Magnetic bearing control system of accurately compensating magnetic suspension control torque gyroscope support rigidity

A technology for controlling torque gyroscope and supporting stiffness, applied in the direction of holding devices and electrical components using magnetic attraction or thrust, it can solve problems such as disturbance, system instability, and poor compensation accuracy, so as to eliminate compensation errors and improve torque output. Accuracy and response speed, overcoming the effect of poor accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

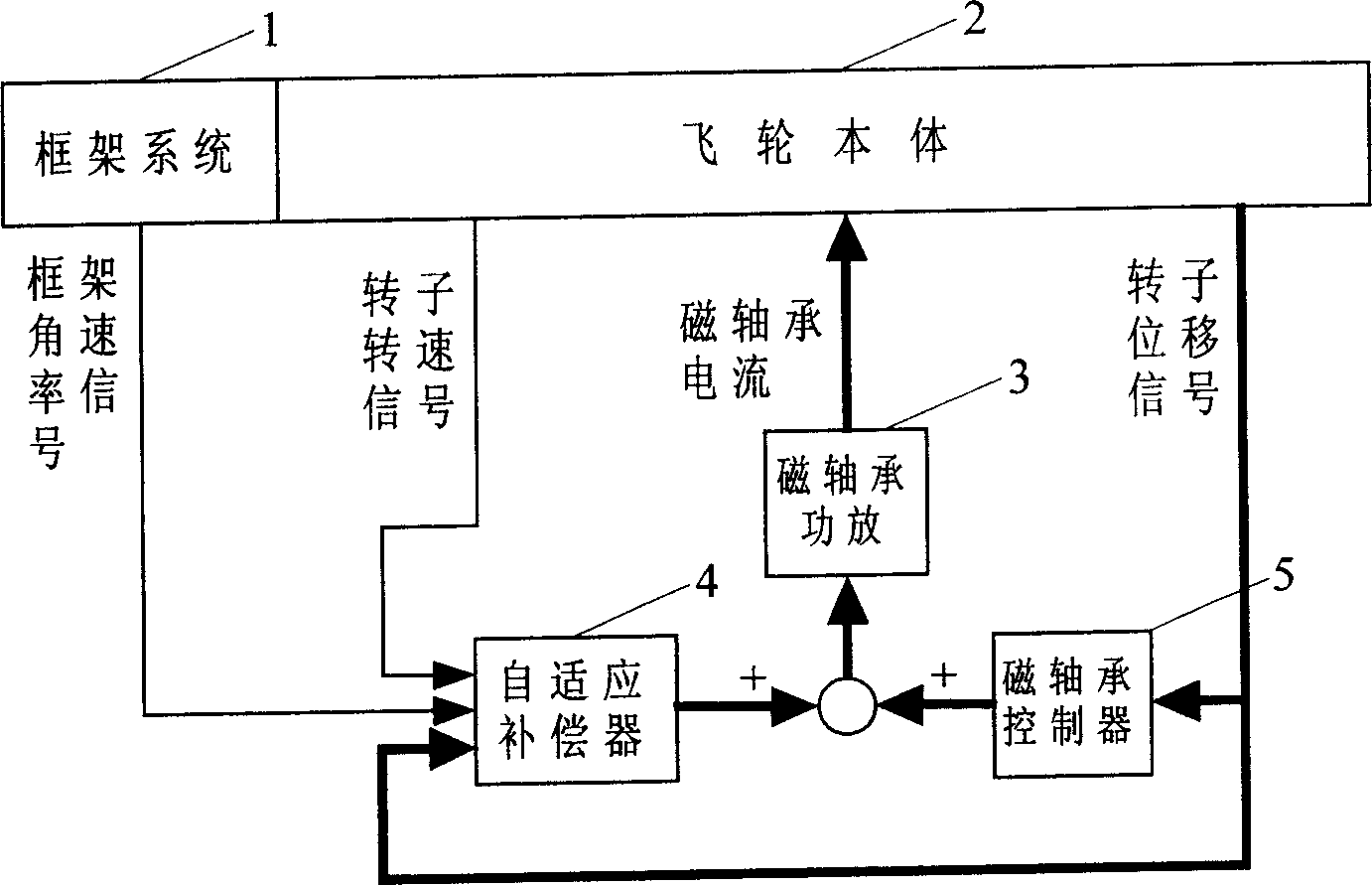

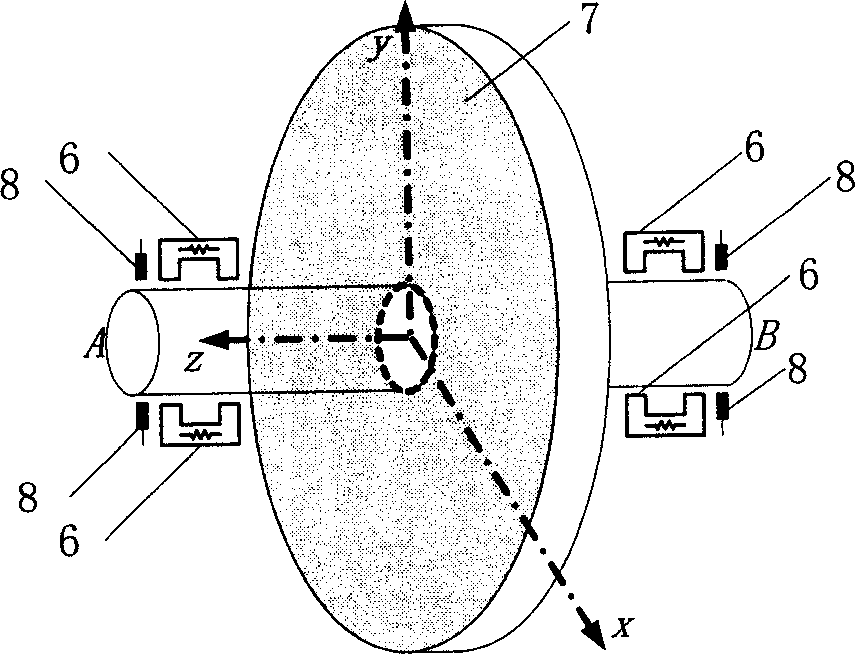

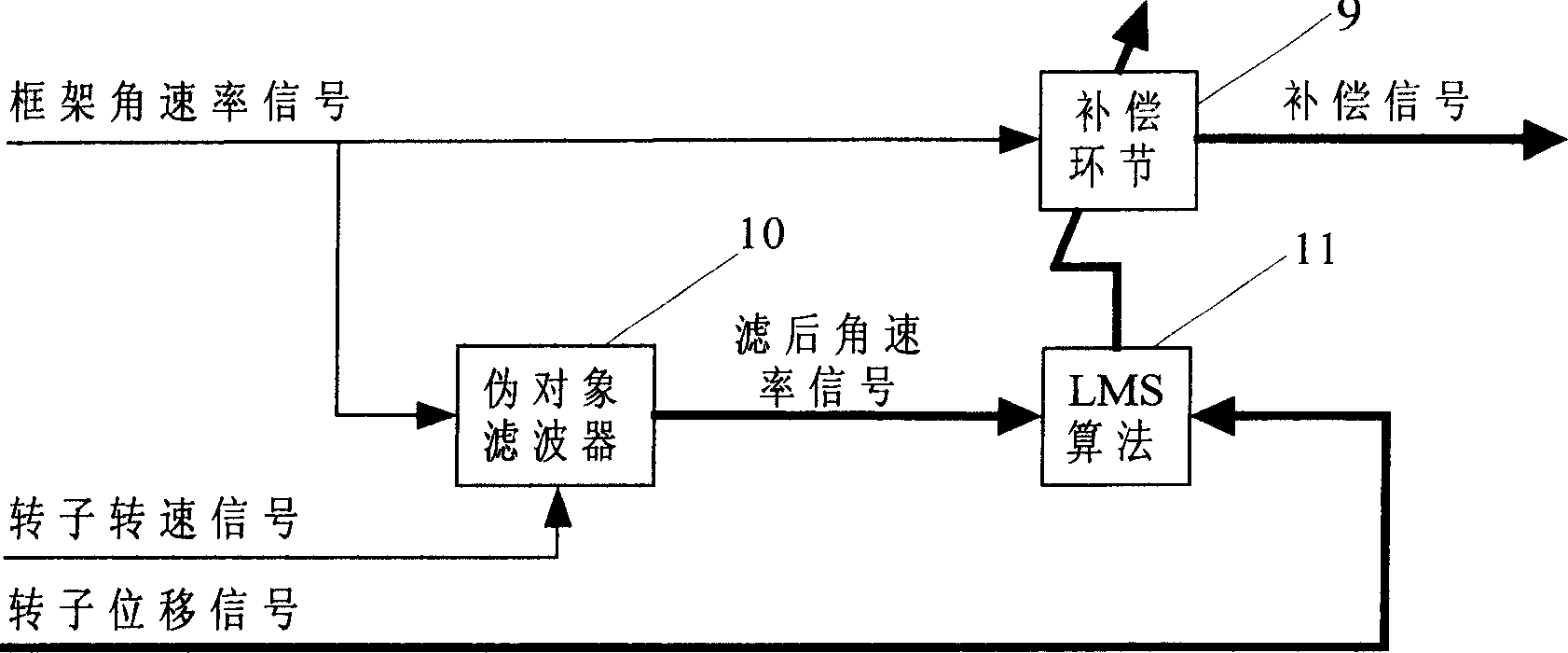

[0014] Such as figure 1 As shown, the present invention mainly includes a flywheel body 2, a magnetic bearing power amplifier 3, and a magnetic bearing controller 5, wherein the flywheel body 2 is composed of a magnetic bearing electromagnet 6, a rotor 7, a displacement sensor 8 and a rotor drive system. For CMG A frame drive system is also required as a device to drive the frame to achieve a given angular rate, and at the same time output the frame angular rate signal required by the magnetic levitation control system; for the flywheel body 2, a rotor motor drive system is also required to drive the rotor 7. The device to make it reach the rated speed, and at the same time output the rotor speed signal required by the magnetic levitation control system. The rotor displacement signal is connected to the controller 5, and the control signal is output after calculation. The frame angular rate signal, rotor speed signal and rotor displacement signal are connected to the adaptive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com