Patents

Literature

2177results about "Flush cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods of simultaneously cleaning and disinfecting industrial water systems

InactiveUS6840251B2Reduce Microbial ContaminationReduce removalDetergent bleaching agentsWater/sewage treatment by neutralisationChlorine dioxideOnline and offline

On-Line and Off-Line methods of simultaneously cleaning and disinfecting an industrial water system are described and claimed. The methods involve the addition to the water of the industrial water system of a Compound selected from the group consisting of the alkali salts of chlorite and chlorate and mixtures thereof; and an acid, followed by allowing the water in the industrial water system to circulate for several hours. The reaction of the alkali salts of chlorite and chlorate and acid produces chlorine dioxide in-situ in the water of the industrial water system. The chlorine dioxide kills microorganisms and the acid acts to remove deposits upon the water-contact surfaces of the equipment. An alternative method involves the use of a chelating agent and a biocide. Other possible cleaning and disinfection reagents may be added as needed including corrosion inhibitors, chelating agents, biocides, surfactants and reducing agents. These cleaning and disinfecting methods work in a variety of industrial water systems including cooling water and boiler water systems.

Owner:ECOLAB USA INC

Methods and composition for cleaning and passivating fuel cell systems

ActiveUS20050245411A1Organic detergent compounding agentsAnionic surface-active compoundsFuel cellsSolvent

A cleaner-passivator composition and method for treating a fuel cell cooling system are described. The cleaner-passivator comprises a complexing agent, a surfactant, a corrosion inhibitor, and a solvent. The cleaner-passivator reduces the contaminants circulating in the fuel cell coolant system that contribute to increasing conductivity in the fuel cell coolant. In addition, the passivator reduces the surface corrosion in the fuel cell system.

Owner:PRESTONE PROD CORP

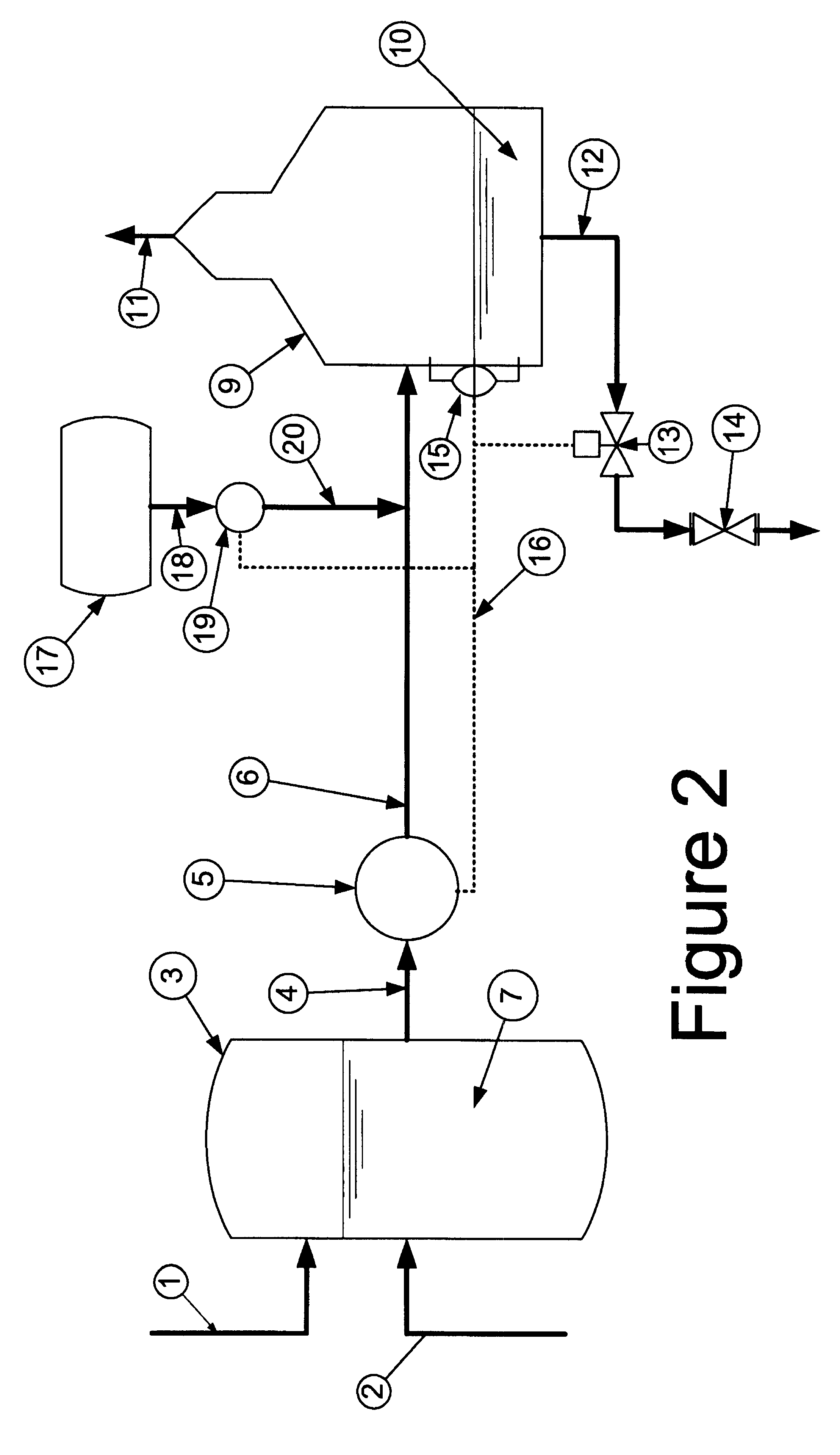

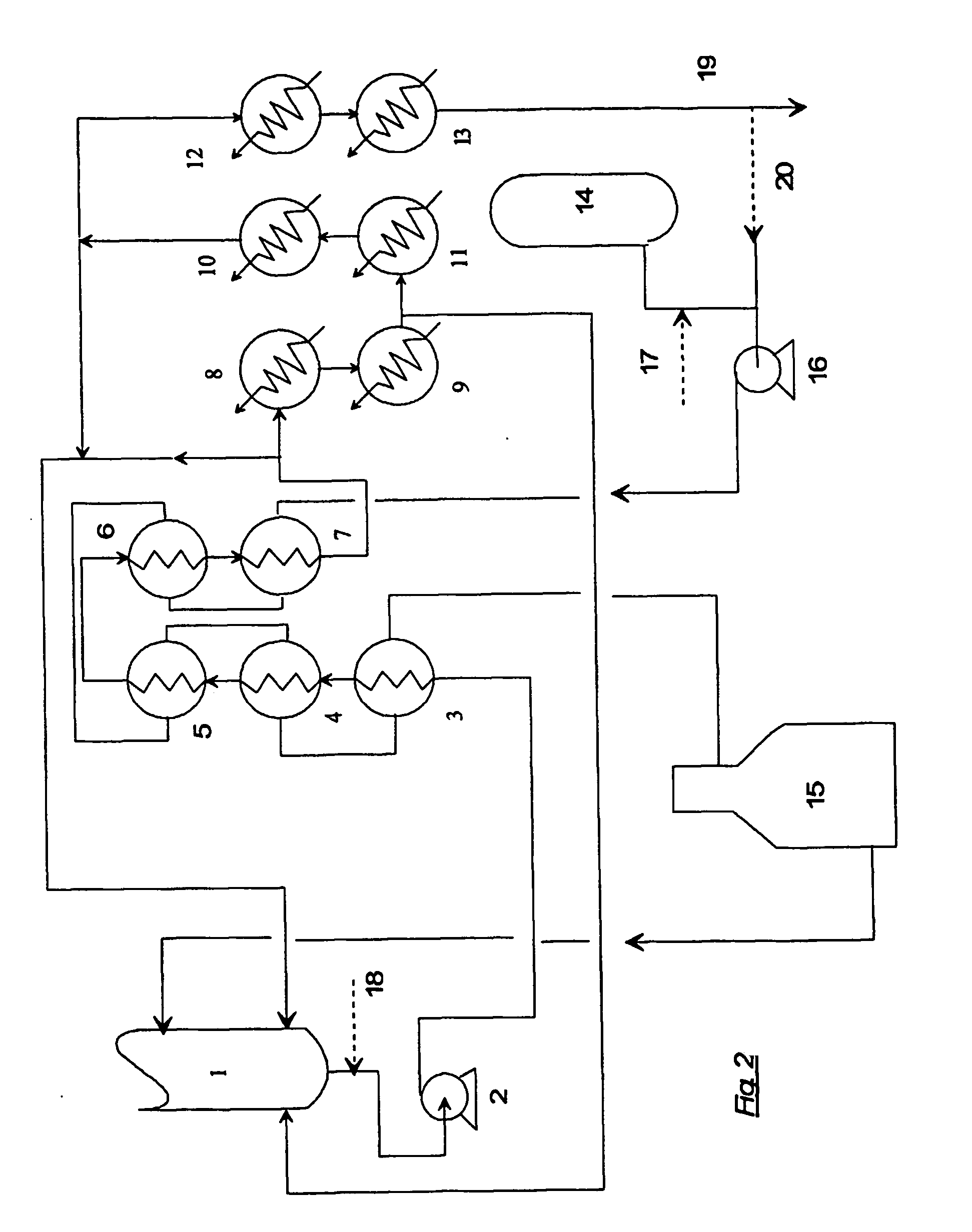

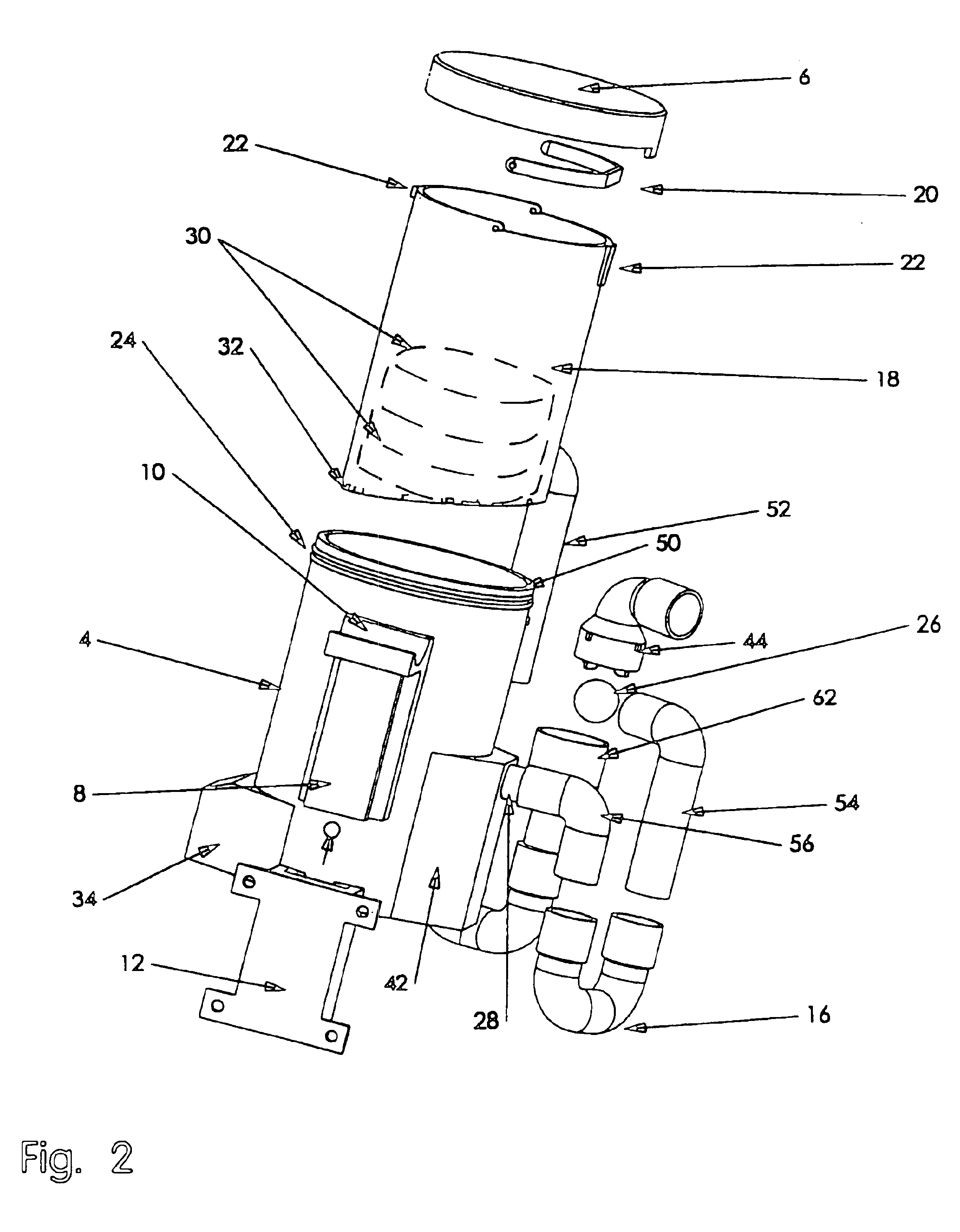

Boiler water blowdown control system

InactiveUS6655322B1Constant flowThe process is simple and accurateBoiler cleaning apparatusMachines/enginesControl systemEngineering

The present invention relates to a method for automatically maintaining the concentration of scale forming minerals in boiler water for boiler systems utilizing bimodal feedwater pumps that deliver a substantially constant feedwater flow to the boiler drum when activated. According to the present invention, the feedwater supply pump and blowdown rate control valve are synchronized to remove boiler water at a predetermined rate when the feedwater pump is activated. The present invention thereby provides a simplified and less expensive method for controlling the concentration of dissolved solids in boiler water despite variations in the steam loads and / or other boiler operation parameters.

Owner:CHEMTREAT

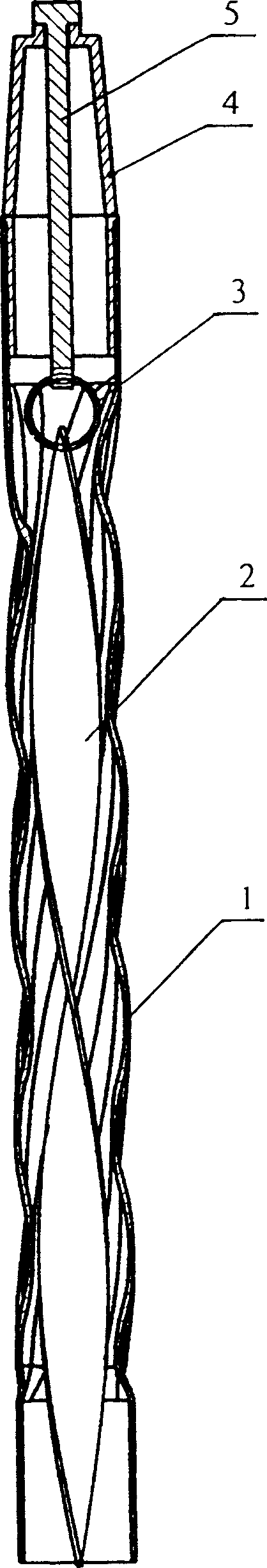

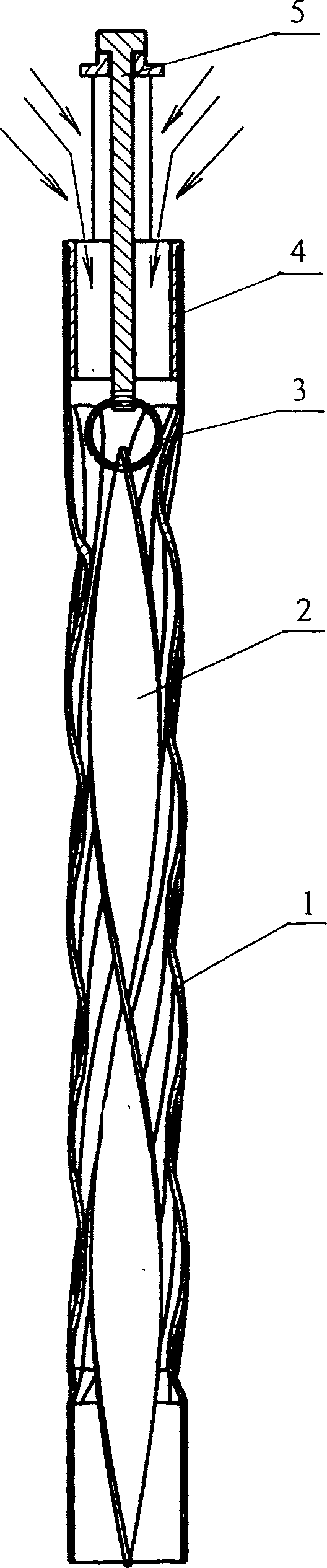

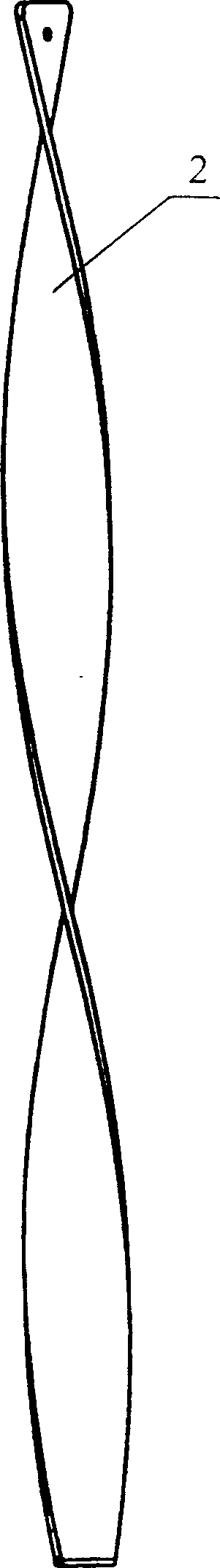

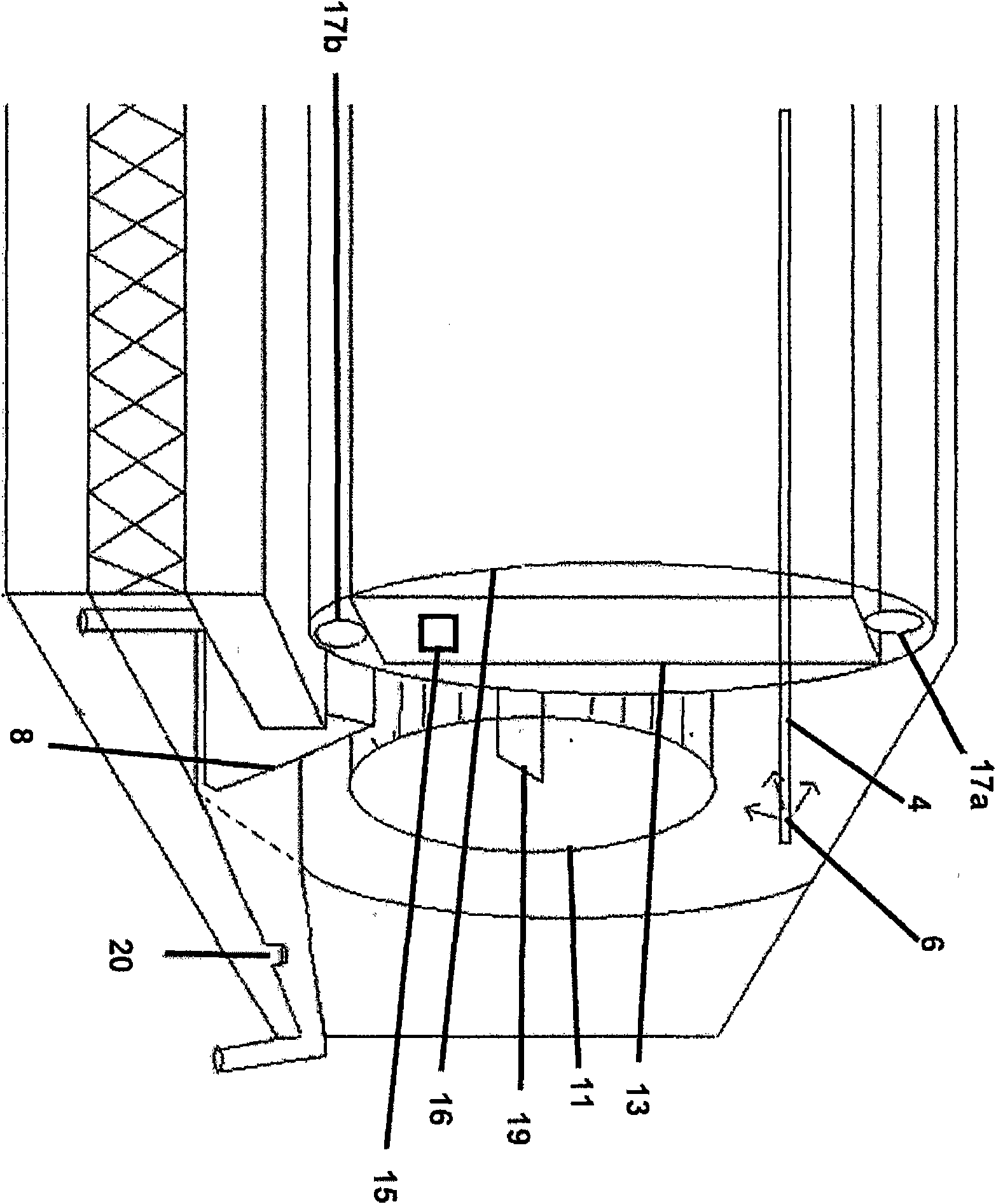

Dual turbulent spiral forced heat exchanging and automatic descaling device

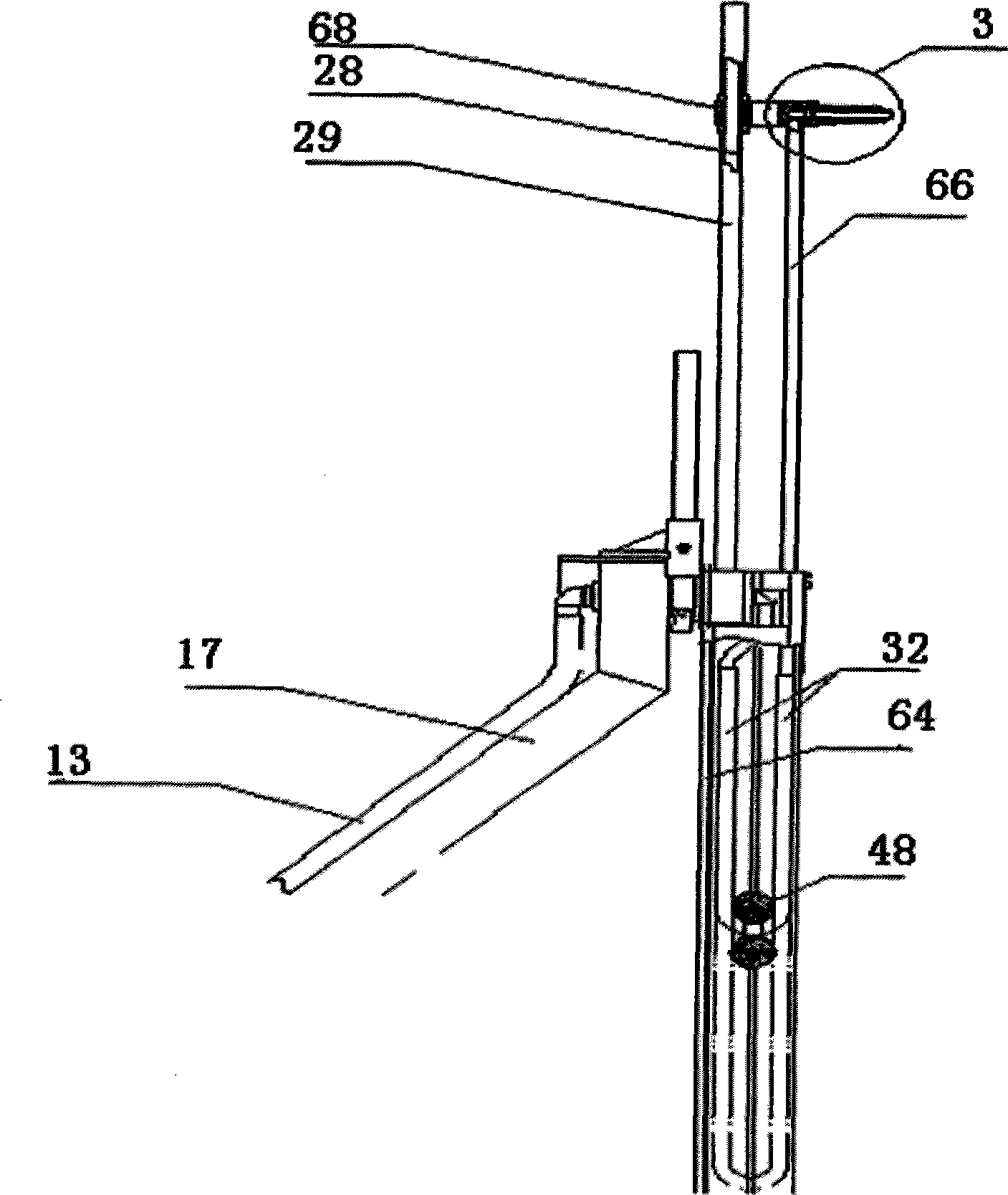

InactiveCN1424554AImprove heat exchange efficiencyLong-term stable jobHeat exchanger casingsFlush cleaningFixed frameStraight tube

A device of intensified heat exchange and automatic descaling in dual turbulation screw type includes screw tube, screw tie, connection rod, fixing frame and rotary rod as small end of the rotary rod sheathed into hole at exle liquid input end of fixing frame to form rotation cooperation, end point of small end of the rotary rod to be connected by connecting piece in hinge joint with end point of one end of the screw tie, the screw tube with external circle and intermediate internal hole being all the straight tube of screw shape and two end parts being round tube shape to be set on external cylindrical surface of cylinder shape end of the fixing frame. The present invention uses technique of combining the screw tube with the screw tie to bring the screw tie to rotate by flowing of fluid in the screw tube to make no fouling within the tube and heat conduction face can carry on desaling automatically under the dual turbulation of the screw tube and tie to enhance more the efficiency of heat exchange.

Owner:ZHEJIANG UNIV

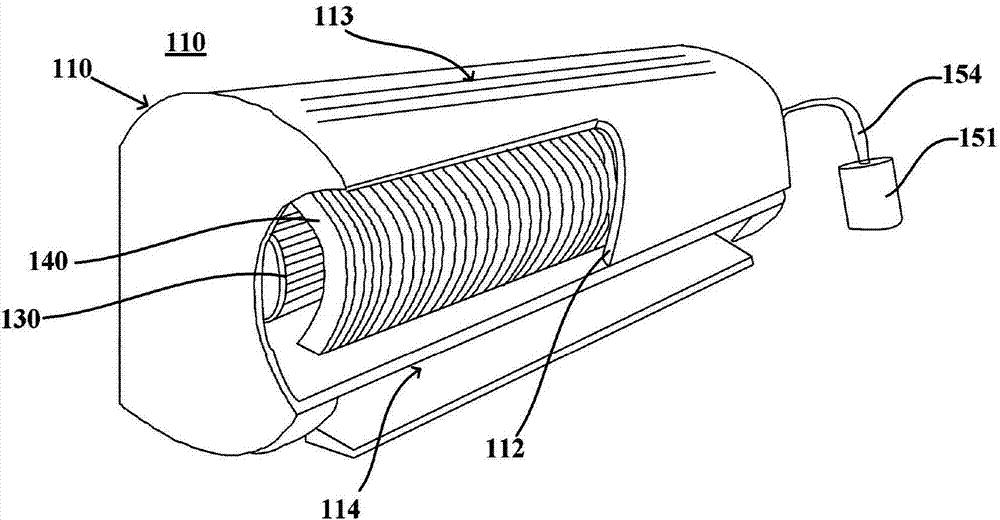

Air conditioner indoor unit with self-cleaning function

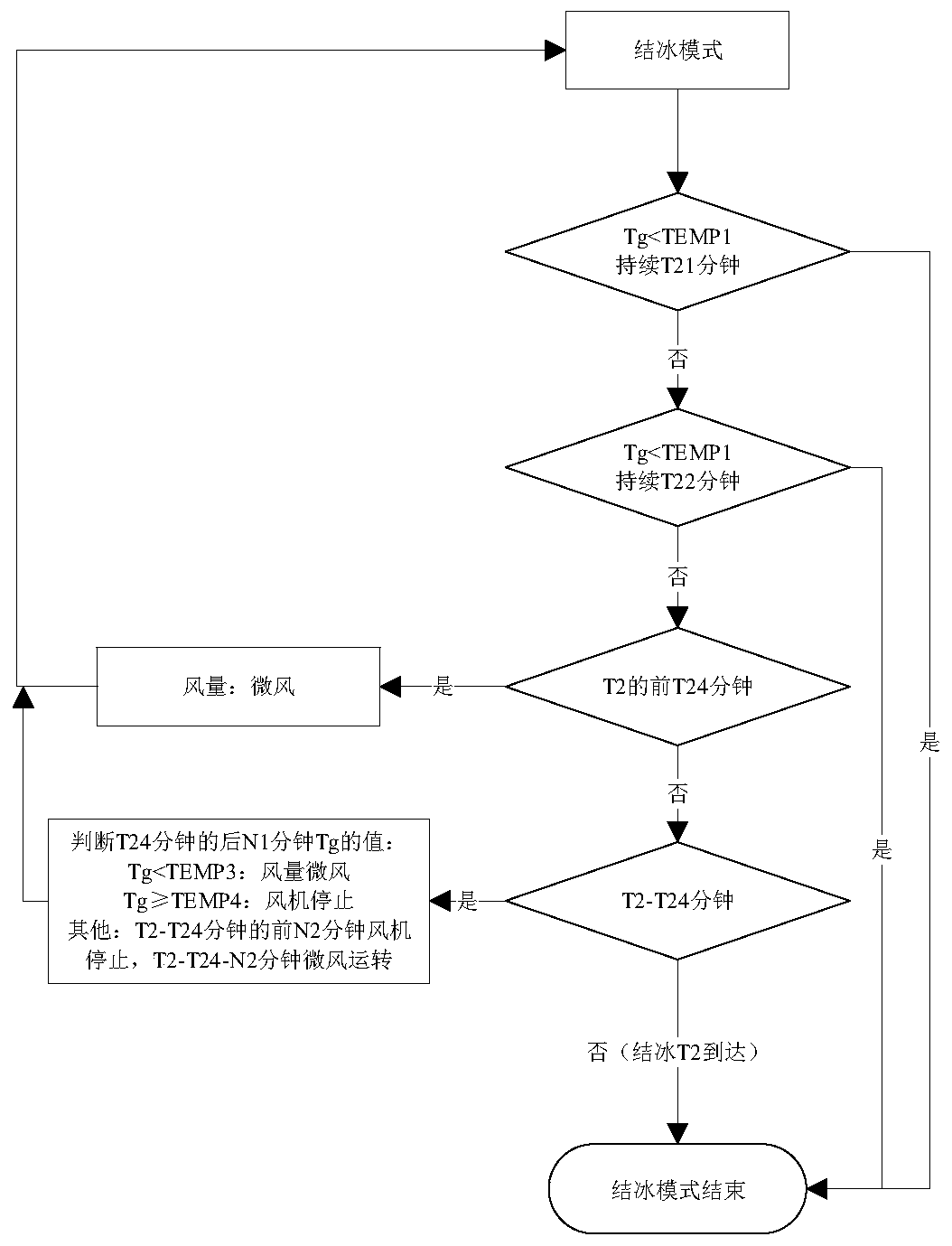

InactiveCN107514682AWith self-cleaning functionIncrease the degree of frost condensationCondensate preventionFlush cleaningEngineeringHeat exchanger

