Patents

Literature

236 results about "Gyrator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A gyrator is a passive, linear, lossless, two-port electrical network element proposed in 1948 by Bernard D. H. Tellegen as a hypothetical fifth linear element after the resistor, capacitor, inductor and ideal transformer. Unlike the four conventional elements, the gyrator is non-reciprocal. Gyrators permit network realizations of two-(or-more)-port devices which cannot be realized with just the conventional four elements. In particular, gyrators make possible network realizations of isolators and circulators. Gyrators do not however change the range of one-port devices that can be realized. Although the gyrator was conceived as a fifth linear element, its adoption makes both the ideal transformer and either the capacitor or inductor redundant. Thus the number of necessary linear elements is in fact reduced to three. Circuits that function as gyrators can be built with transistors and op-amps using feedback.

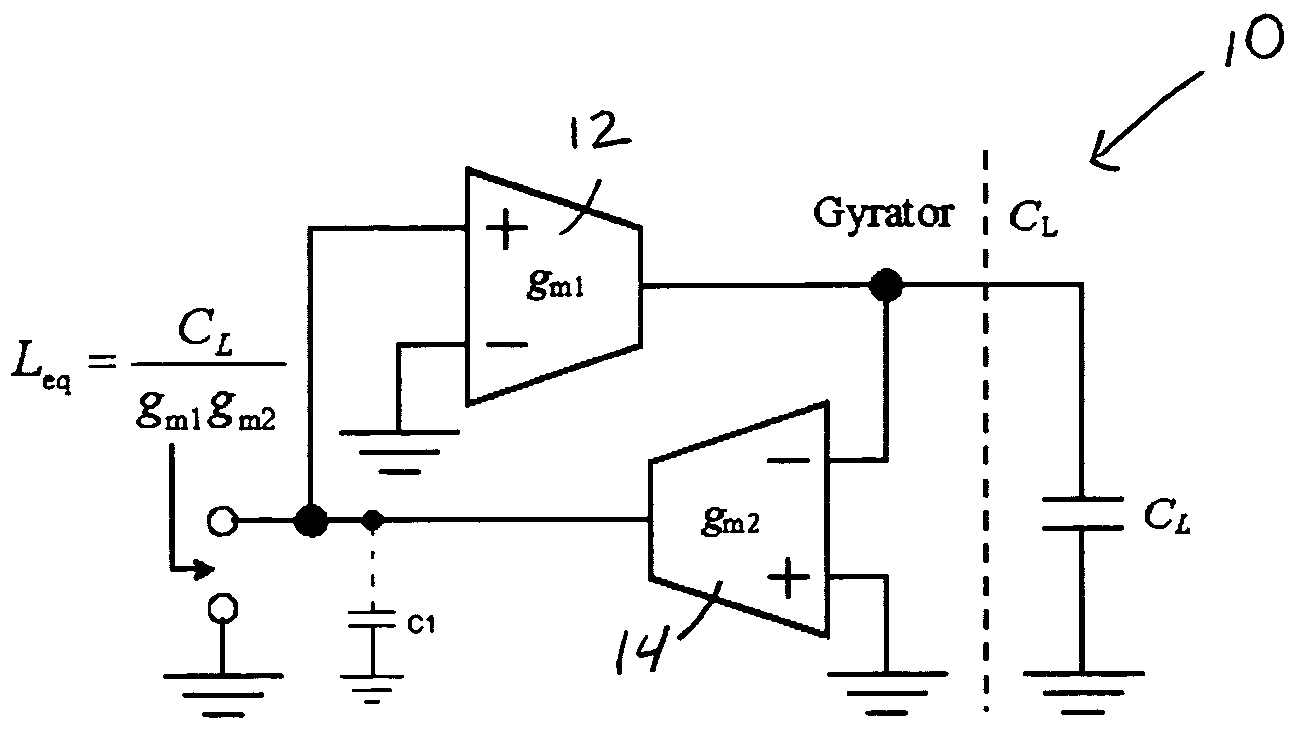

High-frequency active inductor

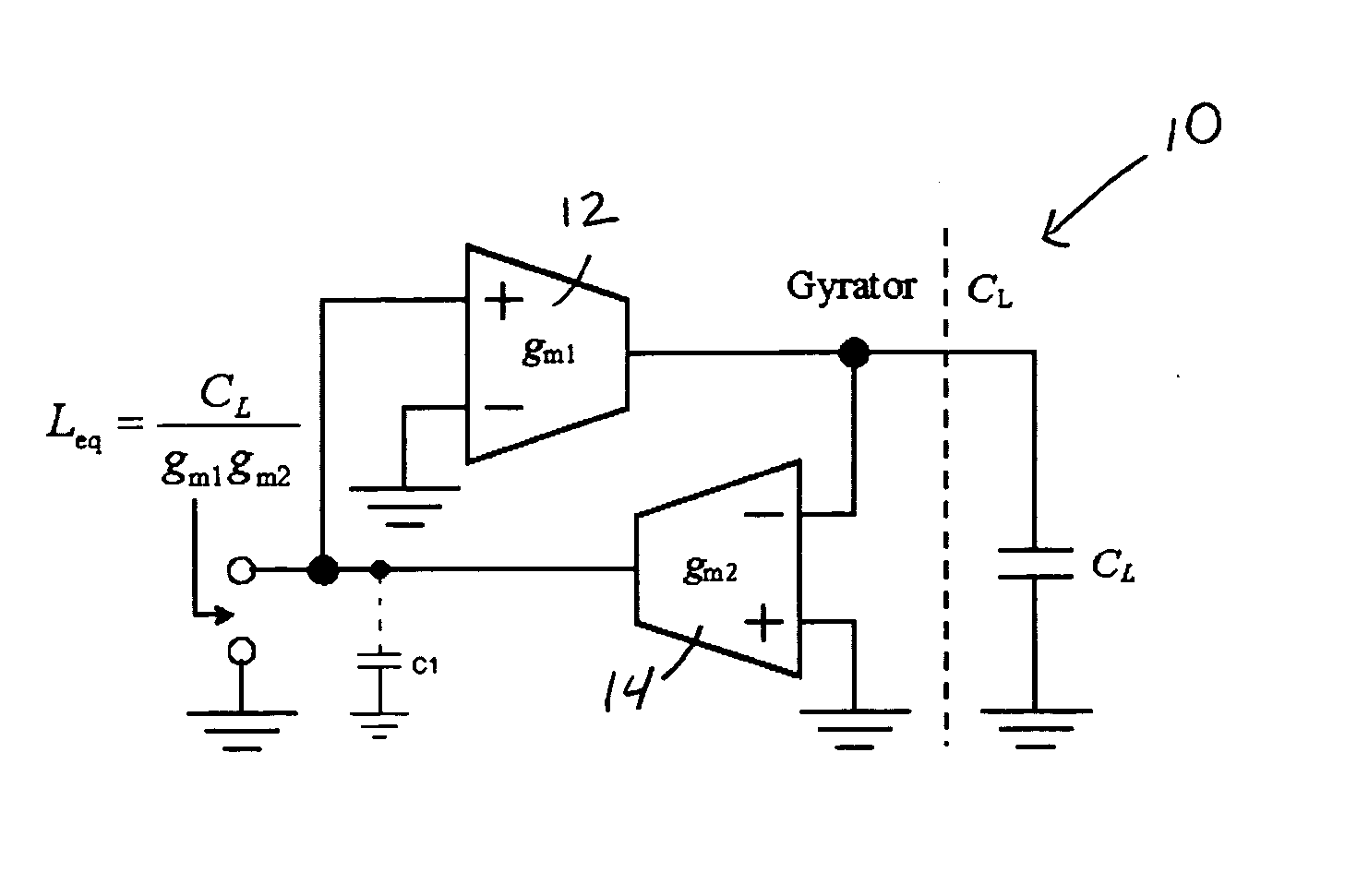

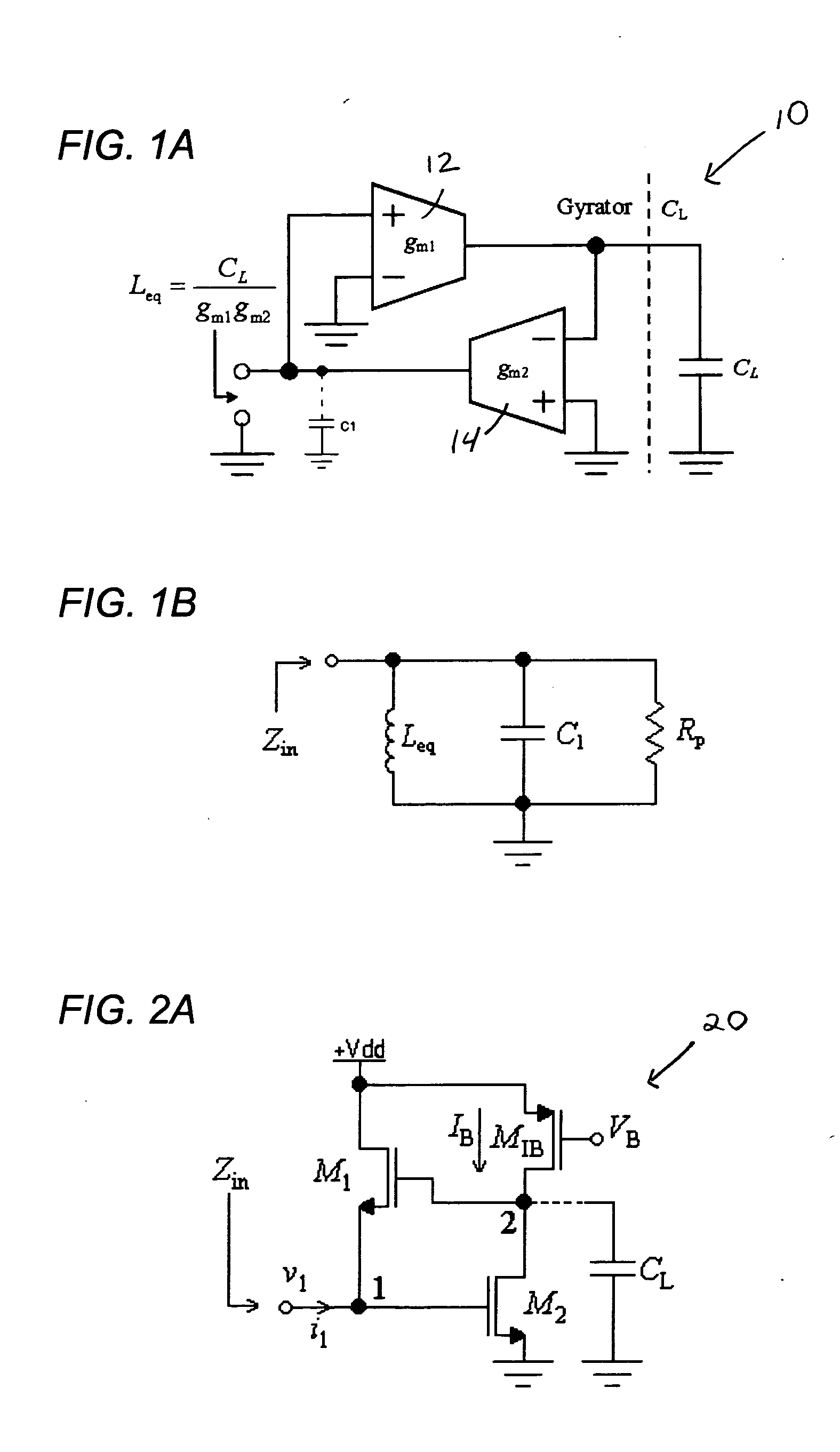

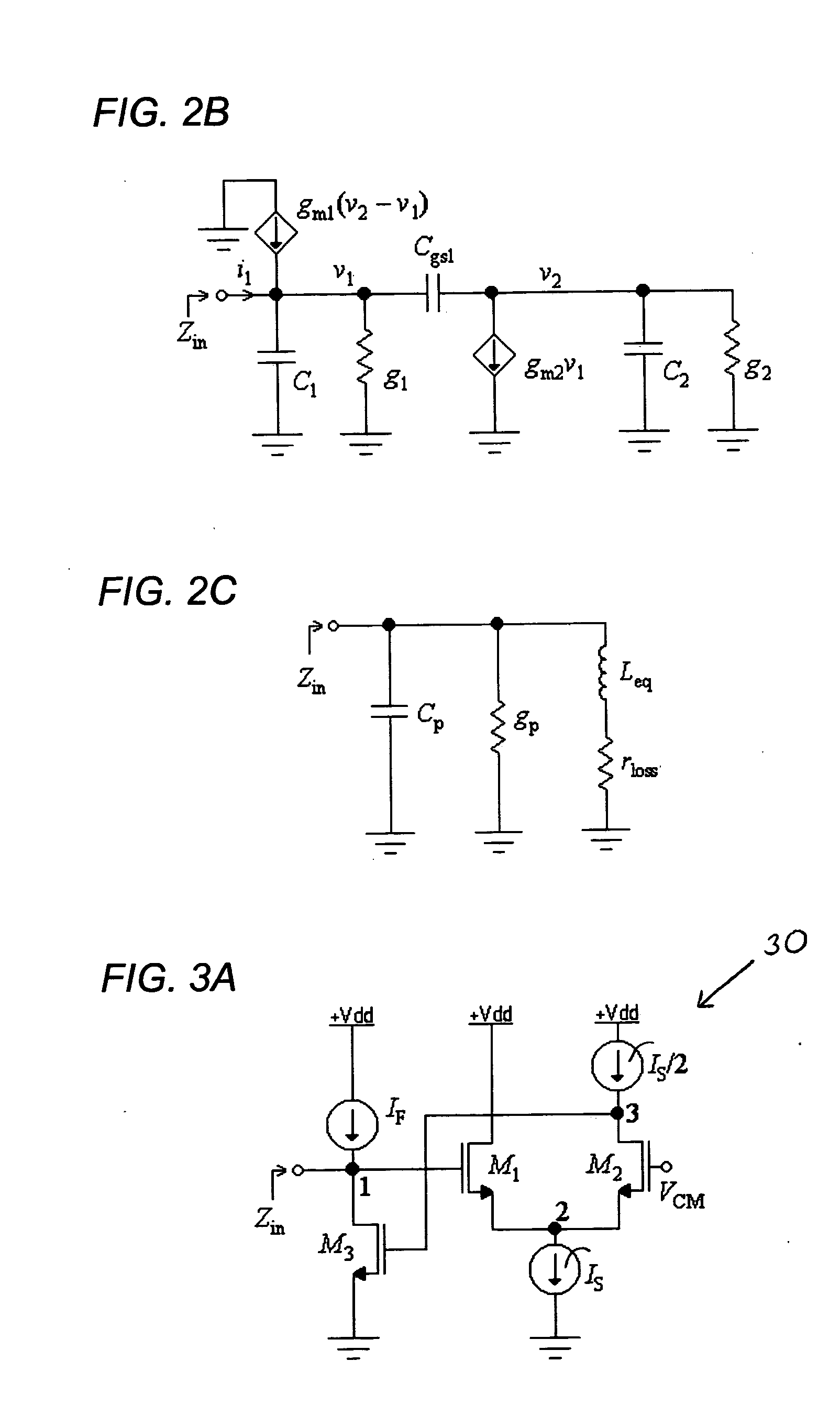

An active inductor circuit implemented in sub-micron CMOS semiconductor technology is usable at gigaHertz frequencies and includes an input node, a non-inverting transconductor circuit comprising a differential pair of NMOS transistors connected to the input node, an inverting transconductor circuit comprising an NMOS transistor connected to an output node of the non-inverting transconductor circuit and connected to the input node in a gyrator feedback configuration. Varactors coupled to the transconductor circuits tune the frequency and Q of the active inductor circuit.

Owner:PORTLAND STATE UNIV

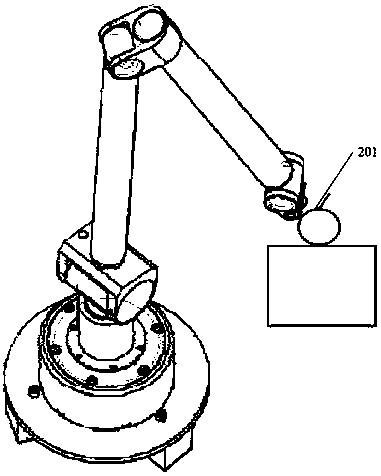

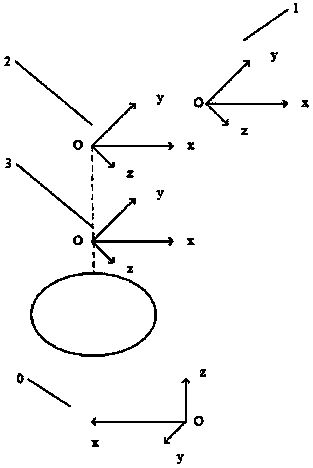

System calibration method for measuring head of coordinate measuring machine

The invention provides a system calibration method for a measuring head of a coordinate measuring machine based on a master ball. The system calibration method comprises the steps of a) putting the standard ball with known radius R on a working platform of the coordinate measuring machine; b) installing the measuring head at a movable end of the coordinate measuring machine, controlling the coordinate measuring machine to move the measuring head according to a proper movement trajectory and completing the point scanning of the master ball on the working platform within a measurement range, wherein the point scanning approximately and uniformly covers the surface of the entire master ball to obtain N groups of data, N is larger than or equal to 200 and each group of data comprises the measuring point numerical value of the measuring head, the three-coordinate position reading of the coordinate measuring machine and the rotating angle of a gyrator; c) on the basis of the operation in the previous step, selecting partial data of the N groups of data, performing coordinate conversion, bringing the data into a spherical constraint equation and solving an over-determined nonlinear equation set by using an improved nonlinear least square method to obtain parameters to be calibrated and complete the system calibration.

Owner:BEIJING INFORMATION SCI & TECH UNIV

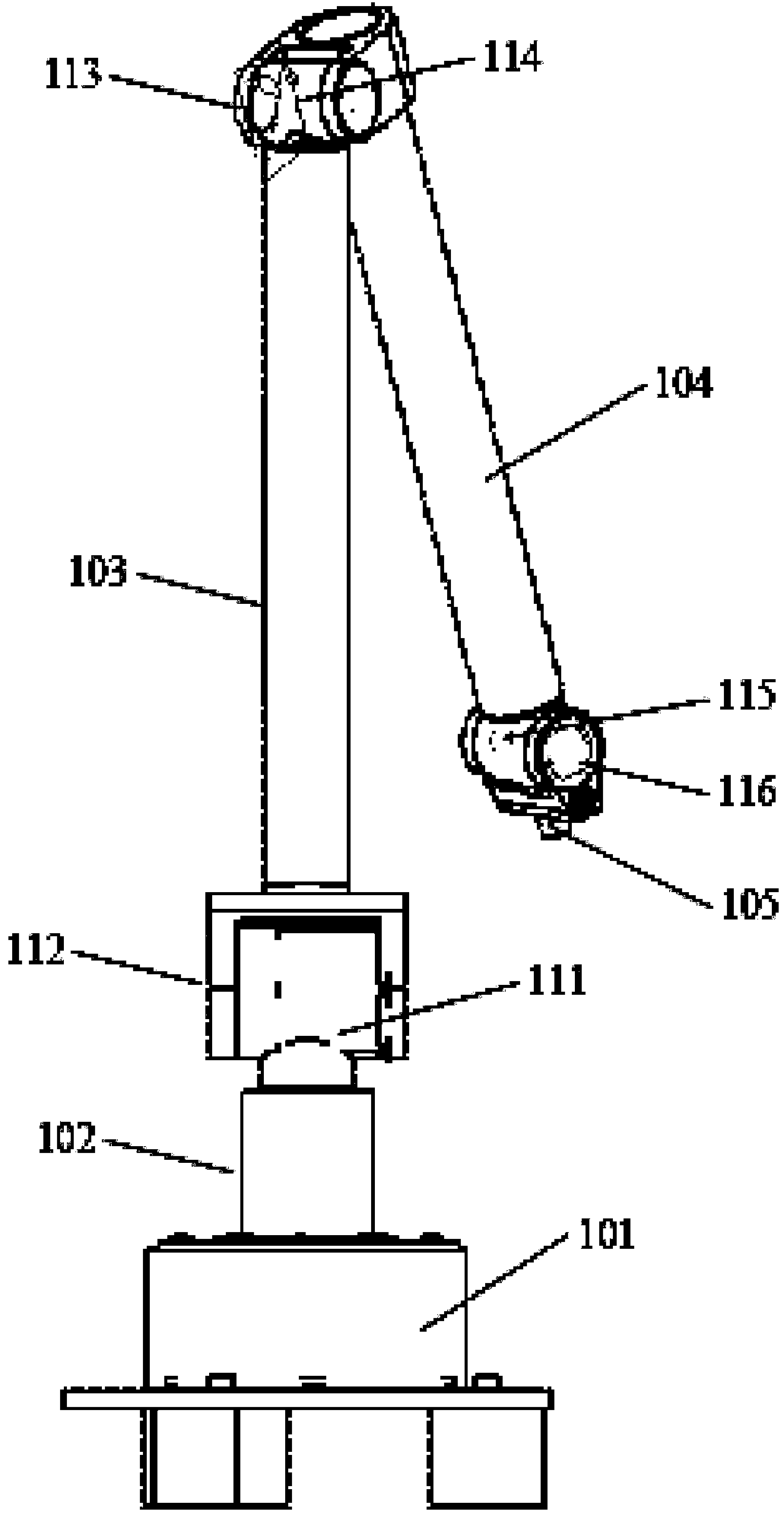

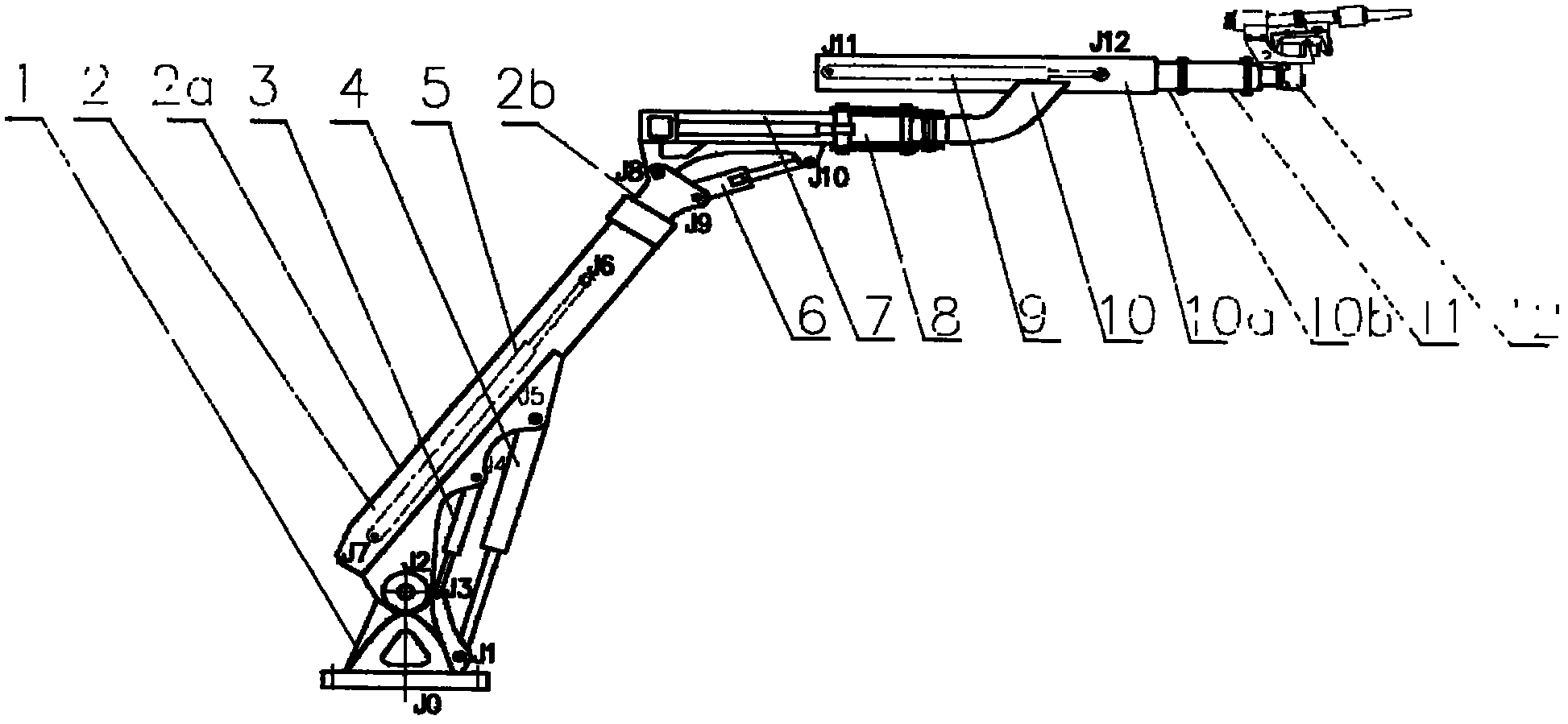

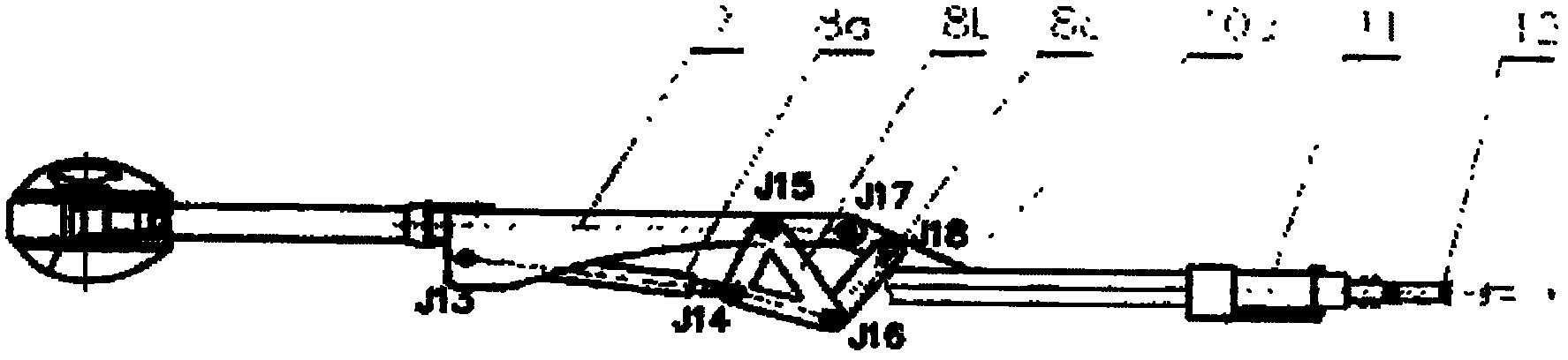

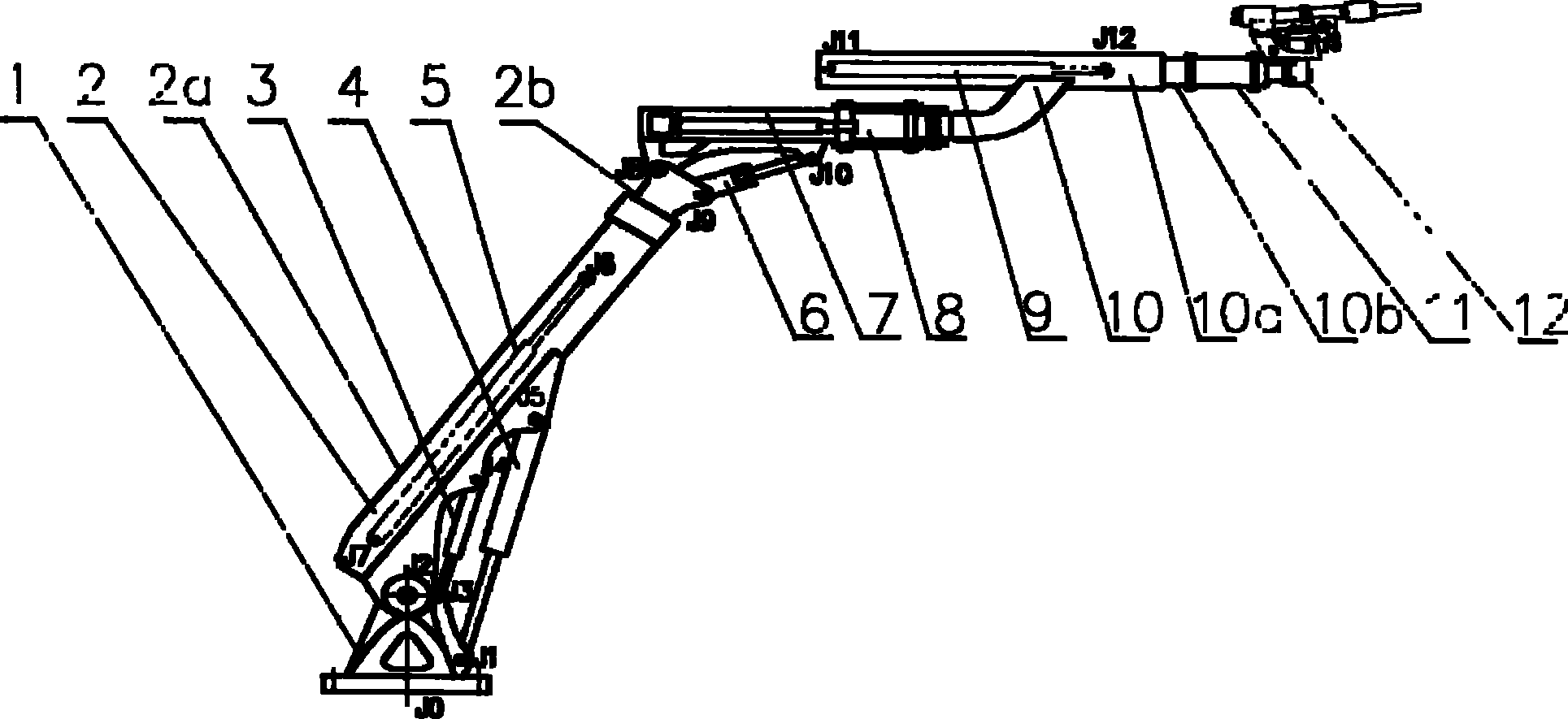

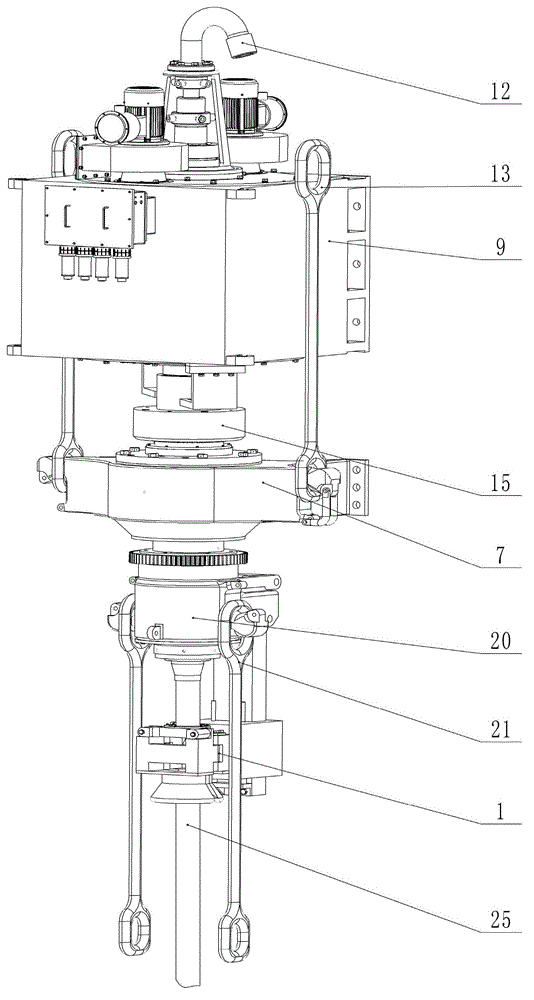

Concrete spray mechanical arm

InactiveCN102080450AExpand the scope of workFlexible movementUnderground chambersBuilding material handlingSprayerEngineering

The invention discloses a concrete spray mechanical arm, which mainly comprises a pivoting support, a large arm, a middle arm, a small arm, a small arm oscillating mechanism, a small arm parallel mechanism and a sprayer wrist gyrator. The pivoting support is arranged on a cement spraying machine frame; the large arm and the small arm are telescopic arms; an outer arm of the small arm is hinged with the middle arm; the sprayer wrist gyrator is arranged at the tail end of an inner arm of the small arm; the small arm parallel mechanism consists of two oil cylinders with the same cylinder diameter and rod diameter; the two oil cylinders are hinged with the pivoting support, an outer arm of the large arm, an inner arm of the large arm and the middle arm respectively; rod cavities are connected and rodless cavities are connected in the two oil cylinders; and the small arm oscillating mechanism consists of an oscillating oil cylinder, a tripod and a pull rod and is hinged with the middle arm and the small arm. The mechanical arm has the advantages of high working efficiency, high working quality and high adaptive capacity.

