Patents

Literature

1597results about "Connection formation by deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

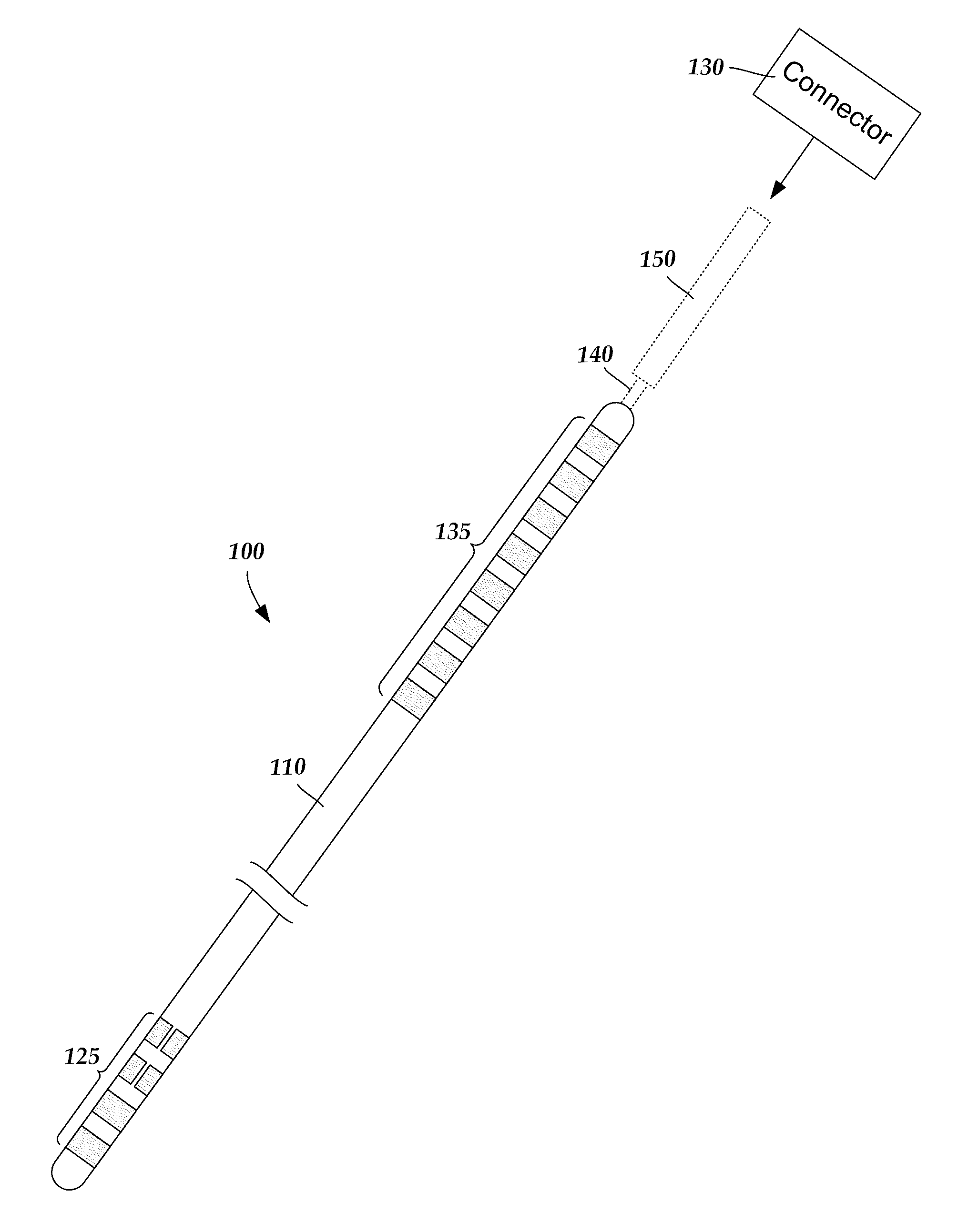

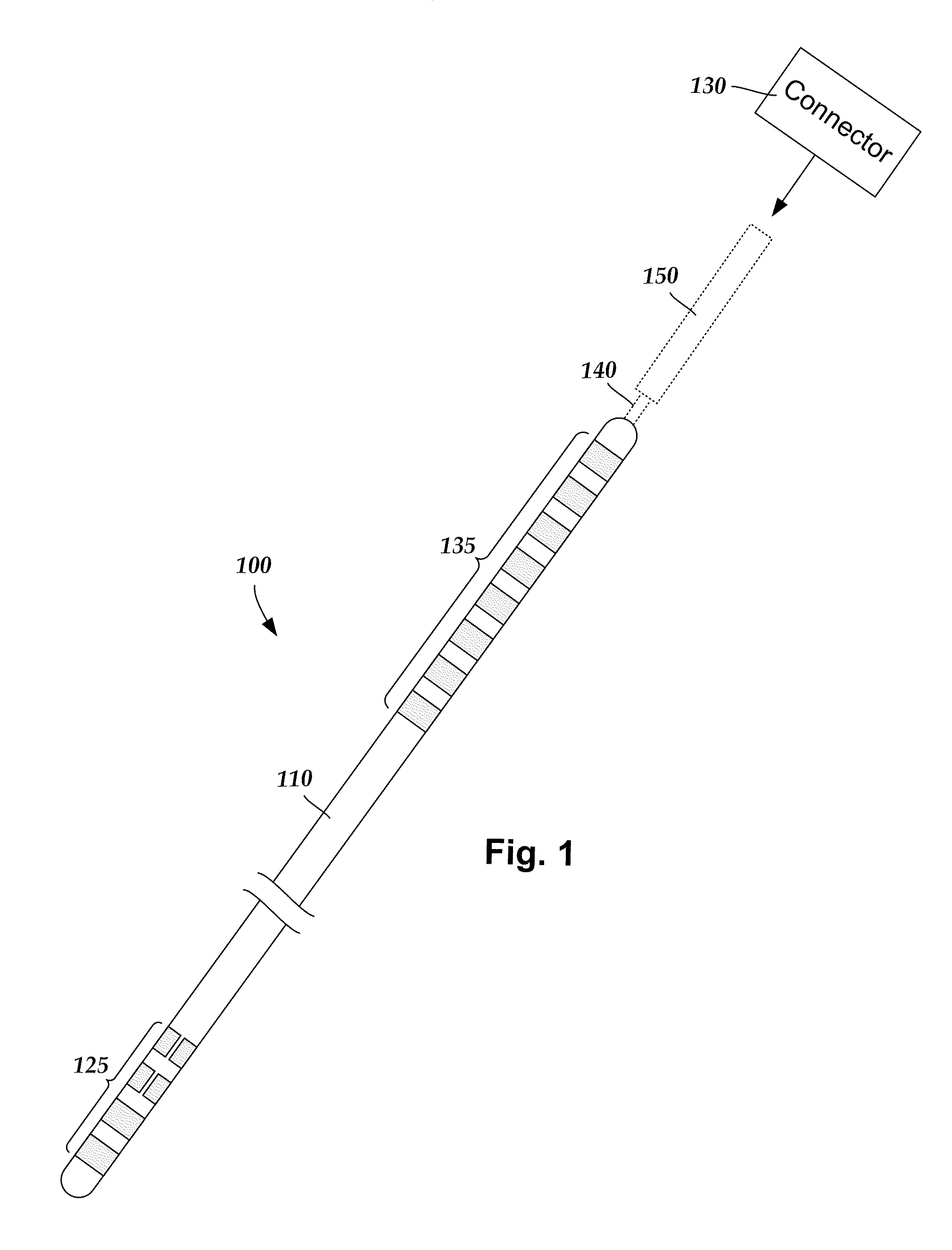

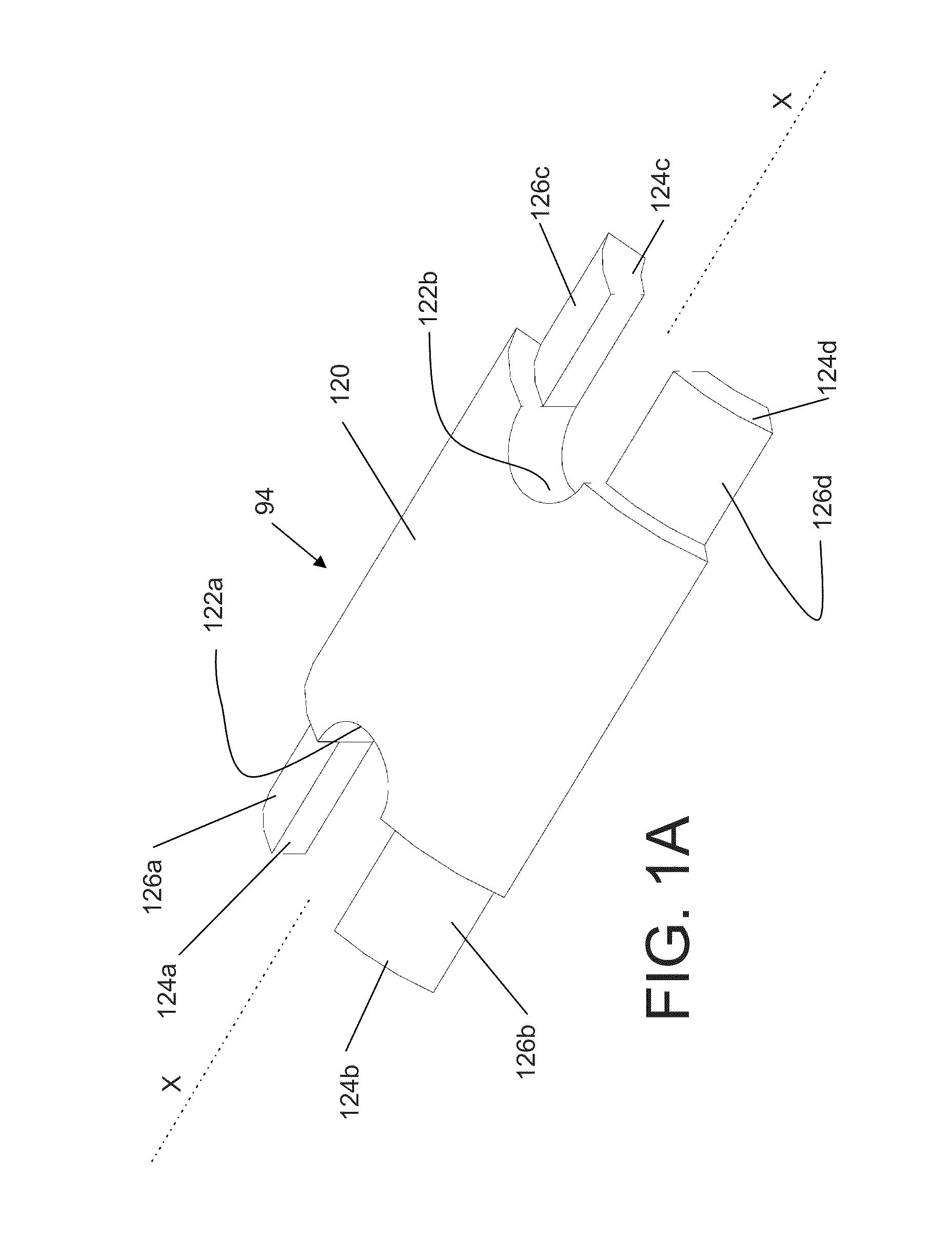

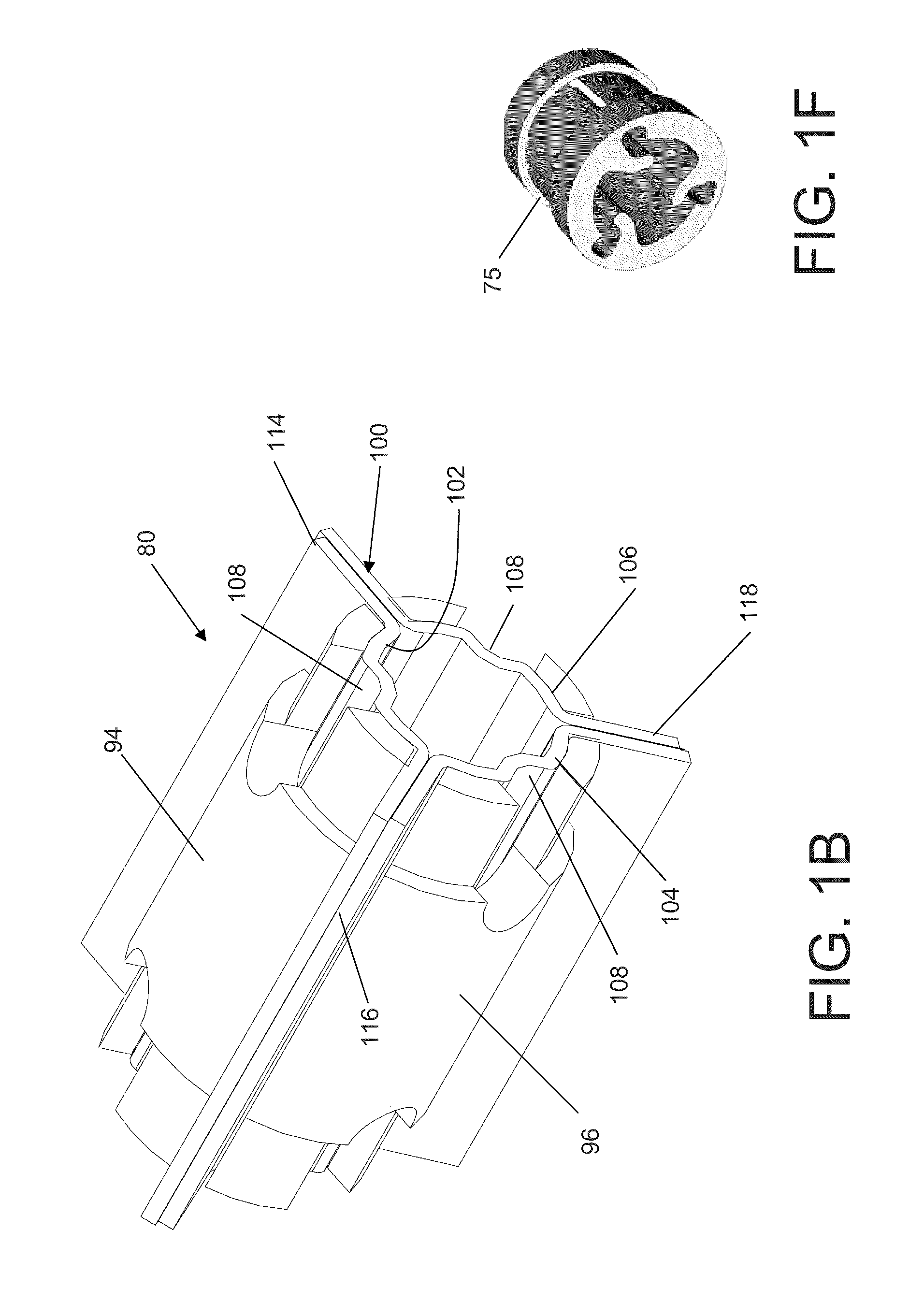

Methods for making leads with radially-aligned segmented electrodes for electrical stimulation systems

ActiveUS20110078900A1Head electrodesConnection formation by deformationElectrical conductorEngineering

Owner:BOSTON SCI NEUROMODULATION CORP

Method of manufacturing a female electrical connector in a single layer flexible polymeric dielectric film substrate

InactiveUS6032359APrinted circuit assemblingElectrically conductive connectionsDielectricConductive coating

A method of making a wiping connection between a male connector and a female connector in a single layer of a flexible polymeric dielectric film substrate having a thickness of less than 0.012 inches is disclosed. A laser directs a beam towards the substrate cutting a smooth pattern through the substrate to define a passage extending through the substrate and providing at least one resilient foldable flap normally closing the passage through the substrate. Next an electrically conductive material is coated on the flexible polymeric dielectric film substrate including a circuit trace providing an electrical contact land area surrounding the pattern extending over the foldable flap to form the female connector. The male connector is then inserted into the female connector through the flexible polymeric dielectric film substrate at the pattern, deflecting the foldable flap and conductive coating into wiping electrical and mechanical engagement with the male connector to secure the male connector to the substrate in electrical contact with the trace circuit.

Owner:CRAIG WILSON & CO

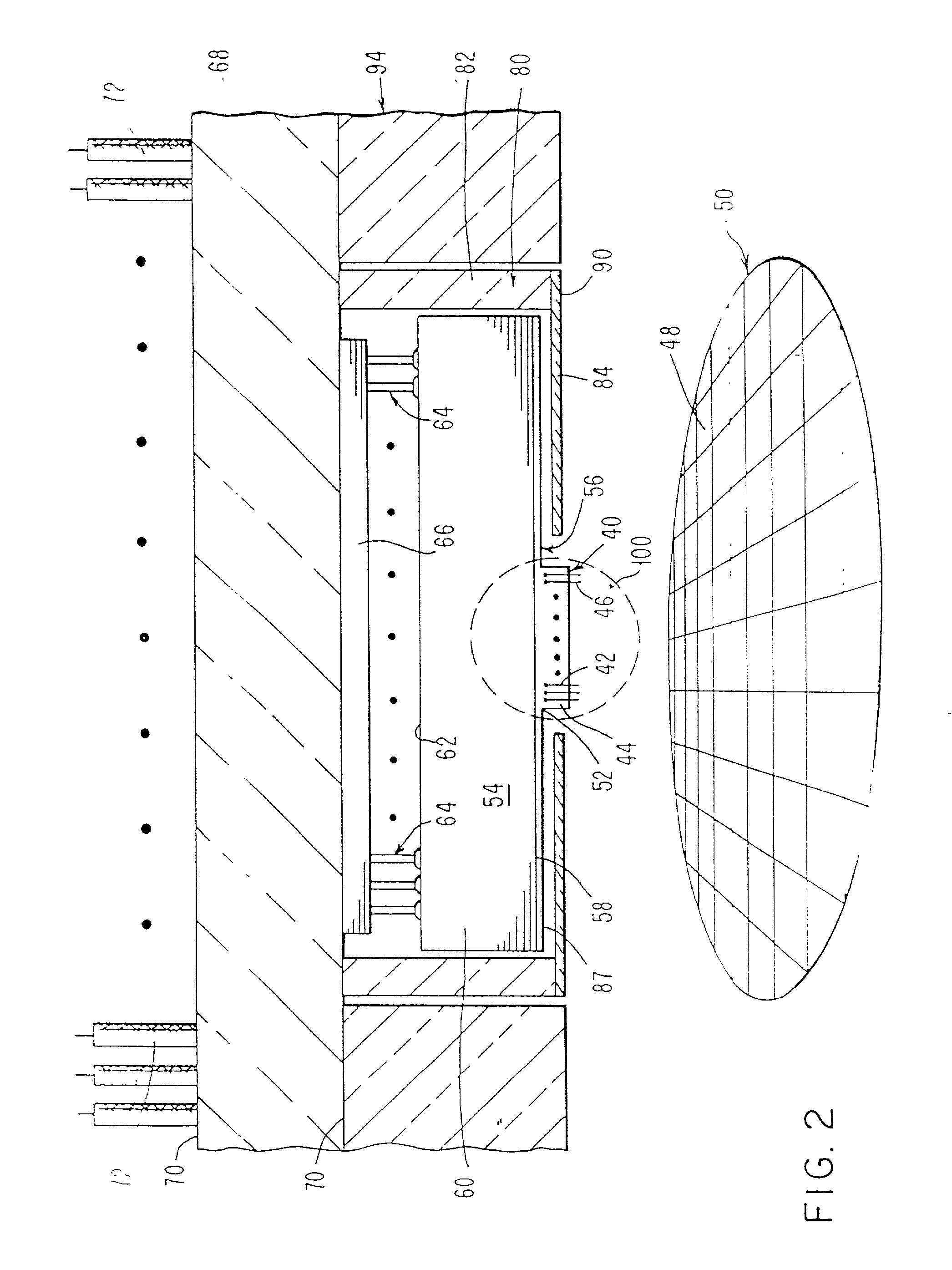

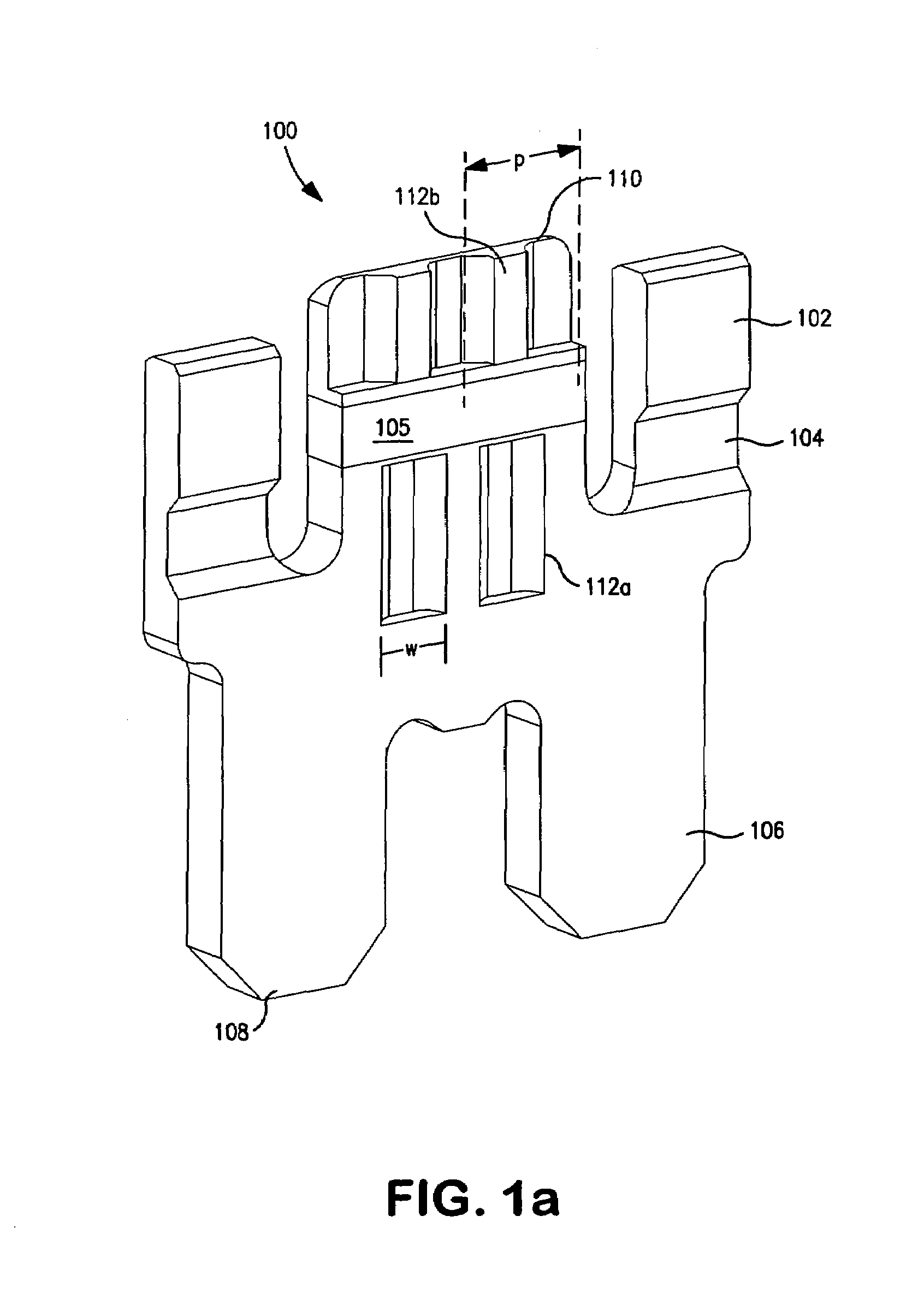

Method for pre-forming conductors for motor rotors and stators

ActiveUS7480987B1Contact member manufacturingWave amplification devicesElectrical conductorEngineering

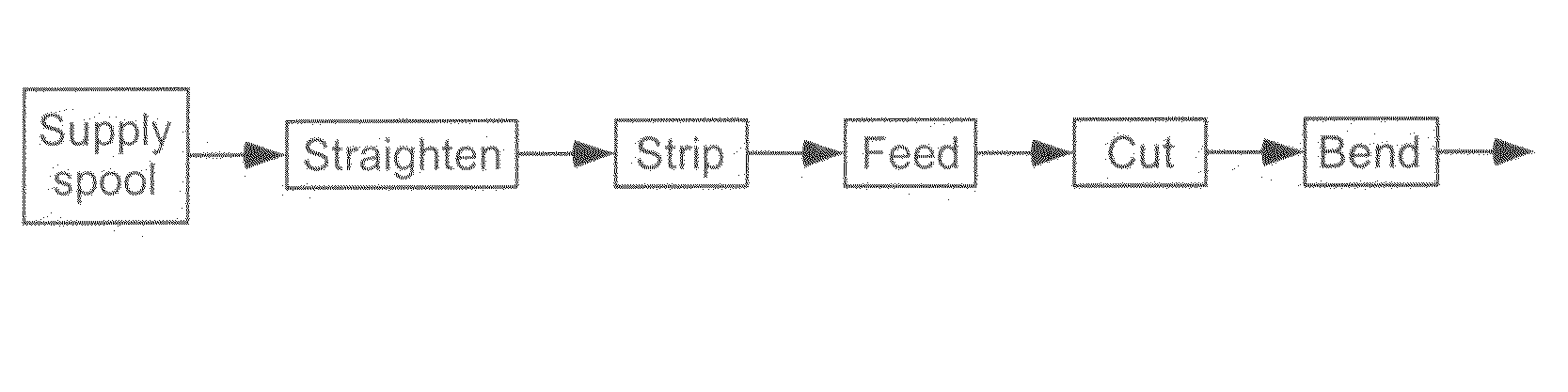

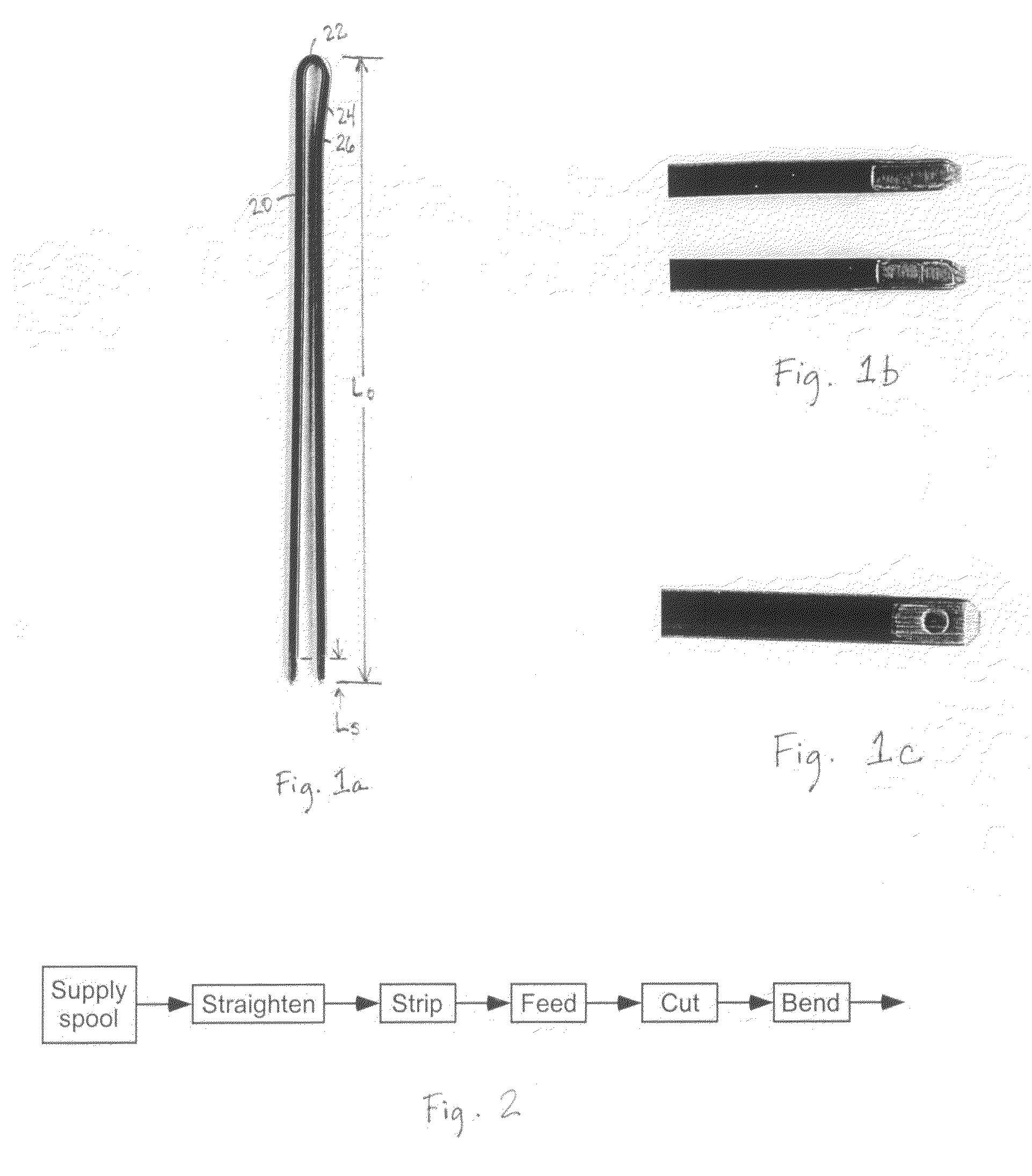

Method and apparatus for pre-forming insulated conductors for motor rotors and stators for use in a next process in forming motor rotors and stators. In accordance with the full exemplary process, insulated rectangular cross-section wire is received from a spool, straightened, stripped over a predetermined length, fed to a bender, cut to length and then bent into the desired hairpin shape and placed on a feeder for the next process. The method and apparatus may be fully automatic, including automatically adjusting itself as required to make hairpin shaped conductors of different lengths, each length having its free ends stripped over a desired length. The method and apparatus for bending, as well as other methods and apparatus disclosed, may be used alone or in other combinations.

Owner:TECNOMATIC

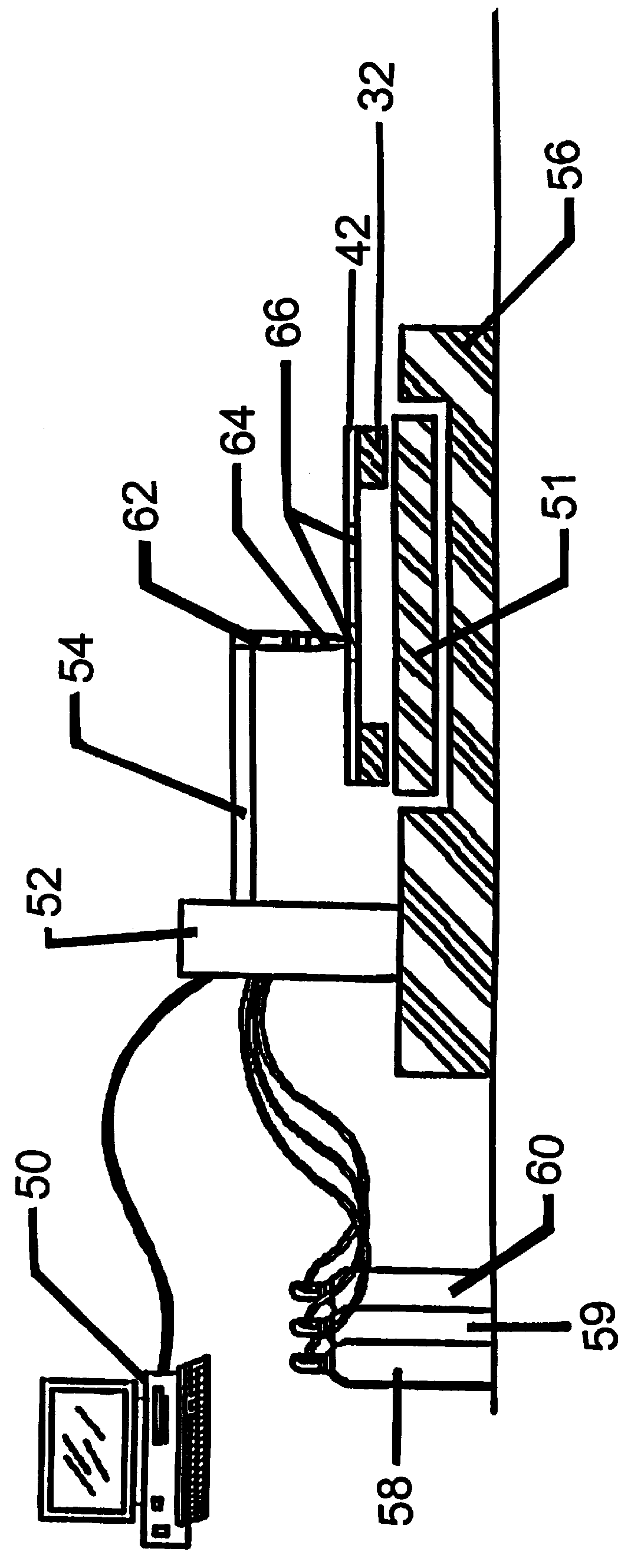

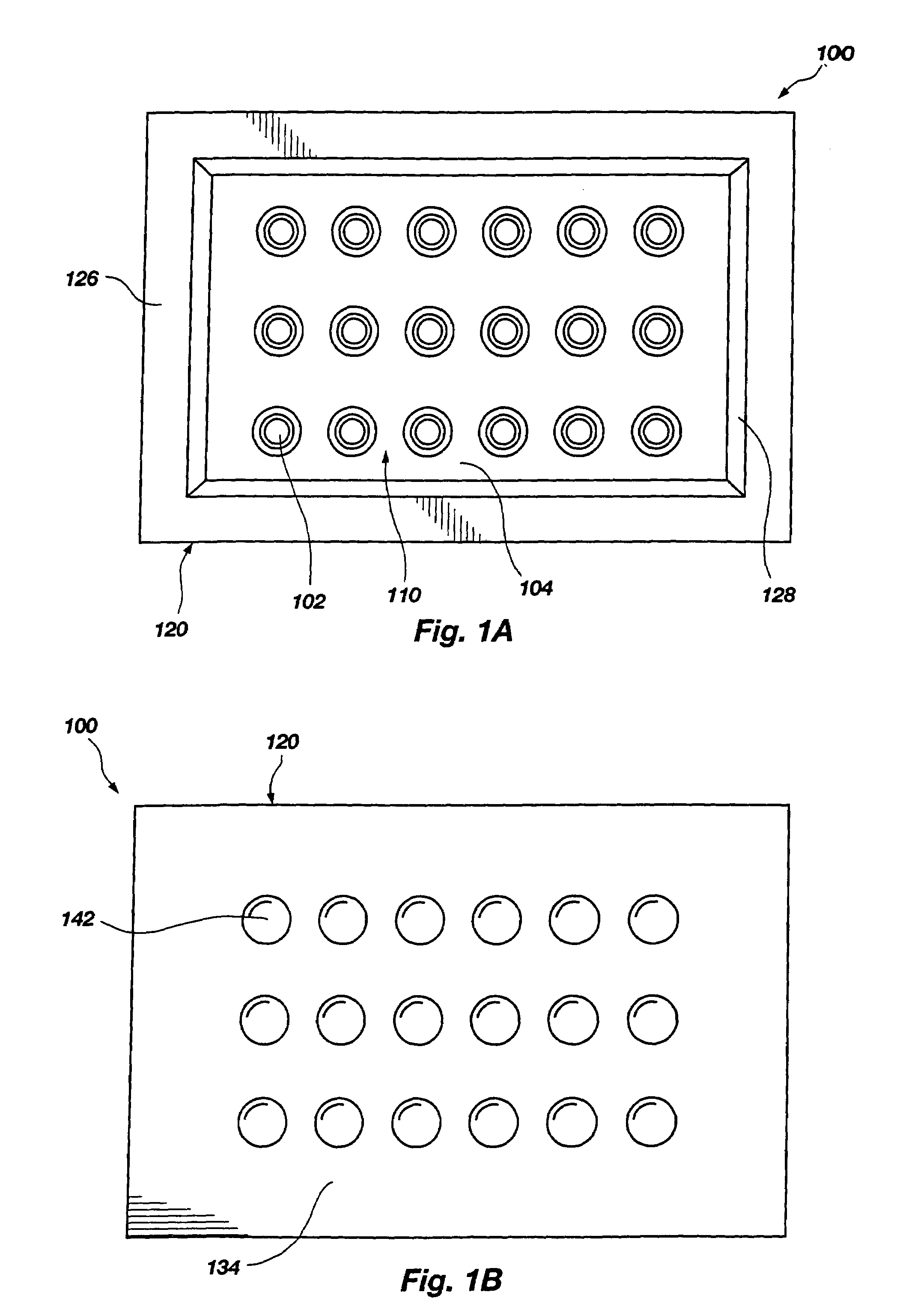

High density integrated circuit apparatus, test probe and methods of use thereof

InactiveUS20070271781A9High performance functional testingHigh-temperature burnElectrically conductive connectionsElectronic circuit testingElastomerElectricity

The present invention is directed to a high density test probe which provides a means for testing a high density and high performance integrated circuits in wafer form or as discrete chips. The test probe is formed from a dense array of elongated electrical conductors which are embedded in an compliant or high modulus elastomeric material. A standard packaging substrate, such as a ceramic integrated circuit chip packaging substrate is used to provide a space transformer. Wires are bonded to an array of contact pads on the surface of the space transformer. The space transformer formed from a multilayer integrated circuit chip packaging substrate. The wires are as dense as the contact location array. A mold is disposed surrounding the array of outwardly projecting wires. A liquid elastomer is disposed ion the mold to fill the spaces between the wires. The elastomer is cured and the mold is removed, leaving an array of wires disposed in the elastomer and in electrical contact with the space transformer The space transformer can have an array of pins which are on the opposite surface of the space transformer opposite to that on which the elongated conductors are bonded. The pins are inserted into a socket on a second space transformer, such as a printed circuit board to form a probe assembly. Alternatively, an interposer electrical connector can be disposed between the first and second space transformer.