The invention provides an air conditioner indoor unit with a self-cleaning function. The air conditioner indoor unit comprises a case, a humidifying assembly, a spray opening and a heat exchanger of the indoor unit. The case comprises a skeleton and a housing, wherein the skeleton is used for supporting a fan and the heat exchanger of the indoor unit, and the housing covers the skeleton and is provided with an air inlet and an air outlet. The humidifying assembly comprises a water tank and an atomization device used for atomizing water in the water tank. The spray opening is formed in the case and located in the air inlet upstream position of the heat exchanger of the indoor unit and used for outputting water mist formed by the atomization device. The humidifying assembly starts the atomization device when the air conditioner indoor unit executes the self-cleaning function, so that the spray opening is utilized to spray out the water mist to flow through the heat exchanger of the indoor unit, and accordingly the frosting degree at the heat exchanger of the indoor unit is improved. The heat exchanger of the indoor unit operates a condenser mode after frosting, and accordingly attached contaminants are taken away by water formed by defrosting. According to the scheme, the problem that a self-cleaning air conditioner cannot generate enough condensed water in the dry environment, and consequently the self-cleaning effect is affected is solved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

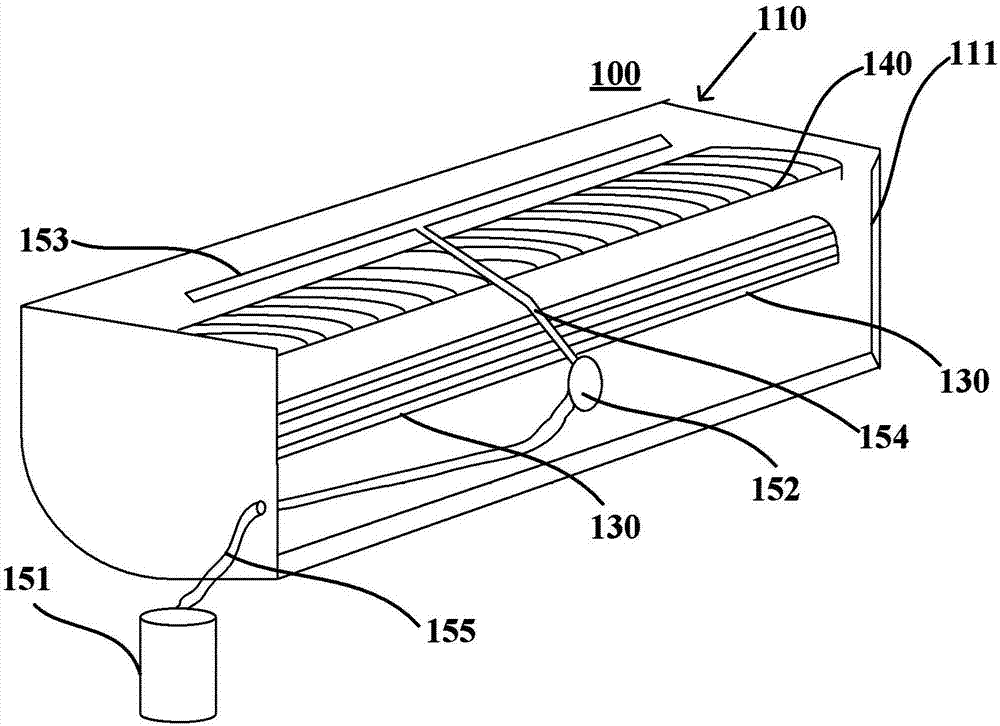

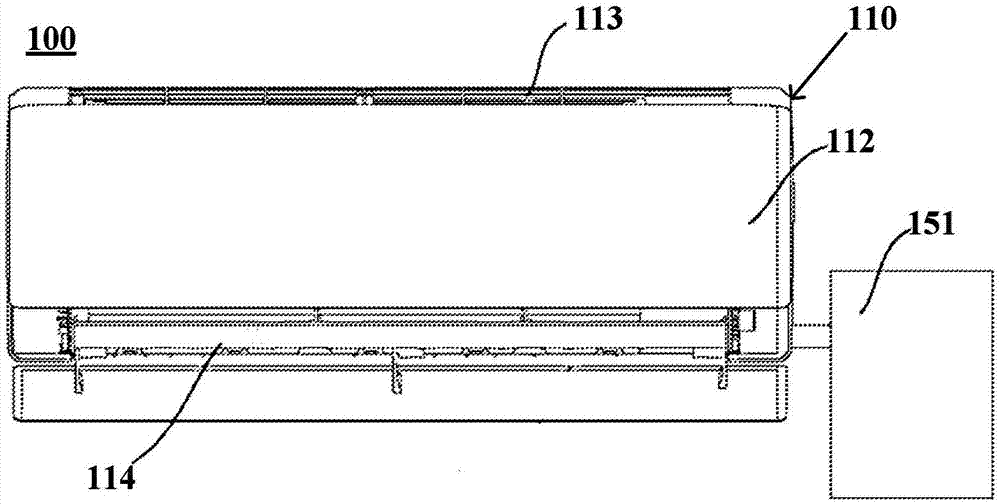

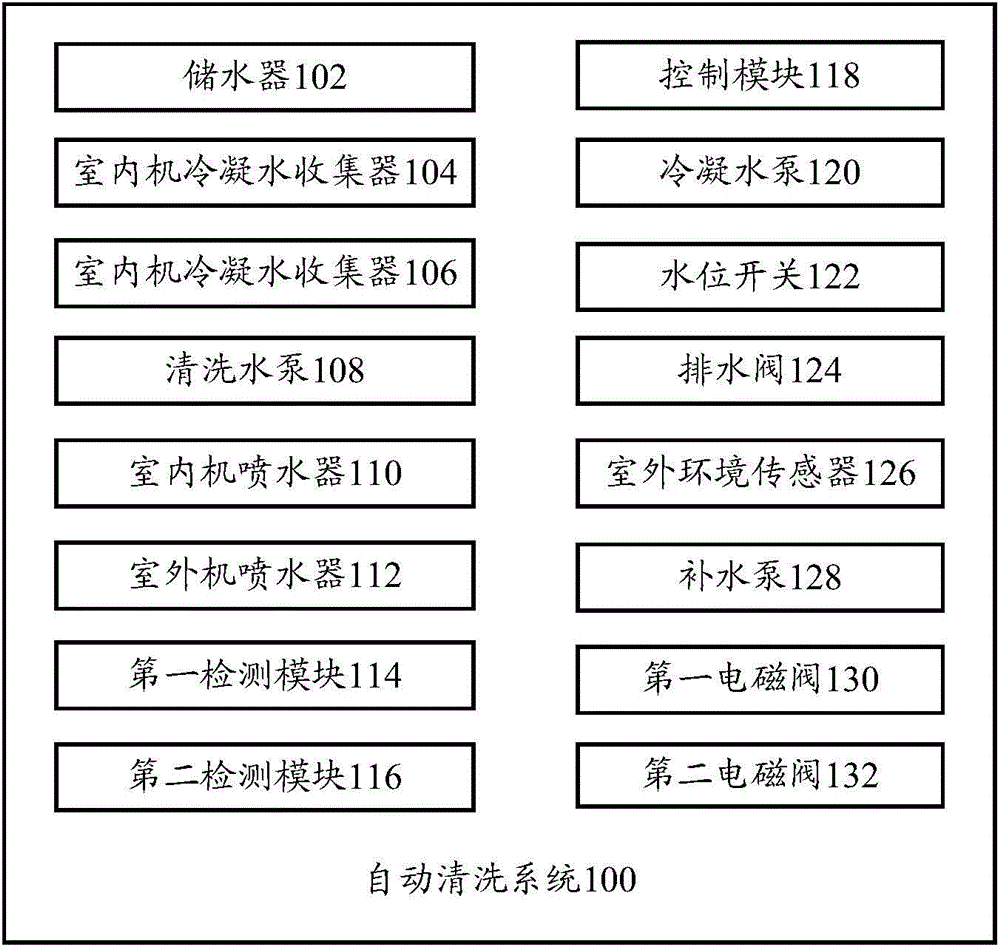

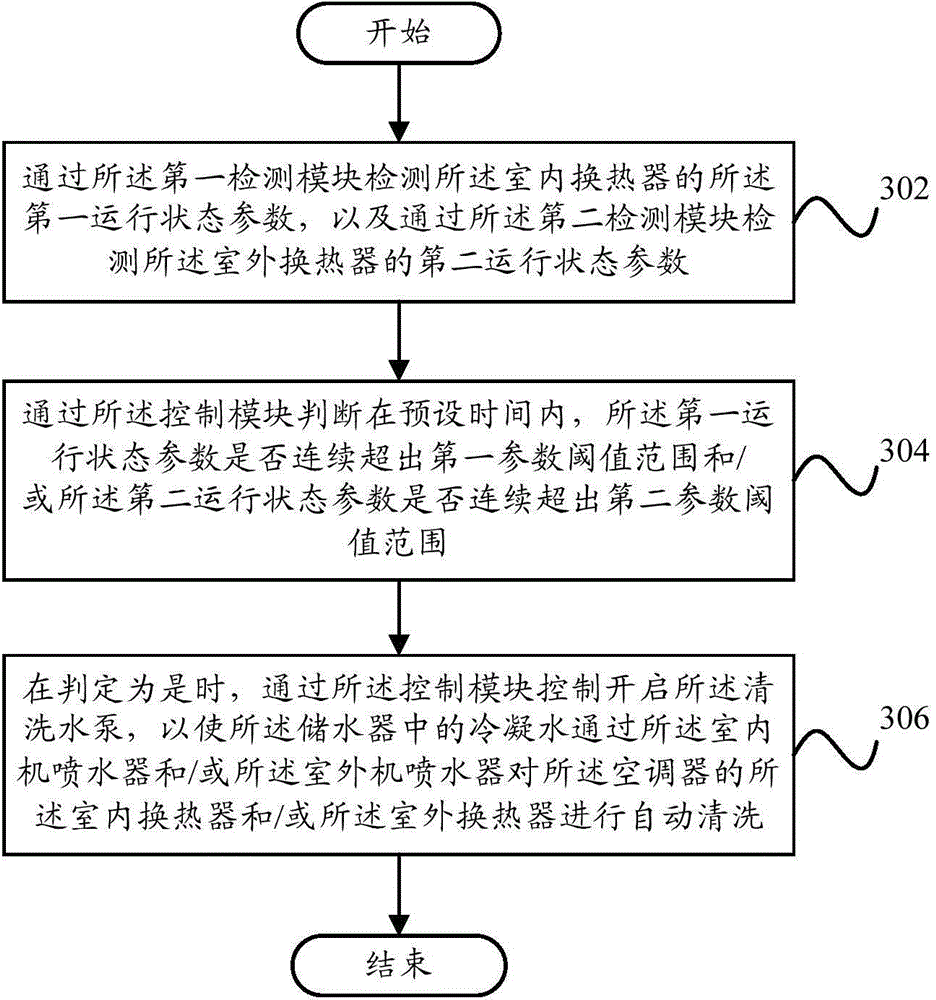

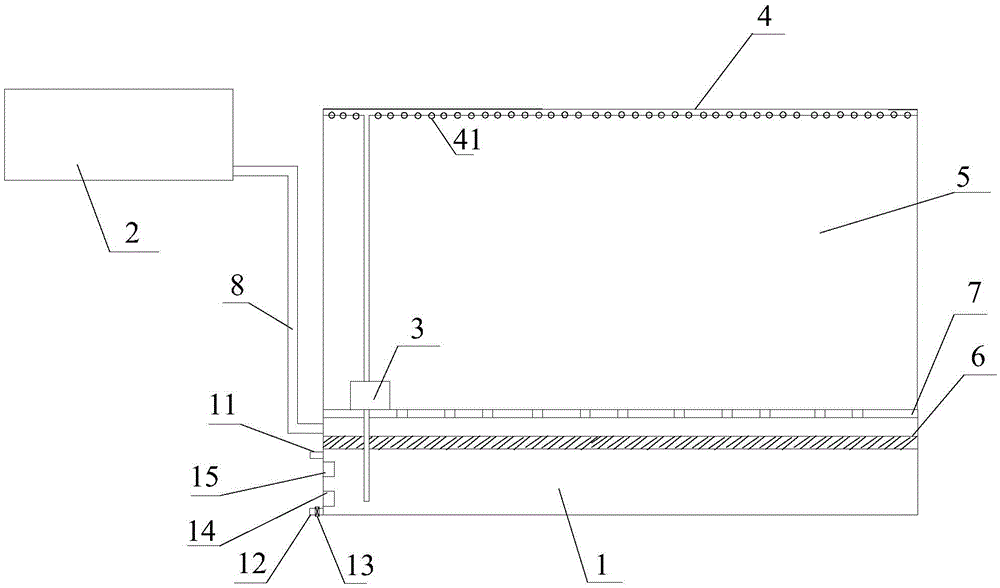

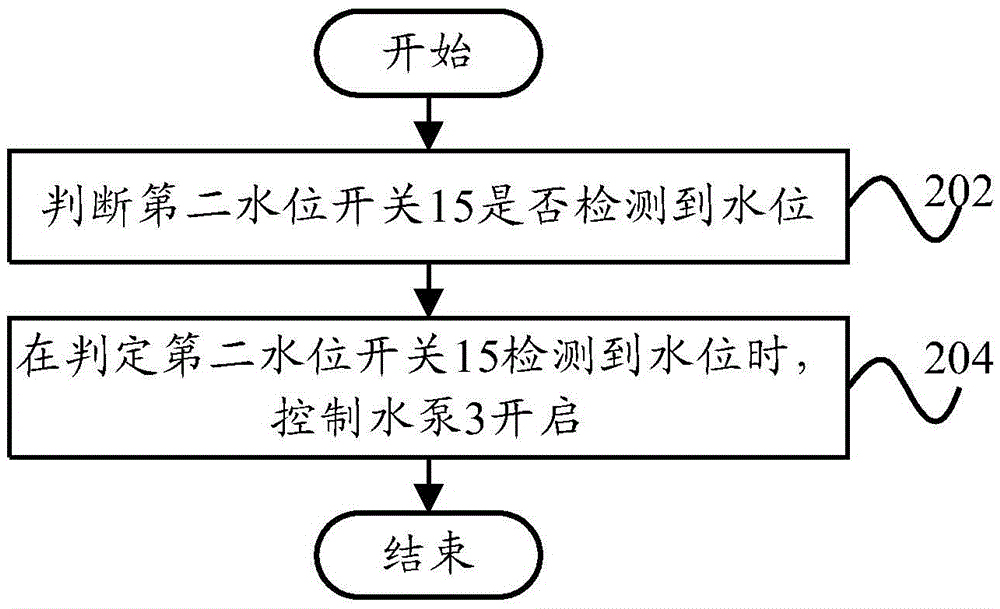

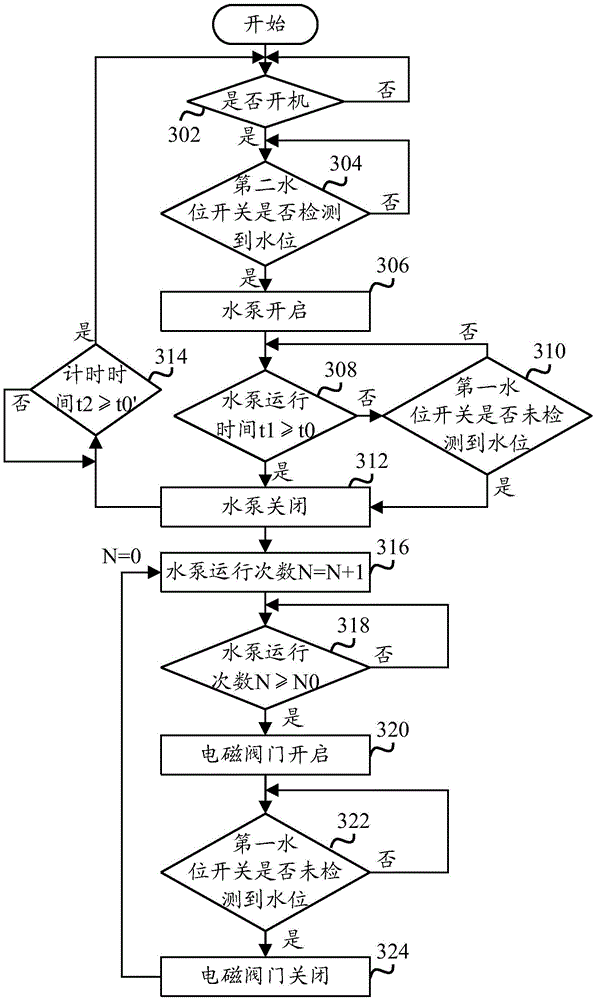

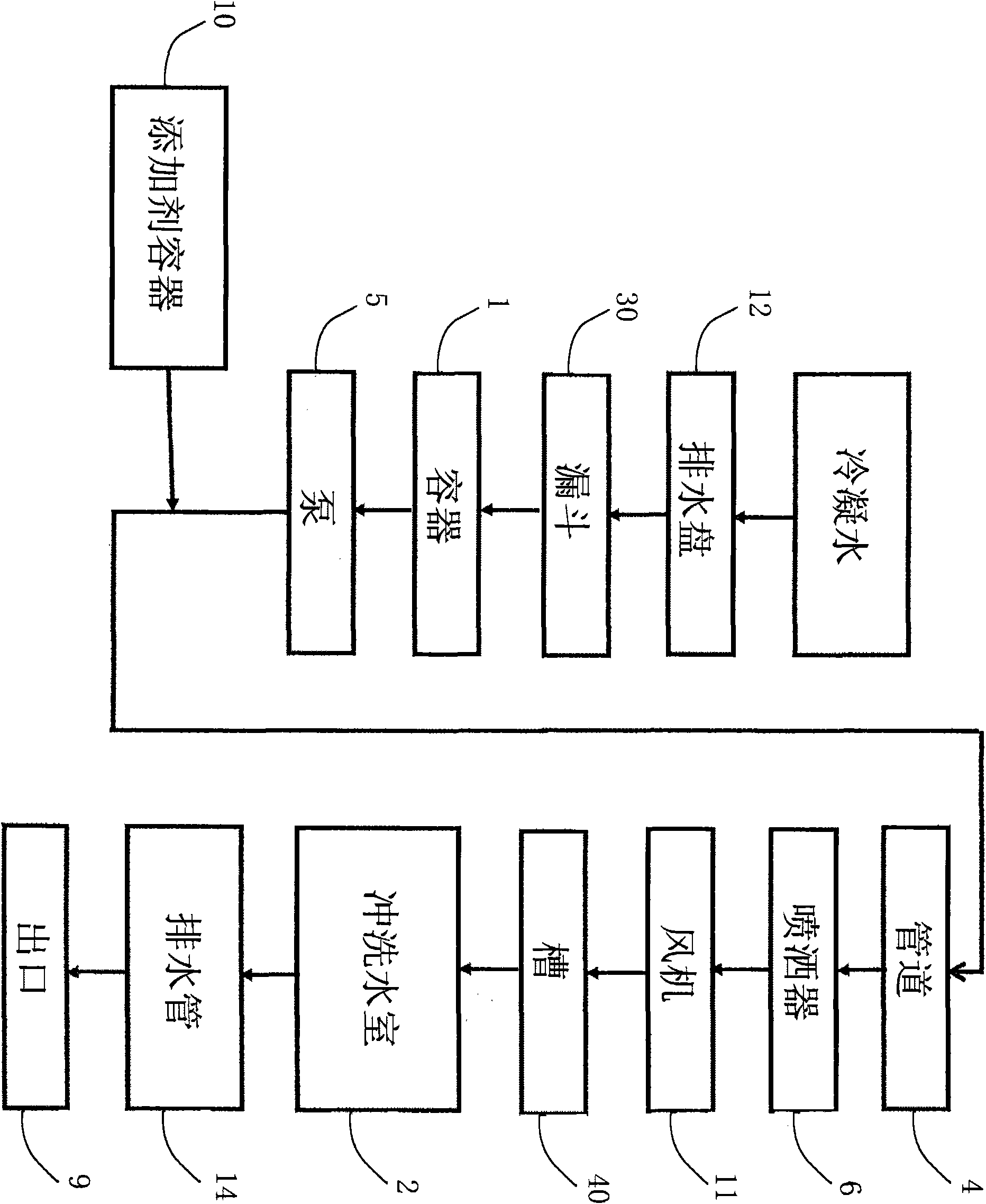

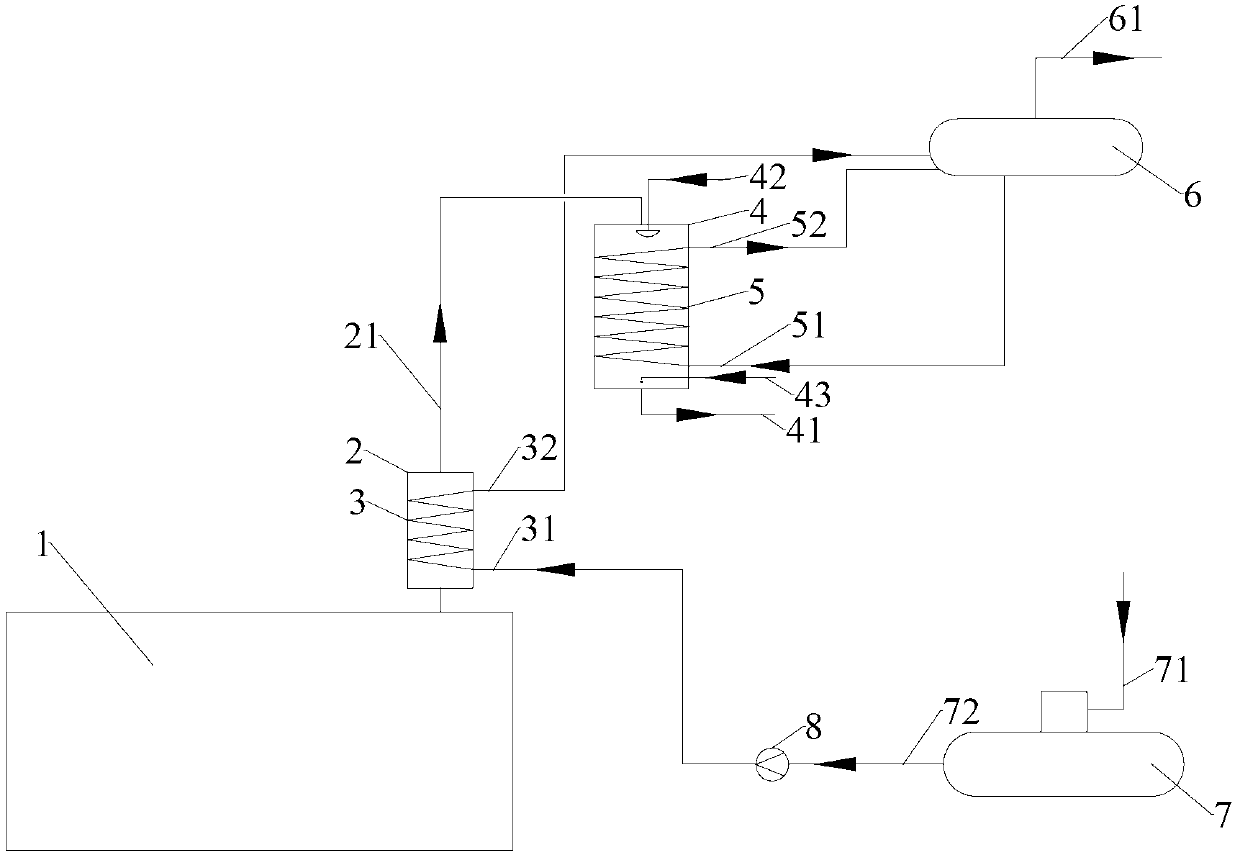

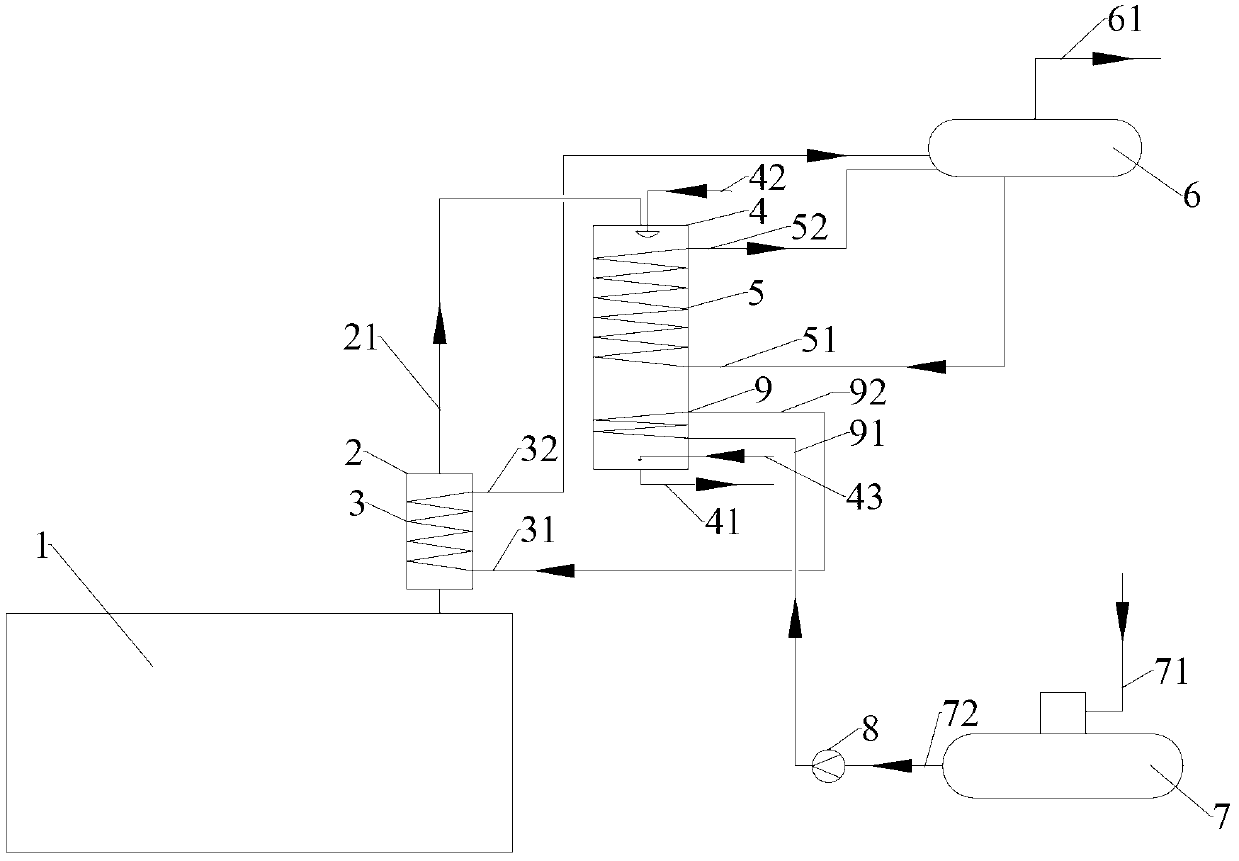

Automatic cleaning system, air conditioner and control method

The invention provides an automatic cleaning system, an air conditioner and a control method. The automatic cleaning system comprises a water storing device of which the first end is connected to an indoor unit condensed water collector and an outdoor unit condensed water collector, a cleaning water pump of which one end is connected to the second end of the water storing device and while the other end is connected to an indoor unit water sprayer and an outdoor unit water sprayer, a first detecting module for detecting the first operation state parameters of an indoor heat exchanger, a second detection module for detecting the second operation state parameters of an outdoor heat exchanger, and a control module for determining whether to start the cleaning water pump to automatically clean the indoor heat exchanger and / or the outdoor heat exchanger according to the first operation state parameters and / or the second state parameters. According to the technical scheme, the system has the advantages that the heat exchangers can be automatically cleaned, so that the timeliness and efficiency of cleaning of the heat exchangers can be effectively improved, and as a result, the operation reliability of the air conditioner can be improved; in addition, the condensed water can be recycled, and thus the water resource can be saved.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

Cleaning agent and cleaning method for air conditioner

InactiveCN101475878AImprove heating efficiencyImprove cooling efficiencyNon-ionic surface-active compoundsFlush cleaningStrong acidsHigh pressure water

The invention discloses a detergent and a cleaning method for a complete air-conditioner, which not only can uniformly and completely remove dirt but also cannot strongly corrupt components and parts such as aluminum, copper and stainless steel, are time-saving and labor saving, safe and reliable, and pollution-free, and have low cost. Raw materials of the detergent are at least two compositions of citric acid, inorganic weak acid and inorganic strong acid; a non-ionic surfactant or a non-ionic surfactant is mixed with an anionic surfactant; and the detergent comprises an oxygen solvent, an acid corrosion inhibitor, and the balance being water. The cleaning method comprises: disassembling a motor and a fan, and taking off the motor and the fan for independent cleaning; preparing the detergent into an aqueous solution according to the proportion of between 10 and 15 percent, hanging the complete air-conditioner after disassembly of the motor and the fan into a cleaning tank, soaking the complete air-conditioner for 30 minutes at normal temperature, and starting ultrasonic waves to clean for 10 to 30 minutes; placing the complete air-conditioner into a washing tank, and using a high-pressure water gun to spray the surface and the inside of the air-conditioner; and using hot blast to dry the air-conditioner at a temperature of 80 DEG C.

Owner:DALIAN SANDAAOKE CHEM

Cleaning device and cleaning method of heat exchanger

The invention provides a cleaning device and cleaning method of a heat exchanger. The cleaning device of the heat exchanger comprises a water storage tank, a water pump and a water spraying device, wherein the water storage tank is used for collecting condensate water generated in the working process of an indoor unit and / or outdoor unit of an air conditioner, a water inlet of the water pump is communicated with the water storage tank, a water inlet of the water spraying device is connected to a water outlet of the water pump, and a water spraying hole facing the heat exchanger of the air conditioner is formed in the water spraying device. According to the technical scheme, the tedious operation of heat exchanger manual cleaning in the prior art is solved, convenience and rapidness of cleaning of the heat exchanger are improved, and reliable running of an air conditioner system is ensured.

Owner:HEFEI MIDEA HEATING & VENTILATING EQUIP

Descaling method of phospheric acid concentration heat exchanger

ActiveCN1724965AEfficient removalRemove completelyOrganic detergent compounding agentsSurface-active detergent compositionsHexamethylenetetraminePhosphoric acid

The invention discloses a method for decaling phosphoric acid concentration heat exchanger, namely a technique of adopting a washing-liquor composed of thin fluosilicic acid solution, organic phosphonic acid sustained-releasing agent and film forming matter and firstly washing the heat exchanger with water and then washing out the foul with the washing liquor. In the washing liquor, the fluosilicic acid is a 5%-20% thin acid, the organic phosphonic acid sustained-releasing agent includes amino tri- sub-methylene phosphoric acid, hydroxyl sub-ethyl di-phosphoric acid and hydroxyl-l, 1-subethyl di-phosphoric acid; the film forming matter includes nitrous phenylhydroxylamine ammonium salt and wuluotuopin as well as sodium molybdate. As using, adding in surface active agent alkyl sulphonate. The invention can make high efficiency and thorough decaling the graphite heat exchanger and simultaneously effectively control the corrosion of the washing liquor to the equipment and as compared with traditional washing methods, the invention improves the productivity of the equipment.

