Patents

Literature

327results about How to "Avoid affecting production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

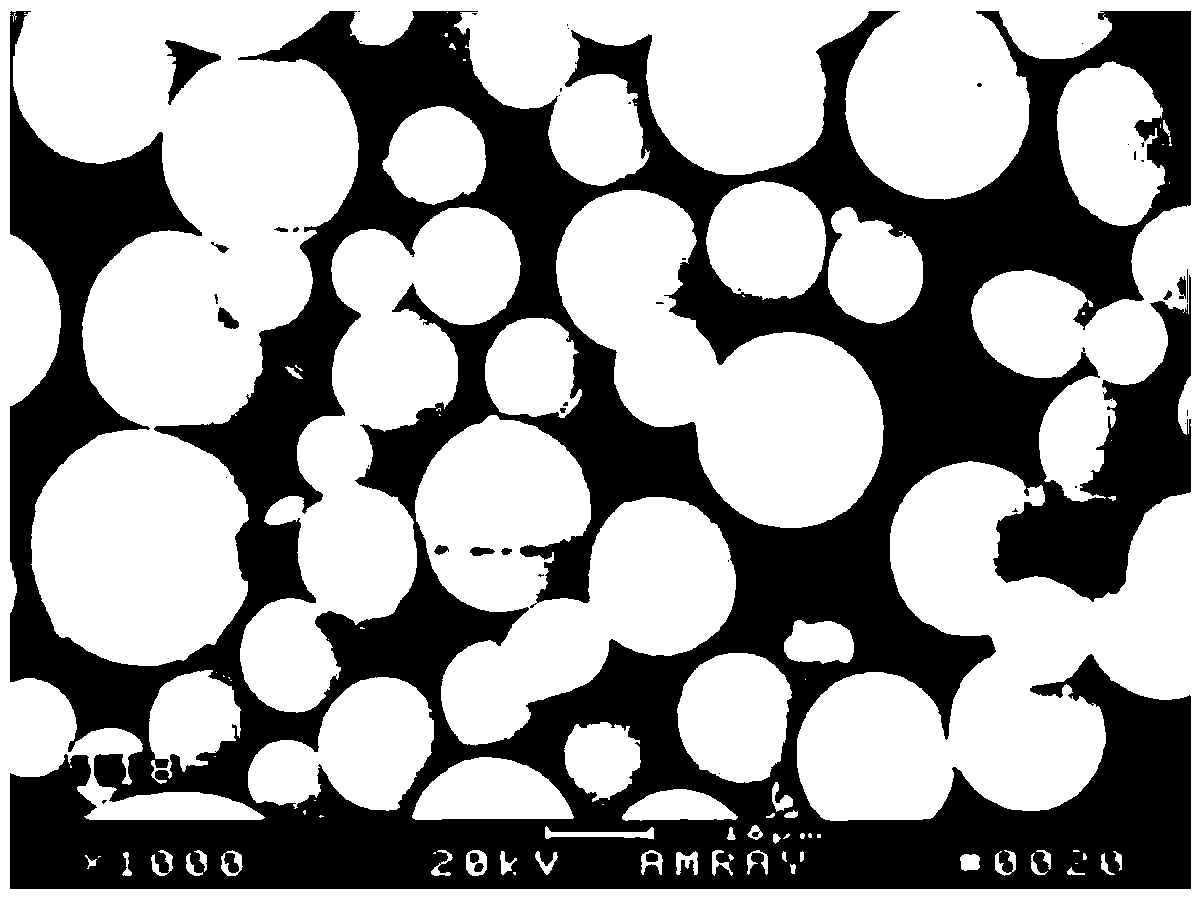

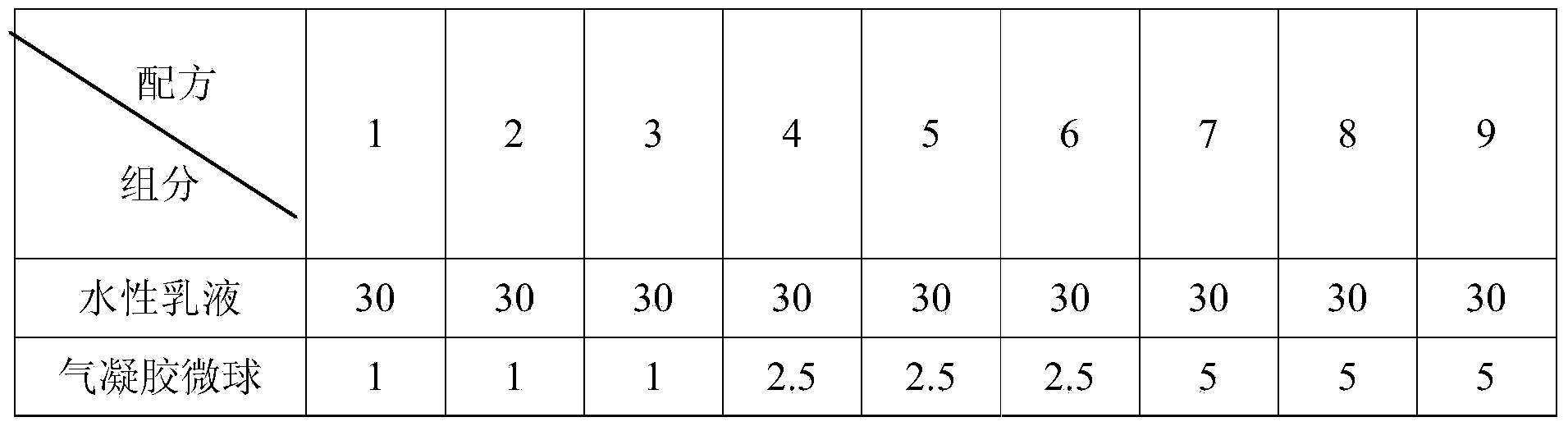

Microspherical SiO2 aerogel compound heat-insulating/warm-keeping external wall paint and preparation method thereof

InactiveCN103709868ALow thermal conductivityImprove insulation effectSilicaPolyurea/polyurethane coatingsWater basedEmulsion

The invention discloses microspherical SiO2 aerogel compound heat-insulating / warm-keeping external wall paint and a preparation method thereof. The paint comprises the following components: 1-20 parts by weight of microspherical SiO2 aerogel powder, 10-20 parts by weight of titanium white, 10-20 parts by weight of water-based emulsion, 20-35 parts by weight of filler and 20-30 parts by weight of other paint assistant. According to the invention, the microspherical SiO2 aerogel and the titanium white are compounded, so that the paint has low heat transfer coefficient and high sunlight reflectivity, thus ensuring that the paint has excellent heat-insulating / warm-keeping property; meanwhile, the directly prepared hydrophobic SiO2 aerogel is micron-level microspheres of 1-50 mu m, thus avoiding causing the problems on defoaming and flowability to paint production in the efflorescence process of large aerogel; and the addition of the hydrophobic microspherical SiO2 greatly enhances the brushability of the paint.

Owner:GUANGZHOU TAIXIANG IND NEW MATERIAL TECH XINFENG CO LTD

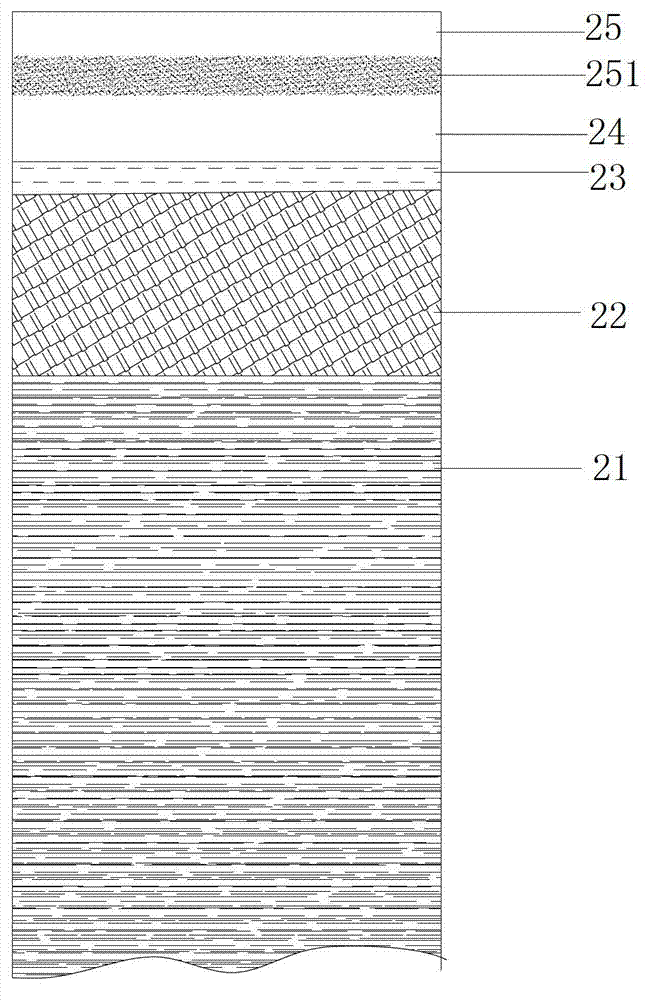

Reclamation method for sunk paddy field caused by mining in mountainous regions

ActiveCN103039147AImprove applicabilityEasy to operateSoil lifting machinesSoil-working methodsWater leakageSoil science

The invention relates to a reclamation method for a sunk paddy field caused by mining in mountainous regions and belongs to the technical field of improvement and utilization of environment, ecology and damaged fields. The method includes: performing topsoil stripping to fissured positions where fissures are created by mining sinking and lead to water leakage of the paddy field; covering water holding materials on fissured areas after topsoil stripping; compacting the covered water holding materials, pouring slurry and standing; performing topsoil backfilling and grinding to the fissured areas after slurry pouring and standing, and flattening to enable the fissured areas to be a whole with pieces of the paddy field around the fissured areas; and irrigating, nourishing and improving the paddy field after backfilling and grinding. By the method, the cultivation land where the fissures are created by mining sinking and lead to water leakage of the paddy field can restore the paddy field utilization mode and reach production level of a normal paddy field as soon as possible, a stable self-maintaining farmland ecological system can be formed, a paddy field protecting system can be formed, soil microbial content can be increased, physicochemical property of soil can be improved, and benign farmland ecological system circulation can be formed.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

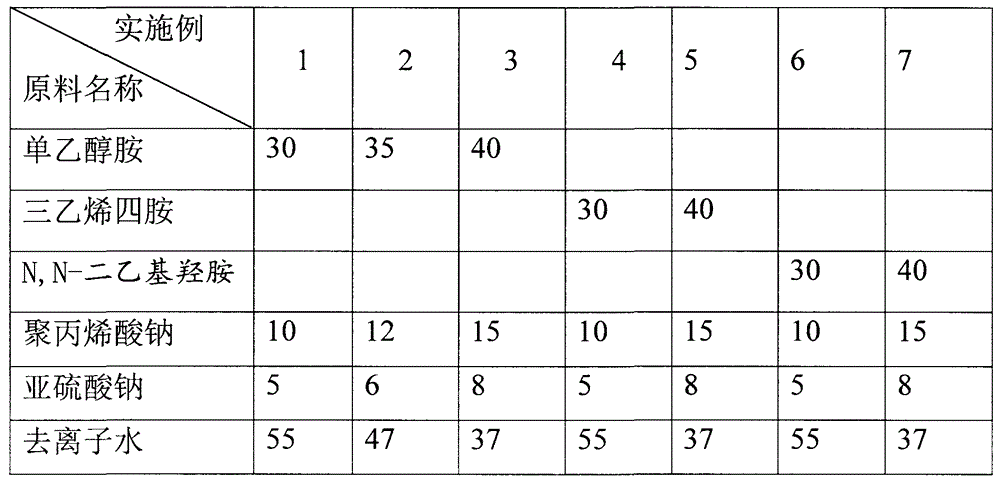

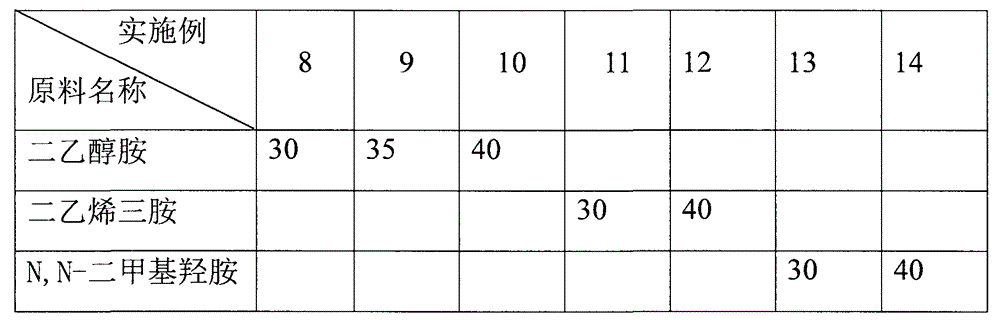

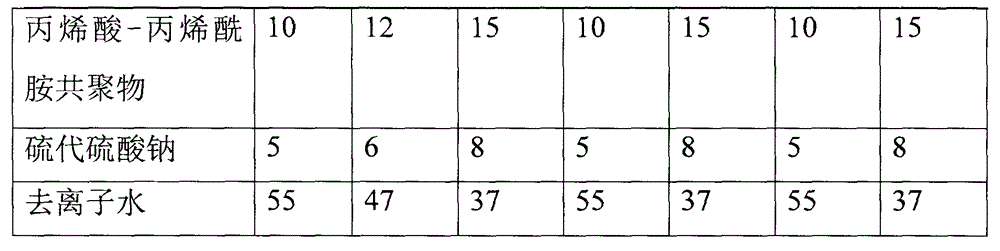

Butter inhibitor for MTO (methanol to olefins) device alkaline washing towers and preparation method thereof

InactiveCN105884566AStable stateImprove performanceHydrocarbon purification/separationHydrocarbonsSolubilityStable state

The invention discloses a butter inhibitor for MTO (methanol to olefins) device alkaline washing towers and a preparation method thereof, belonging to the field of petrochemical industry. The butter inhibitor is characterized by comprising (a) 20-50 wt% of polymerization inhibitor, (B) 5-20 wt% of dispersing agent, (C) 2-10 wt% of antioxidant and (D) 20-73 wt% of solvent. The preparation method comprises the following steps: sequentially adding the polymerization inhibitor, dispersing agent, antioxidant and solvent into a container according to percentage by weight under ordinary pressure, and stirring for 20-60 minutes to obtain the butter inhibitor for MTO device alkaline washing towers. Various components of the inhibitor have favorable water solubility, so that the inhibitor prepared according to the proportion has uniform and stable state and reliable performance. Besides, the inhibitor has the advantages of accessible raw materials and simple production process, and is convenient to use.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

Coal mining method for co-mining gas in mine

ActiveCN102061918ALower oxygen levelsSuppress spontaneous combustionUnderground miningSurface miningHigh concentrationHigh pressure

The invention relates to a coal mining method for co-mining gas in a mine. A method for injecting nitrogen in a sealed manner is adopted to close an upper drift and a lower drift of a stope face to ensure that the concentration of gas in a closed space is over 20%, the concentration of oxygen is lower than 12%, so that the explosive hazard of the gas is eliminated, and high-concentration gas in a roadway is drained so as to be utilized. A safety pressure-relief roadway needs to be remained in the mine with dangers of coal and gas outburst, and is used for releasing high-pressure gas generated by coal and gas outburst, and improving disaster resistant capability of the mine. An air regulating system is arranged in the closed space for regulating air, and a worker operates in the closed space under the condition that the safety protection is well done. Due to adoption of the method, the problem of gas explosion is solved fundamentally, the utilization ratio of gas is improved, fire disasters of the coal mine are eliminated fundamentally, the oxidation corrosion of various metal equipments is reduced, and simultaneously the equipment does not have anti-explosion requirements. As workers breathe air carried per se, the occurrence of respiratory occupational diseases is avoided. Therefore, the coal mining method for co-mining gas has extremely large popularization value.

Owner:CHINA UNIV OF MINING & TECH

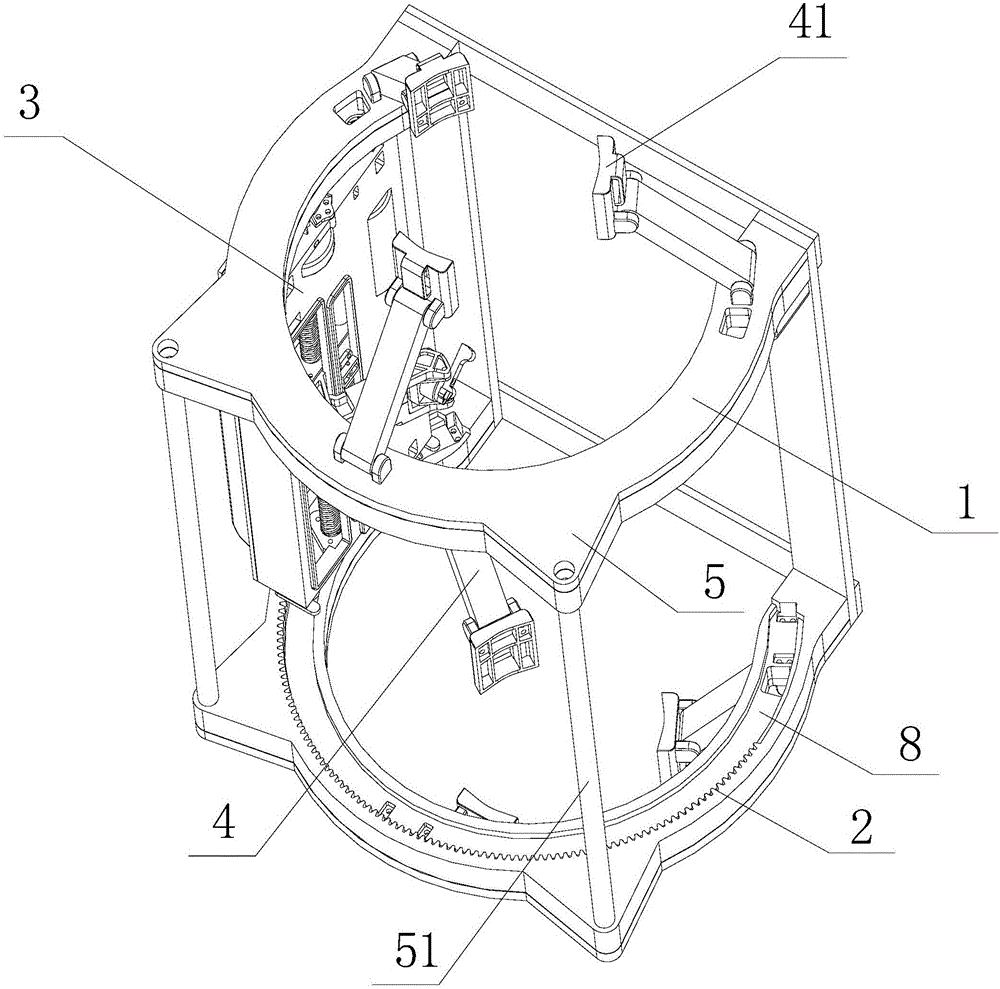

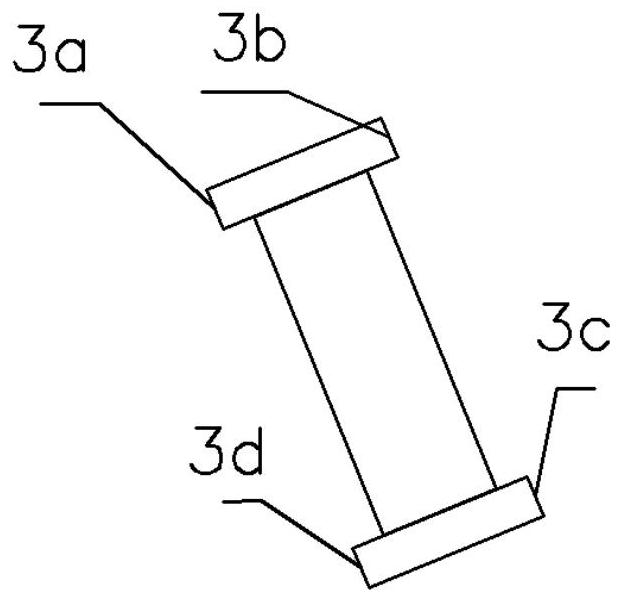

Rubber tapping machine and rubber tapping method

ActiveCN106034978ASolve labor intensitySolve the problem of insufficient fineness of manual tappingForestryEngineeringUltimate tensile strength

The invention discloses a rubber tapping machine and a rubber tapping method. The rubber tapping machine comprises a fixation frame, the top surface and the bottom surface of the fixation frame are respectively provided with annular planet gears in opposite arrangement, a knife rest assembly is installed between the top surface and the bottom surface of the fixation frame, the knife rest assembly is internally provided with a leading screw along a vertical direction, a rubber tapping assembly is installed on the leading screw and can be driven by the leading screw to vertically move along the leading screw, the rubber tapping assembly comprises a knife rest which is installed on the leading screw and can move vertically along the leading screw, one side of a cutter head swing arm is hinged to the knife rest through a torsion spring, the other side is hinged to a swing seat, the swing seat is provided with a cutter head angle adjustment seat, the top end of the cutter head angle adjustment seat is provided with a cutter head and a knife depth limiting member, and the knife rest is also provided with a knife collecting assembly which can overcome an elastic force of the torsion spring to draw the cutter head swing arm to the knife rest. The rubber tapping machine disclosed by the invention replaces labor with automatic machinery, realizes unmanned automatic rubber tapping for rubber trees, and solves the problems of large manual rubber tapping labor intensity and low manual rubber tapping precision to the maximum degree.