Owner:GLOBALFOUNDRIES INC

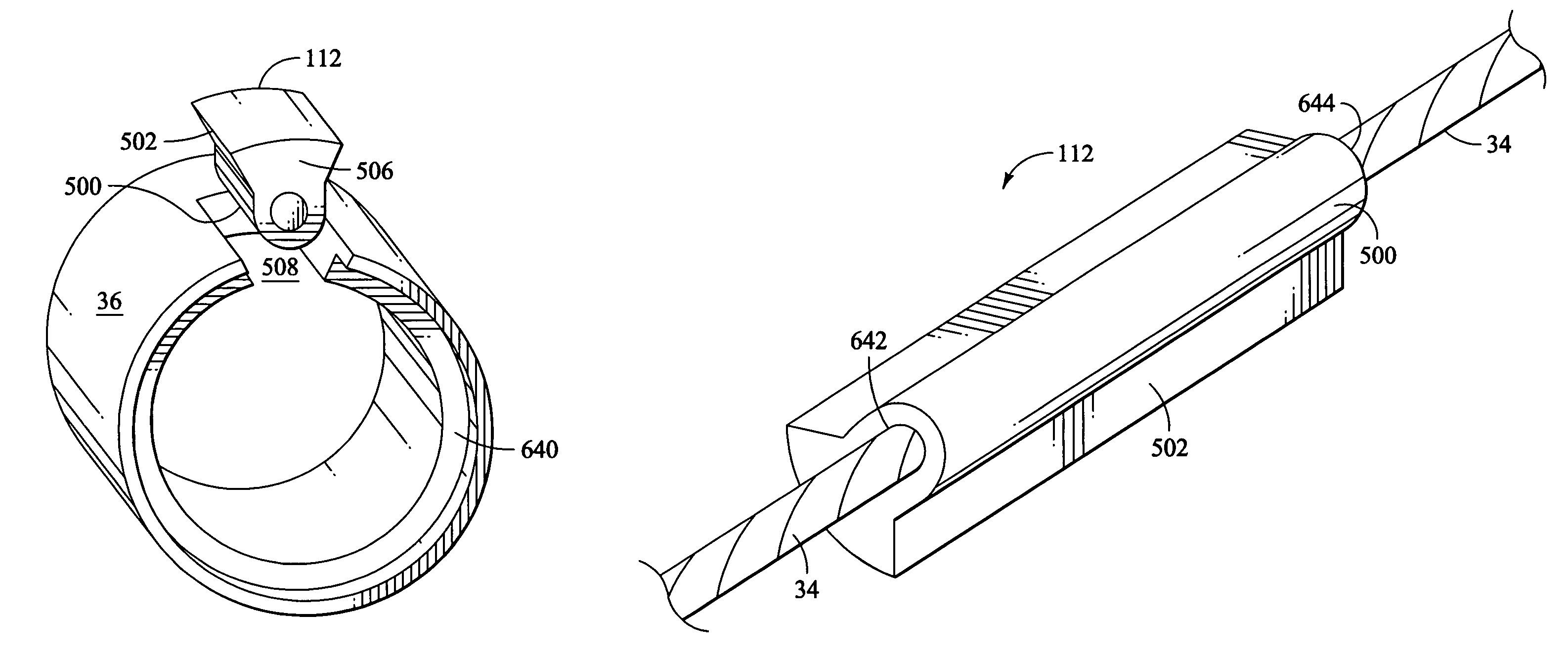

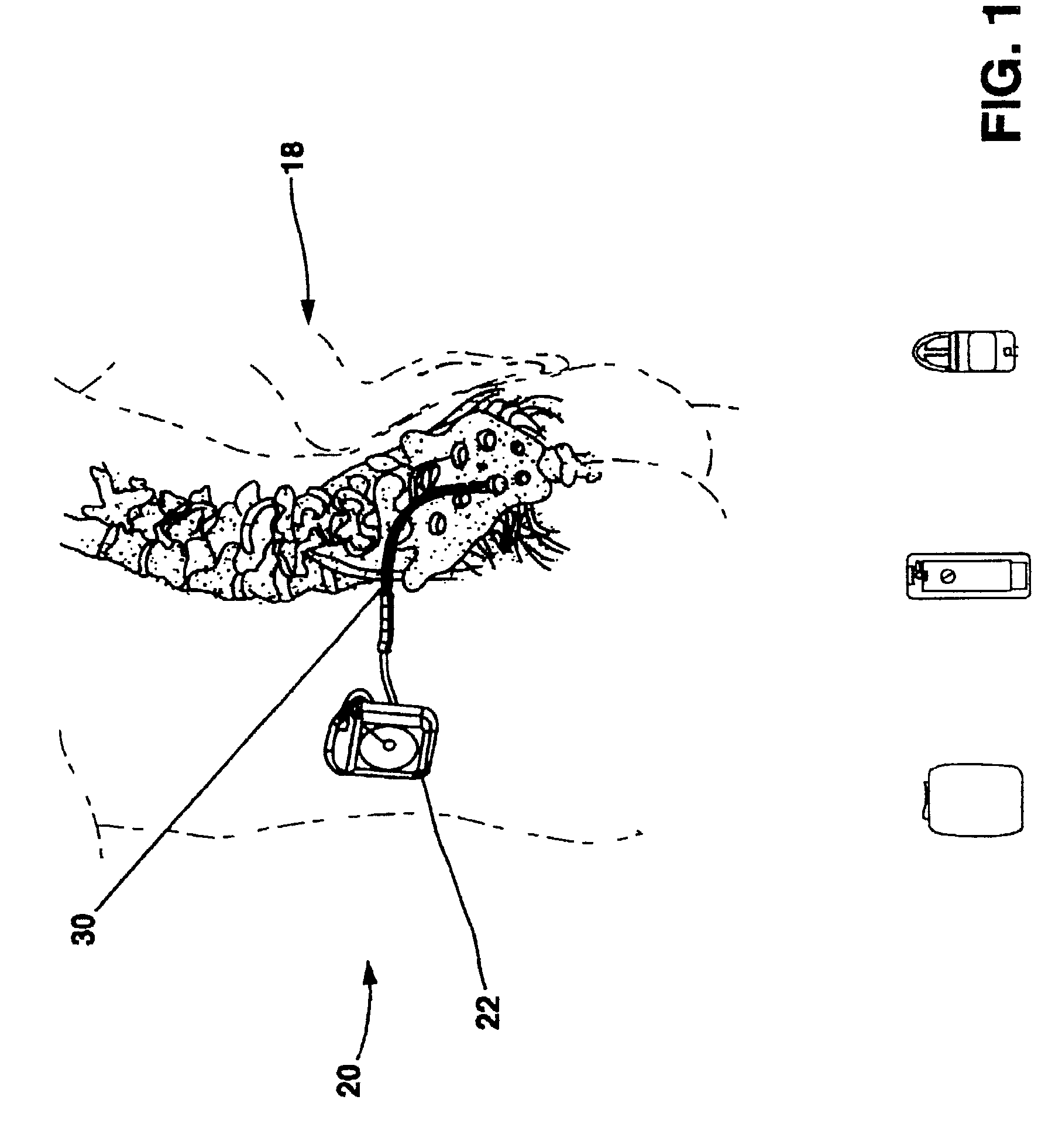

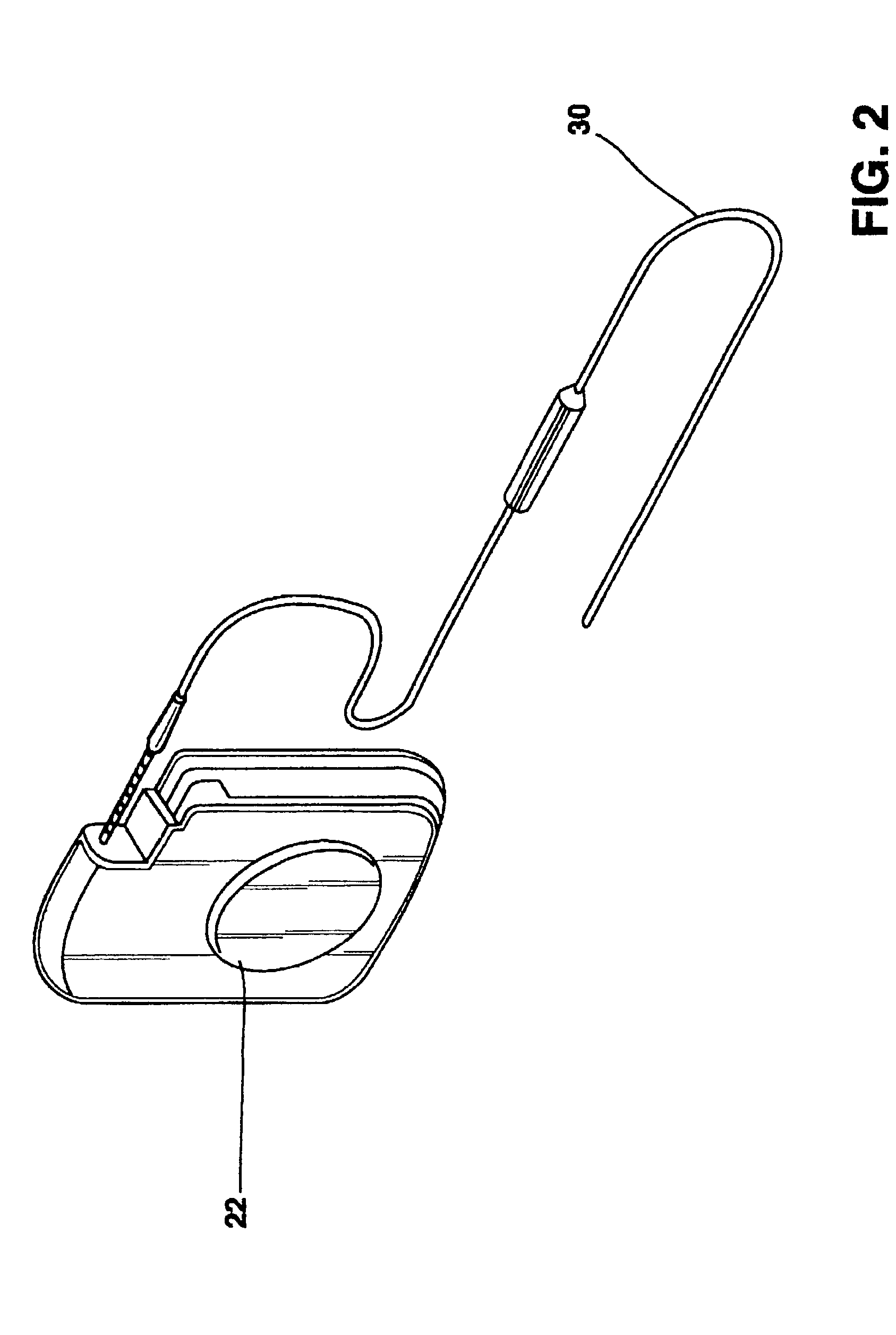

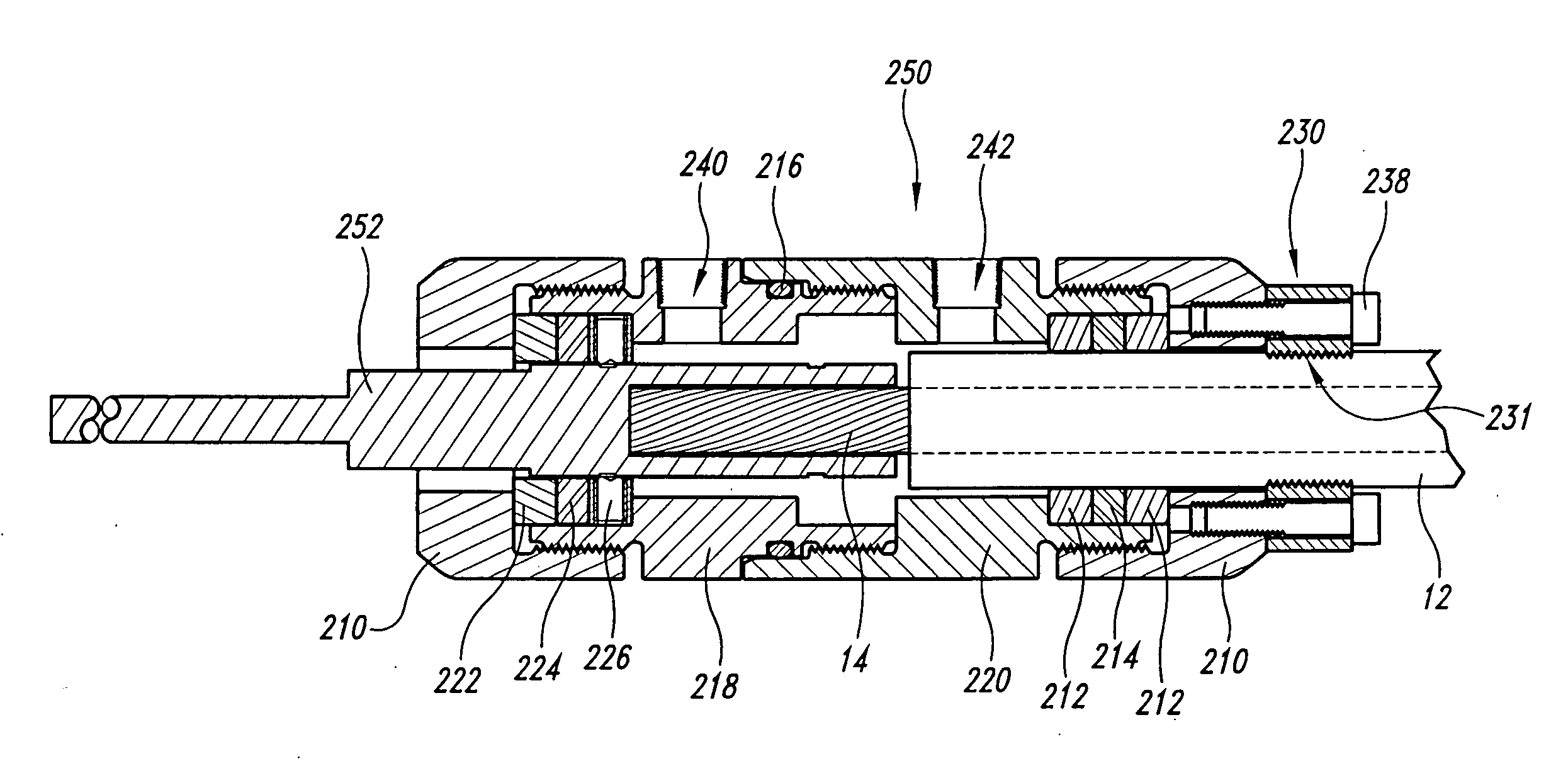

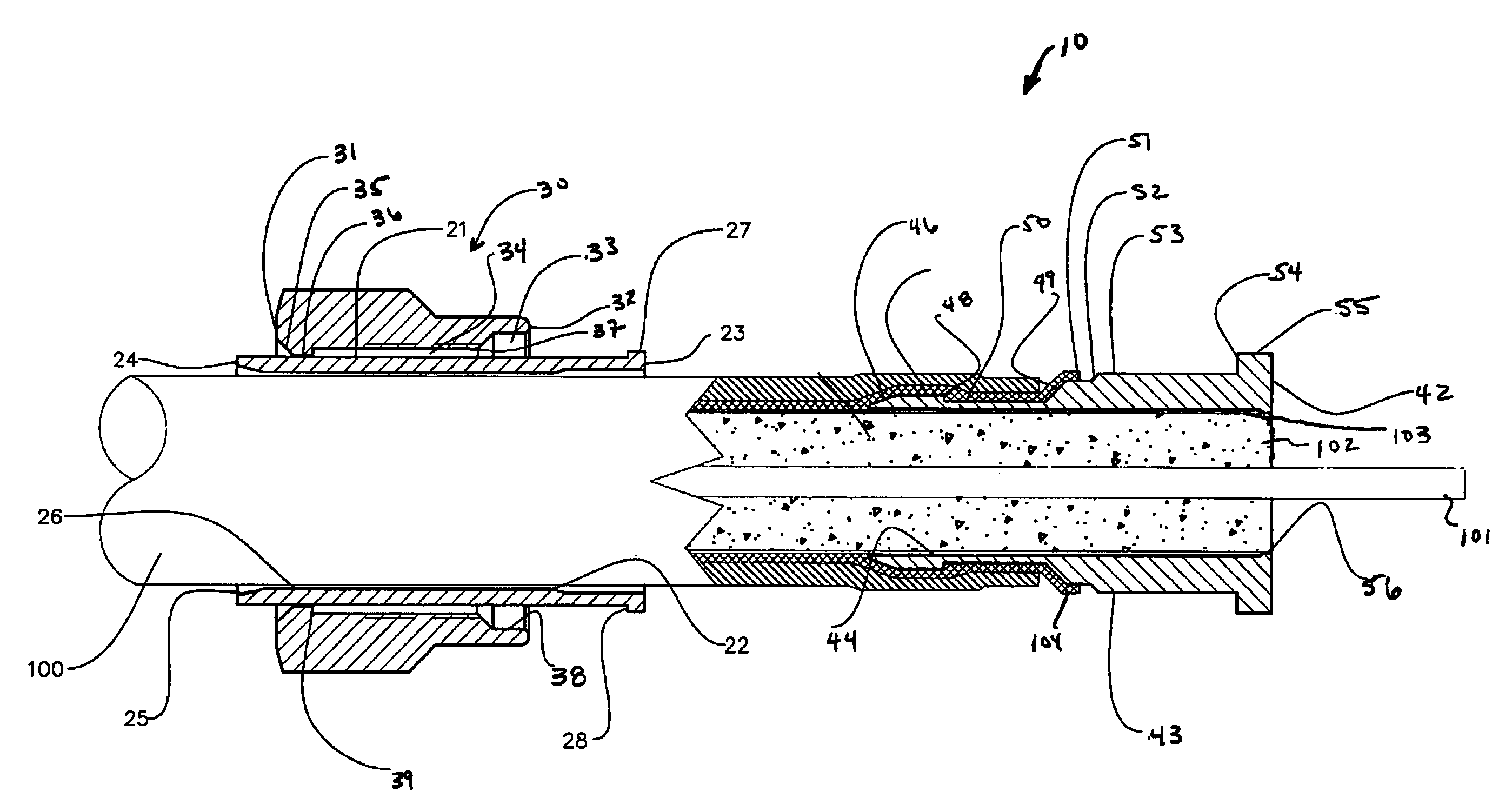

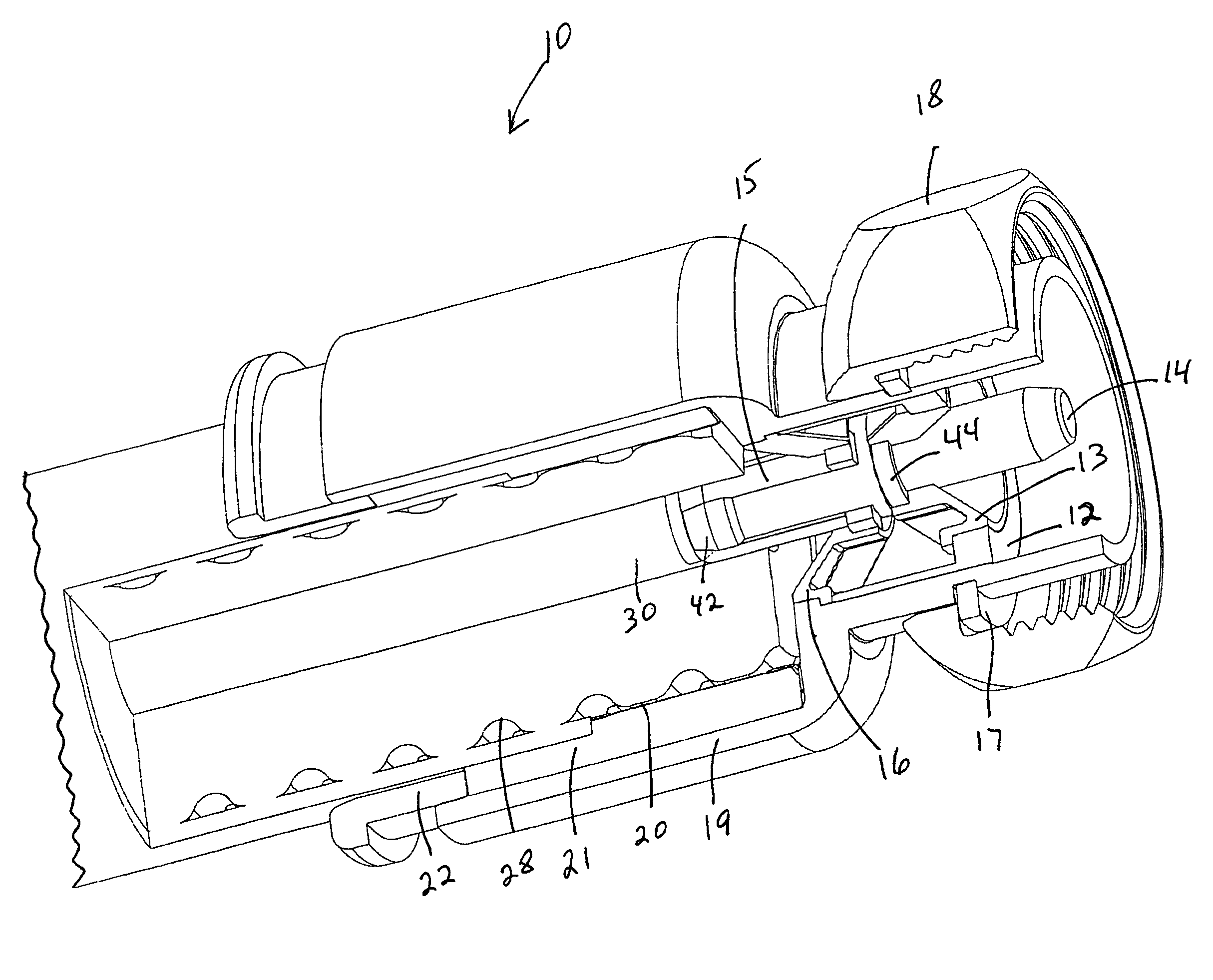

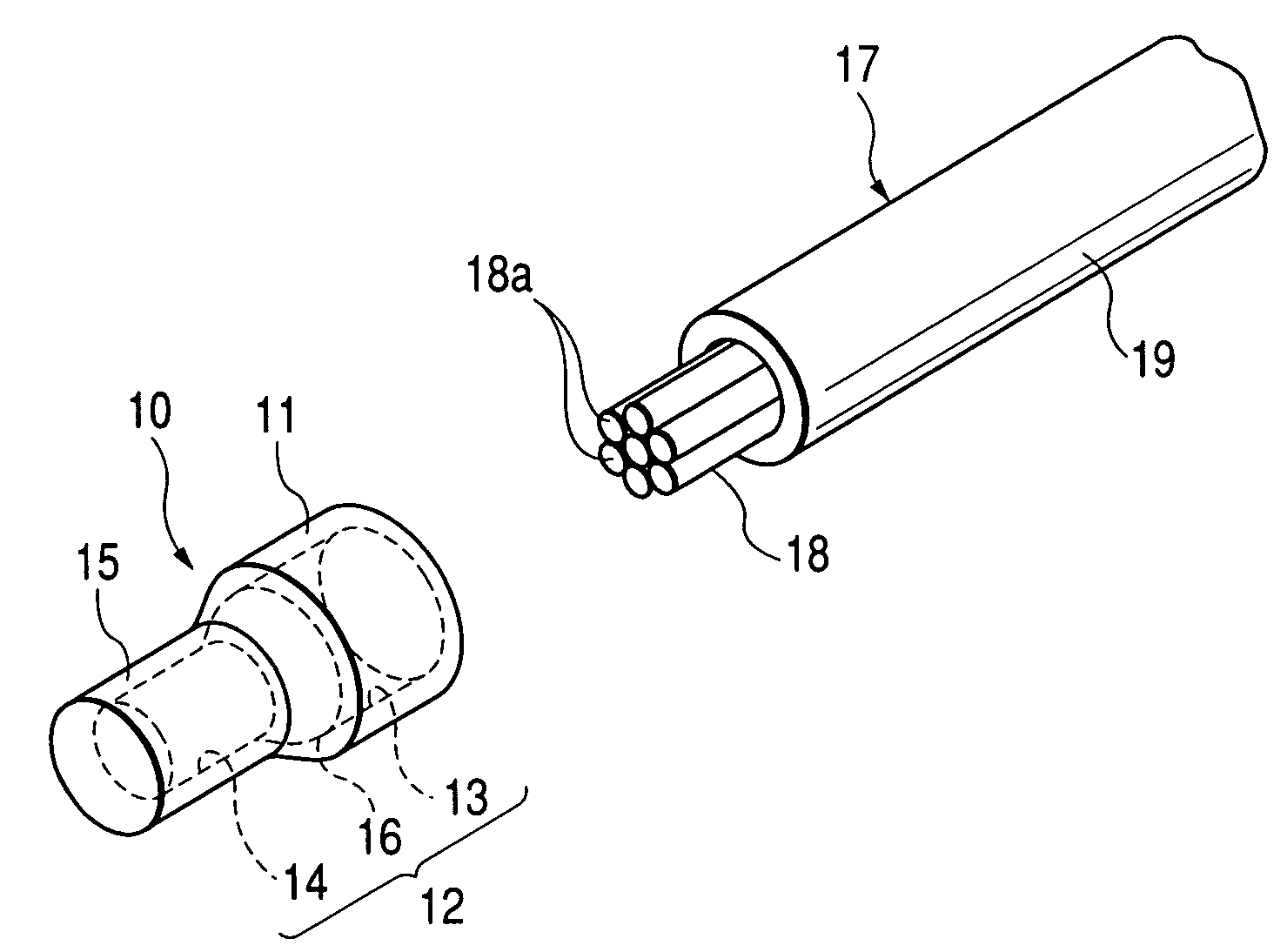

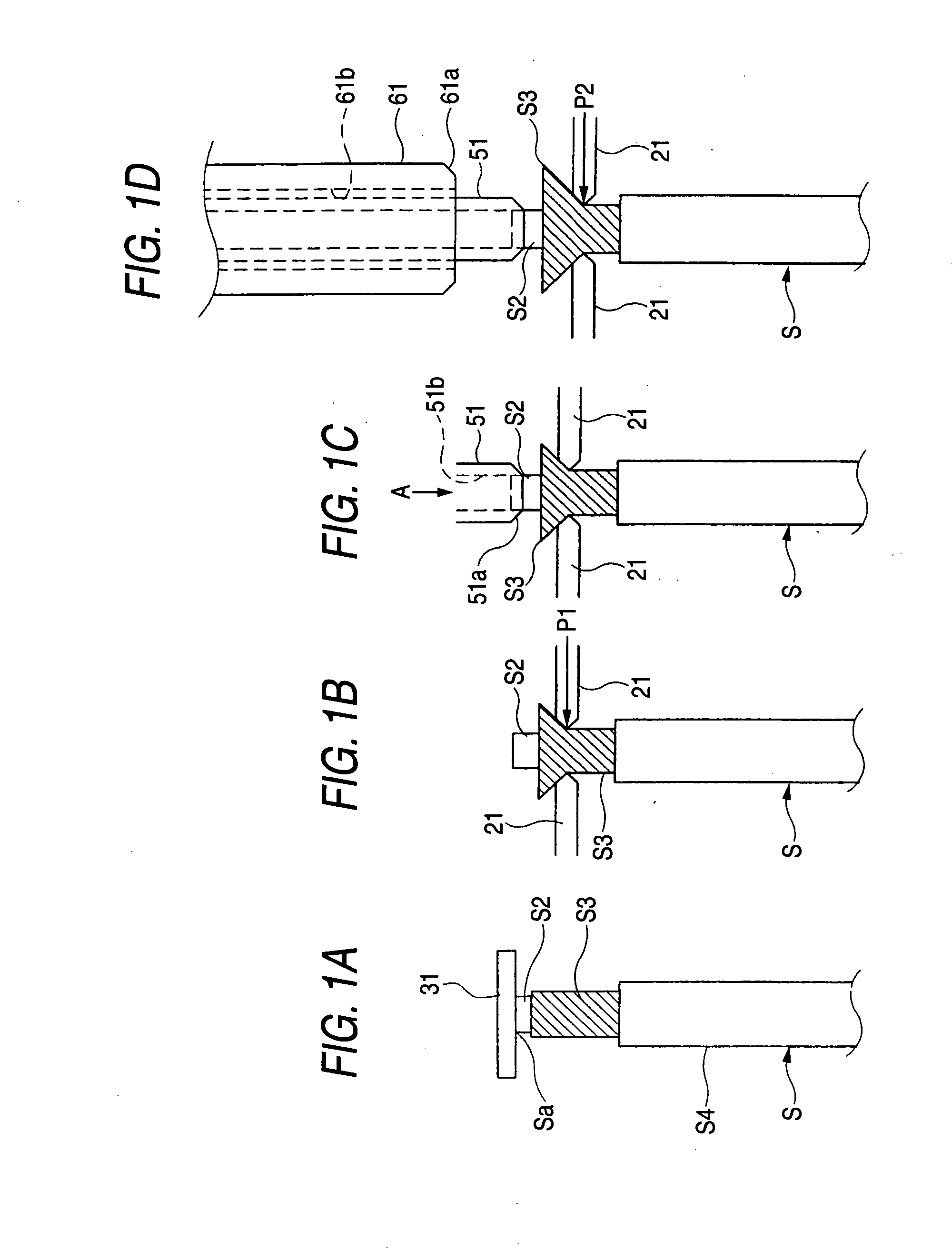

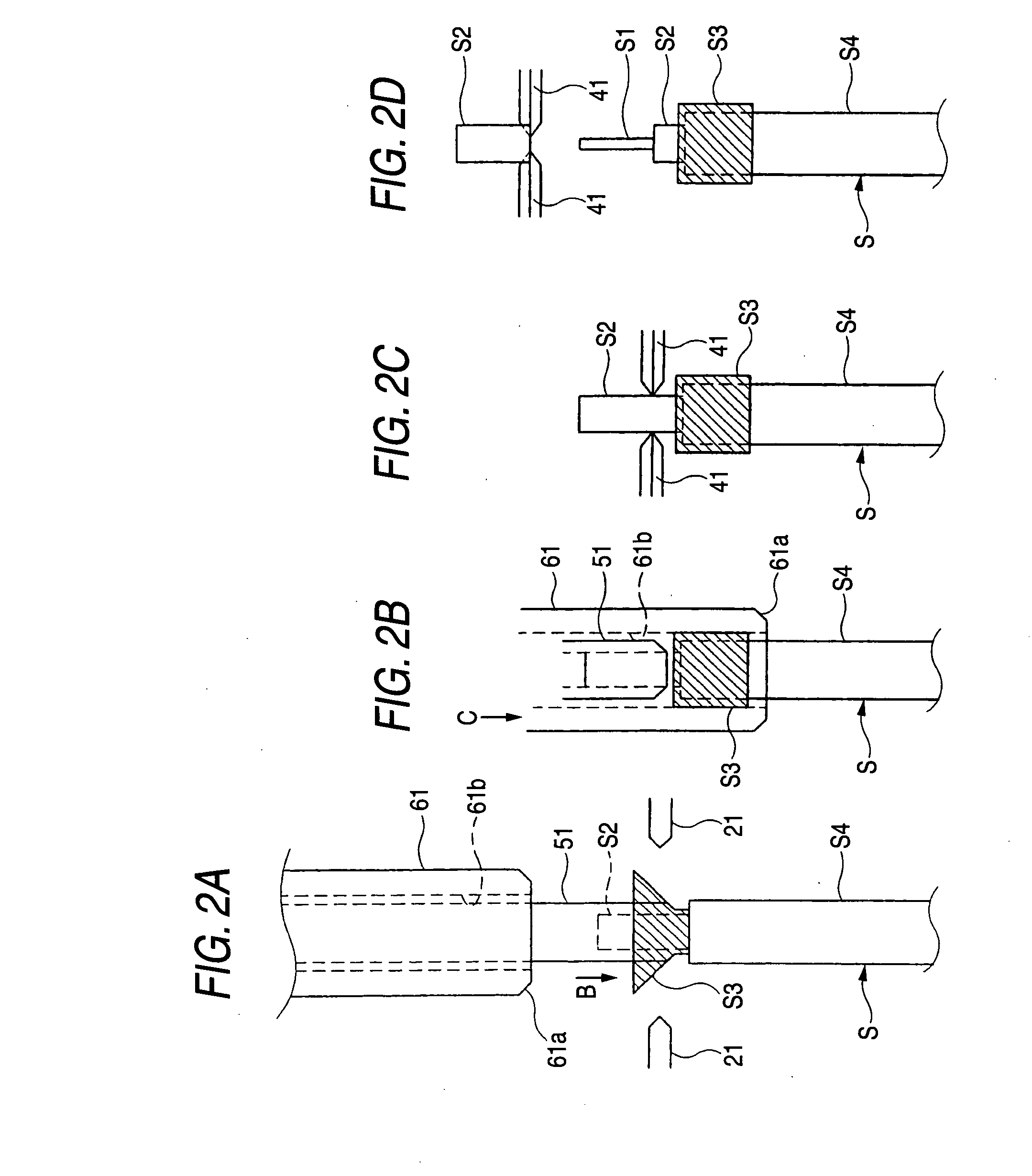

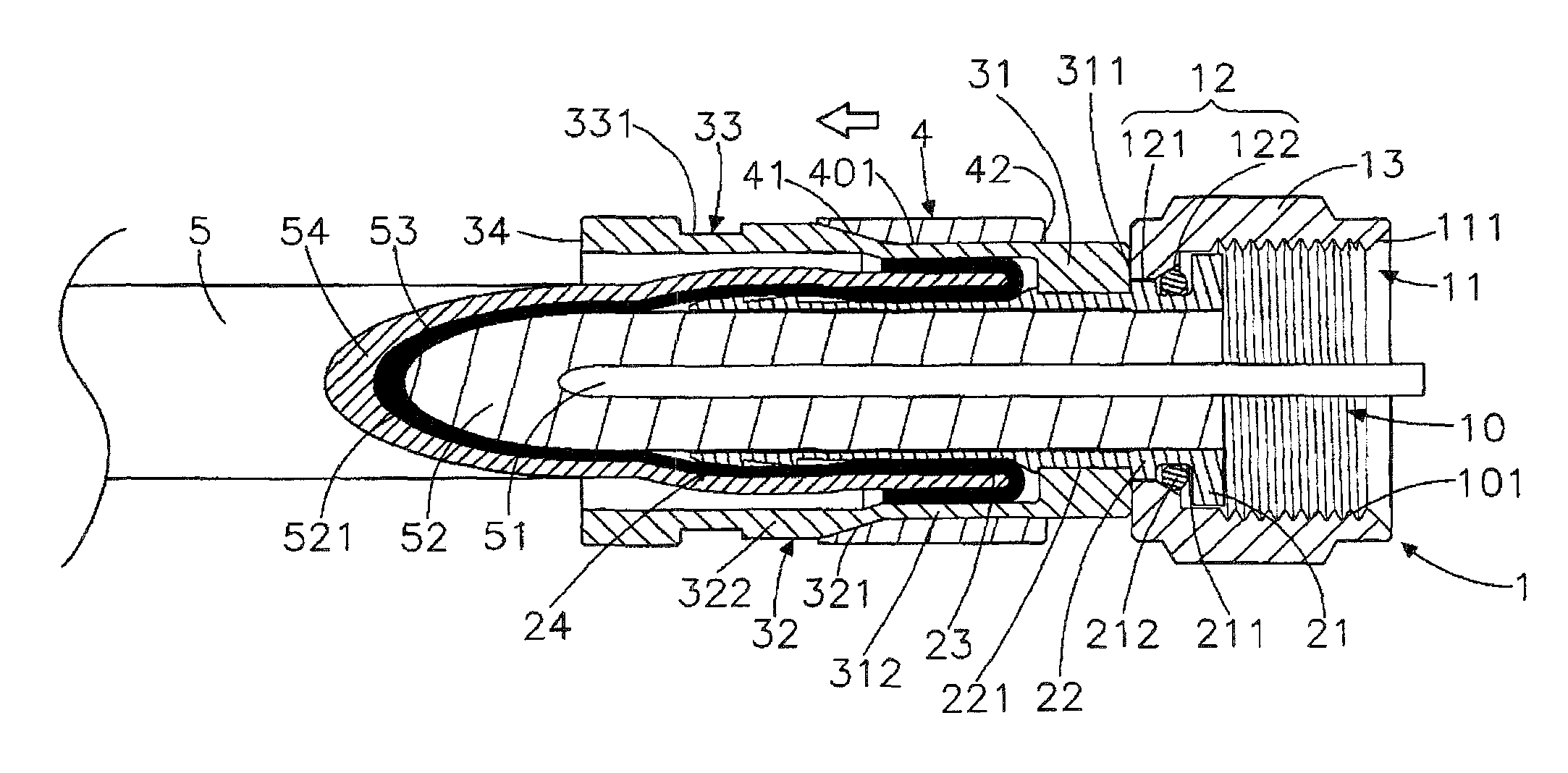

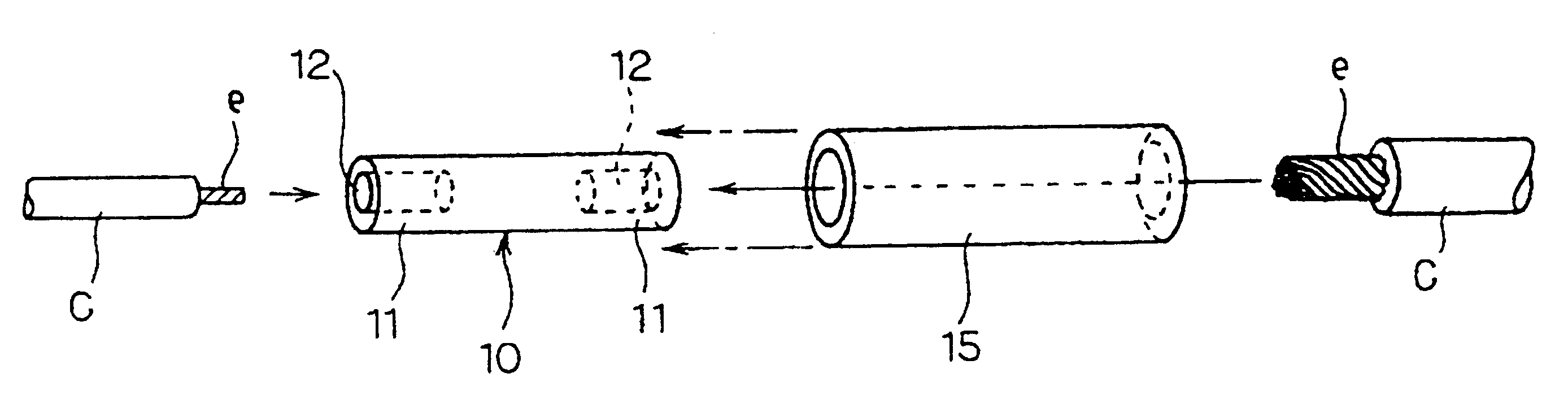

Method for performing a coplanar connection between a conductor and a contact on an implantable lead

InactiveUS7856707B2Reduce conductor bending momentImprove reliabilityElectrically conductive connectionsInternal electrodesElectrical conductorCoupling

An implantable lead for a medical device with a coplanar coupling for connecting a conductor to a contact reduces conductor bending moments to improve lead reliability. The implantable lead comprises a lead body having a proximal end and a distal end, at least one conductor, at least one contact carried on the proximal end, at least one contact carried on the distal end, and at least one coupling. The lead body has an exterior surface. The conductor is contained in the lead body and extends from the lead proximal end to the distal end. The conductor is also electrically insulated. The contact carried on the proximal end is electrically connected to the conductor. The coupling has a conductor coupling and a contact coupling. The conductor coupling is placed over the conductor and attached to the conductor. The contact coupling exits the lead body and has a weld to connect the contact coupling to the contact. The contact coupling is configured to exit the conductor lumen and mate with the contact while retaining the conductor coplanar to the lead body.

