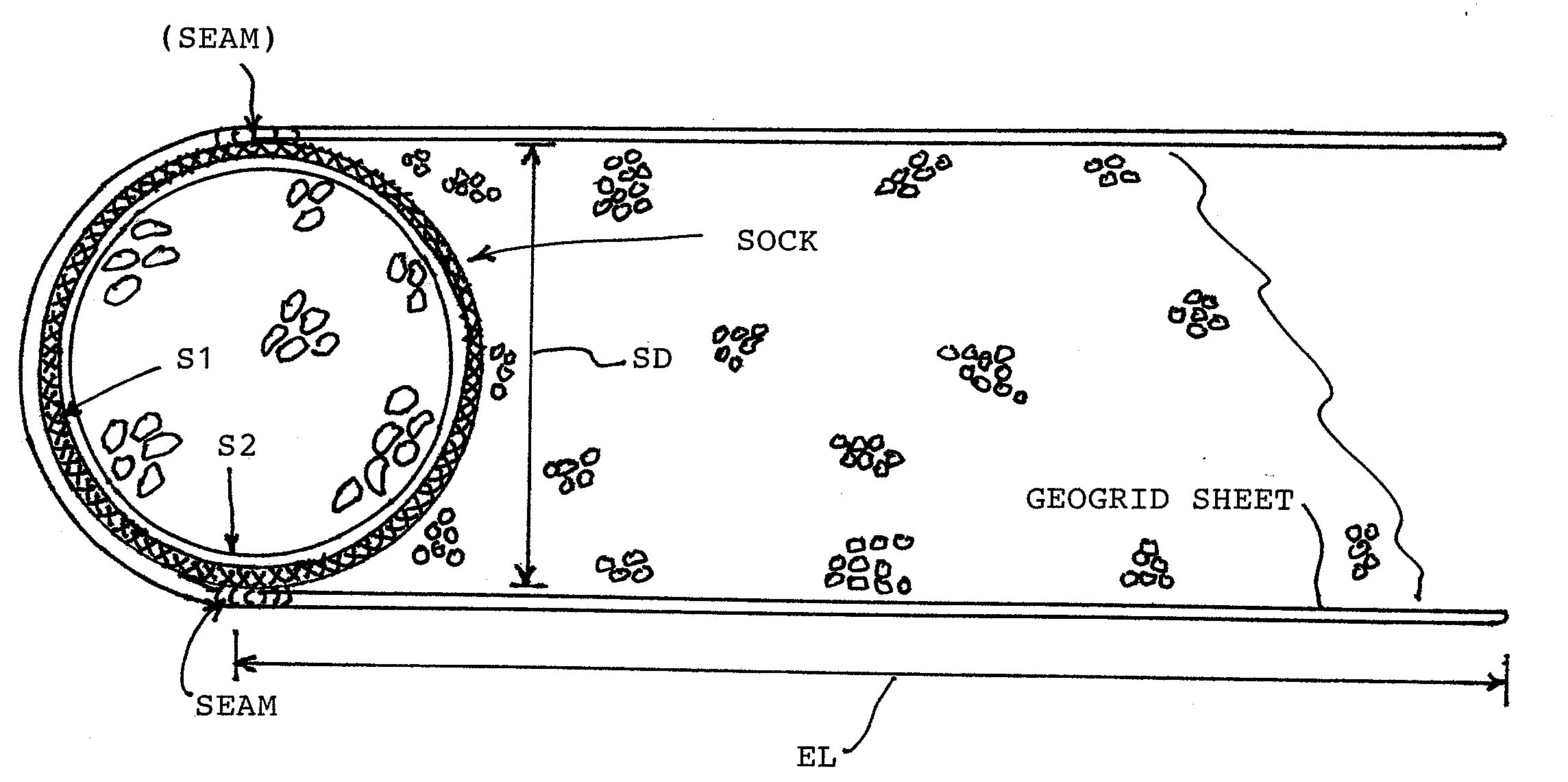

Tubular sock module with integrated geogrid extensions for constructing stabilized-earth walls and slopes

A self-supporting earth facing module has a tubular sock to be filled with compost or fill material and a geogrid sheet which wraps around the circumference of the tubular sock with upper and lower extensions extending lengthwise to one side of the sock. The geogrid sheet is joined by a high-strength seam to the circumference of the sock. The module forms an integrated unit that can be used to form sequenced horizontal earth layers and serve as facing for a geosynthetically stabilized earth wall or slope. The sock may be vegetation-supportive and have built-in connectable irrigation tubing. The modules are installed in consecutive vertical lifts with a granular interlock zone to provide a connection medium for tying adjacent modules to each other and to the reinforced soil zone, and which may include connection to supplemental geogrids that extend the width of the reinforced zone for taller slopes and walls.

Owner:MILLER STANLEY MARK +1

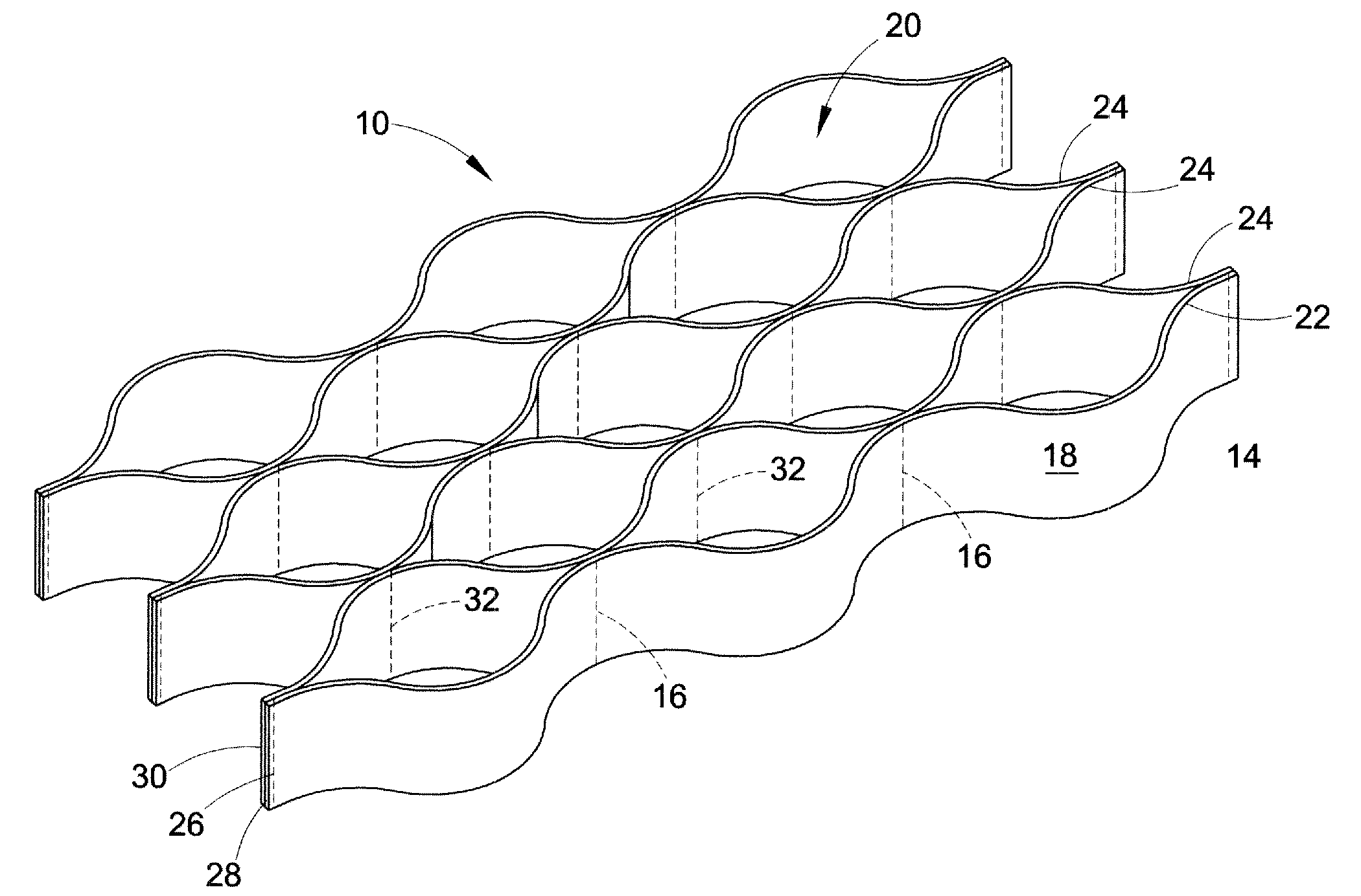

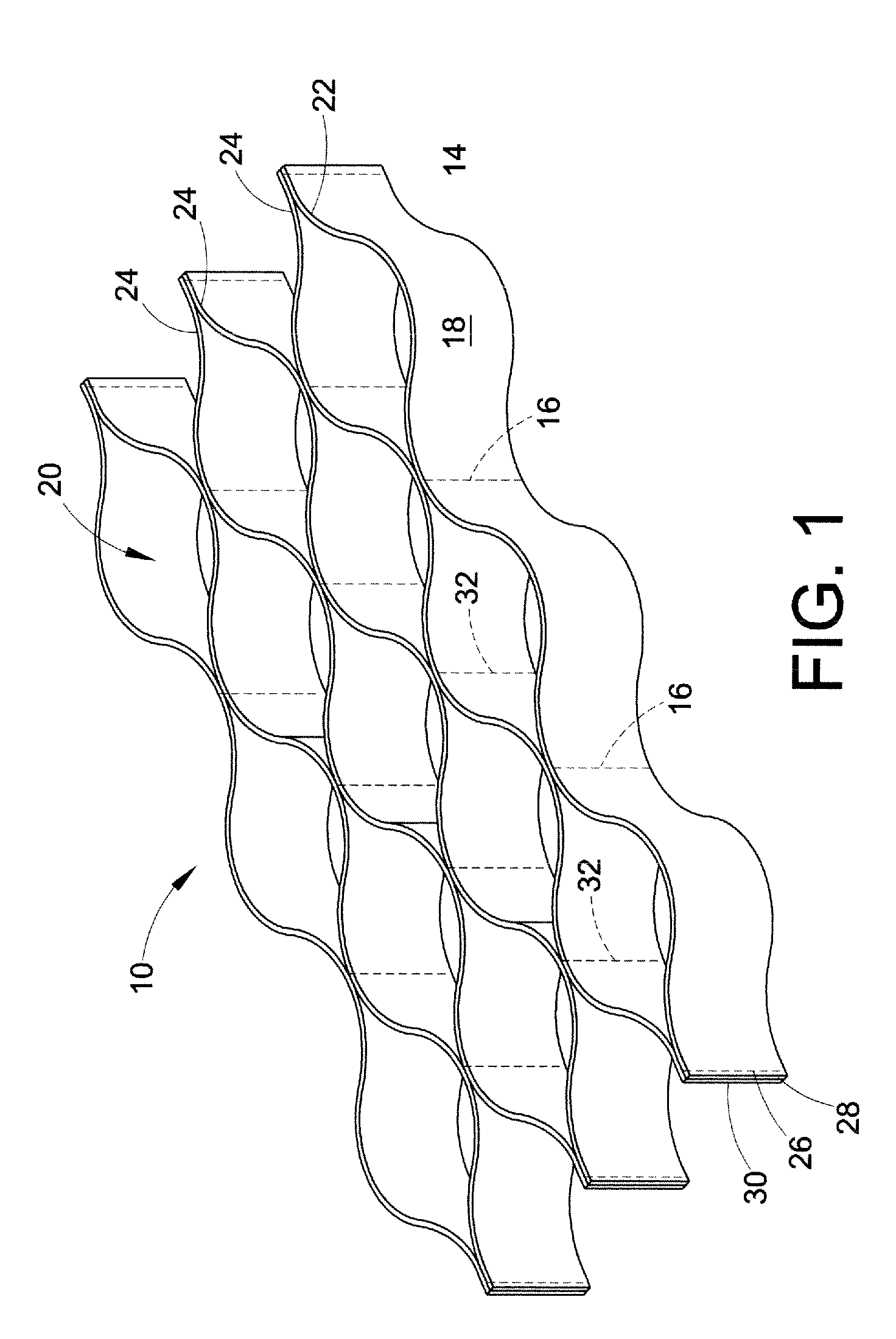

Geocell for load support applications

ActiveUS20100080659A1Rigid enoughAccept high stressPaving reinforcementsArtificial islandsGeocellsThermal expansion

A geocell is disclosed that has high strength and stiffness, such that the geocell has a storage modulus of 500 MPa or greater at 23° C.; a storage modulus of 150 MPa or greater at 63° C. when measured in the machine direction using Dynamic Mechanical Analysis (DMA) at a frequency of 1 Hz; a tensile stress at 12% strain of 14.5 MPa or greater at 23° C.; a coefficient of thermal expansion of 120×10−6 / ° C. or less at 25° C.; and / or a long term design stress of 2.6 MPa or greater. The geocell is suitable for load support applications, especially for reinforcing base courses and / or subbases of roads, pavement, storage areas, and railways.

Owner:GEOTECH TECHNOLOGIES LTD

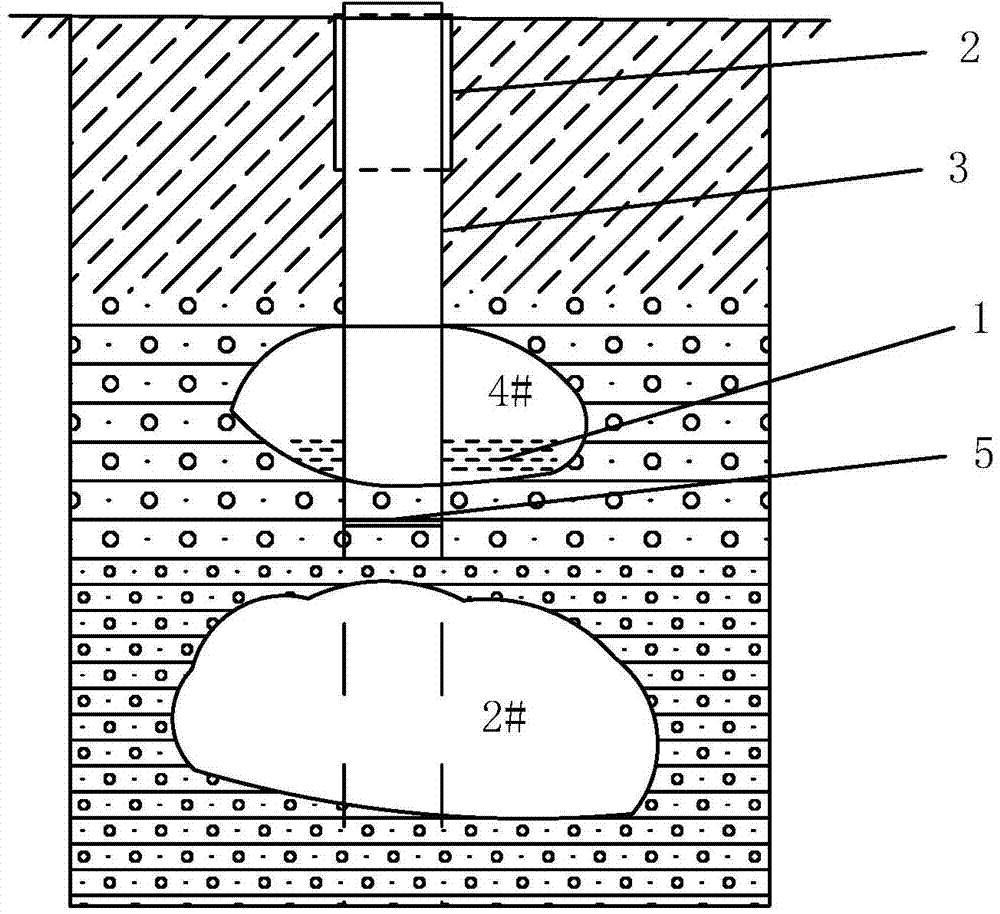

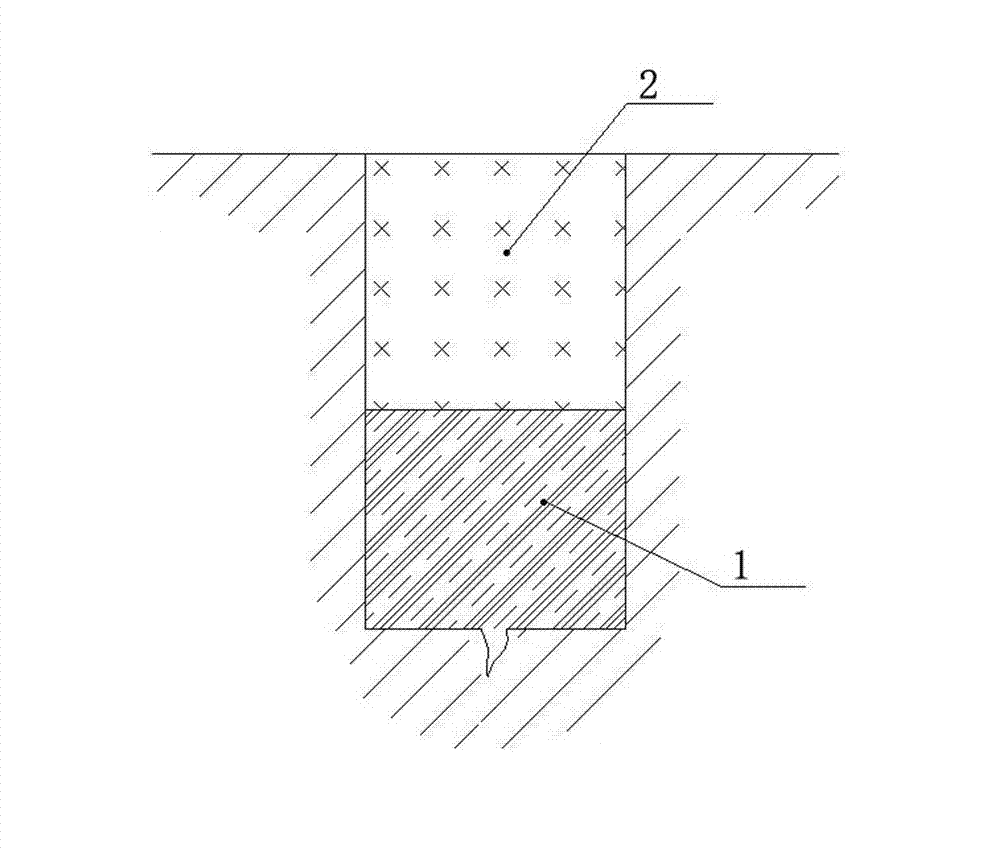

Drilling pile drilling construction method of bead-type karst area

ActiveCN103485336AThe method steps are simpleReasonable designDrill bitsEmbankmentsWater sourceKarst

The invention discloses a drilling pile drilling construction method of a bead-type karst area, wherein a drilling pile penetrates through an underground river karst cave from top to bottom. The method includes the steps of (1) measuring and sampling, (2) lowering and fixing a steel casing, and (3) drilling, wherein a percussion drill is used, drilling is carried out from top to bottom through the lowered steel casing until the percussion drill reaches a designed depth, and in the drilling process, the wall is protected through slurry; in the drilling process, when the percussion drill drills the underground river karst cave from top to bottom, the underground river karst cave is firstly processed, and then the percussion drill is used for drilling downwards; when the underground river karst cave is processed, the process is as follows: drilling of an inner protection casing installation hole, lowering of an inner protection casing, continuous drilling and plugging of a water source. The method is simple in step, reasonable in design, low in investment cost, convenient to achieve and good in construction effect, the drilling construction process of a drilling pile penetrating through the underground river karst cave can be easily, conveniently and quickly completed, cost is low and quality is high.

Owner:中铁建安工程设计院有限公司 +1

Landfill structure using concept of multi-layered reactors and method for operating the same

InactiveUS20050201831A1Easy to controlReduce the environmentLandfill technologiesSolid waste disposalEnvironmental engineeringLandfill gas

The invention relates to a landfill structure and a method for operating the same and, more particularly, to a landfill structure using a concept of multi-layered reactors, a method for making efficient use of landfill gas generated from the landfill, a method for early stabilizing the landfill and a method for reducing environmental contaminants generated from the landfill.

Owner:ENV21

Flowing backfill and preparation and construction method thereof

InactiveCN101857409AAvoid pollutionImprove liquidityRoadwaysEmbankmentsAbutmentUltimate tensile strength

The invention relates to a flowing backfill, belonging to the field of civil engineering. The flowing backfill comprises the following components by weigh part: 100 parts of cement, 500-1000 parts of soil and 250-450 parts of water, wherein the ratio of the cement and the soil is controlled between 0.1 and 0.2, and the ratio of the water and a solid material is controlled between 0.41 and 0.43. A construction method of the flowing backfill comprises the following steps: firstly, clearing a foundation pit; secondly, preparing the flowing backfill according to the requirements; finally, carrying out on-site pouring and maintaining, wherein the pouring of the flowing backfill can be pumped or filled in the specified position by the diversion of sliding grooves without compacting or vibrating, and after completing the pouring, the flowing backfill needs to be covered with alpine meadow soil to be maintained for over 24h before allowing vehicles and pedestrians to pass through. The flowing backfill provided by the invention has the characteristics of self-compacting, environmental protection, economy, adjustable strength and the like, and is suitable for bridge abutment backfill, road widening subgrade backfill, underground engineering and pipeline construction backfill and the backfill of construction foundation pits with narrow operating space and the like.

