Patents

Literature

236 results about "Industrial Facility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparatus and method for CO2 recovery

InactiveUS20060204425A1Improve energy efficiencyImprove regeneration efficiencyCombination devicesCarbon compoundsProduct gasProcess engineering

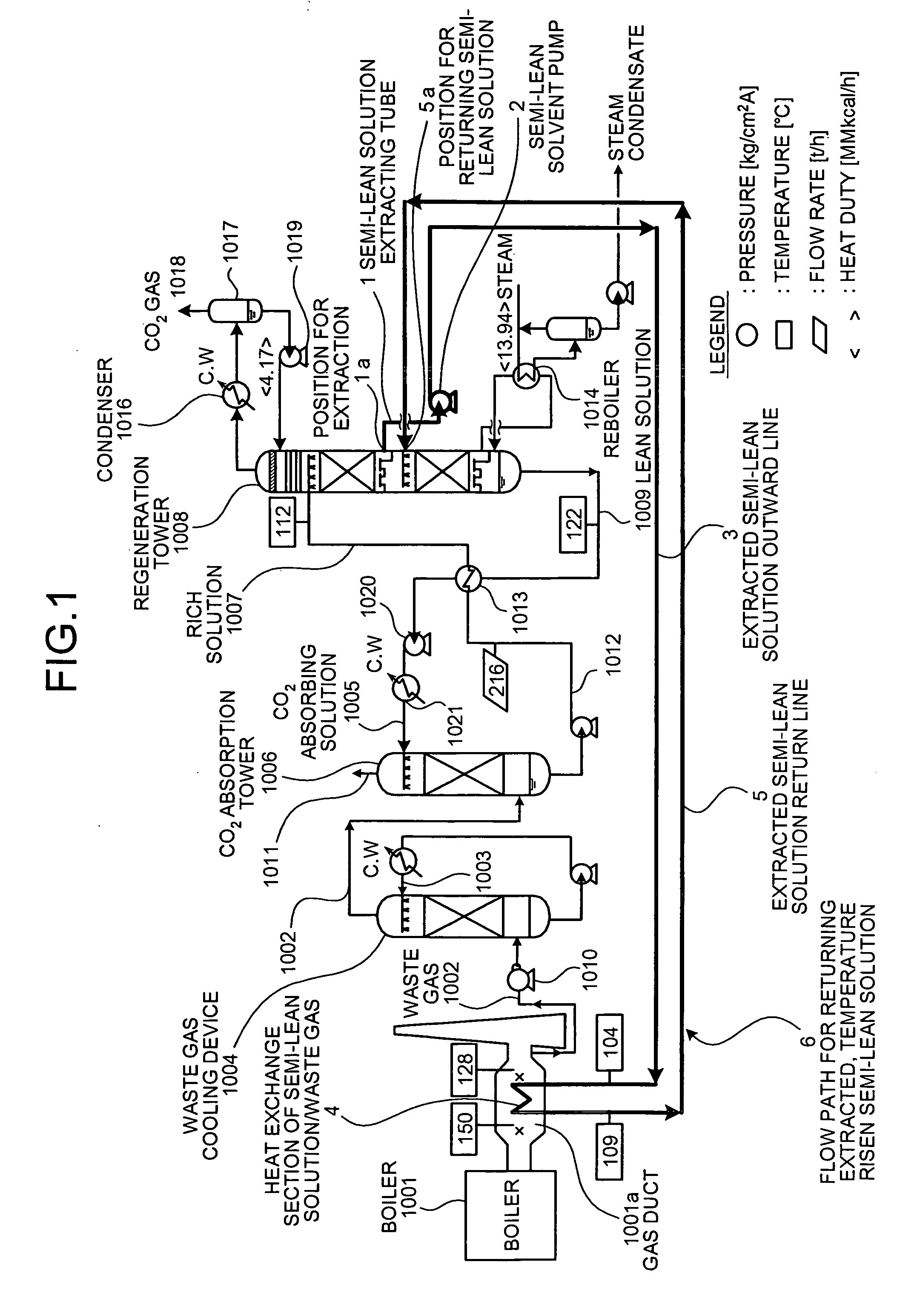

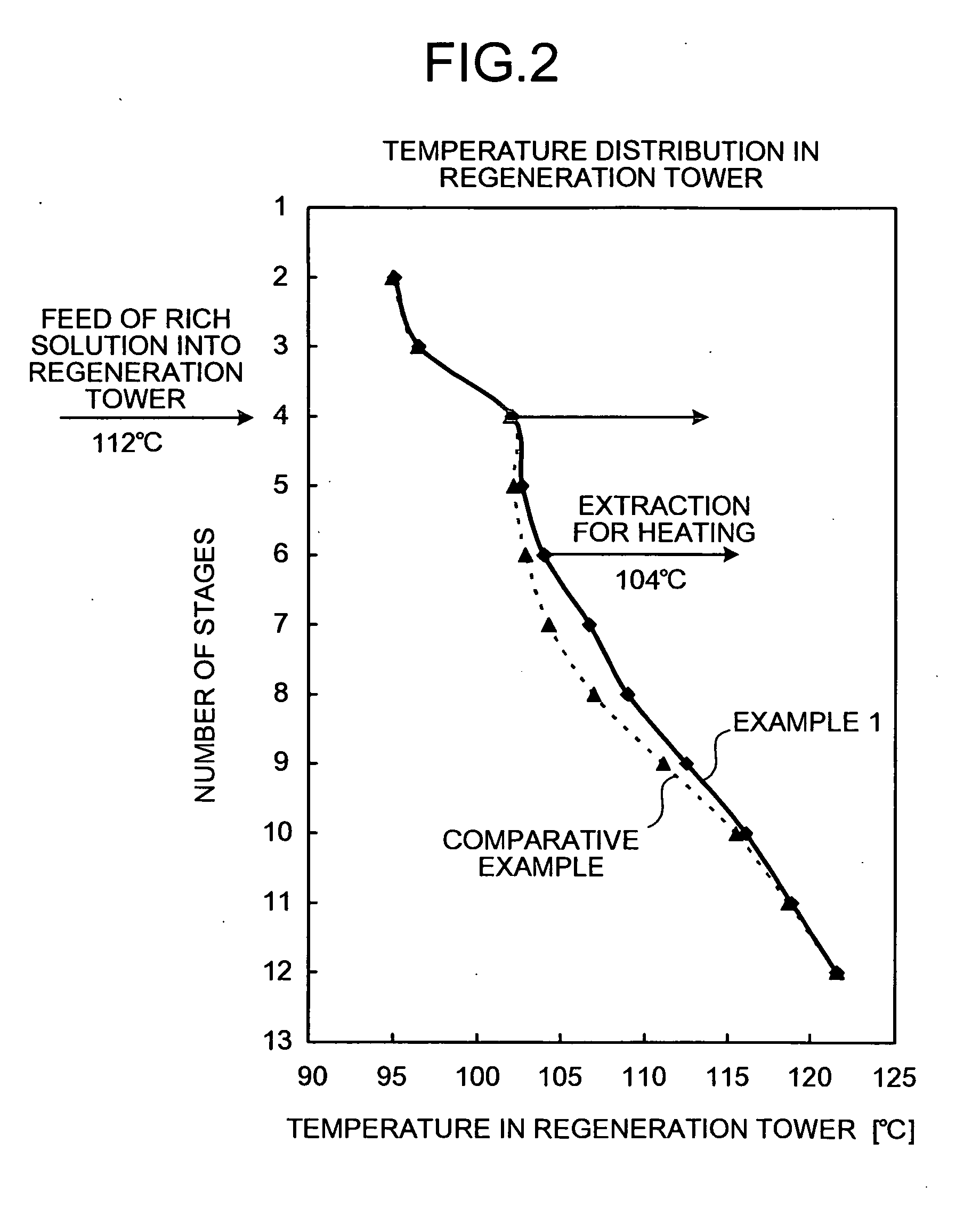

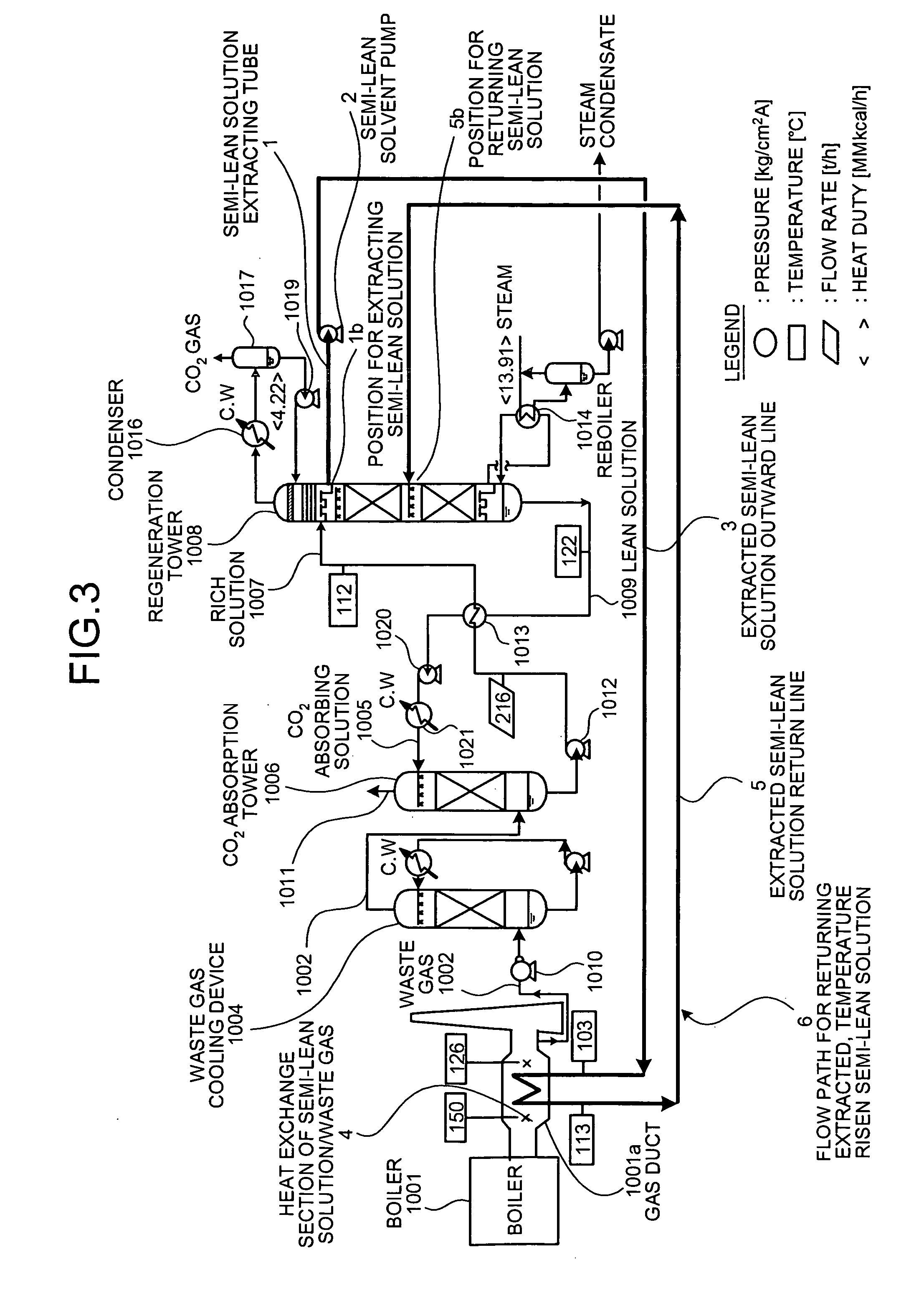

An apparatus and a method for recovering CO2 are provided in which an energy efficiency is improved. The apparatus for recovering CO2 includes a flow path for returning extracted, temperature risen semi-lean solution into a regeneration tower wherein at least a part of the semi-lean solution obtained by removing a partial CO2 from a rich solution infused in a regeneration tower from an upper part of the regeneration tower is extracted, raised its temperature by heat exchanging with a high-temperature waste gas in a gas duct of an industrial facility such as a boiler, and then returned into the regeneration tower.

Owner:MITSUBISHI HEAVY IND LTD +1

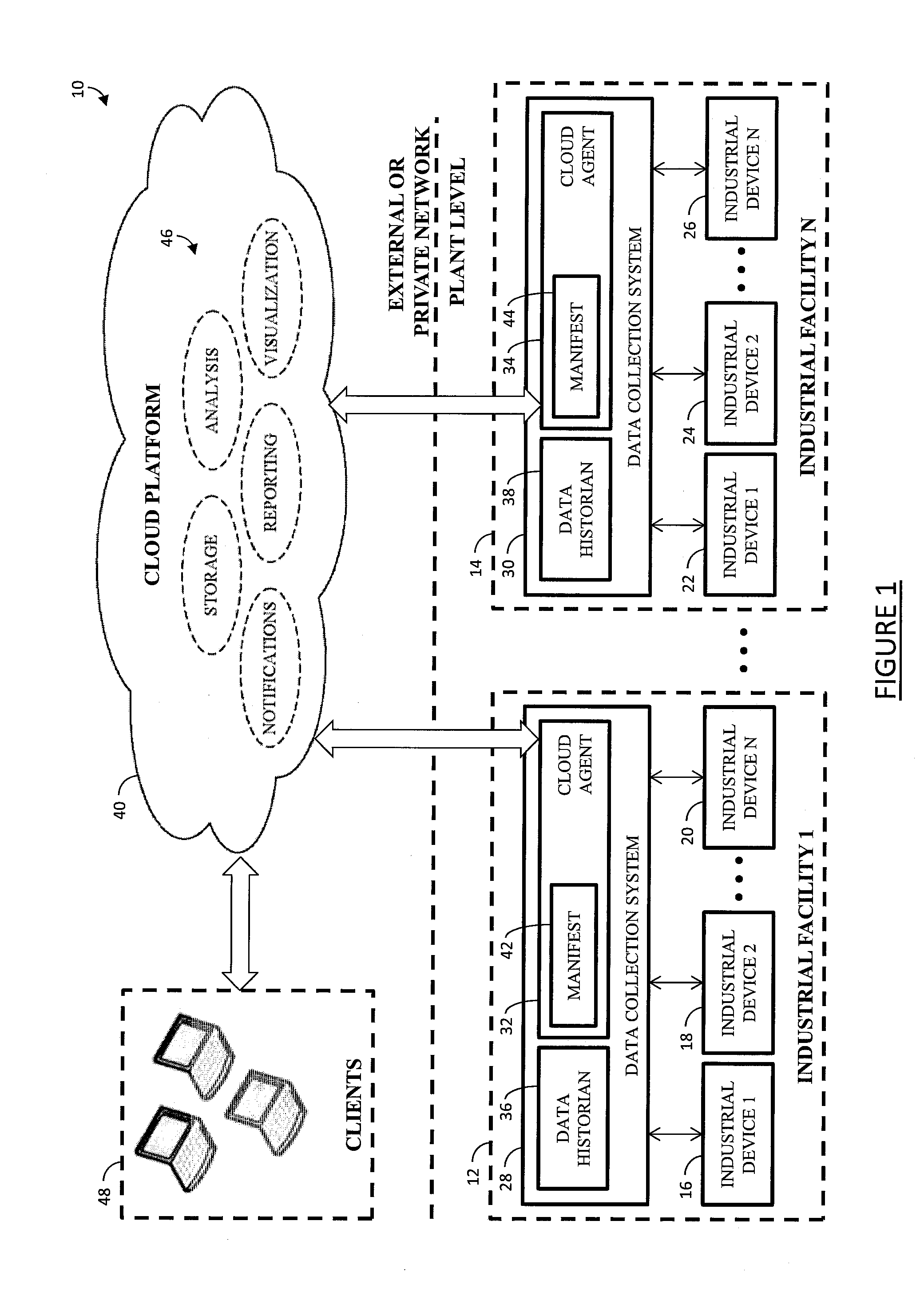

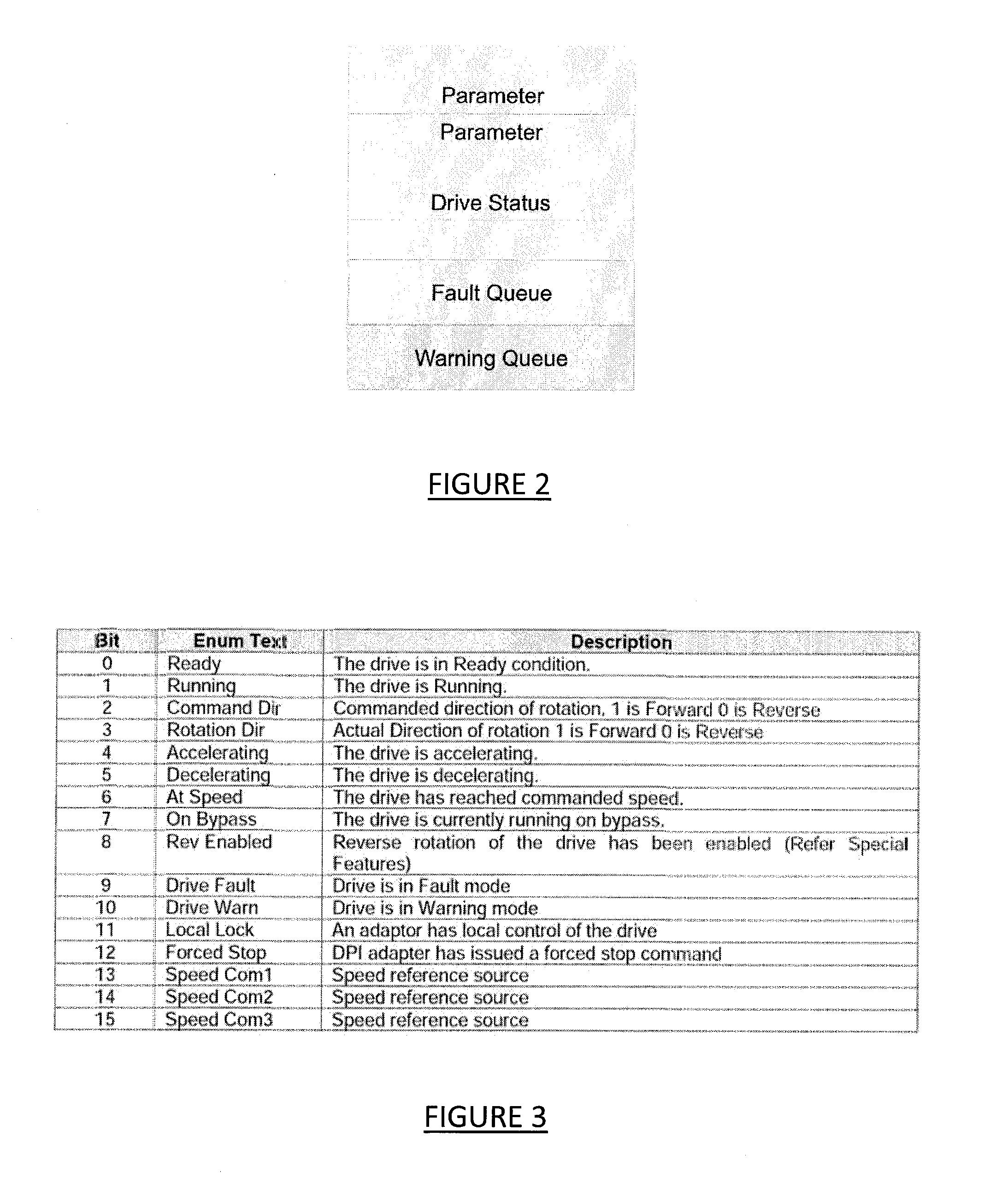

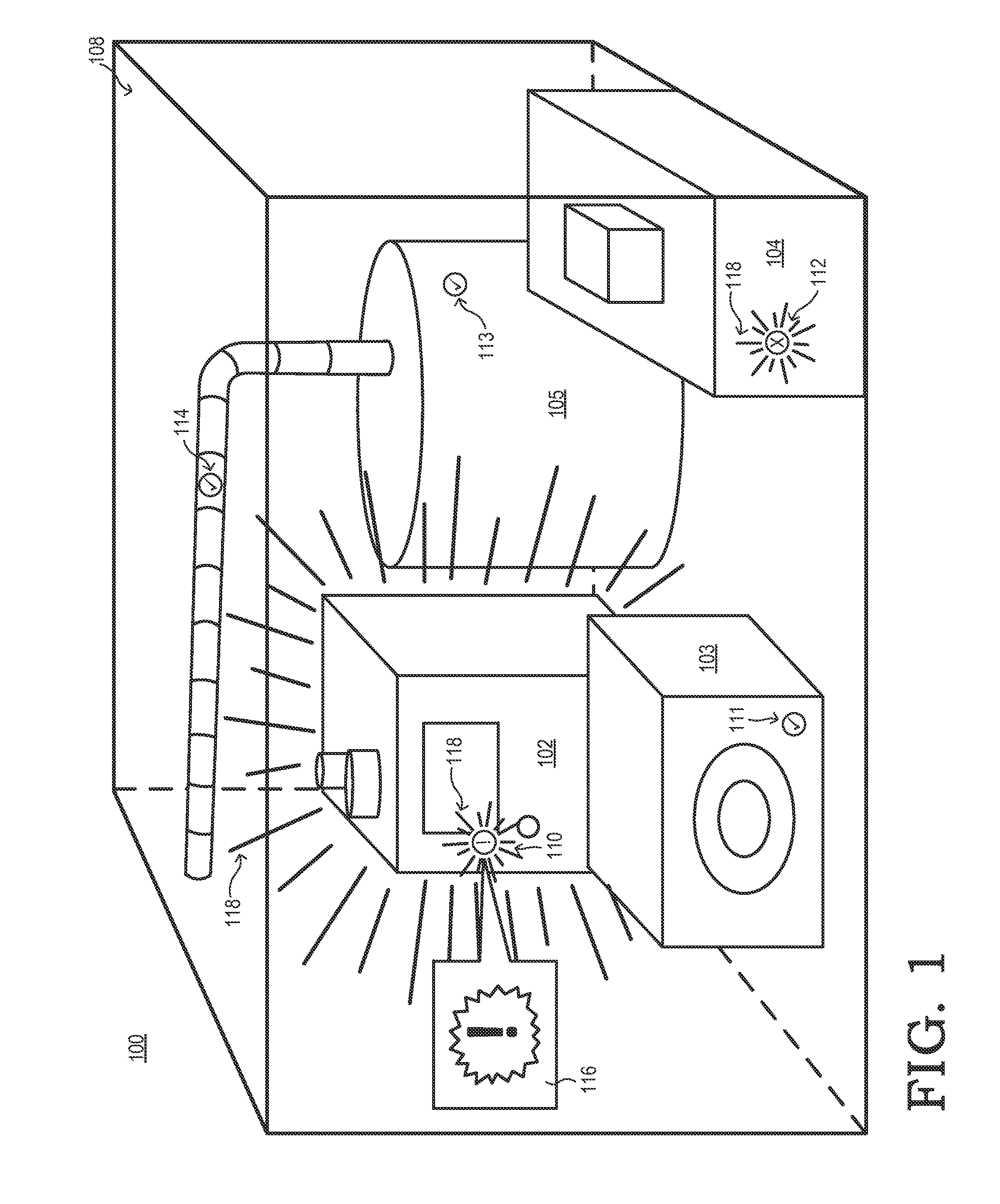

Cloud based drive monitoring solution

ActiveUS20140129688A1Easy to monitor remotelyTesting/monitoring control systemsDigital computer detailsCloud baseMonitoring system

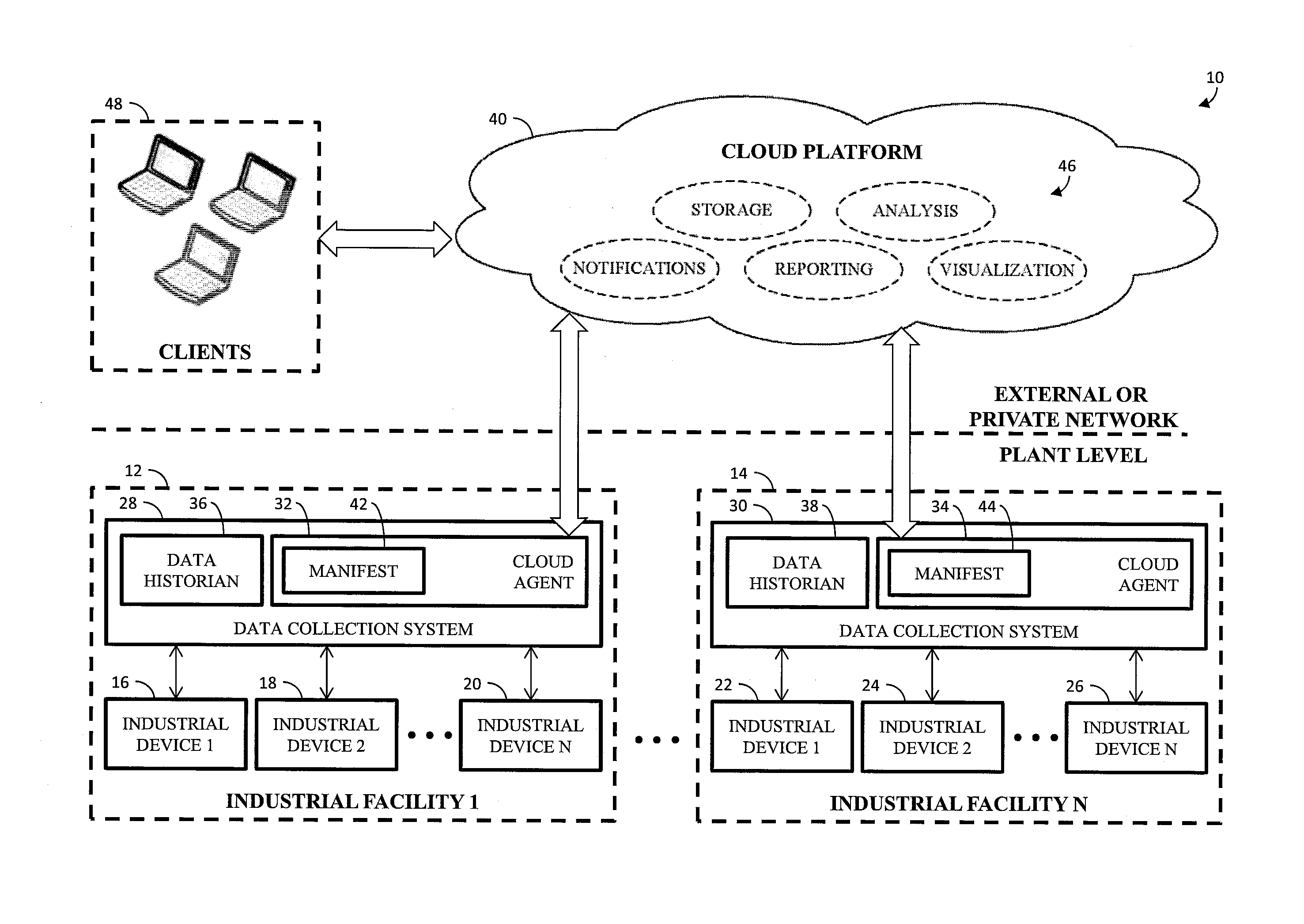

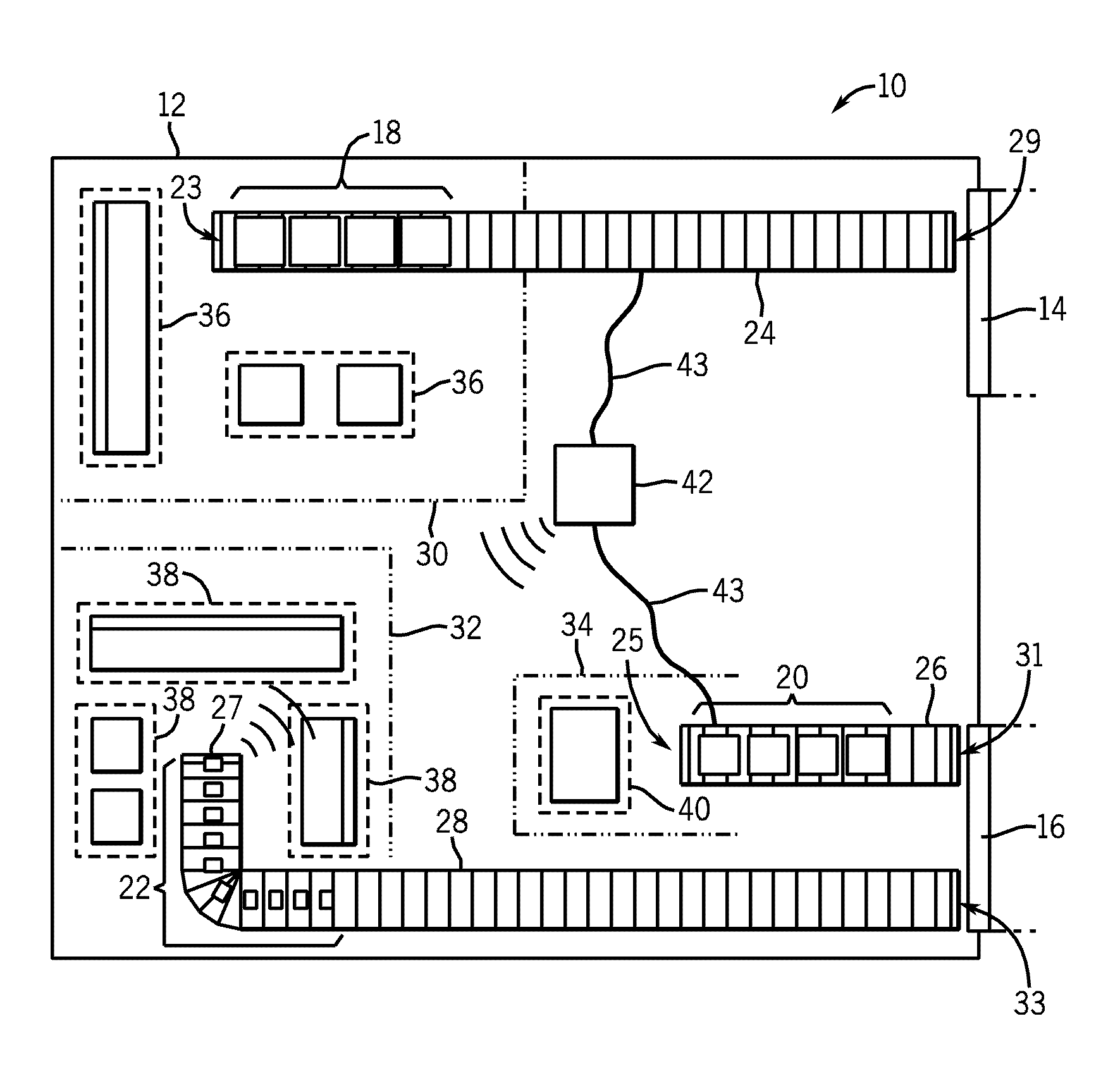

A cloud-based remote monitoring system and method monitor an industrial facility. The industrial facility includes one or more industrial devices. A cloud agent located at the industrial facility is configured to, by at least one processor, collect data indicative of a past and / or a present state of the industrial devices according a manifest specific to the industrial facility. The cloud agent is further configured to send the collected data to a remote cloud platform according to the manifest dynamically reconfigure the cloud agent without interrupting the collecting and the sending. The cloud platform processes the sent data to facilitate remote monitoring of the industrial devices.

Owner:ROCKWELL AUTOMATION TECH

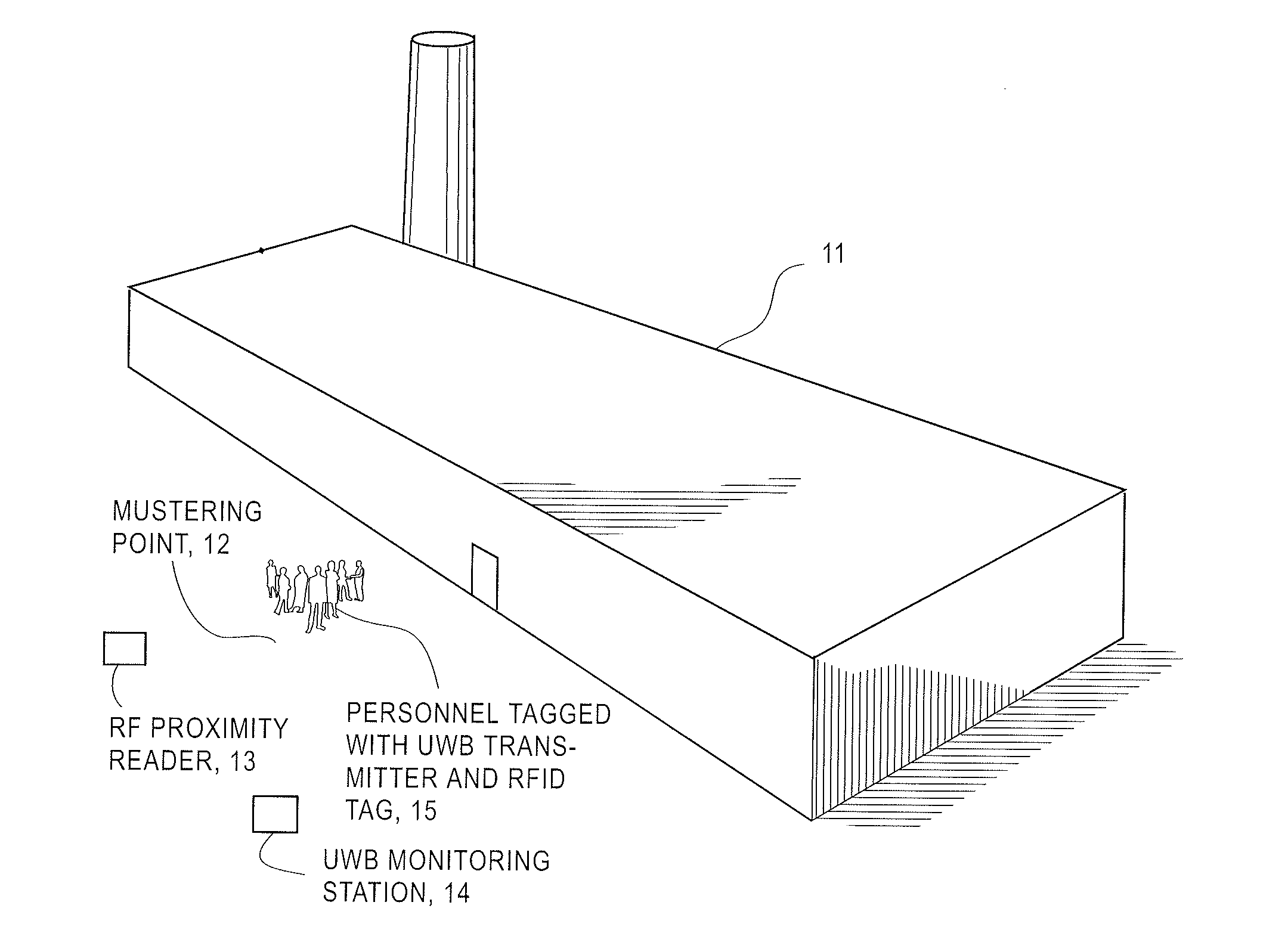

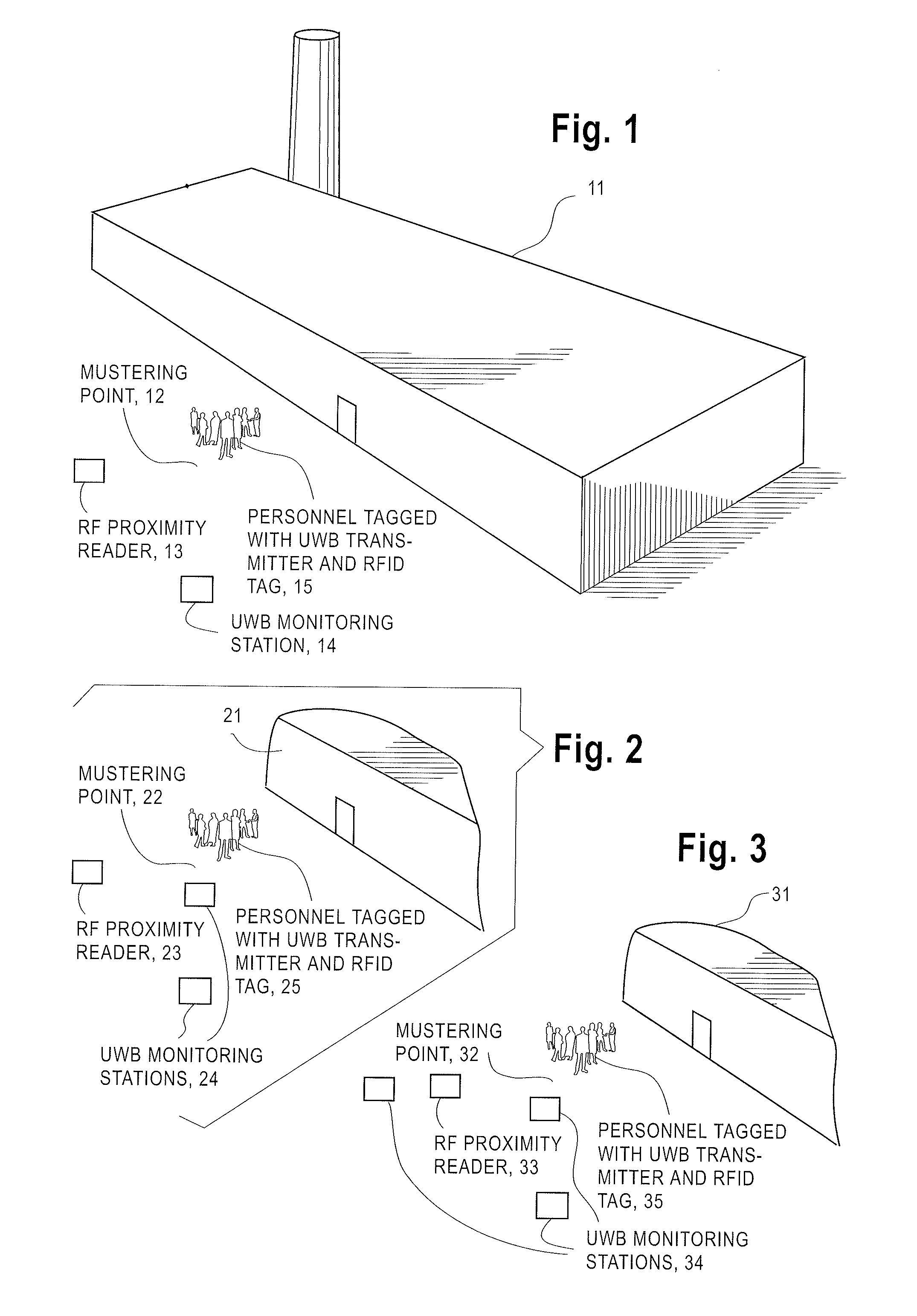

Method for accounting for people in emergencies in industrial settings

A method for accounting for individuals in an emergency at industrial facilities utilizing Ultra-Wideband (UWB) transmitters associated with individuals or objects and UWB monitoring stations. Identification information received from the UWB transmitters by UWB monitoring stations are communicated along with time of arrival information to a computer which calculates the location of the UWB transmitter. The system can be used despite severe multi-path effects and can provide location information in 3 dimensions. The system can optionally include proximity-based RF equipment for access control or otherwise for identification in specific locations. Information from the proximity-based RF equipment is also sent to the computer which also receives information from the UWB monitoring stations.