Owner:CHANGSHA KEDA INTELLIGENT EQUIP INC CO

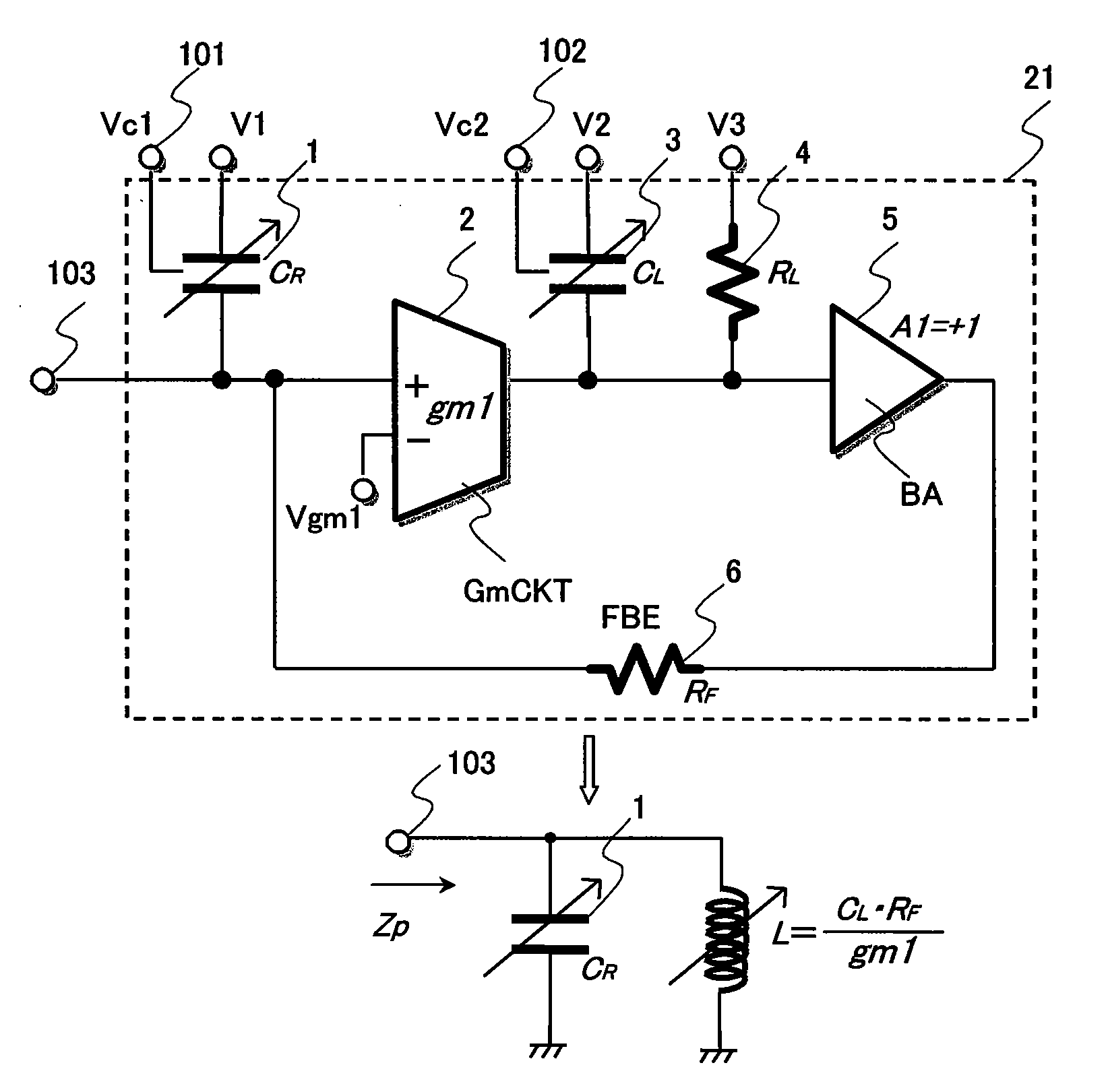

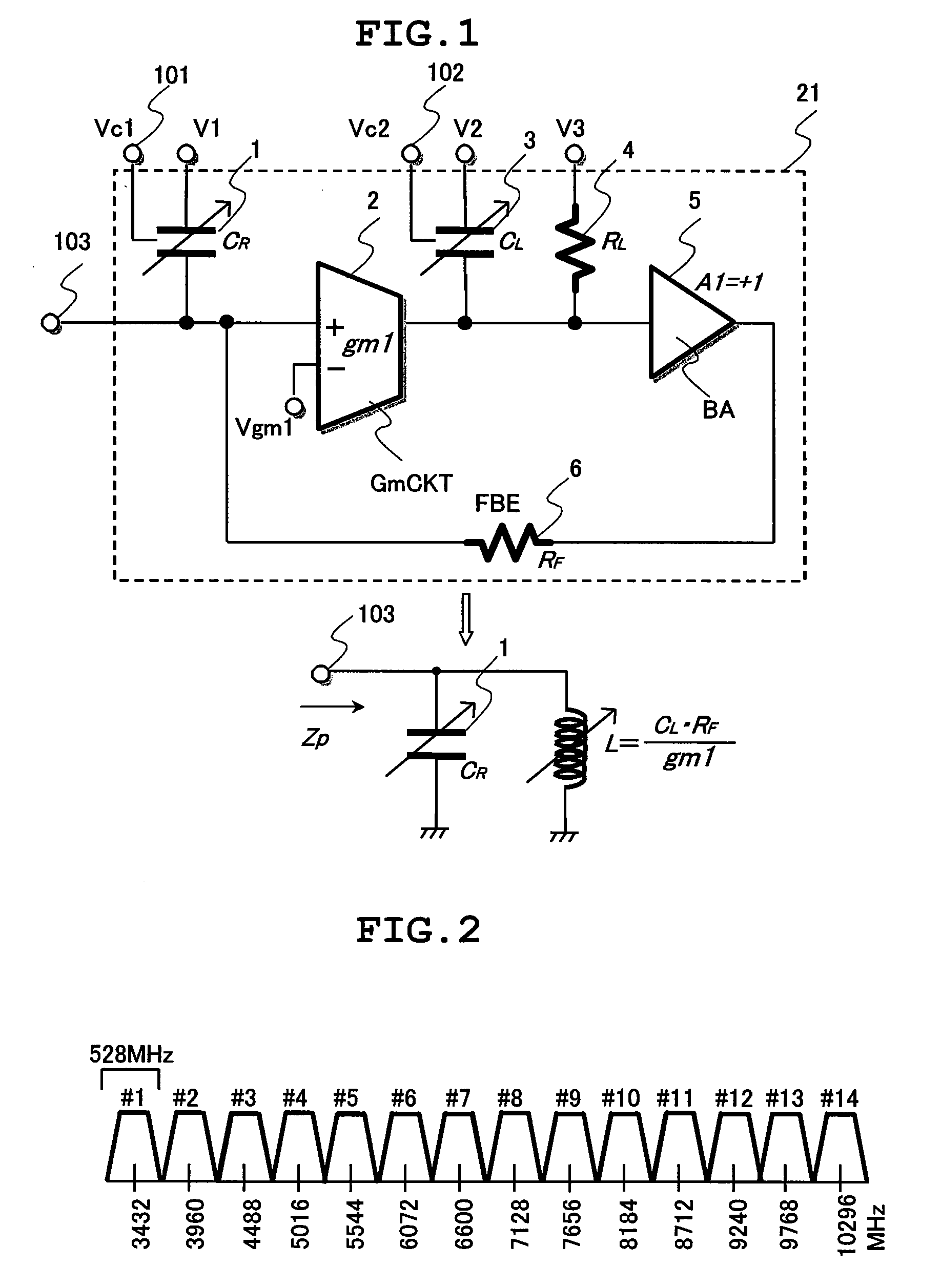

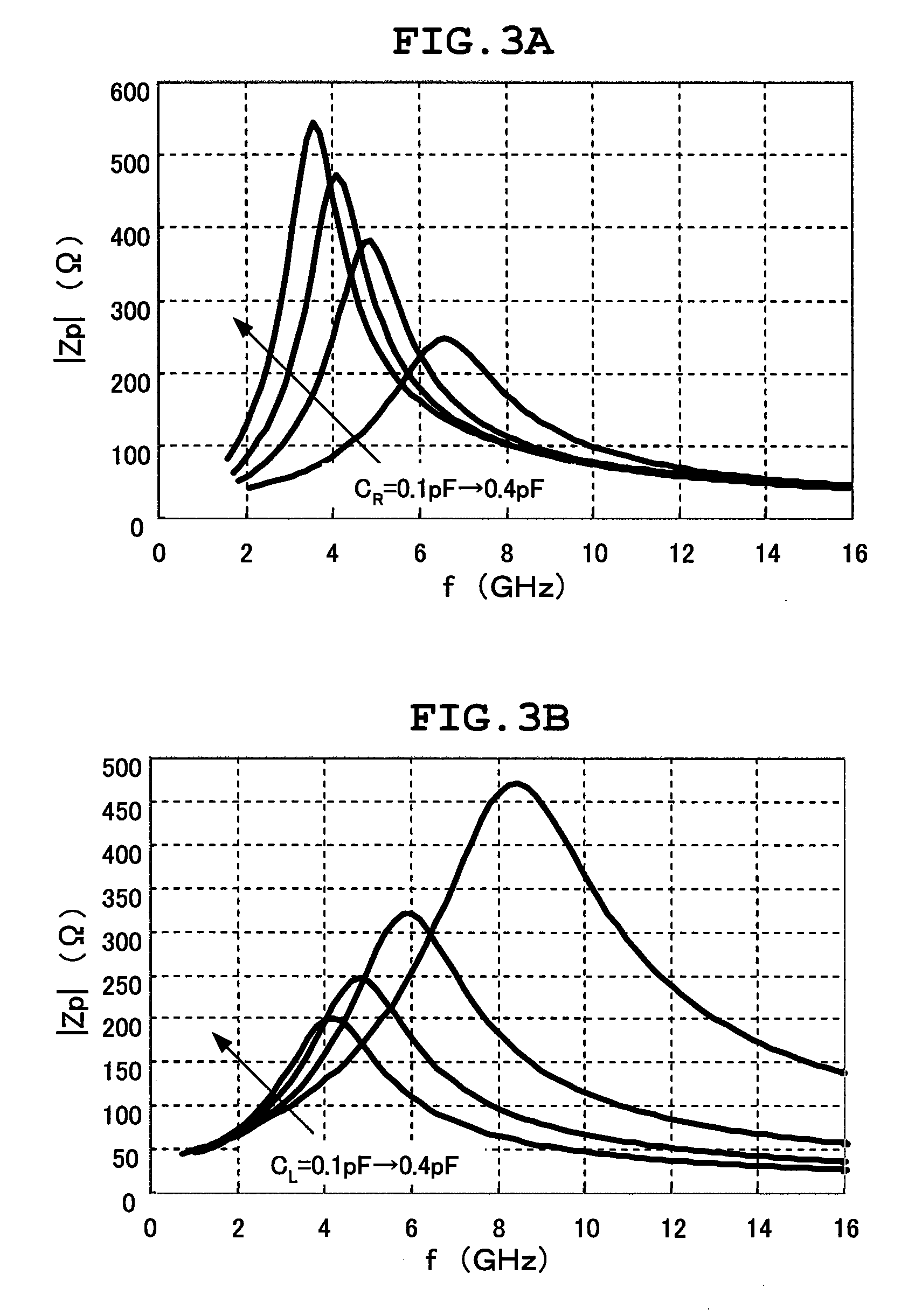

Active resonant circuit with resonant-frequency tunability

The present invention is directed to provide a low-power-consumption wide-range RF signal processing unit having a small chip occupation area. A semiconductor integrated circuit has, on a semiconductor chip, a resonant circuit including a first capacitor having a capacitance which can be controlled by a first control signal of a first control terminal, and a gyrator for equivalently emulating an inductor by including a second capacitor having a capacitance which can be controlled by a second control signal of a second control terminal. The capacitance and the inductor form a parallel resonant circuit. At the time of changing parallel resonant frequency, the capacitances of the first and second capacitors are coordinately changed. The parallel resonant circuit is suitable for an active load which is connected to an output node of an amplifier.

Owner:RENESAS ELECTRONICS CORP

Magnetless non-reciprocal devices using modulated filters

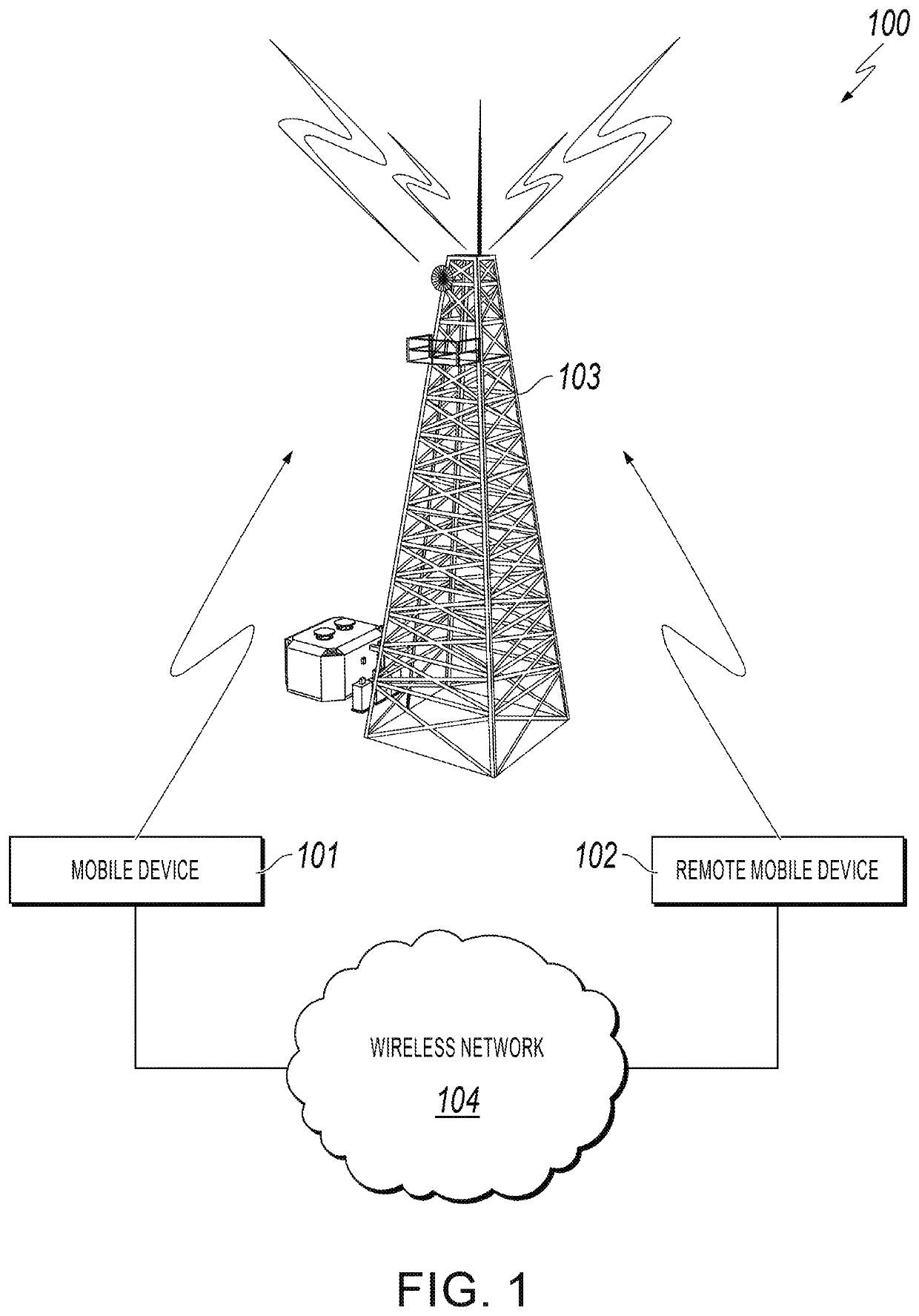

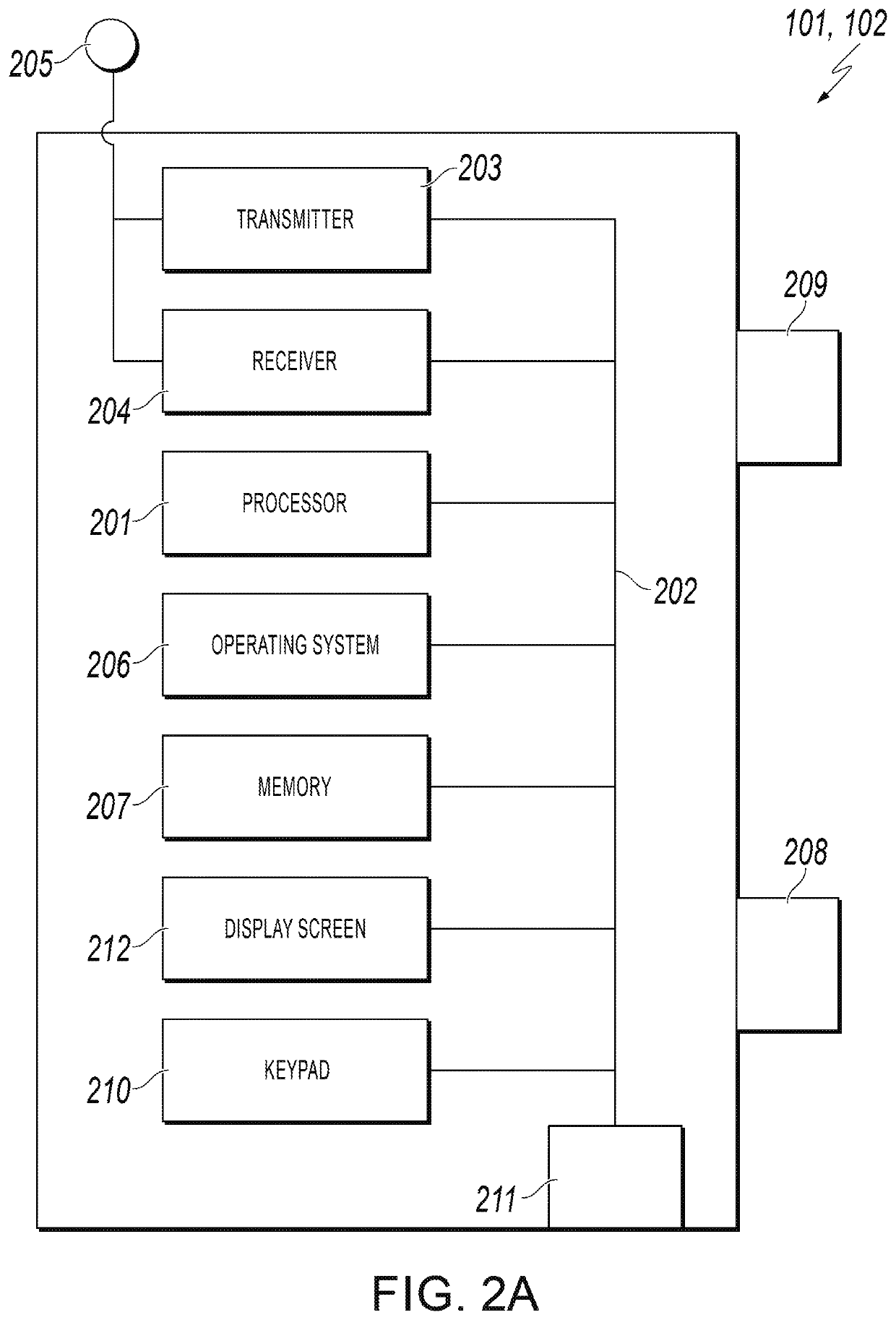

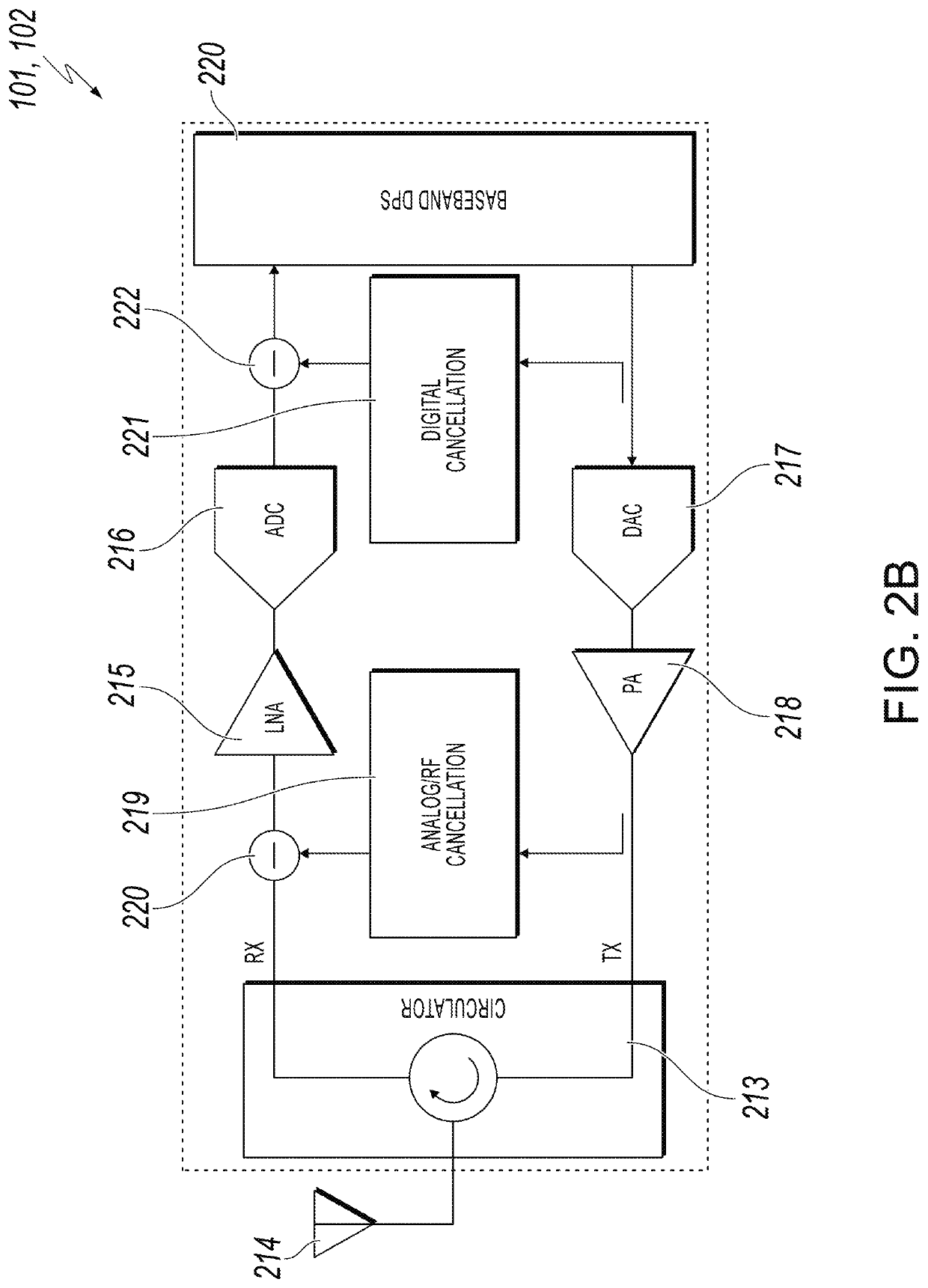

A magnet-free non-reciprocal device realized using modulated filters. The device includes one or more filters in one or more branches, where each branch connects two ports or a port and a central node. The poles and zeros of each of the first, second and third filters are modulated in time such that degenerate modes at each pole and zero is split thereby destructively interfering at one or more output ports and adding up at another output port allowing non-reciprocal transmission, isolation and / or non-reciprocal phase shift. The device is able to realize a magnet-free full-duplex communication scheme implementing a magnet-free circulator for radio frequency cancellation or a magnet-free isolator or gyrator.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

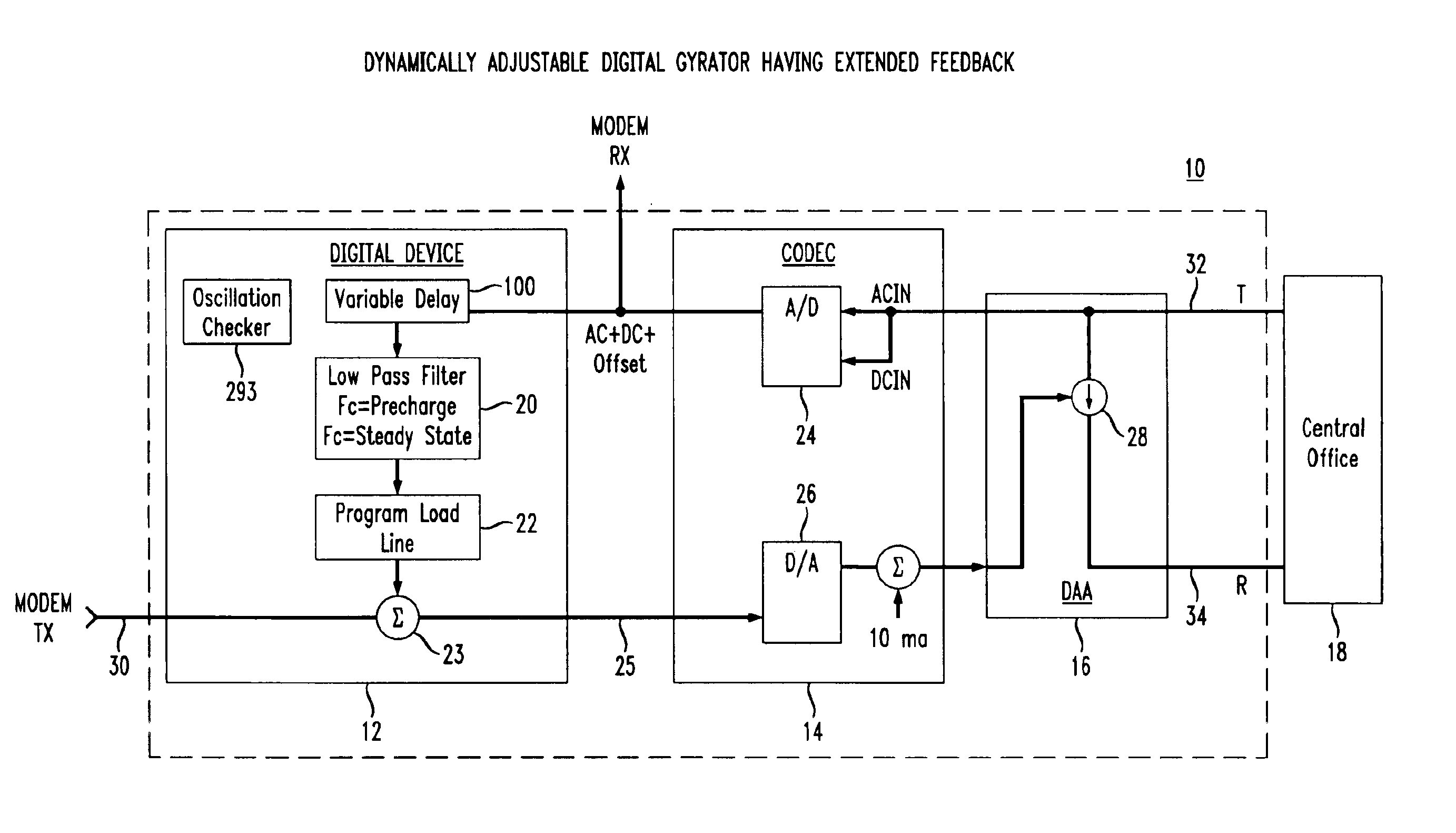

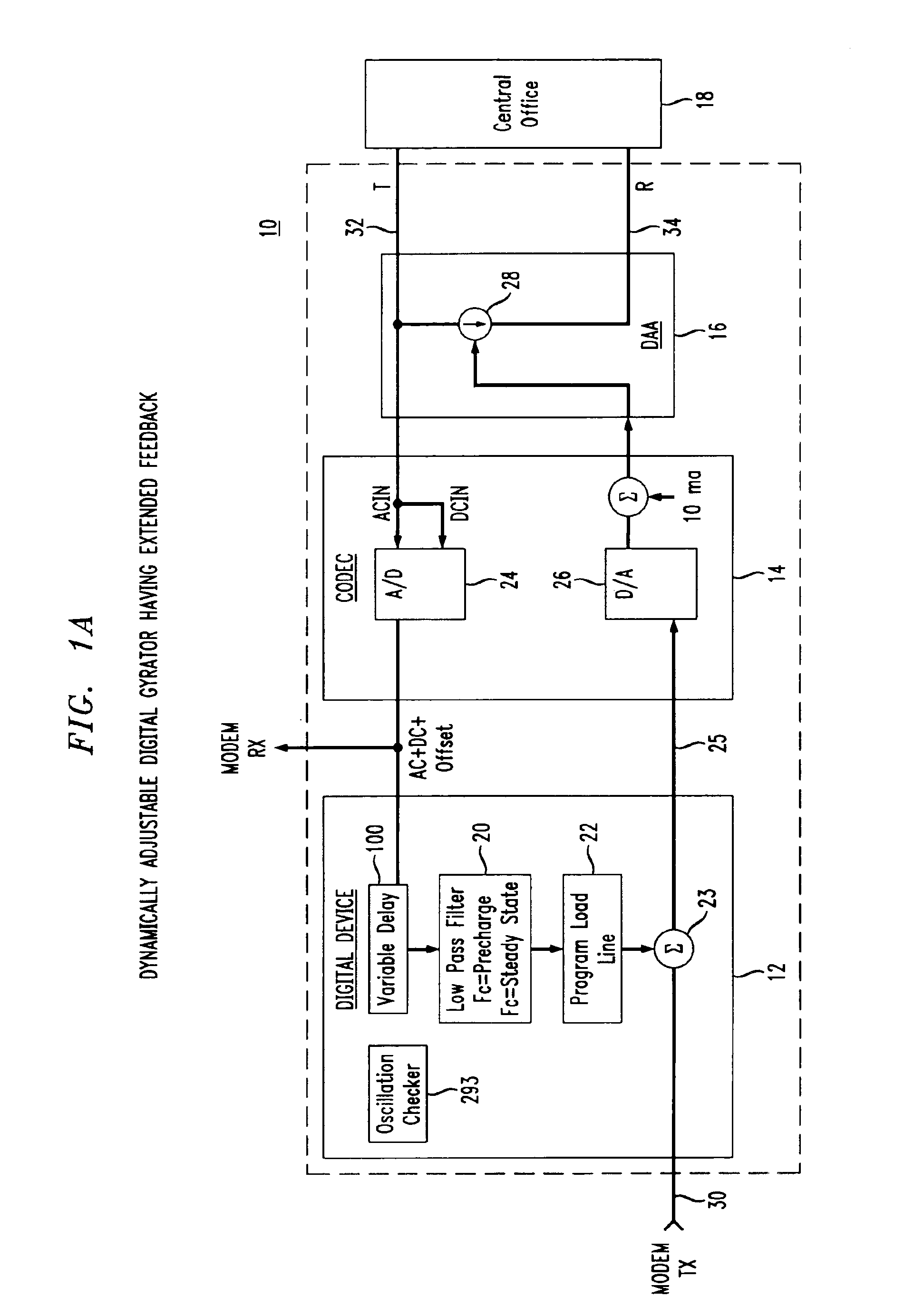

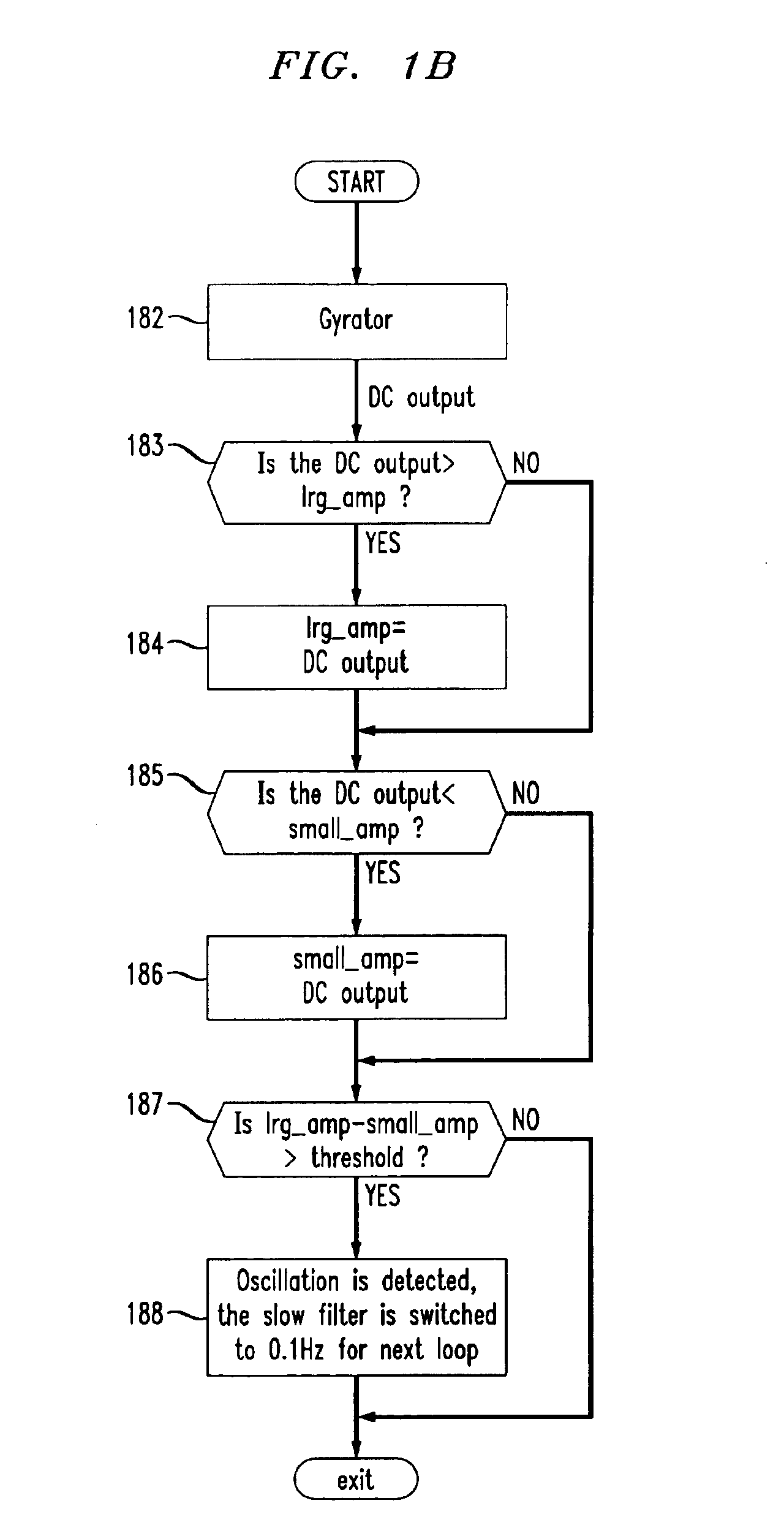

Dynamically adjustable digital gyrator having extendable feedback for stable DC load line

InactiveUS6888938B2Dampen detectedInterconnection arrangementsSubstations coupling interface circuitsModem deviceLow-pass filter

A dynamically adjustable digital gyrator device for a telephone line interface (e.g., a DAA) utilizing extended feedback and a dynamically adjustable filter to achieve stable convergence in the control of DC line current on a telephone line a short period of time. The low pass filter of the digital gyrator includes at least two (2) different fast filter settings and at least two (2) different slow filter settings based on possible load terminations (e.g., PBX, TAS, etc.), which can be determined based on the dynamic detection of an oscillation on the line. For instance, in a disclosed example, a voice band modem system is allowed to go off-hook with a 1 Hz cutoff low pass filter, and then the output of the low pass filter is checked for an oscillation. If an oscillation is detected, then the poles and / or zeroes of the low pass filter cutoff are changed to a slower convergence rate cutoff frequency (e.g., to 0.1 Hz). As a result, the exemplary voice band modem will converge stably and quickly (e.g., in less than 1 second) before dialing begins. By controlling the DC line current digitally, software can be used to set the DC line current in accordance with predefined characteristics. Predefined characteristics can be set to accommodate varying country specifications instead of using switches to control resistors and capacitors.