Owner:BEIJING UNIV OF TECH

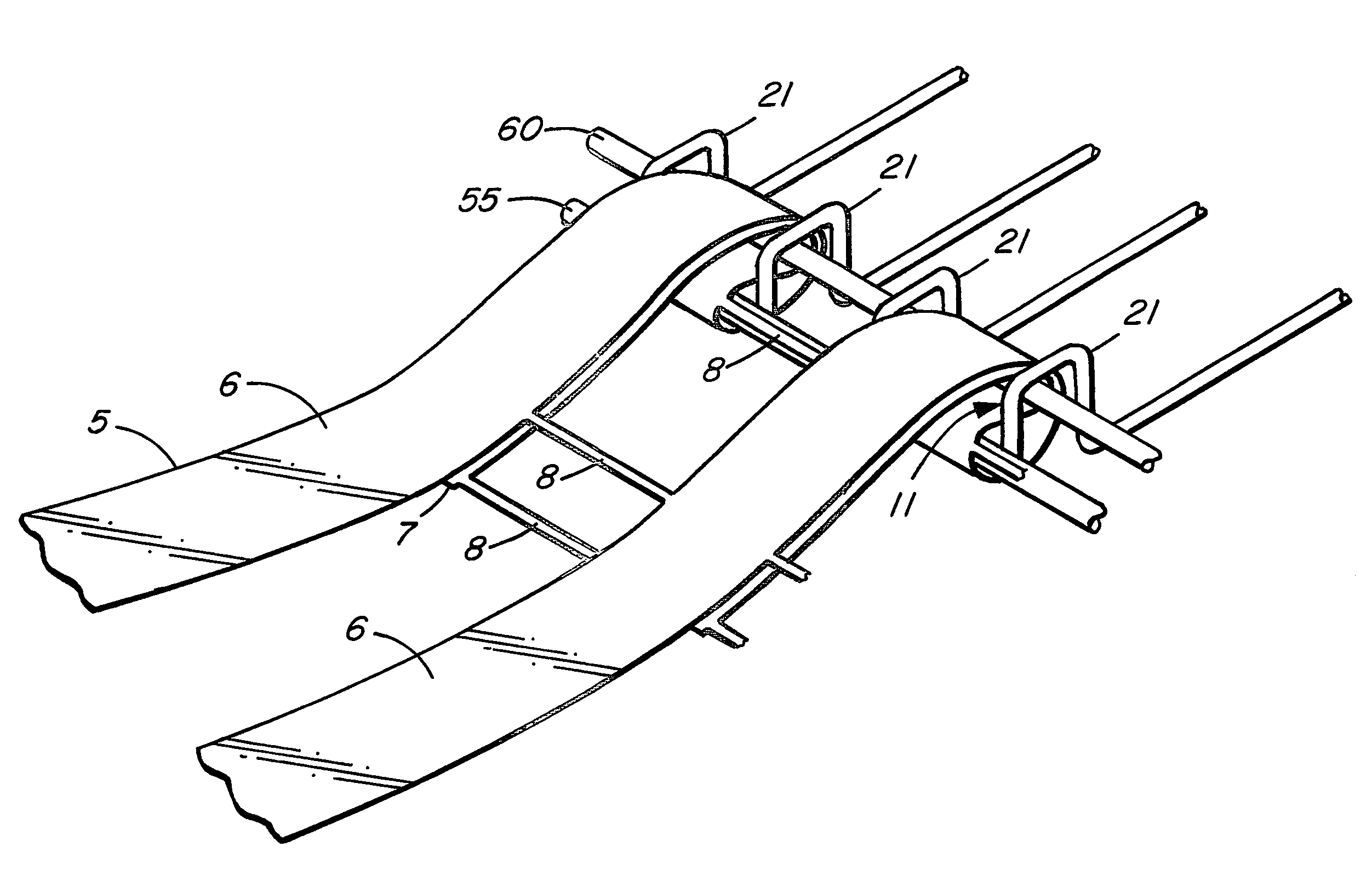

Apparatus and method for stabilizing an earthen embankment

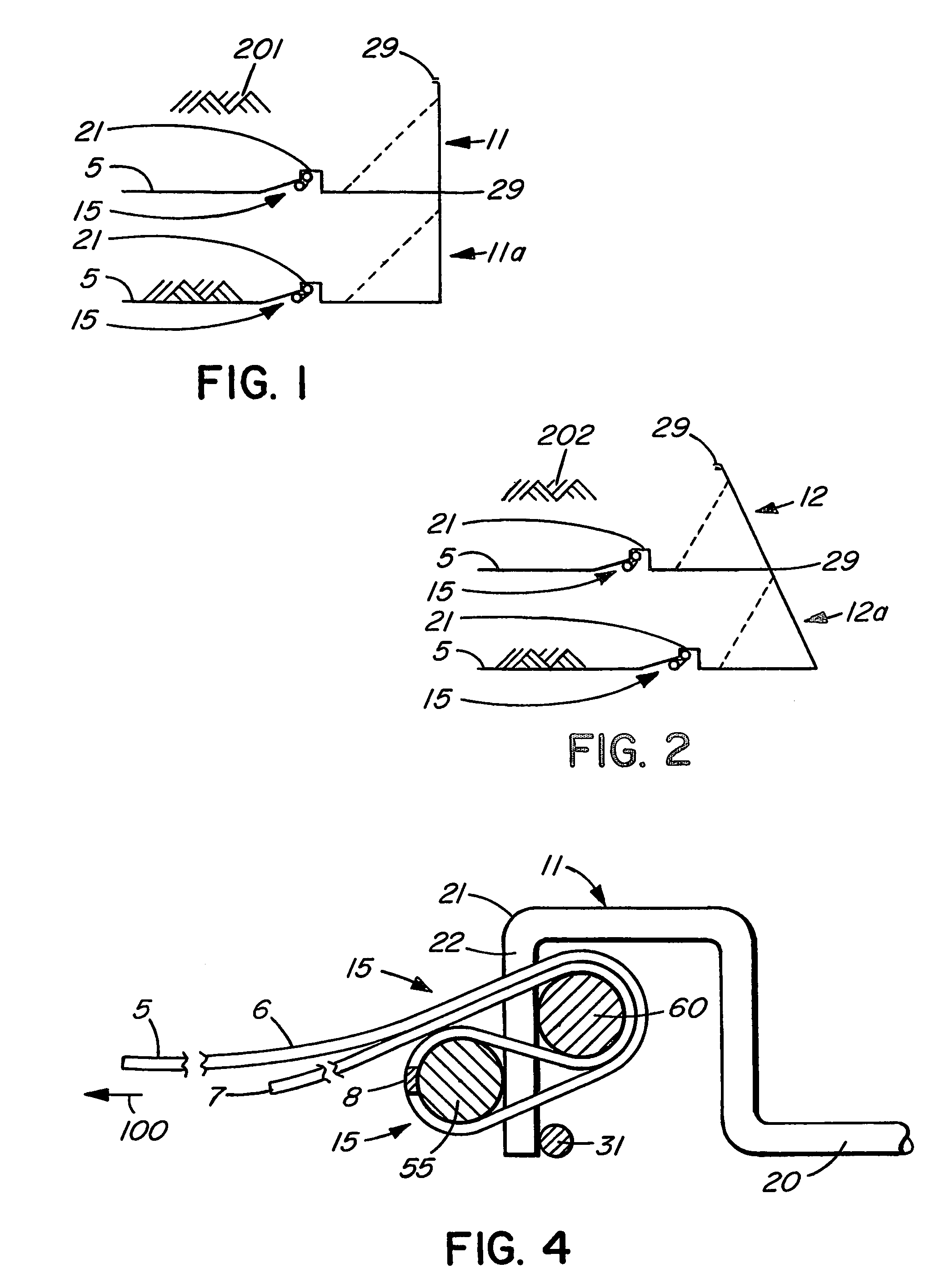

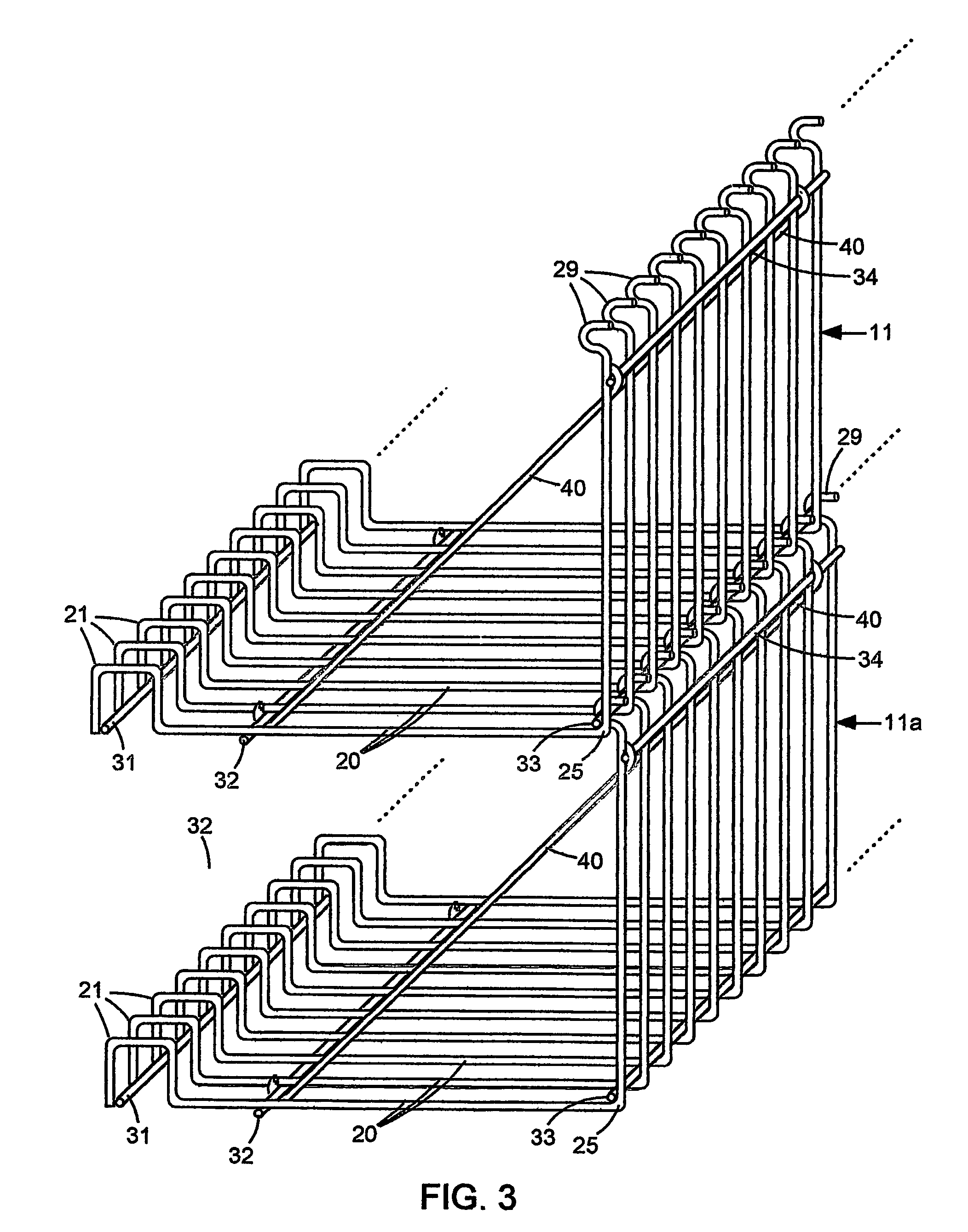

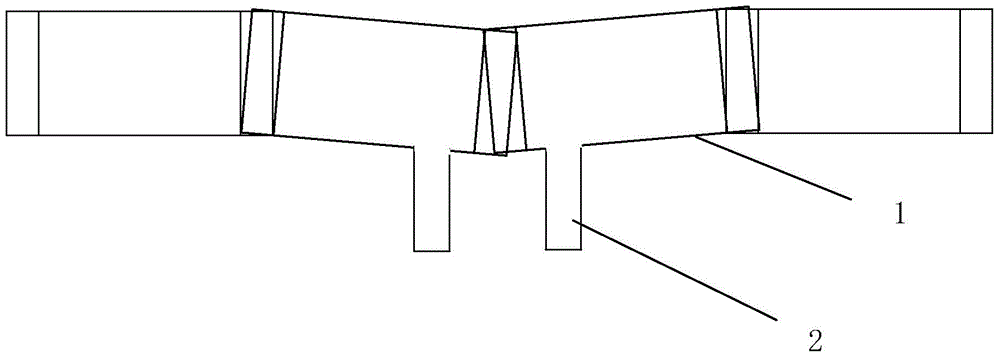

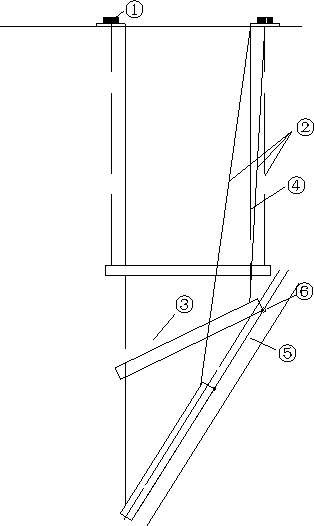

A structure for stabilizing an earthen embankment comprises an embankment support for restraining movement of at least a part of the embankment, a flexible fiber geogrid (5) extending longitudinally through the embankment from a first end portion secured to the support to a second end portion, and anchor means (55, 60, 11) for securing one of the end portions. The anchor means comprises a pair of anchor rods (55, 60) extending transversely in relation to the geogrid, and means (11) for limiting movement of the anchor rods. The end portion secured by the anchor means is wrapped back and forth around the anchor rods so as to tighten thereon when the geogrid is pulled in longitudinal tension away from the anchor means. A method of anchoring a flexible fiber geogrid to a support utilizing such anchor rods is also disclosed.

Owner:M D S K ENTERPRISES

Underground pipeline sedimentation repair high polymer membrane bag grouting method

ActiveCN104652415AIncreased durabilityImprove performancePipe elementsEmbankmentsSocial benefitsEngineering

The invention relates to an underground pipeline sedimentation repair high polymer membrane bag grouting method. The method comprises the following steps: (1) detecting a sunken pipe segment, and determining a grouting scheme; (2) drilling a membrane bag accommodating hole; (3) placing a membrane bag; (4) injecting a high polymer material into the membrane bag; (5) lifting the pipe segment; (6) filling a gapped region and reinforcing a soft soil layer. The high polymer material is a non-water-reaction bi-component high polymer material. The method has the advantages of rapidness, minimal invasiveness, light mass, high toughness, economical efficiency, durability and the like, lifting repair of an underground sedimentation pipe segment can be rapidly realized, and a novel advanced, efficient, economical and practical scheme is provided for underground pipeline sedimentation repair. The method is successfully applied to a plurality of underground pipeline lifting projects, and has great economic and social benefits and wide development and application prospects.

Owner:SAFEKEY ENG TECHZHENGZHOU

Thickener for excavating slurry, excavating slurry using the the thickener, and cast-in-place underground pile work method and underground continuius wall work method using the excavating slurry

InactiveUS20040121916A1Reduce the presence of air bubblesConstruction works can be stably conductedEmbankmentsExcavationsSlurry wallEmulsion

Subjects for the present invention are to provide a thickening agent for excavation stabilizing slurries which has excellent cement contamination resistance, is difficult to putrefy, and is prevented from bubbling, which may be problematic in construction works, and to provide an excavation stabilizing slurry containing the thickening agent and a cast-in-place underground pile method and an diaphragm wall construction method each using the slurry. The present invention provides a thickening agent for excavation stabilizing slurries which contains an emulsion thickening with an alkali, wherein in a strong agitation bubbling test of a mixture prepared by adding an alkaline substance to the thickening agent, the resulting mixture has an apparent specific gravity of 1.05 g / ml or higher as measured immediately after the strong agitation and has an apparent specific gravity of 1.10 g / ml or higher as measured at 10 minutes after the strong agitation. This thickening agent is used to prepare an excavation stabilizing slurry.

