Patents

Literature

181results about How to "Efficient and stable production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for manufacturing microfibrillated cellulose fiber

ActiveUS7381294B2Efficient and stable productionQuality improvementNon-fibrous pulp additionNatural cellulose pulp/paperCellulose fiberSlurry

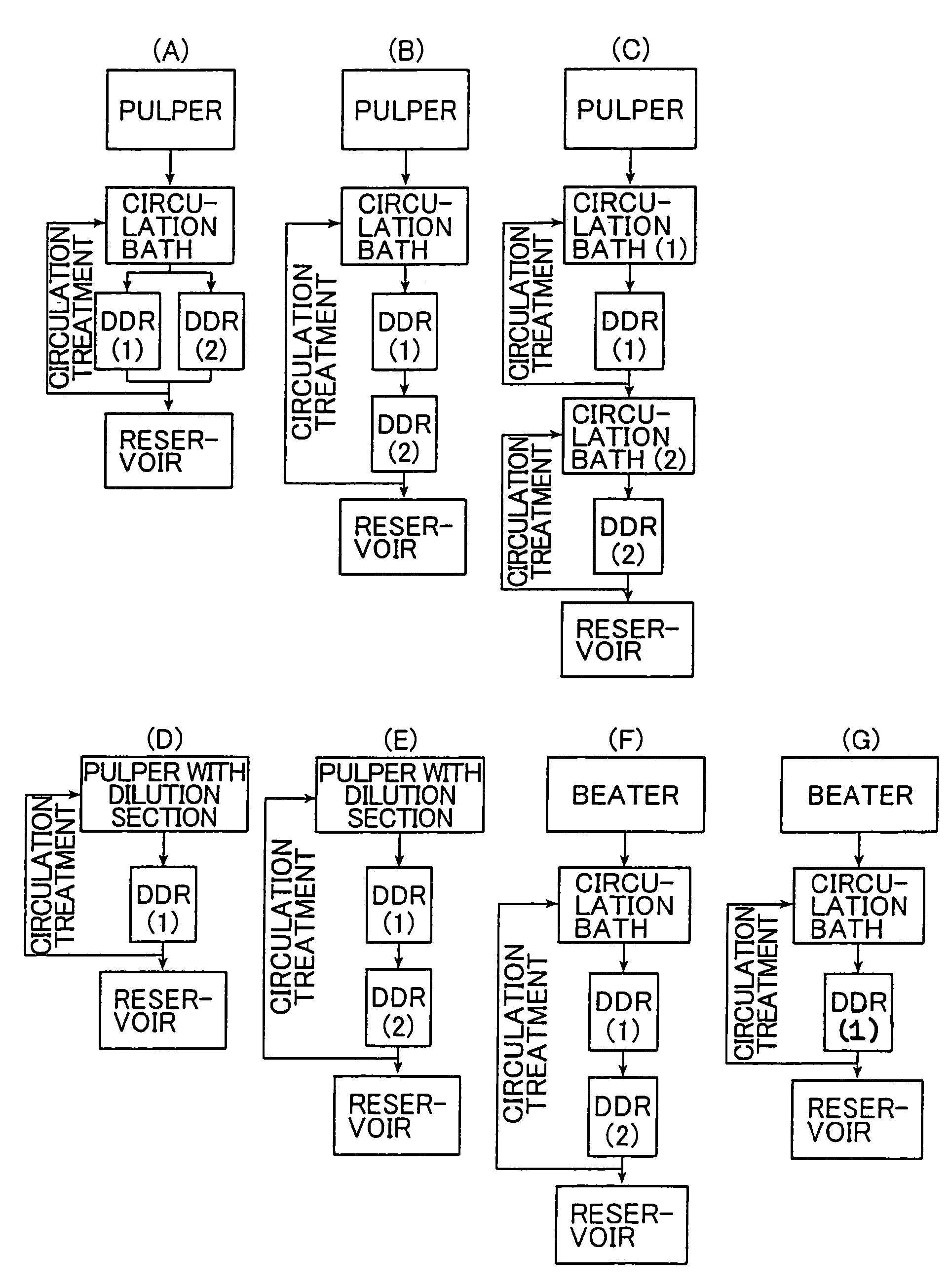

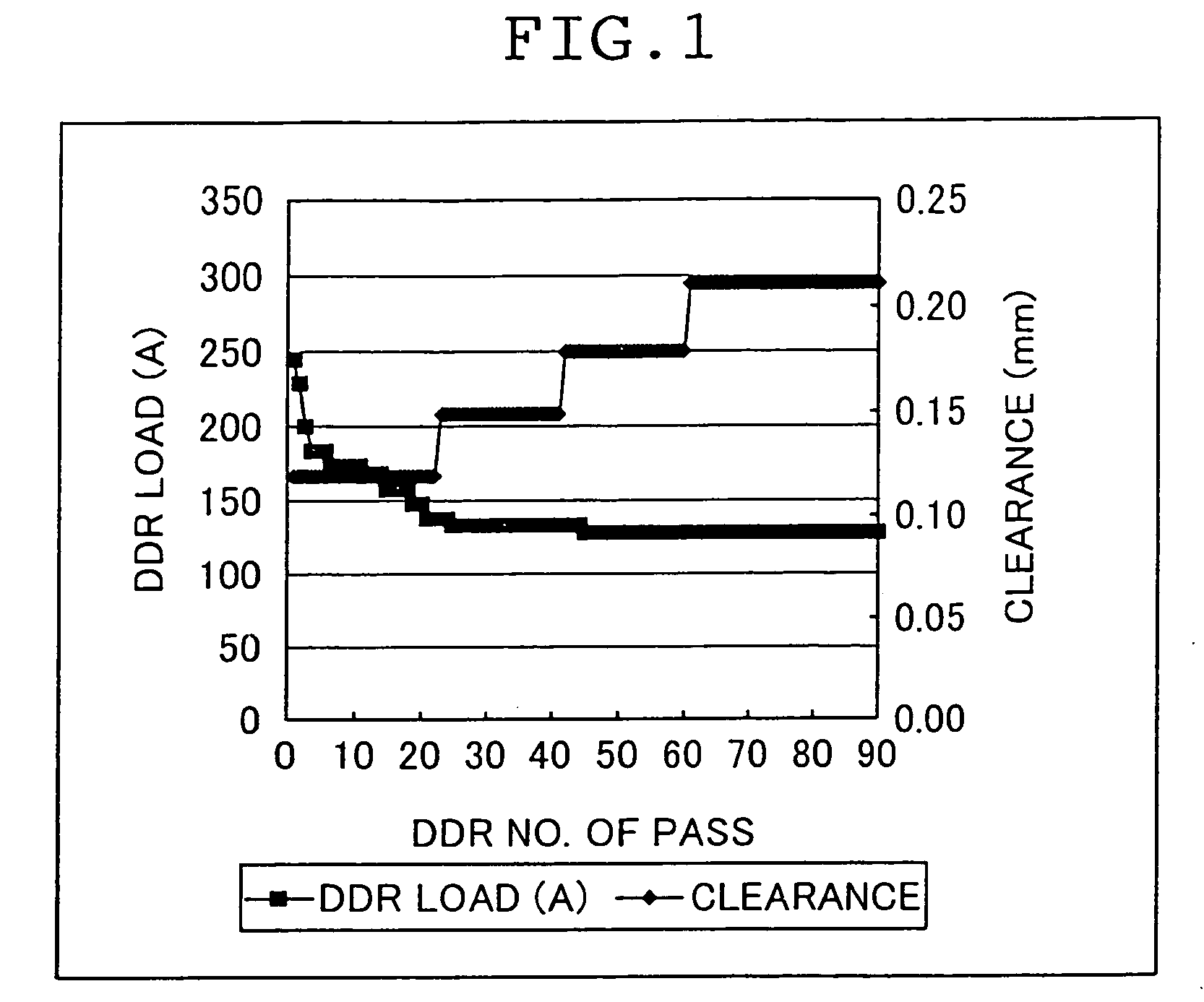

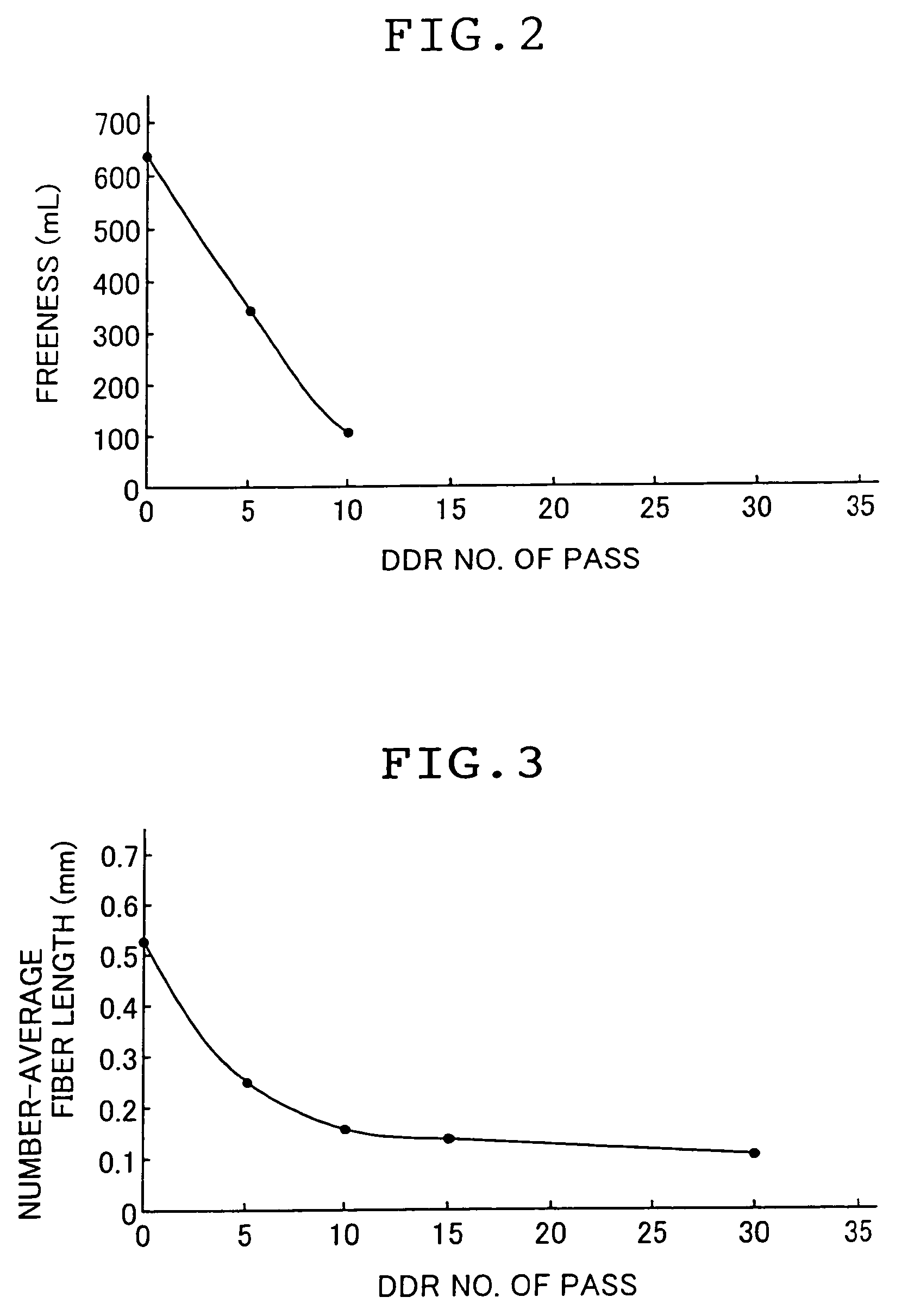

A method for producing a microfibrillated cellulose, which comprises subjecting a slurry containing a pulp having a solids concentration of 1 to 6 wt % to the treatment with a disc refiner repeatedly ten times or more, to thereby prepare a microfibrillated cellulose having a number average fiber length or 0.2 mm or less and an amount of water hold of 10 mL / g or more, the amount representing the volume of water capable of being held by a unit weight of the cellulose fiber. The method allows the production of a microfibrillated cellulose having high quality with stability and with good efficiency.

Owner:DSG INT LTD

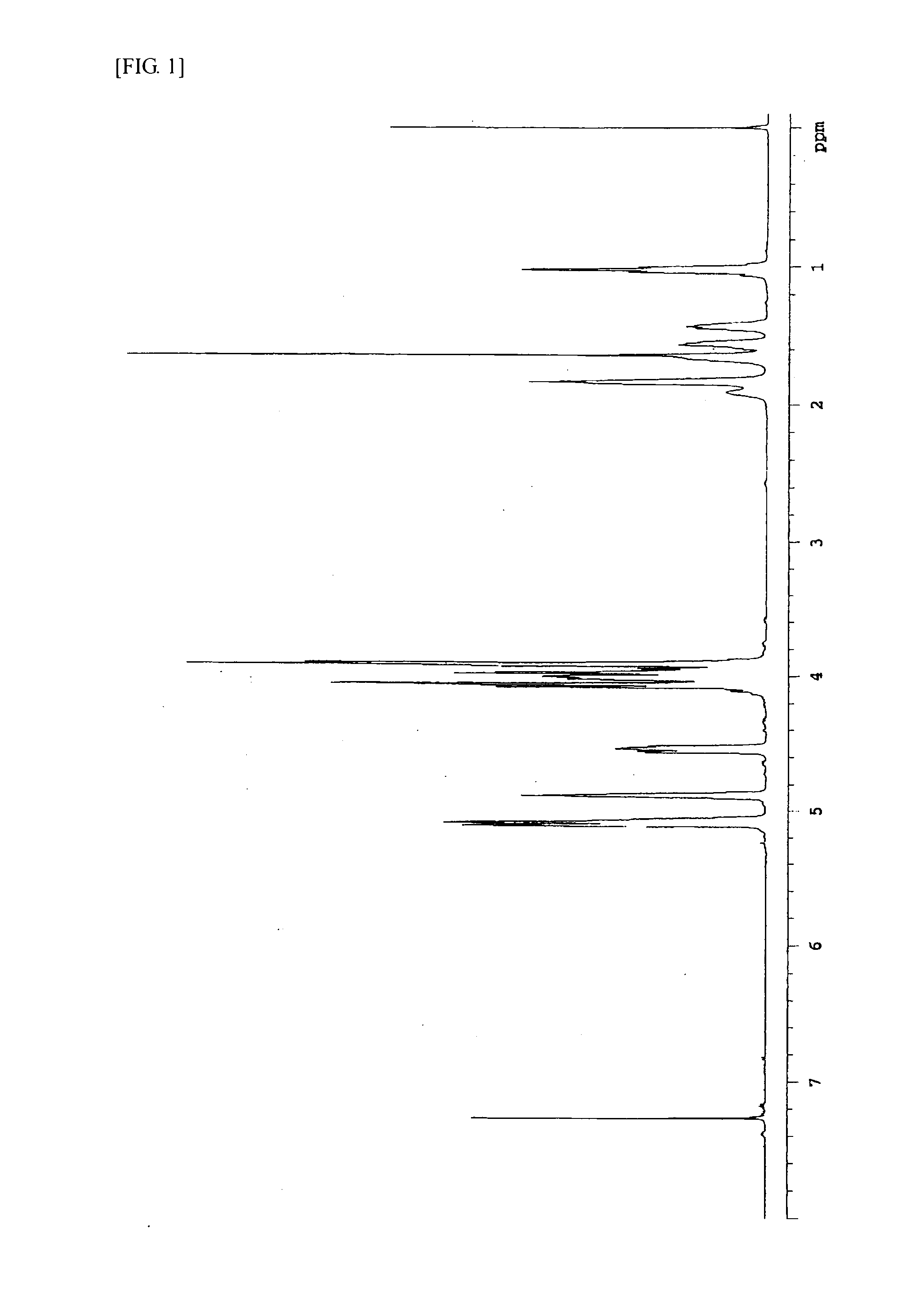

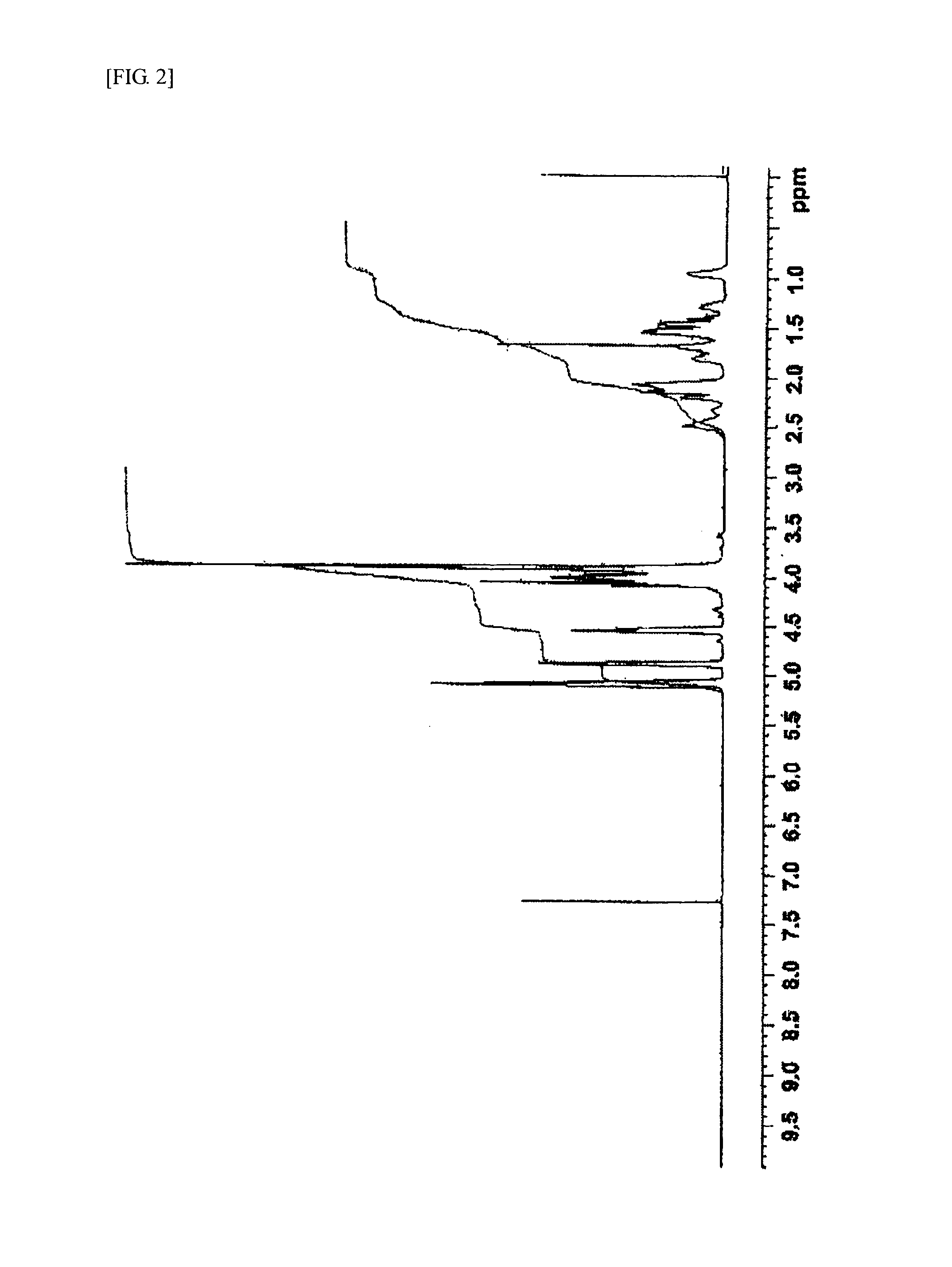

Glycolic acid copolymer and method for production thereof

A glycolic acid copolymer comprising (a) 80 to less than 95% by mole of glycolic acid monomer units, (b) 5.0 to 20.0% by mole of non-glycolic, hydroxycarboxylic acid monomer units, and (c) 0 to 0.10% by mole of diglycolic acid monomer units, the non-glycolic, hydroxycarboxylic acid monomer units (b) constituting a plurality of segments each independently consisting of at least one monomer unit (b), wherein the segments have an average chain length of from 1.00 to 1.50 in terms of the average number of monomer unit or units (b), the total of the components (a), (b) and (c) being 100% by mole, the glycolic acid copolymer having a weight average molecular weight of 50,000 or more.

Owner:ASAHI KASEI CHEM CORP

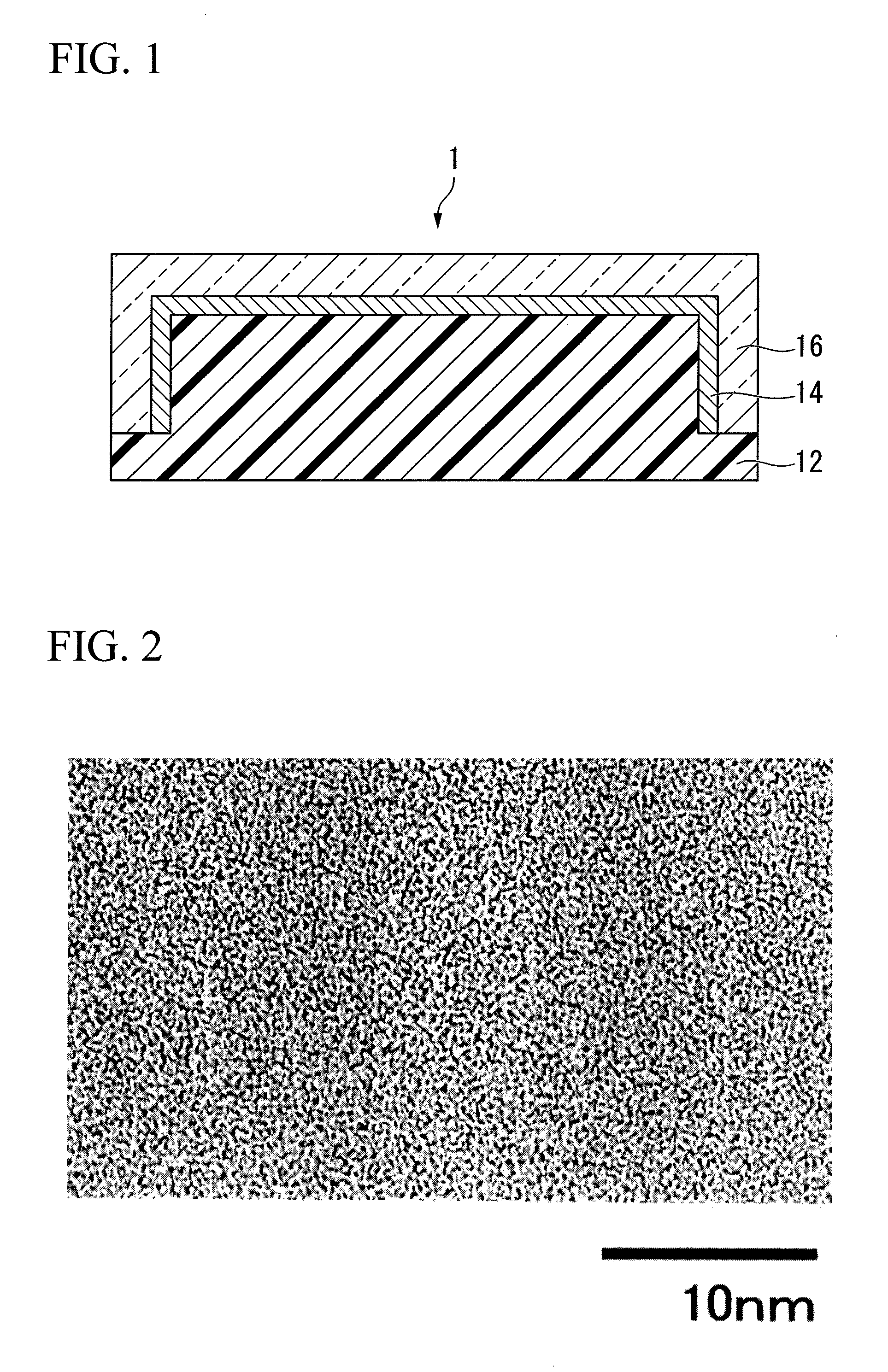

Radio wave transmitting decorative member and the production method thereof

ActiveUS20110273356A1Efficient and stable productionLow costVacuum evaporation coatingSputtering coatingAlloyMetal

The radio wave transmitting decorative member and the method of producing thereof efficiently and stably of the present invention is provided with radio wave transmitting properties as well as mirror-surface like metallic luster, hardly loses its metallic luster, and can be produced at a low cost. The method of producing a radio wave transmitting decorative member, having a substrate, a transparent organic material layer, and a light reflecting layer formed of an alloy composed of either silicon or germanium and a metal provided between the substrate and the transparent organic material layer; wherein the light reflecting layer is formed from a target having an alloy composed of either silicon or germanium, and of a metal with the use of a DC magnetrons sputtering.

Owner:SHIN-ETSU POLYMER CO LTD

Glycolic acid copolymer and method for production thereof

A glycolic acid copolymer comprising (a) 80 to less than 95% by mole of glycolic acid monomer units, (b) 5.0 to 20.0% by mole of non-glycolic, hydroxycarboxylic acid monomer units, and (c) 0 to 0.10% by mole of diglycolic acid monomer units, the non-glycolic, hydroxycarboxylic acid monomer units (b) constituting a plurality of segments each independently consisting of at least one monomer unit (b), wherein the segments have an average chain length of from 1.00 to 1.50 in terms of the average number of monomer unit or units (b), the total of the components (a), (b) and (c) being 100% by mole, the glycolic acid copolymer having a weight average molecular weight of 50,000 or more.

