Full-automatic double-end harness crimping machine

A fully automatic, first-line technology, applied in the direction of connection, connection and connection by deformation, circuit/collector parts, etc., to achieve the effect of high precision, low energy consumption, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

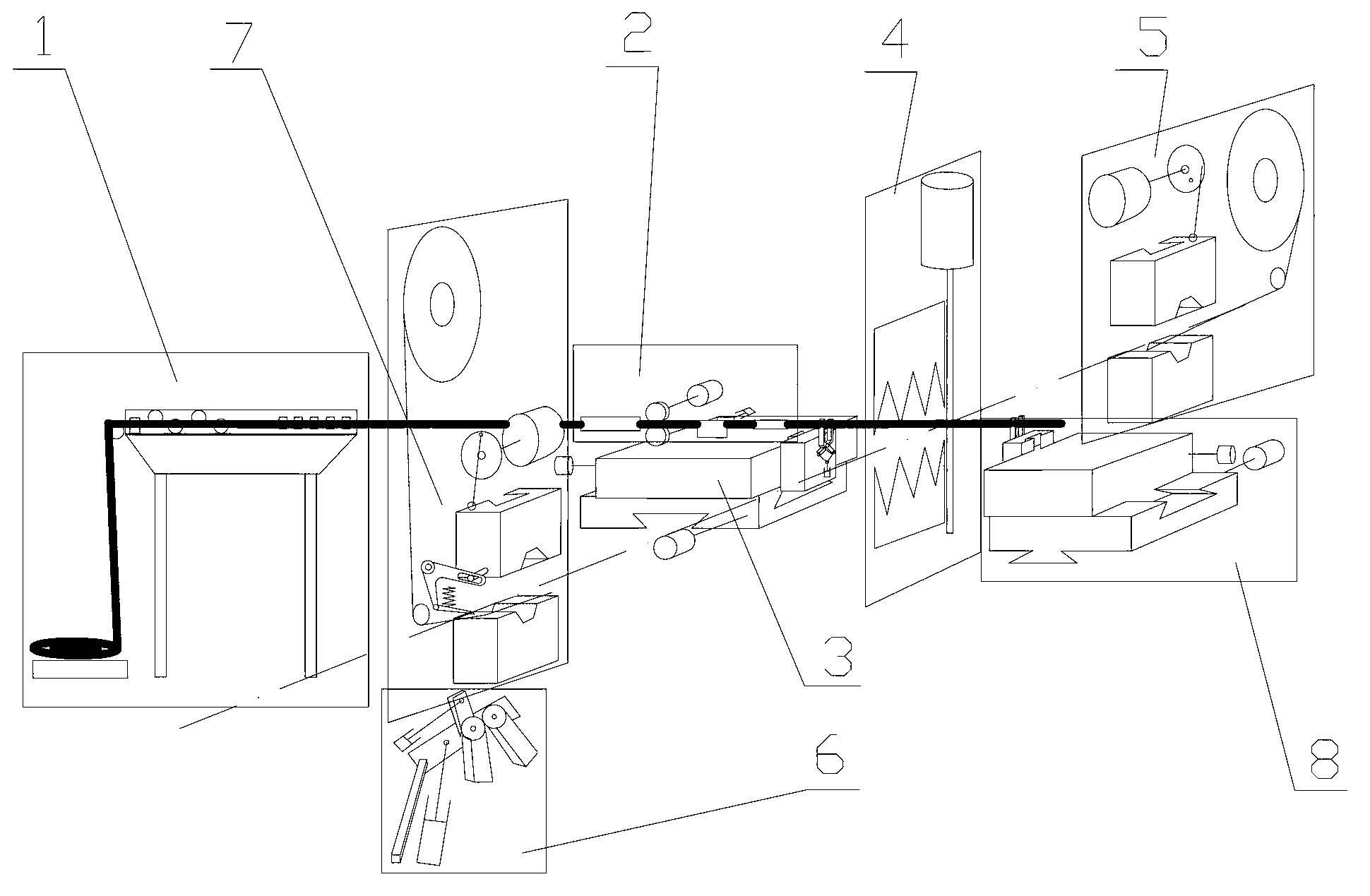

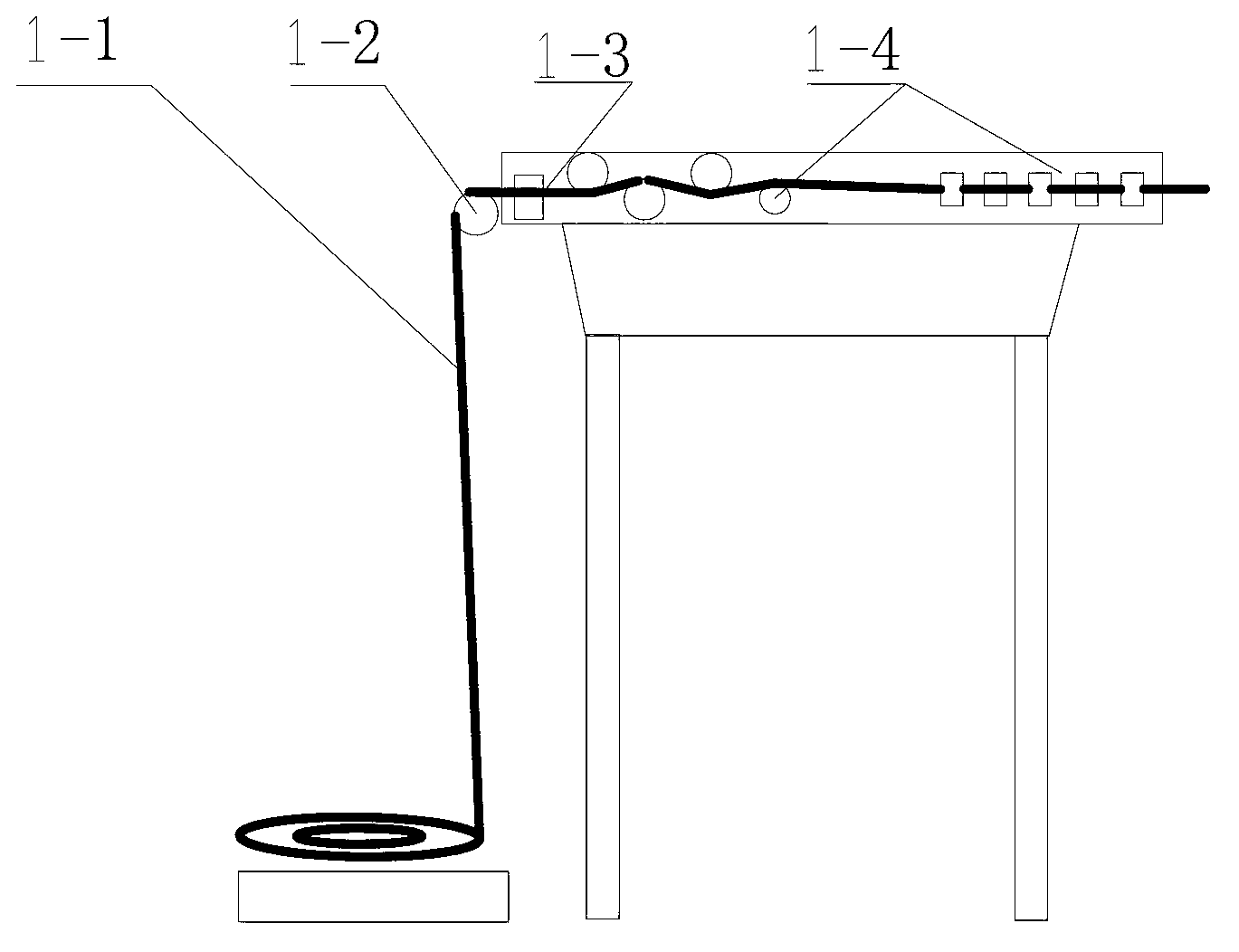