Owner:NIPPON SHOKUBAI CO LTD

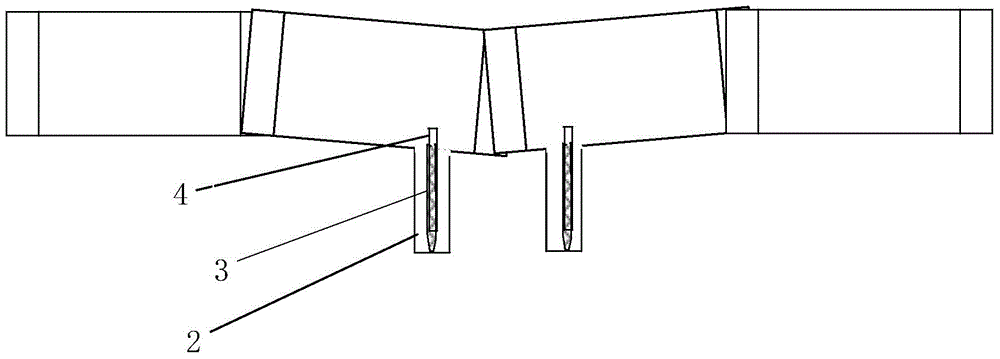

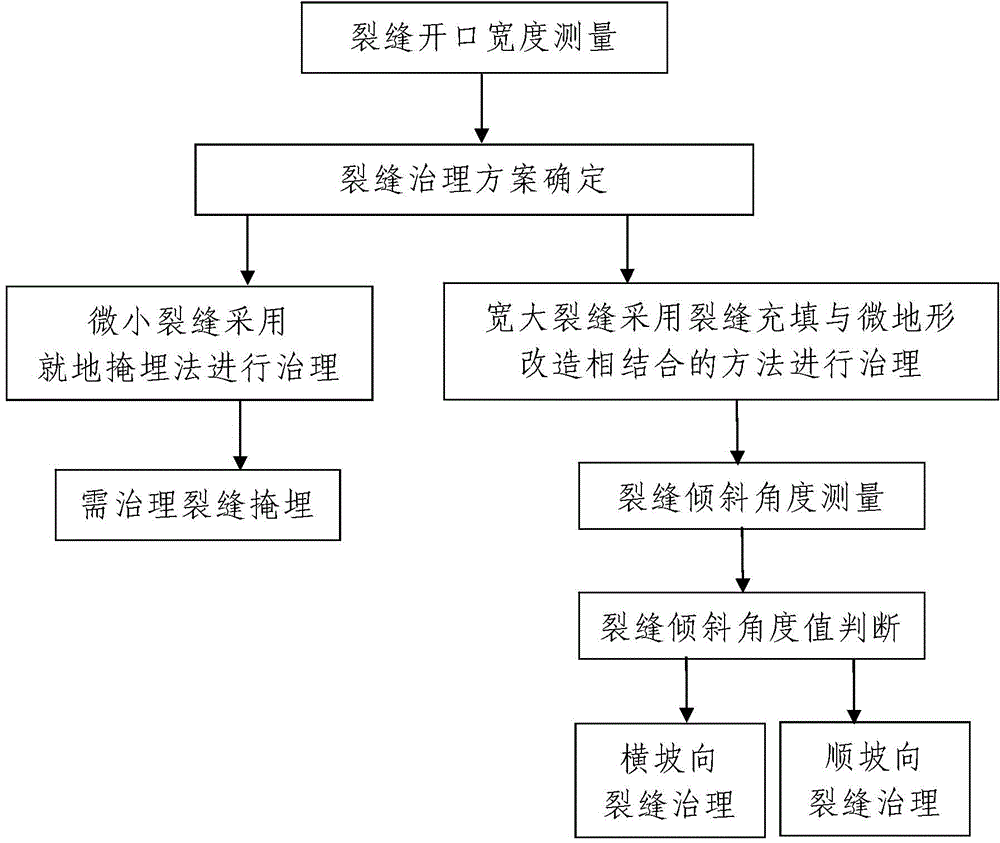

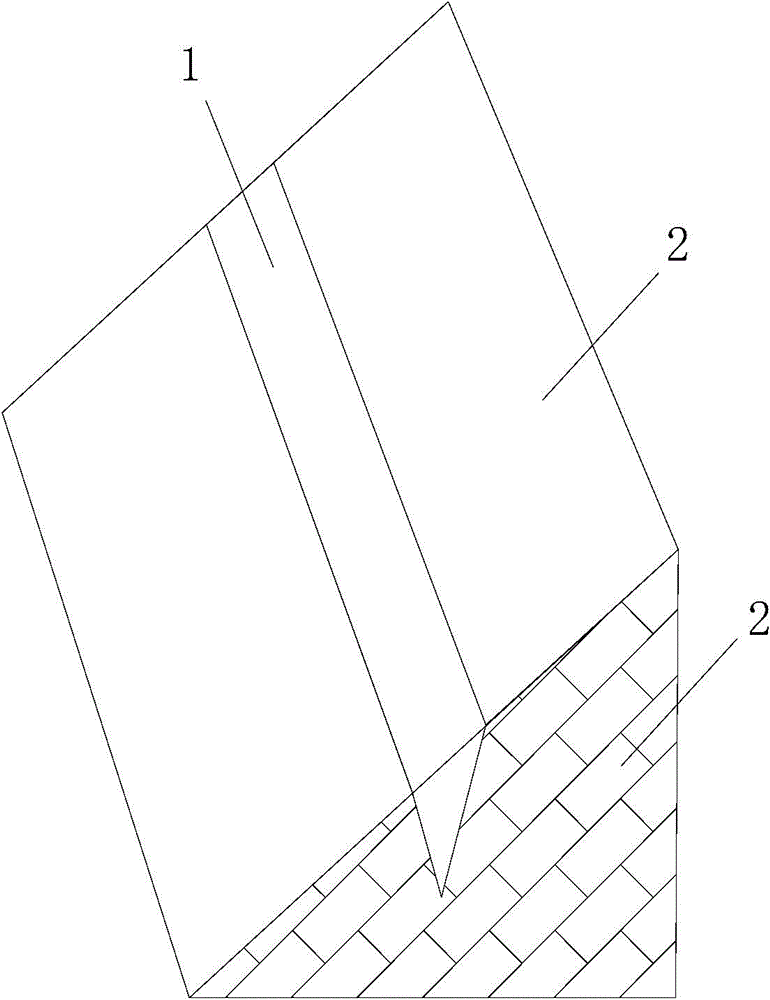

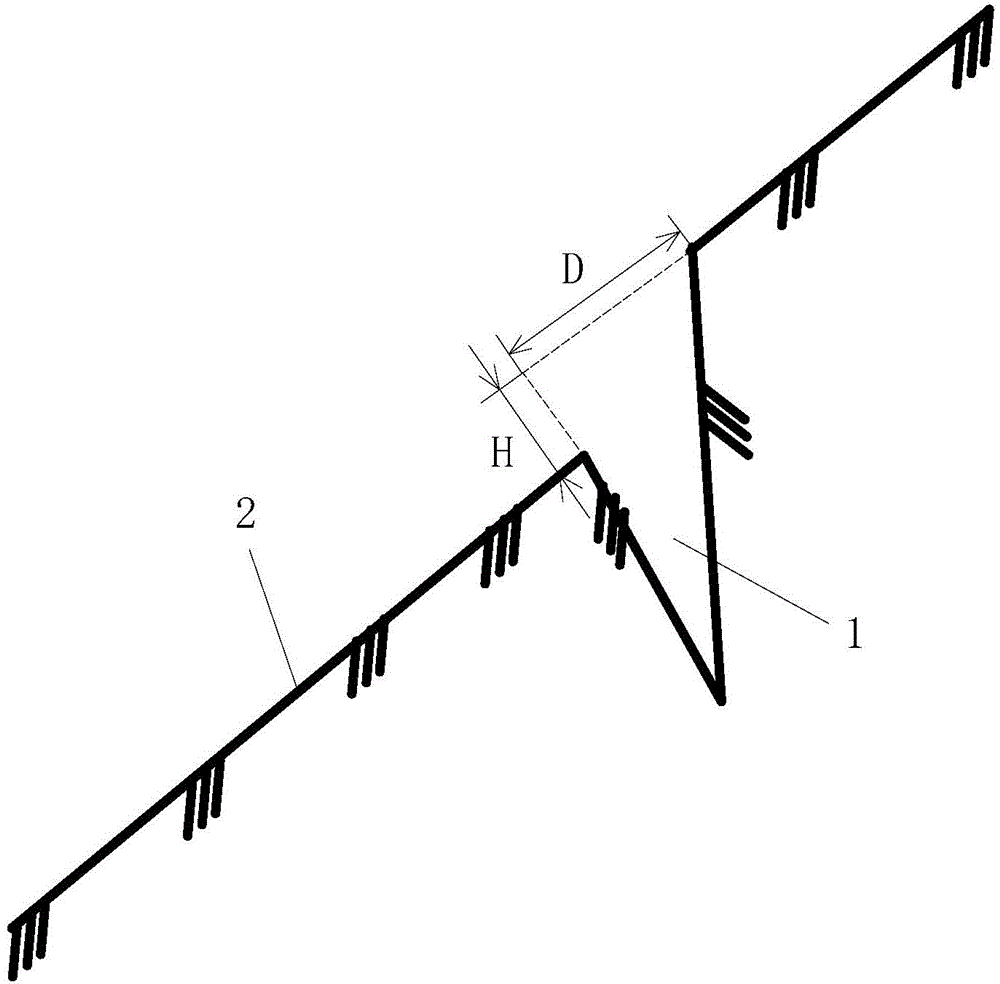

Coal mining subsidence area administration method for loess hilly-gully region

InactiveCN104652451AThe method steps are simpleReasonable designEmbankmentsCultivating equipmentsMedicineLandform

The invention discloses a coal mining subsidence area administration method for a loess hilly-gully region. The method comprises the following steps: 1, measuring the width of a crack opening; 2, determining a crack administration scheme, wherein the crack administration scheme is an on-site filling method or a combined crack filling and micro-slope reconstruction administration method; 3, performing crack administration, wherein a crack to be administrated is filled with a soil body when the on-site filling method is adopted; the combined crack filling and micro-slope reconstruction administration method for administration comprises the following steps: 301, measuring an inclination angle of the crack; 302, judging an inclination angle value of the crack; 303, performing cross slope crack administration; 304, along-slope crack administration; 4, repeating step 1 to step 3 for many times until all subsided cracks in a loess slope of a coal mining subsidence area are administrated. The steps are simple, the method is reasonable in design, convenient to implement and construct and shorter in construction cycle, and has good administration effects, and the coal mining subsidence area of the loess hilly-gully region can be effectively administrated.

Owner:XIAN UNIV OF SCI & TECH

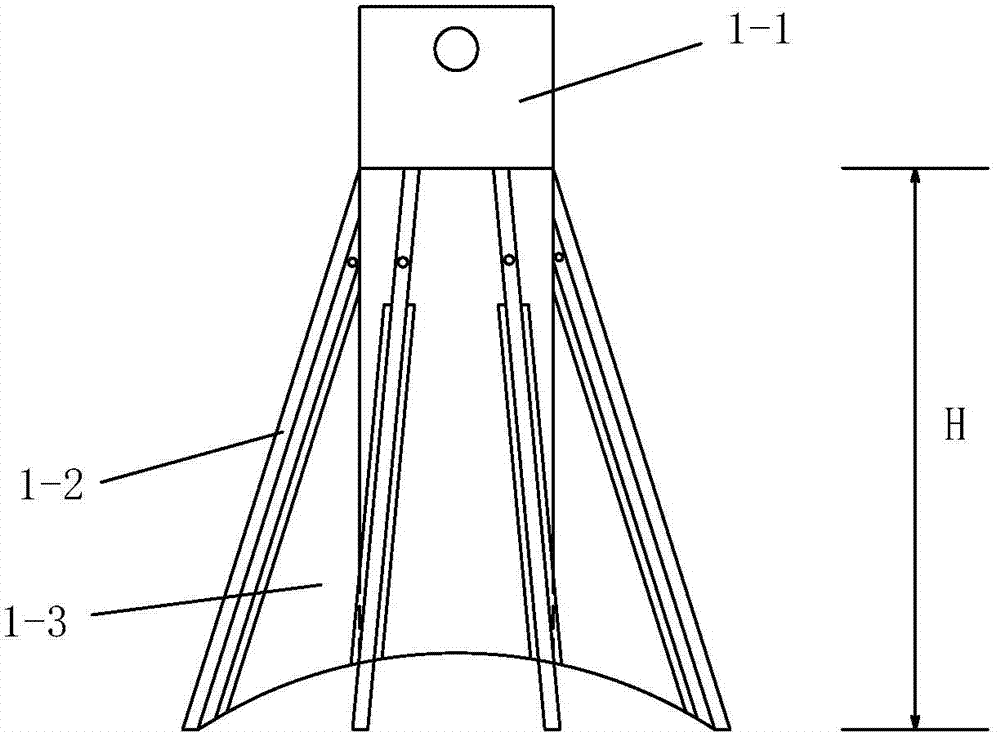

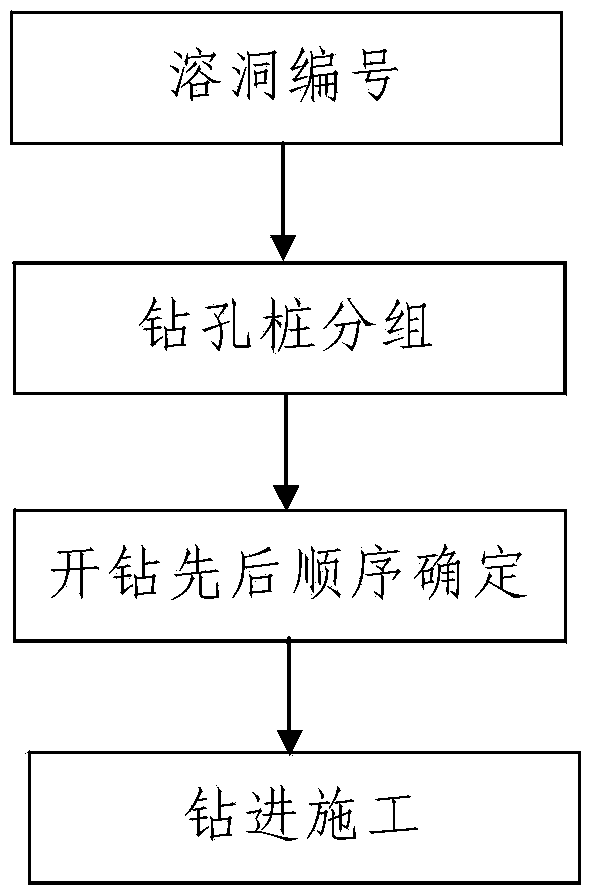

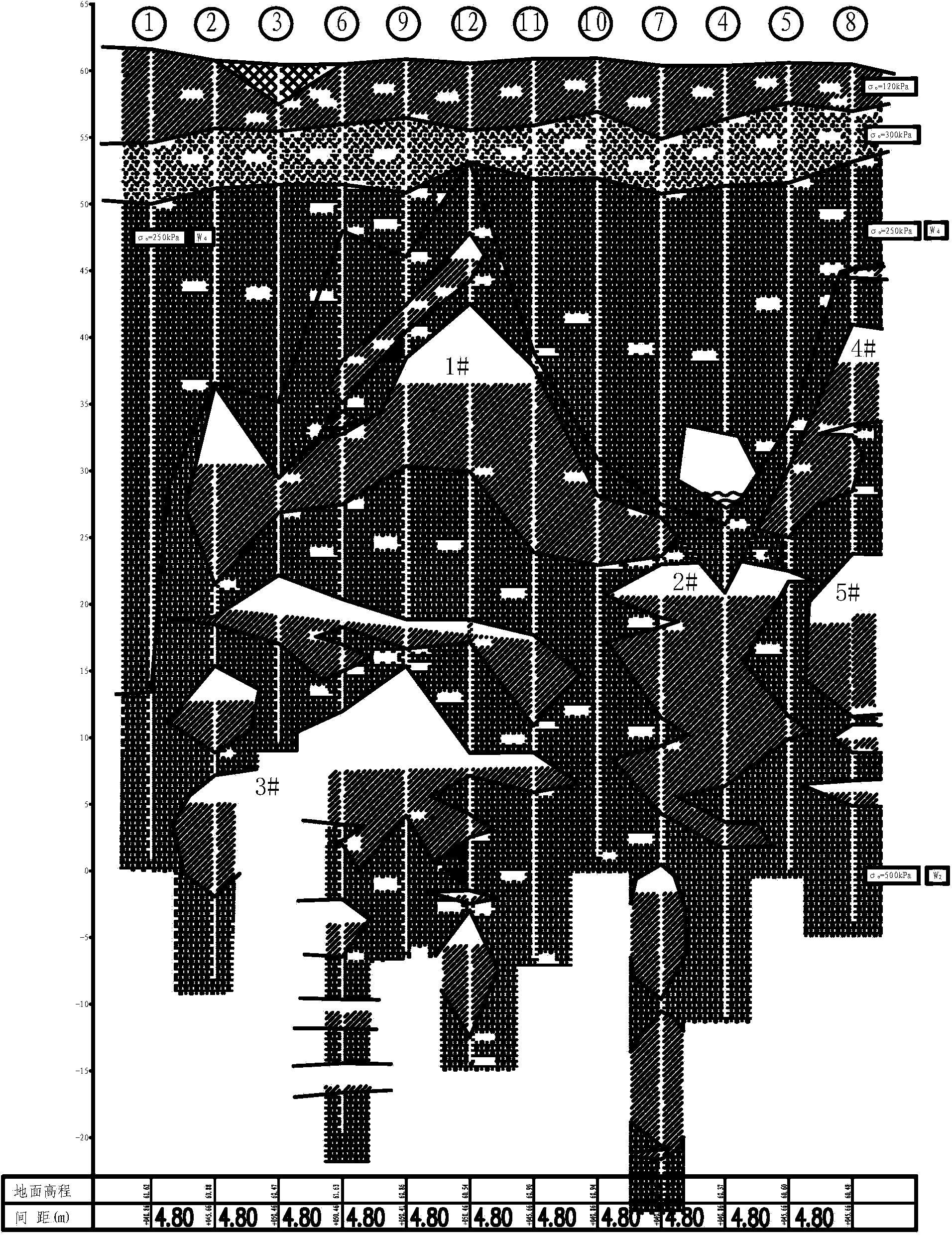

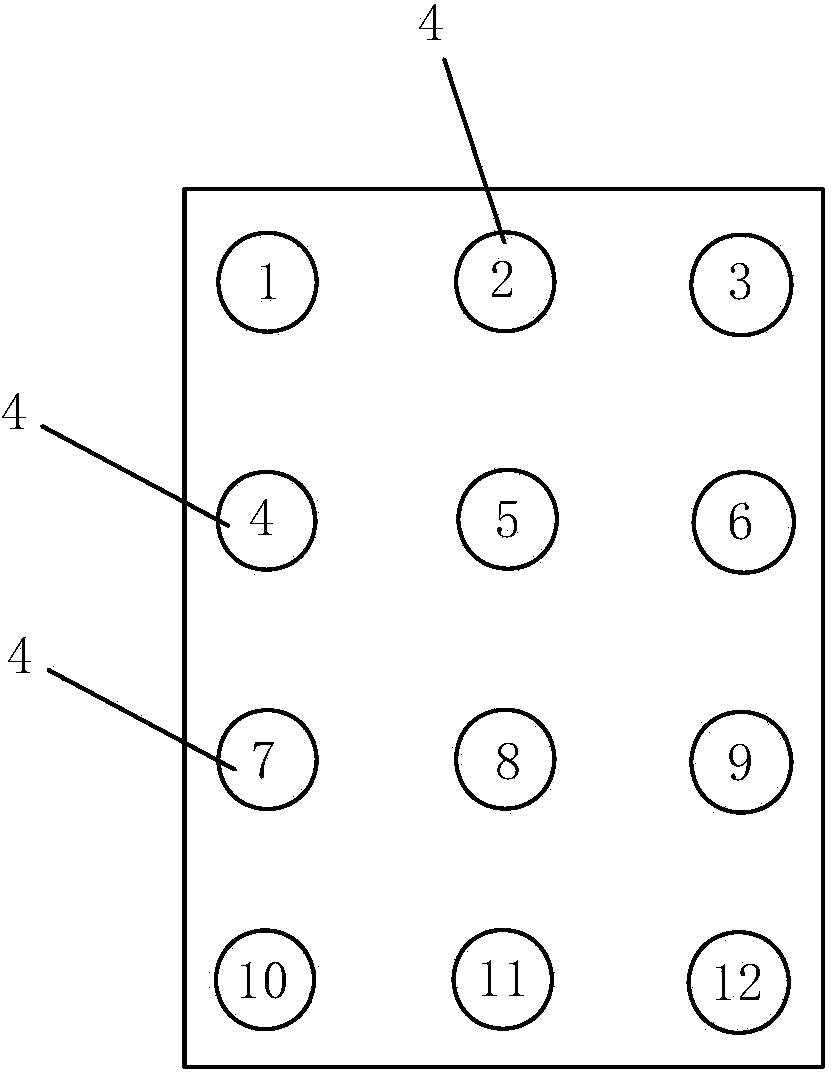

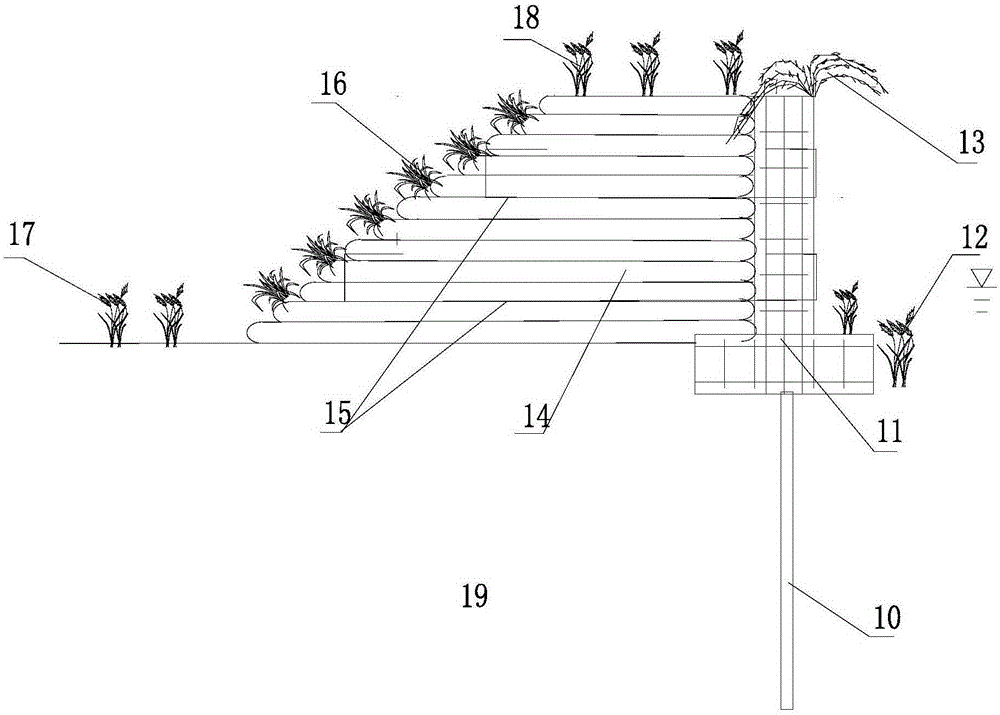

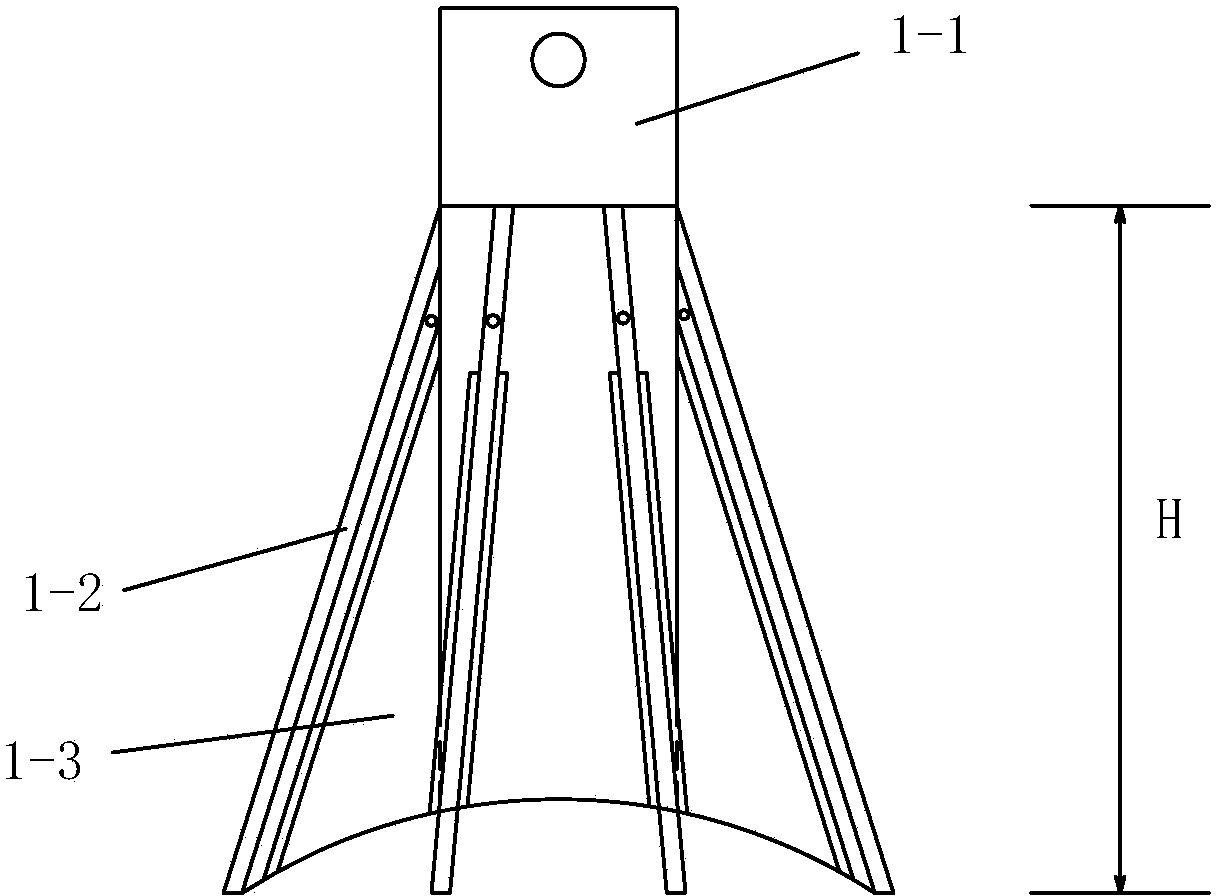

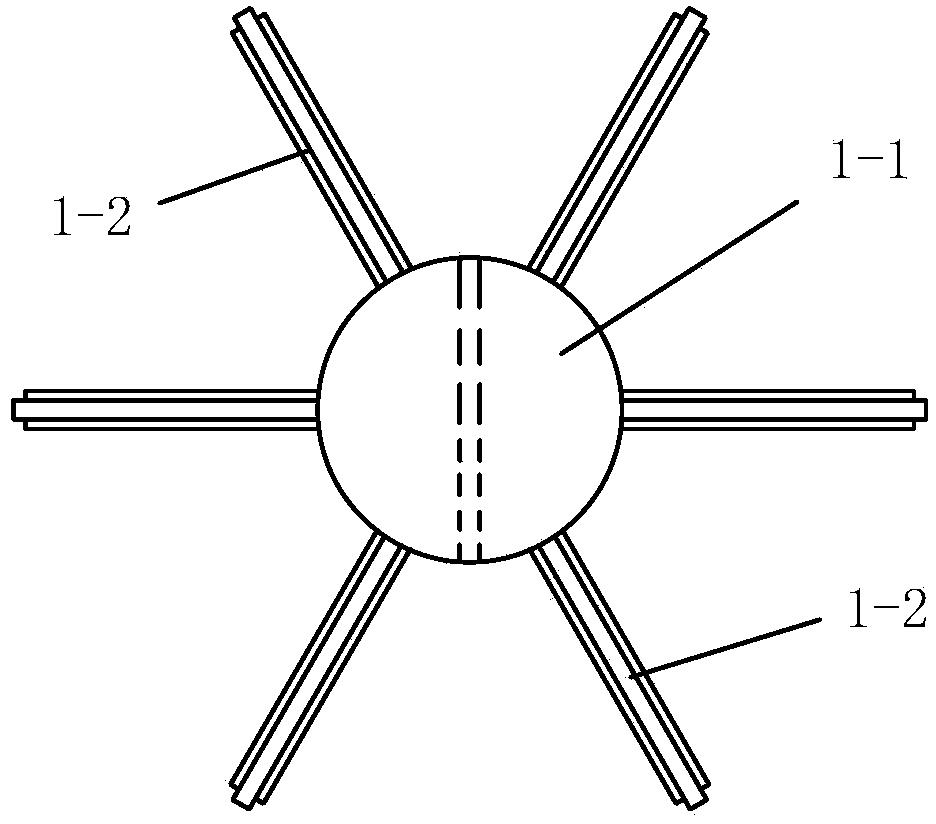

Technology for constructing deepwater bridge underwater pier large-diameter bored piles in bead-stringed type karst areas

ActiveCN103526748AThe process steps are simpleReasonable designEmbankmentsBulkheads/pilesStart timeUnderwater

The invention discloses a technology for constructing deepwater bridge underwater pier large-diameter bored piles in bead-stringed type karst areas. A pile foundation of a constructed underwater pier comprises the multiple first bored piles, and the first bored piles all penetrate through a plurality of karst caves successively from top to bottom. The technology includes the steps of (1) numbering the karst caves, (2) grouping the bored piles: dividing the multiple first bored piles into multiple groups according to serial numbers of the karst caves which are penetrated from top to bottom, and enabling the karst caves which are penetrated by all first bored piles in the same groups from top to bottom for the first time to be the same, (3) determining the drilling starting sequence: determining the drilling starting sequence of all first bored piles in the same group in the step (2), and enabling the drilling starting time of the first bored piles, farther away from the middle of the karst cave penetrated for the first time, in the same group to be earlier, and (4) carrying out drilling construction. The technology is simple in step, reasonable in design, low in investment cost, convenient to achieve and good in construction effect, and large-diameter bored pile construction processes can be easily, conveniently and rapidly completed with low cost and high quality.

