Patents

Literature

1843results about How to "Solve for uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

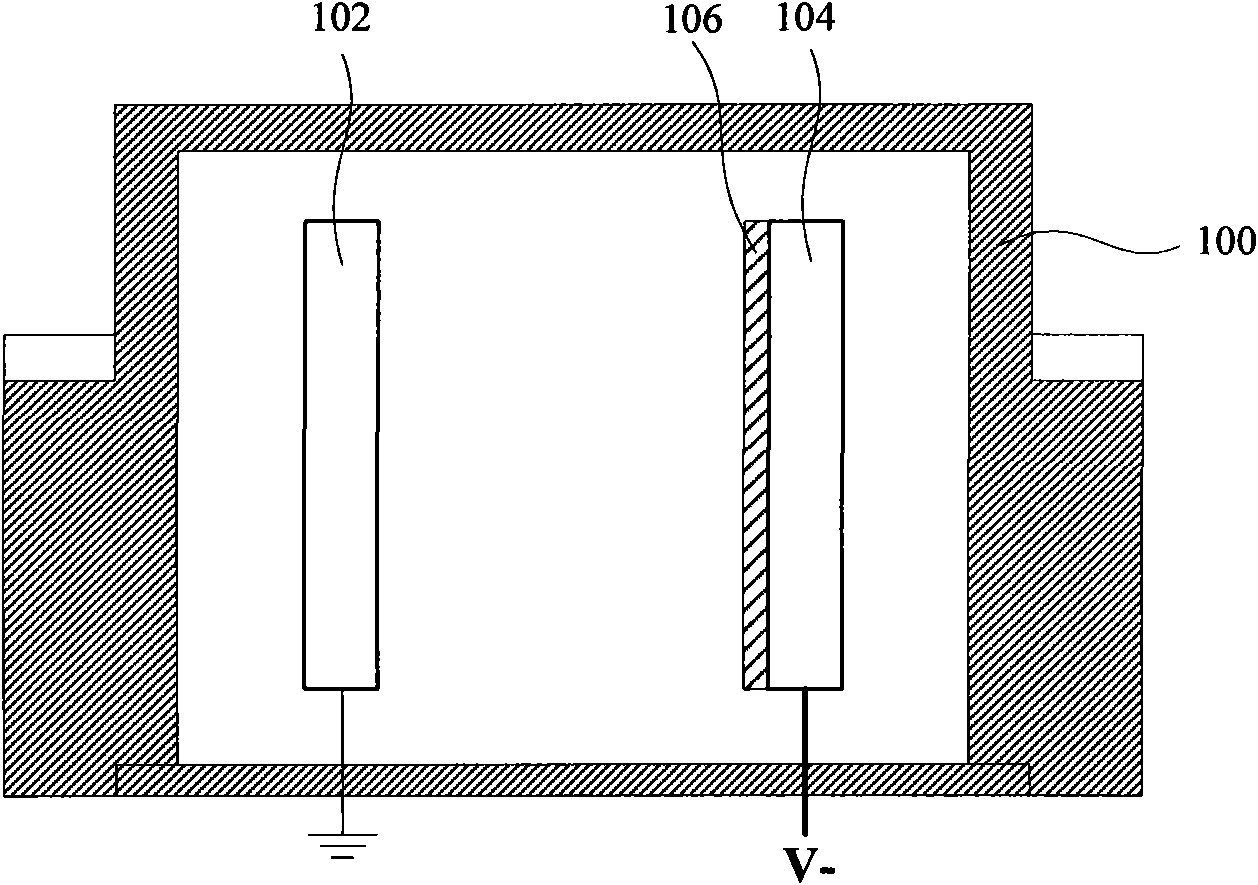

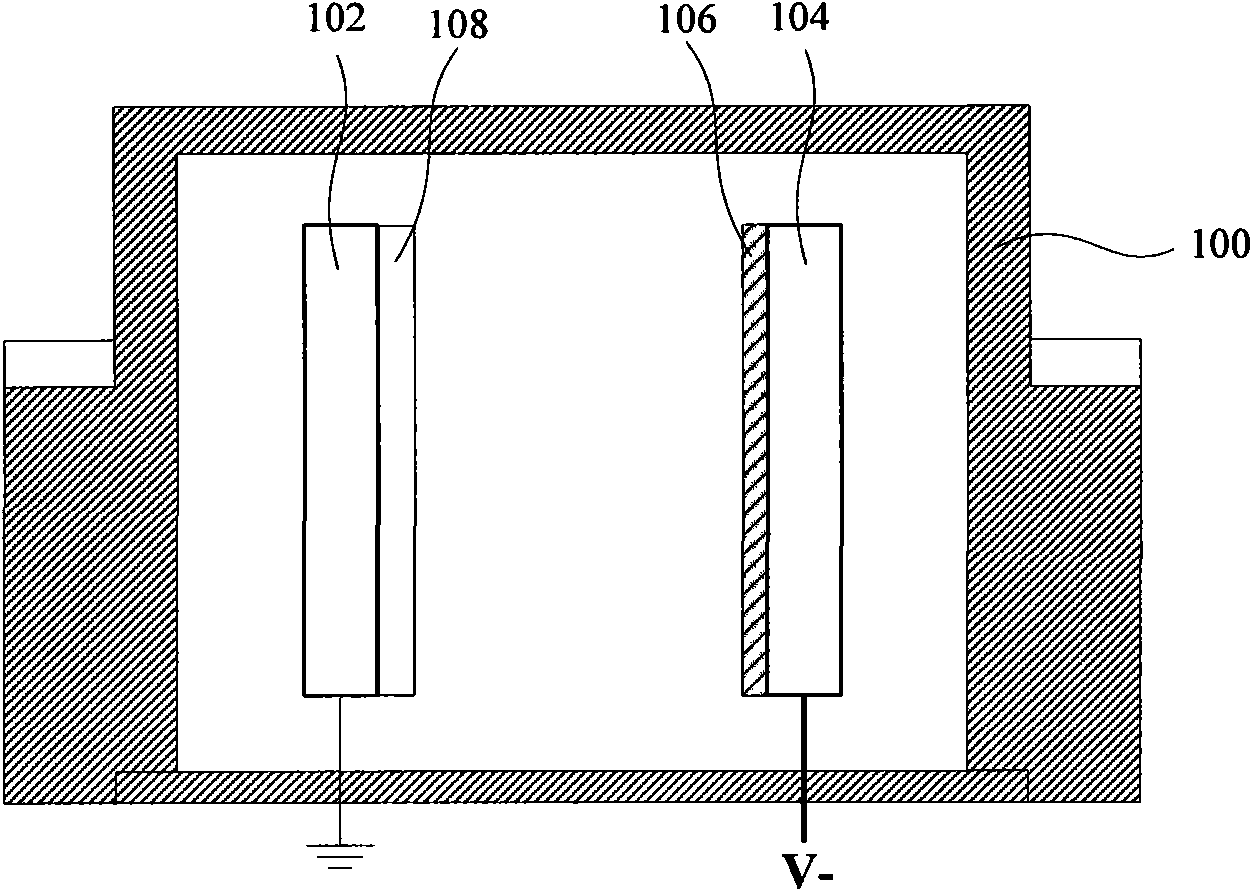

Film deposition method

InactiveCN101609858ASolve the problem of uniformity of depositionSolve for uniformityFinal product manufactureVacuum evaporation coatingReaction chamberNanotechnology

The invention discloses a film deposition method which comprises the following steps: placing a first electrode plate used as an anode and a second electrode plate used as a cathode in parallel in a reaction chamber, wherein the surface of the second electrode plate facing to the first electrode plate is provided with a sacrificial layer; putting a substrate on the surface of the first electrode plate facing to the sacrificial layer; leading etching gas into the reaction chamber; grounding the first electrode plate, and applying DC negative voltage to the second electrode plate; ionizing the etching gas into a plasma so as to etch the sacrificial layer, and depositing a film on the surface of the substrate. The film deposition method can improve the performance, particularly the stability of the film and the uniformity of large-area film deposition.

Owner:GS SOLAR FU JIAN COMPANY +1

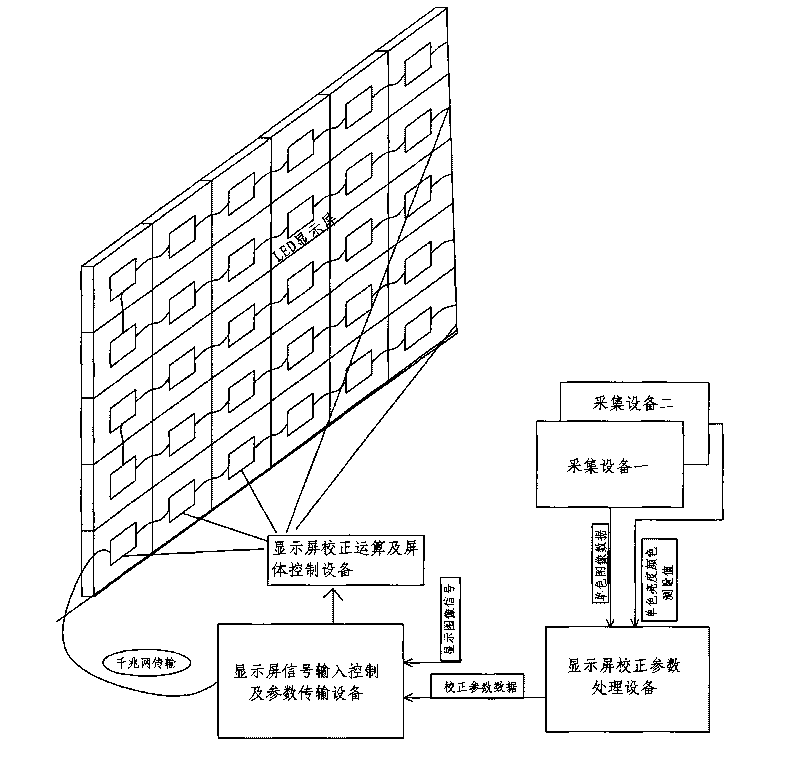

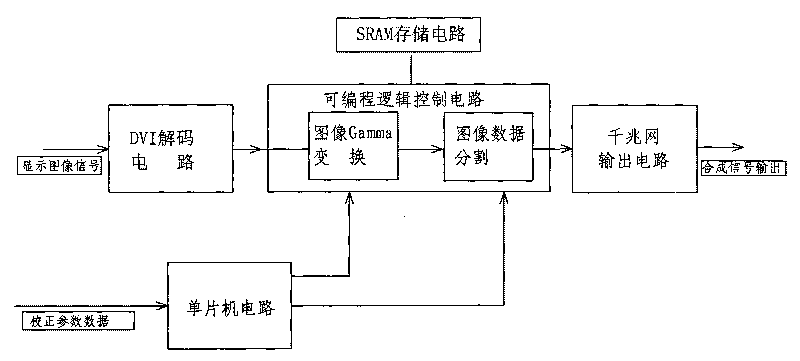

System and method for on-site point-by-point calibration of brightness and chrominance of the whole screen of LED display screen

InactiveCN101692326AReduce processing costsUniform pixelStatic indicating devicesInput controlSingle point

The invention discloses a system and a method for on-site point-by-point calibration of the brightness and chrominance of the whole screen of an LED display screen. The system comprises LED display screen optical parameter acquisition equipment, display screen calibration parameter processing equipment, display screen signal input control and parameter transmission equipment and display screen calibration operation and screen control equipment. The method comprises the following steps: acquiring image data of information on original red, green and blue values of a single point in the lightened part of the LED display screen and values of actual brightness and colors when single colors of red, green, blue and while are displayed; and determining the calibration coefficients of the single point to realize calibration. The method acquires data by in a way of uniformly distributing the luminous points of the display screen in arrays which have the same point number and shape and alternately distributed at equal intervals, thereby avoiding clear horizontal and vertical patterns which use an acquisition area as a unit and are caused by the jump of regional edge calibration data when an original suborigin acquires data and interference among adjacent points caused by reduced pixel pitch and ensuring the calibration effect.

Owner:HUIZHOU DESAY INTELLIGENT TECH

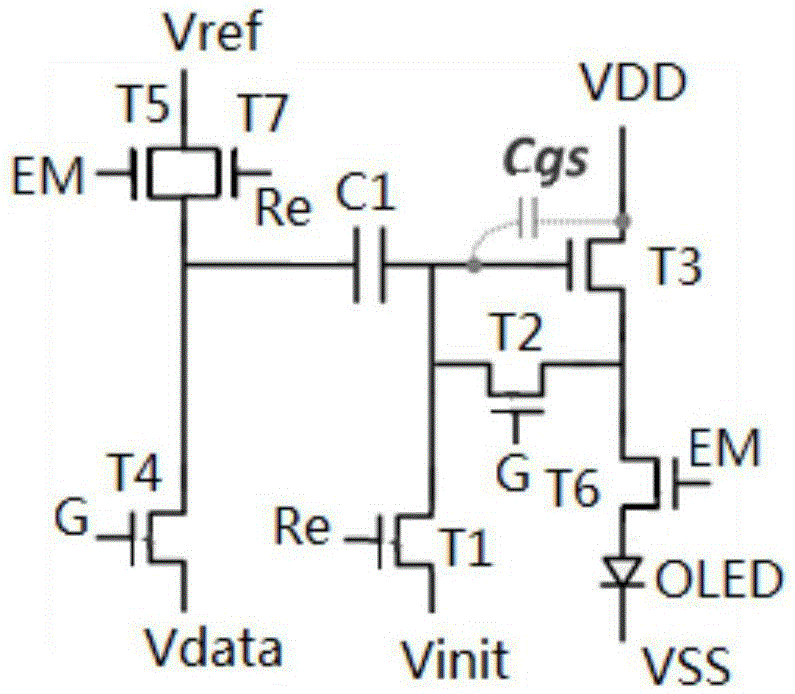

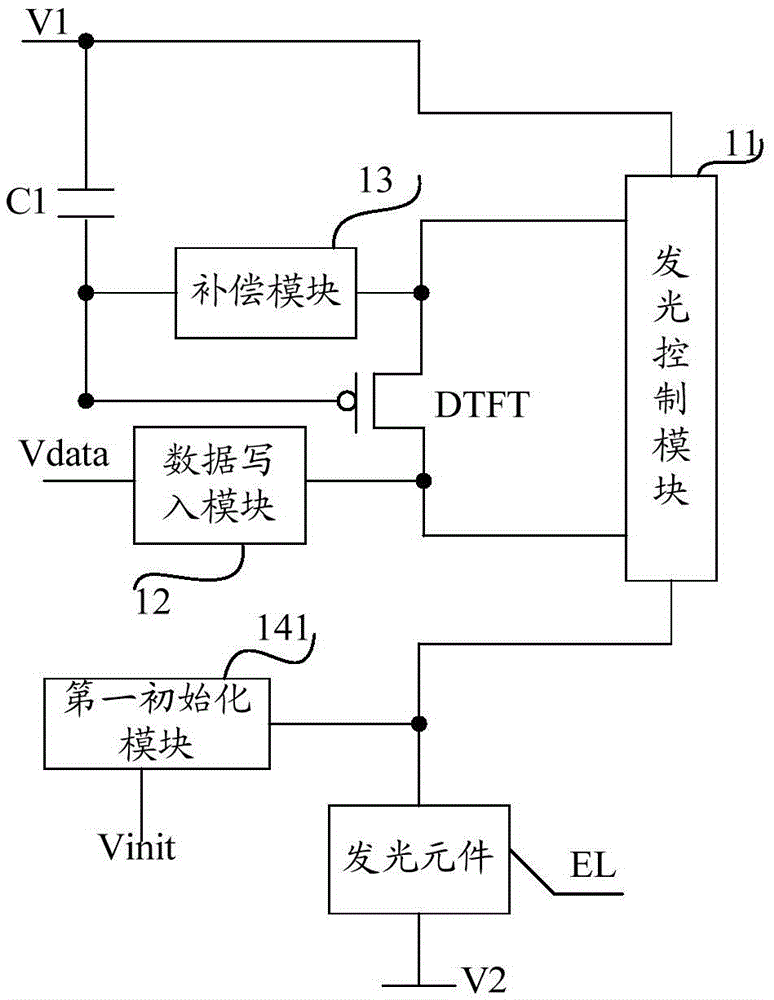

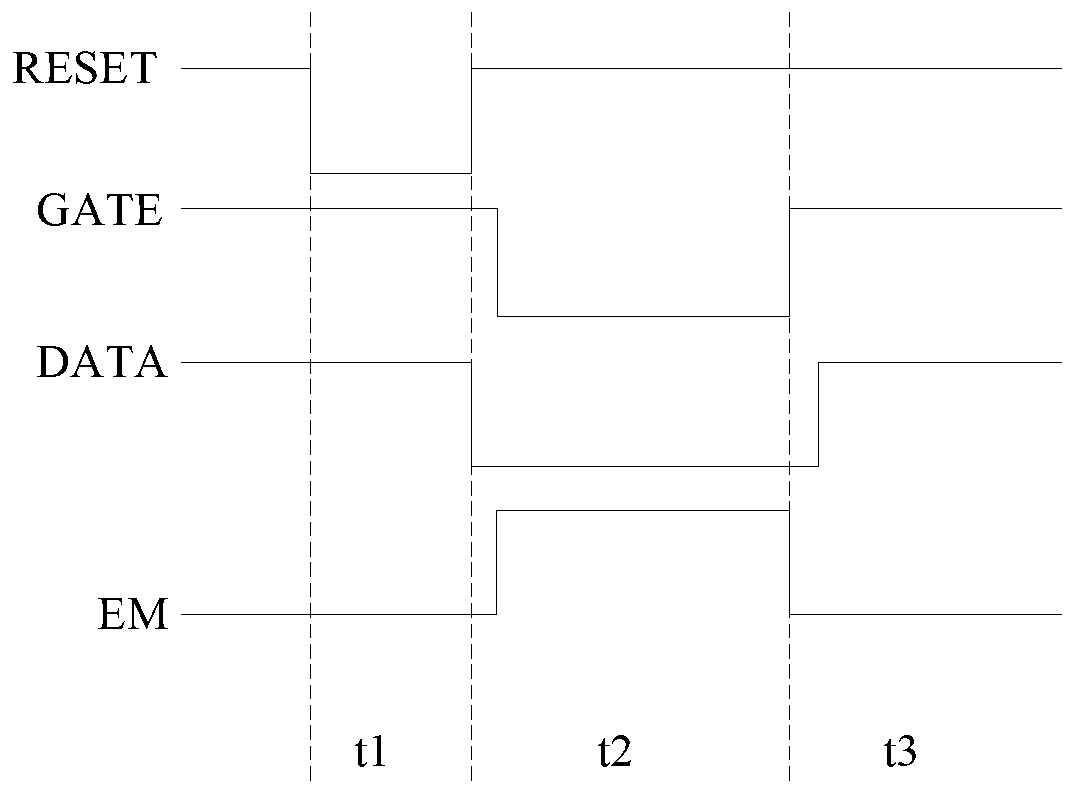

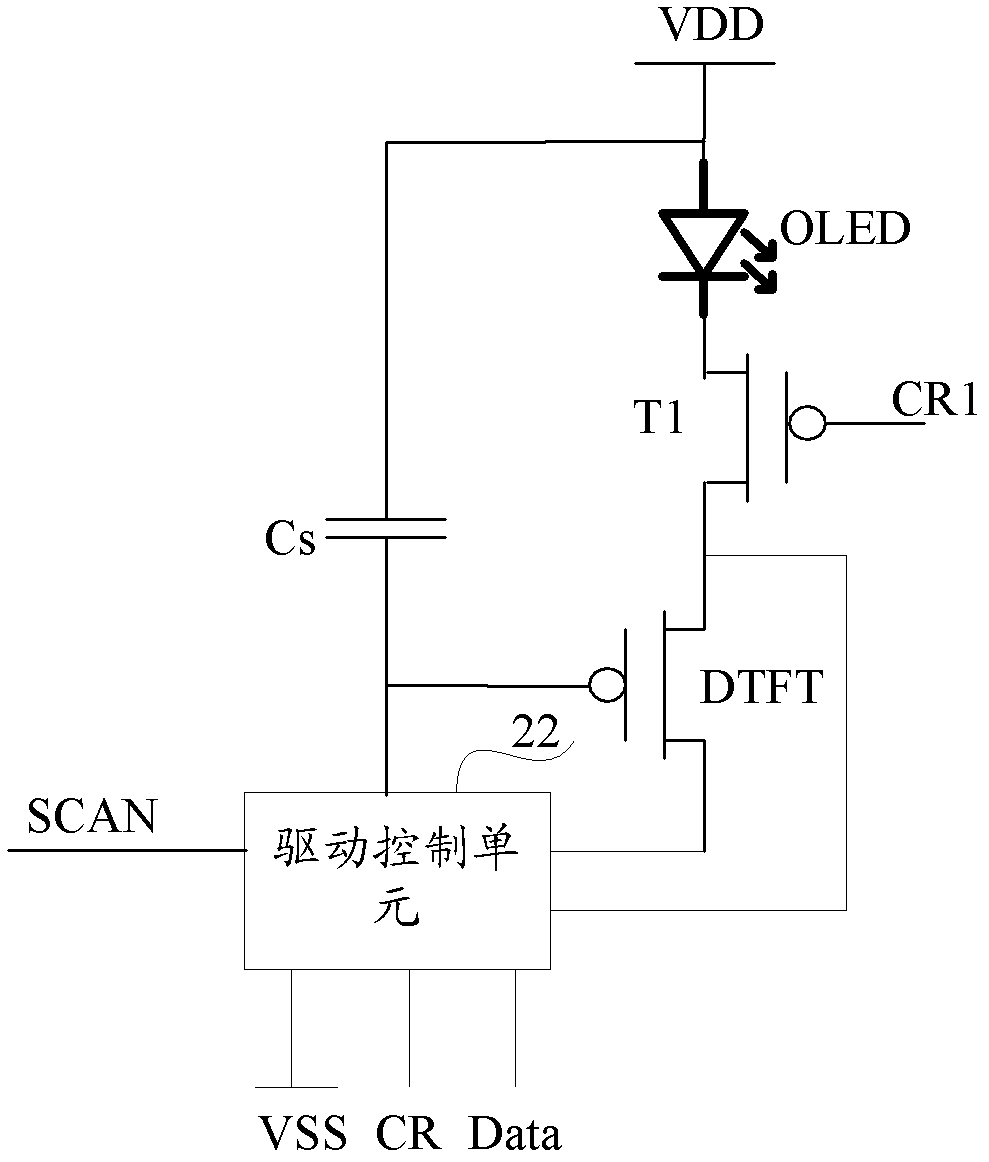

Pixel circuit and driving method thereof, array substrate, display panel and display device

ActiveCN105679236ASolve for uniformityReduce the reference voltage lineStatic indicating devicesCapacitanceDisplay device

The invention provides a pixel circuit and a driving method thereof, an array substrate, a display panel and a display device. The pixel circuit comprises a light-emitting component, a driving transistor, a first storage capacitor, a light-emitting control module, a data write-in module and a compensation module. The data write-in module controls data voltage Vdata to be written into a second pole of the driving transistor in the compensation stage; and the compensation module controls a first pole of the driving transistor to be connected with the grid electrode of the driving transistor in the compensation stage to control the driving transistor to be conducted and control the conduction current of the driving transistor to flow from the second pole of the driving transistor to the first pole of the driving transistor until the electric potential of the grid electrode of the driving transistor is Vdata+Vth, wherein the Vth is a threshold voltage of the driving transistor. The problem that the threshold voltage of the driving transistor cannot be compensated in the light-emitting stage, and thus uniformity of brightness of the display panel is poor in the prior art is solved.