Owner:BP CORP NORTH AMERICA INC +1

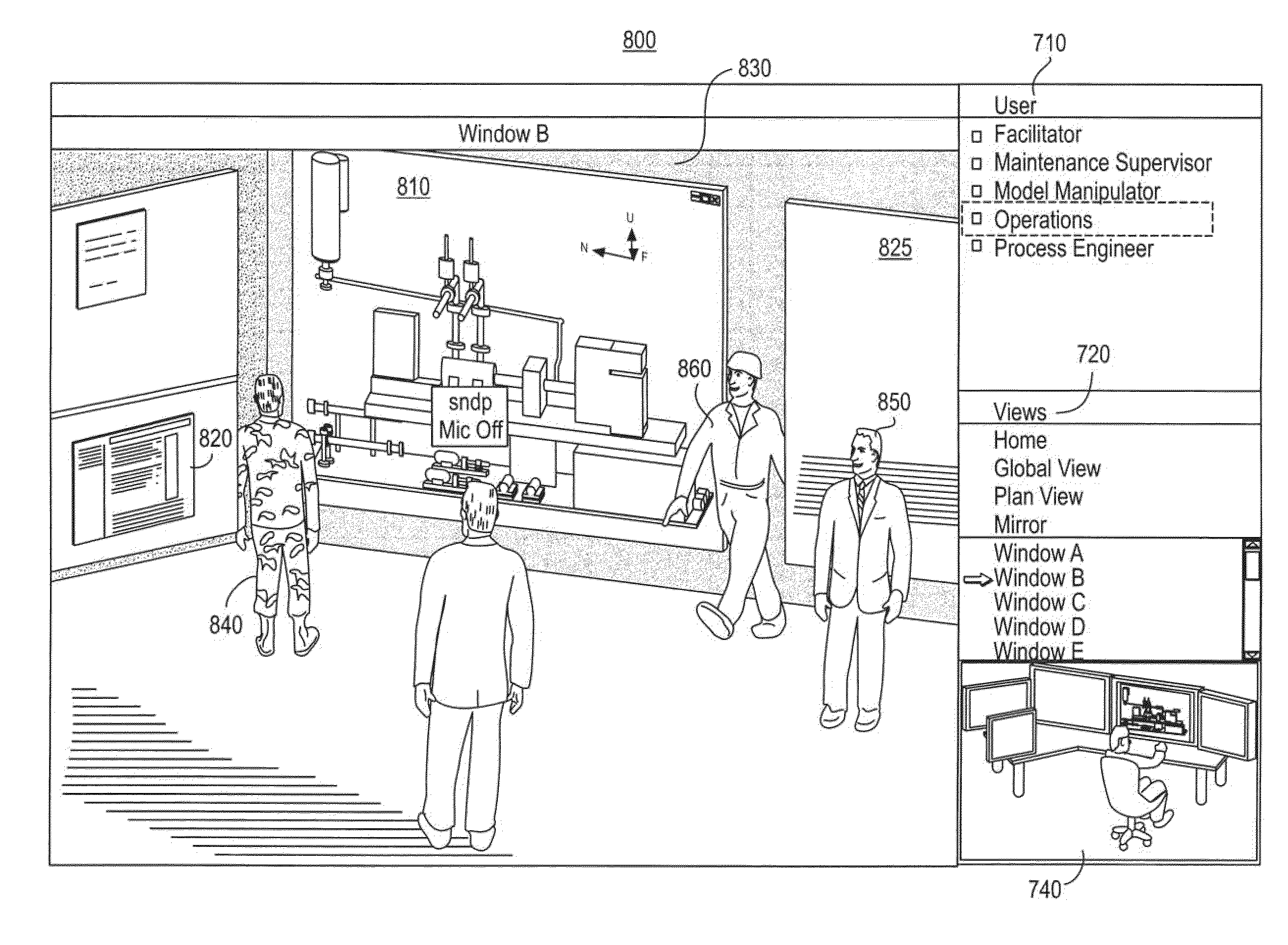

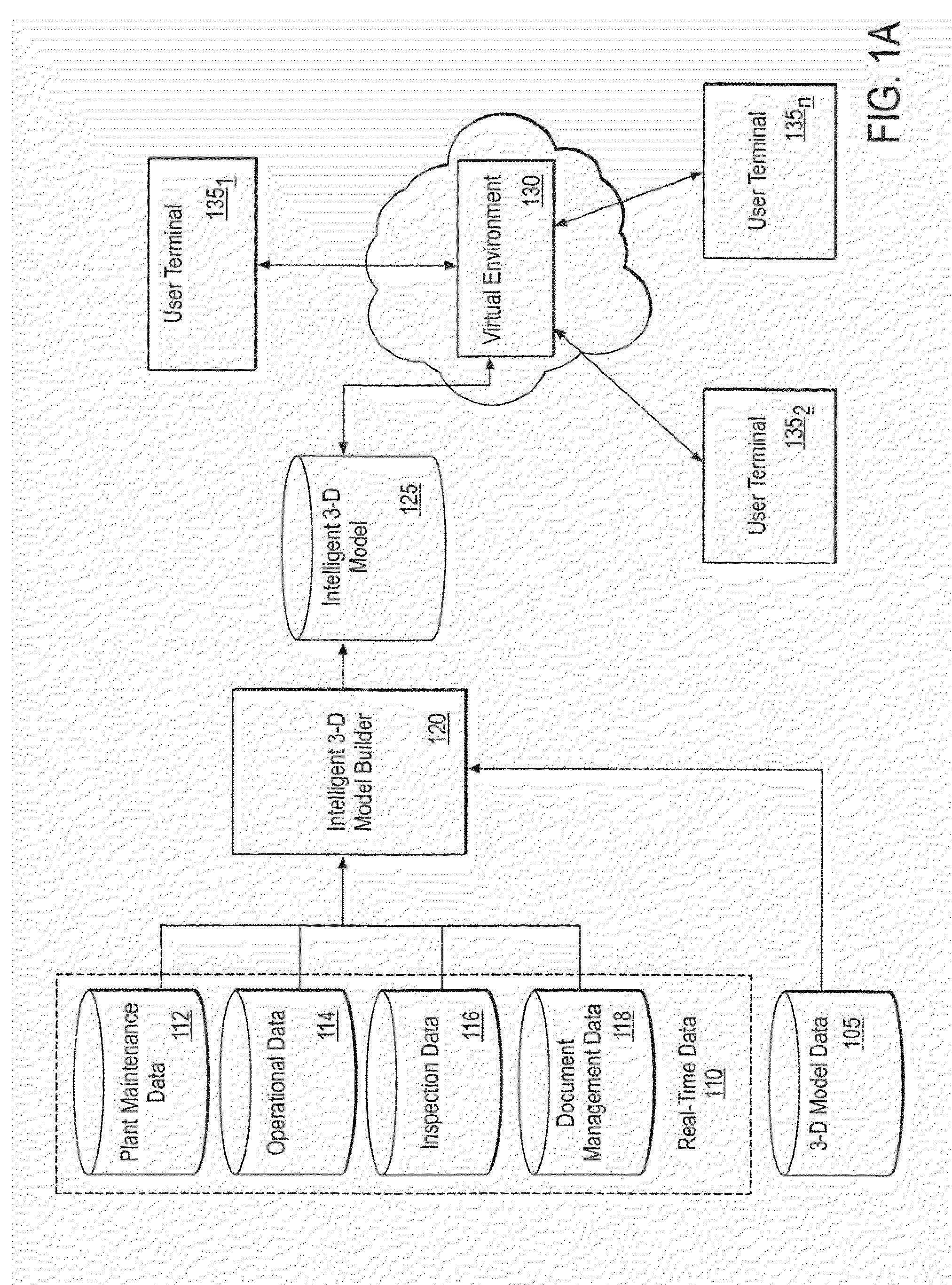

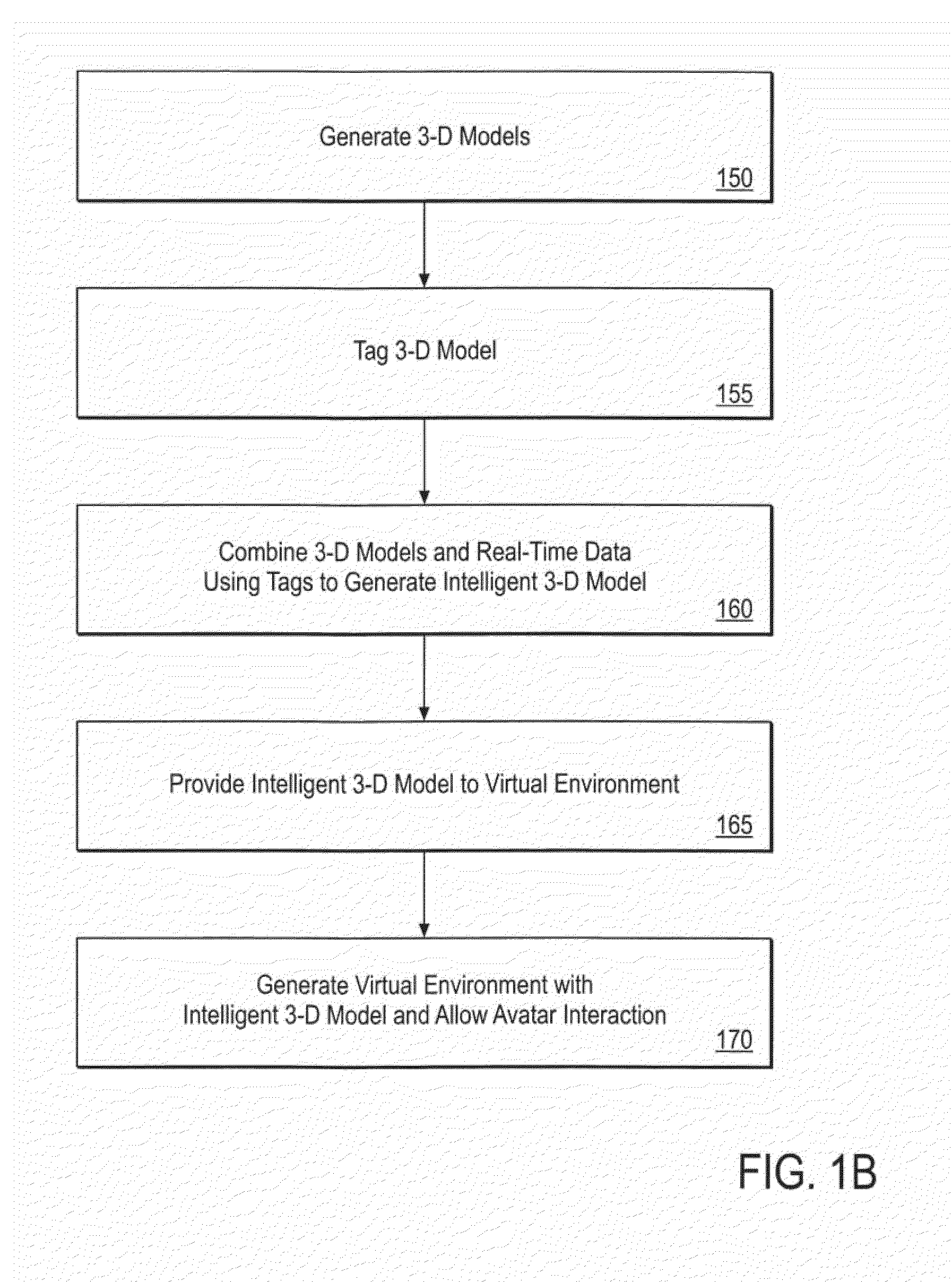

System and method for immersive operations intelligence

InactiveUS20100257464A1Effective trainingImprove securityInput/output for user-computer interactionOffice automationBusiness activitiesIndustrial Facility

Systems and methods are provided for conducting business activities related to an industrial facility to achieve immersive operations intelligence. Immersive technology is used visualize a subject facility, and to access resources that may be required to design, test, operate, maintain and improve the facility. Resources may include personnel, data, models, work flows, historical data, and real-time data, e.g., audio, video, sensor, instrumentation data, etc.

Owner:CHEVROU USA INC

Method for accounting for people in emergencies in industrial settings

ActiveUS20080030359A1Accurate locationPosition fixationSatellite radio beaconingUltra-widebandMulti path

A method for accounting for individuals in an emergency at industrial facilities utilizing Ultra-Wideband (UWB) transmitters associated with individuals or objects and UWB monitoring stations. Identification information received from the UWB transmitters by UWB monitoring stations are communicated along with time of arrival information to a computer which calculates the location of the UWB transmitter. The system can be used despite severe multi-path effects and can provide location information in 3 dimensions. The system can optionally include proximity-based RF equipment for access control or otherwise for identification in specific locations. Information from the proximity-based RF equipment is also sent to the computer which also receives information from the UWB monitoring stations.

Owner:BP CORP NORTH AMERICA INC +1

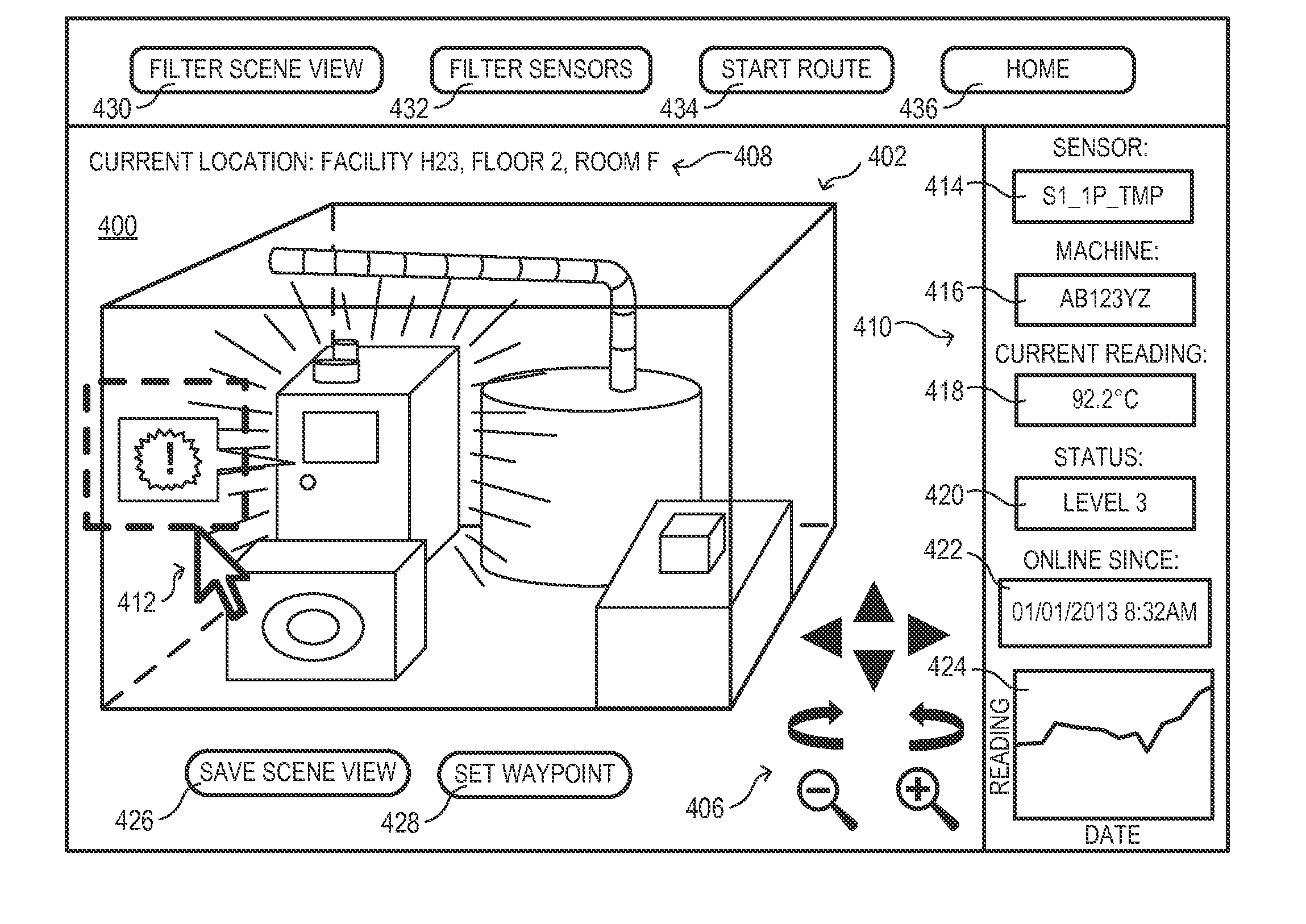

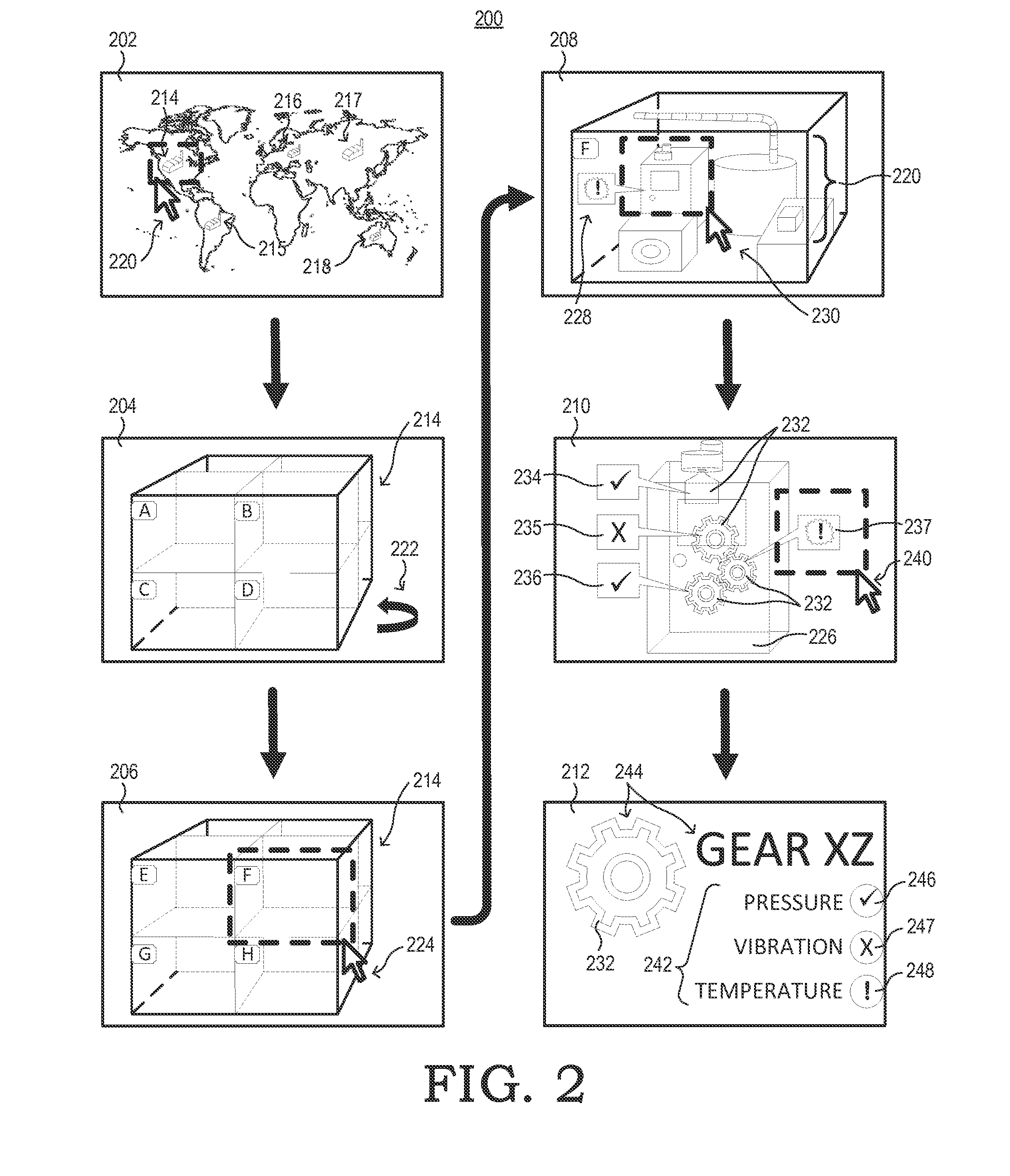

System and method for multi-dimensional modeling of an industrial facility

A facility modeling system renders graphical representations of machines and their environment in a facility model to facilitate monitoring of machine parameters and health. A sensor control module communicates with a plurality of sensors detecting machine parameter data for machines housed in a facility. The machine parameters may include any information that may directly or indirectly indicate the status of a machine or a part of a machine. The information collected from the sensors is incorporated into the facility model (a graphical rendering of the facility) which may provide any of a variety of multi-dimensional views of the facility. A GUI allows a user to navigate through the facility model to identify and monitor the status of the sensors. The sensor status may be indicated by an icon, callout, change in a display characteristic of a facility, machine, part, space, or item, a combination of these, and the like.