Owner:AGERE SYST GUARDIAN

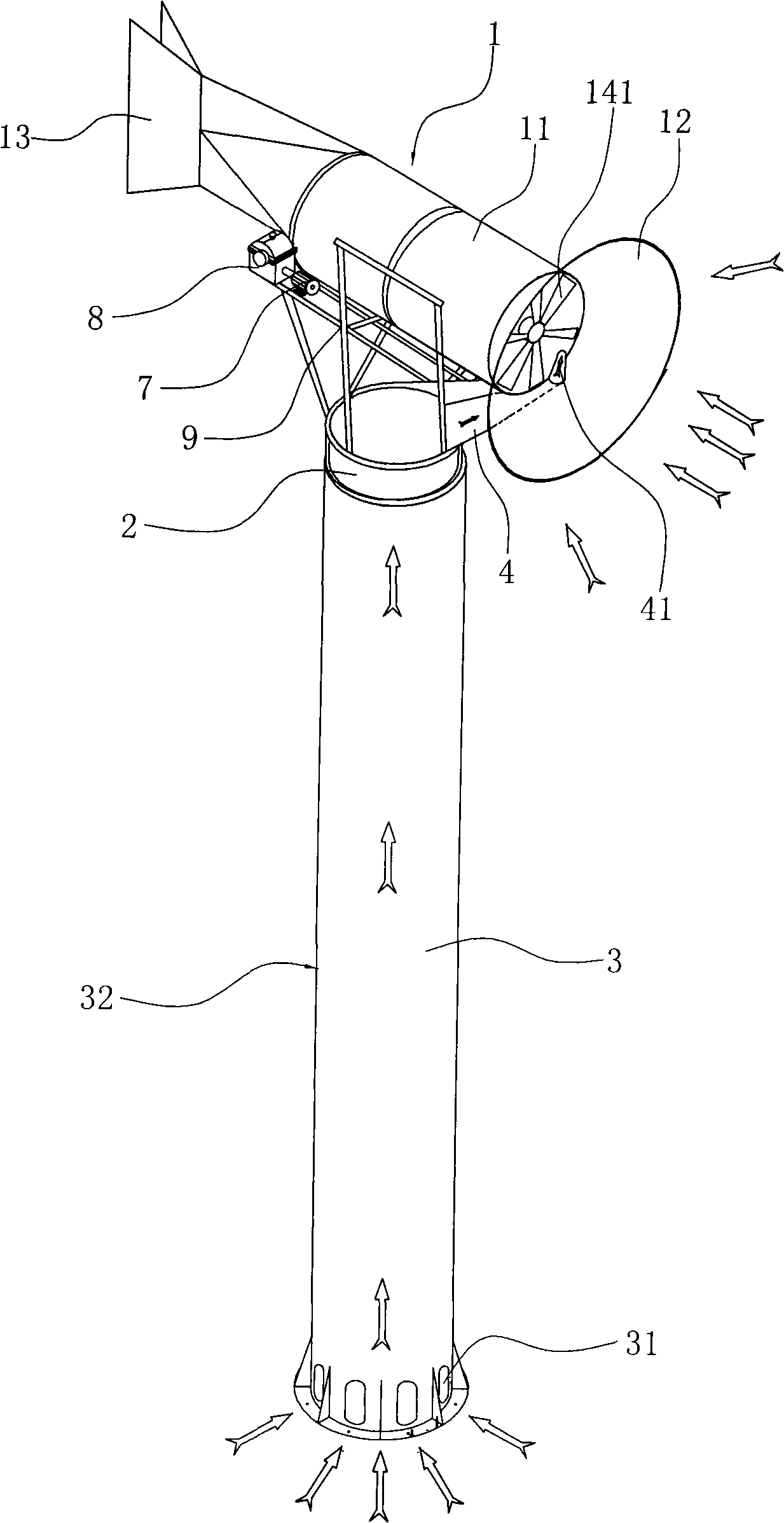

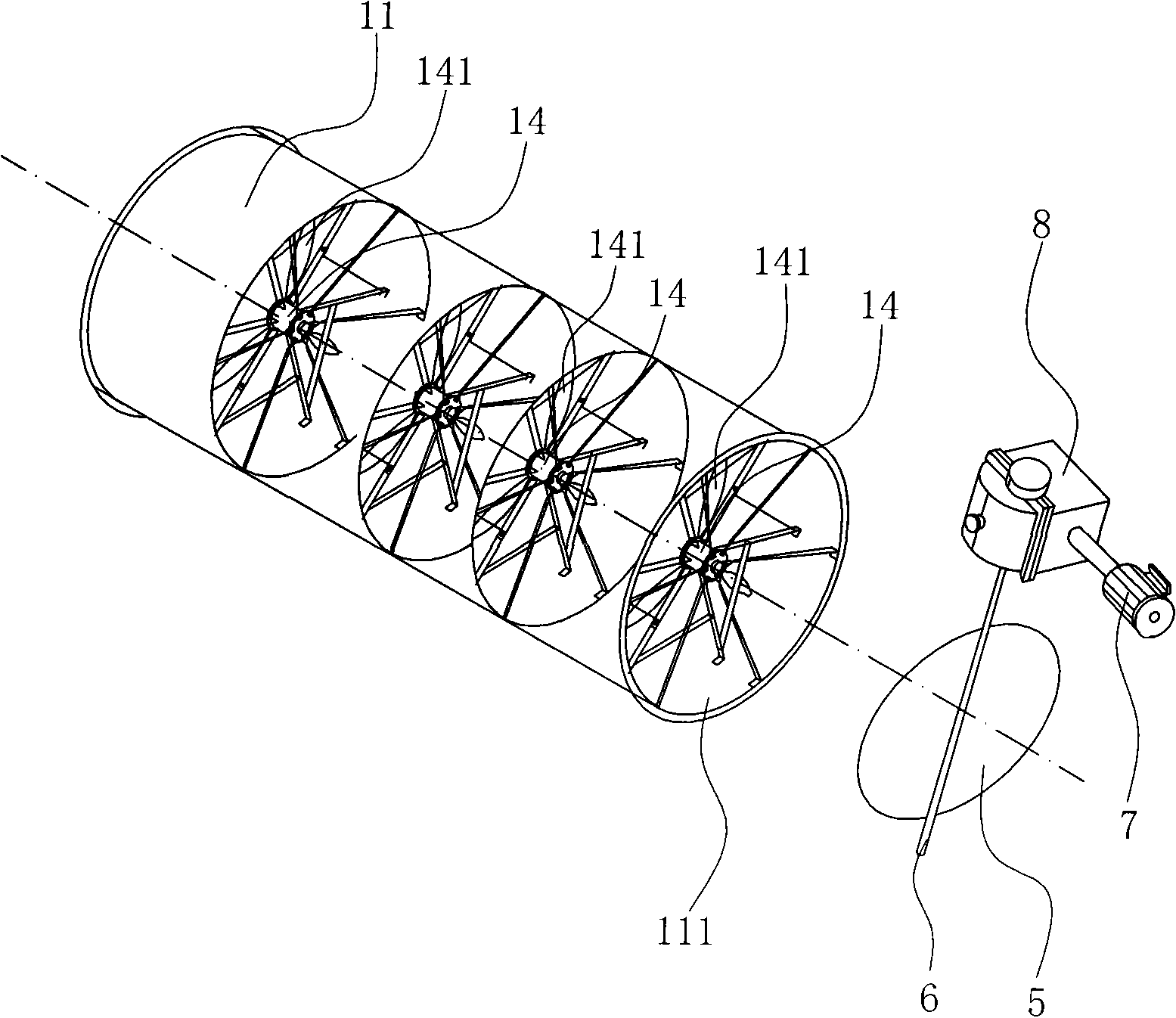

Wind collection type barrel type cross axis power generation system

InactiveCN101338731AImprove power generation efficiencyWind motor controlWind motor combinationsElectricityEngineering

The present invention relates to a wind collecting type cylindrical horizontal-shaft generating system, which is provided with a high tower; wherein, the top end of the high tower is provided with a gyrator (2); a hollow shell (11) and a wind-collecting cover (12) are fixed on the gyrator (2); tail fins (13) are arranged on the rear end of the shell (11); an aerogenerator (14) provided with wind wheels (141) is mounted in the shell (11); the high tower is a hollow wind duct (3); a plurality of air inlets (31) are arranged on the sidewall of the lower end of the wind duct (3); the gyrator (2) is hollow; a wind-guiding cover (4) which is communicated with the wind duct (3) is arranged on the gyrator (2); the air outlet end of the wind-guiding cover (4) guides the air flow in the wind duct (3) to a neighboring wind wheel (141). While utilizing the outside wind energy, the generating system also ingeniously guides the upward air flow generated by the air convection caused by geothermal energy to the wind wheels of the aerogenerator through the wind duct, so that the wind wheels are blown to rotate, so the generating system can simultaneously effectively utilize geothermal energy and wind energy to generate electricity.

Owner:宁波银风能源科技股份有限公司

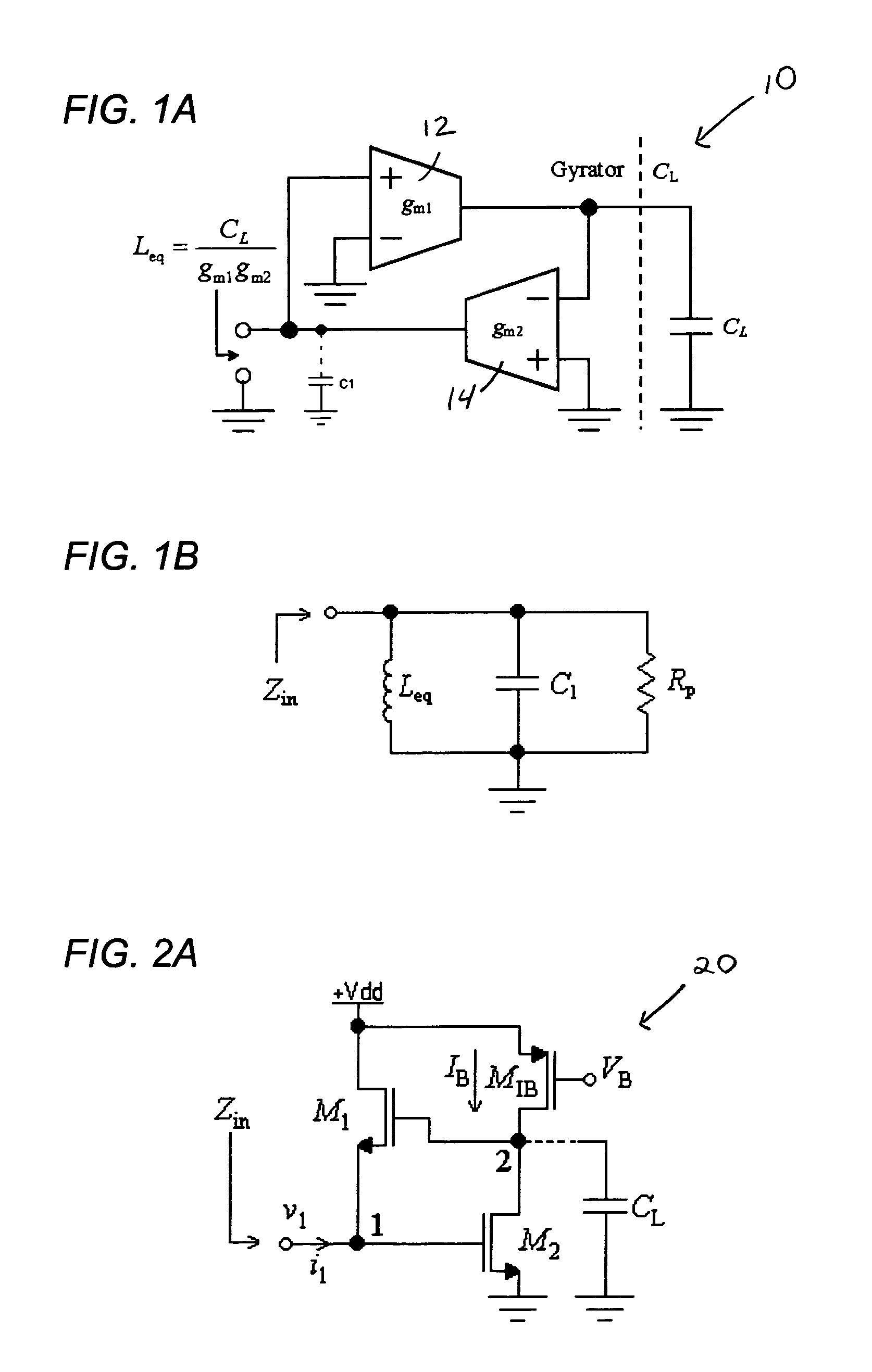

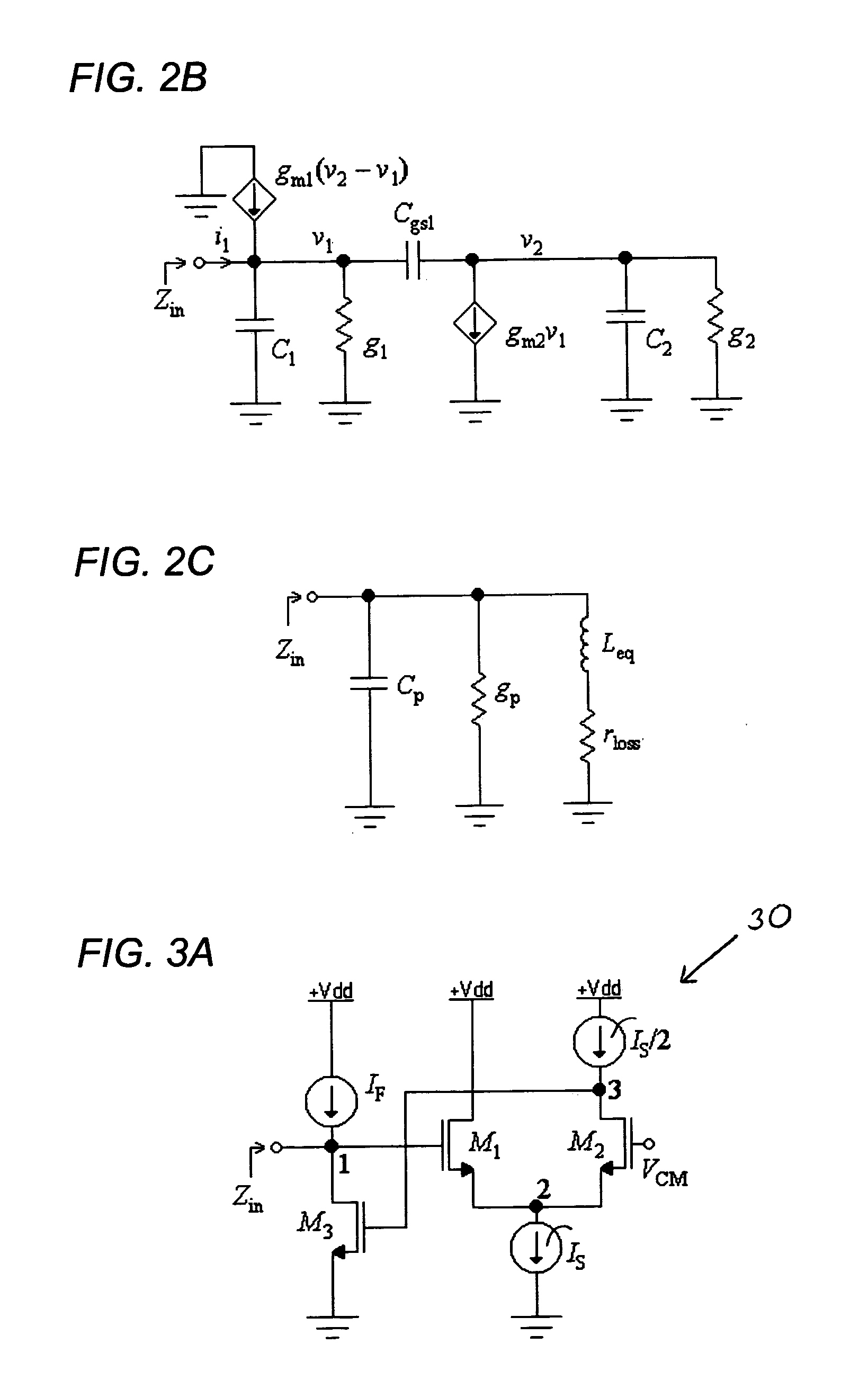

High-frequency active inductor

InactiveUS20050083151A1Effective structureNetwork simulating reactancesDifferential amplifiersCMOSEngineering

An active inductor circuit implemented in sub-micron CMOS semiconductor technology is usable at gigaHertz frequencies and includes an input node, a non-inverting transconductor circuit comprising a differential pair of NMOS transistors connected to the input node, an inverting transconductor circuit comprising an NMOS transistor connected to an output node of the non-inverting transconductor circuit and connected to the input node in a gyrator feedback configuration. Varactors coupled to the transconductor circuits tune the frequency and Q of the active inductor circuit.

Owner:PORTLAND STATE UNIV

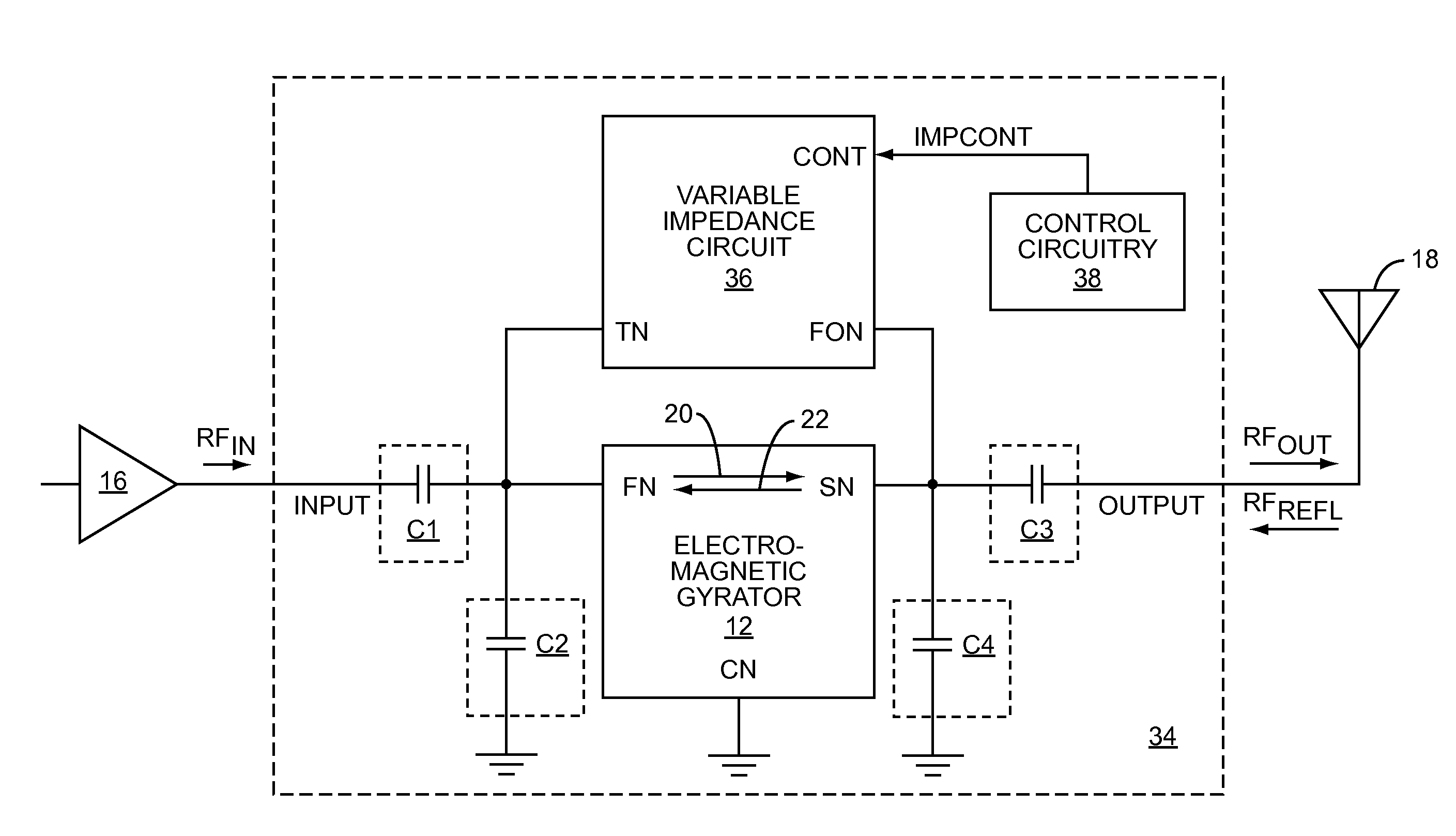

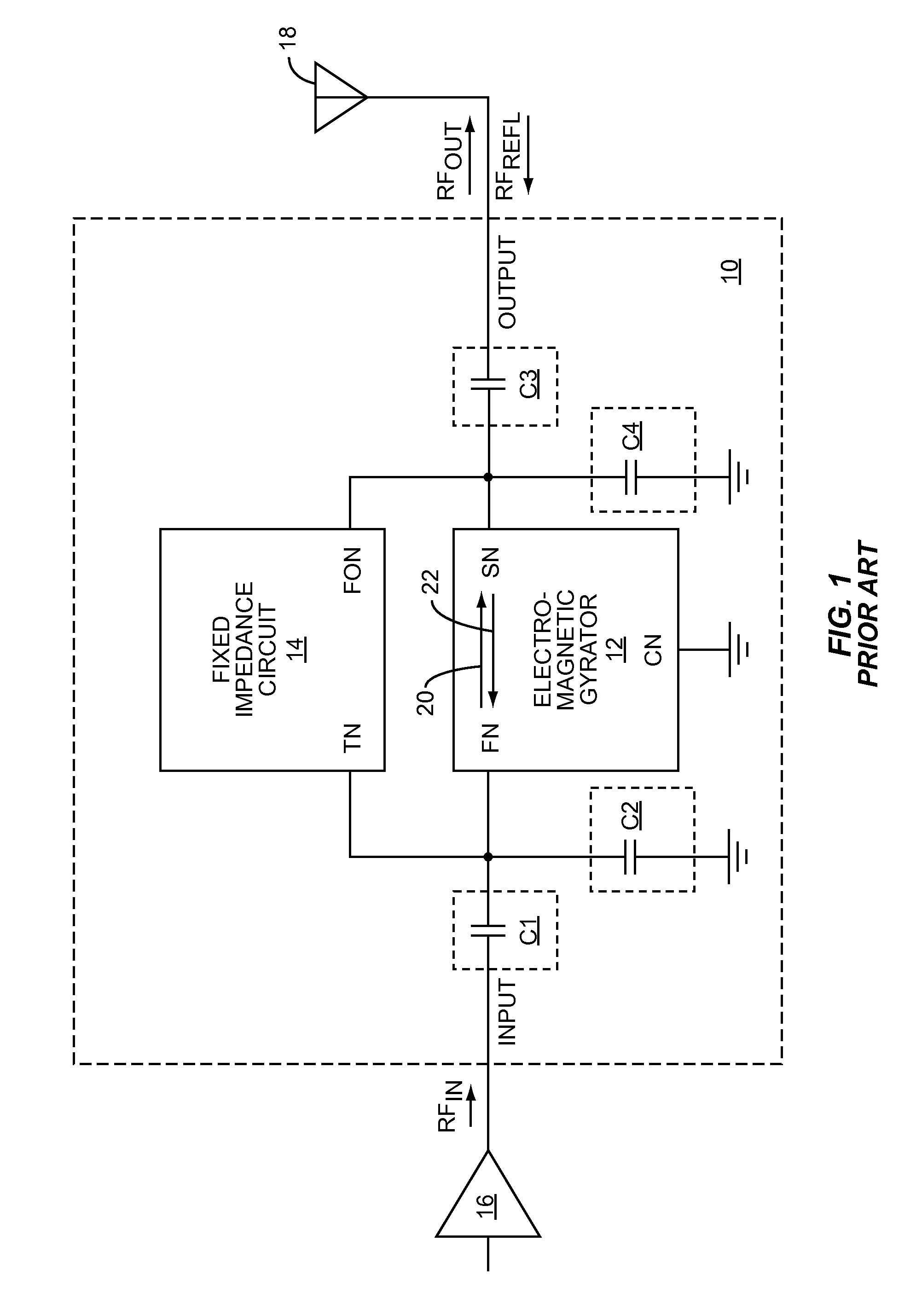

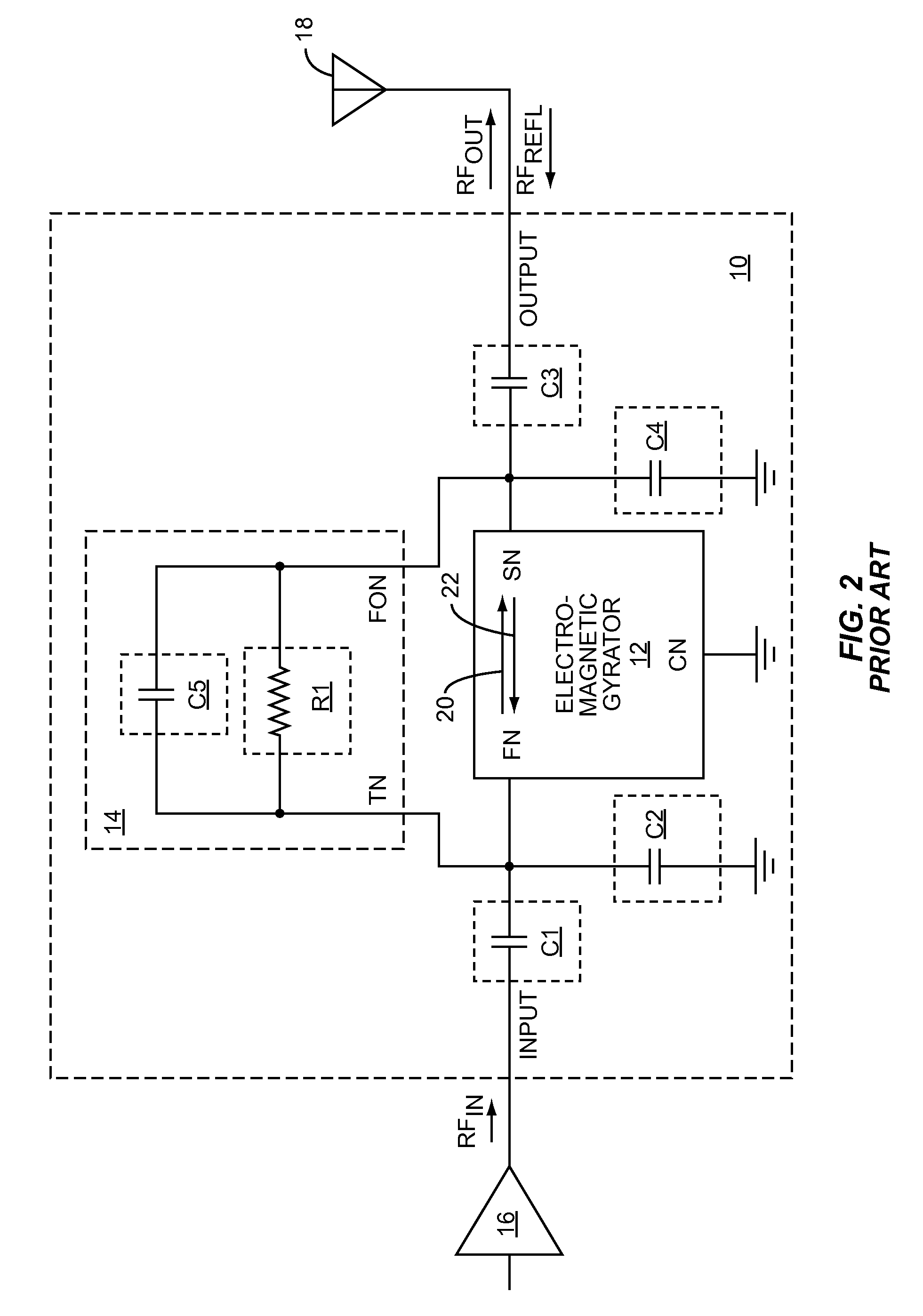

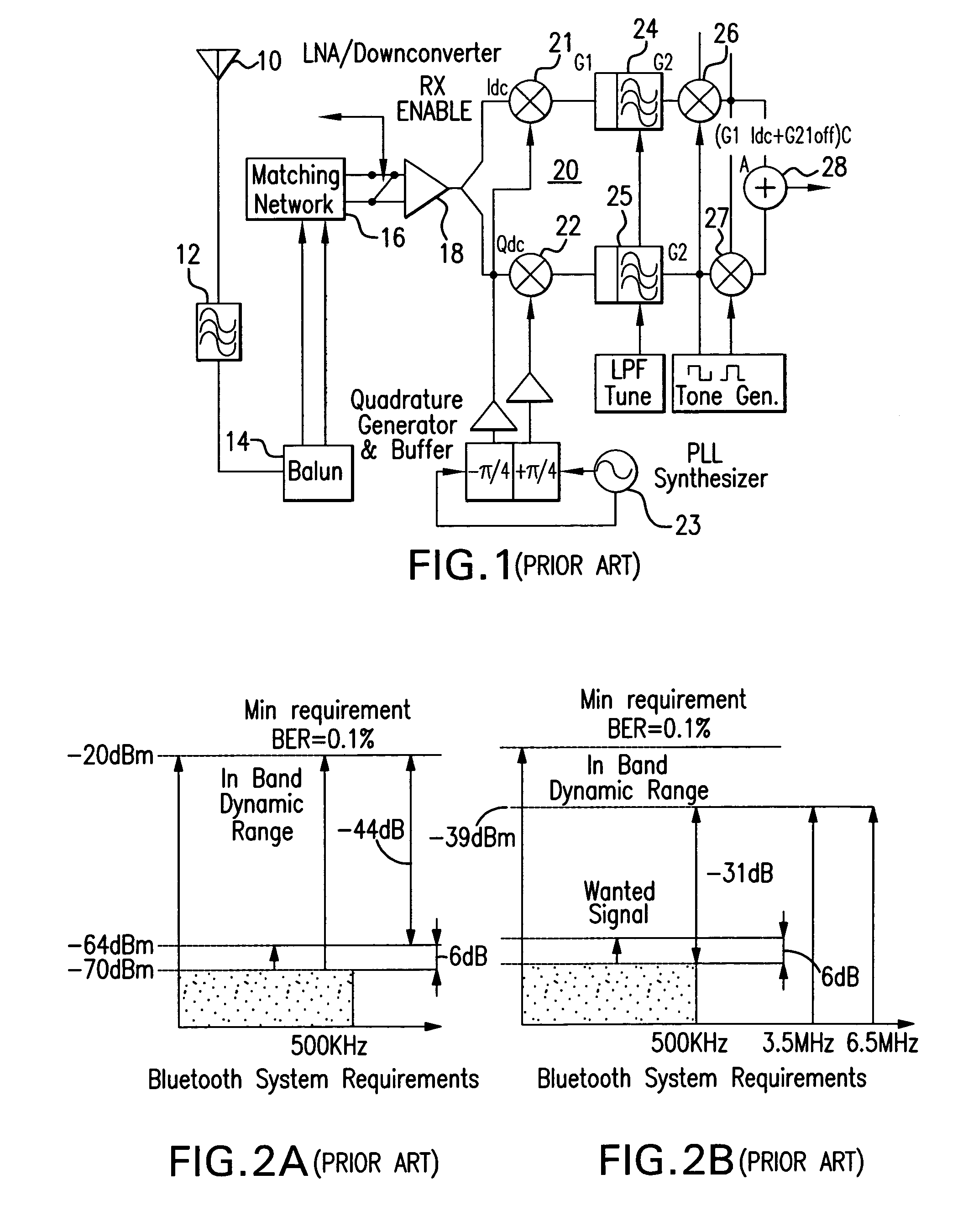

Frequency-adjustable radio frequency isolator circuitry

InactiveUS8130054B1Ensure adequate isolationSufficient isolationOne-port networksCoupling devicesBandpass filteringRadio frequency

The present invention relates to a frequency-adjustable radio frequency (RF) isolator that may operate as a bandpass filter when processing RF signals in a forward direction and may operate as a notch filter when processing RF signals in a reverse direction. The notch filter has a notch frequency, which is adjustable to provide adequate isolation from reflected signals at a specific operating frequency. The frequency-adjustable RF isolator may include an electro-magnetic gyrator coupled to a variable impedance circuit, which may present a variable impedance to the electro-magnetic gyrator. The notch frequency may be dependent on the variable impedance. The notch filter may be a single-notch filter or may be a multiple-notch filter.