Owner:NINGBO CIHEVEA TECH CO LTD

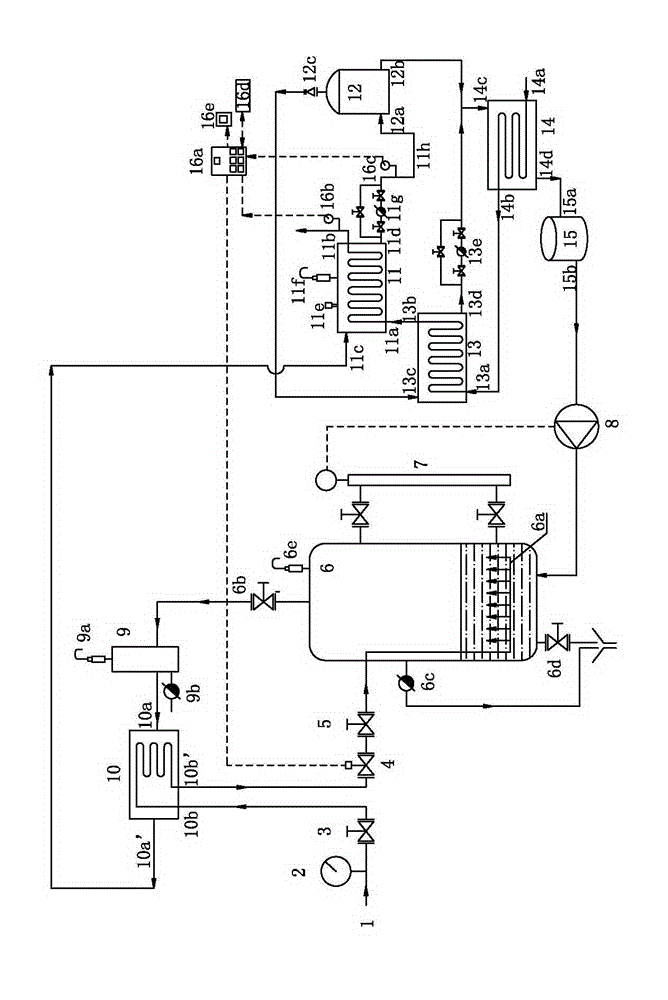

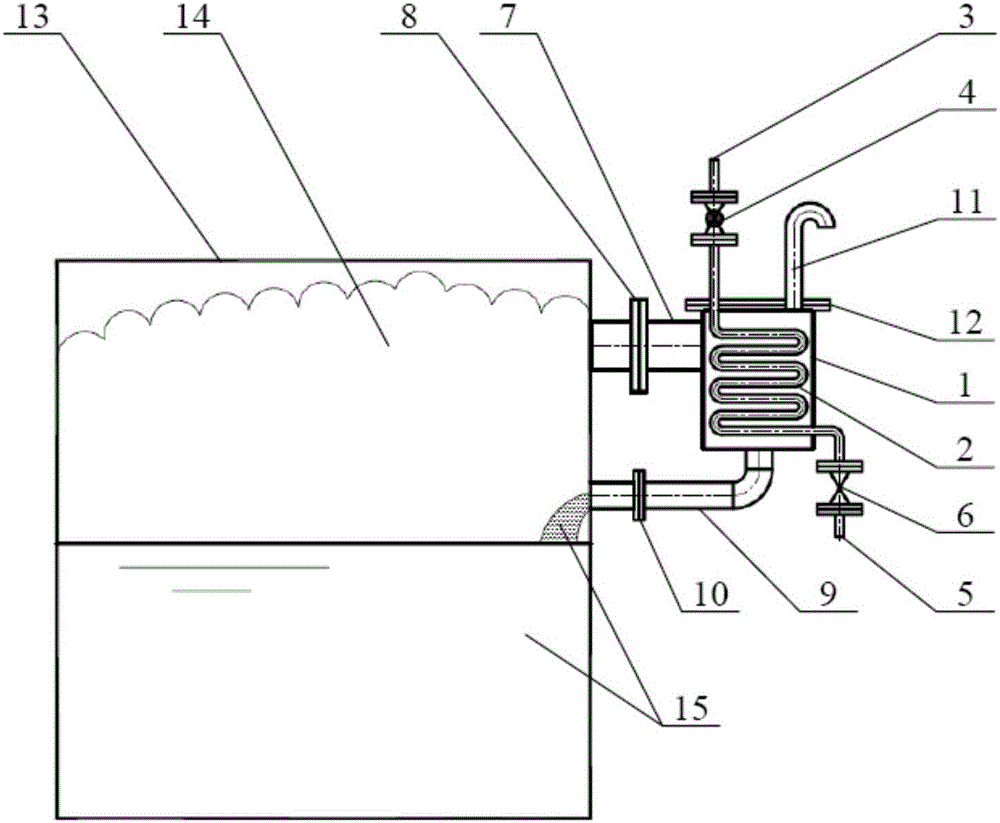

Outer drying steam triple-effect heat exchange system

InactiveCN102878547AIncrease moisture contentReduce moisture contentSuperheating controlWater bathsDry heat

The invention relates to an outer drying steam triple-effect heat exchange system. A flow divider is arranged in the liquid phase space of a water-bath-type saturated steam generator, and a steam discharge pipeline of the flow dividier is sequentially provided with a steam water separator and a steam drying heat exchanger; overheated steam enters the flow divider through a pressure control valve; wet saturated steam from the saturated steam generator is heated into dry saturated steam by overheated steam; the dry saturated steam enters a main steam heat exchanger and becomes high-temperature condensation water after materials are heated for the third time; flash steam of the high-temperature condensation water heats the materials in the flash steam heat exchanger for the second time; condensed flash steam enters the condensation water heat exchanger; the condensation water in the high-temperature condensation water continuously releases sensible heat to heat the material for the first time; the condensation water after temperature reduction enters a water collecting tank, and is pumped into the saturated steam generator by a water supplying pump; and the aperture of the pressure control valve is regulated by a PLC (programmed logic controller) according to the material outlet temperature. The system achieves cascading utilization of steam heat energy, guarantees that the steam heat energy can be used up, and improves the energy efficiency.

Owner:YIHENG ENERGY SAVING TECH JIANGSU

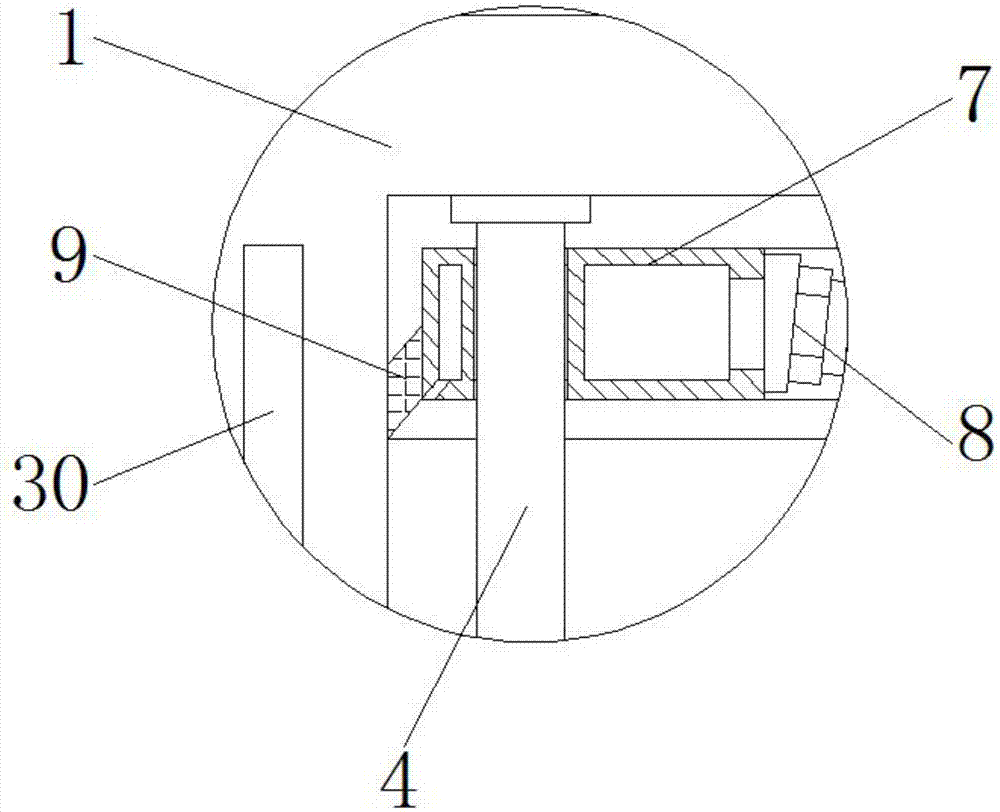

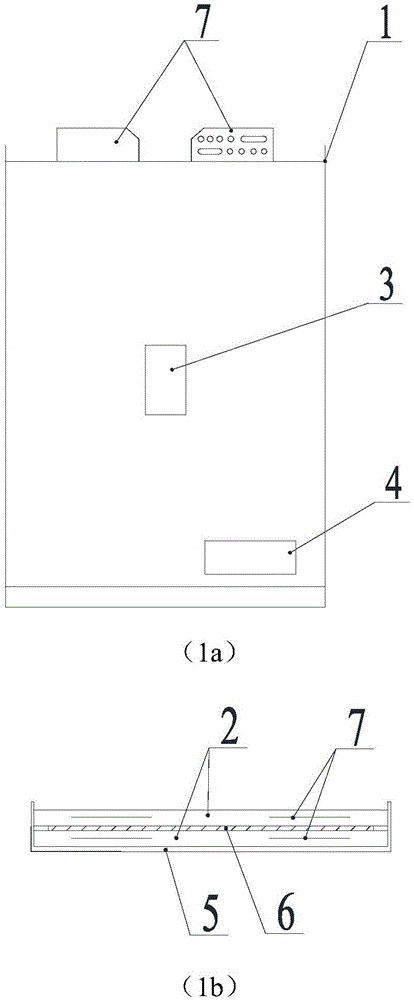

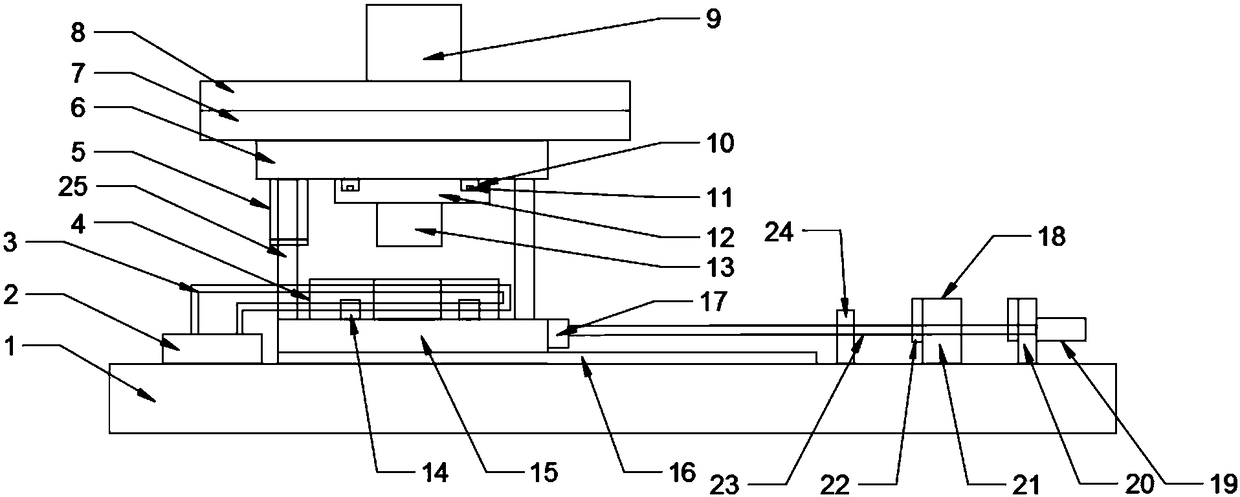

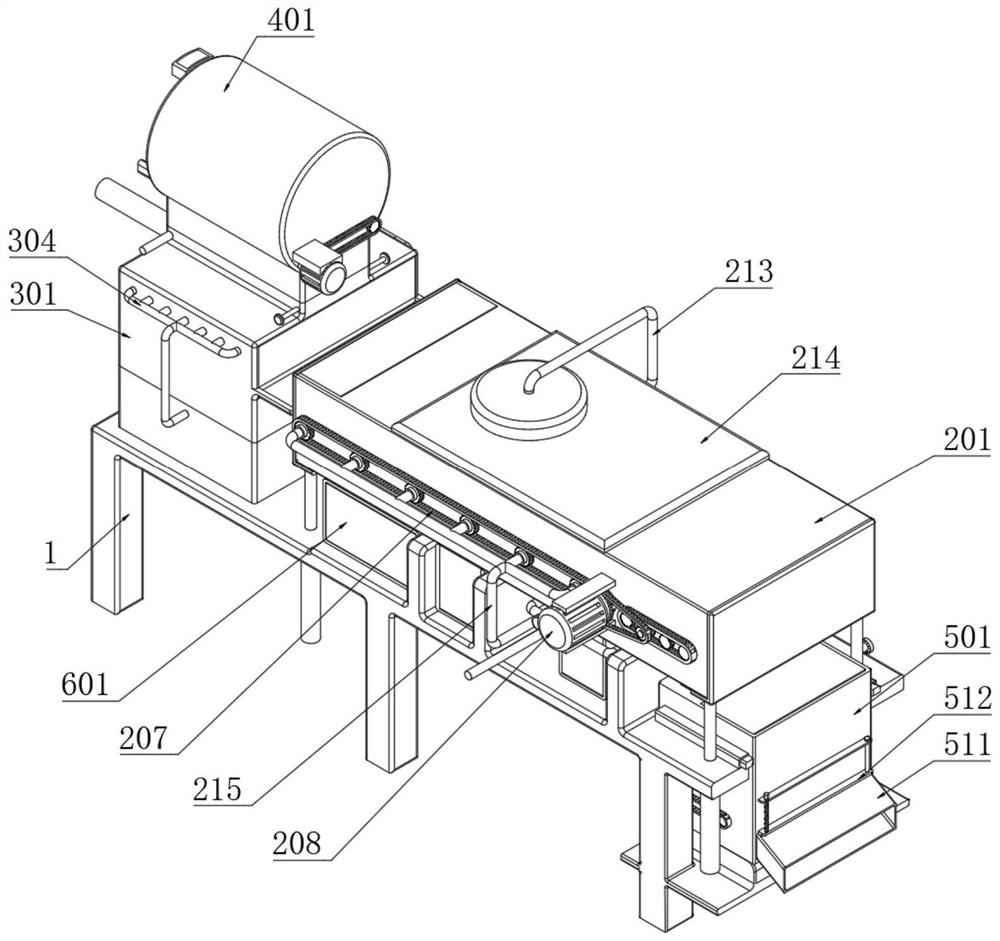

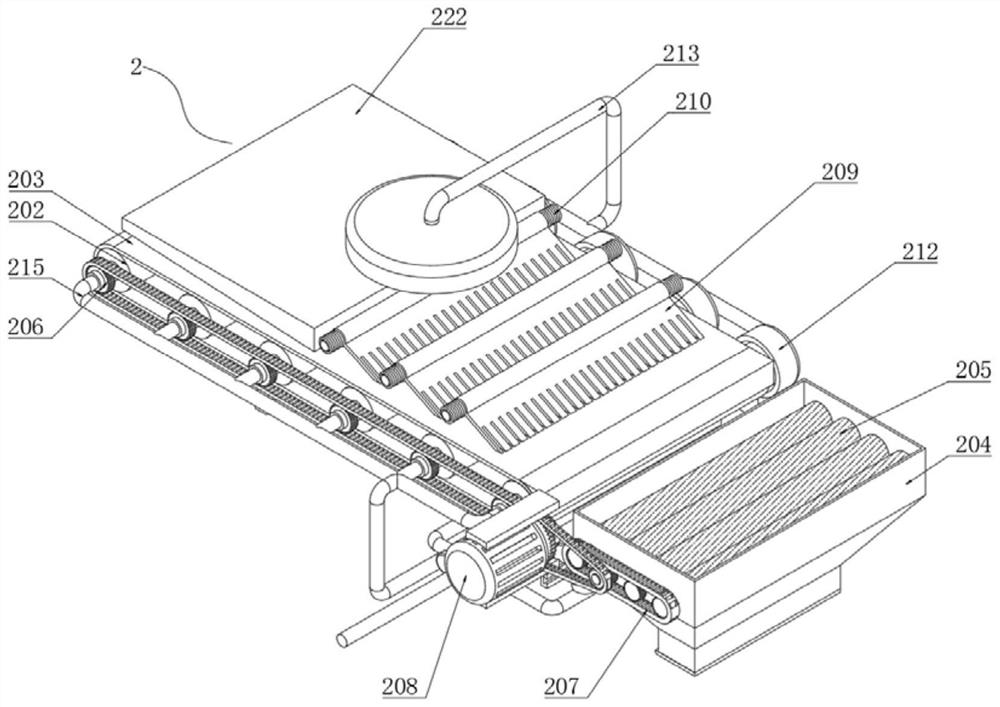

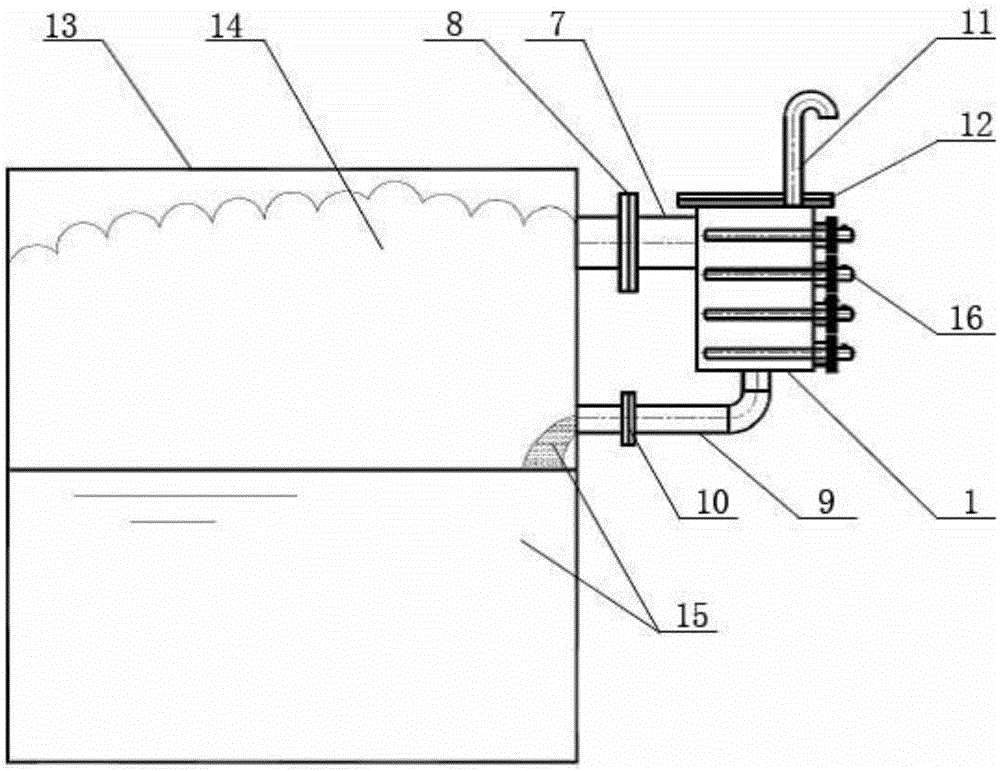

Lubricating oil heating and stirring device capable of being automatically cleaned on basis of large equipment

InactiveCN107998945AAvoid affecting productionEasy to operateTransportation and packagingRotary stirring mixersSprayerPulp and paper industry

The invention discloses a lubricating oil heating and stirring device capable of being automatically cleaned on the basis of large equipment, and relates to the technical field of automobile accessoryproduction. The device comprises a box, and a stirring bin and a machine bin are sequentially arranged in the box from top to bottom; a guide column is fixedly arranged on the left side of the stirring bin, and a screw rod is rotationally connected to the top of the right side of the stirring bin; the bottom of the screw rod penetrates through the bottom of the stirring bin and extends into the machine bin, and the bottom of the screw rod is rotationally connected with the bottom of the machine bin; a first bevel gear is fixedly arranged on the surface of the screw rod and located in the machine bin. According to the lubricating oil heating and stirring device capable of being automatically cleaned on the basis of the large equipment, a high-pressure pipe can be moved up and down throughthe screw rod, a high-pressure sprayer can spray out chemicals at a high speed, and the inner wall of the stirring bin and spiral stirring blades can be flushed; oil stains on the inner wall can be scraped by a scraping plate, the inner wall can be kept clean, and the situation that residual lubricating oil in the box is not cleaned up for a long time and goes bad and accordingly product next timeis affected is avoided; the device is easy to operate and saves time and labor..