Owner:UPTIME SOLUTIONS LLC

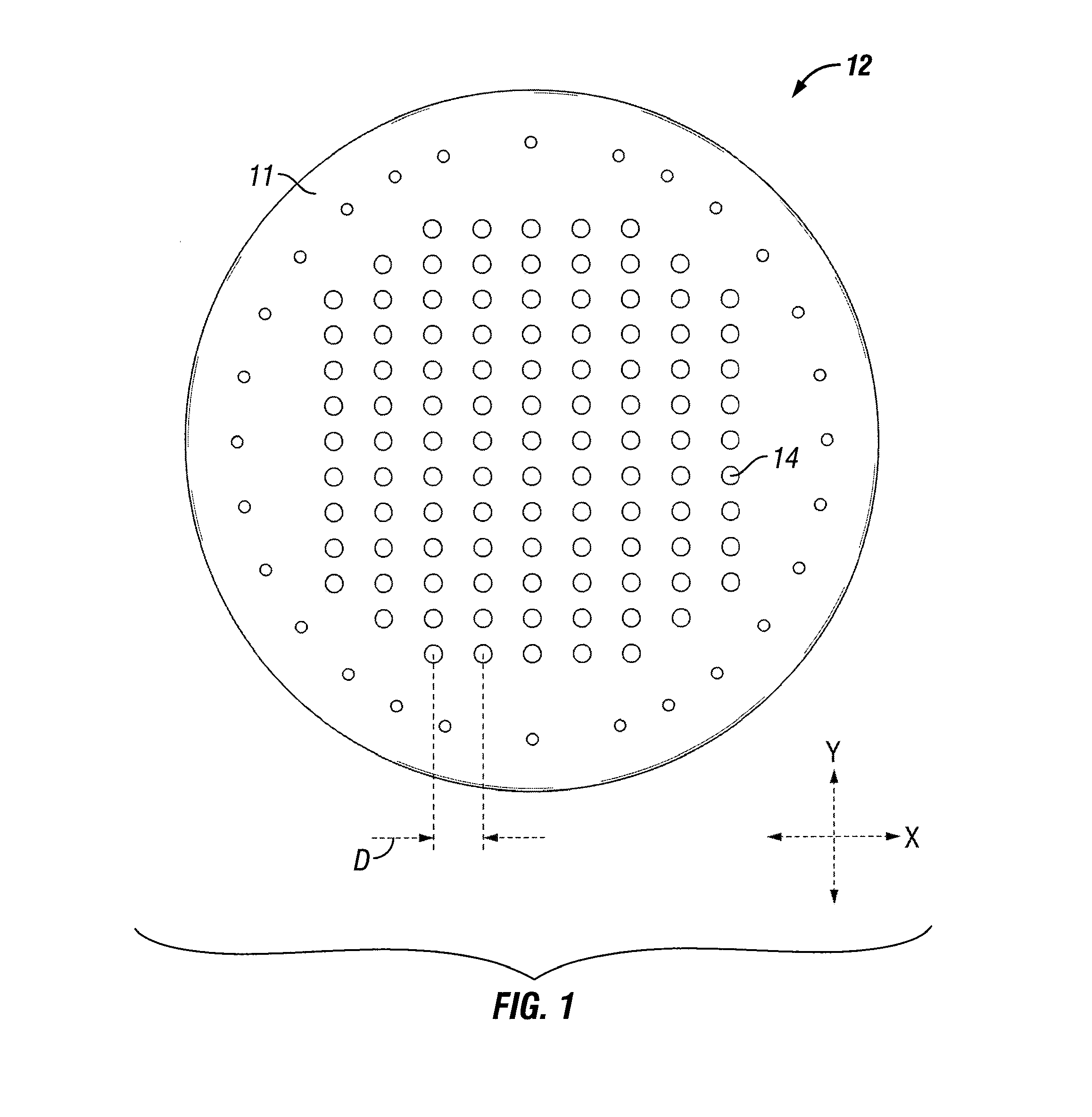

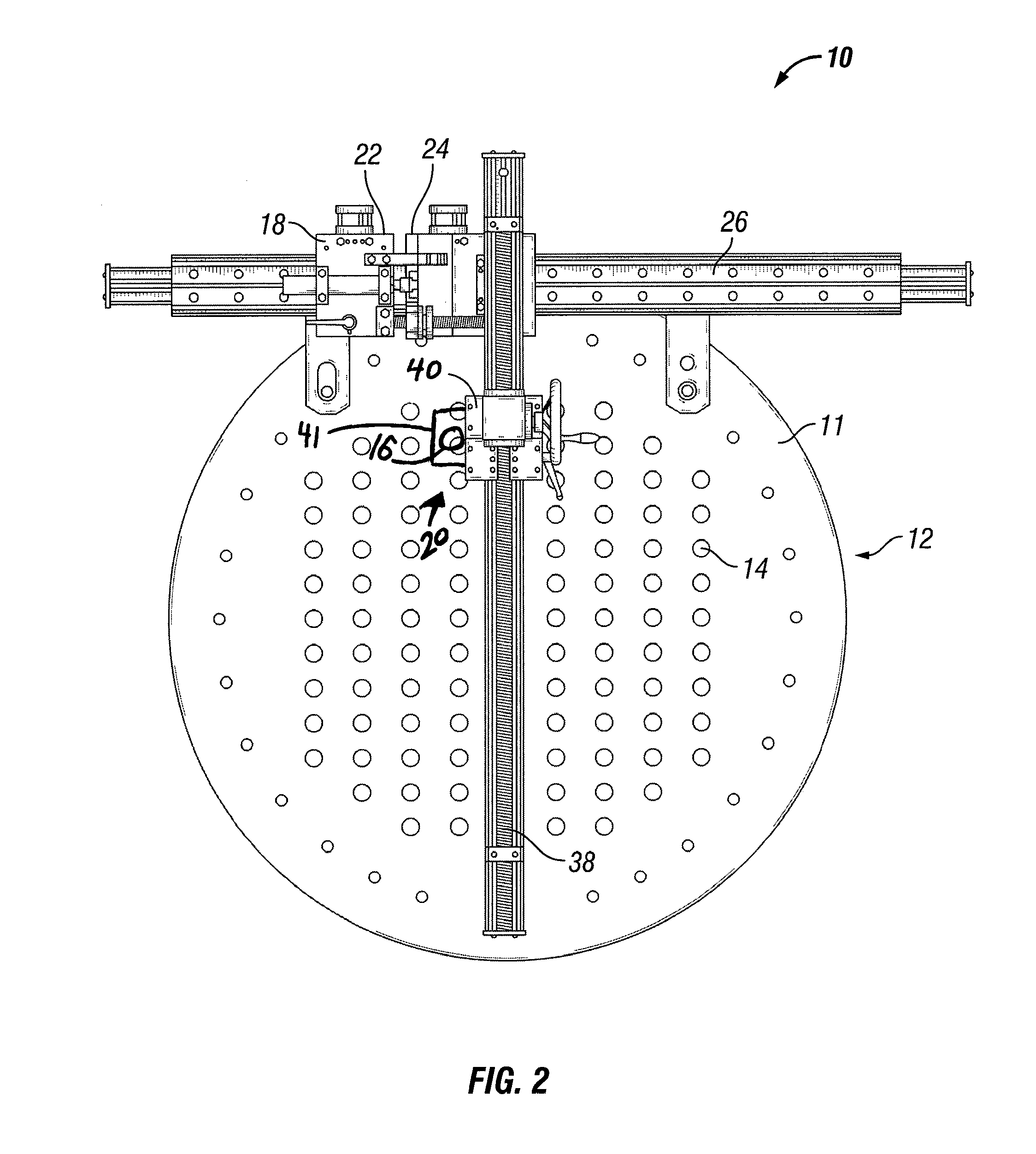

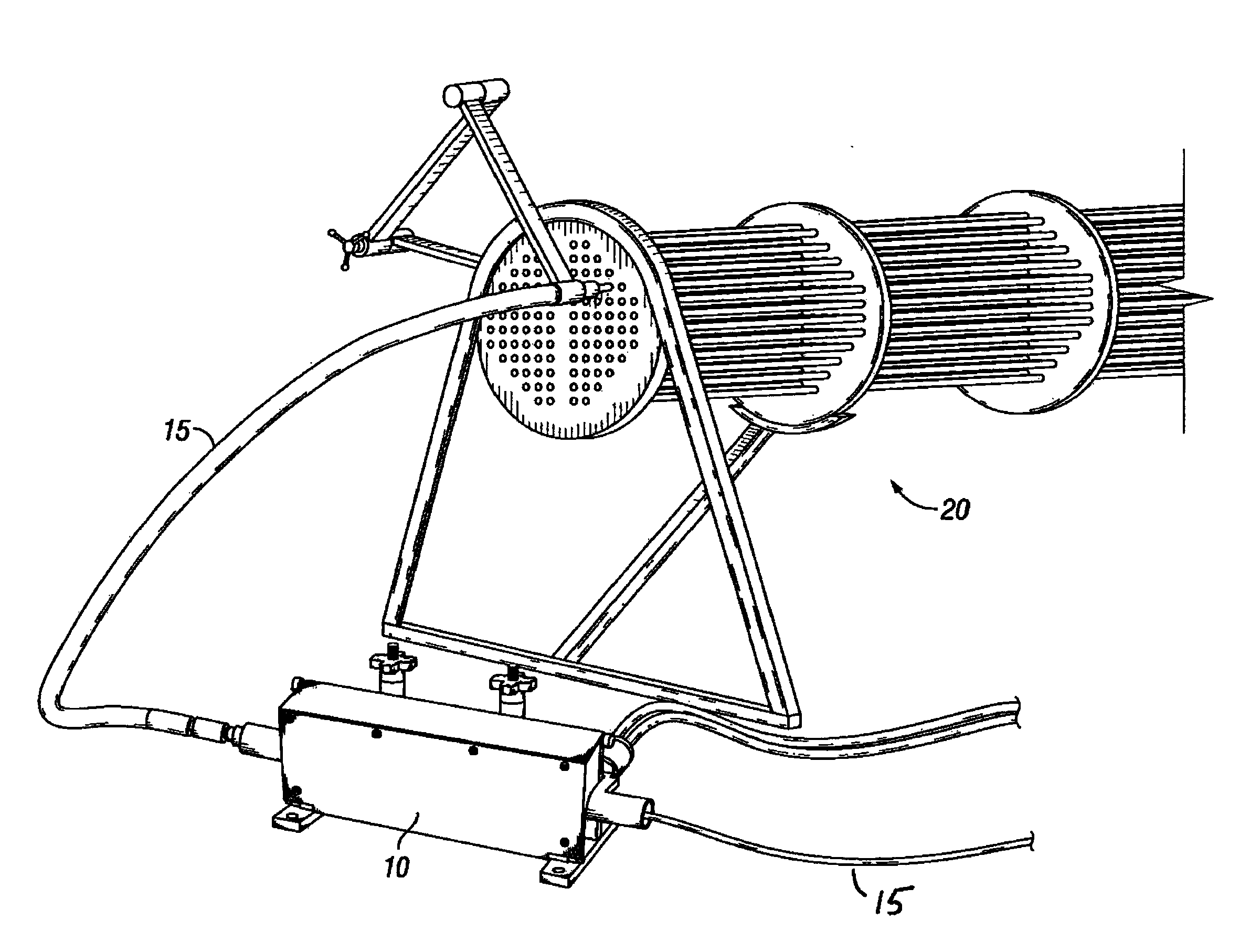

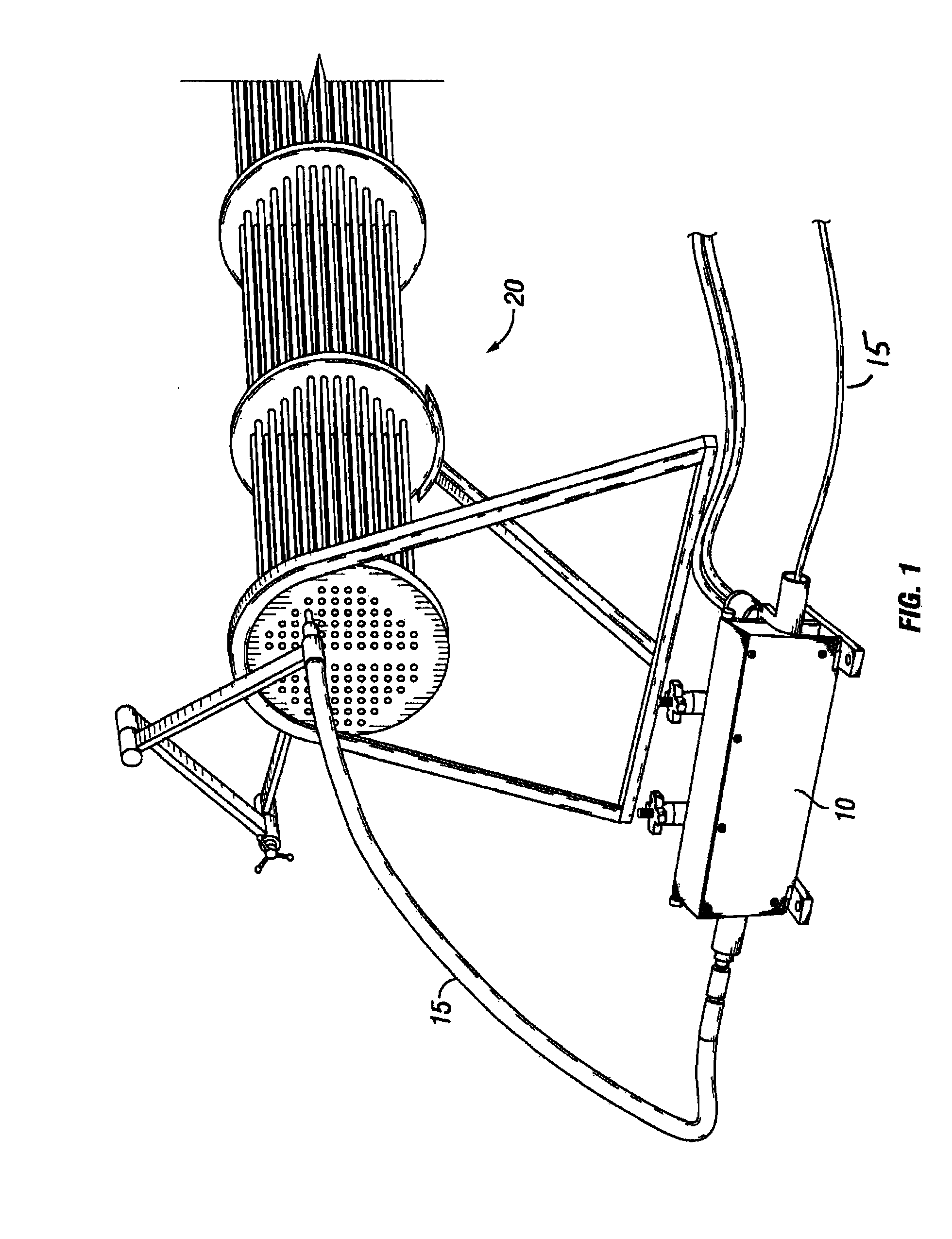

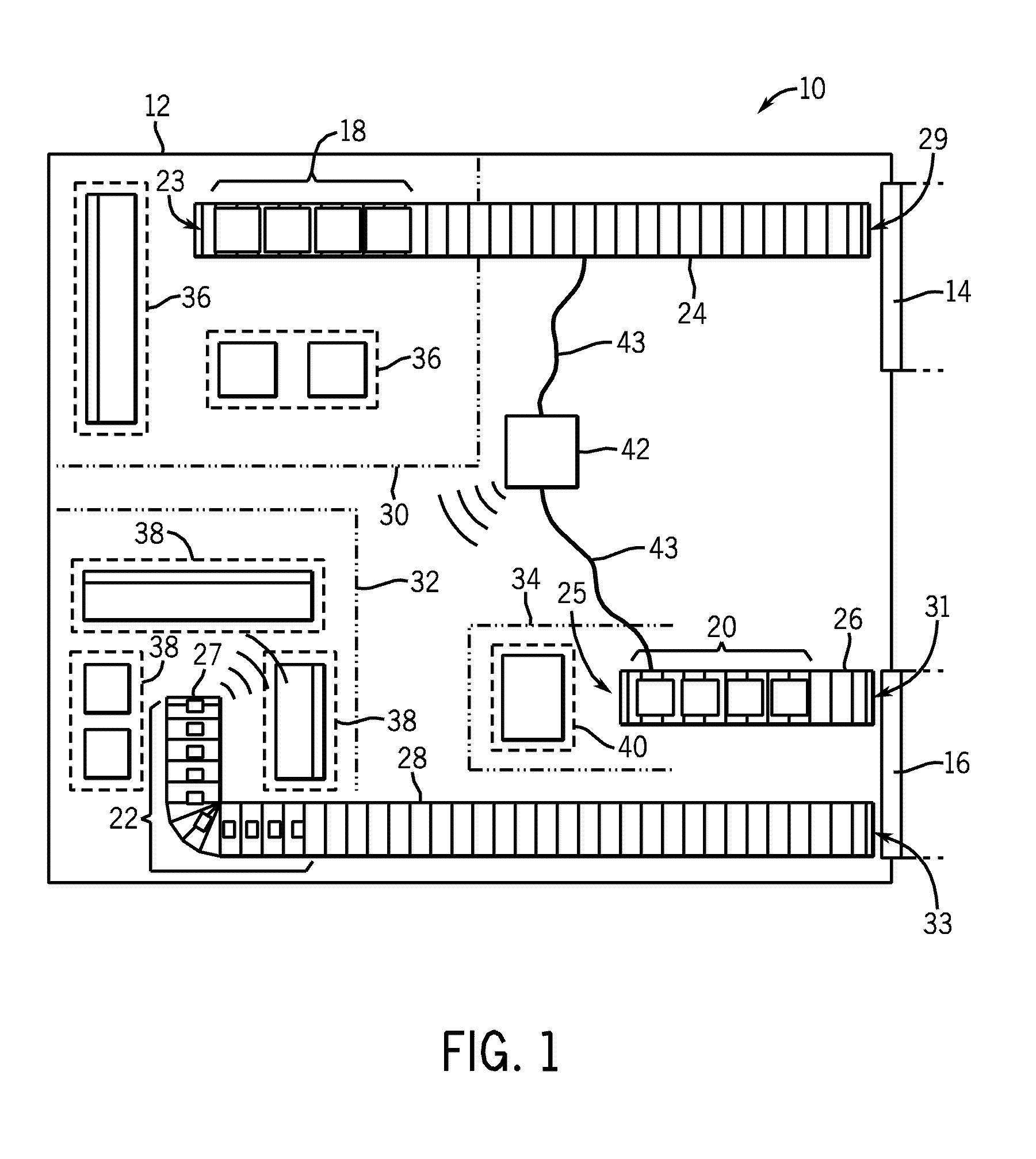

Semi-automated heat exchanger tube cleaning assembly and method

ActiveUS20120067370A1Adjustable distanceHollow article cleaningHair combsPetrochemicalProcess engineering

A heat exchanger tube cleaning assembly and method is provided. The assembly can allow for semi-automated tube cleaning of a heat exchanger or other piping or equipment used in an industrial facility such as, for example, a petrochemical plant or oil refinery.

Owner:HYDROCHEM

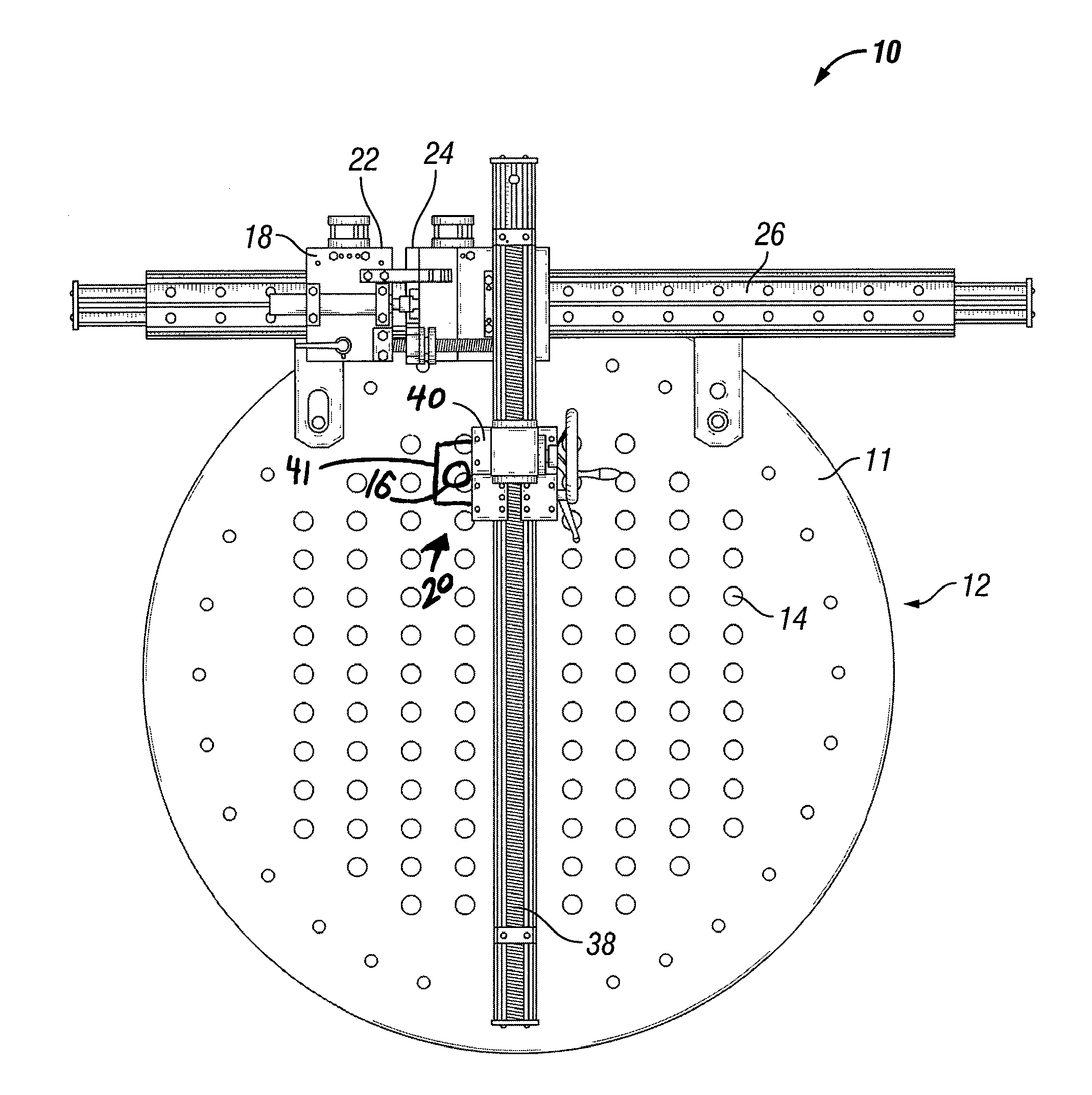

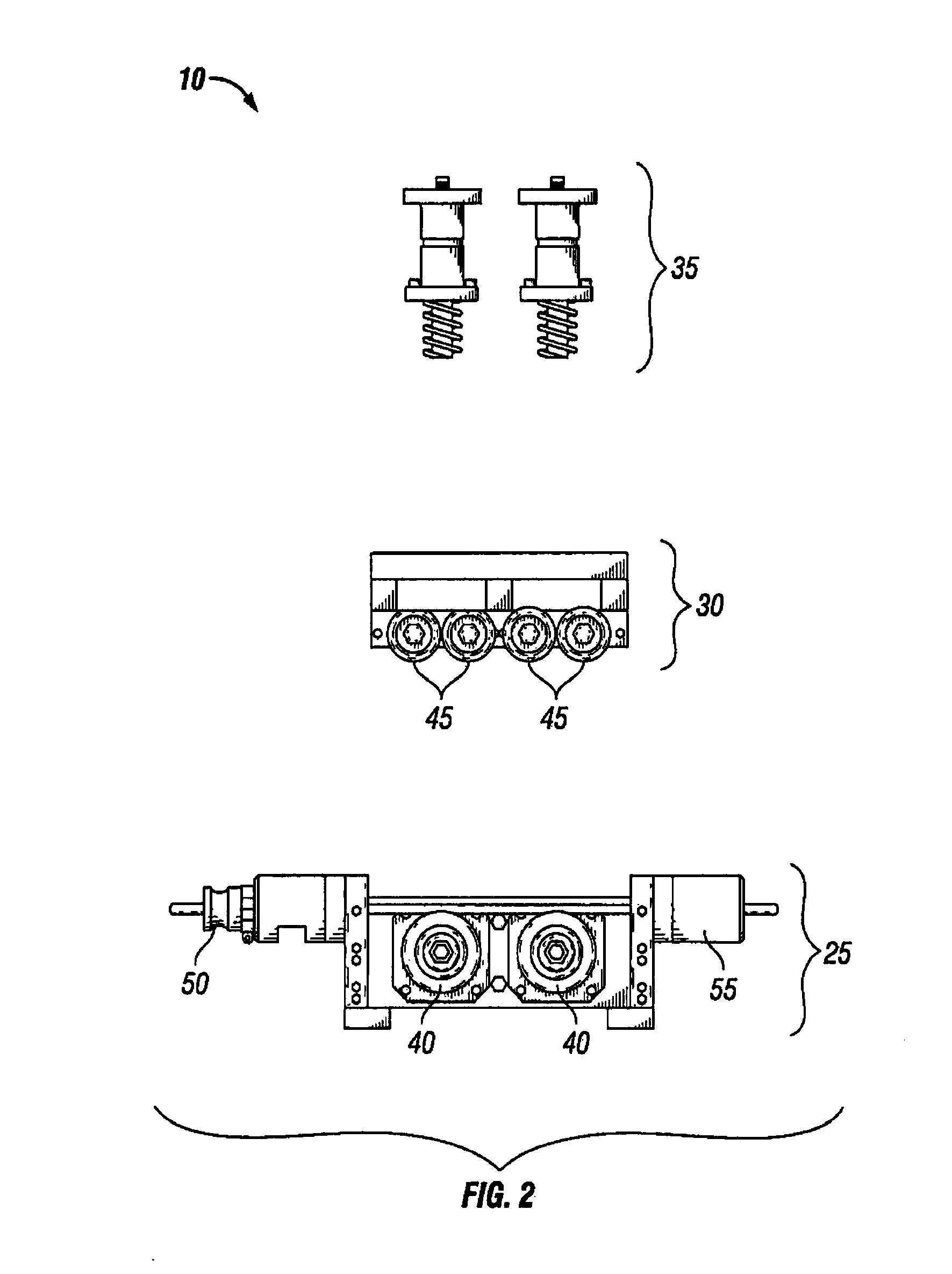

Driving apparatus for one or more cleaning lances

ActiveUS20110155174A1Hollow article cleaningNon-rotary device cleaningIndustrial equipmentEquipment use

A driving apparatus can be utilized to control the cleaning movements of one or more cleaning lances with respect to certain industrial equipment such as a heat exchanger. For example, driving apparatus can be utilized to feed an additional length of cleaning lance to the tubes of exchanger, or to retract cleaning lance from the tubes of exchanger as desired. In general, driving apparatus can be used to clean a variety of types of pipes, tubing and equipment used in industrial facilities.

Owner:HYDROCHEM

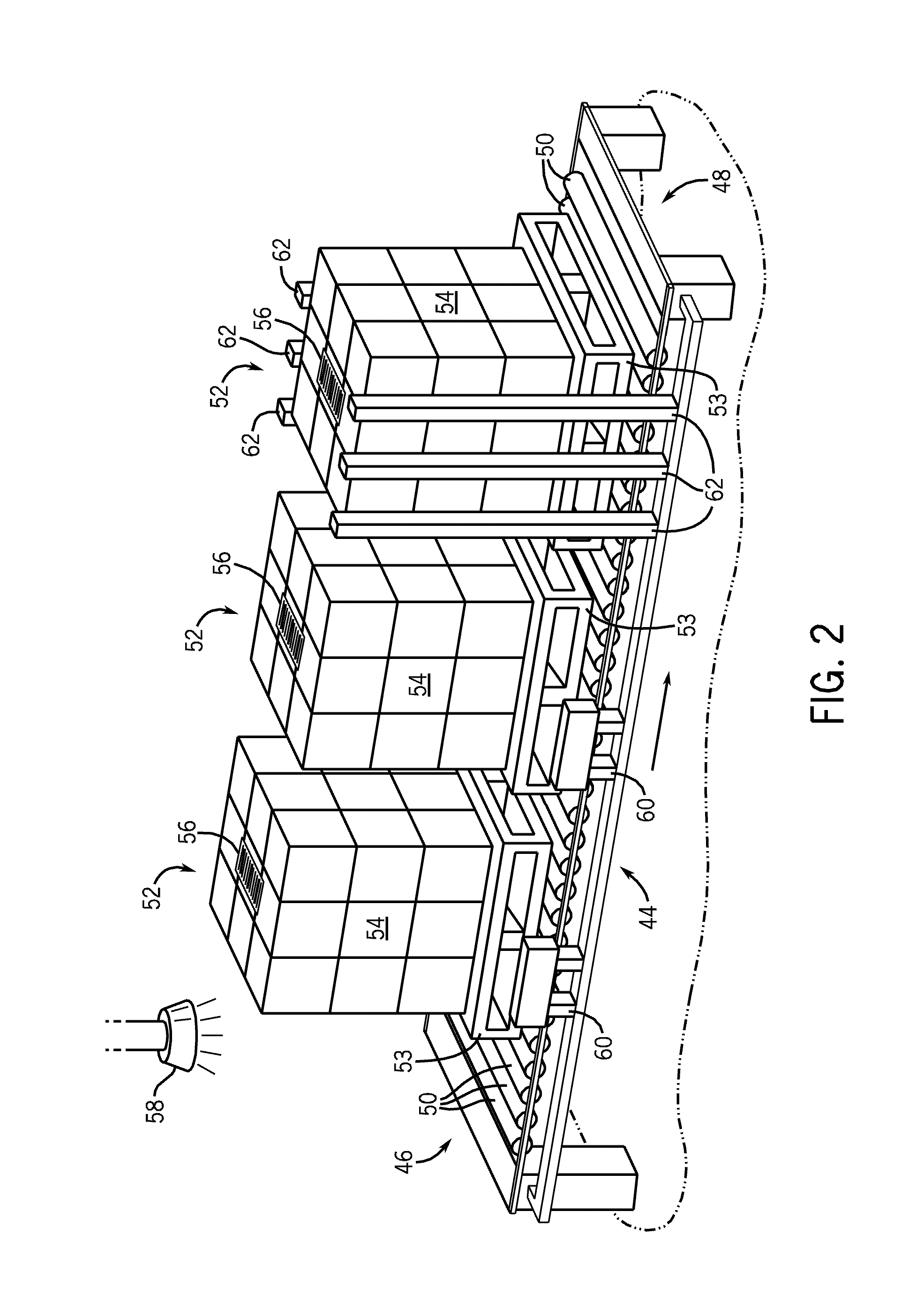

Welding inventory tracking, storing, and distribution system

InactiveUS20080035727A1CommerceSpecial data processing applicationsDistribution systemInventory management

A system and method for tracking, storing, and distributing inventory of welding-type consumables within an industrial facility includes conveyors for moving and storing welding-type consumables on pallets or other shipment units to the proper work zones. Various sensors or detectors are employed at the loading and unloading ends of the conveyors to provide data for determining quantity, type, and / or location information for monitoring inventory or even automated reordering. Therefore, such a system and method provides robust, reliable, and inexpensive inventory management that can be adaptable and compatible with multiple brands, types, and shipment varieties of inventory materials.

Owner:ILLINOIS TOOL WORKS INC

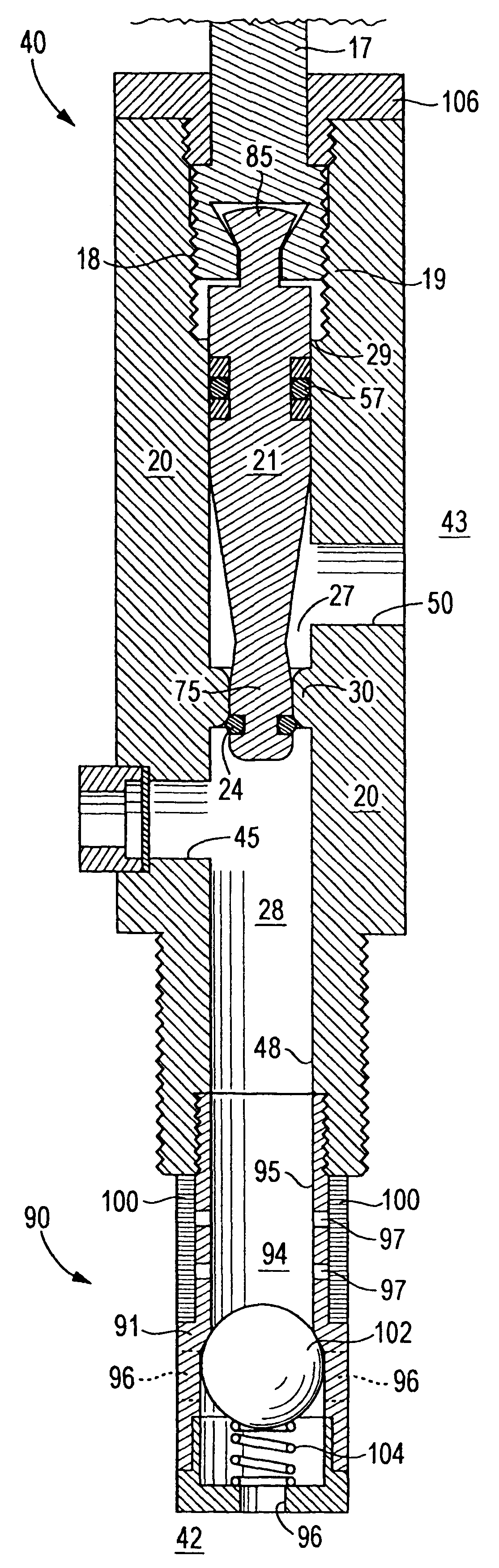

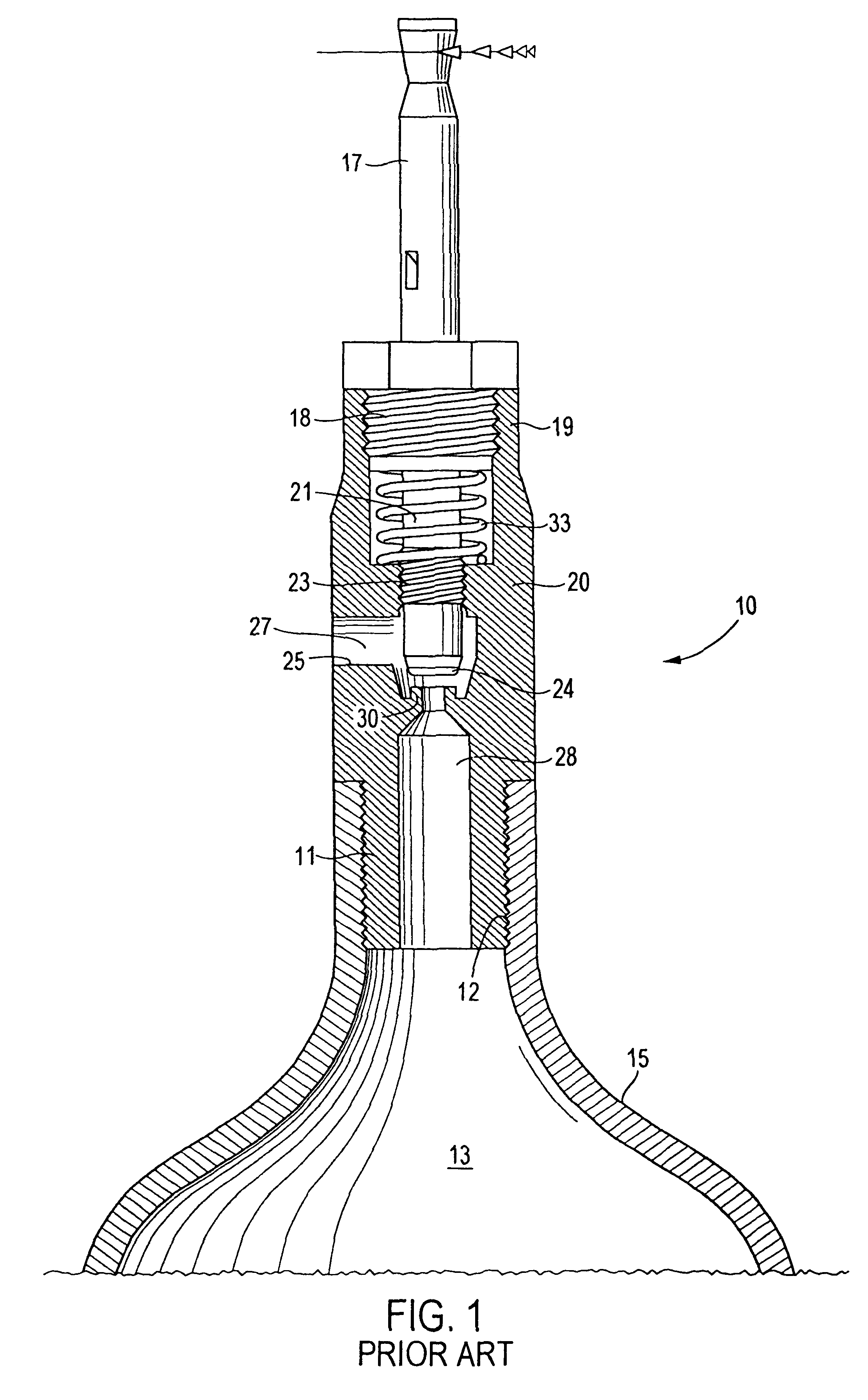

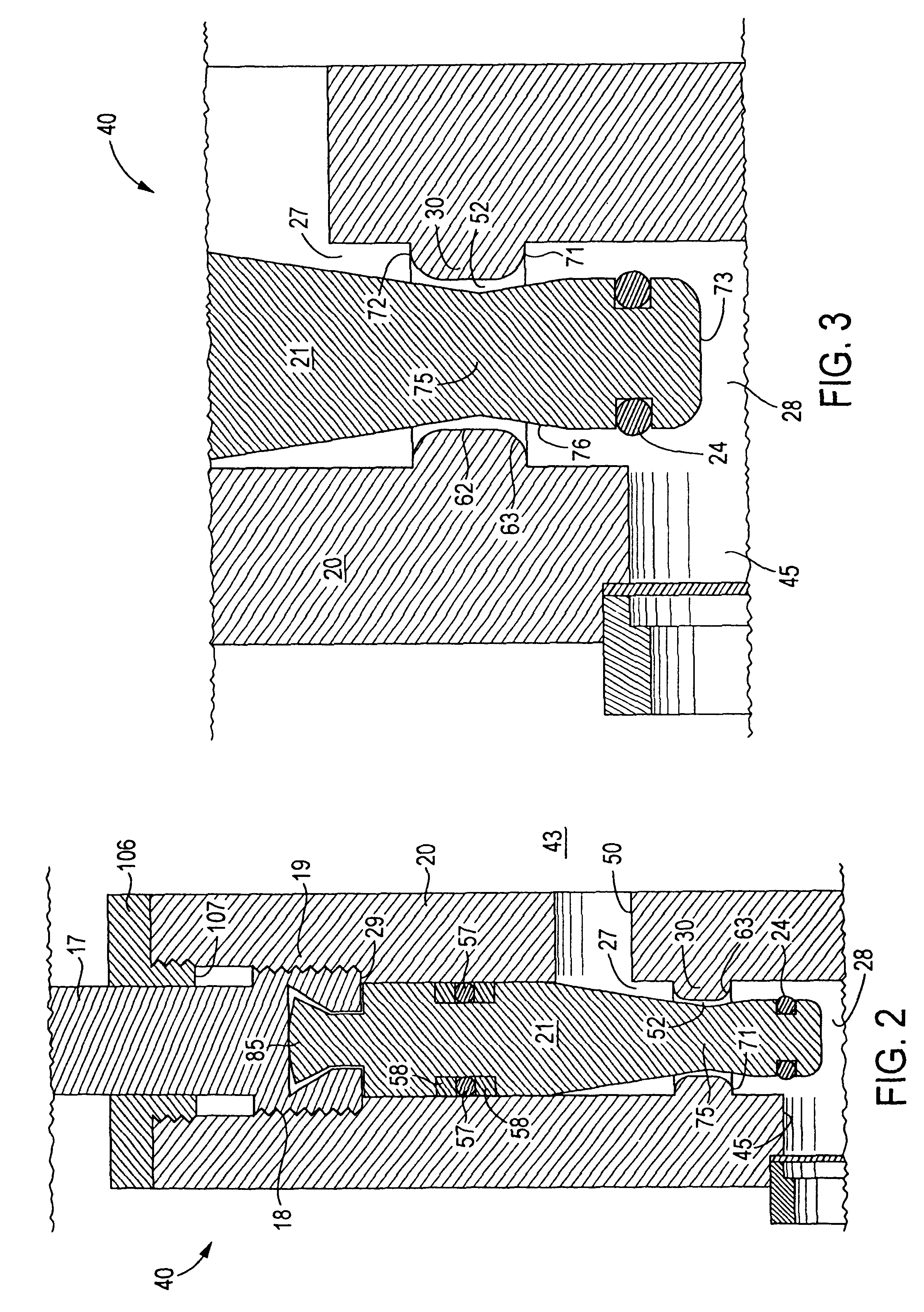

Cylinder valve and bayonet check-filter with excess-flow protection feature

InactiveUS6607007B1Reduce the risk of fireLower potentialFunctional valve typesContainer filling methodsOxygen systemHigh pressure oxygen

A valve apparatus especially well-suited for use in gaseous oxygen delivery systems. A valve apparatus is provided that substantially reduces the risk of fire in high-pressure oxygen systems. The apparatus is particularly well-suited for use as a plug valve on ordinary cylinder containers, but may be beneficially used in any pressurized gas system, particularly oxygen systems such as those encountered in many industrial facilities. The wetted portion of the valve is isolated from threaded portions to prevent particulate contamination of the gas stream. The valve seat is located to protect it from direct impact of high-velocity gas streams. The inventive valve, and its associated inventive check-filter and excess-flow prevention features, reduces the potential for hazardous combustion at valve points within oxygen delivery systems.

Owner:LUXFER INC

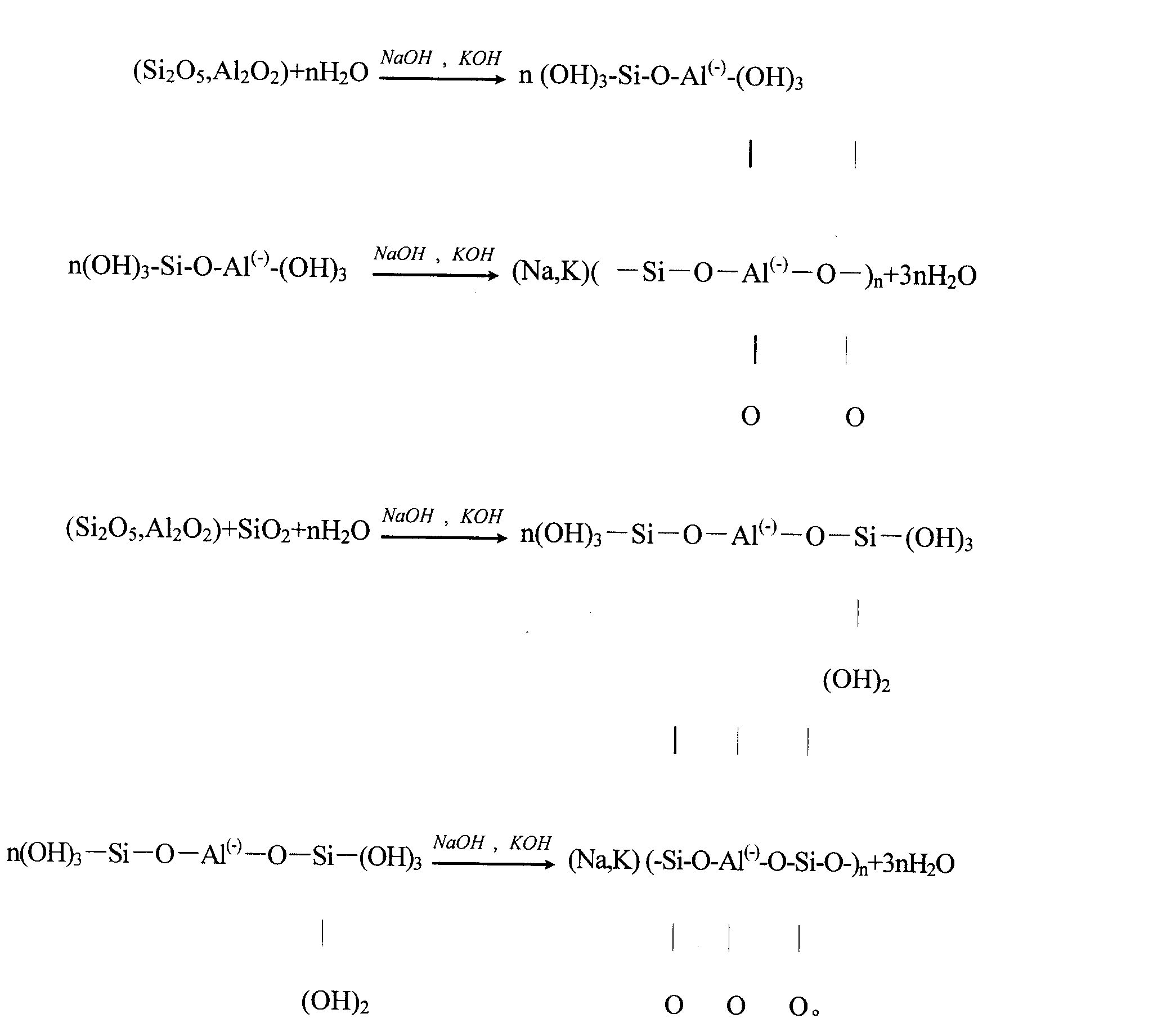

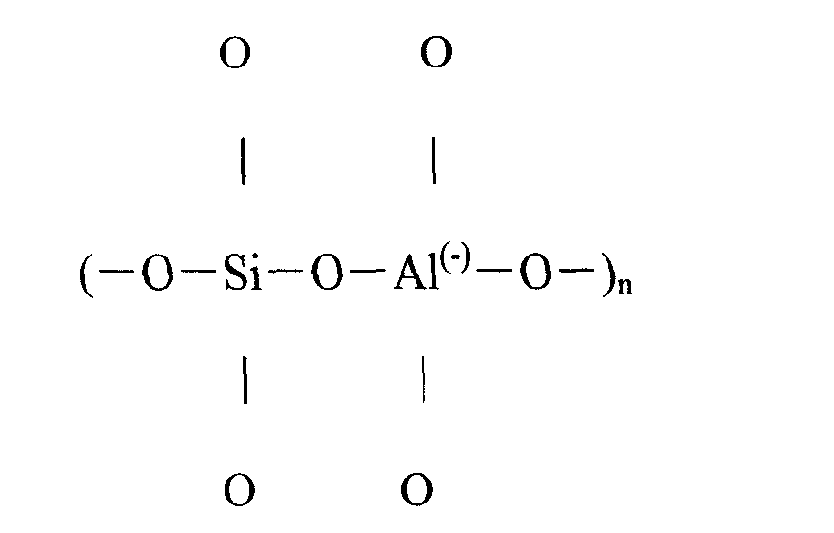

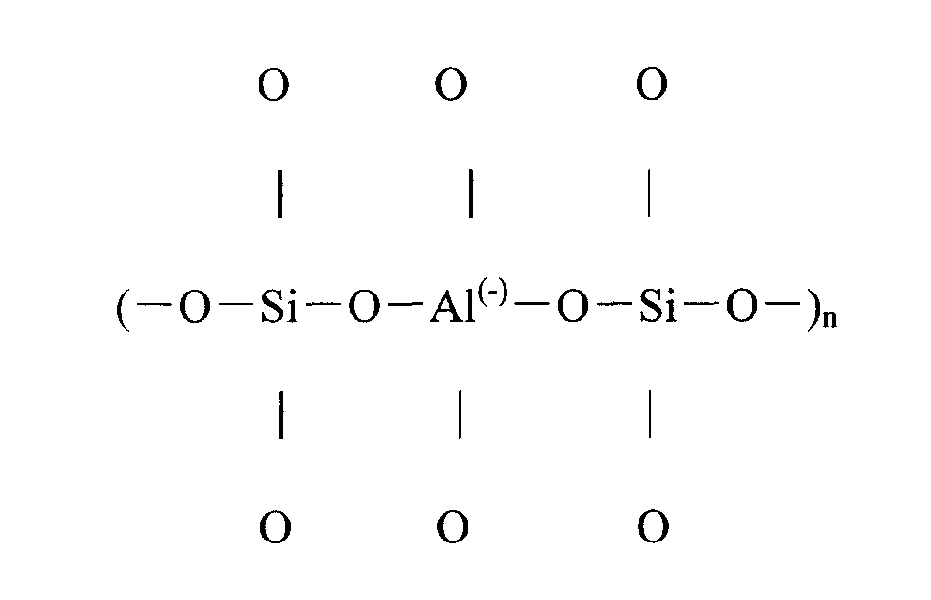

Polymeric aluminium-silica fireproof heat insulation material and preparation method thereof

The invention discloses an insulating refractory material of polymerized silicon and aluminum and the preparation method, applied in construction and industrial facilities, which is characterized in that: excitation, gas evolution and polymerization are carried out for industrial wastes abundant in aluminum oxide, silicon dioxide, and the complex of the silicon dioxide and aluminum oxide, so as to obtain a three-dimensional aluminum silicate minerals with an internal structure made of a plurality of phases from amorphous to semi-crystalline inside, and an internal form in silica tetrahedron and alumina tetrahedron; a plurality of molecules are linked mainly through ionic or covalent bonds, the mechanical properties of the inorganic concretion are externally presented. The raw materials are composed of silicon and aluminum materials as kaolin, fly ashes, coal gangue, cinder, and red mud; without adding any gelled materials, a high temperature and corrosion resistant porous long-chain structure is formed with an intensity over 0.8MPa and a thermal conductivity coefficient of 0.087 (kilocalorie / meter x hour x centigrade). The insulating refractory material is applied not only for the heat insulation wallboards in the building but also for the heat insulation and preservation of the industrial thermal pipelines and facilities.

