Patents

Literature

1737results about "Non-rotary device cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

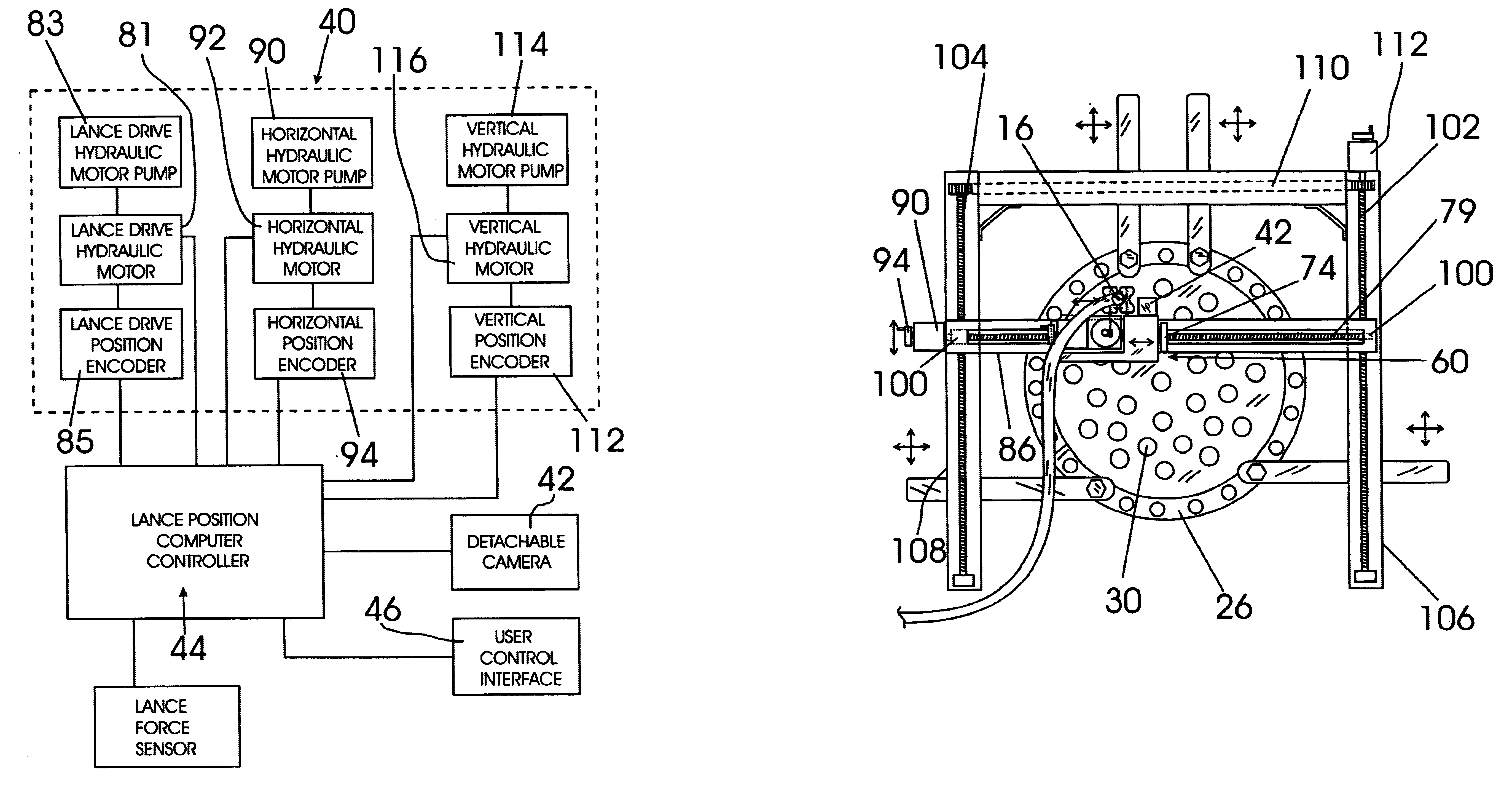

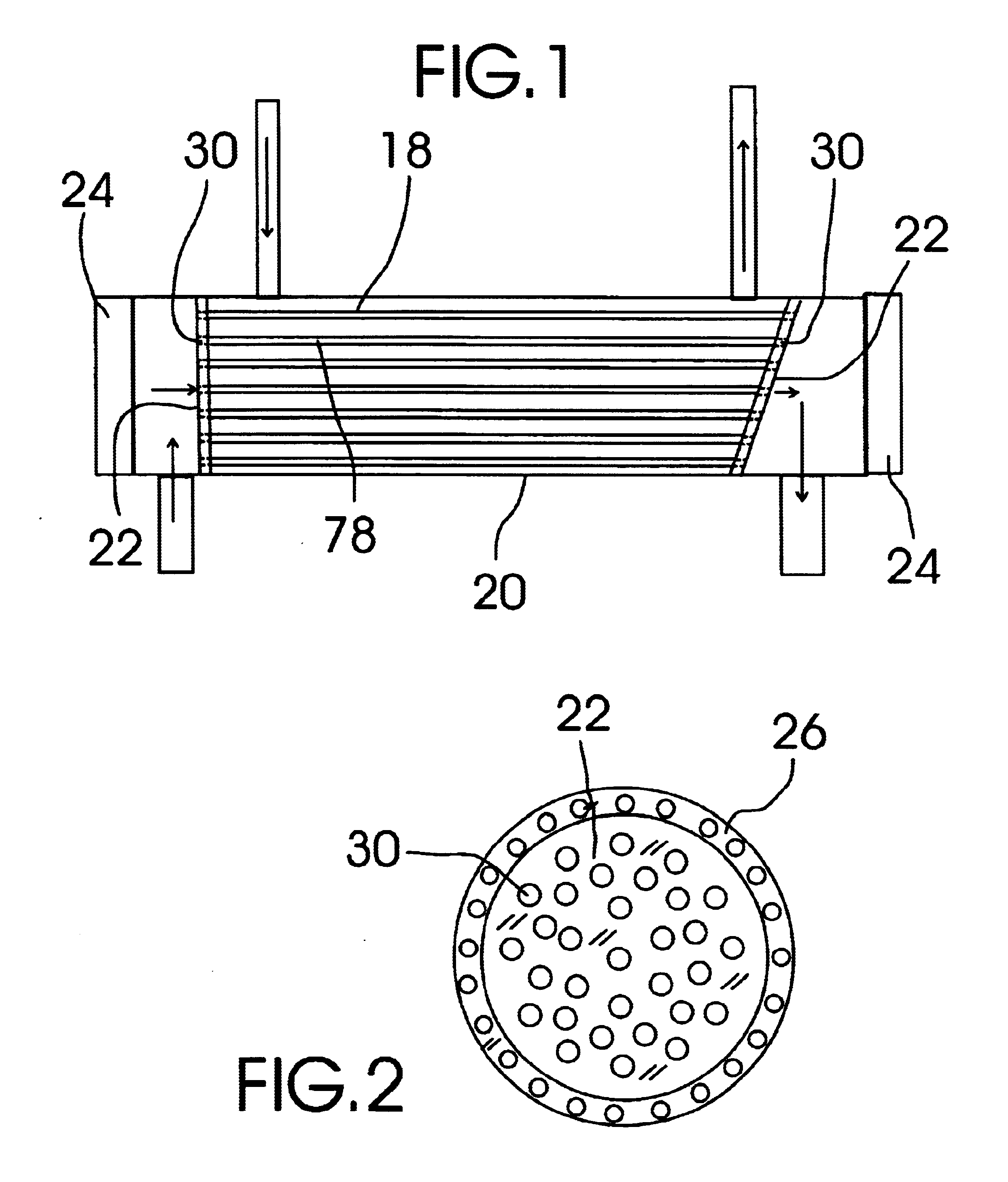

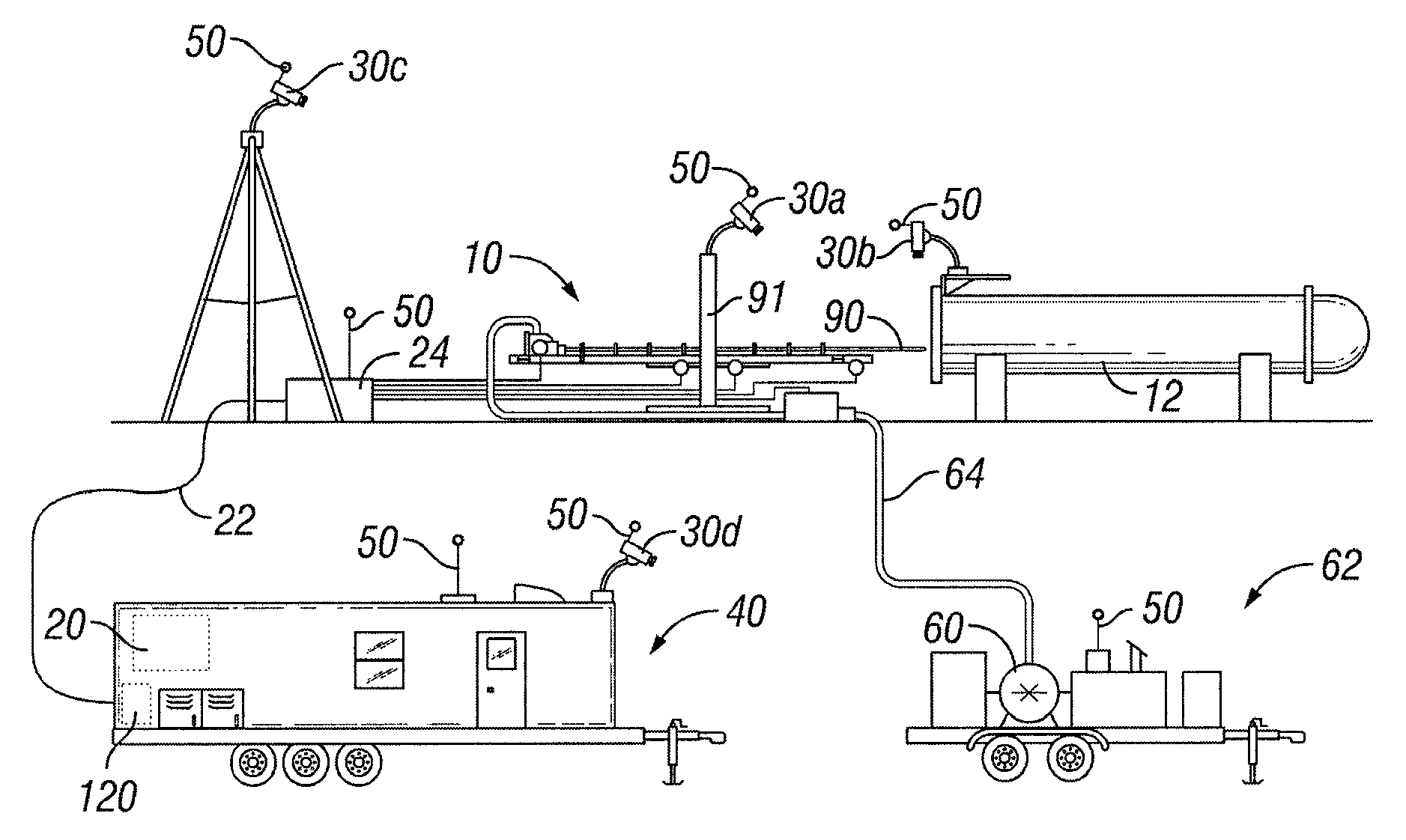

Heat exchanger exchange-tube cleaning lance positioning system

A heat exchanger exchange-tube cleaning lance positioning system that includes a three axis cleaning lance positioning mechanism that is attachable to the end of a heat exchanger and that is controlled by a lance position computer controller that determines the locations of each of the openings of the exchange-tubes of the heat exchanger by analyzing an image signal generated by a camera mounted to the three axis cleaning lance positioning mechanism and then positions a connected exchange tube cleaning lance into and through each of the exchange-tube passageways to clean the exchange-tube passageways automatically.

Owner:BALZER BRENT A

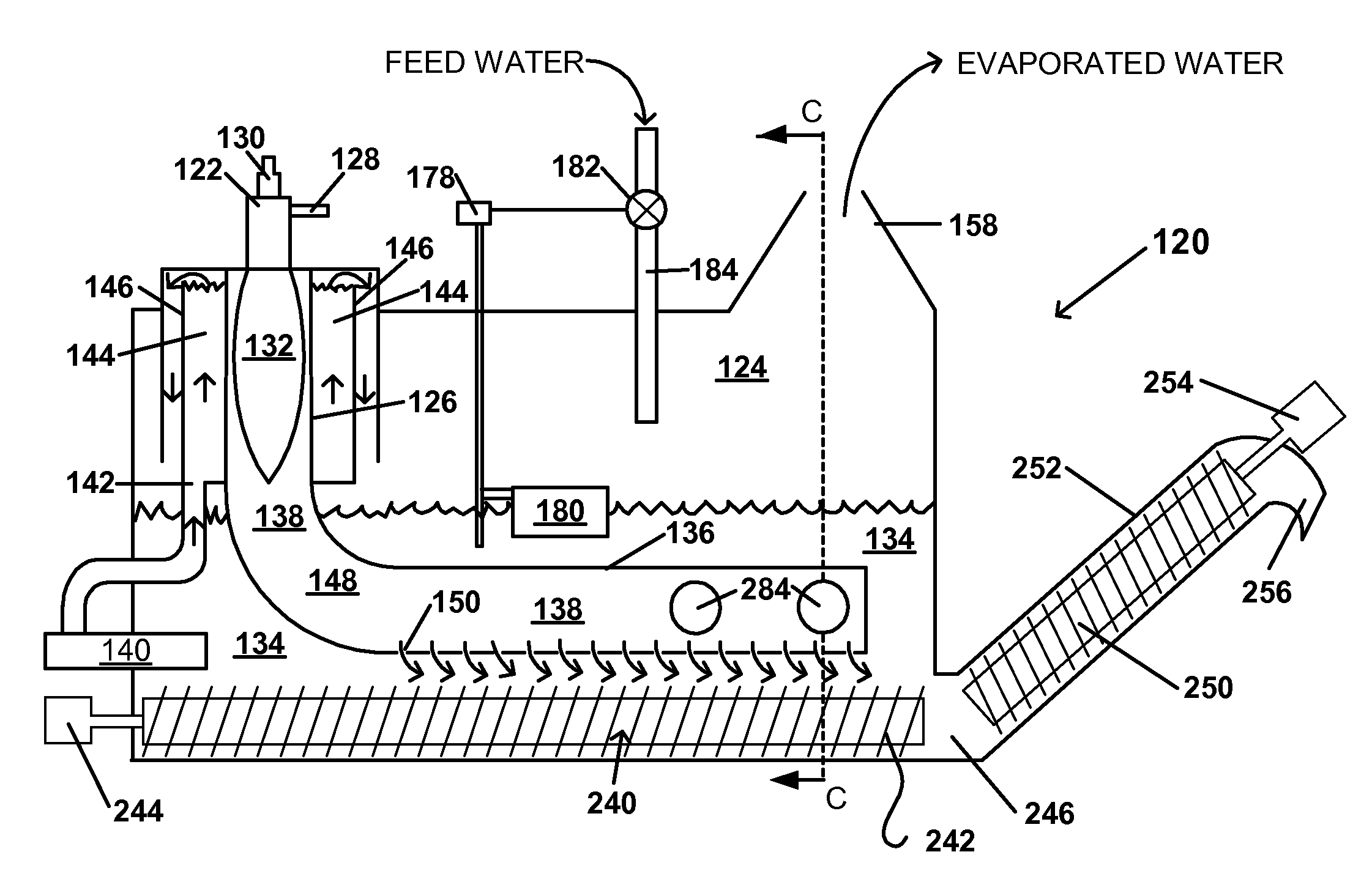

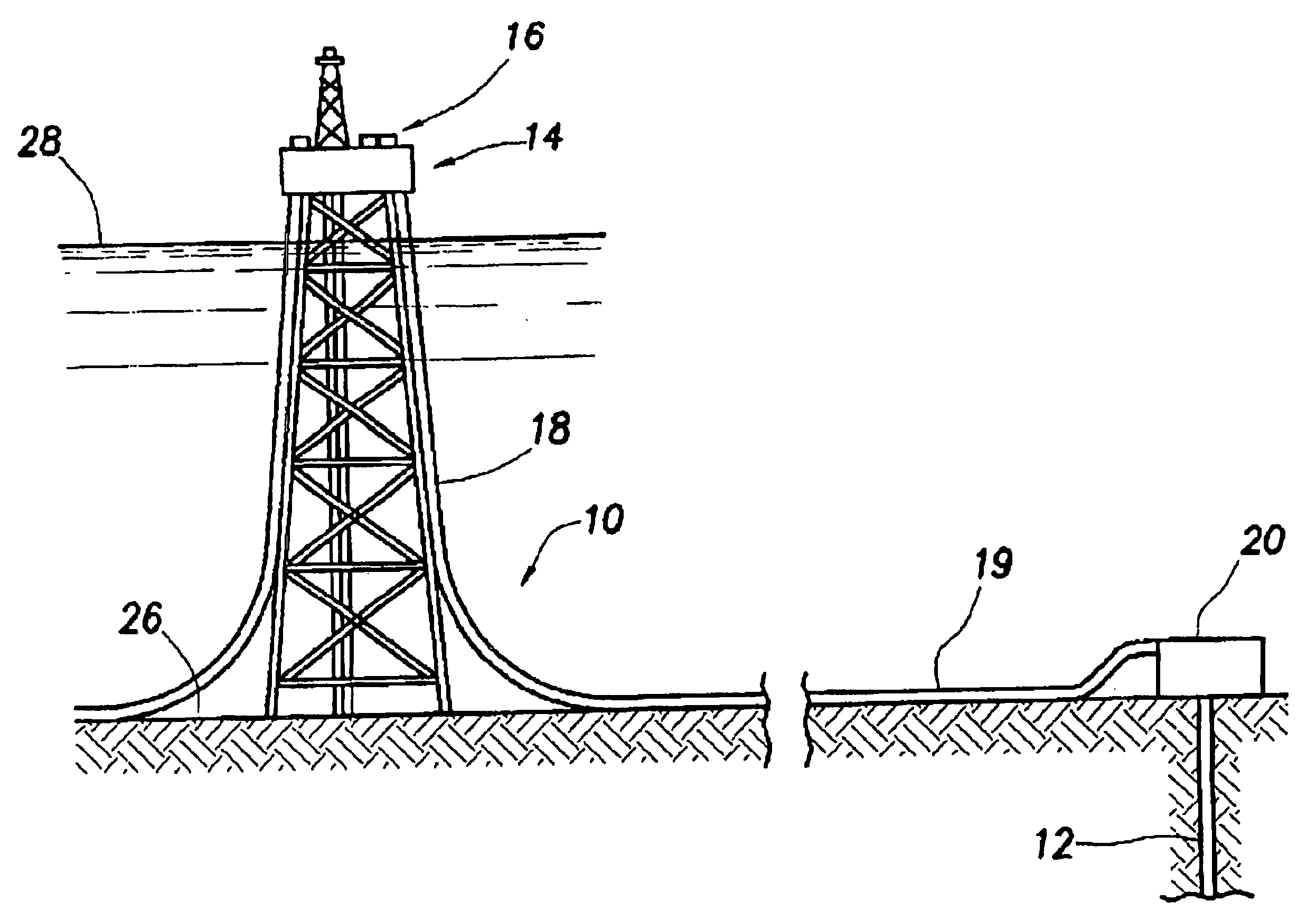

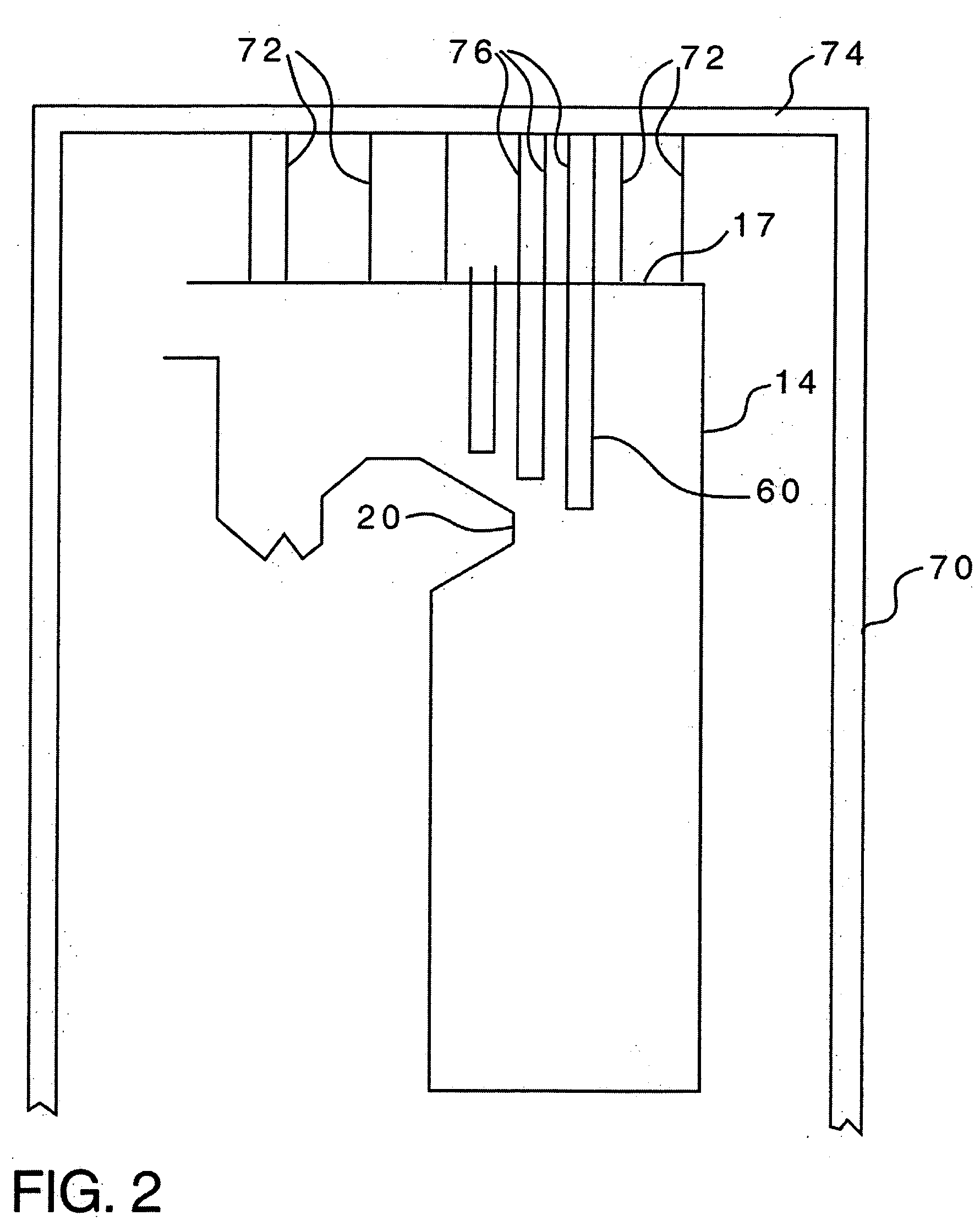

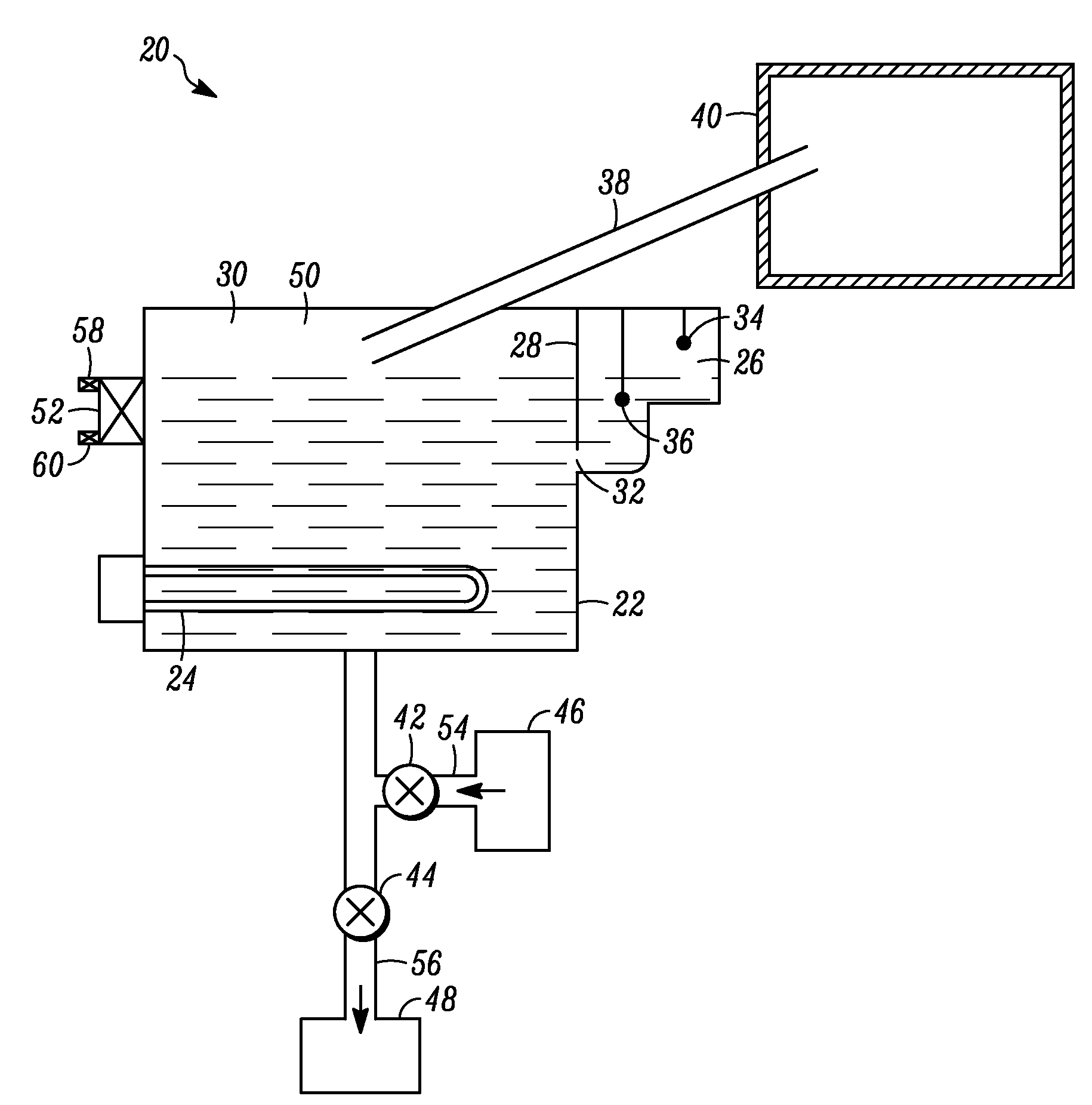

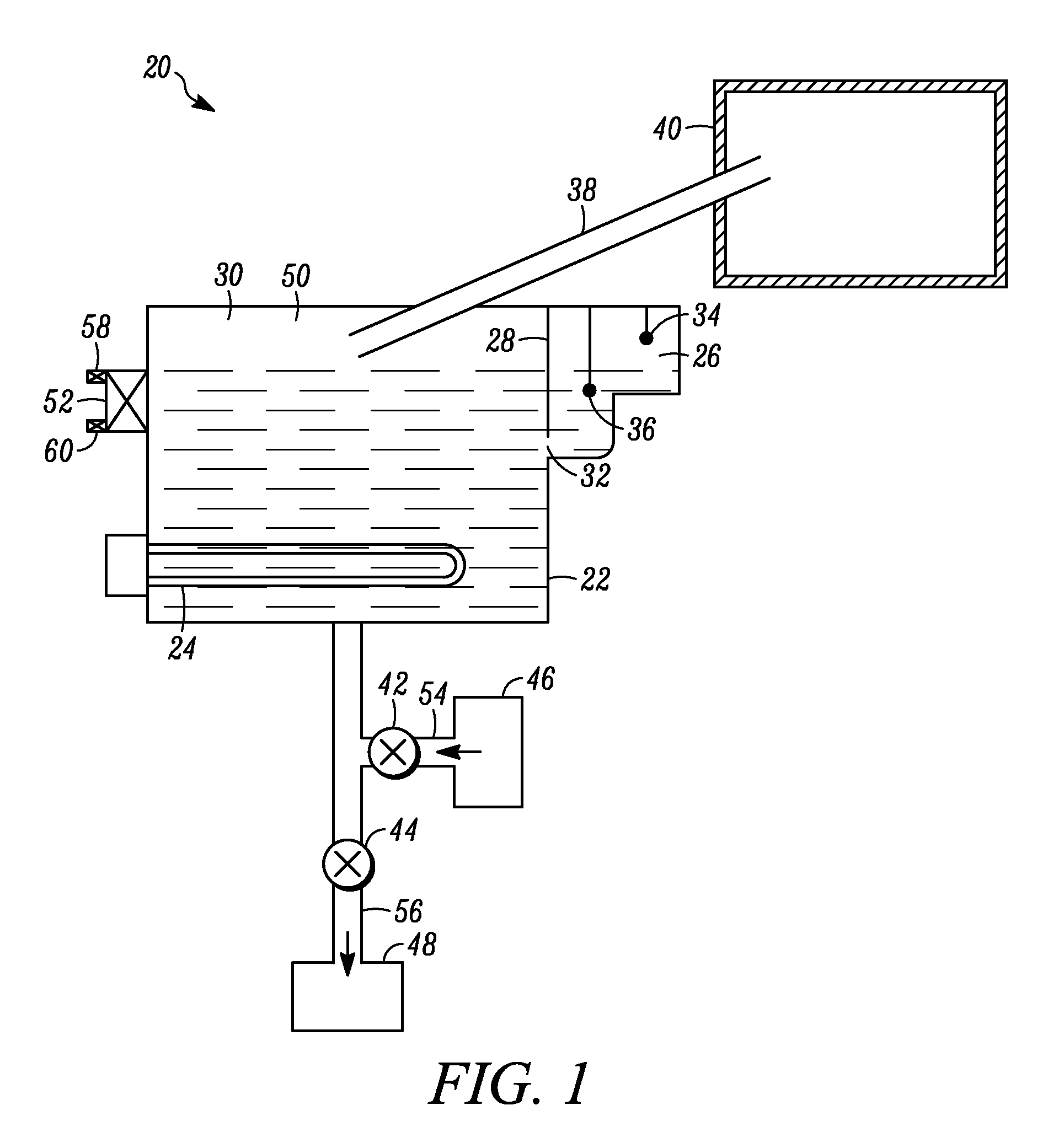

Submerged combustion disposal of produced water

InactiveUS7845314B2Easy to handleEasy disposalBoiler cleaning apparatusSedimentation separationCombustion systemCombustion chamber

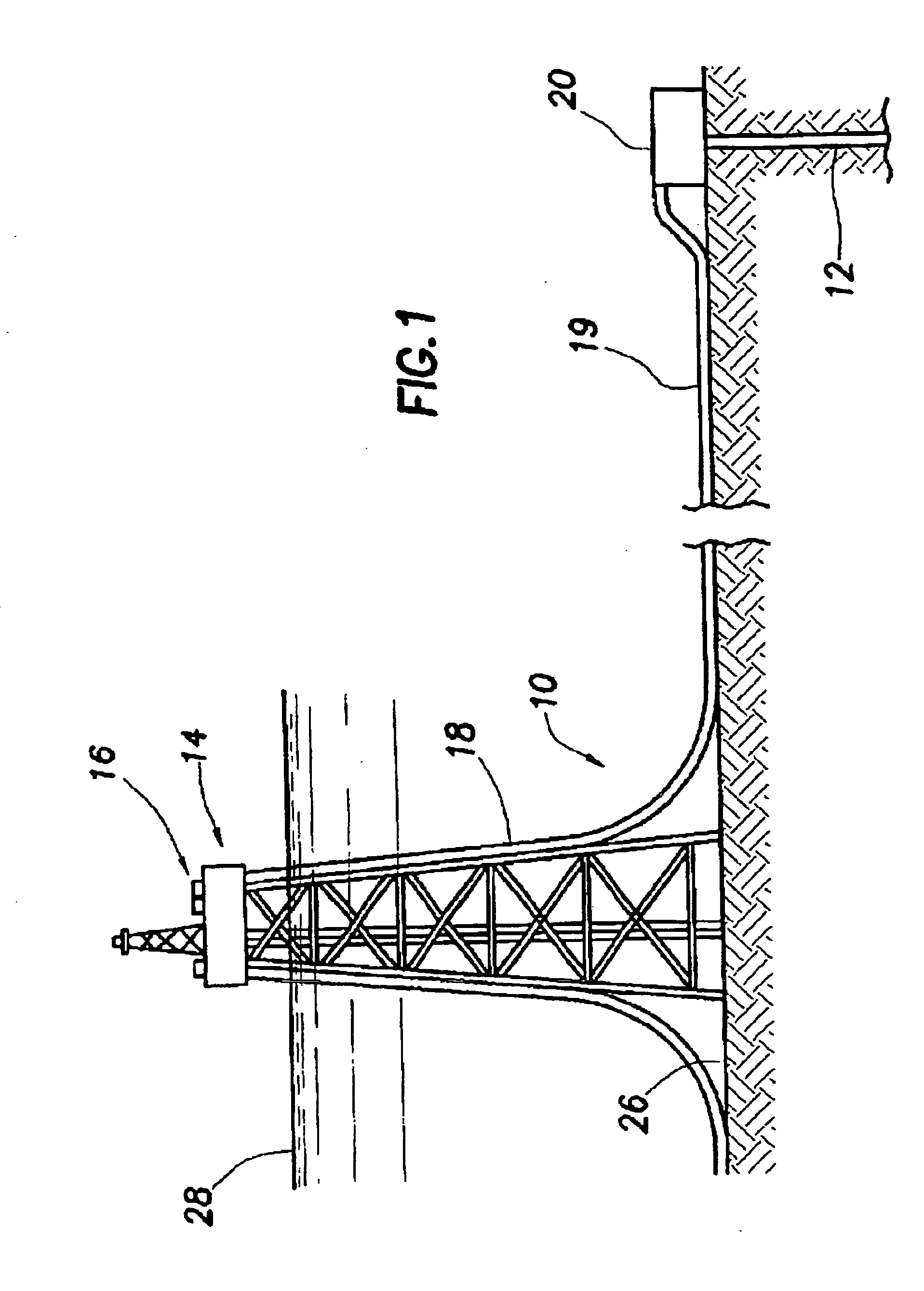

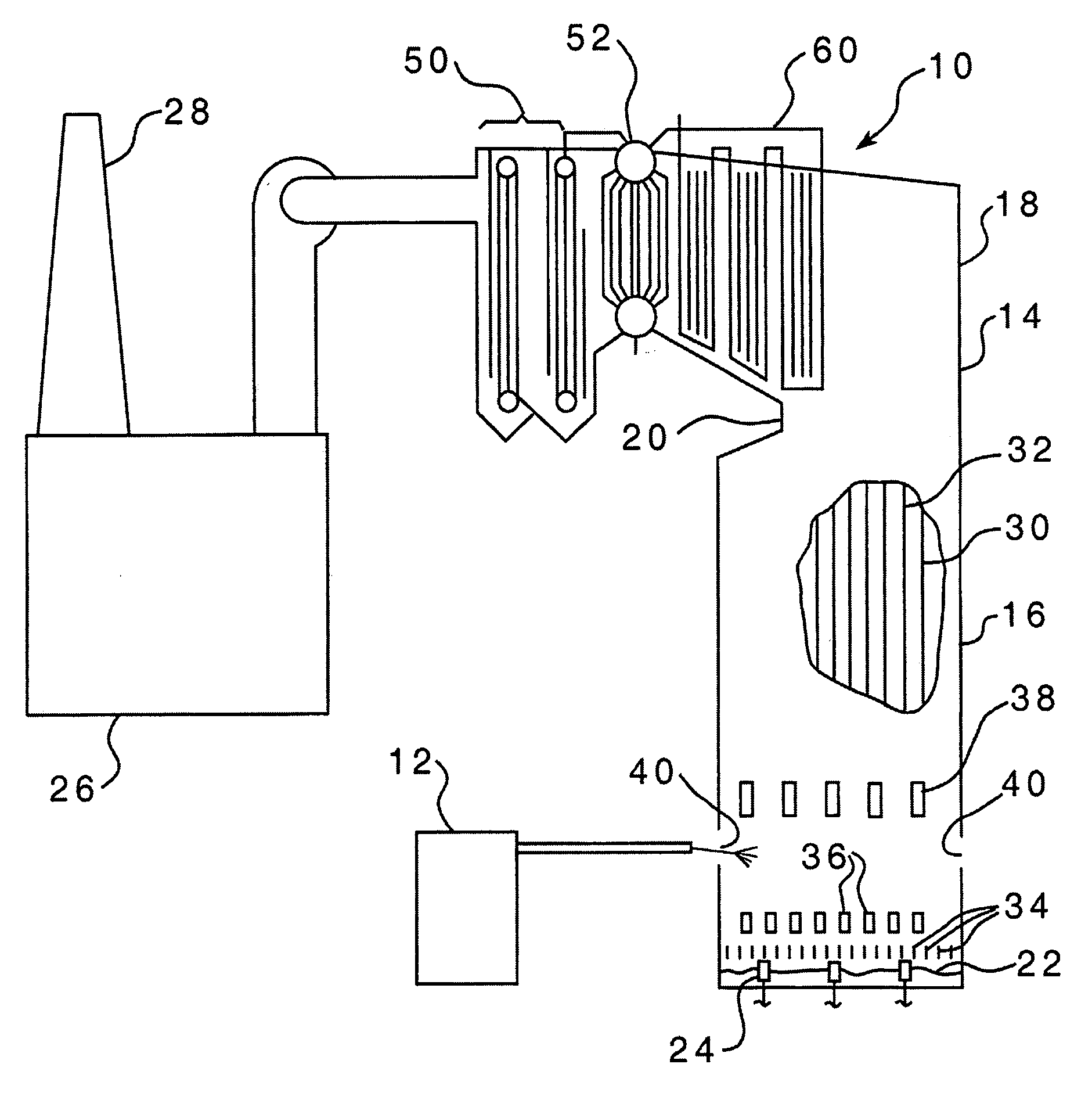

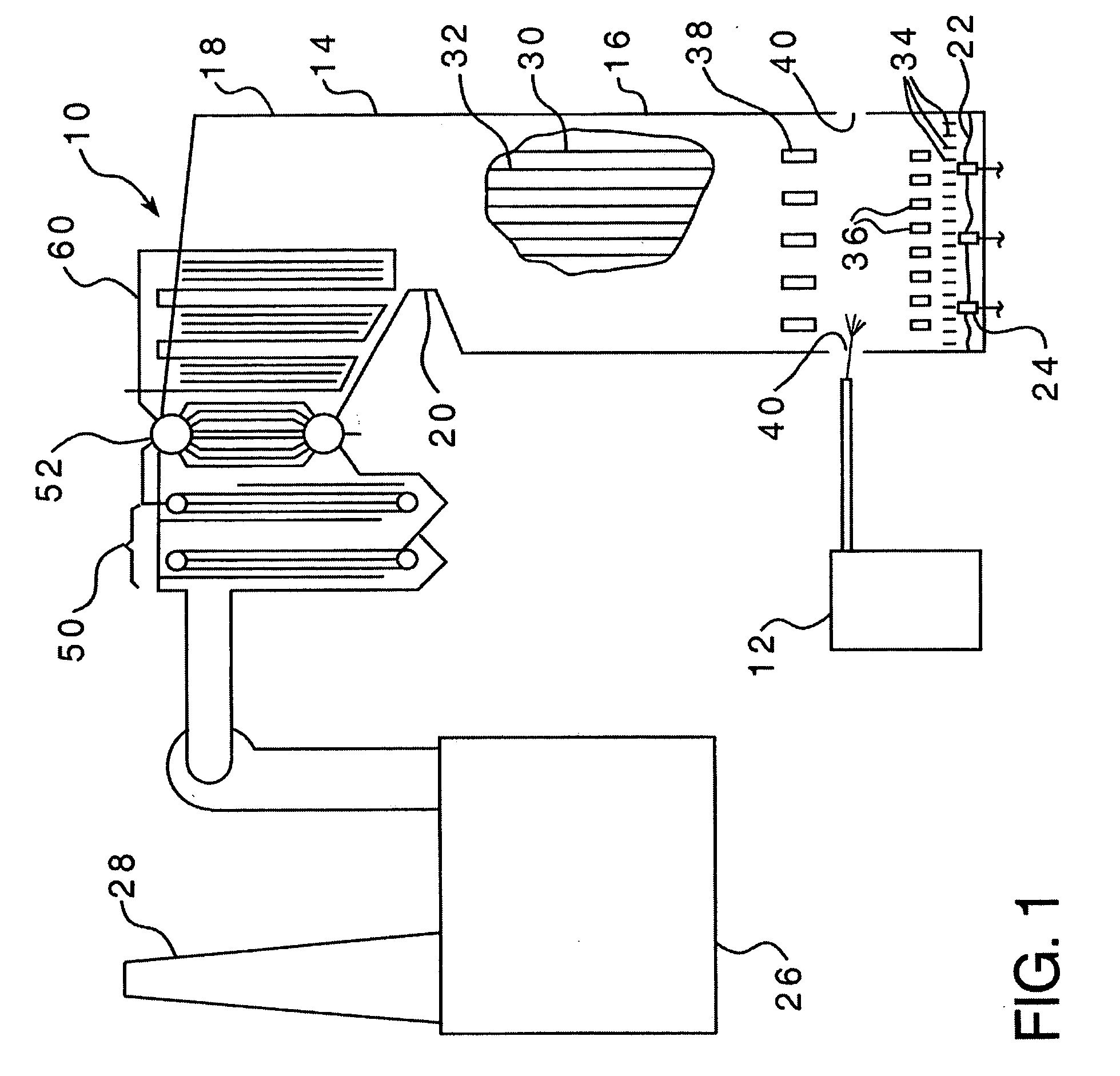

The present invention relates to a method of disposing of produced water and to a produced water disposal apparatus including a container for receiving and holding produced water; and a burner having a combustion chamber, wherein at least a portion of the combustion chamber is submerged in the water and the submerged portion of the combustion chamber comprises a sparger tube through which combustion gases emerge into, mix with and agitate the water. The present invention further relates to a mechanism for removing debris from the produced water disposal apparatus. In one embodiment, heat is supplied from an externally operated combustion system, rather than the submerged combustion. In one embodiment, the apparatus provides a concentrator, in which a solute can be removed and recovered from an aqueous medium containing the solute.

