Patents

Literature

376 results about "Wire cutter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A wire catcher is a tool used to protect military personnel in open vehicles against taut-wire traps.

Intramedullary Fixation Device for Small Bone Fractures

InactiveUS20090275946A1Aggressive curveAdd flexiblyInternal osteosythesisJoint implantsFixation pointCurve shape

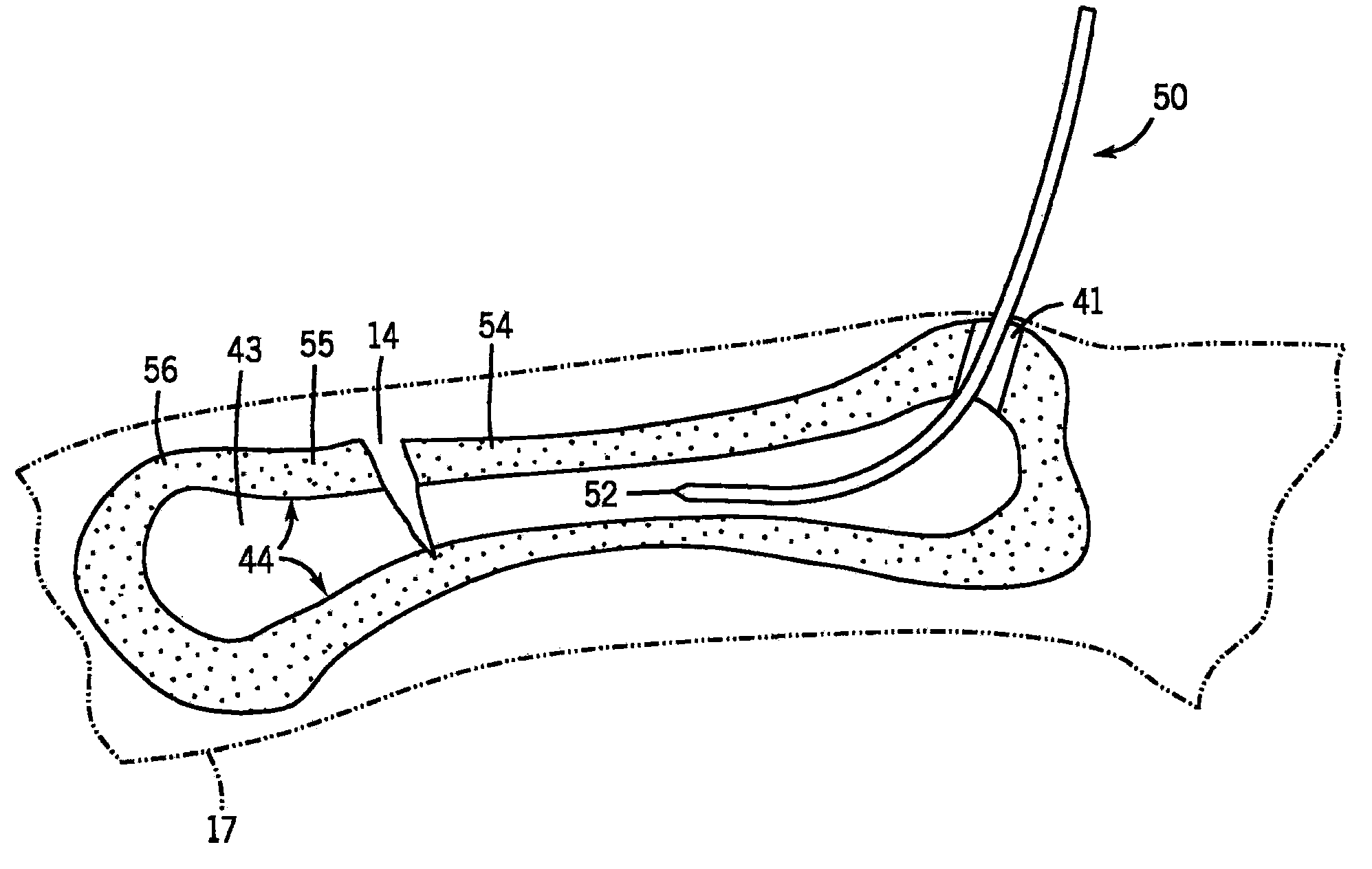

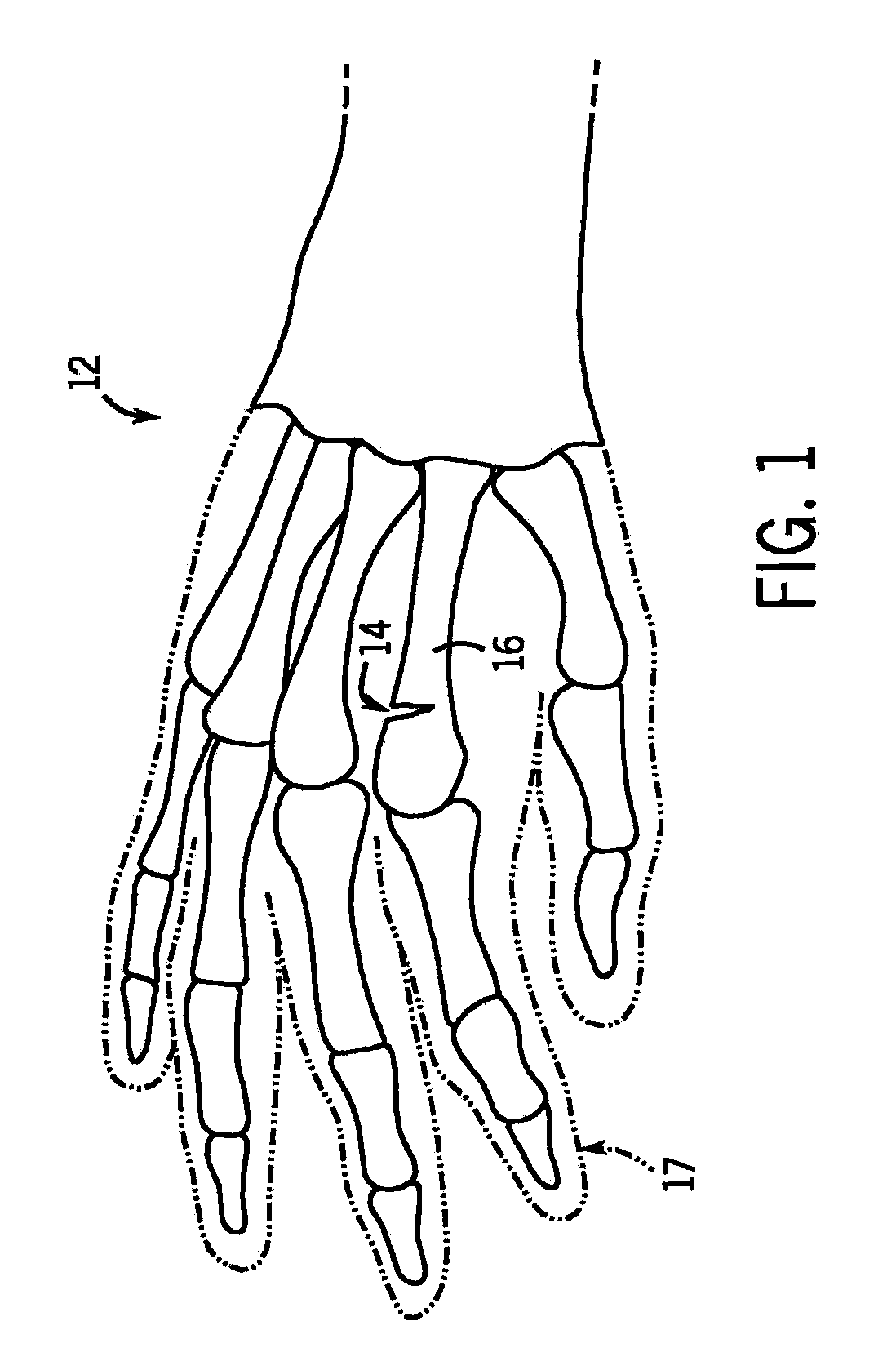

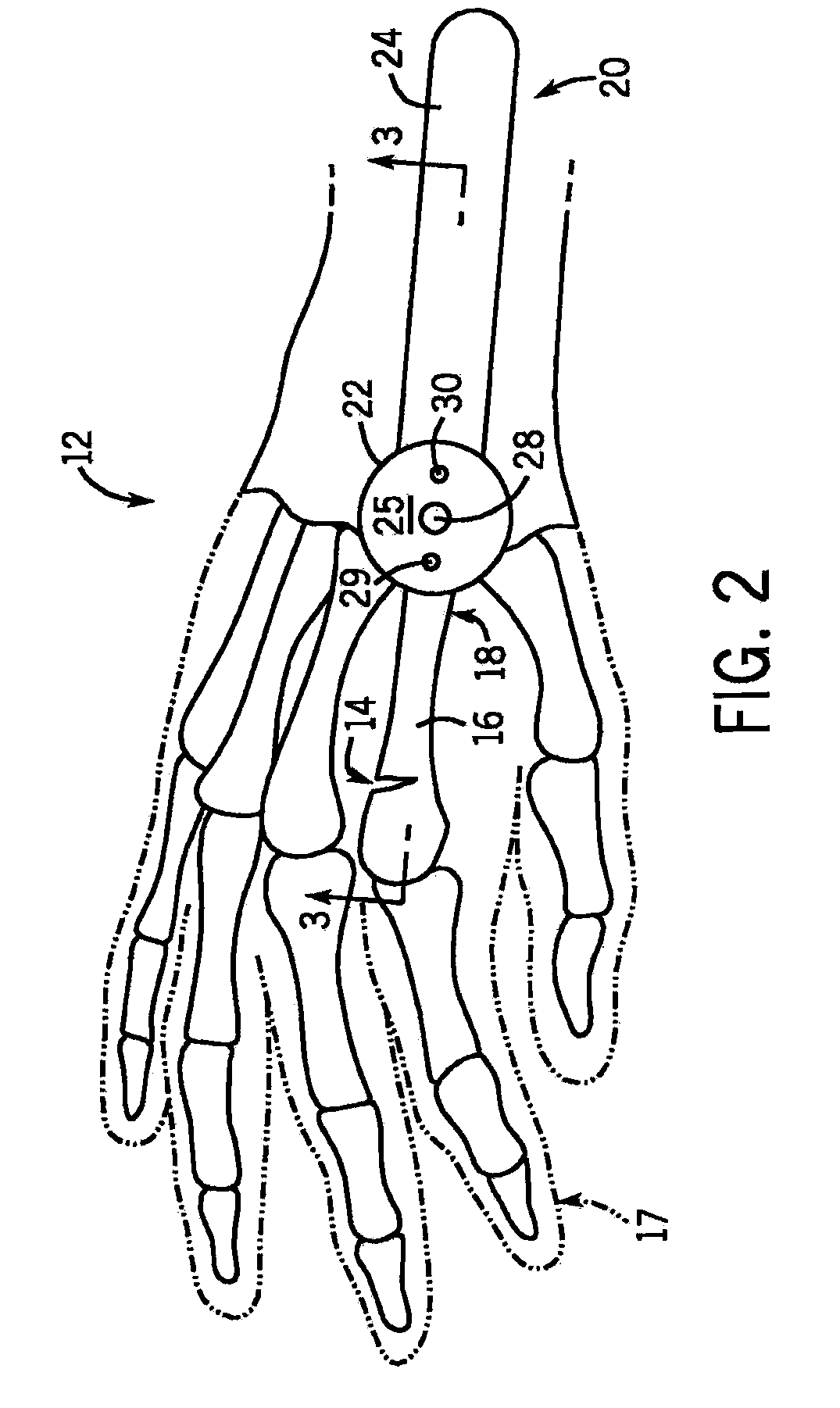

A fracture fixation system particularly useful for bones of the hand and foot is disclosed. The system uses curved shape-memory alloy (e.g., Nitinol) wires that have a predetermined radius of curvature to accommodate different sized bones. These shape-memory alloy wire forms can be inserted into phalanx, metacarpal or metatarsal bones via a percutaneous technique. The technique uses small skin incisions; a specialized drill guide that has holding K-wires to maintain fixation of the drill guide to the bone so that it does not lose the insertion point; a specialized drill as well as a specialized wire cutter and advancement tool to make sure that the level of the wire is below the level of the outer cortical bone. Shape-memory alloy (e.g., Nitinol) based wires with a pre-bent curve have an advantage over the typical standard K-wire in that they can spring back to their predetermined memory shape when inserted into the intramedullary canal of the bone and heated, i.e., a more aggressive curve. By increasing their bending or flexion to increase the arc of curvature, this allows fixation points for the wire, essentially locking it to bone.

Owner:MAYO FOUND FOR MEDICAL EDUCATION & RES

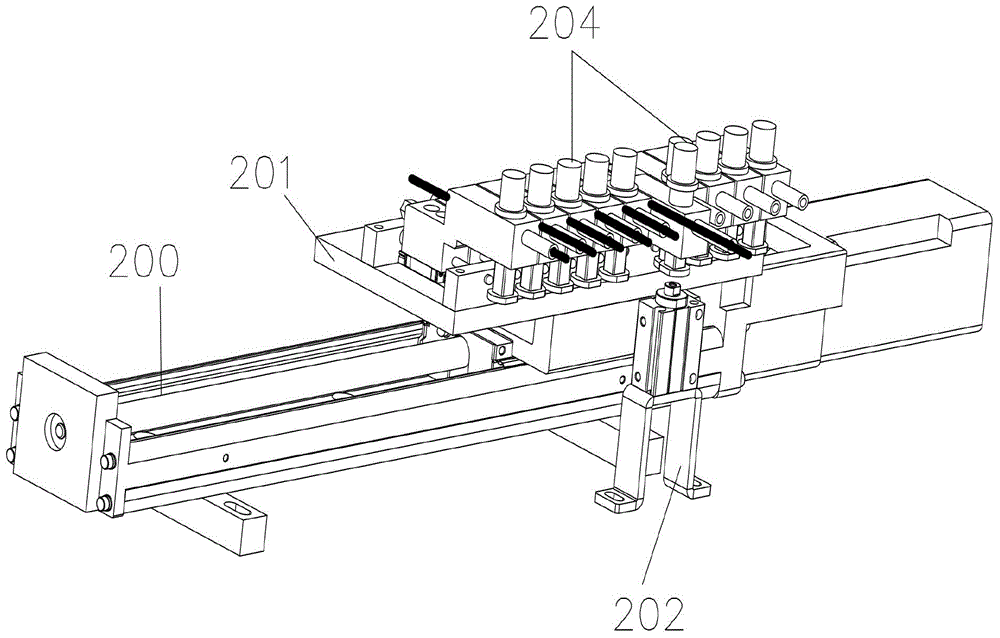

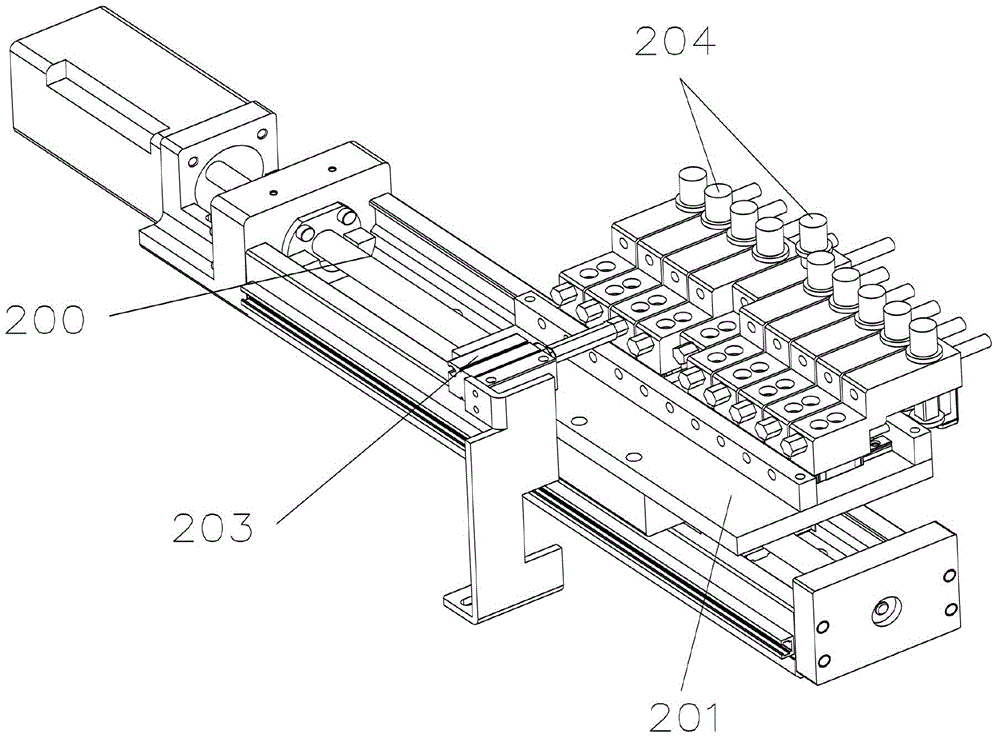

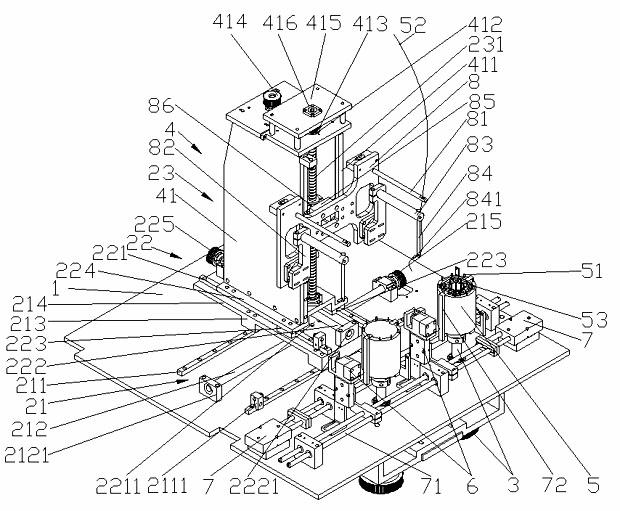

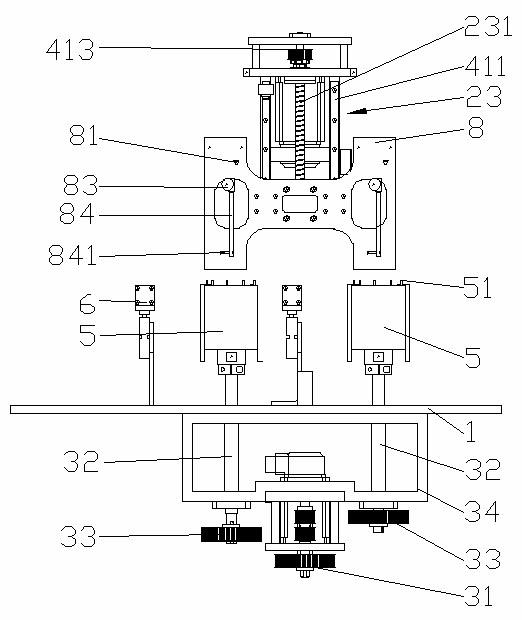

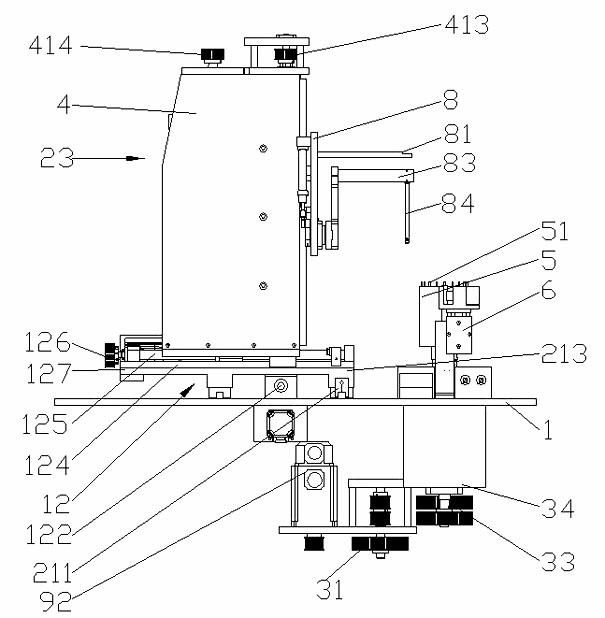

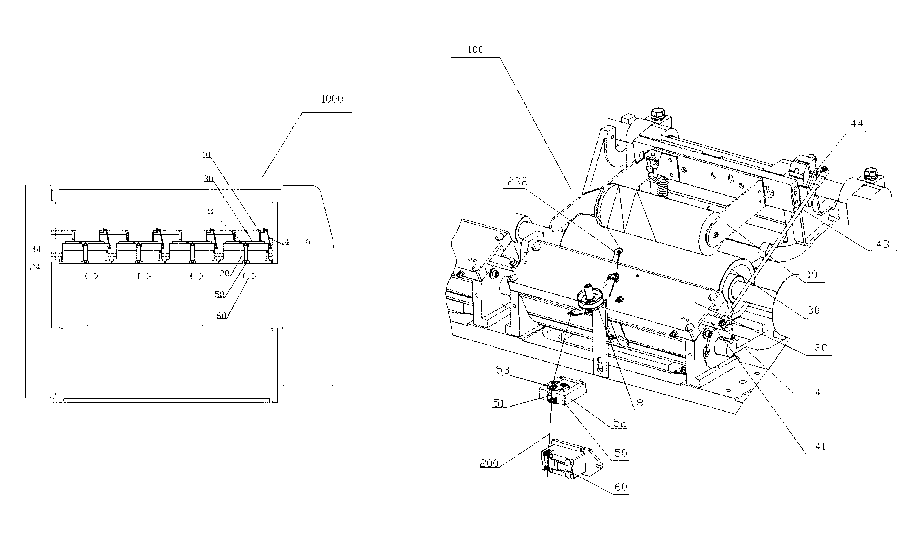

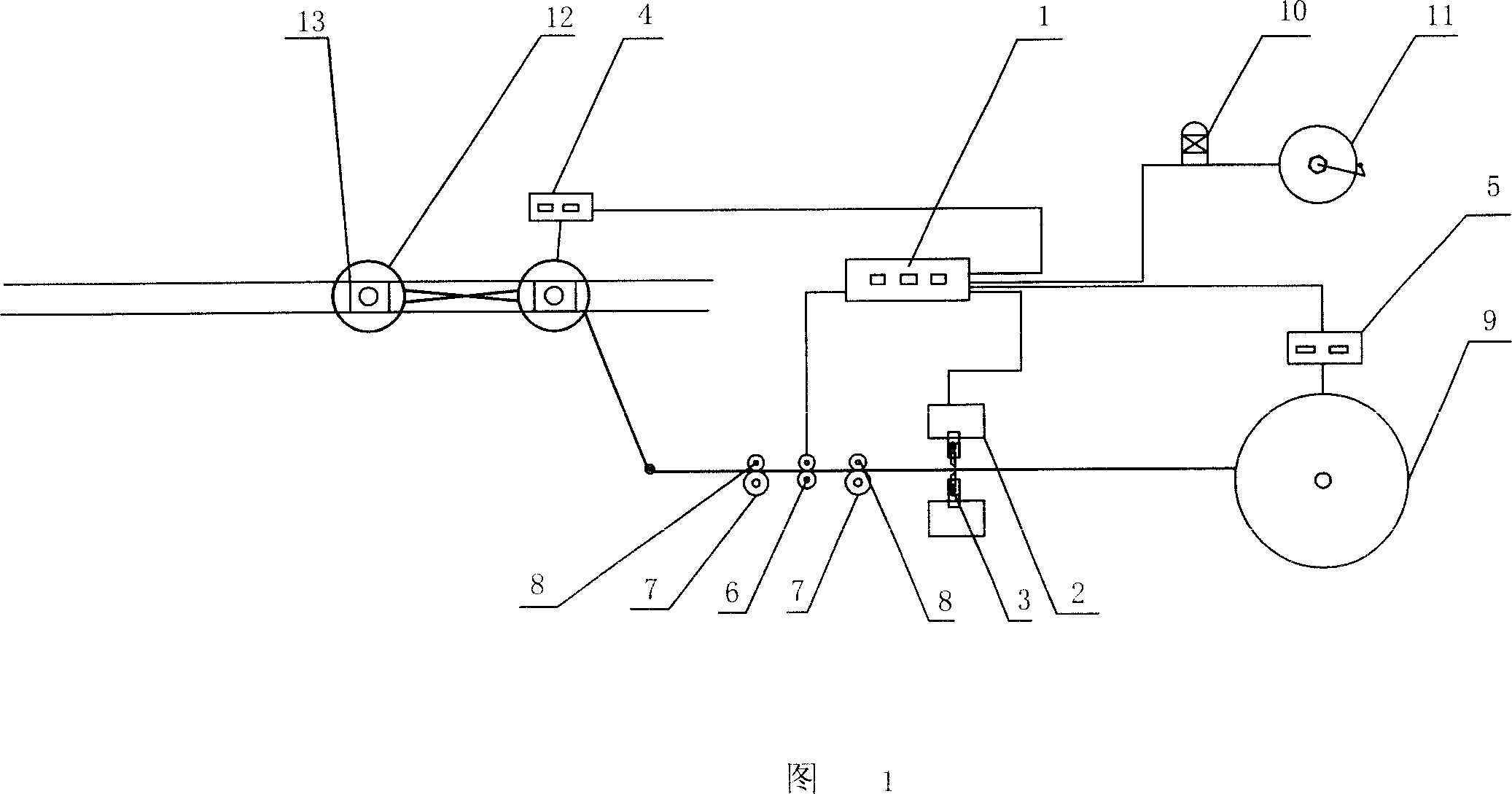

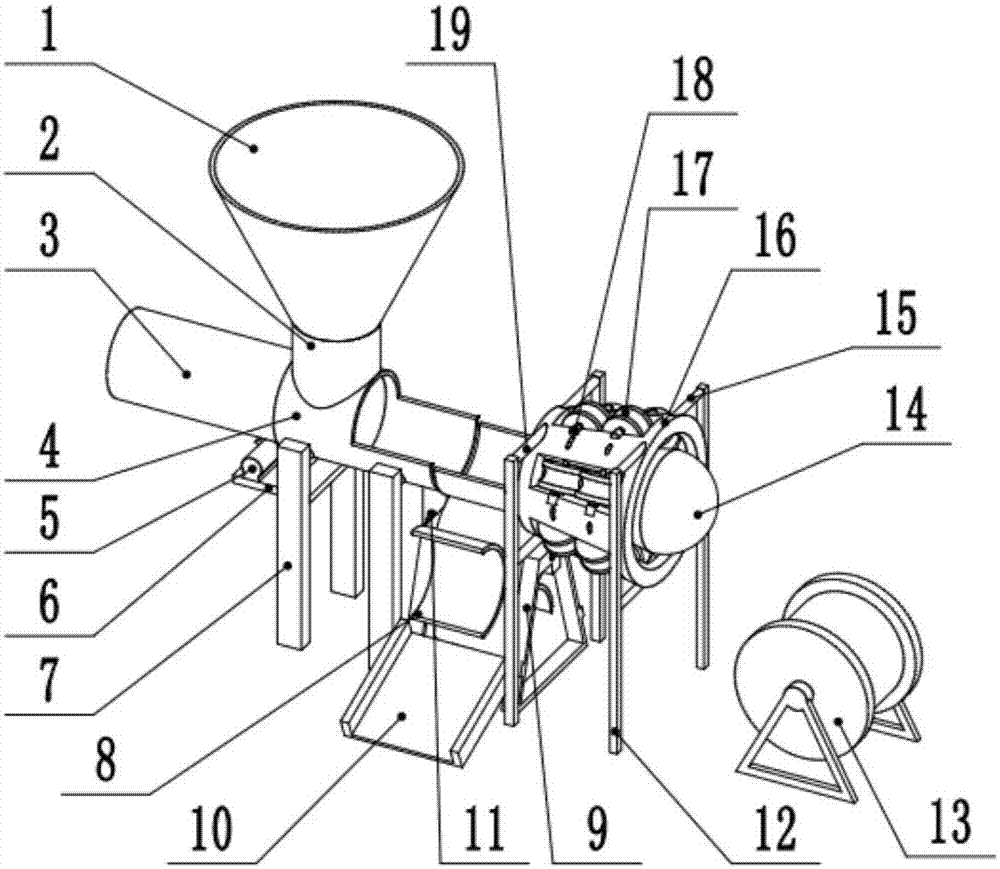

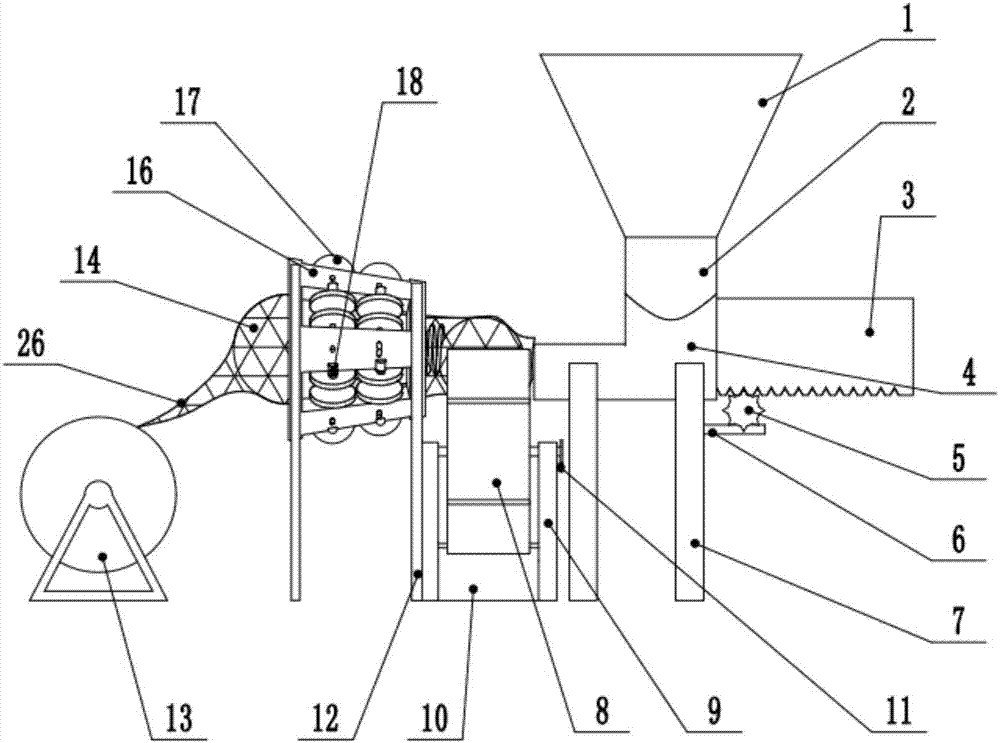

Full-automatic insertion machine with two pressed ends

ActiveCN104701707ARealize automatic crimpingQuality assuranceContact member assembly/disassemblyConnection formation by deformationWire rodEngineering

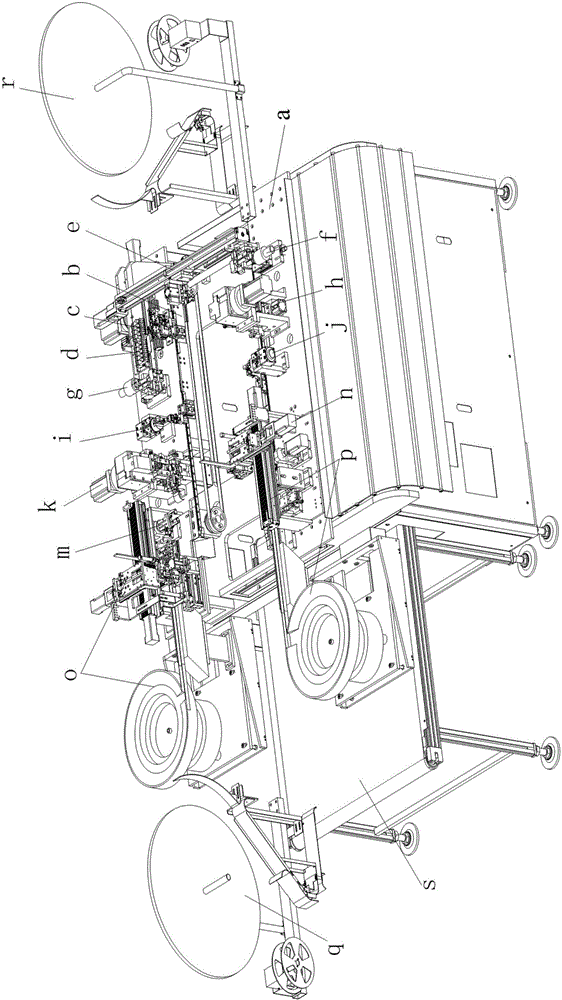

The invention relates to the technical field of mechanical automatic equipment, in particular to a full-automatic insertion machine with two pressed ends. The insertion machine comprises an operating platform on which a wire feeding mechanism, a wire cutter mechanism, a wire conveying mechanism, two peeling mechanisms, two turnover mechanisms, two pressing mechanisms, two terminal steering mechanisms and two terminal insertion mechanisms, wherein the wire feeding mechanism used for conveying wire rods of wiring harness to an appointed position one by one is arranged on the operating platform, the wire cutter mechanism is used for cutting off the wire rods to form wire sections, and the wire conveying mechanism is used for moving the wire sections to the appointed positions for the corresponding processing; the two peeling mechanisms are used for peeling and cutting the skins of the wires at the tips of the wire sections, the two turn-over mechanisms are used for rotationally controlling the wire sections, the two pressing mechanisms are used for pressing the terminals on the tips of the wire sections, the two terminal steering mechanisms are used for rotating the wire sections connected with terminals in a pressing way and the two terminal insertion mechanisms are used for inserting the terminals of the wire sections into a glue cover. According to the full-automatic insertion machine provided by the invention, the automatic crimping of the wire terminals can be realized by the arrangement and movement relationship of the above mechanisms, the wires of the terminals crimped can be automatically cut and inserted into the glue cover, so as to form a final harness finished product.