Owner:中国安华(集团)总公司

Niobium and vanadium-containing economical high-strength and high-weather-resistance hot rolled H-shaped steel and rolling method thereof

InactiveCN101736207AGood weather resistanceGood welding performanceTemperature control deviceMetal rolling arrangementsReduction rateWeather resistance

The invention discloses a niobium and vanadium-containing economical high-strength and high-weather-resistance hot rolled H-shaped steel, which is characterized by comprising the following chemical compositions in percentage by weight: 0.07 to 0.12 percent of C, 0.30 to 0.55 percent of Si, 1.30 to 1.55 percent of Mn, 0.020 to 0.045 percent of P, 0.001 to 0.010 percent of S, 0.25 to 0.35 percent of Cu, 0.20 to 0.30 percent of Cr, 0.15 to 0.30 percent of Ni, 0.04 to 0.08 percent of V, 0.02 to 0.05 percent of Nb, 0.006 to 0.030 percent of Als and the balance of Fe and residual trace impurities. The invention also discloses a rolling method for the H-shaped steel, wherein the soaking temperature of a casting blank is 1,195 to 1,225 DEG C; the start rolling temperature of a breaking down mill is 1,100 to 1,150 DEG C; the finish rolling temperature of the breaking down mill is 980 to 1,030 DEG C; the start rolling temperature of a universal roughing mill is 900 to 950 DEG C; the finish rolling temperature of the universal roughing mill is 800 to 870 DEG C; and a control total rolling reduction rate of a universal rolling area is more than or equal to 50 percent. By the method, the hot rolled H-shaped steel with high strength, high toughness, high weather resistance and good welding performance can be prepared. At the same time, because the steel has simple metallurgic components, relatively low alloying production cost, economy and practicability, the hot rolled H-shaped steel is the ideal hot rolled H-shaped steel used for manufacturing railway vehicles, freight semi-trailers and other industrial facilities needing the high-strength and high-weather-resistance steel.

Owner:MAANSHAN IRON & STEEL CO LTD

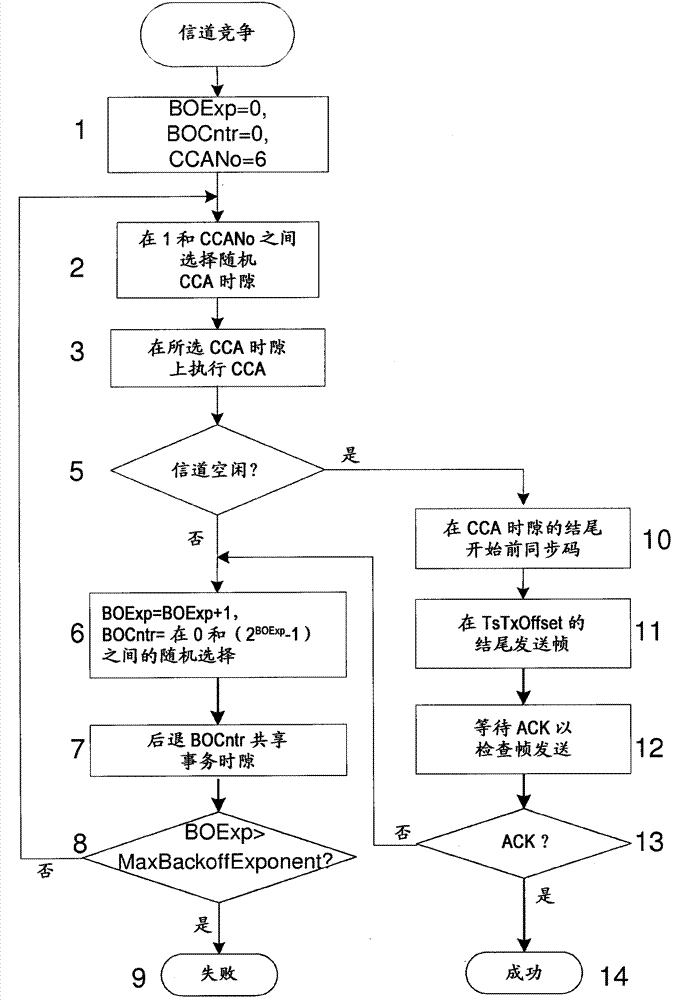

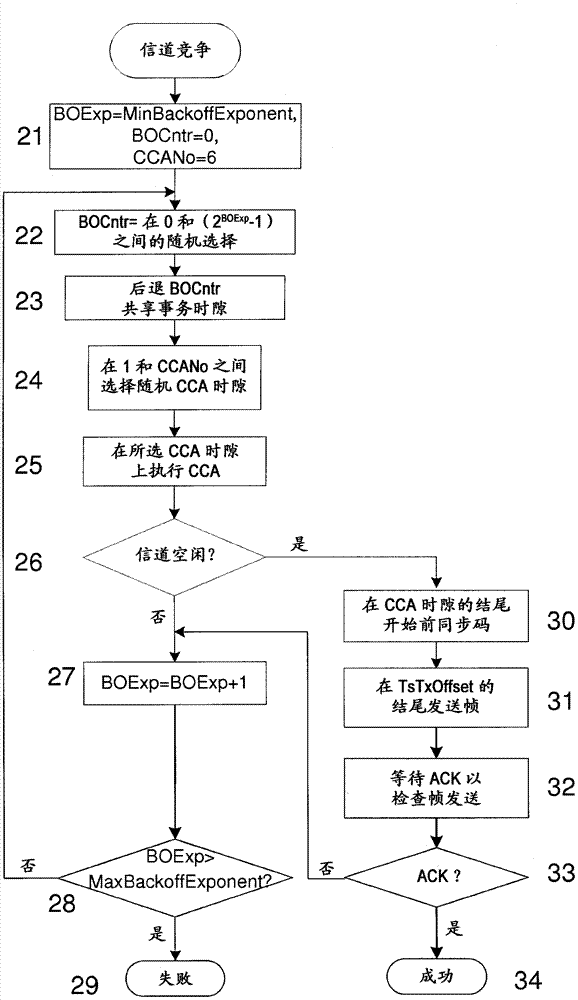

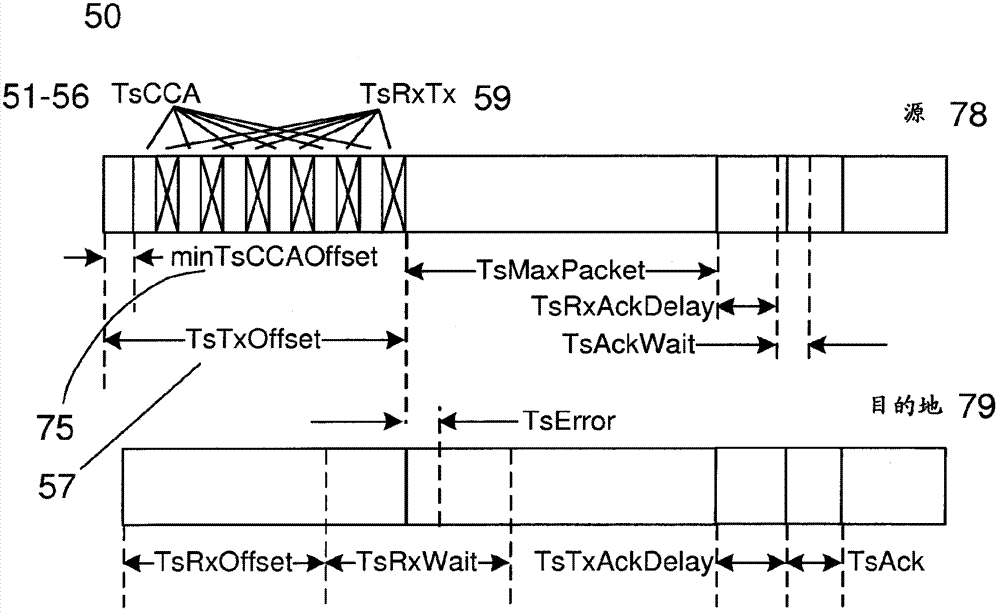

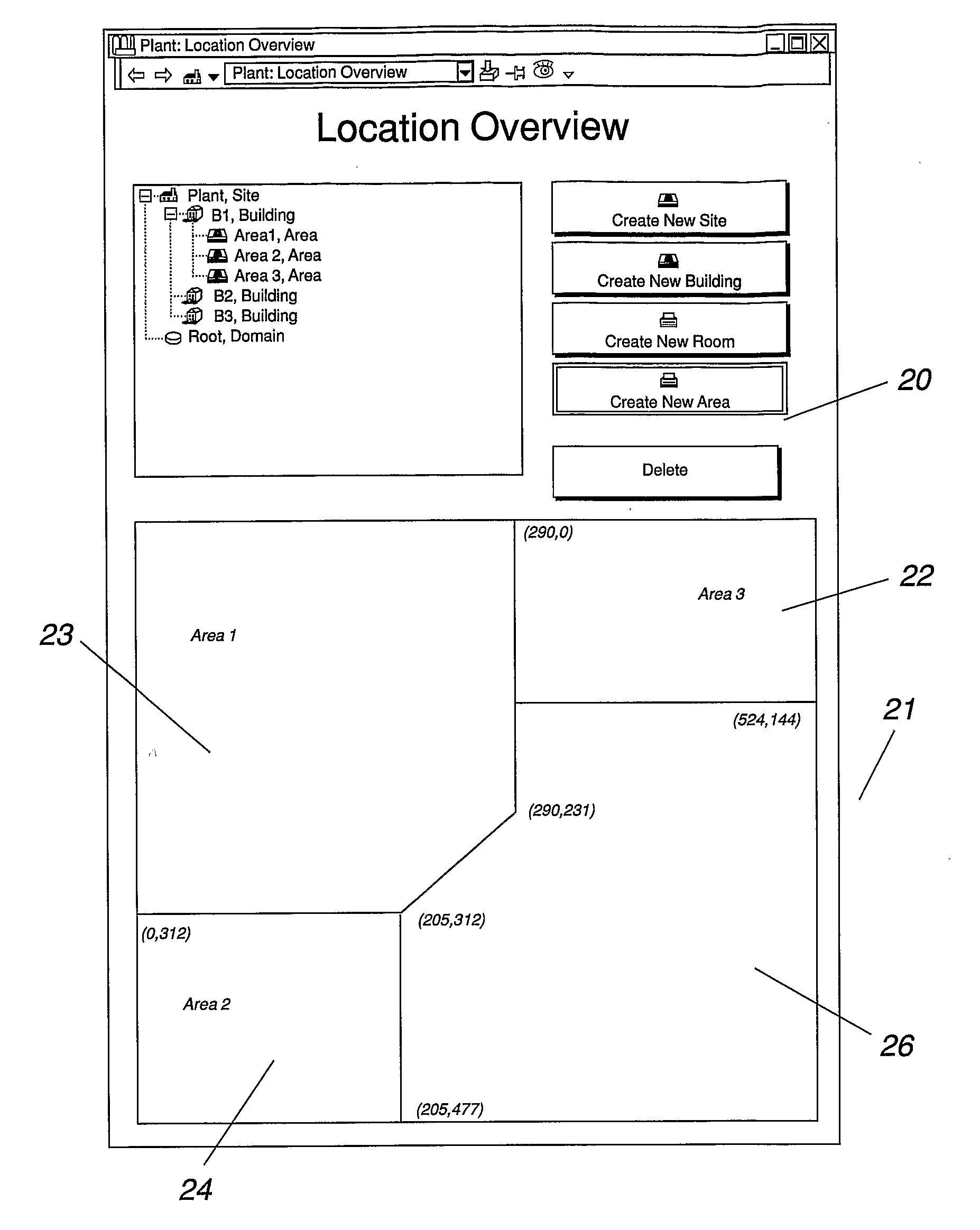

Wireless communication method and system with collision avoidance protocol

ActiveCN103026774AImprove performanceImprove throughputNetwork topologiesTime-division multiplexTime division multiple accessHybrid protocol

The invention concerns a method for providing wireless communication between a source node and a destination node in a wireless network wherein said wireless network uses a time division multiple access (TDMA) protocol. One or more dedicated TDMA transaction timeslots (60-71) are arranged in a superframe. The superframe comprises at least one dedicated transaction slot forming a hybrid protocol with two or more shared transaction slots 50 per superframe. The method is of particular advantage when practised with a WirelessHART protocol wireless sensor network and when used for monitoring and control equipment and processes in an industrial installation. A computer program, and a wireless node and a wireless network using the inventive method are also disclosed.

Owner:ABB (SCHWEIZ) AG

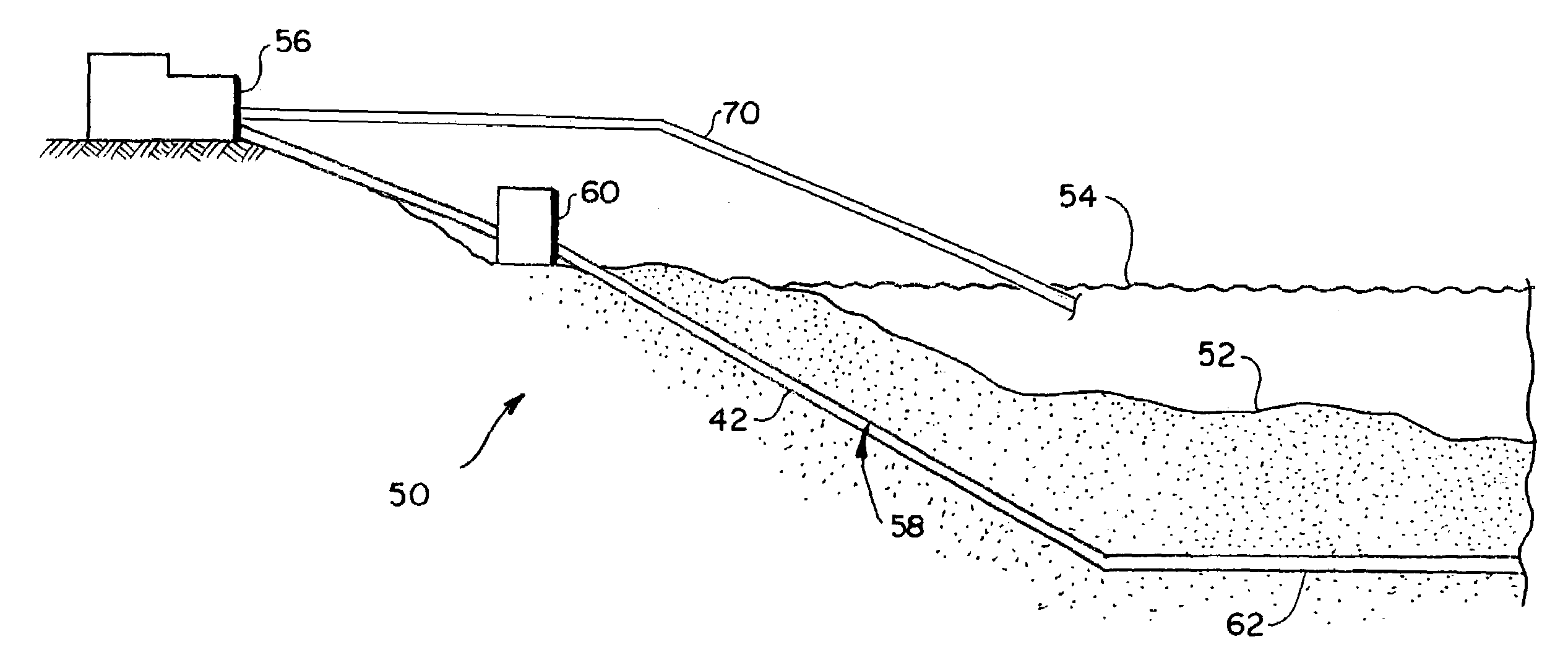

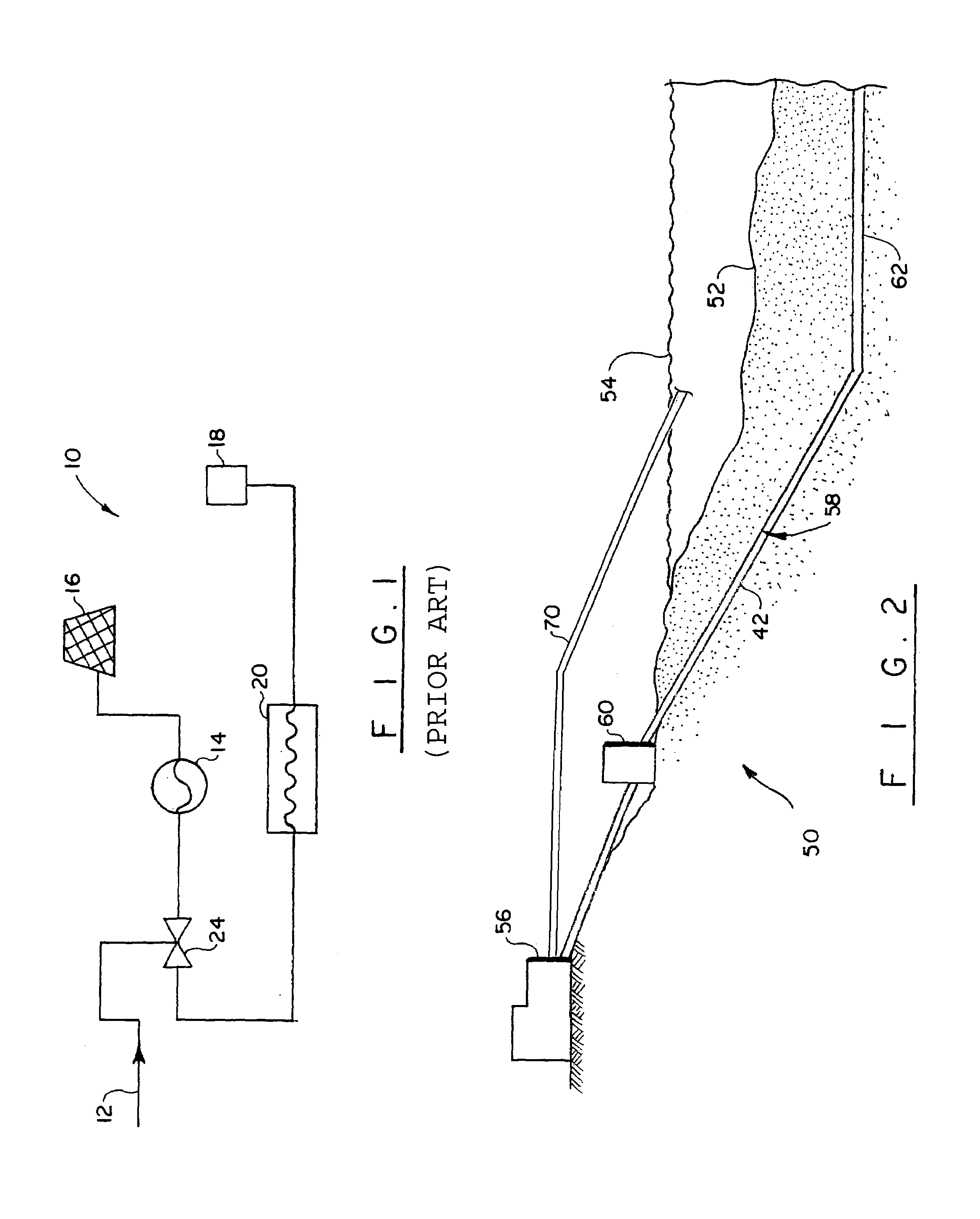

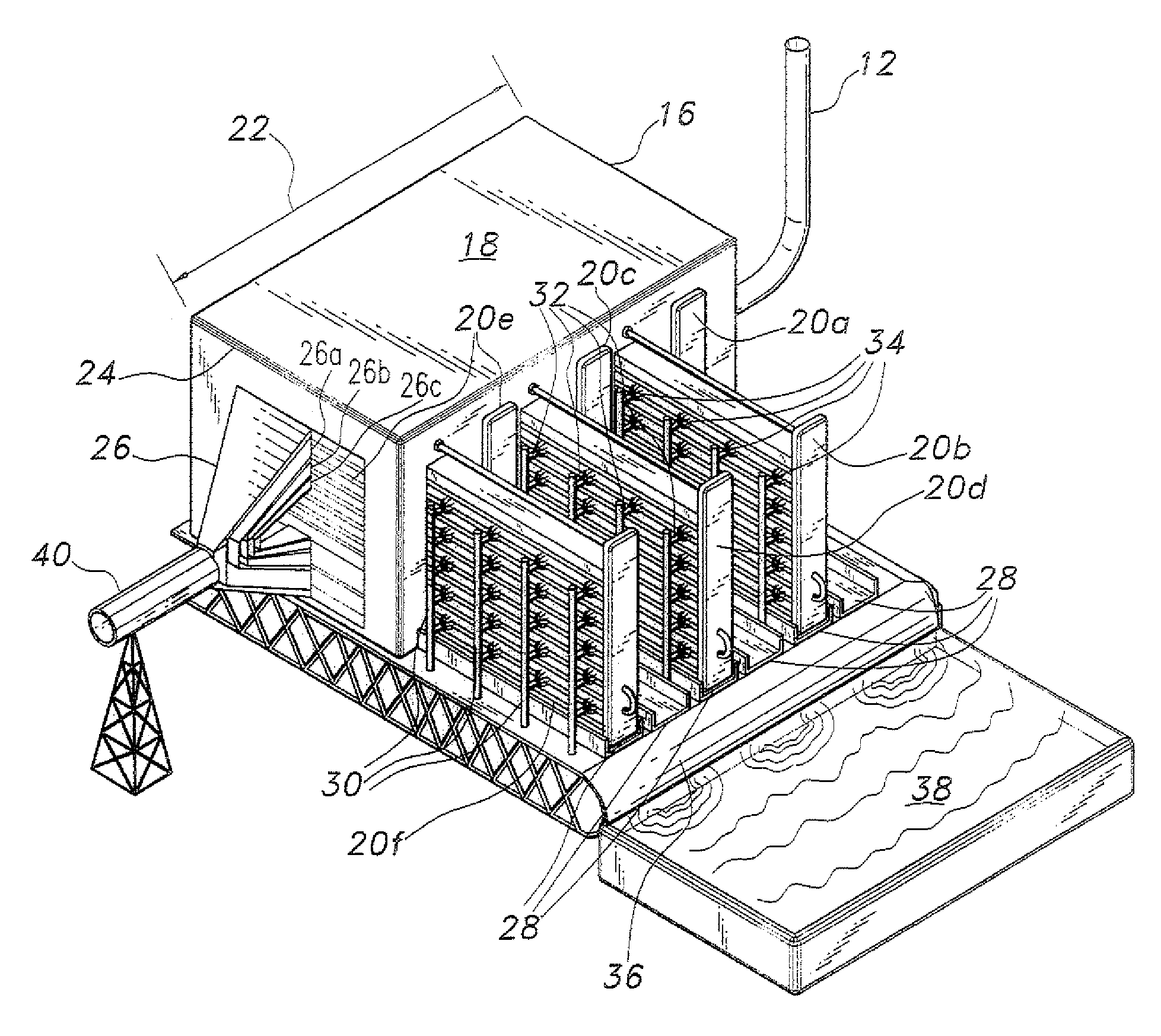

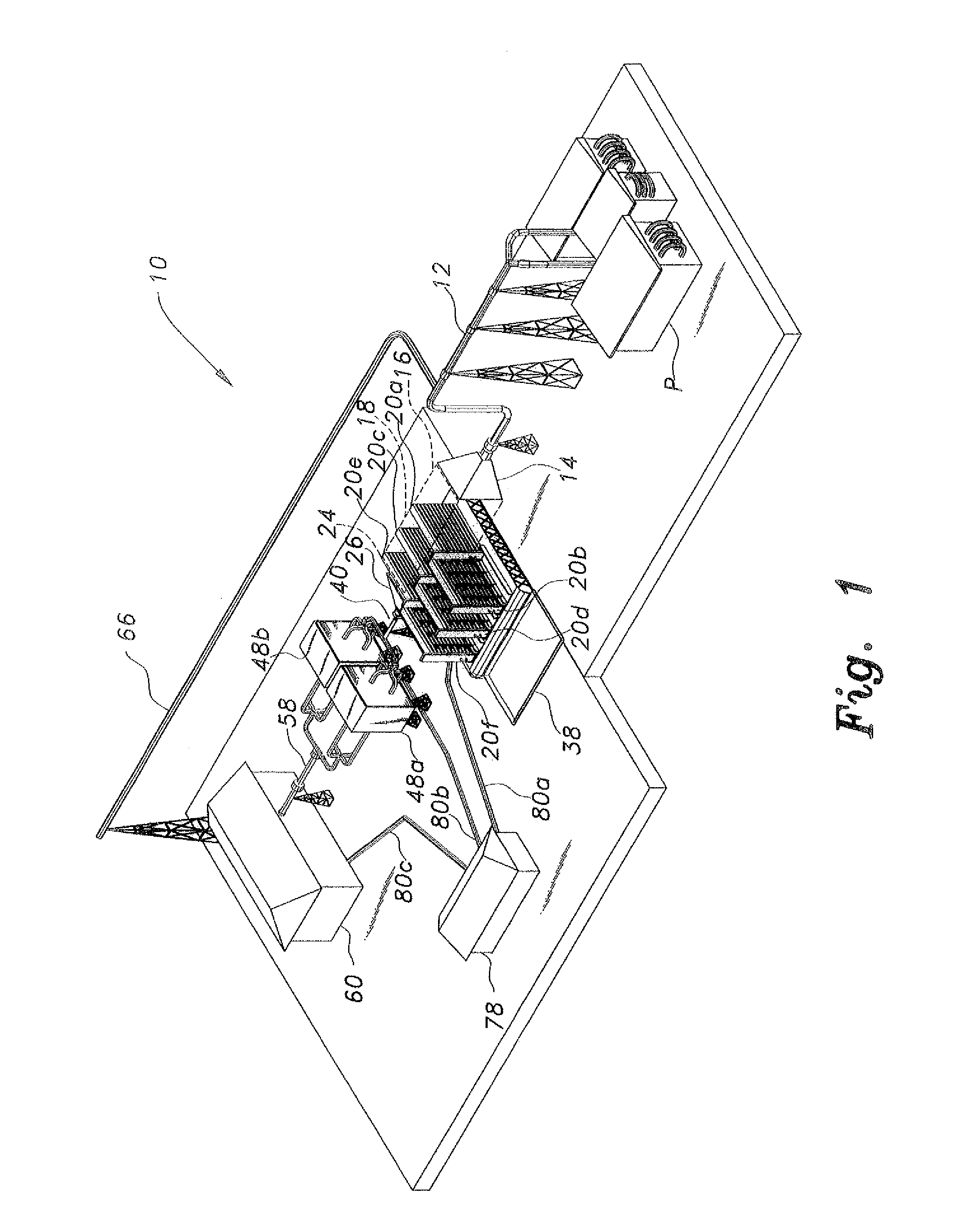

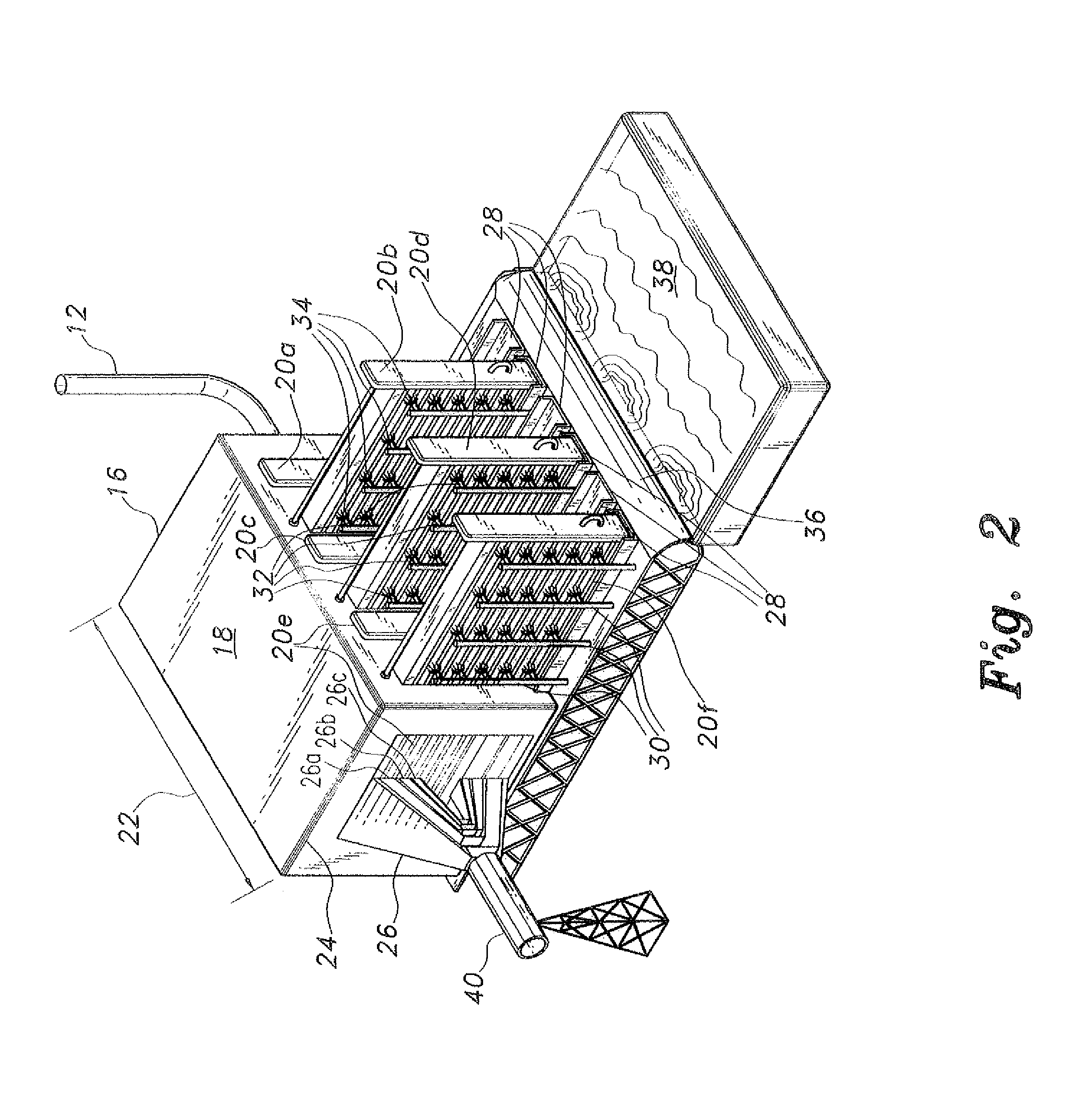

Cooling water intake system

InactiveUS7118307B2Reduce or eliminate any planktonic organismsWater cleaningDomestic cooling apparatusPower stationEngineering

A cooling water intake system is configured to minimize entrainment, impingement and thermal plumes associated with the operation of onshore industrial facilities, such as a power plant, and includes a delivery system guiding ground waters from under the sand bottom of the water reservoir including oceans, seas, lakes and rivers to the industrial facilities.