Owner:TDU LLC

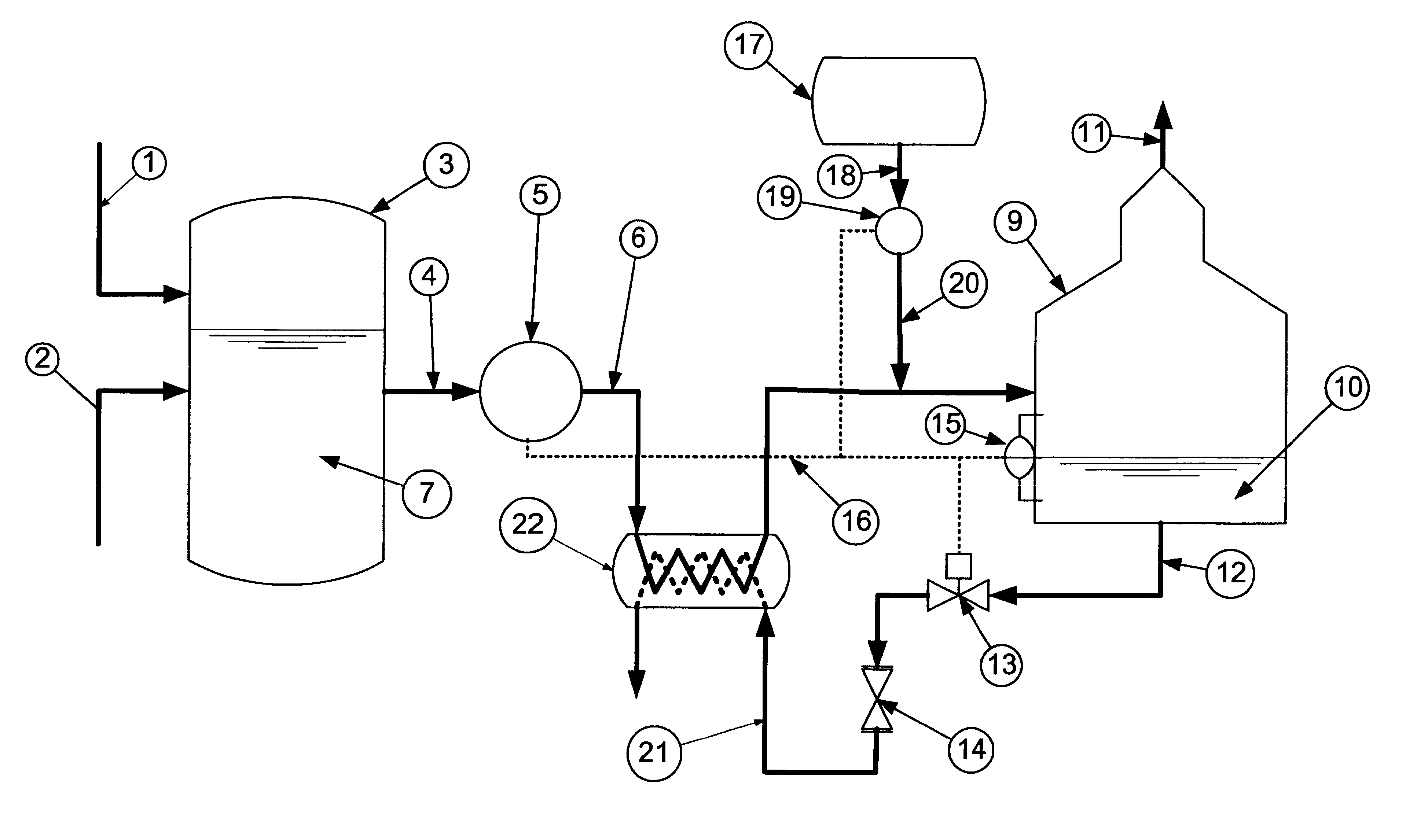

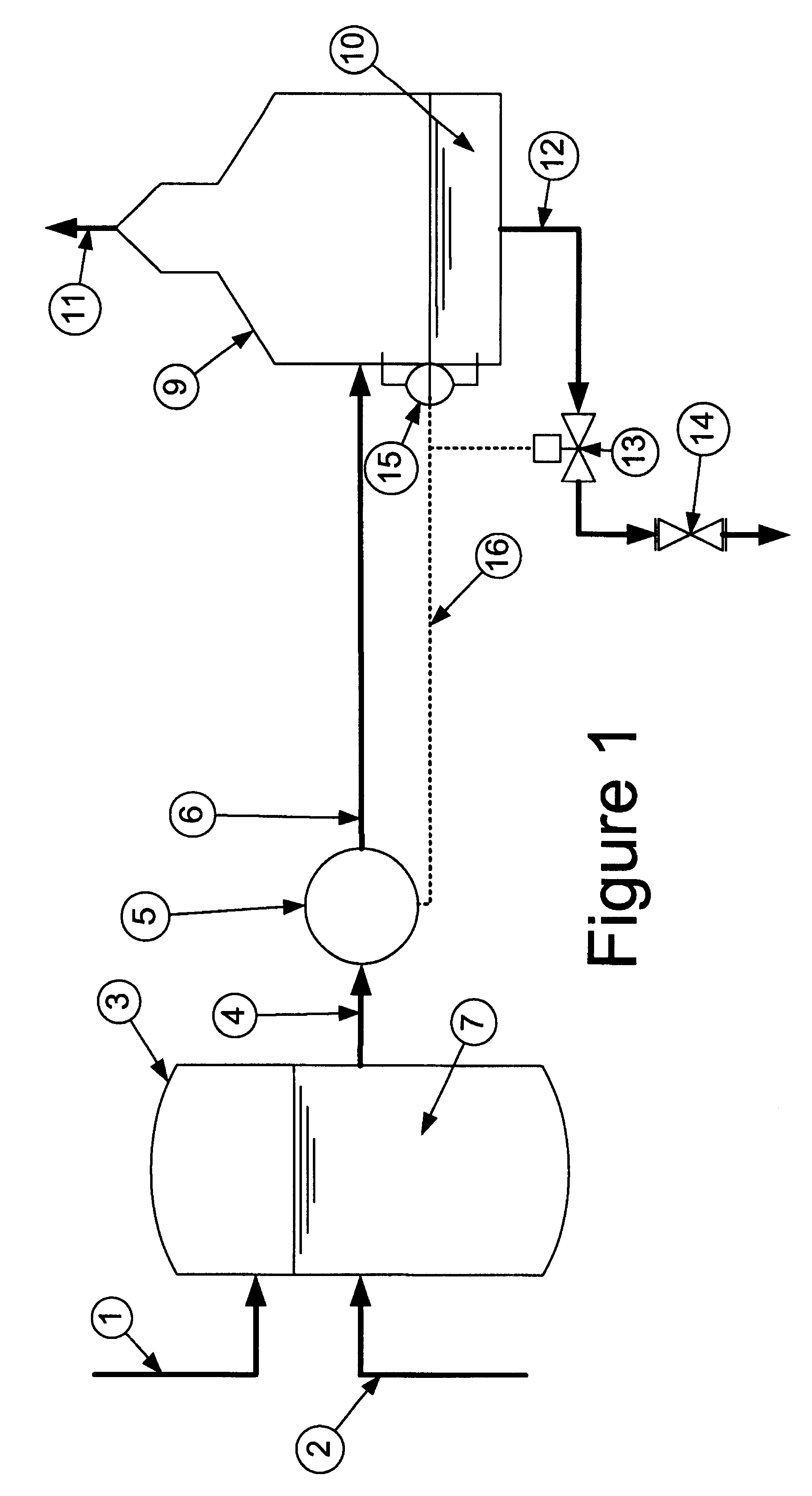

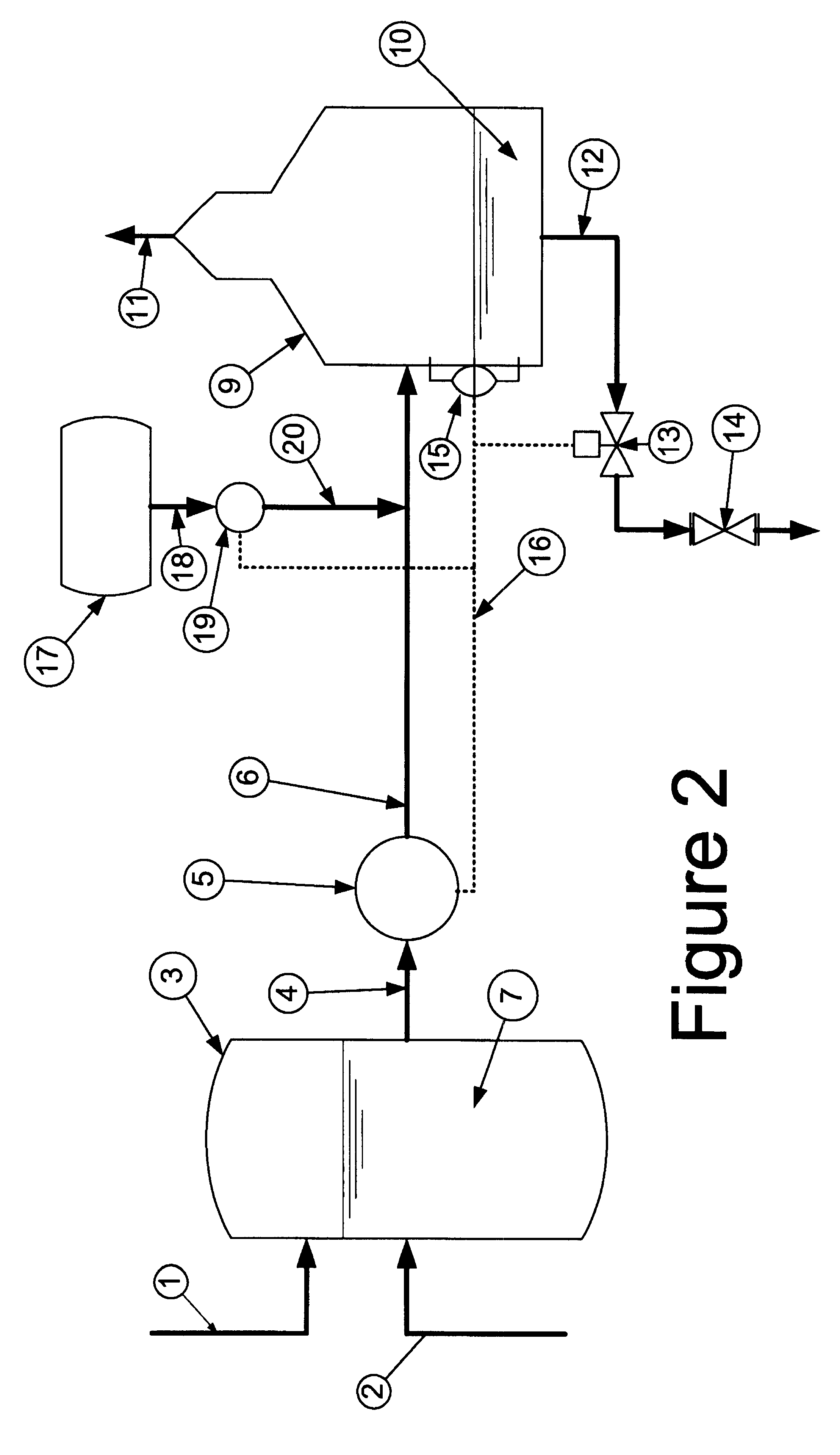

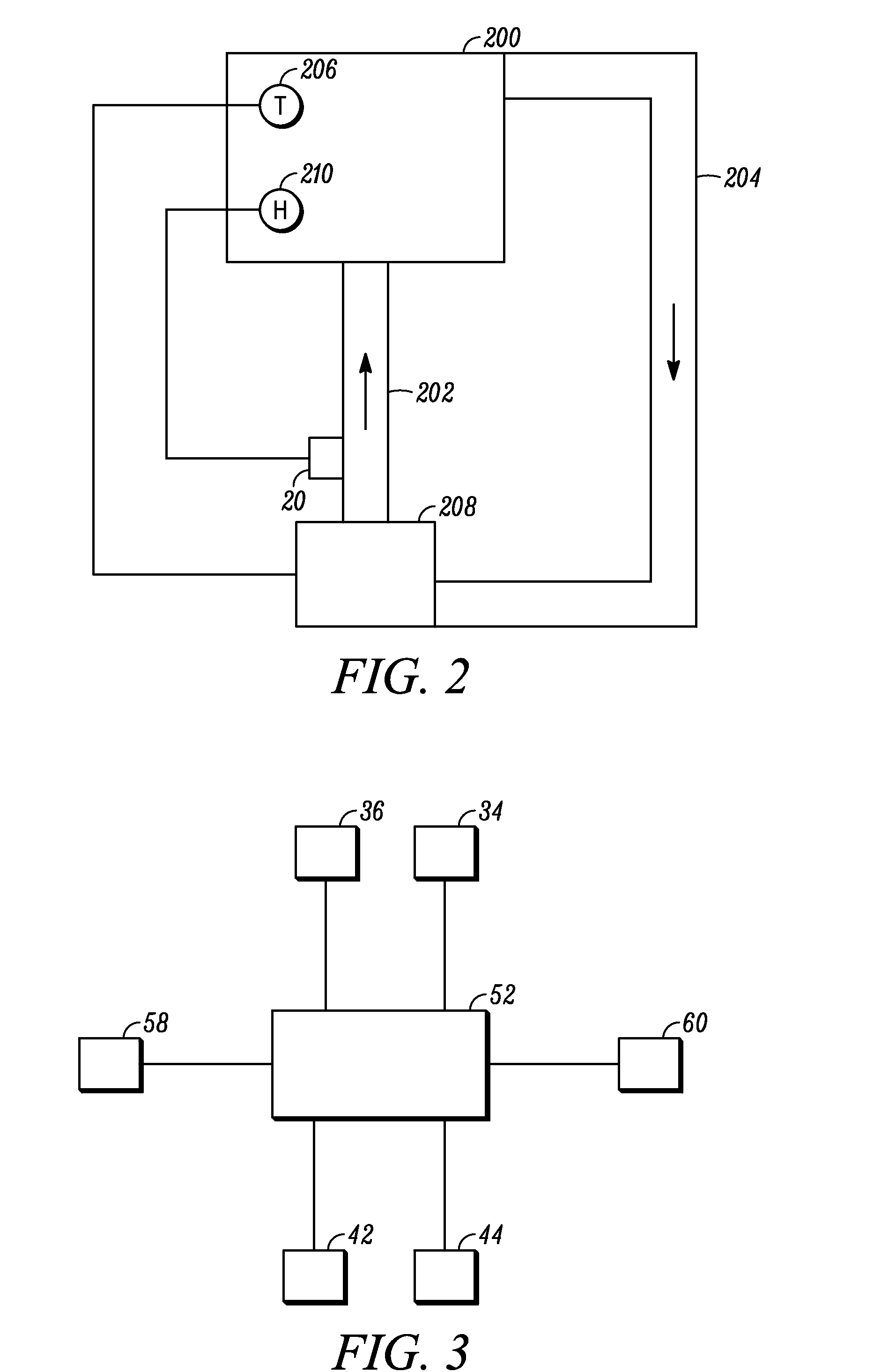

Boiler water blowdown control system

InactiveUS6655322B1Constant flowThe process is simple and accurateBoiler cleaning apparatusMachines/enginesControl systemEngineering

The present invention relates to a method for automatically maintaining the concentration of scale forming minerals in boiler water for boiler systems utilizing bimodal feedwater pumps that deliver a substantially constant feedwater flow to the boiler drum when activated. According to the present invention, the feedwater supply pump and blowdown rate control valve are synchronized to remove boiler water at a predetermined rate when the feedwater pump is activated. The present invention thereby provides a simplified and less expensive method for controlling the concentration of dissolved solids in boiler water despite variations in the steam loads and / or other boiler operation parameters.

Owner:CHEMTREAT

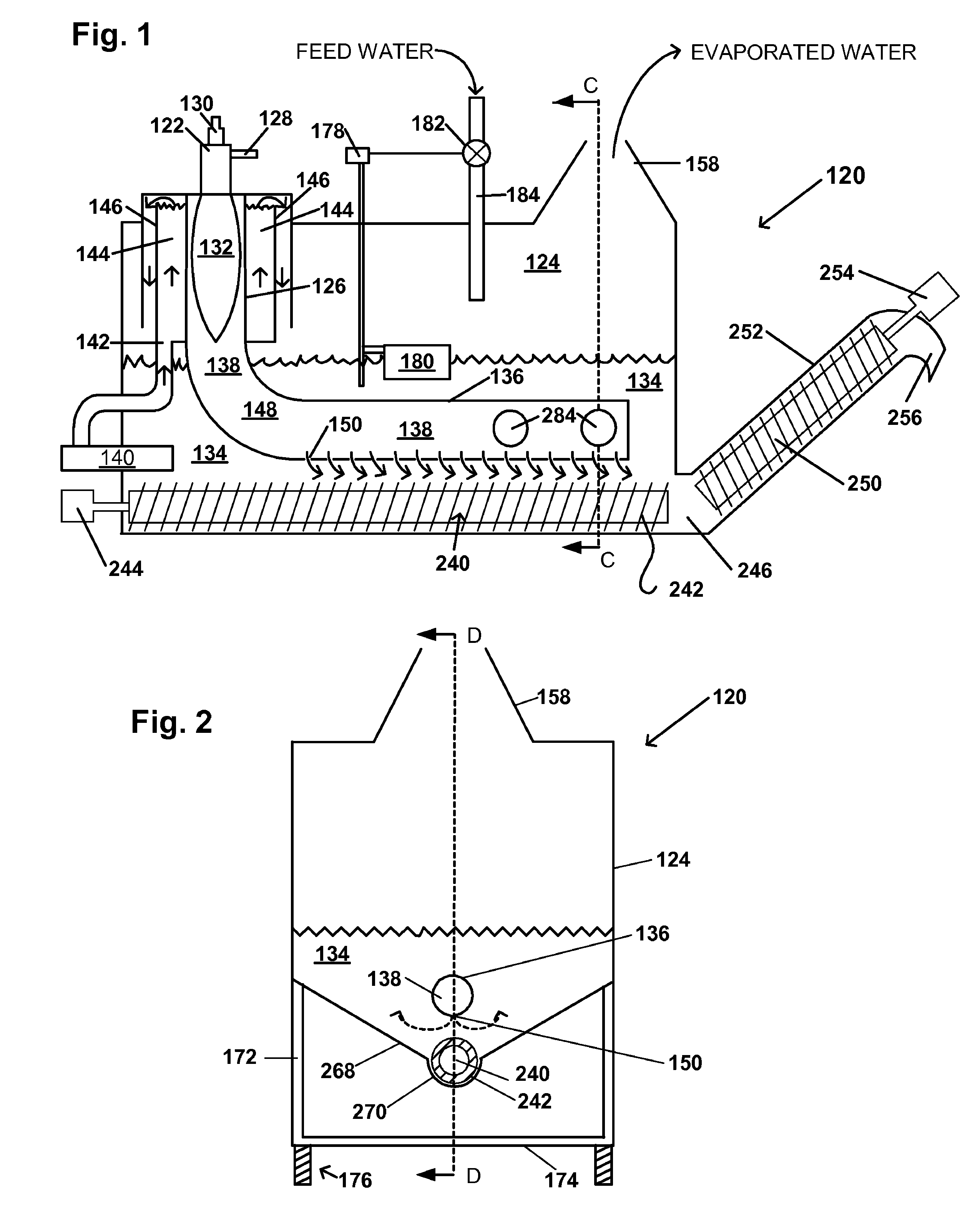

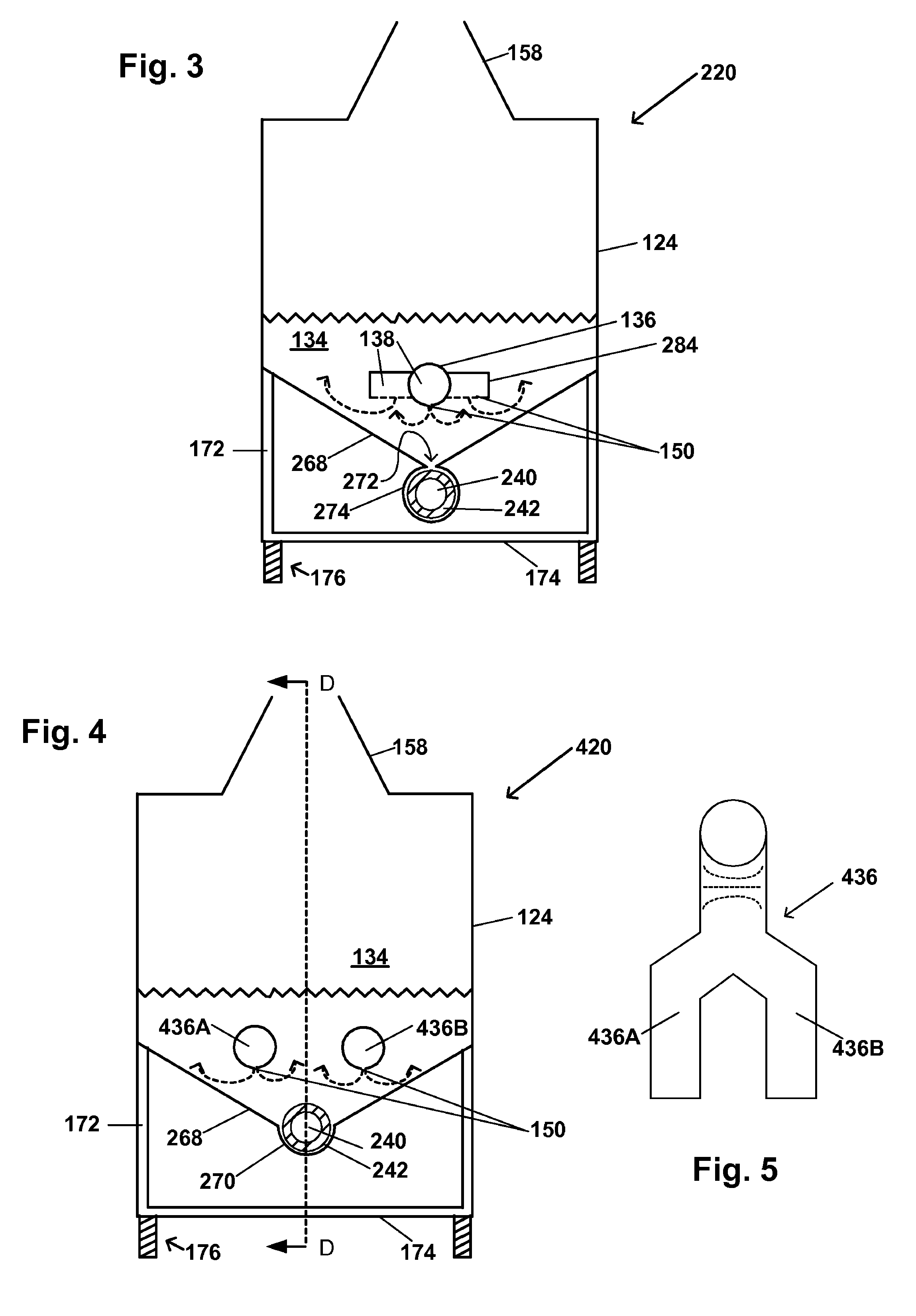

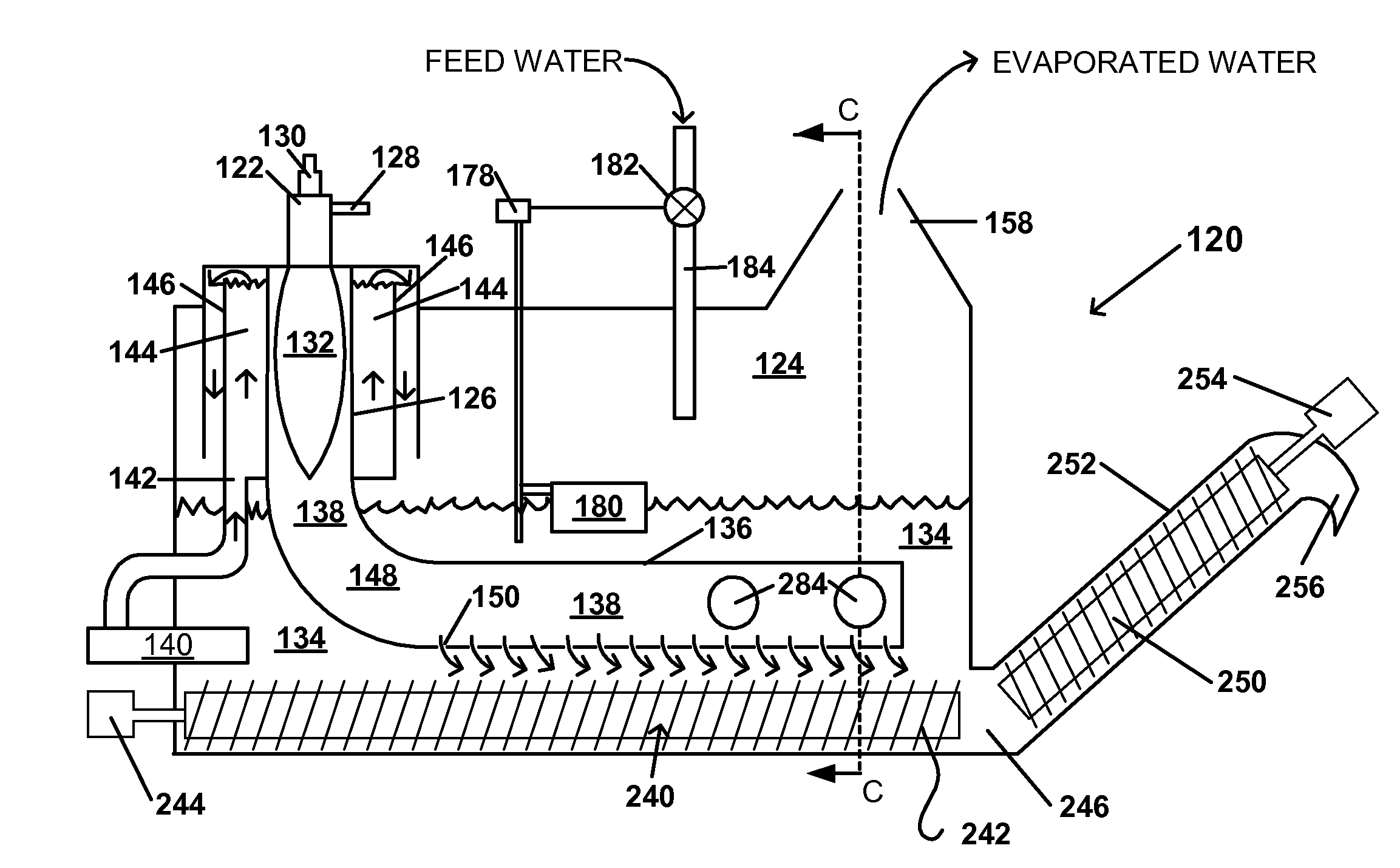

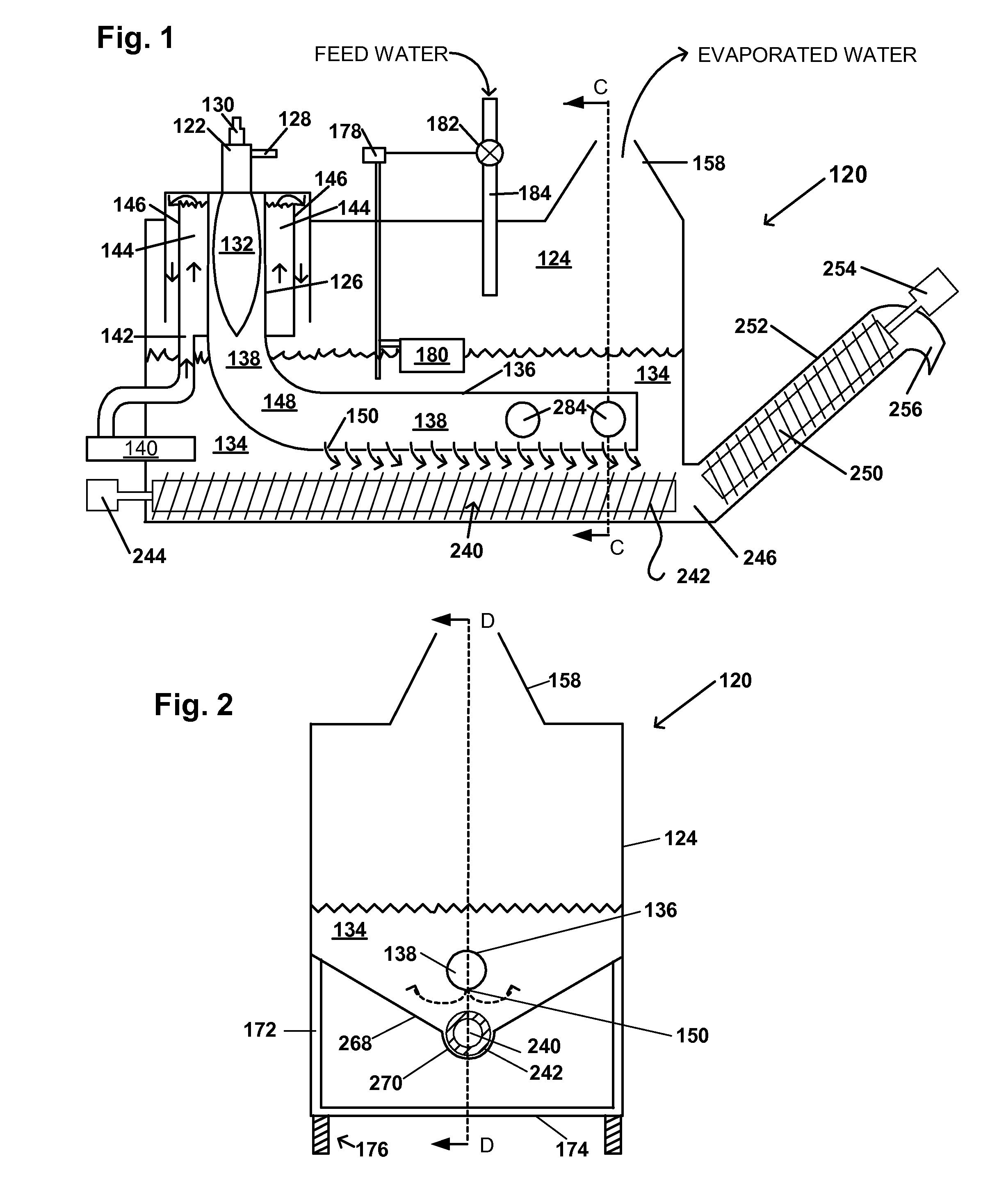

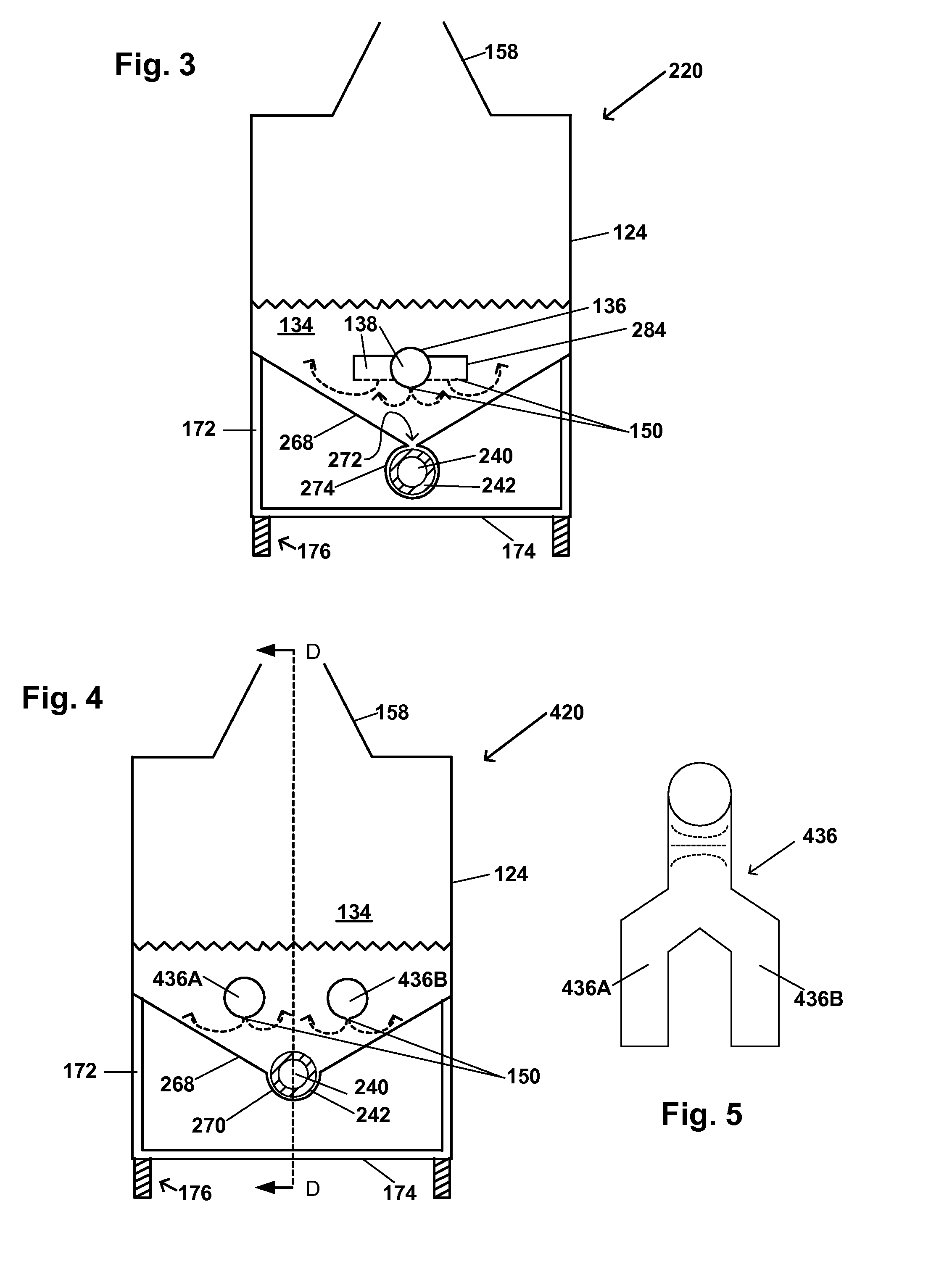

Submerged combustion disposal of produced water

InactiveUS20080110417A1Easy to handleEasy disposalBoiler cleaning apparatusSedimentation separationCombustion systemCombustion chamber

The present invention relates to a method of disposing of produced water and to a produced water disposal apparatus including a container for receiving and holding produced water; and a burner having a combustion chamber, wherein at least a portion of the combustion chamber is submerged in the water and the submerged portion of the combustion chamber comprises a sparger tube through which combustion gases emerge into, mix with and agitate the water. The present invention further relates to a mechanism for removing debris from the produced water disposal apparatus. In one embodiment, heat is supplied from an externally operated combustion system, rather than the submerged combustion. In one embodiment, the apparatus provides a concentrator, in which a solute can be removed and recovered from an aqueous medium containing the solute.