Owner:ASAHI KASEI CHEM CORP

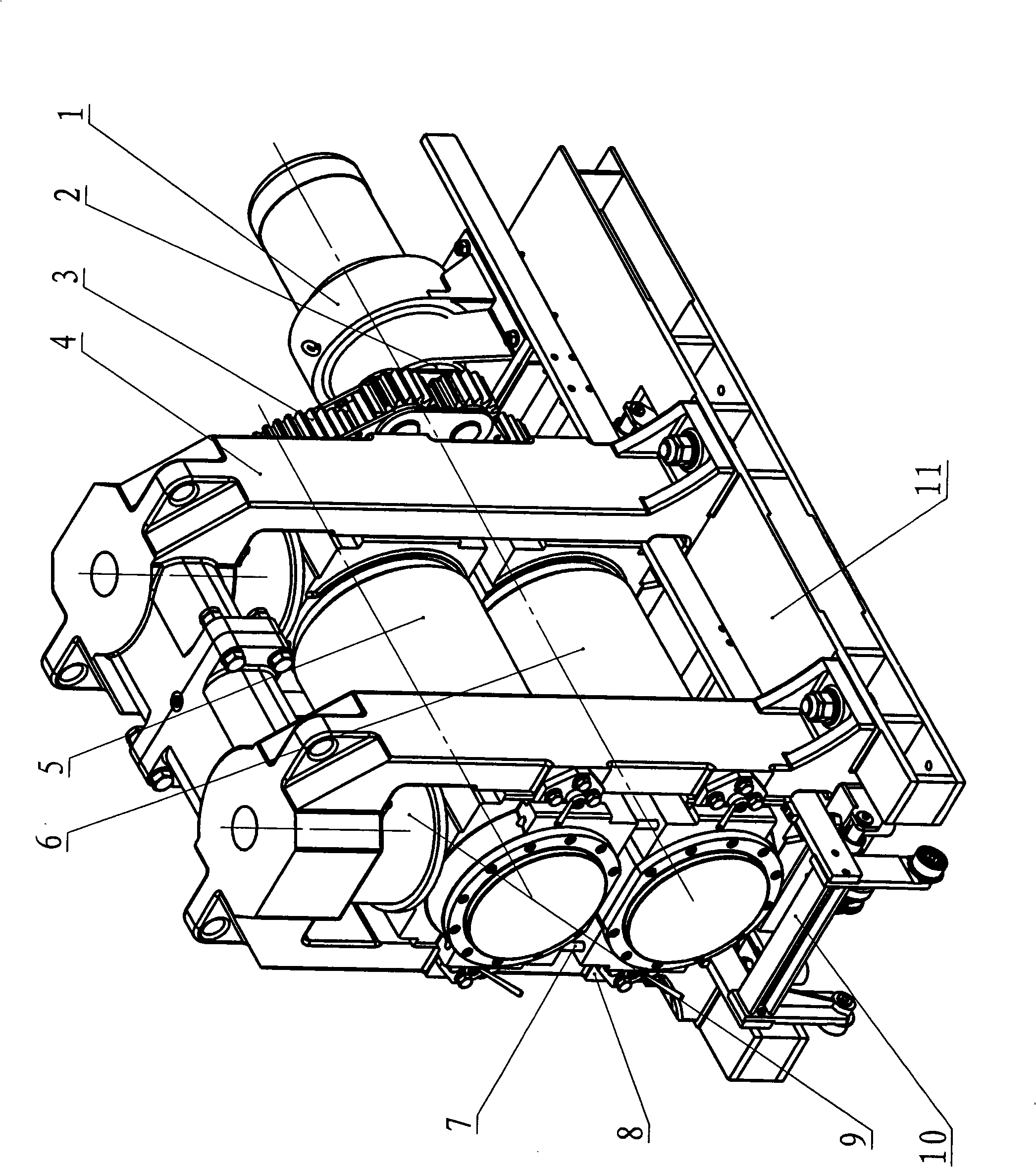

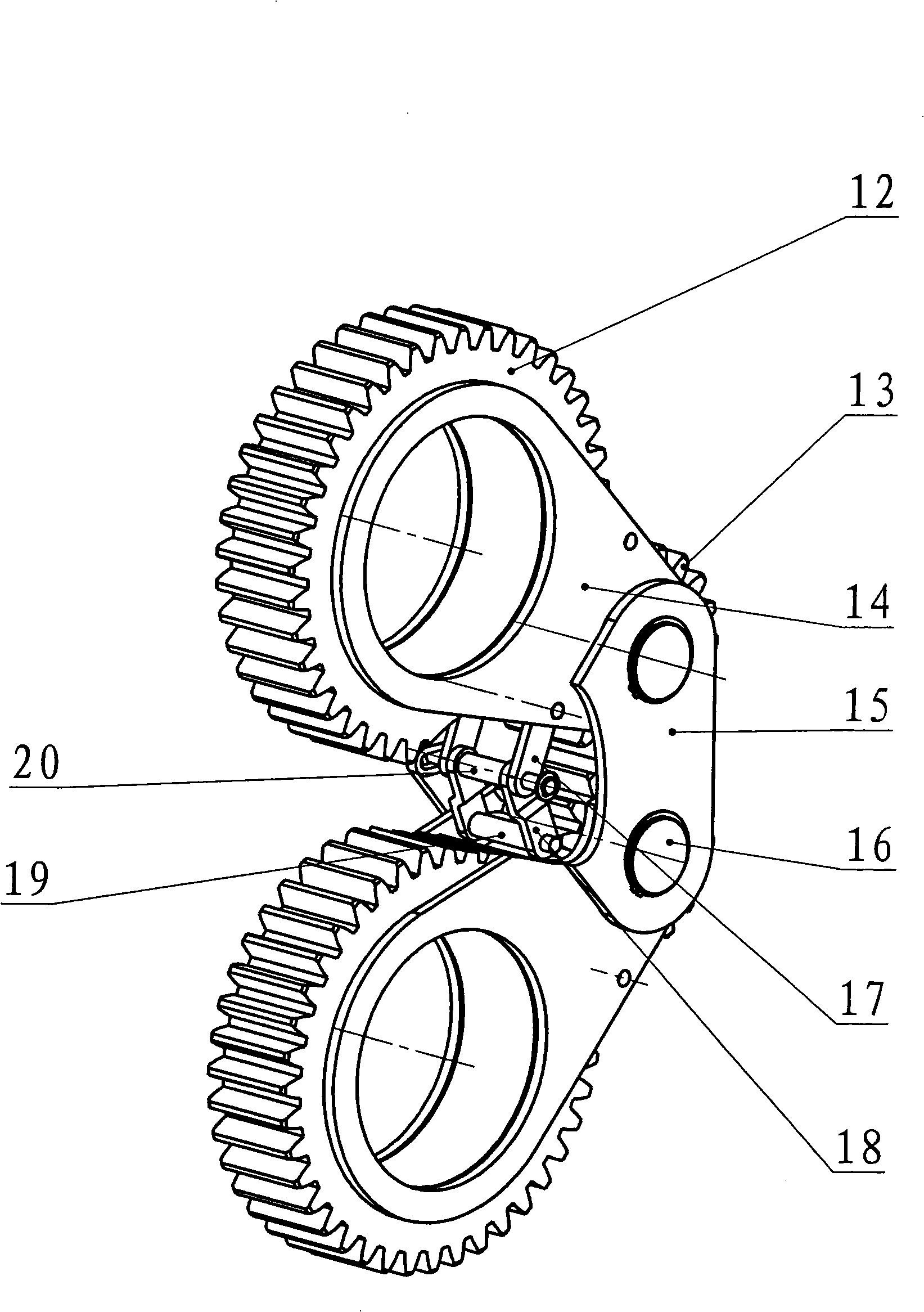

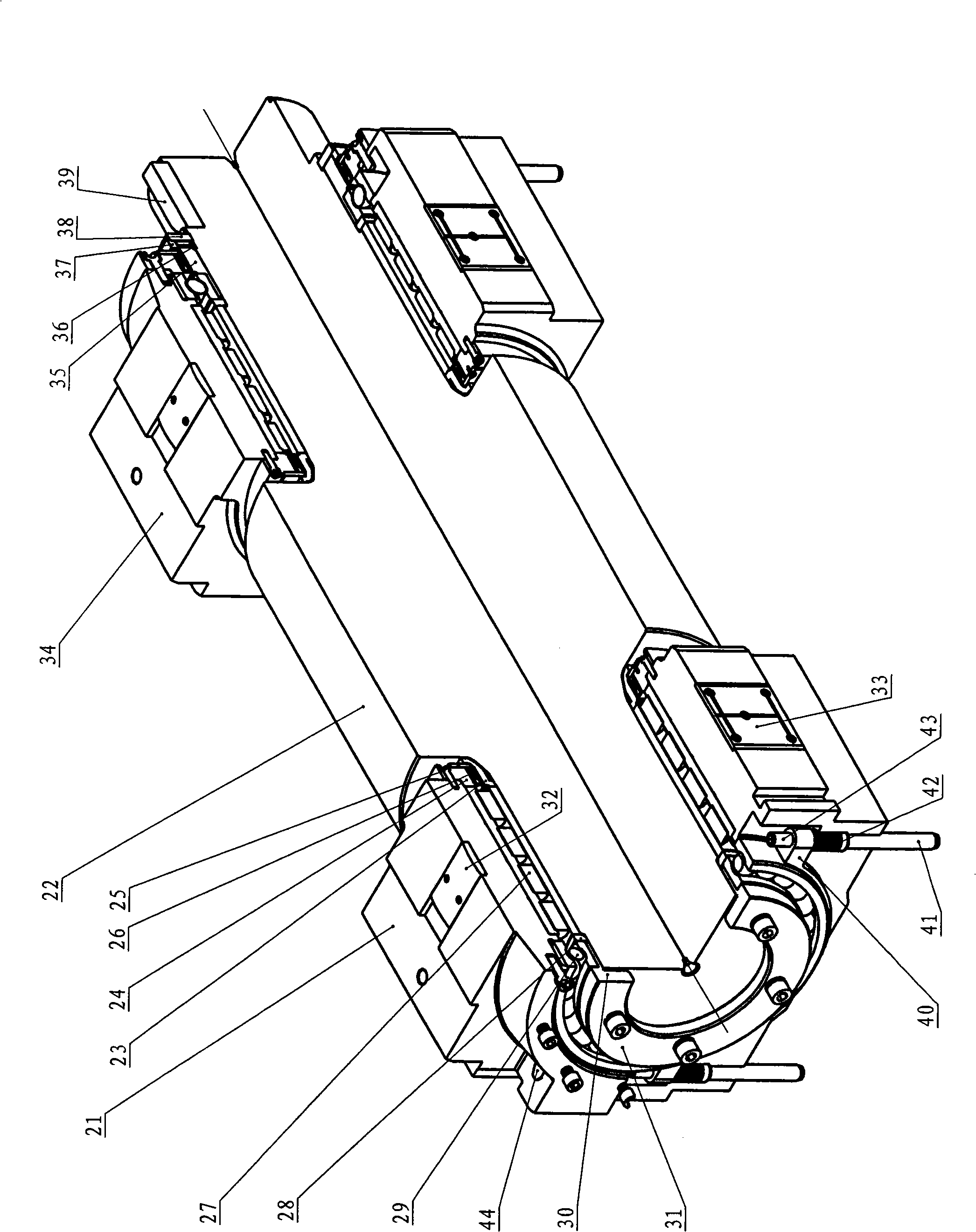

Strip mill of thin film

InactiveCN101347791AEfficient and stable productionEasy to change rollsMetal rolling stand detailsRolling mill drivesAutomatic controlEngineering

The invention provides a film band and strip rolling mill, consisting of a motor-reducer device, an elastic pin coupling device, a balance symmetric gear transmission device, a front stander device and a rear stander device, a lower roller system device, an upper roller system device, a roller system bearing radial windage eliminating device, a left baffle device of a roller, a right baffle device of the roller, an electro-hydraulic servo press-down device, a roller changing device and a base; the film band and strip rolling mill is characterized in that the size of the roller seam can be automatically controlled by adopting an electro-hydraulic servo control technology, thus stably producing battery electrodes which meet the quality standard without compressing air source from external part; meanwhile, the developed balance symmetric transmission device, the roller system bearing radial windage eliminating device, the roller left baffle device, the roller right baffle device and the roller changing device lead the adjustment and maintenance of the rolling mill to be simple and convenient, The invention is an ideal film band and strip rolling mill which has the advantages of improving the precision of battery electrodes, improving the productivity of the rolling mill and overcoming the shortages of the prior art.

Owner:张清

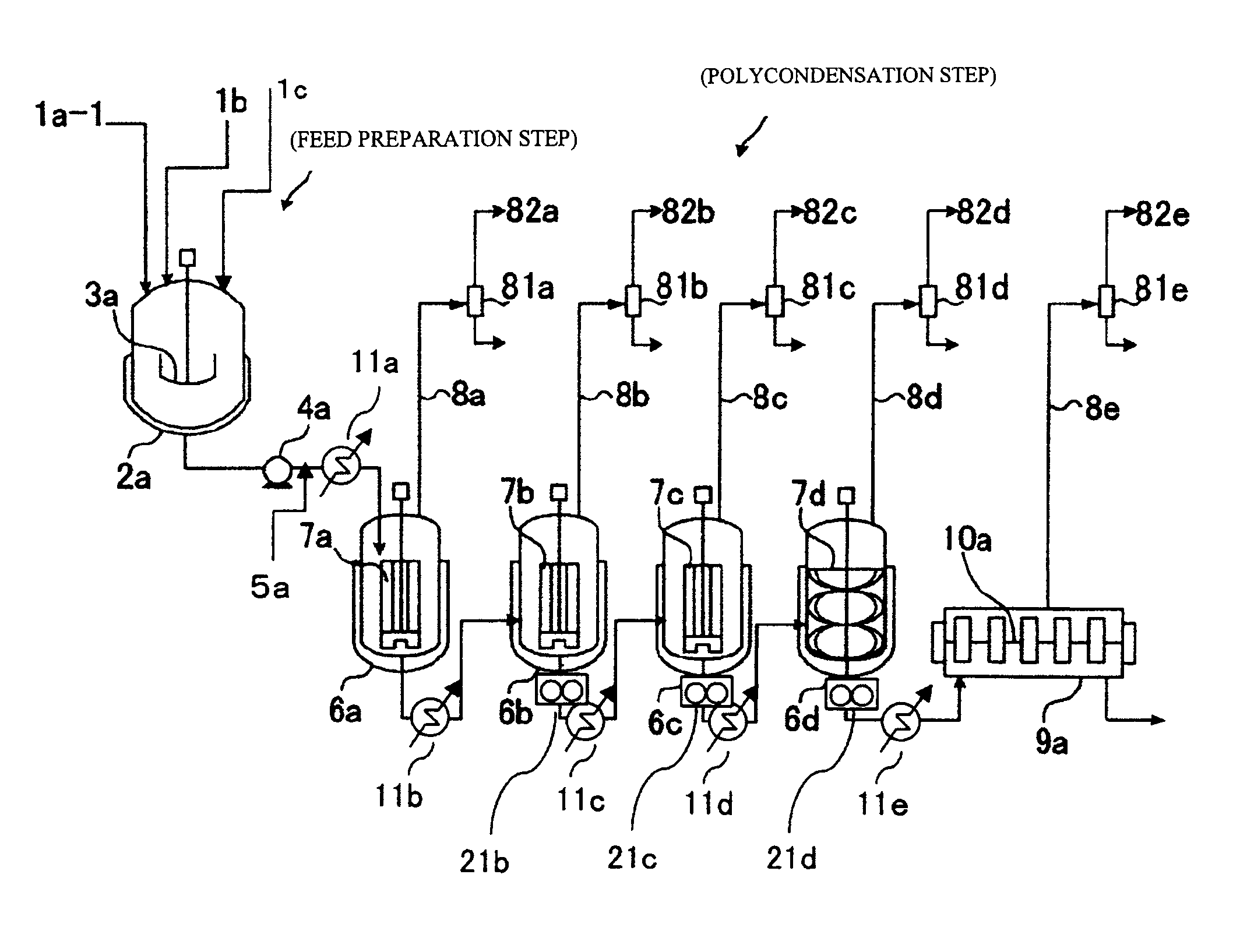

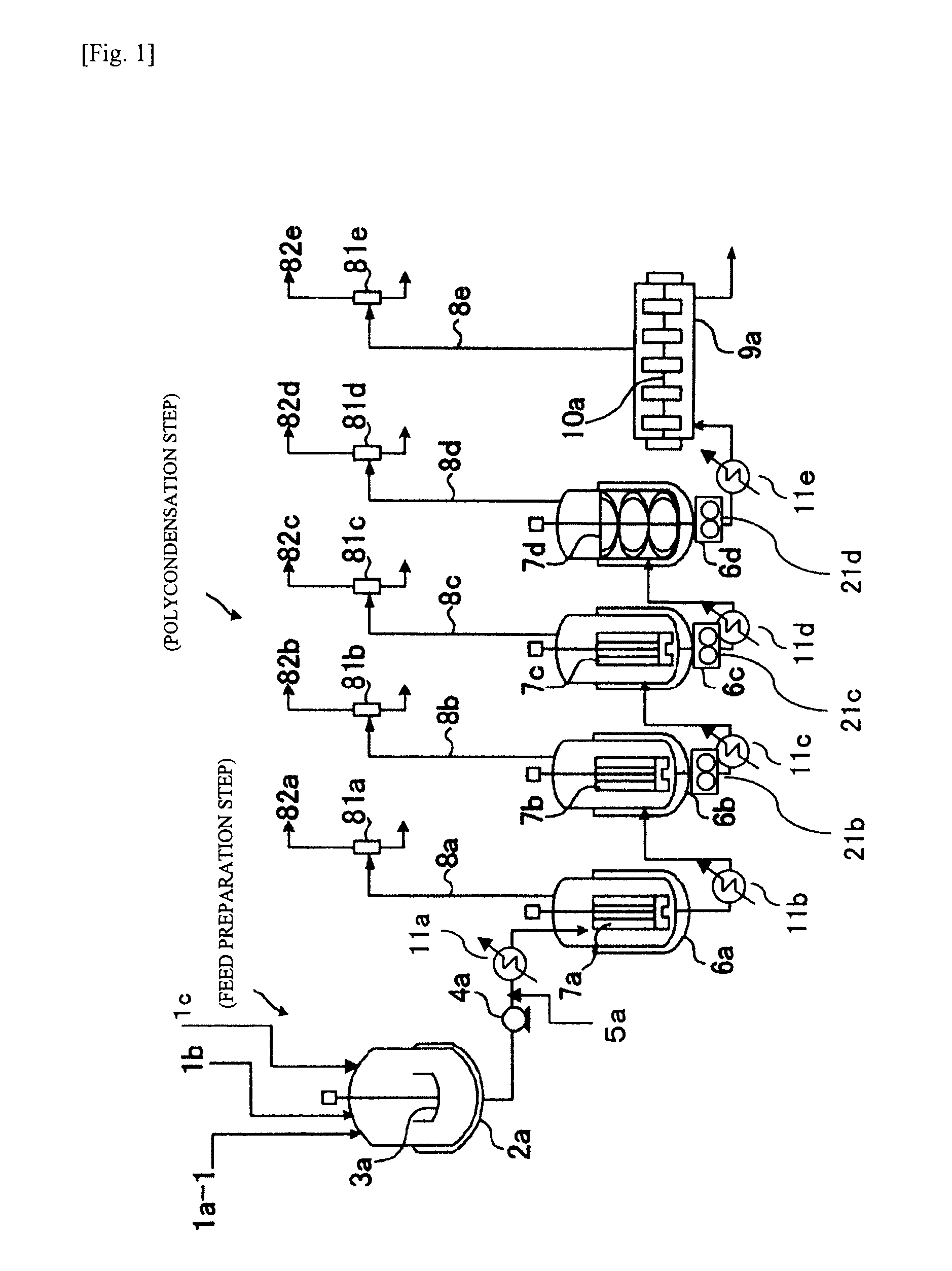

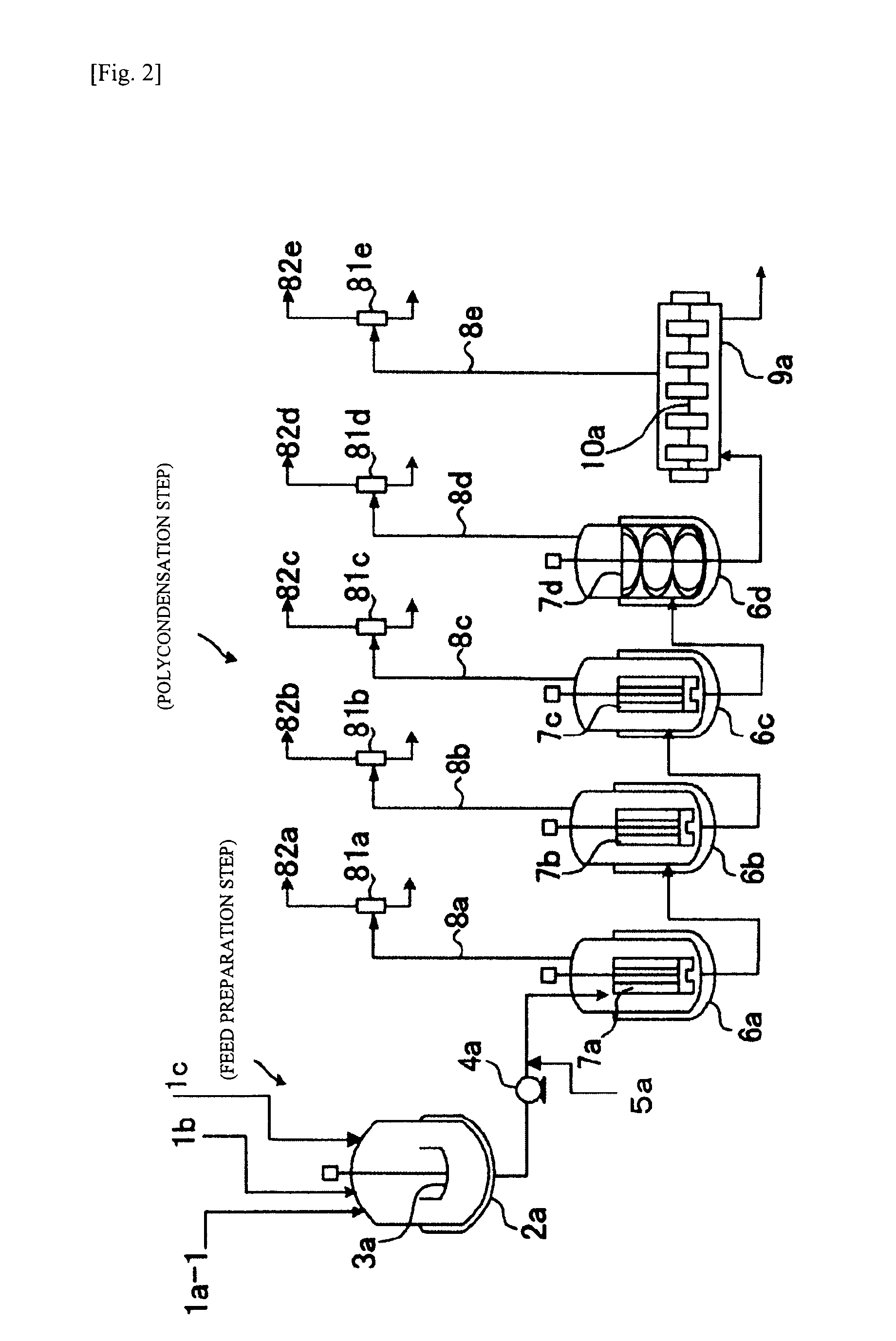

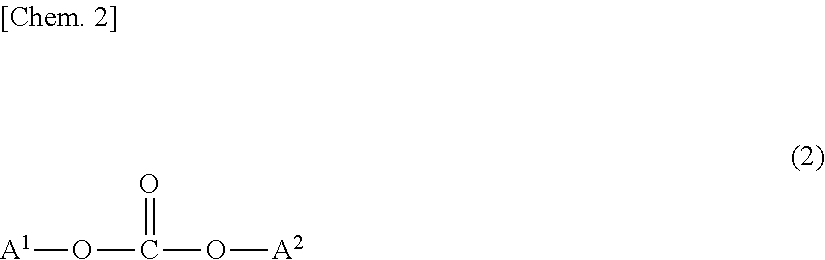

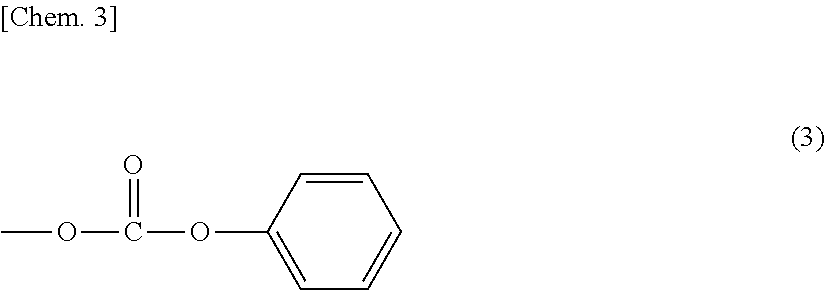

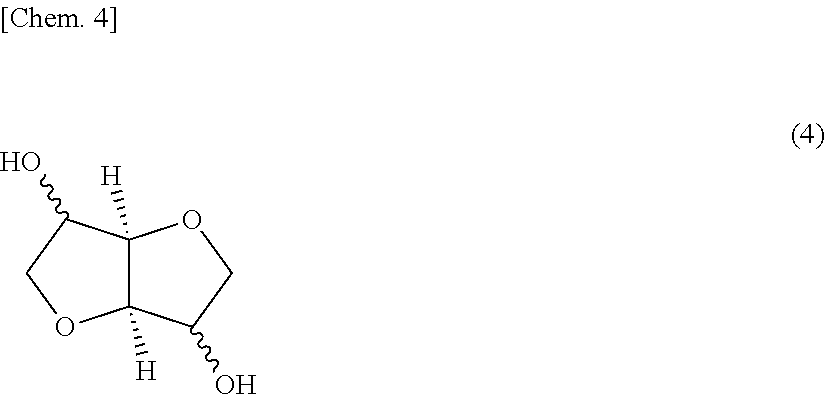

Processes for producing polycarbonate and molded polycarbonate articles

ActiveUS20110003101A1Efficient and stable productionLow refractive indexFlexible coversWrappersHeat resistanceRefractive index

A subject for the invention relates to processes for producing a polycarbonate containing a plant-derived starting material and to molded articles thereof, the polycarbonate having excellent mechanical strength, heat resistance, a low refractive index, a large Abbe number, low birefringence, and excellent transparency. The invention relates to a process for producing a polycarbonate which includes a step in which one or more dihydroxy compounds including a dihydroxy compound having at least one linking group —CH2—O— in the molecule thereof are reacted with a carbonic acid diester in the presence of a polymerization catalyst, wherein the dihydroxy compound having at least one linking group —CH2—O— in the molecule thereof has a formic acid content lower than 20 ppm. The invention further relates to a molded article constituted of a polycarbonate or a composition of the polycarbonate, the polycarbonate being a polycarbonate which contains constituent units derived from a dihydroxy compound having at least one linking group —CH2—O— in the molecule thereof and has an Abbe number of 50 or larger and a 5% weight loss temperature of 340° C. or higher.

