Patents

Literature

4190results about "Apparatus for removing/armouring cables" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

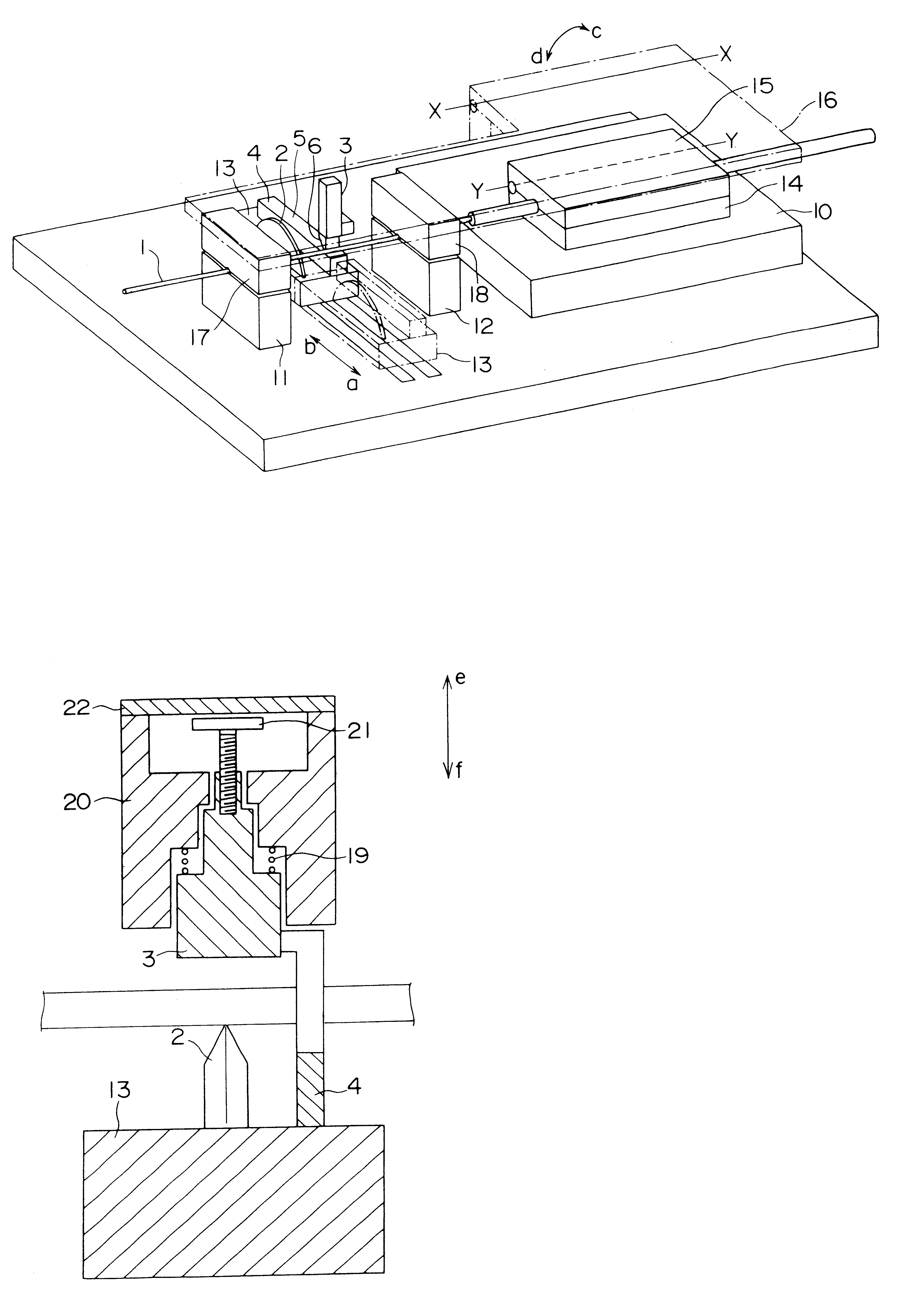

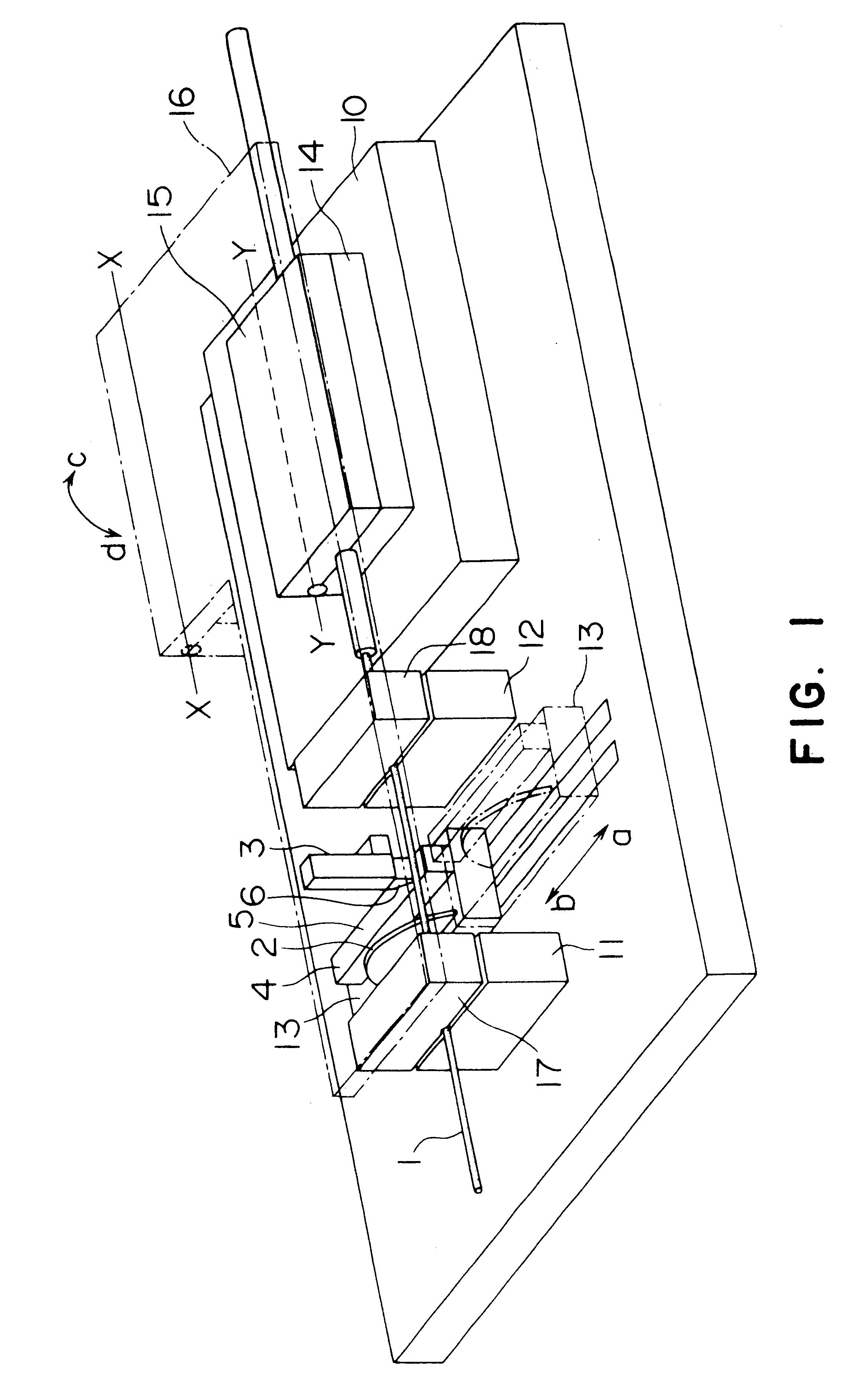

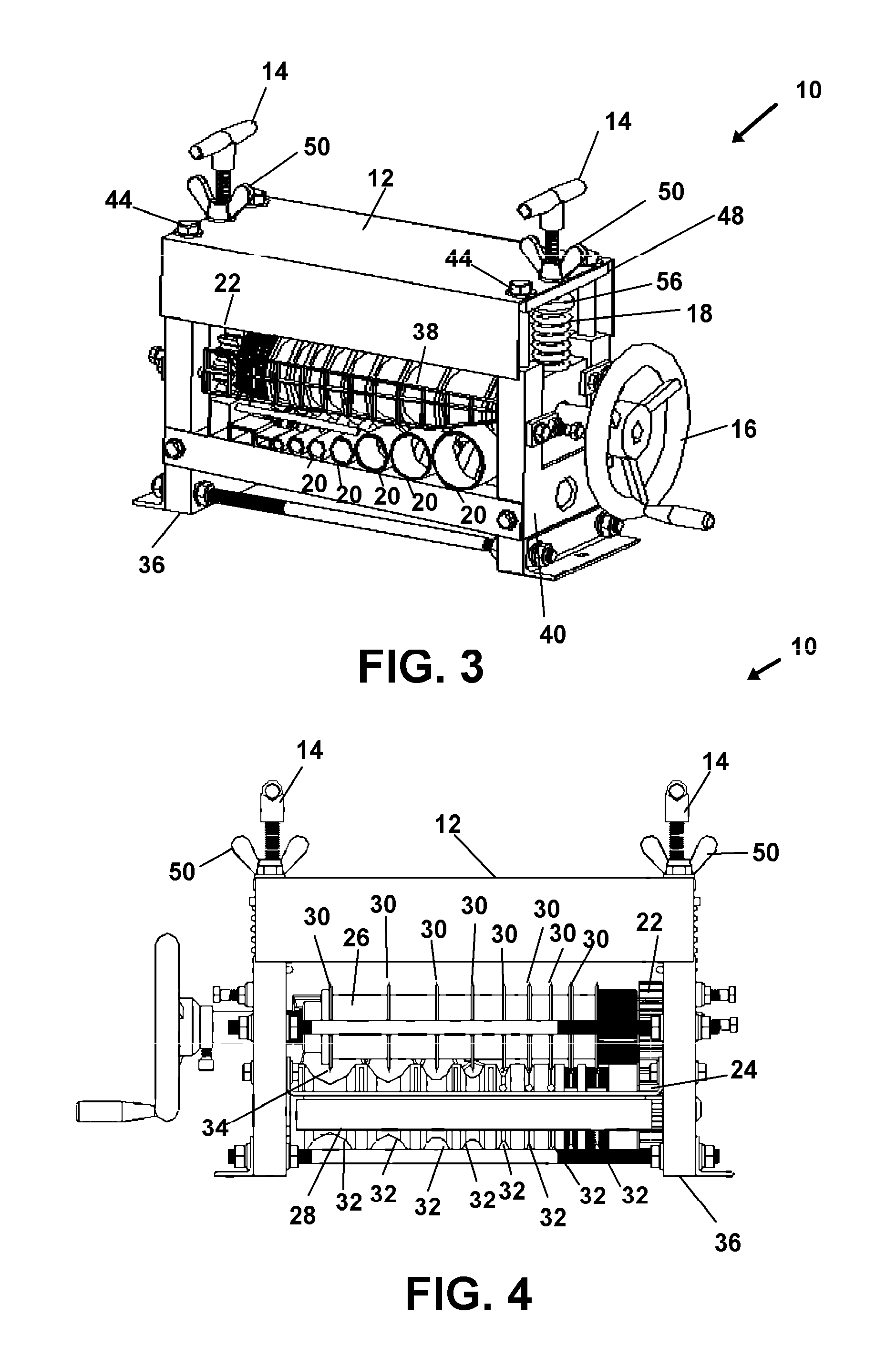

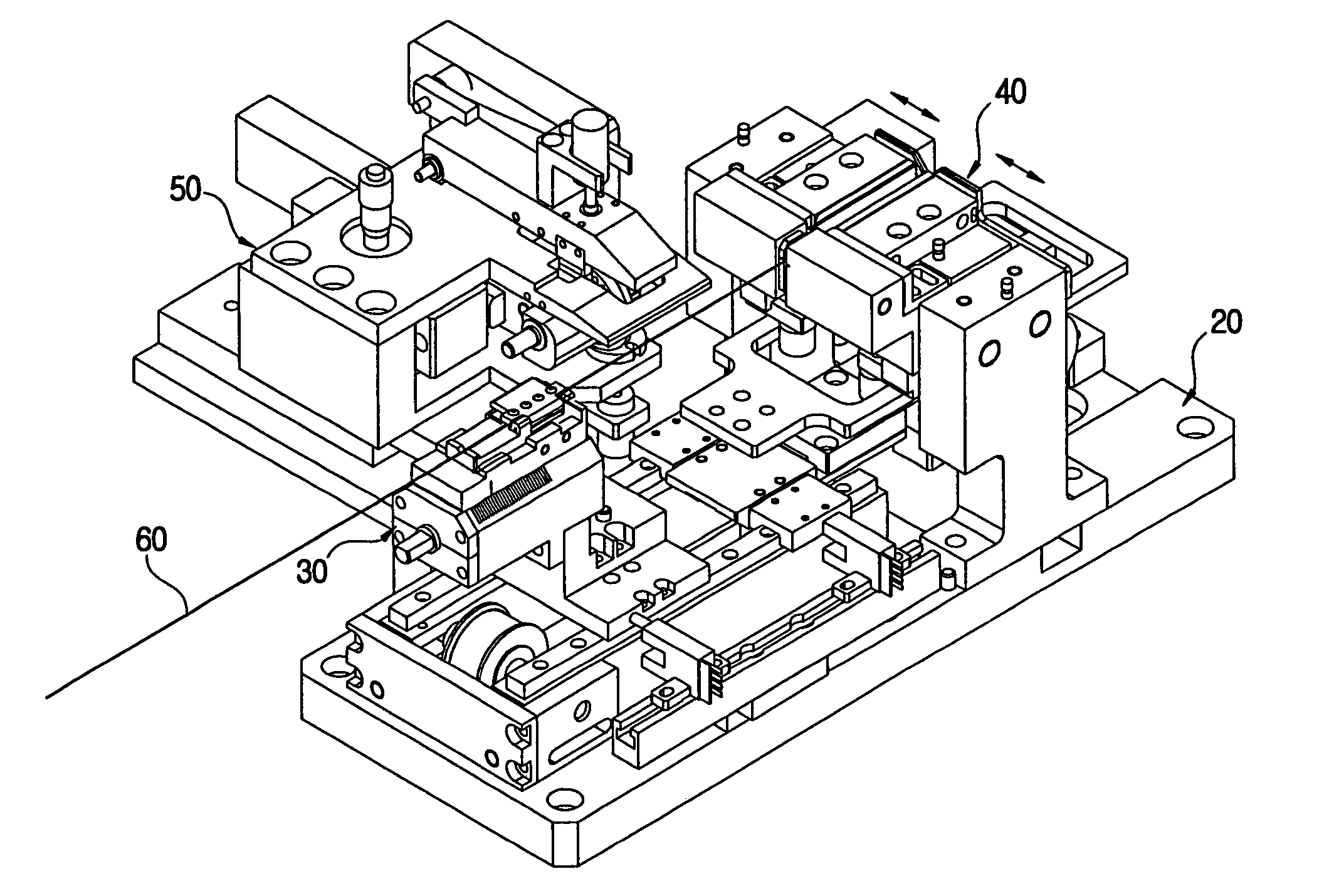

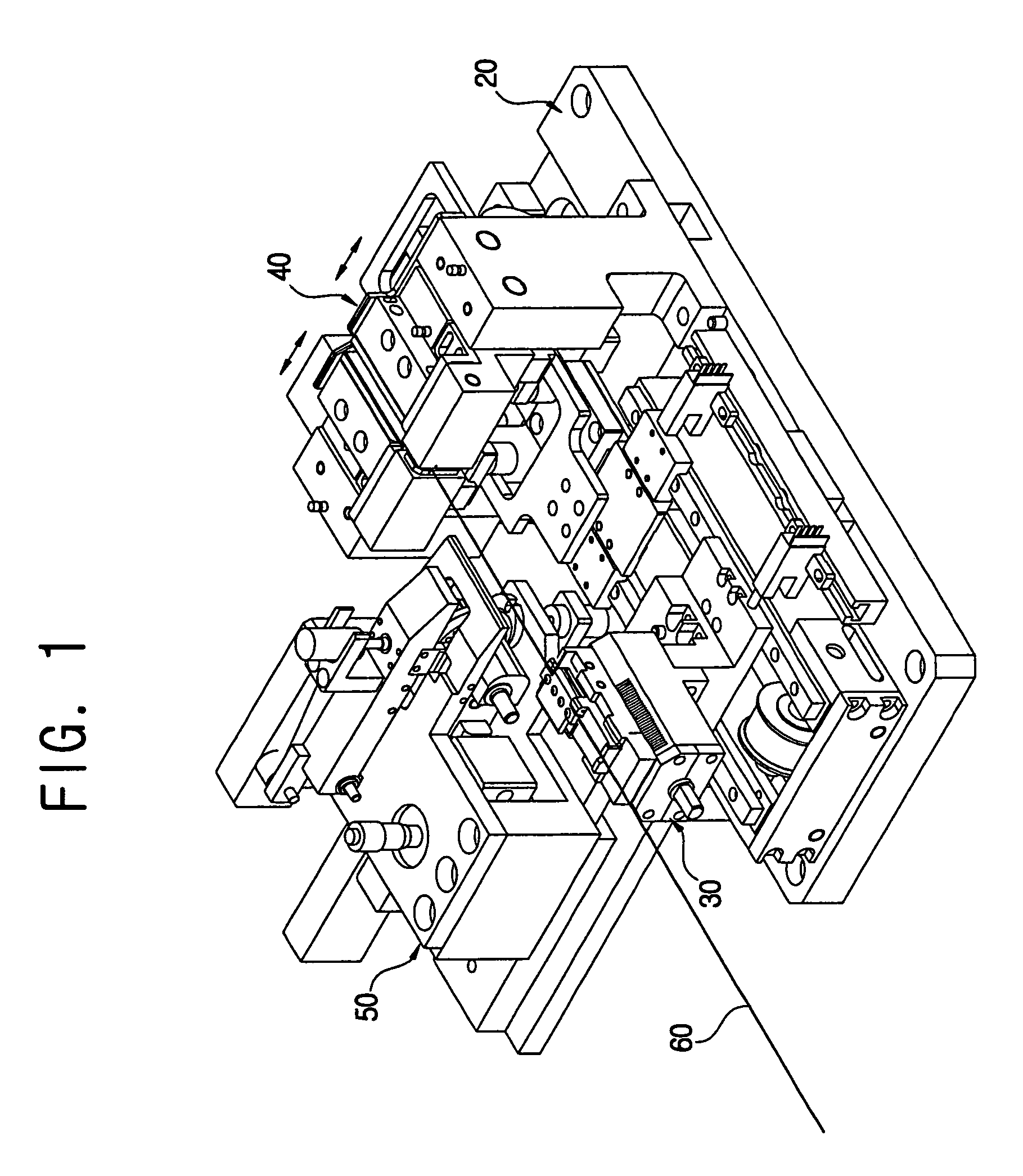

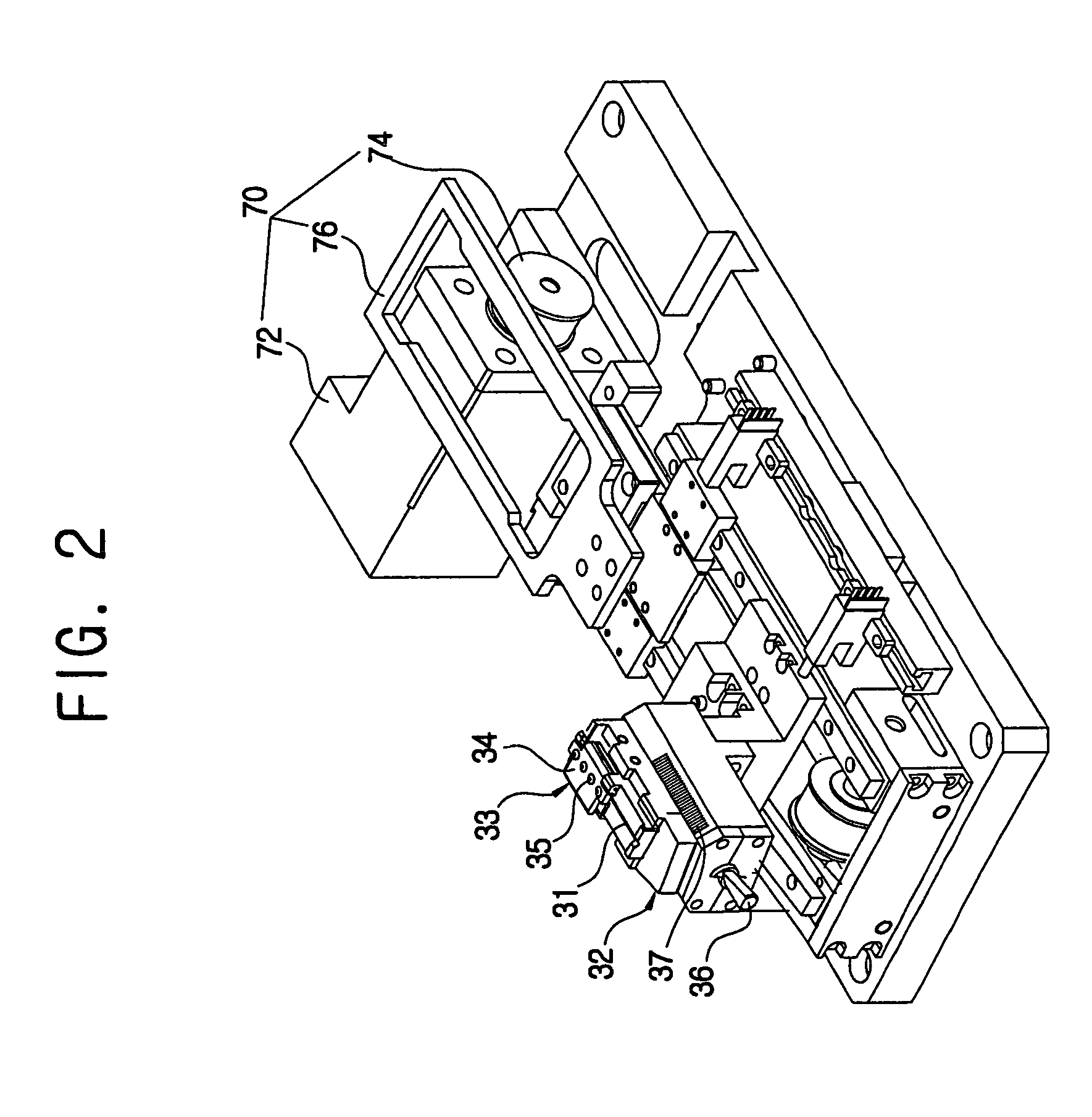

Continuous cable processing apparatus

InactiveUS20050050713A1Practical to useTimely processingApparatus for cutting/splicing cablesOther manufacturing equipments/toolsEngineeringCable transport

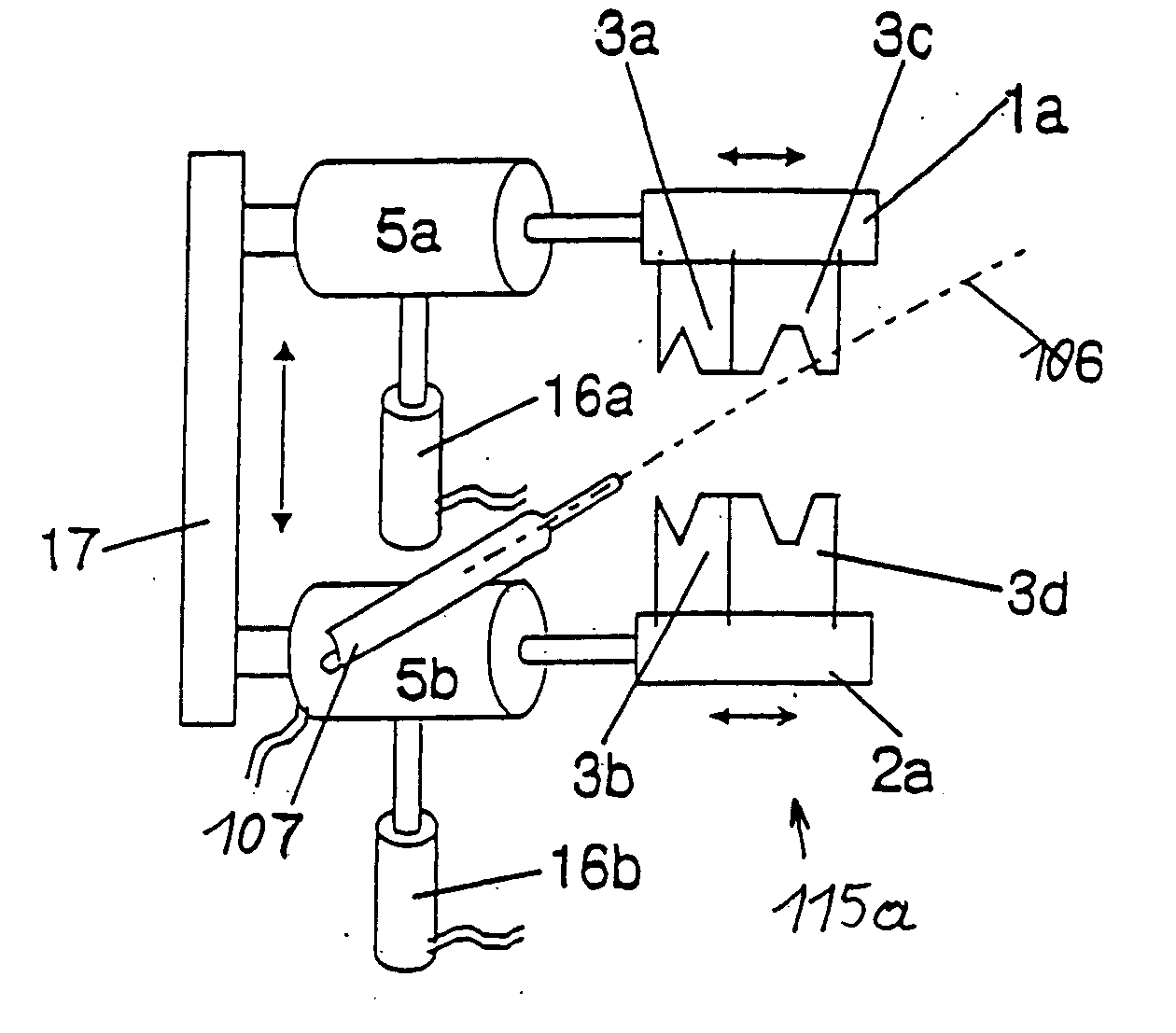

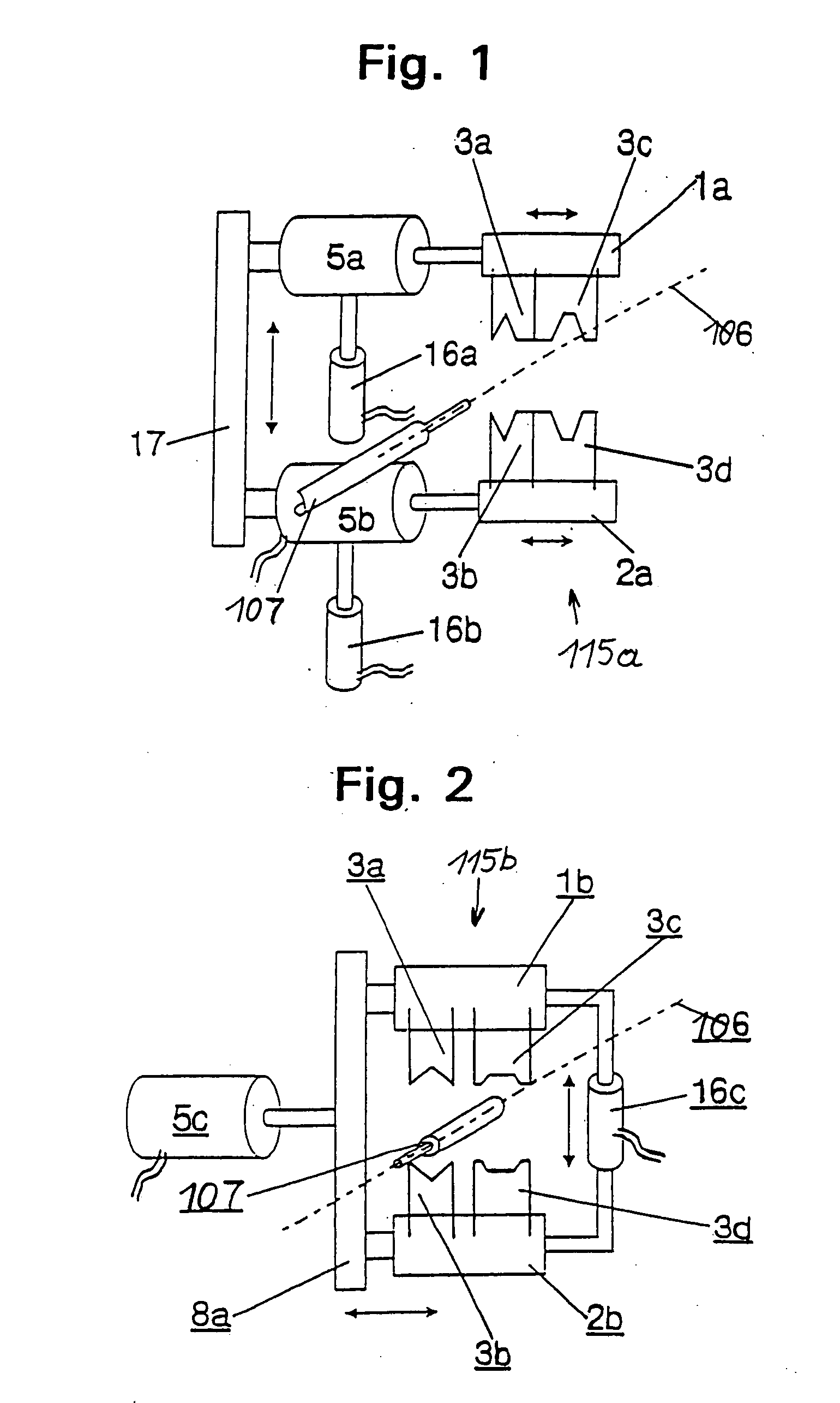

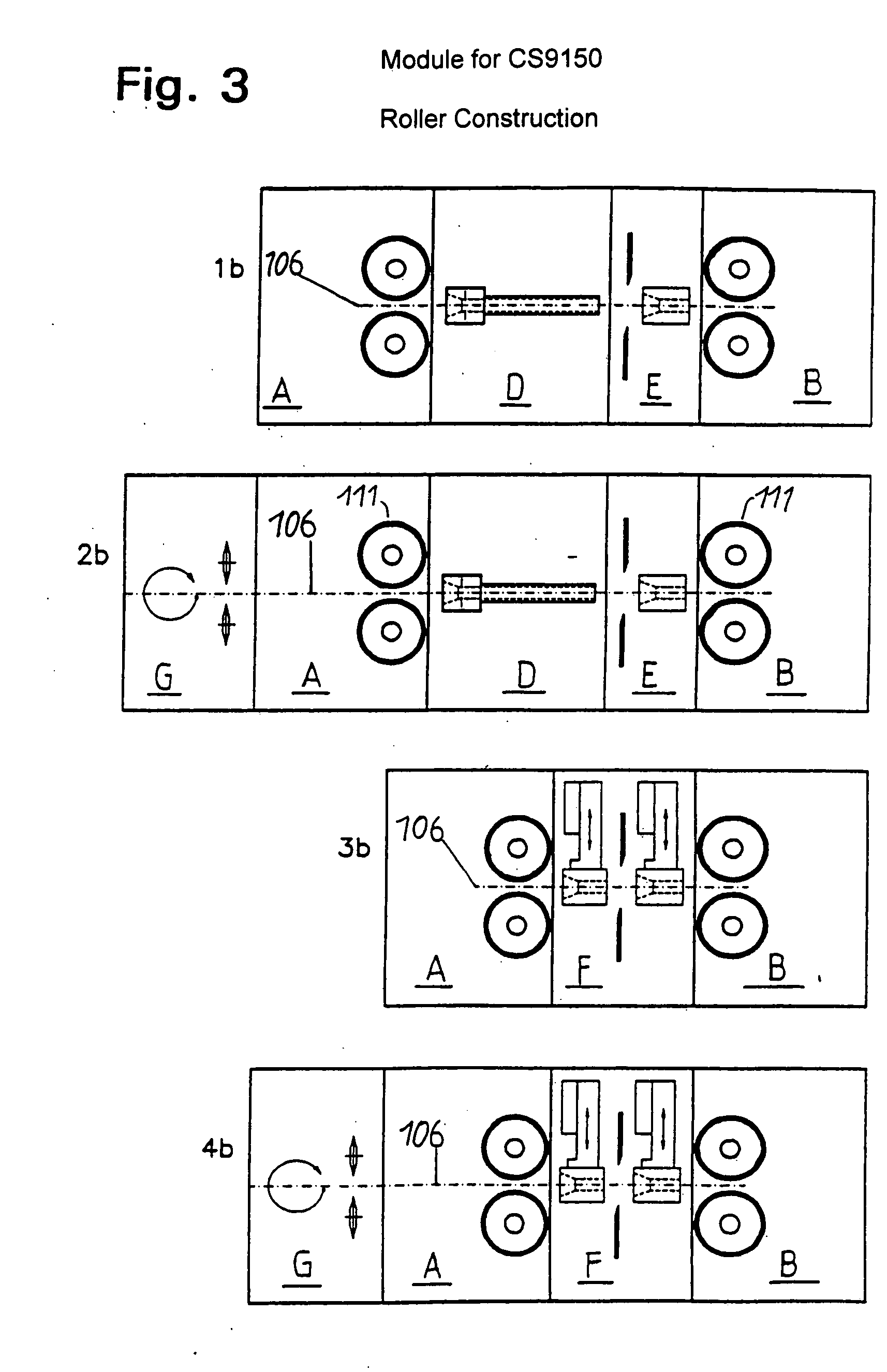

A continuous cable processing apparatus for producing cable sections with processed ends comprises a cable transport apparatus having at least one transport means for moving and holding the cable in the axial direction and, transversely thereto, a knife station. According to a special variant, two transport means are arranged in the longitudinal cable direction on both sides of the knife station and, after the cable has been cut through, each hold one of the cable end regions produced on cutting, so that said end regions are movable in the longitudinal cable direction. At least one of these end processing stations is arranged transversely with respect to the longitudinal cable direction, adjacent to the knife station and at least one transport means is movable transversely with respect to the longitudinal cable direction so that a cable end region can be fed to the end processing station.