Owner:BOE TECH GRP CO LTD +1

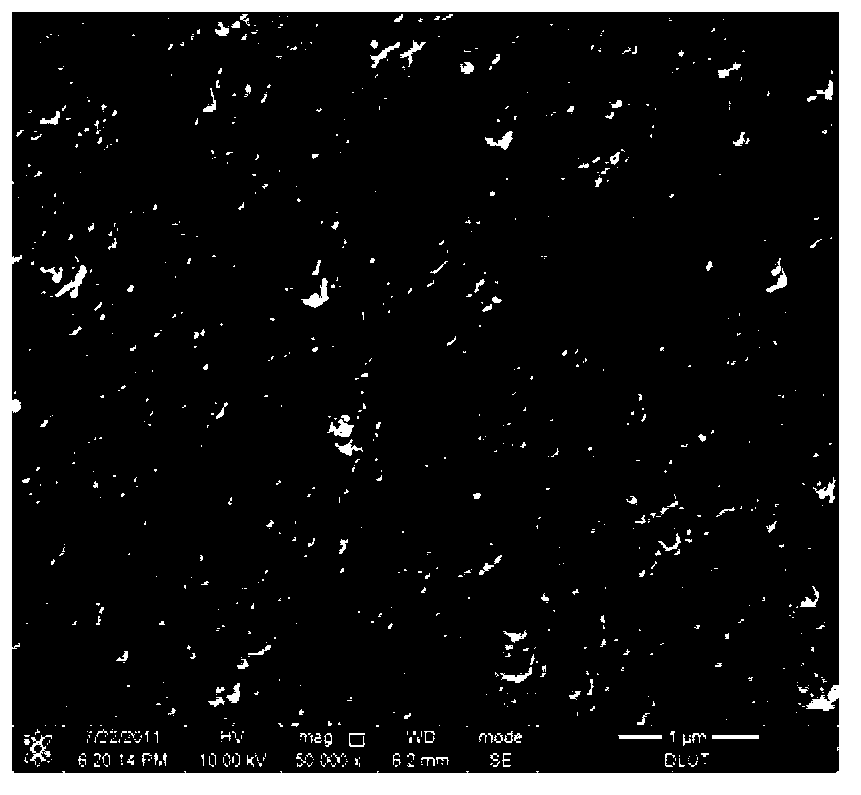

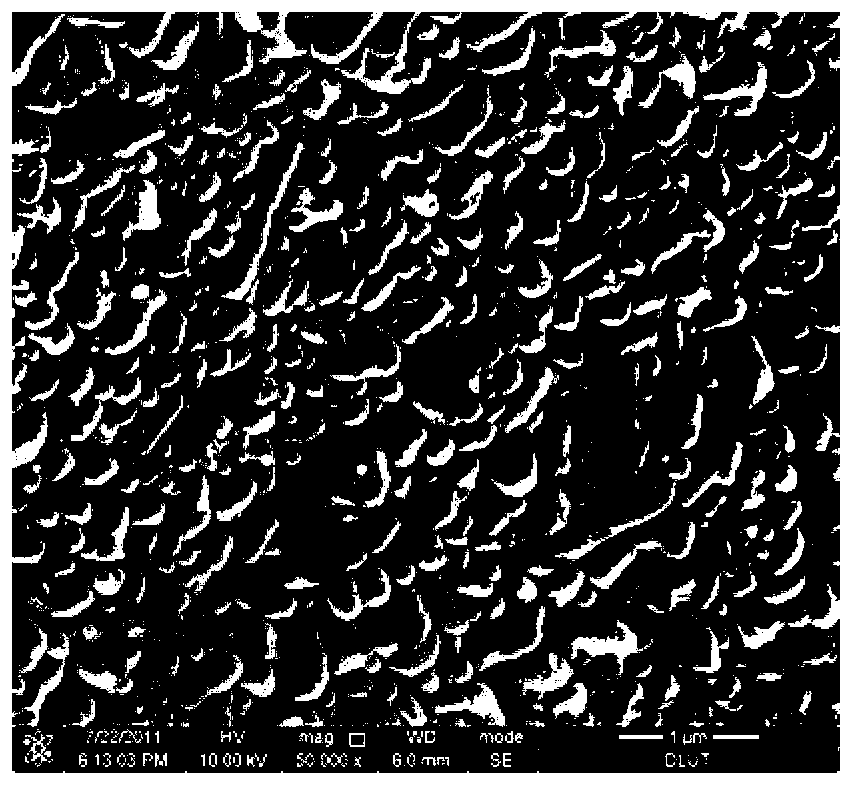

Preparation method of metal organic framework ZIF-8 (zero insert force-9) film

ActiveCN102794115ASolve the bonding problemEvenly distributedSemi-permeable membranesMetal-organic frameworkActive point

The invention provides a novel preparation method of a high-performance continuous ZIF-8 (zero insert force-8) film for the high-performance separation and purification of gas, and mainly aims at solving the combination problem among a continuous even growth film, a film and a carrier of the ZIF-8 film. The preparation method is mainly characterized by comprising the following steps of: previously introducing growth point and a combination point on the surface of a porous carrier to form a thin layer of zinc oxide coating layer taken as a finished film, and growing in an inducing way to form the continuous even ZIF-8 film. An active point of the film homogeneous nucleation is introduced, the combination force problem between the film and the surface of the carrier is solved, and the surface of the carrier is modified by the coating layer, so that the high-quality film can be preferably formed. Compared with the conventional preparation method of the ZIF-8 film, the novel method adopted by the invention not only is high in film-forming effective mass, simple in process, and convenient for large-scale preparation and amplification, so that the method has a potential application prospect and a wide application value.

Owner:DALIAN UNIV OF TECH

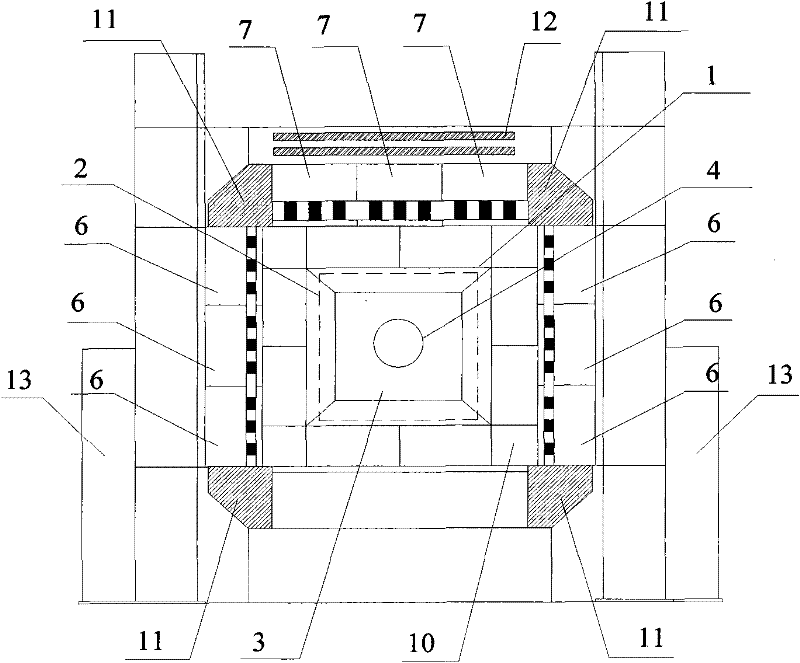

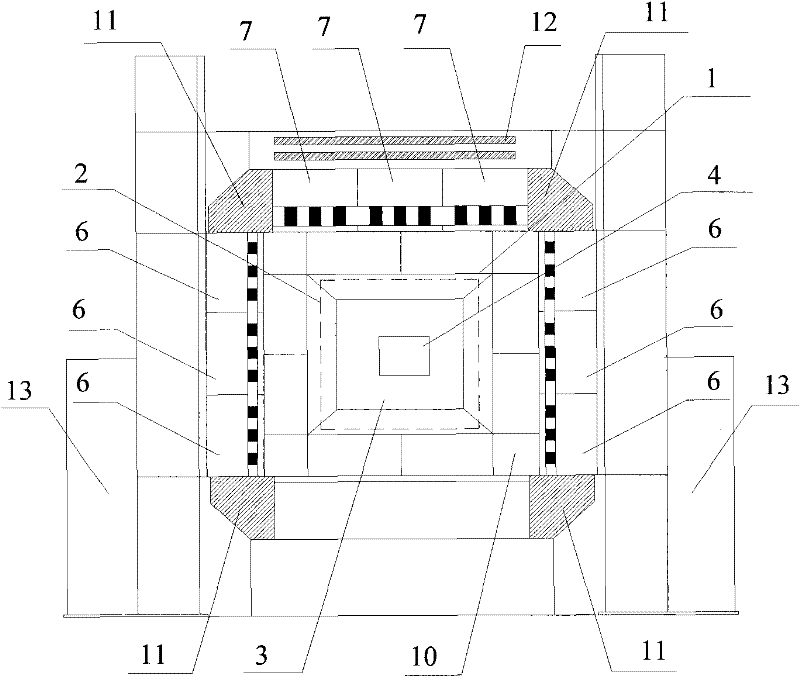

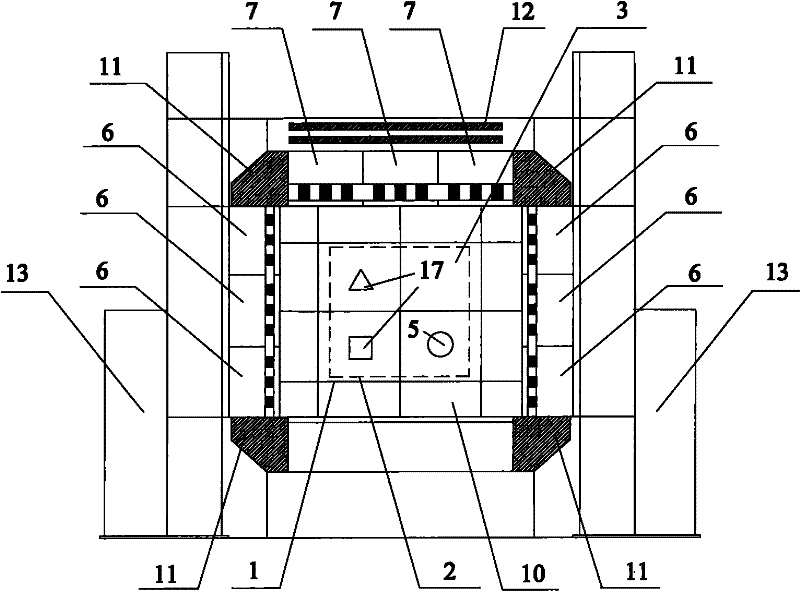

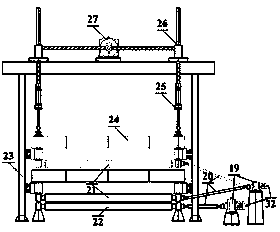

Multifunctional model test system for tunnel and underground engineering

InactiveCN102235942AWith a multi-purpose functionRealize simulationStructural/machines measurementPilot systemRock tunnel

The invention relates to a multifunctional model test system for tunnel and underground engineering. The test system comprises a rail, a model box, a servo-controlled test loading device, a rotating seat, rotating shafts and a bracket, wherein the rail is arranged on the upper part of the test system; the model box is arranged on the middle part of the test system and comprises an outer frame, an inner frame and an organic glass plate; the servo-controlled test loading device comprises a horizontal loading jack and a vertical loading jack; the rotating shafts are arranged on the two sides of the middle part of the test system; and the rotating seat is arranged on the back surface of the upper part of the test system and is connected with the bracket through a rotating loading cylinder. The system can perform a model test on a block system, rock tunnel excavation, a tunnel chamber, a tunnel group, a side slope, shield excavation and building traversing, has a facade rotating loading function, effectively solves the technical problem that a strain field is required to have a wide uniformity range and a high uniformity degree in the model test, and can well simulate the stress environment of tunnels existing in a rock-soil body.

Owner:TONGJI UNIV

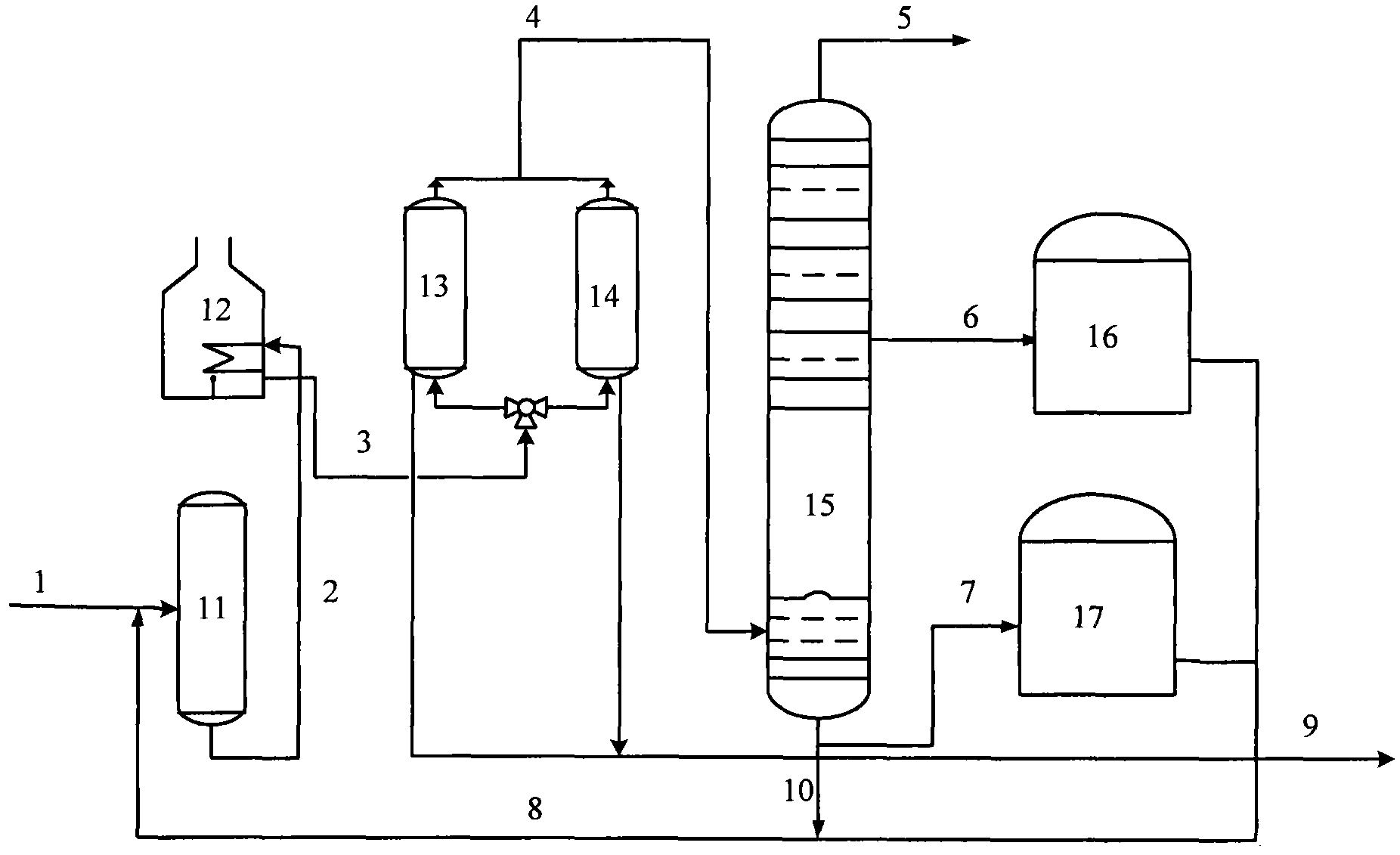

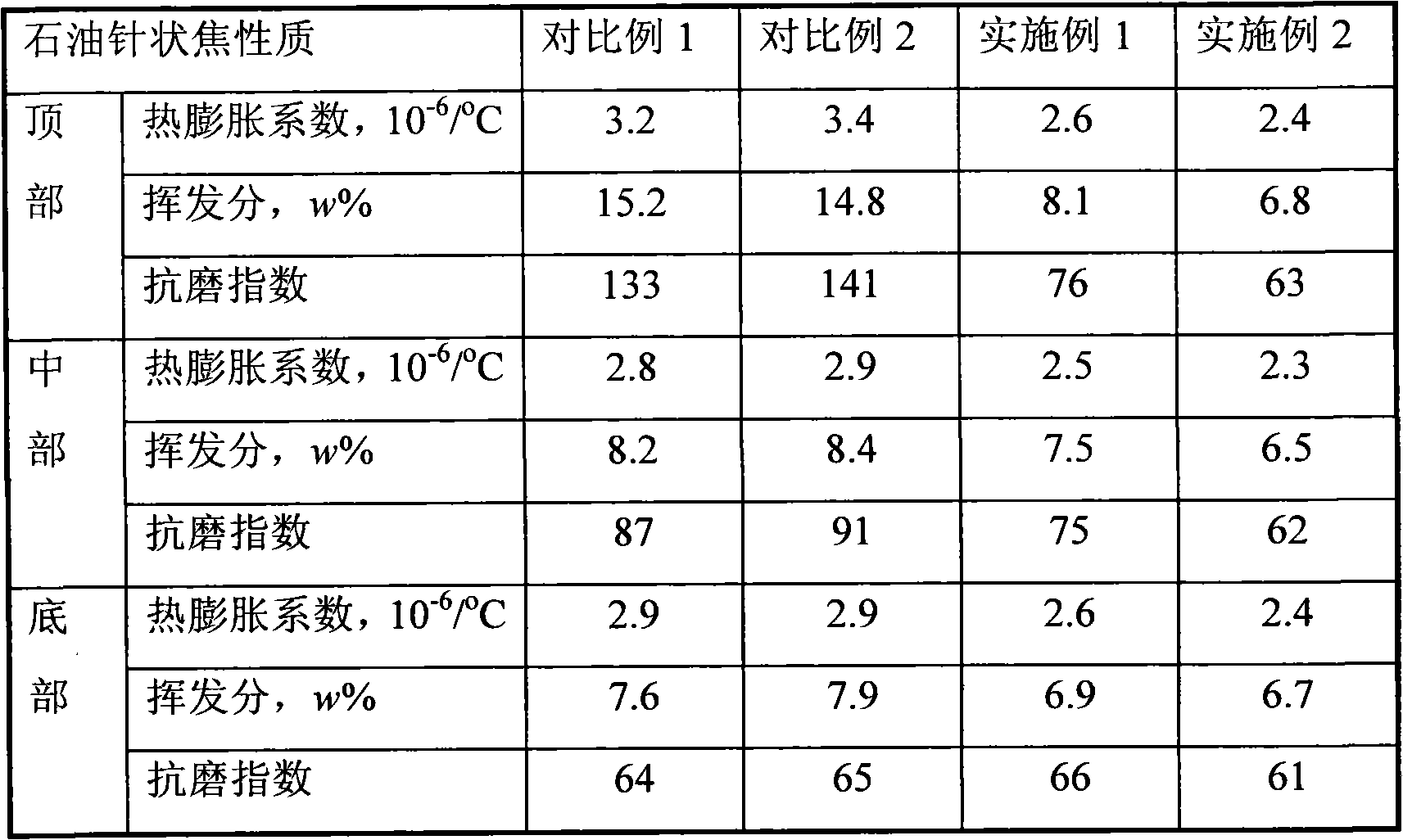

Production method of homogeneous petroleum needle coke

ActiveCN103184057AImproved Anti-wear IndexSolve for uniformityTreatment with plural serial stages onlyCoking carbonaceous materialsHeating furnaceTower

The invention relates to a production method of a homogeneous petroleum needle coke. The method comprises the steps of: (1) heating the raw material for needle coke production to a relatively low temperature of 400-480DEG C by a heating furnace, then leading the raw material into a coking tower to make the coking raw material form flowable intermediate phase liquid crystals; (2) when the low temperature fresh raw material charging stage is completed, gradually raising the temperature of a heating furnace outlet, and at the same time, charging the coking heating furnace with a fresh raw material and heavy distillate oil from a fractionating tower; and (3) when the materials in the coking tower reach a curing coking temperature, charging the coking heating furnace with the coking intermediate distillate oil generated in step (1), and simultaneously raising the coking heating furnace feed temperature to make the internal temperature of the coking tower reach 460-510DEG C, thus finishing high temperature curing of petroleum coke. The method provided in the invention can make the properties of needle coke at different parts inside the coking tower more uniform.