Owner:TDU LLC

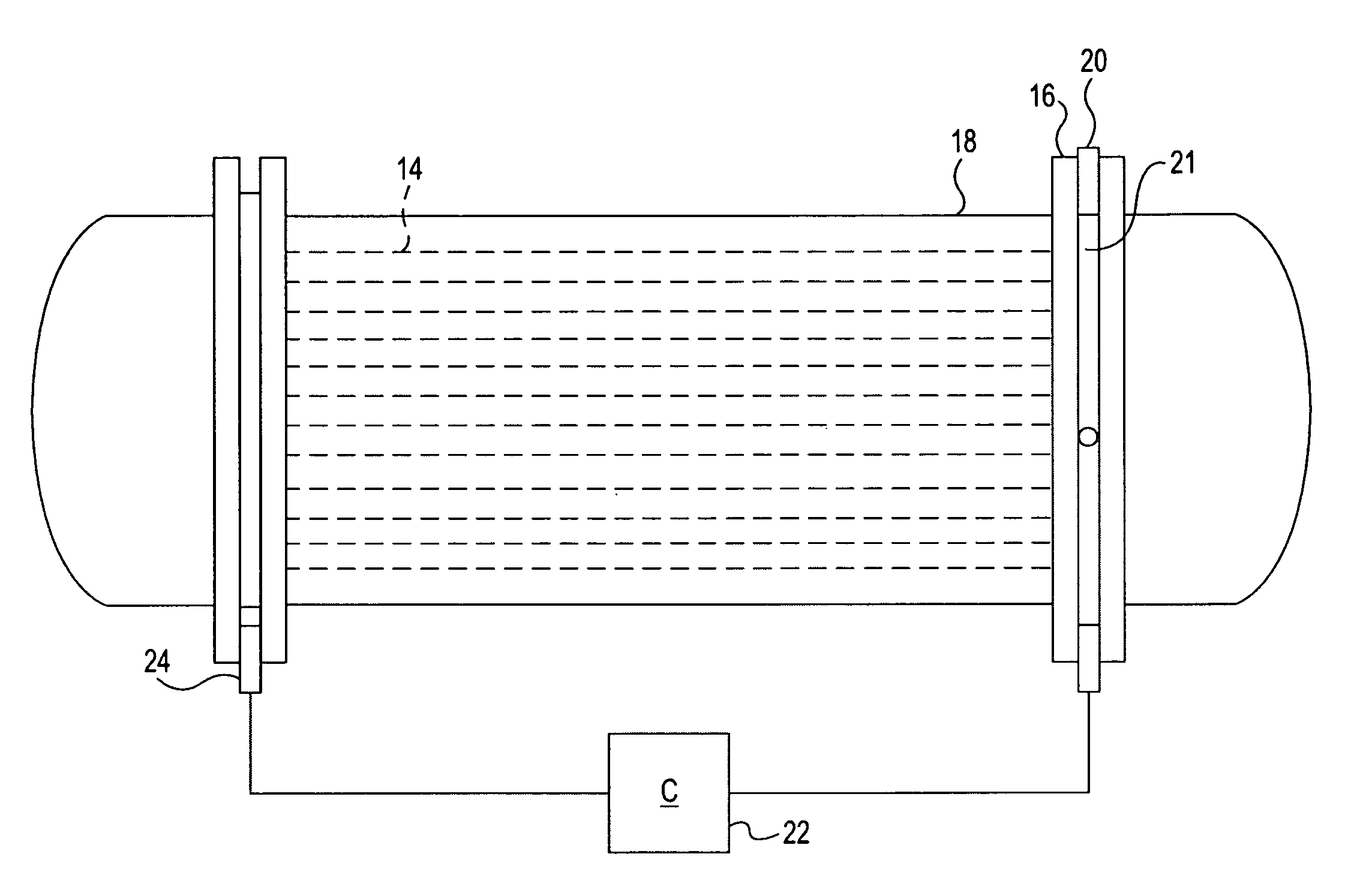

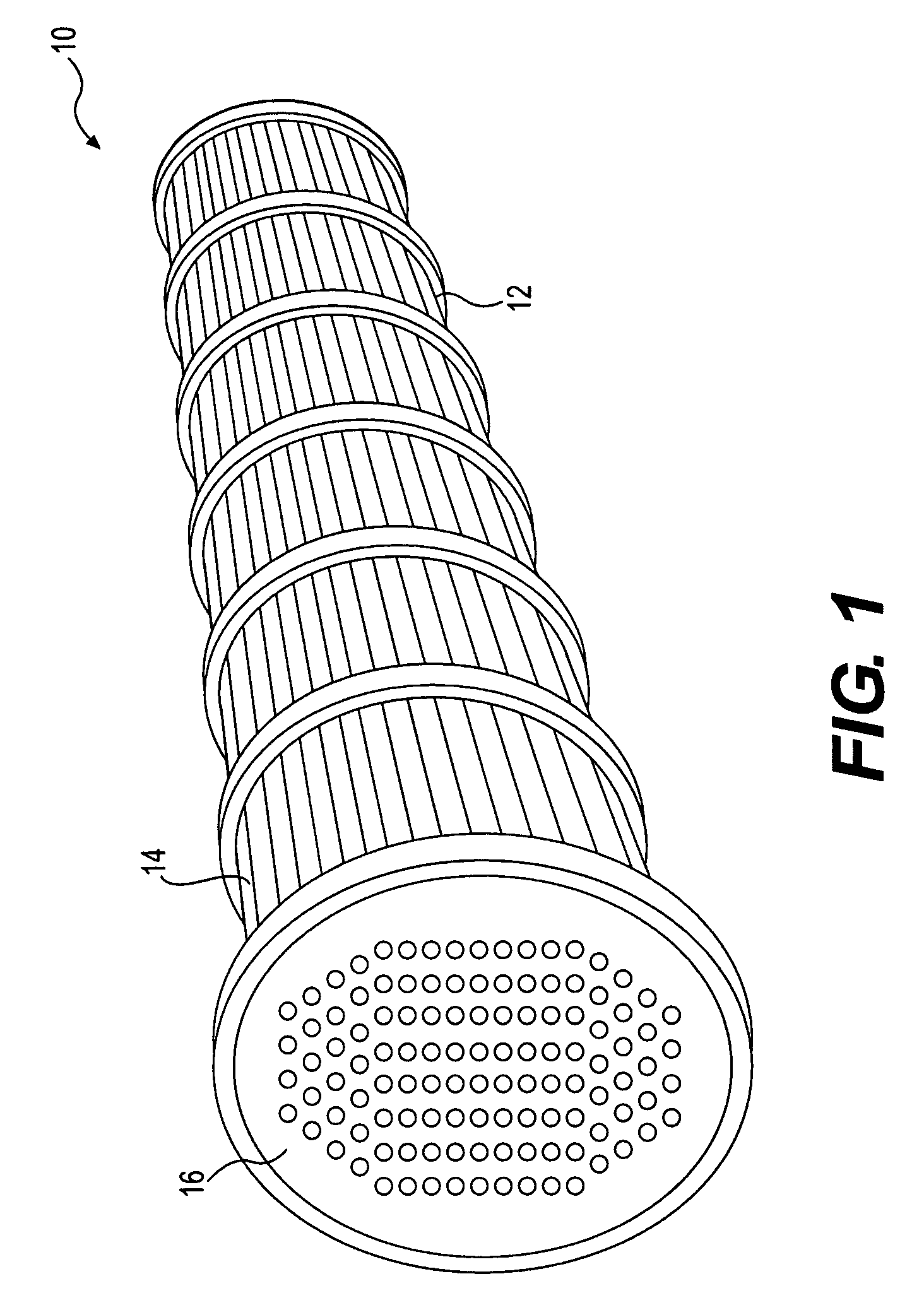

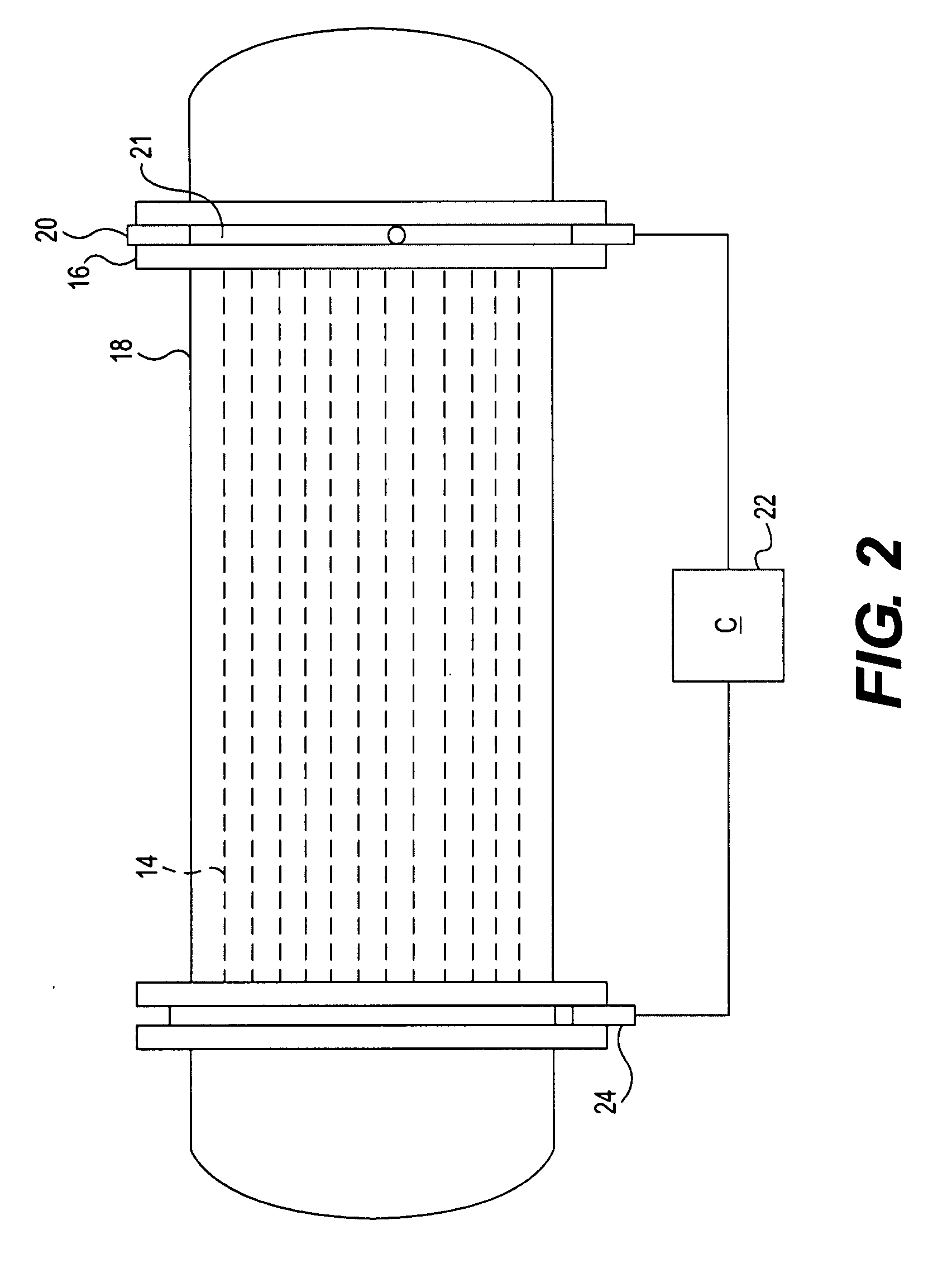

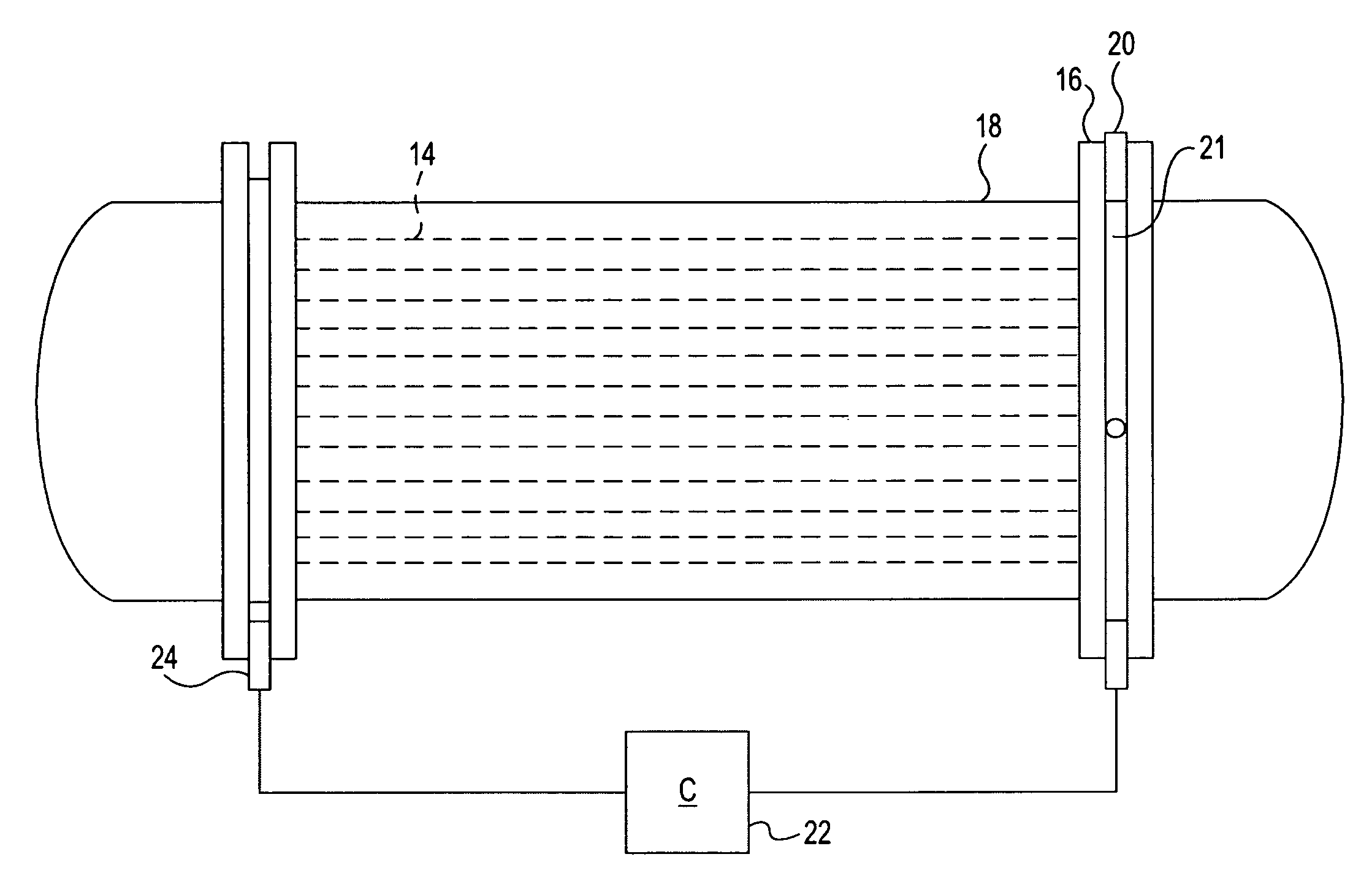

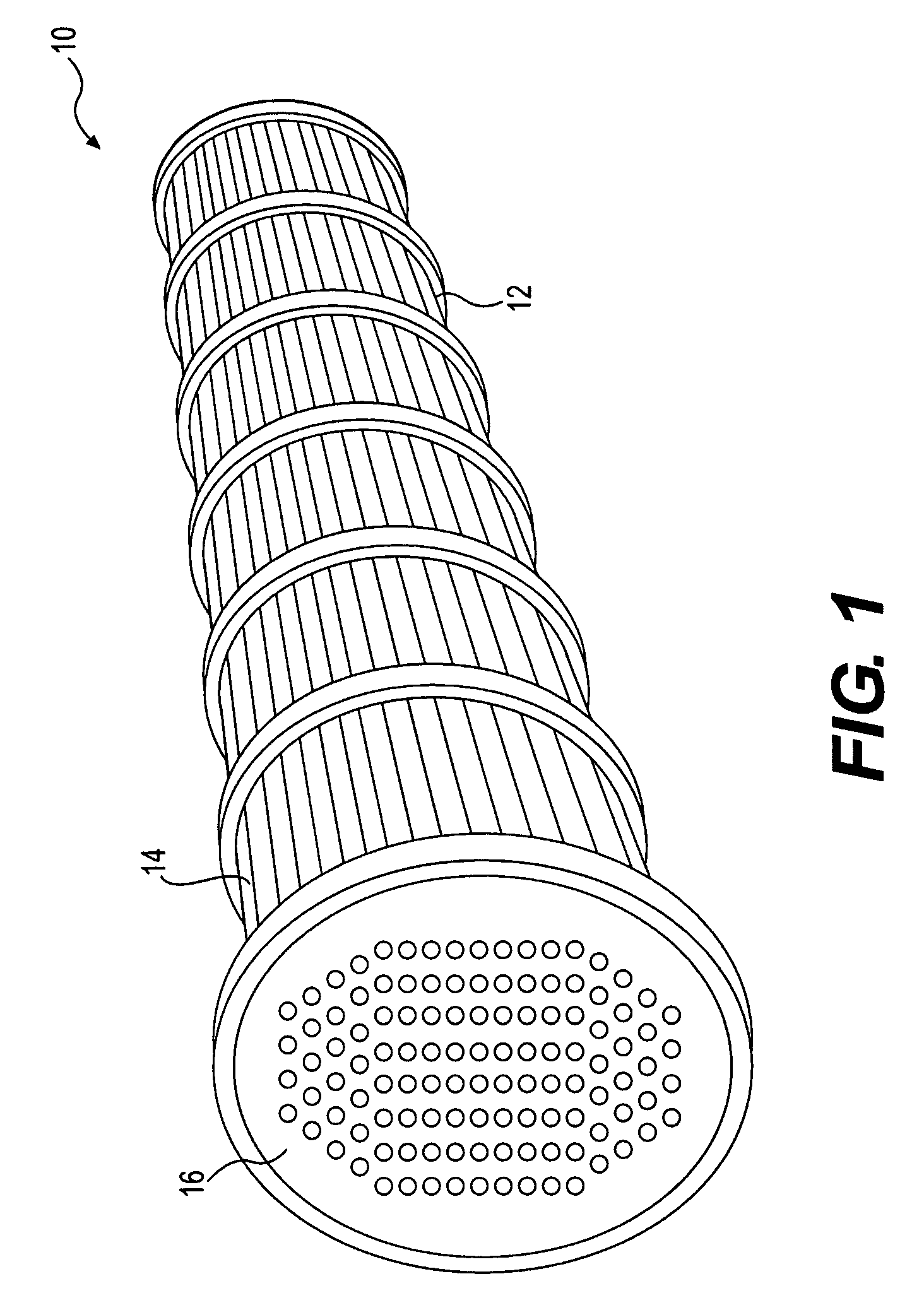

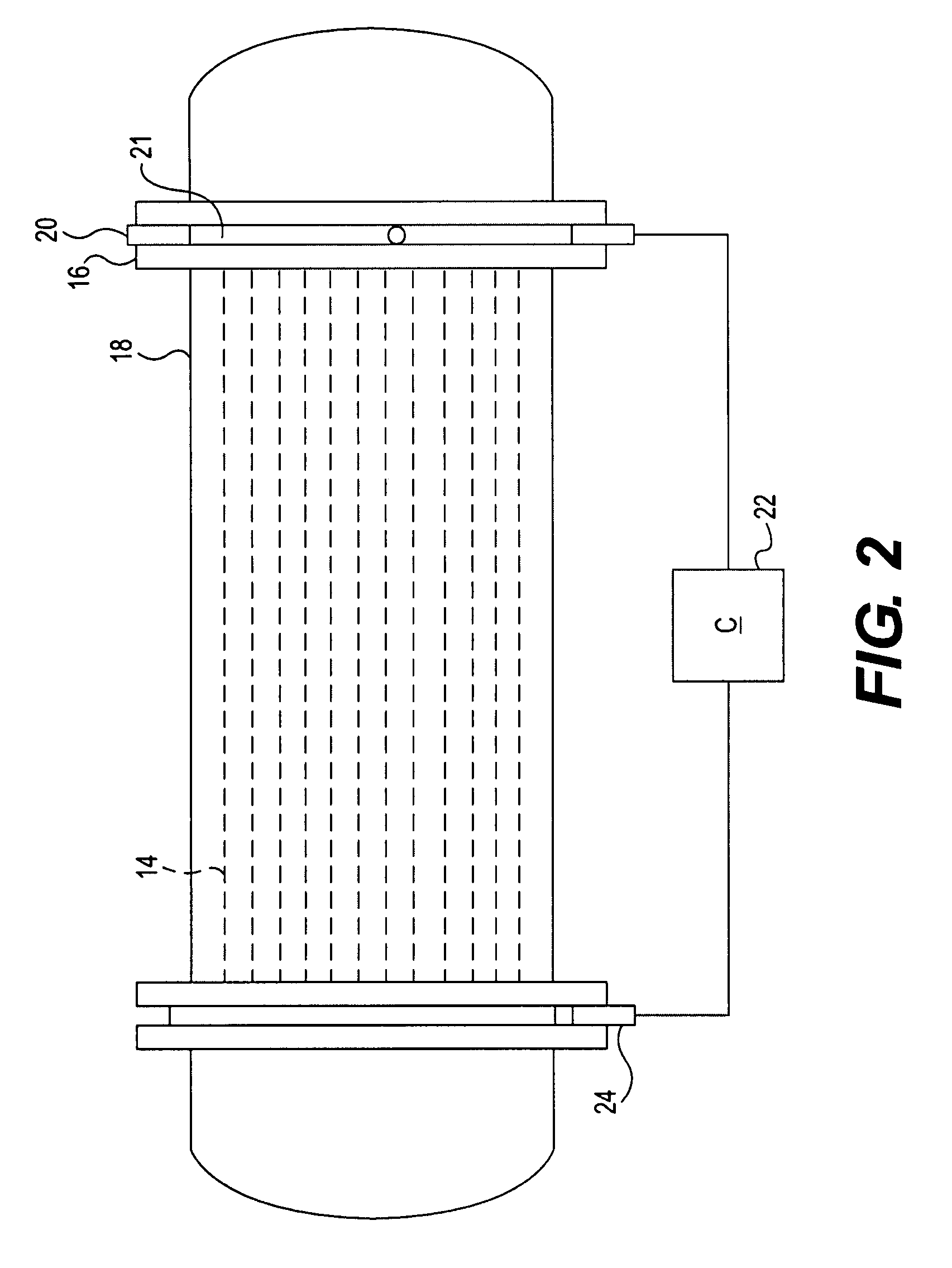

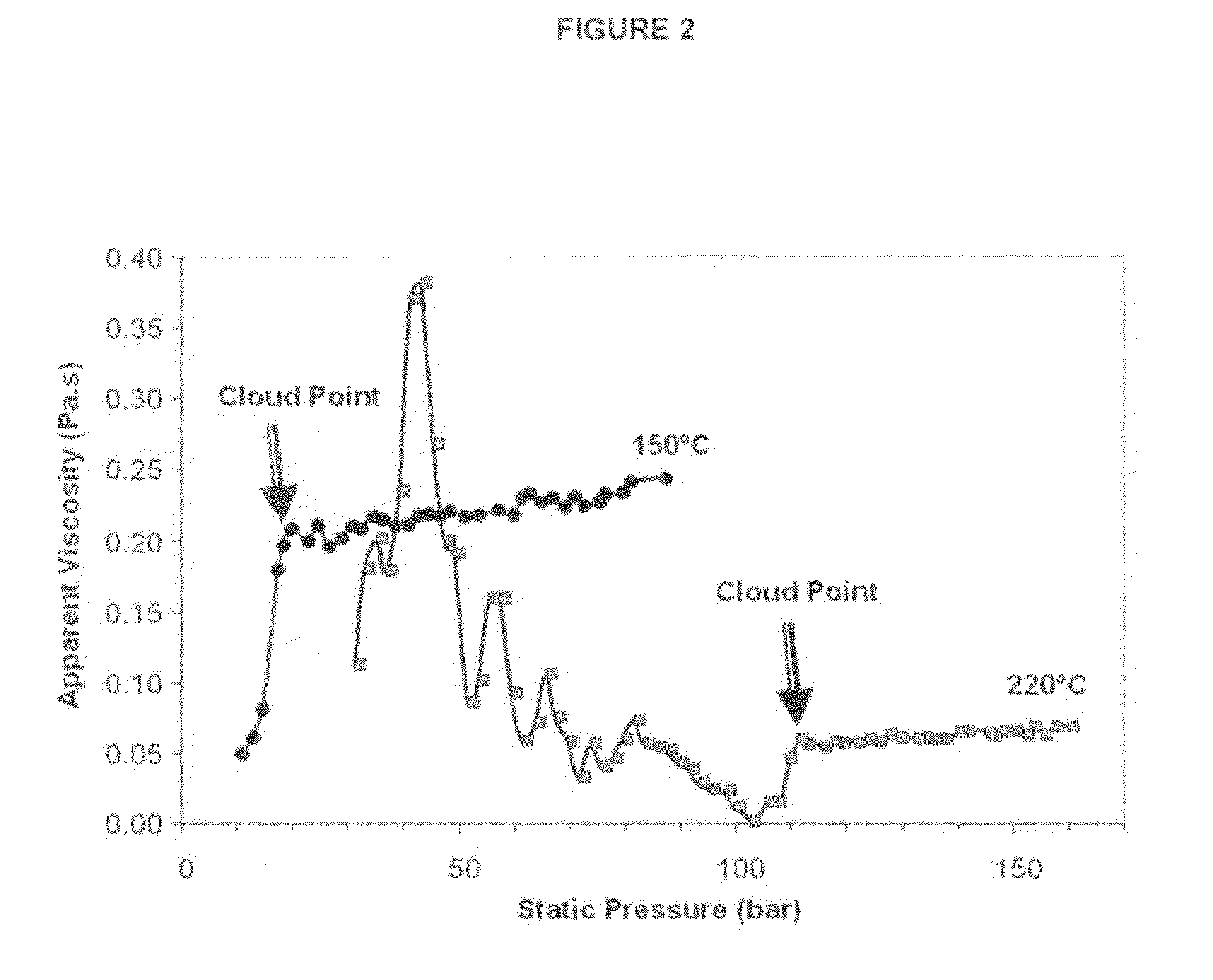

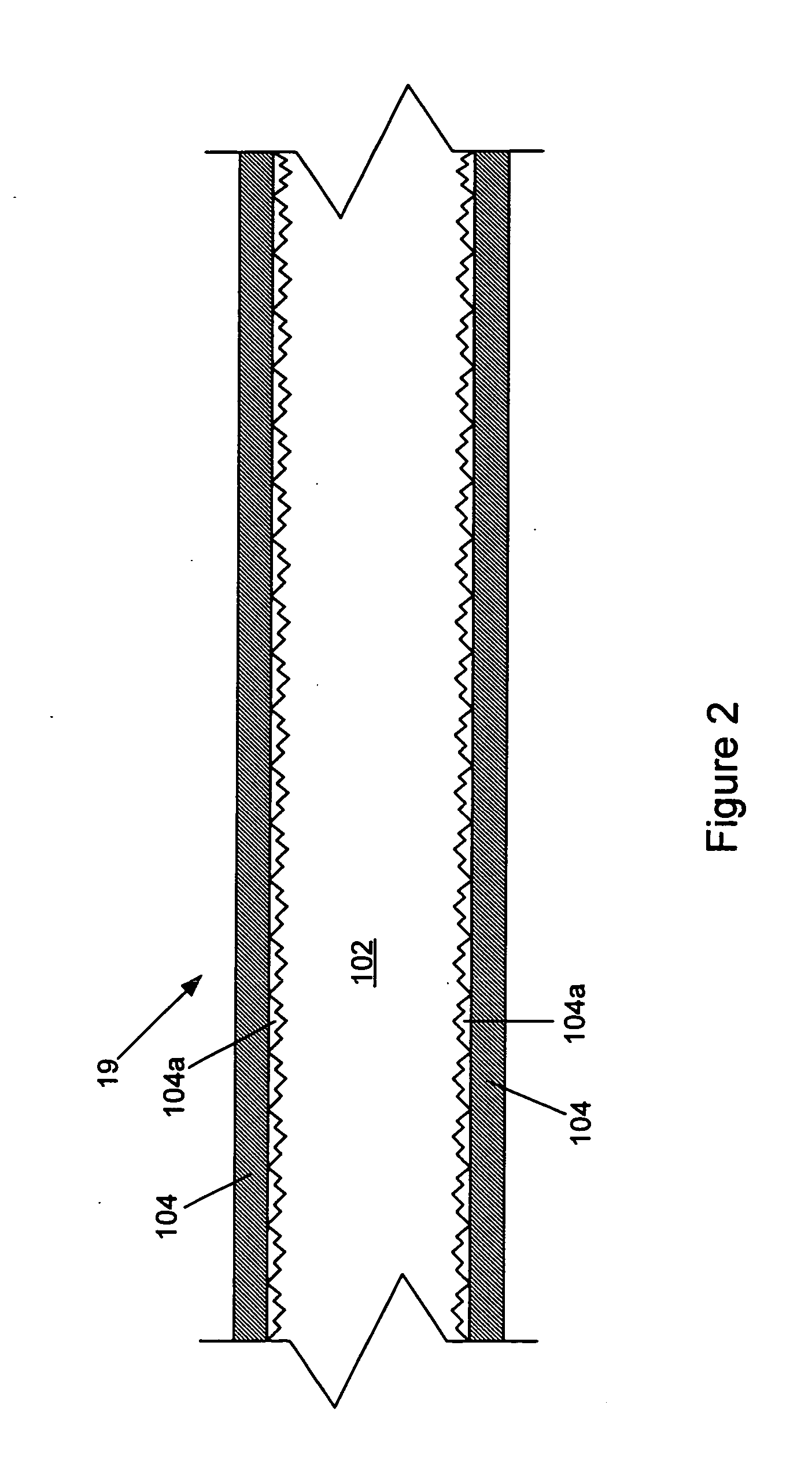

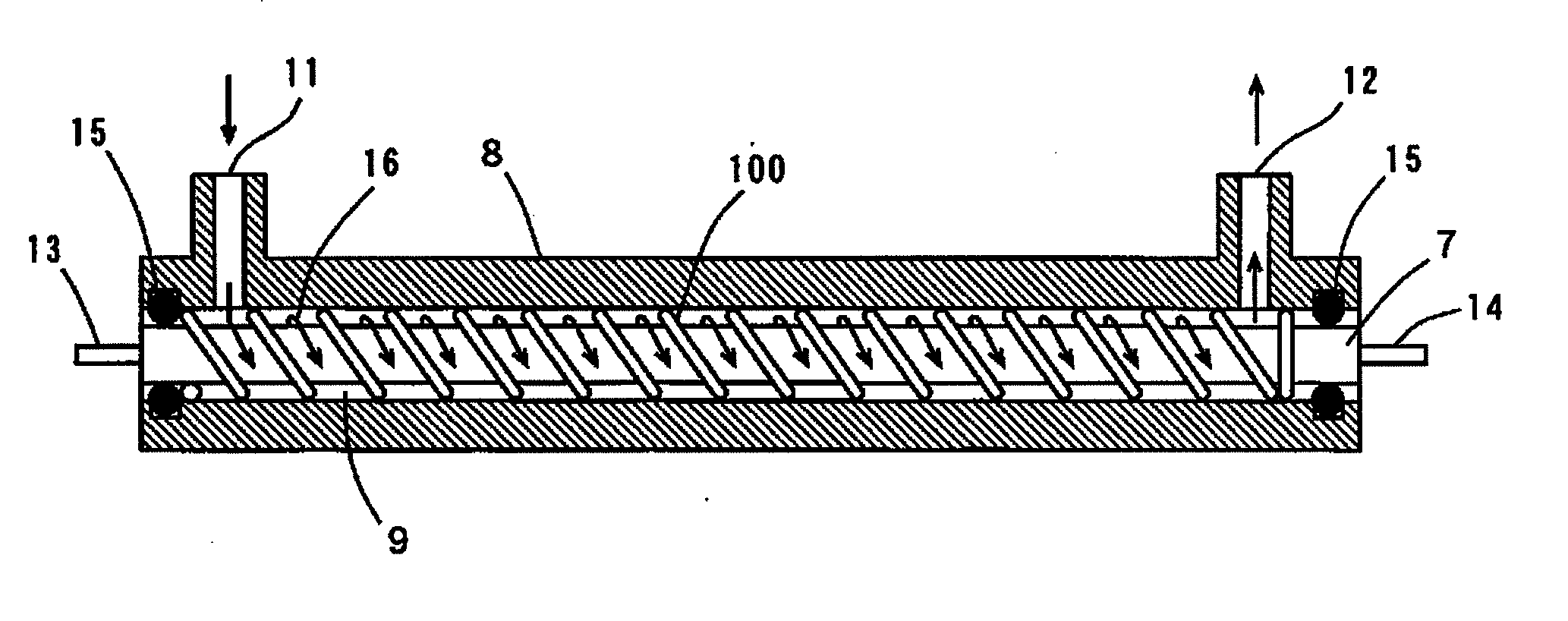

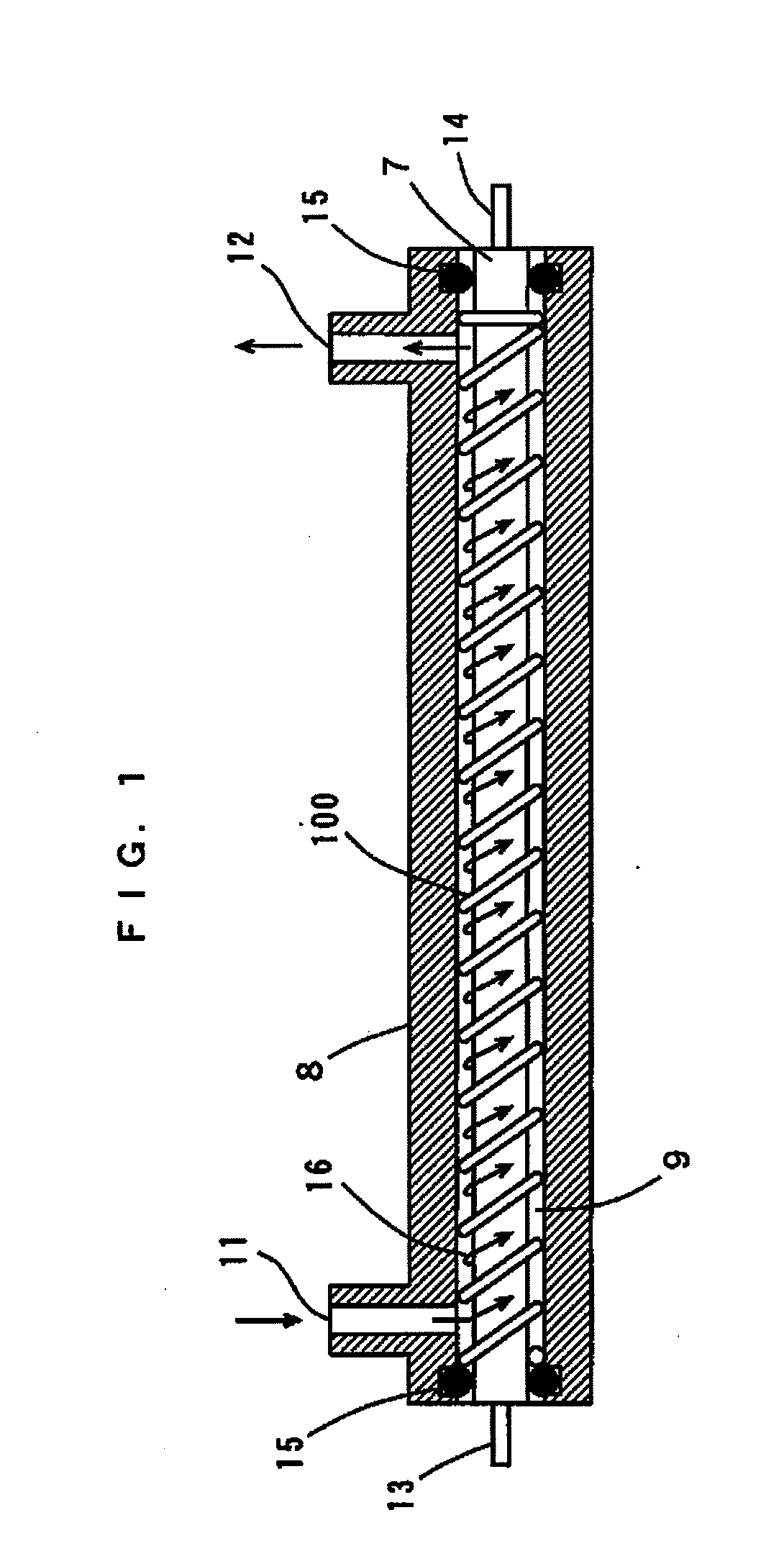

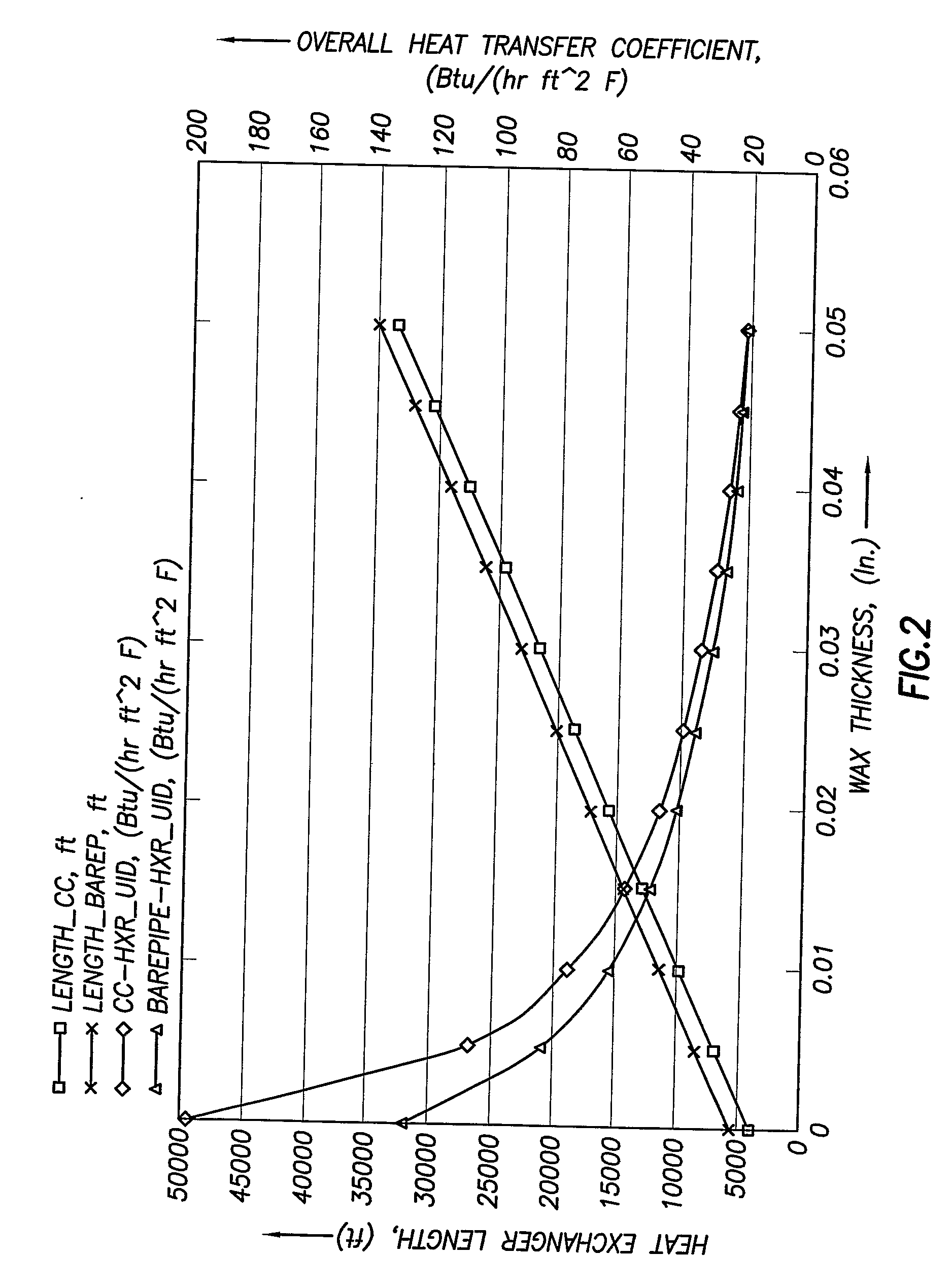

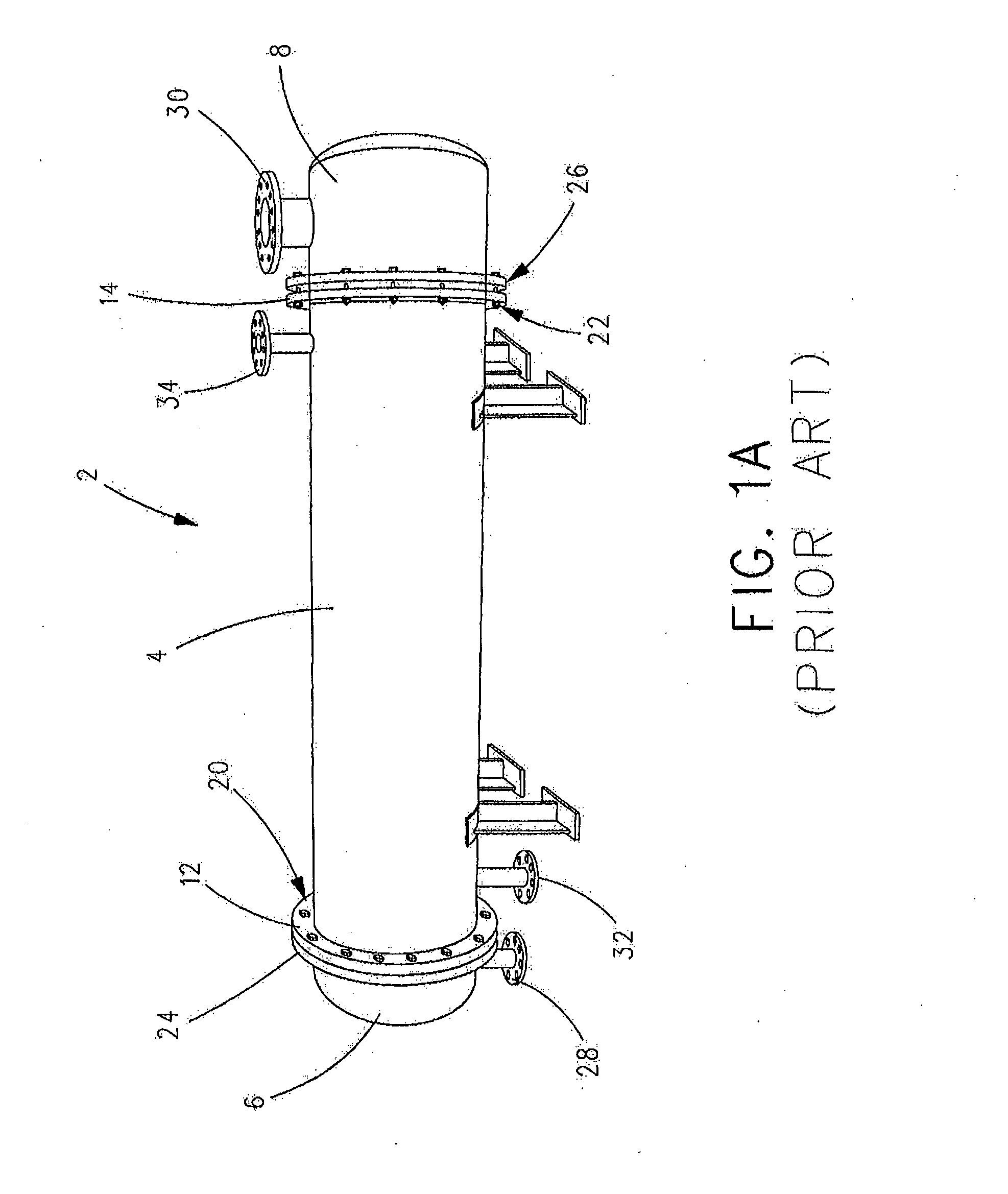

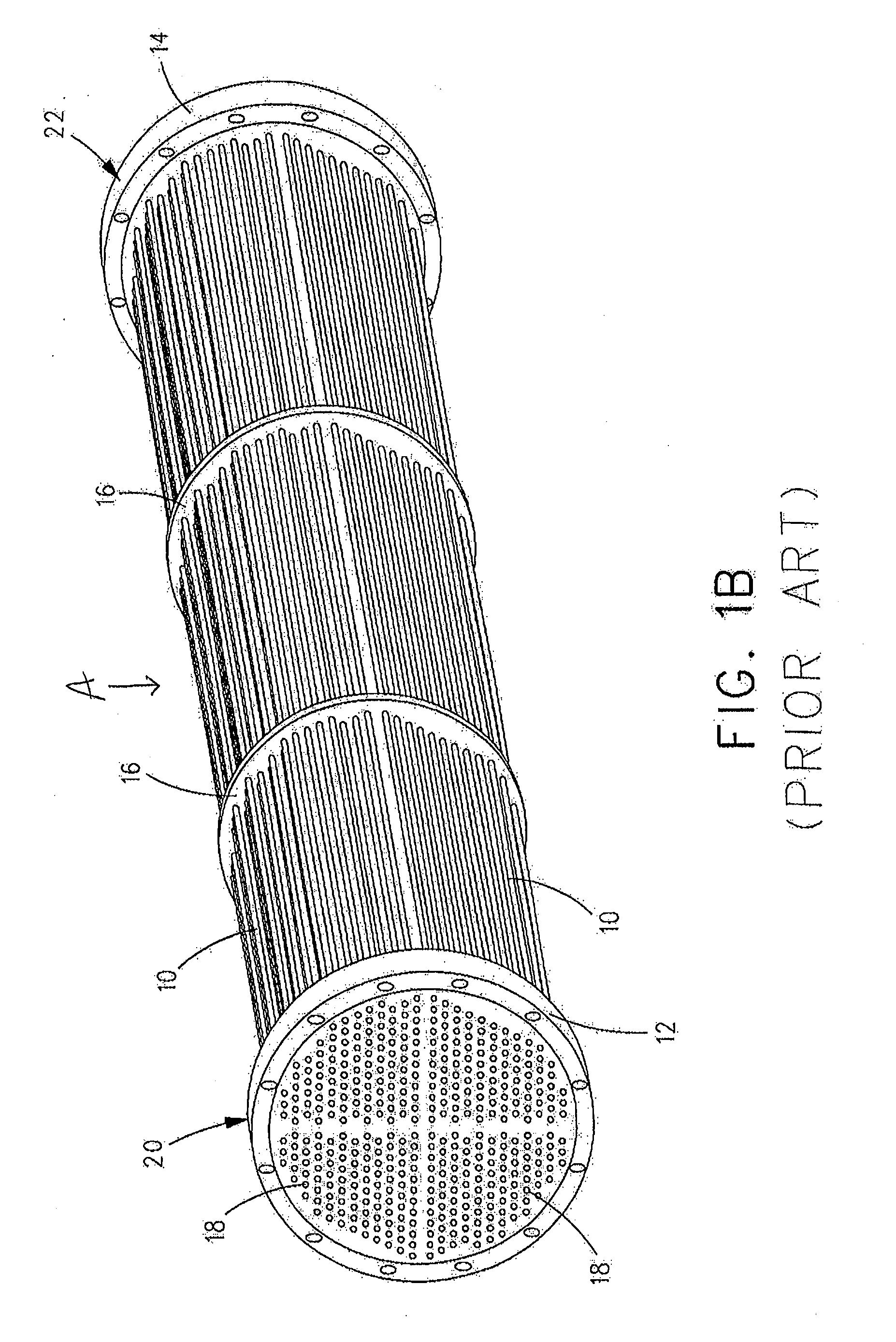

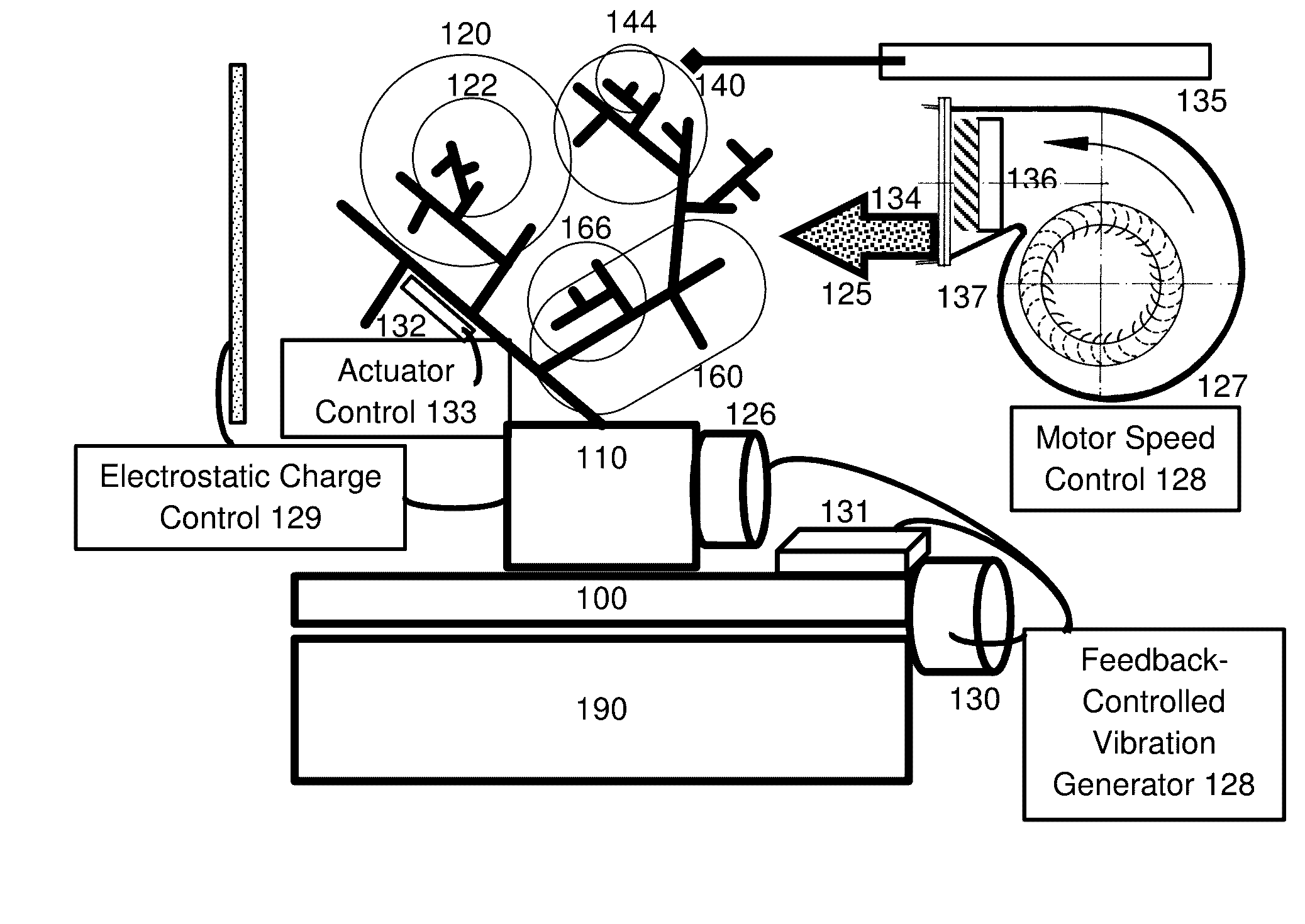

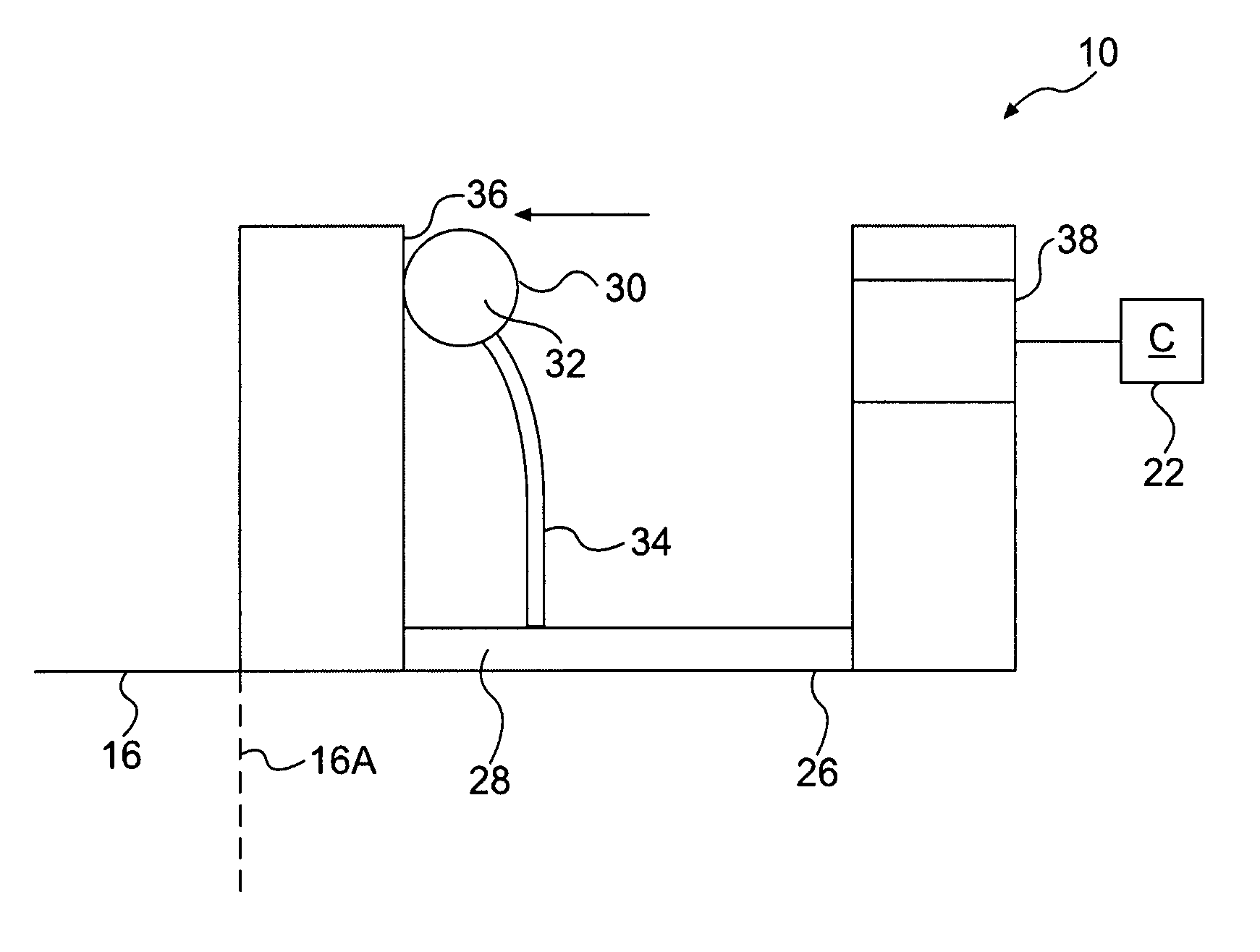

Mitigation of in-tube fouling in heat exchangers using controlled mechanical vibration

InactiveUS20070267176A1Reduce dirtCombustion processCorrosion preventionPlate heat exchangerEngineering

Fouling of heat exchange surfaces is mitigated by a process in which a mechanical force is applied to a fixed heat exchanger to excite a vibration in the heat exchange surface and produce shear waves in the fluid adjacent the heat exchange surface. The mechanical force is applied by a dynamic actuator coupled to a controller to produce vibration at a controlled frequency and amplitude output that minimizes adverse effects to the heat exchange structure. The dynamic actuator may be coupled to the heat exchanger in place and operated while the heat exchanger is on line.

Owner:EXXON RES & ENG CO