Owner:WENGFU (GRP) CO LTD +1

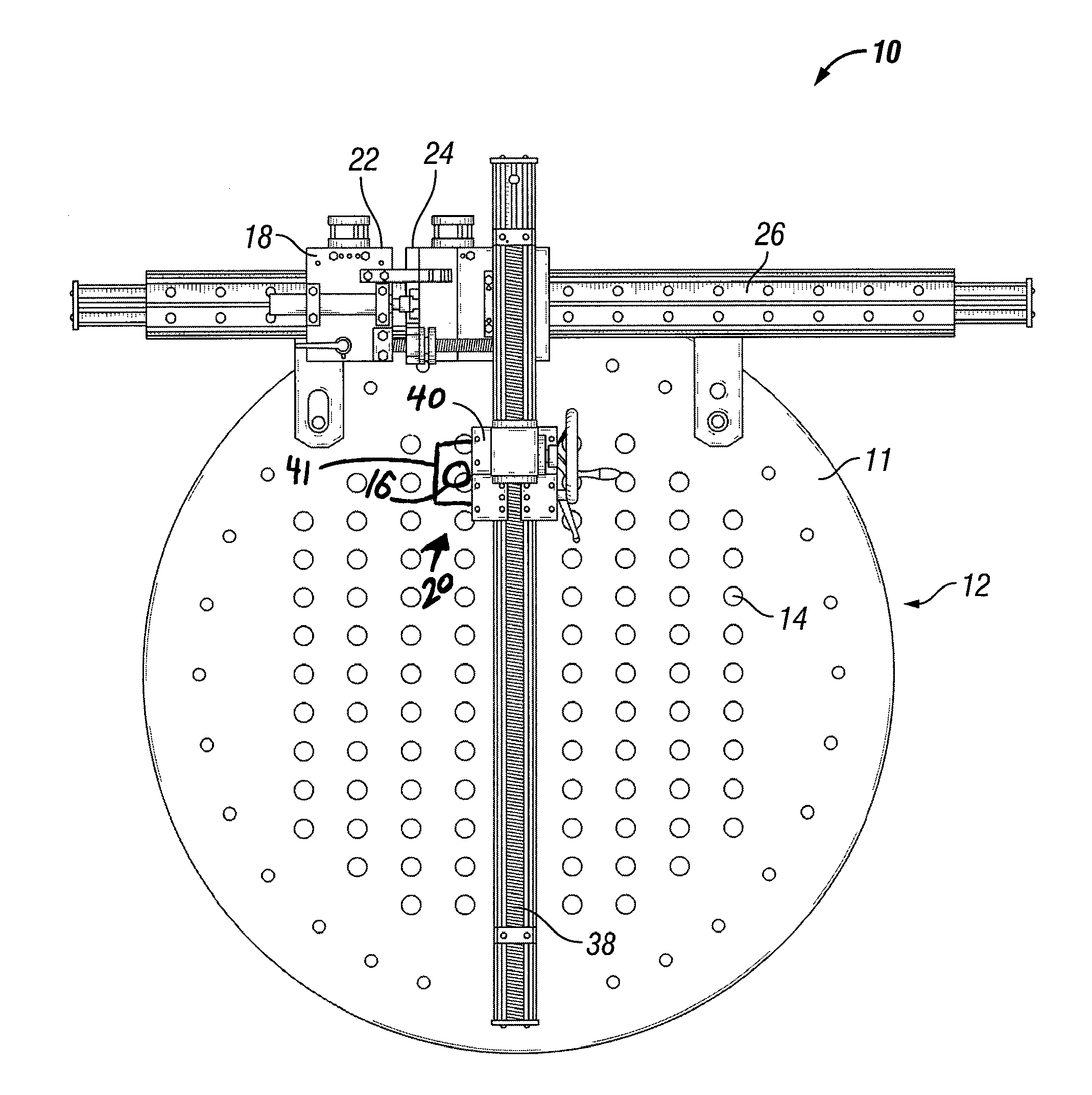

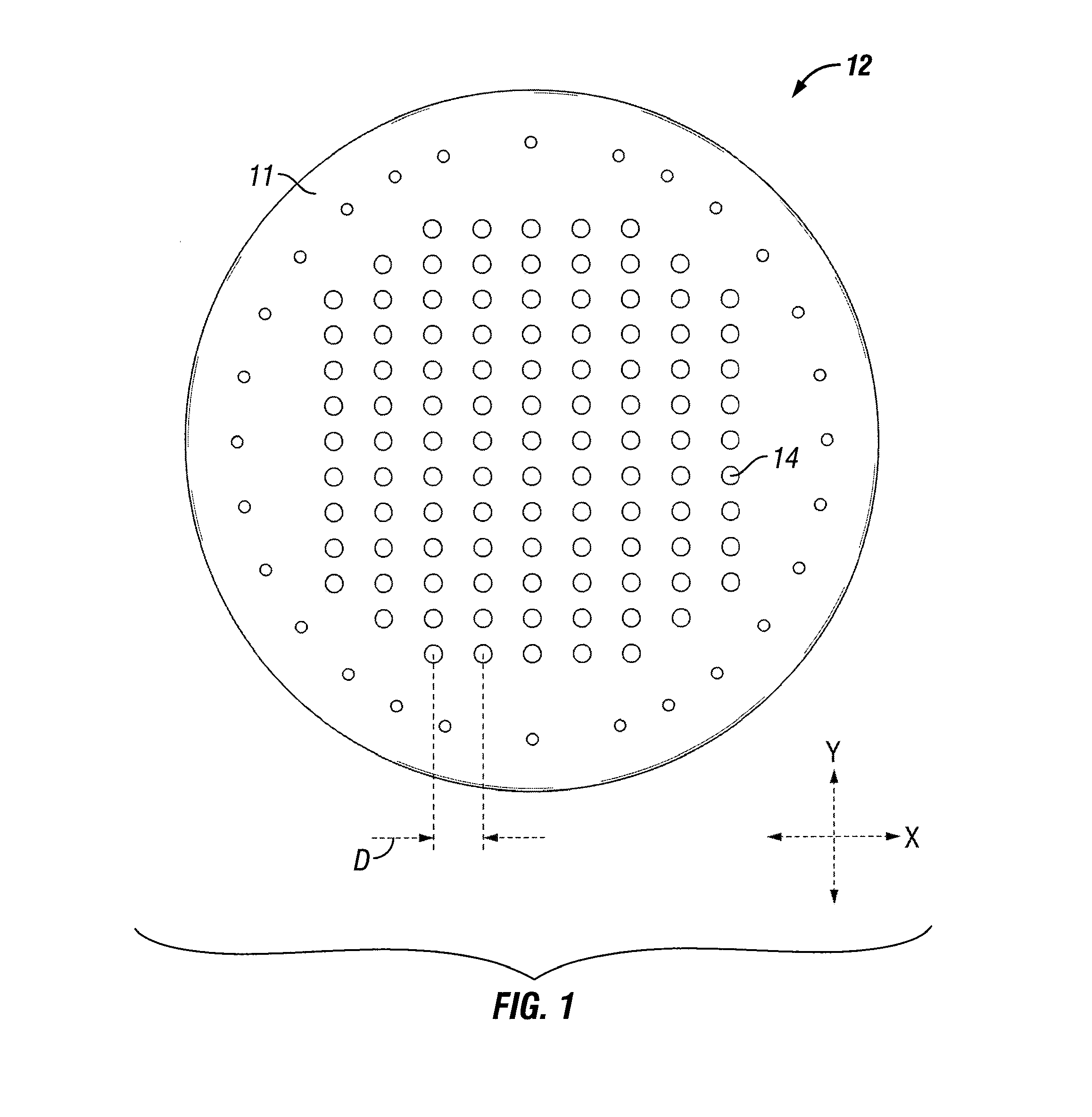

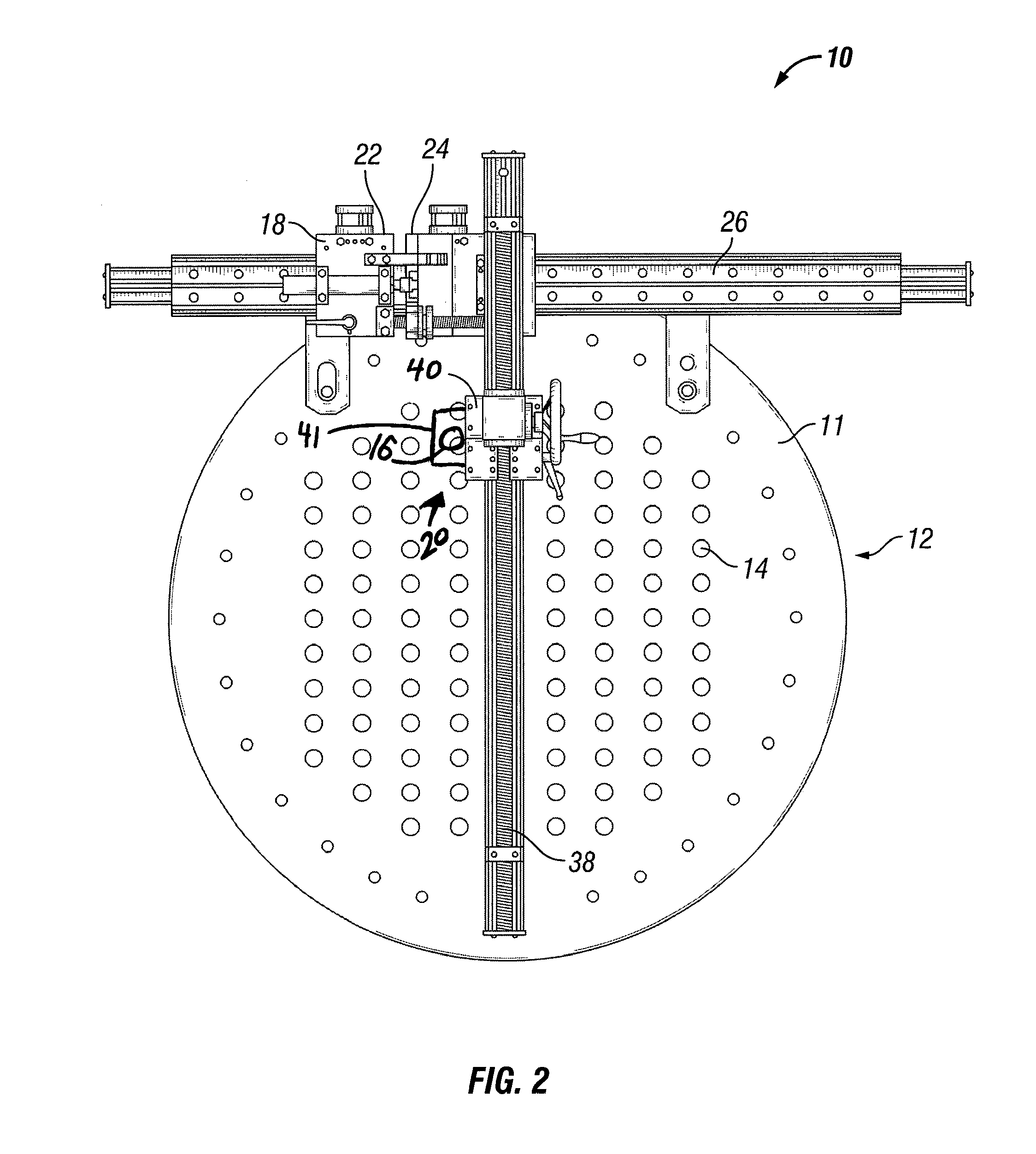

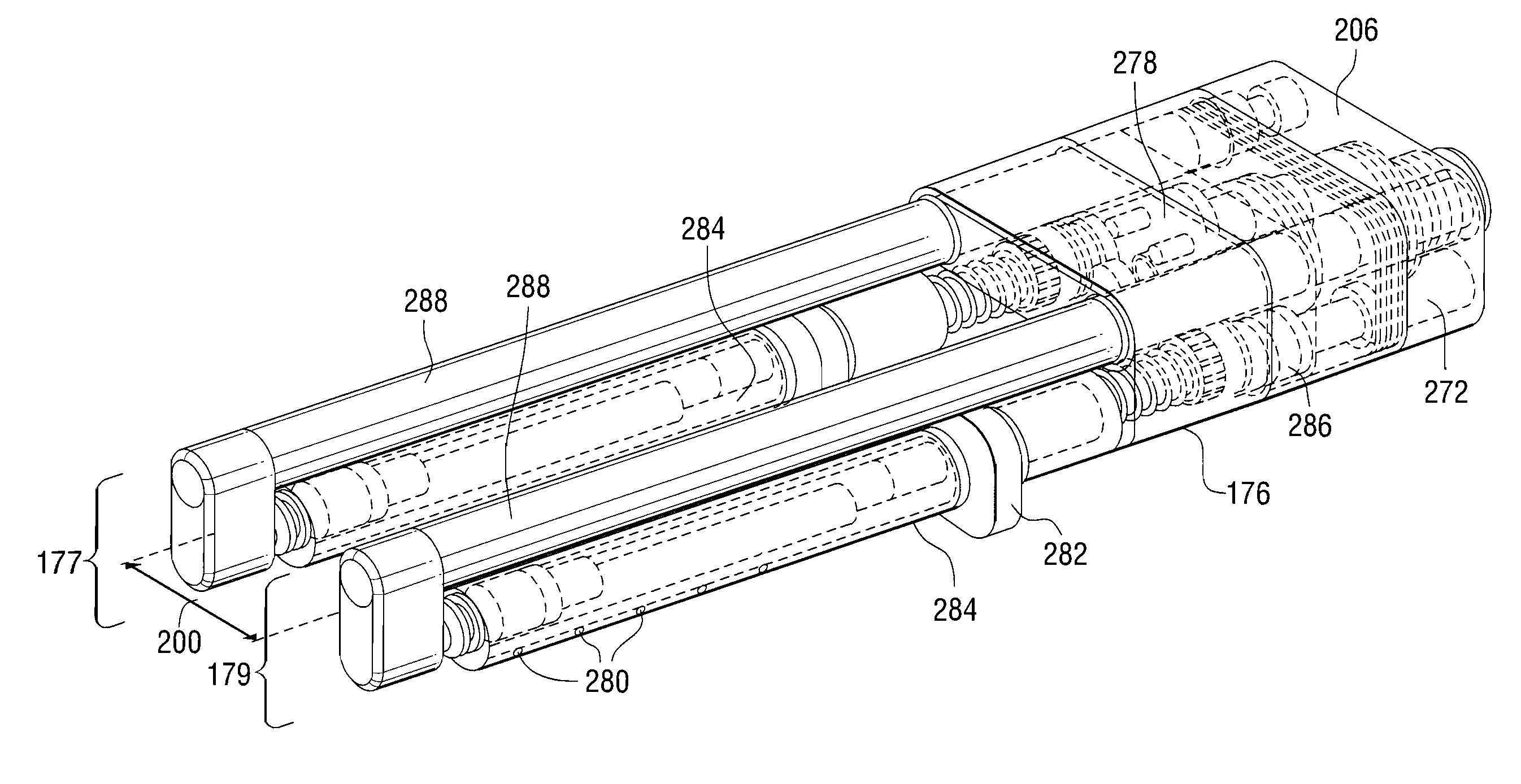

Semi-automated heat exchanger tube cleaning assembly and method

ActiveUS20120067370A1Adjustable distanceHollow article cleaningHair combsPetrochemicalProcess engineering

A heat exchanger tube cleaning assembly and method is provided. The assembly can allow for semi-automated tube cleaning of a heat exchanger or other piping or equipment used in an industrial facility such as, for example, a petrochemical plant or oil refinery.

Owner:HYDROCHEM

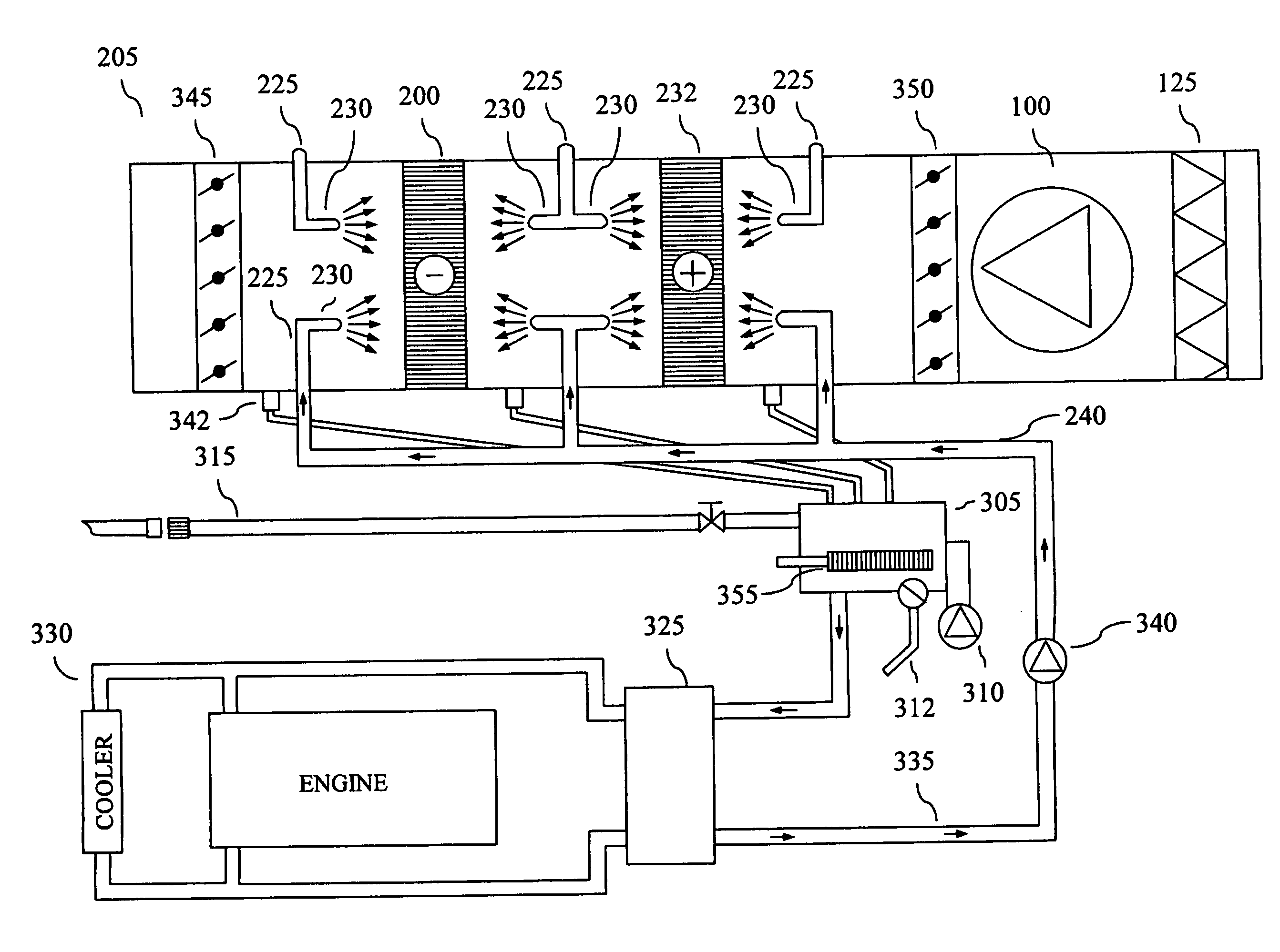

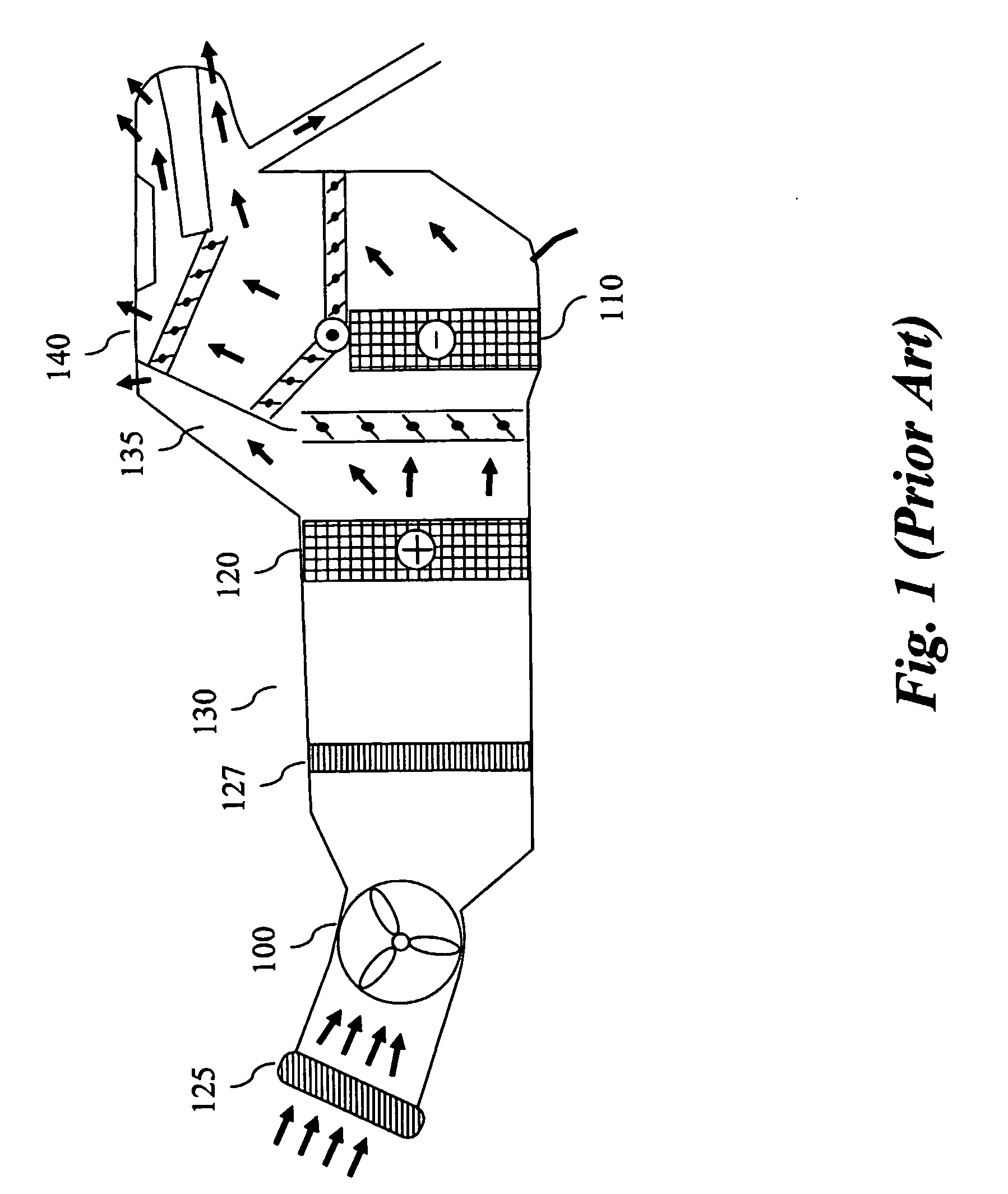

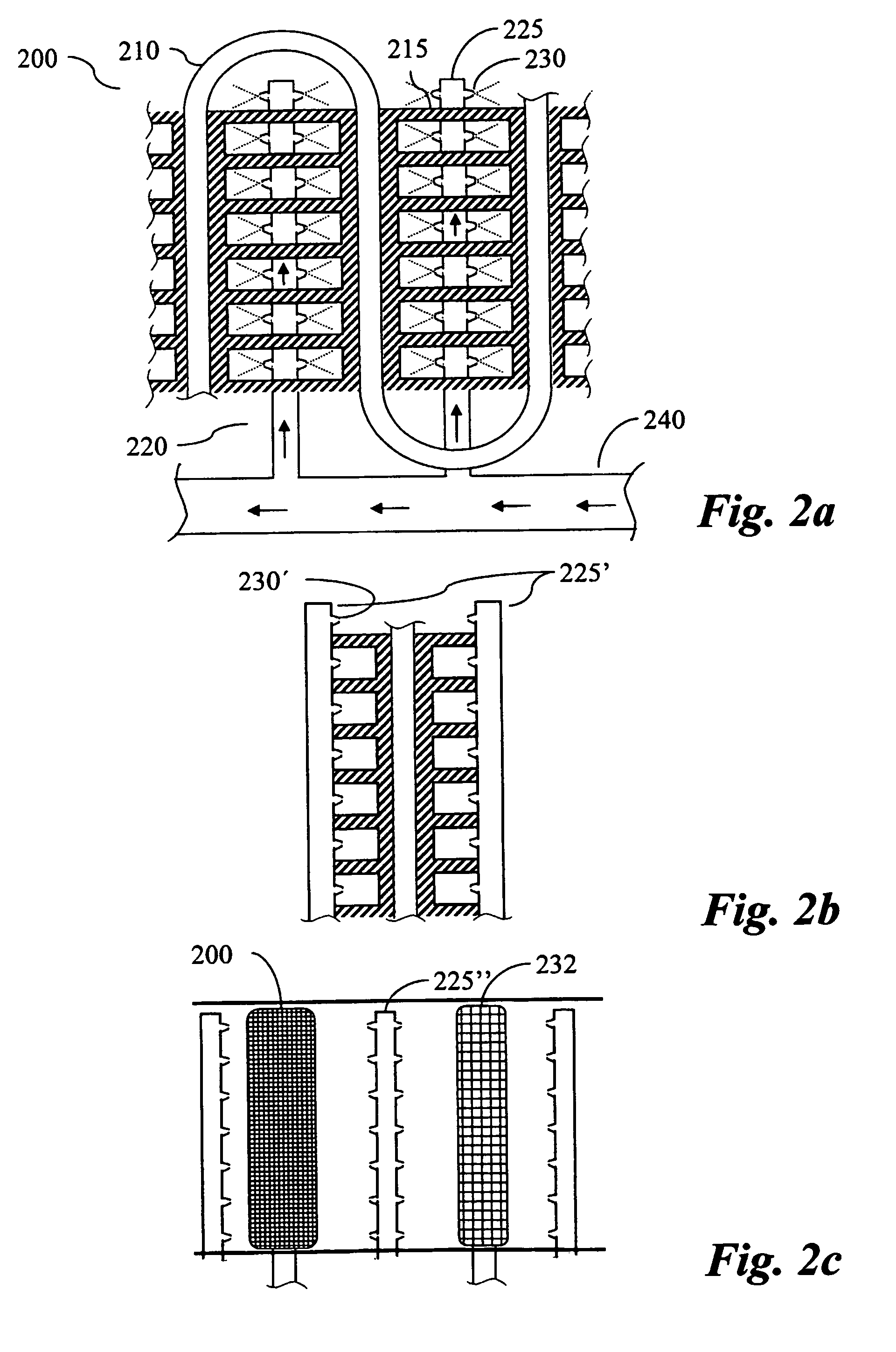

Air conditioner cleaning apparatus and method

InactiveUS20070125520A1Less discomfortImprove air qualityMechanical apparatusAir-treating devicesEngineeringPollution

A cleaning apparatus, system and method for parts of the heating / cooling system of an vehicle. The apparatus effectively impedes odour and pollution originating from micro-organisms growing on the cooling and heating units. The cleaning assembly 220 includes of distribution tubes 225 provided with nozzles 230 arranged to spray cleaning substance onto the surfaces of the cooling and / or heating units 200, 232. The distribution tube preferably extends through at least a portion of the plurality of heating / cooling flanges 215 of the heating / cooling units and the nozzles are provided in the spaces formed between two adjacent flanges.

Owner:NUTSOS MIKAEL

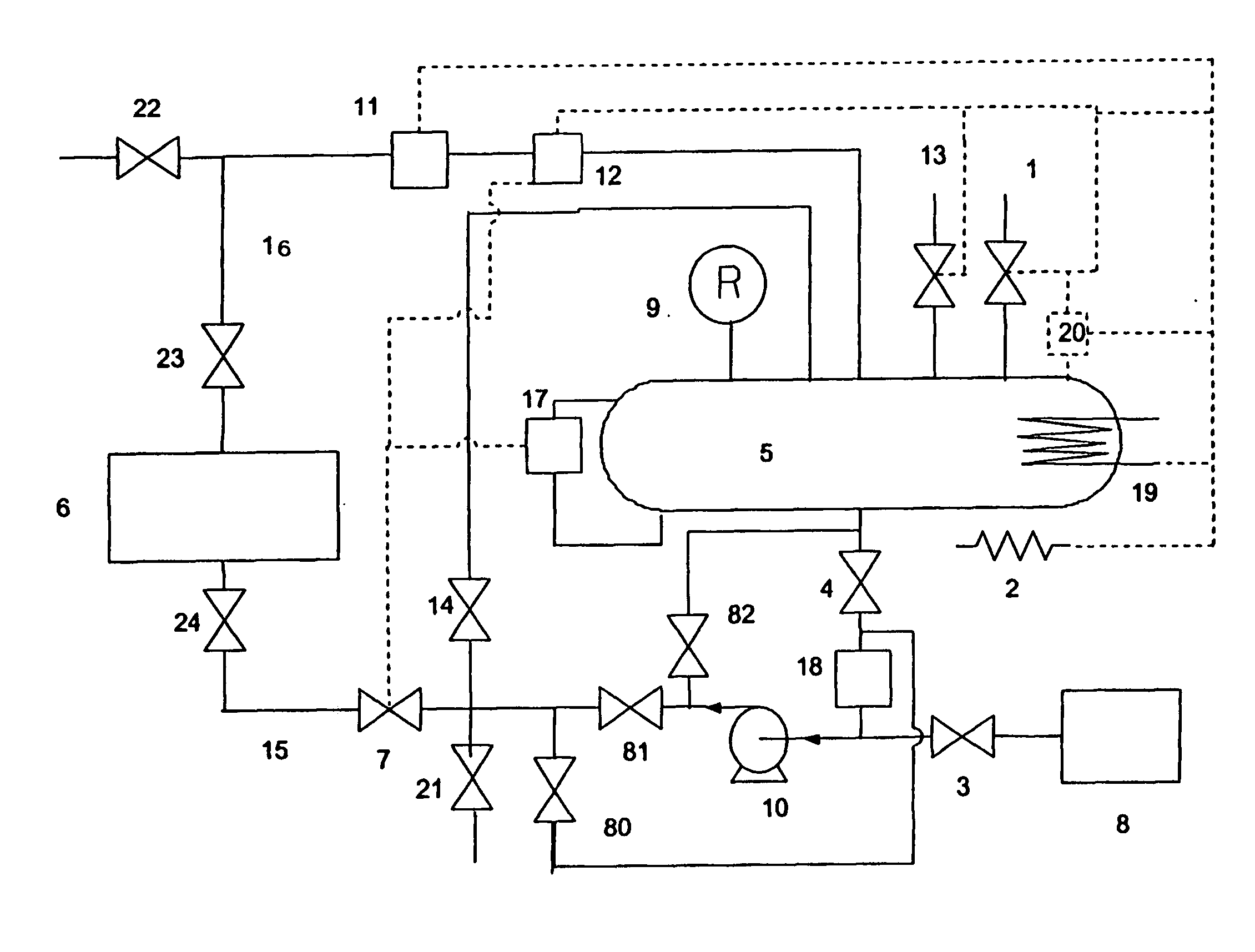

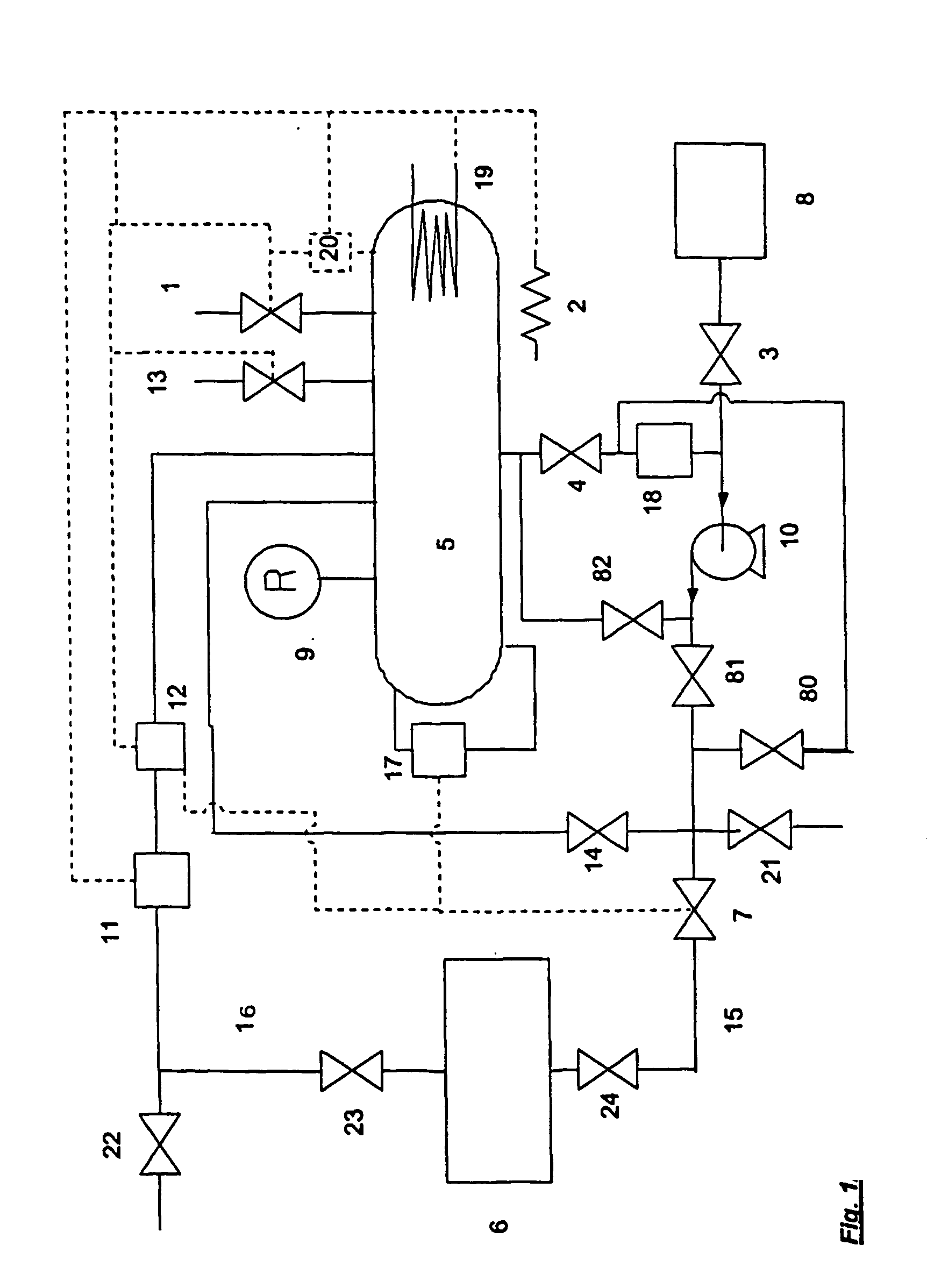

Method and system for maintenance of an air-condition unit

It is provided a system for cleaning a blower and an air inlet filter of an air condition unit using condensed water. The system includes a reservoir for condensed water, a first sub-system for facilitating flowing pressurized liquid in a duct having spraying outlets, and a second sub-system for removal of sprayed liquid out of the air condition unit. The cleaning liquid includes condensed water and a cleaning additive. The air inlet filter may rotate on a pair of pulleys, and the filter is exposed to the sprayed liquid by rotating a pulley while spraying. The system includes barriers disposable in a separating position between the cleaned parts and other objects. The system also includes a manipulating handle or an electric motor, for placing the barrier. Electrical circuitry may automatically initiate cleaning the parts on turning-off the air condition unit. The system include a chamber for a cleaning additive and a mixing mechanism for mixing the cleaning additive with the condensed water. The sub-system for removal of sprayed liquid out of the air condition unit includes a drain tray, a used water chamber and a drain pipe.