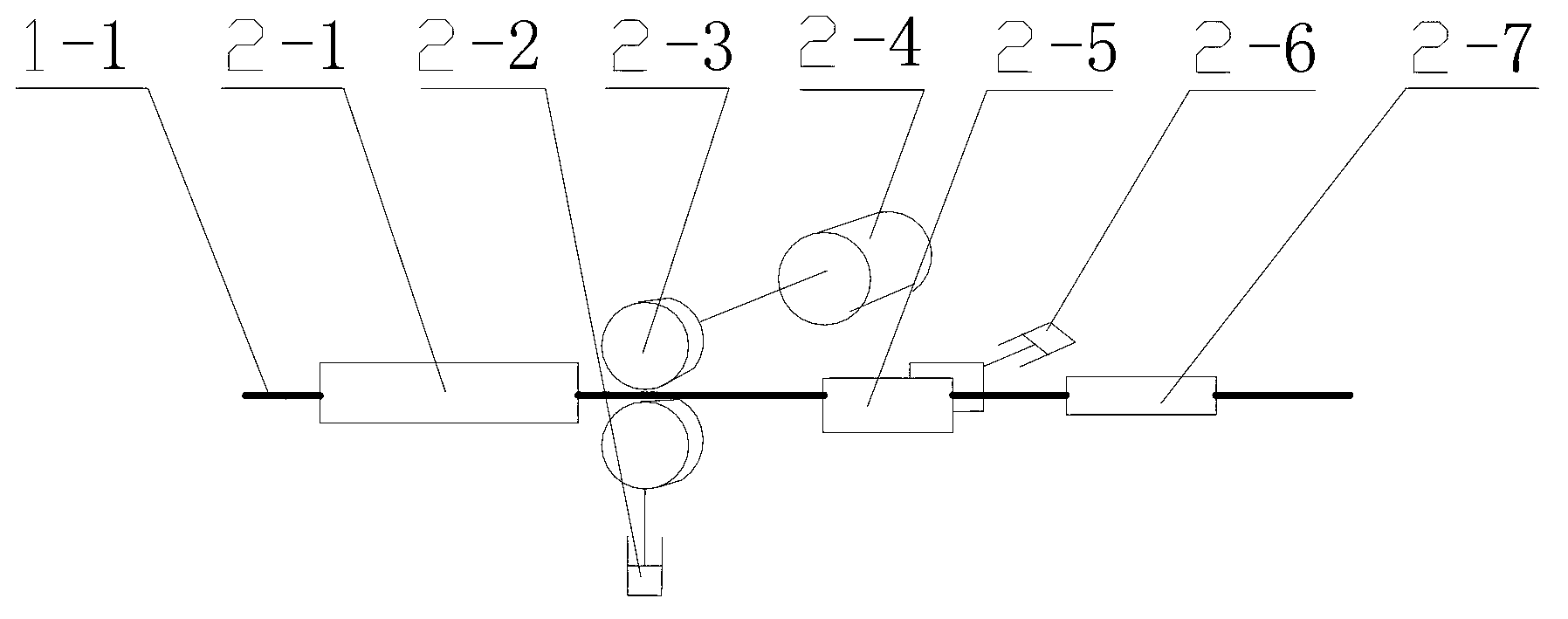

[0028] See figure 1 , A fully automatic double-head wire harness crimping machine, the crimping machine includes a wire pay-off device 1, a wire feed device 2 and a cutting and peeling device 4 arranged in sequence on the frame. The cutting and peeling device 4 is provided with upstream movement on the left side Positioning device 3, the right side of the cutting and peeling device 4 is provided with a downstream mobile positioning device 8. The upstream mobile positioning device 3 and the downstream mobile positioning device 8 have the same structure. The wire feeding device 2 is fixed to the upstream mobile positioning device 3, and the cutting and peeling device 4 There is a thread crimping device 5 on the front, and a thread crimping device 7 behind the cutting a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com