Patents

Literature

3095 results about "Moving frame" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mathematics, a moving frame is a flexible generalization of the notion of an ordered basis of a vector space often used to study the extrinsic differential geometry of smooth manifolds embedded in a homogeneous space.

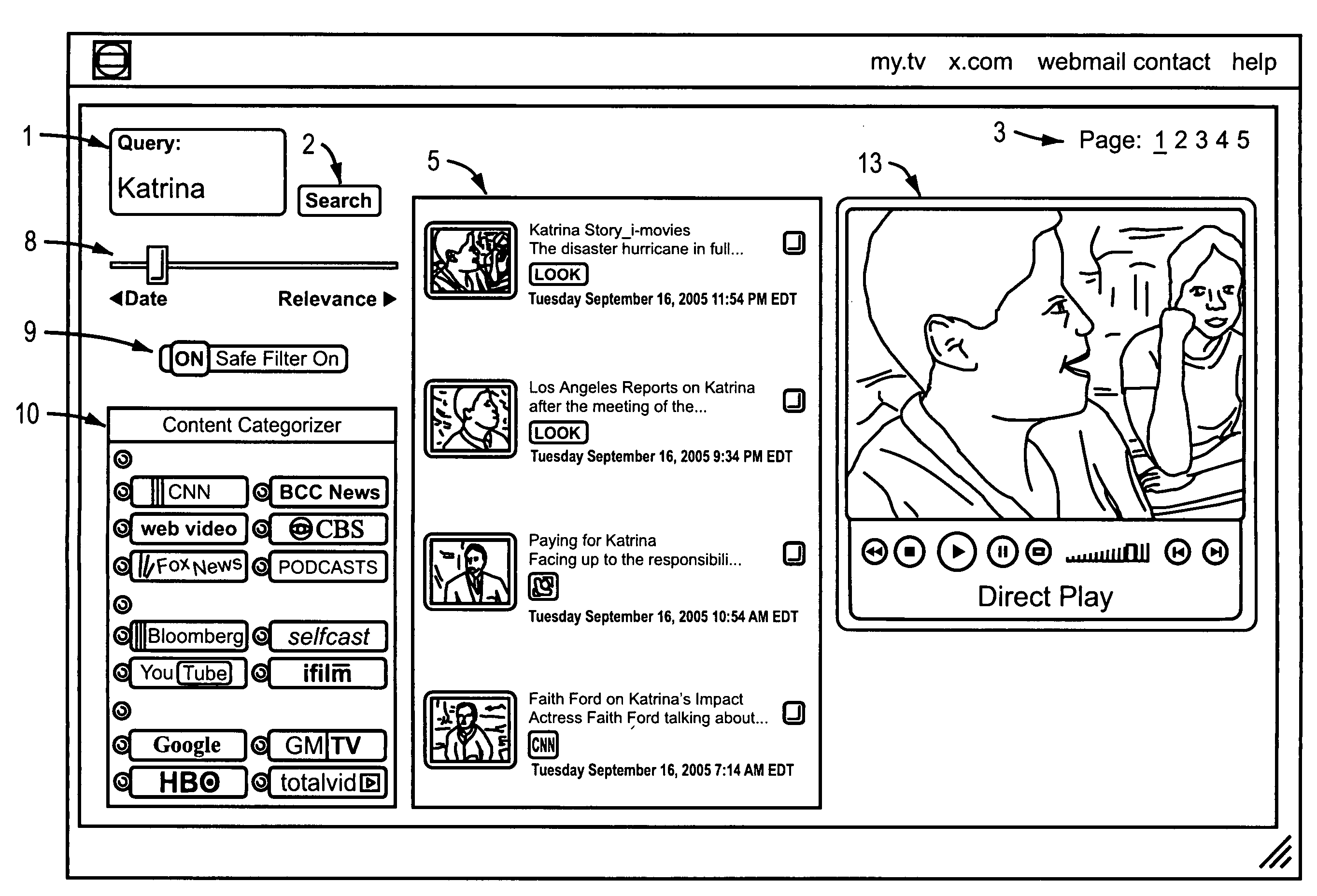

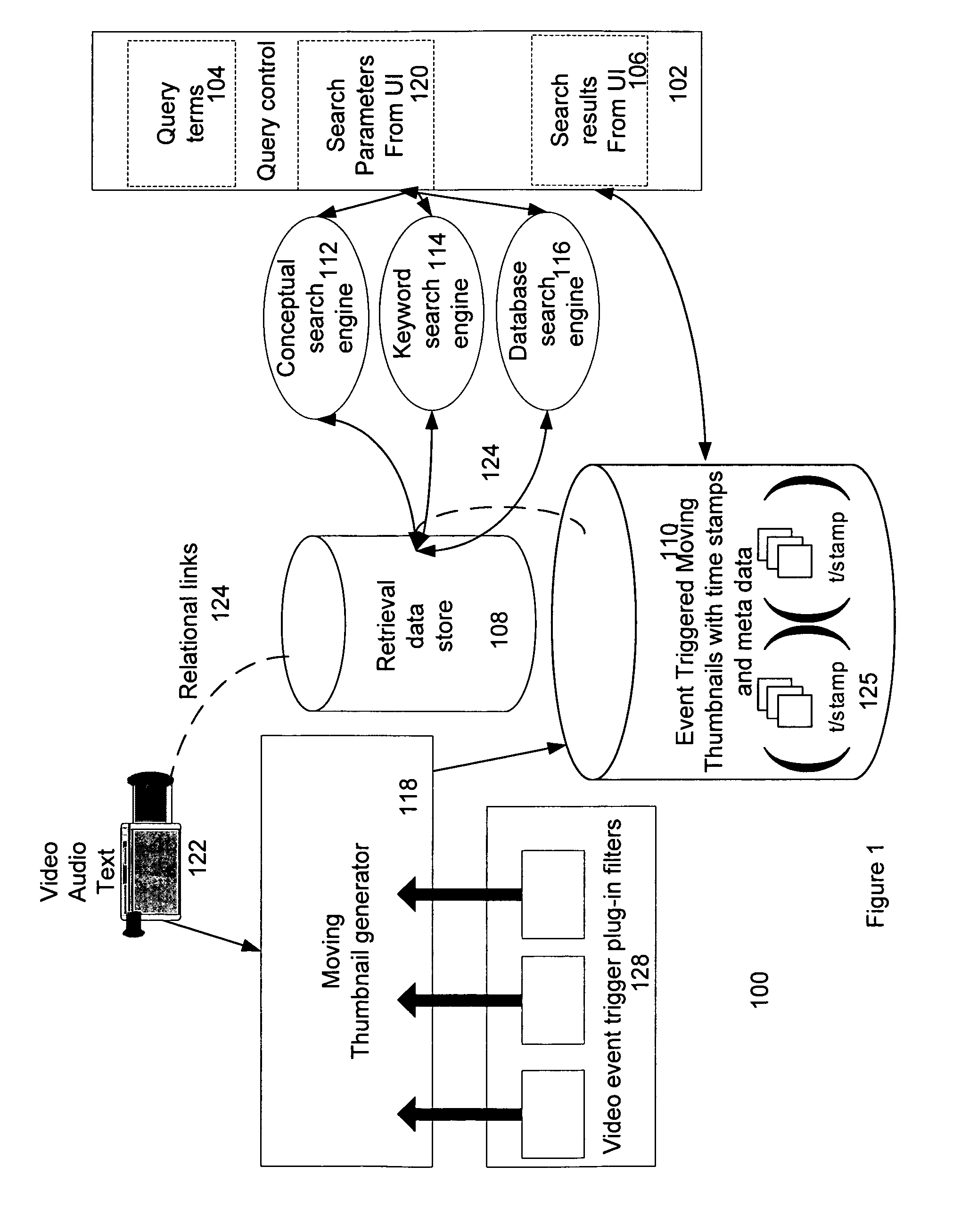

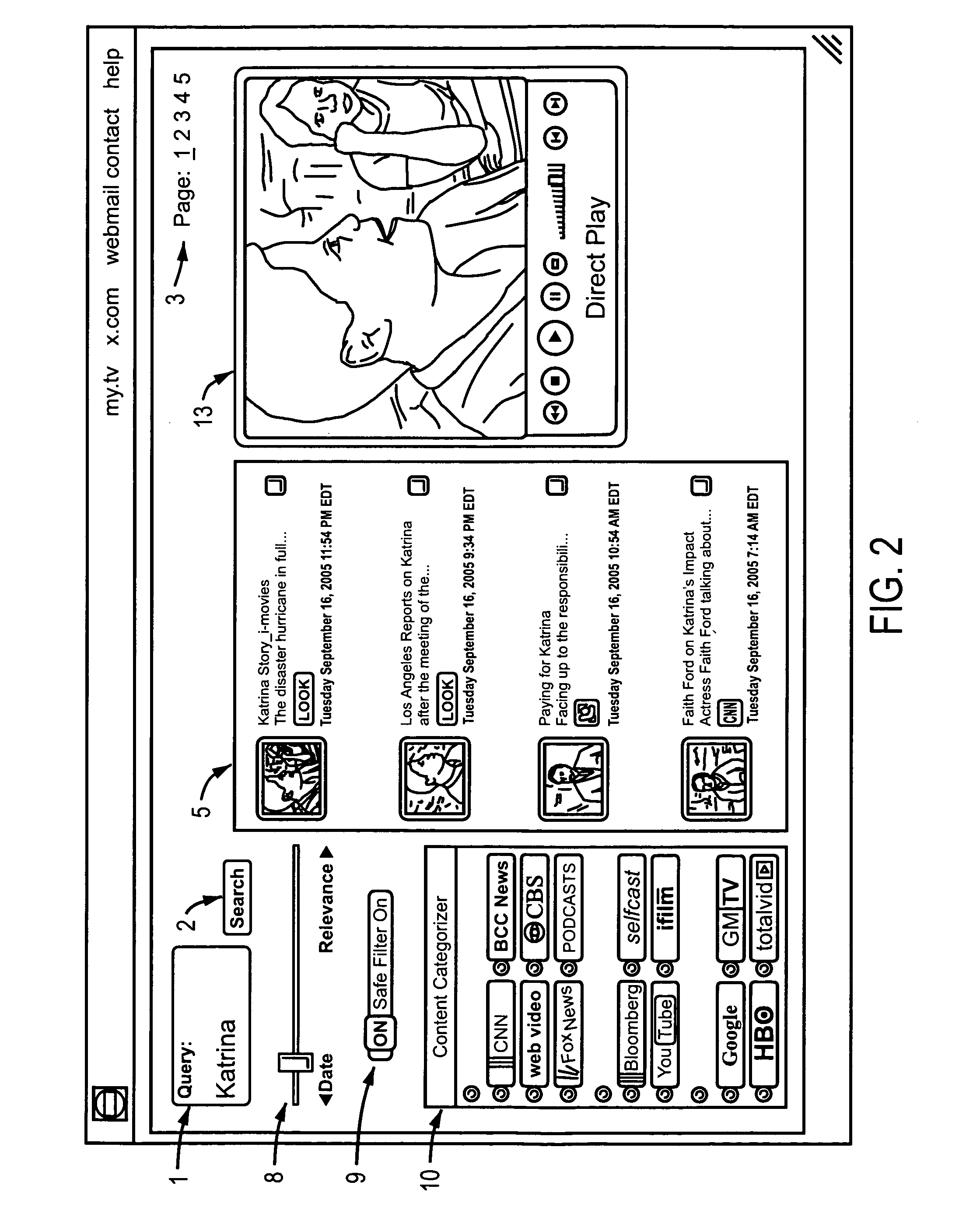

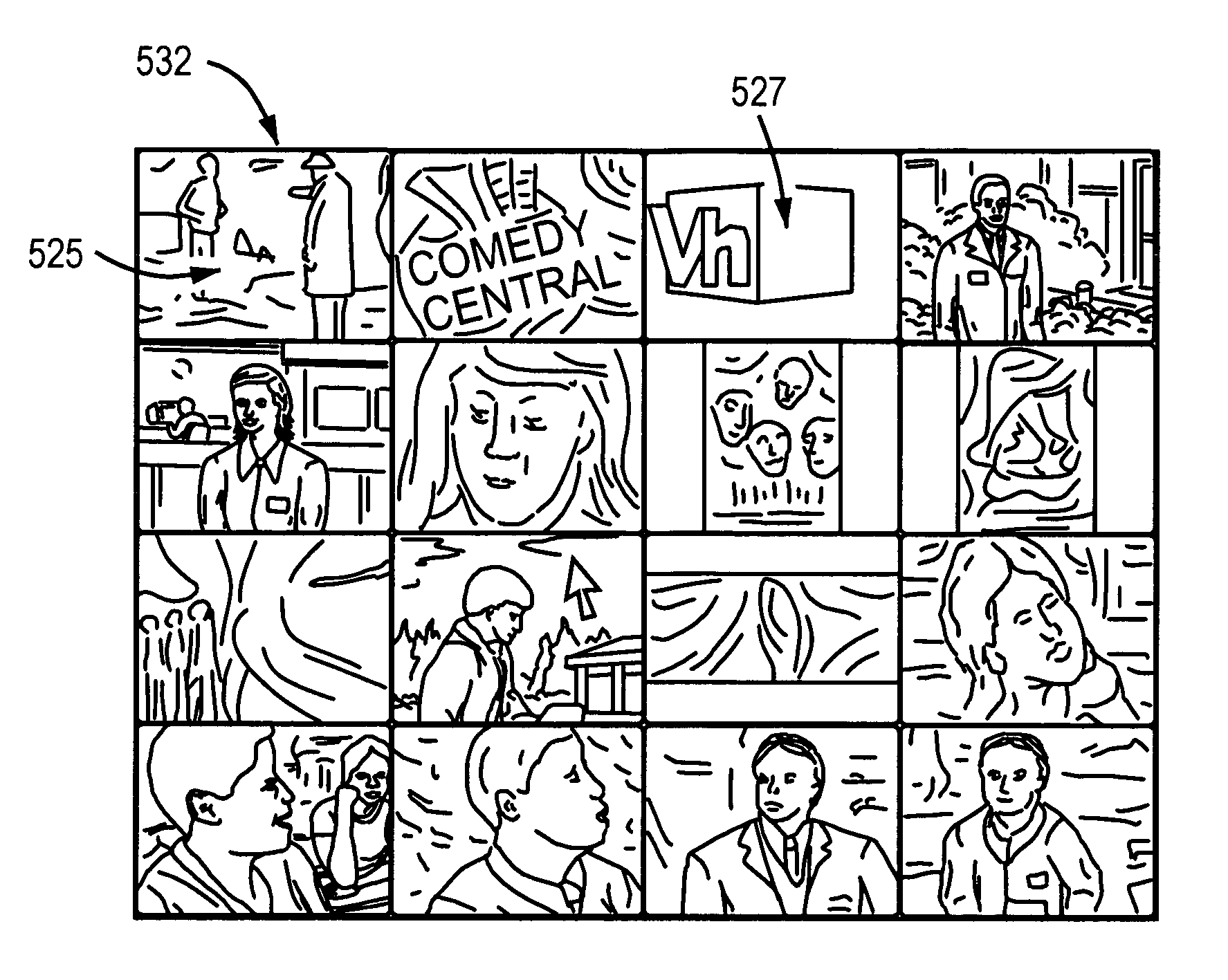

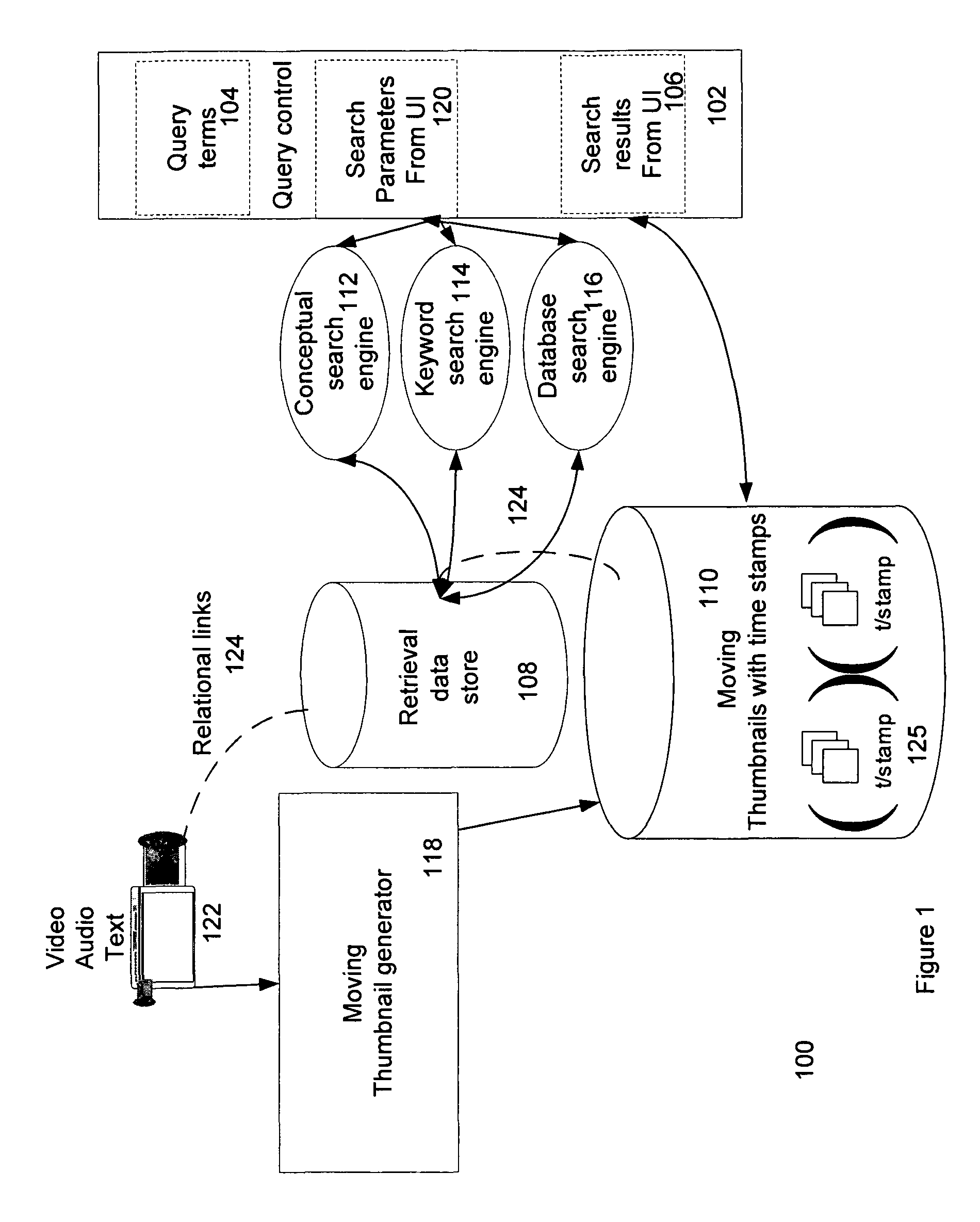

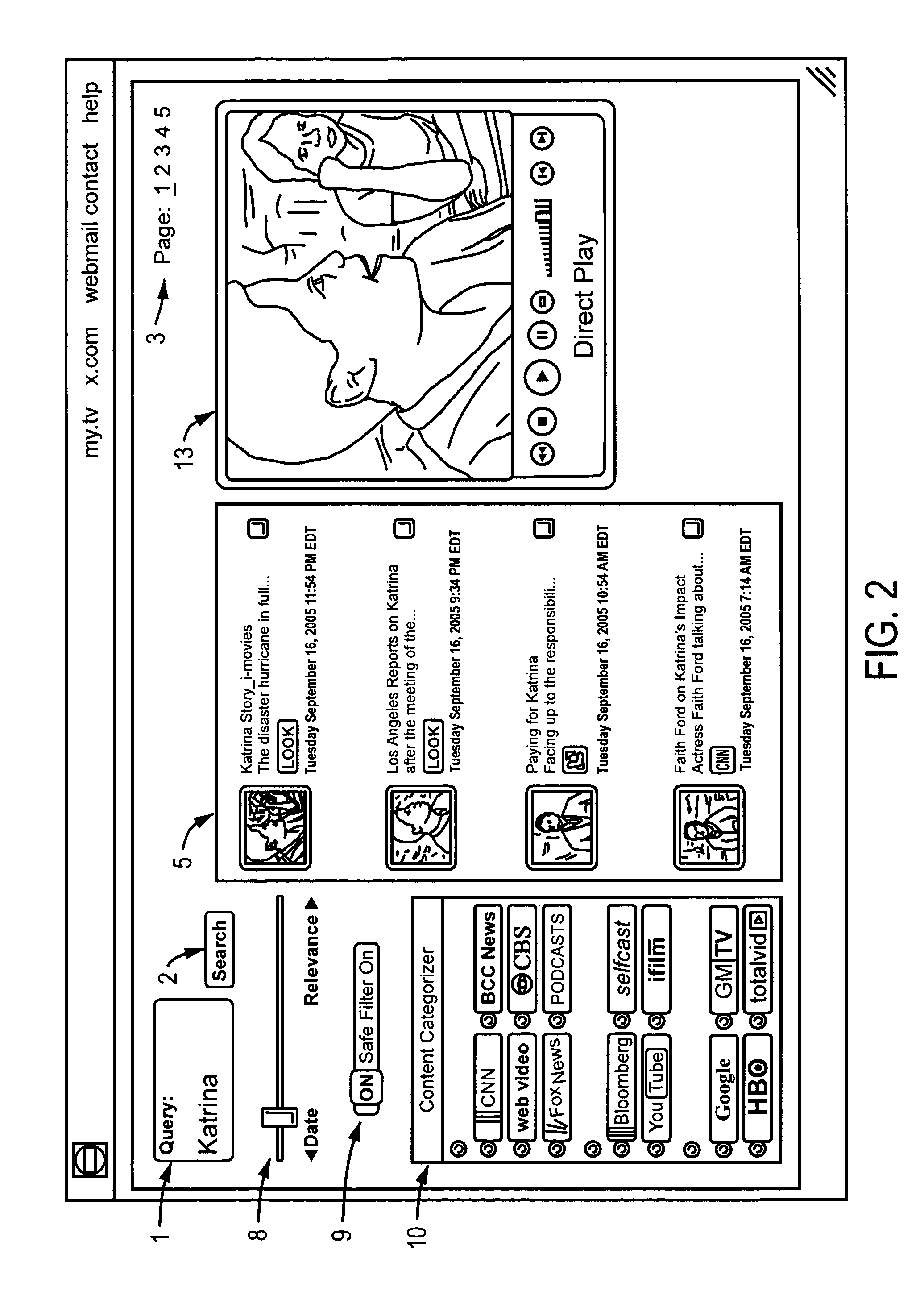

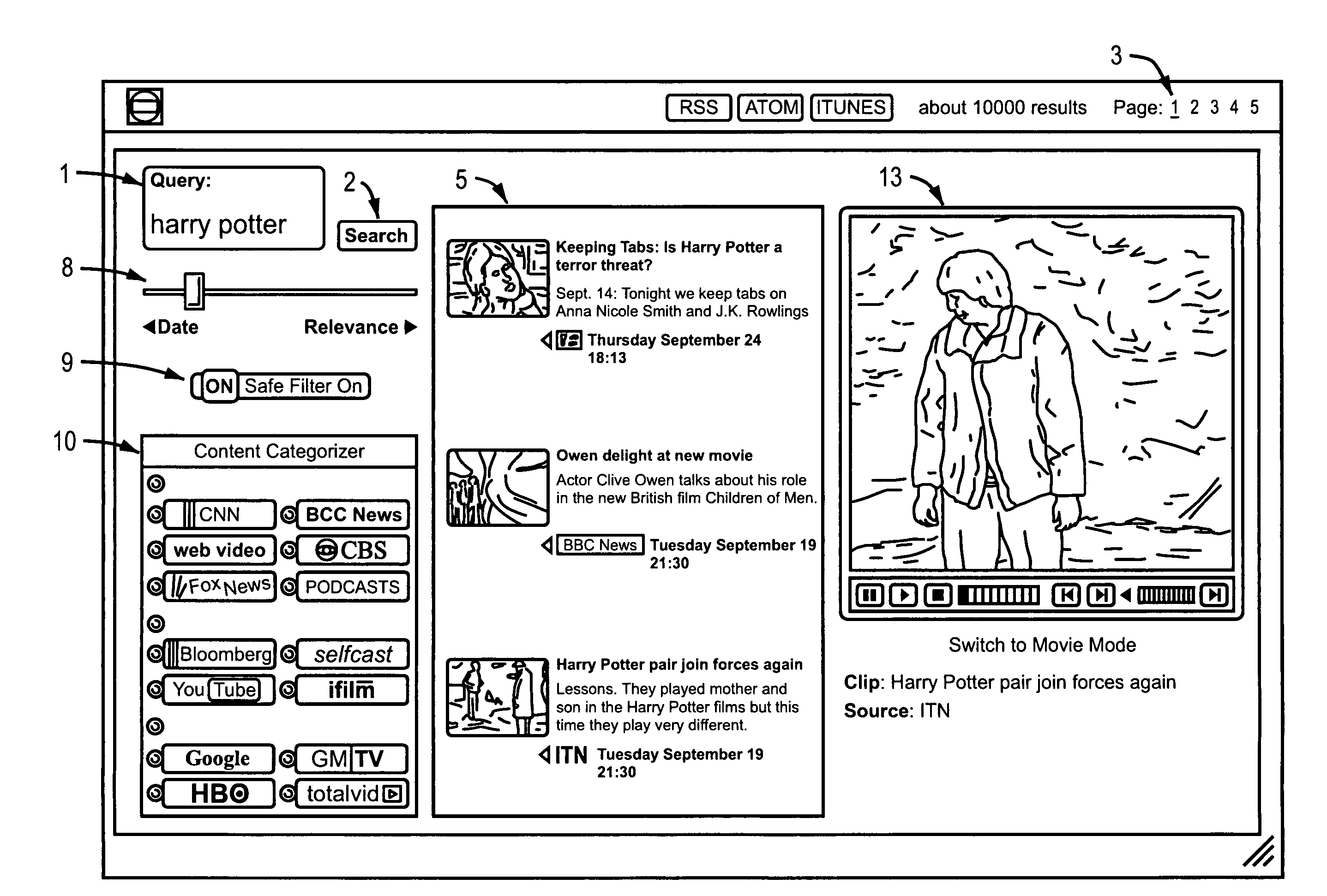

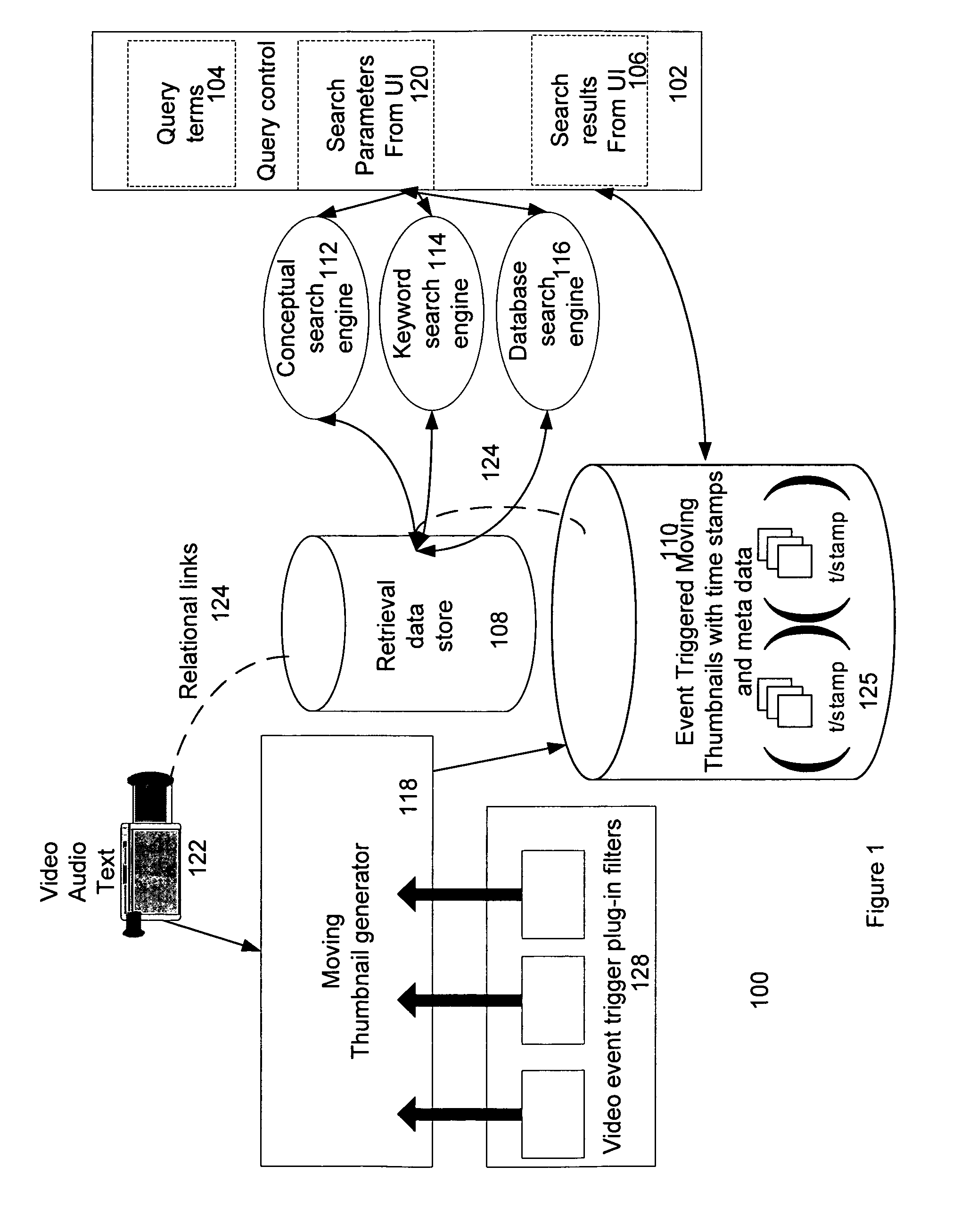

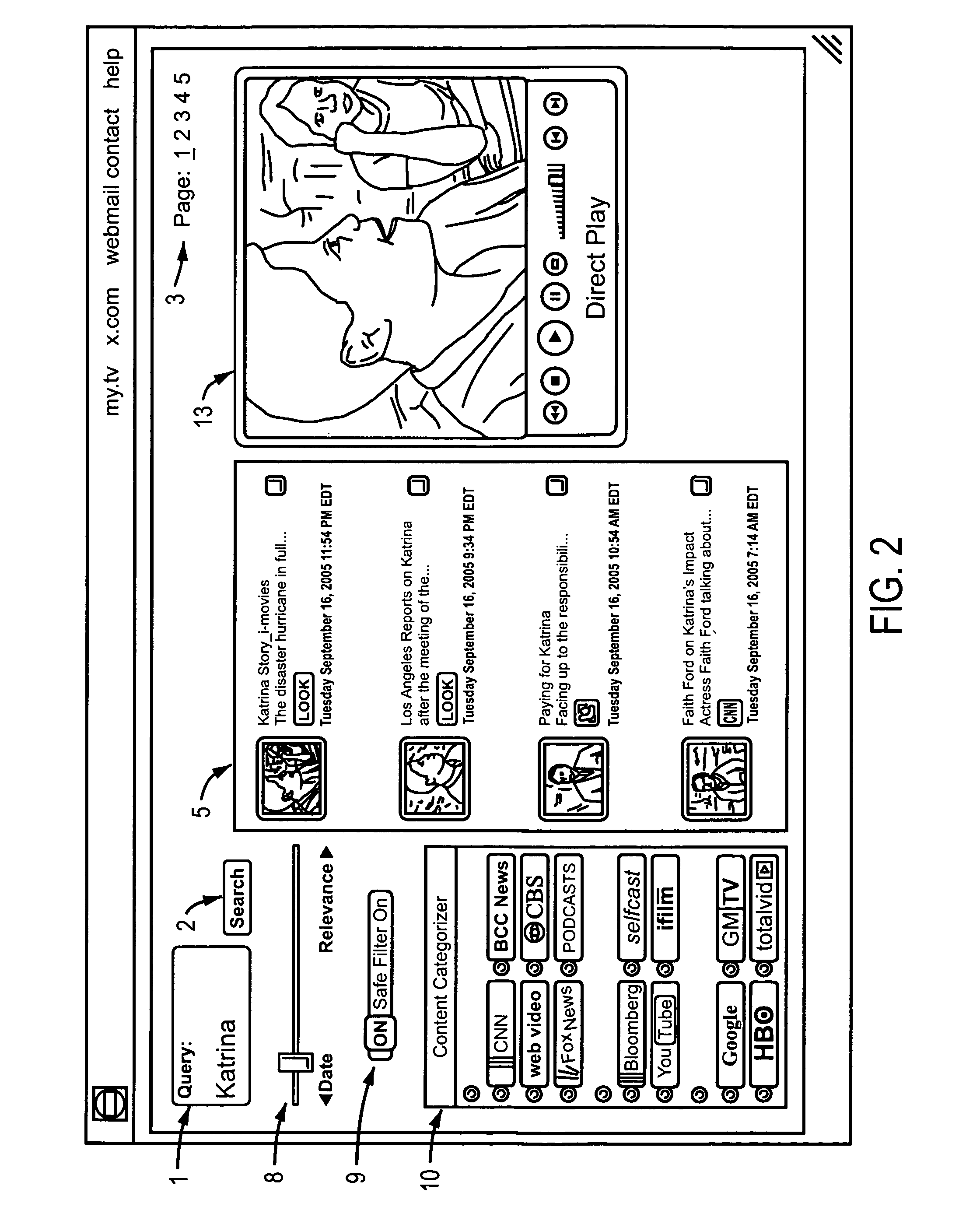

Various methods and apparatus for moving thumbnails with metadata

ActiveUS20080086688A1Metadata video data retrievalSpecial data processing applicationsThumbnailMoving frame

Various methods, apparatuses, and systems are described for a moving thumbnail generator. The moving thumbnail generator generates one or more moving thumbnails that are tagged and time-stamped to arbitrary video trigger events that take place in an associated original video file. Each of the moving thumbnails has two or more moving frames derived from its associated original video file at a portion in the original video file that is tagged and time-stamped to one or more relevant video trigger events in order for the generated moving thumbnail to summarize a visual content of the associated original piece of video file to a user. The tag carries information about content that takes place in the original video file and metadata about that content including a time reference to frames that are contextually relevant to the reason why a viewer of the thumbnail might be interested in viewing that thumbnail.

Owner:RHYTHMONE

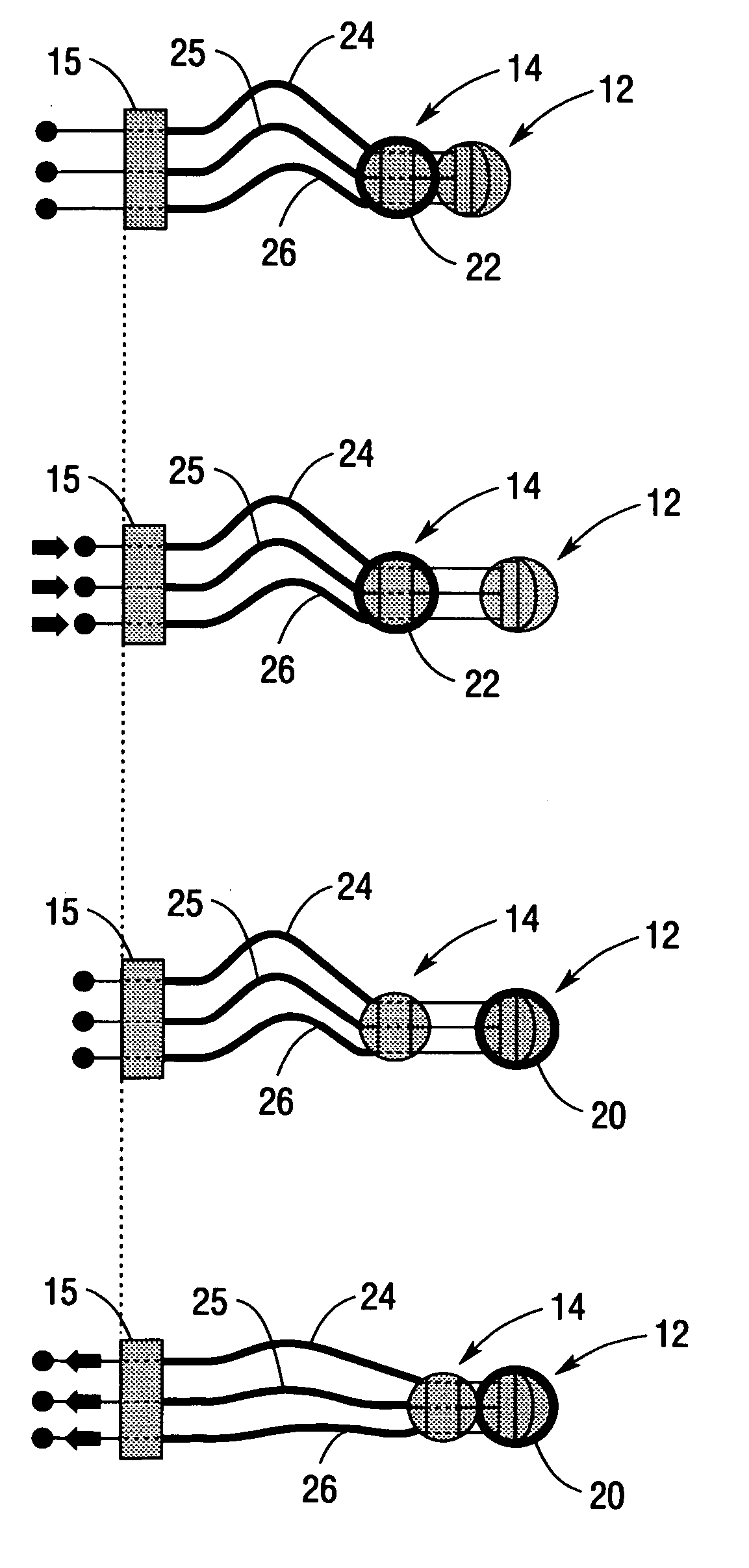

Robot for minimally invasive interventions

Rather than trying to immobilize a living, moving organ to place the organ in the fixed frame of reference of a table-mounted robotic device, the present disclosure teaches mounting a robot in the moving frame of reference of the organ. That task can be accomplished with a wide variety of robots including a miniature crawling robotic device designed to be introduced, in the case of the heart, into the pericardium through a port, attach itself to the epicardial surface, and then, under the direct control of the surgeon, travel to the desired location for treatment. The problem of beating-heart motion is largely avoided by attaching the device directly to the epicardium. The problem of access is resolved by incorporating the capability for locomotion. The device and technique can be used on other organs and on other living bodies such as pets, farm animals, etc. Because of the rules governing abstracts, this abstract should not be used in construing the claims.