Owner:丹巴杰纳

Cleaning method

ActiveUS20050139238A1Detergent mixture composition preparationHollow article cleaningHydrocotyle bowlesioidesProcess engineering

The method for cleaning chemical process and hydrocarbon processing apparatuses is performed by establishing a closed flow circulation loop, under specific operating conditions and in the presence of hydrocarbon-based fluids. The cleaning method is monitored by performing chemical / physical analysis. After cleaning the apparatus(es) can be immediately inserted back into the process. An optional degassing step can also be performed, in case the apparatus(es) has to be disassembled for inspection of maintenance.

Owner:FERRARA

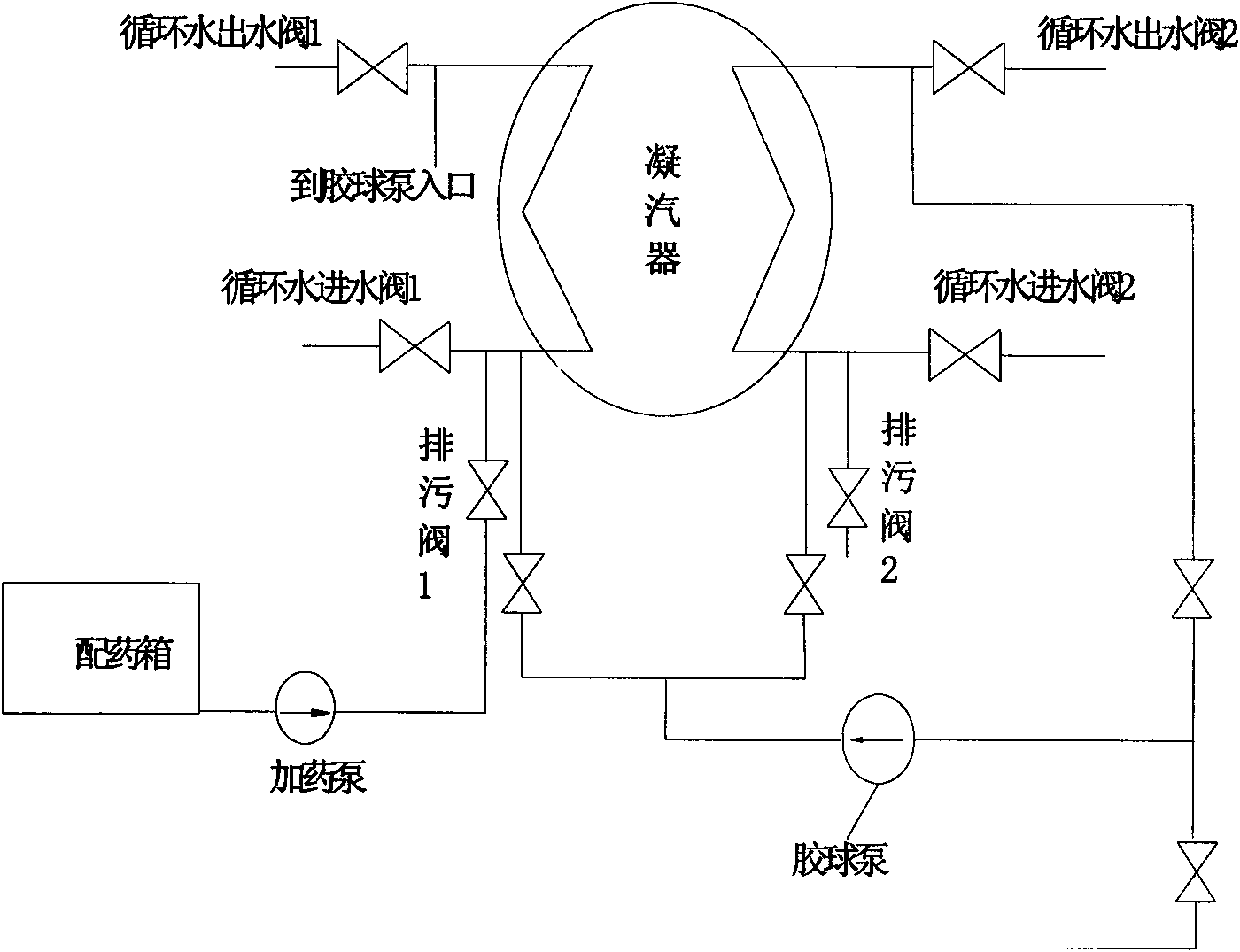

Method for cleaning copper tubes of condenser

A method for cleaning copper tubes of a condenser relates to the cleaning of heat transfer pipelines. The method comprises the following steps: the first step, closing an inlet valve and an outlet valve of circulating water after a turbine condenser is shut down; the second step, flushing the copper tubes of the condenser with clean water; the third step, injecting acid chemical cleaning liquor at water side of the condenser for soak cleaning; the fourth step, neutralizing soak solution with sodium hydroxide; the fifth step, flushing the copper tubes of the condenser with clean water; the sixth step, rinsing the copper tubes of the condenser with clean water; and the seventh step, replacing membrane, and commissioning after cleaning. Compared with the original method of cleaning with chemical agents to be added to a circulating water tank, the method is characterized in that chemical cleaning liquor is added to a single turbine condenser, which can help clean fouling off the copper tubes and improve vacuum degree of the turbine while ensuring no corrosion of the copper tubes, and has the advantages of low agent consumption, low cost, low corrosion rate, good cleaning effect and saving cleaning time. The method can be widely applied to cleaning and maintenance of the copper tubes of the condensers in power plants.

Owner:WENGFU (GRP) CO LTD

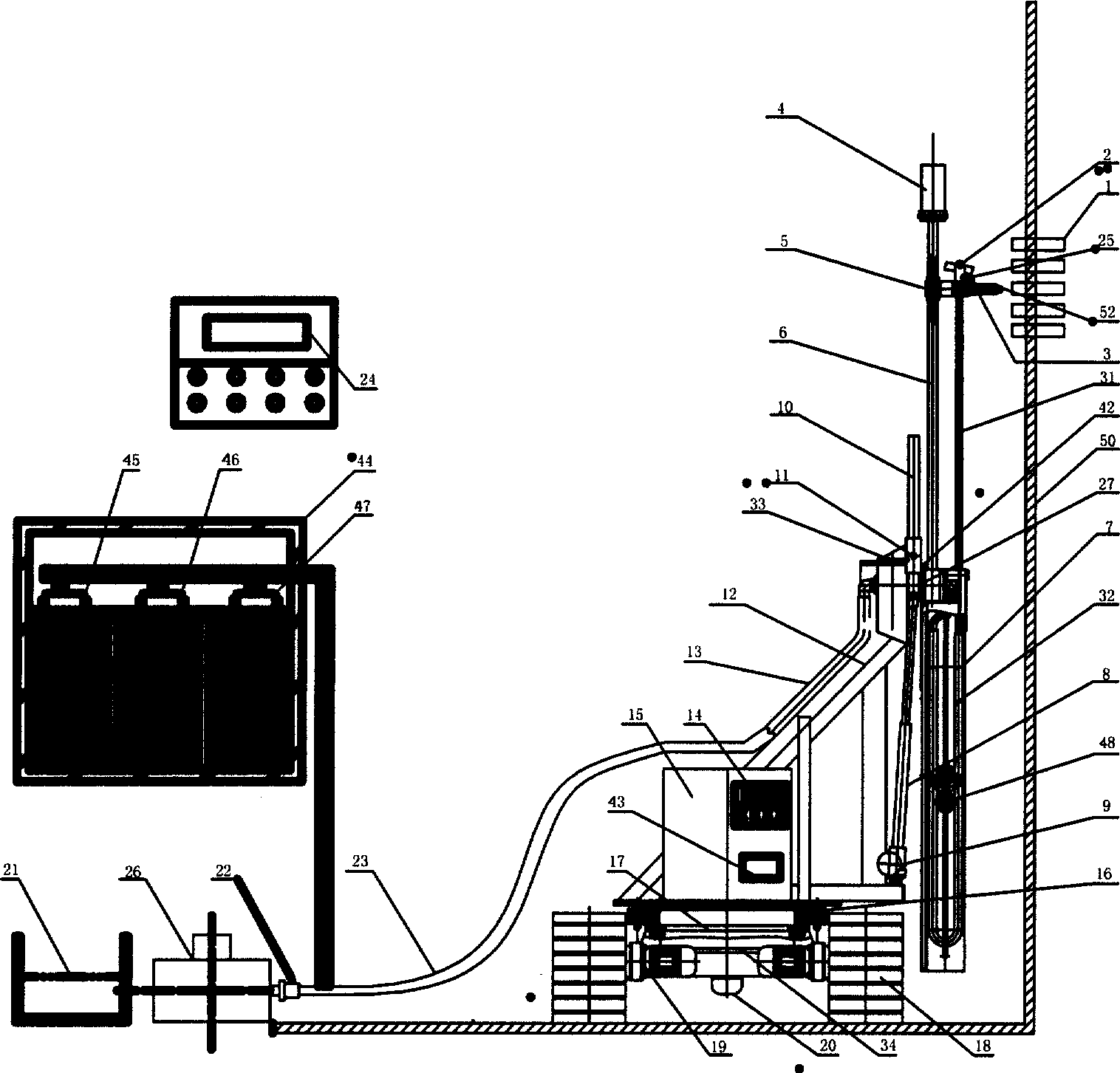

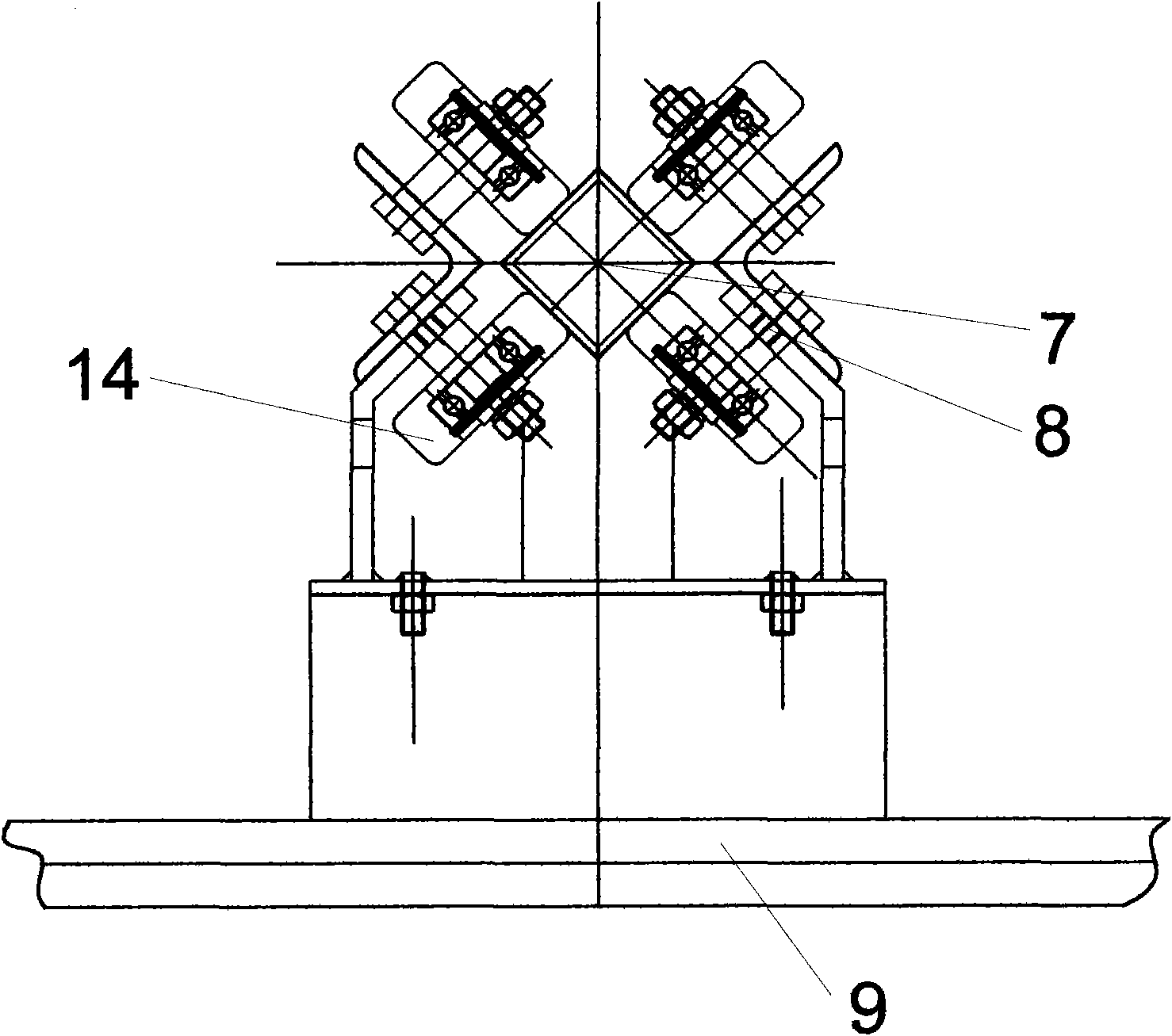

Intelligent movable cleaning robot for condenser

ActiveCN101430176AAchieving autonomous mobilityAchieve precise positioningFlush cleaningManipulatorDrive shaftEngineering

The invention discloses a condenser intelligent moving and cleaning robot, which can be used in the field of large scale cleaning equipment and comprises a track running mechanism, a cleaning mechanism, and an electric control mechanism. A spray gun is connected on a spray gun running rest of a cleaning arm. The spray gun is provided with a underwater TV camera and connected with a cleaning media source by a communicating tube. The cleaning arm is connected with a cleaning arm running bracket component by a drive shaft. The drive shaft of the cleaning arm is connected with an electric push rod. The cleaning arm running bracket component is arranged on a pivoting support which is arranged on the track running mechanism by the running bracket component. The right front end of the top of the spray gun, the front end and the back end of a mounting plate of the pivoting support and the front position and the back position of a track support are provided with sonar sensors. The robot has few joints, simple structure, convenient processing and assembling, can automatically move in a water chamber of the condenser to finish the precise position and efficient cleaning of copper pipes of the condenser, has wide application range and high degree of automation.

Owner:HUNAN UNIV

System and method for maintaining efficiency of a fractal heat sink

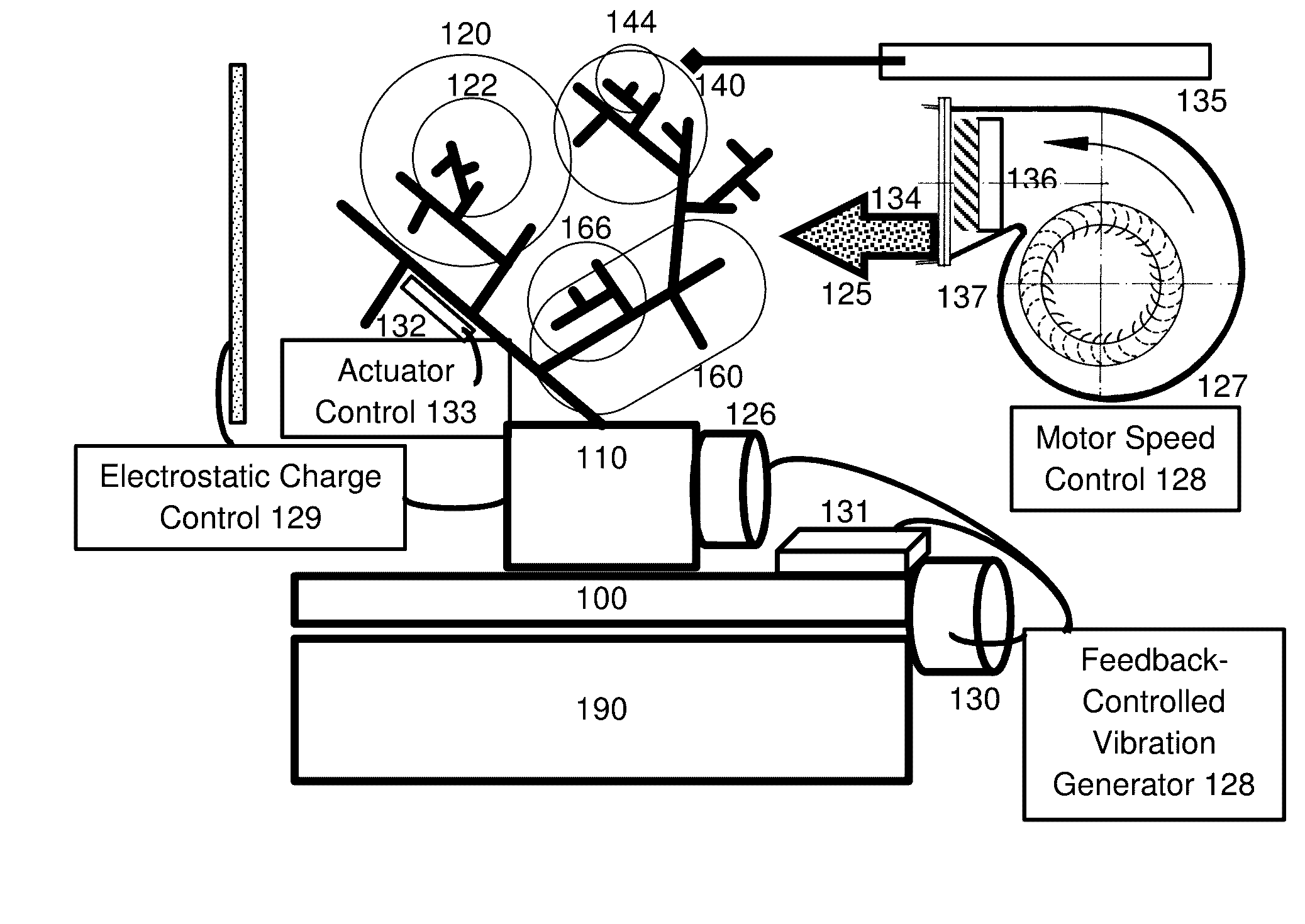

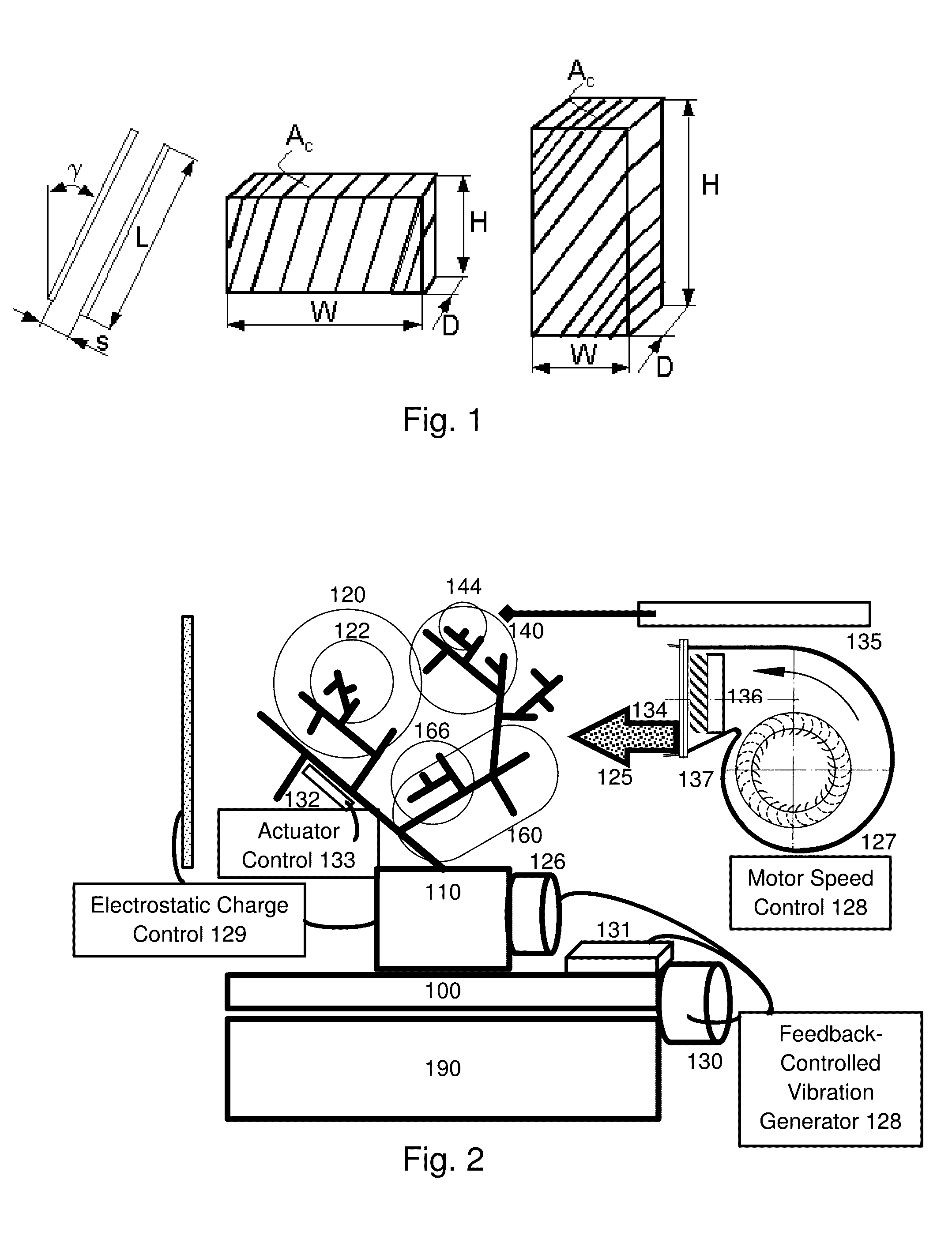

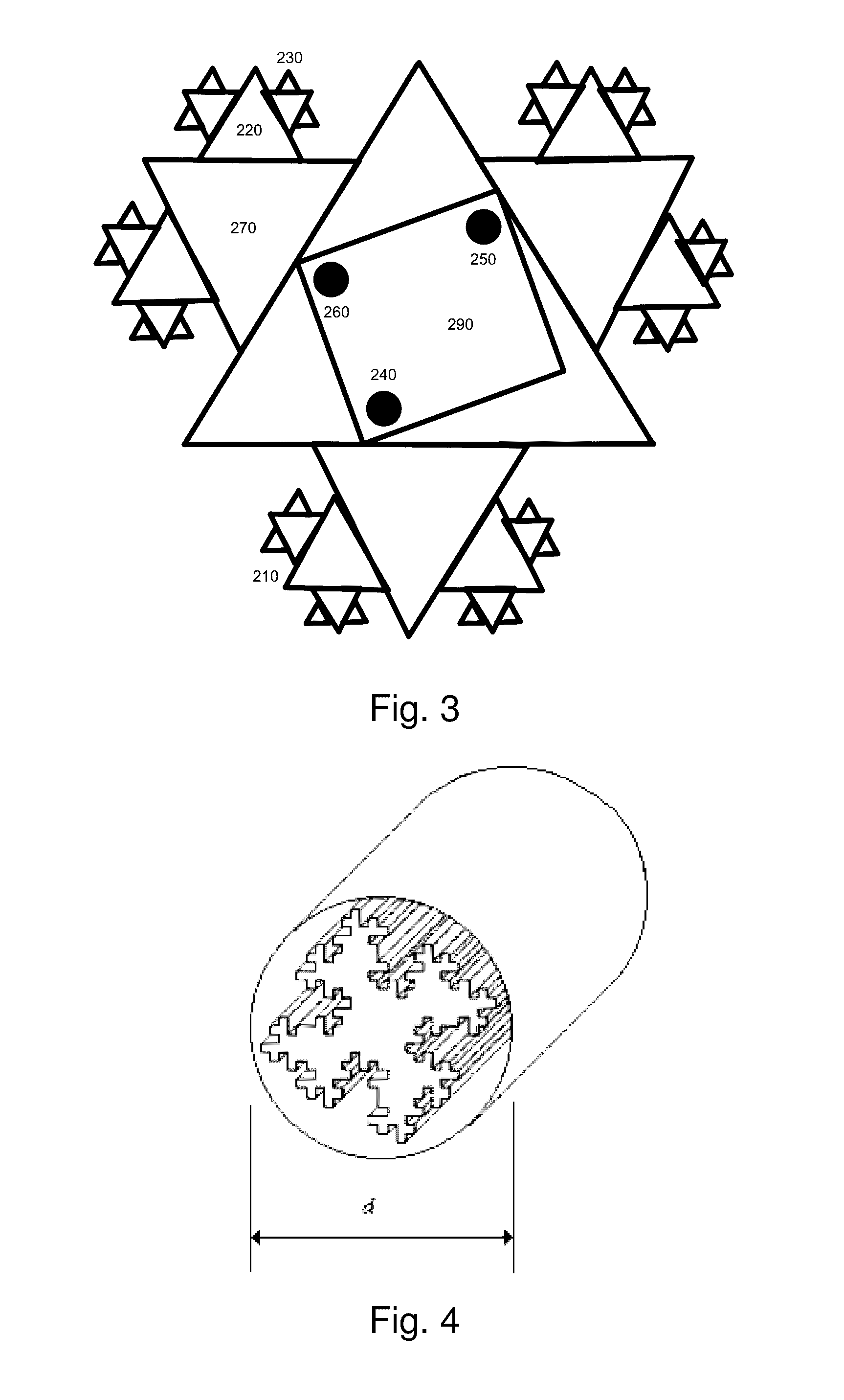

ActiveUS20160320149A1Large specific surface areaSmall surface areaHeat exhanger finsIndirect heat exchangersEngineeringHeat transfer fluid

A heatsink comprising a heat exchange device having a plurality of heat exchange elements each having a surface boundary with respect to a heat transfer fluid, having successive elements or regions having varying size scales. According to one embodiment, an accumulation of dust or particles on a surface of the heatsink is reduced by a removal mechanism. The mechanism can be thermal pyrolysis, vibration, blowing, etc. In the case of vibration, adverse effects on the system to be cooled may be minimized by an active or passive vibration suppression system.

Owner:FRACTAL HEATSINK TECH

Methods of simultaneously cleaning and disinfecting industrial water systems

InactiveUS20050150520A1Reduced pHDetergent bleaching agentsWater/sewage treatment by neutralisationChlorine dioxideOnline and offline

On-Line and Off-Line methods of simultaneously cleaning and disinfecting an industrial water system are described and claimed. The methods involve the addition to the water of the industrial water system of a Compound selected from the group consisting of the alkali salts of chlorite and chlorate and mixtures thereof; and an acid, followed by allowing the water in the industrial water system to circulate for several hours. The reaction of the alkali salts of chlorite and chlorate and acid produces chlorine dioxide in-situ in the water of the industrial water system. The chlorine dioxide kills microorganisms and the acid acts to remove deposits upon the water-contact surfaces of the equipment. An alternative method involves the use of a chelating agent and a biocide. Other possible cleaning and disinfection reagents may be added as needed including corrosion inhibitors, chelating agents, biocides, surfactants and reducing agents. These cleaning and disinfecting methods work in a variety of industrial water systems including cooling water and boiler water systems.

Owner:ECOLAB USA INC

On-line heat exchanger cleaning method

InactiveUS20060219266A1Reduce operating costsIncrease run lengthDetergent mixture composition preparationHollow article cleaningOil processingSolubility

A method for the on-line cleaning of a heat exchanger used with petroleum process fluids which create coke deposits of asphaltenic origin on the exchanger tubes. The asphaltenes are removed by re-dissolution in a solvent oil of high solubility power for the asphaltenes. Certain asphaltenic crudes are useful as solvents in view of their chemical similarity to the asphaltene coke precursors; also useful are refined petroleum fractions such as gas oils which are also characterized by their solvency for asphaltenes. The solvent oil may be admitted to the heat exchanger following withdrawal of the process fluid and then allowed to soak and dissolve the asphaltene coke precursors after which the resulting solution may be withdrawn and the exchanger returned to use without being at any time disconnected from its associated process unit.