Owner:CHINA PETROLEUM & CHEM CORP +1

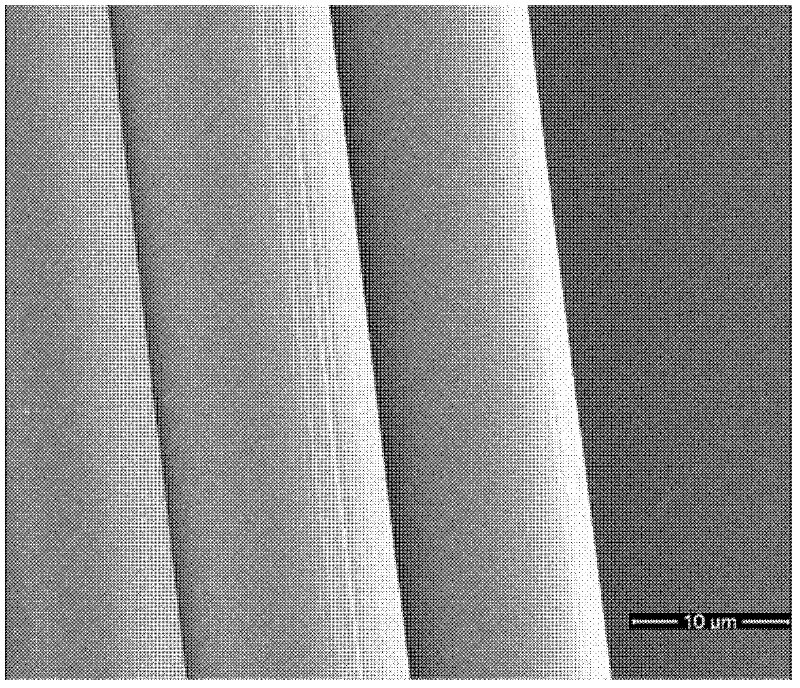

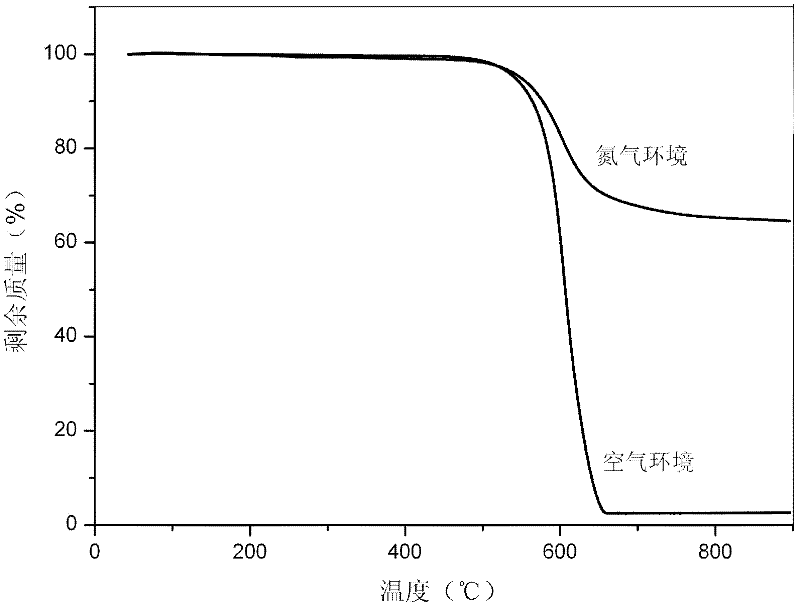

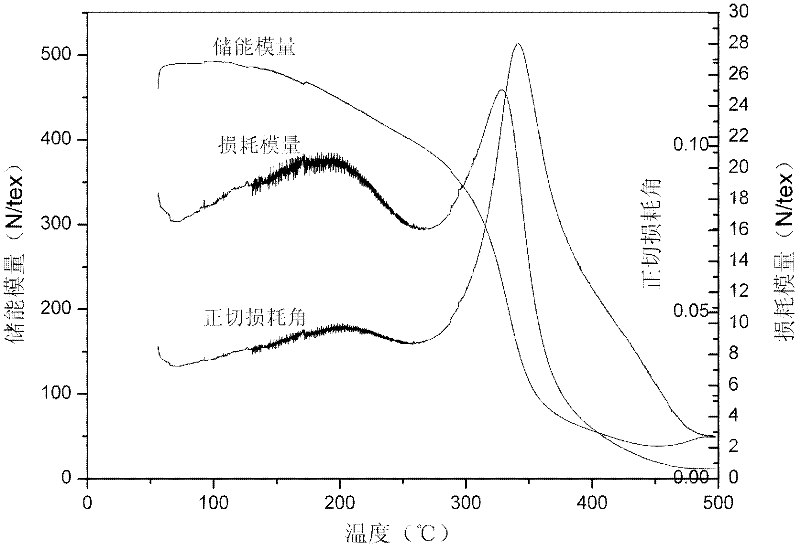

High-strength high modulus polyimide fiber and preparation method thereof

ActiveCN102345177AImprove performanceReasonable molecular structureArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention relates to high-strength high modulus polyimide fiber and a preparation method thereof, which belongs to the high performance organic fiber technical field. The fiber comprises the polyimide fiber which is prepared by biphenyltetracarboxylic dianhydride (BPDA), para-phenylene diamine (pPDA) and 2-(4-aminophenyl)-5-aminobenzimidazoles (BIA), wherein the mol ratio of pPDA to BIA is 1:10-3:1, other di-amine and di-anhydride monomers are added in the synthesis process, a gradient temperature reaction method and a one step continuous preparation method are used in the preparation process, so that the difficulties for synthesizing and processing due to the content increase of 2-(4-aminophenyl)-5-aminobenzimidazoles are solved, the problems of poor homogeneity and stability of thefiber performance can be solved, and the high-strength high modulus polyimide fiber can be obtained, the strength can reach 4.5GPa, the modulus can reach 201GPa, and the raw material source is wide, the spinning process can be continuously performed, the method has low cost and high efficiency which is capable of realizing the industrial production.

Owner:JIANGSU XIANNUO NEW MATERIAL TECH

Guided tissue regeneration membrane and its preparation method

The invention relates to a guided tissue regeneration membrane, which comprises a compact coating and a loose coating, wherein the compact coating is composed of collagen-I or collagen-I composite hyaluronic acid; and the loose coating is composed of collagen-I or collagen-I composite calcium salt. A preparation method of the guided tissue regeneration membrane comprises the following steps of: preparing a collagen solution or a collagen and hyaluronic acid mixed solution by the use of acetic acid; injecting the solution into a self-made die, and drying it in the air to prepare the compact coating; injecting the collagen solution or a mixed liquor of the collagen solution and calcium salt onto the compact coating, and uniformly spreading; precooling the die at ultralow temperature, followed by freeze-drying to prepare the guided membrane with the compact coating and loose coating structure; carrying out vacuum high-temperature crosslinking and chemical crosslinking; and finally cleaning. The regeneration membrane has good histocompatibility and mechanical strength, low antigenicity and strong guided tissue regeneration capability. Its degradation rate in vivo is 3-8 months. The method is easy to operate, is suitable for automatic and continuous large-scale production, and solves the problems of large size of collagen membrane and material uniformity during industrial production.

Owner:SHENZHEN LANDO BIOMATERIALS

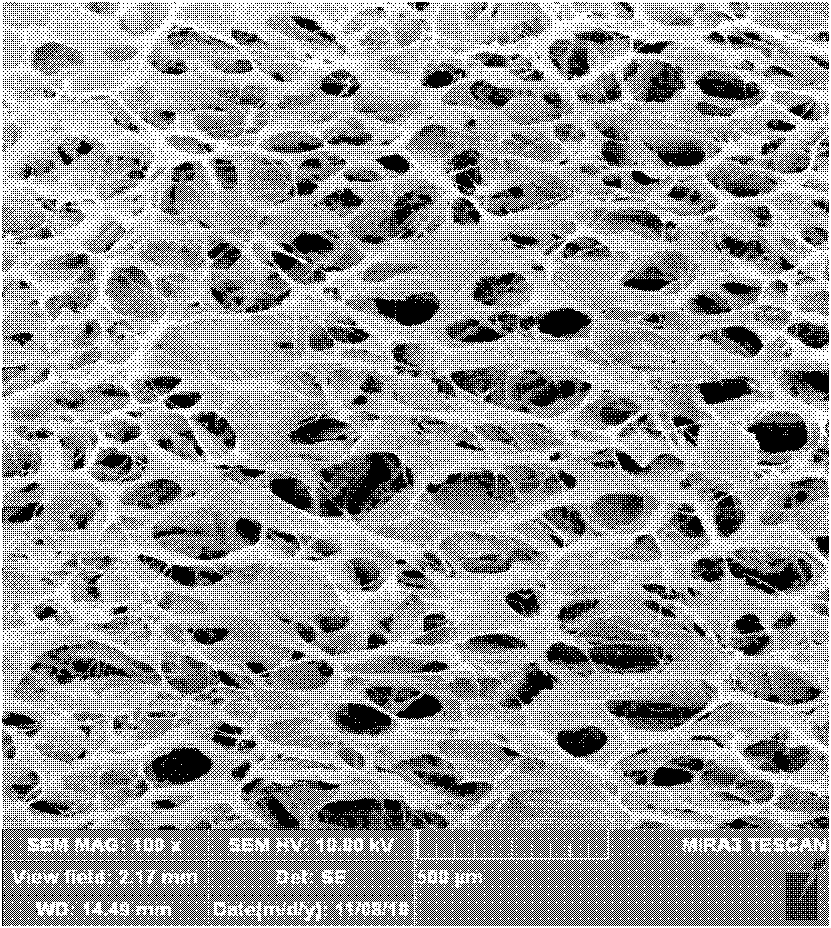

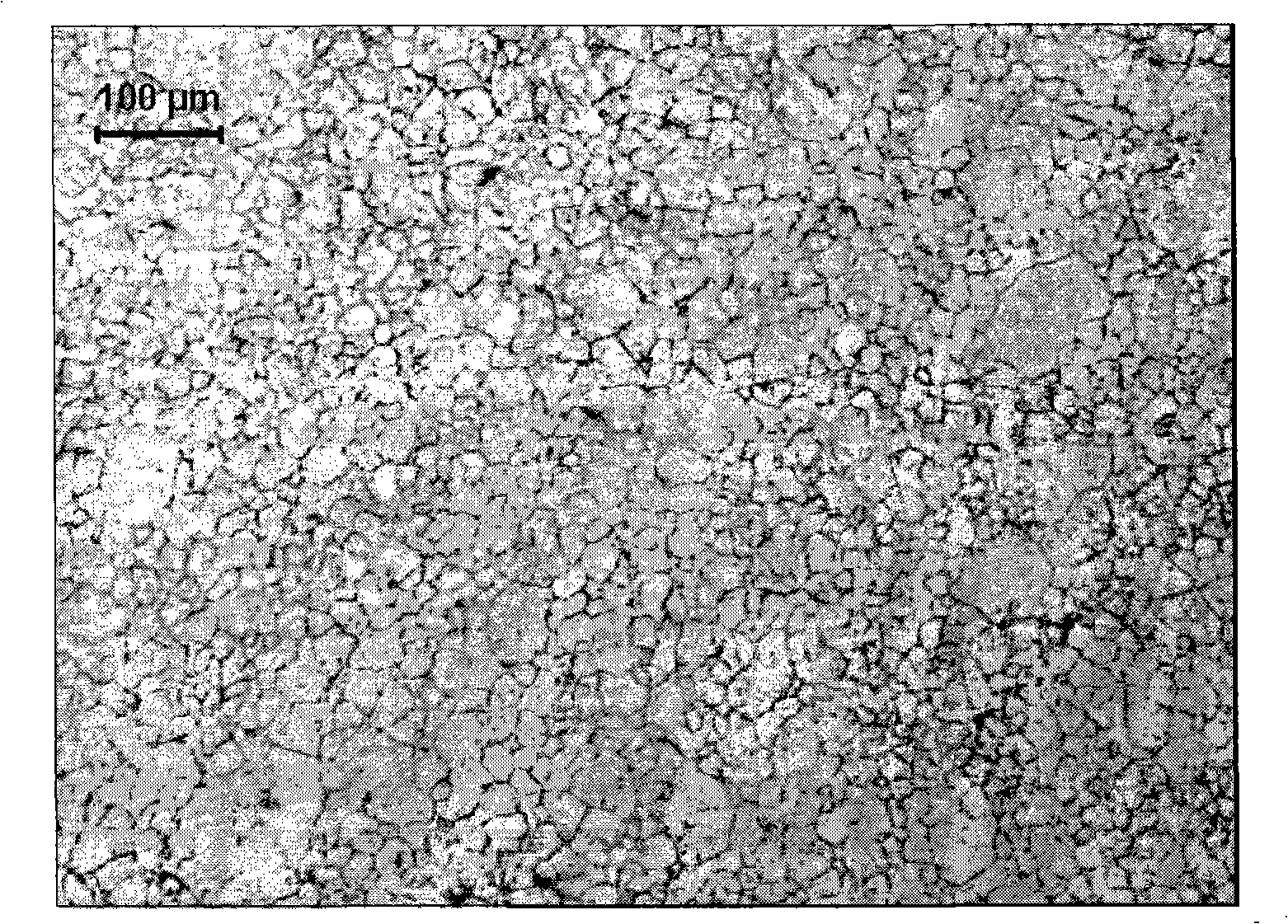

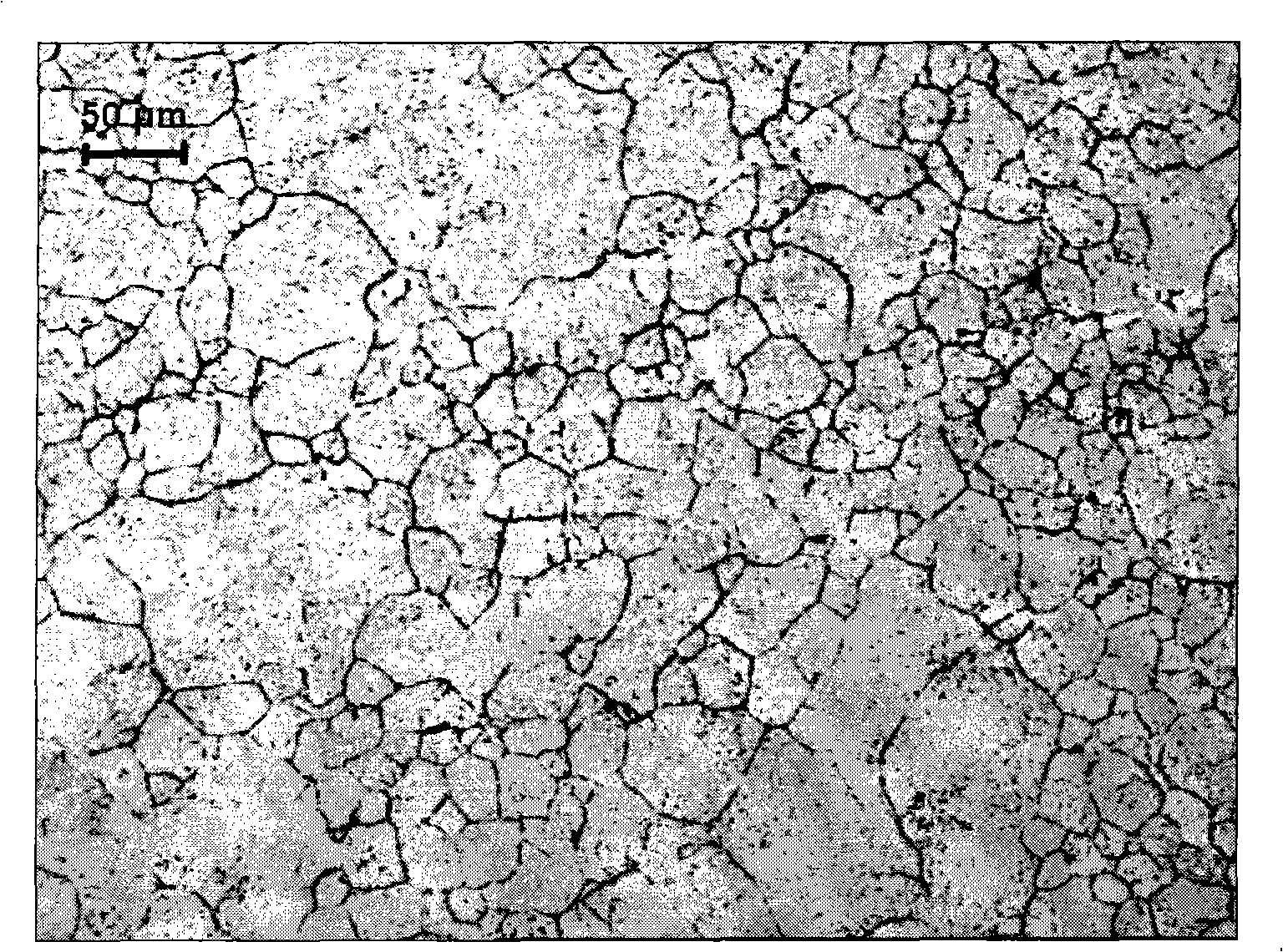

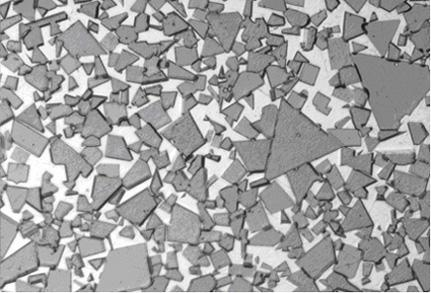

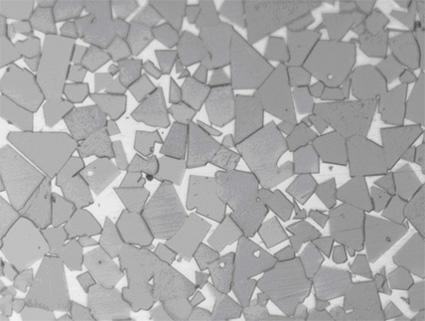

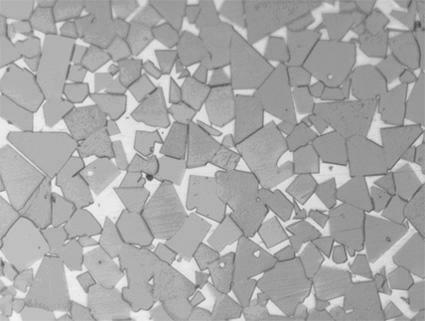

Ultra-supercritical steel organization display method

ActiveCN101270498ASolve the thicknessSolve for uniformityPreparing sample for investigationEtchingElectrolysis

The invention relates to the technical field of metallographical sample preparation and tissue observation. The invention relates to a tissue display method for ultra-supercritical steel with the advantages of high alloy content, high anti-corrosion and excellent oxidation resistance in particular. The technique steps of the method includes: firstly adopting a standard grinding-polishing method on an ultra-supercritical steel sample; then selecting a commonly used electrolyte to carry out electrolytic etching with high voltage and high current on the sample; finally combining a mechanical polishing method to finally display a clear original austenite crystal grain boundary. The invention can clearly, completely and independently display the original austenite crystal grain boundary of the ultra-supercritical steel; thereby being able to fully reflect the size and the distribution of the original austenite crystal grain and solving the problem of being harder to precisely assess the thickness and the uniformity of the ultra-supercritical steel tissue.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for making stewed duck with bean sauce

InactiveCN101715974ASolve processabilitySolve for uniformityFood preparationBiotechnologyAdditive ingredient

The invention relates to the field of food processing and discloses a method for making a stewed duck with bean sauce. In the invention, injection seasoning technology, vacuum massaging technology and compression marinating technology are integrated into a novel processing technique. The stewed duck with bean sauce made by the invention has the advantages of rich sauce fragrance, tender meat quality, proper elasticity and unique taste. The method overcomes the defects that the traditional stewed ducks with bean sauce cannot be pickled uniformly and the making period is too long, can effectively keep nutrient components in the duck, and can prolong the shelf life of the finished product. The raw materials and making parameters of the method are quantified, so the method can ensure the stable quality of products, facilitates the quality control, and has a prospect for large-scale industrialized production.