Owner:SHENZHEN JAPAN MACHINE KING CO LTD

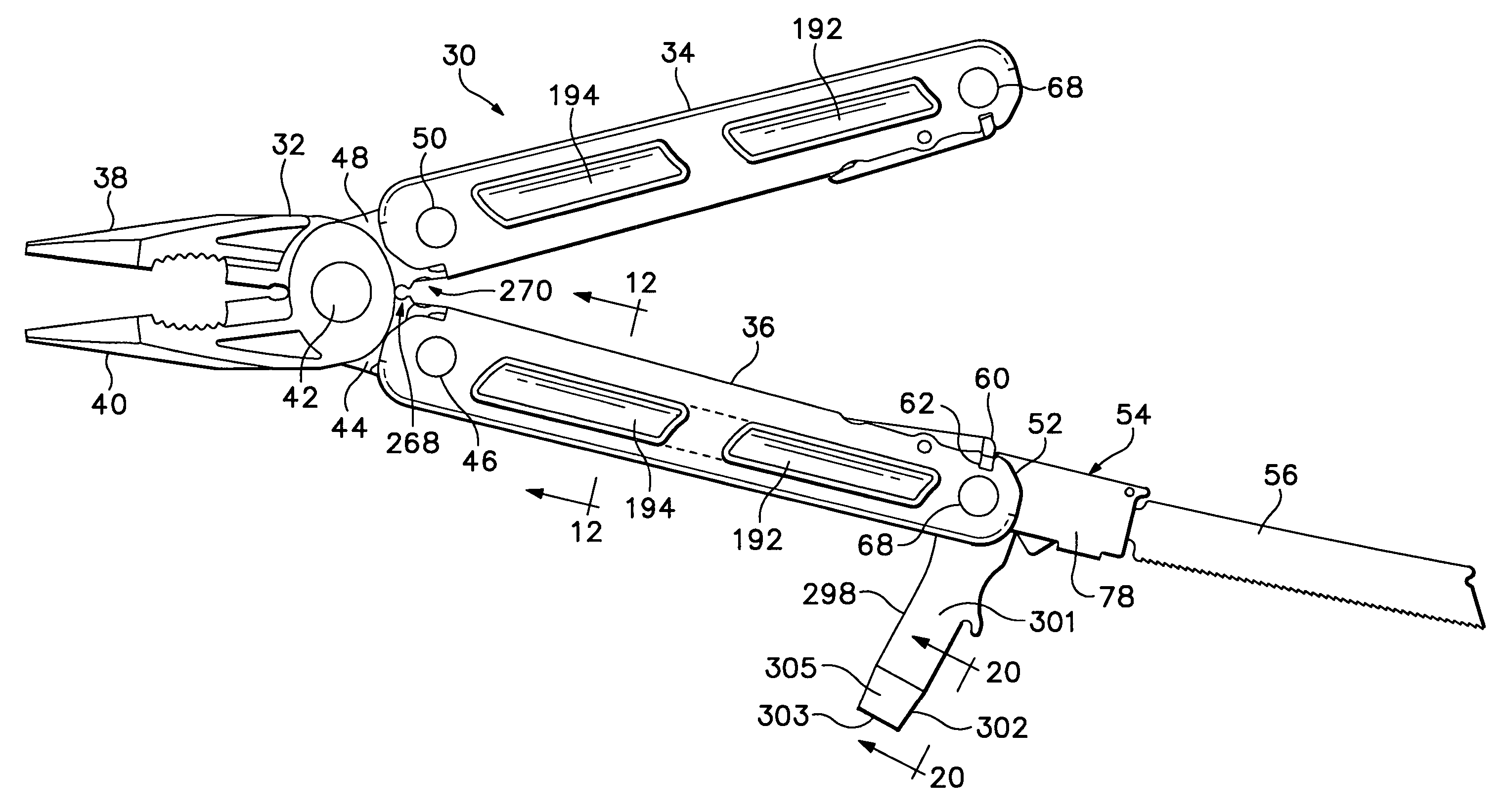

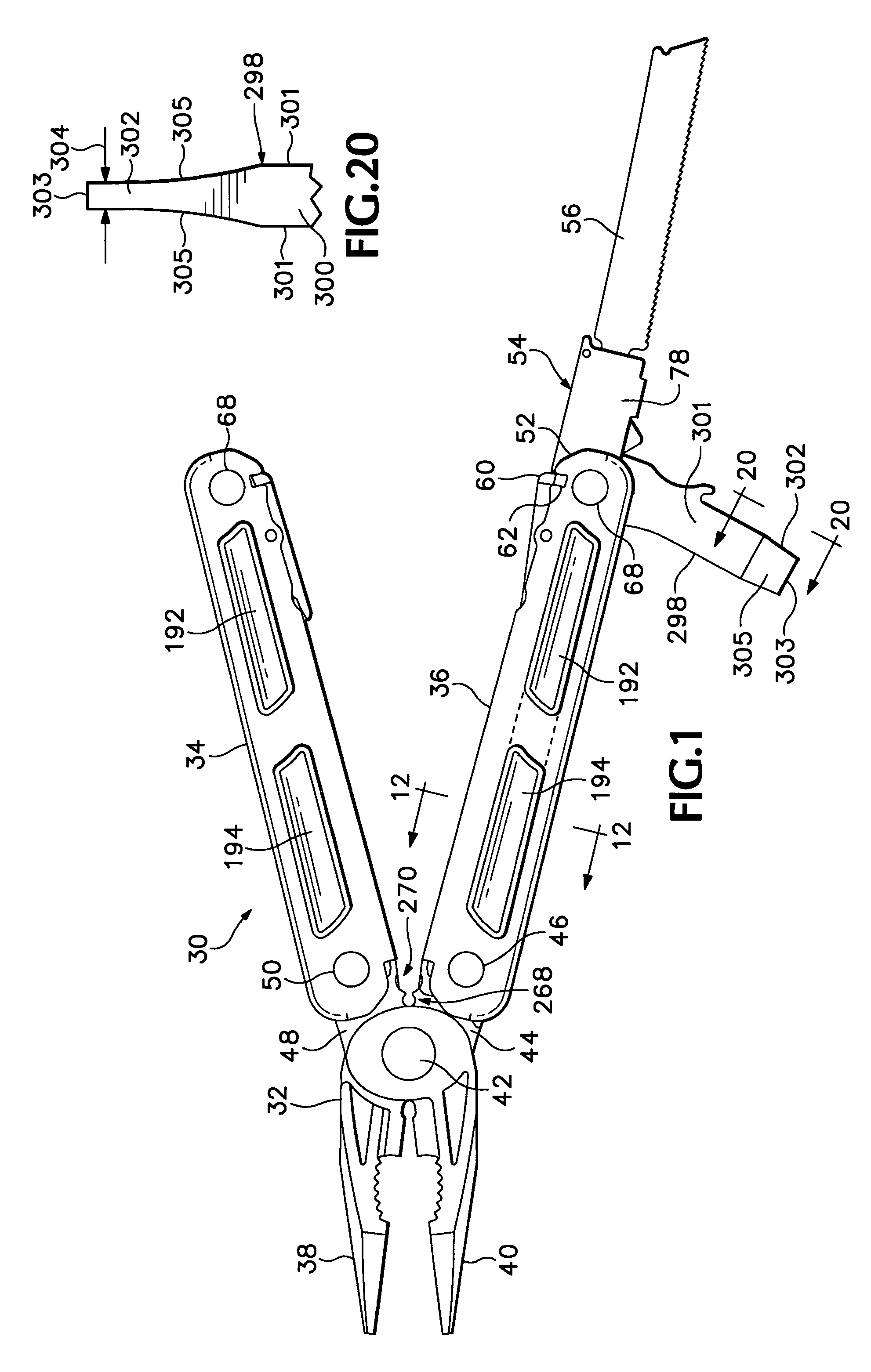

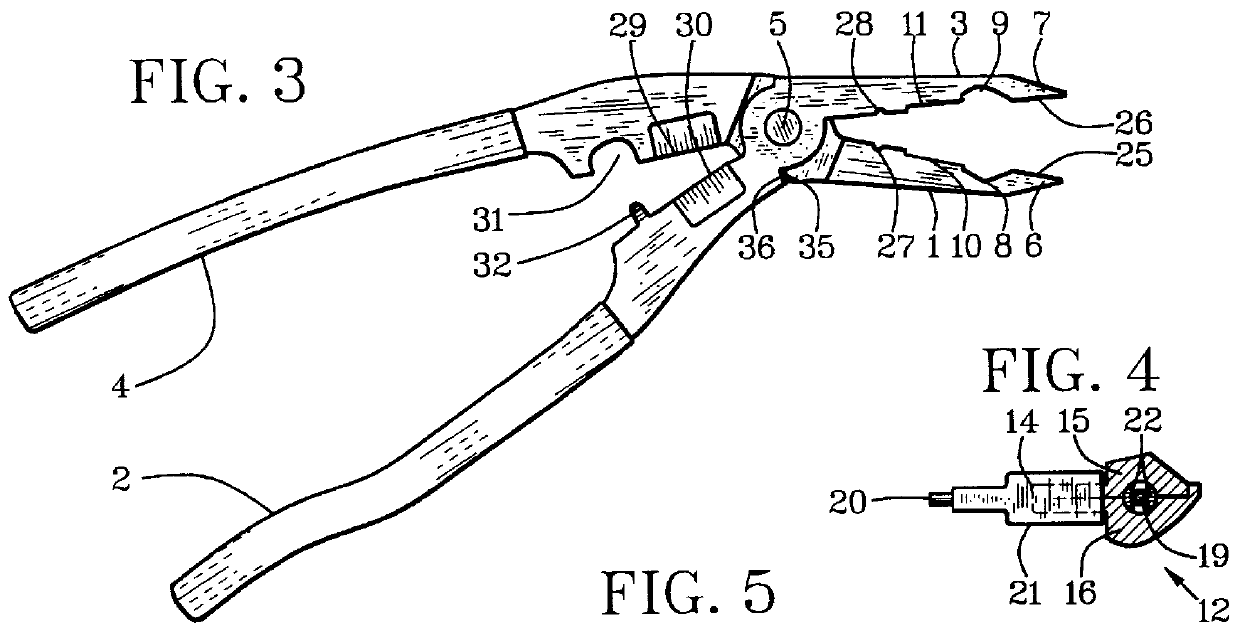

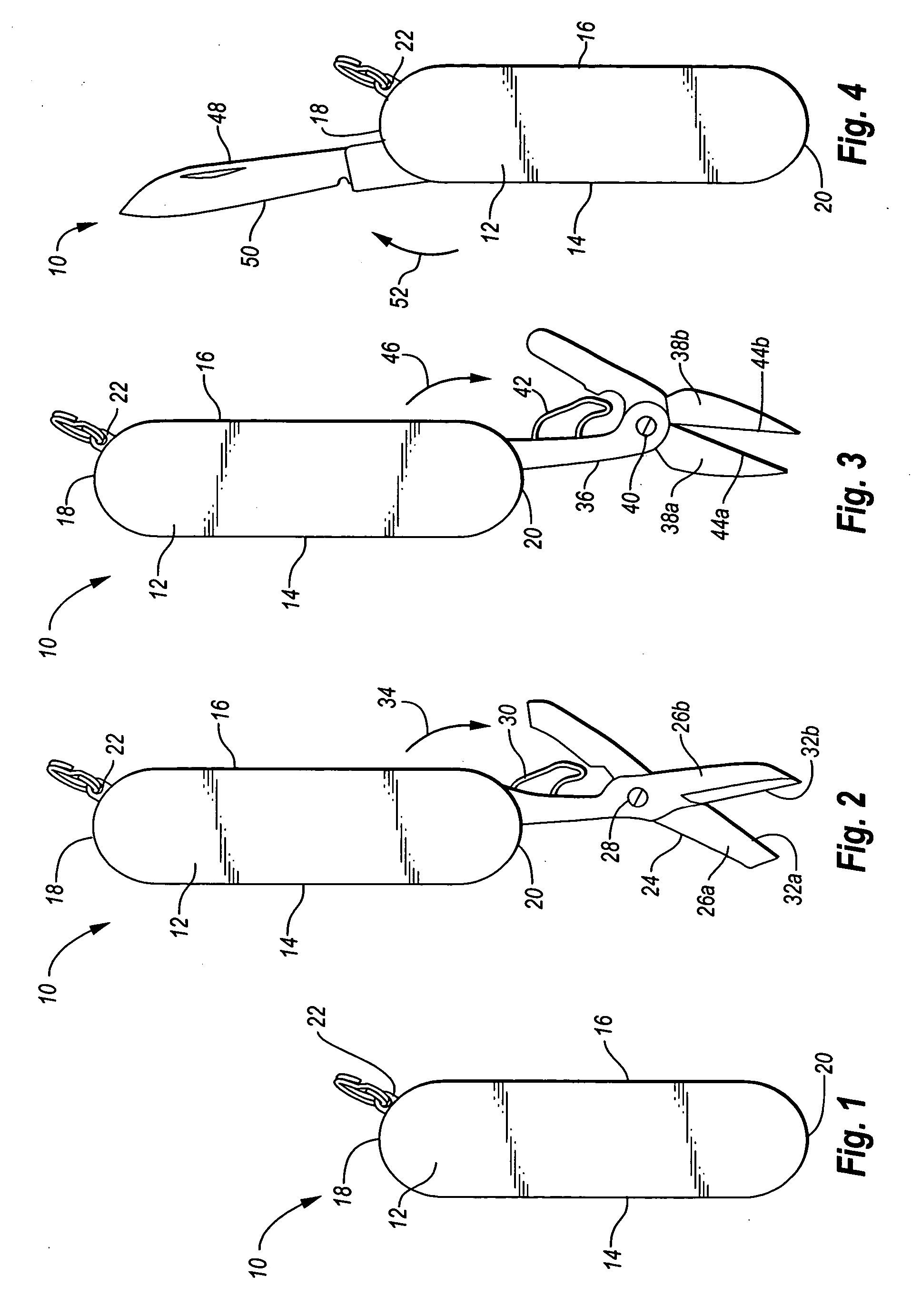

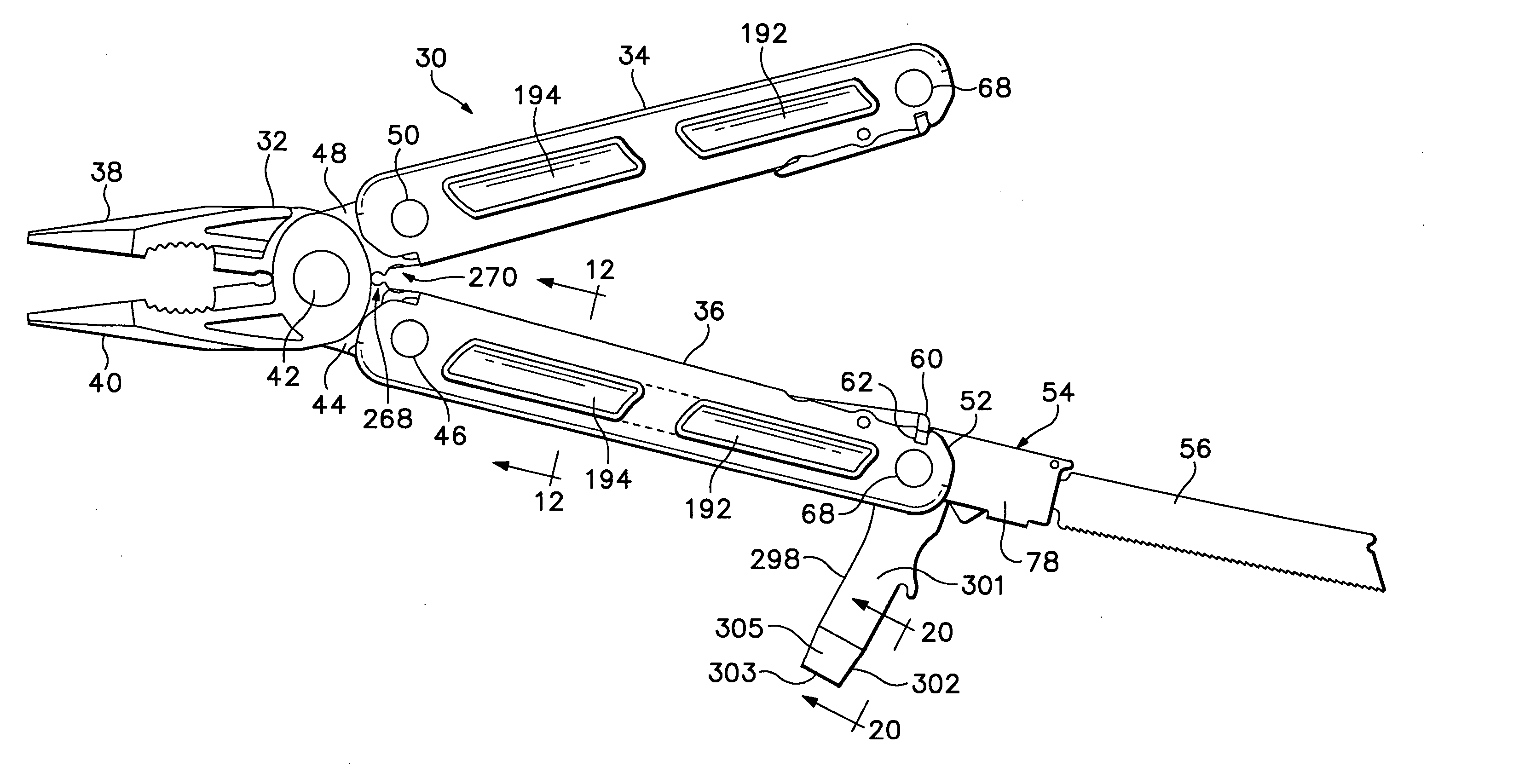

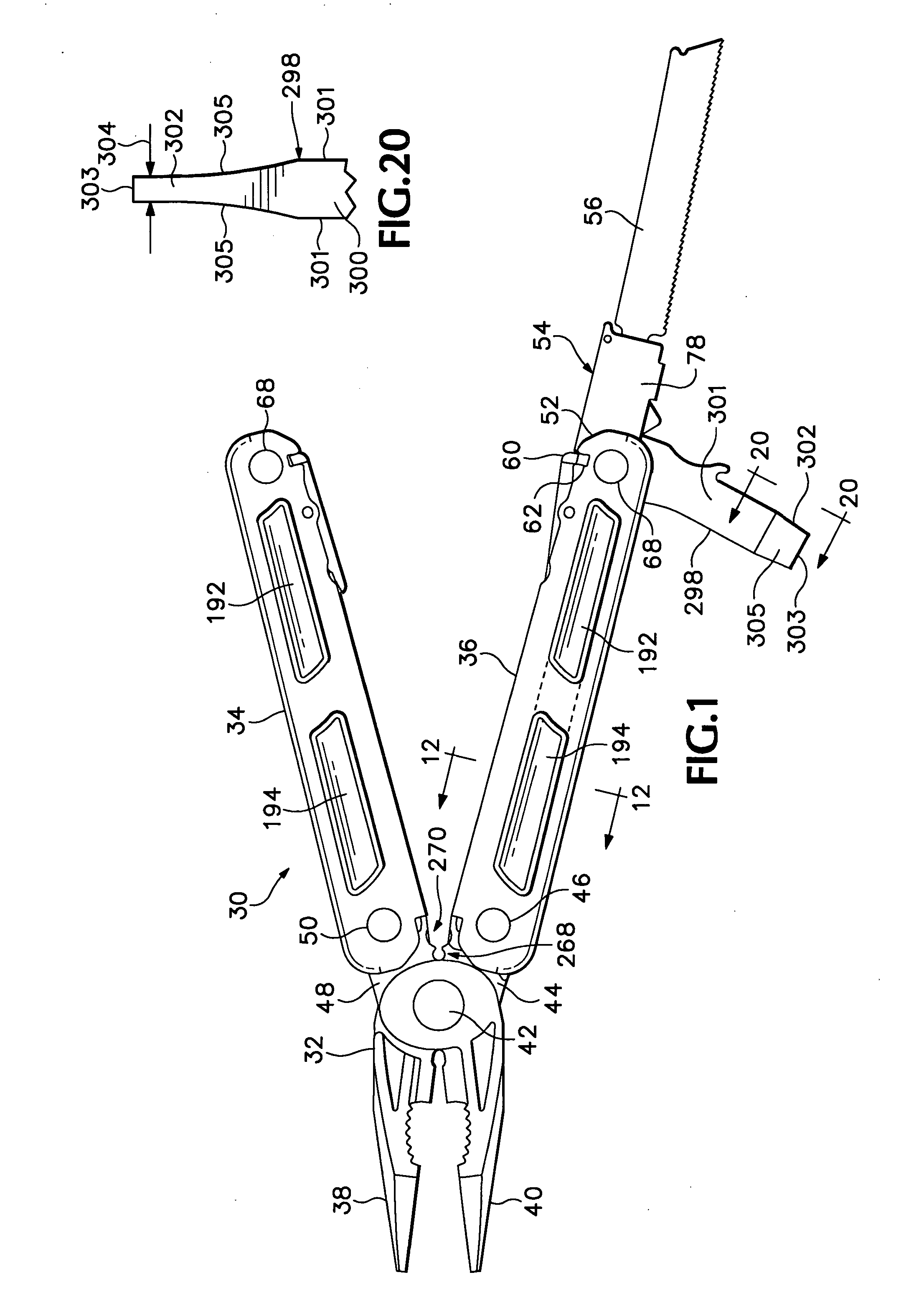

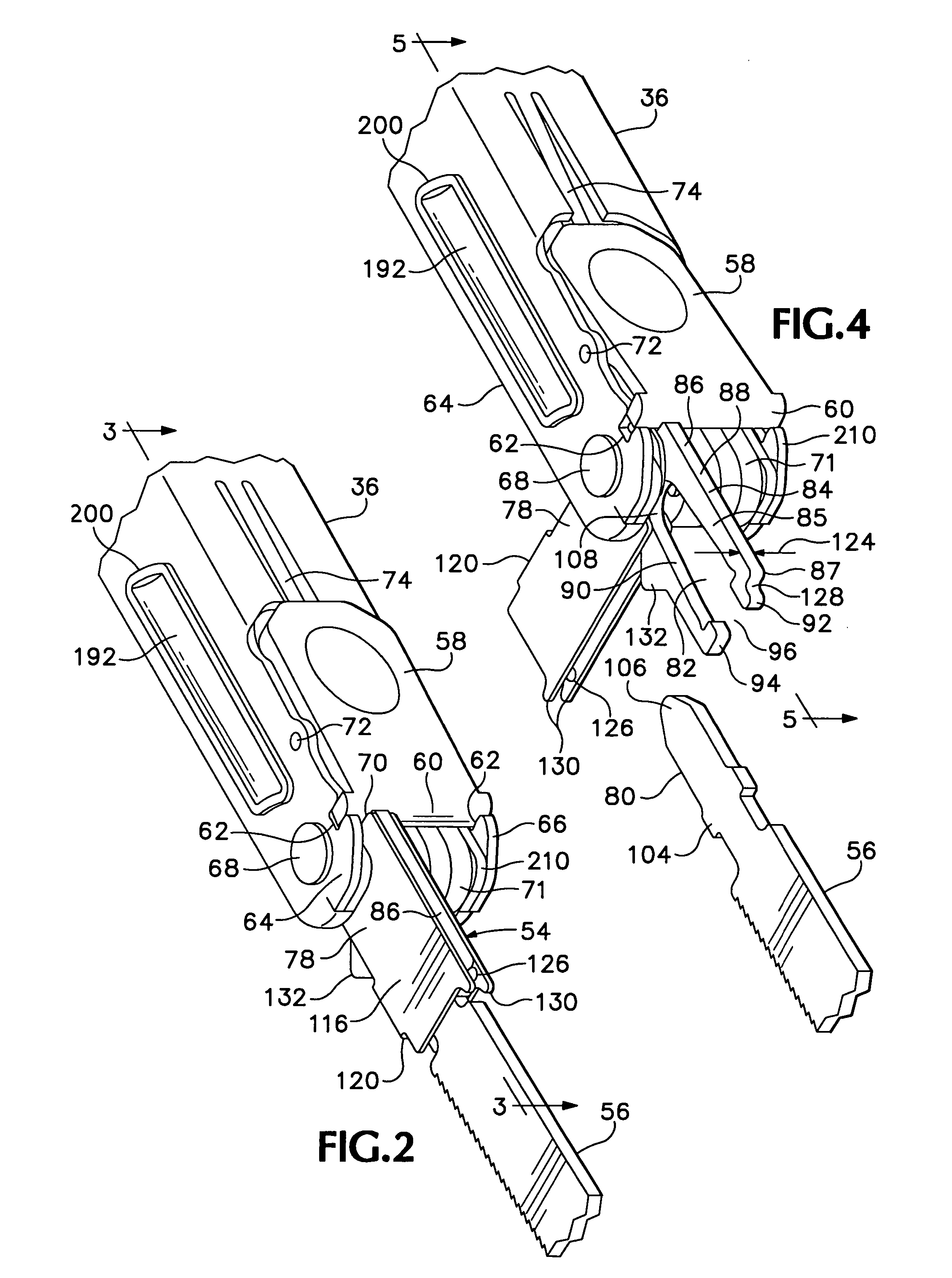

Multipurpose tool including holder for replaceable tool blades

A multipurpose folding hand tool including a tool holder permitting exchanges of blades. The tool may include a folding scissors including a spring that is moved into operative engagement with a scissors handle to open the scissors handles apart from each other only as the scissors approaches an extended, operative position with respect to the handle of the folding land tool, within which it may be stowed. A resilient grip member is incorporated in one of the handles of the folding multipurpose hand tool. A wire cutter and a crimping tool are located on pliers jaw tangs, between the pliers pivot and the foldable handles of the tool.