Owner:EXXON RES & ENG CO

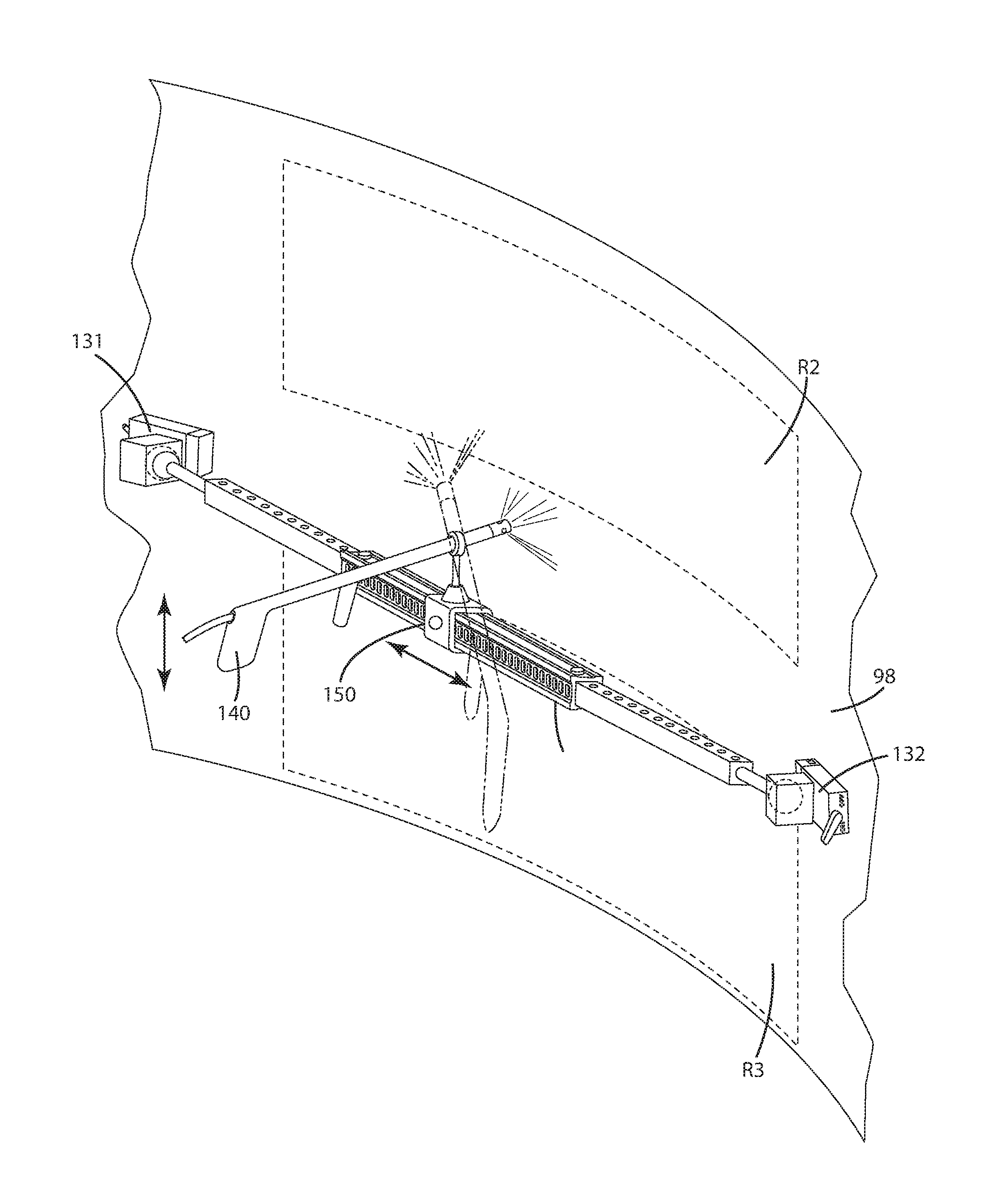

Magnetic mount for blasting equipment and related methods

InactiveUS20160243597A1Improve securityEffective protectionHollow article cleaningStationary tubular conduit assembliesProximity sensorEngineering

A water blasting apparatus and related method are adapted to clean equipment. The apparatus includes a track having telescoping rails, a connector moveable along the track, and a water blasting device adapted to shoot water at a pressure above 1000 psi, joined with the connector. One or more rare earth magnets join the track with a ferromagnetic structure, thereby holding it in a fixed orientation relative to the equipment to be cleaned. The apparatus can include a proximity sensor to ensure the track is adequately anchored, and an auto shut-off system when it is not. The method can include connecting the water blasting device to the track, magnetically coupling the track to a structure so that the nozzle is proximal equipment, and so that the elongated track is maintained in a fixed orientation, and shooting water at high pressure toward the equipment, while safely restraining the water blasting device.

Owner:PSI PRESSURE SYST

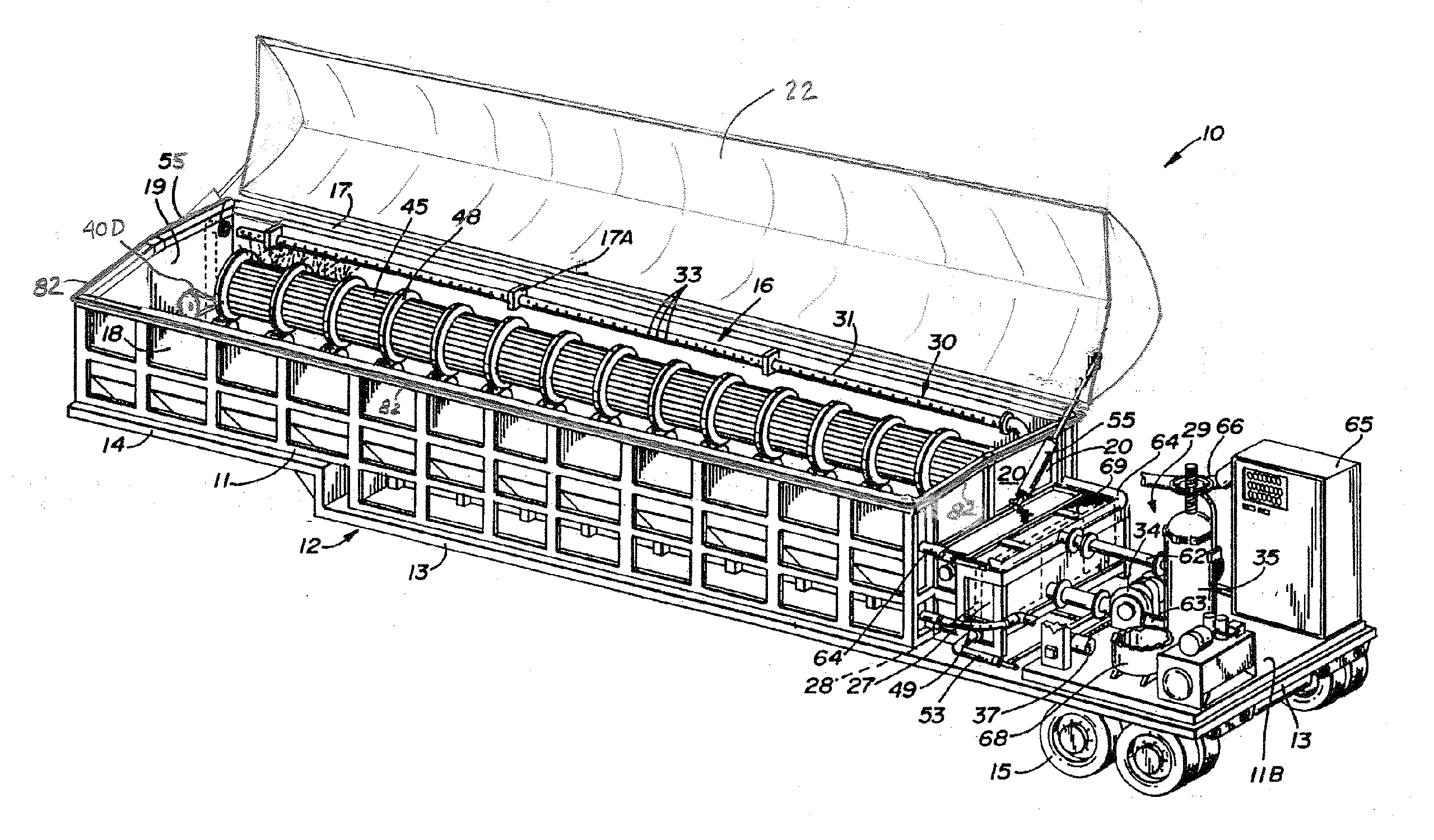

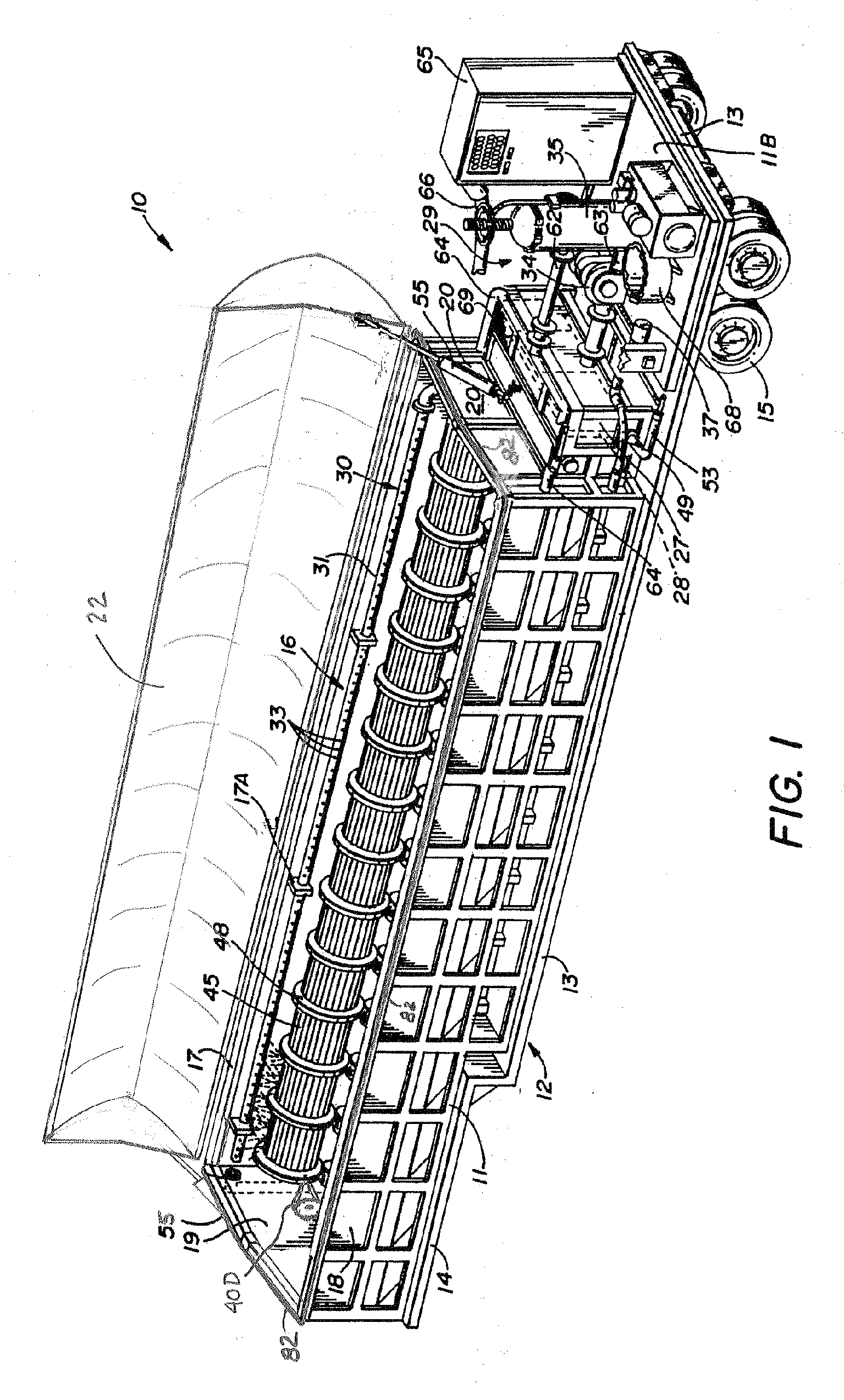

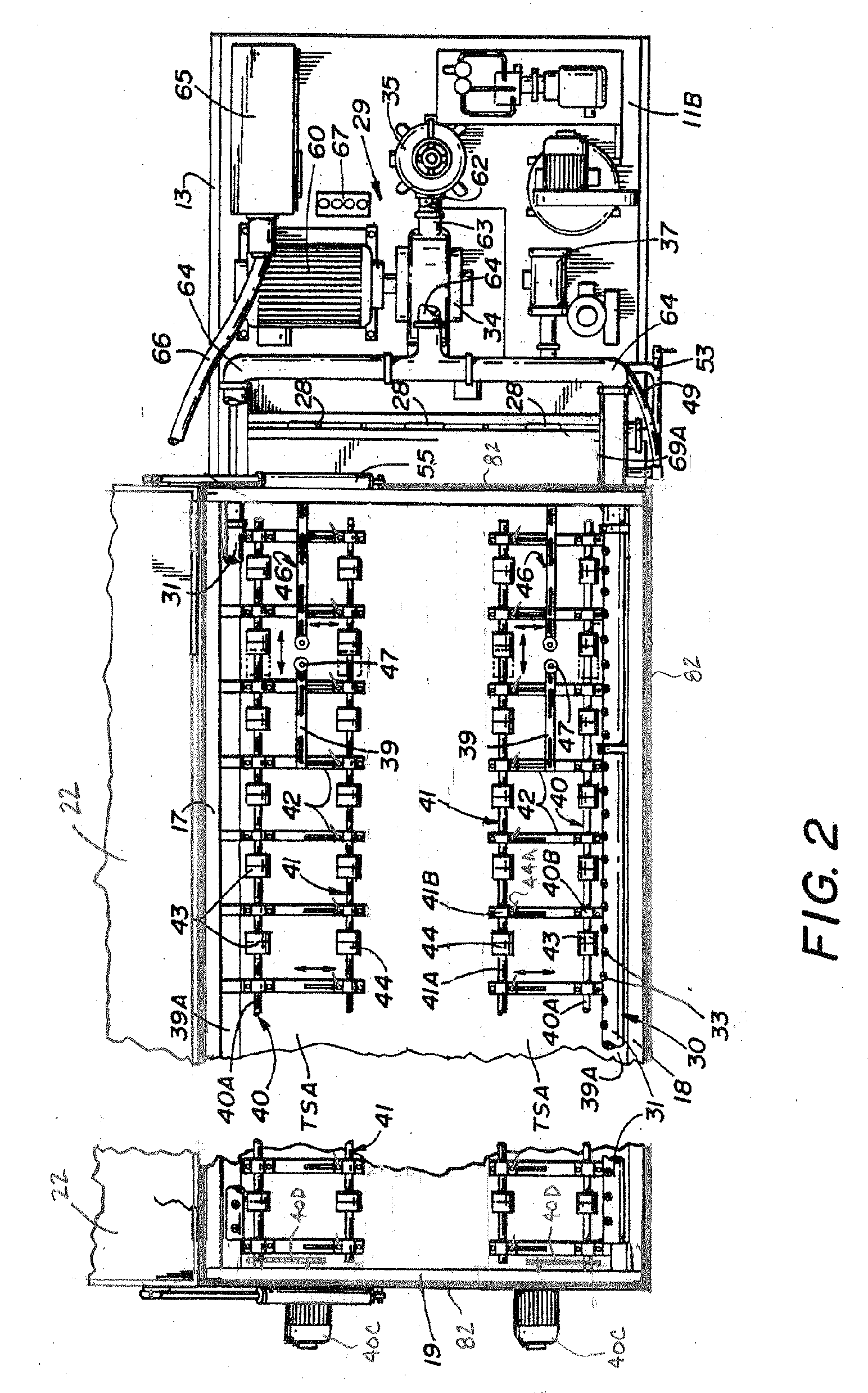

Method and system for cleaning heat exchanger tube bundles

InactiveUS20060185691A1Overcome problemsHollow article cleaningCleaning using toolsEngineeringOxygen

A method and system utilizing a mobile cleaning unit for providing cleaning of heat exchanger tube bundles. The mobile cleaning unit utilizes a pressurized seal positioned about top door of the cleaning enclosure to provide a fluid and vapor lock of the cleaning enclosure. An oxygen purging system of the cleaning enclosure, the cleaning fluid reservoir, and the control panels provides additional safety. The mobile cleaning unit can use cleaning fluid produced at the facility site and return the cleaning fluid to the facility site for reprocessing after the heat exchanger tube bundles are cleaned.

Owner:NAT HEAT EXCHANGE CLEANING CORP

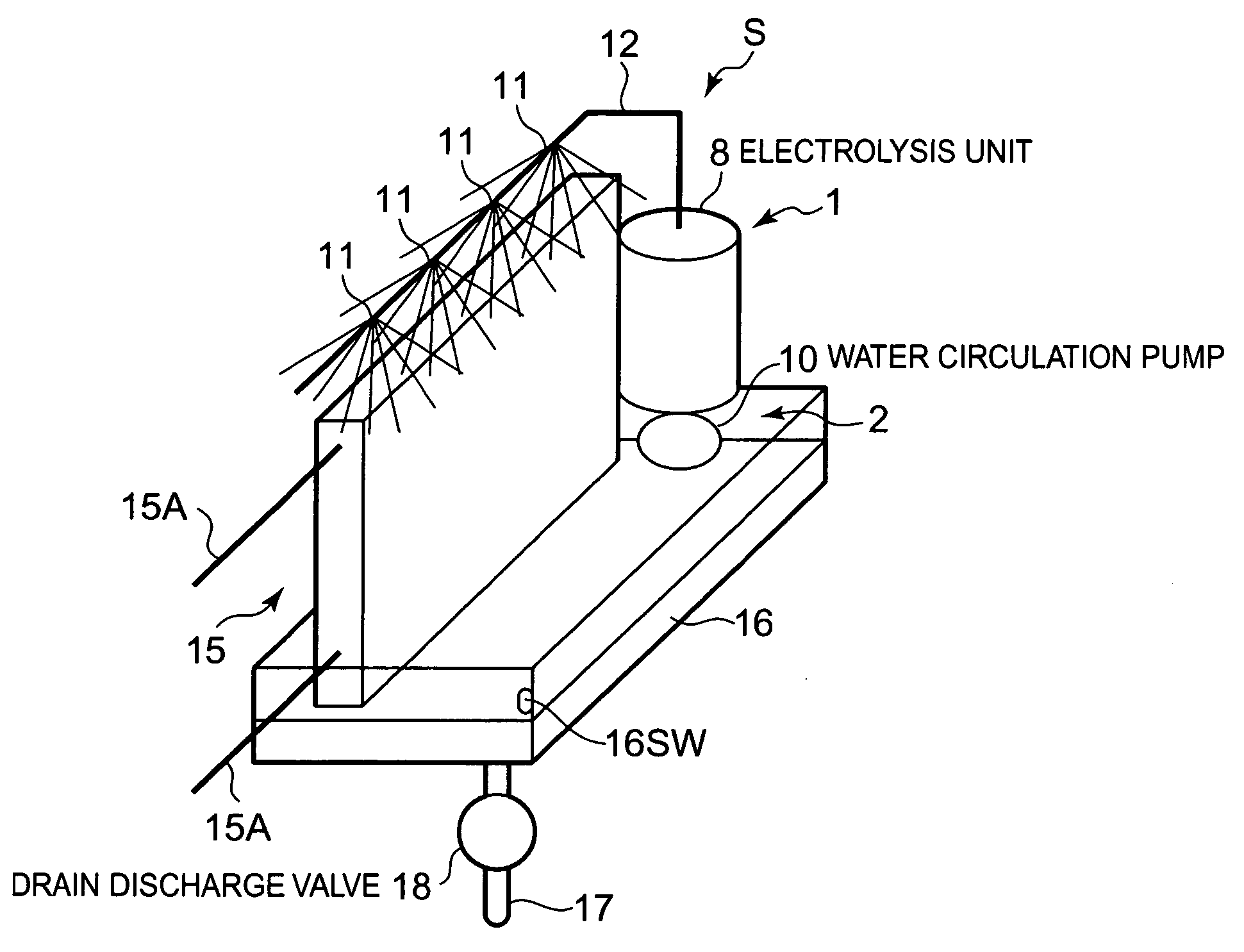

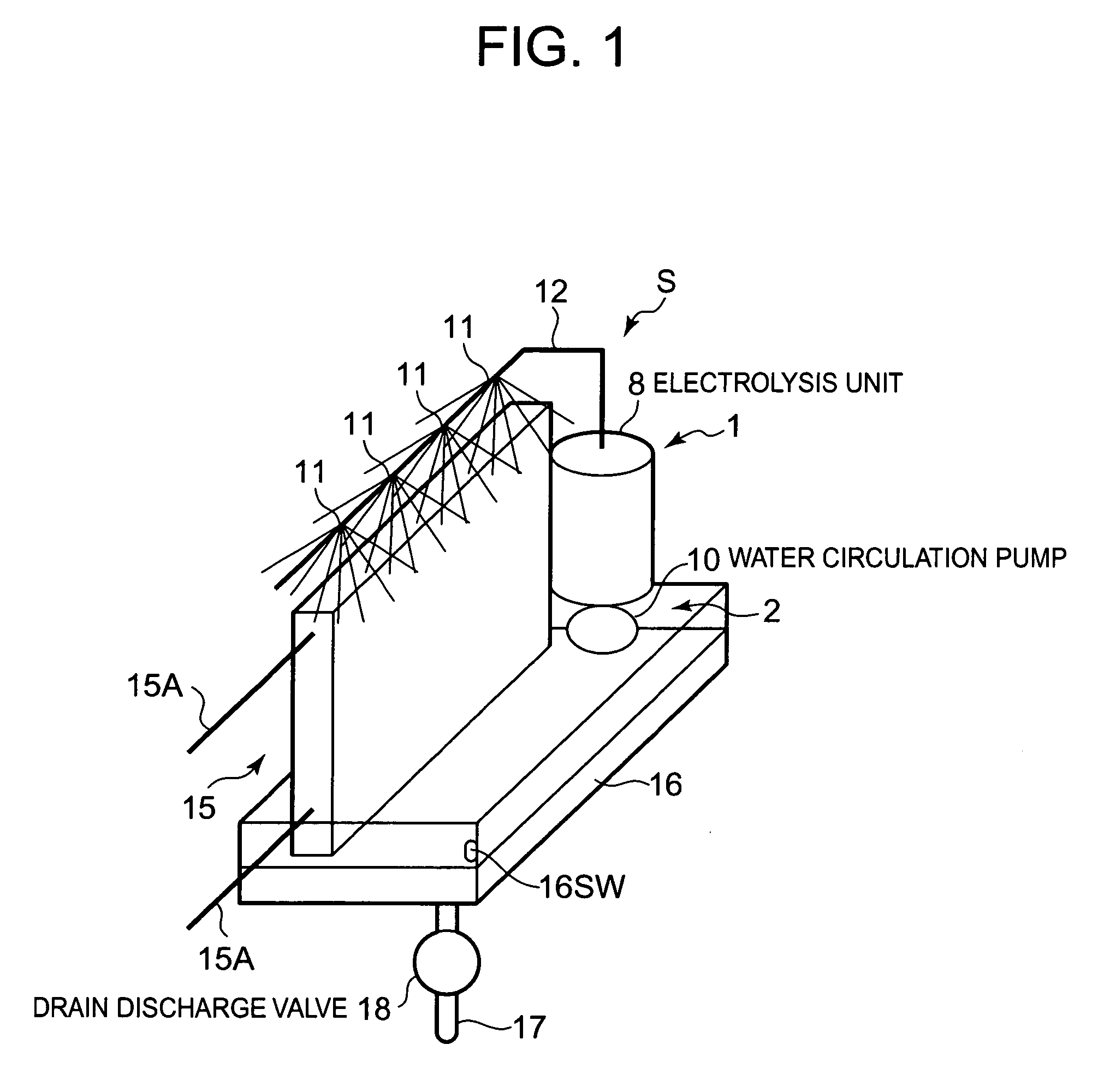

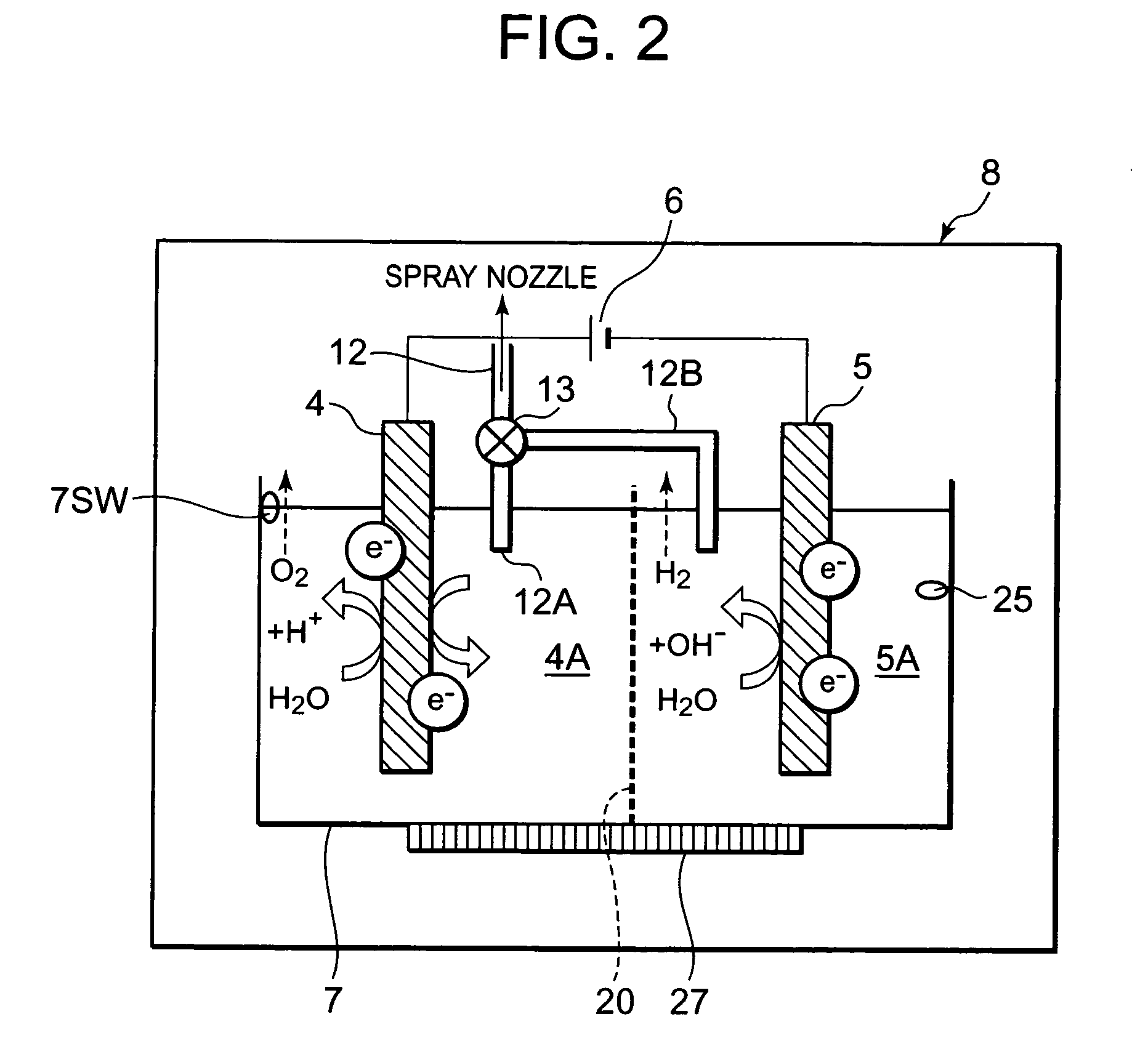

Cleaning device for heat exchanger

InactiveUS20080149475A1Good removal effectIncrease volumeCellsWater treatment parameter controlElectrolysed waterControl cell

There is disclosed a cleaning device for a heat exchanger which safely and effectively cleans the heat exchanger and which can sufficiently obtain a deodorizing effect and a sterilization effect. The cleaning device for the heat exchanger includes an electrolysis unit for treating dew condensation water of the heat exchanger by an electrochemical technique, a supply unit for supplying electrolytic water produced by the treatment performed by this electrolysis unit to an outer surface of the heat exchanger, and an control unit for controlling the electrolysis unit and the supply unit, and the control unit allows the electrolysis unit to electrolytically treat the dew condensation water of the heat exchanger and produce the electrolytic water, and allows the supply unit to supply the produced electrolytic water to the outer surface of the heat exchanger.