Owner:CHINA RAILWAY 20 BUREAU GRP

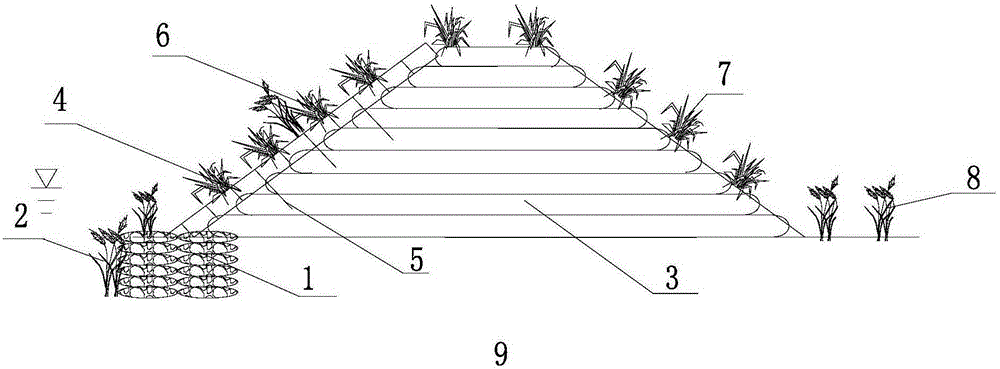

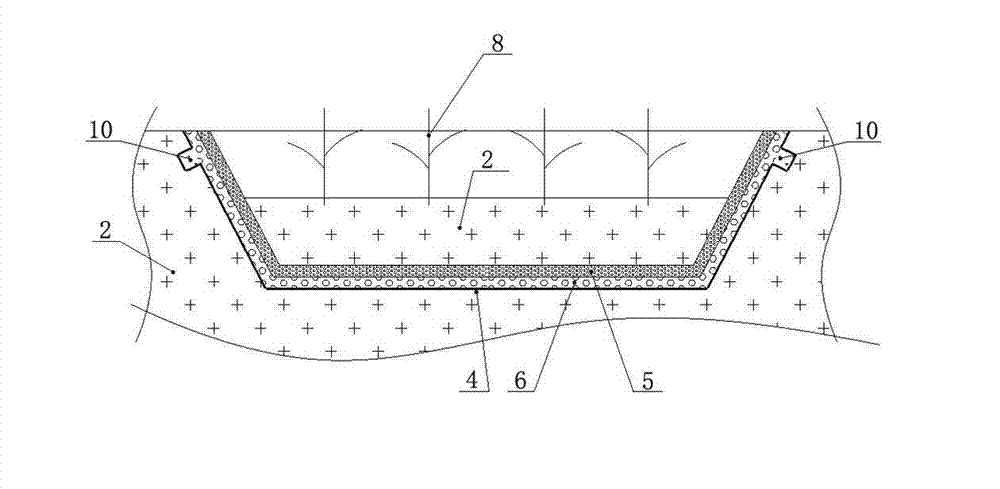

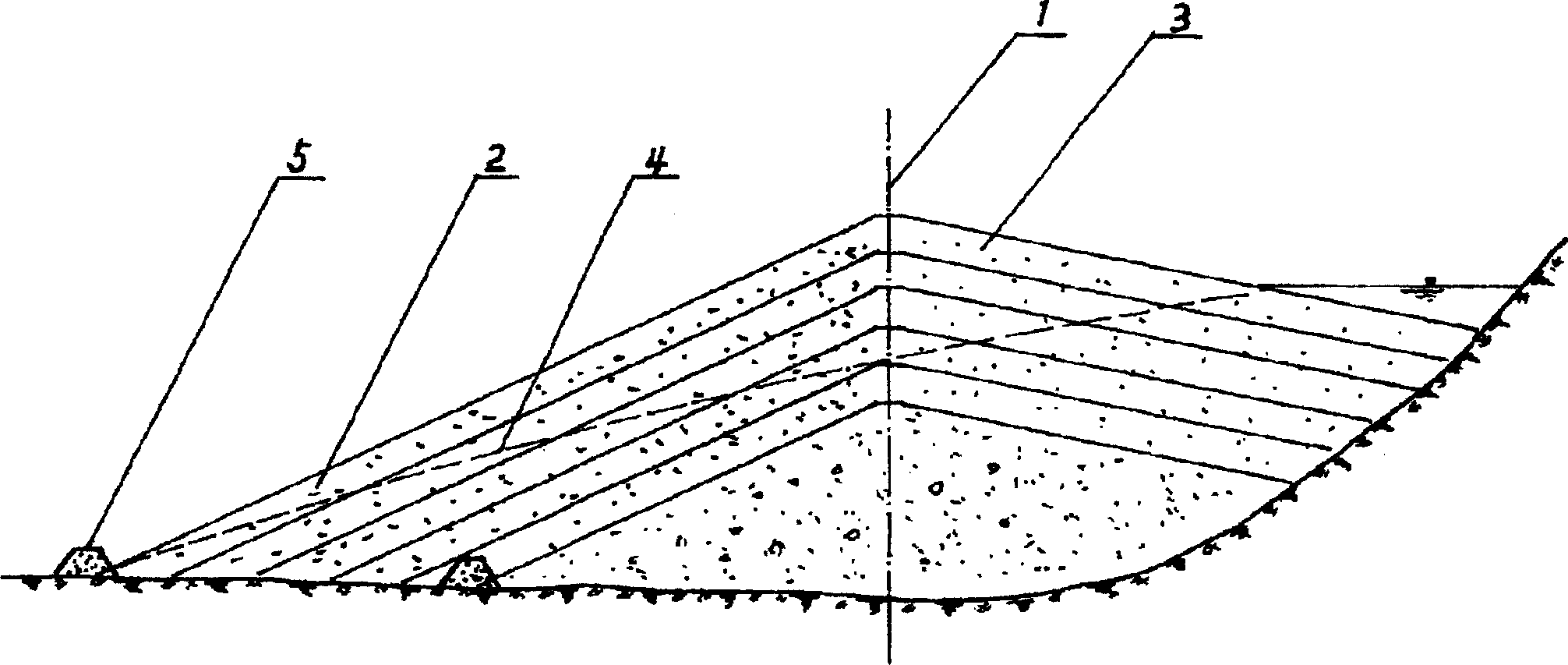

Large filling bag ecological embankment and revetment building method for river lake channel

The invention provides a large filling bag ecological embankment and revetment building method for a river lake channel. The method comprises the steps that (1), on the basis of cleaning and leveling, an embankment structure is filled with cleaned river lake bottom mud layer by layer through the large filling bag technology until the embankment structure reaches up to a designed elevation of the embankment top and the height of 0.5-1 m beyond the designed elevation is reserved through filling construction; (2), the cleaned river lake bottom mud is filled through a land pump, or special complete equipment and corresponding construction technologies are adopted to directly conduct mechanical paving and filling, and then the filled cleaned river lake bottom mud is sewn into bags; and (3), filling soil materials of the large geotextile filling bag embankment structure are taken from local resources, the bottom mud obtained through river lake regulation and channel excavation and cleaning is used as the filling soil materials, the initial water content of the filling soil materials is controlled within the range from 50%-80%, and the large filling bag embankment structure which is layered appropriately is adopted according to the practical situation. According to the method, the design is reasonable, the process is simple, construction is easy, operation is convenient, cost is low, popularization is easy, the ecological functions are good, and the method is applicable to ecological management and ecological channel construction of river lakes in soft soil areas.

Owner:NANJING HYDRAULIC RES INST

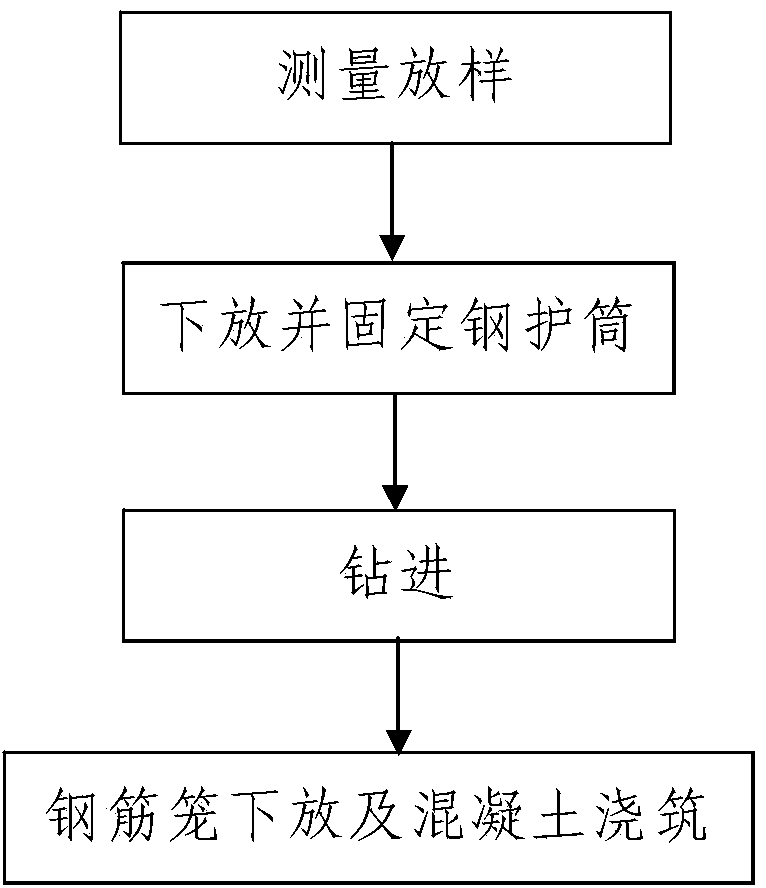

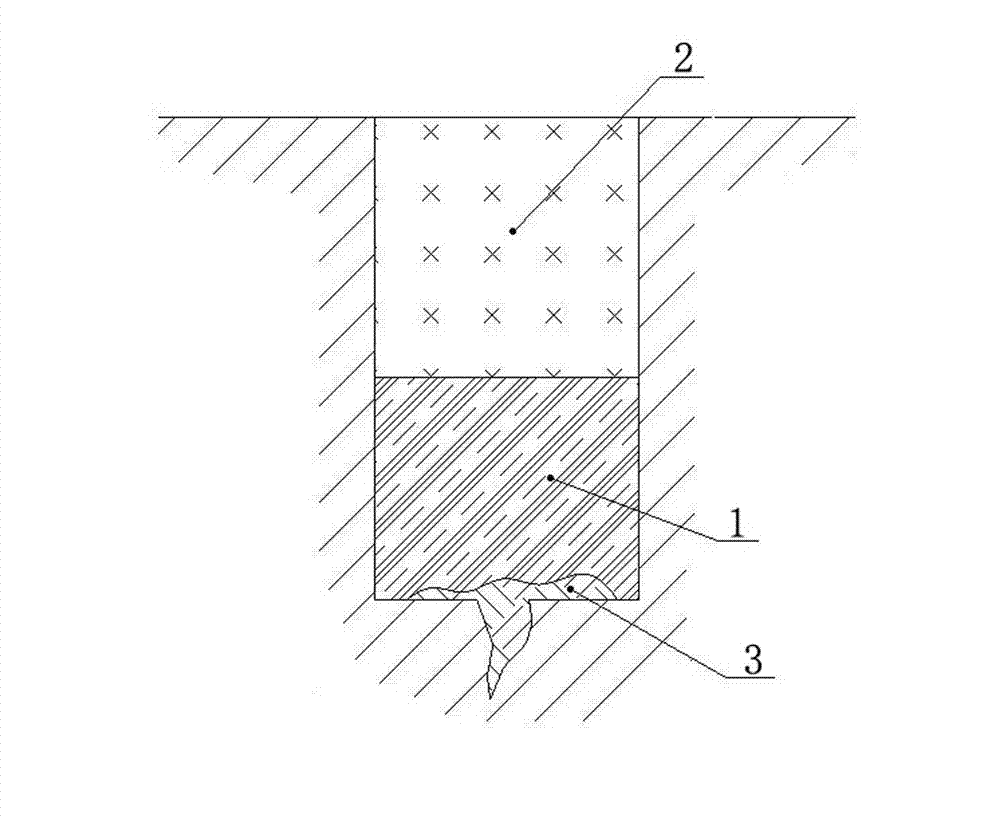

Karst-area underwater bridge pier drilled pile construction method

ActiveCN103469789AThe method steps are simpleReasonable designDrill bitsEmbankmentsEnergy transferUnderwater

The invention discloses a karst-area underwater bridge pier drilled pile construction method. The construction drilled pile passes through one or more karst caves from top to bottom according to the following steps that (1) measuring staking-out is conducted; (2) a steel protection barrel is put downwards and fixed; (3) drilling is carried out, namely, the steel protection barrel is put downwards and drilled from top to bottom through a percussion drill until the designed depth is reached, a slurry breast wall is adopted in the drilling process, when the drilled pile is drilled to enter the karst caves needing passing from top to bottom in the drilling process, an energy transfer method is firstly adopted to process the karst caves needing passing under the current state, then downward drilling is continuously carried out through the percussion drill; (4) a steel reinforcement cage is put downwards and concrete pouring is conducted. The karst-area underwater bridge pier drilled pile construction method is simple in step, reasonable in design, low in input cost, convenient to achieve, good in construction effect and capable of simply, conveniently and fast finishing the karst-area drilled pile construction process at a low cost in a high-quality mode.

