Patents

Literature

1009results about How to "Guaranteed cutting quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

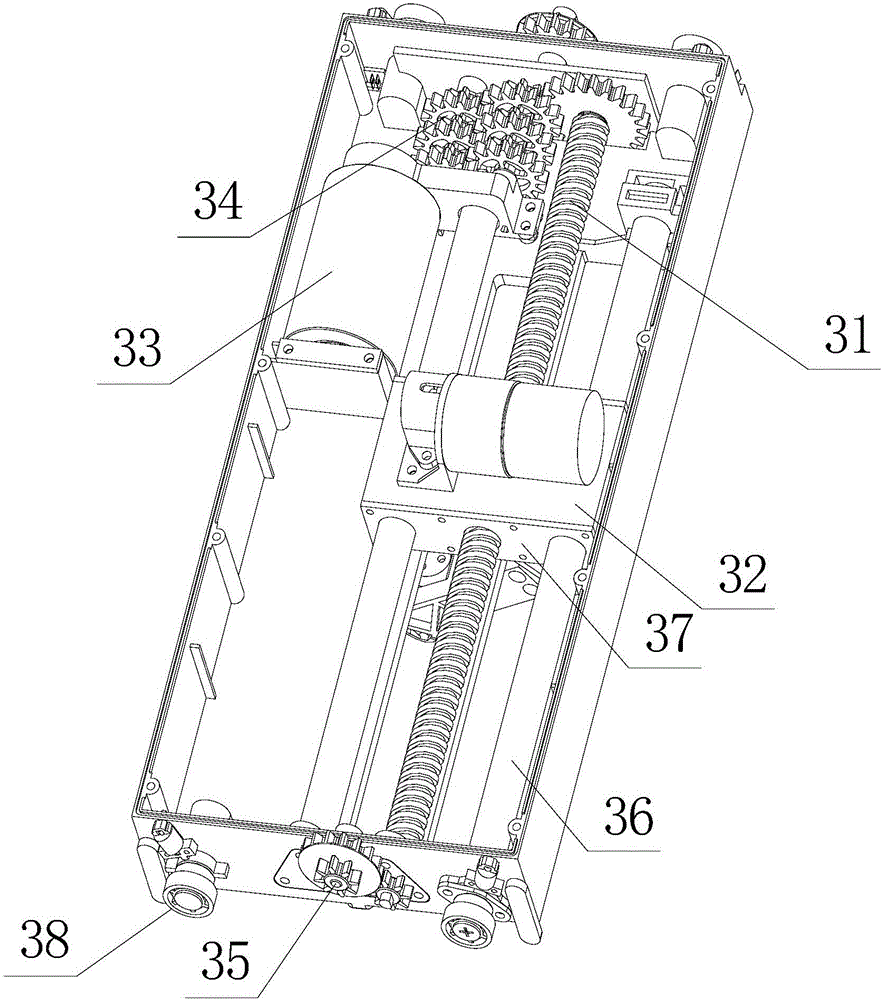

Rubber tapping machine and rubber tapping method

PendingCN107711410ARealize unmanned automatic tappingSolve labor intensityForestryEngineeringUltimate tensile strength

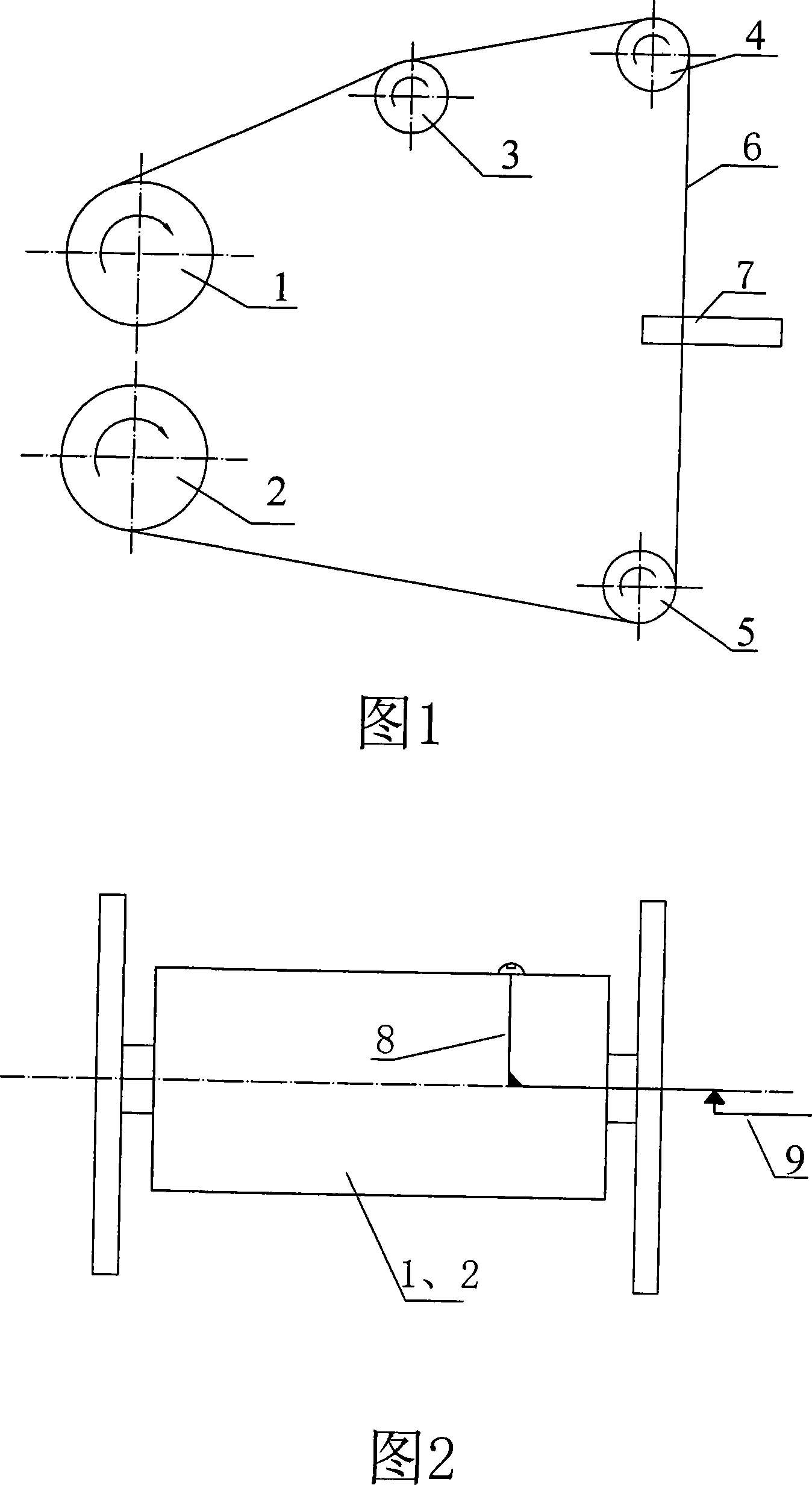

The invention discloses a rubber tapping machine and a rubber tapping method. The rubber tapping machine comprises support rods, a knife rest assembly and a rubber tapping knife assembly. A side of one of the support rods is connected with a side of the other support rod by flexible guide rails, the other side of each support rod is connected with the other side of the other support rod by tightening belts, and the flexible guide rails are opposite to the tightening belts on the sides opposite to the flexible guide rails; the knife rest assembly is provided with a motor, two track wheels capable of rolling along the outer sides of the flexible guide rails are mounted at the upper end and the lower end of the knife rest assembly, a lead screw and more than one fixing rod are further mountedin the knife rest assembly along the vertical directions, and the track wheels and the lead screw can be driven by the motor in the knife rest assembly to rotate. The rubber tapping machine and the rubber tapping method have the advantages that labor can be replaced by automatic machinery, accordingly, rubber can be automatically tapped from rubber trees in an unmanned manner, and the problems ofhigh labor intensity of manual rubber tapping and insufficient fineness of manual rubber tapping can be solved to the greatest extent.

Owner:NINGBO CIHEVEA TECH CO LTD

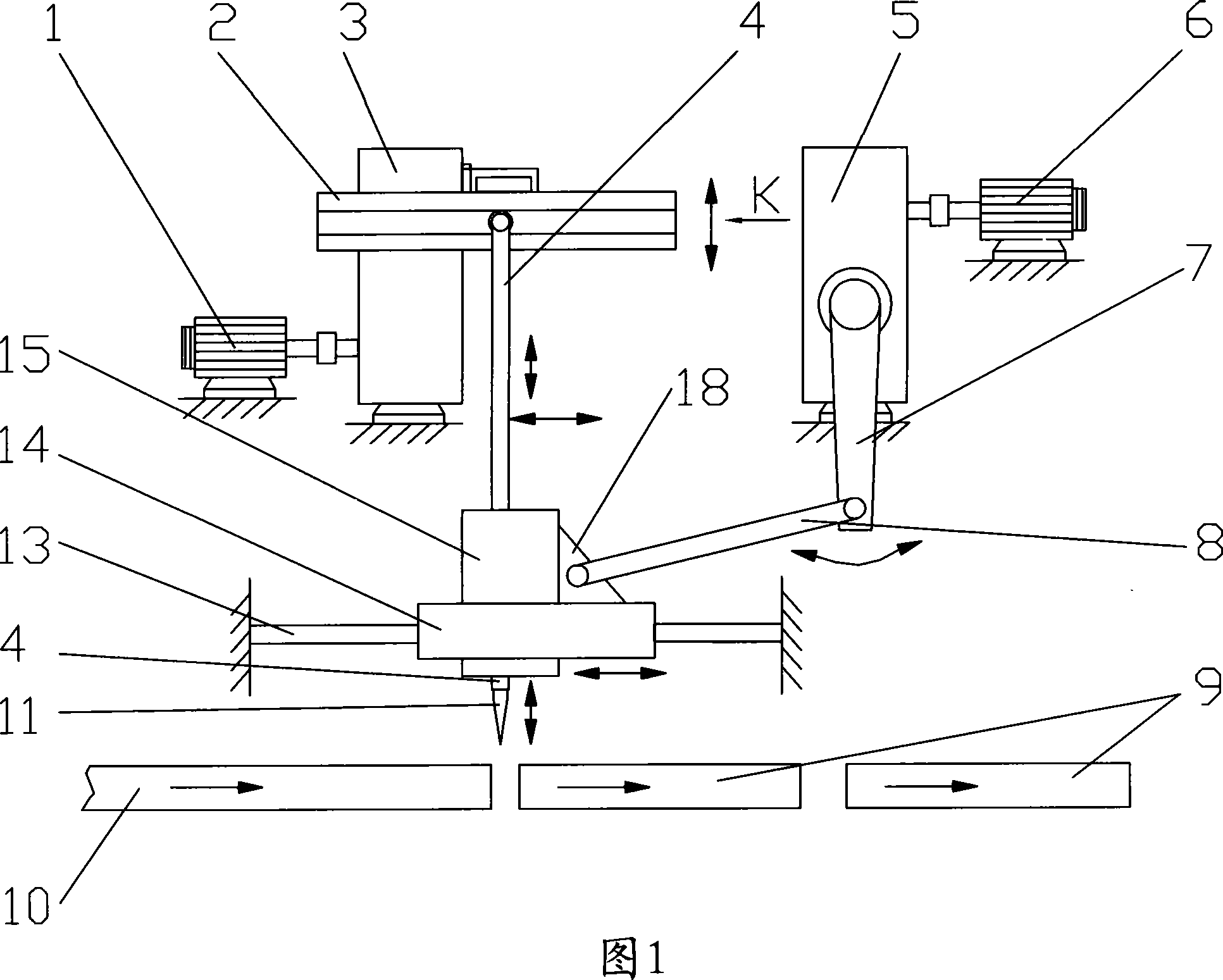

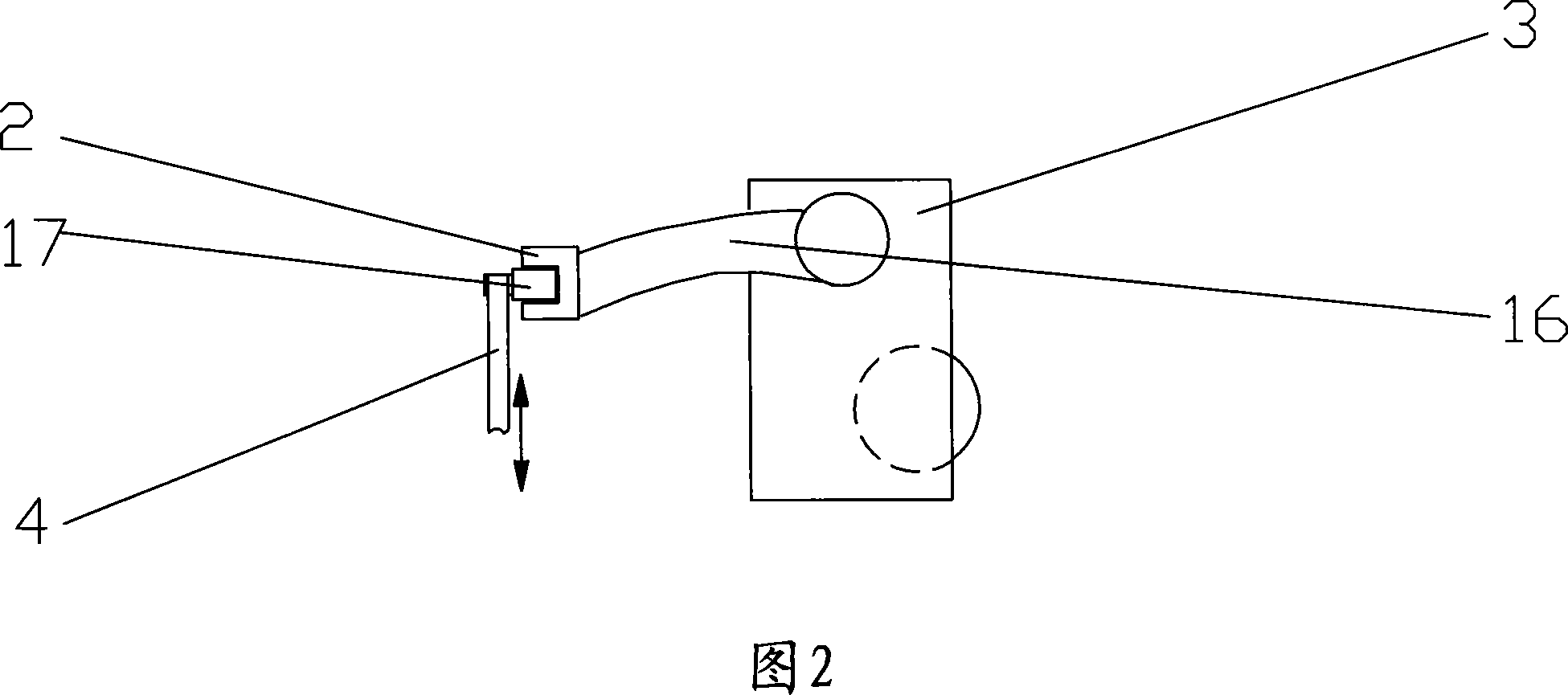

Monocrystalline silicon high-efficient composite cutting method and cutting system thereof

InactiveCN101138869AImprove cutting effectSave the texture processFine working devicesMetalElectric spark

An efficiently composite cutting method of monocrystalline silicon is characterized in that a monocrystalline silicon rod for cutting is installed and nipped at an electric spark linear cutting machine; metallic thread which is concreted with diamond grinding material is used as cutting wire to make the electric spark linear cutting; the advantages that the processing speed of the electric spark linear cutting is high and the cutting effect of the diamond grinding material at the metallic thread of the concreted grinding material is good are completely exerted; the purpose to realize the quickly and efficiently cutting towards the monocrystalline silicon rod is achieved; at the same time the surface of the cut monocrystalline silicon naturally forms a fleece-faced texture which has the effect of anti-reflection. The present invention has a series of advantages of simple method, high efficiency of processing, good quality etc.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

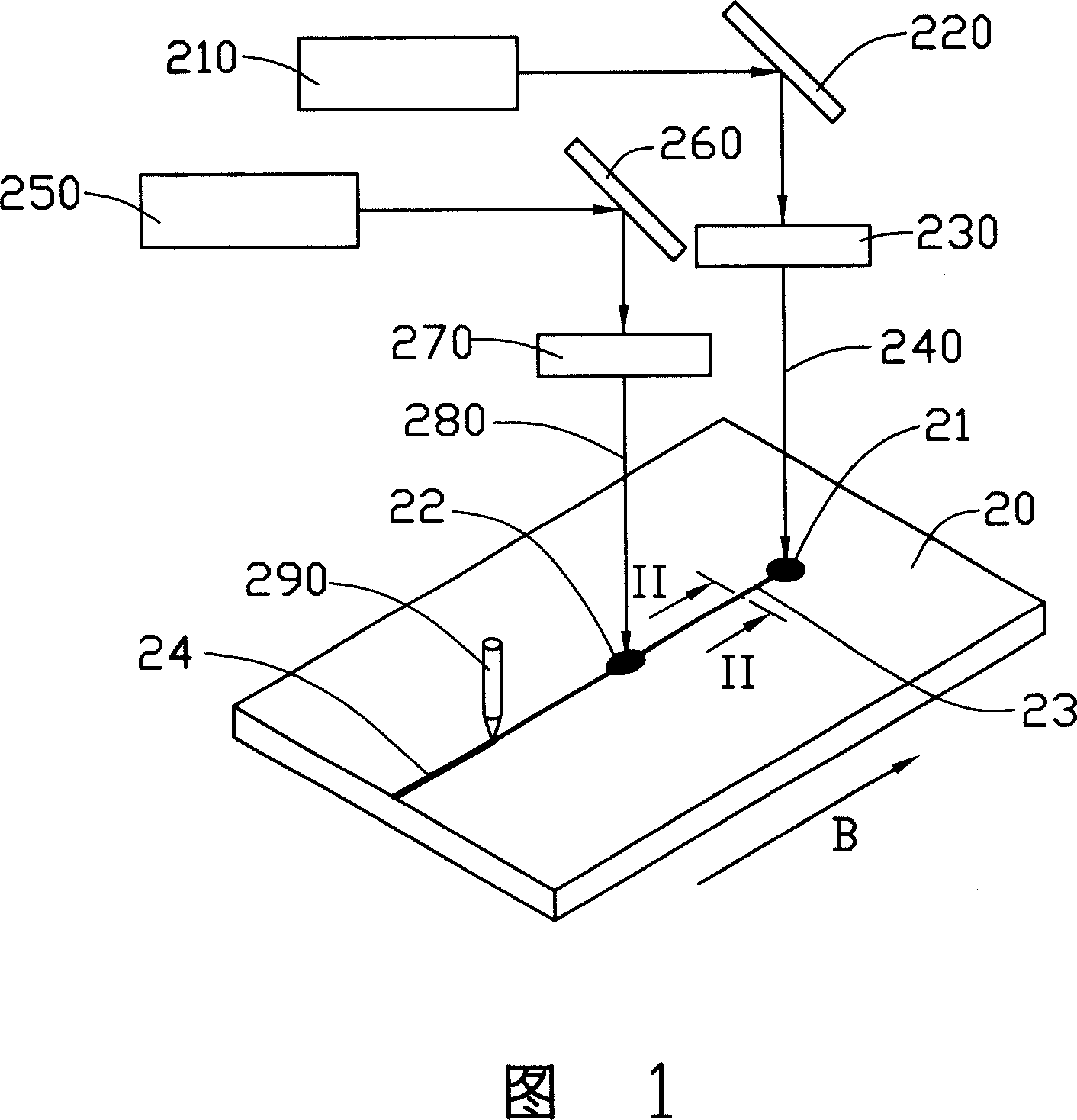

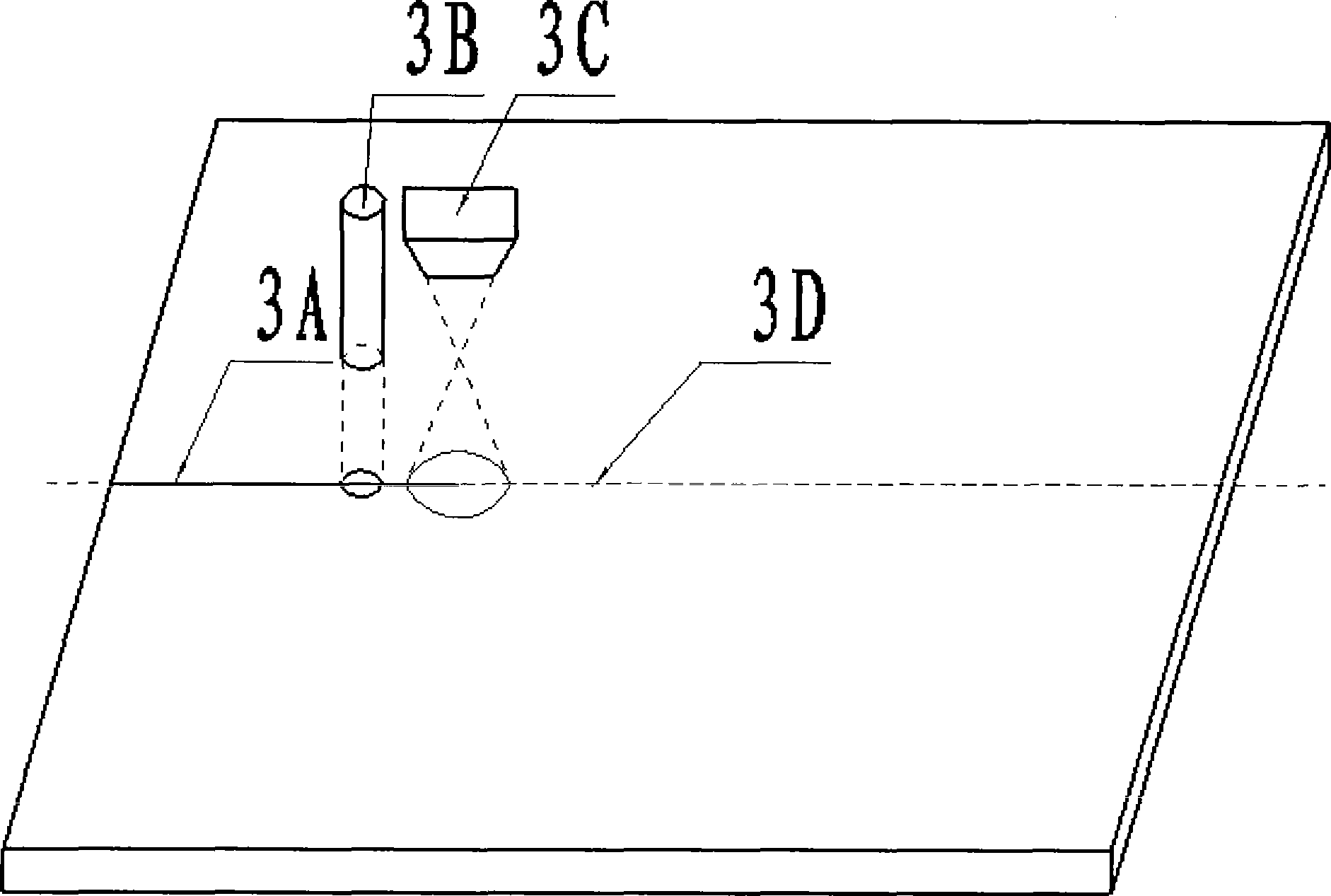

Method for cutting crisp material substrate

InactiveCN101121220AAvoid defectsGuaranteed cutting qualityFine working devicesGlass severing apparatusSolid-state laser deviceHigh energy

A method for processing a brittle substrate includes first providing a brittle substrate having a substrate surface. Then applying a first laser beam onto the brittle substrate surface to form a pre-cut groove in the brittle substrate, the first laser beam being generated by a solid-state laser device. A second laser beam is then applied onto the brittle substrate surface along the precut groove to heat the brittle substrate, the second laser beam being generated by a gas laser device. Finally, a coolant is applied onto the brittle substrate along the pre-cut groove so as to cause formation of a through crack in the brittle substrate. The first laser beam can be generated by a solid-state laser device, the first laser beam should be of narrow diameter and high energy density, so the first laser beam can form a pre-cut groove rapidly and accurately without generation of micro-cracks, in addition, the pre-cut groove should have a better uniformity and linearity.