Owner:LEATHERMAN TOOL GROUP

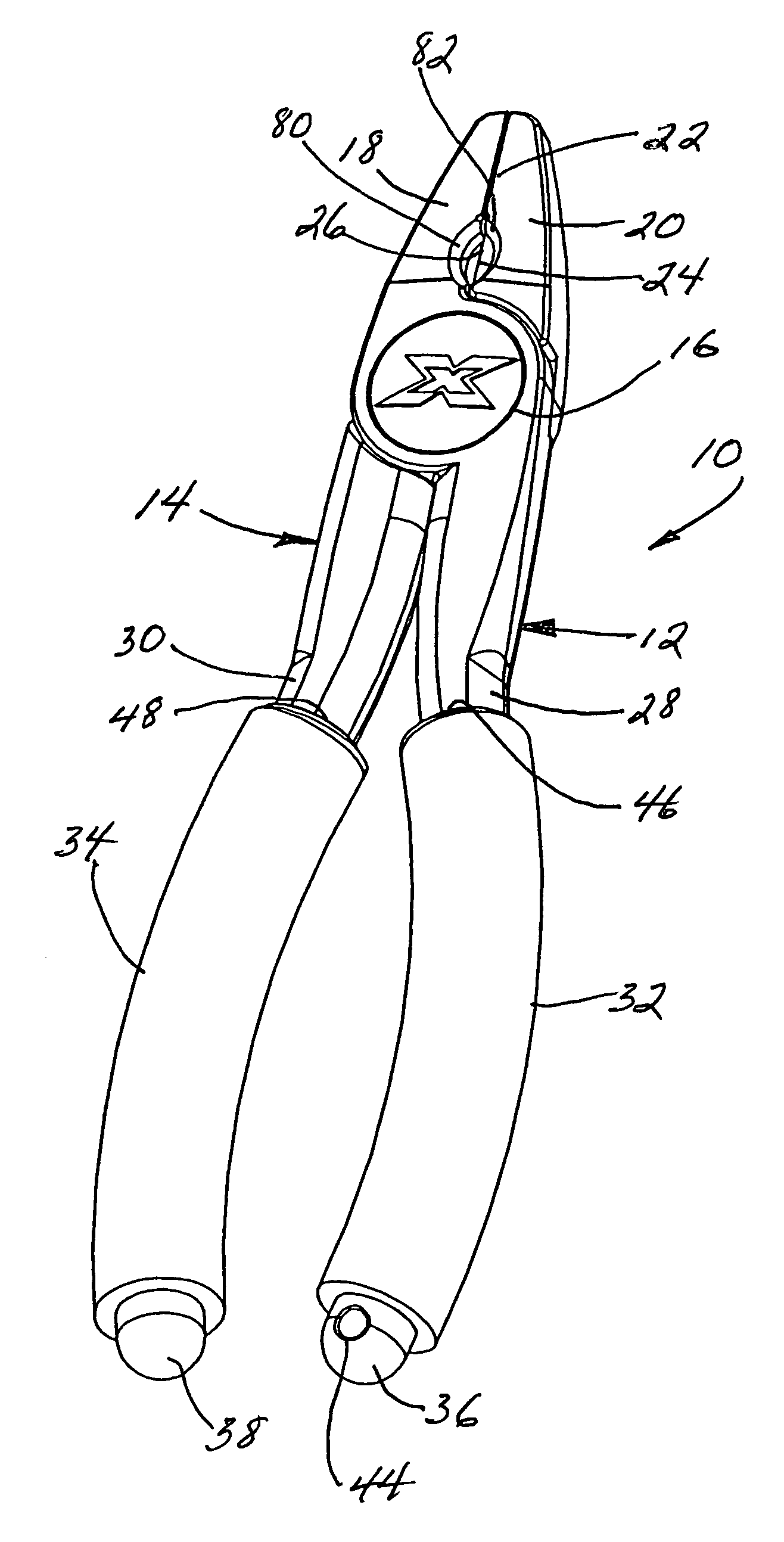

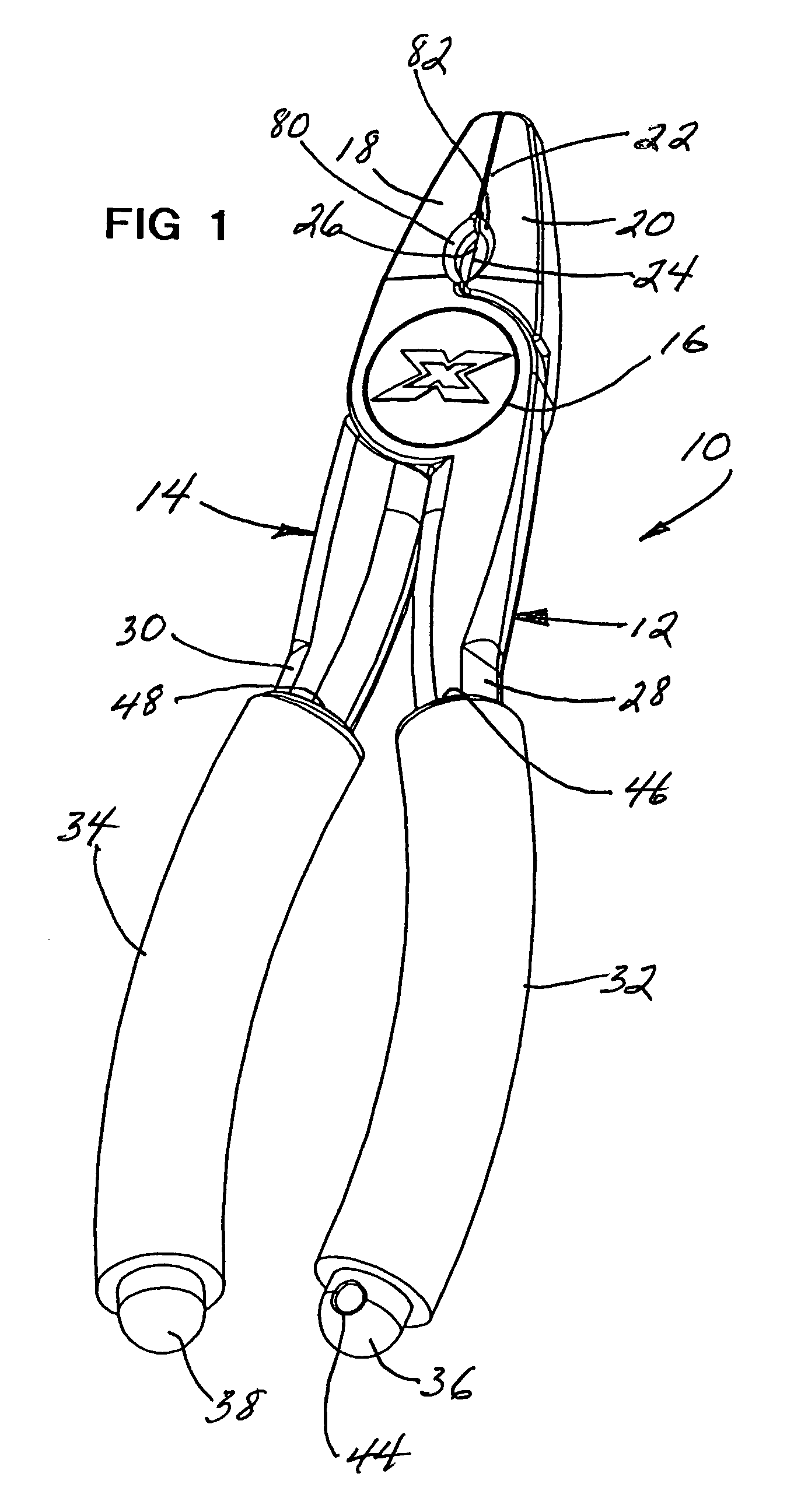

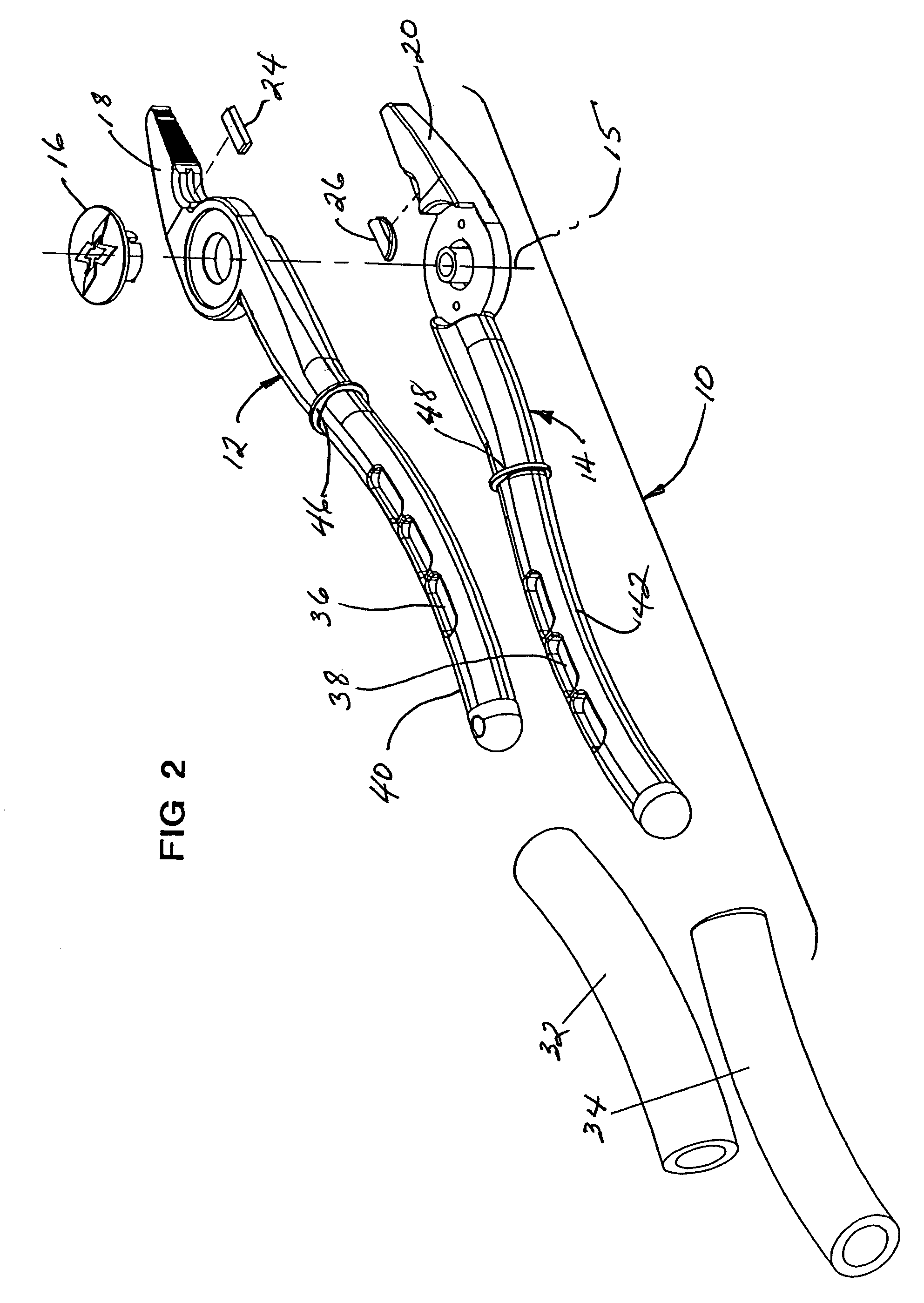

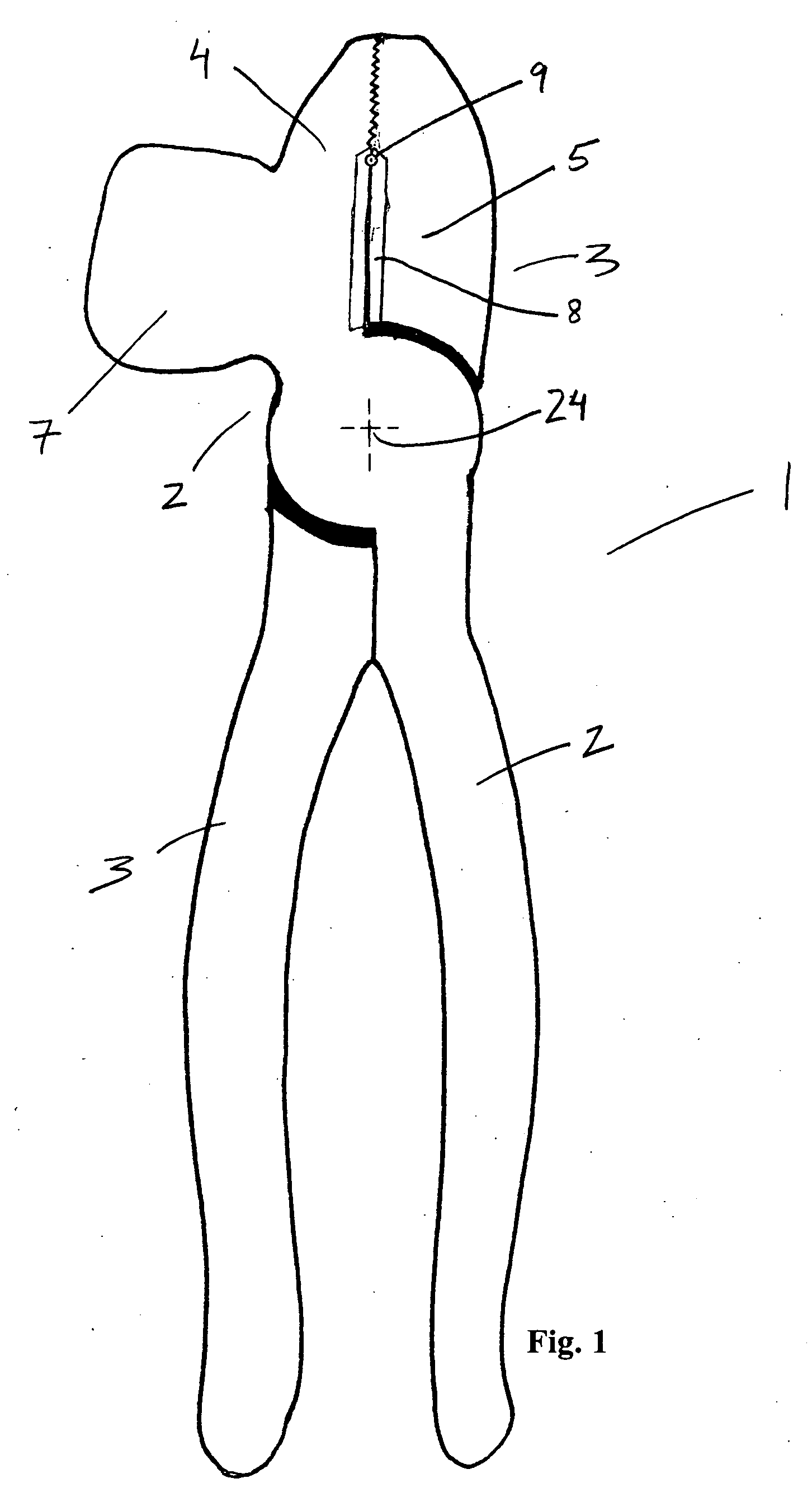

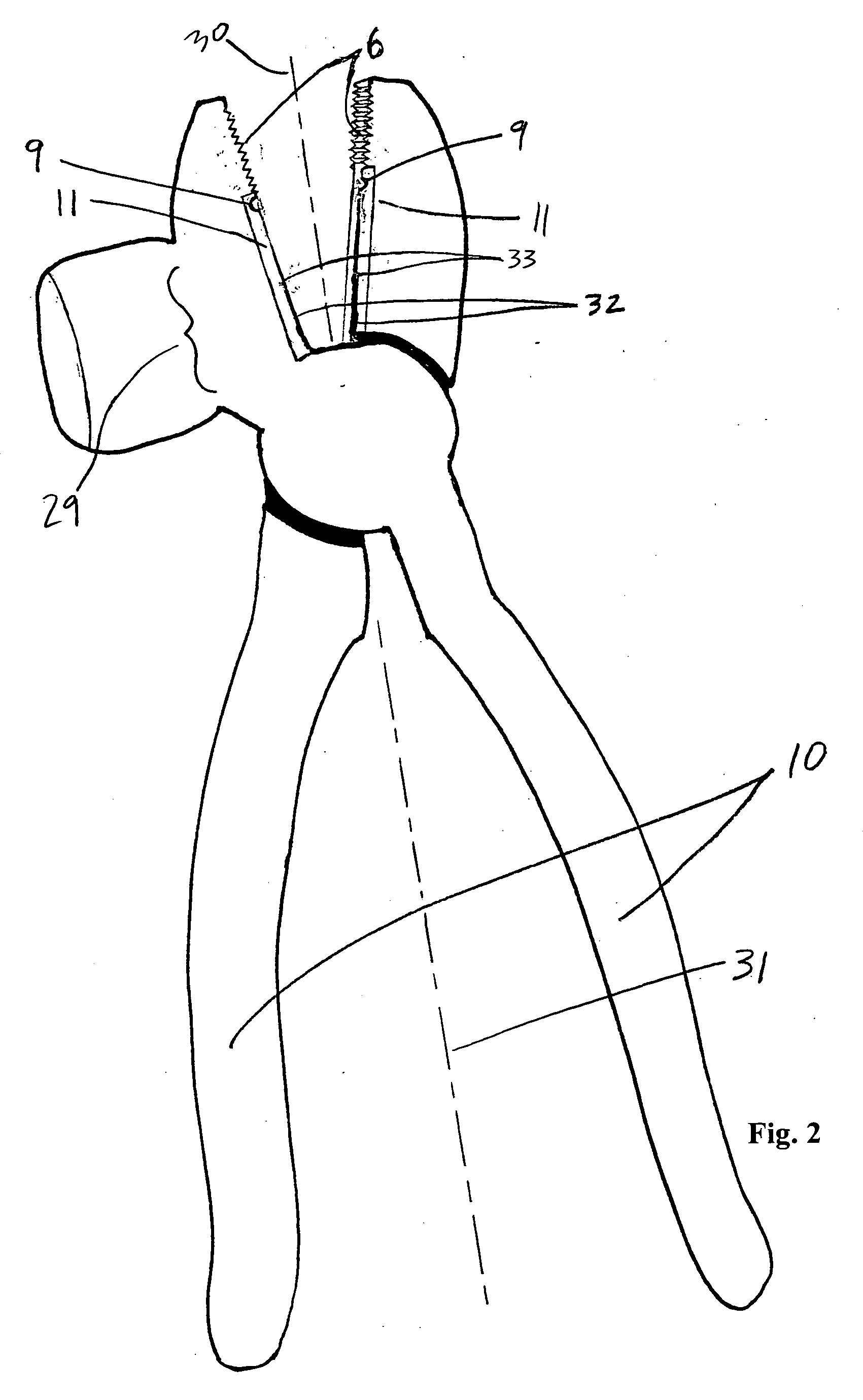

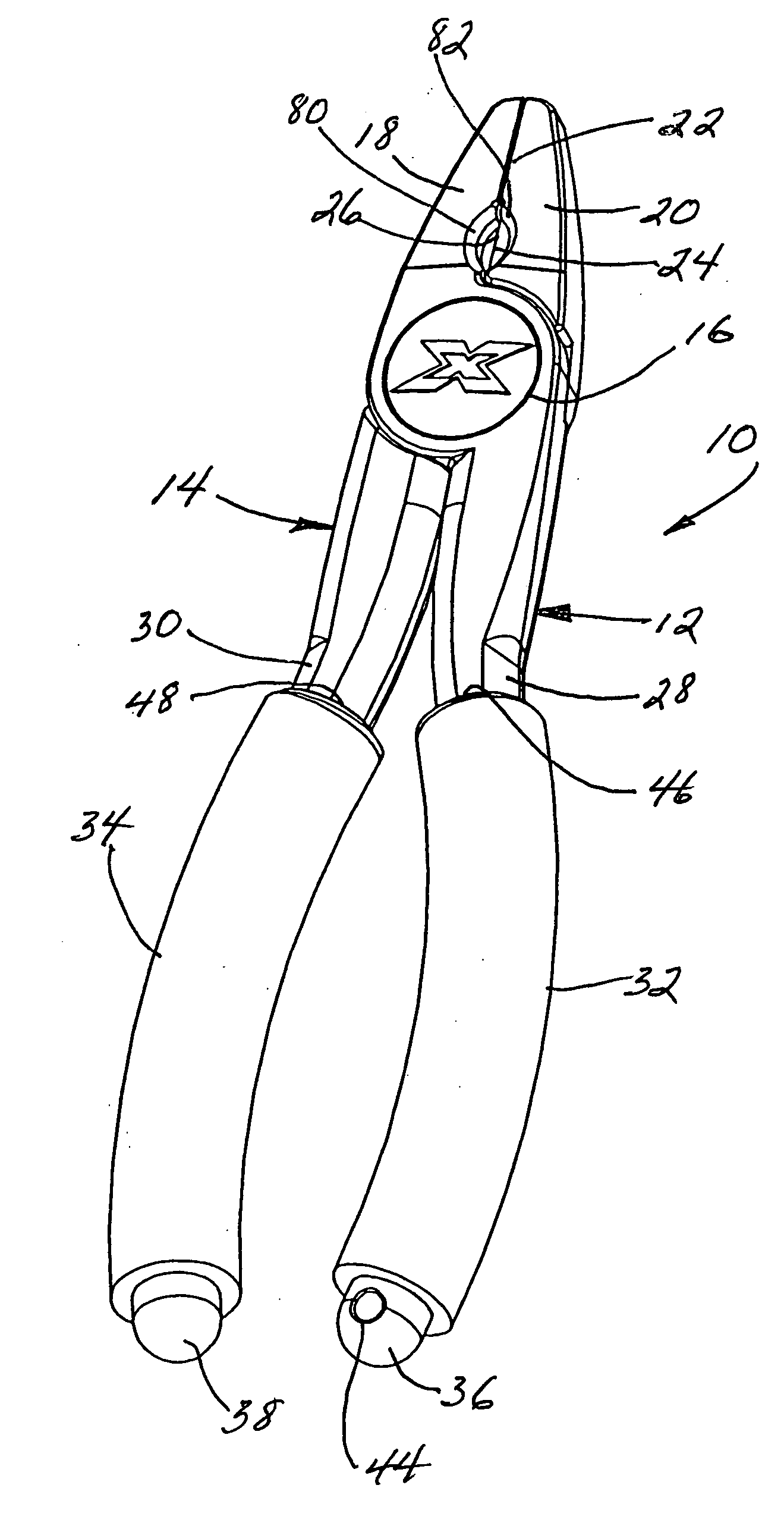

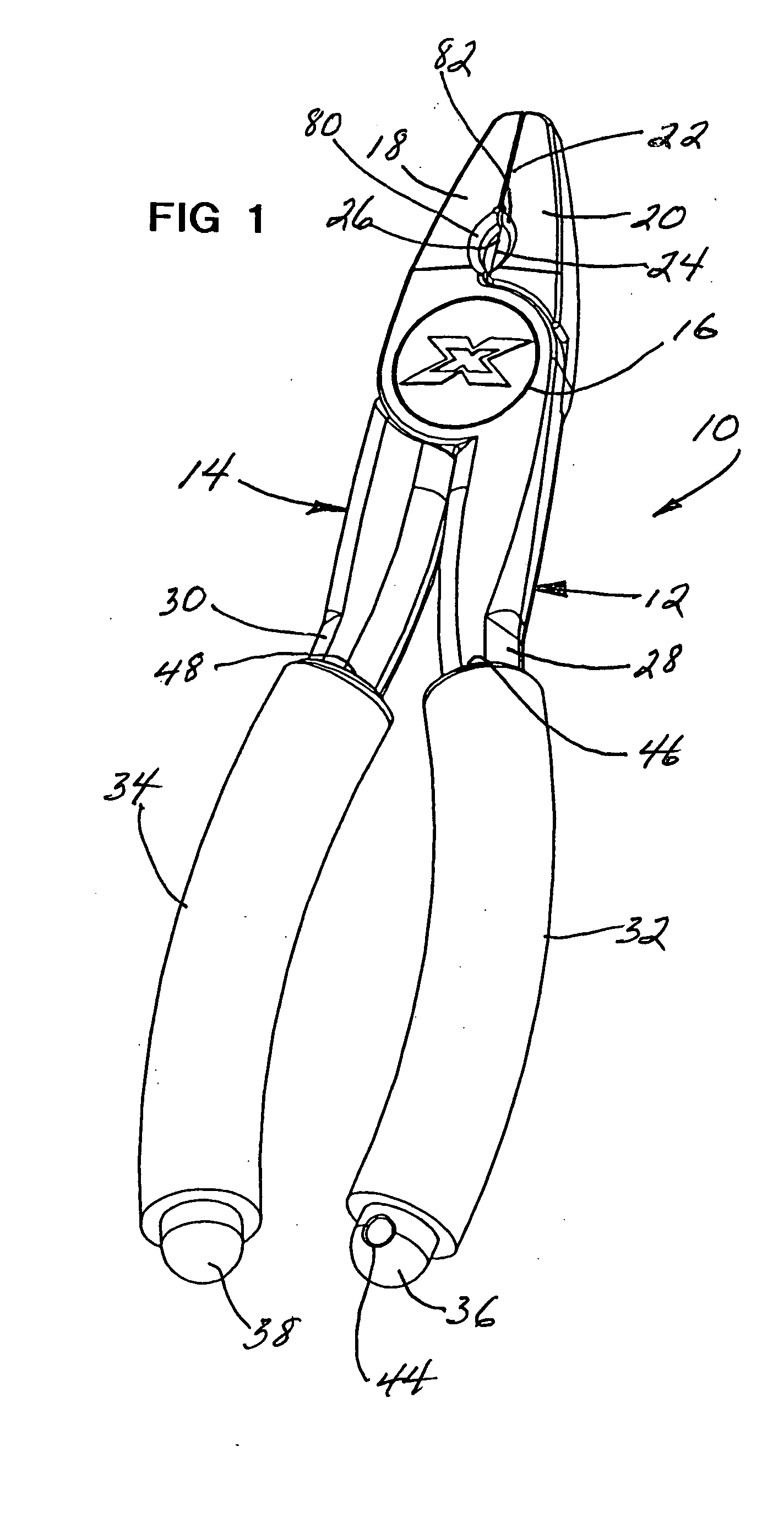

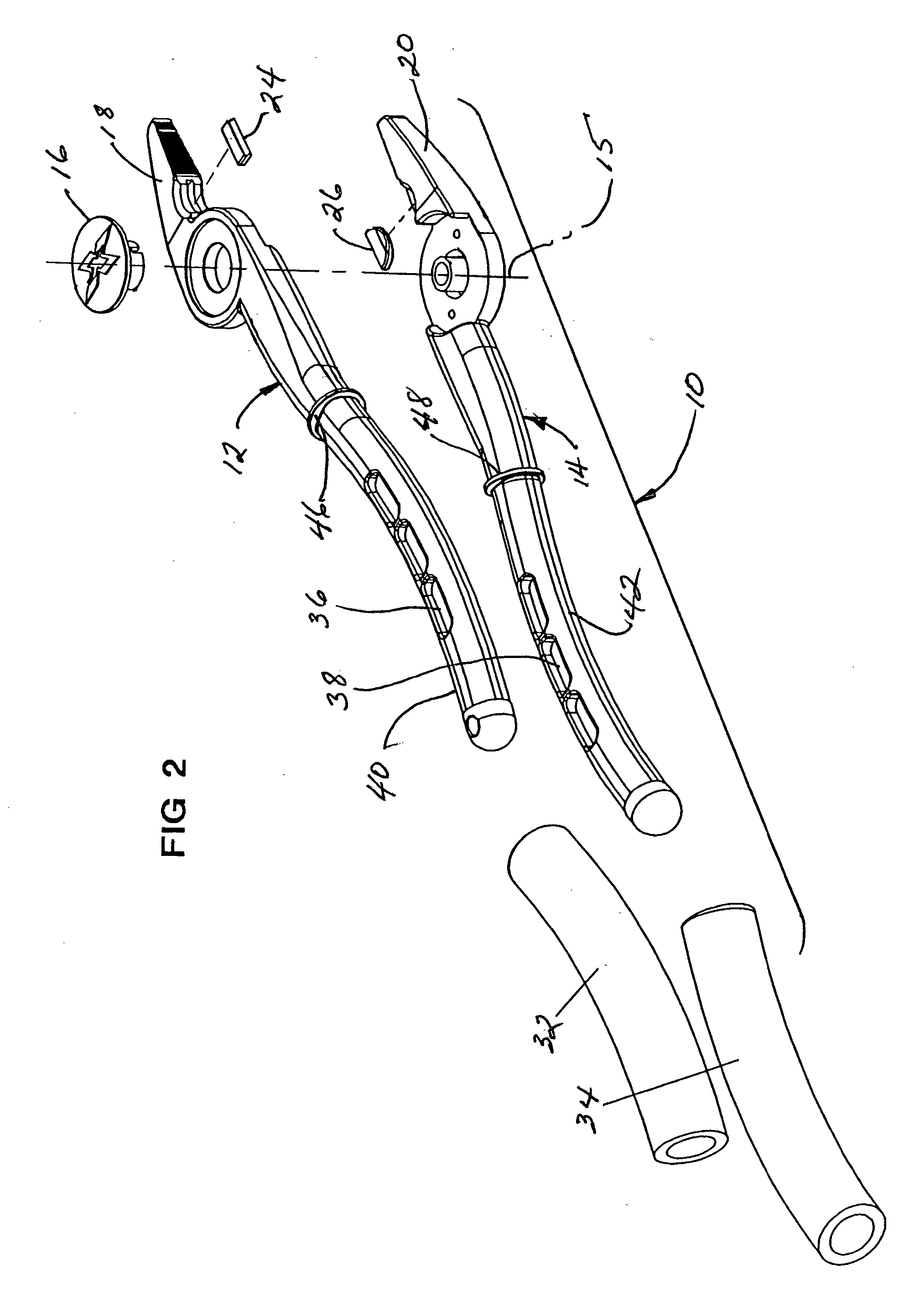

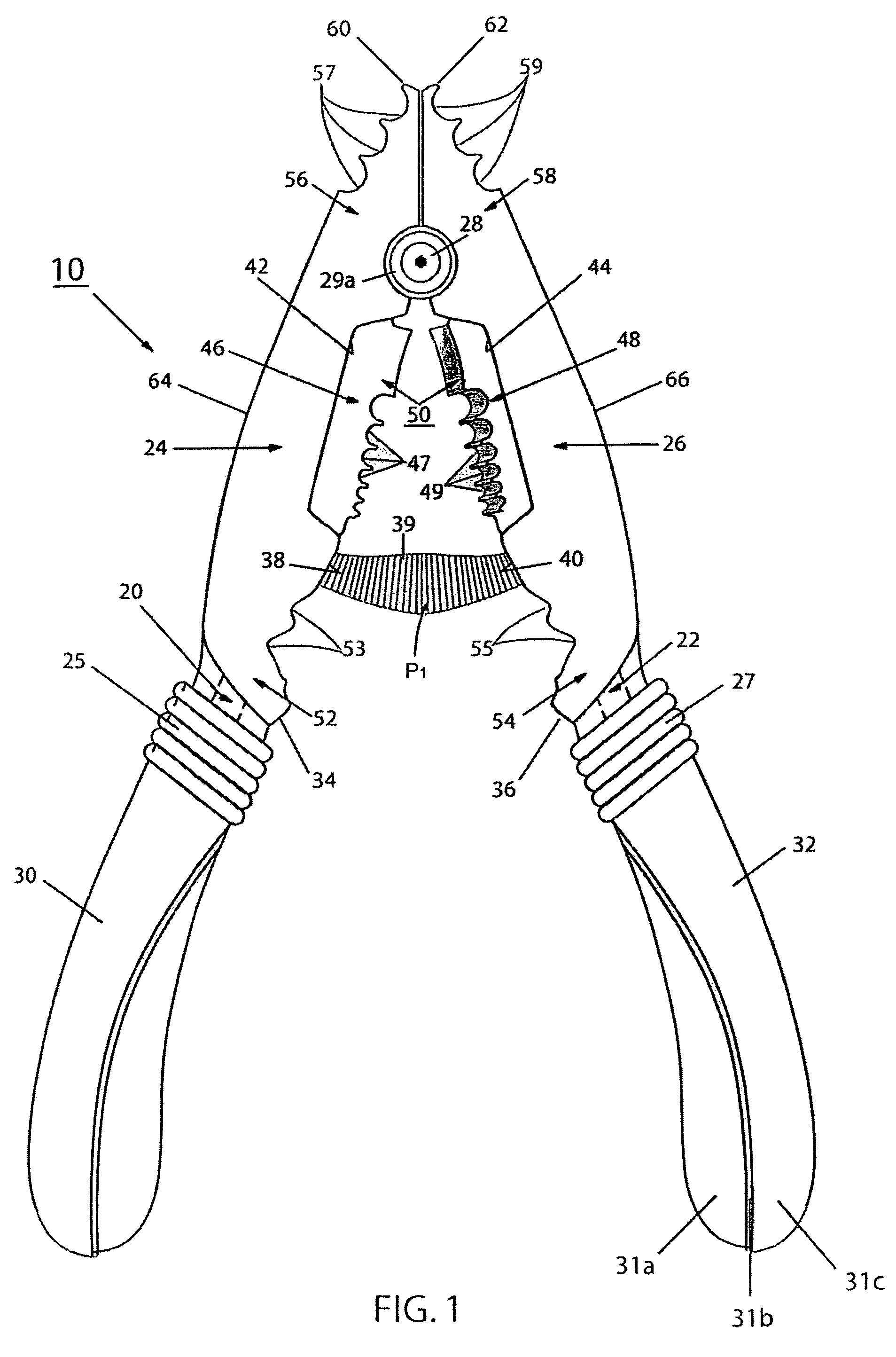

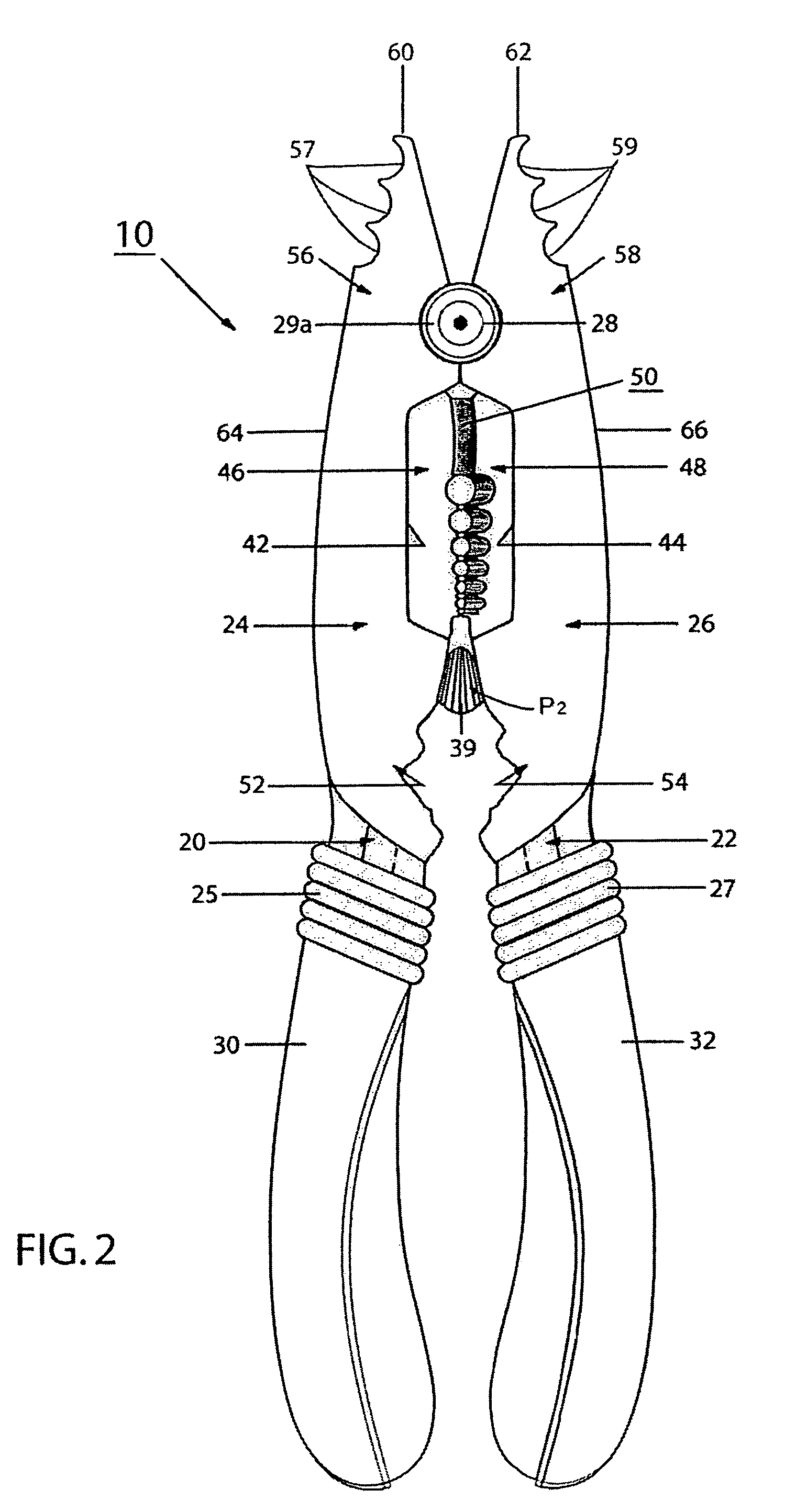

Non-metallic hand pliers with wire cutter

InactiveUS6966244B2Efficient arrangementReduce arrangementPliersMetal working apparatusEffective densityWire cutting

A pair of preferably substantially buoyant-in-water hand pliers comprising a pair of non-metallic lever members each having a handle portion and a jaw portion and formed of material preferably having a density greater than water. The lever members are pivotally connected together at common central portions between the jaw and handle portions. Each handle portion preferably has one or more outwardly opening cavities formed into a side surface of the handle portions. An elongated tubular sheath preferably formed of material buoyant in water covers and sealingly encloses the cavities whereby the effective density of the pliers is less than that of water. An effective, durable, non-corrosive wire cutting arrangement is also provided, the components uniquely configured and supported in the non-metallic jaw portions.

Owner:SHAKESPEARE CO

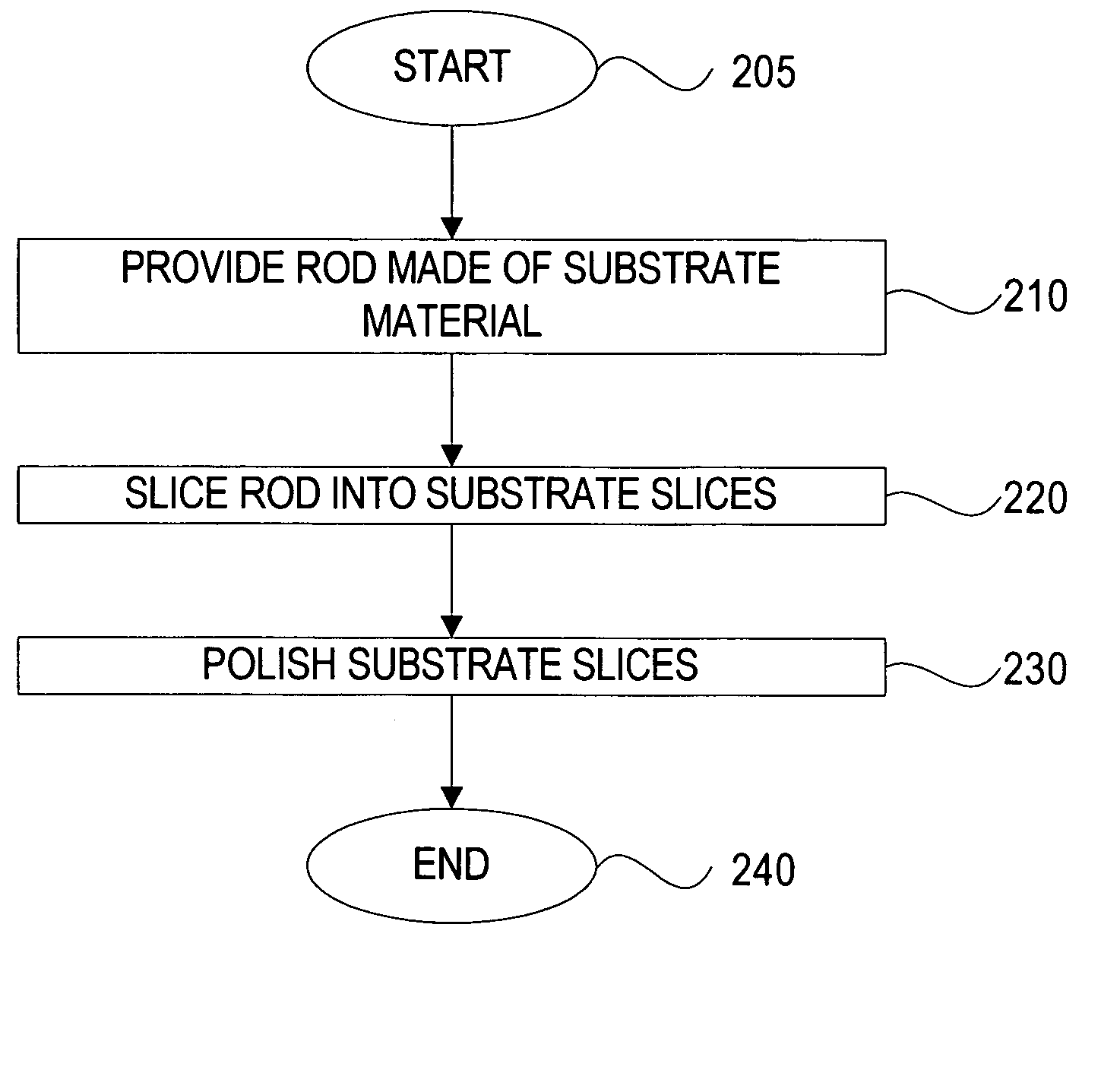

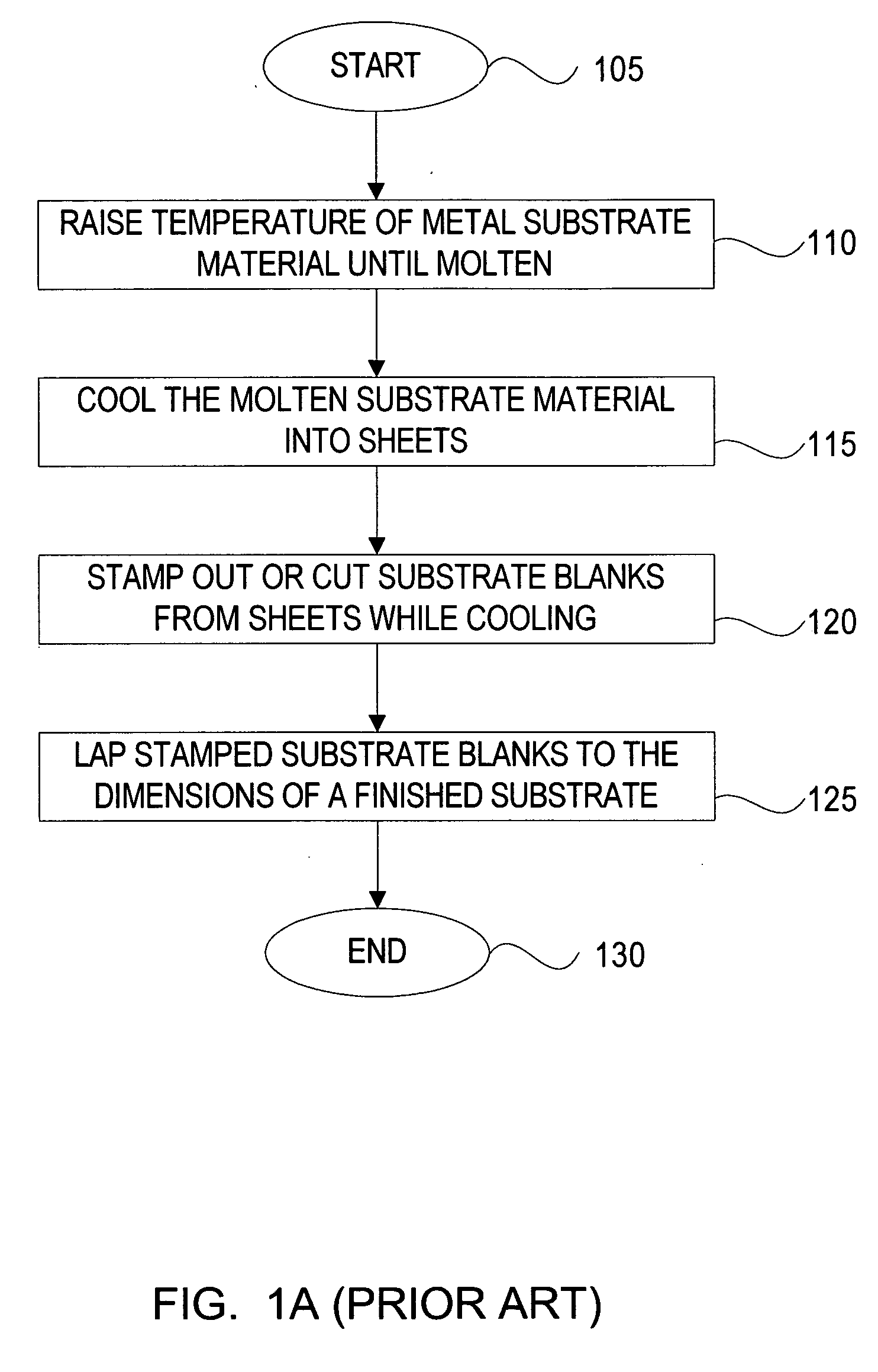

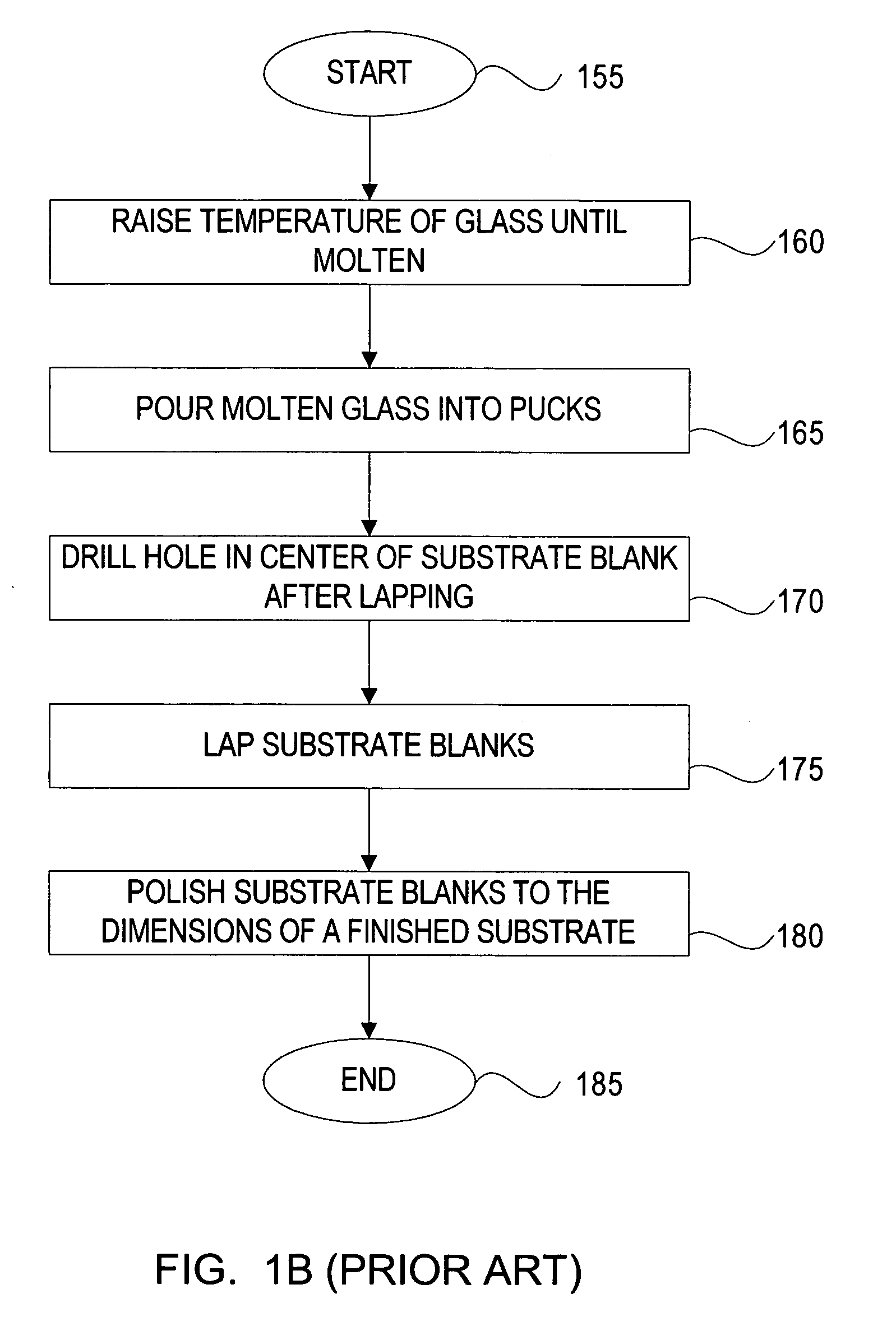

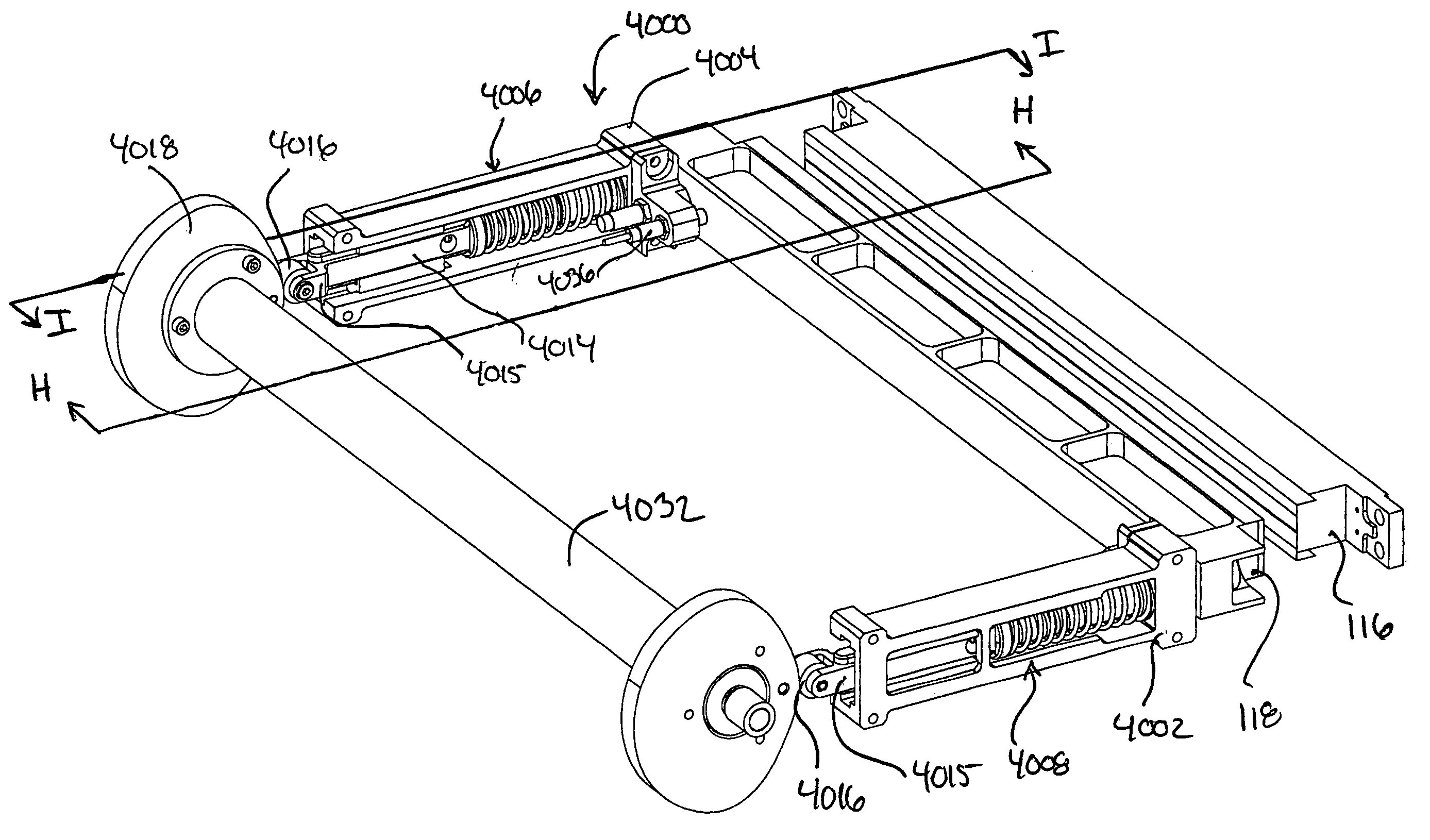

Method of making substrates for media used in hard drives

InactiveUS20060109591A1Simpler and cheapLow costRecord information storageDisk carriersHard disc driveEngineering

A method for making substrates is disclosed. The method comprises providing a rod, which is made out of a substrate material and has an outside diameter substantially the same size as the outside diameter of a finished substrate and an inside diameter substantially the same size as the inside diameter of the finished substrate. The rod is cut with a multi-wire cutter to make a substrate slice substantially the same size as a finished substrate. The multi-wire cutter has wires positioned to substantially match the final thickness of the finished substrate. Additionally the cutting process is facilitated by using slurry and by providing a rocking motion between the rod and the wires of the multi-wire cutter so that the wires contact the rod in a rocking motion with respect to a normal to the center of the rod.