Owner:MEDTRONIC INC

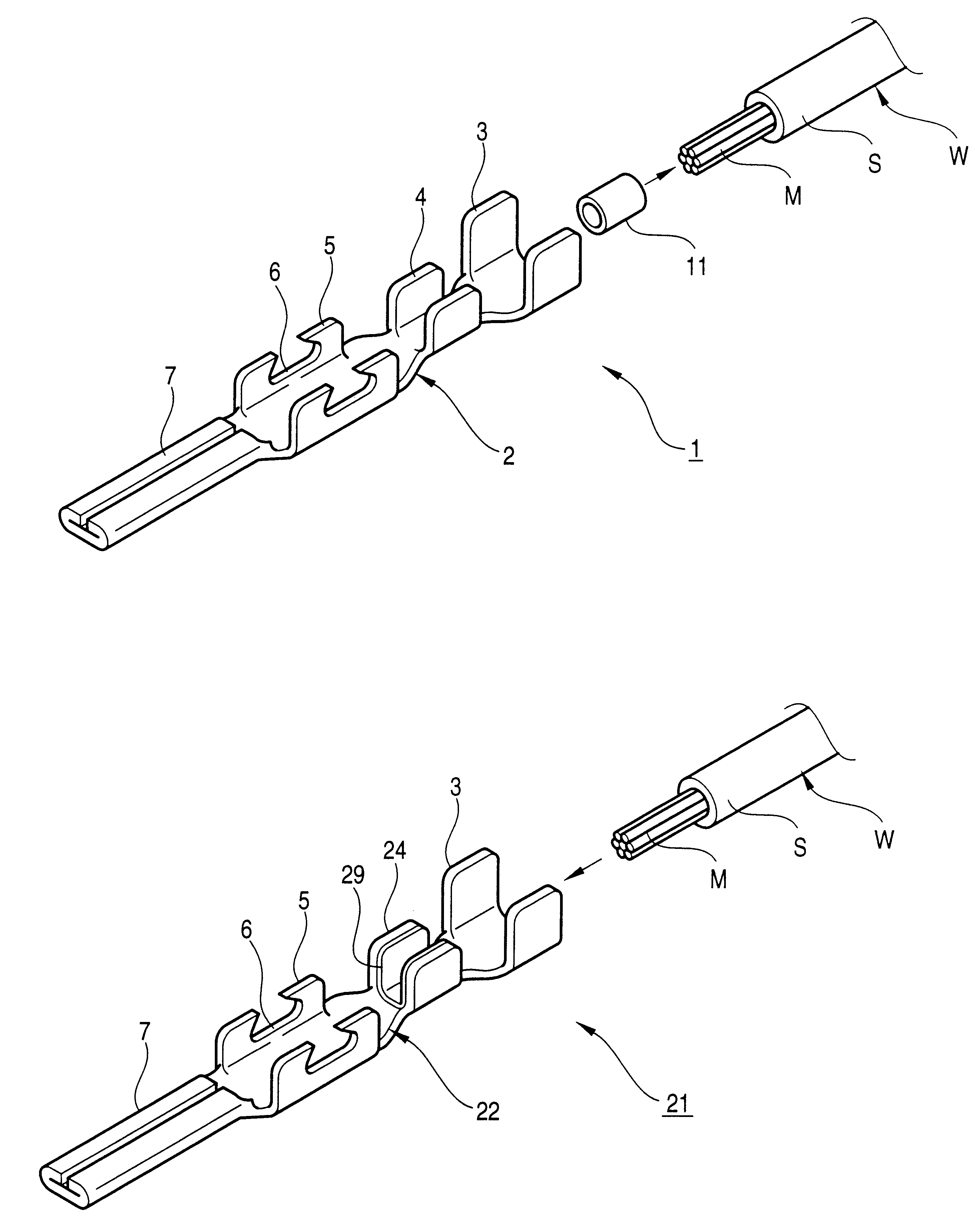

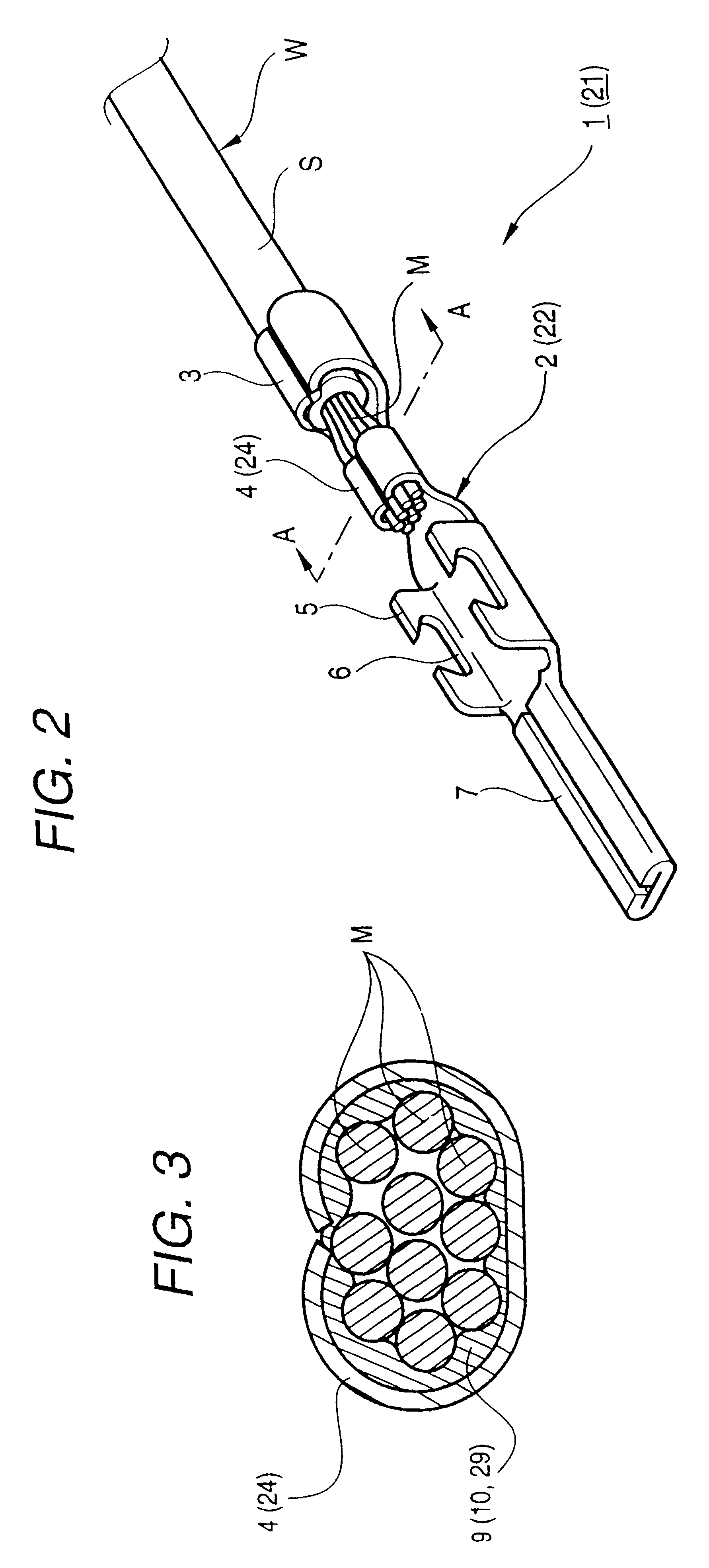

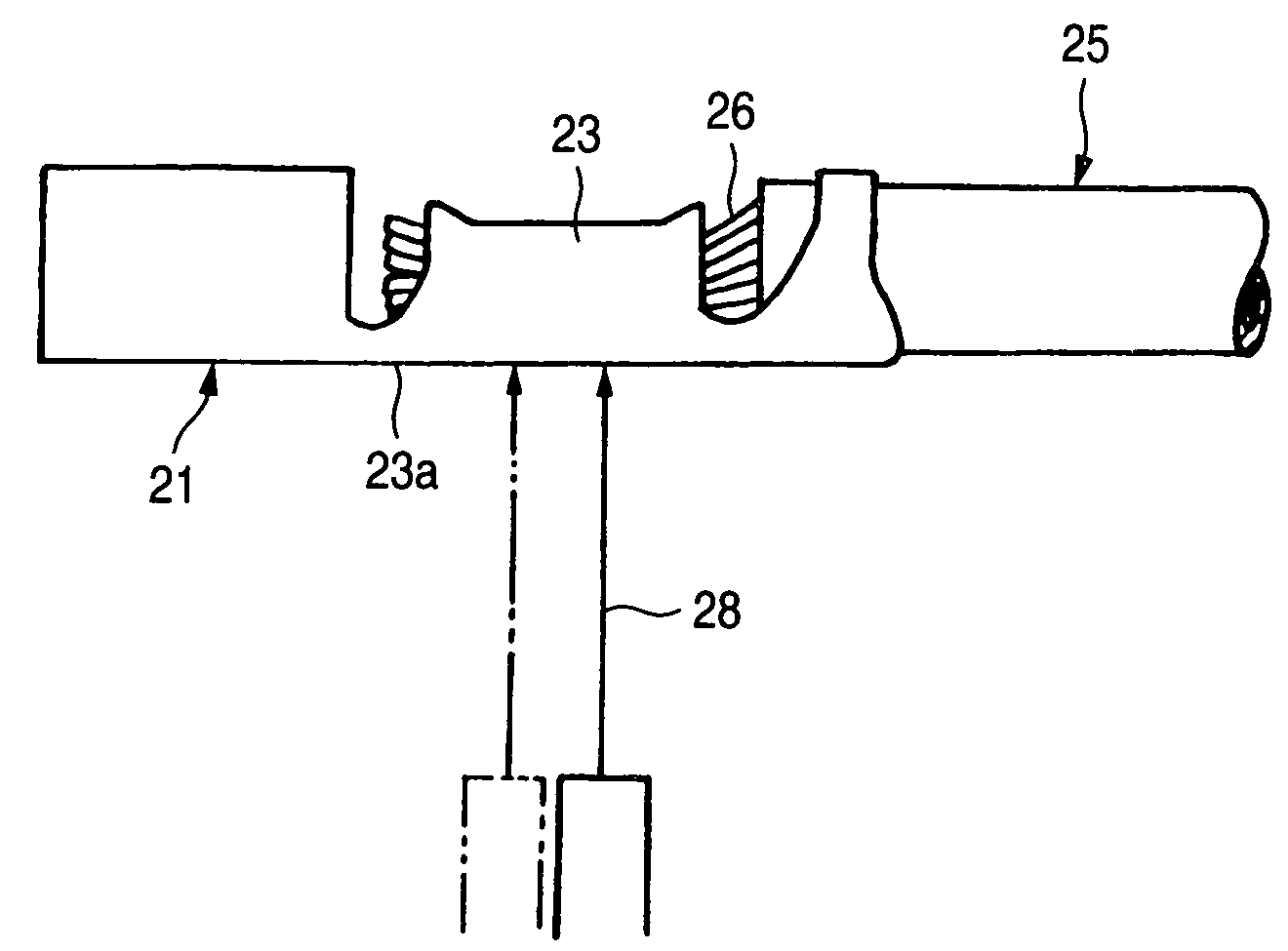

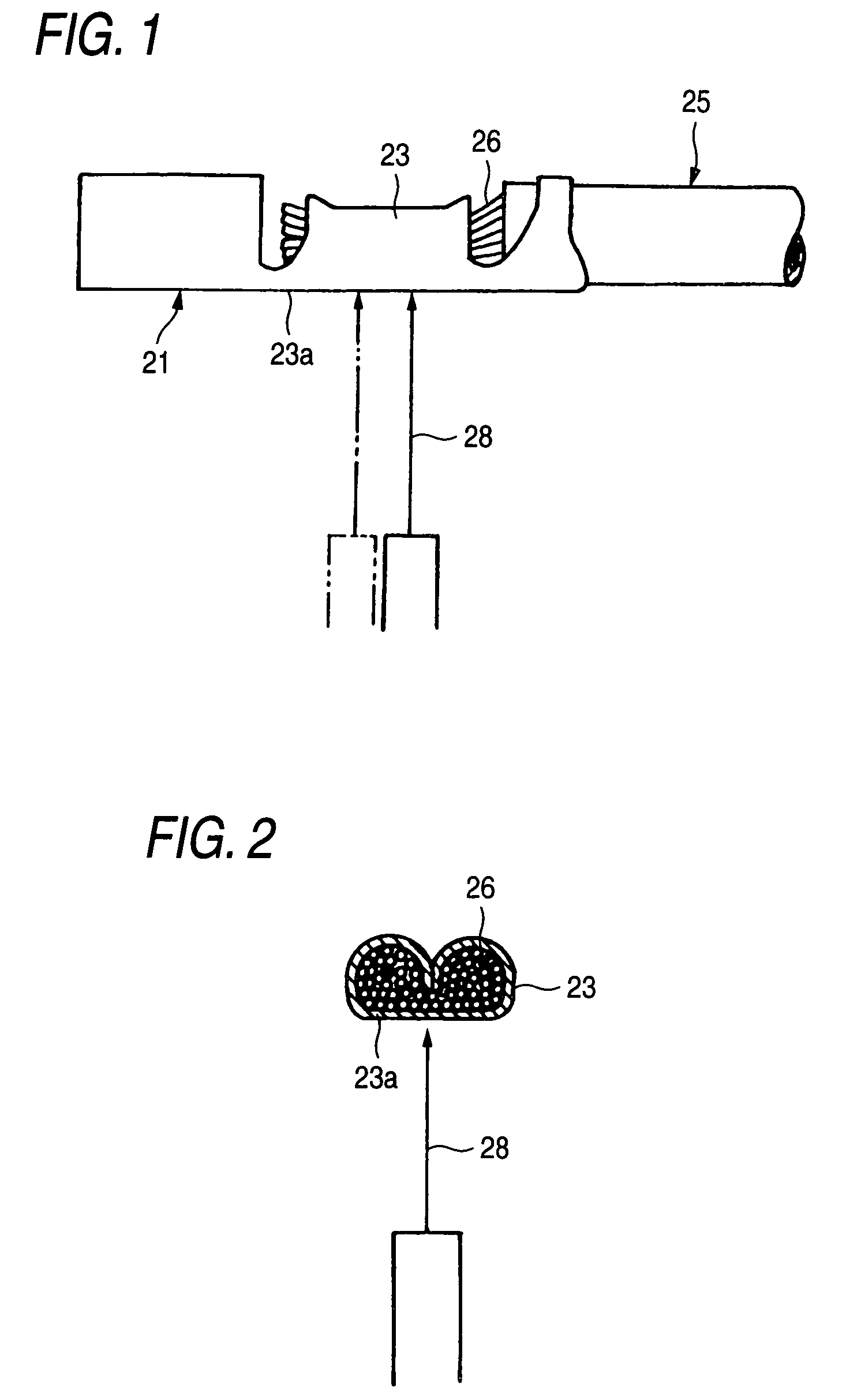

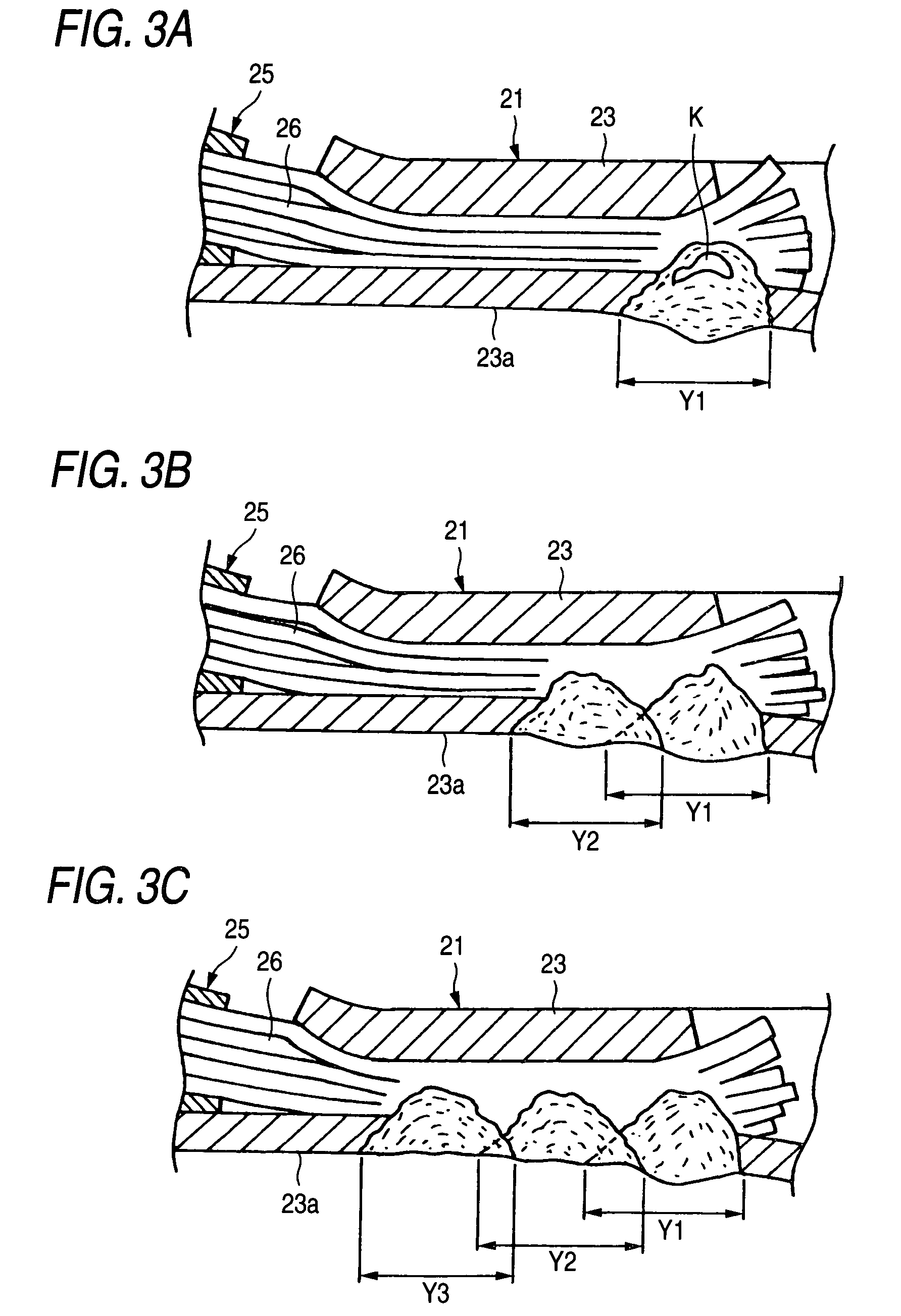

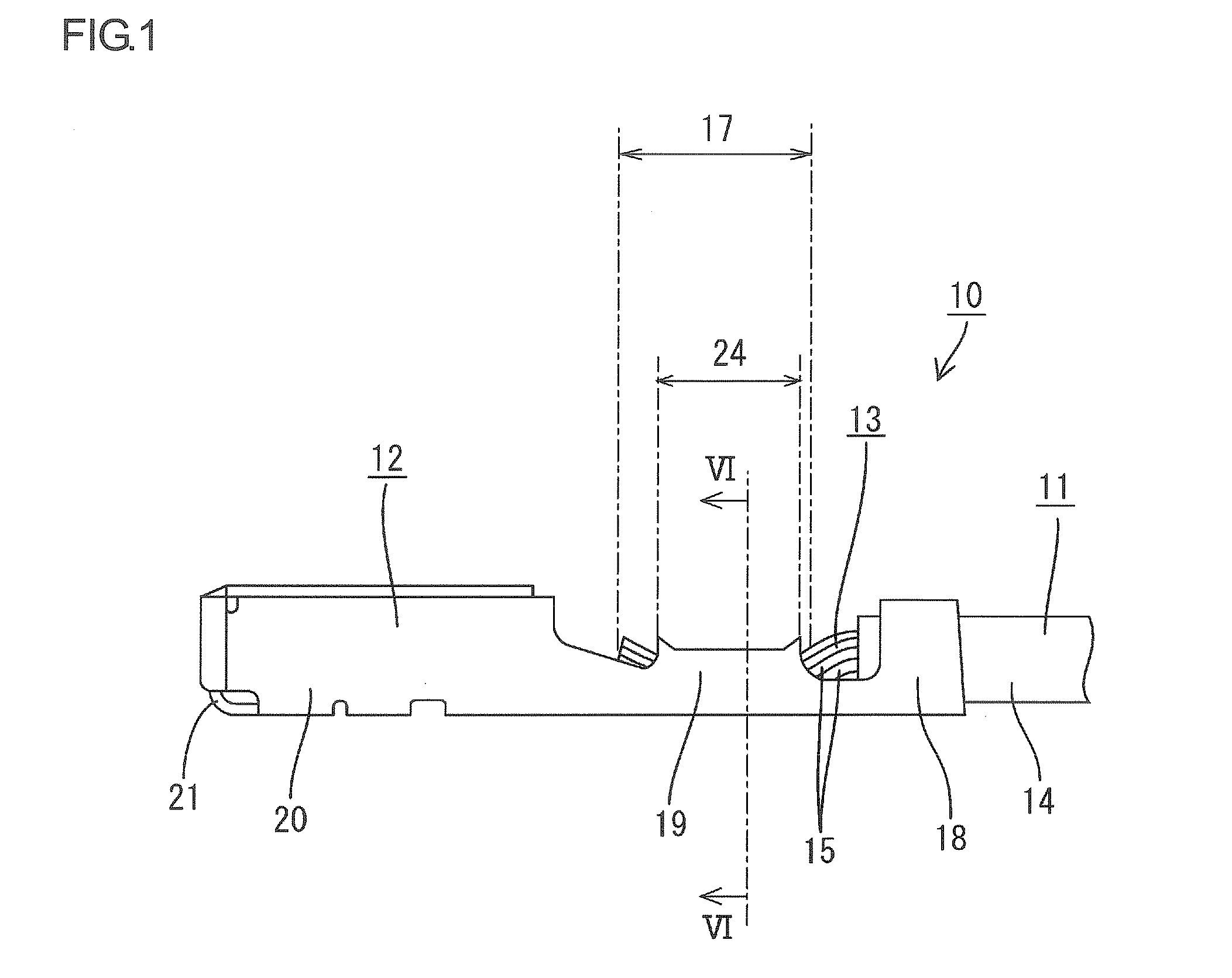

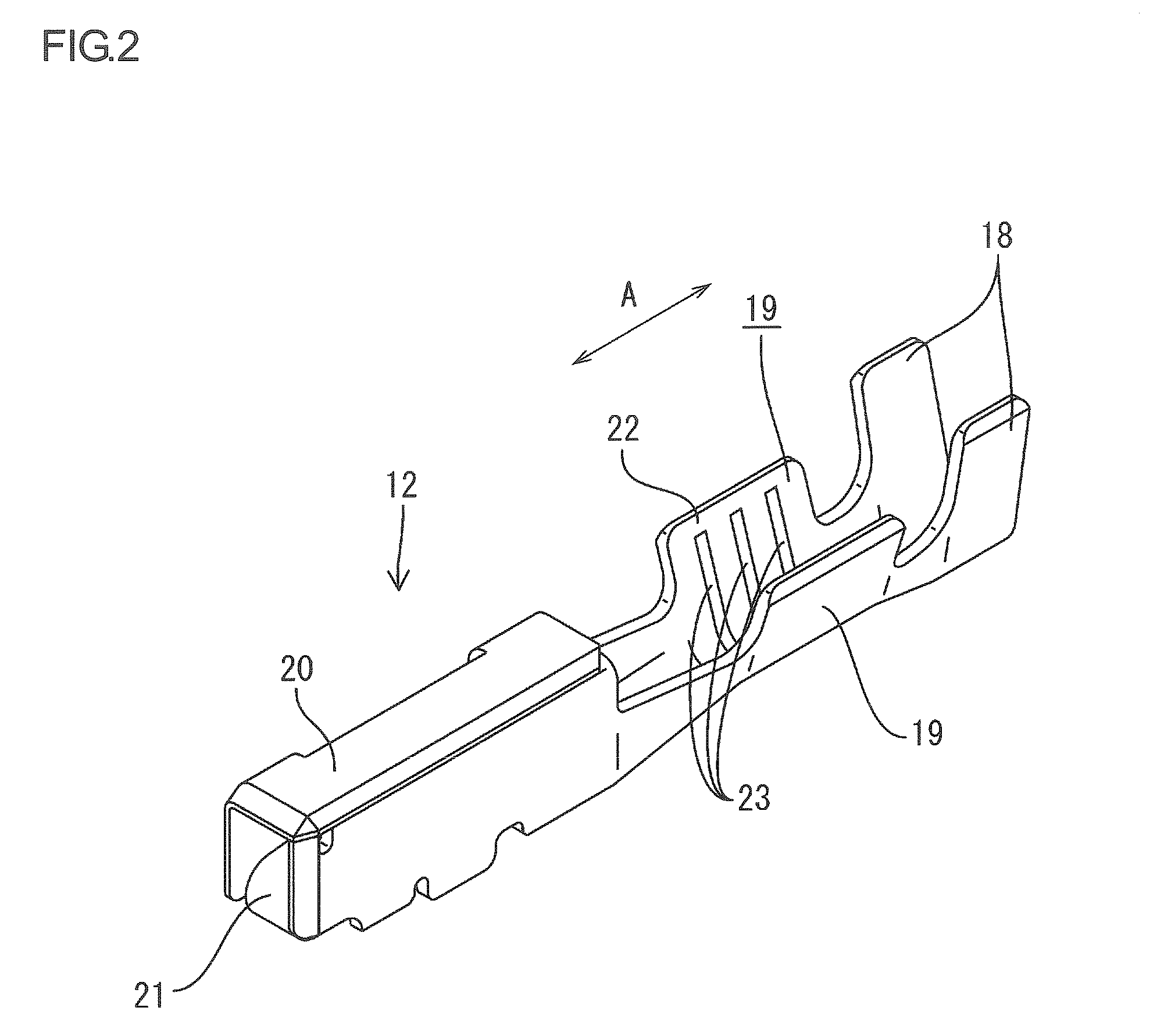

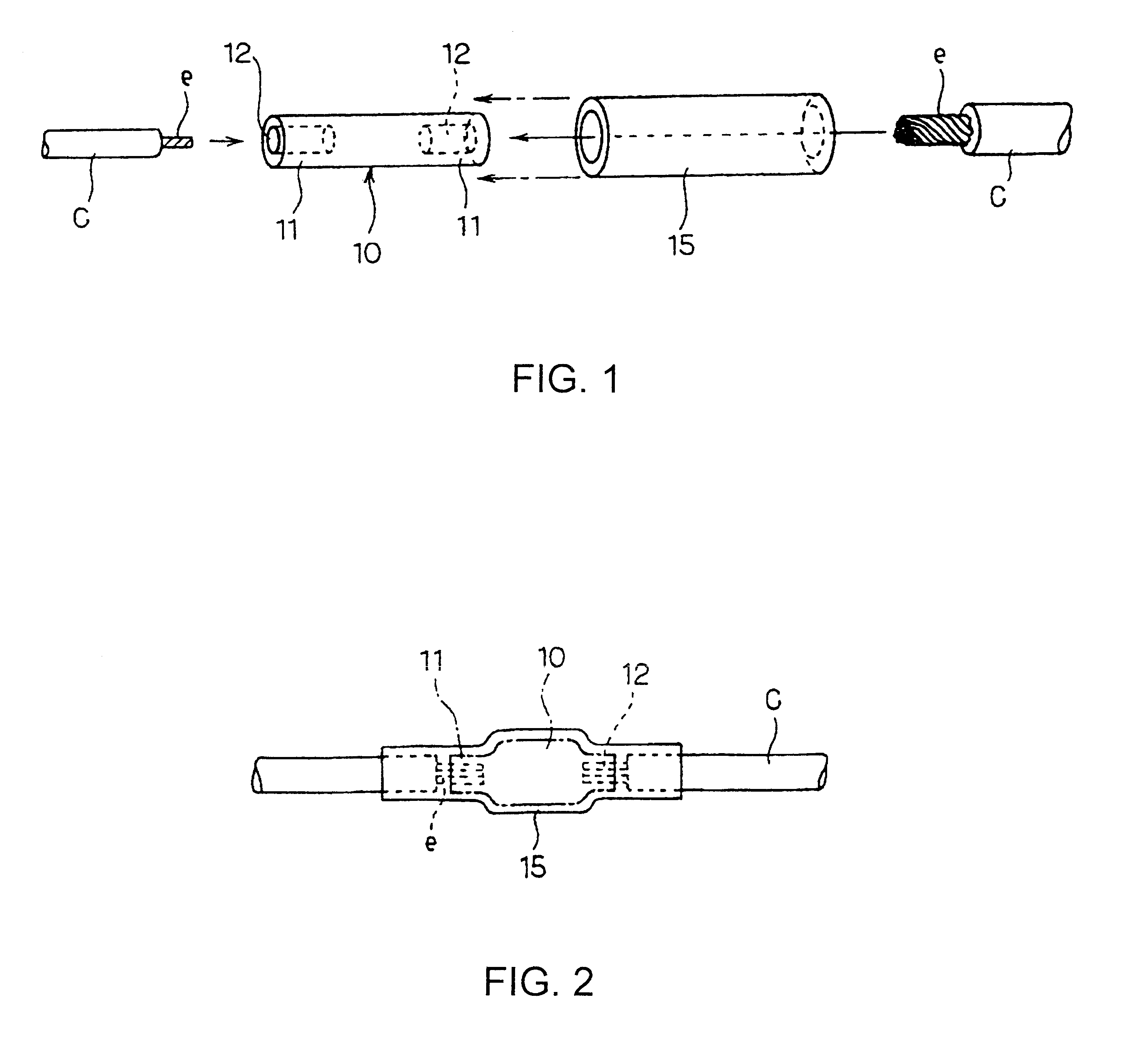

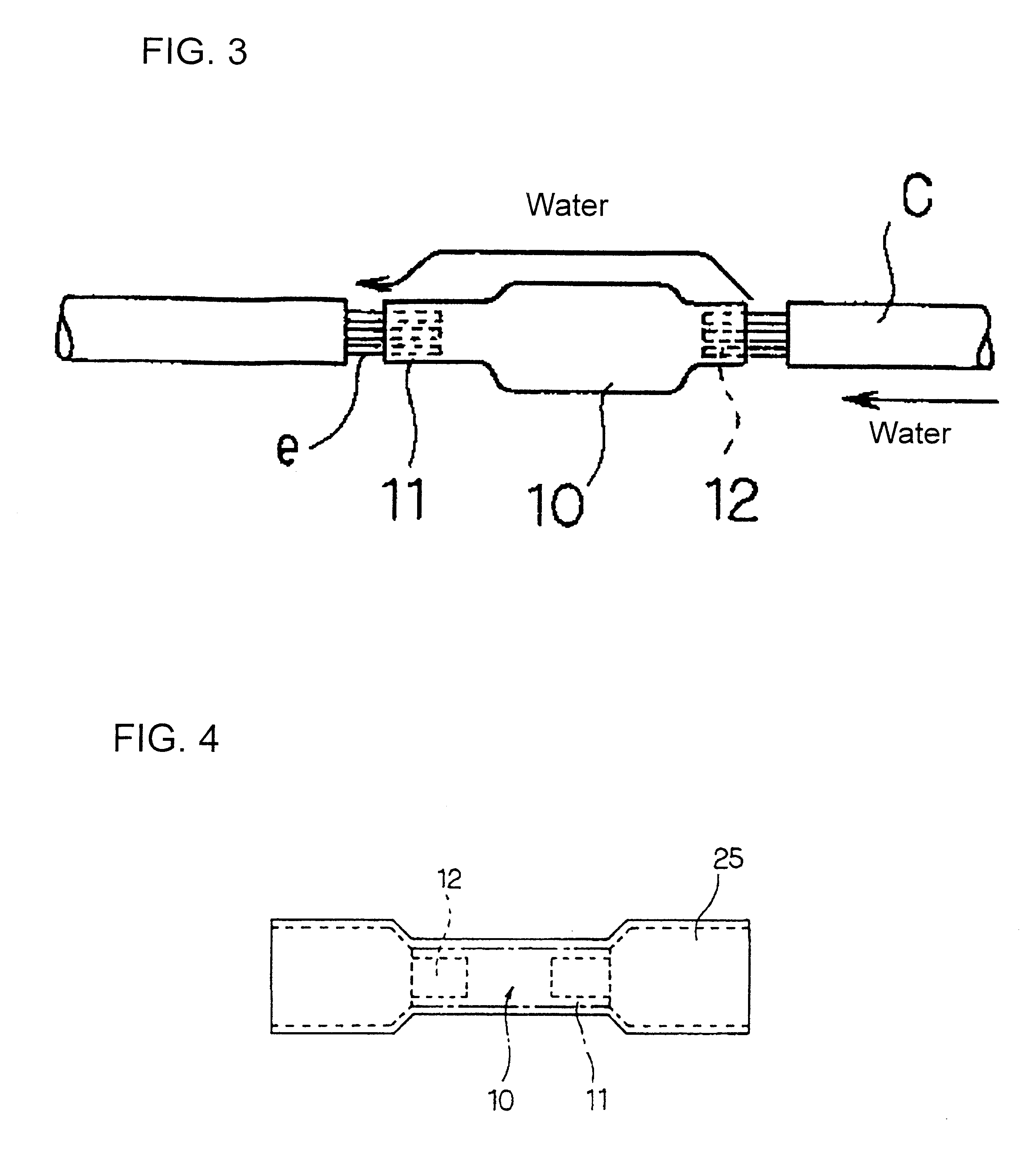

Method of and structure for connecting electric wire and connecting terminal

InactiveUS6334798B1Soldered/welded conductive connectionsConnections effected by permanent deformationElectrical conductorEngineering

In a structure 21 for connecting an electric wire and a connecting terminal in the invention, a ductile metal film 29 is formed in advance on an inner surface of a conductor caulking portion 24 of a crimp terminal 22 by such as plating, vacuum deposition, or adhesion. Then, the conductor caulking portion 24 in the rear portion of the crimp terminal 22 is caulked onto core wire portions M in a state of being stripped and extended in the axial direction from an end of a sheathed wire W to thereby establish connection. Subsequently, the metal film 29 is fused on heating. Accordingly, the ductile metal film 29 enters gaps between the inner surface of the conductor caulking portion 24 and the core wire portions M and between adjacent ones of the core wire portions M by the caulking stress. Hence, the area of contact between the conductor caulking portion 24 and the core wire portions M via the metal film 29 increases, and conductivity improves, thereby making it possible to suppress heat generation.

Owner:YAZAKI CORP

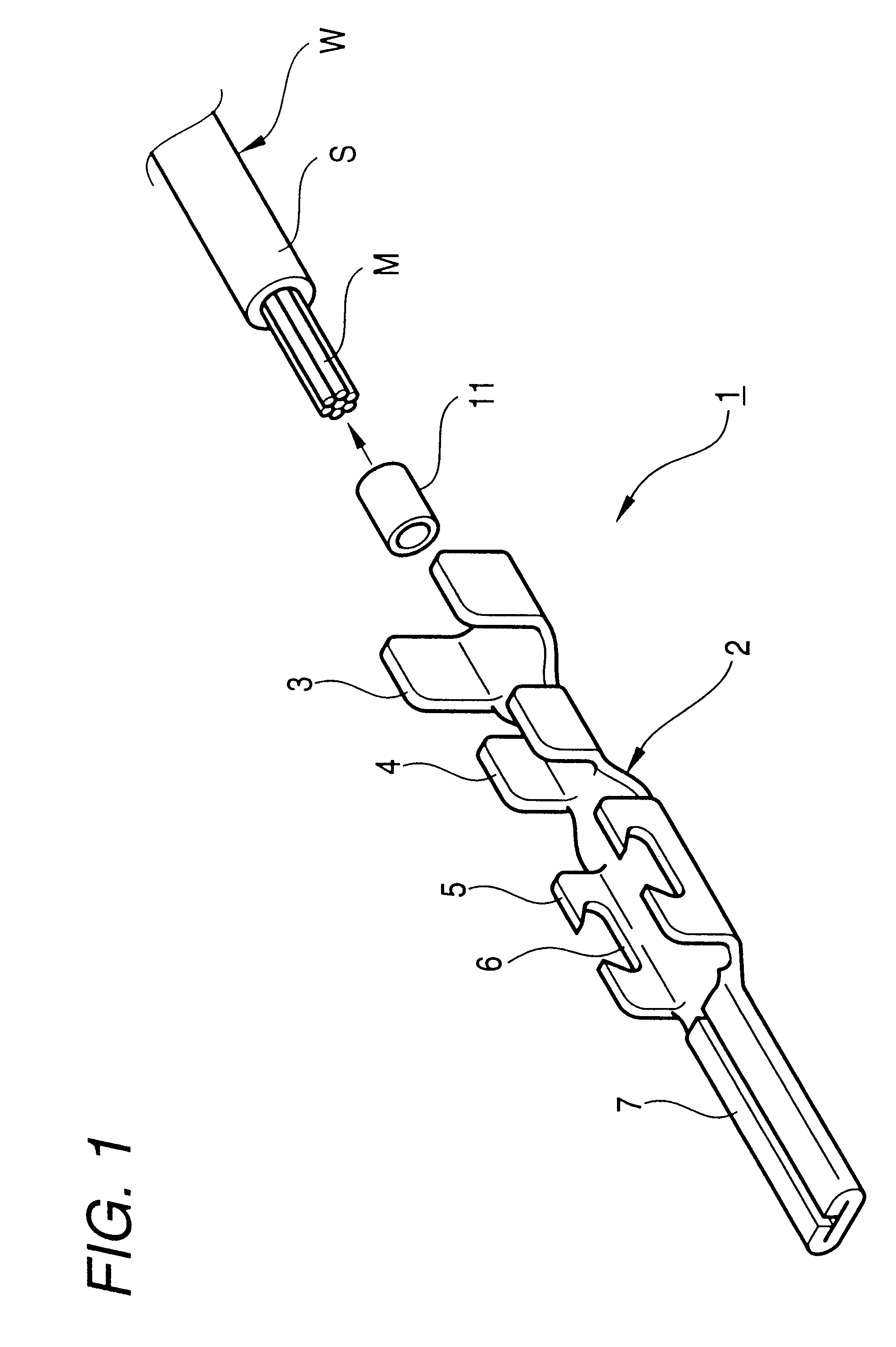

Method of connecting terminal and electric wire

ActiveUS7174633B2Few partsLow costPrinted circuit assemblingElectrically conductive adhesive connectionsEpoxyElectricity

The invention comprises filling a conductive adhesive on a hole end of a wire connection part in tubular shape of the terminal which has an electric contact part at one side and the wire connection part at the other side, inserting an electric wire from a hole opening of the wire connection part toward the hole end, and reducing evenly a size of a tubular wall of the wire connection part, thereby causing the conductive adhesive to infiltrate into a space of the electric contact part or between wires. The invention also comprises tightening the tubular wall of the wire connection part by a rotary swaging process. Further, the conductive adhesive is a nickel paste which is a mixture of nickel powders in a liquid epoxy resin based binder. In addition, at least one of a core wire portion of the electric wire or the terminal is aluminum or aluminum alloy.