Owner:张文凯

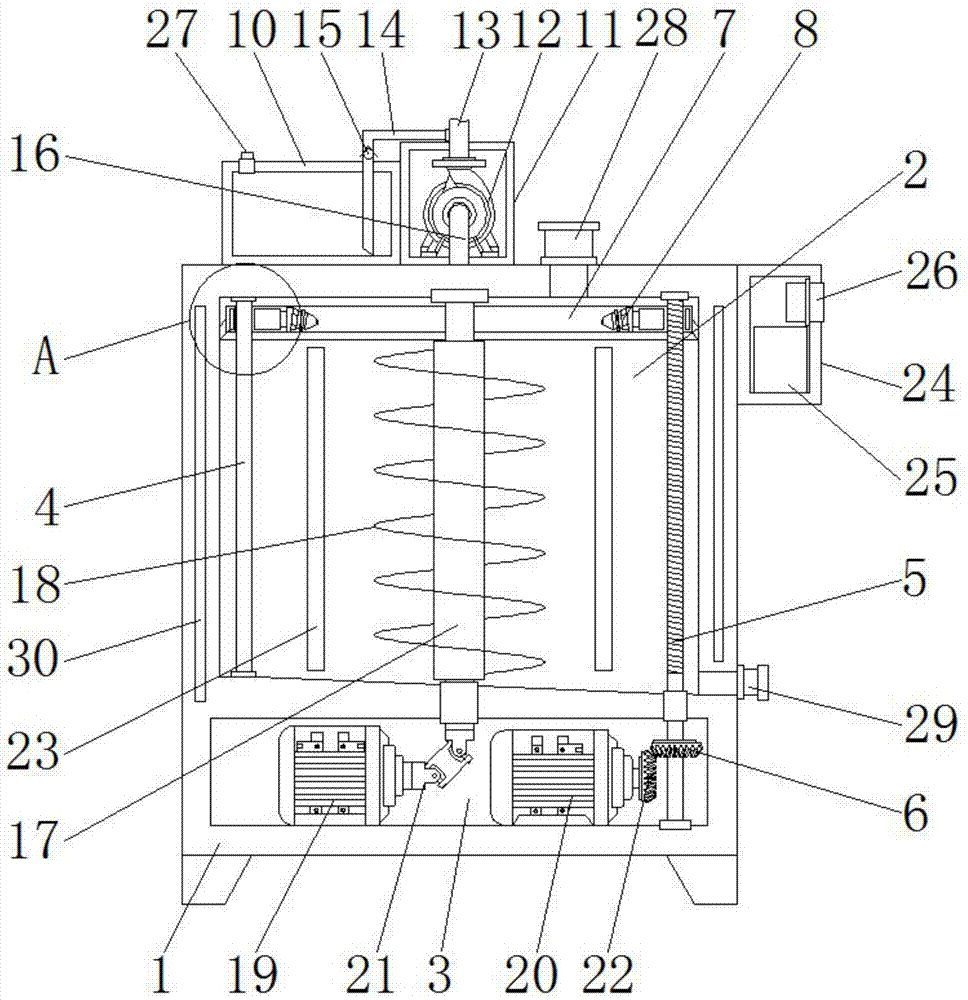

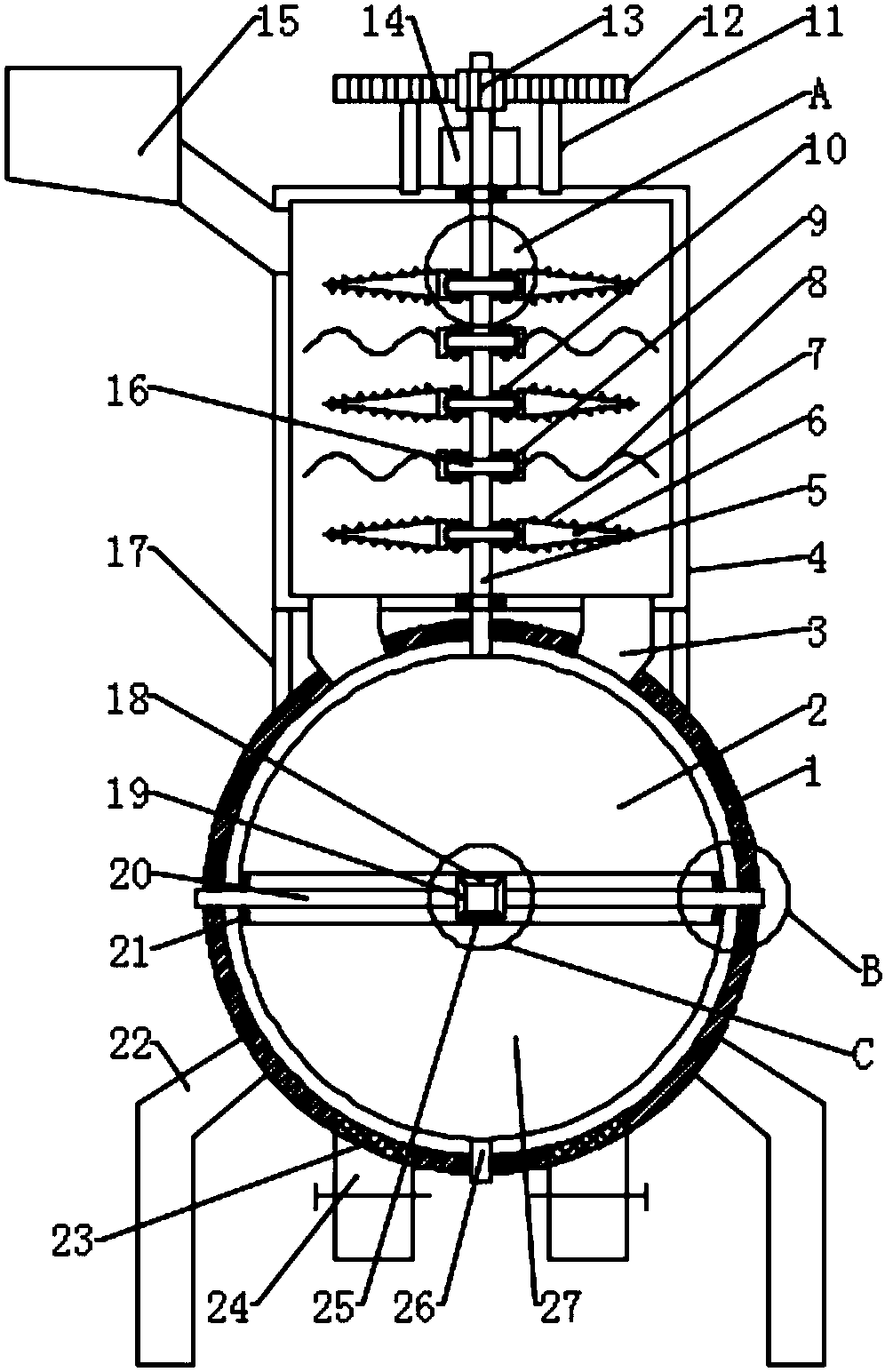

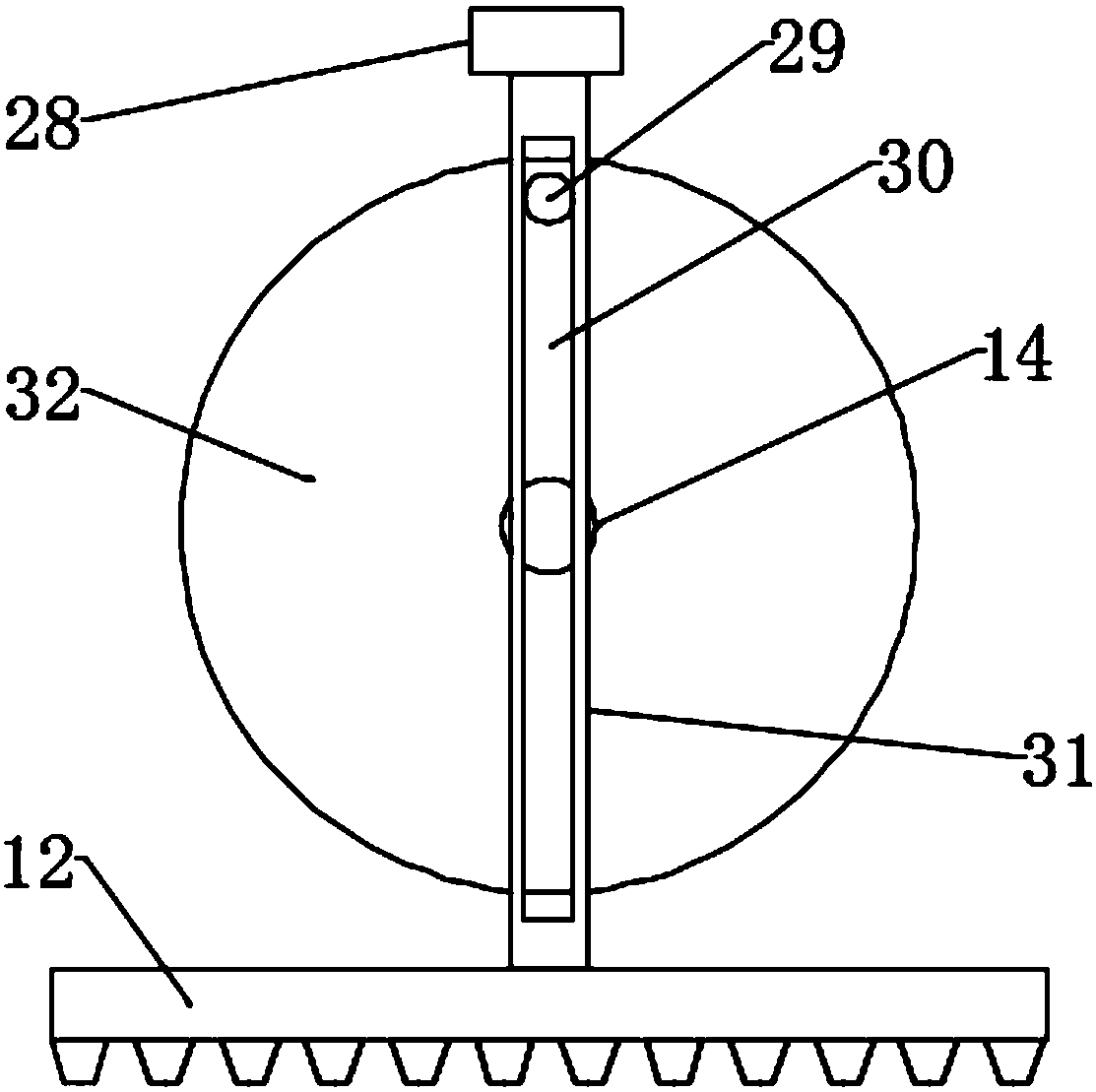

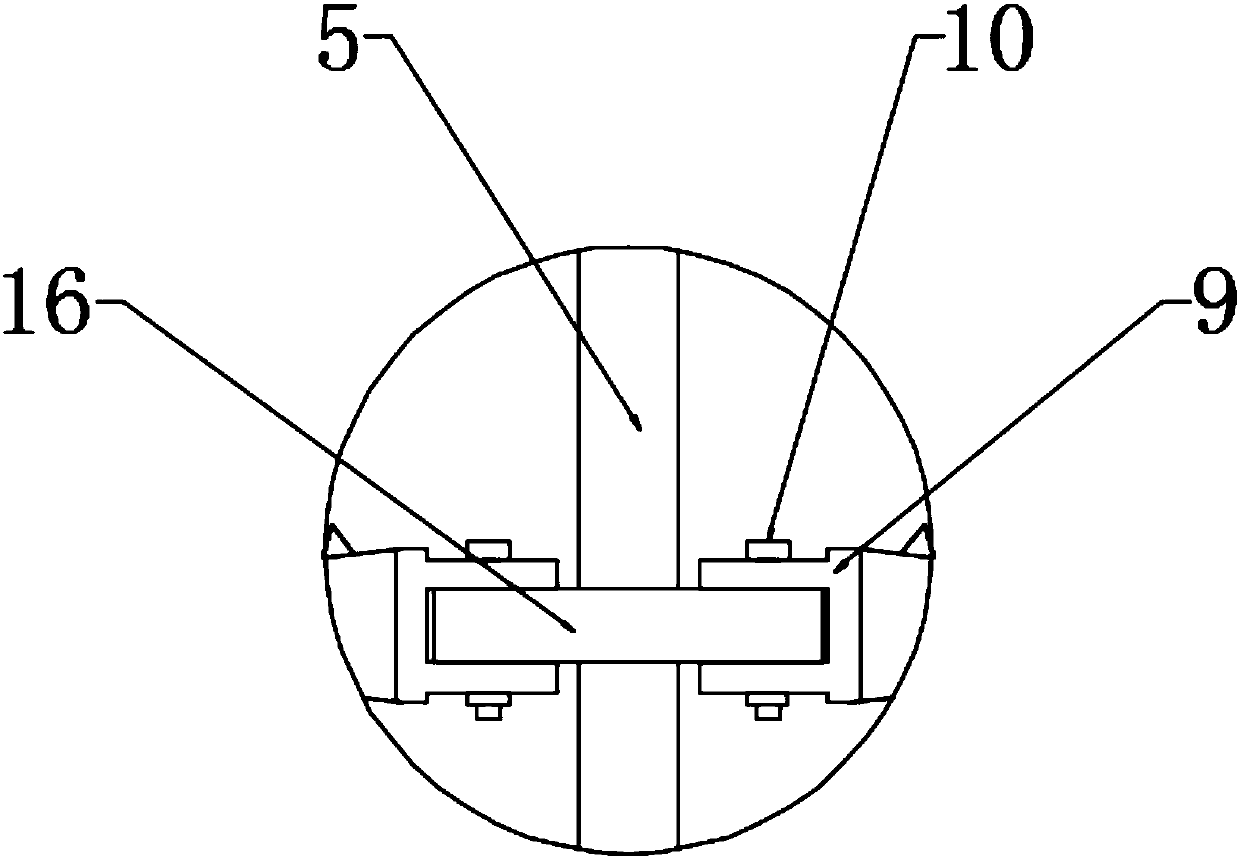

Smashing and grinding all-in-one machine of traditional Chinese medicine

PendingCN107716068AEasy maintenanceImprove crushing efficiencyGrain treatmentsCircular discGear wheel

The invention discloses a smashing and grinding all-in-one machine of traditional Chinese medicine. The smashing and grinding all-in-one machine includes a grinding shell body, a smashing tube, a gear, a gear rack, a moving rod, a circular disk, a motor, a grinding shell body, an upper grinding hemisphere, a lower grinding hemisphere, an annular baffle, a first bevel gear, a second bevel gear anda third bevel gear. The smashing and grinding all-in-one machine is provided with the motor, the circular disk, the moving rod, the gear rack and the gears. By driving positive and negative rotation of a conical smashing blade and a spiral smashing blade in a matched mode, smashing efficiency is high. The conical smashing blade and the spiral smashing blade are installed in a staggered mode, and the traditional Chinese medicine can be smashed through different smashing modes; the smashing efficiency is improved; the smashing and grinding all-in-one machine is provided with a U-shaped seat, bolts and a flange plate; the conical smashing blade and the spiral smashing blade are dismounted through the bolts; a worker can repair and maintain conveniently; the smashing and grinding all-in-one machine is provided with the upper grinding hemisphere, the lower grinding hemisphere, the first bevel gear, the second bevel gear and a third bevel gear; and by driving negative rotation of the upper grinding hemisphere and the lower grinding hemisphere in a matched mode, the grinding efficiency is improved.