Owner:SUBSTRATUM INTAKE SYST

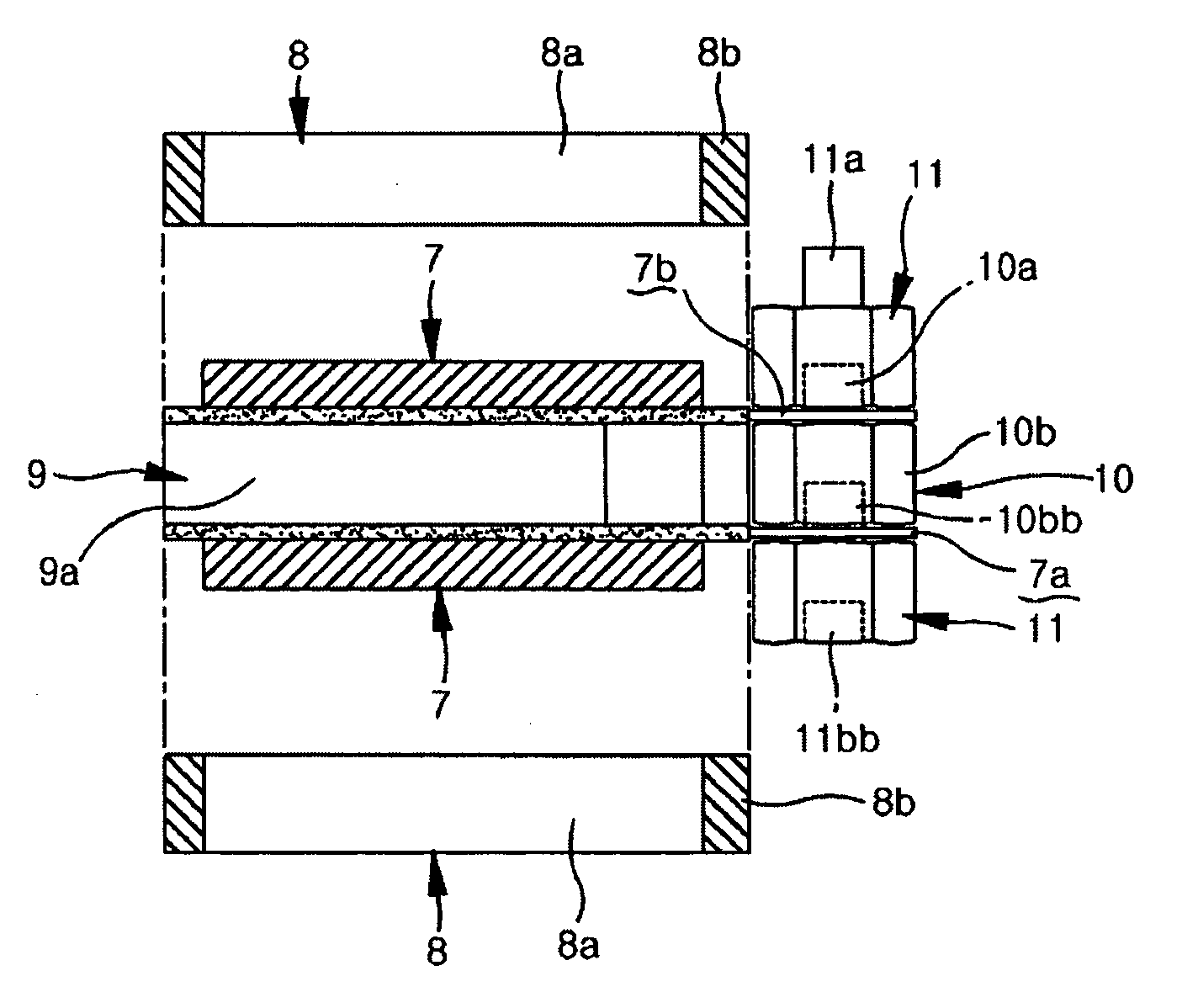

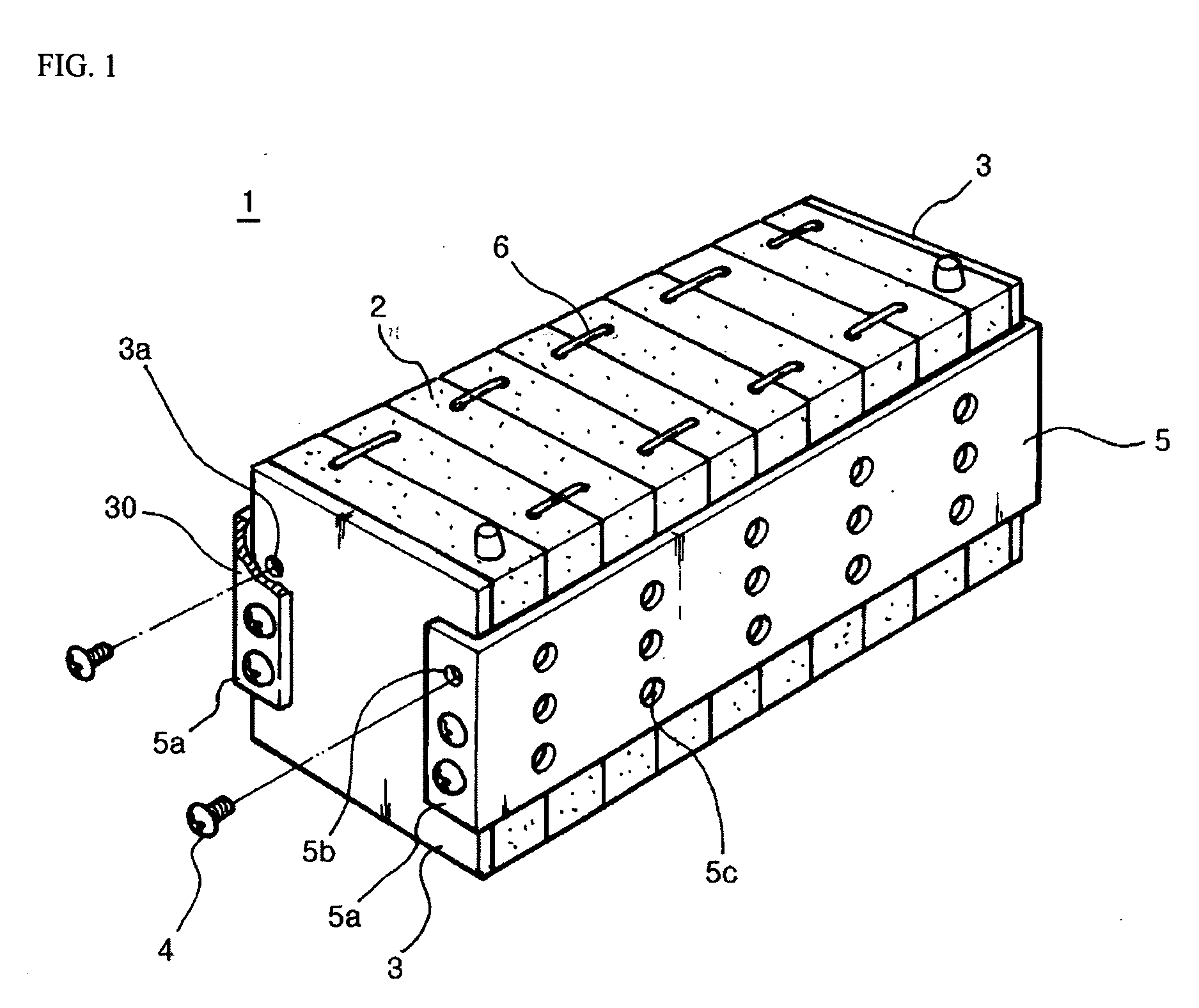

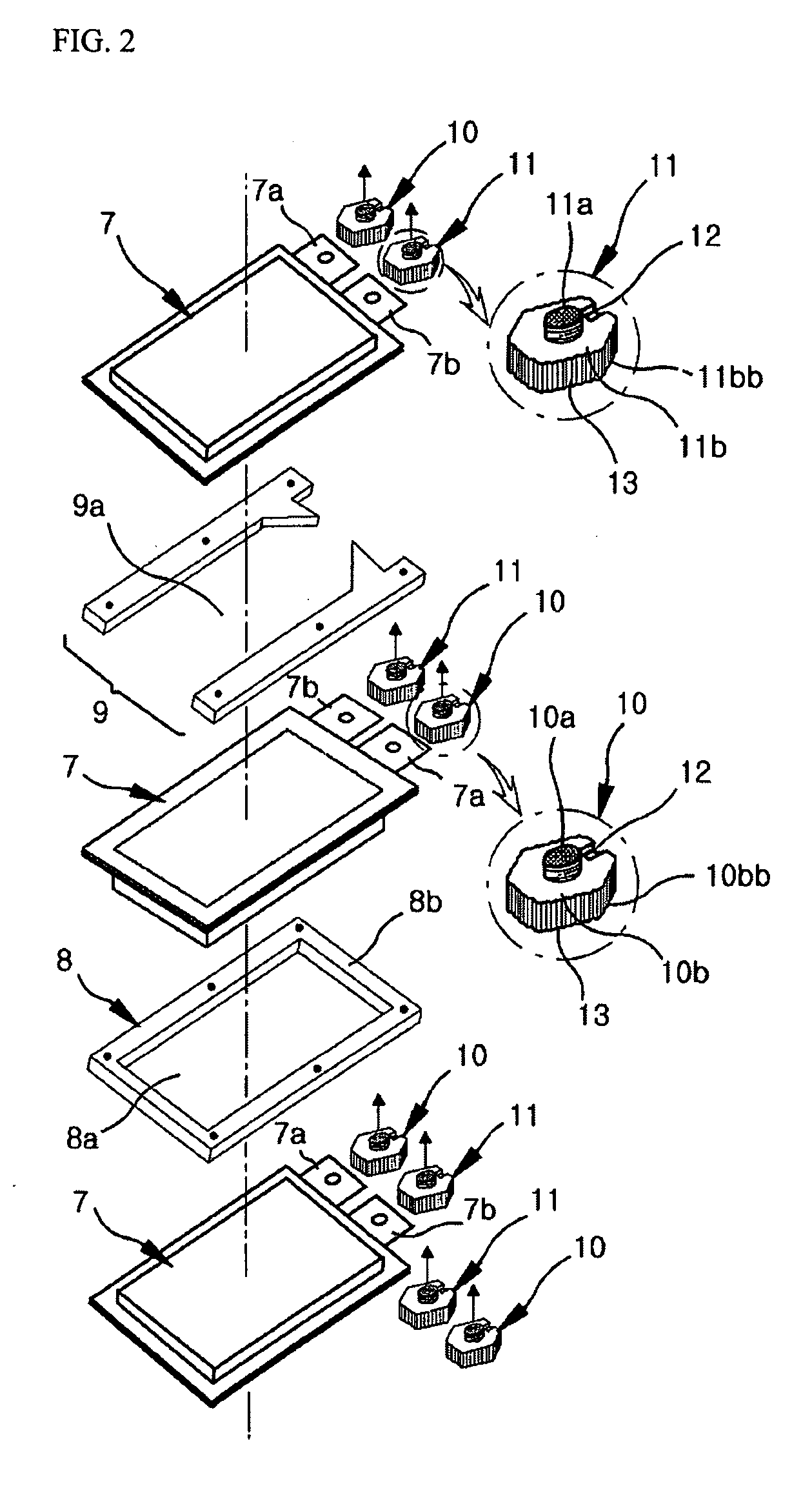

Secondary battery module

ActiveUS20060083980A1Conveniently and rapidly manufacturedFixed state stablePrimary cell to battery groupingCurrent conducting connectionsEngineeringElectric vehicle

A secondary battery module comprises at least two battery cells laminated to a designated depth, in which an air guide block is interposed between leveled surfaces of the neighboring battery cells and a fixing block is interposed between protruded surfaces of the neighboring battery cells, the air guide blocks and the fixing blocks are fixed to each other using fasteners, and corresponding electrode terminals of the neighboring battery cells are interconnected in series by conductive and insulating connection members serving as bolts and nuts, thereby being conveniently installed in various industrial facilities and electric vehicles.

Owner:LG ENERGY SOLUTION LTD

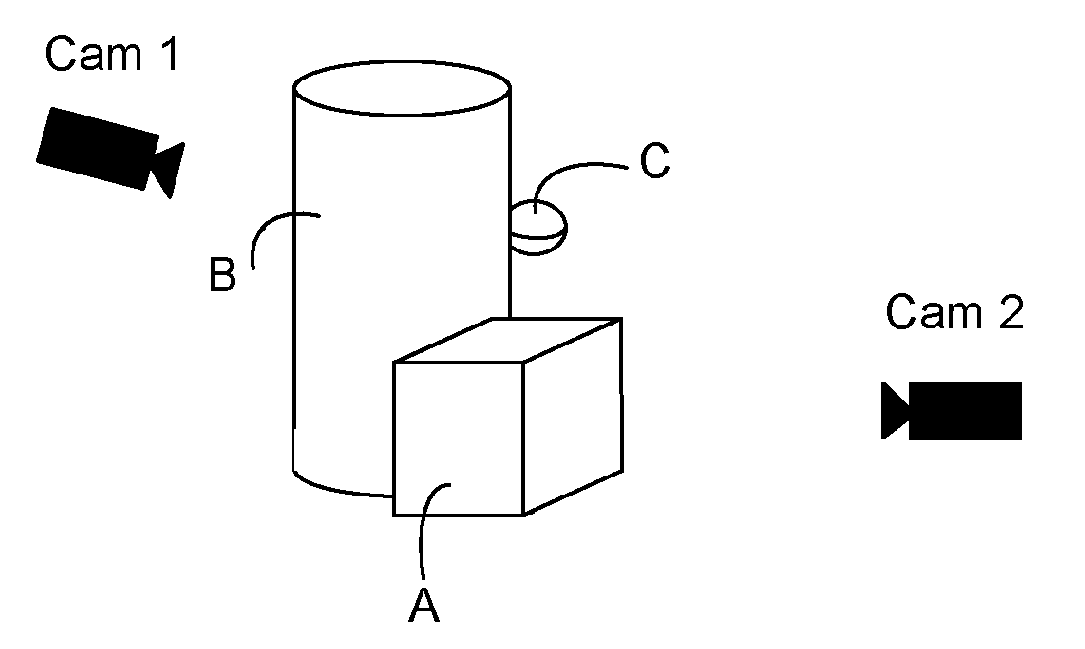

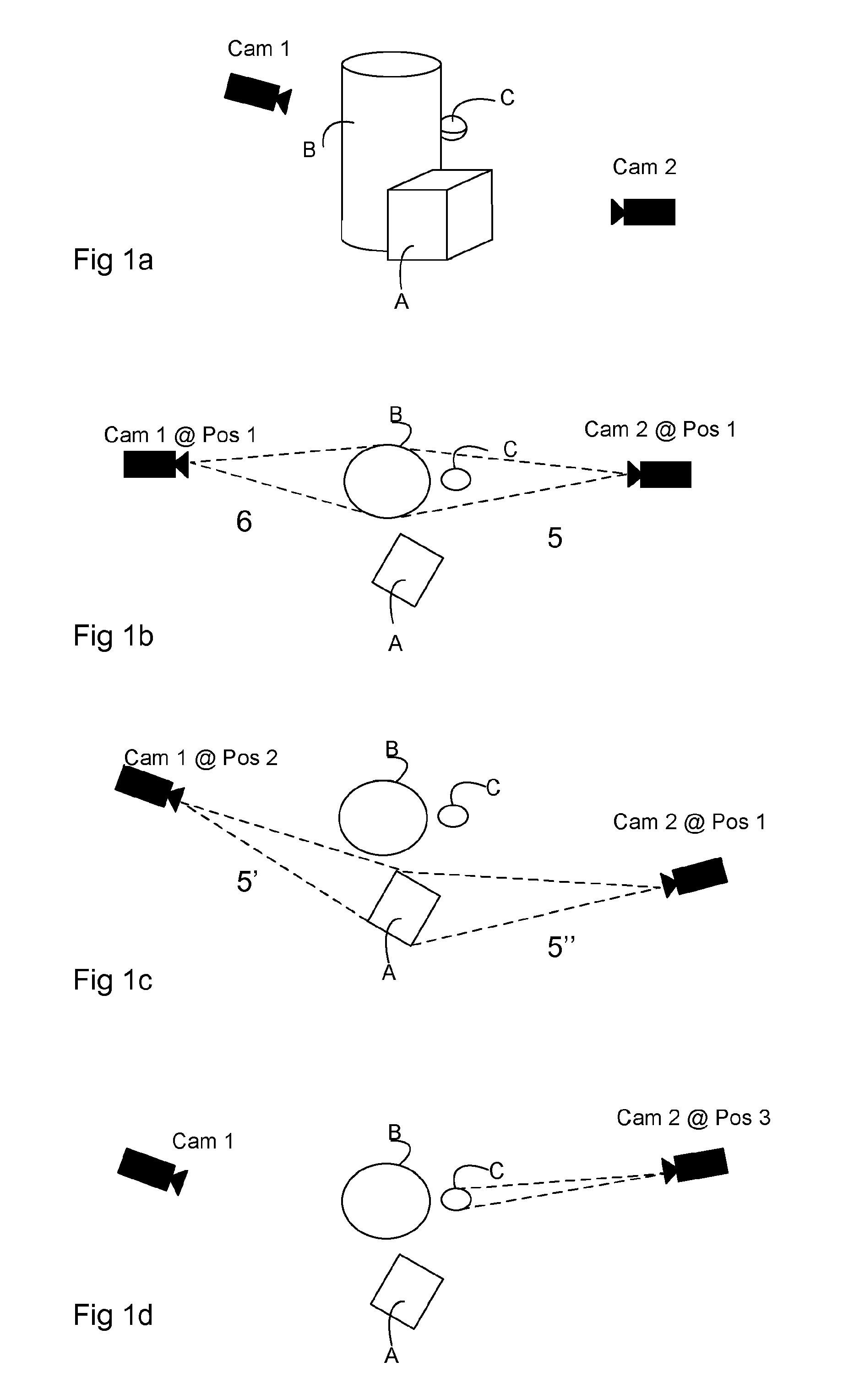

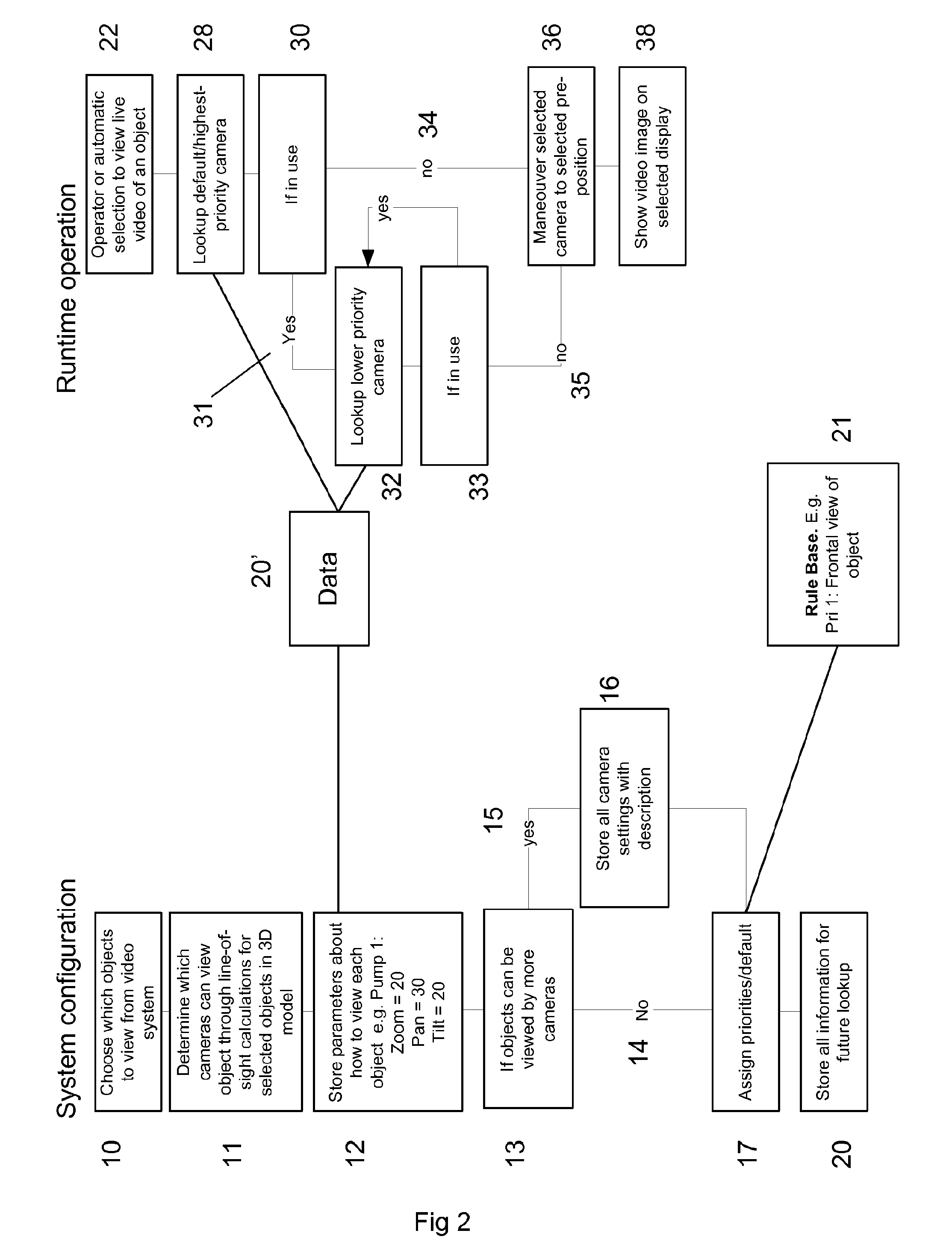

Method for operating remotely controlled cameras in an industrial process

InactiveUS20110199487A1Shorten the timeSimply and quickly capture imageTelevision system detailsClosed circuit television systemsComputer graphics (images)Video camera

A method to operate a camera to focus on a selected object or a process object of interest in an industrial installation, and automatically calculating which camera or cameras are in line of sight of the object of interest utilizing measurements on a 3D model of the installation and the cameras. A system is also described. The camera may be automatically operated to move, or pan or tilt or zoom the camera so as to point and focus on the process object of interest. A video stream or an image of the object of interest is then generated and displayed.

Owner:ABB RES LTD

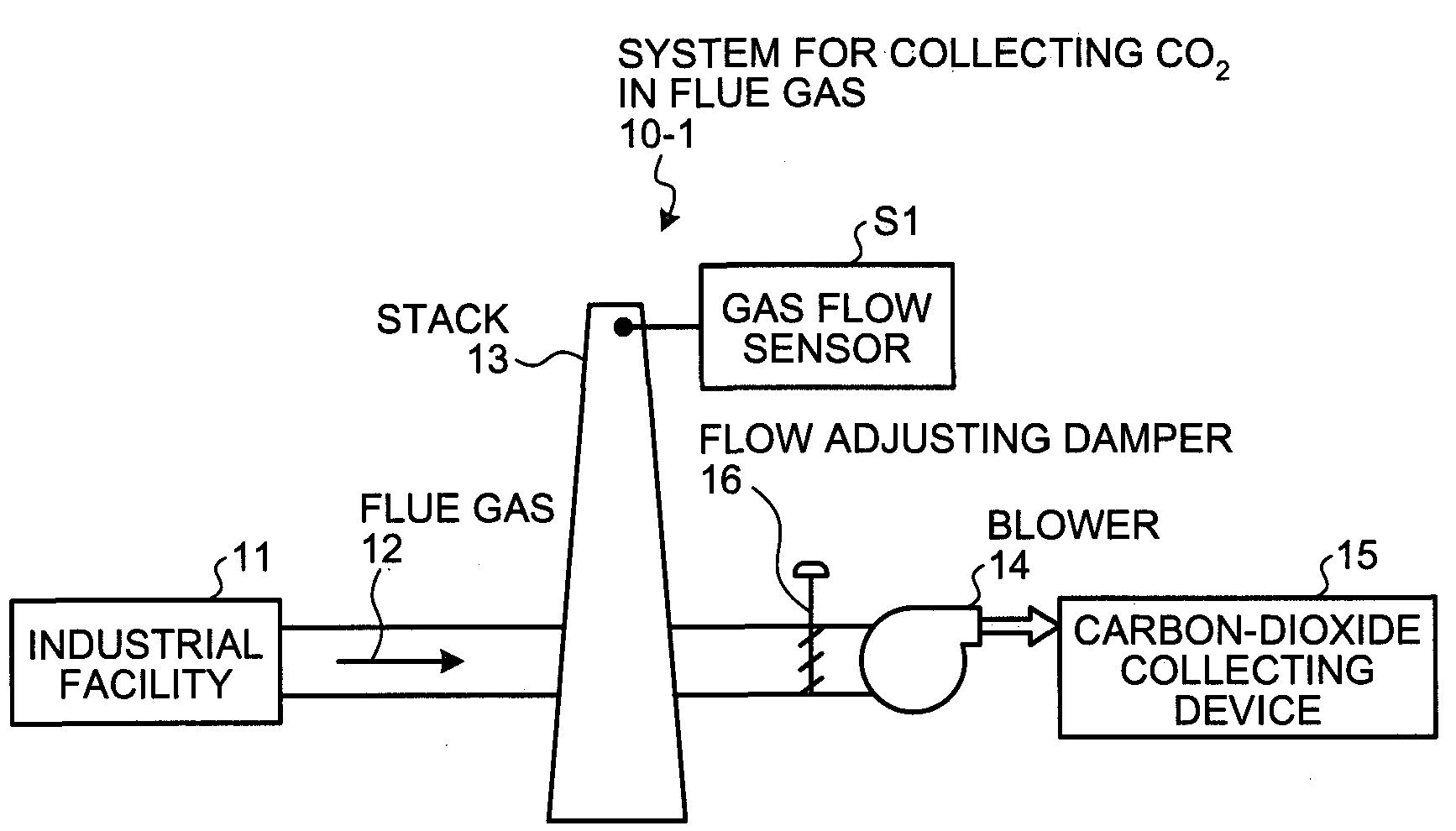

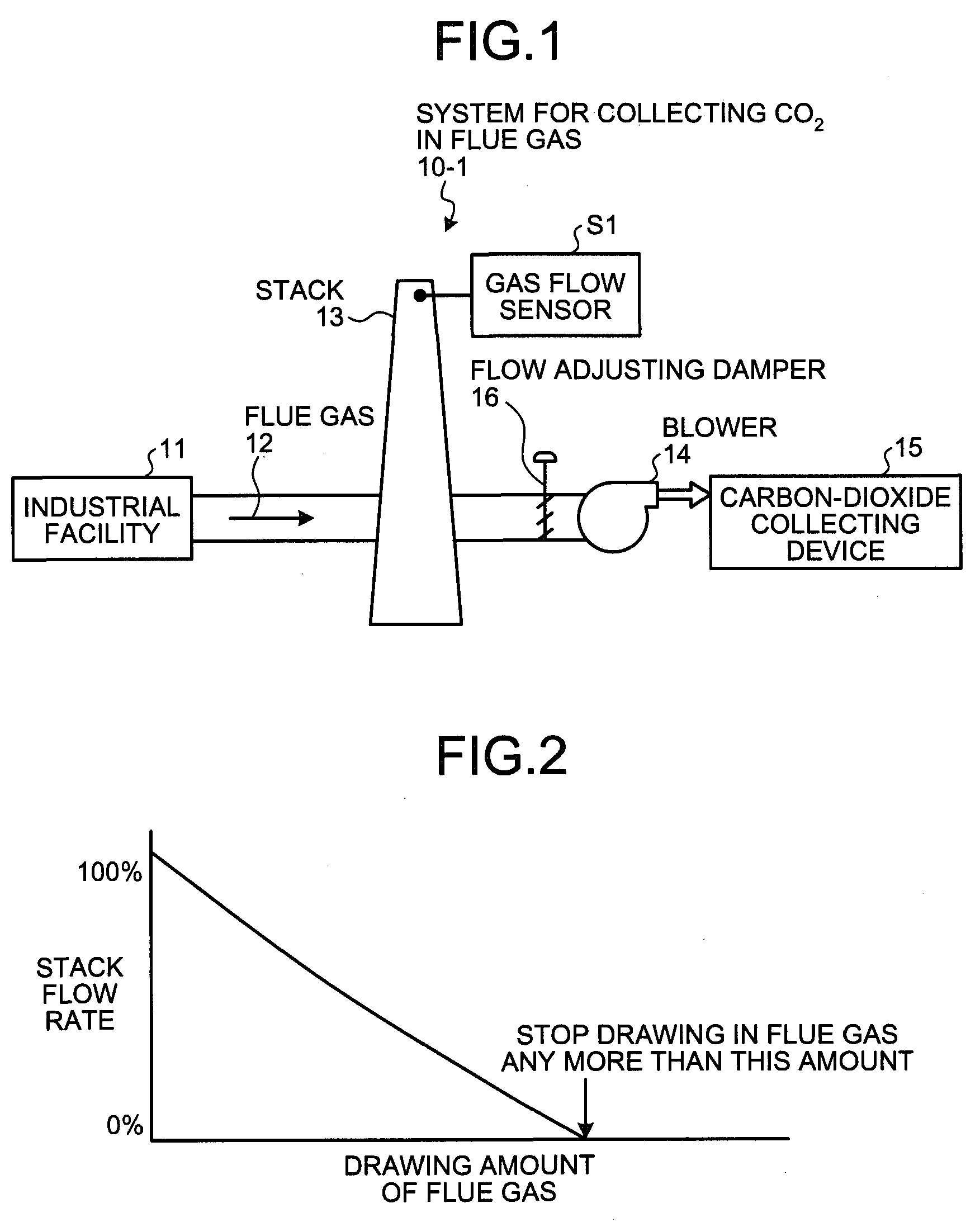

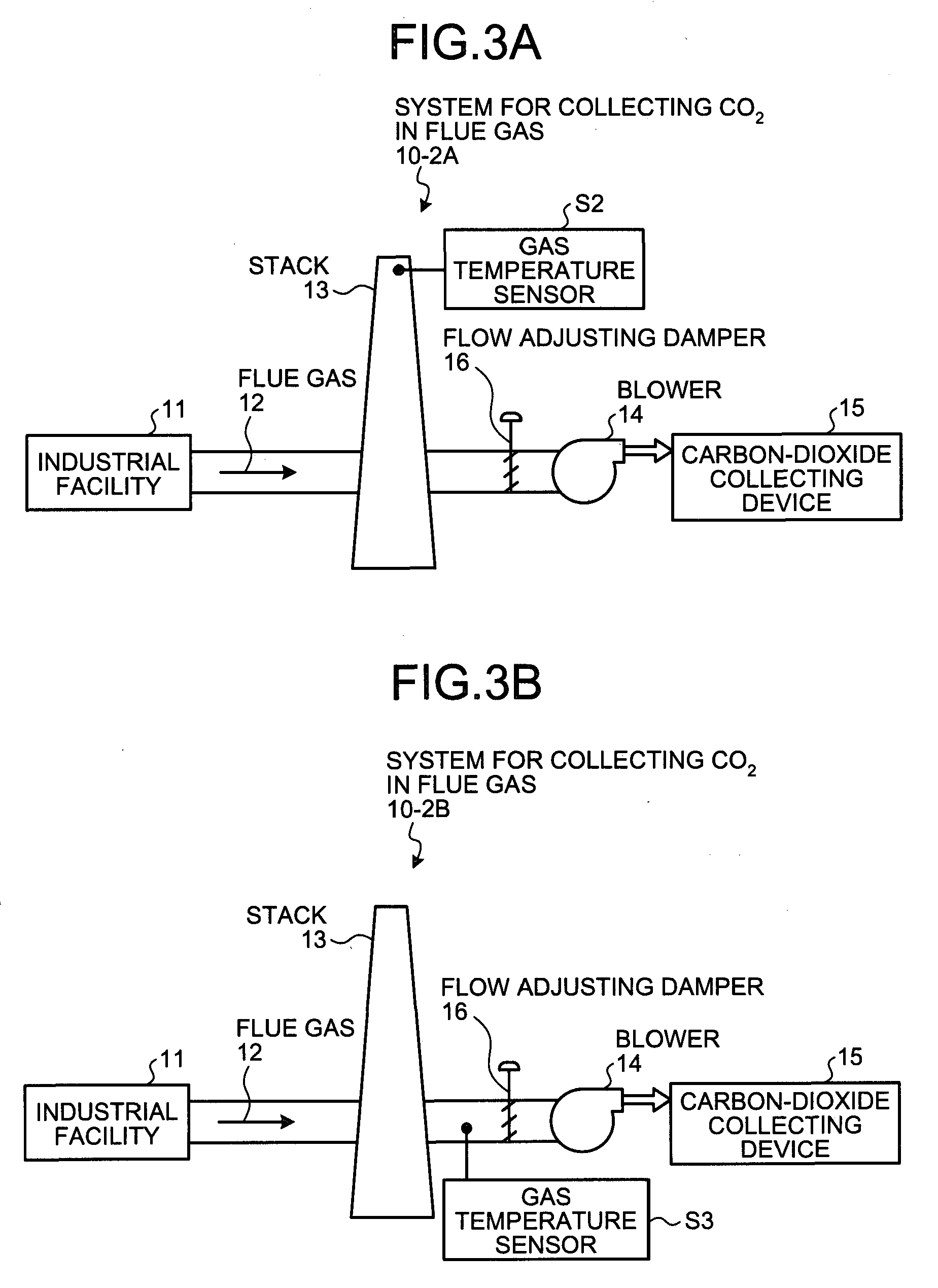

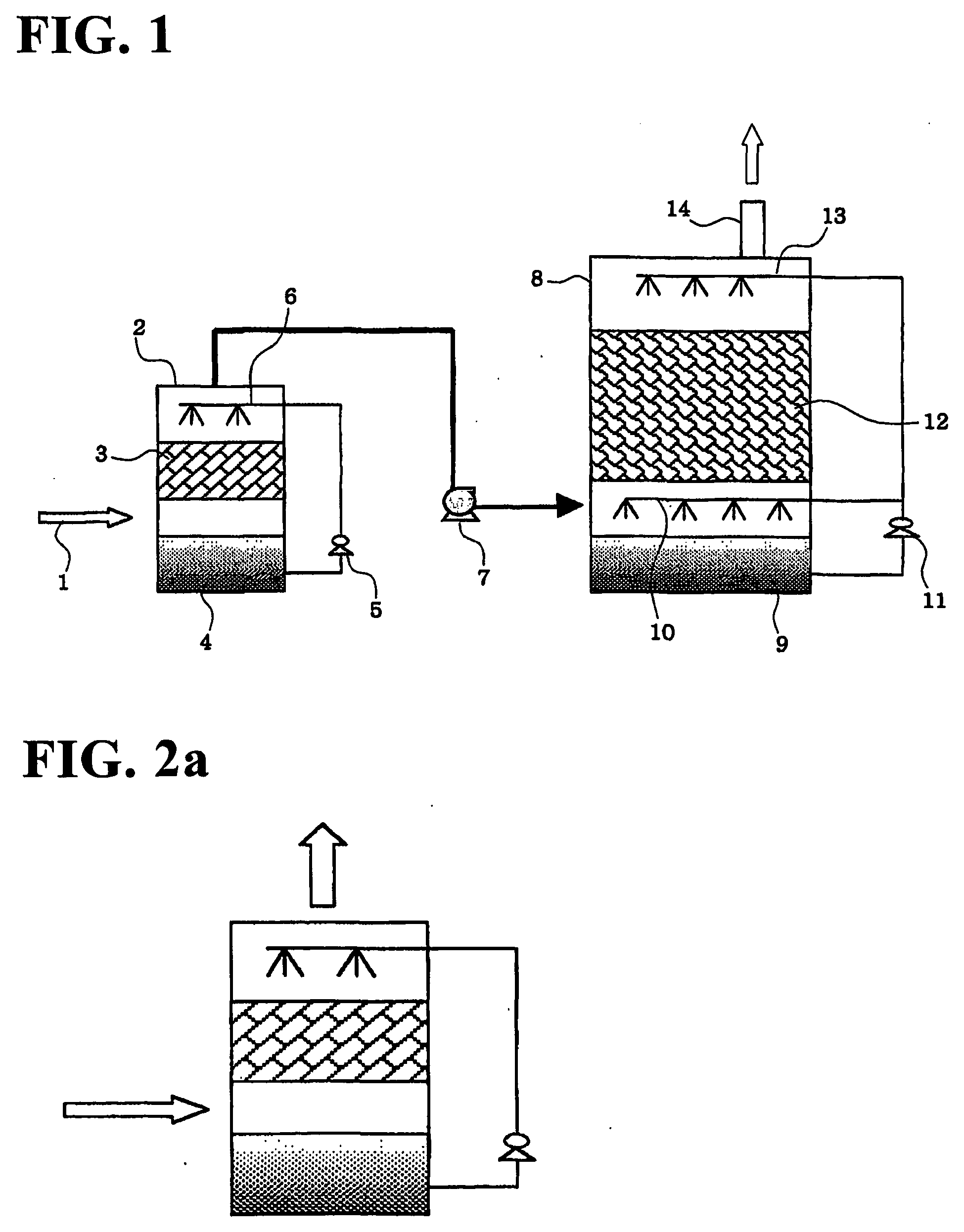

System for collecting carbon dioxide in flue gas

A system for collecting carbon dioxide in flue gas includes a stack that discharges flue gas discharged from an industrial facility to outside, a blower that is installed at the downstream side of the stack and draws the flue gas therein, a carbon-dioxide collecting device that collects carbon dioxide in the flue gas drawn in by the blower, and a gas flow sensor arranged near an exit side within the stack. A drawing amount of the flue gas by the blower to the carbon-dioxide collecting device is increased until an flow rate of the flue gas from the stack becomes zero in the gas flow sensor, and when the discharged amount of flue gas from the stack becomes zero, drawing in any more than that amount is stopped, and the carbon dioxide in the flue gas is collected while the flue gas is drawn in by a substantially constant amount.