Owner:QORVO US INC

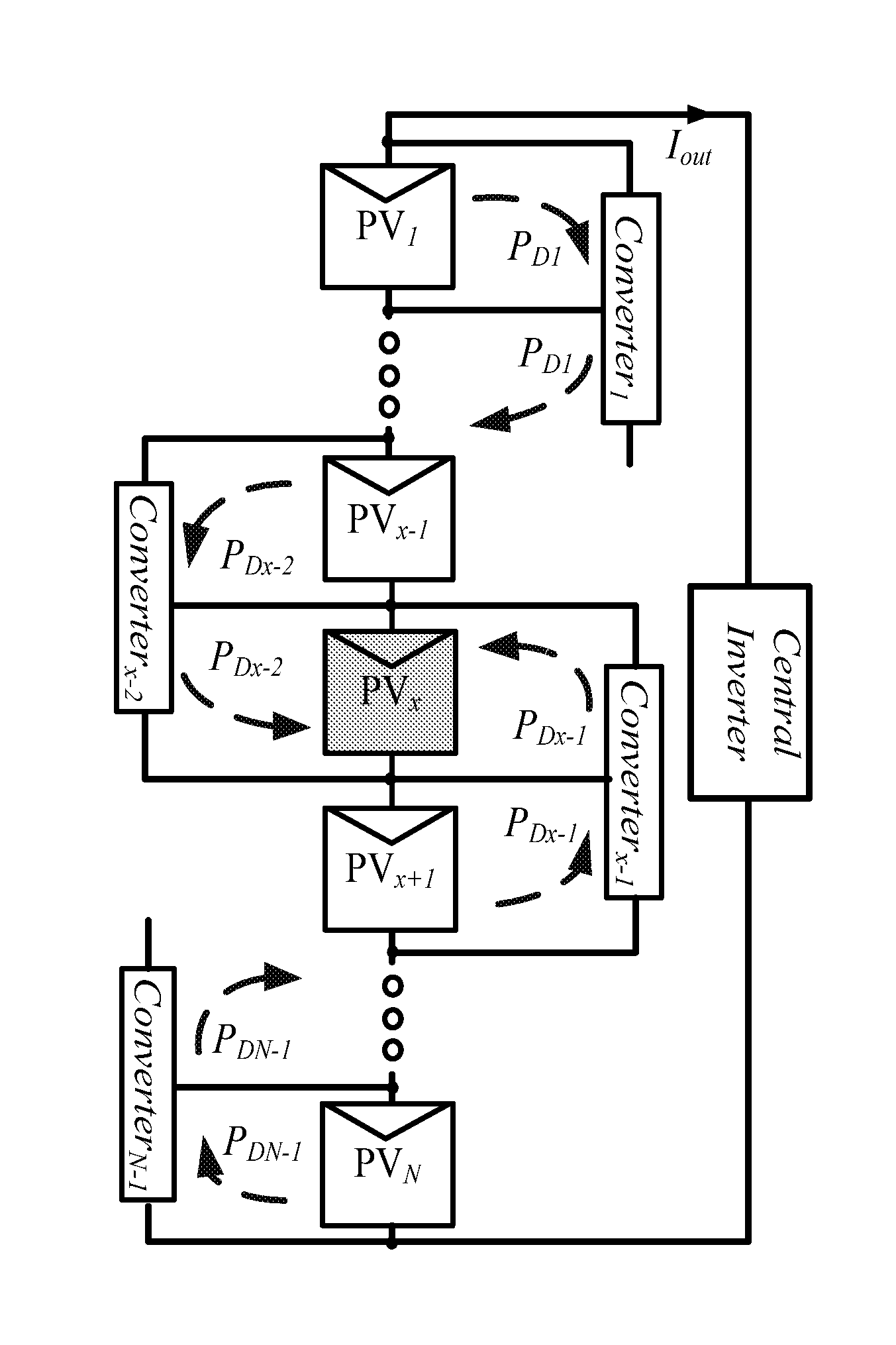

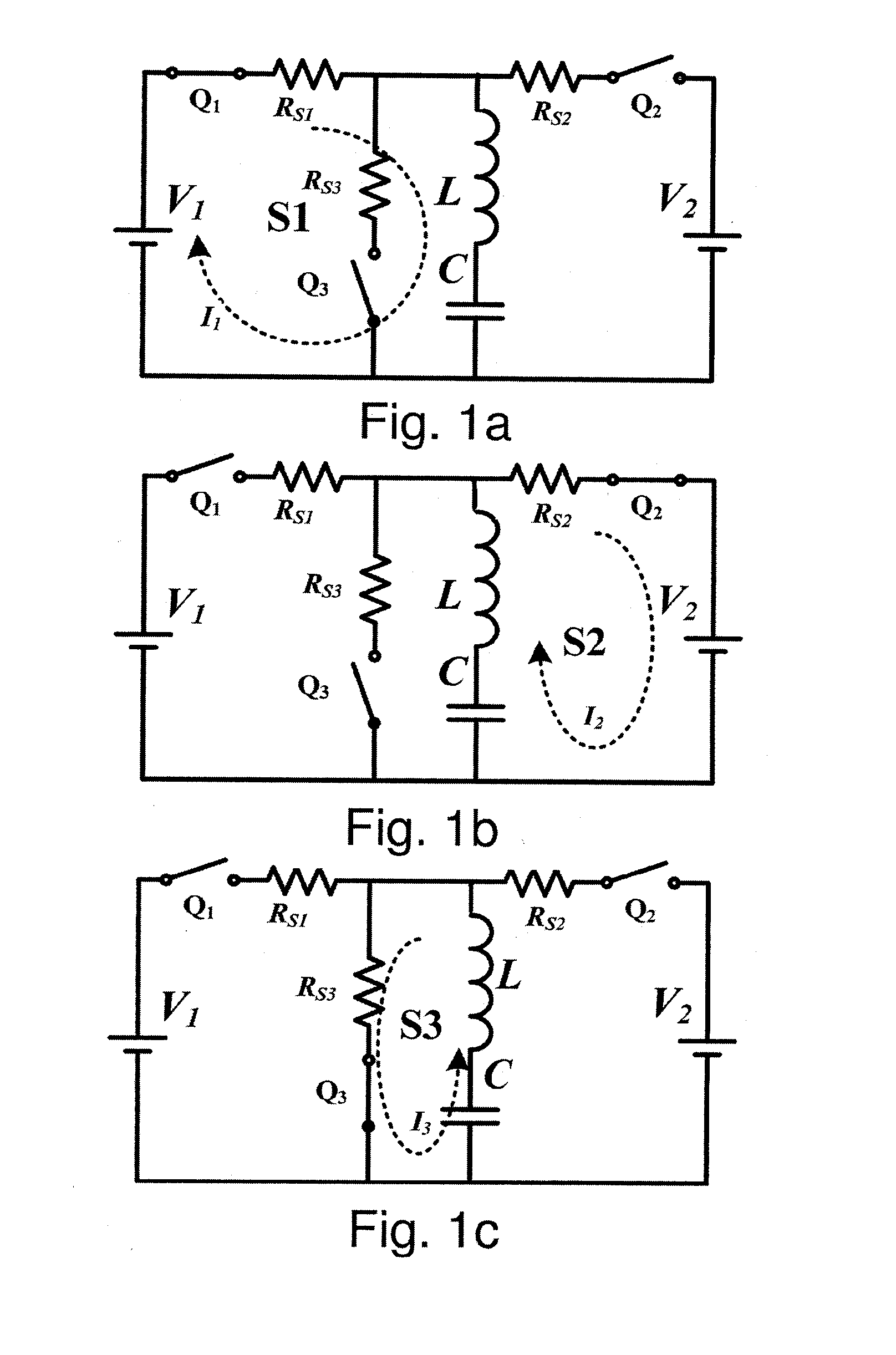

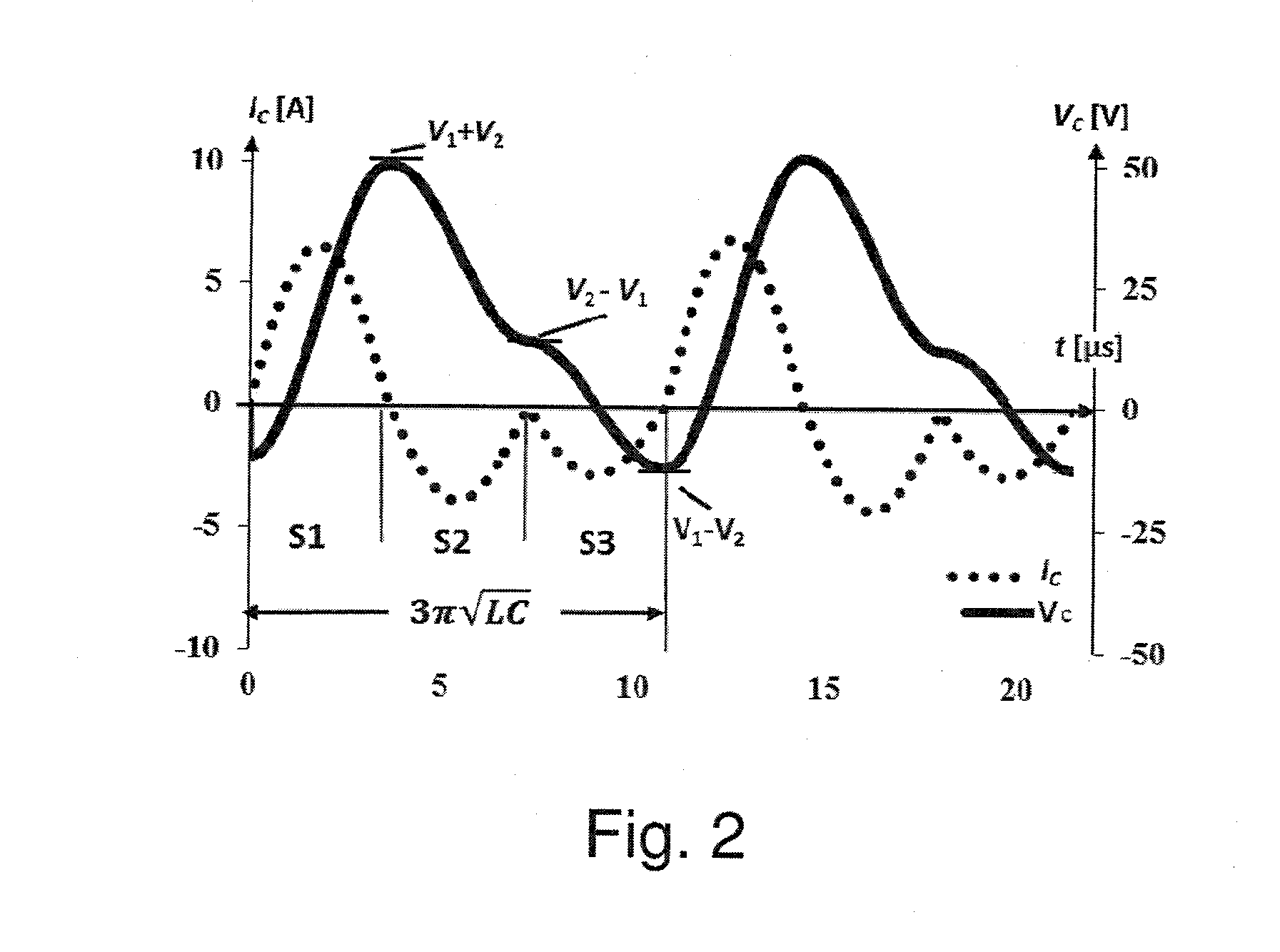

Resonant switched-capacitor gyrator-type converter with local mppt capability for pv cells

InactiveUS20150214887A1Energy can transferBatteries circuit arrangementsEfficient power electronics conversionEngineeringPower extraction

A method for increasing the power extraction capability out of Differential Power Processor (DPP) system, which consists of a chain of N serially connected PV elements and an array of N-1 gyrator-type converters which are current sourcing resonant Switched Capacitor Converters (SCCs), each of which being connected in parallel with two adjacent PV elements. Accordingly, local MPPT is continuously performed, by each gyrator-type converter, to one of its two connected PV elements by sinking or sourcing current to / from the neighbouring PV element. Whenever a mismatch in the MPPs is detected, the gyrator-type converters are used to provide the difference in current that is required for each of the PV elements to operate at its MPP, such that the amount of power processed by each gyrator-type converter in the chain is linearly proportional to its location in the chain, with respect to the mismatched PV element.

Owner:BEN GURION UNIVERSITY OF THE NEGEV

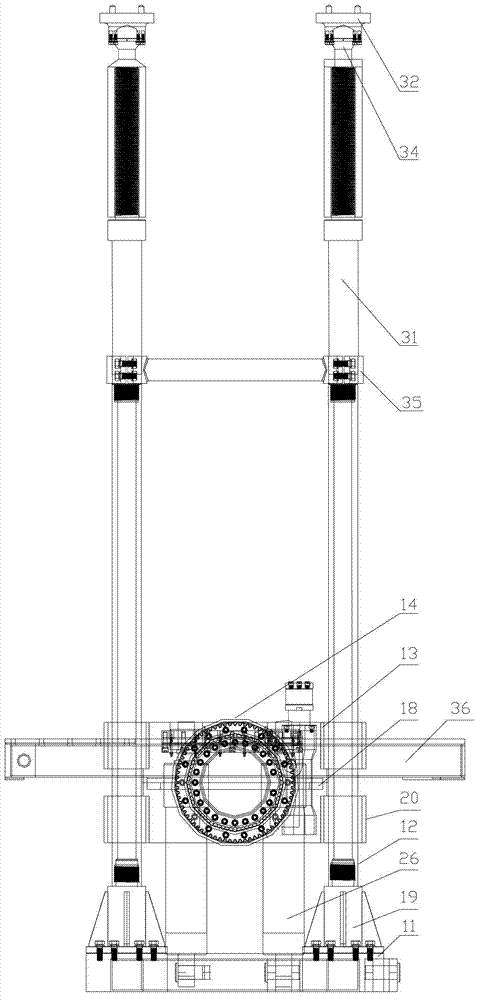

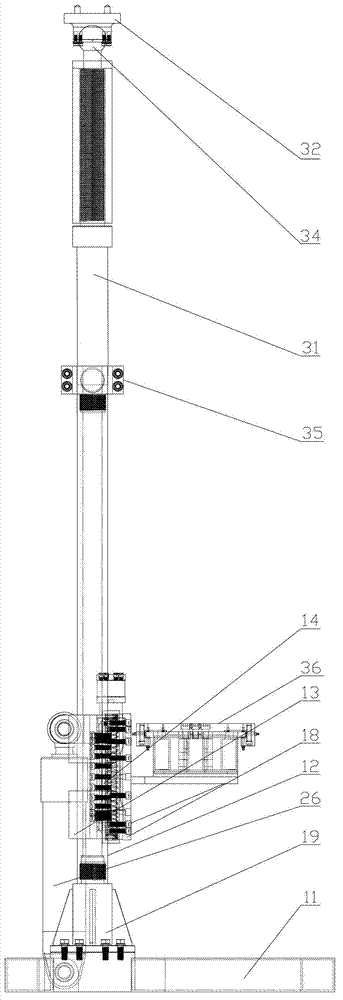

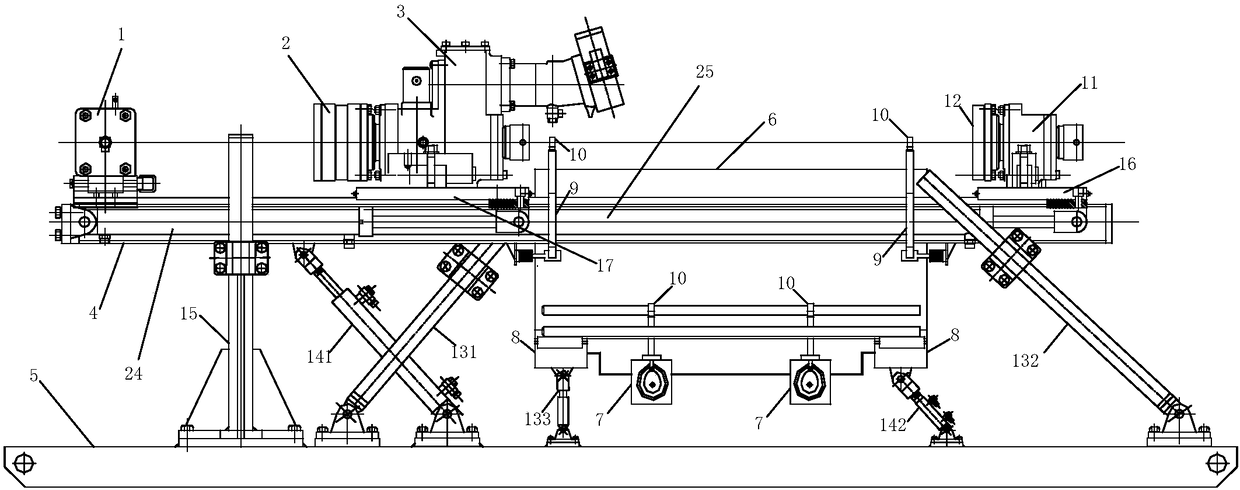

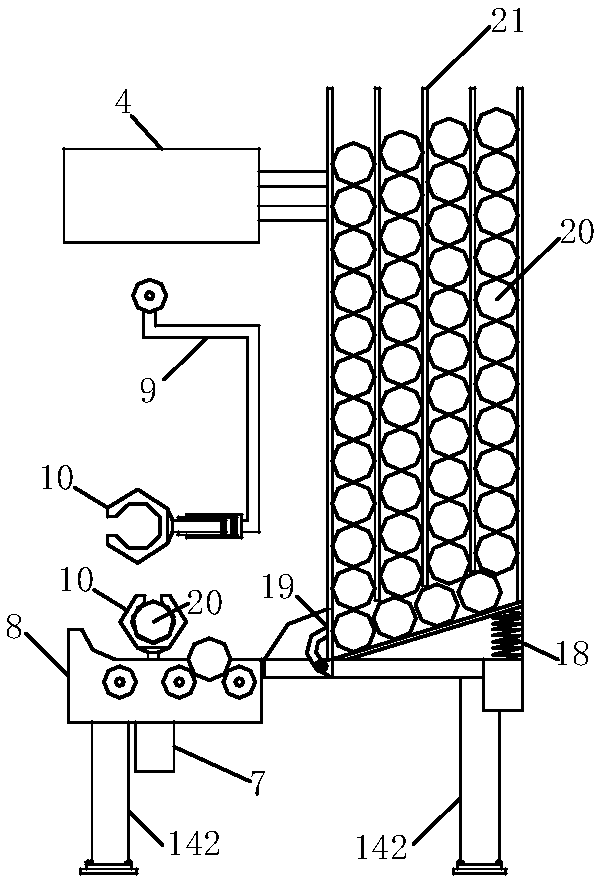

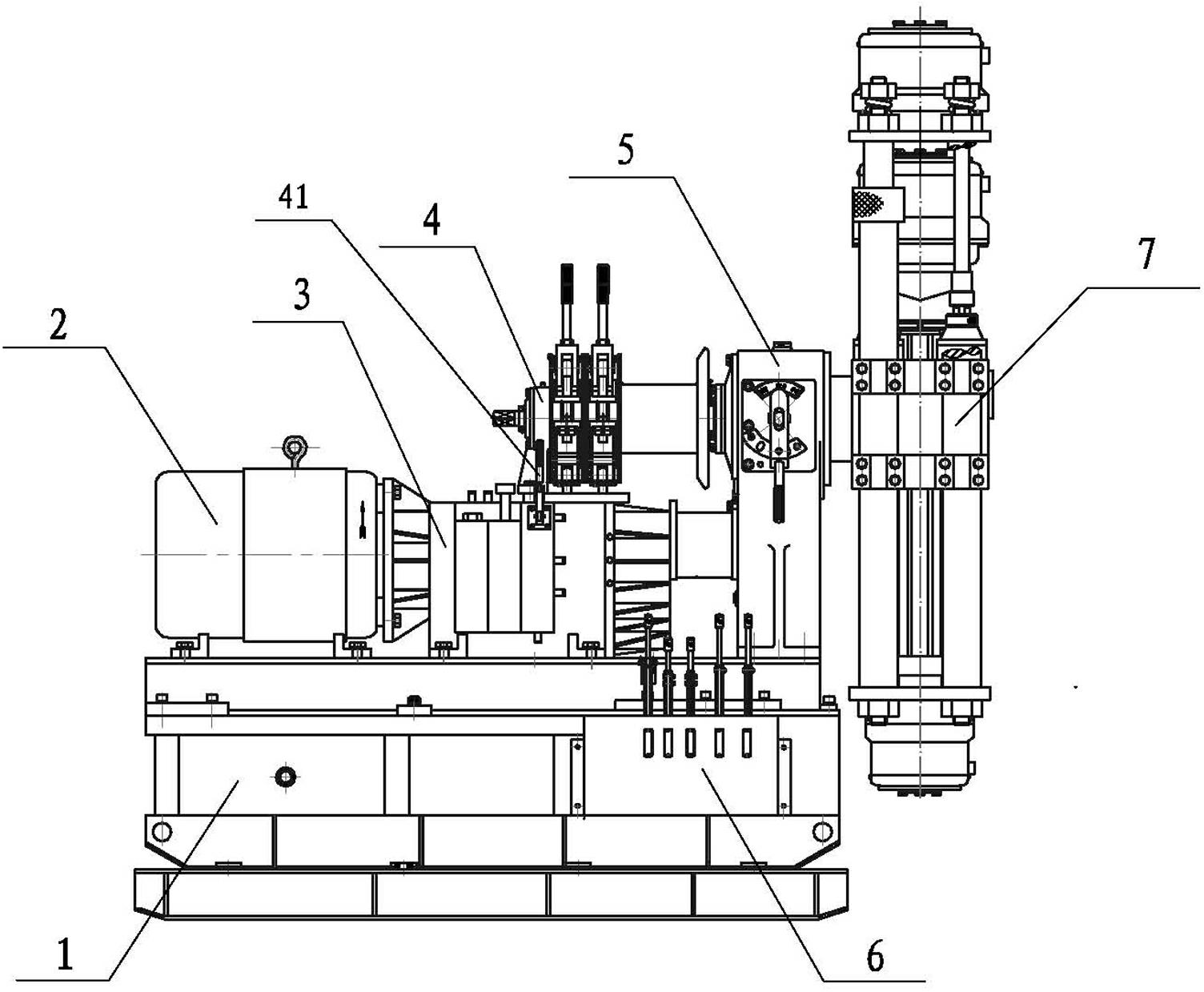

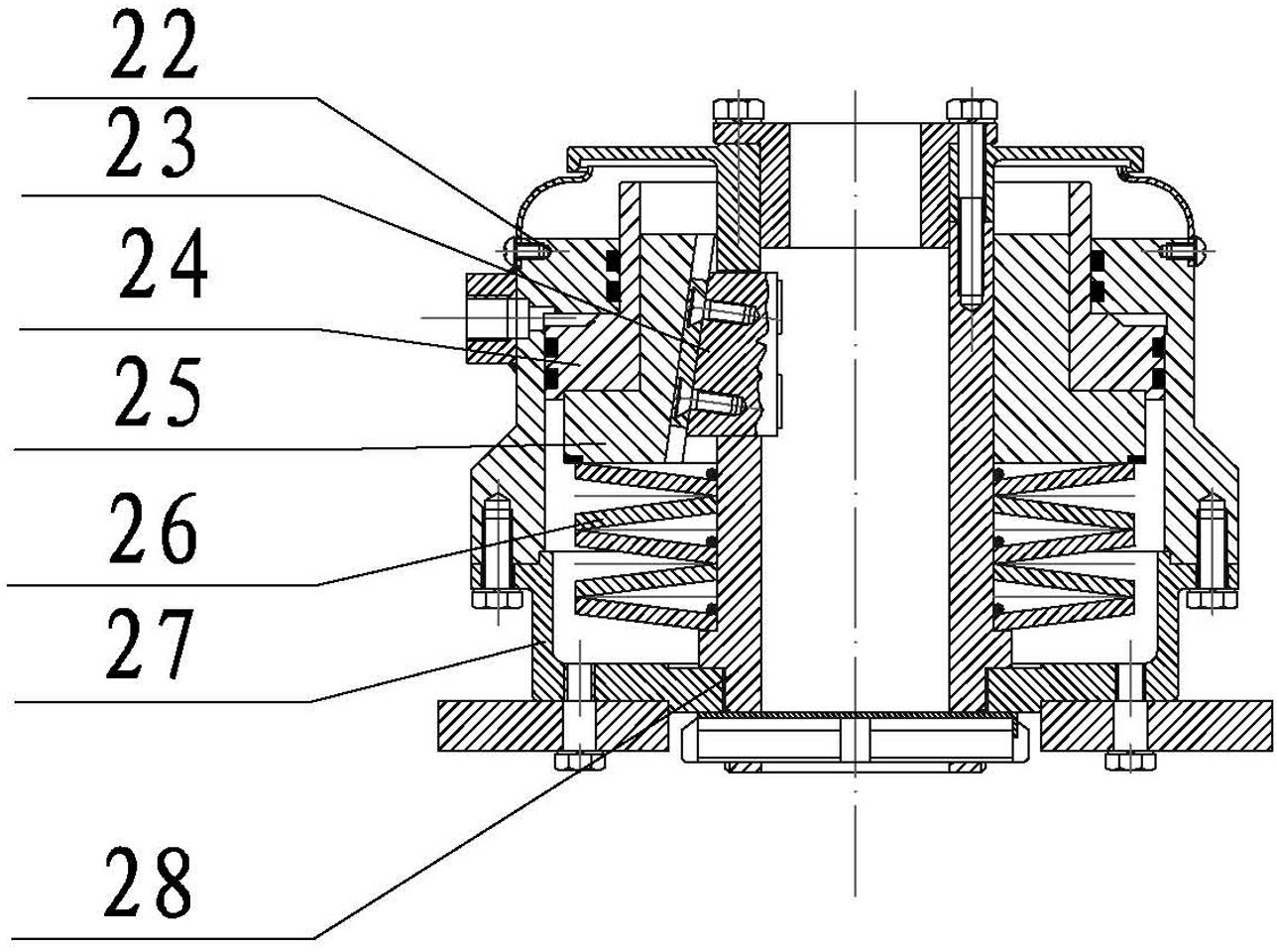

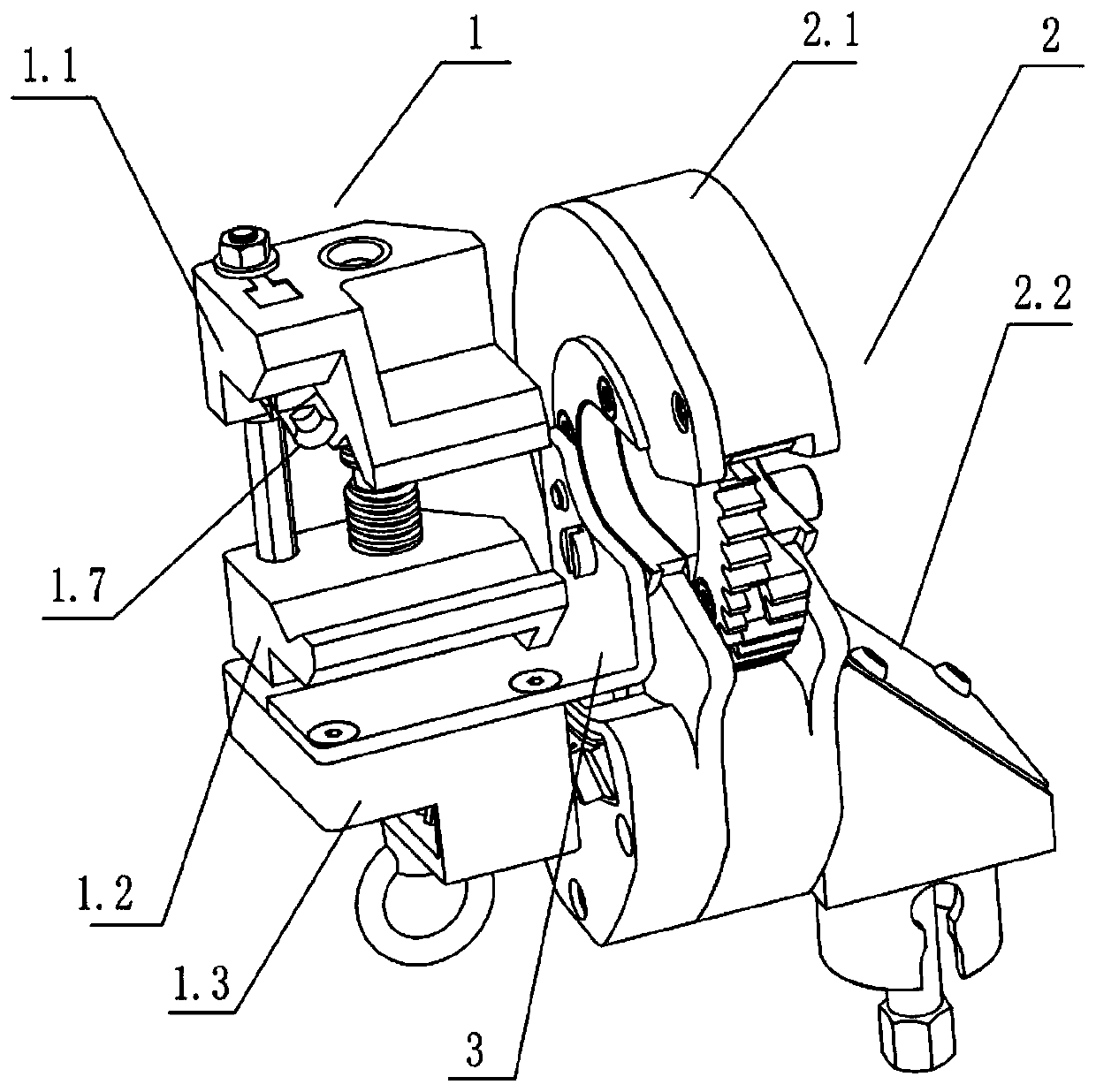

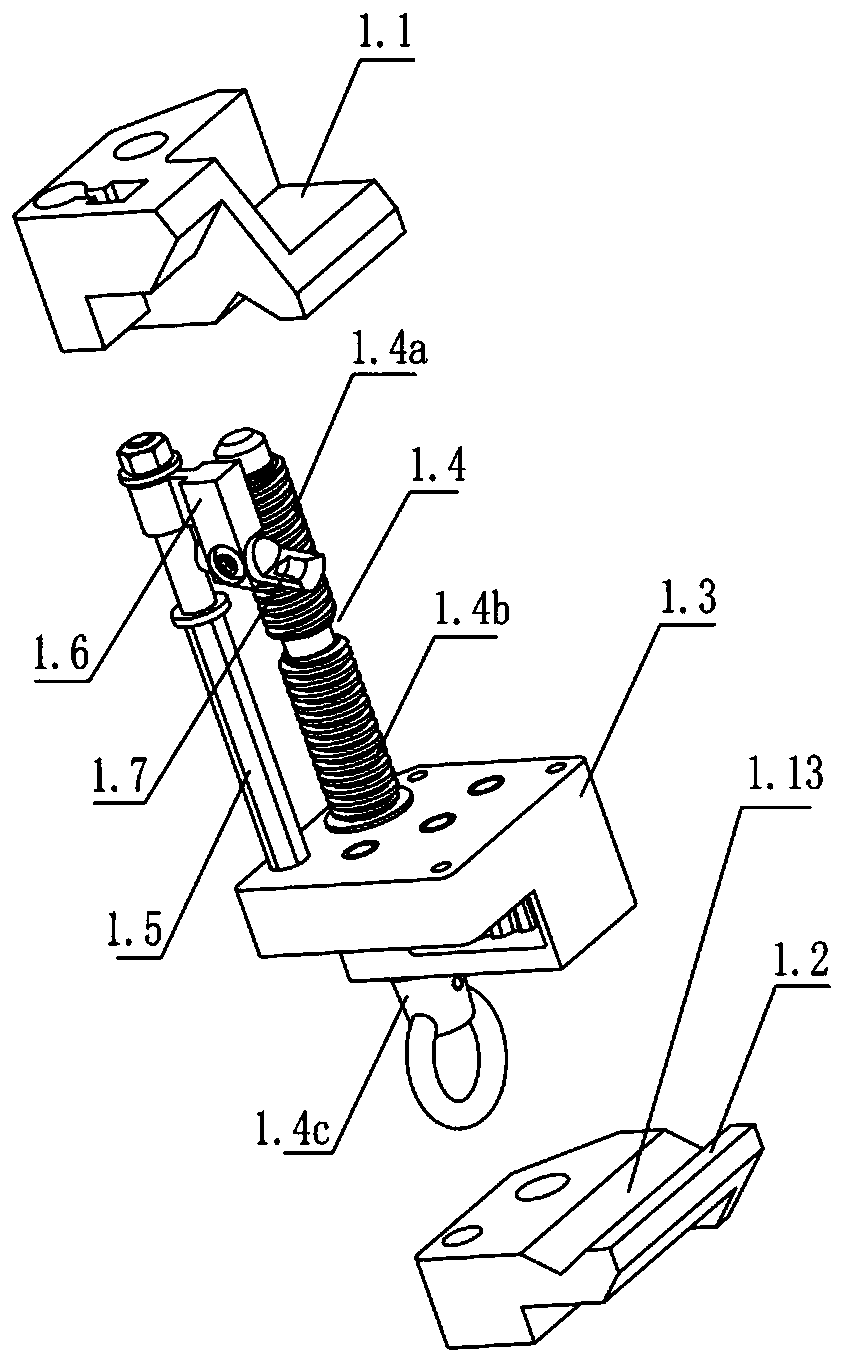

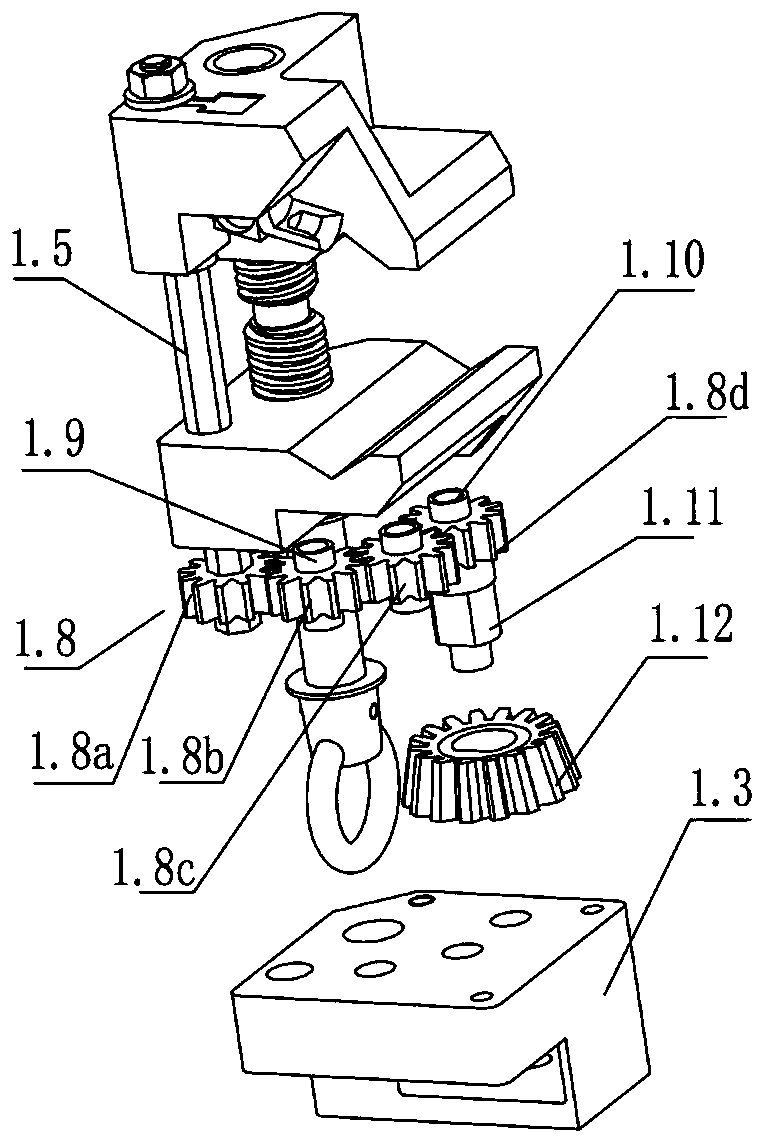

Universal rotating drilling machine

ActiveCN103046866AHeight adjustableRealize automatic adjustmentConstructionsDerricks/mastsMechanical engineeringDrilling machines

The invention discloses a universal rotating drilling machine. The universal rotating drilling machine comprises a base, an upright post, a gyrator installation base, a first driving device, a gyrator device and a main machine installation base, wherein the upright post is fixed on the base, the gyrator installation base is slidingly connected with the upright post, the first driving device is used for driving the gyrator installation base to slide up and down along the upright post, the gyrator device is arranged on the gyrator installation base and comprises a second driving device, a transmission device and a rotating disk, the transmission device is in transmission connection with the second driving device, the rotating disk is connected with the transmission device, and the main machine installation base is fixedly connected with the rotating disk. Thus, according to the universal rotating drilling machine, the adjustment range of the drilling angle of the drilling machine is large, workers are not required during adjustment of the drilling direction, and the labor intensity is low.

Owner:CHONGQING PINGSHAN MINING ELECTROMECHANICAL EQUIP

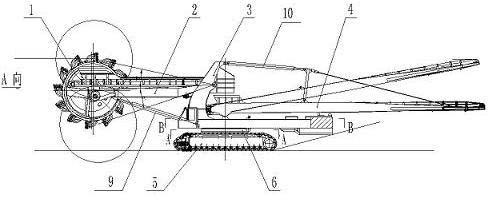

Bucket wheel excavator

The invention discloses a bucket wheel excavator which comprises a bucket wheel mechanism, a material receiving arm, an L-beam, a discharging arm (4), a walking mechanism, a large central gyrator and a small central gyrator, wherein the bucket wheel mechanism is arranged at the front end of the material receiving arm; the back end of the material receiving arm is hinged on the upper part of the L-beam; one end of the discharging arm is supported on the small central gyrator, and the other end of the discharging arm is connected to the top of the L-beam through a pull rod; the large central gyrator is arranged between the L-beam and a central frame; the small central gyrator is arranged on the central frame; the bucket wheel mechanism consists of a hydraulic motor, a bucket wheel speed reducer, a bucket wheel shaft, a bucket wheel body and a hopper; the bucket wheel shaft is arranged between two bearing seats at the front end of the material receiving arm; the bucket wheel speed reducer and the hydraulic motor are arranged at one end of the bucket wheel shaft, and the bucket wheel body is arranged at the other end of the bucket wheel shaft; and the hopper is fixed on the bucket wheel body. A power system of the entire bucket wheel excavator adopts a full-hydraulic mode, is provided with an engine, does not need to be connected with power electricity, has high yield, a wide application field, low noise and low pollution, and is free and flexible.