Owner:CARNEGIE MELLON UNIV +1

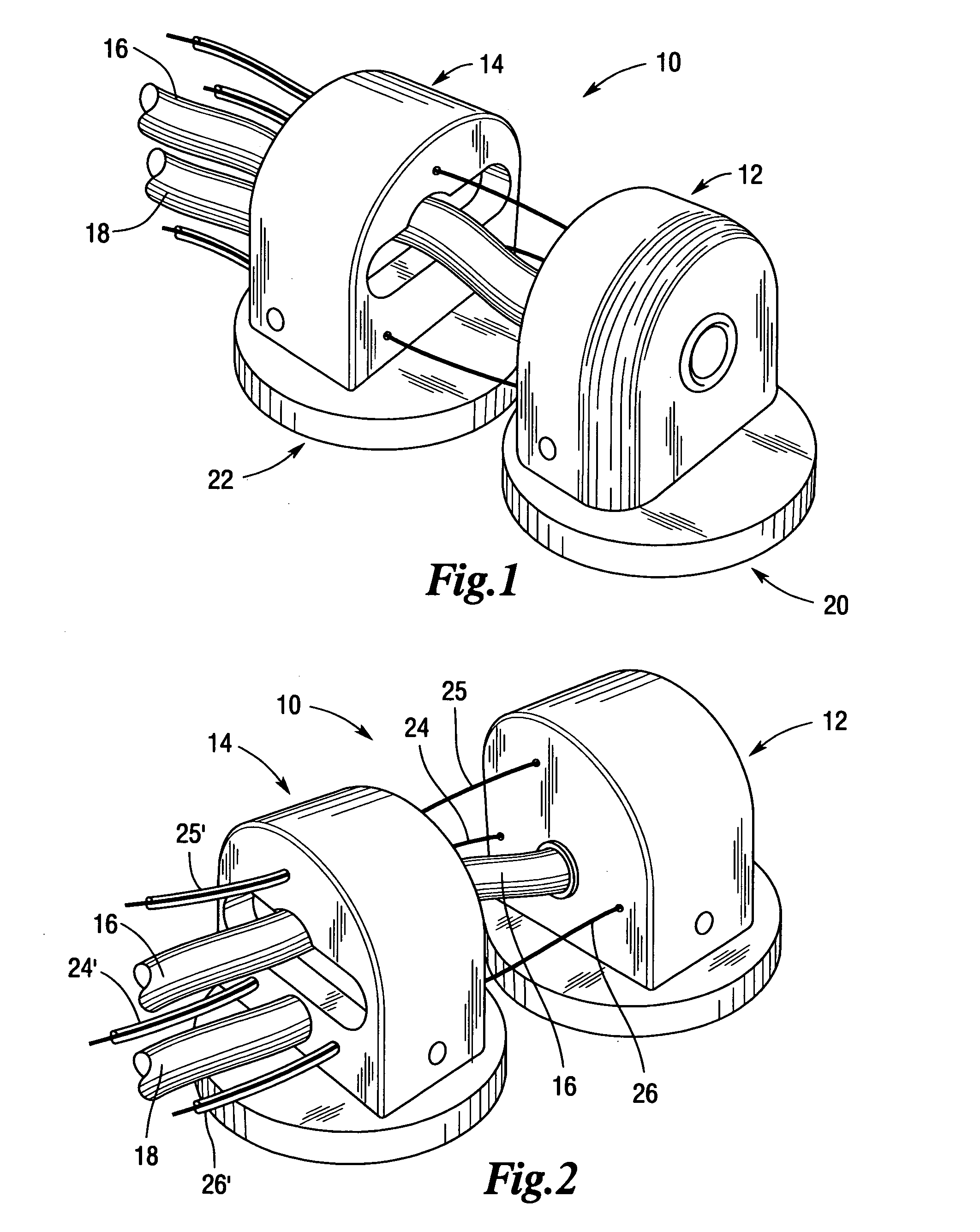

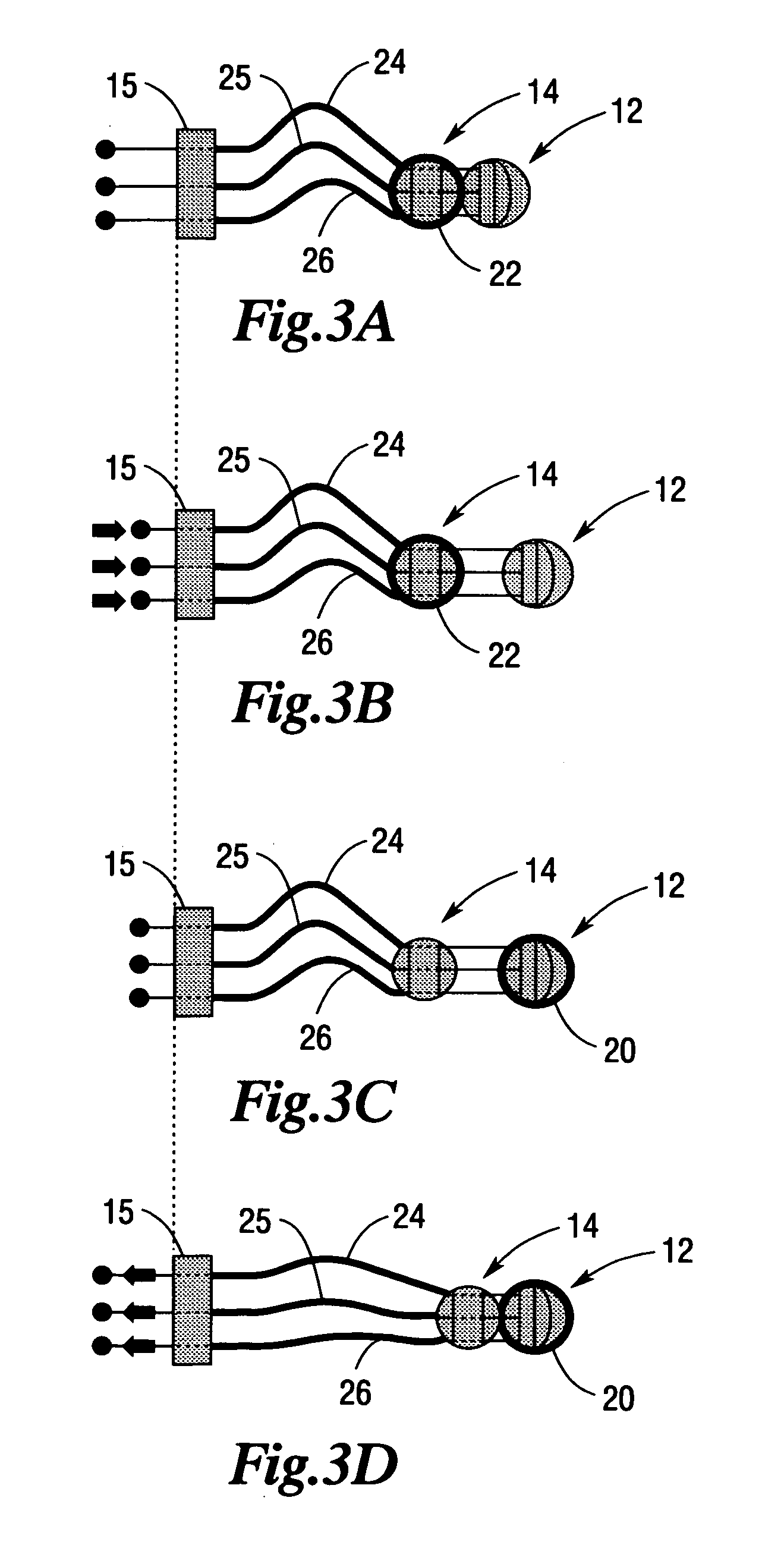

Various methods and apparatuses for moving thumbnails

ActiveUS8078603B1Video data browsing/visualisationDigital data processing detailsThumbnailMoving frame

Various methods, apparatuses, and systems are described for a moving thumbnail generator. The moving thumbnail generator generates one or more moving thumbnails that are visually and aurally representative of the content that takes place in an associated original video file. Each of the moving thumbnails has two or more moving frames derived from its associated original video file. Each moving thumbnail is stored with a relational link back to the original video file in order so that the moving thumbnail can be used as a linkage back to the original video file.