Owner:夏威夷

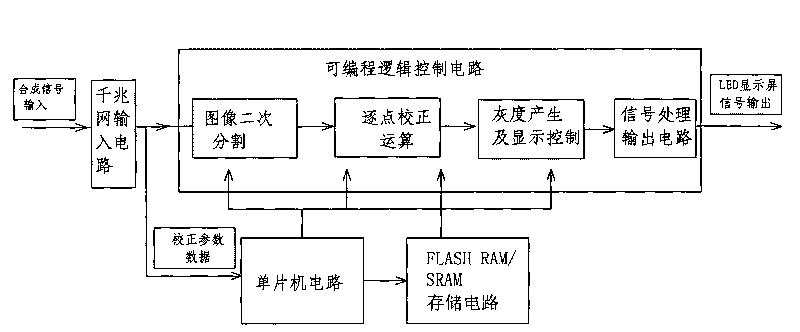

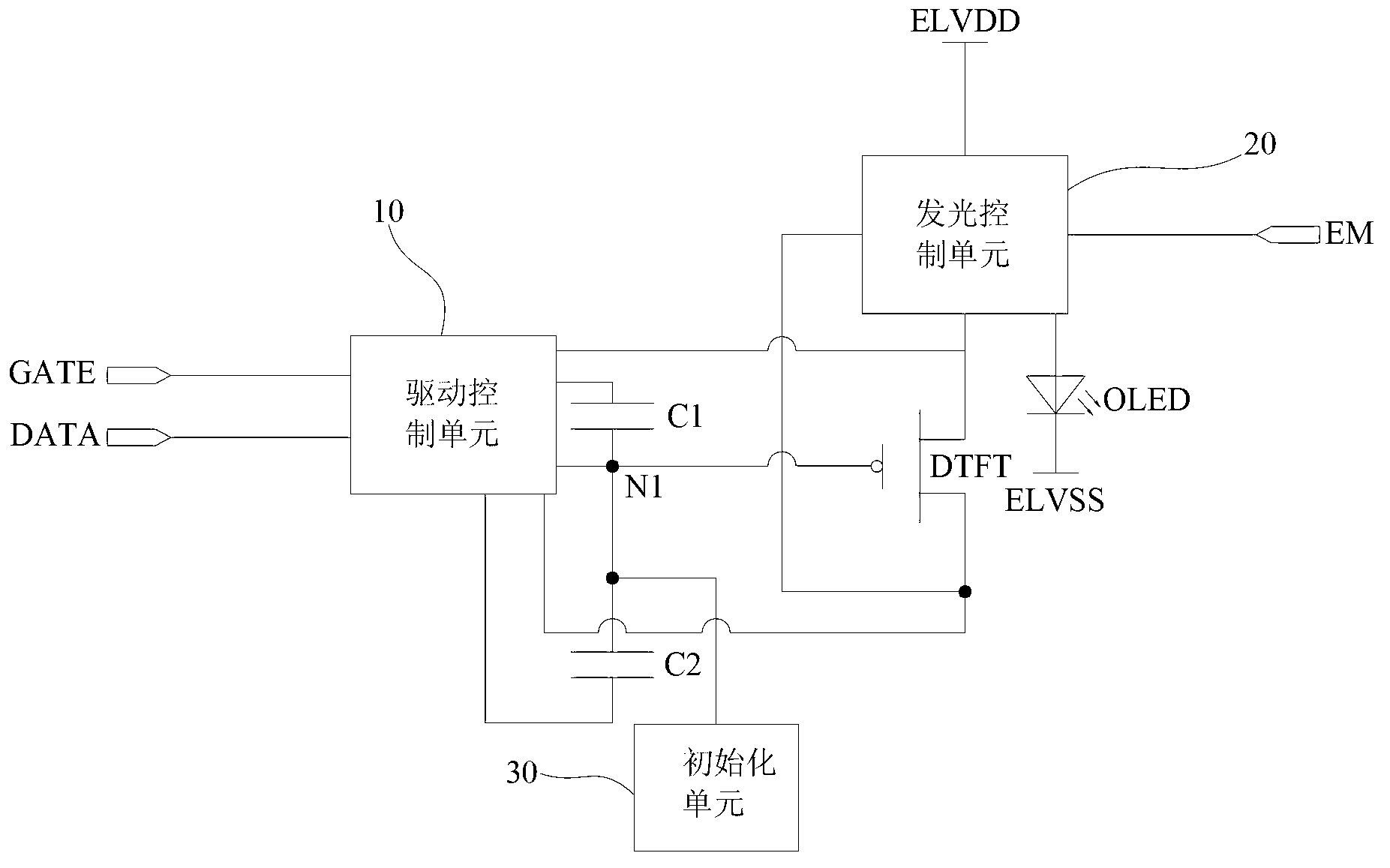

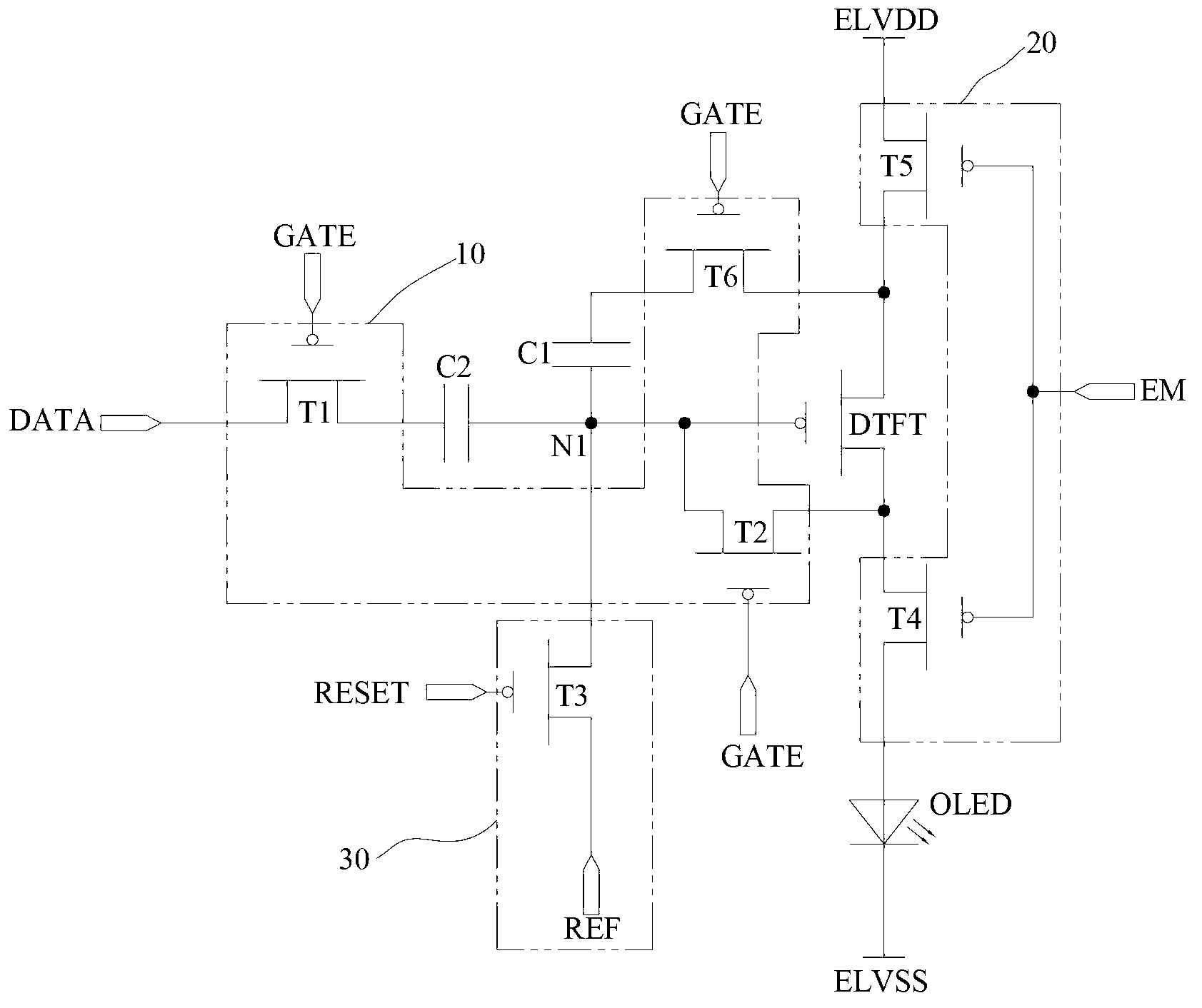

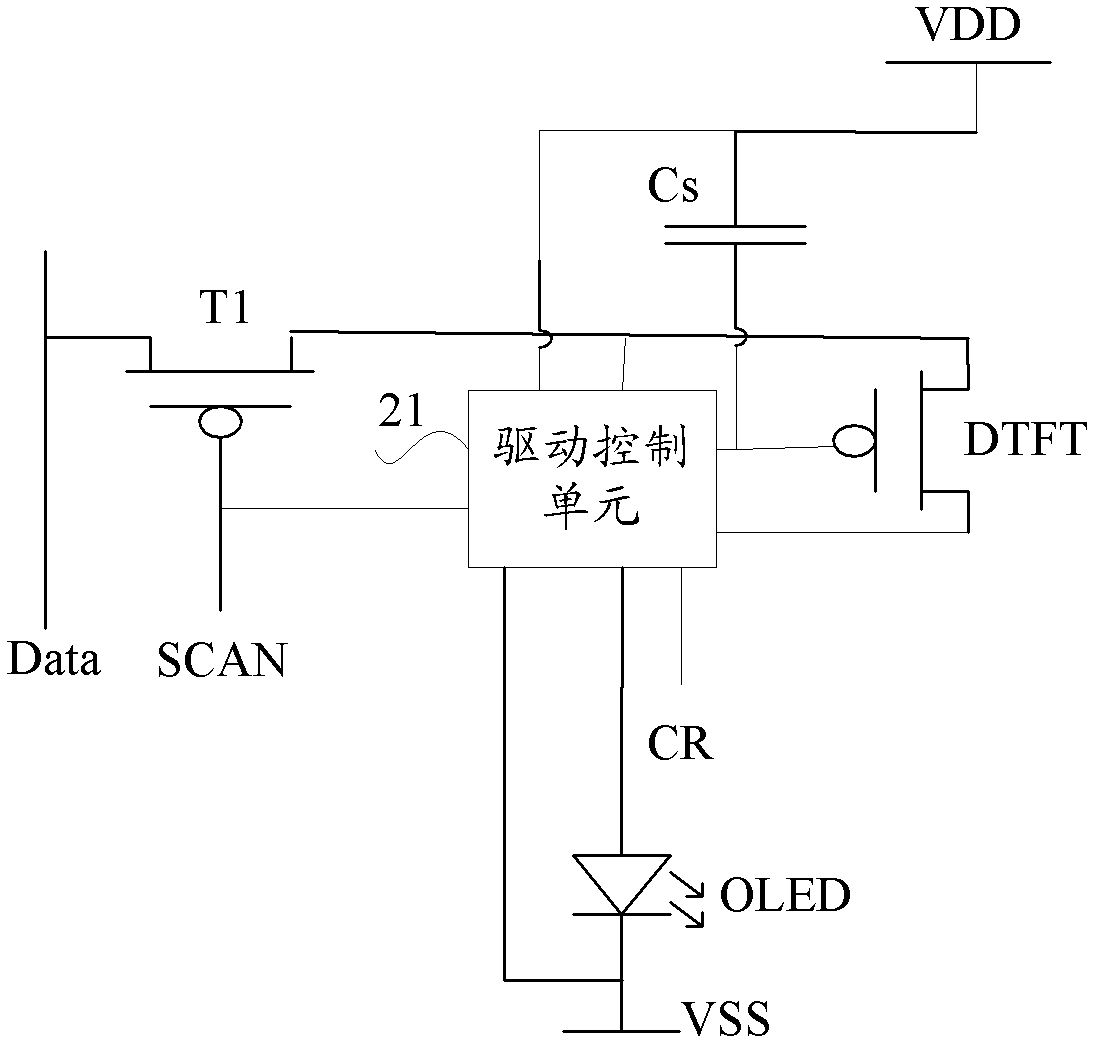

Pixel circuit and organic light emitting display

The invention relates to a pixel circuit and an organic light emitting display. The invention provides the pixel circuit which comprises a drive thin film transistor and a light emitting diode, wherein the light emitting diode is connected in series between a low level input end and a high level input end of a drive power supply. The pixel circuit further comprises a first capacitor and a drive control unit, wherein a first end of the first capacitor is electrically connected with a first pole of the drive thin film transistor by the drive control unit; a second end of the first capacitor is connected with a grid of the drive thin film transistor; a second pole of the drive thin film transistor is electrically connected with the grid of the drive thin film transistor by the drive control unit; and the drive control unit is connected with a grid line and a data line. The invention further provides the organic light emitting display. The pixel circuit can output the uniform current, so that the brightness of a light emitting diode in the pixel circuit is uniform, and the display brightness of the organic light emitting display comprising the pixel circuit is uniform.

Owner:BOE TECH GRP CO LTD

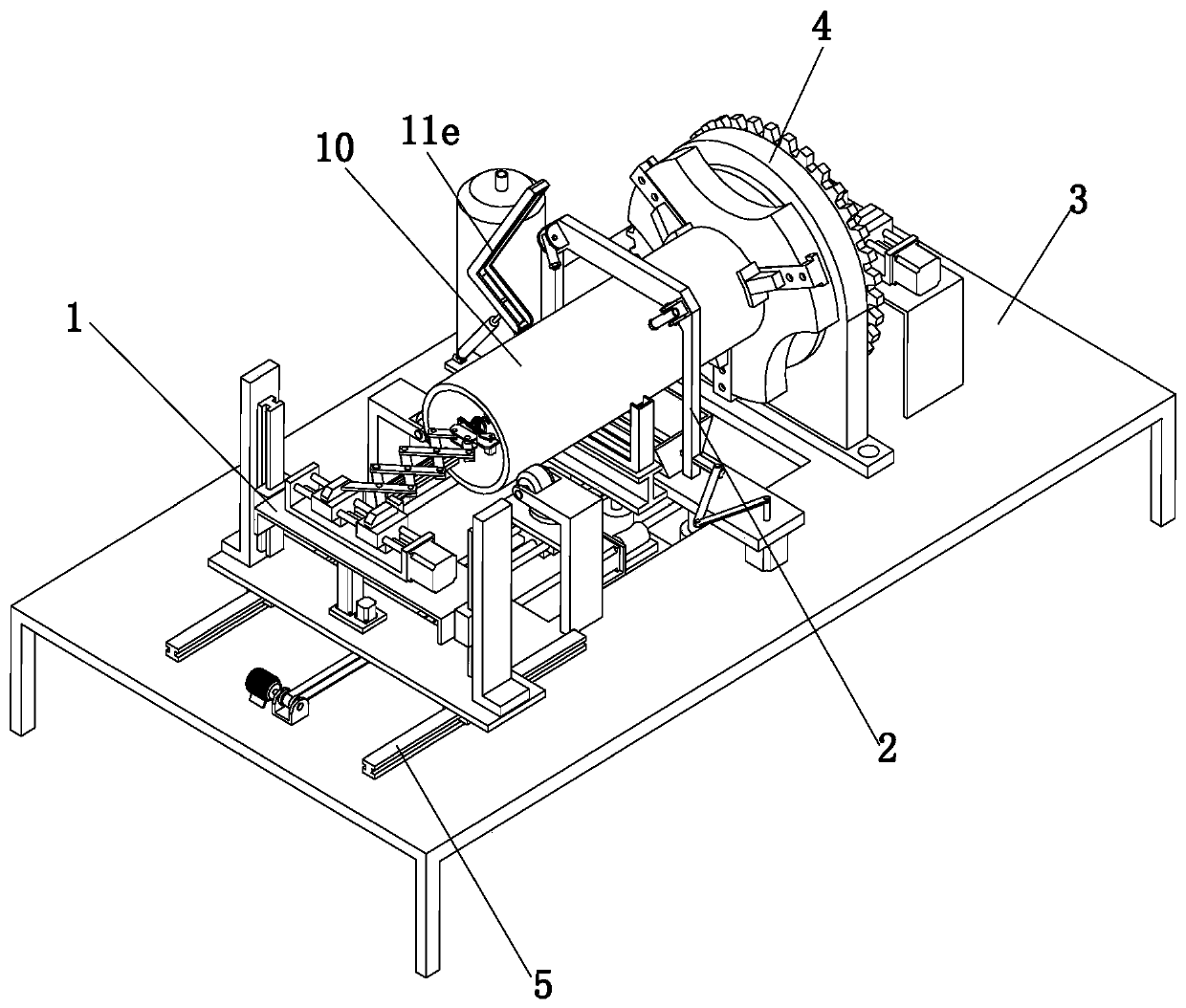

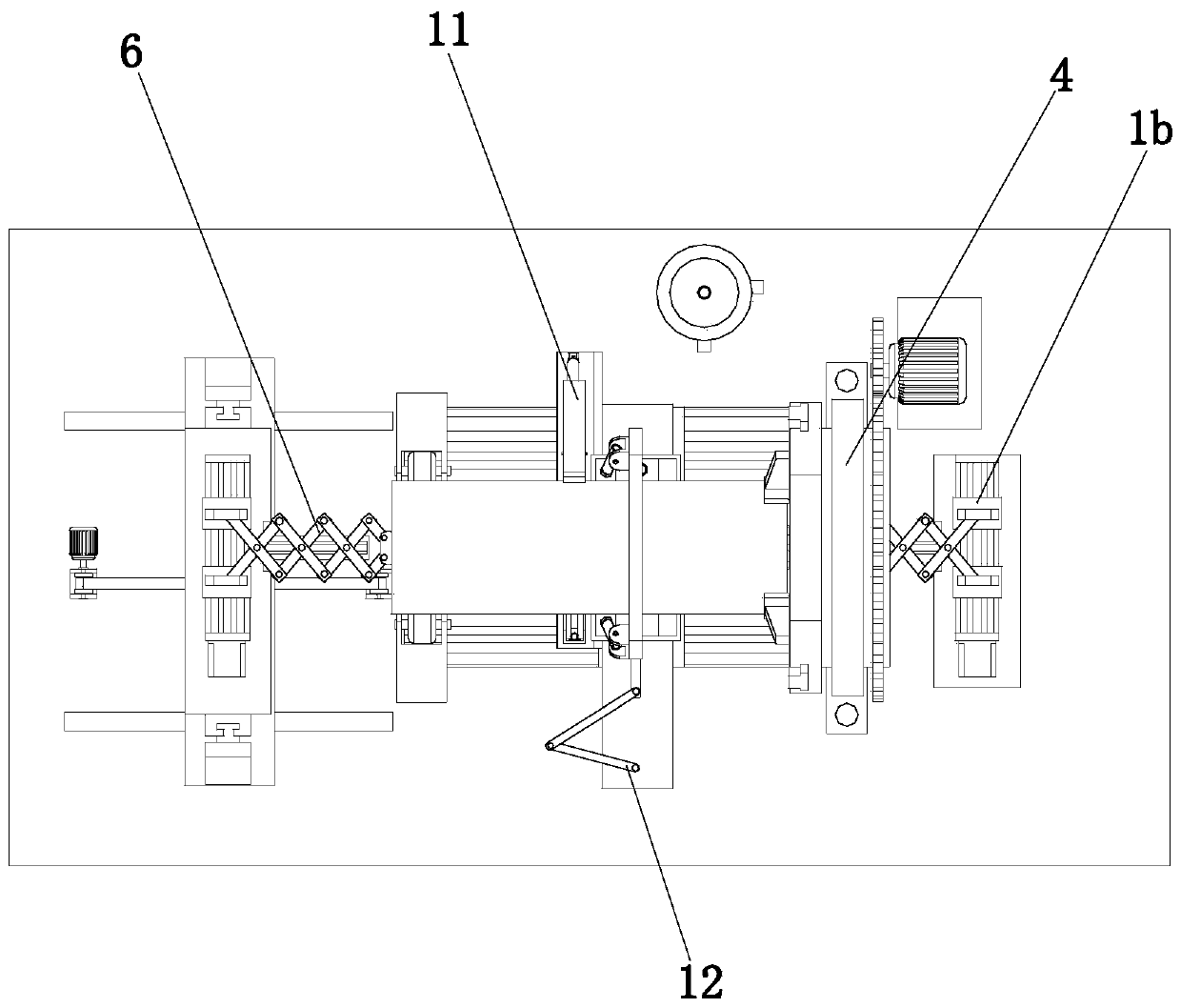

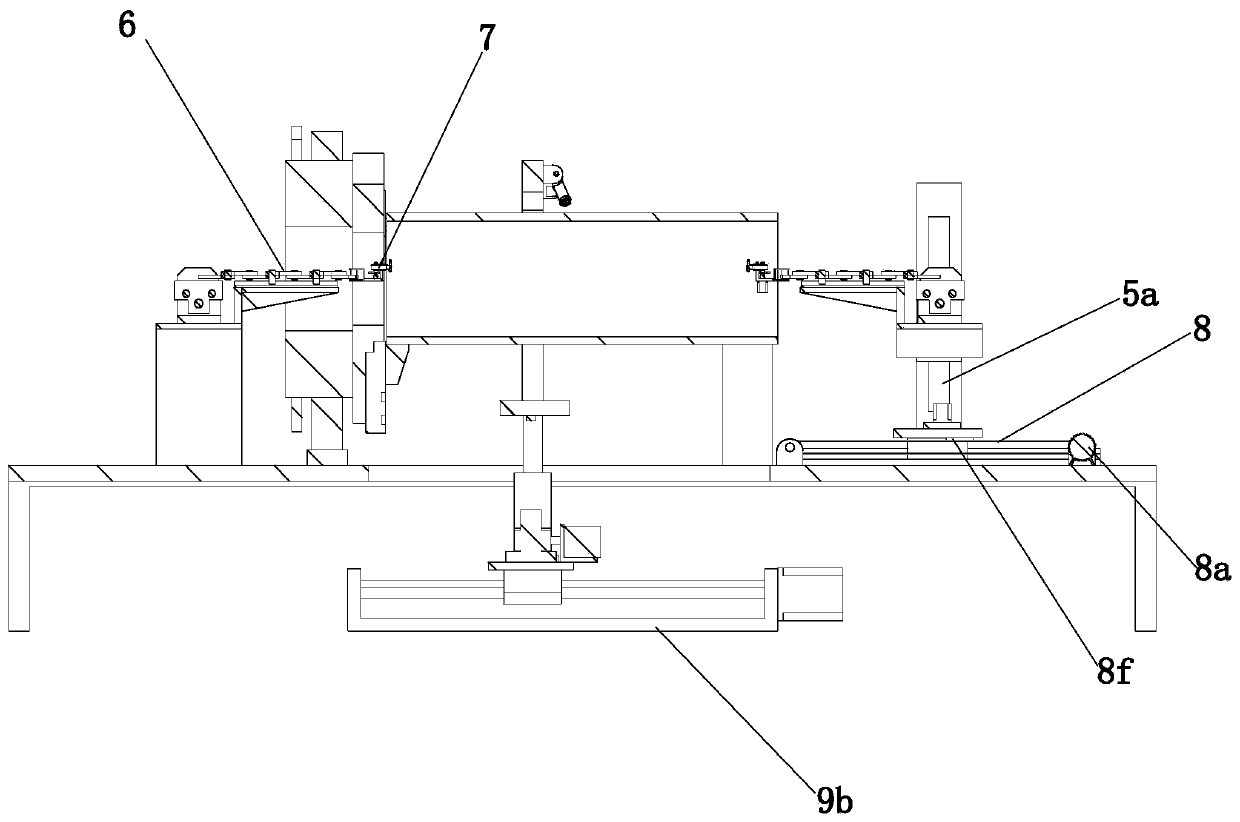

Automatic spraying machine for inner wall and outer wall of steel pipe

ActiveCN109746144AAvoid Unsprayed SituationsSolve the difficulty of spraying the entire inner wall of the steel pipePretreated surfacesCoatingsEngineeringAutomation

The invention discloses an automatic spraying machine for the inner wall and the outer wall of a steel pipe, and belongs to the field of steel pipe spraying equipment. The automatic spraying machine comprises an inner wall spraying mechanism, an outer wall spraying mechanism, an operation table and a rotating mechanism, wherein the inner wall spraying mechanism comprises a first spraying assembly,a second spraying assembly and a material moving assembly; the first spraying assembly and the second spraying assembly comprise an extending and feeding component and a rotating and spraying component; the material moving assembly comprises a lifting component, a material moving plate and a material moving component; and the lifting component is arranged at the top of the material moving plate.According to the automatic spraying machine disclosed by the invention, the inner wall spraying mechanism can extend to the inner part of the steel pipe and automatically perform the operation of uniform spraying on the inner wall of the steel pipe, the situation that the local inner wall of the steel pipe is not sprayed is avoided; and the operation of spraying can be automatically performed on the outer wall of the steel pipe through the outer wall spraying mechanism, so that the automation degree is high, and the situation that a worker manually performs the operation of spraying on the outer wall of the steel pipe is not needed.

Owner:浙江金汇休闲制品有限公司

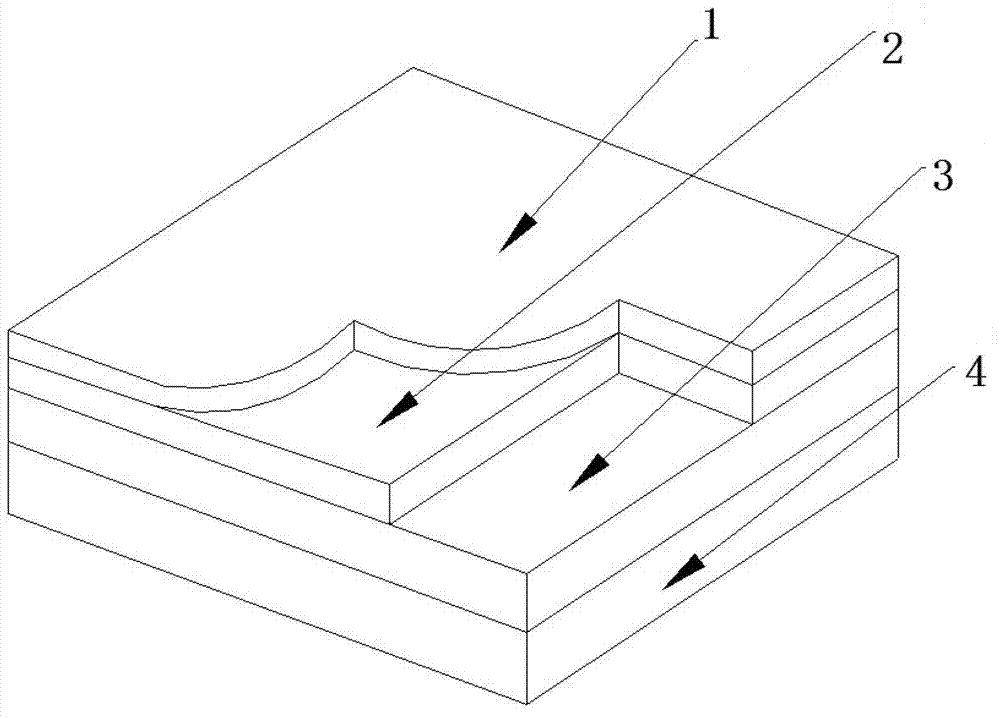

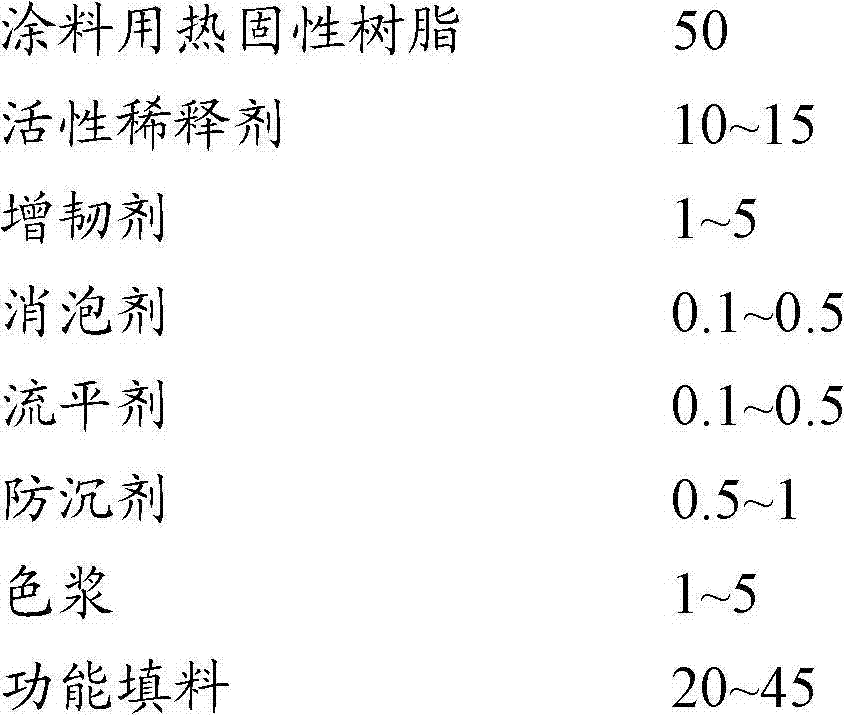

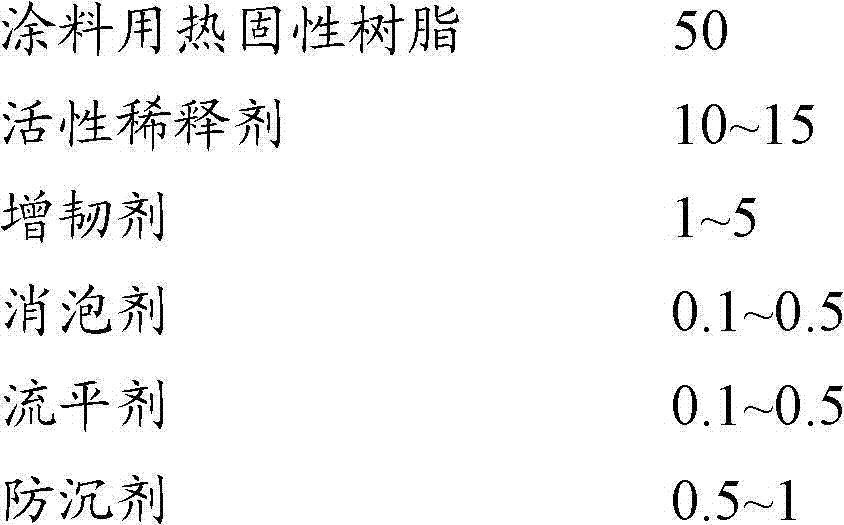

Thermosetting resin composite facing material and preparation method thereof

ActiveCN102808334AIncrease the physical and chemical properties of instant noodlesImprove scratch resistanceSynthetic resin layered productsTextiles and paperResin coatingHigh integrity

The invention discloses a thermosetting resin composite facing material, which comprises a fiber reinforced layer, and a decorative layer and a basic layer which are respectively coated on the upper surface and the lower surface of the fiber reinforced layer. The decorative layer and the basic layer are made of functional thermosetting resin coating. By using the thermosetting resin composite facing material, the organic combination of a thermosetting resin coating layer and a fiber fabric layer is realized, and the obtained material has the advantages of high integrity, uniform performance, convenience in field laying, fewer gap and excellent performance. The excellent physical and chemical performance of thermosetting resin is inherited, the toughness of the material is increased, the material is more convenient and rapid to install and the application scope is wider. The invention additionally discloses a preparation method of the thermosetting resin composite facing material.