Owner:中铁建安工程设计院有限公司 +1

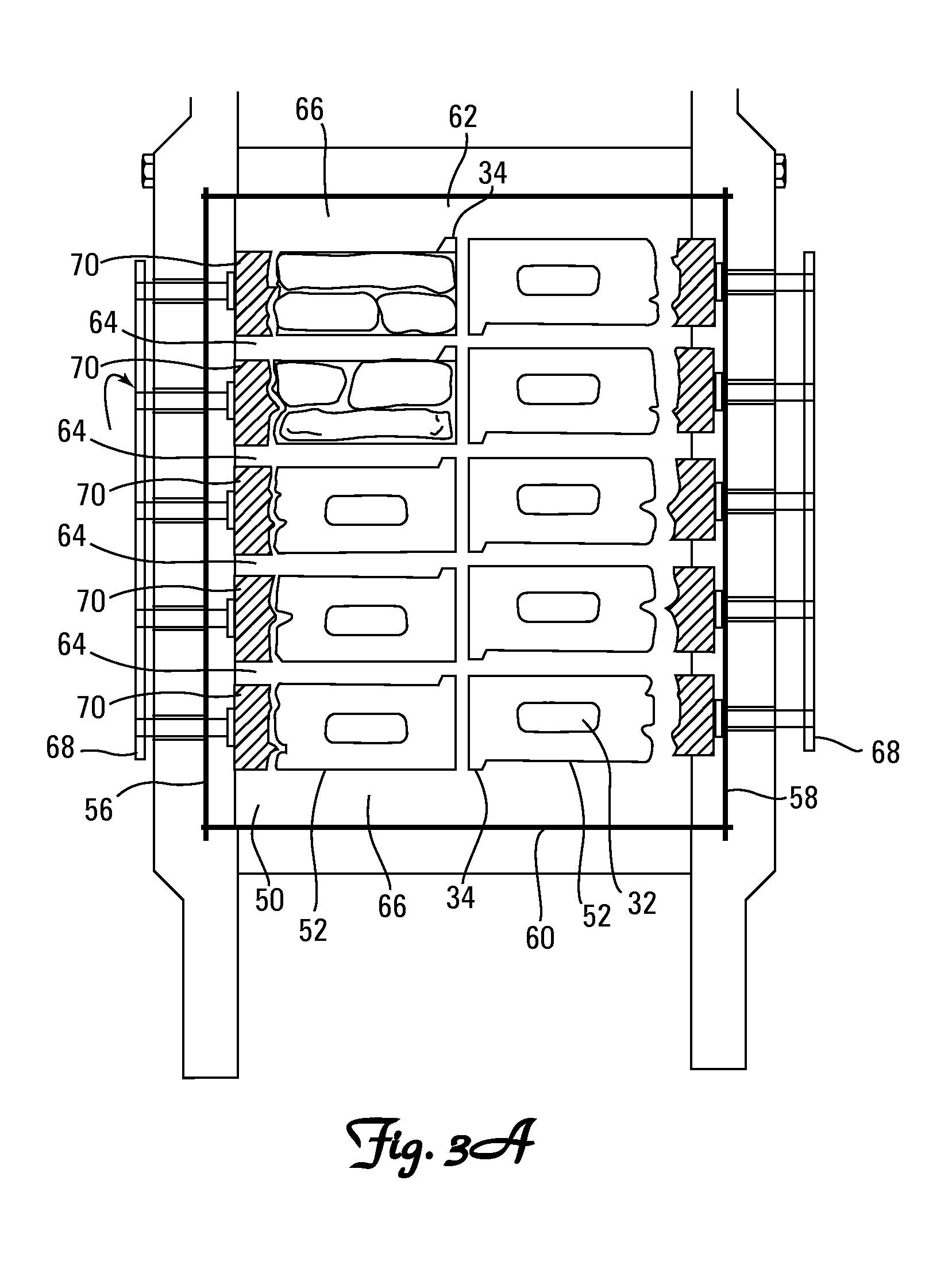

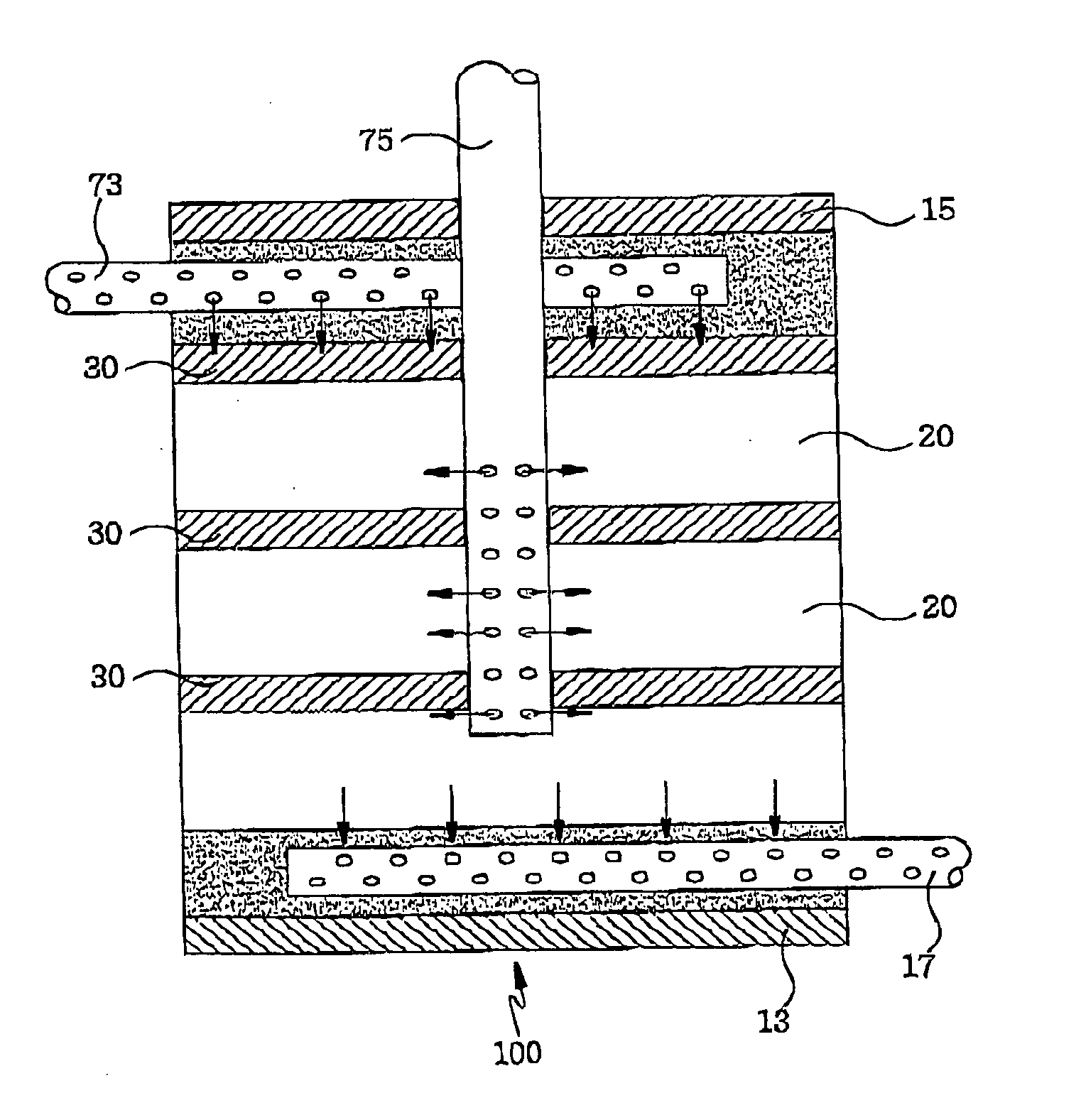

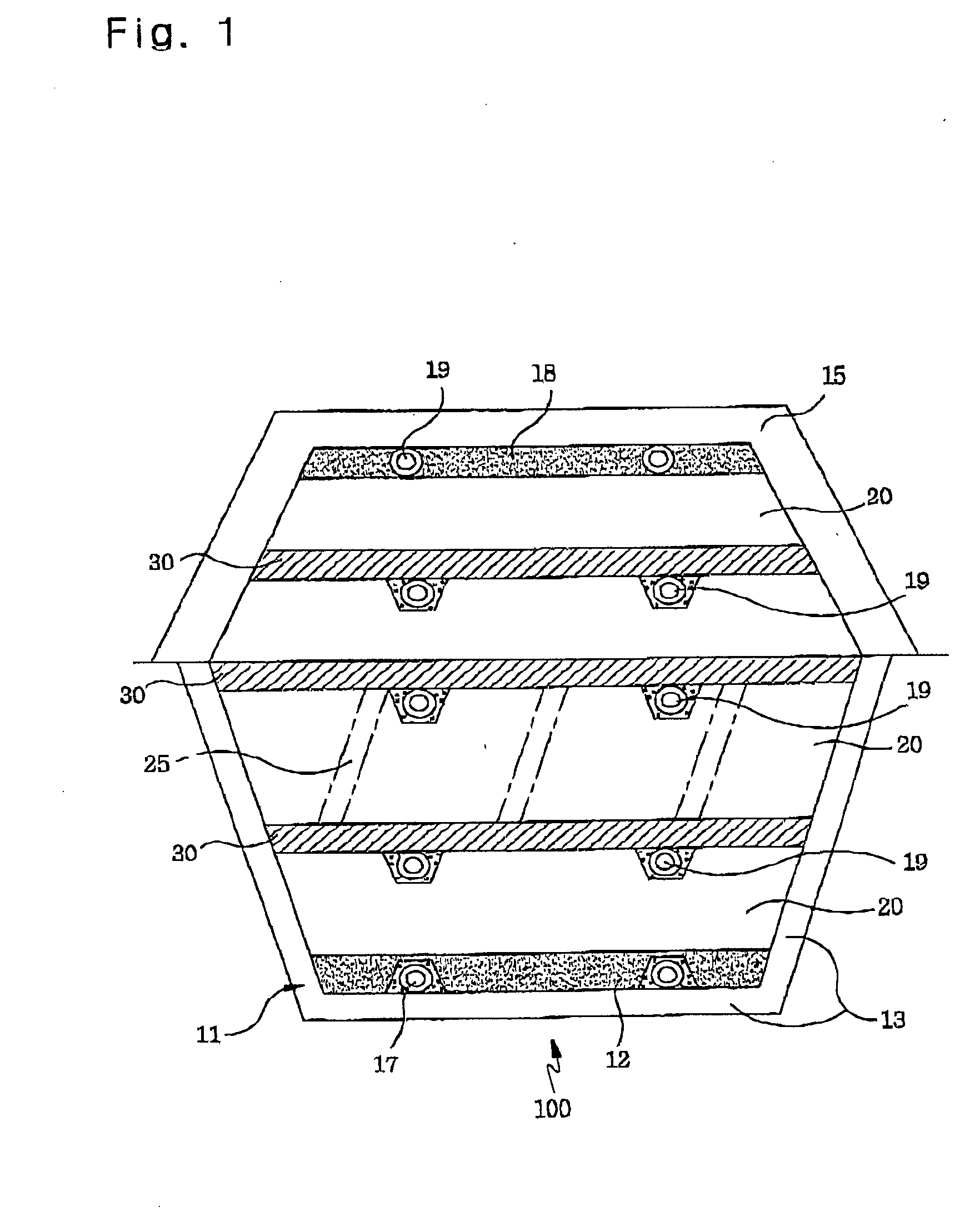

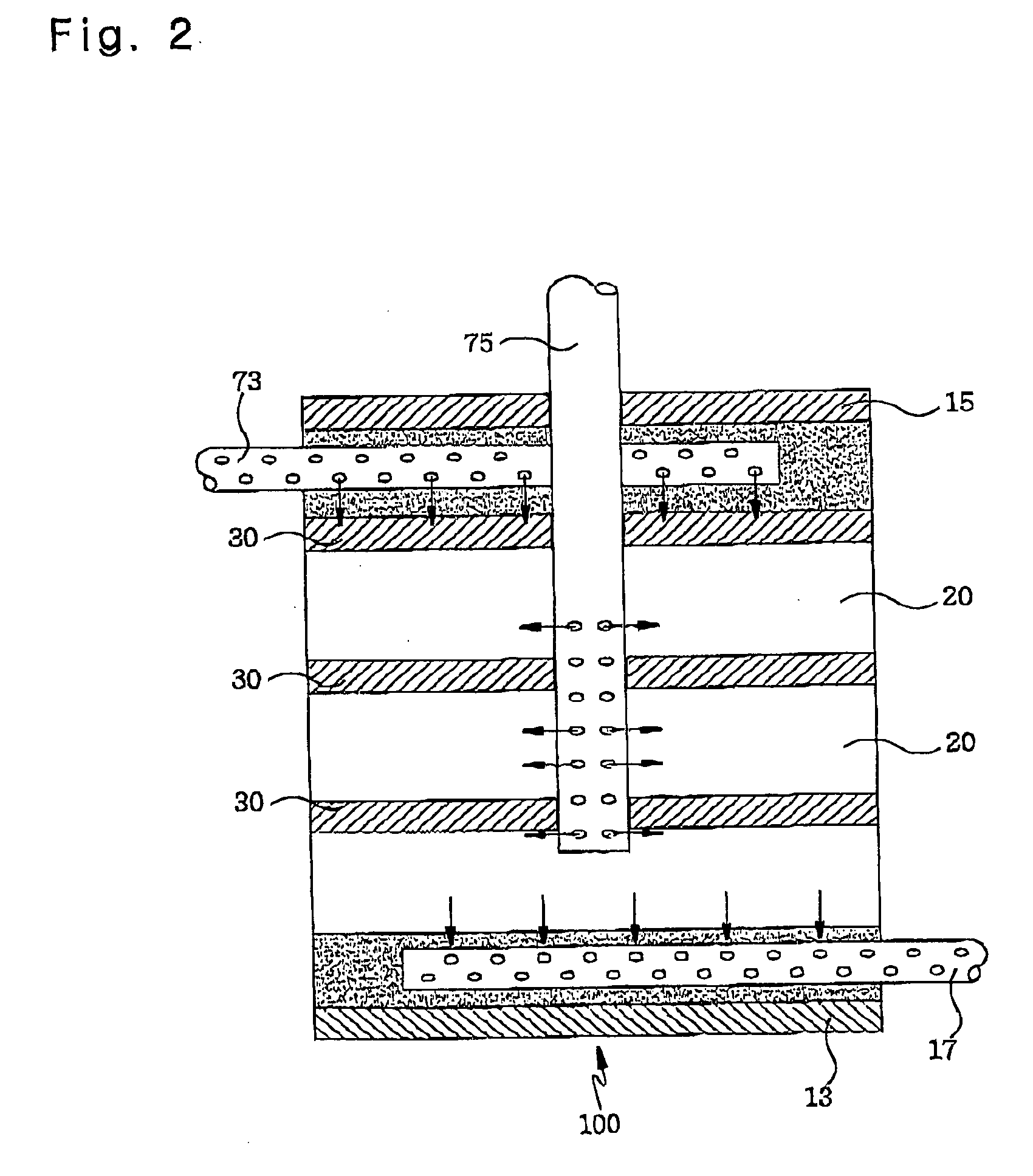

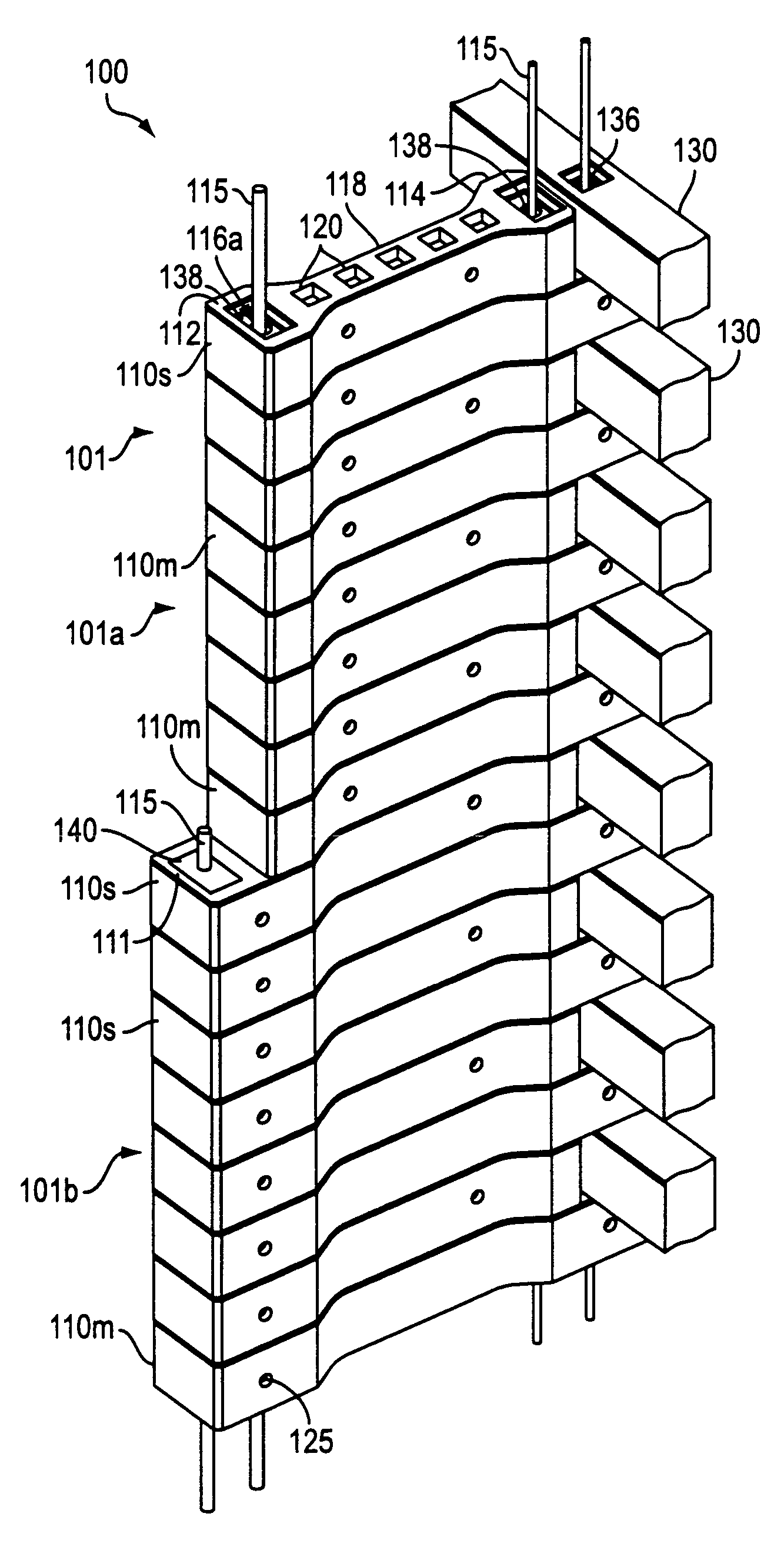

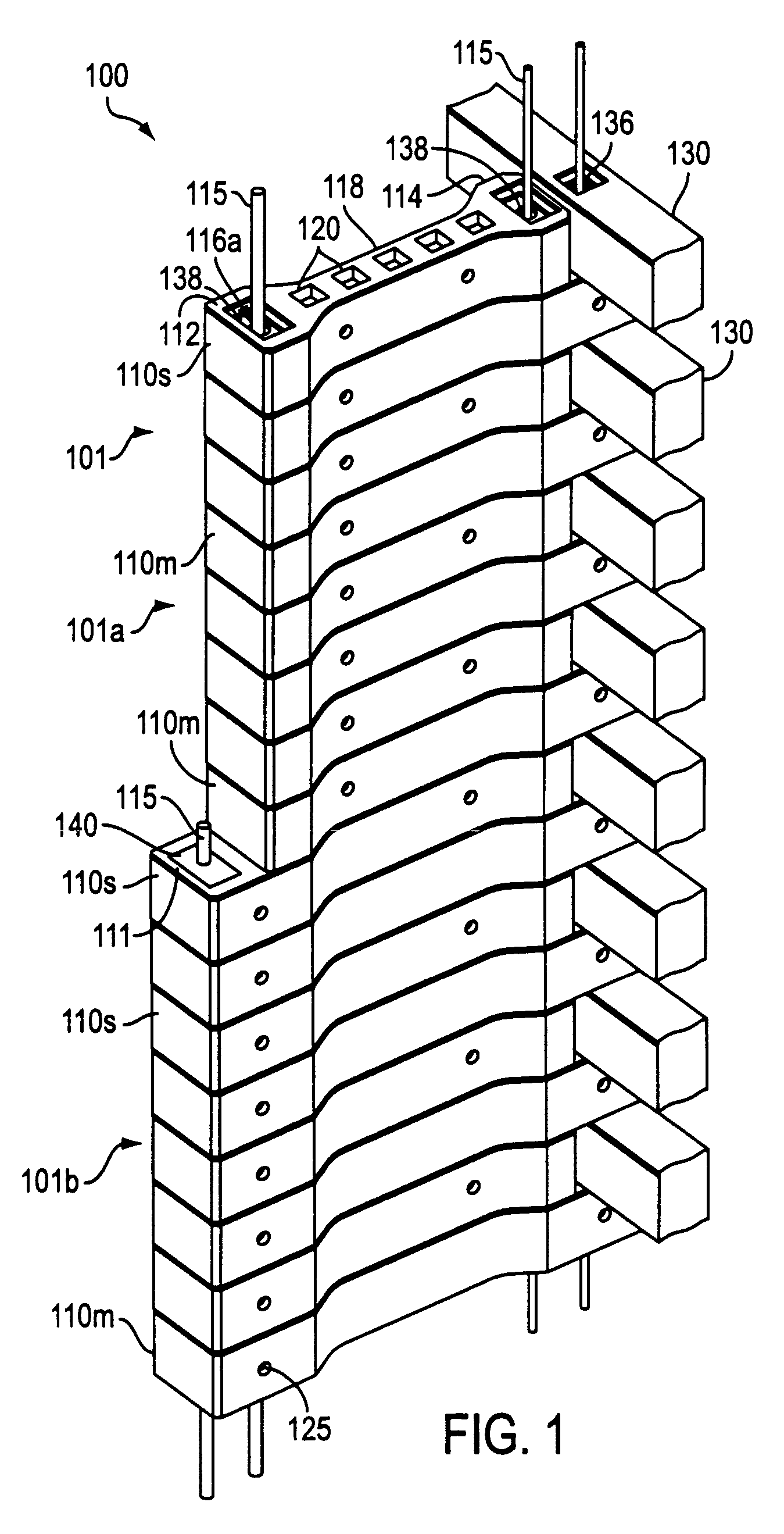

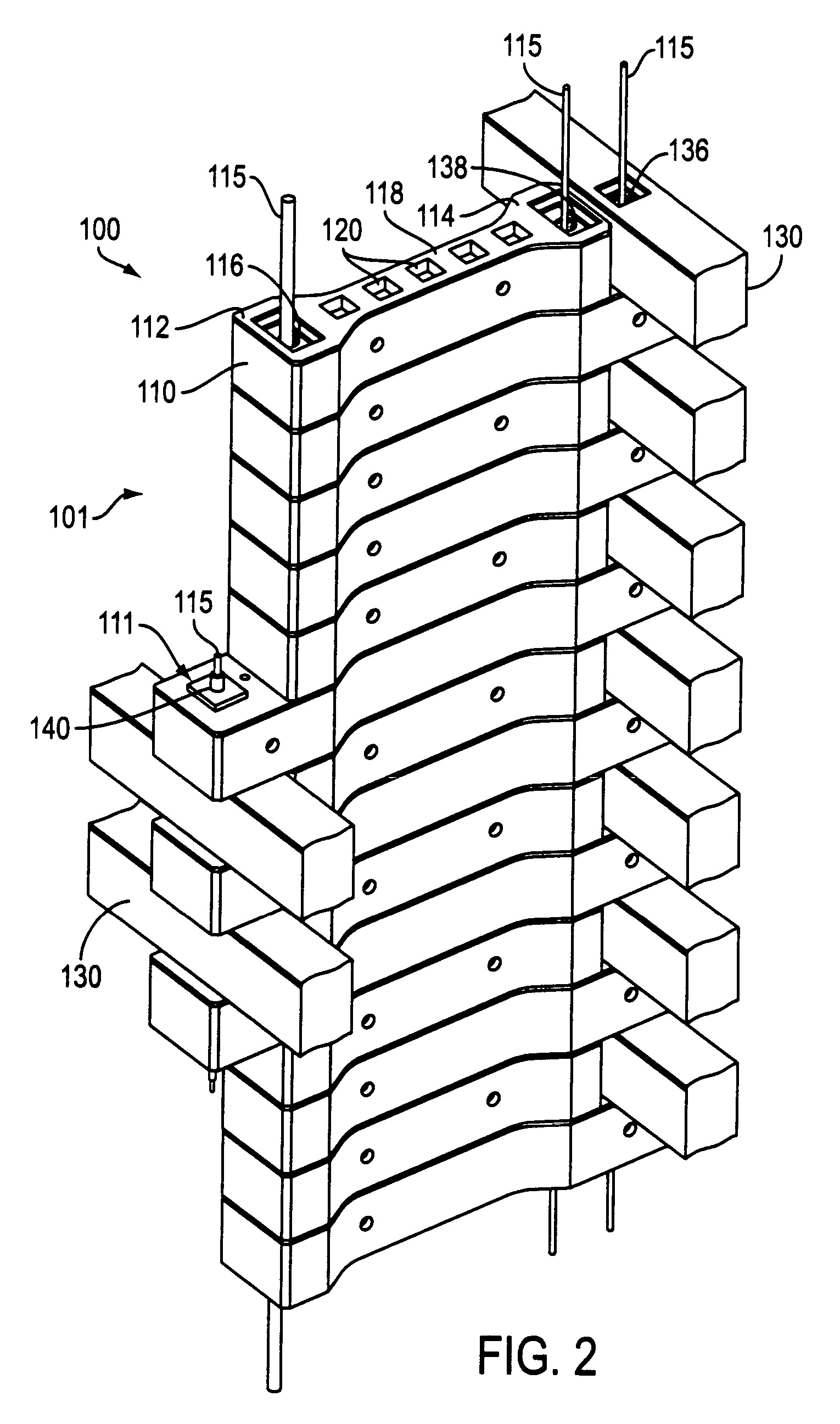

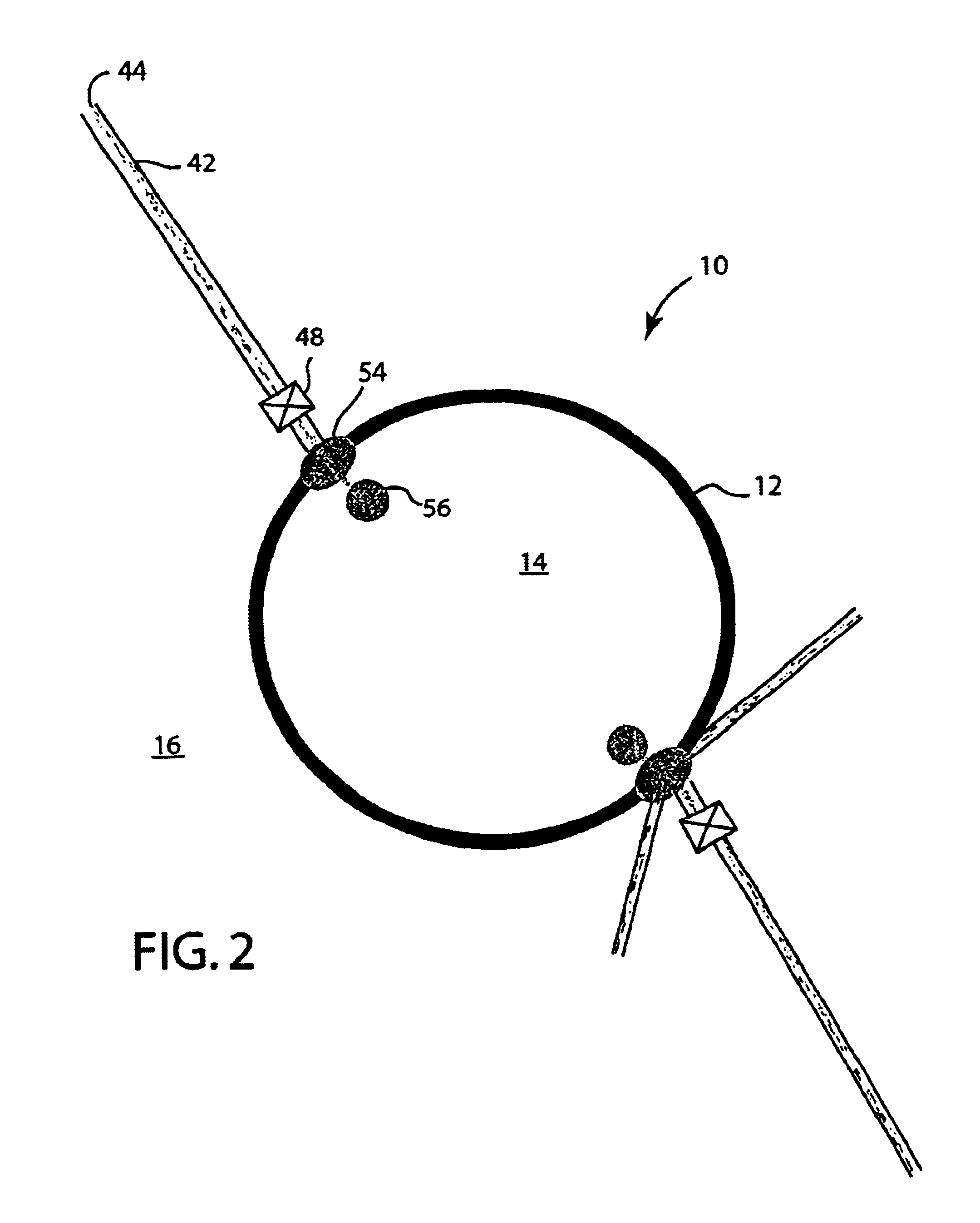

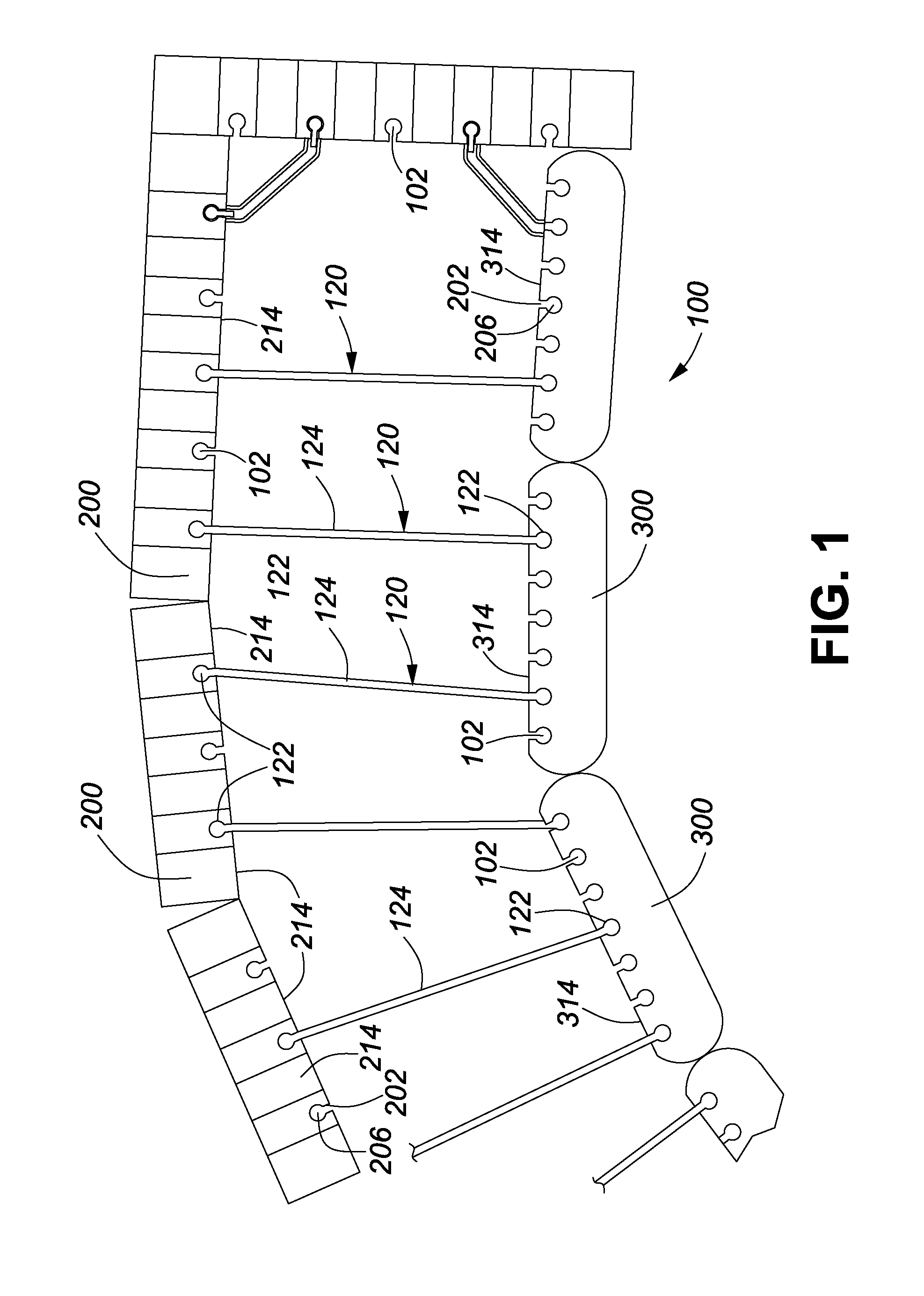

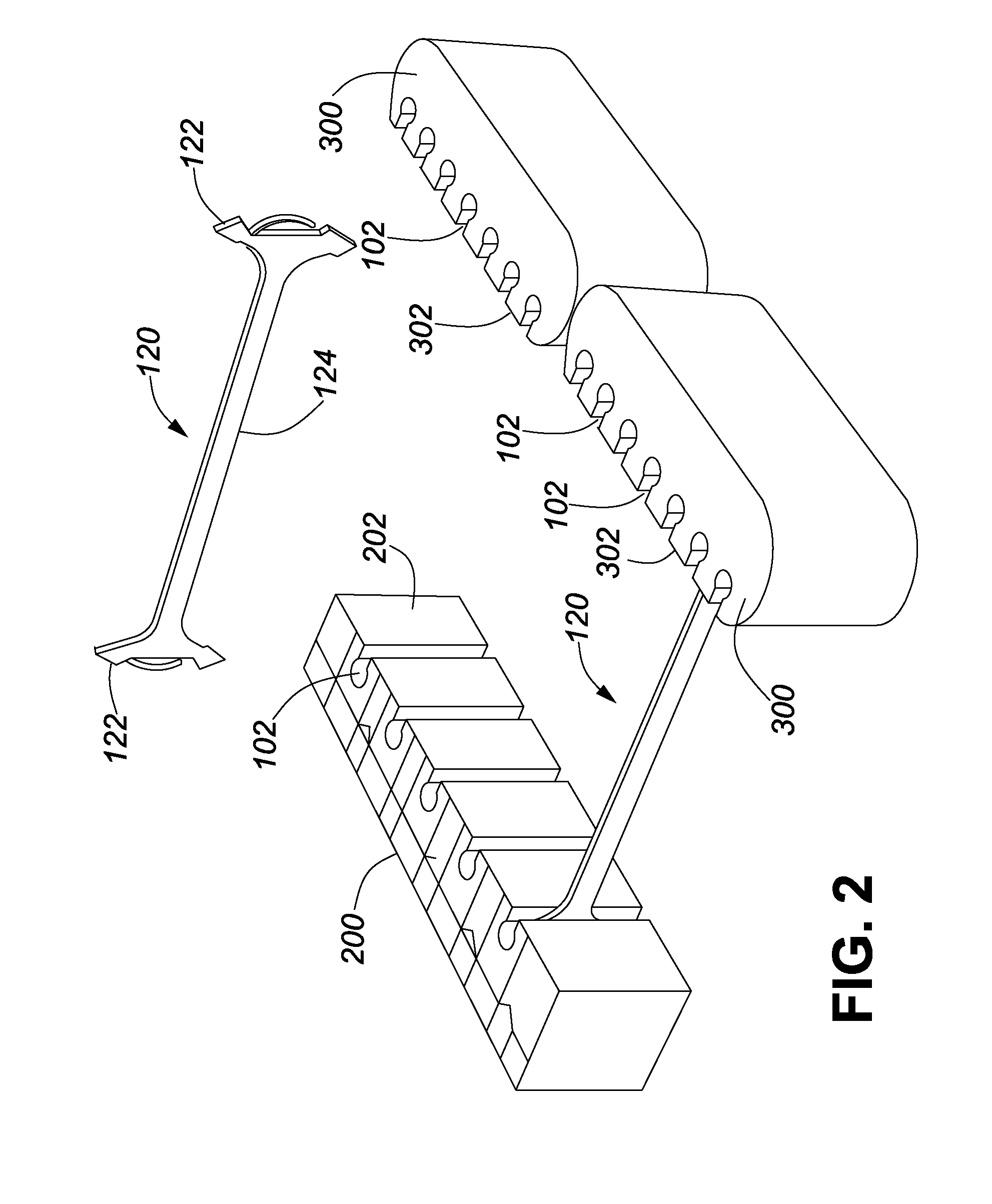

Pre-stressed modular retaining wall system and method

InactiveUS7086811B2Simple structureImprove quality controlArtificial islandsBallastwayPre stressPre stressing

The present invention relates to a system and method for constructing a pre-stressed modular construction for supporting or retaining an applied load. In particular, the present invention relates to a system and method for pre-stressed modular retaining walls. The system comprises a plurality of header stacks constructed from a variety of header units. The header stacks are coupled by structural members. Active reinforcement elements are used to induce a pre-stressing force into the header stacks to support or retain the applied load. A method for constructing the modular construction is provided.

Owner:CGL SYST

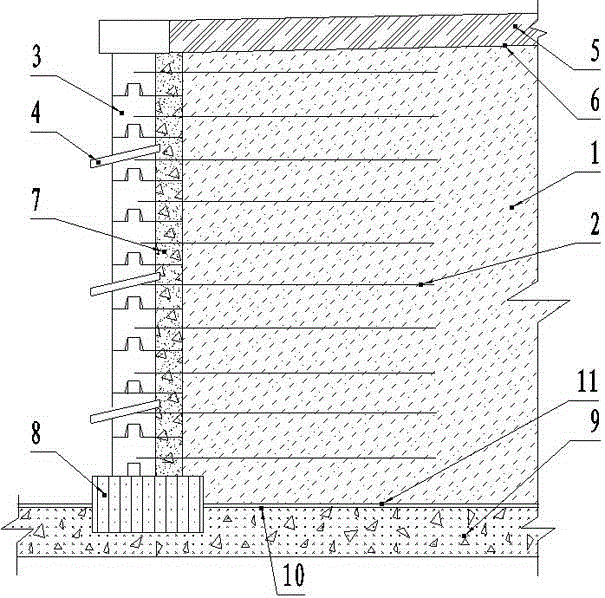

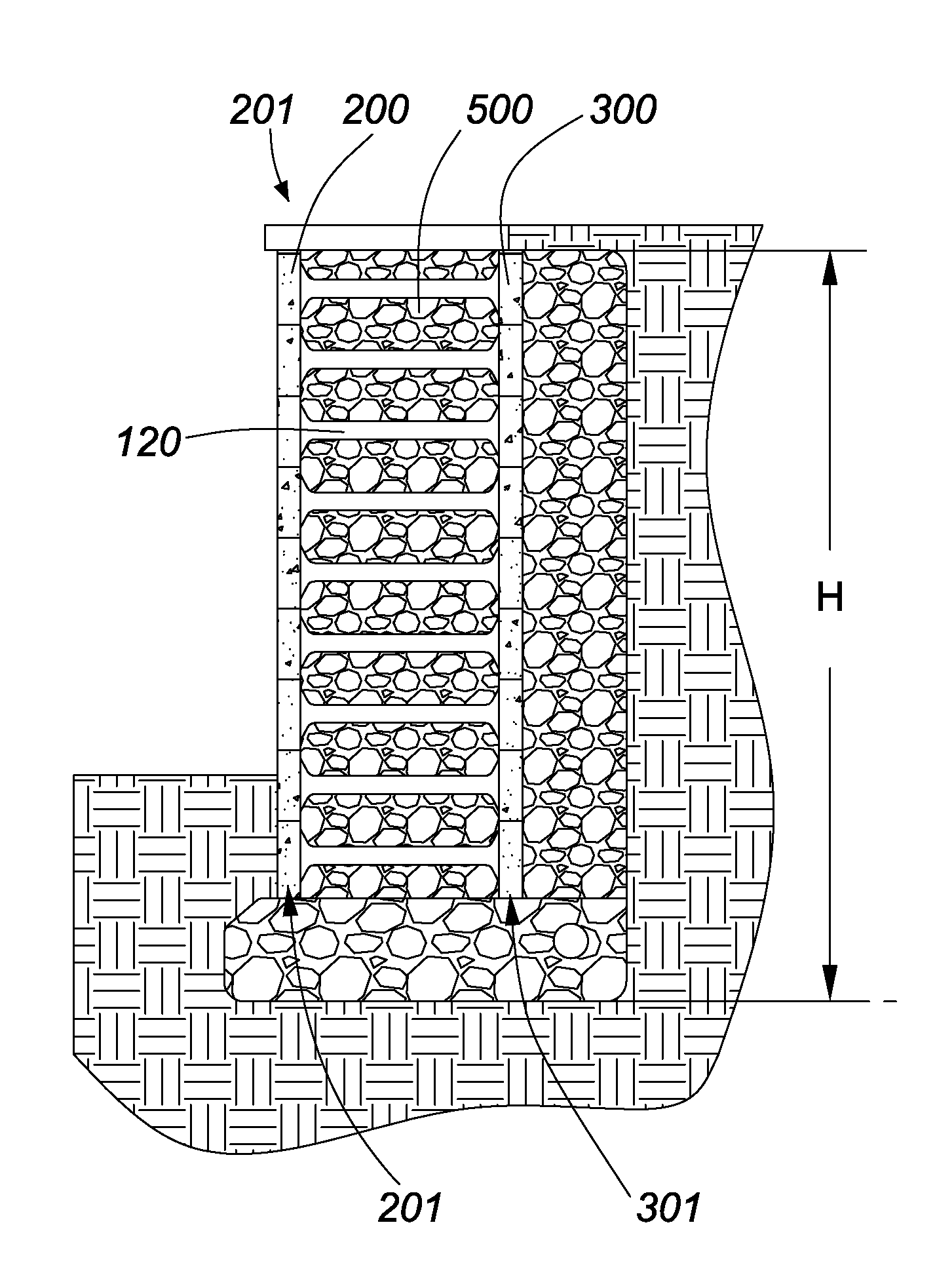

Construction method of retaining wall by a prefabricated module panel geogrid reinforcement tailing sand

ActiveCN104480963AImprove carrying capacityImprove stabilityArtificial islandsEmbankmentsWater dischargeCapillary water

The invention discloses a construction method of retaining wall by a prefabricated module panel geogrid reinforcement tailing sand, which belongs to the technical field of civil construction. The method comprises the steps of processing foundation, prefabricating a concrete module and a sand gravel cushion layer, carrying out the foundation construction, building panels layer by layer, laying a sand gravel reversed filter layer, geogrid reinforcement tailing sand padding and a water discharge pipe, and finally constructing a capping layer. The tailing sand is comprehensively utilized as the padding; the construction speed of the prefabricated concrete module panels is high, so that the retaining wall is good in deformation adapting capacity and stress performance; the first single-direction geogrid is laid in the tailing sand padding layer by layer, so that the stability of the wall body can be improved; two-directional geogrid and nonwoven geotechnical cloth are laid on the bottom gravel cushion layer, so that the stress and deformation can be homogenized, the rising of capillary water can be reduced, and the water discharged out of the retaining wall is filtered; The gravel reversed filter layer and the water discharge pipe, which are arranged between the panel and the tailing sand as well as the composite geotechnical cloth and one film and cement improved soil capping layer, which are laid on the top, can adjust the load on the top of the wall, so that permeation of the rainy water is reduced, and the discharge of the permeated water can be guided.