Owner:MITSUBISHI HEAVY IND LTD +1

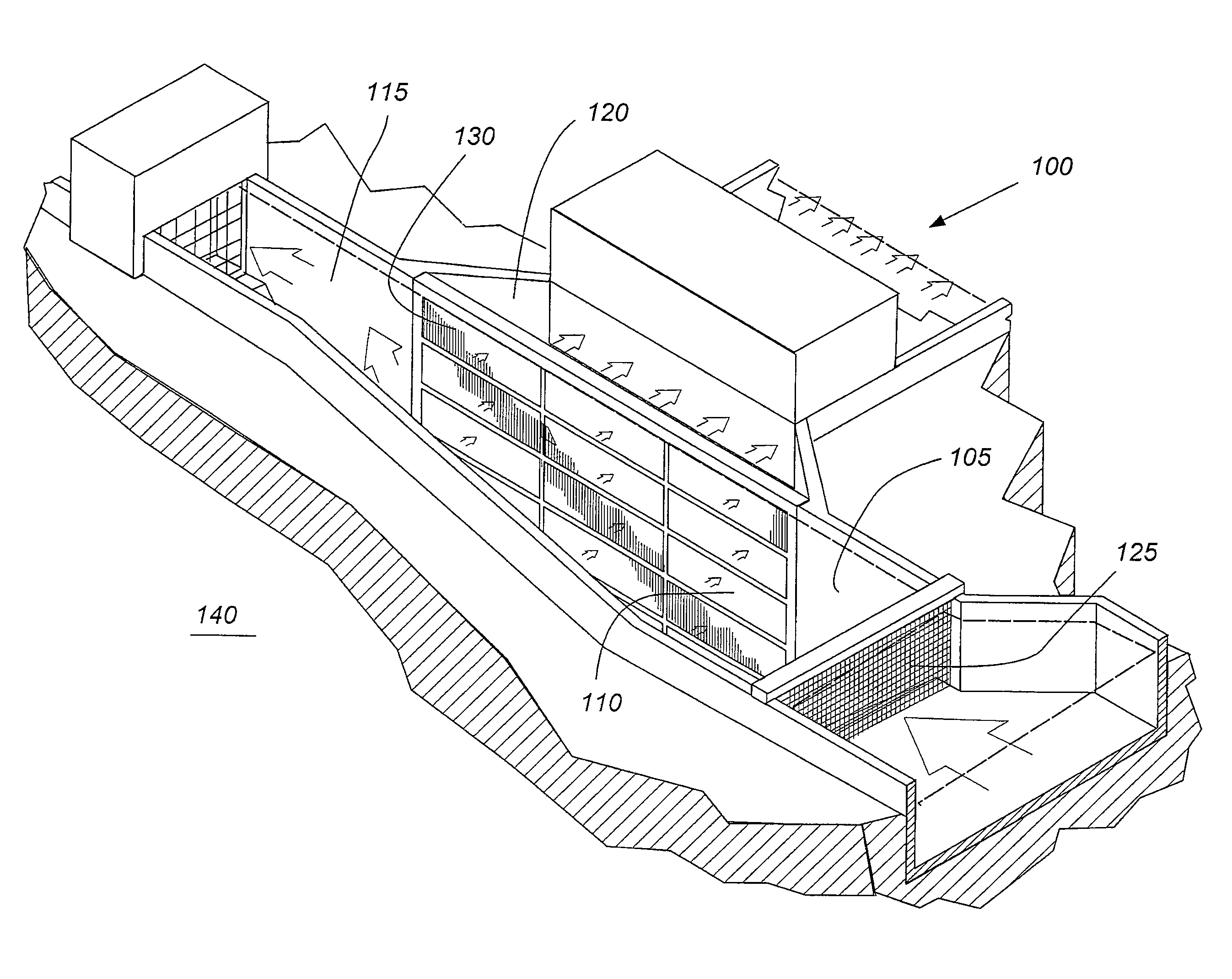

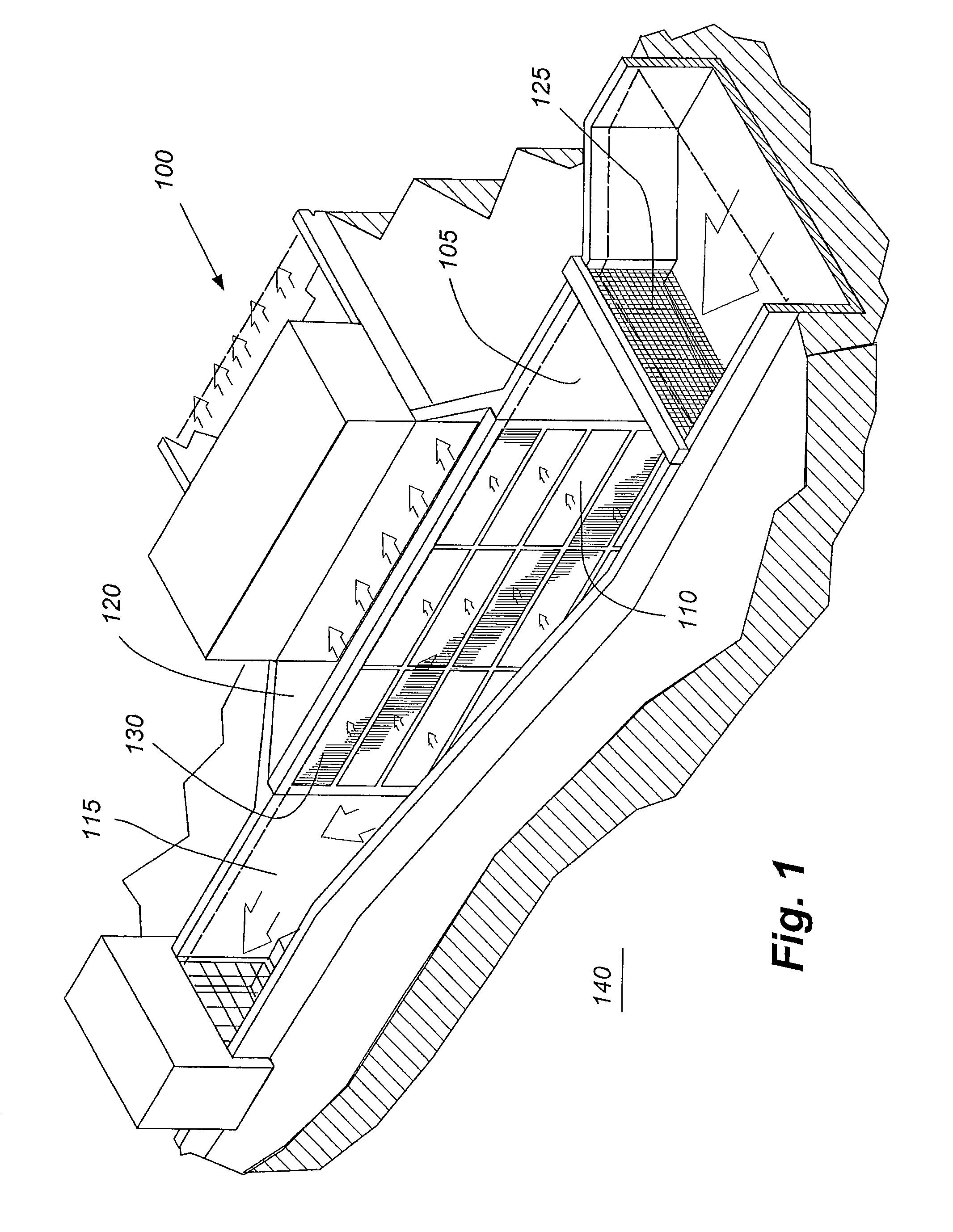

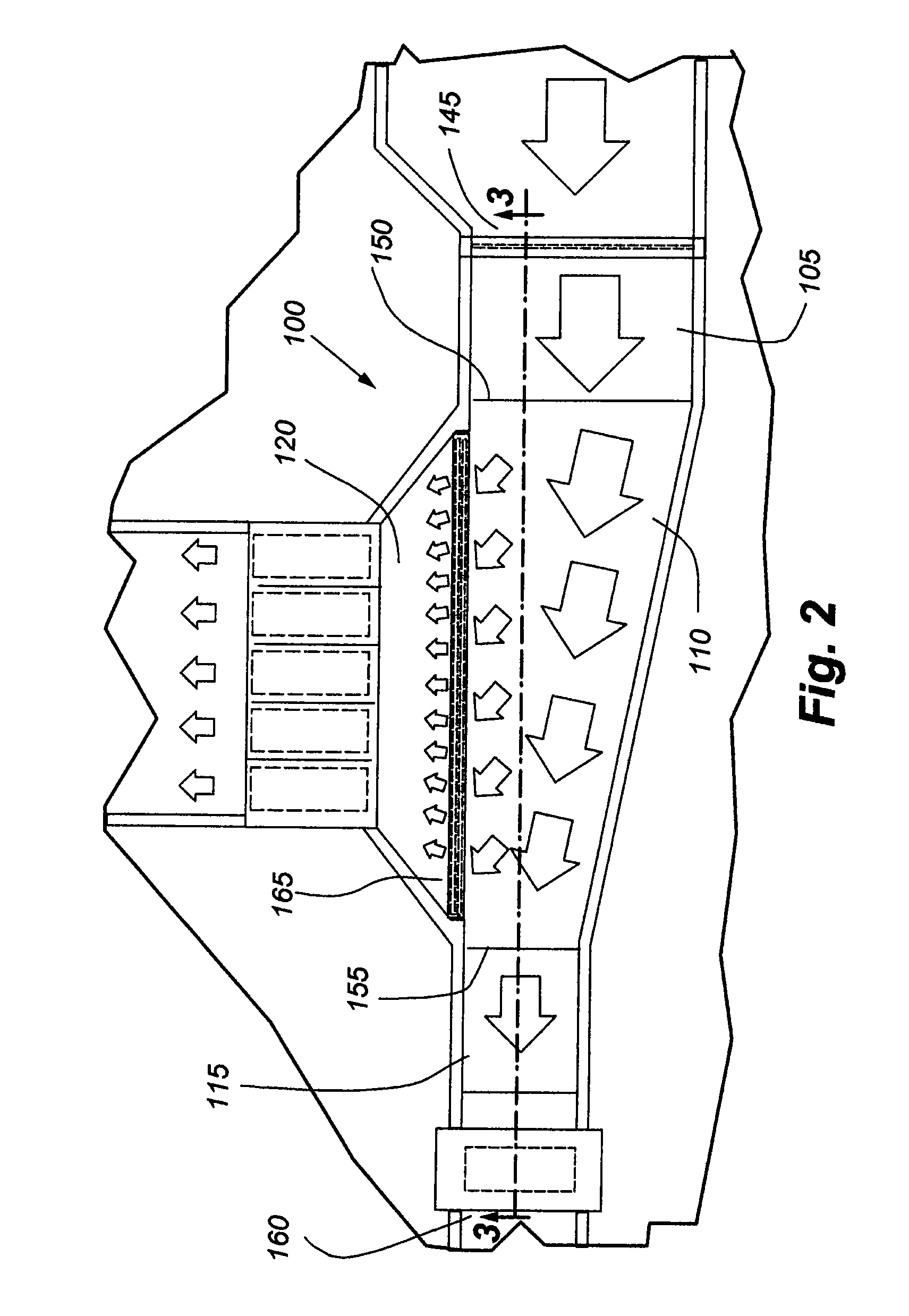

Water intake structure

Owner:CH2M HILL ENGINEERS

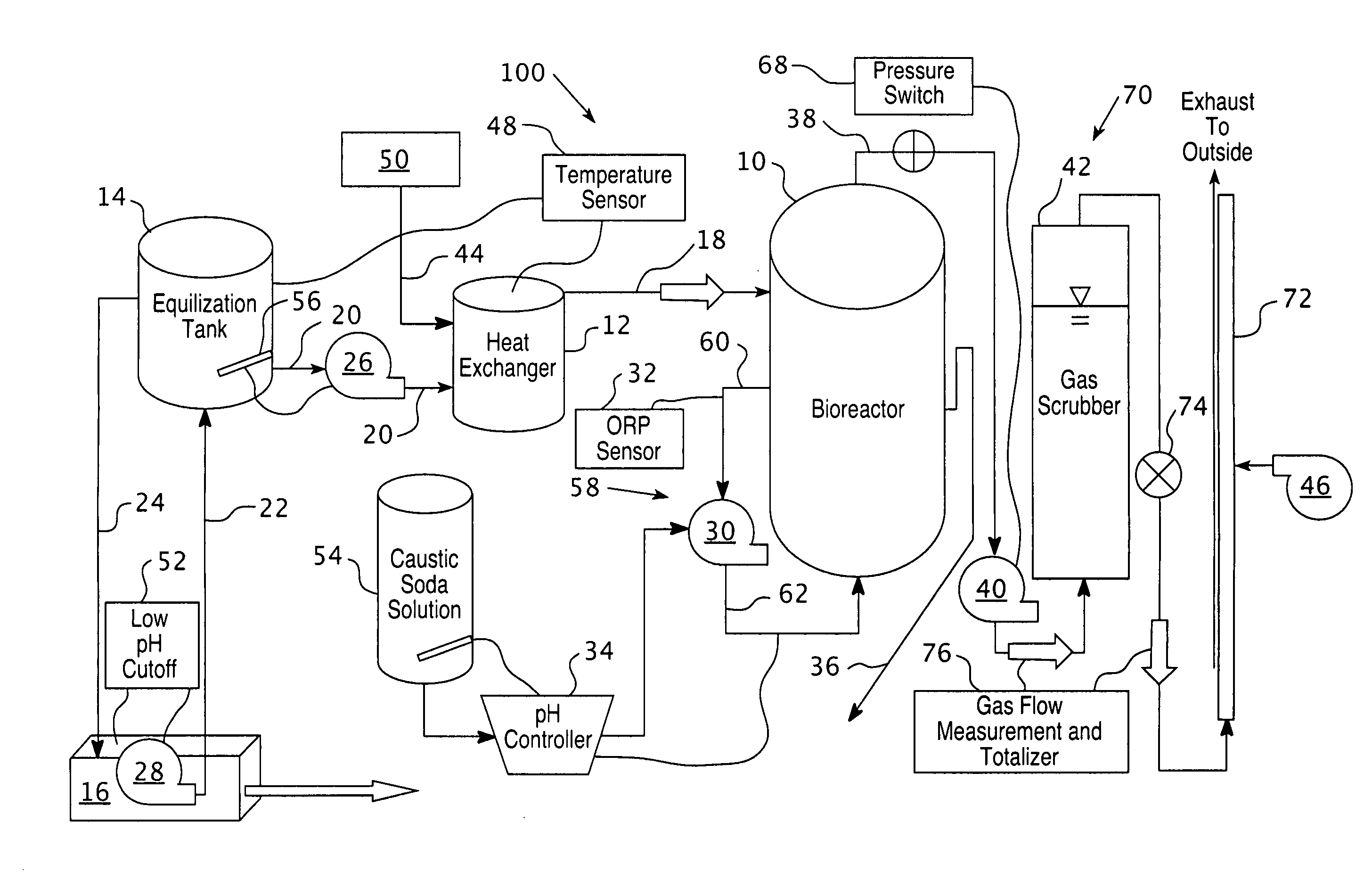

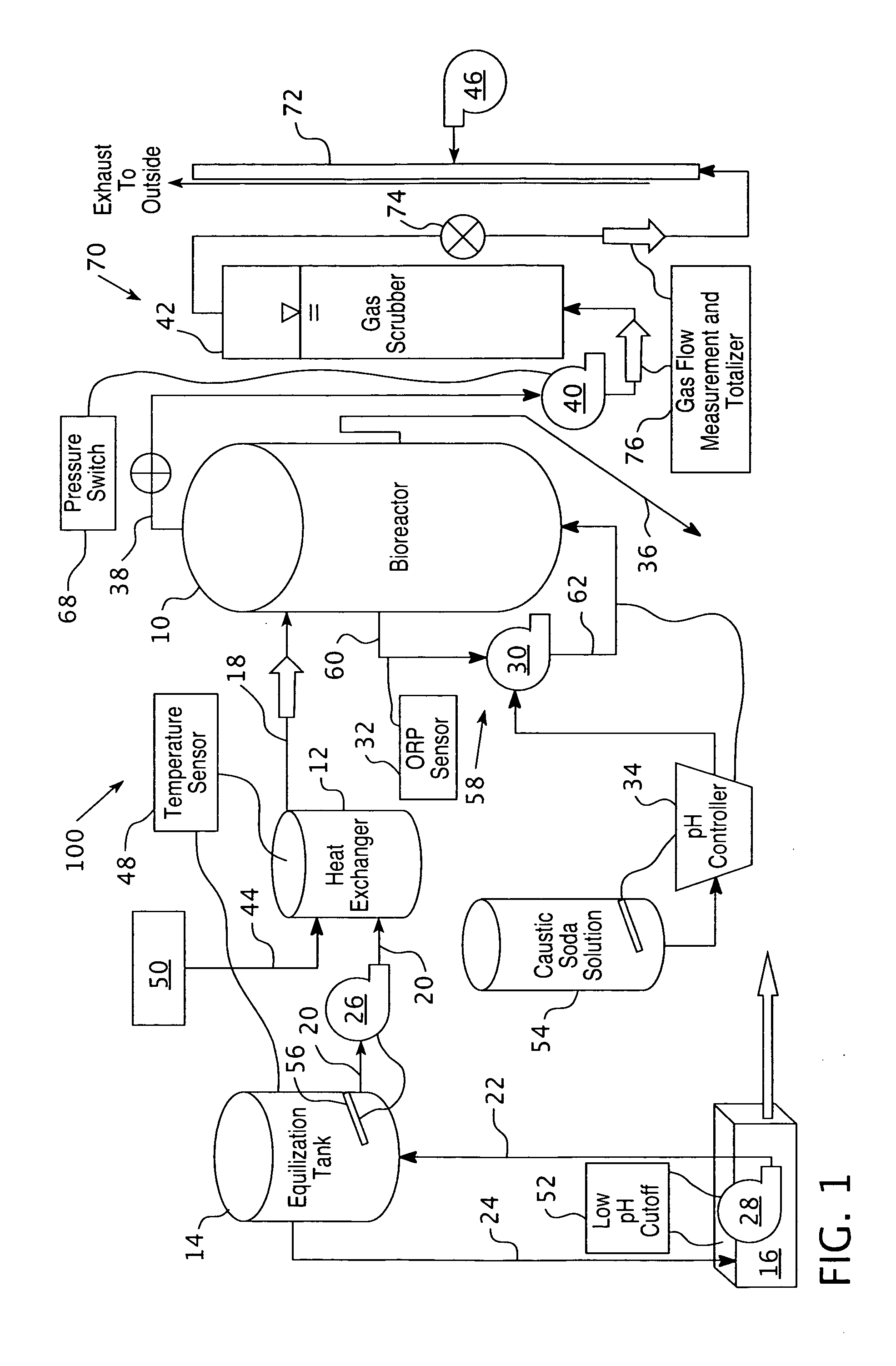

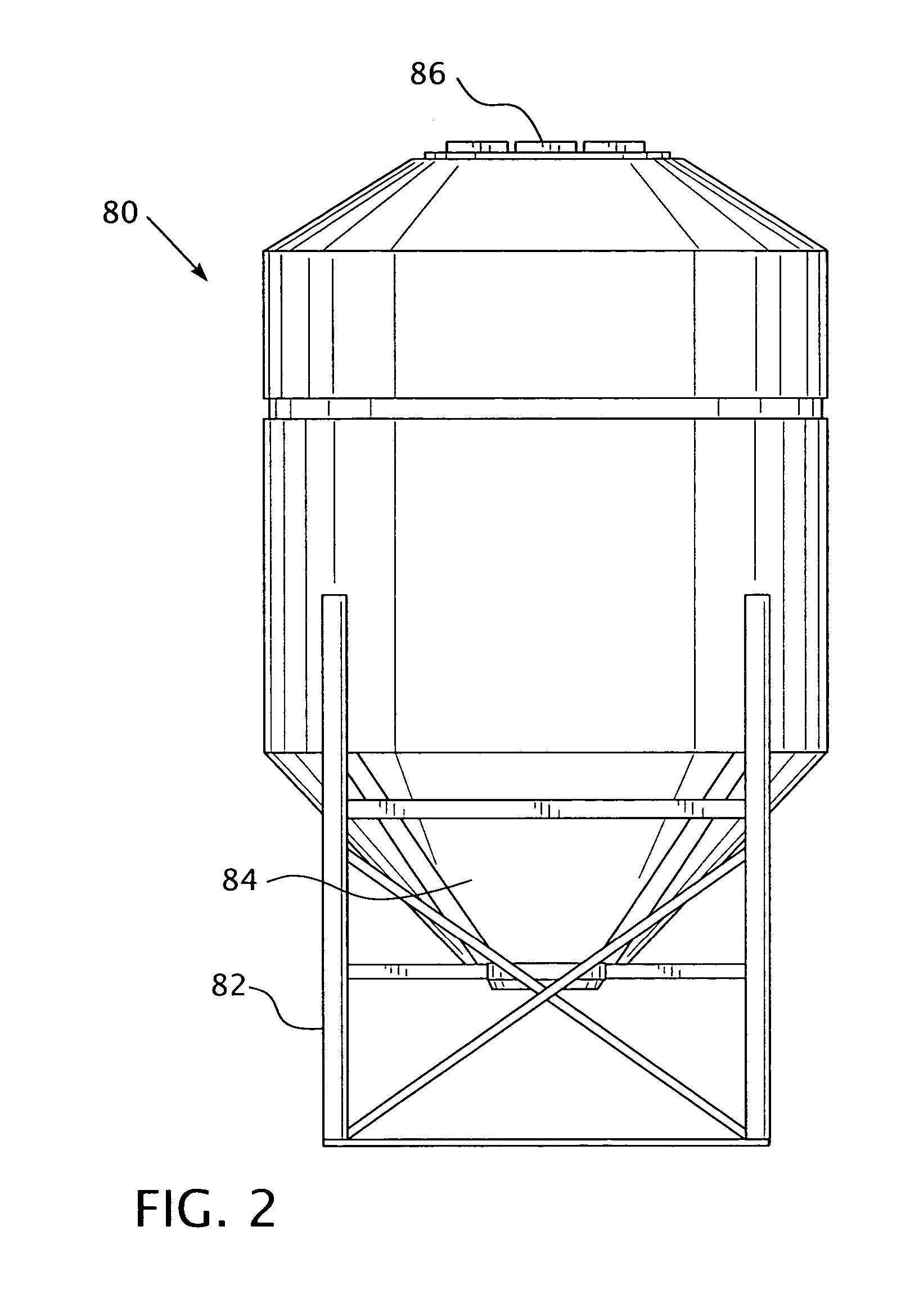

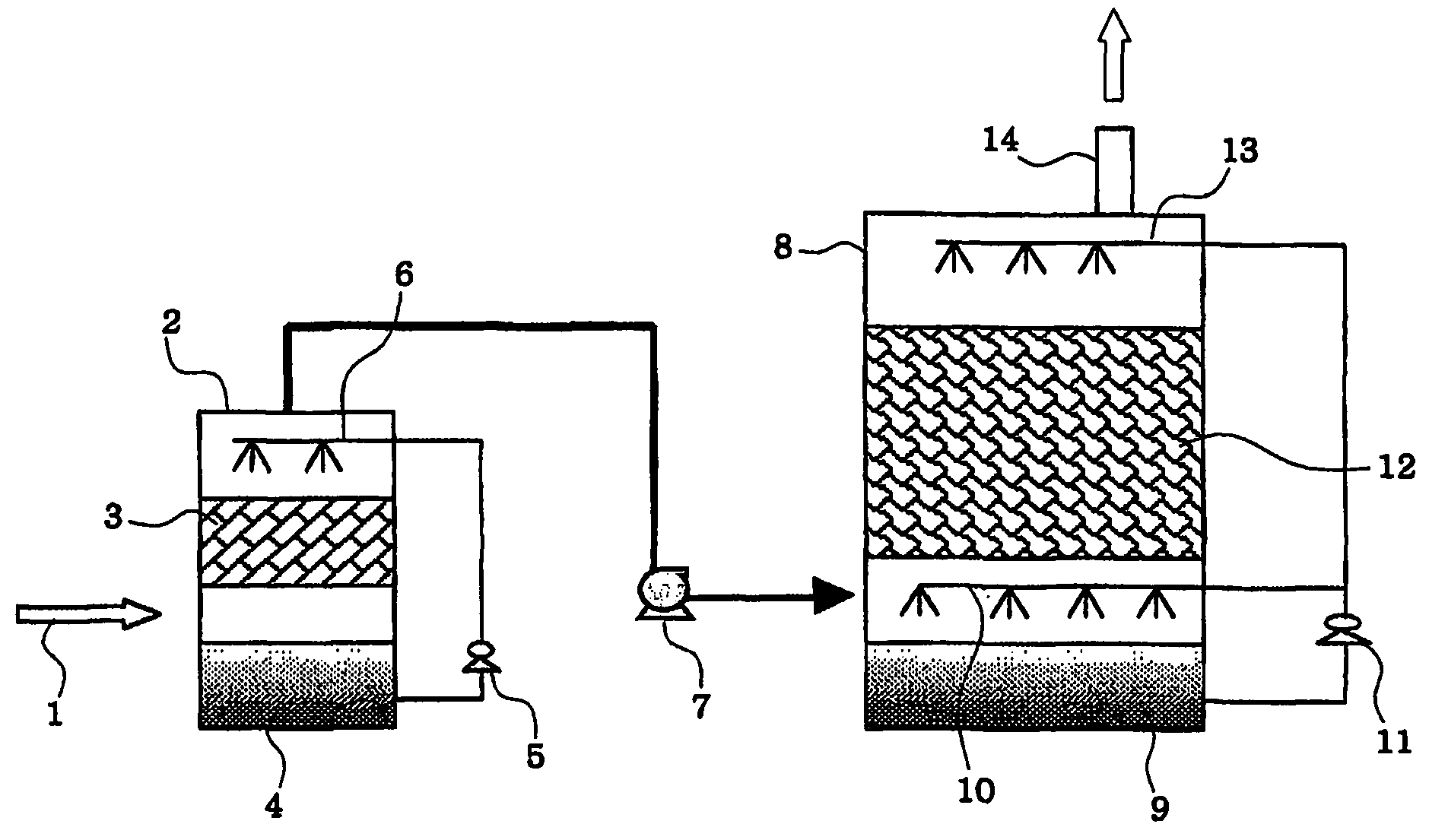

Hydrogen producing apparatus utilizing excess heat from an industrial facility

InactiveUS20060275894A1Easy to combineBioreactor/fermenter combinationsBiological substance pretreatmentsProcess engineeringBioreactor

The present invention provides a hydrogen production apparatus, where a bioreactor is combined with an industrial facility such that the industrial facility heats an organic feed material prior to conveyance of the organic feed material into the bioreactor. The apparatus includes a bioreactor, a feed container, a heating means such as a heat exchanger and an industrial facility with a heat waste source.

Owner:FELDER MITCHELL +2

Economical high-strength high-weatherability hot-rolled H beam steel containing vanadium and nitrogen and rolling method thereof

InactiveCN101760704AHigh strengthImprove toughnessTemperature control deviceChemical compositionNitrogen

The invention discloses a economical high-strength high-weatherability hot-rolled H beam steel containing vanadium and nitrogen, the weight percentages (wt percent) of chemical composition are as follows: 0.07 percent to 0.12 percent of C, 0.30 percent to 0.55 percent of Si, 1.30 percent to 1.55 percent of Mn, 0.020 percent to 0.045 percent of P, 0.001 to 0.010 percent of S, 0.25 percent to 0.35 percent of Cu, 0.20 percent to 0.30 percent of Cr, 0.15 percent to 0.30 percent of Ni, 0.07 percent to 0.12 percent of V, 0.010 percent to 0.015 percent of N and 0.006 percent to 0.030 percent of Als, and the rest is iron and residual trace impurities. The invention also discloses a rolling method for the H beam steel; the cast slab-soaking temperature is 1190 DEG C to 1050 DEG C; and the finish rolling temperature of a universal finishing mill is 800 DEG C to 870 DEG C. By the method, a hot-rolled H beam with high strength, high tenacity, high weatherability and good welding performance can be obtained. Meanwhile, since the metallurgical composition of the steel is simple, the alloying production cost is low, the steel is economical and practical, and the hot-rolled H beam is an ideal hot-rolled H beam for the production of railway vehicles and freight semitrailers and the construction of other industrial facilities needing the height-strength and weatherable steel.

Owner:MAANSHAN IRON & STEEL CO LTD

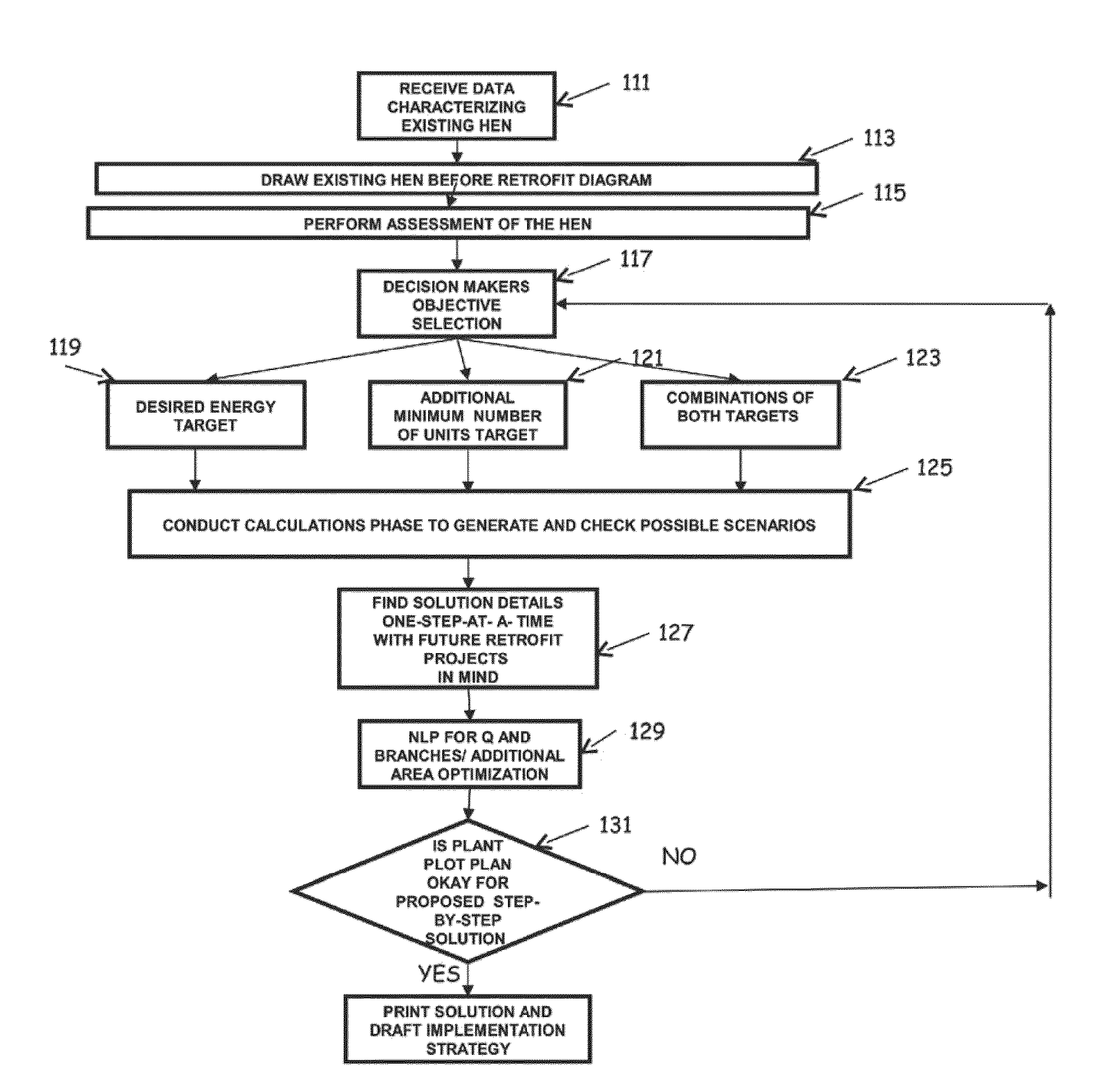

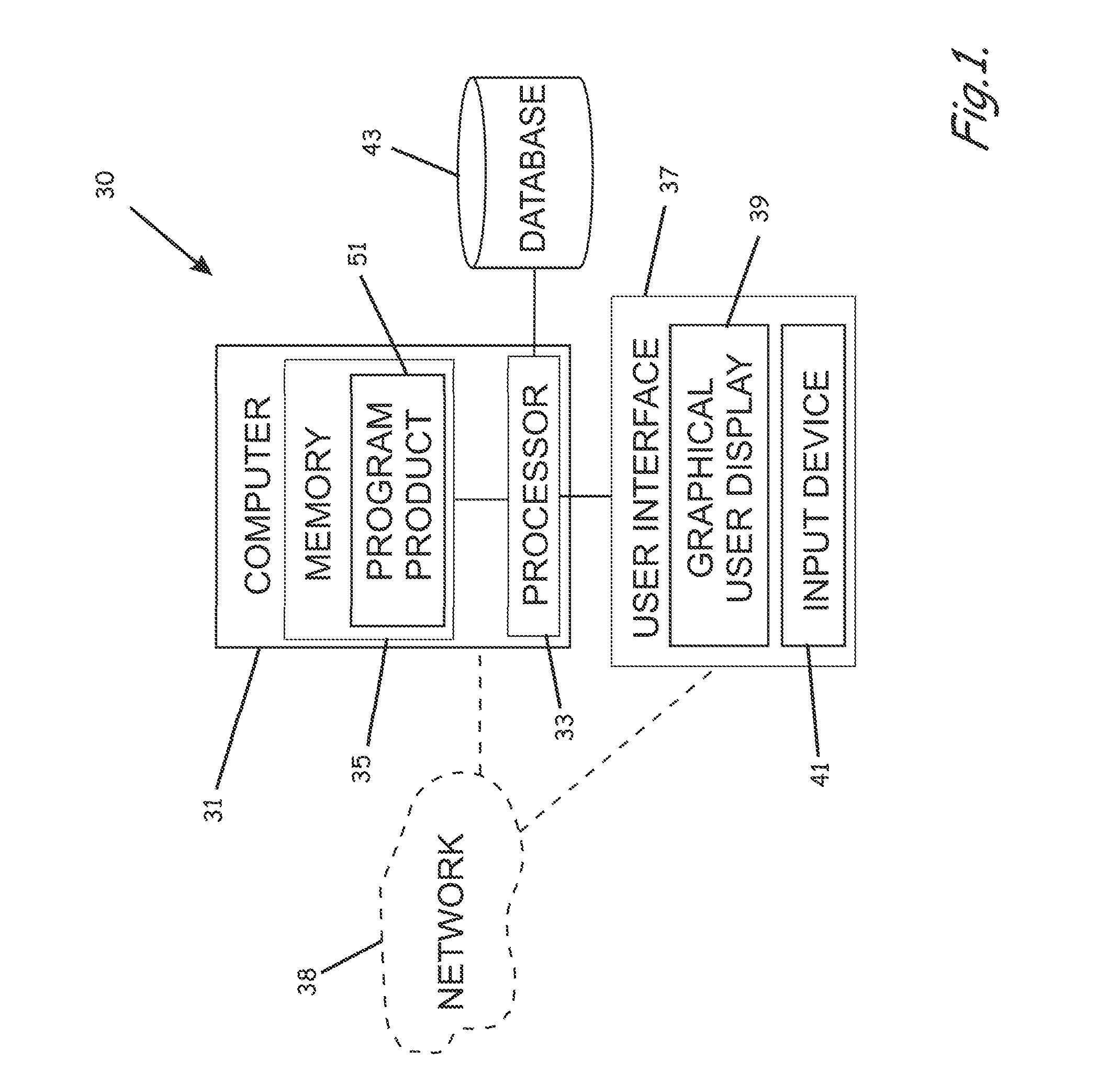

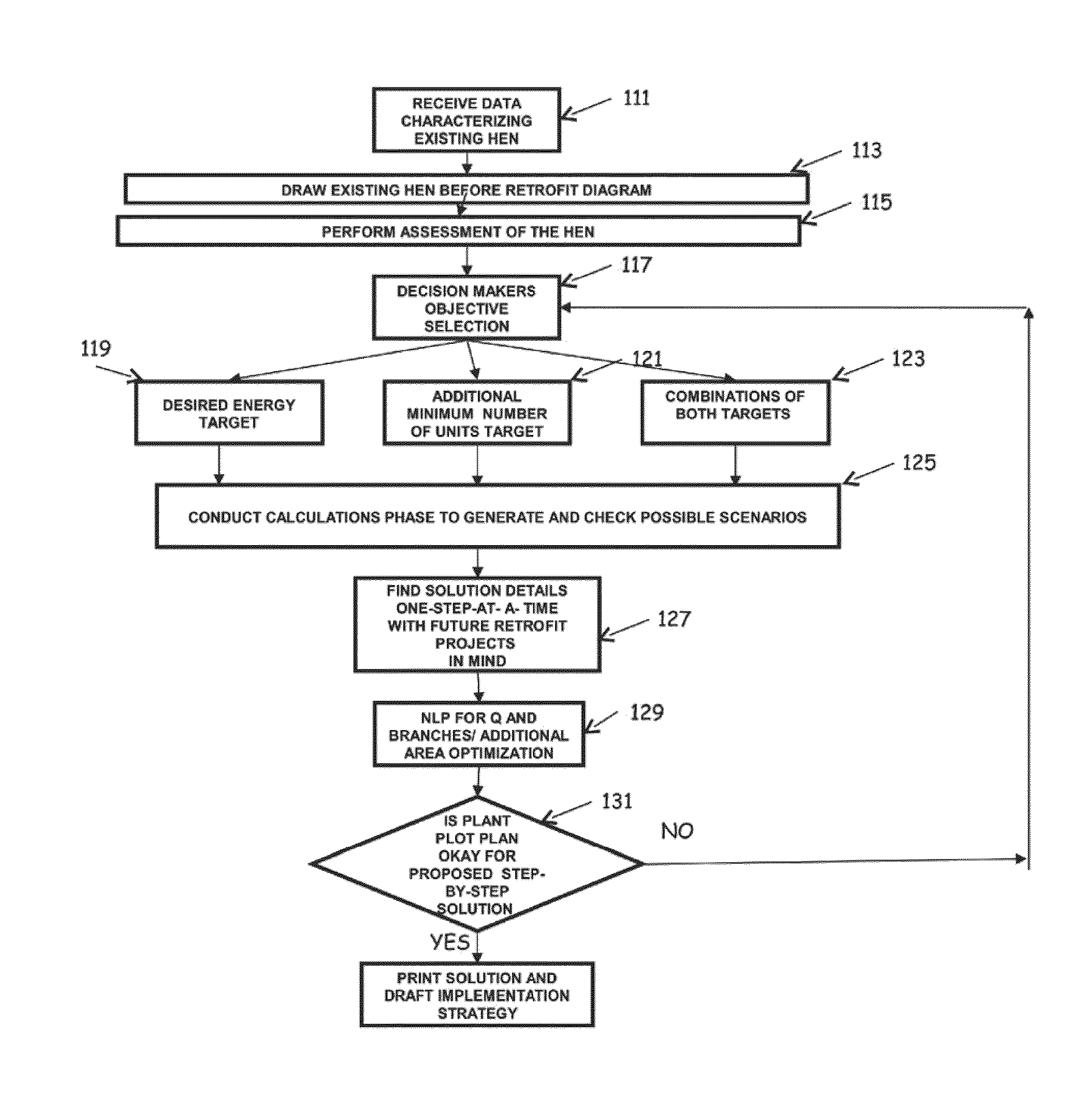

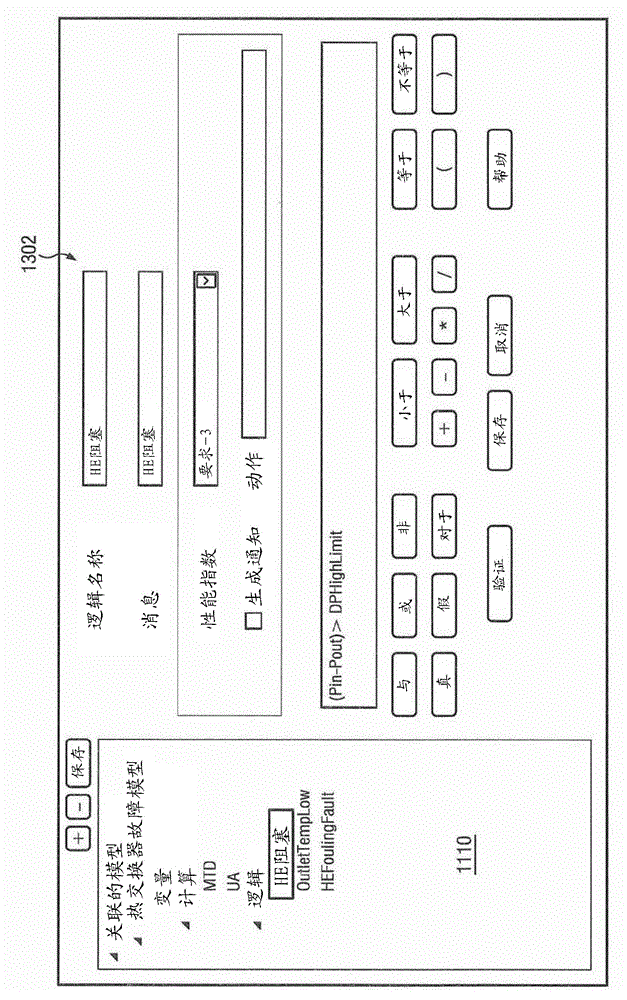

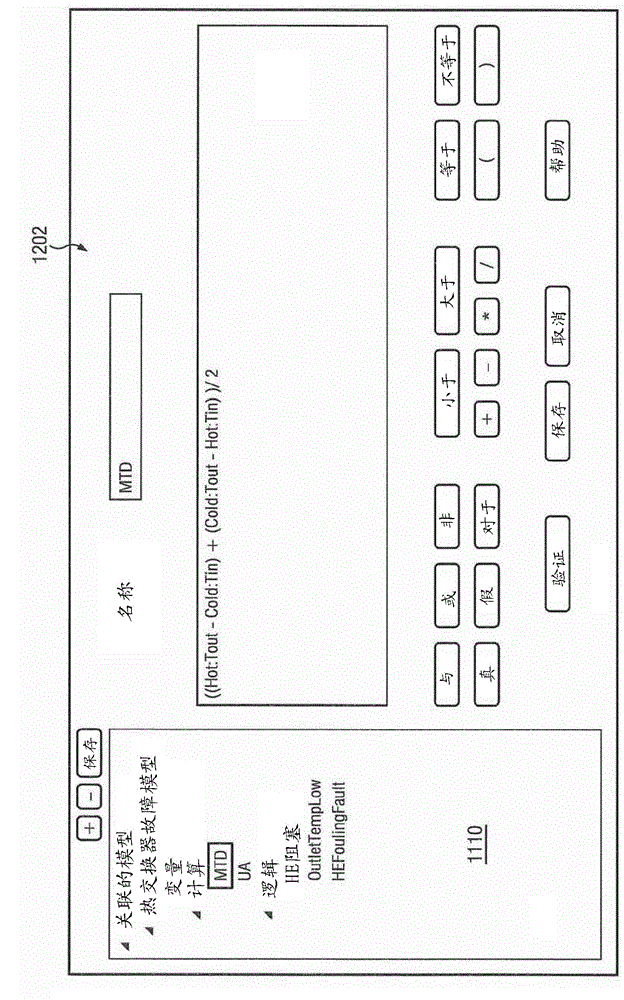

Systems and program product for heat exchanger network energy efficiency assessment and lifetime retrofit

ActiveUS20110178835A1Eliminating lost-in-topology energyMinimal additionAir-treating devicesComputer controlExchange networkProcess engineering

Systems and program product for managing / assessing heat exchanger network energy efficiency and retrofit for an industrial facility, are provided. An embodiment of a system can include a heat exchanger network analysis and design computer and heat exchange network analysis and design program product configured to cause the heat exchange network analysis and design computer to perform various operations including those for determining an optimal heat exchanger network retrofit projects sequence extending between a current heat exchanger network retrofit project satisfying a current desired waste energy recovery goal and a future heat exchanger network retrofit project satisfying the final waste energy recovery goal. The heat exchanger network retrofit projects sequence can be configured so that each subsequent project within the heat exchanger network retrofit projects sequence does not contradict any of the previous projects within the heat exchanger network retrofit projects sequence.