Owner:RHYTHMONE

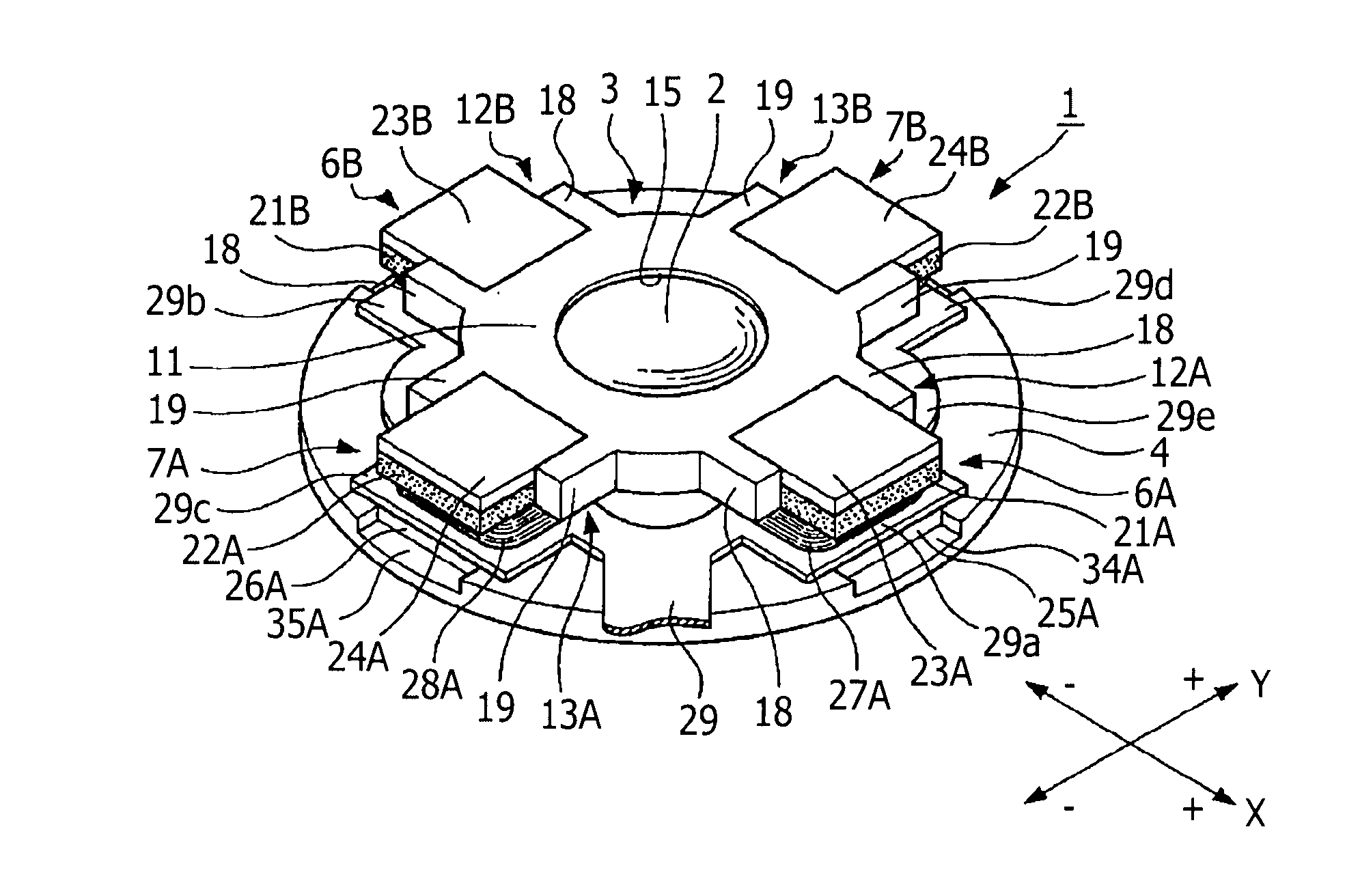

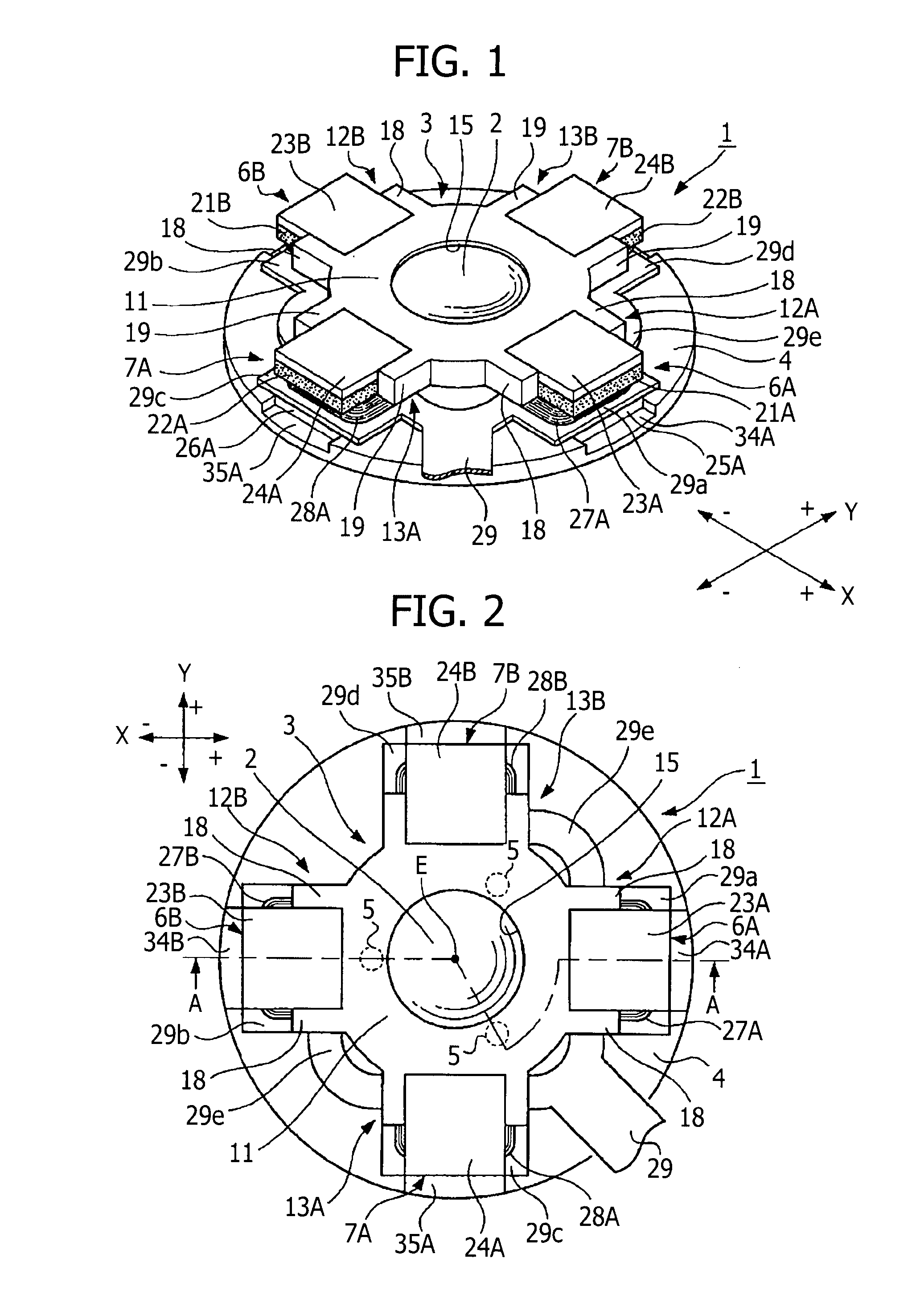

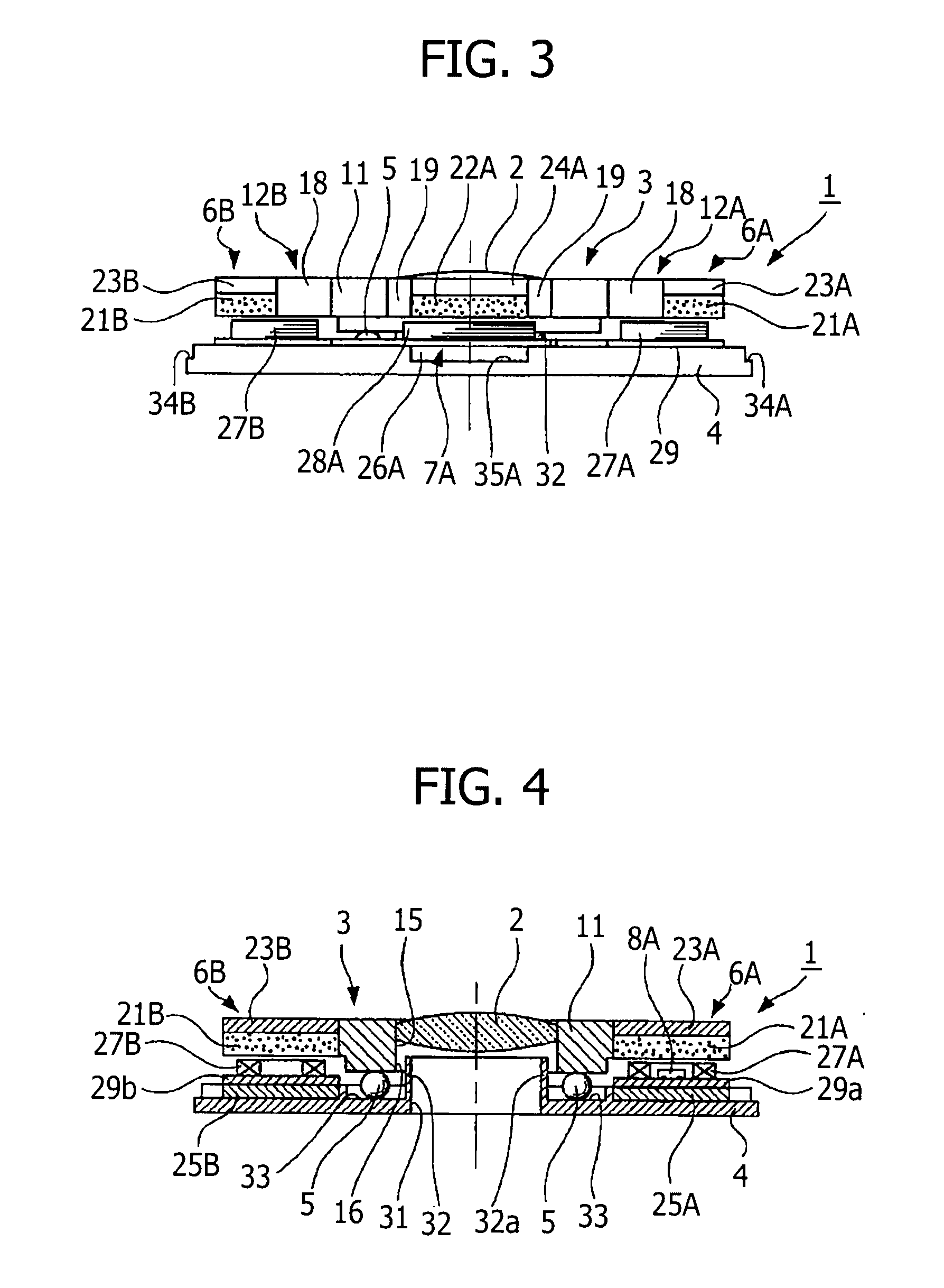

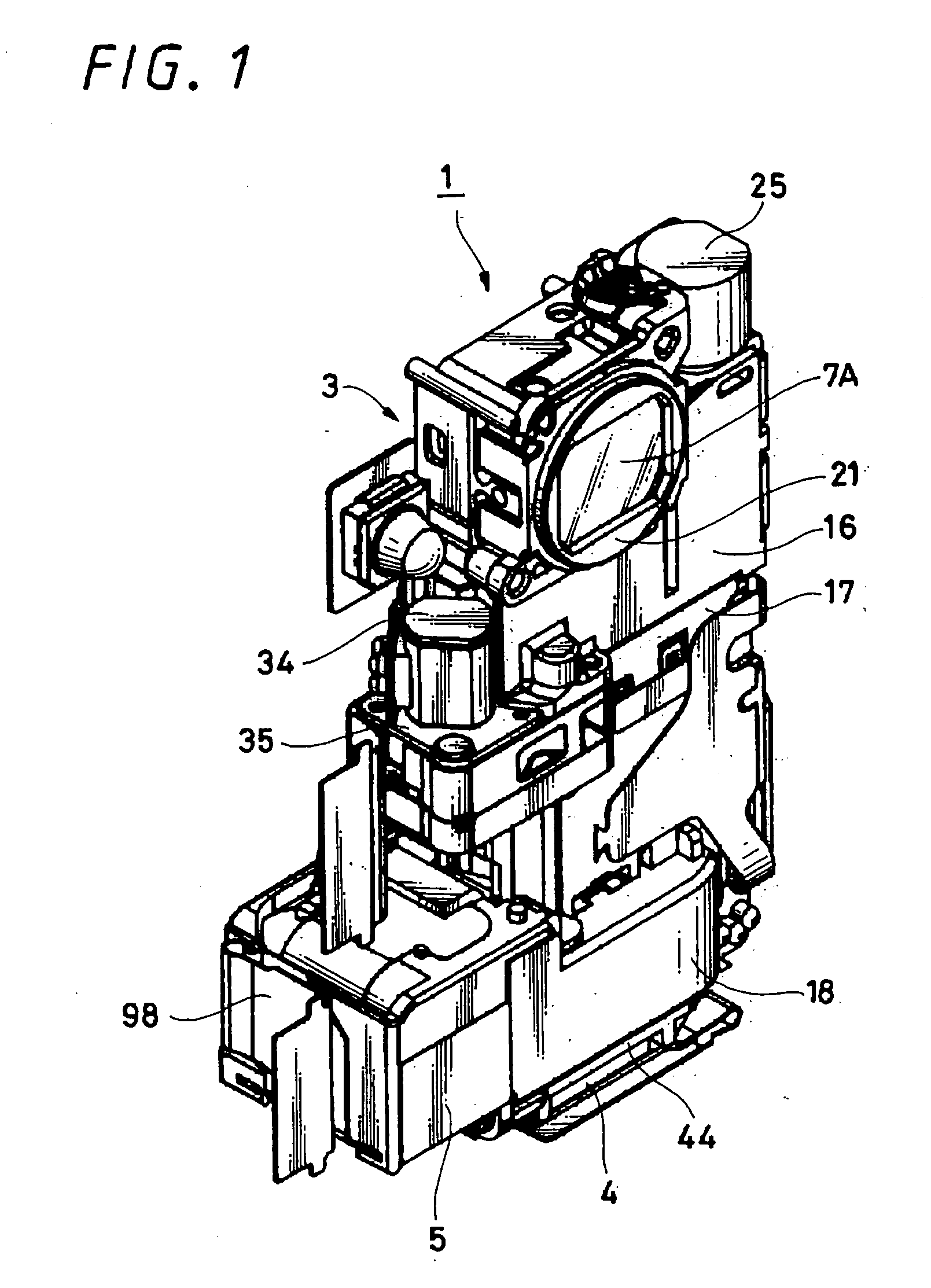

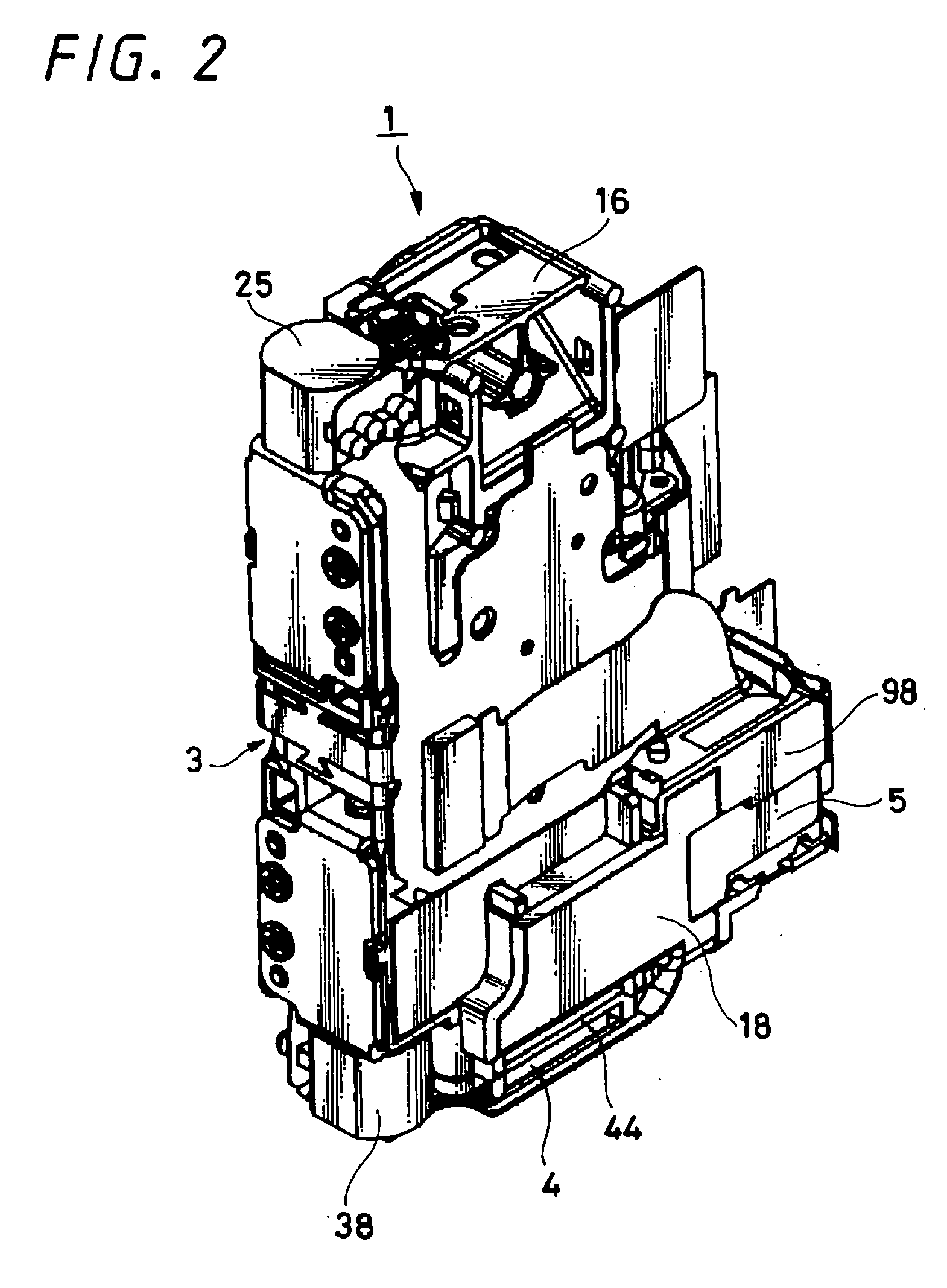

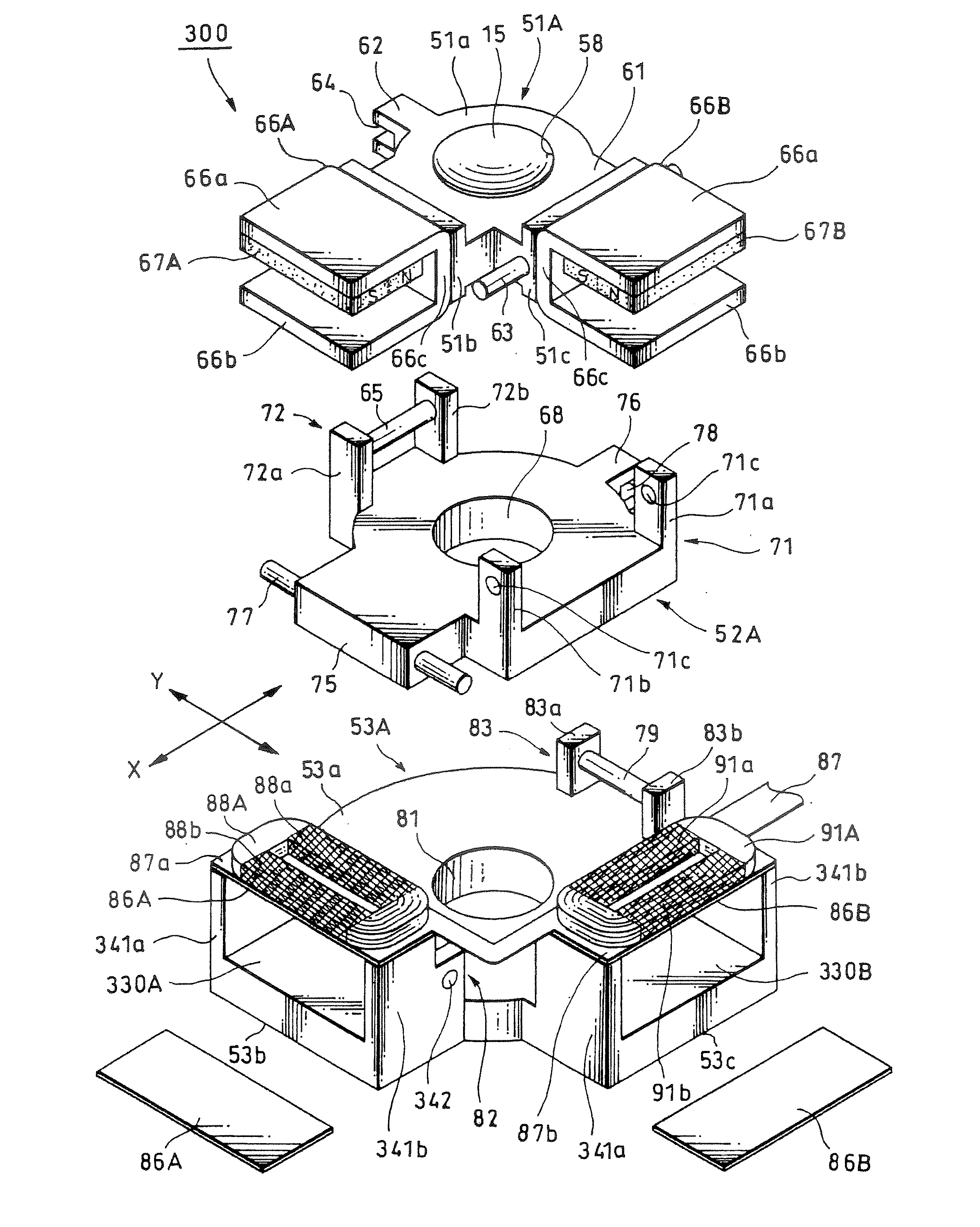

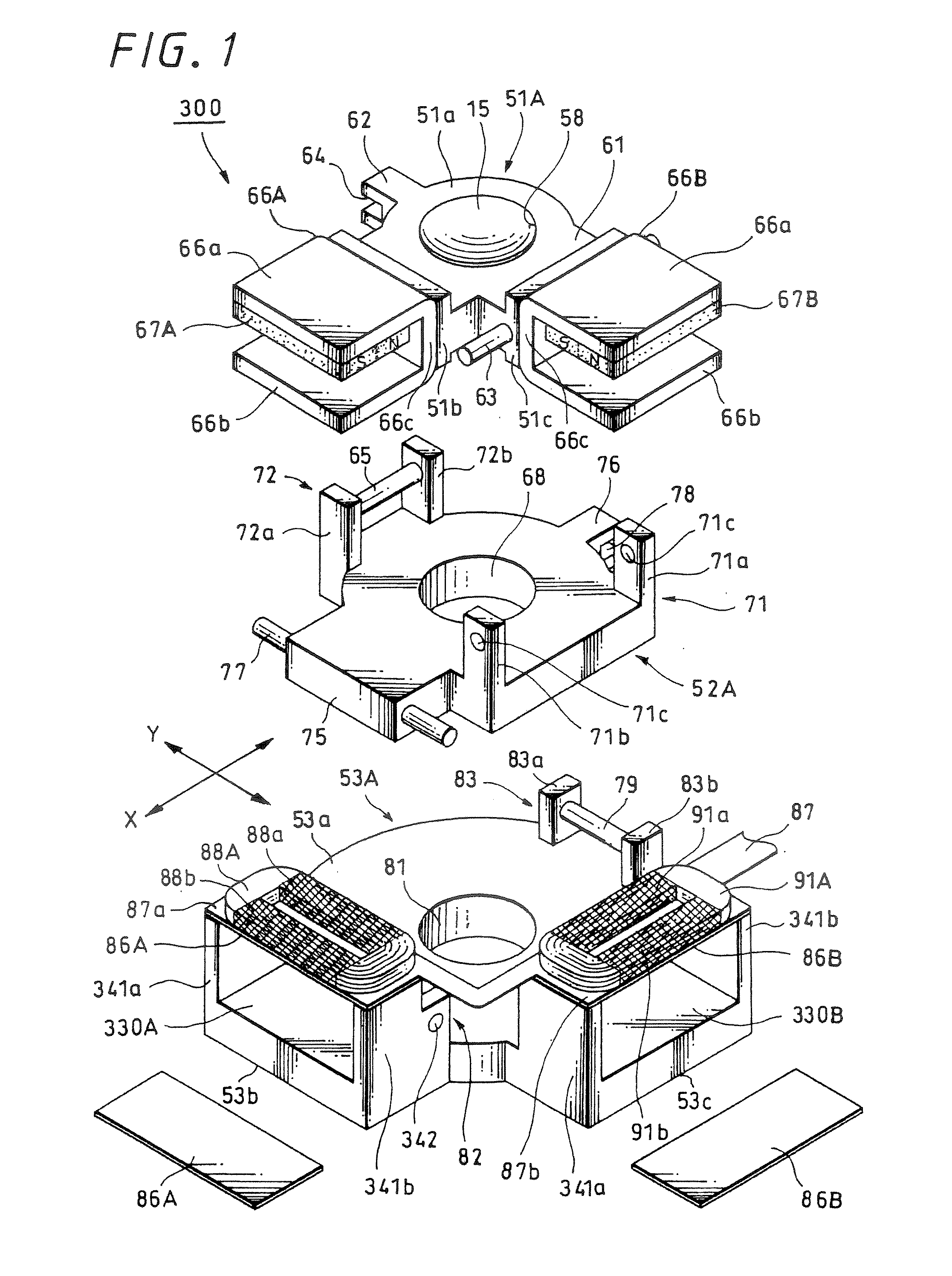

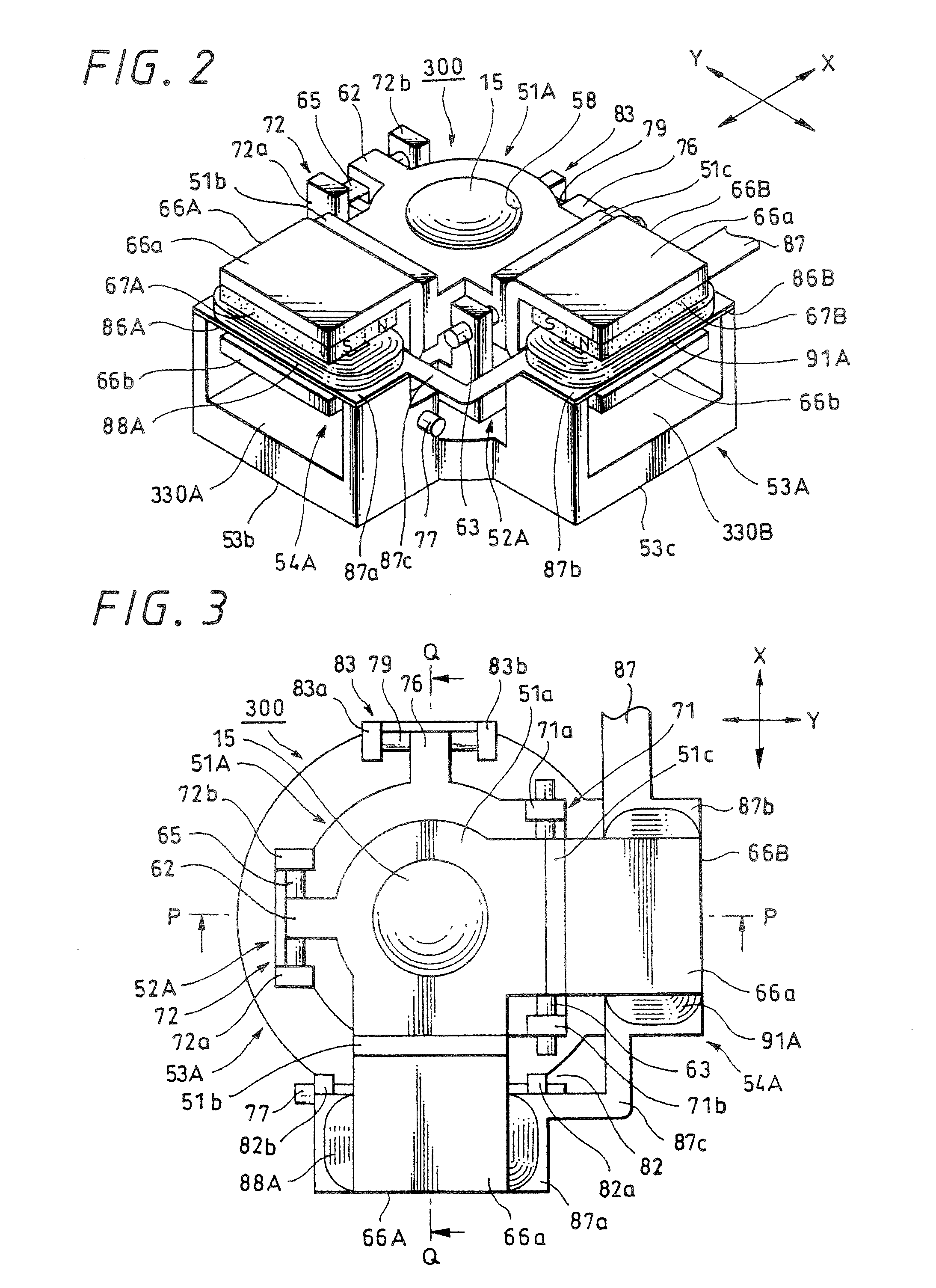

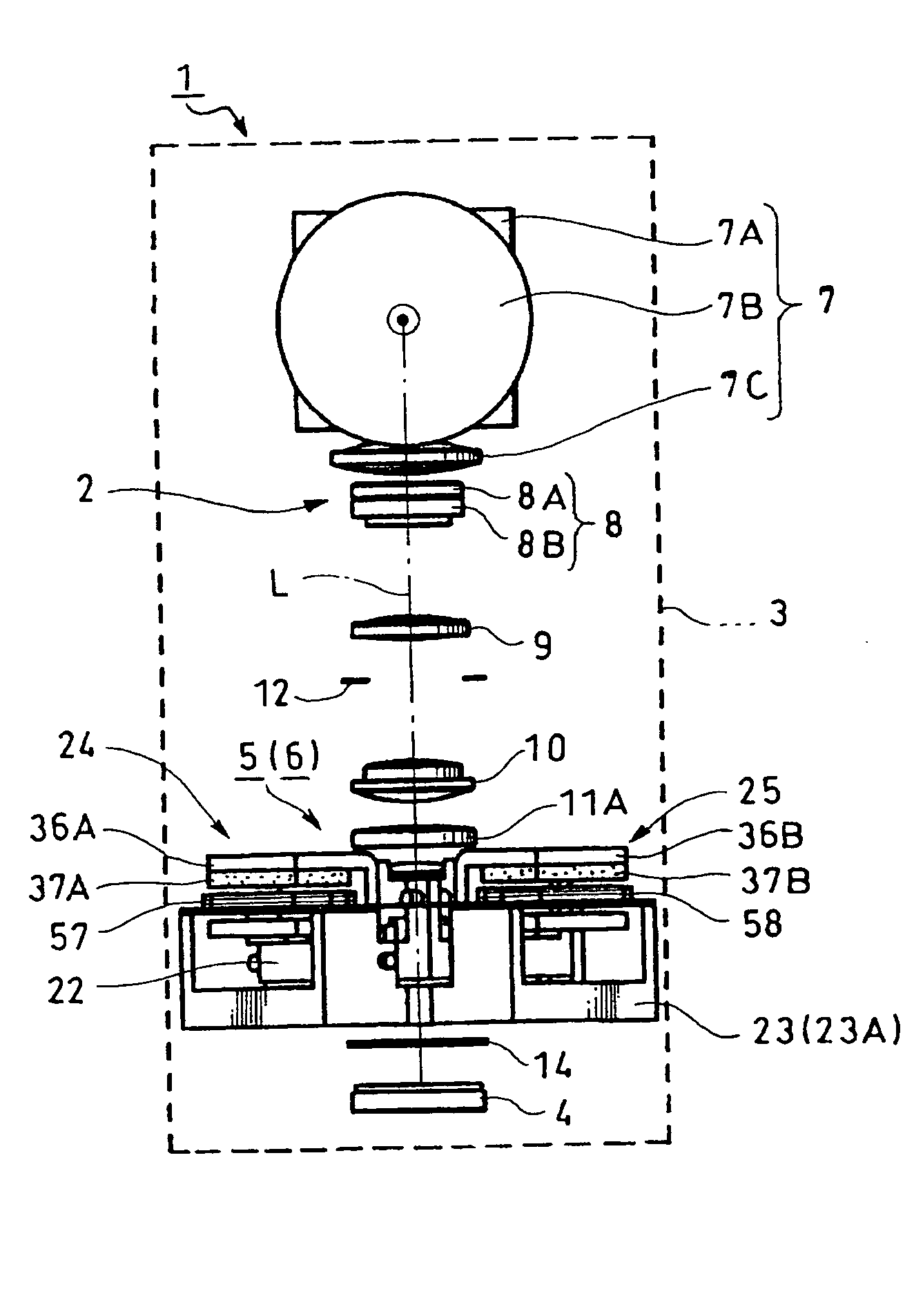

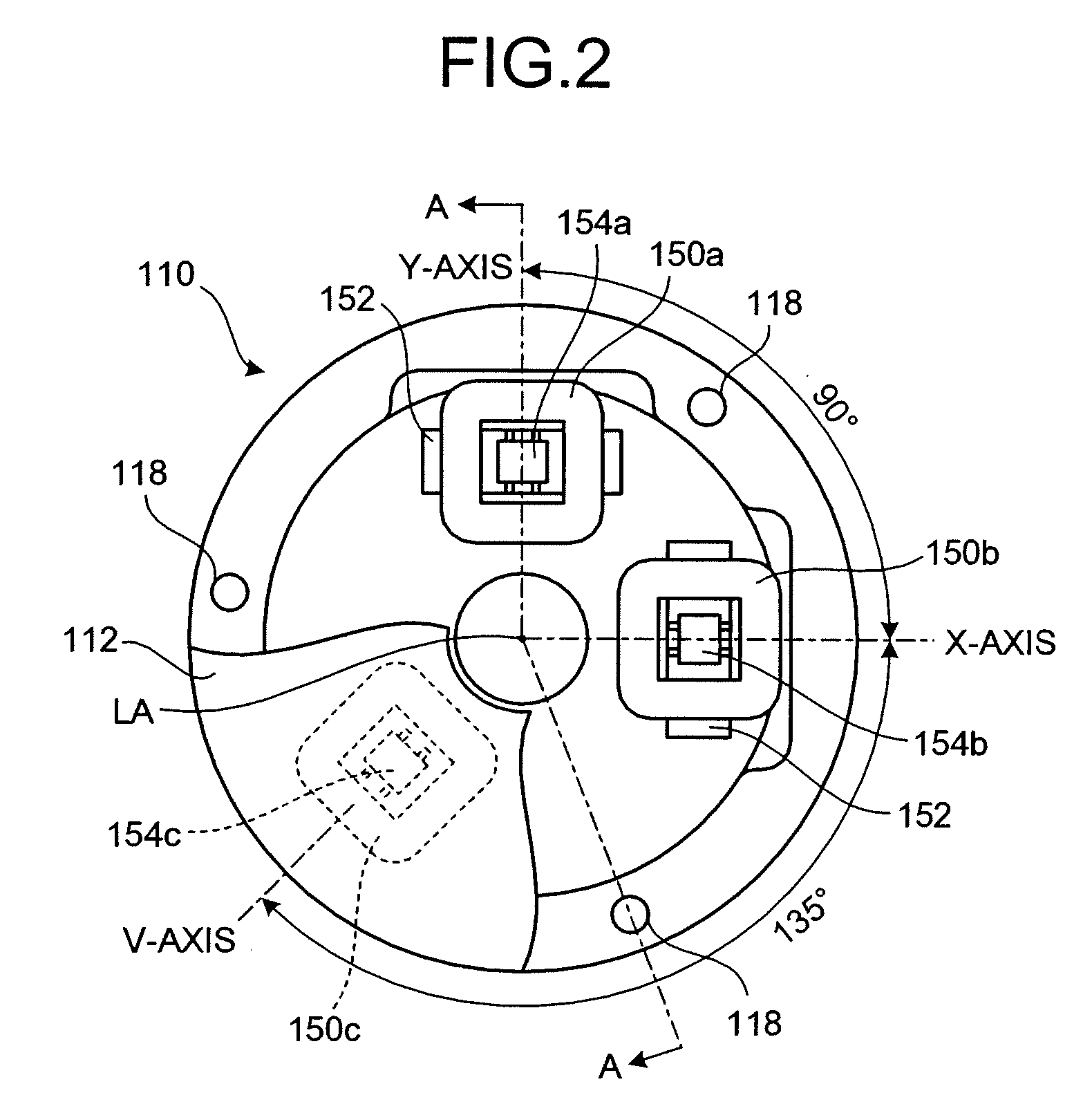

Image blur correction apparatus, lens barrel, and image capture apparatus

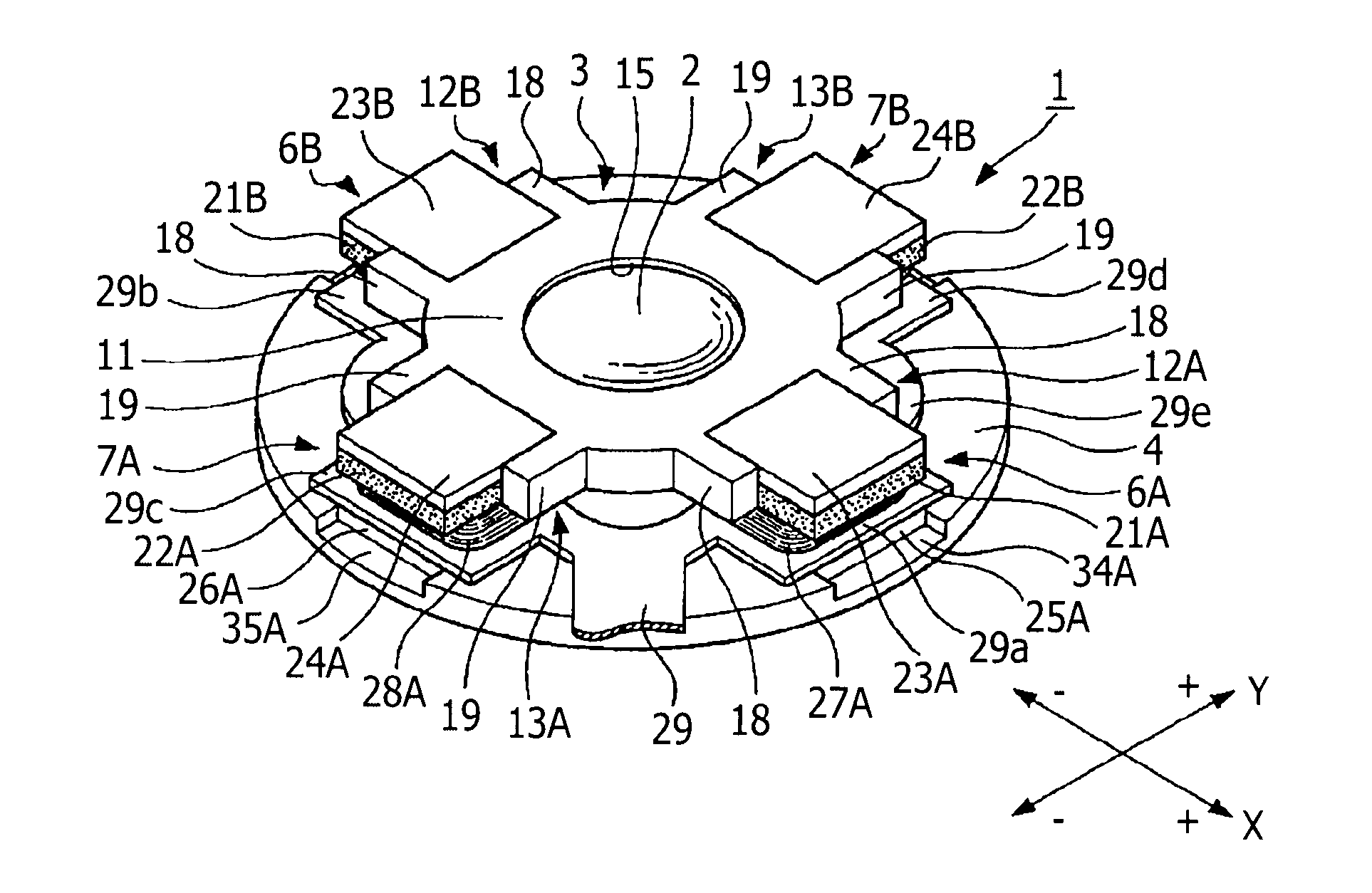

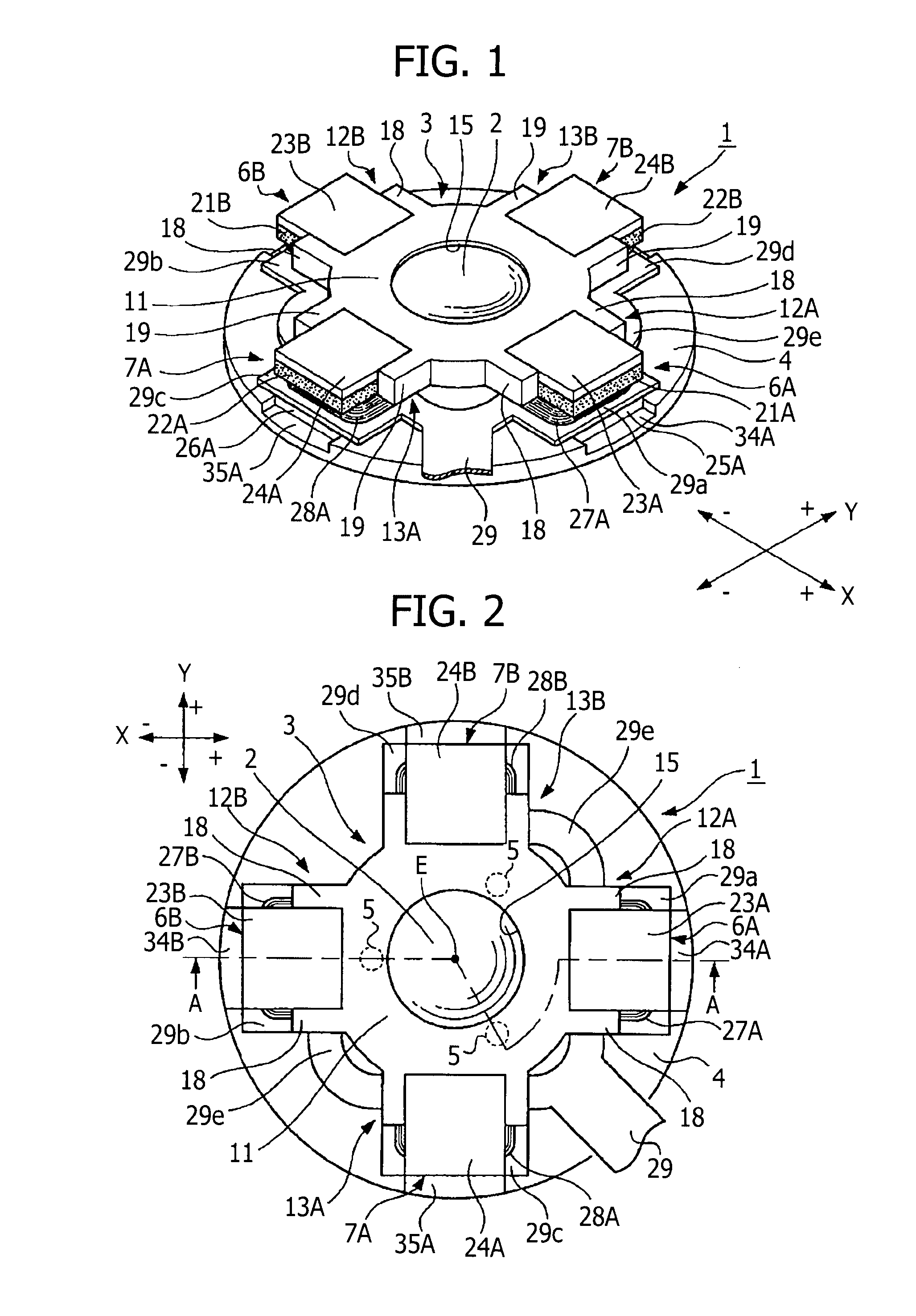

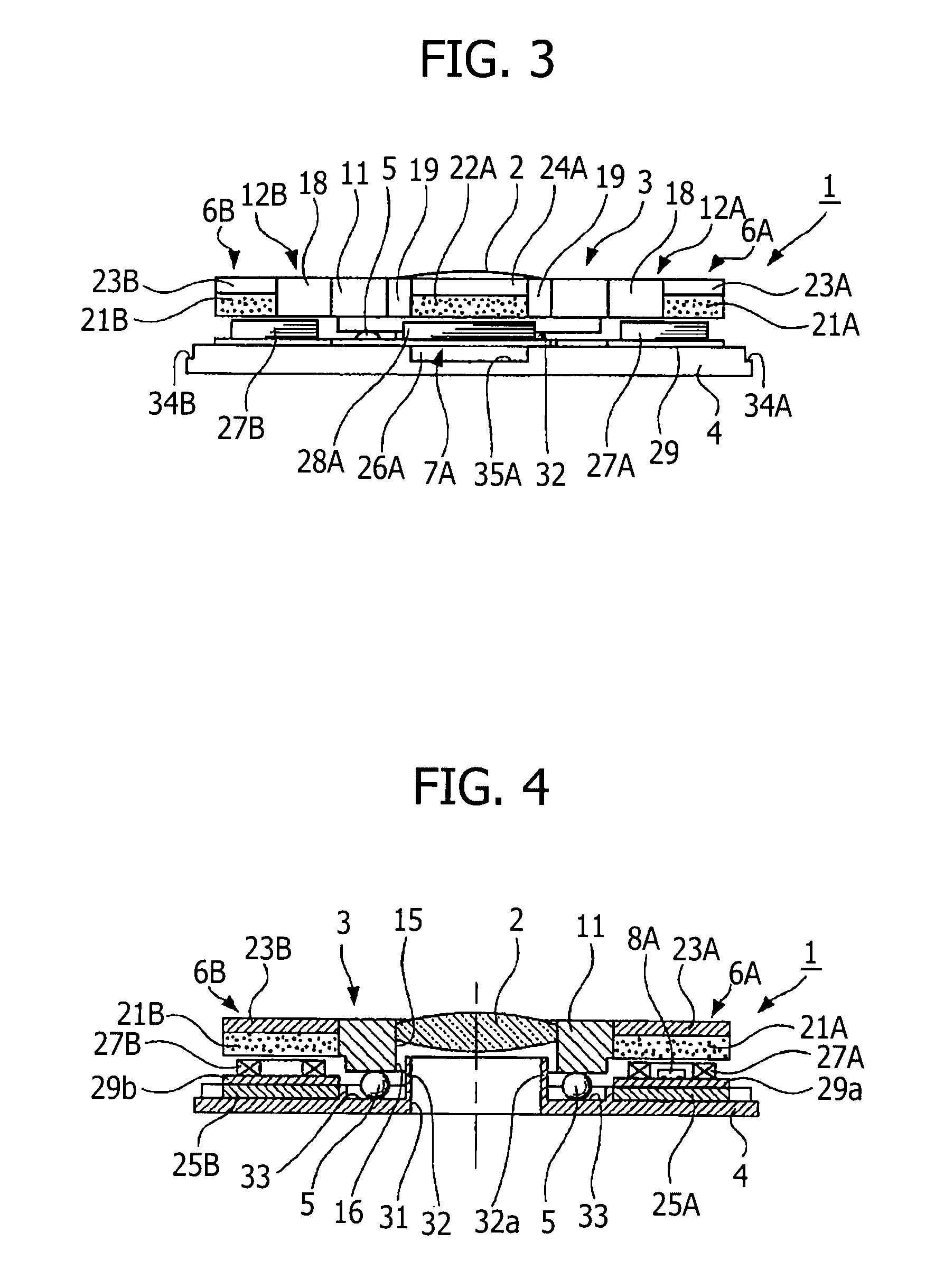

An image blur correction apparatus includes a correction lens for correcting image blurs in a lens system, a moving frame for holding the correction lens, a support frame for movably supporting the moving frame through a move guide on a plane orthogonal to an optical axis of the correction lens, a first electric actuator for generating a first force to move the moving frame in a first direction orthogonal to the optical axis of the correction lens, a second electric actuator for generating a second force to move the moving frame in a second direction which is a direction orthogonal to the optical axis of the correction lens and is also orthogonal to the first direction, and an operation limit mechanism for limiting the moving frame from moving in the first direction and the second direction, and preventing the moving frame from rotating in the limit position.

Owner:SONY CORP

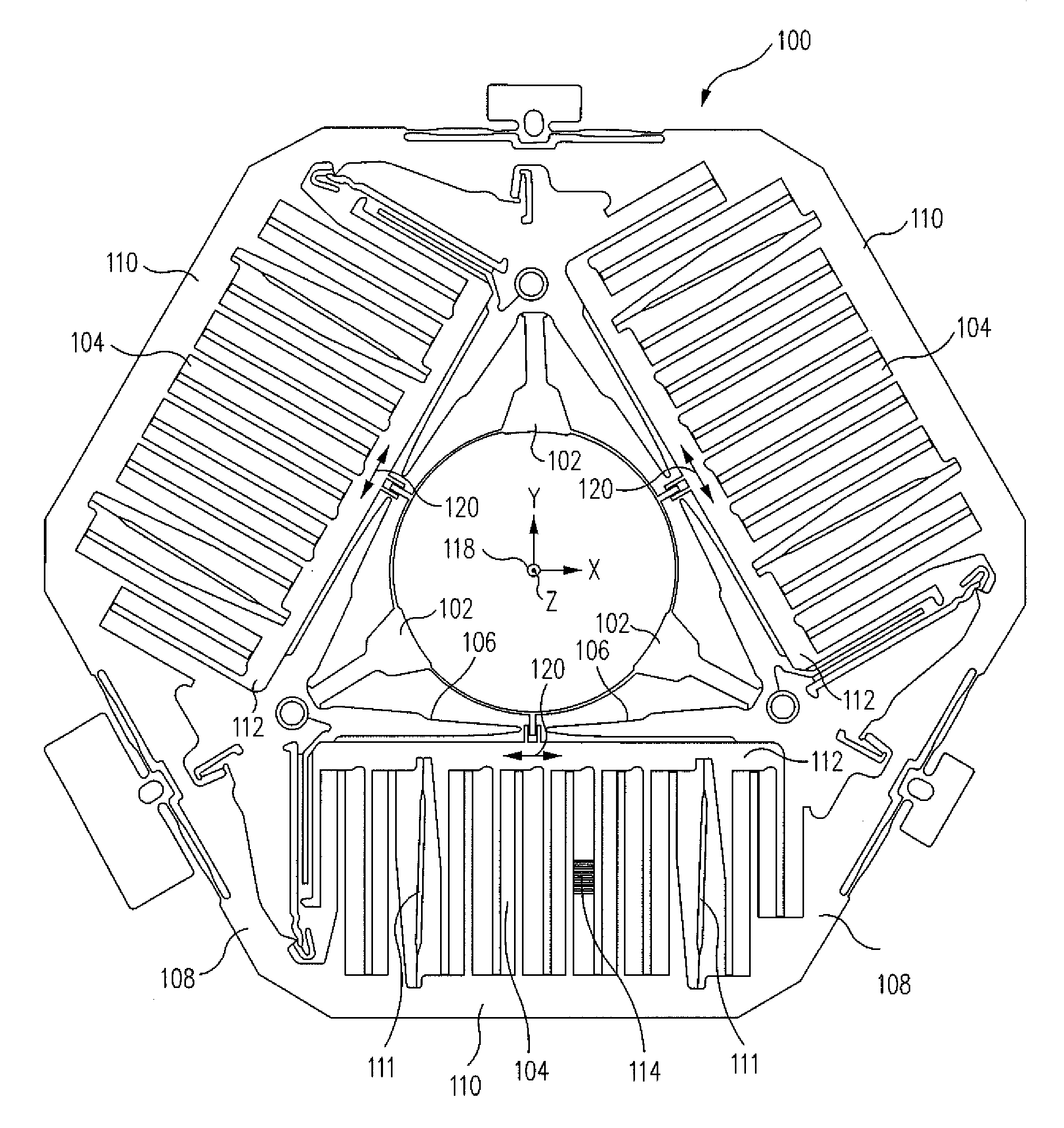

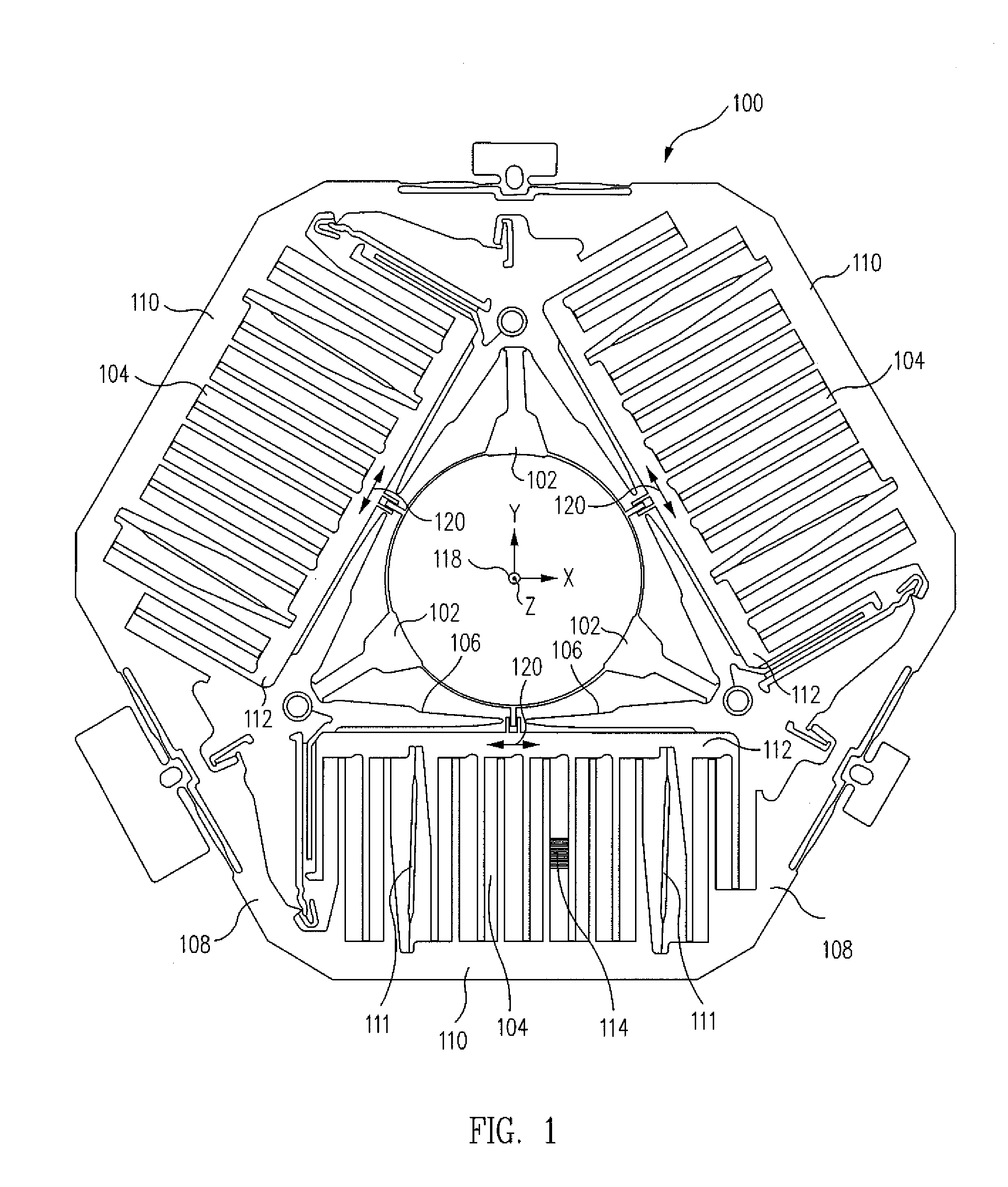

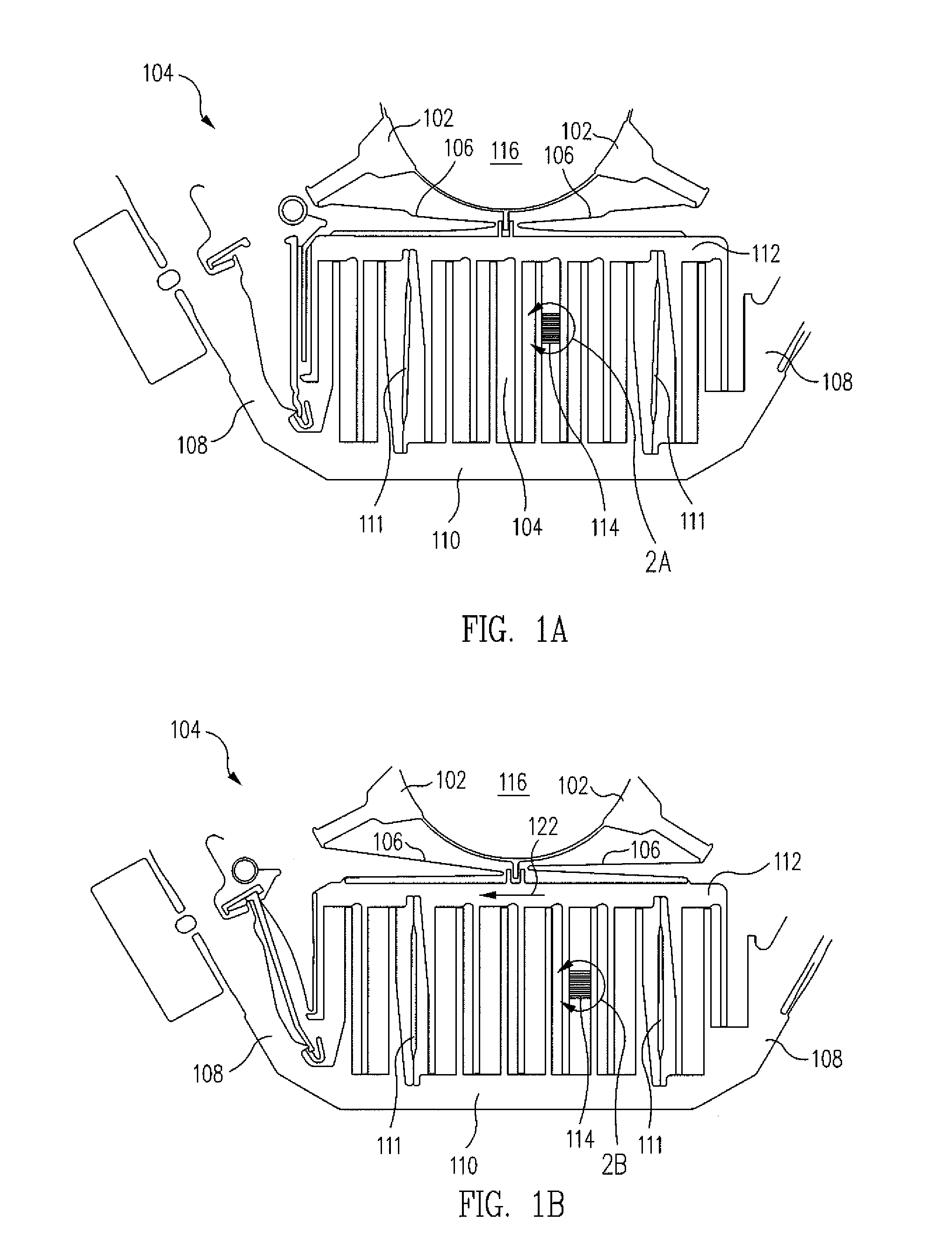

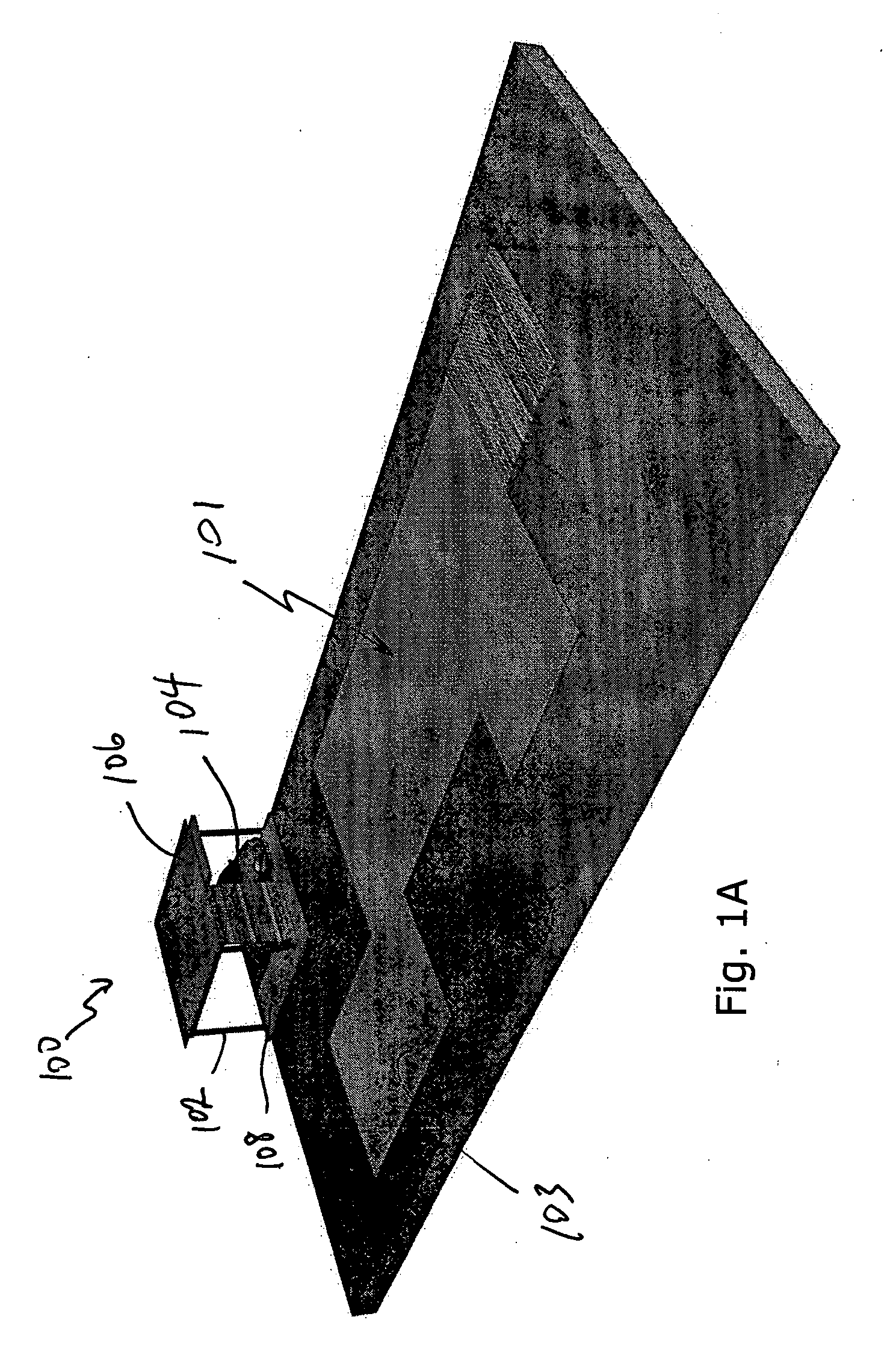

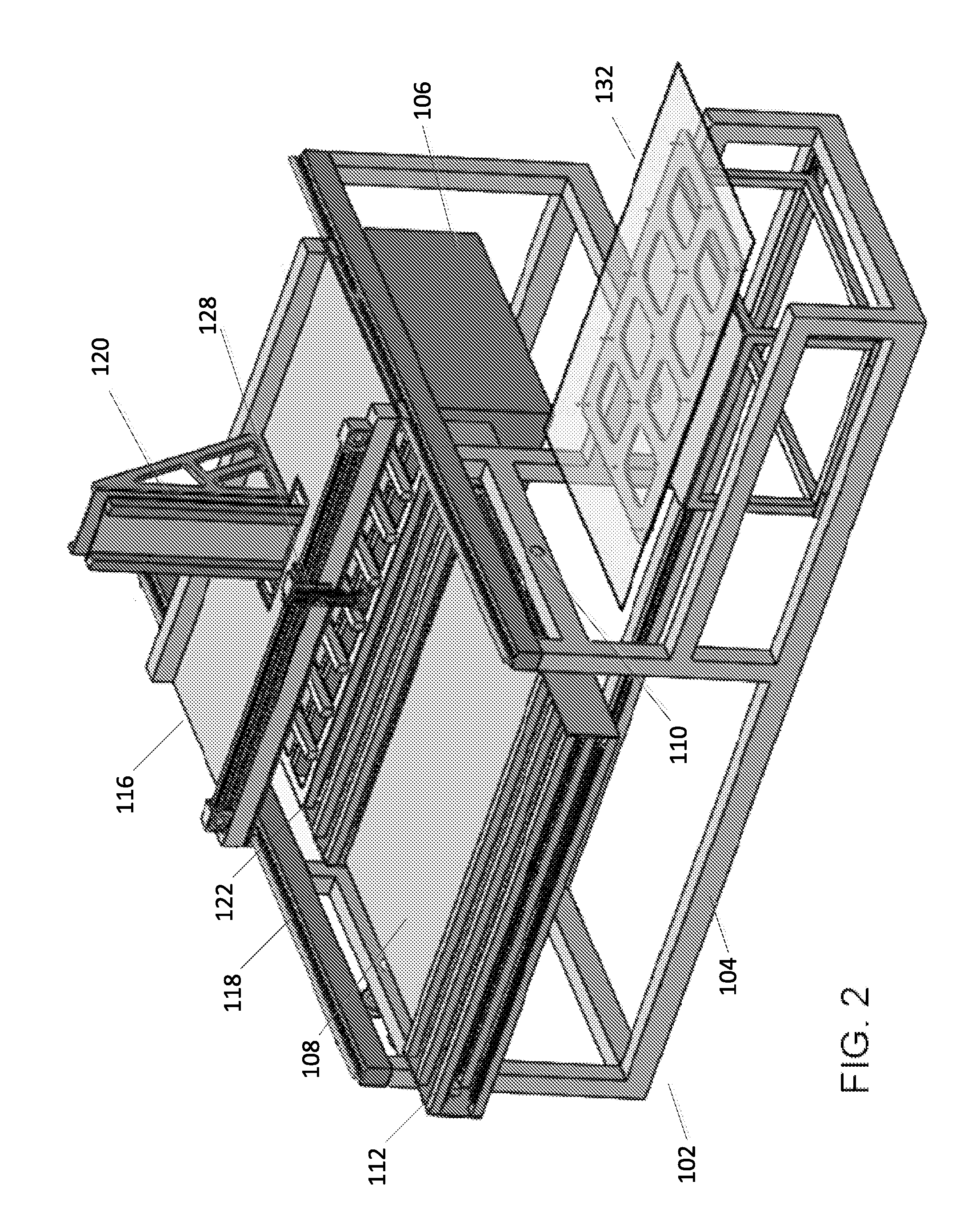

MEMS actuator device deployment

ActiveUS20120081598A1Small and simpleTelevision system detailsProjector focusing arrangementFixed frameActuator

A method for making an actuator device includes forming a substantially planar structure having a stage resiliently supported for movement within a plane of the structure, an actuator coupled to an outer periphery of the stage and operable to apply a force acting in the plane and tangentially to the stage when actuated, the actuator comprising a fixed frame and a moving frame resiliently supported for reciprocal movement relative to the fixed frame by a motion control flexure, and an outer frame surrounding and supporting the stage and the actuator. The moving frame is moved to a deployed position that is coplanar with, parallel to and spaced apart from the fixed frame at a selected distance, and the moving frame is then fixed at the deployed position for substantially rectilinear, perpendicular movement relative to the fixed frame.