Owner:MITSUBISHI CHEM CORP

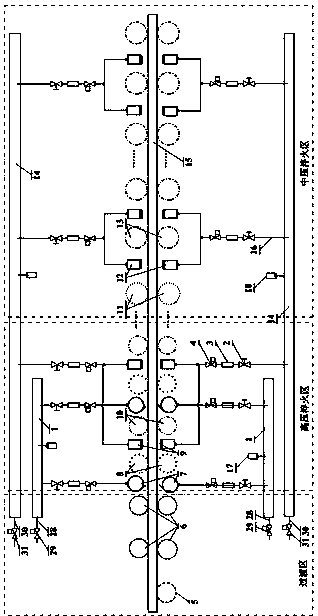

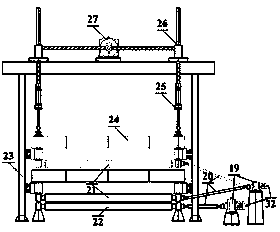

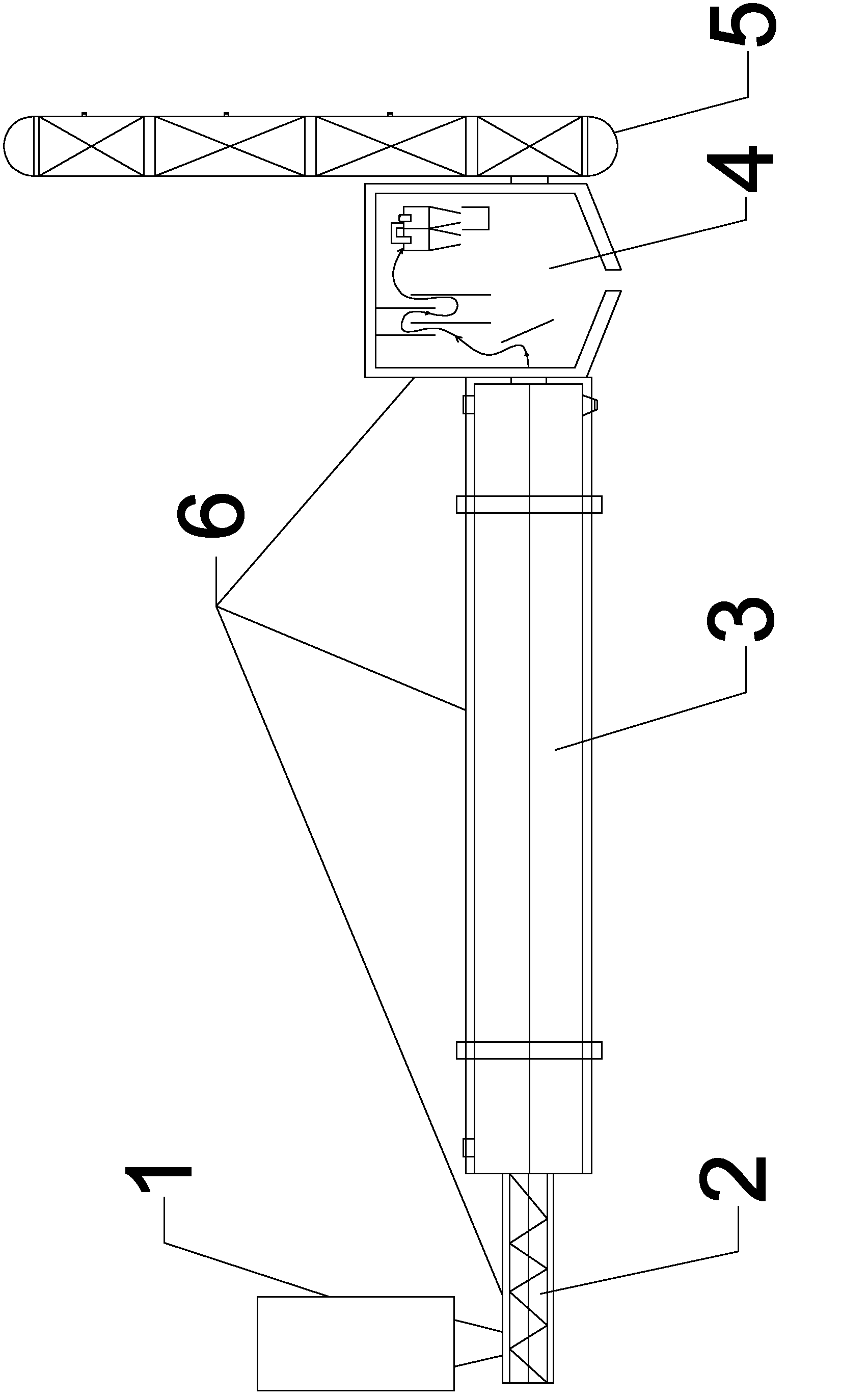

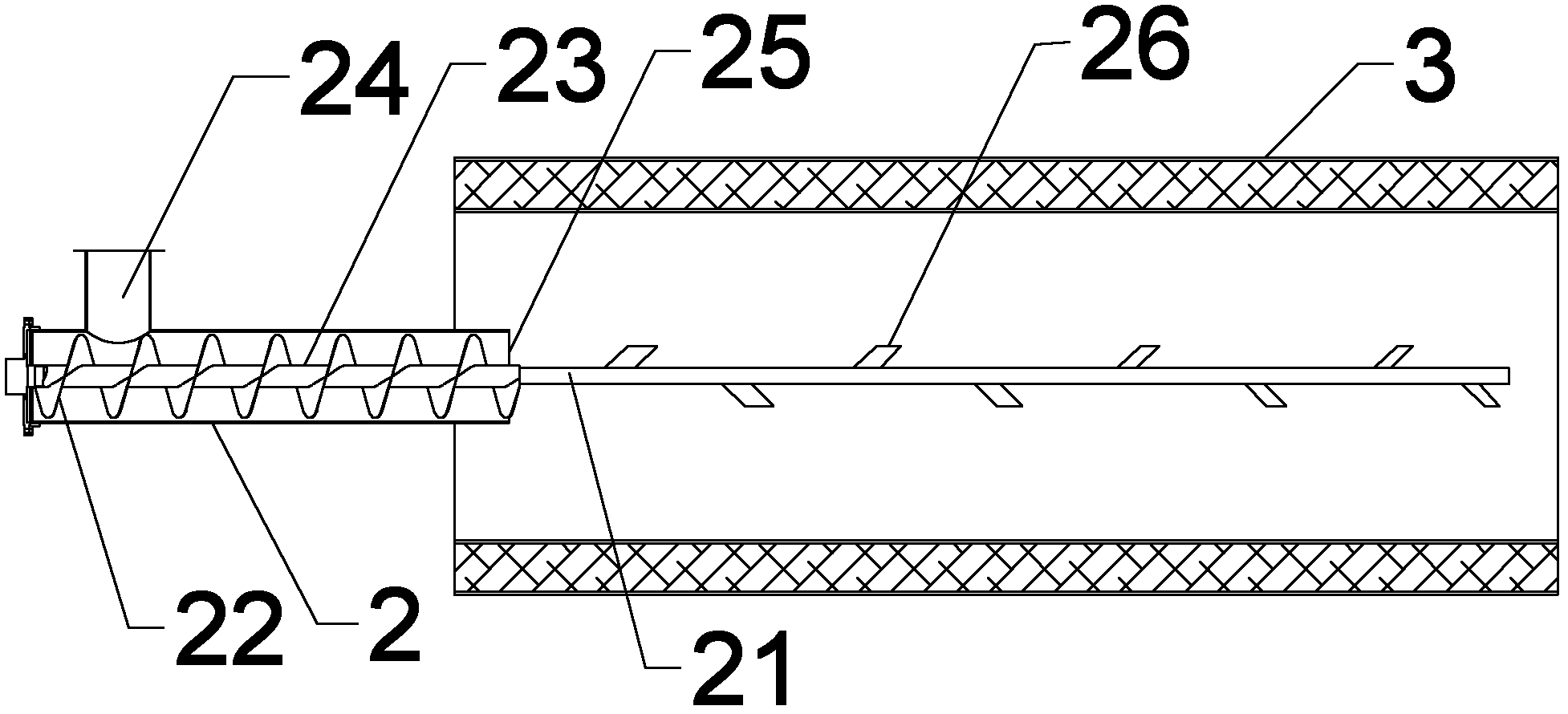

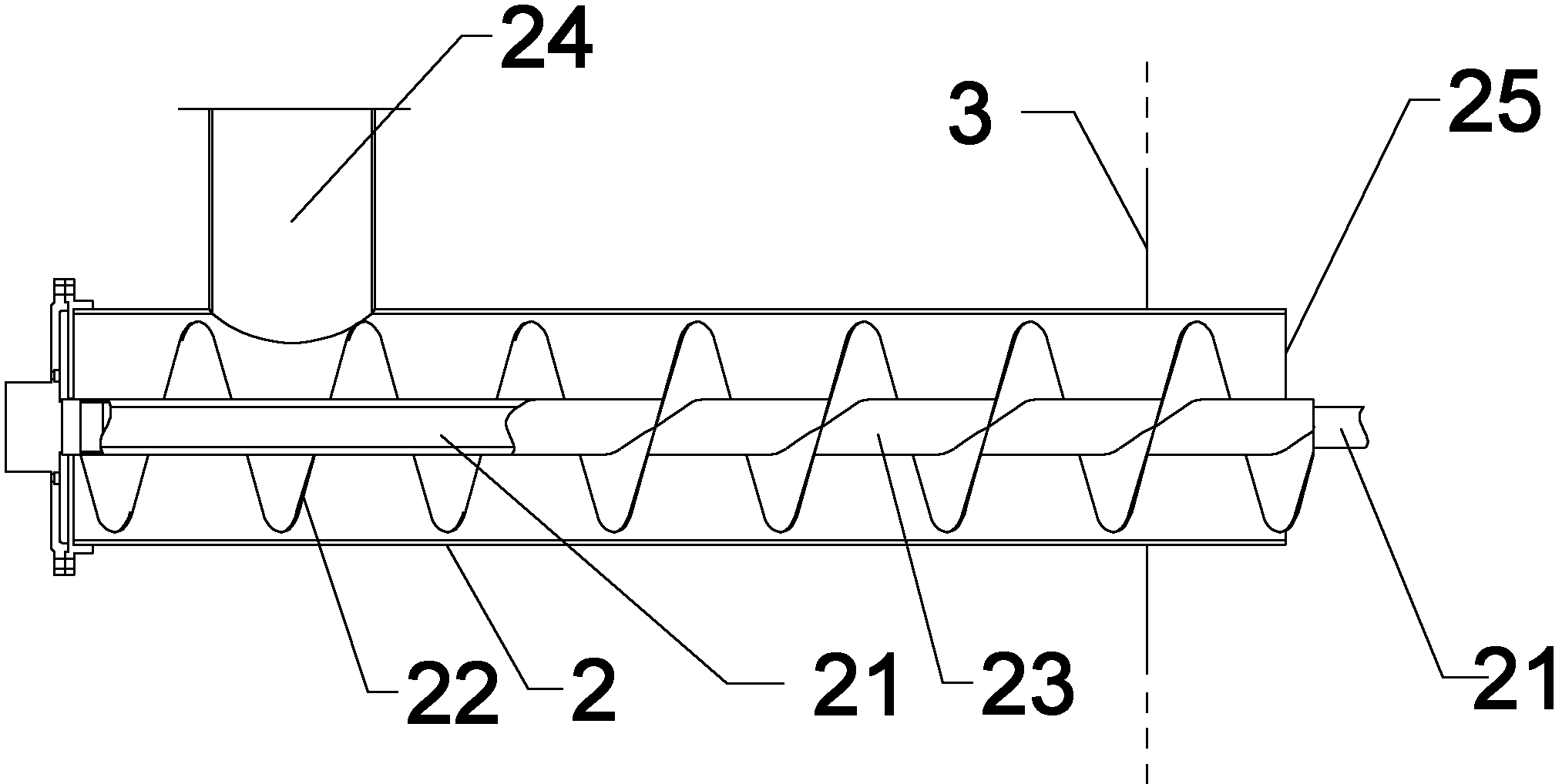

Continuous roller type quenching cooling system for steel plates

ActiveCN103834791AStable productionEfficient and stable productionFurnace typesHeat treatment furnacesHigh pressureQuenching

The invention discloses a continuous roller type quenching cooling system for steel plates. The continuous roller type quenching cooling system comprises a water spray system, a water supply system, a conveying roller system and a frame lifting system; the working regions of the cooling system orderly include a transition region, a high-pressure quenching region and a medium-pressure quenching region; in the high-pressure quenching region and the medium-pressure quenching region, nozzles and conveying rollers are symmetrically arranged up and down along the steel plates, and an upper nozzle and an upper roller are fixed on a movable upper frame, while a lower nozzle and a lower roller are fixed on a fixed frame. The continuous roller type quenching cooling system has the advantages that a roller type quenching manner is introduced into the quenching of ultra-thick steel plates, so that the problems of low cooling speed, poor cooling uniformity, poor batch production stability, unachievable manual intervention, and the like on quenching process of traditional immersion quenching are solved, and therefore, high-intensity uniformed quenching and high-efficiency stable production of the ultra-thick steel plates are achieved.

Owner:NORTHEASTERN UNIV

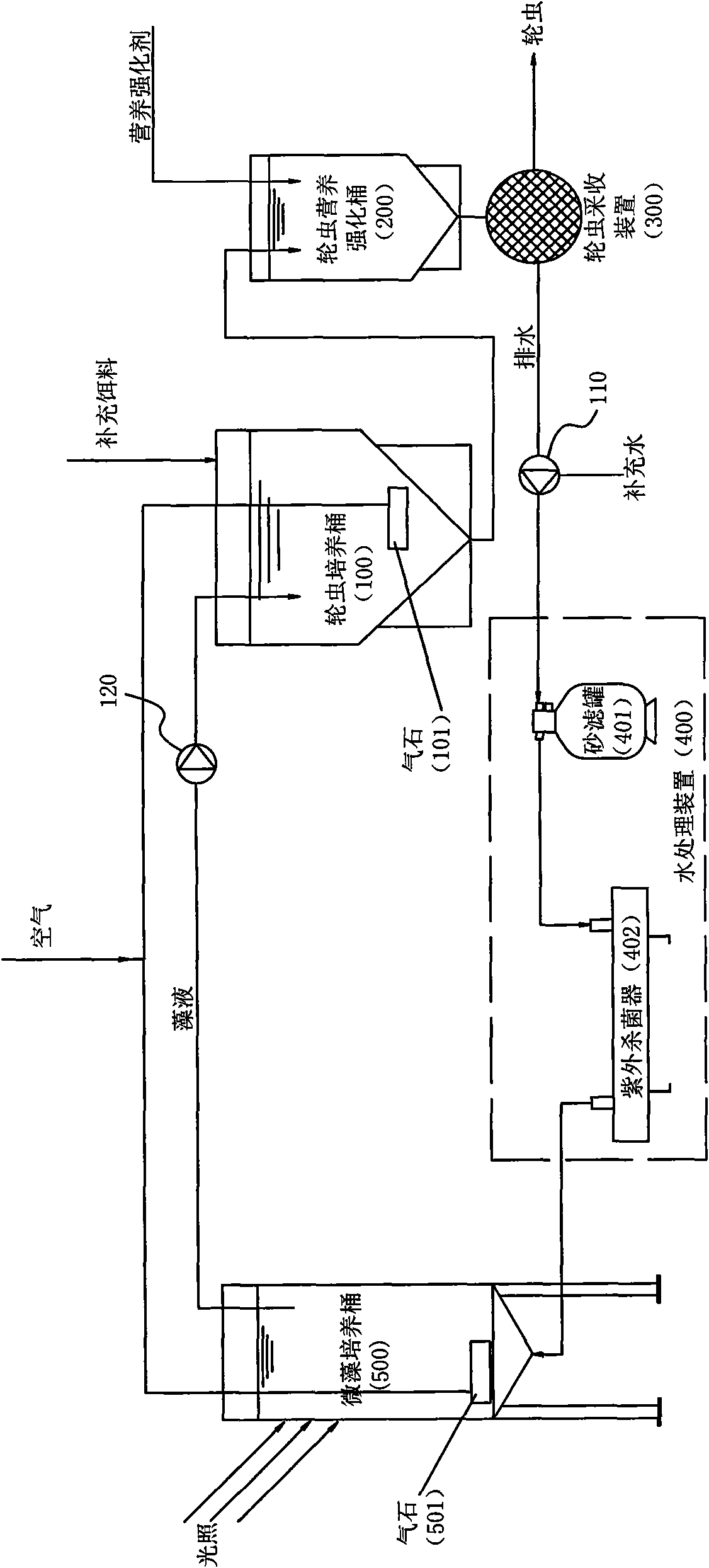

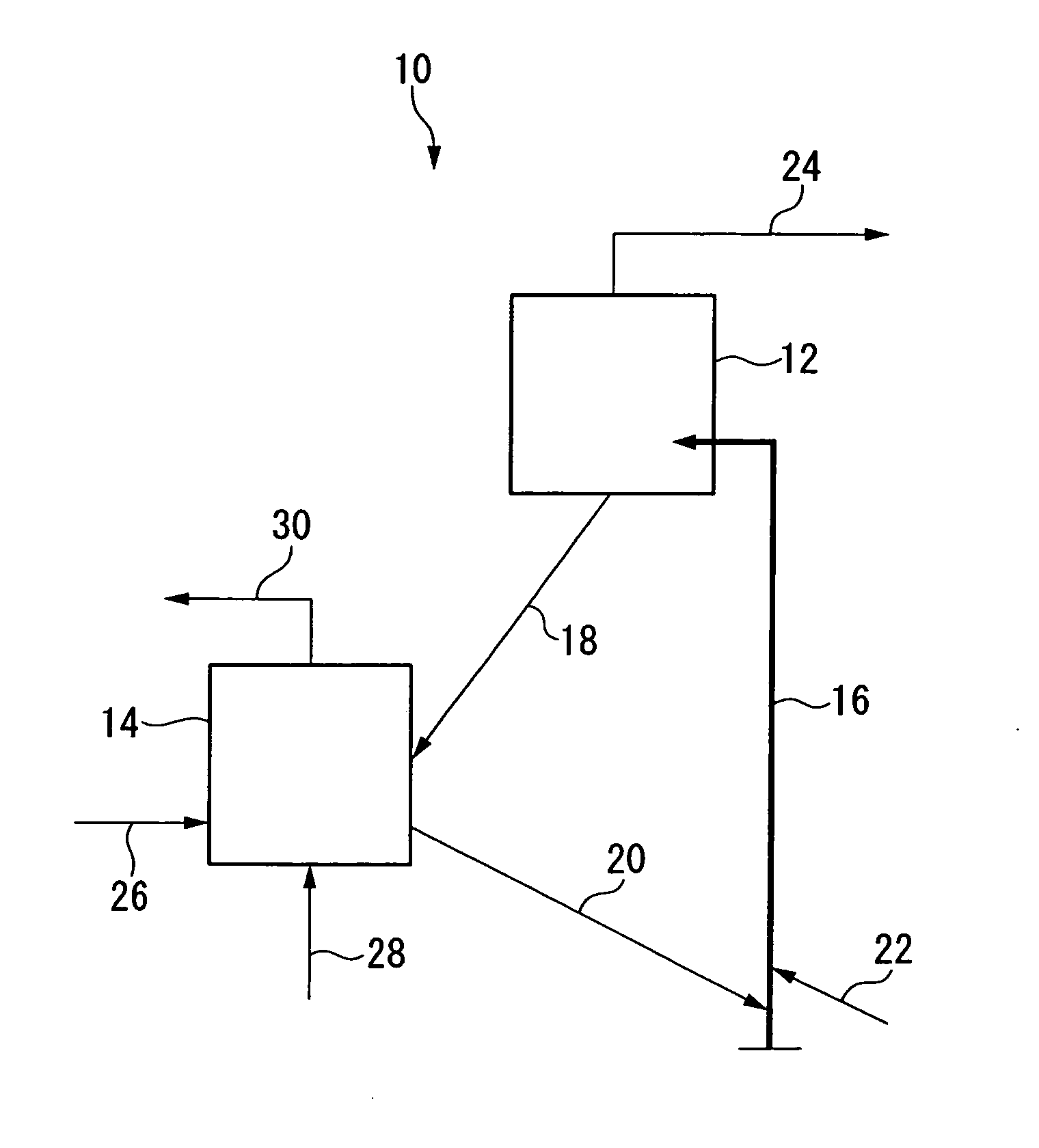

Closed circulating rotifer continuous culturing system

InactiveCN101653106AEfficient and stable productionImprove and enhance nutritional qualityUnicellular algaeAnimal husbandryWater resourcesNutrition quality

The invention provides a closed circulating rotifer continuous culturing system which comprises at least one group of rotifer culturing barrels, at least one group of rotifer culturing reinforcement barrels, a rotifer harvesting device, a water treatment device and at least one group of microalgae culturing barrels, wherein the output ends of the rotifer barrels are connected with the rotifer culturing reinforcement barrels, the output ends of the rotifer culturing reinforcement barrels are connected with the rotifer harvesting device, the rotifer harvesting device is connected with the watertreatment device, the output end of the water treatment device is connected with the microalgae culturing barrel, and the microalgae culturing barrel is communicated with the rotifer culturing barrels. The invention adopts a special microalgae culture control technology, a water treatment technology and a chemostat theory, realizes the recycle of rotifer culture water the continuous production ofrotifers, saves water resources and reduces emission of harmful substances under the condition of ensuring that the rotifers can be efficiently and stably produced; meanwhile, the invention performs nutrition reinforcement to the cultured rotifers, improves and strengthens the nutrition quality of the rotifers, and achieves the purpose of the invention.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