Mitigation of in-tube fouling in heat exchangers using controlled mechanical vibration

Fouling of heat exchange surfaces is mitigated by a process in which a mechanical force is applied to a fixed heat exchanger to excite a vibration in the heat exchange surface and produce shear waves in the fluid adjacent the heat exchange surface. The mechanical force is applied by a dynamic actuator coupled to a controller to produce vibration at a controlled frequency and amplitude output that minimizes adverse effects to the heat exchange structure. The dynamic actuator may be coupled to the heat exchanger in place and operated while the heat exchanger is on line.

Owner:EXXON RES & ENG CO

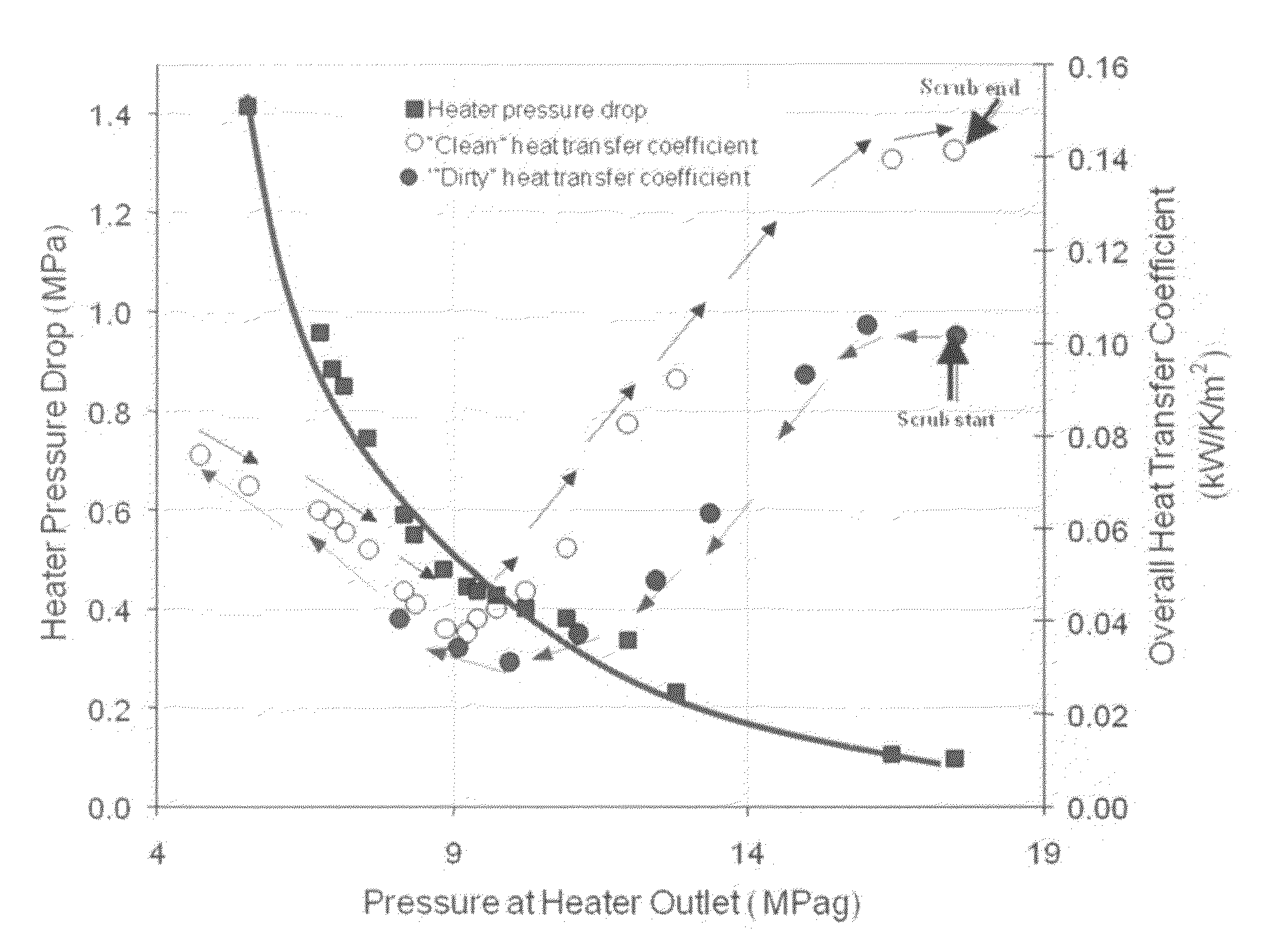

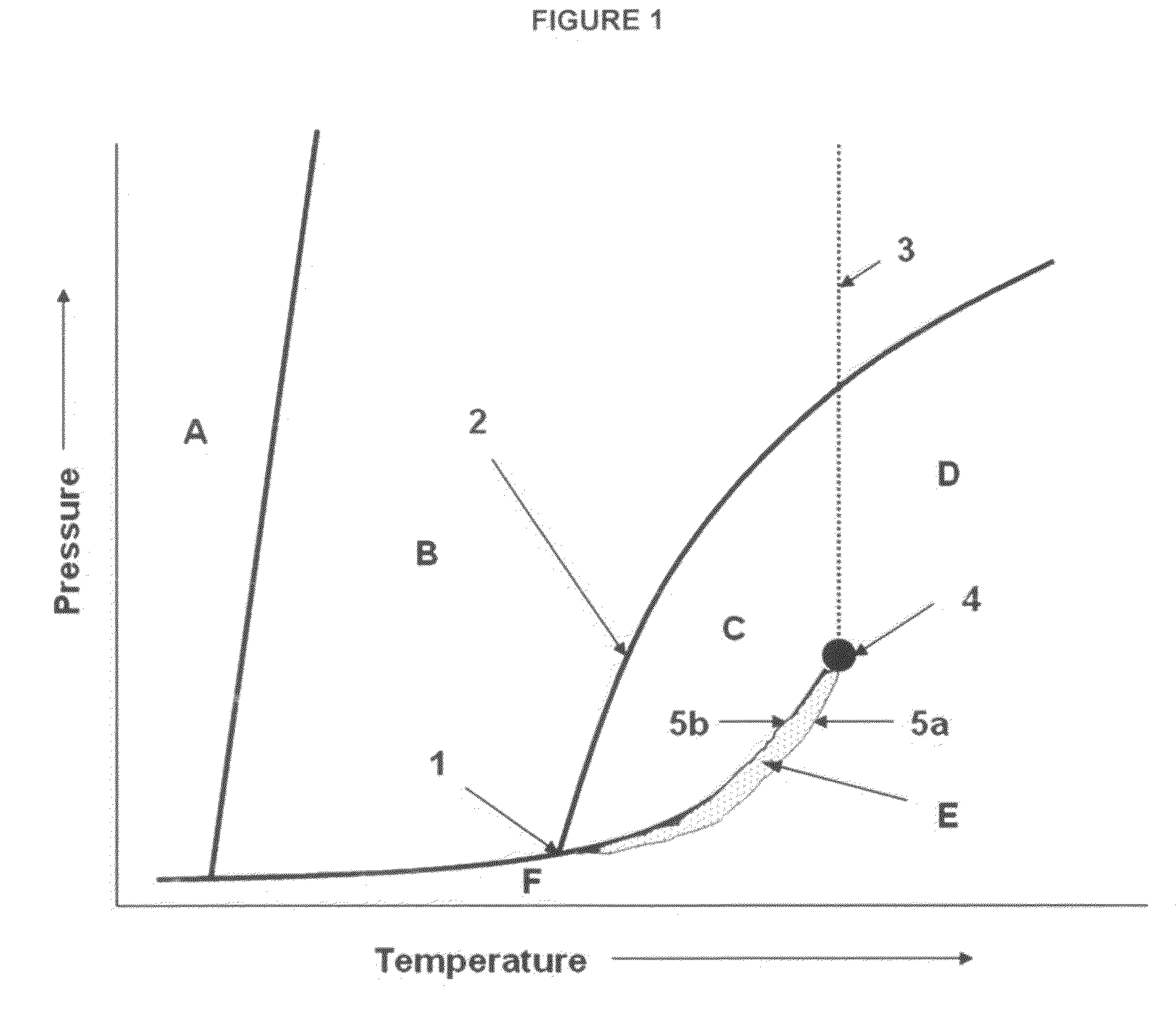

High temperature process for solution polymerization

ActiveUS7650930B2Avoid accumulationIncrease forceHollow article cleaningVapor condensationPlate heat exchangerEmulsion polymerization

A process for the solution polymerization of olefins with improved on-stream time is provided. The solution polymerization process of the current invention comprises a method for the on-line removal of foulant material from one or more heat exchangers downstream of a polymerization reactor. Removal of foulant material is accomplished by deliberately applying a positive pressure differential across a heat exchanger. In the process of the current invention, reactor shut down is not required for the purpose of cleaning foulant material from a heat exchanger.