Owner:DIGITALPTICS MEMS

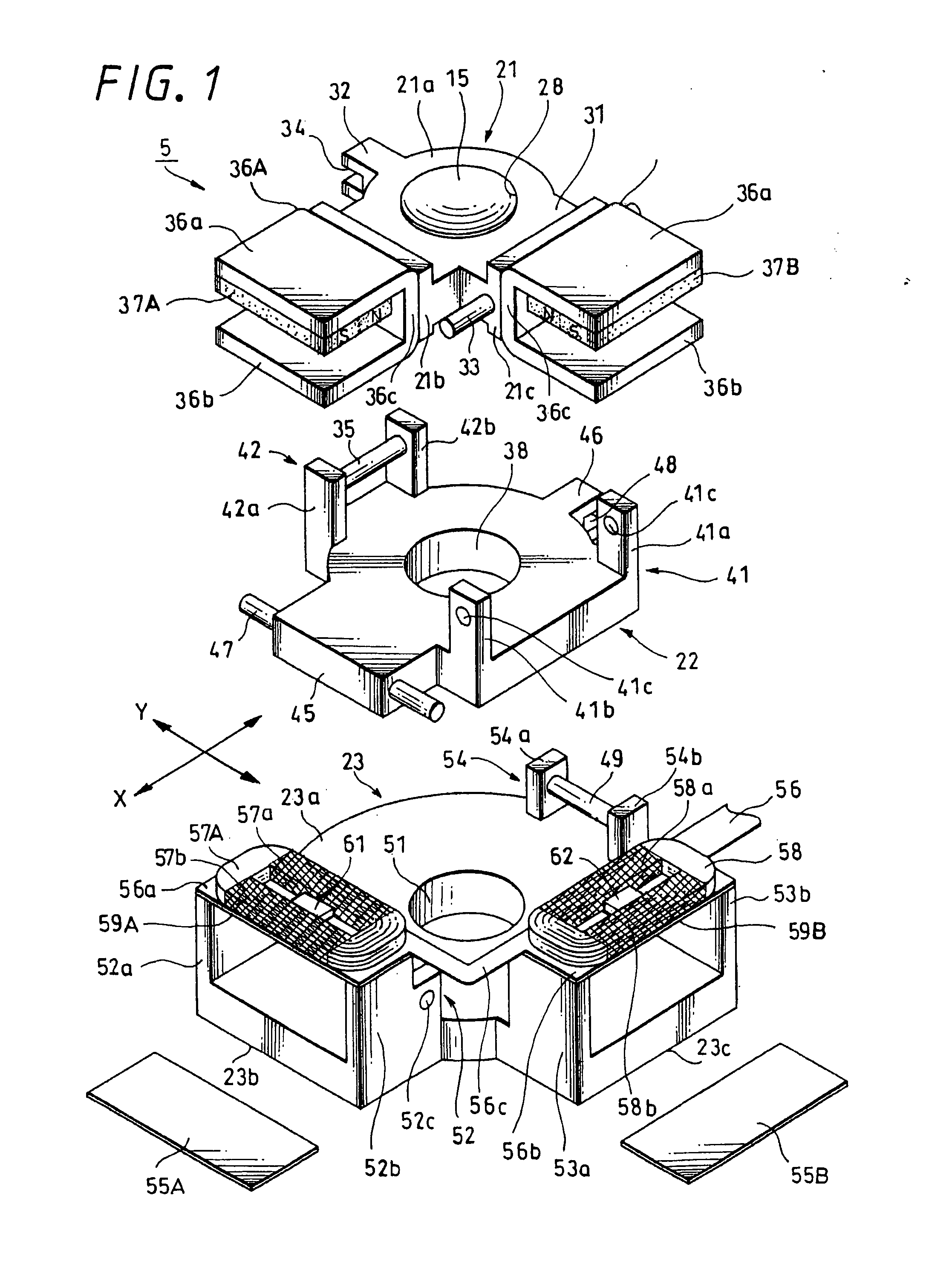

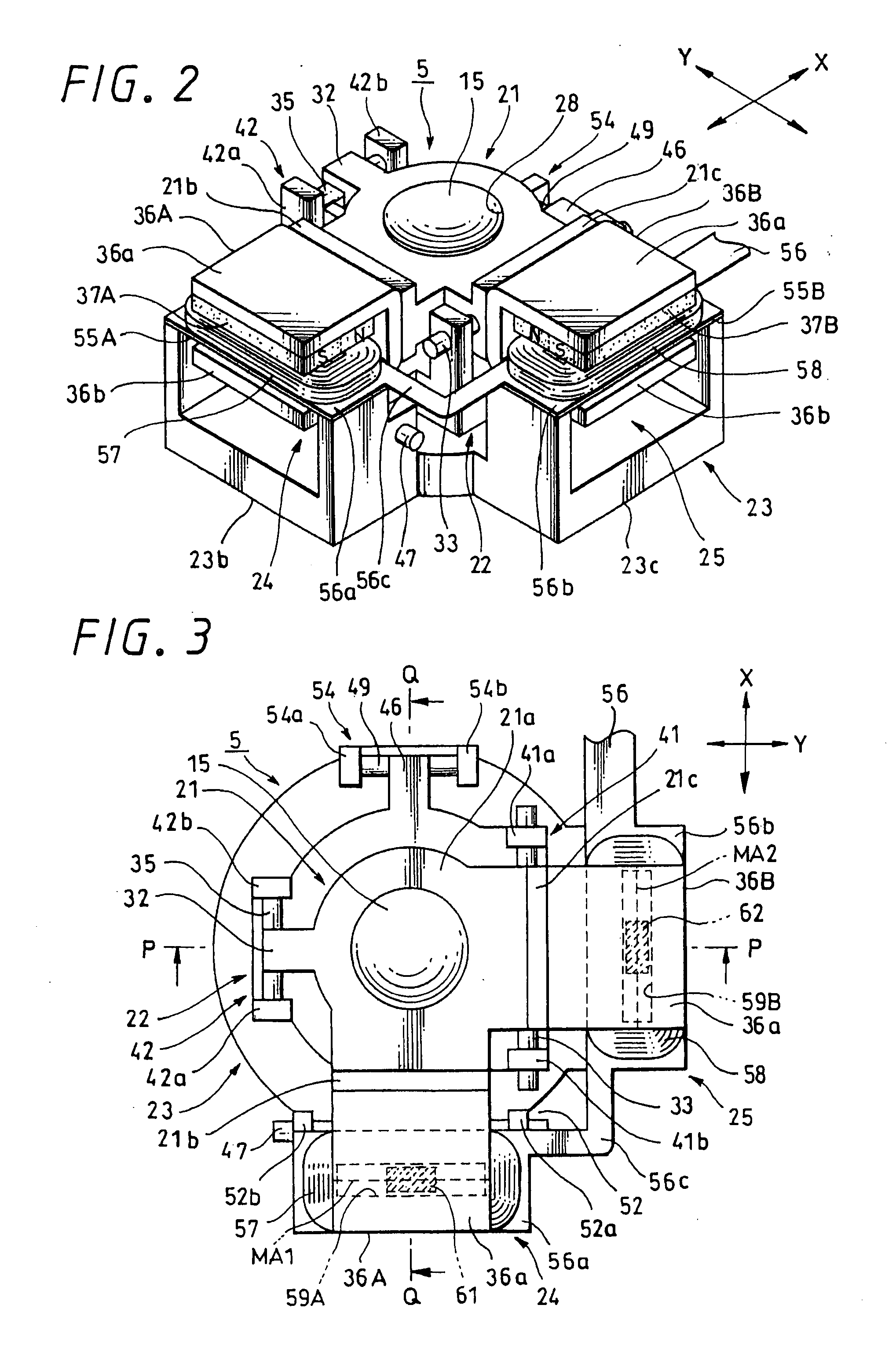

Image stabilizer, lens apparatus and imager apparatus

InactiveUS20070009244A1Change densityMutual interferenceTelevision system detailsPrintersMagnetic tension forceOptical axis

An image stabilizer can steady blurry images. The image stabilizer includes first and second Hall elements and a yoke with a magnet fixed thereto, the yoke including a projected portion to escape magnetic flux from the edge portion of the magnet. In the state in which one of magnets and a coil supporting holder are fixed to a moving frame and in which the optical axis of the correcting lens is matched with the optical axis of the lens system, the first and second Hall elements are moved to the first and second directions so that the first and second Hall elements are properly positioned at the positions in which magnetic force received by the two Hall elements from the magnet becomes a reference value, whereafter the other of the magnets and the coil supporting member are fixed to a supporting frame.

Owner:SONY CORP

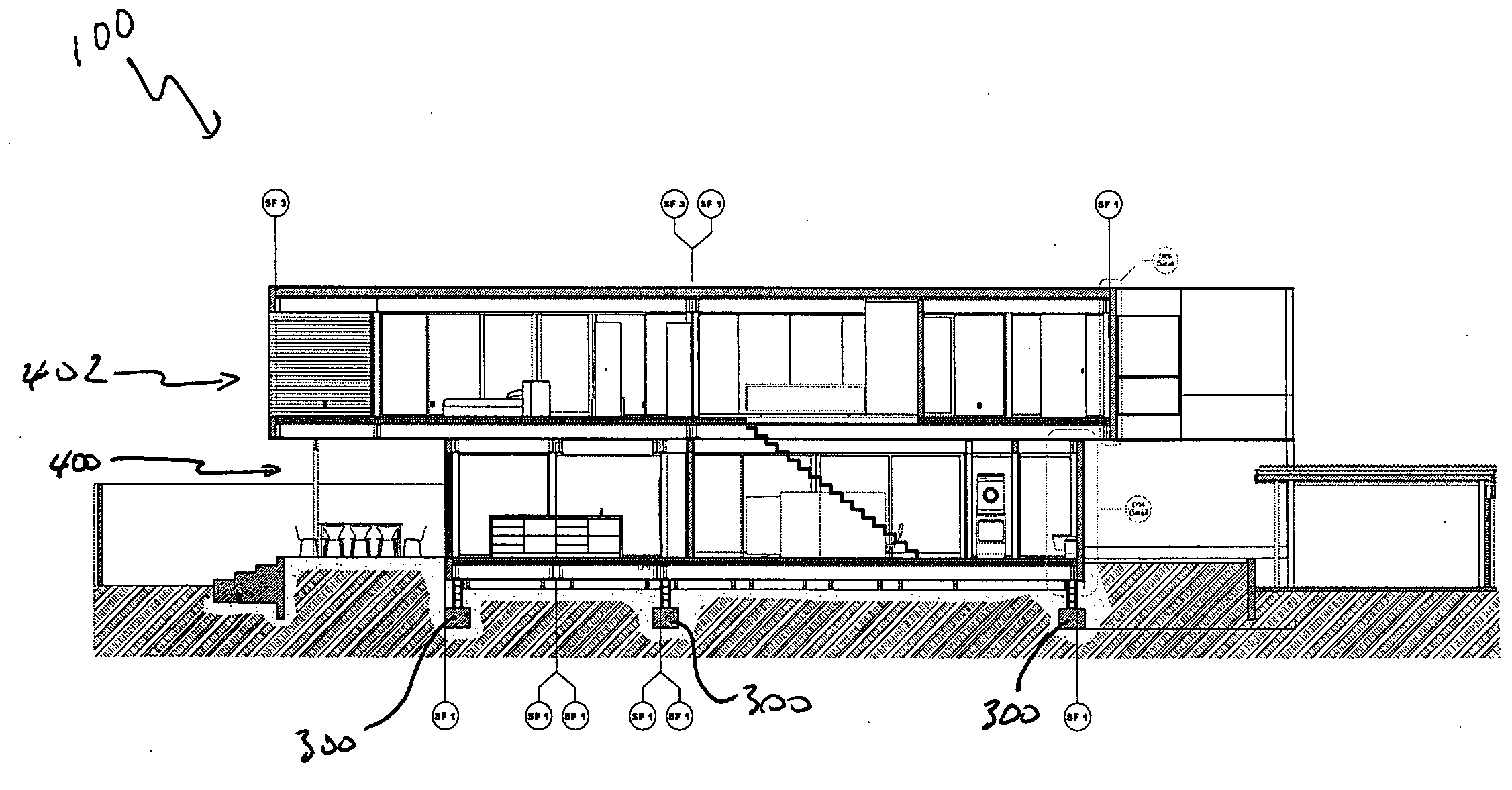

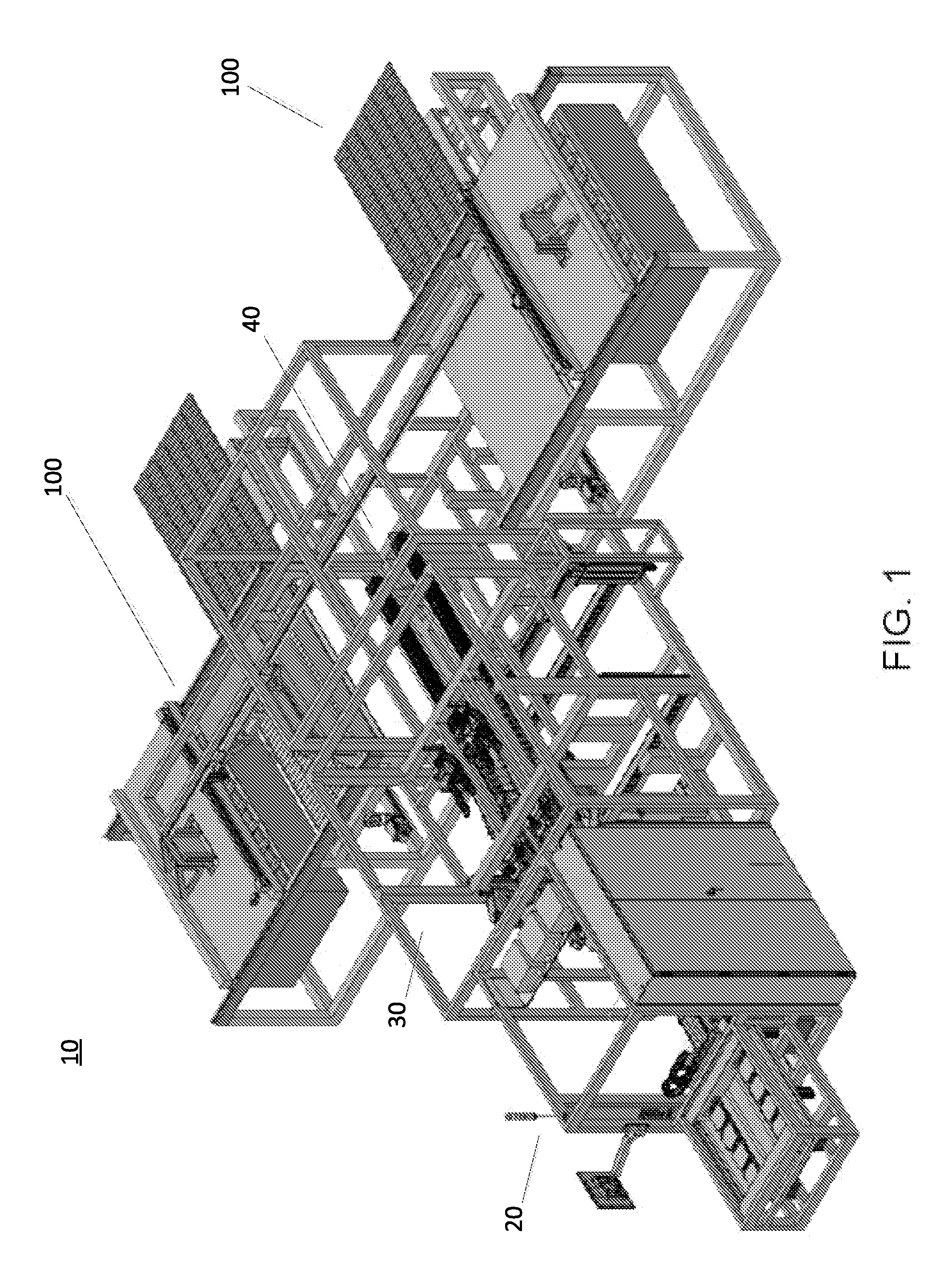

Affordable, sustainable buildings comprised of recyclable materials and methods thereof

InactiveUS20080276553A1Easy to manufactureGood flexibilityBuilding roofsTreadsComputer moduleEngineering

An affordable, sustainable building, comprising substantially entirely mass-produced, prefabricated constituent parts manufactured off-site, the prefabricated constituent parts comprising a foundation, a frame module comprising a plurality of frames, wherein the frame module is secured to the foundation, a reversible connector to connect the plurality of frames to form the frame module, a wall panel configured to be mounted onto the frame module, a floor panel configured to be mounted onto the frame module, and a ceiling panel configured to be mounted on to the frame module. Each constituent part forms part of a library of parts from which the constituent parts are selected. The constituent parts are preferably made in standardized sizes to facilitate efficient mass production. The constituent parts are predominantly made of recyclable material so as to be environmentally friendly. Computer software may be developed to facilitate design and construction of the affordable, sustainable building and to calculate proper attachment points for lifting and moving frame modules.

Owner:INGJALDSDOTTIR ERLA DOGG +1

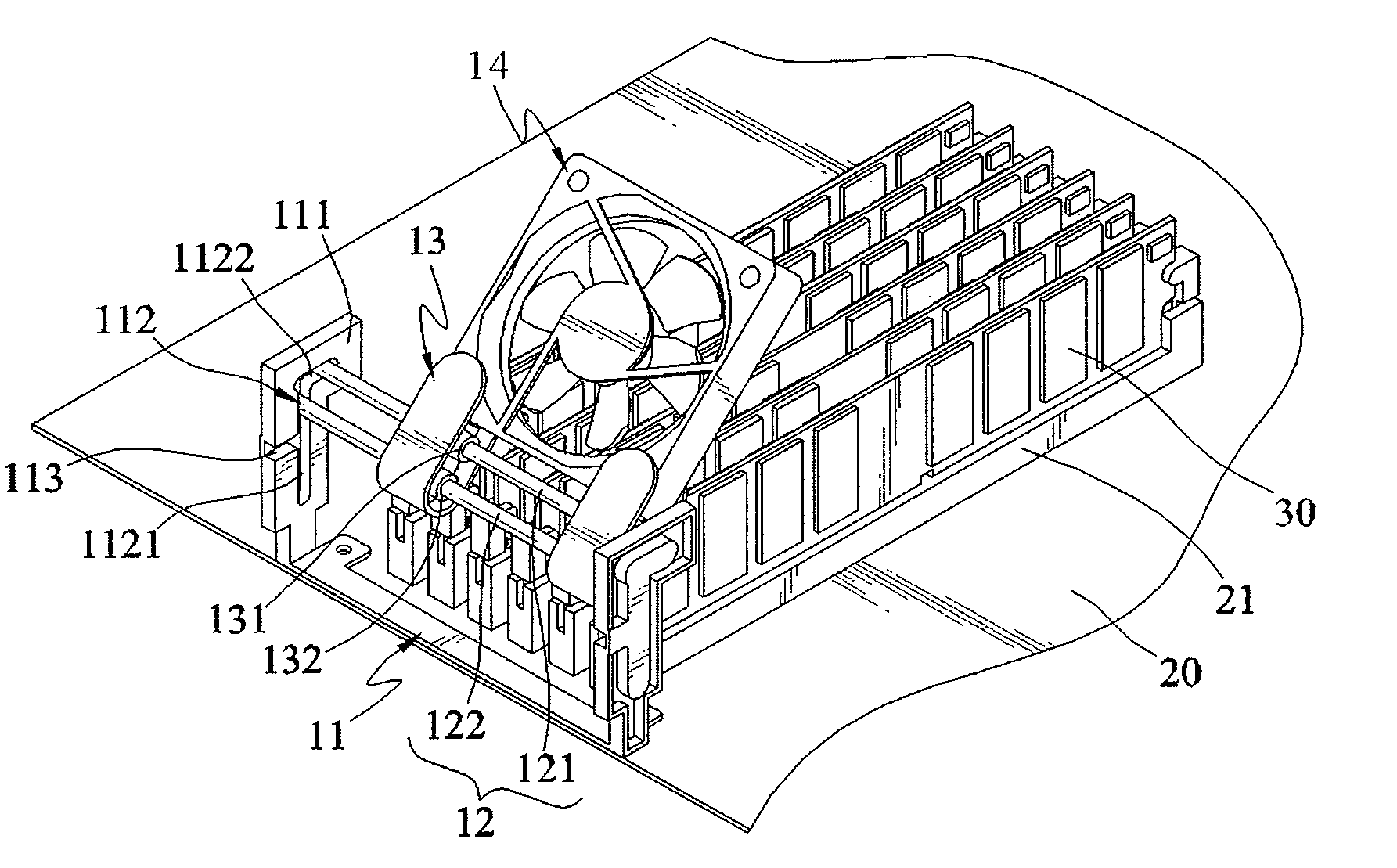

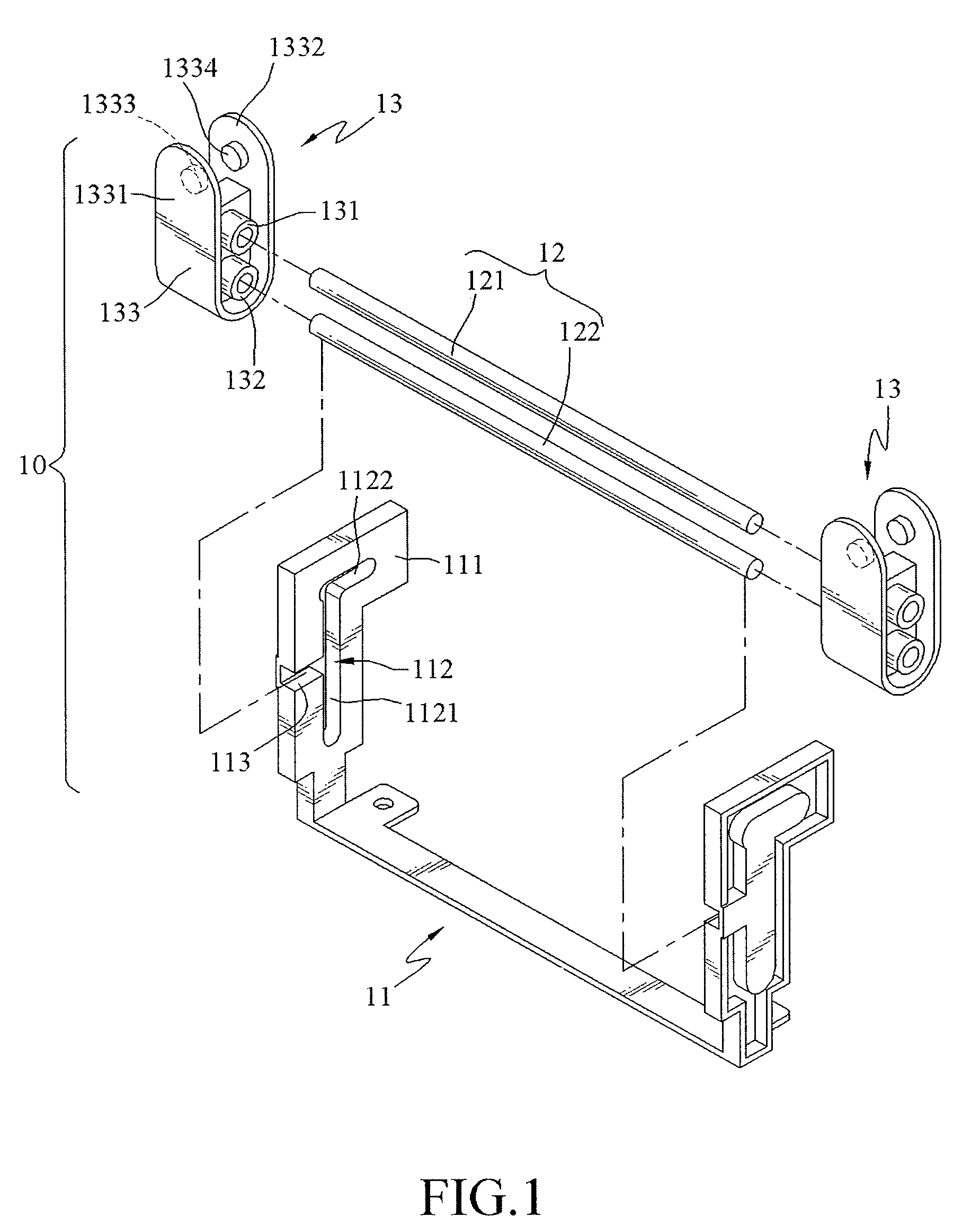

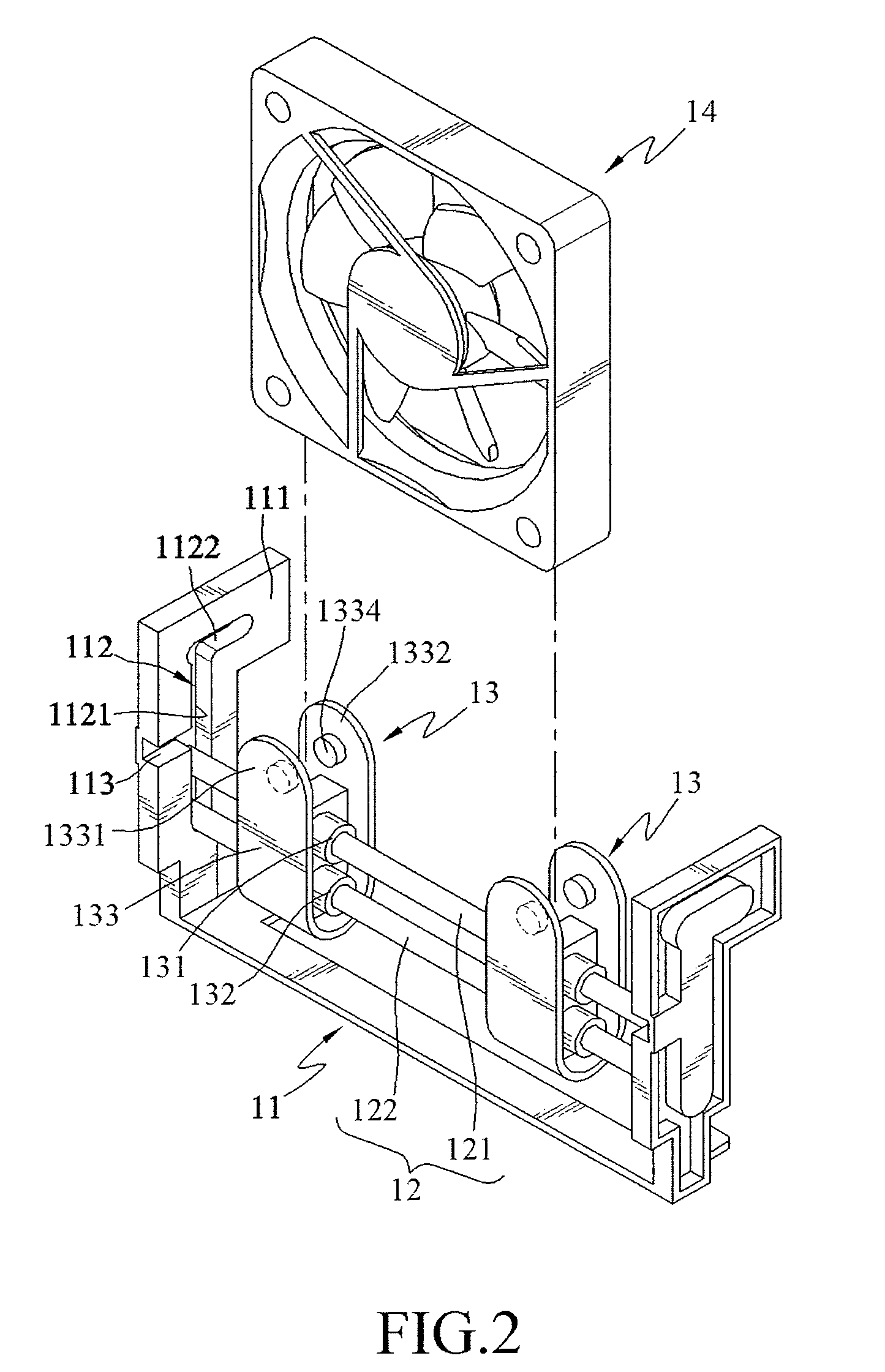

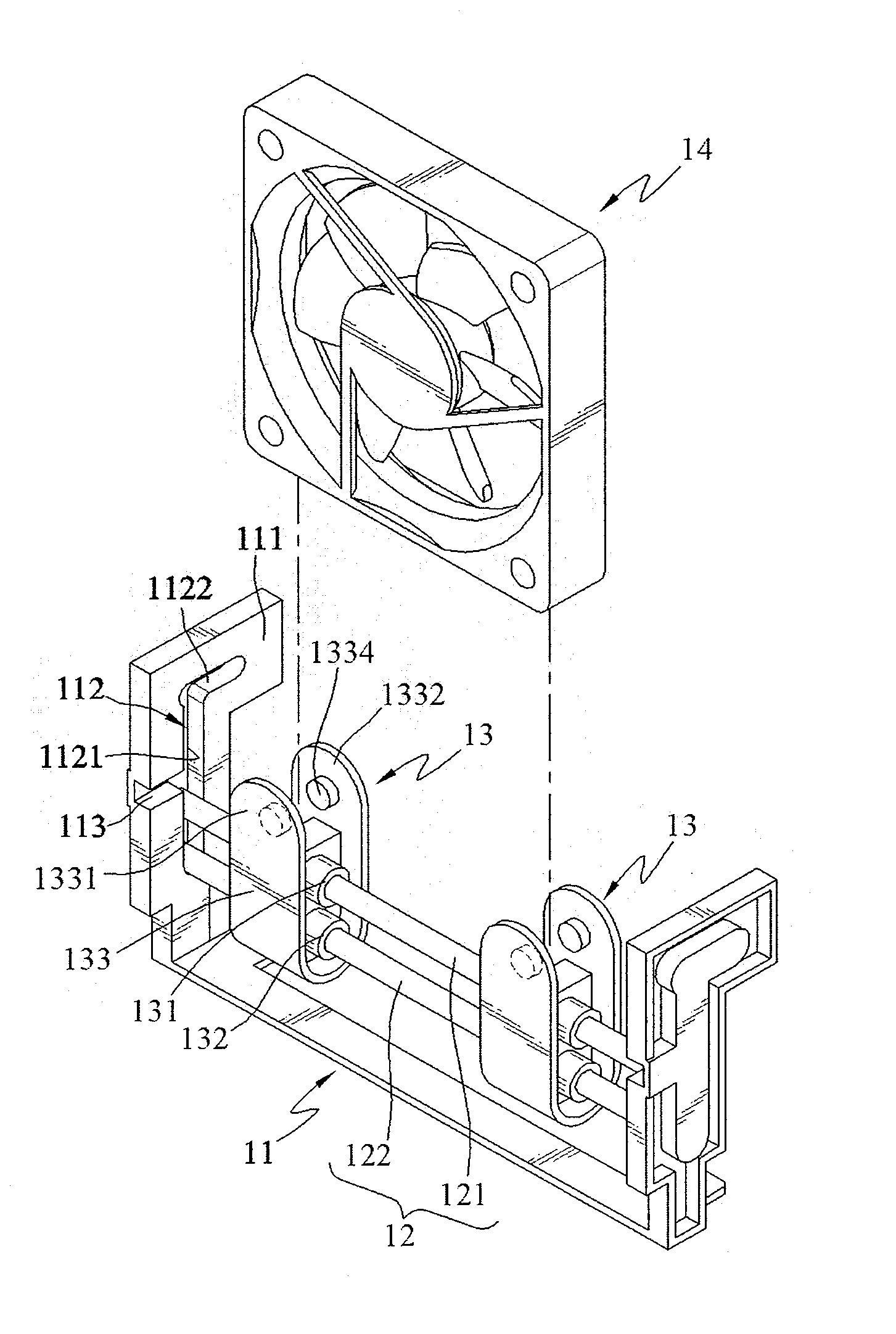

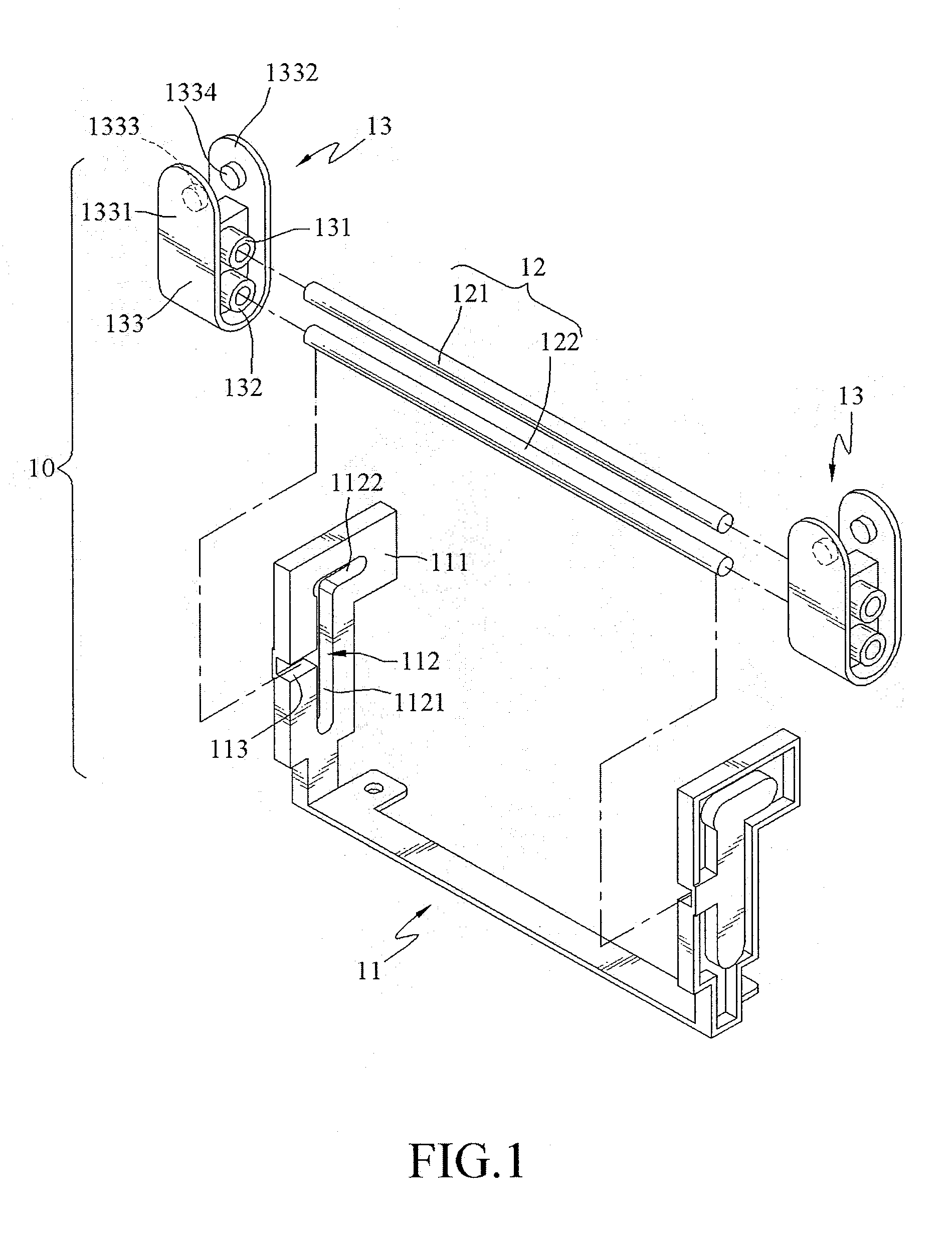

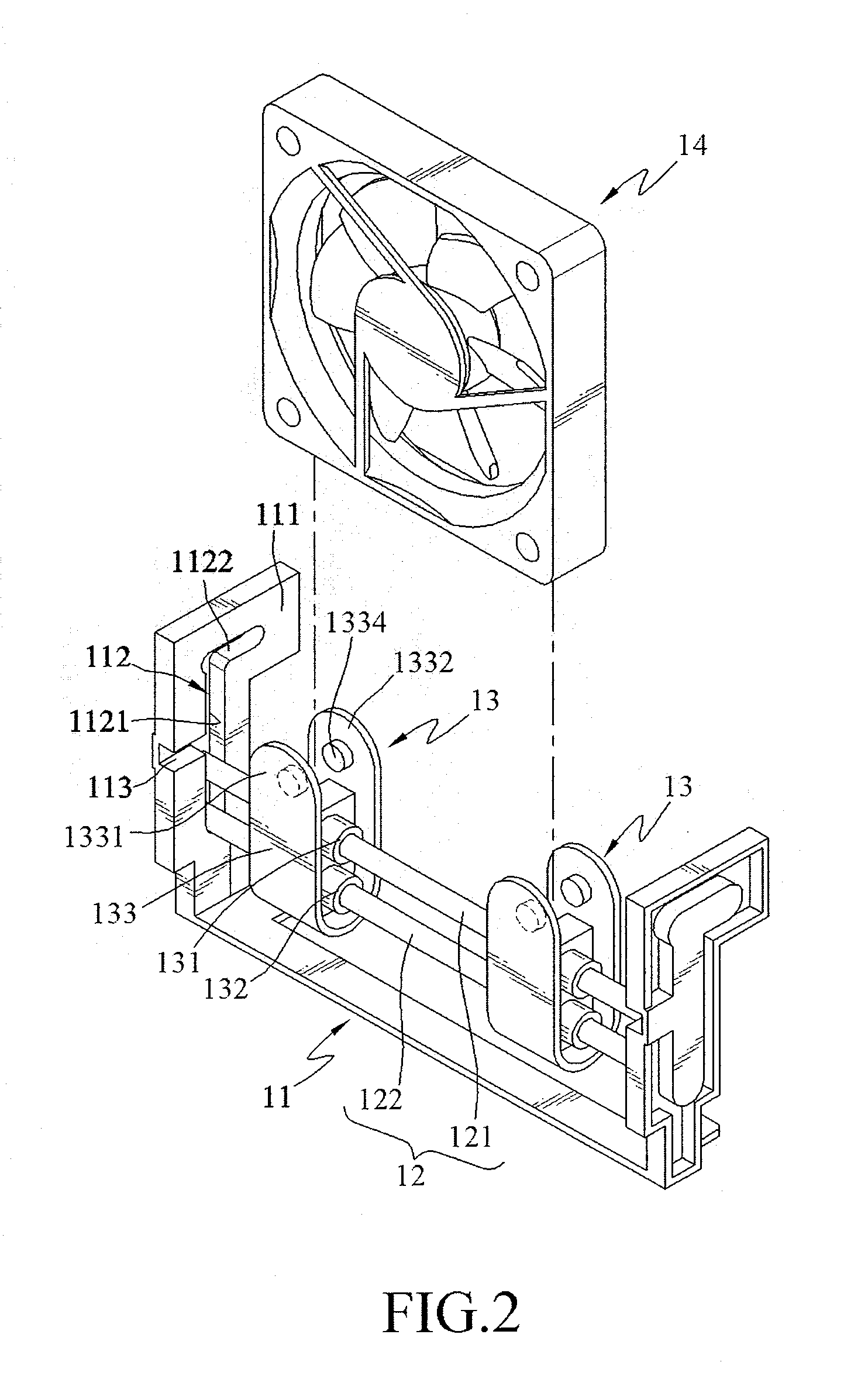

Heat dissipation device

InactiveUS7580259B2Digital data processing detailsCooling/ventilation/heating modificationsSoftware engineeringEngineering

A heat dissipation device for dissipating heat from a plug-in electronic component, such as a memory is provided. The heat dissipation device includes a base frame, a moving frame, and a retaining cover. The base frame is disposed at one side of the electronic component. The moving frame is movably mounted on the base frame. A heat dissipation fan is mounted on the retaining cover, and the retaining cover is also movably mounted on the moving frame. In this manner, the heat dissipation fan has at least a retraction position where the heat dissipation fan is not overlaid above the electronic components so as to plug or remove the electronic component, and a heat dissipation position where the heat dissipation fan dissipates heat from the corresponding electronic component. Furthermore, the heat dissipation position changes in accordance with actual heat dissipation requirements, thereby providing an optimal heat dissipation mode.