Owner:ZHENGZHOU UNIV

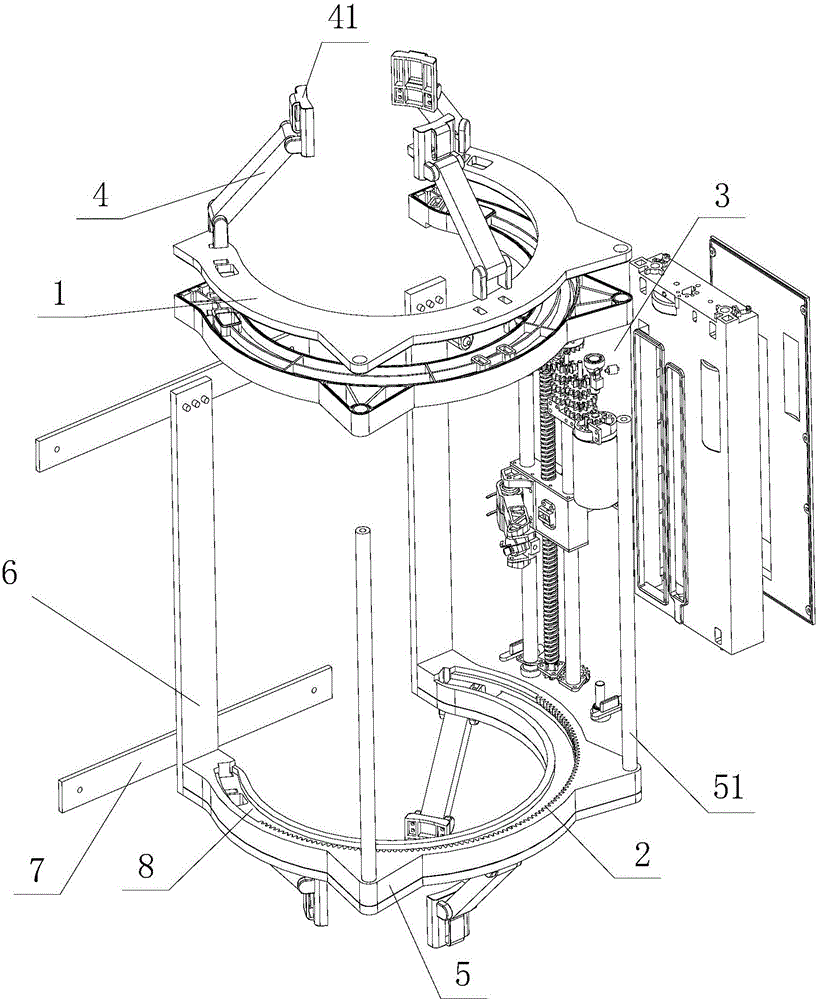

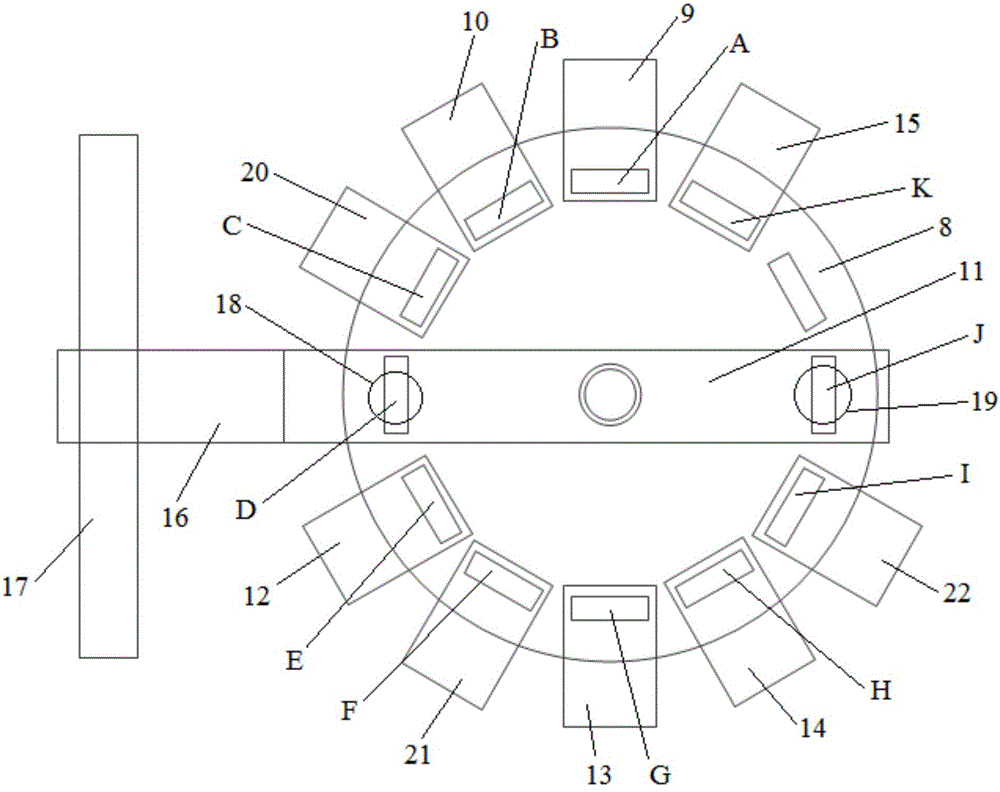

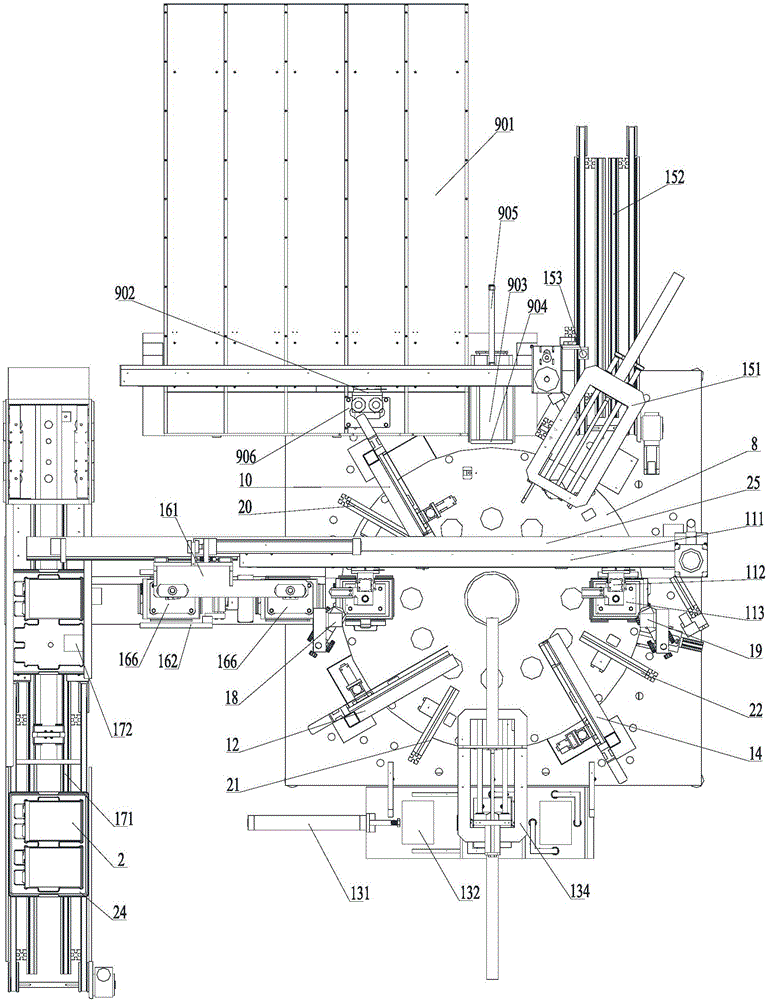

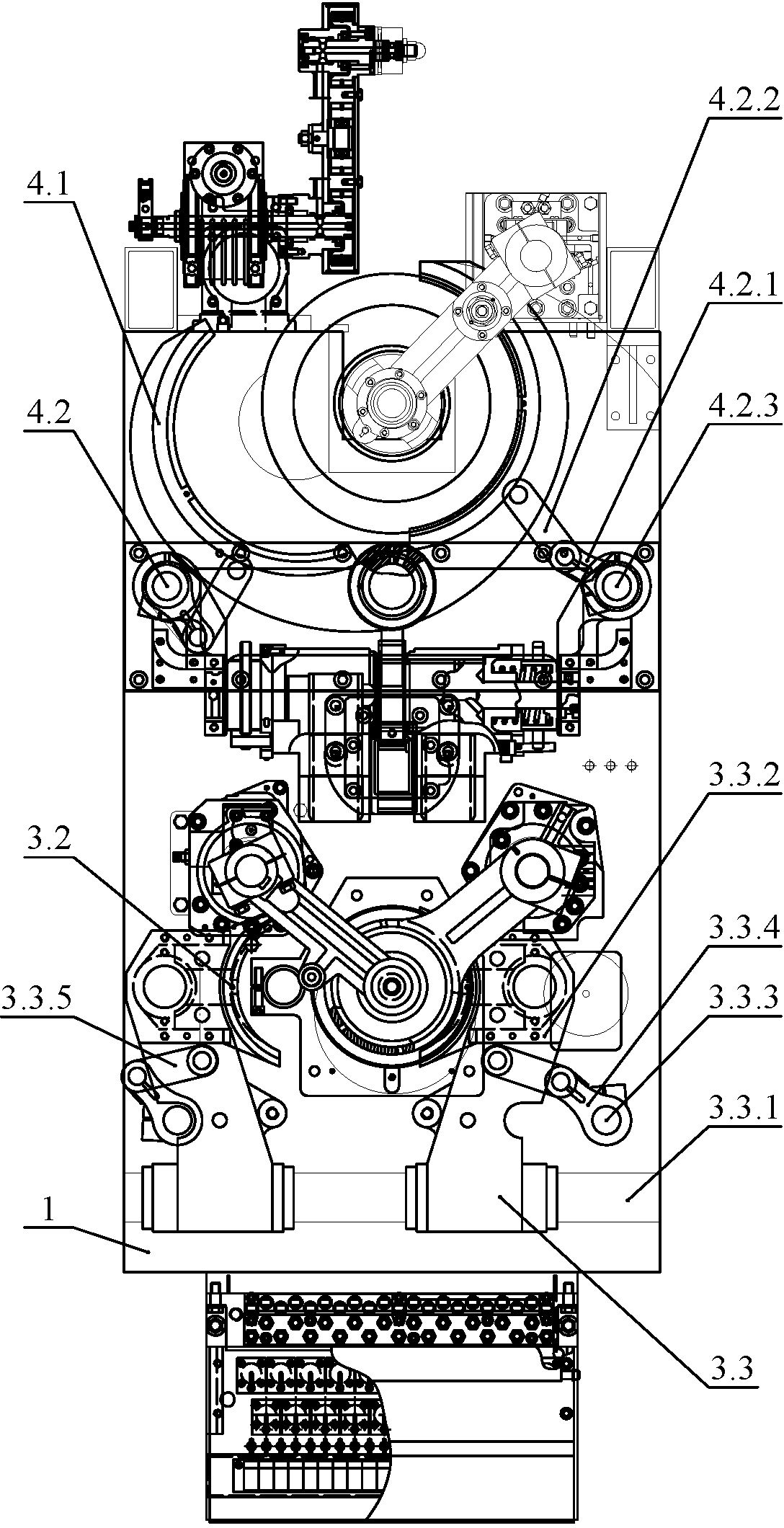

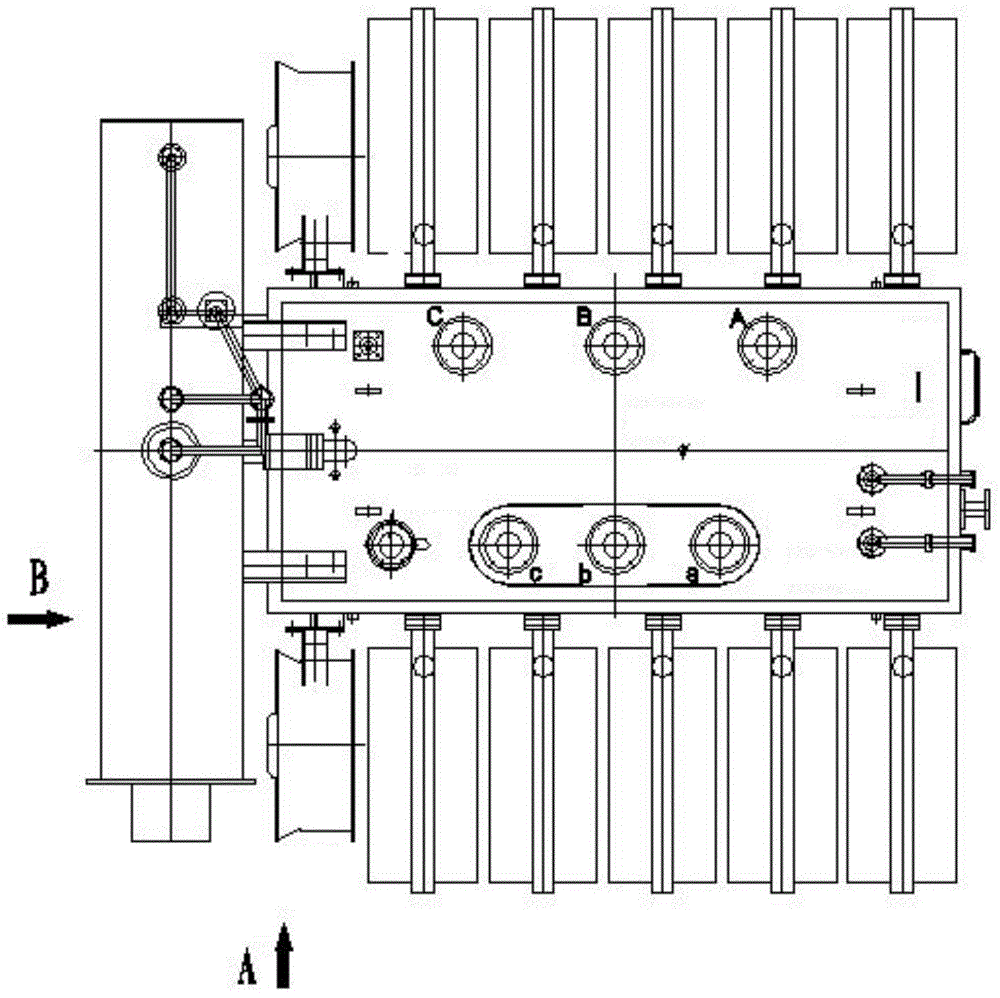

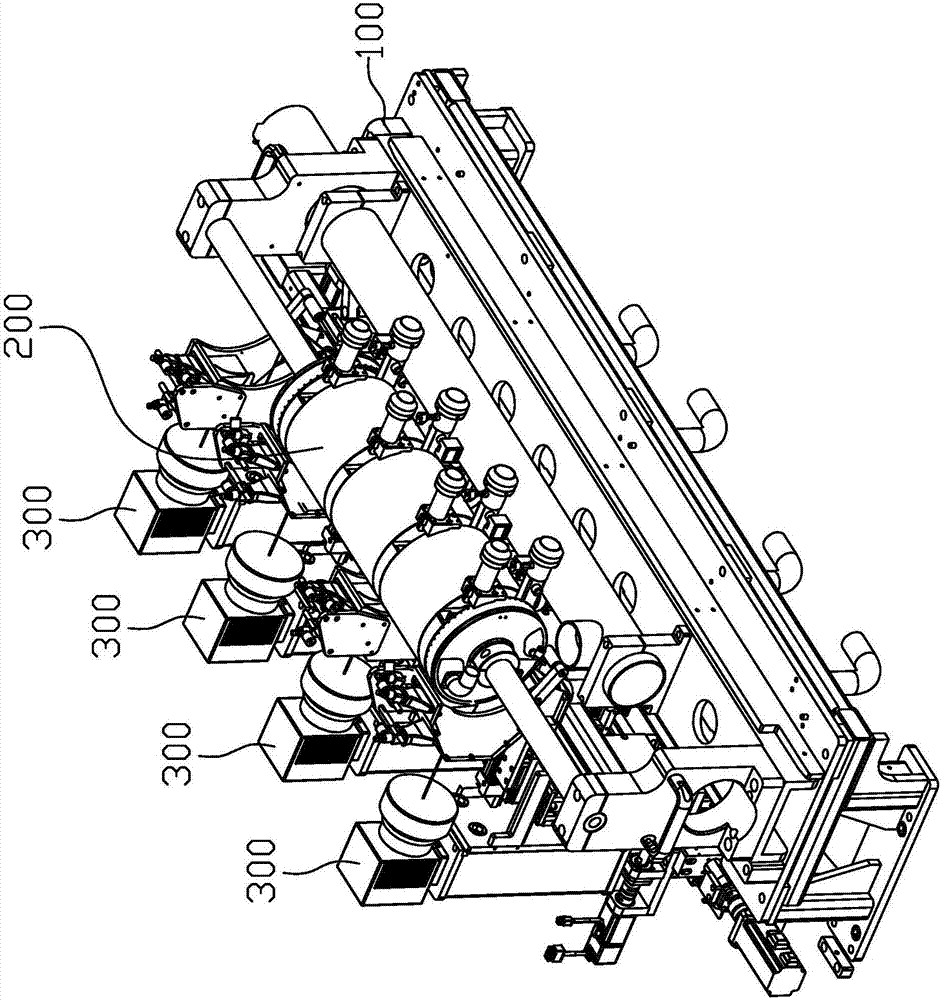

Multi-station rotary disc type machine for automatically installing cell into box

ActiveCN105958102AIncrease productivityHigh degree of automationAssembling battery machinesFinal product manufactureState of artCell turnover

The invention relates to a multi-station rotary disc type machine for automatically installing a cell into a box. The machine comprises an operational rotary table, a radiating plate feeding mechanism arranged on a radiating plate feeding station, a radiating plate glue coating assembly arranged on a radiating plate glue coating station, a cell feeding mechanism which is erected above a first cell feeding station and a second cell feeding station, a cell glue coating assembly arranged on a cell glue coating station, a thermal insulation pad feeding mechanism arranged on a thermal insulation pad feeding station, a thermal insulation pad glue coating assembly arranged on a thermal insulation pad glue coating station, a finished product discharging mechanism arranged on a finished product discharging station, a cell turnover mechanism, and a cell transferring mechanism, wherein the operational rotary table is equipped with the radiating plate feeding station, the radiating plate glue coating station, the first cell feeding station, the cell glue coating station, the thermal insulation pad feeding station, the thermal insulation pad glue coating station, the second cell feeding station and the finished product discharging station. Compared with the prior art, the multi-station rotary disc type machine for automatically installing the cell into the box has the advantages of high production efficiency, high assembling precision, convenience in data retroactivity, and the like.

Owner:上海捷新动力电池系统有限公司

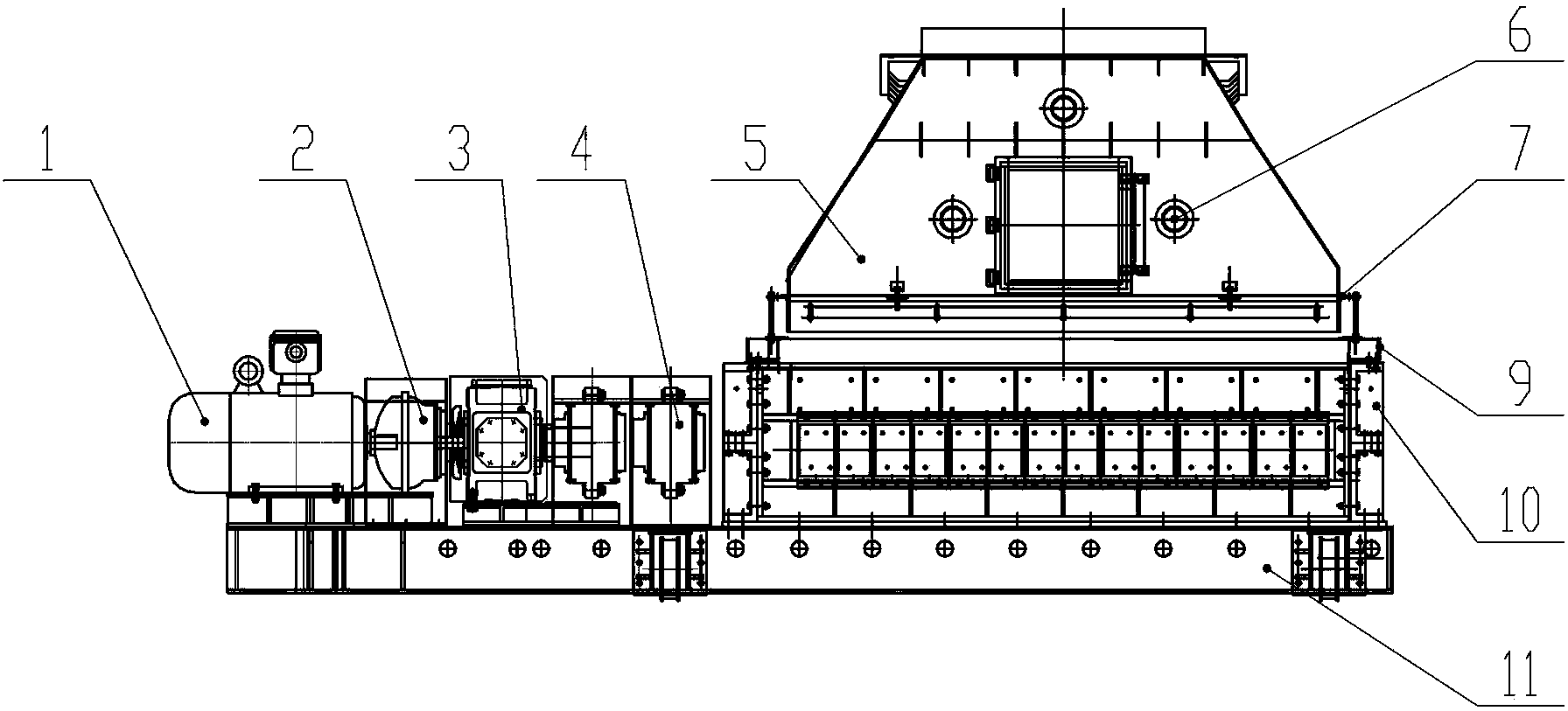

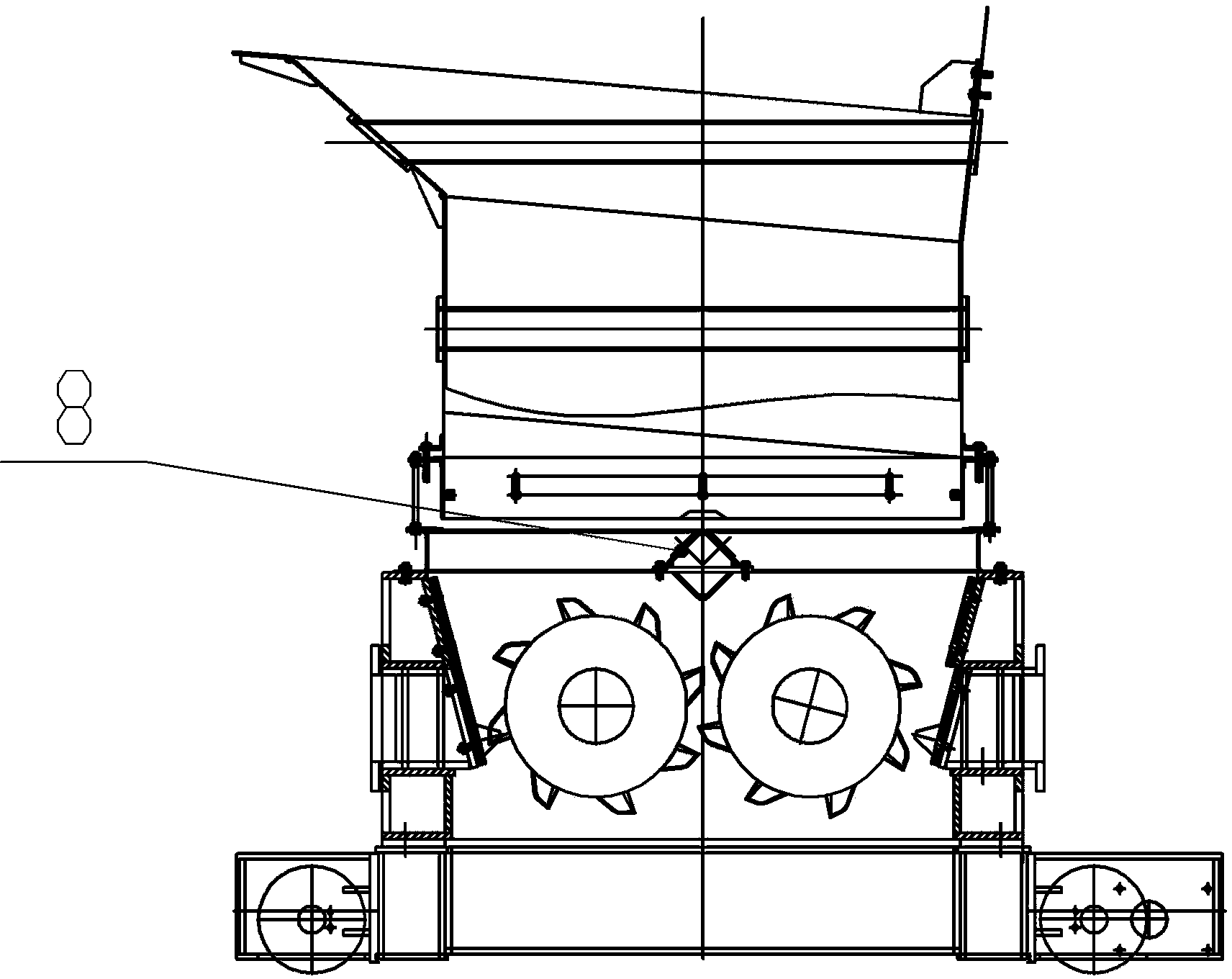

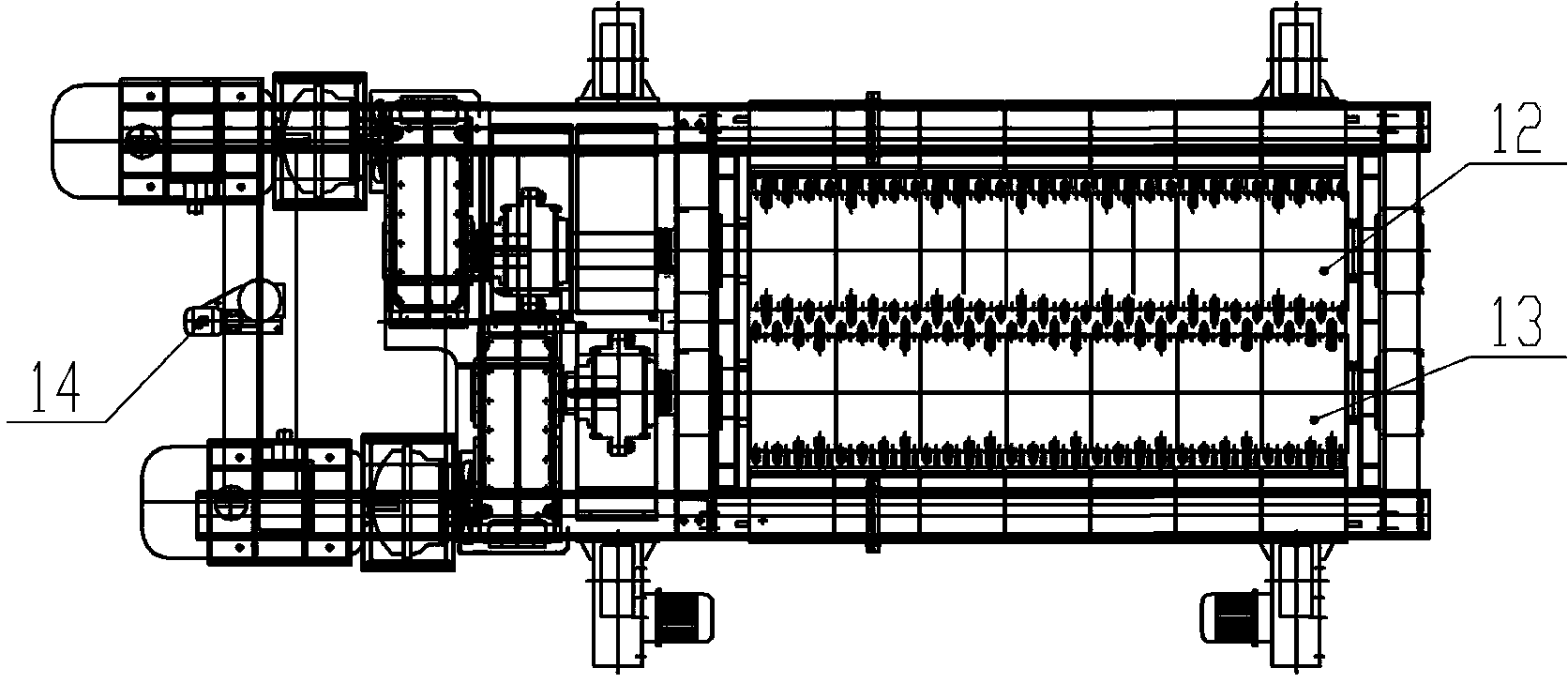

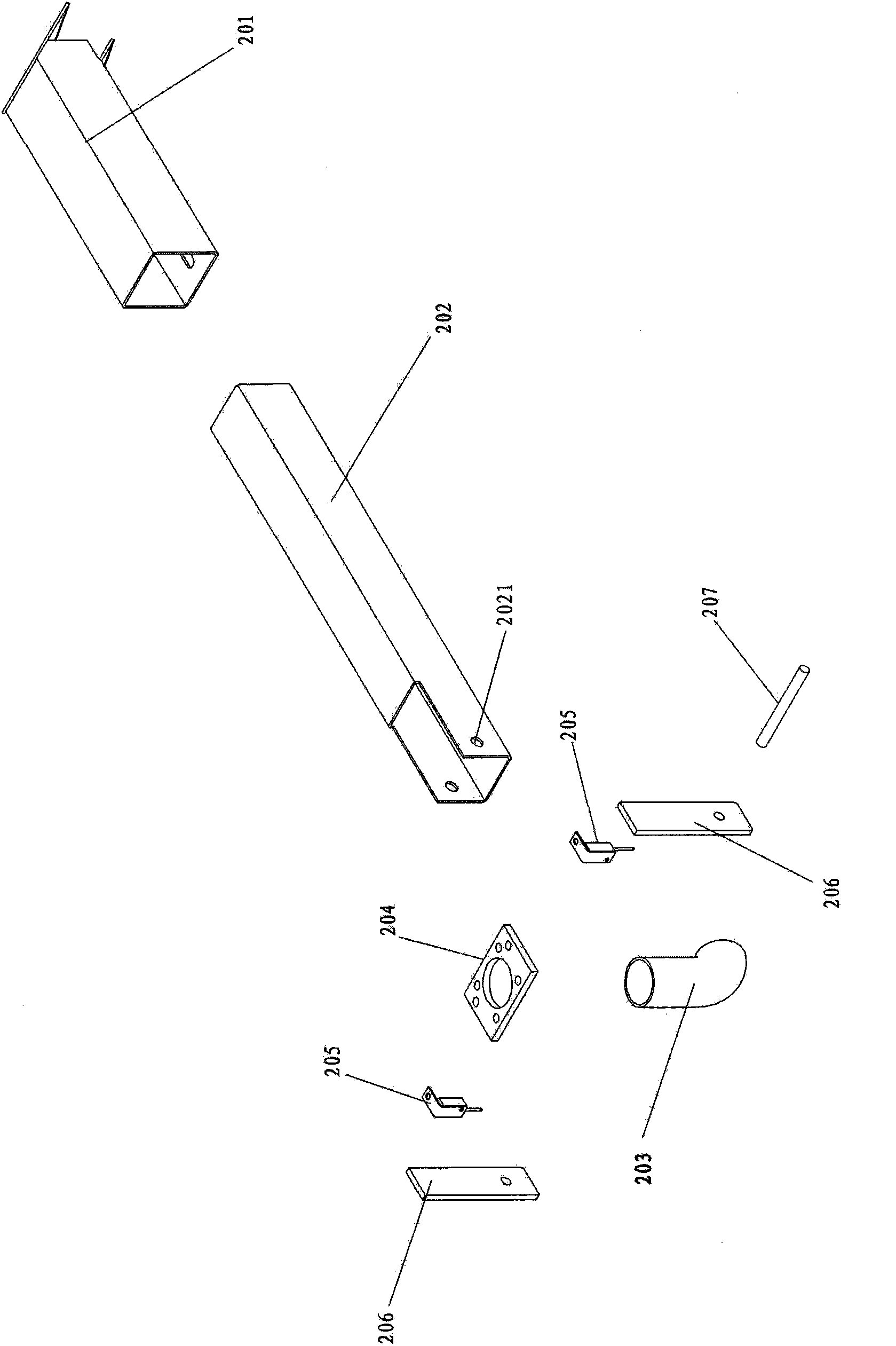

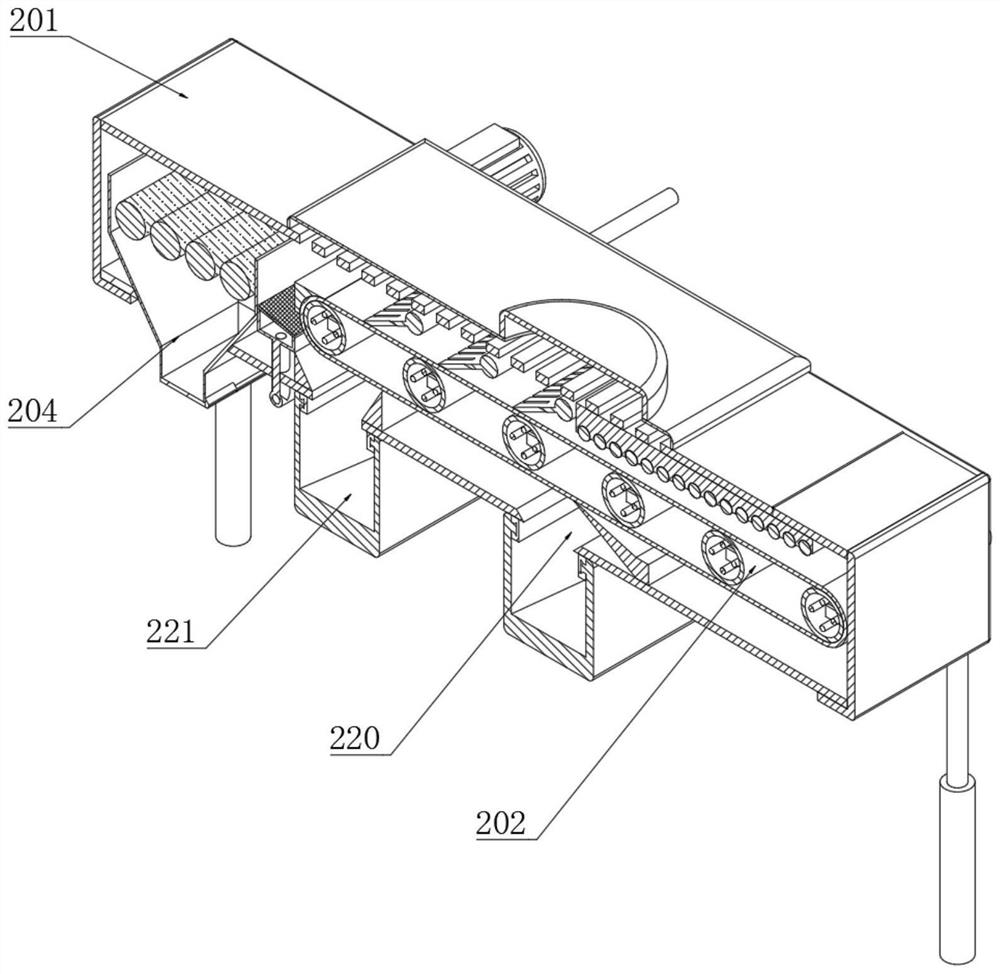

Large efficient screening-type double-toothed roll crusher provided with distribution device

The invention discloses a large efficient screening-type double-toothed roll crusher provided with a distribution device. The double-toothed roll crusher comprises a crushing device and the distribution device. The crushing device comprises a crushing drive motor, a fluid coupling, a reducer, a double-drum gear coupling, a crushing box, a base support, a left toothed roll, a right toothed roll and a lubricating grease pump, wherein the crushing drive motor, the fluid coupling, the reducer and the double-drum gear coupling form two sets of crushing drive units; and the two sets of crushing drive units are connected wit the left toothed roll and the right toothed roll inside the crushing box respectively. The distribution device comprises a distribution chute, an adjustable distribution stick, a movable connecting bracket, a distribution seat and a fixed connecting bracket, wherein the fixed connecting bracket and the distribution seat are fixed on the crushing box of the crushing device, the distribution chute is fixed at a discharge port of a material output belt machine head, and the distribution chute is connected with the crushing box through the movable and fixed connecting brackets. According to the large efficient screening-type double-toothed roll crusher, the problems of capital investment, equipment movement and the like of crushing equipment combined by a plurality of devices are solved fundamentally, the labor intensity of daily equipment maintenance is reduced, and the mining of surface mine materials is accelerated.