Owner:SCHLEUNIGER HLDG

Cable sleeve and method of installation

InactiveUS7025509B2Prevent snaggingFlat surfaceInsulated cablesCoupling light guidesEngineeringStress relief

Owner:DAFOCOM SOLUTIONS

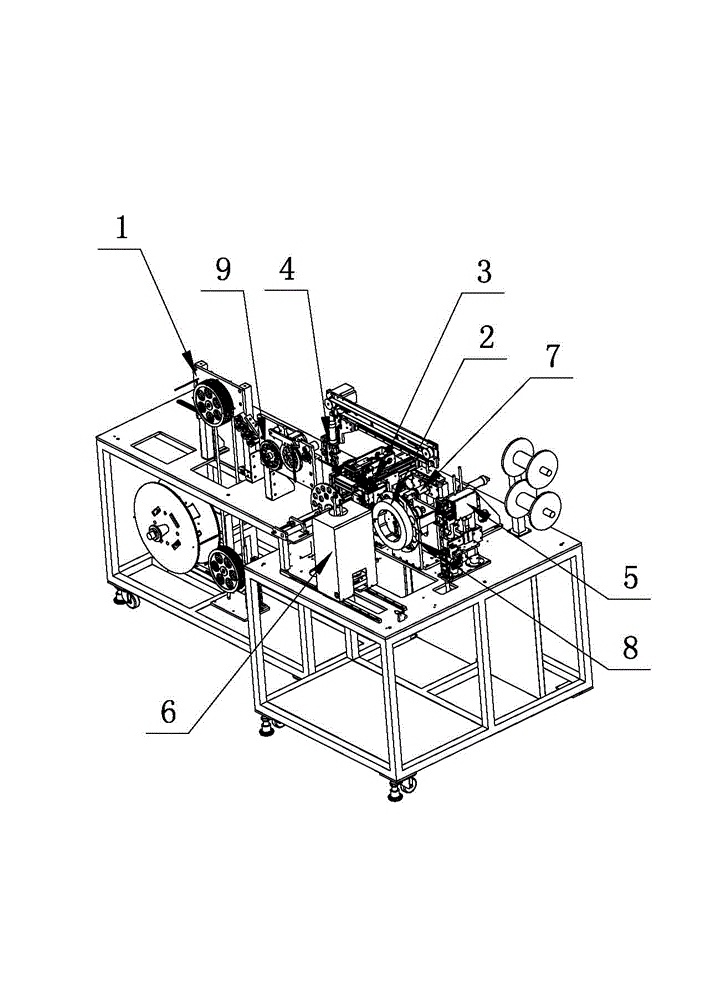

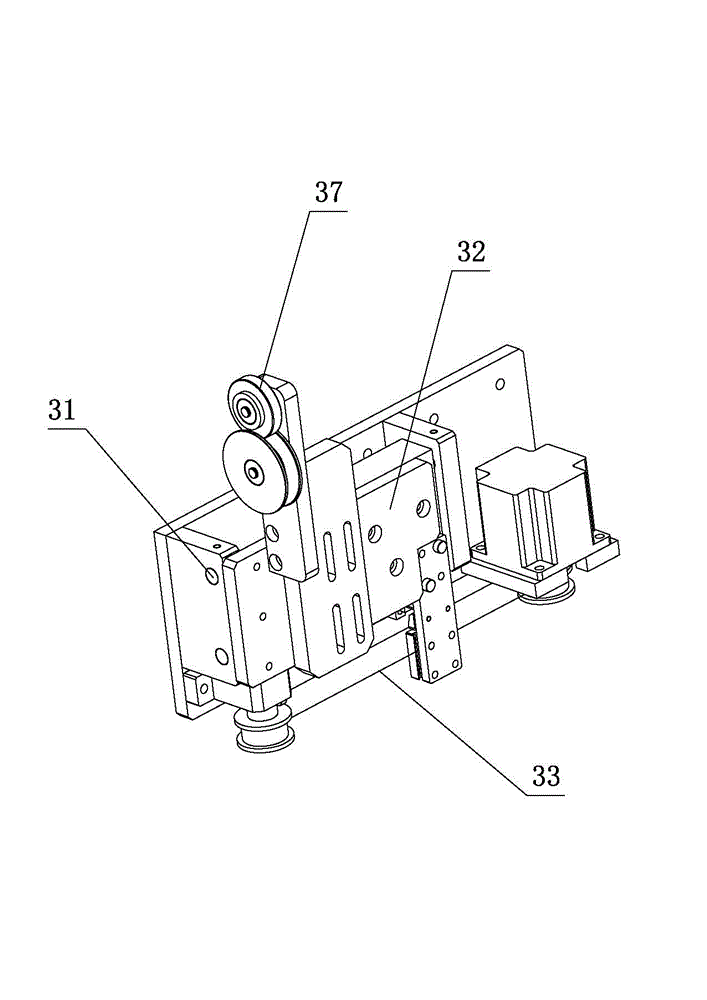

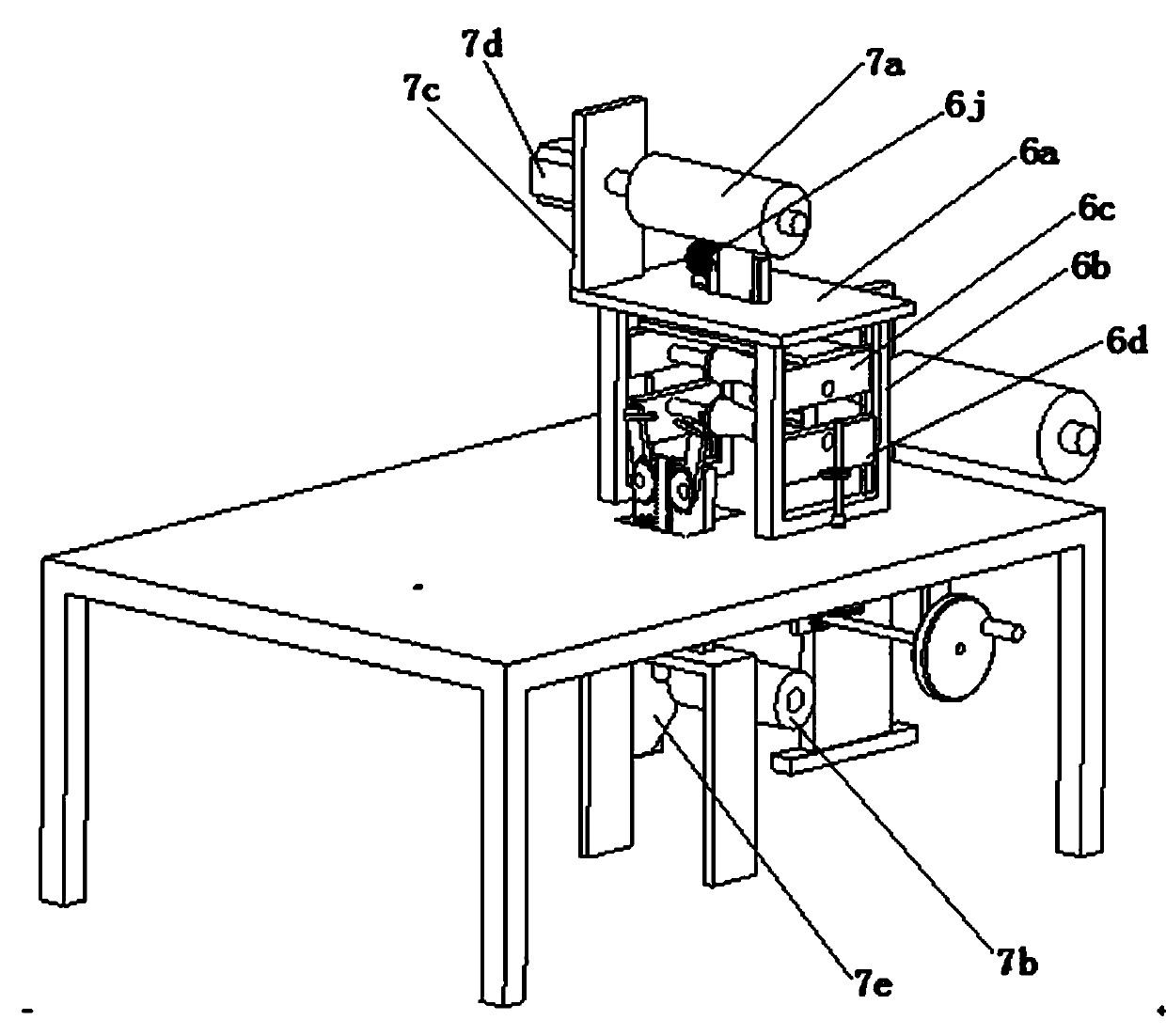

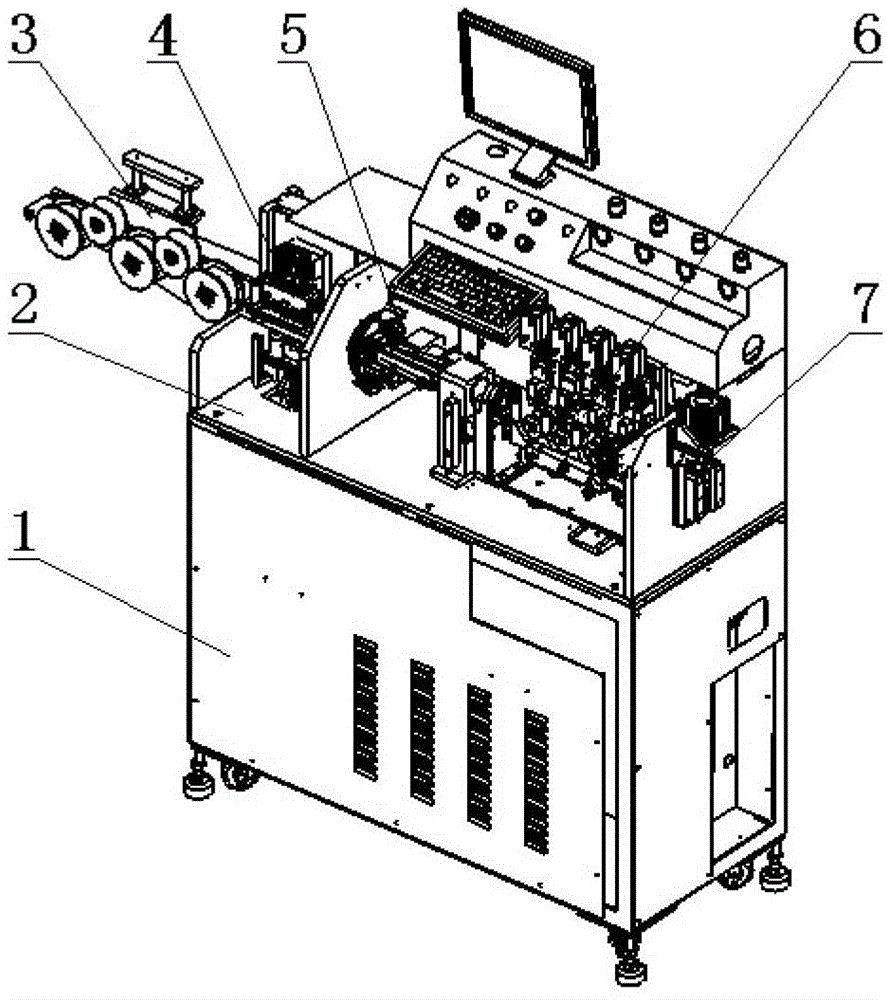

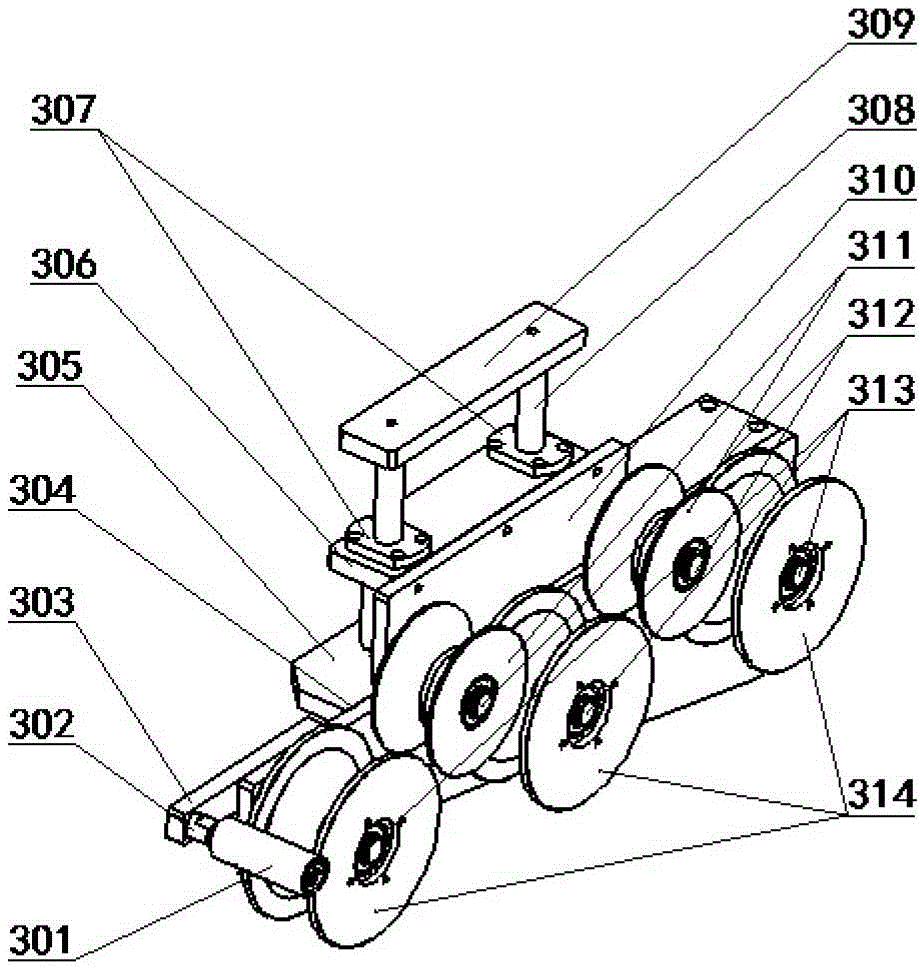

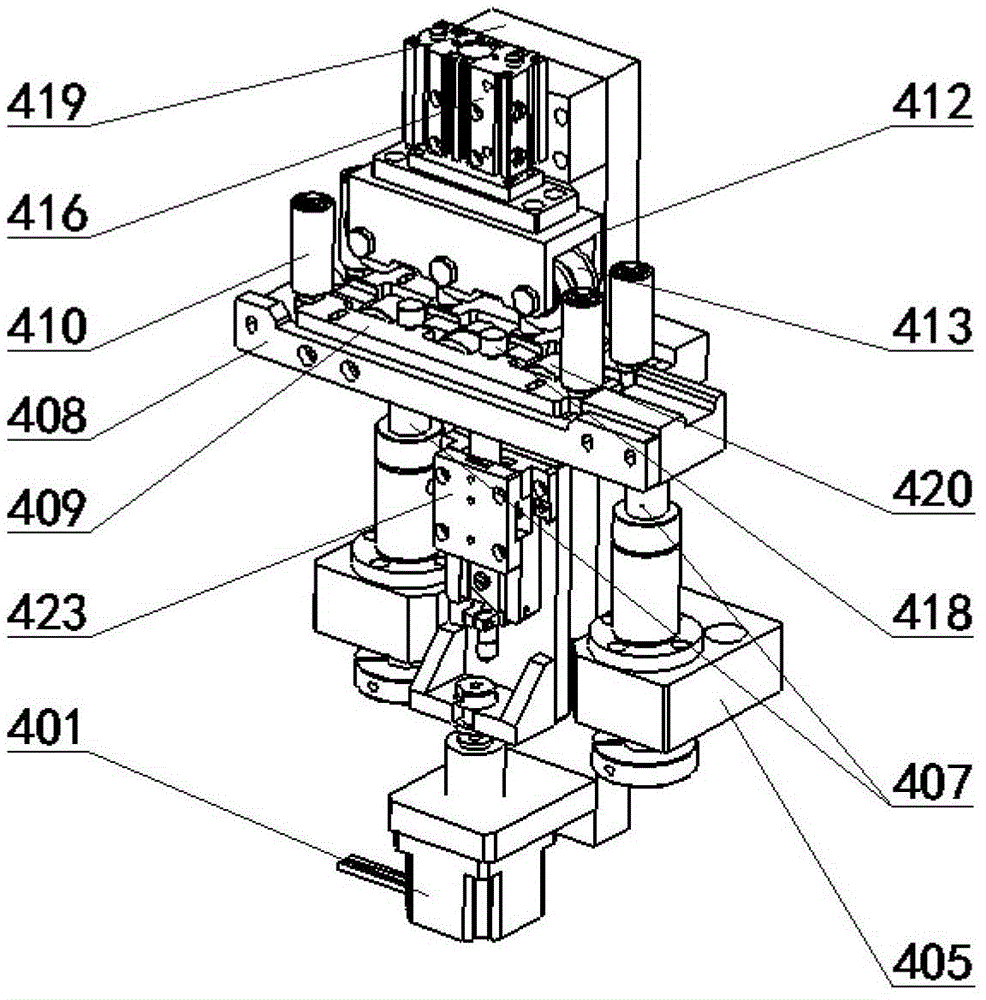

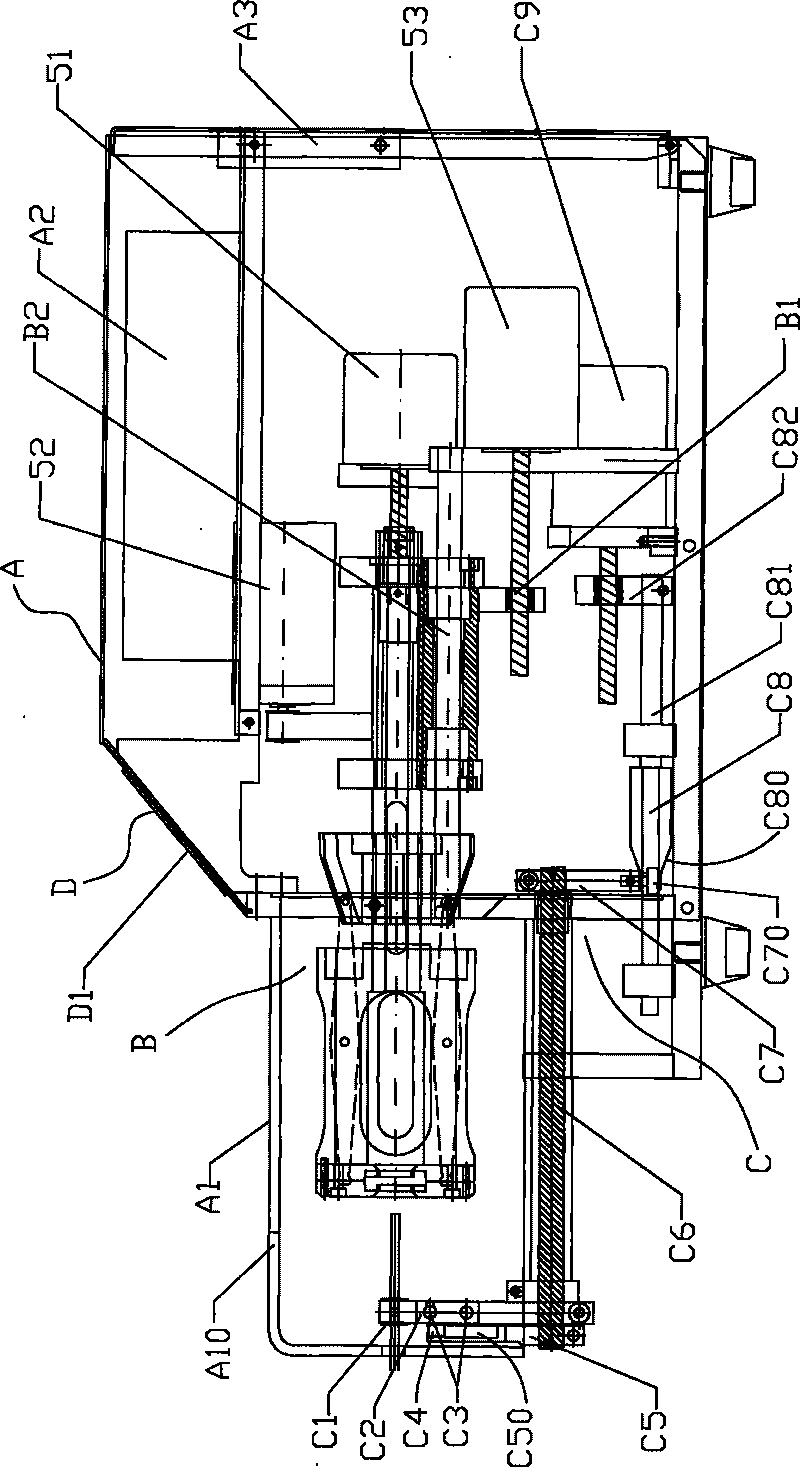

Automatic wire winding, binding and cutting integrated machine and automatic winding, binding and cutting method thereof

InactiveCN102941936AReduce manufacturing costFilament handlingBundling machine detailsWire rodWire cutting

The invention relates to the technical field of mechanical automation production devices, in particular to an automatic wire winding, binding and cutting integrated machine and automatic winding, binding and cutting method thereof. The integrated machine comprises a frame, a wire releasing device, a wire feeding device, a wire winding device, a ribbon tightening device, a ribbon contour device and a ribbon cutting device are arranged on the frame, a wire is pulled to the wire winding device through the wire feeding device and is automatically clamped, fixed and wound by the wire winding device, an annular wire coil is formed after the wire is wound, a ribbon cut off by the ribbon cutting device is conveyed to the wire coil by the ribbon contour device and is further tightened onto the wire coil by the ribbon tightening device, the wire is cut off by the wire feeding device, the wire coil is automatically unloaded by a wire clamping and coil unloading device, the winding, binding and cutting process of the whole wire coil is finished, the wire can be peeled and accuracy of the length of the wire coil can be controlled according to requirements of a customer, fully automatic unmanned operation of wire winding / length counting, wire binding, compensation, wire cutting, peeling and coil unloading is realized, and the manufacturing cost of an enterprise is reduced.