Owner:MICRO-STAR INTERNATIONAL

Image stabilizer, lens device and imager apparatus

InactiveUS20070133967A1Image can be preventedIncreasing costPrintersProjectorsOptical axisMoving frame

An image stabilizer includes a driver having a coil and magnet, where a correcting lens on a moving frame is moved by the driver in a first direction perpendicular to an optical axis of a lens system and in a second direction perpendicular to the first direction and optical axis, and an optical axis of the correcting lens corresponds with the optical axis of the lens system. The coil and magnet are fixed to the moving frame and a supporting frame; the driver includes first and second coils for moving the correcting lens in the first and second directions, and a magnet applying magnetic force to those coils; and thrust generated from the first and second coils are directed in the first and second directions, each forming an angle of approximately 45° with a line connecting the optical axis of the correcting lens and the center of a lens barrel.

Owner:SONY CORP

Image stabilizer, lens device and imaging apparatus

InactiveUS20070188620A1Increase consumptionIncrease temperatureTelevision system detailsPrintersMagnetic tension forceDriver/operator

An image stabilizer includes a driver having a coil and magnet, where a correcting lens on a moving frame is moved by the driver in a first direction perpendicular to an optical axis of a lens system and in a second direction perpendicular to the first direction and optical axis, and an optical axis of the correcting lens corresponds with the optical axis of the lens system. The coil and magnet are fixed to the moving frame and a supporting frame; the driver includes first and second coils for moving the correcting lens in the first and second directions, and a magnet applying magnetic force to those coils; and thrust generated from the first and second coils are directed in the first and second directions; a magnetic member attracted to or repelled by the magnet is provided in the vicinity of the first and second coils.

Owner:SONY CORP

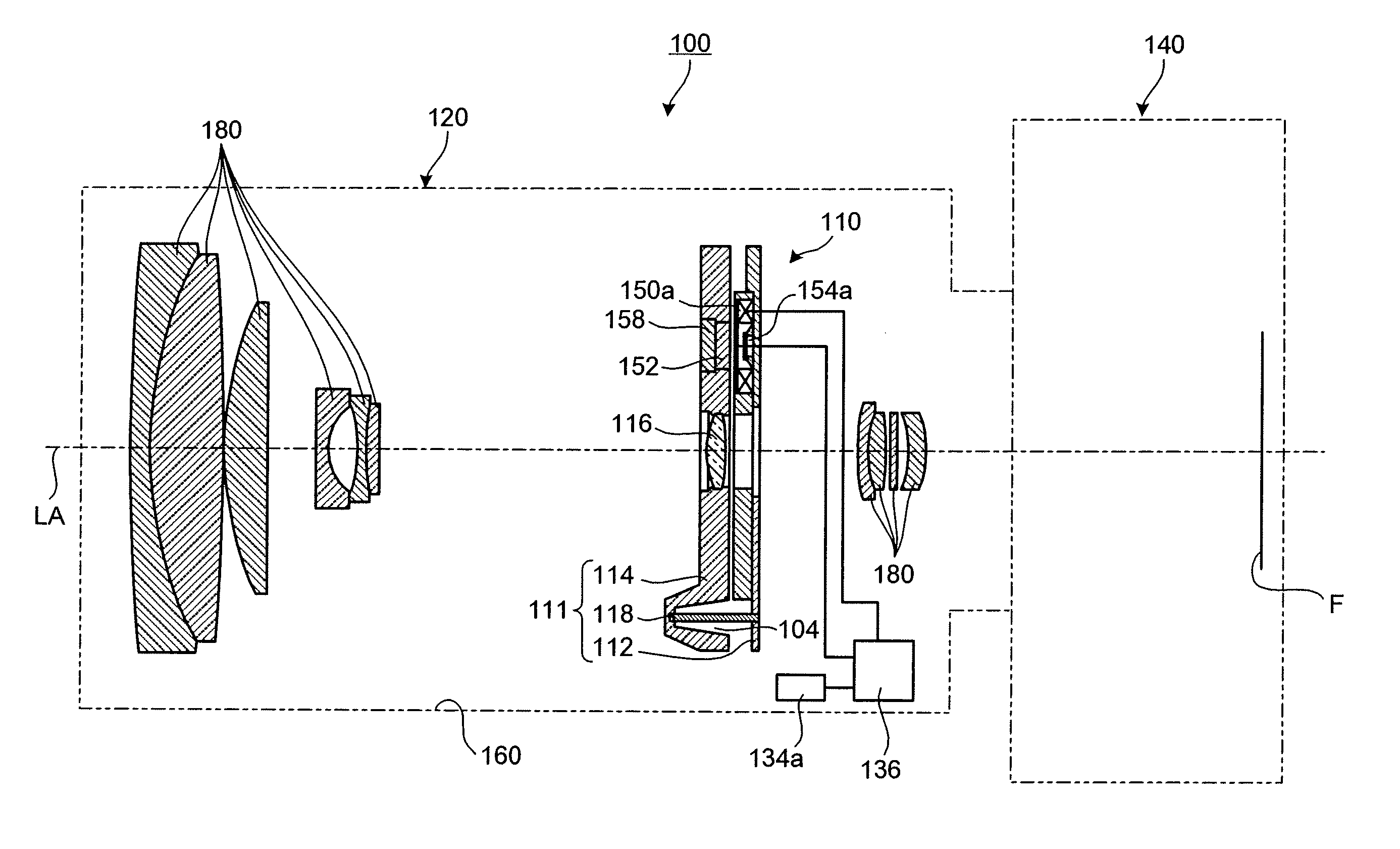

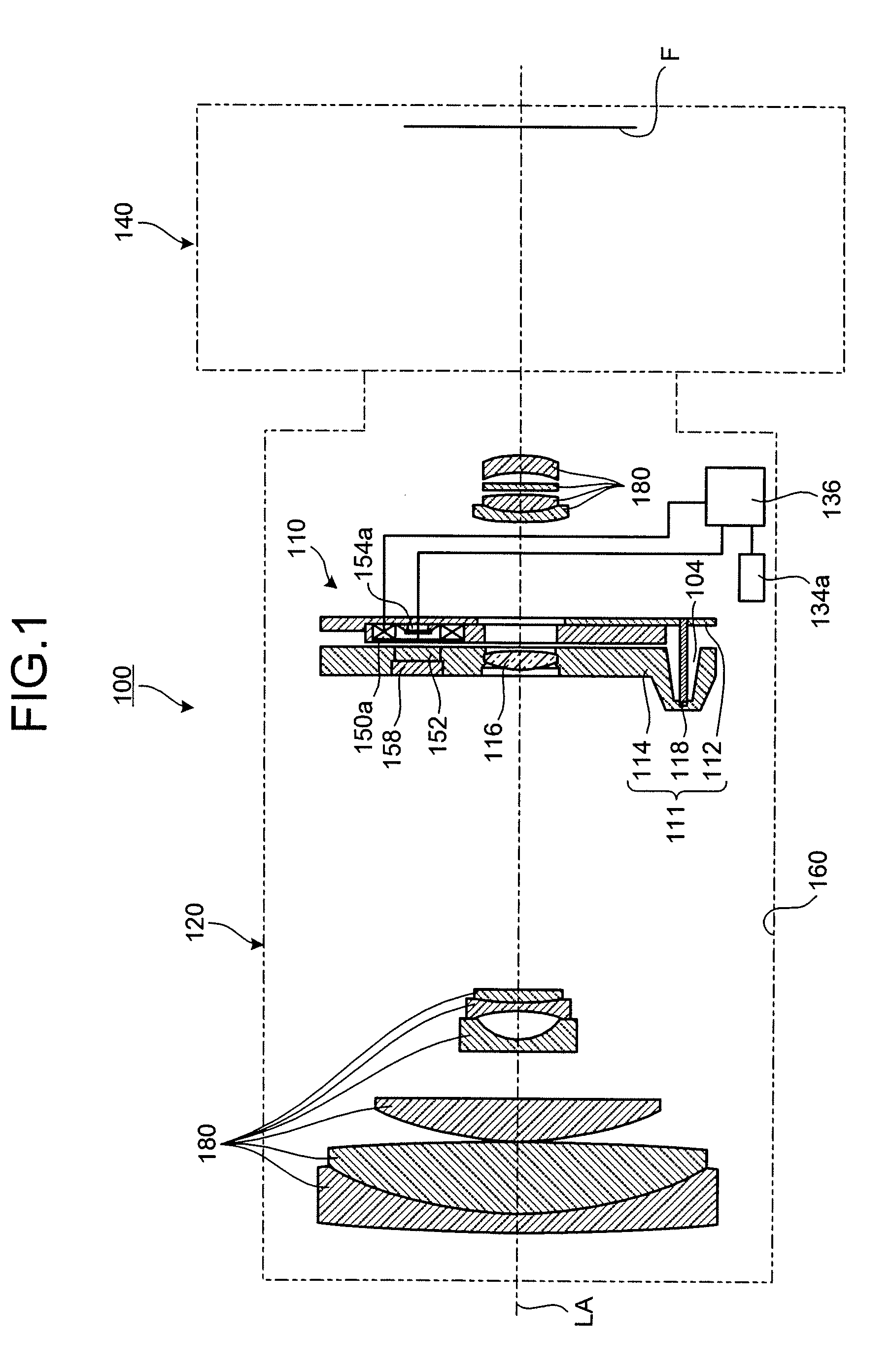

Parallel moving device, actuator, lens unit, and camera

A parallel moving device includes a fixed plate provided on an enclosure side, a moving frame provided on an optical system side, and three columnar members that are provided between the fixed plate and the moving frame and that support the fixed plate and the moving frame so as to enable movement of the moving frame in a direction substantially perpendicular to an optical axis of the optical system. These columnar members are formed with an elastic member that connects the fixed plate and the moving frame in the direction along the optical axis and supports the moving frame in parallel with the fixed plate.

Owner:TAMRON

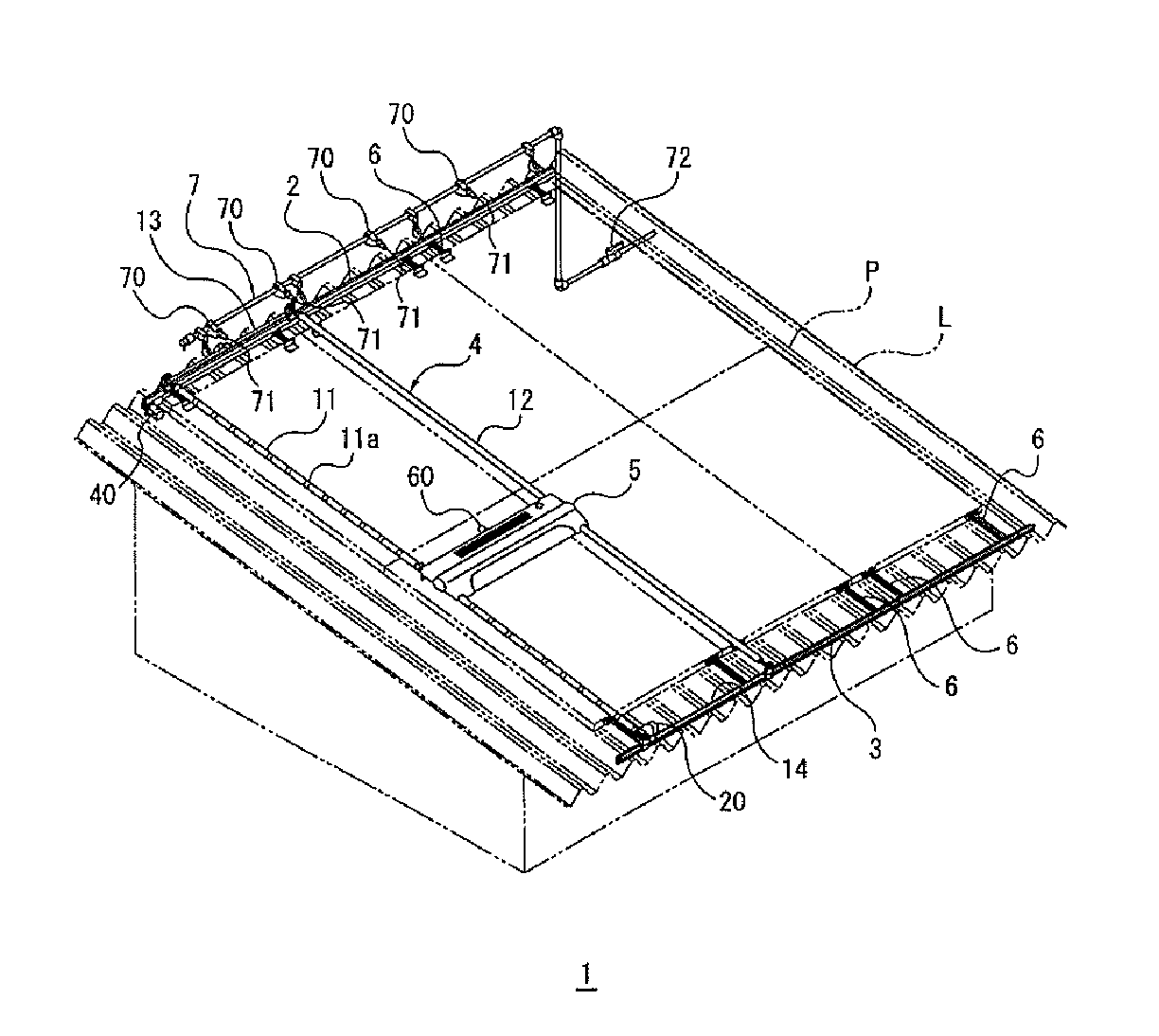

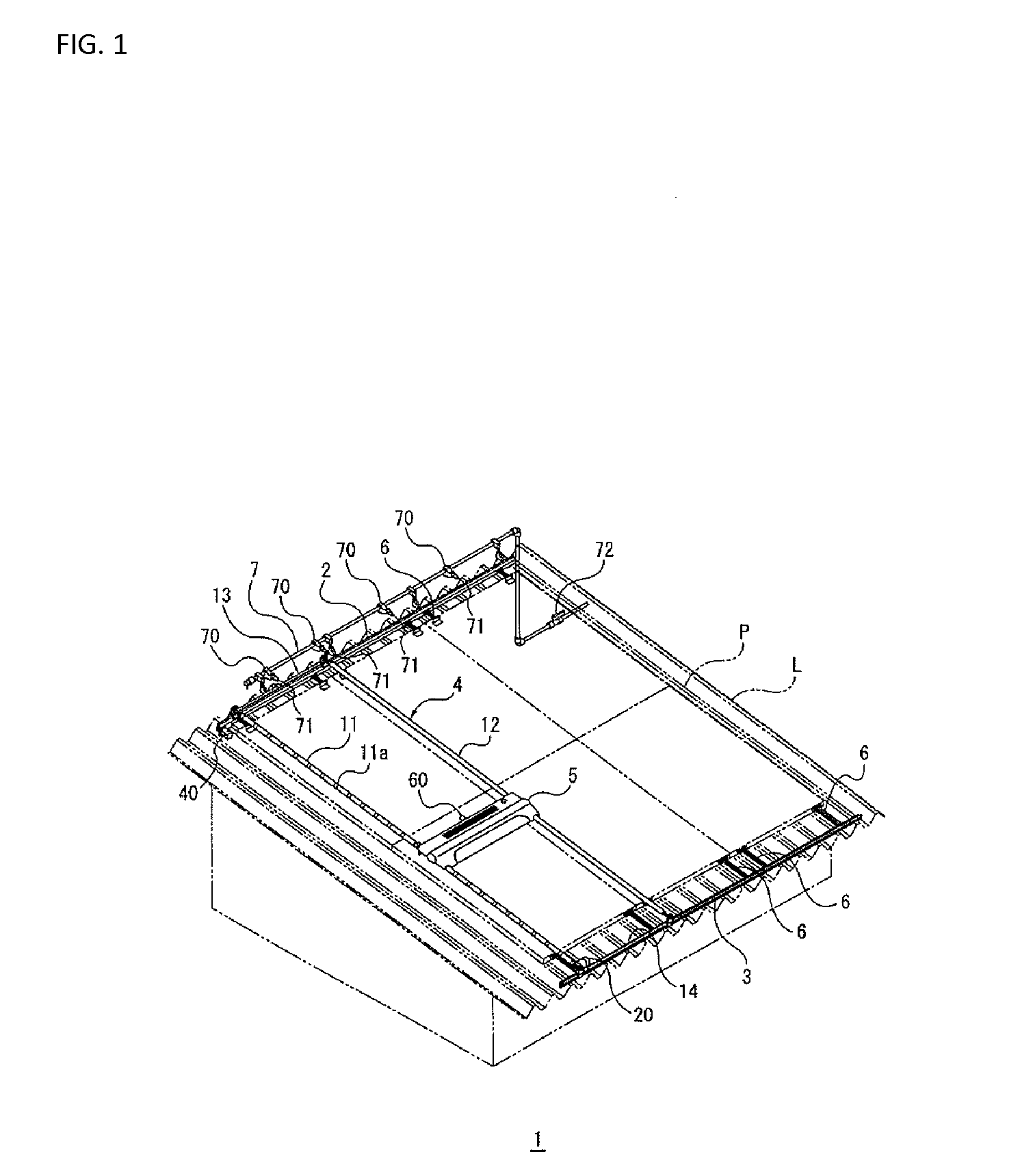

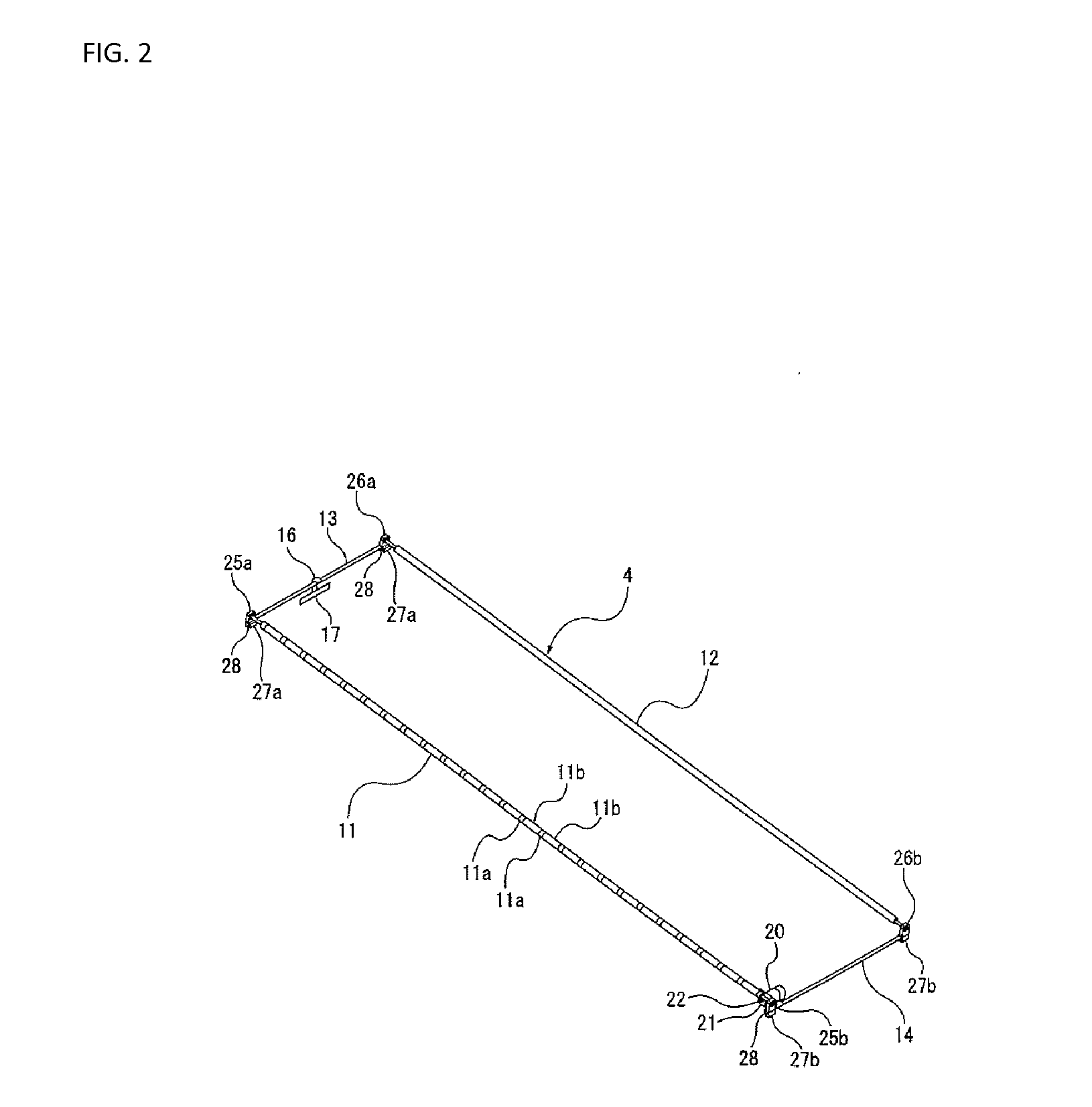

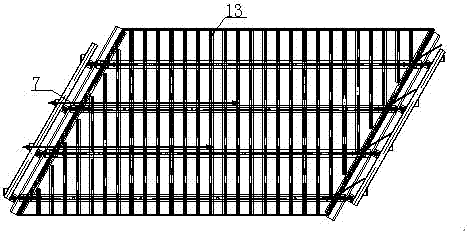

Solar Generation Panel Washing Device

InactiveUS20150244311A1Light weightSimple configurationSolar heating energyElectrostatic cleaningReciprocating motionEngineering

A solar generation panel washing device is provided with a pair of upper and lower fixed guide rails for providing along an upper end and a lower end respectively of a solar generation panel. Also provided is a moving frame for movement in a horizontal direction over the fixed guide rails, the moving frame being provided with a pair of left and right moving guide rails over which a cleaner element is for moving in a vertical direction. Washing an entire surface of the panel is possible through the movement in a vertical direction by the cleaner element and the movement in a horizontal direction by the moving frame. Rotary motion of one of the moving guide rails is transferred into reciprocating motion of the cleaner element in the vertical direction by a non-contact power transfer mechanism of magnetic members respectively provided to the moving guide rails and the cleaner element.