Owner:SEAGATE TECH LLC

Universal tracked mobile platform for military robot

InactiveCN101850792AExtended range of motionImprove athletic abilityEndless track vehiclesControl mannerSimulation

The invention relates to a universal tracked mobile platform for a military robot. The universal tracked mobile platform can flexibly adjust gravity centre distribution and position attitude to increase the range of activity; the overall platform follows a principle of compact design, and has the characteristics of light weight, portability and miniature size; a reserved expansion area can be provided with various functional modules such as a multi-freedom-degree mechanical arm, a bubble gun, a wire cutter, a small-sized communication relay station, small arms and the like; therefore action competence and application range of the universal tracked mobile platform are increased greatly; and convenience for assembling various military robots and specialized robots is brought. The universal tracked mobile platform operates stably and reliably by adopting an intelligent control mode and self-diagnosis technology.

Owner:武汉若比特机器人有限公司

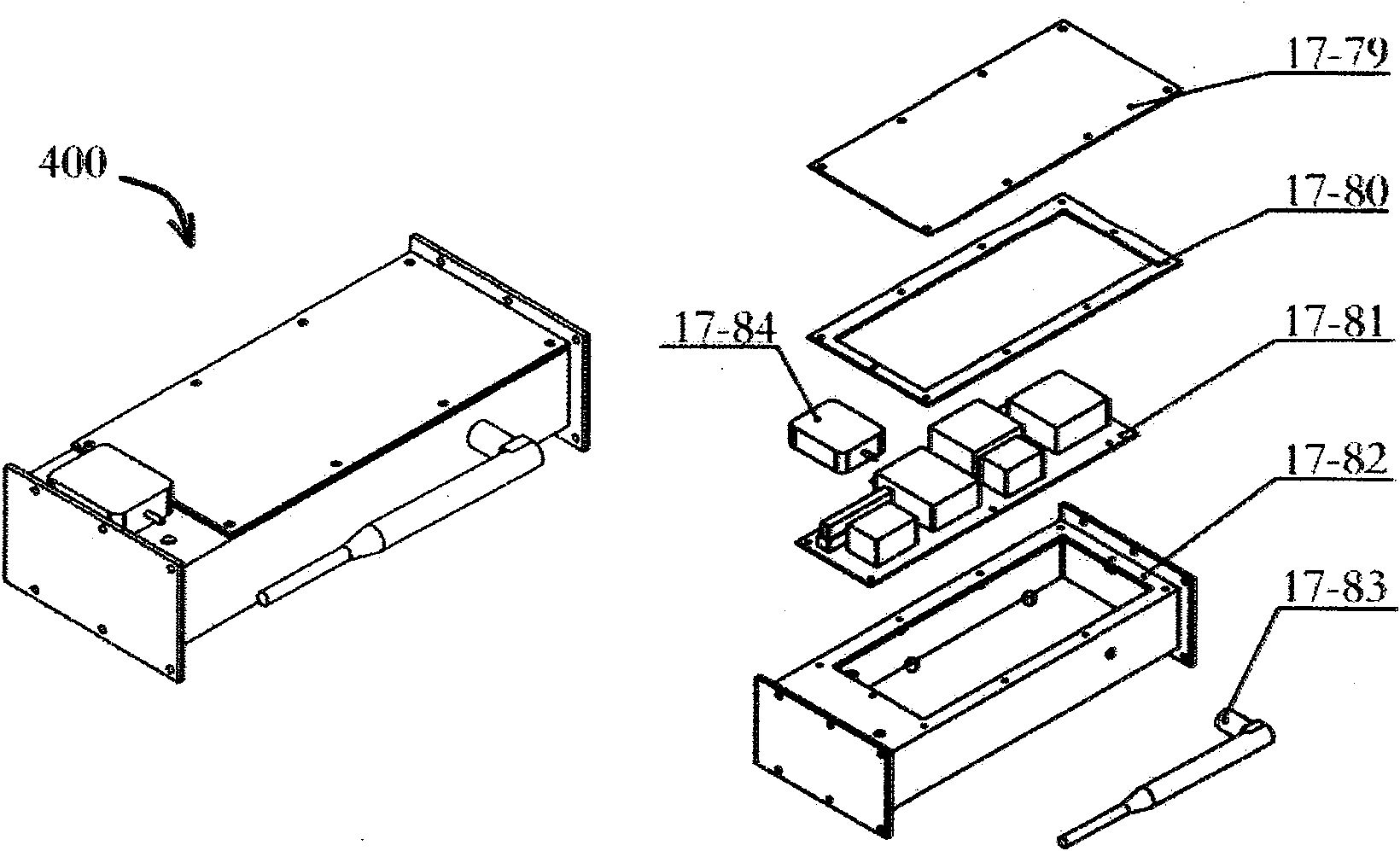

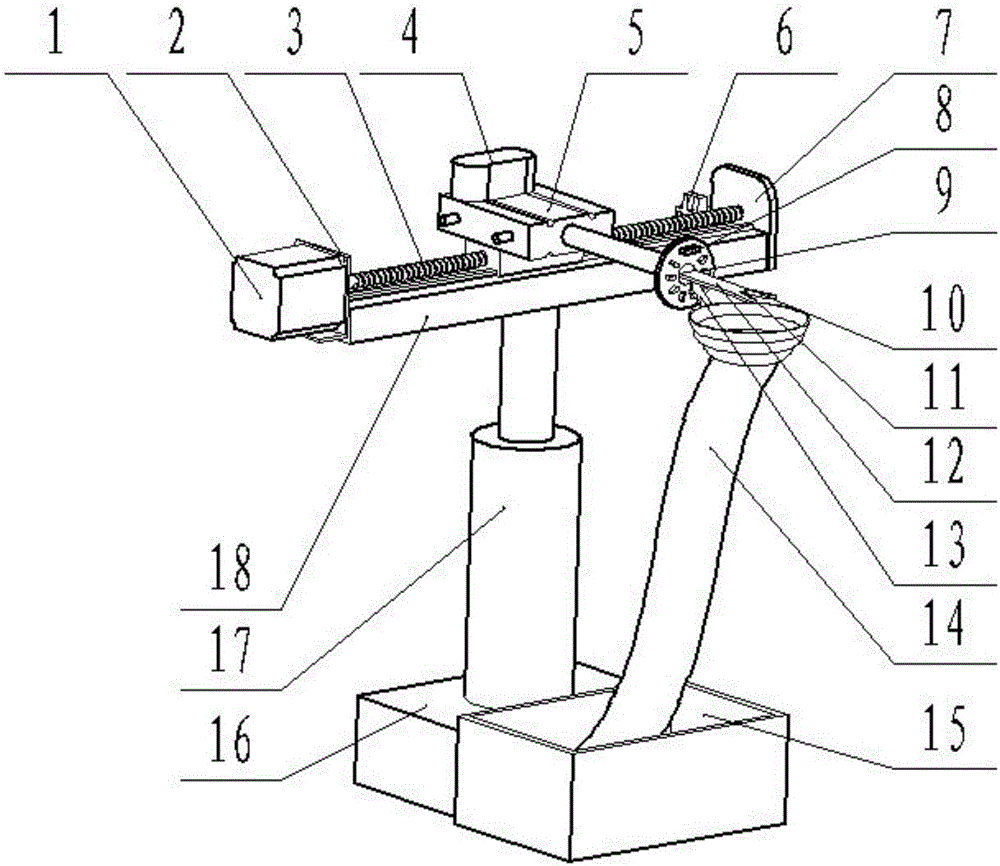

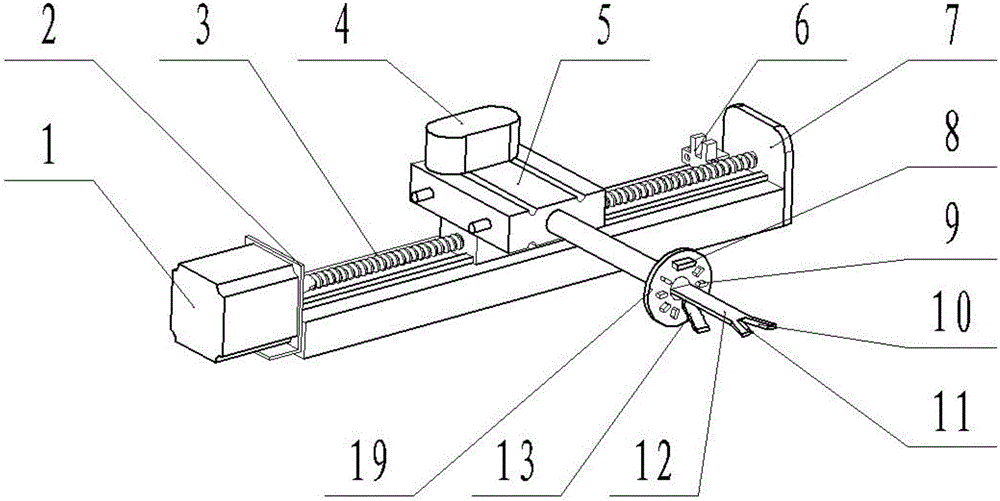

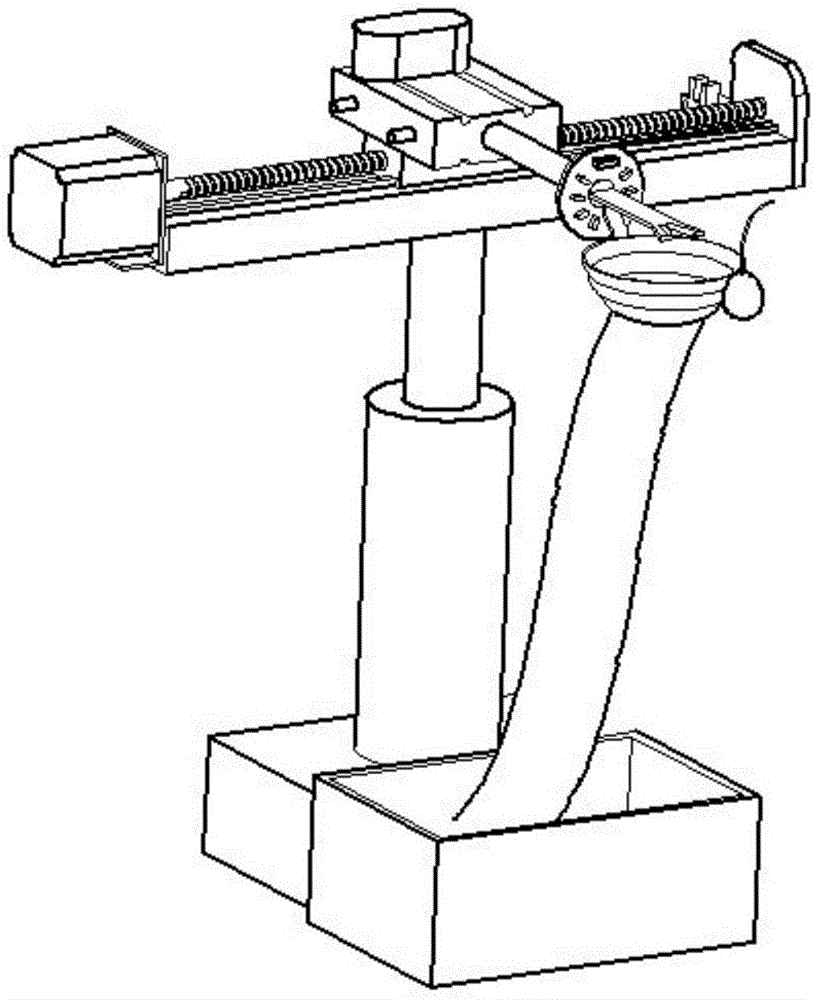

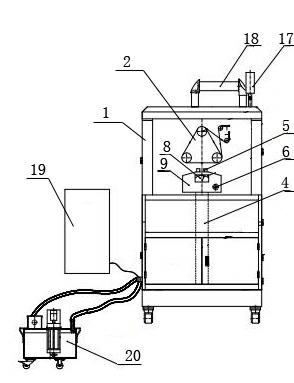

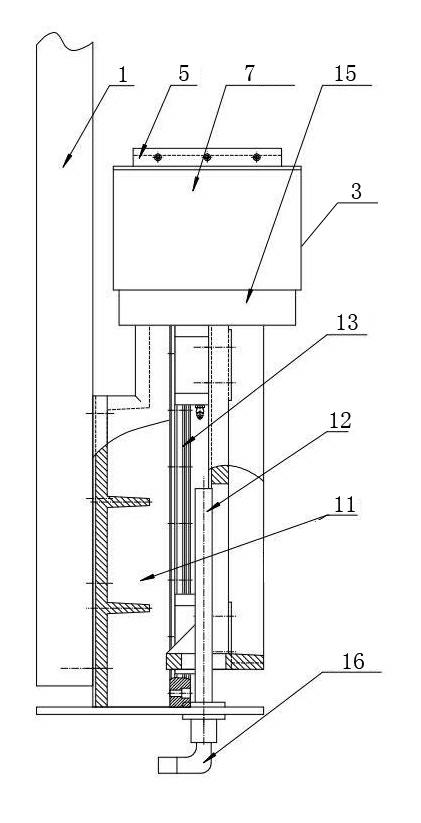

Internal and external wire-winding type motor stator wire-winding device, wire-winding control method and winding method

ActiveCN102684420AAdapt to winding requirementsConvenient and fast circular winding actionManufacturing dynamo-electric machinesElectric machineProgrammable logic controller

The invention relates to an internal and external wire-winding type motor stator wire-winding device, a wire-winding control method and a winding method. The internal and external wire-winding type motor stator wire-winding device comprises a base plate, and a position movement mechanism and a cage type wire-winding mechanism, which are arranged on the base plate, wherein a supporting arm which can perform three-dimensional motion is carried on the position movement mechanism; a wire-winding driving mechanism is arranged on the supporting arm; an electric control module is arranged in a control cabinet under the base plate; and the whole machine also comprises power equipment and a synchronous rotary mechanism which supplies power to the position movement mechanism and the cage type wire-winding mechanism. The control method comprises the following steps that: (1) a programmable logic controller (PLC) unit sends a pulse command, a motor and an air cylinder receive the pulse command from the PLC unit, and the supporting arm drives a wire-winding fixing plate to perform three-dimensional motion; (2) the cage type wire-winding mechanism performs wire-winding motion; and (3) the air cylinder drives a wire cutter to finish cut-off motion of a copper wire.

Owner:珠海市台金科技有限公司

Peeling apparatus and peeling method

InactiveCN104347449AImprove stripping efficiencyLow costLamination ancillary operationsLaminationWire cutterMoving parts

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

Combination tool

At least one embodiment of the inventive technology may be a combination tool apparatus that comprises a first tool part having a first plier jaw and a second tool part having a second plier jaw rotatable relative to an axis of rotation; compressive grip surfaces; a hammer head; a wire cutter element; a wire stripper element; and a handle. In certain of the many embodiments, the hammer head may be established within certain dimensional constraints relative to other part(s) of the tool, and / or the apparatus may not comprise a nail pulling claw.

Owner:SIEBECK ROY

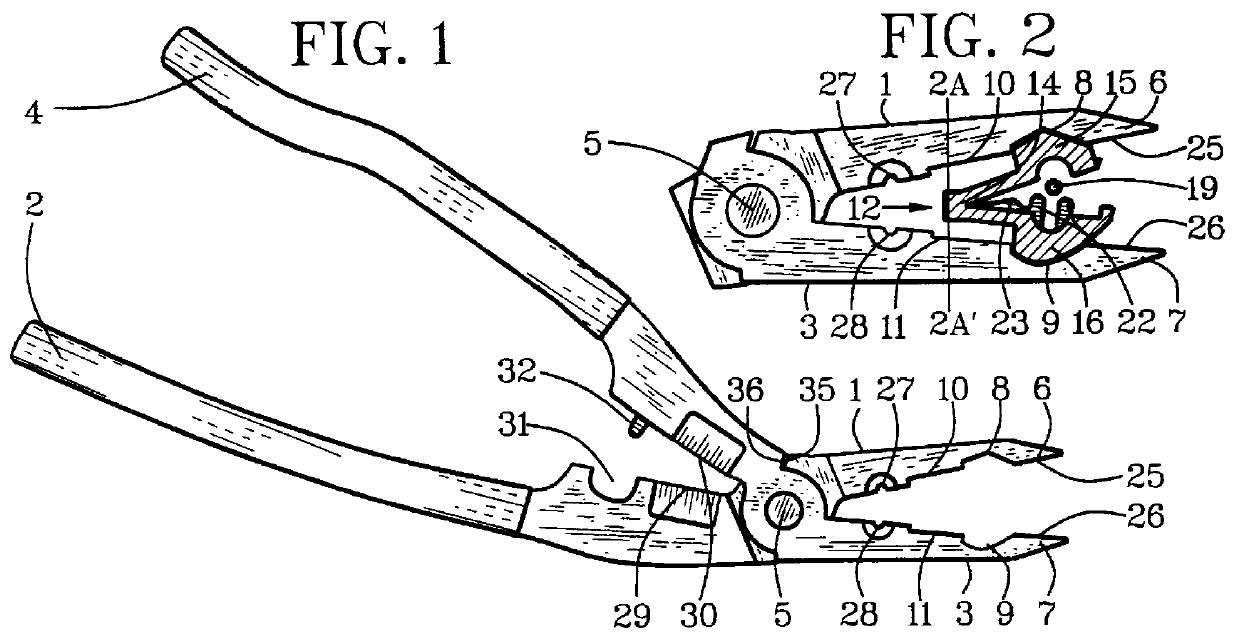

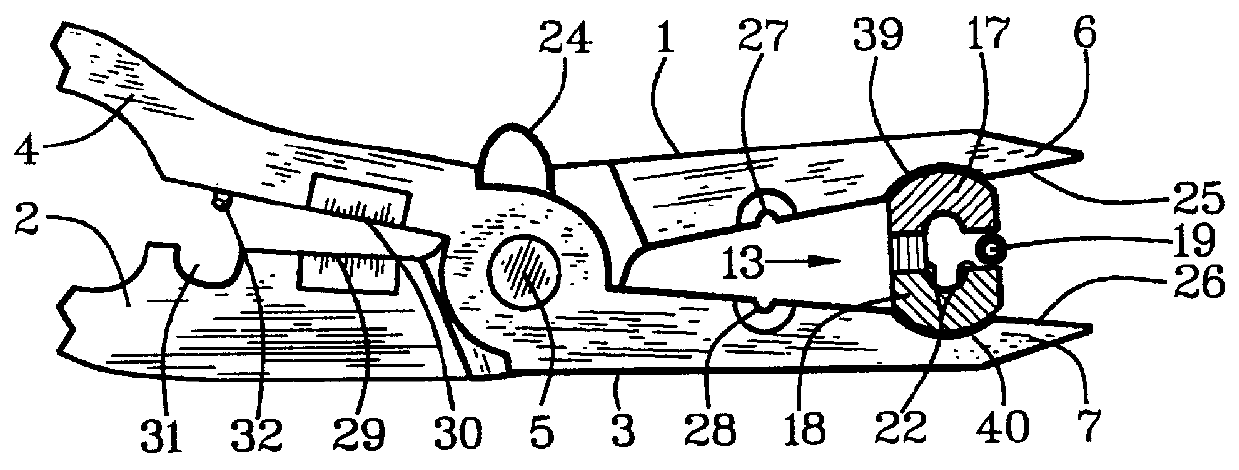

Electrical T fastener pliers and method

An electrical T-fastener pliers has jaws (1, 3) with grip bays (8, 9, 39, 40) that are positioned on T-joint fastener jaws (15, 16, 17, 18) to be clamped onto targeted wires (19) by hand-squeezing handles (2, 4) of the electrical pliers. Jaws of the T-joint fasteners (12) are pressured against jaws of the pliers by outward pressure of outwardly sprung T-joint fasteners against designedly opened pliers jaws or optionally by inward pressure of the pliers jaws against jaws of unsprung T-joint fasteners (13). This provides a spring-pressured containment of a T-joint fastener while the pliers are being positioned in T-joining relationship to targeted electrical wiring. The handles can be extended at angles from the jaws to position a bottom handle designedly removed from a working surface in order to provide finger space between a working surface and in order to facilitate positioning the jaws under wires in close proximity to surfaces. Select wire-processor tooling such as wire strippers (27, 28, 33, 34), crimpers (31, 32) and wire cutters (29, 30) is provided on the jaws and on the handles for particular use conditions.