Owner:温增璟

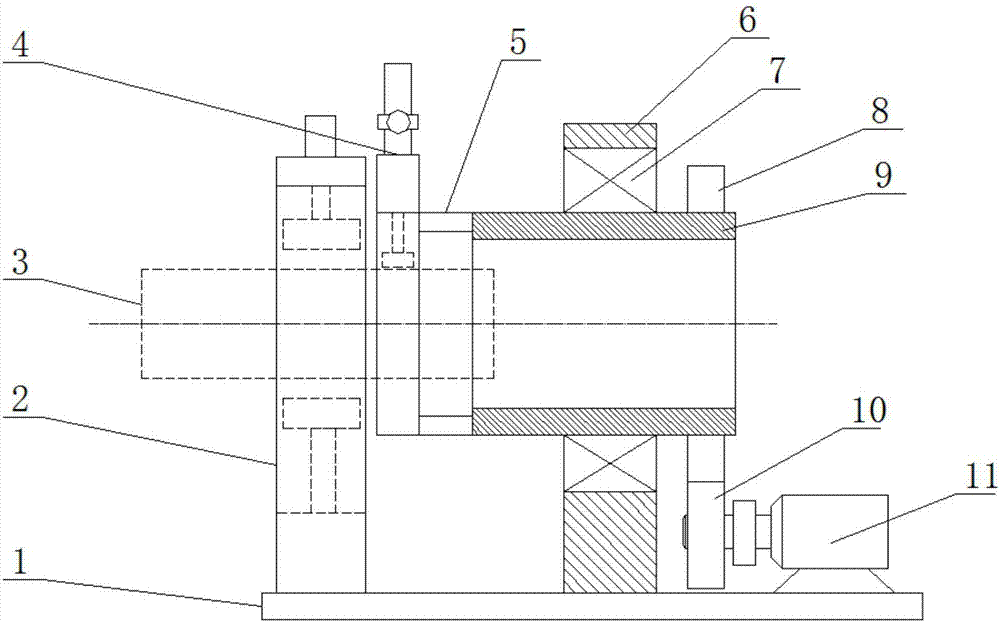

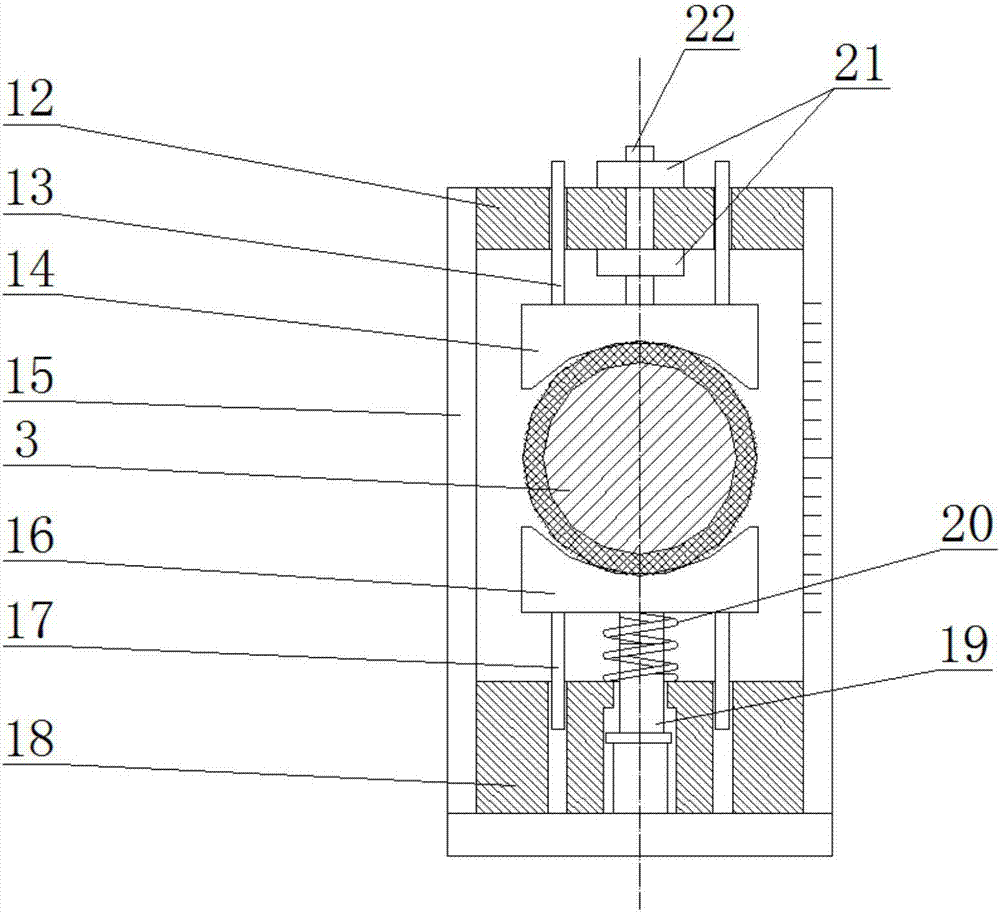

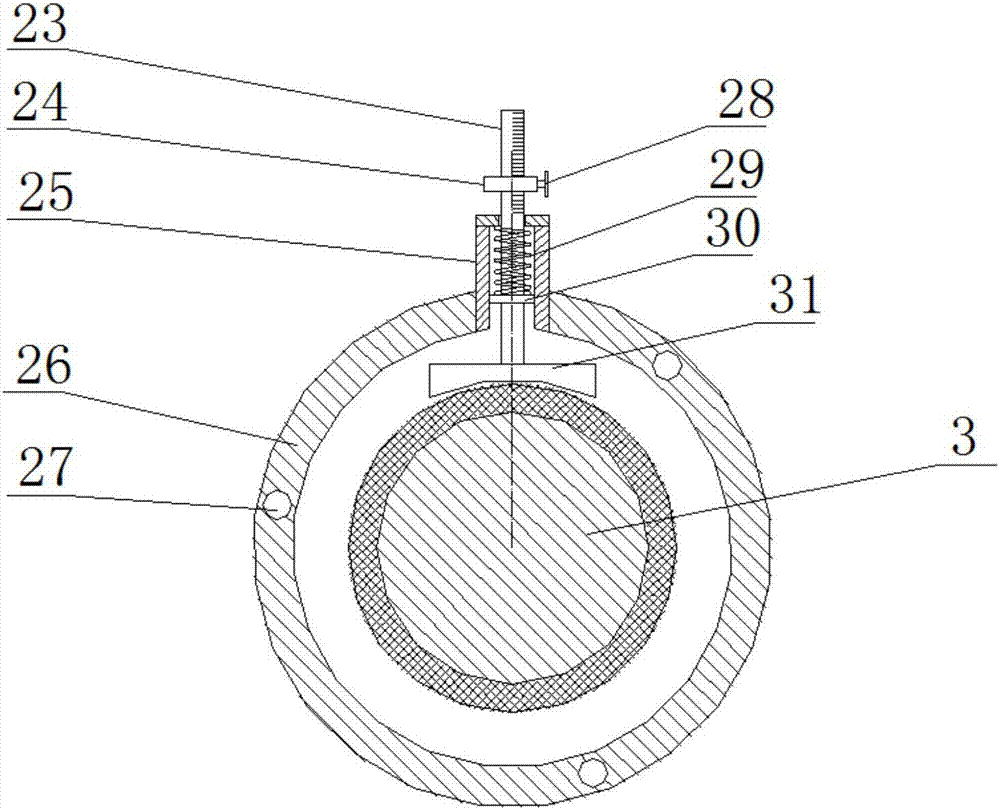

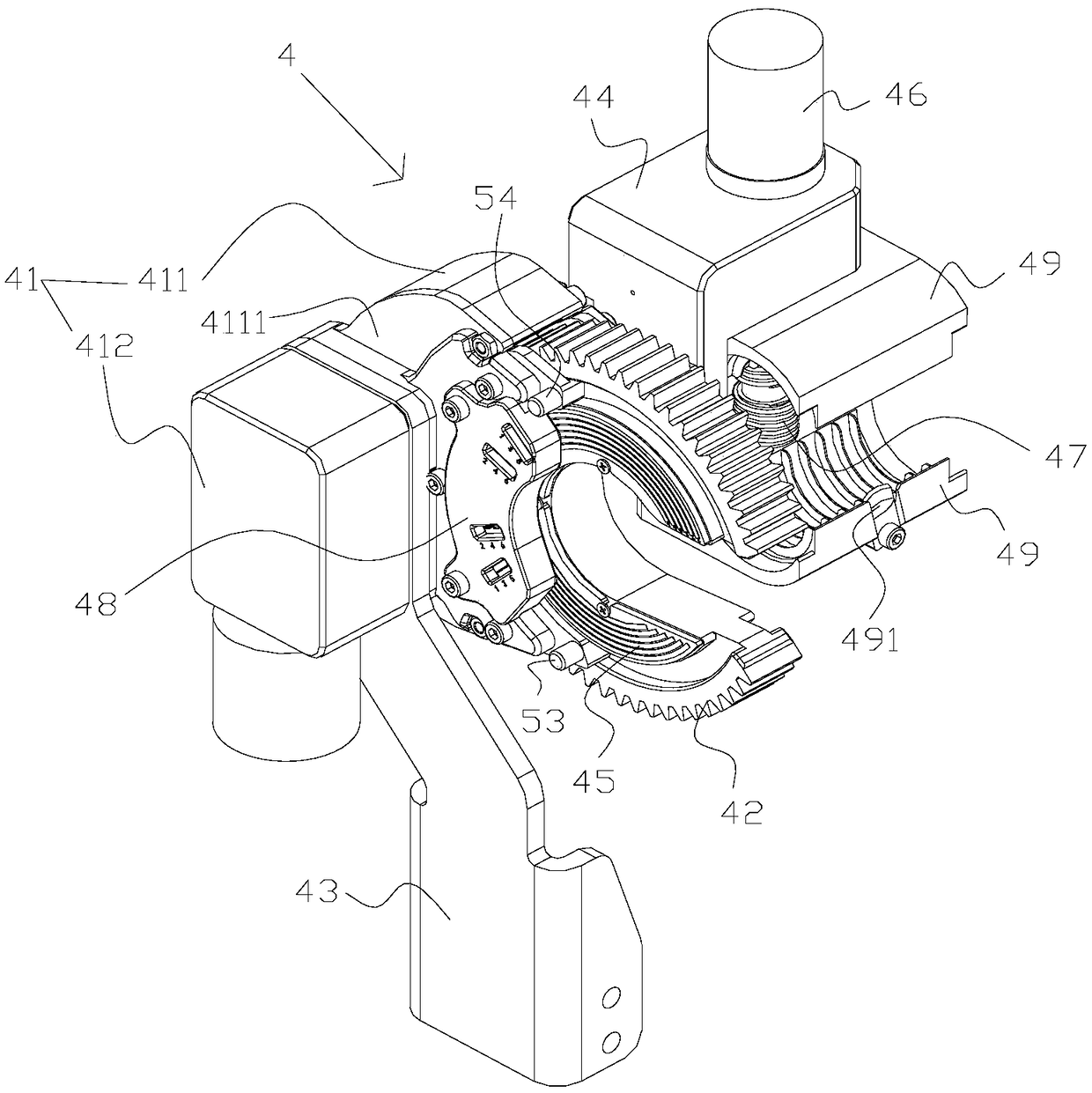

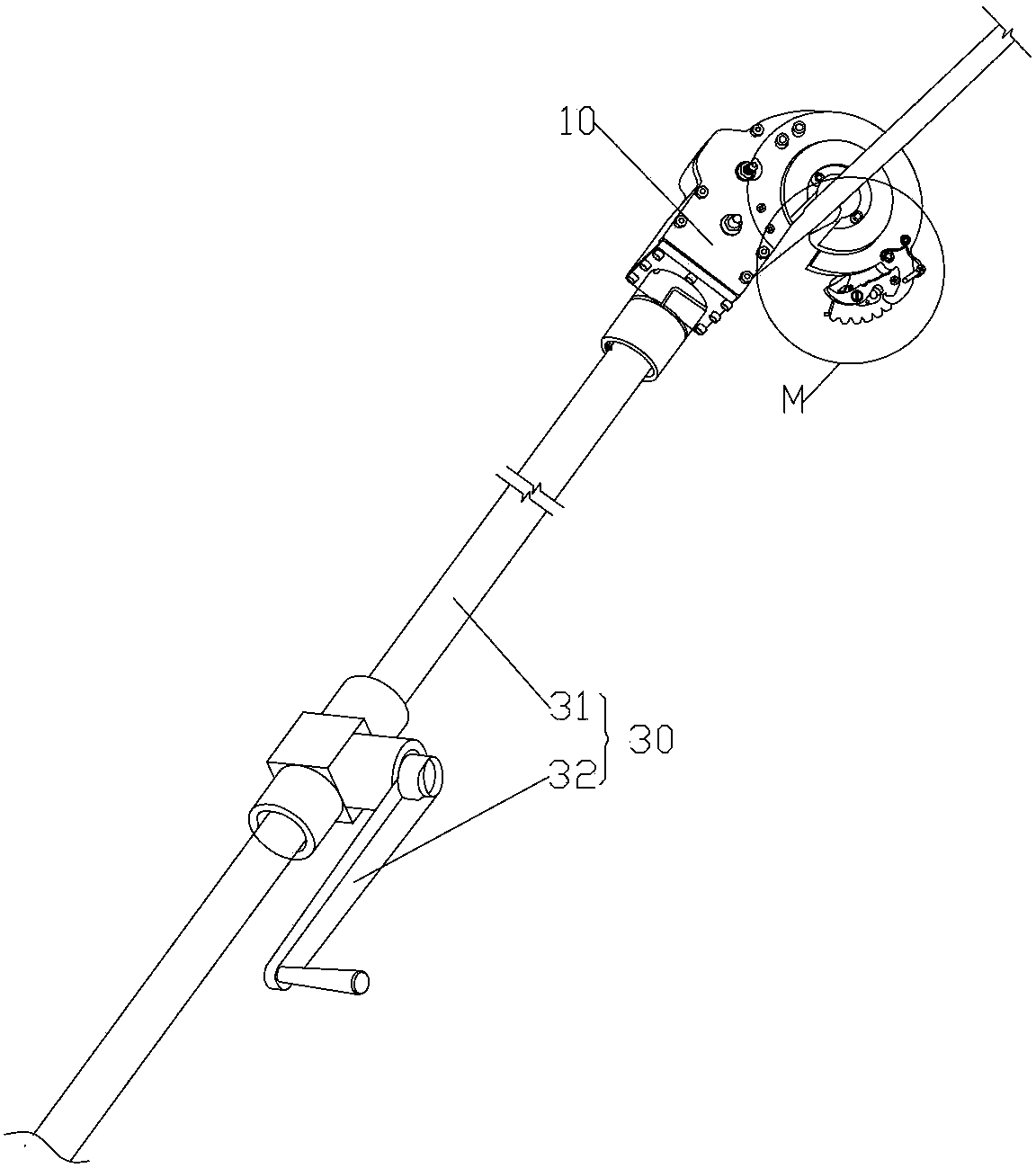

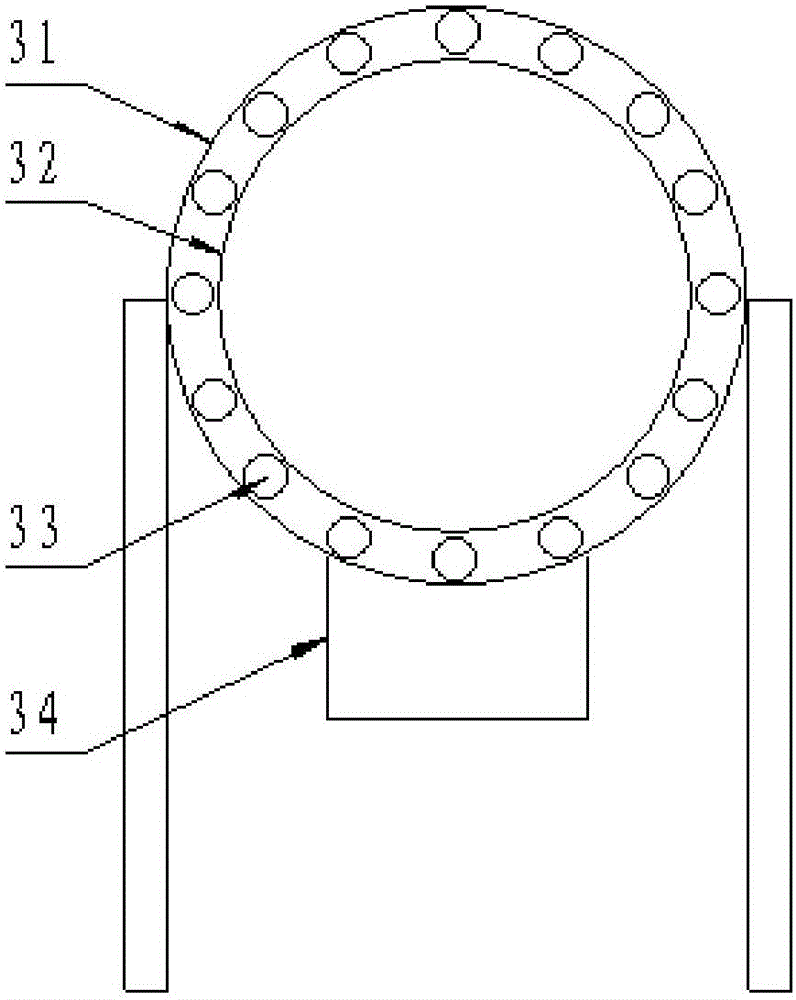

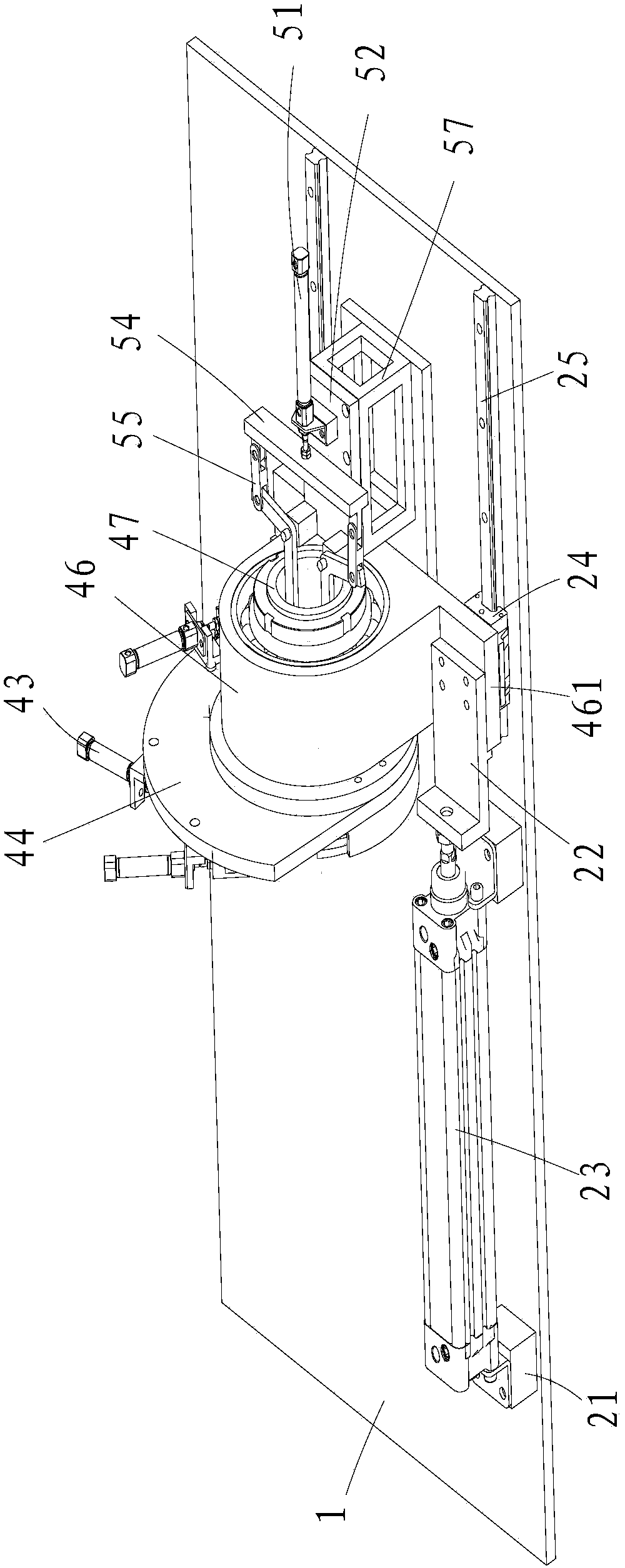

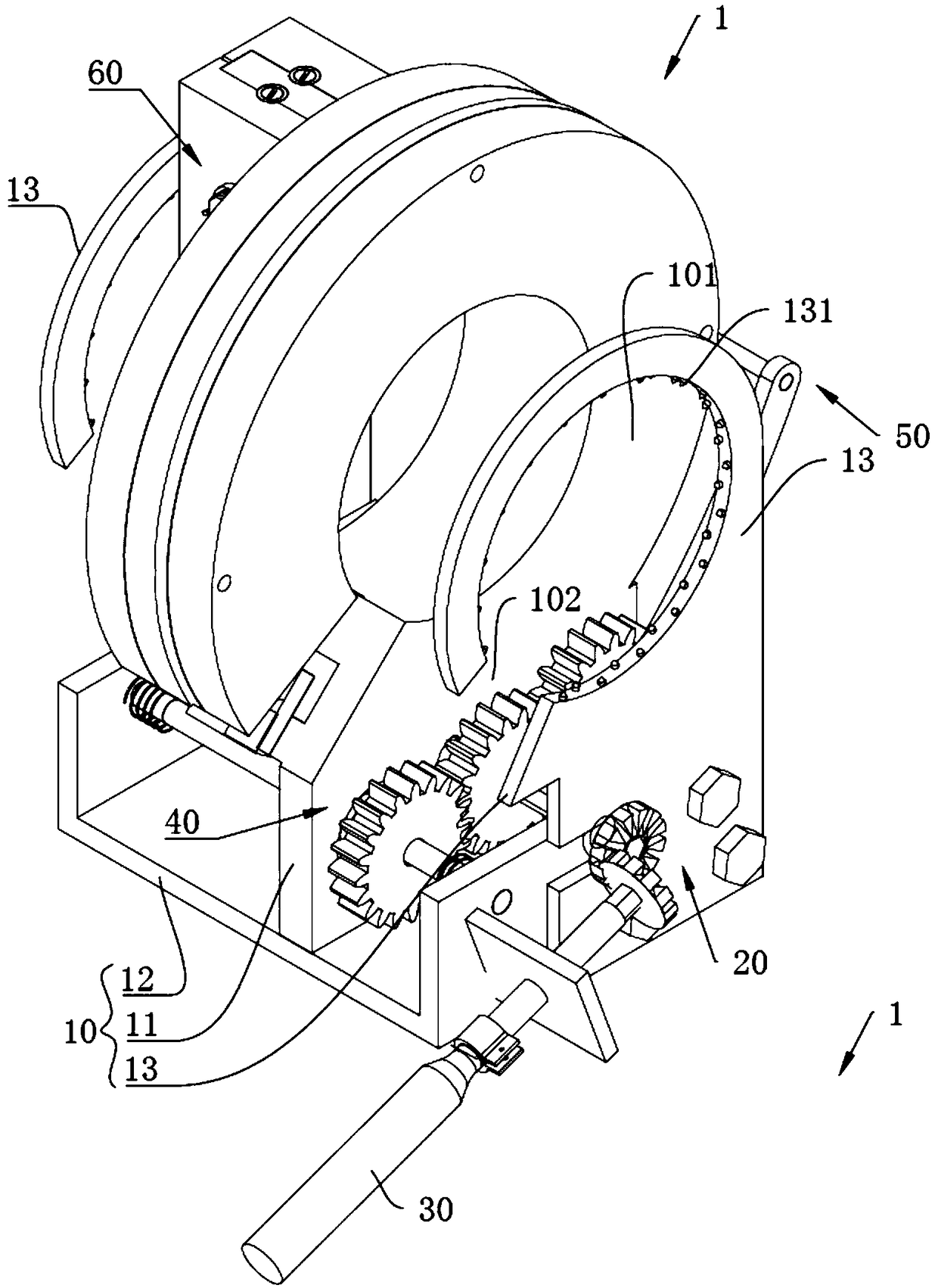

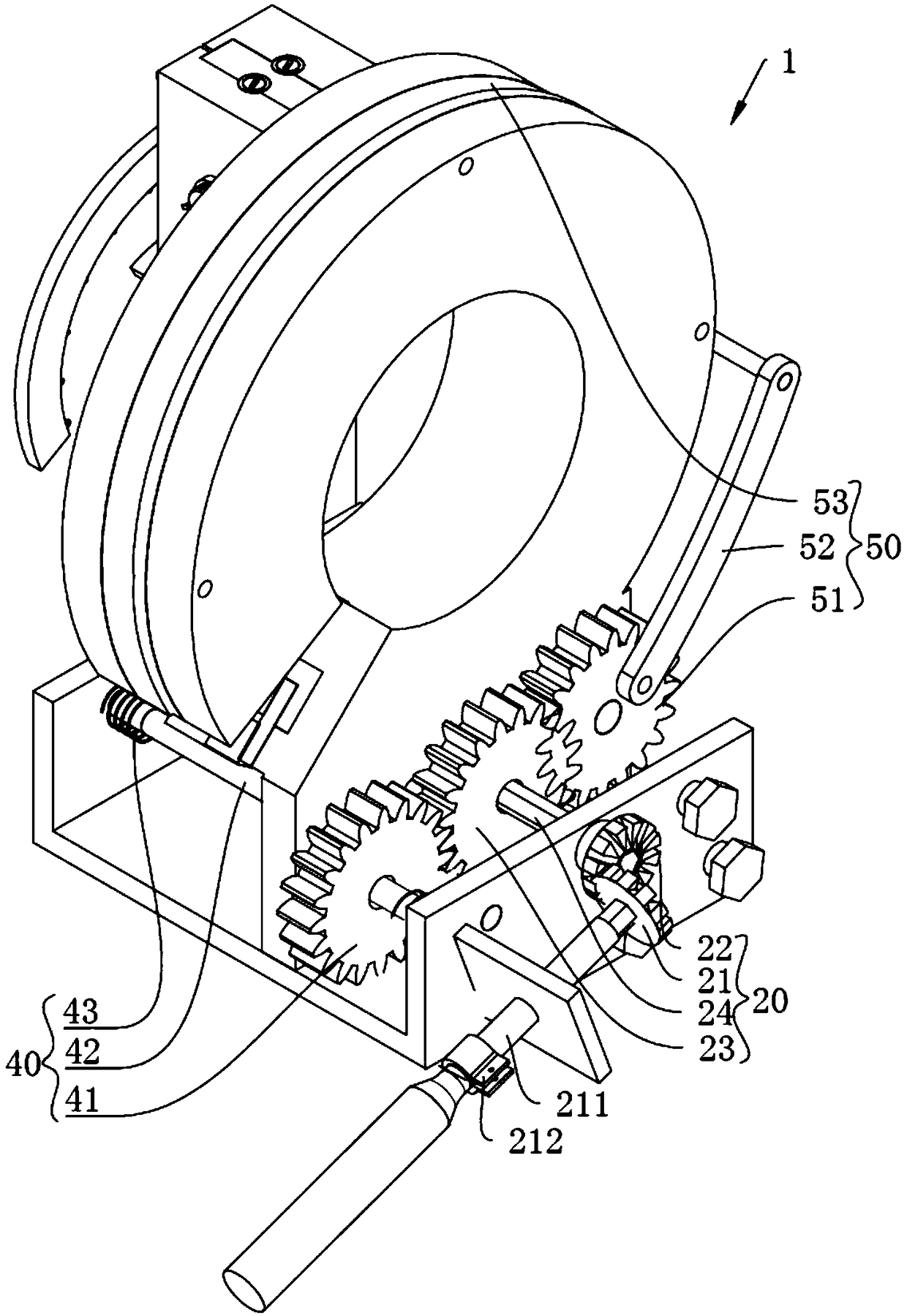

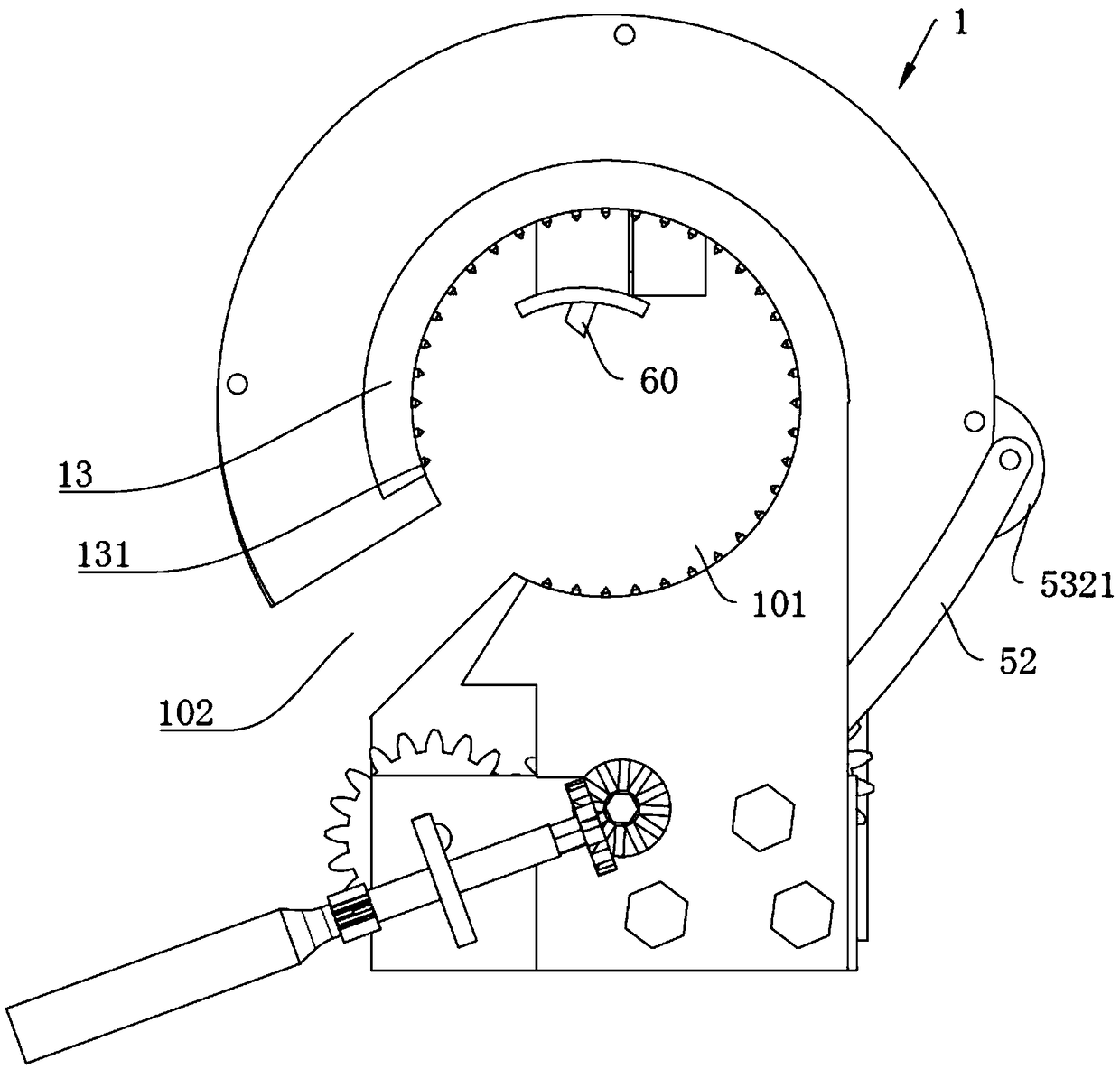

Cable rotation stripping device

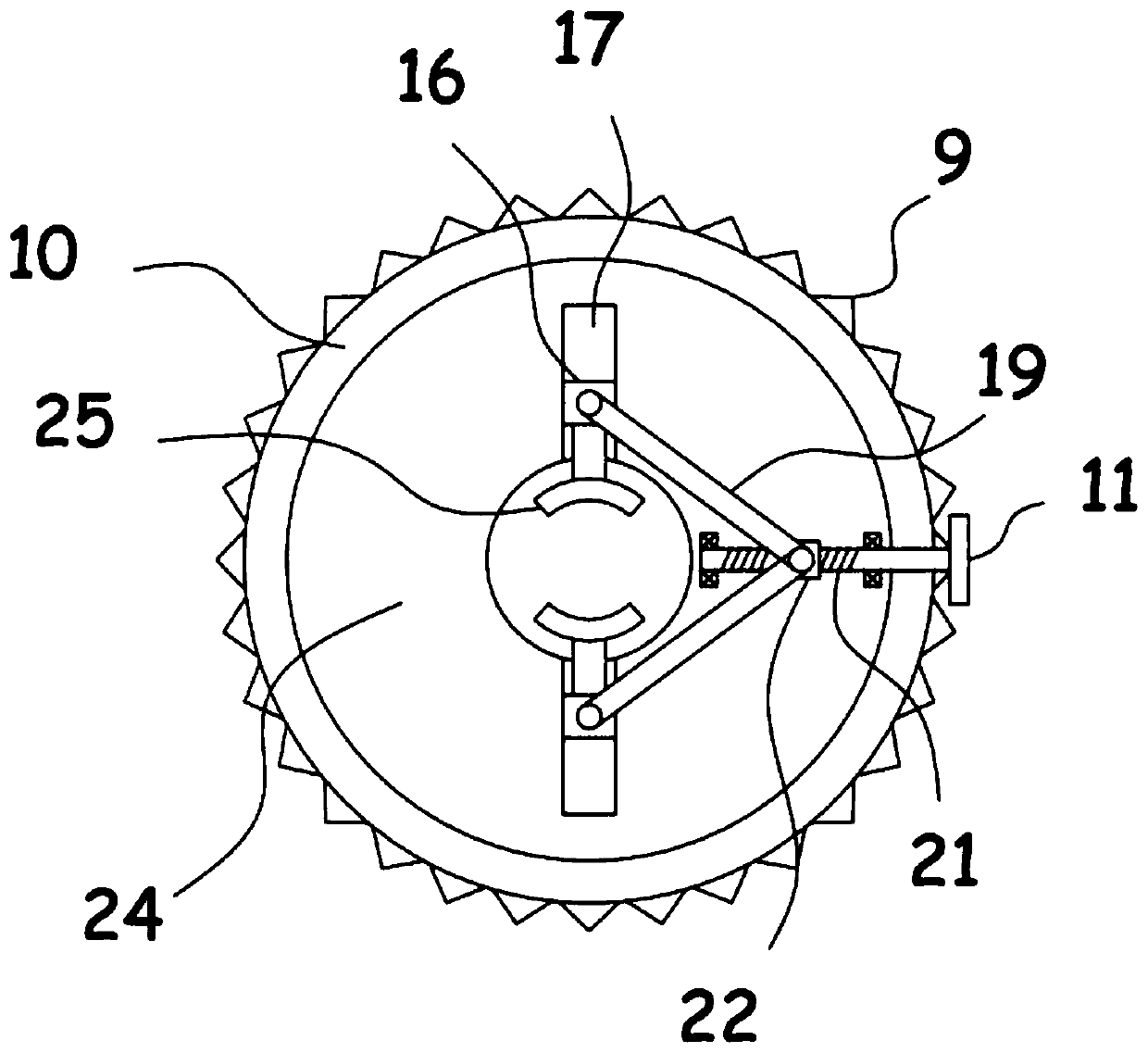

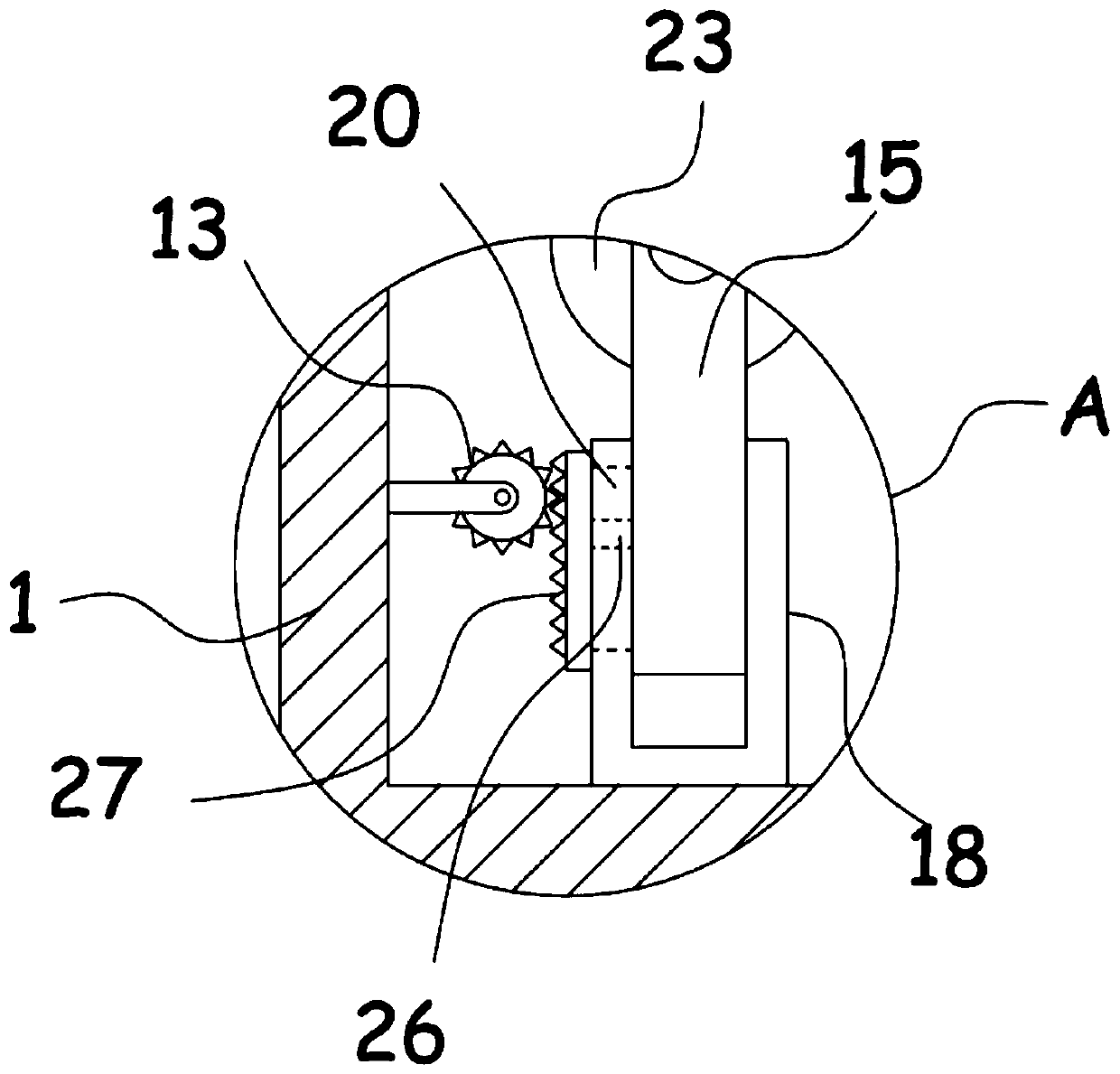

InactiveCN106998047AEasy wiringImprove work efficiencyMechanical energy handlingApparatus for removing/armouring cablesRadial positionEngineering

The invention provides a cable rotation stripping device which comprises a bottom plate. A bearing is arranged on the bottom plate. A rotatable hollow rotating shaft is arranged in the bearing. A rotary drive mechanism is arranged on one side of the hollow rotating shaft. A cutter mounting ring is arranged on the other side of the hollow rotating shaft. The cutter mounting ring is arranged coaxially with the hollow rotating shaft. A cutter adjustment device is arranged on the cutter mounting ring. A cutter which is used for cutting a cable is arranged on the cutter adjustment device. The cutter adjustment device is used for adjusting the radial position of the cutter in the cutter mounting ring, so as to ensure that the rotating cutter always contacts the cable. An adjustable gripping device which is used for gripping the cable is arranged on one side of the cutter mounting ring. The adjustable gripping device is used for adjusting the cable, so that the cable is coaxial with the hollow rotating shaft. The device is capable of fast stripping cables, and especially large cables. In the stripping process, the internal cable core is not accidentally cut off.

Owner:NANJING INST OF RAILWAY TECH

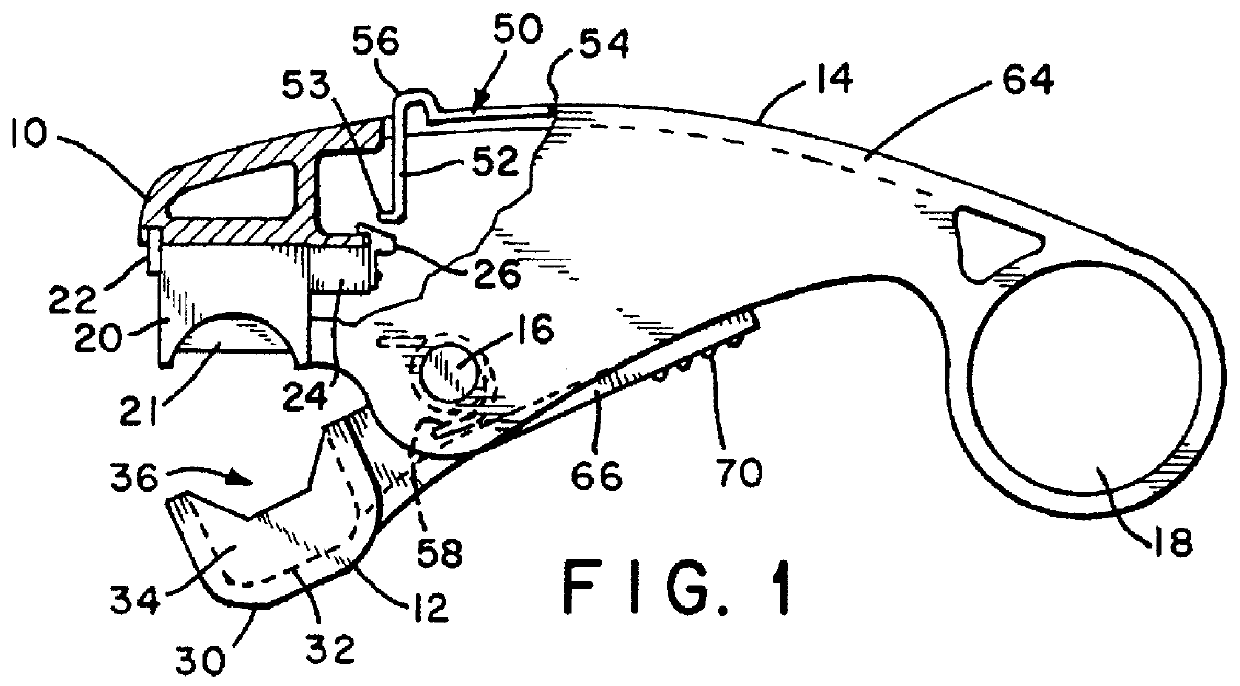

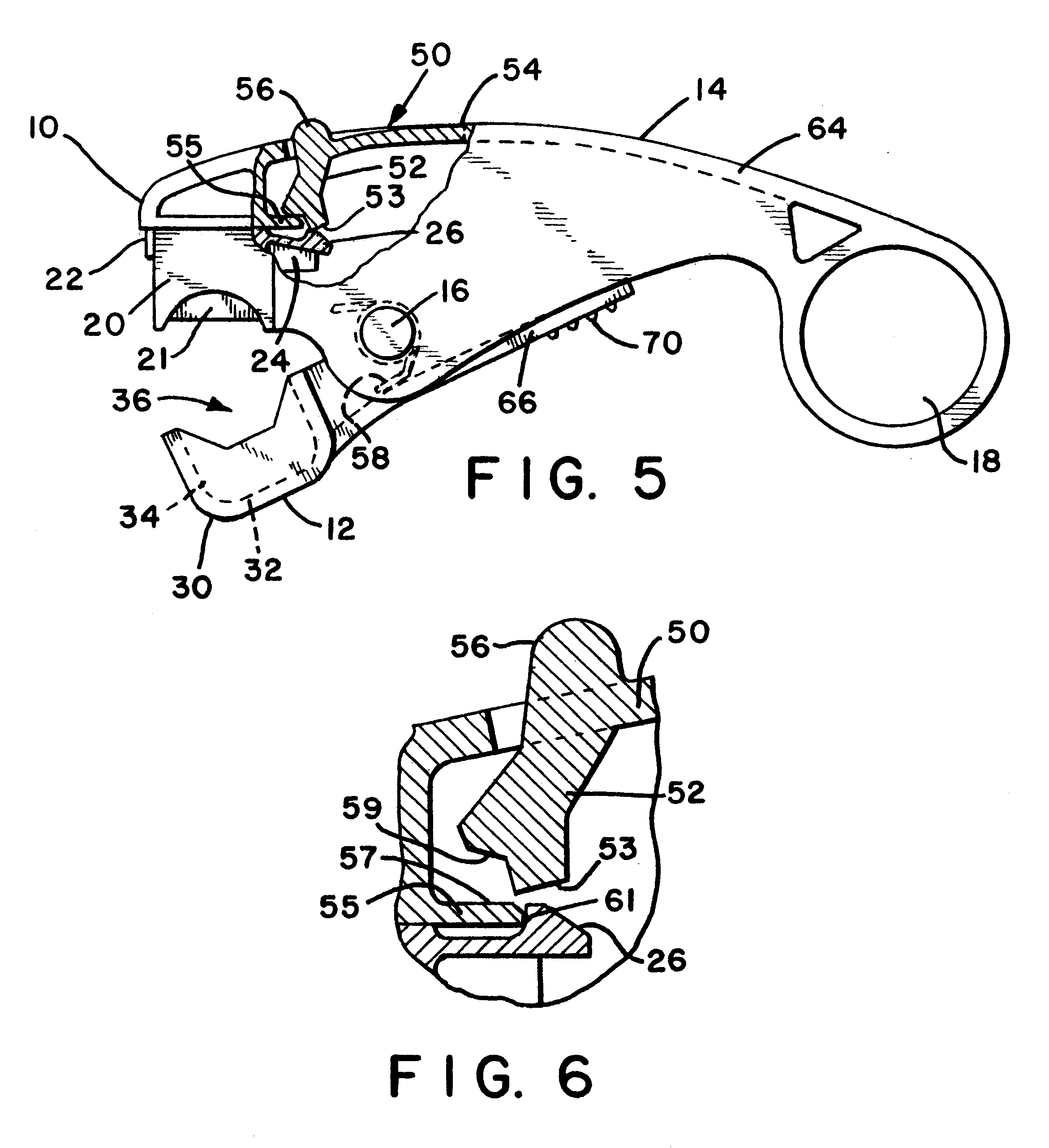

Optical fiber cleaver

An optical fiber cleaver, comprising a blade capable of applying a scratch to the outer peripheral surface of an optical fiber and a pusher pushing the optical fiber to cleave it at the scratched part, wherein it further comprises a reverse-running prevention mechanism which prevents the blade which was moved directly and gave scratch to the optical fiber from being directly moved reversely and giving scratch again to the optical fiber, the reverse-running prevention mechanism comprises a cam moved directly in connection with the blade and a cam follower being in contact with the cam and capable of directly moving the pusher, and the cam presses the pusher automatically against the optical fiber for cleavage after the optical fiber has been scratched by the blade and, after the scratch has been given completely, locked with the cam follower so as to suppress the cam from being moved directly in the reverse direction.

Owner:FURUKAWA ELECTRIC CO LTD

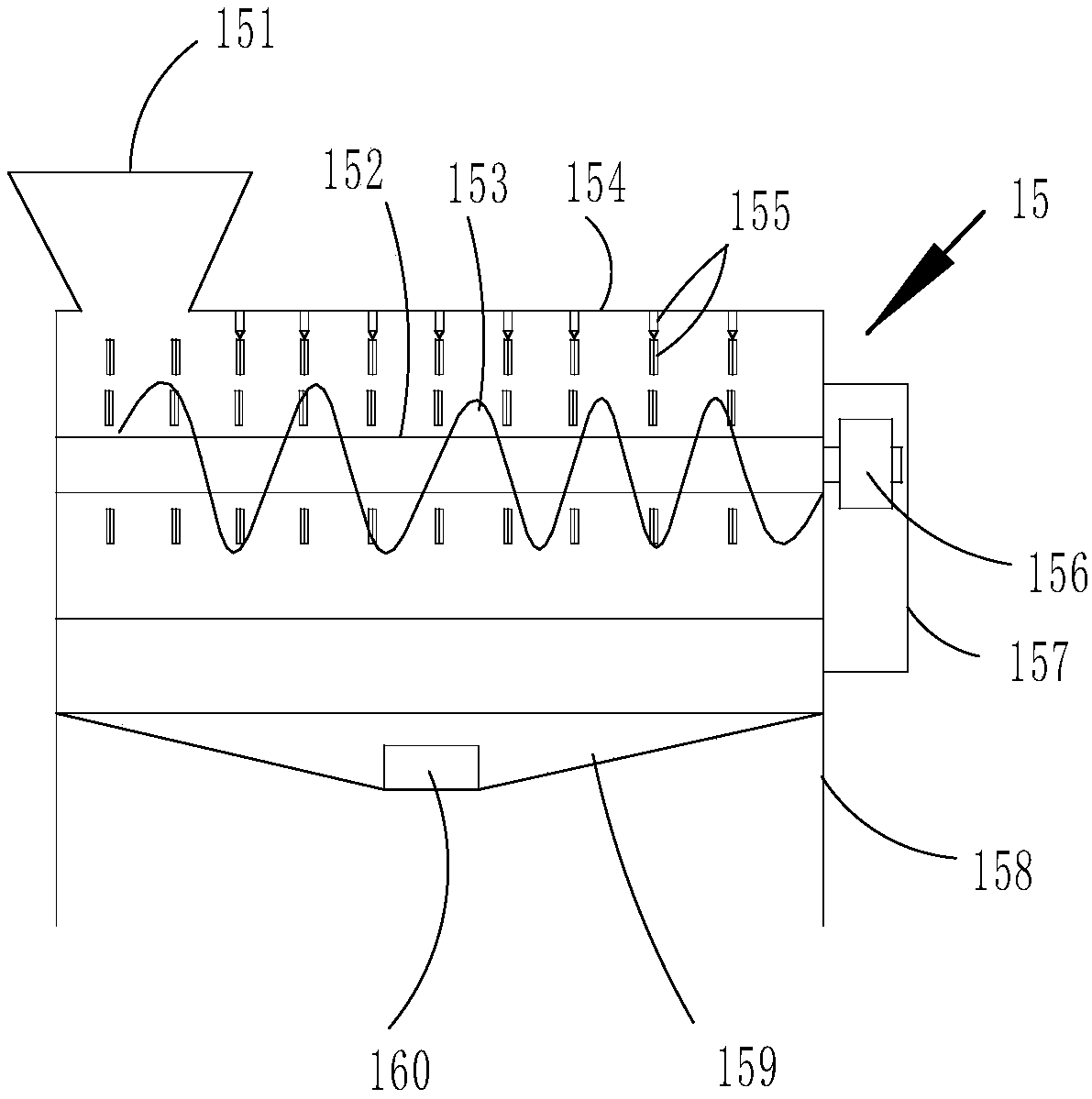

Waste Cable Recovery System

ActiveCN109036736AImprove recycling effectAvoid stickingBasic electric elementsApparatus for removing/armouring cablesEngineeringCopper

The invention provides a waste cable recovery system and belongs to the technical field of waste cable reuse. The system includes frame, pay-off roll, straightening device, cutting device, cop core winding roller, two cooling devices, two cutting devices and crushing device. A let-out roller, a straightening device, a cutting device and a cop core winding roller are arranged in sequence from one end of that frame, two cooling device and two cutting devices are arranged between the cutting device and the cop core winding roller and are symmetrically arranged on both sides of the frame, the cooling device is close to the frame, and the cutting device is far away from the frame. The invention provides a waste cable recovery system, by carrying out straightening first, and Cutting, Cut off thecable sheath after cooling, the cable sheath after the cutting-off falls into the lower crushing device for crushing, copper core is wound on the copper core winding roller along a straight line, after straightening the cable sheath, adhesion and incessant cutting of the cable sheath can be avoided, thereby avoiding scratching the copper core, the cable sheath is cut off after cooling, and is easy to cut and crushing.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +1