Owner:YAZAKI CORP

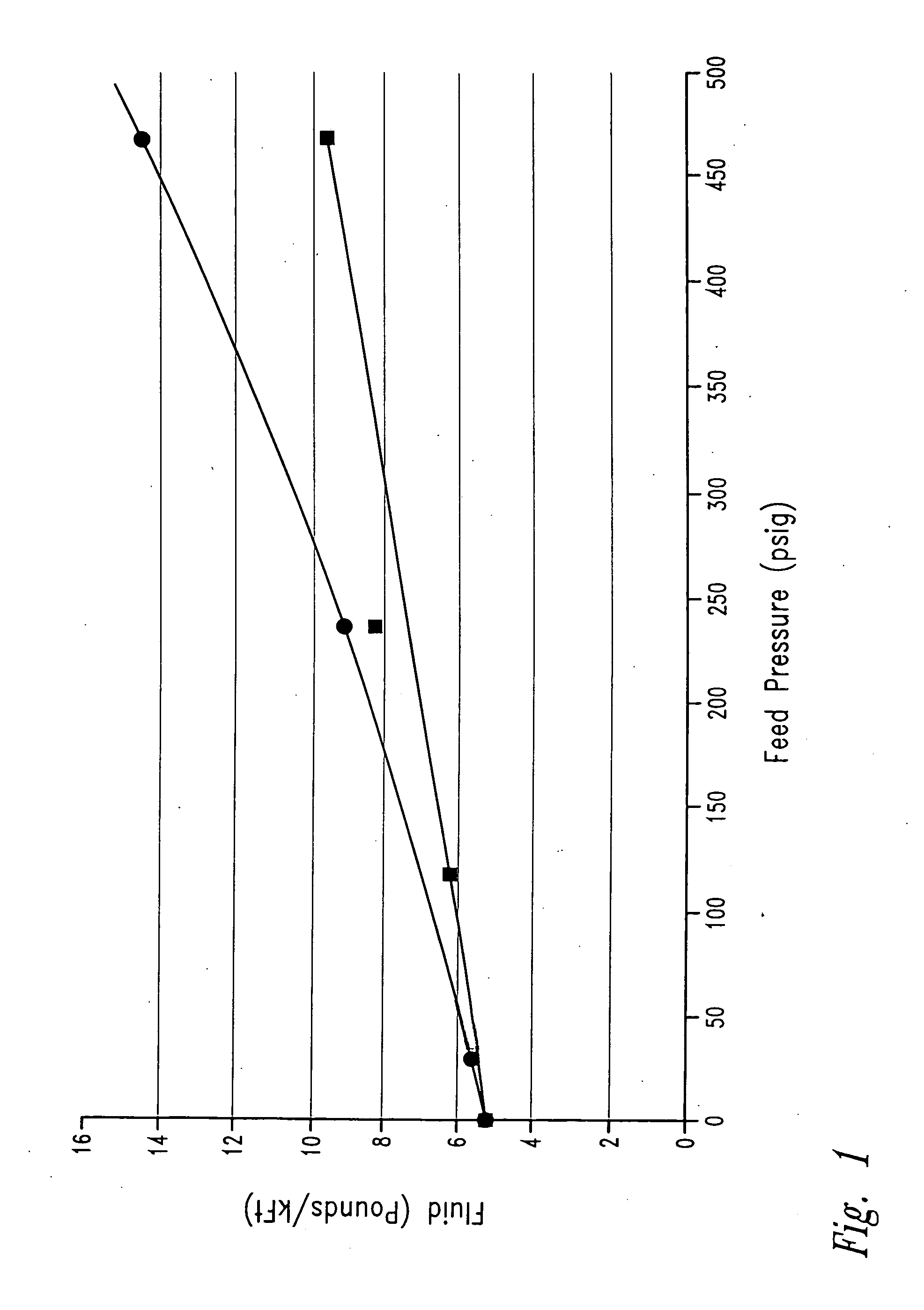

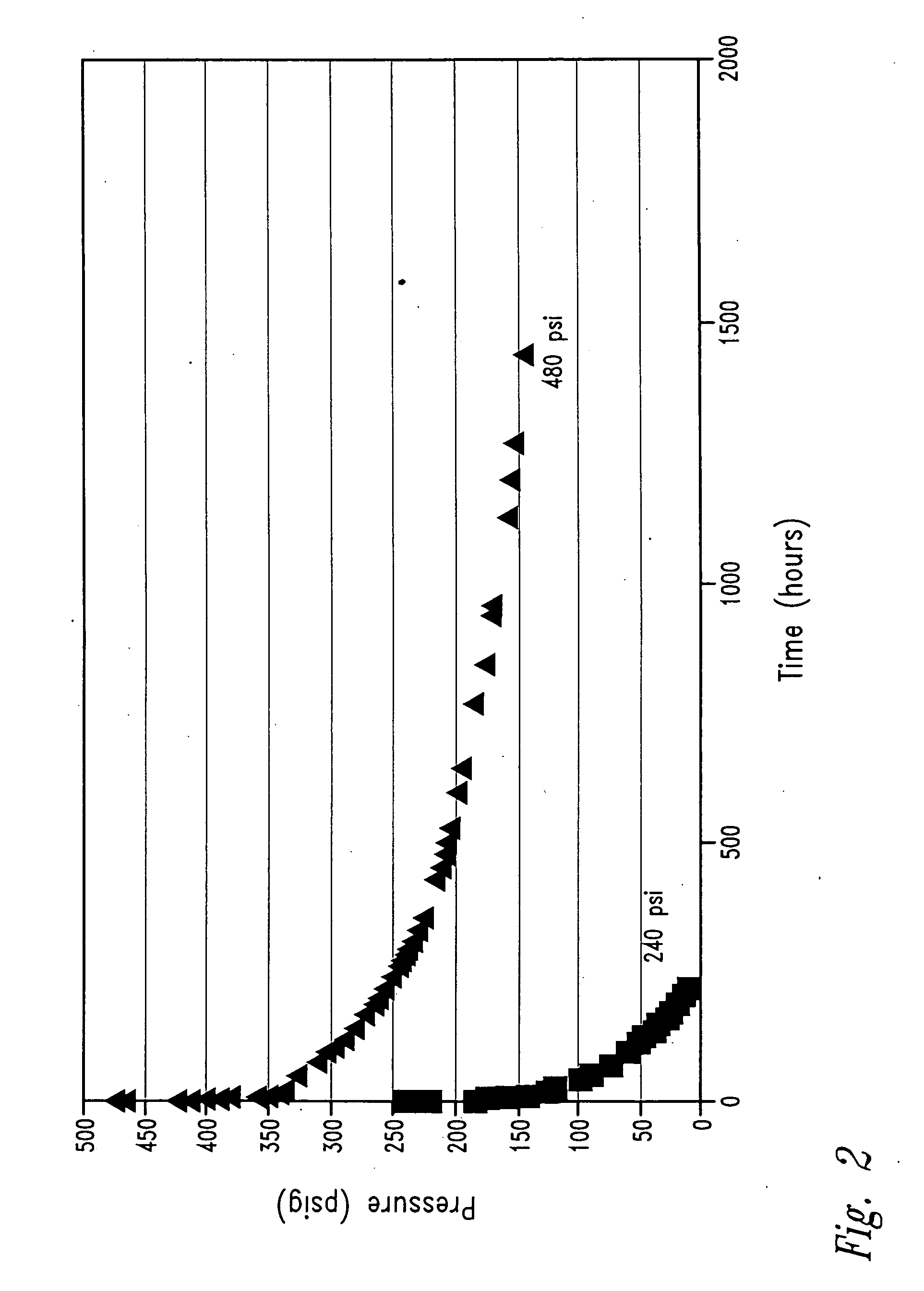

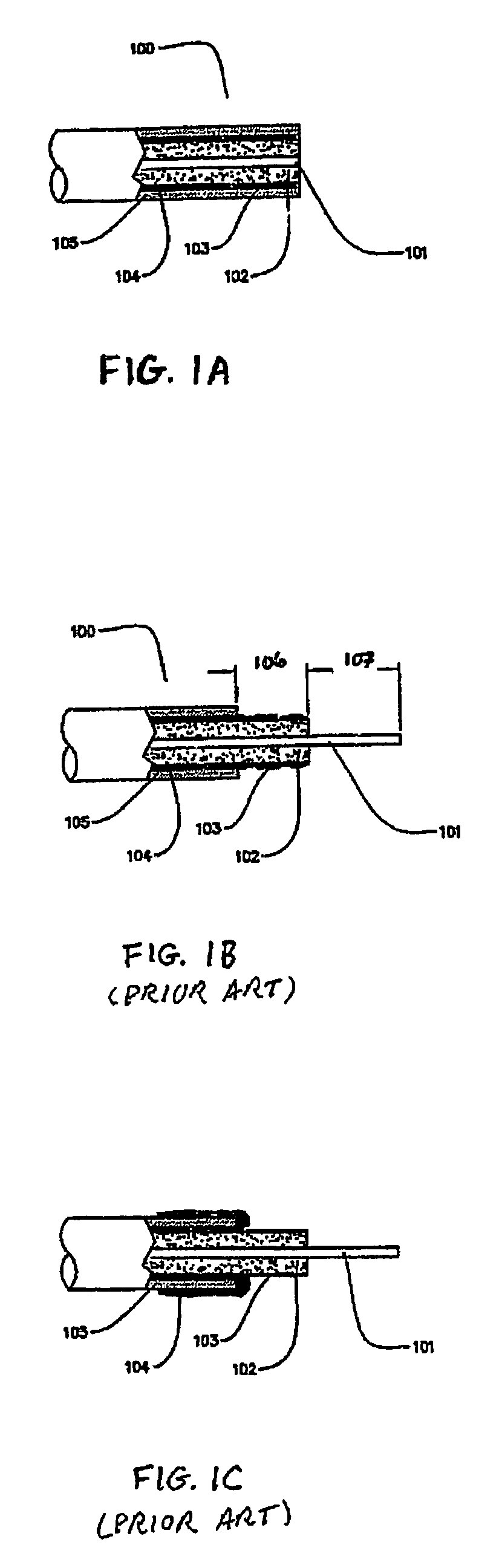

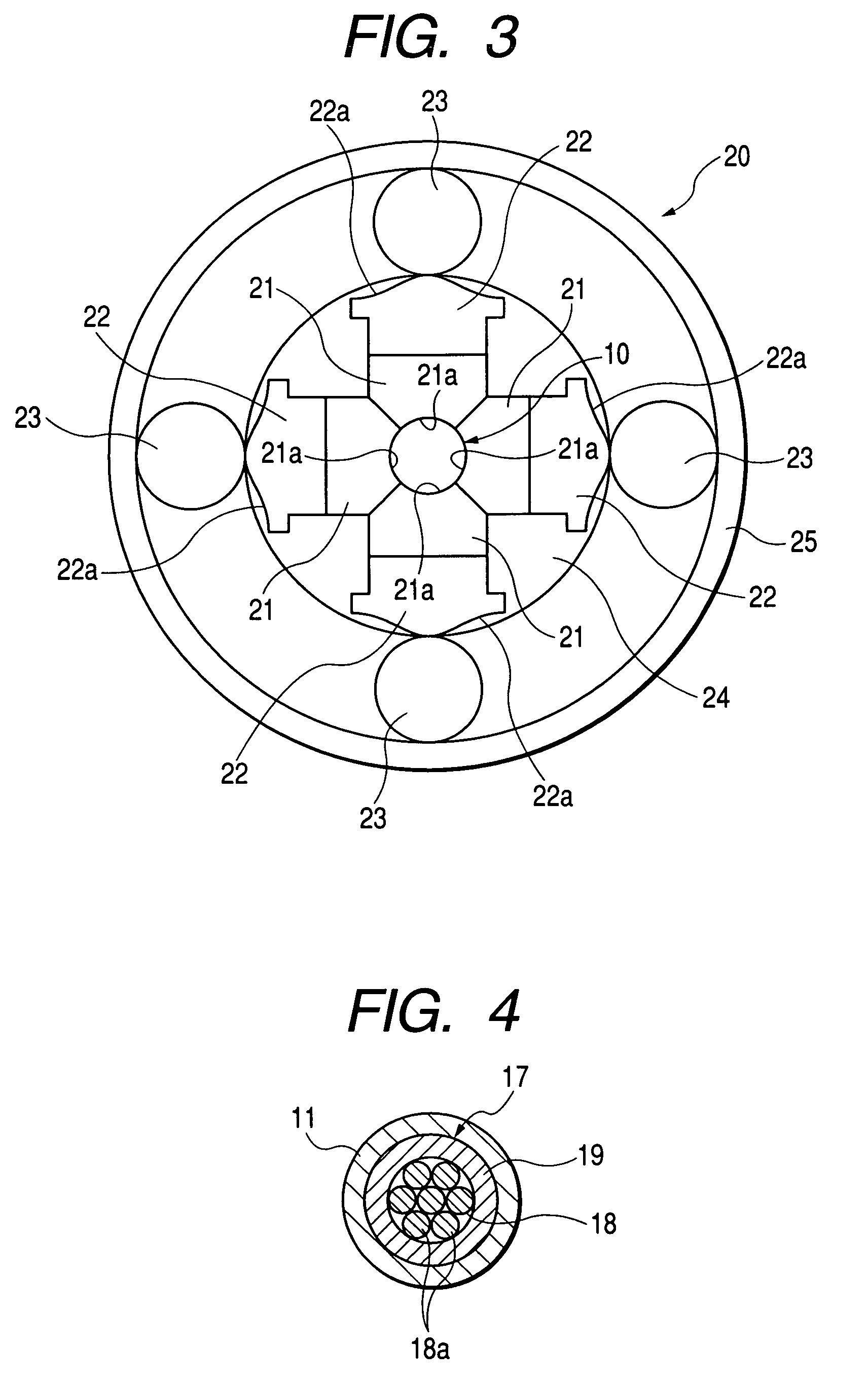

Method for treating electrical cable at sustained elevated pressure

ActiveUS20100095521A1Effective treatmentExcellent dielectric propertiesClimate change adaptationPower cables with screens/conductive layersElectrical conductorPolymer insulation

A method for enhancing the dielectric properties of an electrical cable segment having a central stranded conductor encased in a polymeric insulation jacket and an interstitial void volume in the region of the conductor, including filling the interstitial void volume with a dielectric property-enhancing fluid at a pressure below the elastic limit of the polymeric insulation jacket, and confining the fluid within the interstitial void volume at a residual pressure greater than about 50 psig, with the pressure being imposed along the entire length of the segment but below the elastic limit of the polymeric insulation jacket. Preferably, the residual pressure is sufficient to expand the interstitial void volume along the entire length of the cable segment by at least 5%.

Owner:NOVINIUM LLC

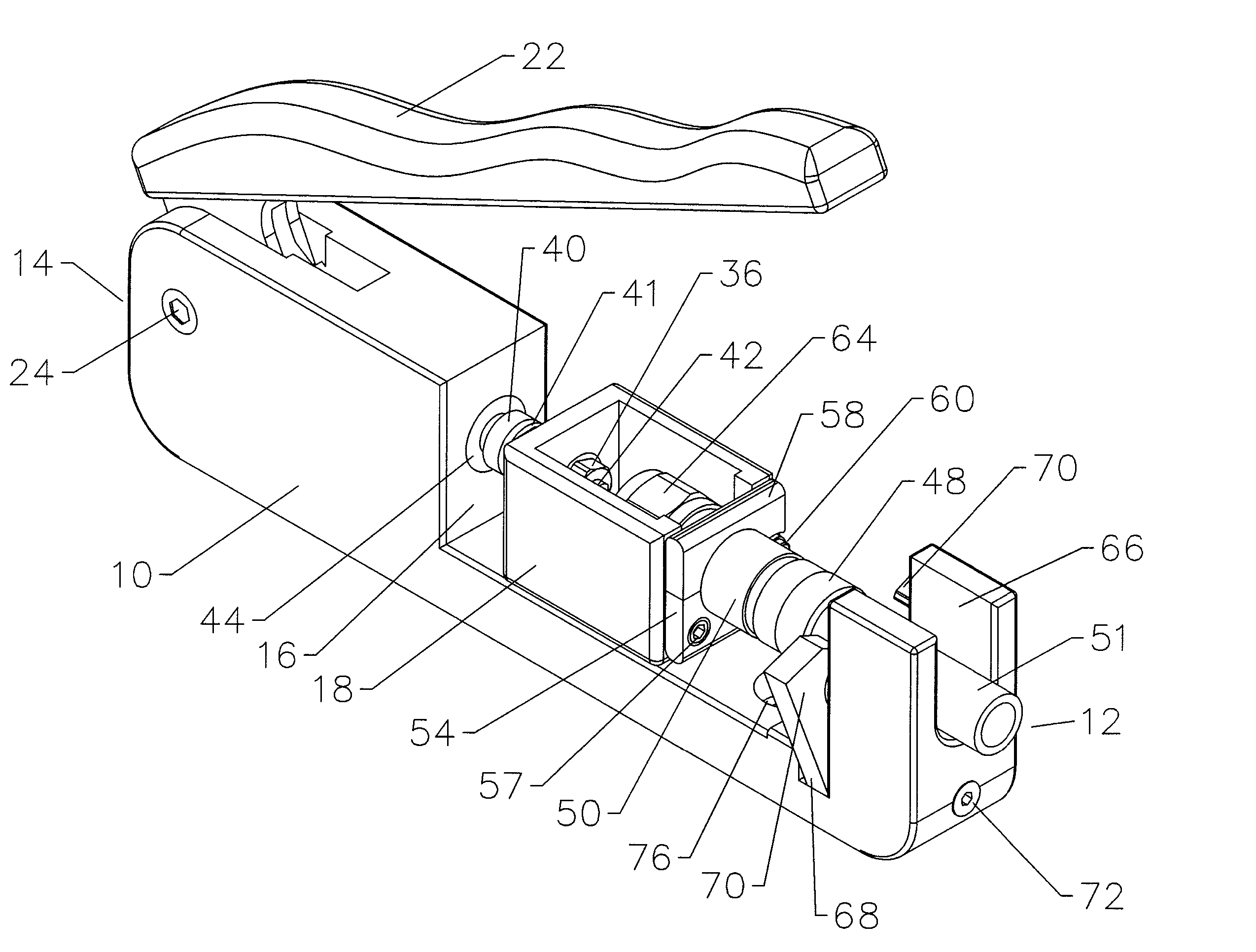

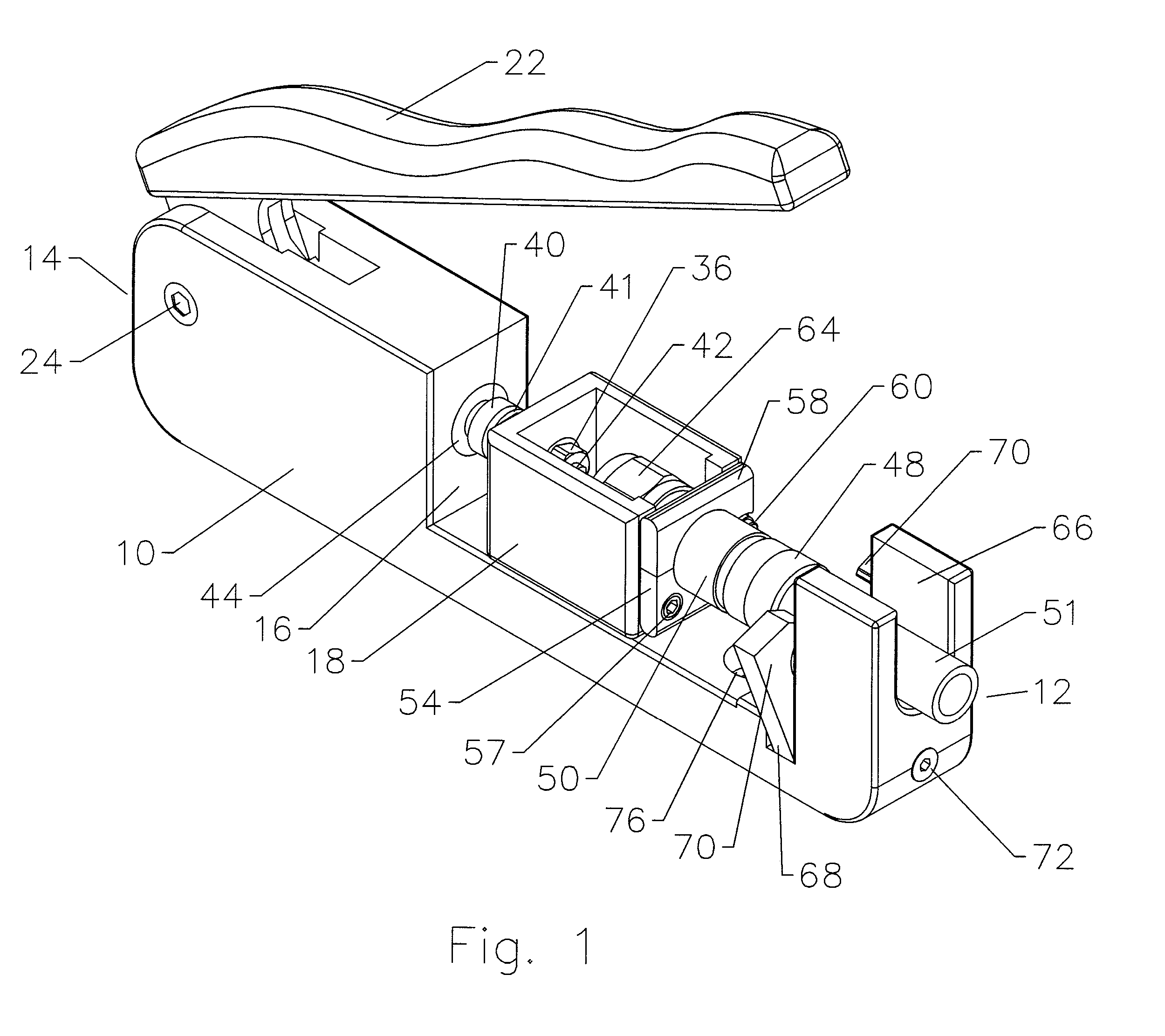

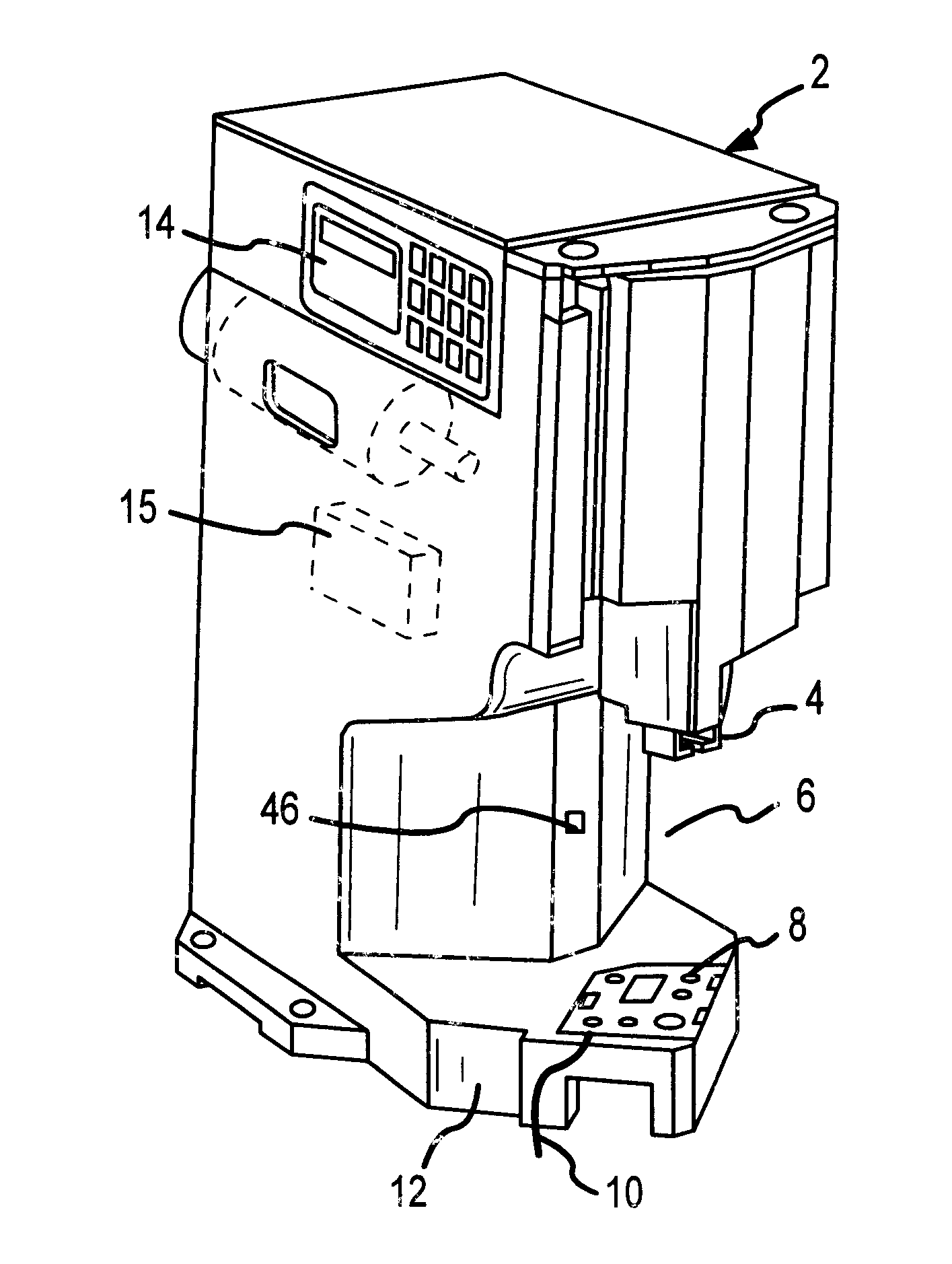

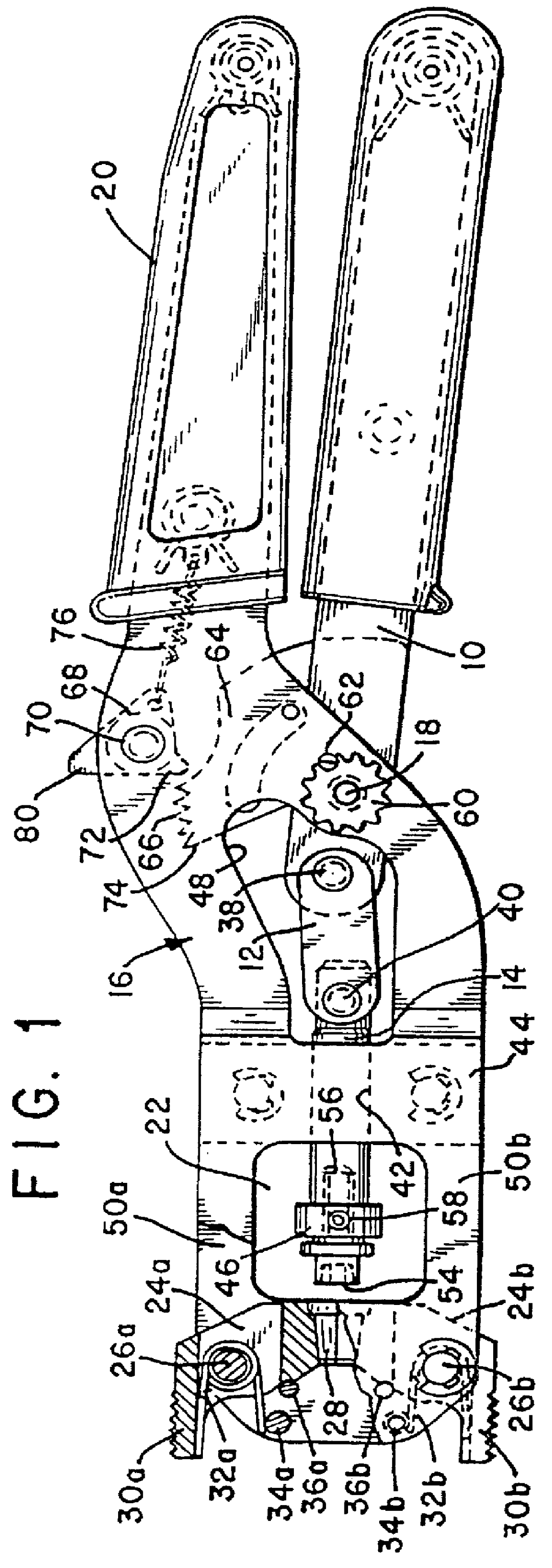

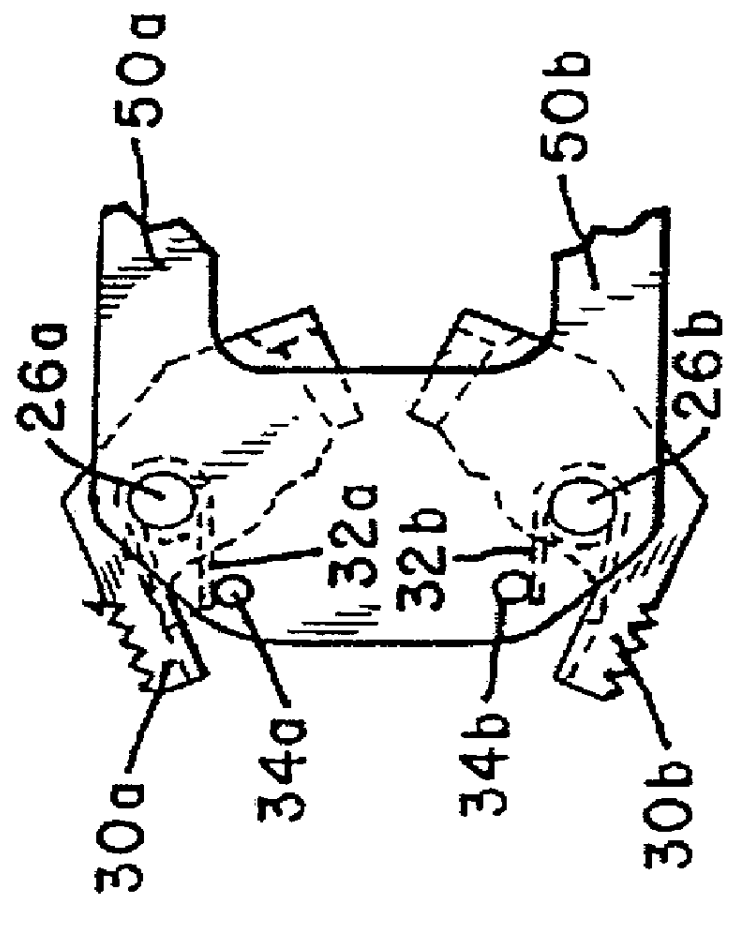

Connector axial compression tool

InactiveUS7120997B2Prevent movementCost effectiveElectrically conductive connectionsCable junctionsAxial compressionEngineering

A connector axial compression tool having a lever end and a cable end, with a body slidably supporting a cradle in a cavity formed in the body. The cradle is slidable via a handle which pivots about the body, linked to the cradle by a lever mechanism. The cradle has a shoulder clamp adapted to mate with a connector body. Operation of the handle moves the cradle towards and away from a cable end of the cavity, against a cable clamp through which the cable may pass but against which a cable clamp sleeve of the connector abuts, axially compressing the connector to couple it to the cable. Because the shoulder clamp holds the connector body rather than pressing against the connector interface, a wide range of different connectors may be used with the same tool, without causing damage to the connector interface of the various connectors.

Owner:ANDREW LLC

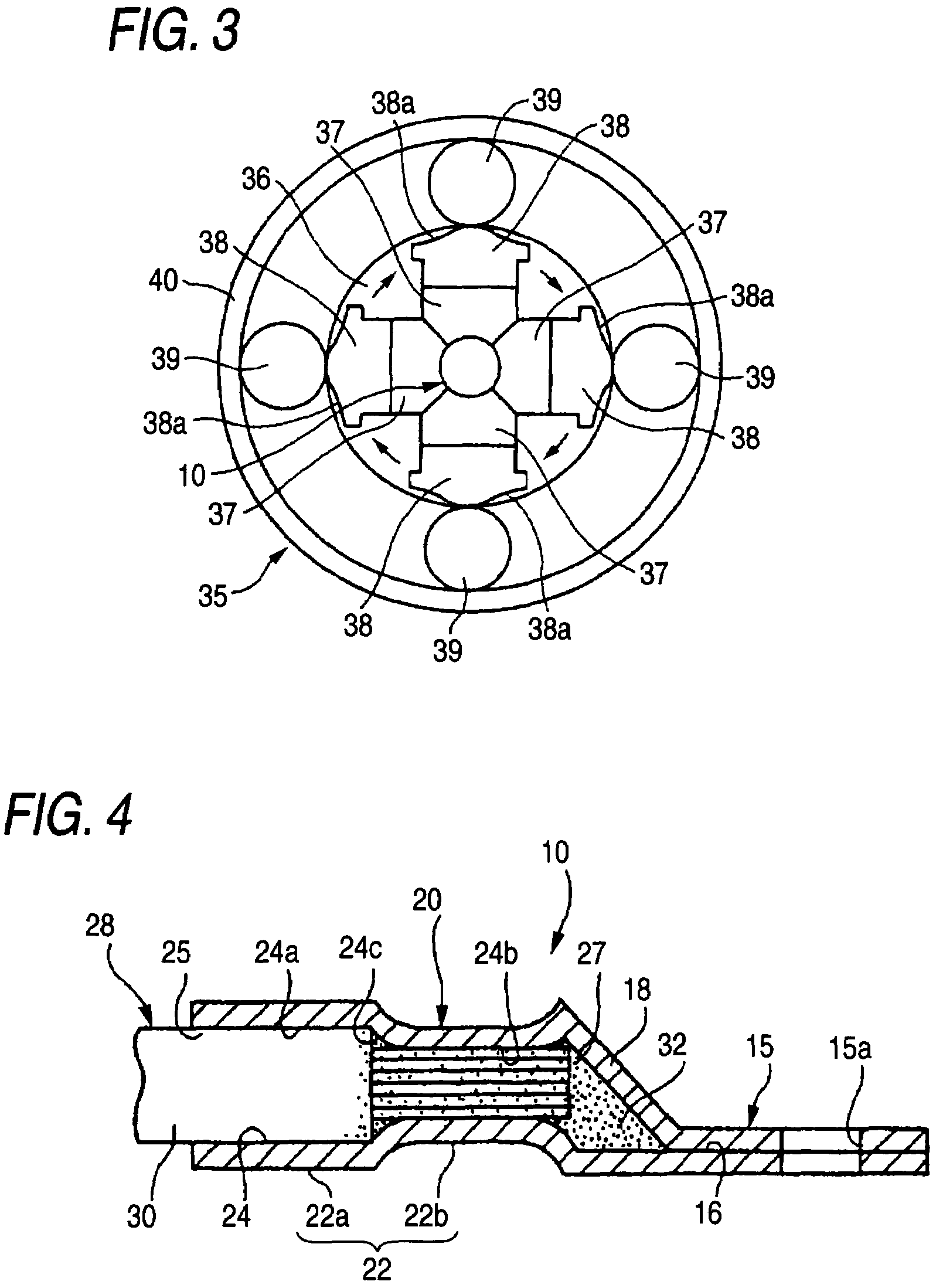

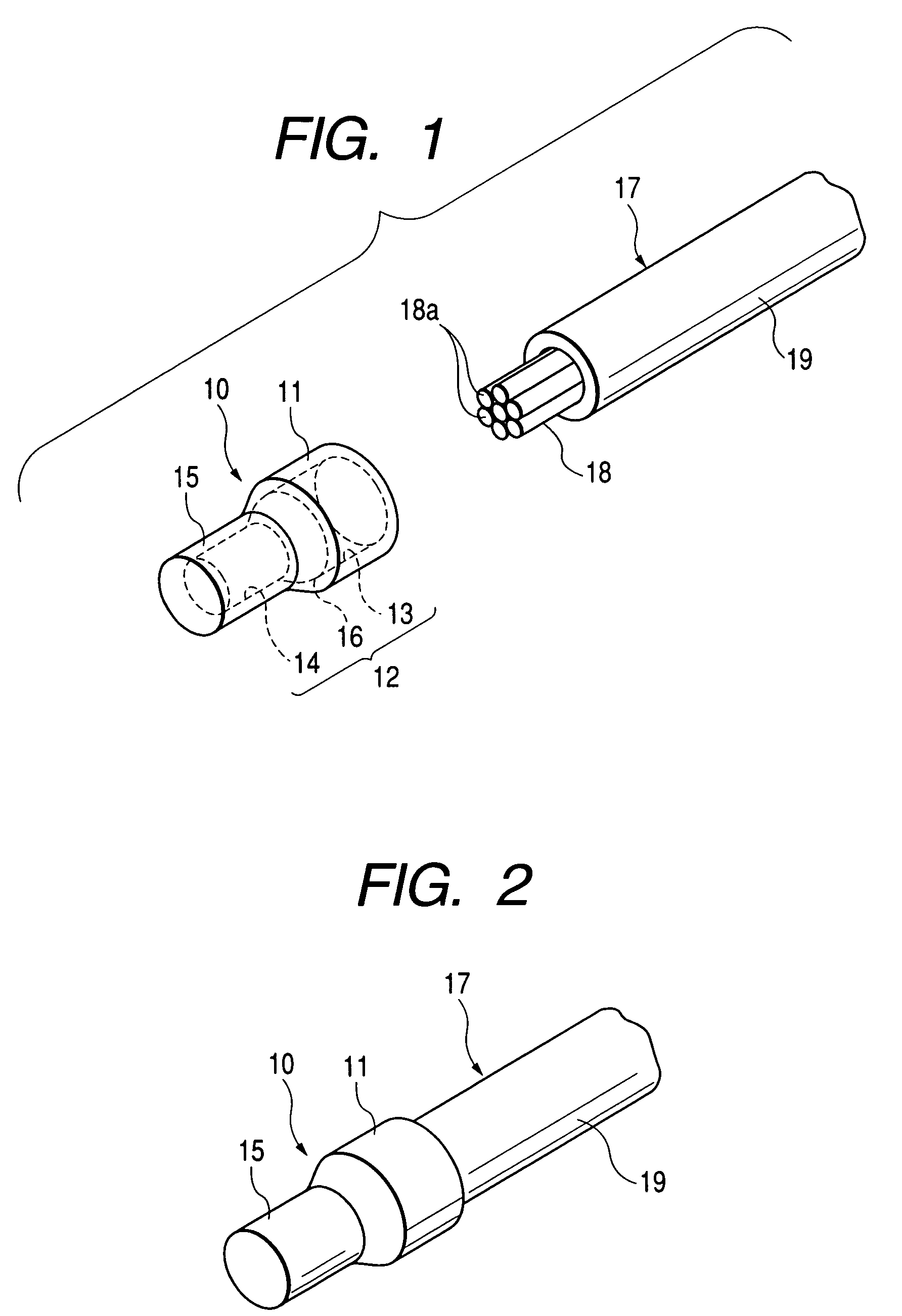

Medical leads with segmented electrodes and methods of fabrication thereof

ActiveUS20100269338A1Increase surface areaContact member manufacturingElectrically conductive connectionsBiomedical engineeringMedical treatment

In one embodiment, a process, for fabricating a medical lead for stimulation of tissue of a patient, comprises: providing a plurality of wires; increasing an exterior surface area of each wire of the plurality of wires; arranging the plurality of wires angularly around a longitudinal axis; extruding polymer material of the plurality of wires; forming a lead body with a proximal end and a distal end after performing the extruding; and forming a plurality of terminals at a proximal end of the lead body; forming a plurality of segmented electrodes at a distal end of the lead body.

Owner:ADVANCED NEUROMODULATION SYST INC

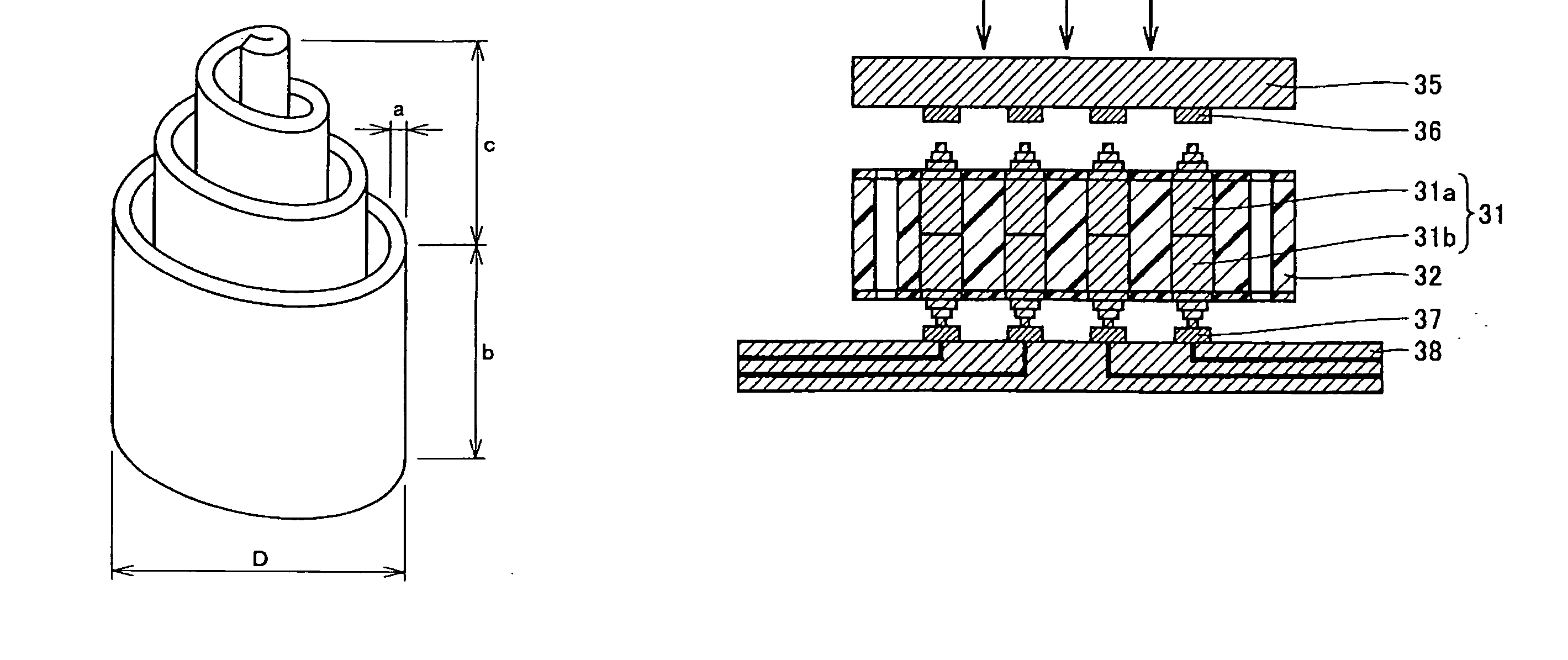

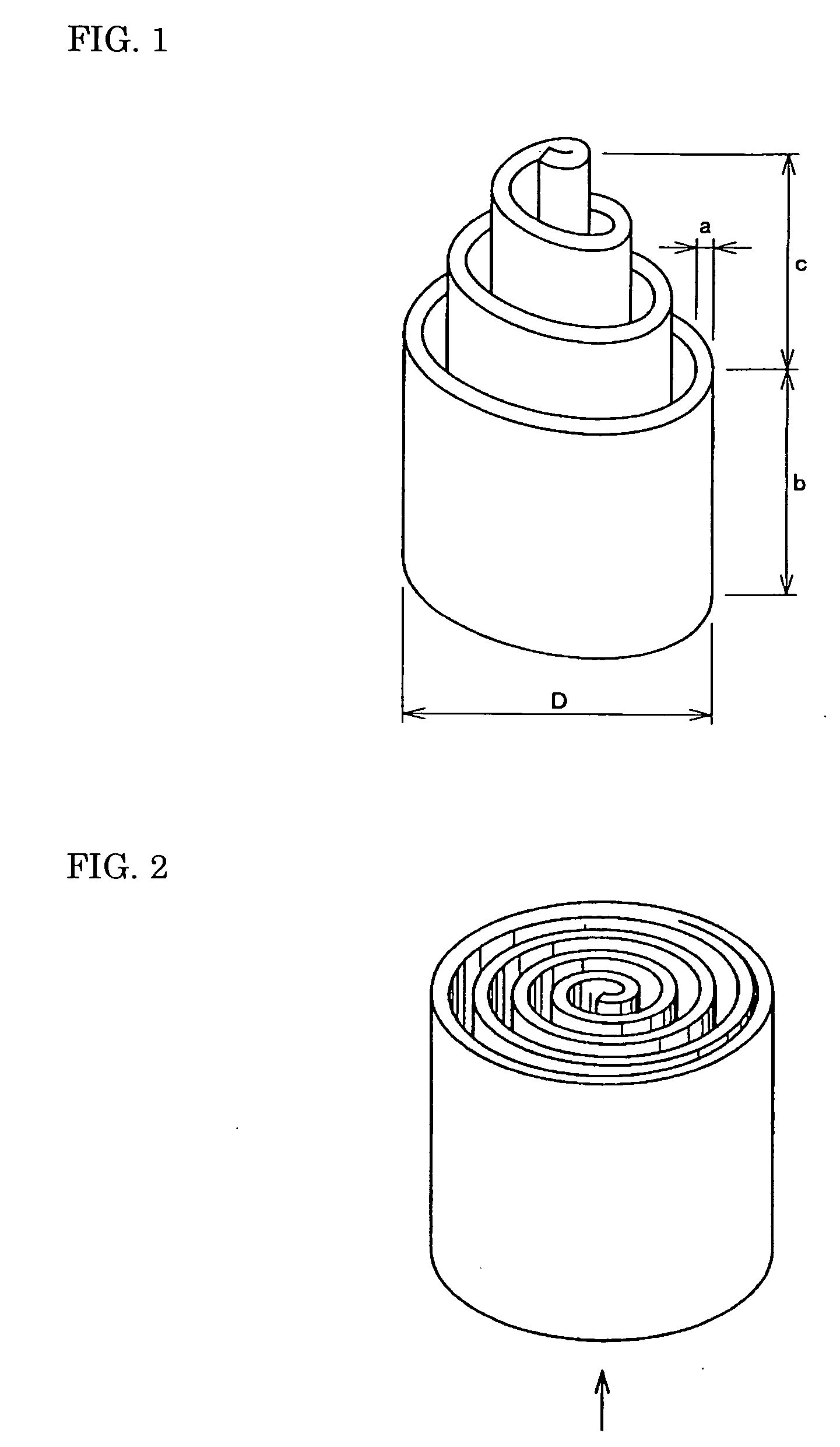

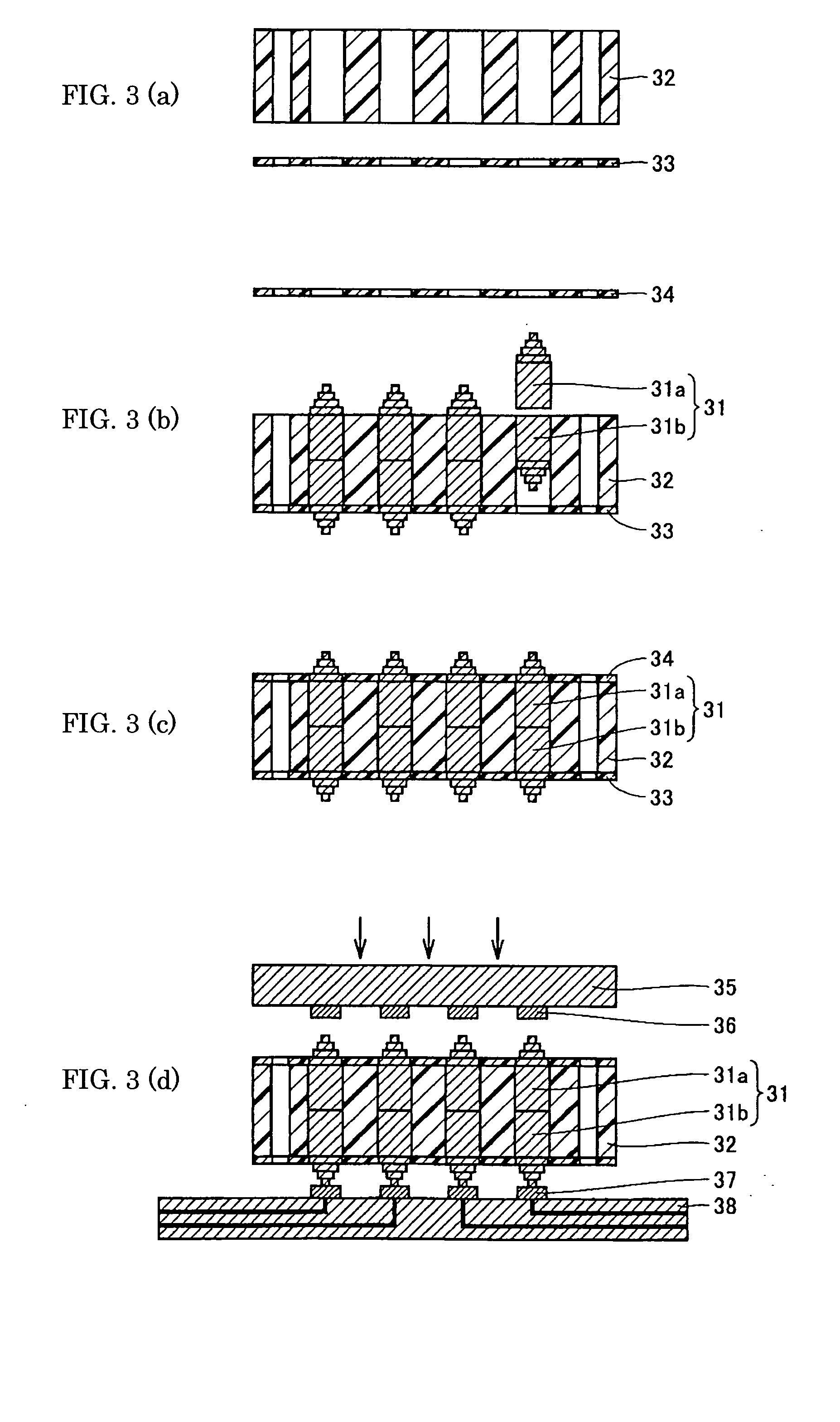

Method of manufacturing protruding-volute contact, contact made by the method, and inspection equipment or electronic equipment having the contact

InactiveUS20050088193A1Low costImprove reliabilityContact member manufacturingManufacture of electrical instrumentsCouplingCoil spring

A method of manufacturing a protruding-volute contact for attaining electrical continuity with an electrode of electronic equipment or inspection equipment, the method comprising the steps of forming a plastic mold (resist structure) with a metal mold; forming a layer consisting of metallic material on the plastic mold (resist structure) by means of electroforming; and performing convex formation of a metal microstructure made from the layer consisting of metallic material so as to form a spiral spring that protrudes volutedly outward. With such method, an inspection contact or coupling contact having high reliability and capable of attaining electrical continuity of large electric current can be produced at low cost.