Owner:FOXSEMICON INTEGRATED TECHNOLOGY (SHANGHAI) INC +1

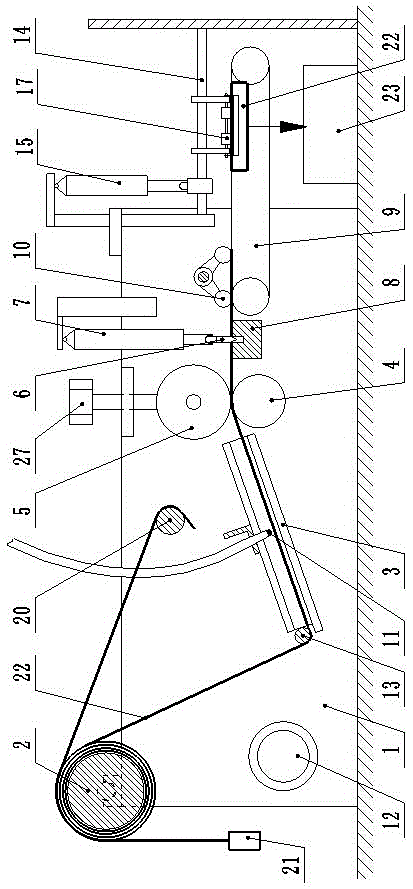

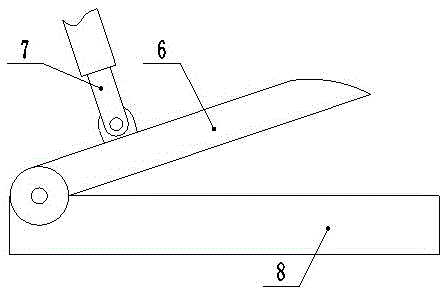

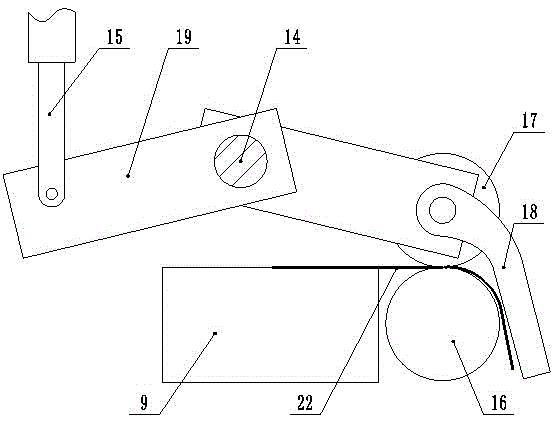

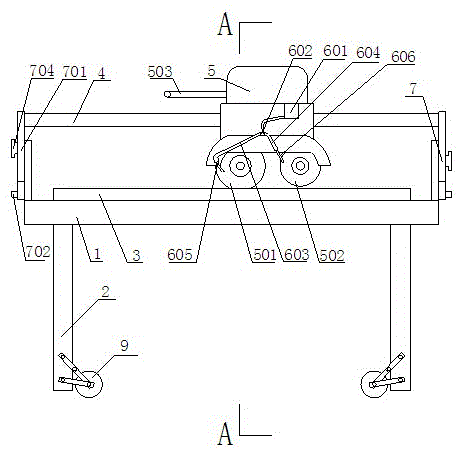

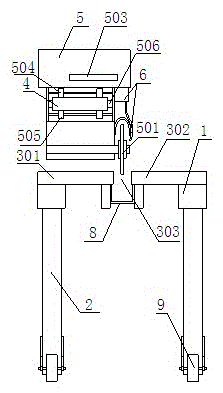

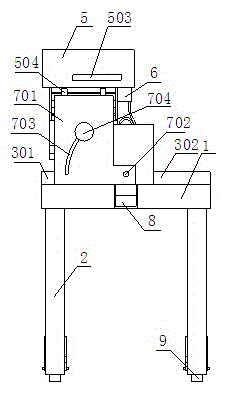

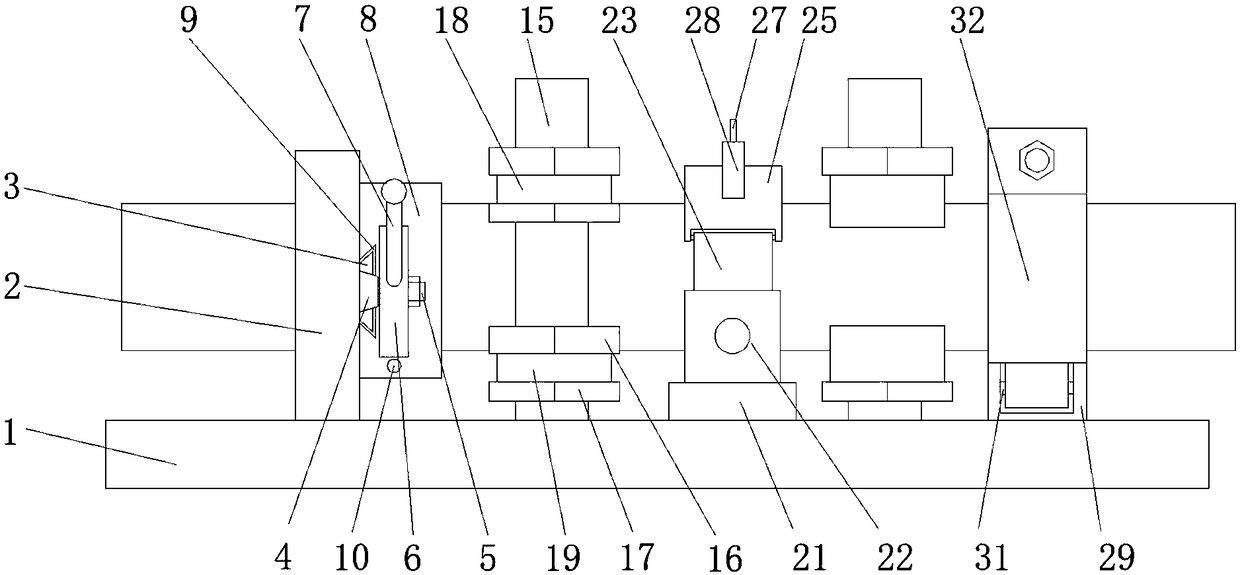

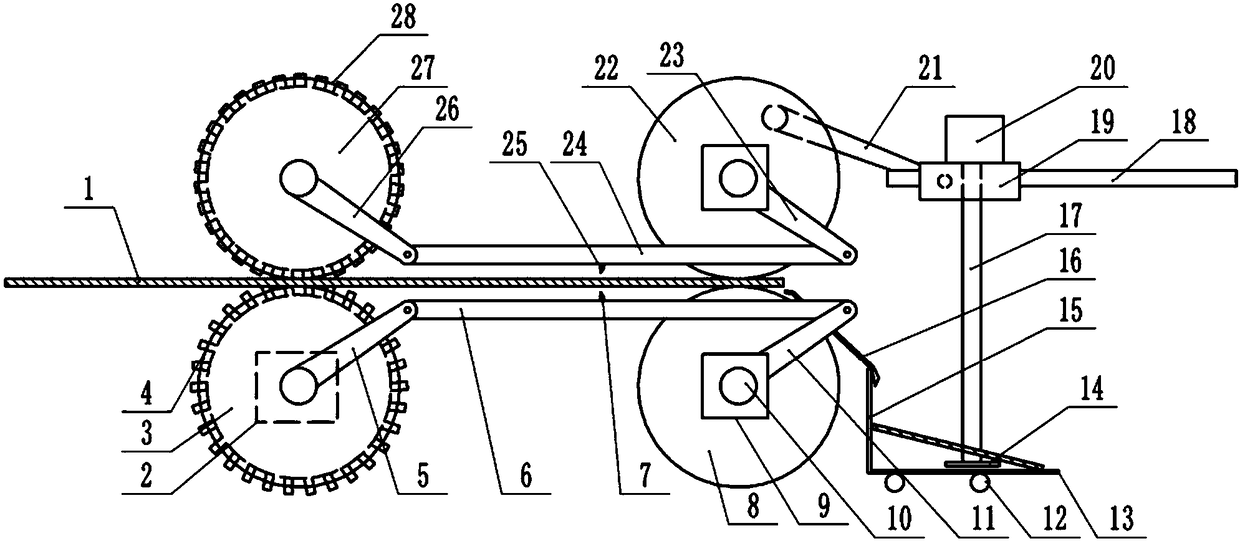

Automatic cutting and conveying device of trademark paper of woven bags or mesh bags

InactiveCN105538380ARealize automatic croppingRealize automatic one-shot moldingSevering textilesMetal working apparatusFixed frameTrademark

The invention discloses an automatic cutting and conveying device of trademark paper of woven bags or mesh bags and belongs to the technical field of automatic manufacture of the woven bags or the mesh bags. The technical problem to be solved is to provide an automatic cutting and conveying device of trademark paper of woven bags or mesh bags, achieve full automation of sewing of the trademark paper and save labor cost and time cost. The technical scheme adopted by the invention is as follows: a paper winding shaft is mounted at one end of a box body; a fixing frame is mounted inside the box body; a circular reversing rod is arranged on one side near the paper winding shaft; a driving conveying wheel, a cutting device, a conveying belt and an unloading device; the unloading device is mounted at the top of an outlet section of the conveying belt; a conveying device of a host for sewing the woven bags or the mesh bags is arranged at the lower part of the outlet section of the conveying belt; a plurality of mark points are uniformly arranged on trademark paper of the paper winding shaft; a trademark paper movable end passes through the fixing frame, the driving conveying wheel and the cutting device and is clamped between a second pressing wheel and the conveying belt; a probe is mounted on the fixing frame and corresponds to a mark point path of the trademark paper.

Owner:XINJIANG TIANLI PLASTIC CHEM CO LTD

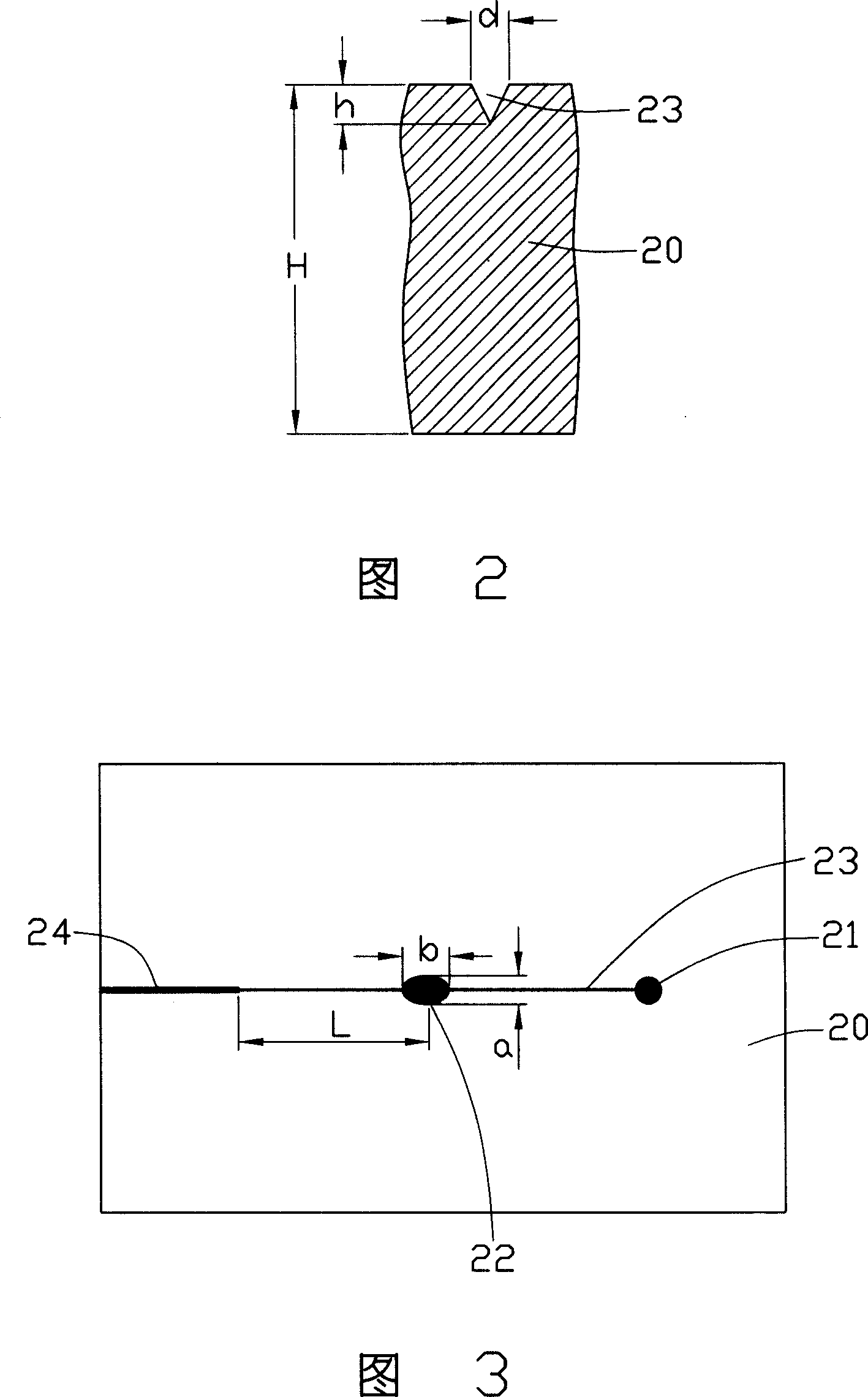

Cutting method of fragile material substrate

InactiveCN101444875ALow powerGuaranteed cutting qualityFine working devicesGlass severing apparatusSurface roughnessLaser beams

The invention discloses a cutting method of a fragile material substrate. The cutting method comprises the following steps: firstly, irradiating and heating edges of the fragile material substrate along a predetermined cutting direction by a laser beam A with the power of 30-50W to manufacture an initial penetrable slit the length of which is not longer than 20mm and the width of which is shorter than 0.01mm; then irradiating to heat the substrate from the tip of the initial penetrable slit along the predetermined cutting direction by a laser beam B with the power of 5-15W, and subsequently performing forced cooling on the fragile material substrate by a coolant to cause the fragile material substrate to crack along the predetermined cutting direction. The cutting method of the fragile material substrate can help greatly reduce the power of the laser for the subsequent cutting by obtaining the initial penetrable slit, and ensure the cutting quality and the cutting speed, wherein, surface roughness of a cut side of a liquid crystal glass substrate is 50mum or less.

Owner:ZHEJIANG UNIV OF TECH

Ceramic cutting device

InactiveCN105014802AEnsure consistencyGuaranteed grinding qualityEdge grinding machinesWorking accessoriesCutting selfEngineering

The invention discloses a ceramic cutting device, and belongs to the technical field of cutting equipment. The ceramic cutting device comprises a support, a plurality of supporting feet, a cutting table, a guide rail, a cutting machine and a water spray device. The supporting feet are connected with the support and used for supporting the support to keep horizontal. The cutting table is fixed to the support. The guide rail is arranged above the cutting table. The cutting machine is arranged on the guide rail in a sleeving manner and can move left and right relative to the guide rail. Through the fixed guide rail and the cutting machine arranged on the guide rail in the sleeving manner, the cutting machine can only move along the guide rail, and the cutting quality is guaranteed; and meanwhile, a grinding wheel matched with a cutting wheel is arranged, and a cut cutting opening is ground in the cutting process. Due to the fact that the grinding wheel is fixedly arranged relative to the cutting wheel, the consistency of the grinding degree is guaranteed, and the grinding quality is guaranteed. The ceramic cutting device is simple in structure and convenient to operate, cutting and grinding can be achieved at the same time, the production efficiency is improved, and the production cost is lowered.

Owner:HUBEI AODIAO IND

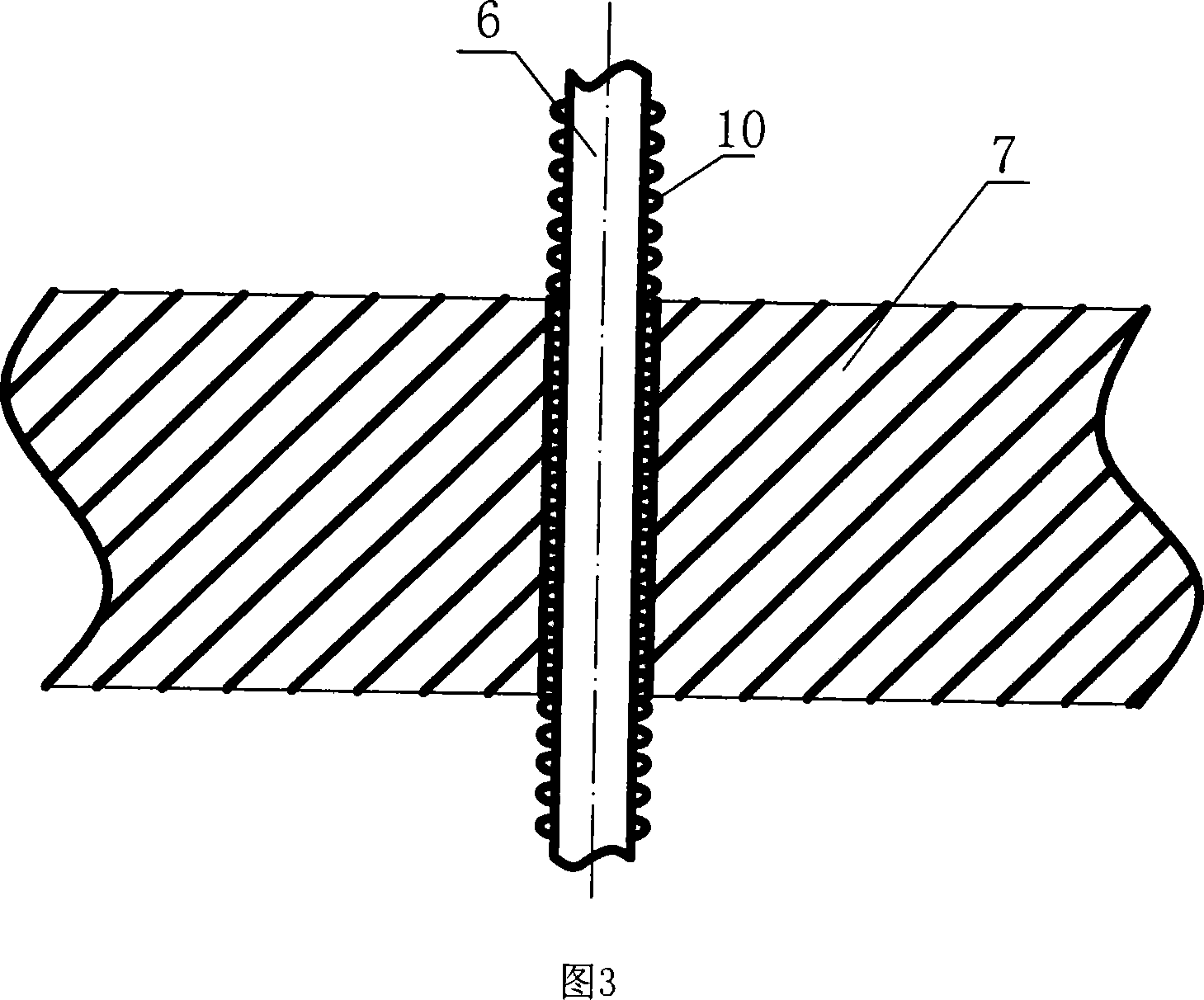

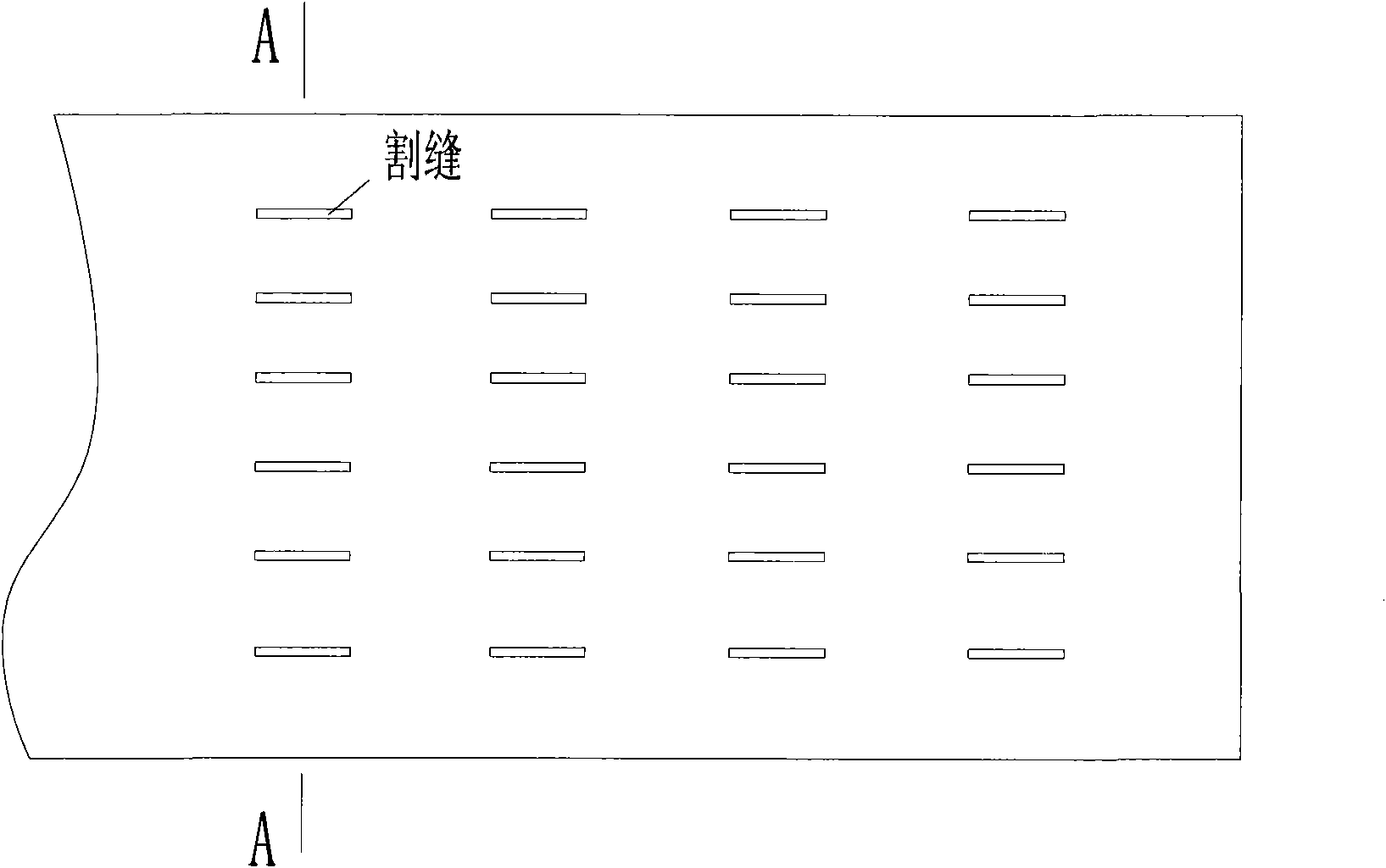

Laser processing method for steel sieve tube slit

InactiveCN101890582AGuaranteed trafficGuaranteed flow rateLaser beam welding apparatusLaser processingChemical reaction

The invention discloses a laser processing method for a steel sieve tube slit. One end point of one long edge of the slit is used an initial point. The method comprises the following steps of: perforating a hole at the initial point of a cut by using pulse laser, and then finishing the cutting of the whole slit from the initial point by using continuous laser. During cutting, oxygen is used as an auxiliary gas, the metal at a cutting point is further heated by using reaction heat released by the reaction of the oxygen and the molten iron at the cutting point, meanwhile the molten iron is changed into ferroferric oxide with good liquidity by using chemical reaction, and the ferroferric oxide is blown away the cutting point by using airflow so as to ensure continuous cutting. The processing method solves the problems of irregular slit shape, slag adhesion at the cut and oblique blowing trace in the conventional laser cut sieve tube slit.