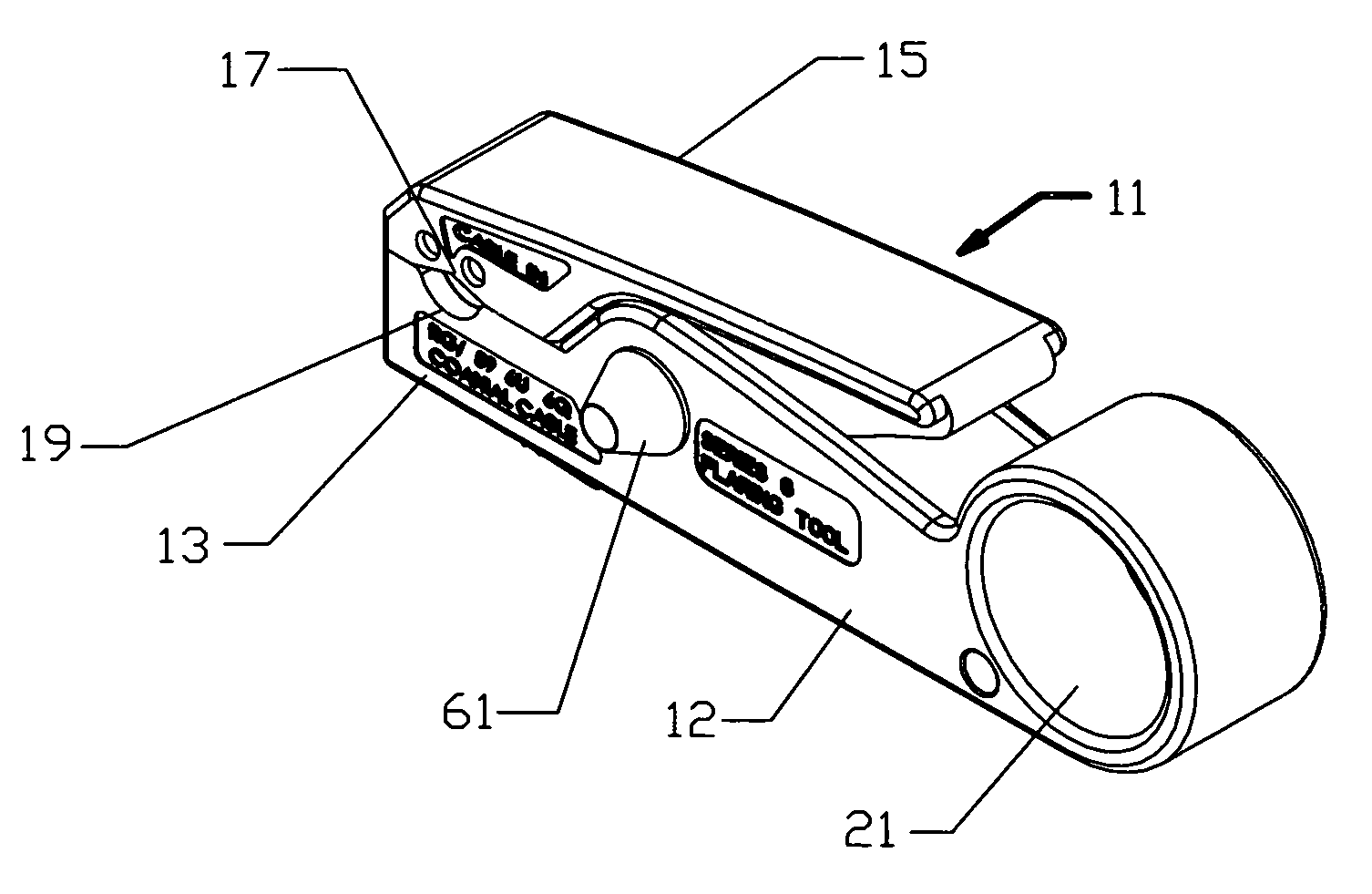

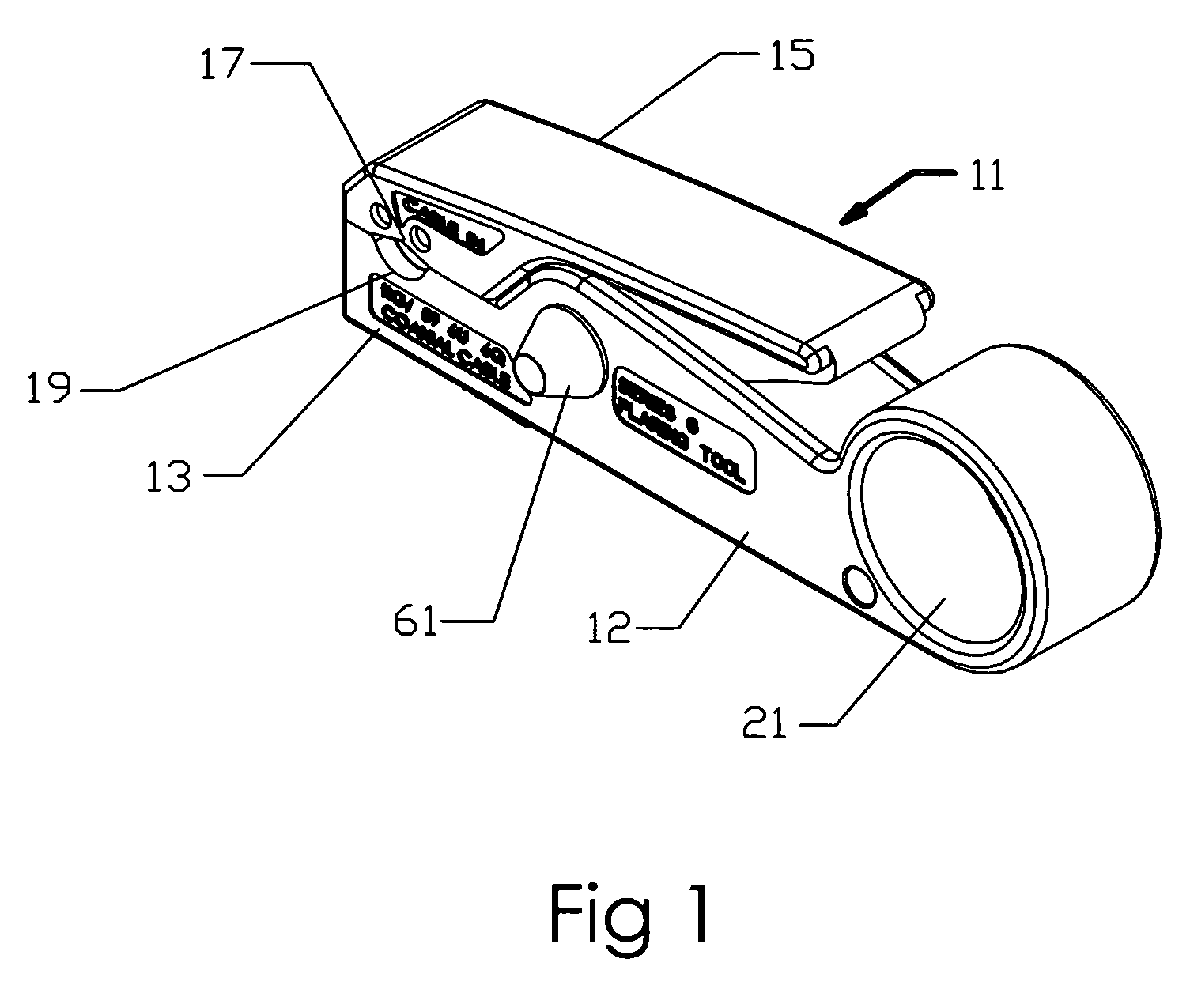

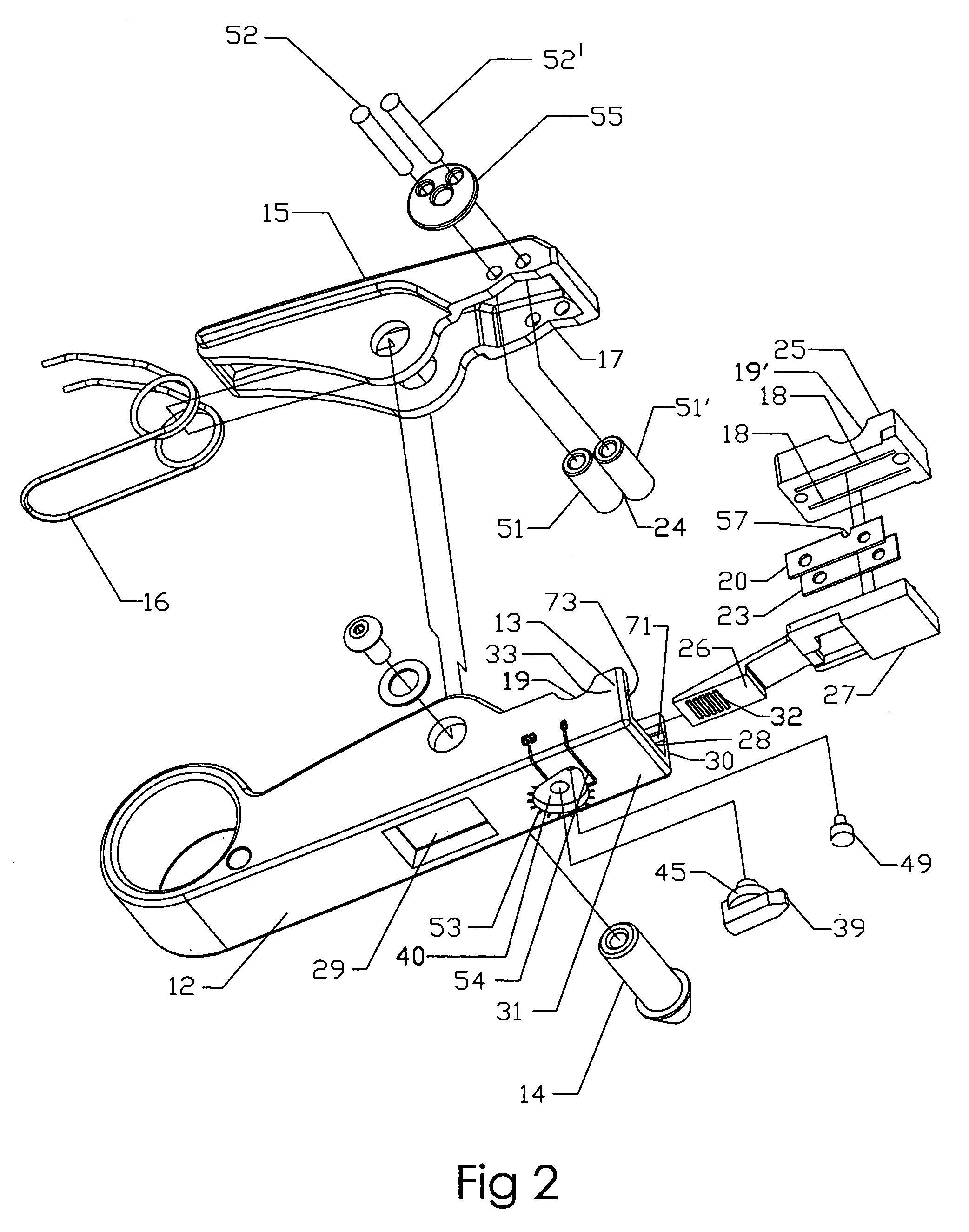

Single drop trimmer

A handheld coaxial cable trimmer tool has a removable and interchangeable blade cartridge and support insert so that the tool can easily be used with different types of coaxial cables without the need for additional tools. The cartridge is easily removed from the tool by pressing on a flexible lever on the top of the tool and the support insert snaps in and out of the tool without the need for separate fasteners.

Owner:RIPLEY TOOLS

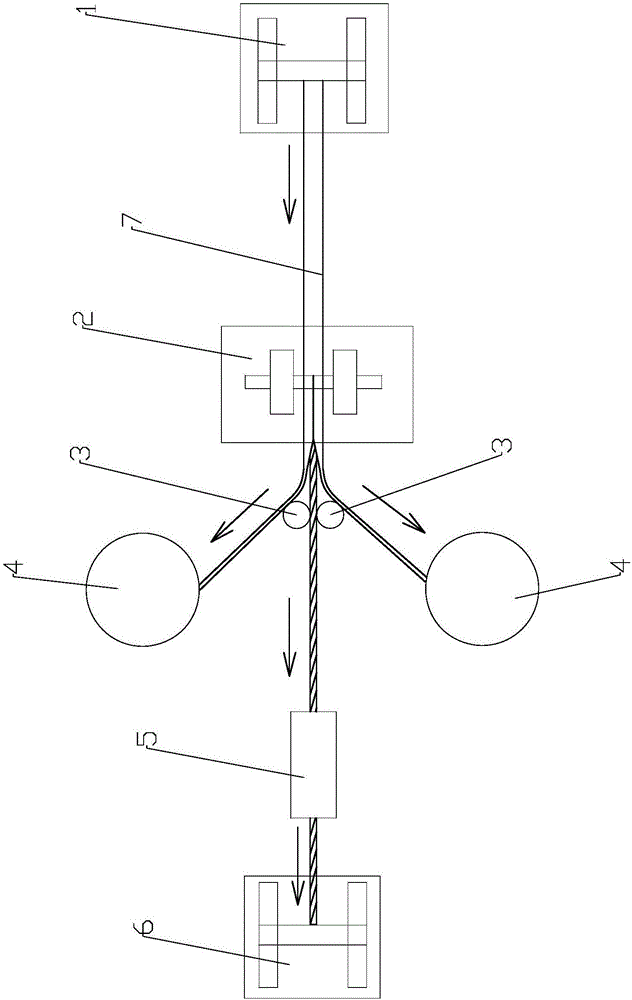

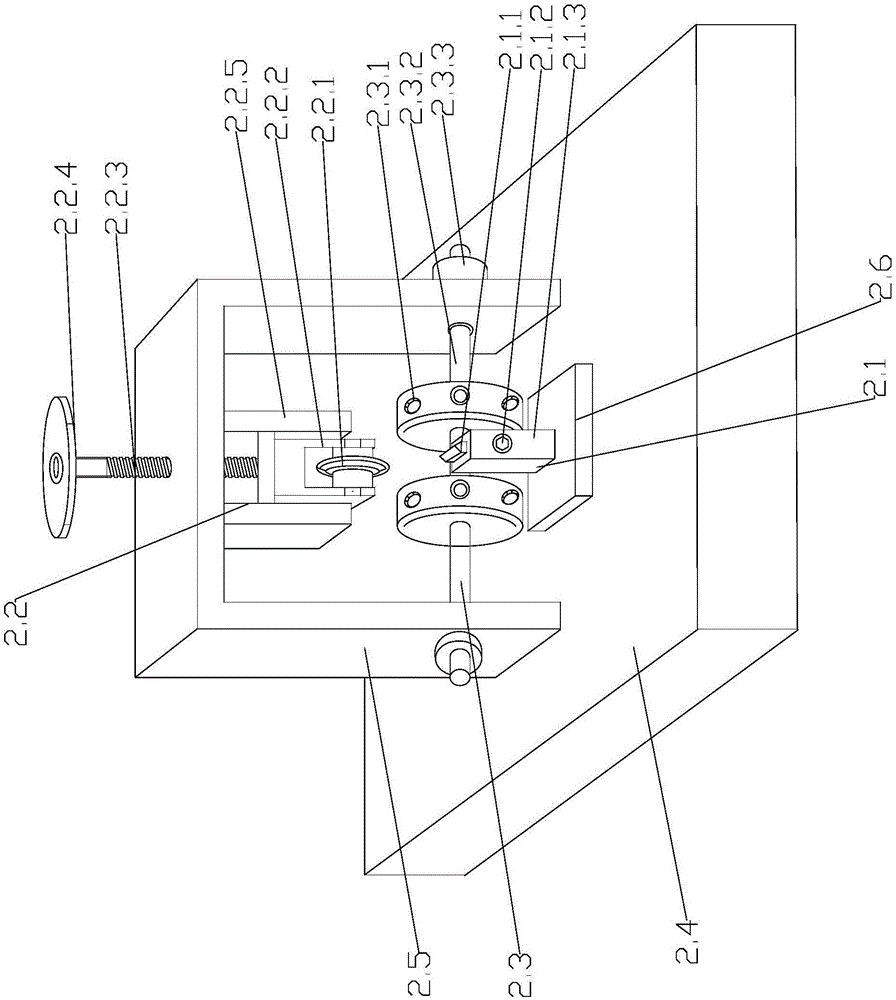

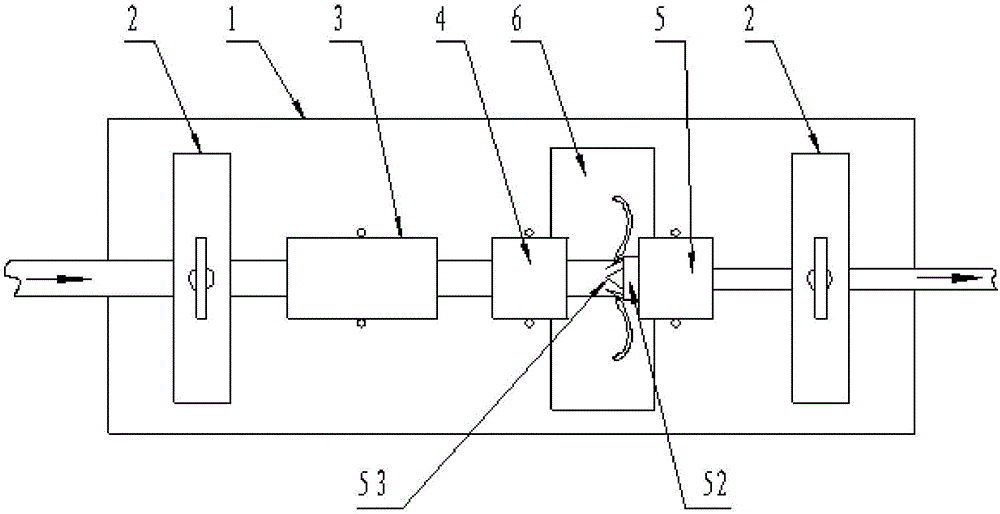

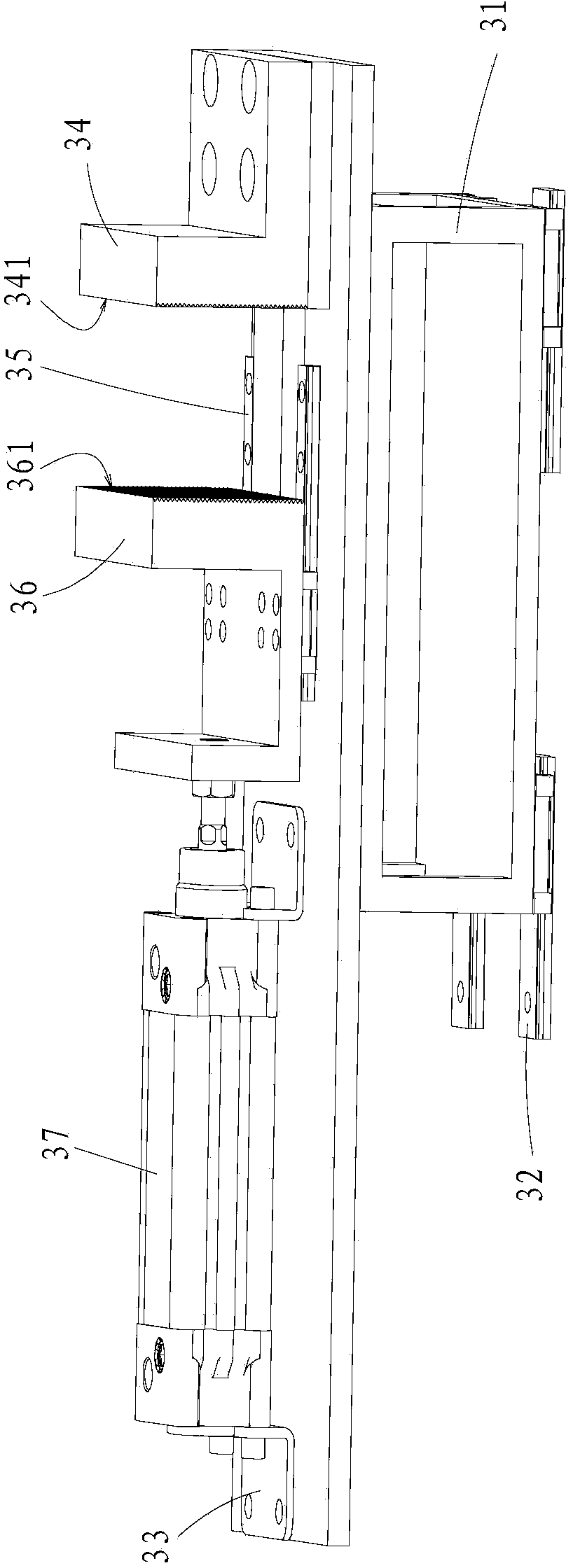

Automatic and continuous cable peeling and separating device and method

ActiveCN106300154AAutomatic continuous separationSimple structureApparatus for removing/armouring cablesElectrical conductorEngineering

The invention relates to a wire cable peeling device, in particular to an automatic and continuous cable peeling and separating device, and belongs to the technical field of cable peeling devices. The automatic and continuous cable peeling and separating device comprises a pay-off device, a cable cutting device, a tension machine and a take-up device. Two limiting stand columns are arranged between the cable cutting device and the tension machine. A packaging hub is arranged on one side of each limiting stand column. The cable cutting device comprises a fixed cutter mechanism, a movable cutter mechanism, a cable limiting mechanism, a cutting supporting base, a fixed cutter base and a movable cutter base. A cable conductor and a wrapping material can be automatically and continuously separated, the conductor can be repeatedly used, the wrapping material can be automatically packaged and recovered; the peeling and separating work efficiency is high, the separating effect is good, and the device is suitable for separating various wire cable conductors and wrapping materials.

Owner:WUXI HUANENG ELECTRIC CABLE

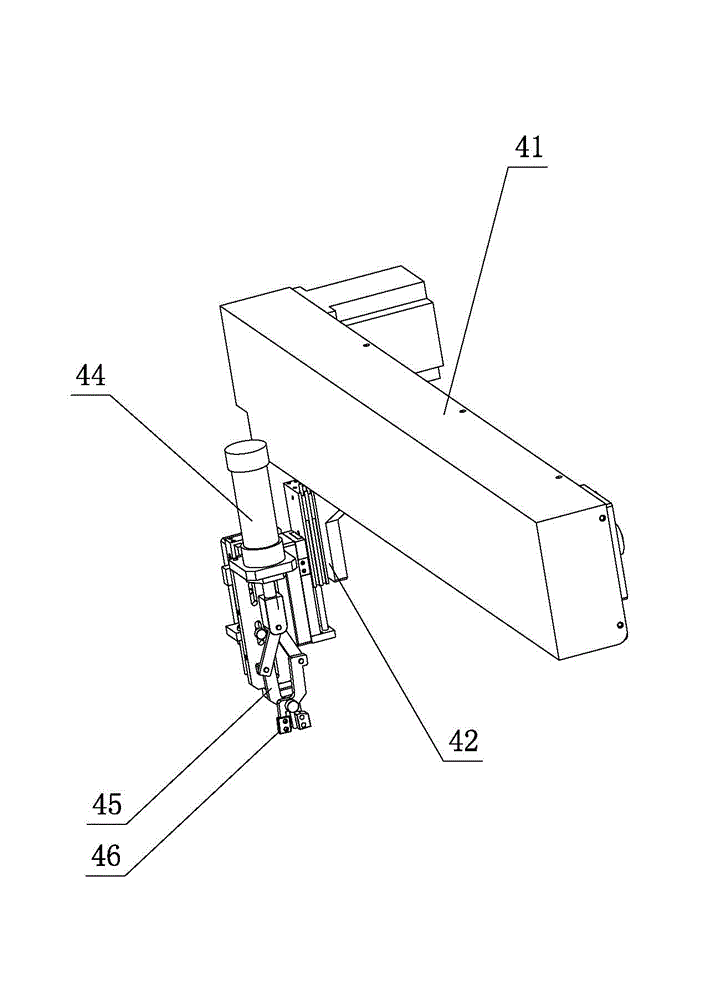

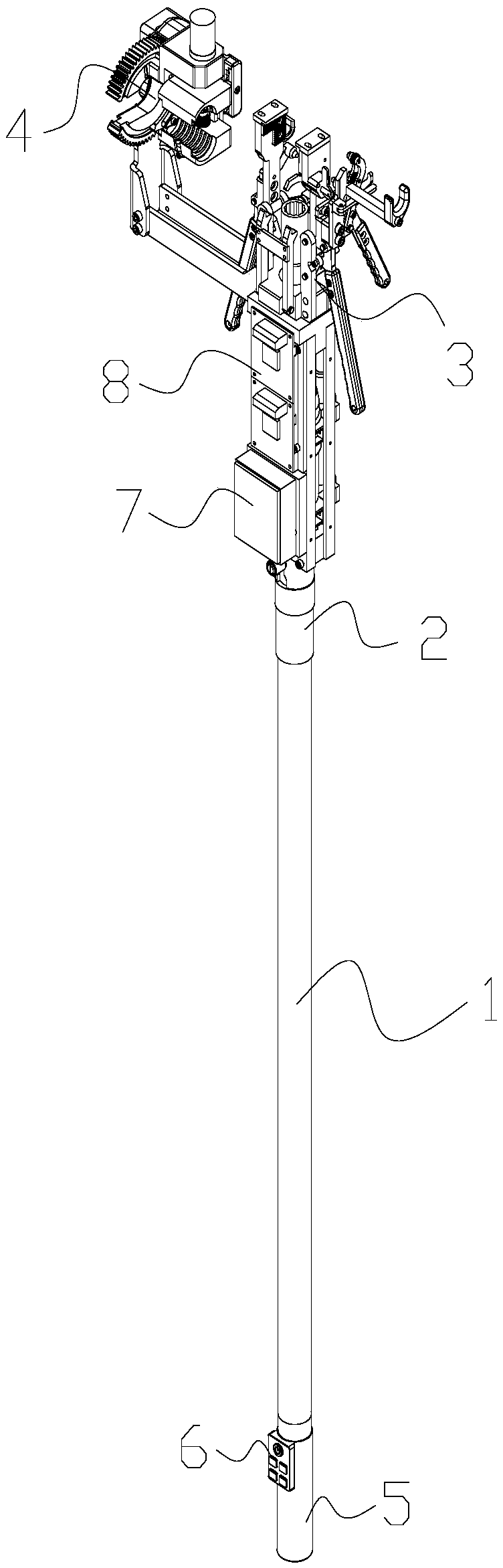

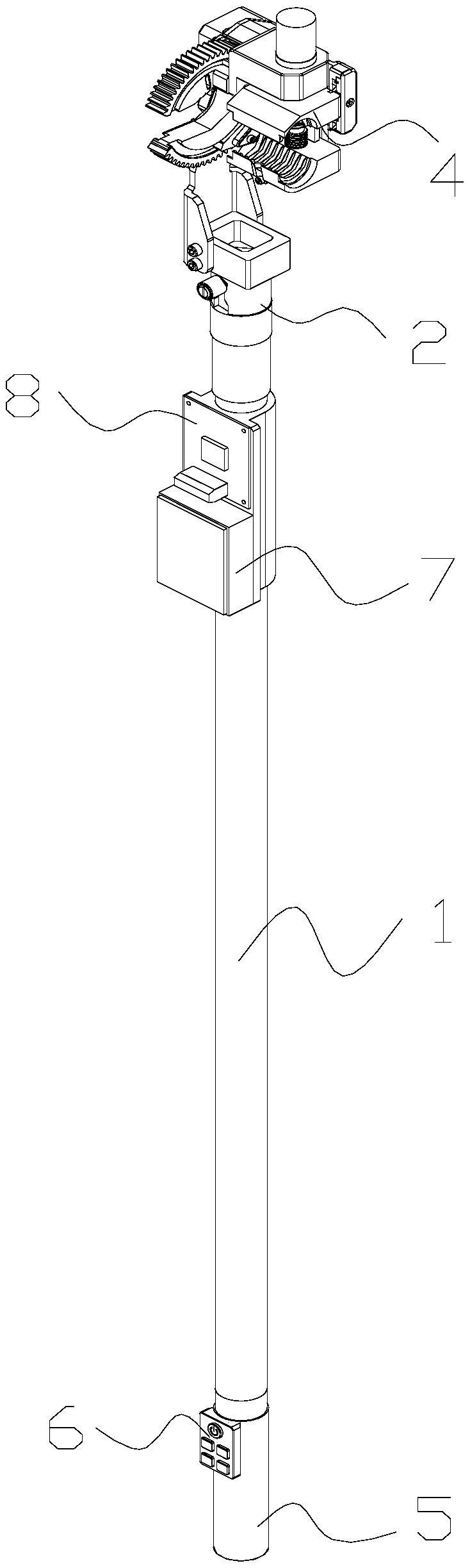

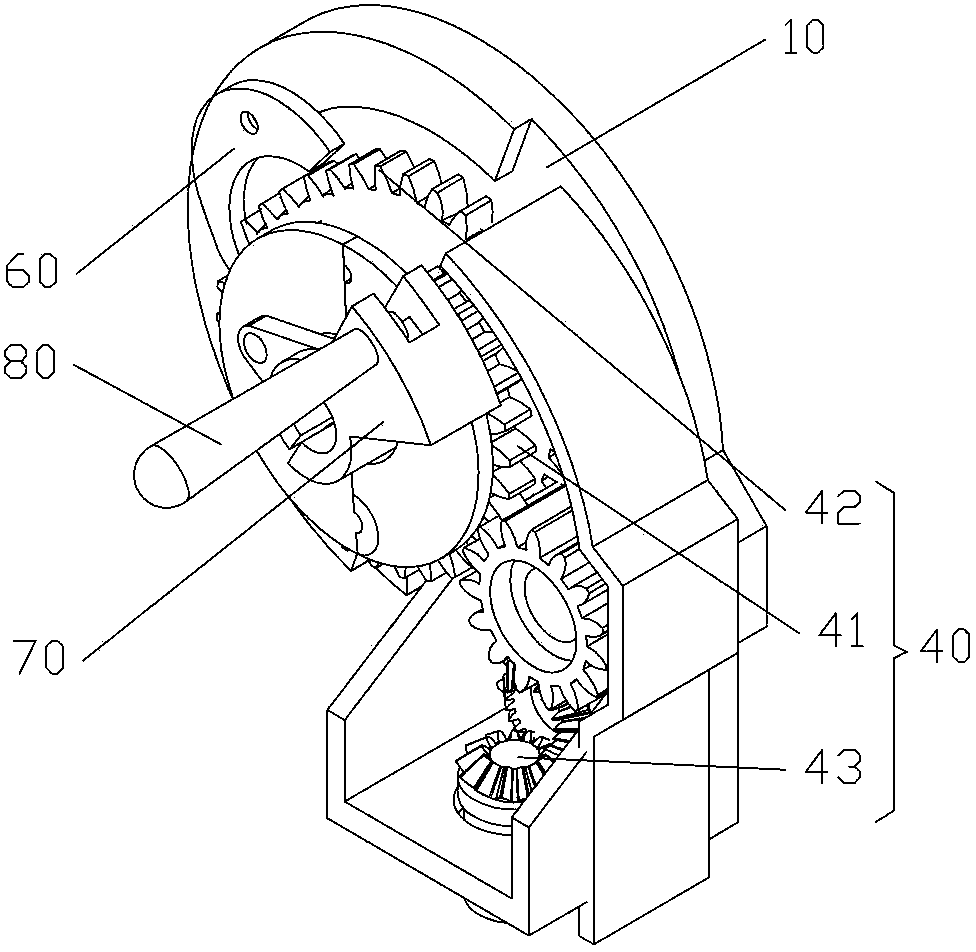

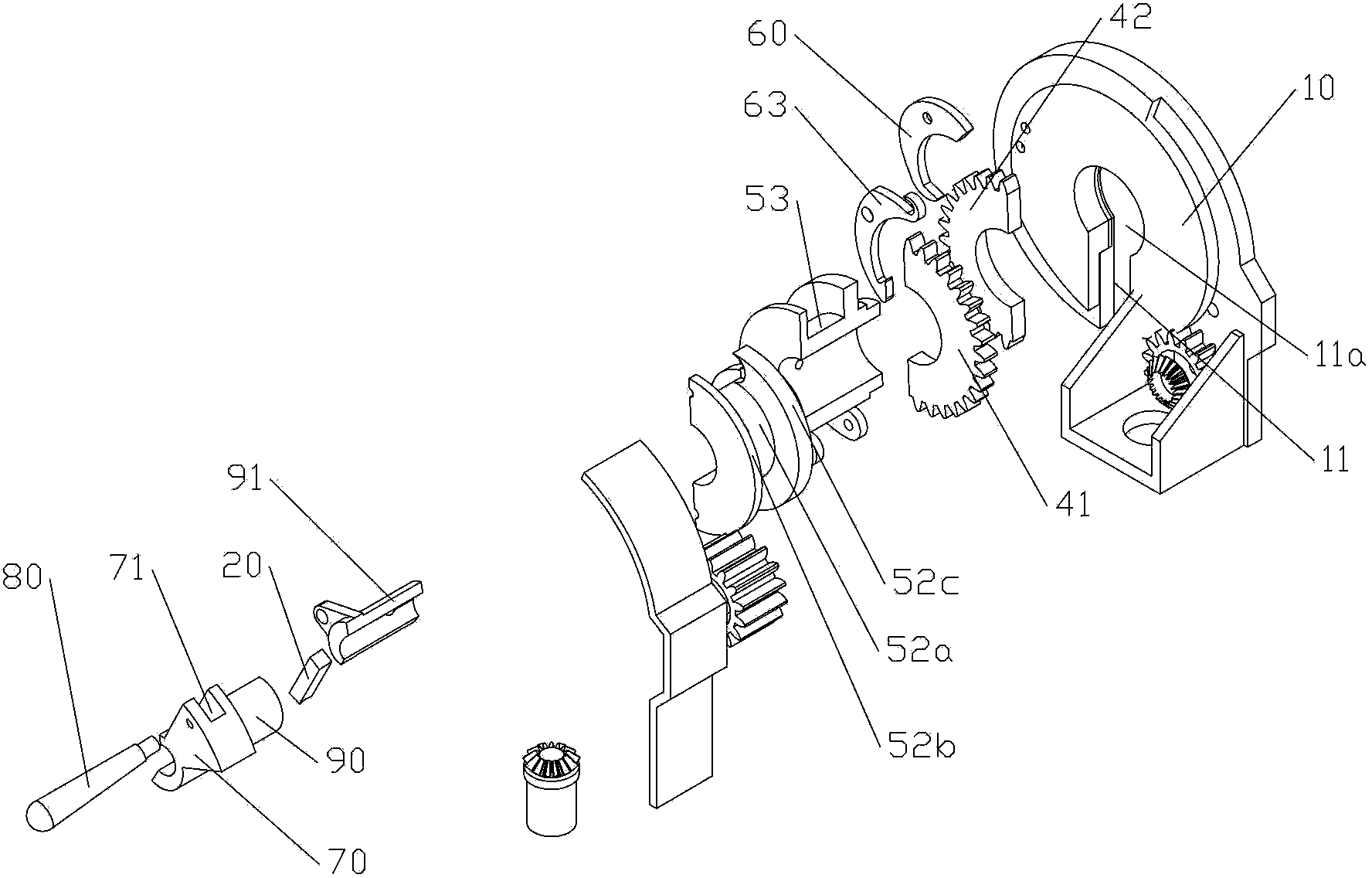

Electric stripping device for cable

PendingCN109119946AQuick peelNo manual operationApparatus for removing/armouring cablesInsulation layerDrive motor

The invention belongs to the field of cable stripping and particularly relates to an electric stripping device for a cable, which comprises an electric stripper, wherein the electric stripper comprises a stripping part; the stripping part comprises a stripping clamp for clamping the cable; and a stripping tool is arranged on the stripping clamp. The electric stripper also comprises a driving partfor driving the stripping part to rotate around the clamped cable. The electric stripping device for the cable has the beneficial effects that through mutual match between a rotation driving motor andan opening-closing driving motor, the stripping clamp can clamp a transmission cable, the stripping tool is inserted to a cable insulation layer, quick stripping is realized, the whole stripping process is driven by power, and manual operation is not needed.