Owner:SUMITOMO ELECTRIC IND LTD

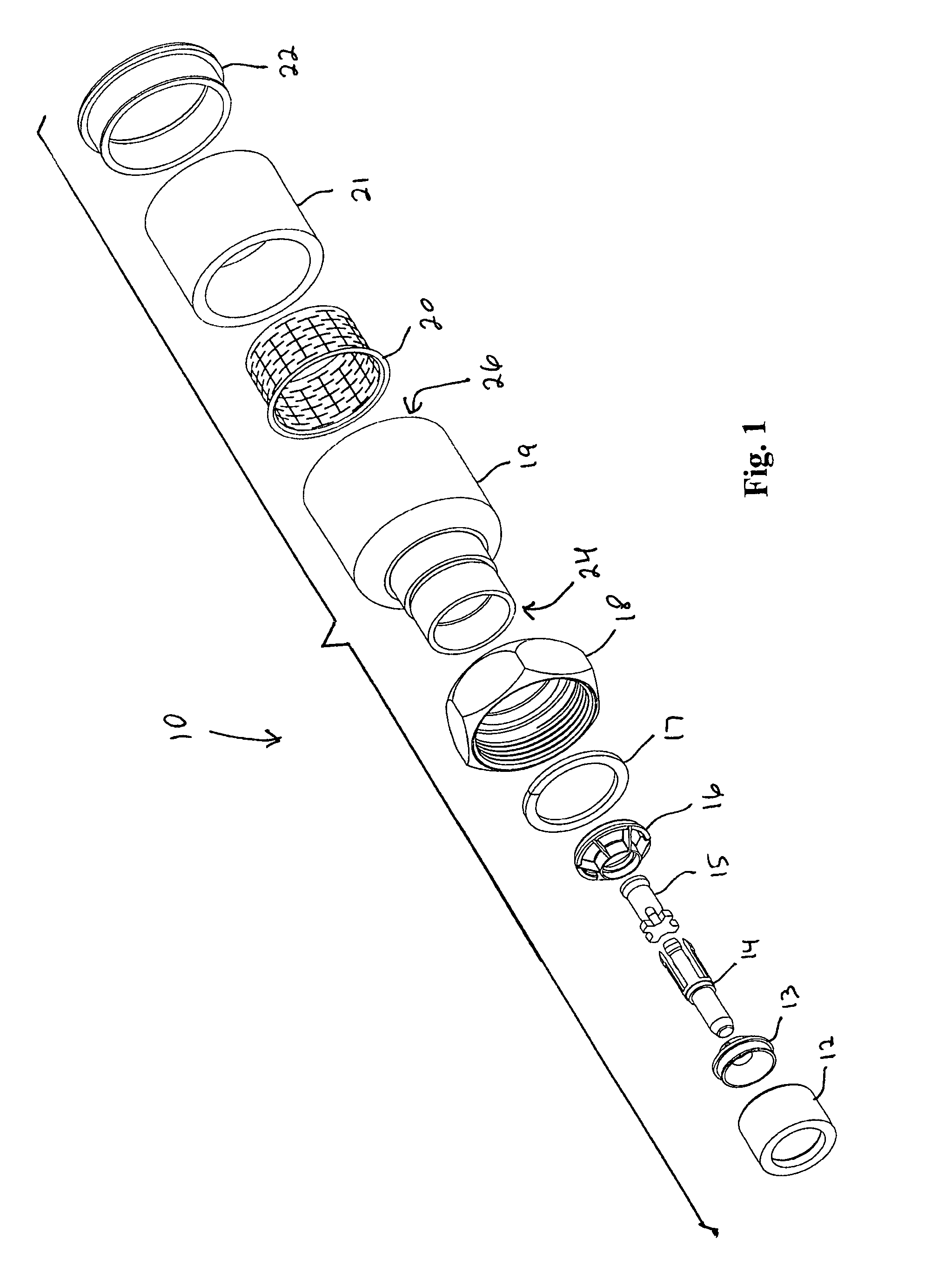

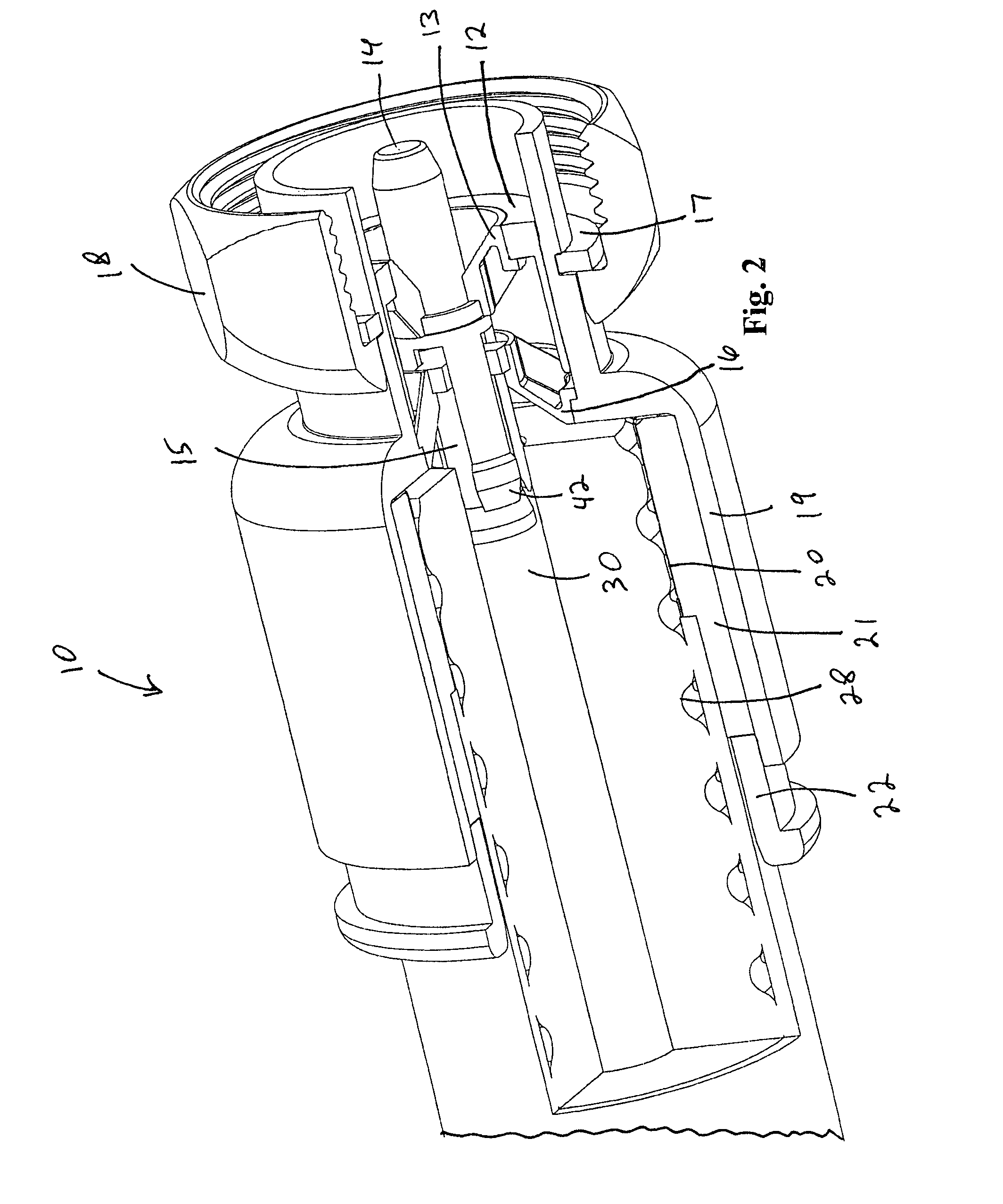

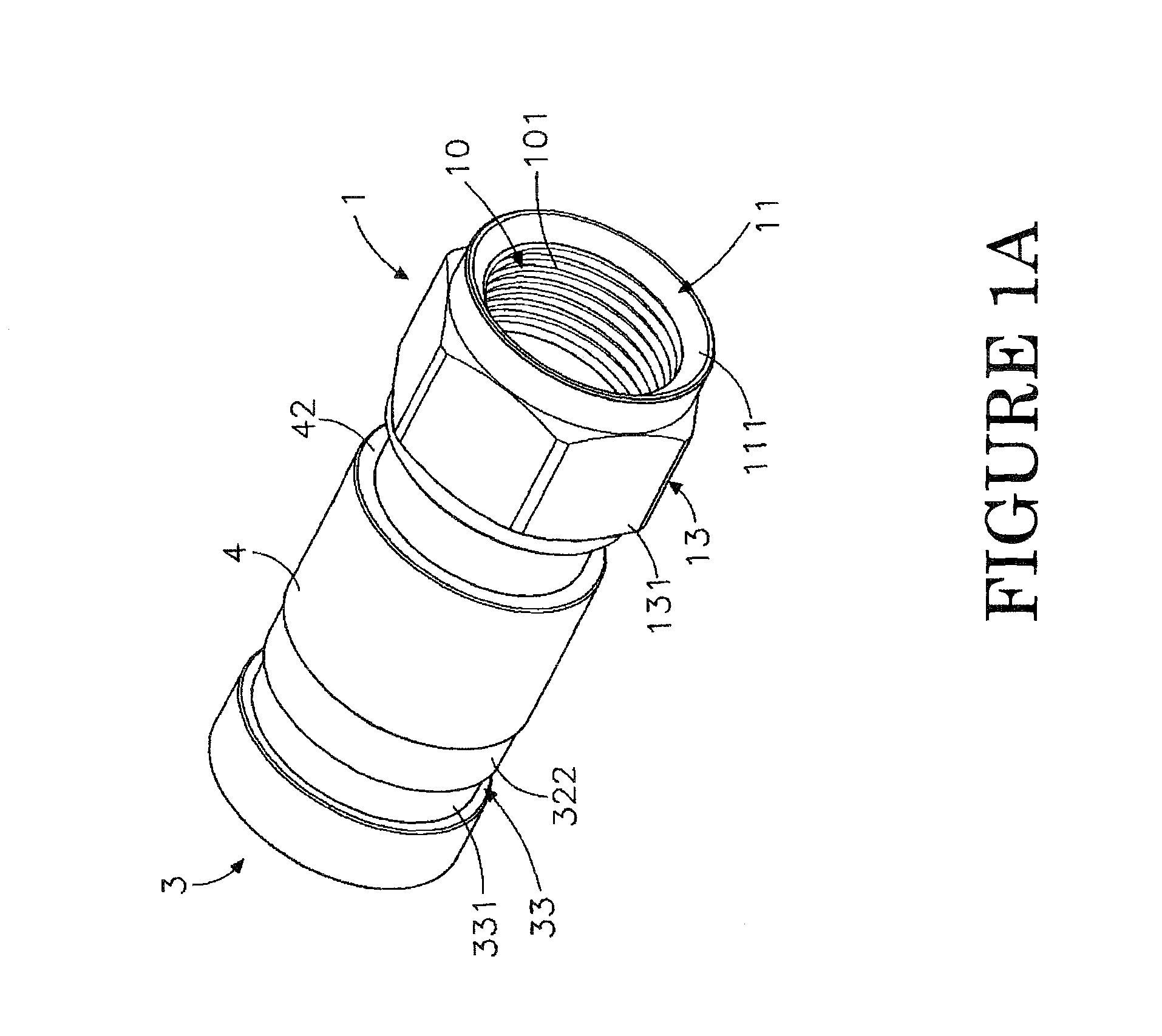

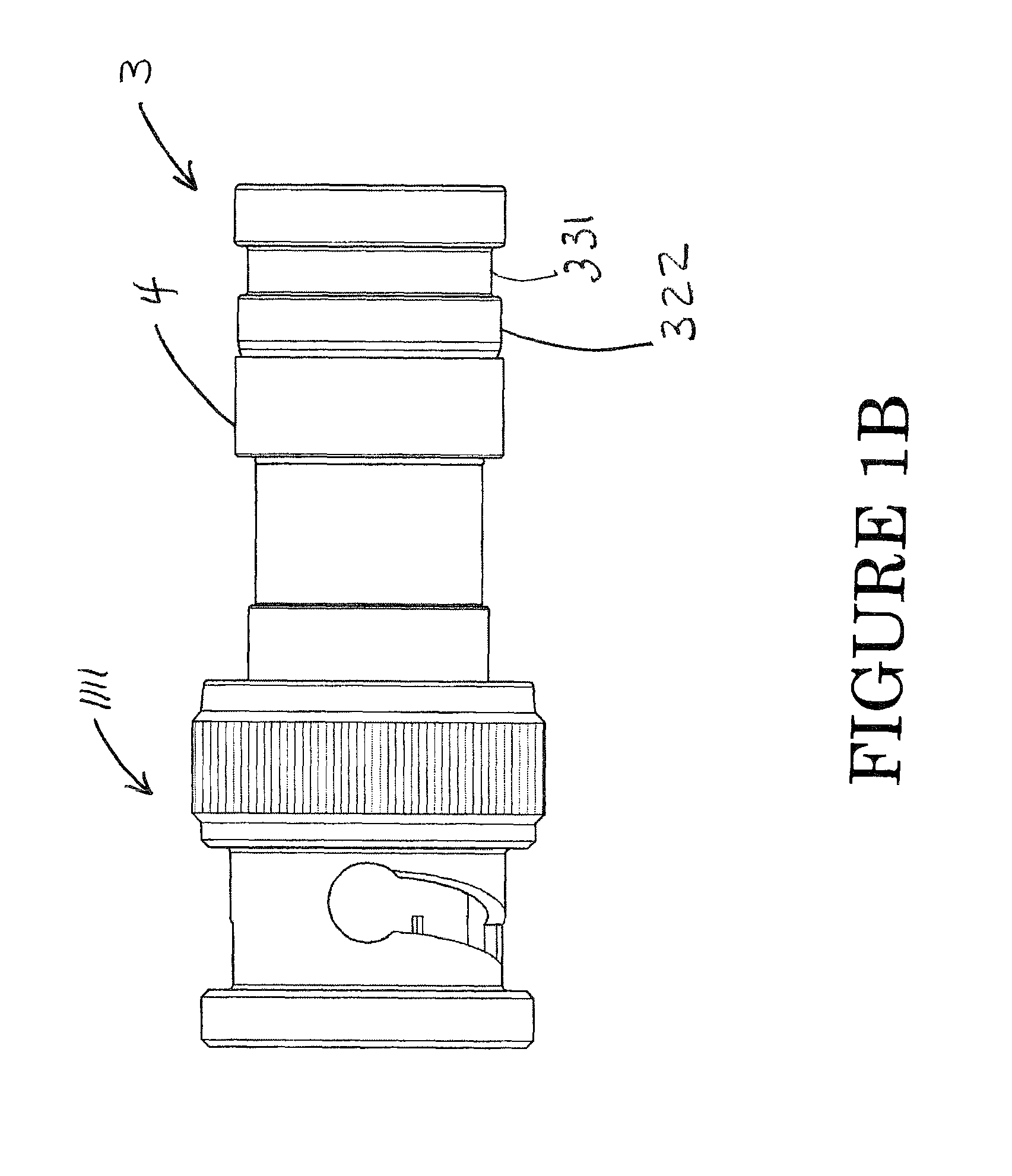

Coaxial connector and coaxial cable connector assembly and related method

ActiveUS7371112B2CostSufficient retentionElectrically conductive connectionsCoupling device detailsCoaxial cablePatch cable

A method of making a coaxial cable assembly is disclosed, the assembly comprising a coaxial cable and a connector, or connector termination, on at least one end of the cable. A connector, comprised of connector components, is also disclosed. The method comprises placing connector components into contact with the cable before the connector components are assembled into a connector. The connector is assembled simultaneously with securing the connector to the cable to make a coaxial cable assembly. A method of preparing coaxial cable in a manner suitable for making coaxial cable assemblies is also disclosed. The coaxial cable assembly can be a jumper, or a lead.

Owner:PPC BROADBAND INC

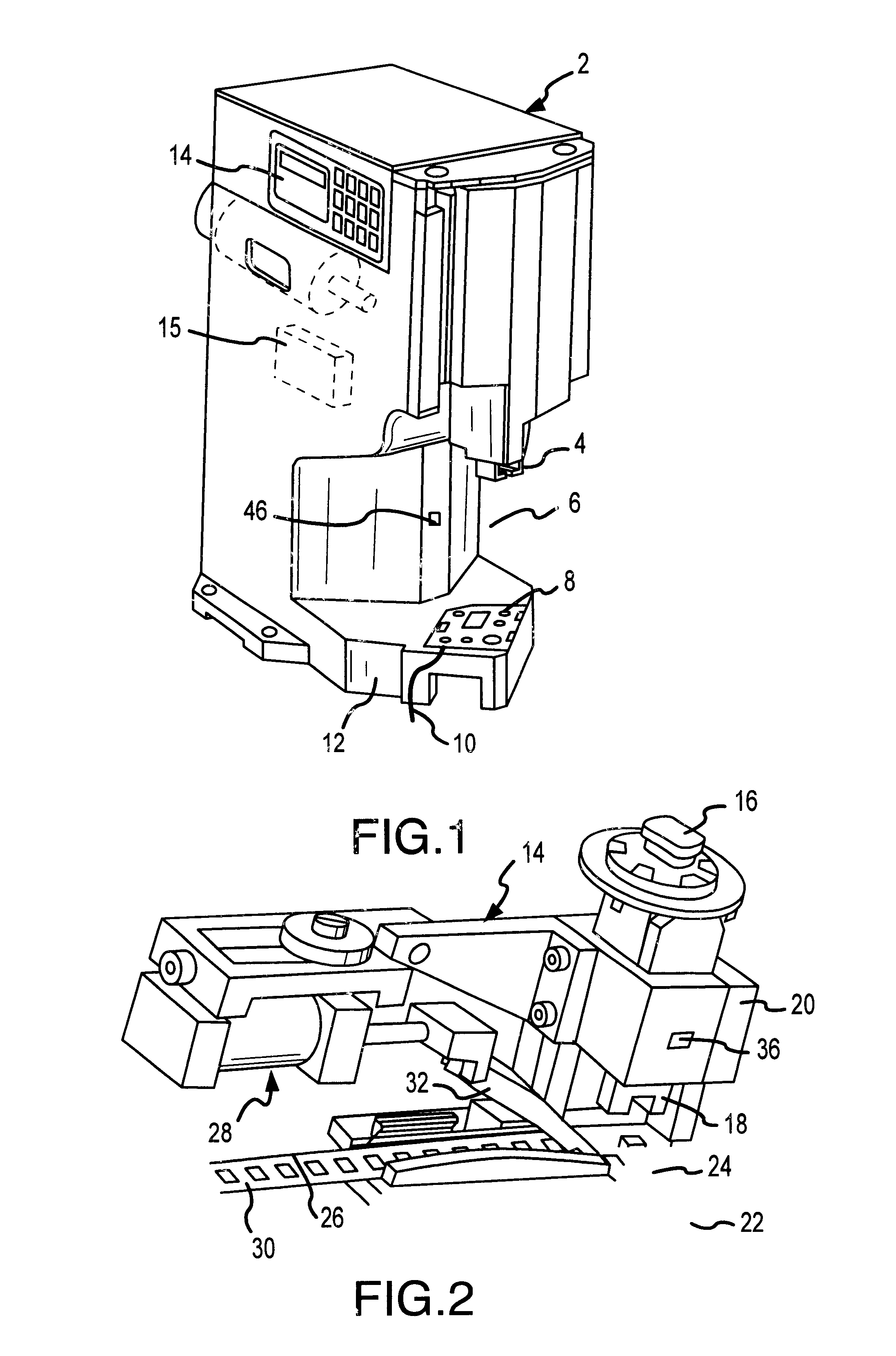

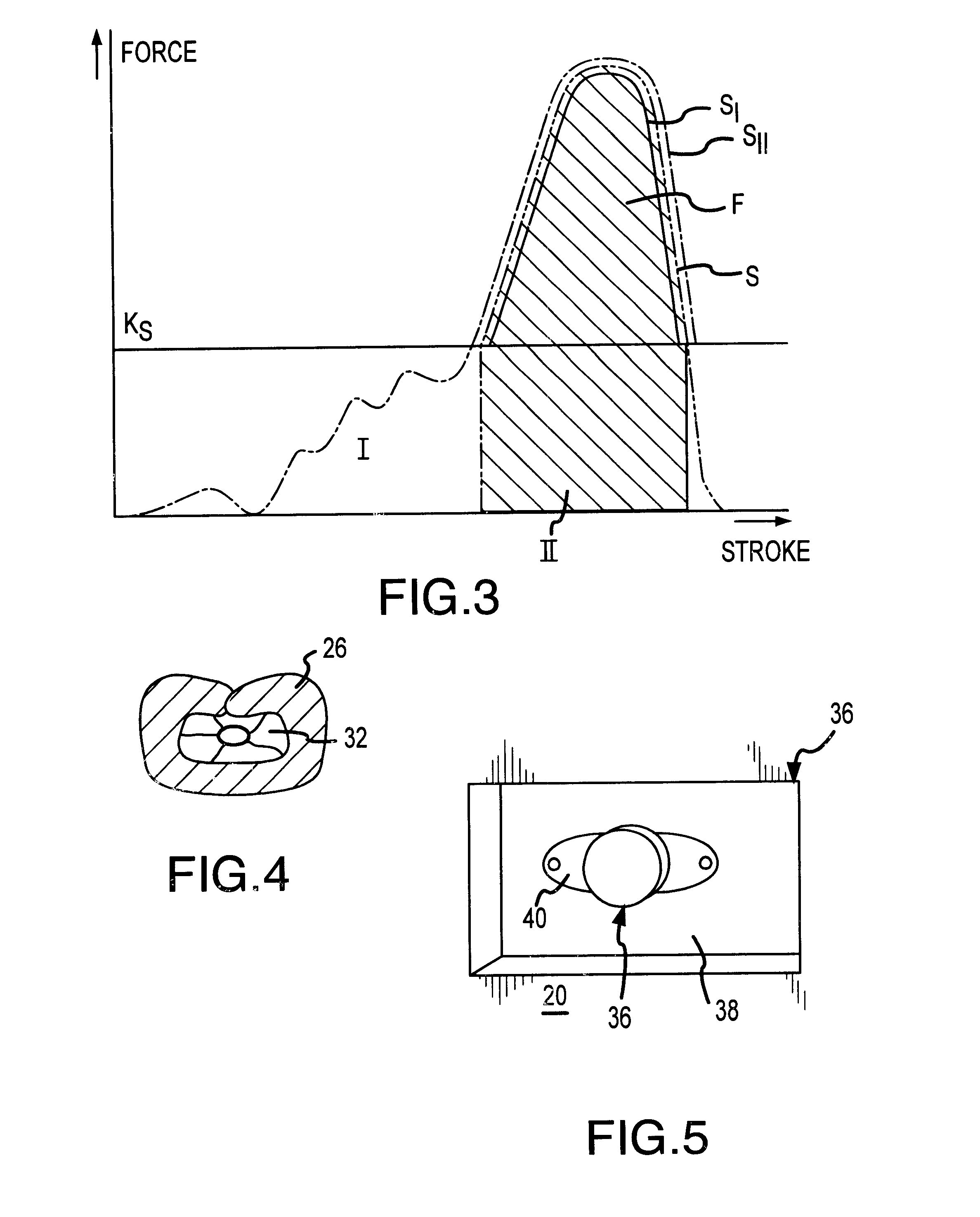

Method for quality assurance of crimp connections produced by a crimping device and crimping tool and crimping device therefor

InactiveUS6418769B1Automatic control devicesShaping safety devicesQuality assuranceMechanical engineering

The method for quality assurance of crimping connections made by a crimping device having an exchangeable tool with two tool parts uses a tool that is provided with an electronic data storage device. The electronic data storage device stores tool-specific nominal data derived from a nominal force-stroke characteristic line of a nominal crimping action of the tool. A crimp connector is fastened to the end of an electrical cable by placing the end of the electrical cable and the crimp connector between the two tool parts and moving the two tool parts relative to one another for carrying out the crimping action. The force-stroke characteristic line of the two tool parts is measured during the crimping action. The measured force-stroke characteristic line is compared to the stored nominal data.

Owner:SLE TECH GMBH

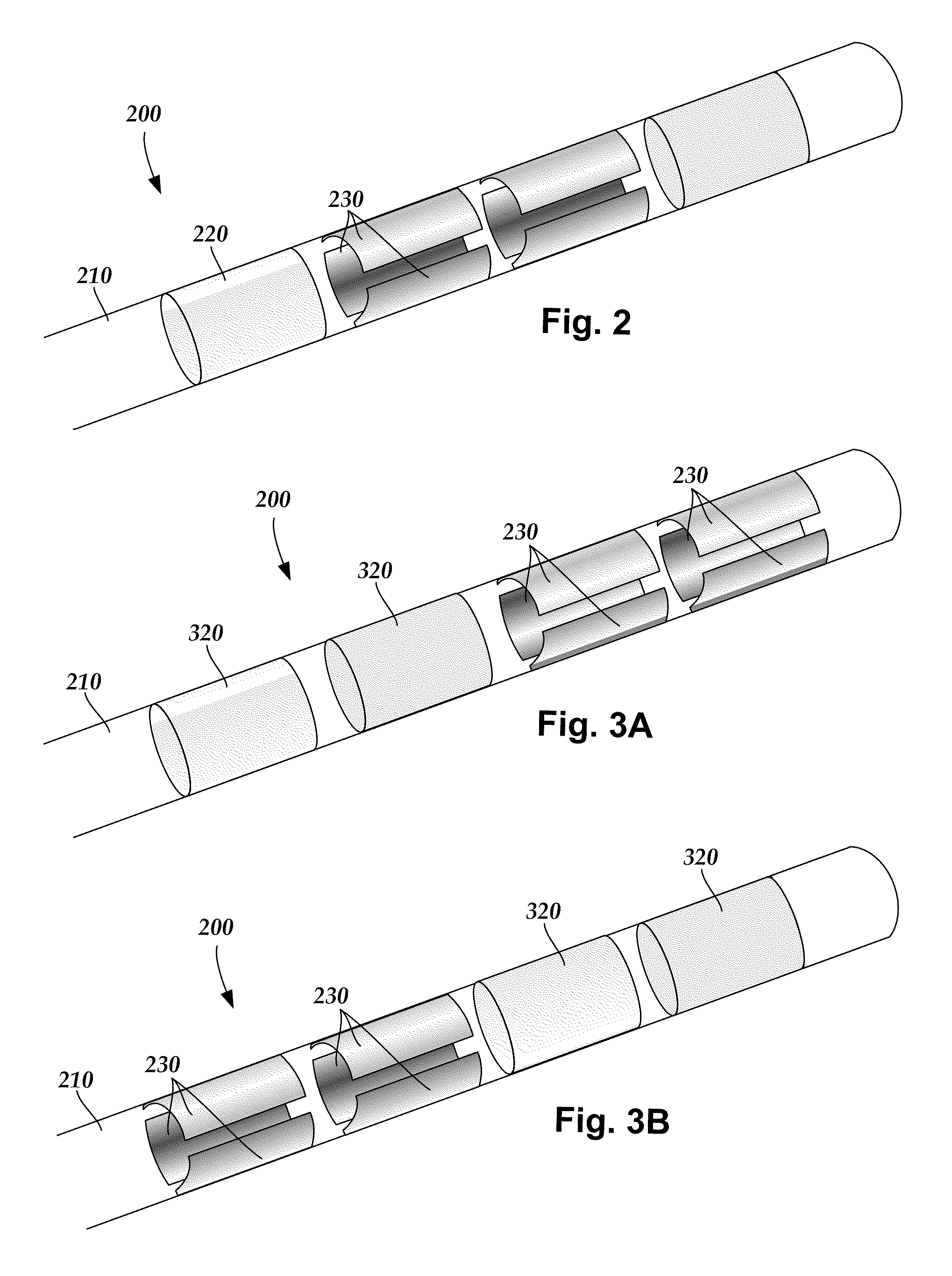

Cable connector expanding contact

InactiveUS7527512B2Engagement/disengagement of coupling partsElectrically conductive connectionsInterference fitElectrical conductor

An expanding contact used within a cable connector to make a solid connection with a hollow center conductor of a coaxial cable includes two pieces, a pin and a guide. The pin includes a plurality of slots which form a like plurality of fingers, while the guide includes a plurality of tabs which fit into the plurality of slots. Ends of the fingers include a ramped portion which interacts with a ramped portion of the guide. When the pin is pushed against the guide, the fingers are pushed outward because of the ramped portions of the fingers sliding against the ramped portion of the guide. Before the ends are pushed outward, the pin / guide combination can slide easily into and out of the hollow center conductor, but when the fingers are pushed outward, the fingers make a substantial interference fit with the inner walls of the hollow center conductor.