Owner:北京宏诚拓业科技发展有限公司 +1

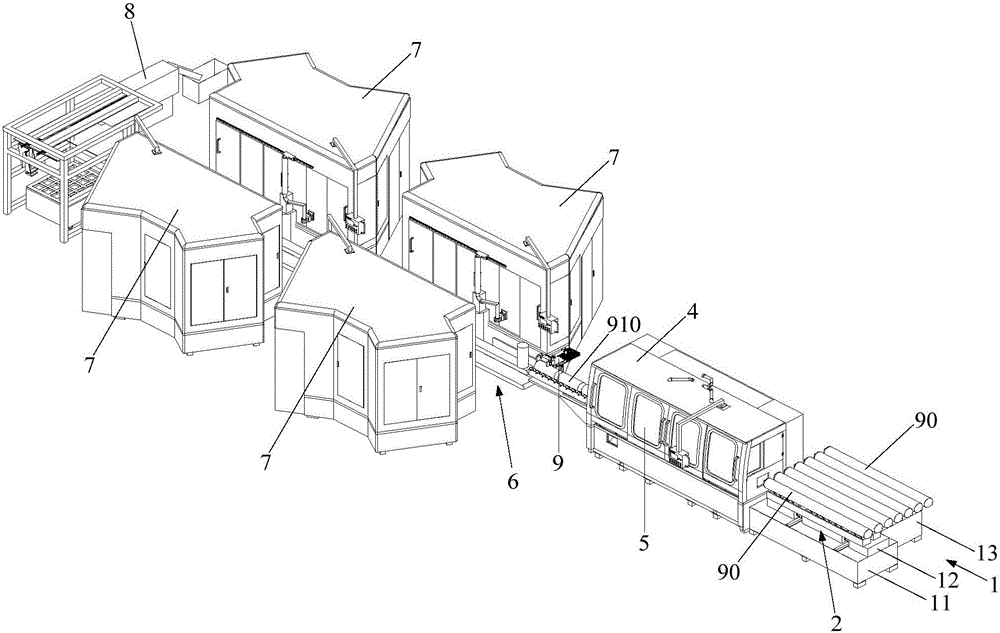

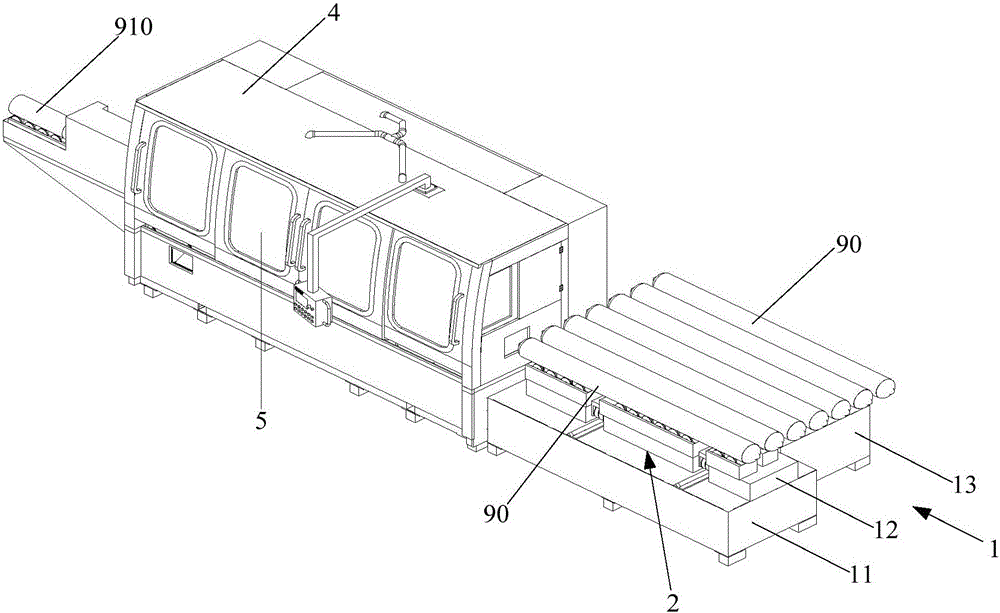

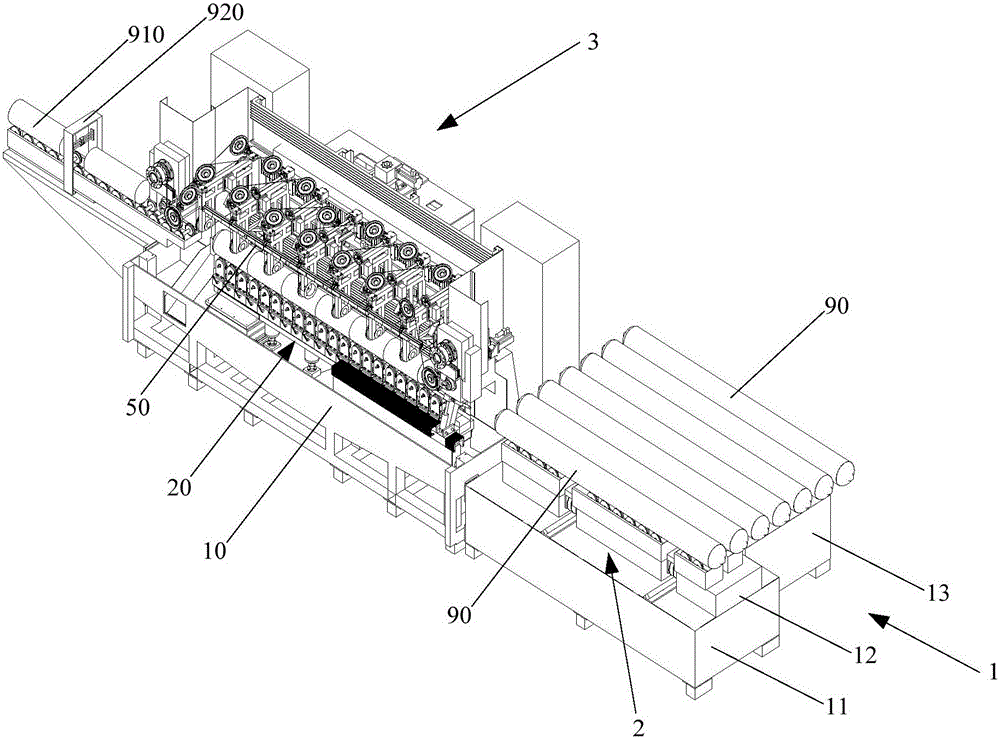

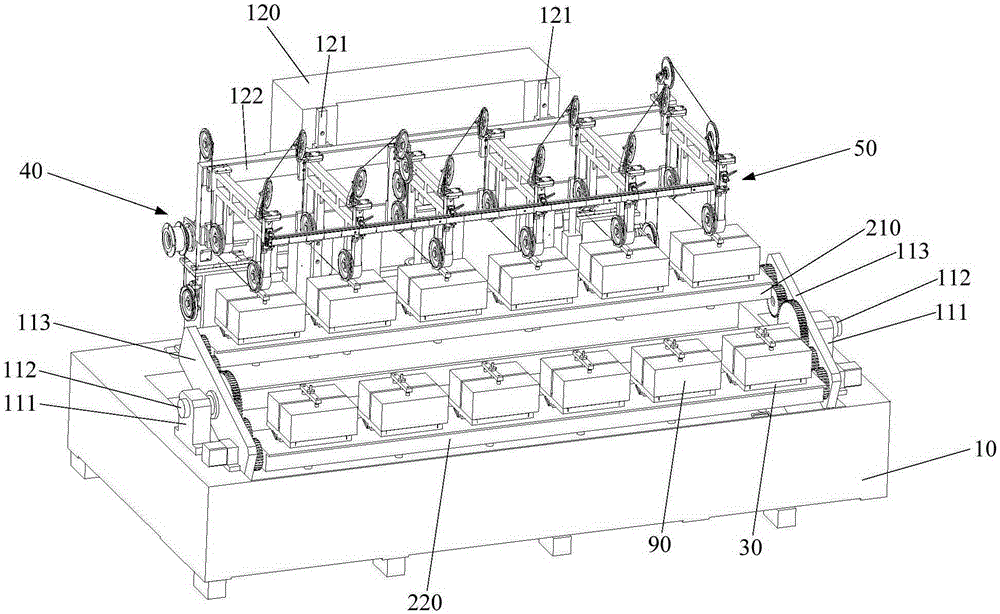

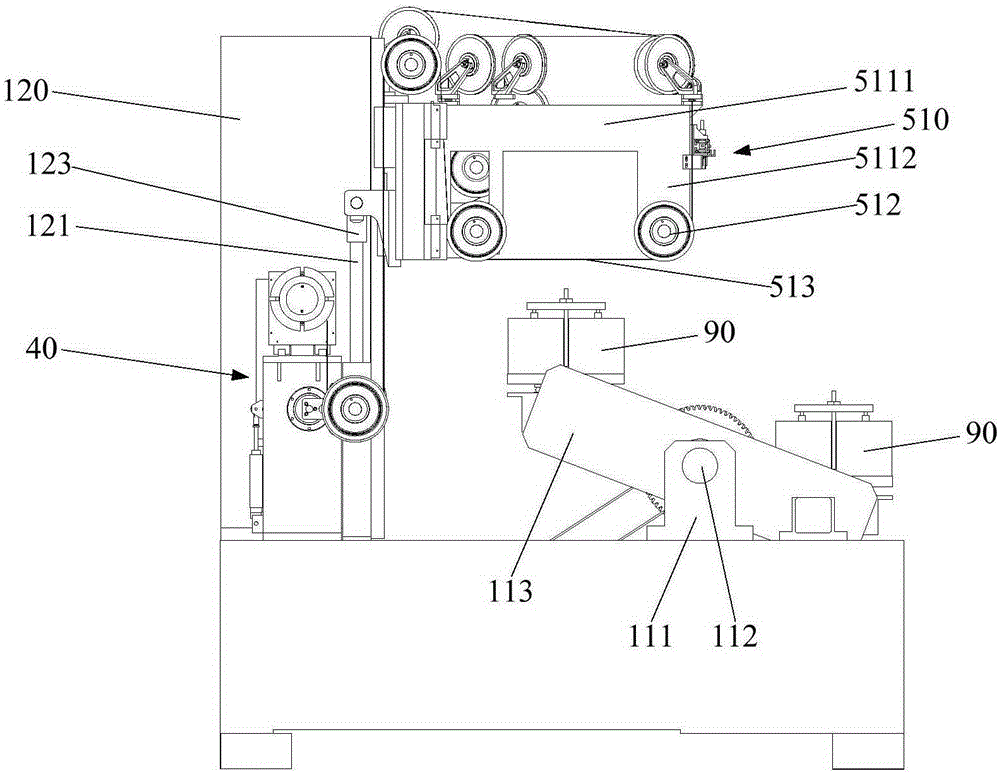

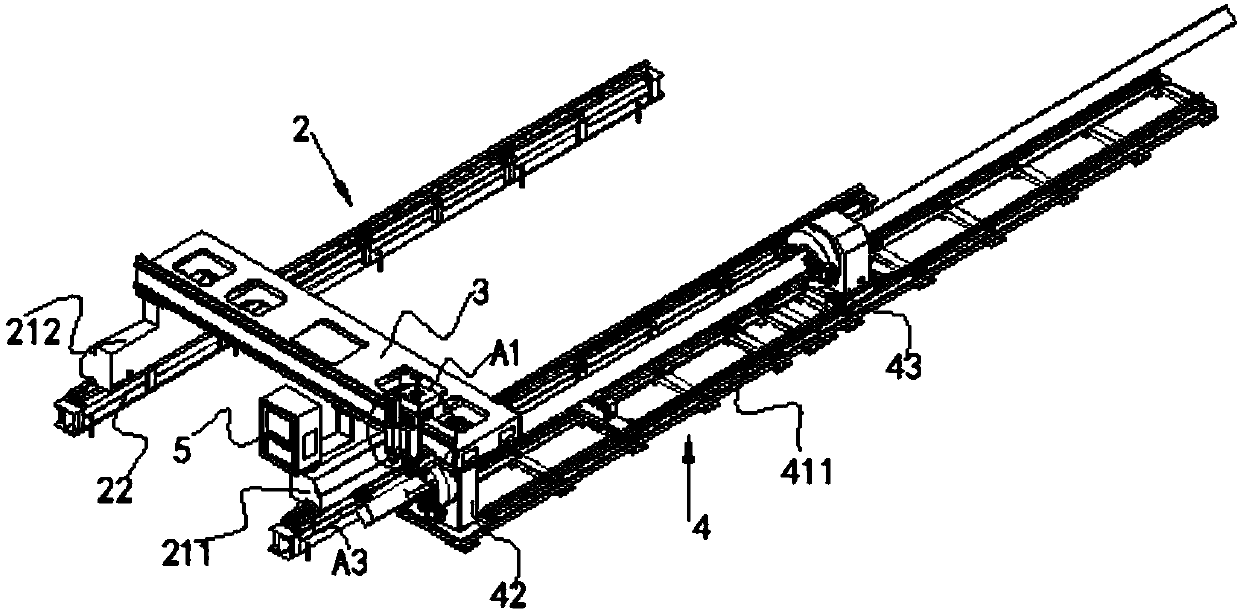

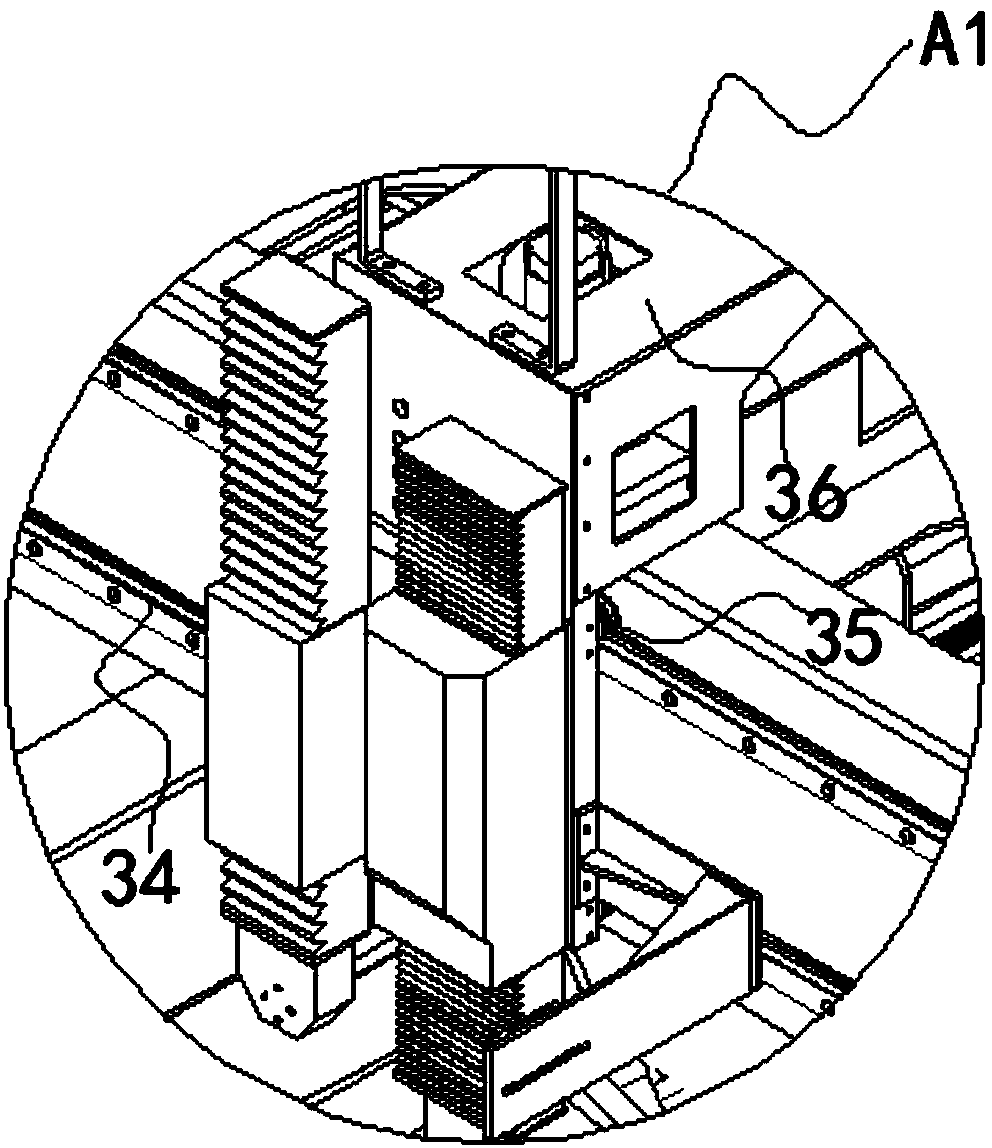

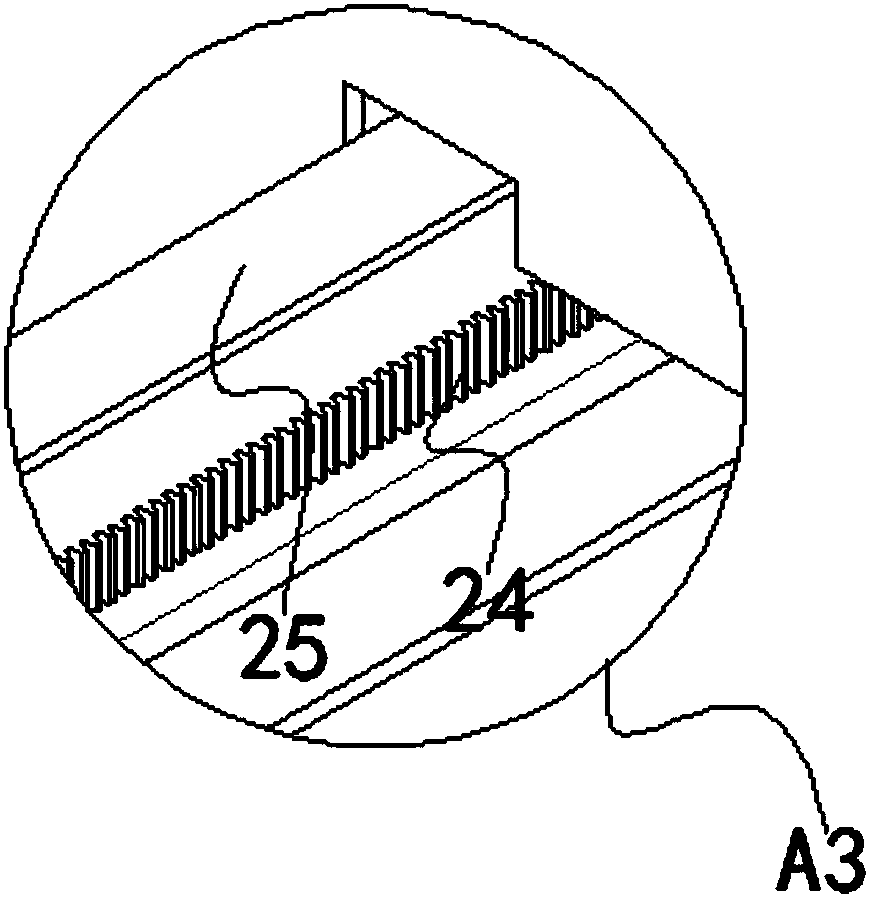

Silicon rod line production system and silicon rod line production method

ActiveCN105946126AGuaranteed not to collideGuaranteed cutting qualityFine working devicesPlane surface grinding machinesSiliconMachining

The invention discloses a silicon rod line production system and a silicon rod line production method. The silicon rod line production system comprises feeding equipment, cutoff equipment, silicon rod conveying equipment and a silicon rod combined machining machine, wherein the feeding equipment is used for conveying silicon rods to be cut to the feeding region; the cutoff equipment is in linkage with the feeding equipment and used for conducting cutoff work on the silicon rods which are to be cut and conveyed through the feeding equipment from the feeding region and cutting the silicon rods into multiple cut silicon rod sections; the silicon rod conveying equipment is in linkage with the cutoff equipment and used for conveying the cut silicon rod sections; and the silicon rod combined machining machine is arranged beside the silicon rod conveying equipment and used for conducting square cutting work, surface milling work, rounding work and polishing work on the cut silicon rod sections obtained from the silicon rod conveying equipment. By the adoption of the silicon rod line production system, the silicon rods to be cut are conveyed to the feeding region through the feeding equipment, the silicon rods to be cut are cut into multiple cut silicon rod sections through the cutoff equipment, the cut silicon rod sections are discharged in sequence through the silicon rod conveying equipment, and the square cutting work, surface milling work, rounding work and polishing work are conducted on the cut silicon rod sections through the silicon rod combined machining machine.

Owner:TDG NISSIN PRECISION MACHINERY CO LTD

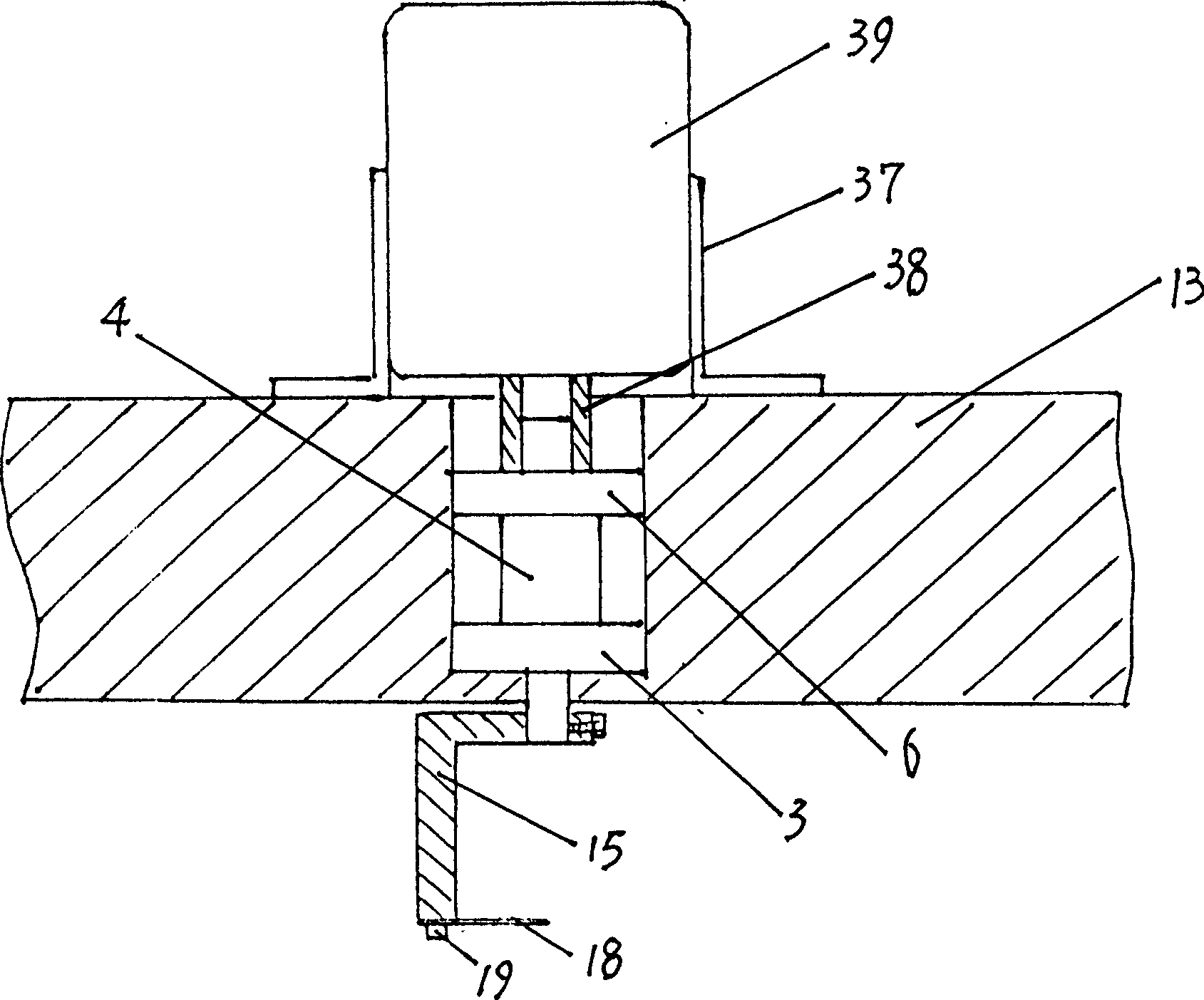

Bottle mouth cutting mechanism of automatic bottle blow molding machine

ActiveCN1654189AEliminate movement errorsGuaranteed cutting qualityDomestic articlesMetal working apparatusBlow moldingMolding machine

The bottle mouth cutting mechanism as one auxiliary mechanism for automatic bottle blowing and molding machine includes one bottle holding device, one moving device and one bottle mouth flash edge cutting device. The bottle holding device is connected to one inner and outer mold plate pair capable of being opened and closed in the automatic bottle blowing and molding machine; the moving device is set on the bottle holding device; and the bottle mouth flash edge cutting device is set on the moving device and over the bottle holding device. The said structure makes the three parts of the bottle holding device, the moving device and the bottle mouth flash edge cutting device connected into one integral and this results in high cutting quality, simple integral structure and high cutting efficiency.