Owner:HENAN ZHENYUAN TECH

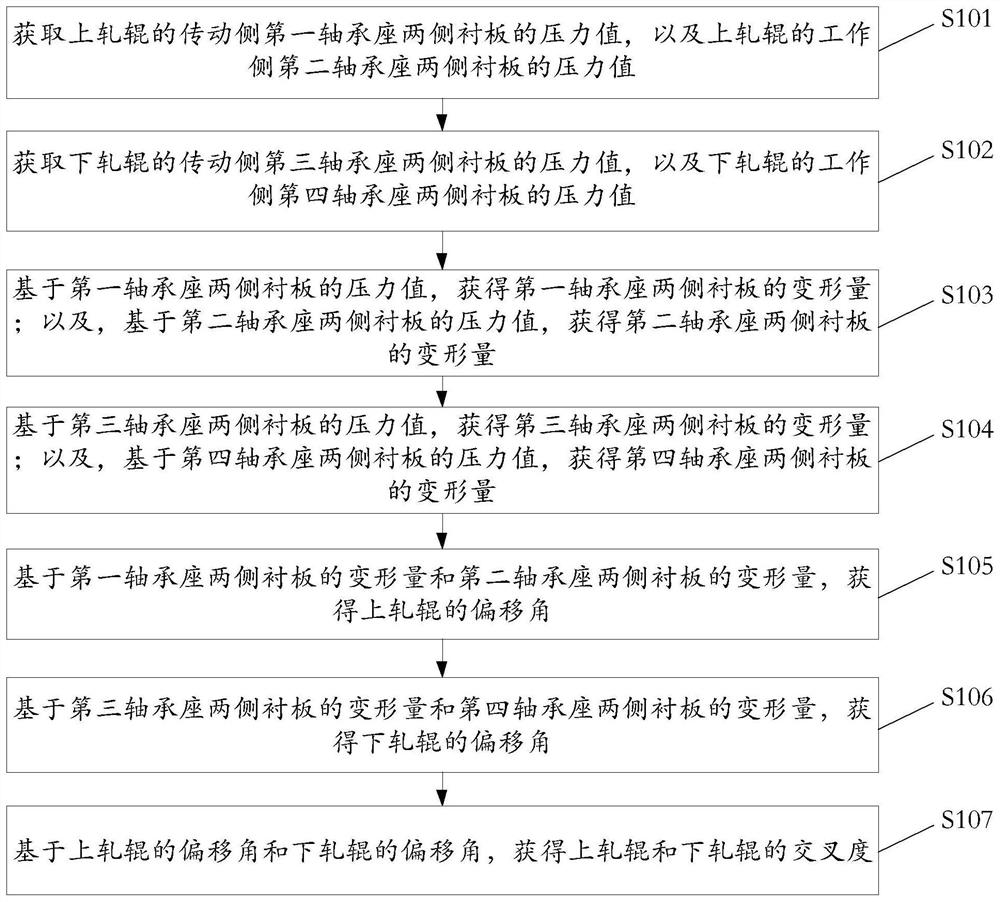

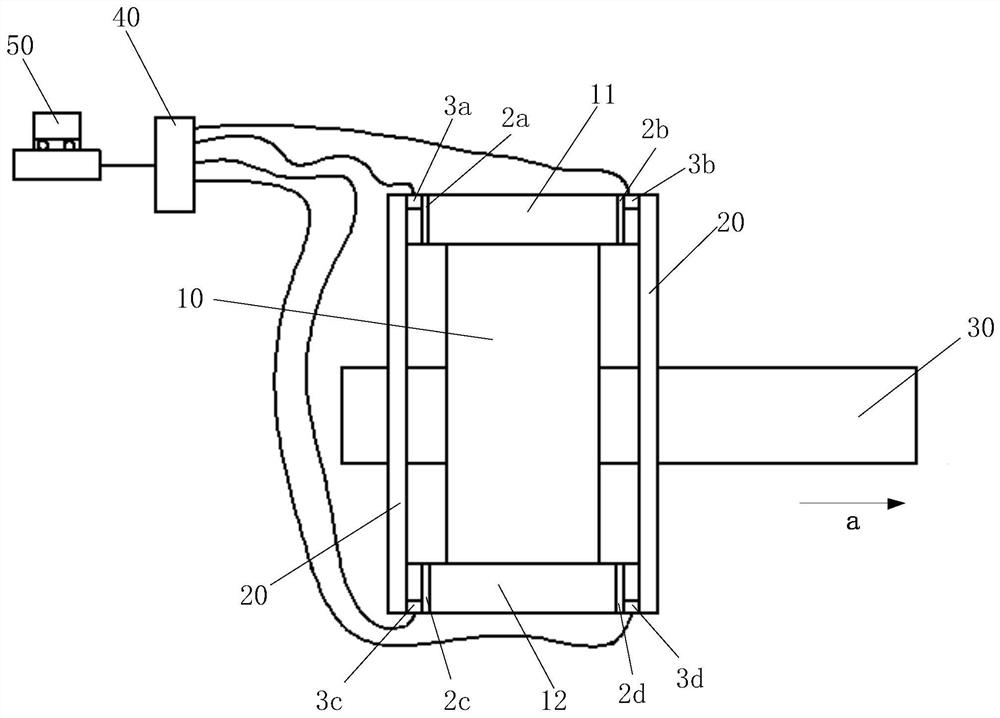

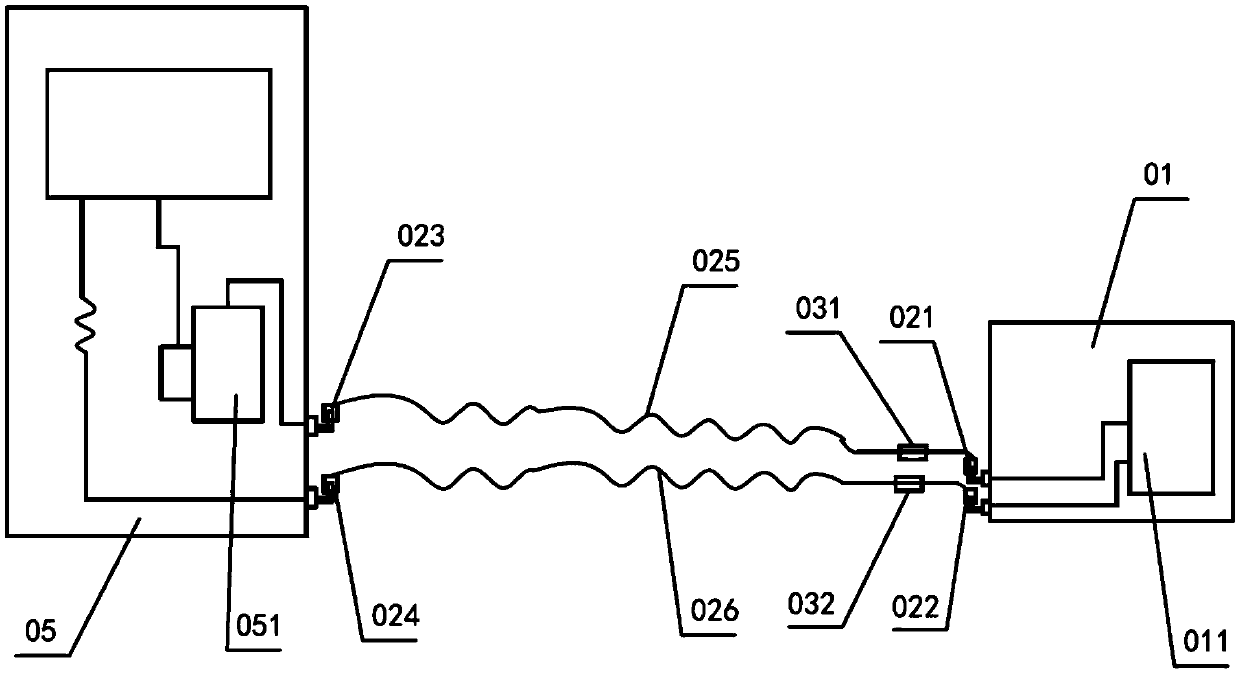

Method and device for measuring cross degree of rolling mill roll system

ActiveCN111659738AAccurate measurementAvoid affecting productionMeasuring devicesMetal rolling arrangementsEngineeringStructural engineering

The invention discloses a method for measuring a cross degree of a rolling mill roll system. The method is applied to the running process of a rolling mill and comprises the following steps that pressure values of lining plates on two sides of a first bearing seat on a transmission side of an upper roll and pressure values of lining plates on two sides of a second bearing seat on a working side ofthe upper roll are acquired; pressure values of lining plates on two sides of a third bearing seat on a transmission side of a lower roll and pressure values of lining plates on two sides of a fourthbearing seat on a working side of the lower roll are acquired; on the basis of the pressure values, the deformation of the lining plates on the two sides of each bearing seat is acquired, and a deviation angle of the upper roll and a deviation angle of the lower roll are acquired; and on the basis of the deviation angle of the upper roll and the deviation angle of the lower roll, the cross degreeof the upper roll and the lower roll is acquired. According to the method, the technical effect of dynamically measuring the cross between the rolls under the condition of no shutdown is realized. Meanwhile, the invention further provides a device for measuring the cross degree of the rolling mill roll system and a computer readable storage medium.

Owner:武汉钢铁有限公司

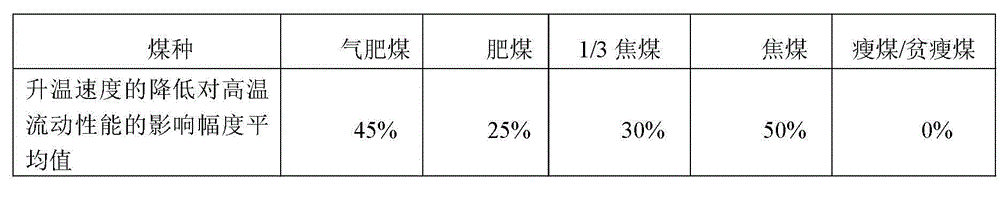

Coking coal blending method of wide carbonization chamber coke oven

The invention discloses a coking coal blending method of a wide carbonization chamber coke oven. The method comprises a step of blending various single coking coals, wherein each single coking coal comprises the following components in percentage by weight: 16-25% of lean coal and meager lean coal, 10-20% of fat coal 1#, 17-29% of 1 / 3 coking coal, 15-20% of coking coal 1#, 6-20% of coking coal 2#, 5-10% of coking coal 3#, 6-10% of gas-fat coal and fat coal 2# and the balance of other random available coking coal of which the volatile component content Vdaf is less than or equal to 35%; the maximum Gieseler fluidity of the compound coal is 600-1,400ddpm; and the volatile components account for 24-27%. The method disclosed by the invention effectively reduces the coal preparation cost, overcomes adverse impact on the high-temperature flowing property of the coking coal caused by the heating speed reduction in a coking process of the wide carbonization chamber coke oven, effectively reduces the graphite accumulation speed on the oven top and improves the coke quality and the coke output.

Owner:武汉钢铁有限公司

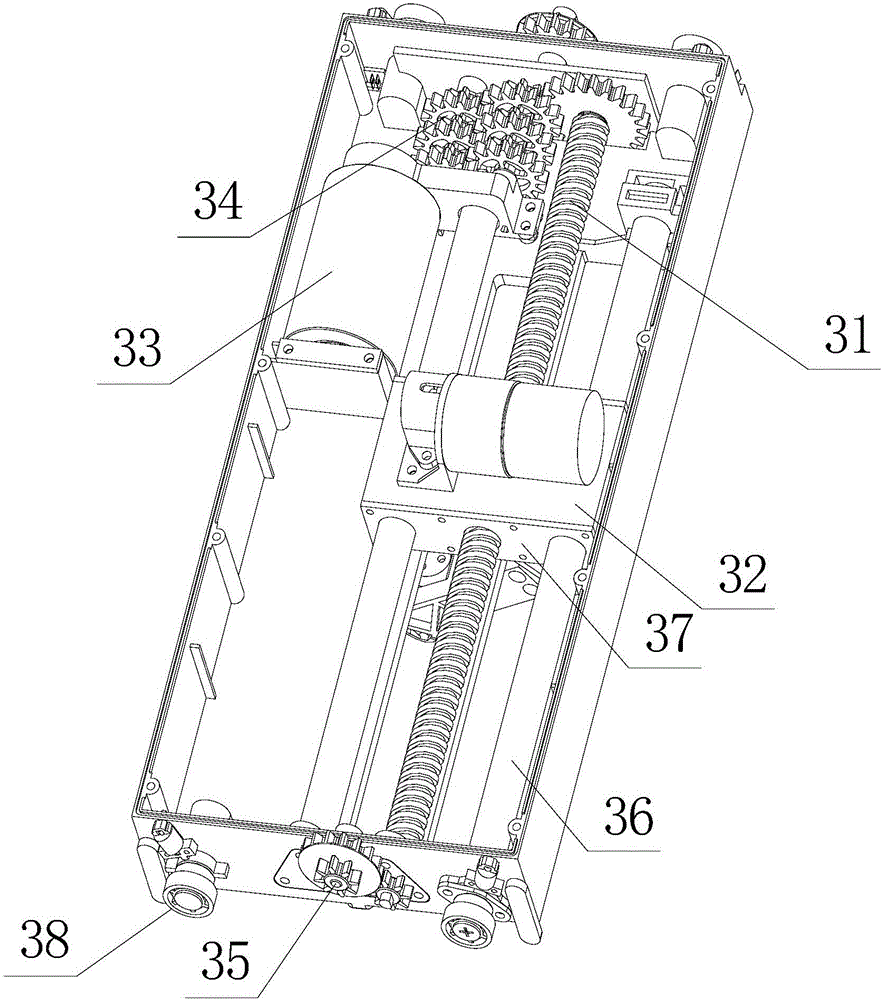

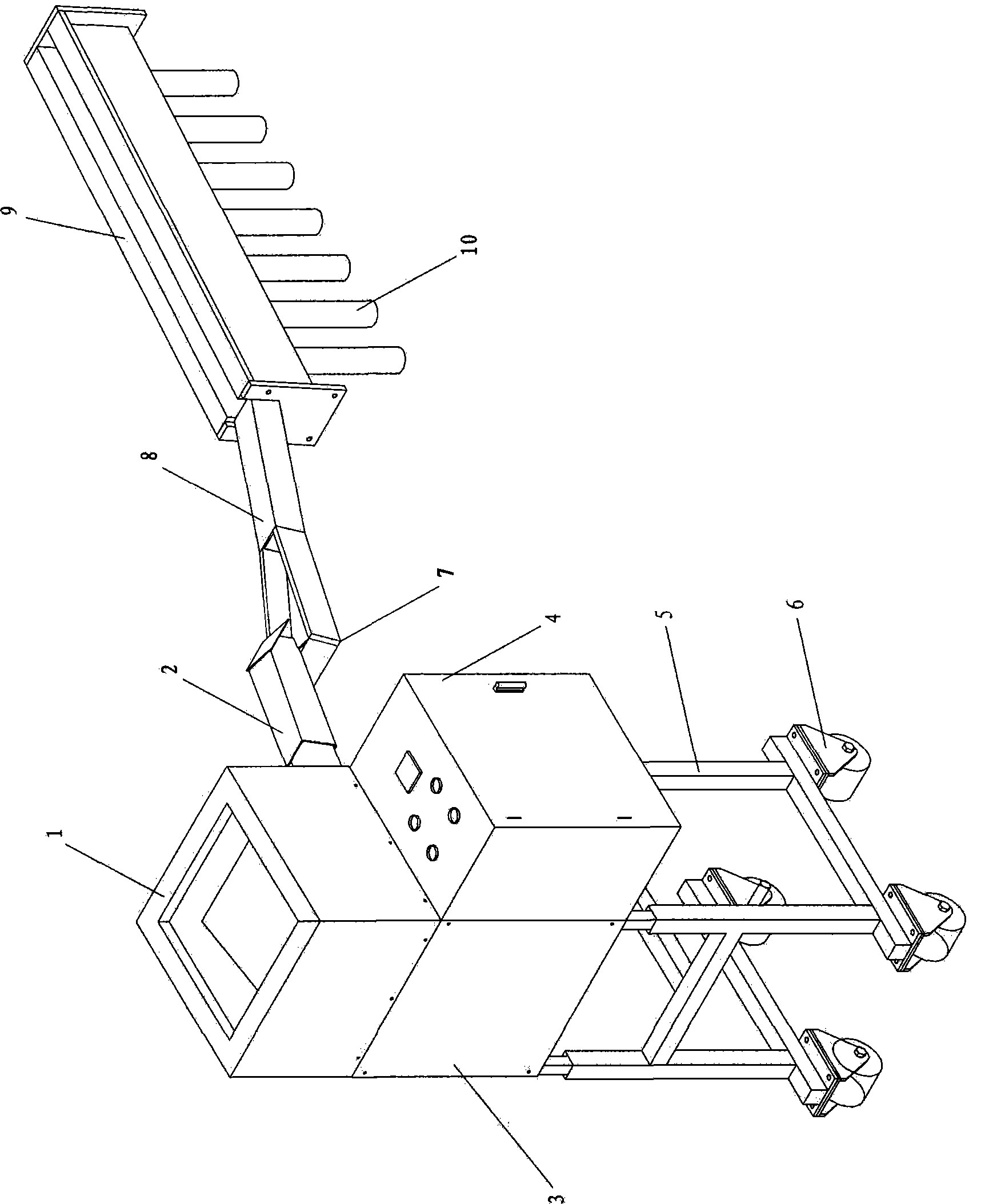

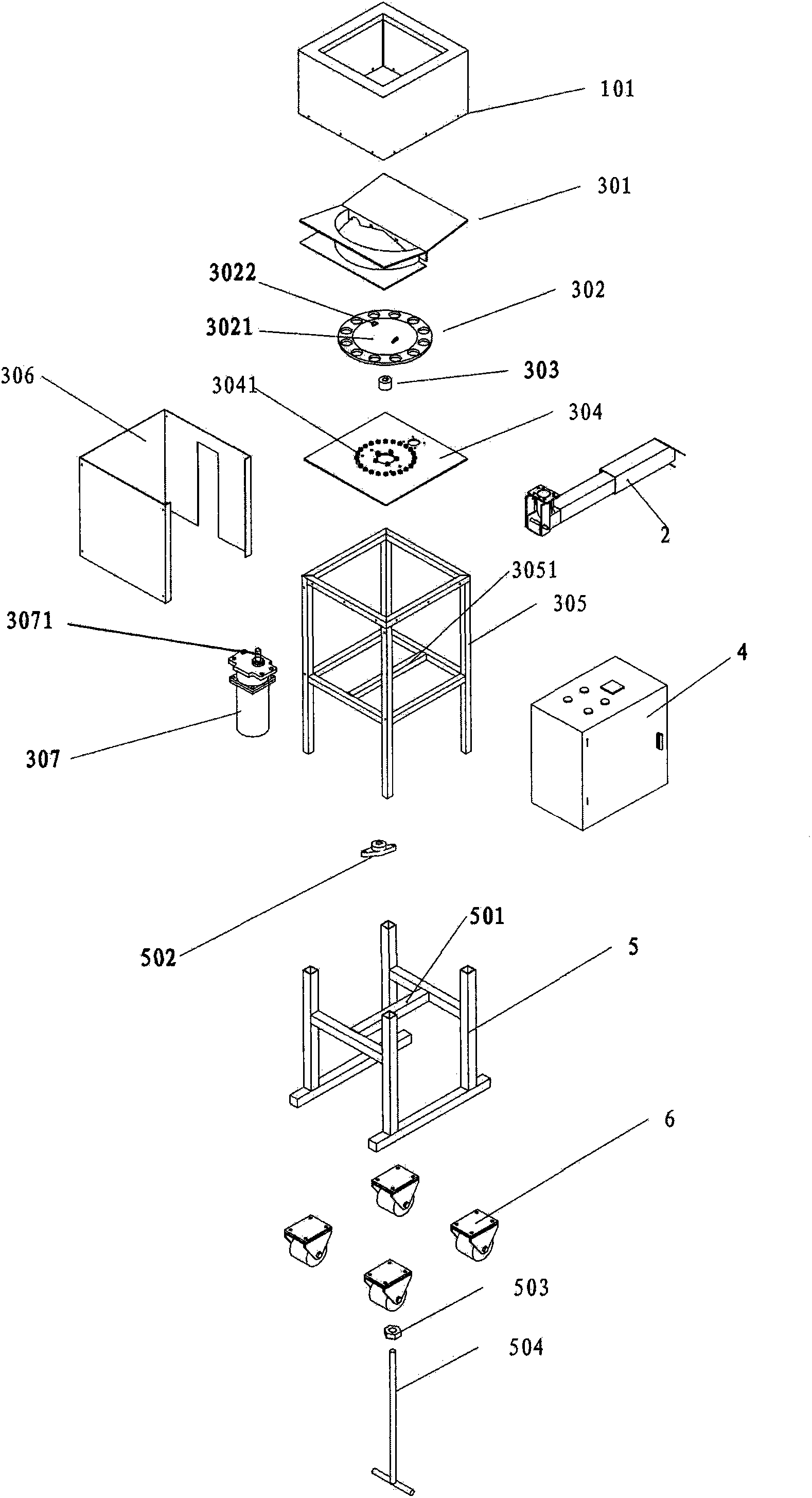

Automatic copper ball feeder

InactiveCN102618909AAvoid affecting productionSave human effortElectrolysis componentsAutomatic controlEngineering

The invention discloses an automatic copper ball feeder, which belongs to the technical field of copper feeders for electroplating equipment titanium baskets and comprises a ball box with an inner ball guide device, a feeder, an electrical box and a stand with firmly connected casters at the bottom. The ball box, the feeder, the electrical box and the stand are mutually and fixedly connected in a mechanical way. A ball guide passage is connected onto the feeder and communicated with a channel through a chute and a ball guide duct while the lower portion of the channel is connected with a titanium basket. The automatic copper ball feeder is capable of automatically controlling copper balls to be fed into the titanium basket and capable of automatically controlling the mount of copper balls to be fed and feeding speed and counting the total amount, so that production efficiency and production quality of electroplating equipment are improved and cost is reduced.