Owner:JOHN MEZZALINGUA ASSOC INC

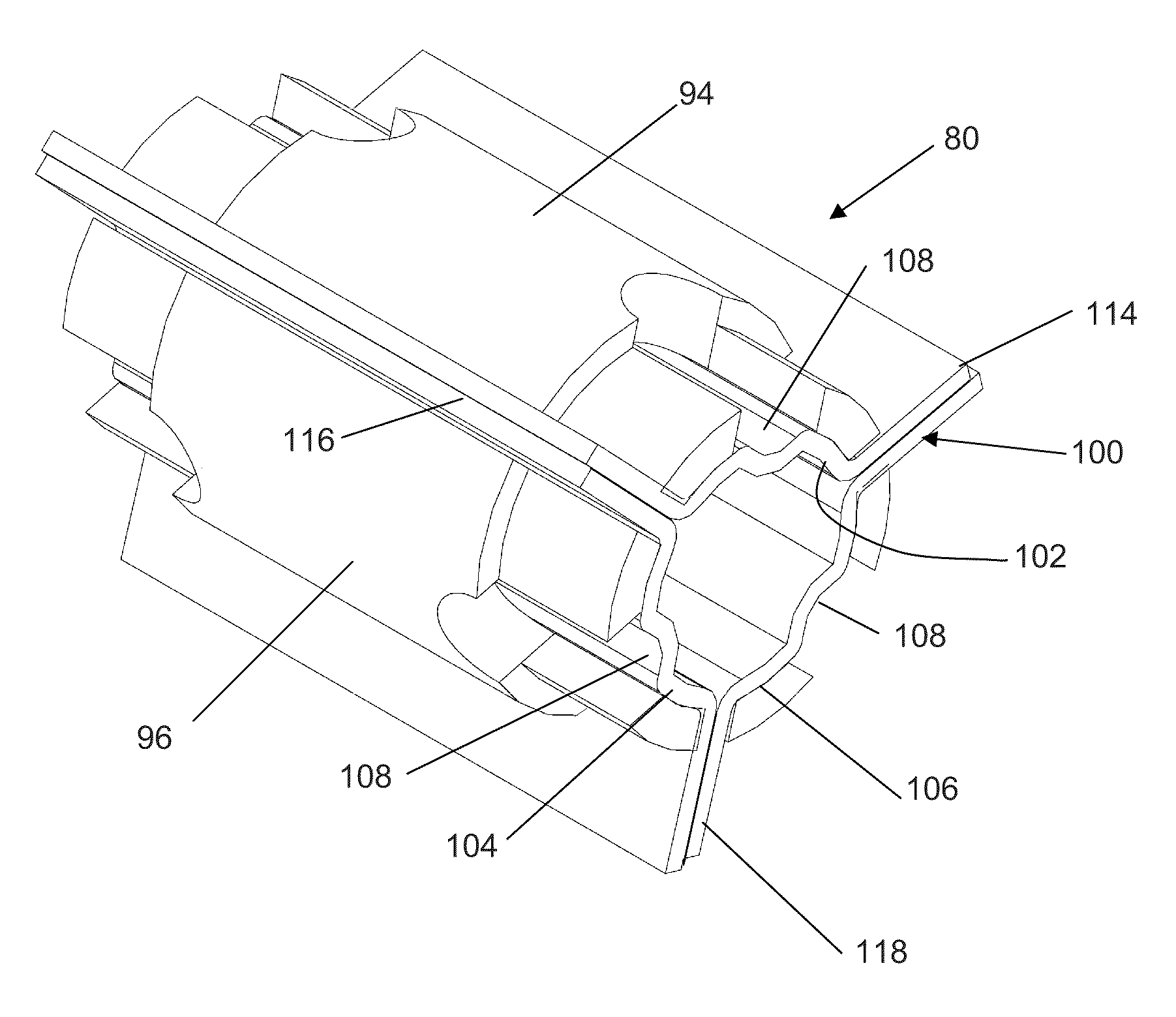

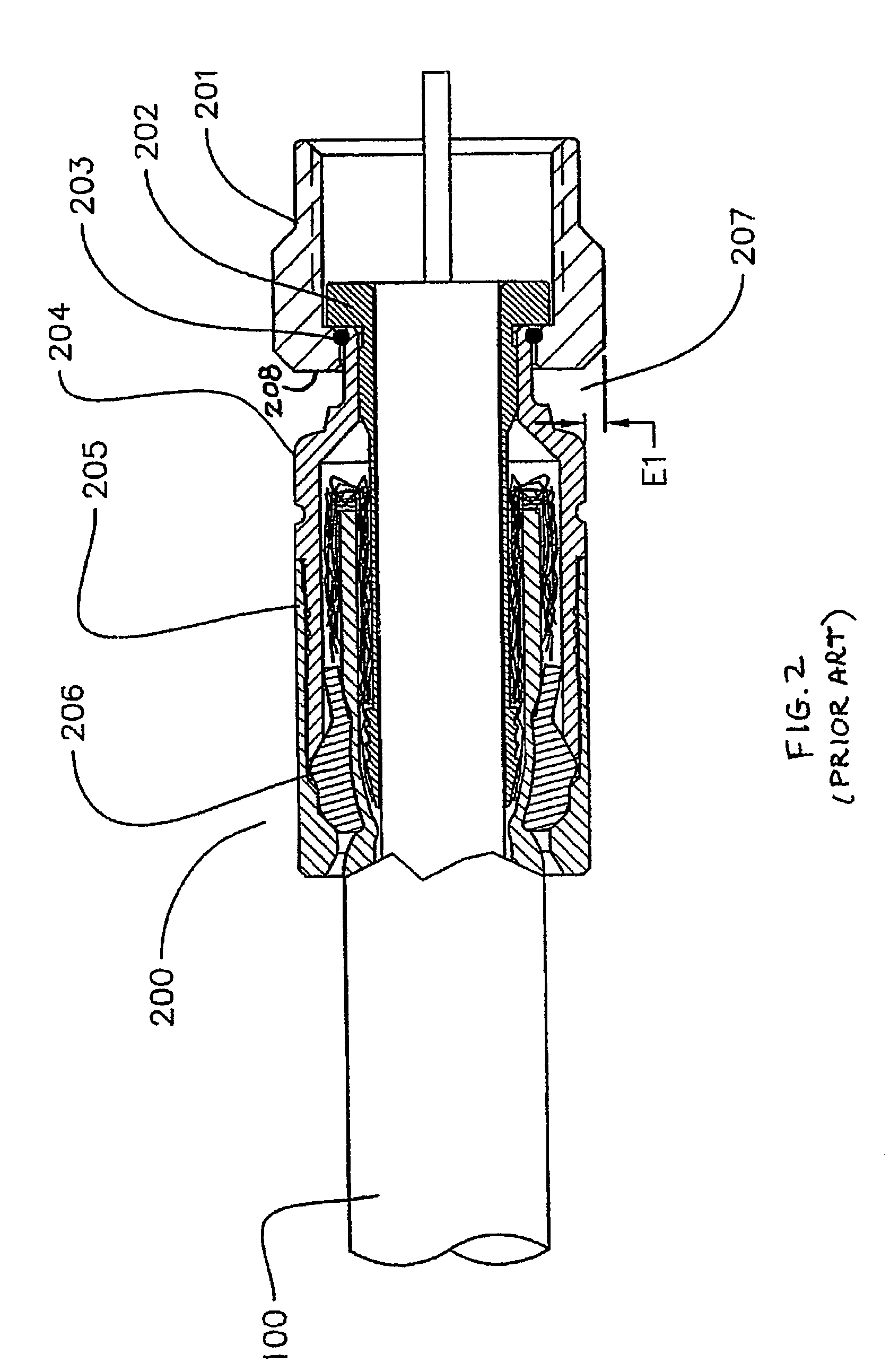

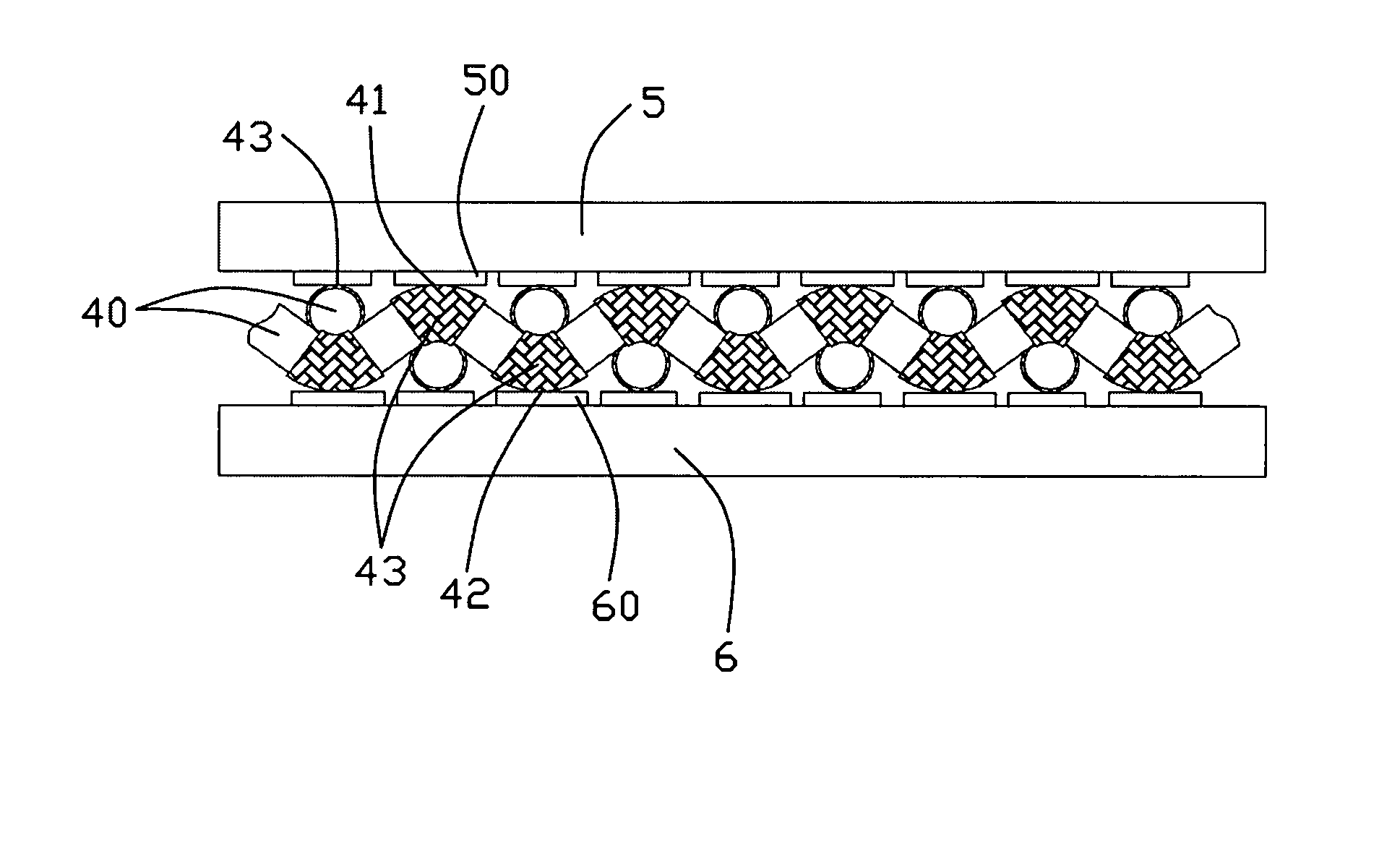

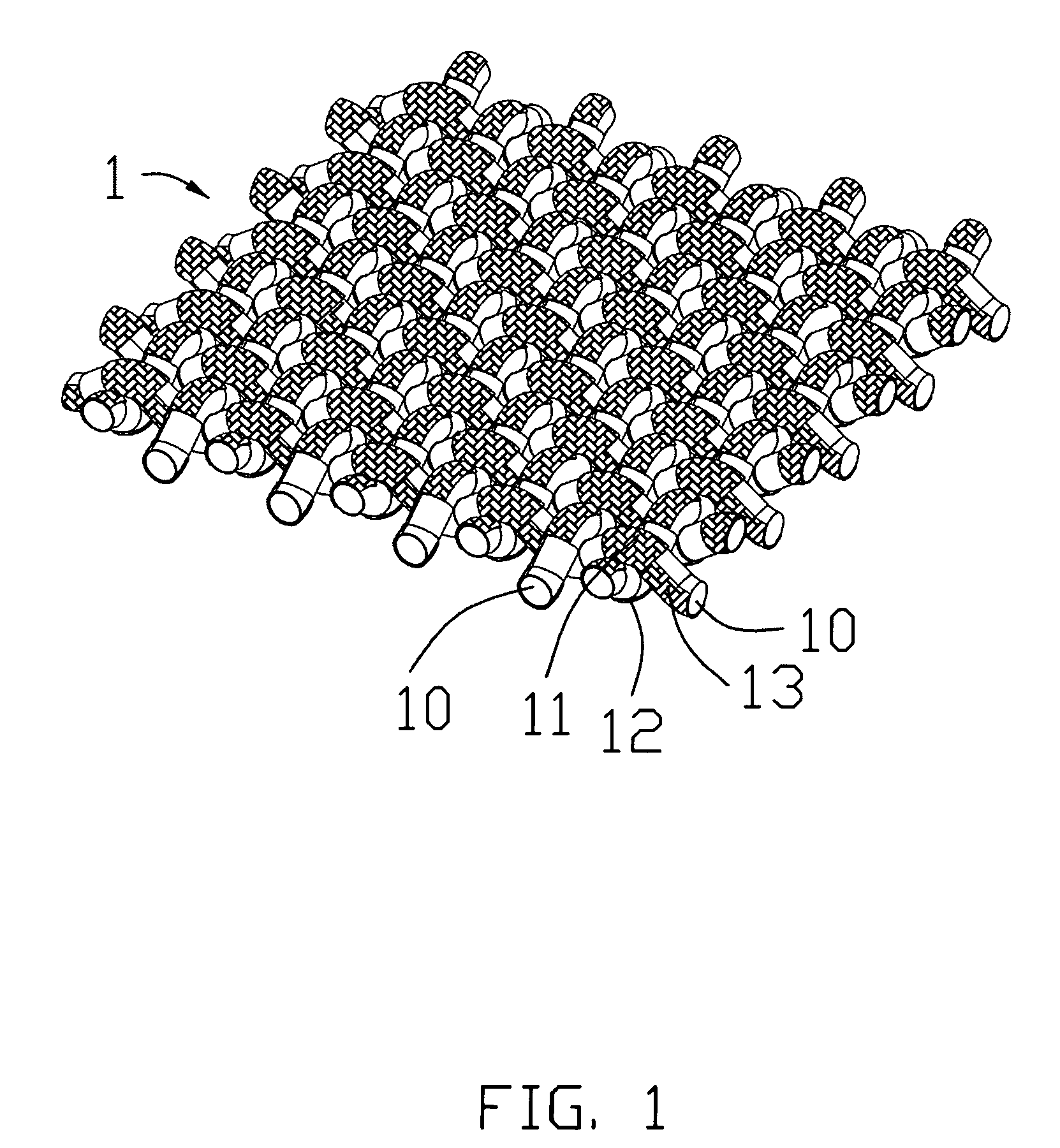

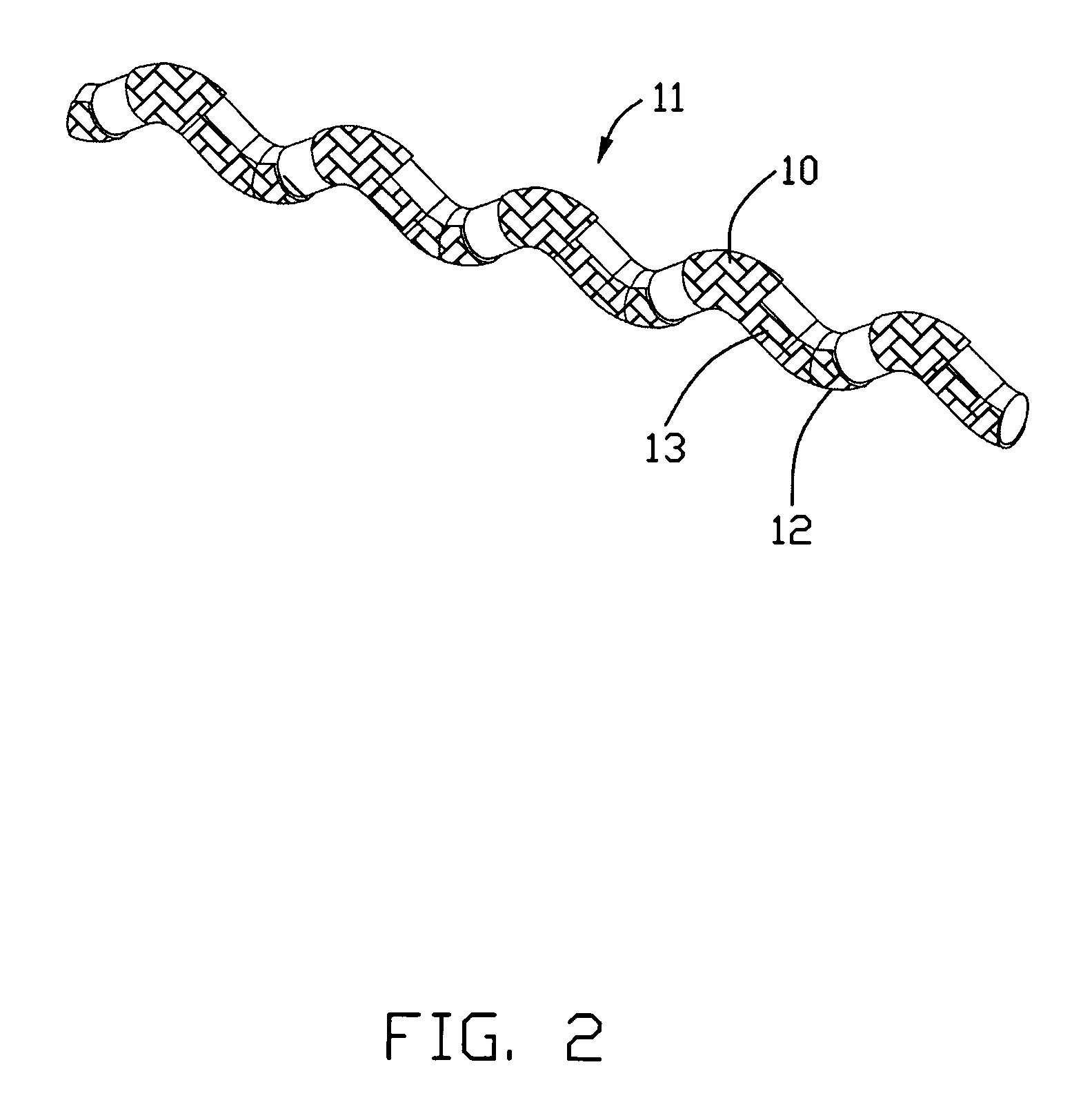

Low profile electrical interposer of woven structure and method of making same

InactiveUS8367942B2Low profilePrinted electric component incorporationCoupling device detailsInterposerEngineering

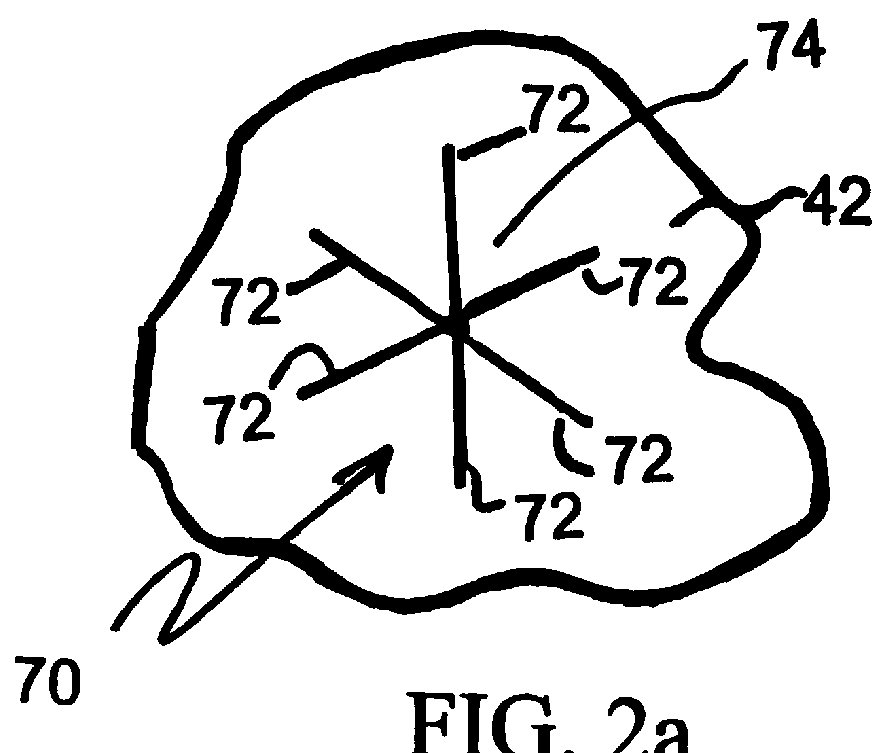

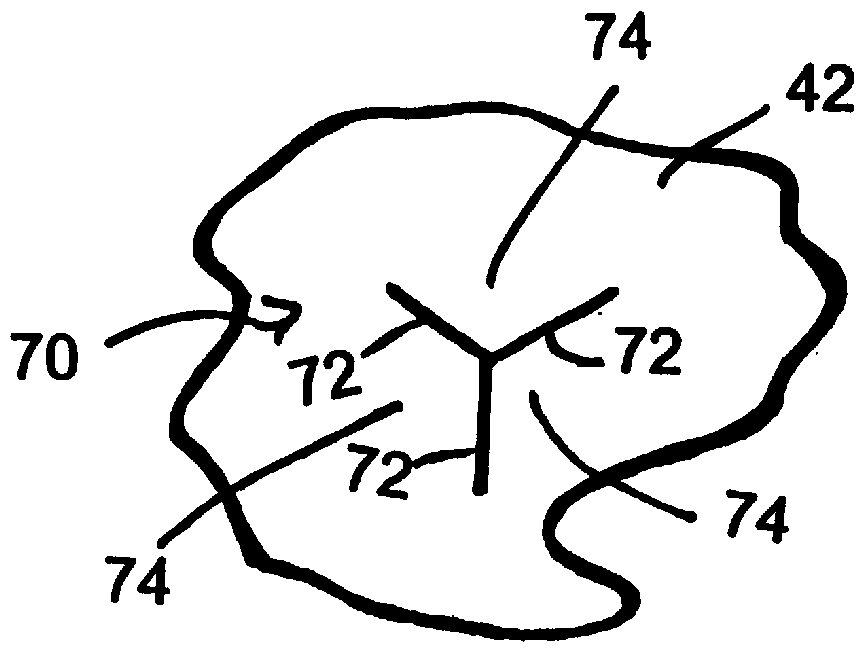

An electrical interposer for connecting two electronic devices includes a plurality of first cores with undulating structure extending in a first direction and a plurality of second cores with undulating structure extending in a second direction angular with the first direction. Each first core has first peaks and first valleys alternately arranged in the first direction and each first peak is electrically connected with a corresponding neighboring first valley but insulated from others. Each second core has second peaks and second valleys alternately arranged in the second direction and each second peak is electrically connected with a corresponding neighboring second valley but insulated from others. The first cores and the second cores interlace with each other to reach a woven structure with the first peaks and the second peaks jointly constituting an upper interface, and the first valleys and the second valleys jointly constituting a lower interface.

Owner:HON HAI PRECISION IND CO LTD

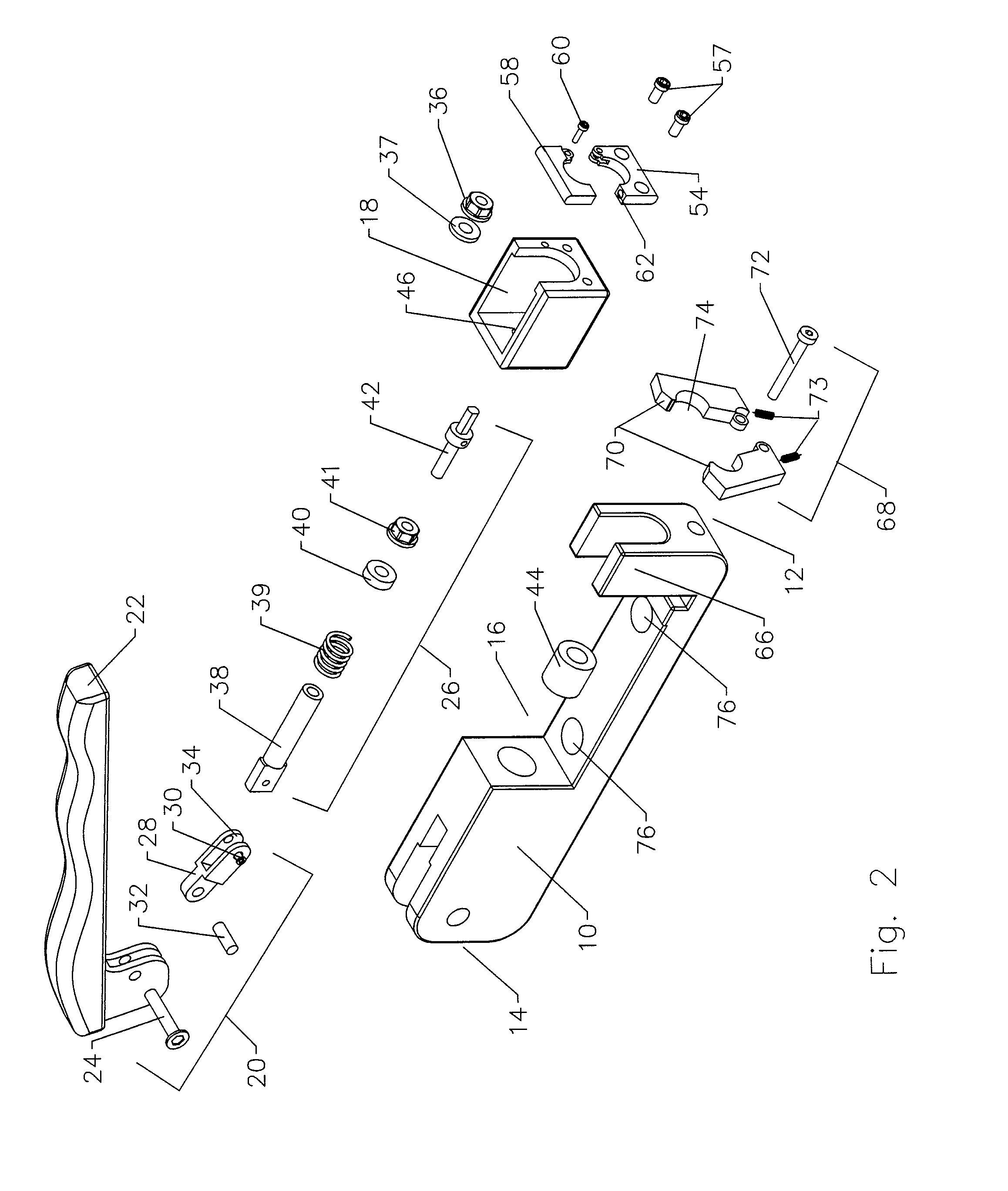

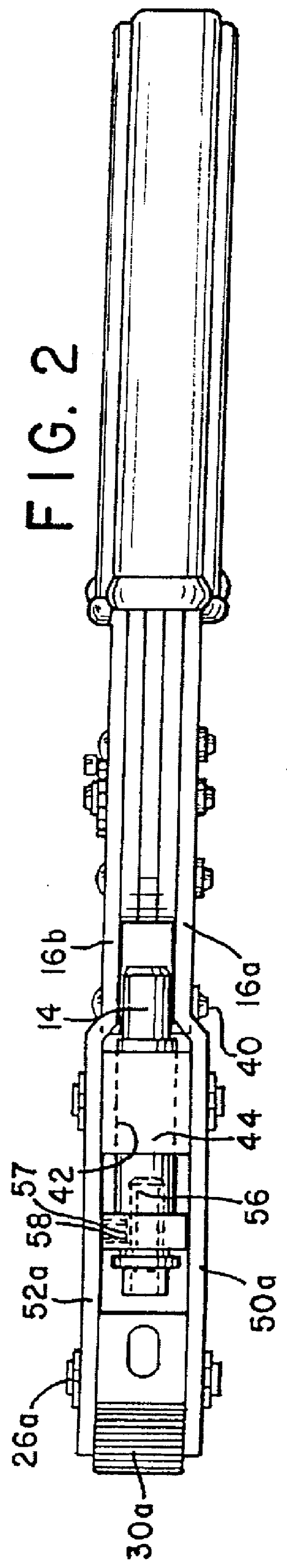

Radial taper tool for compressing electrical connectors

InactiveUS6112404ALight weightReduce material costsShaping toolsPliersElectrical connectorMechanical engineering

A tool for attaching a connector to an end of a cable by compressing the connector axially and driving it into a tapered cavity uses a light rigid O-frame. The tapered cavity is formed in a pair of die halves which are both pivoted to the frame and which are provided with oppositely mounted handles, allowing the dies to be opened by squeezing the handles together. Two different adjustment means are provided and the tool is provided with a full-cycle ratchet mechanism to ensure complete compression of the connector during each use.

Owner:RIPLEY TOOLS

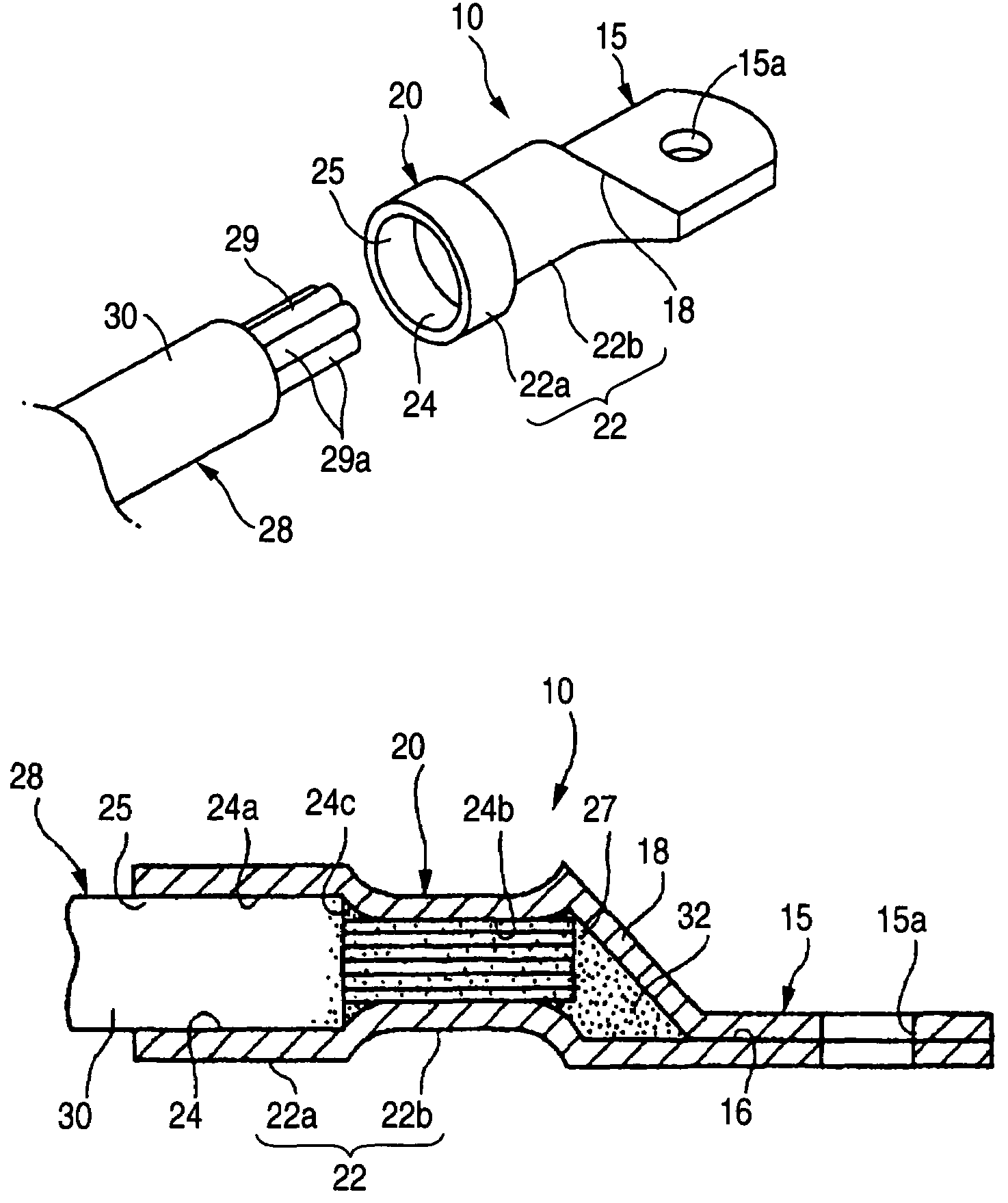

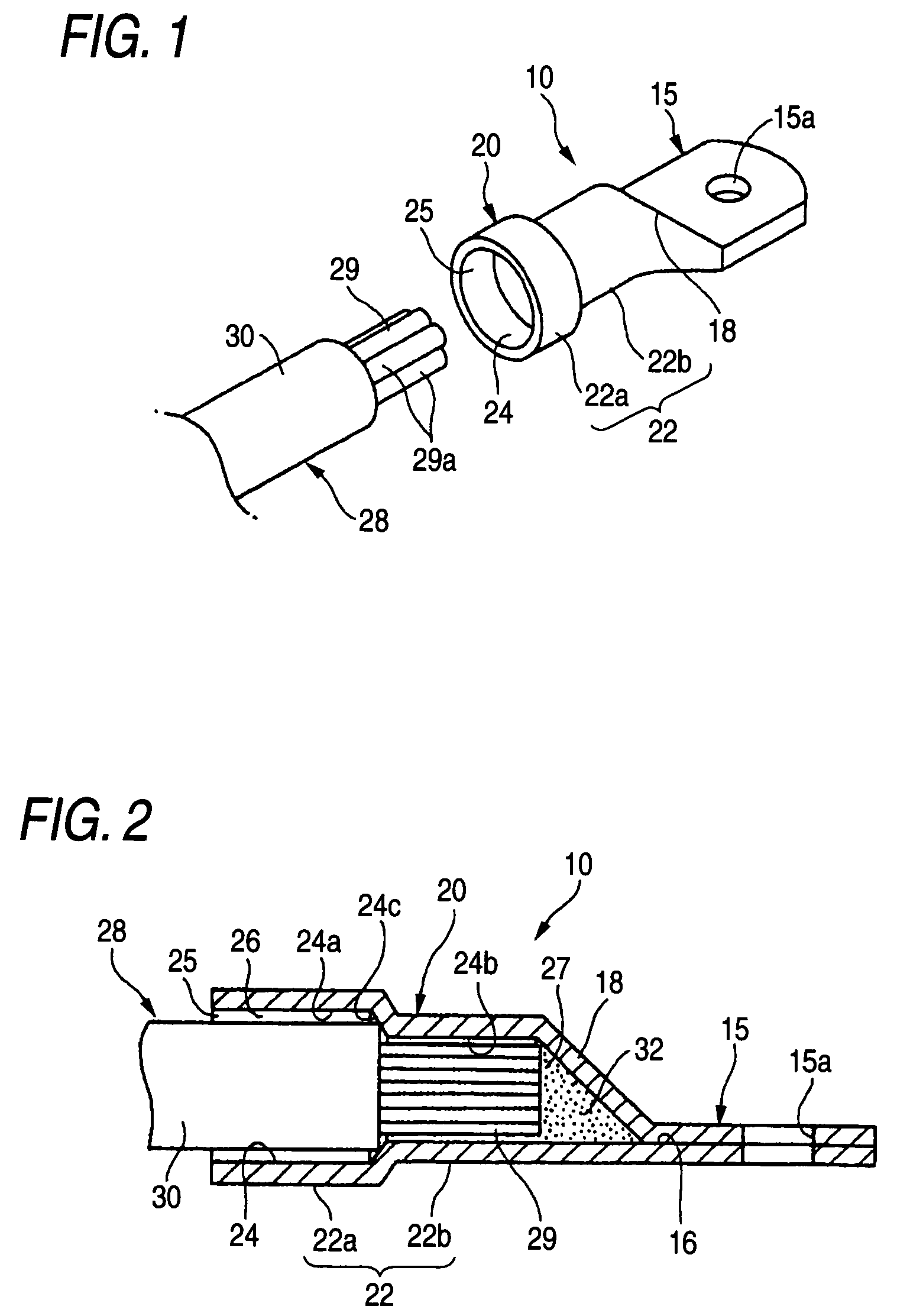

Method of connecting wire and terminal fitting

InactiveUS7374466B2Treatment effectAvoid damageSoldered/welded conductive connectionsCoupling contact membersElectric wireElectrical and Electronics engineering

A method of connecting a terminal fitting and an electric wire, includes the steps of: providing a terminal fitting; providing an electric wire in which a core wire is covered with an insulating sheath; providing a conductive connecting member formed with an insertion hole; inserting the electric wire into the insertion hole of the connecting member; compressing the connecting member radially inwardly so as to caulk an inserted portion of the electric wire uniformly over a whole periphery thereof; and welding the connecting member and the terminal fitting by applying ultrasonic wave.

Owner:YAZAKI CORP

Method of processing end portion of shielded wire and end portion processing apparatus

ActiveUS20070173122A1Increase productionShaping toolsElectrically conductive connectionsEngineeringBraid

An end portion processing apparatus for processing an end portion of a shielded wire in which part of an outer sheath has been removed such that an exposed braid disposed between an inner sheath and the outer sheath extends from a distal end of the outer sheath, includes a wire clamp portion which positions the end portion of the shielded wire in an open condition of the wire clamp portion, and clamps the end portion of the shielded wire, a pair of claw portions which strikes against the exposed braid radially thereof at the clamped end portion of the shielded wire to expand the end portion of the braid, a first pipe portion which is disposed in a standby position on a line of extension of the clamped end portion of the shielded wire, and is fitted onto an outer periphery of the inner sheath, a second pipe portion which is provided on an outer periphery of the first pipe portion in concentric relation thereto, and is slid toward the shielded wire to fold back the expanded braid on the outer sheath, and a control portion which controls the operations of the claw portions, the first pipe portion and the second pipe portion.

Owner:YAZAKI CORP

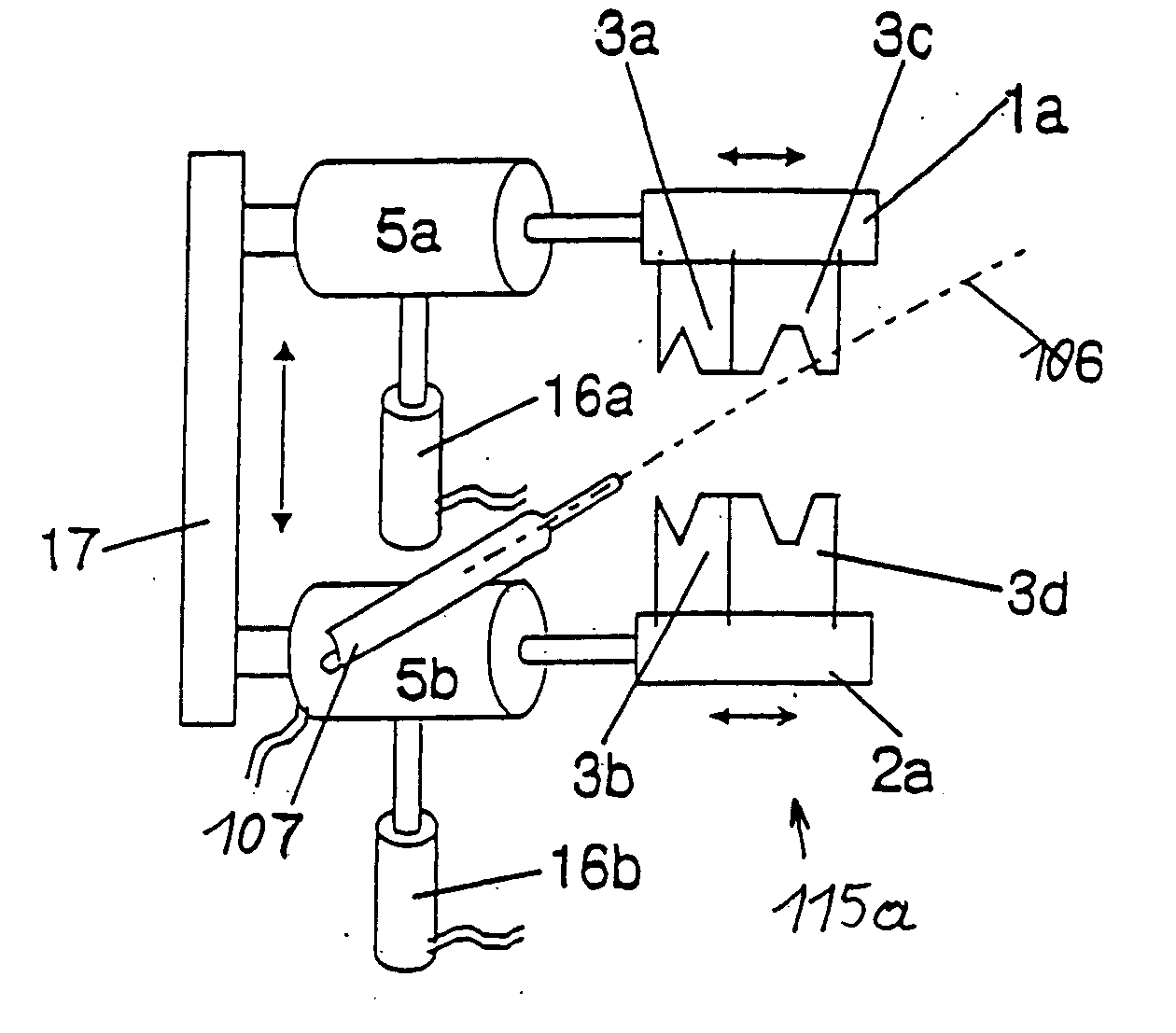

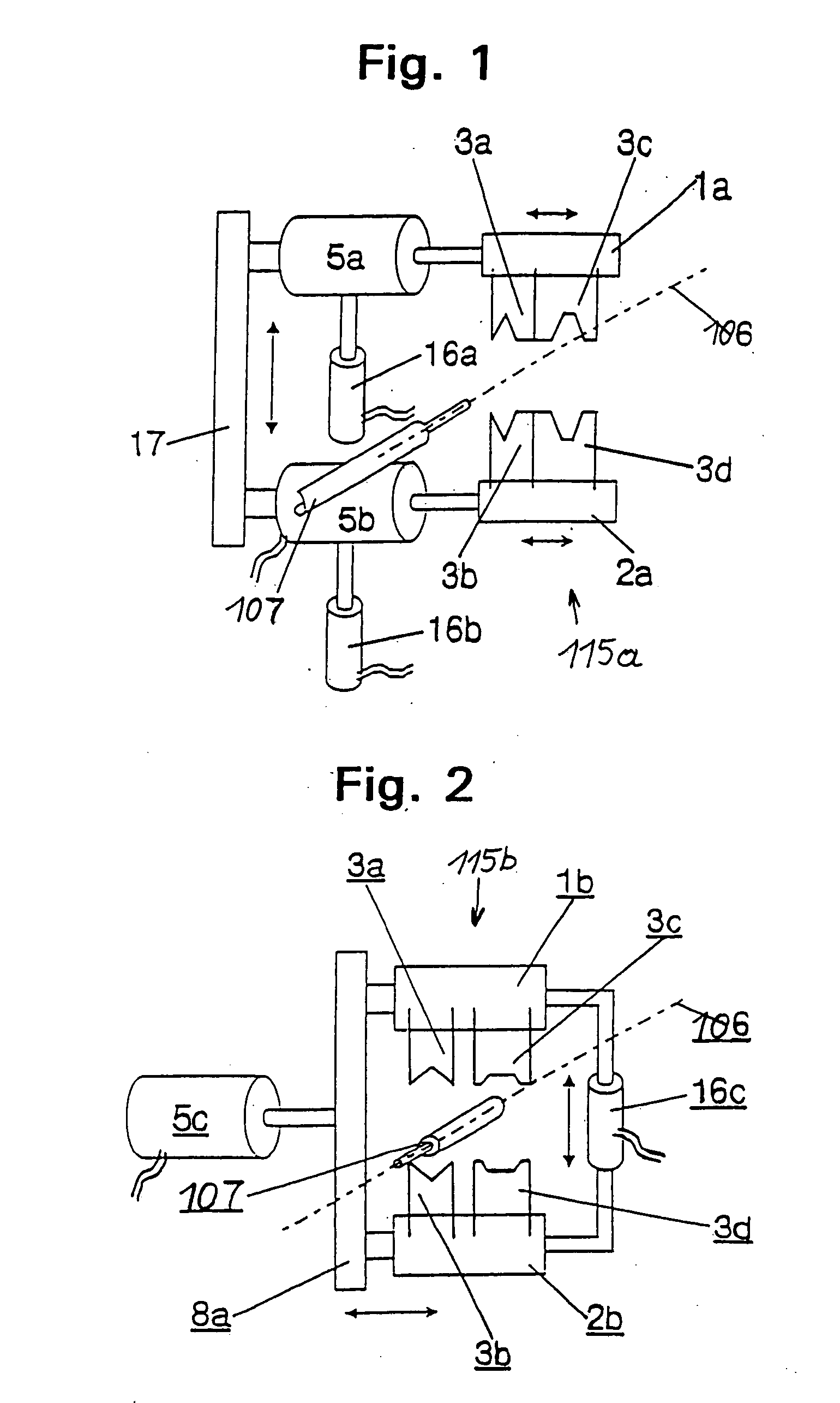

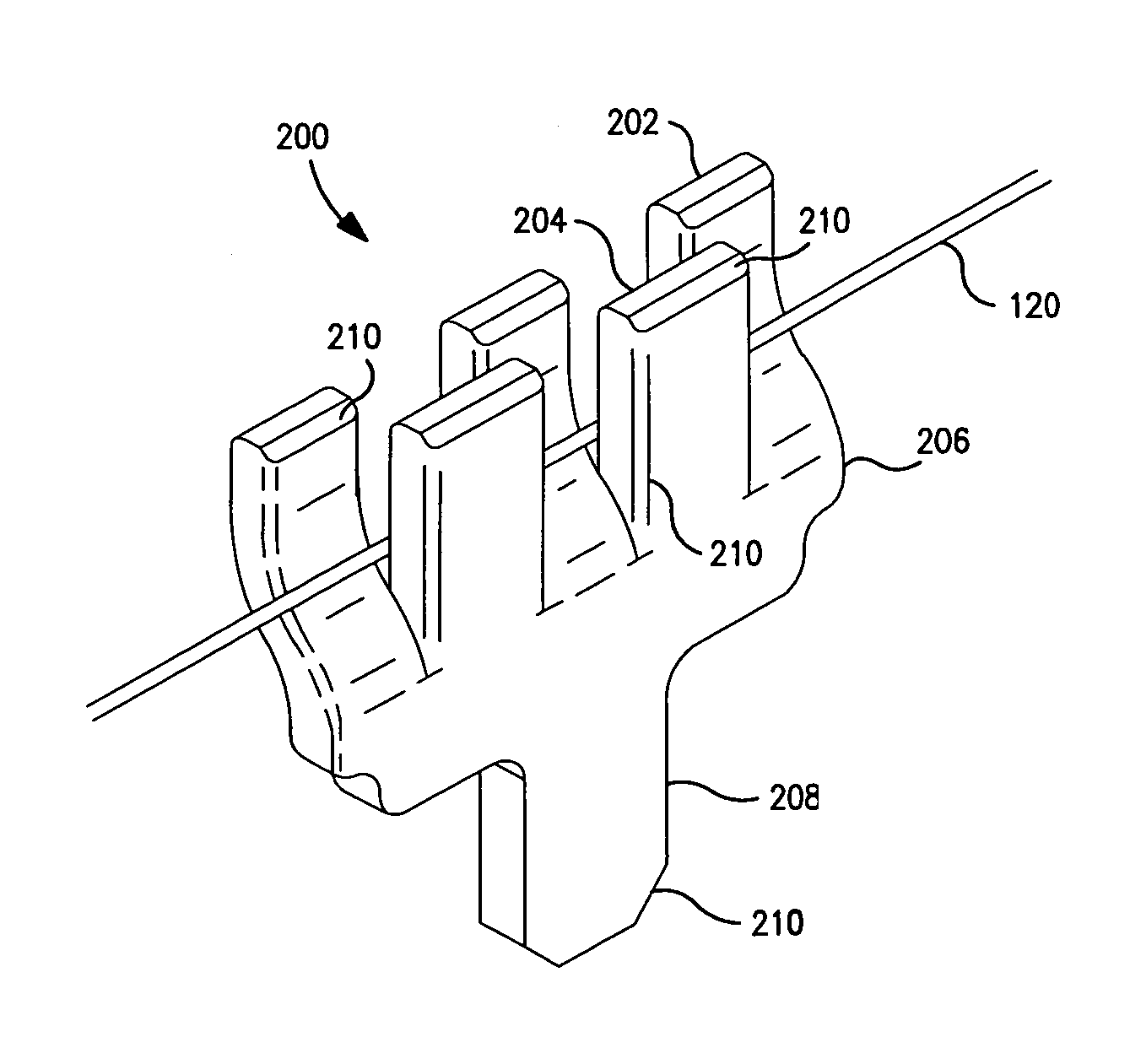

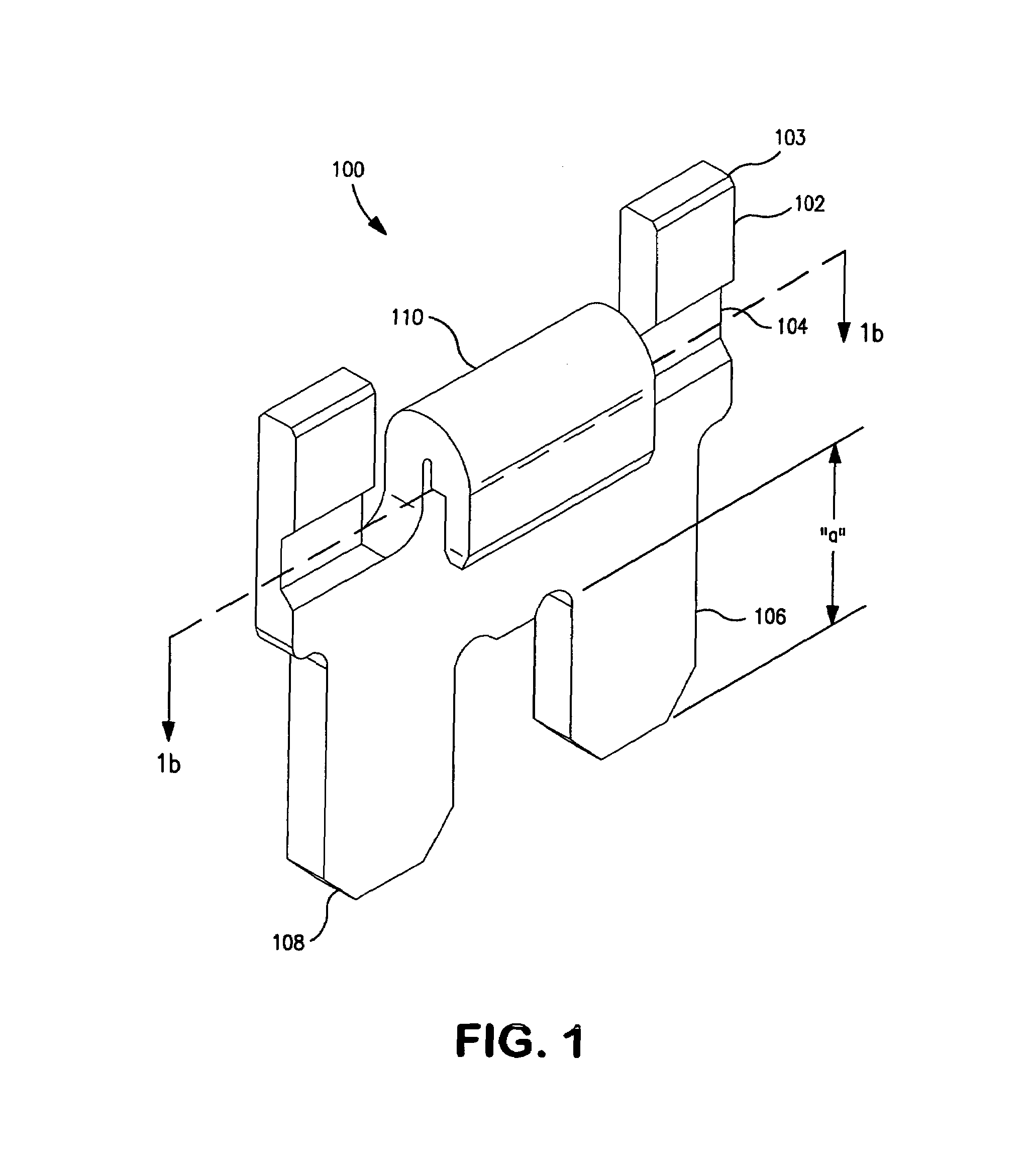

Continuous cable processing apparatus

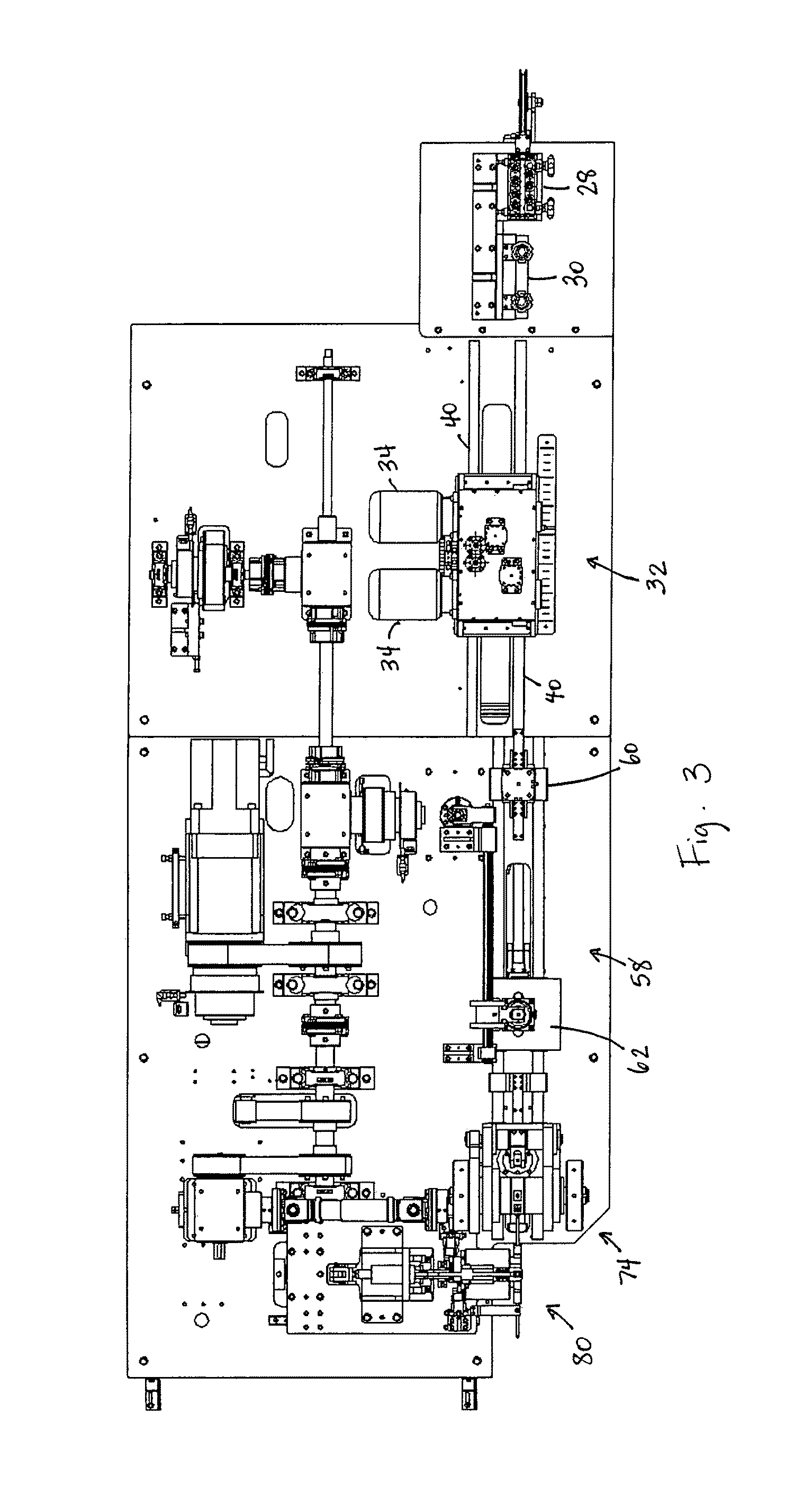

InactiveUS20050050713A1Practical to useTimely processingApparatus for cutting/splicing cablesOther manufacturing equipments/toolsEngineeringCable transport