Owner:HANGZHOU JIUHE NEW MATERIAL

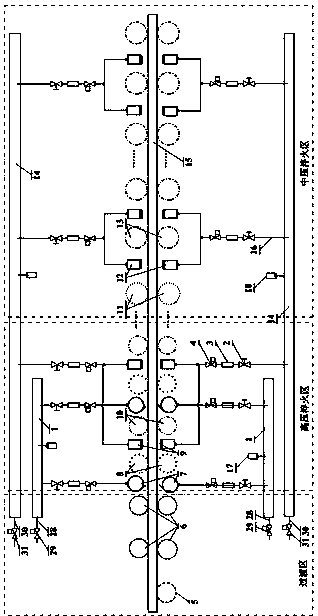

Continuous roller type quenching cooling system for steel plates

ActiveCN103834791AStable productionEfficient and stable productionFurnace typesHeat treatment furnacesHigh pressureQuenching

The invention discloses a continuous roller type quenching cooling system for steel plates. The continuous roller type quenching cooling system comprises a water spray system, a water supply system, a conveying roller system and a frame lifting system; the working regions of the cooling system orderly include a transition region, a high-pressure quenching region and a medium-pressure quenching region; in the high-pressure quenching region and the medium-pressure quenching region, nozzles and conveying rollers are symmetrically arranged up and down along the steel plates, and an upper nozzle and an upper roller are fixed on a movable upper frame, while a lower nozzle and a lower roller are fixed on a fixed frame. The continuous roller type quenching cooling system has the advantages that a roller type quenching manner is introduced into the quenching of ultra-thick steel plates, so that the problems of low cooling speed, poor cooling uniformity, poor batch production stability, unachievable manual intervention, and the like on quenching process of traditional immersion quenching are solved, and therefore, high-intensity uniformed quenching and high-efficiency stable production of the ultra-thick steel plates are achieved.

Owner:NORTHEASTERN UNIV

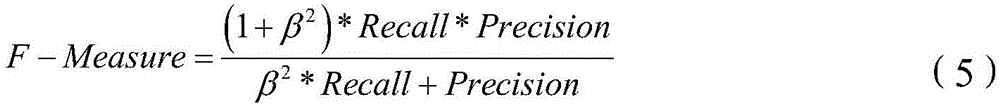

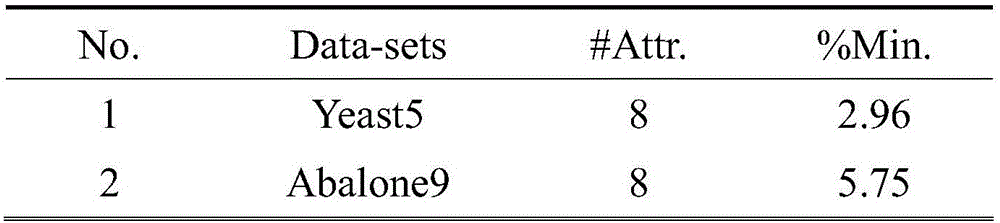

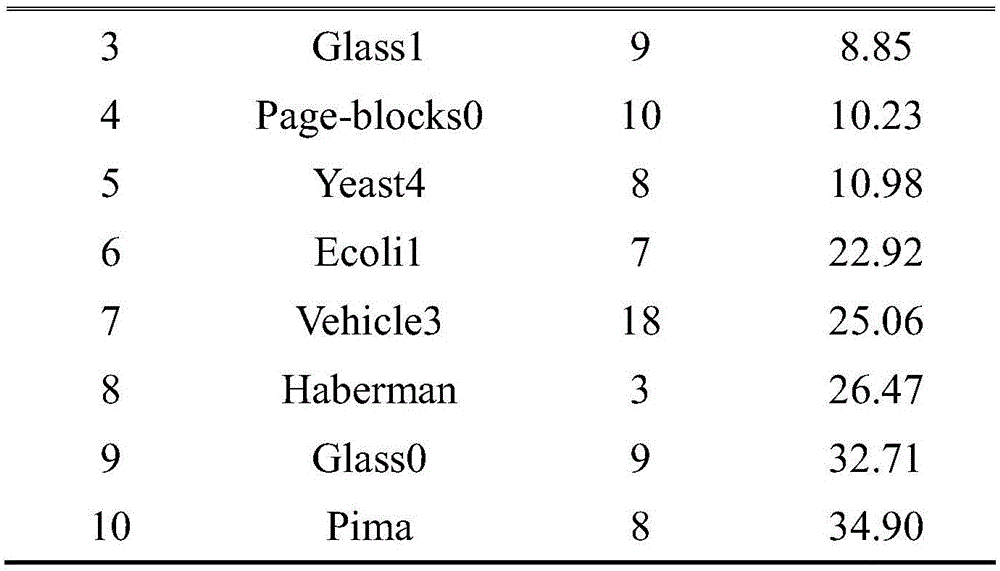

Classification method based on improved DBSCAN-SMOTE algorithm

InactiveCN105930856AEasy to handleSolve for uniformityCharacter and pattern recognitionAlgorithmClassification methods

The invention relates to a classification method based on an improved DBSCAN-SMOTE algorithm for an intra-class unbalanced condition in data sample space processing, firstly, in a data sample set, which are belongs to boundary samples is judged, the boundary samples are divided into majority boundary samples and minority boundary samples, and cluster is performed on the boundary samples in a majority boundary sample space; a PSO algorithm is adopted to optimize oversampling rate of the boundary samples and safe samples in cluster, oversampling with different sampling rates is performed on minority boundary samples through an SMOTE algorithm; wherein the cluster is based on the improved DBSCAN algorithm, the algorithm can generate cluster of minority, perform oversampling in the sample cluster, and can fully resolve the problem of uneven distribution and data fragment or small disjunct in intra-class unbalance.

Owner:SHENZHEN ETTOM TECH CO LTD

Refined rice processing method

InactiveCN104815714AGuaranteed purityHigh purityGrain huskingGrain polishingBroken riceMoisture measurement

The invention discloses a refined rice processing method. The refined rice processing method comprises the following steps of rice screening, stone removal, magnetic separation and rice shelling, rice-bran separating, secondary shelling, thickness grading, moisture measurement and drying or atomizing, rice milling and white rice grading, rice cooling, polishing, color sorting, secondary white rice grading and moisture content detection, and packaging. The refined rice processing method comprises a plurality of impurity removal steps, and consequently, the purity of rice is guaranteed, the produced rice is high in purity, and the safety and the processing efficiency in the processing process are guaranteed. In the rice shelling and rice milling steps of the refined rice processing method, the material temperature is strictly controlled so that the material can be always kept in a relative low temperature appropriate environment, and the crack ratio and the broken rice rate can be reduced and the complete particle rate can be increased; the original faint scent of rice is maintained. The refined rice processing method is used for solving the problems of surface damage and uneven polishing in the rice polishing process by controlling the polishing water temperature and the dampening amount; as a result, the surfaces of all the rice grains polished can be kept smooth and clean, and the quality guarantee period of the rice can be prolonged.

Owner:ANHUI YOUYUAN FOOD

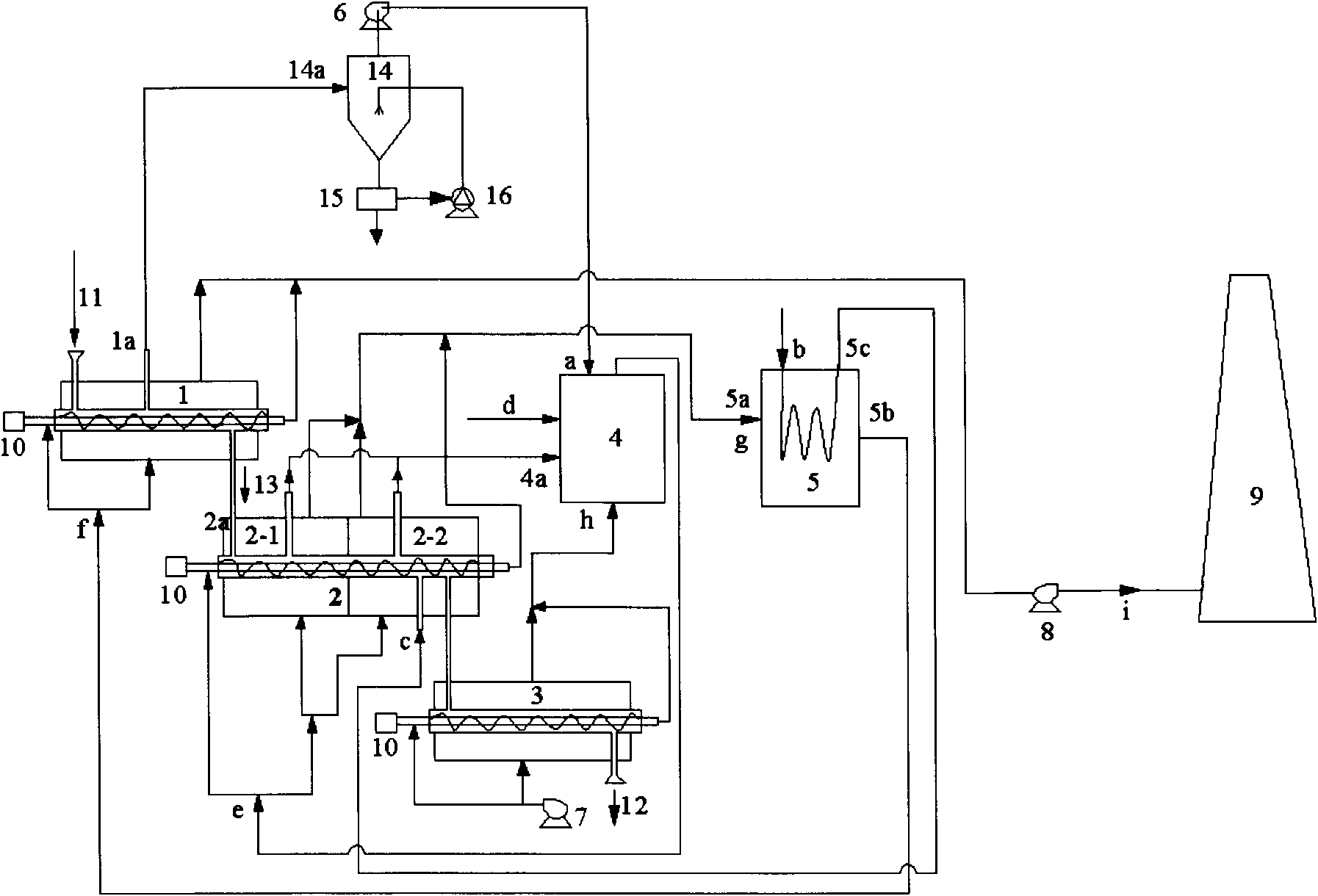

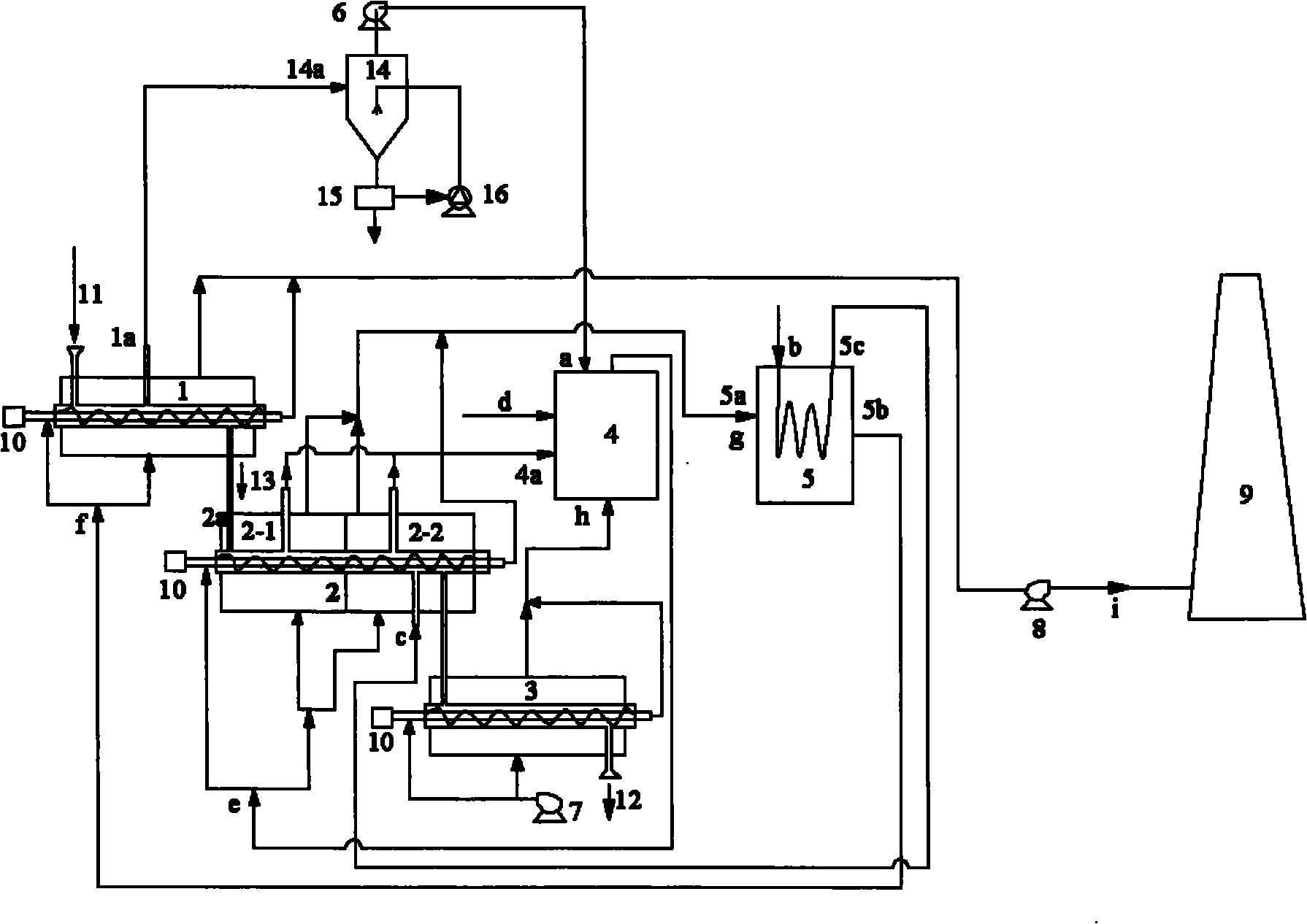

Device and method for continuously preparing active carbon by biomass in bulk

InactiveCN101885487ASolve for uniformityAvoid intermediate manual linksCarbon compoundsEnergy inputCombustionCarbonization

The invention relates to a device and a method for continuously preparing active carbon by a biomass in bulk. The invention is characterized in that the device comprises a spiral dryer (1), a spiral carbonization activation device (2), a spiral cooling device (3), a combustion furnace (4), a waste heat boiler (5), a circulating fan (6), a blower (7), an induced fan (8), a chimney (9), a velocity modulation motor (10), a spray tower (14), a waste liquor circulation pool (15), and a circulation water pump (16), wherein the spiral dryer (1) is provided with a feed port (11), a waste air outlet(1a), a material outlet after drying (13), a coil and a sleeve; and the spiral carbonization activation device (2) comprises a carbonization section (2-1) and an activation section (2-2) communicated with the carbonization section (2-1). By using the invention, the defects of low heat utilization efficiency, low drying / carbonization / activation efficiencies, discontinuous production course and the like in the existing active carbon preparation technology are overcome.

Owner:SOUTHEAST UNIV

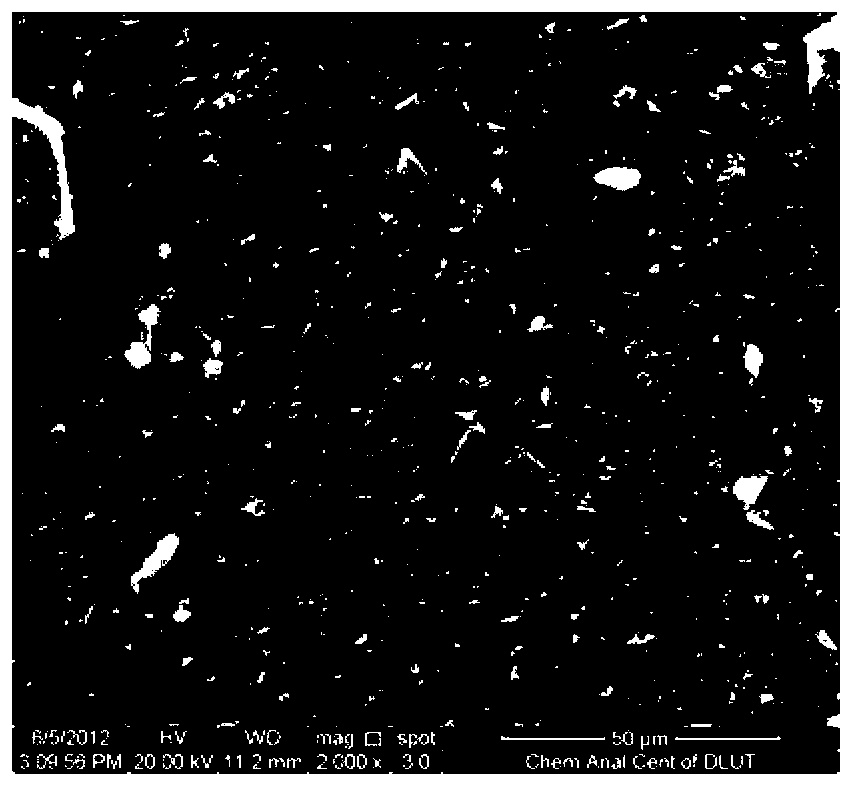

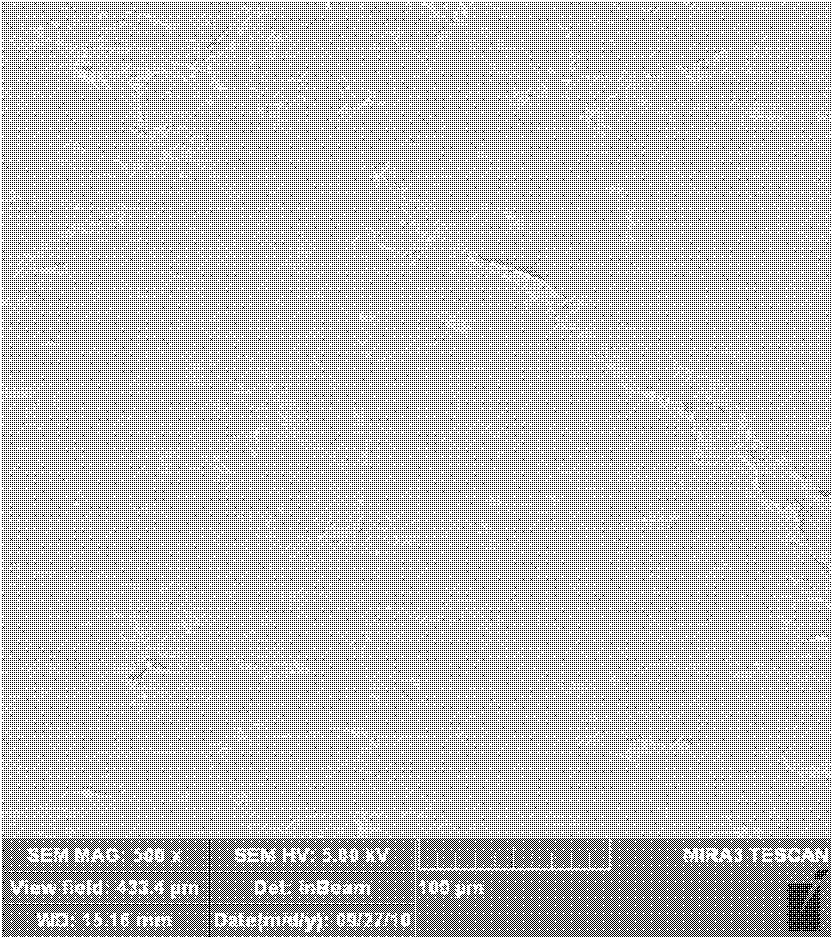

Preparation method of superfine low-sodium alpha-alumina powder with high activity

The invention discloses a preparation method of superfine low-sodium alpha-alumina powder with high activity. Industrial aluminum hydroxide is taken as a raw material; alkali is removed and adsorbed by adding an acid; a compound mineralizer is added to calcine; the superfine low-sodium alpha-alumina powder with high activity, of which the mean grain size D50 is 0.2-1.0micron, is obtained by combining dry ball milling with wet ball milling; the sodium content is 0.01%-0.05%; and the content of the alpha phase is 97%-99%. The problems that the alpha-alumina is high in sodium content, uneven in grain size, poor in sintering activity and the like are solved, special requirements of high-performance ceramic, grinding and polishing materials and the like are met, and the method has the advantages of being simple in process, environmentally friendly, low in cost and the like, and is suitable for large-scale production.