Owner:PROTRUST

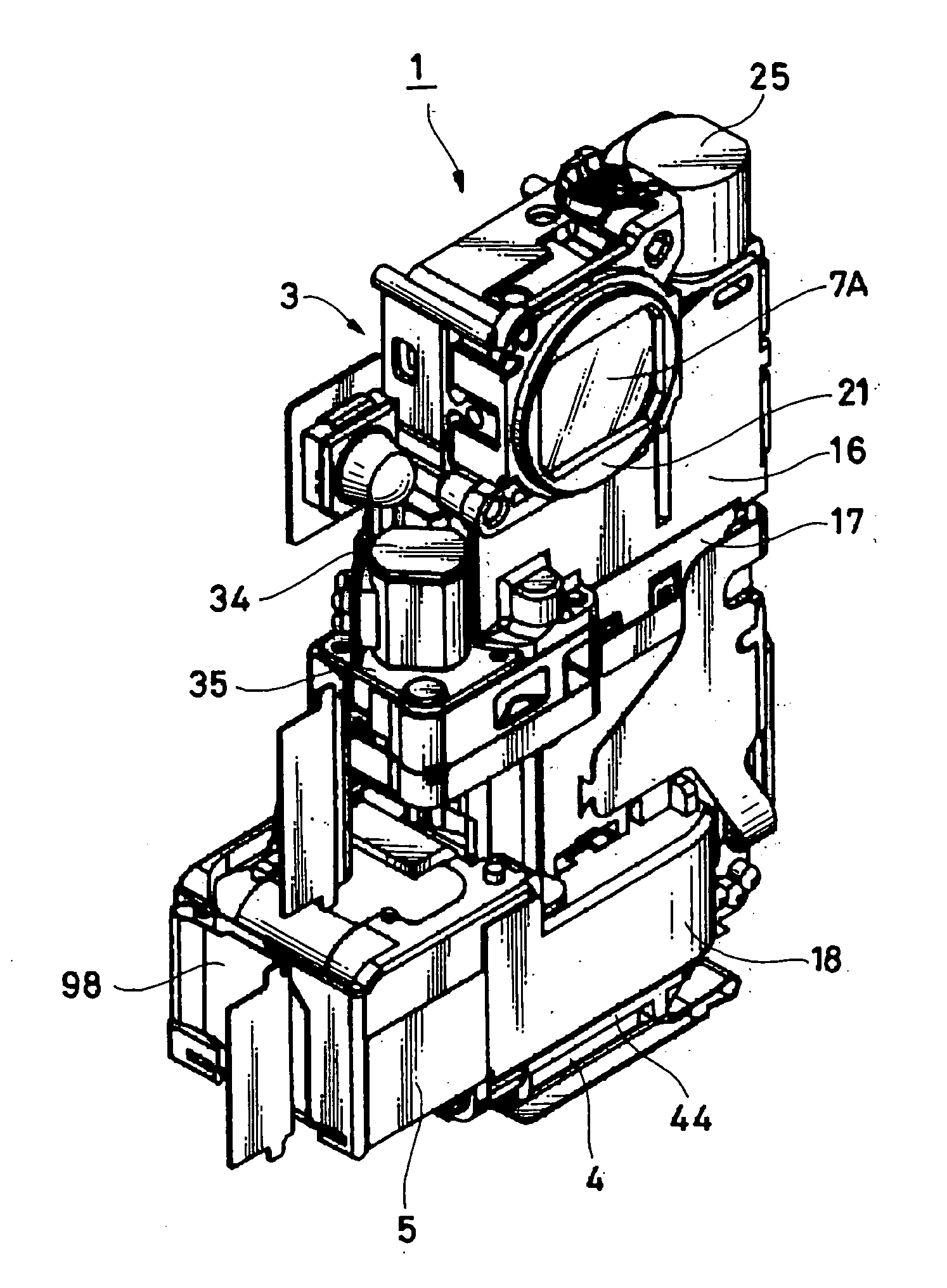

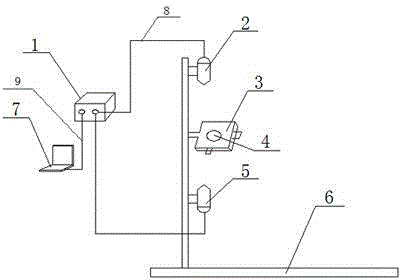

Aircraft engine mounting vehicle

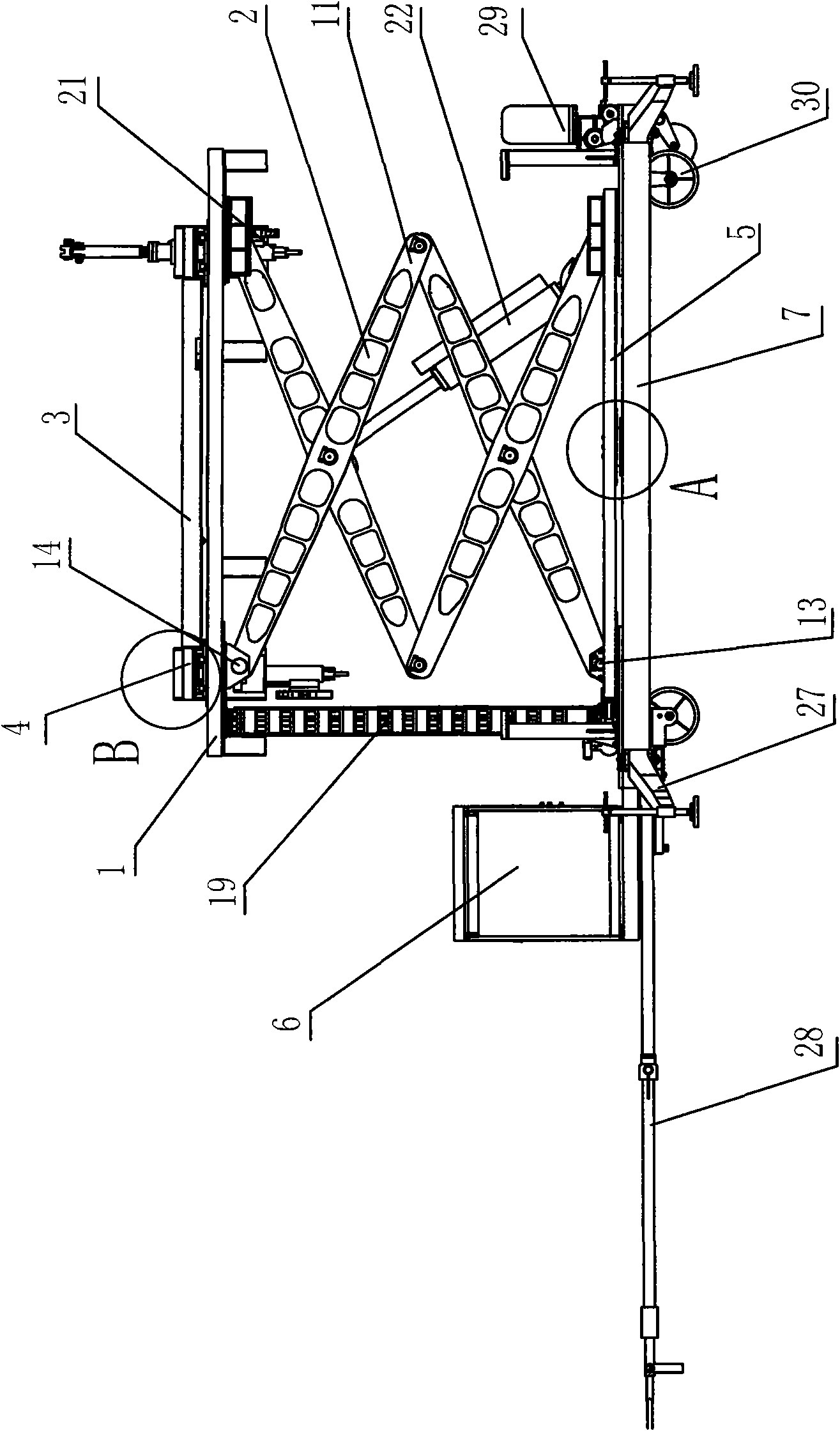

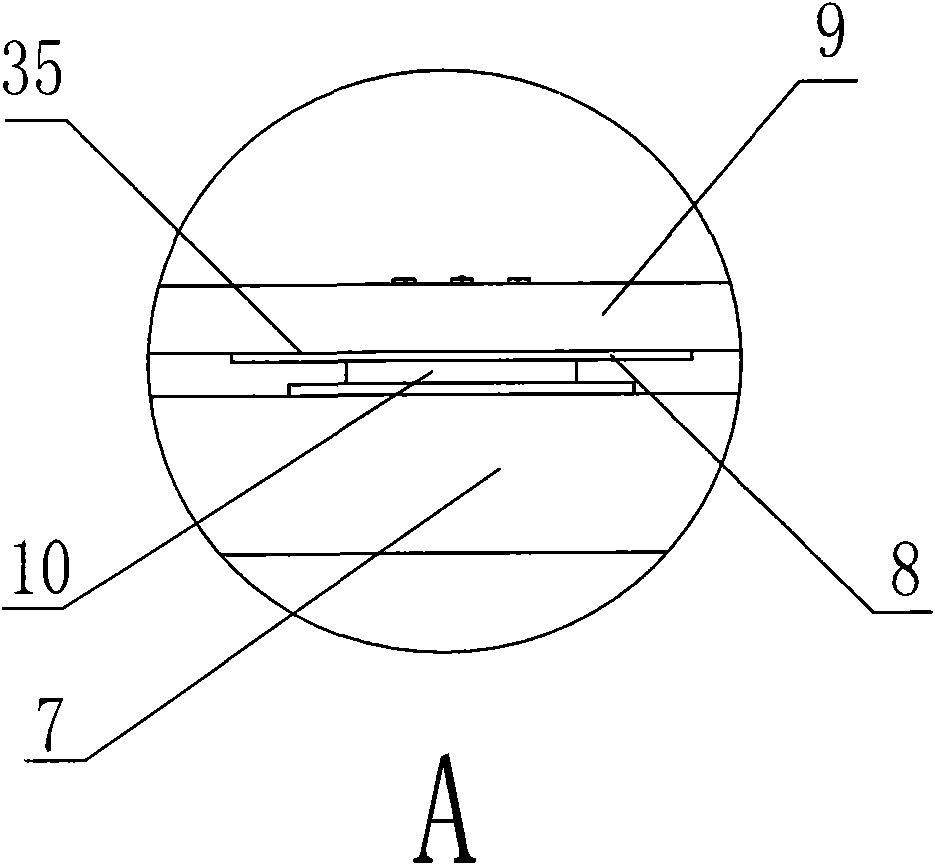

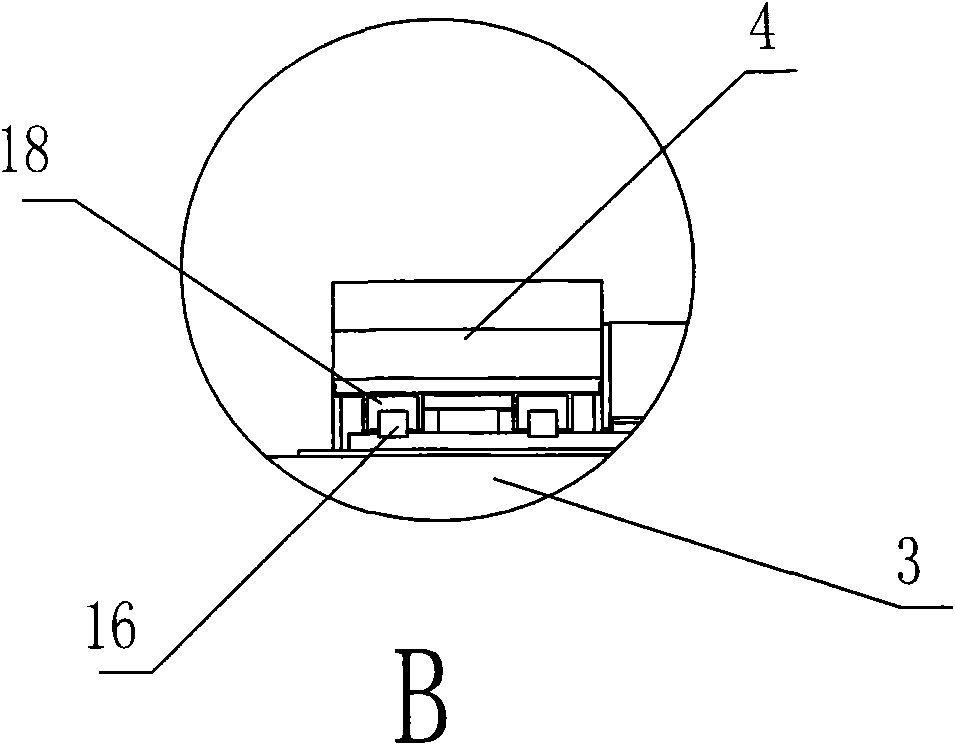

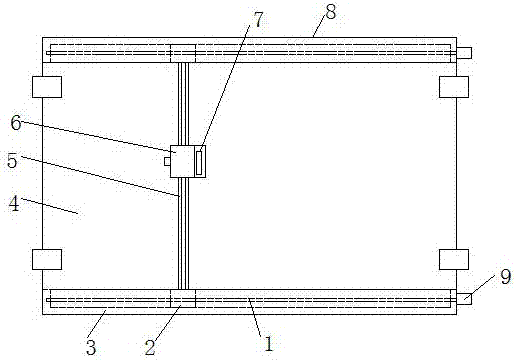

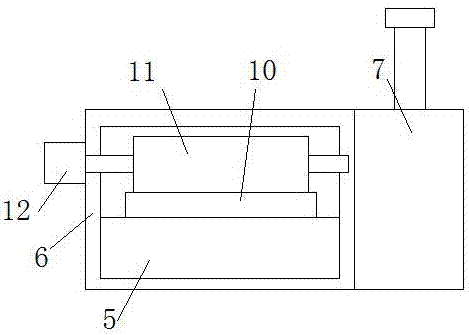

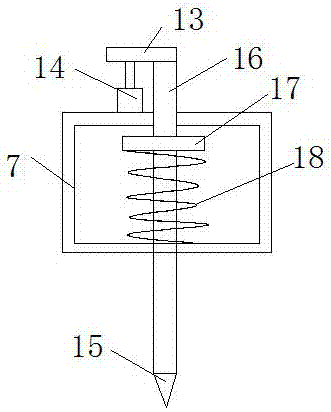

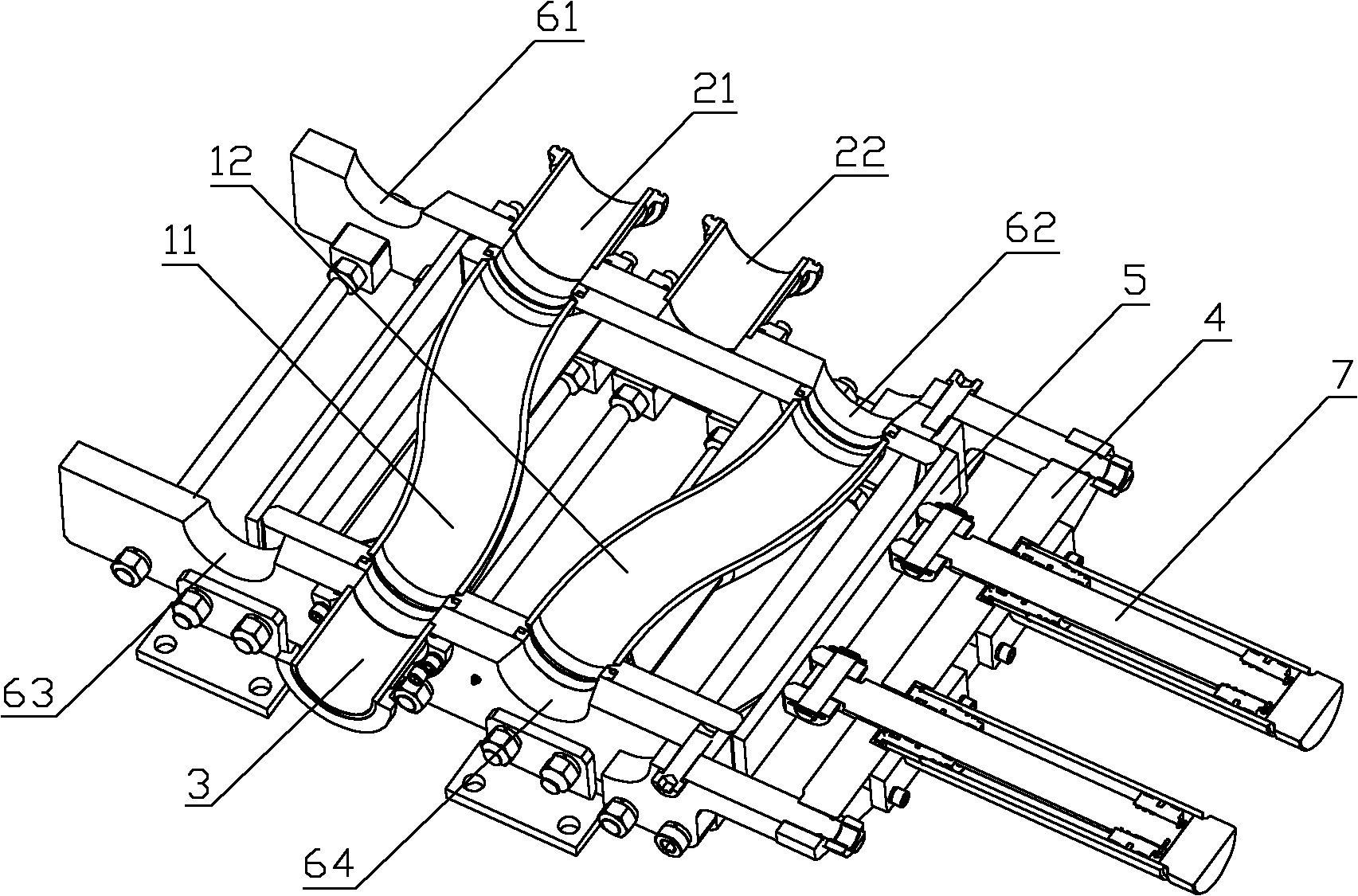

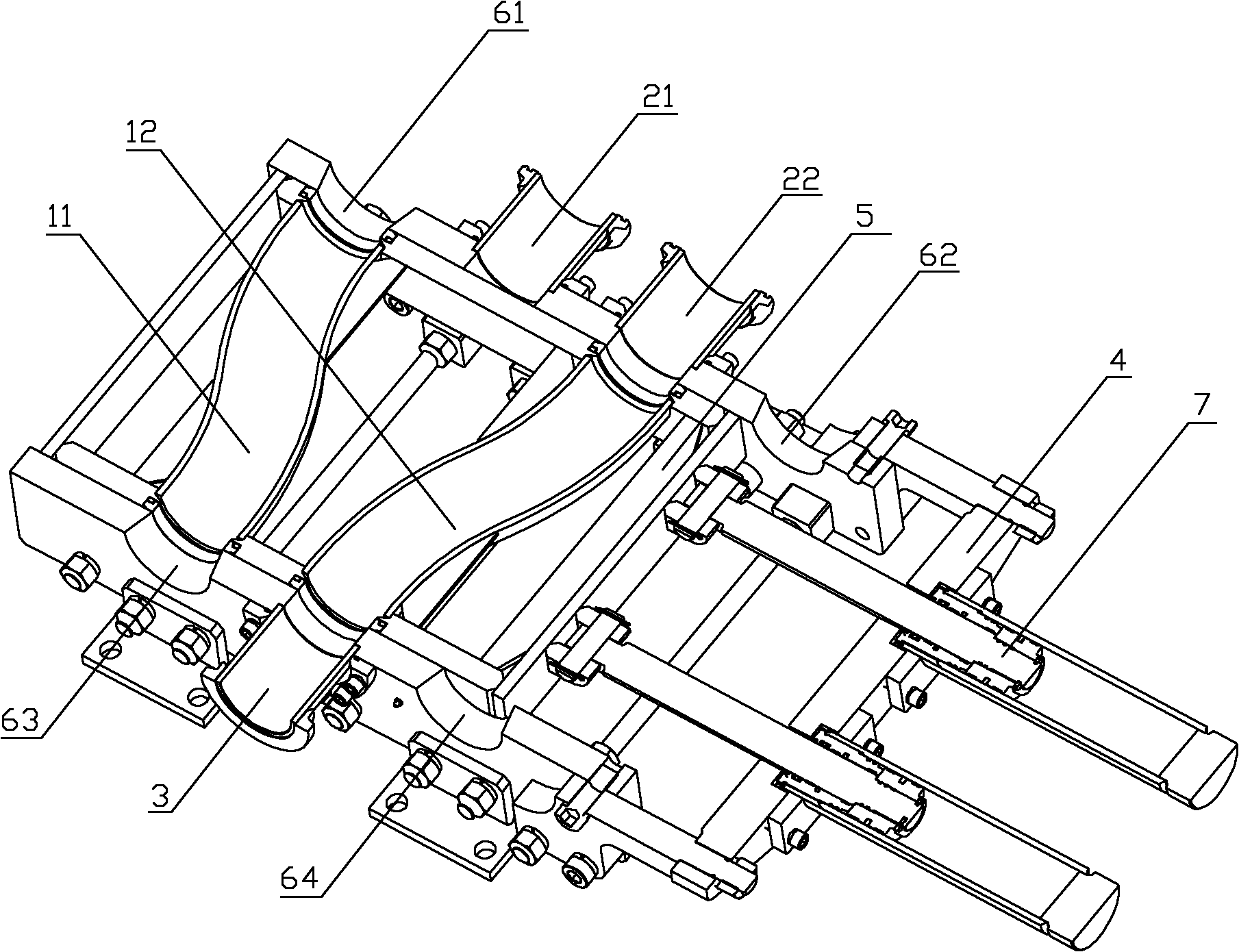

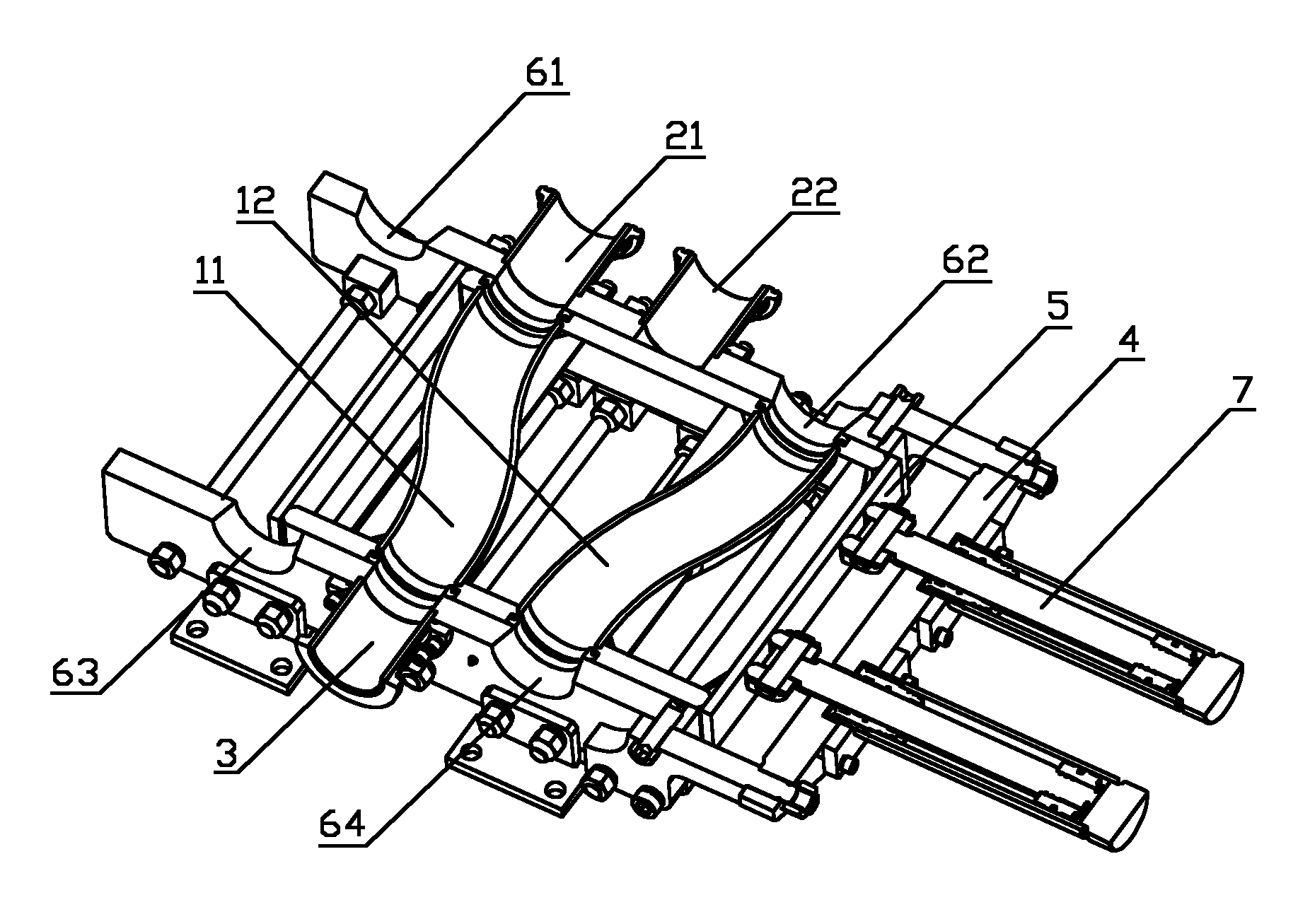

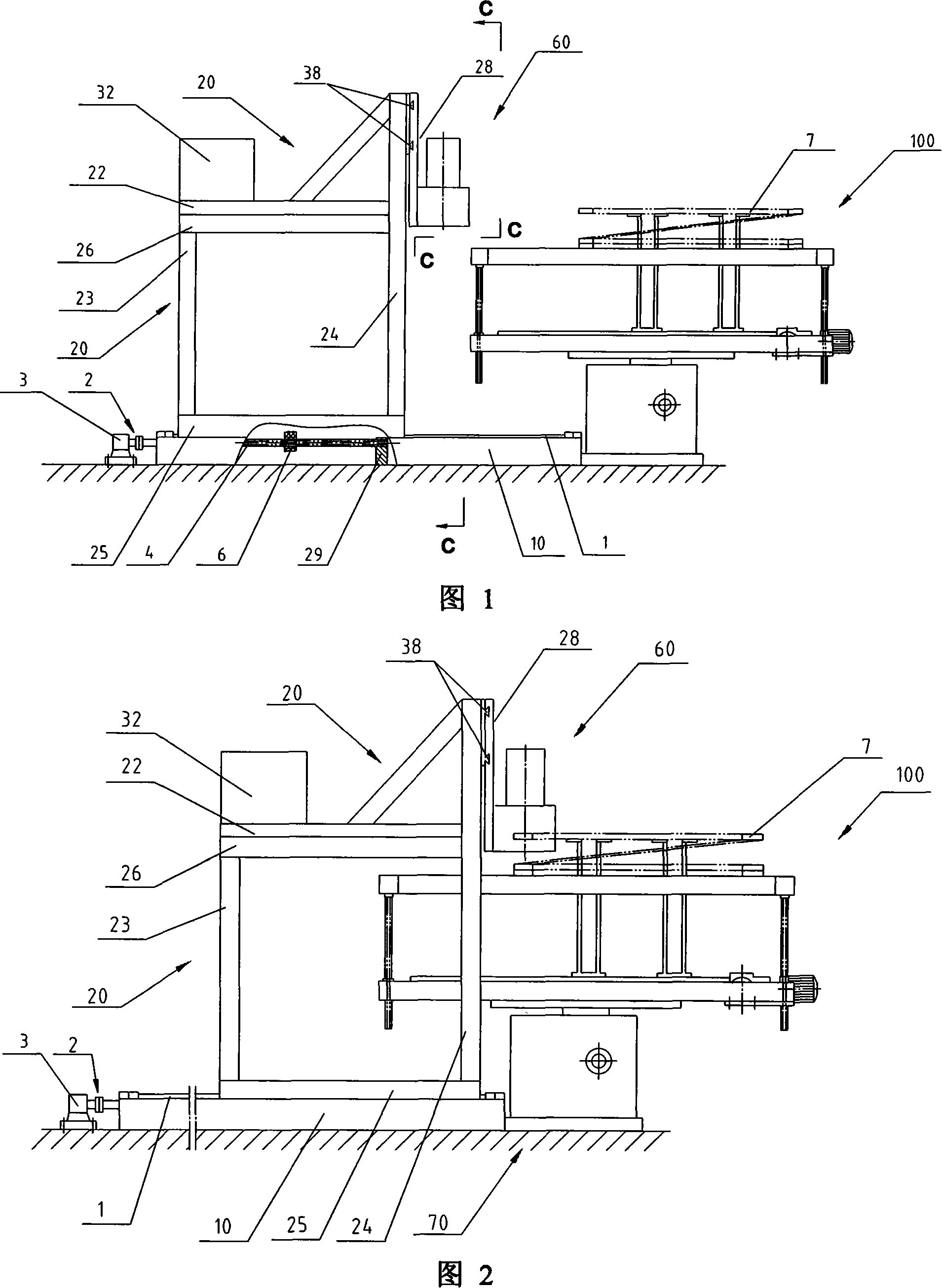

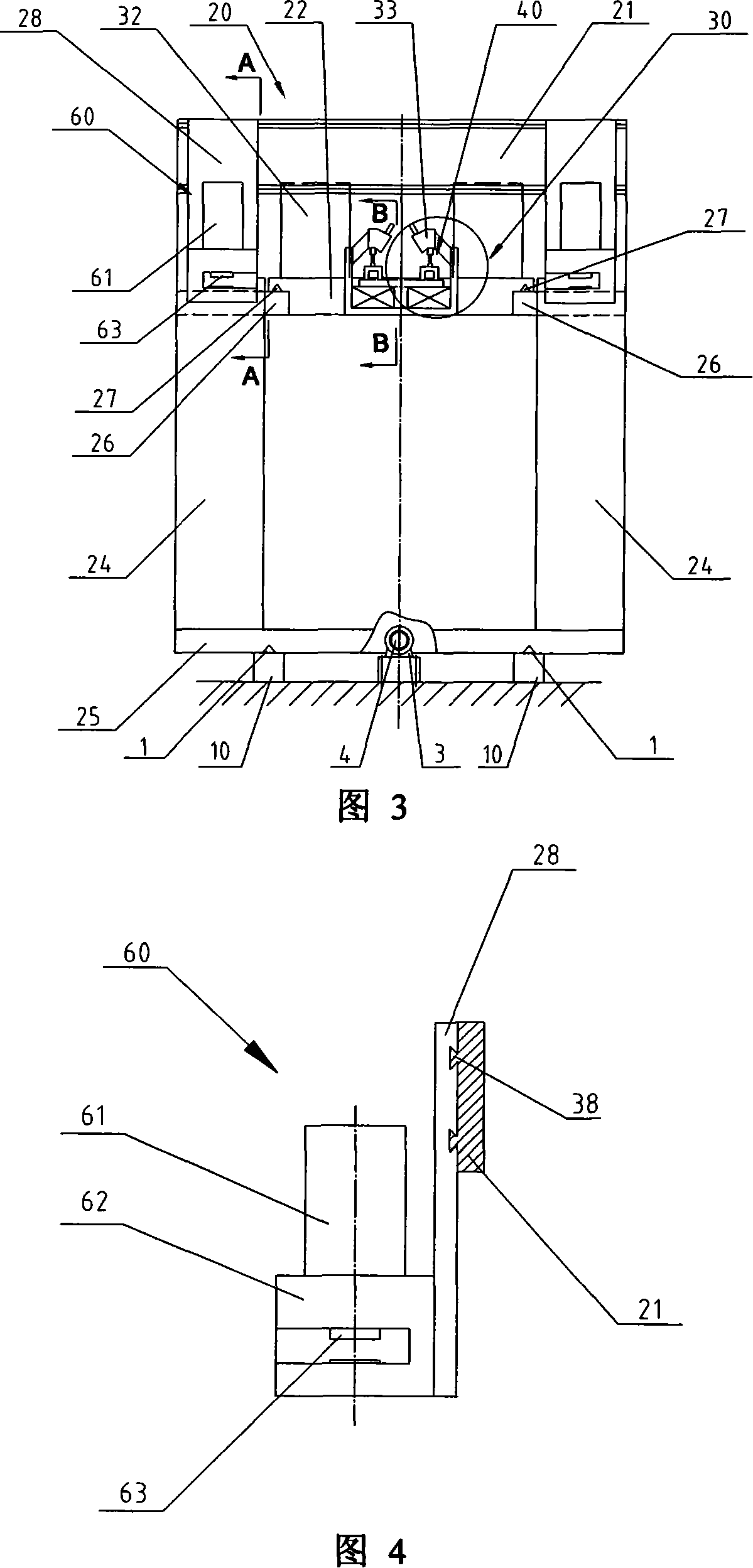

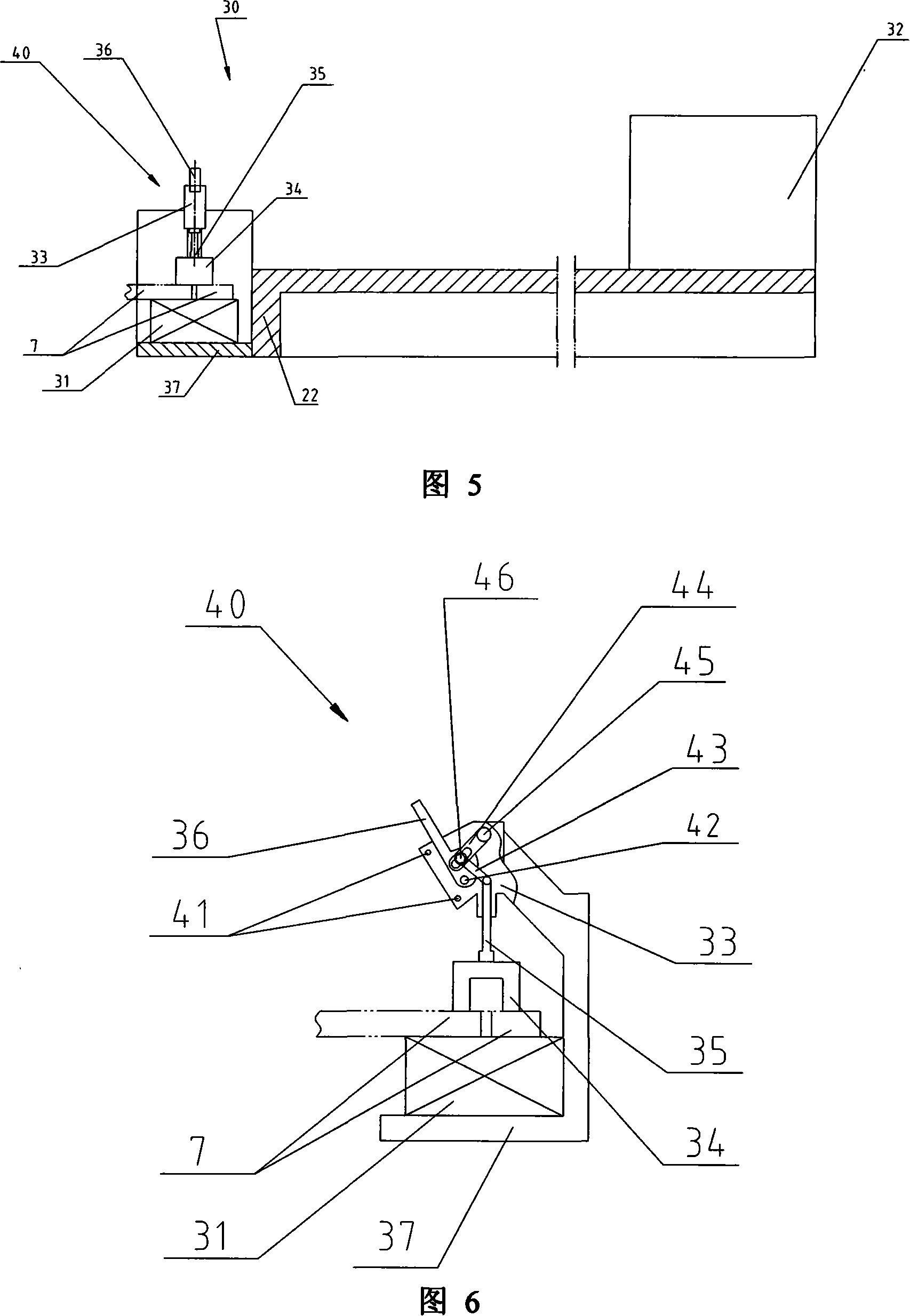

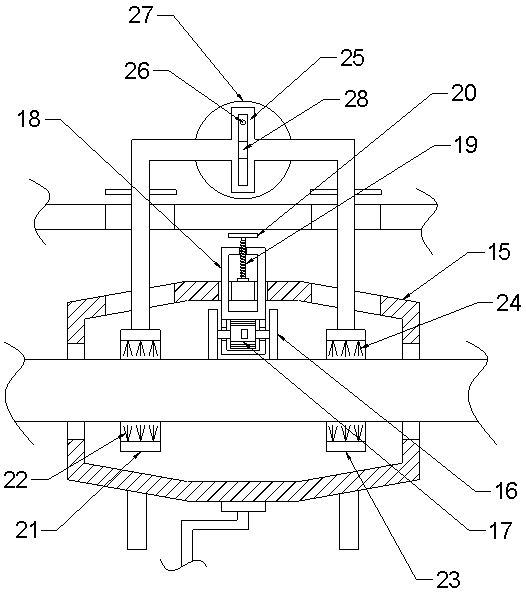

InactiveCN102009340AHigh loading and unloading positioning accuracyHigh degree of automationAircraft assemblyMetal working apparatusAviationControl system

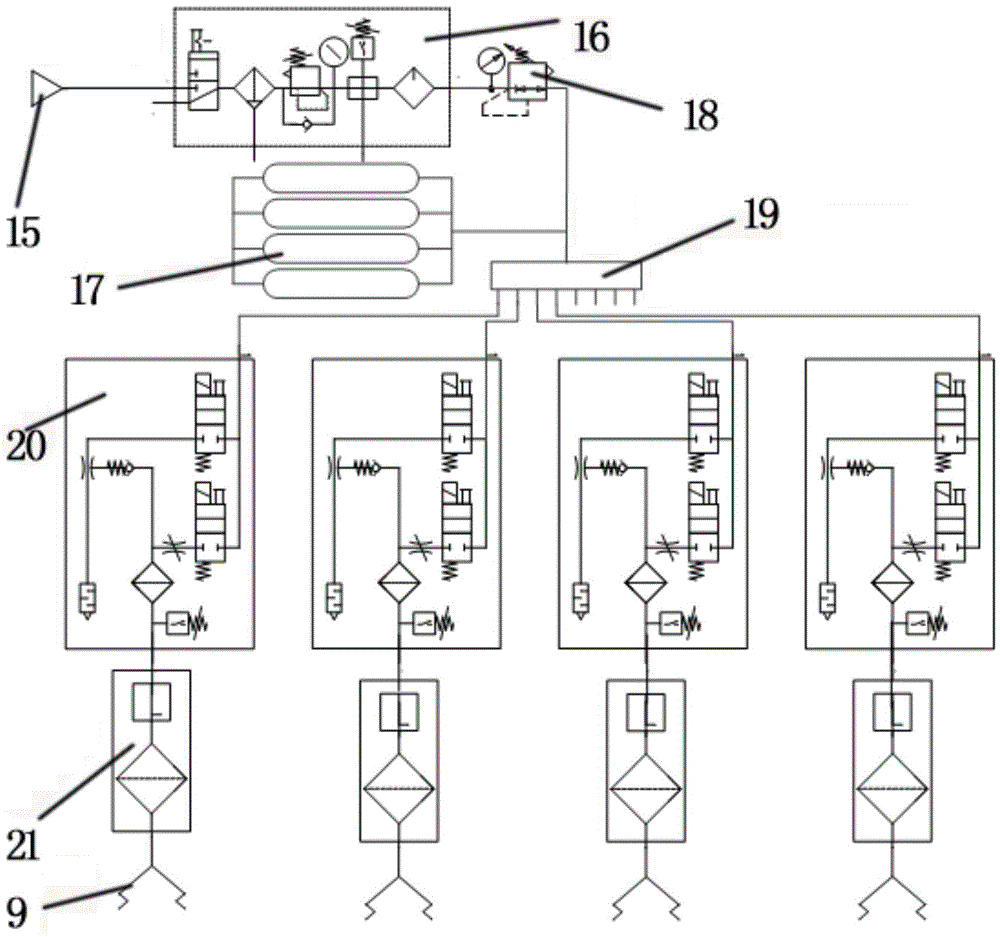

The invention discloses an aircraft engine mounting vehicle. The aircraft engine mounting vehicle comprises a lifting bracket (1), a shear type lifting mechanism (2), a back-and-forth moving frame (3), a left-right moving frame (4), a rotating disk mechanism (5), an electrohydraulic servo control system (6) and a vehicle body (7), wherein the lifting bracket (1) is provided with a longitudinal linear guide rail (15); the back-and-forth moving frame (3) is provided with a transverse linear guide rail (16) and a longitudinal slide block (17); the left-right moving frame (4) is provided with a transverse slide block (18); and the electrohydraulic servo control system (6) comprises a control unit (20) and an executing unit (21). In the aircraft engine mounting vehicle, a closed-loop servo control system consisting of the linear guide rail, a high-accuracy sensor, a high-response spaceflight servo valve, a precise servo oil cylinder and a programmable logic controller (PLC) is adopted, so 0.1mm absolute accuracy fine adjustment can be realized; and the aircraft engine mounting vehicle has the advantages of improving the aircraft engine assembling and disassembling efficiency and reducing the assembling and disassembling cost, along with high assembling, disassembling and positioning accuracy of an engine, and high automation degree and maneuverability.

Owner:成都立航科技股份有限公司

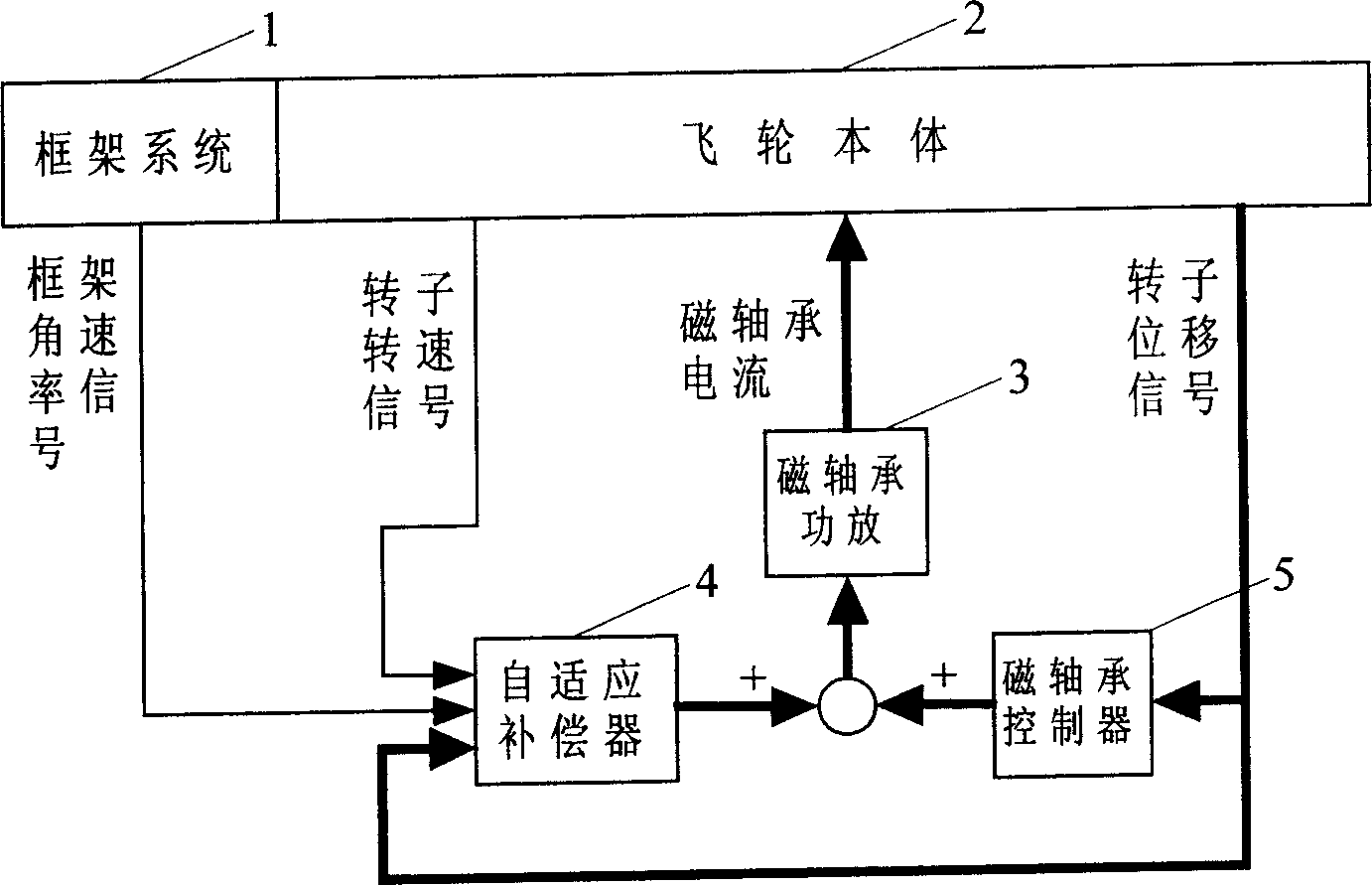

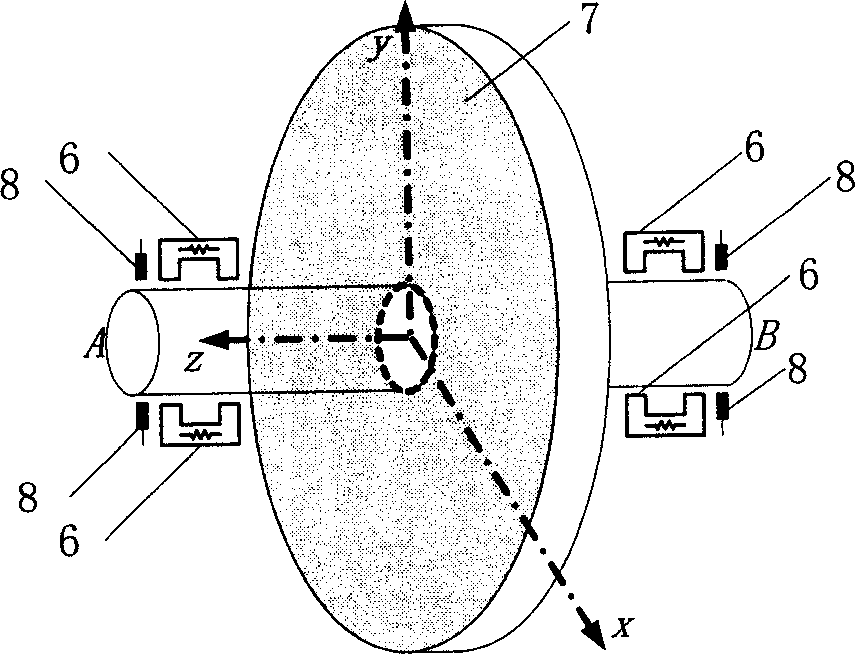

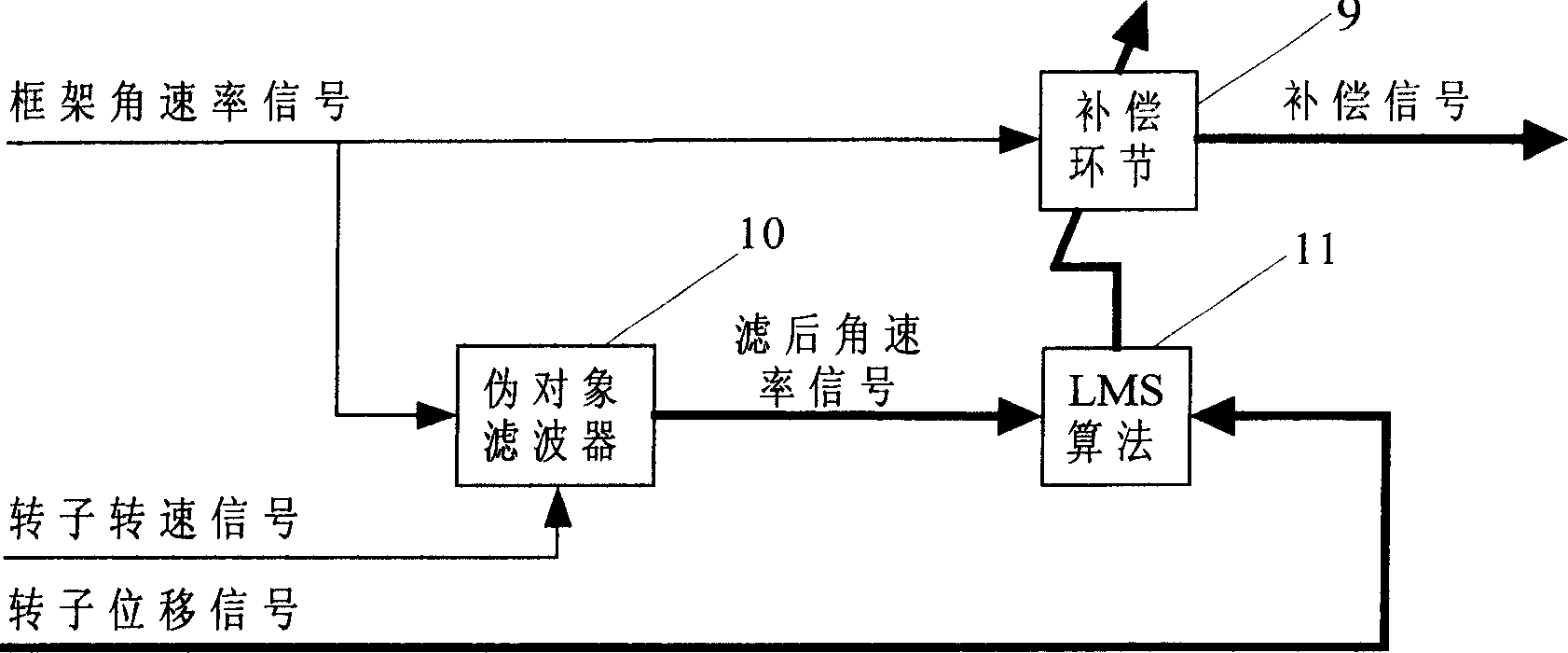

Magnetic bearing control system of accurately compensating magnetic suspension control torque gyroscope support rigidity

InactiveCN1710800AAvoid the risk of increased displacementDoes not intensifyMagnetic holding devicesMagnetic bearingGyroscope

The disclosed control system includes flywheel body, power amplifier for magnetic bearing, controller for magnetic bearing and adaptive compensator. Through collecting signals including angular rate of frame, speed of rotor, and displacement of rotor, the adaptive compensator carries out adaptive compensation calculation. Sum of calculated compensation quantity and the output of controller for magnetic bearing is connected to the power amplifier for magnetic bearing in order to eliminate disturbing moment on rotor of magnetic suspension caused by moving frame. The invention lowers displacement of rotor caused by rotation of frame, raises response speed and precision of angular rate of frame, and improves response speed and precision of moment output of magnetic suspension control moment.