Owner:NOVA CHEM (INT) SA

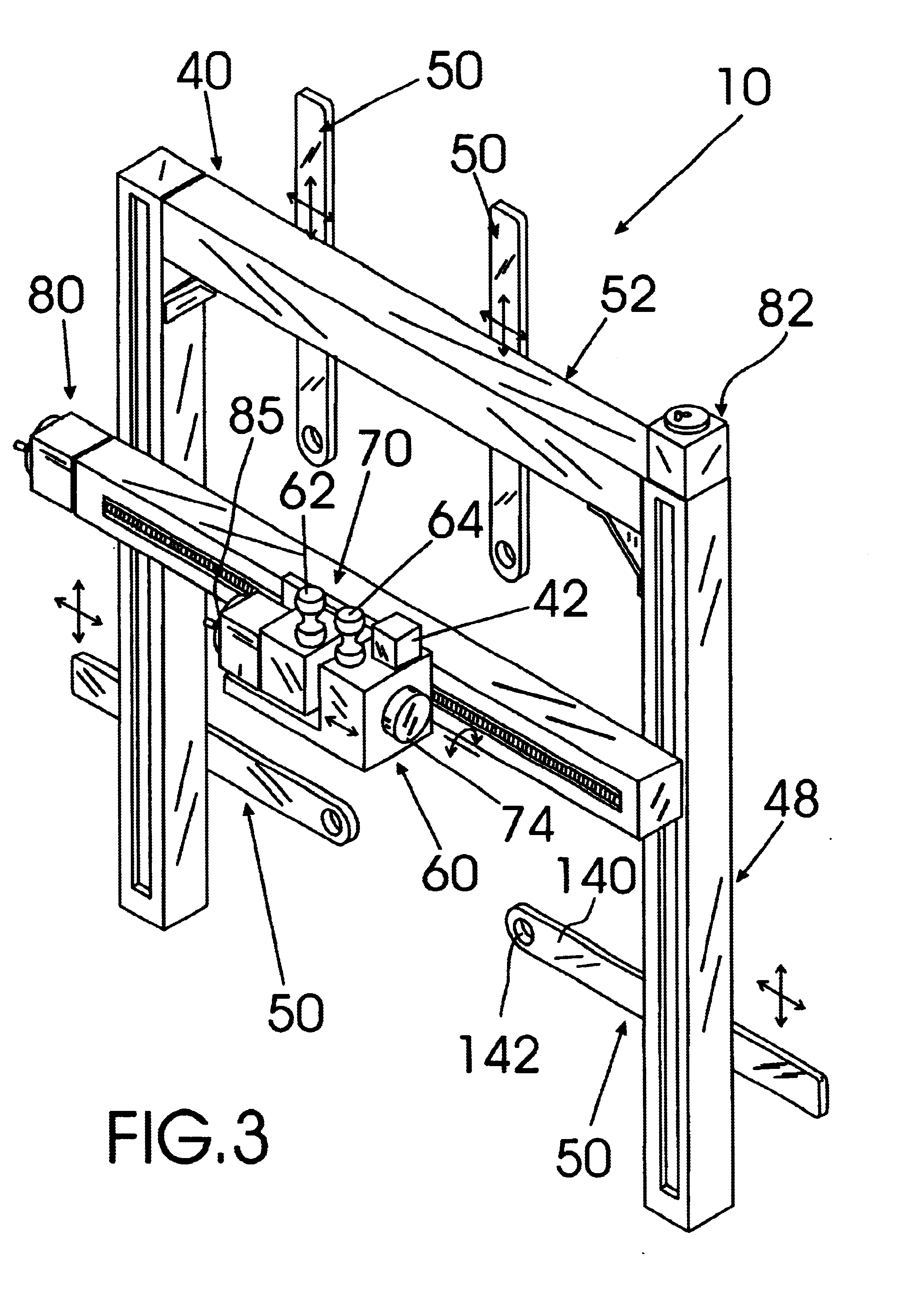

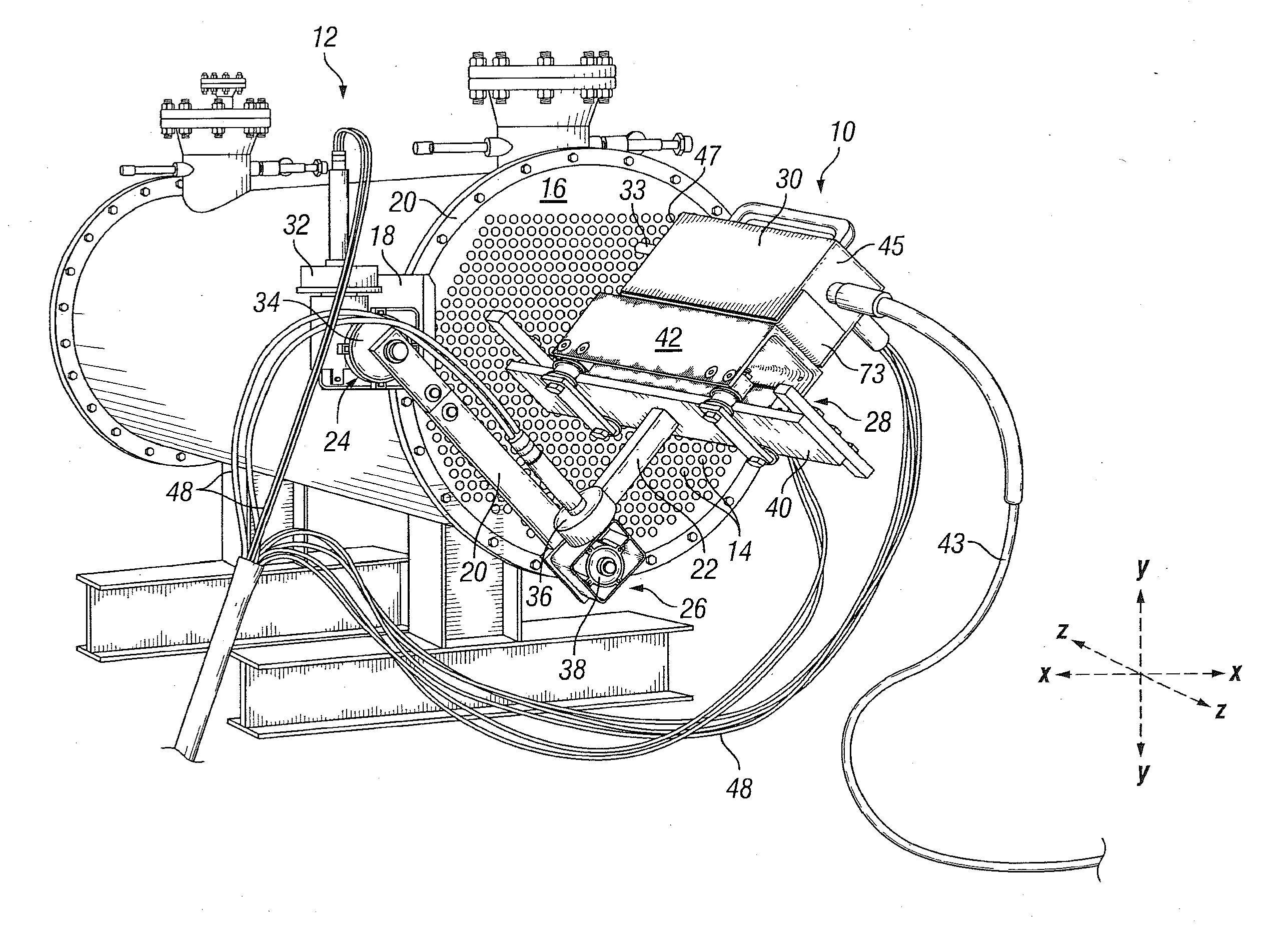

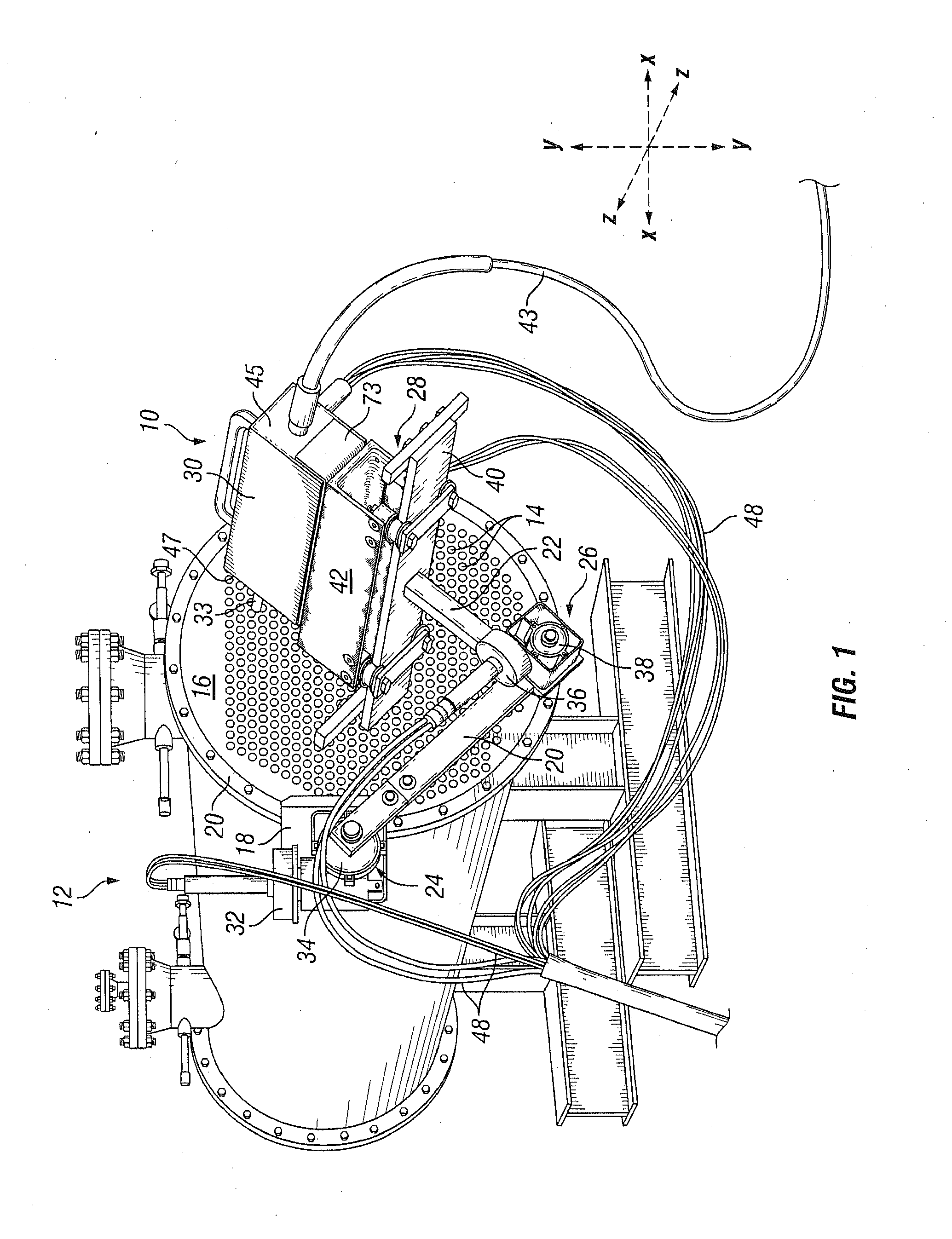

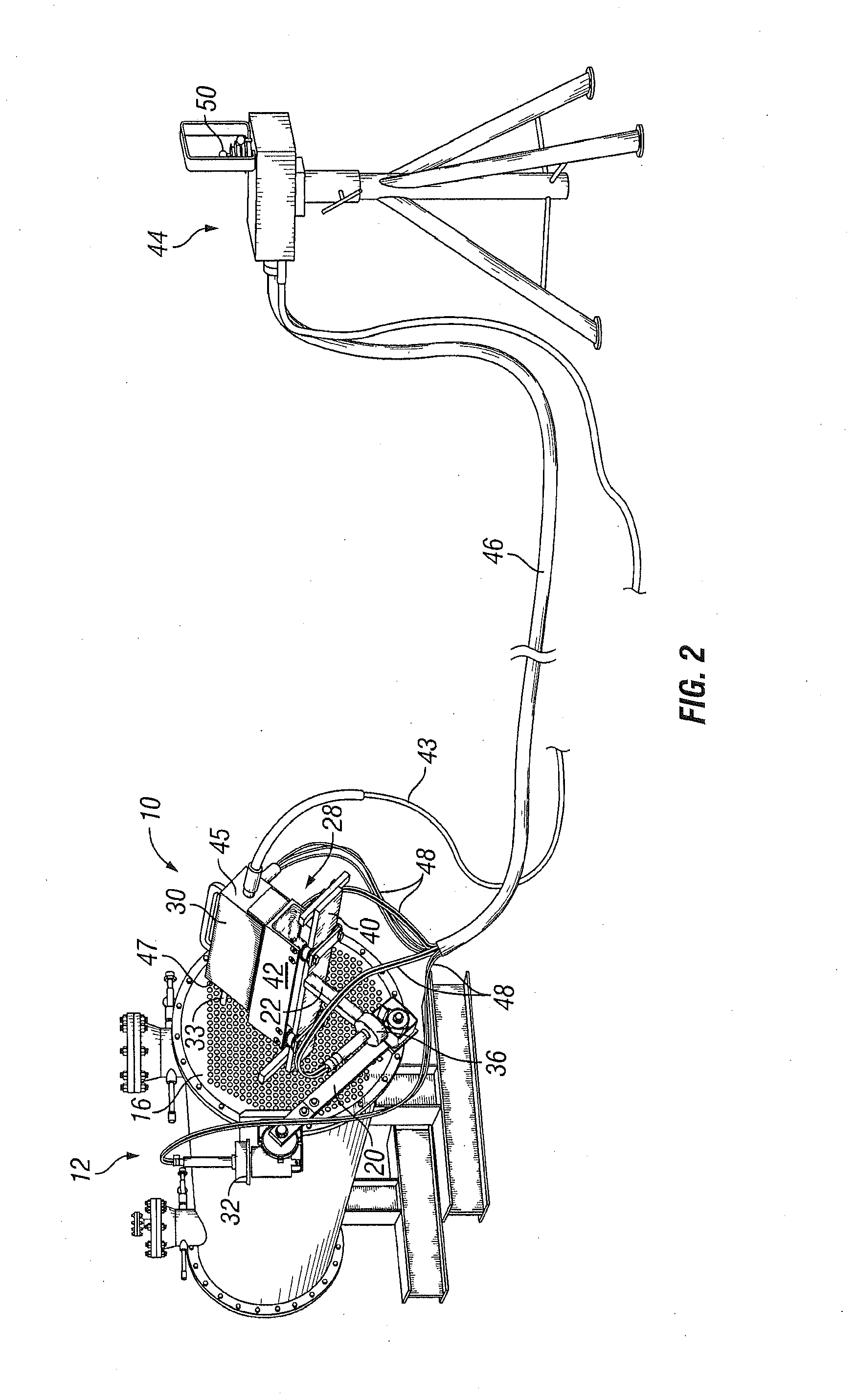

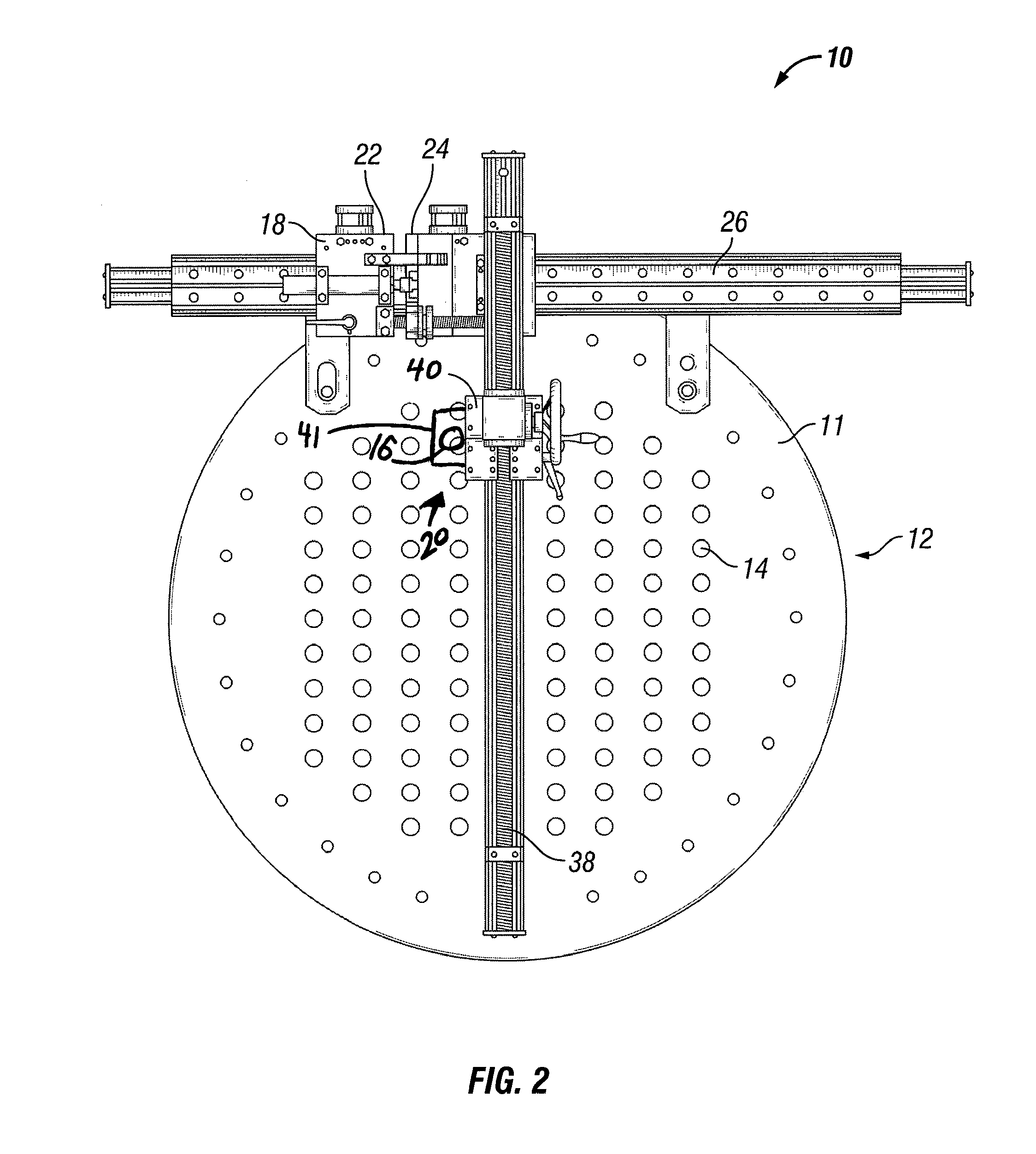

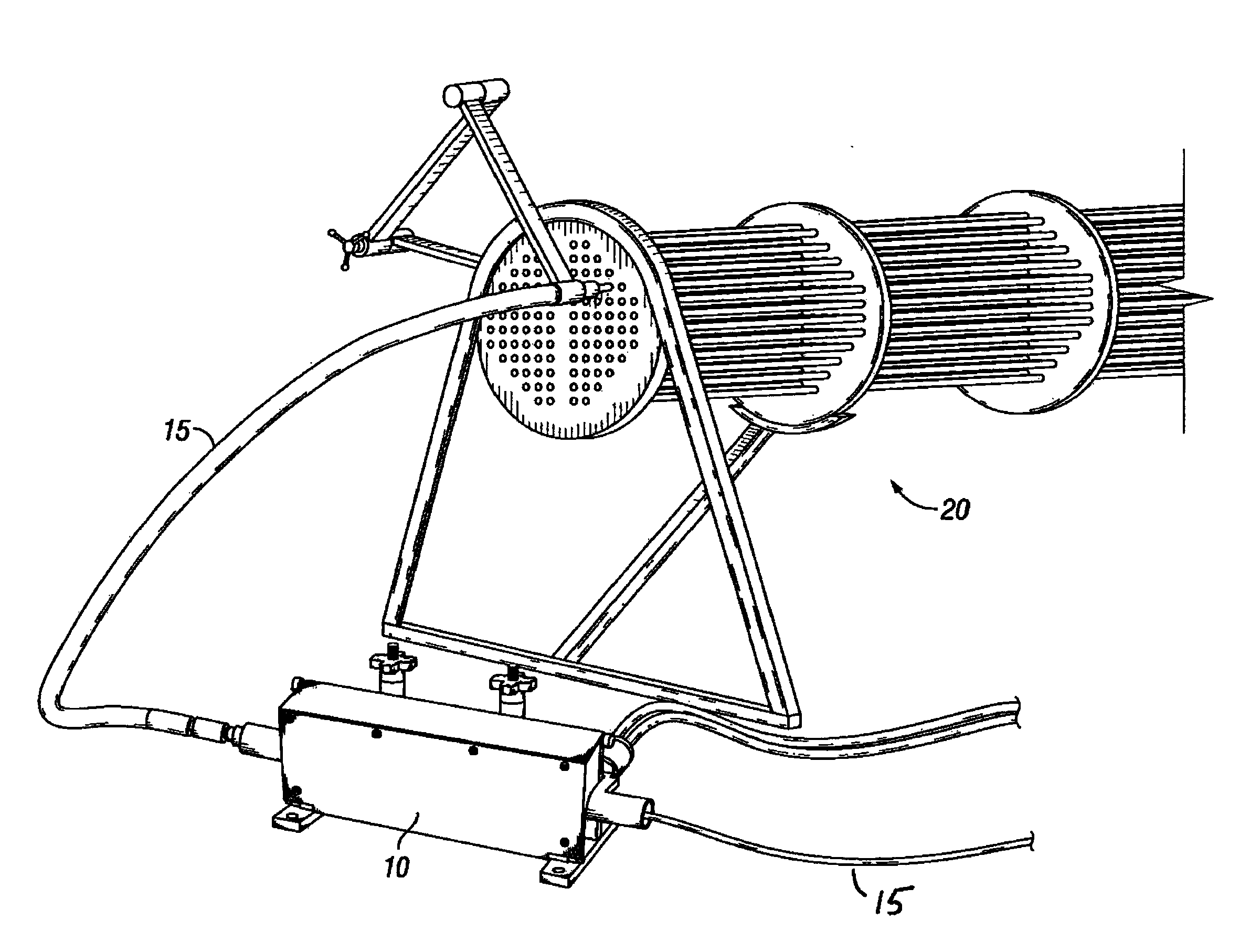

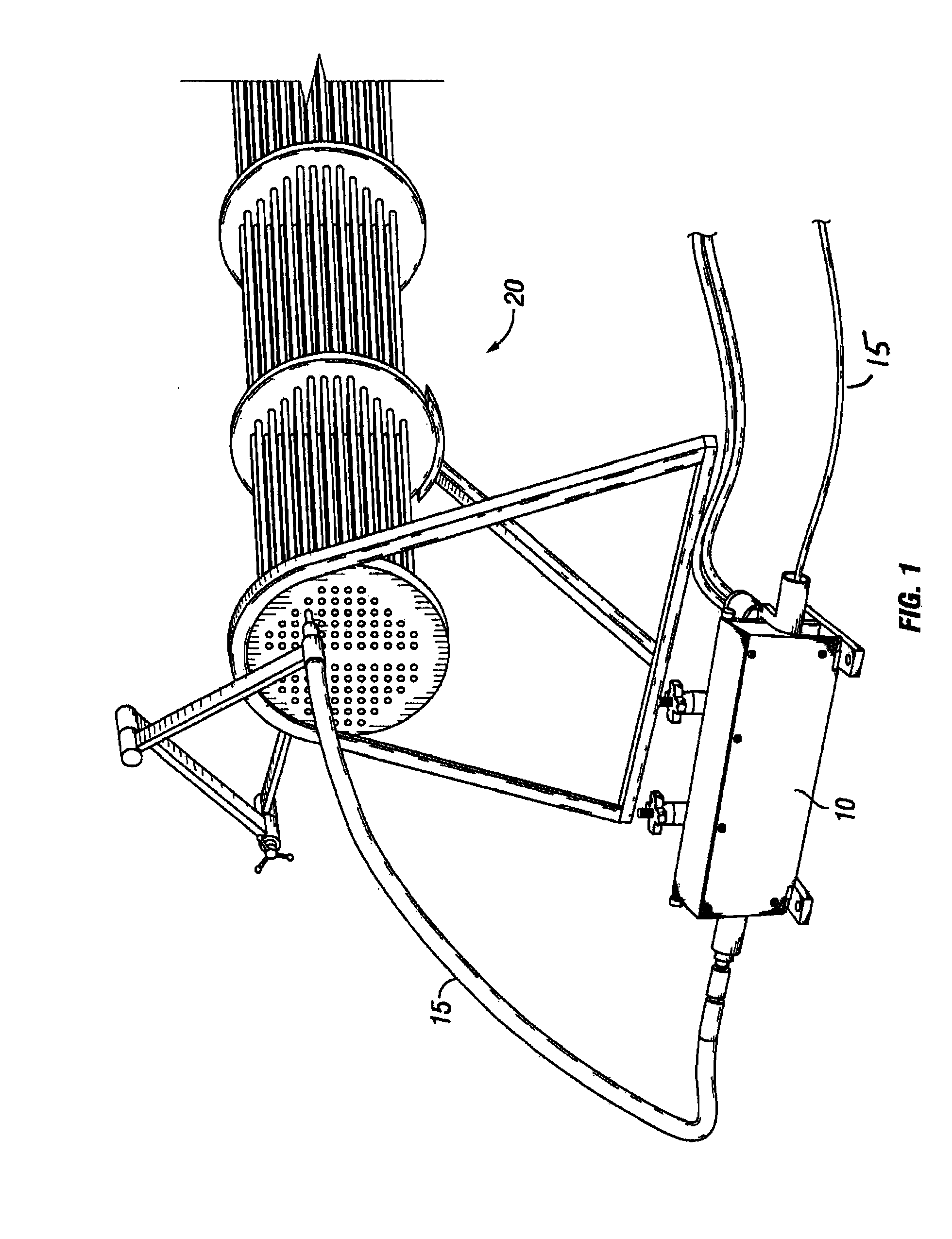

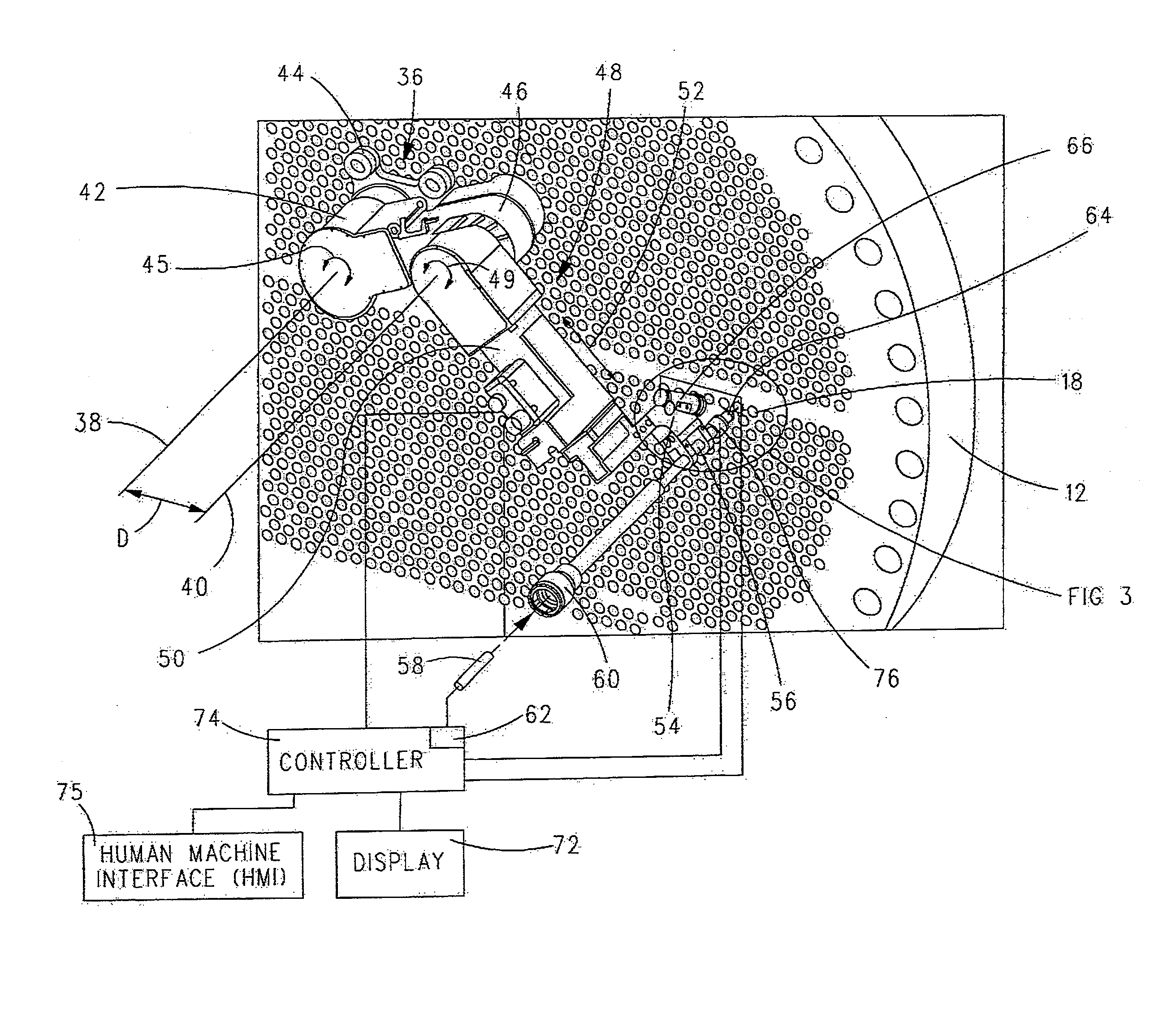

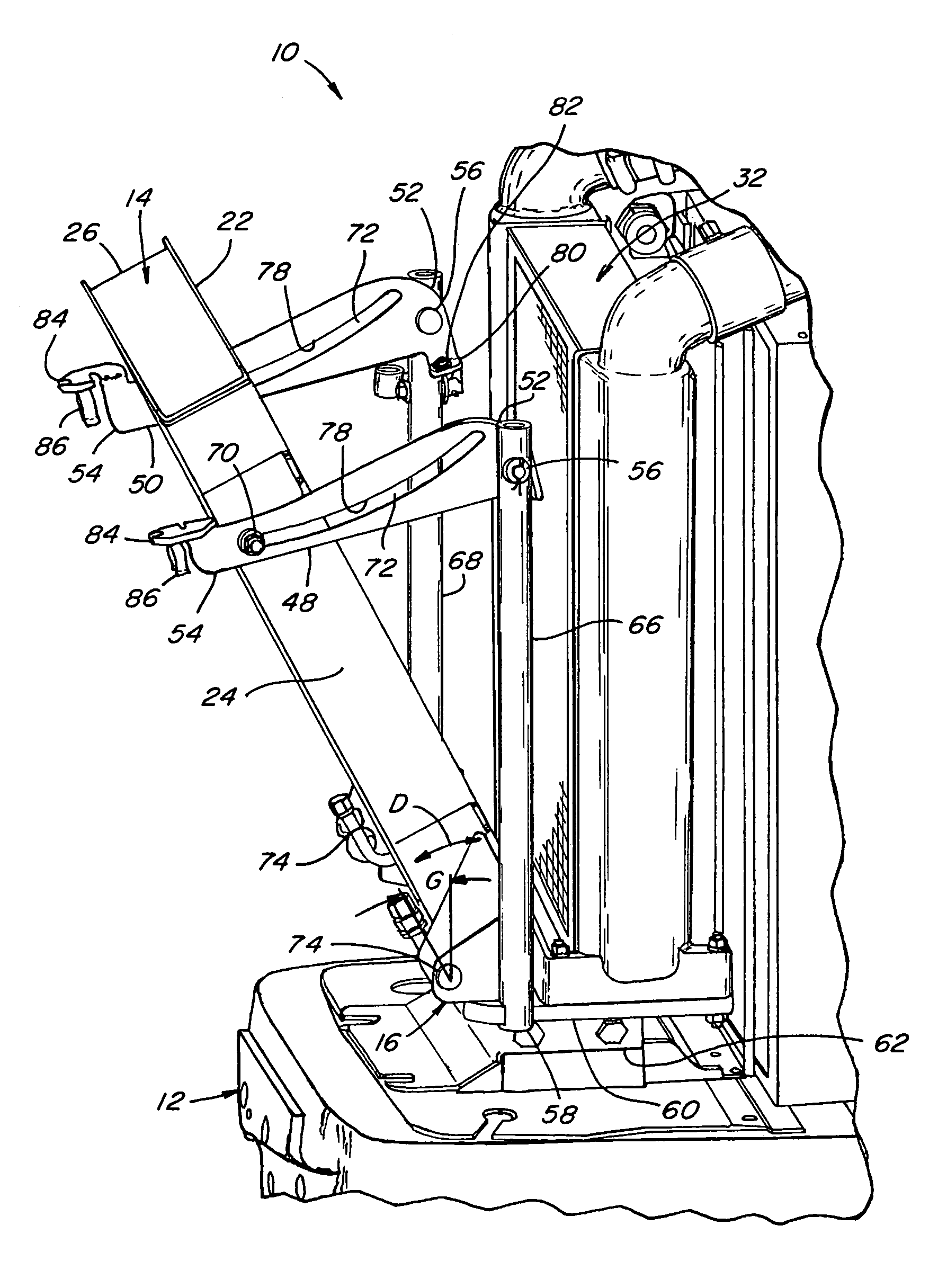

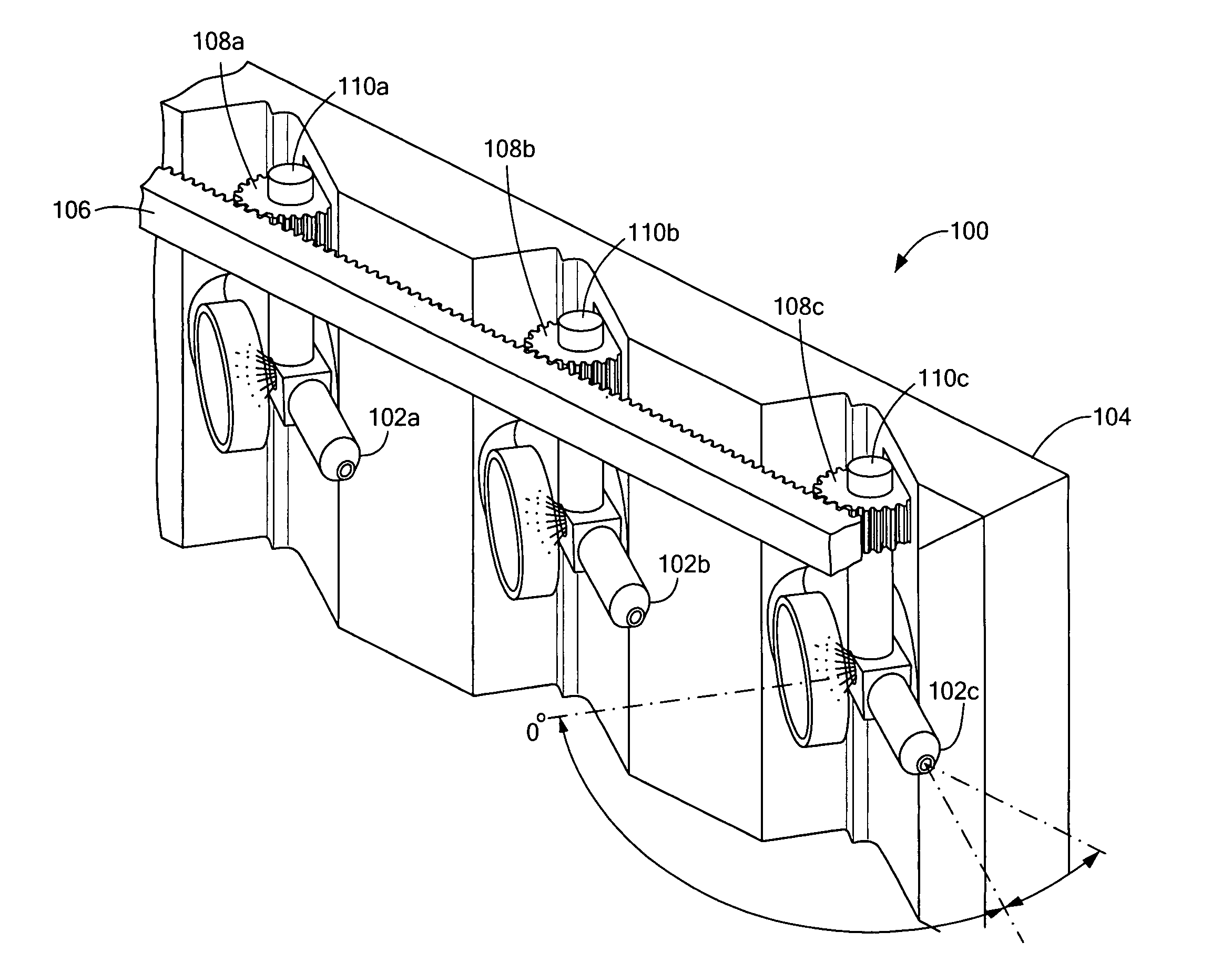

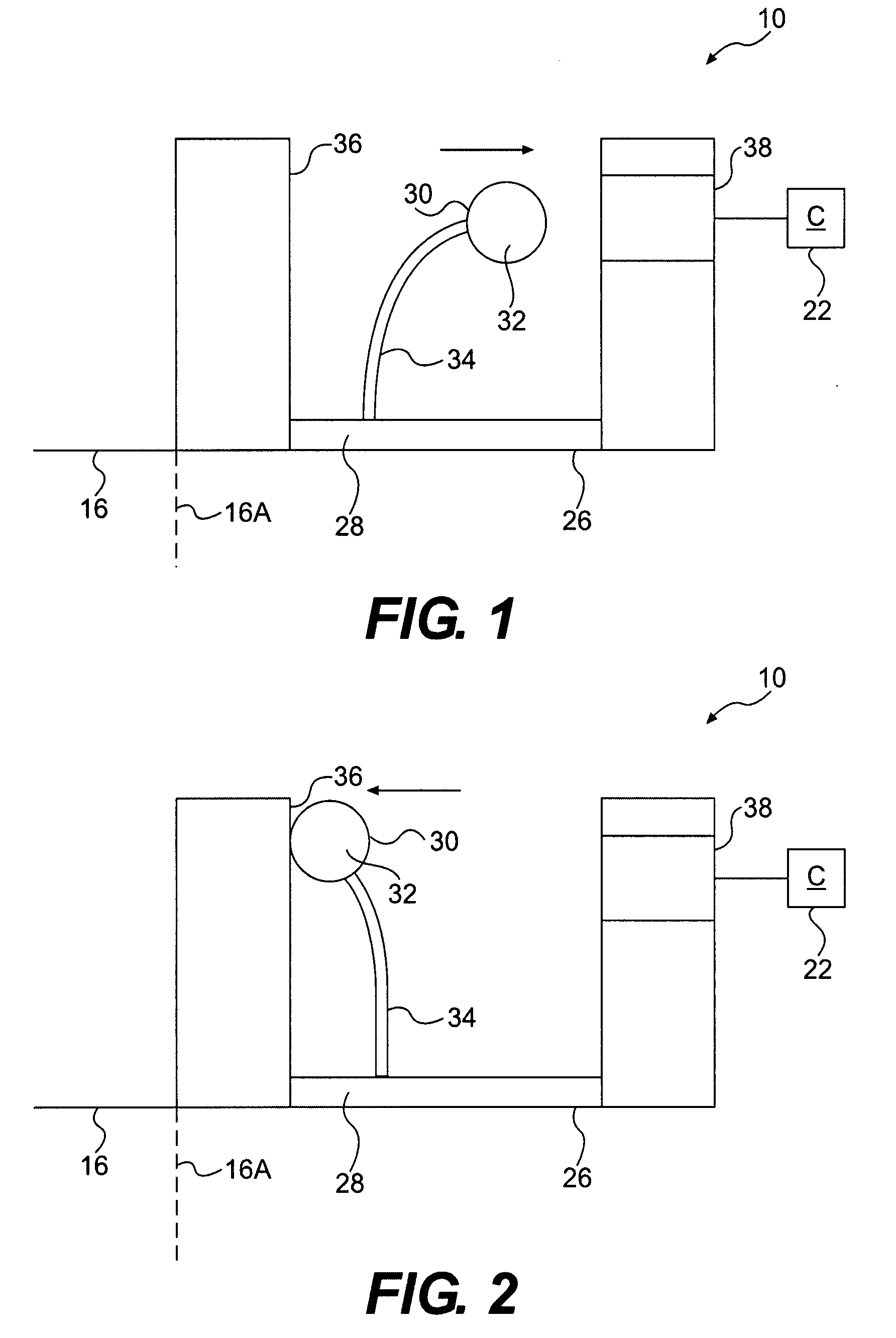

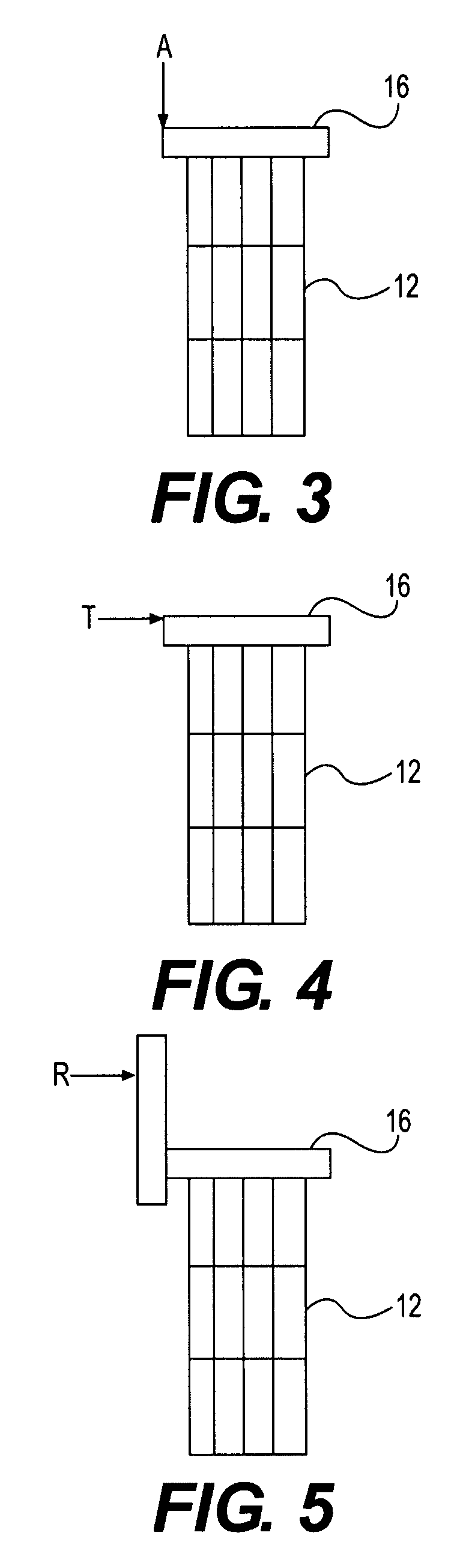

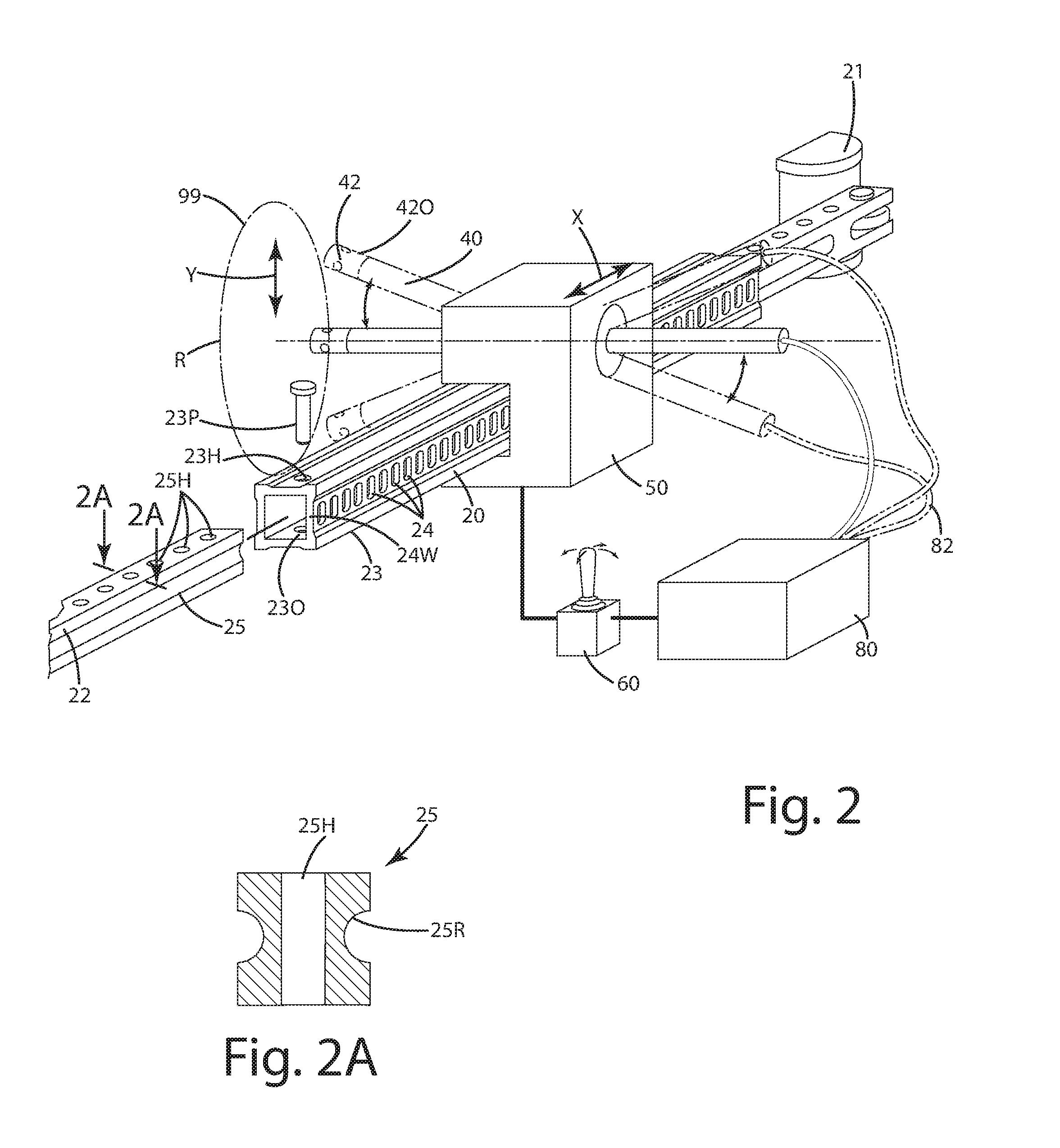

Heat exchanger cleaning tool with three axis control

A tool for cleaning a heat exchanger that includes a lance, and an articulated arm fixedly attached to the heat exchanger at a first end, and associated with the lance at a second end. The articulated arm has at least two joints so that the articulated arm can move the lance along two axes in a plane substantially parallel to the tube face of the heat exchanger. The tool further includes a lance transport mechanism attached to the second end of the articulated arm that moves toward and away from the tube face of the heat exchanger in a direction substantially perpendicular to the tube face, the lance transport mechanism attached to the lance so that the lance moves toward and away from the tube face along with the lance transport mechanism.

Owner:CLEAN HARBORS IND SERVICES INC

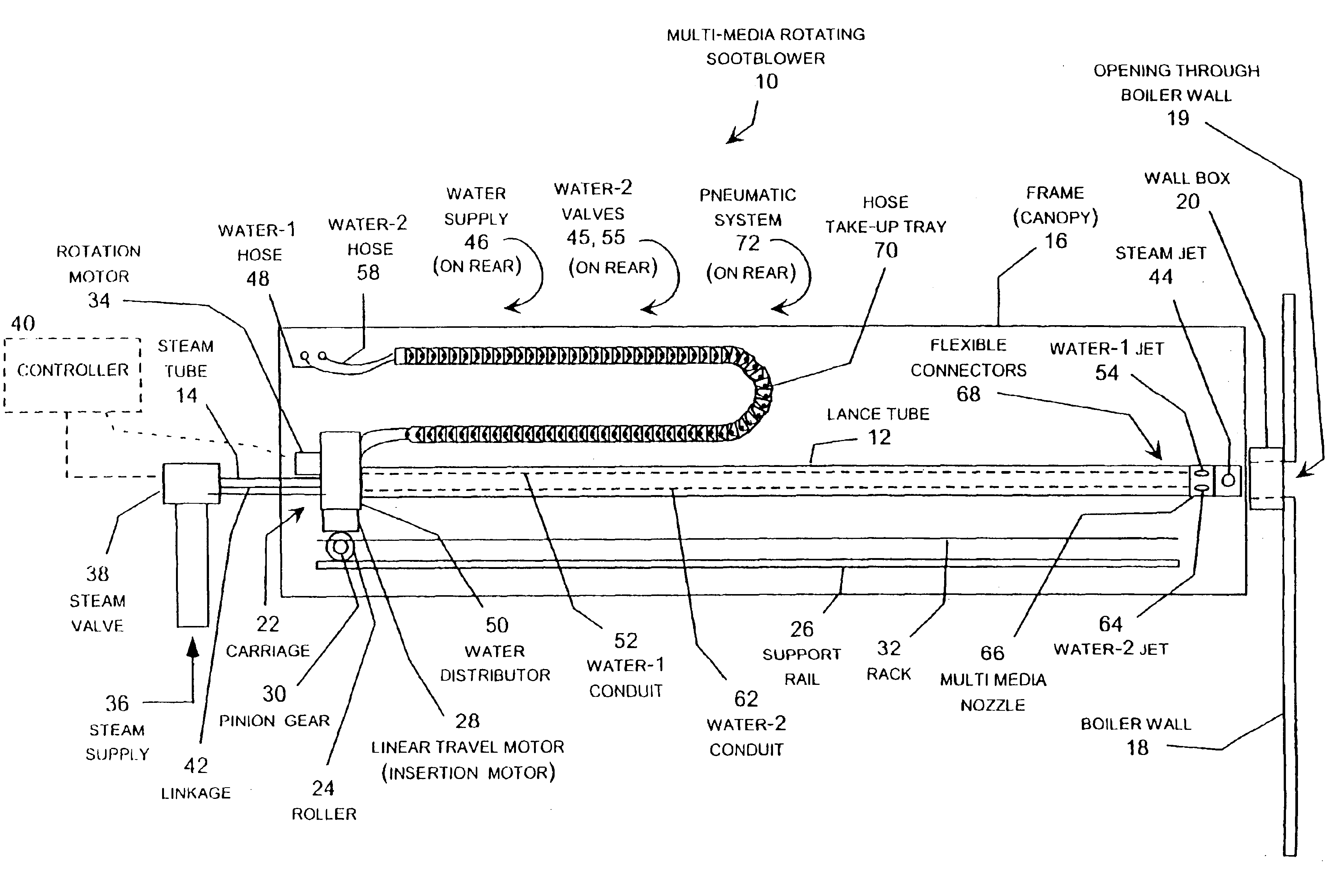

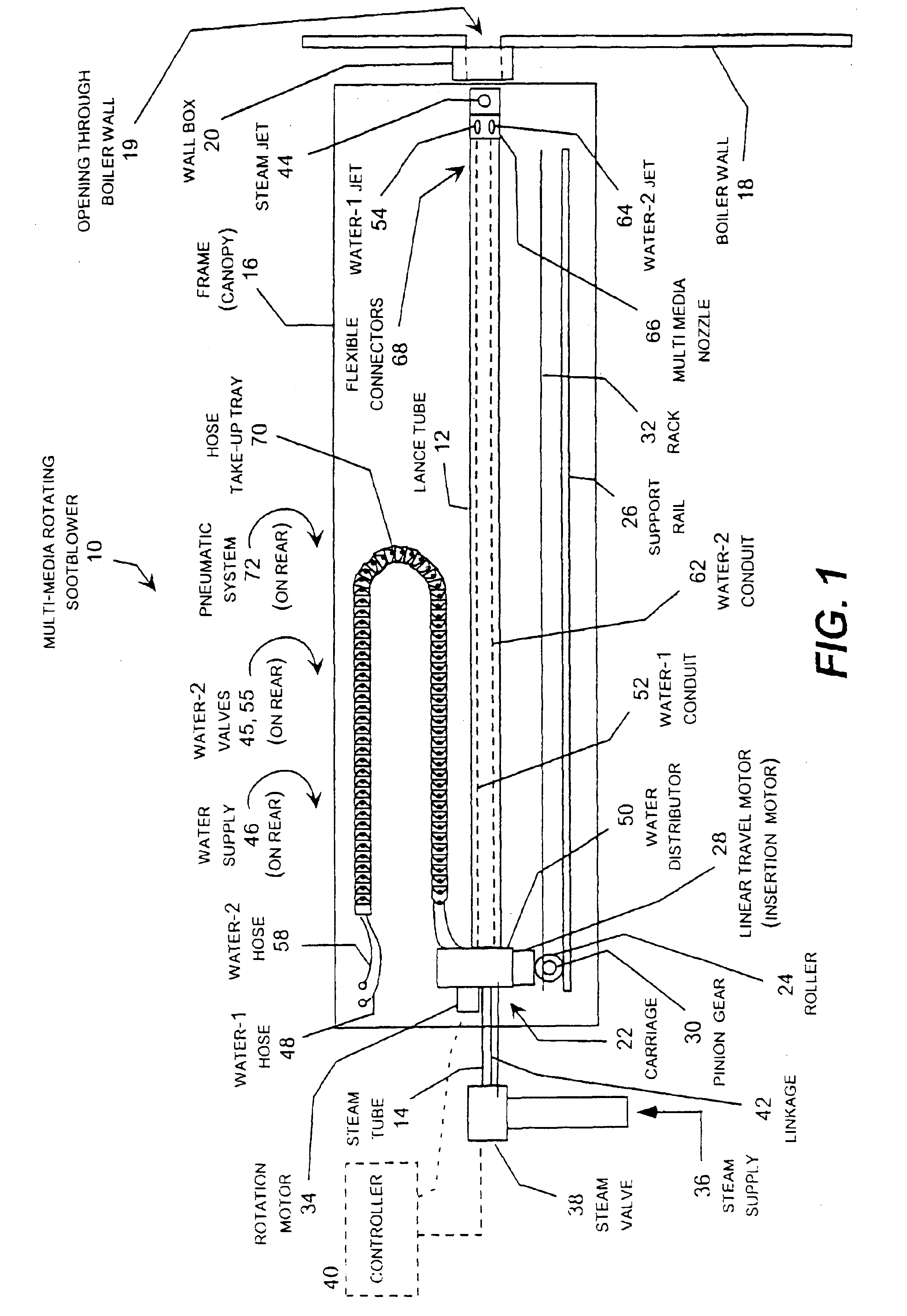

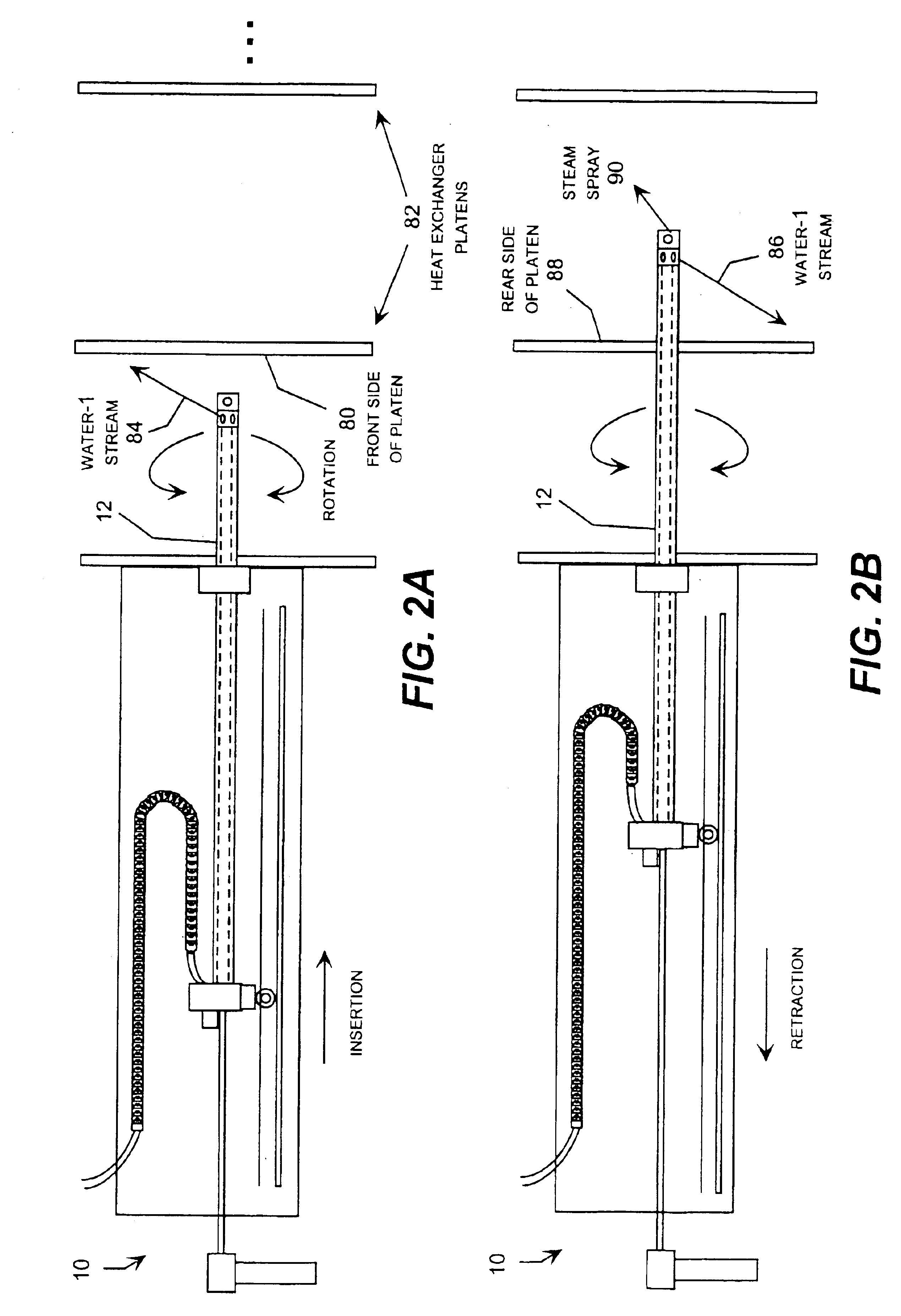

Multi-media rotating sootblower and automatic industrial boiler cleaning system

ActiveUS6892679B2Avoiding unnecessary thermal stressUnnecessary thermal stressMechanical cleaningPressure cleaningRegimenControl system

A multi-media rotating sootblower that includes multiple rotating and individually controlled cleaning fluid applicators, such a set of steam nozzles and two sets of water nozzles, and an automatic boiler cleaning system using these sootblowers. The boiler superheater typically includes a system of these sootblowers to clean a number of large platens that are arranged in rows. The boiler may also include additional boiler cleaning equipment, including water cannons to clean the furnace, and conventional steam sootblowers to clean other heat exchangers of the boiler. A number of sensors, including heat transfer gauges that measure the heat transfer at the furnace wall, strain gauges that measure the weight of slag deposits on platens, and boiler cameras are used to monitor slag accumulations within the boiler. A control system uses this sensor data to automatically operate the boiler cleaning system to implement an automatic boiler cleaning regimen.

Owner:CLYDE IND

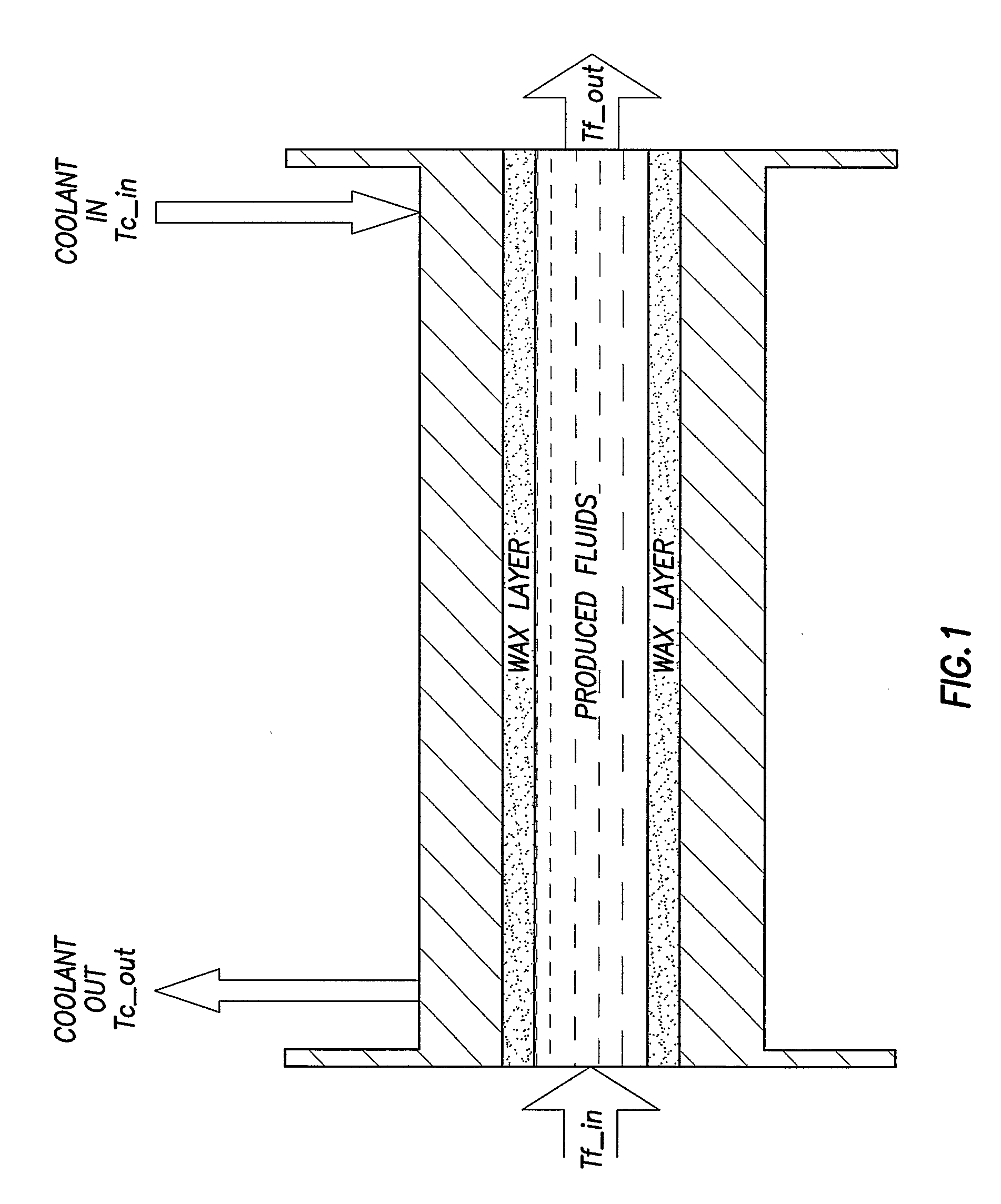

Pipes, systems, and methods for transporting hydrocarbons

InactiveUS20060186023A1Little strengthFlow propertiesFluid removalWall shearHydrocotyle bowlesioides

There is disclosed a method of transporting a produced fluid through a pipe while limiting deposits at a desired pipe inner-wall location comprising providing a pipe having an inner surface roughness Ra less than 2.5 micrometers at said desired pipe inner-wall location, forcing the produced fluid through the pipe, wherein the produced fluid has a wall shear stress of at least 1 dyne per centimeter squared at said desired pipe inner-wall location.

Owner:SHELL OIL CO

Method of determining individual sootblower effectiveness

ActiveUS20060065291A1Hollow article cleaningBoiler cleaning apparatusBoiler furnaceProcess engineering

A method of cleaning a heat transfer element within a boiler furnace is provided. The method includes the steps of allowing a furnace to operate and deposit ash on a heat transfer element, determining an efficiency rate for at least one cleaning element, and managing the cleaning element based on the efficiency rate.