Owner:HAXTON MICHAEL L

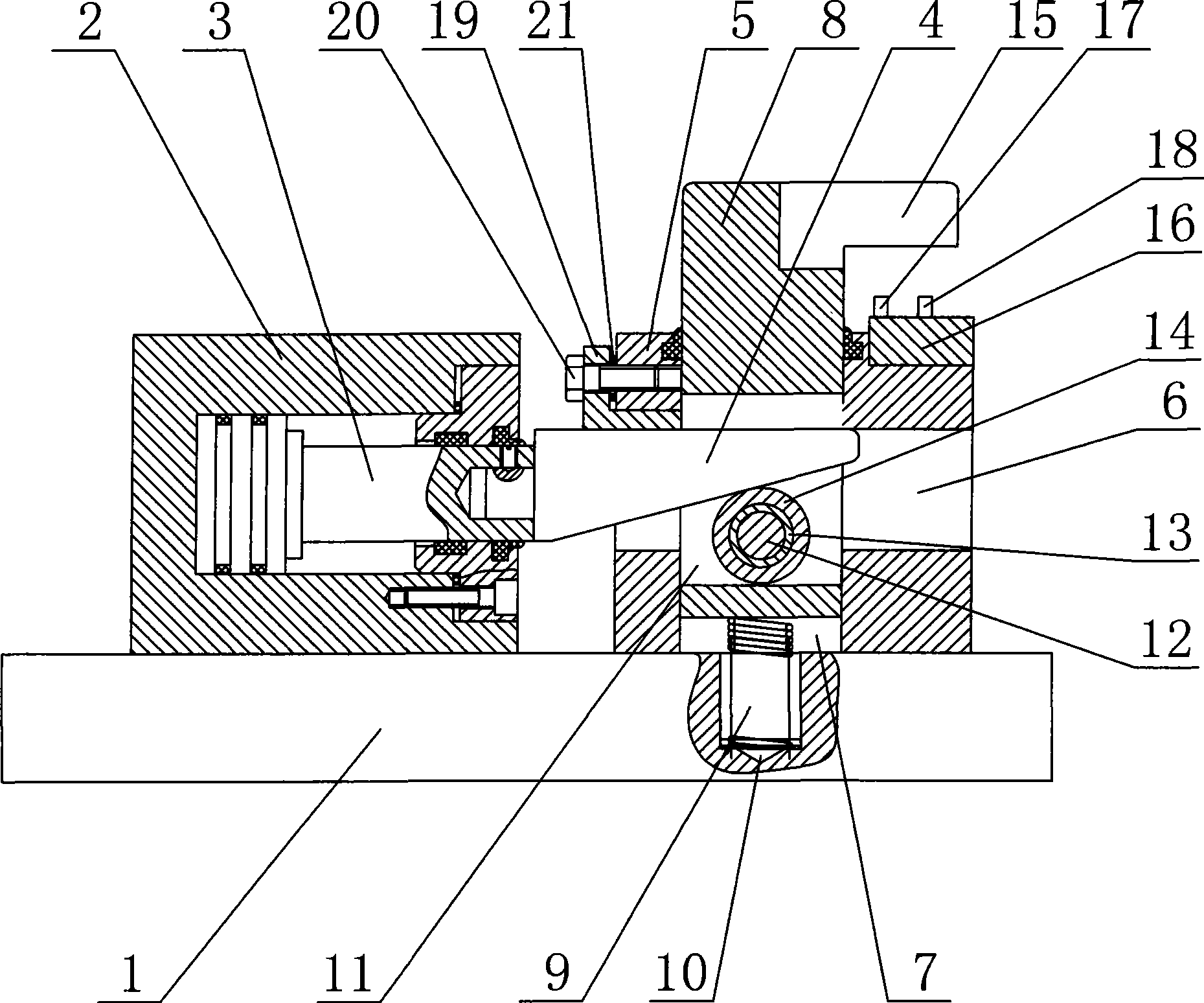

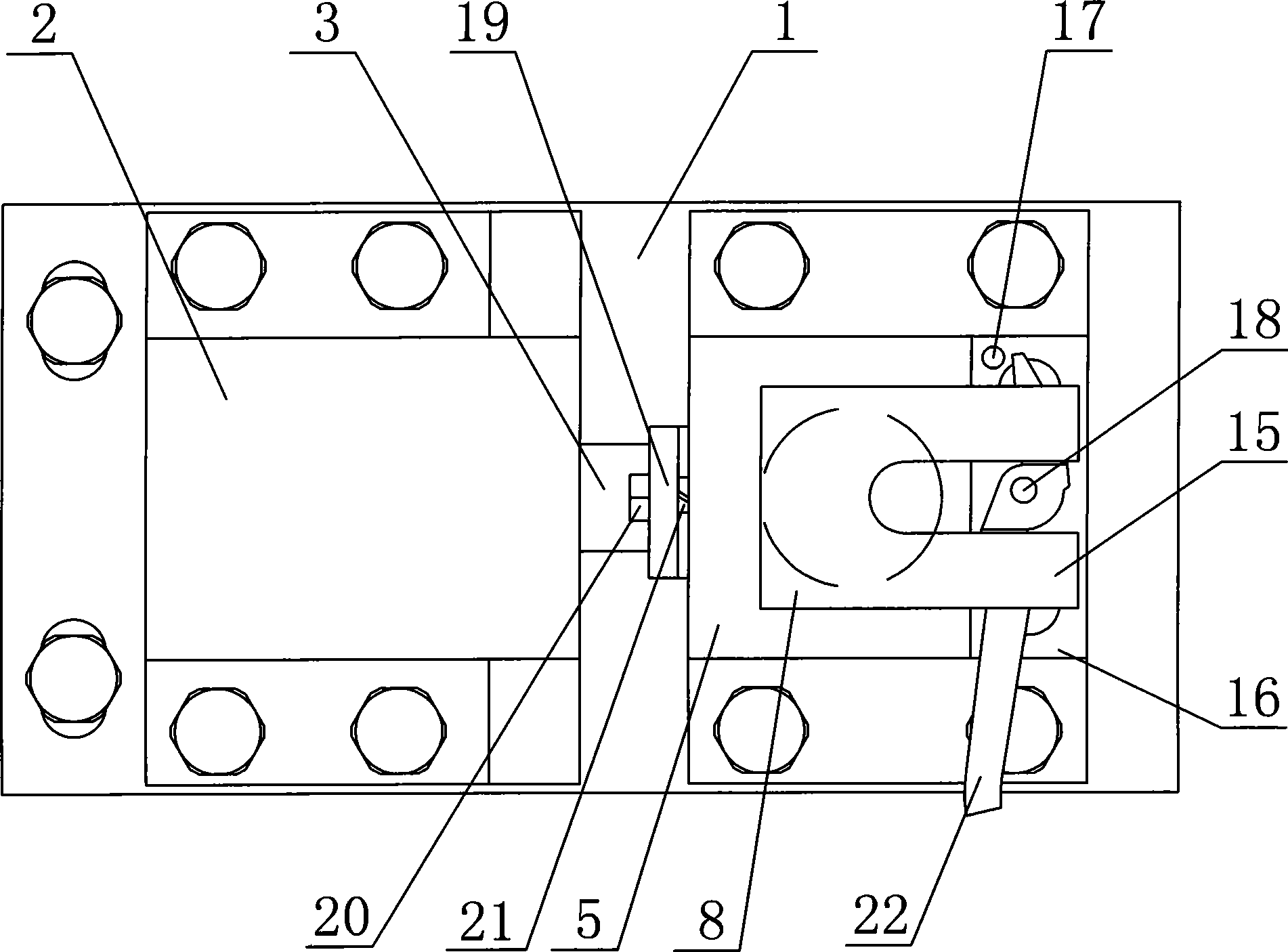

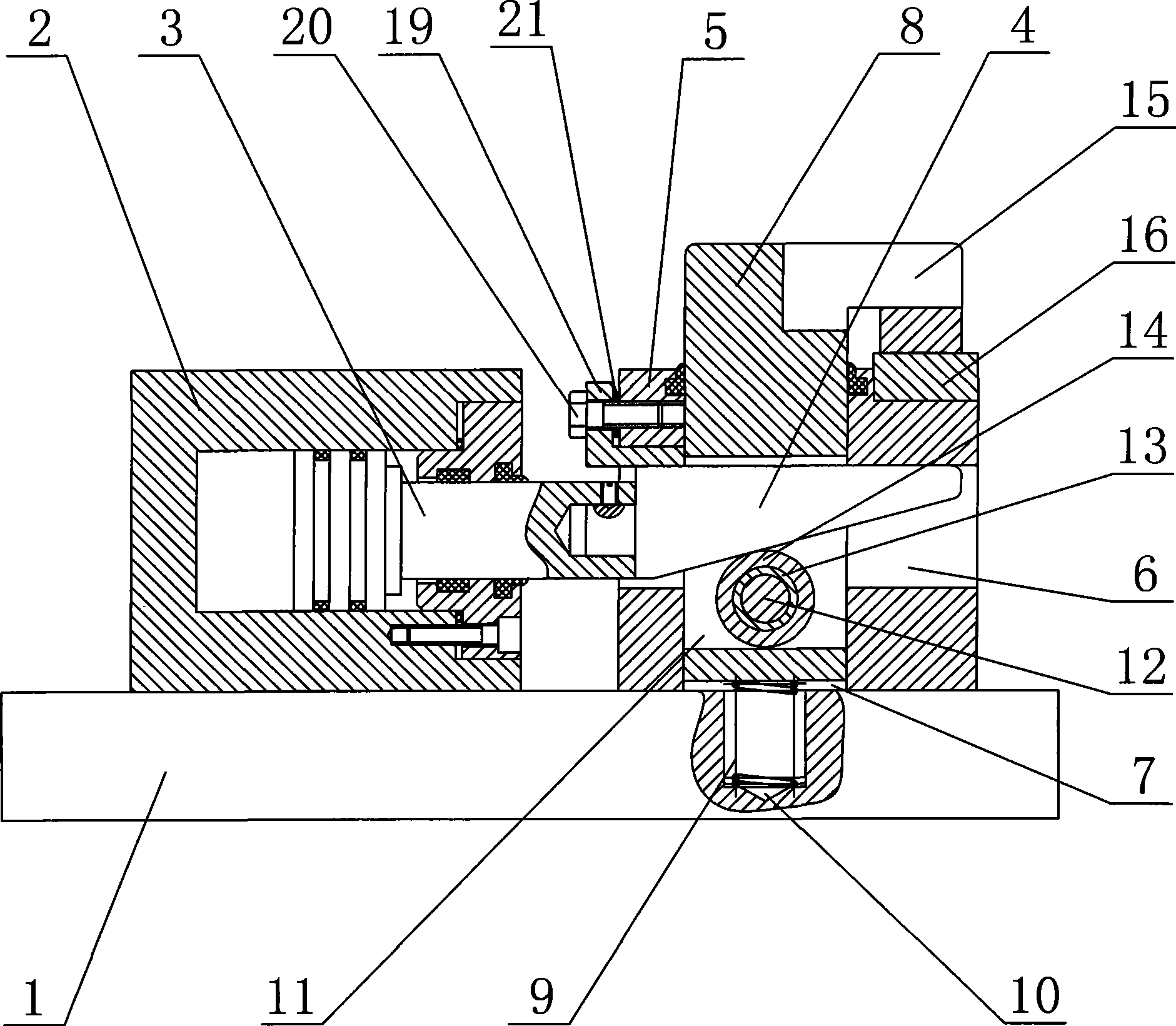

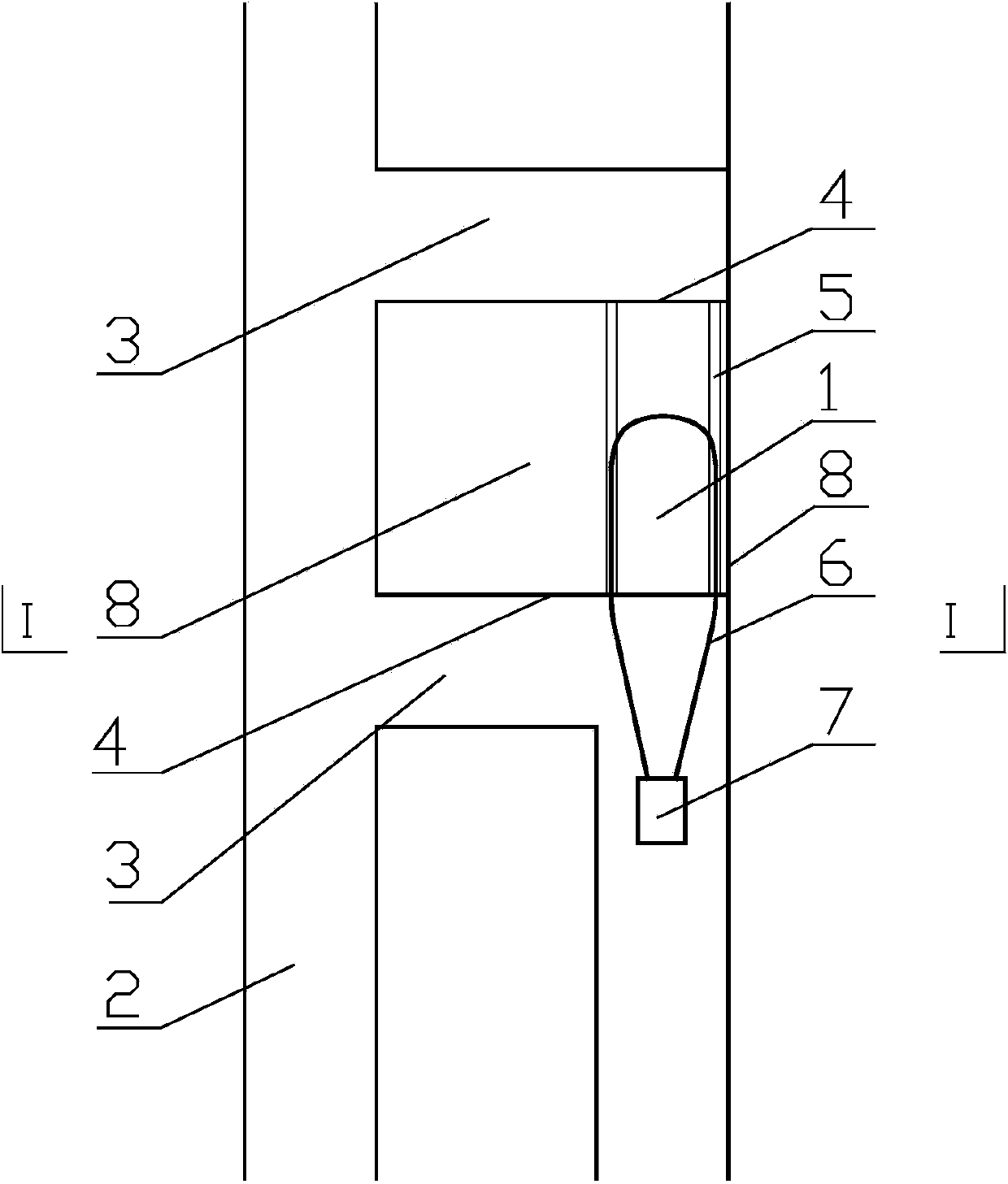

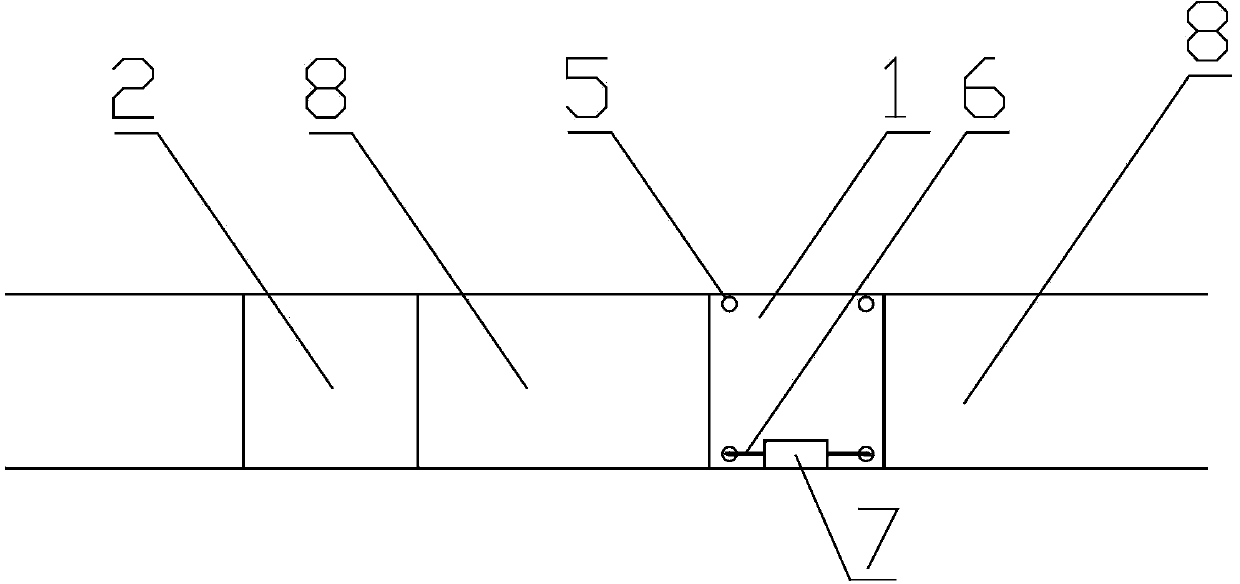

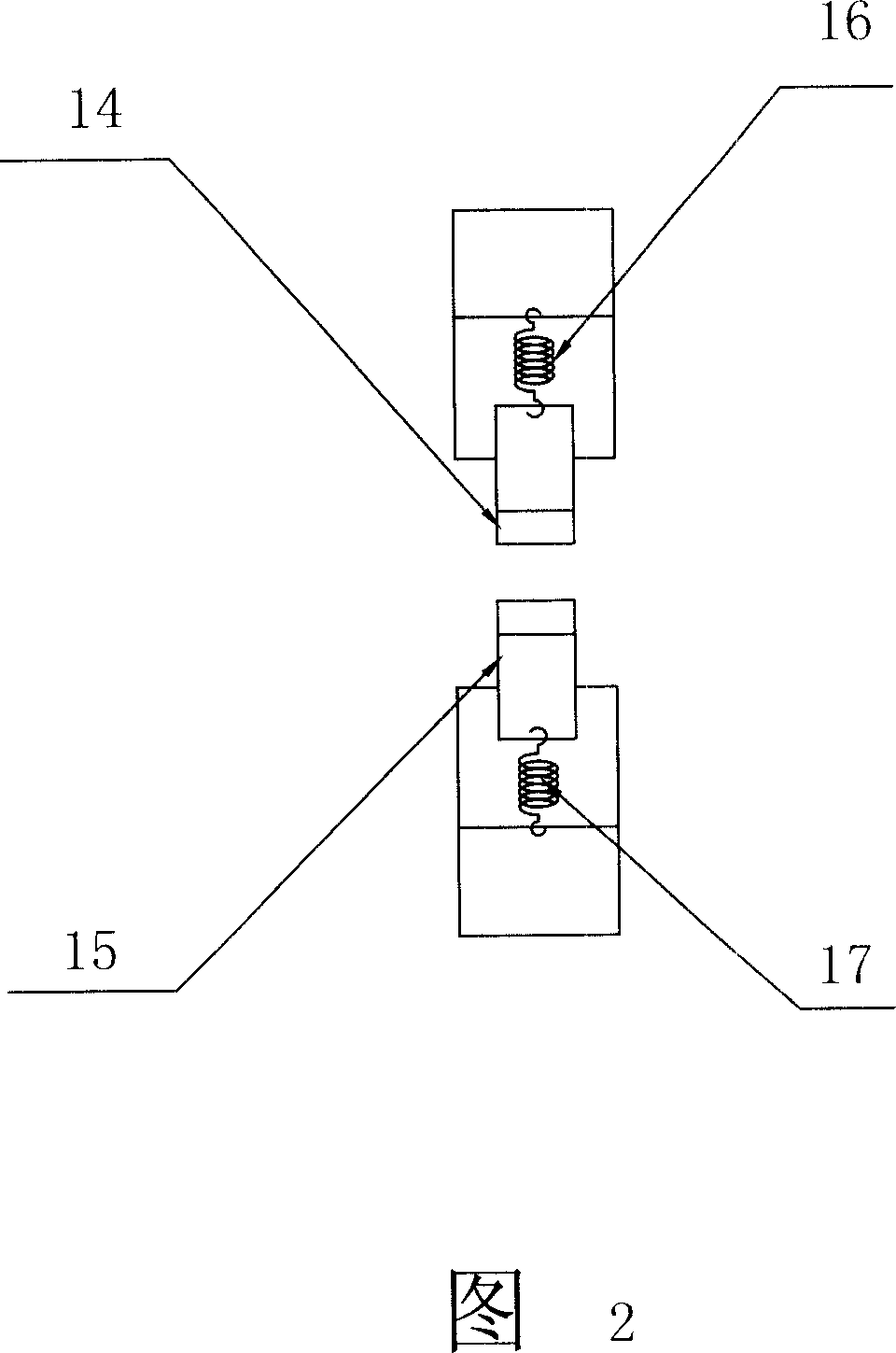

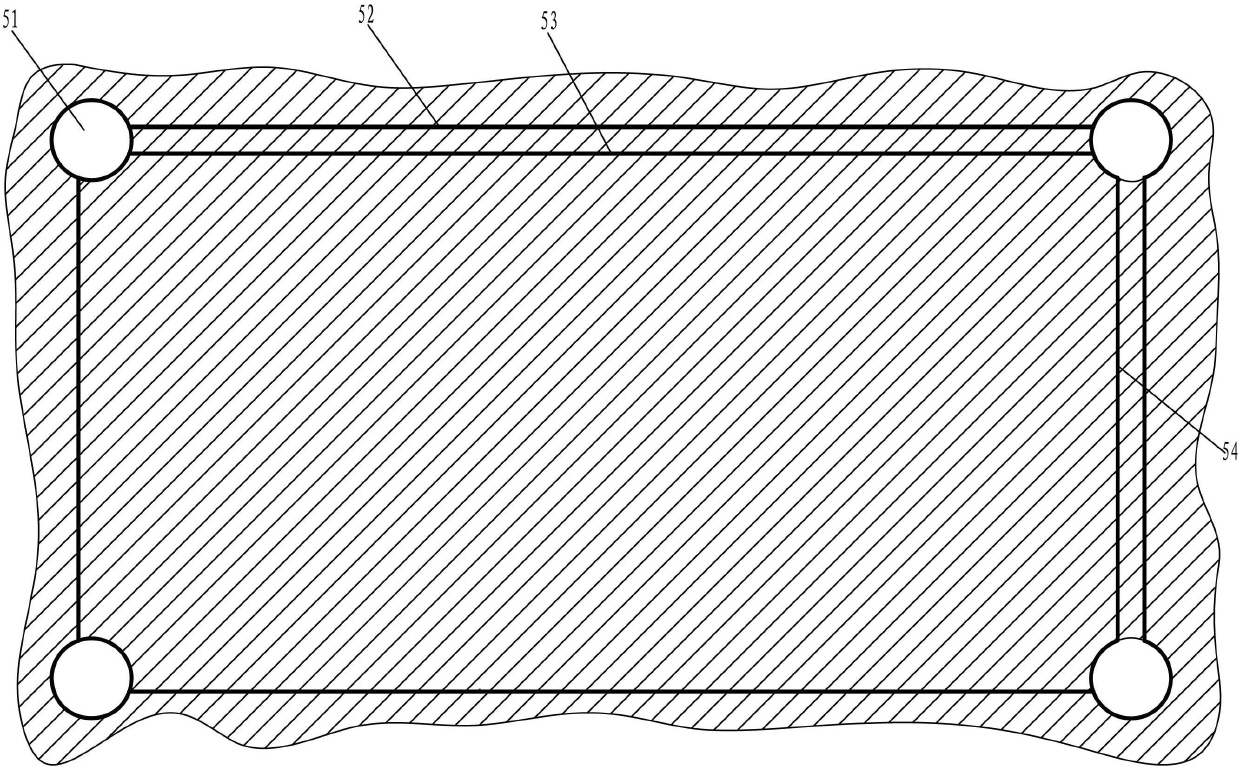

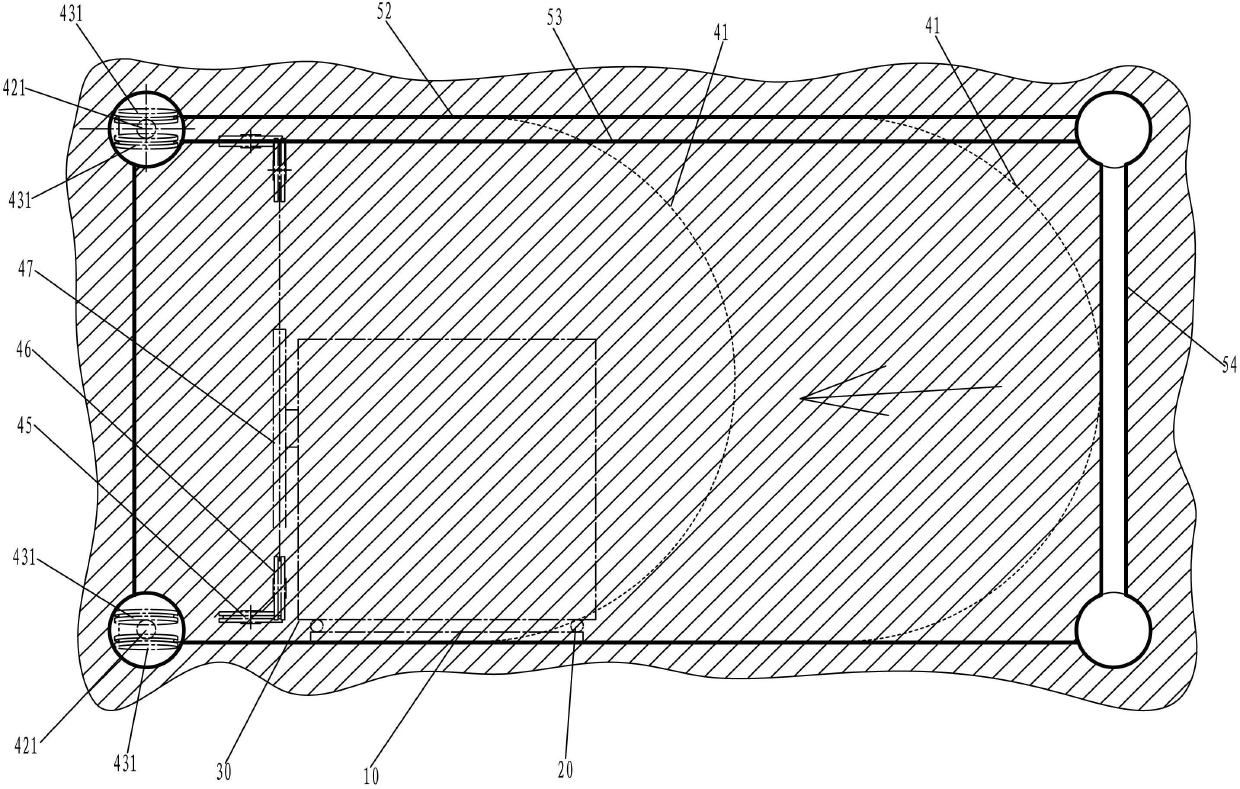

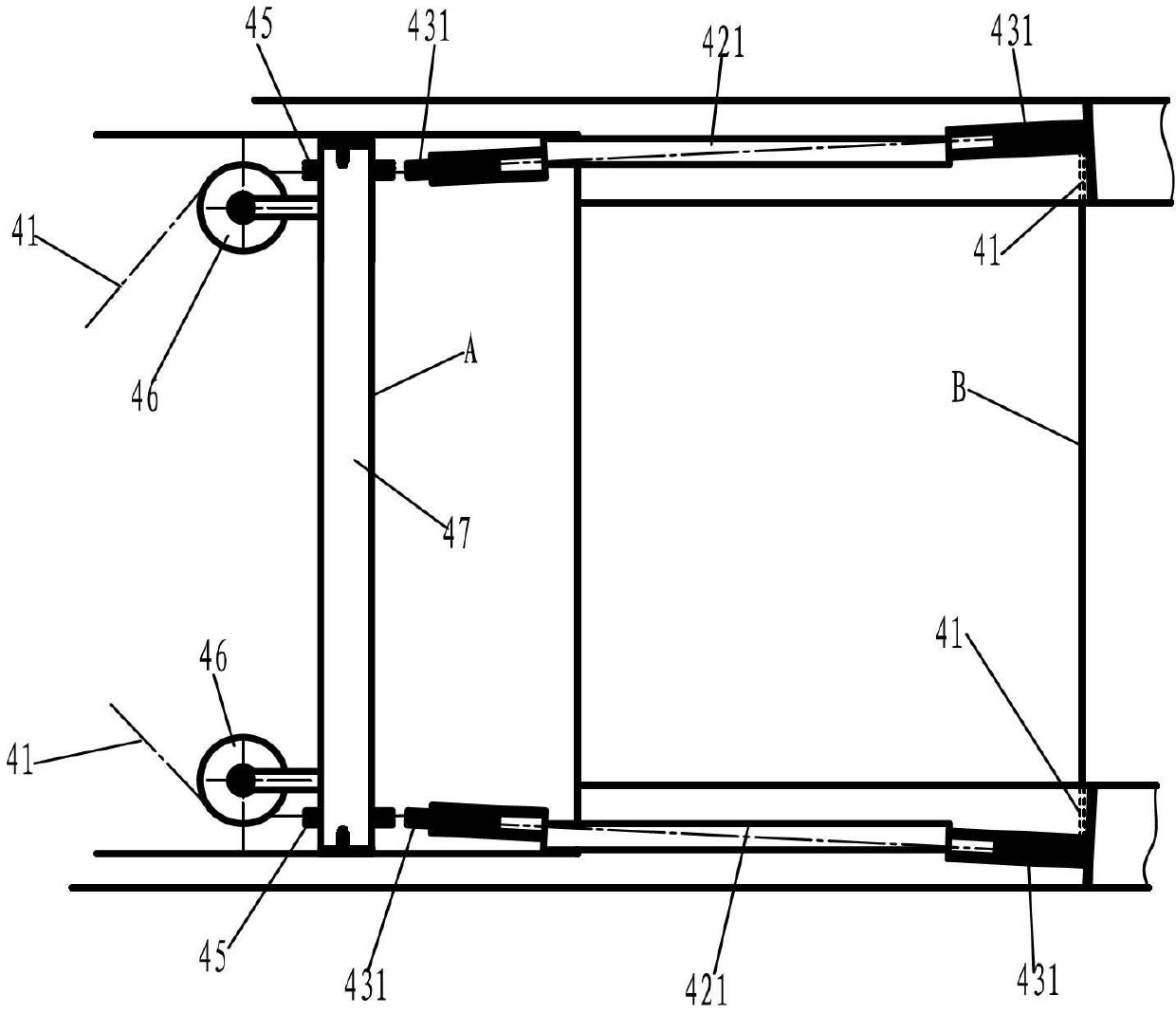

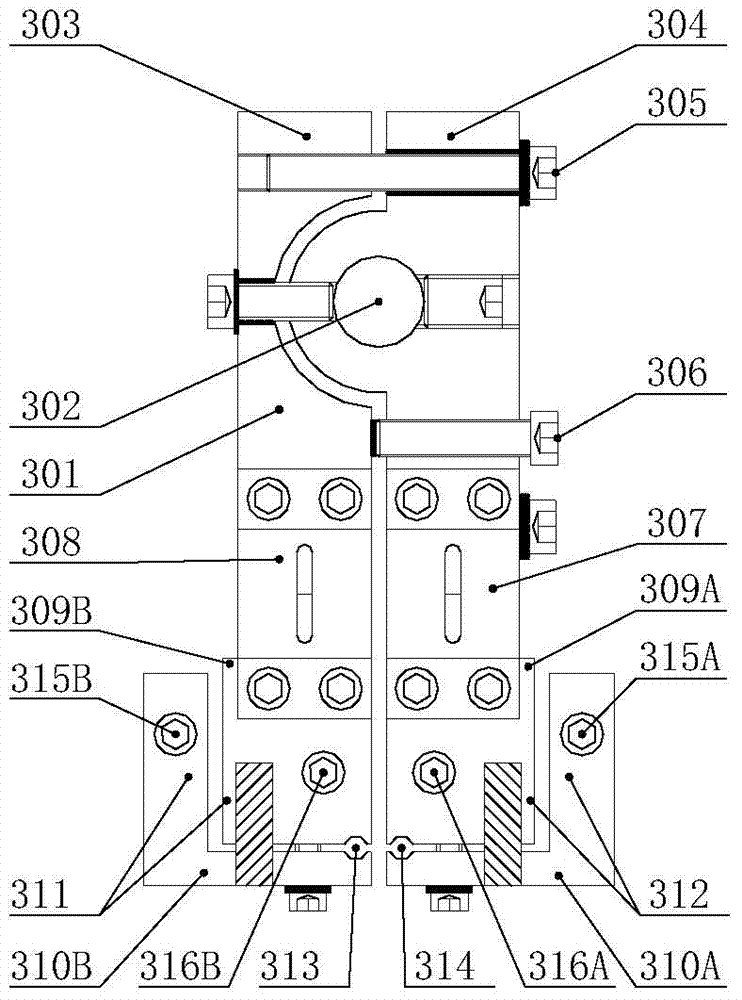

Special fixture for wire plier milling flutes

InactiveCN101434043AReduce setup timeReduce workloadMilling equipment detailsPositioning apparatusFluteHydraulic cylinder

The invention discloses a special clamp for a wire-cutter milling groove capable of quickly clamping a wire-cutter part, which comprises a bottom plate, wherein the bottom plate is provided with a hydraulic cylinder; a wedge block is connected with one end of a piston in the hydraulic cylinder; the bottom plate is provided with a permanent seat; the inside of the permanent seat is provided with a transverse through hole along the motion direction of the piston; the wedge block can slide in the transverse through hole; the middle of the permanent seat is also provided with a vertical through hole; a movable briquette is arranged in the vertical through hole; a spring is arranged on the lower end of the movable briquette; the inside of the movable briquette is provided with a through hole; the wedge block passes through the through hole; a shaft is arranged in the through hole; a roller wheel is sleeved on the shaft; the circumference of the roller wheel is contacted with the lower bevel edge of the wedge block; a bump is arranged on the upper lateral part of the movable briquette; and a jaw block is arranged under the bump, is fixed on the permanent seat, and is provided with a retainer ring and a pin. The special clamp is suitable for clamping the wire-cutter part so as to carry milling groove processing on the part.

Owner:ZHANGJIAGANG YUCHENG MASCH C0 LTD

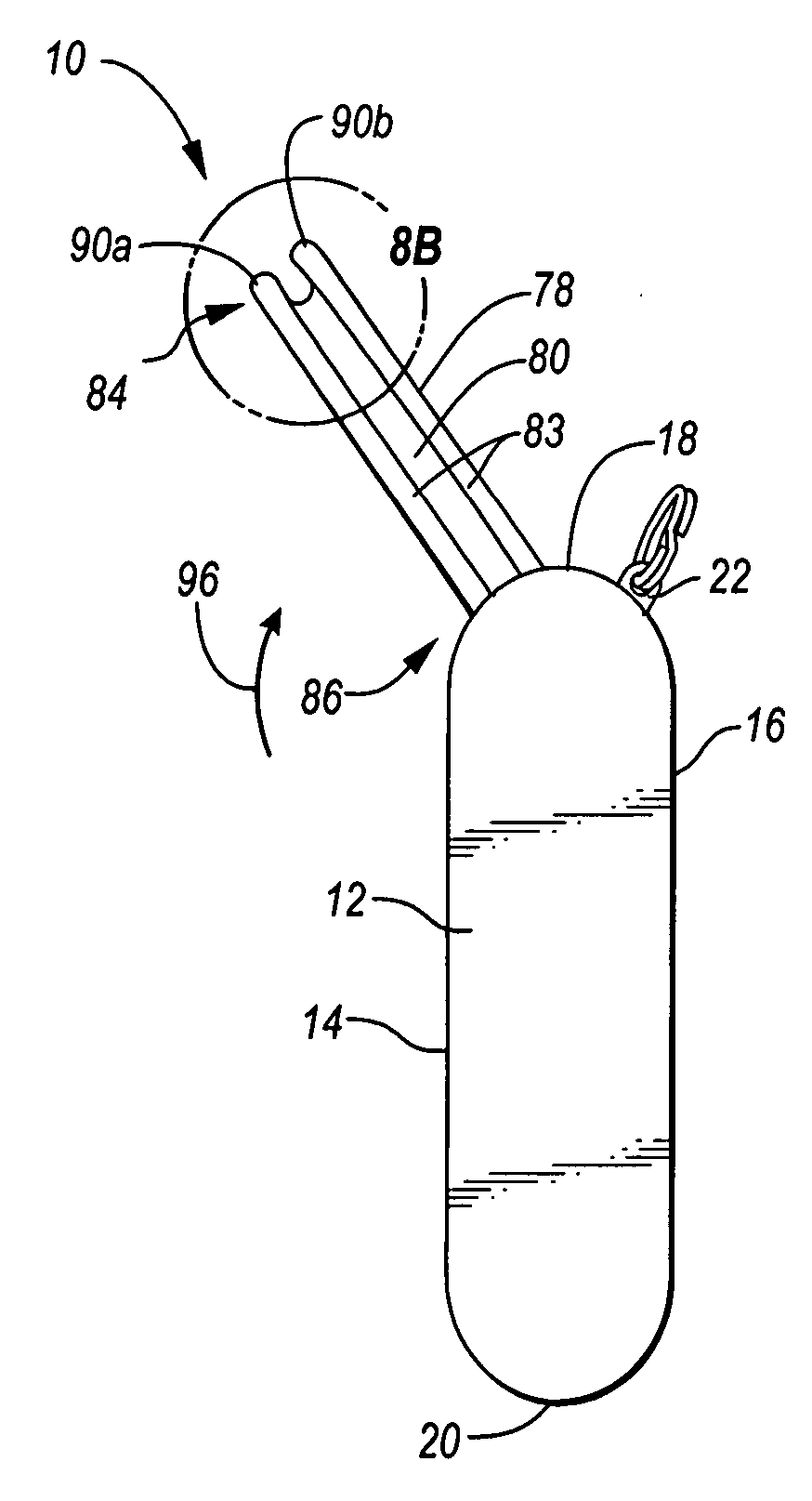

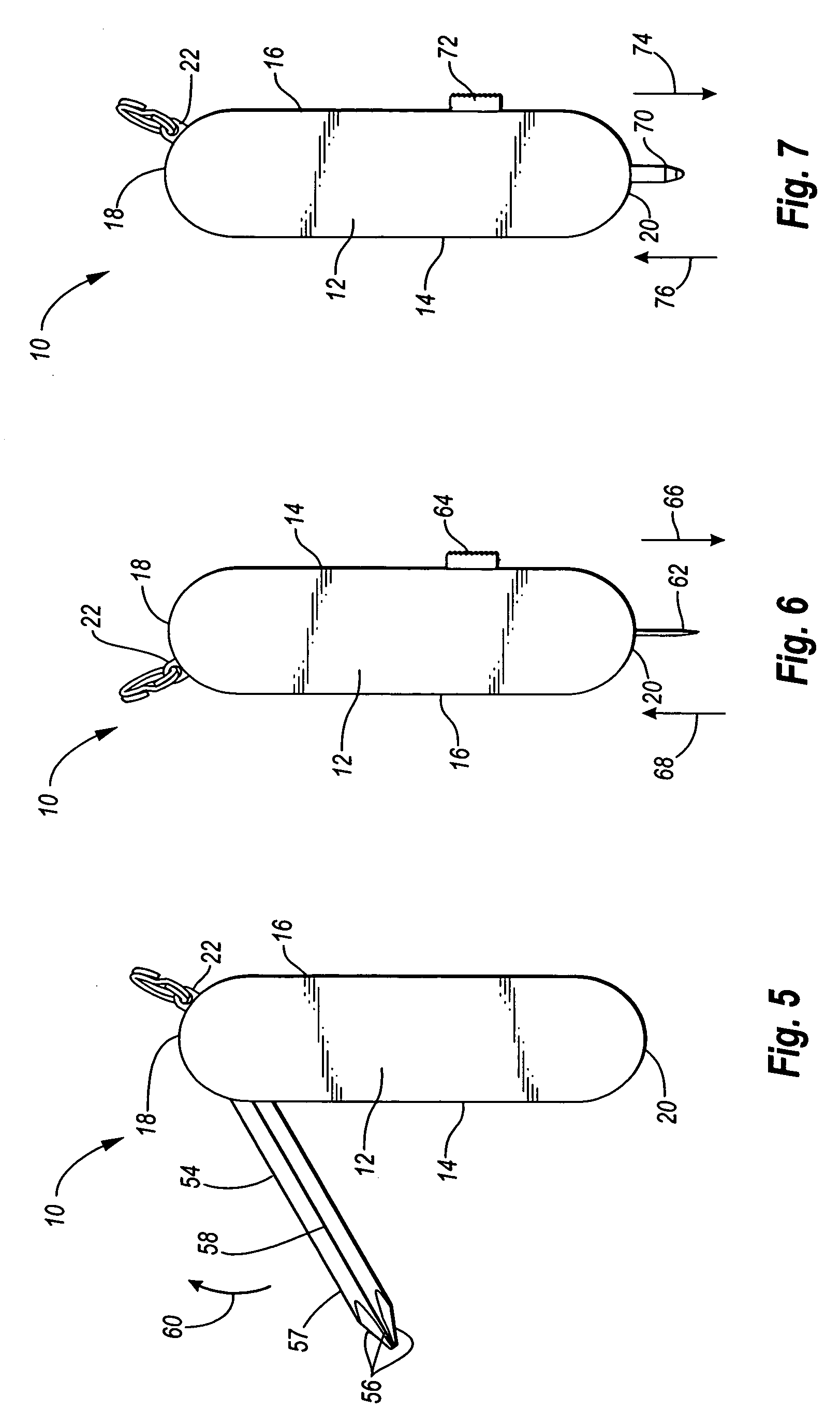

Fishing tool

InactiveUS20050278865A1Reduce decreaseSave spaceOther angling devicesMetal working apparatusEngineeringBottle

A fishing tool may include one or more components or tools that are movable between a retracted, storage position and an extended, use position. The fishing tool may include, for example, scissors and a pair of pliers, which may provide generally smooth clamping surfaces that may help a user put down a fishhook's barb. The fishing tool may also include a screwdriver combined with a hook hone. In addition, the fishing tool may include a pen and a needle member that is preferably sized and configured to be used to clean an eye of a fishhook and / or detangle knots in a fishing line. Further, the fishing tool may include a nail knot tool that is sized and configured to remove fishhooks and may include a combined screwdriver, bottle opener and wire cutter, if desired. The fishing tool may be coupled to a lanyard and a line clipper may also be coupled to the lanyard to create a fishing tool system.

Owner:WEST MICHAEL

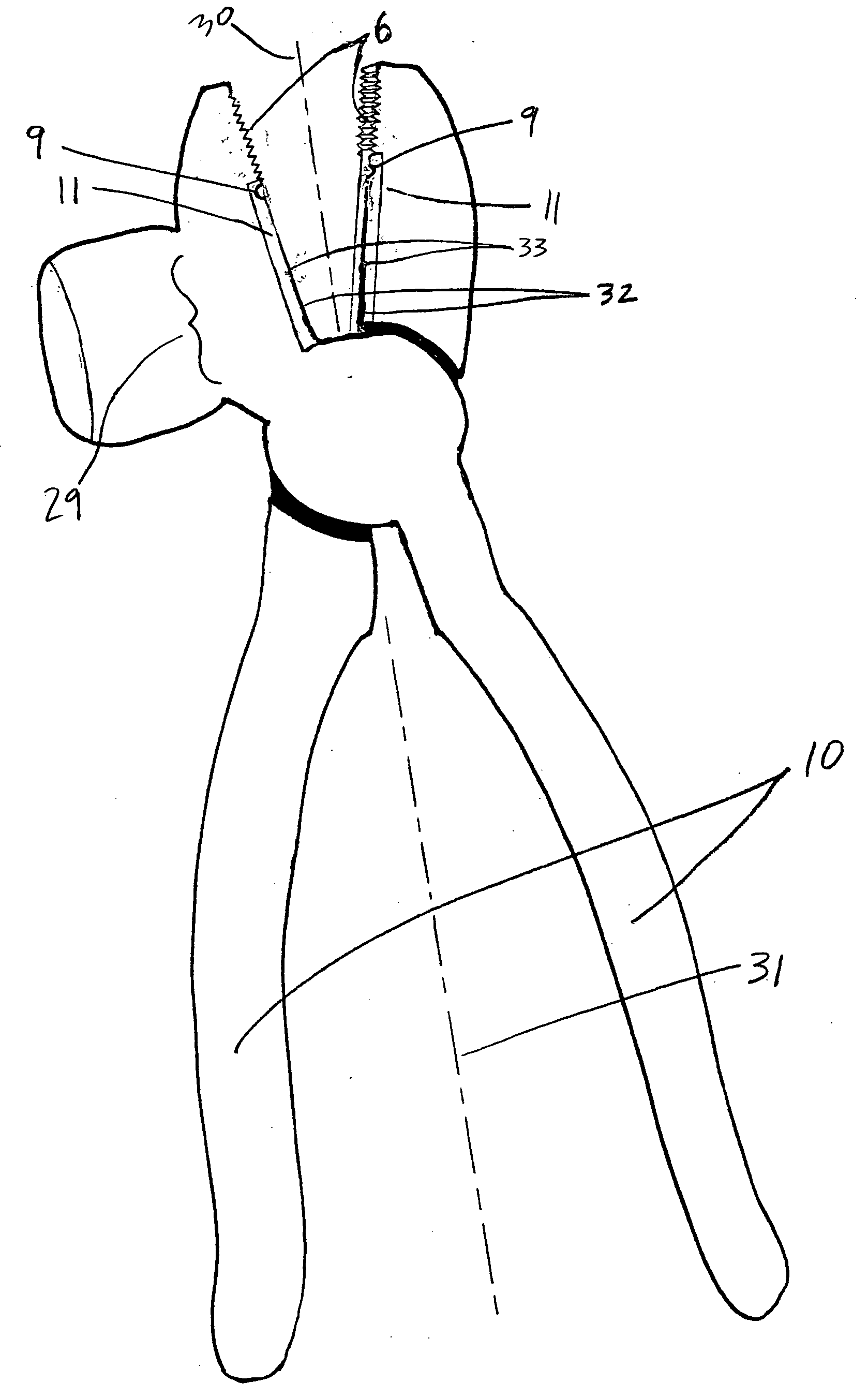

Non-metallic hand pliers with wire cutter

InactiveUS20050097998A1Efficient arrangementBuoyant in waterPliersMetal working apparatusEffective densityWire cutting

A pair of preferably substantially buoyant-in-water hand pliers comprising a pair of non-metallic lever members each having a handle portion and a jaw portion and formed of material preferably having a density greater than water. The lever members are pivotally connected together at common central portions between the jaw and handle portions. Each handle portion preferably has one or more outwardly opening cavities formed into a side surface of the handle portions. An elongated tubular sheath preferably formed of material buoyant in water covers and sealingly encloses the cavities whereby the effective density of the pliers to less than that of water. An effective, durable, non-corrosive wire cutting arrangement is also provided, the components uniquely configured and supported in the non-metallic jaw portions.

Owner:SHAKESPEARE CO

Chain pliers with wire stripper

A multi-function pliers for installing various hanging light fixtures and electrical connections needed for the installation of the hanging light fixtures. The multi-function pliers includes a pivot pin member; first and second movable jaw members rotatably mounted about the pivot pin member; and a pair of first and second movable handles detachably connected to the first and second movable jaw members, respectively, for pivotal movement of the first and second handles relative to the pivot pin member. Each of the first and second movable jaw members includes an interior side wall and an exterior side wall. Each of the interior side walls includes a recess aperture therein; each of the recess apertures are for detachably receiving a wire cutter member therein; and the wire cutter members cooperate to form a wire cutter assembly. Each of the wire cutter members includes a plurality of different sized cutters, respectively, for cutting and stripping electrical wire. Each of the interior side walls further includes a crimping section having a plurality of crimping apertures thereon for closing and crimping a chain link; and the crimping sections cooperate to form a crimping assembly. Each of the exterior side walls includes a spreader member having a plurality of spreader apertures thereon for spreading apart and opening a chain link; and the spreader members cooperate to form a spreader assembly.