Owner:大连重工通用设备有限责任公司

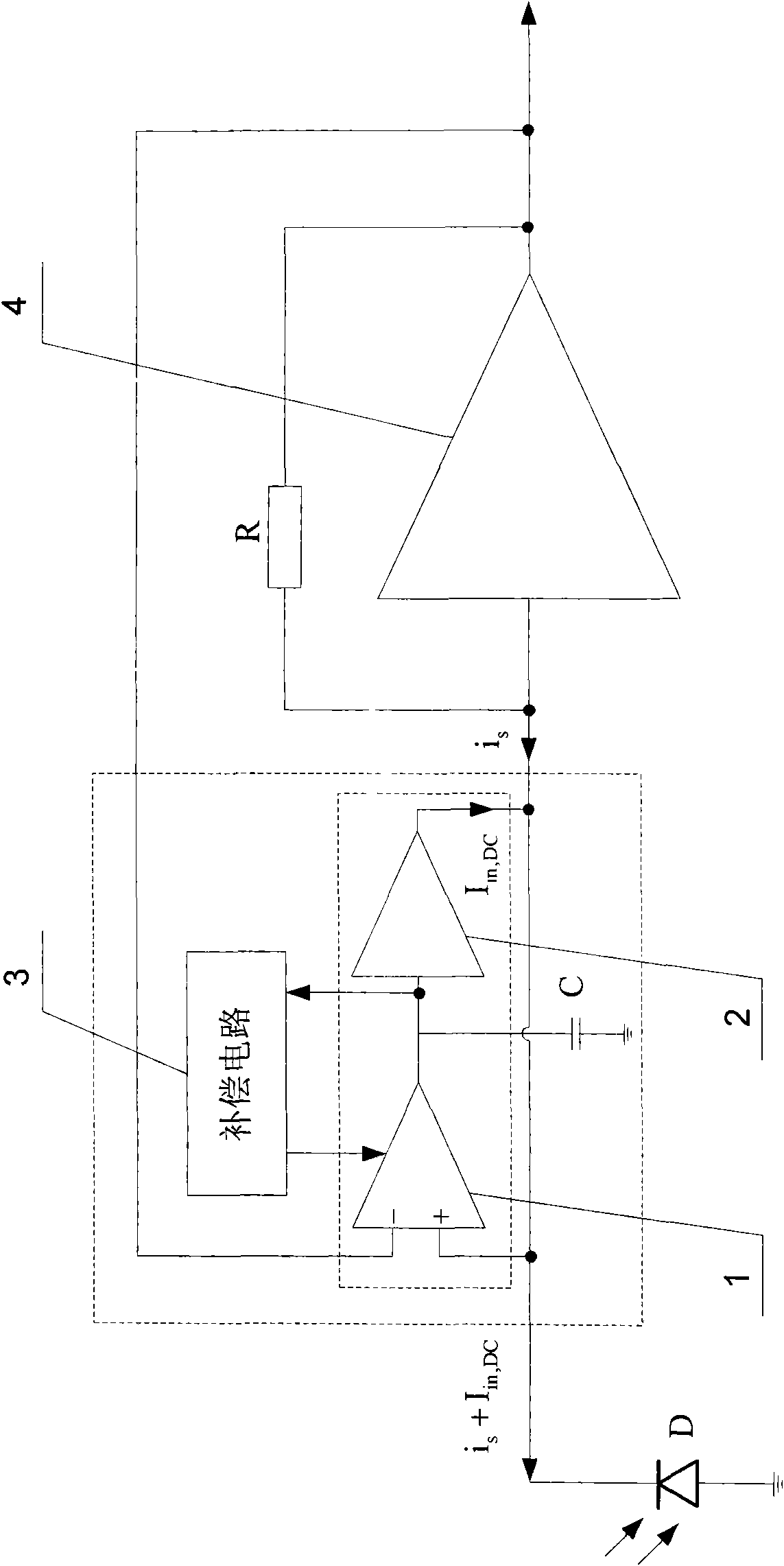

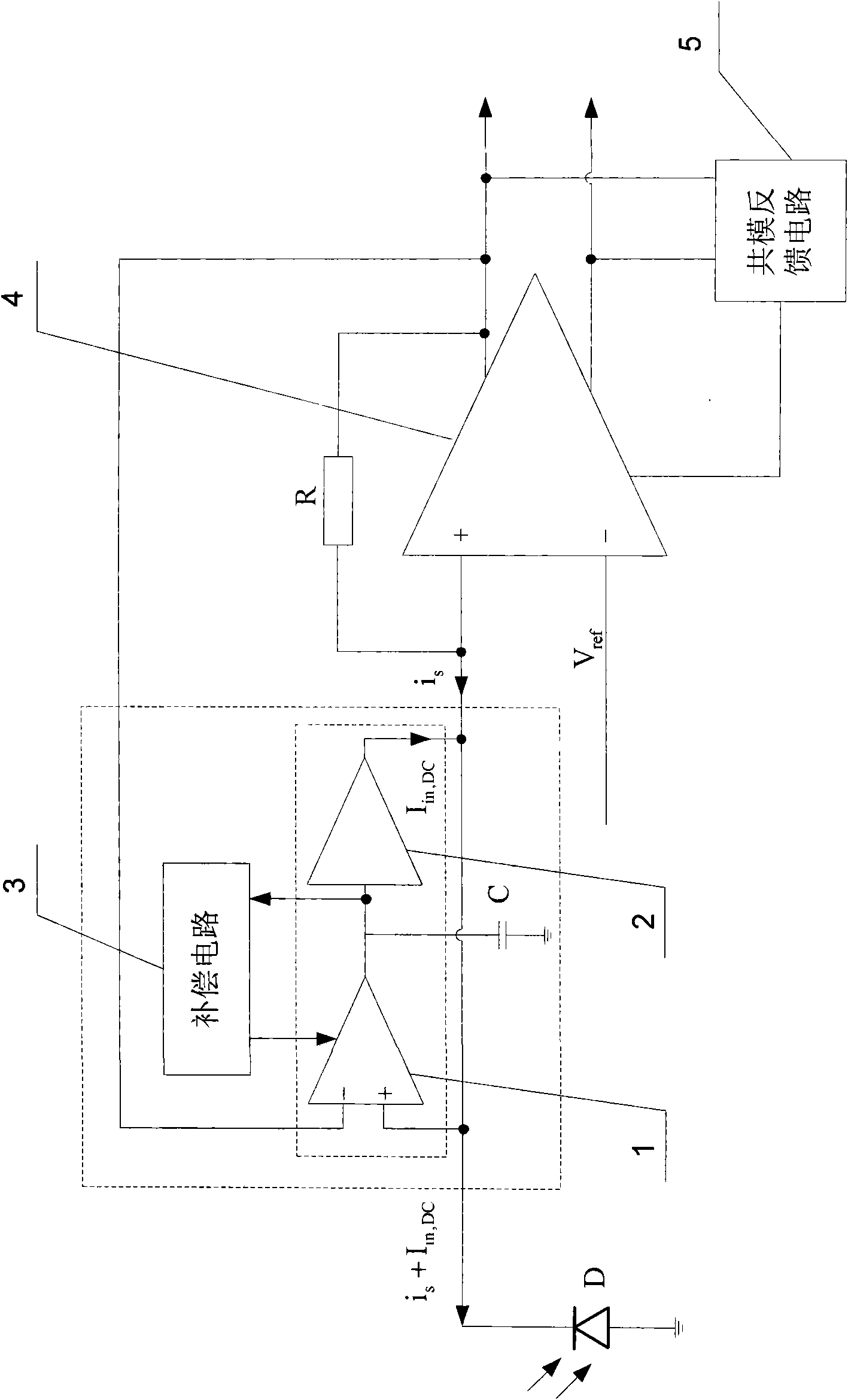

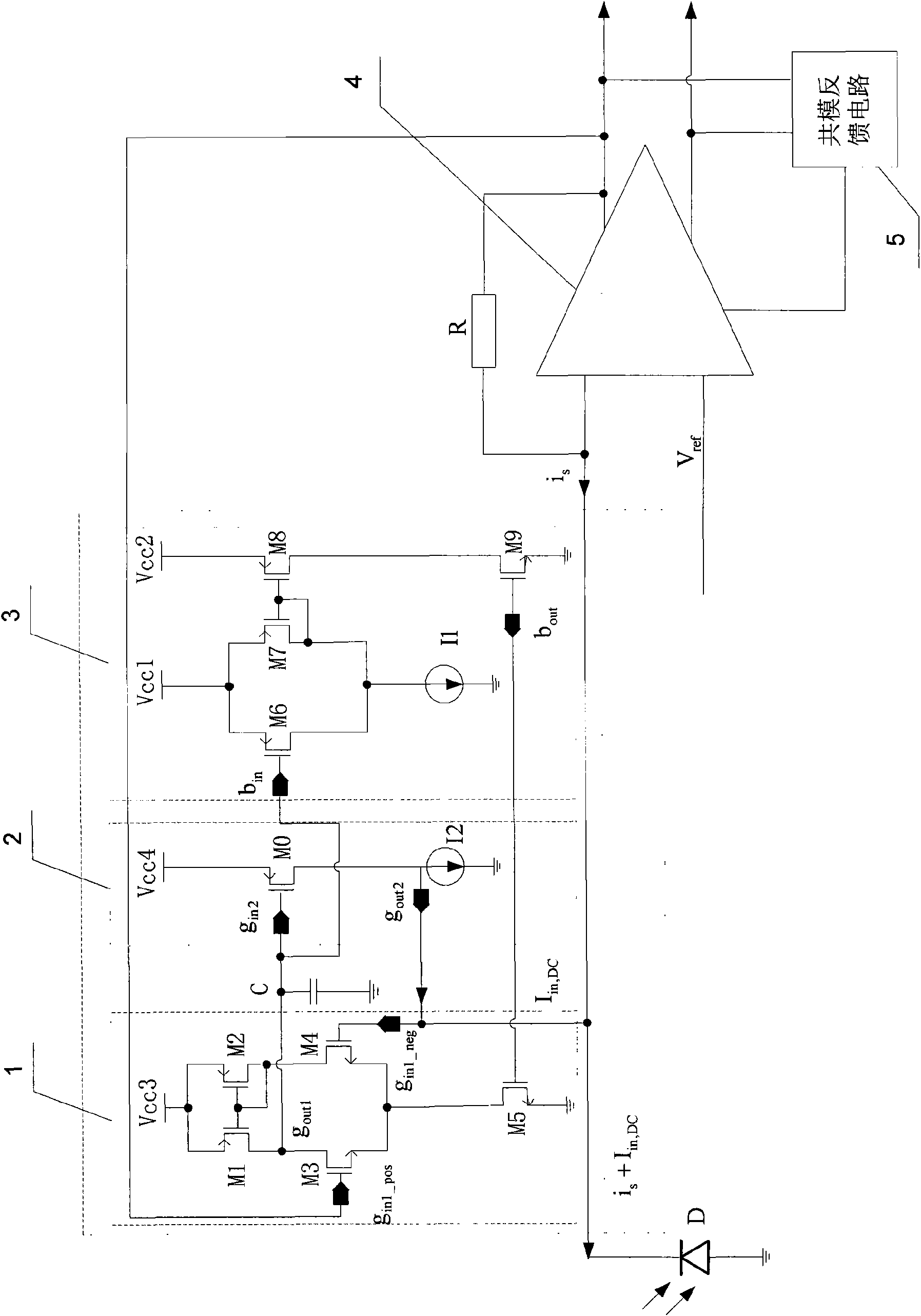

DC interference suppressor circuit used for transimpedance preamplifier of infrared receiving system

InactiveCN101552644AImprove stabilitySuppression of interfering signalsLogic circuits coupling/interface using field-effect transistorsElectromagnetic transmissionAudio power amplifierTransimpedance amplifier

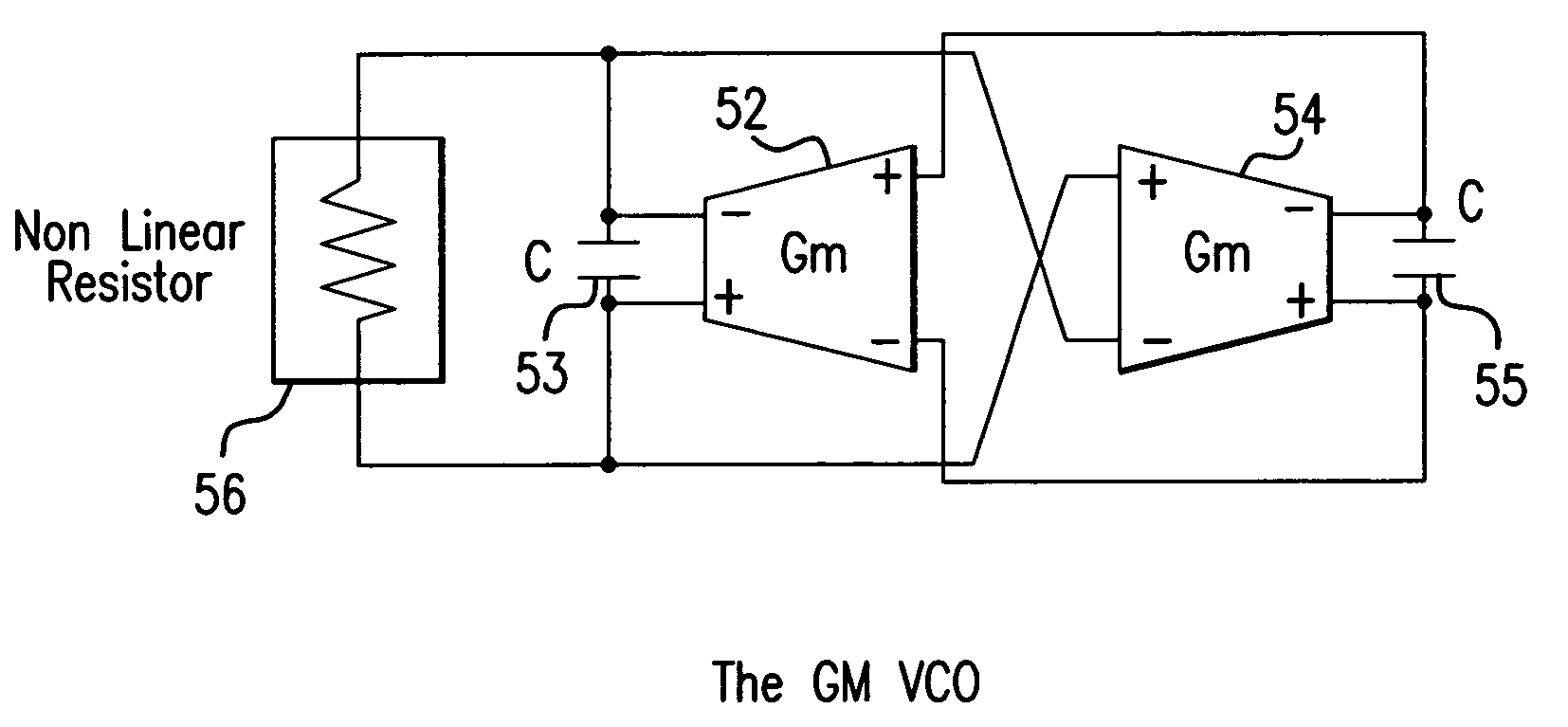

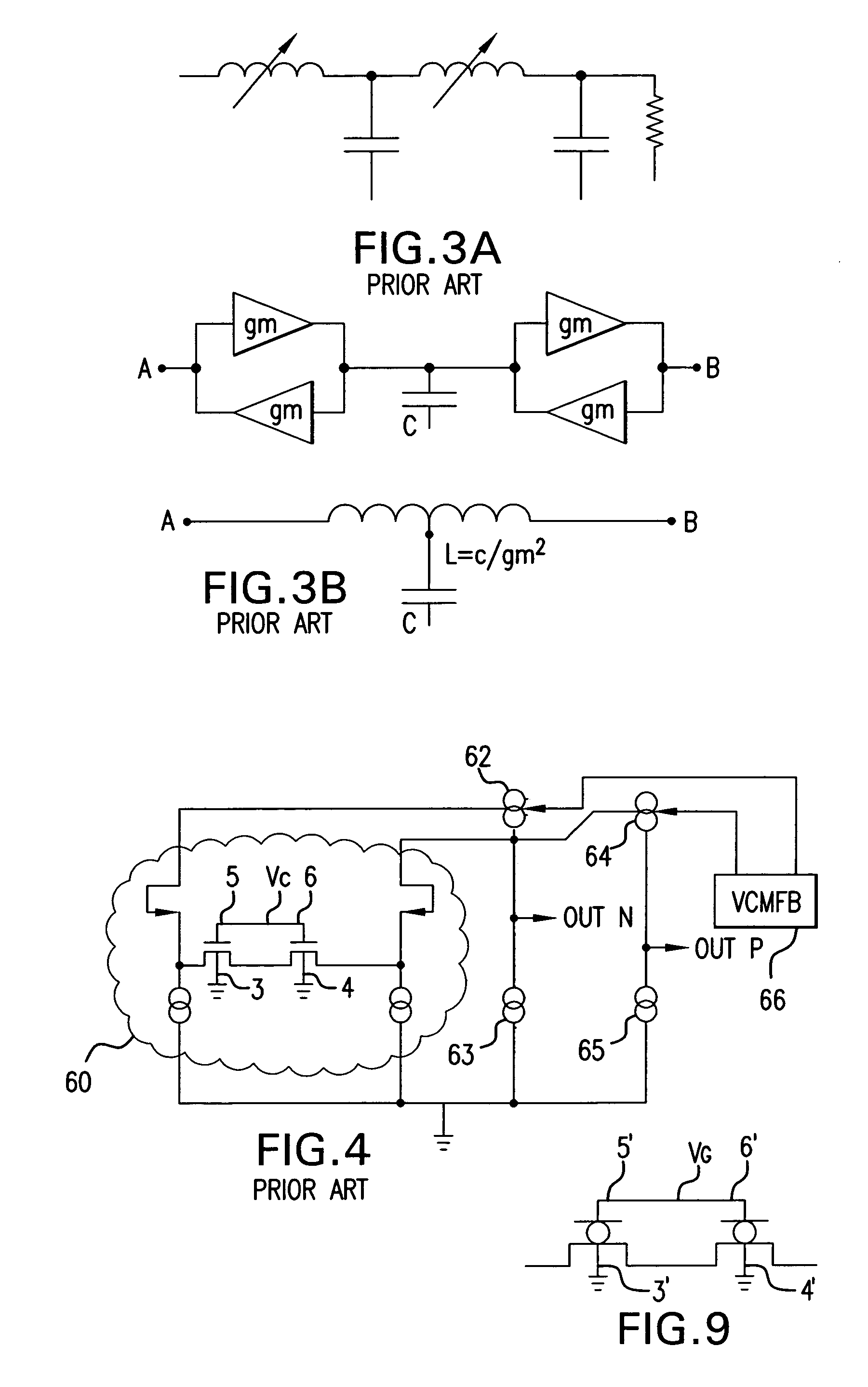

A DC interference suppressor circuit used for transimpedance preamplifier of infrared receiving system belongs to the field of circuit design. The aim of the invention is to settle a problem of inferior suppression effect of transimpedance preamplifier of infrared receiving system to DC interference. The gyrator of the invention comprises two operational transconductance amplifiers. The output end of first operational transconductance amplifier is connected with the input end of second operational transconductance amplifier. The connection point leading-out wire of two operational transconductance amplifiers is connected with one end of capacitor C. The other end of capacitor C is grounded. The connection point leading-out wire of two operational transconductance amplifiers is also connected with the input end of compensating circuit. The output end of compensating circuit is connected with a bias voltage signal input end of first operational transconductance amplifier. The output end of second operational transconductance amplifier is connected with the non-inverting input end of first operational transconductance amplifier and is taken as one end of DC interference suppressor circuit. The non-inverting input end of first operational transconductance amplifier is taken as the other end of DC interference suppressor circuit.

Owner:HARBIN INST OF TECH

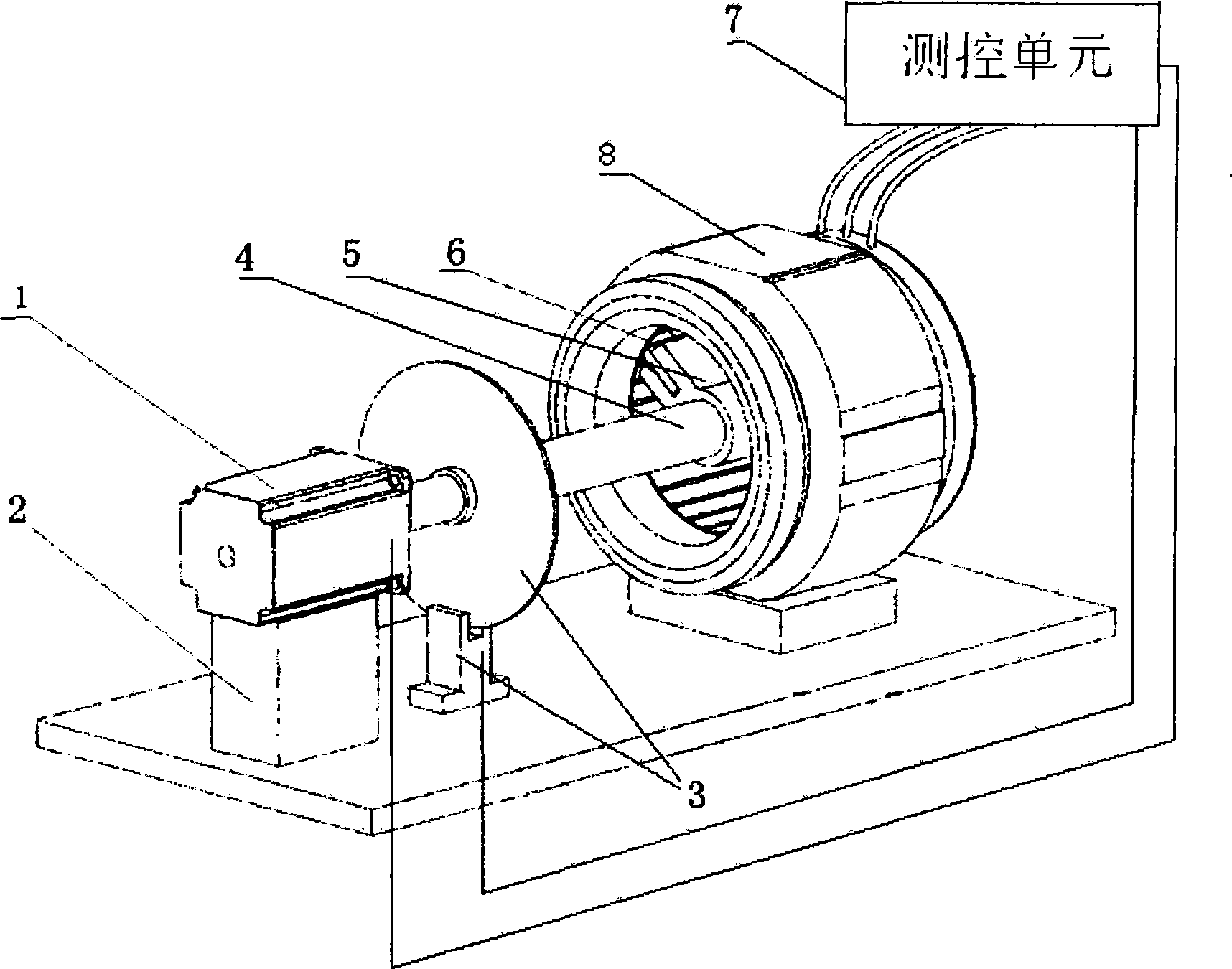

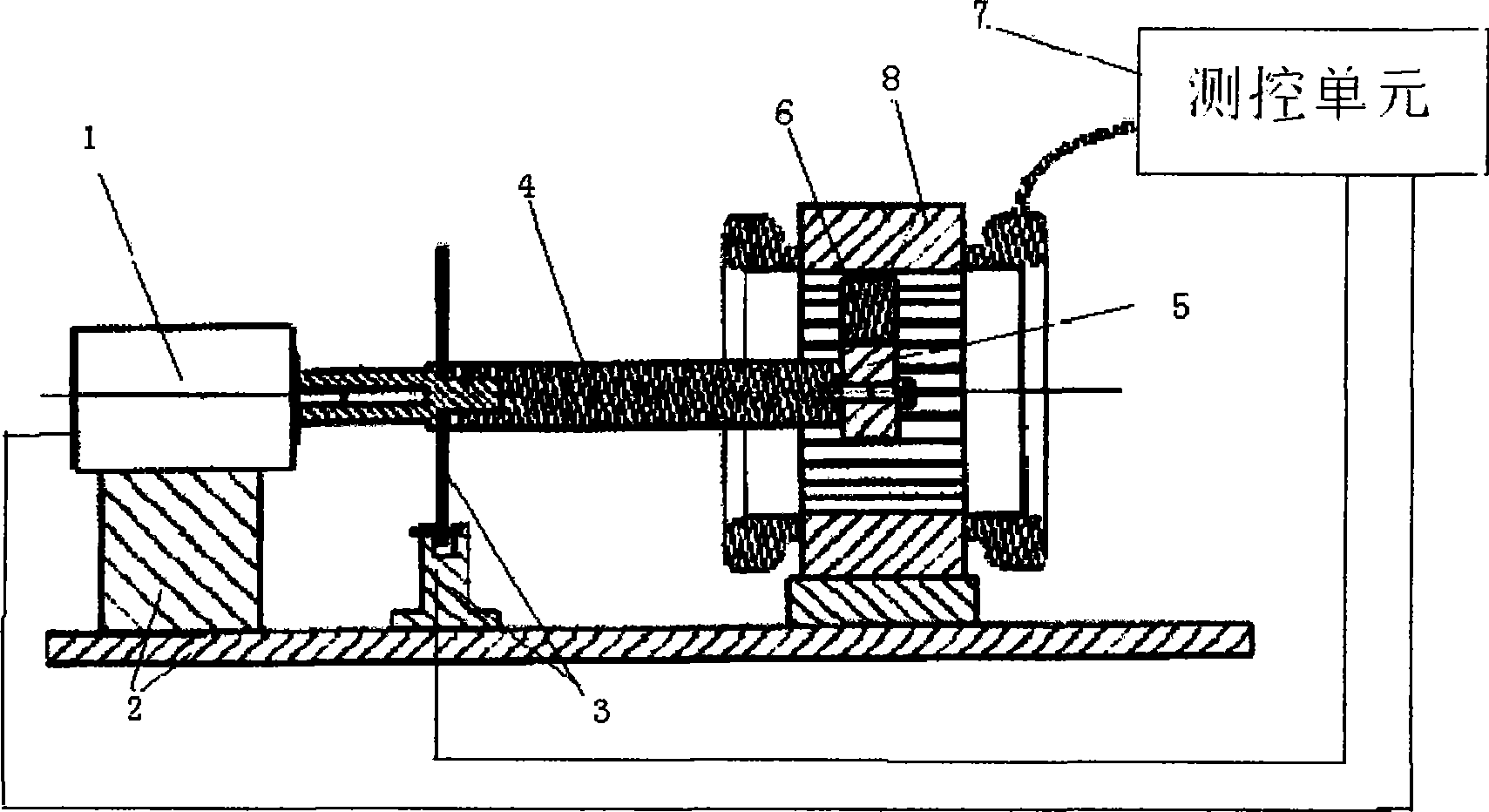

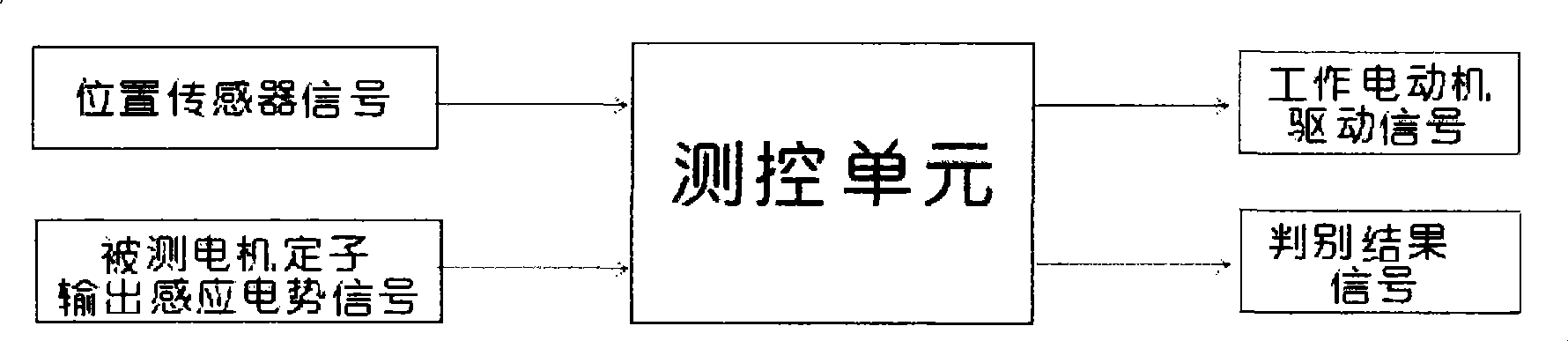

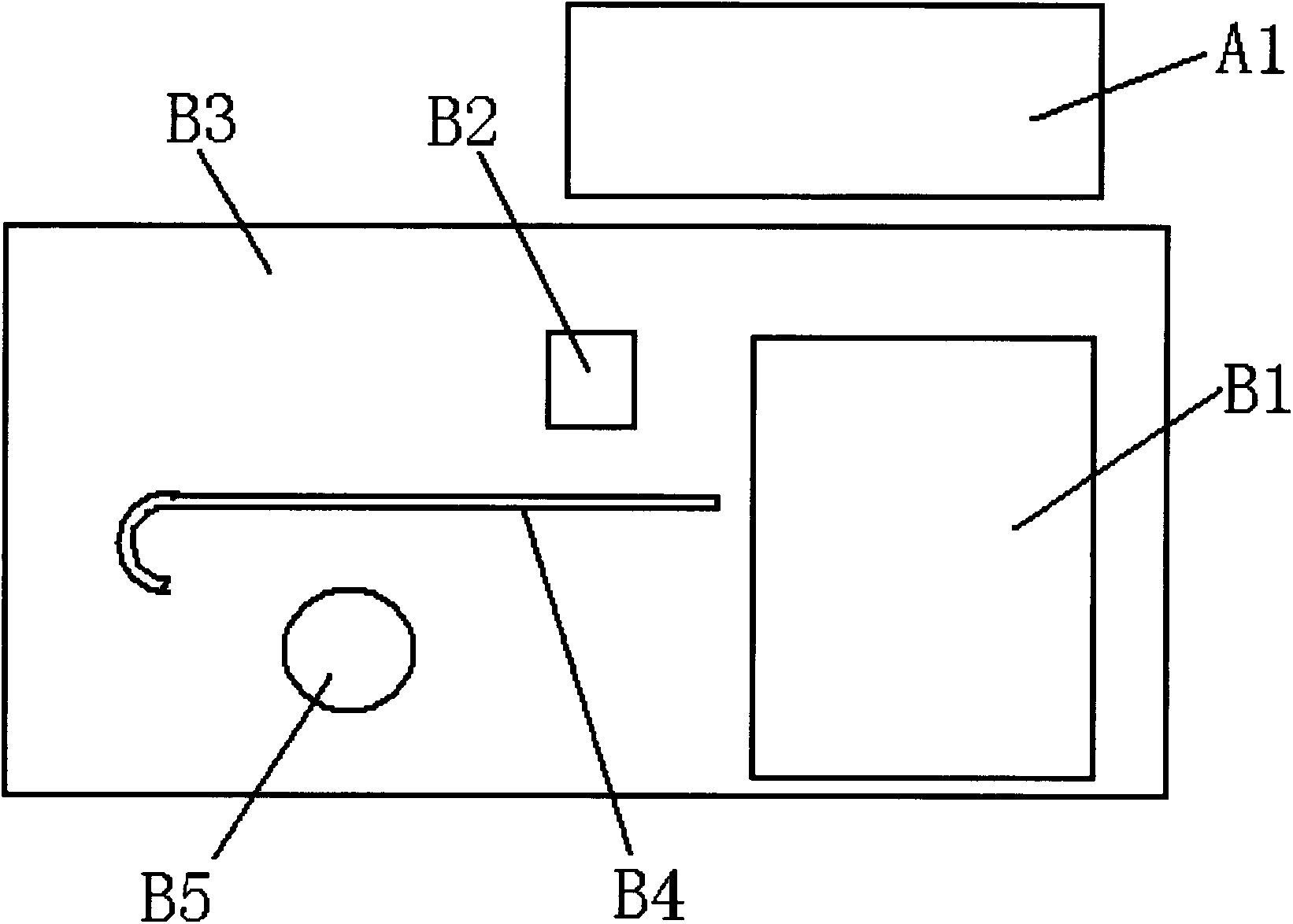

Electric motor stator scanning detection apparatus

ActiveCN101369003AQualityUsing electrical meansDynamo-electric machine testingLocation detectionElectric machine

The invention relates to a scan detection device for a motor stator, which uses a working motor to drive a detecting magnet to rotate and scan along the near surface of the motor stator being detected, and the magnetic flux variety of the detected motor stator generated by the rotation and canning makes the detected motor stator to generate induced electromotive force, and the quality of the detected stator can be determined through detecting the circumferential induced electromotive force distribution curve of the detected stator by a measurement control unit and comparing with the circumferential induced electromotive force distribution curve of the qualified stator with the same size. A realization method of the invention is as follows: the device is composed of a working motor, a fixing bracket, a position sensor, a coupling spindle, a gyrator body, the detecting magnet and the measurement control unit. The position sensor is divided into two parts of a moving component and a position detecting component, and two components are respectively fixed on a rotating shaft or the coupling spindle of the working motor and on the fixing bracket. The gyrator body is fixed on the rotating shaft or the coupling spindle of the working motor, and the detecting magnet is fixed on the gyrator body and near the surface of the detected motor stator. The detecting device not only can detect the malfunction of the stator, but also can indicate which position or azimuth has quality problem around the circumference of the stator.