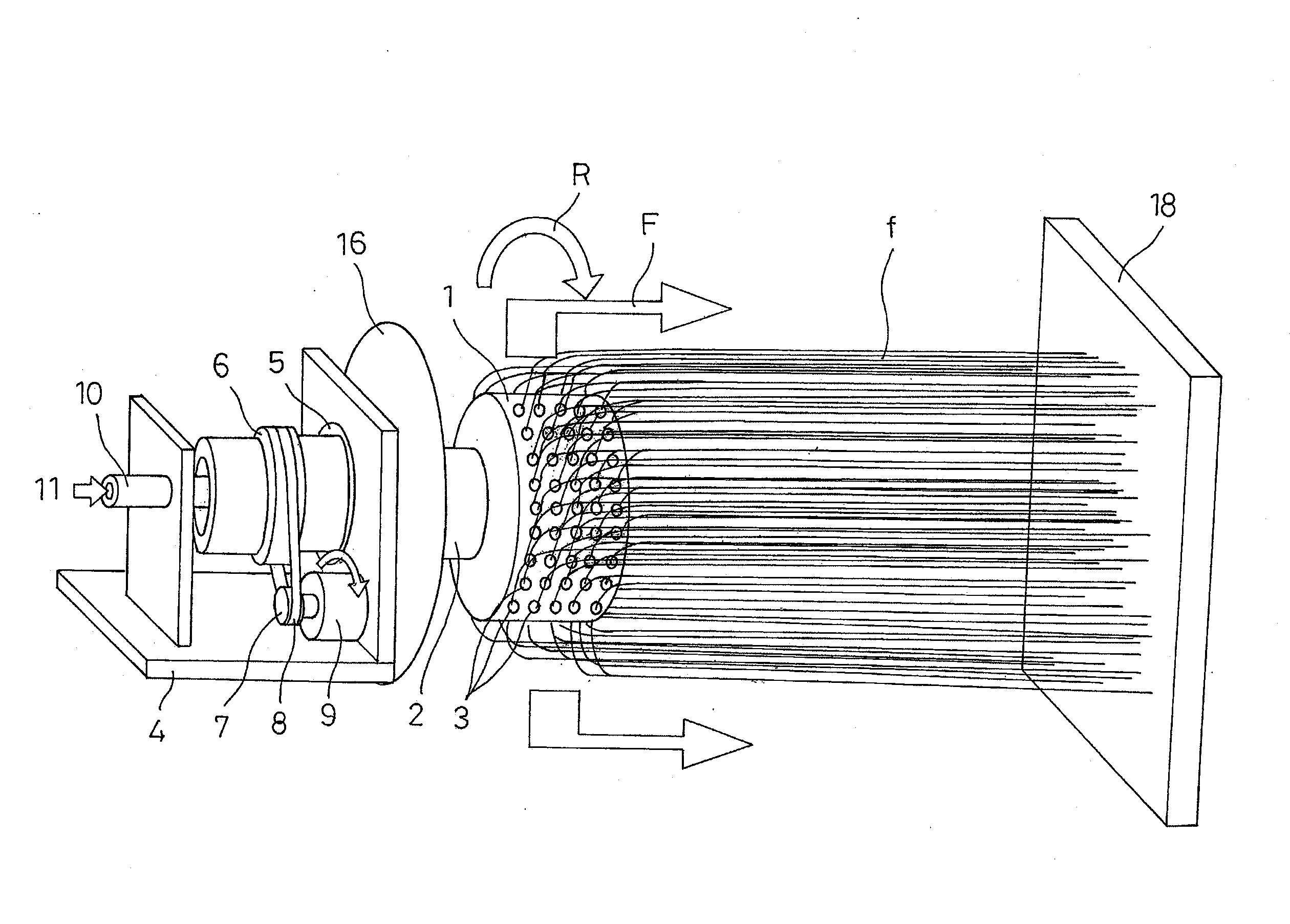

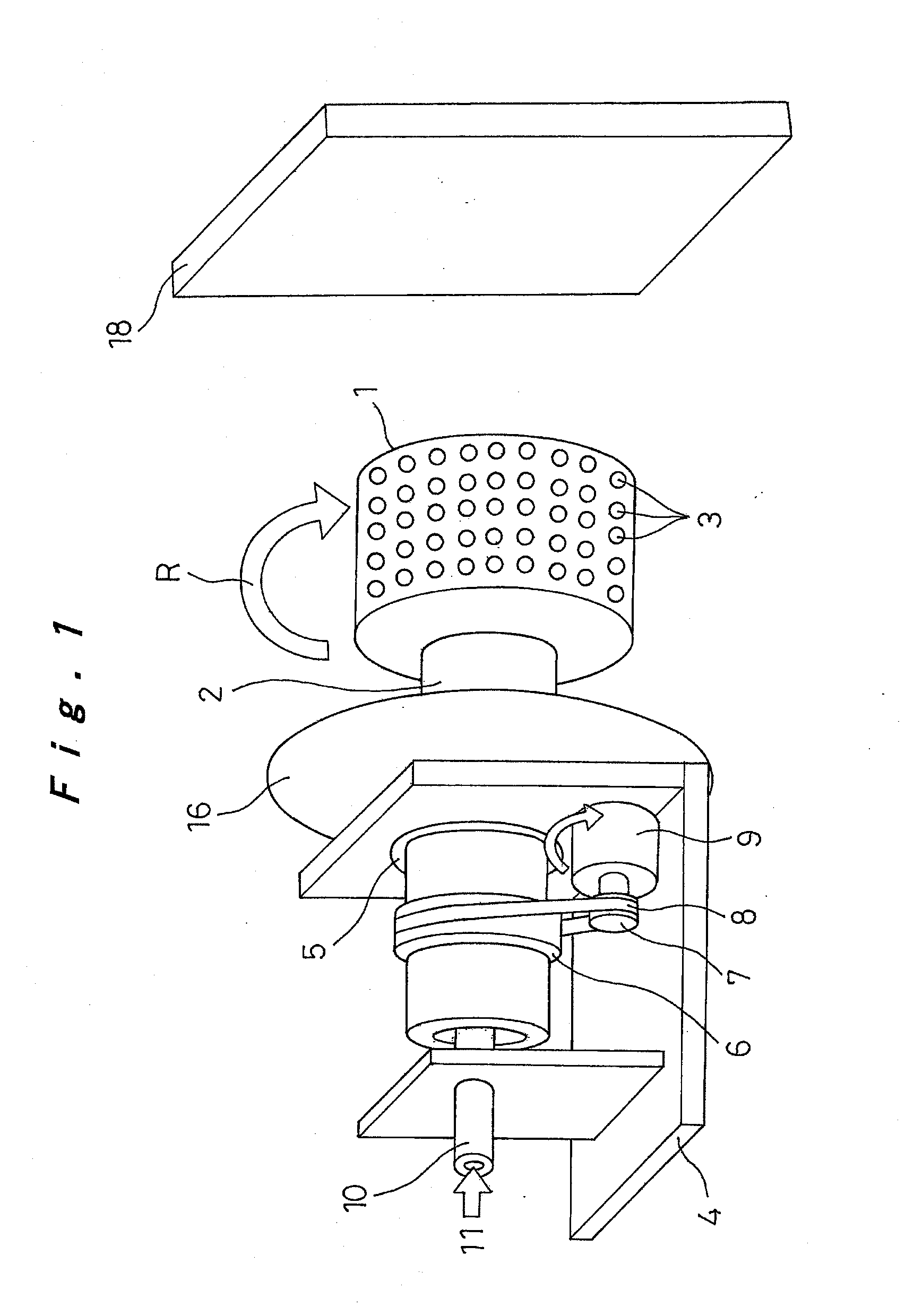

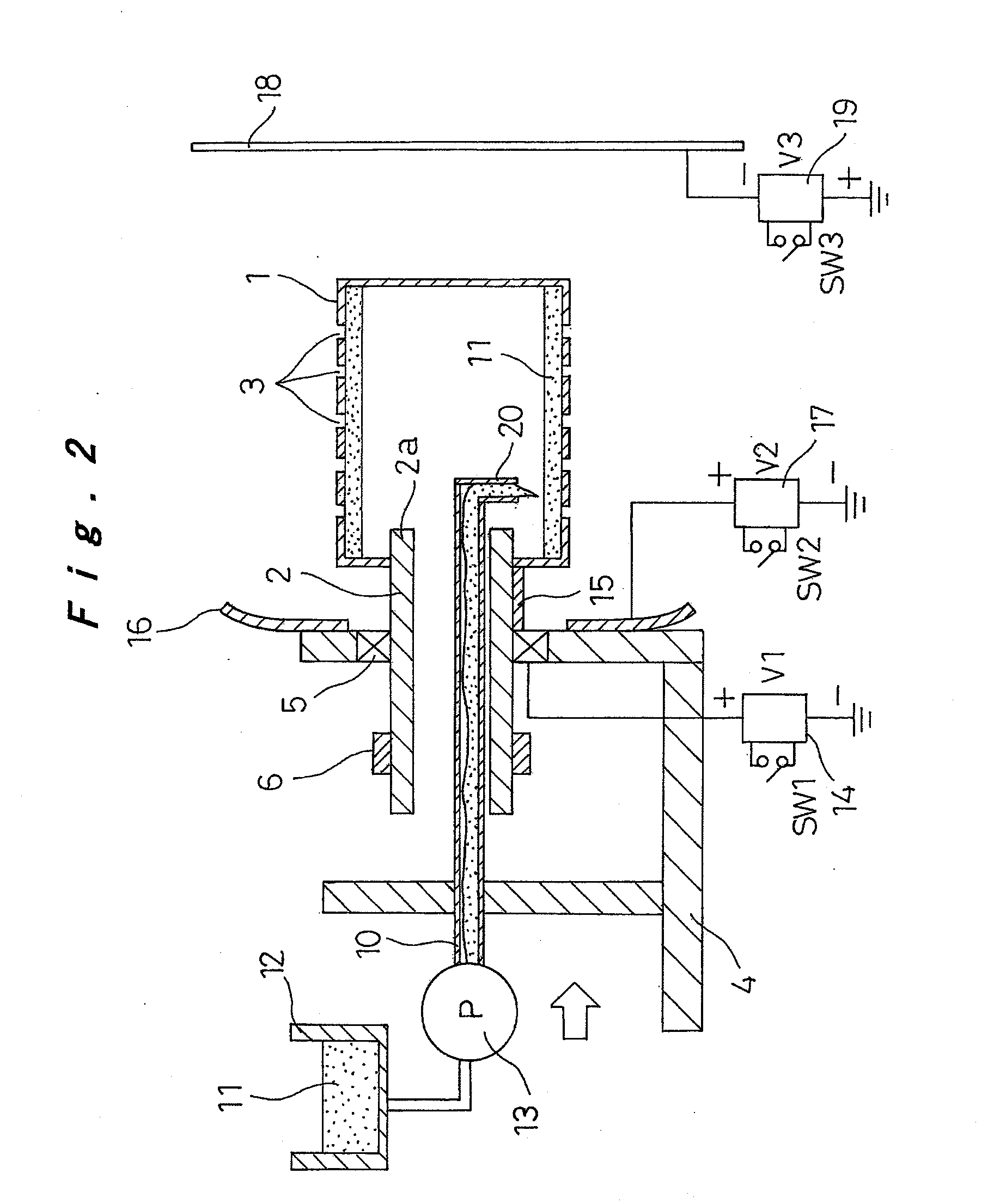

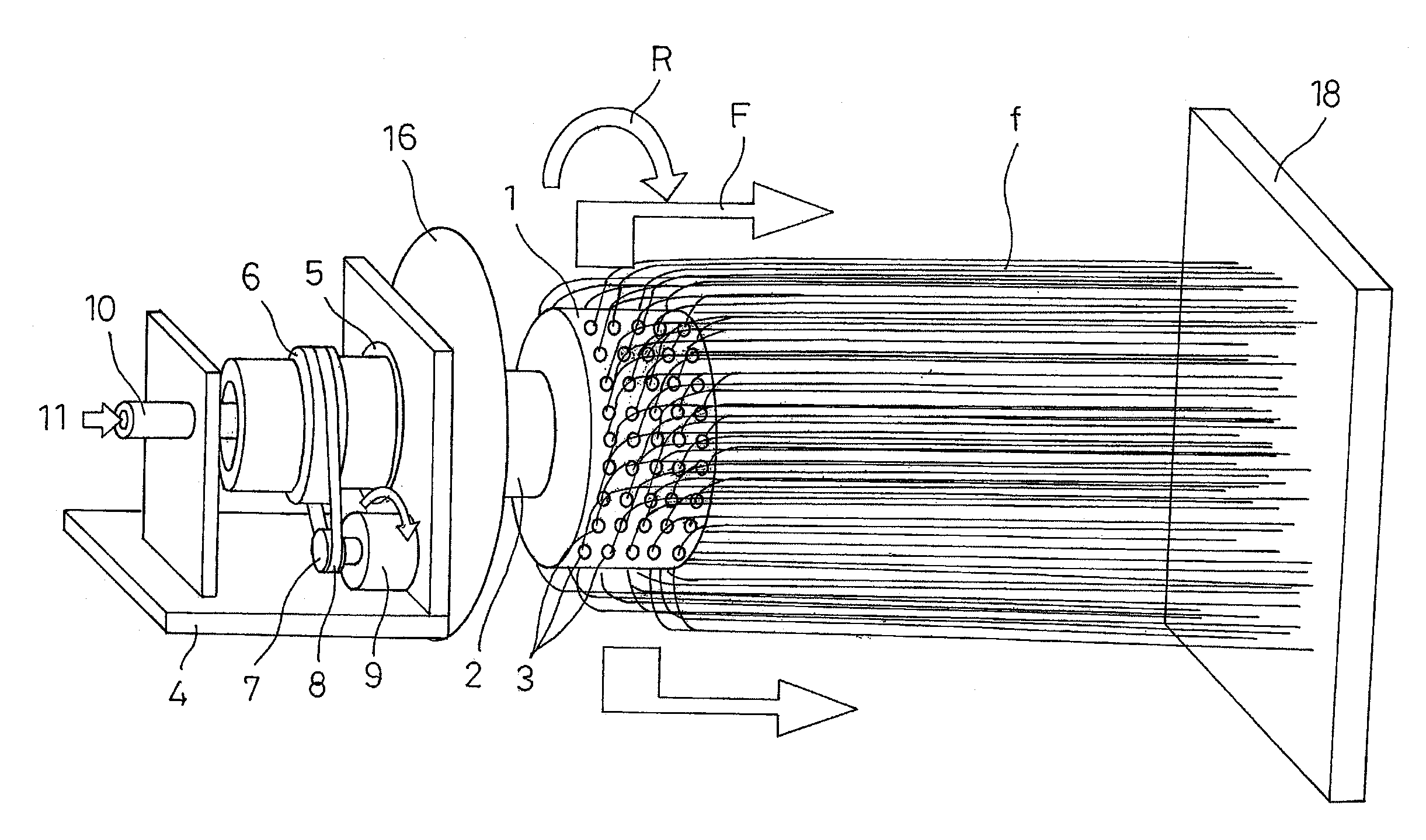

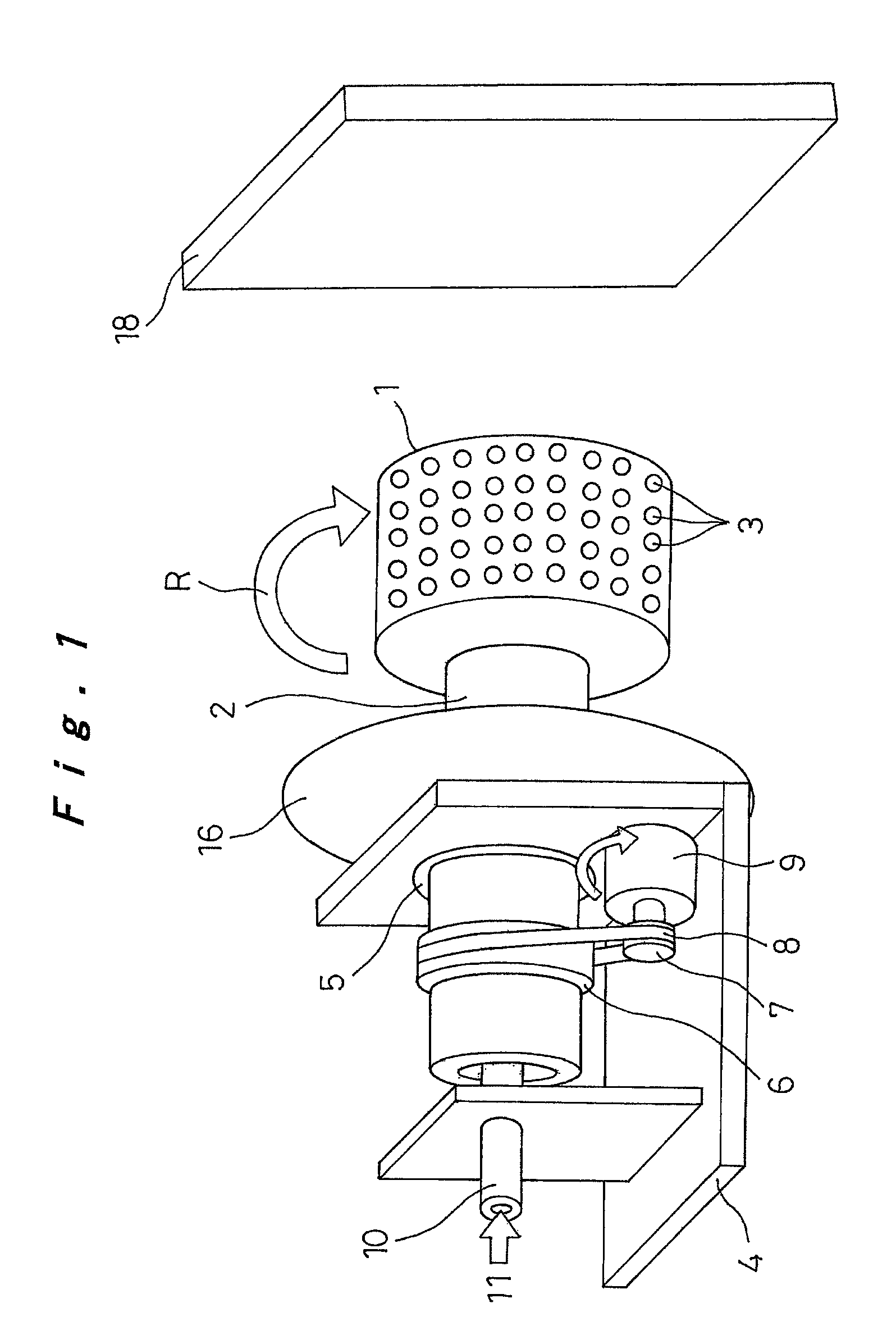

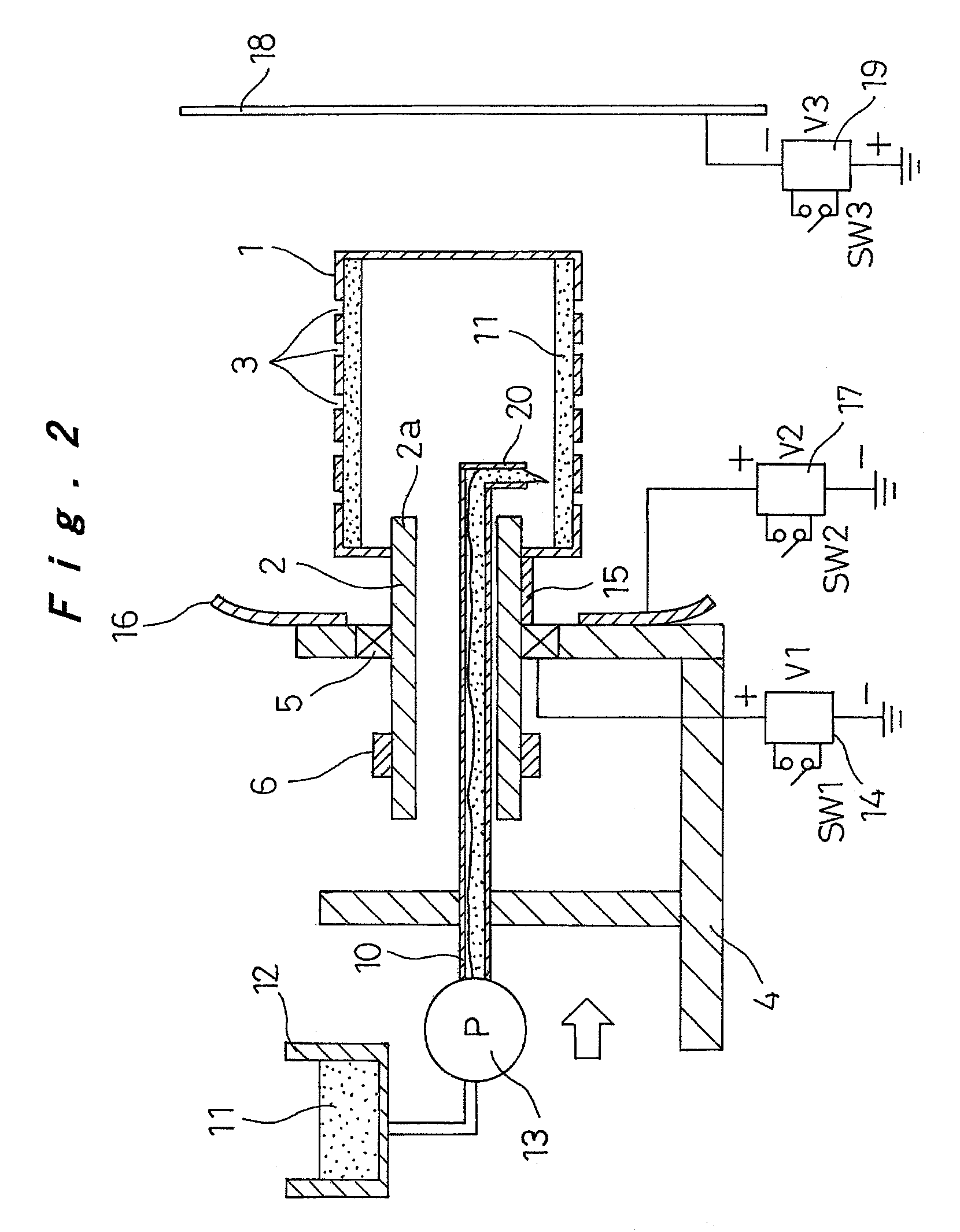

Method and apparatus for producing nanofibers and polymer web

ActiveUS20100072674A1Efficient and stable productionEnsure efficient flowElectric discharge heatingFilament/thread formingProduction rateNanofiber

Nanofibers are formed from a polymer material by rotating a conductive rotating container having a plurality of small holes while supplying a polymer solution formed by dissolving a polymer material in a solvent into the rotating container, charging the polymer solution discharged from the small holes of the rotating container by charging means, and drawing the discharged filamentous polymer solution by centrifugal force and an electrostatic explosion resulting from evaporation of the solvent. The nanofibers from this production step are oriented and made to flow from one side toward the other side in a shaft center direction of the rotating container by a reflecting electrode and / or blowing means, or those nanofibers are deposited, to produce a polymer web. The nanofibers and the polymer web using these nanofibers can be produced uniformly by a simple configuration with good productivity.

Owner:PANASONIC CORP

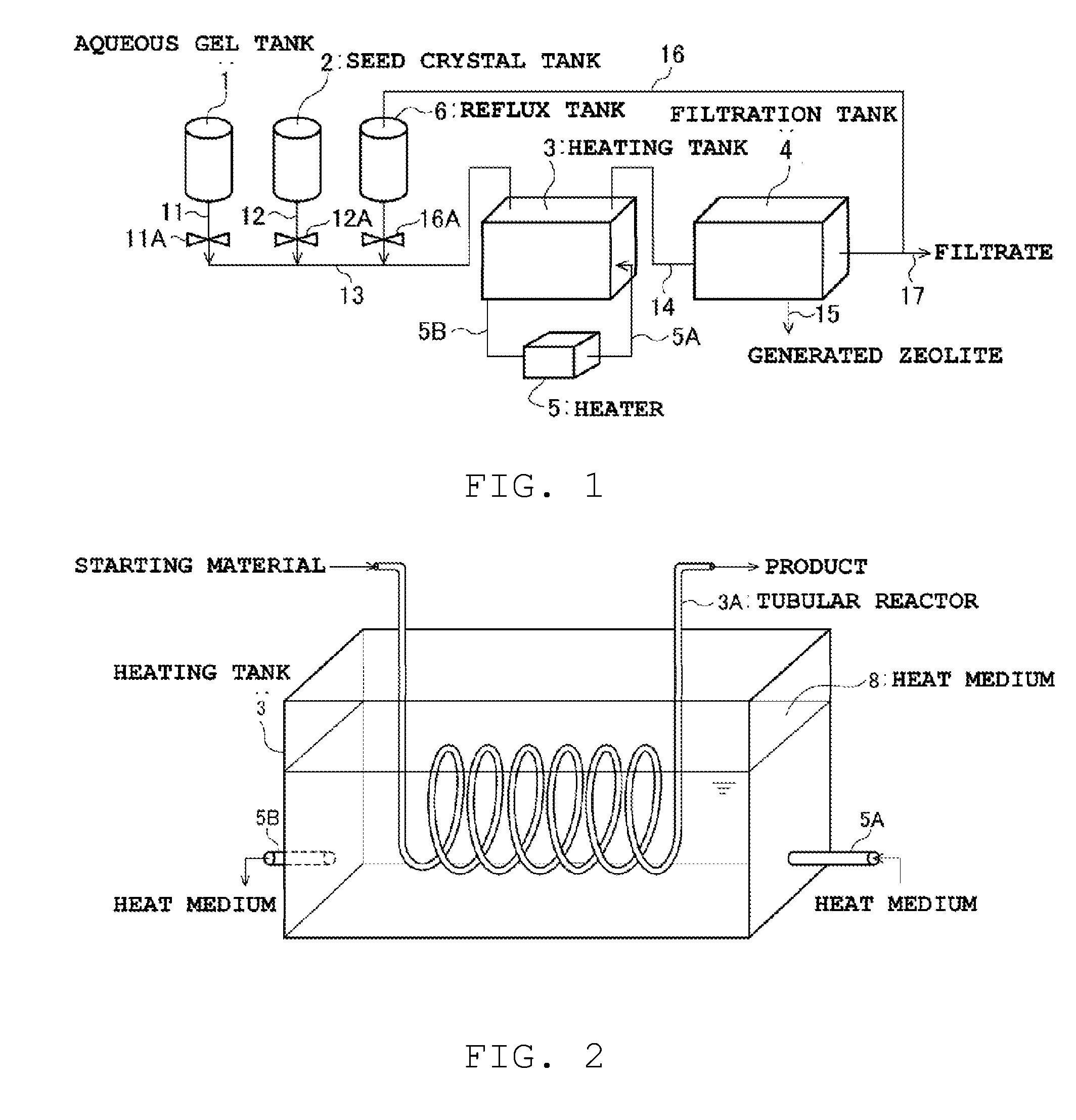

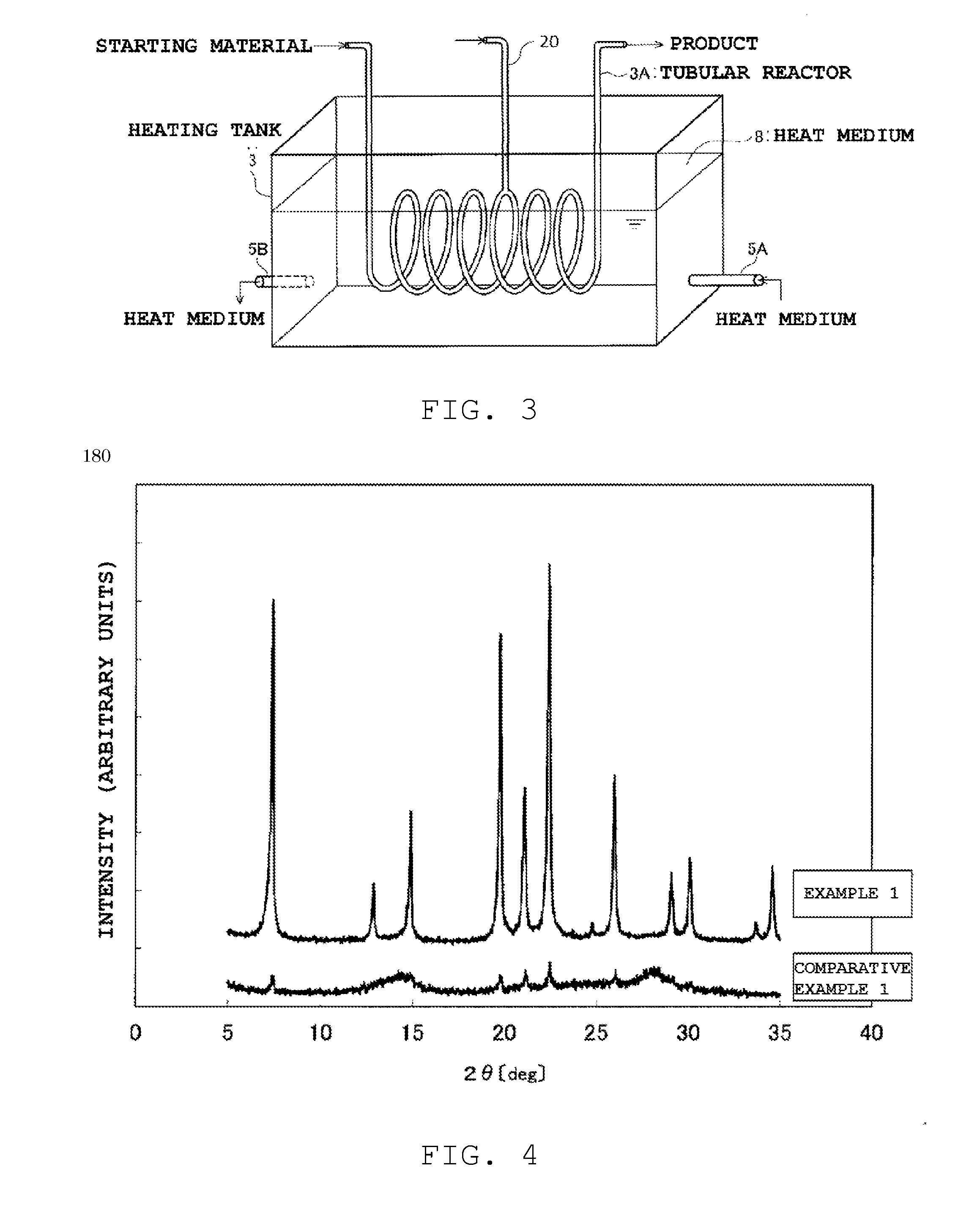

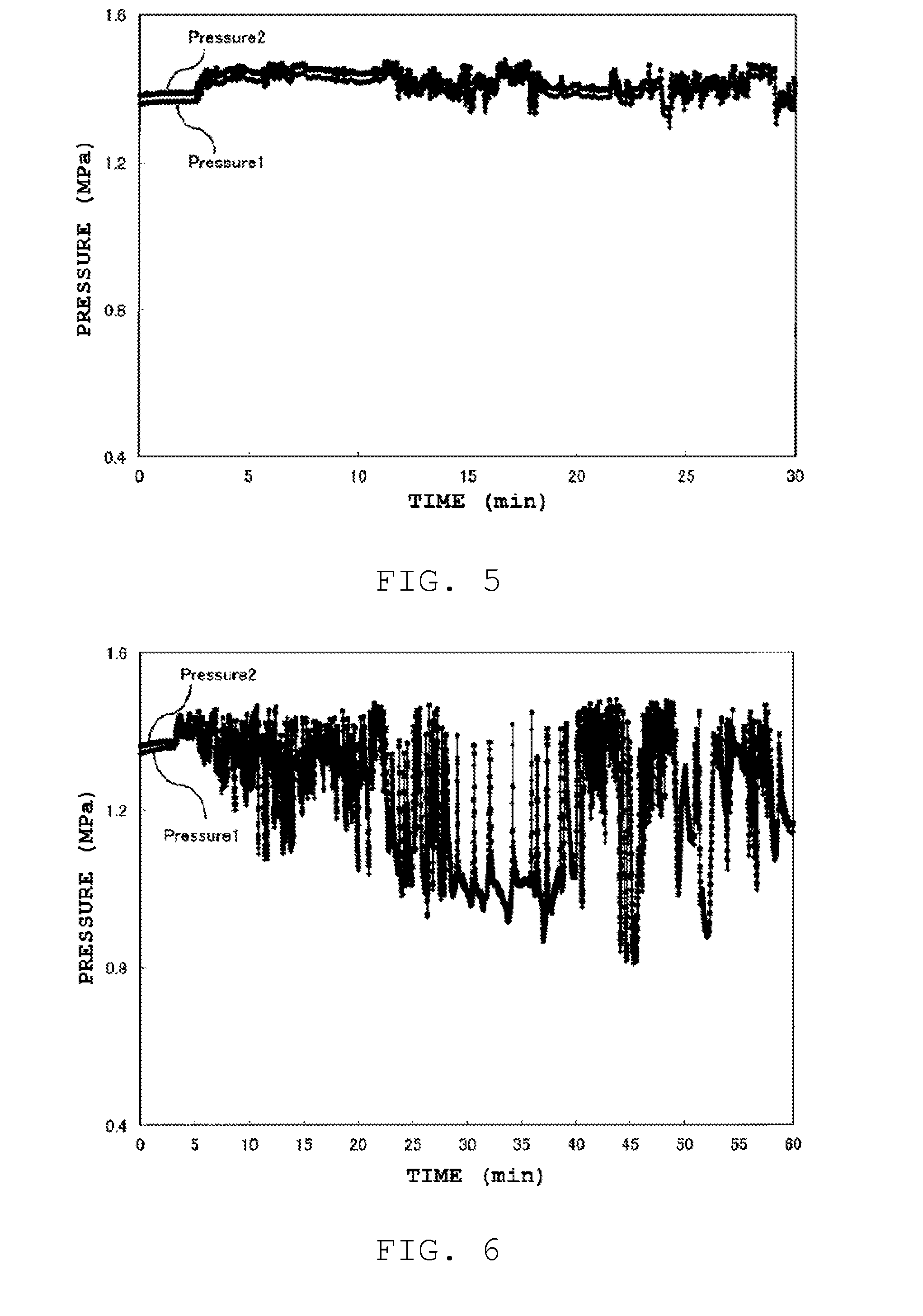

Zeolite production method

ActiveUS20160115039A1Efficient and stable productionShort timeAluminium compoundsMolecular sieve catalystsHigh ratePhosphoric acid

Provided is a method for continuous production of zeolite in which a starting material is continuously supplied to a tubular reactor to produce an aluminophosphate zeolite that contains, in the framework structure, at least aluminum atoms and phosphorus atoms or an aluminosilicate zeolite having 5≦SiO2 / Al2O3≦2000. The tubular reactor is heated using a heat medium; a ratio (volume) / (lateral surface area) of the volume (inner capacity) to the lateral surface area of the tubular reactor is 0.75 cm or smaller; and seed crystals are added to the starting material. Through using a small-diameter tubular reactor and heating with a heat medium, it becomes possible to heat sufficiently the entirety of a starting material (zeolite precursor gel) in a short time, and to allow reaction to proceed at a high rate. The occurrence of irregular pressure fluctuations during continuous production of the zeolite can be prevented by adding seed crystals.