Owner:BIBI LAWRENCE

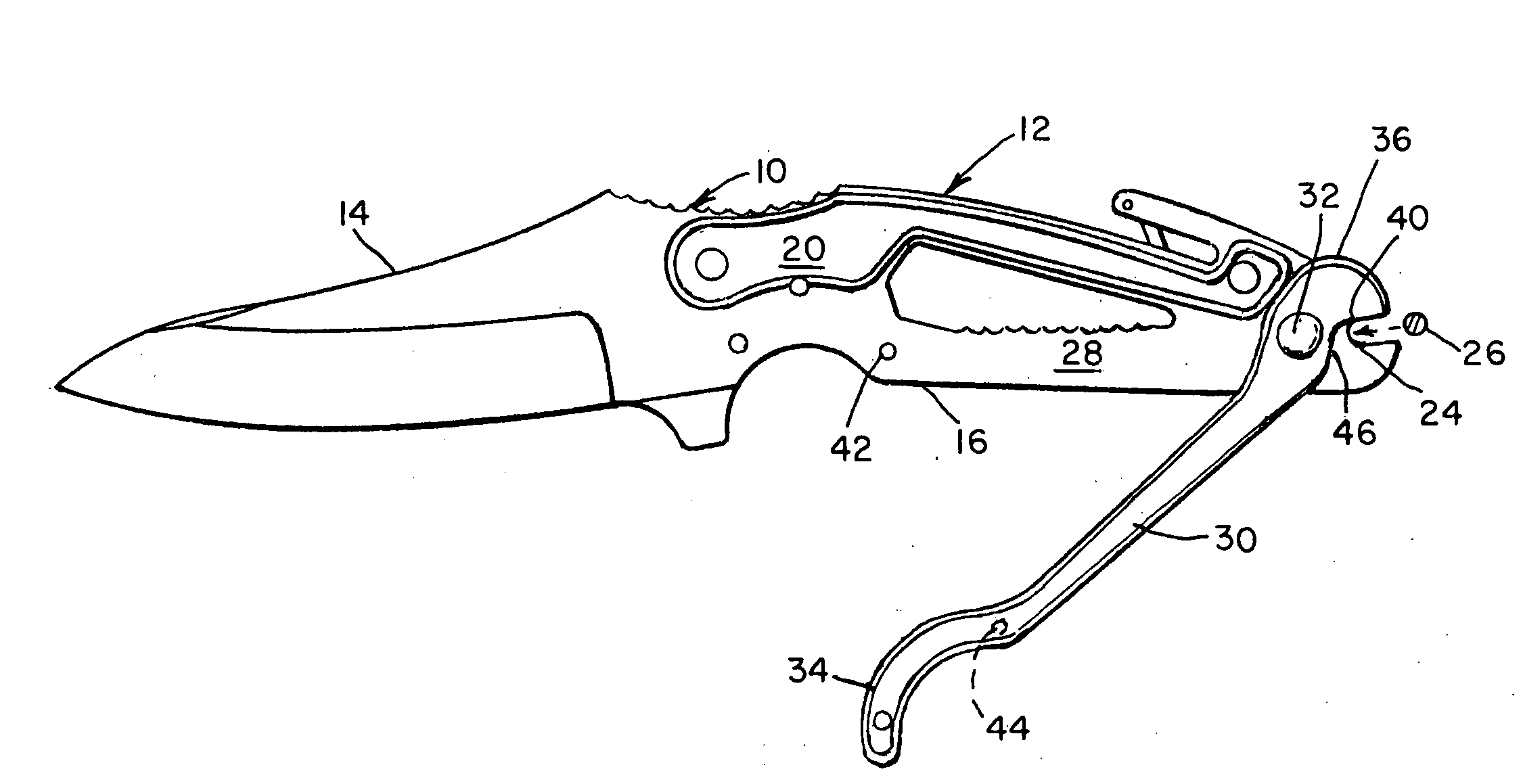

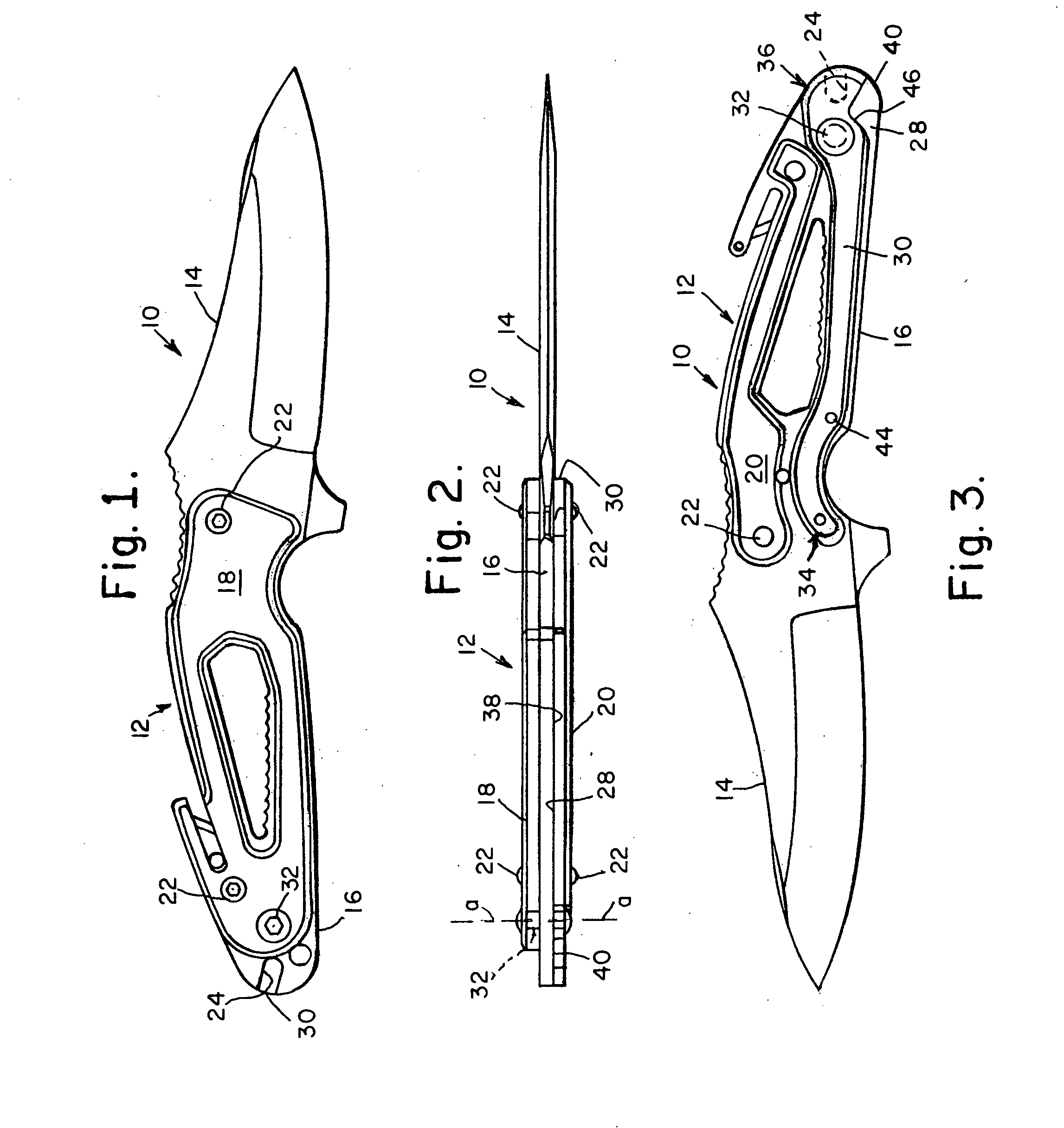

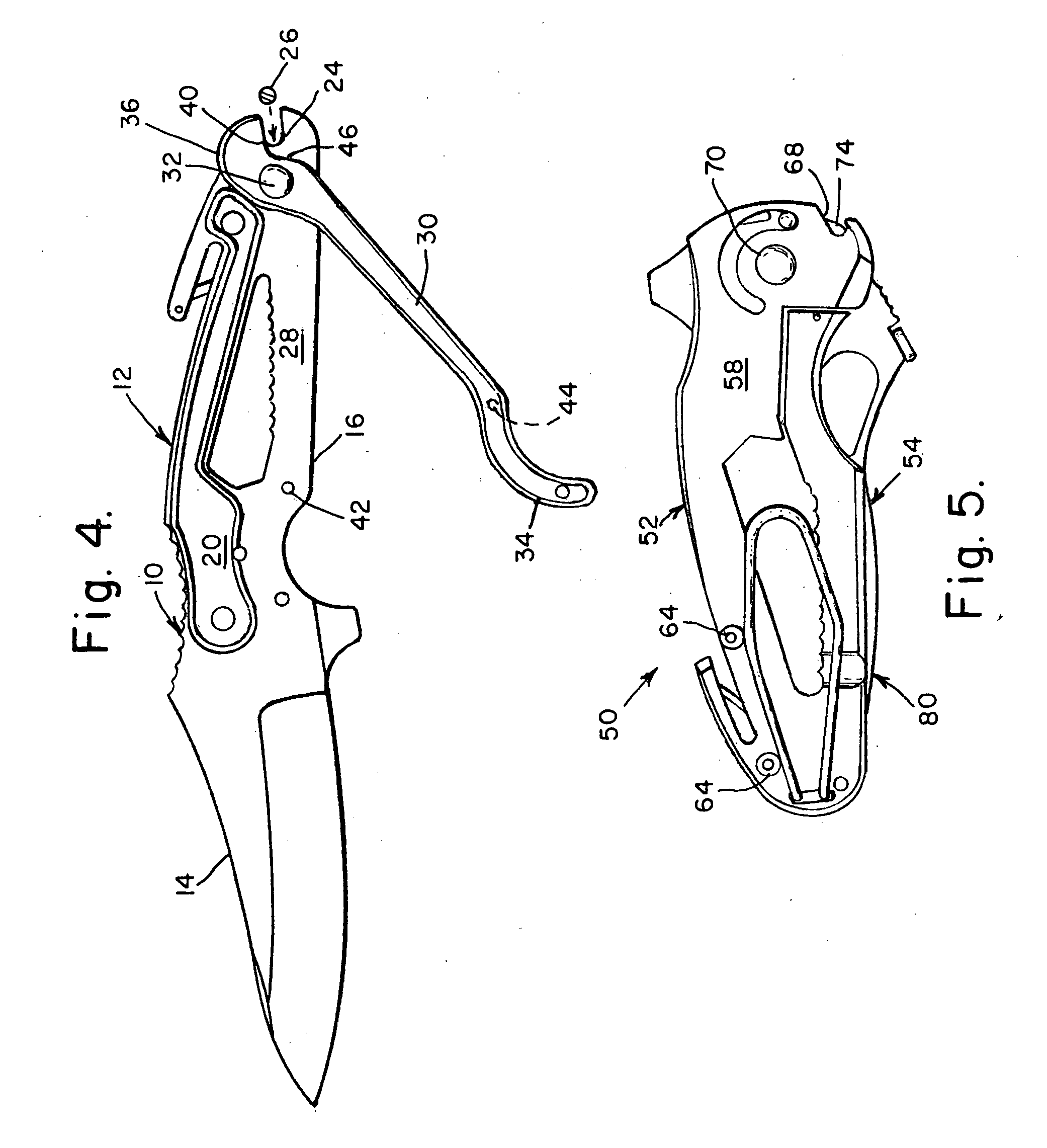

Knives with wire cutter

InactiveUS20080110029A1Easily employable wire cuttingEasily employable wire cutting capabilityThrusting weaponsWeapon componentsEngineeringWire cutter

Combined knife and wire cutter apparatus including both fixed blade knife and folding knife embodiments. Both such embodiments comprise an elongate handle including at least one notch along an edge thereof for receiving a segment of a wire; and an elongate member pivotably secured to the handle and having a first end portion and a second end portion, the elongate member pivotable about a pivot axis in a first rotational direction with the first end portion moving away from the handle and in a second rotational direction with the first end portion moving toward the handle, the second end portion including a cutting edge situated for traversing the at least one notch when the elongate member is pivoted about the pivot axis.

Owner:SUREFIRE LLC

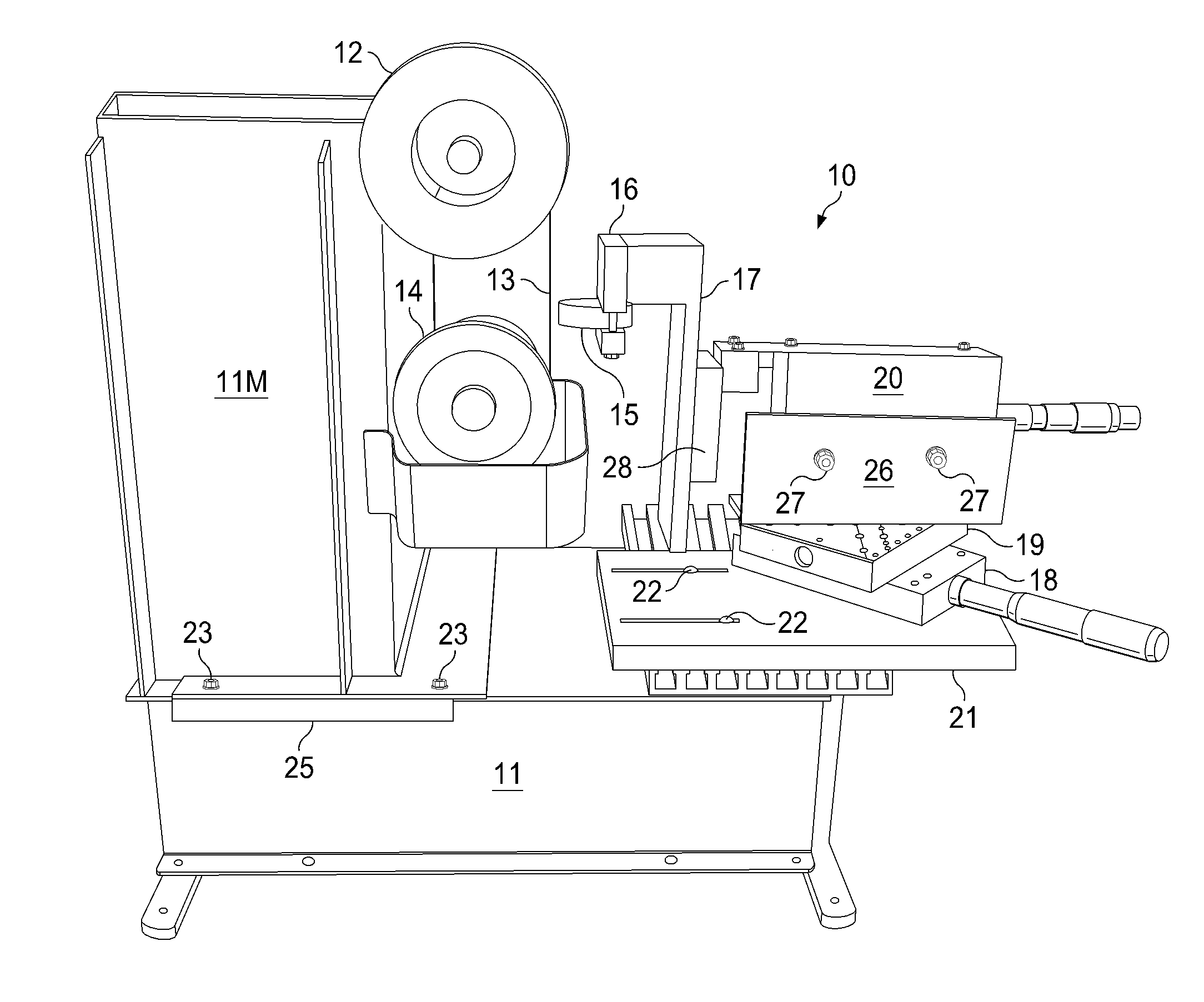

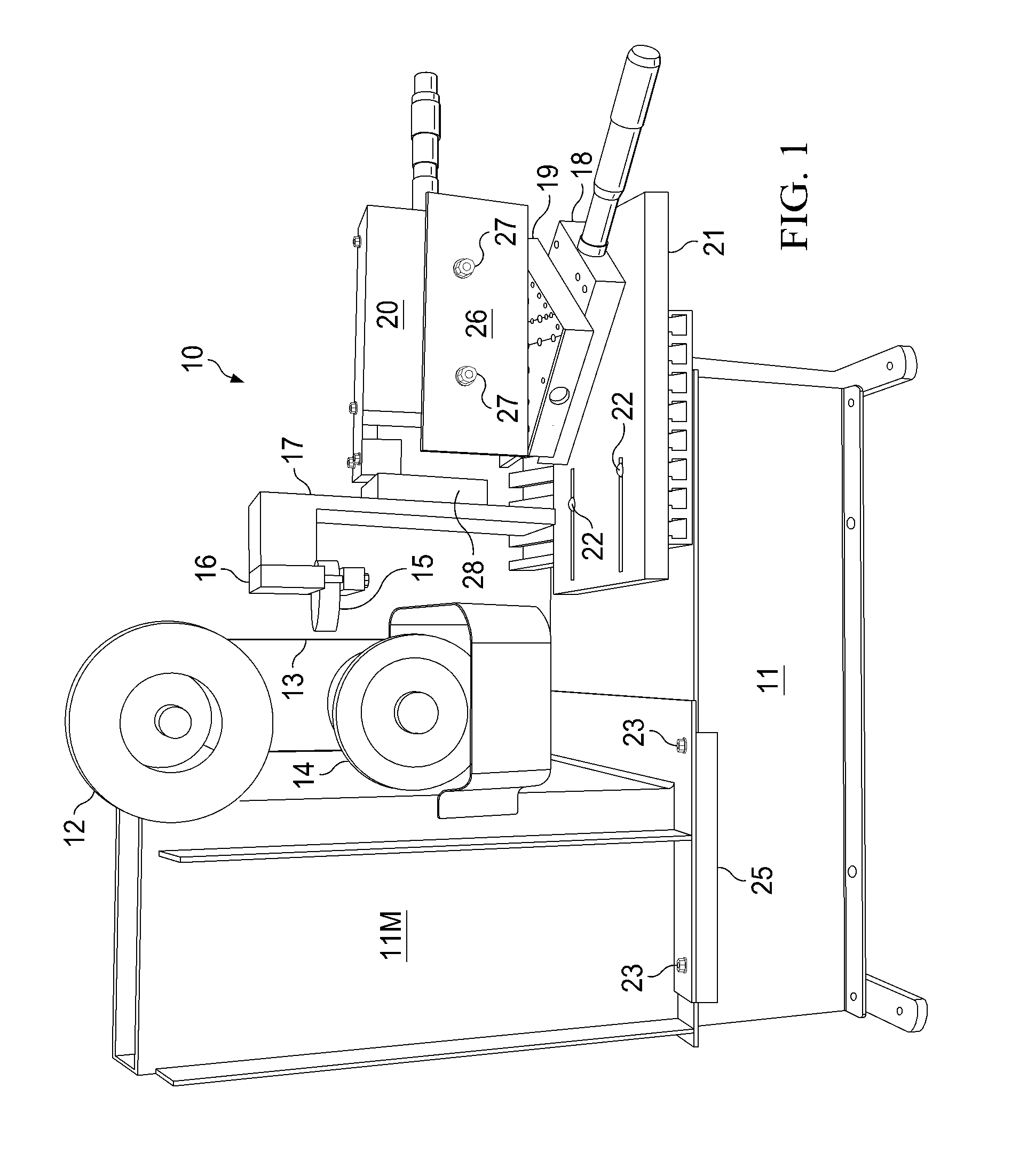

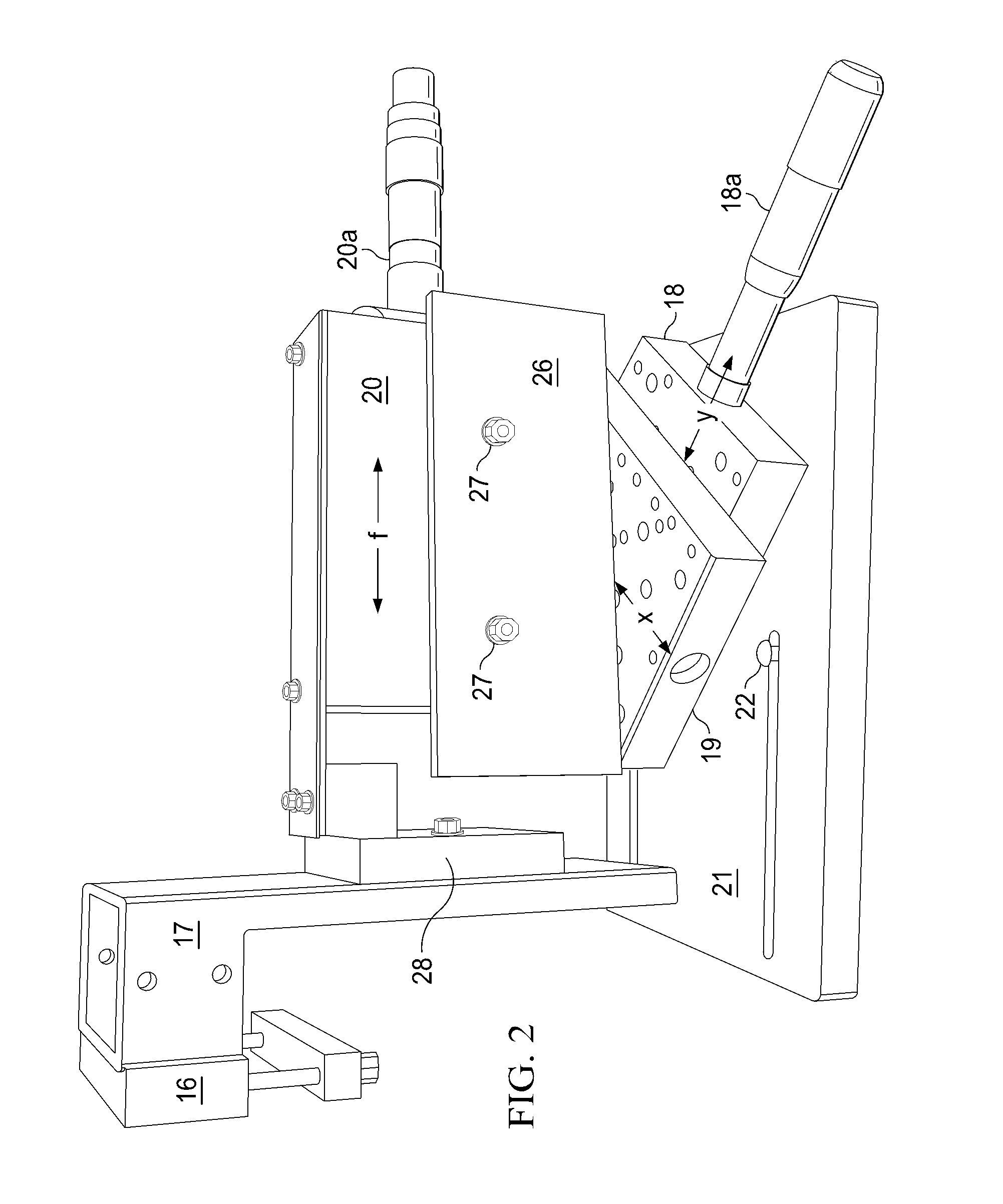

Sample preparation apparatus for direct numerical simulation of rock properties

A sample preparation apparatus and method of preparing a rock sample using such an apparatus, as useful in connection with the digital numerical simulation of properties of the rock. The disclosed apparatus includes a fixably mounted diamond wire cutter. Three linear translation stages are coupled to a specimen holder. One of the translation stages moves the specimen in a direction parallel to the plane of the cutting wire. The other two translation stages move the specimen in different directions from one another, and when actuated together, advance the specimen into the wire for short distances in a direction out of the plane of the cutting wire. Short piecewise linear cuts are made in the specimen, to provide a sample of the desired shape with a small cross-section.

Owner:BP CORP NORTH AMERICA INC

Underground cutting mining method of process ore

InactiveCN103615249AOvercome harmAvoid destructionUnderground miningSurface miningEconomic benefitsWire cutter

The invention discloses an underground cutting mining method of process ore. The method concretely comprises the following steps: (1) firstly, digging a tunnel in the side of an ore body, and transversely tunneling from the tunnel to the ore body so as to form a chamber access, wherein the chamber access penetrates through the ore body, and the upper and lower sides of the ore body are provided with two free surfaces; (2) drilling in one free surface, and respectively drilling in four corners of the free surface so as to obtain four drill holes which penetrate through the two free surfaces; (3) passing a wire saw through the drill holes in the same side; (4) connecting the wire saw to a wire cutter, starting the wire cutter, driving the wire saw to cut the ore body between the drill holes, so that the ore body is completely separated from surrounding ore bodies or surrounding rocks. The underground cutting mining method is simple in operation, small in labor intensity, good in safety, and high in economic benefits. The ore exploited by the method disclosed by the invention is regular in shape, large in size and high in process value.

Owner:CHINA NEW BUILDING MATERIALS DESIGN & RES INST

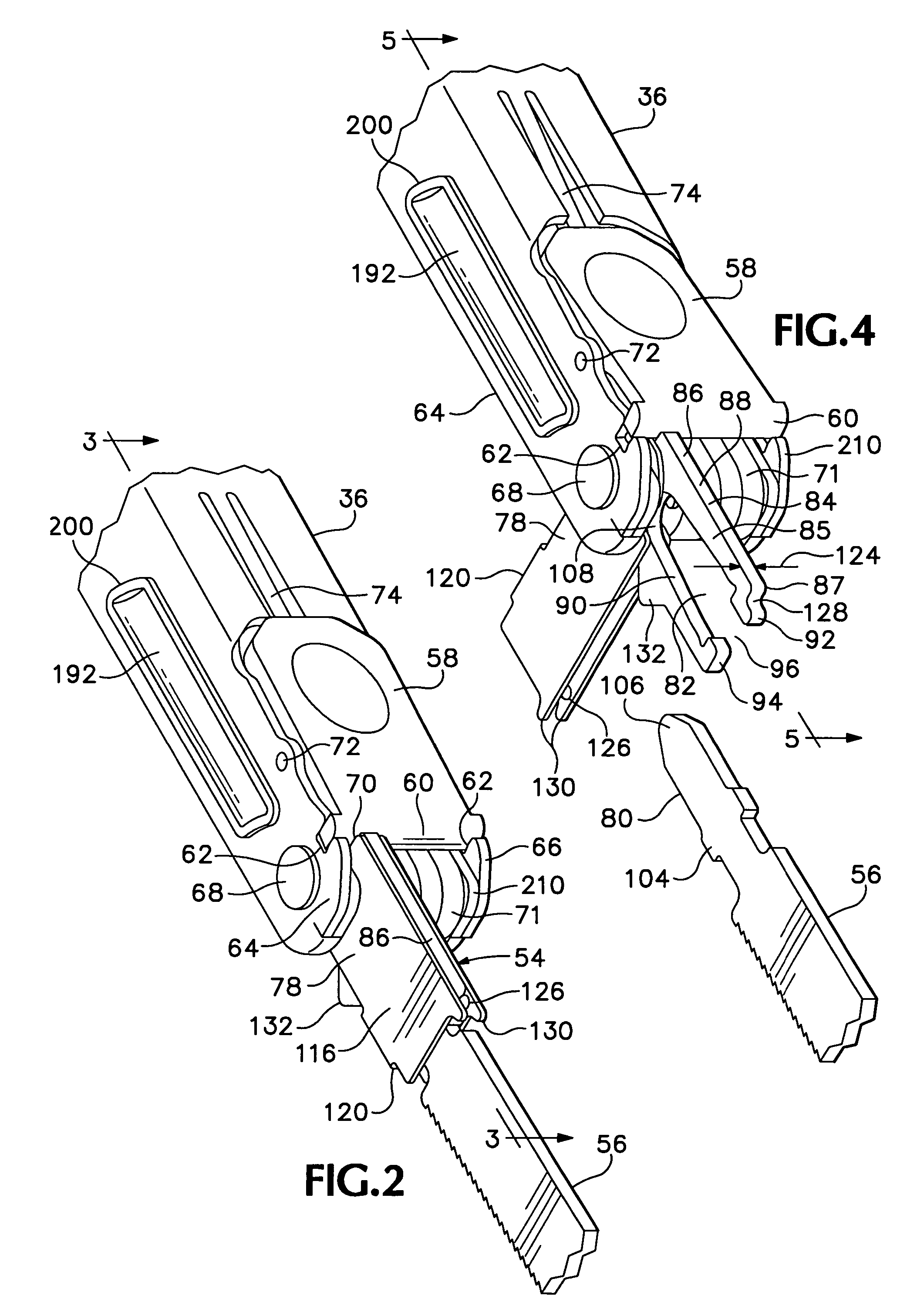

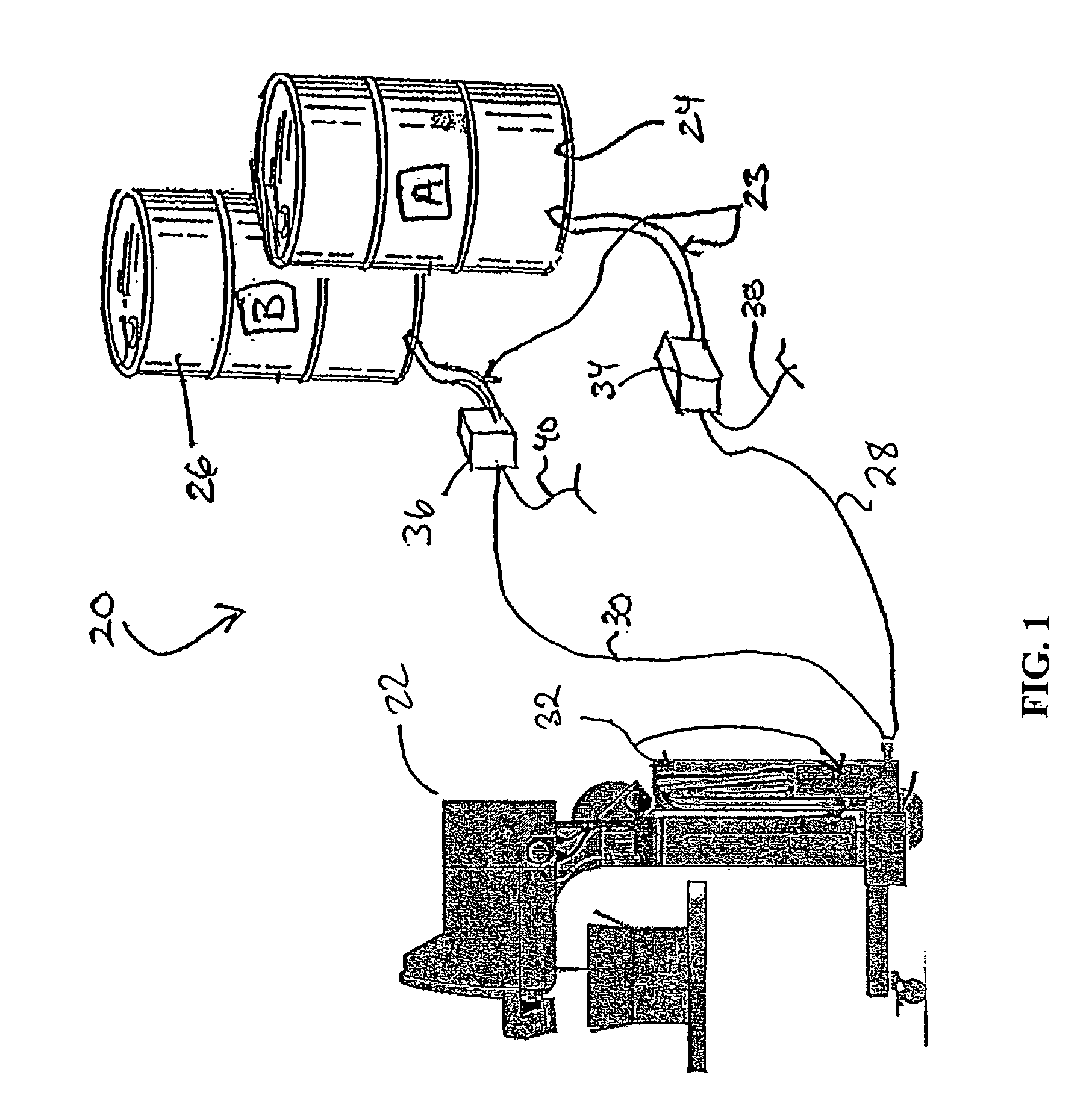

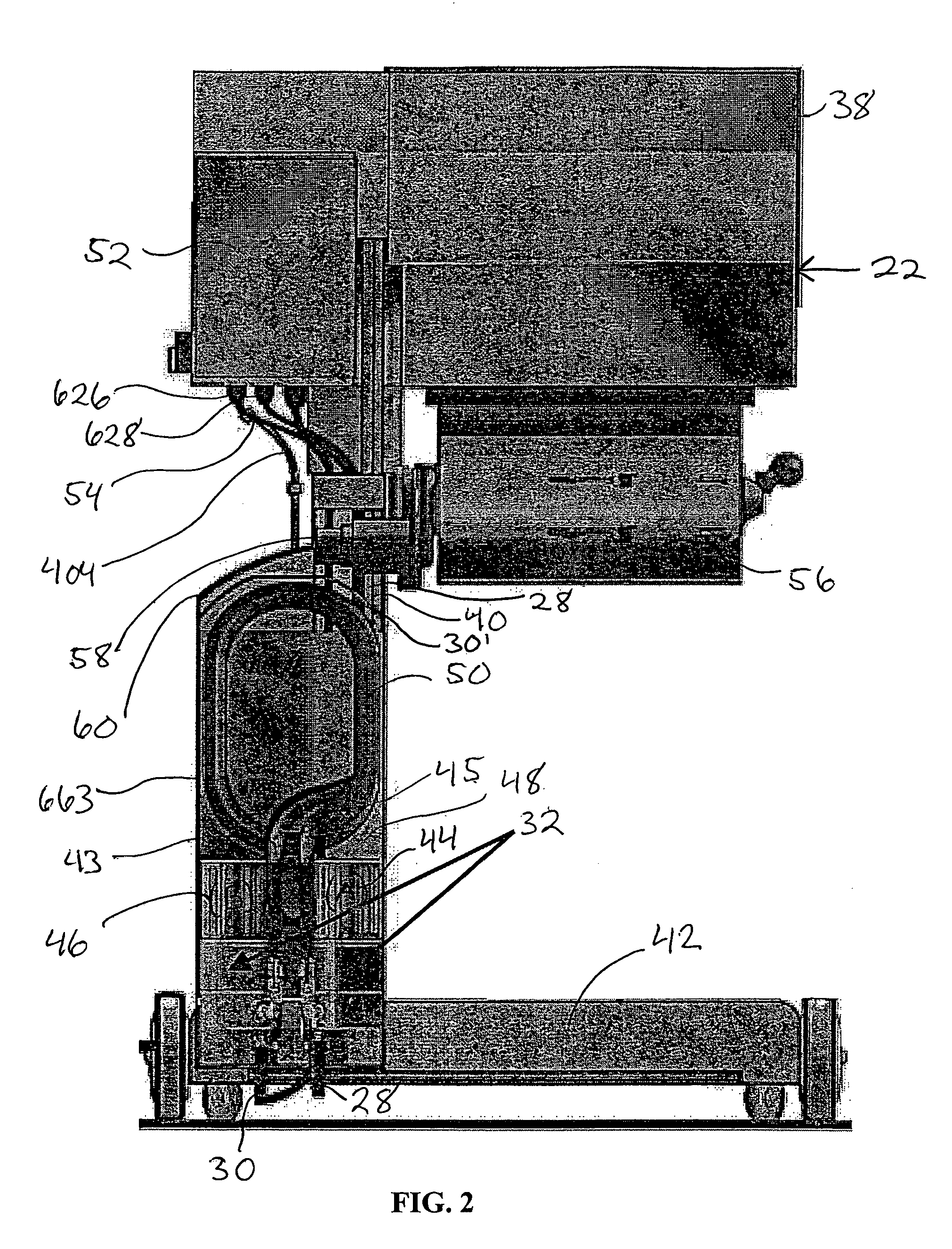

Dispensing system with end sealer assembly and method of manufacturing and using same

An end sealer shifting assembly, comprising a transmission, a push rod assembly which is driven by the transmission, and end seal compression jaw in driving engagement with the push rod assembly, and a compliance assembly for jaw compliance with a contact member (e.g., a heater wire cutter cross cut jaw) when the jaw is driven into a compression relationship with the contact member. The compliance device preferably includes springs and the transmission assembly preferably includes a cam device with a second spring working to retain a contact relationship and work together with the compliance spring. A method of assembling such a device and operating such a device is also featured.