Owner:ZHANGJIAGANG TONGDA MACHINERY

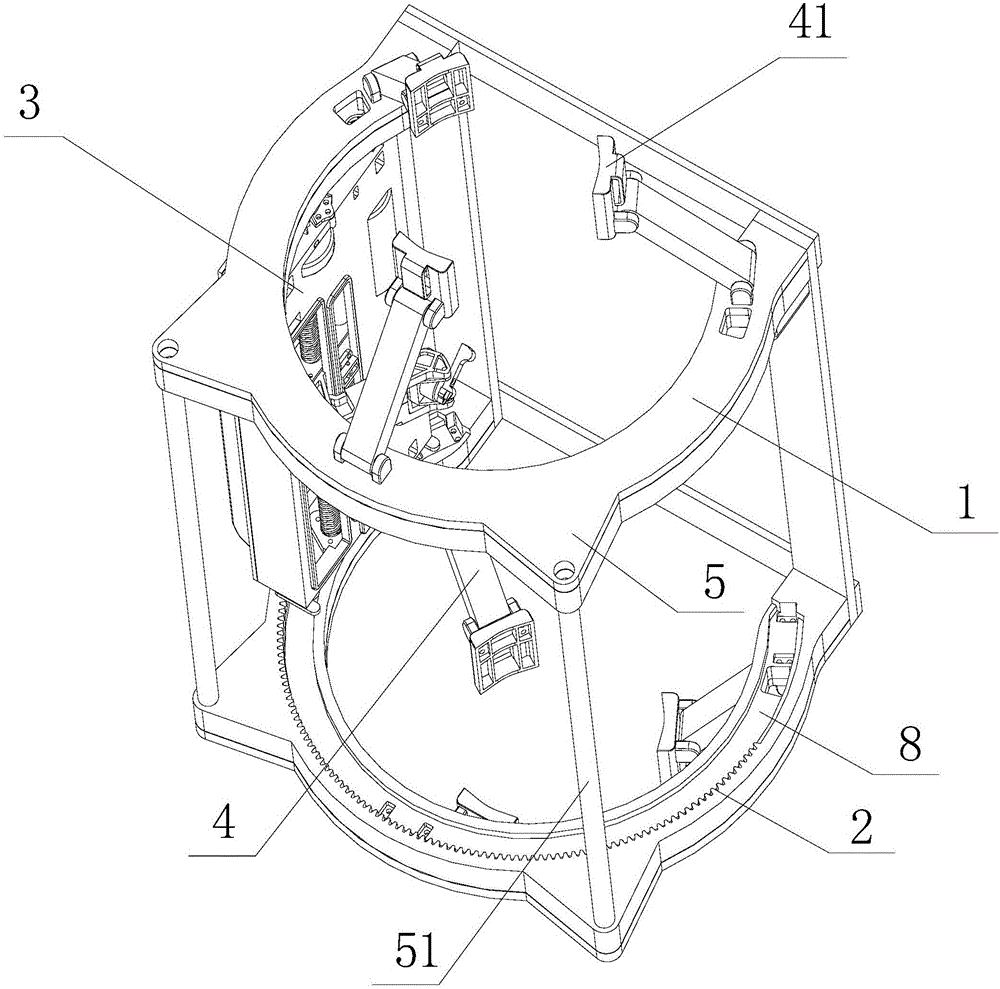

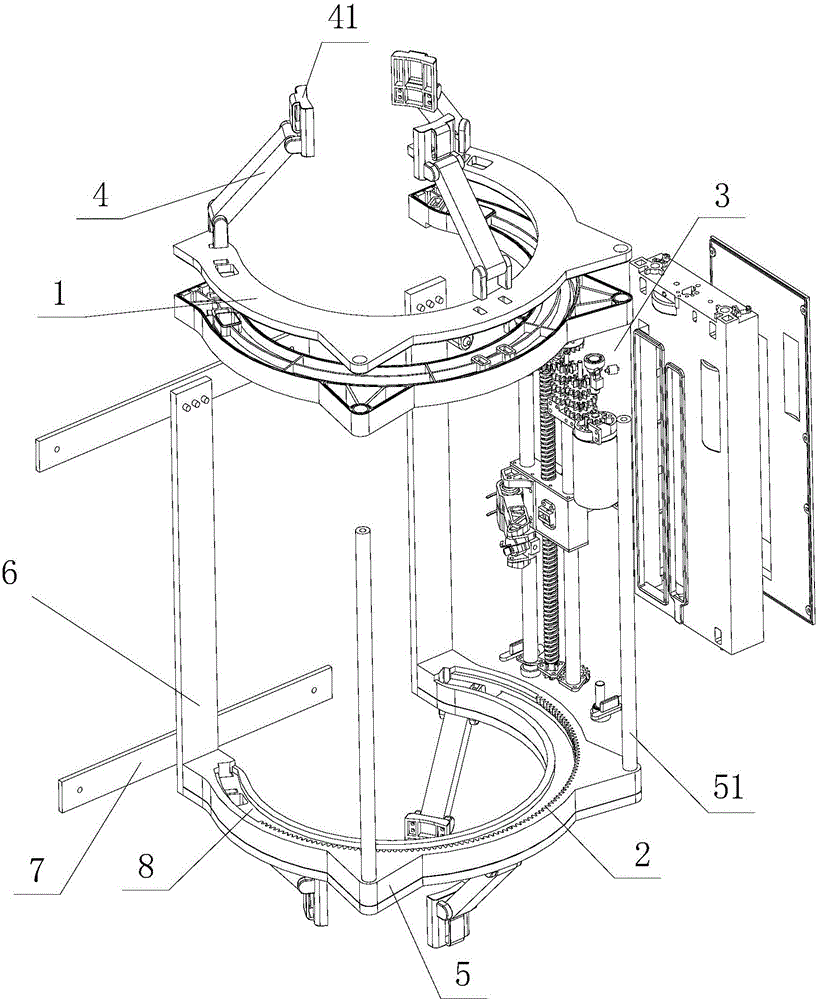

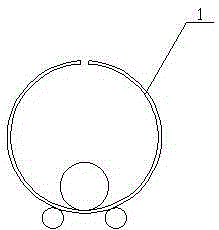

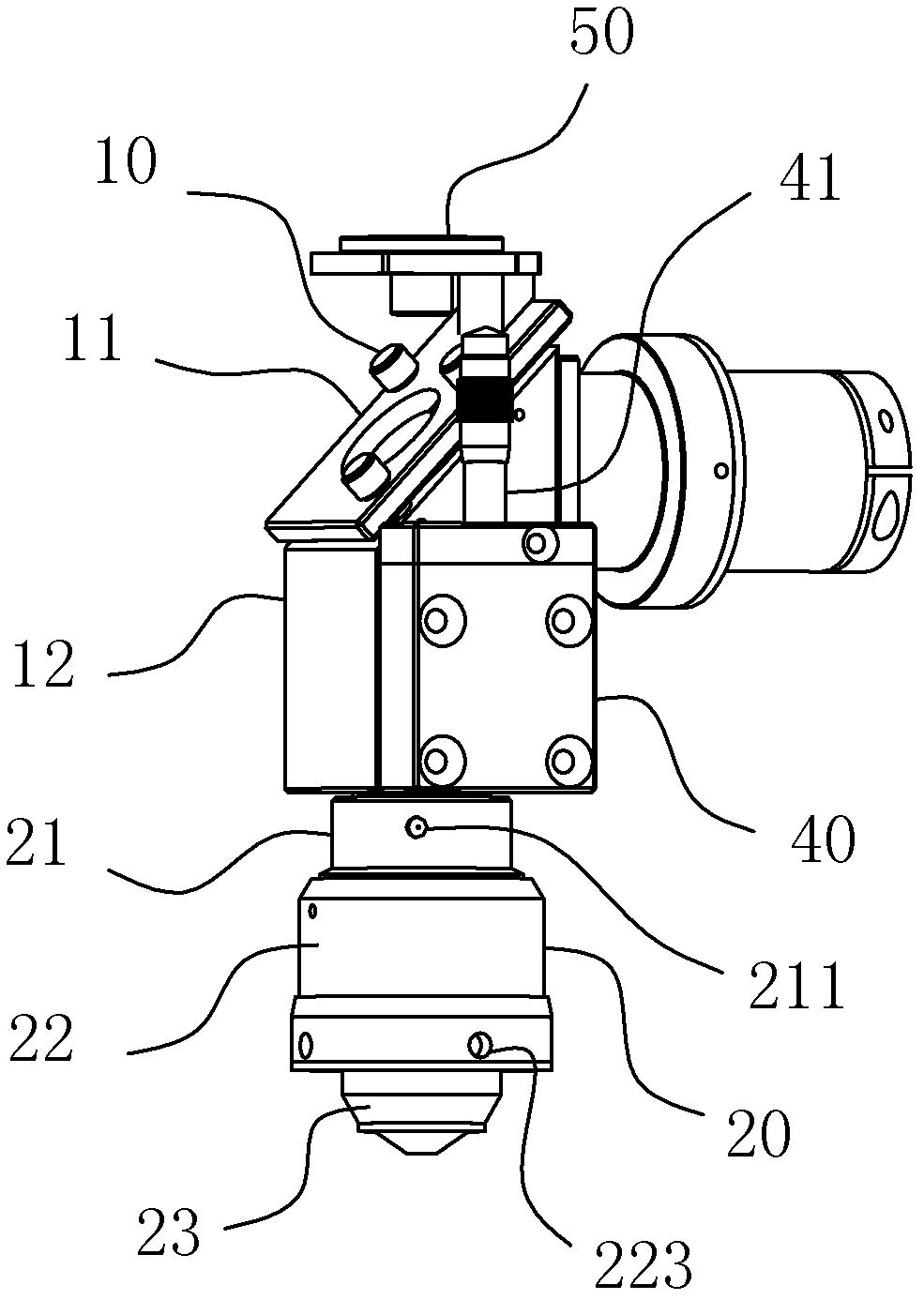

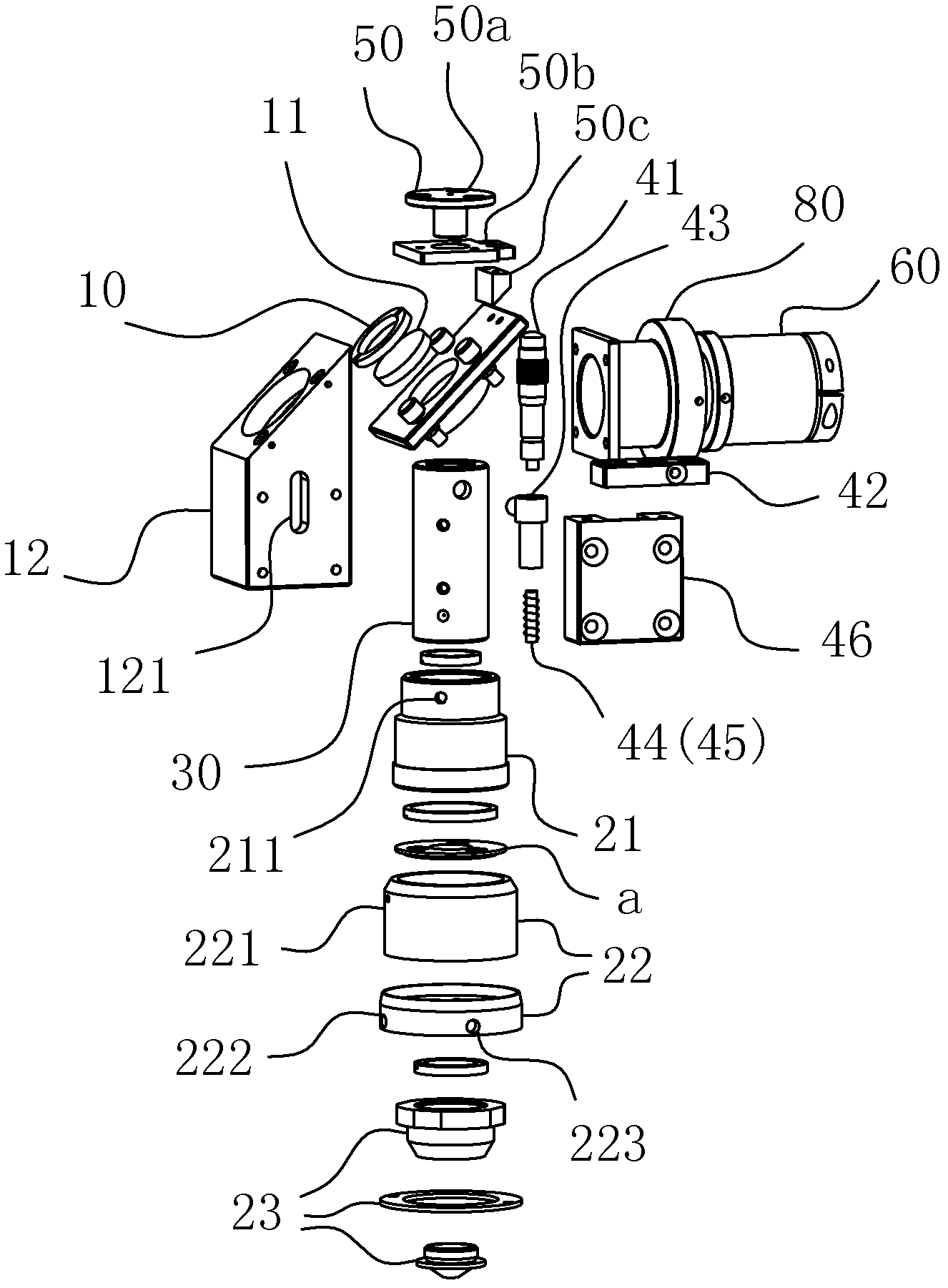

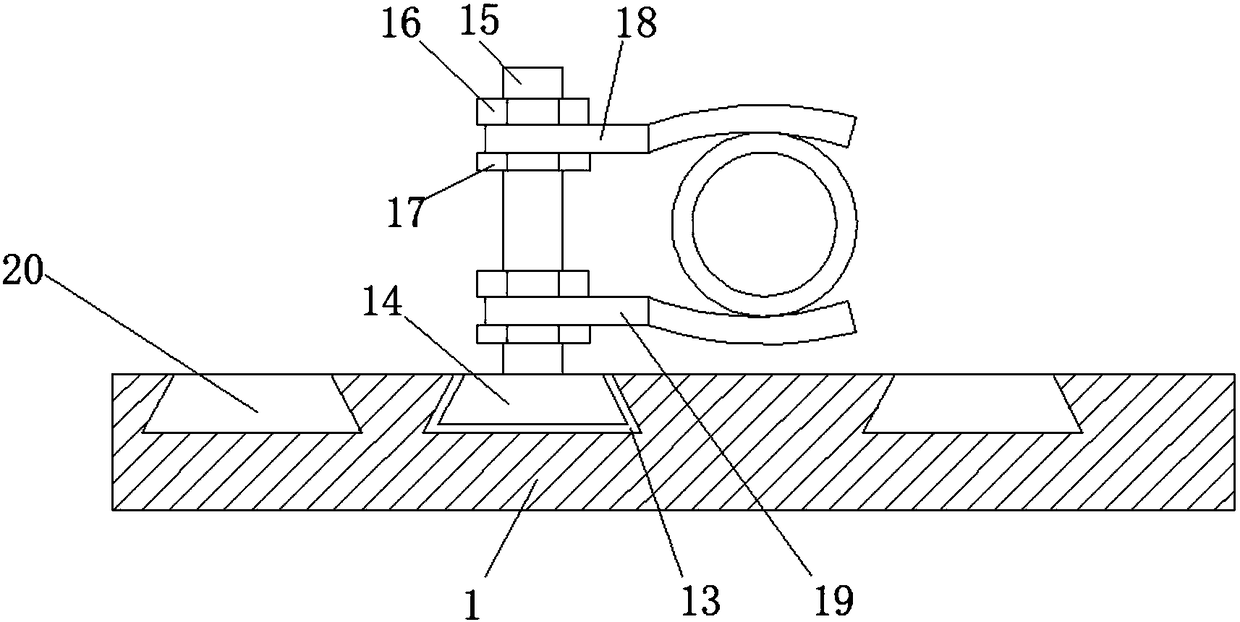

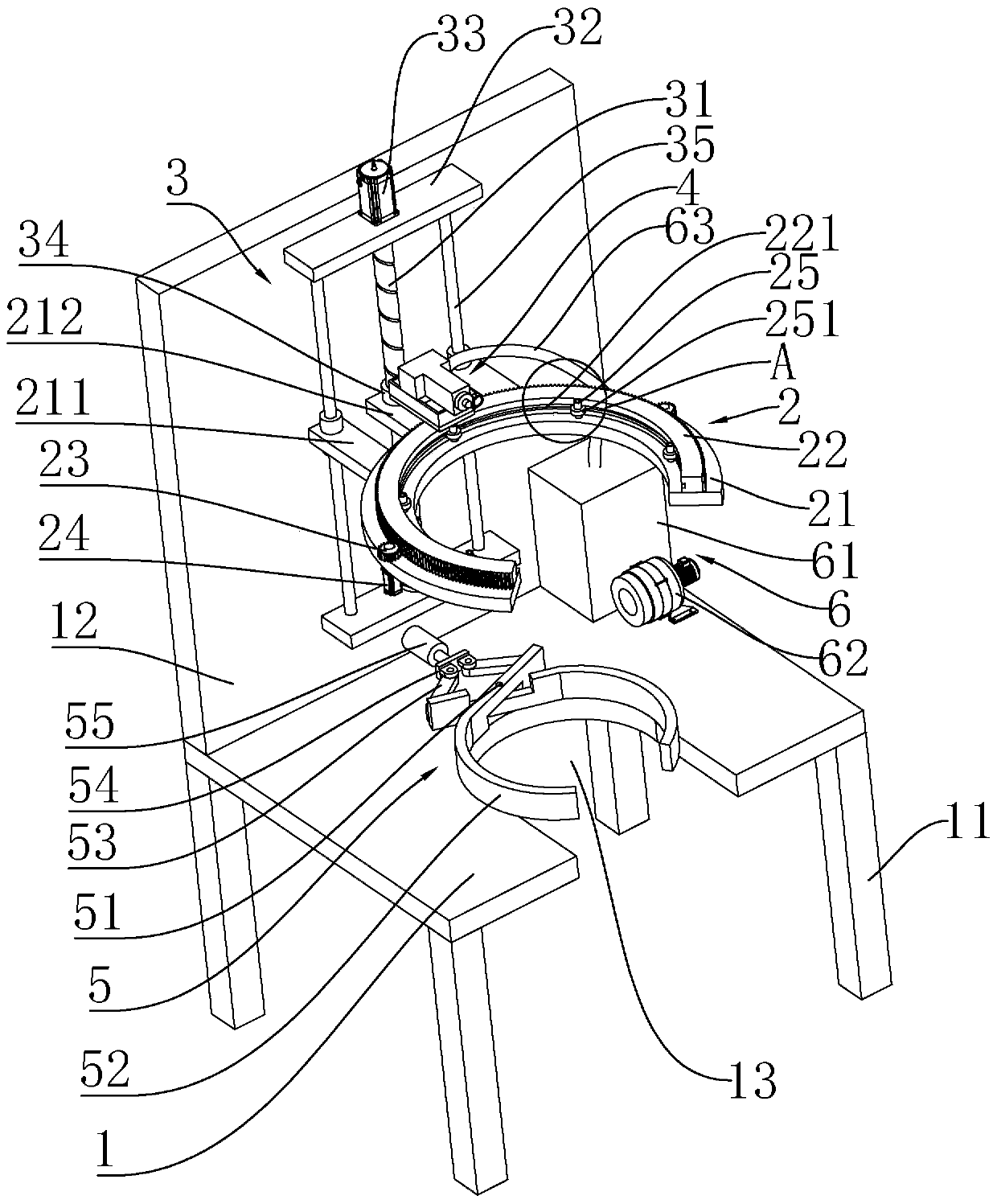

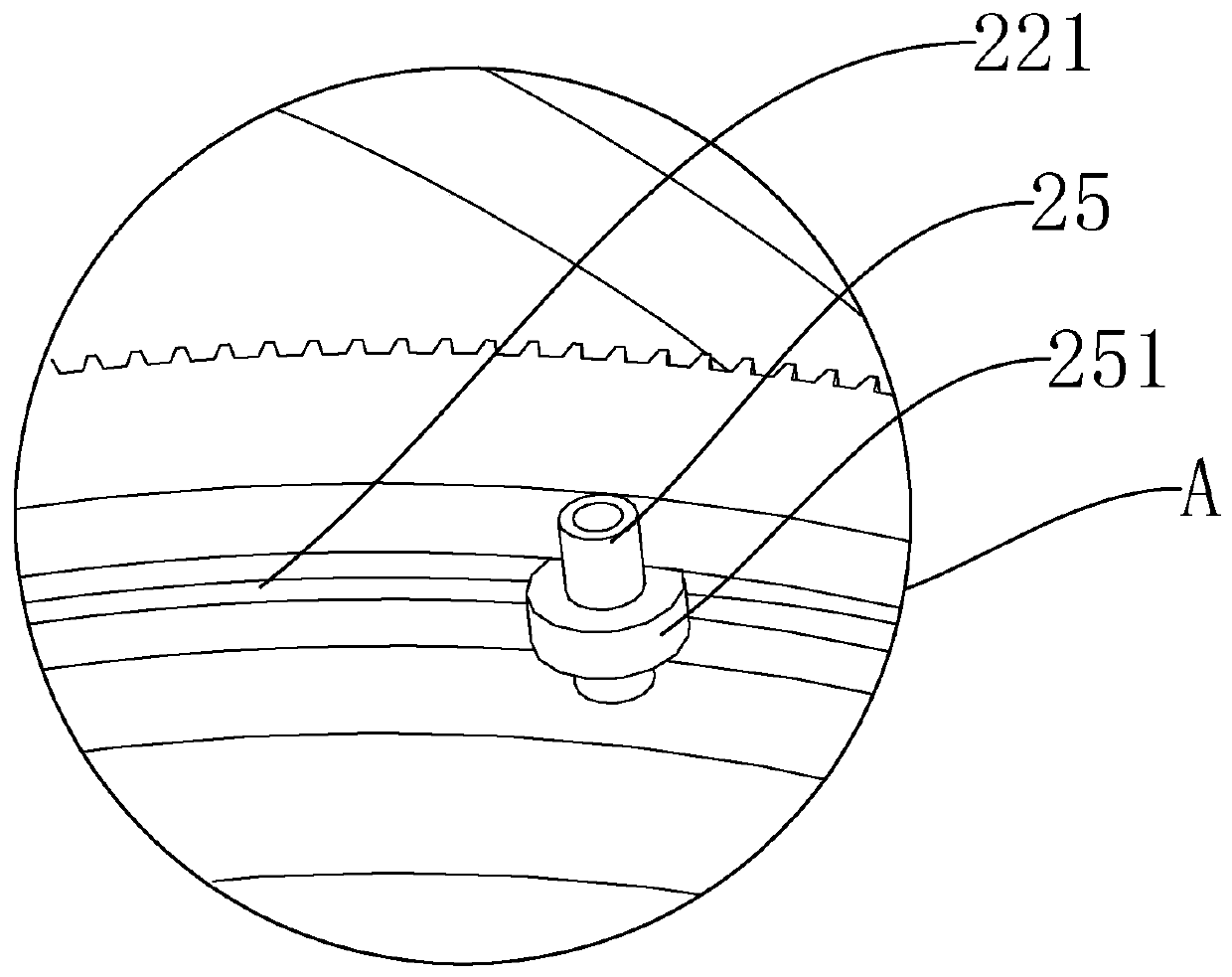

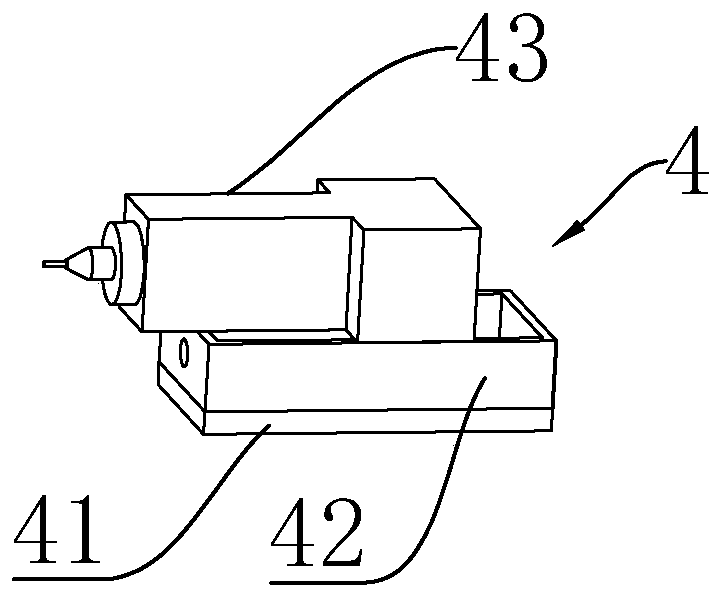

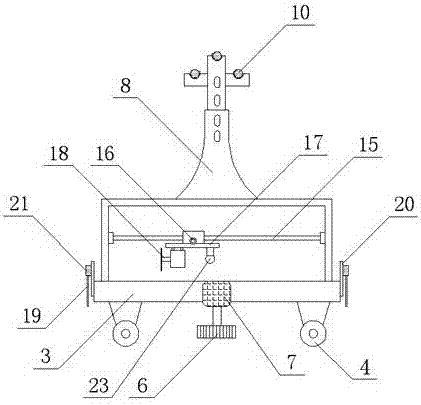

Rubber tapping machine and rubber tapping method

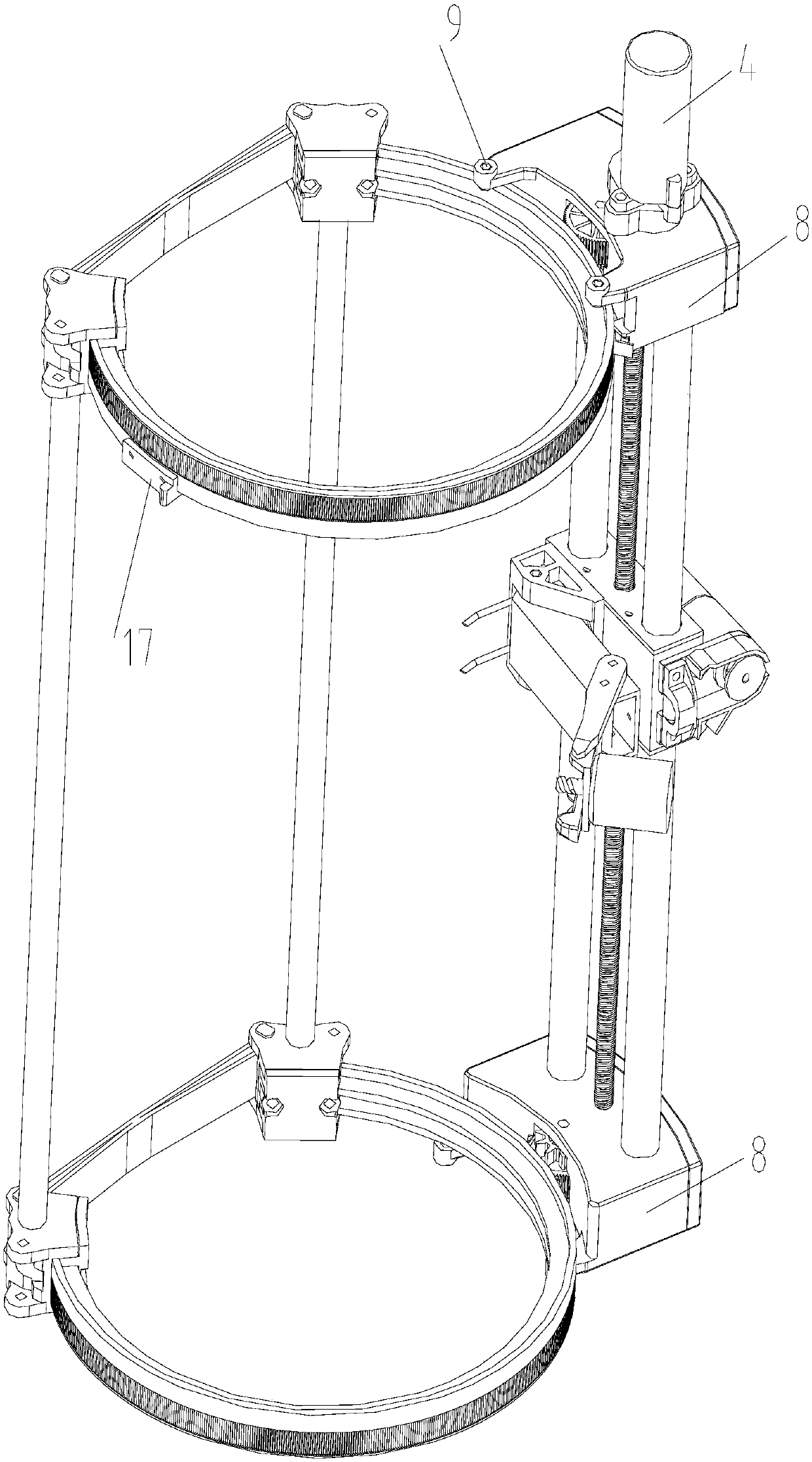

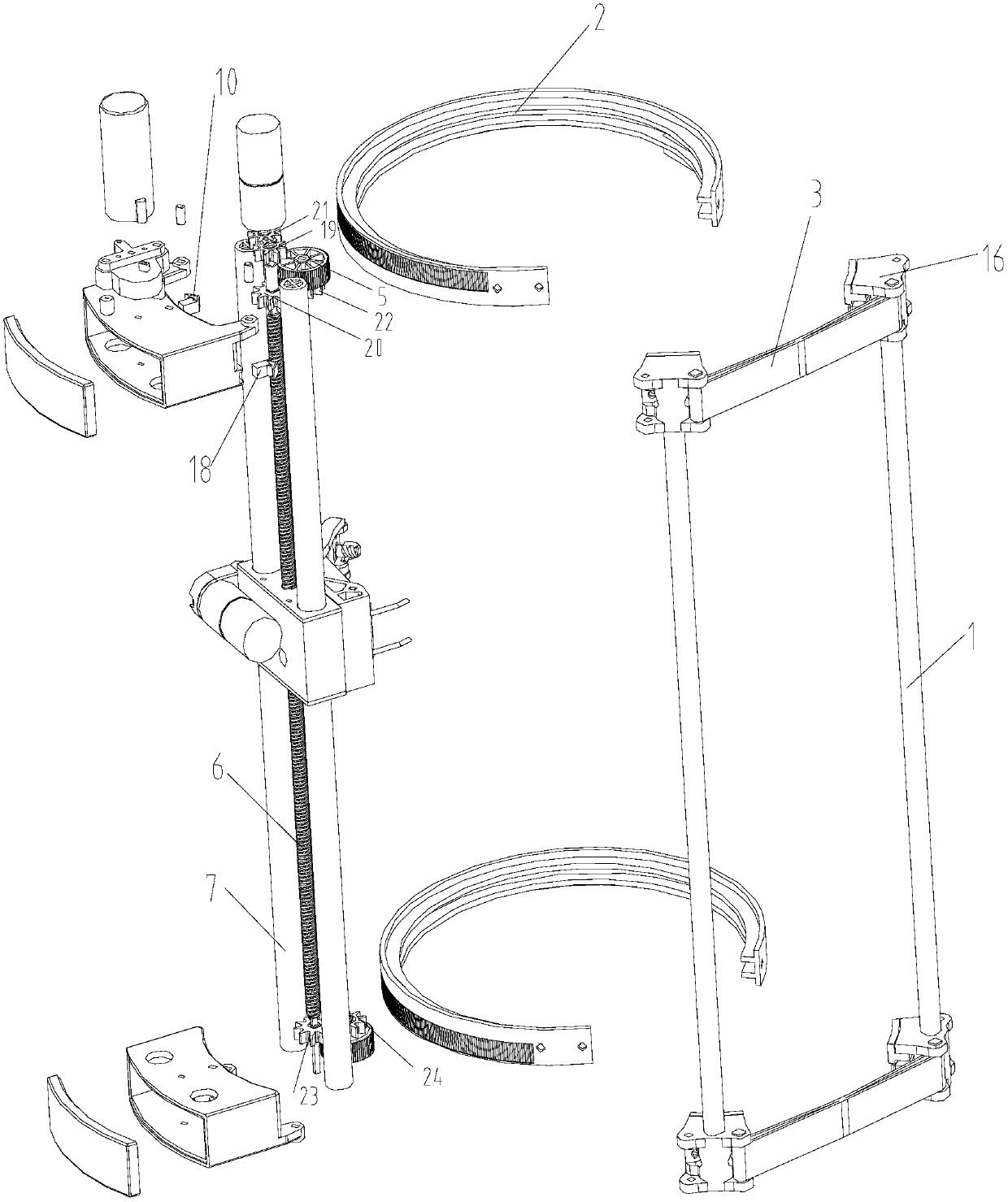

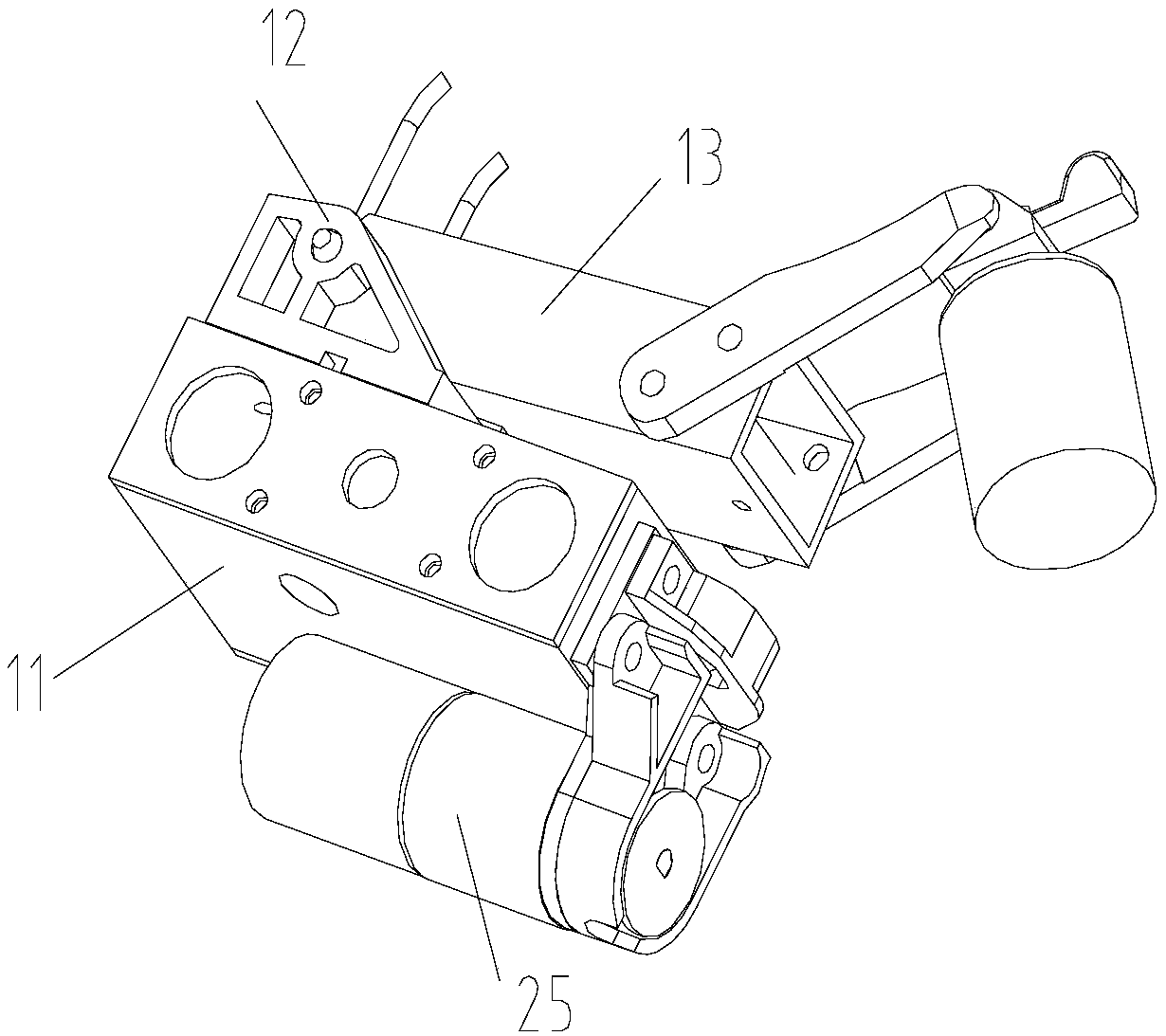

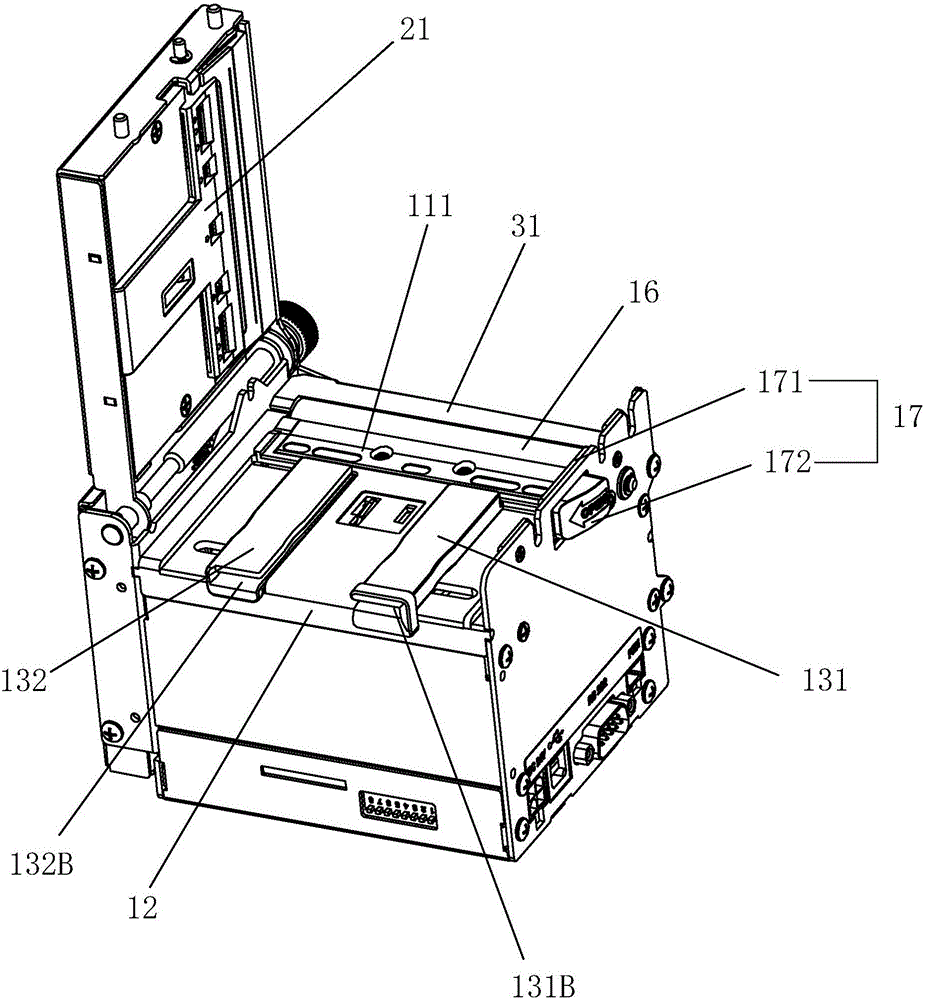

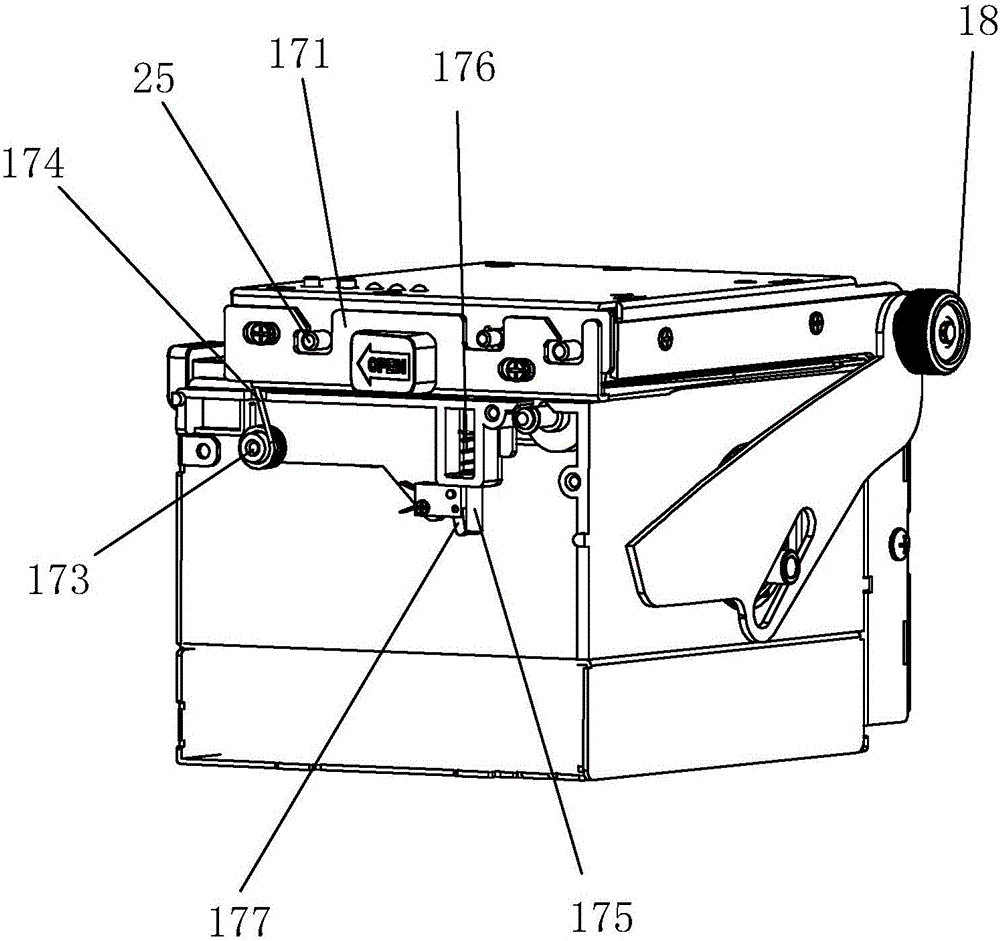

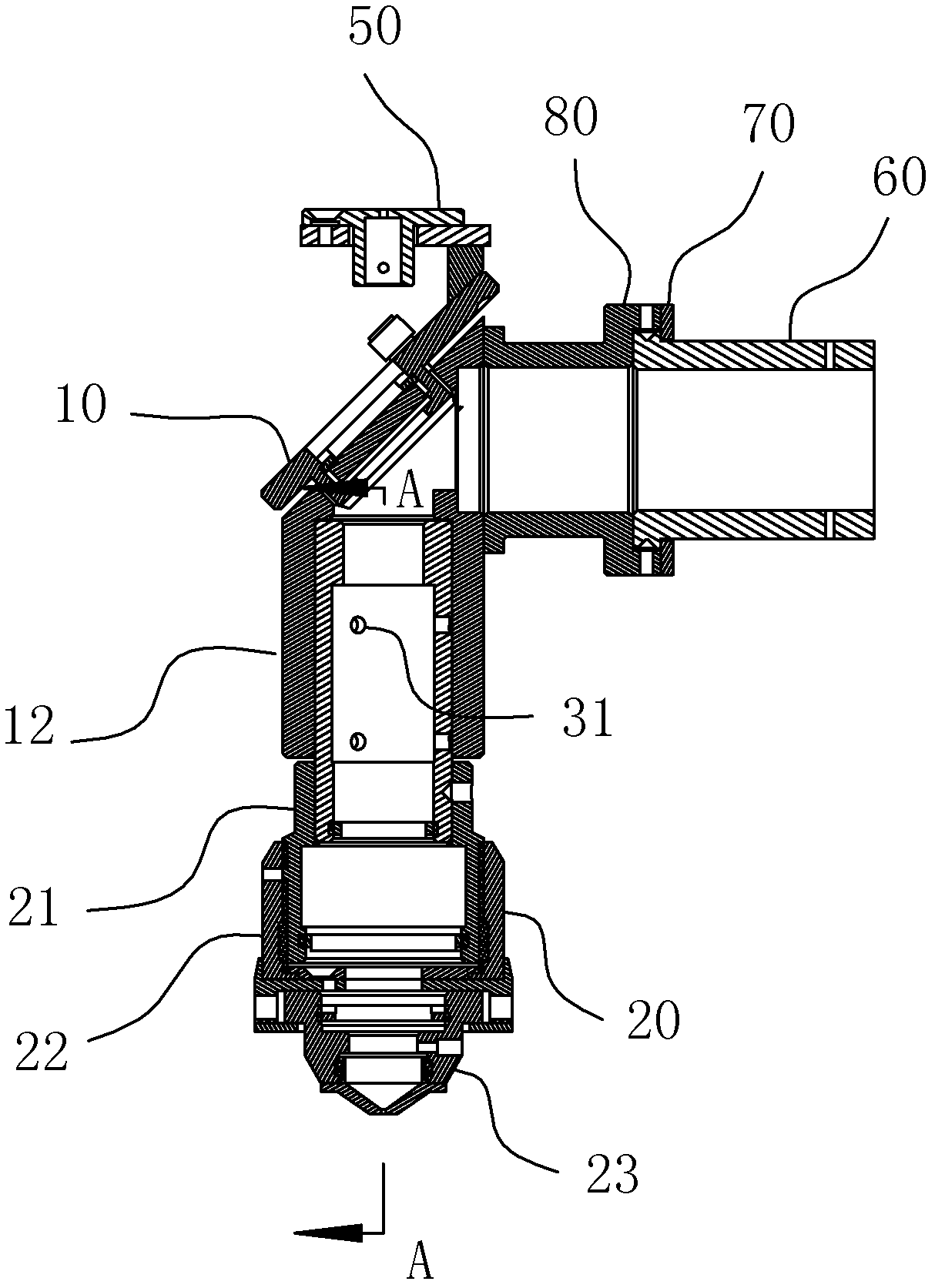

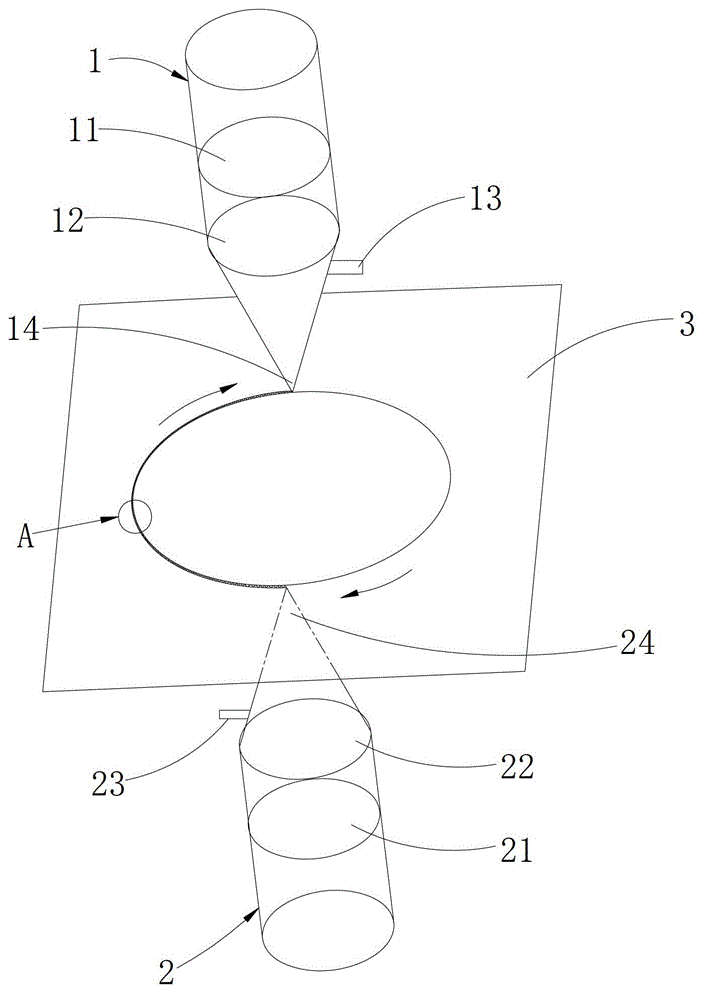

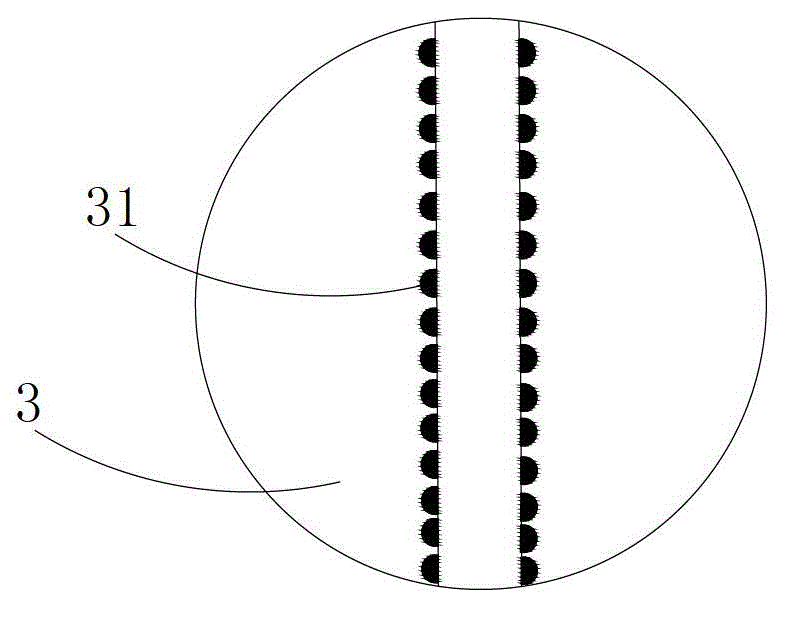

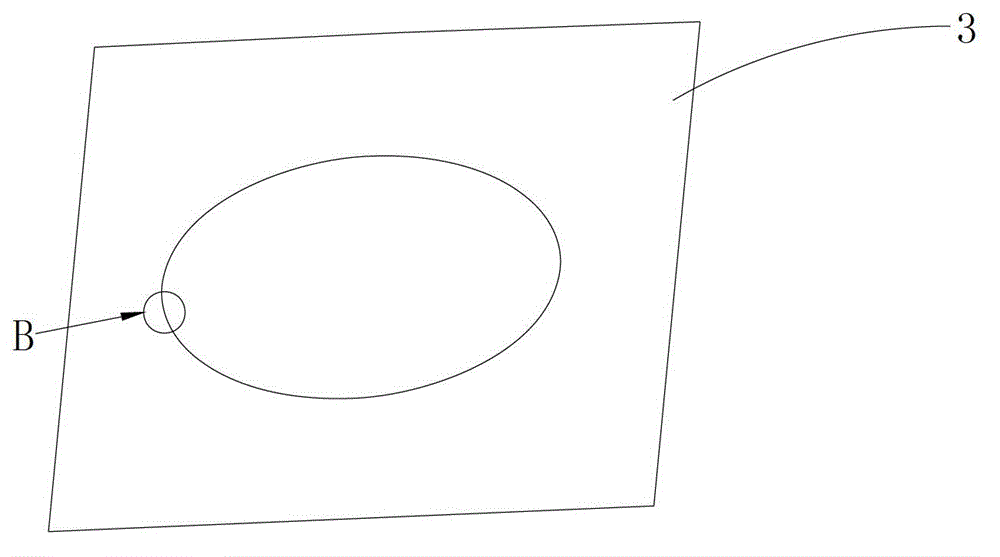

ActiveCN106034978ASolve labor intensitySolve the problem of insufficient fineness of manual tappingForestryEngineeringUltimate tensile strength

The invention discloses a rubber tapping machine and a rubber tapping method. The rubber tapping machine comprises a fixation frame, the top surface and the bottom surface of the fixation frame are respectively provided with annular planet gears in opposite arrangement, a knife rest assembly is installed between the top surface and the bottom surface of the fixation frame, the knife rest assembly is internally provided with a leading screw along a vertical direction, a rubber tapping assembly is installed on the leading screw and can be driven by the leading screw to vertically move along the leading screw, the rubber tapping assembly comprises a knife rest which is installed on the leading screw and can move vertically along the leading screw, one side of a cutter head swing arm is hinged to the knife rest through a torsion spring, the other side is hinged to a swing seat, the swing seat is provided with a cutter head angle adjustment seat, the top end of the cutter head angle adjustment seat is provided with a cutter head and a knife depth limiting member, and the knife rest is also provided with a knife collecting assembly which