Owner:INT PAPER CO

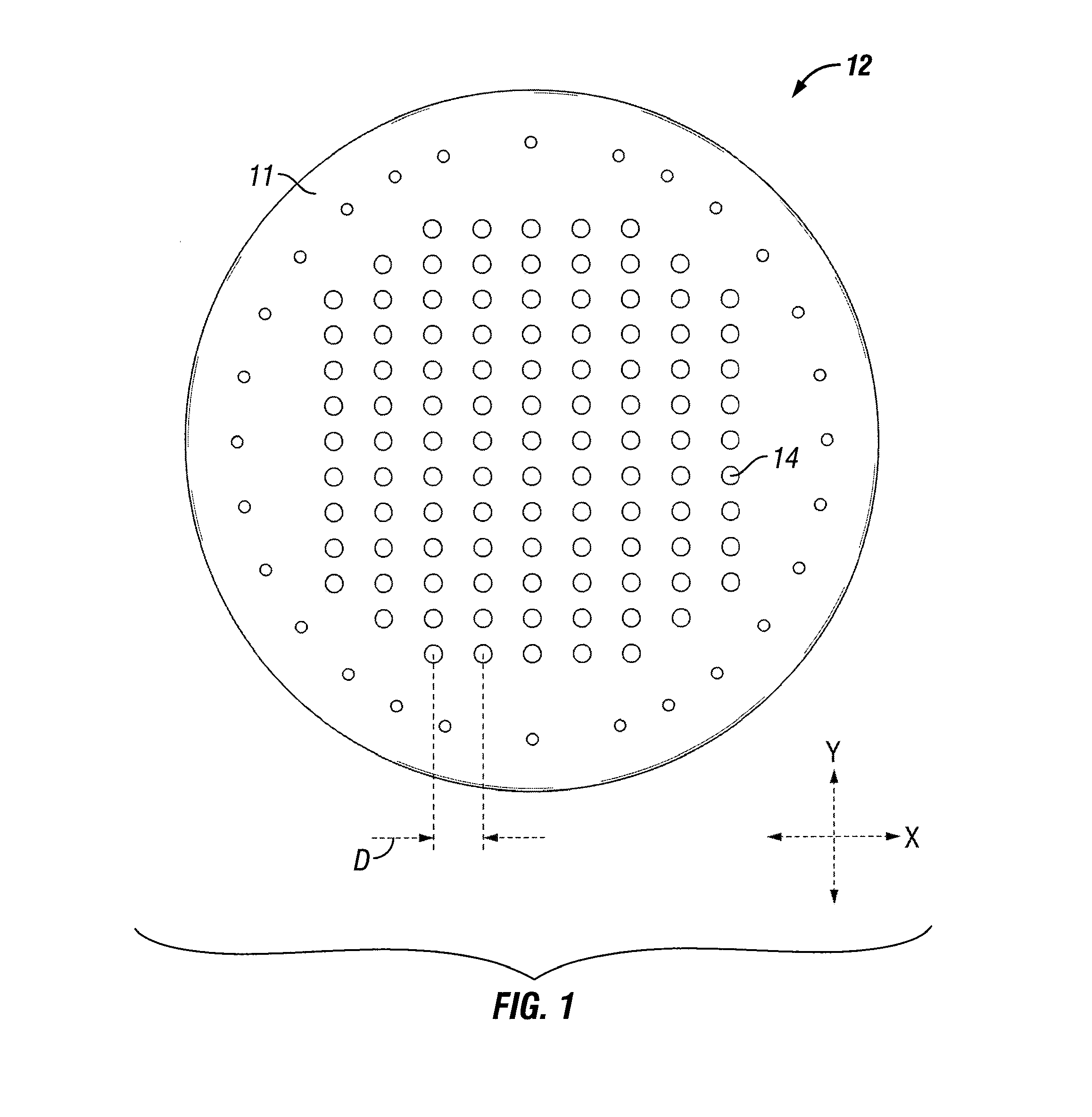

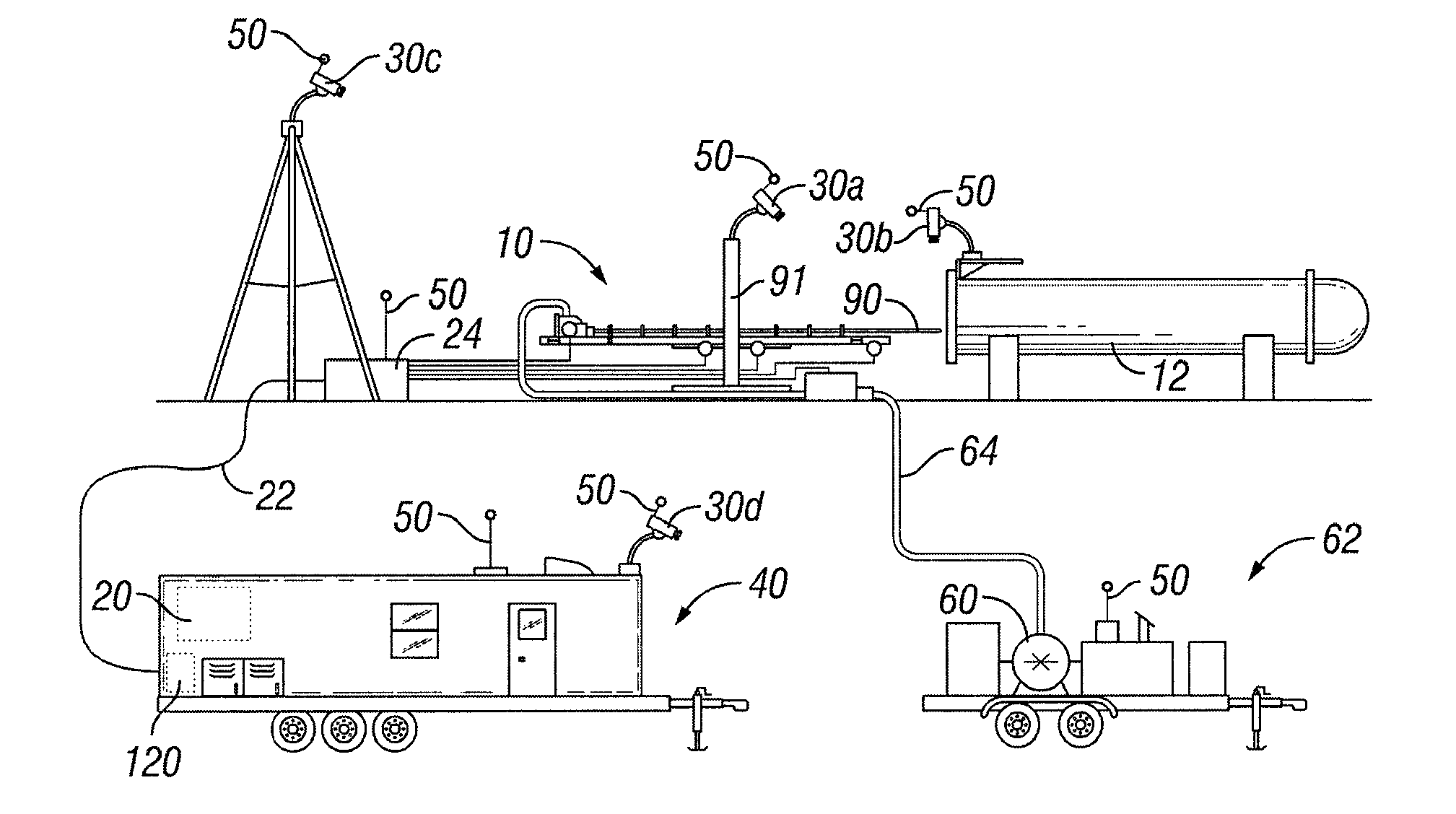

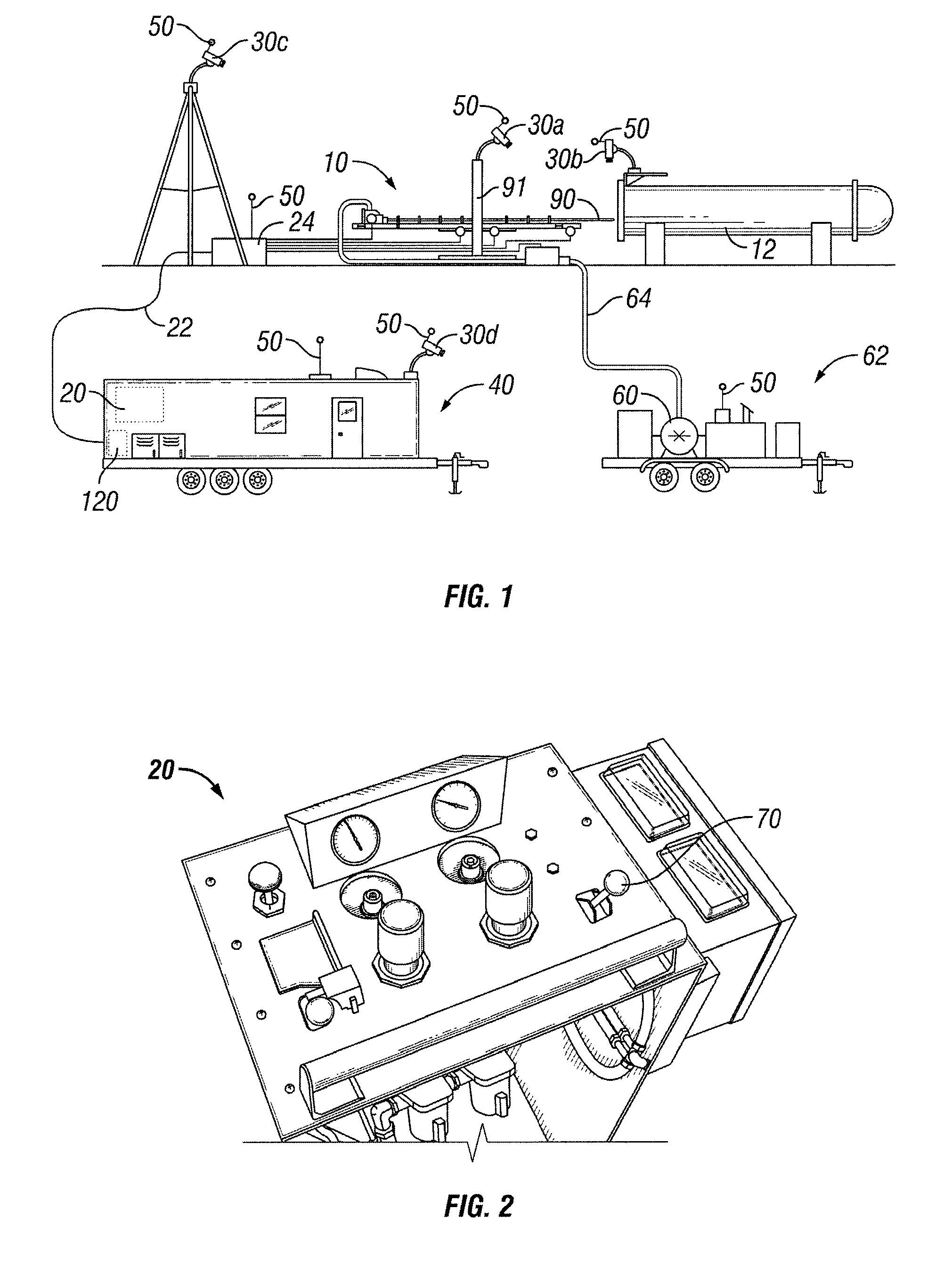

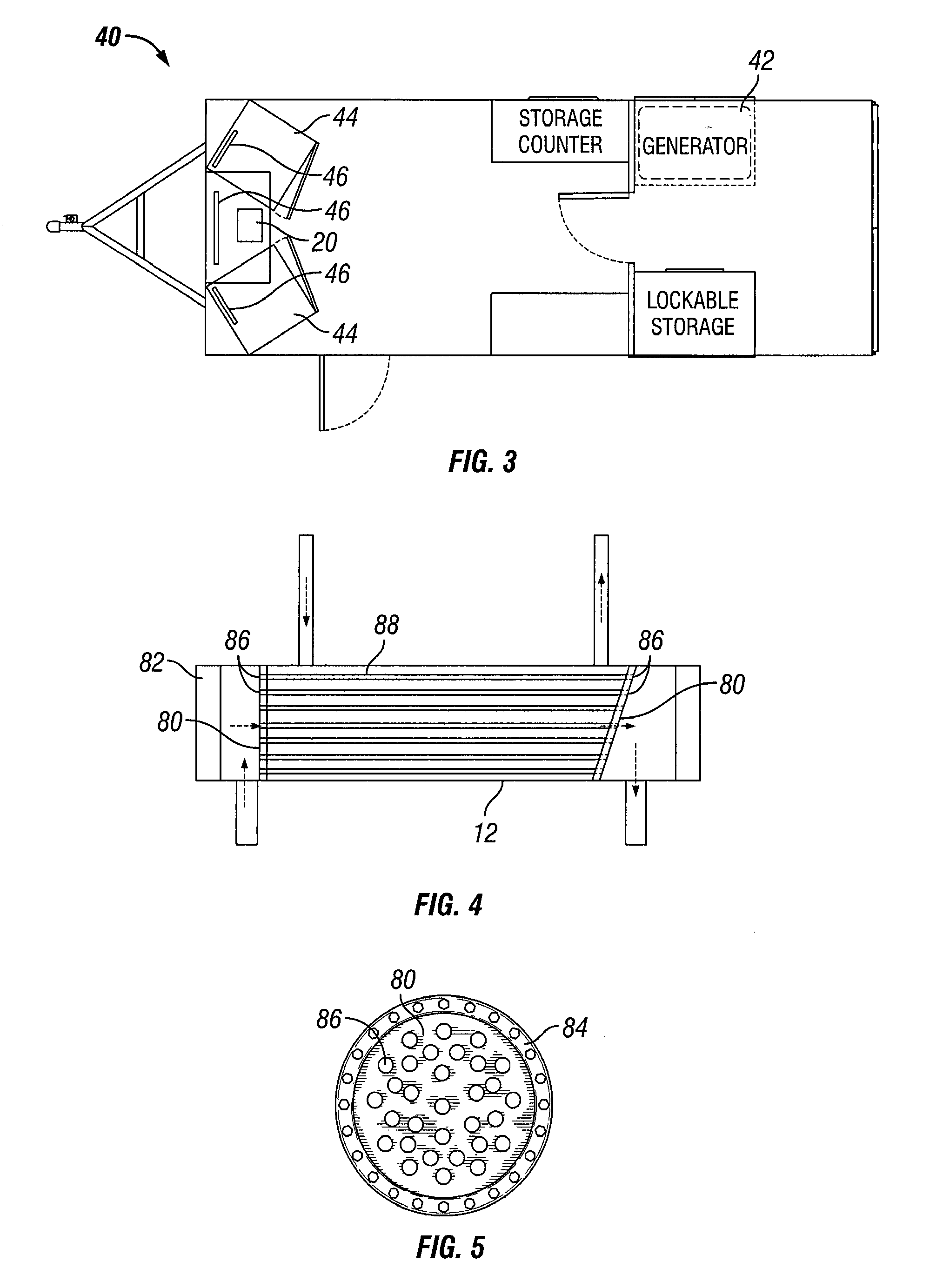

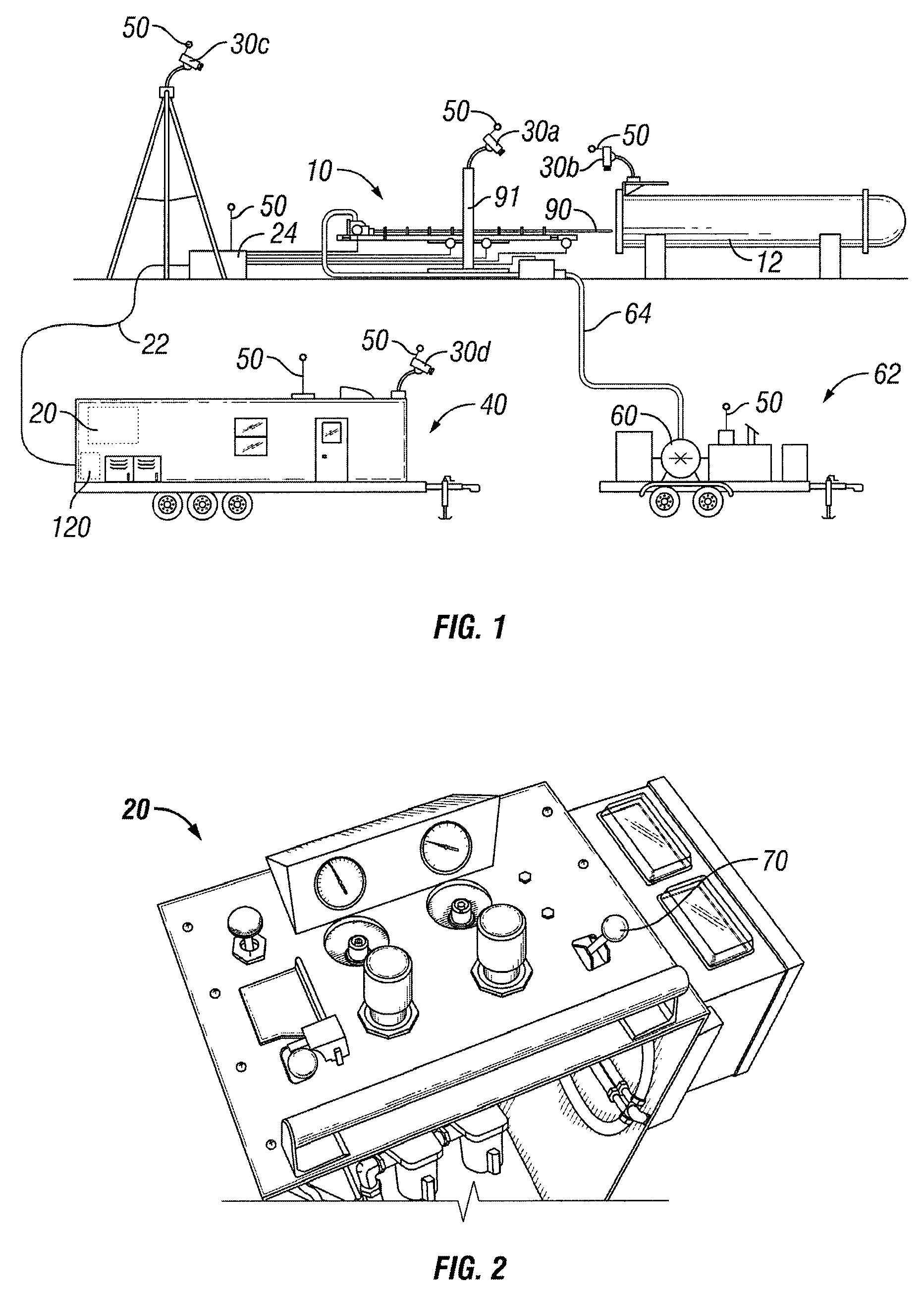

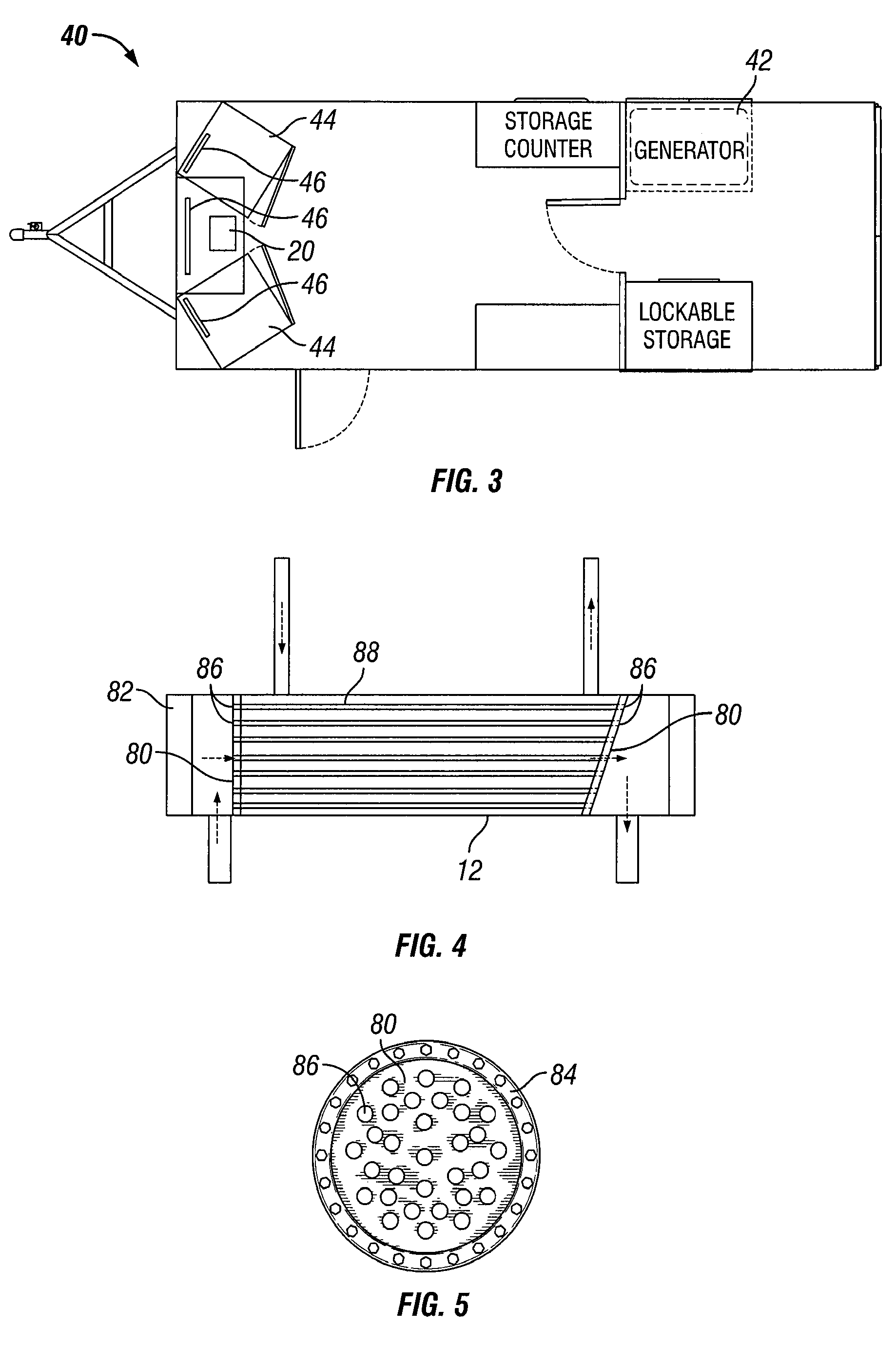

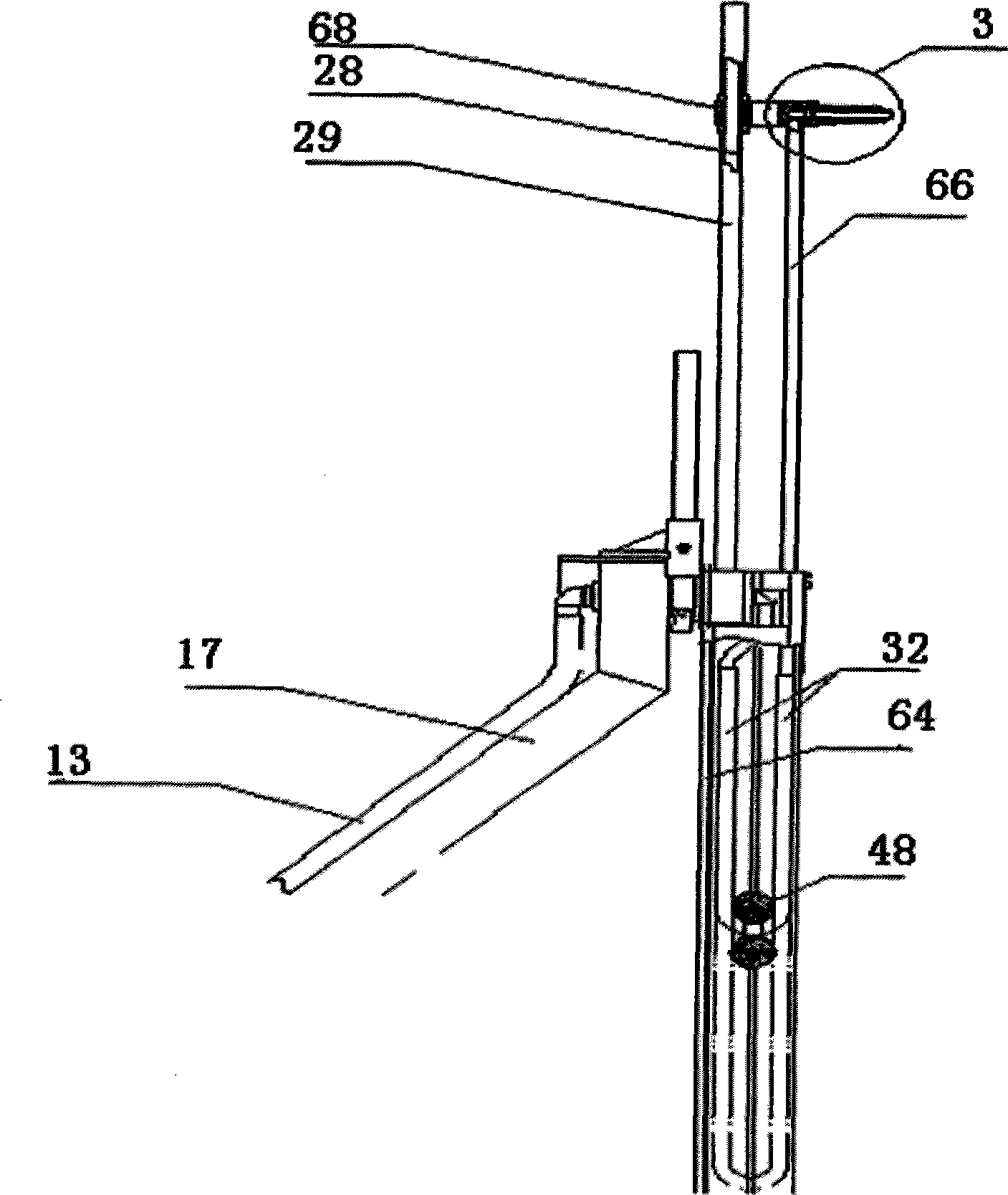

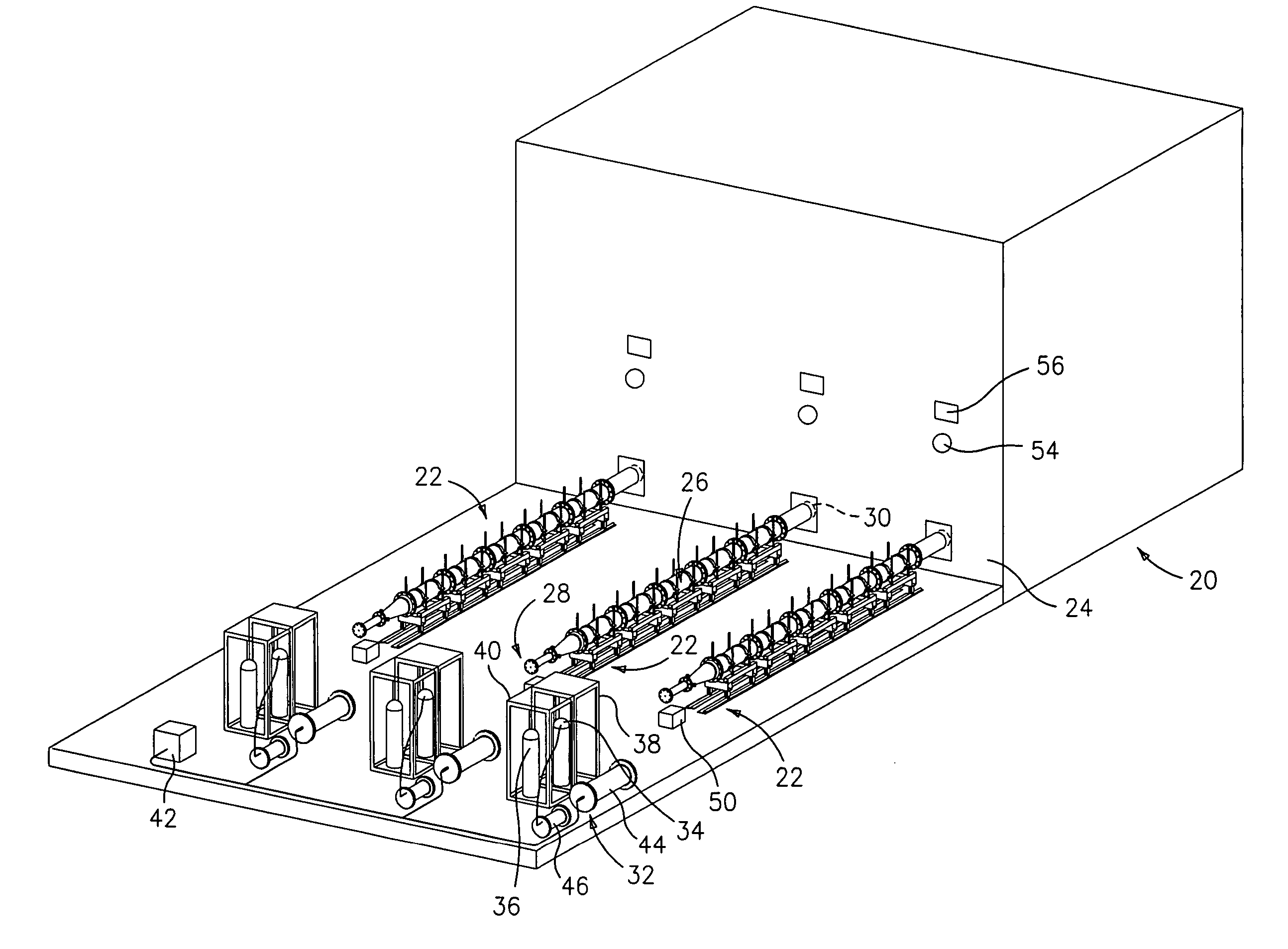

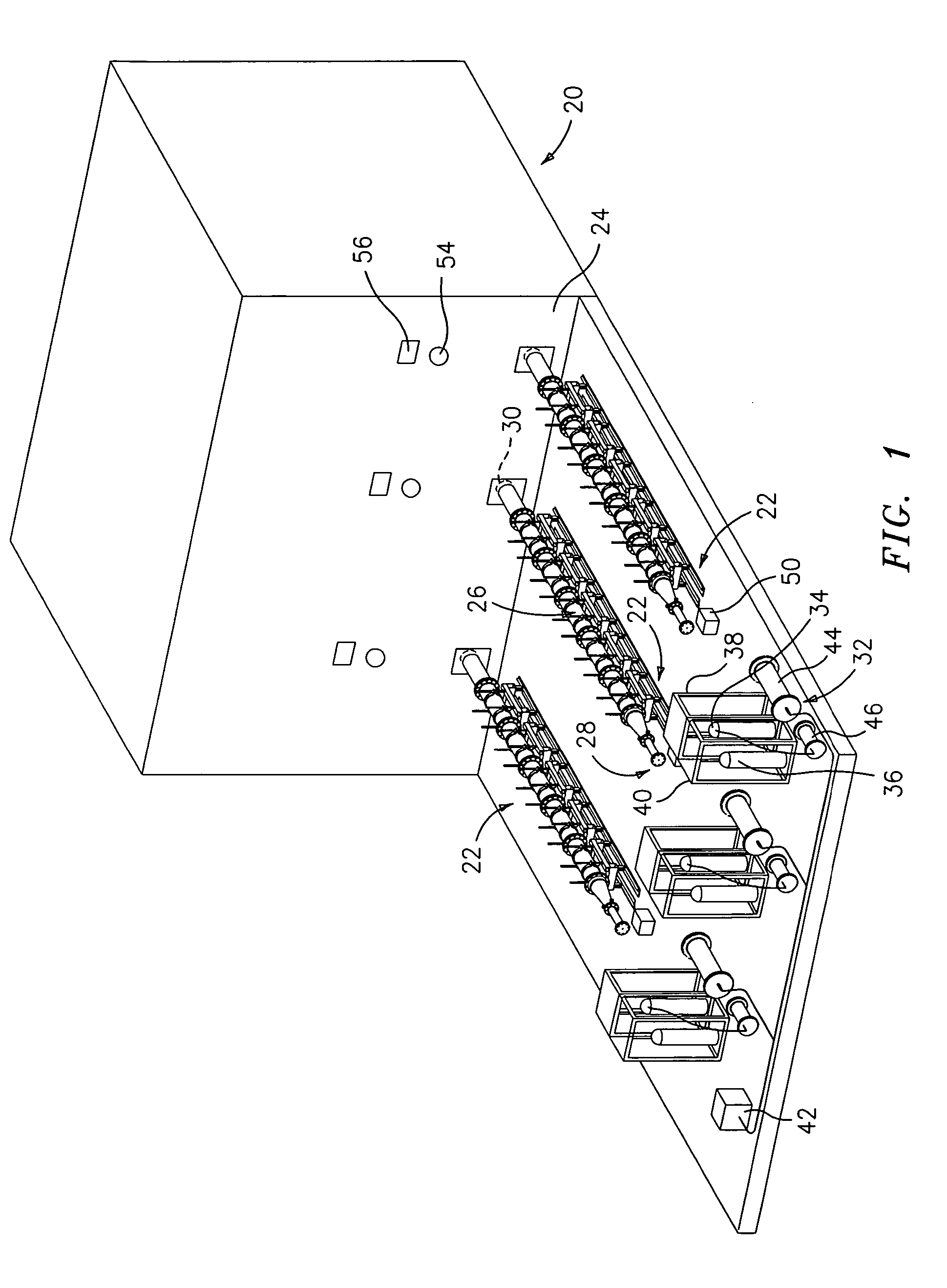

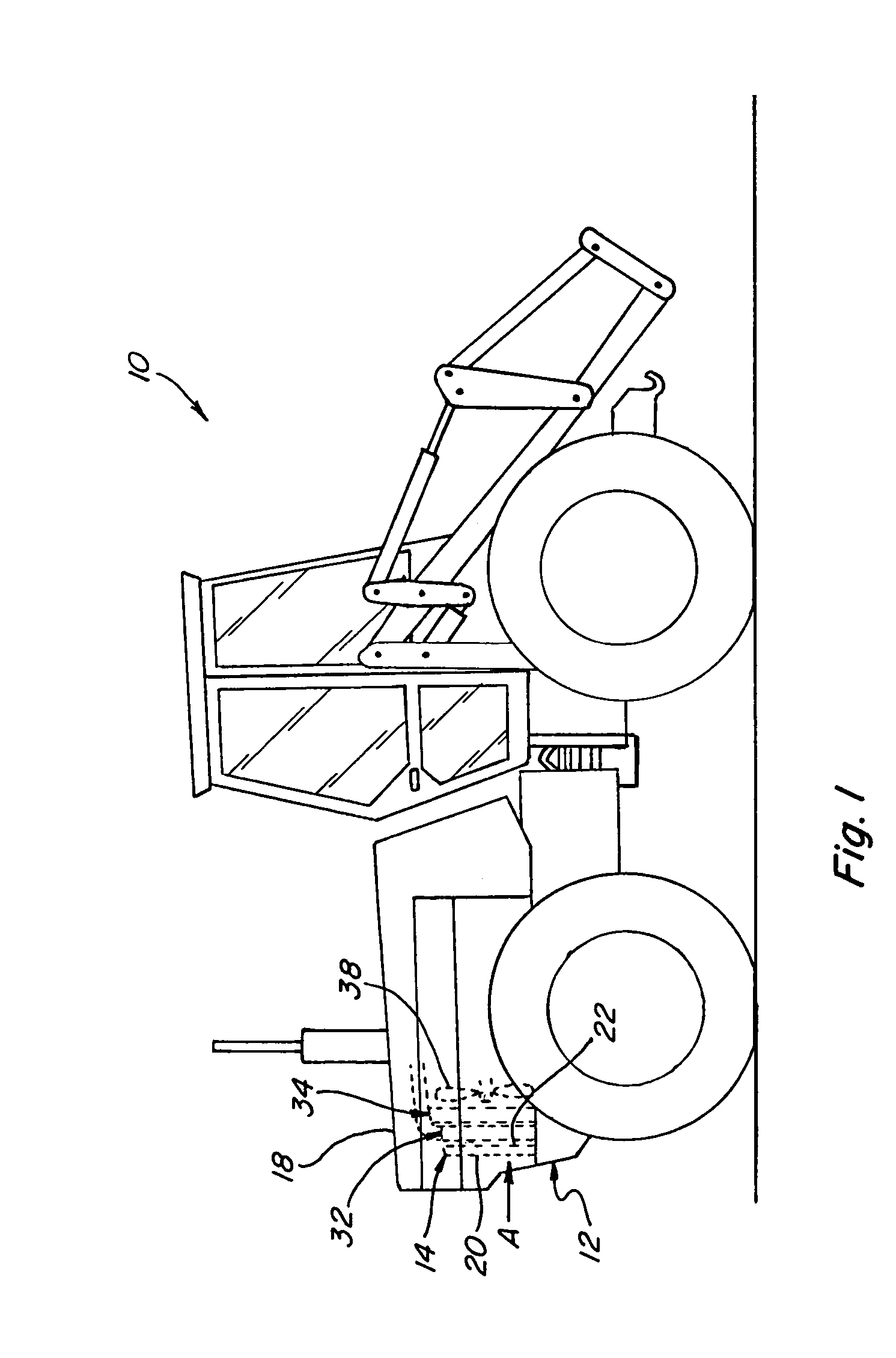

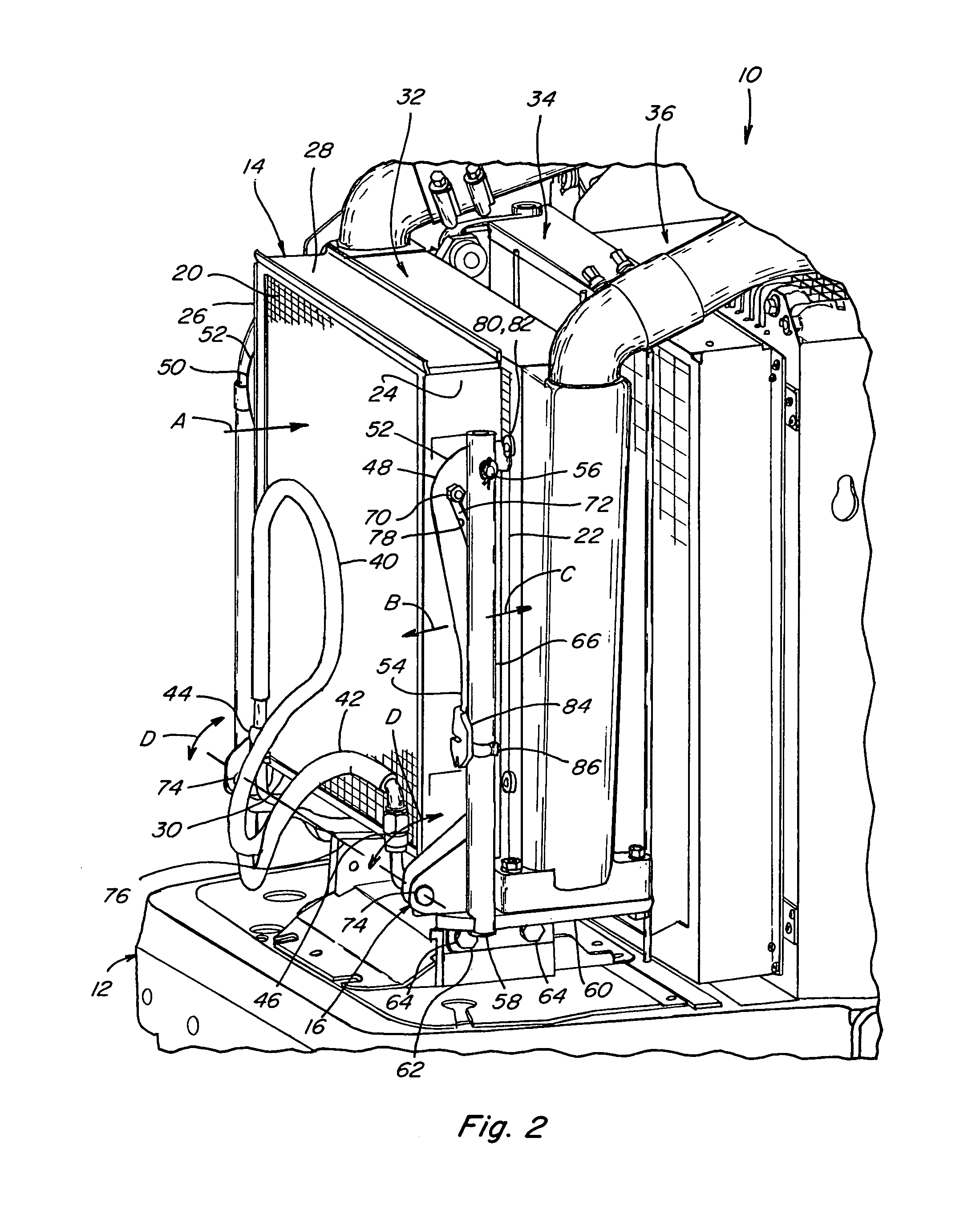

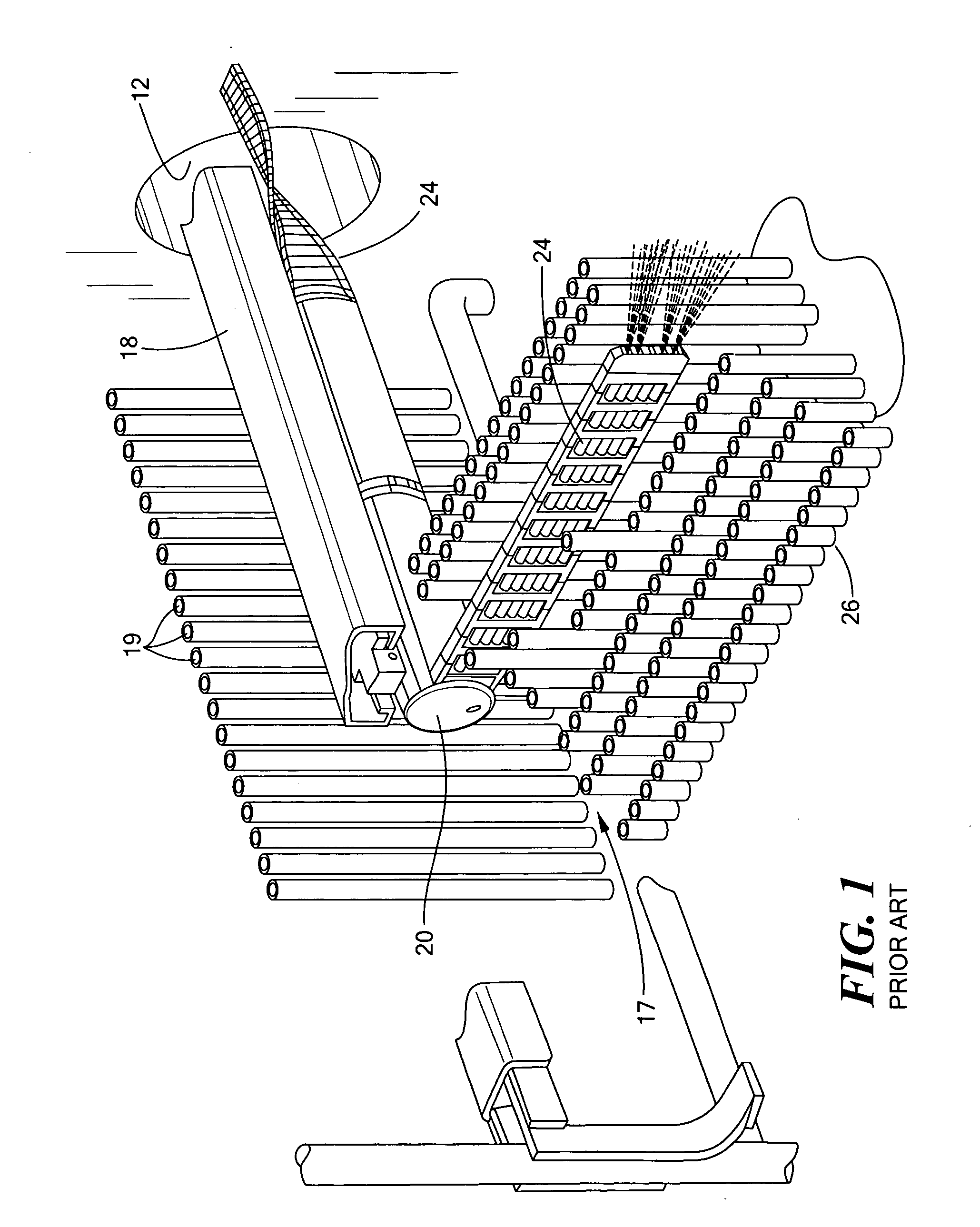

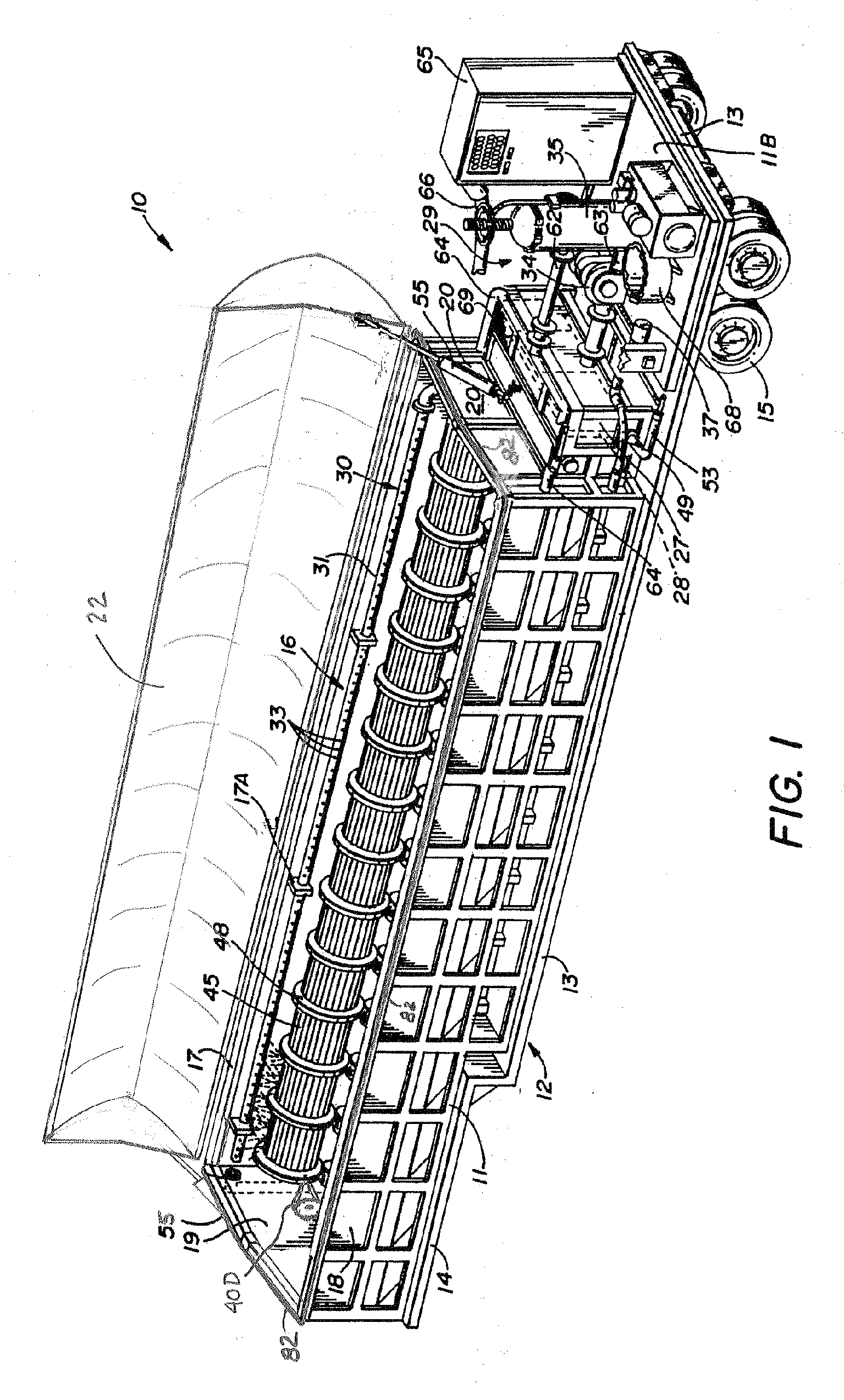

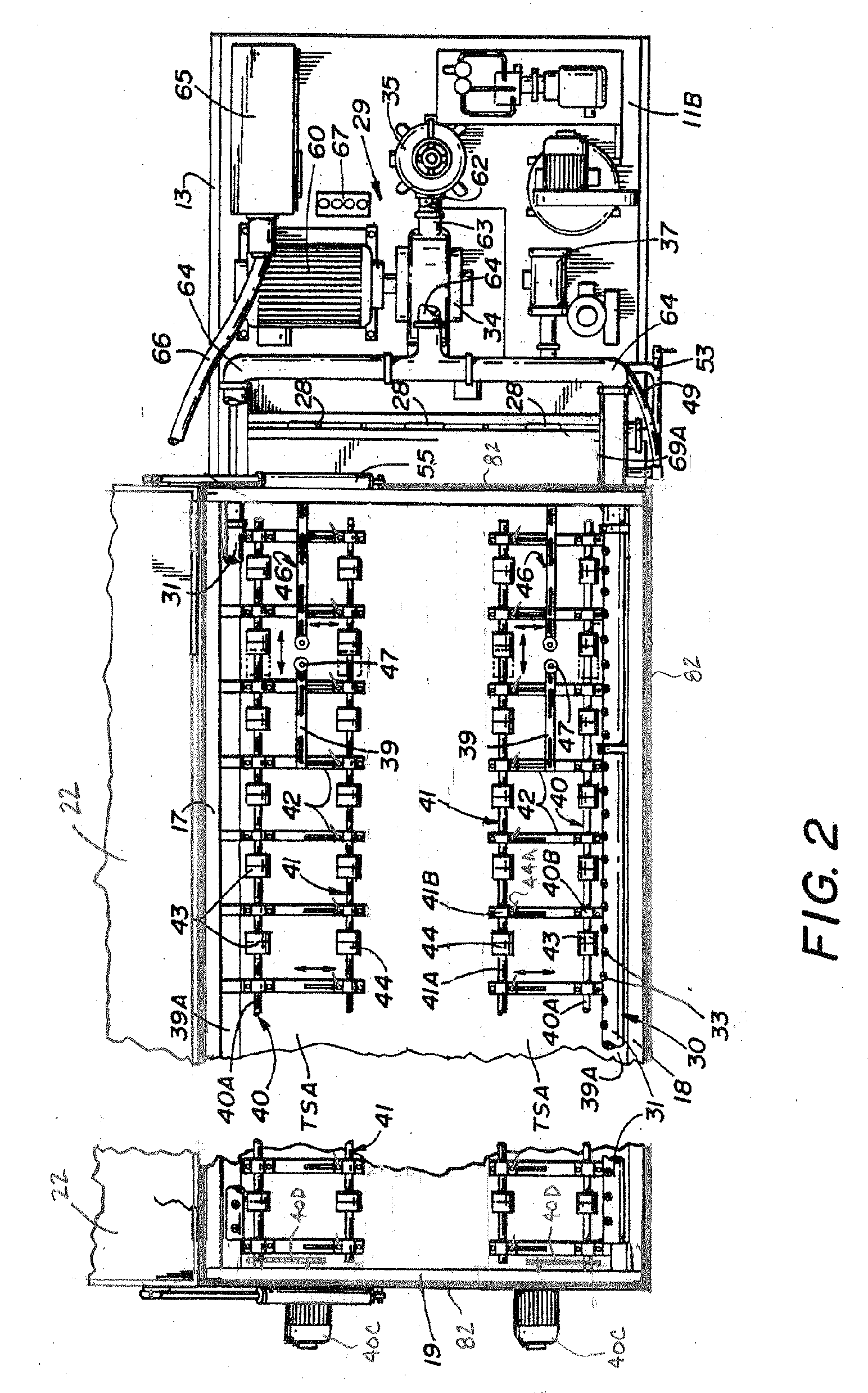

Semi-automated heat exchanger tube cleaning assembly and method

ActiveUS20120067370A1Adjustable distanceHollow article cleaningHair combsPetrochemicalProcess engineering