Owner:PREGIS INTELLIPACK CORP

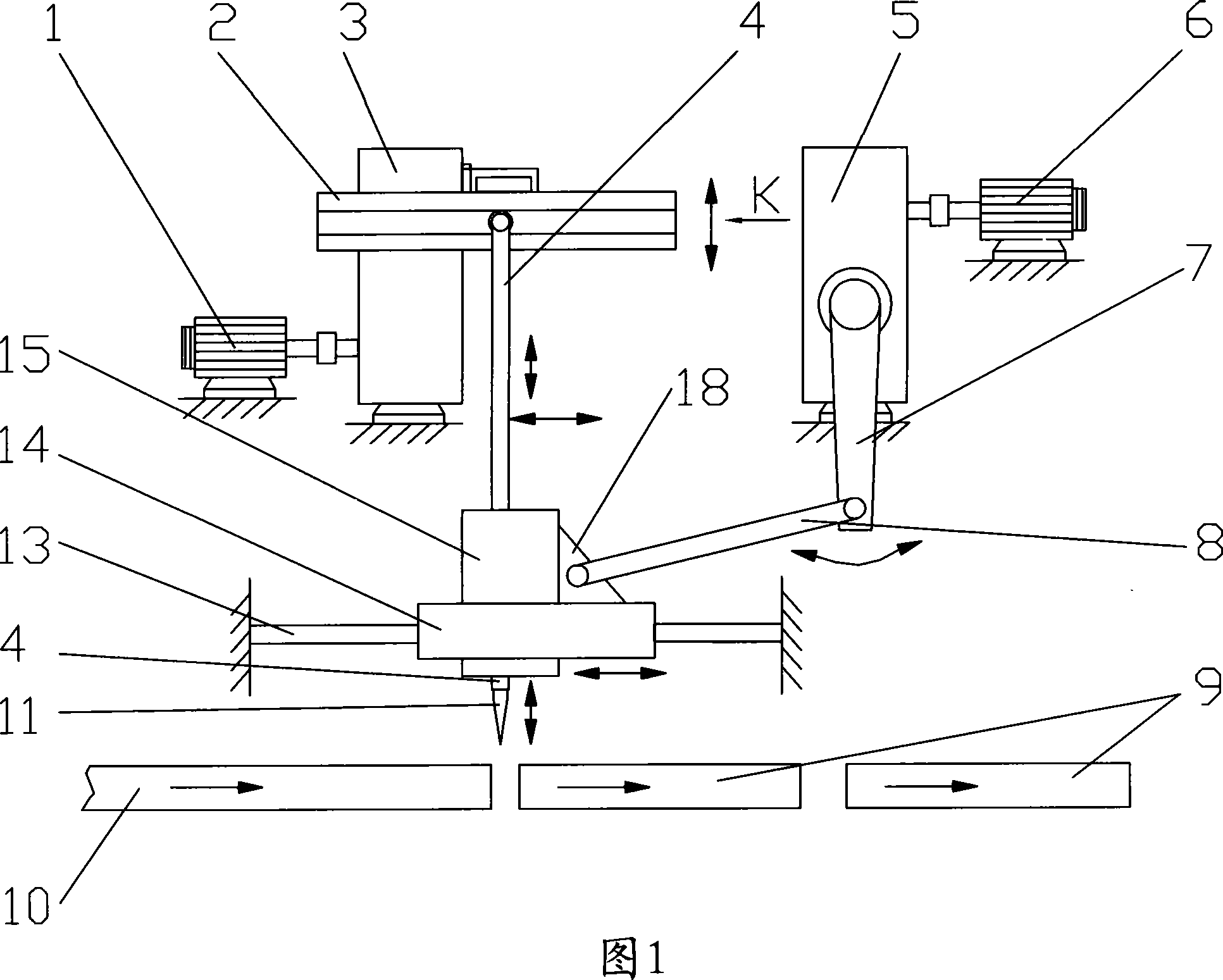

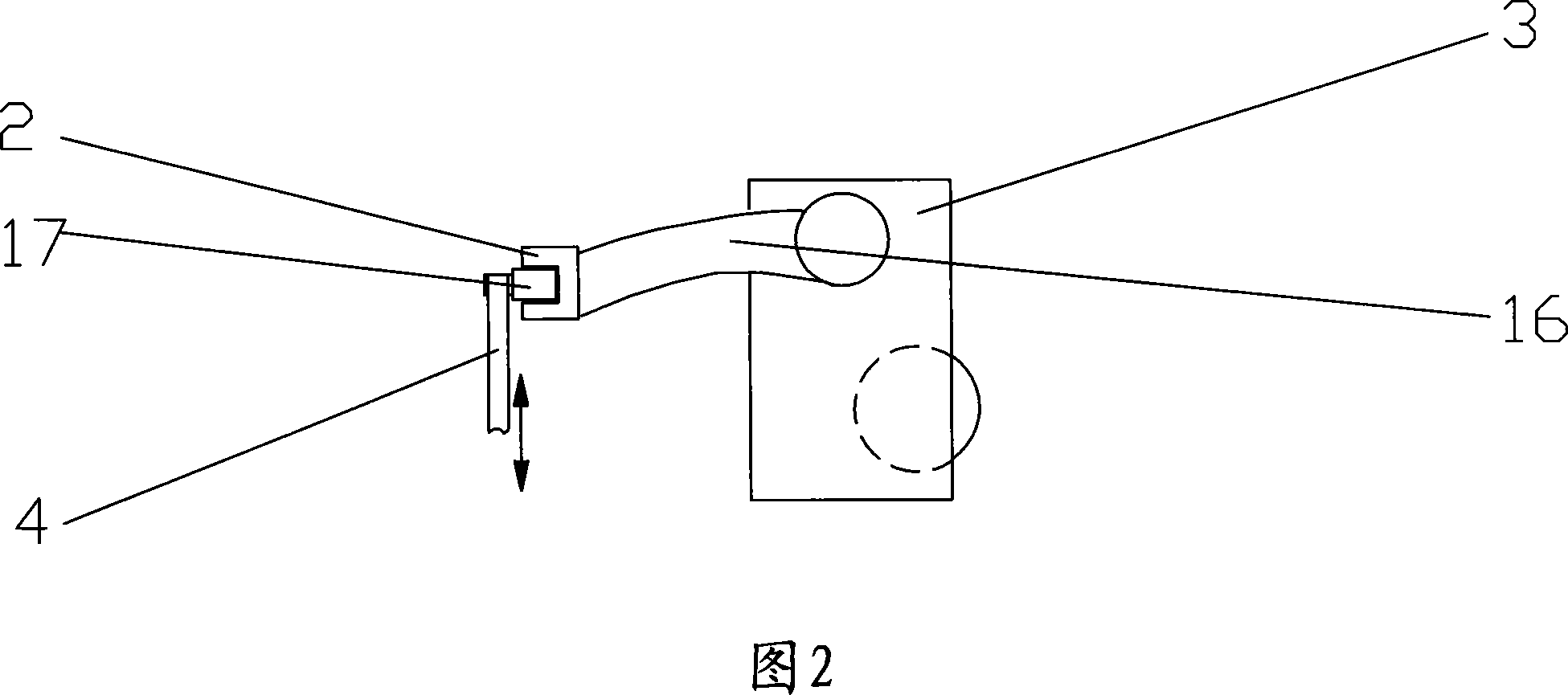

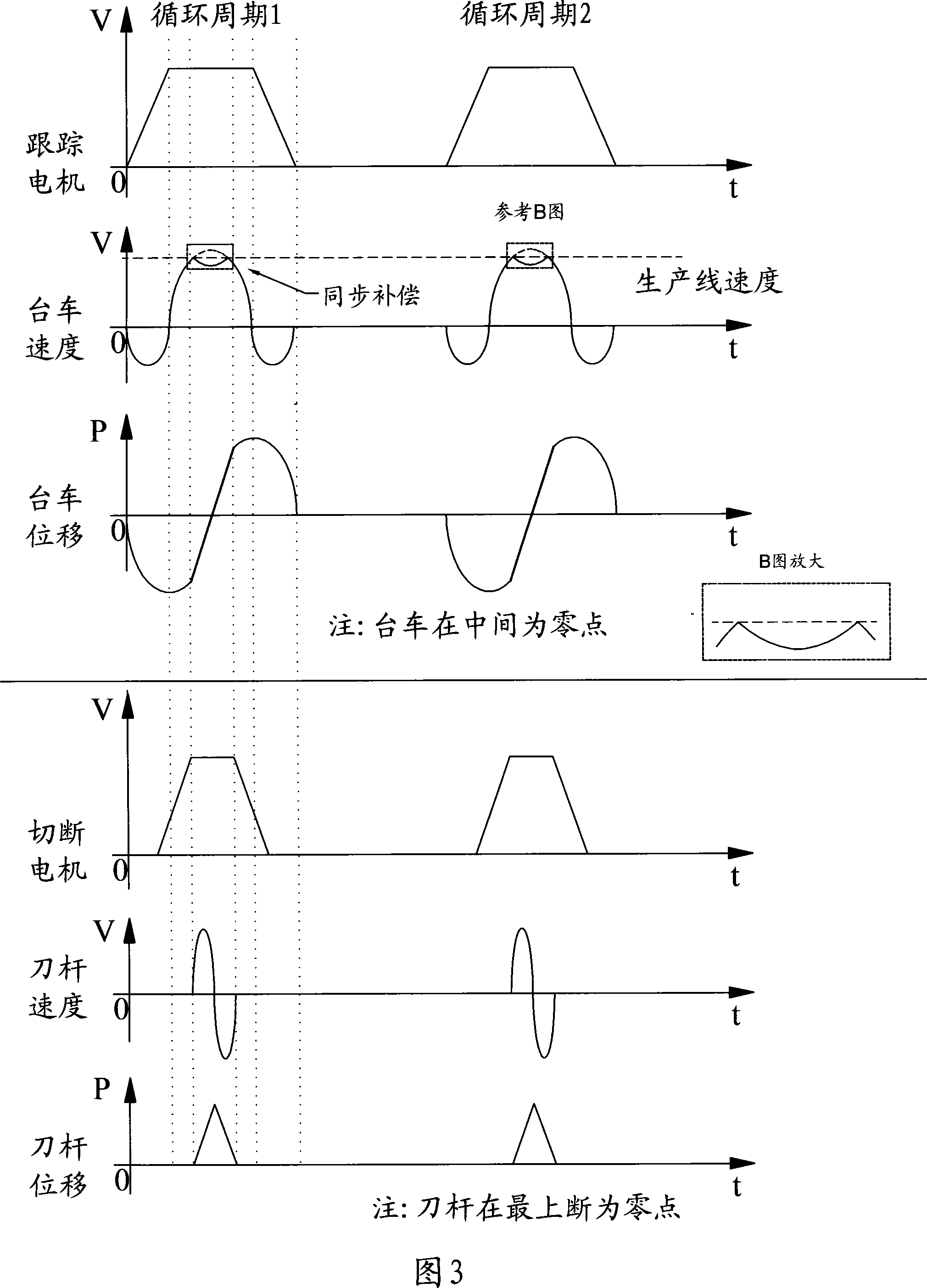

Flying shears with high speed and definite length

InactiveCN101032731AImprove work efficiencyHigh synchronization accuracyStock shearing machinesWire rodThrough transmission

The present invention relates to metal wire cutter, and is especially one kind of high speed fixed-length flying shears, which includes two motors, and two independent cam mechanisms. Each of these two cam mechanisms is connected to one of the motors and the shears through transmission mechanism. During cutting, these two motors may be controlled separately to change speeds and thus the cut length without need of stop. The present invention has high work efficiency, reduced labor strength, synchronous operations in two direction and high cut quality.

Owner:大连立达工业设备有限公司

Multipurpose tool including holder for replaceable tool blades

A multipurpose folding hand tool including a tool holder permitting exchanges of blades. The tool may include a folding scissors including a spring that is moved into operative engagement with a scissors handle to open the scissors handles apart from each other only as the scissors approaches an extended, operative position with respect to the handle of the folding land tool, within which it may be stowed. A resilient grip member is incorporated in one of the handles of the folding multipurpose hand tool. A wire cutter and a crimping tool are located on pliers jaw tangs, between the pliers pivot and the foldable handles of the tool.

Owner:LEATHERMAN TOOL GROUP

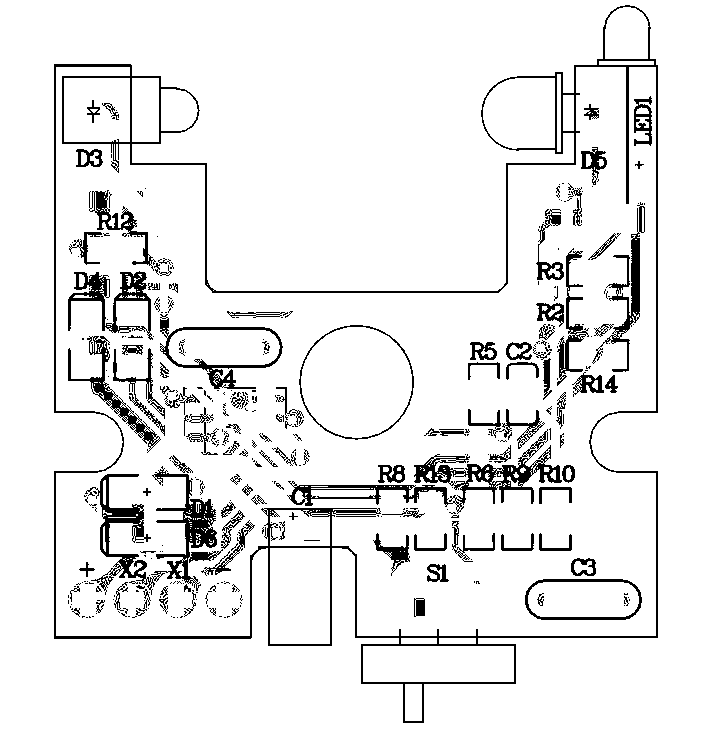

Automatic slack bobbin winder

The invention discloses an automatic slack bobbin winder, comprising a winding device, a variable amplitude yarn guide device, a fixed-length control device, a tension regulating device and a host control device, all of which are arranged on a frame and driven by a friction roller motor and a groove drum motor, respectively, wherein the winding device comprises a winding rack, a friction roller and a groove drum; the variable amplitude yarn guide device comprises a variable amplitude guide rail, a tension spring, a movable pull rod and an adjustable rotating rod; and the fixed-length control device comprises an infrared light-operated yarn detector, a wire cutter, an alarm indicator lamp and a reset button, as well as a singlechip for controlling the devices, wherein the singlechip is connected to the host control device through an RS-485 bus. In the technical scheme, the automatic slack bobbin winder is simple in structure, rational in design, low in cost, and low in noise; and when in use, the automatic slack bobbin winder is capable of conveniently and accurately realizing the functions of pineapple-shaped forming, fixed length and automatic stopping on yarn breakage, and capable of realizing high-quality slack winding, improving the quality of dyeing in subsequent procedures and achieving smooth unwinding, thus improving the working efficiency and economic benefit of factories.

Owner:JIANGSU ZHONGKE RUISAI POLLUTION CONTROL ENG

Constant length wire cutter

InactiveCN1931533APrecise length controlReduce lossesMeasurement devicesFilament handlingMeasuring instrumentLength measurement

The constant length wire cutter includes a length measuring instrument, a power set, a shearing unit, a non-return unit, a wire storing unit and a wire collecting unit. The length measuring instrument measures the length of wire or cable, and when the measured length is equal to the set value, it outputs one signal to the power set, the wire storing unit and the wire -collecting unit. The power set, after receiving the signal, drives the shearing unit to cut the wire or the cable, the wire -storing unit receiving the signal stores the wire or cable, and the wire collecting unit receiving the signal stops collecting. The present invention can cut wire or cable in constant length.

Owner:何仁

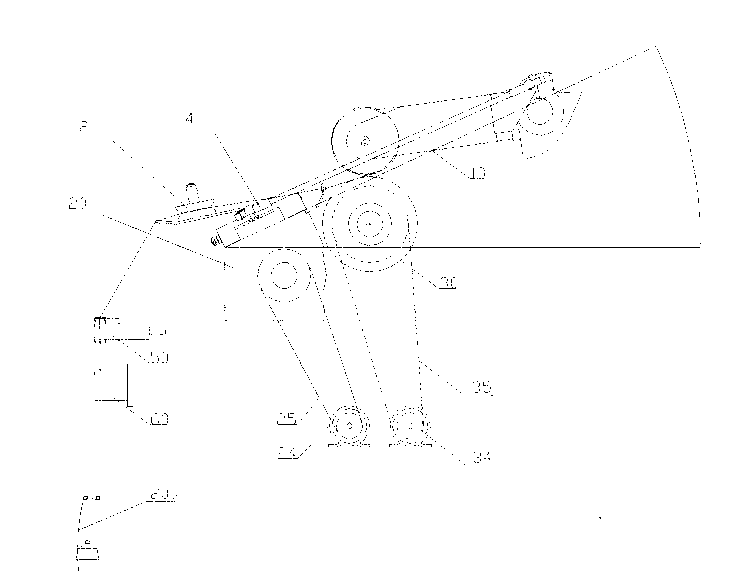

Electric heating cutting type strawberry picking terminal executor and corresponding picking mechanism and method

InactiveCN107517656ARealize the whole process of automatic harvestingPrevent dehydrationPicking devicesMultiple sensorAgricultural engineering

The invention provides an electric heating cutting type strawberry picking terminal executor and a corresponding picking mechanism and a method, and relates to the field of an agricultural picking robot; the electric heating cutting type strawberry picking terminal executor is composed of a terminal executor, a corrugated pipe, a containing box, a moving platform and a lifting mechanism, wherein the terminal executor further comprises a stepping motor, an L-shaped installing plate, a ball screw, an electric heating wire power supplier, an air cylinder, a limiting switch, a side vertical plate, a Kinect sensor, a light supplementing unit, a right electric heating wire cutter blade, a left electric heating wire cutter blade, a terminal telescopic plate, a connector, a slide rail and an installing disk. The cutting place of a strawberry fruit stem is coagulated for being heated, and water loss can be effectively prevented; through acquiring and sensing the working environment and strawberry information in real time through fusing information of multiple sensors, the full automatic strawberry harvesting work is realized during the processes of aligning fruits, closing to the fruit stem and electric heating cutting on the basis of not damaging the strawberry; besides, the terminal executor also solves the technical difficulties that the manual strawberry picking wastes time and labor, and the strawberry picking is easy to get injury and water is easy to loss.

Owner:谷新运

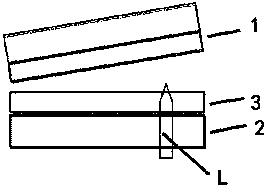

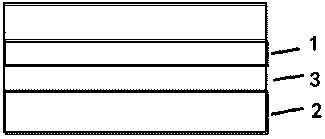

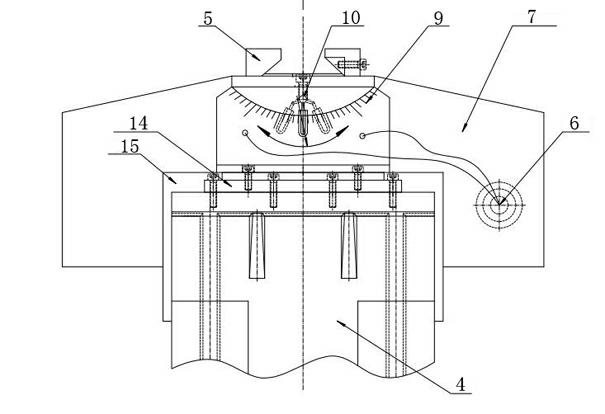

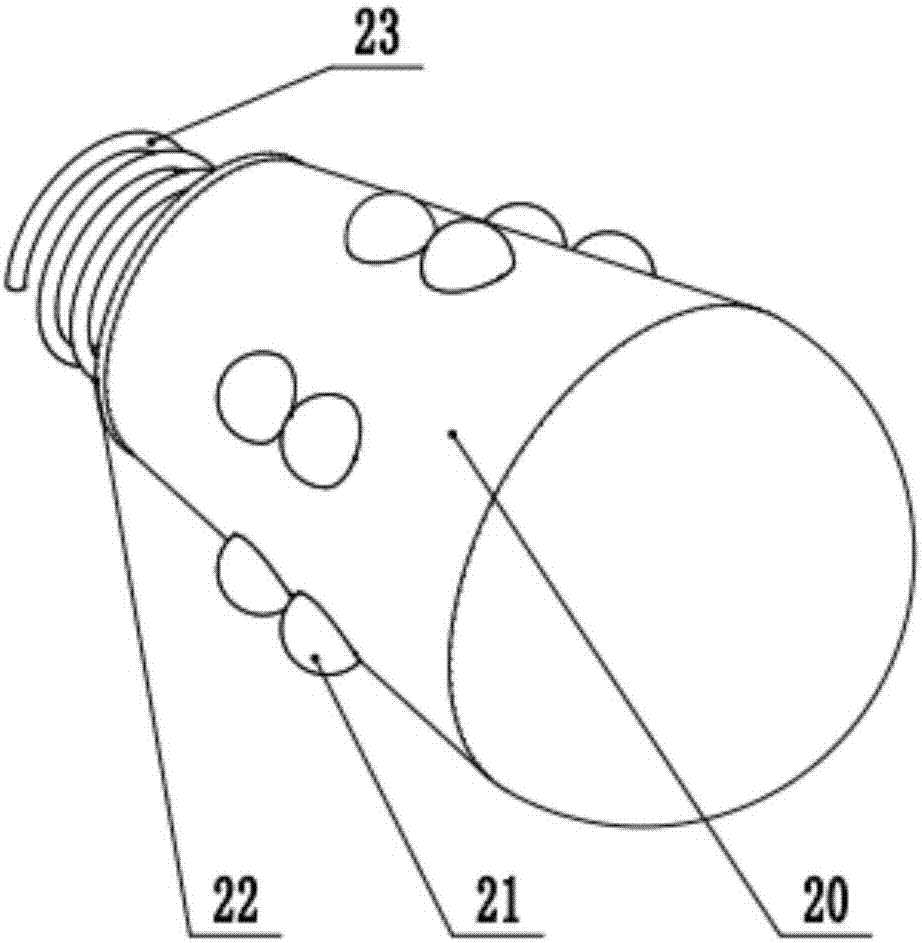

Multi-wire cutter special for sapphire

InactiveCN102189612AFast cutting speedIncrease net speedWorking accessoriesFine working devicesWire cuttingEngineering

The invention relates to a multi-wire cutter special for sapphire, which belongs to the technical field of cutting devices special for sapphire. The technical scheme is as follows: the multi-wire cutter comprises a cutter body (1), a cutting wire mechanism (2), a swing working platform and a lifting body (4), wherein the cutting wire mechanism is arranged on the upper part of the cutter body, the swing working platform is arranged at the lower part of the cutting wire mechanism, the lifting body is connected with the swing working platform and drives the swing working platform to move up and down, and the swing working platform per se swings left and right to ensure that a workpiece on the swing working platform is matched with the cutting wire mechanism so that multi-wire cutting of the sapphire can be completed. The multi-wire cutter is used for adjusting the cutting angle of the sapphire dynamically, and ensures that the angle of a sapphire material can be continuously adjusted with the swing working platform when the sapphire material is cut so that a cutting wire is in less contact with the material and additional friction force is reduced; meanwhile, the feeding speed of the cutting wire can be greatly increased, the problem of low cutting speed caused by high hardness of the sapphire is solved, and the speed is improved to 2-4 times of that of the common multi-wire cutter.

Owner:唐山晶玉科技股份有限公司

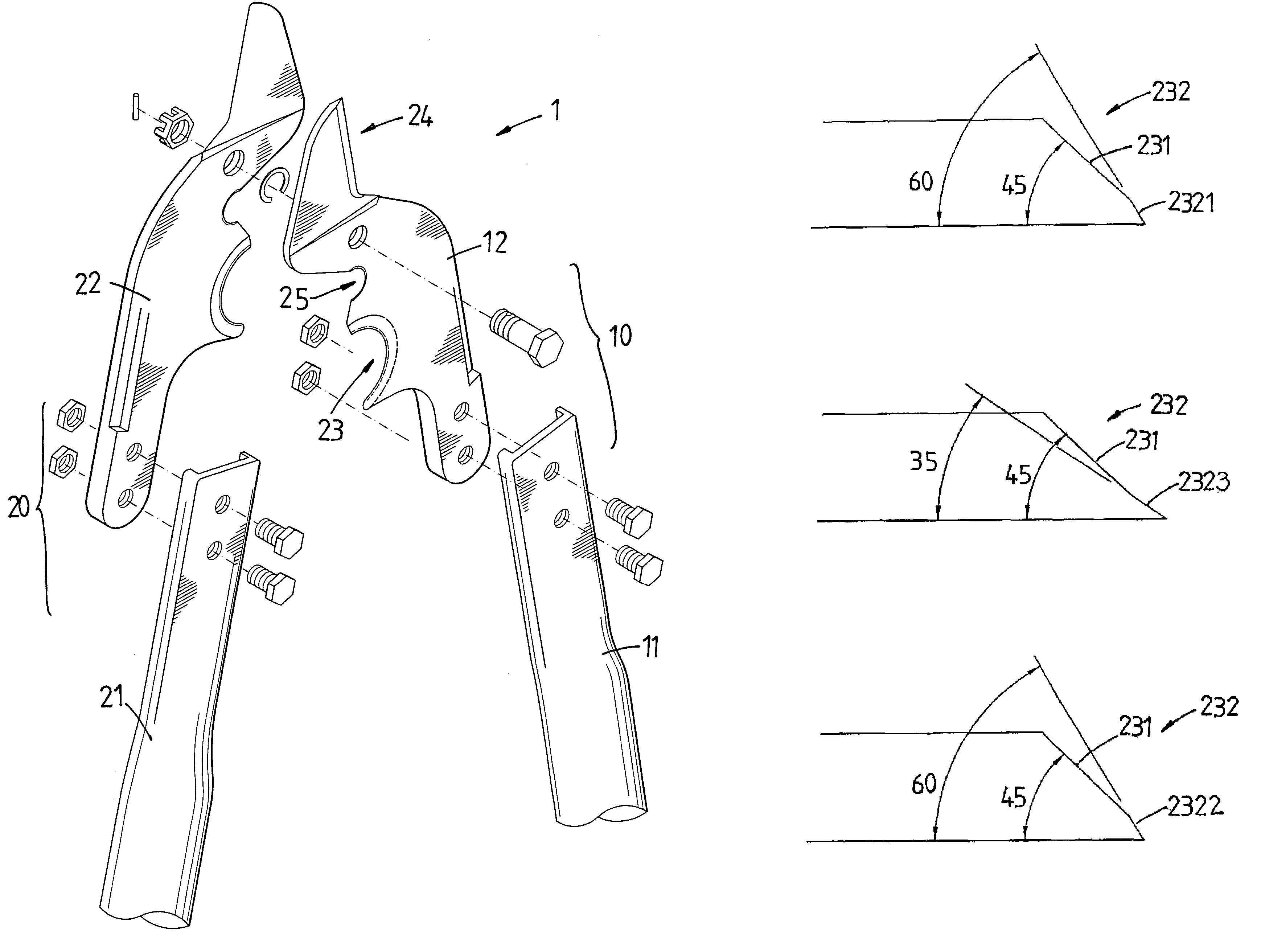

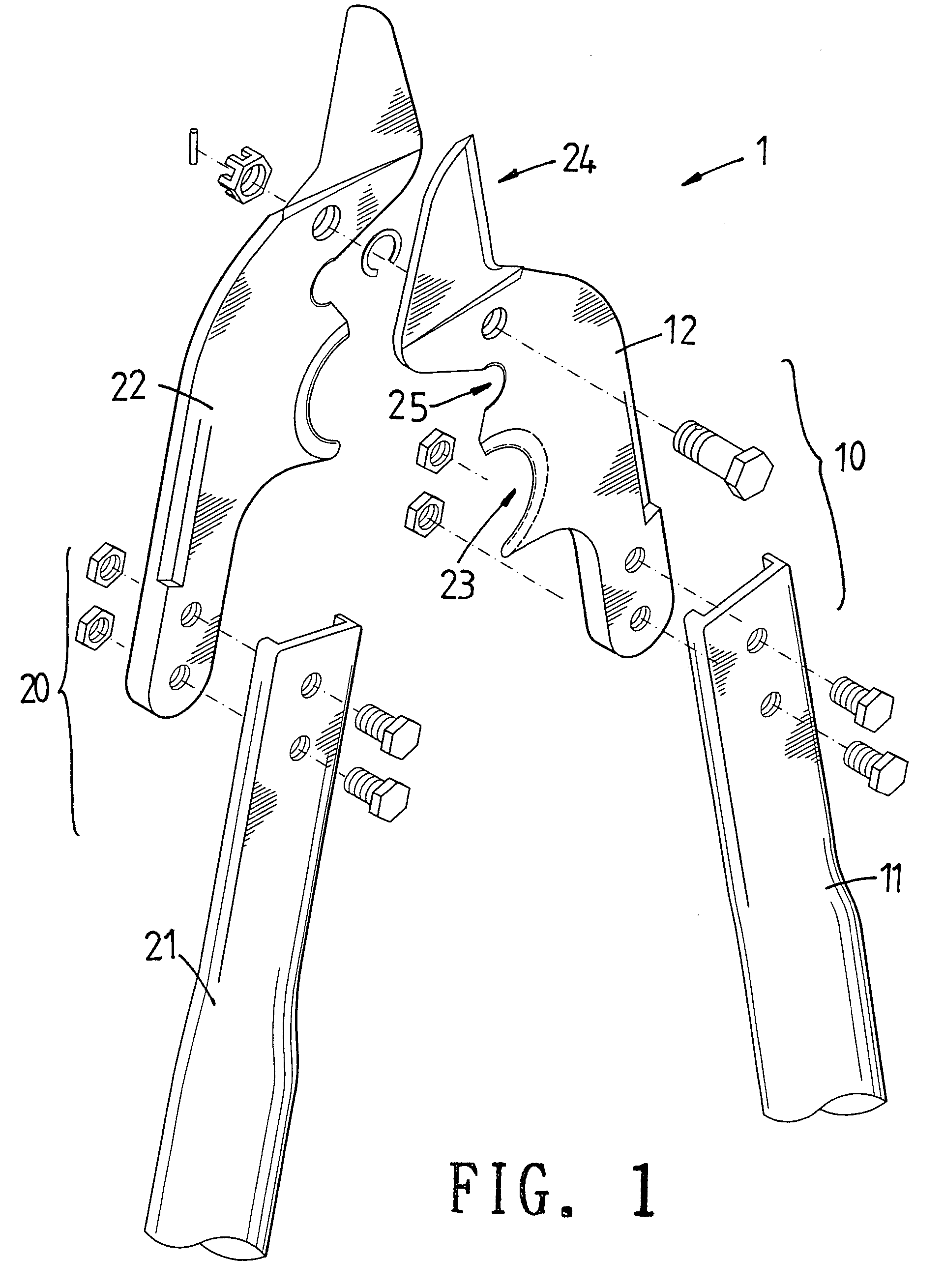

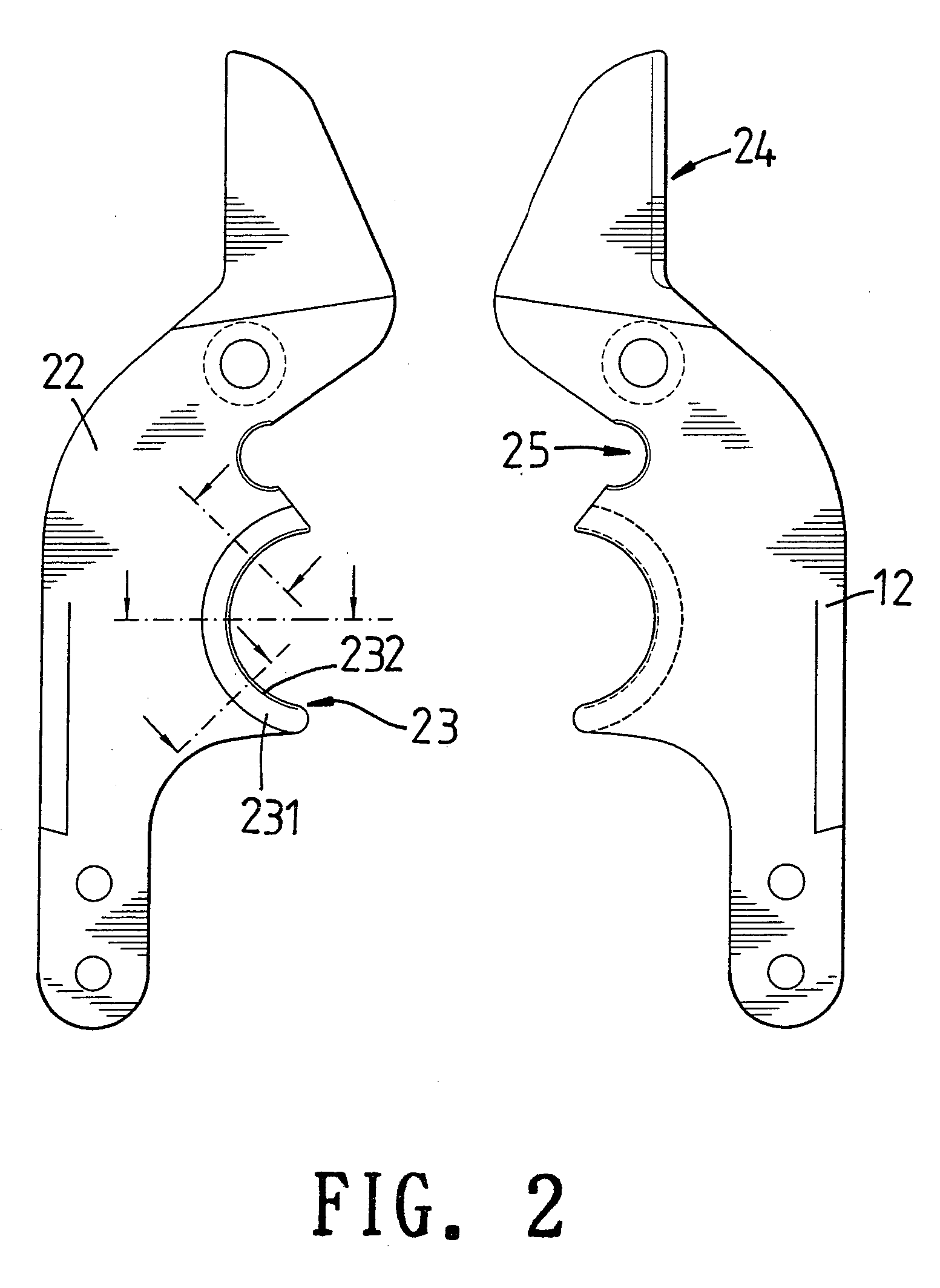

Cutting edges for wire cutters

A wire cutter includes two jaws pivotably connected with each other and each jaw has a curve cutting edge which includes a cutting portion which includes a first section, a second section and a third section which is located between the first and second sections. Each of the first section and the second section has a first side surface and a second side surface, and a first angle of 60 degrees is defined between the first side surface and the second side surface. The third section has a third side surface and a fourth side surface, a second angle of 35 degrees is defined between the third side surface and the fourth side surface. The wires are pushed toward the second sections and cut by the second sections.

Owner:HSIEH CHIH CHING

Apple net sleeving device

The invention relates to an apple net sleeving device, and belongs to the field of fruit packaging. The apple net sleeving device is composed of a feeding groove, a limiting pipe, a top rod, a guiding groove, a feeding motor, a motor supporting plate, a first frame, a rotating guiding groove, a second frame, a discharging plate, a discharging motor, a third frame, a net sleeve roller, a hemisphere net support, a rear transverse beam, a net support outer frame, a guiding wheel, a guiding motor, a front transverse beam, a net support inner frame, a guiding bead, an electric heating wire cutter, a spring, a base wheel and a base wheel shaft, specifically, a sleeve net is supported by a net support, apples are pushed to move forward by the top rod for net sleeving, the sleeve net is cut by the electric heating wire cutter, and discharging is conducted by the rotating guiding groove. When the apple net sleeving device is in work, transmission is stable, continuous net supporting and net sleeving can be conducted, the qualified rate of net sleeving is high, noise is small, and efficiency of apple net sleeving is greatly improved.

Owner:浙江五峰汽车轴承制造有限公司

Sawing wire cutter for cave mining of mineral materials and cave mining method for mineral materials

The invention discloses a sawing wire cutter for the cave mining of mineral materials and a cave mining method for mineral materials. The sawing wire cutter comprises a support, a guide track, a main motor, a feed mechanism and a sawing wire cutting mechanism. The sawing wire cutting mechanism comprises a sawing wire and at least one extending part, the main motor is transmissively connected with the sawing wire, so that the sawing wire can cut a cut surface, at least part of the extending part is located between a working face and the cut surface, the working face is parallel to or intersects the cut surface, at least one first guide pulley is arranged on the extending part, the tangent line of the first guide pulley is matched with the cut surface, and the sawing wire is led from the cut surface to the main motor by the first guide pulley. Since the guide pulley arranged on the extending part can lead the sawing wire to the working face from the cut surface, the cut surface is separated from the working face, the cut surface can be machined as long as the main motor, the guide track, the feed mechanism and the like are placed on the working face, so that the back of mineral material can be cut off from a mine mountain, the sawing wire cutter can be utilized for cave mining, the cut surface is smooth, and the cutting efficiency is high.