Owner:BEIHANG UNIV

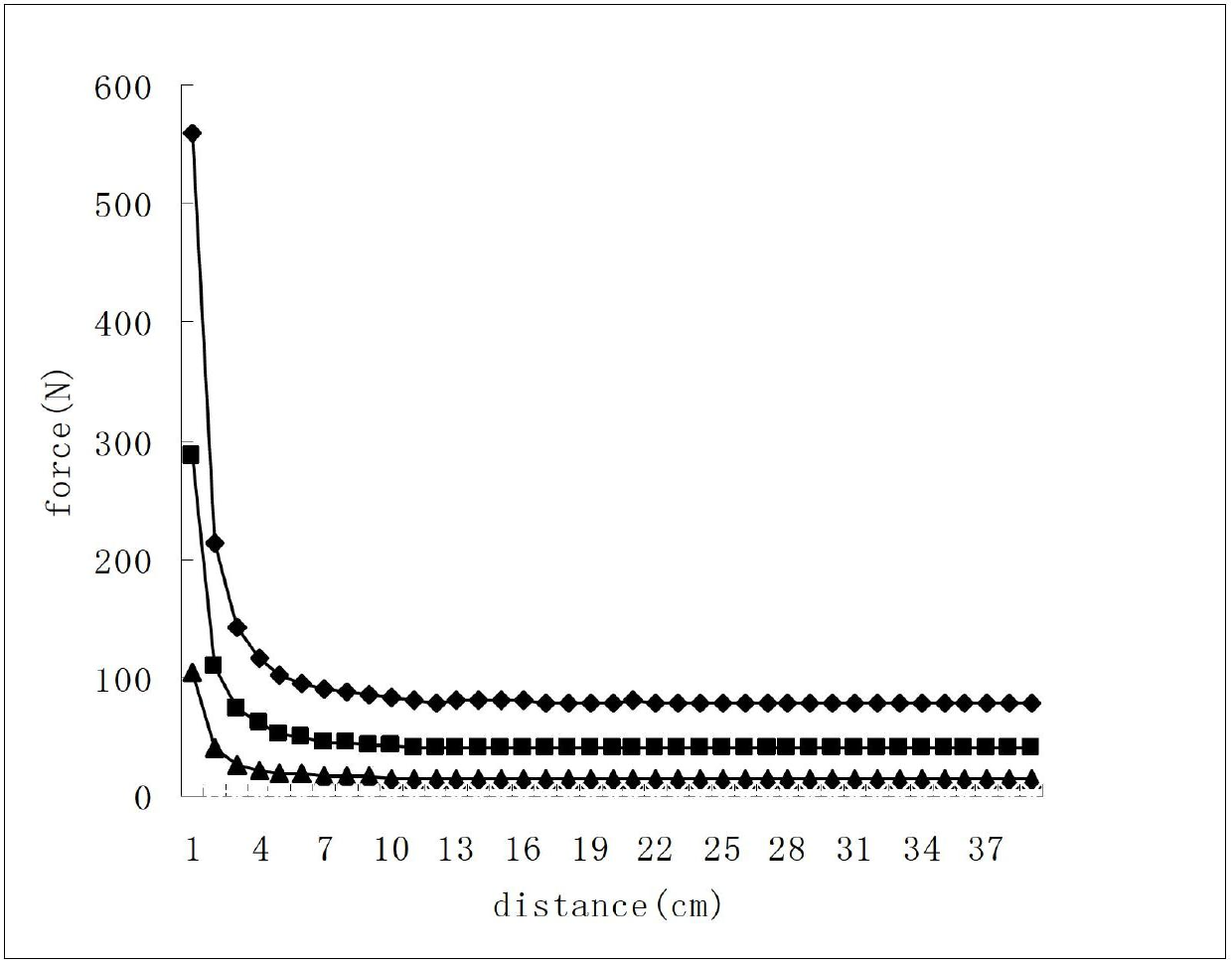

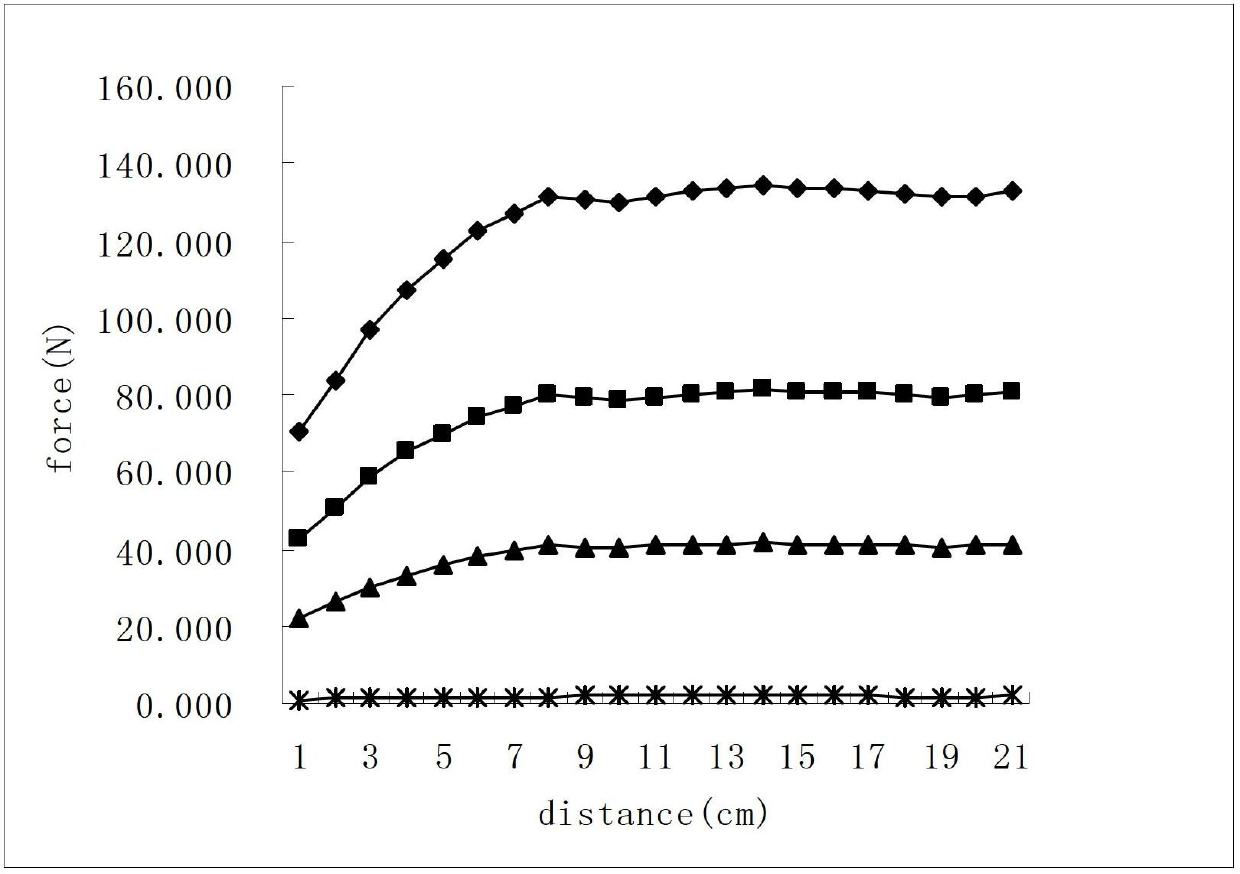

Non-contact engine thrust testing method and device

InactiveCN102680238AGet actual thrustAffecting workEngine testingApparatus for force/torque/work measurementMoving frameLinear fitting

The invention provides a non-contact engine thrust testing method and a non-contact engine thrust testing device. The method comprises the following steps of performing analog calculation by using computational fluid dynamic (CFD) software to acquire the radius of a smooth supporting panel which can accord with the condition that an engine can work normally and determine the critical mounting distance; and determining the mounting position of the testing device according to an analog calculation result, obtaining a relation between thrust and the distance by a plurality of times of non-contact measurement, performing first-order linear fitting and obtaining the thrust value at a position in which the mounting distance is 0 by using a linear fitting equation, wherein the thrust value is a pneumatic thrust value generated by the engine. The method and the device do not have an obvious requirement on the structure of the engine; the engine body is not required to be mounted on a moving frame; a phenomenon that the panel cannot be smoothly mounted is avoided; and the actual thrust generated by the engine can be obtained by performing thrust measurement a plurality of points.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

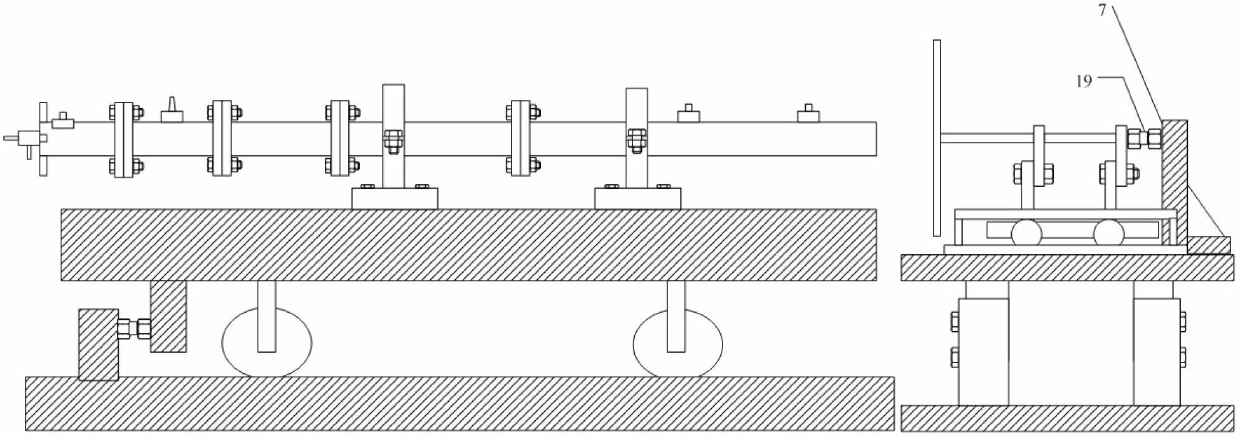

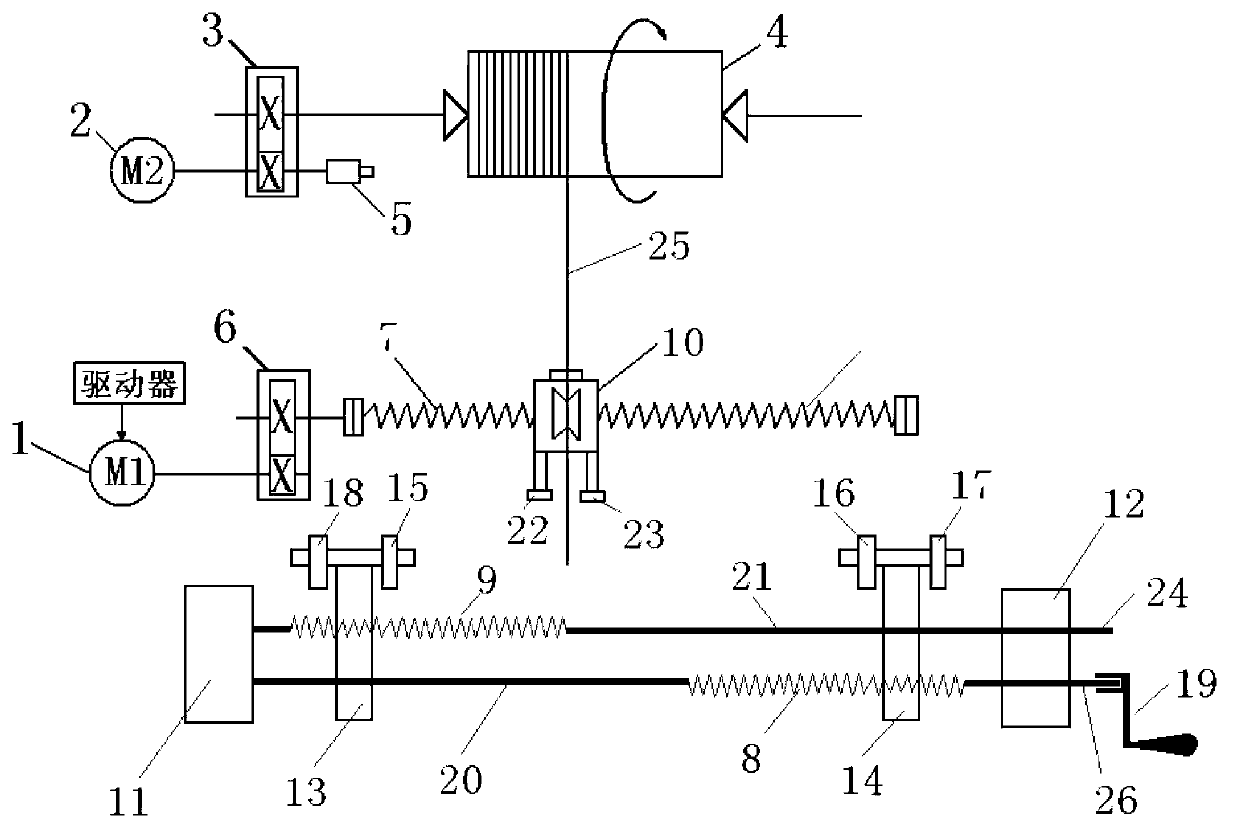

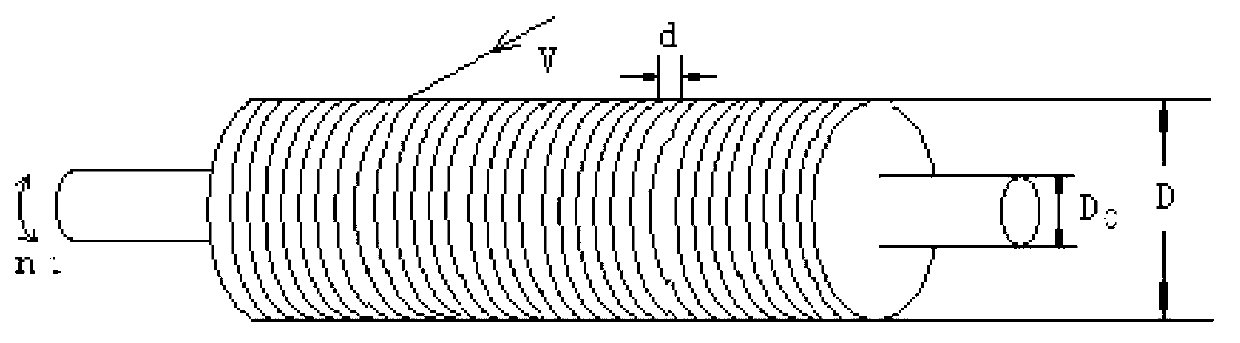

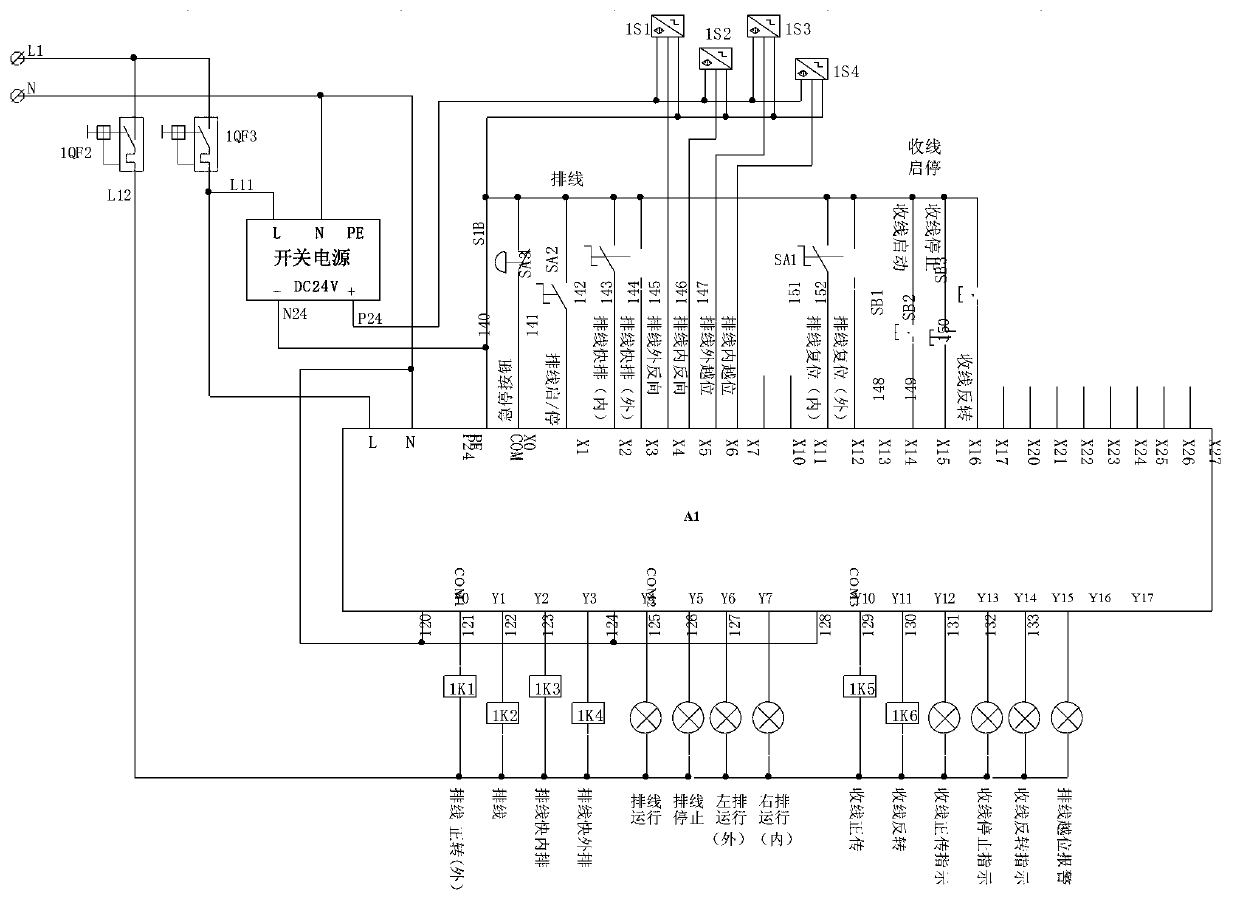

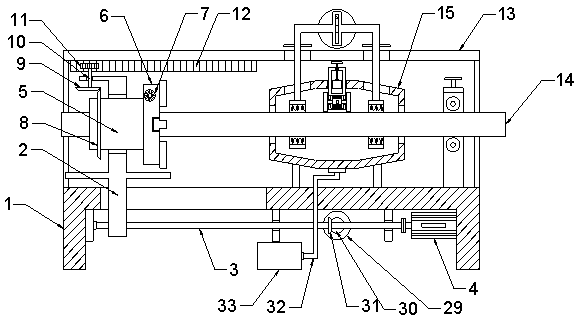

Automatic wire and cable take-up and winding displacement device

ActiveCN103021576AAutomatically adjust cable spacingLarge adjustment rangeFilament handlingCable/conductor manufactureEngineeringConductor Coil

The invention discloses an automatic wire and cable take-up and winding displacement device. The automatic wire and cable take-up and winding displacement device comprises a rolling motor, a take-up reel and an automatic winding displacement mechanism. The take-up reel is under drive control of the rolling motor, the automatic winding displacement mechanism comprises a winding displacement mechanism and an automatic reversing mechanism, the winding displacement mechanism comprises a winding displacement lead screw and a winding displacement machine, the winding displacement lead screw is driven by a winding displacement motor, the winding displacement machine is mounted on the winding displacement lead screw, the winding displacement machine and the winding displacement lead screw form a nut and lead screw machine structure, the automatic reversing mechanism comprises a left reversing proximity switch and a right reversing proximity switch, and the left reversing proximity switch and the right reversing proximity switch are mounted on two lower sides of the winding displacement machine, respectively correspond to two ends of the winding displacement machine, are controlled by a controller and are respectively mounted on a left moving frame and a right moving frame. The automatic wire and cable take-up and winding displacement device is provided with the automatic winding displacement mechanism comprising the winding displacement mechanism and the automatic reversing mechanism, the winding displacement mechanism comprises the winding displacement machine and the winding displacement lead screw which form the nut and lead screw machine structure, the automatic reversing mechanism is provided with the two reversing proximity switches controlled by the controller, and accordingly problems of high mechanical abrasion and loud noise when a gear structure is used for reversing are avoided.

Owner:郑州天河通信科技有限公司 +2

Heat dissipation device

InactiveUS20060291170A1Increase costHeat dissipationDigital data processing detailsCooling/ventilation/heating modificationsSoftware engineeringElectronic component

A heat dissipation device for dissipating heat from a plug-in electronic component, such as a memory is provided. The heat dissipation device includes a base frame, a moving frame, and a retaining cover. The base frame is disposed at one side of the electronic component. The moving frame is movably mounted on the base frame. A heat dissipation fan is mounted on the retaining cover, and the retaining cover is also movably mounted on the moving frame. In this manner, the heat dissipation fan has at least a retraction position where the heat dissipation fan is not overlaid above the electronic components so as to plug or remove the electronic component, and a heat dissipation position where the heat dissipation fan dissipates heat from the corresponding electronic component. Furthermore, the heat dissipation position changes in accordance with actual heat dissipation requirements, thereby providing an optimal heat dissipation mode.

Owner:MICRO-STAR INTERNATIONAL

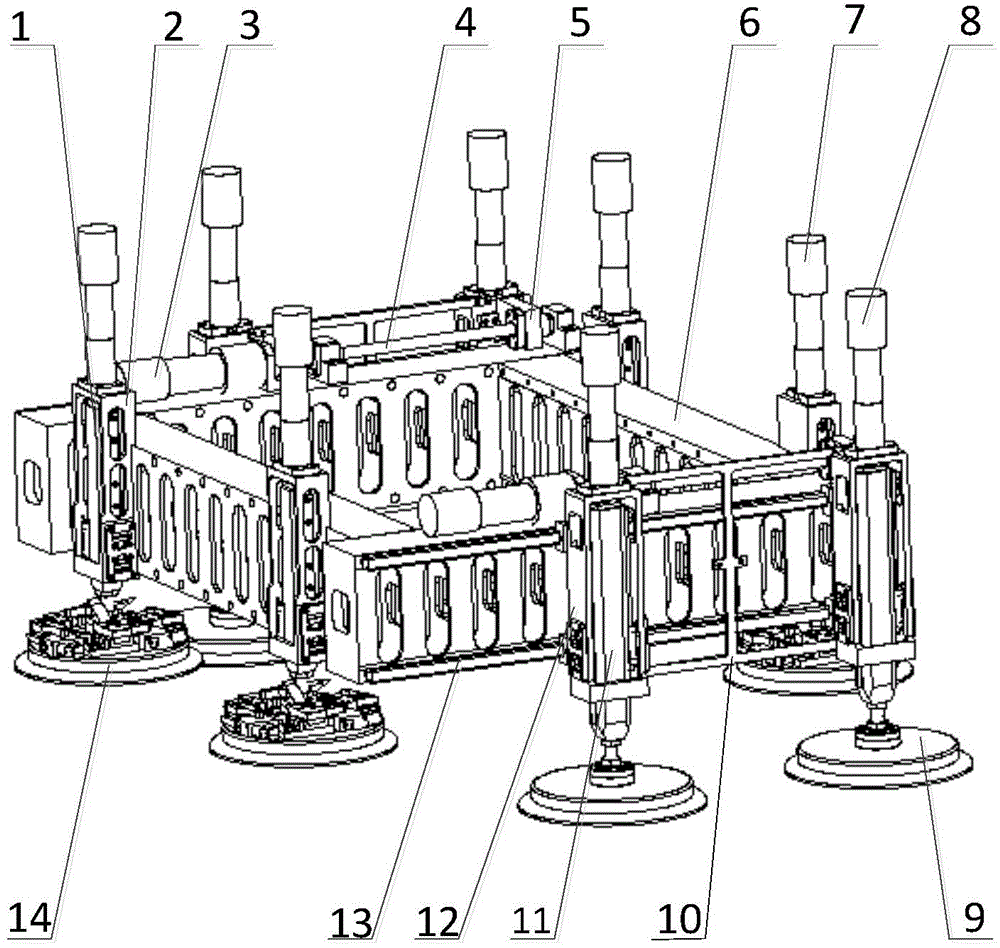

Walking mechanism and walking method of crawling robot

The invention discloses a walking mechanism of a crawling robot. The walking mechanism is characterized by comprising a moving frame, a plurality of outer legs and a plurality of inner legs, wherein the moving frame is rectangular; the outer legs are symmetrically mounted on two symmetrical lateral sides of the moving frame, and the inner legs are symmetrically mounted on the other two symmetrical lateral sides of the moving frame; each outer leg comprises an outer-leg frame and a telescopic leg arranged in the outer-leg frame; each inner leg comprises an inner-leg frame and a telescopic leg arranged in the inner-leg frame; suction cups are mounted at the bottoms of the outer legs and the inner legs; the telescopic legs of the outer legs are connected with the moving frame, and the moving frame ascends and descends with the telescopic legs of the outer legs; the inner-leg frames are rigidly connected with the moving frame, and the inner-leg frames ascend and descend with the moving frame; the outer-leg frames are mounted on the moving frame through guide rails; transverse feed motors are mounted on the moving frame, and the transverse feed motors drive transverse feed screws; the inner legs and the outer legs are both provided with longitudinal feed motors, and the longitudinal feed motors drive longitudinal feed screws.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Image blur correction apparatus, lens barrel, and image capture apparatus

An image blur correction apparatus includes a correction lens for correcting image blurs in a lens system, a moving frame for holding the correction lens, a support frame for movably supporting the moving frame through a move guide on a plane orthogonal to an optical axis of the correction lens, a first electric actuator for generating a first force to move the moving frame in a first direction orthogonal to the optical axis of the correction lens, a second electric actuator for generating a second force to move the moving frame in a second direction which is a direction orthogonal to the optical axis of the correction lens and is also orthogonal to the first direction, and an operation limit mechanism for limiting the moving frame from moving in the first direction and the second direction, and preventing the moving frame from rotating in the limit position.

Owner:SONY CORP

Glass cutting device

The invention discloses a glass cutting device. The includes a placement plate, fixed blocks are disposed on both sides at the top of the placement plate, one mutually closer side walls of the two fixed blocks are respectively equipped with a sliding chute, first motors are fixed on one end side walls of the fixed blocks through screws, output shafts of the first motors are connected to threaded rods, the threaded rods are rotatably connected in the sliding chutes and are in threaded connection with sliding blocks, the sliding blocks are slidably connected in the sliding chutes, the two sliding blocks are connected by a cross bar, a gear rack is disposed at the top of the cross bar, the cross bar is externally sleeved with a movable frame, a second motor is fixed on one side wall of the movable frame through a screw, an output shaft of the second motor is connected to a gear located inside the movable frame, and the gear is engaged with the gear rack. The glass cutting device provided by the invention can drive a cutting head to do up, down, left, right, front and back multidirectional movement so as to cut glass into arbitrary shape, and the cutting effect is good.

Owner:盐城市宁润玻璃制品有限公司

Material conveying system and conveying pipe switching device thereof

The invention discloses a conveying pipe switching device of a material conveying system, comprising a first pipeline and a second pipeline and also comprising a fixed frame and a moving frame. The outer side of the fixed frame is fixedly connected with a discharging pipe and a feeding pipe, the first pipeline and the second pipeline are fixedly connected with the moving frame, one side of the fixed frame is provided with a first leading-in hole and a second leading-in hole, the other side of the fixed frame is correspondingly provided with a first leading-out hole and a second leading-out hole; and the moving frame is connected with a power part and switches between a first working position and a second working position relative to the fixed frame by the power device. Accordingly, the pipelines can be cleaned without dismounting the conveying pipe switching device from the system pipeline, and the pipelines can be conveniently cleaned in time. The invention also discloses a material conveying system comprising the conveying pipe switching device.

Owner:SANY HEAVY IND CO LTD (CN)

Soldering machine with movable rotating function

InactiveCN101108437AGuaranteed smoothAvoid collisionWelding/cutting auxillary devicesAuxillary welding devicesWater wheelRotation function

The invention provides a mill welding machine with moving and rotating function, which comprises a base, a main frame, a moving frame, an induction mill welding structure, a worktable and a clamp; a drive structure is arranged at the bottom of the main frame, which is composed of a screw rod connected with a motor and a nut at the bottom of the main frame; a sliding way which is parallel to a lead rail is arranged on the main frame; the moving frame is supported on the sliding way, an induction mill welding structure is provided at one side of the worktable close to the moving frame; the worktable and the clamp are fixed two lead rails at one side of the base, which comprises a worktable of the supporting work piece and a clamp of the clamp work piece. The beneficial effect of the invention is that: the invention has simple structure and advanced technology, which is suitable for symmetric work piece at the position of welding opening. The forming structure can ensure the welding opening flat, which is especially suitable for large and middle size water wheel dynamo rotor coil with adopting four corner welded purple copper bar. After one side of the work piece is finished welding, the main frame returns, the worktable drives the coil rotate by 180 degree, and proceed welding to the other side of the work piece.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

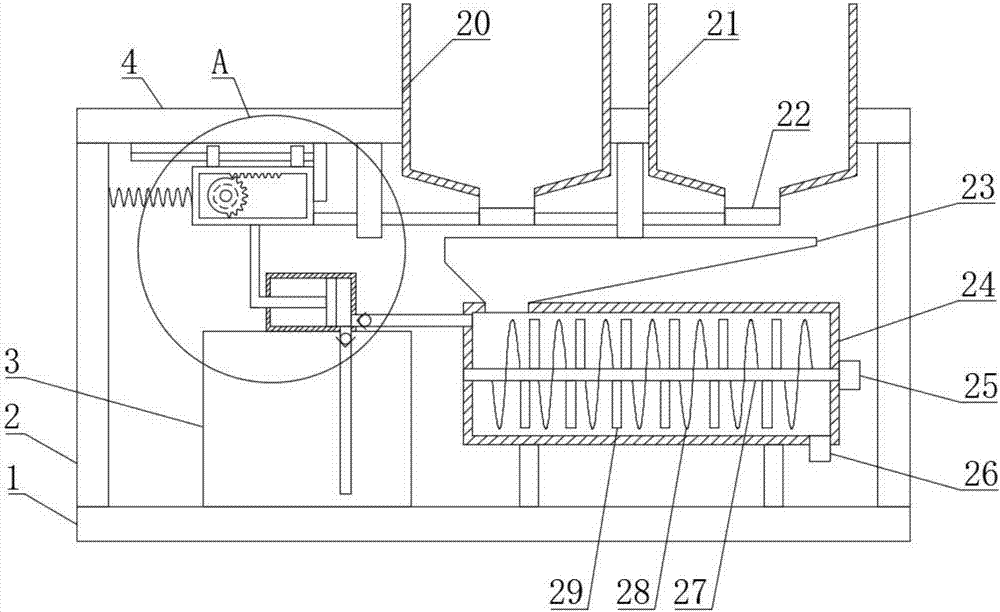

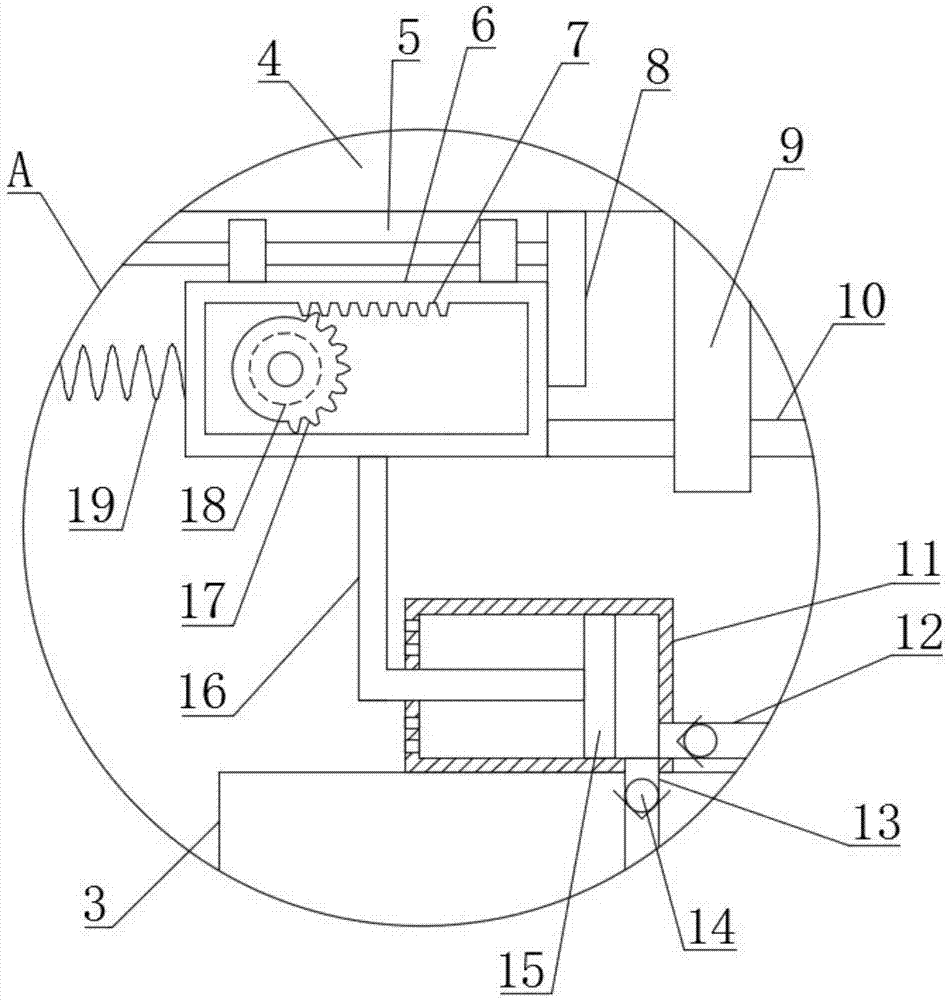

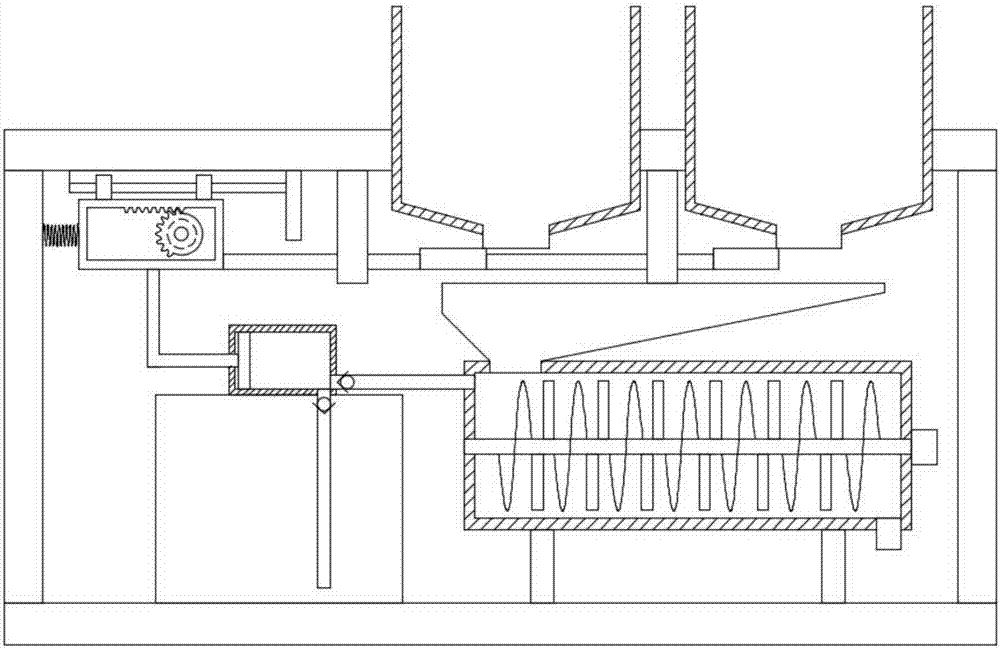

Efficient concrete quantified stirring device

InactiveCN107139328AStir wellNo manual controlDischarging apparatusCement mixing apparatusGear wheelArchitectural engineering

The invention discloses a high-efficiency concrete component mixing device, which comprises a base, a support plate is fixedly arranged at the left and right ends of the base through a support rod, a cement tank and a gravel tank are fixedly arranged on the support plate; a slide rail is arranged on the left side of the bottom of the support plate , the lower part of the slide rail is slidingly connected with the moving frame through the slider, the left end of the moving frame is connected with the left support rod through the spring, the right end of the moving frame is connected with the first moving rod, and two cover plates are arranged on the first moving rod, inside the moving frame A rack is arranged on the top, and a first motor is fixedly arranged on the top of the support plate through a bracket. The motor shaft at the top of the first motor is connected with a gear, and the gear meshes with the rack; the right side of the base is also fixed with a mixing bucket through a bracket. The invention drives the moving frame to move left and right through the cooperation of incomplete gears and springs, so that the cover plate is intermittently opened and closed, and the amount of cement and sandstone is basically the same each time, and the component stirring is carried out. The amount of stirring at one time is not much, and the stirring more fully.