Owner:SHANGHAI AOBOOR ELECTRONICS

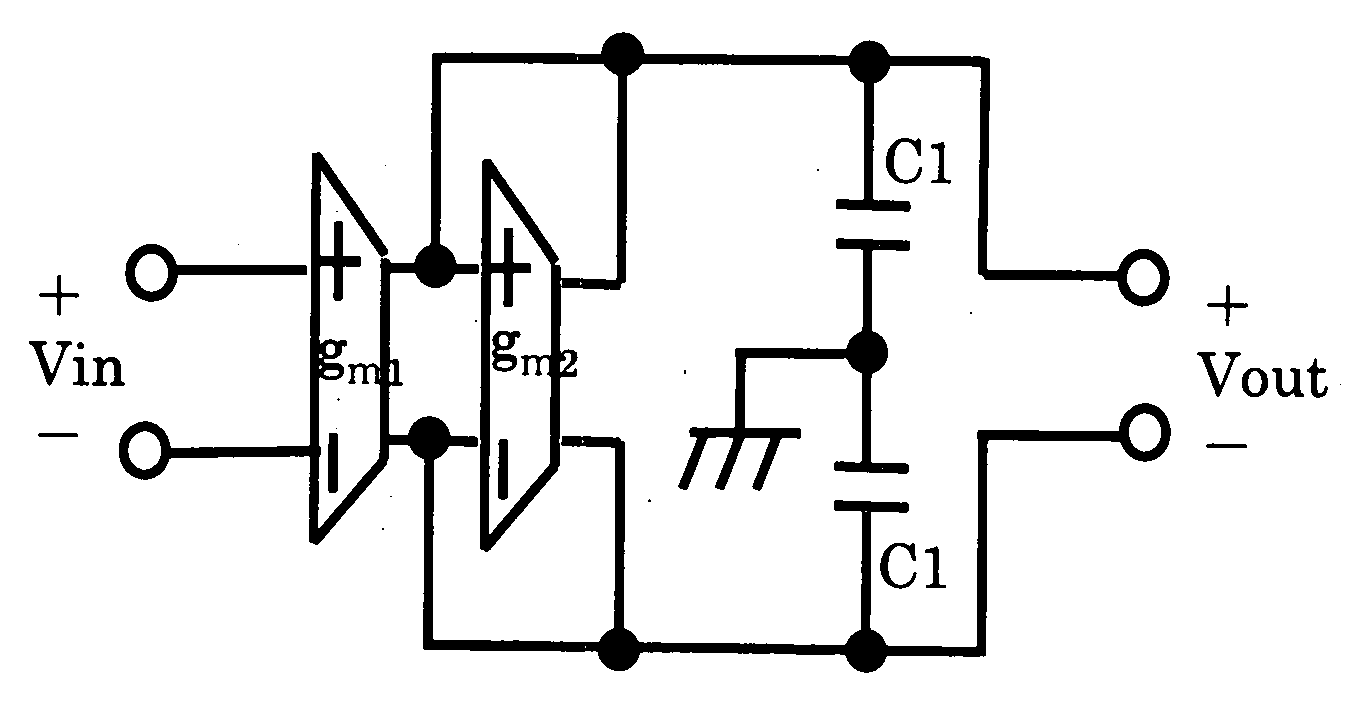

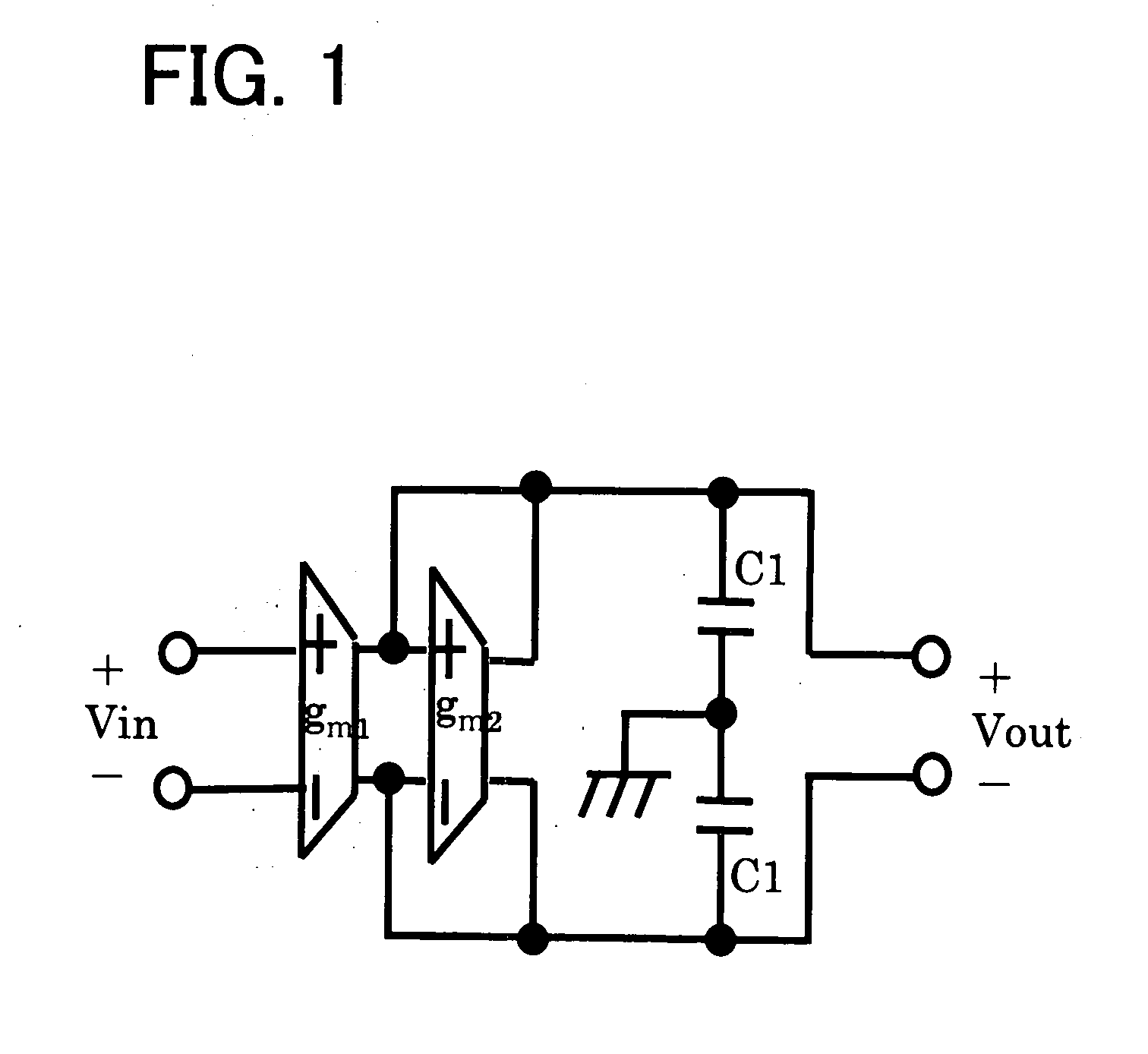

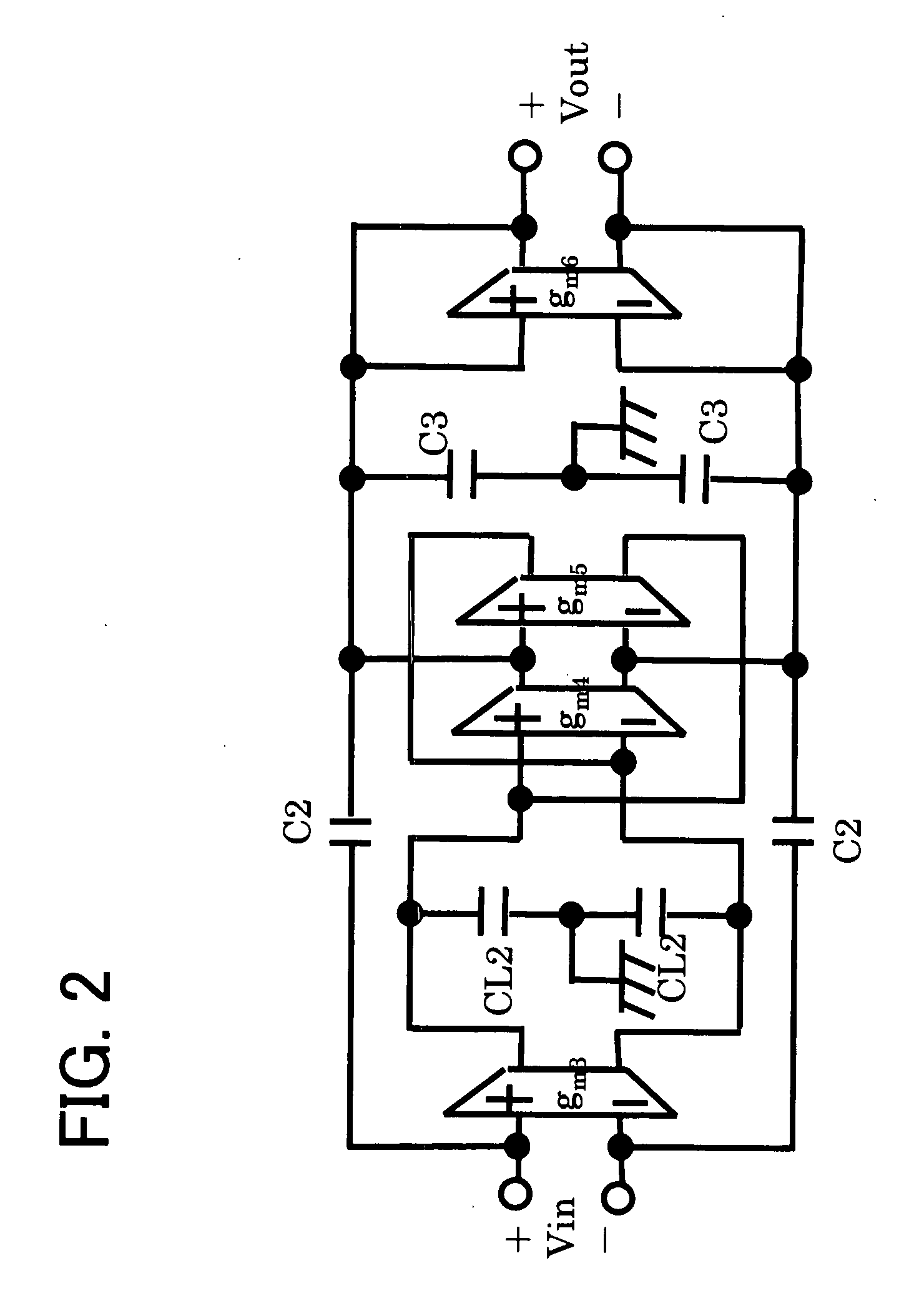

Complex filter circuit

InactiveUS20070182480A1Reduced characteristicsTotal current dropOscillations generatorsTransmissionCapacitanceUltrasound attenuation

Disclosed is a complex elliptic filter having an order of three or higher which receives two differential signals that differ in phase from each other by 90 degrees are applied and outputs two differential signals that differ in phase from each other by 90 degrees. The complex filter circuit has internally at least two circuit blocks that include a capacitor connected in series with a coupler (gyrator). The complex filter is a third-order inverse Chebychev filter having an equiripple stopband of 40-dB attenuation amount. Alternatively, the coupler (gyrator) between elliptic capacitors is removed. Alternatively, the elliptic capacitors are made substantially equal to the capacitor arranged in parallel therewith. Alternatively, the gm value of an OTA and the capacitance value are each in an integral ratio represented substantially by a geometric progression of 2.

Owner:NEC ELECTRONICS CORP

Gyrator with loop amplifiers connected to inductive elements

InactiveUS6025765AImprove phase noiseLarge oscillationImpedence convertorsNetwork simulating reactancesCapacitanceGyroscope

A gyrator includes shunt or feedback nodal capacitors and shunt lossy inductors without shunt load resistors. The effective nodal capacitance is reduced by the introduction of the shunt lossy inductors. The inductors act to discriminate against injected power supply noise, resulting in improved oscillator phase noise. The inductors produces less drop dc voltage than the resistive load, so that larger linear oscillation is obtained with improved oscillator phase noise.

Owner:NORTEL NETWORKS LTD

Unique code printing screening industrial fool-proofing device and printing method thereof

ActiveCN103963483APut an end to the trouble of human errorRealize automatic fool-proof functionTypewritersOther printing apparatusBarcodeEngineering

The invention provides a unique code printing screening industrial fool-proofing device which comprises an upper computer and an equipment cabinet internally provided with a barcode printer, a fixed type scanner and a label gyrator. The invention further provides a barcode label printing method of the unique code printing screening industrial fool-proofing device. In the industrial application of the unique code printing screening industrial fool-proofing device and the printing method thereof, the functions of generating, printing and verifying of unique codes are integrated, the trouble of errors caused by human factors is eliminated fundamentally, and the full automatic fool-proofing function is achieved. For all the labels printed by the printer, the unique fool-proofing feature of the labels can be screened in time after the labels are printed. If omissions and errors occur in the printing process, records are available for checking. The integration of functions from printing to screening is achieved, and the complexity of implementation is lowered. Full automation from the generating to the printing of the barcodes and then to the finished products through screening is achieved, and manual operation is completely avoided. Furthermore, after the printing is interrupted, printing is performed after the memory of the cache of the printer is cleared, a next printing instruction is directly jumped to, and code repetition is avoided.

Owner:SUZHOU BYCODELABEL INFORMATION TECH CO LTD

Three-dimensional vector vertebra recovery device

InactiveCN101292924AAvoid fracturesAvoid spinal misalignmentNon-surgical orthopedic devicesButtocksEngineering

A three-dimensional vector spine rehabilitation device comprises a pedestal with a lift pole, an abdomen section which is fixedly arranged at the left upper side of the lift pole, a buttocks section which is fixedly arranged at the right upper side of the lift pole, a head section which is connected with the abdomen section, a plurality of soft mattresses and an oxter rod. The buttocks section comprises a clutch device which is fixed at one side of the lift pole, a buttocks section support frame which is articulated with the lift pole and can rotate towards the lateral side and a gyrator which is articulated at the pedestal and can ensure the buttocks section support frame swinging up and down. The clutch device comprises a long tooth row, a short tooth row and an interacting rod which is arranged correspondingly to the tooth rows. Two end sides of the interacting rod are designed as handle rods. The buttocks section support frame is provided with a head section support frame of the head section which is corresponding to the handle rods of the interacting rod, and one side of the head section support frame is provided with the handle rod. The present invention adopts the interacting rod at the buttocks section to rotate correspondingly under the buttocks section support frame to cause the buttocks section support frame to make the lateral rotation movement at the left or at the right correspondingly to the lift pole, and the gyrator is used for swinging the buttocks section to be lifted vertically, so as to pull the spine synchronously.

Owner:高福懋

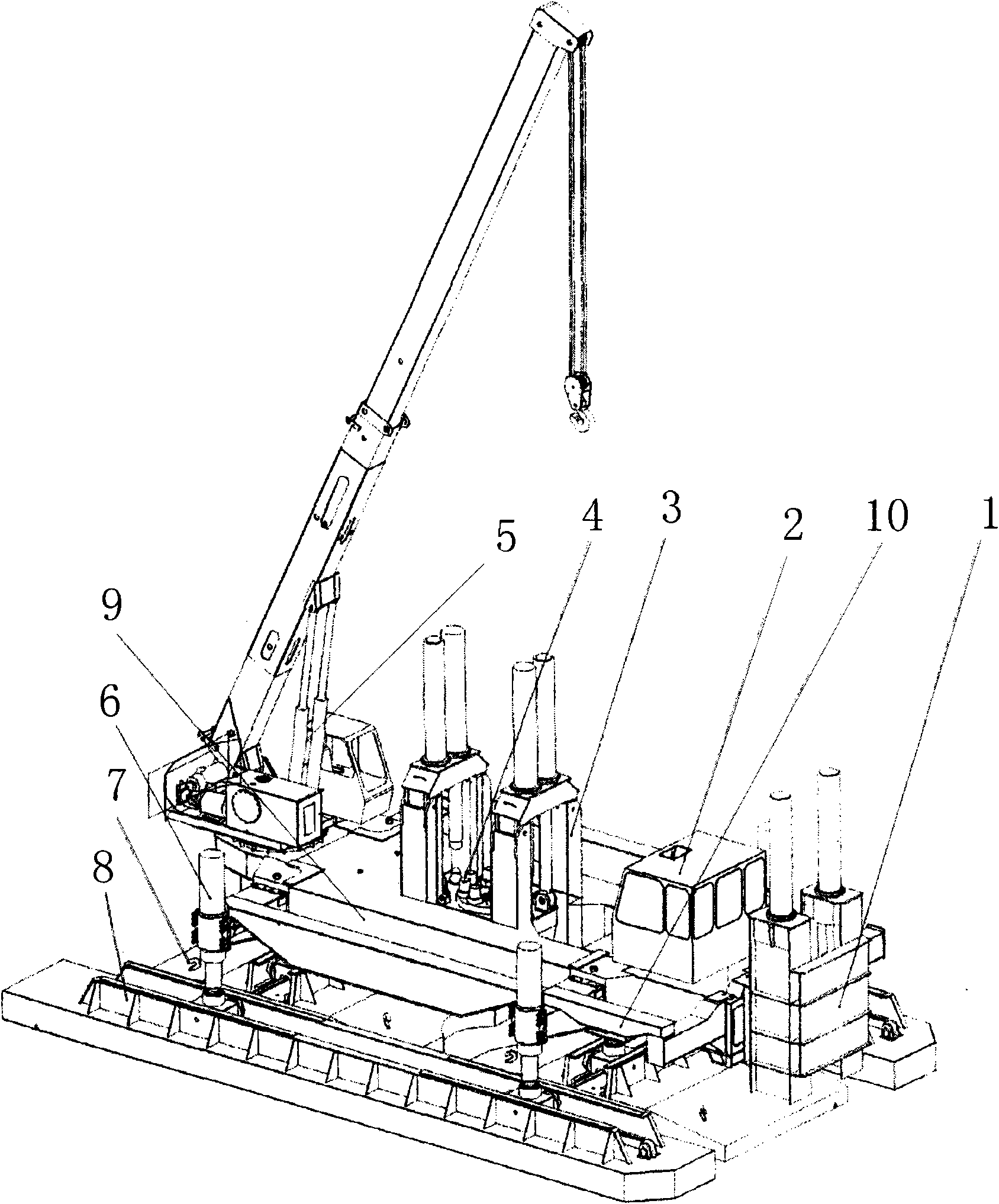

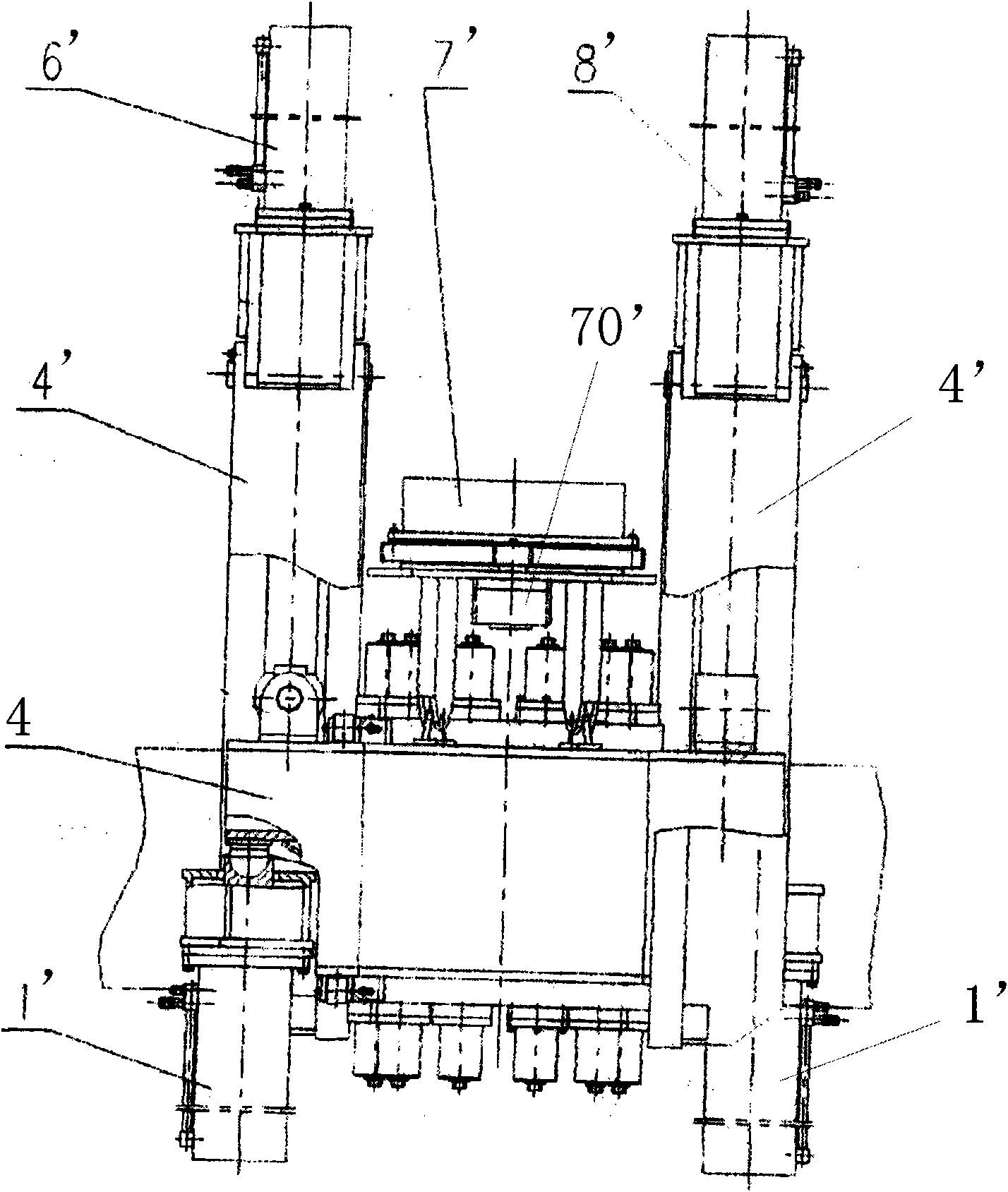

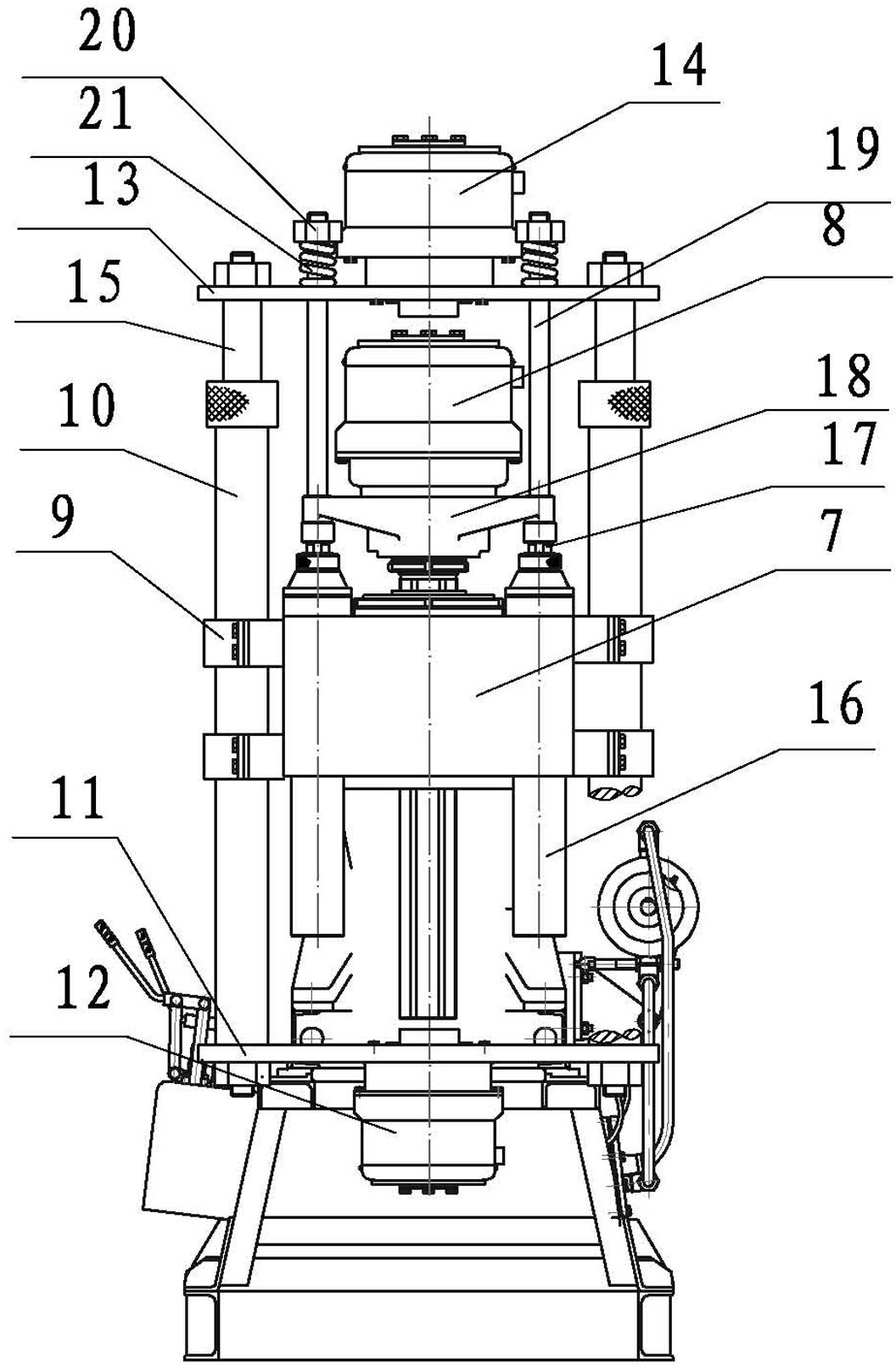

Holding type major diameter static pressure sinking pipe cast-in-place pile construction method and pile-pressing machine thereof

InactiveCN101586337AImprove construction qualityReduce noiseBulkheads/pilesSteel barHigh frequency vibration

The invention provides a holding type major diameter static pressure sinking pipe cast-in-place pile construction method, which comprises the steps of: A, measuring and positioning; B, moving the pile-pressing machine in situ; C, moving the pile shoe in situ; D, lifting the steel sleeved pile pipe; E, checking the centering of the steel sleeved pile pipe; F, pressing the pipe; G, jointing the pipe; H, pressing the pipe again; I, stopping pressing the pipe; J, placing a steel bar cage; K, placing concrete; L, drawing the pipe out. The invention further provides a pile-pressing machine, which has a body composed of a walking mechanism, a crane, a counterweight structure and a frame. The pile-pressing machine is characterized in that: a pile-pressing bench is disposed on the frame; the pile-pressing bench comprises a pile-pressing upright column, a main pile-pressing cylinder, an accessory pile-pressing cylinder, a hydraulic gyrator, and a pile clamping box; pile clamping cylinders are transversely disposed on the pile clamping box; and a driving sleeve is disposed on the vertical through hole of the hydraulic gyrator. The invention utilizes the advantages of low noise and high frequency vibration of static pile-pressing construction process, and fully plays the advantages of high bearing capacity and stable construction quality of major diameter sinking pipe cast-in-place pile.

Owner:洪子云

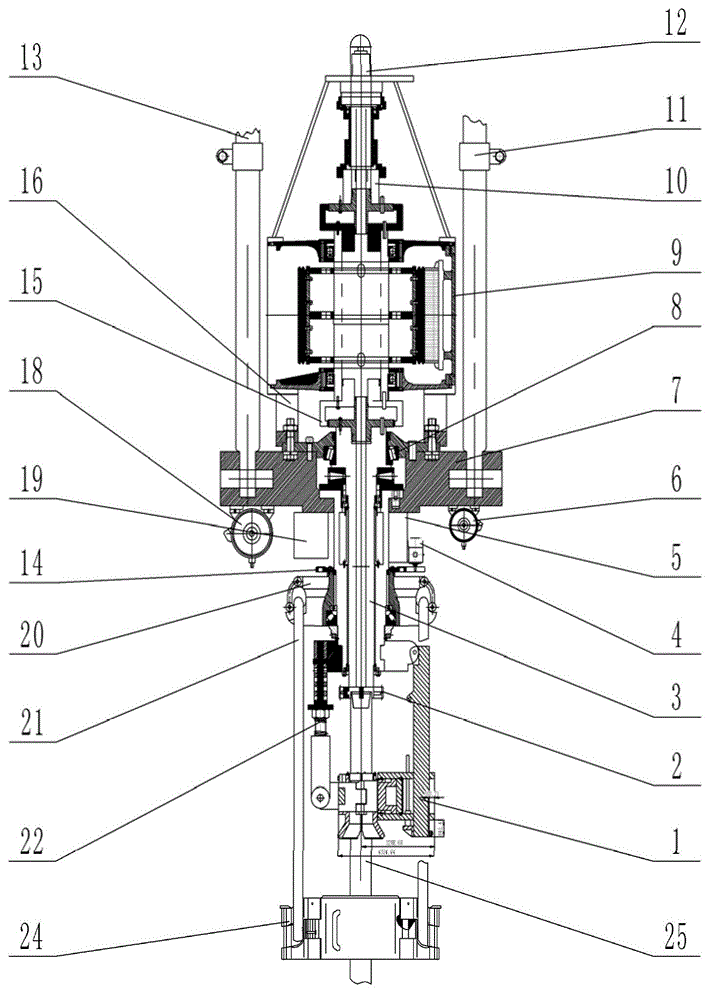

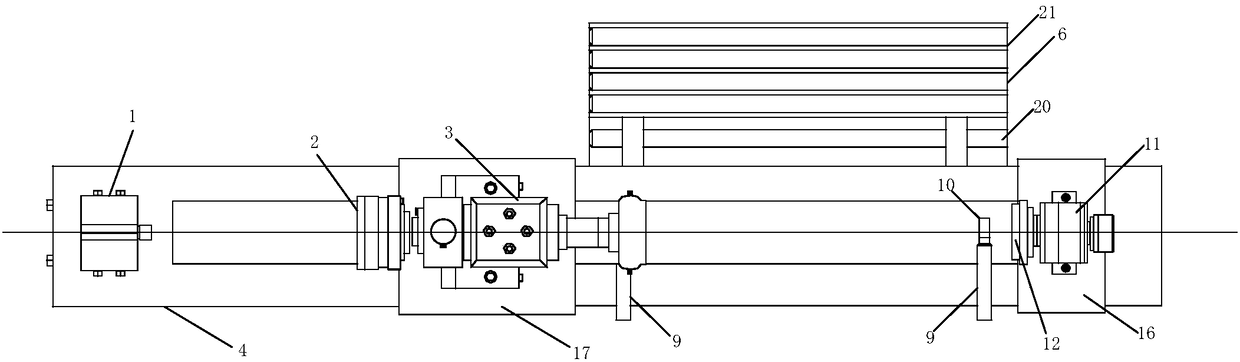

Deep-hole geological prospecting drill

InactiveCN102943617APrevent bouncy ridesReduce pollutionDrilling rodsConstructionsFrequency conversionPermanent magnet synchronous motor

The invention relates to a deep-hole geological prospecting drill which comprises a frequency conversion permanent magnet synchronous motor, a bearing box, a hydraulic oil box, a gyrator, a rotary motor, a water faucet for slurry circulation, a back-up wrench for moving or fixing a drilling rod, and a lifting ring, wherein a center shaft of the frequency conversion permanent magnet synchronous motor is a hollow shaft, the hollow shaft of the motor is communicated with the water faucet, a hollow shaft of the bearing box extends downwards to form the bearing box, a bearing is arranged on the annular outer side of the hollow shaft of the bearing box and is connected with the bearing box, the gyrator is arranged on the bearing extending out of the bearing box in a sleeving manner, a hollow shaft of the drilling rod is communicated with the hollow shaft of the bearing box, and one end of the lifting handle is connected with the two sides of the bearing box. According to the invention, as the frequency conversion permanent magnet synchronous motor is used to directly drive the drilling rod to rotate, a gear reduction box is not needed, the maintenance cost for daily use is reduced, the transmission efficiency is improved, the energy utilization rate is increased, the energy consumption and the carbon emission are reduced, and the pollution to the environment is also reduced.

