Continuous roller type quenching cooling system for steel plates

A cooling system, steel plate technology, applied in quenching device, furnace, heat treatment equipment and other directions, can solve problems such as inability to solve technical problems, and achieve the effect of solving low cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

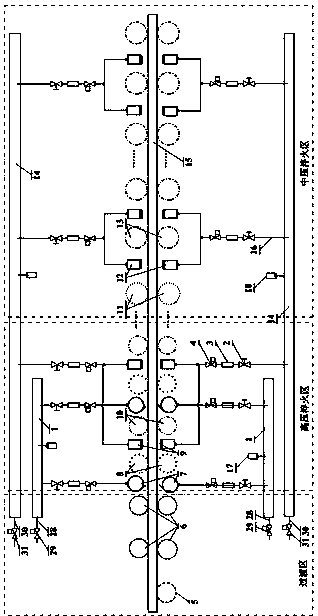

[0023] This embodiment provides the operation technical scheme when the high-pressure quenching zone and the medium-pressure quenching zone of the continuous roller quenching and cooling system of the extra-thick steel plate of the present invention are used at the same time, such as figure 1 , 2shown. Before the steel plate leaves the heat treatment furnace, the water supply system supplies cooling water to the nozzles opened in the high-pressure quenching zone according to the quenching process’s demand for water supply flow and water supply pressure in the high-pressure quenching zone. The slit nozzle 7 supplies high-pressure water, and the high-density I-type nozzle 9 supplies medium Pressurized water, use the pressure sensor on the diversion water collection pipe and the pressure relief pipeline regulating valve to form a closed loop to control the water supply pressure of each nozzle in the high pressure quenching area, use the flow meter and regulating valve on the bran...

Embodiment 2

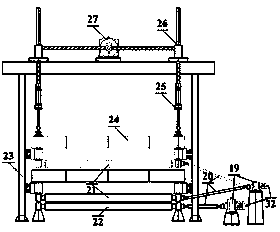

[0025] This embodiment provides the operation technical scheme when the medium-pressure quenching zone of the continuous roll quenching cooling system for extra-thick steel plate of the present invention is used alone, such as figure 1 , 2 shown. Before the steel plate comes out of the heat treatment furnace, the water supply system supplies cooling water to the opened nozzles in the medium-pressure quenching zone according to the quenching process’s demand for water supply flow and water supply pressure in the medium-pressure quenching zone. The regulating valve forms a closed loop to control the water supply pressure of each nozzle in the medium-pressure quenching zone, and uses the flowmeter and regulating valve on the water supply pipeline to form a closed loop to control the water supply flow of each nozzle in the medium-pressure quenching zone; at the same time, the moving frame 24 of the high-pressure quenching zone passes The motor lifting method is lifted to the non-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com