Owner:THE UNIV OF TOKYO +1

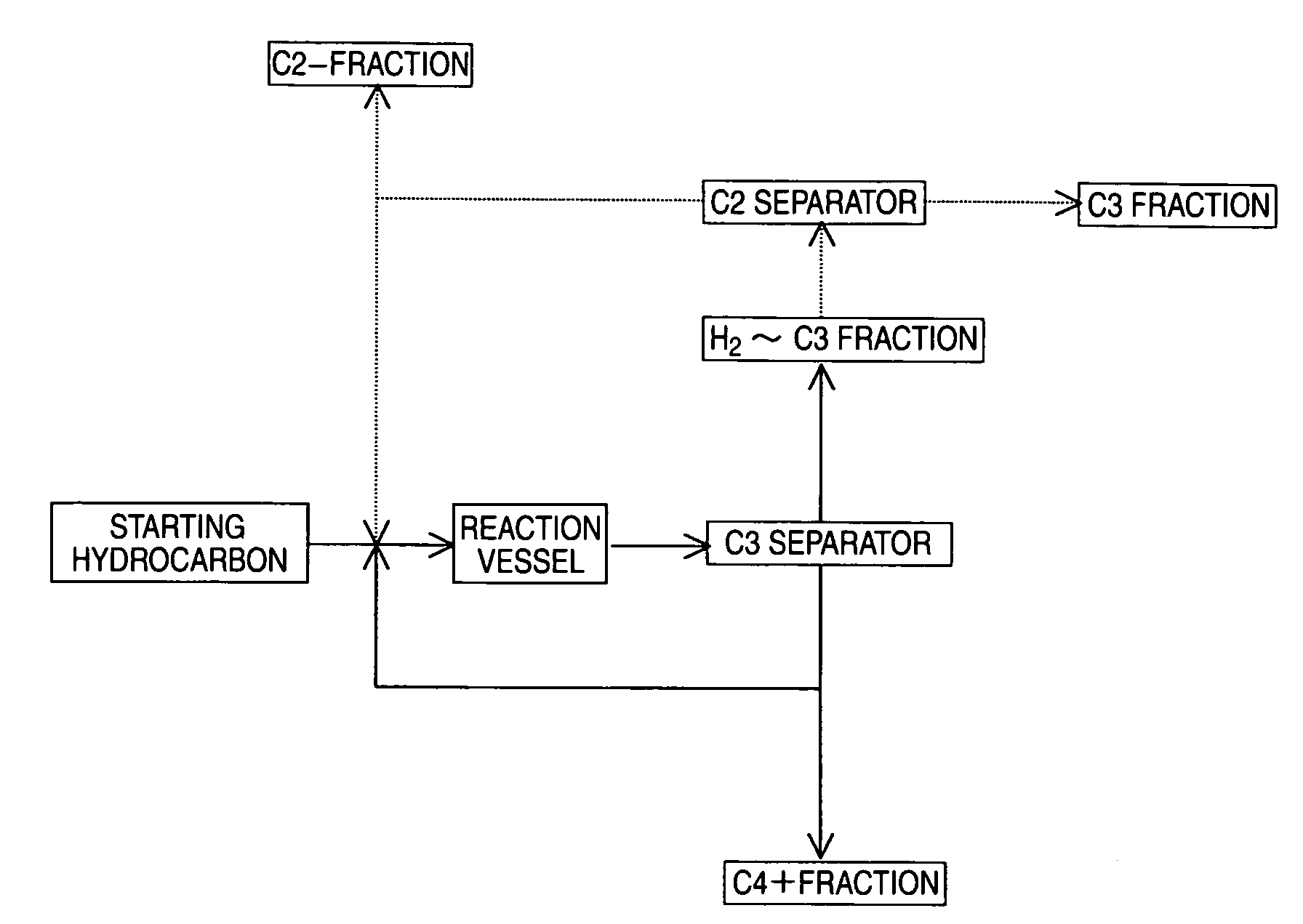

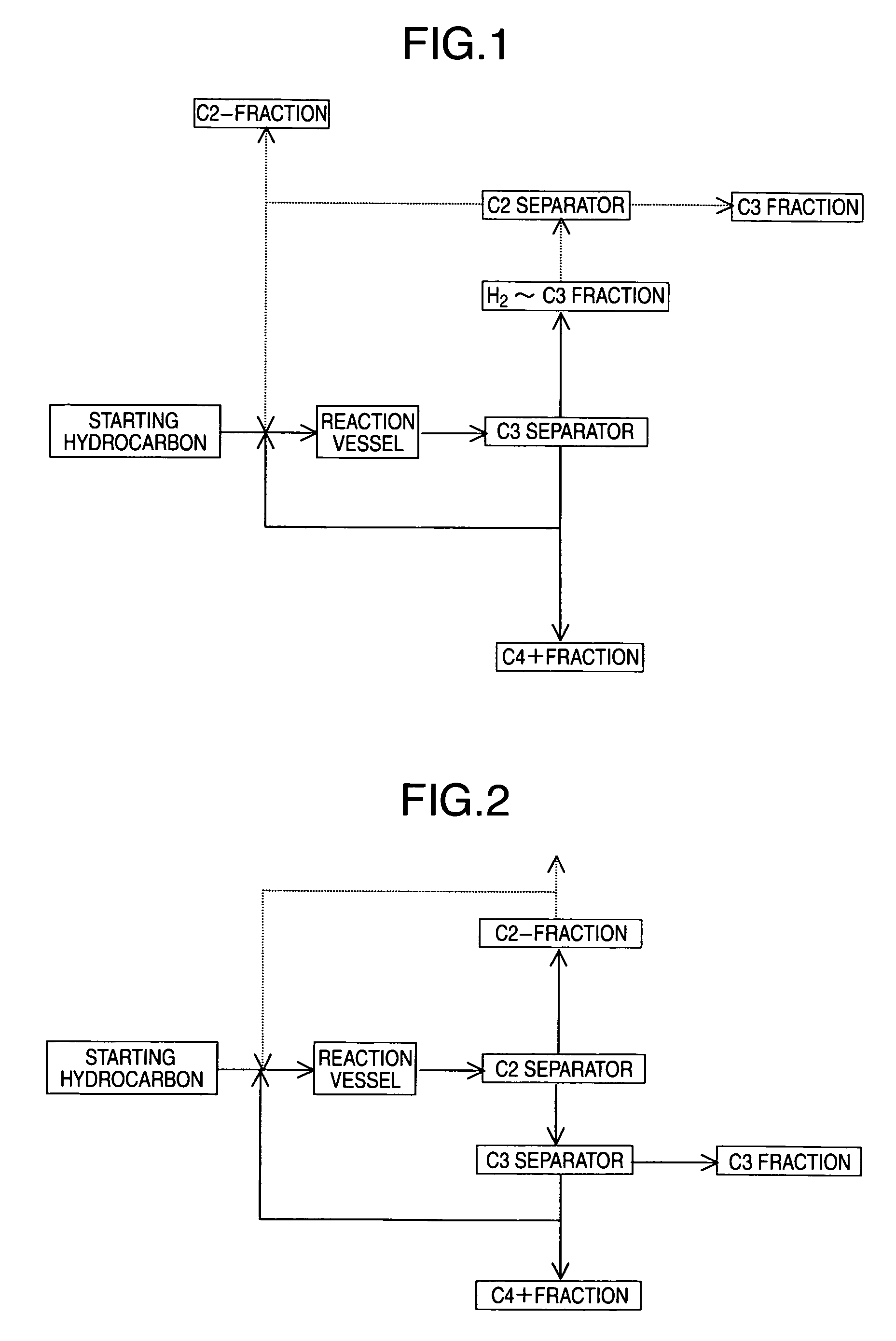

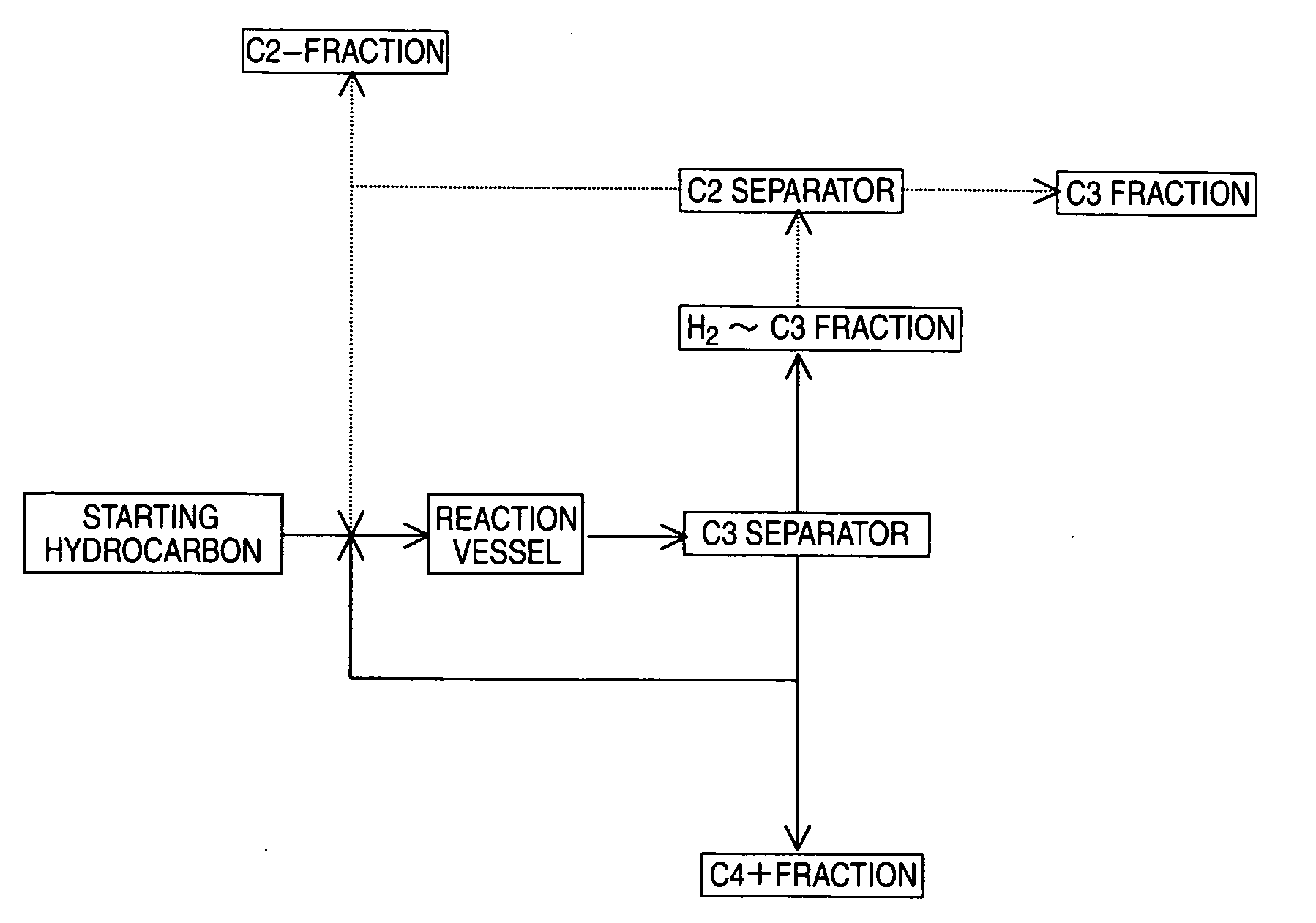

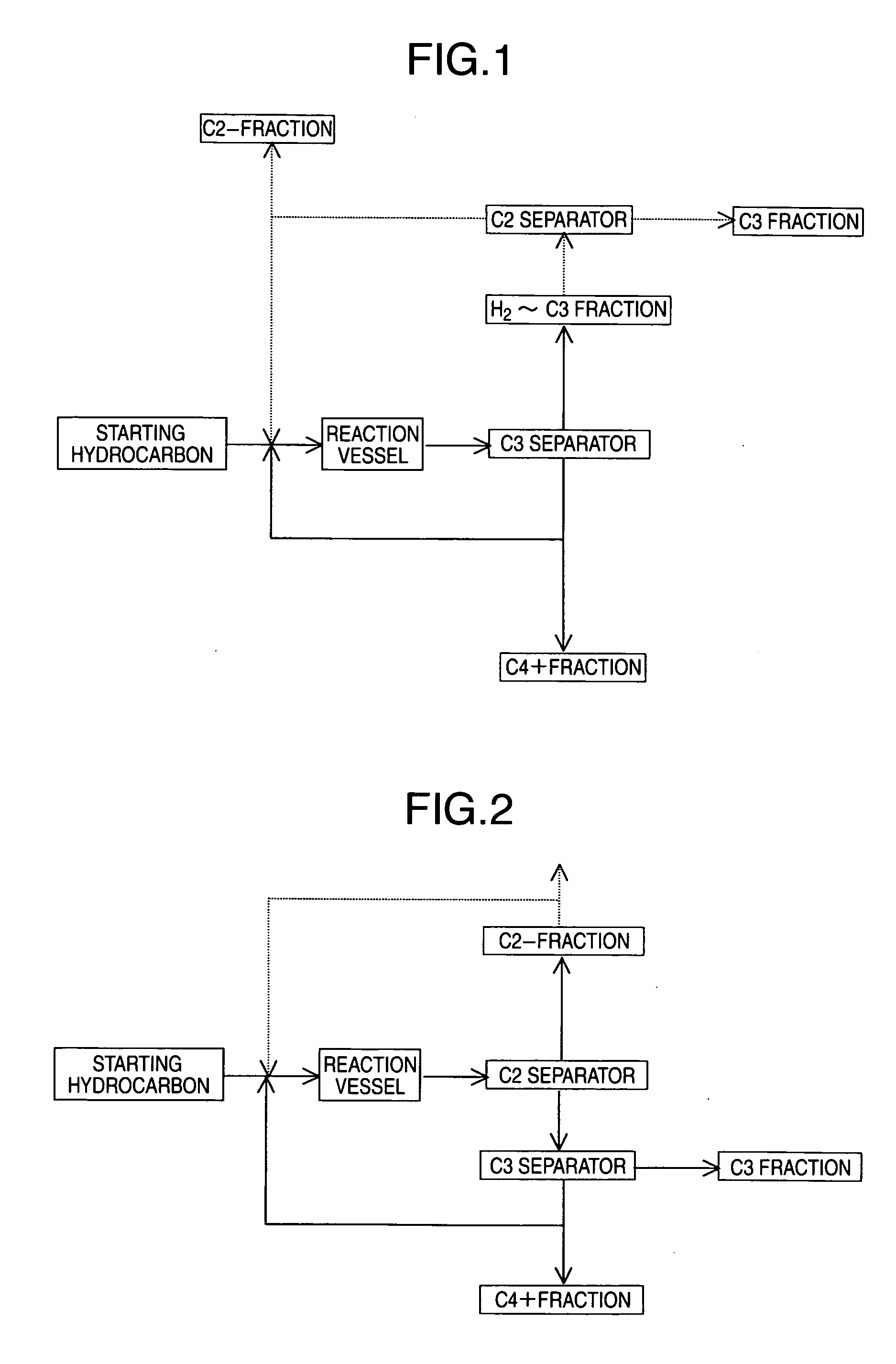

Process for producing ethylene and propylene

ActiveUS7754934B2Efficient and stable productionTreatment with plural serial cracking stages onlyCatalytic crackingHydrogenEthylene

A process for efficiently and stably producing ethylene and propylene which comprises bringing a hydrocarbon feedstock comprising at least one C4-12 olefin into contact with a zeolite-containing catalyst to obtain a reaction mixture containing ethylene and propylene, separating the reaction mixture into a fraction comprising ingredients ranging from hydrogen to C3 hydrocarbons and a fraction comprising C4 and higher hydrocarbons, and recycling the C4 and higher hydrocarbons as they are to a reactor.

Owner:ASAHI KASEI KK

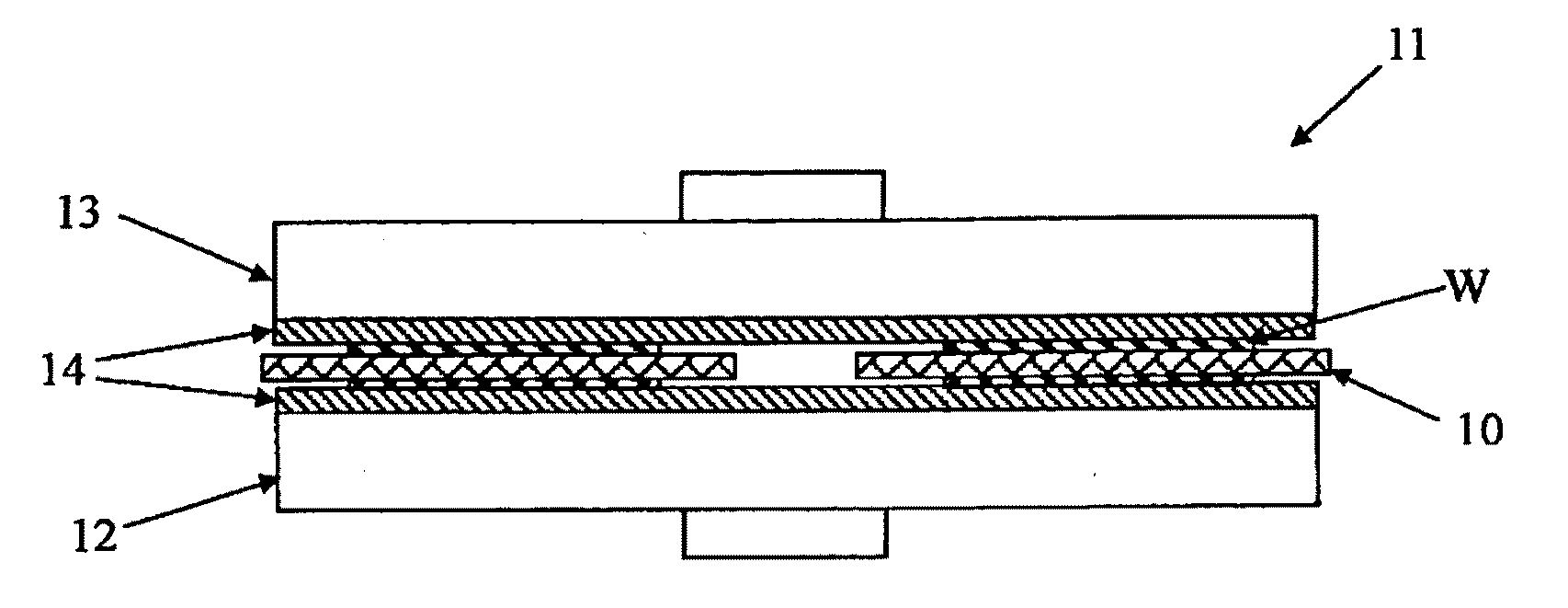

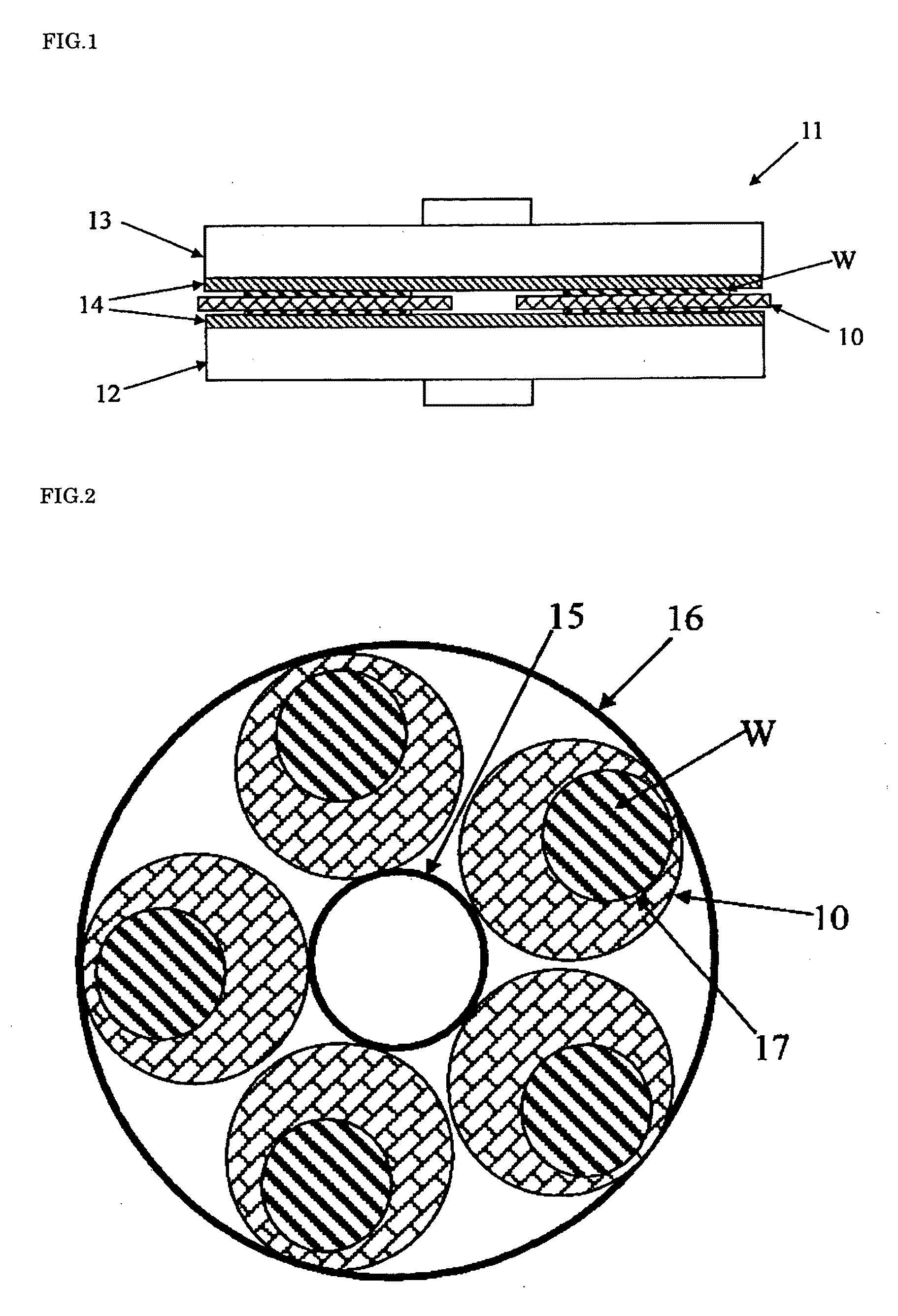

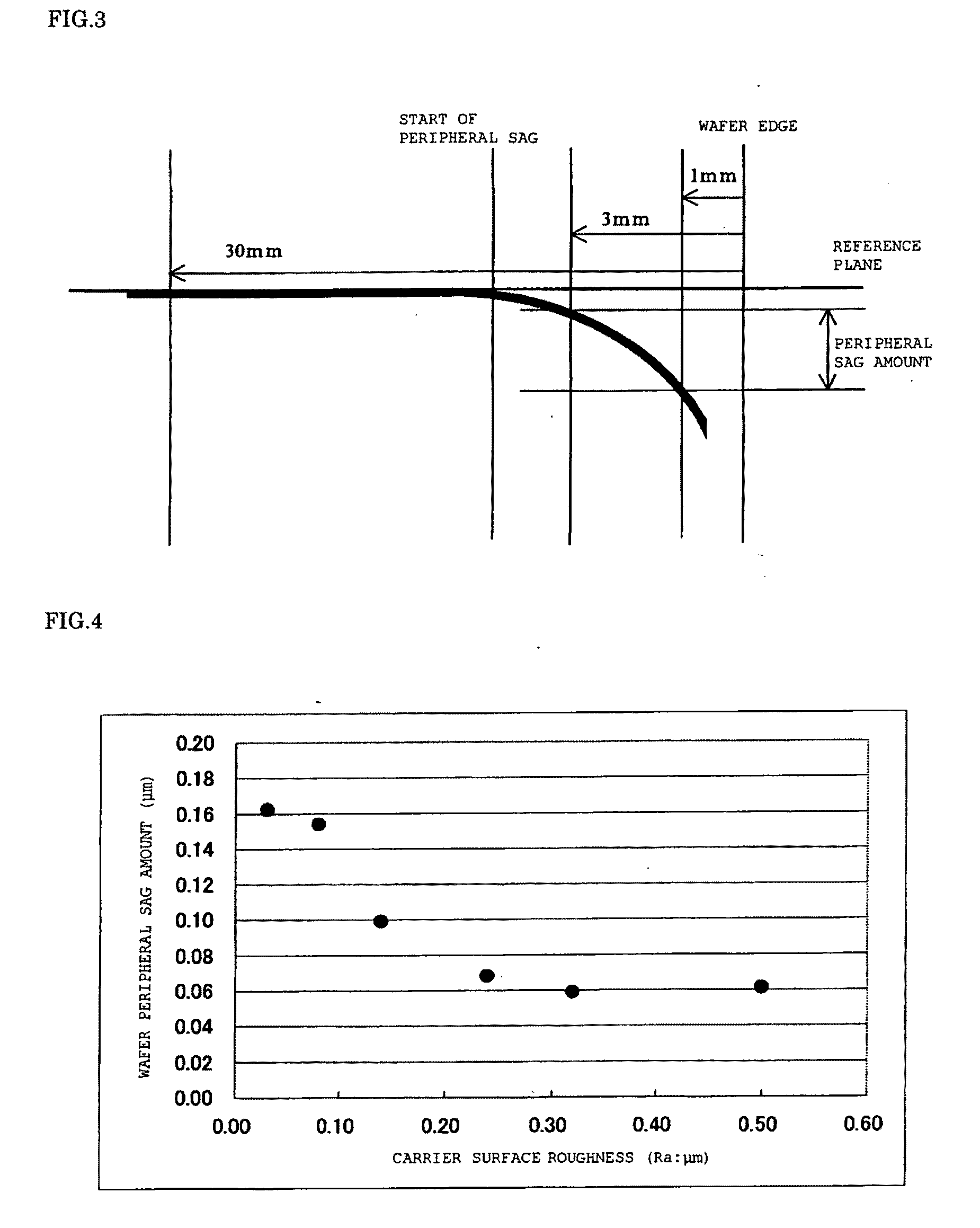

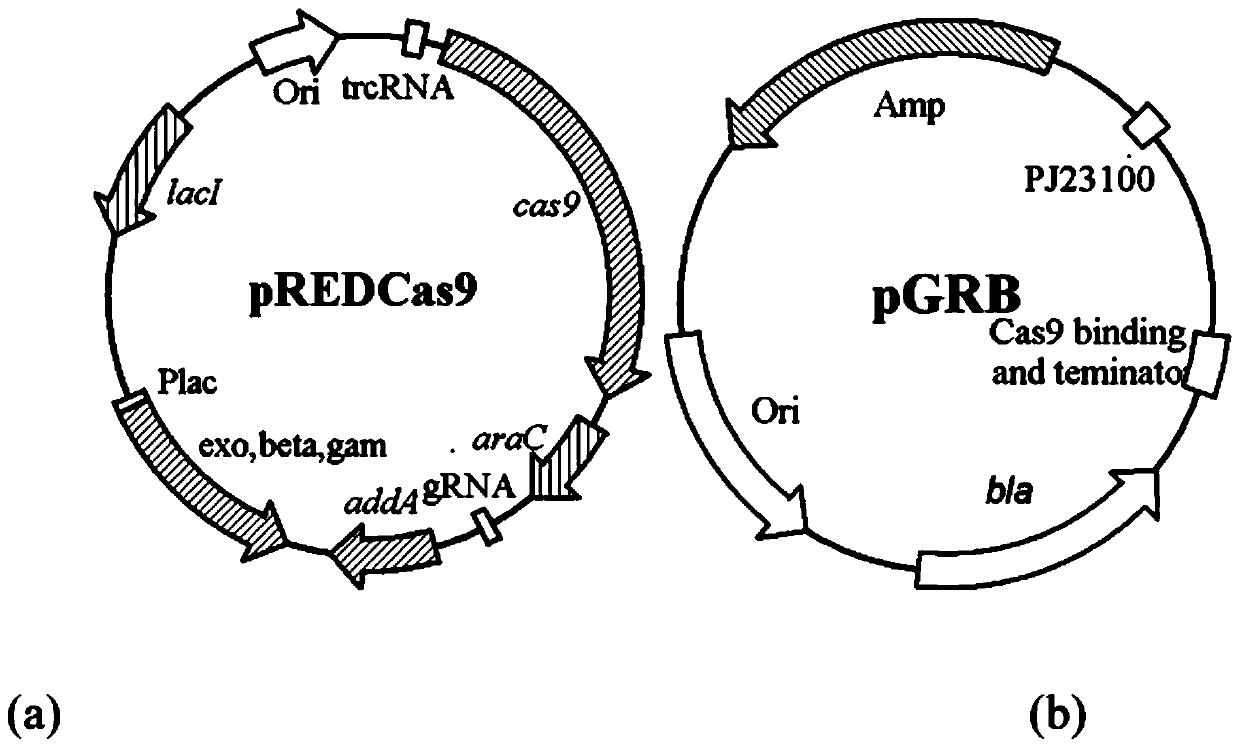

Carrier for double-side polishing apparatus, double-side polishing apparatus using the same, and double-side polishing method

InactiveUS20090305615A1Low costEfficient and stable productionEdge grinding machinesPolishing machinesSurface roughnessTitanium

The present invention provides a carrier for double-side polishing apparatus which is set between upper and lower turn tables having polishing pads attached thereto and has a holding hole in which a semiconductor wafer sandwiched between the upper and lower turn tables is held at the time of polishing in a double-side polishing apparatus, wherein a material of the carrier is titanium, and surface roughness of the titanium carrier is 0.14 μm or above in terms of Ra. As a result, there can be provided the carrier for double-side polishing apparatus, a double-side polishing apparatus, and a double-side polishing method that can stably and efficiently produce a high-quality wafer having reduced wafer peripheral sag and a high flatness at the time of double-side polishing of a semiconductor wafer.

Owner:SHIN-ETSU HANDOTAI CO LTD

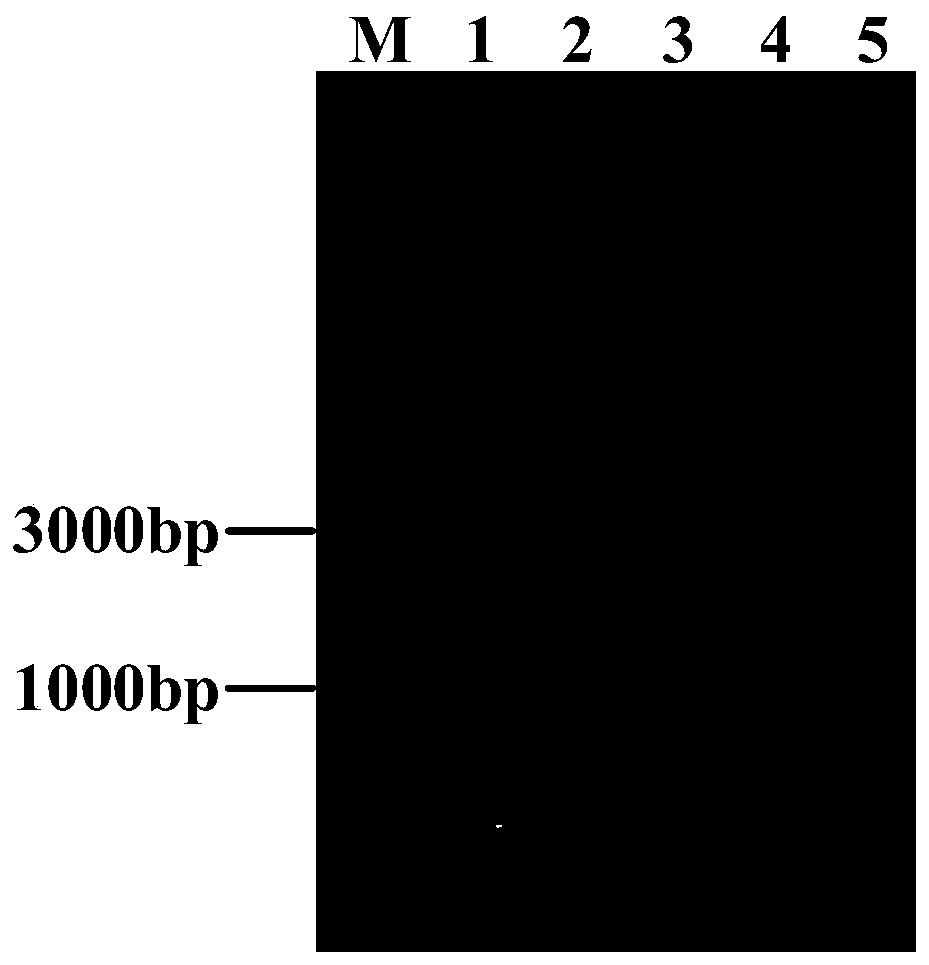

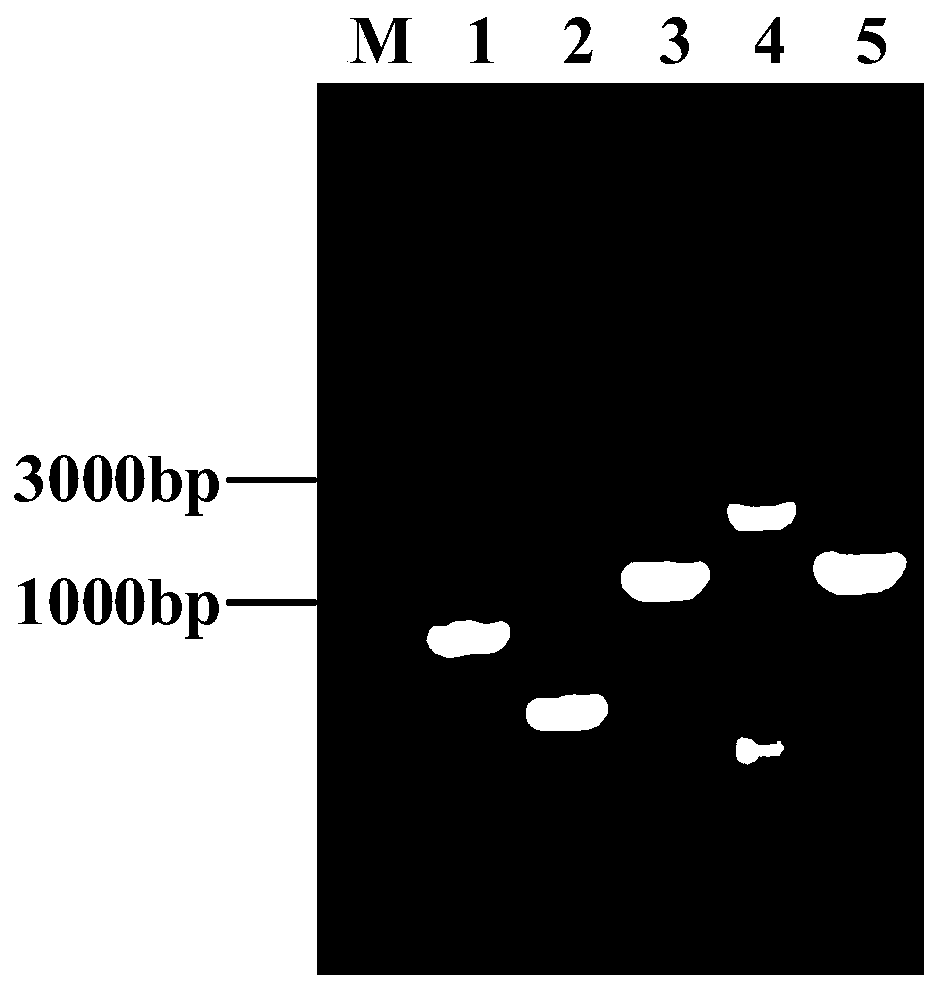

Genetically engineered bacterium for producing L-arginine and construction method and application thereof

ActiveCN110964683AShorten the growth cycleClear genetic backgroundBacteriaHydrolasesEscherichia coliCarbamyl Phosphate

The invention discloses a genetically engineered bacterium for producing L-arginine and a construction method and application thereof. According to the invention, a gene for encoding carbamyl phosphate synthetase and a gene for encoding L-arginine biosynthetic pathway enzyme are integrated in escherichia coli; a synthetic route of arginine in escherichia coli and metabolic flux related to argininein a whole amino acid metabolic network are analyzed and reconstructed to obtain genetically engineered bacteria which are clear in genetic background, do not carry plasmids, are not mutated and canstably and efficiently produce L-arginine; and the genetically engineered bacteria have good L-arginine production capacity.