Owner:童红妃

Various methods and apparatus for moving thumbnails with metadata

ActiveUS8196045B2Metadata video data retrievalSpecial data processing applicationsThumbnailMoving frame

Various methods, apparatuses, and systems are described for a moving thumbnail generator. The moving thumbnail generator generates one or more moving thumbnails that are tagged and time-stamped to arbitrary video trigger events that take place in an associated original video file. Each of the moving thumbnails has two or more moving frames derived from its associated original video file at a portion in the original video file that is tagged and time-stamped to one or more relevant video trigger events in order for the generated moving thumbnail to summarize a visual content of the associated original piece of video file to a user. The tag carries information about content that takes place in the original video file and metadata about that content including a time reference to frames that are contextually relevant to the reason why a viewer of the thumbnail might be interested in viewing that thumbnail.

Owner:RHYTHMONE

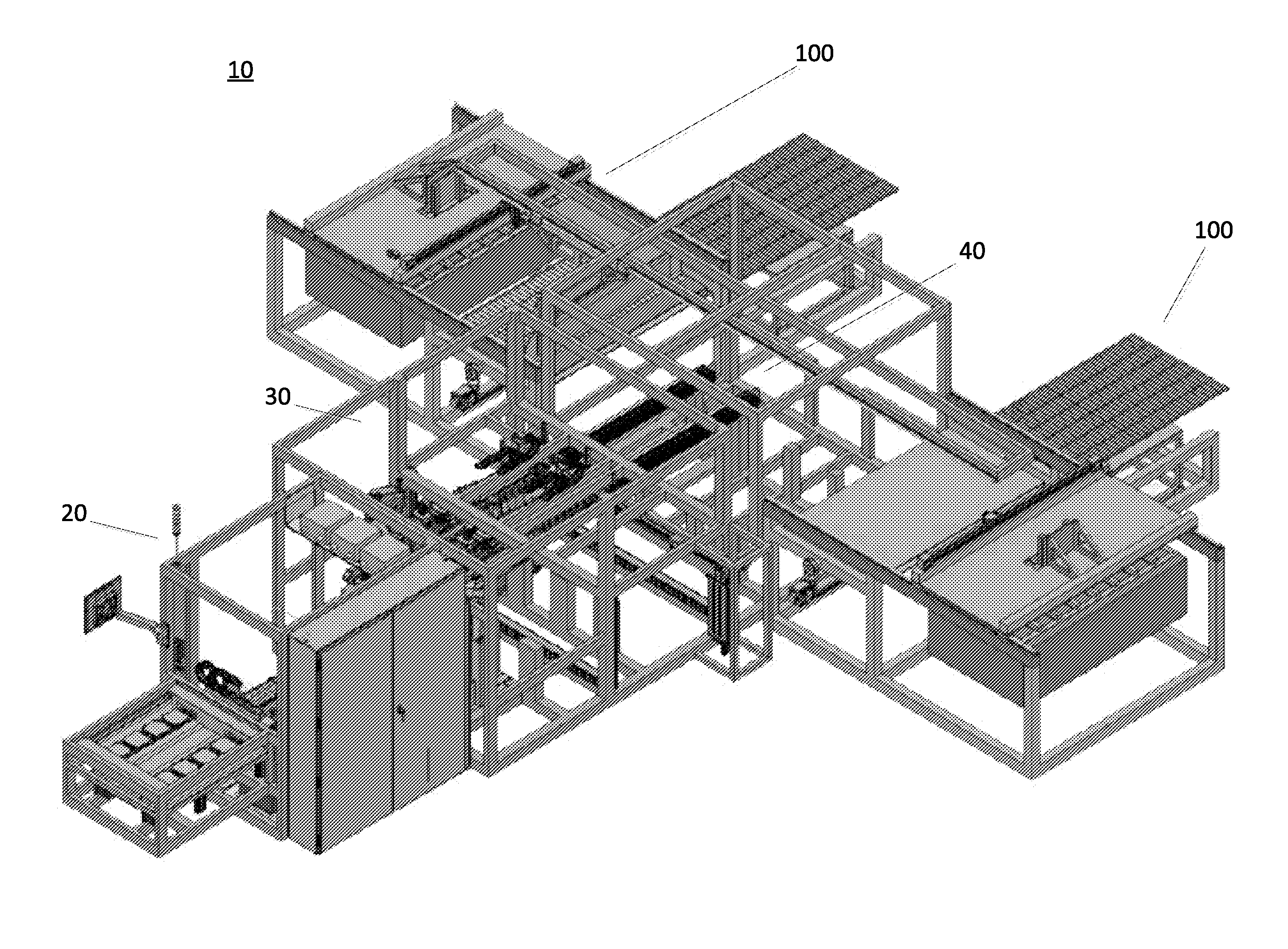

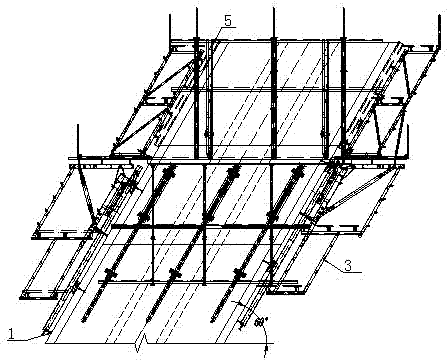

Systems and method for precision automated placement of backsheet on pv modules

A method for constructing a photovoltaic (PV) substrate. A moving frame can be lowered towards a stack of back sheets and a back sheet of the stack of back sheets may be secured to the moving frame. The back sheet can be transferred from the moving frame to a vacuum table. An adhesive can be dispensed to the back sheet using an adhesive dispenser. At least one string may be placed onto the adhesive applied to the back sheet. The vacuum table can be rotated, and the back sheet can be released from the vacuum table onto a glass sheet.

Owner:TESLA INC

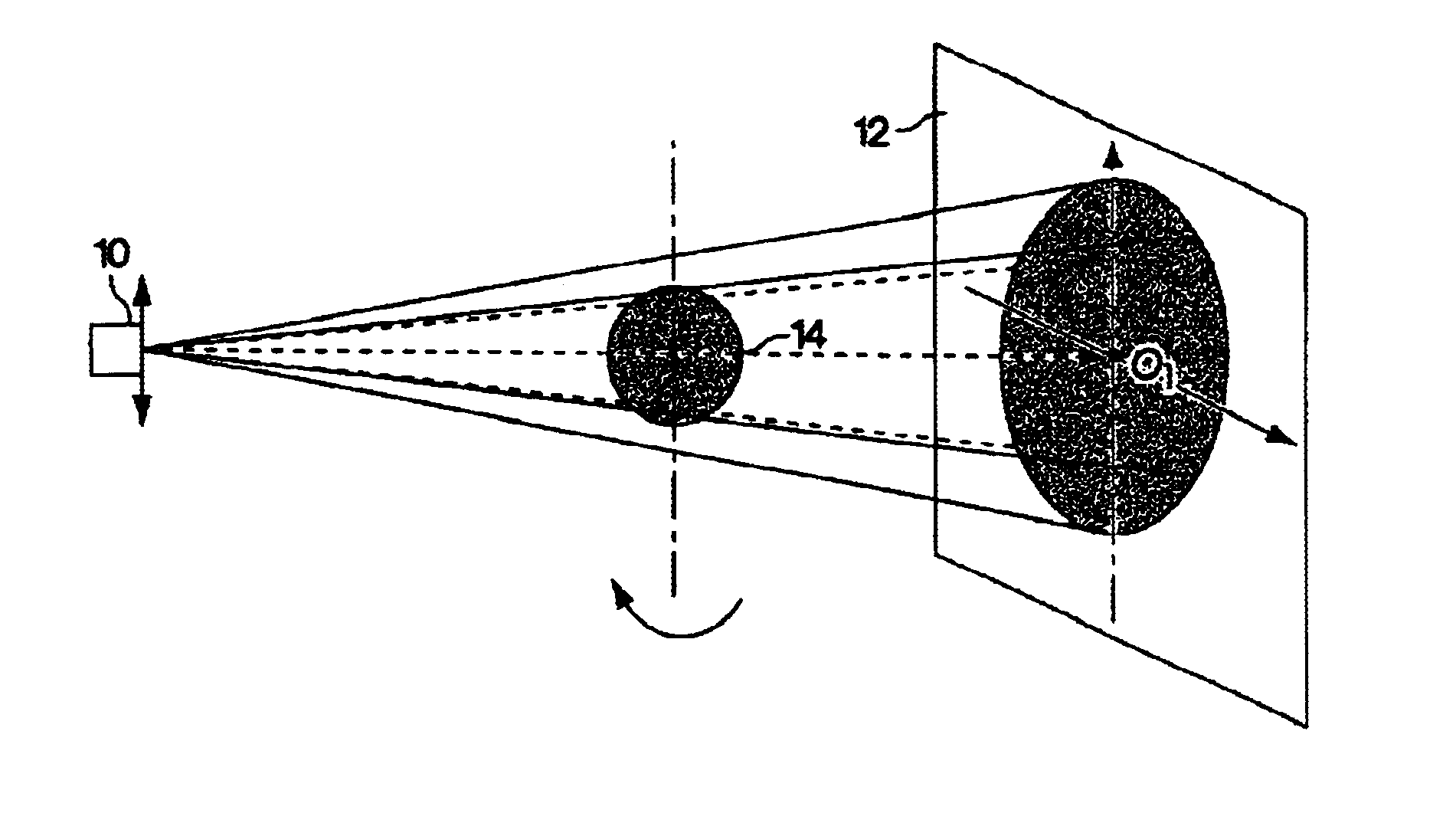

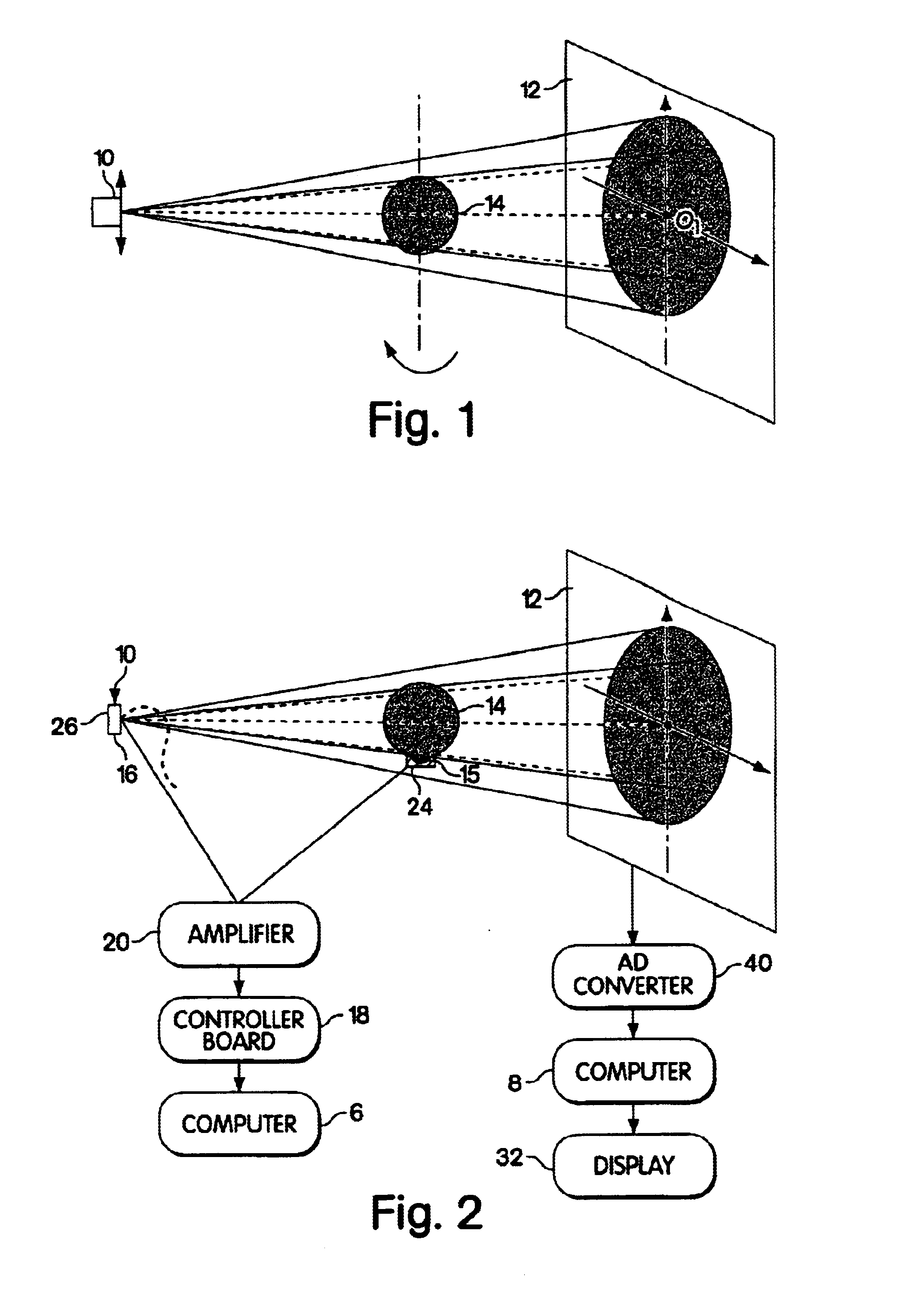

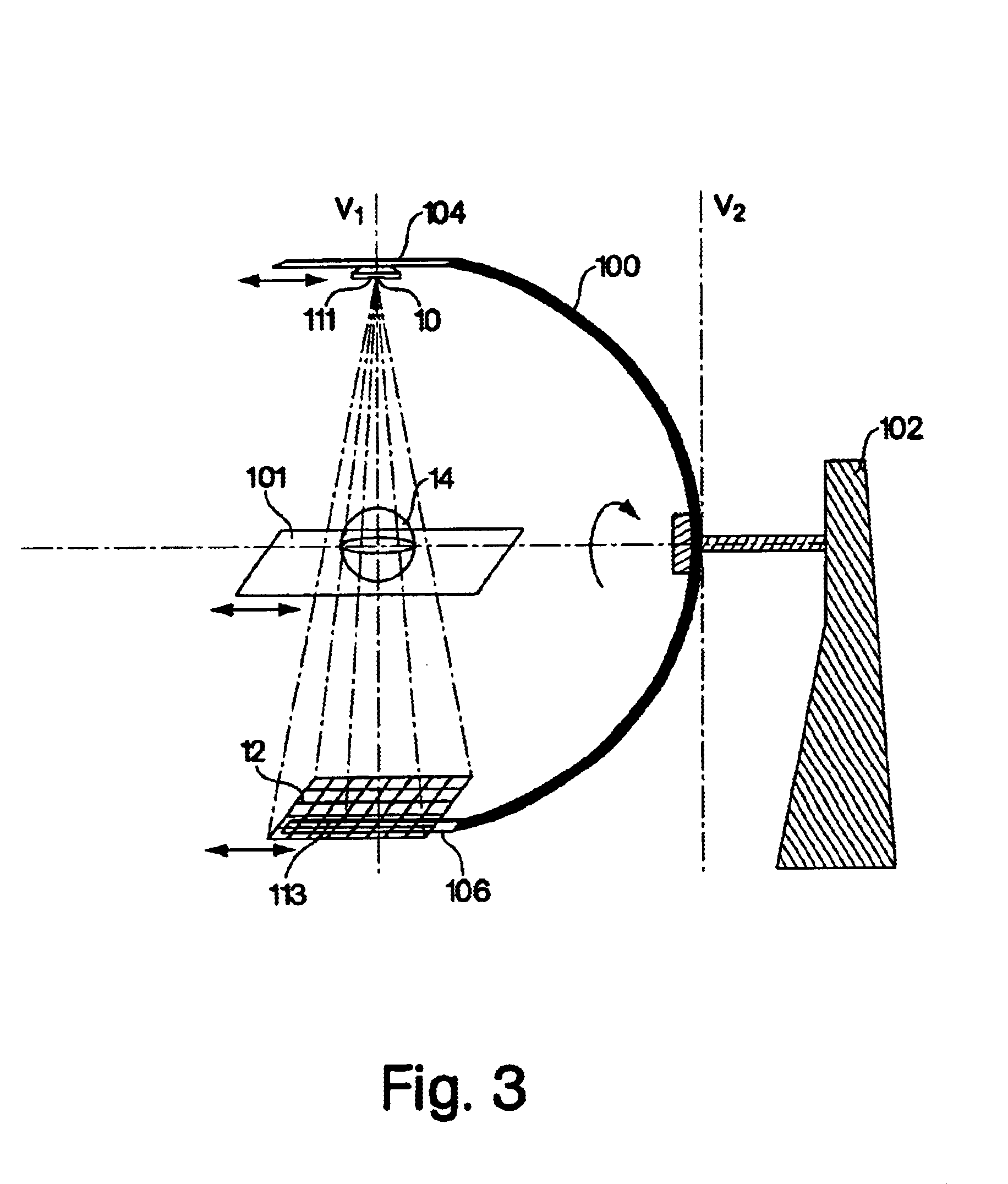

True 3D cone-beam imaging method and apparatus

InactiveUS6865246B2Improve sampling performanceAccurate measurementReconstruction from projectionMaterial analysis using wave/particle radiationRadon transformRadiation attenuation

A three-dimensional image of an object scanned with a plurality of cone-beam projections from a number of source positions is reconstructed using a method wherein intermediate transform functions are obtained from two-dimensional images of radiation attenuation in the scanned object. The intermediate transform functions are then filtered over a set of parallel planes using a moving-frame technique. The second-order radial derivative of the Radon transform can then be backprojected to generate an intermediate, locally-reconstructed, three-dimensional image. After repetition of this process, the plurality of intermediate, locally reconstructed, three-dimensional images are summed to obtain an ultimate, reconstructed, three-dimensional image of the object. In particular embodiments, the source and detector are displaced along helical paths and radiation scans of the object are taken at multiple positions along the paths.

Owner:MIT TECH LICENSING OFFICE

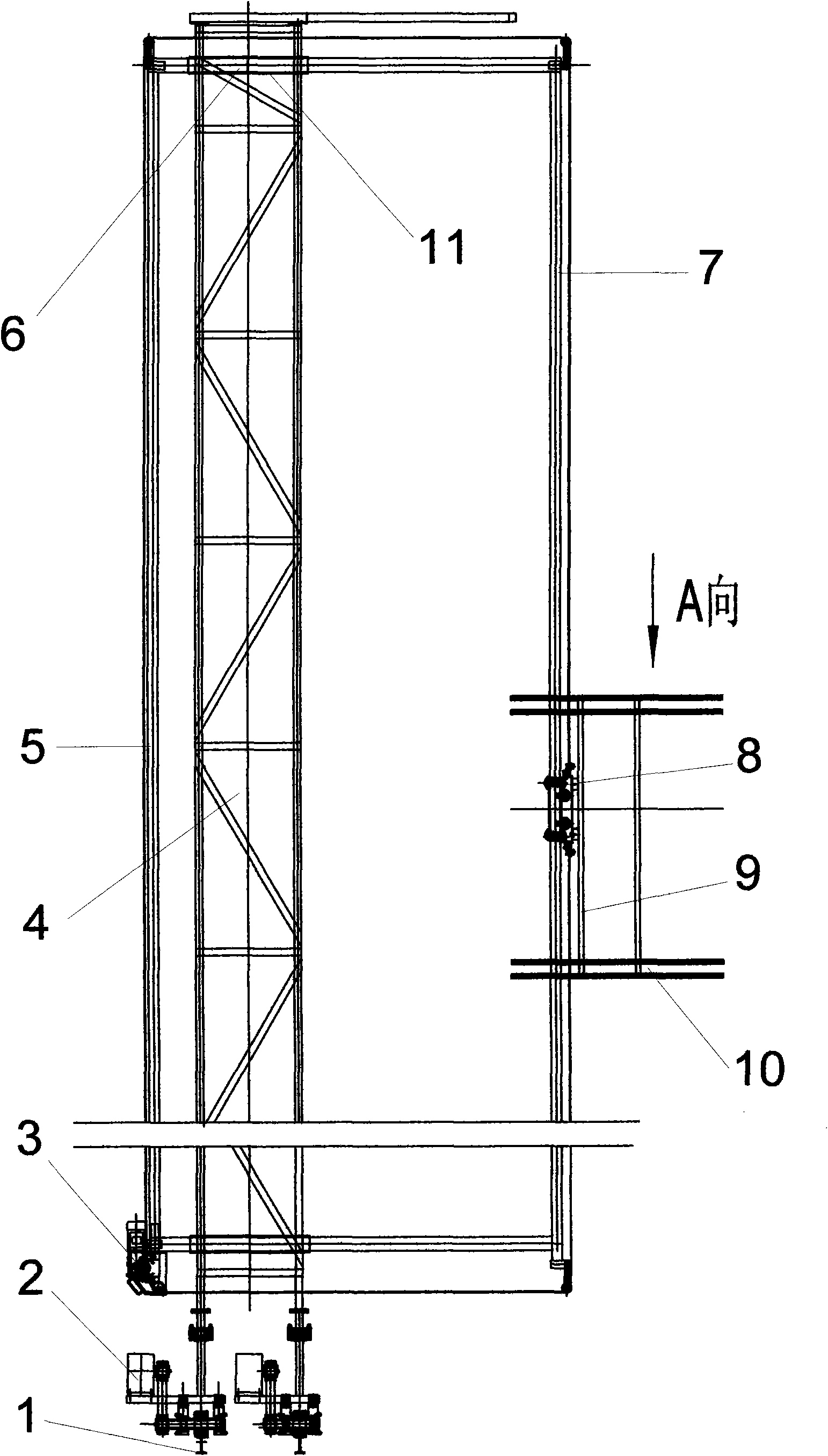

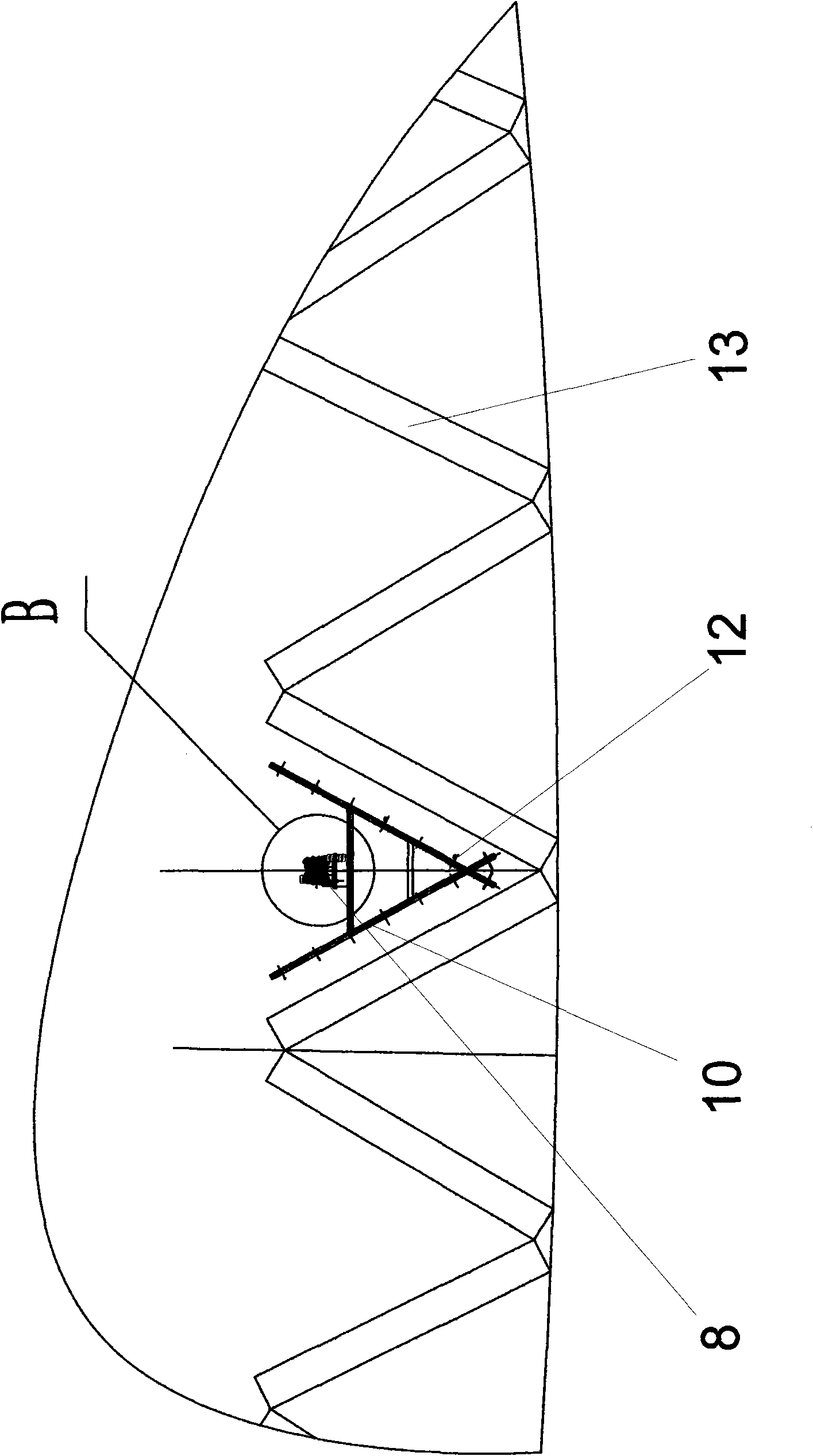

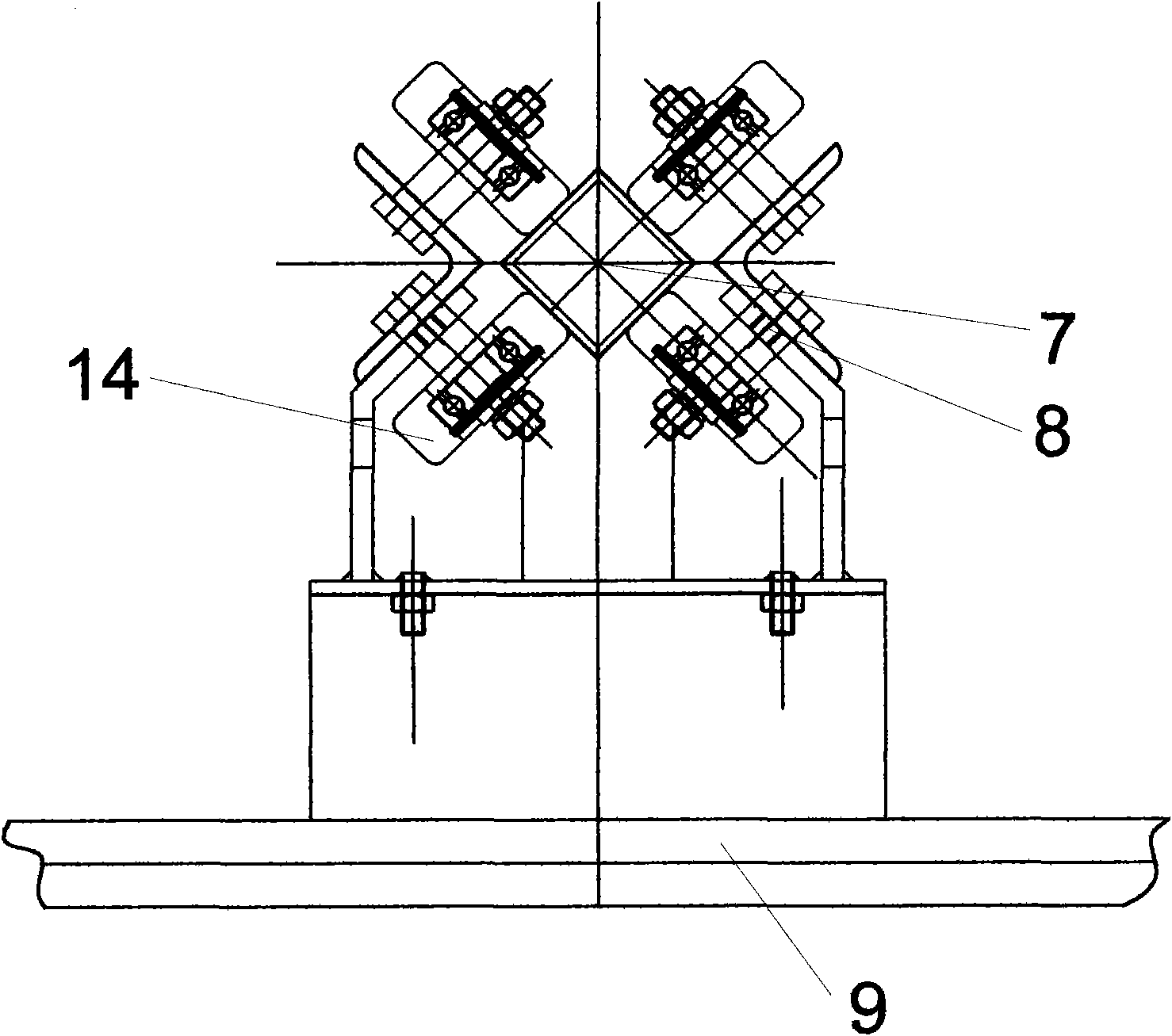

Automatic cleaning device of indirect air cooler for power station

ActiveCN101672600AEasy to cleanStepless adjustable working pressureFlush cleaningAutomatic controlPower station

The invention relates to an automatic cleaning device of an indirect air cooler for a power station, comprising a cleaning mechanism. The automatic cleaning device is technically characterized in thata closed annular track which is provided with a traveling truss with a traveling driving device is arranged near the air cooler inside a tower; the traveling truss is provided with a vertical type horizontal moving frame and a guide limit mechanism of the vertical type horizontal moving frame; the vertical type horizontal moving frame is provided with a vertical moving guide rail which is sequentially provided with a vertical traveling mechanism and a vertical driving mechanism; the vertical traveling mechanism is provided with the cleaning mechanism which comprises at least two rows of cleaning tube bundles, cleaning nozzles are distributed on the cleaning tube bundles, the spraying directions of the cleaning nozzles are perpendicular to the cleaning surface of the air cooler, and the cleaning tube bundles are connected with a high-pressure water generation device through high-pressure tubes. The invention has high automation degree and convenient operation and realizes the running along the track, the horizontal movement of the traveling truss and the vertical cleaning of the cleaning mechanism, thereby completing the interlocking automatic control.

Owner:SHENYANG ACAD OF INSTR SCI +1

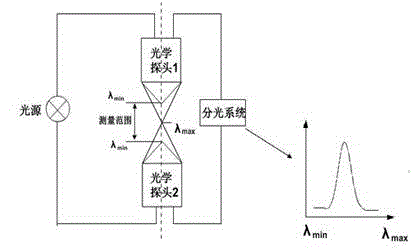

Lens center thickness measuring device and method based on double face confocal measurement

InactiveCN104613881ASolve the problem of identifying false peaksRealize measurementUsing optical meansSpectrographLength wave

The invention discloses a lens center thickness measuring device based on double face confocal measurement. The device is characterized by comprising a controller with a spectrograph, an optical probe I, a two-dimensional moving frame, a lens clamp, an optical probe II, a support and a computer. The optical probe I, the two-dimensional moving frame and the optical probe II are all fixed on the support, the lens clamp is clamped on the two-dimensional moving frame, the controller is connected with the optical probe I and the optical probe II through optical fibers, the two-dimensional moving frame is located between the two optical probes, and the computer is connected with the controller with the spectrograph through a data line. The device has the advantage that 1 each optical probe is only required to detect first peak of return wavelength, the problem that the false peak is required to be recognized under the condition that a lens is coated by a film is solved, and thickness measurement of the lens coated by the film is achieved; 2 two optical probes are utilized to reduce errors caused by the fact that light enters the lens to be refracted and reflected, and measurement accuracy is improved; 3 the method can be used for thickness measurement of the opaque object allowing double-face reflection, and the measurement range of the confocal measurement is expanded.

Owner:JIANGSU YUDI OPTICAL CO LTD

Steel pipe grinding device for machining

PendingCN109571162AAchieve rotationEasy to polishRevolution surface grinding machinesGrinding drivesBristleEngineering

The invention discloses a steel pipe grinding device for machining. The steel pipe grinding device comprises a base, a steel pipe and a rust removal barrel fixedly connected with the base. A moving frame is arranged above the base, a rotation barrel is embedded in the moving frame, and one side of the rotation barrel is fixedly connected with a three-jaw chuck. Symmetric grinding abrasive wheels are arranged at the middle position of the rust removal barrel. Through the arrangement of the rotation barrel embedded in the moving frame and rotationally connected with the moving frame, a bevel gear ring, a rolling gear and a rack plate, self-rotation during transverse steel pipe feeding is achieved, and subsequent steel pipe circumference face comprehensive grinding and scrubbing cleaning areconvenient. Through the arrangement of a swinging frame, a first rust removal brush barrel with steel wire bristles and a second rust removal brush barrel with soft bristles, the spindle-shaped rust removal barrel and an industrial dust collector are matched, so that iron scraps are conveniently collected in a centralized manner, and operation environment pollution is avoided.

Owner:HUNAN UNIV OF SCI & ENG

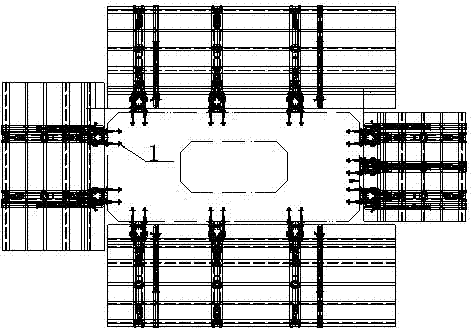

Hydraulic climbing formwork construction method for leaning tower of cable-stayed bridge

The invention discloses a hydraulic climbing formwork construction method for a leaning tower of a cable-stayed bridge. The method comprises the following steps: measuring and positioning the leaning tower and embedding an embedded part; erecting a formwork and pouring a first section of concrete, and mounting an anchoring system, a bearing bolt (1) and a climbing frame (3); mounting a bearing frame and a bearing platform on the anchoring system; mounting a template moving frame and an upper platform system, using the upper platform system for erecting the formwork, embedding the embedded part and pouring a second section of concrete of a tower column; mounting a lower platform and de-molding by moving the upper platform system; mounting the anchoring system in a third stage and mounting a climbing guide rail (5) and a guide rail supporting leg (6); operating a hydraulic system, lifting the whole frame to the third stage of the tower column, and mounting a lower-layer platform; assembling the mould by moving the upper platform system, embedding the embedded part and pouring a fourth section of concrete of the tower column; and operating the hydraulic system, lifting the whole frame to the fourth stage of the tower column, and entering into a circulating construction stage. According to the method provided by the invention, the mounting of the template is quickly and efficiently finished under the condition of the leaning tower column and the work load of mounting the template and the bracket is saved.

Owner:RAILWAY NO 10 ENG GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com