Owner:SAUDI ARABIAN OIL CO

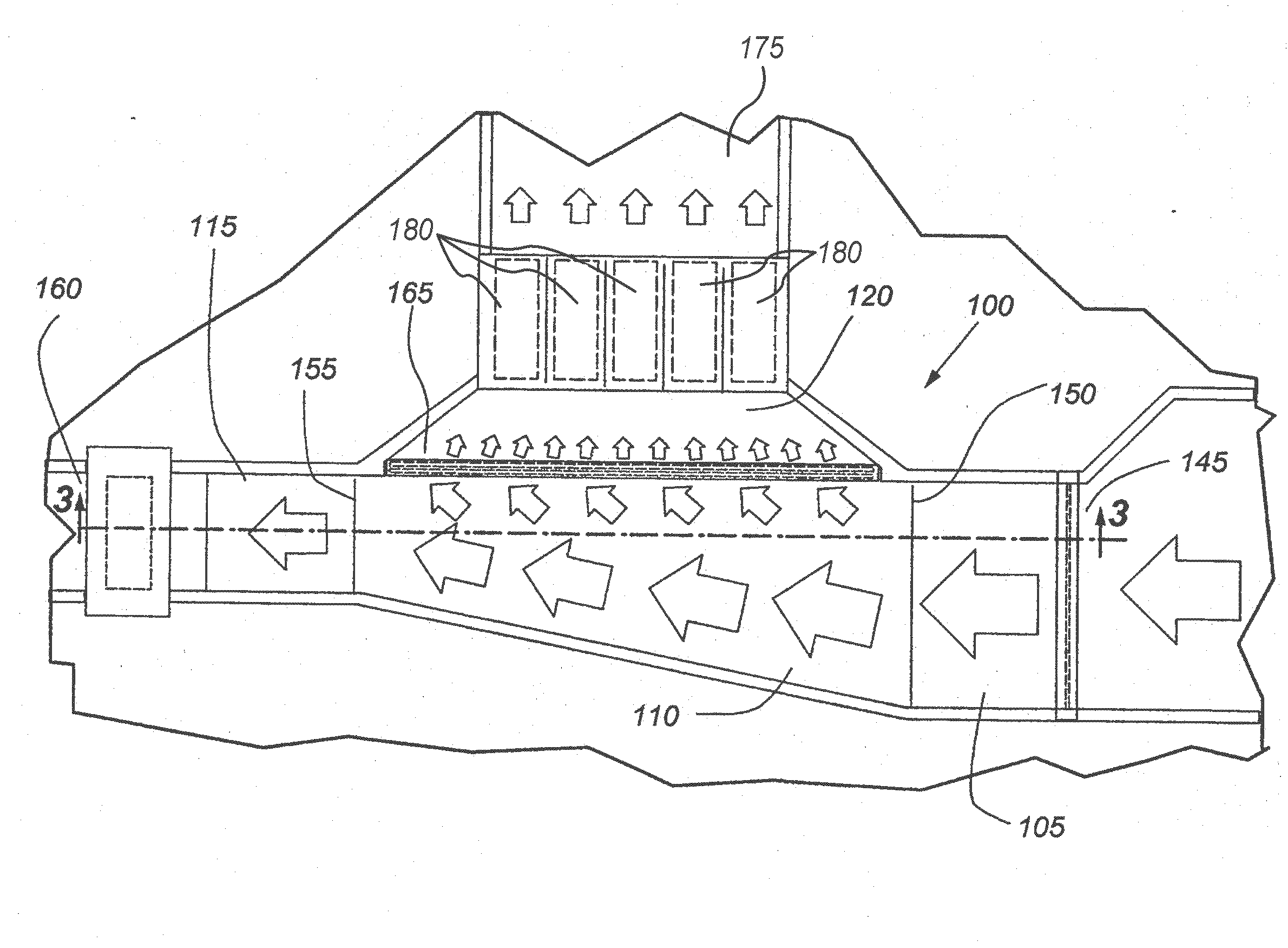

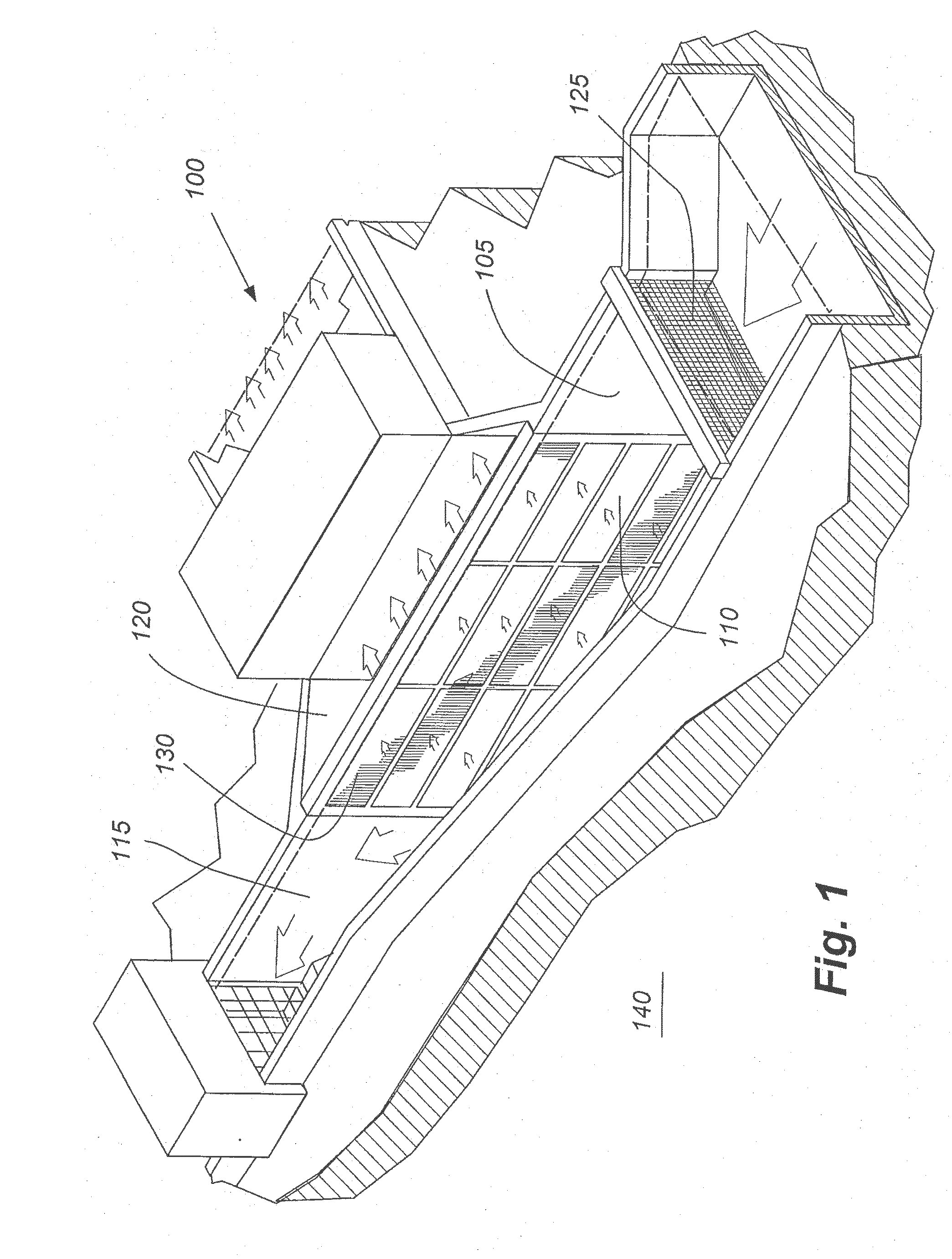

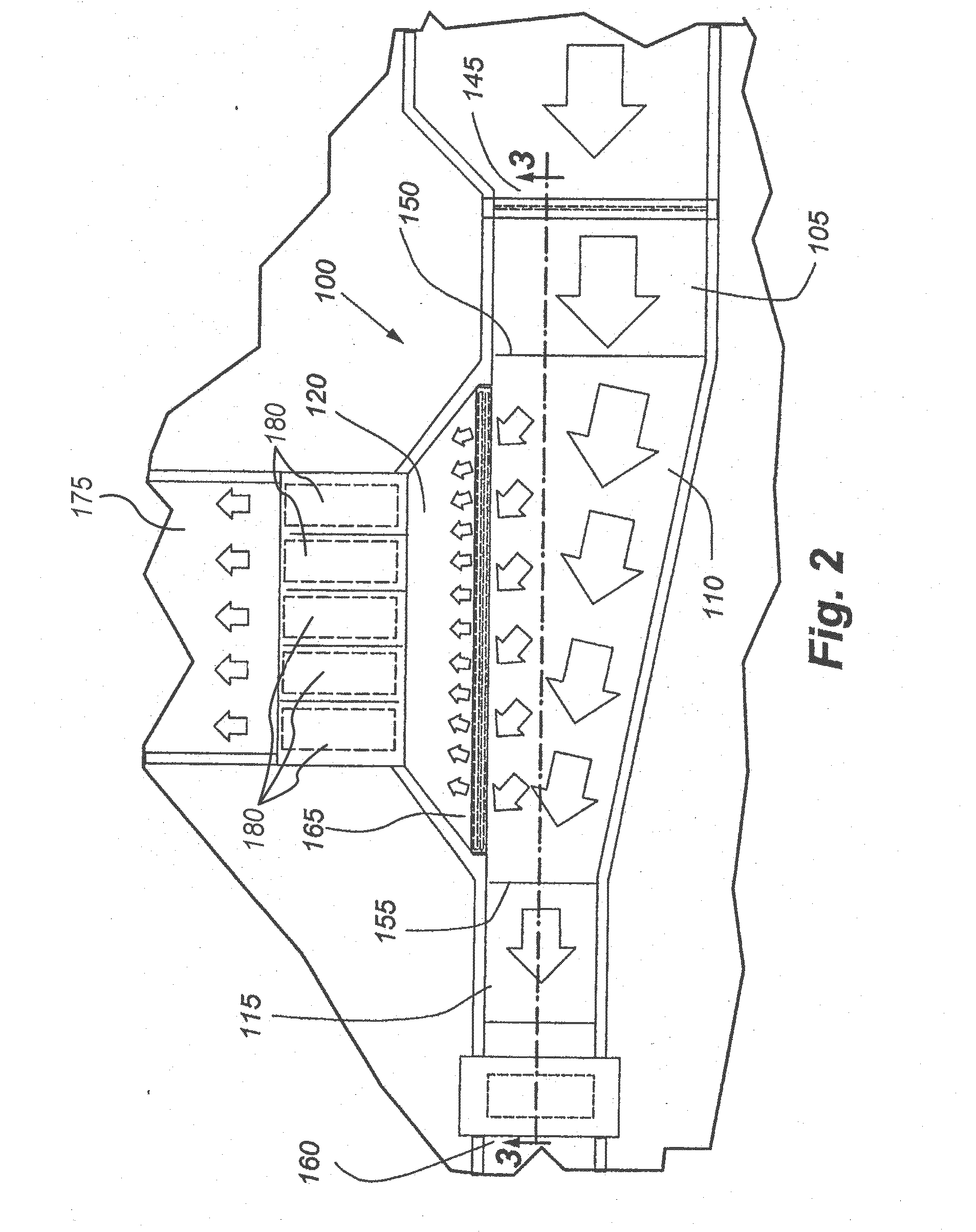

System for decontaminating industrial output gases

The system for decontaminating industrial output gases may process both particulate and gaseous emissions from industrial facilities. The system may be located with or adjacent to an industrial facility or at some distance from the facility. In one embodiment the system includes a subsystem of alternating active and inactive filters, and a wash subsystem cleaning the inactive filters during the cycle. The wash water is captured in a basin for further processing of the chemical particulates therein. Fans located downstream of the filters draw the gaseous industrial output through the filters. Remaining vapor passes to a classification plant where the gases are separated into their constituent elements or compounds. Gases that to are allowed to escape may be burned, and the resulting gases recirculated through the system. Another embodiment is adapted for processing steam, and cools the steam for use as liquid water, rather than allowing it to escape as vapor.

Owner:ALSAFFAR ABDULREIDHA A T A

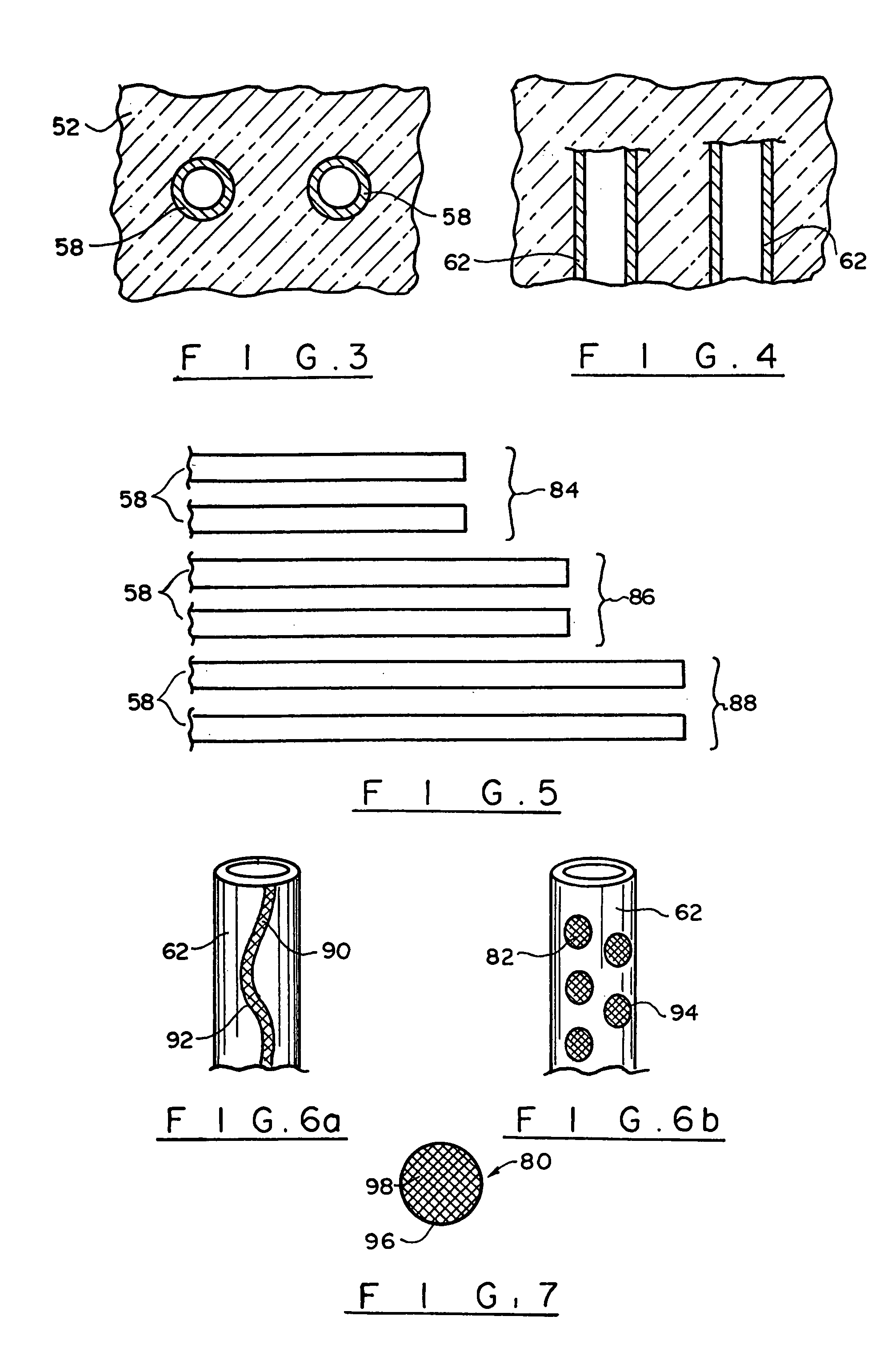

Water intake structure

Water intake structures for power plants and other industrial facilities may include an inflow channel, a deep well, an outflow channel, and an intake channel. These structures include a fish screen, such as a wedge-wire screen or the like, positioned between the deep well and the intake channel to separate fish, fish larvae and fish eggs from water supplied to the intake channel from the deep well. One or more circulating or sweep flow pumps are positioned proximate an outlet of the outflow channel. The sweep flow pumps are used to maintain a sweep flow through the deep well of the intake structure to help sweep fish, fish larvae and fish eggs away from the fish screen and into the outflow channel. The screens are provided in multiple embodiments to include symmetrical shaped bars or wires, and asymmetric shaped bars or wires. One configuration of the asymmetric shaped bars or wires includes a trailing edge protrusion that creates centrifugal forces in the flow of water to enhance separation of particles from the water stream.

Owner:CH2M HILL

Biofilter system equipped with inlet load equalizer for removing volatile organic compounds

InactiveUS20040137610A1Preventing decrease of VOC treatment efficiencyStable processing efficiencyBioreactor/fermenter combinationsGas treatmentBio filtrationBiological filter

Disclosed is a biofilter system for removing volatile organic compounds, generated from various industrial facilities, such as petrochemical plants, refining plants and paint plants, and environmental facilities including sewage treatment plants. The biofilter system comprises a volatile organic compound (VOC) load equilizing portion, a VOC-containing contaminated air transferring portion, a biofiltering portion, and a storing portion for adjusting pH and nutrients in the biofiltering portion. By using such system, an offensive odor and VOC evolved from various industrial facilities and environmental facilities can be efficiently controlled. In addition, even in production processes and storage facilities at which high VOC concentration regulating materials are discontinuously discharged, VOC can be effectively removed.

Owner:Q BIO TECH

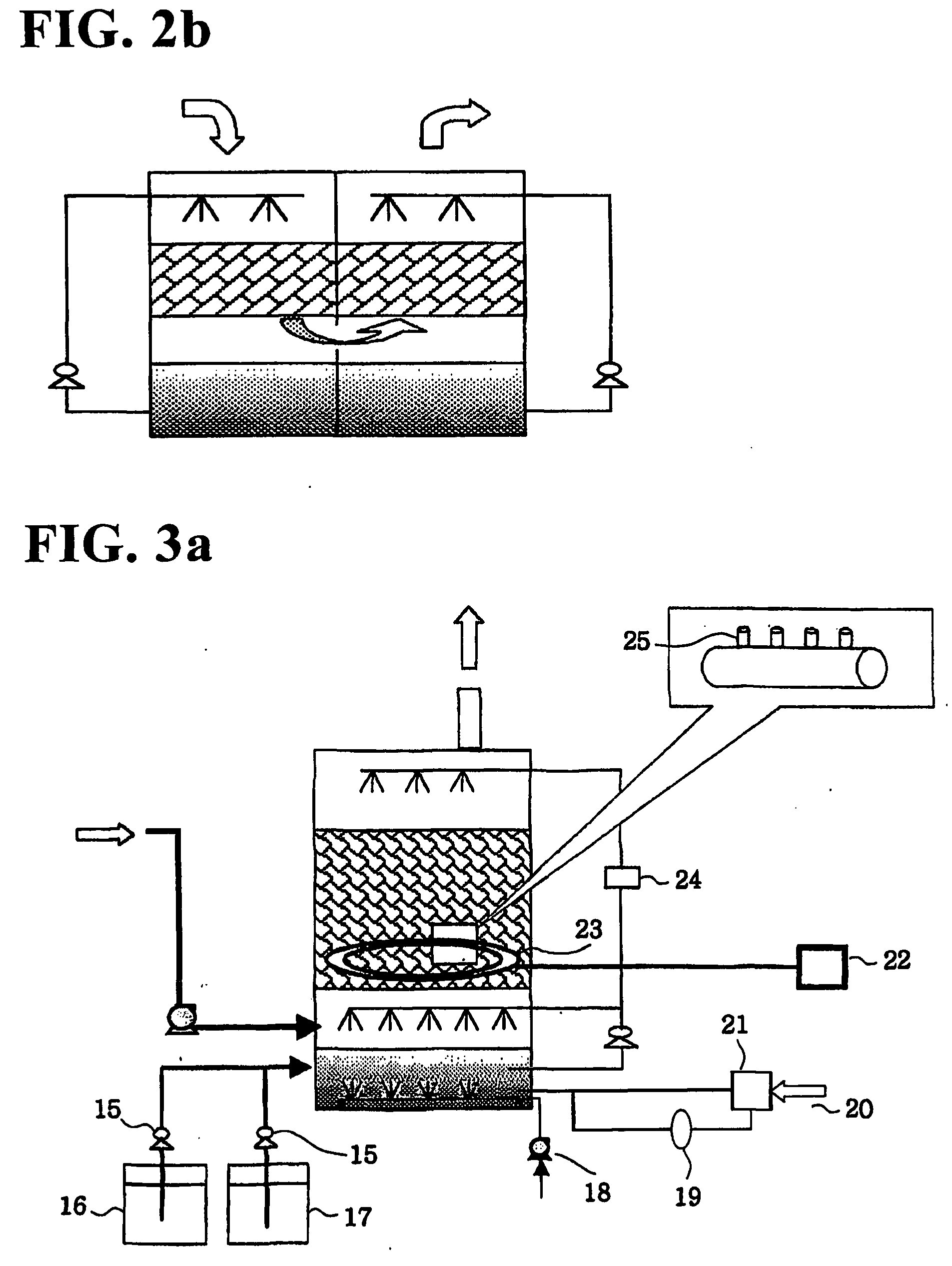

Method for Positioning and a Positioning System

ActiveUS20080284649A1Easy to operateReliable integrationSimulator controlPosition fixationInformation processingControl system

A method for recording a position of at least one component in a location system of a control system of an industrial facility for an industrial process. A model of the facility is created, including position coordinates for major parts of the facility. The model is stored in a location system storage. A component is identified. A mobile information processing device is placed adjacent the component and position coordinates are detected for the mobile information processing device. Identification information of the component and position coordinates of the mobile information processing device are stored in the location system storage.

Owner:ABB (SCHWEIZ) AG

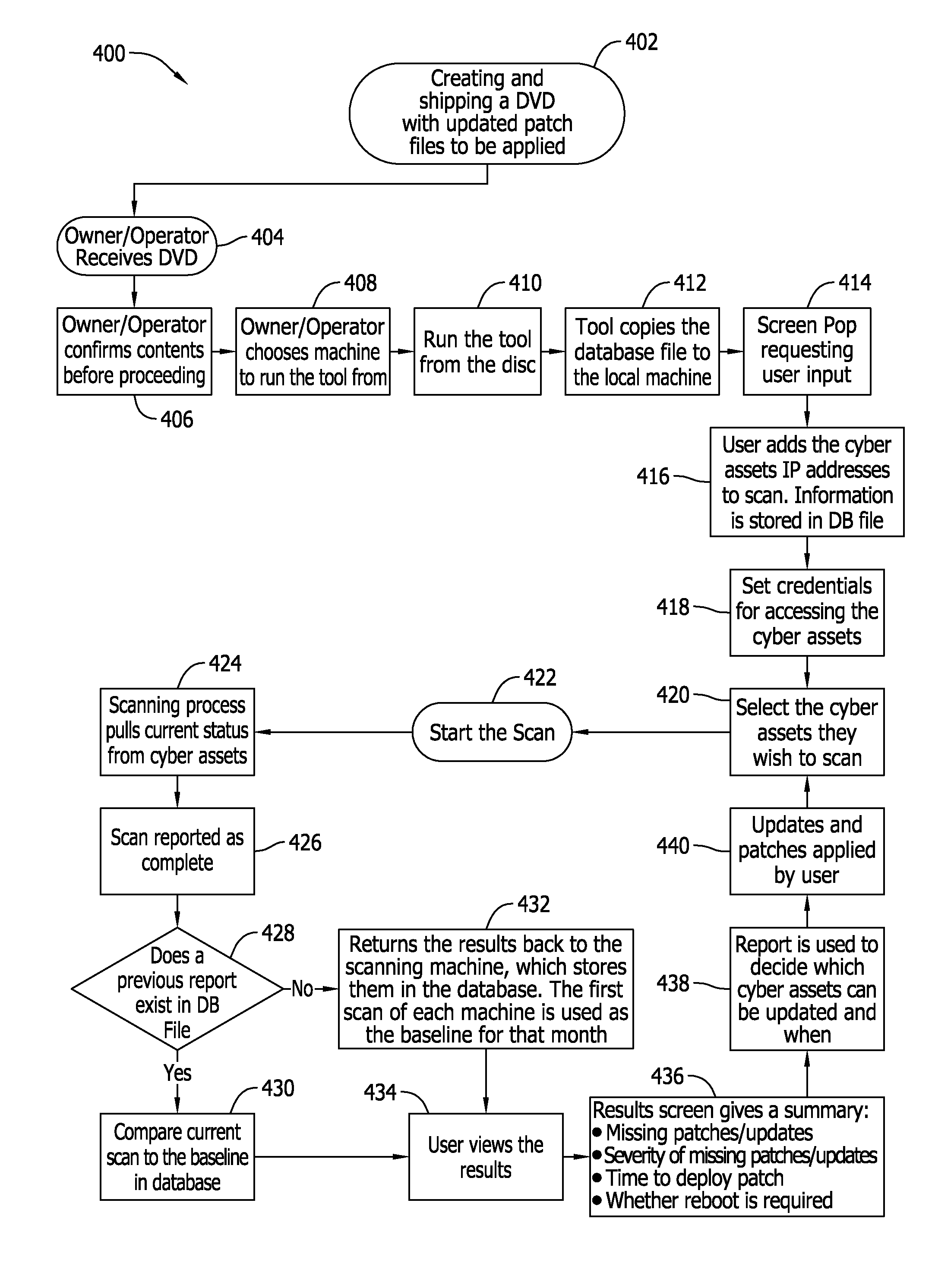

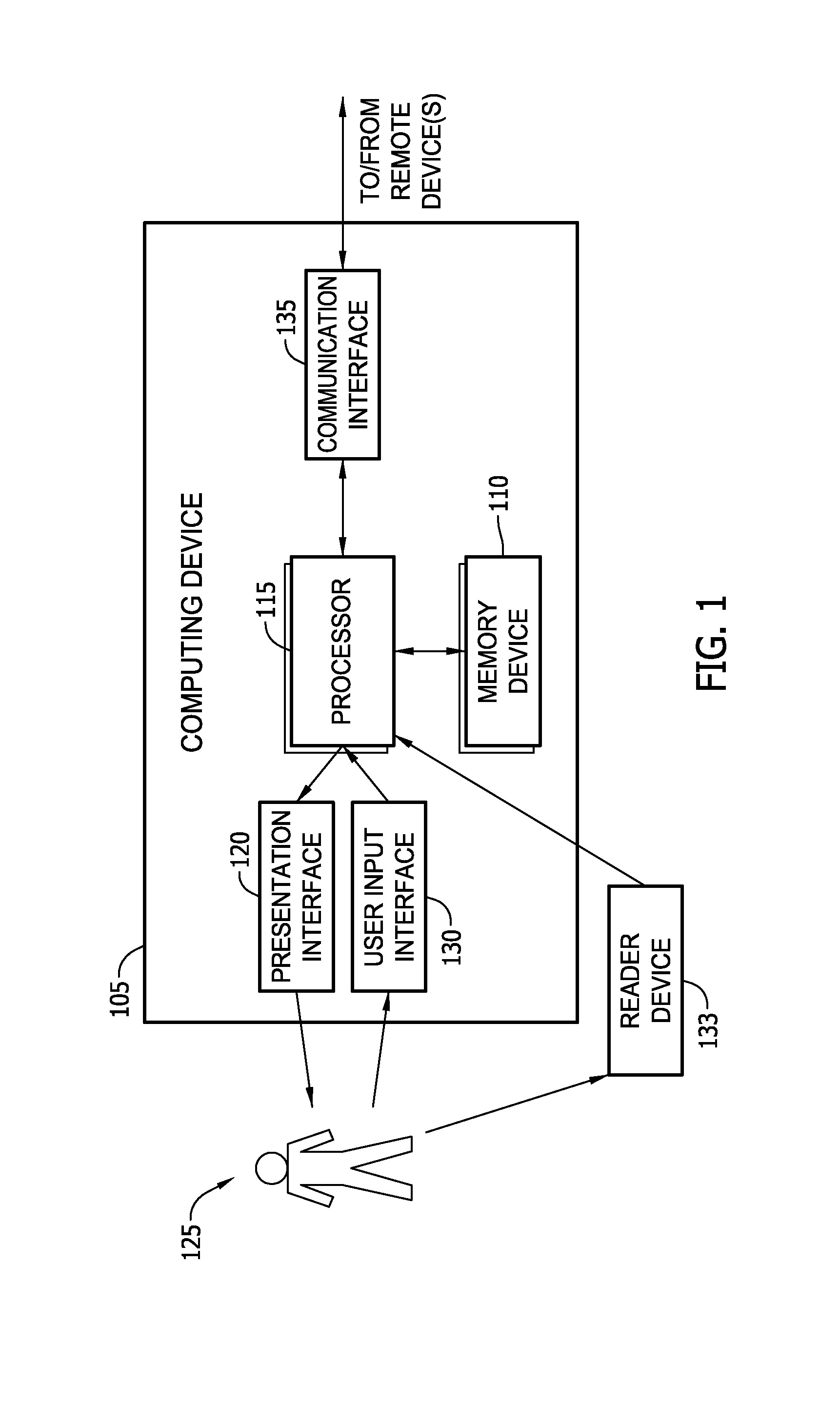

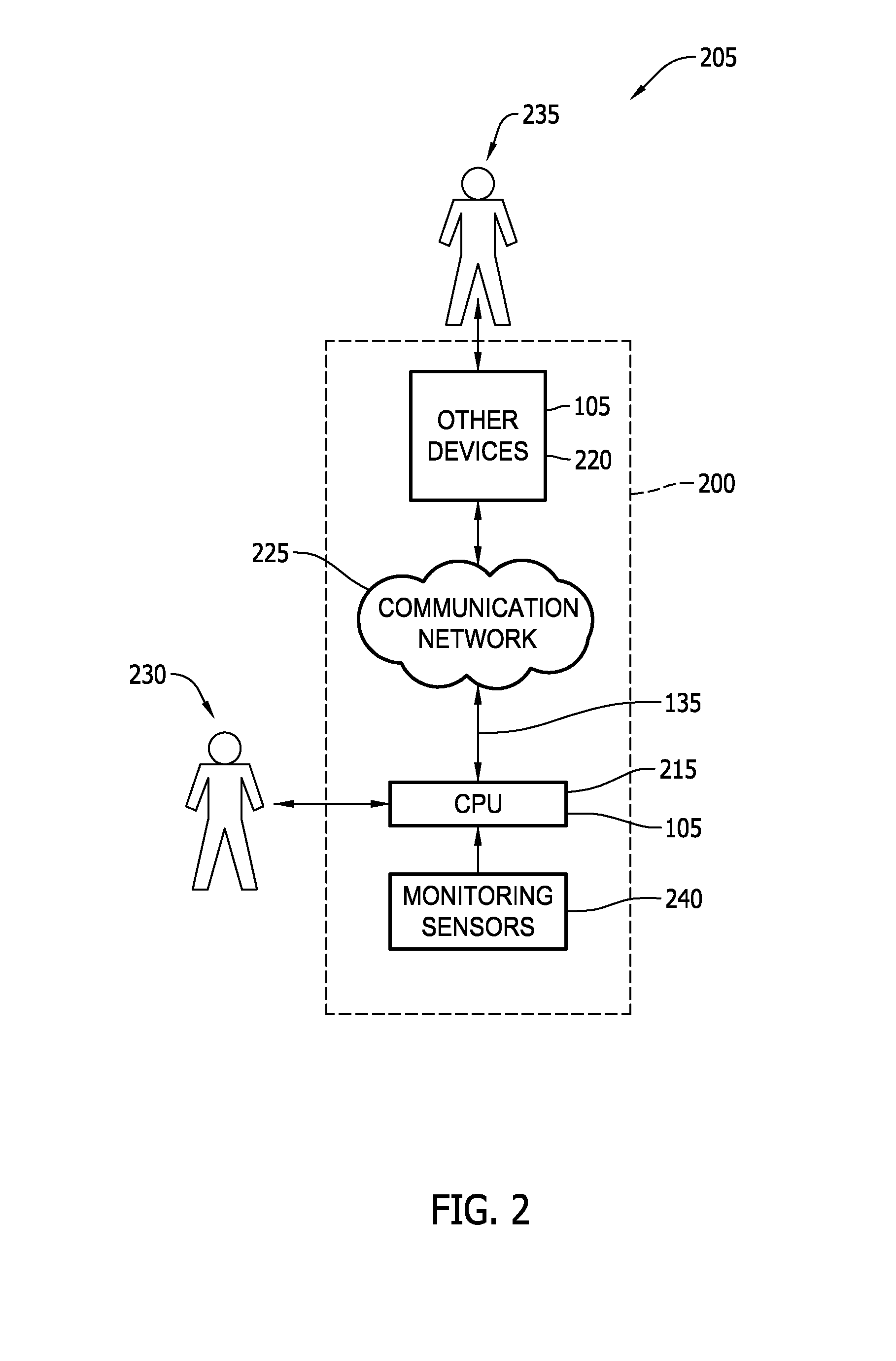

Method and system for use in facilitating patch change management of industrial control systems

An offline patch change management system for an industrial facility includes at least one reader device configured to read patch update information stored on computer-readable storage media inserted therein. The industrial facility includes an industrial control system that includes at least cyber asset. The system also includes a memory device coupled to the reader device. The memory device is configured to store the patch update information. The system further includes a processor coupled to the memory device. The processor is programmed to scan the at least one cyber asset. The processor is also programmed to generate a scan report including a patch status for at least one patch not operatively resident on the at least one cyber asset. The scan report includes a deployment temporal period value for deployment of the patch.

