Flying shears with high speed and definite length

A fixed-length and flying shear technology, which is applied in the direction of shearing devices, shearing machine equipment, and devices for shearing forming blanks, can solve the problems of poor synchronization of cutting and feeding, waste of time, and high labor intensity, so as to improve synchronization accuracy and ensure Improvement of incision quality and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

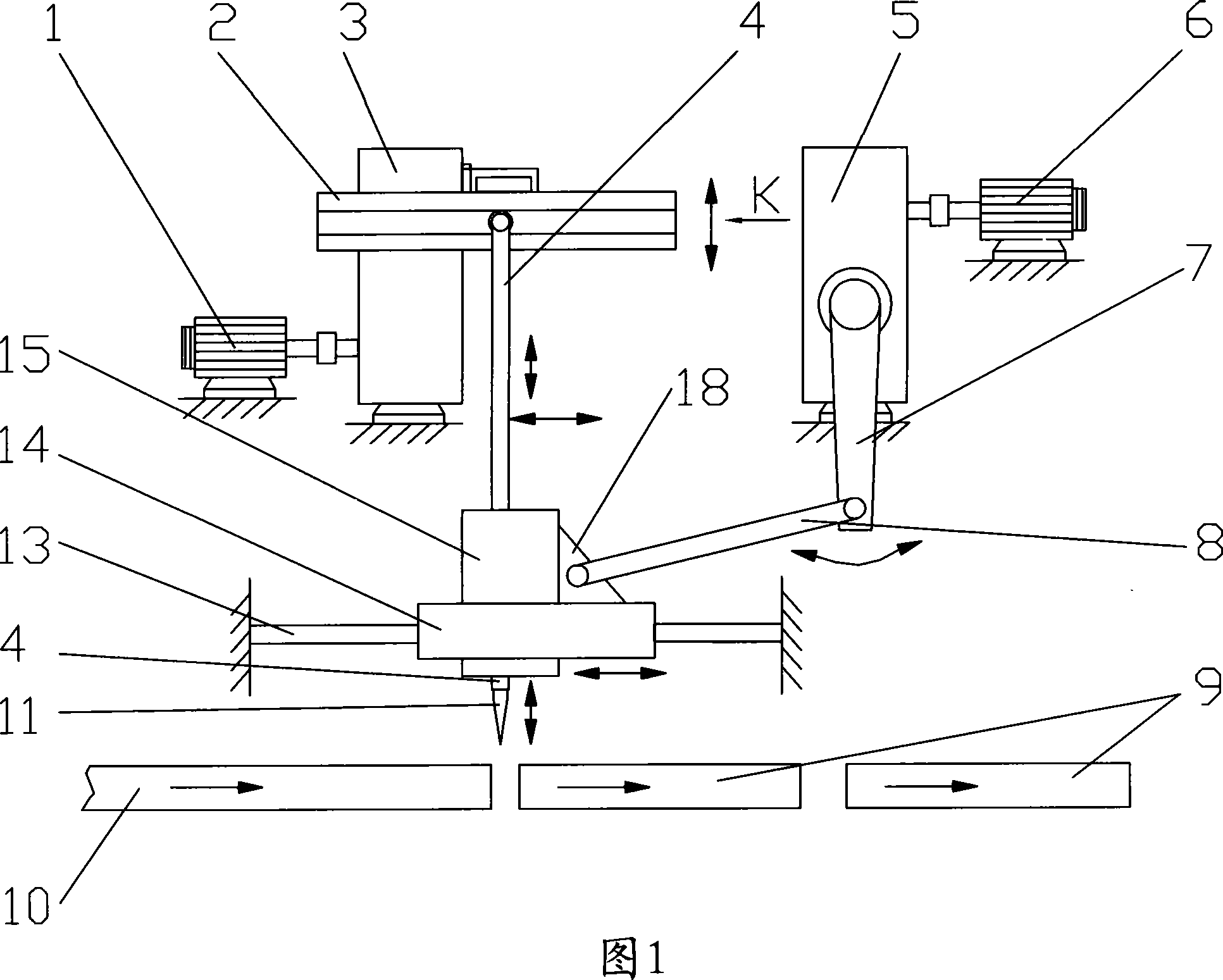

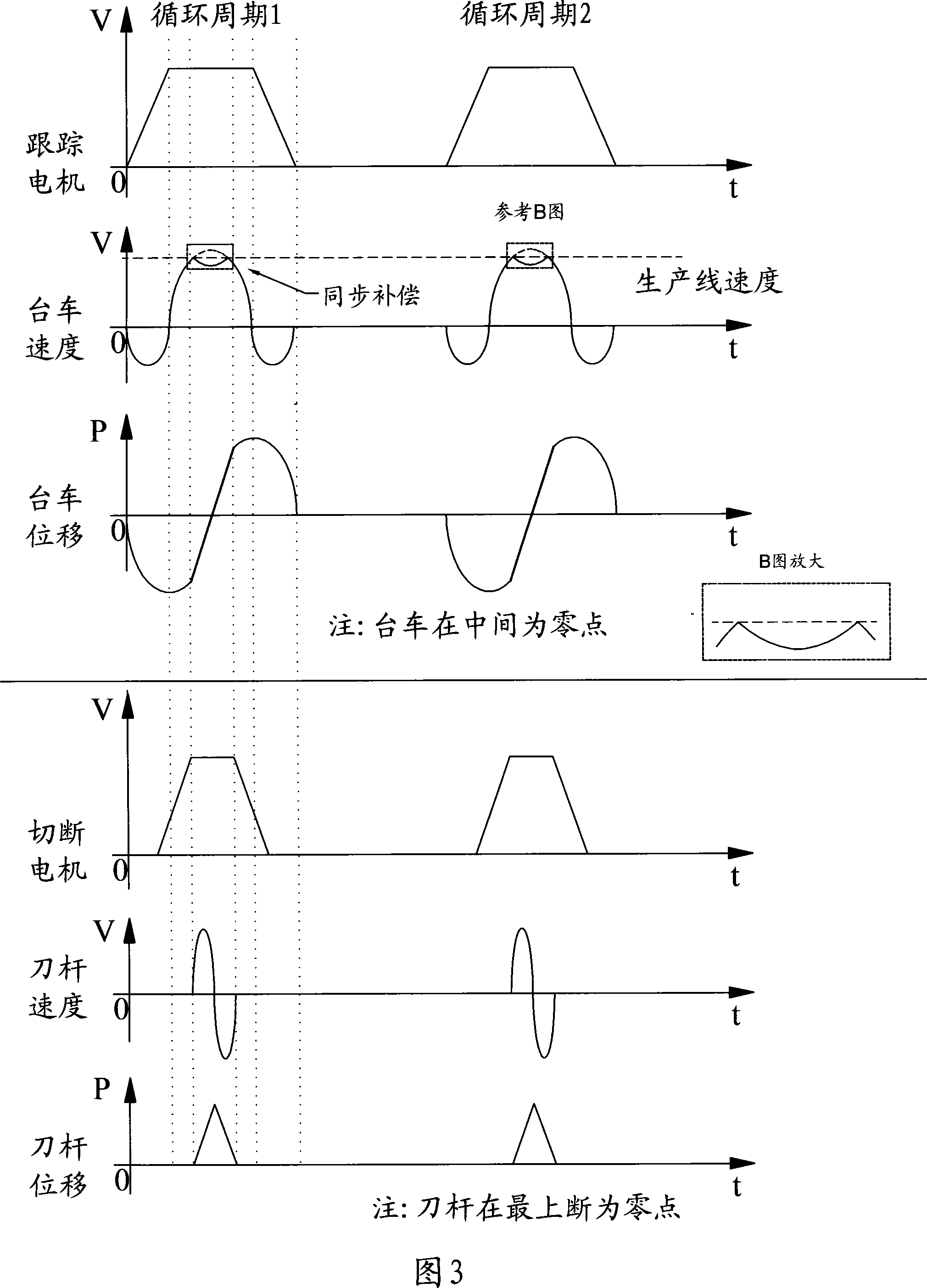

[0010] As shown in the figure: 5 is the first cam mechanism, the input shaft of the first cam mechanism 5 is connected with the motor 6 through a shaft coupling, and its output shaft is connected with one end key of the first rocker arm 7, and the first rocker arm 7 The other end is pivotally connected with one end of the swing rod 8 through a pin shaft, and the other end of the swing rod 8 is pivotally connected with the connecting plate 18 through a pin shaft. The connecting plate 18 is fixedly connected with the mobile car 14 and the cutter bar cover body 15. The mobile car 14 is provided with a guide sleeve and is set on the guide rod 13. The guide rod 13, the first cam mechanism 5, and the motor 6 are all fixedly connected with the frame. .