can overcome an elastic force of the torsion spring to draw the cutter head swing arm to the knife rest. The rubber tapping machine disclosed by the invention replaces labor with automatic machinery, realizes unmanned automatic rubber tapping for rubber trees, and solves the problems of large manual rubber tapping labor intensity and low manual rubber tapping precision to the maximum degree.

Owner:NINGBO CIHEVEA TECH CO LTD

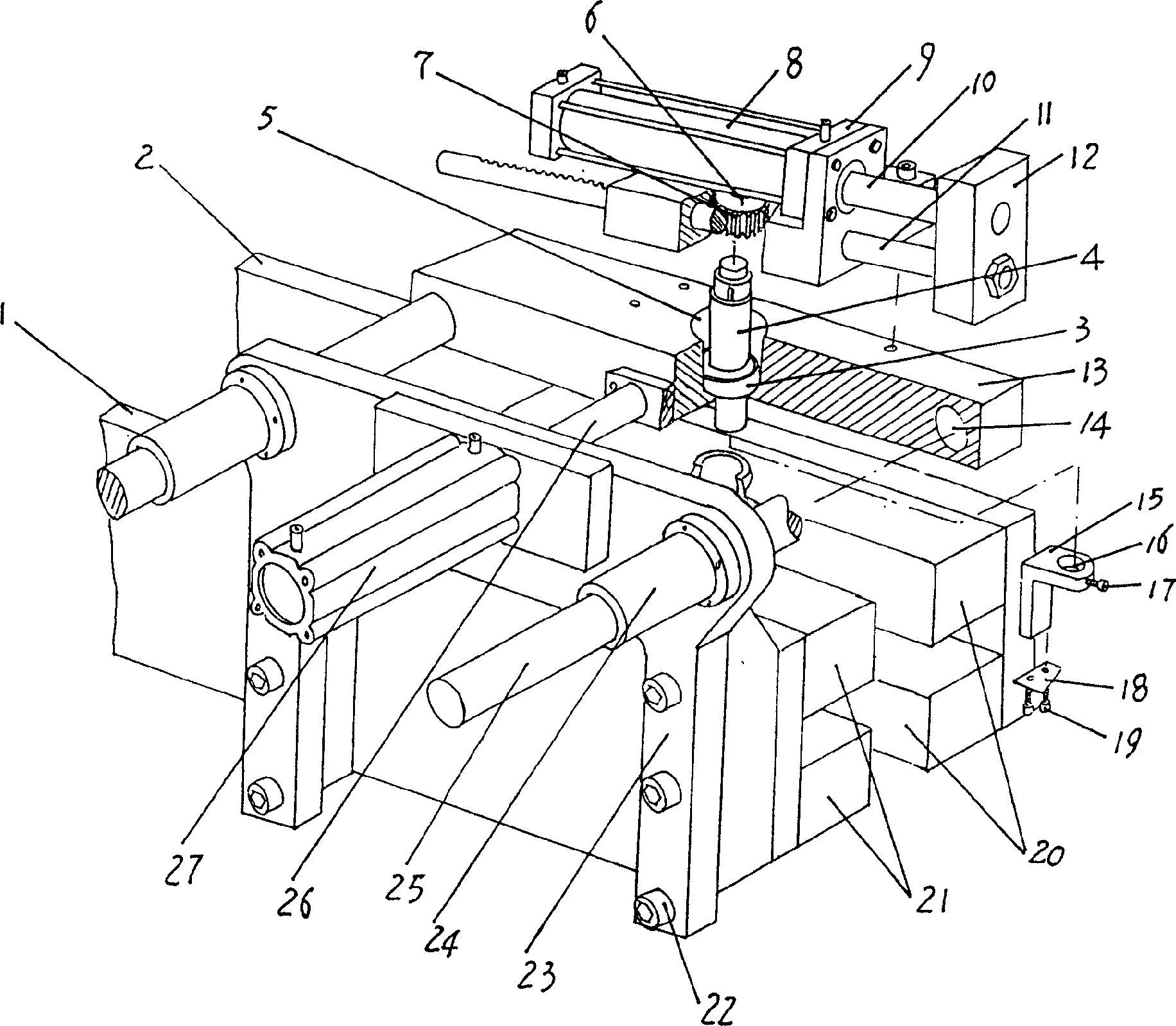

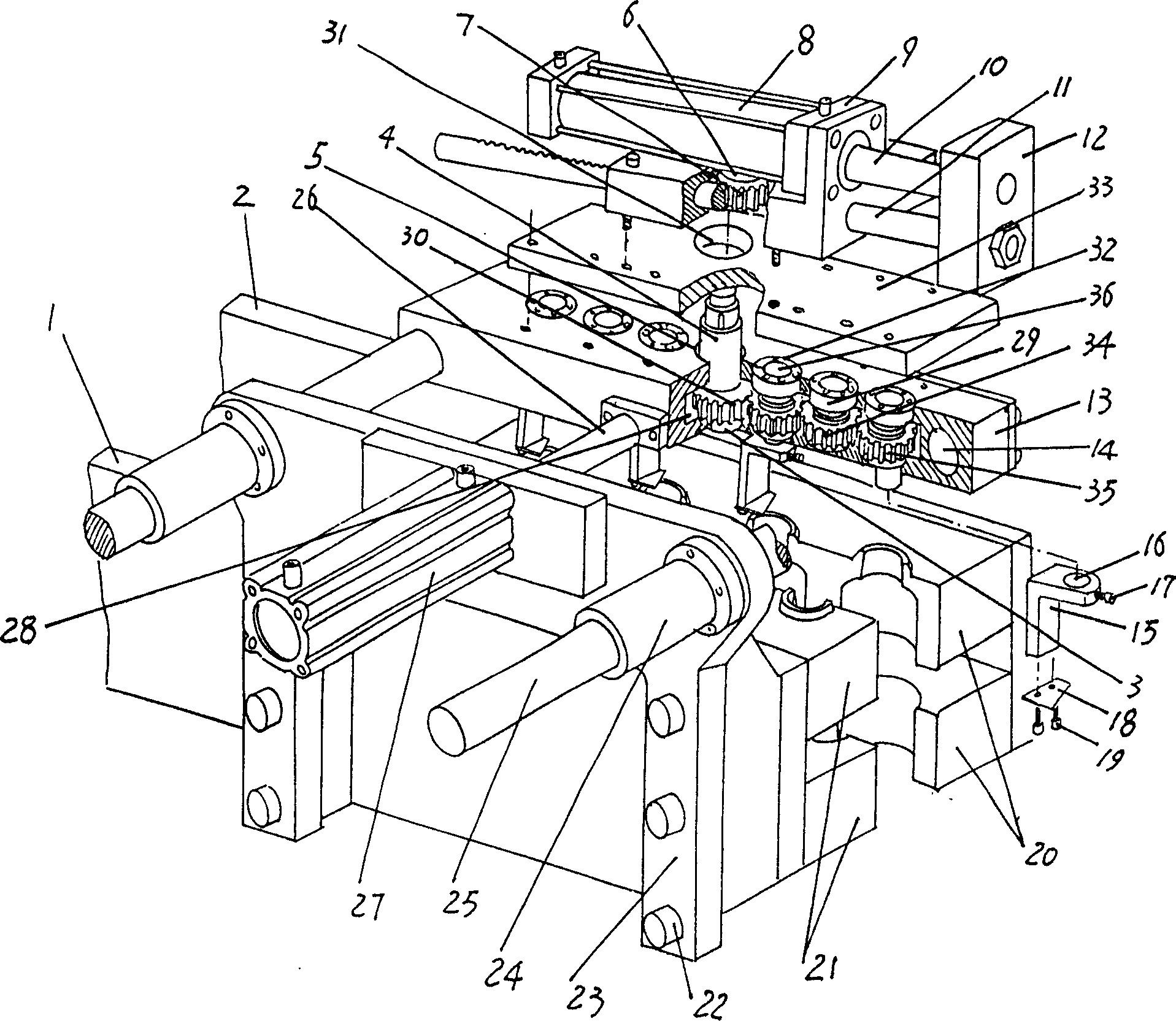

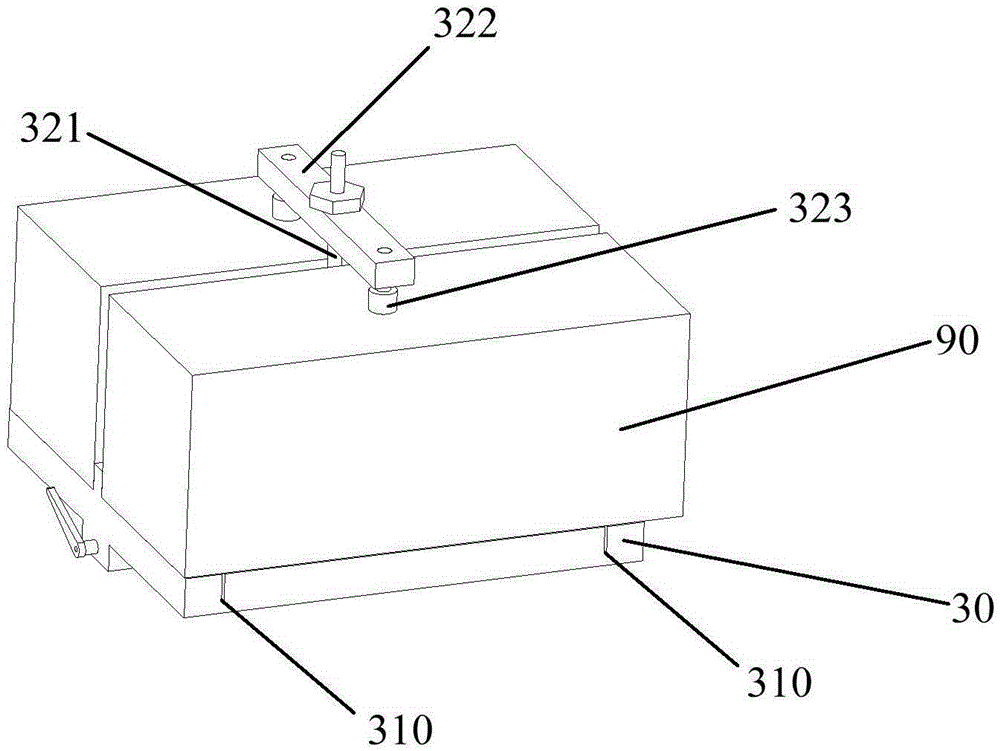

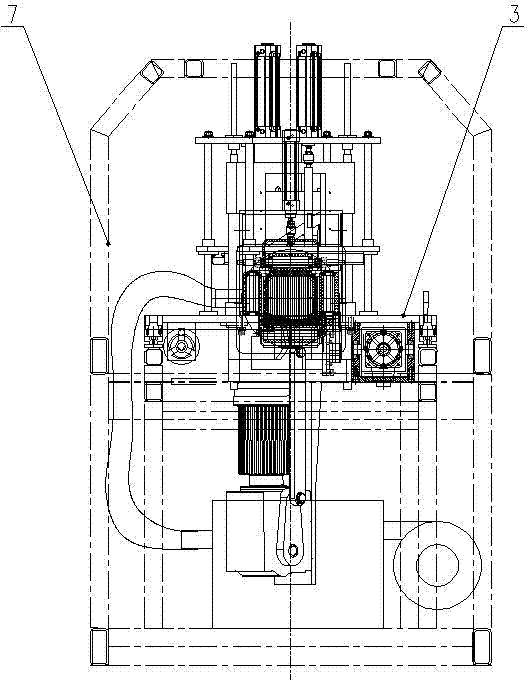

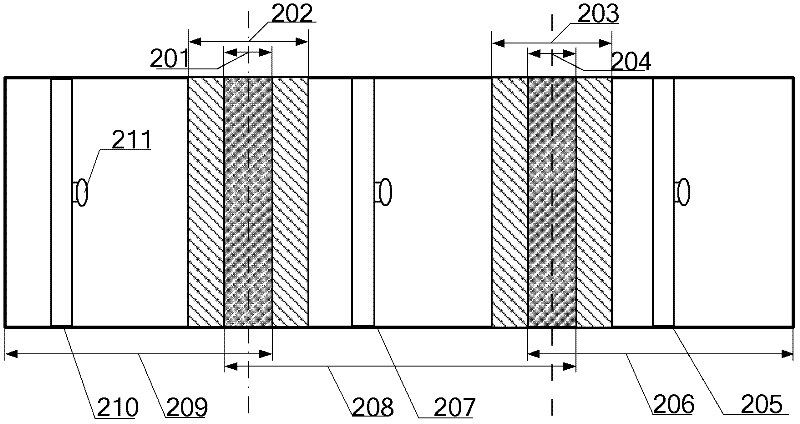

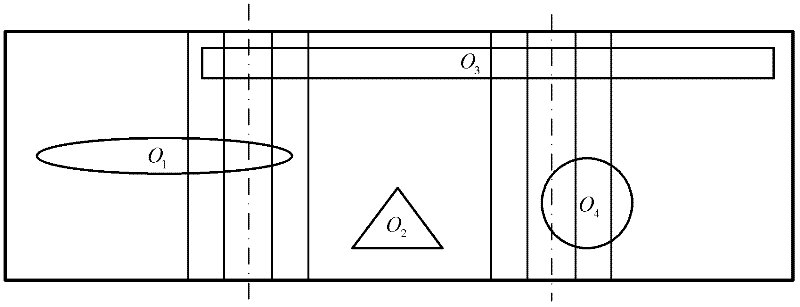

Wire cutting device and method for polycrystalline silicon

ActiveCN105196434AOrdered Head and Tail ResectionGuaranteed cutting qualityWorking accessoriesFine working devicesVertical planeWire cutting

The invention discloses a wire cutting device and method for polycrystalline silicon. The wire cutting device for the polycrystalline silicon comprises a base, a material bearing device, a rack and a wire cutting apparatus. The material bearing device is arranged on the base and provided with a first-station platform and a second-station platform in a rotating mode through a rotating mechanism, the first-station platform and the second-station platform rotate along the same circumference in a vertical plane and are located at the two ends of the same diameter of the circumference, and the first-station platform and the second-station platform rotate are both provided with a plurality of bearing plates used for bearing the polycrystalline silicon to be cut. The rack is arranged on the base and is close to the material bearing device. The wire cutting apparatus is arranged on the rack and arranged above a material conveying device in a liftable mode through a lifting mechanism and comprises a plurality of wire cutting units used for cutting the polycrystalline silicon to be cut. The wire cutting device and method for the polycrystalline silicon have the advantages that the structure is simple, operation is convenient, cutting precision is high, and cutting efficiency is high.