Owner:BEIJING INST OF EXPLORATION ENG

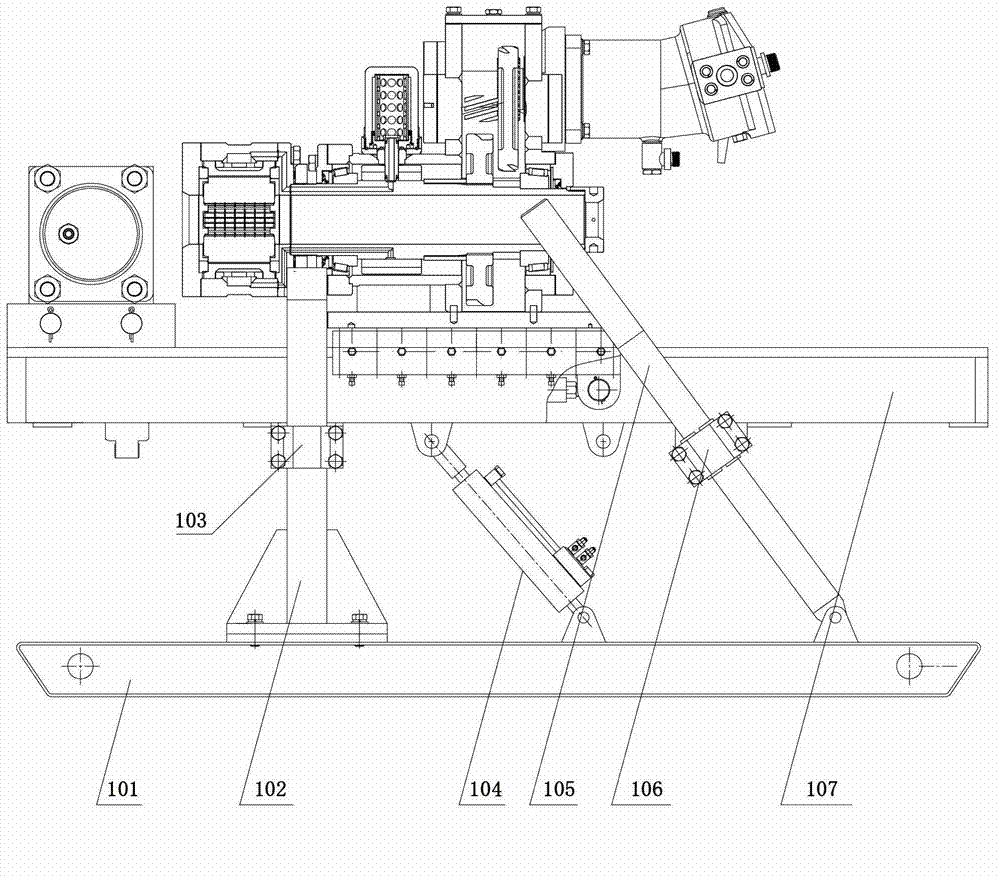

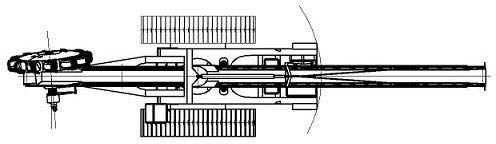

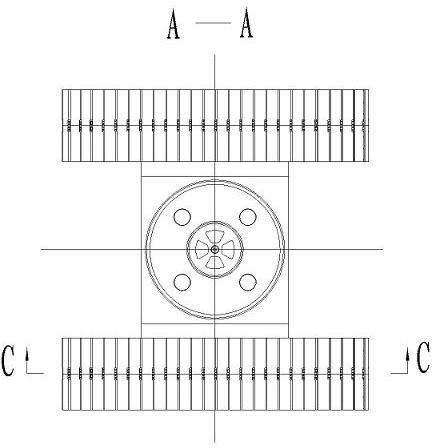

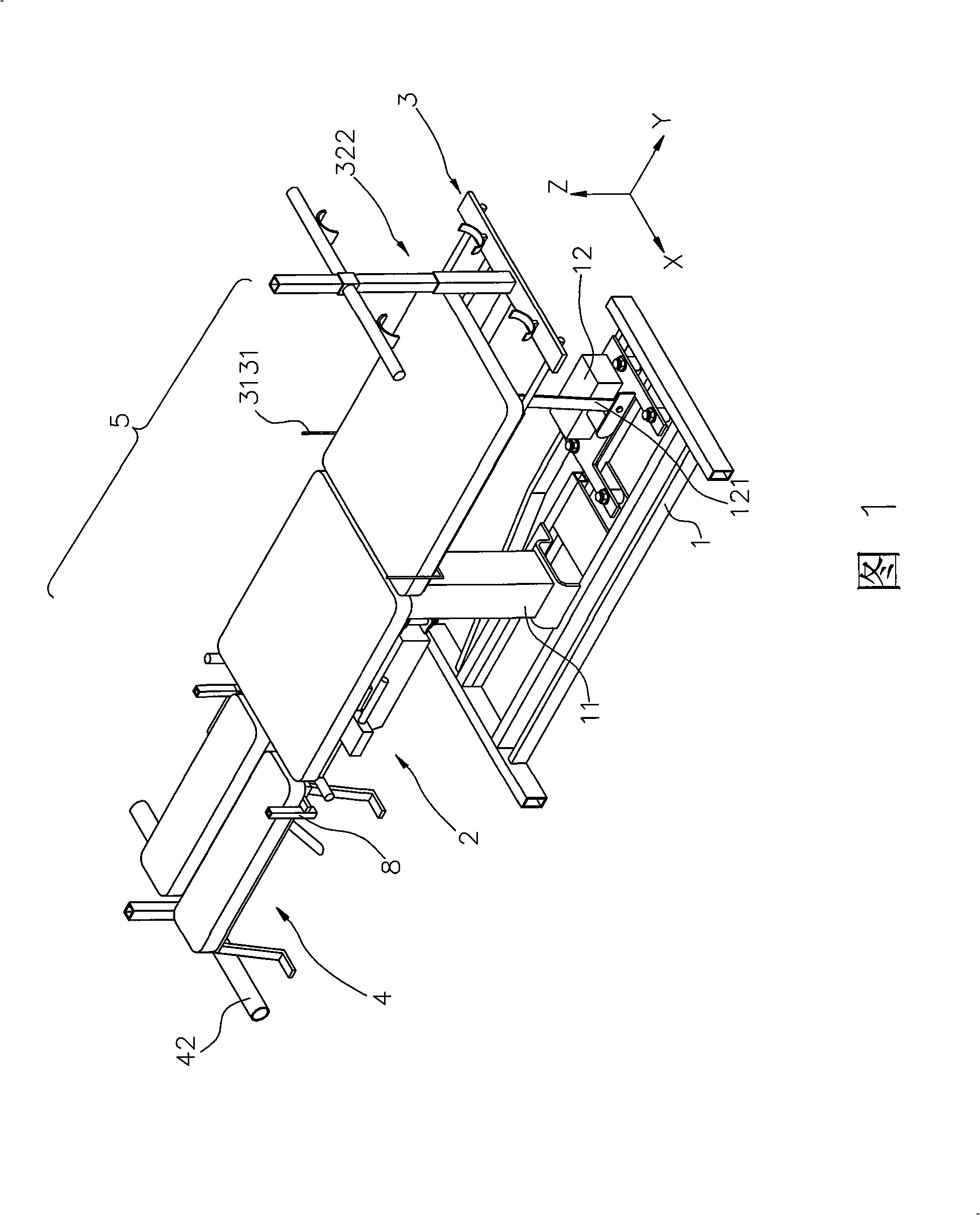

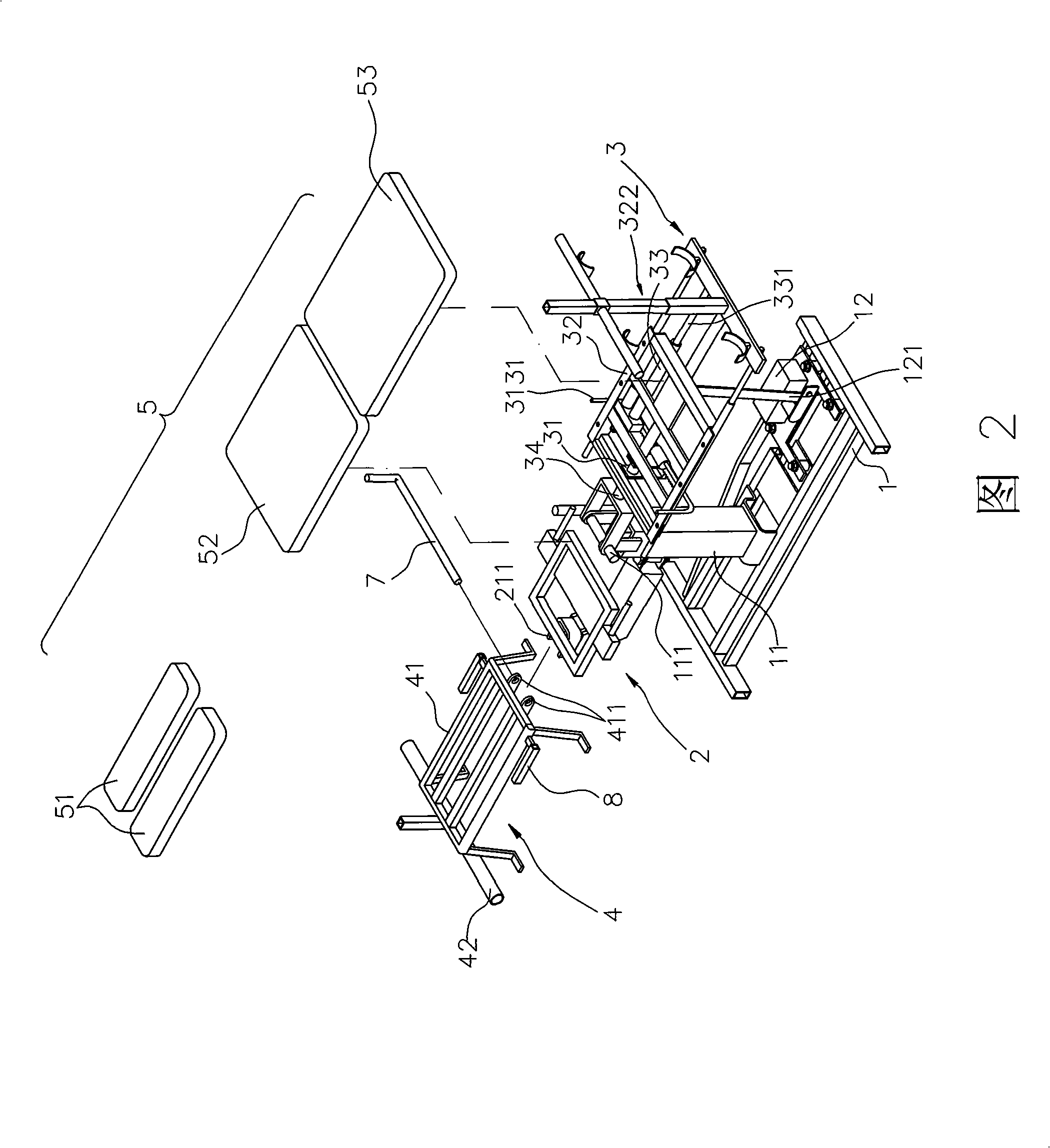

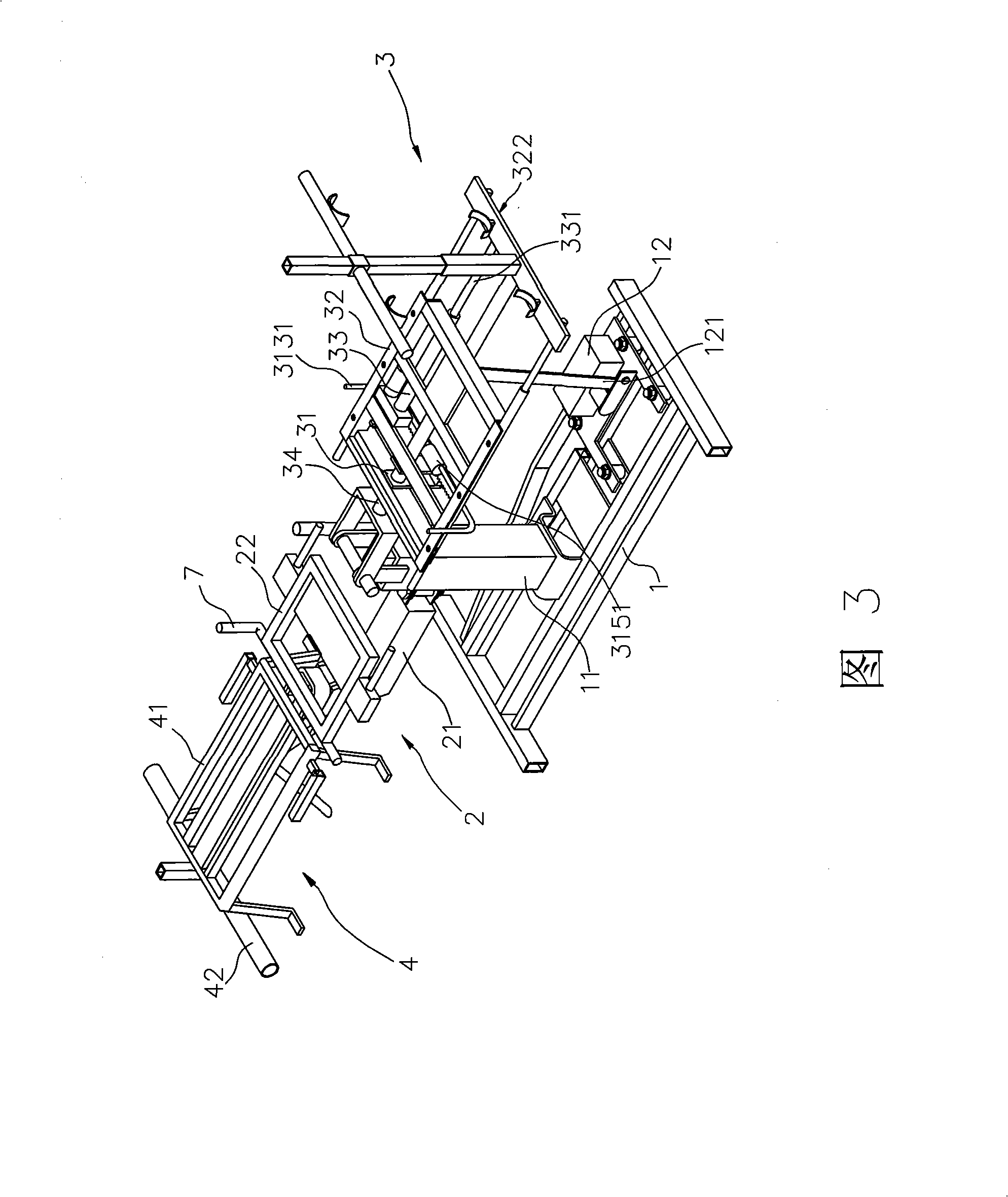

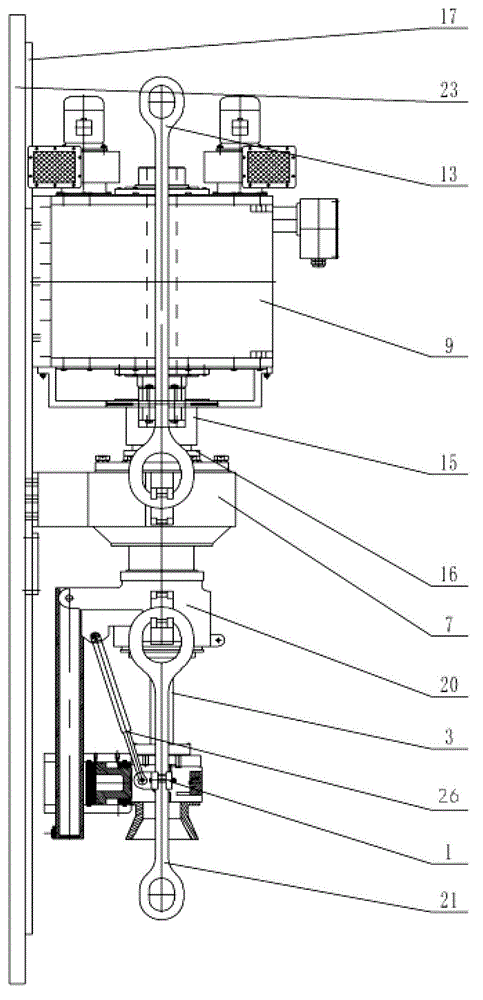

Tunnel drilling machine with drill rod automatic loading and unloading functions for remote control

The invention provides a tunnel drilling machine with drill rod automatic loading and unloading functions for remote control. A base is connected with a sliding frame through a supporting mechanism, and a clamping device is arranged at the front end of the sliding frame. The front half part of the sliding frame is slidably connected with an upper drag plate, and the upper drag plate is provided with an upper gyrator. A rotor of the upper gyrator is provided with an upper clamping disc, and the front half part of the sliding frame is provided with an upper oil cylinder. The movable column end of the upper oil cylinder is connected with the upper drag plate, and the rear half part of the sliding frame is slidadbly connected with a lower drag plate. The lower drag plate is provided with a lower gyrator, a rotor of the lower gyrator is provided with a lower clamping disc. The rear half part of the sliding frame is provided with a lower oil cylinder, and the movable column end of the loweroil cylinder is connected with a lower drag plate. A rod outlet is formed in one side of the bottom of a drill rod box, one end of a transmitter is located at the rod outlet, and the other end of thetransmitter is provided with a lifting device. A cam is hinged to the other end of the transmitter, and the cam is connected with a manipulator through a connecting rod. One end of a rotary arm is hinged to the sliding frame, and the other end of the rotary arm is slidably connected with the manipulator. The tunnel drilling machine has the beneficial effect that a drill rod and a water swivel canbe automatically and efficiently mounted and dismounted under remote control.

Owner:SHANDONG UNIV OF SCI & TECH

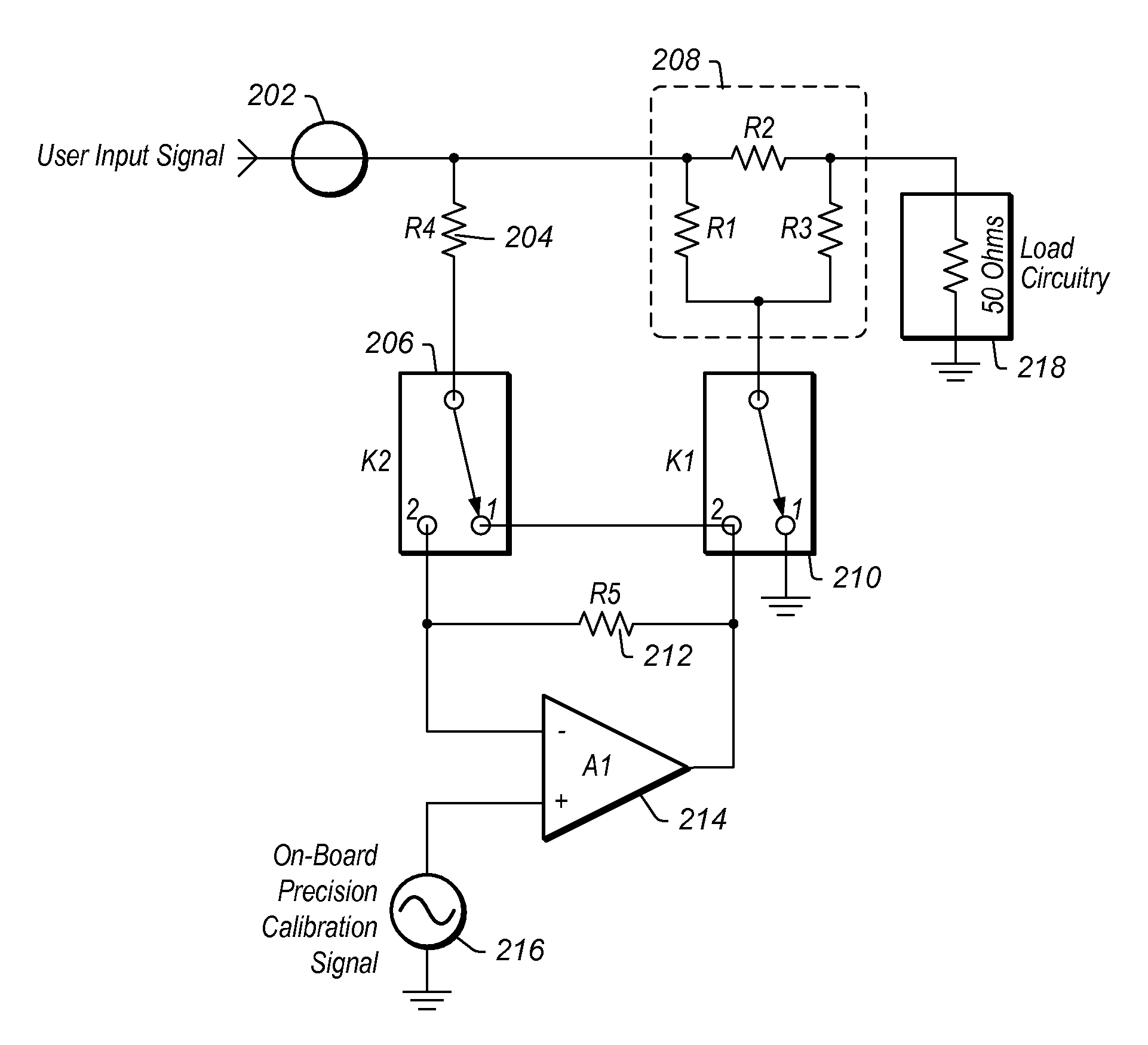

Self-Calibration Circuit With Gyrated Output Impedance

ActiveUS20090322310A1Without degrading RF performanceImpedence matching networksMultiple-port networksLoad circuitElectrical resistance and conductance

Various embodiments of a self-calibration circuit may solve the problem that arises in high performance oscilloscopes and in particular, RF oscilloscopes, of internally providing a precision calibration signal without degrading the bandwidth, flatness of the frequency response, and input return loss of the oscilloscope. The self-calibration circuit may be configured to implement an impedance transformation technique where active and passive circuit elements with carefully chosen values are configured in an impedance converter. During self-calibration, switching elements comprised in the self-calibration circuit may be toggled to create a servo loop comprising an amplifier within the circuit, with an attenuator and resistive component acting as feedback elements. The circuit may hence become an impedance gyrator and behave as a precision source with an impedance matching the input impedance of the load circuit.

Owner:NATIONAL INSTRUMENTS

Broadband, Nonreciprocal Network Element

InactiveUS20060279171A1Impedence networksPiezoelectric/electrostriction/magnetostriction machinesPhase shiftedGyration

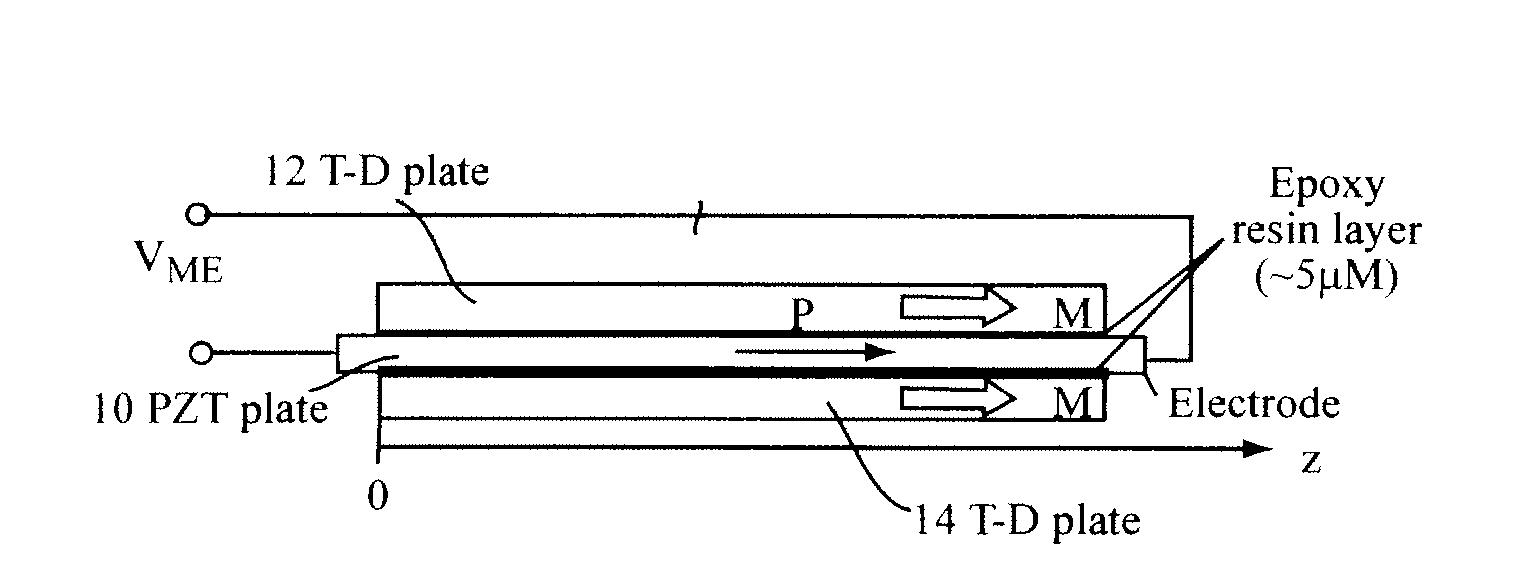

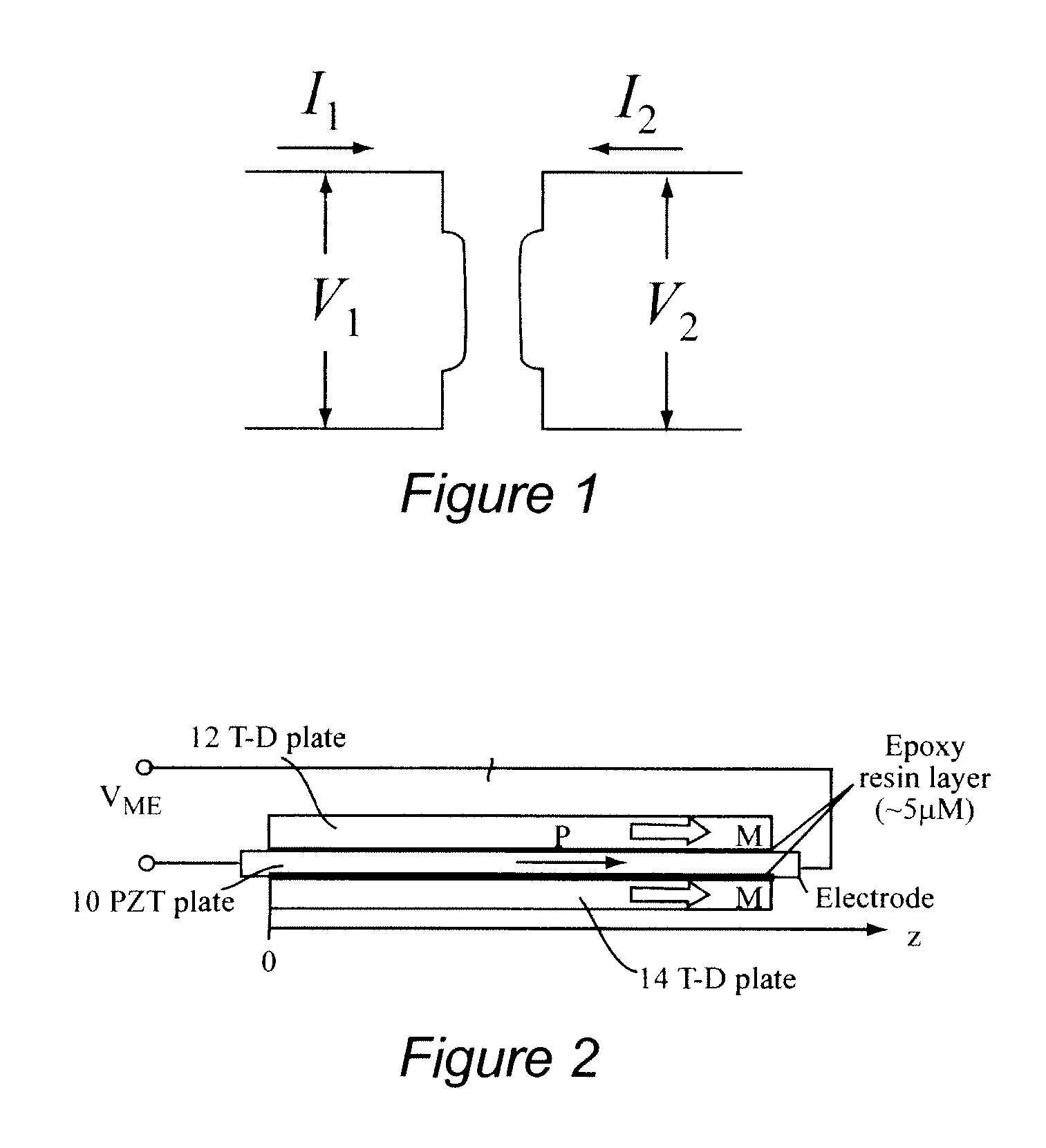

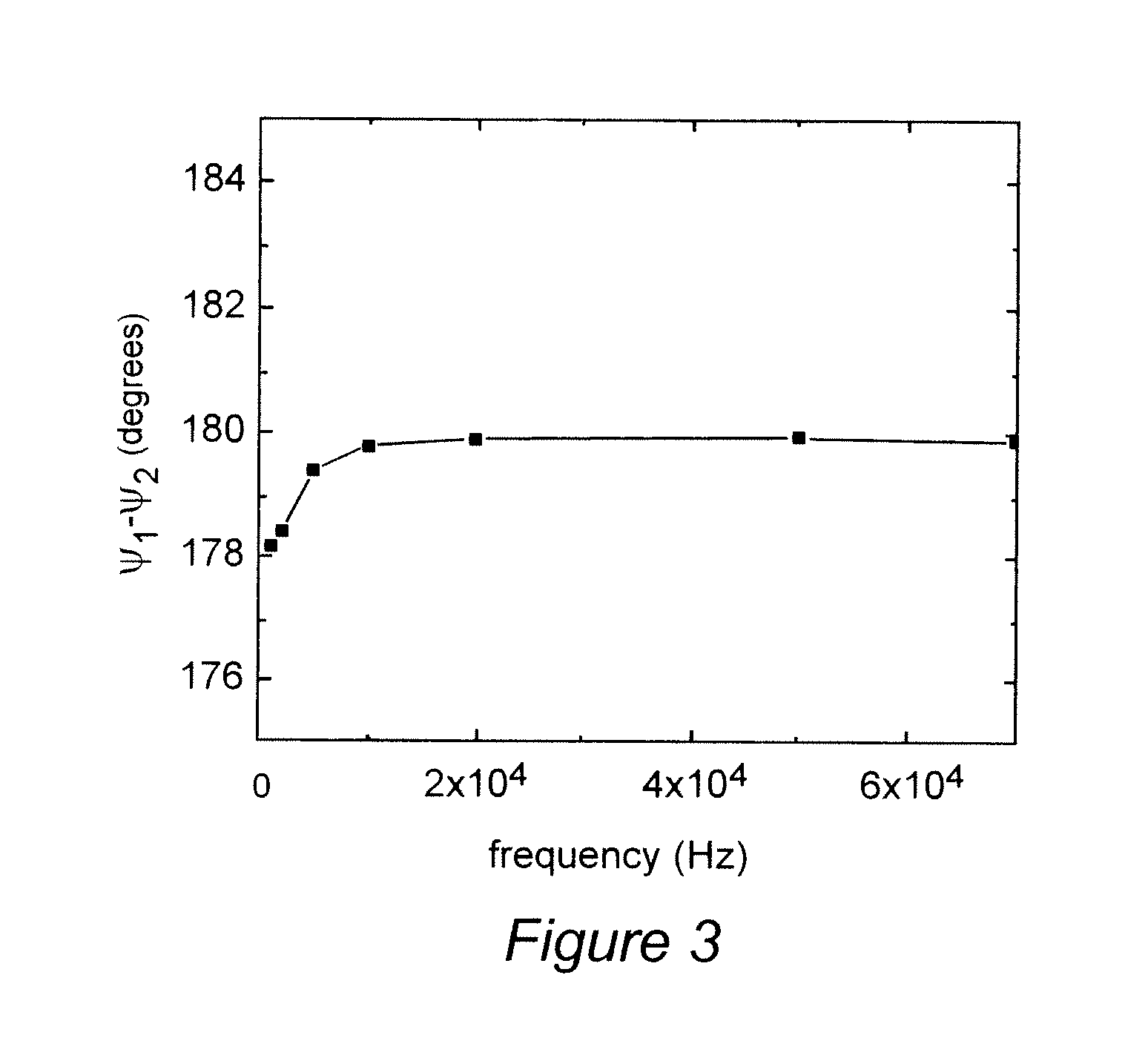

A magneto-electric (ME) gyrator, which is a discrete, passive network element, comprises a laminated composite of piezoelectric and magnetostrictive layers. The ME gyrator approximately meets the following criteria: V1=−αI2, V2=αI1 (1a) where V is voltage, I is current, and α is a conversion (or gyration) coefficient between voltage and current and non-reciprocity is manifested as a 180° phase shift between open and short circuit (I,V) conditions, and α c0ɛeffμeff≈1(1b)where c0 is the speed of light in vacuum, εeff is the effective relative dielectric constant, and μeff is the effective relative permeability.

Owner:NOVGOROD STATE UNIV +1

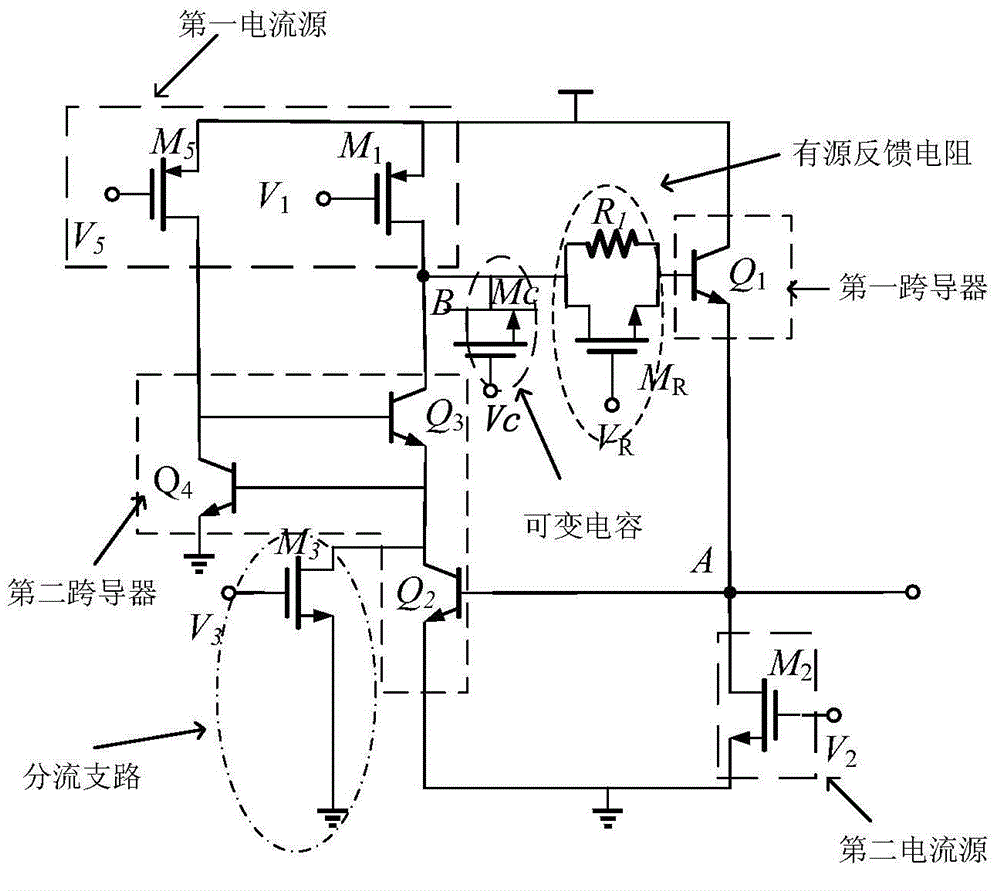

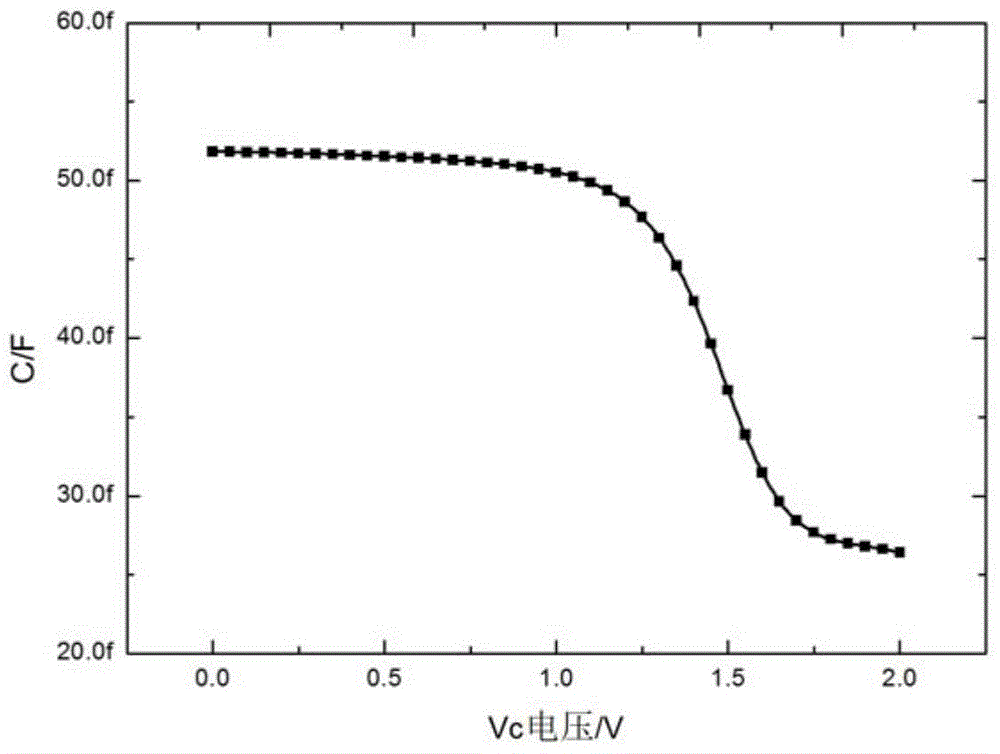

Broadband active inductor with high Q value

ActiveCN105071784AReduce zero frequencyWorking bandwidthMultiple-port active networksCapacitanceEngineering

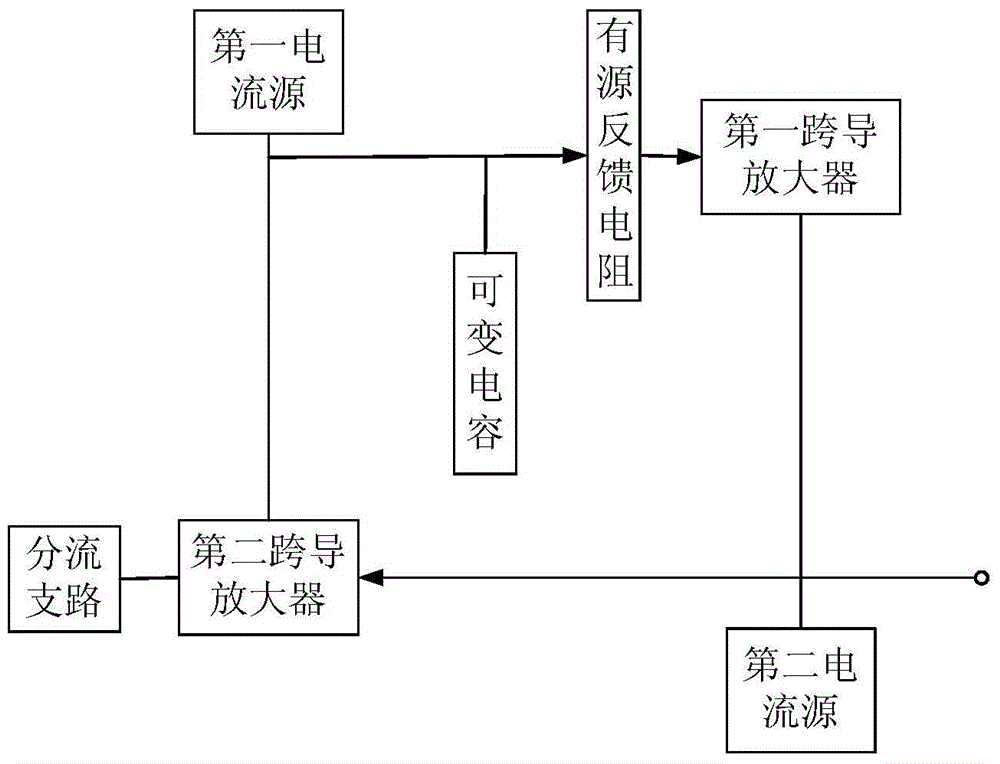

The invention provides a broadband active inductor with a high Q value. The active inductor comprises a first trsanscondutance amplifier, a second trsanscondutance amplifier, an active feedback resistor, a variable capacitor, a first current source, a second current source, and a shunting branch. The two trsanscondutance amplifiers are connected end to end so as to form a gyrator. By means of the gyrator, the input capacitance of the first trsanscondutance amplifier gyrates to be equivalent inductance. The first current source supplies current to the second trsanscondutance amplifier. The second current source supplies current to the first trsanscondutance amplifier. A voltage-modulated composite transistor with common-emitter and common-base structure is applied to the negative-trsanscondutance amplifier so that the output impedance of the amplifier is increased, thereby reducing zero point frequency and widening a bandwidth. The active feedback resistor and the variable capacitor improve a quality factor Q, an equivalent inductance value, and the adjustability of the quality factor Q and the equivalent inductance value. By means of the coordinated adjustment of the gate voltage of each transistor and the capacitance value of the variable capacitor, the active inductor achieves a broad band, a high Q value, and the adjustability of the bandwidth and the Q value.