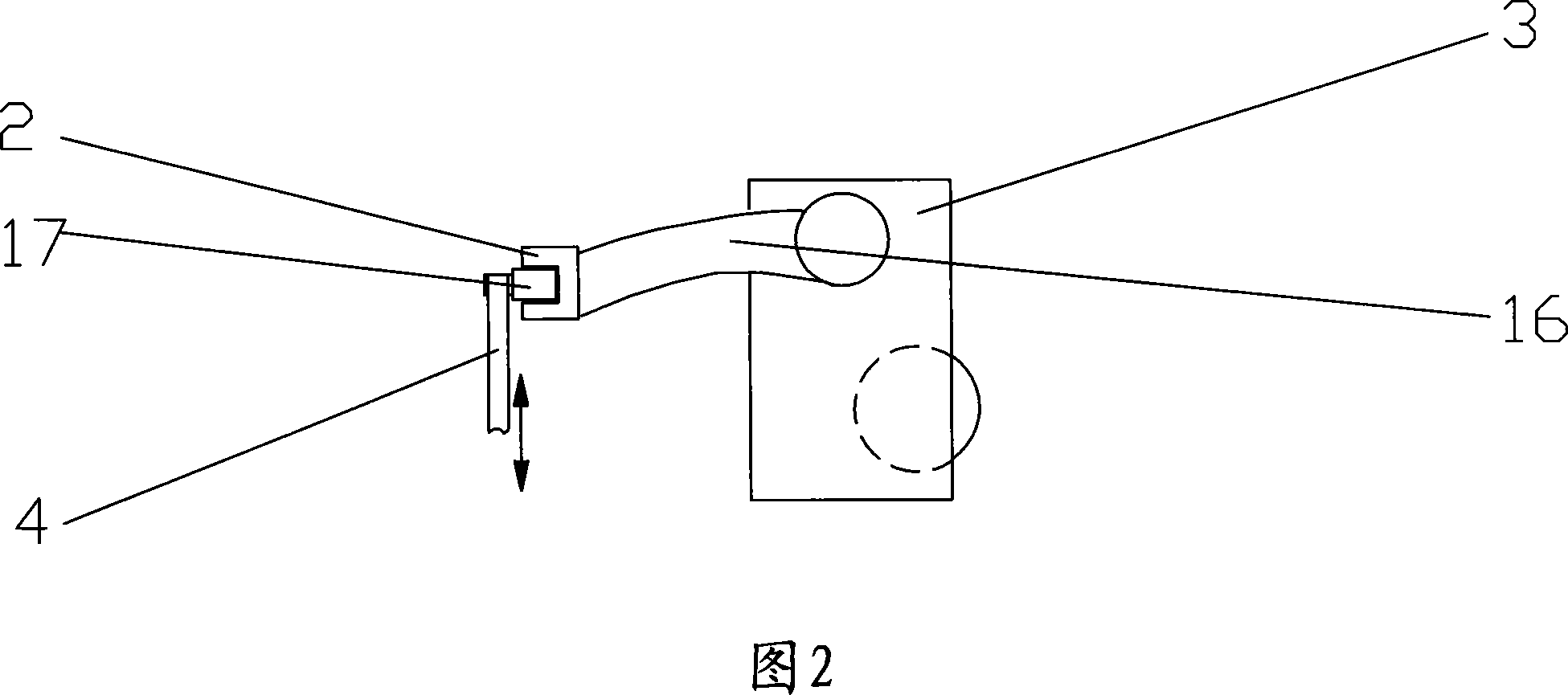

[0011] The input shaft of the second cam mechanism 3 is connected with the cutting motor 1 through a coupling, the output shaft of the second cam mechanism 3 is keyed to one end of the second rocker arm 16, and the other end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com