Robot technology of on-line cleaning power plant steam condenser using high pressure water jet

A high-pressure water jet and cleaning robot technology, which is applied in the cleaning of rotating equipment, cleaning of heat transfer devices, and cleaning of non-rotating equipment, can solve the problems of reducing the service life of the unit, cannot effectively remove scale, and cannot remove scale in time. Effects of reducing coal consumption, extensive applicability, and avoiding economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

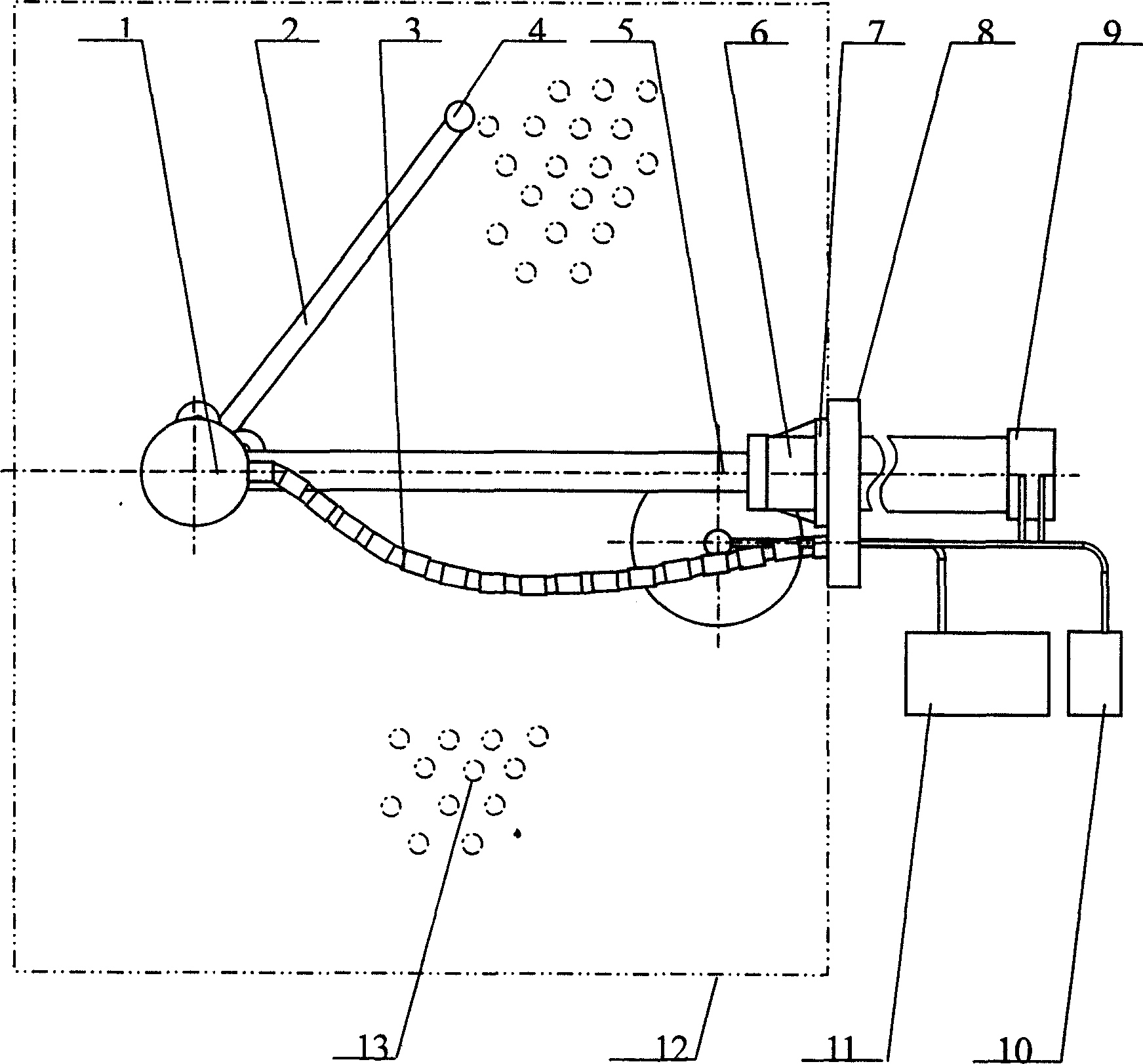

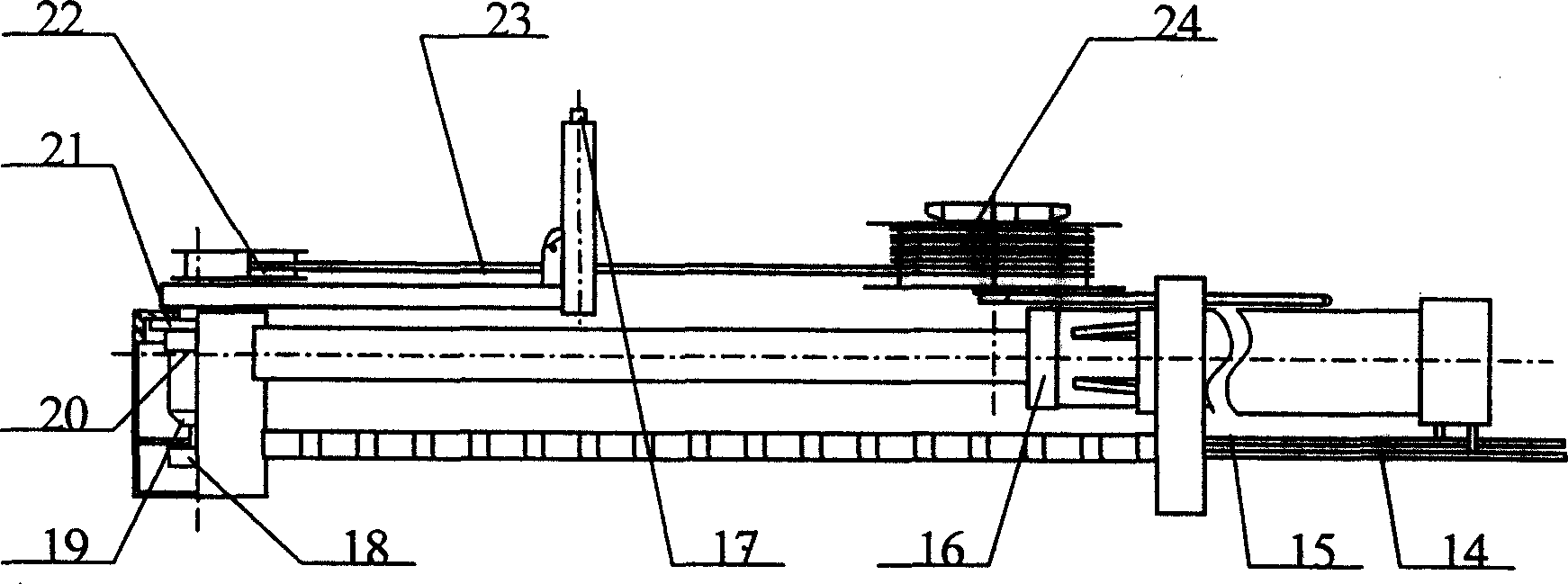

[0011] The high-pressure water jet on-line cleaning robot of the power plant condenser is mainly composed of a mechanical arm positioning device, a high-pressure water pipe retractable system and a computer control system. The high-pressure water pipe retractable system is connected by a high-pressure water pump, a pipeline system and a control valve. The high-pressure water pump station, the positioning device of the mechanical arm is composed of the telescopic mechanical arm 5, the hydraulic rotary device set at the front of the telescopic mechanical arm 5, and the rotary mechanical arm 2 connected to the hydraulic rotary device. The hydraulic rotary device includes a buoyancy balance shell 1 , the hydraulic gyrator 20 inside the buoyancy balance shell 1, the hydraulic servo system 19 that drives the hydraulic gyrator 20 to rotate, and the precision angula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com