Owner:CAS HEFEI INST OF TECH INNOVATION +1

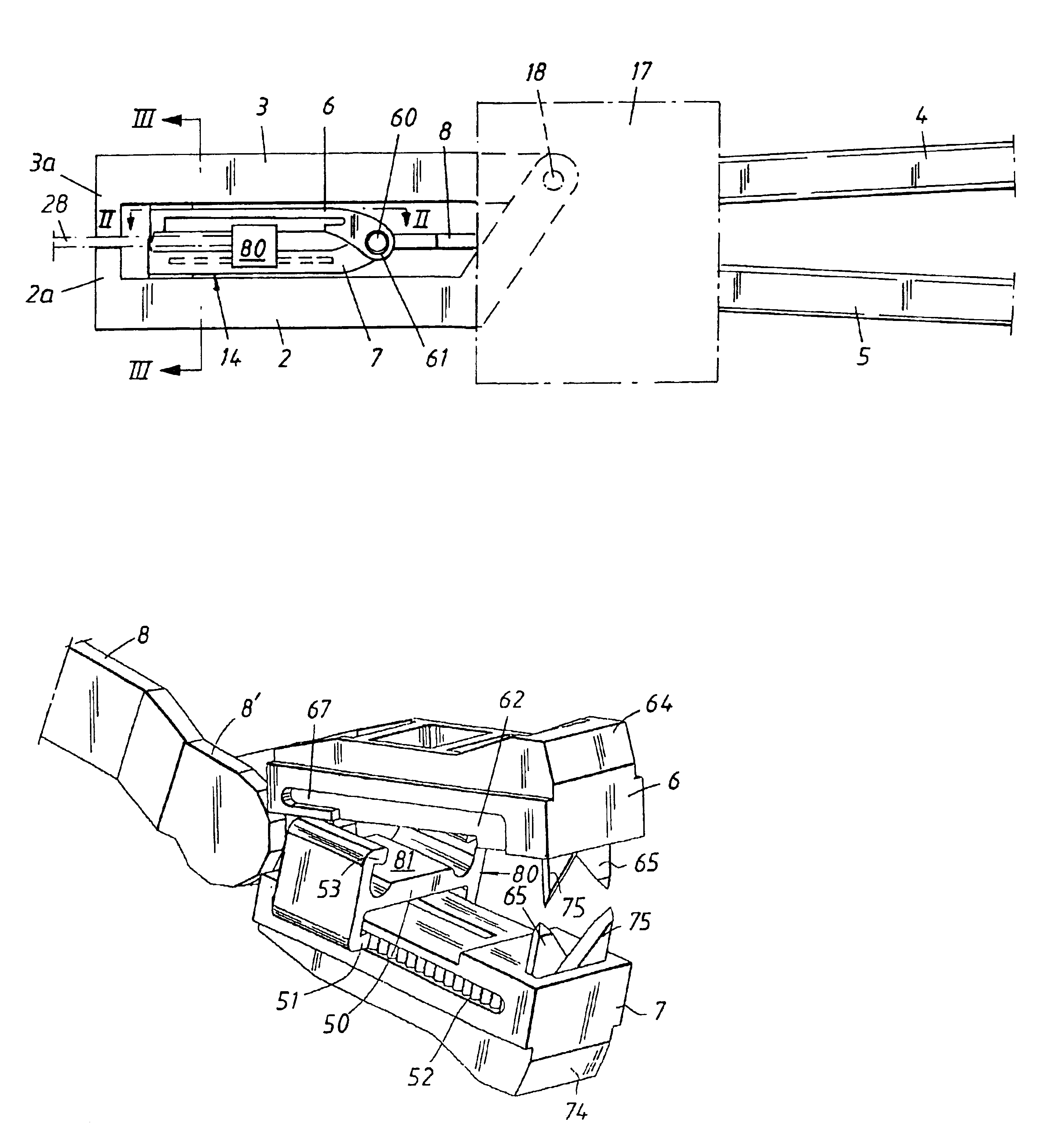

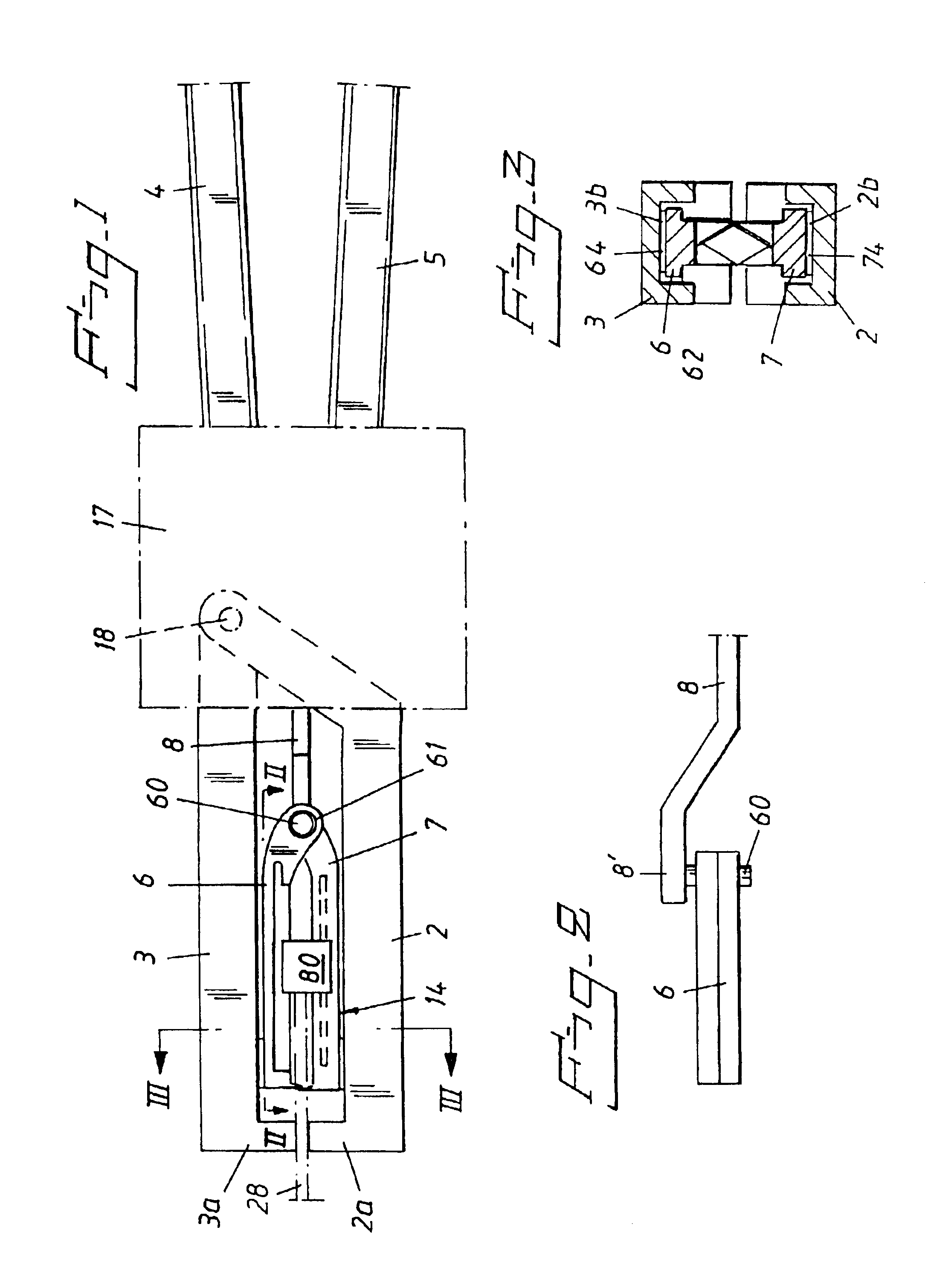

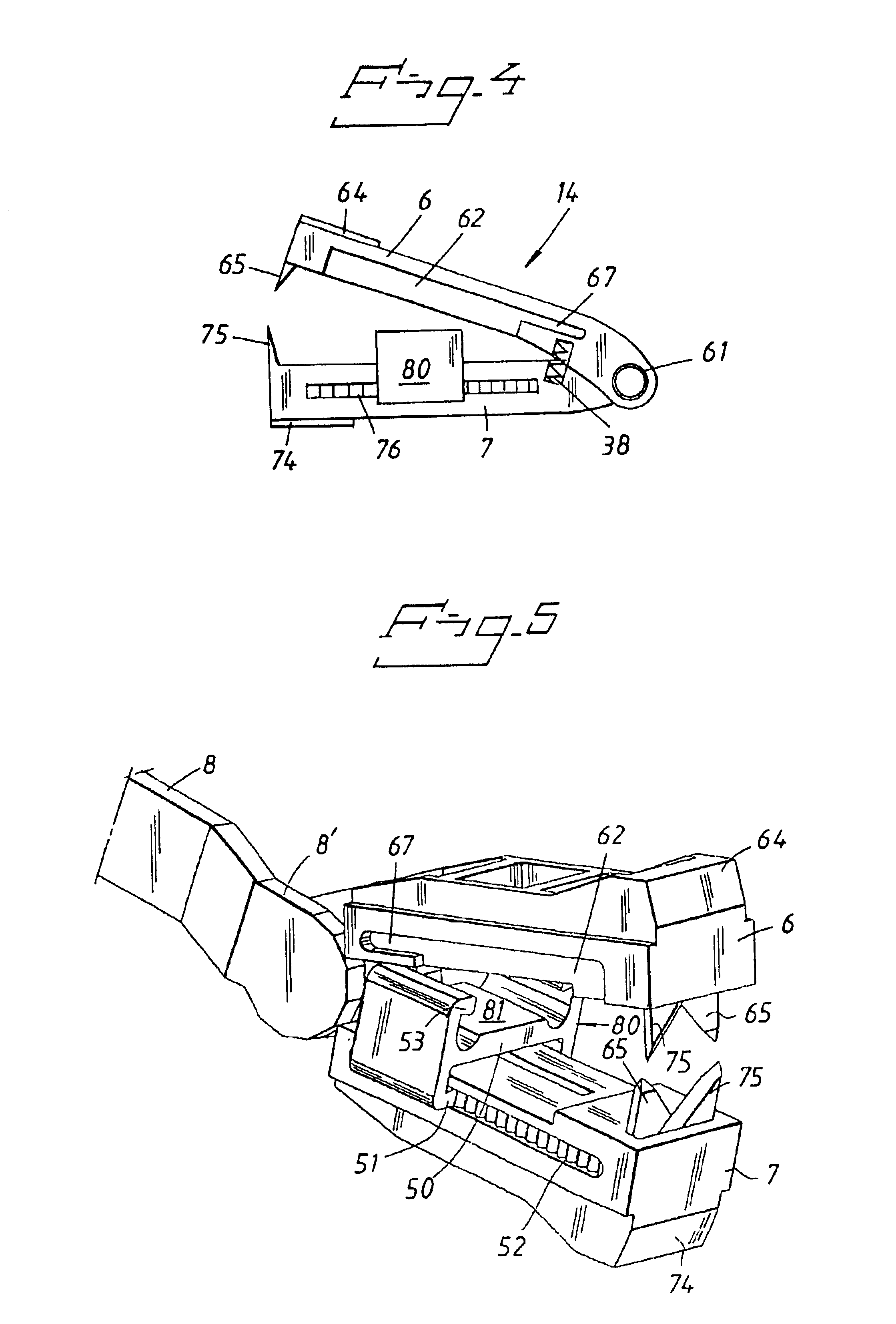

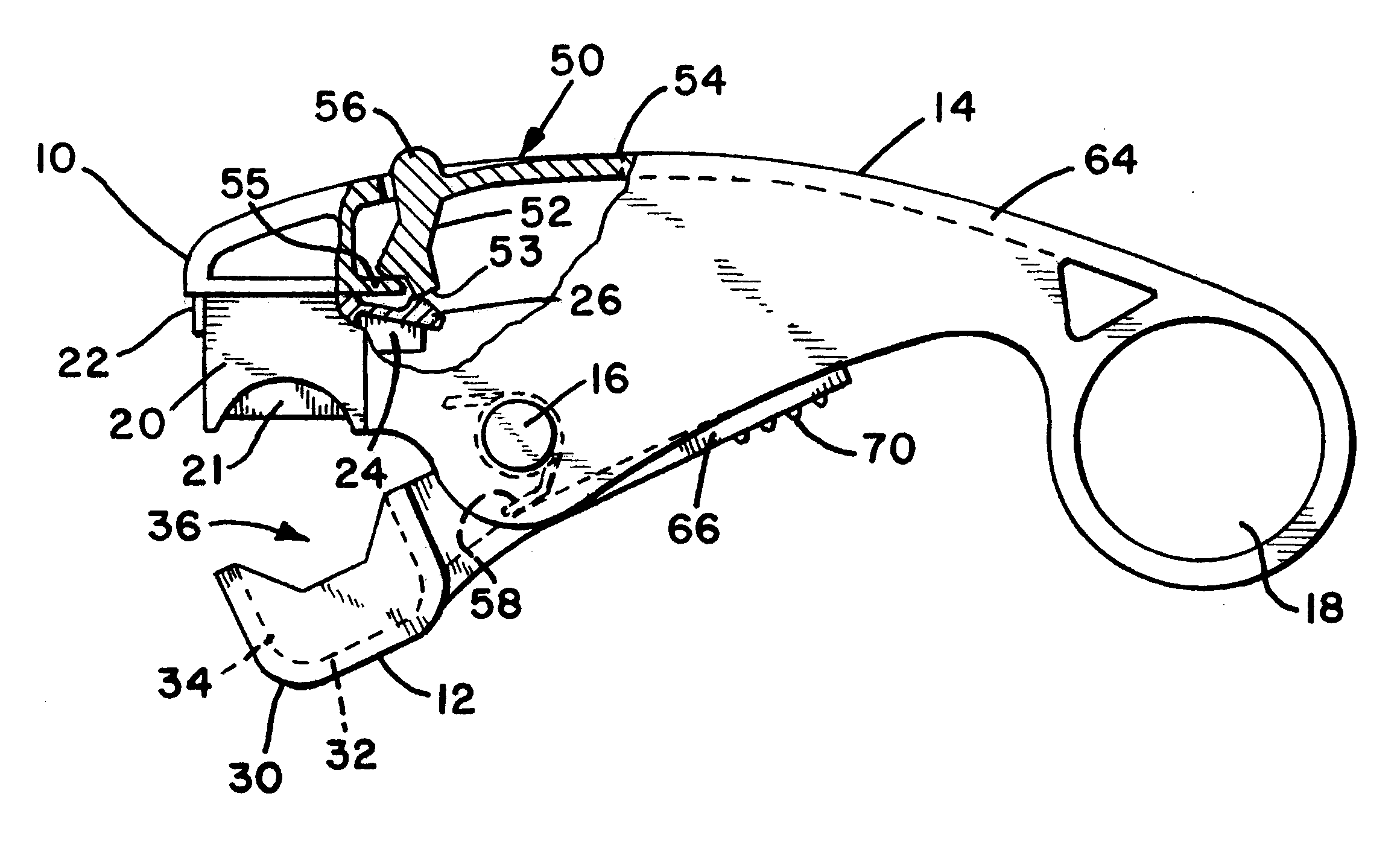

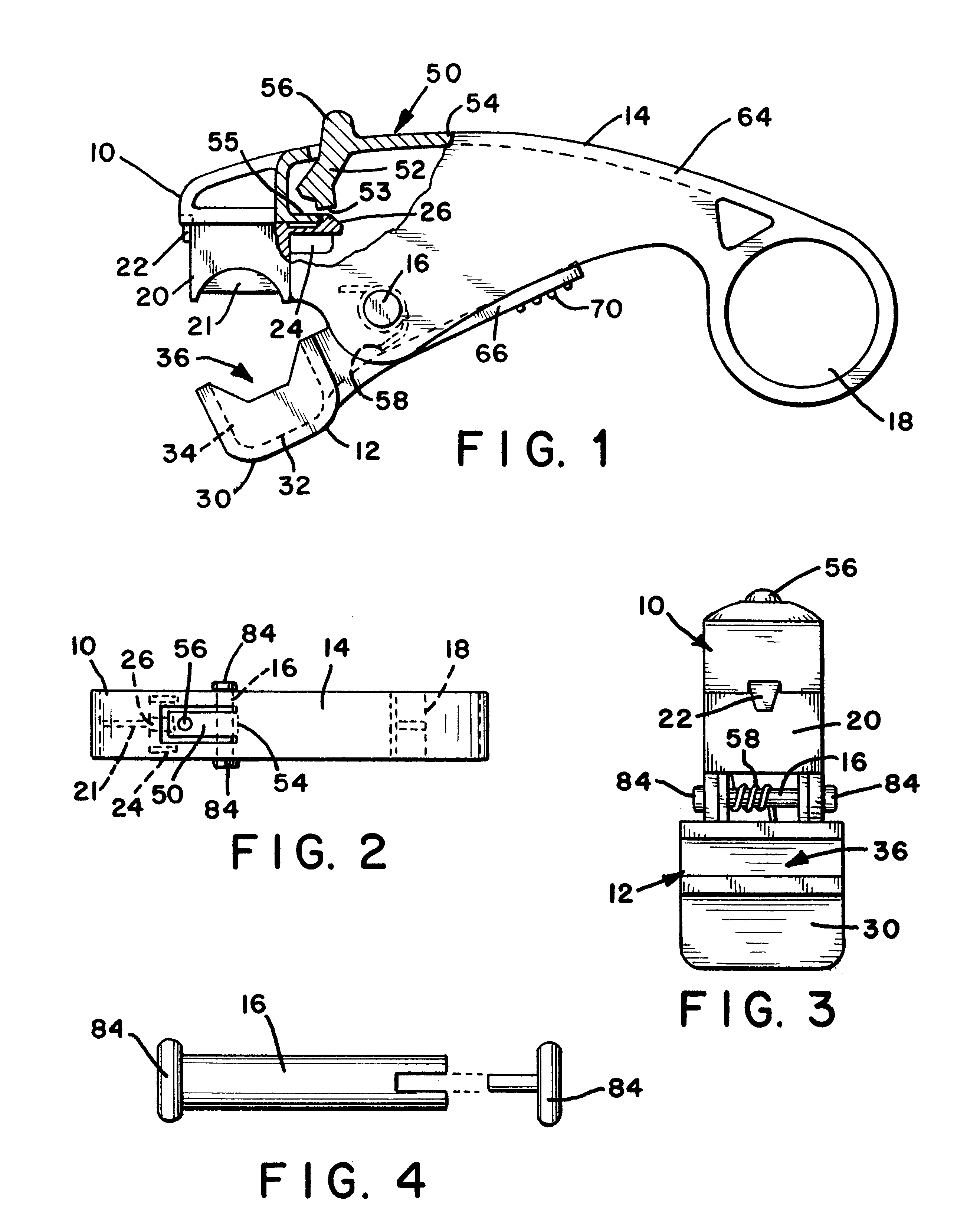

Cable-stripping pliers

ActiveUS6910401B2Easy to replaceEasy to lockMetal working apparatusApparatus for removing/armouring cablesEngineeringBiomedical engineering

Cable-stripping pliers having between its clamping jaws a cutting unit with mutually co-acting arms including cutting elements. The cutting unit has an abutment body which is movable in the longitudinal direction of the pliers and which limits the stripping length. The body Includes a latching device for latching the arms together in their closed state. The latching device includes a latching finger that engages a recess in the other arm when the abutment body is displaced to one end and the arms are brought together. The Cable-stripping pliers is arranged so that the cutting unit is removed easily when the clamping jaws are open and the cutting unit is in its closed state.

Owner:PRESSMASTER

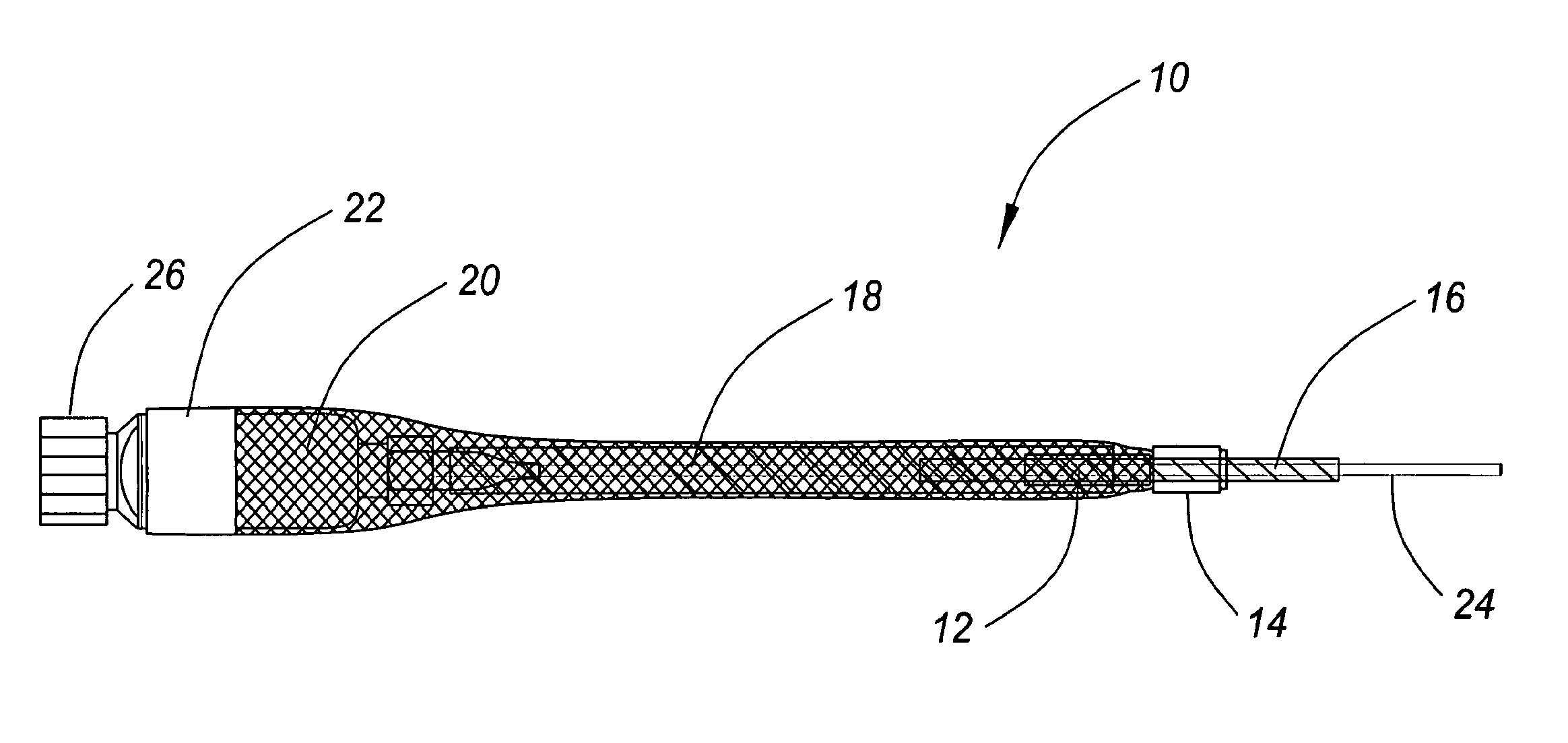

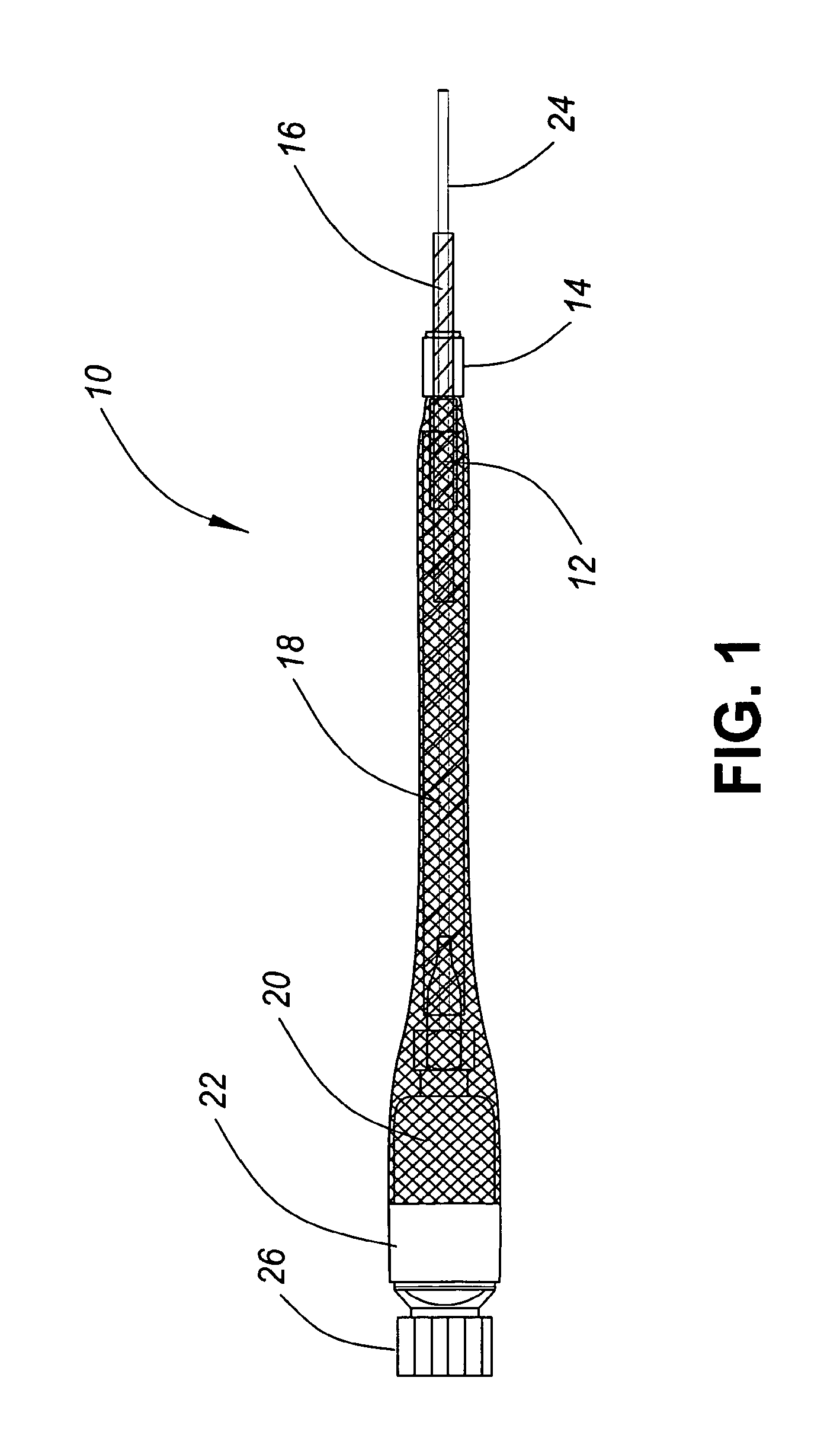

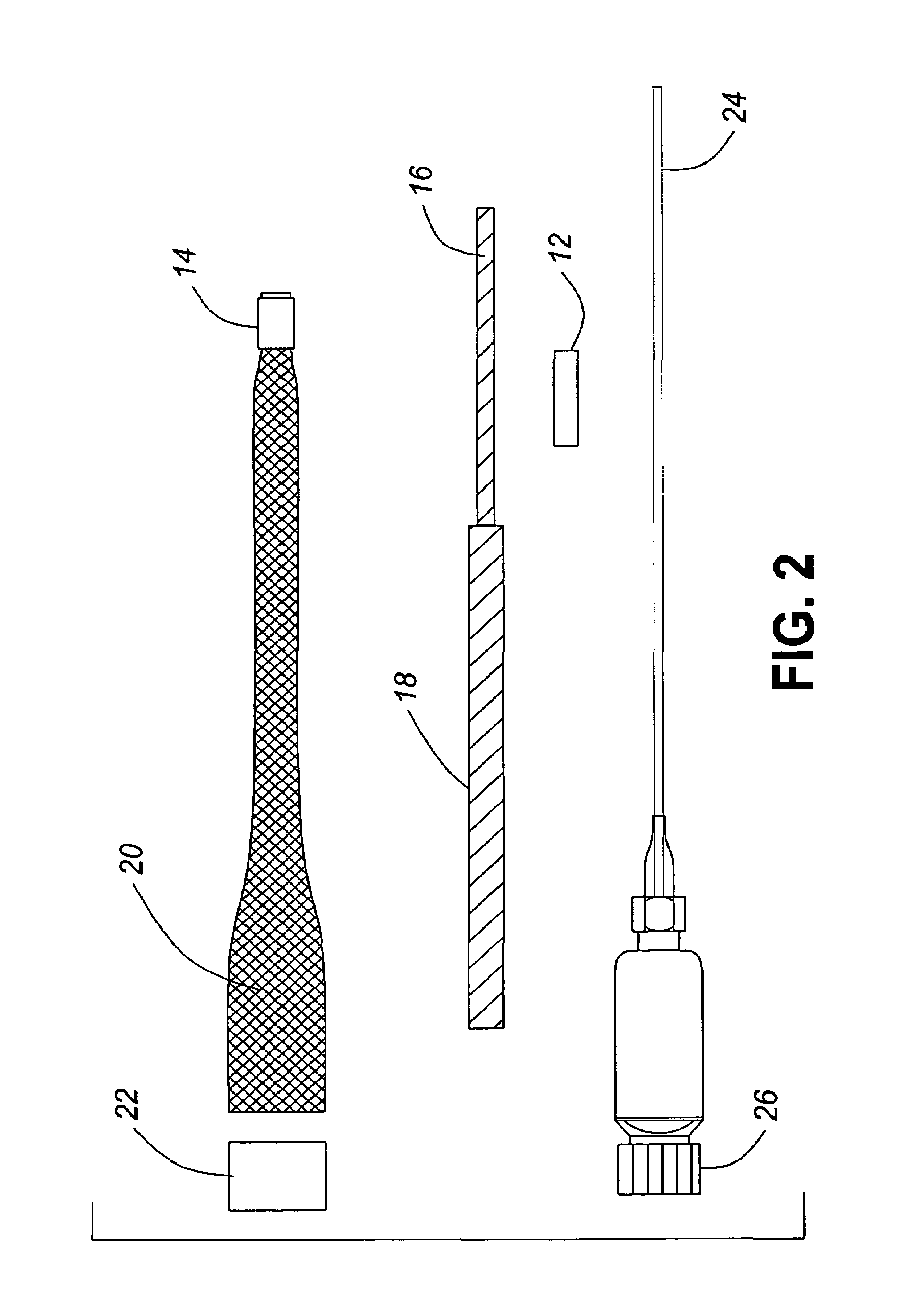

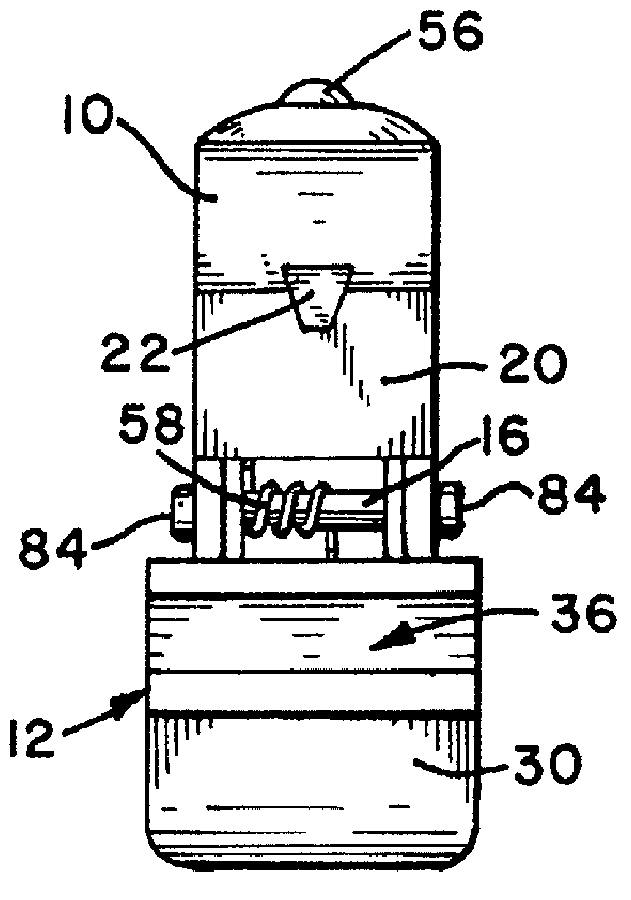

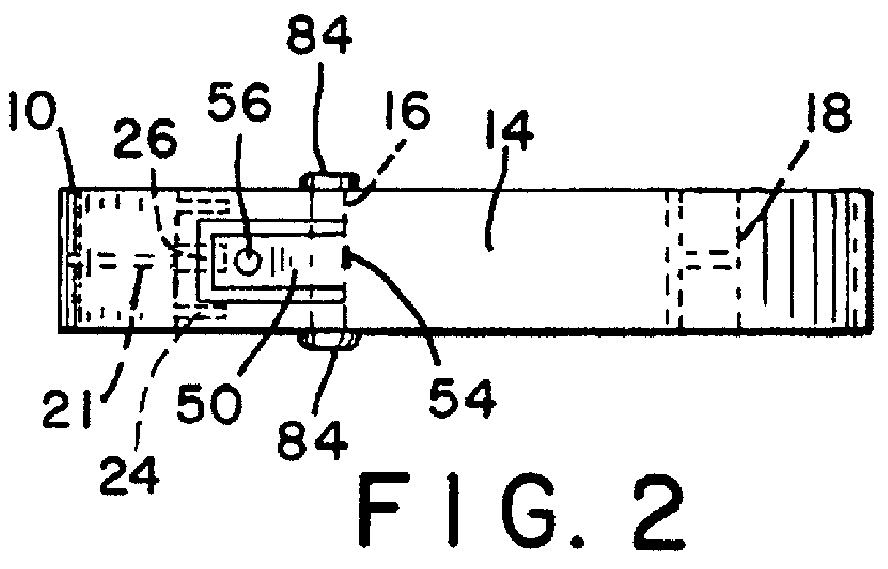

Coaxial cable preparation tool and method of use thereof

InactiveUS7694420B2Improve reliabilityMetal working apparatusApparatus for removing/armouring cablesDielectricElectrical conductor

A coaxial cable preparation tool is provided wherein the tool includes a body, having a first end and a second end, the first end including a first cavity configured to accommodate insertion of a coaxial cable therein. An outer conductor blade is located near the first end of the body and is movably operable with the body to cut an outer jacket, an outer conductor, and an inner dielectric of the cable when the cable is inserted into the first cavity. A center conductor chamfering member is positioned at the back of a second cavity, the second cavity extending from the second end of the body. A dielectric coring blade is positioned within the second cavity, and a jacket stripping blade is positioned at least partially within the second cavity. A corresponding method of coaxial cable preparation is provided.

Owner:JOHN MEZZALINGUA ASSOC INC

Insulated wire stripping device

ActiveCN104253398AWill not affect normal power consumptionImprove satisfactionApparatus for removing/armouring cablesApparatus for overhead lines/cablesEngineeringUser satisfaction

The invention provides an insulated wire stripping device which comprises a base, a cutting unit and an insulating rod operating component. The base comprises a first opening allowing a wire to penetrate. One end of the first opening is provided with a first wire accommodating hole. The cutting unit comprises a cutter which moves around the axis of the first wire accommodating hole. The cutter is connected with the base in a pivoted manner. The first end of the insulating rod operating component is connected with the base and provided with a drive part for driving the cutter. By the insulating rod operating component, a worker can strip the wire under an electrified condition, normal power utilization of citizens and enterprises is unaffected, and user satisfaction is increased. In addition, the insulated wire stripping device is simple in structure and low in manufacturing cost.

Owner:STATE GRID CORP OF CHINA +2

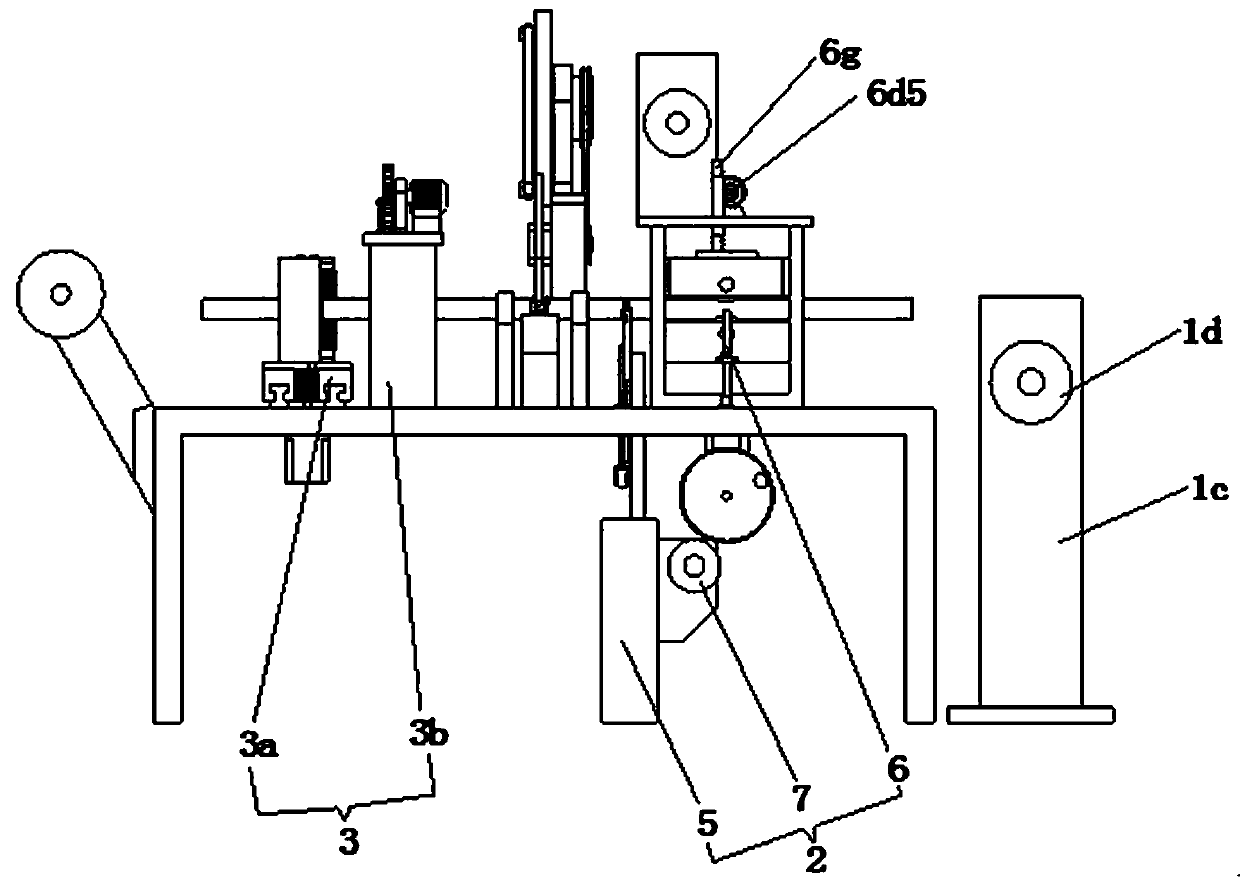

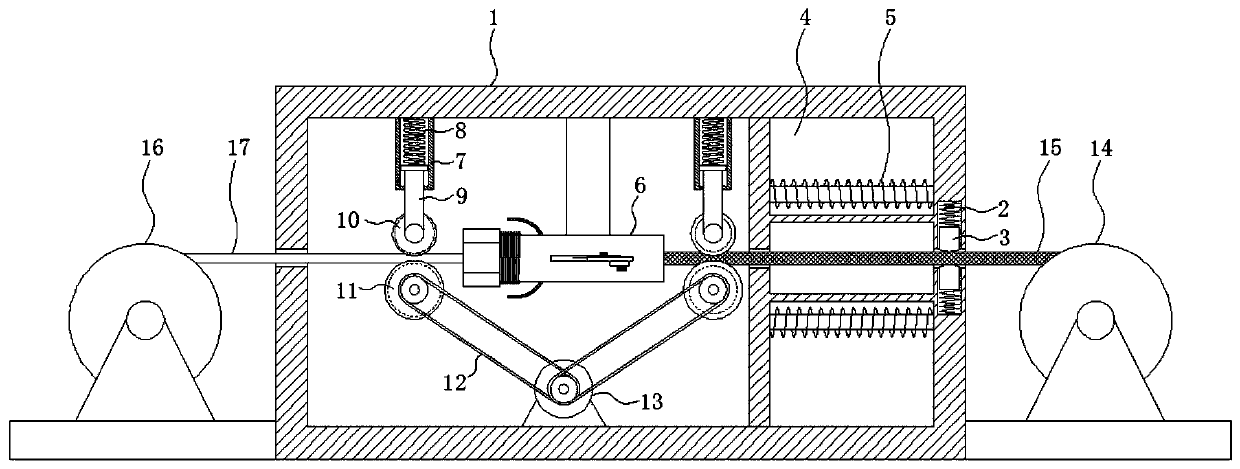

Automatic stripping and recycling device for waste cable

ActiveCN109842061AReduce laborTroubleshoot technical issues with strippingBasic electric elementsApparatus for removing/armouring cablesFixed frameConductor Coil

The invention discloses an automatic stripping and recycling device for waste cables. The automatic stripping and recycling device belongs to the technical field of cable stripping equipment, and comprise a workbench, wherein the top part of the workbench is provided with a cable stripping mechanism, a cable straightening mechanism and a cable cutting mechanism, the cable stripping mechanism comprises a cable limiting assembly, a transverse cutting assembly and a waste sheath winding assembly, the cable straightening mechanism comprises a transverse straightening assembly and a longitudinal straight-pressing assembly, the left end of the workbench is provided with a left fixing frame and an unwinding roller, and the right end of the workbench is provided with a right fixing frame and a material collecting roller. The automatic stripping and recycling device can strip cable sheathes of different diameters by means of the cable stripping mechanism, so that the sheathes of the cables aredivided into two sections and the winding operation can be automatically completed by means of the waste sheath winding assembly, and the cable straightening mechanism can automatically straighteningthe passing cables, so as to avoid the transverse cutting assembly from cutting bent cables and damaging the cables.