Owner:SHIJIAZHUANG TIEDAO UNIV

Prevention and treatment method for full-mechanized caving mining collapse trap area water disaster for shallow-buried ultra-thick coal seam

ActiveCN102817366APrevent infiltrationEnsure safetyUnderground miningProtective foundationVegetationTherapeutic effect

The invention discloses a prevention and treatment method for full-mechanized caving mining collapse trap area water disaster for a shallow-buried ultra-thick coal seam, and solves the problem that an especially reasonable and optimal prevention and treatment method is lacked for the prevention and treatment of the mining collapses trap area of the shallow-buried ultra-thick coal seam. A 37 lime earth filling compaction-loess backfilling method is adopted to treat a crack group in the collapses trap area to prevent surface water from infiltrating into an underground working face; a trap bottom surface of the collapses trap area is in a slope design; an HDPE (high-density polyethylene) membrane and a natural pebble bed are used for seepage-prevention and river-diversion processing, backfilling, earthing, and planting herbal vegetation; a side slope of the collapses trap area is provided with a drainage channel so as to prevent a great quantity of rainfall from infiltrating into the underground working face in one time; two roadways of the underground working face are respectively provided with a water-proof valve to separate a mine from a goaf; and the mine safety is guaranteed. The method disclosed by the invention has the advantages of reasonable parameter, low construction cost, good prevention and treatment effect, strong adaptability, good safety and the like, and is especially suitable for the prevention and treatment method for full-mechanized caving mining collapse trap area water disaster for the shallow-buried ultra-thick coal seam.

Owner:DATONG COAL MINE GRP

Phosphogypsum-sludge combined curing treatment method

InactiveCN101579683APrevent affecting the curing effectIn situ pavingsSolid waste disposalSludgePhosphogypsum

The invention discloses a phosphogypsum-sludge combined curing treatment method. The method can combine curing treatment for sludge and industrial waste phosphogypsum produced in civil engineering and hydraulic engineering. The method comprises the following implementation steps: a, measuring the water content of the phosphogypsum, water content of the sludge and clay content; b, fragmentizing the phosphogypsum; c, mixing the phosphogypsum and the sludge; d, adding a curing agent into the mixture; and e, shelving the mixture. The phosphogypsum-sludge mixed aggregates after curing treatment can be used as an earthwork stuffing for paving roads, filling dams and the like, and also can be used as solid wastes to be piled or directly embedded so as to save large amount of heap site selection charge and anti-seepage treatment charge; therefore, the method has large economic benefit and environmental benefit.