Owner:海宁市日进科技有限公司

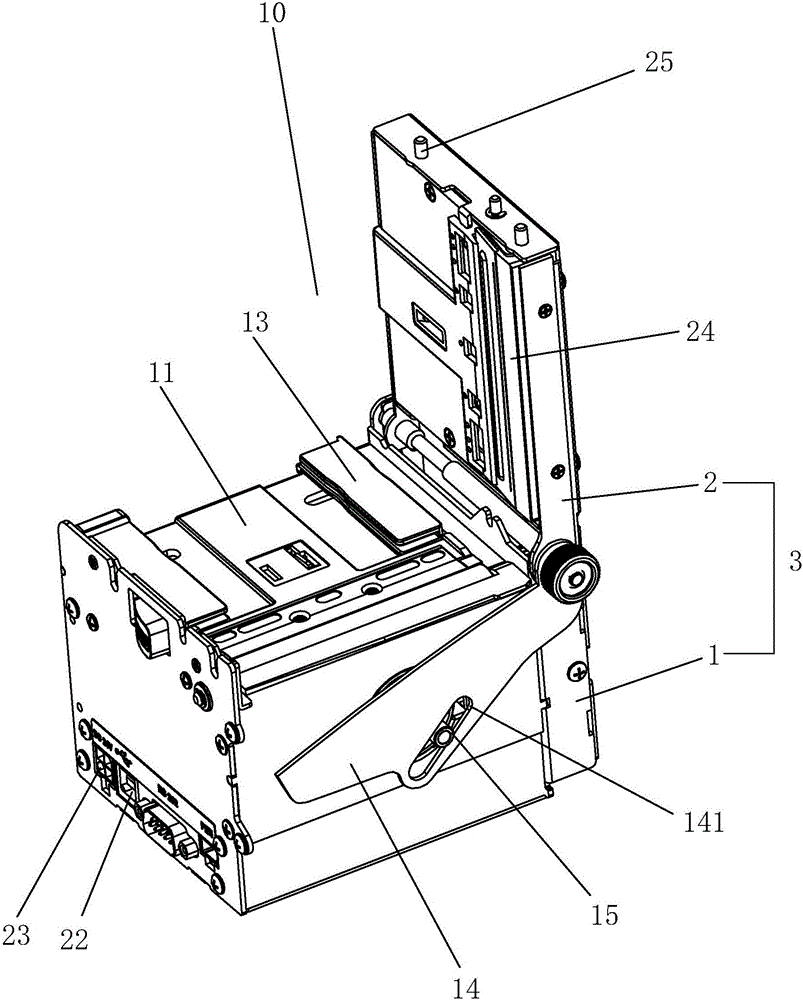

Bill printer capable of automatically cutting thick paper

ActiveCN105835544AShorten the timeReduce distanceTypewritersOther printing apparatusInlet channelEngineering

The invention discloses a bill printer capable of automatically cutting thick paper. The bill printer comprises a cabinet formed by a base and an upper cover, wherein the base and the upper cover are rotatably connected to each other through a rotary shaft, a paper outlet is formed in the front side of the cabinet, and a movable cutter at front lower side of the paper outlet, a driving device for driving the movable cutter to reciprocate and a paper inlet channel behind the paper outlet are arranged on the based. The movable cutter is rotatably connected to the front end of the rotary shaft, and a fixed cutter is fixed on the cabinet and situated at the front upper side of the paper outlet and tightly cooperates with the movable cutter. A side cover is arranged on the back side of the base, and an elastic push-pressing device is arranged on the side cover. When a bill is cut, the cutters are pushed and pressed by the push-pressing device, so that the distance between the movable cutter and the fixed cutter is very short, and cutting the bill is easy. Burrs on the cut edges can be reduced. The bill printer is applicable to cutting thick paper.

Owner:励能(深圳)科技有限公司

Building technology for pile leg of self-elevating wind power vessel

The invention relates to a building technology for a pile leg of a self-elevating wind power vessel. The building technology mainly comprises the following steps that cylinders are rolled, wherein rolling is carried out on the two ends, the middle part is rolled after the two ends are rolled in place, rolling is carried out in place again, longitudinal seam welding is carried out after positioned welding, and final roundness restoration is carried out; the cylinders are welded, wherein the cylinders are matched, an assembling machine is used for assembling, positioning welding is carried out, and finally welding is carried out; pre-assembling is carried out in a workshop, wherein the overall linearity of a reference section, the gap and the alignment tolerance are adjusted, technological flanges are assembled and welded in place, and the cross central line, the height reference line and the central line of a bolt hole are marked out on the reference section; bolt holes are cut, wherein an upper section and a lower section are rotated to the position of a saddle-shaped cutting machine, the central line of the pile leg is adjusted to be parallel to a track of the saddle-shaped cutting machine, and cutting is carried out according to the marked lines. The building technology has the advantages that various building requirements of the pile leg can be ensured, meanwhile, the building efficiency can be improved, and the building cost can be reduced.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

Dual-cutter dual-angle fixed-length crank cutting device

InactiveCN103568061AContinuously adjustable cutting lengthReduce wasteMetal working apparatusCrankControl cell

A dual-cutter dual-angle fixed-length crank cutting device is formed by two groups of cutting units, two groups of compacting units, two synchronous moving worktables, two groups of cutter heating units, a preheating heat, a conveying unit, a rack and a control unit; angles of cutting blades of the cutting units and the intervals of the moving worktables are adjustable; the cutting units, the compacting units and the cutter heating units are respectively mounted at table surfaces of the two synchronous moving worktables; the moving table surfaces are connected with the rack by linear guide tracks. The preheating unit is fixed on one synchronous worktable and moves along with the worktable. The conveying unit is fixedly connected onto the other synchronous moving worktable and moves together along with the worktable. The preheating unit and the conveying unit are fixedly connected with the rack. Cooperative actions of all the units are controlled by the control unit, the dual-cutter dual-angle fixed-length crank cutting device realizes the online automatic cutting of plastic linear section bars with the fixed length at 45-90 degrees, and the cutting length ranges from 600mm to 3100mm.

Owner:上海海弋机电科技有限公司

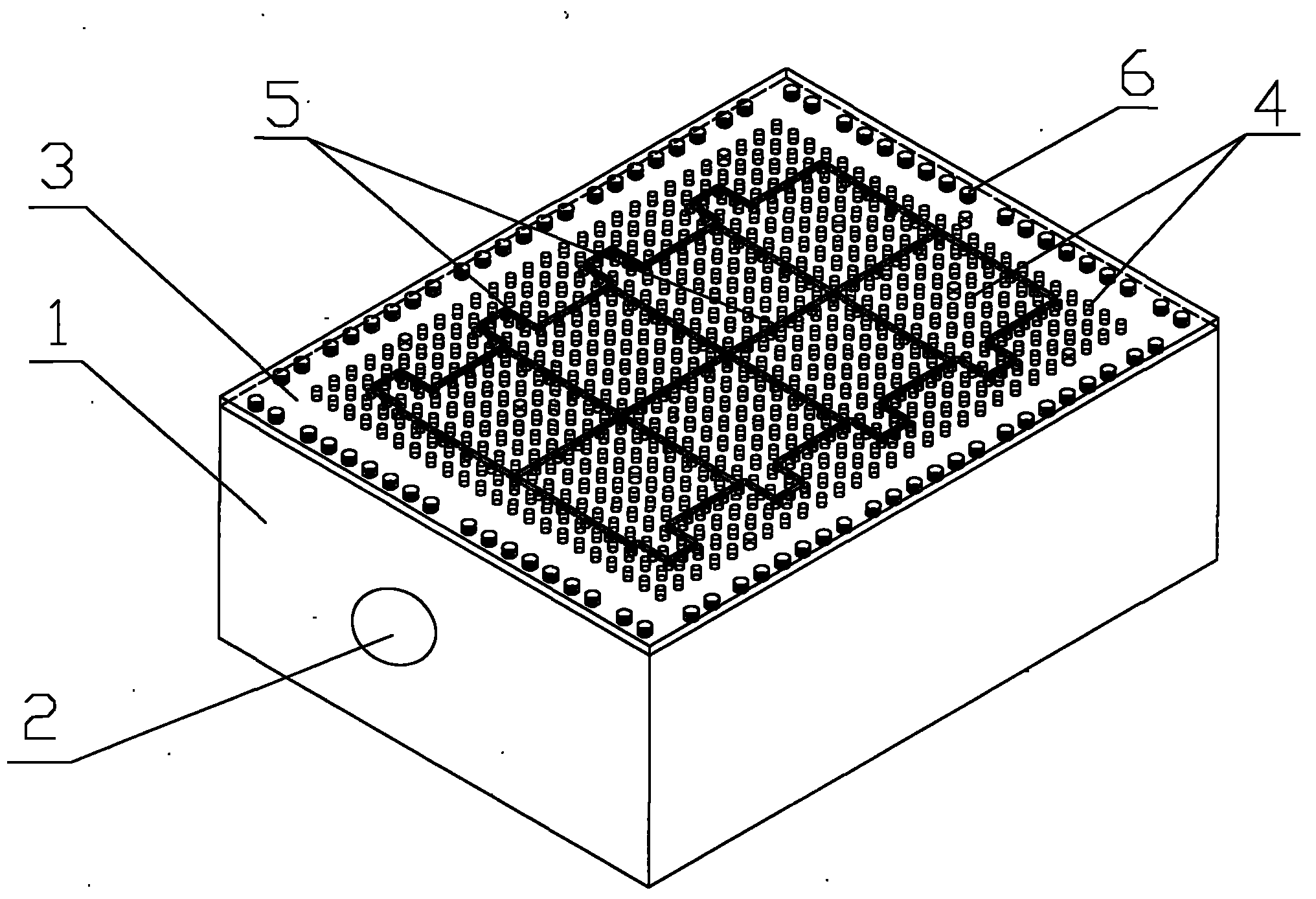

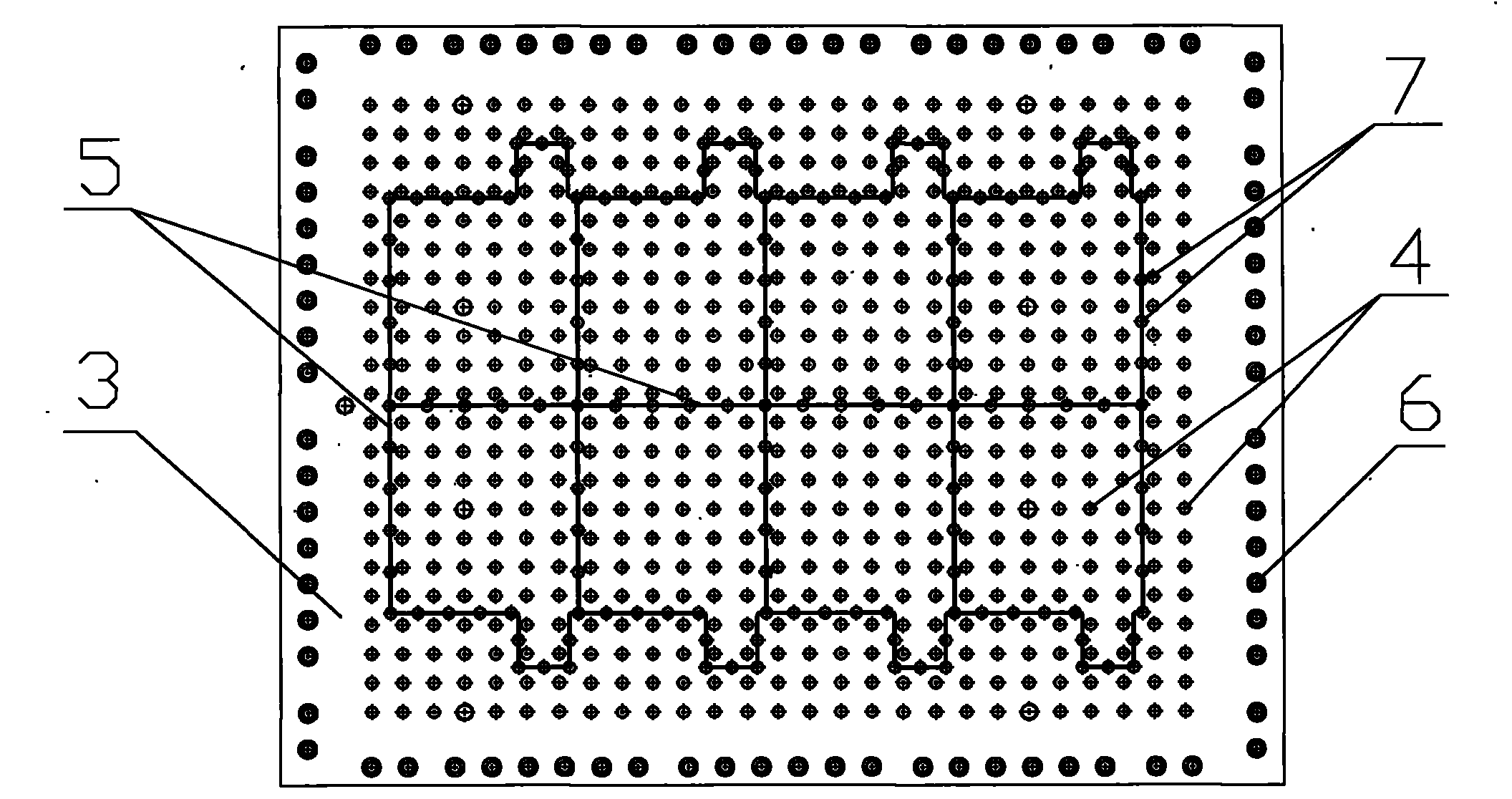

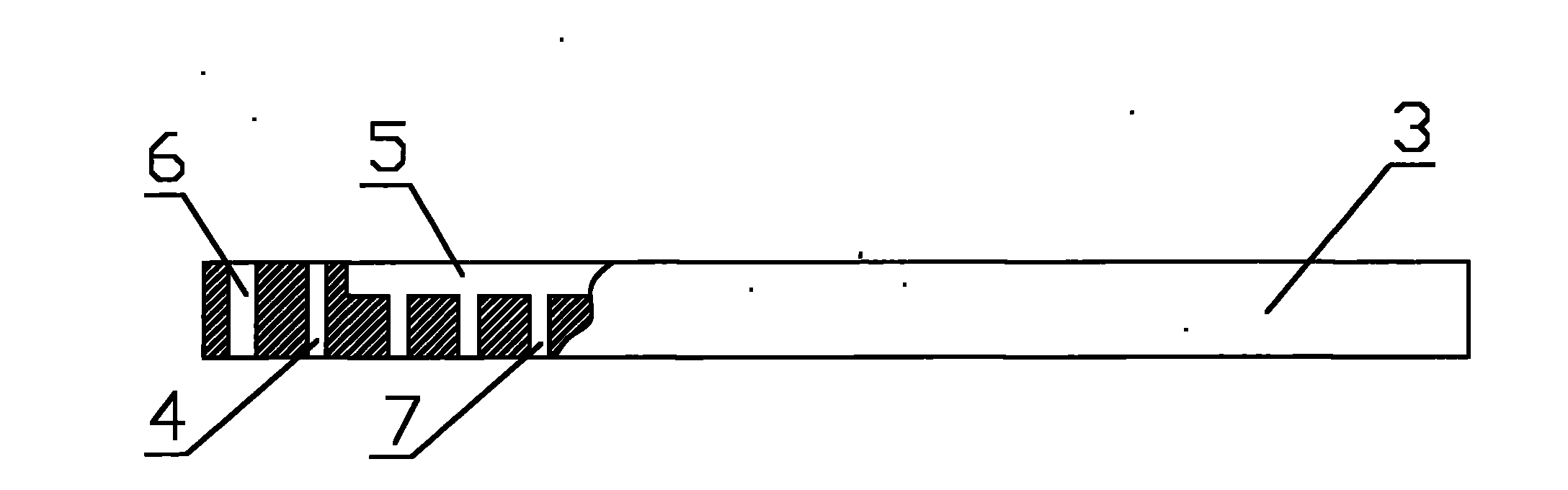

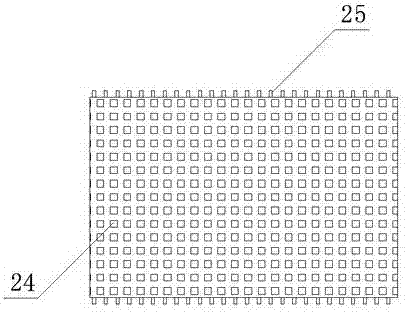

Vacuum adsorption device of battery pole piece

InactiveCN101774087ANo warpingNo situationLaser beam welding apparatusPlanar substrateElectrical battery

The invention provides a vacuum adsorption device of a battery pole piece, which is suitable for laser cutting operation and has simple structure and strong practicality. The device comprises a sealed cavity which is provided with vents communicated with a vacuum generator; the key point is that the top surface of the cavity is a plane substrate provided with plural adsorption through holes; the substrate is provide with an indent clearance groove along the cutting line of the battery pole piece; the cavity and the vacuum generator form a vacuumizing device; under the vacuumizing action of the vacuum generator, the battery pole piece can be tightly adsorbed on the substrate without lifting and bending or collapsing; the substrate is provided with the indent clearance groove along the cutting line of the battery pole piece, thus avoiding the uneven substrate as the substrate is cut and scratched when laser light beams cut the substrate during laser cutting, ensuring the cutting quality of subsequent battery pole pieces, and prolonging the service life of the substrate. The device has simple and reasonable structure, favorable adsorption effect and better popularization and application values.

Owner:CHERY AUTOMOBILE CO LTD

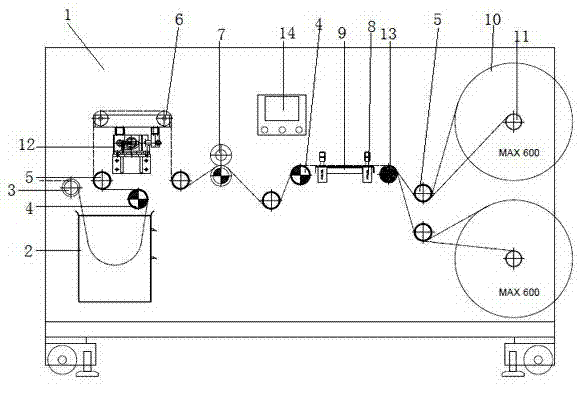

Automatic splitting machine

InactiveCN103693495AFor precise cuttingCompact structureArticle deliveryWebs handlingProgrammable logic controllerEngineering

The invention discloses an automatic splitting machine, which comprises a body, a programmable logic controller (PLC), and a roll release shaft, a material storage box, a flattening mechanism, a splitting mechanism, a receiving mechanism and a rolling mechanism which are fixedly connected with the body, controlled by the PLC and sequentially arranged in the feeding direction, and also comprises a plurality of driving rollers and tension shafts. The automatic splitting machine has the advantages that the automatic splitting machine is compact in integral structure, small in floor area, high in speed and efficiency, accurate in splitting, easy to operate and stable in work, material putting deviation is corrected by a deviation rectifying mechanism, the tension is well controlled and timely adjusted through the tension shafts and a tension detector in the working process, and the splitting quality is guaranteed; moreover, the negative pressure material storage box can effectively prevent a material from being deformed or damaged in the material storage box due to gravity action.

Owner:珠海嘉威自动化科技有限公司

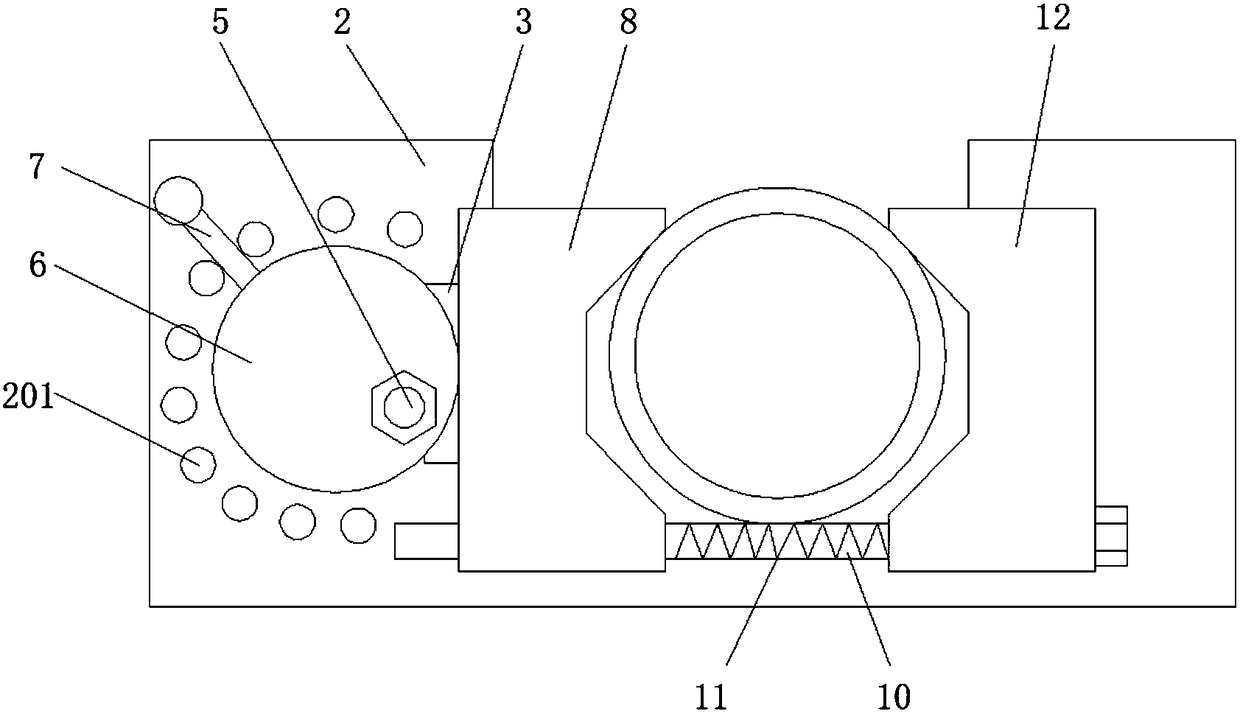

Clamping hole tool of cutter and using method of clamping hole tool

InactiveCN107020417AGuaranteed cutting qualityEasy to cutMetal sawing devicesMetal sawing accessoriesDrive shaftEngineering

The invention discloses a clamping hole tool of a cutter and a using method of the clamping hole tool. The clamping hole tool comprises a base and a feeding base, wherein a slide rail is fixedly arranged at the left side of the top of the base; the bottom of the feeding base is fixedly arranged on the slide rail through a slide block and is in sliding connection with the slide rail; a supporting frame is welded on the position, at the right side of the feeding base, at the rear end of the top of the base; a gas pump is fixedly mounted on the top of the supporting frame; a transmission shaft of the gas pump penetrates through the supporting frame and is fixedly connected with a telescopic pole; the bottom of the telescopic pole is fixedly connected with a limiting block; a pressure plate is fixedly arranged on the bottom of the limiting block; a cutting base is fixedly mounted at the right side of the top of the base; a material return base is fixedly arranged on a position, at the right end of the cutting base, at the right side of the base; and a regulating base is arranged at the right side of the rear end of the material return base. The clamping hole tool is simple and reasonable in structural design, is convenient to operate, saves time and labor, is safe and stable, ensures rod cutting quality and velocity, is wide in scope of application, and is beneficial for spreading and popularizing.