A heat exchanger tube cleaning assembly and method is provided. The assembly can allow for semi-automated tube cleaning of a heat exchanger or other piping or equipment used in an industrial facility such as, for example, a petrochemical plant or oil refinery.

Owner:HYDROCHEM

Air conditioner cleaning apparatus and method

InactiveUS20070125520A1Less discomfortImprove air qualityMechanical apparatusAir-treating devicesEngineeringPollution

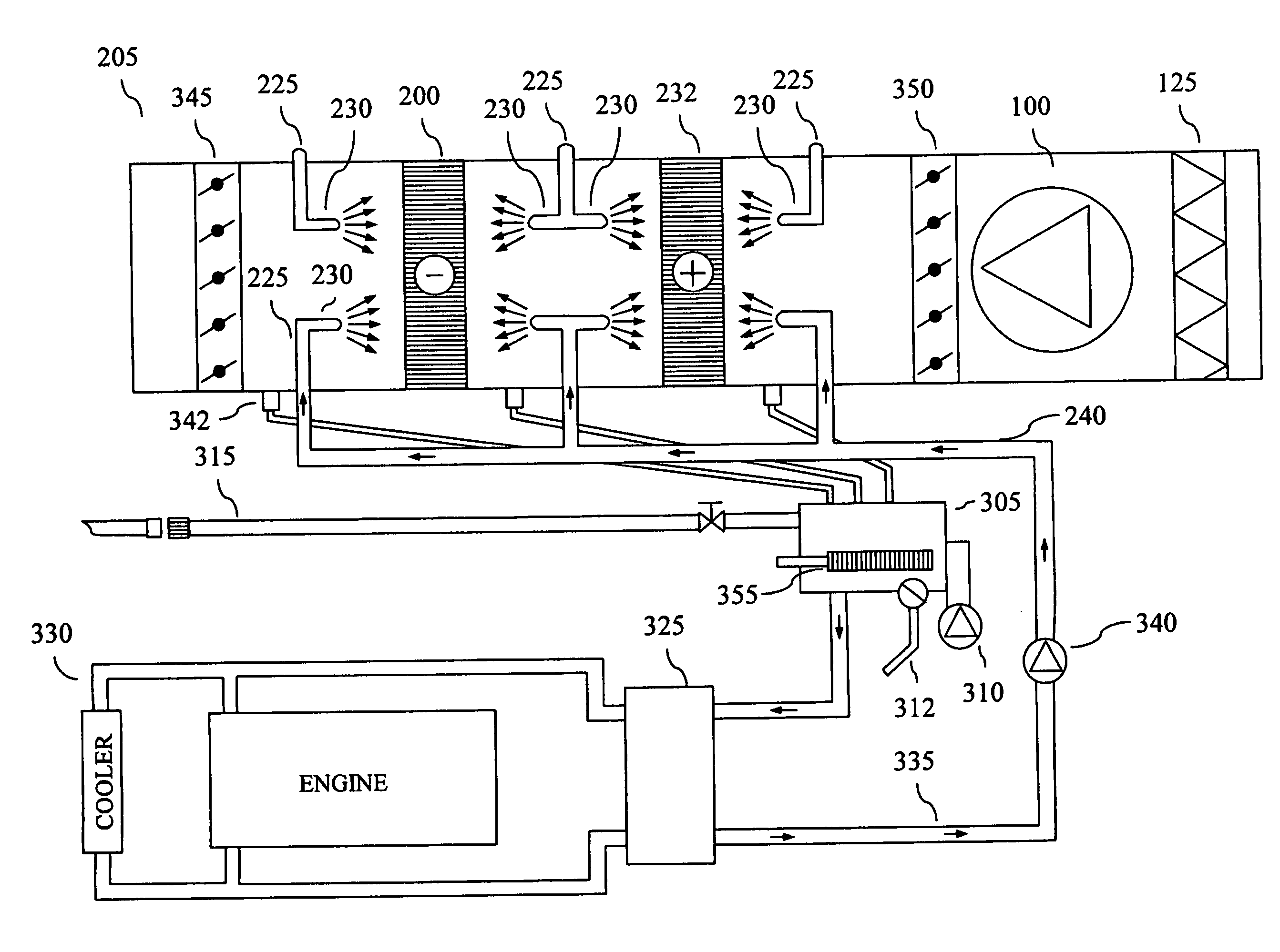

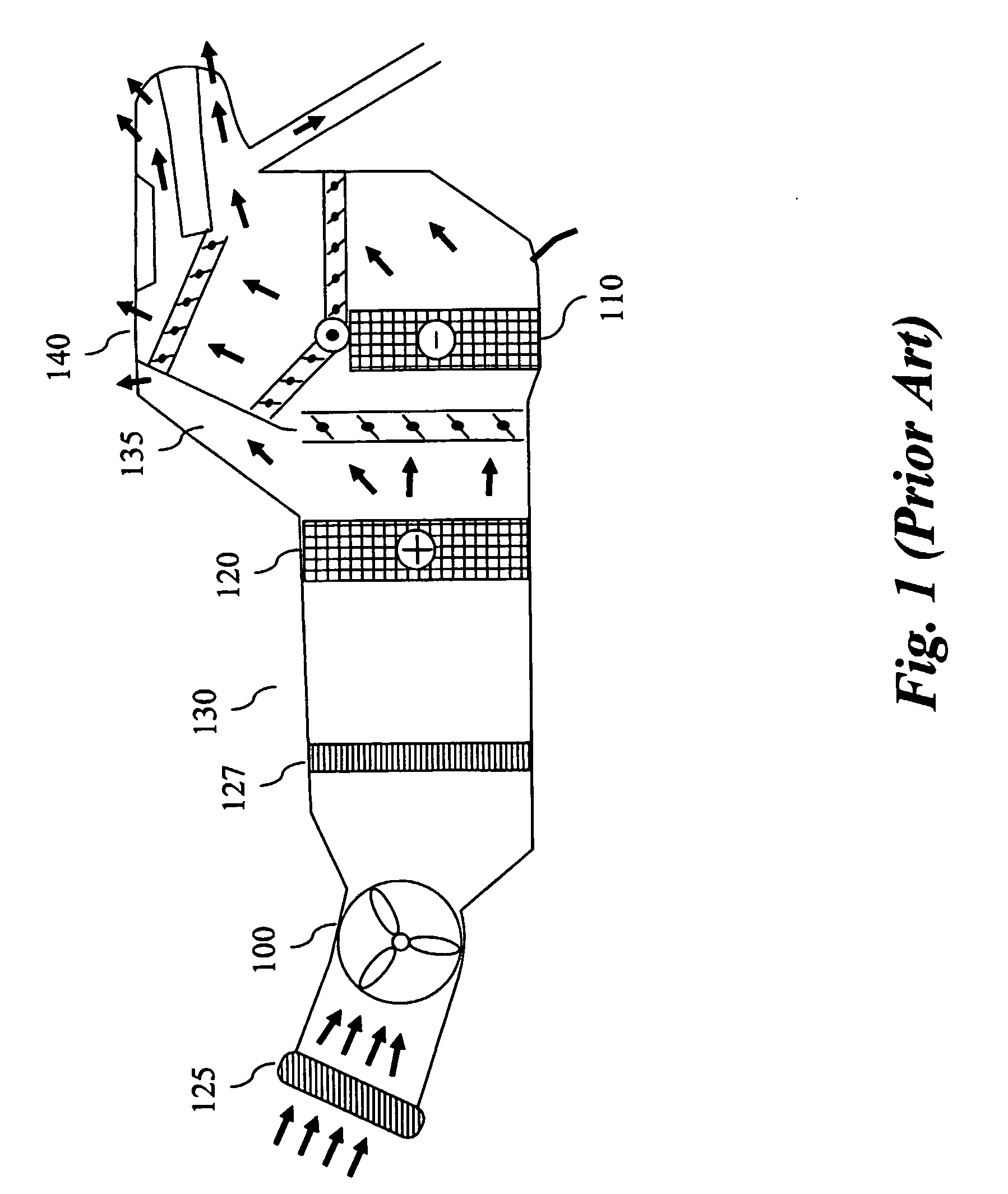

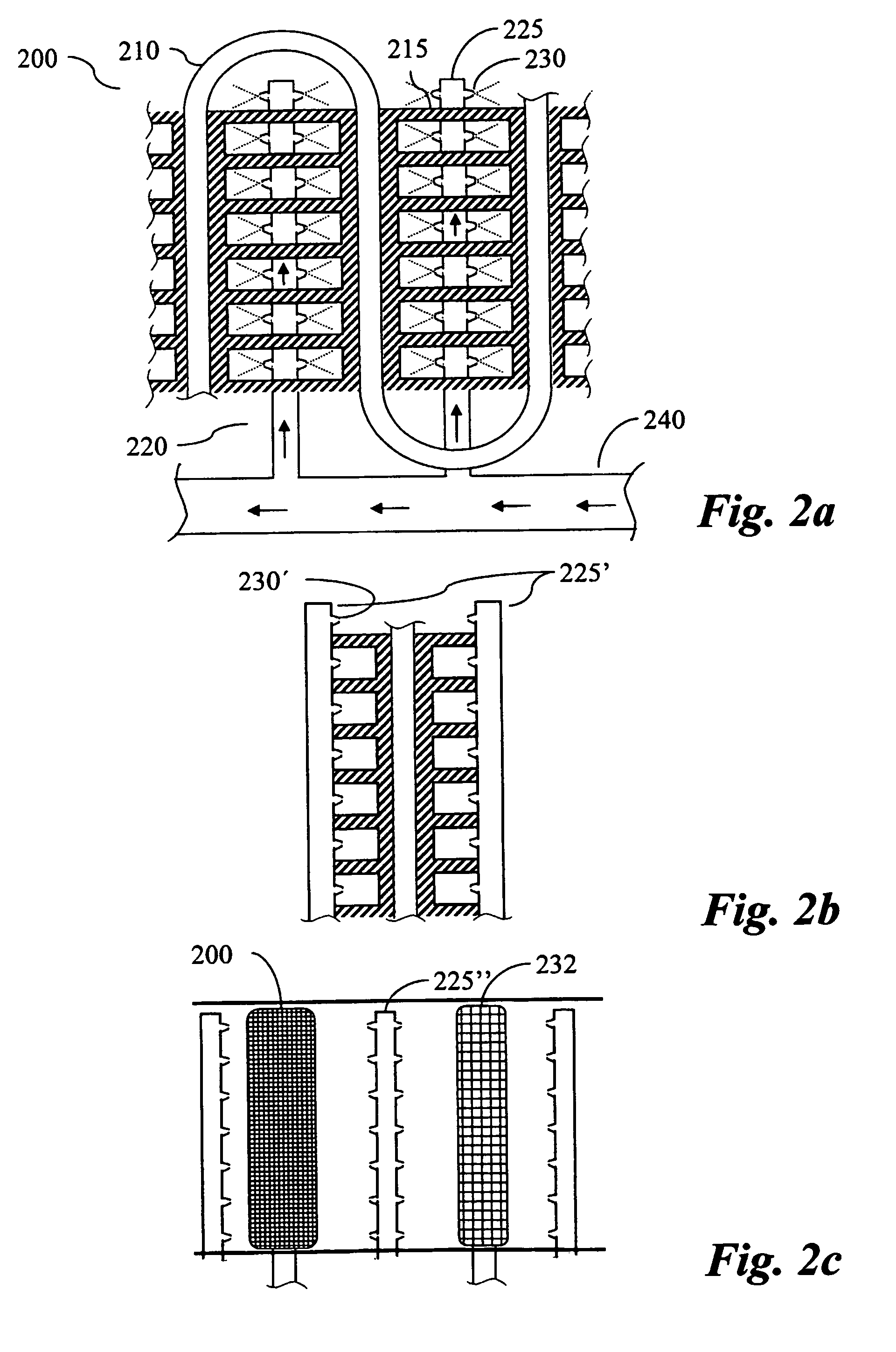

A cleaning apparatus, system and method for parts of the heating / cooling system of an vehicle. The apparatus effectively impedes odour and pollution originating from micro-organisms growing on the cooling and heating units. The cleaning assembly 220 includes of distribution tubes 225 provided with nozzles 230 arranged to spray cleaning substance onto the surfaces of the cooling and / or heating units 200, 232. The distribution tube preferably extends through at least a portion of the plurality of heating / cooling flanges 215 of the heating / cooling units and the nozzles are provided in the spaces formed between two adjacent flanges.

Owner:NUTSOS MIKAEL

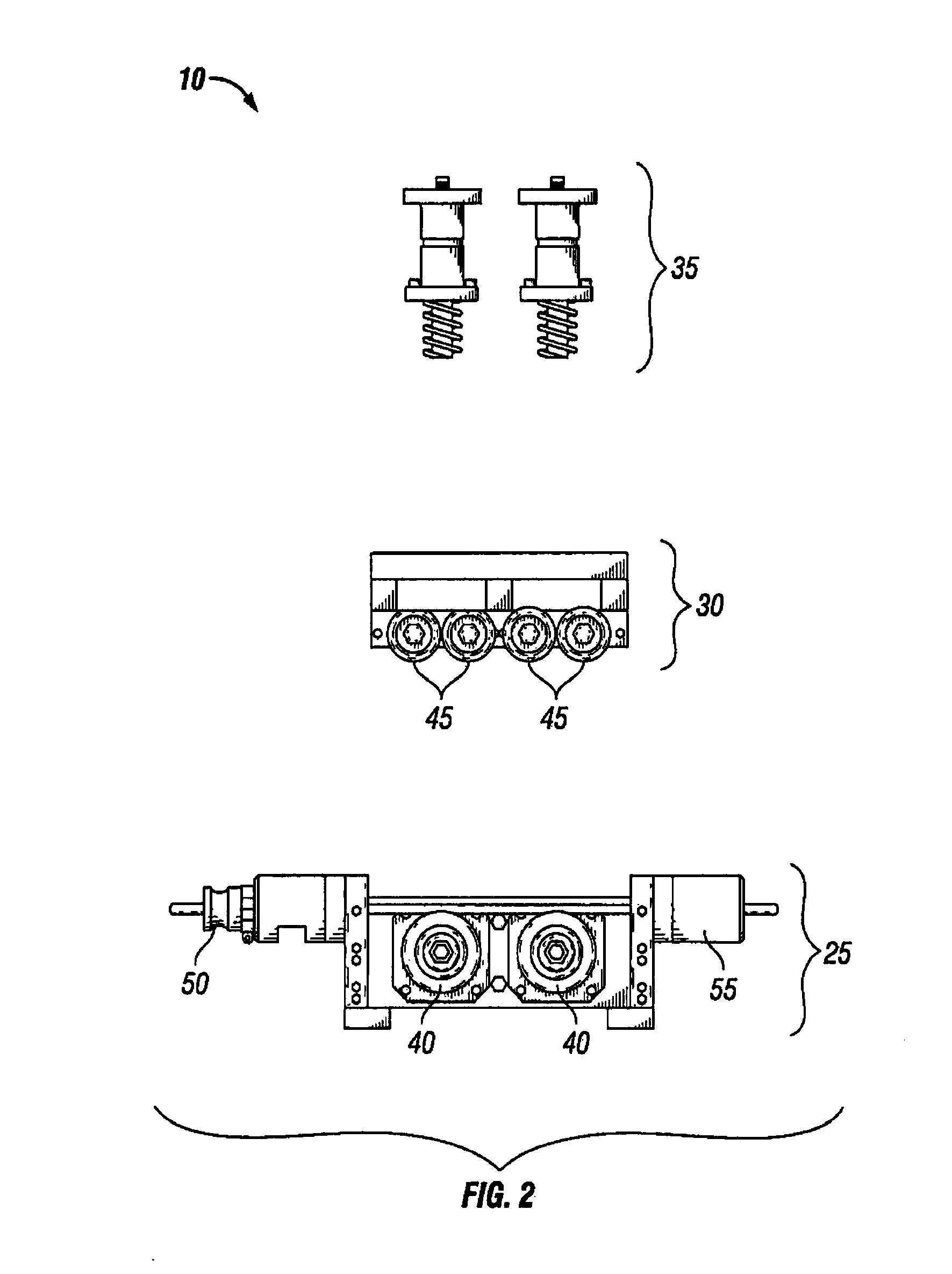

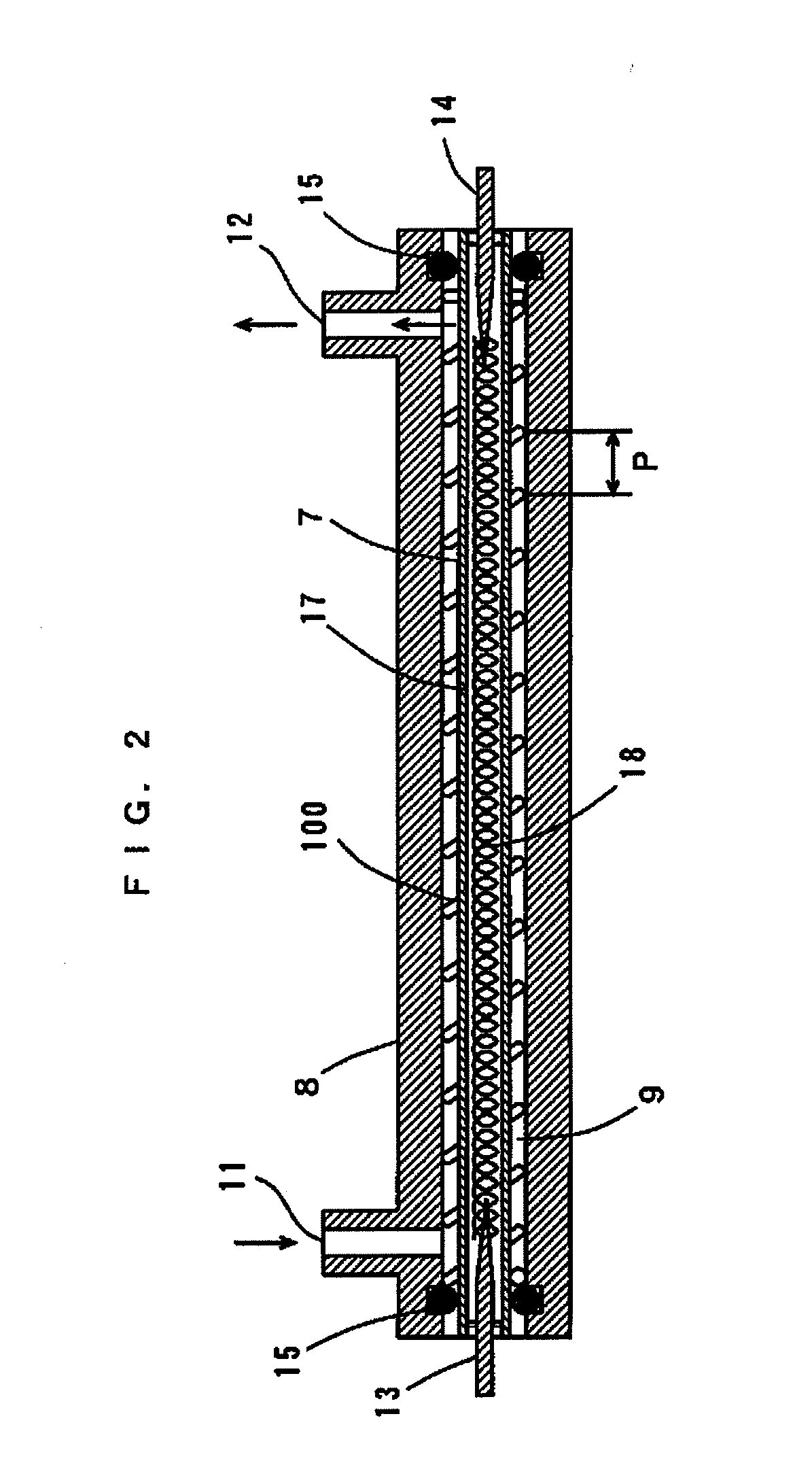

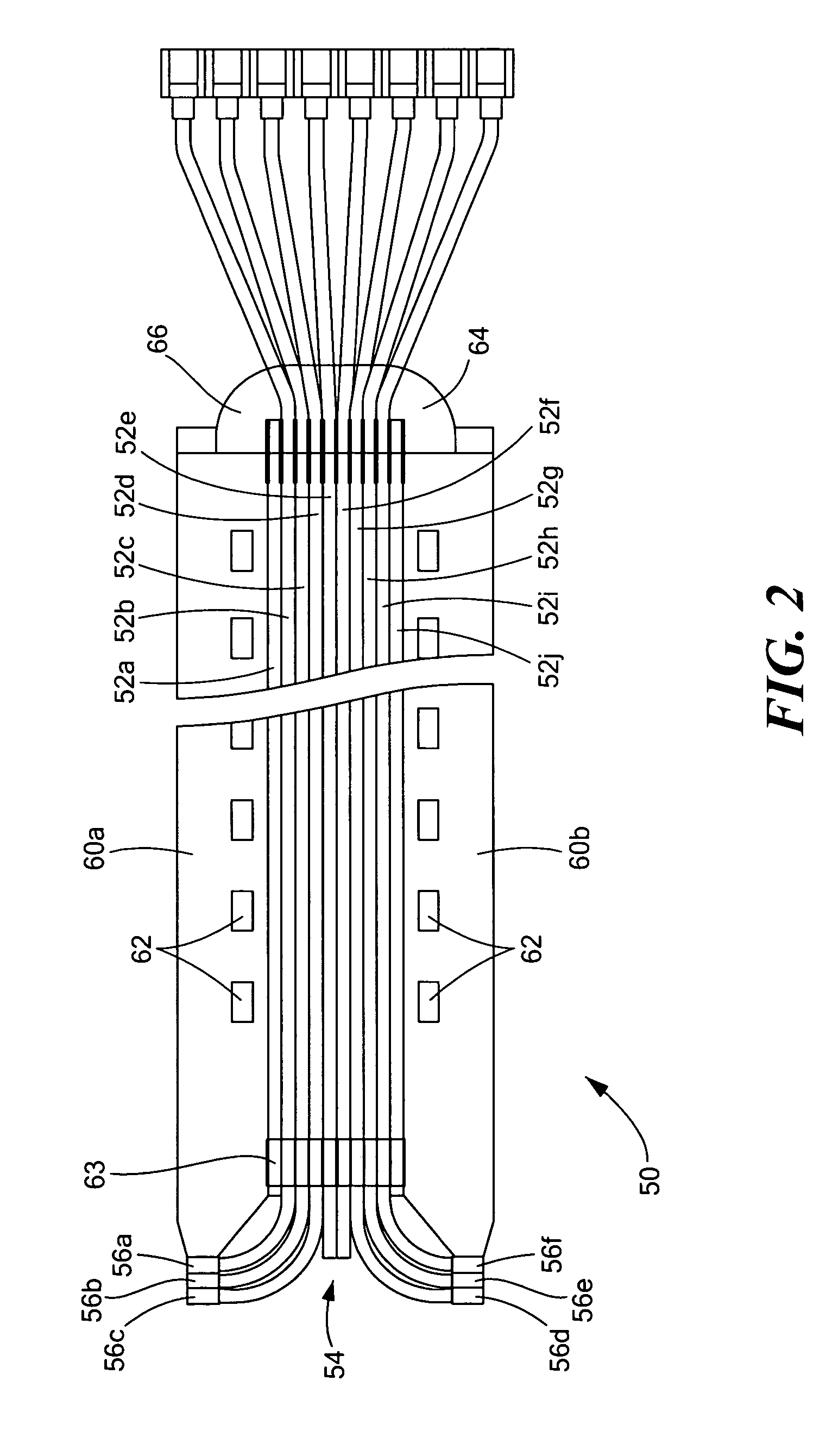

Driving apparatus for one or more cleaning lances

ActiveUS20110155174A1Hollow article cleaningNon-rotary device cleaningIndustrial equipmentEquipment use

A driving apparatus can be utilized to control the cleaning movements of one or more cleaning lances with respect to certain industrial equipment such as a heat exchanger. For example, driving apparatus can be utilized to feed an additional length of cleaning lance to the tubes of exchanger, or to retract cleaning lance from the tubes of exchanger as desired. In general, driving apparatus can be used to clean a variety of types of pipes, tubing and equipment used in industrial facilities.

Owner:HYDROCHEM

Heat exchanger

InactiveUS20110036544A1Reduce and prevent adhesionSolution to short lifeOther washing machinesLavatory sanitoryPlate heat exchangerCoil spring

A heat exchanger comprises a substantially pillar sheathed heater, a substantially cylindrical case, and a spiral spring. The sheathed heater is accommodated in the case. The spring is provided so as to be wound around an outer peripheral surface of the sheathed heater. Thus, a spiral flow path is formed among an outer peripheral surface of the sheathed heater, an inner peripheral surface of the case, and the spring. The spring functions as a flow velocity conversion mechanism, a turbulent flow generation mechanism, a flow direction conversion mechanism, and an impurity removal mechanism. A water inlet and a water outlet are respectively arranged at positions eccentric from a central axis of the case on a side surface of the case.

Owner:PANASONIC CORP

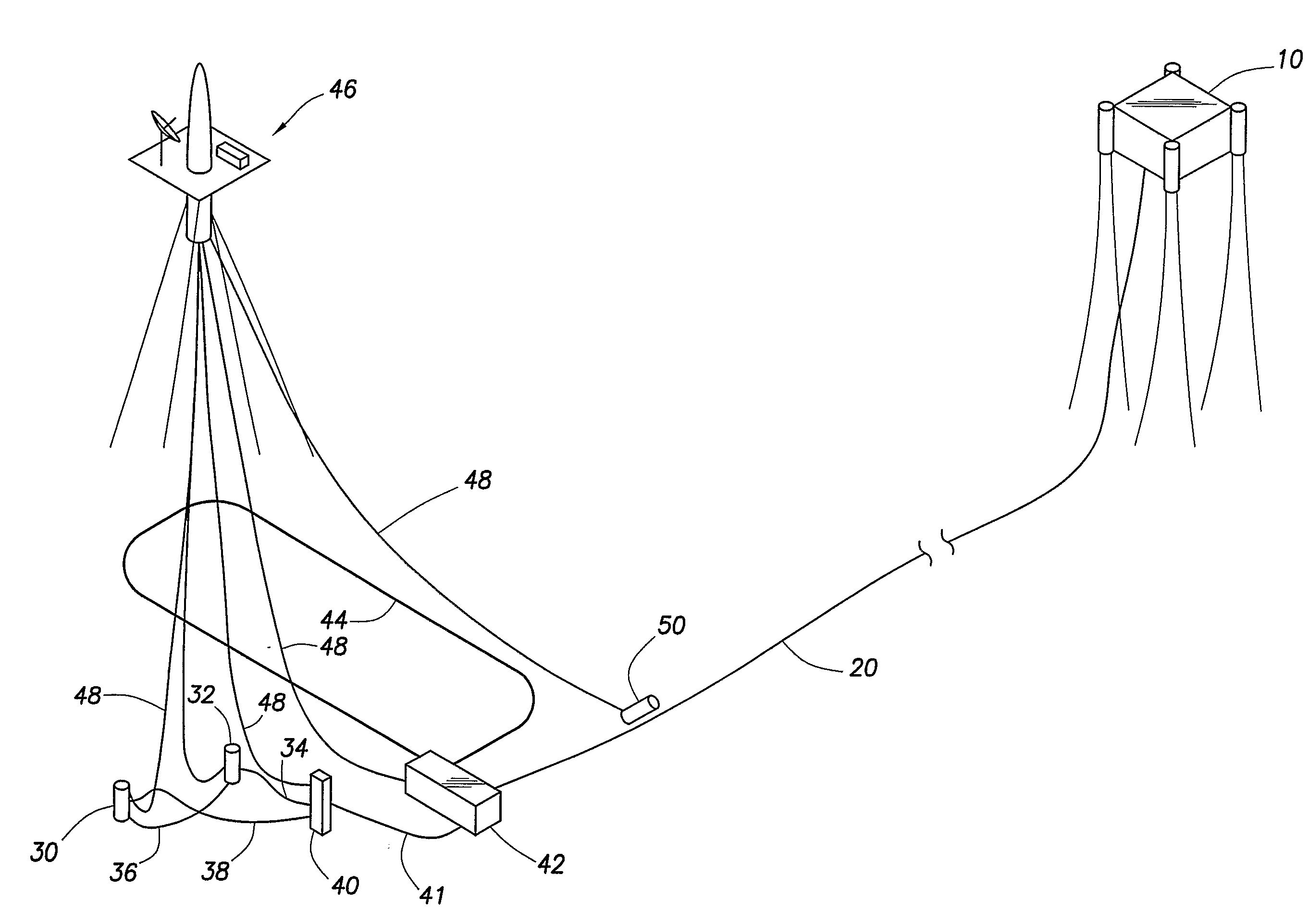

Method and Apparatus for a Cold Flow Subsea Hydrocarbon Production System

A system for assuring subsea hydrocarbon production flow in pipelines by chilling the hydrocarbon production flow in a heat exchanger and causing solids to form, periodically removing deposits and placing them in a slurry utilizing a closed loop pig launching and receiving systems.

Owner:SHELL OIL CO

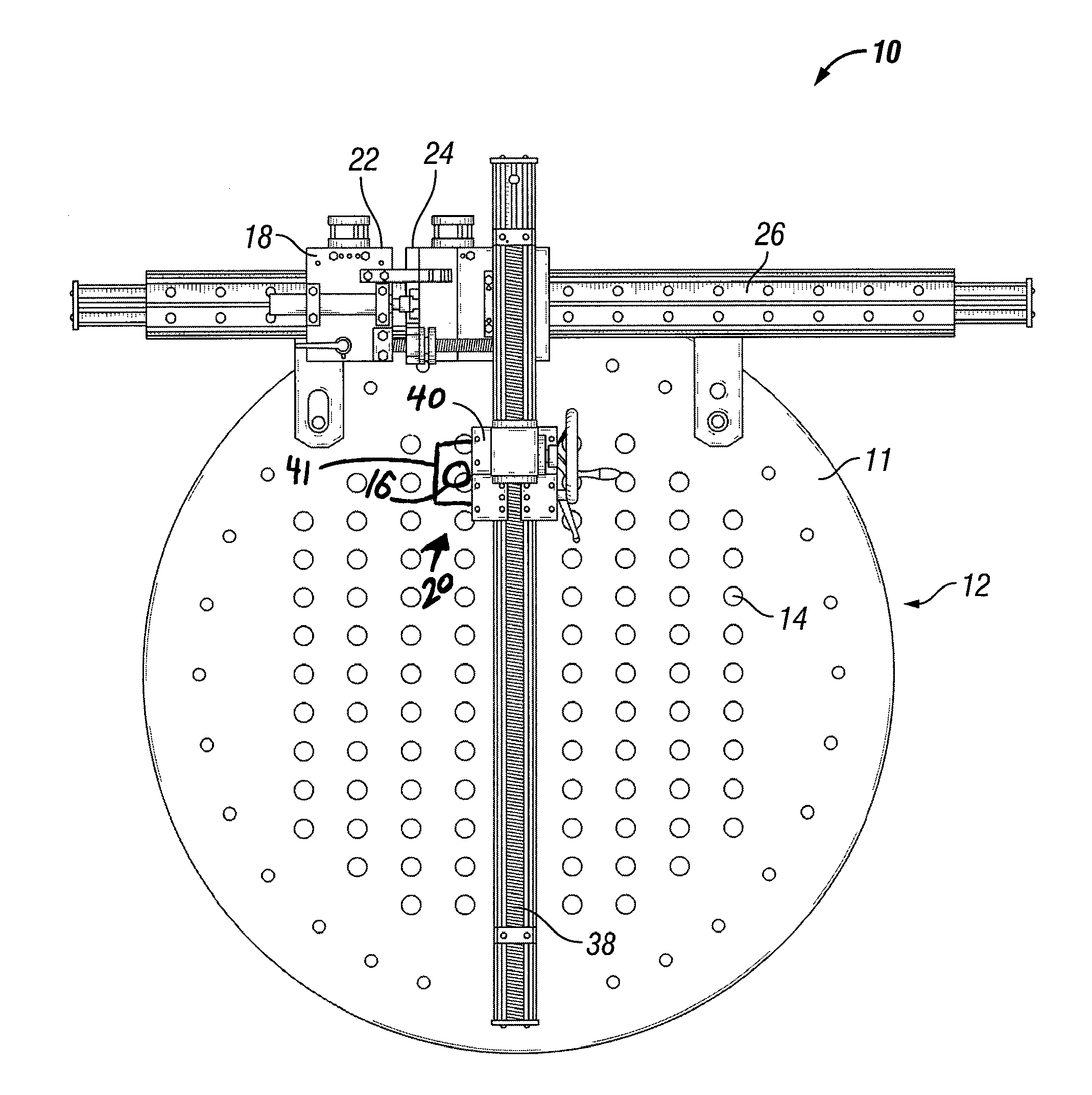

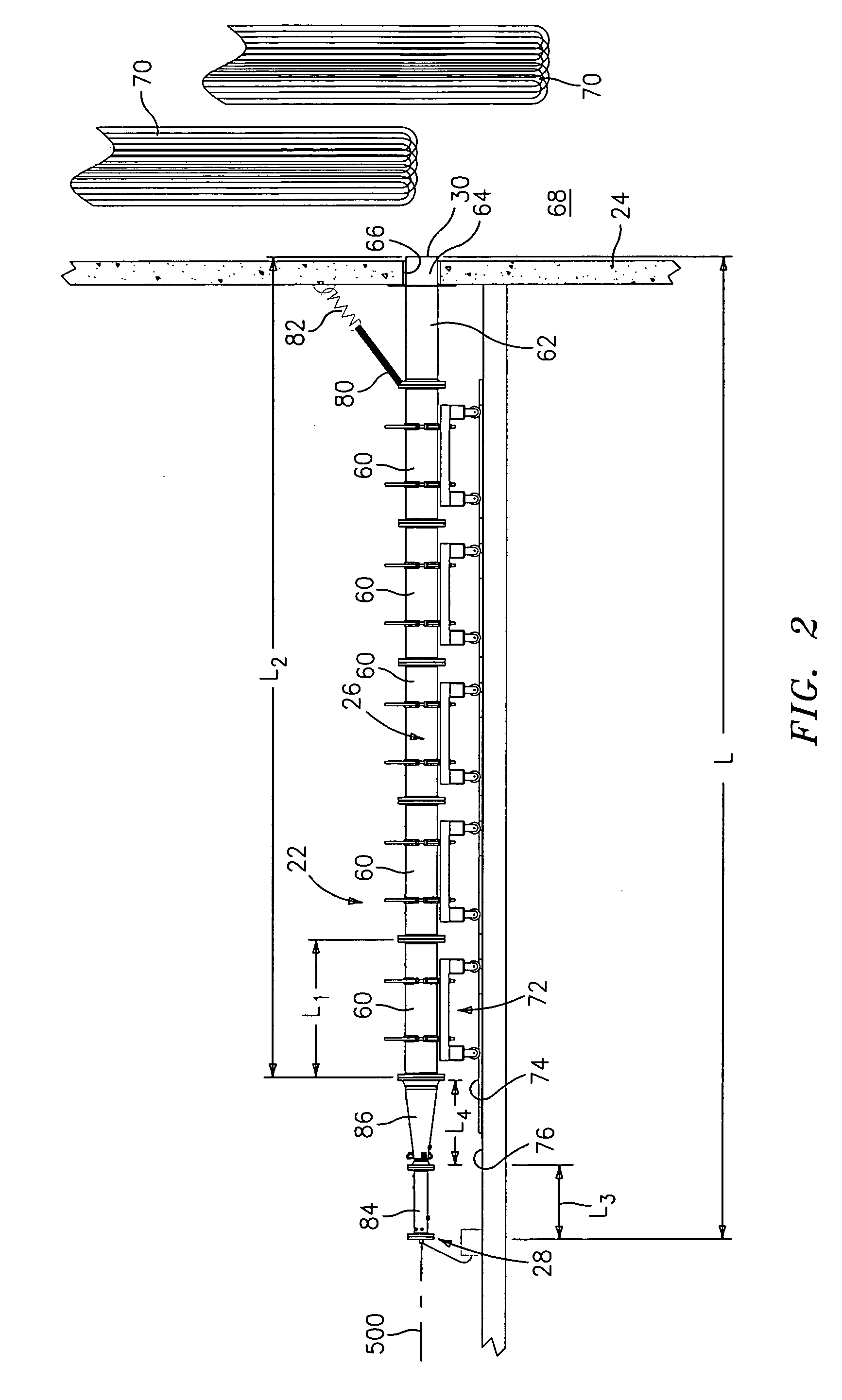

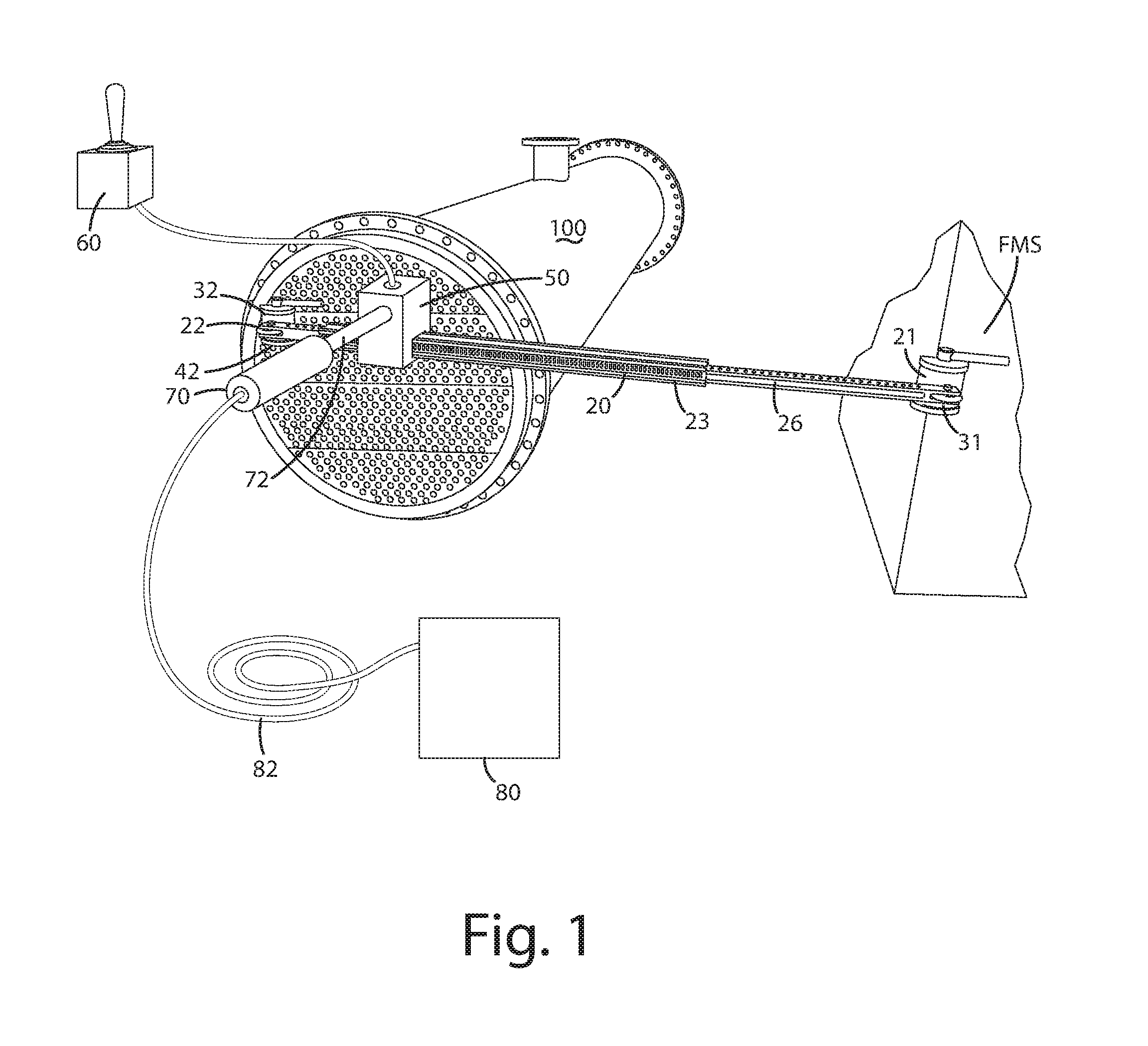

Automated heat exchanger tube cleaning assembly and system

ActiveUS20090255557A1Clean effectHollow article cleaningVehicle position/course/altitude controlSurvey resultThree dimensional measurement

An automated heat exchanger tube cleaning assembly and system are provided. The present system can automatically (without ongoing human intervention) survey the tube sheet of a heat exchanger in three-dimensions, convert and record the survey results as a digital file in three-dimensions, and then, according to sequential parameters input via custom software, automatically coordinate via computer one or more cleaning devices to effect the cleaning of each desired tube of the heat exchanger.