Owner:BAKER HUGHES INC

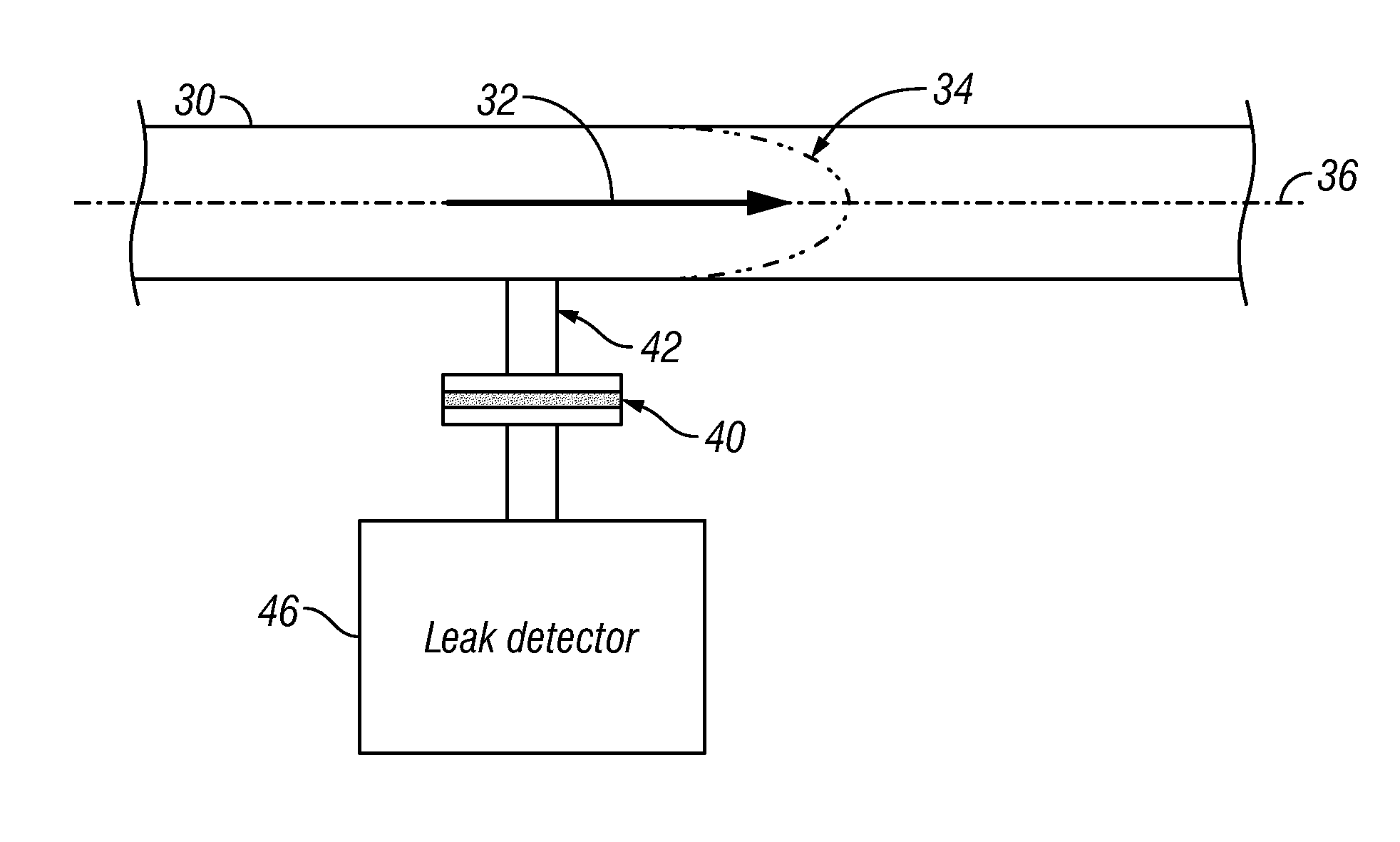

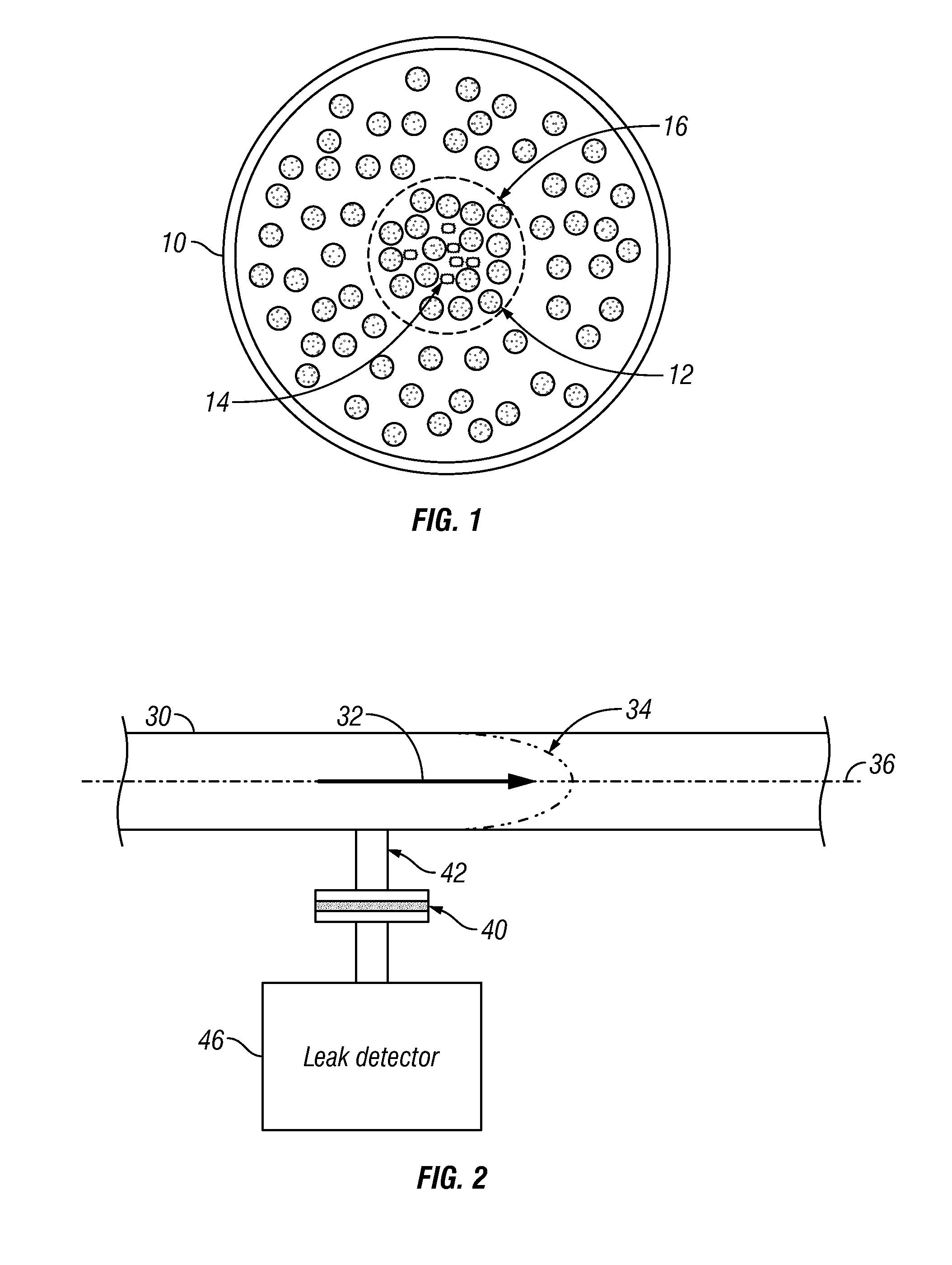

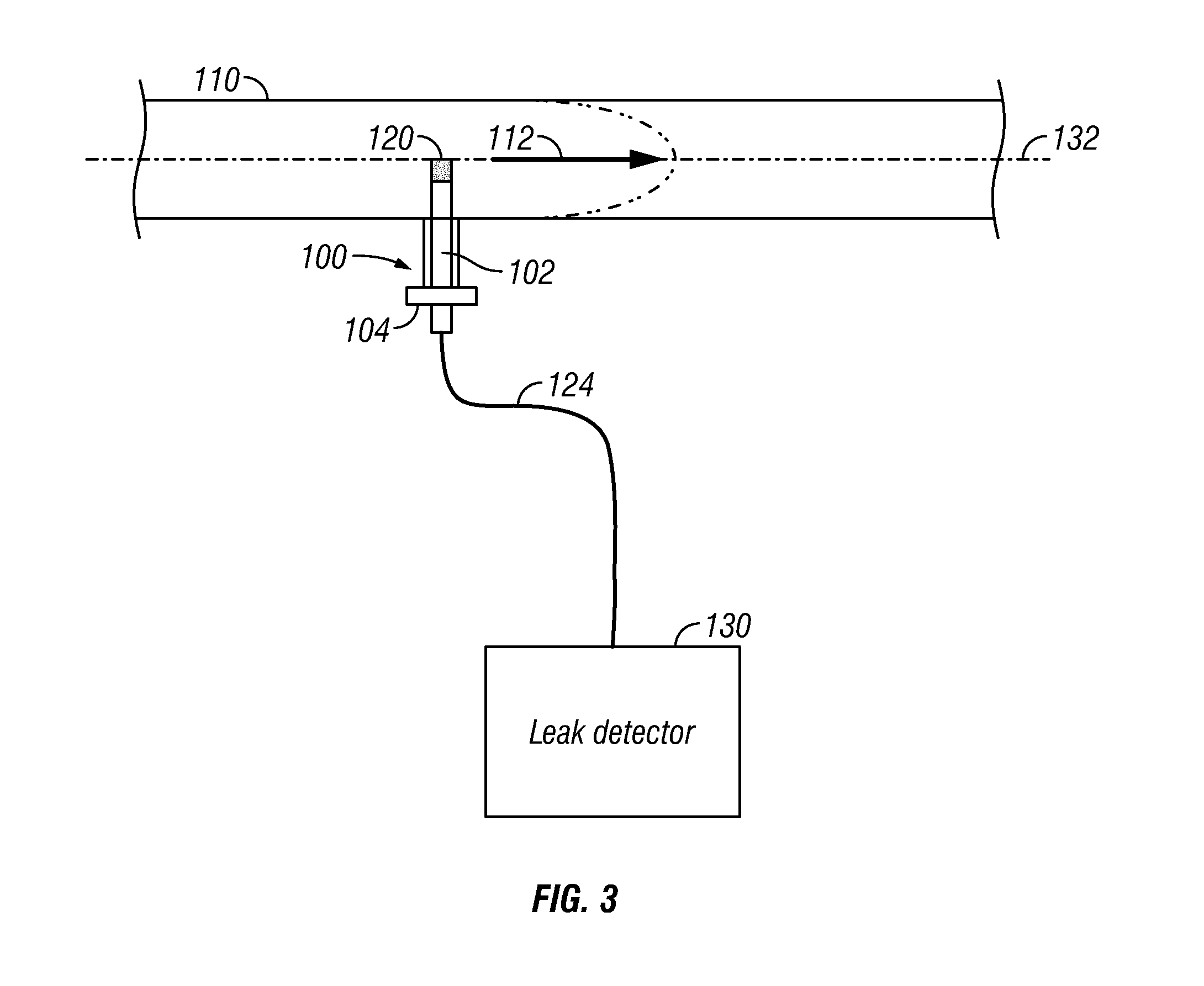

Leak test probe for use in industrial facilities

InactiveUS20110290006A1Simple and highly reliable and efficient leak test processShorten the timeDetection of fluid at leakage pointPower stationTest measurement

Methods and apparatus are provided for performing accurate, repeatable leak test measurements in wet, dusty and / or fluid-filled systems, such as a power plant, with no special sampling pumps, carrier gases or separators required. A leak detector probe is installed directly in a pipe or other component carrying a gas flow to be tested and is coupled to the inlet of a leak detector. The leak detector probe includes a test gas permeable membrane, which is positioned in the gas flow to be tested. The test gas permeable membrane may, for example, be positioned in a central region of a pipe in the flow of gas toward the evacuation pump. In some embodiments, the position of the leak detector probe in the pipe or other component may be adjustable.

Owner:AGILENT TECH INC

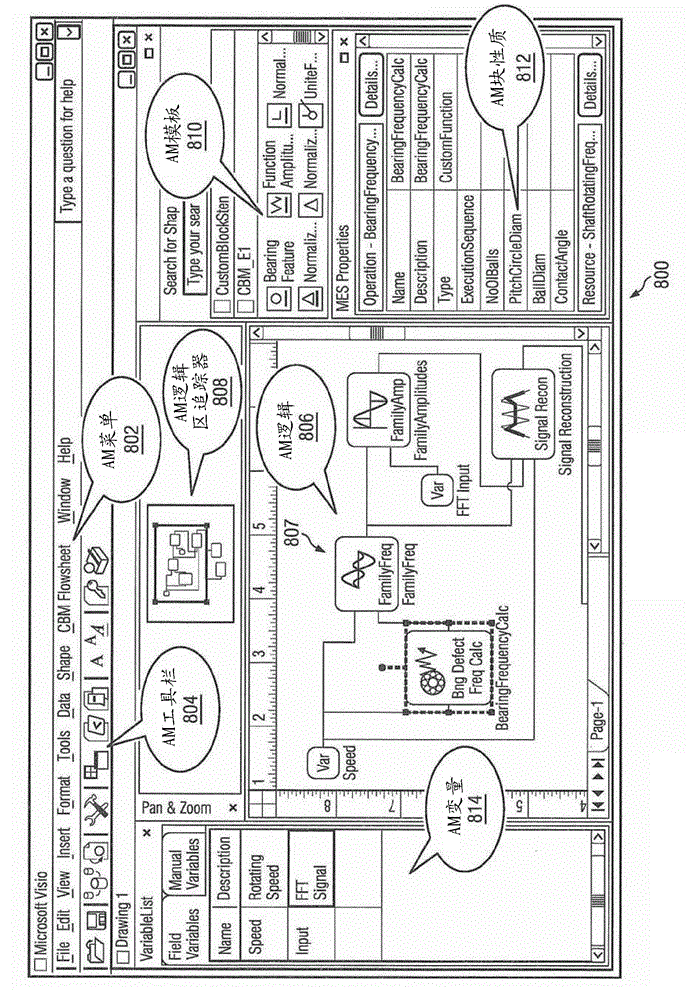

Large-scale comprehensive real-time monitoring framework for industrial facilities

A method includes associating multiple real-time applications with a framework. The real-time applications include applications for monitoring or controlling equipment in at least one industrial facility. Each application has at least one input variable and at least one output variable. The method also includes identifying relationships between the input and output variables of the applications to identify data dependencies. The method further includes receiving data updates at the framework and notifying at least one of the applications of the data updates based on the data dependencies to support data-driven operation of the framework. The data-driven operation of the framework provides data to the applications to support performance monitoring of the equipment, analysis of the equipment's operation, and / or identification of abnormal equipment conditions.

Owner:HONEYWELL INT INC

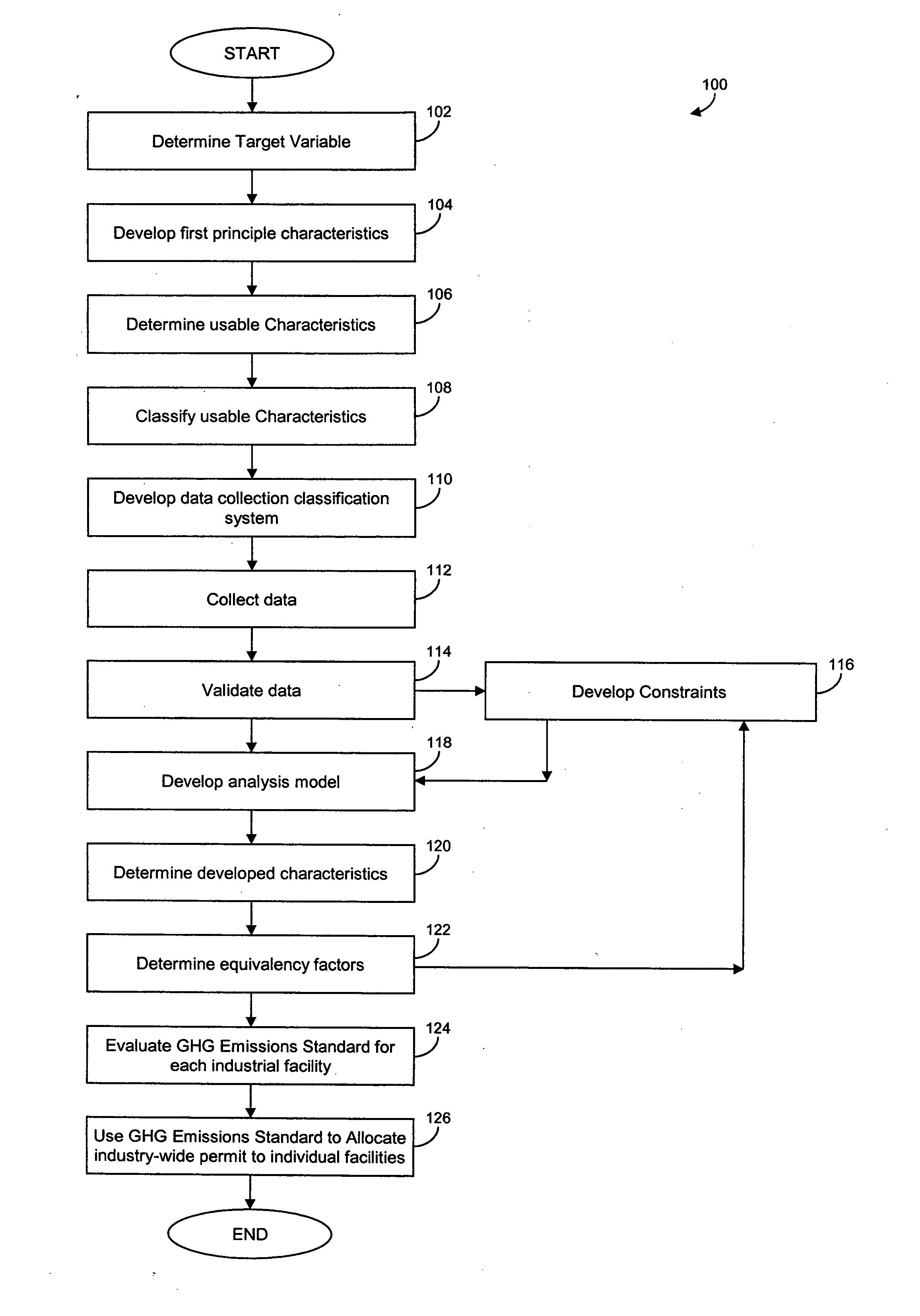

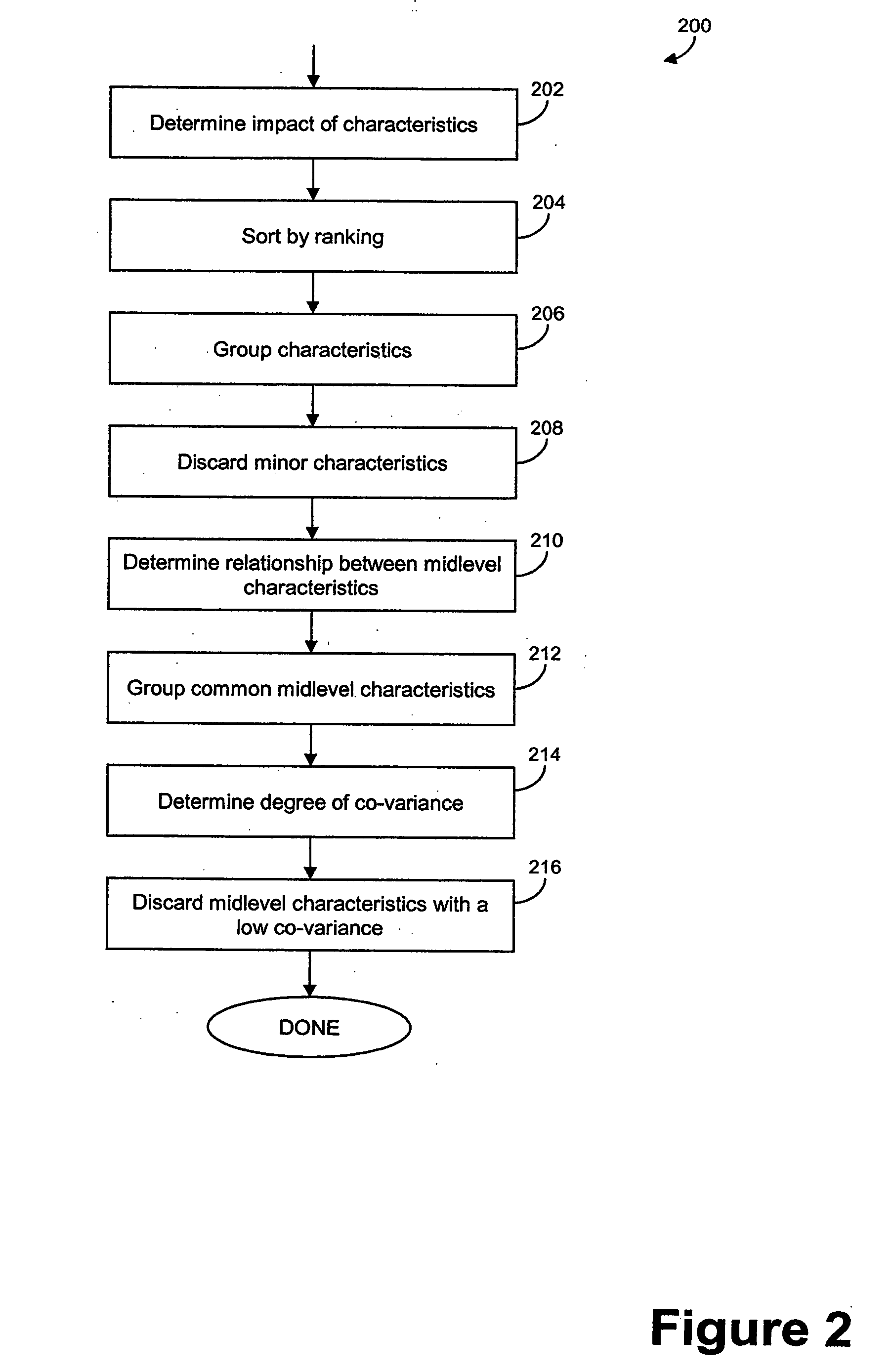

Method and system for greenhouse gas emissions performance assessment and allocation

The present invention provides a system and method for determining equivalency factors for use in comparative performance analysis of industrial facilities by determining a target variable and a plurality of characteristics of the target variable. Each of the plurality of characteristics is ranked according to value. Based on ranking value, the characteristics are divided into categories. Based on the sorted and ranked characteristics, a data collection classification system is developed. Data is collected according to the data collection classification system. The data is validated, and based on the data, an analysis model is developed. The analysis model then calculates the equivalency factors for use in one embodiment in performance measurement and equitable benchmarking of green house gas (GHG) emissions from industrial facilities for the purposes of allocating GHG emission allowances for permits, licenses, etc.

Owner:HSB SOLOMON ASSOCS

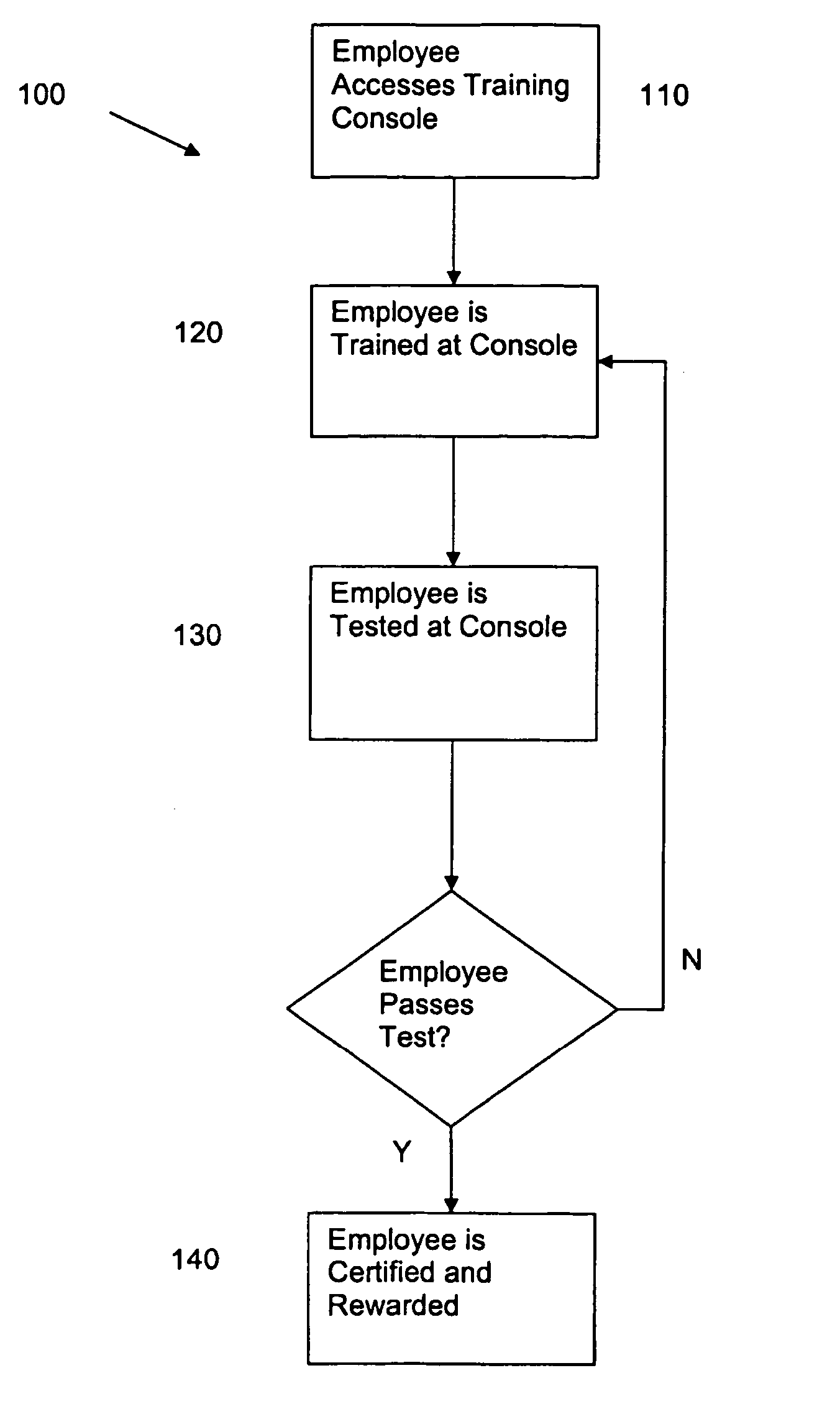

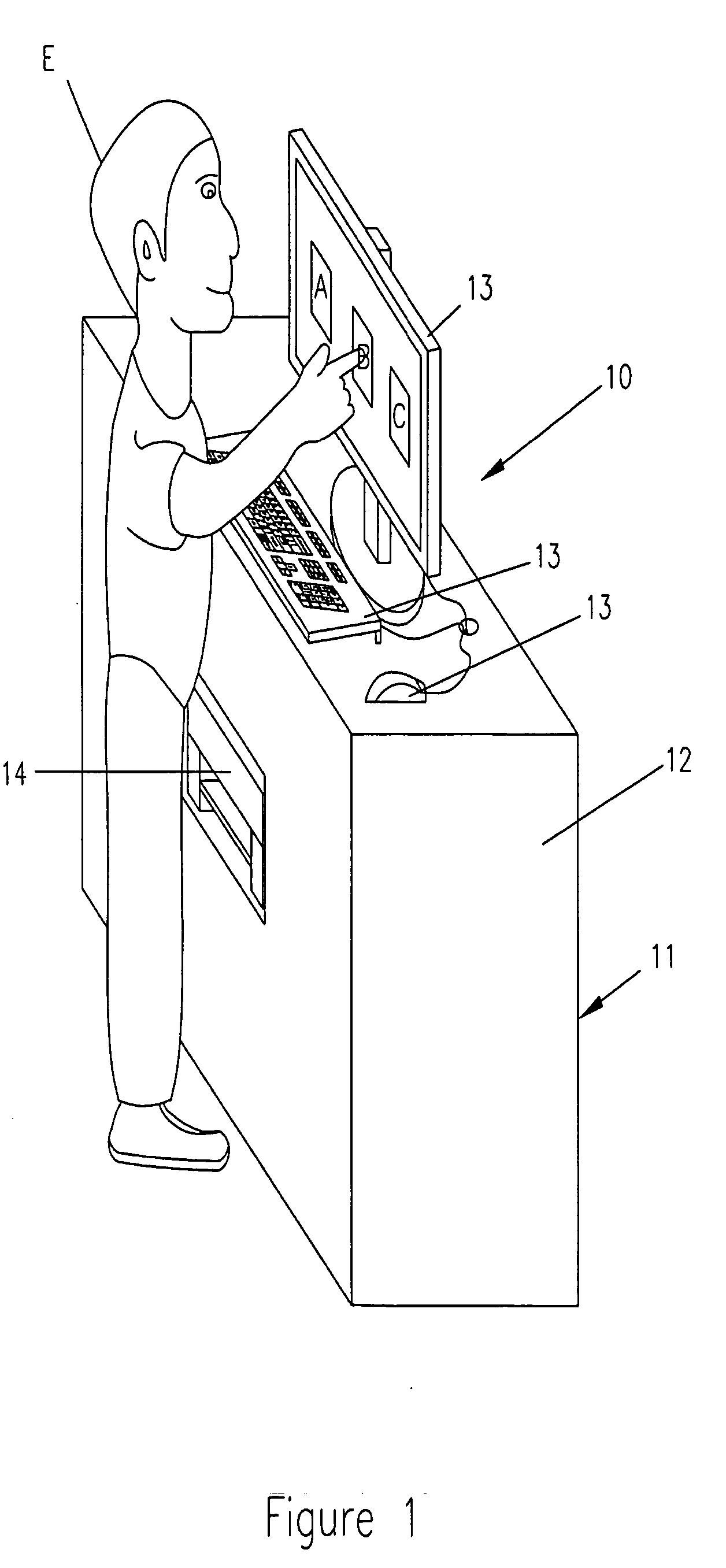

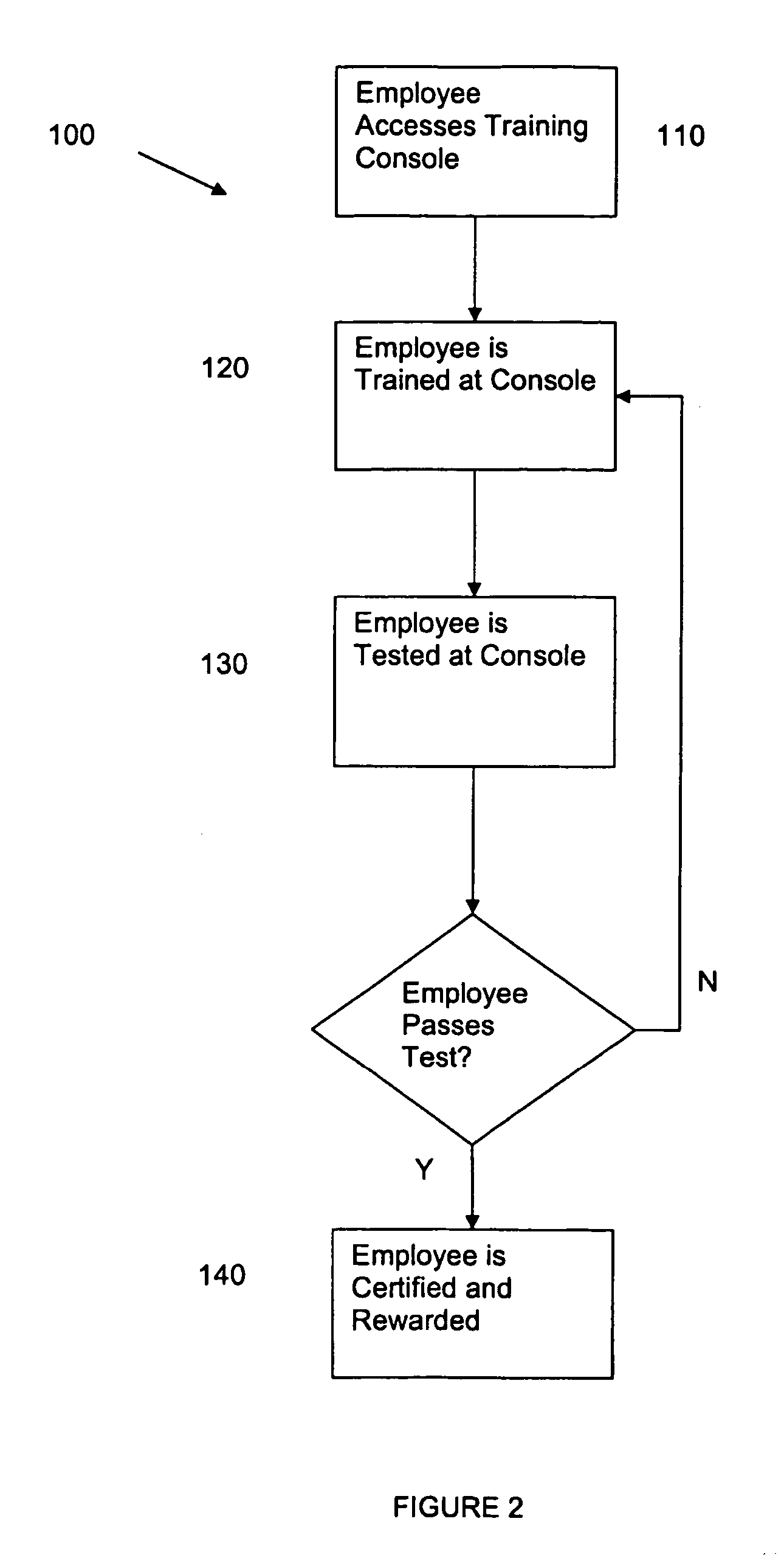

Method of training and rewarding employees

InactiveUS20060204948A1Efficient managementEasy to manageOffice automationElectrical appliancesComputer printingComputer science

A system and method of training and rewarding an employee is disclosed. The system includes a console, including a computer system; a software program, installed on the computer system for training and testing the employee; an input device, mounted on the console, and operatively connected to the computer system in the console; and a printer, mounted within the console, operatively connected to the computer system in the console to print a reward for the employee. The method includes the steps of providing the console at an industrial facility; training the employee using the software program; testing the employee at the console; and generating a reward for the employee after the employee successfully tests.

Owner:SIMS WILLIAM JR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com