Owner:广西朗琨科技有限公司

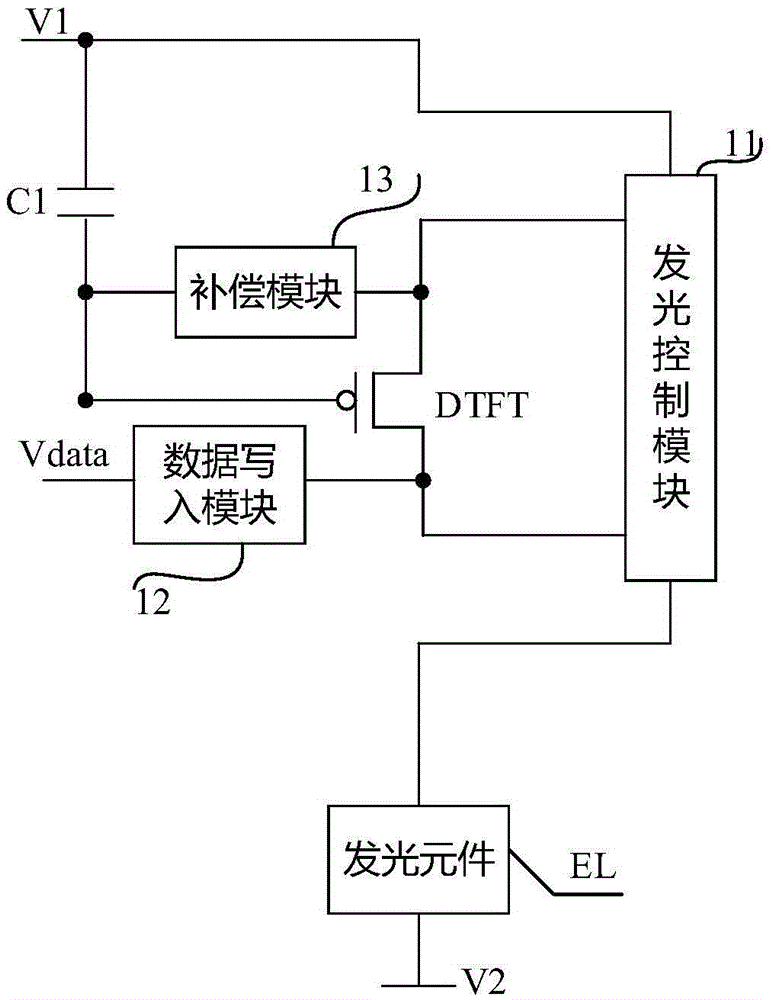

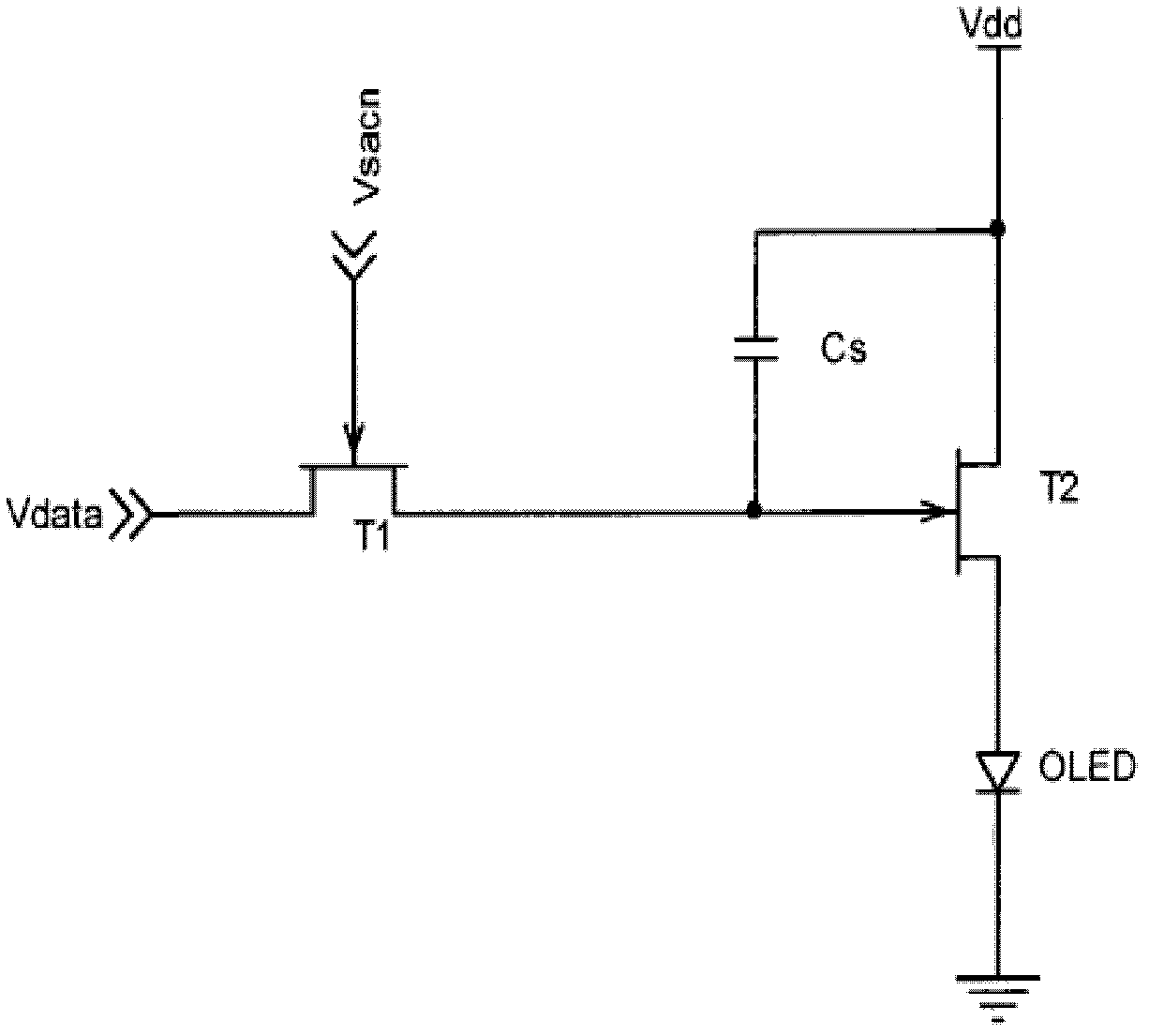

Pixel unit driving circuit and method, pixel unit and display device

ActiveCN102708791ASolve for uniformitySolve attenuationStatic indicating devicesCapacitanceUltrasound attenuation

The invention provides a pixel unit driving circuit, a pixel unit driving method, a pixel unit and a display device. The pixel unit driving circuit comprises a driving thin film transistor, a first switch element, a storage capacitor and a driving control unit, wherein the source of the driving thin film transistor is connected with a data wire through the first switch element; the drain of the driving thin film transistor is respectively connected with a positive electrode of an organic light emitting diode (OLED) and the low level output end of a driving power supply; the source of the driving thin film transistor is connected with the high level output end of the driving power supply through the driving control unit; the gate of the driving thin film transistor is connected with the drain of the driving thin film transistor through the driving control unit; and the driving control unit controls the driving thin film transistor to work in a saturated region and voltages of the gate and the source of the driving thin film transistor to compensate for threshold voltage by controlling charging and discharging of the storage capacitor. By the invention, the problems of non-uniform brightness of an OLED panel and brightness attenuation are solved.

Owner:BOE TECH GRP CO LTD +1

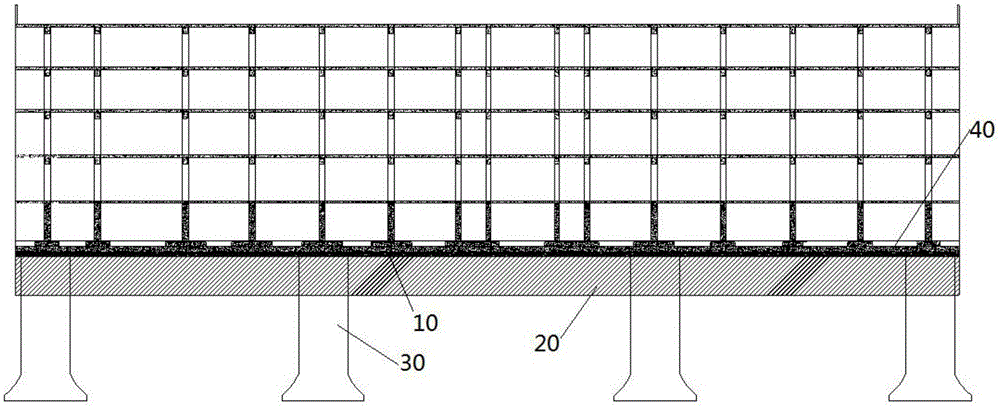

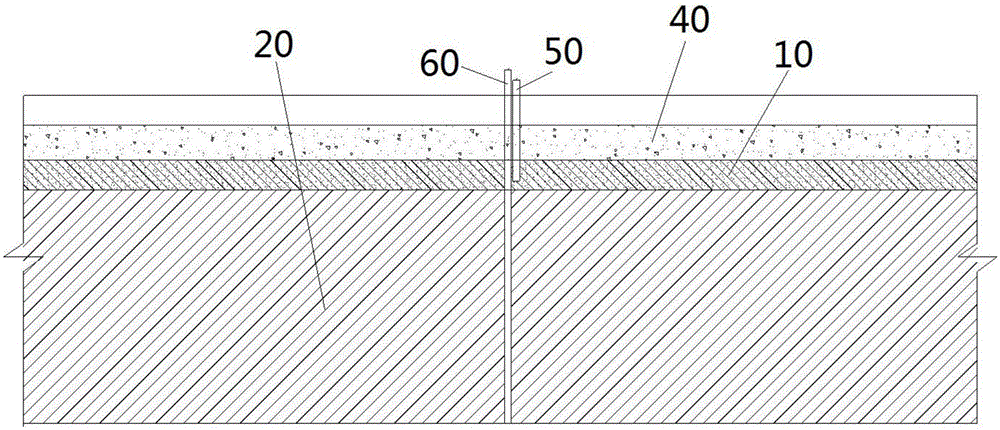

Grouting reinforcement and rectification method suitable for high-rise building structure

ActiveCN107435346ASolve for uniformityTo achieve reinforcementFoundation engineeringSupporting systemStructure of the Earth

The invention provides a grouting reinforcement and rectification method suitable for a high-rise building structure. The method comprises the steps from S10 to S30, wherein in the step S10, grouting filling reinforcement is conducted on an original cushion layer under an original concrete valve plate, and the original cushion layer and grout are solidified to form a cushion layer reinforcement and strengthening layer; in the step S20, after the cushion layer reinforcement and strengthening layer is formed, grouting filling reinforcement is carried out on an original foundation under the original cushion layer, and the original foundation and grout are solidified to form a foundation reinforcement platform; in the step S30, after the foundation reinforcement platform is formed, a plurality of pile foundation grouting holes are vertically formed in the lower surface of the foundation reinforcement platform at intervals, grout is injected into the pile foundation grouting holes to form an under-column pile foundation. The cushion layer reinforcement layer, the foundation reinforcement platform and the under column pile foundation form a three-dimensional supporting system in the mode that the layers are reinforced layer by layer from top to bottom; the purpose of building foundation reinforcement and lifting rectification integration is achieved, and the problems that a building is not uniform in settlement and a rectification foundation is lifted are successfully solved.

Owner:BEIJING HENGXIANG HONGYE FOUND REINFORCEMENT TECH CO LTD

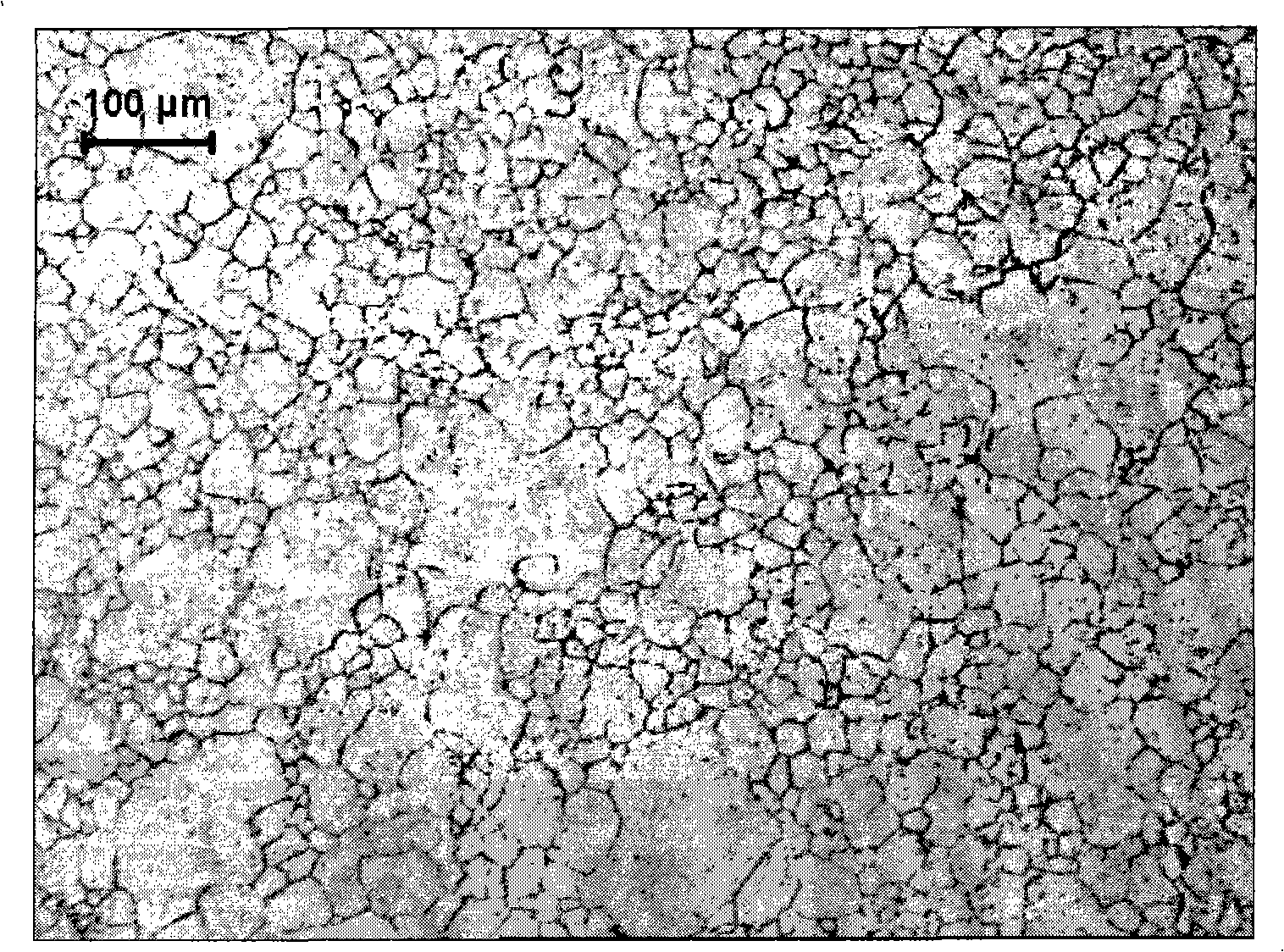

Ultra-thick hard alloy, and preparation method and application thereof

The invention discloses an ultra-thick hard alloy, a preparation method and application thereof. The raw material of the ultra-thick hard alloy comprises the following components in percentage by weight: 10.0-10.5% of Co and the balance of WC. The preparation method comprises the following steps of pretreatment, raw material preparation, wet grinding, spray drying, compression moulding and sintering. According to the invention, technical conditions of each component and technical conditions of each step are selected preferentially, and common technical problems in the preparation of ultra-thick ally in China, such as non-even grains, poor anti-impact toughness and thermal fatigue resistance and too many pores. The ultra-thick hard ally has excellent thermal conductivity, impact toughness and thermal fatigue resistance, cross breaking strength is larger than or equal to 3,100Mpa, the hardness is 86-87HRA, the coercive force is 3.0-4.0KA / m, and WC average grain size is 5-6 microns.

Owner:赣州海盛钨业股份有限公司

Quenching oil for bearings and preparation method thereof

ActiveCN102140570ASolve for uniformitySolve the problem of not being brightQuenching agentsAntioxidantHardness

The invention relates to the technical field of quenching media in a heat treatment link in bearing production, in particular to quenching oil for bearings and a preparation method thereof. Each 100 weight parts of quenching oil comprises the following components in part by weight: 79 to 98.45 parts of base oil, 1 to 8 parts of cooling accelerant, 0.05 to 5 parts of brightening agent and 0.5 to 8parts of antioxidant. The high-end class II base oil is taken as a raw material, and is added with the cooling accelerant, the high temperature antioxidant and the brightening agent in different proportions to form the quenching oil for the bearings; after the bearings are quenched by the quenching oil, the bearings are uniformly silvery, the structure and hardness of the bearings meet or exceed the requirements of national standard, and the deformation of the bearings subjected to heat treatment is reduced by 30 percent than a standard value; meanwhile, the service life of an oil product is 5 years, and the cost of the oil product used in a factory is reduced. Meanwhile, the quenching oil has the advantages of energy conservation and environmental friendliness, and can improve the quality of industrial products.

Owner:CHANGZHOU LONGPONT LUBRICANTS

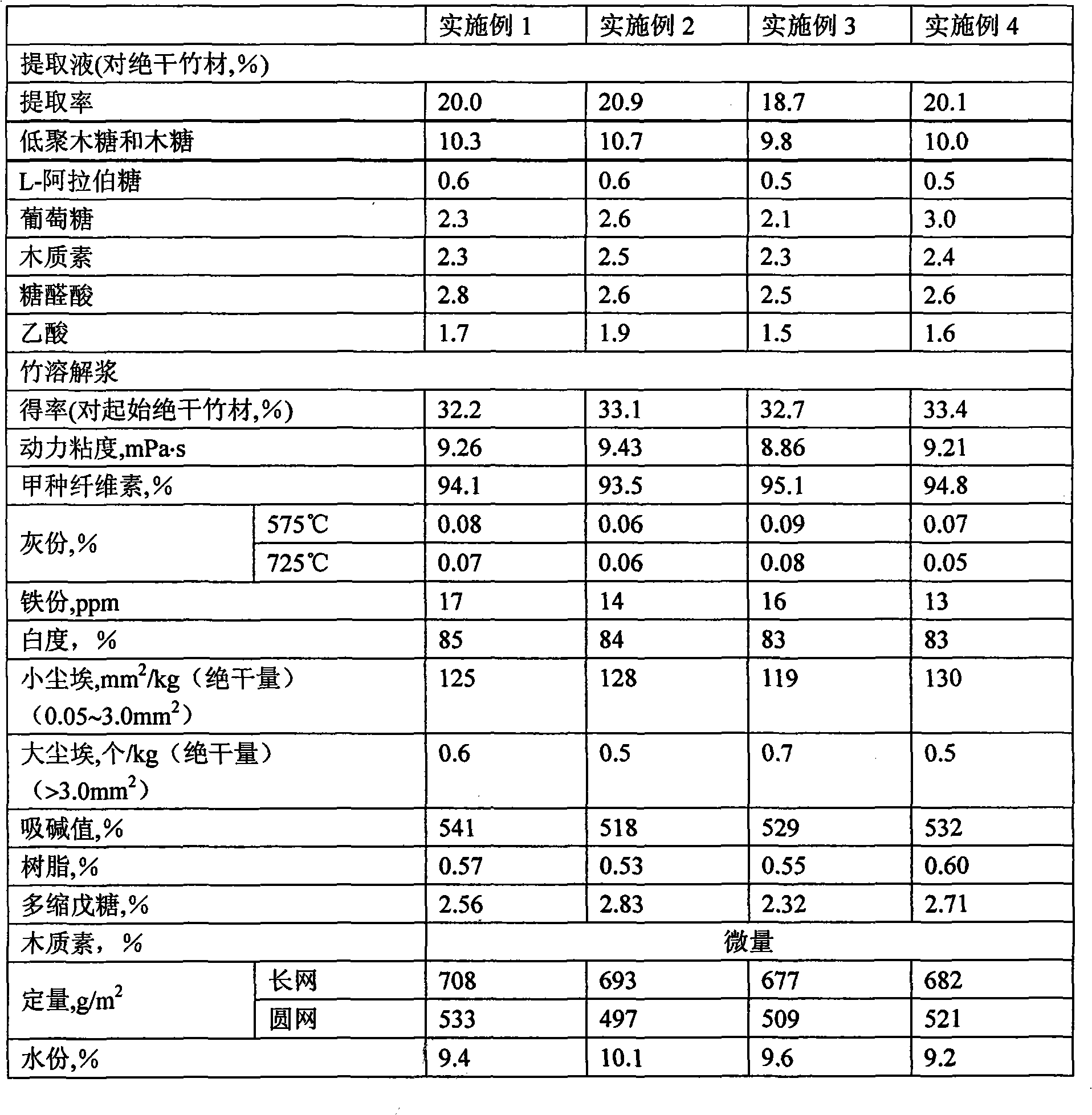

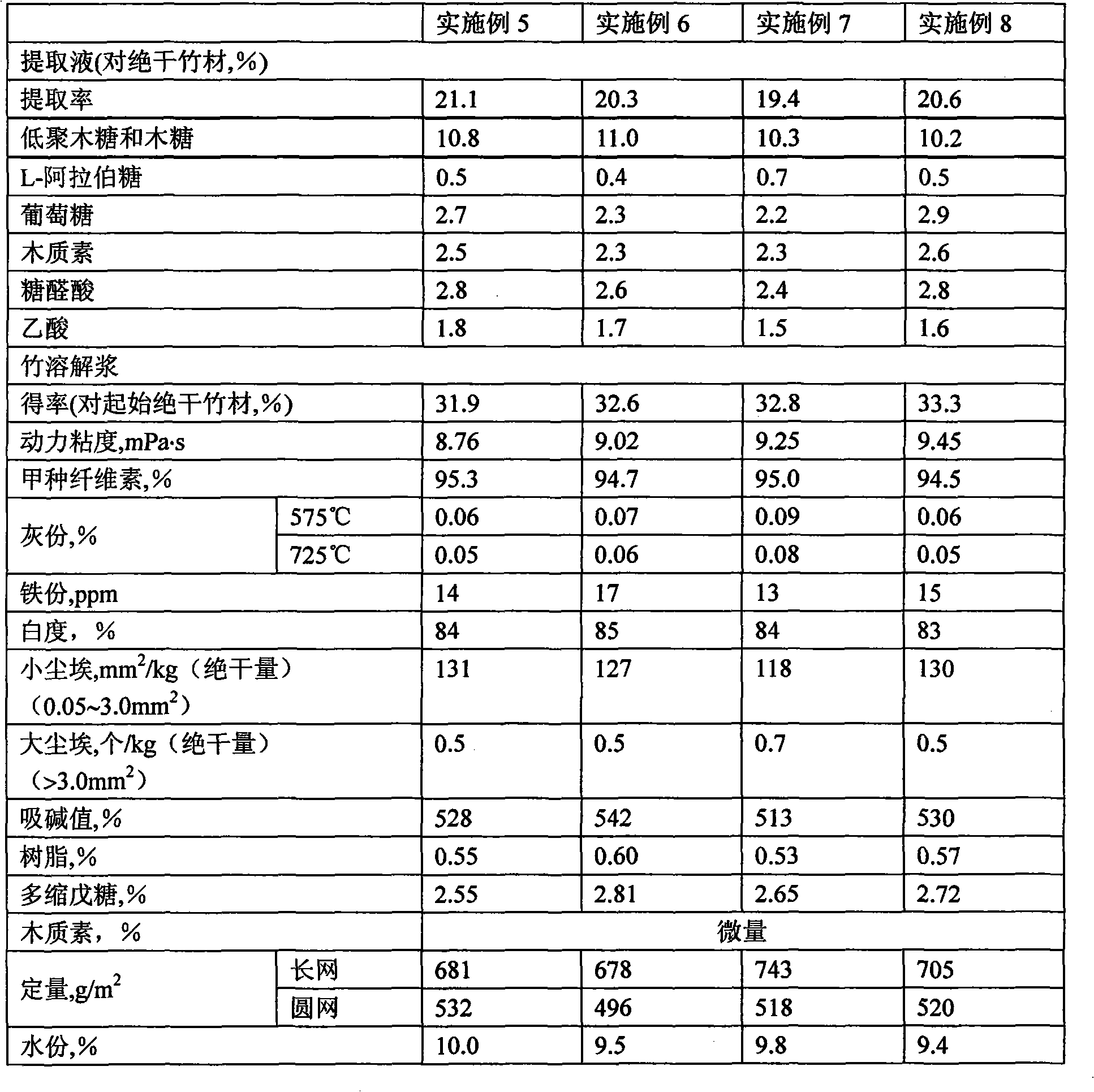

Method for producing bamboo dissolving pulp by pre-extracting hemicellulose and product thereof

InactiveCN101565906AHigh extraction rateReduce the content of non-sugar organic debrisSugar derivativesPretreatment with acid reacting compoundsChemistryViscose

The invention relates to a method for producing bamboo dissolving pulp by pre-extracting hemicellulose and a product thereof; the method includes the following steps of: preparing bamboo wood: preparing the bamboo wood into bamboo sheets or bamboo filaments, and washing the bamboo sheets or bamboo filaments to remove impurity and dirt; prehydrolysis: the technical condition requiring solid-to-liquid ratio of 1:0.4-8.0, hydrolysis temperature of 100-200 DEG C, hydrolysis time of 15-240 minutes and a pH value of 2-5 at a hydrolysis end point; liquid solid separation and washing; collecting filtrate to produce extract; and preparing the dissolving pulp by residue alkaline process. The invention has the advantages that the performance index of the dissolving pulp meets the technical requirement of viscose fiber pulp, cellulose acetate, soluble cotton and cellulose ether dissolving pulp, and the method can extract most pentosane in bamboo wood by controlling the prehydrolysis technical condition, has extremely strong pertinence pertinency for the processing of the bamboo fiber materials, improves the reaction performance and evenness of the bamboo dissolving pulp, and reduces the cost for producing the bamboo dissolving pulp and pre-extracting the hemicellulose.