Owner:浙江阿波罗工具有限公司

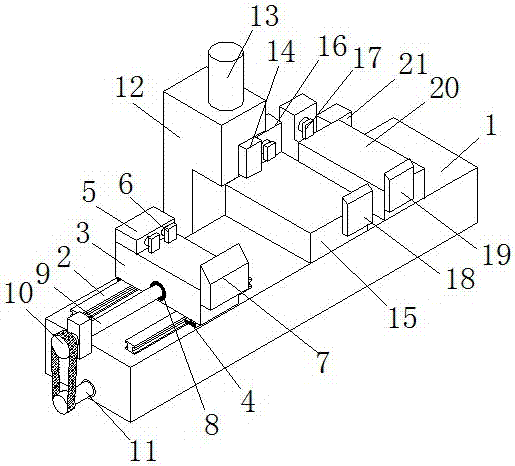

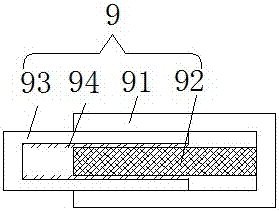

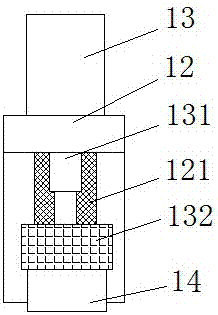

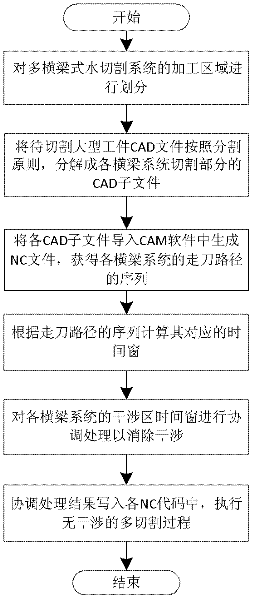

Cutting process offline coordination method of multi-beam type water jet cutting system

InactiveCN102346459ANo need to change KAEliminate interferenceProgramme controlComputer controlNumerical controlComputer-aided

The invention provides a cutting process offline coordination method of multi-beam type water jet cutting system. The method comprises the following steps: dividing a processing area of the multi-beam water cutting system; inputting a CAD (computer-aided design) file of a large workpiece to be cut, and decomposing and allocating the cutting contour accordingly to form the CAD sub-file of the cutting part of each beam system; importing each CAD sub-file into water cutting CAM (computer-aided manufacturing) software to generate an executable NC (numerical control) code file, and reading the NC code file to obtain a sequence of the cutting path of each beam system; calculating a time window executed by each path in each cutting sequence, and coordinating the time windows in an interference area so as to achieve the purpose of avoiding mutual interference between two adjacent beams; and writing the coordination result into the original NC code file, downloading the NC code file to a CNC (computer numerical controller) of each beam system, and executing the multi-beam water cutting process. According to the invention, smooth and non-interference execution of a parallel cutting processes of a water cutting system with more than three beams can be realized.

Owner:SOUTHEAST UNIV

Cutting head

ActiveCN102500920AImprove adjustabilityPrecise control of focus point positionLaser beam welding apparatusLaser processingHigh energy

The invention belongs to the field of laser machining, and particularly relates to a cutting head, which is used for laser fine cutting and comprises a light path incident lens, a light path emergent lens, a reflector component and an adjusting mechanism. The reflector component is used for reflecting light paths, main light enters the cutting head via the light path incident lens and exits the cutting head via the light path emergent lens after being reflected by the reflector component, the light path emergent lens consists of a focusing head component, and the adjusting mechanism can be used for driving the focusing head component to move along a Z-axis direction. When the thickness of a machined workpiece is changed, the purpose of accurately controlling the position of a focal point of the focusing head component can be directly achieved by means of adjusting the Z-axis adjusting mechanism positioned in a cutting head body, high energy of laser within a focal depth range can be sufficiently utilized, machining precision is improved, and accordingly the quality and the stability of cutting of the workpiece are eventually guaranteed. In addition, the cutting head is more convenient and speedy in operation as compared with a traditional laser cutting head troublesome in operation due to the fact that the relative height of a mechanical arm connected with the traditional laser cutting head needs to be integrally adjusted.

Owner:CHERY AUTOMOBILE CO LTD

Laser processing method and laser cutting systems of high molecular workpieces

ActiveCN104014936AEfficient removalGuaranteed cutting efficiencyLaser beam welding apparatusLaser processingBeam splitter

The invention belongs to the technical field of laser processing, and discloses a laser processing method of high molecular workpieces. Two laser cutting heads irradiate the workpieces with two laser beams with different power values, the high-power laser beam moves along a processing track of the workpieces to cut the workpieces by a certain distance, and then the low-power laser beam moves along the processing track of the high-power laser beam for cutting. The invention further discloses two laser cutting systems for realizing the laser processing method, one laser cutting system comprises two laser oscillators, two laser drivers, two industrial personal computers and the two laser cutting heads, and the high-power laser beam and the low-power laser beam can independently controlled to be transmitted; the other laser cutting system comprises a laser oscillator, a laser driver, an industrial personal computer, the two laser cutting heads and a beam splitter used for splitting a laser beam transmitted by the laser oscillator to a high-power laser beam and a low-power laser beam.

Owner:HANS LASER TECH IND GRP CO LTD

Paper product processing and cutting machine with self-cleaning function

InactiveCN107053314APrevent wanderingAvoid the risk of manual feeding and unloadingDirt cleaningMetal working apparatusWorking environmentEngineering

The invention discloses a paper product processing and cutting machine with the self-cleaning function. The paper product processing and cutting machine comprises a workbench; a material guide groove is formed in the working table; one side of the material guide groove is provided with an electric push rod; one end of the electric push rod is connected to a material pushing plate, and the material pushing plate is arranged in the material guide groove; the other end of the material guide groove is provided with a cutting blade; an air blowing pipe is arranged on one side of the cutting blade and is fixedly connected to an air outlet of an electromagnetic valve; an air inlet of the electromagnetic valve is connected to an air pump through an air pipe; a time relay is arranged on one side of the electromagnetic valve; a dust collector is fixedly arranged on the workbench; and a conveyor belt is arranged on one side of the dust collector. According to the paper product processing and cutting machine with the self-cleaning function, automatic material feeding and material taking can be realized through the electric push rod and an air cylinder, injuries caused by manual operation can be avoided, the working efficiency can be improved, paper scraps adhering to a knife edge can be blown down through the air blowing pipe, the cutting quality can be guaranteed, dust generated in the processing process can be absorbed through the dust collector, and the working environment can be improved.

Owner:BEITANG JUNZHI PRINTING PAPER PROCESSING FACTORY

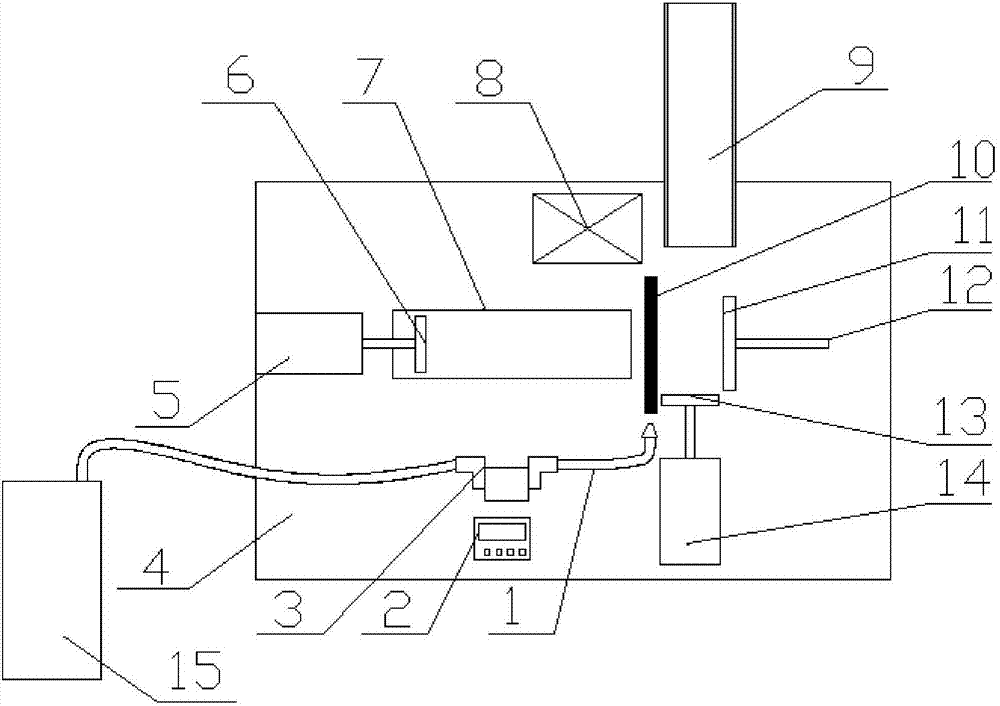

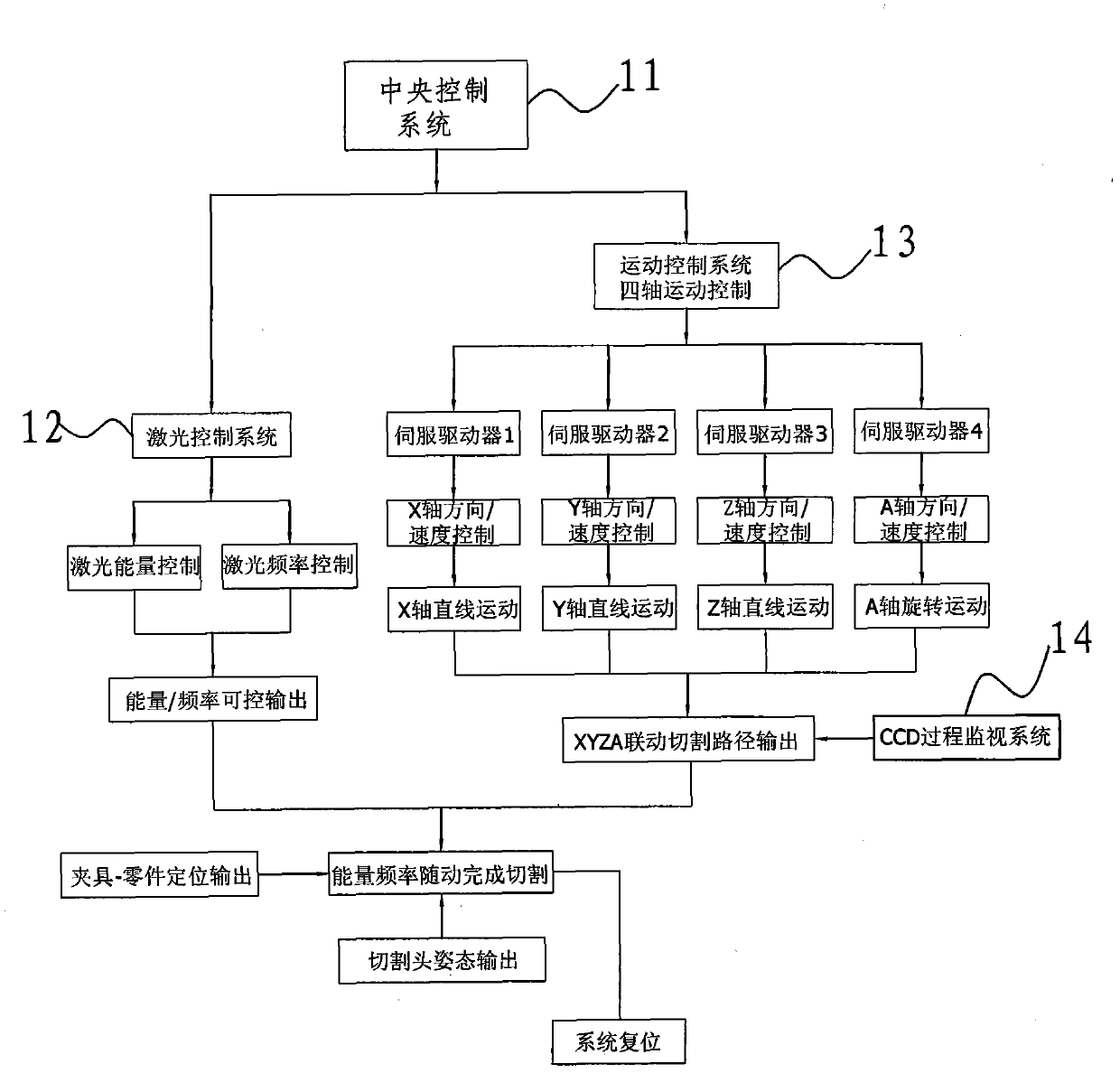

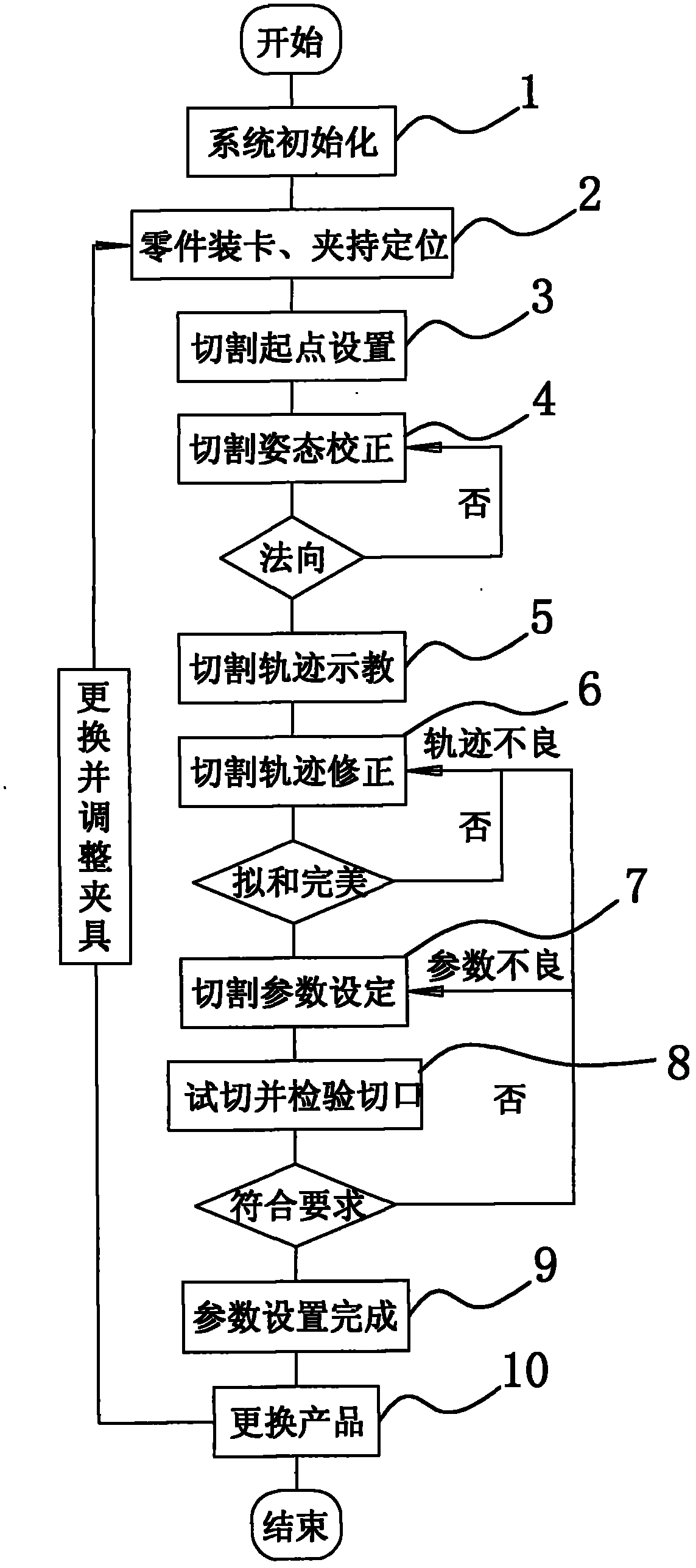

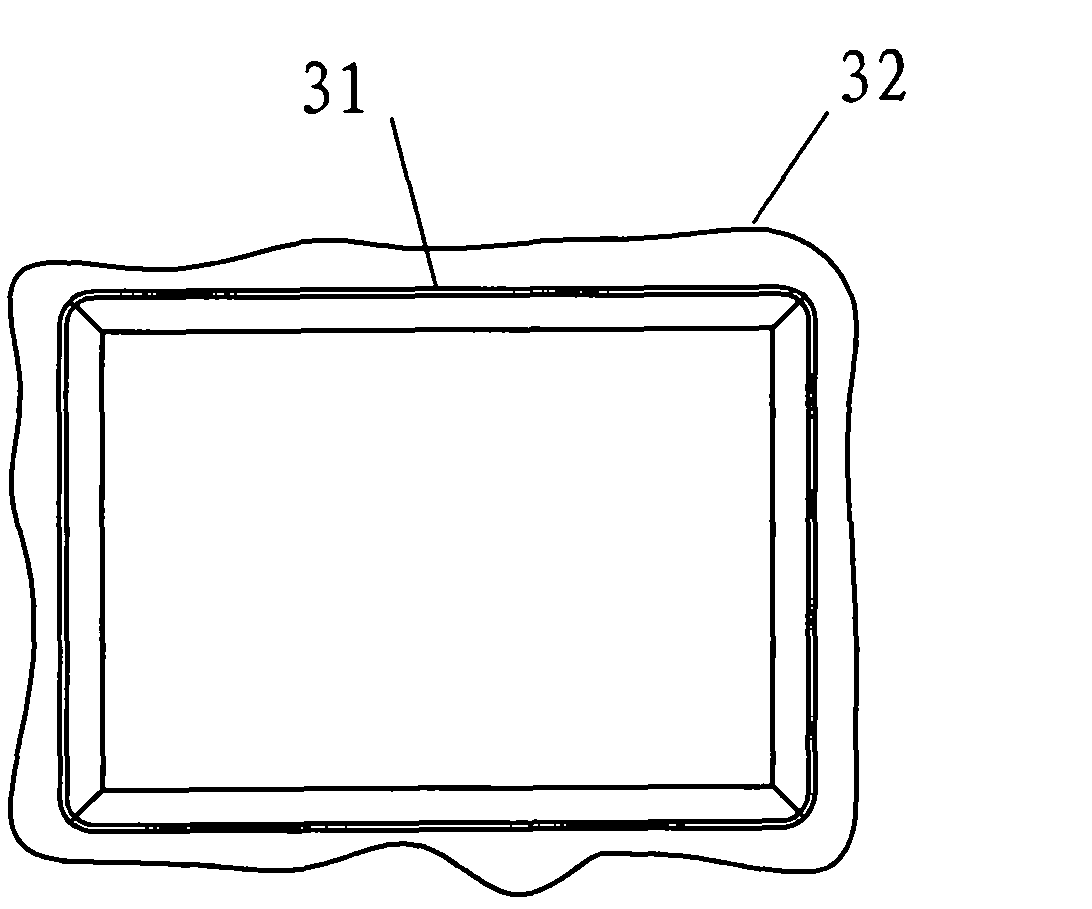

Laser cutting method

InactiveCN102000916ALower requirementGuaranteed continuityLaser beam welding apparatusNumerical controlEngineering

The invention provides a laser cutting method, in particular to a method for removing a water gap of an injection molding and a water gap of a film-covering piece by adopting a cutting path employing teaching programming and related program recording method. The teaching programming method comprises the following steps of: gradually recording the postures and the instant speeds of cutting heads on a curve one by one; associating the data to form continuous cutting motion; and teaching and storing a whole cutting path as a CNC (Computerized Numerical Control) program, wherein regular curves are used for teaching according to the characteristics, and irregular curves are used for teaching by adopting a short line segment fitting method. In the invention, by adopting a mode of controlling the motion of a worktable and the frequency and the energy of laser through program and a working mode of normal cutting, the requirement for operators can be lowered, meanwhile, the processing constancy and the joining continuity between a notch and an arc are ensured, the cutting quality is improved and the application range of laser cutting is further enlarged.