Owner:陈焕宗

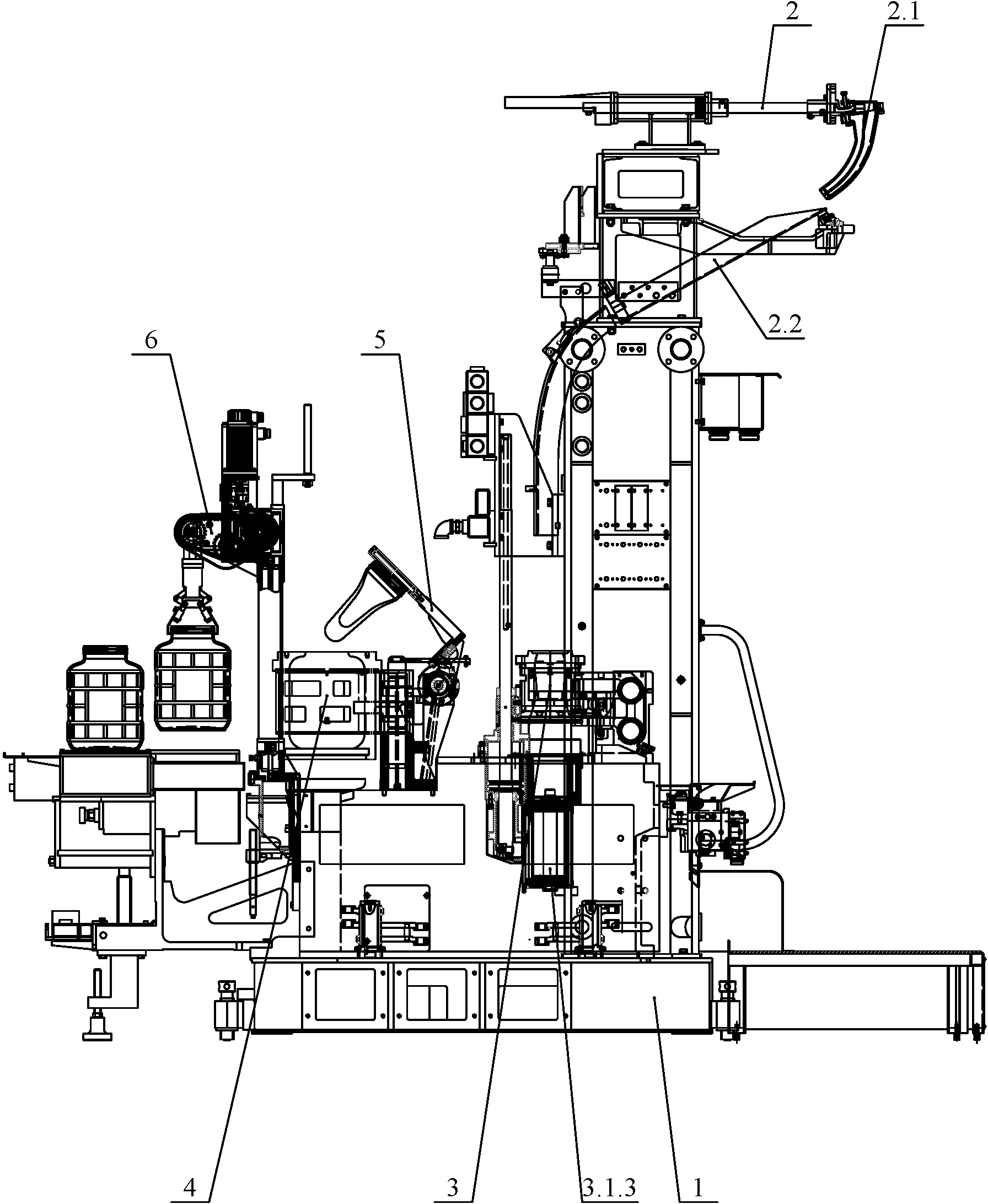

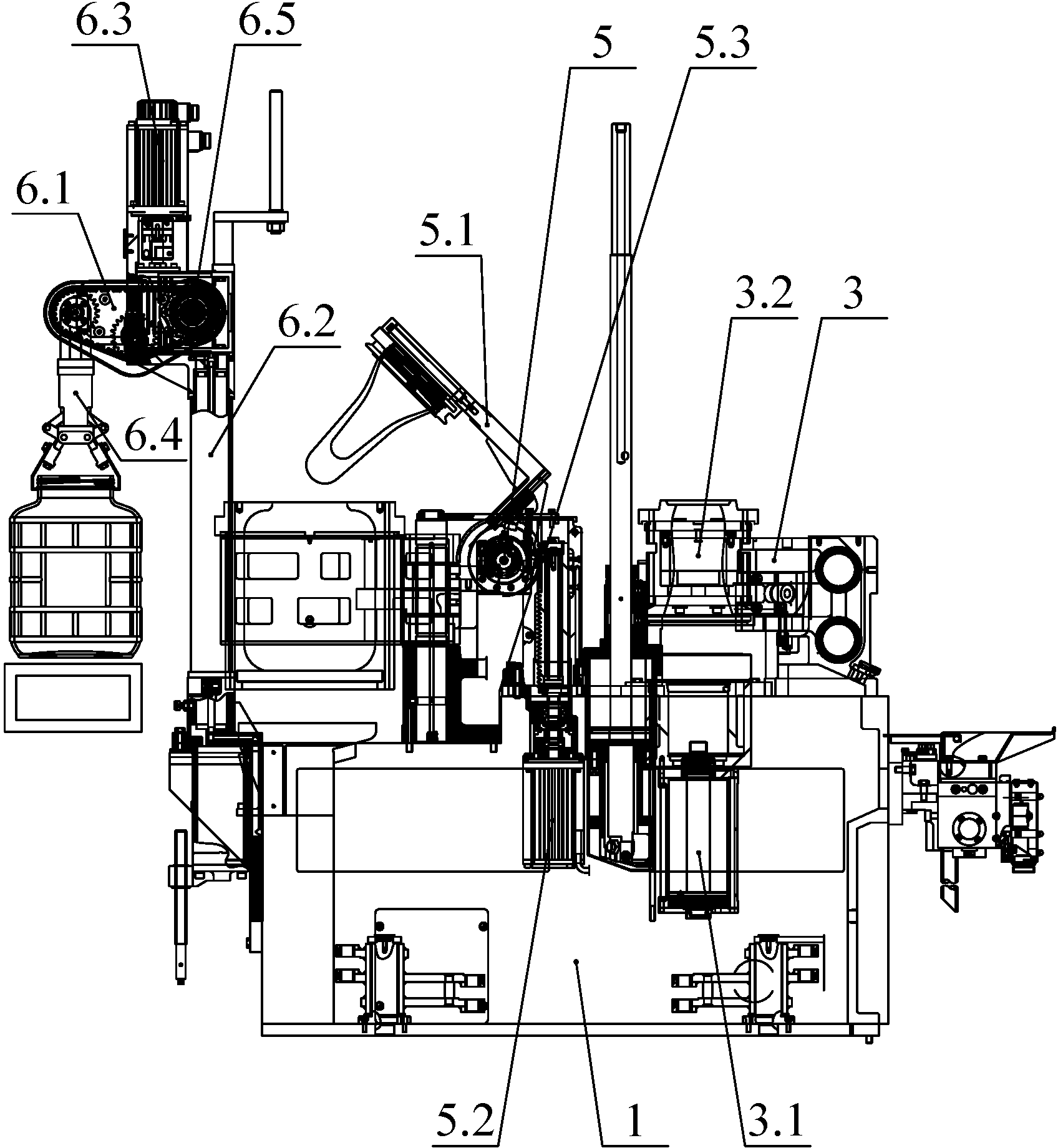

Bottle-making machine and production process for manufacturing extra-large glass bottles

ActiveCN104108856ARealize mechanical automation productionIncrease productionBlowing machine gearingsPress and blow machinesEngineeringBottle

The invention relates to a bottle-making machine and a production process for manufacturing extra-large glass bottles, and belongs to the field of bottle-making machine equipment. The bottle-making machine comprises a rack, and a primary mold forming mechanism, a formed mold forming mechanism and a turnover mechanism which are arranged on the rack, wherein the primary mold forming mechanism comprises a stamping device, a primary mold and a parallel switching mechanism; the stamping device is mounted on the rack; the parallel switching mechanism comprises a horizontal guide shaft mounted on the rack, a clamp arm which sleeves on the horizontal guide shaft, and a first spline shaft, a first rocker arm, a first connecting rod and a first switching cylinder which vertically sleeve at two sides of the rack; one end of the first connecting rod is hinged with the clamp arm while the other end of the first connecting rod is hinged with the first rocker arm; the first rocker arm is connected with the first switching cylinder through the first spline shaft; the primary mold is mounted on the clamp arm. The bottle-making machine has the beneficial effects that the extra-large glass bottles are produced in a manner of automatic mechanized production for replacing manual production, so that the yield of the extra-large glass bottles is increased and the quality of the extra-large glass bottles is improved.

Owner:SHANDONG JIAFENG GLASS MACHINERY

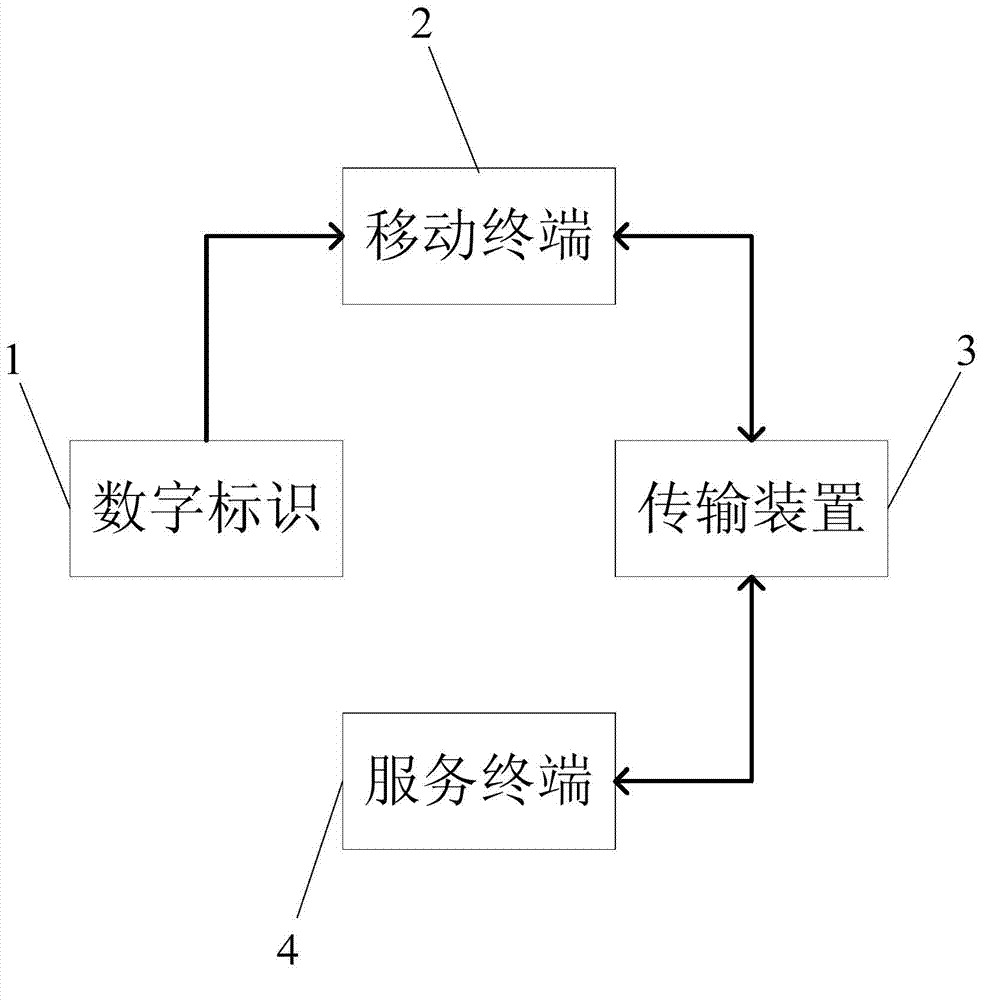

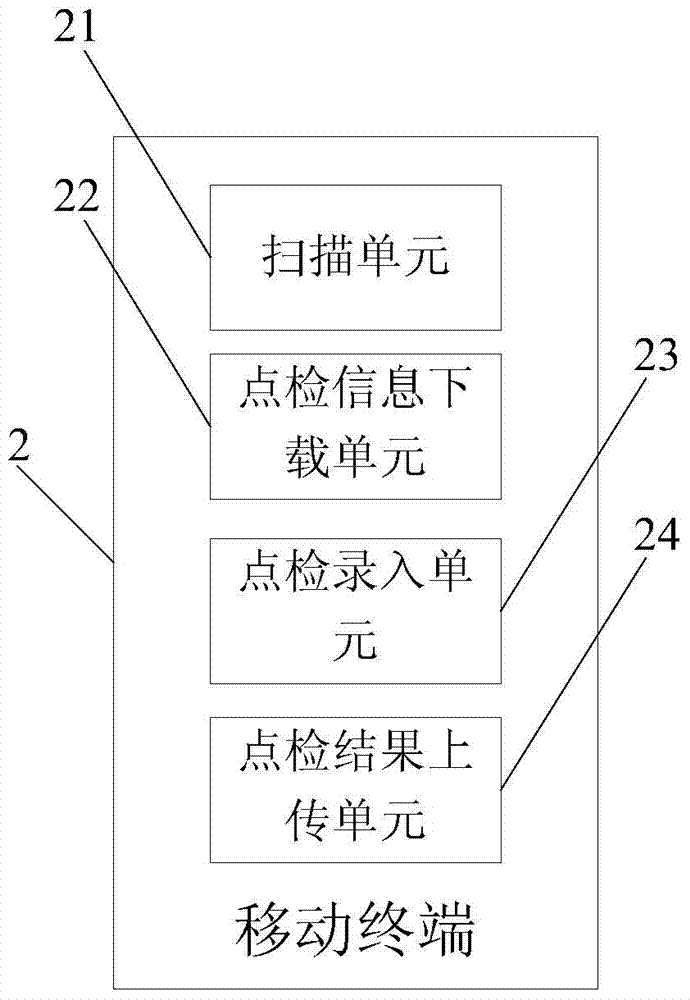

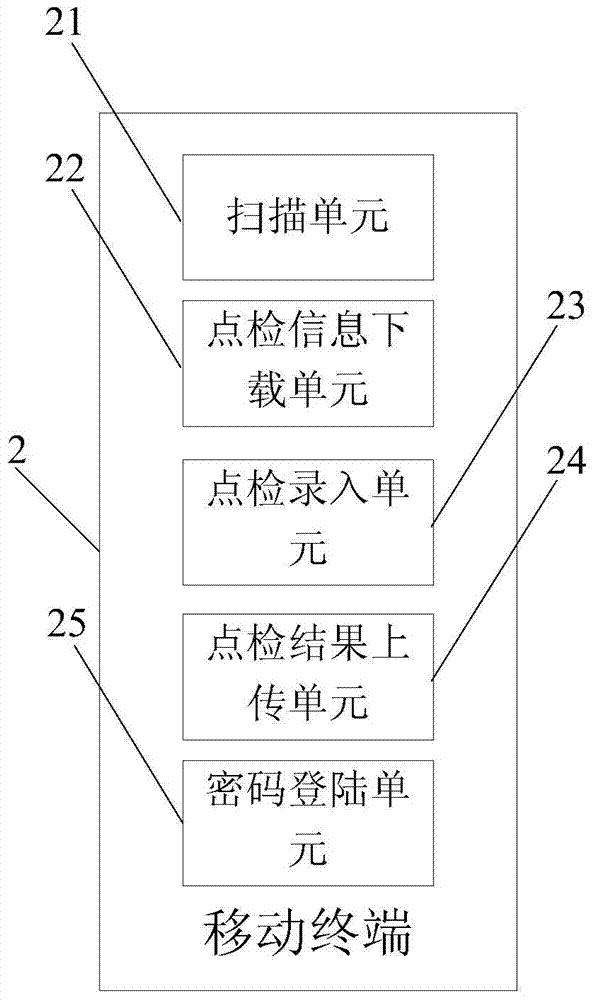

Patrol system

InactiveCN103927793AAvoid affecting productionAvoid mistakesChecking time patrolsThrough transmissionComputer terminal

The invention provides a patrol system and solves the problem that in the prior art, a spot check result is inaccurate and the normal production order is severely impacted. The patrol system comprises a digital identifier, a mobile terminal, a transmission device and a service terminal, wherein the digital identifier is used for determining spot check positions and personnel positions and is arranged on a spot checked device; the mobile terminal is used for scanning the digital identifier to determine the spot check positions and the positions of operators and recording and uploading spot check results; the transmission device is used for transmitting the spot check results of the mobile terminal, is arranged at a using place of the device and is in communication connection with the mobile terminal; the service terminal is used for transmitting spot check information to the mobile terminal through transmission equipment, receiving the spot check results transmitted from the mobile terminal through the transmission device and storing or analyzing the spot check results and is in communication connection with the transmission device. According to the patrol system, the spot checked device can be rapidly and accurately positioned and the spot check results can be rapidly transmitted after the spot check is completed; the spot check accuracy is guaranteed, and meanwhile, the efficiency is increased.

Owner:BEIJING ZHONGDIAN JIANXIANG AUTOMATION TECHCO

Constant-temperature stamping equipment with automatic discharging function

InactiveCN108580627AAvoid affecting productionSuitable temperature rangeShaping toolsNon-rotating vibration suppressionHydraulic cylinderEngineering

The invention discloses constant-temperature stamping equipment with an automatic discharging function. The constant-temperature stamping equipment comprises a base, a cooling device, an upper die assembly, a lower die assembly and a discharging device. The upper die assembly comprises an upper die connecting plate, an upper die base plate, an upper die seat and a male die. A hydraulic cylinder isarranged on the upper die seat, and a guide rail is arranged on the base. The lower die assembly comprises a lower die sliding block and a lower die fixing plate, and the lower die fixing plate is arranged on the guide rail. A female die is arranged on the position, corresponding to the male die, of the lower die sliding block. The discharging device is mounted on one side of the base, and the cooling device is connected with a circuitous pipeline which is arranged in the lower die sliding block. A stroke protecting mechanism is arranged between the male die and the female die. The female diecan keep the appropriate temperature range, thus the stamping quality is improved, and the service life of the equipment is prolonged; and the pneumatic mode is adopted, noise is small, discharging is convenient, and it is guaranteed that the equipment operates stably.

Owner:YANCHENG CHUANLIU AUTO PARTS CO LTD

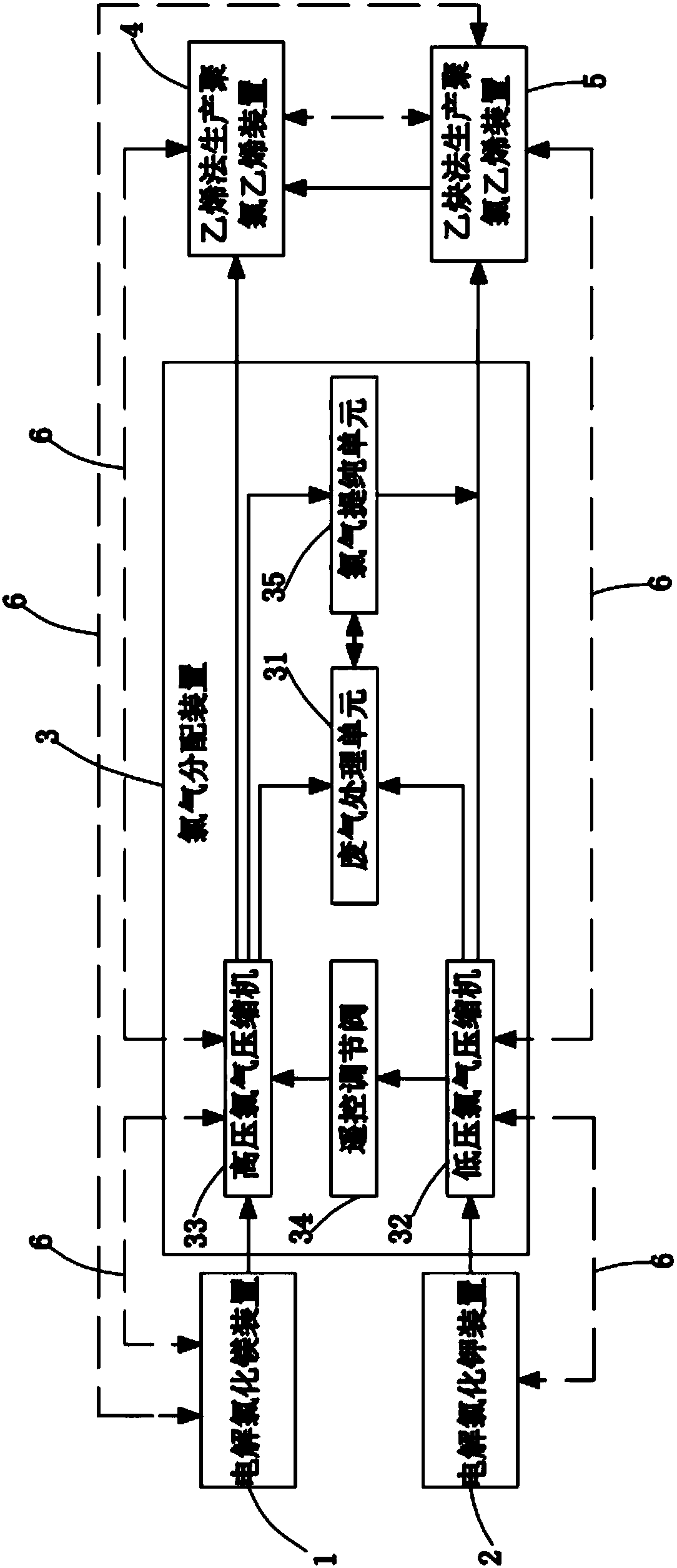

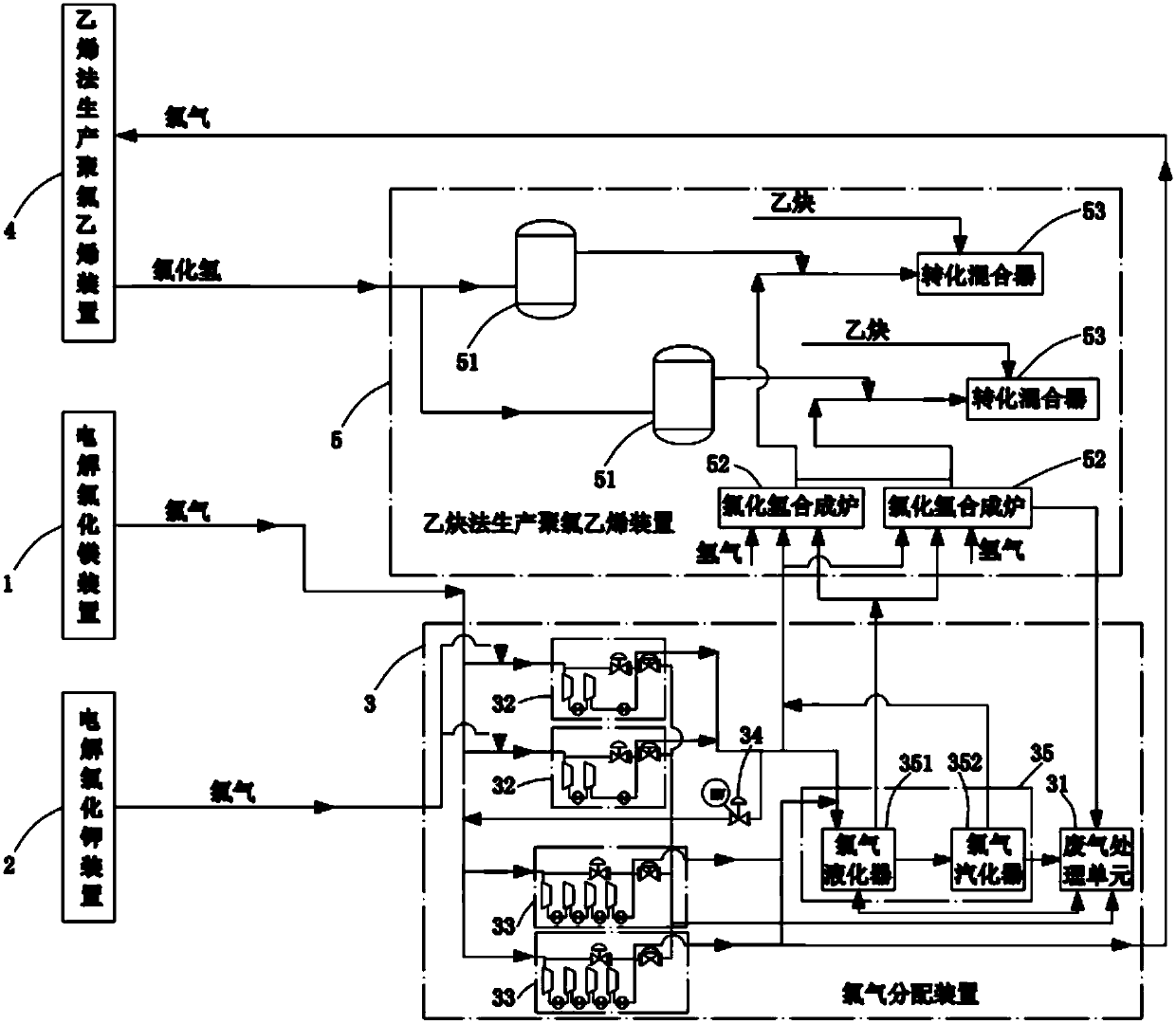

Polyvinyl chloride joint production system and interlocking control method thereof

ActiveCN108047358AAvoid affecting productionImprove securityElectrolysis componentsElectrolysisAutomatic control

The invention discloses a polyvinyl chloride joint production system. The polyvinyl chloride joint production system comprises an electrolytic magnesium chloride device, an electrolytic potassium chloride device, a chlorine distribution device, an ethylene-process polyvinyl chloride production device, an acetylene-process polyvinyl chloride production device and an interlocking device, wherein theinterlocking device comprises a plurality of interlocking signal lines arranged among the devices; when a certain device stops, the interlocking device transmits a stopping signal to an up-down stream device connected with the stopped device through the interlocking signals; the up-down stream device determines whether interlocking stopping is executed or not according to the stopping signals. According to the polyvinyl chloride joint production system disclosed by the invention, the production is safer and more reliable by adopting a control way of the interlocking device, and automatic control can be carried out; once failures or accidents occur, manual operations are reduced; the device can stop once interlocking of the system is carried out; relative to manual operation, the lag is reduced, and the safe production is facilitated.

