Hydraulic climbing formwork construction method for leaning tower of cable-stayed bridge

A technology of hydraulic climbing formwork and construction method, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc. It can solve the problems that ordinary formwork reinforcement schemes are difficult to achieve the construction purpose, and the construction of steel bars and formwork is difficult, so as to achieve strong applicability and superiority, shorter construction period, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

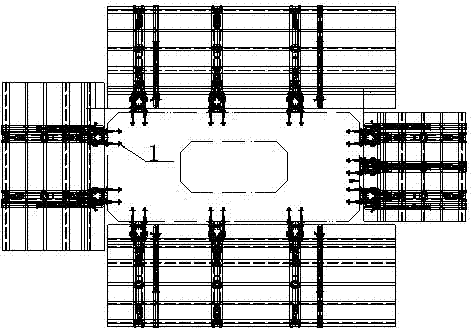

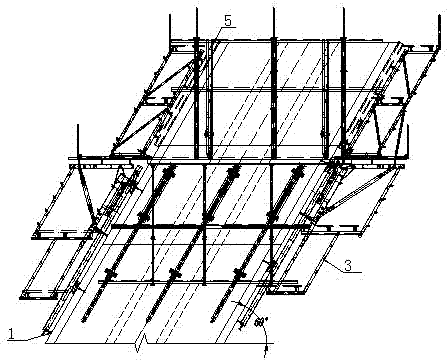

[0031] like figure 1 , 2 As shown, according to the inclination of the main tower body of the construction is 30 degrees or other degrees, the hydraulic climbing formwork system designed for this project mainly includes: formwork, load-bearing system, upper and lower climbing frames, embedded parts, and guide rails , hydraulic system, etc.

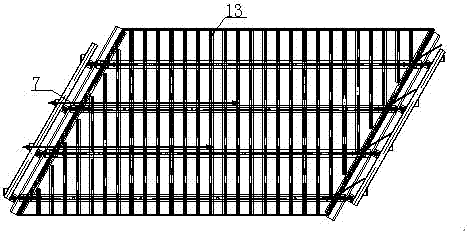

[0032] like Figure 3-6 As shown, the template part is composed of panels, horizontal steel back corrugated 7, connecting claws 8, hoisting components 9, floor nails 10, fiberboard nails 11 and other parts connected. The panel adopts 21mm Visa board 12, the reinforcing rib adopts H200 wooden I-beam 13, and the horizontal steel back corrugation adopts double 14a channel steel 14.

[0033] The wooden formwork is easy to load, disassemble and assemble, and can be assembled into formworks of various sizes within a certain range and degr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com