Owner:BEIJING UNIV OF TECH

High-torque drilling machine with power-shifting gearbox

InactiveCN102536111ASo as not to damagePrevent slippingDrilling rodsConstructionsElevation angleTransfer case

The invention relates to a high-torque drilling machine with a power-shifting gearbox. The high-torque drilling machine comprises a machine frame, a motor, a gearbox body, a transfer case, a windlass, a gyrator and a control part, wherein a piston cylinder is arranged on the gyrator; a piston rod matched with the piston cylinder is arranged on the piston cylinder; a cross beam is fixed on the piston rod; a hydraulic chuck is arranged on the cross beam; four pairs of sleeve pressure plates are arranged on two sides of the gyrator; a sleeve is fixed in each sleeve pressure plate; a fixing plate for a front clamp holder is fixed at the front end of the sleeve; the front clamp holder is arranged on the fixing plate; a sliding rod capable of sliding in the sleeve is arranged at the rear end of the sleeve pipe; a fixing plate for a back clamp holder is fixed on the sliding rod; and a rear clamp holder is arranged on the fixing plate for the back clamp holder. The invention has the benefit effects as follows: 1, all gears in the gearbox are in a normally engaged state, so as to avoid damage on the gears caused by mis-operation; 2, a drill rod can be disassembled conveniently and easily without extra manpower; and 3, the front clamp holder can be used for clamping the drill rod tightly when the drilling machine is used for drilling a hole with an elevation angle, so as to prevent the drill rod from falling down, and avoid safety accidents.

Owner:HANGZHOU XIANGLONG DRILLING EQUIP TECH CO LTD

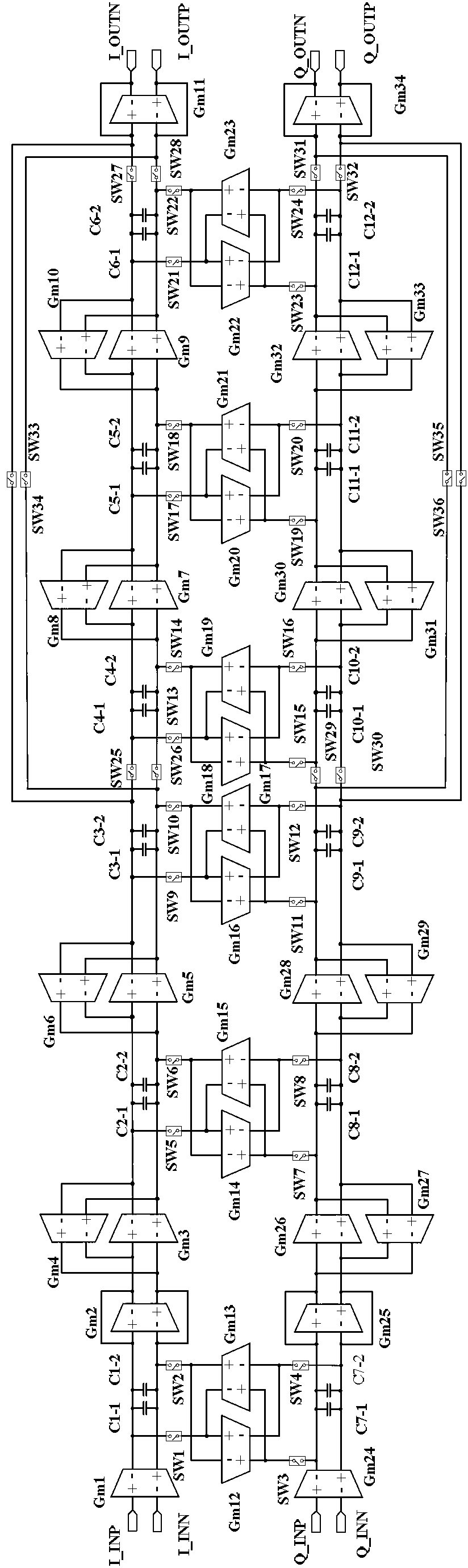

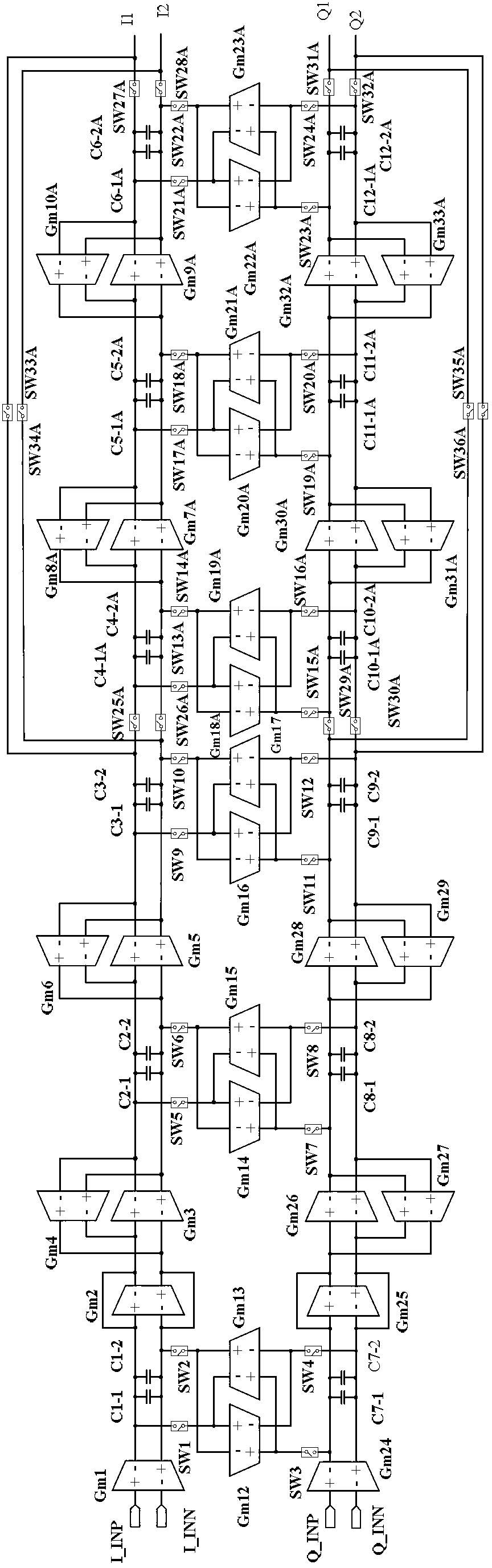

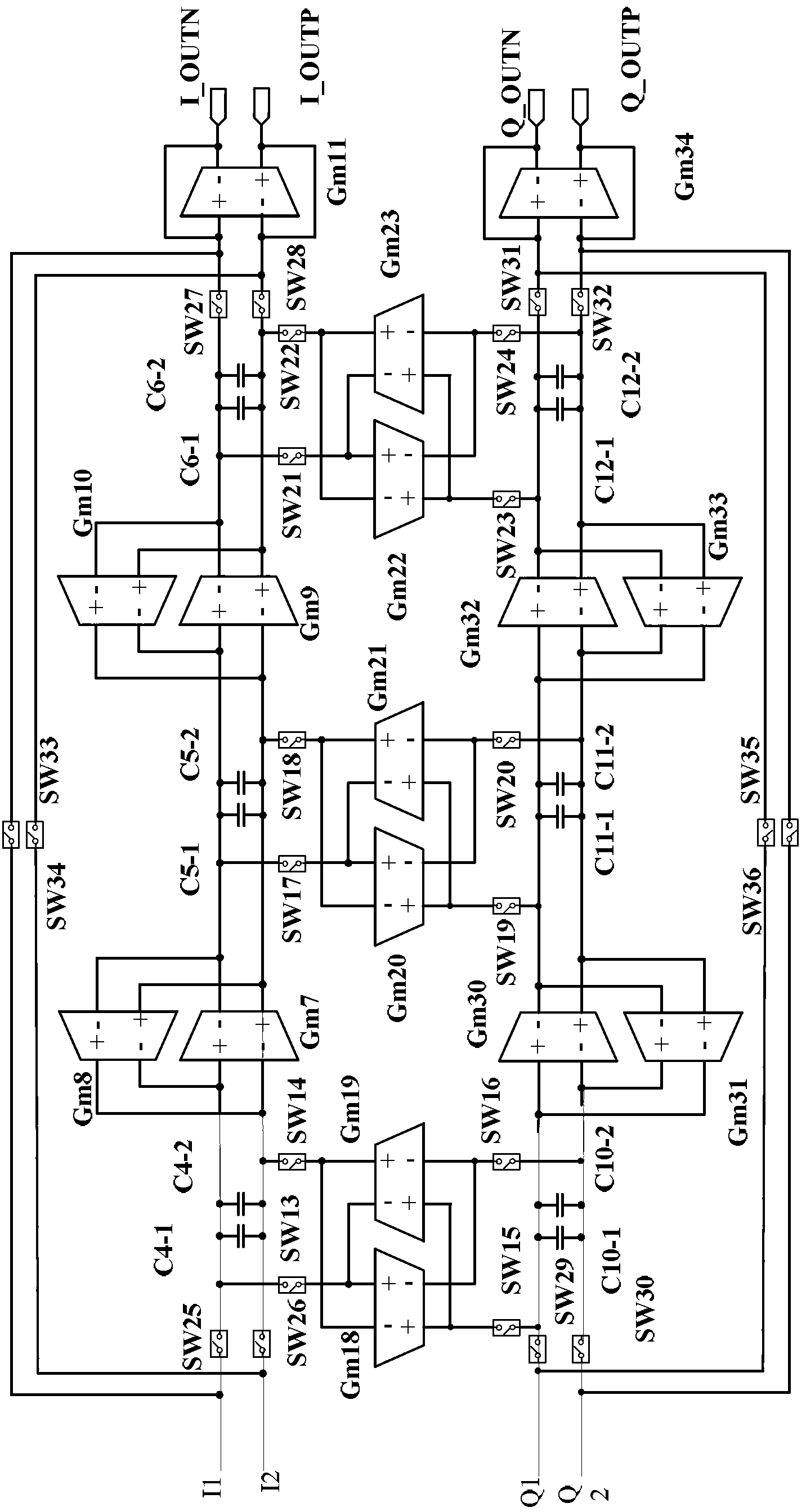

Reconfigurable Gm_C filter circuit

ActiveCN103227620AHardware resources can be reusedEasy to upgradeFrequency selective two-port networksElectronic communicationCoupling

The invention discloses a reconfigurable Gm_C filter circuit which comprises an I path in-phase signal channel, a Q path orthogonal signal channel and a transconductance gyrator group outside the channels. The circuit is characterized in that the I path in-phase signal channel and the Q path orthogonal signal channel are same Gm_C low pass filters with a trapezoid jump coupling structure; symmetrical capacitive elements in the two signal channels are connected through one transconductance gyrator in the transconductance gyrator group outside the channels; and each of the differential input end and the differential output end of each transconductance gyrator in the transconductance gyrator group outside the channels are connected with a digital switch. According to reconfigurable Gm_C filter circuit disclosed by the invention, a Gm_C filter is configured to two working modes, namely, a plurality of band-pass filters and low pass filters through the digital switches, so that switching between the plurality of band-pass filters and low pass filters of the Gm_C filter in the on-chip trapezoid jump coupling structure is realized. Configuration switching among three-order, five-order, seven-order or even higher order of the filters is realized, and the reconfigurable Gm_C filter circuit can be widely applied to electronic communication systems.

Owner:CHONGQING SOUTHWEST INTEGRATED CIRCUIT DESIGN

High-voltage cable stripping device

ActiveCN110011227AImprove peeling efficiencyEasy to operateApparatus for removing/armouring cablesHigh pressureBevel gear

The invention discloses a high-voltage cable stripping device comprising a stripping die and a gyrator. The stripping die comprises an upper clamping block and a lower clamping block, the upper clamping block and the lower clamping block are symmetrically arranged to form a clamping gap for clamping a cable, and a stripping knife is disposed beside the clamping gap formed by the upper and lower clamping blocks. The gyrator includes a gear transmission box and a bevel gear transmission box, and the gear transmission box and the bevel gear transmission box are connected by a gear transmission rod. The stripping die and the gyrator are fixedly connected by a connecting plate, and the gyrator drives the stripping die to rotate through the connecting plate when the gyrator rotates. The high-voltage cable stripping device of the invention can adapt to the cable stripping demands of different wire diameters, the replacement of the stripping die is not needed in stripping the cables of different wire diameters, the working efficiency of a worker is greatly improved, at the same time, the operator is away from a high-voltage wire, and the safety of the operator is ensured to the greatest extent.

Owner:WUHAN LISHIDA ELECTRIC POWER TECH CO LTD

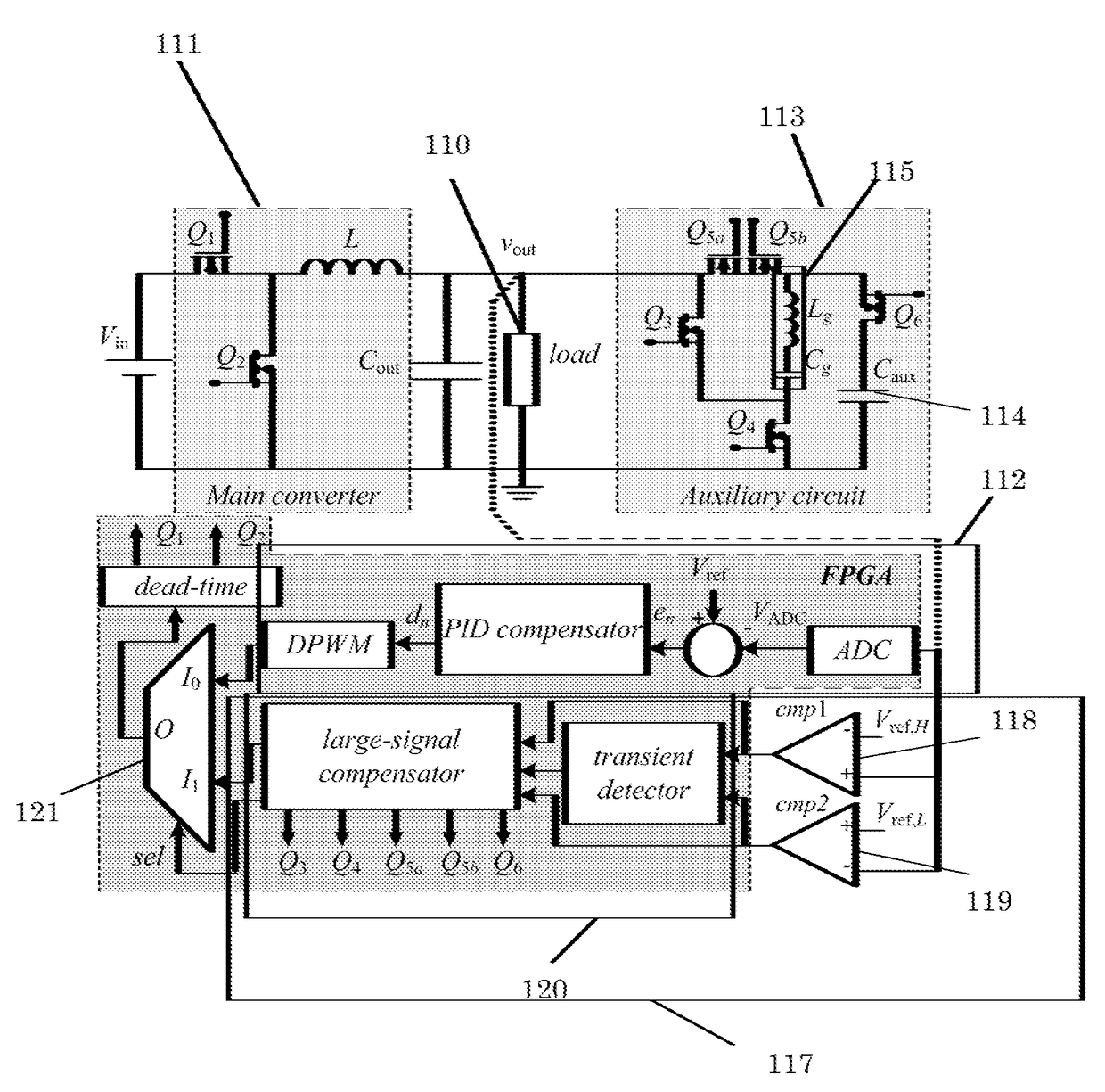

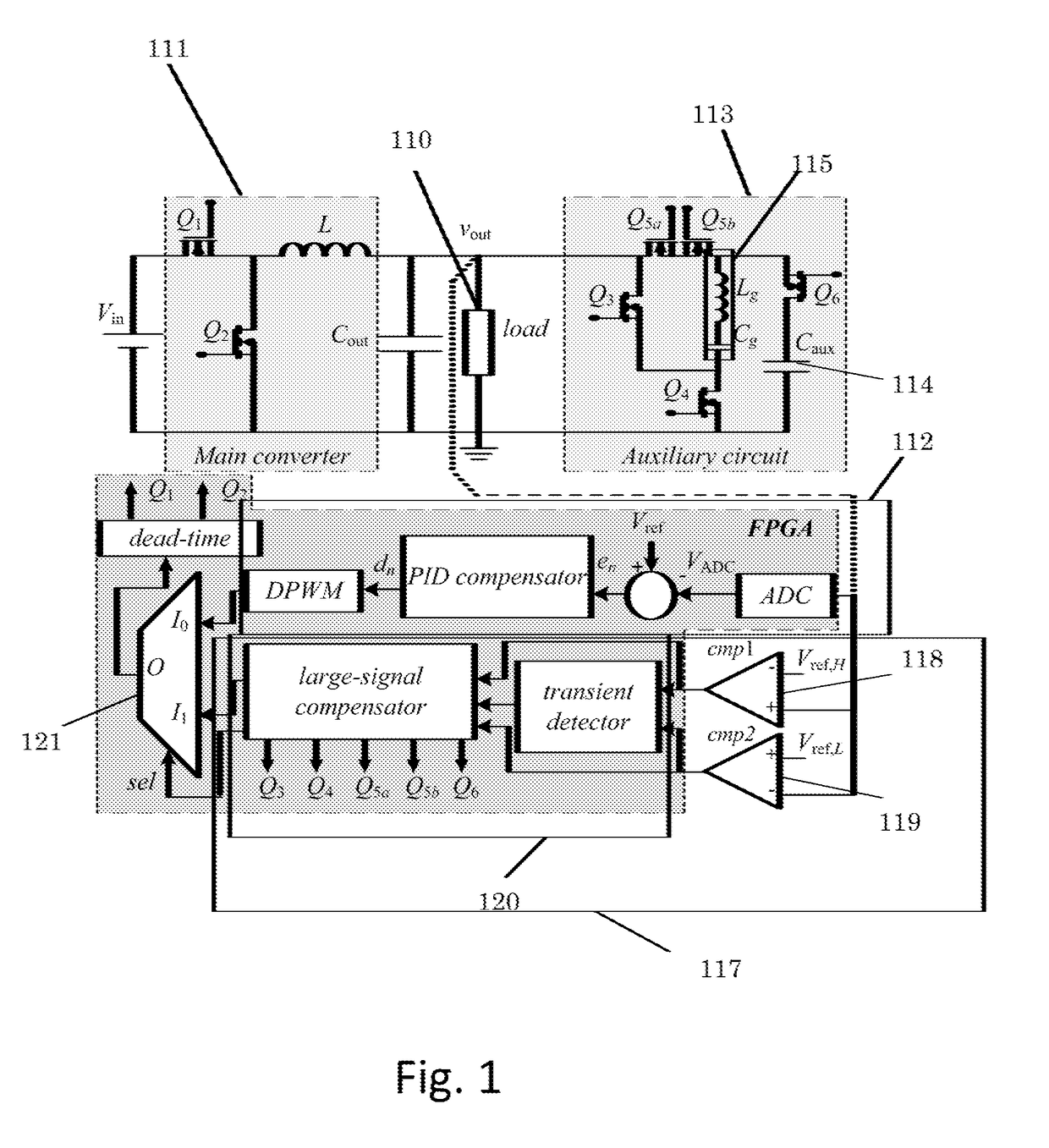

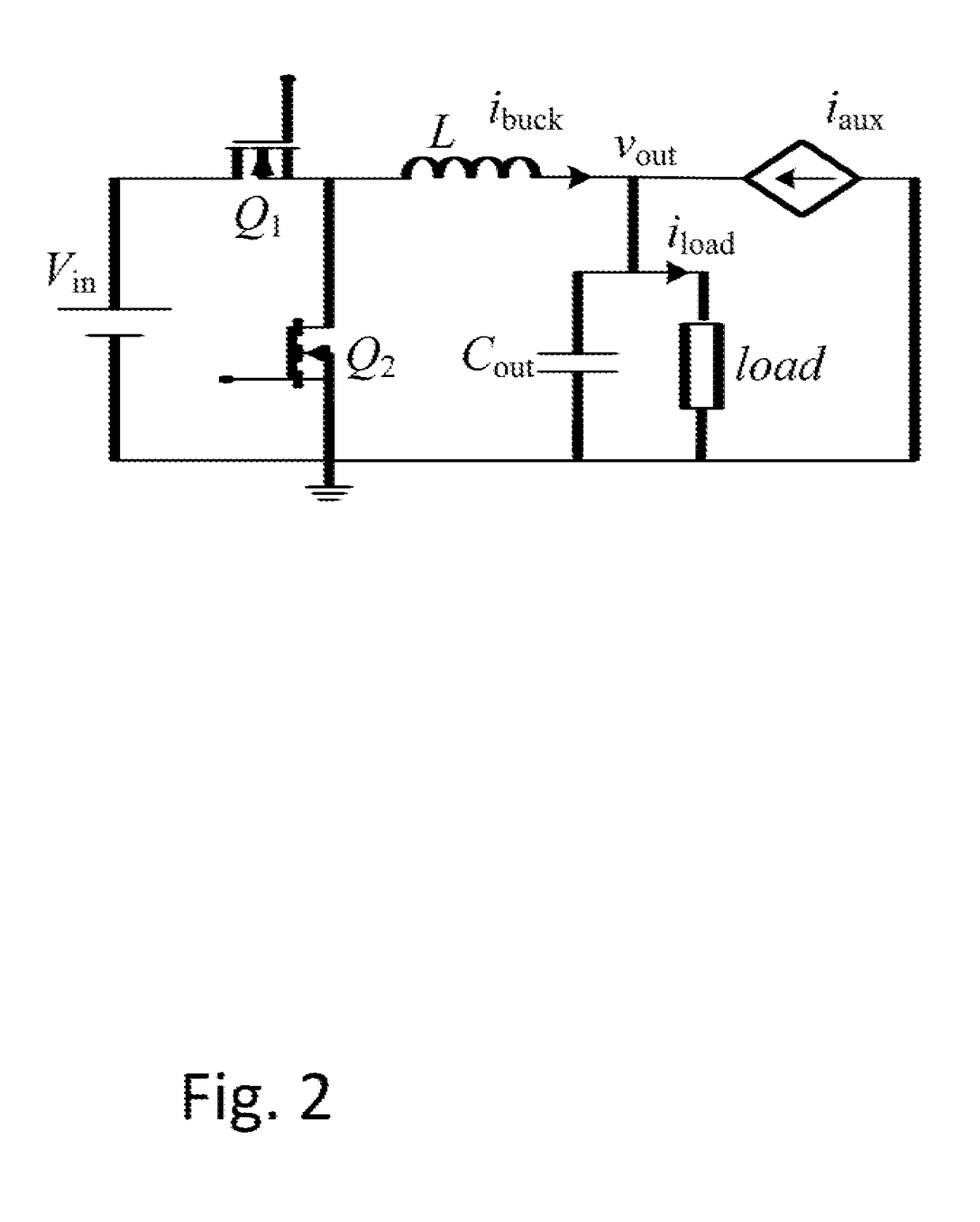

A voltage regulator module using a load-side auxiliary gyrator circuit

ActiveUS20170302172A1Quick changeMaintain loadEfficient power electronics conversionDc-dc conversionCapacitanceVoltage regulator module

The present invention introduces a new compact Voltage Regulator Module (VRM) solution that hybrids a buck converter with a resonant switched-capacitor auxiliary circuit that is connected at the load side. By using a new control concept of the present invention, the auxiliary circuit effectively mimics increased capacitance during loading and unloading transient events, reducing the burden on both the input and output filters, and reduces the current stress.

Owner:B G NEGEV TECH & APPL LTD

Transconductance device employing native MOS transistors

InactiveUS7012487B2Improve noiseImproved response to noiseImpedence convertorsPulse generation by logic circuitsRadio receptionRadio receiver

A system on chip such as a radio receiver has reduced suceptibility to voltages in the bulk silicon by using gyrator elements in the receiver with each gyrator element including a plurality of current sources interconnected to provide output transconductance voltages, and a variable load for the current sources including first and second load resistors each serially connected with one other plurality of current sources. A variable resistance interconnects nodes of the load resistors with the variable resistance comprising a pair of native MOS transistors having low threshold voltages. In a preferred embodiment the first and second load resistors comprise first and second MOS transistors with the pair of native transistors serially connected between source elements of the first and second MOS transistors.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

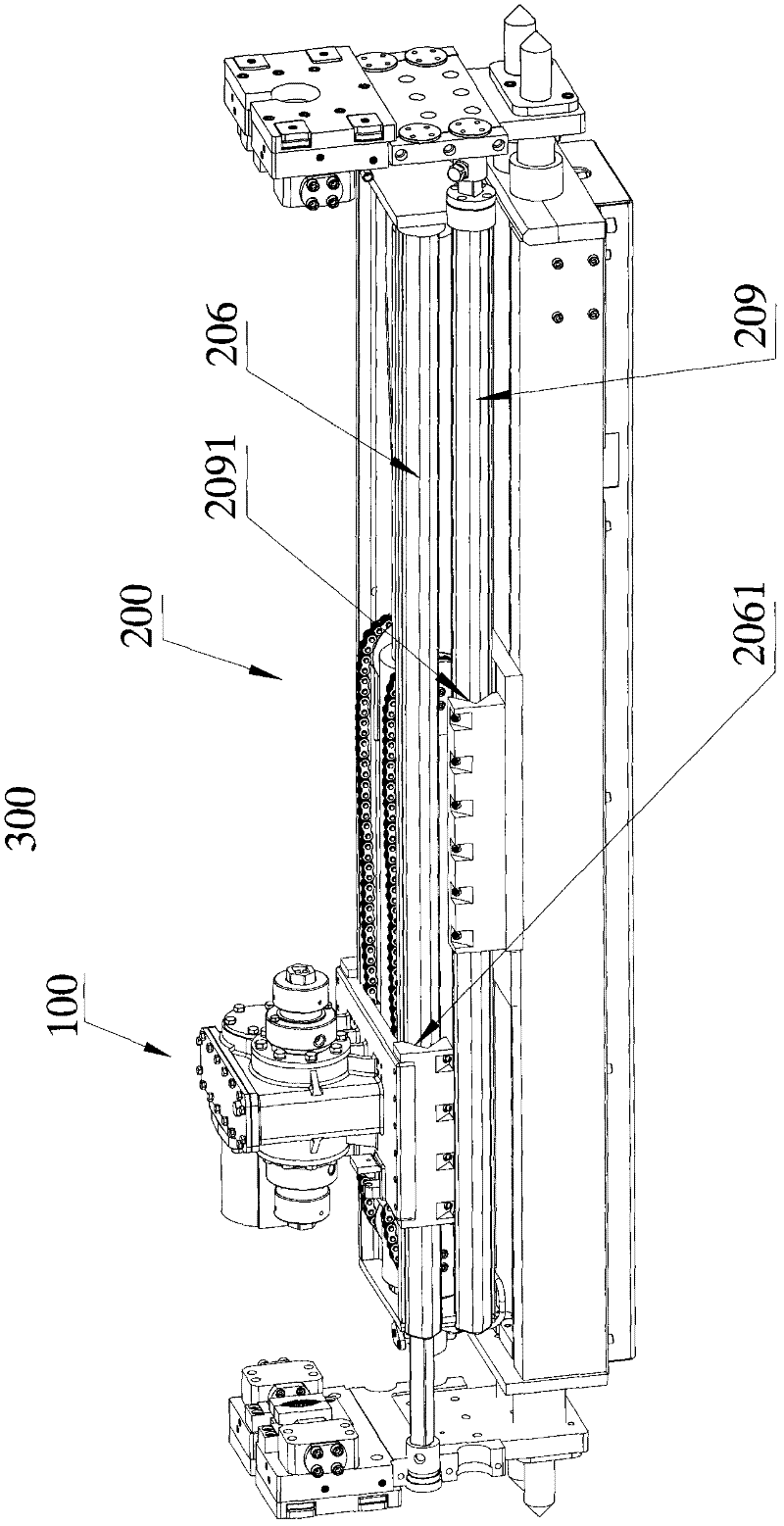

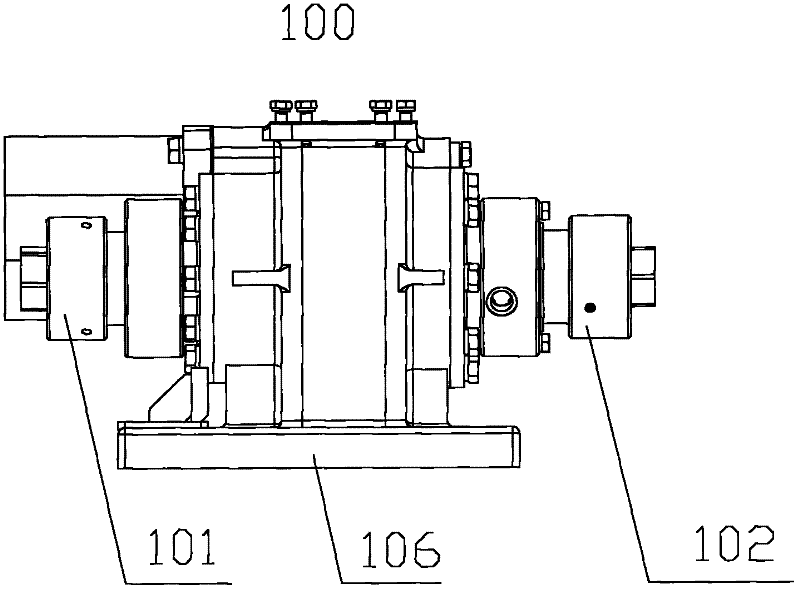

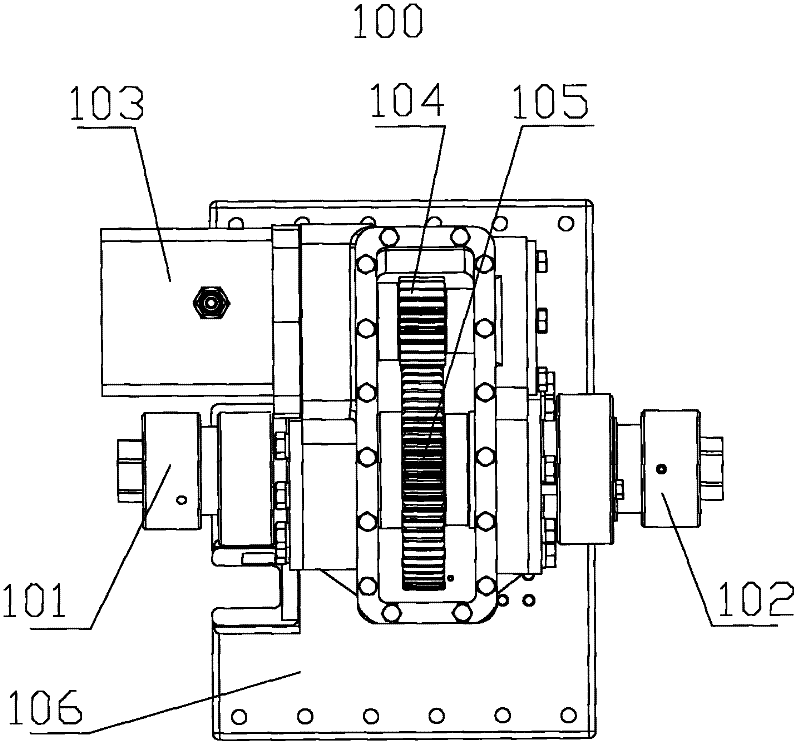

Side anchor rod machine and heading-anchoring machine

The invention provides a side anchor rod machine (300), which comprises a sliding mechanism (200) and a gyrator (100) arranged on the sliding mechanism (200), wherein the gyrator (100) can slide in the sliding mechanism (200); a first drill bushing (101) and a second drill bushing (102) are symmetrically arranged on the gyrator (100); and anchor rods can be arranged on the first drill bushing (101) and the second drill bushing (102). The invention also provides a heading-anchoring machine. Through the side anchor rod machine and the heading-anchoring machine provided by the invention, the purpose of driving the anchor rods at two sides of heading equipment can be fulfilled through the single side anchor rod machine, the structure of the whole heading-anchoring machine is simplified, the weight of the whole machine is reduced, and the cost of the whole machine is saved; and meanwhile, the gyrator can secondarily slide in the sliding mechanism, so that the moving stroke of the side anchor rod machine is greatly improved, and the requirement for driving the anchor rods in a wider tunnel can be met.

Owner:JIKAI HEBEI MECHATRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com