Owner:HANS LASER TECH IND GRP CO LTD

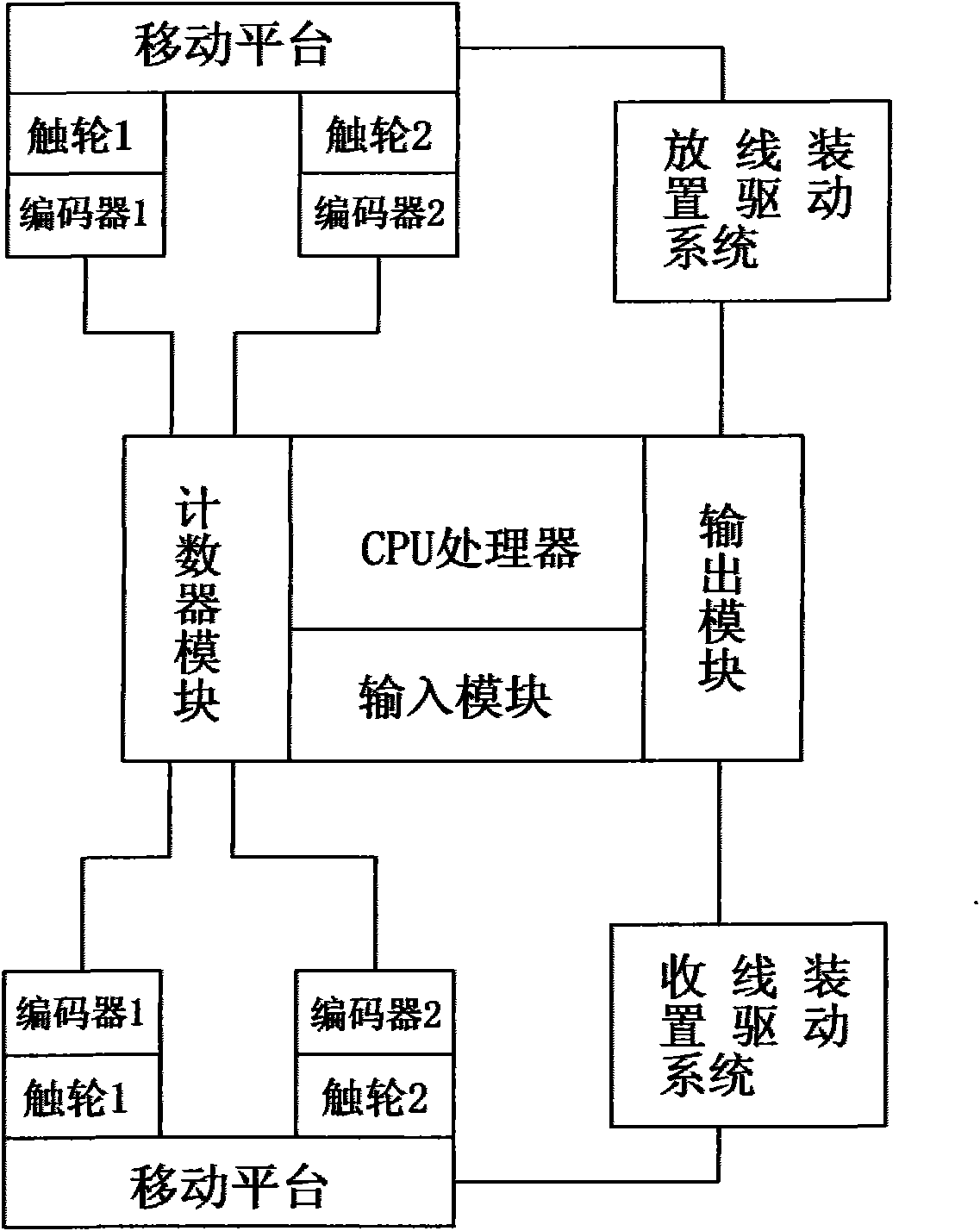

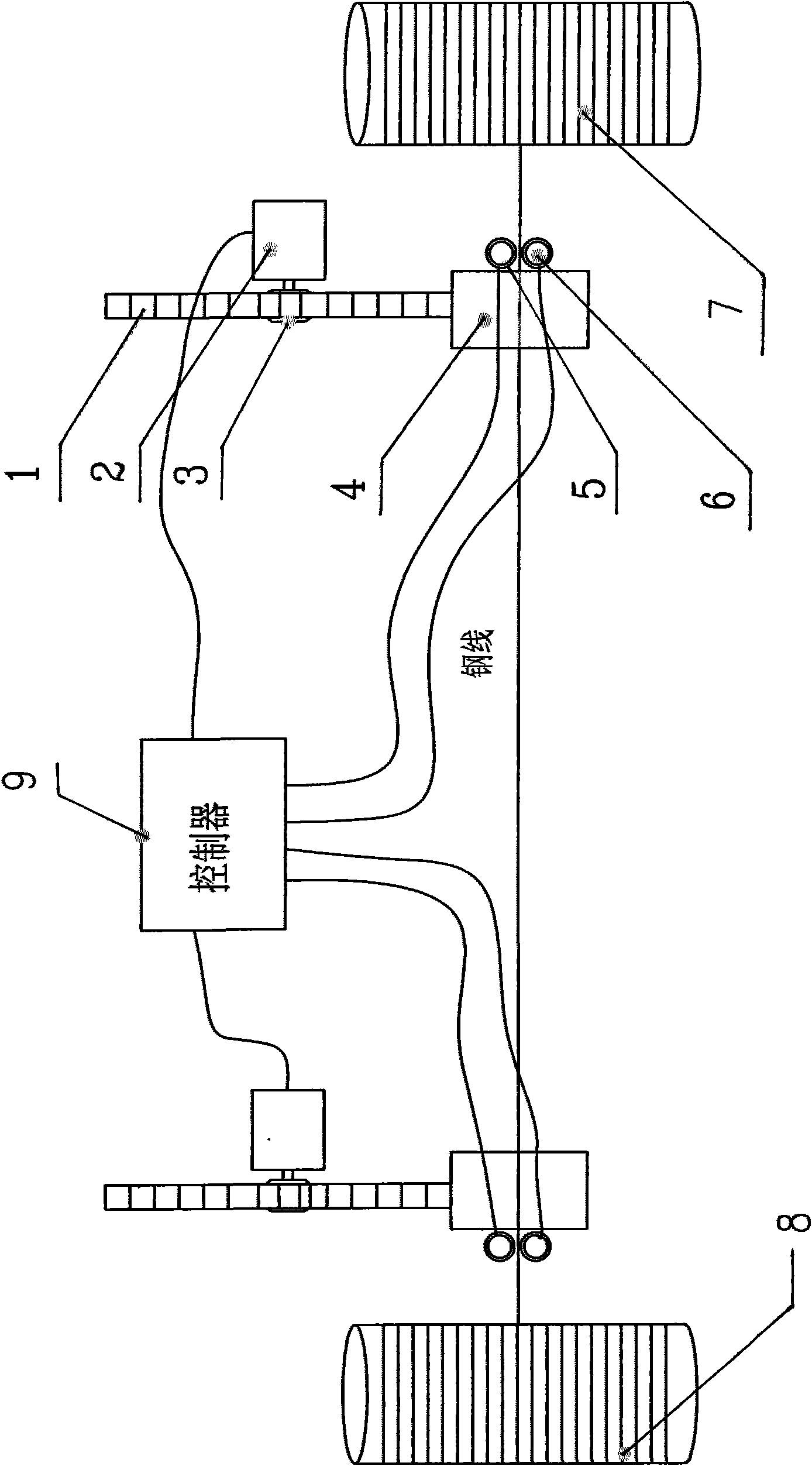

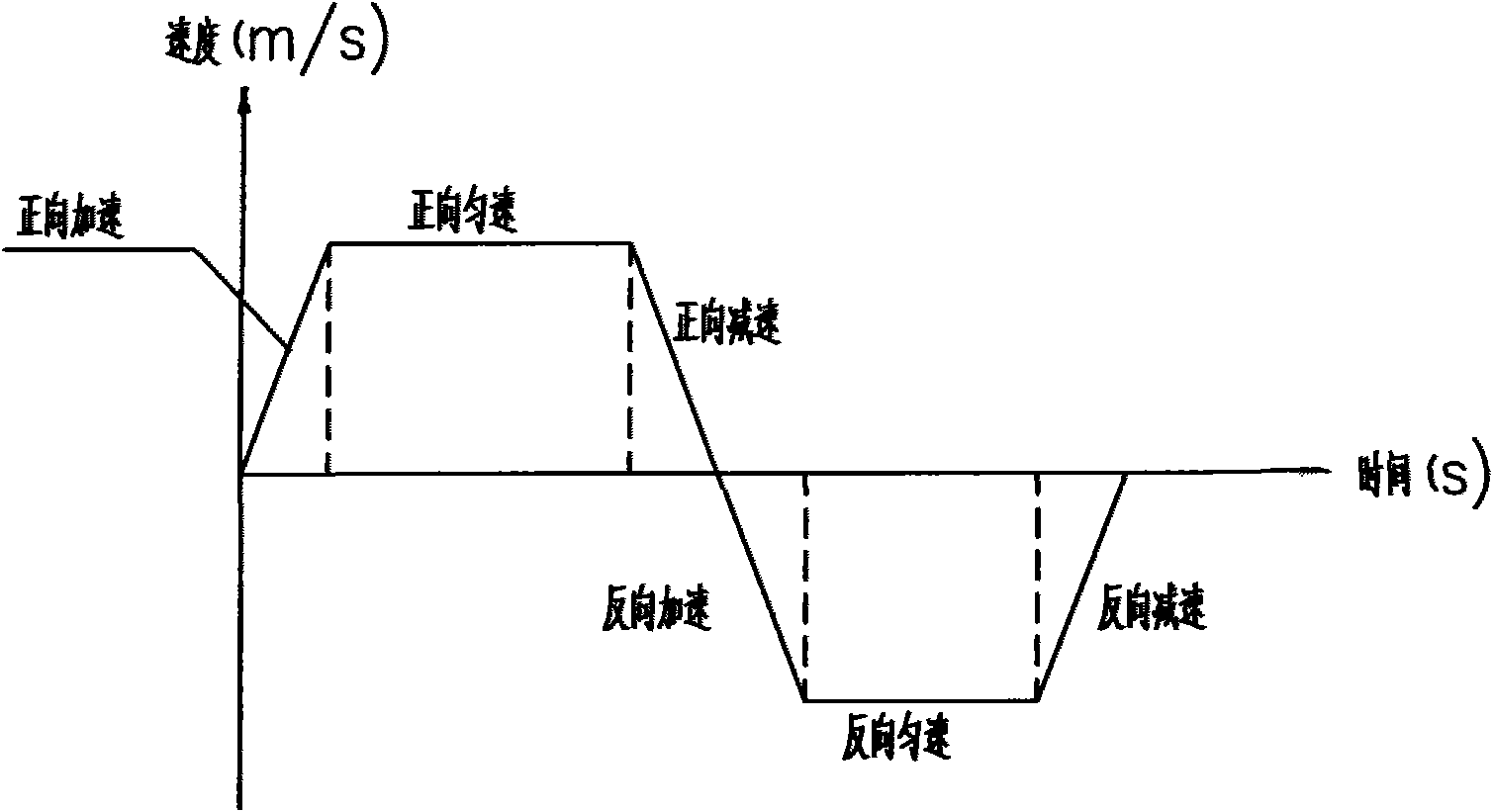

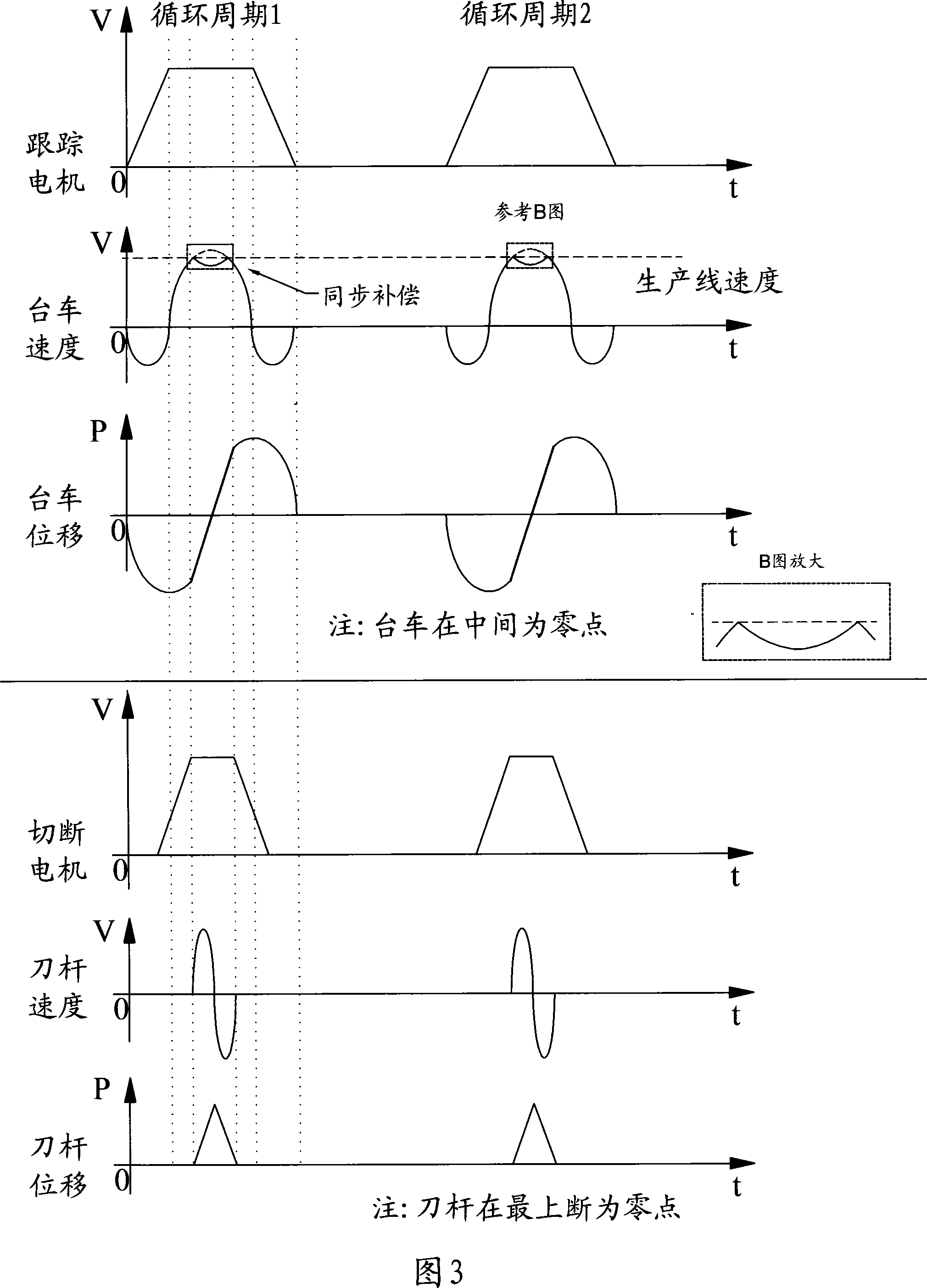

Steel wire drawing and releasing automatic tracing and controlling method and device for multi-wire cutting machine

InactiveCN101596750AEvenly and tightly arrangedImprove reliabilityControl using feedbackFine working devicesEconomic benefitsWire cutting

The invention relates to a steel wire automatic tracing method and an automatic tracing device in a wire drawing device and a wire releasing device of a multi-wire cutting machine. The automatic wire drawing device and the automatic wire releasing device respectively use a servo motor, a gear rack driving transportation platform, wherein, two trolley wheels are arranged on the transportation platform, and a steel wire passes between the two trolley wheels; the transportation platform are respectively provided with two rotary encoders linking with the two trolley wheels; the rotary encoders are connected with a controller which is connected with the servo motor. The motion direction of the servo motor is determined by the two rotary encoders respectively through the controller so as to automatically correct the position of the steel wire in the wire drawing device and the wire releasing device to ensure that the steel wire is closely and uniformly arranged in the wire drawing device and the wire releasing device. The steel wire drawing and releasing automatic tracing and controlling method and the device for multi-wire cutting machine of the invention can reduce broken wires caused by nonuniform wire drawing and releasing of the wire drawing device and the wire releasing device of the multi-wire cutting machine by more than 95%, which increases the reliability of the machine and ensures the cutting quality of the multi-wire cutting machine for hard materials, such as monocrystalline silicon, polycrystalline silicon and the like, so that the economic benefit is increased.

Owner:XINXIANG HUASHENG TIANLONG CNC EQUIP

EVA film hob cutting device of thin-film solar cell

InactiveCN101823268ACompact structureLarge operating spaceMetal working apparatusDrive shaftMachining

The invention relates to a part of a thin-film solar cell manufacturing device, in particular to an EVA film hob cutting device of a thin-film solar cell. The EVA film hob cutting device comprises a knife rest which is used for installing a cutting knife, wherein the bottom of the knife rest is fixedly connected with a slide block, the slide block is mutually matched and positioned with a fixed linear guide track under the slide block, the slide block and the knife rest can move along the linear guide track, an upper knife shaft, a lower knife shaft and a rubber wheel shaft are arranged on the knife rest, one of the upper knife shaft, the lower knife shaft and the rubber wheel shaft is a driving shaft driven by an electric motor, the other two shafts are synchronously driven by the driving shaft through a driving mechanism, the ends of the same sides of the upper knife shaft and the lower knife shaft are respectively provided with an upper hob and a lower hob which can rotate along the upper knife shaft and the lower knife shaft, the edges of the upper hob and the lower hob are provided with interlaced and bonded parts, at least one rubber rolling wheel is arranged on the rubber wheel shaft, and the bottom of the rubber rolling wheel is pressed on the top surface of the linear guide track. The EVA film hob cutting device can automatically cut an EVA film of a thin-film solar cell and has high automation degree and high machining precision.

Owner:镇江市博锐自动化科技有限公司

Diameter-adjustable pipe fitting cutting device and cutting method thereof

PendingCN108555748AFast and easy clampingReduce bending momentGrinding machinesAutomatic grinding controlRound tablePipe fitting

The invention discloses a diameter-adjustable pipe fitting cutting device and belongs to the technical field of pipe fitting cutting. The diameter-adjustable pipe fitting cutting device comprises a baseplate, wherein a clamp support plate is arranged on the left side of the top of the baseplate; a dovetail guide is arranged on the outer wall of the right end of the clamp support plate; a round table lug is arranged on the outer wall of the right end of the clamp support plate and located at the front end of the dovetail guide; a fixed link is arranged at the right end of the round table lug; external threads are formed at the right end of the outer wall of the fixed link; an eccentric round disk sleeves the outer wall of the fixed link; a movable V-shaped block is arranged at the right endof the clamp support plate; and a fastening screw is arranged at the tops of a movable turnover clamp plate and a fixed clamp plate through through holes. The cutting device suitable for pipe fittings with different diameters finishes fixation of the pipe fittings with different diameters through the V-shaped block and a clamp plate component and finishes cutting of the pipe fittings with different diameters through a combined cutting component, so that the university of the pipe fitting cutting device is improved.

Owner:胡亚勇

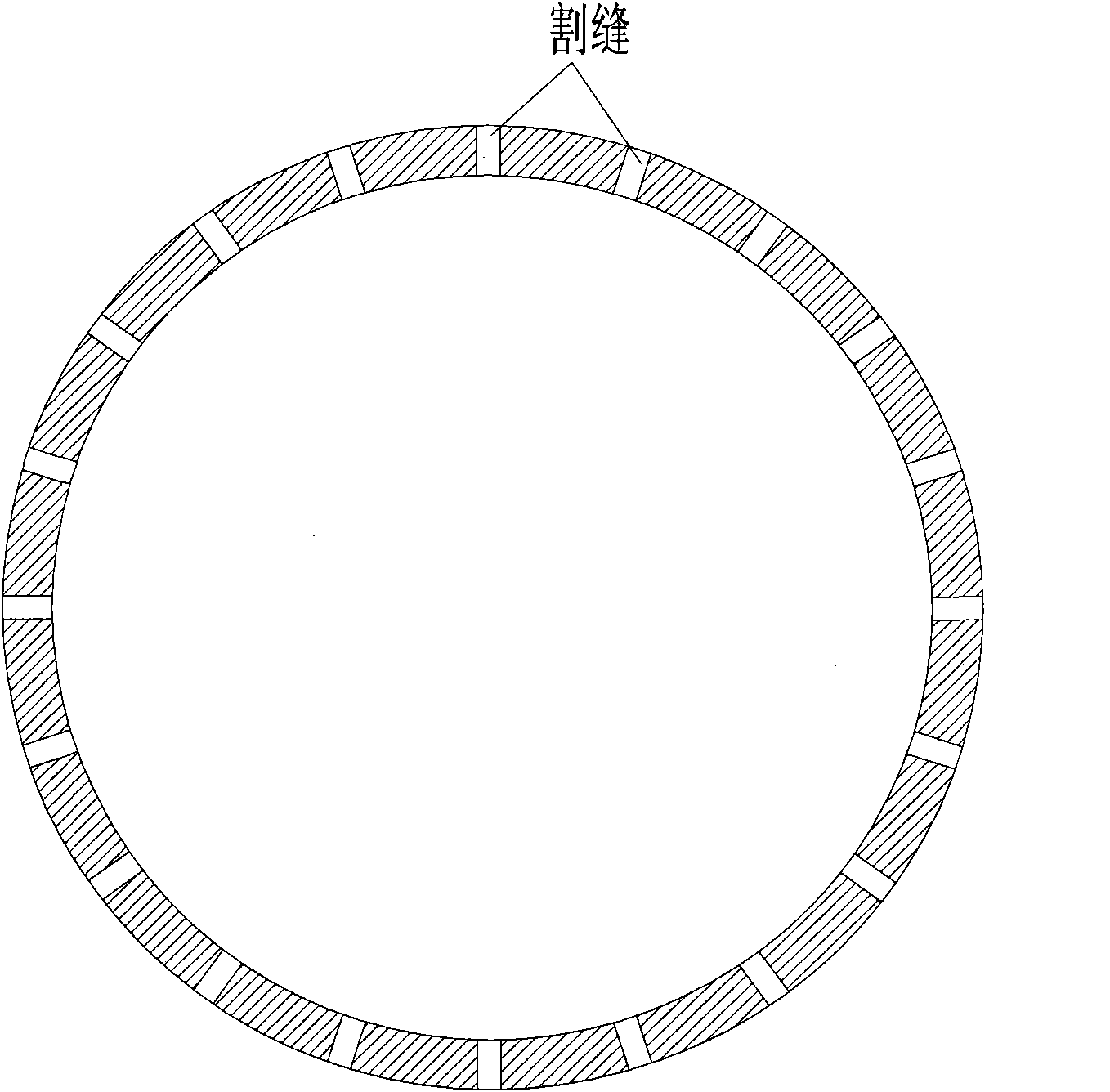

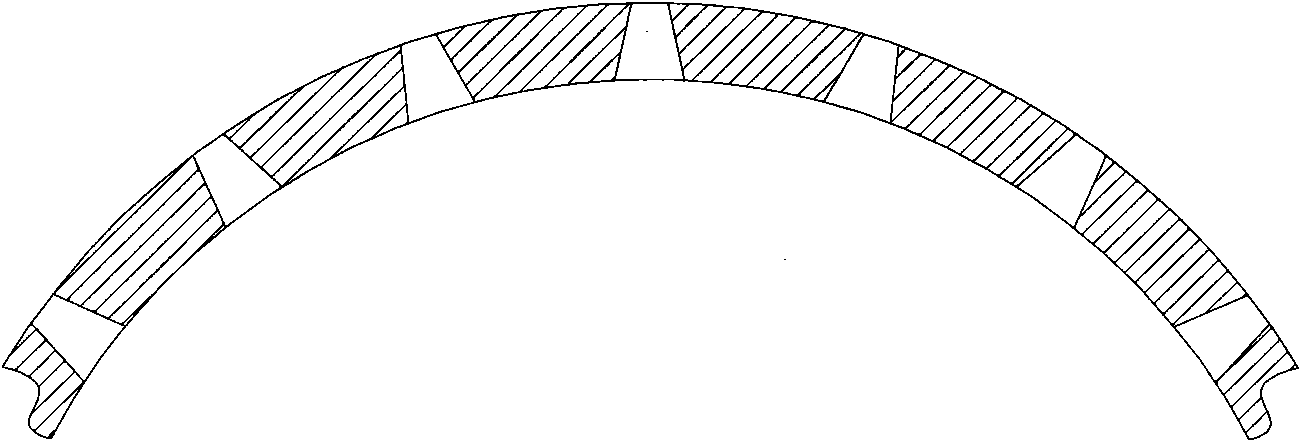

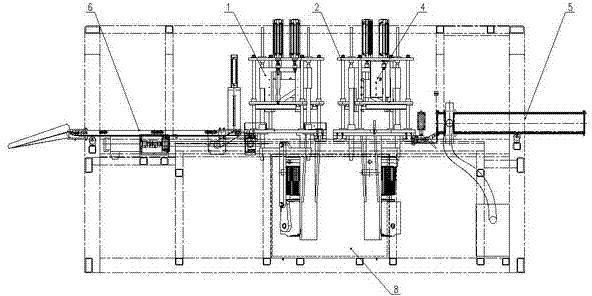

Laser cutting machine

PendingCN111299814ALaser cutting effect is goodAvoid interferenceLaser beam welding apparatusPhysicsElectric machinery

The invention relates to a laser cutting machine. The laser cutting machine comprises a platform, supporting rods are arranged under the platform, a vertical plate perpendicular to the platform is arranged on the rear side of the platform, a lifting mechanism for driving the upper and lower motion of a rotary cutting platform is arranged on the vertical plate, and the rotary cutting platform comprises a circular supporting plate with a front side opening. A circular gear ring with an opening is arranged at the upper end of the supporting plate, gears meshing with the gear ring and oppositely arranged are arranged on one side of the gear ring in the circumferential direction, and each gear is separately connected to a first drive motor. A plurality of rollers abutting against the gear ringand and connected to the supporting plate are arranged on the other side of the gear ring at intervals in the circumferential direction, the gear ring can perform circumferential rotation around a center of the gear ring, a laser cutting assembly is fixedly connected to the upper end of the gear ring, a circular hole with a front side opening is formed in the platform below the supporting plate, and a clamping mechanism is arranged above the circular hole. The laser cutting machine can be applied to cutting of workpieces of different size revolving bodies, a laser beam is accurate in focusing,the perpendicularity is good, the cutting effect is good, the clamping and taking workpiece is convenient and quick, and the processing cost is low.

Owner:北京奥峰铭金属制品有限公司

Gantry type pipe and flat plate cutting machine

PendingCN108015385AImprove efficiencyVersatileWelding/cutting auxillary devicesAuxillary welding devicesEngineeringDigital control

The invention discloses a gantry type pipe and flat plate cutting machine. The gantry type pipe and flat plate cutting machine comprises a cutting assembly, a plate cutting mechanism, a pipe cutting mechanism and a crossbeam. The crossbeam is provided with a transverse driving unit. The cutting assembly is connected with the crossbeam, and a lifting driving unit is arranged on a cutting assembly installing seat. The transverse driving unit comprises a first gear, a first rack, a first motor and a first track. The plate cutting mechanism comprises a machine frame, a machine table and a longitudinal driving unit. The longitudinal driving unit comprises a second gear, a second rack, a second track and a second motor. The pipe cutting mechanism comprises a feeding track, an end chuck, a movable chuck and a feeding driving unit. The end chuck and the movable chuck each comprise clamping parts, a clamping part installing seat and a chuck body. The gantry type pipe and flat plate cutting machine is provided to meet the machining requirements of pipe products in the digital control cutting machining field, and is easy to control, convenient to use and flexible in clamping, reduces the machining cost of pipe products, and widens the cutting machining range of a digital control cutting machine.

Owner:JIANGSU ZHENGHE HEAVY IND CO LTD

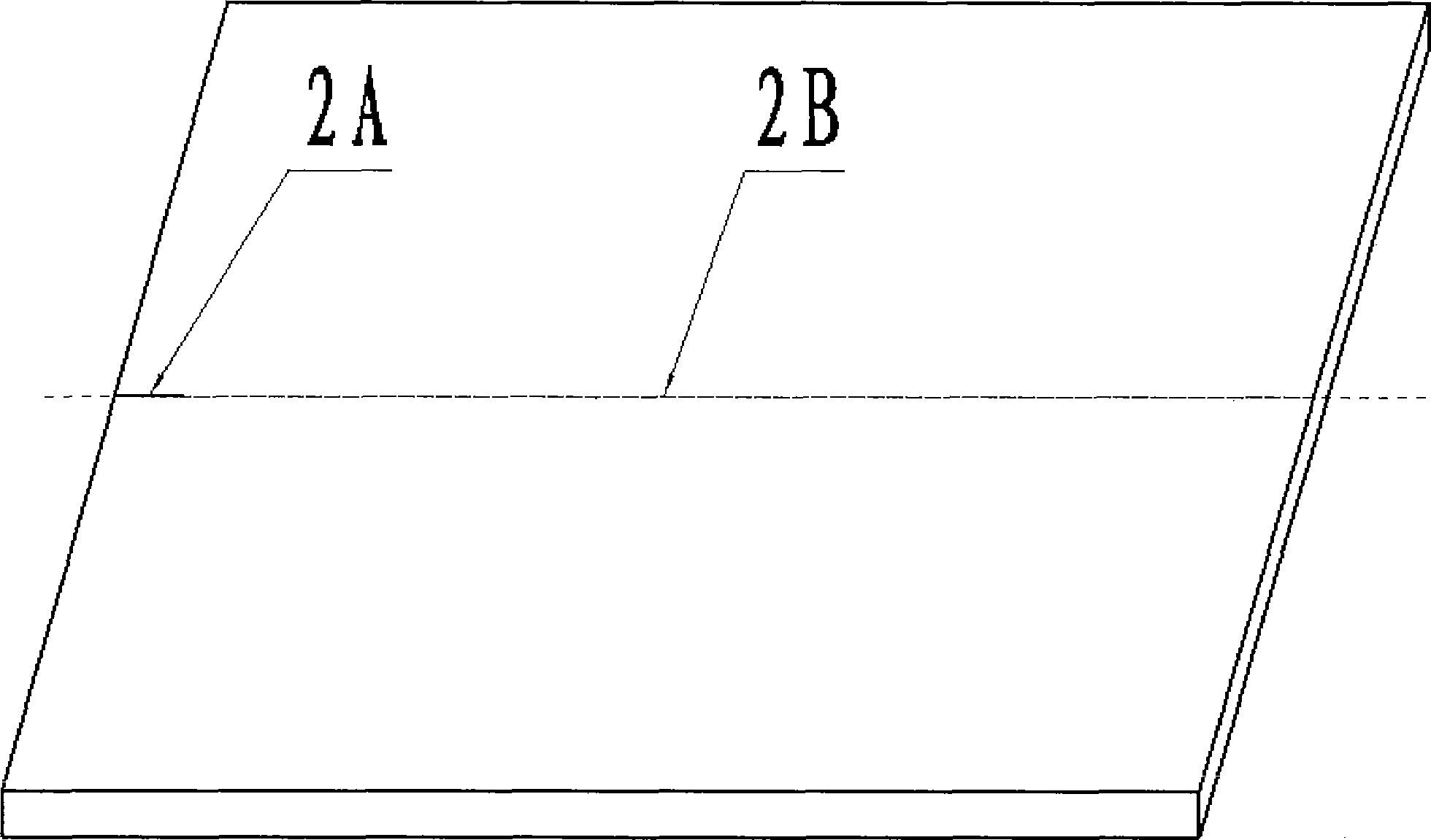

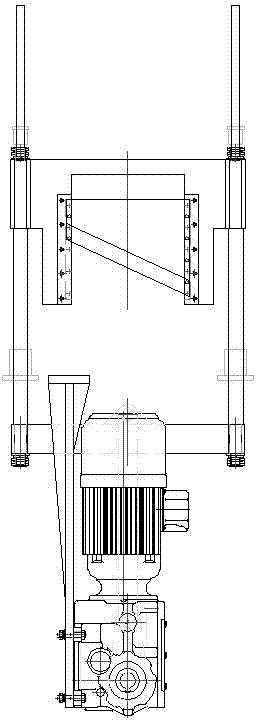

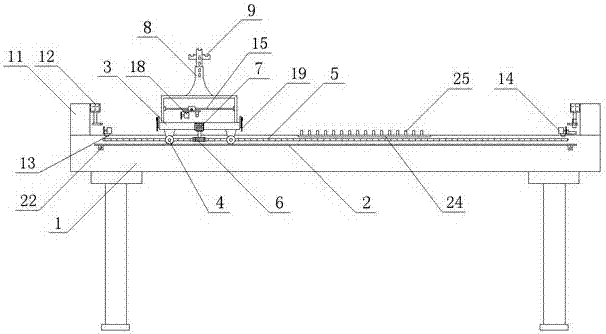

Full-automatic cloth-pulling and tailoring equipment

ActiveCN107190494ARealize unwindingAccurately cut off the materialSevering textilesUltimate tensile strengthAutomation

Disclosed is full-automatic cloth-pulling and tailoring equipment. The full-automatic cloth-pulling and tailoring equipment comprises a cloth-pulling platform (1) and is characterized in that a side face rail (2) is horizontally fixed to the bottom of the side face of the cloth-pulling platform (1), the side face rail (2) is provided with a multifunctional sliding table (3), rollers (4) installed on the multifunctional sliding table (3) are located on the side face rail (2), a side face gear rack (5) is fixed to the position, parallel to the side face rail (2), of the side face of the cloth-pulling platform (1), a stepping motor (7) is installed on the multifunctional sliding table (3), an output shaft of the stepping motor (7) is fixedly provided with a transmission gear (6), and the transmission gear (6) is meshed with the side face gear rack (5). The full-automatic cloth-pulling and cutting equipment is compact in structure, positioning, clamping and cutting of cloth can be automatically completed, after unwinding and cutting are completed, the cloth can be automatically tailored on the cloth-pulling platform, the automation degree is high, the labor intensity of workers is greatly reduced, the tailoring quality and specifications are ensured, and the processing efficiency is high.

Owner:JIHUA 3506 TEXTILE & APPL

Flying shears with high speed and definite length

InactiveCN101032731AImprove work efficiencyHigh synchronization accuracyStock shearing machinesWire rodThrough transmission

The present invention relates to metal wire cutter, and is especially one kind of high speed fixed-length flying shears, which includes two motors, and two independent cam mechanisms. Each of these two cam mechanisms is connected to one of the motors and the shears through transmission mechanism. During cutting, these two motors may be controlled separately to change speeds and thus the cut length without need of stop. The present invention has high work efficiency, reduced labor strength, synchronous operations in two direction and high cut quality.

Owner:大连立达工业设备有限公司

Foaming plate cutting device

ActiveCN108177182AImplement automatic transferAvoid connectionMetal working apparatusGear wheelAgricultural engineering

The invention relates to a foaming plate cutting device. The foaming plate cutting device comprises a rack; the rack is rotatably connected with a first straight gear and a second straight gear; the first straight gear is connected with a first transfer roller, and the second straight gear is connected with a second transfer roller; the first transfer roller is connected with a first crank, and the second transfer roller is connected with a second crank; a third transfer roller and a fourth transfer roller are rotatably connected to the rack; the third transfer roller is connected with a thirdcrank, and the fourth transfer roller is connected with a fourth crank; a first connecting rod is connected between the first crank and the third crank, the two ends of the first connecting rod are rotatably connected to the first crank and the third crank correspondingly, and the first connecting rod is provided with a first cutting knife; a second connecting rod is connected between the secondcrank and the fourth crank, the two ends of the second connecting rod are rotatably connected to the second crank and the fourth crank correspondingly, and the second connecting rod is provided with asecond cutting knife; and a collecting mechanism and a correcting mechanism are arranged on the rack. According to the scheme, moving of a foaming plate and cutting of the cutting knives are conducted simultaneously.

Owner:重庆翰邦汽车配件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com