Technology for increasing capacity of tailings site by building dam along fixed axis

A technology of tailings storage and axis, which is applied in the field of heightening and expansion technology of metal ore tailings storage, which can solve the problems of low structural strength, high dam soaking line, long construction period, etc., and achieve good safety and stability and significant social benefits , The effect of low annual operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

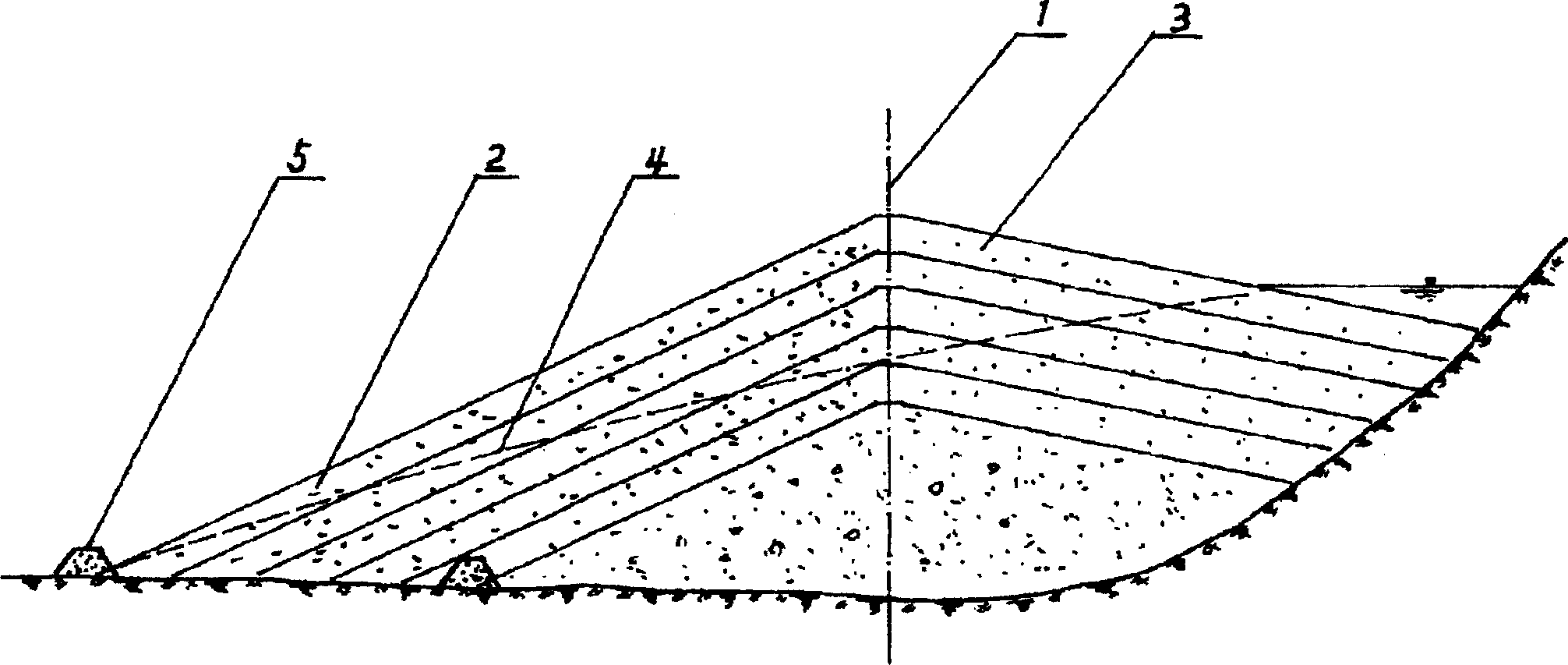

[0008] Taking the tailings pond of Tongban Stone Mining Company as an example, the tailings pond is currently dammed by the upstream method, and it is currently at the end of its storage capacity and service life. The warehouse is heightened and expanded to solve the problem of continuous storage of tailings. With the uppermost sub-dam in the current production state as the fixed axis 1, the dam is built vertically in layers, and the tailings slurry is classified into coarse and fine particles by a hydrocyclone, and the coarse-grained tailings are discharged outside the dam to form a tailings sink. The sand accumulation body 2 and the fine-grained overflow tailings are filled into the reservoir to form a sedimentary body 3, thereby increasing the height of the original tailings reservoir. A water filtration rockfill dam 5 is built downstream of the dam 210m away from the fixed axis of the dam to protect the stability of the slope toe of the final dam body. In order to ensure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com