Owner:江显秋

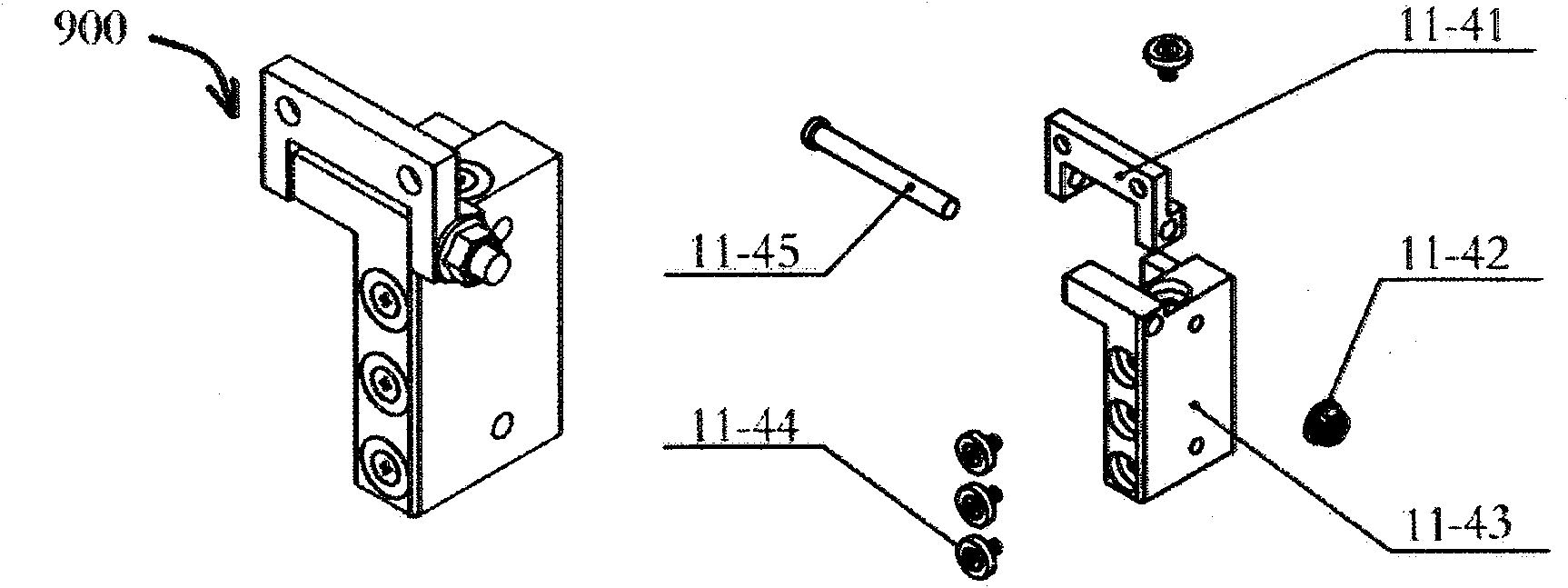

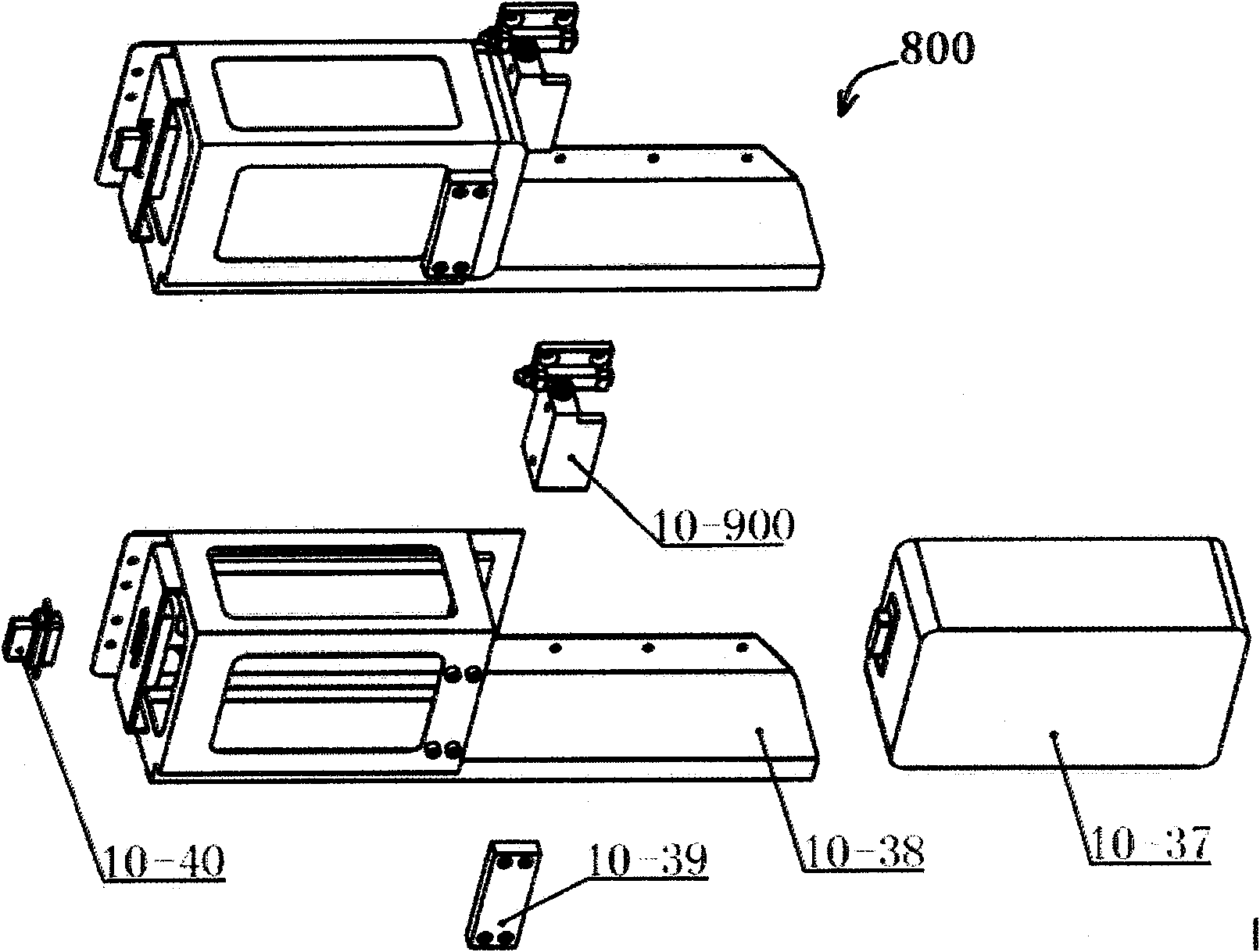

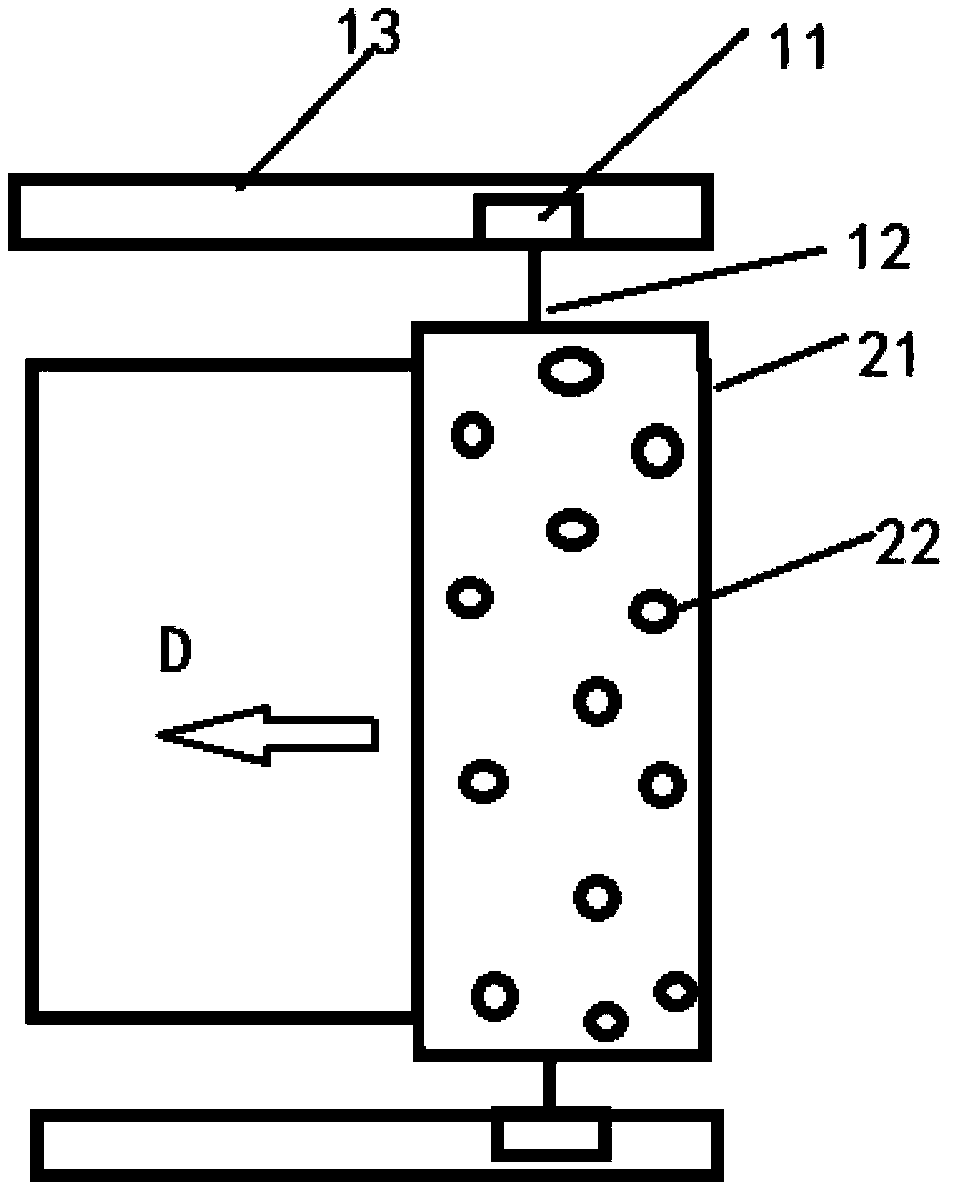

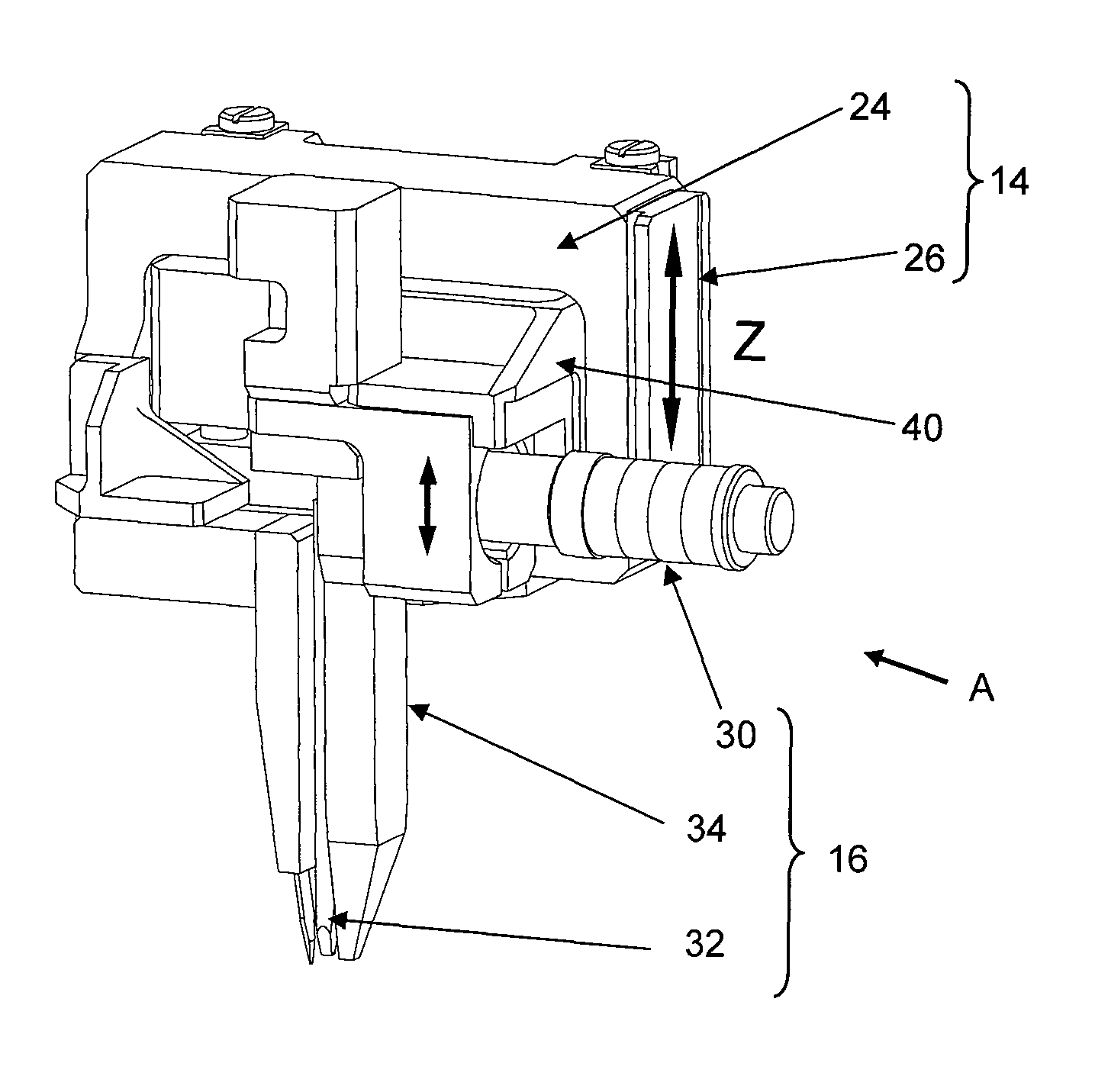

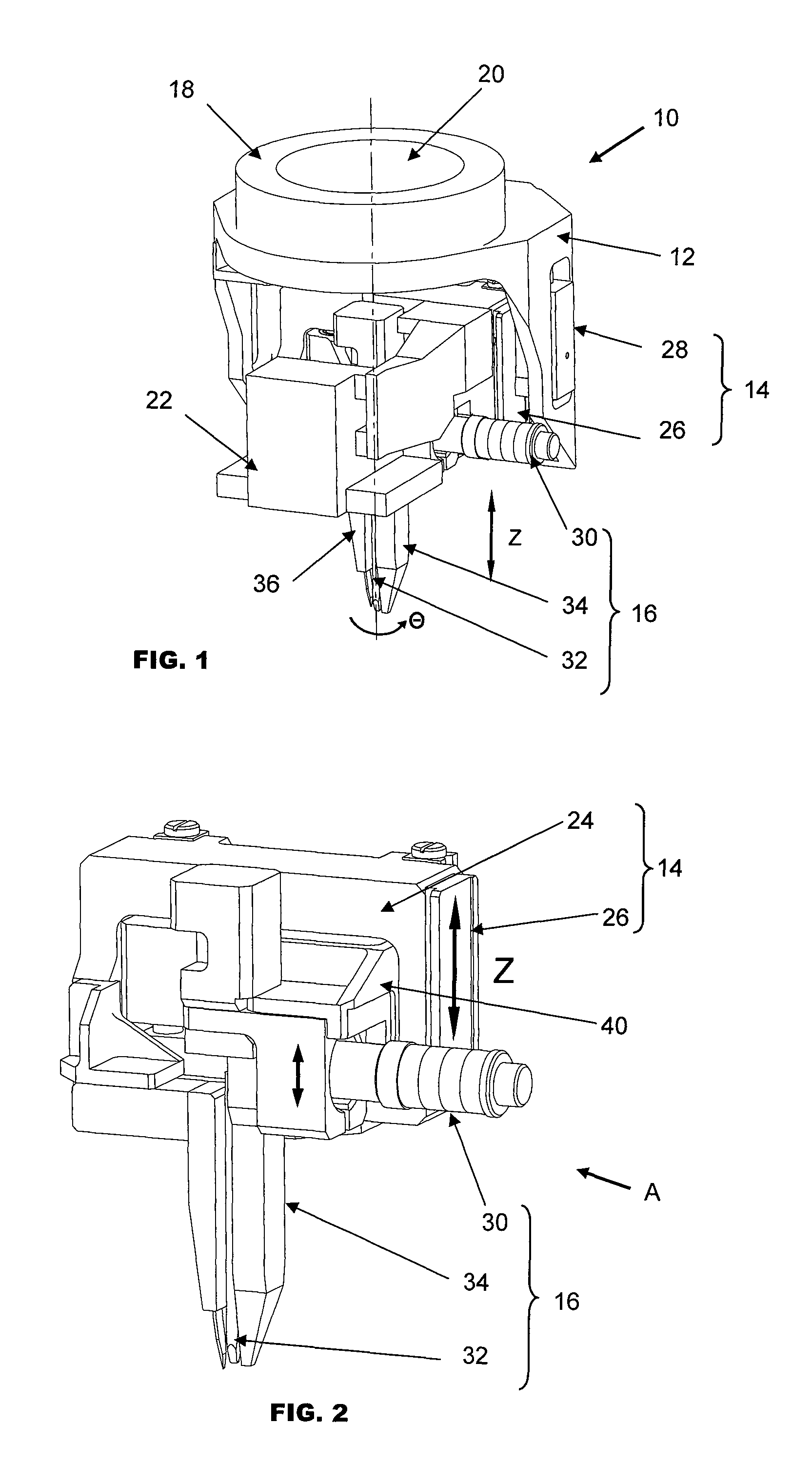

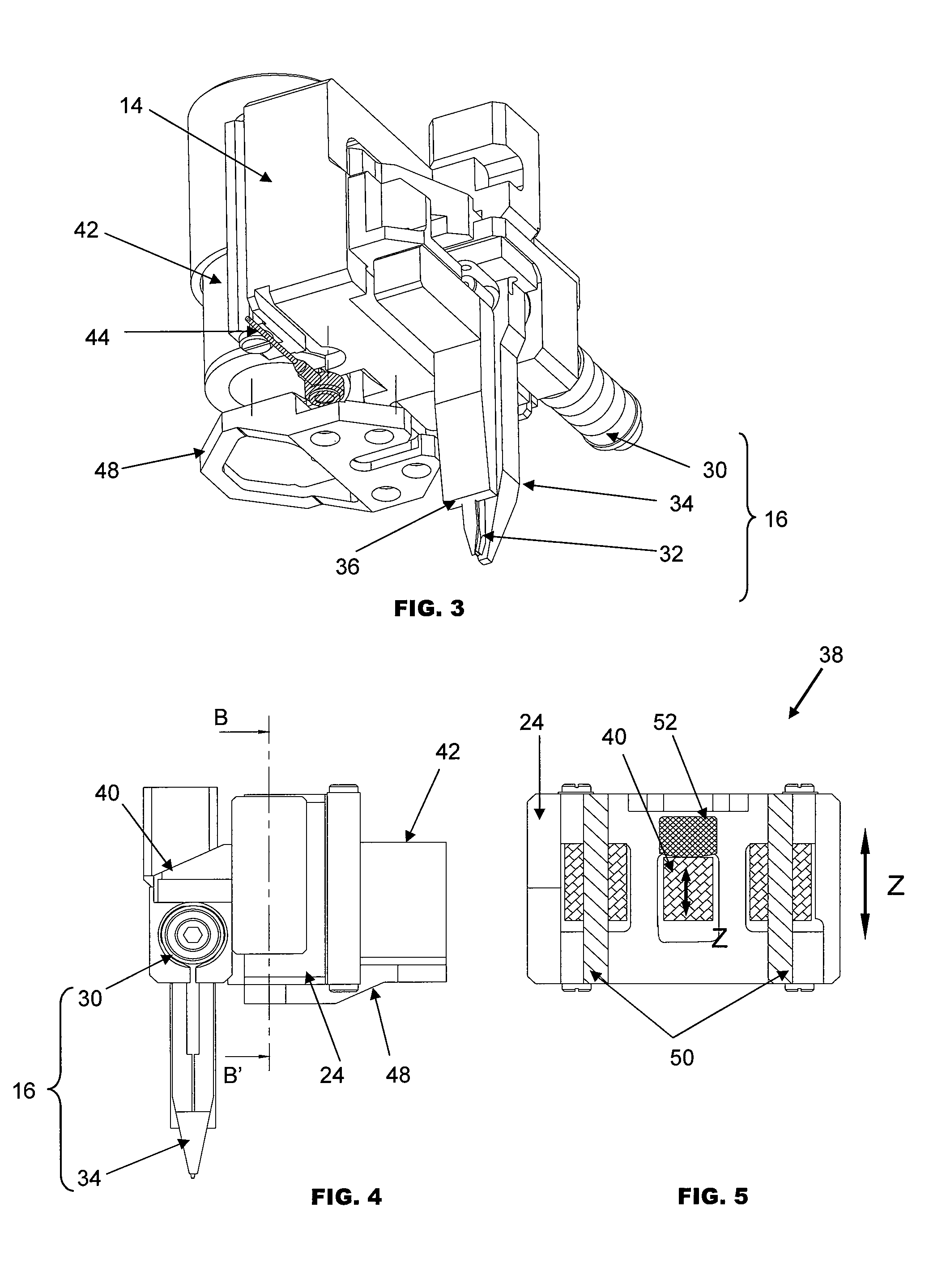

Bond head for heavy wire bonder

ActiveUS7762449B2Easy to controlSolid-state devicesWelding/cutting auxillary devicesWire cutterEngineering

A bonding apparatus for bonding a length of wire comprises a first module which is drivable along a linear axis towards and away from a bonding point and a second module slidably mounted to the first module. A wire cutter is mounted to the first module and a bonding tool is mounted to the second module. A coupling mechanism is operative to lock the second module in fixed relative position to the first module, and to unlock the second module from its fixed relative position to the first module so that the second module is slidable relative to the first module in directions parallel to the linear axis.

Owner:ASM ASSEMBLY AUTOMATION LTD

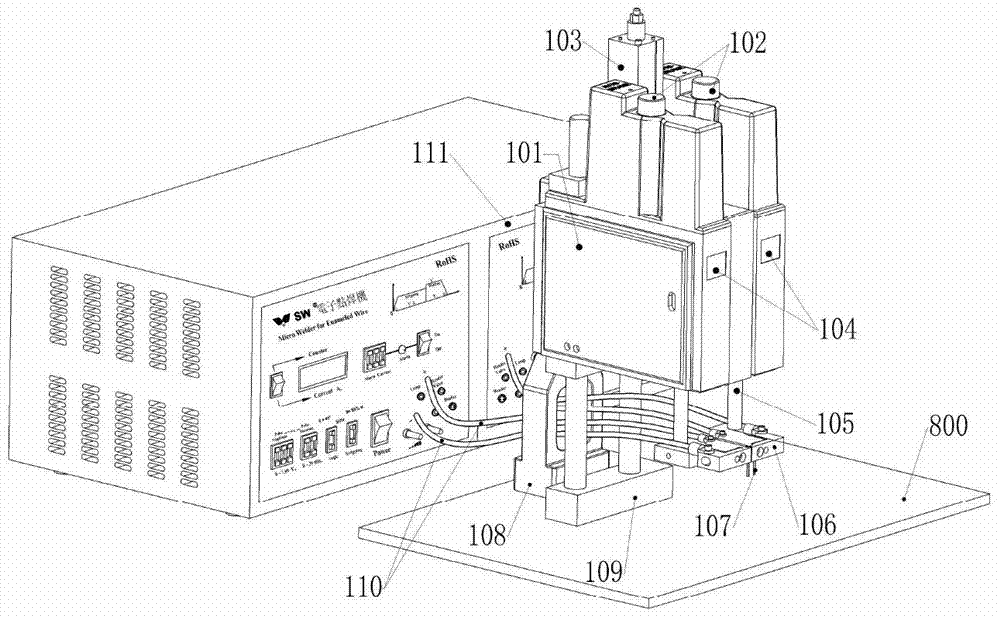

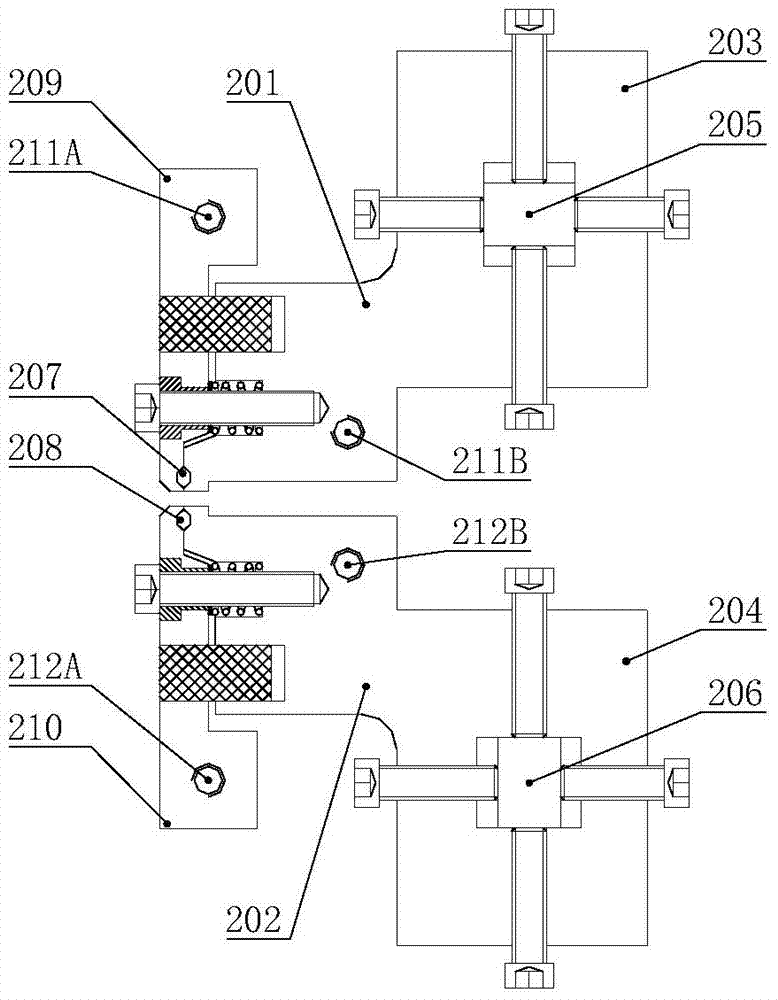

Electronic element automatic welding equipment

ActiveCN103920962AIncrease productivityImprove product qualityMetal working apparatusSoldering auxillary devicesAdhesiveWelding power supply

The invention discloses electronic element automatic welding equipment and relates to the fields of electronic element manufacturing, automation and welding. The electronic element automatic welding equipment comprises a spot welding communication detecting device, an adhesive dispersing device and an automation system. The spot welding communication detecting device comprises two parallel welding head clamps, spot welding noses connected with the welding head clamps, a spot welding power supply, a detecting circuit and tow parallel electrode welding heads with wire cutters. The electronic element automatic welding equipment has the advantages that the spot welding noses with a Z-axis power device, an adhesive dispense nose and an X-axis power device are controlled under the same automatic device for operation, tool clamps are mounted at one step, welding, wire cutting, communication detection and adhesive dispense are completed on the slide table of the same X-axis servo motor, and work efficiency and product quality are increased effectively.

Owner:GUANGZHOU MICRO WELDING EQUIP

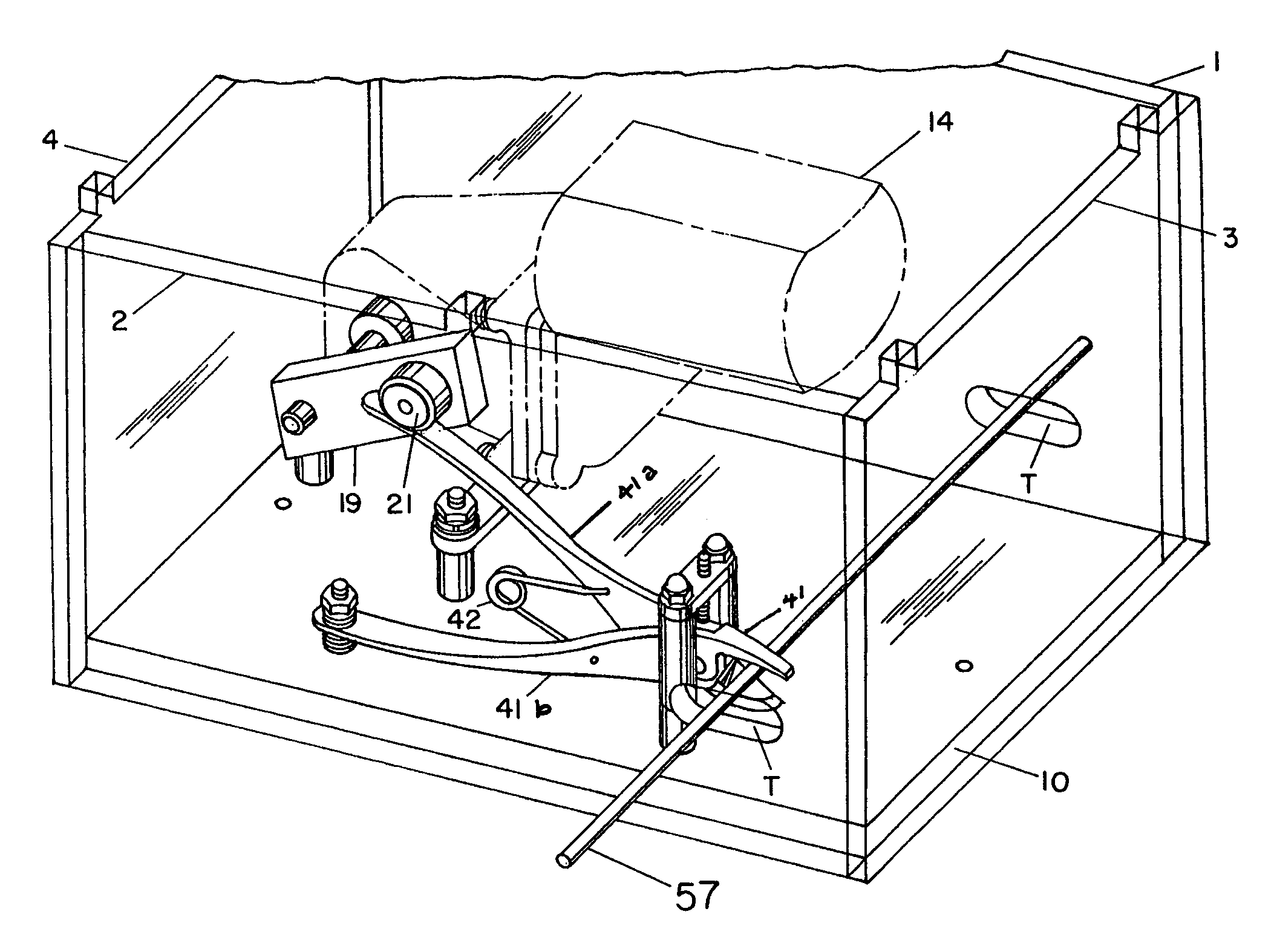

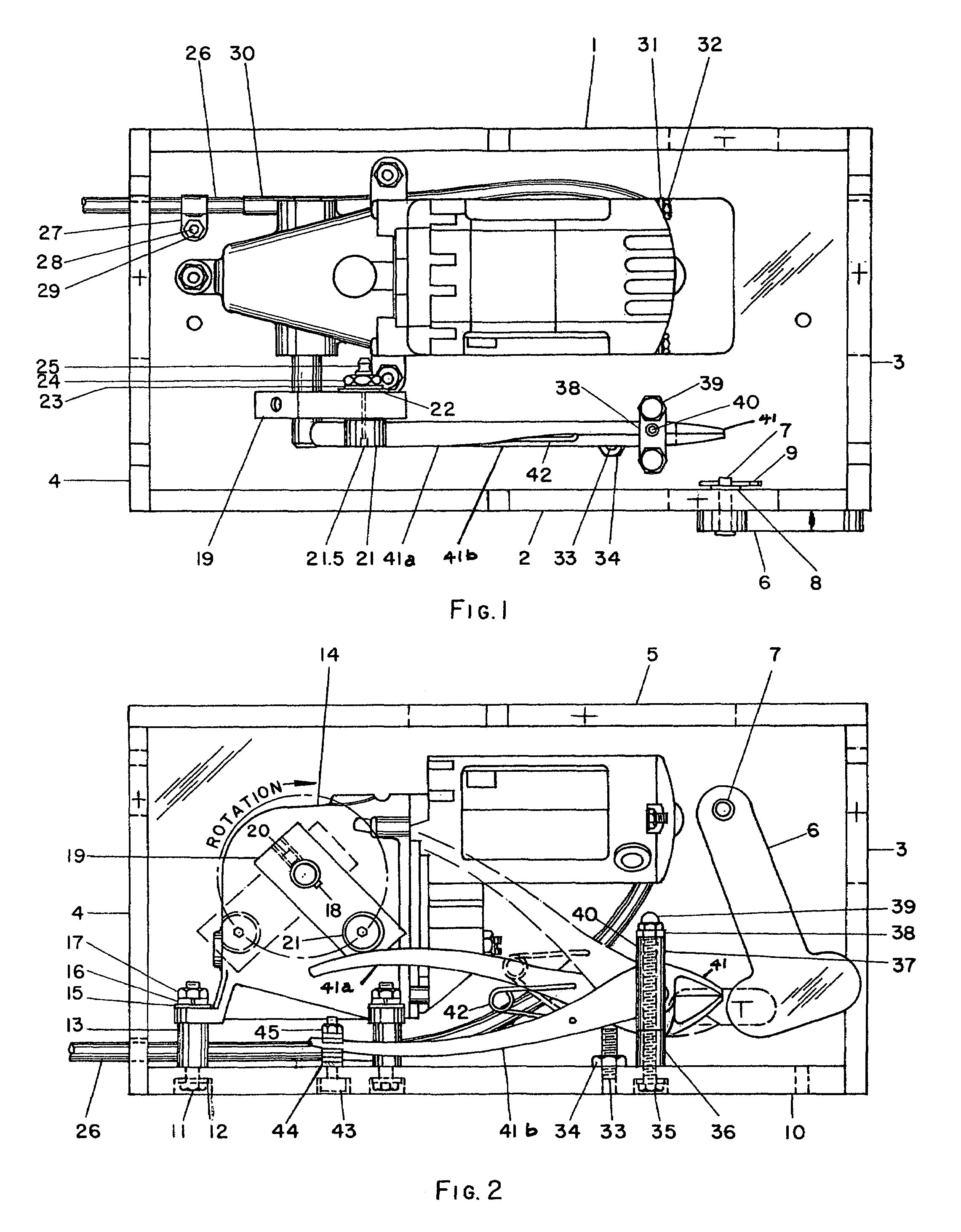

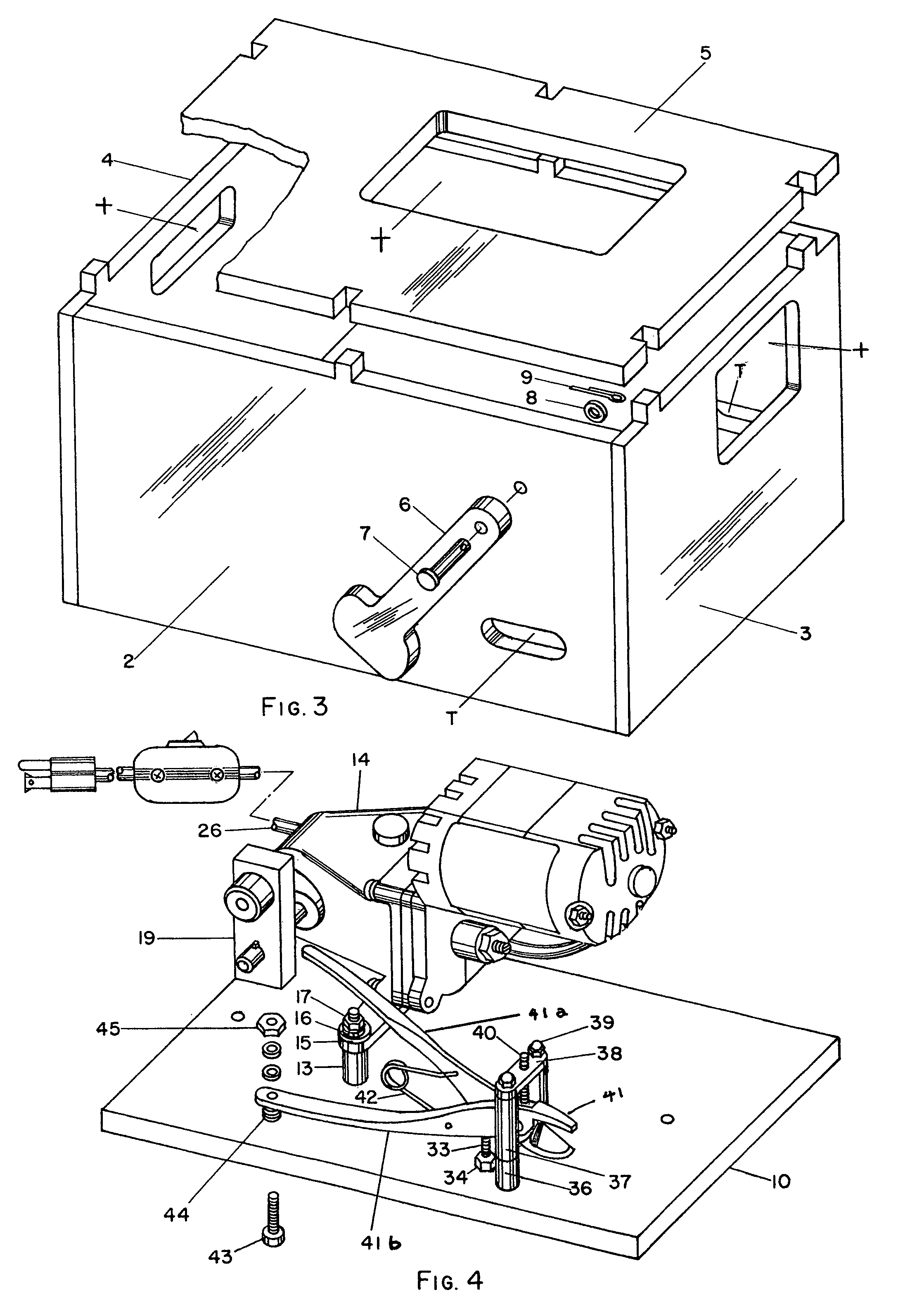

Wire cutter for artificial flower stems

Cutter suitable for artificial flower stems. Typically, plastic coated wire stems are cut with hand cutters to various lengths in preparing artificial floral arrangements. The invention requires far less physical effort by the operator than is required when using conventional wire cutters. In the preferred use of the preferred embodiment of the invention, an uncut stem is inserted crosswise through two elongated holes in the guard housing. When the cutter jaws open, the stem is pushed into the open jaws and is cut to a desired length from the flower end when the jaws close. In the preferred embodiment of the invention a gear reduction motor drives an arm and cam roller assembly. That cam roller forces the top handle of the cutter downward causing the jaws to close. As the cycle continues, the cam roller raises and a spring causes the jaws to open.

Owner:GREENLEE WILFRED EARL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com