Owner:HYDROCHEM

Methods and compositions for on-line gas turbine cleaning

InactiveUS20040016445A1Inorganic/elemental detergent compounding agentsDetergent mixture composition preparationCombustion chamberAromatic solvents

Methods and compositions for on-line cleaning of internal surfaces of selected sections of a hydrocarbon fuel burning gas turbine and associated heat recovery equipment, during operation. Cleaning solutions containing graphite and / or molybdenum-based particles and oil soluble corrosion inhibitors, aromatic solvents, and surfactants are selectively introduced directly into the combustion chamber (combustor) of the gas turbine, into the fuel stream, water washing system, or the combustion air system (hot gas path). The cleaning process dislodges unwanted ash deposit buildup and, thereby restores the gas turbine to rated power. When introduced into the compressor section, the particles impinge on the metal surfaces, cleaning them prior to entering the hot gas section where the process may be repeated. They may also be carried through the exhaust to additionally clean attendant heat recovery equipment, if present.

Owner:LIQUID MINERALS GRP LTD

Automated heat exchanger tube cleaning assembly and system

ActiveUS8057607B2Hollow article cleaningVehicle position/course/altitude controlThree dimensional measurementSurvey result

An automated heat exchanger tube cleaning assembly and system are provided. The present system can automatically (without ongoing human intervention) survey the tube sheet of a heat exchanger in three-dimensions, convert and record the survey results as a digital file in three-dimensions, and then, according to sequential parameters input via custom software, automatically coordinate via computer one or more cleaning devices to effect the cleaning of each desired tube of the heat exchanger.

Owner:HYDROCHEM

Laser Centering of Robotic Arm

ActiveUS20150258694A1Programme-controlled manipulatorMaterial analysis by electric/magnetic meansRobotic armEngineering

In a system and method of working tubes coupled to a tubesheet having a number of holes, wherein each hole in fluid communication with one of the tubes, an end-effector is positioned by a robot in coarse or rough alignment with a first hole in the tubesheet. Via lasers positioned on the end-effector, laser spots are formed on a surface of the tubesheet adjacent the first hole. The laser spots are detected by a camera and the alignment of the end-effector relative to the first hole in the tubesheet is refined via the robot based on the detected pattern of laser spots. The tool is then moved into the tube that is in fluid communication with the first hole in the tubesheet to work on (inspect, plug, sleeve or weld) the tube.

Owner:CORESTAR INT

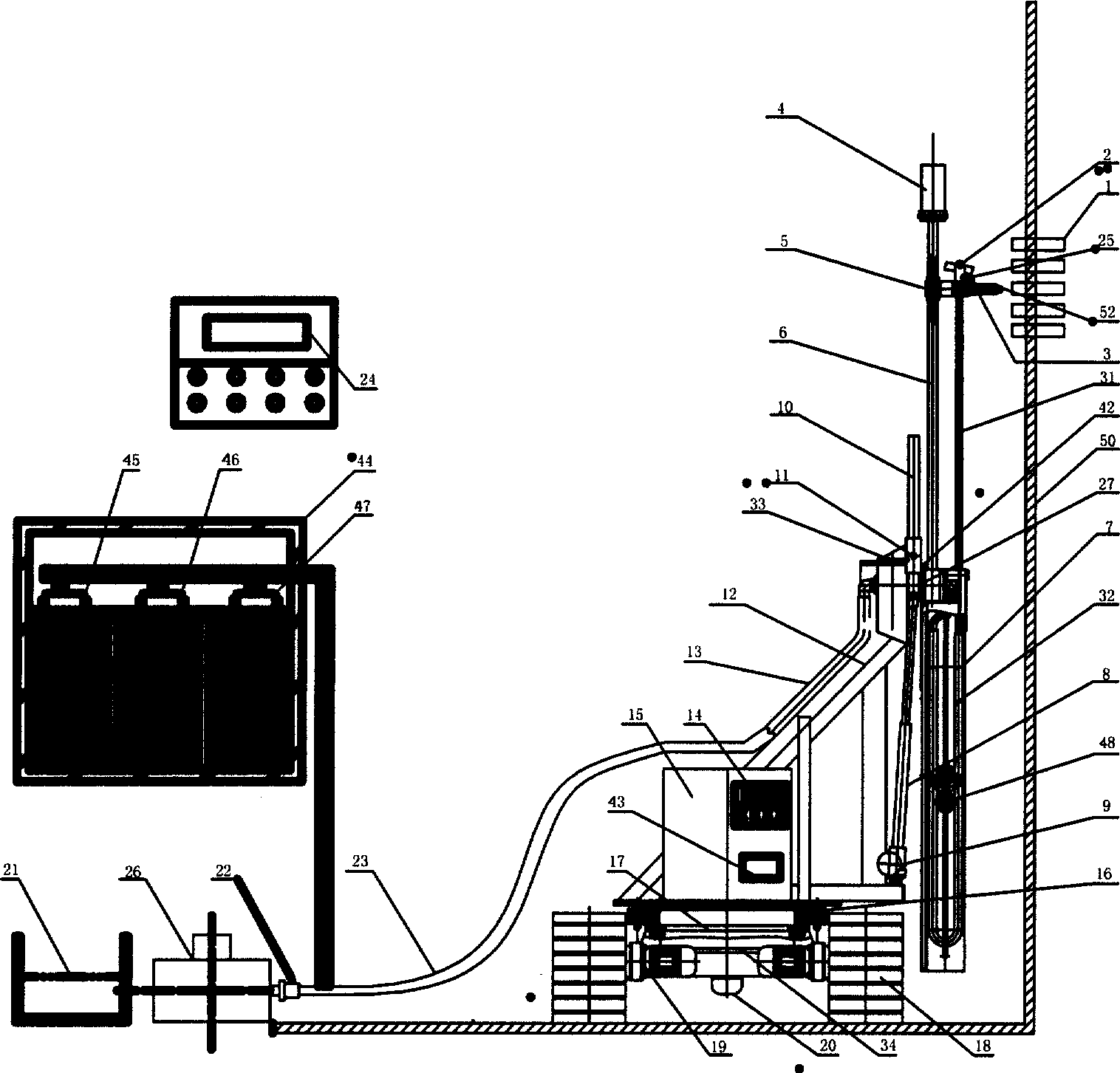

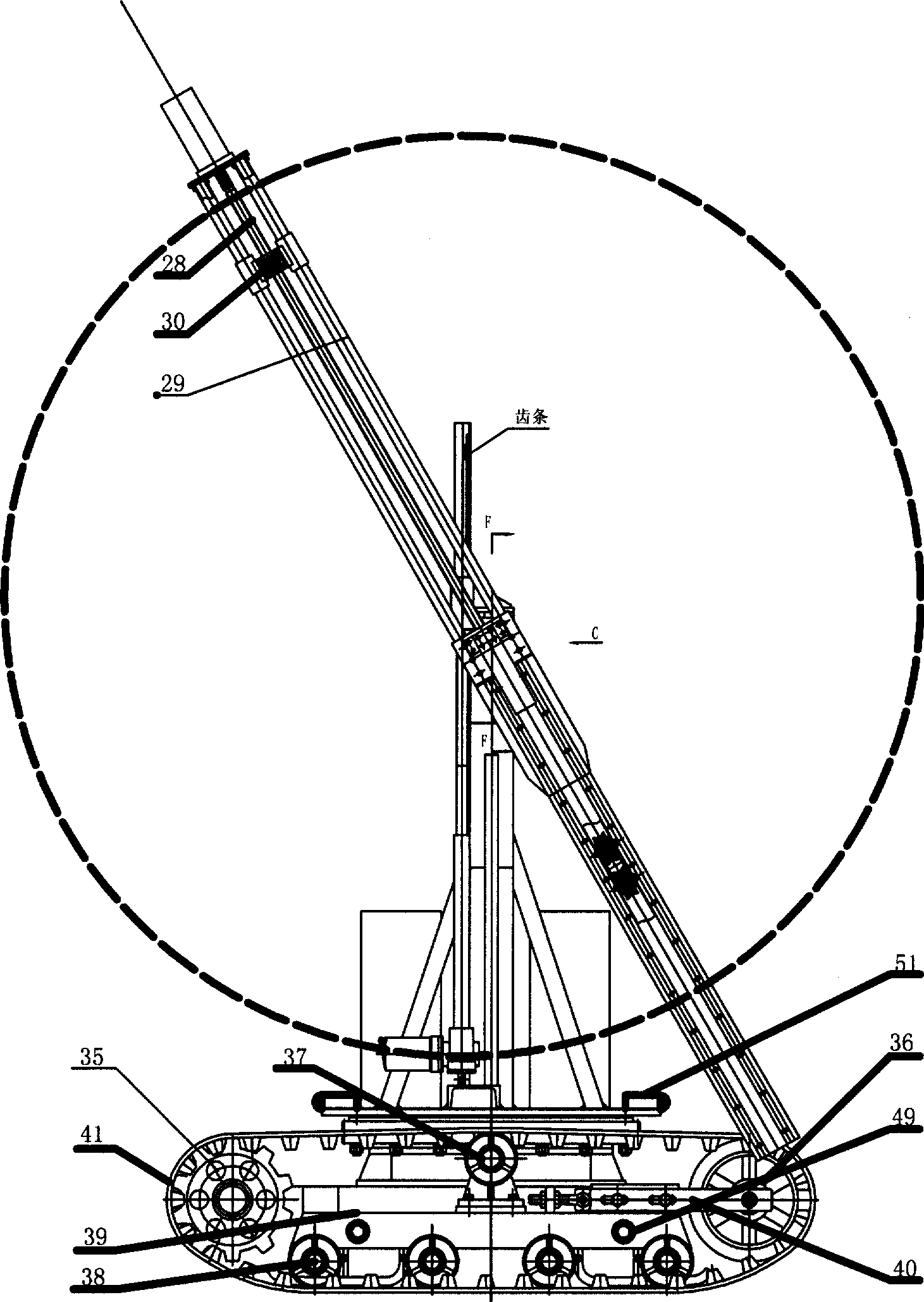

Intelligent movable cleaning robot for condenser

ActiveCN101430176AAchieving autonomous mobilityAchieve precise positioningFlush cleaningManipulatorDrive shaftEngineering

The invention discloses a condenser intelligent moving and cleaning robot, which can be used in the field of large scale cleaning equipment and comprises a track running mechanism, a cleaning mechanism, and an electric control mechanism. A spray gun is connected on a spray gun running rest of a cleaning arm. The spray gun is provided with a underwater TV camera and connected with a cleaning media source by a communicating tube. The cleaning arm is connected with a cleaning arm running bracket component by a drive shaft. The drive shaft of the cleaning arm is connected with an electric push rod. The cleaning arm running bracket component is arranged on a pivoting support which is arranged on the track running mechanism by the running bracket component. The right front end of the top of the spray gun, the front end and the back end of a mounting plate of the pivoting support and the front position and the back position of a track support are provided with sonar sensors. The robot has few joints, simple structure, convenient processing and assembling, can automatically move in a water chamber of the condenser to finish the precise position and efficient cleaning of copper pipes of the condenser, has wide application range and high degree of automation.

Owner:HUNAN UNIV

Control of detonative cleaning apparatus

A shockwave cleaning apparatus cleans one or more surfaces within a vessel. A sensor senses one or more thermodynamic properties associated with the vessel. A control system is coupled to an initiator and a fuel / oxidizer source to control the firing of the apparatus responsive to input from the sensor.

Owner:SHOCKSYST

Apparatus for tilting and securing a heat exchanger

InactiveUS7370690B2Solve the lack of spaceAir-treating devicesVehicle heating/cooling devicesAir conditioningMicro heat exchanger

Apparatus for supporting a heat exchanger such as a condenser of an air conditioning system on a vehicle, for pivotal movement between an operational position and a position angularly related to the operational position, for such purposes as inspection, cleaning, service and maintenance, the apparatus being configured for holding the heat exchanger in the operational position, and for guiding and controlling movement thereof to the tilted position, and holding the heat exchanger in the tilted position.

Owner:BLUE LEAF I P INC

Detection of deposits in steam humidifiers

A humidifier configured to determine when the humidifier requires cleaning. The humidifier includes a tank for containing water, a heater for heating the water in the tank to generate steam, and one or more water level sensors for detecting the level of water in the tank, including detecting water at first level and a second level, where the first level is lower than the second level. The humidifier further includes a drain valve for draining water from the tank and a controller. The controller is configured to open the drain valve to drain water from the tank, measure a time interval required for the water to drain from the second level to the first level, and compare the time interval against a threshold value. If the time interval exceeds the threshold value, then the controller is configured to provide an indication to clean the humidifier. Methods are also disclosed.

Owner:ADEMCO INC

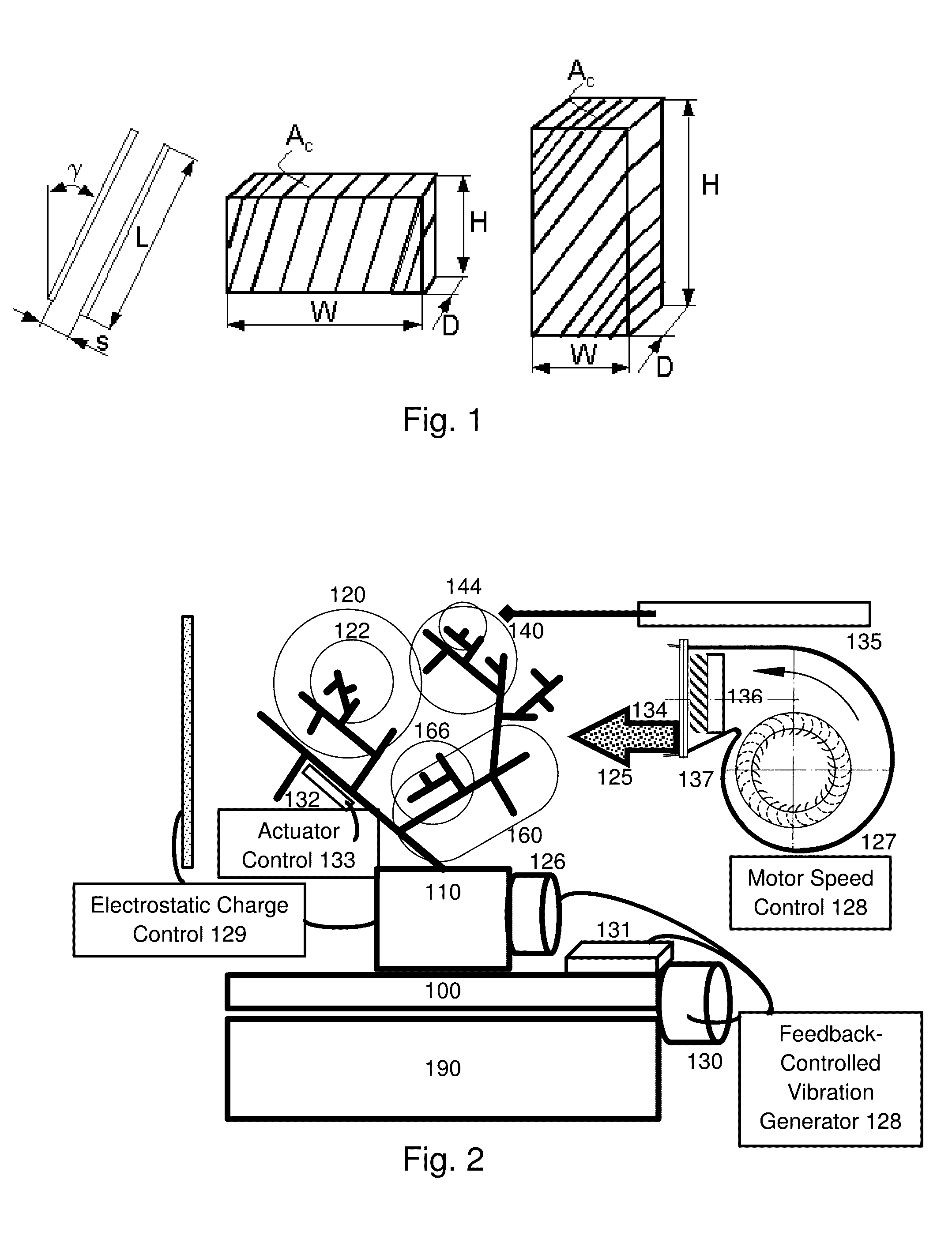

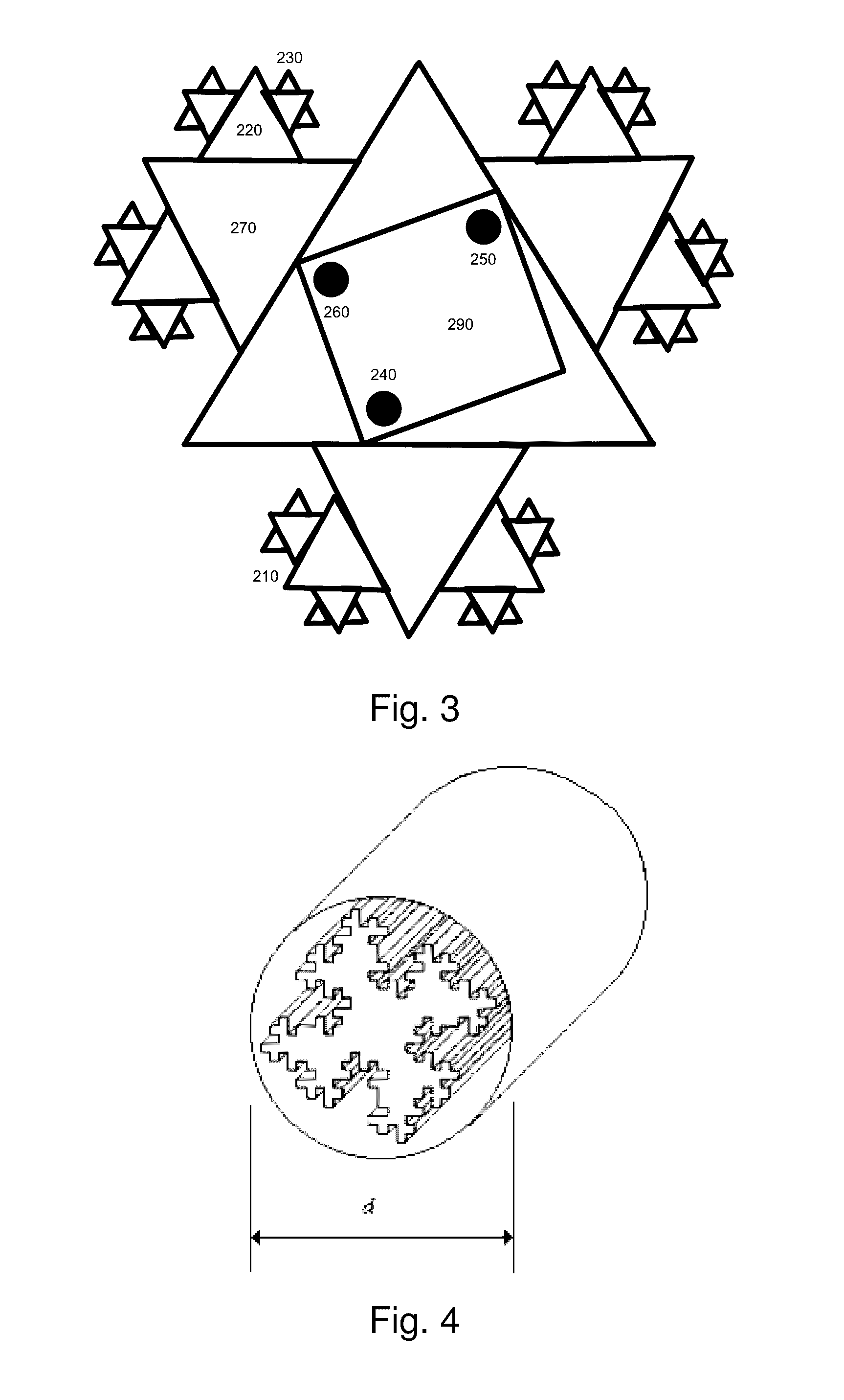

System and method for maintaining efficiency of a fractal heat sink

ActiveUS20160320149A1Large specific surface areaSmall surface areaHeat exhanger finsIndirect heat exchangersEngineeringHeat transfer fluid

A heatsink comprising a heat exchange device having a plurality of heat exchange elements each having a surface boundary with respect to a heat transfer fluid, having successive elements or regions having varying size scales. According to one embodiment, an accumulation of dust or particles on a surface of the heatsink is reduced by a removal mechanism. The mechanism can be thermal pyrolysis, vibration, blowing, etc. In the case of vibration, adverse effects on the system to be cooled may be minimized by an active or passive vibration suppression system.

Owner:FRACTAL HEATSINK TECH

Super-thin water jetting lance

InactiveUS20090211612A1Easy to operateMaximizes hydraulic pressureHollow article cleaningSteam boilersEngineeringNozzle

Owner:FOSTER-MILLER

Device for generating acoustic and/or vibration energy for heat exchanger tubes

InactiveUS20070267175A1Reduce dirtVibration cleaningStationary tubular conduit assembliesWorking fluidAcoustic energy

Owner:EXXON RES & ENG CO

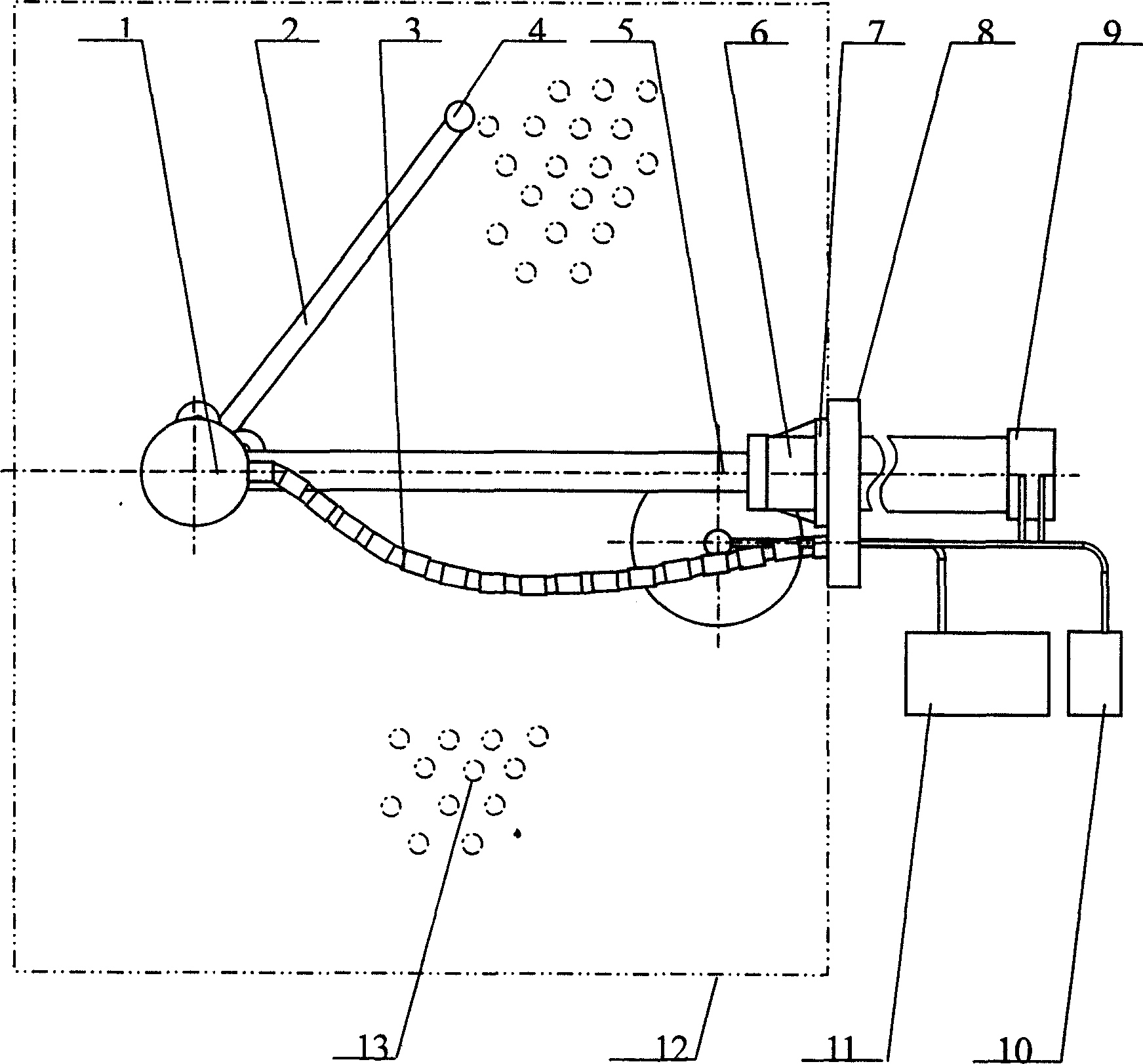

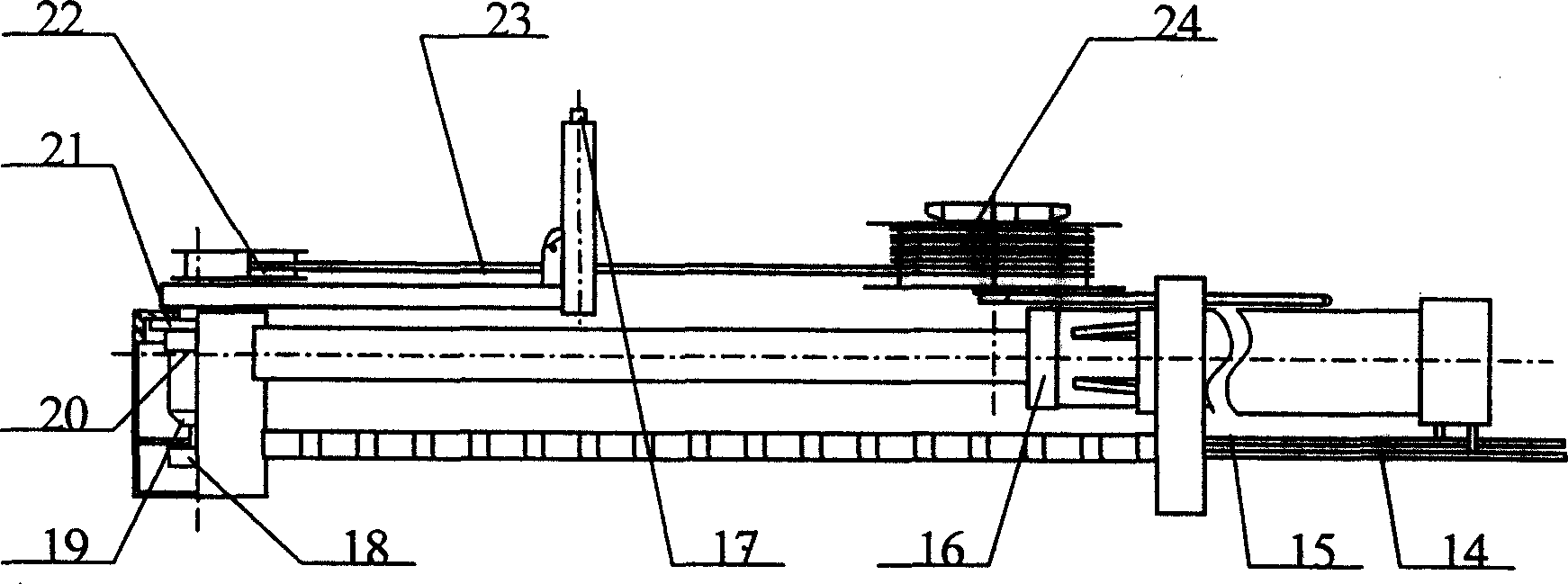

Robot technology of on-line cleaning power plant steam condenser using high pressure water jet

InactiveCN1664486AImprove operational efficiencyMaximize coverage areaRotary device cleaningNon-rotary device cleaningDevice formHigh pressure water

The invention relates to an electric power plant condenser high pressure water shooting flow online washing robot technology that cleans the electric power plant condenser by high pressure water shooting flow. Setting the mechanism arm locating device and high pressure soft tube into the condenser by using the combination method and install structure of locating mechanism arm orientation device formed by extending mechanism arm and rotating mechanism arm, high pressure soft tube manage device, and high pressure spray head control device, locates the spray head on the rotating mechanism arm by computer control system, sends to the inner of the condenser copper pipe, and cleans the dirt in the inner of the condenser copper pipe by high pressure water shooting flow. The generating set needs not stop while cleaning. The invention has advantage of simple structure, no pollution and high reliability.

Owner:CHINA UNIV OF MINING & TECH

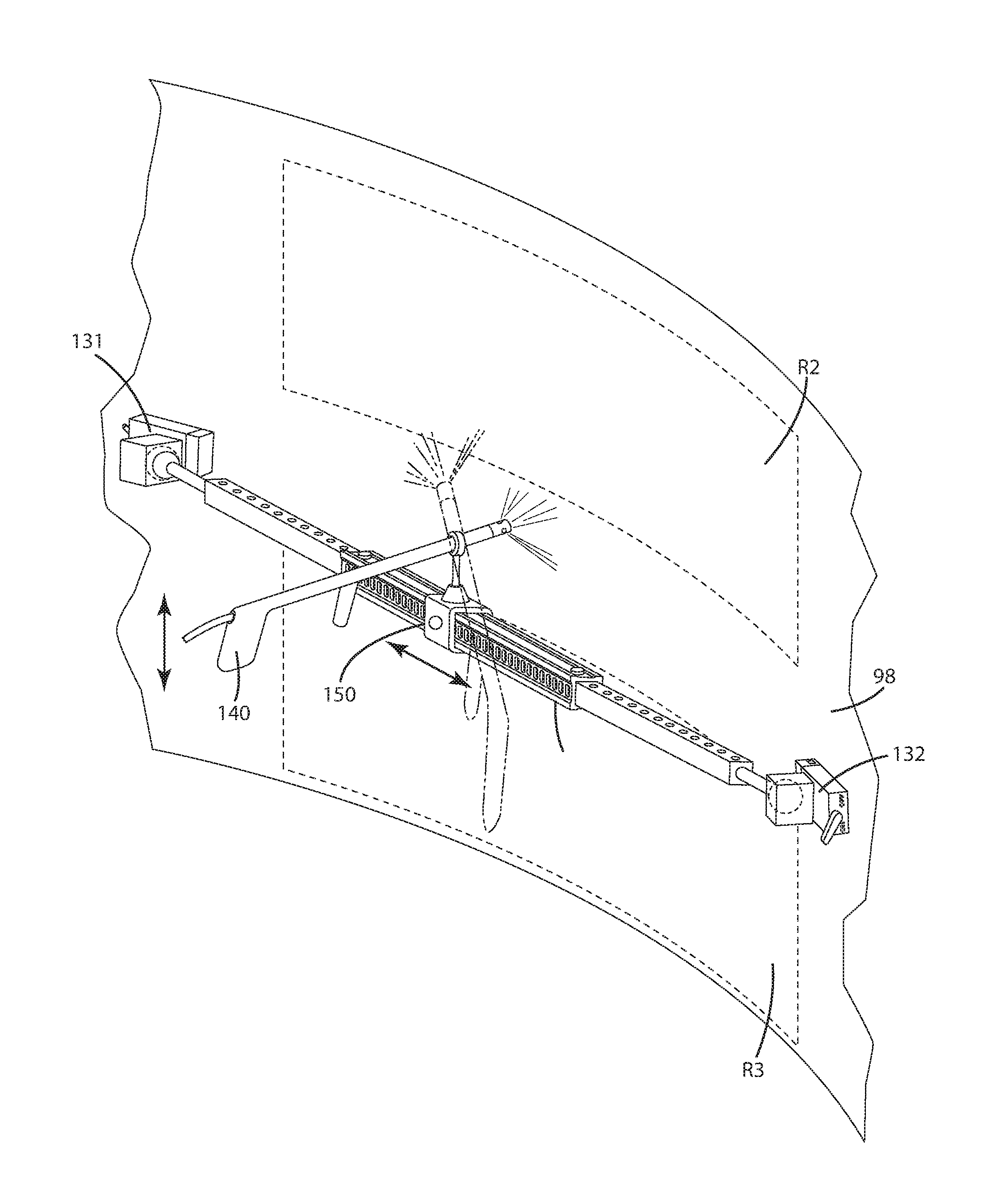

Magnetic mount for blasting equipment and related methods

InactiveUS20160243597A1Improve securityEffective protectionHollow article cleaningStationary tubular conduit assembliesProximity sensorEngineering

A water blasting apparatus and related method are adapted to clean equipment. The apparatus includes a track having telescoping rails, a connector moveable along the track, and a water blasting device adapted to shoot water at a pressure above 1000 psi, joined with the connector. One or more rare earth magnets join the track with a ferromagnetic structure, thereby holding it in a fixed orientation relative to the equipment to be cleaned. The apparatus can include a proximity sensor to ensure the track is adequately anchored, and an auto shut-off system when it is not. The method can include connecting the water blasting device to the track, magnetically coupling the track to a structure so that the nozzle is proximal equipment, and so that the elongated track is maintained in a fixed orientation, and shooting water at high pressure toward the equipment, while safely restraining the water blasting device.

Owner:PSI PRESSURE SYST

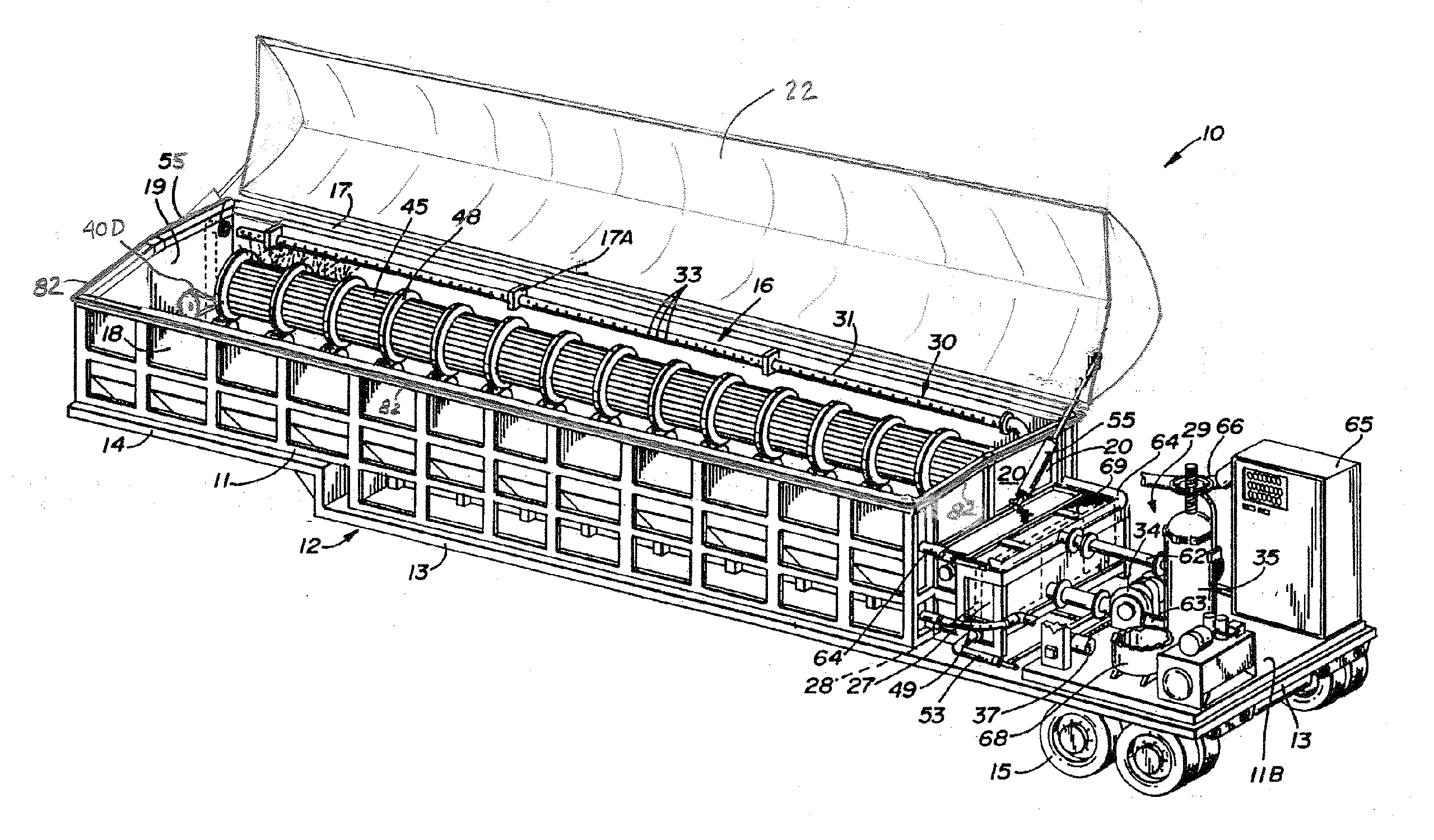

Method and system for cleaning heat exchanger tube bundles

InactiveUS20060185691A1Overcome problemsHollow article cleaningCleaning using toolsEngineeringOxygen

A method and system utilizing a mobile cleaning unit for providing cleaning of heat exchanger tube bundles. The mobile cleaning unit utilizes a pressurized seal positioned about top door of the cleaning enclosure to provide a fluid and vapor lock of the cleaning enclosure. An oxygen purging system of the cleaning enclosure, the cleaning fluid reservoir, and the control panels provides additional safety. The mobile cleaning unit can use cleaning fluid produced at the facility site and return the cleaning fluid to the facility site for reprocessing after the heat exchanger tube bundles are cleaned.

Owner:NAT HEAT EXCHANGE CLEANING CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com