Owner:NINGXIA EPPEN BIOTECH

Process for producing polycarbonate

ActiveUS20110034646A1Efficient and stable productionLow refractive indexSynthetic resin layered productsChemical recyclingPolycarbonateFormic acid

A subject for the invention is to provide a polycarbonate having excellent mechanical strength, heat resistance, a low refractive index, a large Abbe number, reduced birefringence, and excellent transparency. The invention relates to a polycarbonate characterized by being obtained by subjecting one or more dihydroxy compounds including a dihydroxy compound having at least one linking group —CH2—O— in the molecule thereof to melt polycondensation with a carbonic acid diester, and by having a reduced viscosity of from 0.40 dL / g to 1.70 dL / g and a formic acid content lower than 5 ppm by weight.

Owner:MITSUBISHI CHEM CORP

Method for producing ethylene and propylene

ActiveUS7893311B2Efficient and stable productionIncrease resistanceTreatment with plural serial cracking stages onlyCatalytic crackingProtonSilicon dioxide

The invention is to provide a catalyst excellent in product producibility and selectivity, and in coking degradation resistance and regeneration degradation resistance, which is for production of ethylene and propylene through catalytic conversion from a hydrocarbon material. The invention relates to a method for producing ethylene and propylene through catalytic conversion from an olefin, by contacting a hydrocarbon material with a zeolite-containing shaped catalyst satisfying the following requirements (1) to (6), in a reactor:(1) the zeolite is an intermediate pore-size zeolite having a pore size of from 5 to 6.5 angstroms,(2) the zeolite does not substantially contain a proton,(3) the zeolite contains at least one metal selected from the group consisting of metals belonging to the Group IB of the Periodic Table,(4) the zeolite-containing shaped catalyst comprises silica as a binder,(5) the zeolite-containing shaped catalyst has a side-crush strength of at least 2.5 N / mm,(6) the zeolite-containing shaped catalyst has a sodium content of 500 ppm or less as an H-exchange type thereof.

Owner:ASAHI KASEI KK

Process for Producing Ethylene and Propylene

ActiveUS20070265482A1Efficiently and stably produceEfficient and stable productionTreatment with plural serial cracking stages onlyCatalytic crackingChemistryZeolite

A process for efficiently and stably producing ethylene and propylene which comprises bringing a hydrocarbon feedstock comprising at least one C4-12 olefin into contact with a zeolite-containing catalyst to obtain a reaction mixture containing ethylene and propylene, separating the reaction mixture into a fraction comprising ingredients ranging from hydrogen to C3 hydrocarbons and a fraction comprising C4 and higher hydrocarbons, and recycling the C4 and higher hydrocarbons as they are to a reactor.

Owner:ASAHI KASEI KOGYO KK

Method and apparatus for producing nanofibers and polymer web

ActiveUS8110136B2Efficient and stable productionEnsure efficient flowElectric discharge heatingPhysical treatmentProduction rateEvaporation

Nanofibers are formed from a polymer material by rotating a conductive rotating container having a plurality of small holes while supplying a polymer solution formed by dissolving a polymer material in a solvent into the rotating container, charging the polymer solution discharged from the small holes of the rotating container by charging means, and drawing the discharged filamentous polymer solution by centrifugal force and an electrostatic explosion resulting from evaporation of the solvent. The nanofibers from this production step are oriented and made to flow from one side toward the other side in a shaft center direction of the rotating container by a reflecting electrode and / or blowing means, or those nanofibers are deposited, to produce a polymer web. The nanofibers and the polymer web using these nanofibers can be produced uniformly by a simple configuration with good productivity.

Owner:PANASONIC CORP

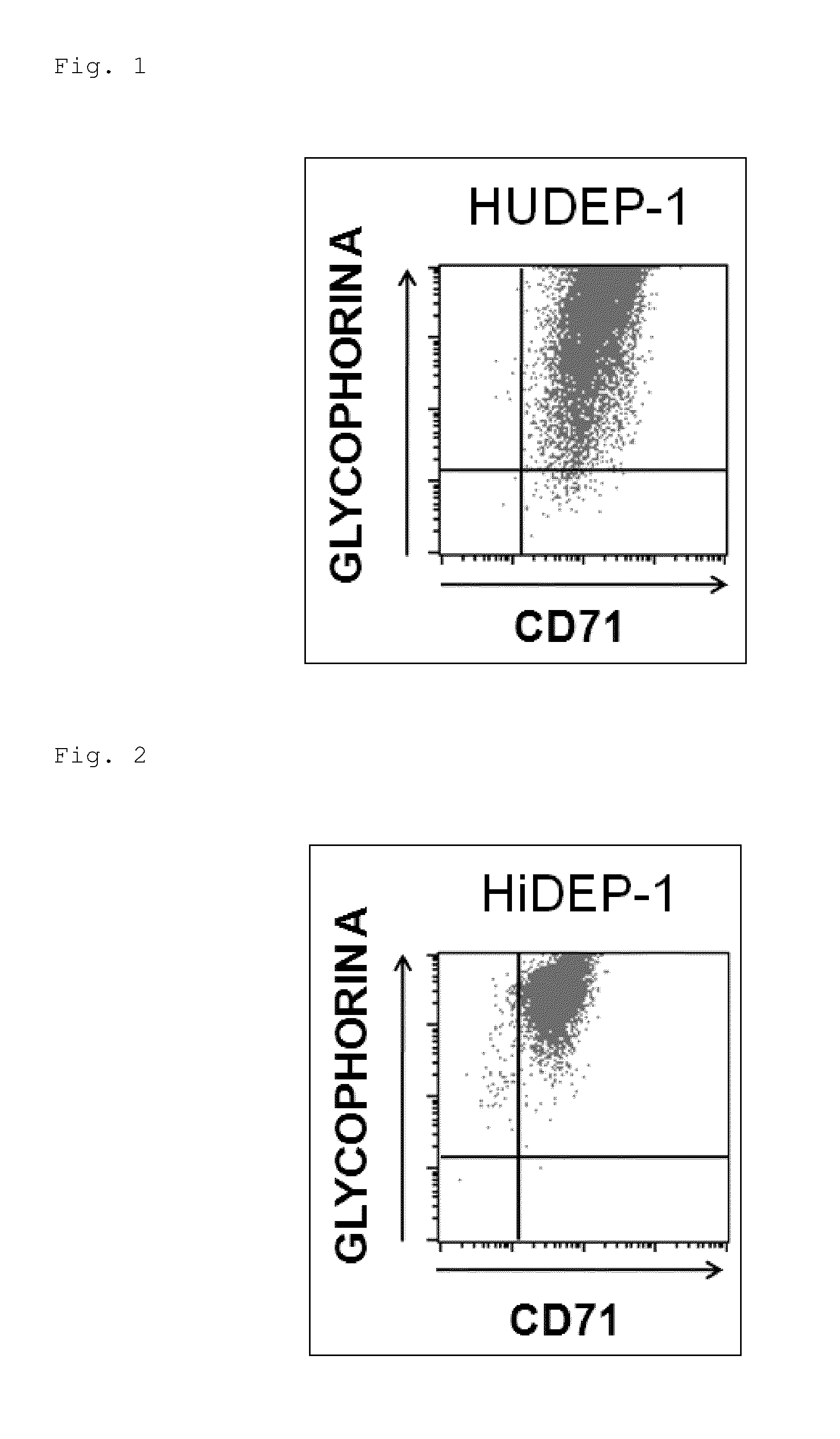

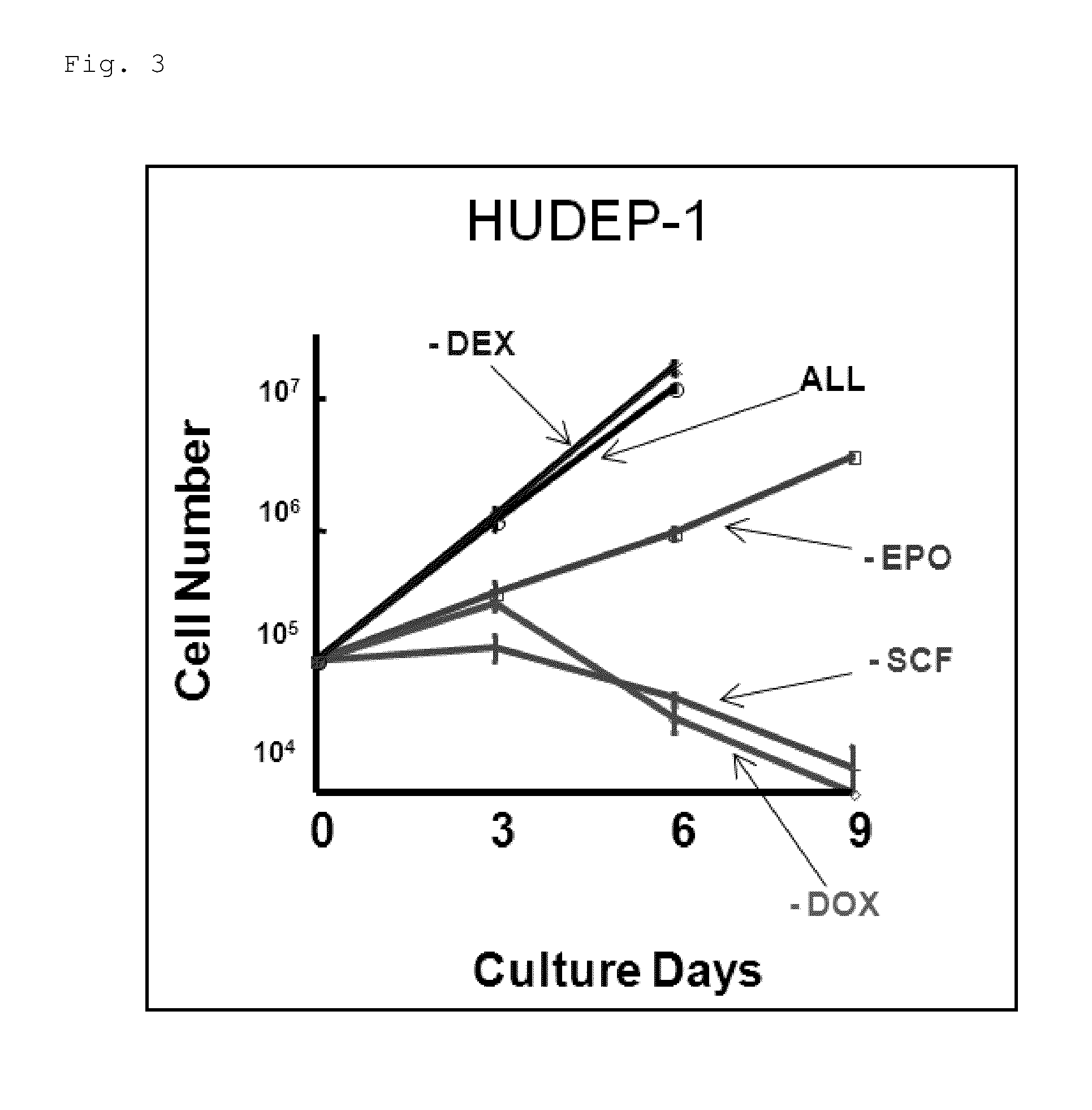

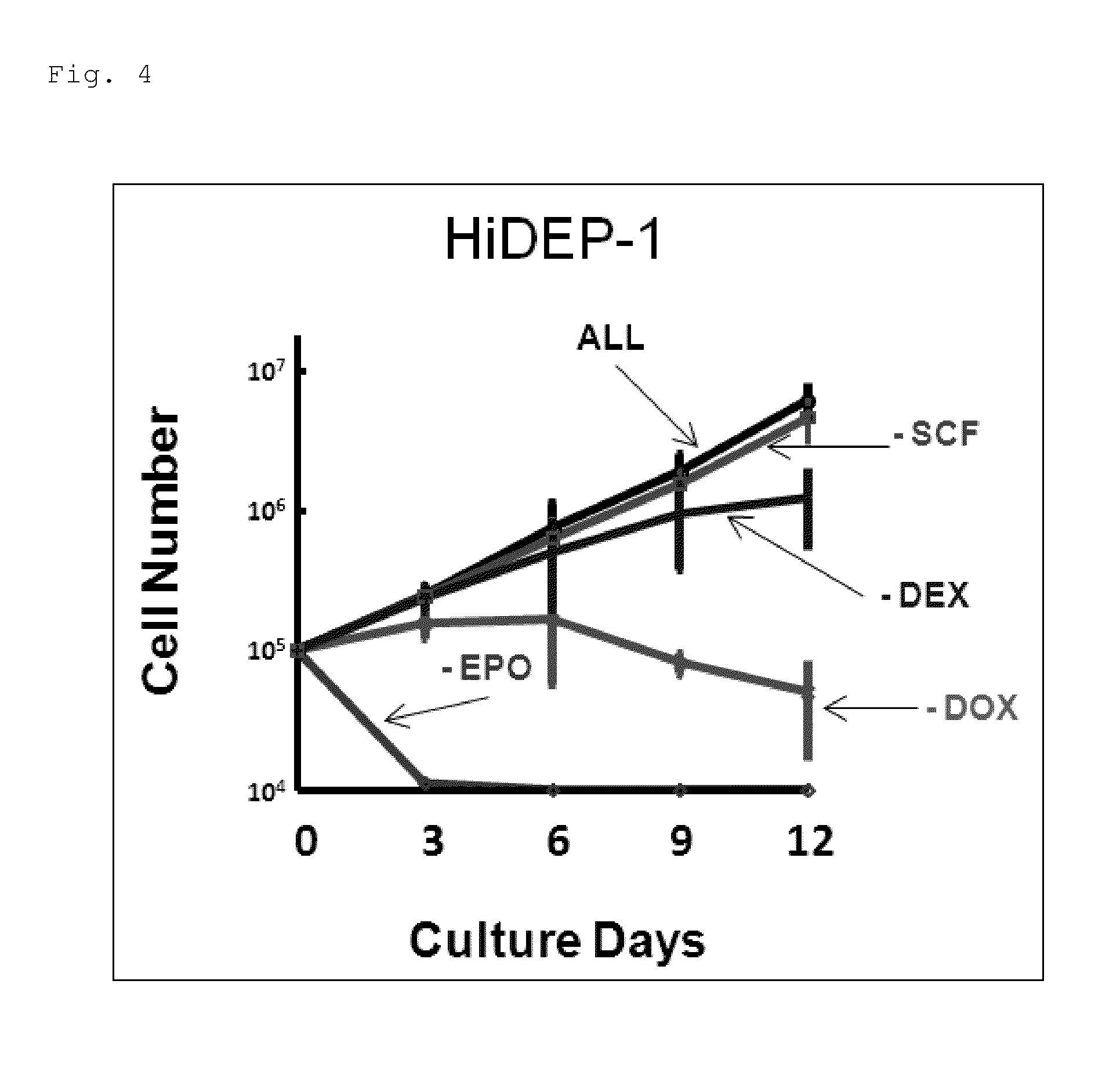

Human erythroid progenitor cell line and method for producing human enucleated red blood cells

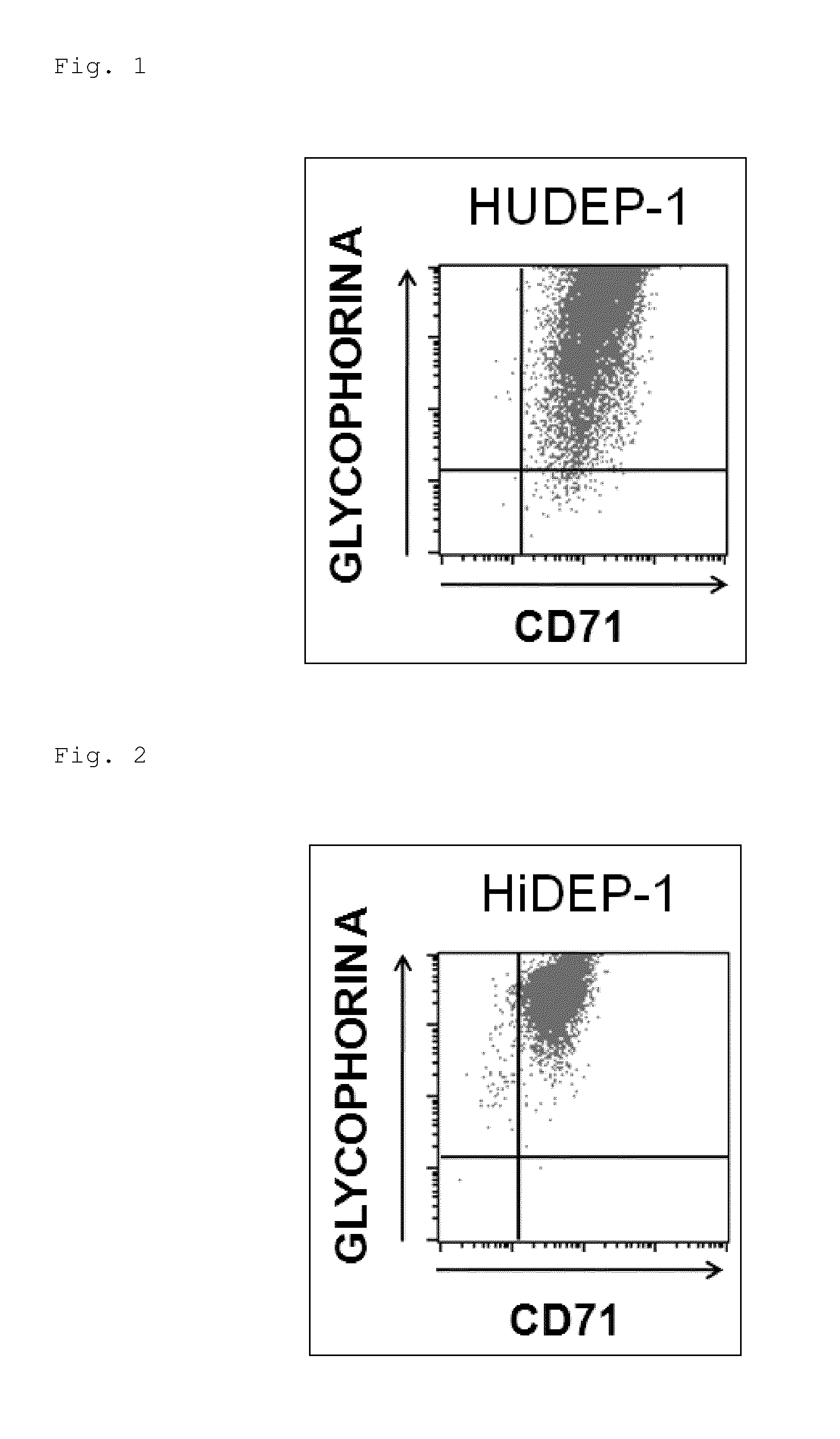

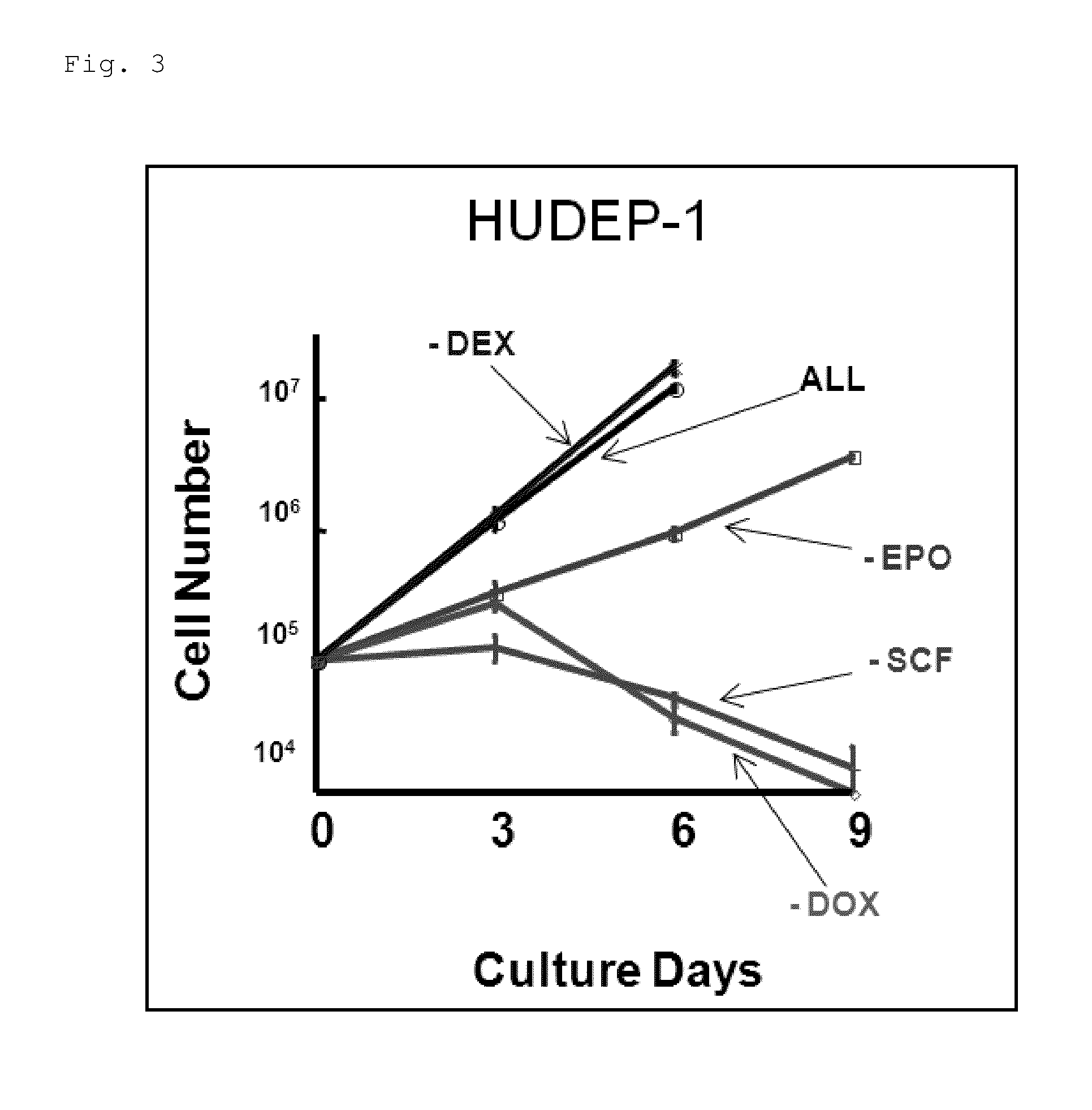

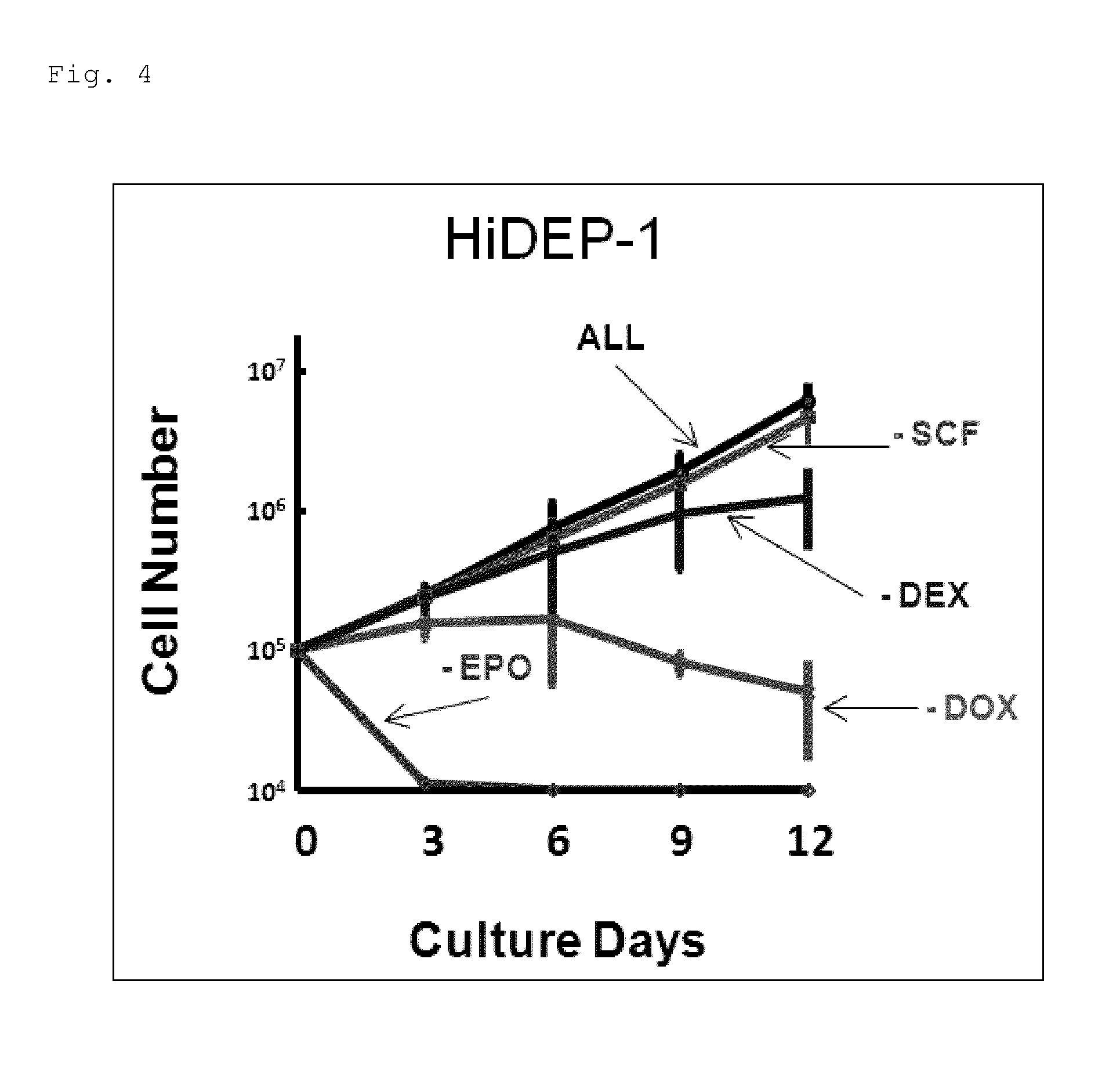

ActiveUS20140024118A1Efficient and stable productionEfficiently induce differentiationSkeletal/connective tissue cellsBlood/immune system cellsGenomic DNAMolecular biology

Provided are: a method for producing an immortalized human erythroid progenitor cell line, enabling efficient and stable production of enucleated red blood cells; and a method for producing human enucleated red blood cells from a human erythroid progenitor cell line obtained by the aforementioned production method. An expression cassette capable of inducing expression of HPV-E6 / E7 genes in the presence of DOX was introduced into the genomic DNA of blood stem cells. Then, the blood stem cells were cultured in the presence of DOX and a blood growth factor. Thereby, immortalized cell lines of human erythroid progenitor cells were established. Further, it was revealed that culturing the cell lines under a condition where the expression of the HPV-E6 / E7 genes was not induced enabled differentiation induction into enucleated red blood cells at a high ratio.