Owner:HOHAI UNIV

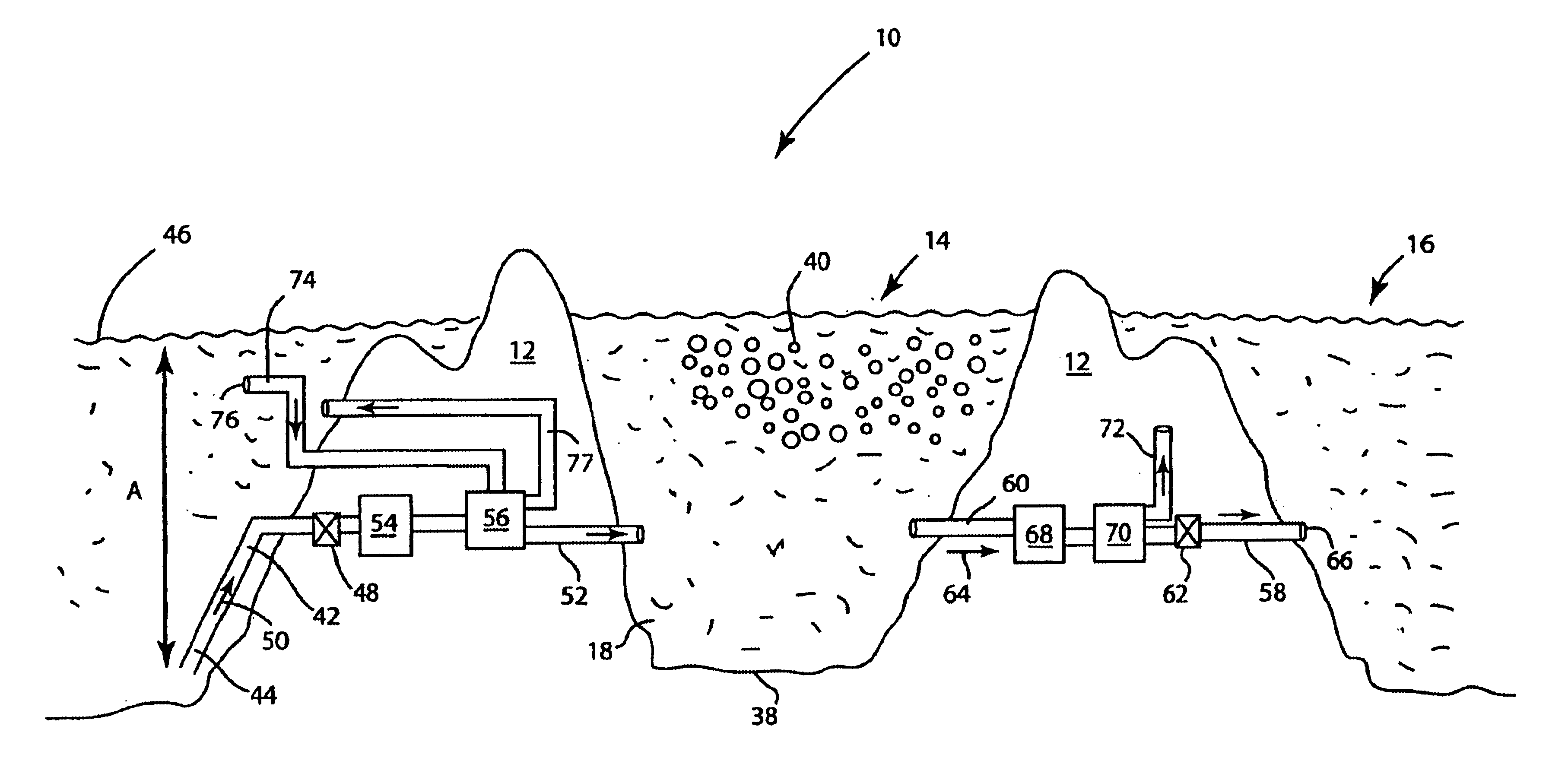

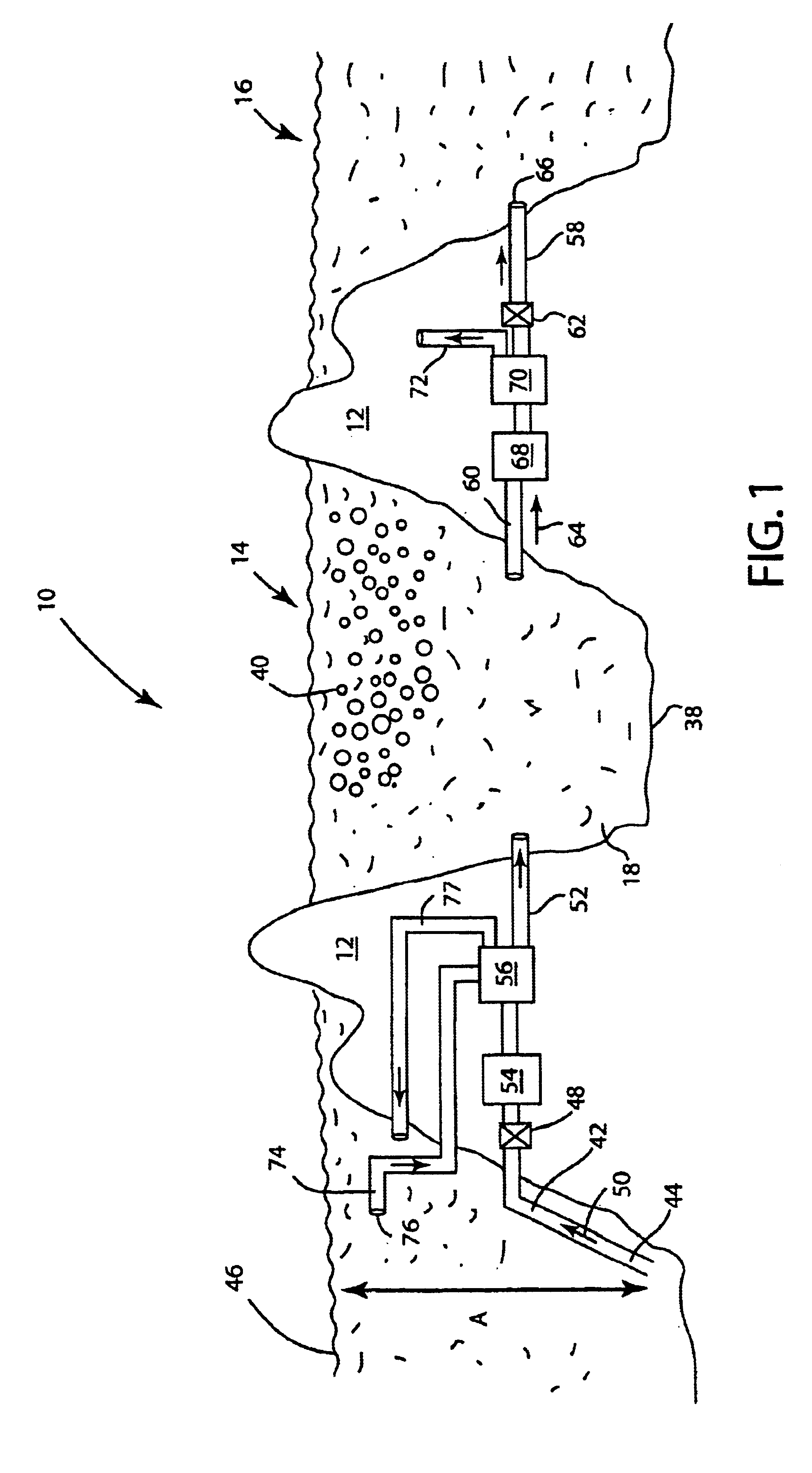

Tidal irrigation and electrical system (TIES)

A tidal irrigation and electrical system used to harness the power of the ocean tide to generate electricity, create sustainable aquaculture, act as a CO2 sink, and generate hydrocarbons. An artificial atoll is created on the continental shelf to define a lagoon completely isolated from the surrounding ocean. As the tides rise and fall, the natural tidal action draws nutrient-rich, cold seawater into the lagoon to stimulate the growth of biolife. As the ocean tide falls, the natural tidal action draws the lagoon water out of the lagoon and through a biofilter to remove the biolife prior to discharge of the water back to the ocean.

Owner:SHERMAN MARTIN T

Retaining wall

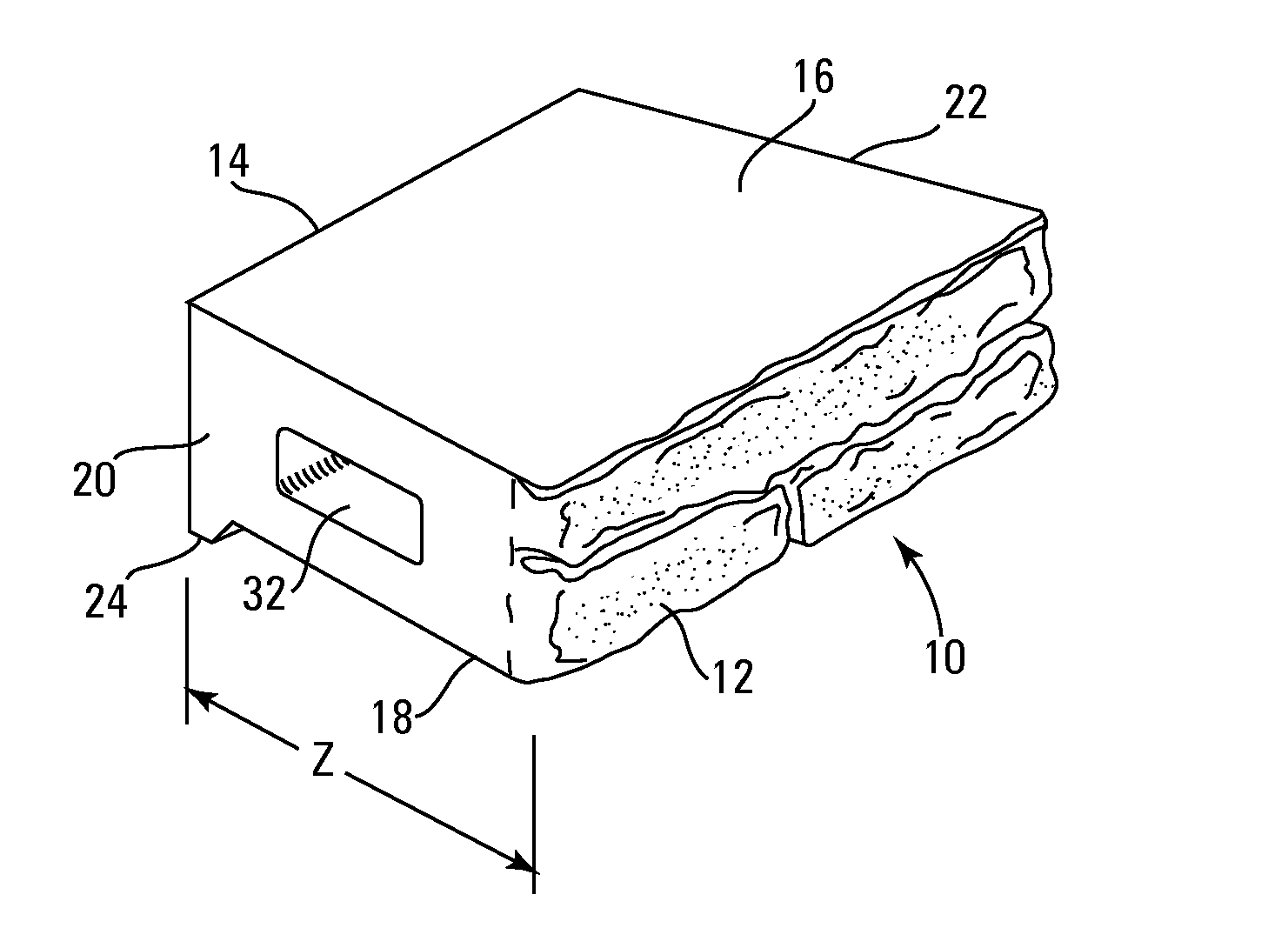

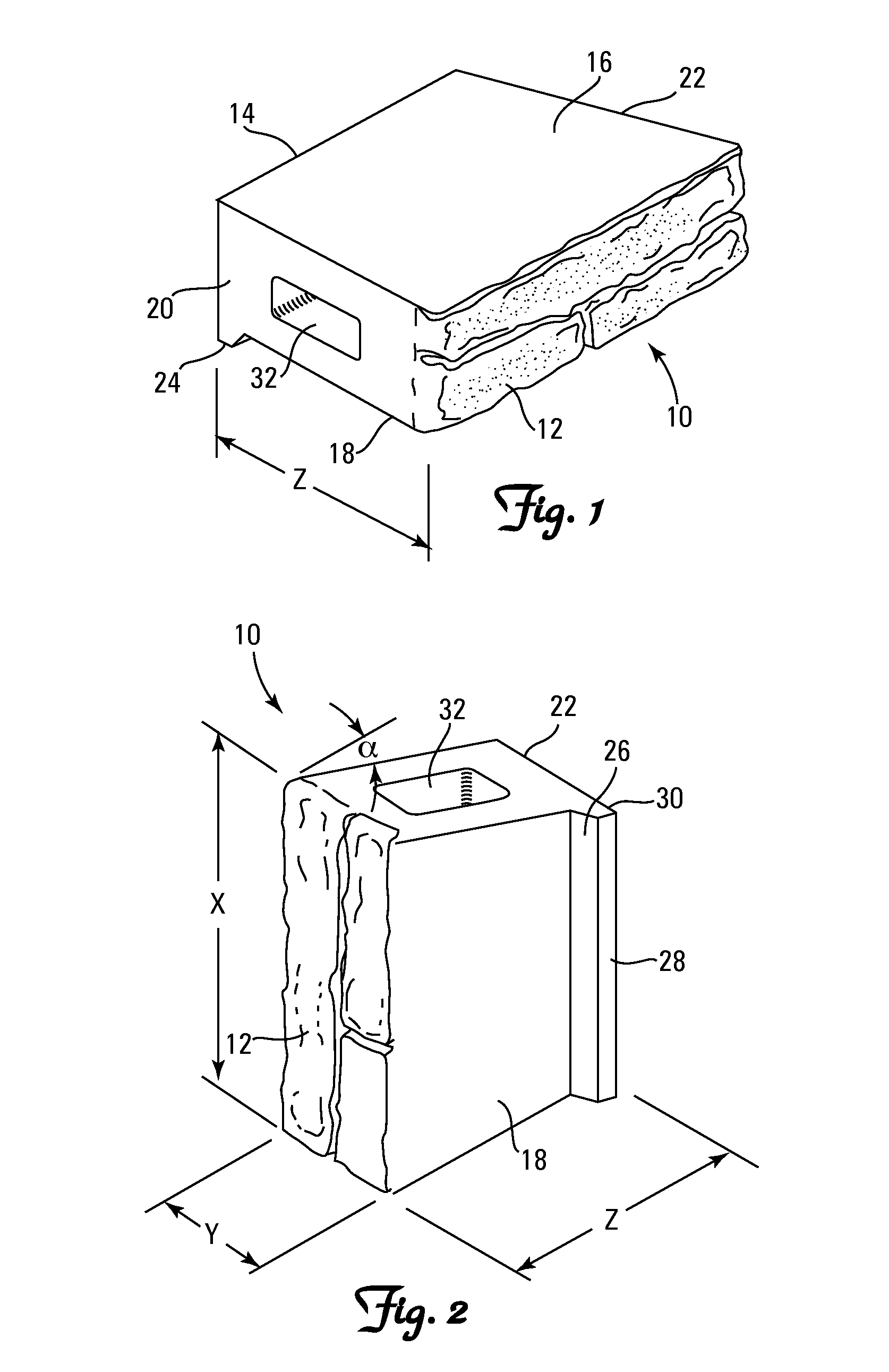

ActiveUS8992131B2Small widthEasy to handle and install manuallyArtificial islandsWallsFilling materialsEngineering

Disclosed is an economical and effective way of producing a modular retaining wall, using only blocks which in and of themselves are of insufficient thickness to function as retaining wall blocks. The modular wall includes backer blocks and facing blocks which are connected by connectors in a back to back, spaced apart arrangement, thereby forming a hollow retaining wall. The hollow wall can be filled with loose filler material to increase the mass and retaining capacity of the wall. Further disclosed are wall components and a wall kit for a modular retaining wall. A double sided decorative wall is also disclosed. The modular wall system allows for the construction of retaining walls and freestanding, double sided, decorative walls forming both straight and curved walls.