Owner:QINGHAI SALT LAKE IND

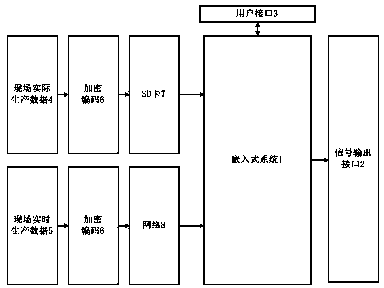

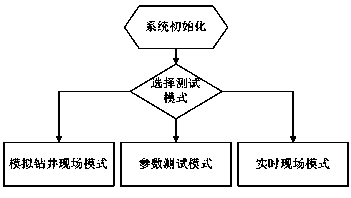

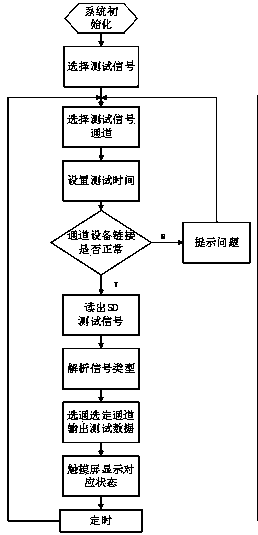

Method for debugging comprehensive logging instrument by means of simulating scene sensor signal

The invention discloses a method for debugging a comprehensive logging instrument by means of simulating a scene sensor signal. A method for simulating scene common station signals and outburst station signals and providing scene real-time data signals is provided, and the technical problem that a signal required by developing and debugging the comprehensive logging instrument and testing response capability of the comprehensive logging instrument to the sudden accident lacks is solved. The method is mainly and technically characterized by comprising the steps that scene practical production data are collected and summarized, the data are stored in an SD card through encryption and encoding, the data are processed through an embedded type system, and the data are output through a signal output interface; according to the scene real-time production data, the real-time data are transmitted to the embedded type system through a proprietary network after encryption and encoding, and the data are output through the signal output interface after being processed through the embedded type system. The situation is created for developing and debugging the comprehensive logging instrument, comprehensively testing the testing response capability of the comprehensive logging instrument to the sudden accident and developing the advanced comprehensive logging instrument.

Owner:SOUTHWEST PETROLEUM UNIV

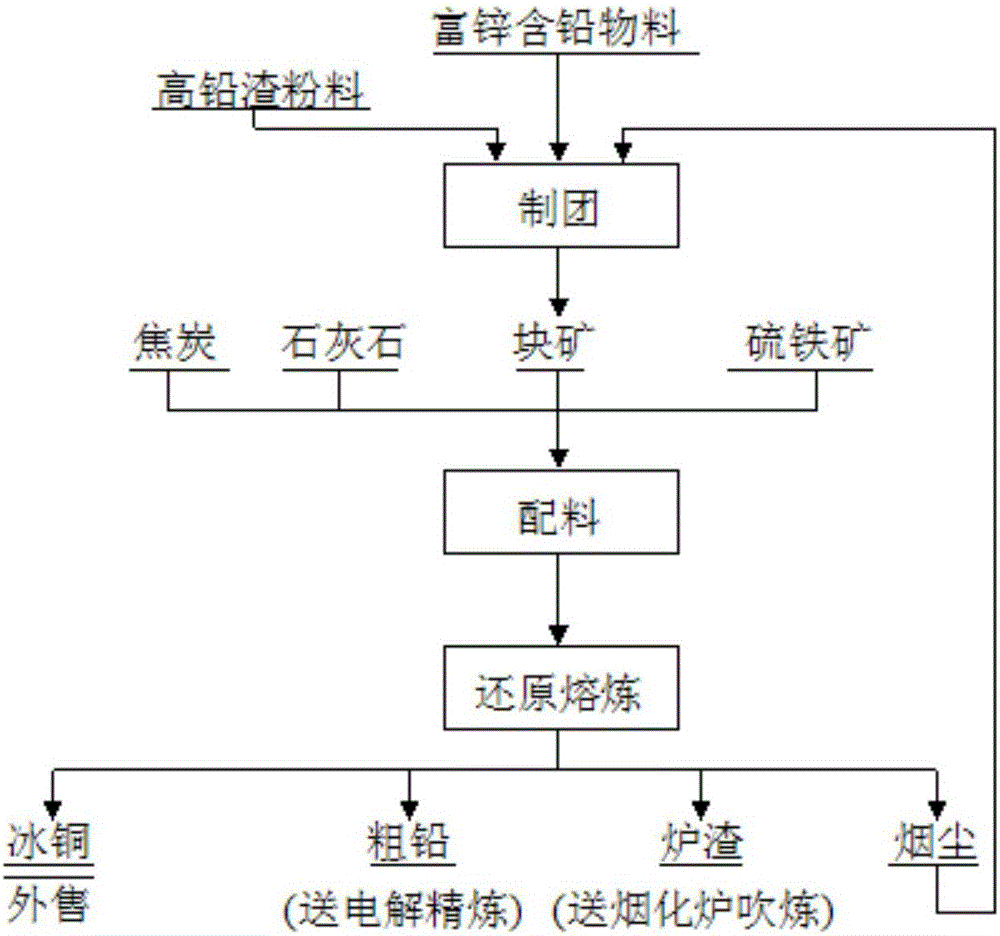

Treatment method of complicated zinc-rich leaded material

The invention discloses a treatment method of a complicated zinc-rich leaded material, which comprises the following steps that (1) the zinc-rich leaded material, a high lead residue powder and soot are taken, mixed, and stirred after water is added, and then is put in a brick making machine to be made into lump ores, and the lump ores are dried for 12-24h in a ventilated place for later use; (2) coke, limestone, iron ore and the lump ores are taken and sequentially put in a blast furnace to be smelted, wherein the smelting temperature of the blast furnace is 900-1300 degrees, the blast pressure is 7-11kpa, the unit blast volume is 24-35Nm<3> / min.m<2>, the dosage of rich oxygen is 500-780m<3> / h, and the oxygen concentration is controlled at 23.5-24.5%; and (3) after the lump ores are smelted by the blast furnace, gold and silver enriched work lead, copper matte, soot and zinc-rich slags are obtained. The gold and silver enriched work lead is sent to be subjected to electrolytic refining, the copper matte acts as a raw material of smelting copper, the soot is rich in leaded zinc and acts as a raw material of smelting leaded zinc or is returned to Step (1) to act as the raw material, and the zinc-rich slags are sent to a fuming furnace to be converted for recovering zinc. The treatment method solves the problems that the zinc-rich leaded material with high content of sulfur is liable to form furnace accretion, and is not treated easily, and zinc and lead can not be recycled effectively.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Soil organic restoration device and soil restoration method for smart agriculture

The invention discloses a soil organic restoration device for smart agriculture. A thermal stripping box is clamped to one side of the top end of a supporting frame, a movable roller is placed on the inner side of the thermal stripping box, a discharging hopper is installed on the inner side of the thermal stripping box, a separation limiting plate is connected to the inner side of the thermal stripping box, a concentration sleeve is welded to one end of the thermal stripping box, and a gas conveying pipe penetrates through one end of the concentration sleeve. A gas inlet end of the gas conveying pipe is installed at the top end of a concentration box in a penetrating mode, a gas outlet pipe penetrates through one end of the movable roller, and a gas outlet end of the gas inlet pipe is installed at the bottom end of a separation box in a penetrating mode. Through a conveying belt, the movable roller and the gas conveying pipe, generated steam is exhausted while soil is subjected to thermal stripping, the moisture content in the thermal stripping box is reduced, and meanwhile, heat is recycled for the second time, so that the movable roller is heated, the temperature of the movable roller is guaranteed, soil is heated while the conveying belt is dried, the soil is prevented from being attached to the surface of the conveying belt, and the treatment effect of the soil is guaranteed.

Owner:芷兰生态环境建设有限公司

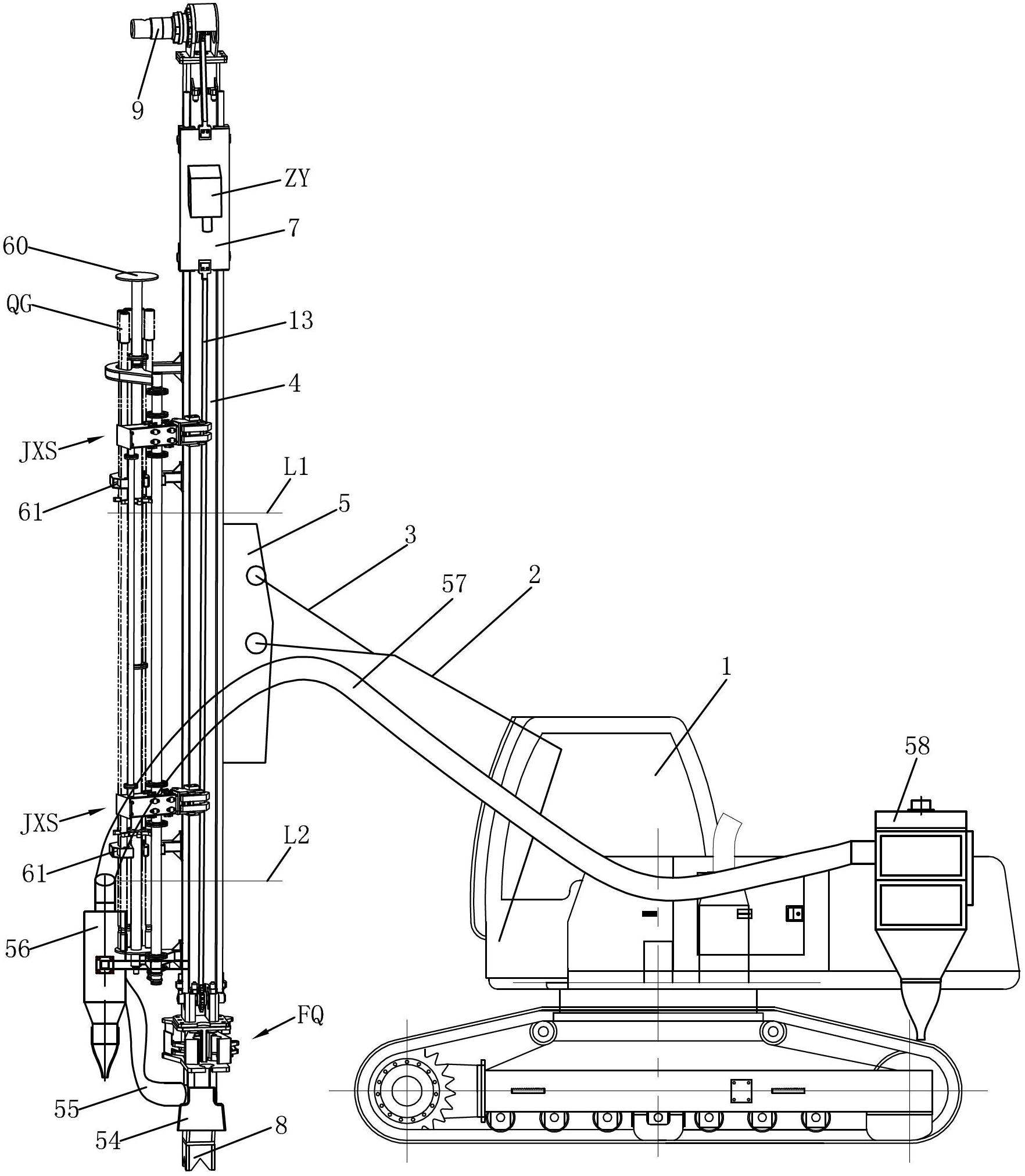

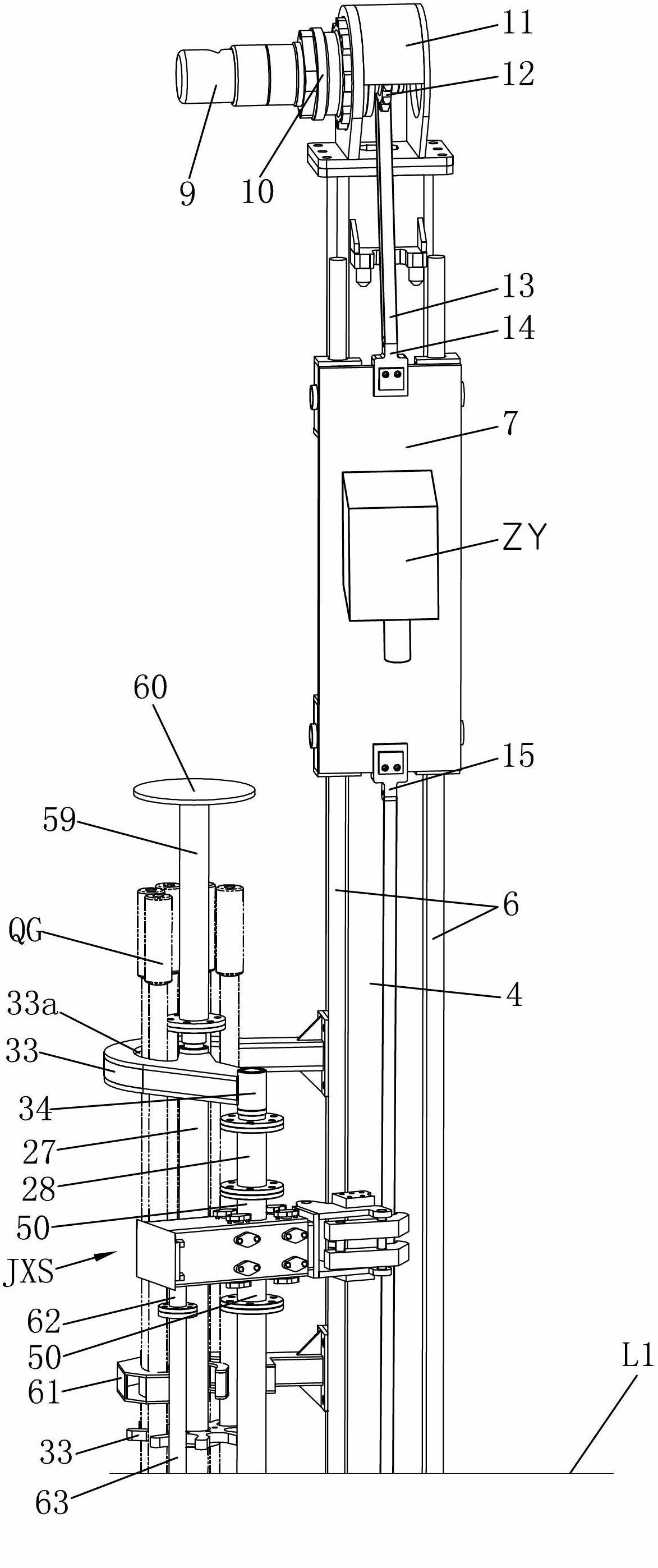

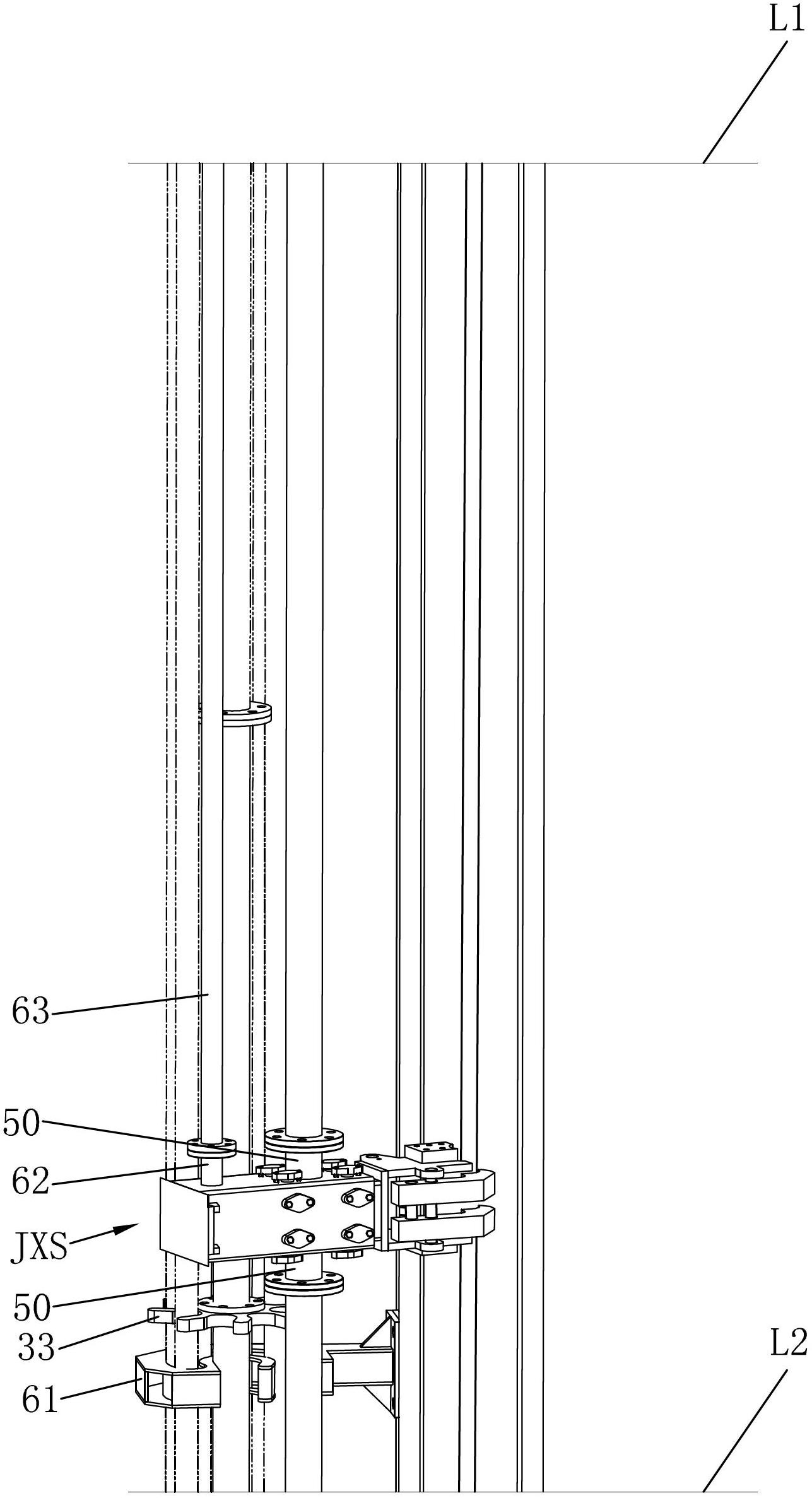

Multifunctional engineering machinery based on excavator platform

ActiveCN102691323AIncrease the lengthAvoid blocking the line of sightMechanical machines/dredgersDrilling machines and methodsControl engineeringSlide plate

The invention discloses multifunctional engineering machinery based on an excavator platform. The front part of an operation arm of an excavator is hinged with an execution oil cylinder; a boring frame is vertically arranged in front of the operation arm; the middle of the rear surface of the boring frame is provided with a connection plate; the middle of the connection plate is hinged with the front end of the operation arm, while the upper part of the connection plate is hinged with the piston rod stretching end of the execution oil cylinder; the left surface of the boring frame is provided with two guide rails which are arranged vertically side by side; and a sliding plate is connected with the two guide rails and also can slide up and down along the guide rails under traction of a traction device. The multifunctional engineering machinery integrates excavation, stone crushing, boring and sand rock blasting, the cost for purchasing the engineering machinery can be reduced for users, construction is facilitated, and multiple drill rods can be connected together as required to increase boring depth, so that the problem of insufficient boring depth in the prior art is solved well; in addition, the multifunctional engineering machinery can prevent dust from flying in front of the excavator and consequently prevents the sight of an operator from being influenced.