Owner:RIKEN

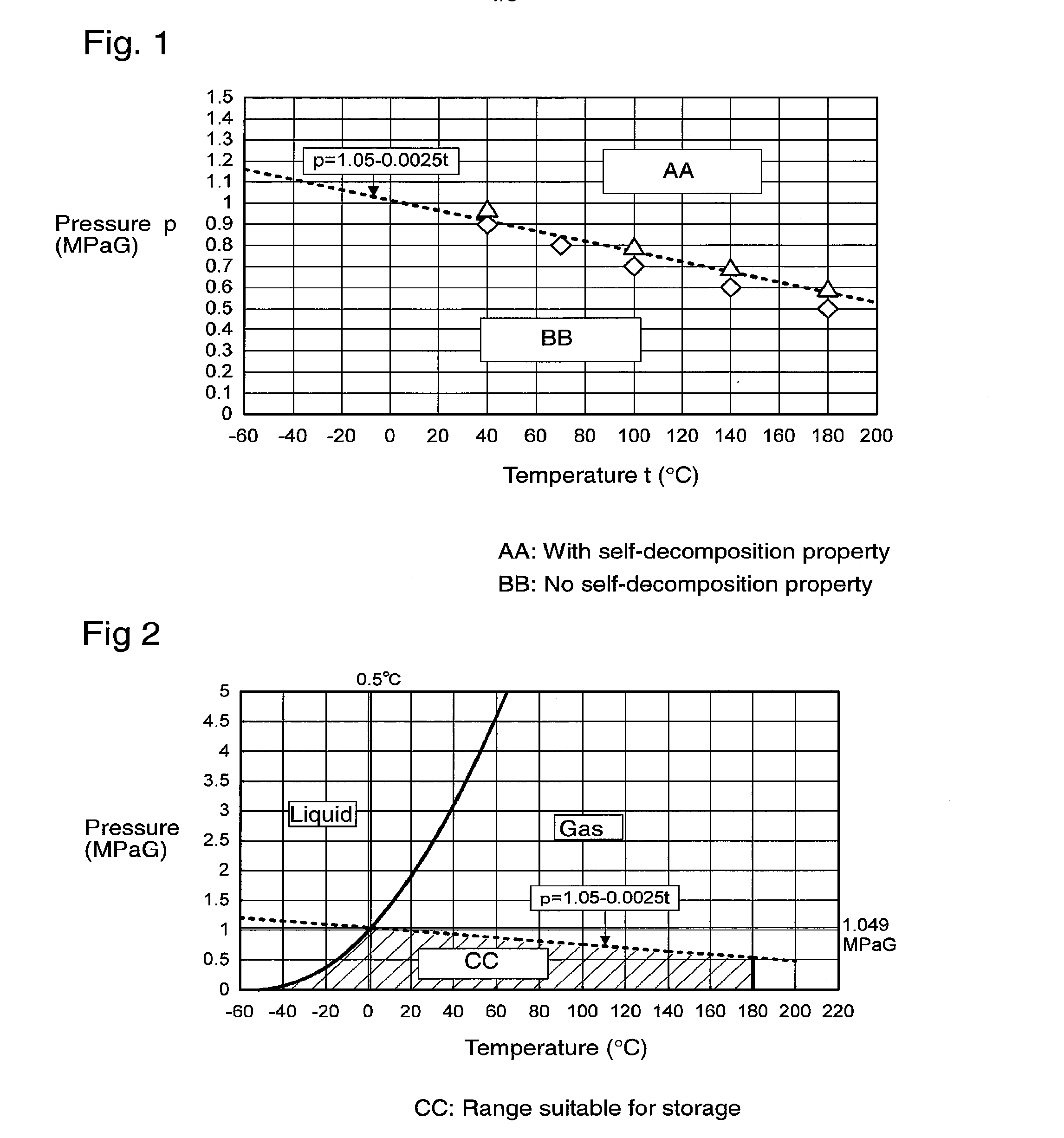

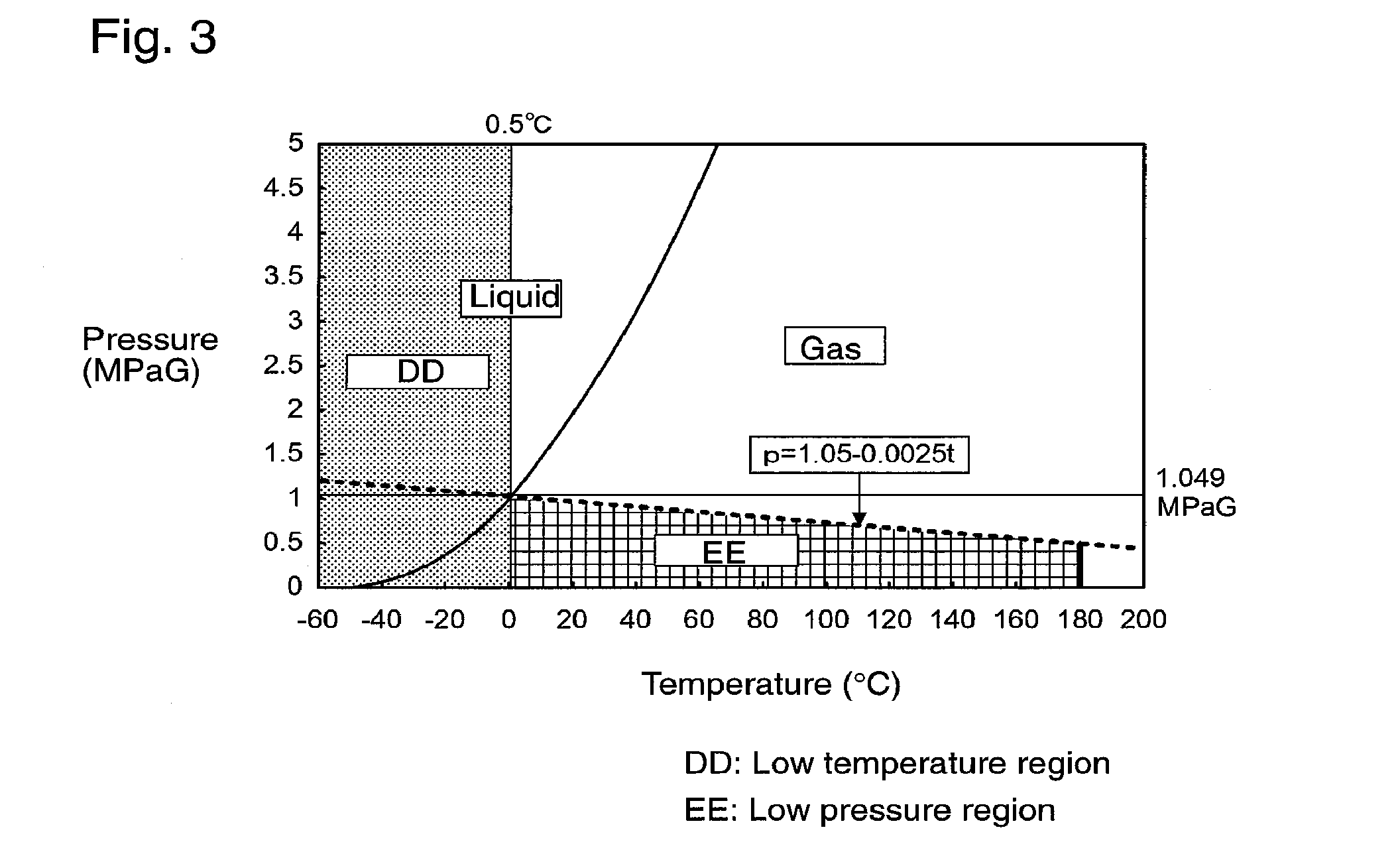

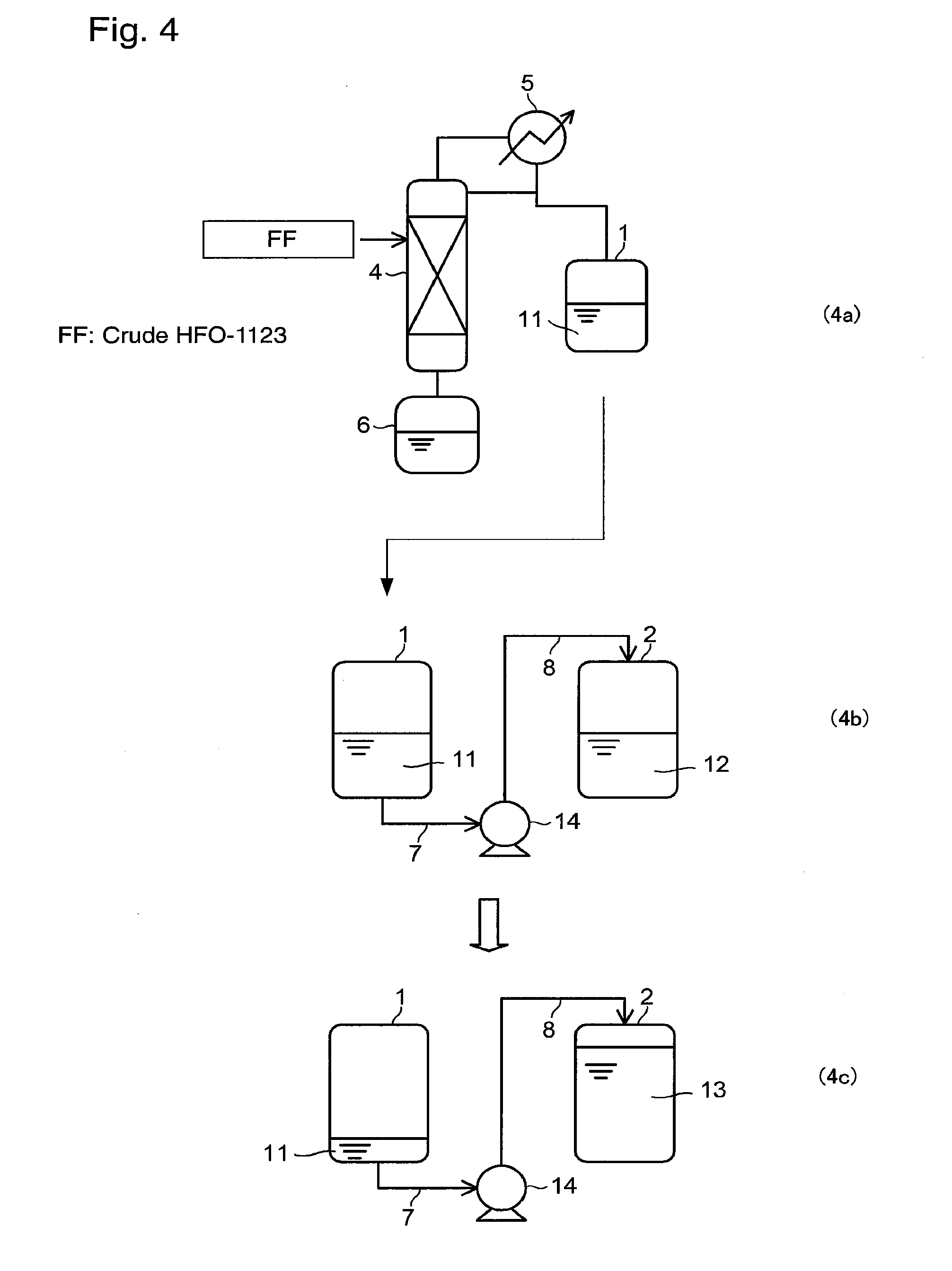

Method for producing working fluid

ActiveUS20160333242A1Less influenceImprove cycle performanceHeat-exchange elementsWorking fluidDecomposition

To provide a method for stably and efficiently producing a working fluid which has less influence over global warming and which can be stably used by a usual operation even though it contains trifluoroethylene (HFO-1123) excellent in the cycle performance.A method for producing a working fluid containing HFO-1123 in a proportion of at most 70 mol %, which comprises mixing a first component containing HFO-1123 in a proportion of higher than 70 mol % stored in a first container, and a second component having no self-decomposition property stored in a second container, by supplying the first component to the second container, by supplying the second component to the first container, or by supplying both the first component and the second component to a separate third container, respectively under the predetermined conditions.

Owner:ASAHI GLASS CO LTD

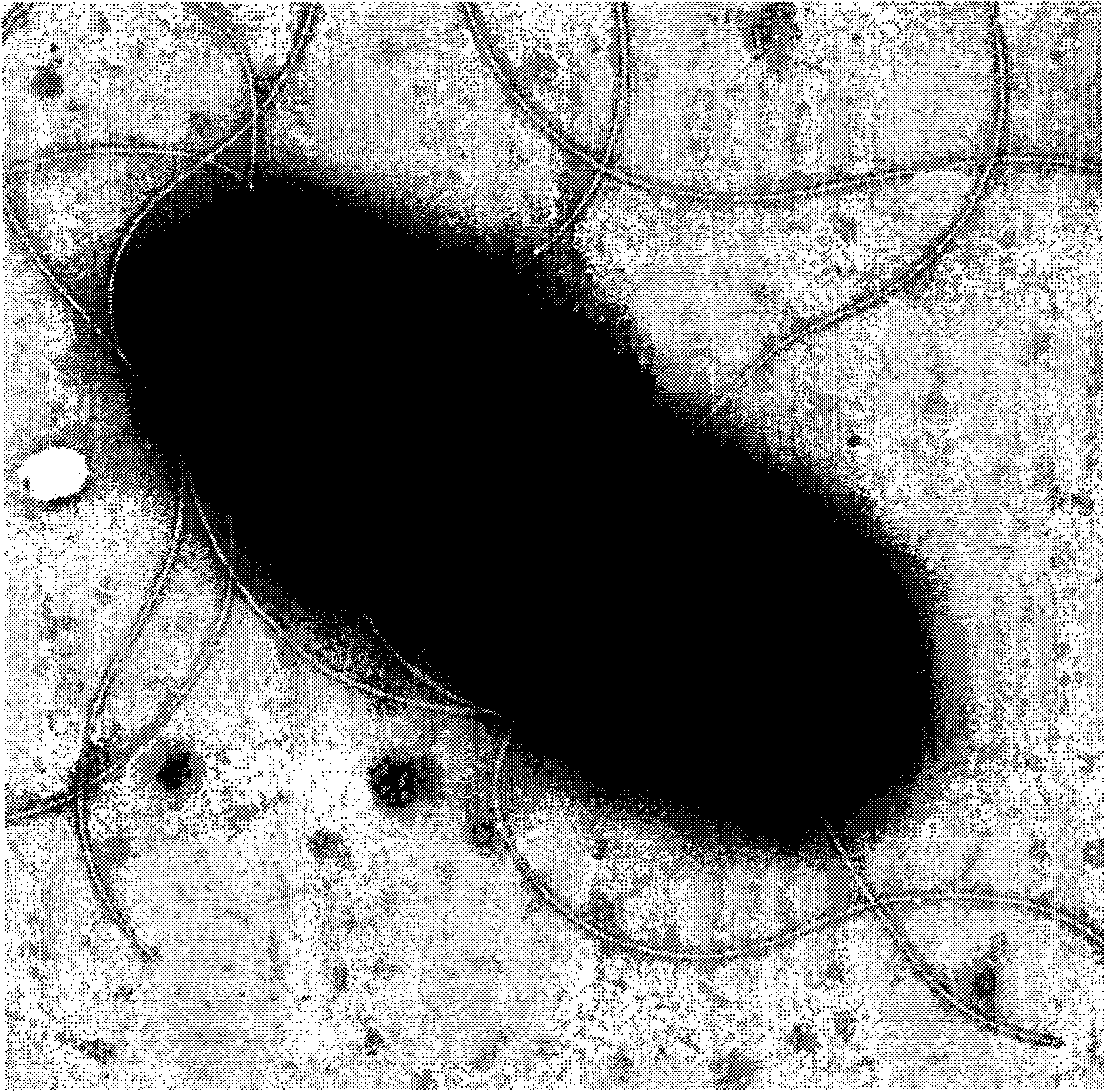

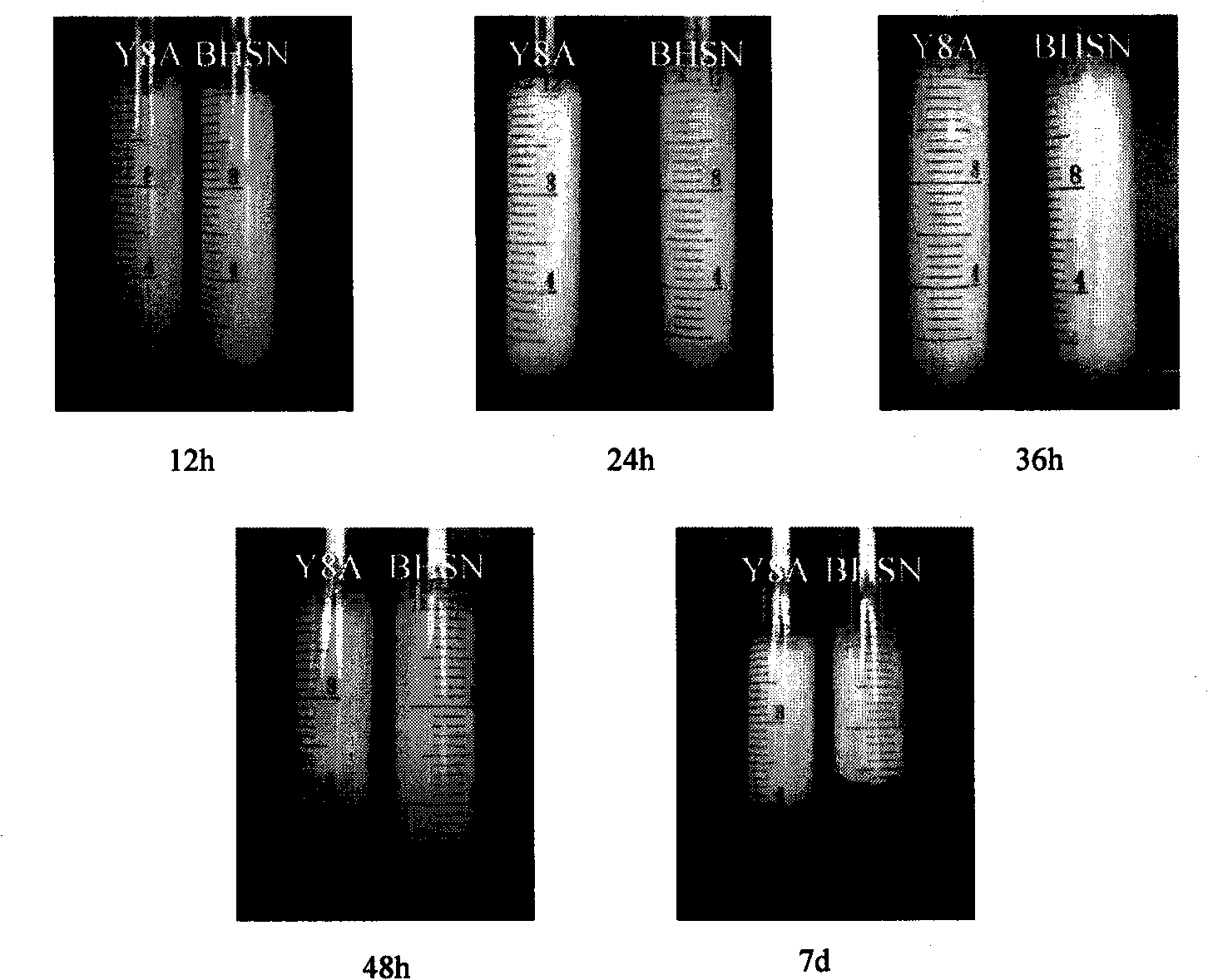

Lipopeptide-producing bacillus pumilus and application thereof

ActiveCN101560483AThe fermentation process is simpleEasy to operateBacteriaWater contaminantsAntibiotic YBacterial strain

The invention discloses a lipopeptide-producing bacillus pumilus, and classification thereof is named to be Bacillus pumilus Y8A which is preserved by China Center for Type Culture Collection (CCTCC) in Wuhan University with the preservation number of CCTCCM 209108. The invention also discloses an application of the lipopeptide-producing bacillus pumilus in promoting the micro-biological degradation process of petroleum and / or cyhalothrin pesticide. Bacterial strain Y8A of the invention can produce lipopeptide biosurfactant with high efficiency and stability, thereby effectively promoting the micro-biological degradation process of petroleum and / or cyhalothrin pesticide degrading bacteria. Bacterial strain Y8A with the function of efficiently producing lipopeptide is expected to work as a new-generation bacteria and cosolvent for antibiotic production and, is widely used in agriculture, medicine, cosmetic and food industries, and can be used for restoration of pollutant environment together with other organic pollution degrading microbes. The bacterial strain is resistant to a plurality of antibiotics with easy fermentation course and convenient operation.