A continuous cable processing apparatus for producing cable sections with processed ends comprises a cable transport apparatus having at least one transport means for moving and holding the cable in the axial direction and, transversely thereto, a knife station. According to a special variant, two transport means are arranged in the longitudinal cable direction on both sides of the knife station and, after the cable has been cut through, each hold one of the cable end regions produced on cutting, so that said end regions are movable in the longitudinal cable direction. At least one of these end processing stations is arranged transversely with respect to the longitudinal cable direction, adjacent to the knife station and at least one transport means is movable transversely with respect to the longitudinal cable direction so that a cable end region can be fed to the end processing station.

Owner:SCHLEUNIGER HLDG

Method of connecting and structure of connecting electric wire and connection terminal

InactiveUS7705265B2Easy to connectIncreasing costSoldered/welded conductive connectionsConnections effected by permanent deformationElectrical conductorIrradiation

After bringing a conductor of an electric wire into press contact to connect with a wire caulking portion of a connection terminal, the conductor and the wire caulking portion are welded to connect by irradiating laser beam to a bottom wall of the wire caulking portion. Laser irradiation is carried out intermittently by three times and the laser irradiation at the second time and thereafter which is carried out later is carried out such that during a time period in which a laser welded portion immediately previously is brought into a predetermined state of elevating temperature, portions or welded regions overlap welded regions in laser irradiation irradiated previously.

Owner:YAZAKI CORP

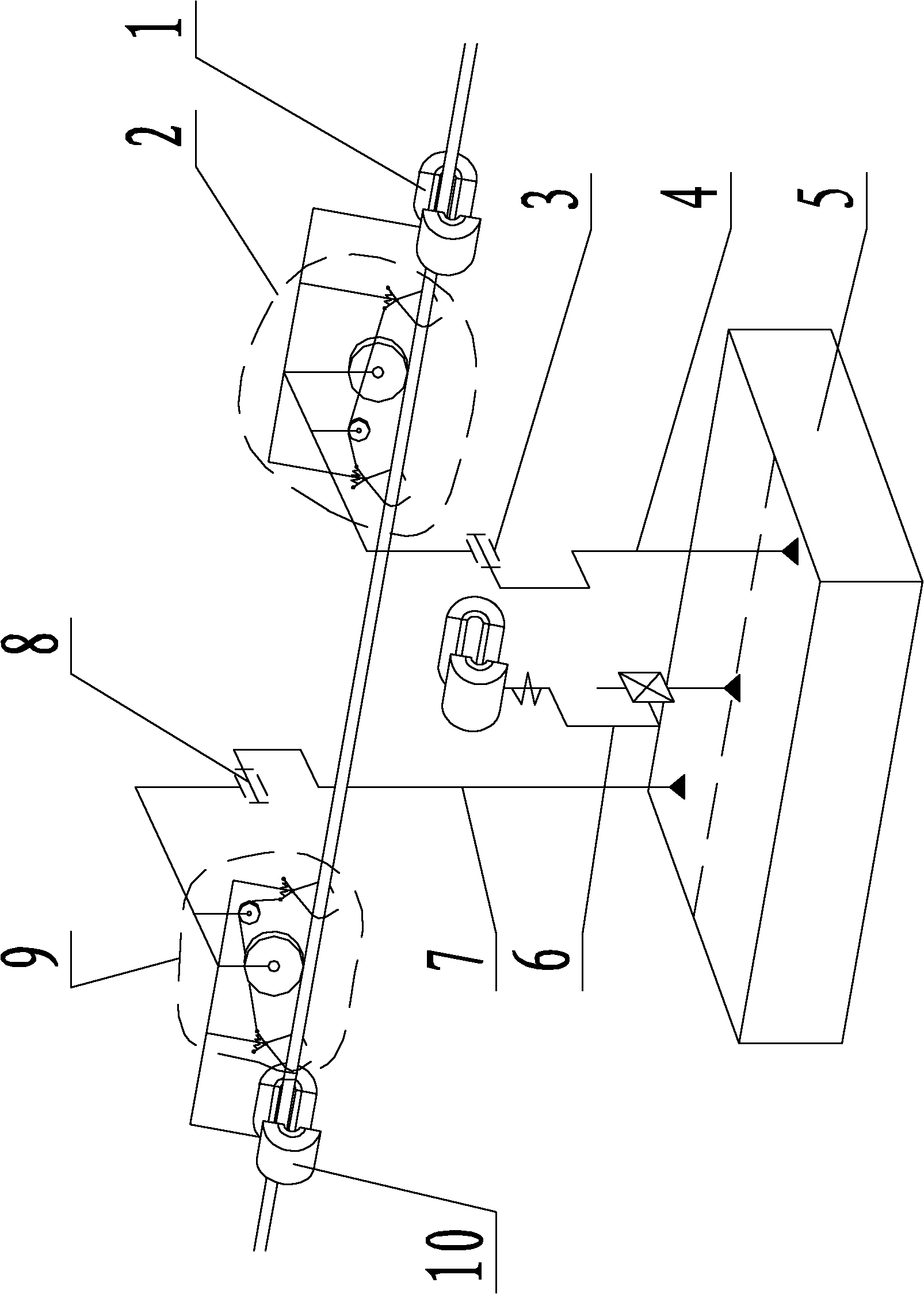

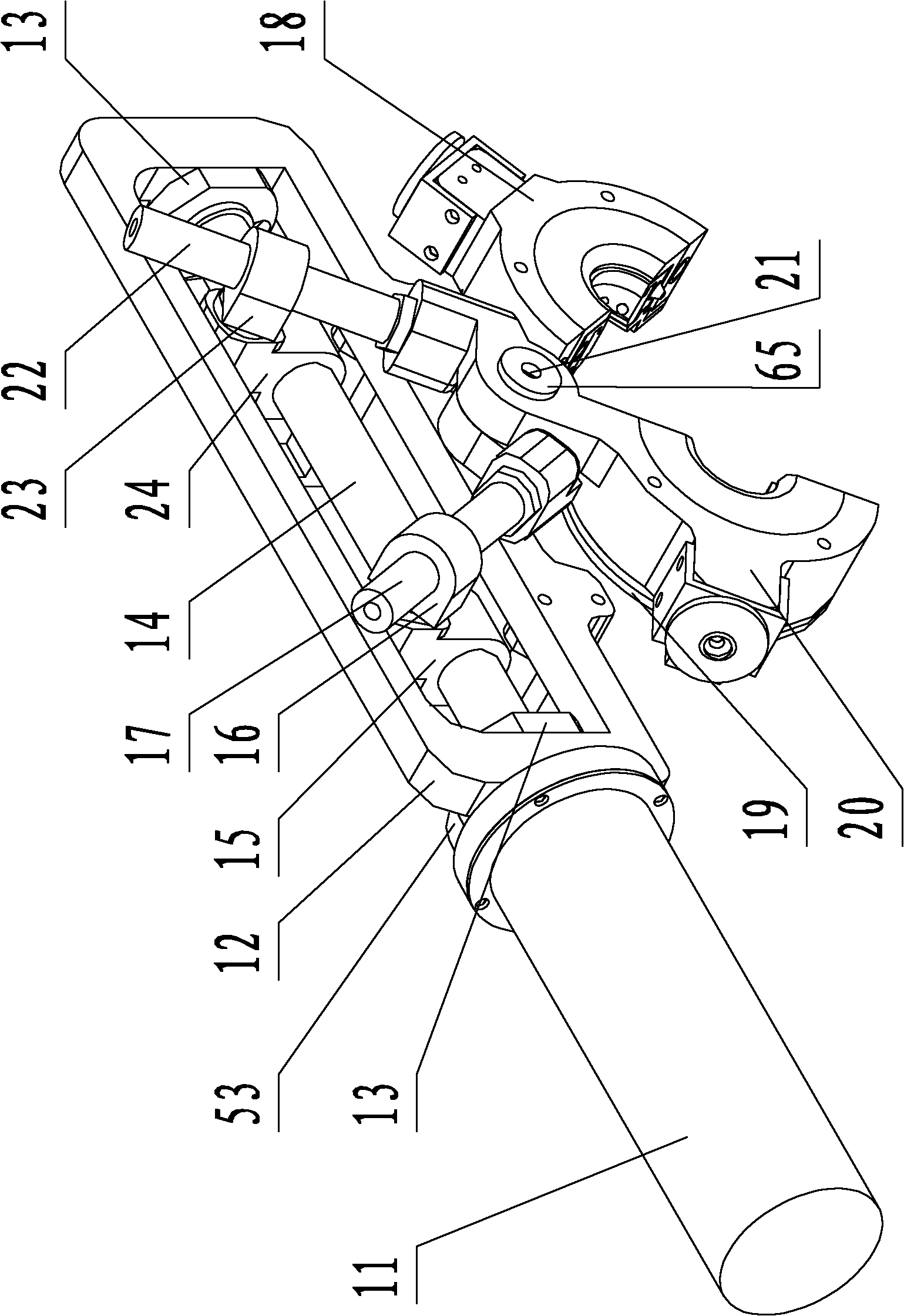

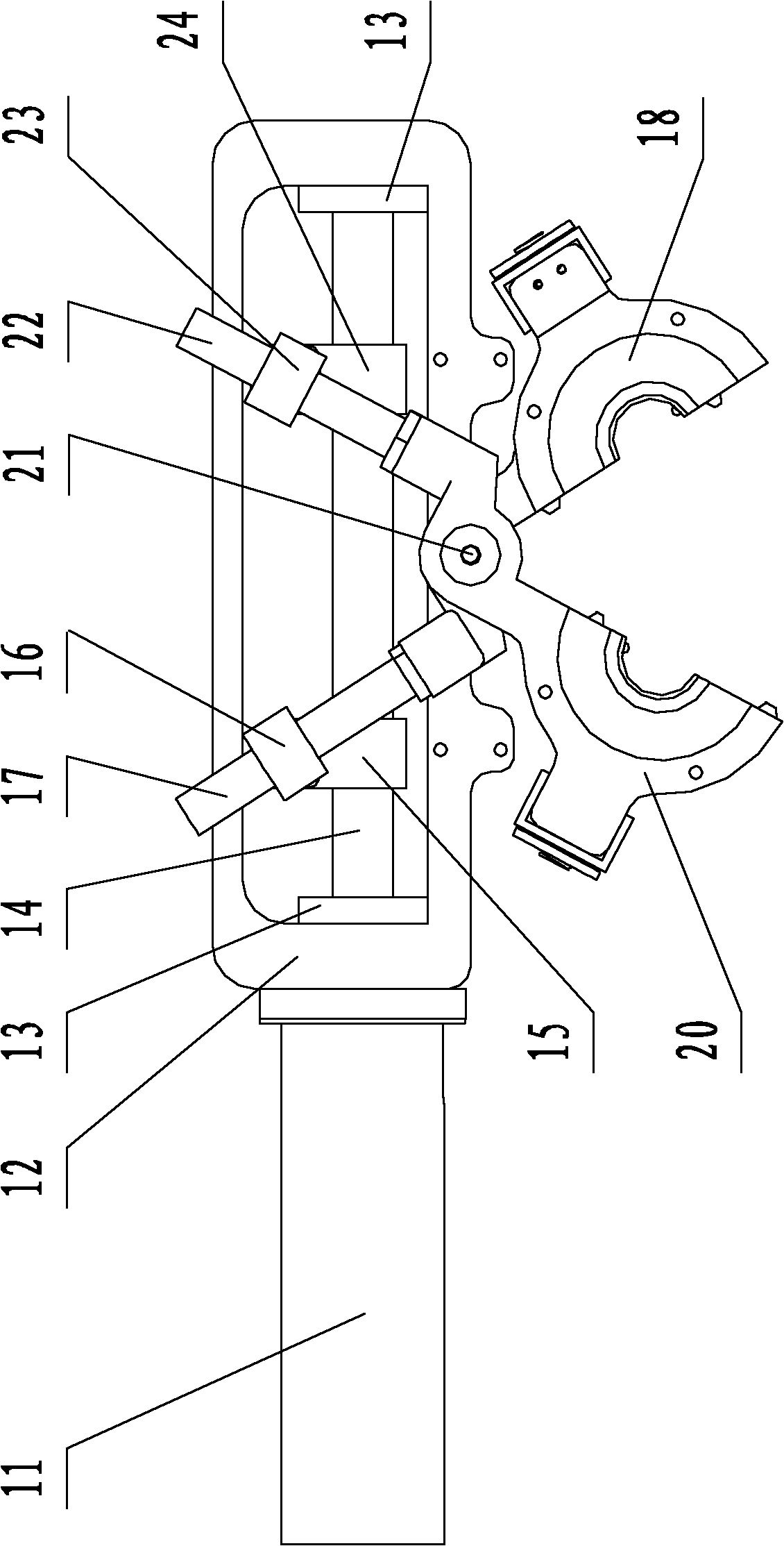

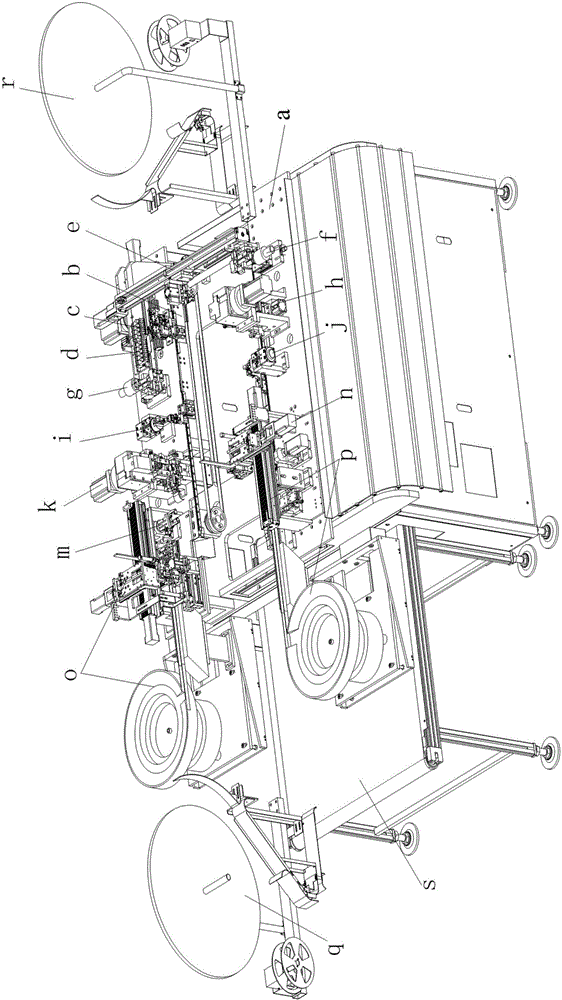

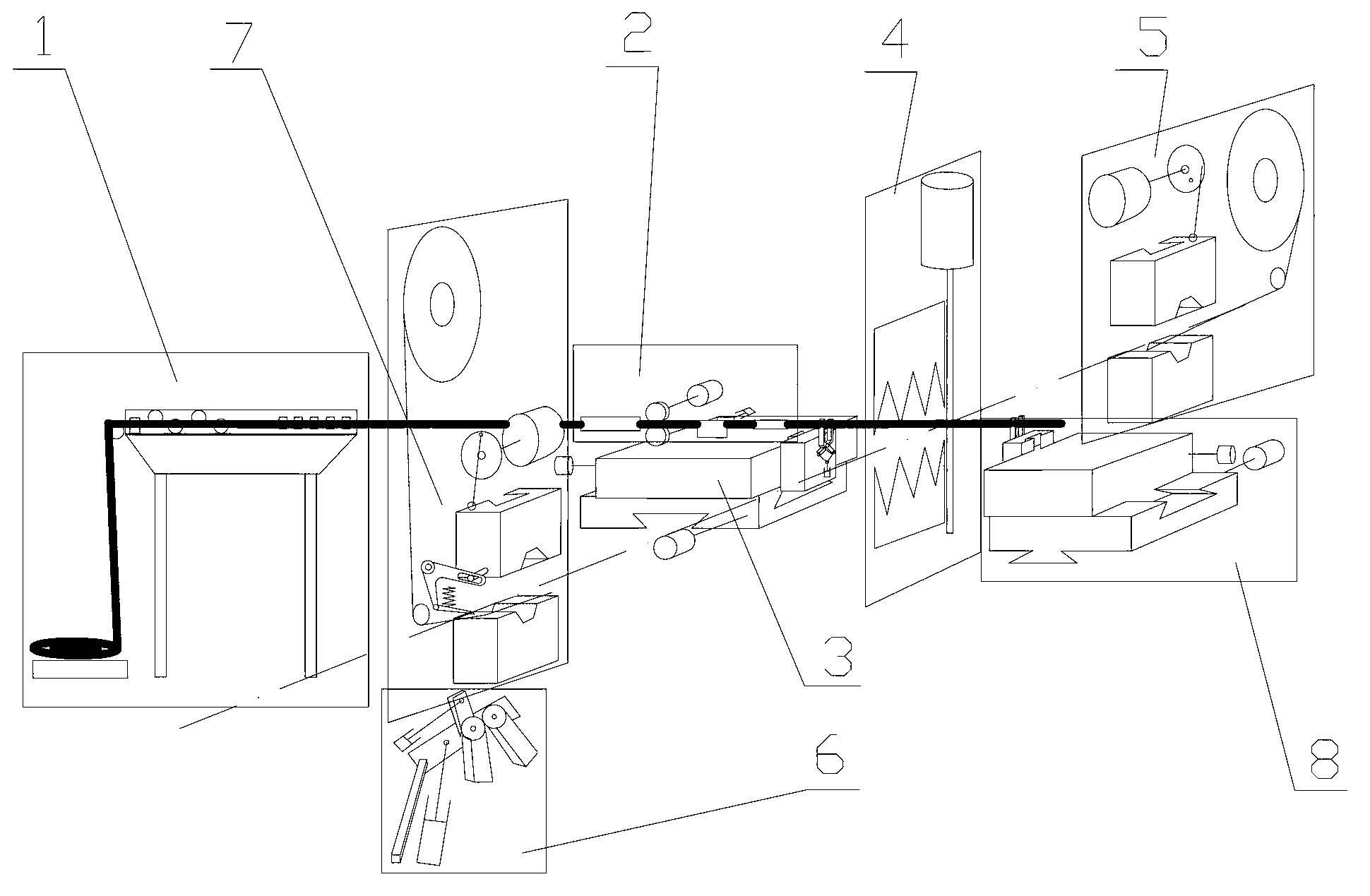

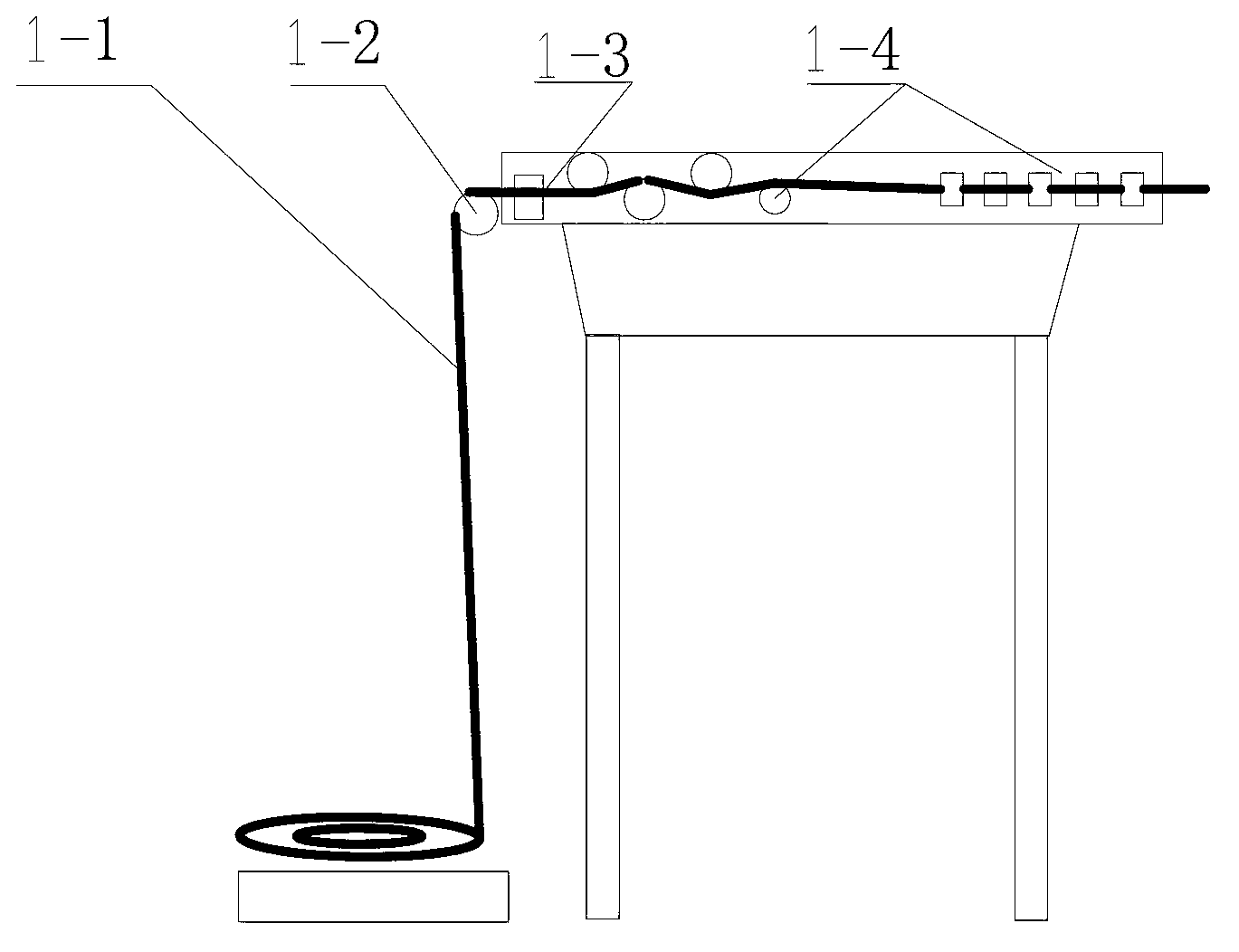

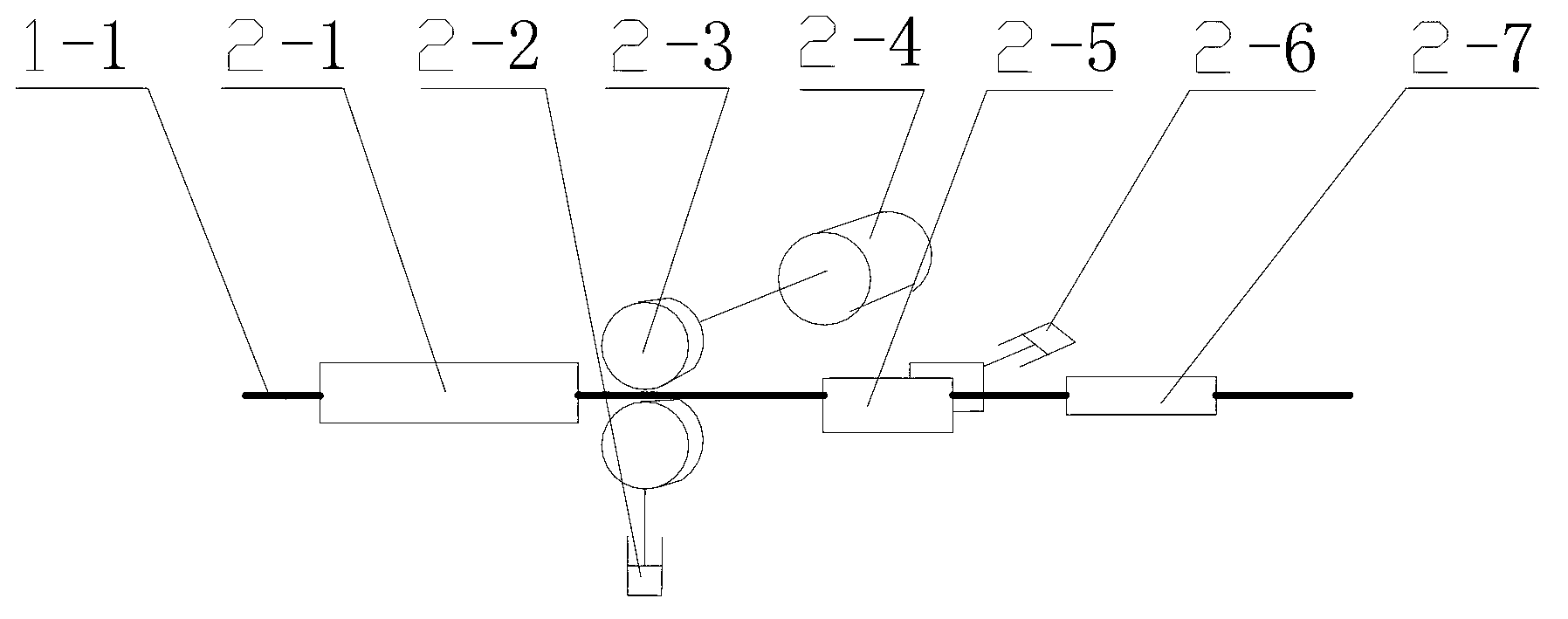

Broken strand crimping work robot mechanism of super-high-voltage power transmission line

ActiveCN102655314AThe threading process is simpleAchieve the purpose of strokingConnections effected by permanent deformationConnection formation by deformationEngineeringObstacle crossing

The invention relates to a power transmission line repairing robot and particularly relates to a broken strand crimping work robot mechanism of a super-high-voltage power transmission line. The broken strand crimping work robot mechanism comprises a front line stroking device, a front walking clamping mechanism, a front arm, an electrical equipment box body, a crimping arm, a rear arm, a rear walking clamping mechanism and a rear line stroking device, wherein one ends of the front arm and the rear arm are respectively and fixedly connected to the electrical equipment box body and the other ends of the front arm and the rear arm are hinged with the front walking clamping mechanism and the rear walking clamping mechanism; the front line stroking device and the rear line stroking device are respectively arranged on the outer sides of the front walking clamping mechanism and the rear walking clamping mechanism; one end of the crimping arm is fixedly connected with the electrical equipment box body; and the other end of the crimping arm is a crimping end and is located between the front walking clamping mechanism and the rear walking clamping mechanism. The broken strand crimping work robot mechanism has the advantages of large climbing angle, good safety protection, short obstacle crossing time, simple obstacle crossing process, simple and efficient line stroking process, small abrasion on the line and good broken strand crimping effect, improves the personal safety, reduces the labor intensity of staff and improves the efficiency.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

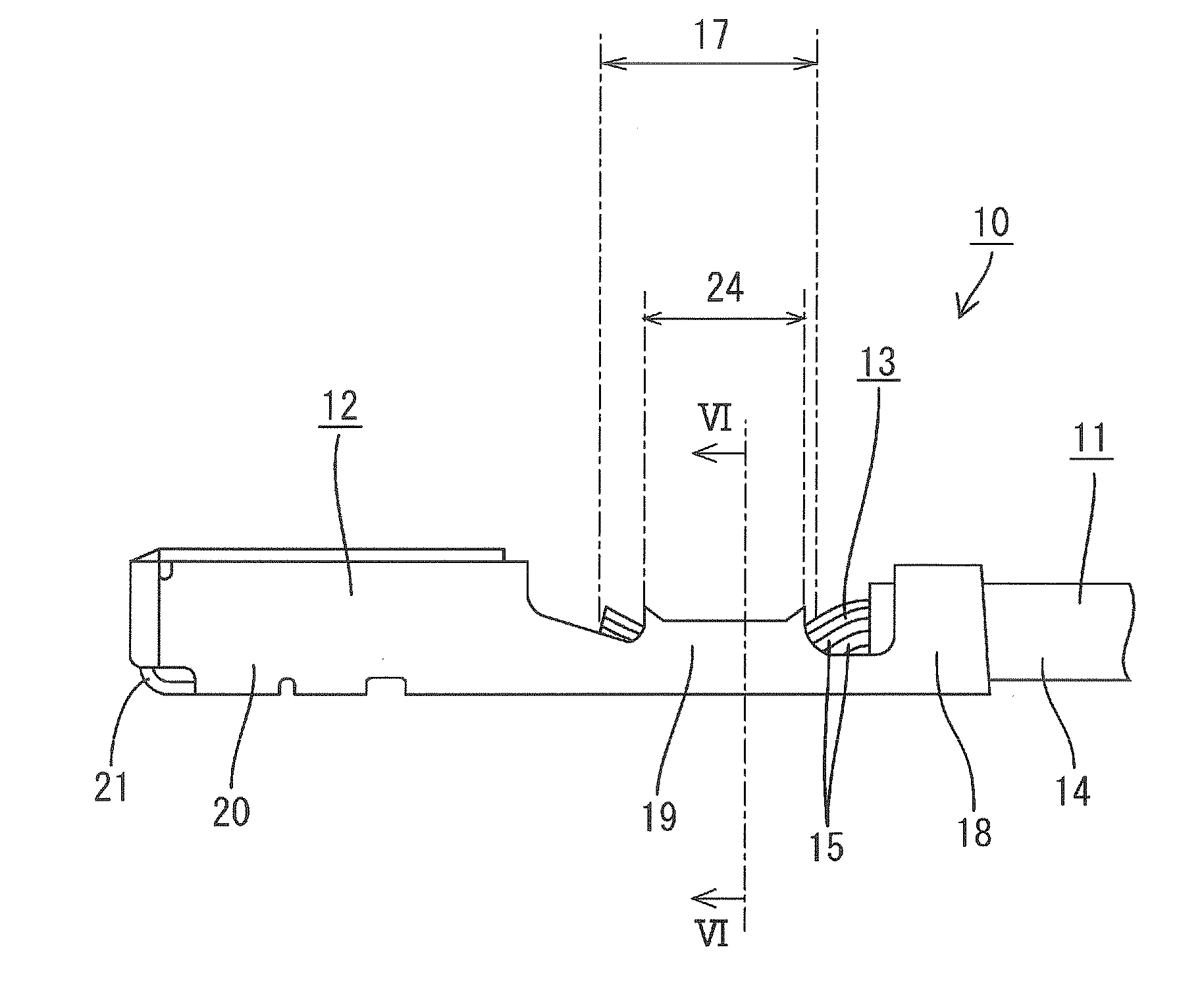

Electric wire with terminal connector and method of manufacturing electric wire with terminal connector

InactiveUS20110094797A1Increase resistanceLower resistanceSoldered/welded connectionsConnections effected by permanent deformationUltrasonic vibrationElectric wire

An electric wire with terminal connector including an electric wire having a core wire including a plurality of wires and a female terminal connector including a wire barrel that is crimped onto the core wire exposed from the electric wire, the following steps are executed. The steps include a step of removing wire insulation covering an outer peripheral surface of the core wire to expose the core wire, a step of holding the exposed core wire with jigs provided in a pair and applying ultrasonic vibration to the core wire via the jigs, and a step of crimping the wire barrel so as to surround a part of the core wire to which the ultrasonic vibration is applied.

Owner:AUTONETWORKS TECH LTD +2

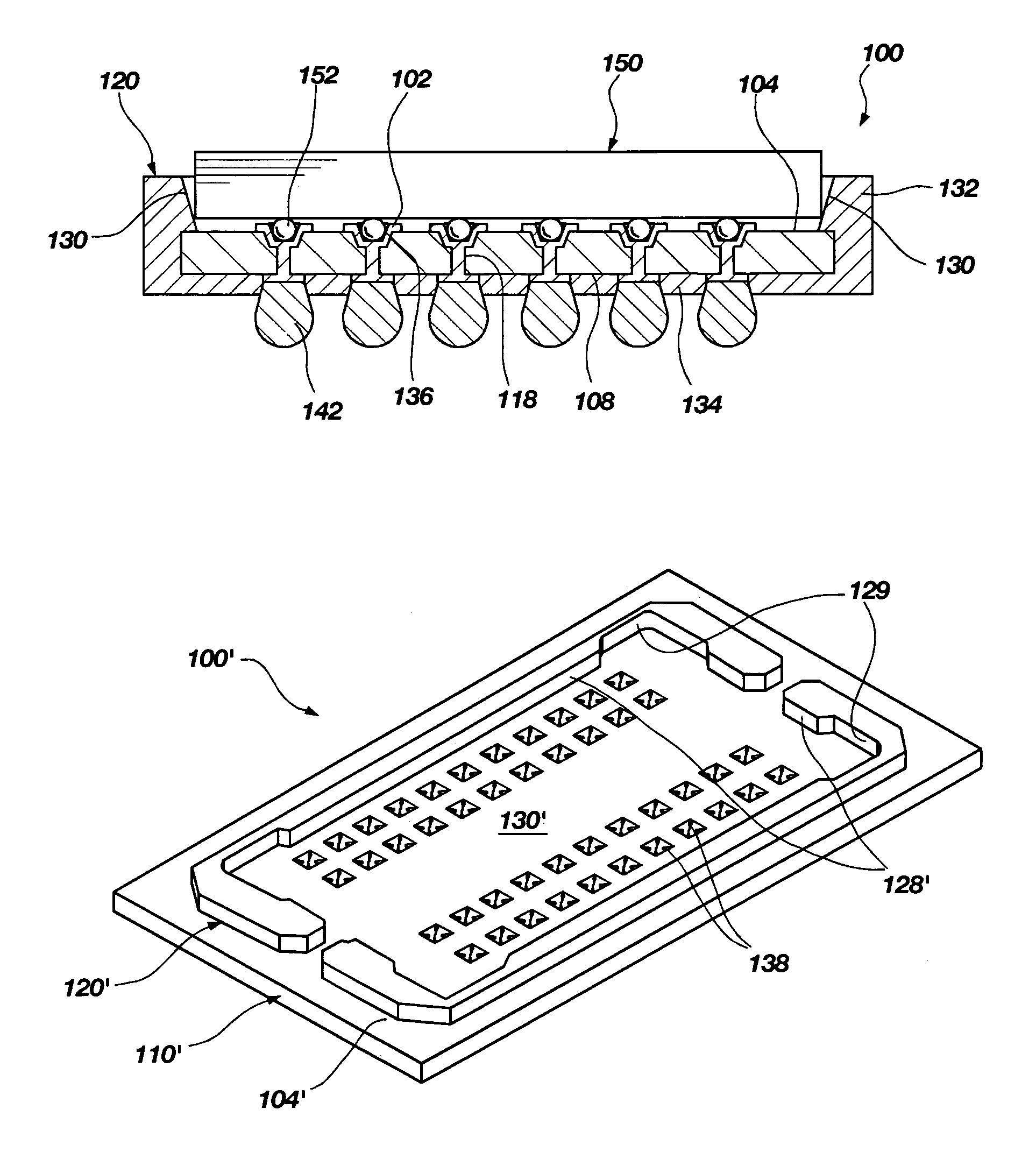

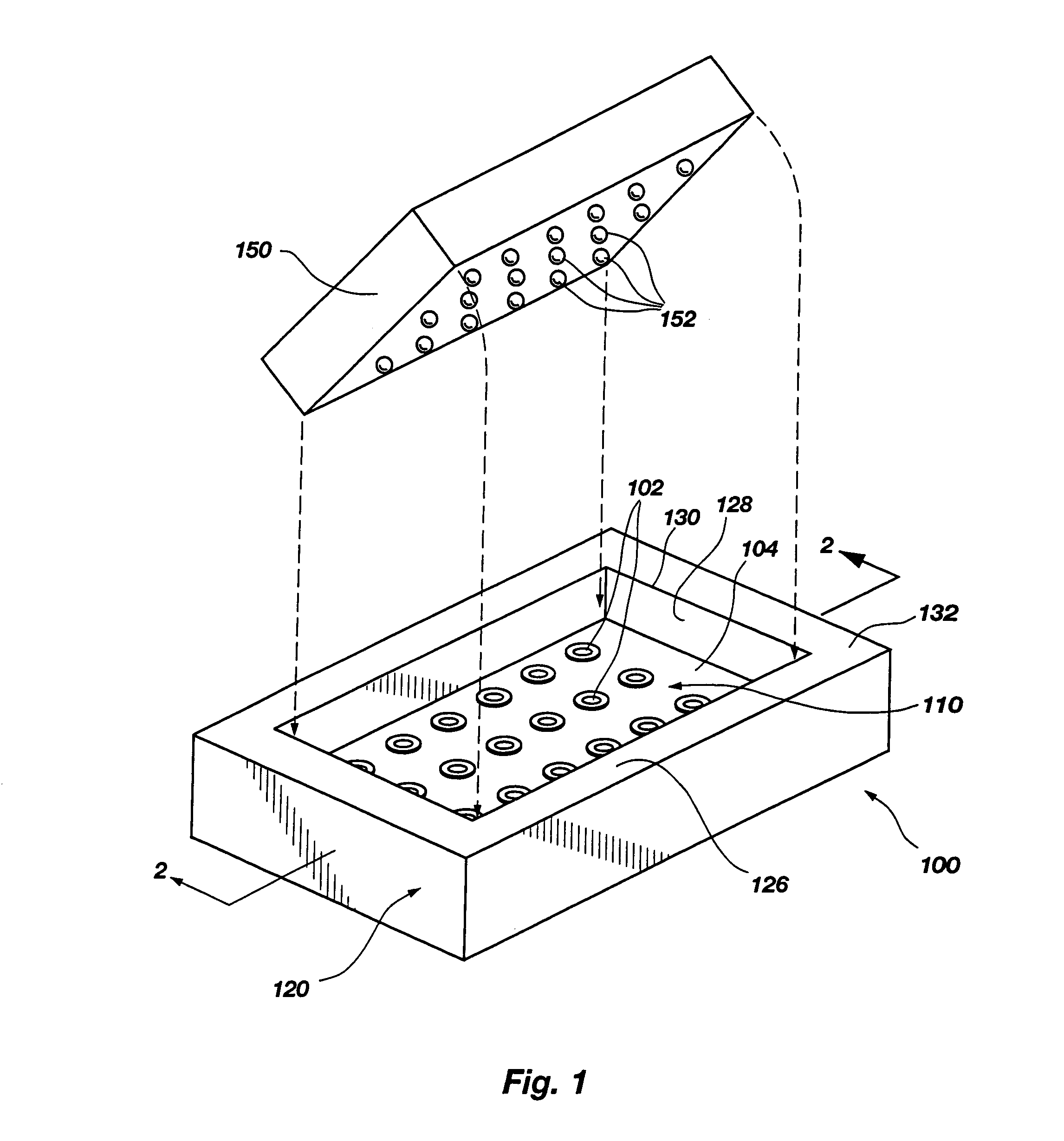

Method for fabricating an interposer

InactiveUS7093358B2Increase contactFacilitate electrical communicationContact member manufacturingSemiconductor/solid-state device detailsInterposerSemiconductor

An interposer including a fence that receives and aligns a semiconductor device, such as a flip-chip type semiconductor device, with an interposer substrate. The fence may include edges that are configured to progressively align a semiconductor device with the interposer substrate. The fence may also include one or more laterally recessed regions to facilitate rough alignment of a semiconductor device with the interposer substrate. Methods for fabricating the fence include the use of stereolithographic and molding processes. When stereolithography is used to fabricate the fence, a machine vision system that includes at least one camera operably associated with a computer may be used to control a stereolithography apparatus and facilitates recognition of the position and orientation of interposer substrates on and around which material is to be applied in one or more layers to form the fence. As a result, the interposer substrates need not be precisely mechanically aligned.