Owner:ANHUI HUATENG AGRI TECH CO LTD

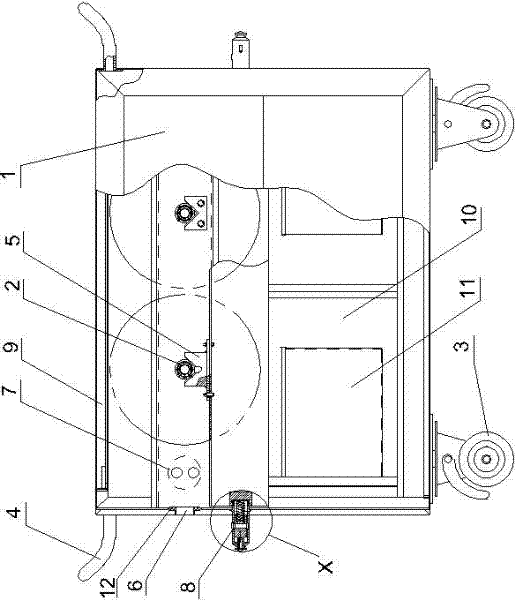

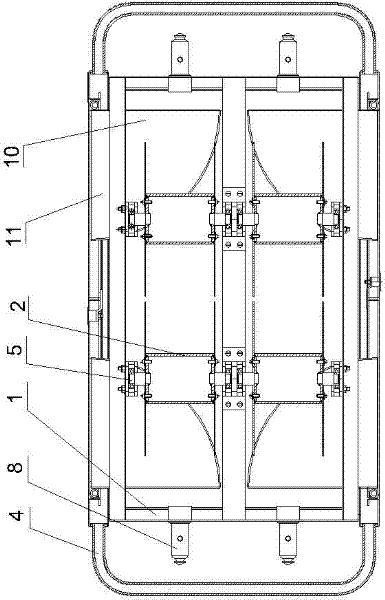

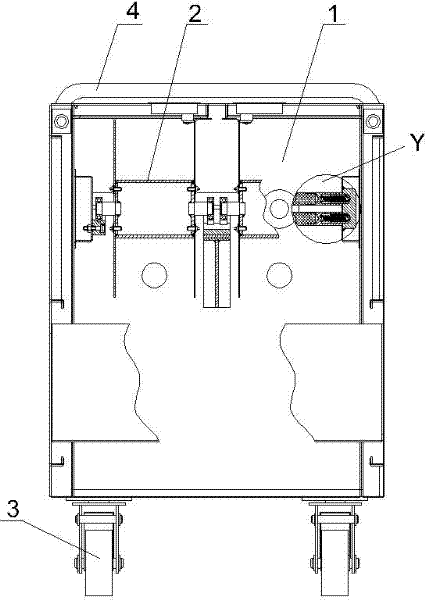

Outgoing line managing device for power construction

ActiveCN102398795ANo wasteEasy to replaceFilament handlingApparatus for removing/armouring cablesBobbinLocking mechanism

The invention provides an outgoing line managing device for power construction. The outgoing line managing device comprises a box body and bobbins, wherein braking wheels are arranged on four corners at the lower end of the box body; the front and back ends of the upper part of the box body are provided with push handles respectively; two rows and two lines of bobbins, i.e., four bobbins in total are arranged in the box body; bearings at the two ends of the bobbins are supported on a rapid assembling bearing base; the front and back wall plates of the box body are provided with outlet holes; a cable guiding mechanism is arranged between each outlet hole and each bobbin; the front and back wall plates of the box body are provided with line end locking mechanisms below the outlet holes; the upper end of the box body is provided with a top cover through a hinge; a tool room is formed below the bobbins in the box body; and the left and right wall plates of the box body are correspondingly provided with tool doors. Due to the adoption of the technical scheme of the invention, standardized and ordered management of the line outlet operation in a power construction site is realized, the line outgoing is convenient, labor is saved, the waste of cables is avoided, conductor cores on the bobbins are easier to replace, and the production efficiency is increased.

Owner:STATE GRID CHONGQING ELECTRIC POWER COMPANY SKILLTRAINING CENT +1

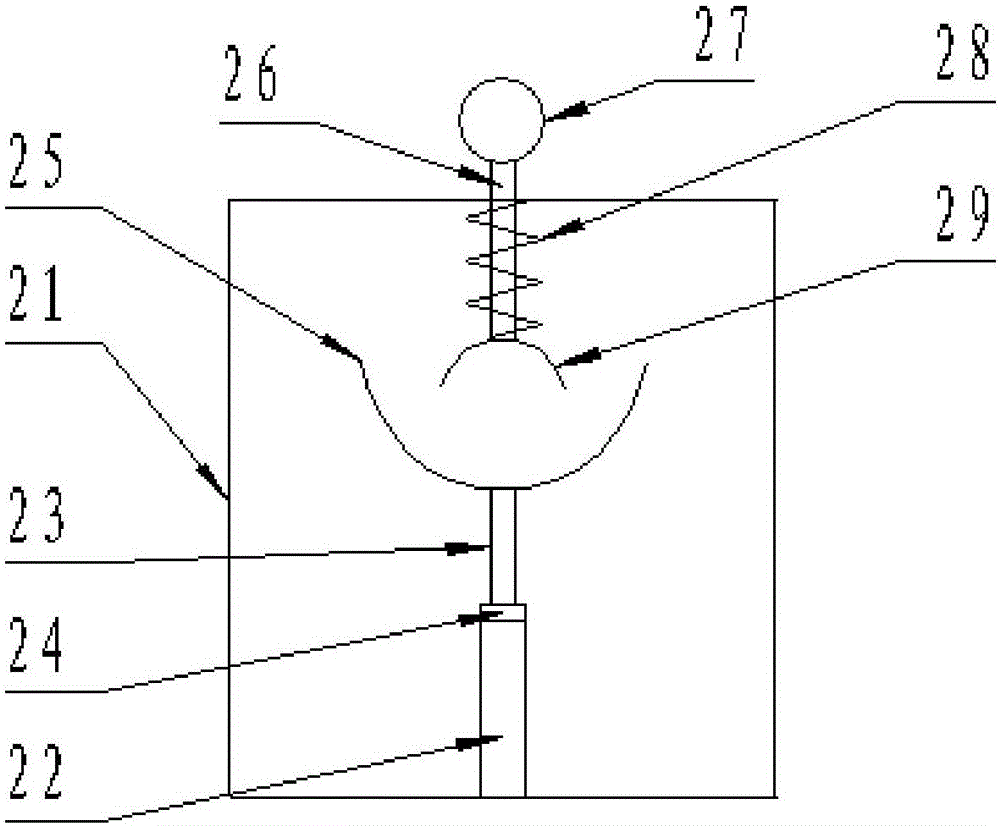

Operation method of electric peeling device for protective cores of waste cables

ActiveCN106329410AReduce labor intensitySave labor costsApparatus for removing/armouring cablesEngineeringProtective relay

Provided is an operation method of an electric peeling device for the protective cores of waste cable. Clamping mechanisms are arranged at the two ends on an operation table. A heater, a cutting mechanism and a stripping mechanism are sequentially arranged along the running direction of cables between the two clamping mechanisms. An insulating layer collection hole is arranged between the cutting mechanism and the stripping mechanism. The operation method comprises the following steps: adjusting the height of the telescopic rods on the clamping mechanisms; adjusting the distance between the blade of a cutter on the cutting mechanism and the inner core of a cable and the distance between the blade of a separator on the stripping mechanism and the inner core of the cable; adjusting the centers of the mechanisms to the same axis line; and heating, cutting and stripping the insulating layer of a to-be-processed cable in sequence. The device has a simple structure. The operation method is simple. The use effect is good. Operation by workers is facilitated. The labor intensity of workers is reduced greatly. The stripping effect is good, and the production efficiency is high. The method is suitable for stripping the rubber sheaths of all kinds of cables. High cable core recovery efficiency is achieved.

Owner:HUATONG CABLE INC

Cable end sheath stripping method and device

ActiveCN103683125ASimple structureCompact layoutApparatus for removing/armouring cablesShortest distanceForce sensor

The invention provides a cable end sheath stripping method and device. Two ends of a cable with the sheath to be stripped are clamped with a clamp so as to fasten the cable; meanwhile, a plurality of groups of different blades are provided according to outside diameter of the cable; the blades are radially fed and contact with the cable first; the condition of contact between the blades and the cable is regulated and controlled through a force sensor; when the blades contact with the cable, the blades are driven to rotate by a drive element so as to cut off the sheath of the cable obtain a circular cut; the blades are then driven by the drive element to axially move along the cable so as to remove the sheath of the cable and finish sheath stripping. The multiple groups of different cutting tools can be arranged on the same device, the different cutting tools can be selected according to different specifications of the cables during use, replacing a fixture is not required, the diameter of the cables which can be cut varies in a large range, the efficiency is high, universality is good, and the cable end sheath stripping method and device is applicable to short-distance stripping for the ends of cables.

Owner:SHENZHEN INST OF ADVANCED TECH

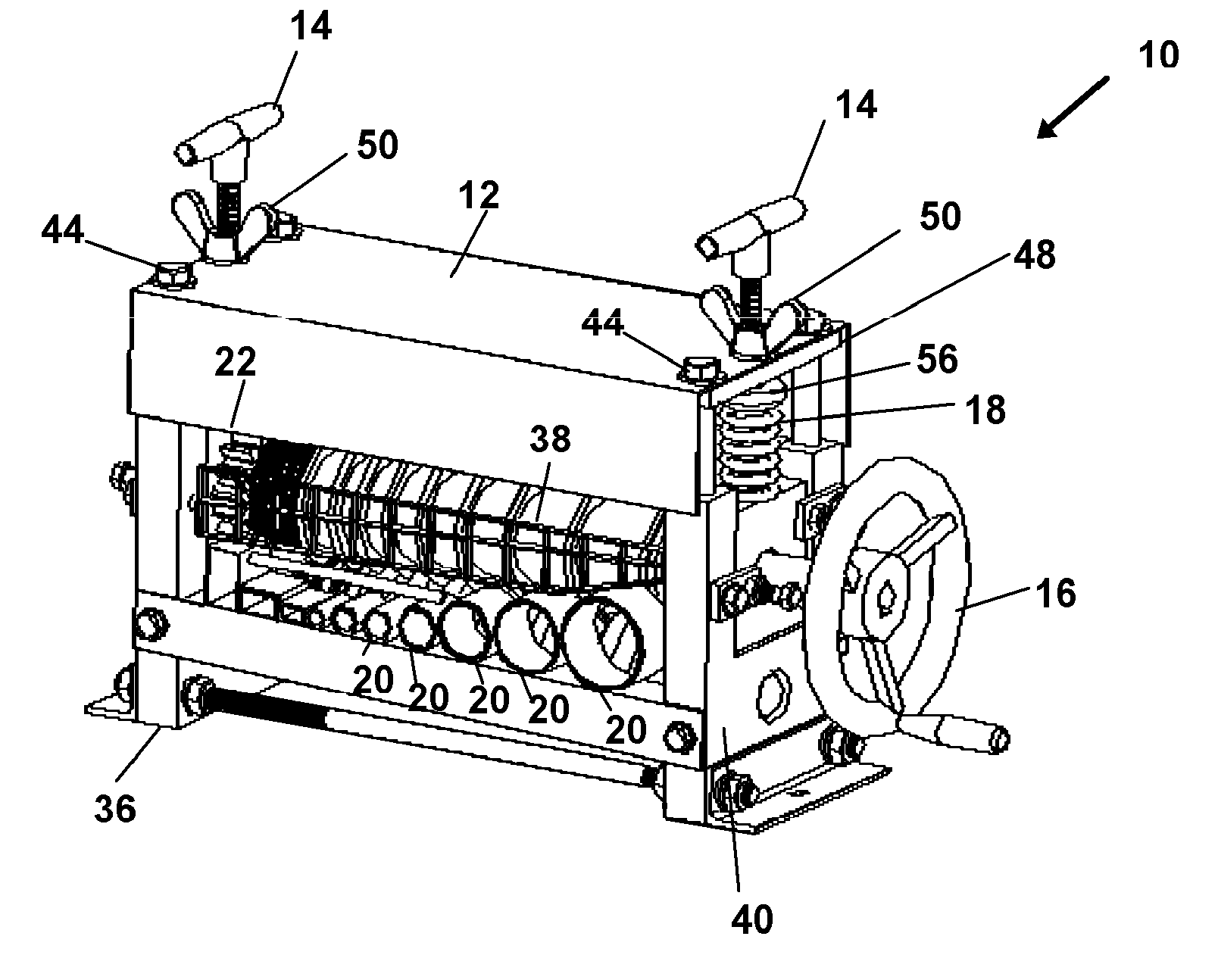

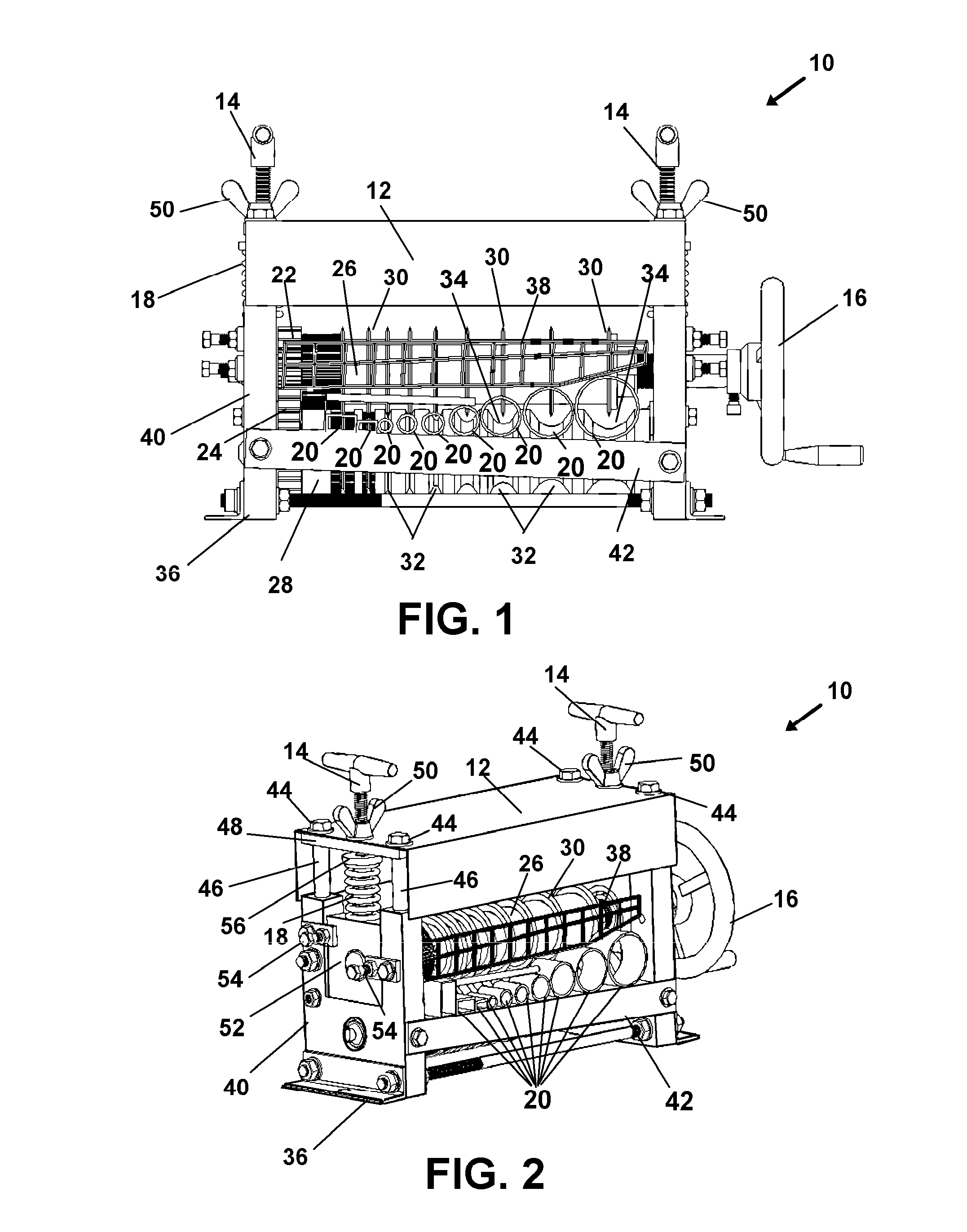

Wire Stripping Device

ActiveUS20120167719A1Easy to useEncourages recyclingBasic electric elementsApparatus for removing/armouring cablesEngineeringElectric wire

A device for removing an insulation jacket from a wire core of an insulated wire or cable is provided for encouraging recycling. The device employs cutting blades engaged to a first roller to cut a slice along the length of an inserted insulated wire or cable. A frictional engagement between the distal edge of the blade and an opposing recess surface provides for translation of the length of wire through the device during rotation of one or both of the blade and recess surface. Translational movement of the blades and a biasing force can enhance the frictional engagement and provide a distance of travel to prevent cutting of the insulated wire or cable.

Owner:THE NEWMAN TRADING COMPANY

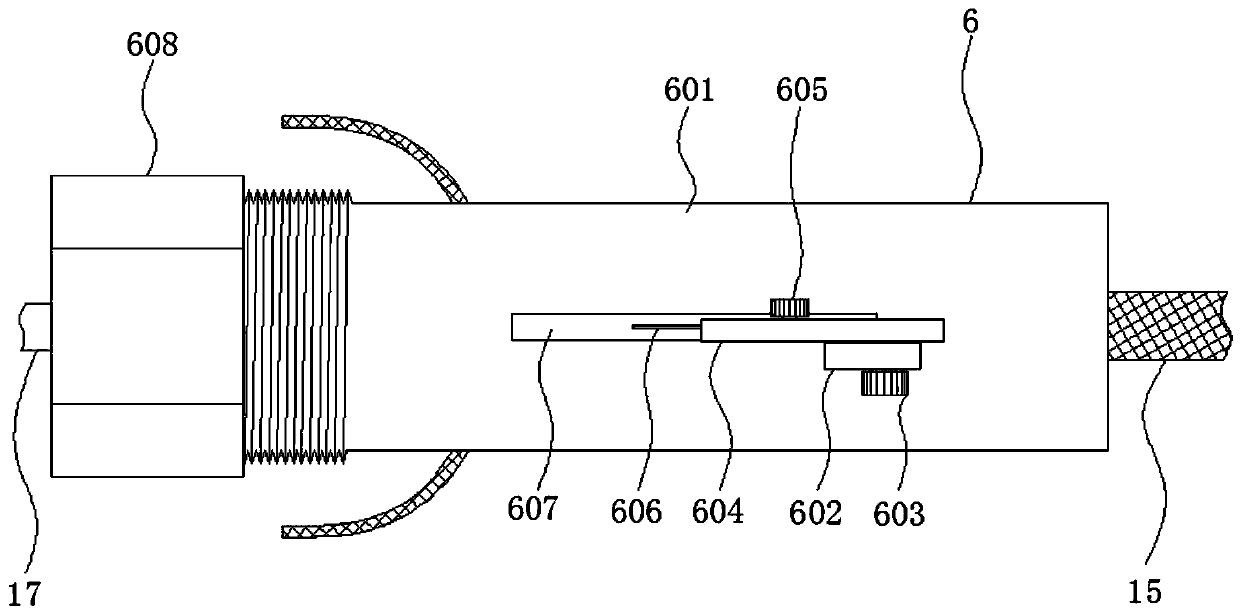

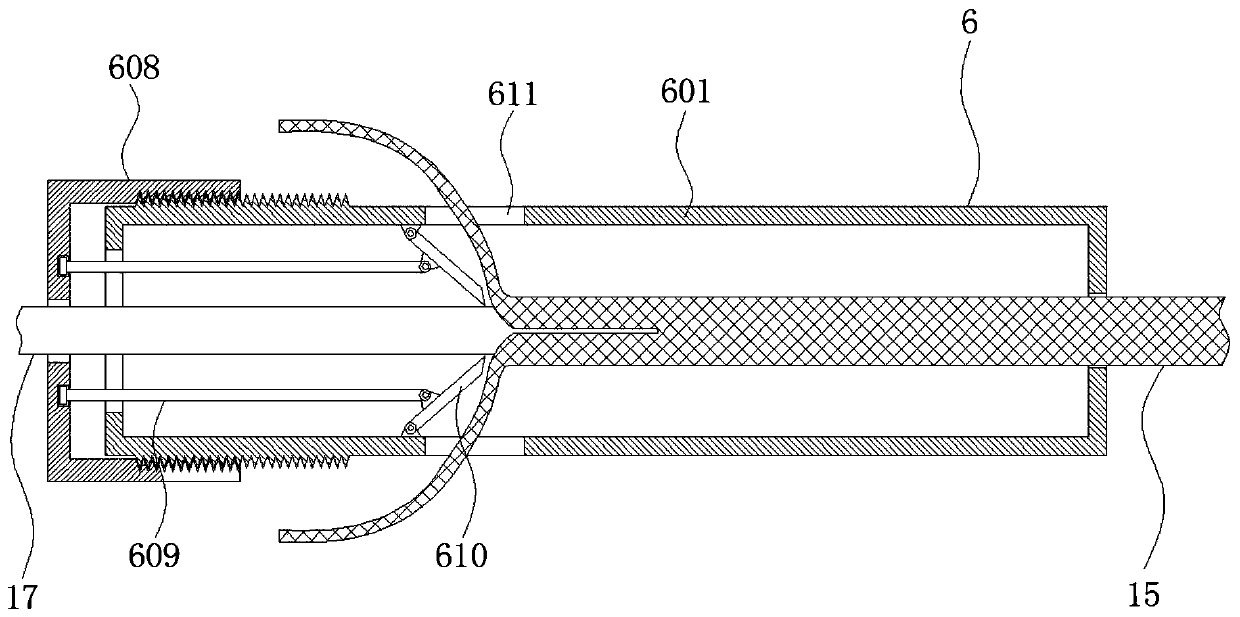

Coaxial cable preparation tool and method of use thereof

InactiveUS20090019704A1Improve reliabilityMetal working apparatusApparatus for removing/armouring cablesDielectricElectrical conductor

A coaxial cable preparation tool is provided wherein the tool includes a body, having a first end and a second end, the first end including a first cavity configured to accommodate insertion of a coaxial cable therein. An outer conductor blade is located near the first end of the body and is movably operable with the body to cut an outer jacket, an outer conductor, and an inner dielectric of the cable when the cable is inserted into the first cavity. A center conductor chamfering member is positioned at the back of a second cavity, the second cavity extending from the second end of the body. A dielectric coring blade is positioned within the second cavity, and a jacket stripping blade is positioned at least partially within the second cavity. A corresponding method of coaxial cable preparation is provided.

Owner:JOHN MEZZALINGUA ASSOC INC

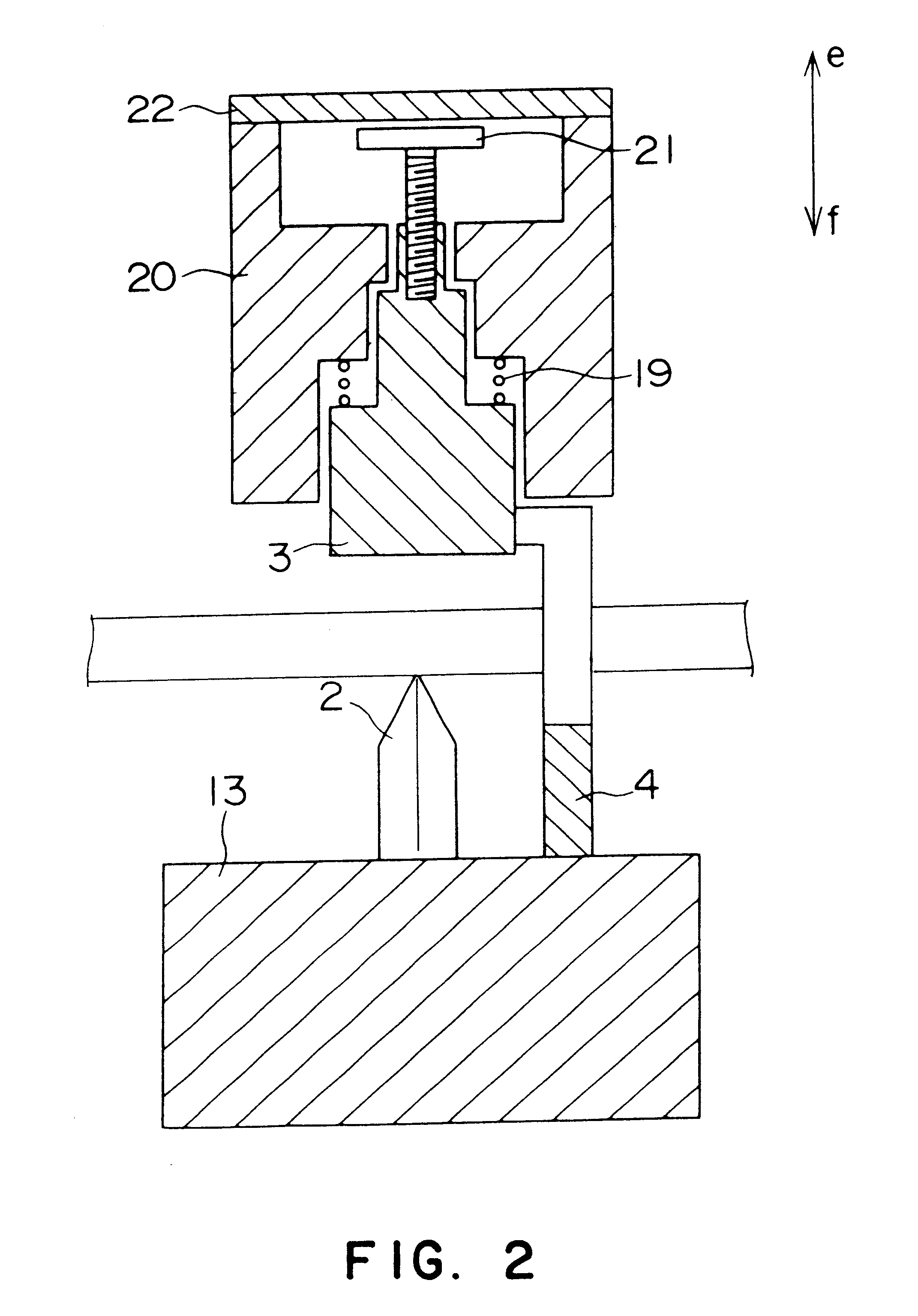

Apparatus for cleaving optical fiber

InactiveUS6978071B2Simple structureImprove work efficiencyCoupling light guidesMetal working apparatusEngineeringOptical fiber

An apparatus to cleave an optical fiber includes a base plate, a jig slidably provided on the base plate and holding the optical fiber, a stripper provided near the jig, and including a hot plate heating a sheath of the optical fiber, a sheath cutter cleaving the sheath of the optical fiber to be stripped, a cleaning part cleaning the optical fiber after the sheath of the optical fiber is stripped according as the jig slides, and a cleaver provided on the base plate and cleaving the optical fiber whose sheath is stripped by the stripper. With this configuration, an apparatus is provided to cleave an optical fiber, in which stripping and cleaning processes are simultaneously performed in a stripper, so that the whole process of cleaving the optical fiber is decreased, and the structure of the apparatus is simplified without the conventional cleaning part.

Owner:SAMSUNG ELECTRONICS CO LTD

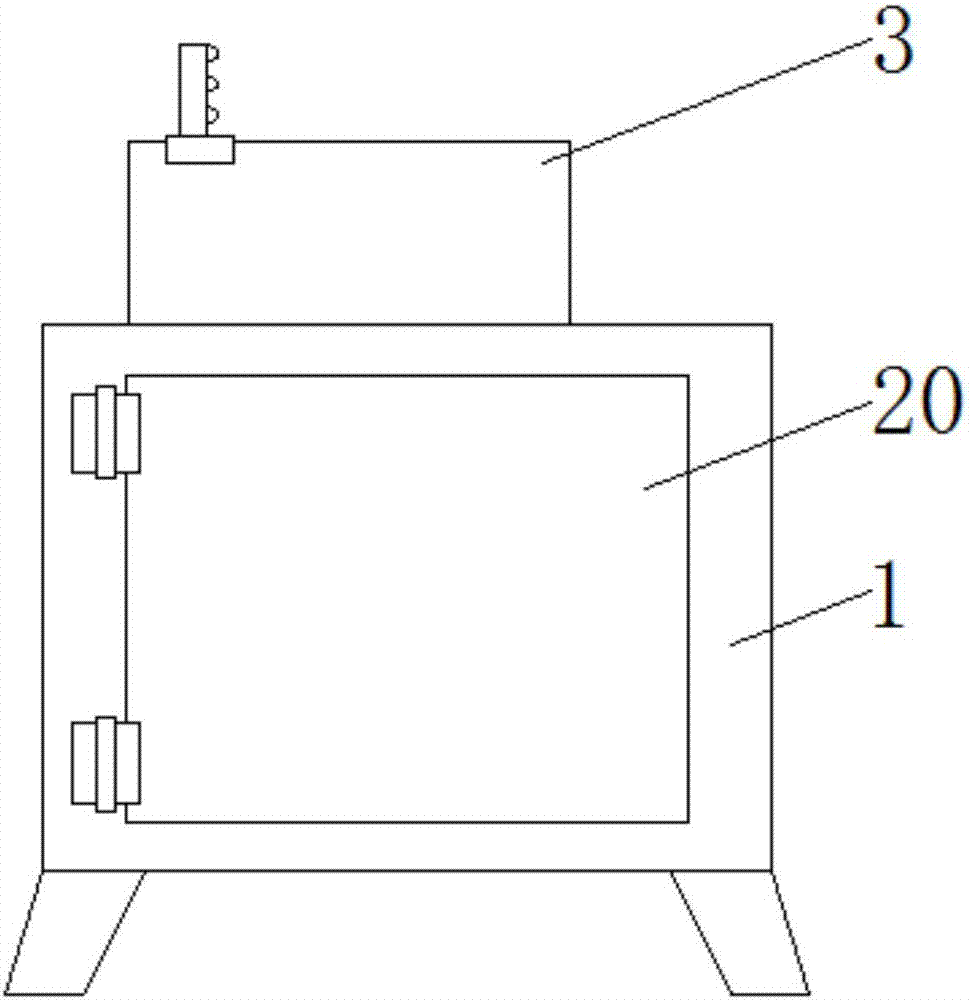

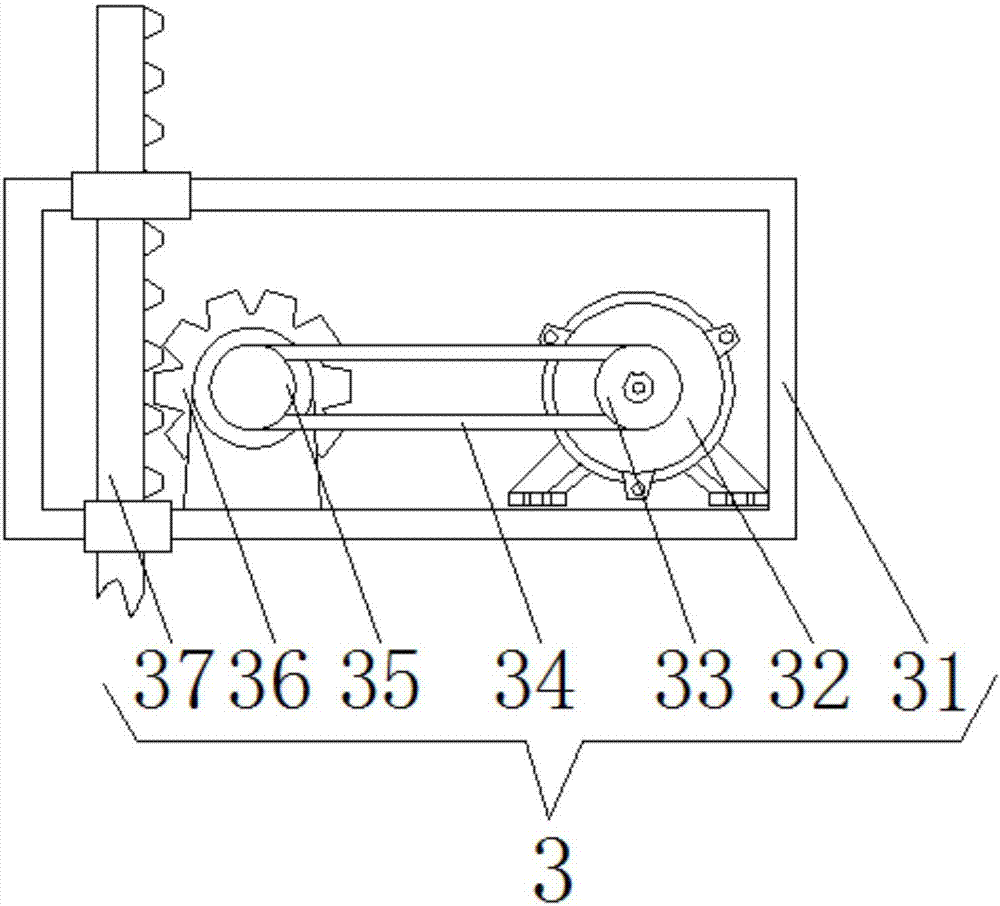

Cable sheath removal and recycling device

InactiveCN107482541AImprove work efficiencyImprove peeling efficiencyFilament handlingApparatus for removing/armouring cablesEngineeringElectric wire

The invention discloses a cable peeling recovery device, which comprises a device outer frame and supporting legs arranged at the bottom of the device outer frame, a cable inlet is opened on the left side wall of the device outer frame, and the inside of the device outer frame is installed in sequence from left to right There are: the first guide wheel is used to guide the cable to move to the right; the pressure plate is used to press the cable and remove the stain on the cable surface, and the lower end of the pressure plate is fixed with a cleaning block; the cutter device is used to cut the cable skin; the second guide wheel is used for Fix the cable above the cutter device and guide the cable to move to the right; the cable skin recovery wheel and the cable core recovery wheel are used to strip the cable inner core from the cable skin and recover the cable inner core and cable skin. The invention solves the problems that the existing electric wire recycling device cannot peel and classify the electric wires, is not suitable for recycling cables with different diameters, and has low working efficiency.