Owner:上海士林纤维材料有限公司

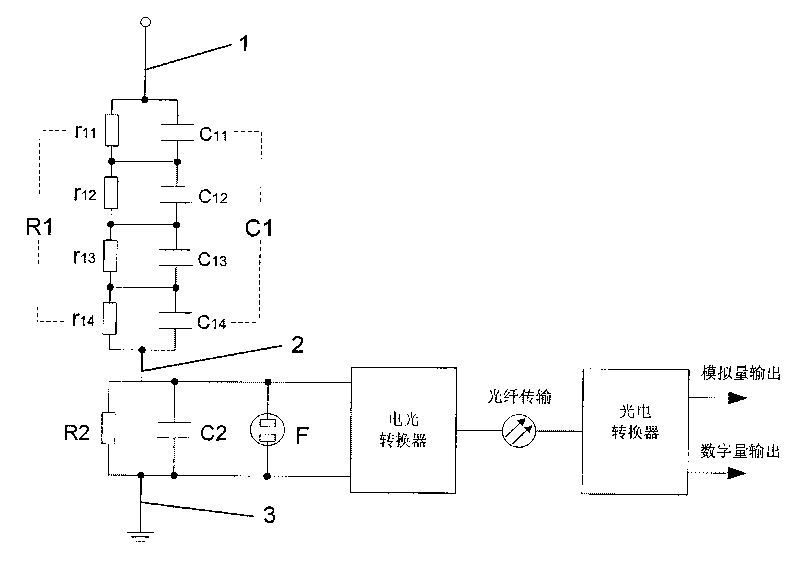

Gas insulation-based DC high voltage measuring device

ActiveCN101713793AReduce distractionsReduce volumeNon-electrical signal transmission systemsCurrent/voltage measurementCapacitanceLow voltage

The invention relates to the DC high voltage transmission test technology of a power system, and discloses a gas insulation-based DC high voltage measuring device, which comprises a high voltage unit, a low voltage unit, a base, and an insulated sleeve fixed on the base; the high voltage unit is connected in series with the low voltage unit, and a high voltage terminal, a medium voltage terminal and a low voltage terminal are respectively led out; the high voltage unit is arranged in the insulated sleeve which is sealed by upper and lower end covers and is filled with SF6 gas; the high voltage terminal is led out from the upper end cover, and the medium voltage terminal is led out from the lower end cover and is connected with the low voltage unit; the high voltage unit and the low voltage unit respectively consist of voltage divider modules which are connected in series, and the series of the voltage divider modules forming the high voltage unit is greater than that of the voltage divider modules forming the low voltage unit; and the voltage divider modules consist of voltage sharing capacitors and divider resistors which are connected in parallel.