Owner:SANYO ELECTRIC CO LTD

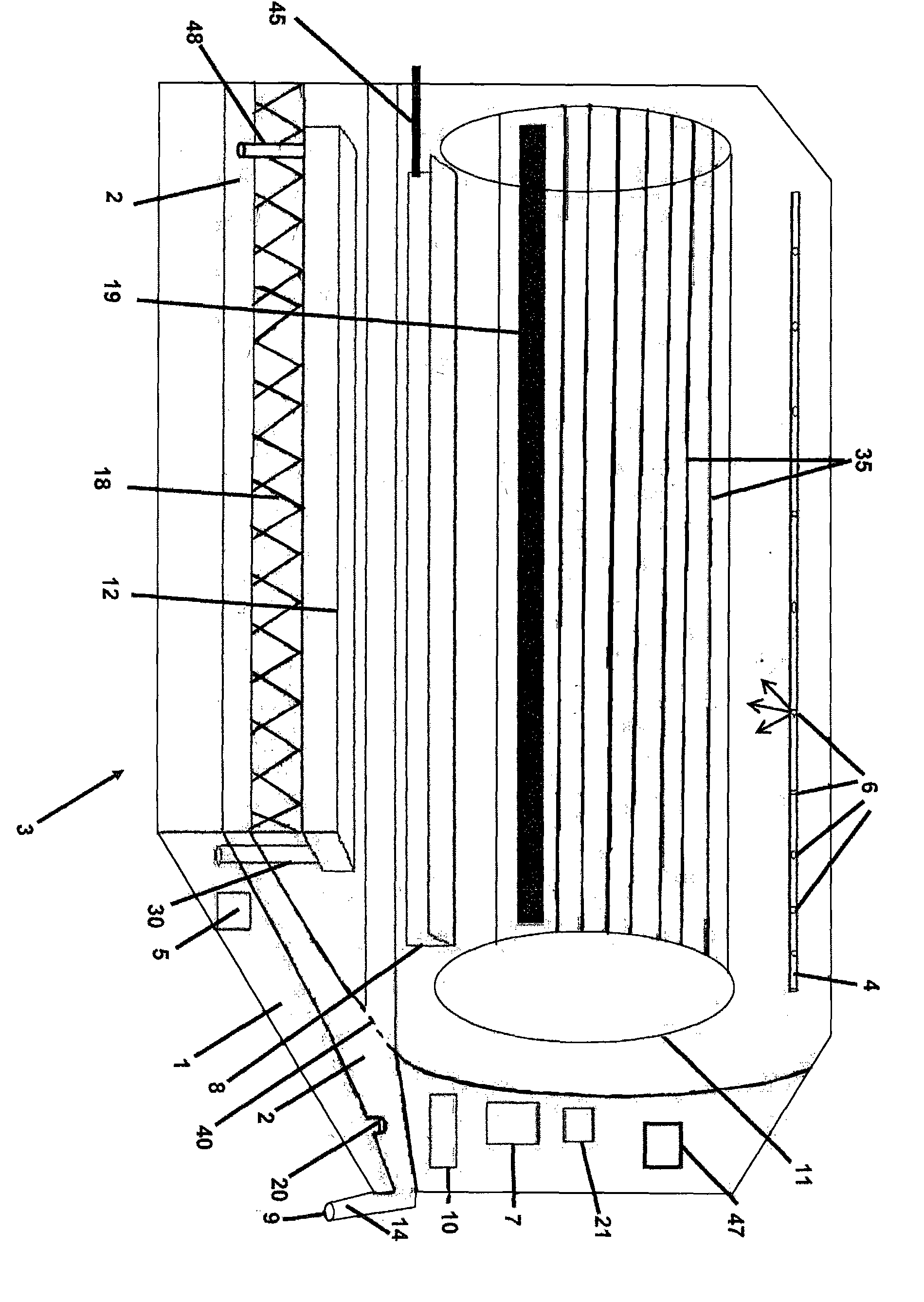

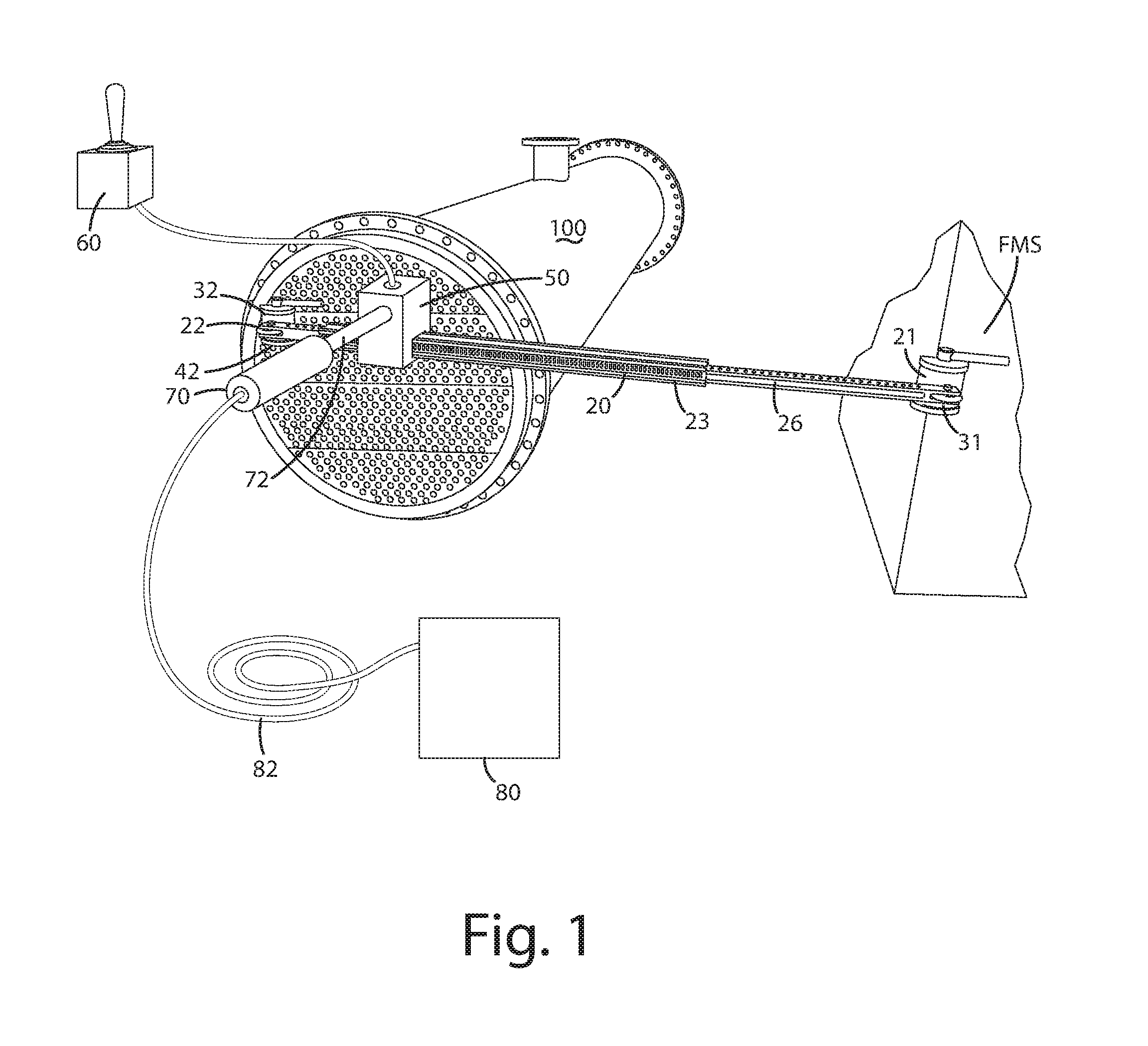

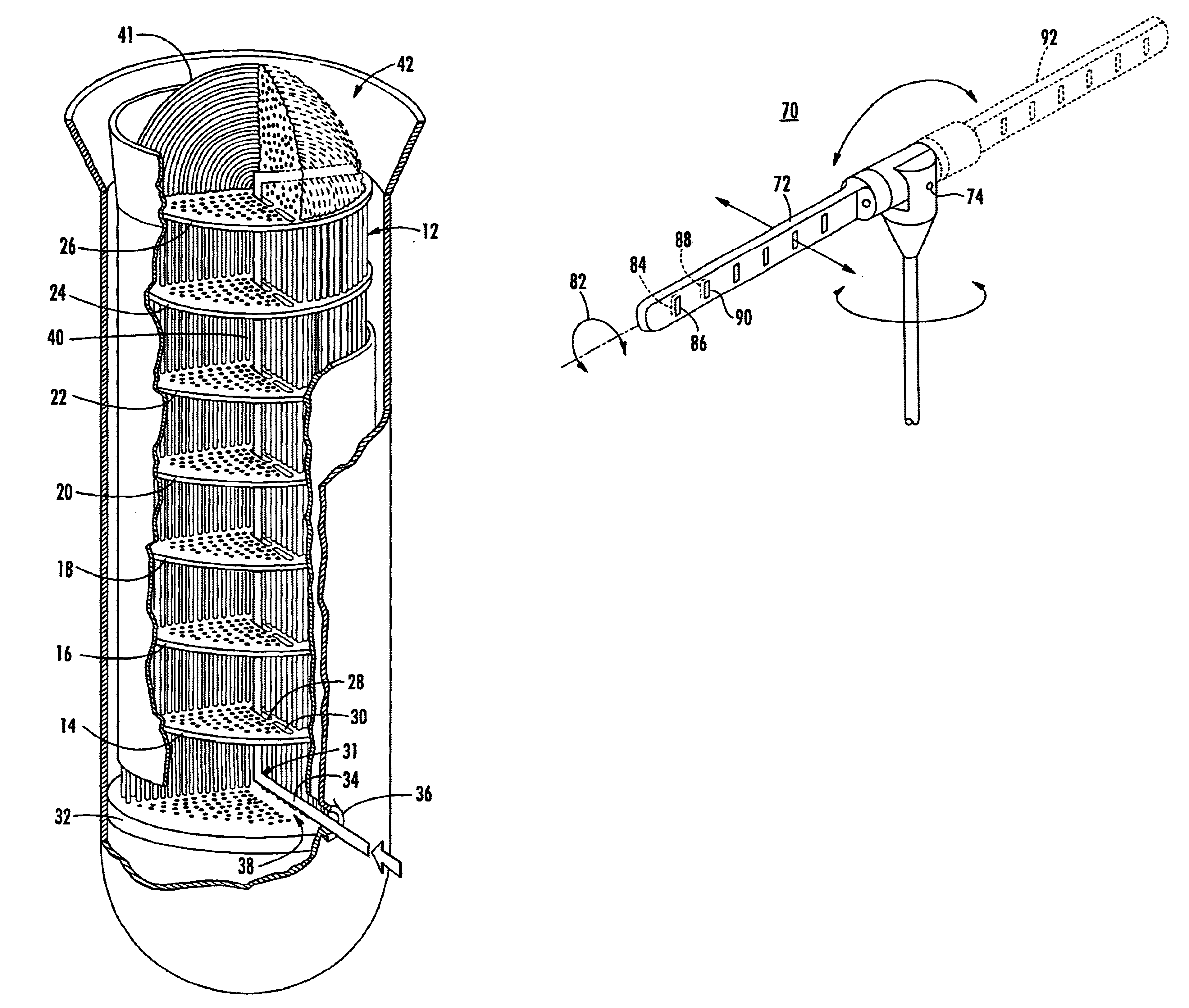

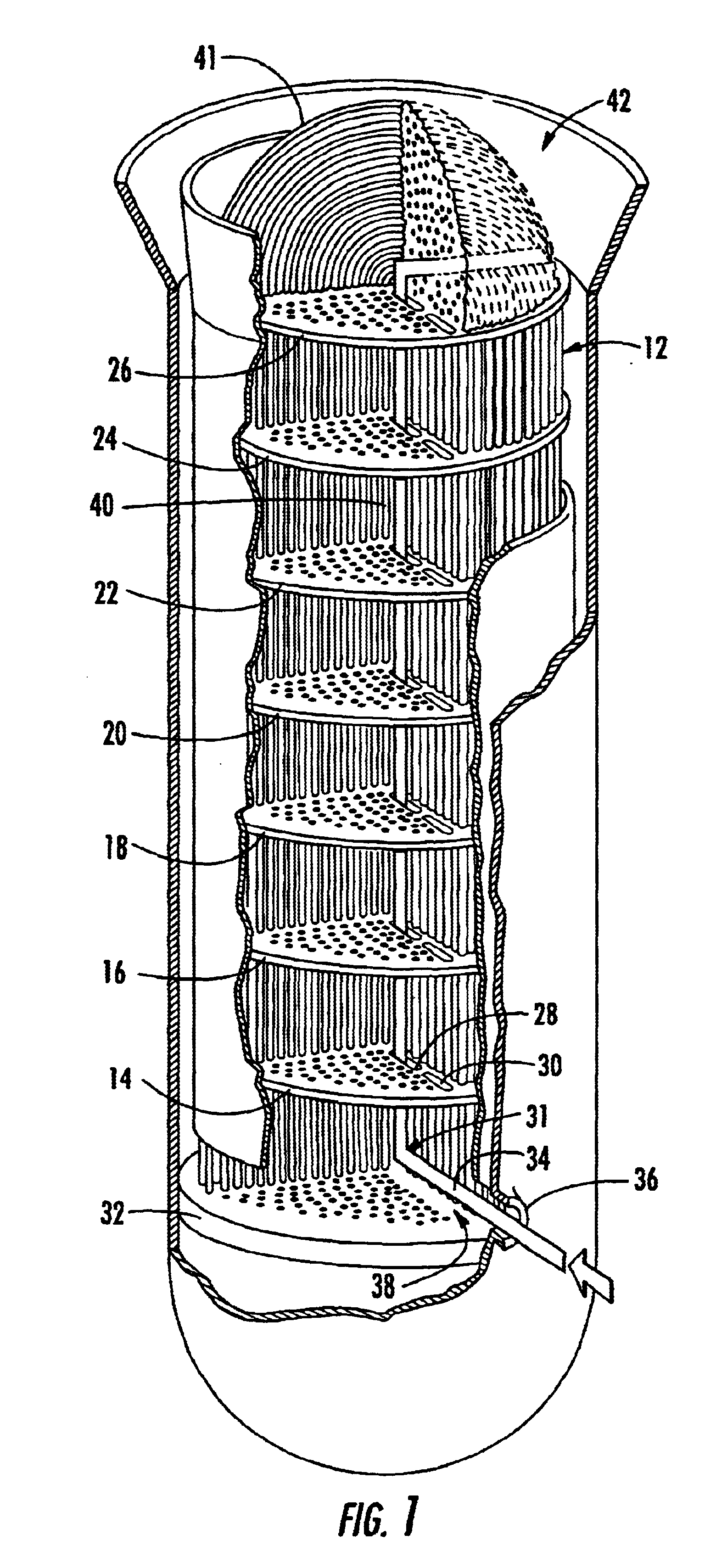

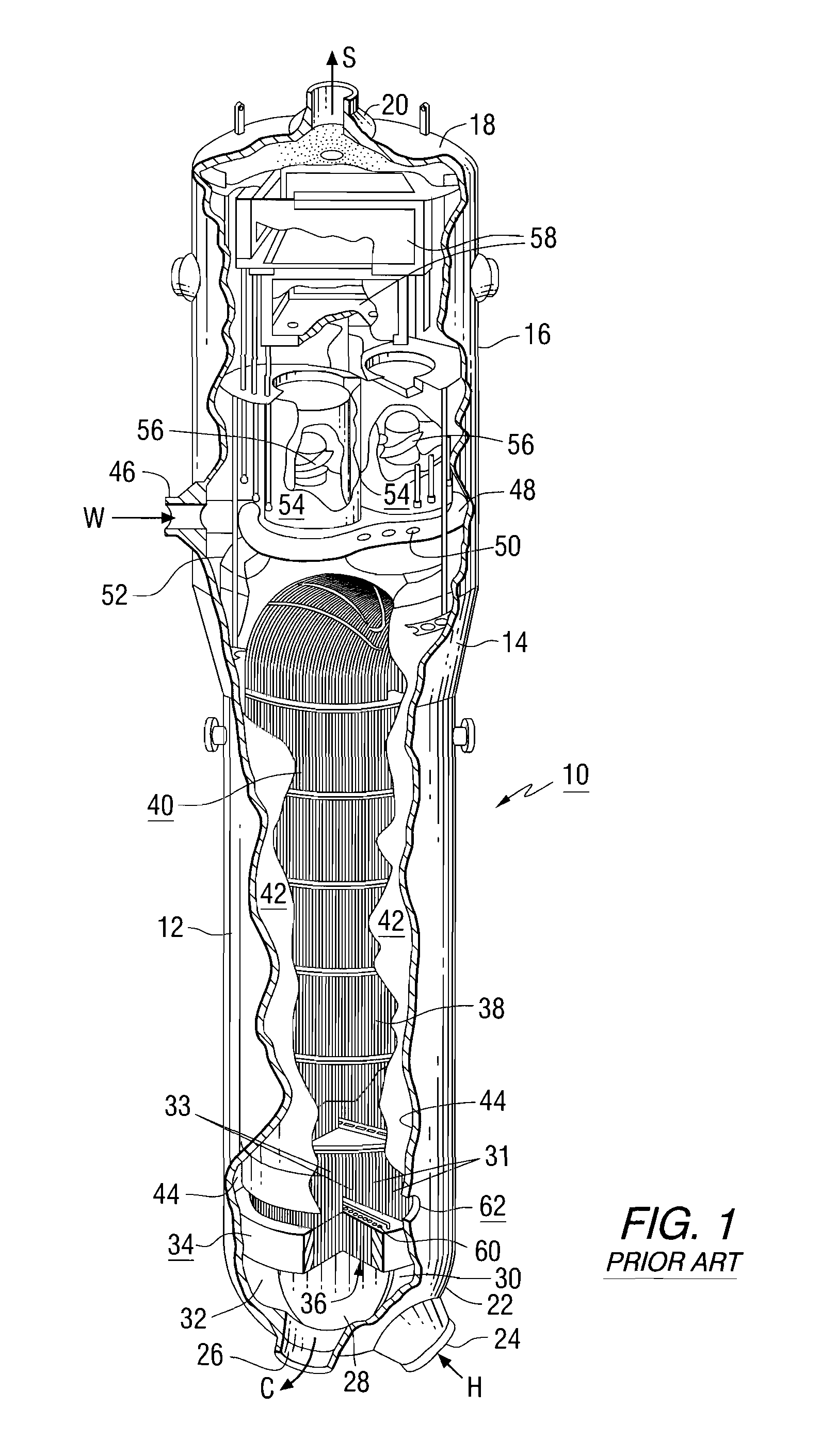

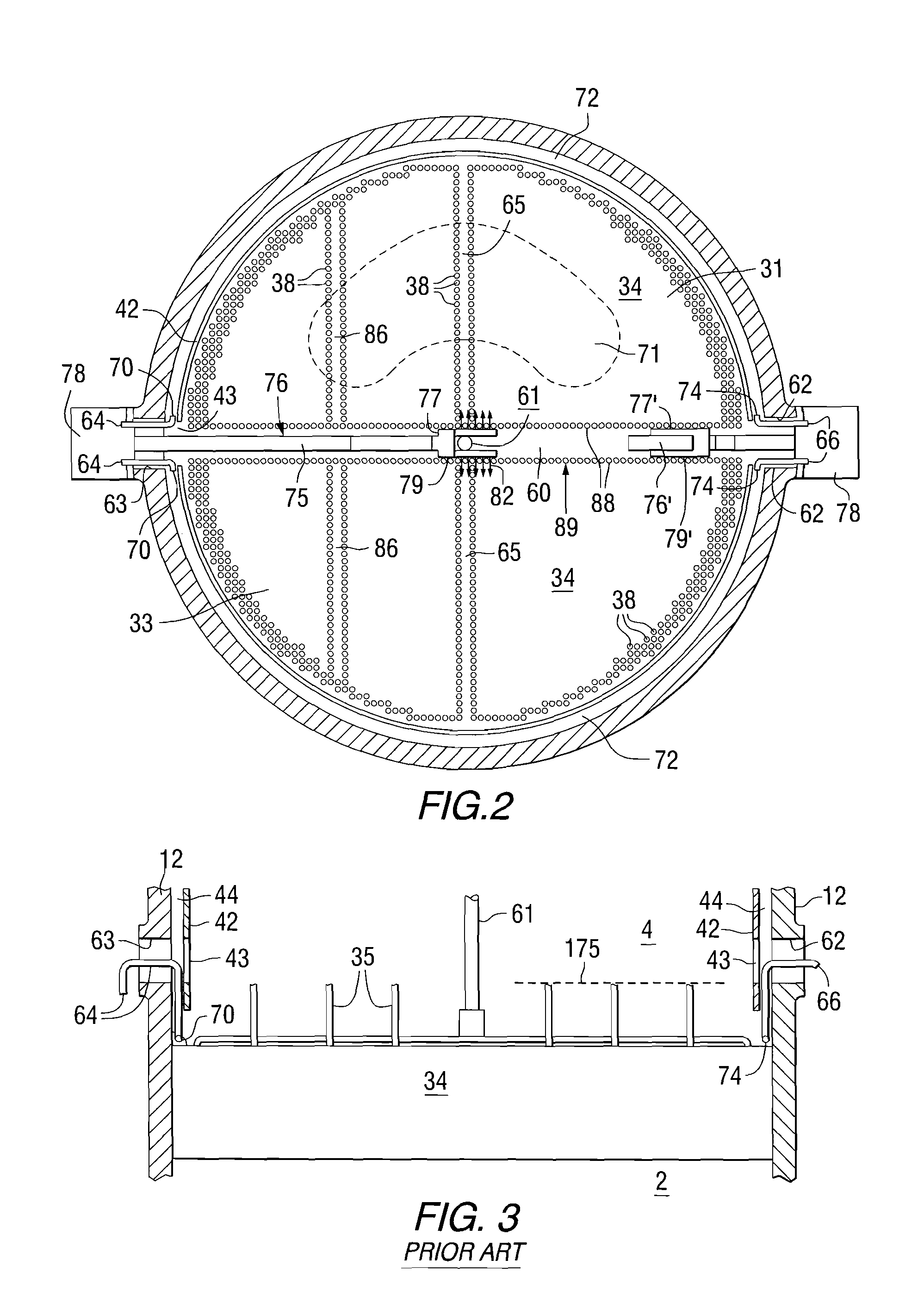

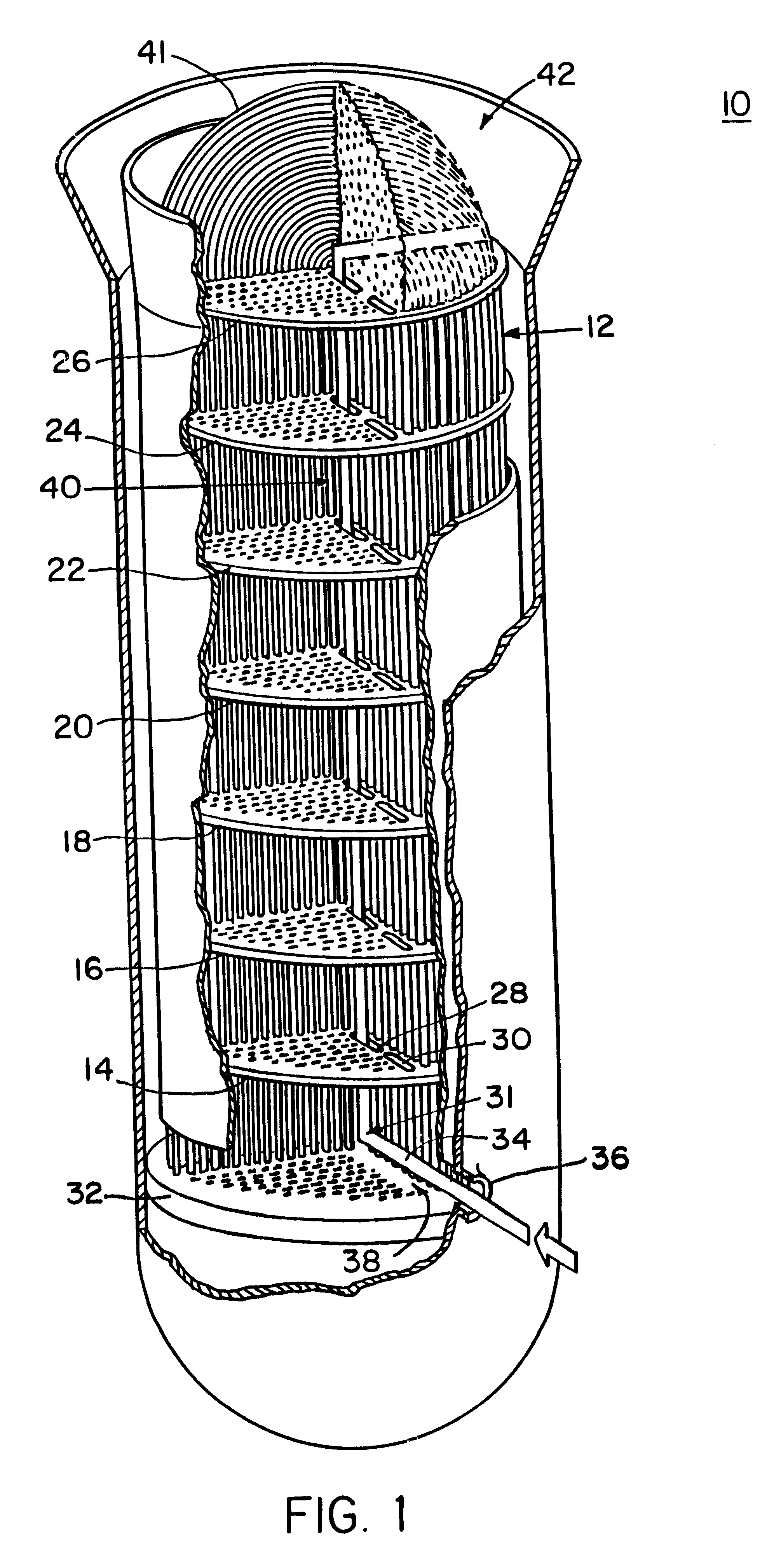

Upper bundle steam generator cleaning system and method

InactiveUS6672257B1Eliminate needOvercome disadvantagesBoiler cleaning apparatusMachines/enginesEngineeringThermodynamics

An upper bundle steam generator cleaning, inspection, and repair system including a deployment support device receivable within the steam generator to raise a cleaning device, an inspection device, and / or a tool up to the upper bundles of the steam generator.

Owner:FOSTER-MILLER

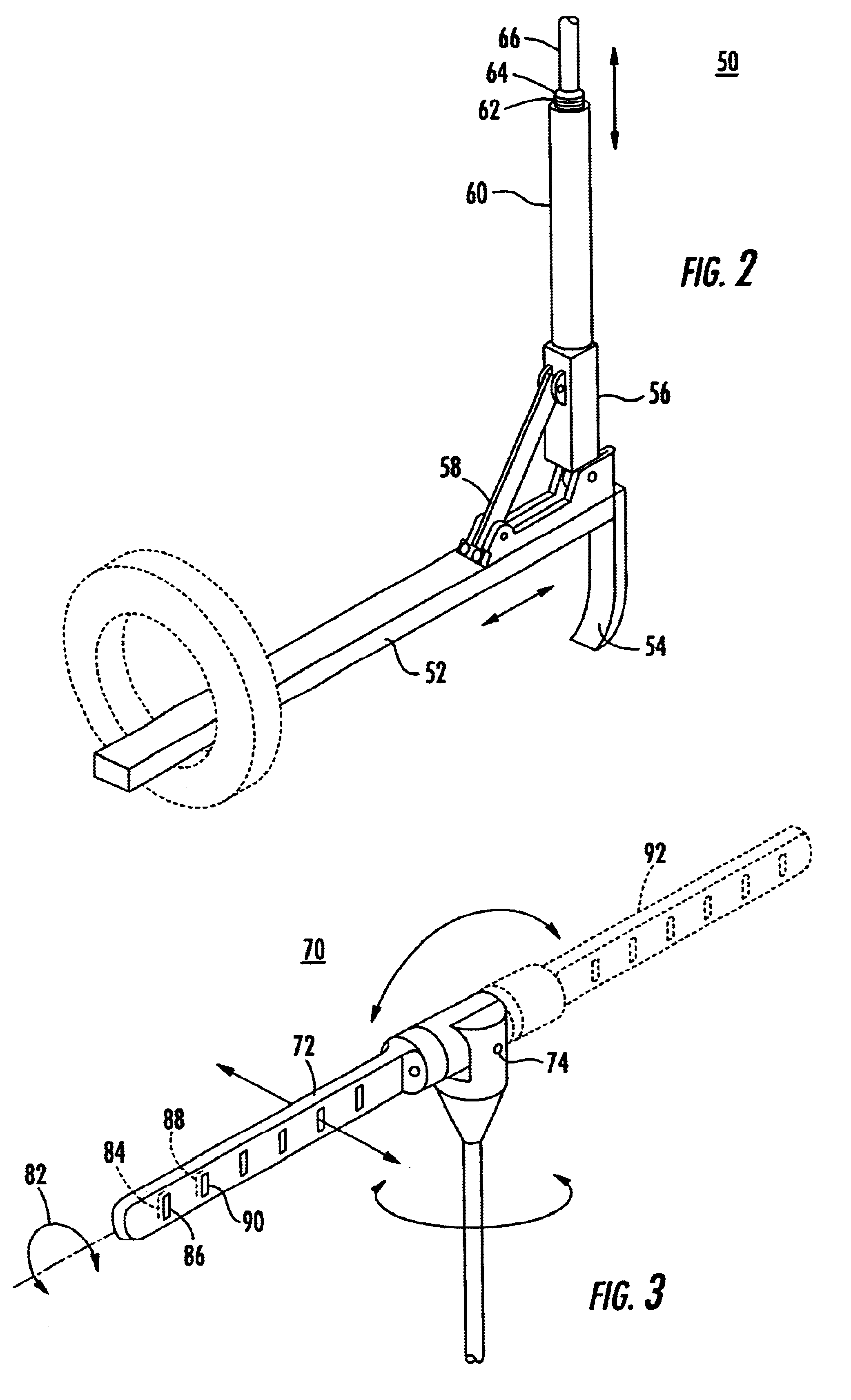

Steam generator dual head sludge lance and process lancing system

A method of cleaning sludge from the tube sheet (34) of a nuclear steam generator (10) includes introducing a moveable sludge lance (76) said moveable sludge lance having duel lance heads (77) through handholes (62) in the side of the generator and into a central tube lane (60) having a central stay rod (61) and sludge lancing with high pressure fluid through the row 1 tubes (85) in the tube lane, where the distance (200) between the dual lance heads (77) is wide enough to allow the dual lance heads to extend beyond the central stay rod (61).