Owner:邹晶明

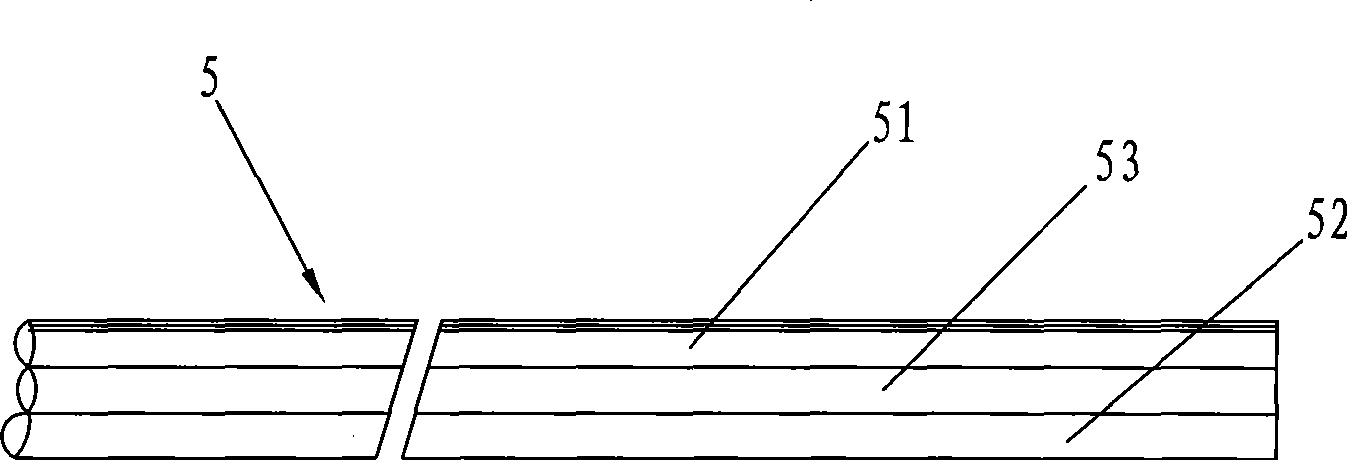

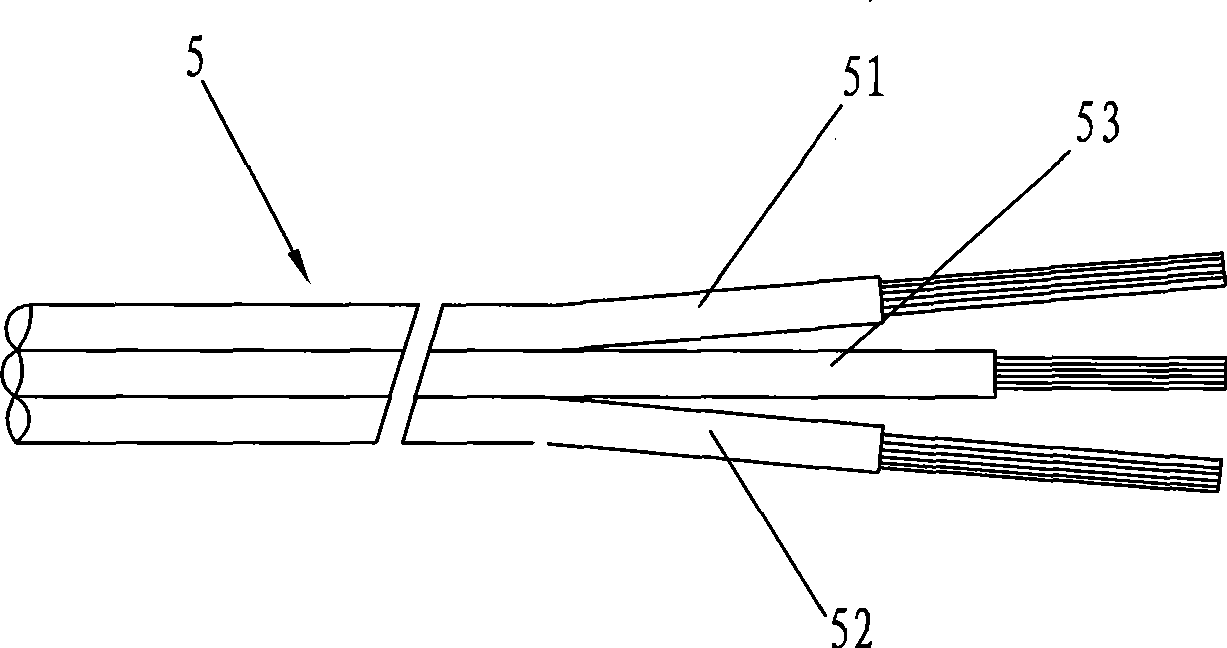

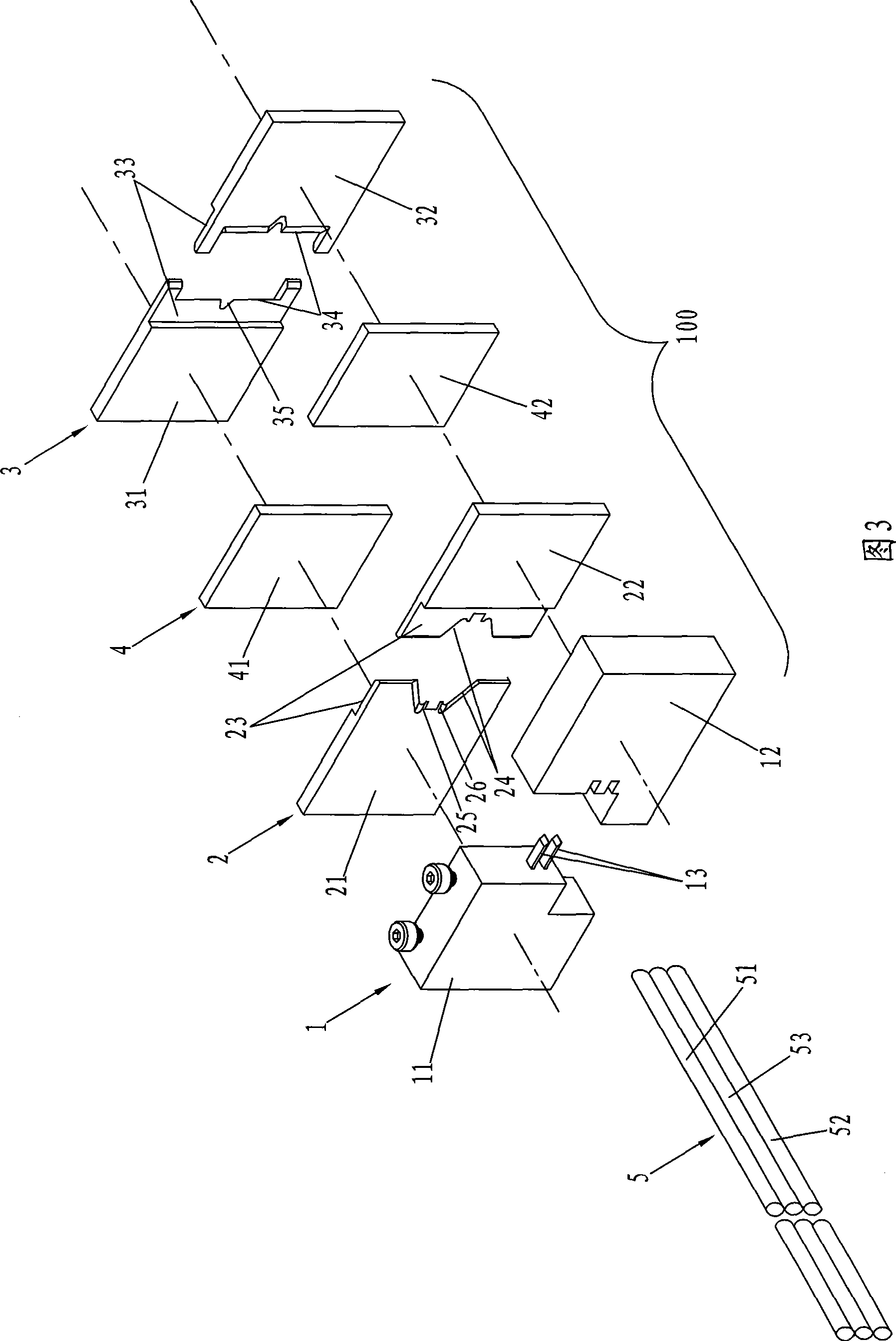

Cutting tool assembly for peeling three bundle of parallel core wires and peeling machine using the same

InactiveCN101431223AQuick peelEasy to removeLine/current collector detailsApparatus for removing/armouring cablesEngineeringMechanical engineering

The invention relates to a three-bundle parallel core wire stripping toolbox and a stripping machine using the toolbox. The toolbox first branches off three bundles of parallel core wires by a branch cutting die, then precutting process is carried out on skins of the core wires at two sides and in the middle by a first cutting die and a second cutting die respectively, and a partition board arranged between the first cutting die and the second cutting die can ensured that a certain distance exists between the cutting positions of the core wires at two side parts and the core wire in the middle, so as to meet market requirements. The stripping machine precuts the skin at the end parts of the core wires by the toolbox driven by a first cylinder, and then drives the toolbox and the first cylinder to move along the core wire extending direction by a second cylinder, so that the toolbox can move to strip the precut skins under the condition that the core wires keep motionless, therefore, the manual work manner in the prior art can be replaced, the skins at the end parts of the core wires can be stripped off rapidly and conveniently, and the invention is suitable for mass production is high, thus improving the stripping efficiency.

Owner:LINOYA ELECTRONIC TECHNOLOGY CO LTD

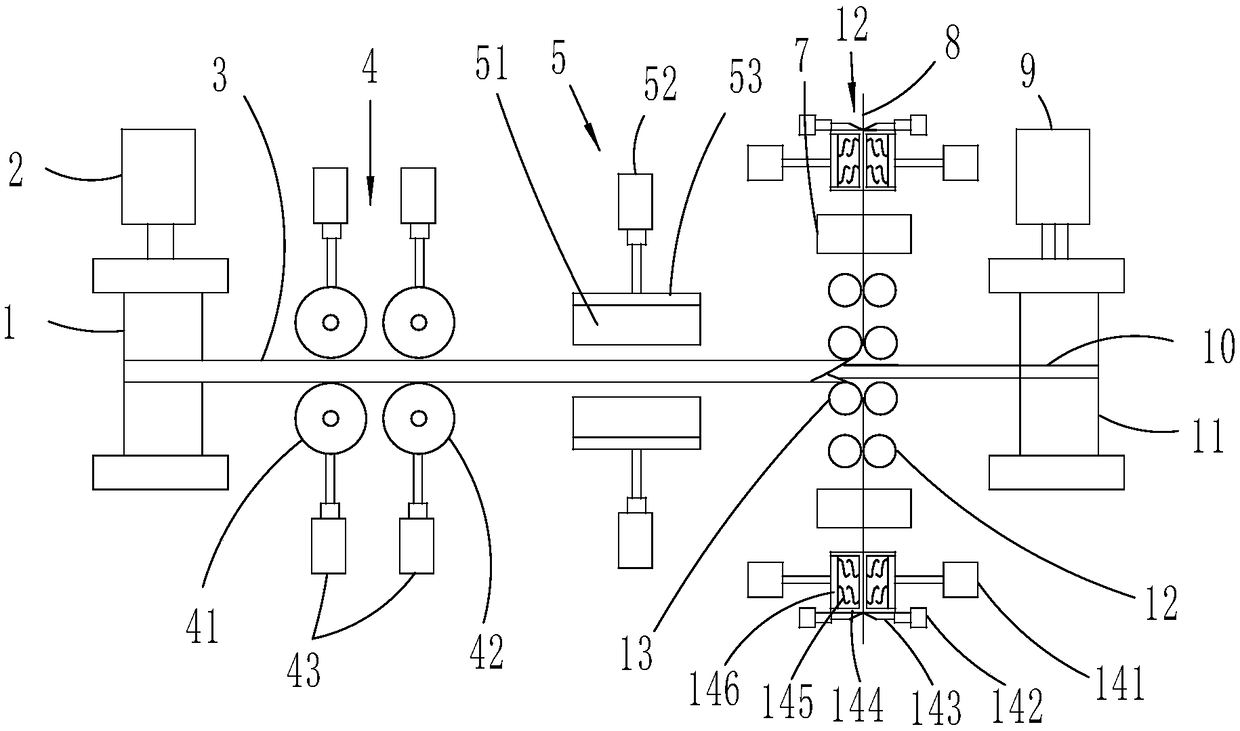

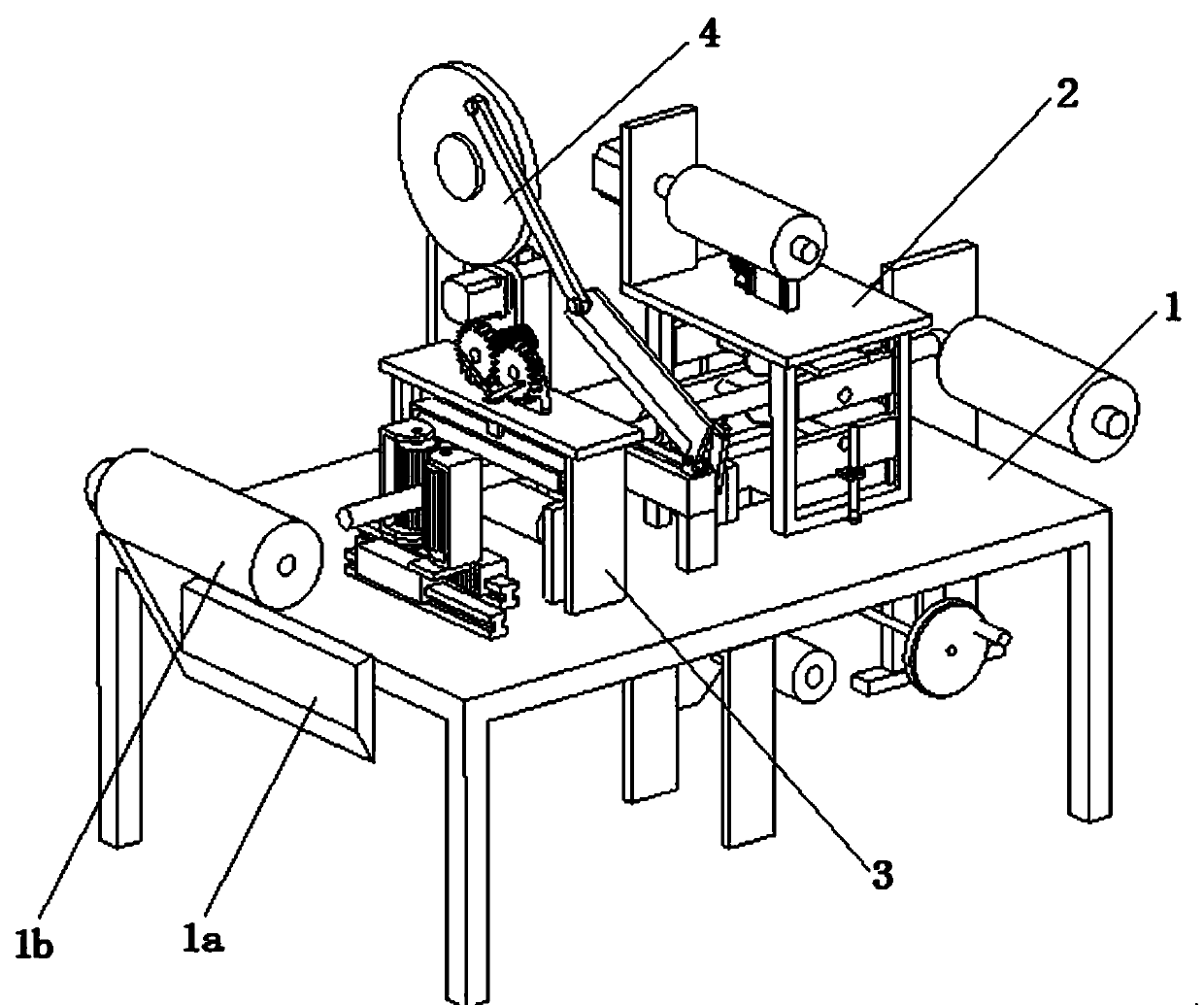

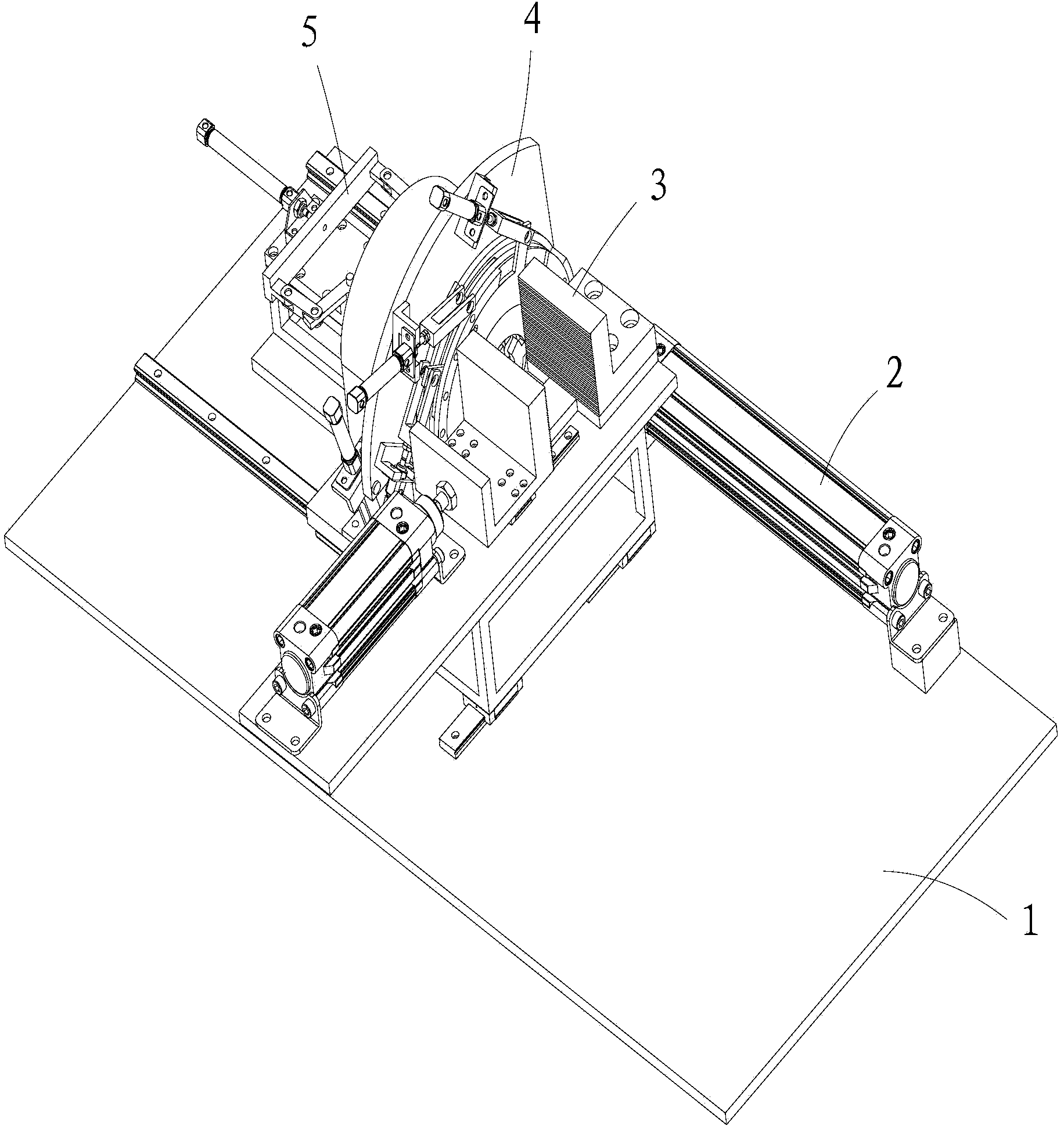

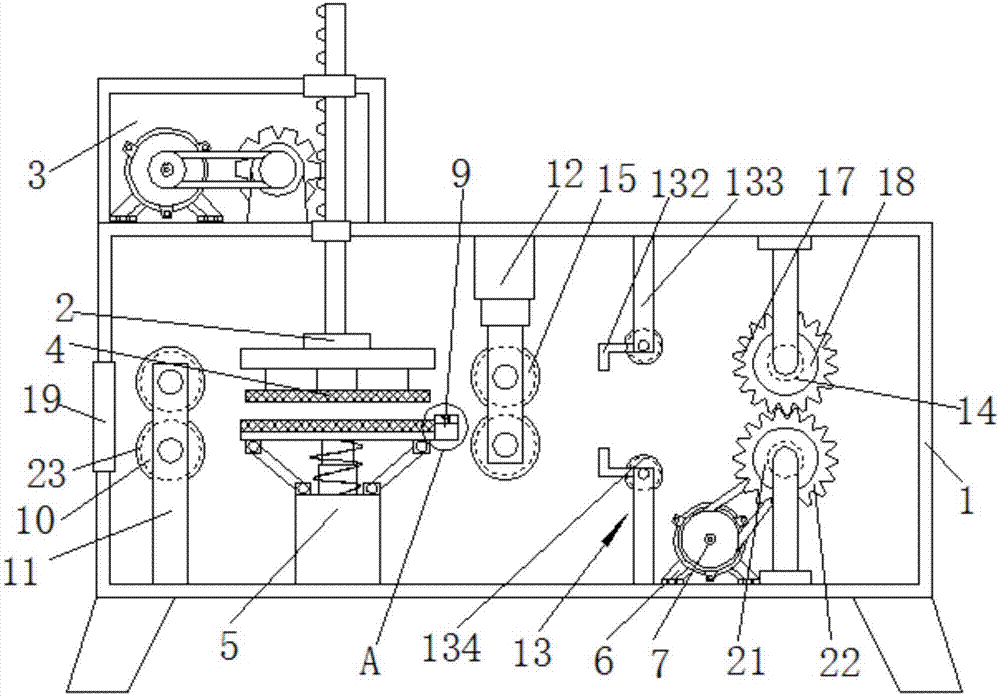

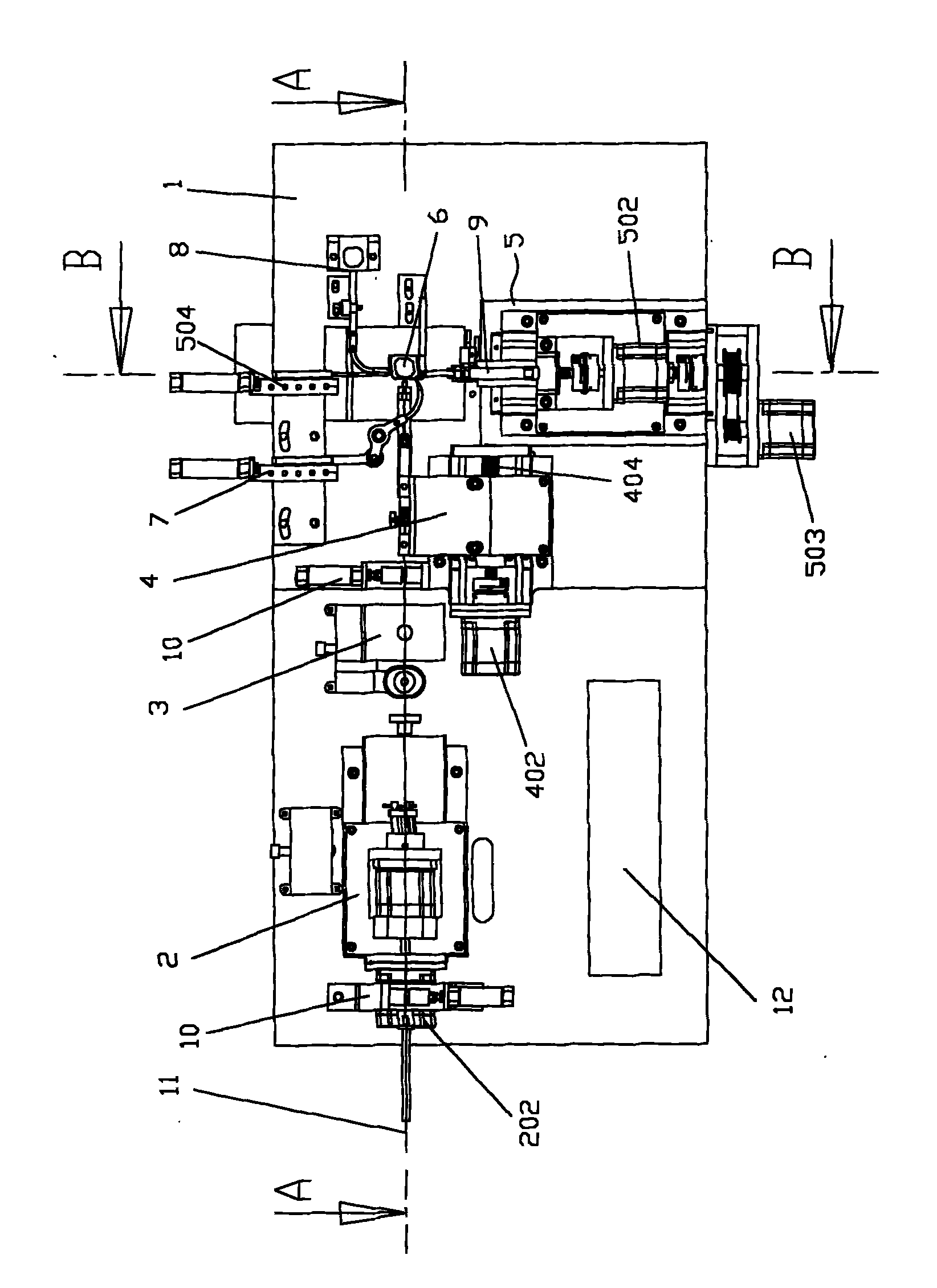

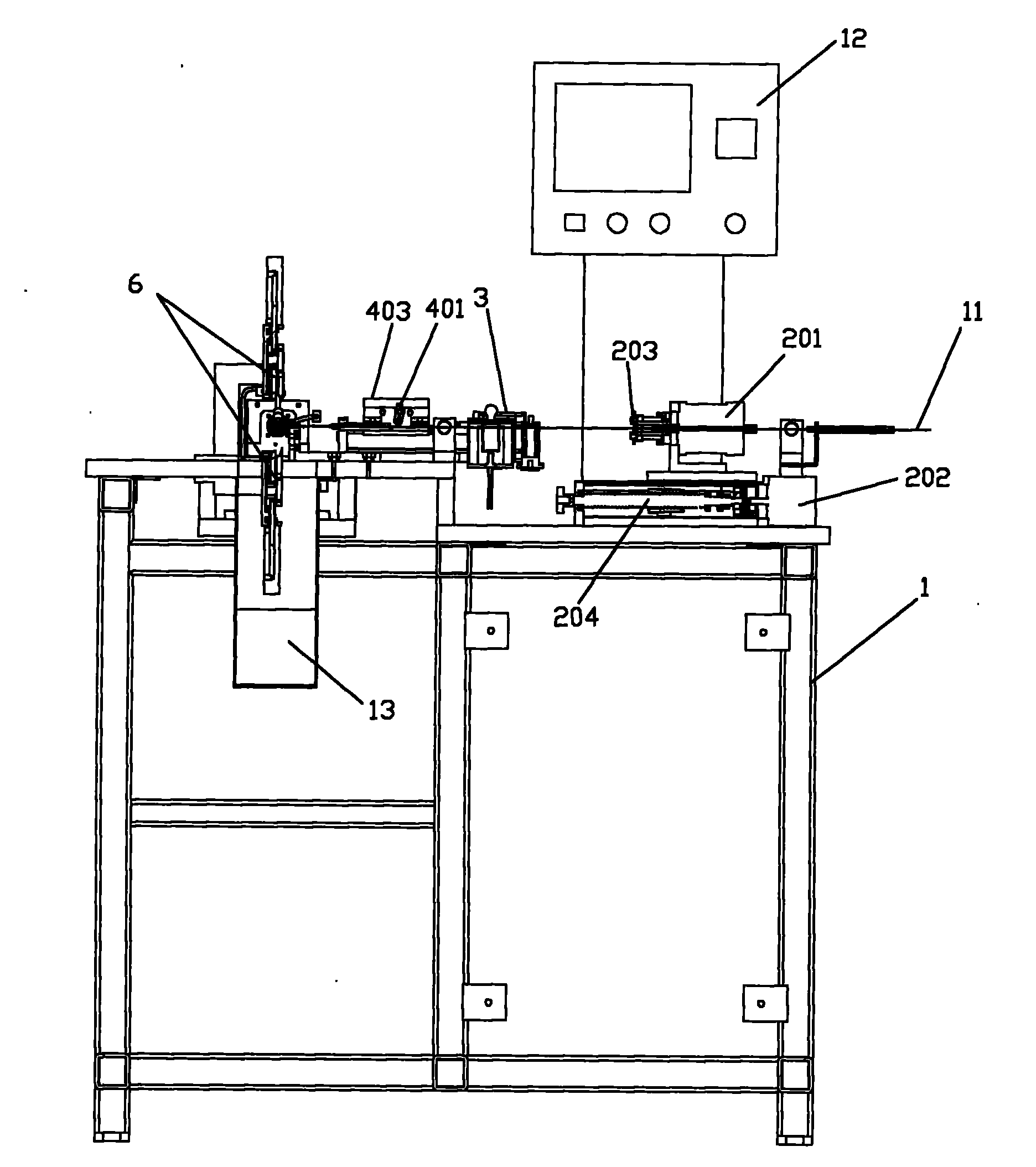

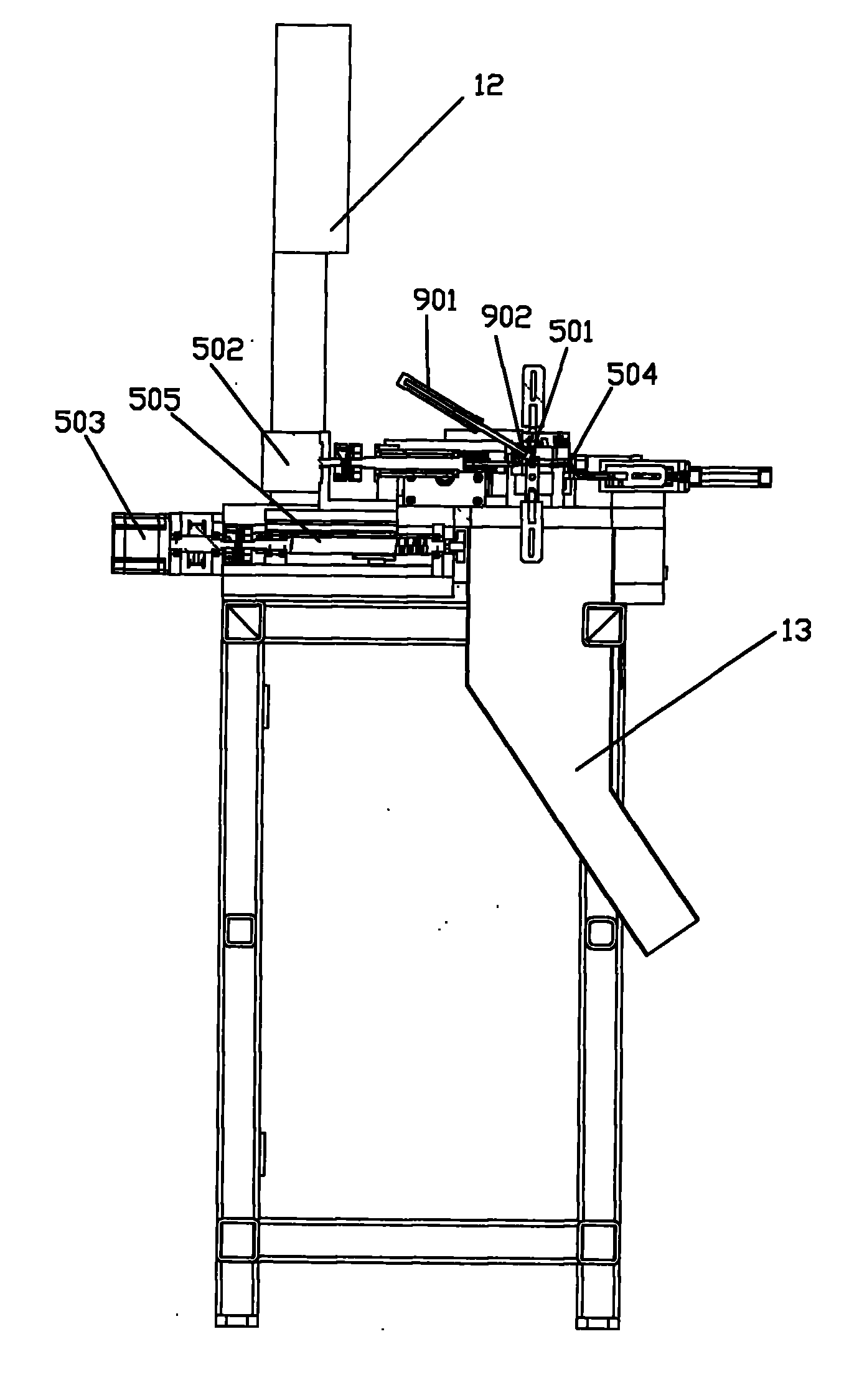

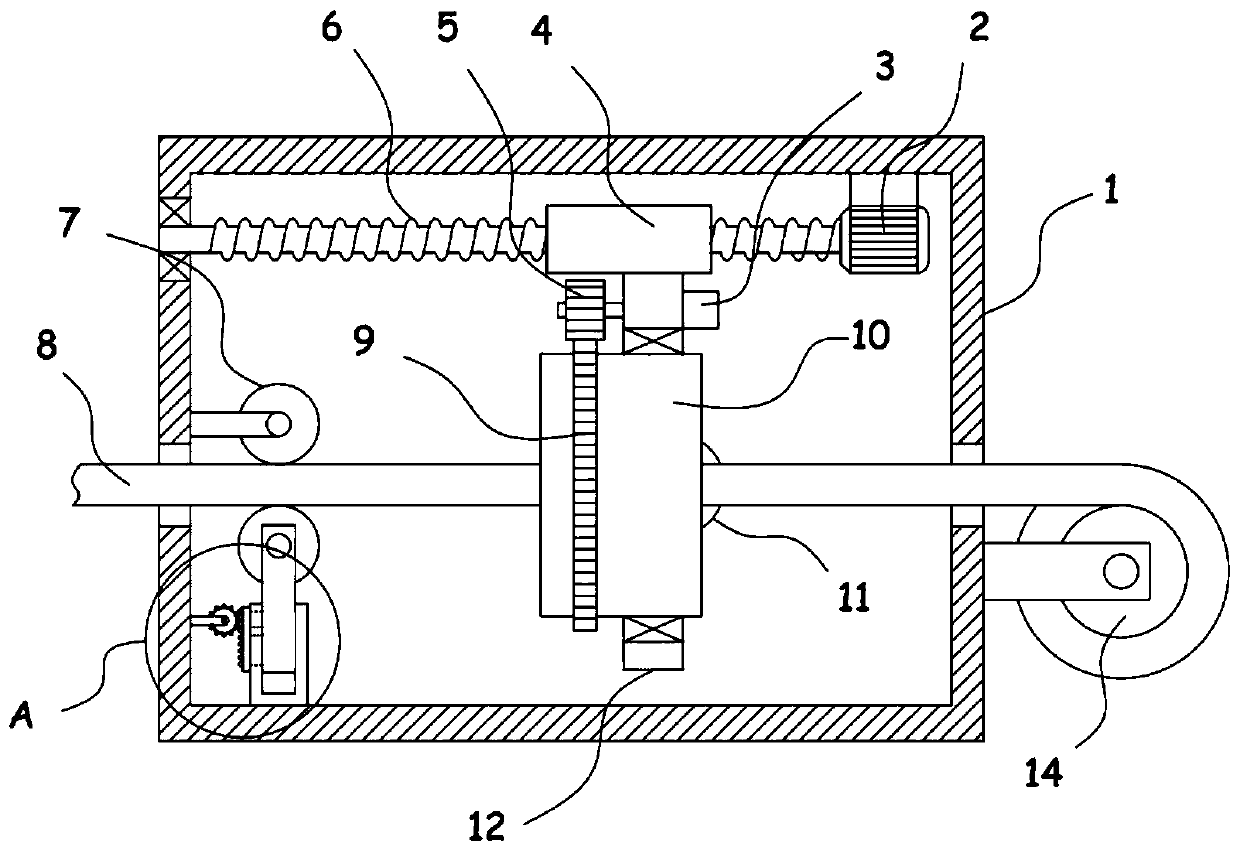

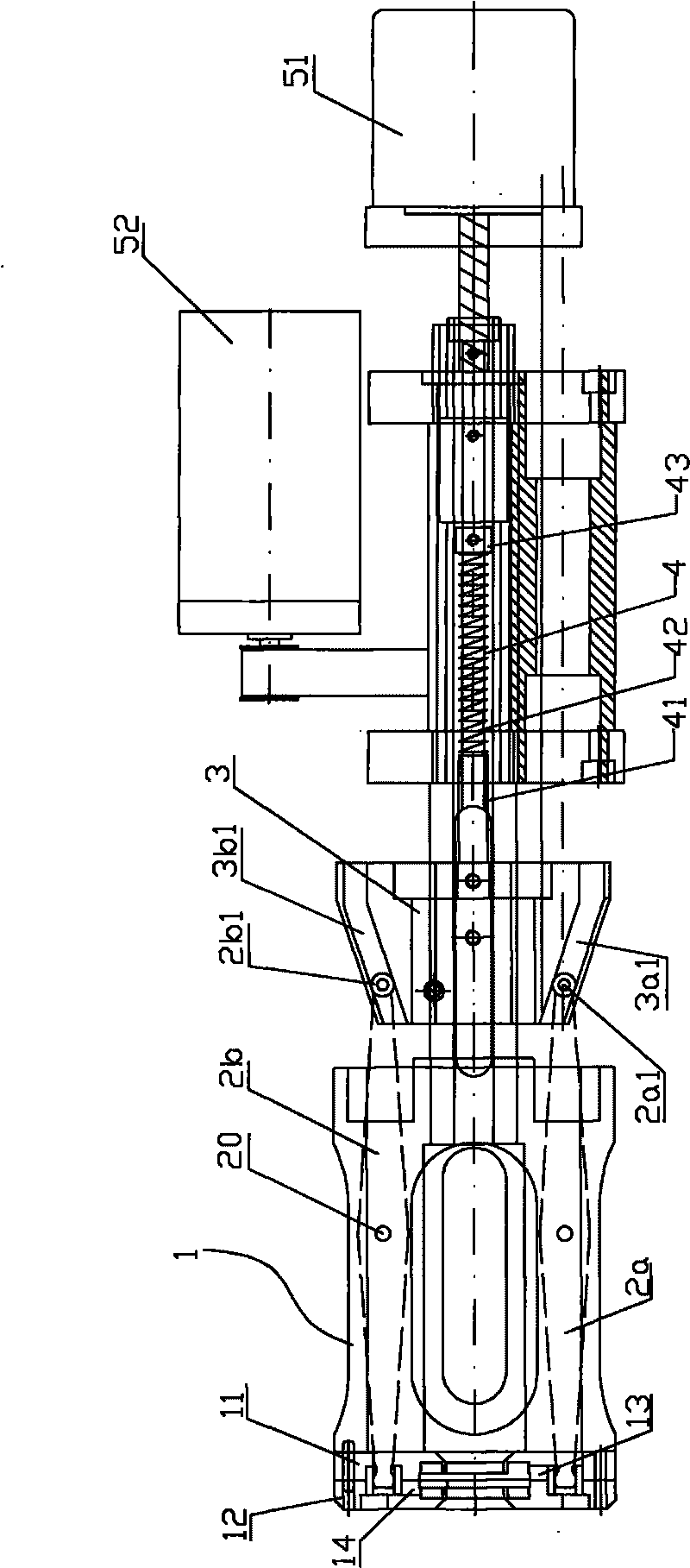

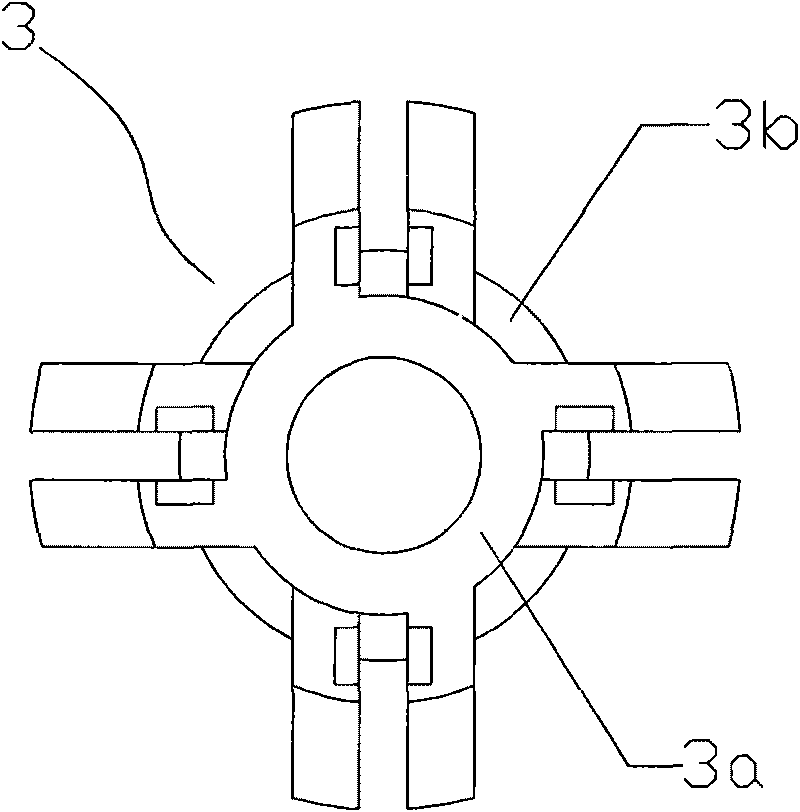

Full-automatic coiling machine

InactiveCN101847507AGuaranteed accuracy requirementsEven number of turnsLine/current collector detailsApparatus for removing/armouring cablesElectronic communicationCopper wire

The invention discloses a full-automatic coiling machine with high processing precision, high production efficiency and one-step processing and shaping. The full-automatic coiling machine comprises a work bench (1), a peeling mechanism (2), a solder machine (3), a wire feeding mechanism (4), a coiling mechanism (5), a break-in device (6) and a main controller, wherein the peeling mechanism (2), the solder machine (3), the wire feeding mechanism (4), the wire feeding mechanism (5) and the break-in device (6) are successively arranged on the work bench (1), and the main controller controls the above components to act; a copper wire to be coiled passes through the inner part of the solder machine (3) to plate a tin layer on the surface thereof after an oxide layer is peeled off by the peeling mechanism (2); the wire feeding mechanism (4) can guide the copper wire to the coiling mechanism (5); the coiling mechanism (5) comprises a coiling shaft (501) which coils the copper wire into a coil, and can move back and forth along the axial direction of the coiling shaft (501); after finishing coiling, the break-in device (6) cuts off the copper wire guided to the coiling shaft (501). The invention can be widely applied in processing no-core coils in the field of electronic communication.