Owner:NANJING AGRICULTURAL UNIVERSITY

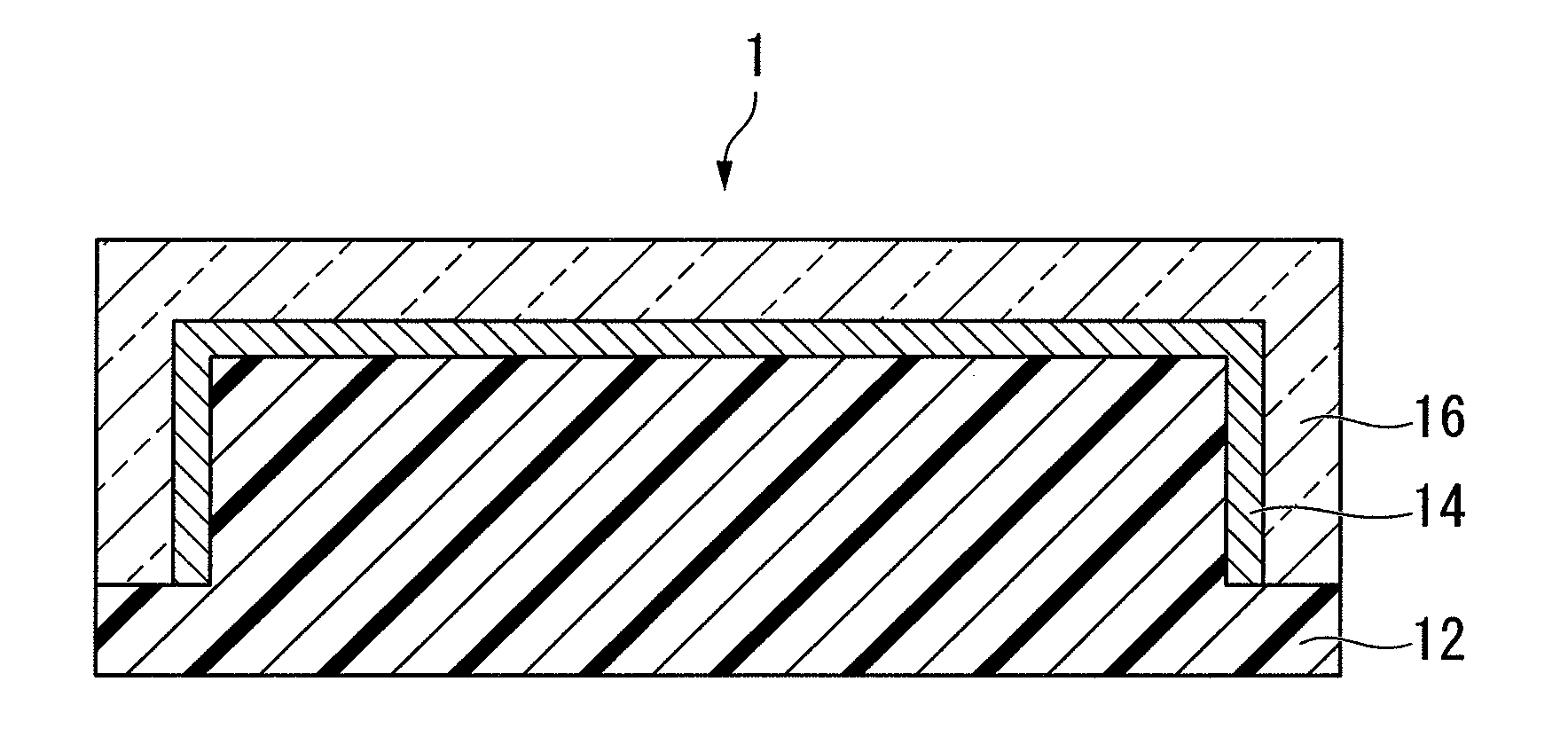

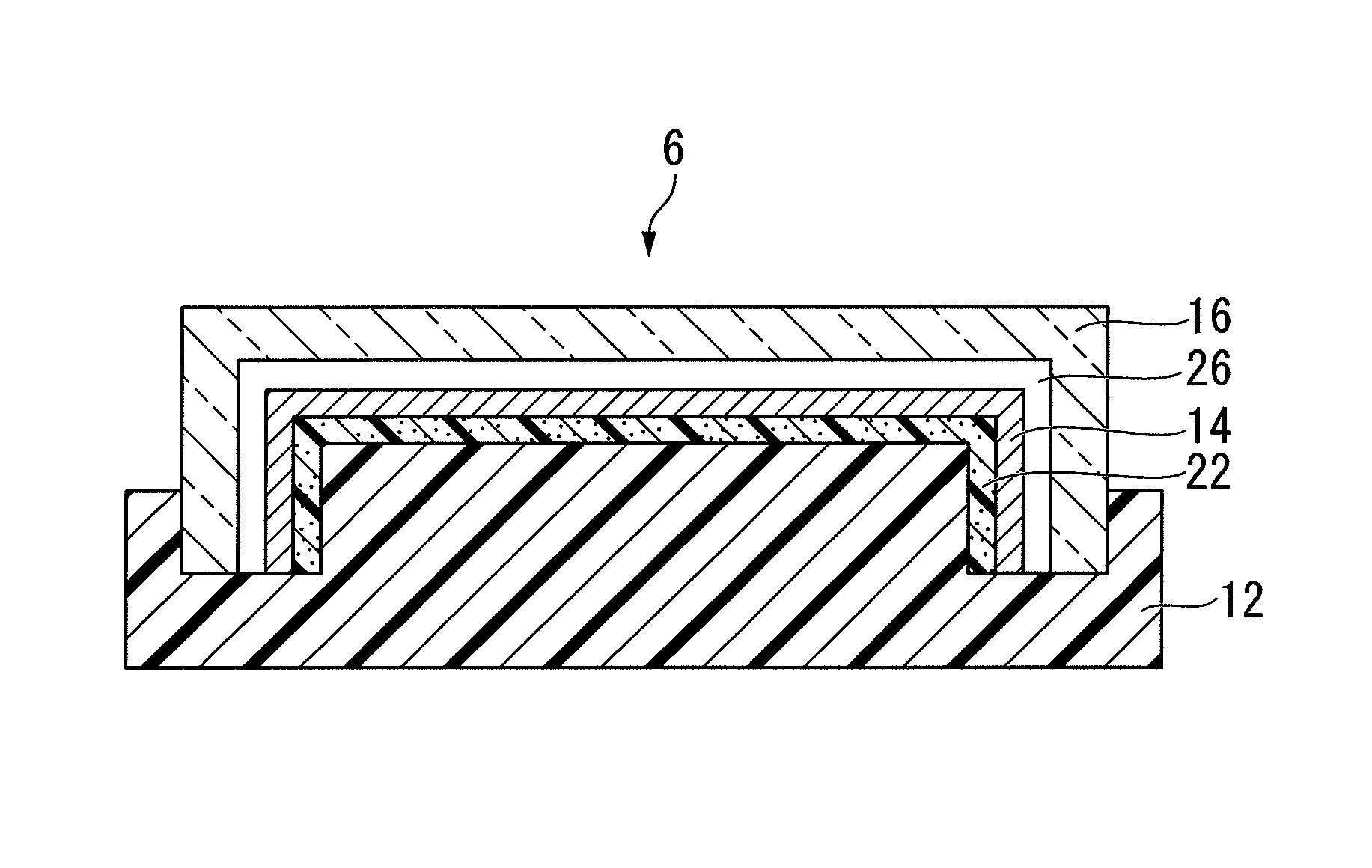

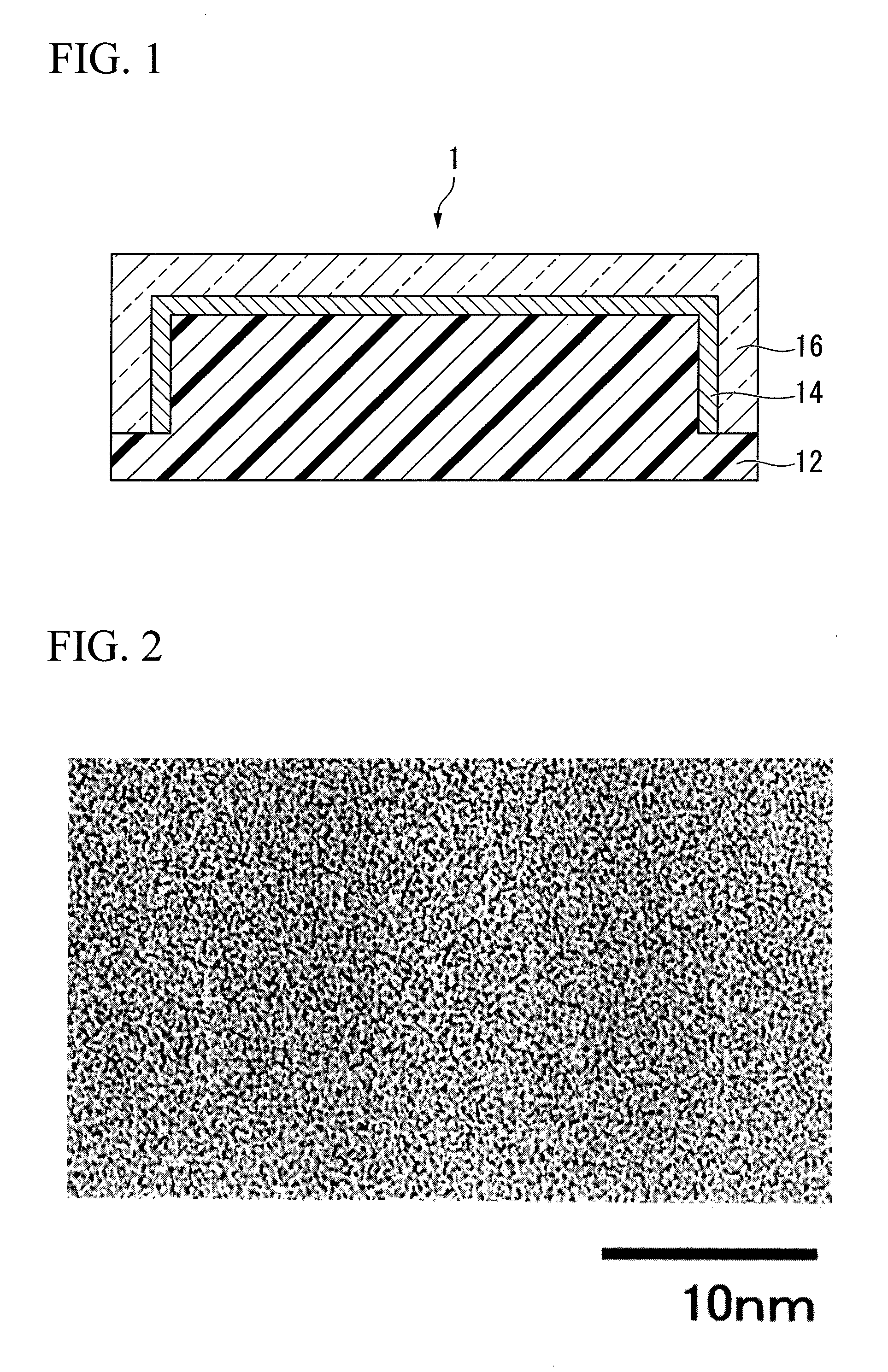

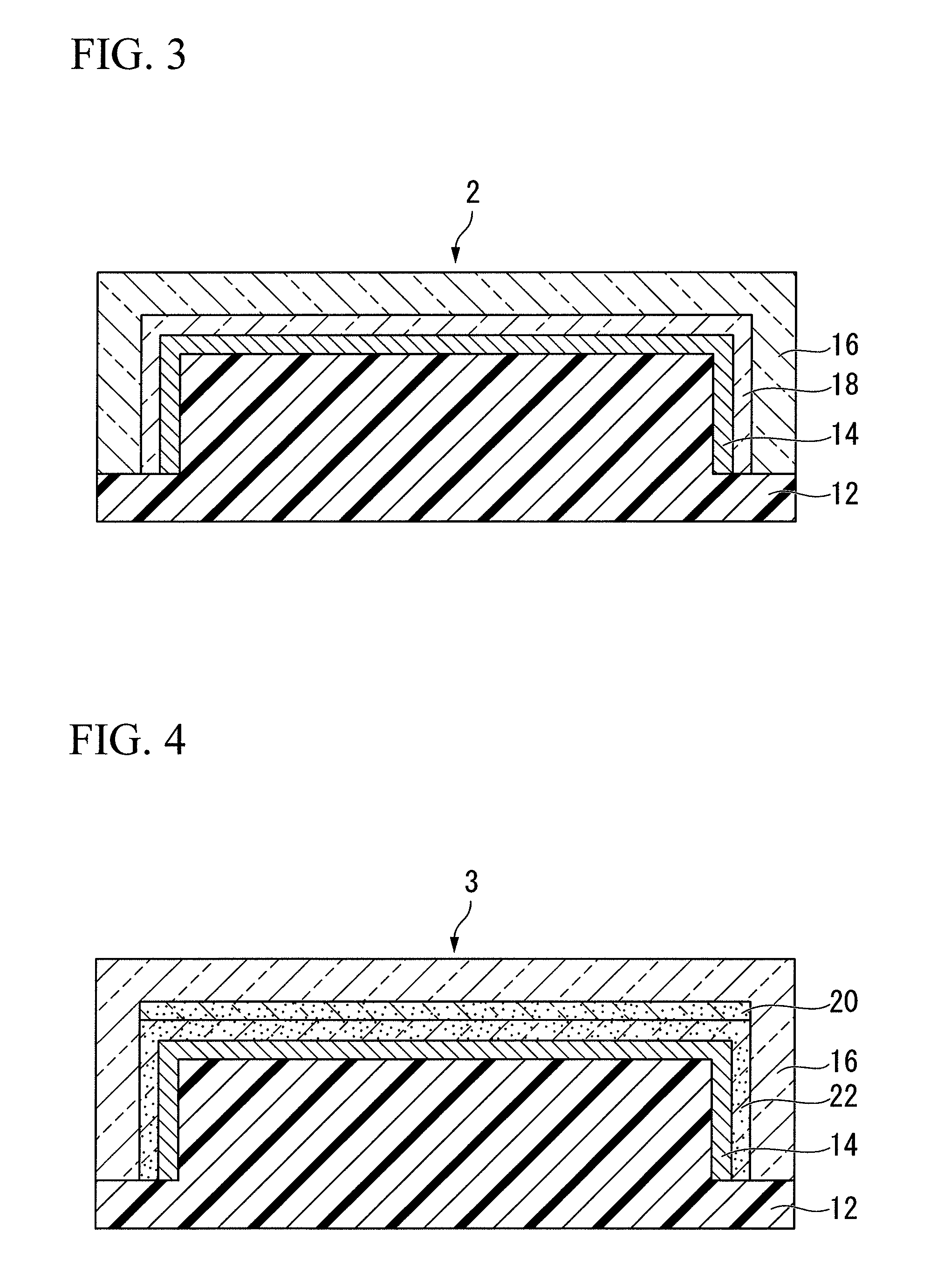

Radio wave transmitting decorative member and the production method thereof

ActiveUS8816932B2Low costEfficient and stable productionVacuum evaporation coatingSputtering coatingAlloyMetal

The radio wave transmitting decorative member and the method of producing thereof efficiently and stably of the present invention is provided with radio wave transmitting properties as well as mirror-surface like metallic luster, hardly loses its metallic luster, and can be produced at a low cost. The method of producing a radio wave transmitting decorative member, having a substrate, a transparent organic material layer, and a light reflecting layer formed of an alloy composed of either silicon or germanium and a metal provided between the substrate and the transparent organic material layer; wherein the light reflecting layer is formed from a target having an alloy composed of either silicon or germanium, and of a metal with the use of a DC magnetrons sputtering.

Owner:SHIN-ETSU POLYMER CO LTD

Polycarbonate resins and processes for producing the same

ActiveUS20120232243A1Efficient and stable productionImprove performanceChemical recyclingPolycarbonateStructural unit

The invention is to provide polycarbonate resins having excellent light resistance, transparency, hue, heat resistance, thermal stability, and mechanical strength and to provide processes for efficiently and stably producing a polycarbonate resin which stably shows those performances. The invention includes: polycarbonate resins which at least contain structural units derived from a dihydroxy compound having the portion represented by the following general formula (1) as part of the structure thereof and which have specific properties; and processes for producing the polycarbonate resins.[Chem. 1]CH2—O (1)(The case where the portion represented by general formula (1) is part of —CH2—O—H is excluded.)

Owner:MITSUBISHI CHEM CORP

Human erythroid progenitor cell line comprising HPV E6/E7 operably linked to an inducible promoter and method for producing human enucleated red blood cells

ActiveUS8975072B2Efficient and stable productionEfficiently induce differentiationVectorsGenetically modified cellsCulture cellGenomic DNA

Provided are: a method for producing an immortalized human erythroid progenitor cell line, enabling efficient and stable production of enucleated red blood cells; and a method for producing human enucleated red blood cells from a human erythroid progenitor cell line obtained by the aforementioned production method. An expression cassette capable of inducing expression of HPV-E6 / E7 genes in the presence of DOX was introduced into the genomic DNA of blood stem cells. Then, the blood stem cells were cultured in the presence of DOX and a blood growth factor. Thereby, immortalized cell lines of human erythroid progenitor cells were established. Further, it was revealed that culturing the cell lines under a condition where the expression of the HPV-E6 / E7 genes was not induced enabled differentiation induction into enucleated red blood cells at a high ratio.

Owner:RIKEN

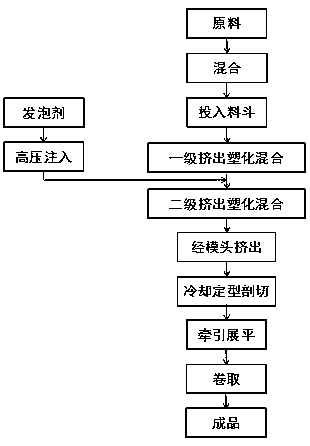

Preparation method of high-rate polylactic acid foaming sheet

The invention provides a preparation method of a high-rate polylactic acid foaming sheet. The preparation method comprises the steps of primary extrusion, secondary extrusion, and extrusion of the foaming sheet; and the high-rate polylactic acid foaming sheet is prepared from the following raw material components in parts by weight: 88-94 parts of polylactic acid, 1-2 parts of a nucleating agent,2-5 parts of a foaming agent, and 2-5 parts of an auxiliary. The difficulties of low foaming rate, low strength and the like due to use of carbon dioxide in industrial production are effectively solved, and the prepared polylactic acid sheet with the high foaming rate and excellent surface performance can be used in the fields such as food packaging and disposable full-degradable meal boxes.

Owner:CHTC BIO BASED MATERIAL ENG & TECH NINGBO CO LTD

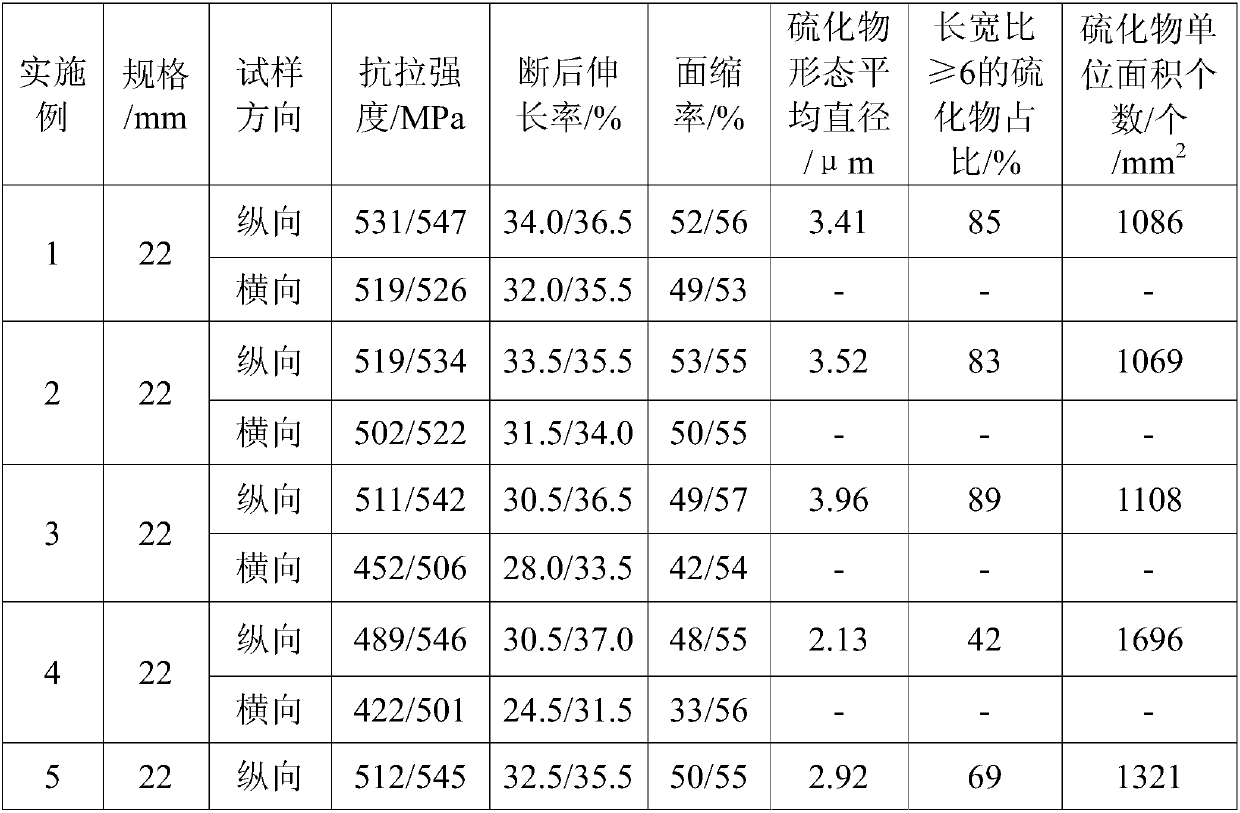

Composite low-carbon free-cutting steel and production method thereof

The invention relates to composite low-carbon free-cutting steel with excellent mechanical performance and a production method thereof. Through adjustment for the dosages and proportions of key elements, and control and optimization for a refining slagging process, continuous casting cooling conditions and a rolling temperature, efficient and stable production for the low-carbon free-cutting steelis realized, and effective control for sulfides is realized while the wear of silicon oxides with high hardness and aluminium oxides with high hardness on a tool; and through introduction for elementB, and control for N / B proportion, the adding time of the element B, and cooling separation for the element B, the positive effect of a BN-class graphite structure and the positive effect of the composite inclusion of the BN-class graphite structure for the oxides and sulfides are adequately exerted, the cutting machining performance of the low-carbon free-cutting steel is further improved, the dependence of the cutting performance on a sulfur content is reduced to a certain extent, and the anisotropy of the mechanical performance of materials is reduced, and through adding for elements Cu, Cr and the like, simultaneous consideration and balance for the low-carbon steel in the aspects of free-cutting performance and mechanical performance are effectively realized.

Owner:ZENITH STEEL GROUP CORP +1

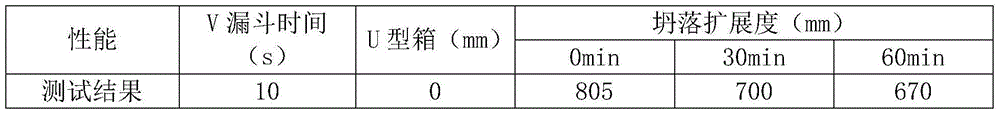

Lightweight self-compacting concrete and preparation method thereof

InactiveCN103553450AEfficient and stable productionDoes not involve miningWork performanceUltimate tensile strength

The invention discloses lightweight self-compacting concrete comprising the components of cement, limestone powder, calcined expanded clay, sintered shale ceramic sand, an air-entraining agent, a thickener, a viscosity regulator, a water-reducing agent, and water with a ratio of (450-550): (20-70): (750-900): (100-300): (1-30): (1-30): (0.1-2): (5-15): (170-210). The invention also discloses a preparation method of the concrete. The method has the advantages that: calcined expanded clay and sintered shale ceramic sand are adopted as aggregates, and the performance of the lightweight concrete is regulated by adding the air-entraining agent, the thickener, the viscosity regulator, and the water-reducing agent, such that various working performances satisfy the requirements of self-compacting concrete. The concrete has good anti-segregation performance, excellent pumping performance, self-compacting performance, and high strength. With the viscosity regulator, the production of the lightweight self-compacting concrete is more stable and efficient. Also, natural sand is not adopted as the aggregate, such that sand and gravel mining is not involved in the production, and environment-protection significance is provided.

Owner:JIANGSU MINGHE GRP

Method for producing aromatic hydrocarbons

InactiveUS20120012504A1The process is stable and efficientEfficient and stable productionMolecular sieve catalystsMolecular sieve catalystNaphthaFluidized bed

A method for producing aromatic hydrocarbons in which at least one feedstock oil selected from the group consisting of LCO produced from an FCC apparatus, hydrotreated LCO, naphtha and straight-run gas oil is brought into contact with a reforming catalyst inside a fluidized bed reactor, wherein the method includes transporting a reforming catalyst that has been extracted from the fluidized bed reactor to a heating tank, heating the reforming catalyst in the heating tank to a temperature at least as high as the reaction temperature inside the fluidized bed reactor, and following heating, transporting the heated reforming catalyst to the fluidized bed reactor.

Owner:CHIYODA CORP +1

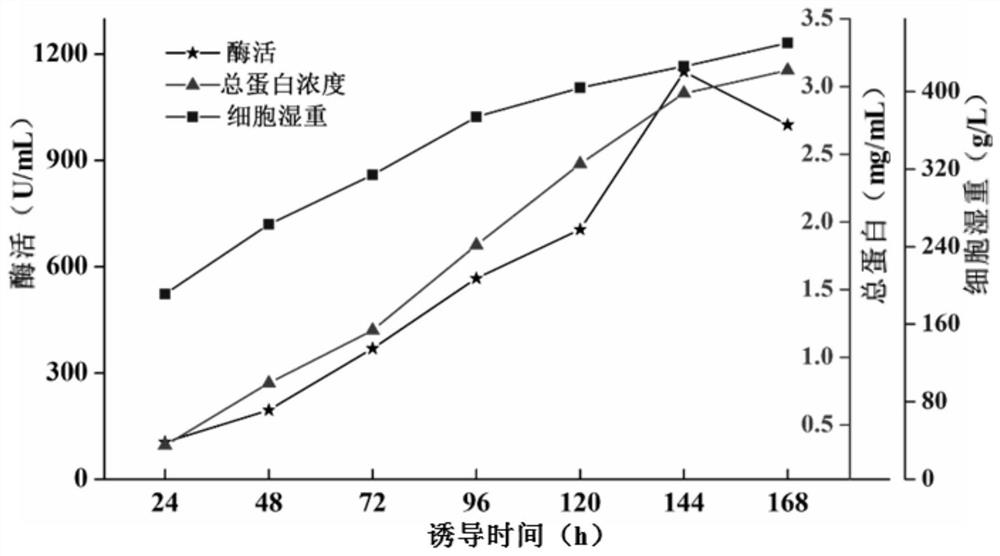

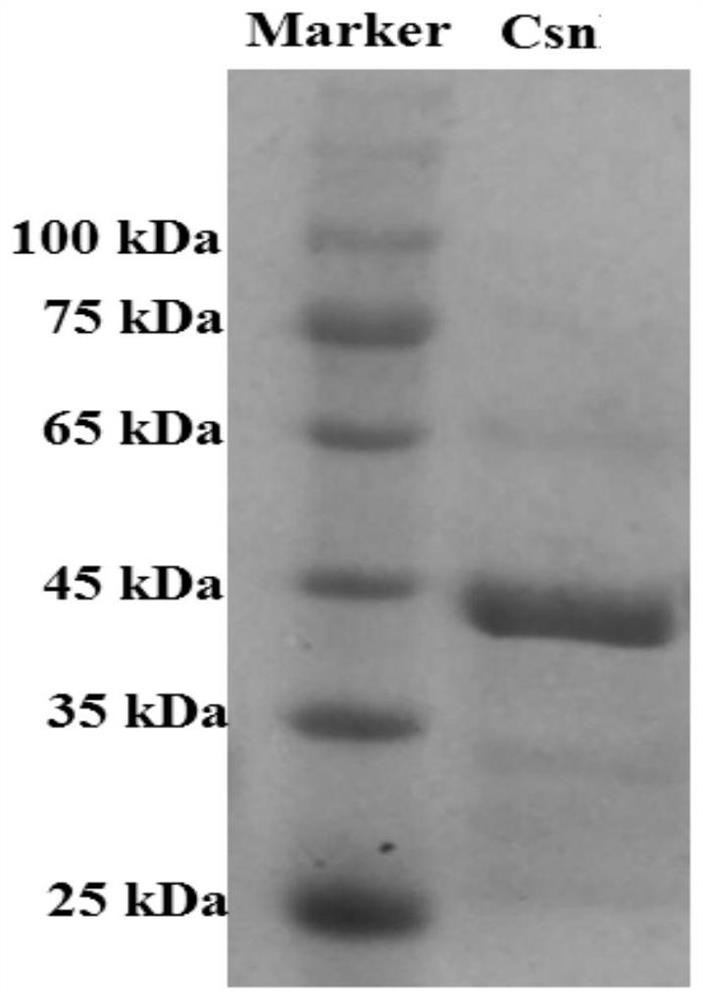

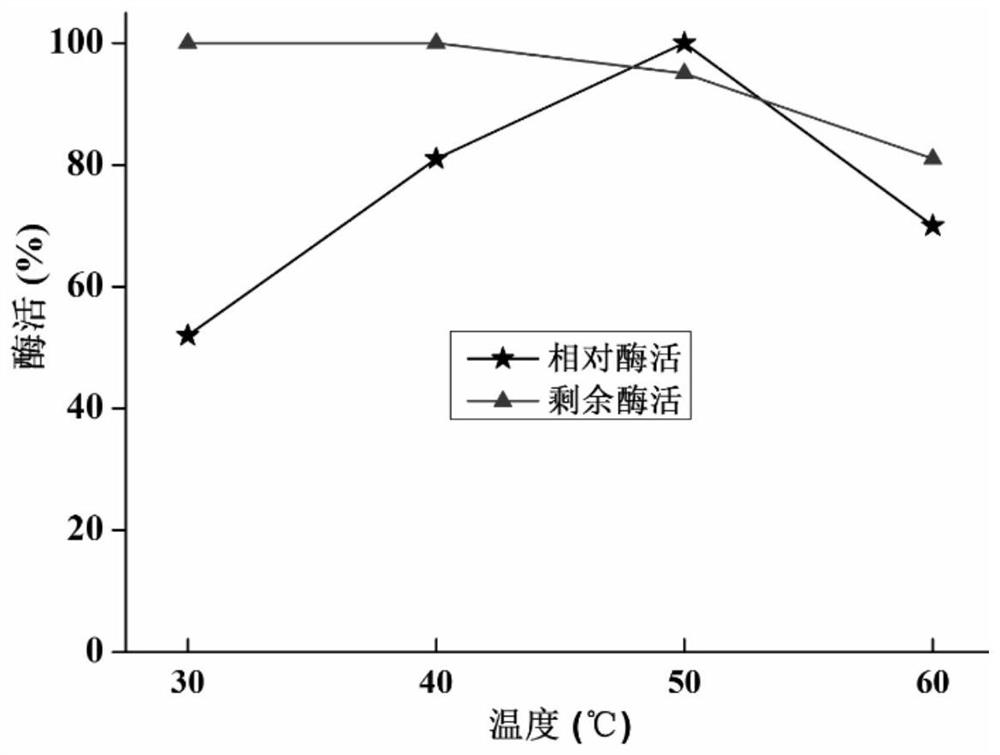

Chitosanase gene, chitosanase as well as preparation method and application of chitosanase

PendingCN111893125AIncreased sequence stabilityImproved codon adaptationFungiMicroorganism based processesChitosanaseGenetic engineering

The invention belongs to the technical field of gene engineering, and particularly relates to a chitosanase gene, chitosanase as well as a preparation method and application of the chitosanase. A nucleotide sequence of the chitosanase gene csn is as shown in SEQ ID NO: 1, and the chitosanase gene csn is obtained by comprehensively optimizing the sequence of the chitosanase from lichtheimia ramosaaccording to the preference of pichia pastoris codons. An amino acid sequence of the chitosanase Csn is as shown in SEQ ID NO: 2. The chitosanase Csn is fungal chitosanase, not only enriches the variety and source ways of the chitosanase, but also has relatively high enzymatic activity, shows good stability in relatively wide temperature and pH ranges, and has good application prospects and industrial values.

Owner:深圳润康生态环境股份有限公司

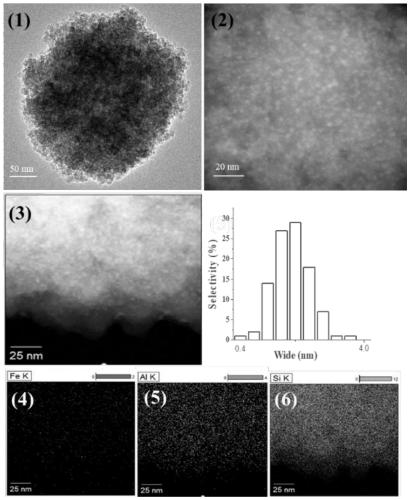

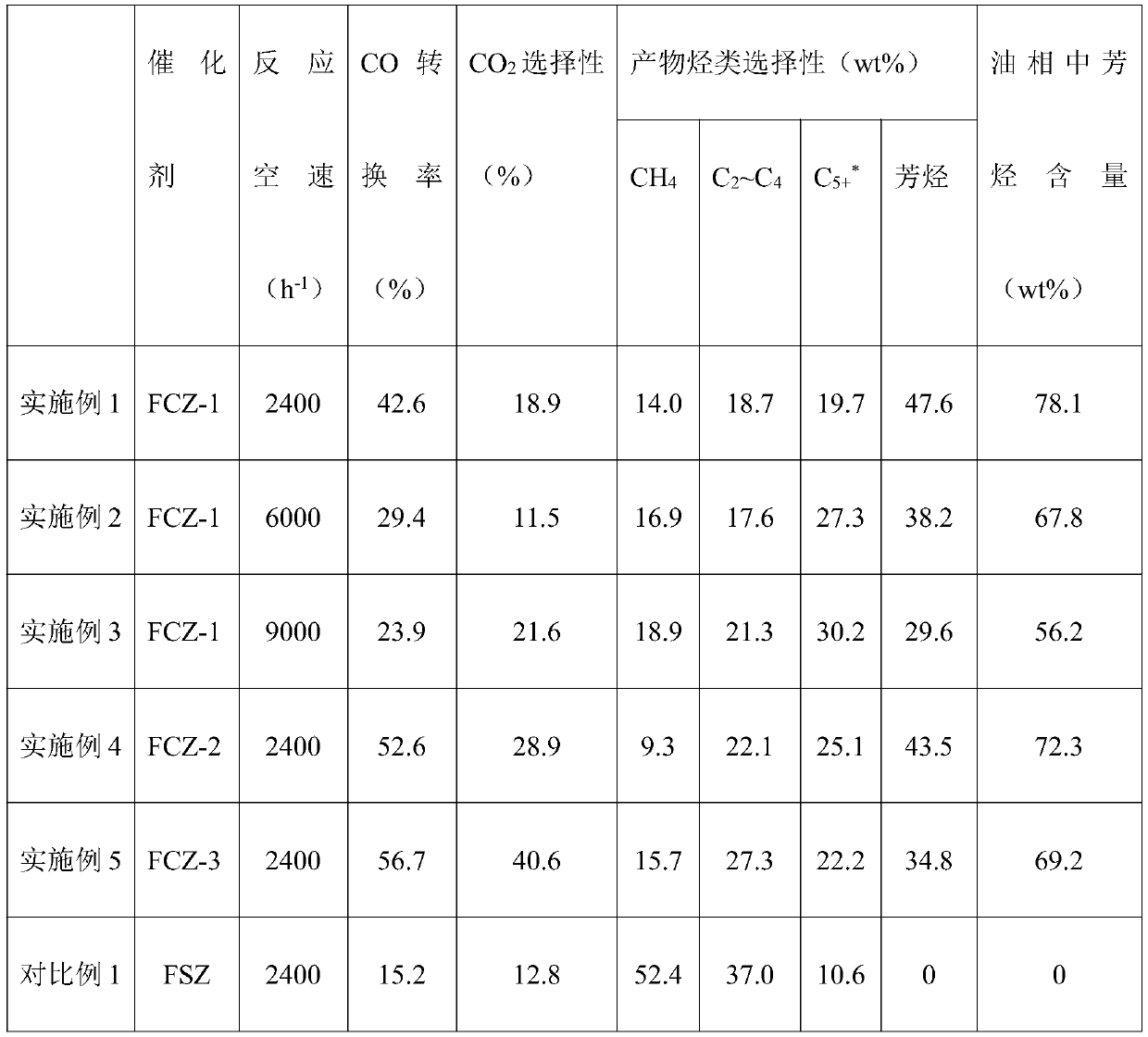

Core-shell iron-based catalyst for directly producing aromatic hydrocarbon from synthesis gas as well as preparation method and application of the core-shell iron-based catalyst

ActiveCN111375444AHigh selectivityLow selectivityMolecular sieve catalystsLiquid hydrocarbon mixture productionMolecular sievePtru catalyst

The invention discloses a core-shell iron-based catalyst for directly producing aromatic hydrocarbon from synthesis gas. According to the catalyst, a nano ZSM-5 molecular sieve with the silica-aluminaratio of 30-200 is used as a shell layer, and surface pre-modified nano metal oxide particles are used as a core; the particle size of the nano metal oxide is 1-3 nm, the nano metal oxide is uniformly distributed, and the content of metal elements is 0.1-7% wt; wherein the aromatic hydrocarbon is C7-C11 aromatic hydrocarbon. The catalyst provided by the invention has high CO conversion rate and high aromatic hydrocarbon selectivity; the CO conversion rate can reach 42.6%; the selectivity of aromatic hydrocarbons in total hydrocarbons reaches 47.6%; the content in an oil phase reaches 78.1%; in addition, aromatic hydrocarbon products are concentrated, the selectivity of by-products CO2 and CH4 is low, the CO2 selectivity is only about 18.9%, the CH4 selectivity is only about 14.0%; the problems that the aromatic hydrocarbon selectivity and yield are low, the selectivity of by-products CO2 and CH4 is high, and the CO utilization rate is low are solved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Low-temperature pyrolysis device for coal

InactiveCN102618304AEfficient and stable productionAvoid reheatingIndirect heating destructive distillationSpecial form destructive distillationEngineeringTower

A low-temperature pyrolysis device for coal is characterized by comprising a feeder, a reactor, a dust remover and a separating tower according to the reaction sequence, wherein the feeder is used for providing raw coal for the reactor; the reactor is used for conducting pyrolysis on the raw coal; the dust remover is used for conducting dust removing treatment on volatile substances generated during the pyrolysis of the reactor, and is heated all the time during the working process; and the separating tower is used for separating the volatile substances treated with dust removing. The low-temperature pyrolysis device has the advantages that pipeline blockage can be reduced, so as to ensure stable and efficient low-temperature pyrolysis for the coal; and as the comparatively purer volatile substances treated by the dust remover are prevented from being heated again, the purposes of energy conservation, environmental protection and very high efficiency are realized.

Owner:苏忠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com