Owner:WESTINGHOUSE ELECTRIC CORP

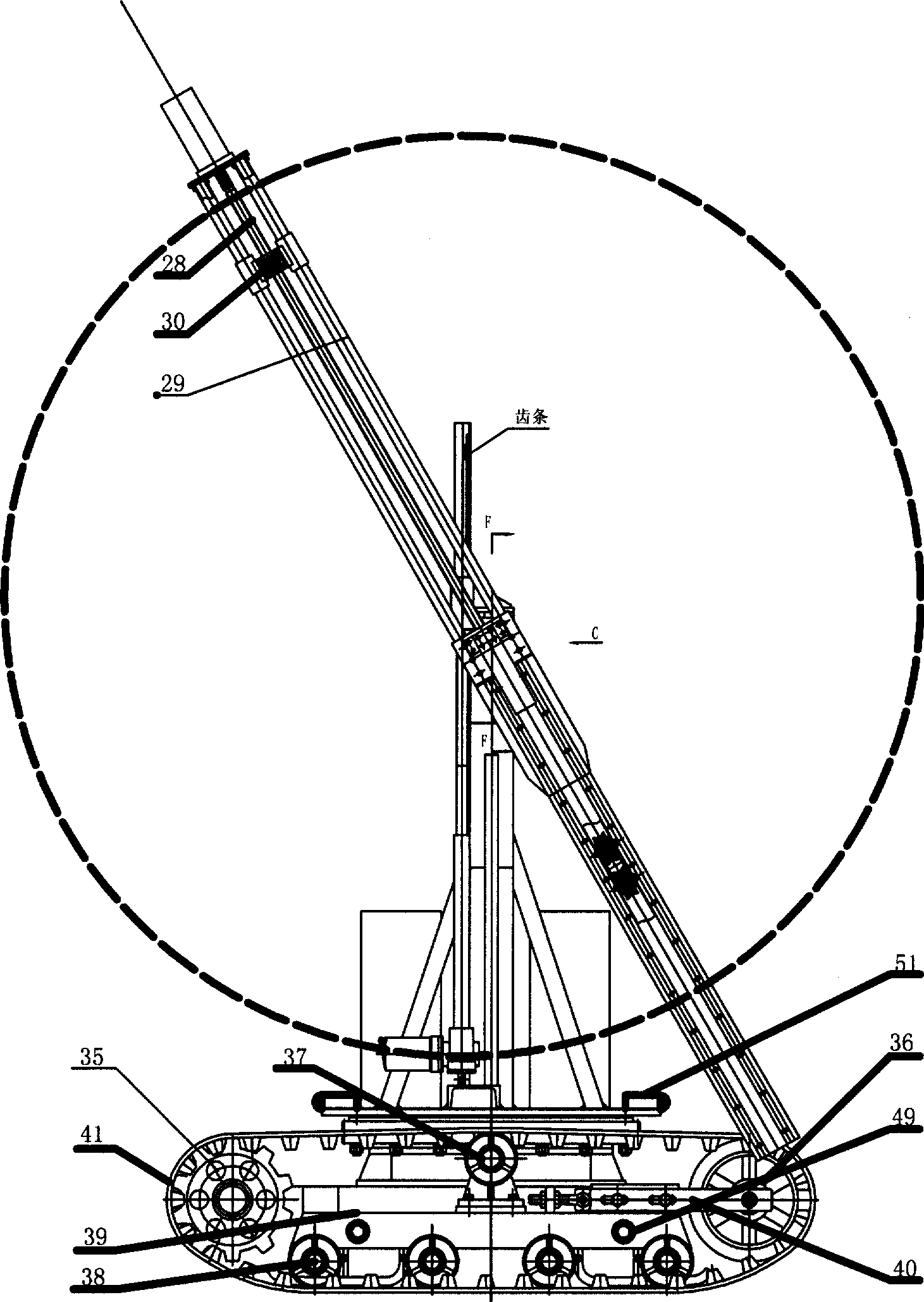

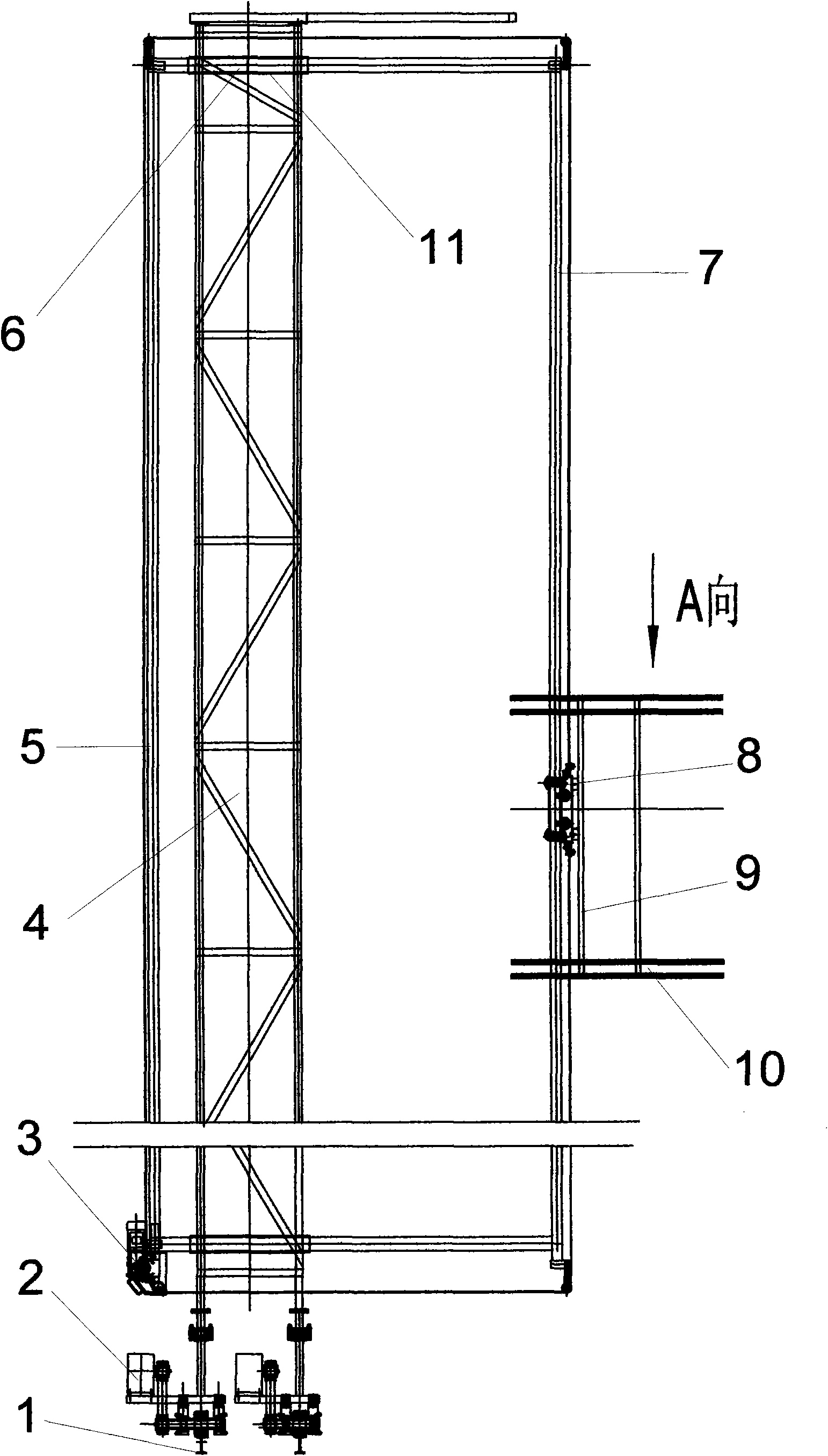

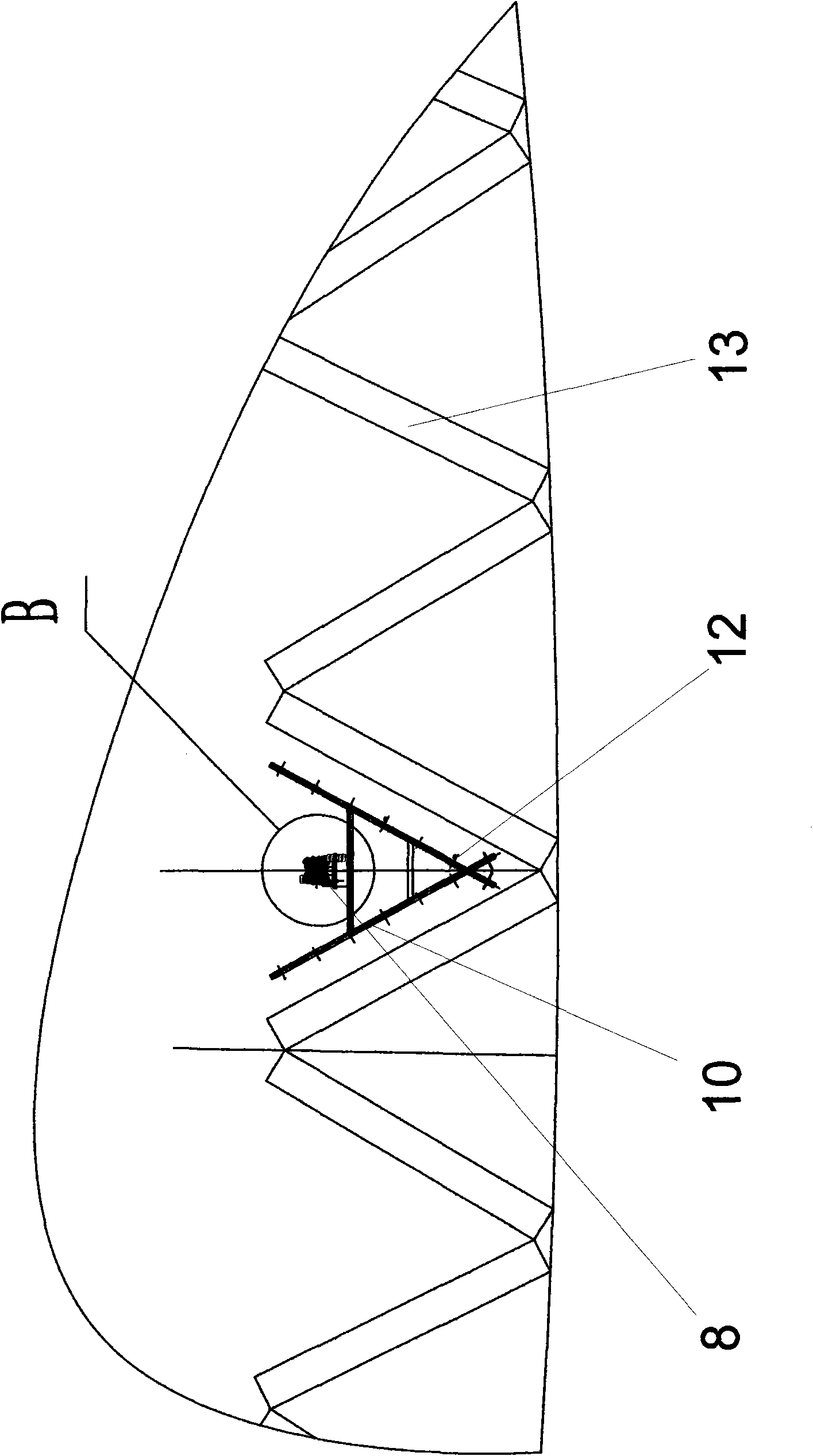

Automatic cleaning device of indirect air cooler for power station

ActiveCN101672600AEasy to cleanStepless adjustable working pressureFlush cleaningAutomatic controlPower station

The invention relates to an automatic cleaning device of an indirect air cooler for a power station, comprising a cleaning mechanism. The automatic cleaning device is technically characterized in thata closed annular track which is provided with a traveling truss with a traveling driving device is arranged near the air cooler inside a tower; the traveling truss is provided with a vertical type horizontal moving frame and a guide limit mechanism of the vertical type horizontal moving frame; the vertical type horizontal moving frame is provided with a vertical moving guide rail which is sequentially provided with a vertical traveling mechanism and a vertical driving mechanism; the vertical traveling mechanism is provided with the cleaning mechanism which comprises at least two rows of cleaning tube bundles, cleaning nozzles are distributed on the cleaning tube bundles, the spraying directions of the cleaning nozzles are perpendicular to the cleaning surface of the air cooler, and the cleaning tube bundles are connected with a high-pressure water generation device through high-pressure tubes. The invention has high automation degree and convenient operation and realizes the running along the track, the horizontal movement of the traveling truss and the vertical cleaning of the cleaning mechanism, thereby completing the interlocking automatic control.

Owner:SHENYANG ACAD OF INSTR SCI +1

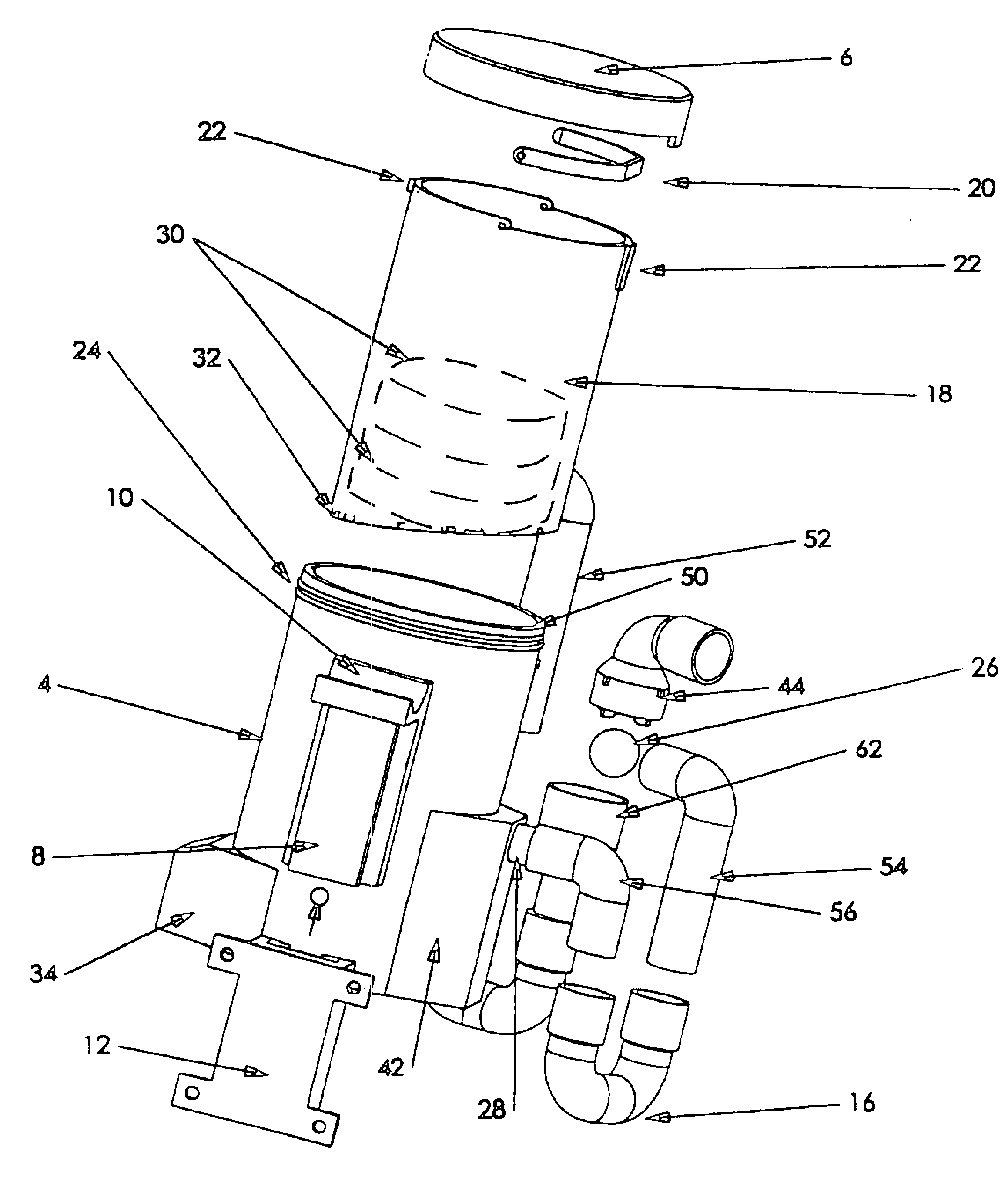

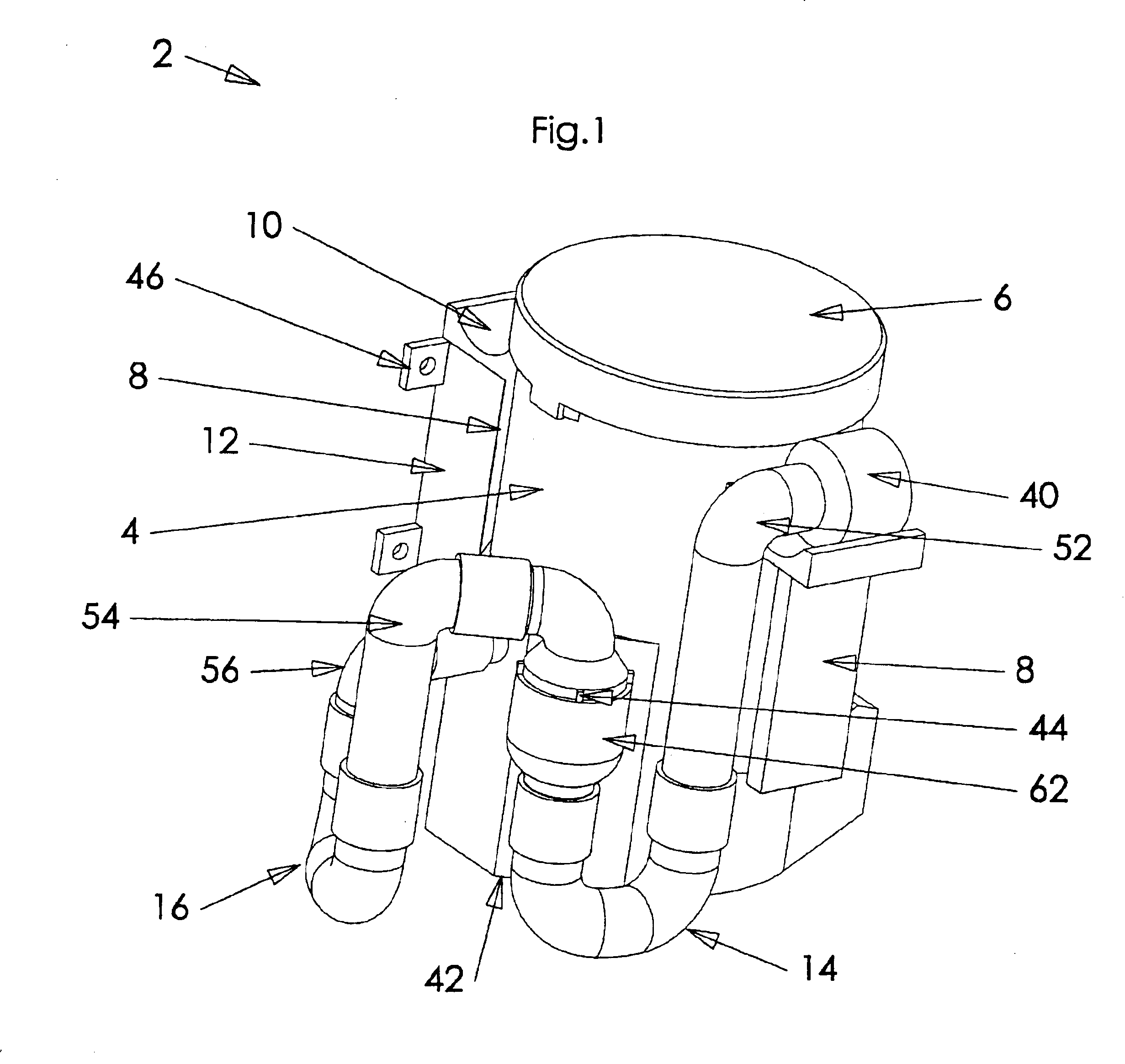

Dual p-trap and valve air conditioner discharge water saver system

A gravity-assisted water saving system, and method of use, utilized for collecting condensate from an air conditioning system, sanitizing it, and then diverting it for constructive use. It has a chamber with an inclined bottom surface, a removable basket for containing tablets used for sanitizing swimming pool water or bleach tablets used for laundry sanitizing purposes, a double P-trap assembly on its water inlet side that prevents sanitizing vapors from entering the air conditioning system to which it is connected, a removable cap sealing its top opening to prevent escape of sanitizing vapors into the atmosphere, and an optional mounting bracket for enhanced stabilization against a stationary object. Inflow tubing connected to the chamber permits ready attachment of the present invention to an air conditioning condensate discharge pipe, while a discharge tube in an inferior position transports reclaimed water to its location of subsequent use.

Owner:RECTORSEAL LLC

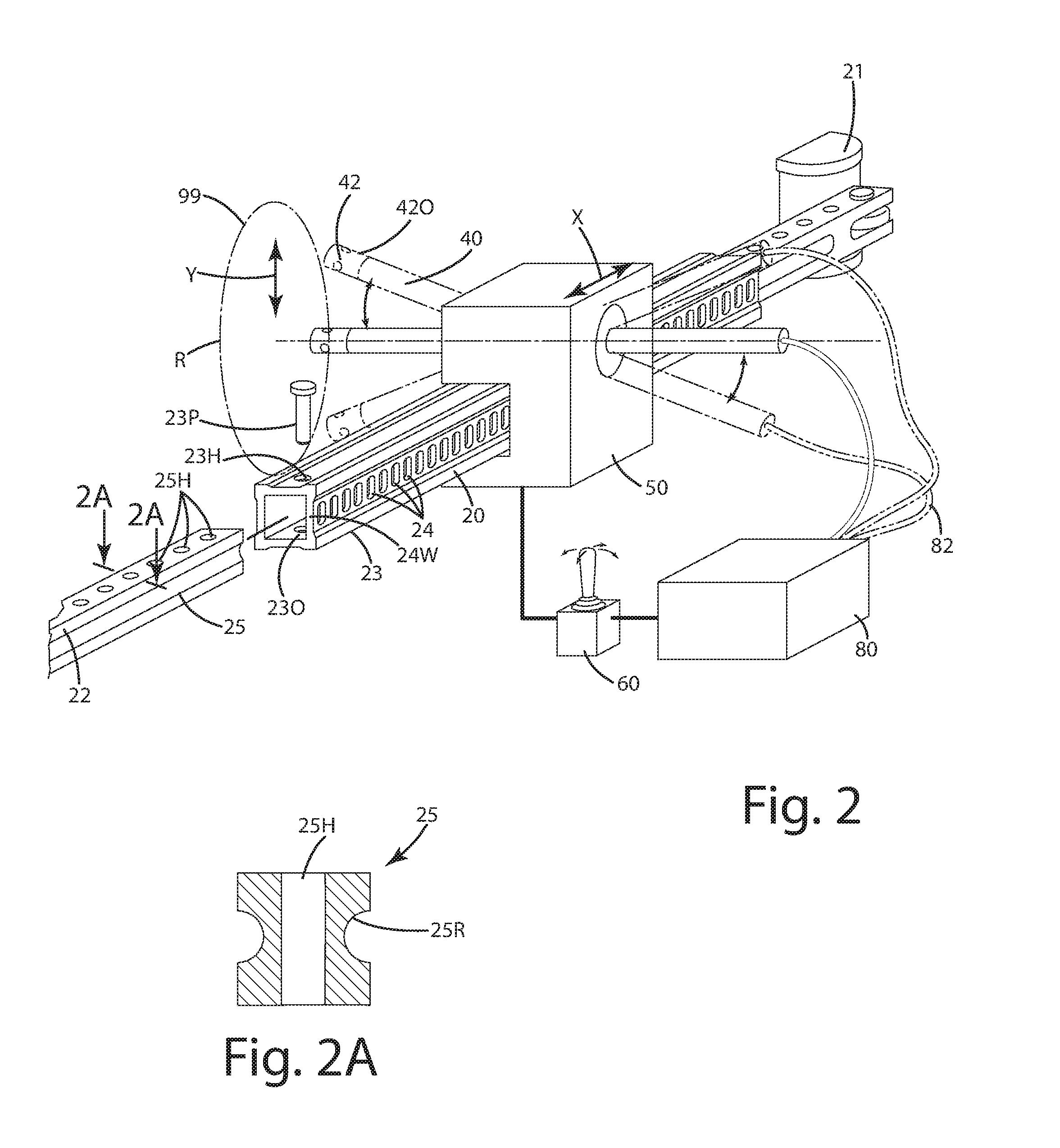

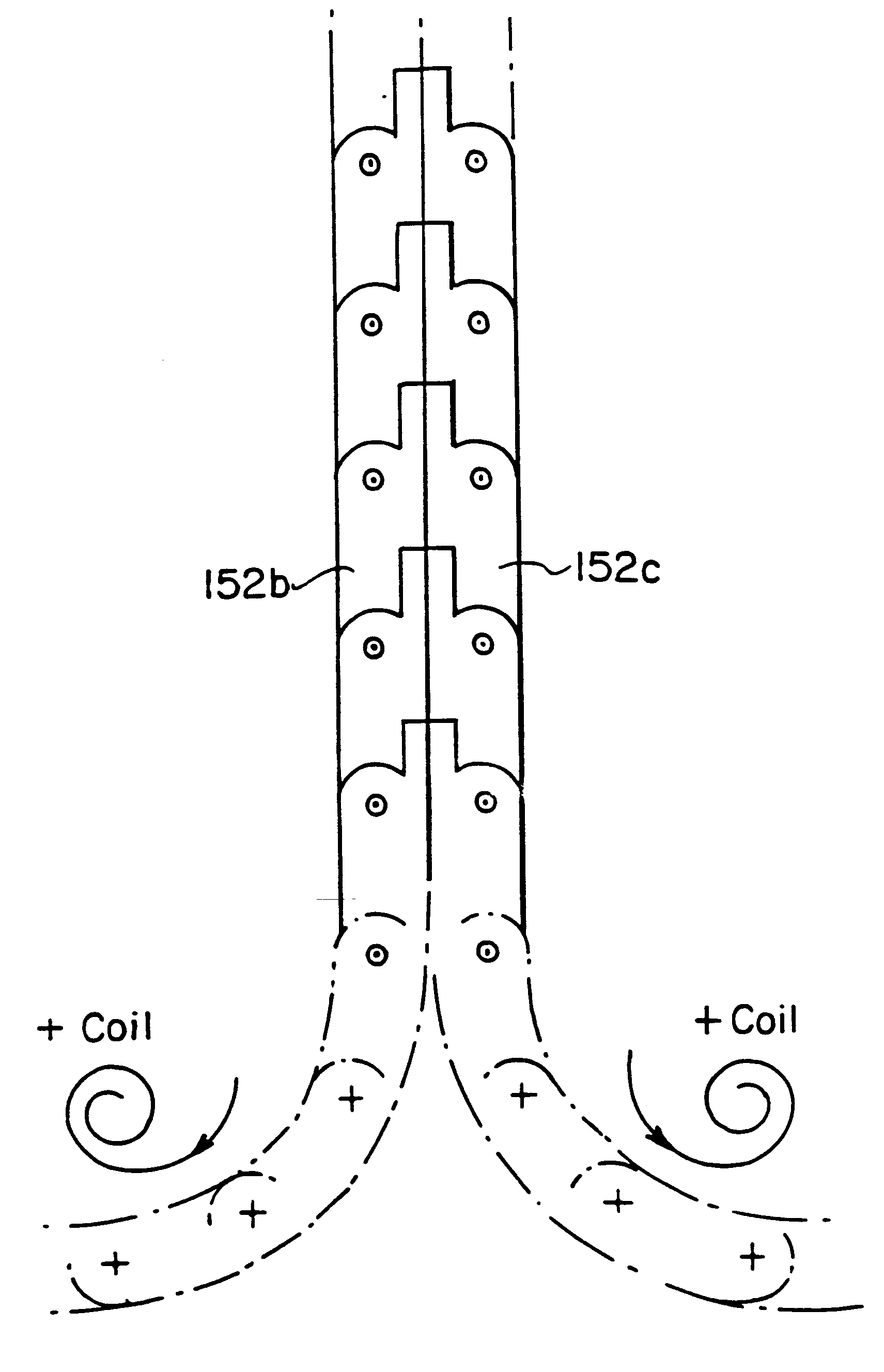

Deployment system for an upper bundle steam generator cleaning/inspection device

InactiveUS6543392B1Overcome disadvantagesEliminate needElectrostatic cleaningBoiler cleaning apparatusEngineering

A deployment system for an upper bundle steam generator cleaning / inspection device, the deployment system including an elongated body feedable through an access in a steam generator shell proximate the tube sheet of the steam generator, the elongated body flexible in one configuration to bend into a position for extension up through flow slots in support plates of the interior of the steam generator, and rigid in another configuration for positioning and supporting cleaning / inspection devices up through the steam generator proximate the upper tube bundles of the steam generator; and a drive device for driving the elongated body up through the support plates and for retracting the elongated body back down through the support plates.