Owner:珠海恒阳科技有限公司

Multifunctional full-automatic rapid wire-stripping machine

ActiveCN103151736AEnsure cutting accuracyGuaranteed characteristicsApparatus for removing/armouring cablesAutomatic controlStepper

The invention discloses a multifunctional full-automatic rapid wire-stripping machine which comprises a frame, wherein a working base plate is arranged on the frame, a feeding guide mechanism, a transverse cutting wire stripping mechanism, an annular cutting wire stripping mechanism, a traction mechanism and a cutting mechanism are sequentially fixed on the working base plate from left to right in a cable moving direction. The multifunctional full-automatic rapid wire-stripping machine has the beneficial effects that all motors adopt either stepper motors or servo motors, so that cutting precision and an automatic control characteristic of the multifunctional full-automatic rapid wire-stripping machine are guaranteed; and the unique ways of transverse cutting, annular cutting and cutting are matched so that the cutting quality is guaranteed and the working efficiency is greatly improved.

Owner:天津伍嘉联创科技发展股份有限公司

Power cable recycling and stripping device

InactiveCN110265929AEffective peelingImproved size adaptabilityApparatus for removing/armouring cablesPower cableEngineering

The invention discloses a power cable recycling and stripping device, and relates to the technical field of power cable winding. The power cable recycling and stripping device comprises a support frame, wherein the inner top of the support frame is fixed with a servo motor I, the support frame is internally provided with an annular cutting mechanism used for stripping a cable, the servo motor I is in drive connection with a translation mechanism which is used for driving the annular cutting mechanism to move in the transverse direction and includes a threaded sleeve, and the support frame is internally provided with a conveying mechanism used for conveying the cable sheath. According to the invention, the annular cutting mechanism is set to perform annular cutting on the sheath of the cable so as to achieve a cutting effect for the sheath, the translation mechanism drives the annular cutting mechanism to move in the transverse direction so as to pull off the sheath of the cable from the main body, and a lead screw can be driven to rotate through rotating a handwheel so as to adjust the distance between two arc-shaped blades, thereby adjusting the cutting depth of the arc-shaped blades into the cable sheath according to the actual diameter of the cable. The whole stripping process of the cable is very efficient. Meanwhile, the device has greater cable size adaptability.

Owner:万元强

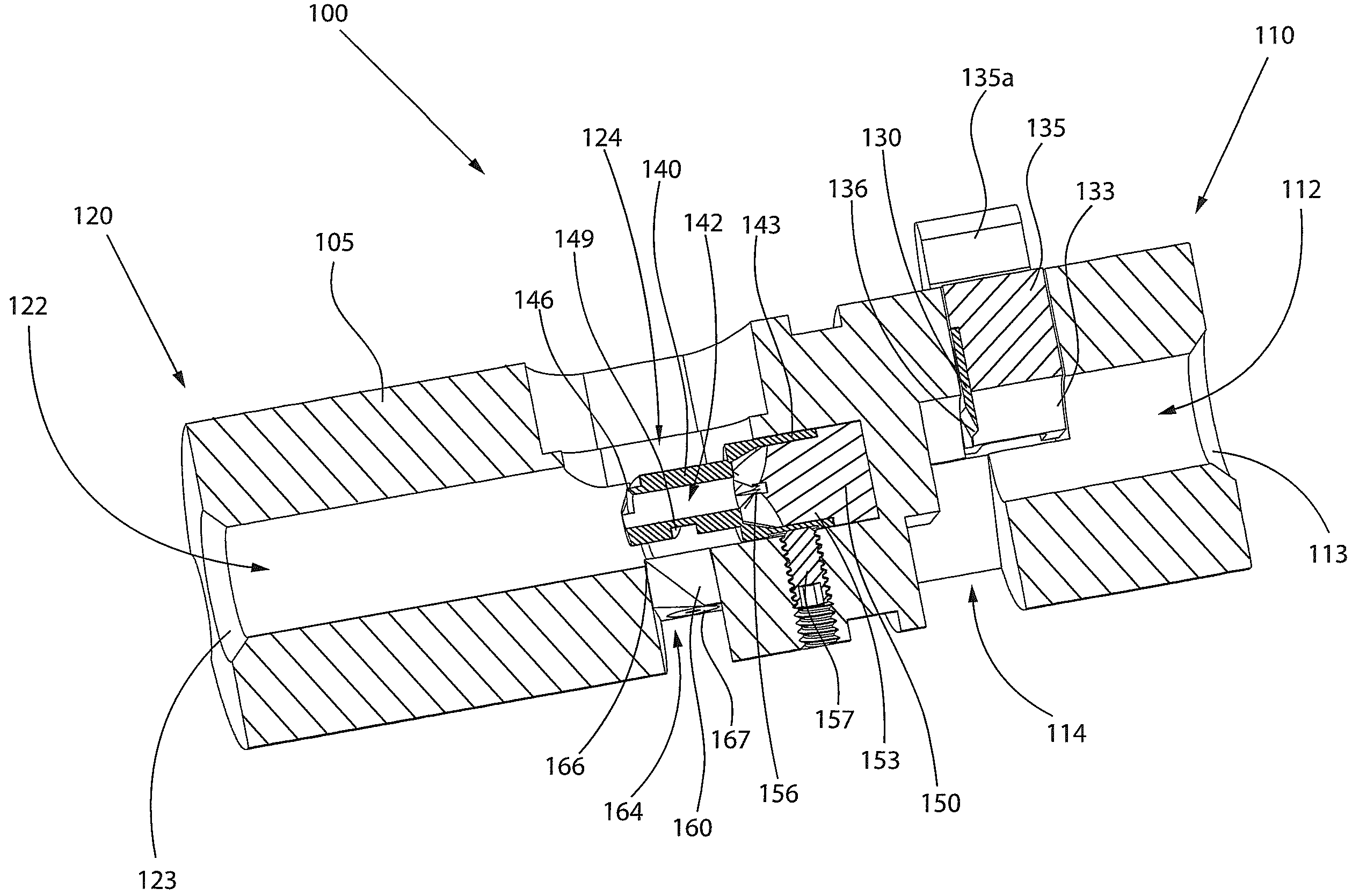

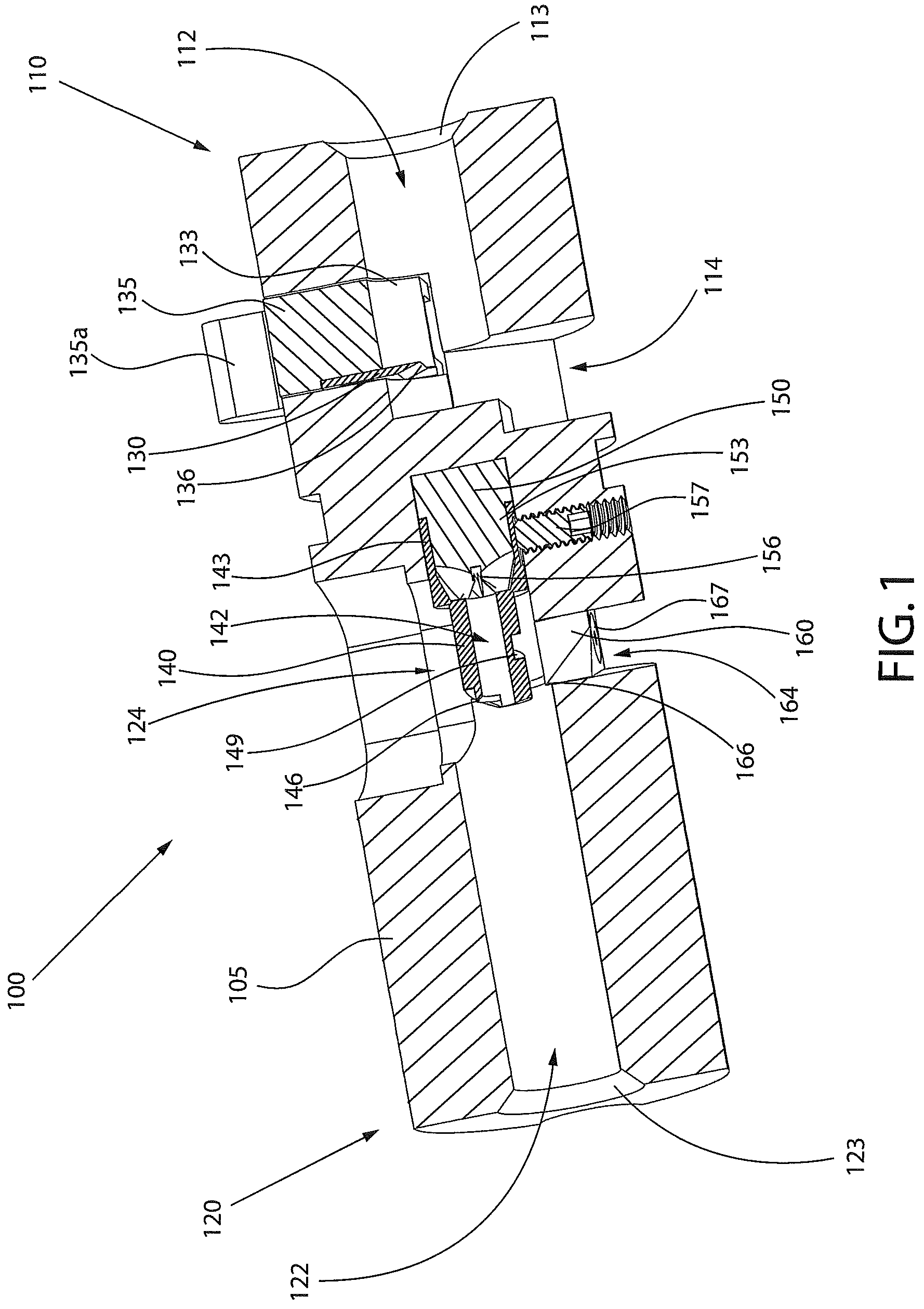

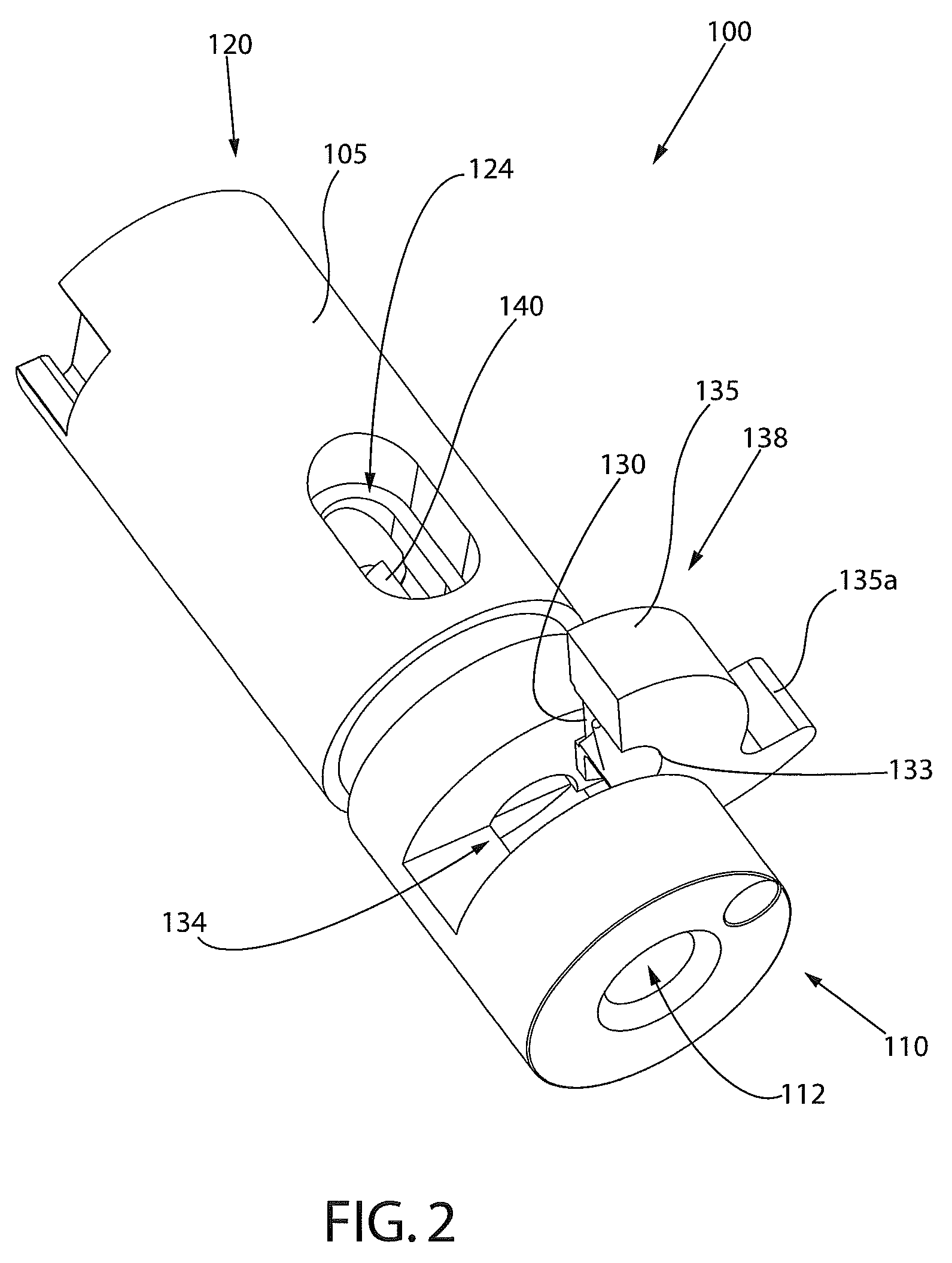

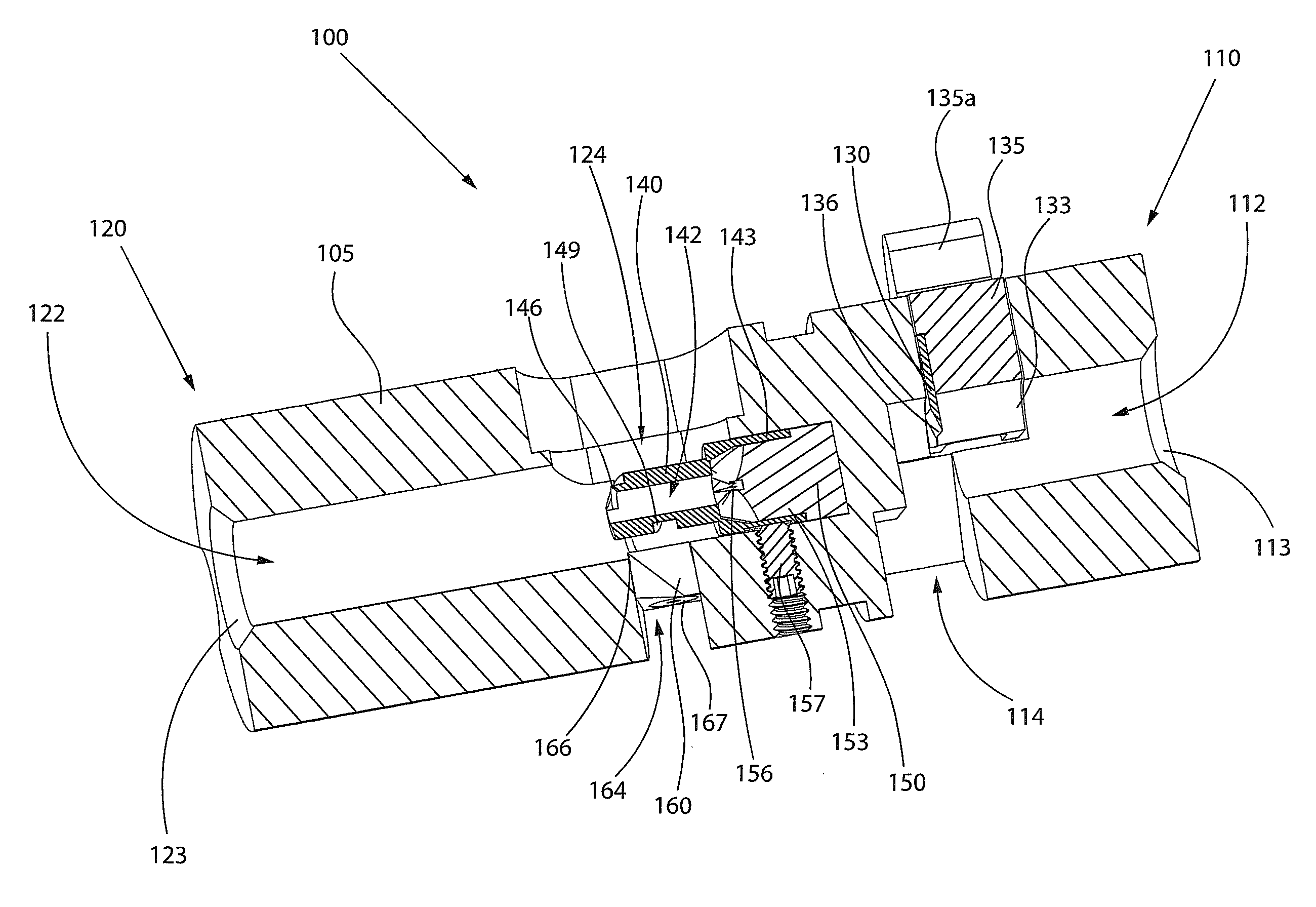

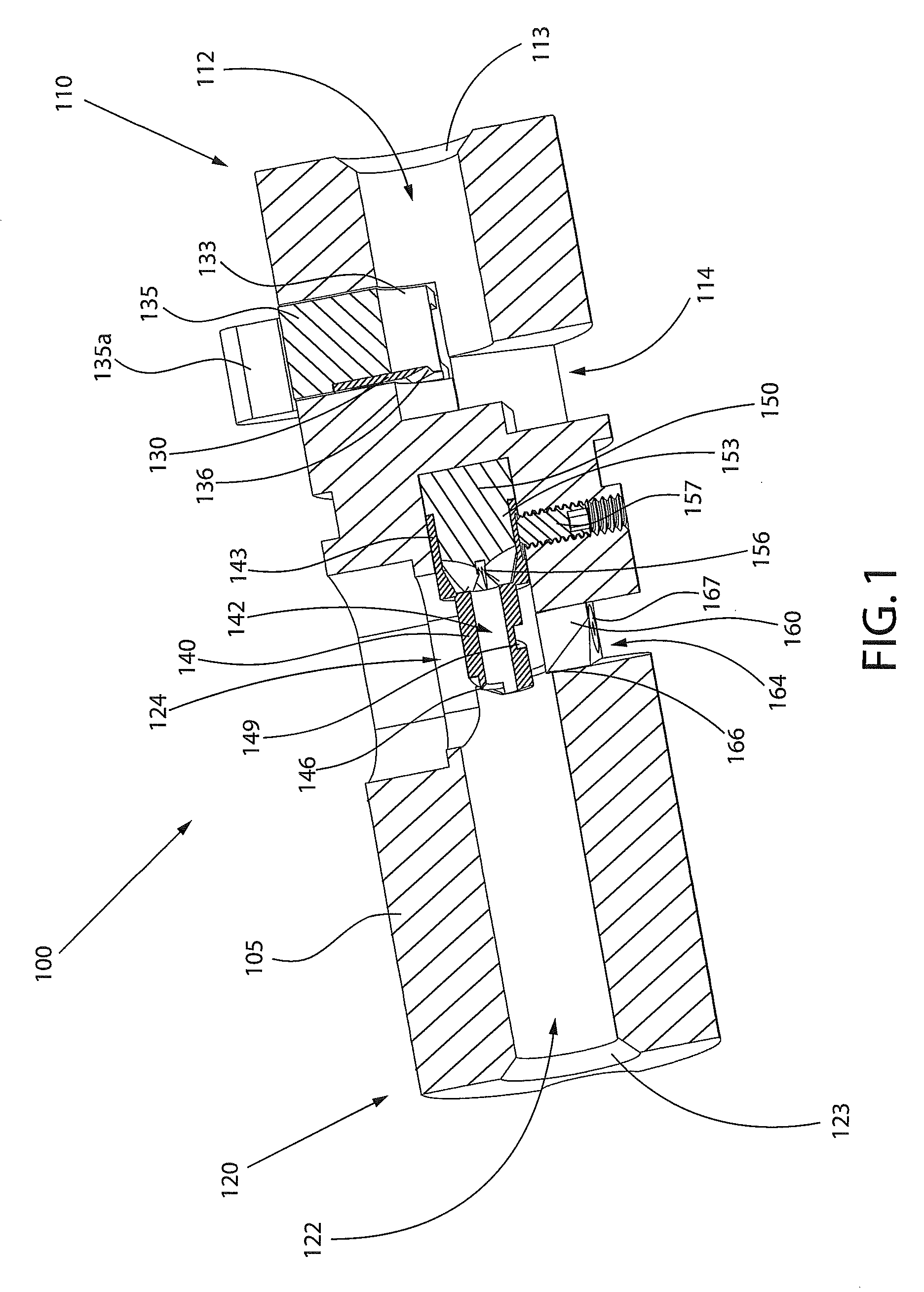

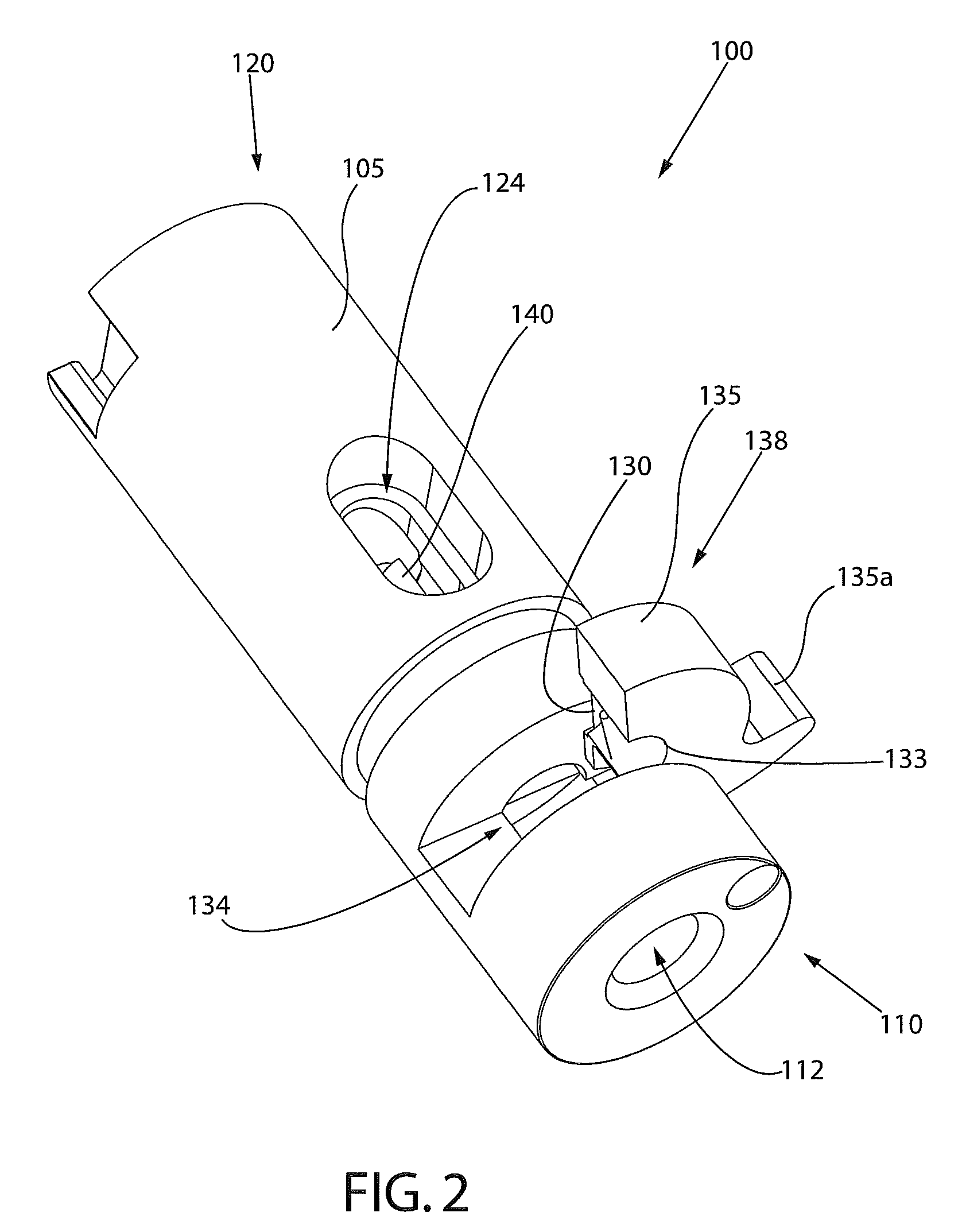

Single drop trimmer with limited cartridge release

InactiveUS6253641B1Easy to removeEasy to replacePliersMetal working apparatusCoaxial cableMechanical engineering

A handheld coaxial cable trimmer tool has a removable and replaceable blade cartridge. The blade cartridge snaps into the tool with a hook engagement and is easily removed from the tool by pressing on a flexible lever on the top of the tool. The flexible lever has limited motion to protect it and the cartridge from being overstressed.

Owner:RIPLEY TOOLS

Coaxial line stripping machine

ActiveCN101764379APrevent deviationEnsure positioning accuracyLine/current collector detailsApparatus for removing/armouring cablesTool bitCoaxial cable

The invention relates to a coaxial line stripping machine, which is provided with a case. A tool bit unit, a line clamping unit and a control unit are arranged in the case; the tool bit unit is provided with a rotating tool bit seat which is provided with a cutter arm and a positioning tool arm; the middle parts of the cutter arm and the positioning tool arm are pivoted to the rotating tool bit seat together; and the tool bit unit is also provided with a tool-pushing seat which is formed by detachably embedding a blade tool-pushing seat and a positioning blade tool-pushing seat along the axial line. The invention can control the tool bit unit and the line clamping unit by using a control system of the control unit and can flexibly control whether various motors need to simultaneously run or not, the running speed and the like according to the requirement, thereby realizing the operations of stripping in a multilayer, layer by layer, rotating and other ways. The invention solves the problems of inaccurate cable positioning, low cutting precision and the like of a traditional coaxial line stripping machine.

Owner:DONGGUAN WINGUD MECHANICAL EQUIP CO LTD

Charged wire stripping device

PendingCN108963888ATo achieve the peeling effectLabor savingApparatus for removing/armouring cablesElectronic waste recyclingLinear motionEngineering

A charged wire stripping device of the invention comprises a wire stripper body, a wire stripping mechanism, a transmission mechanism and an insulating rod. The wire stripper body is provided with a threading hole, and the threading hole is provided with an opening allowing a wire to pass through along the radial direction of the threading hole. The wire stripping mechanism and the transmission mechanism are arranged on the wire stripper body. The insulating rod can drive a linear motion component to do linear motion and drive a circular motion component to do circular motion simultaneously through the transmission mechanism. The wire stripping mechanism includes a linear motion component, a circular motion component and a cutter. The linear motion component and the circular motion component can drive the cutter to do linear motion along the axis of the threading hole and do circular motion with the axis of the threading hole as an axis. The charged wire stripping device needs less labor during wire stripping. Usually, one person can hang the wire stripper body to a wire and then drive the cutter through the insulating rod to strip the wire in a charged state. The wire stripping efficiency is high, and the wire stripping effect is good. A stripped wire can be reliably and electrically connected with other wires during energizing, and the energizing effect is better.

Owner:陈平武

Automatic stripping device for power communication cable recycling

InactiveCN110265932AImprove practicalityEasy to cutBasic electric elementsApparatus for removing/armouring cablesResistance wireEngineering

The invention provides an automatic stripping device for power communication cable recycling, which relates to the technical field of communication cable recycling. The automatic stripping device for power communication cable recovery includes a frame. An extruding block is fixedly connected inside the right inner wall of the frame through a first spring. A heating box is arranged on the right side inside the frame. A heating resistance wire is fixedly connected inside the heating box. A stripping device is fixedly installed inside the frame. A cylinder is fixedly installed at the top end of the inside of the frame. A pressure bar is fixedly connected inside the cylinder through a second spring. The bottom end of the pressure bar is rotationally connected with a driven wheel. The automatic peeling device for power communication cable recycling facilitates the cutting and removing of the sheath. The blade can be easily adjusted and replaced, which makes the device highly practical. Because a push plate is added, there is no need for the blade to cut off the sheath completely, the scratch of the surface of the copper core is avoided, and the wear of the blade is reduced.

Owner:朱兴兴

Adjustable stripping tool

InactiveUS7216431B2Reduce manufacturing costExtremely compactMetal working apparatusApparatus for removing/armouring cablesCoaxial cableHand held

Owner:PPC BROADBAND INC

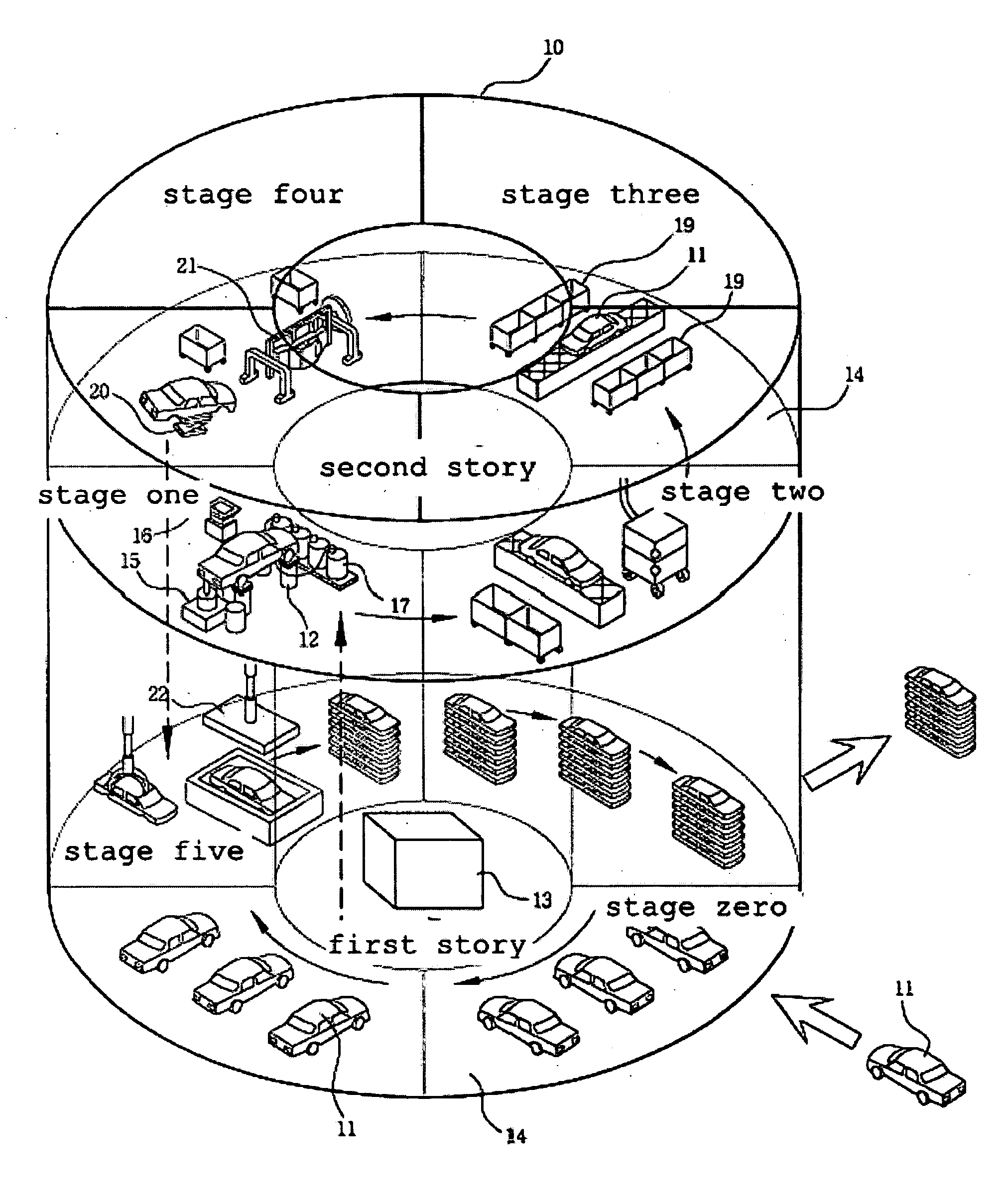

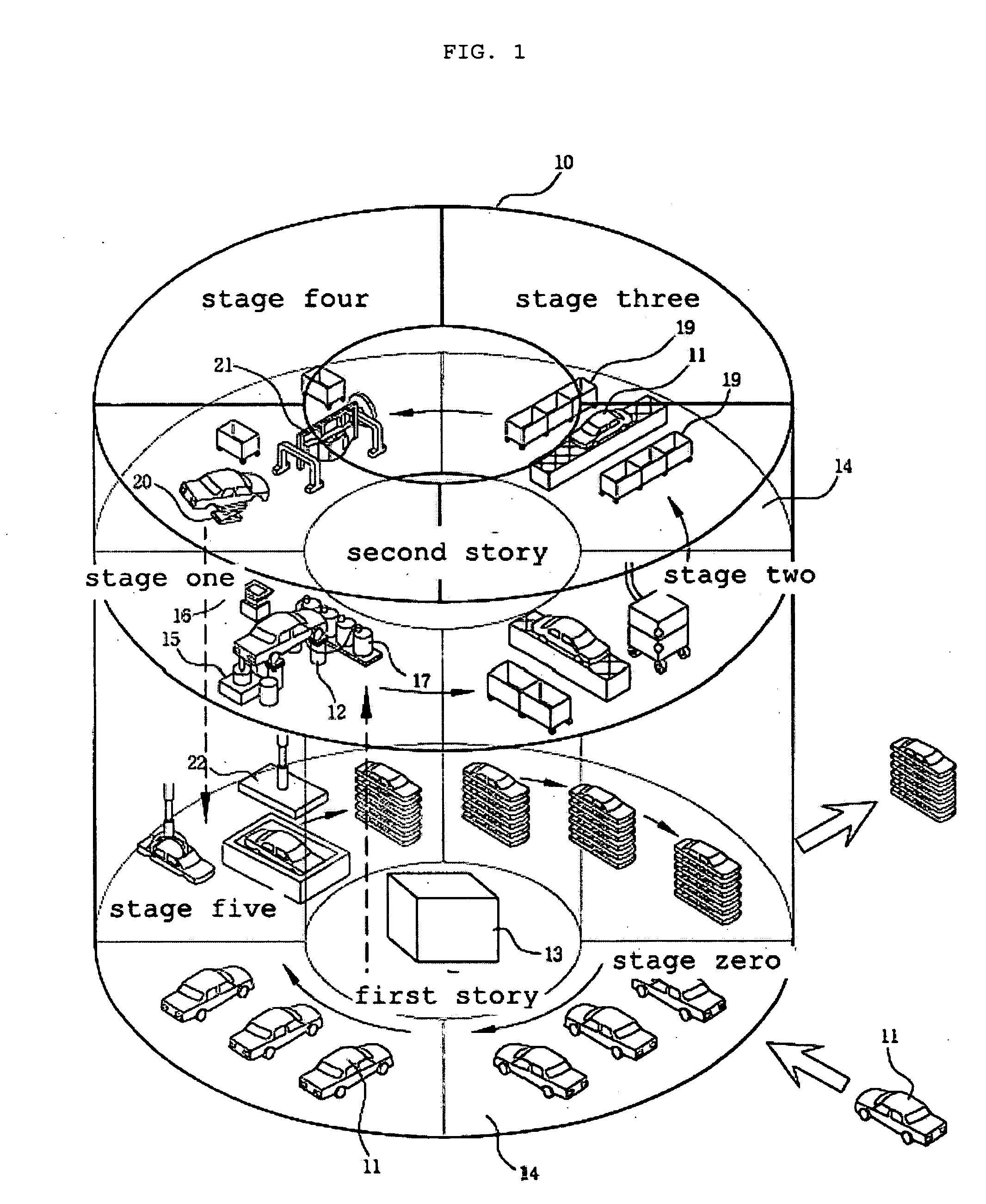

System for method of disassembling end-of-life vehicles

InactiveUS20070124906A1Shortening time spent disassembling component partLow costVehicle dissasembly recoveryBasic electric elementsMobile vehicleFloor level

A disassembling process of end-of-life vehicles (ELVS) takes place in a circular two-story structure. An elevator moves a vehicle between stories of the structure, and a conveyor system moves the vehicle between facilities in each story. The first and last steps in the disassembling process take place on the first story and the other steps take place in facilities arranged sequentially around the perimeter of the second story.

Owner:HYUNDAI MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com