Owner:XIAN HIGH VOLTAGE APP RES INST CO LTD

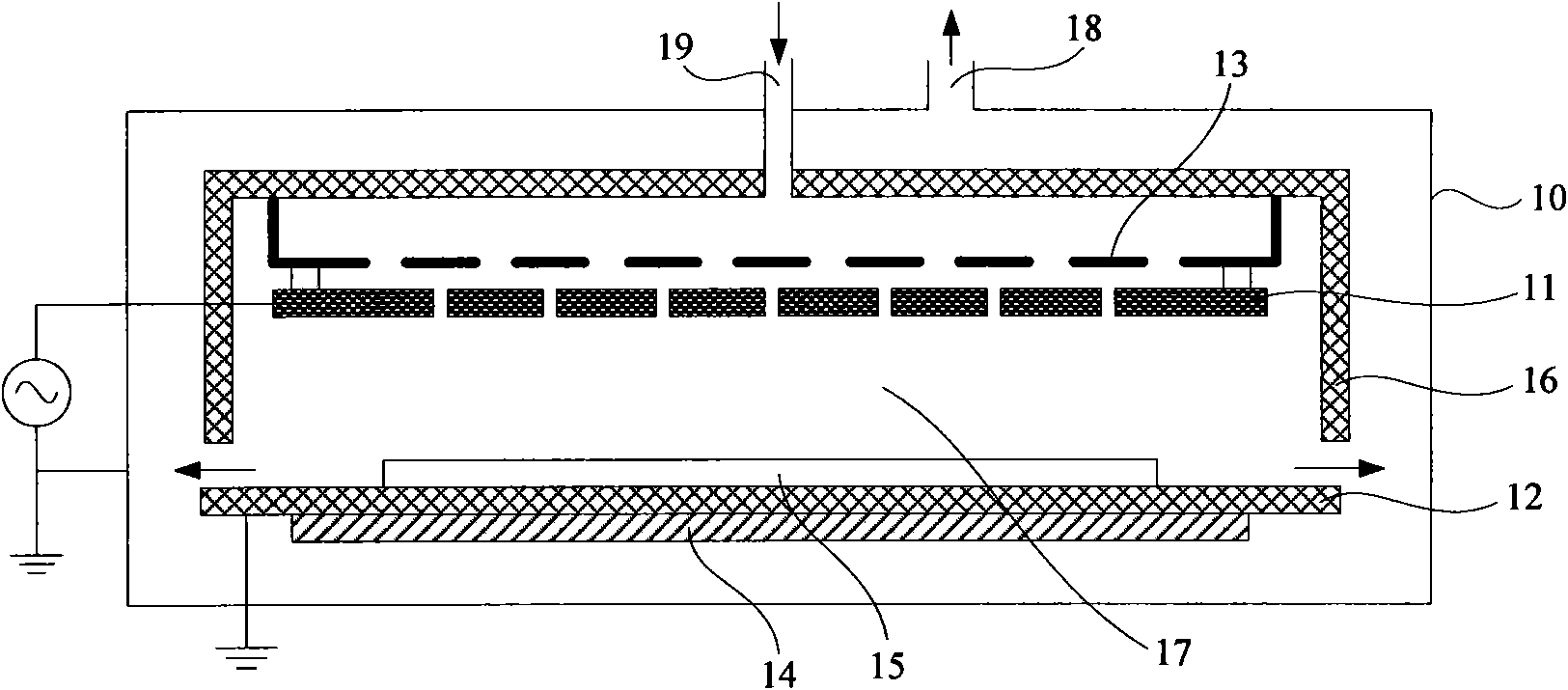

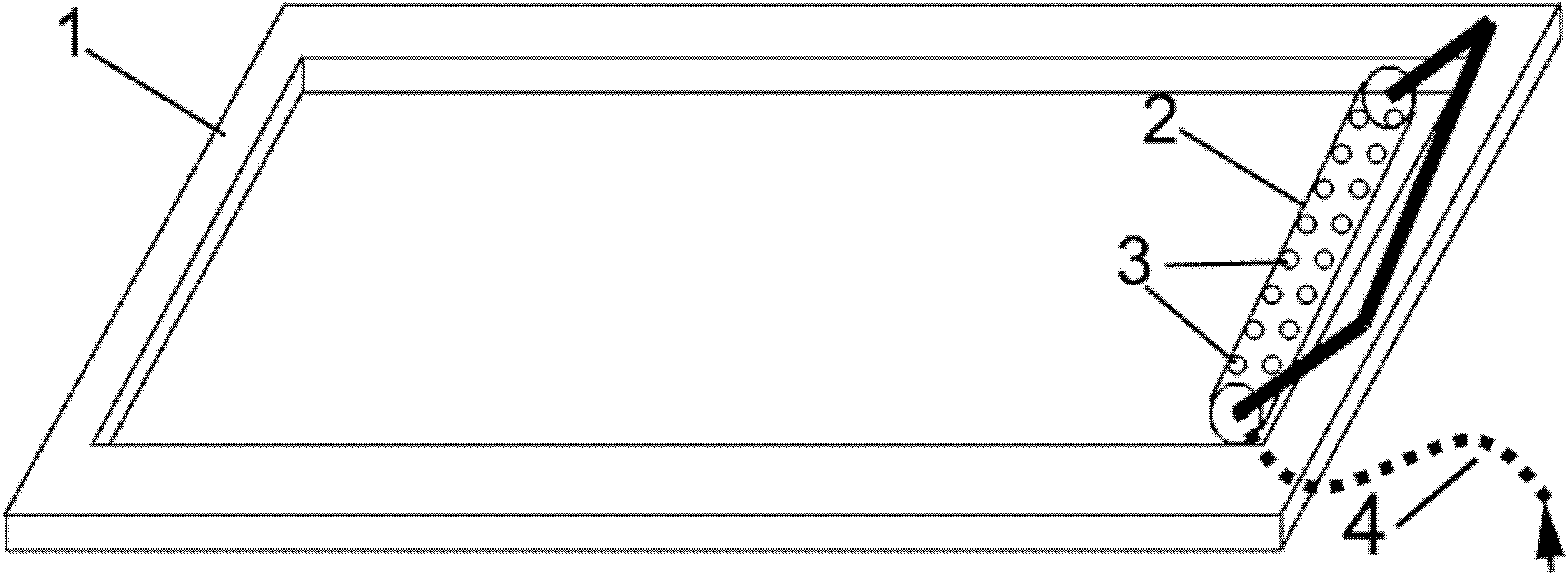

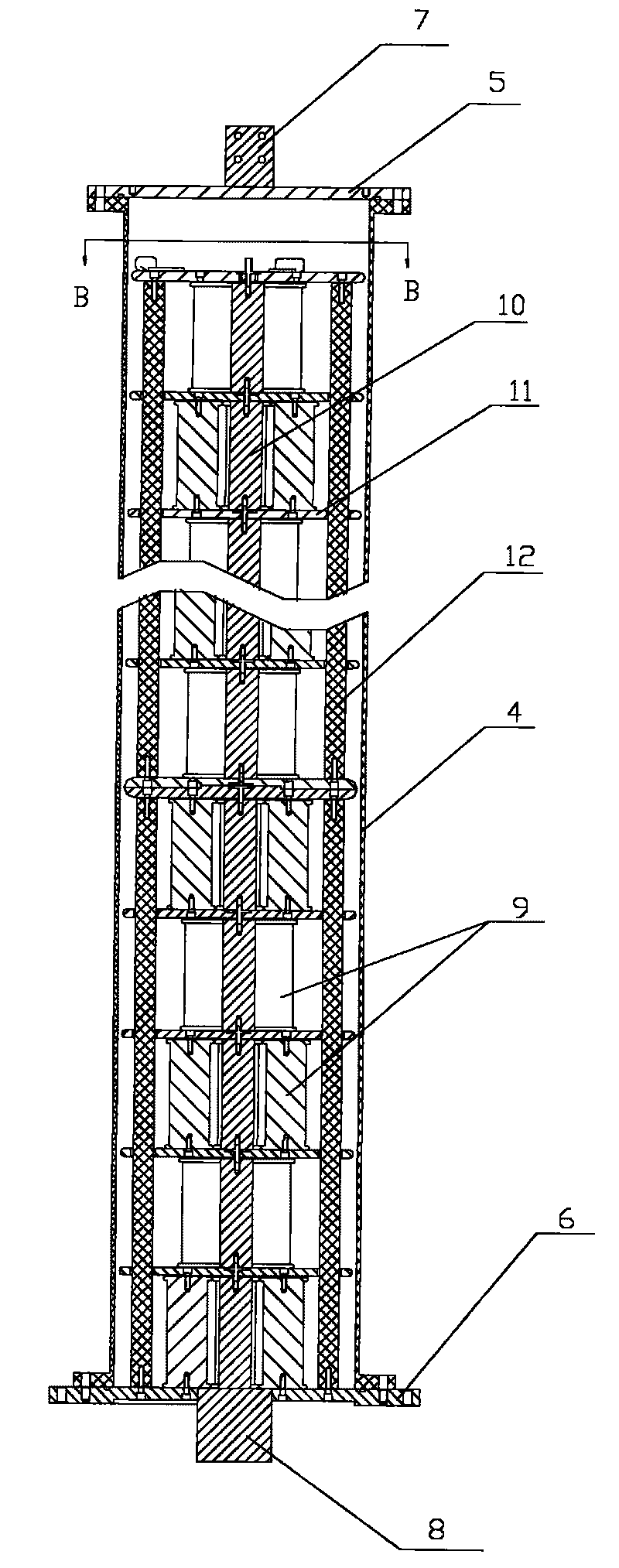

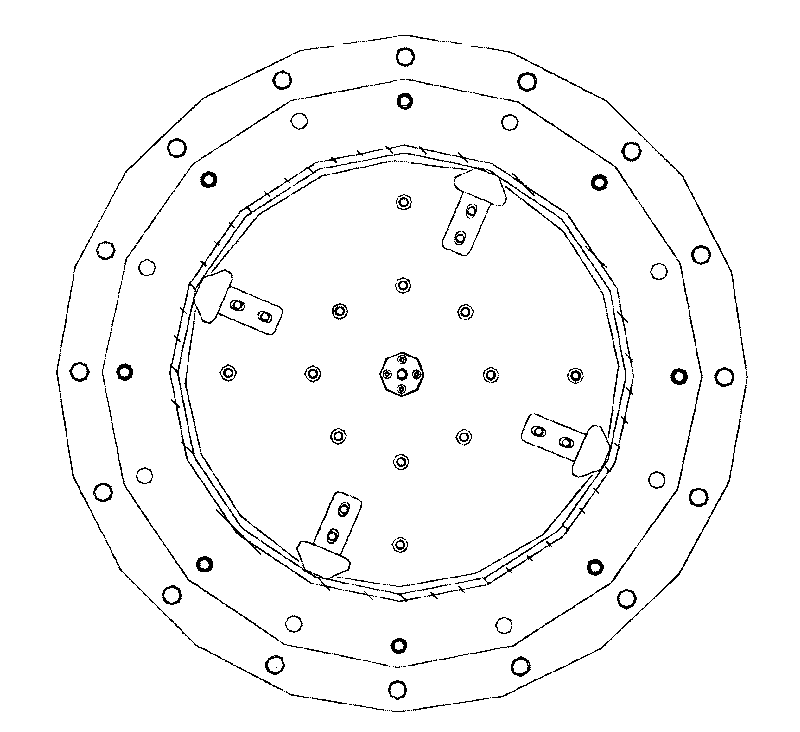

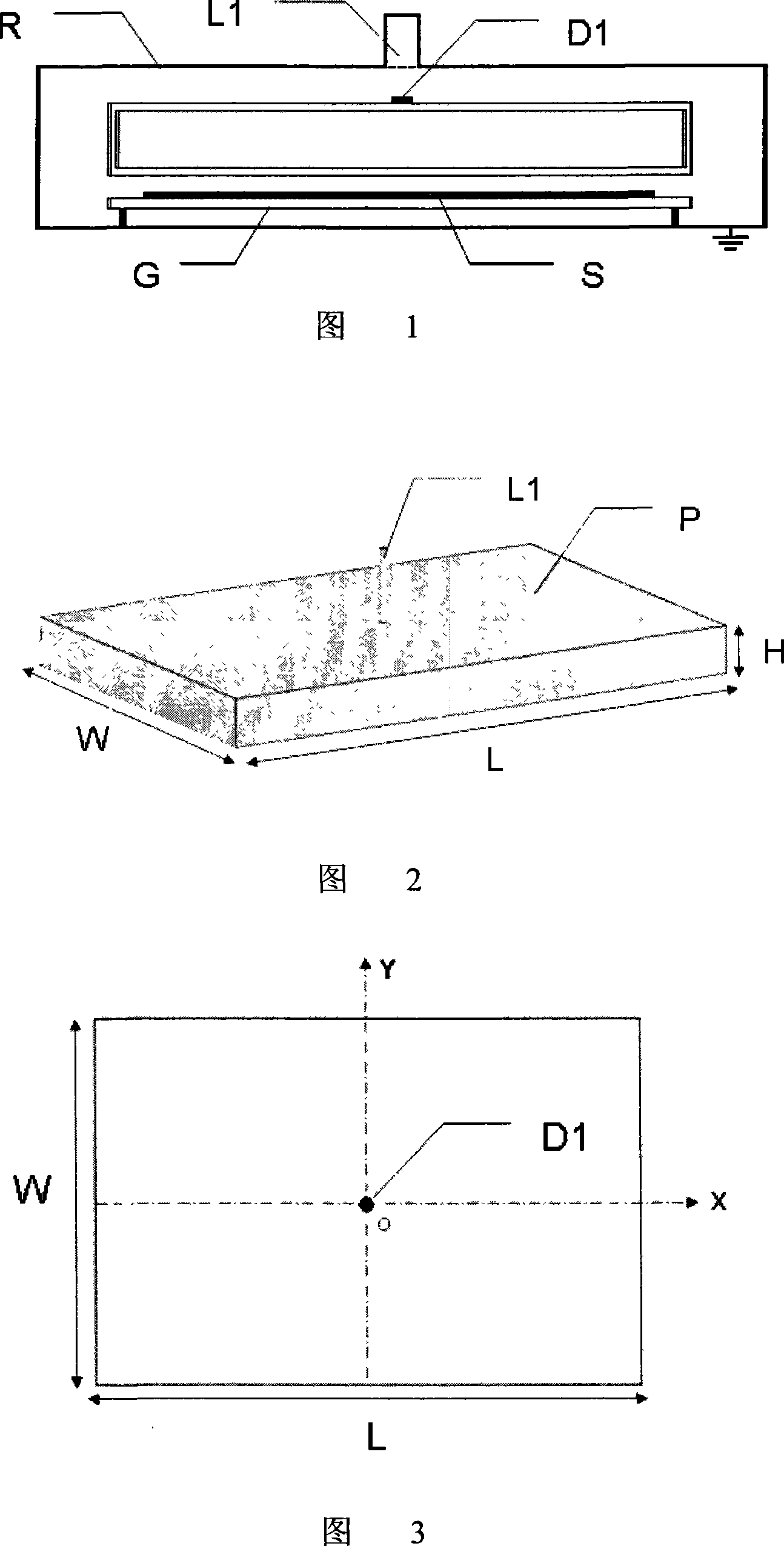

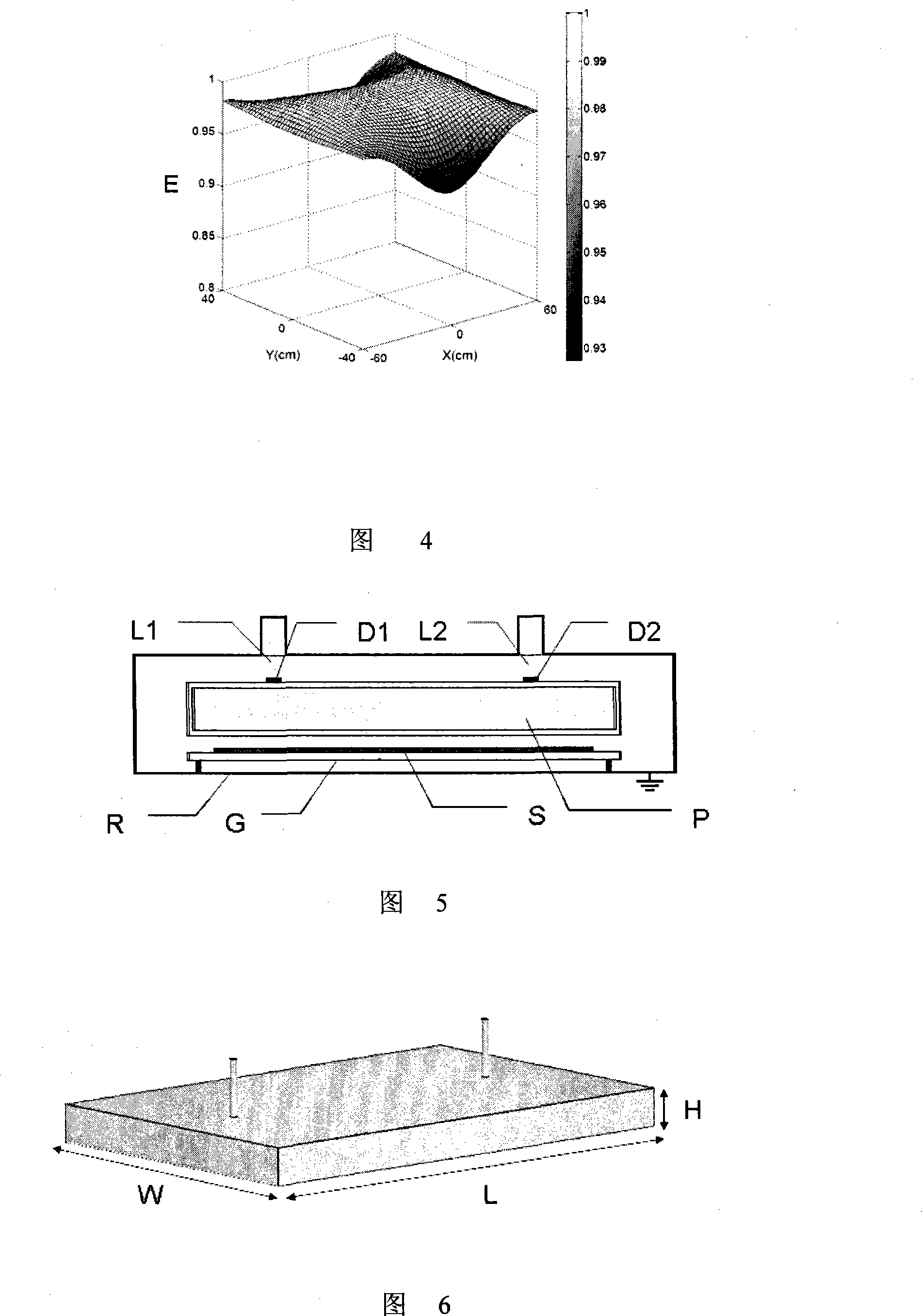

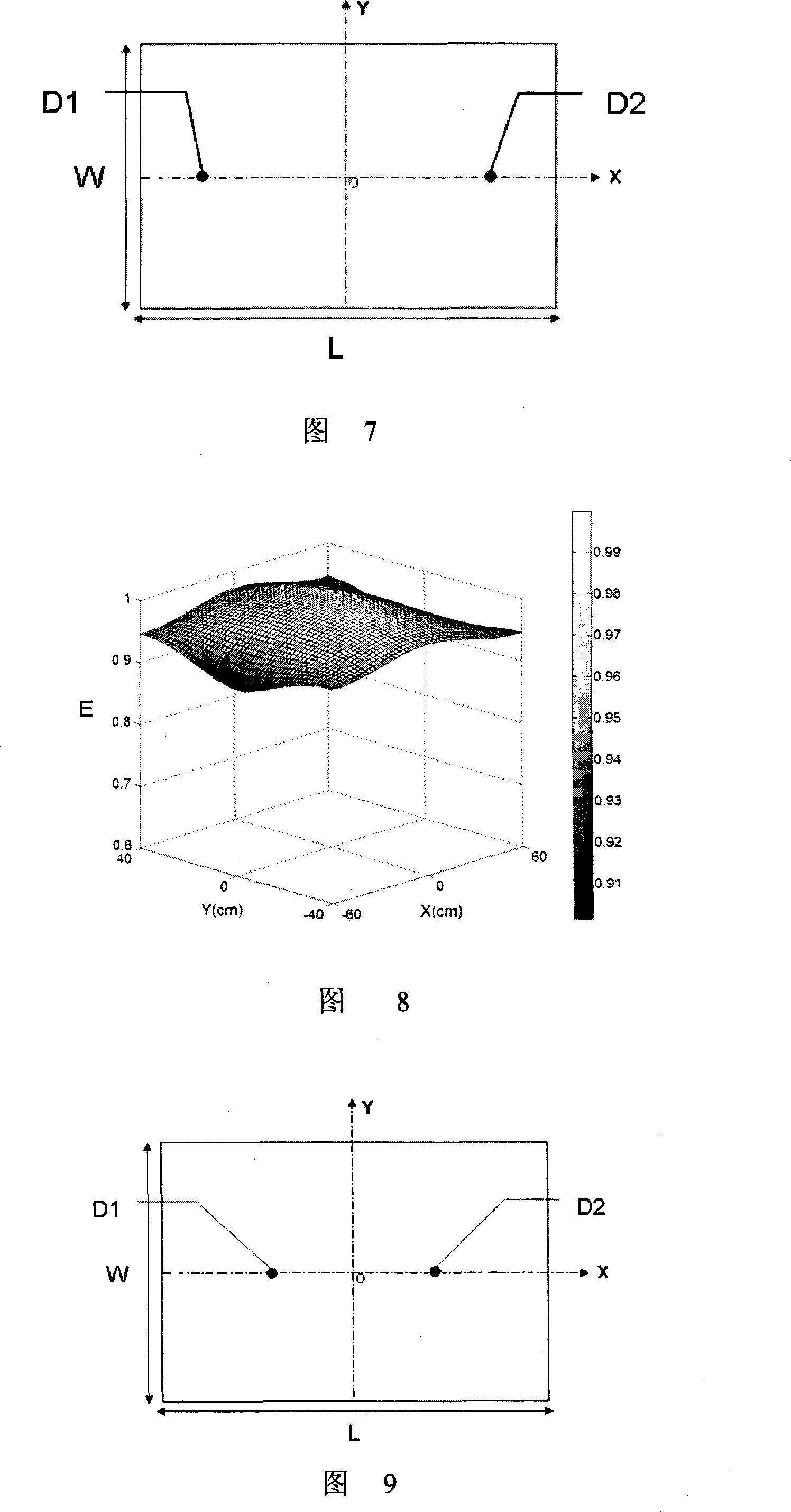

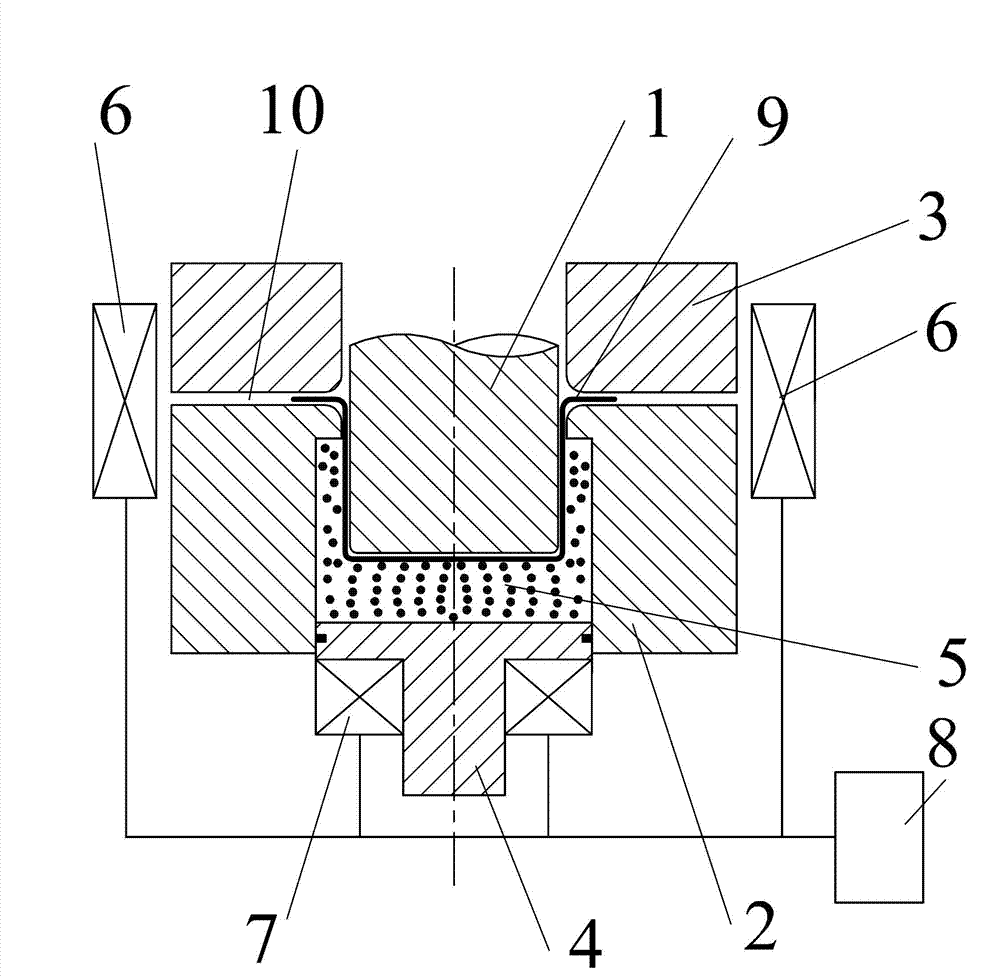

Large area VHF-PECVD reaction chamber back feed-in type parallel plate electrode capable of obtaining even electric field

InactiveCN101187016AImprove uniformitySolve for uniformityChemical vapor deposition coatingParallel plateElectrical battery

The invention discloses a back feed-in parallel plate power electrode capable of achieving a large-area reaction chamber of VHF-PECVD with uniform electric fields, which includes a parallel plate power electrode plate and a power feed-in connection port and is characterized in that the power feed-in connection port is positioned on the back side of the power electrode plate of which the front face is opposite to a substrate S. The invention employs optimized distribution of the position of the electric power feed-in port to suppress logarithm singular point effect and standing wave effect of electric potential near the electrode feed-in port, ensuring great improvement of the uniformity of electric field distribution, thereby being capable of avoiding the problem that electric field distribution is uneven due to the employment of feed-in mode of electrode edge power. The invention resolves the problem of uniformity of electric potential distribution of the large-area electrode plate, which lays the groundwork for the research and development of thin films deposition and etching systems of the large-area VHF-PECVD and can powerfully promote industrialization process of matrix technique of silicon thin film solar cells and thin film transistors.

Owner:NANKAI UNIV

A kind of magnesium alloy solder containing rare earth element Er and preparation method thereof

InactiveCN102294553ASolve severe segregationSolve the coarse grainWelding/cutting media/materialsSoldering mediaRare-earth elementSlag

The invention relates to a magnesium alloy brazing filler metal containing a rare-earth element Er and a preparation method thereof, and belongs to the technical field of magnesium alloy connection. The magnesium alloy brazing filler metal comprises the following components in percentage by weight: 40-55% of Mg, 39-55% of Zn, 1-5% of Al and 0.1-1.5% of Er, wherein the Er is uniformly distributed.The preparation method comprises the steps of arranging alloy ingots in a preheat crucible, heating under protective atmosphere and mechanical stirring, fishing slag after the alloy ingots are completely fused, stopping heating brazing filler metal, stirring the brazing filler metal, applying ultrasonic waves on the fused brazing filler metal after the brazing filler metal is cooled to 380-600 DEG C, inserting an ultrasonic rod preheated to 300-700 DEG C into a brazing filler metal liquid level with the ultrasonic frequency of 18-22kHz, ultrasonic intensity of 0.5-5W / cm2 and the time of 10-150s, standing still after moving out the ultrasonic rod after ending, pouring the brazing filler metal liquid into a mould and air cooling to room temperature. The number of dendritic crystals of the obtained product is obviously reduced, crystal grains are refined, and the strength and the toughness are improved.

Owner:BEIJING UNIV OF TECH

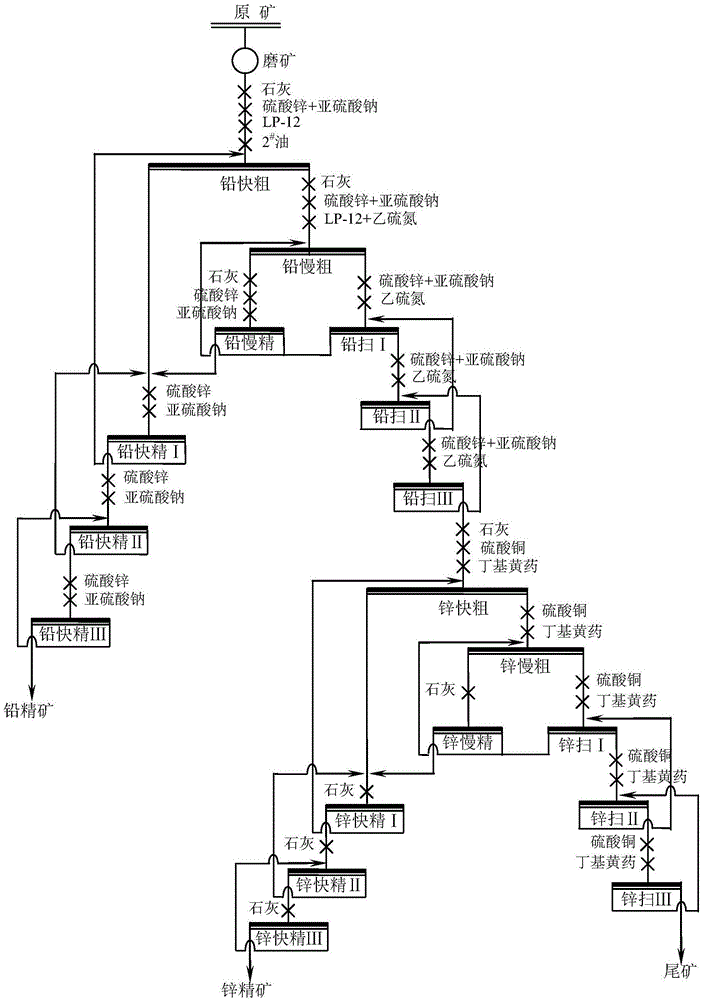

Ore dressing method for lead-zinc-silver poly-metallic ores

The invention provides an ore dressing method for lead-zinc-silver poly-metallic ores. Lead-silver concentrates and zinc concentrates are finally obtained through the steps of raw ore grinding, lead fast roughing, lead slow roughing, lead scavenging, lead fast concentration, lead slow concentration, zinc fast roughing, zinc slow roughing, zinc scavenging, zinc fast concentration and zinc slow concentration. The lead-zinc-silver poly-metallic ores sorted by the ore dressing method provided by the invention are good in sorting index and high in separation efficiency; the ore dressing method is a lead-zinc-silver ore dressing method which is stable, efficient, strong in adaptive capacity, good in sorting effect, high in comprehensive recovery index and low in production cost and is suitable for popularization and application.

Owner:DONGSHENGMIAO MINING LLC +2

Water-retention soilless culture medium

InactiveCN102715068ASolve for uniformityLarge water storage capacityAgriculture gas emission reductionCultivating equipmentsSodium BentonitePhosphate

The invention discloses a water-retention soilless culture medium, belonging to the field of agriculture cultivation technique. The water-retention soilless culture medium comprises the following components in percentage by weight: 20-30 percent of organic fertilizer, 10-15 percent of grass carbon, 16-20 percent of fine sand, 8-12 percent of rough sand, 8-12 percent of vermiculite, 5-8 percent of perlite, 5-7 percent of calcium potassium magnesium powder, 3-6 percent of weathered coal, 3-5 percent of ground phosphate rock, 1-2 percent of bentonite, and 0.4-0.8 percent of water-retention agent, wherein the organic fertilizer is prepared by mixing, fermenting and bubbling animal excrements, plant straws and the like, and has moisture rate of 8-15 percent after being aired and screened, the granularity of grass carbon, vermiculite and perlite is smaller than 60 meshes, and the granularity of other components is less than 80 meshes. The preparation method comprises the steps of weighing all components according to proportion, agitating and mixing, drying, inspecting, metering and packaging. The water-retention soilless culture medium has the advantages of being simple in production technique, reasonable in proportion and excellent in applicability, and can be widely applied for breeding and transplantation of tree seedlings and grasses, as well as vegetable, fruits, grains, flowers, trees and the like in drought, deserts and salinization regions.

Owner:雷文东

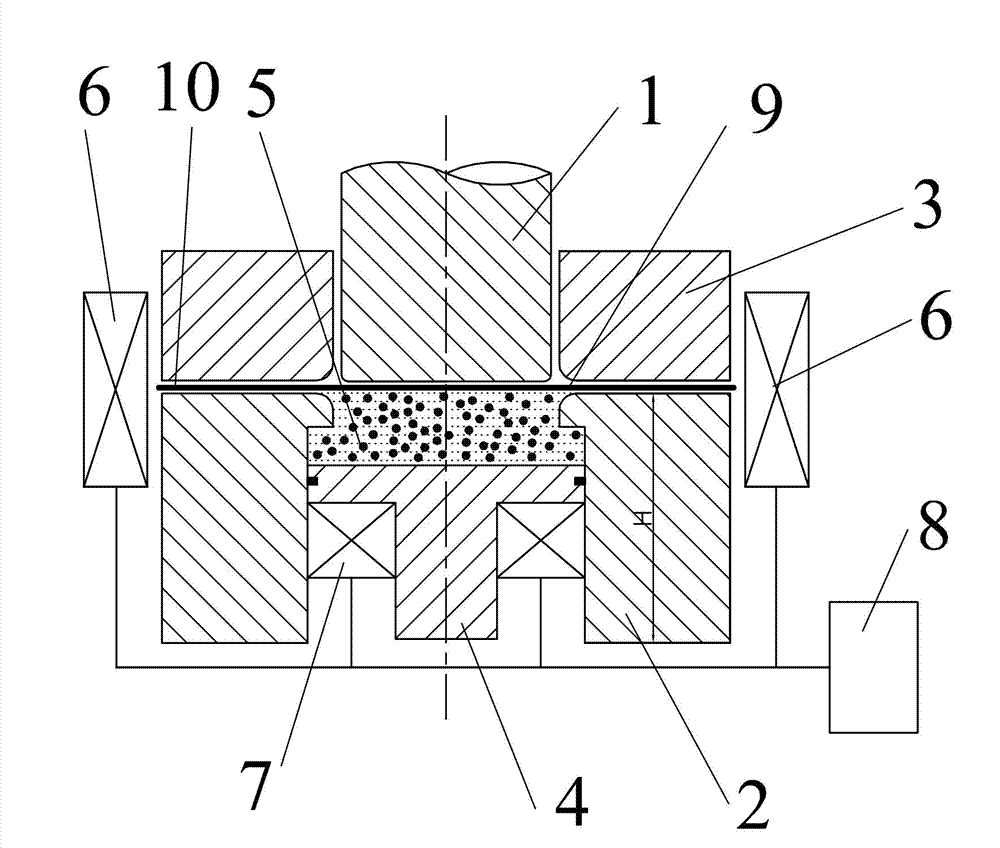

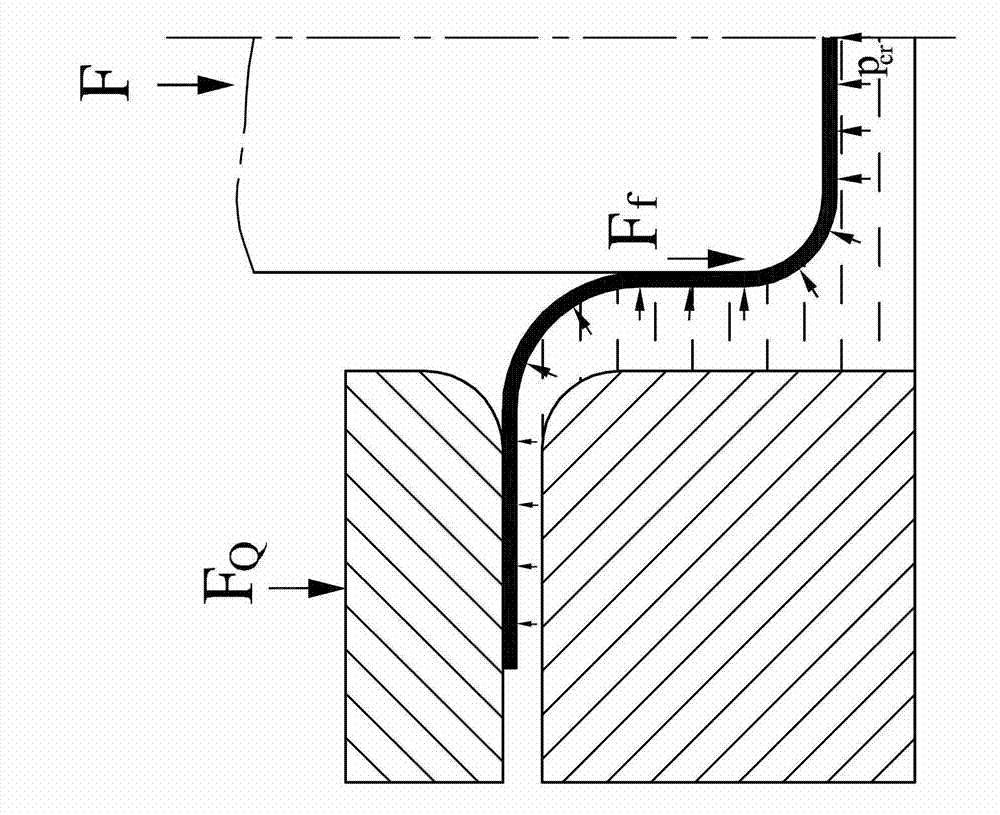

Sheet material hydro-mechanical deep drawing forming device and method using magnetic medium to pressurize

The invention provides a sheet material hydro-mechanical deep drawing forming device and a sheet material hydro-mechanical deep drawing forming method using a magnetic medium to pressurize, belongs to the technical field of hydro-mechanical deep drawing, and solves the technical problems in a traditional sheet material hydraulic forming process that wrinkles are formed, the deformation uniformity is poor and the like, caused by the reason that overflowing pressure of a flange region is reduced, when a sealing ring is not used in order to realize overflowing and lubrication. A sealed hydraulic chamber formed by a concave die and a lower plunger piston is used for containing the magnetic medium; a convex die can penetrate through an edge pressing ring to drive a plate blank to move downwards to enter the sealed hydraulic chamber formed by the concave die and the lower plunger piston; a first coil is arranged on the periphery of the outer side of the flange region formed by the concave die and the edge pressing ring; a second coil is arranged on a pull rod of the lower plunger piston; and a magnetic control unit is used for controlling the sizes of magnetic fields generated by the first coil and the second coil. Firstly, a certain amount of the magnetic medium is poured into the hydraulic chamber and the edge pressing ring is moved downwards after the plate blank is placed; the viscosity and the pressure value of the magnetic mediums on a flange and in the hydraulic chamber are respectively adjusted and controlled through the magnetic fields; and a punching head is moved downwards until a plate piece is formed. The sheet material hydro-mechanical deep drawing device and the sheet material hydro-mechanical deep drawing method using the magnetic medium to pressurize are suitable for hydro-mechanical deep drawing formation of a sheet material.

Owner:HARBIN UNIV OF SCI & TECH

Ultraviolet dual-curing conductive adhesive and preparation method thereof

ActiveCN104046315AHigh bonding strengthImprove performancePolyureas/polyurethane adhesivesElectrically-conducting adhesivesPolymer scienceSilanes

The invention discloses an ultraviolet-heat dual-curing adhesive composition and a preparation method thereof. The ultraviolet dual-curing adhesive composition comprises the following components in percentage by mass: 20-50% of polyurethane modified epoxy monoacrylate, 10-25% of reactive diluent, 5-40% of conductive filler, 1-5% of silane coupling agent, 1-5% of photoinitiator and 1-5% of heat curing agent. The ultraviolet-heat dual-curing adhesive is high in curing speed; after a few seconds of ultraviolet irradiation, the acrylate double-bond group in the system can be quickly cured, so that the adhesive has preliminary bonding strength; and then by means of heating, the epoxy group is further subjected to crosslinking and curing according to a heat curing mechanism, thus further improving the bonding strength of the adhesive. The adhesive has high bonding strength and favorable conductivity, and can meet the bonding requirements of devices in electronic industry and the like. Besides, the adhesive disclosed by the invention is solventless, simple to operate, high in curing speed, high in bonding strength and suitable for batch production on a production line.

Owner:YONGZHOU FUXING ELECTRONICS SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com