Owner:FOSTER-MILLER

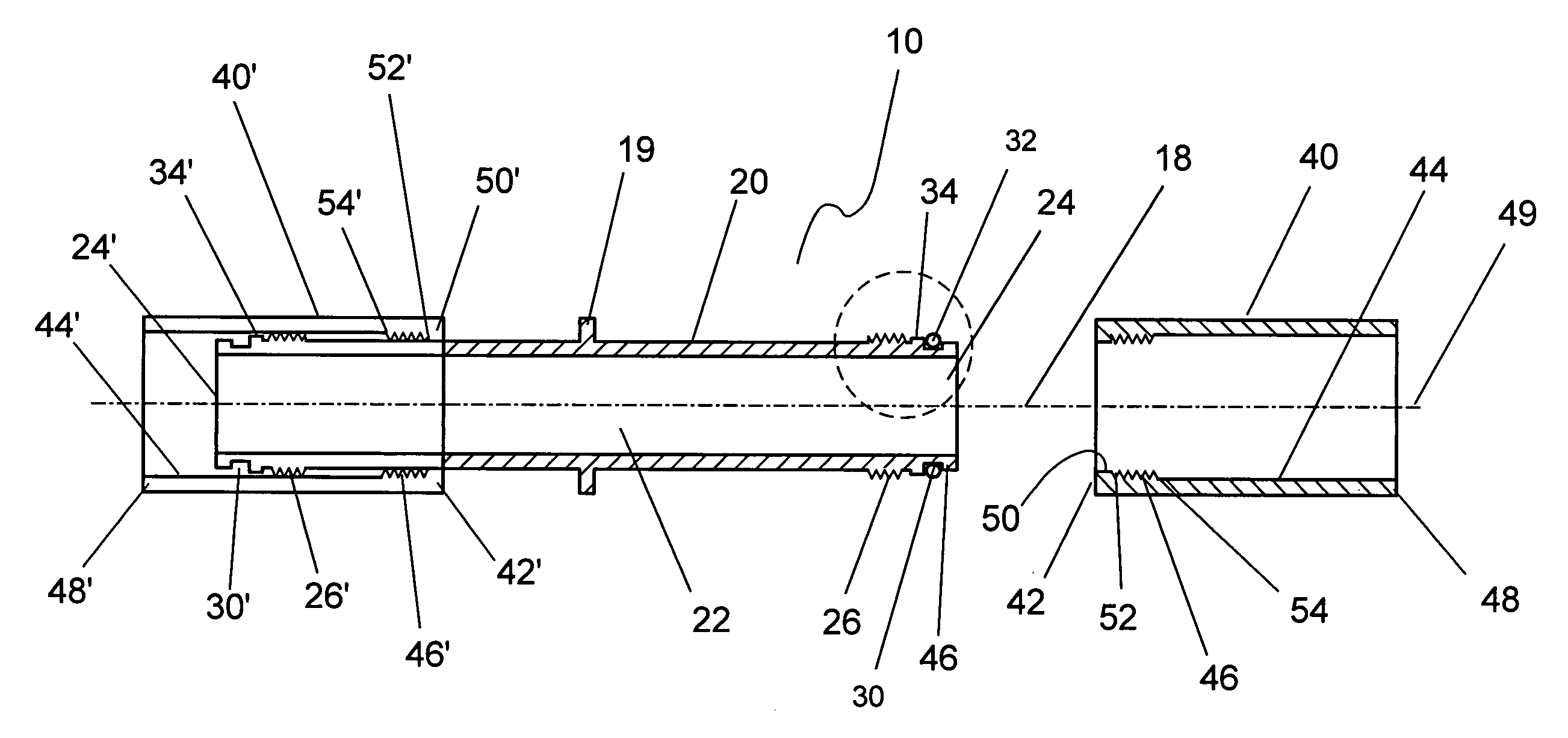

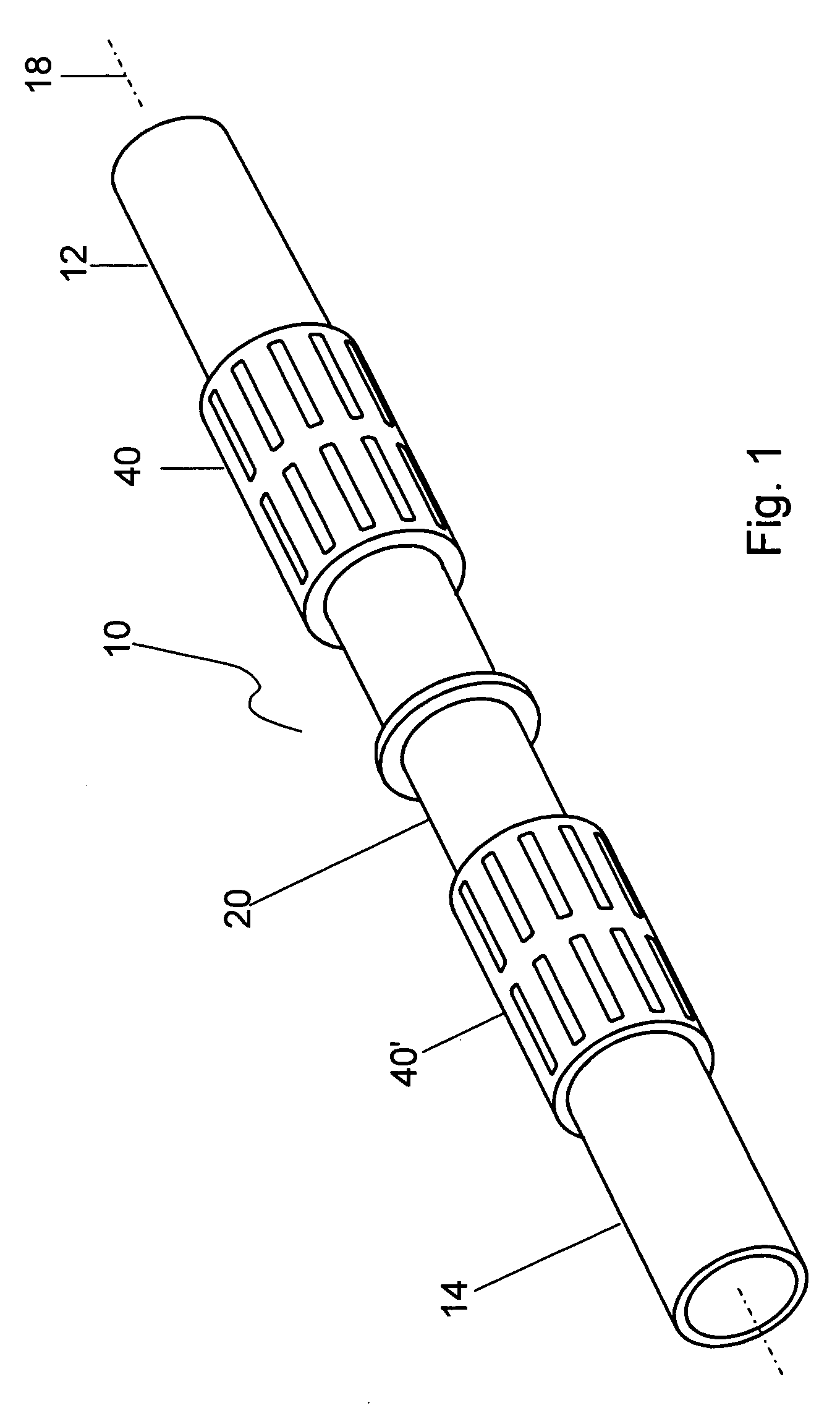

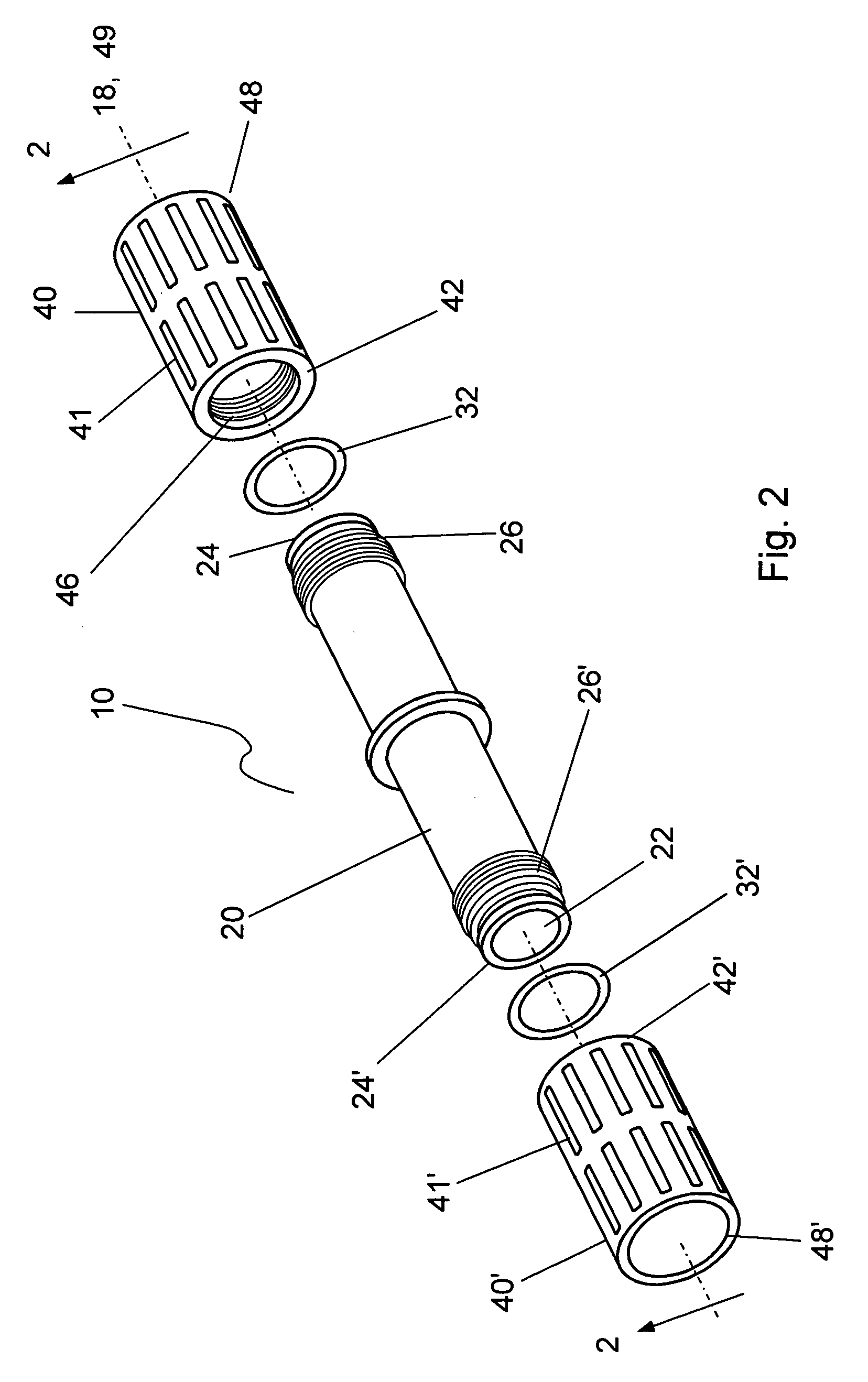

Slide coupling fitting for connecting conduits

InactiveUS7111873B1The relative position is appropriateSleeve/socket jointsCondensate preventionCouplingCatheter

A slide coupling fitting for connecting a tubular conduit and the method of use are provided. The fitting includes a tubular body, two opposing open ends, and an external threaded section on an exterior of the tubular body adjacent to each open end; and two tubular sliding couplers, each having an internal diameter slightly larger than an external diameter of the tubular body, and each being connected to one of the open ends of the tubular body, respectively, and coaxial with the tubular body. Each tubular sliding coupler has an internal threaded section adjacent to an inner end which is closer to a longitudinal center of the tubular body, and a smooth interior at an opposing outer end for slidably engaging a tubular conduit. The internal threaded section is complementary to the external threaded section of the tubular body for mutual engagement.

Owner:COOGLE GREGORY

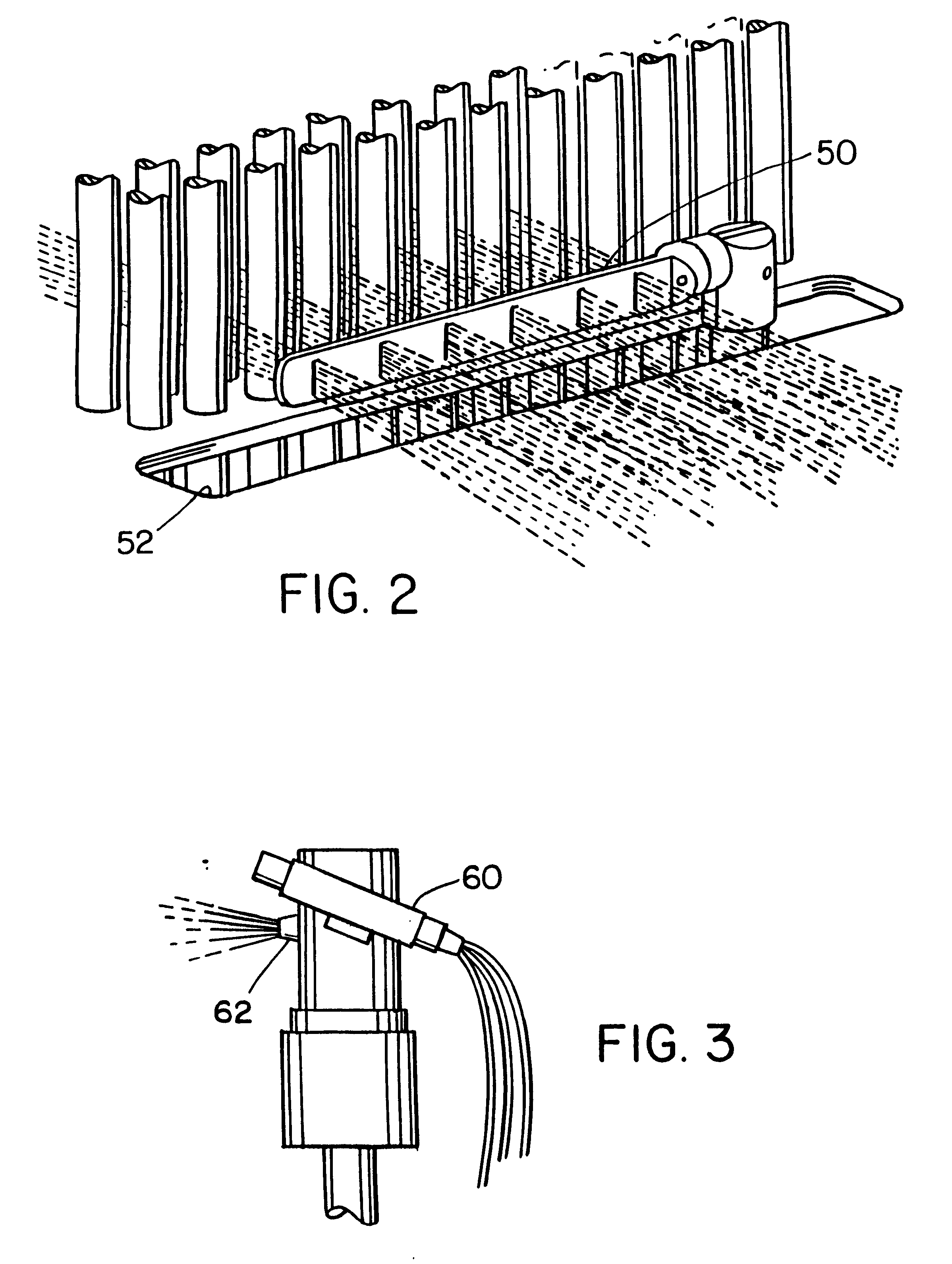

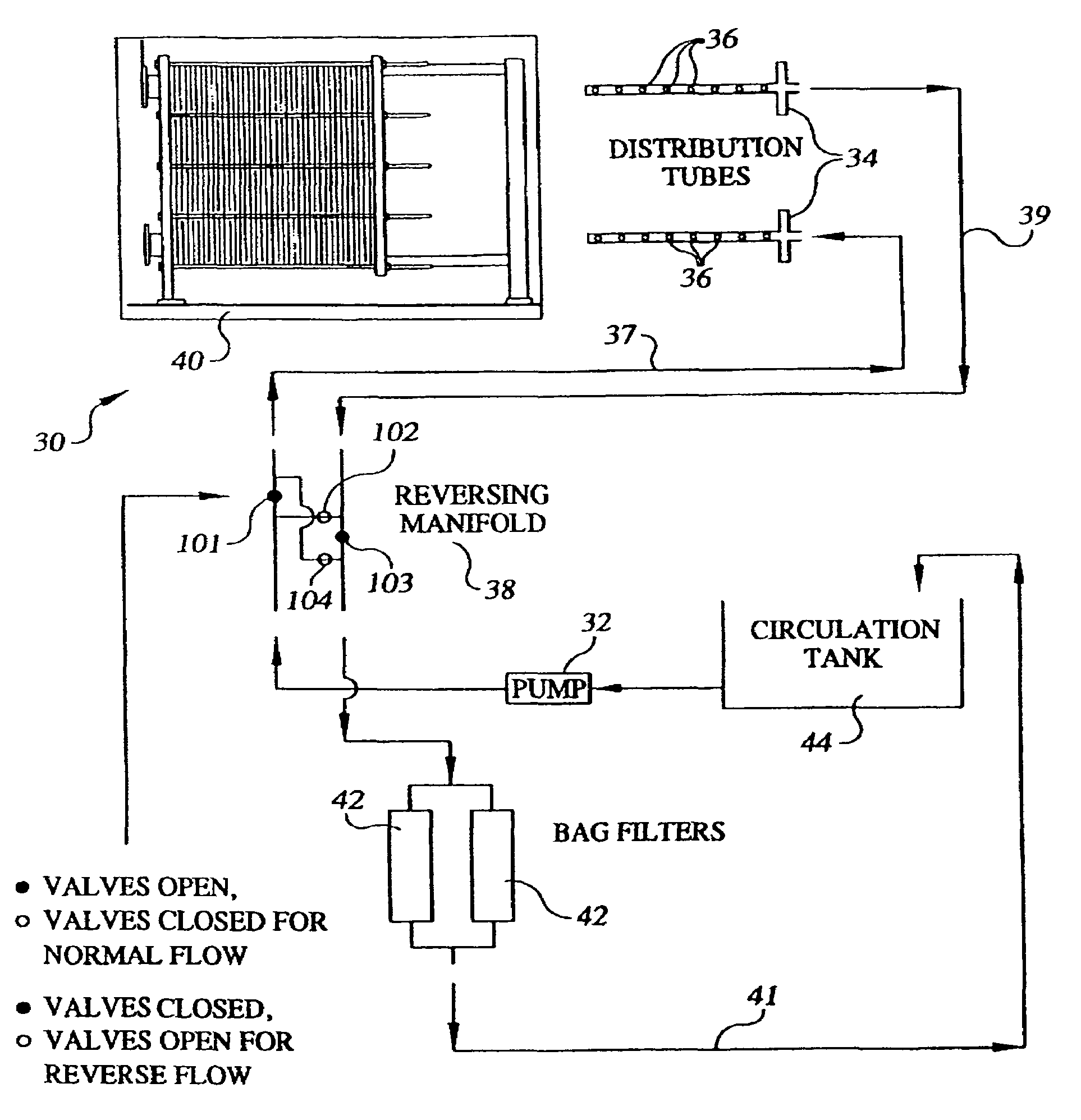

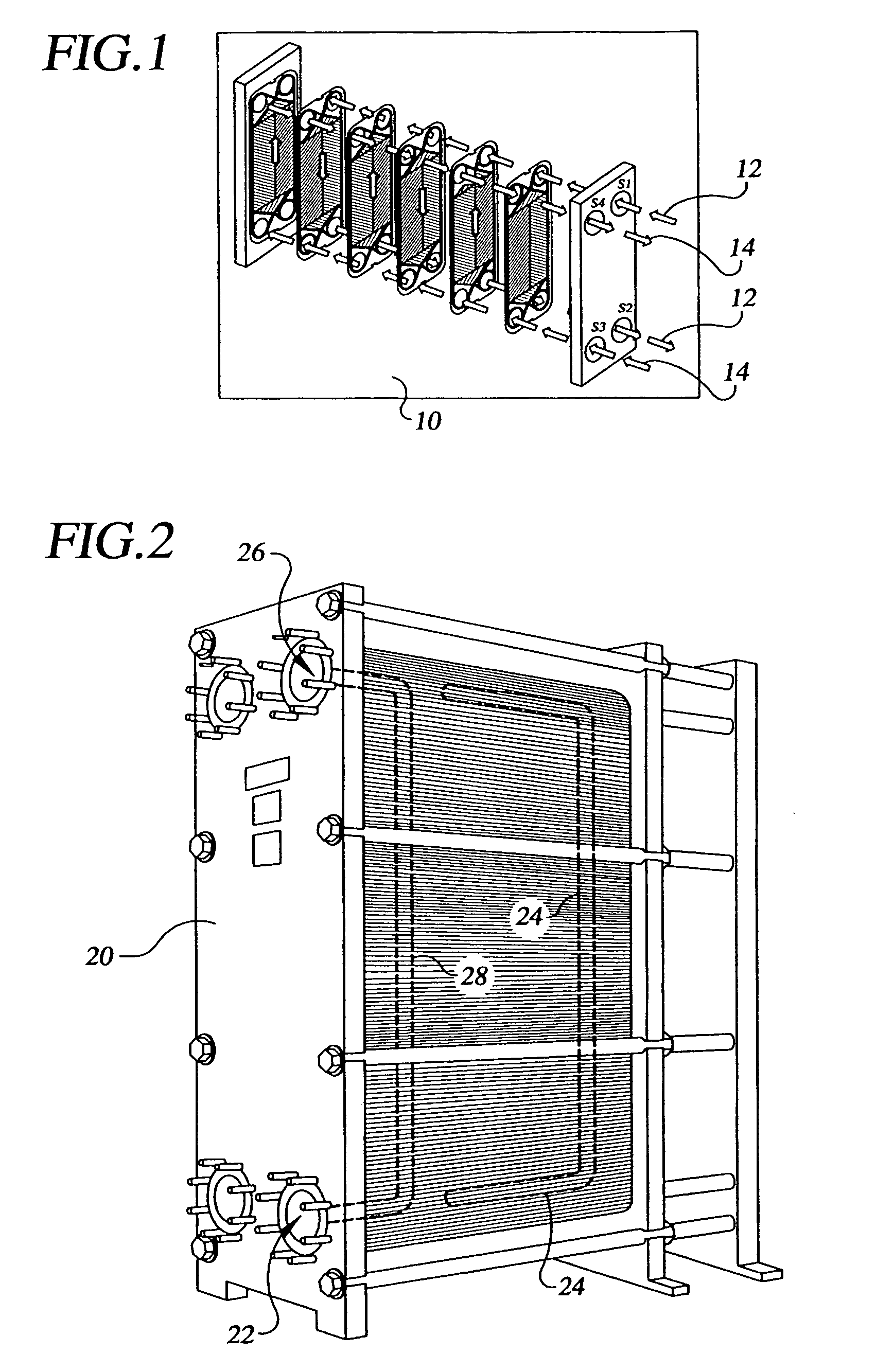

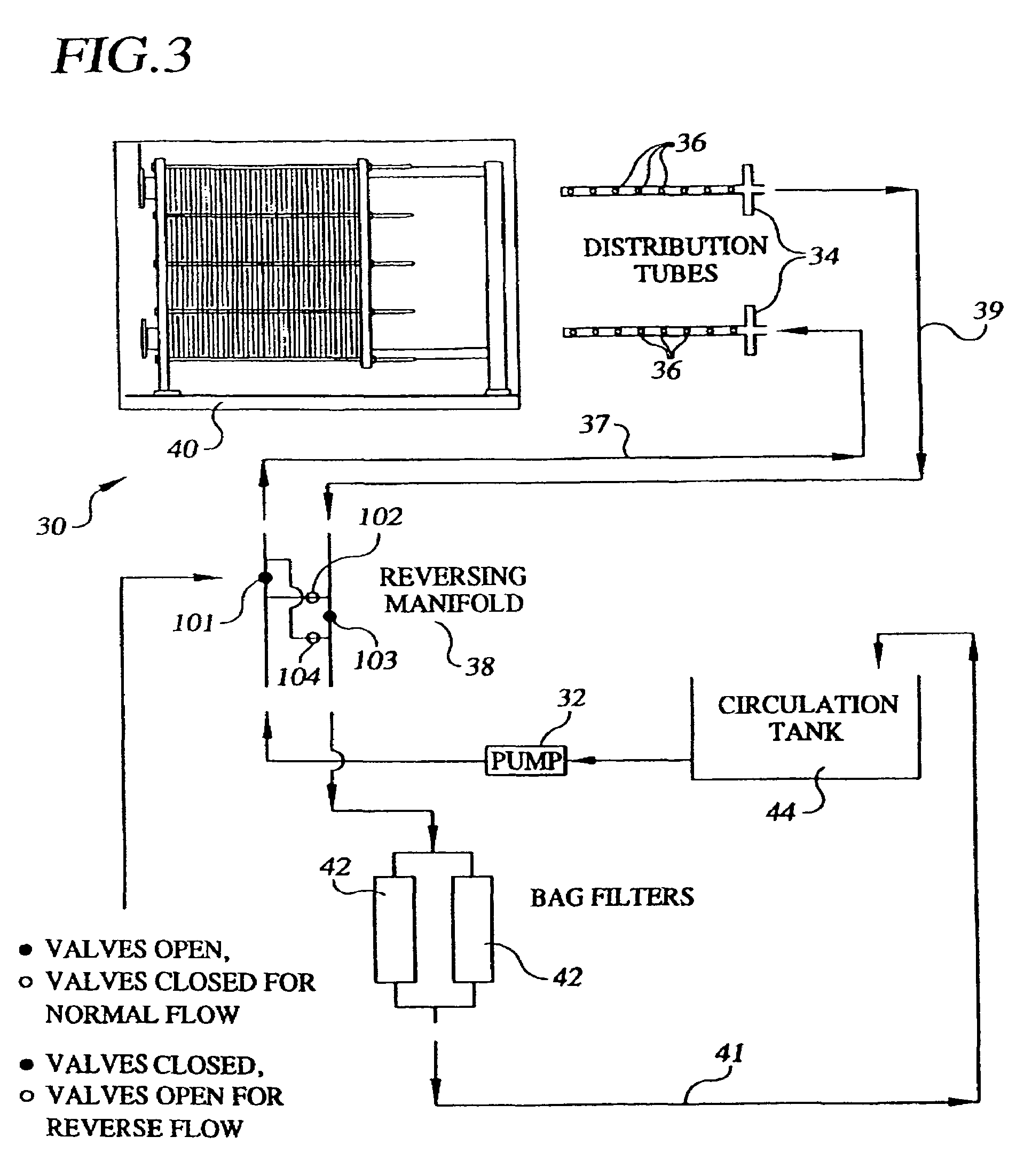

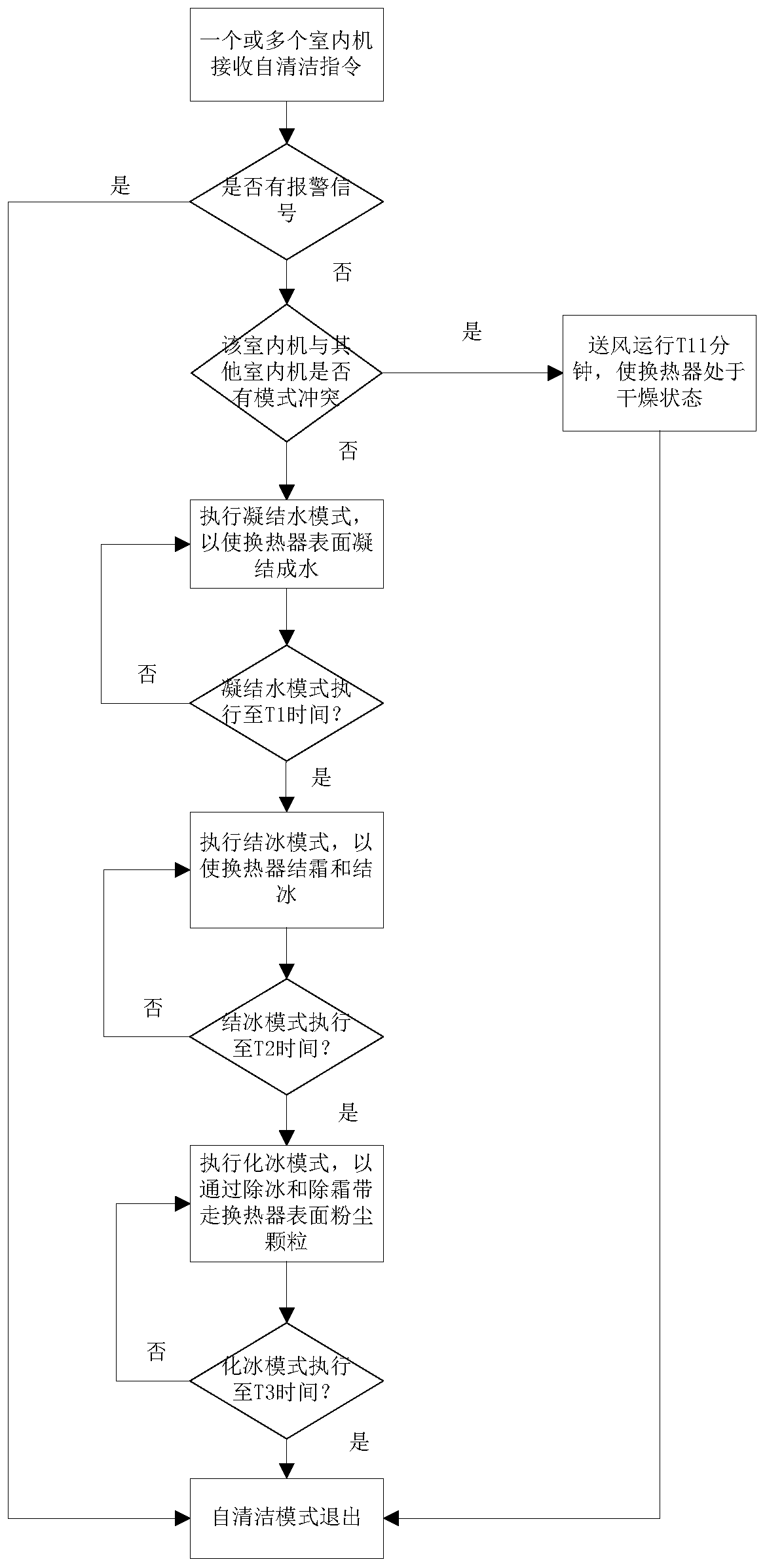

Portable cleaning apparatus and method for single pass plate and frame heat exchangers

InactiveUS6978793B1Reduce the amount requiredEasy extractionCombustion processHollow article cleaningParticulatesWorking fluid

A portable apparatus and method for chemically cleaning a single pass plate and frame heat exchanger allows the cleaning solution to be uniformly distributed across the plate pack. This portable system of one pump of preferably 10-horsepower, capable of 300 gallons per minute flow through a discharge port; at least two distribution / collection tubes with apertures of predetermined diameter and predetermined placement; one reversing manifold; two bag filters; and one circulation tank with a capacity at least on the order of 150 to 200 gallons; attaches to a single pass plate and frame heat exchanger. The single pass plate and frame heat exchanger is configured with at least two removable flanges that, once removed, allow for the installation of the distribution / collection tubes. The apertures in the distribution / collection tubes are placed facing downwards depending upon the direction of the operational fluid to enhance a vacuuming effect for particle and debris removal during cleaning. The distribution / collection tubes are skewed off-center of the flanges, with an ability to be rotated in at least four different directions off-center, and generally located towards the bottom of the single pass plate and frame heat exchanger to facilitate particulate removal and uniform distribution of cleaning solution.

Owner:PHEX

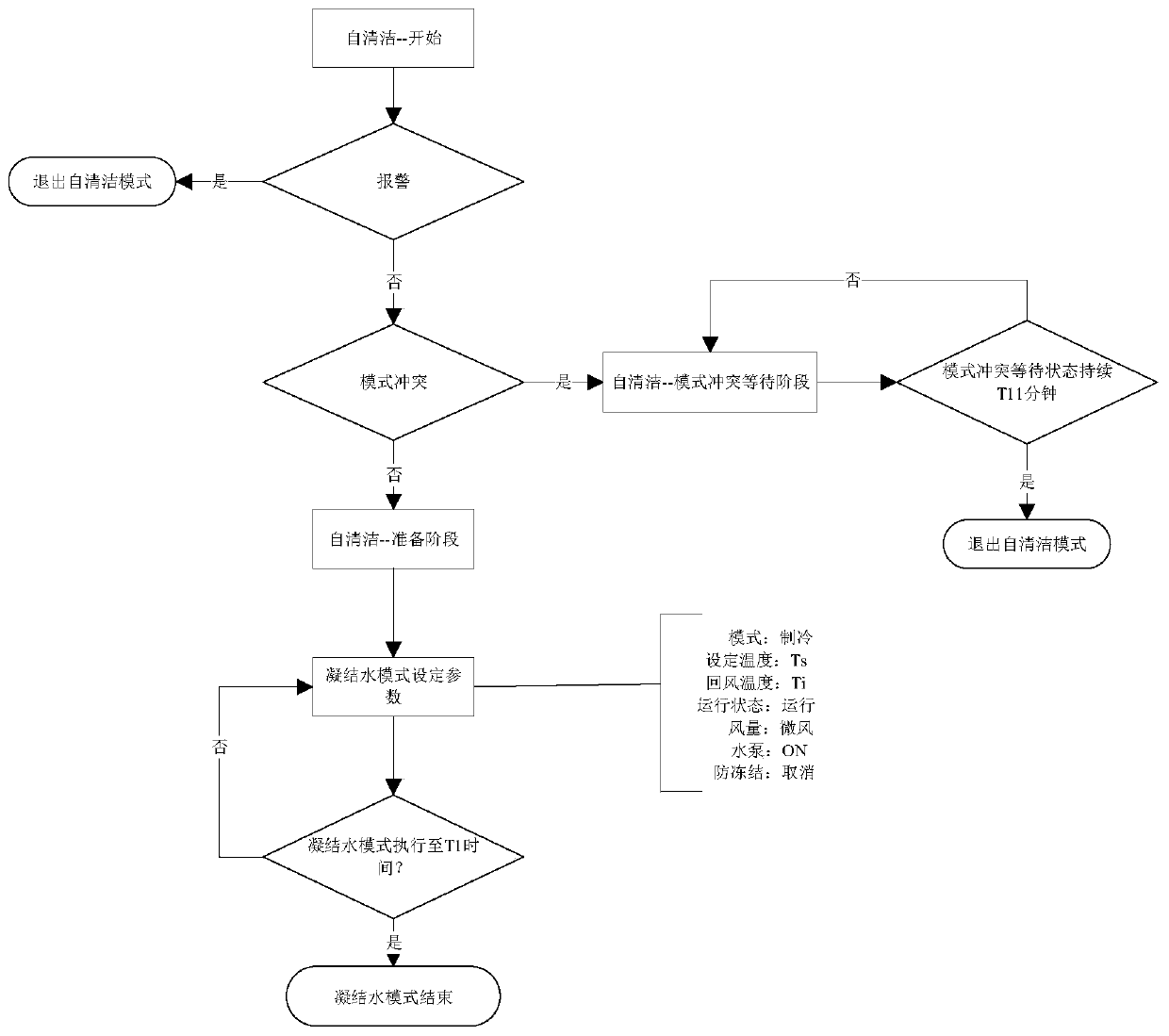

Multi-split air conditioner and control method thereof

ActiveCN109855191ANo running conflictsGuaranteed uptimeMechanical apparatusSpace heating and ventilation safety systemsComputer programHeat exchanger

The invention provides a multi-split air conditioner and a control method thereof. The multi-split air conditioner comprises multiple indoor units with heat exchangers, each indoor unit comprises a controller, each controller comprises a processor and a storage, a computer program is stored in each storage, and when each computer program is executed by the corresponding processor, the following steps including that when a certain or multiple indoor units receive a self-cleaning instruction, whether an alarm is given out in a multi-split system or not is detected, and whether running modes of other indoor units conflict with the running mode of the self-cleaning indoor unit or not is detected are executed. The control method is based on the multi-split air conditioner. Any one or multiple indoor units can execute the self-cleaning mode, the control method ensures that the indoor unit executing the self-cleaning mode does not have running confliction with the other indoor units, and themulti-split air conditioner can stably run.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

Method for recovering waste heat from coke oven raw gas

ActiveCN103131432AQuality assurancePrevent poppingCoke oven safety devicesEnergy inputWater vaporCoke oven

The invention relates to a method for recovering waste heat from a coke oven raw gas. The method utilizes water as a heat exchange medium, water exchanges heat with the raw gas having a temperature of about 650-750DEG C in a riser heat exchanger, the temperature of the raw gas subjected to the heat exchange decreases to 480-550DEG C, the heat exchange medium forms a vapor-water mixture after heating, and enters a vapor bag, and the vapor-water mixture is separated to form high temperature water and saturated vapor by a vapor-water separator in the vapor bag; the raw gas discharged from the riser heat exchanger undergoes heat exchange in a bridge tube heat exchanger, the temperature of the raw gas subjected to the heat exchange decreases to 280-350DEG C, and the high temperature water obtained after the separation of the vapor-water separator undergoes heat exchange by the bridge tube heat exchanger, enters the vapor bag and generates saturated vapor, wherein the outer wall of the heat exchanger is cleaned through high-pressure ammonia water intermittent spray or water vapor intermittent blow in the bridge tube; and finally the temperature of the raw gas is reduced to 80-85DEG C by adopting ammonia water, and then the raw gas enters a gas collection tube. The method furthest recovers the waste heat of the raw gas and guarantees the continuous normal work of the heat exchangers under a complex condition.

Owner:BEIJING RISUN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com