Owner:LES MATERIAUX DE CONSTR OLDCASTLE CANADA

X-ray fluuorroscopy device

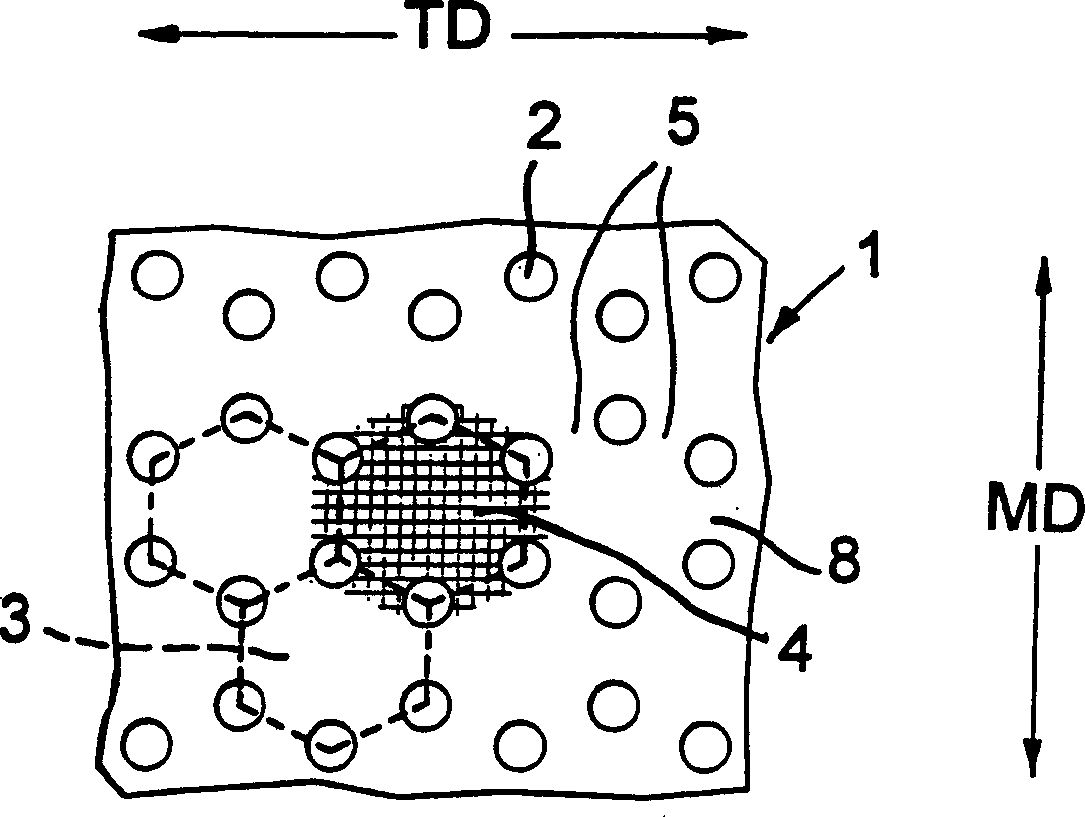

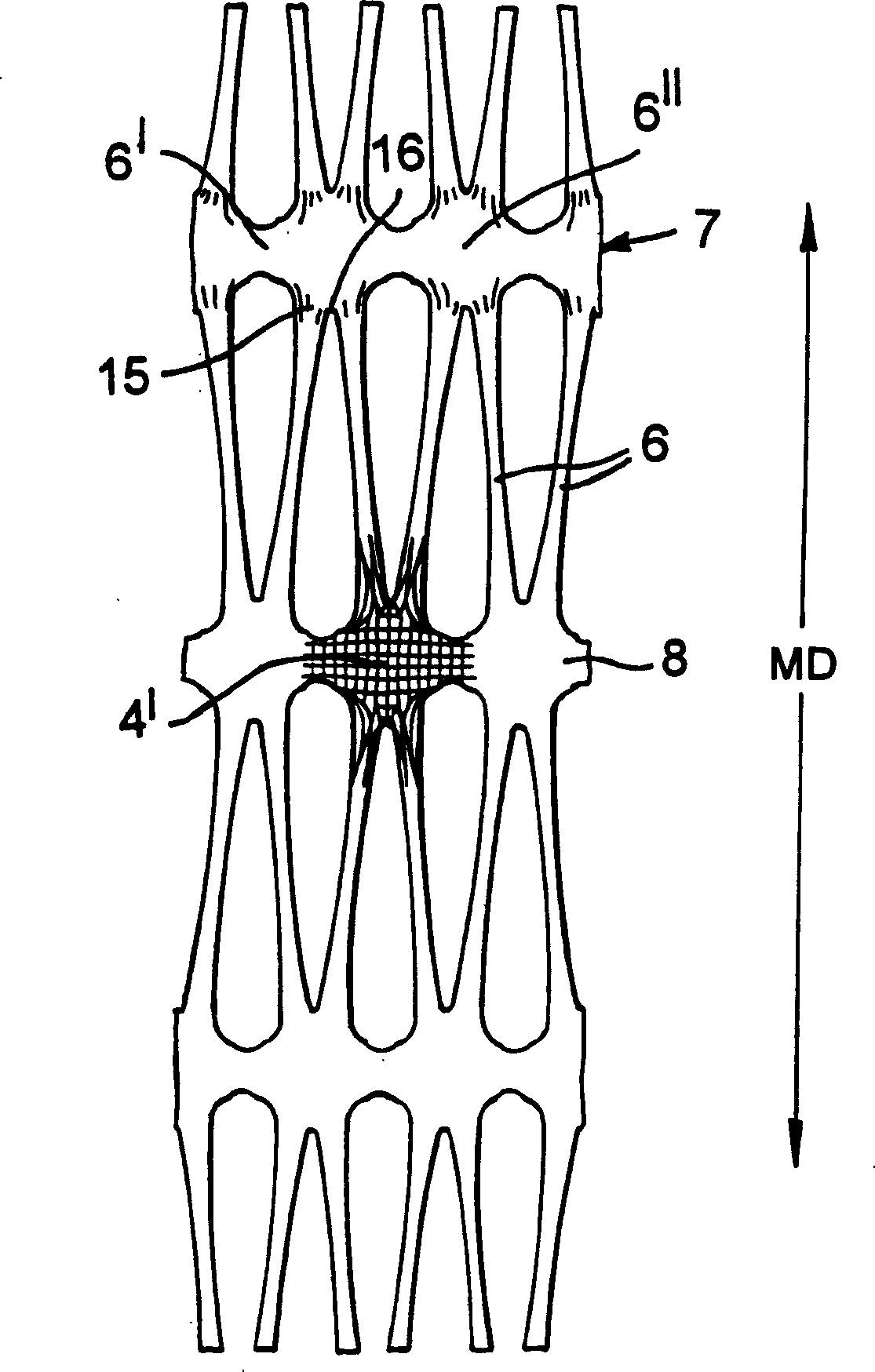

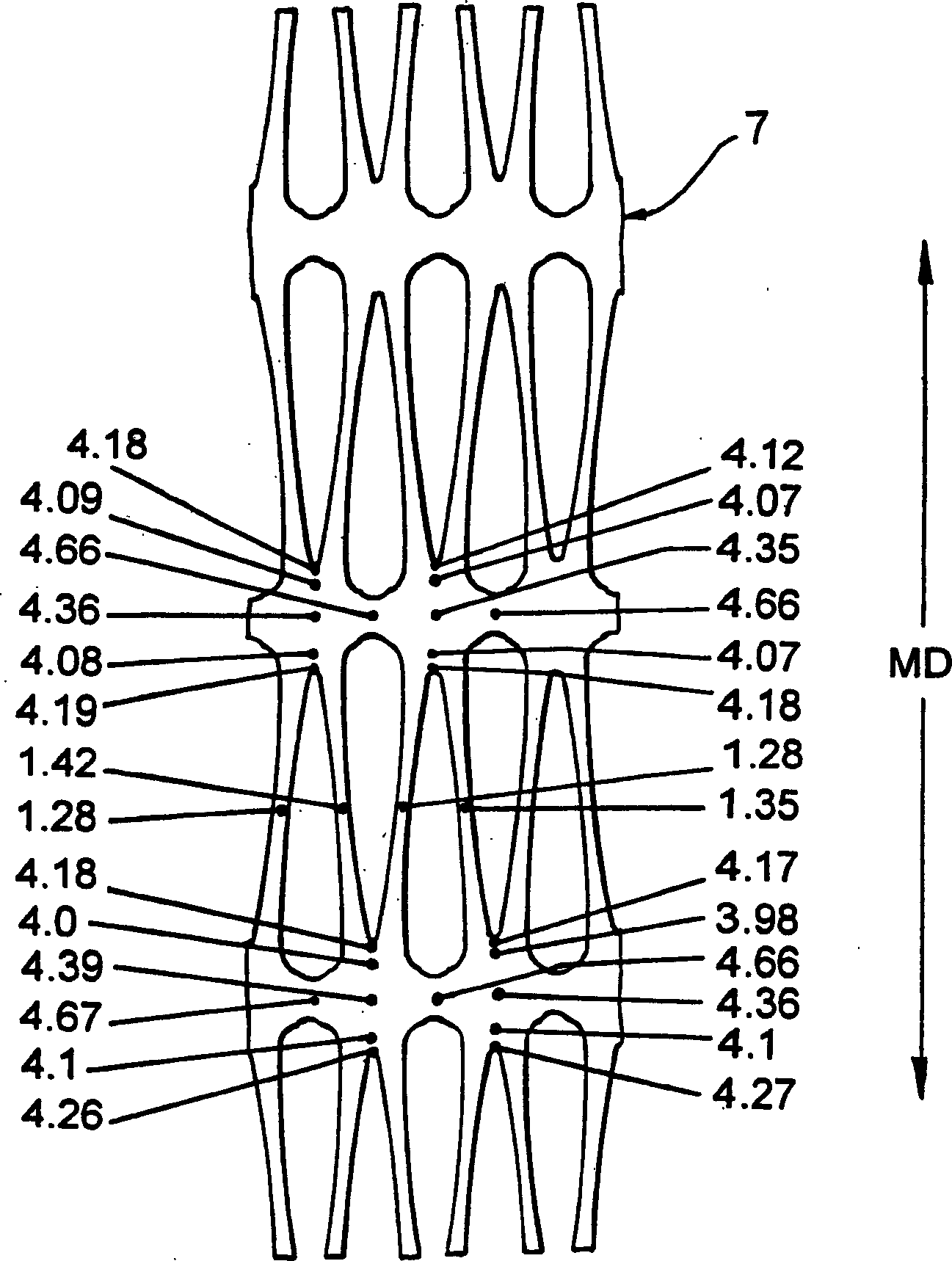

To make an oriented plastics material geogrid in which oriented strands form triangular meshes with a junction at each corner and six of the strands meet at each junction, a plastics material sheet starting material has holes in an array of hexagons, opposite holes of each hexagon being aligned in the machine direction, and the starting material is stretched first in the machine direction and secondly in the transverse direction. In the eventual geogrid, the centre portions of the hexagons in the starting material form the junctions. The centres of the junctions are slightly biaxially oriented, but at the edges of the junctions, the orientation of the edge of substantially each strand runs around the edge of the respective junction and into the edge of the next strand. During the second stretch, restraint can be applied in the first stretch direction and discontinued before the material is allowed to relax in the second stretch direction.

Owner:TENSAR TECH

Panel construction method of concrete faced rock-fill dam

ActiveCN101906768APrevent structural cracksDelay uneven settlementEmbankmentsEarth-fill damsArchitectural engineeringRebar

The invention provides a panel construction method of concrete faced rock-fill dam, sequentially including the following procedures: vertical joint cushion layer and sloping surface renovating, emulsified asphalt spraying, reinforcing steel bar system safety, side form sealing up system safety, slip form system safety, concrete pouring, form removal maintenance and peripheral joint and vertical joint sealing up construction; wherein the concrete pouring adopts 'semi-closed type' chute warehousing, and pouring to the top in one step is carried out on the panel. The panel construction method of concrete faced rock-fill dam provided by the invention can carry out one-step construction of panel, thus reducing differential settlement among various dam materials after panel concrete construction, preventing structural crack of concrete panel after retaining water and avoiding that the top of the primary panel is cavity as construction is carried out by stages, so as to ensure the dam to operate safely.

Owner:SINOHYDRO ENG BUREAU 15

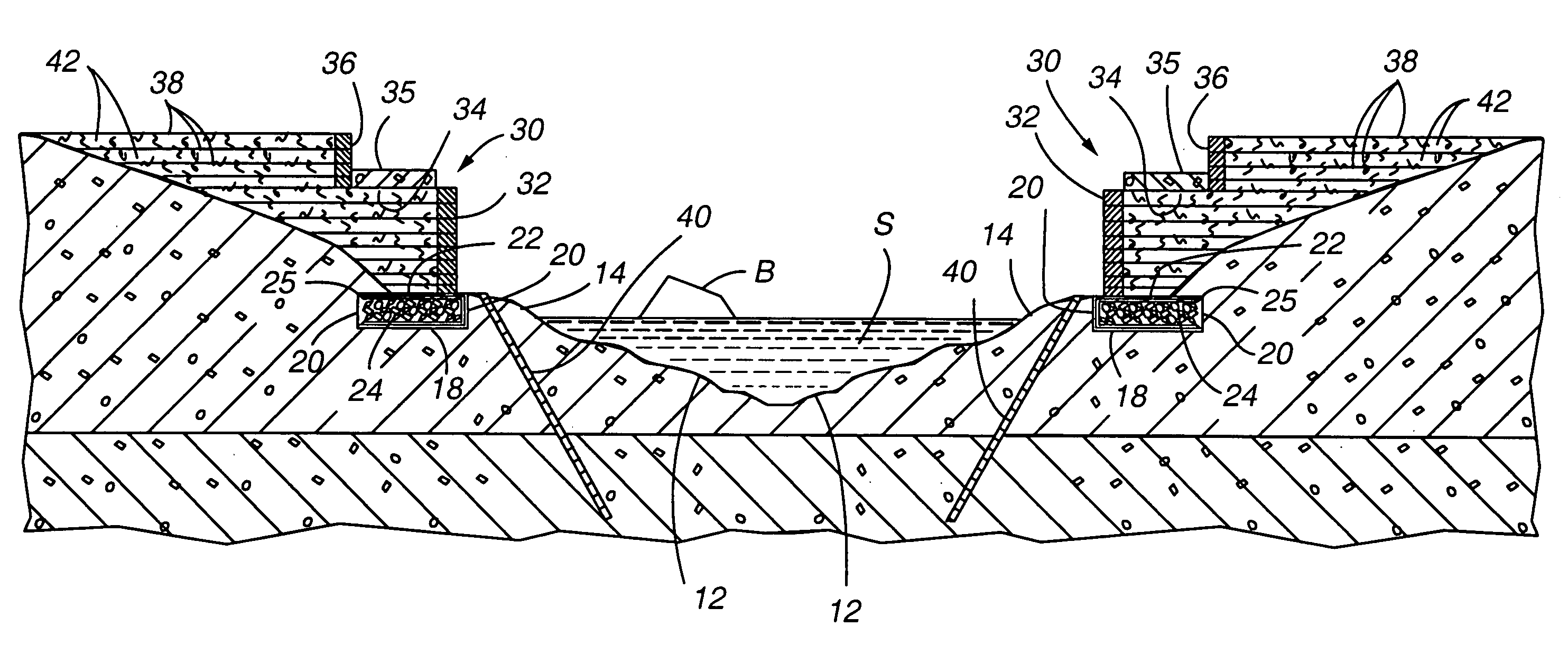

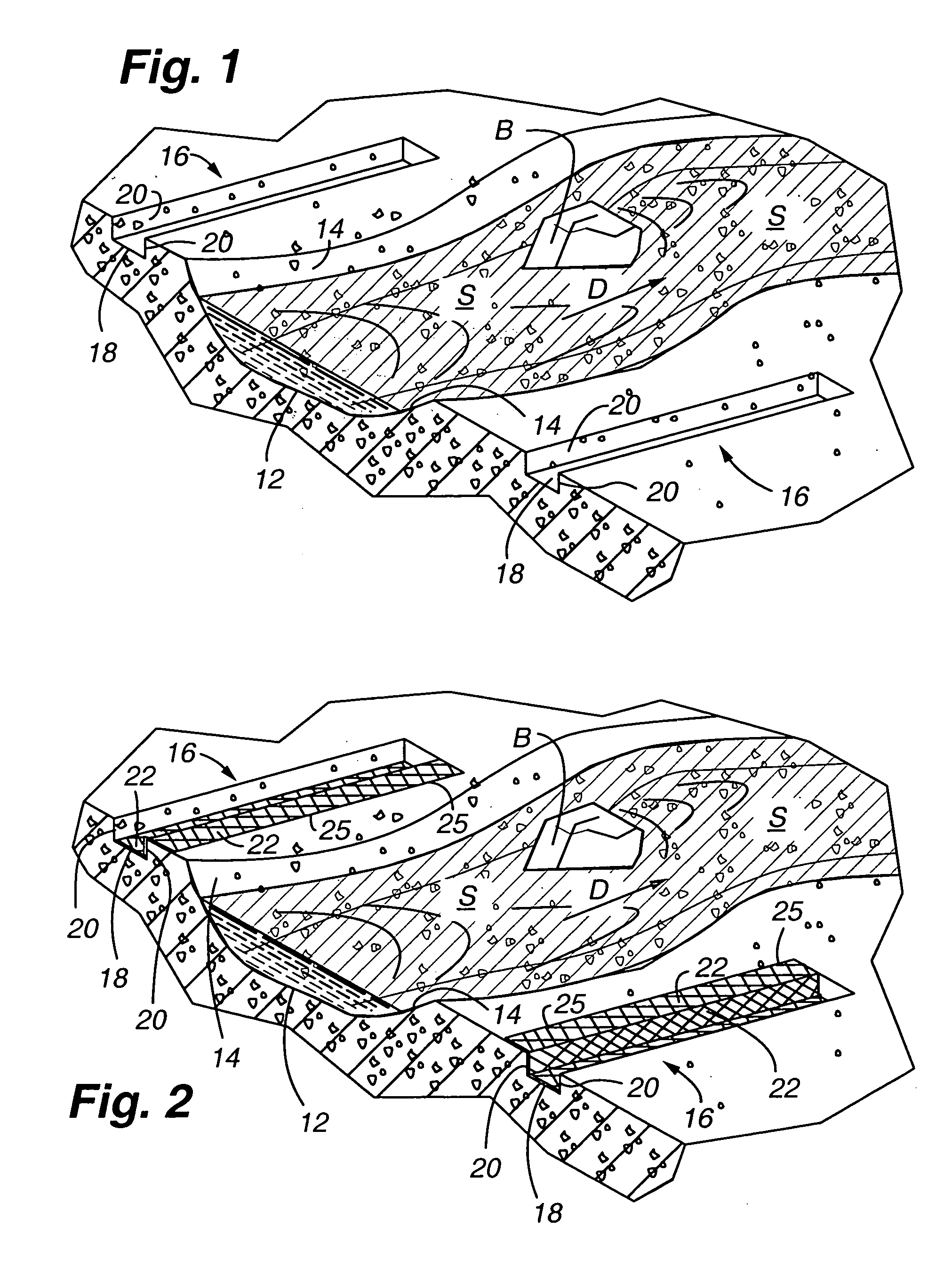

Subsurface platforms for supporting bridge/culvert constructions

ActiveUS6890127B1Prevent and greatly reduce natural scouring actionAvoid actionArtificial islandsProtective foundationEngineeringConstruction aggregate

A scour platform to prevent scour of a moving body of water is constructed by placing an excavation adjacent to the body of water. The excavation is spaced laterally from the body of water and extends up or downstream a desired length. A stabilizing sheet material covers the bottom of the excavation. Aggregate is placed within the excavation over the sheet material, and a free end of the sheet material is then folded back over the upper surface of the emplaced aggregate. Any remaining gaps between the excavation and the sheet material may be backfilled and compacted as necessary. The scour platform is completed once the free end of the sheet material is folded back over the aggregate. For additional prevention of scour, micropiles may be emplaced between the scour platform and the body of water.

Owner:SOIL-NAIL HLDG LLC

Construction method of long open-cut tunnel

ActiveCN101725149ASmall sizeImprove binding efficiencyUnderground chambersEmbankmentsWater levelGround water level

The invention discloses a construction method of a long open-cut tunnel, comprising the following steps of: after reducing ground water level by utilizing precipitation of a tube well, carrying out the slope excavation to be the designed height, sequentially constructing a bed course, waterproof roll and inverted arch and filling, carrying out secondary lining by using inner and outer mould trolleys, constructing external coverage and waterproof engineering, back-filling and compacting. The invention has the advantages that: the construction method has strong scene maneuverability, is easy to popularize, ensures the construction safety, and improves the construction quality of the long open-cut tunnel.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

Dry heaping and wet discharging combined tailing heaping and discharging method

ActiveCN103397645AGuaranteed continuitySolve the heap problemBarrages/weirsEmbankmentsTailings damWater discharge

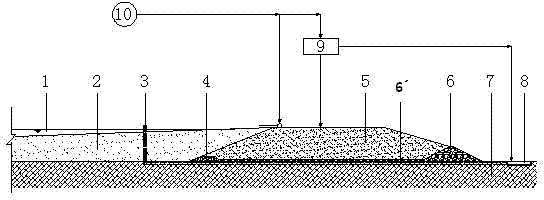

The invention discloses a dry heaping and wet discharging combined tailing heaping and discharging method. Tailing slurries are discharged from a dressing plant (10), part of the tailing slurries enter a pressing and filtering dehydration workshop (9) to be dehydrated and filtered, dry tailings are used for piling up a dry tailing dam (5), the left tailing slurries are transferred to the inner side of the top of the dry tailing dam (5) to be discharged into a tailing bank, and wet tailings (2) are deposited on the upstream slope of the dry tailing dam (5); at the beginning of the formation of the dry tailing dam (5), a cofferdam (4) used for blocking the wet tailings (2) and floods is arranged on the inner side of the bottom of the dry tailing dam (5); a horizontal water discharging member (6') between the bottom of the dry tailing dam (5) and a dam base (7), and a prismatic water discharging member (6) is arranged at the downstream slope toe of the dry tailing dam (5). By the method of heaping and discharging granule tailings, the problem of difficulty in piling up the dam with the granule tailings can be solved, mine construction speed can be increased, tailing tank investment and operation cost are reduced, and economic benefits of the mine are improved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Loess high fill in hill removing and gully filling projects and construction method of loess high fill

InactiveCN106193062AImprove seismic performanceImprove vibration resistanceEmbankmentsSoil preservationGeomembraneCrushed stone

The invention discloses loess high fill in hill removing and gully filling projects and a construction method of the loess high fill, and relates to the technical field of high fill processing. The loess high fill and the construction method are used for solving the problem that in the prior art, because of high fill deep excavation, saturated yielding is caused and finally differential settlement of foundations and side slope deformation damage are caused. The loess high fill in the hill removing and gully filling projects is sequentially composed of a lime pile composite foundation layer, a rubble water drainage layer and a loess layer from bottom to top. By means of the loess high fill in hill removing and gully filling projects and the construction method of the loess high fill, the compression strength, tensile strength and shear strength of the whole loess high fill are improved, and the anti-seismic and anti-shock performance of the loess high fill are enhanced; and by laying and combining a composite geomembrane, a rubble layer and a three-dimensional composite water drainage net, water drainage channels inside the high fill are formed, and the phenomenon that because of high fill deep excavation, saturated yielding is caused and finally differential settlement of the foundations and side slope deformation damage are caused is effectively eliminated.

Owner:NORTHWEST UNIV(CN)

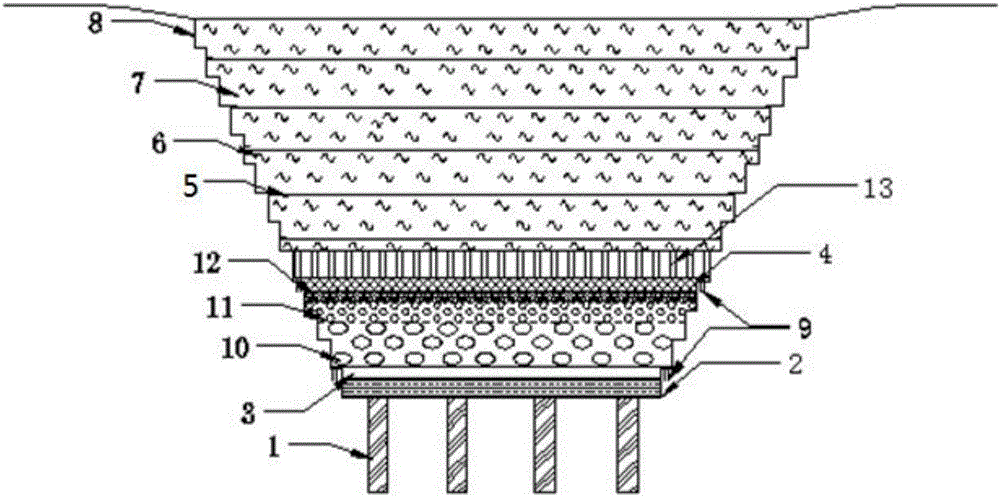

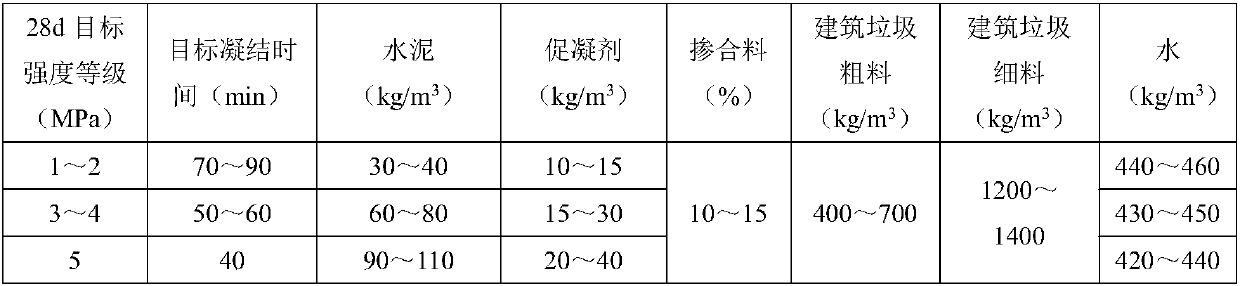

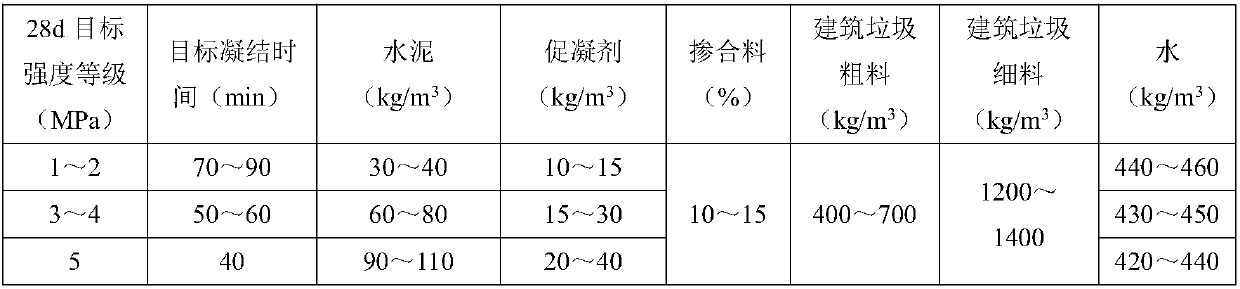

Road pipe trench quick backfill material produced with building wastes and construction technology thereof

The invention discloses a road pipe trench quick backfill material produced with building wastes and a construction technology thereof. The backfill material is prepared by mixing a building waste renewable coarse material, a building waste renewable fine material, cement, sprayed concrete coagulator shrinkage reducing agent, admixture and water. Building waste renewable products are classified and managed strictly in specification and quality, and are treated with other engineering technologies, so that the material fully utilizes building waste renewable aggregates of various specifications,and meets the technological requirements of pipe trench backfill and requirement of quick setting and hardening at the same time; the hardened material is adjusted in mechanical strength according toengineering need, 2h strength adjustment range is 0.2-1.0MPa, and 28d strength adjustment range is 1.0MPa-6.0MPa. The material utilizes building waste renewable materials generated in city construction to the maximum degree and is quick hardening, early strengthening low-strength concrete suitable for backfilling of city road pipe trenches and grooving.

Owner:BEIJING UNIV OF TECH

Technology for increasing capacity of tailings site by building dam along fixed axis

InactiveCN1356436ALarge expansion capacityGood stability and securitySolid waste disposalEmbankmentsCycloneMining engineering

A technology for increasing the capacity of tailing site for metal mine features that the dam of the said tailing site is further built upward vertically along the axis of upper sub-dam and a hydraulic cyclone is used to discharge the coarse particles outside the damp and stack the fine particles inside the dam. Its advantages include high effect, and high safety.

Owner:王柏纯

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com