Owner:MICRON TECH INC

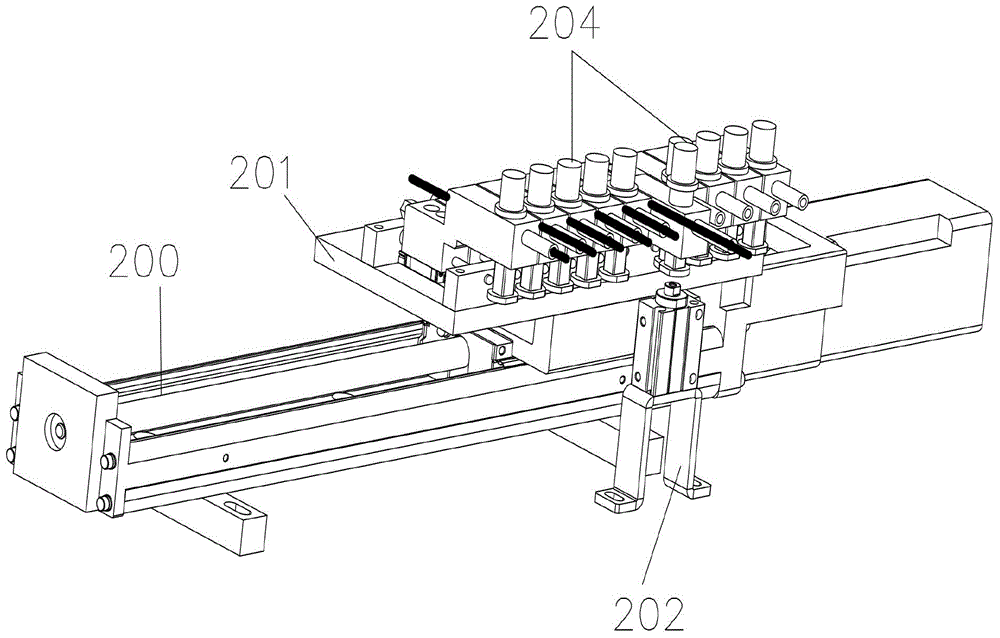

Full-automatic insertion machine with two pressed ends

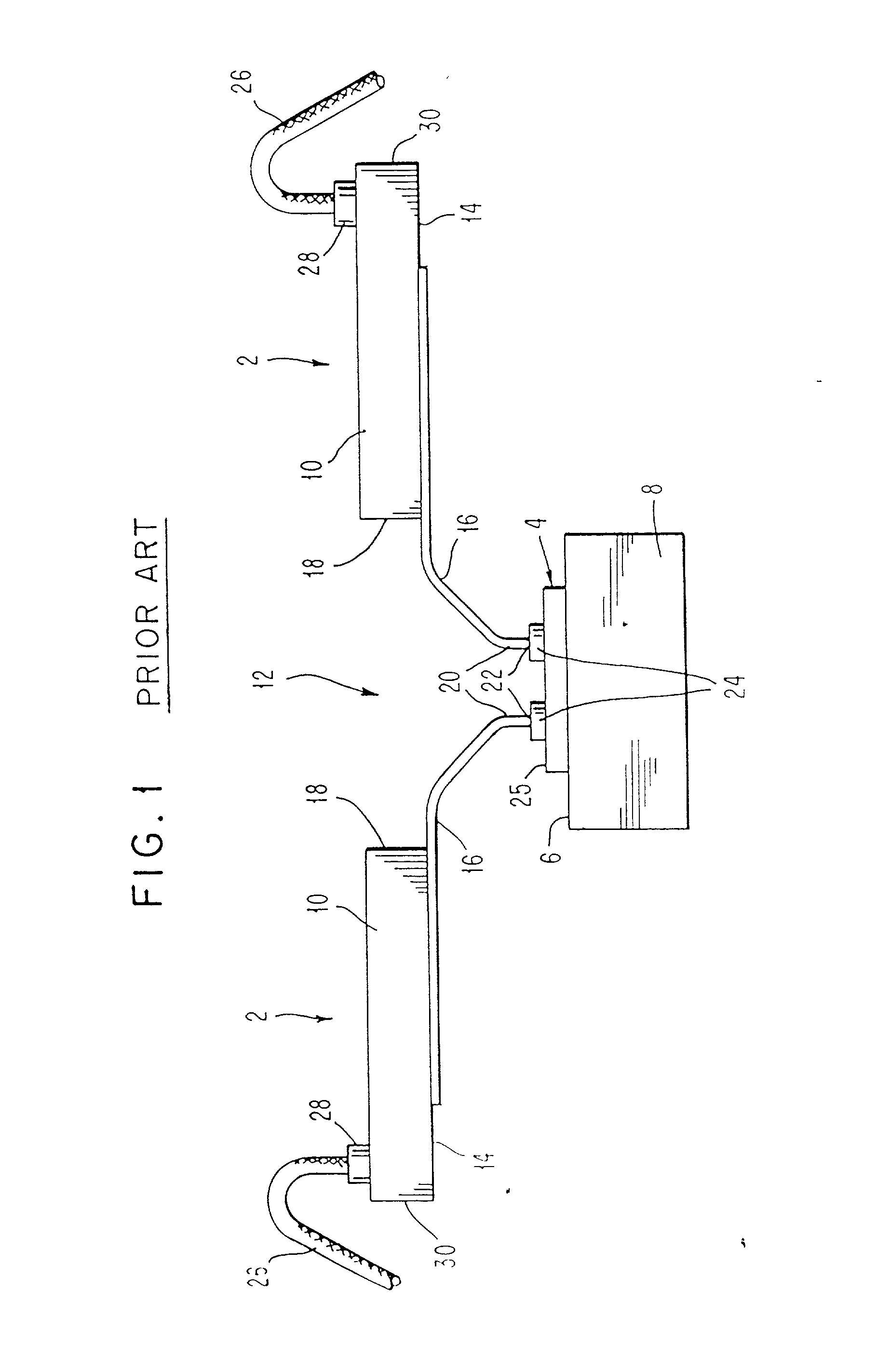

ActiveCN104701707ARealize automatic crimpingQuality assuranceContact member assembly/disassemblyConnection formation by deformationWire rodEngineering

The invention relates to the technical field of mechanical automatic equipment, in particular to a full-automatic insertion machine with two pressed ends. The insertion machine comprises an operating platform on which a wire feeding mechanism, a wire cutter mechanism, a wire conveying mechanism, two peeling mechanisms, two turnover mechanisms, two pressing mechanisms, two terminal steering mechanisms and two terminal insertion mechanisms, wherein the wire feeding mechanism used for conveying wire rods of wiring harness to an appointed position one by one is arranged on the operating platform, the wire cutter mechanism is used for cutting off the wire rods to form wire sections, and the wire conveying mechanism is used for moving the wire sections to the appointed positions for the corresponding processing; the two peeling mechanisms are used for peeling and cutting the skins of the wires at the tips of the wire sections, the two turn-over mechanisms are used for rotationally controlling the wire sections, the two pressing mechanisms are used for pressing the terminals on the tips of the wire sections, the two terminal steering mechanisms are used for rotating the wire sections connected with terminals in a pressing way and the two terminal insertion mechanisms are used for inserting the terminals of the wire sections into a glue cover. According to the full-automatic insertion machine provided by the invention, the automatic crimping of the wire terminals can be realized by the arrangement and movement relationship of the above mechanisms, the wires of the terminals crimped can be automatically cut and inserted into the glue cover, so as to form a final harness finished product.

Owner:SHENZHEN JAPAN MACHINE KING CO LTD

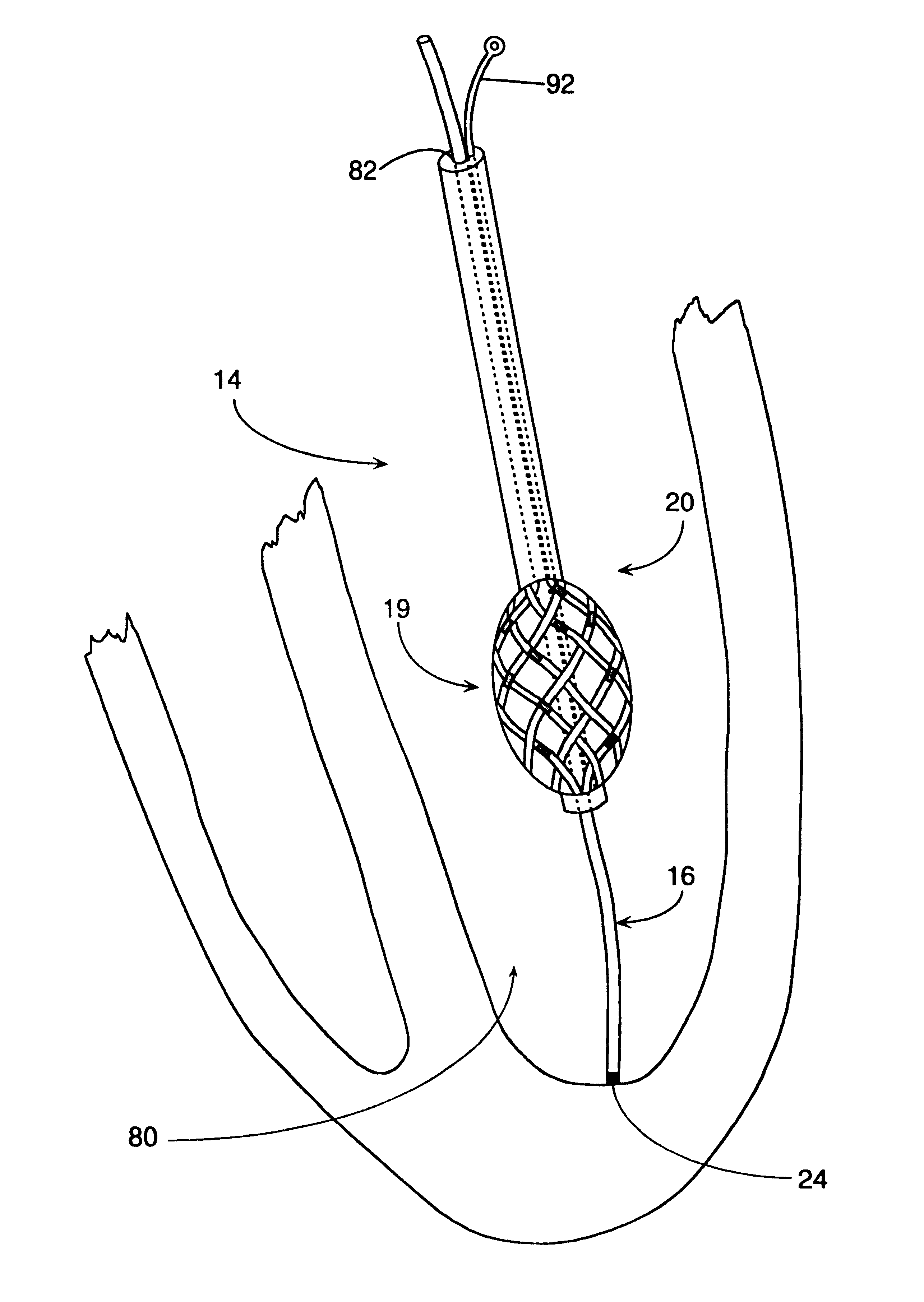

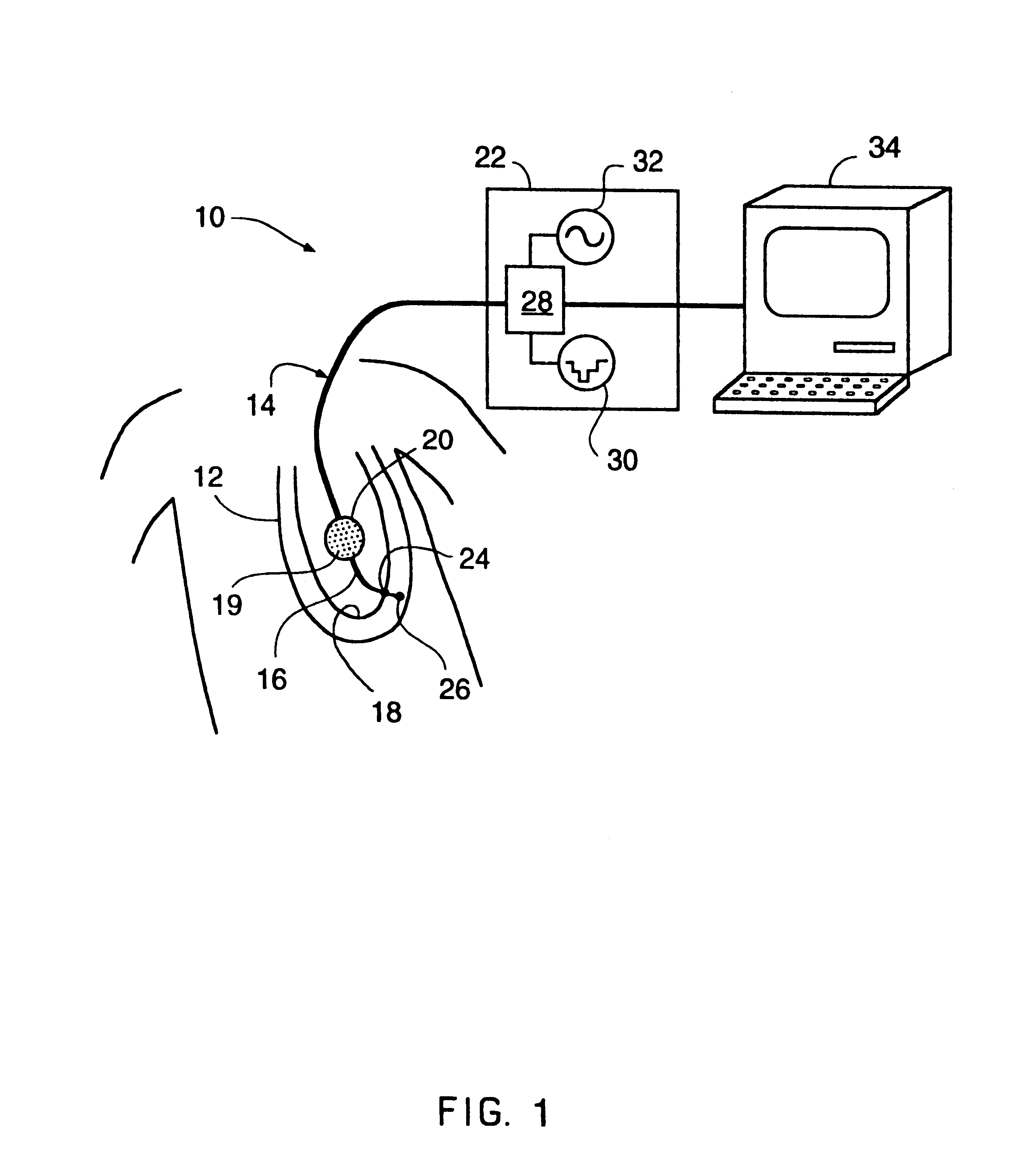

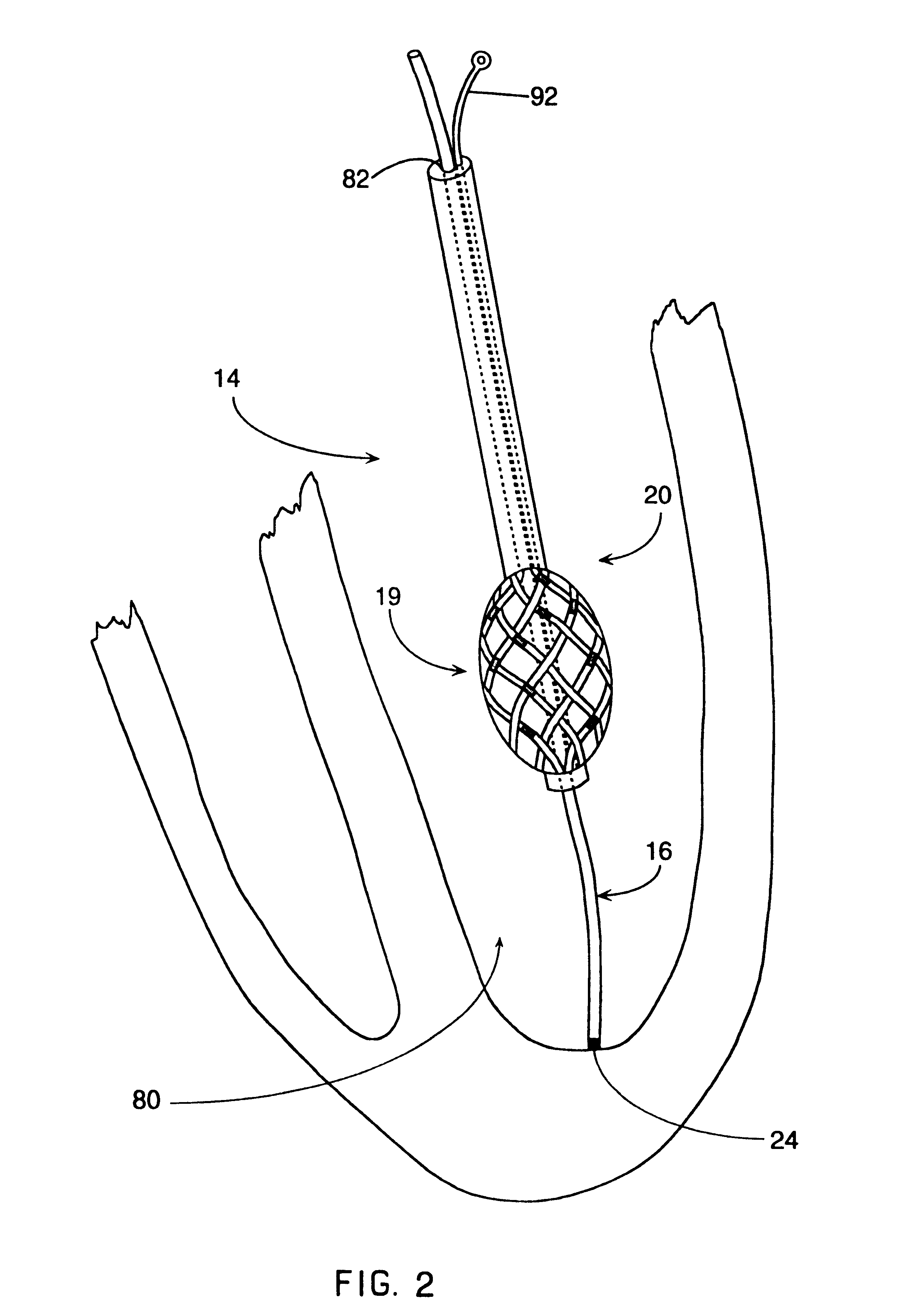

Method of construction an endocardial mapping catheter

A method of constructing a mapping catheter is described where the catheter has numerous electrodes each associated with a single connection in a plug. The method consists of first arranging a plurality of wires in the desired relationship, with each of the wires running to a connection in a plug. Next, a single electrode is formed on each wire. Because it is often difficult to associate a particular connection with a particular plug, an electrical signal is then applied to a single one of the wires. The electrical signal can be applied to the connection or to the electrode. The electrical signal is then found among by examining either the electrodes or the connections, depending on which where the electrical signal was applied. Once the electrical signal is discovered, a map can be made between the connections and the electrodes.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

Coaxial cable connector having a barrel to deform a portion of a casing for crimping a coaxial cable

ActiveUS8517764B2Electrically conductive connectionsConnection formation by deformationCoaxial cableEngineering

An electrical connector for use with coaxial cables includes deformable cylindrical casing and a slidably engaged barrel.

Owner:EZCONN

Apparatus and methods for filament crimping and manufacturing

ActiveUS7650914B2Reduce distortionContact member manufacturingShape memory alloy connectionsEngineeringMechanical engineering

Owner:AUTOSPLICE SYST

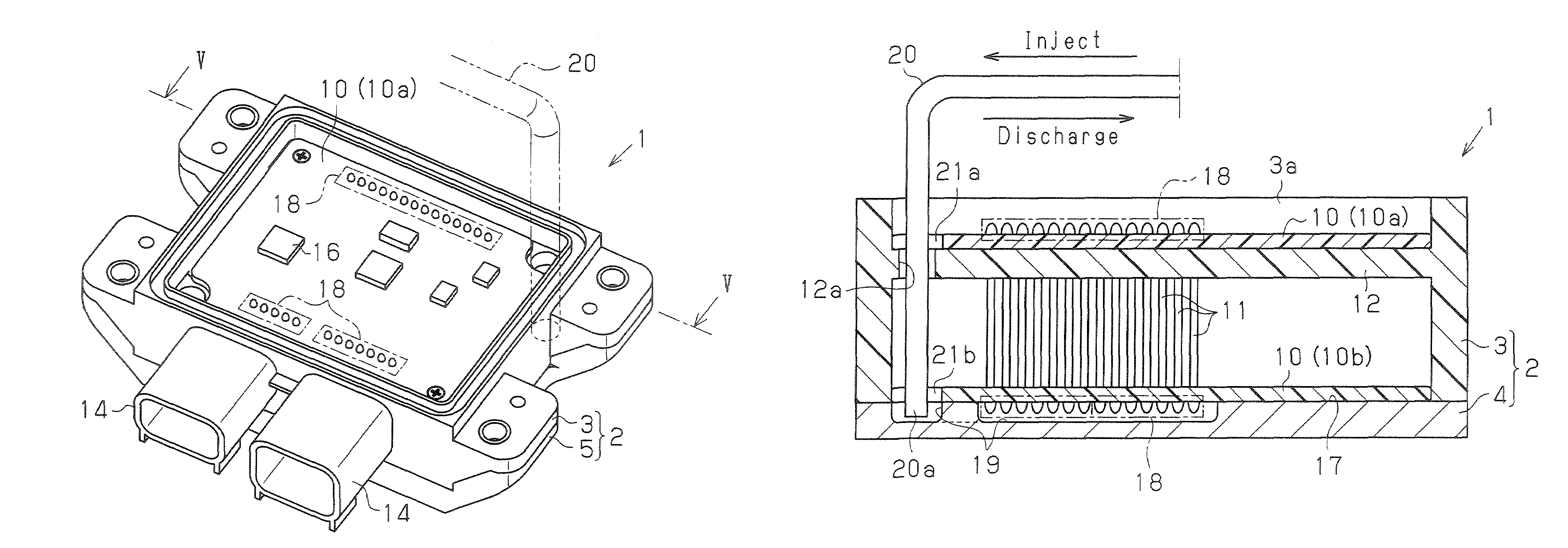

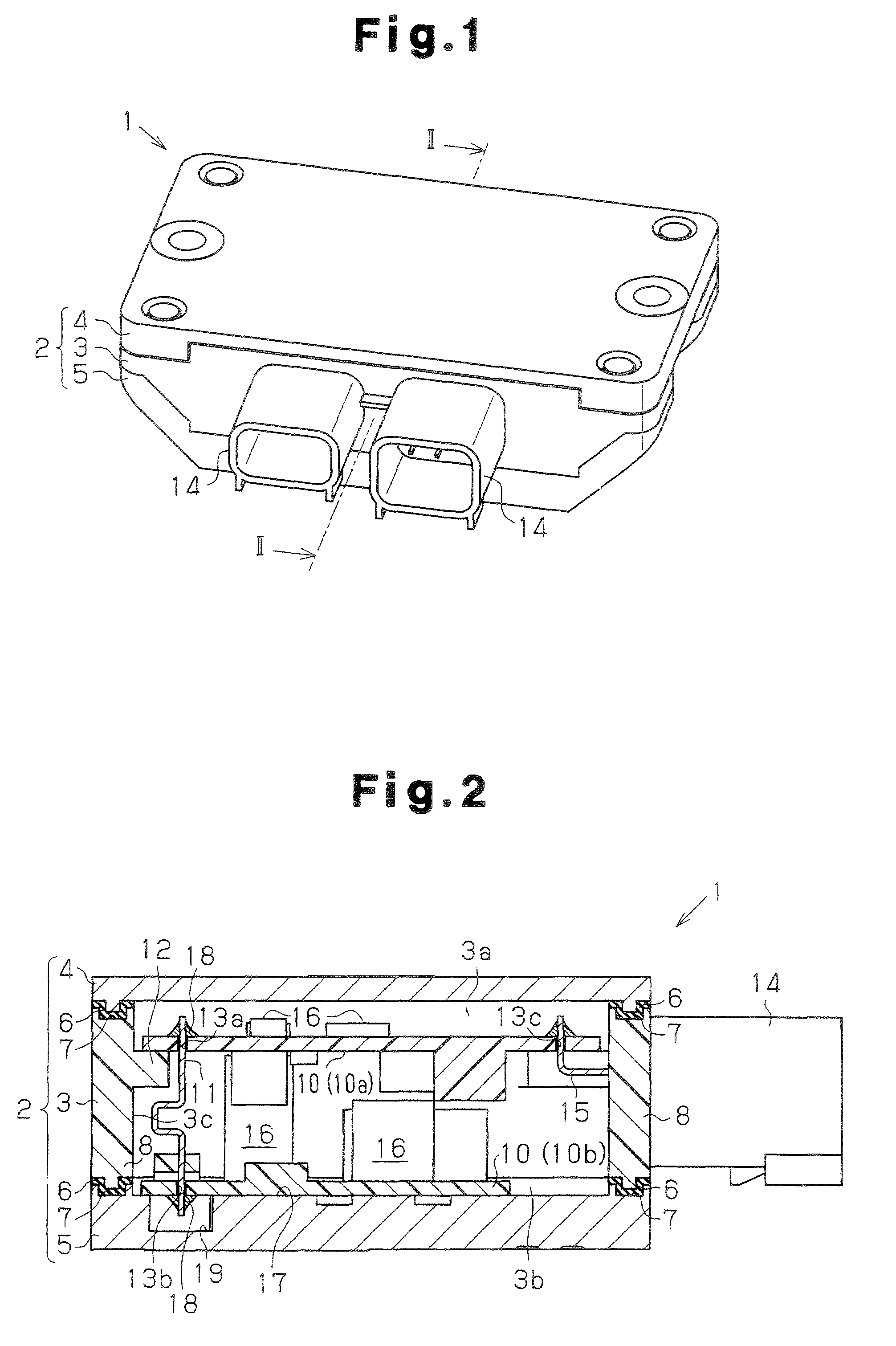

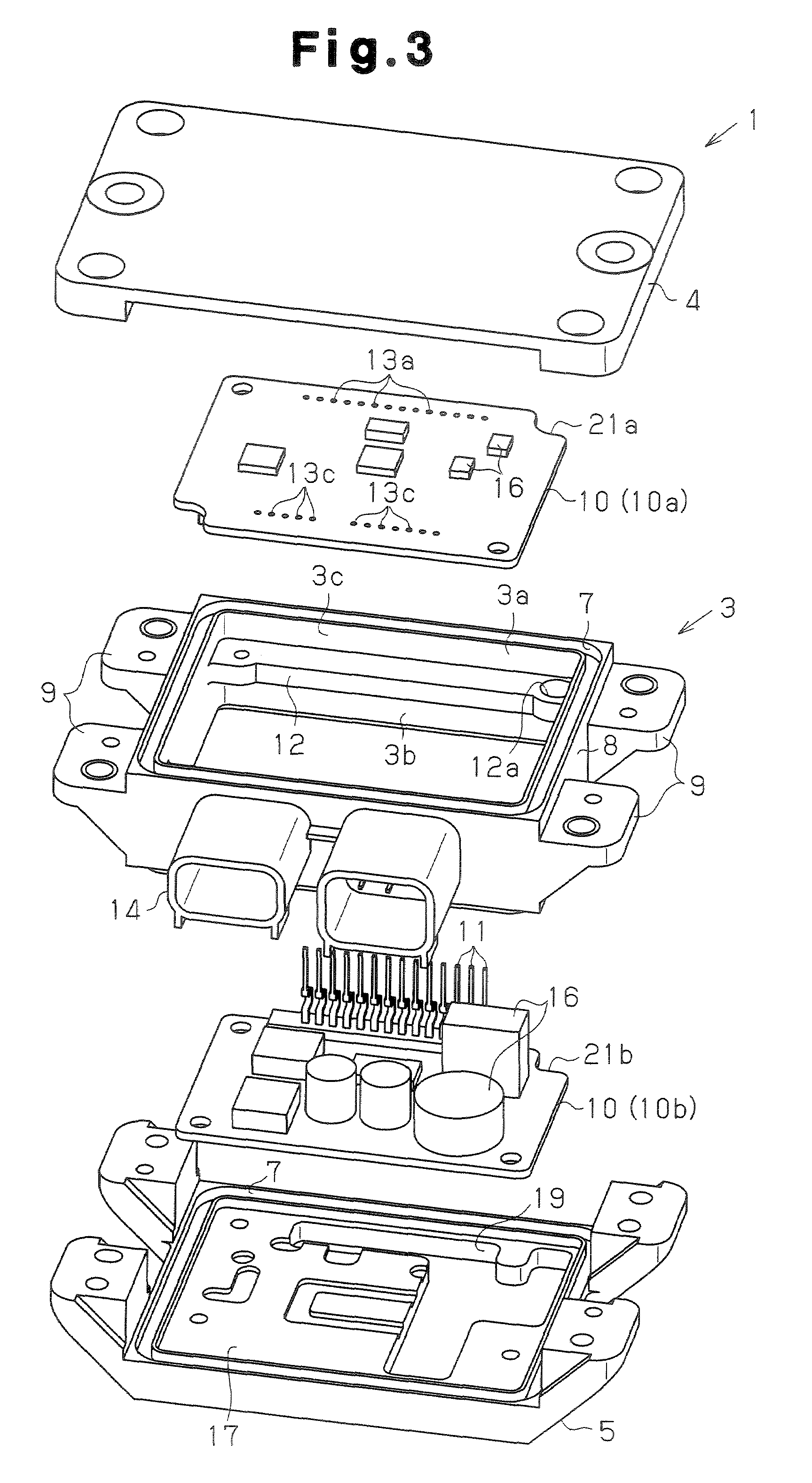

Method for applying coating agent and electronic control unit

InactiveUS7679923B2Simple application of coatingSemiconductor/solid-state device detailsPrinted circuit aspectsElectrical connectionEngineering

A method for easily applying a coating agent to an electronic circuit board accommodated in a housing without leaving uncoated portions. The method includes mounting the electronic circuit board to the housing, performing an electrical connection process in the electronic circuit board, and filling the housing with the coating agent (anti-moisture agent) to immerse the electronic circuit board in the coating agent.

Owner:JTEKT CORP

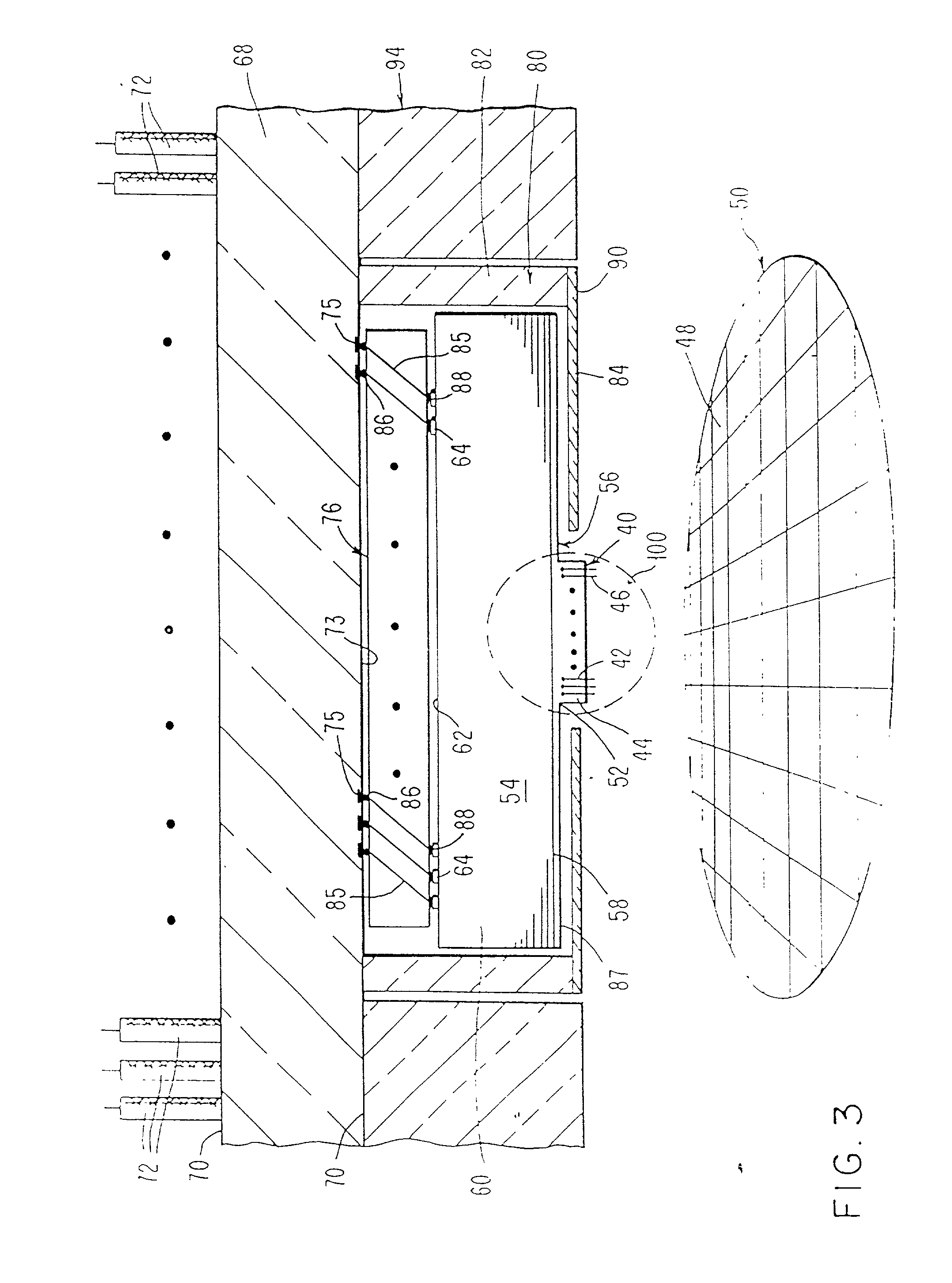

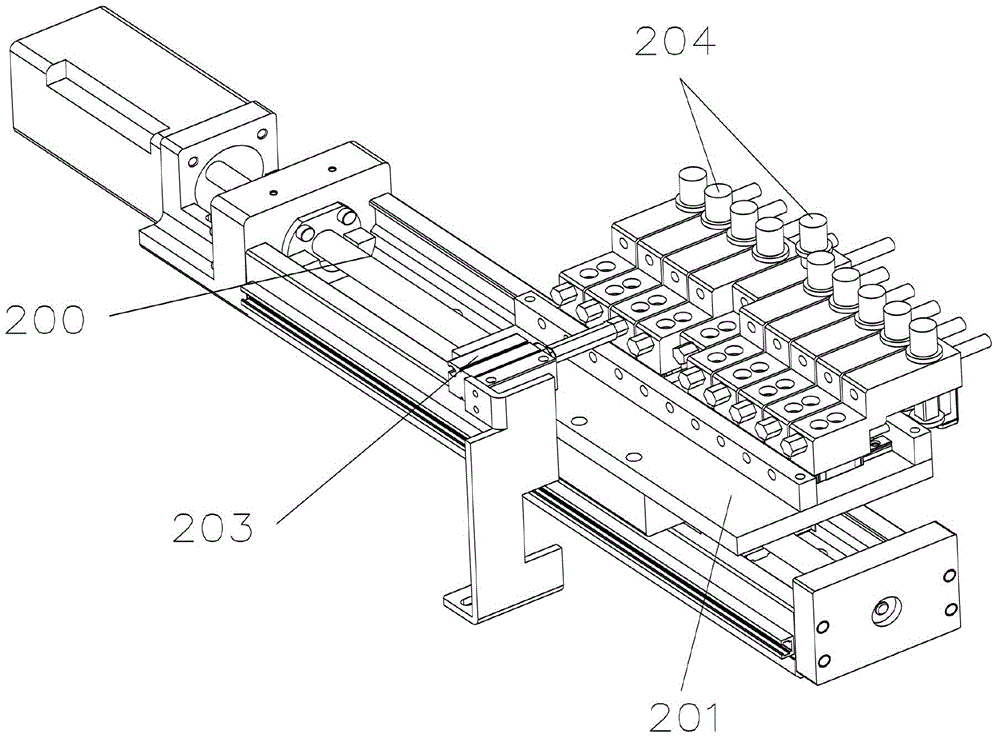

Full-automatic double-end harness crimping machine

InactiveCN103022853AImprove qualityNo human intervention requiredConnection formation by deformationEngineeringAutomatic testing

The invention discloses a full-automatic double-end harness crimping machine which comprises a pay-off device, a feeding device and a cutting and stripping device. The pay-off device, the feeding device and the cutting and stripping device are disposed in sequence. An upper movable positioning device is arranged on the left side of the cutting and stripping device. A lower movable positioning device is arranged on the right side of the cutting and stripping device. The upper movable positioning device and the lower movable positioning device are the same in structure. The feeding device is fixed on the upper movable positioning device. A wire head crimping device is arranged in front of the cutting and stripping device. A wire tail crimping device is arranged in rear of the cutting and stripping device. The wire head crimping device and the wire tail crimping device are the same in structure. A wire picker is arranged on the right side of the wire tail crimping device. The full-automatic double-end harness crimping machine allows for integrative operation of automatic fixed-length feeding, automatic cutting, automatic stripping and automatic front-rear wire terminal crimping, and allows for full line production safely and automatically. Therefore, the full-automatic double-end harness crimping machine is high in production efficiency, low in power consumption, stable in product quality, high in precision and adaptable to large-scale batch production.

Owner:TIANJIN LIGAN TECH +1

Crimping terminal for connection between electric cables

InactiveUS6658735B2Avoid flowCouplings bases/casesConnections effected by permanent deformationAdhesiveElectric cables

Owner:SUMITOMO WIRING SYST LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com