Owner:CHONGQING DIMA IND

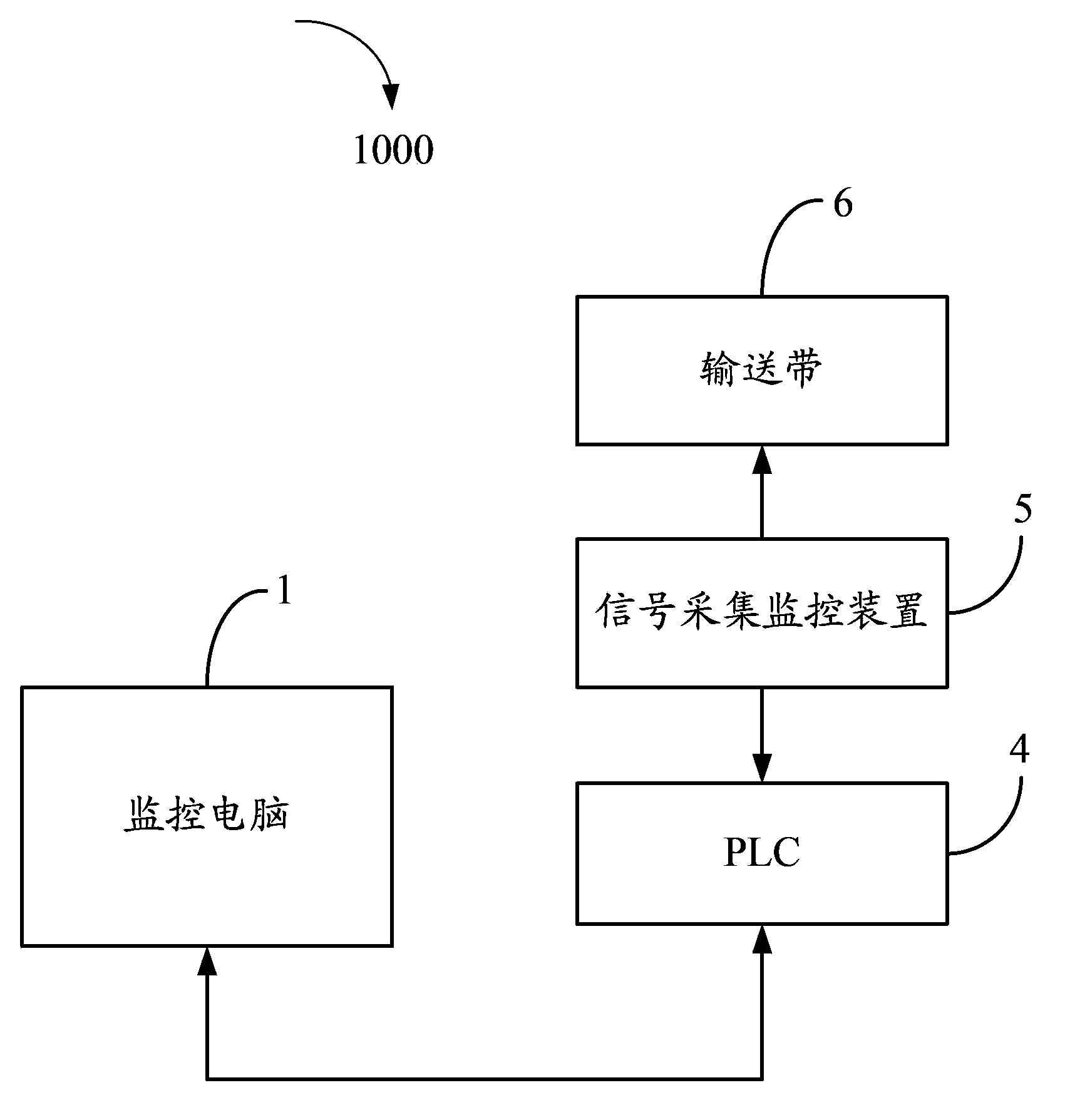

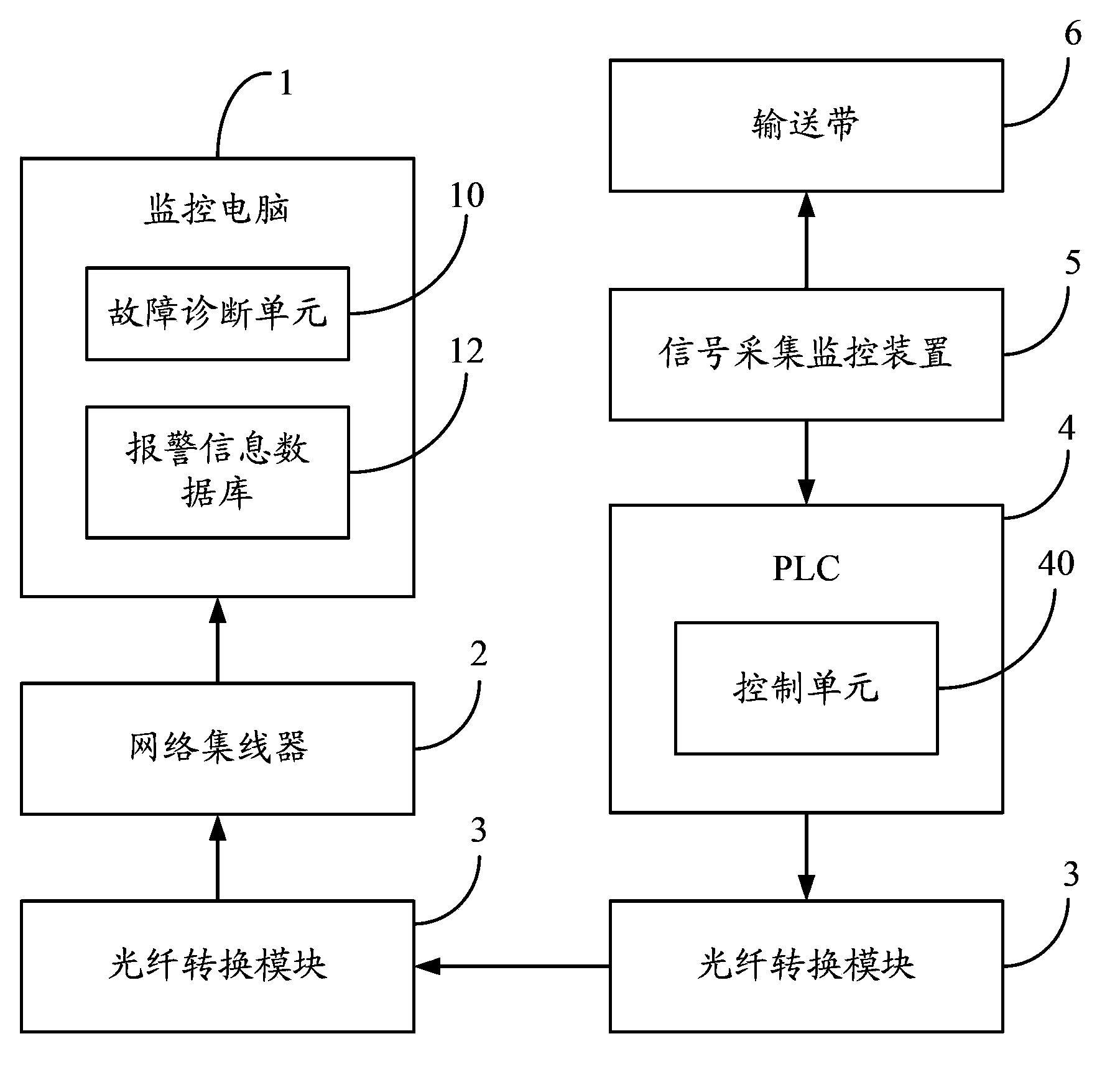

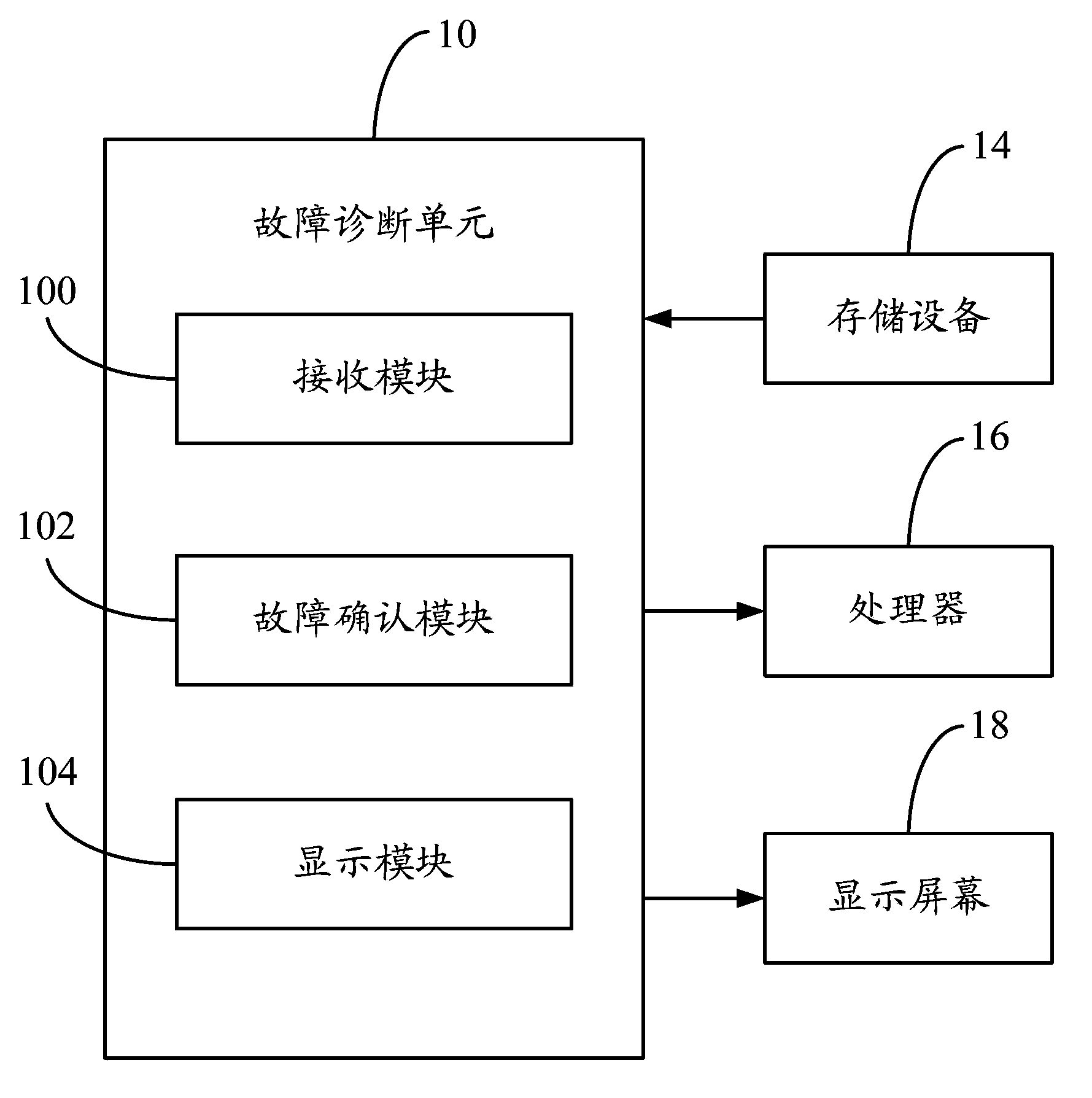

System and method for remote fault diagnosis of conveying belt

ActiveCN103569623AAvoid affecting productionFind faults in timeControl devices for conveyorsProgrammable logic controllerEngineering

The invention provides a method for the remote fault diagnosis of a conveying belt. The method comprises the steps: monitoring the operating status of the conveying belt by using a signal acquiring and monitoring device, and acquiring an operating status signal of the conveying belt; receiving the operating status signal by a programmable logic controller which controls the operation of the conveying belt, and diagnosing whether the conveying belt is in a fault or not according to the operating status signal; if a diagnostic result shows that the conveying belt is in the fault, triggering an alarm signal corresponding to the fault; receiving the alarm signal by a monitoring computer, and extracting corresponding alarm information from a pre-prepared alarm information database according to the alarm signal, wherein the alarm information comprises the location and reason of the fault; displaying the alarm information on the monitoring computer. The invention further provides a system for the remote fault diagnosis of the conveying belt. By using the method and the system, the fault of the conveying belt can be diagnosed remotely, so as to avoid the influence on paper roll production.

Owner:GOLD EAST PAPER JIANGSU

Heating defoaming device

The invention relates to a heating defoaming device. The heating defoaming device comprises a defoaming box installed at the upper portion of the side face of an alkali liquid circulating tank and multiple heating devices arranged in the defoaming box. Multiple foam inflow pipes are arranged on the side face of the defoaming box and connected with the alkali liquid circulating tank through foam inlets of the foam inflow pipes respectively. An alkali liquid backflow pipe is arranged at the bottom of the defoaming box and connected with the alkali liquid circulating tank through an alkali liquid backflow port. The heating defoaming principle is used, redundant foam in the alkali liquid circulating tank overflows and automatically flows into the defoaming box to be heated and broken, and the situation that production is affected due to the fact that other defoaming media are used and contaminates or dilutes alkali liquid is avoided.

Owner:WISDRI ENG & RES INC LTD

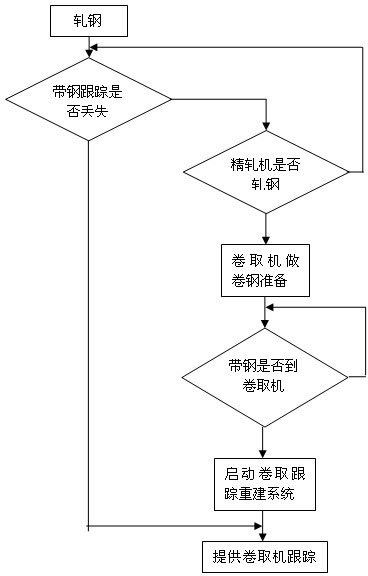

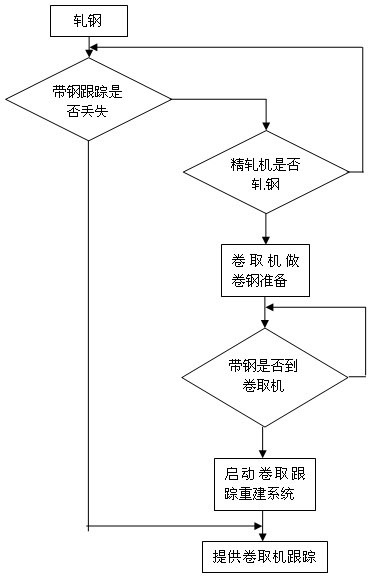

A Control Method for Coiler Tracking Loss Reconstruction in Hot Rolling Line

ActiveCN102284504AAvoid affecting productionTrack Signals AccuratelyRoll mill control devicesMetal rolling arrangementsProduction lineControl system

The invention relates to a control method for preventing lost coiling tracking from causing steel scraps in a hot continuous rolling strip steel production line. The technical scheme comprises the following steps of: A, determining lost tracking of finish-rolling and coiling rolling strip steel; B, ensuring normal speed acceleration of a coiling block and a wrapper roller and steel coiling preparation by a coiler by using a rolling signal of a tracking-free rolling mill as a trigger signal of speed acceleration of a coiler mandrel and the wrapper roller; C, determining whether the strip steelreaches the coiler, when the strip steel reaches the coiler, starting a coiling tracking reconstructing system, and providing normal head and tail tracking signals for each control system of the coiler; and D, determining head and tail positions of the strip steel by integration on the strip steel speed. The invention has the advantages that the lost tracking can be automatically distinguished bya computer system and software thereof, the tracking reconstructing system is automatically started, an accurate tracking signal is provided for the coiler, normal steel coiling of the coiler is realized, and the steel scraps are avoided being coiled to influence normal production. The method has the characteristics of scientificity, applicability and accuracy.

Owner:TANGSHAN GUOFENG IRON & STEEL

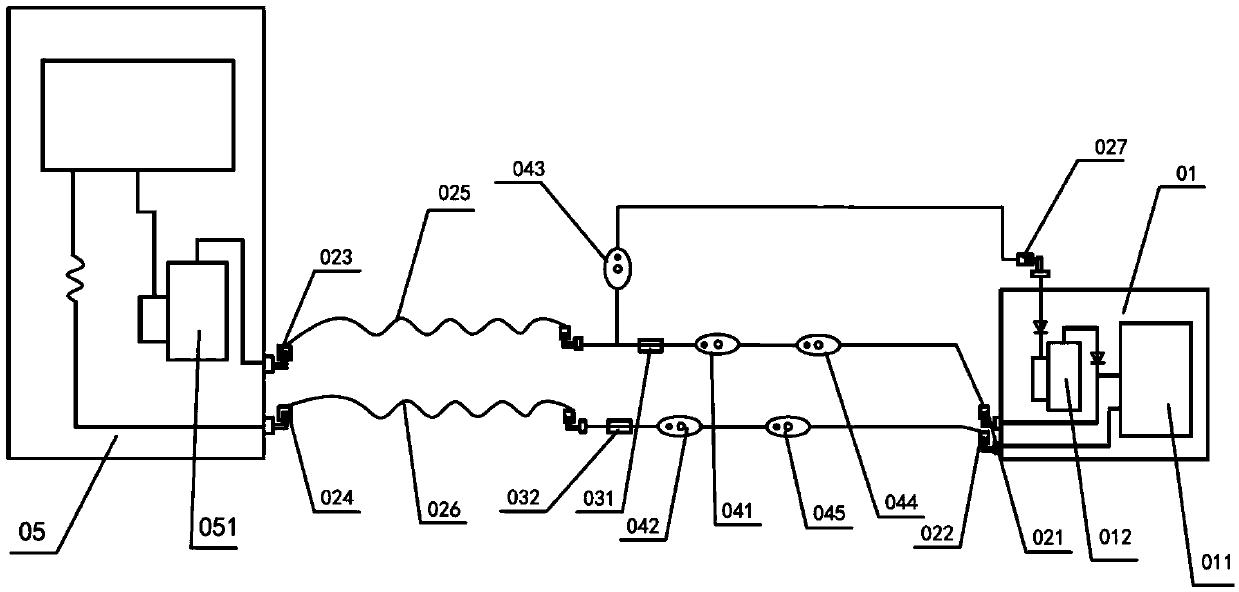

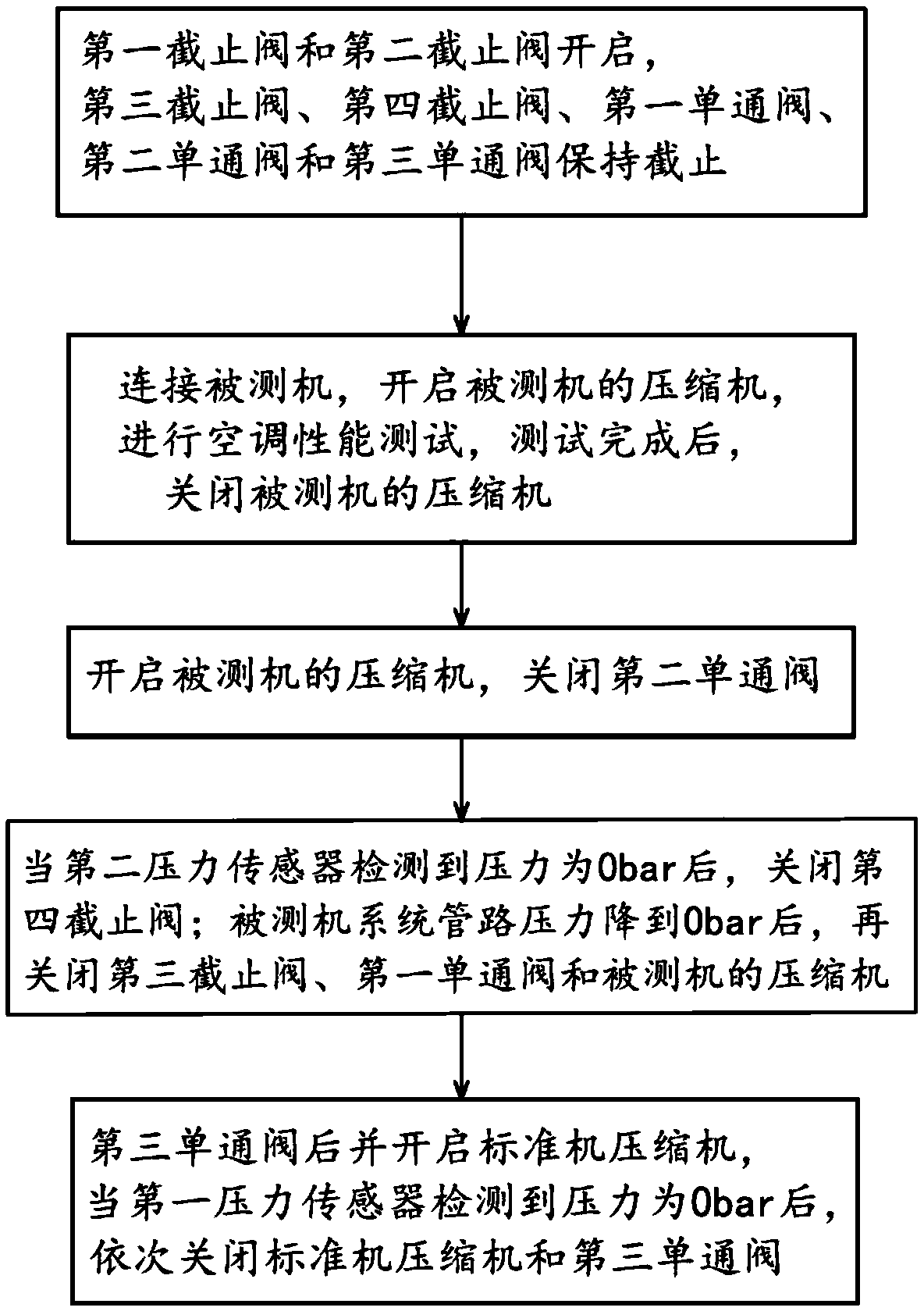

Air conditioner performance detection system and method and standard machine weighing method

ActiveCN105372084AAvoid wastingAvoid pollutionStructural/machines measurementMonitoring systemVALVE PORT

The invention provides an air conditioner performance detection system. The system comprises a detection standard machine and a detection system pipeline, the standard detection machine is internally provided with a condenser and a standard machine compressor, the two ends of the condenser are connected with a first stop valve and a second stop valve respectively, a first pressure sensor is connected with the first stop valve via a first one-way valve, a third stop valve is connected with the first pressure sensor via a steam side pipeline, a second pressure sensor is connected with the second stop valve via a second one-way valve, a fourth stop valve is connected with the second pressure sensor via a liquid side pipeline, an air exhausting port of the standard machine compressor is connected with the liquid input end, and a fifth stop valve is connected with a pipeline between the steam side pipeline and the first pressure sensor via a third one-way valve. During detection, an air conditioner to be detected is connected with the third stop valve and the fourth stop valve, and after the performance of the air conditioner is detected, the standard machine compressor exhausts refrigerant in the pipeline of the monitoring system and the air conditioner, the refrigerant is prevented from being charged and discharged repeatedly, and resource waste is further avoided.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

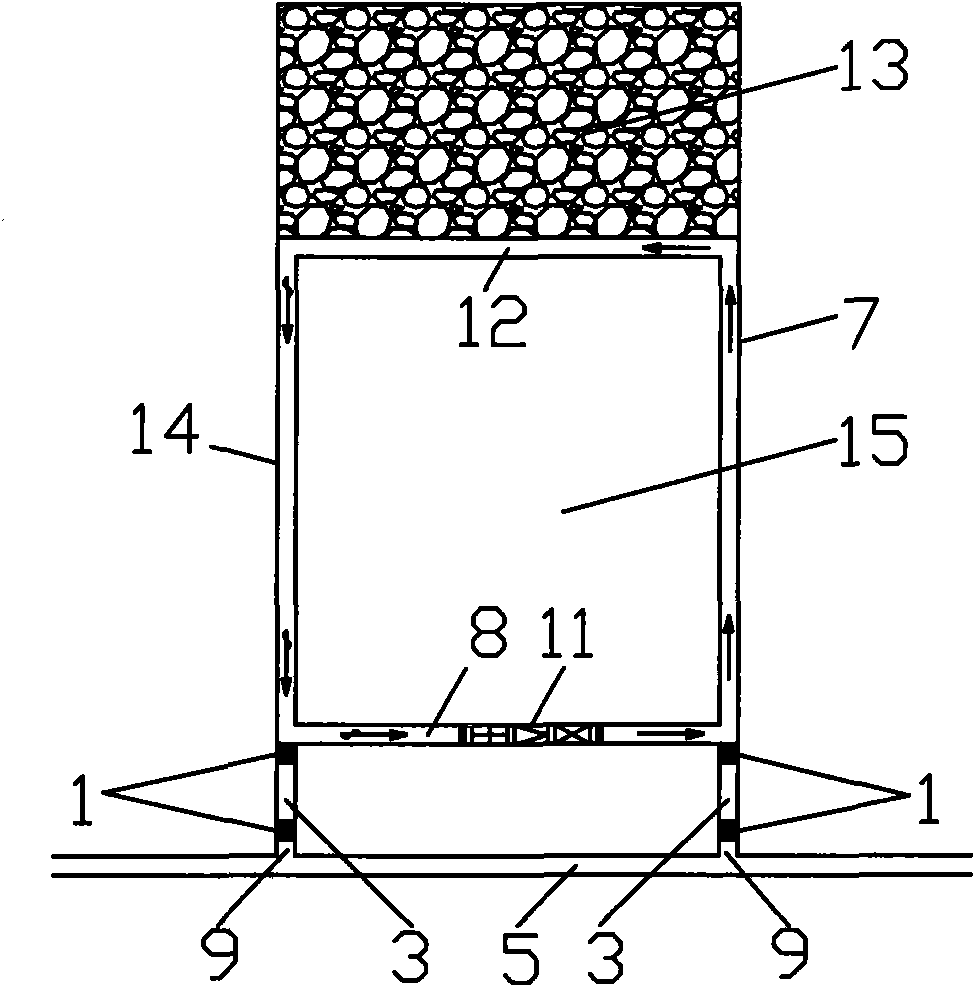

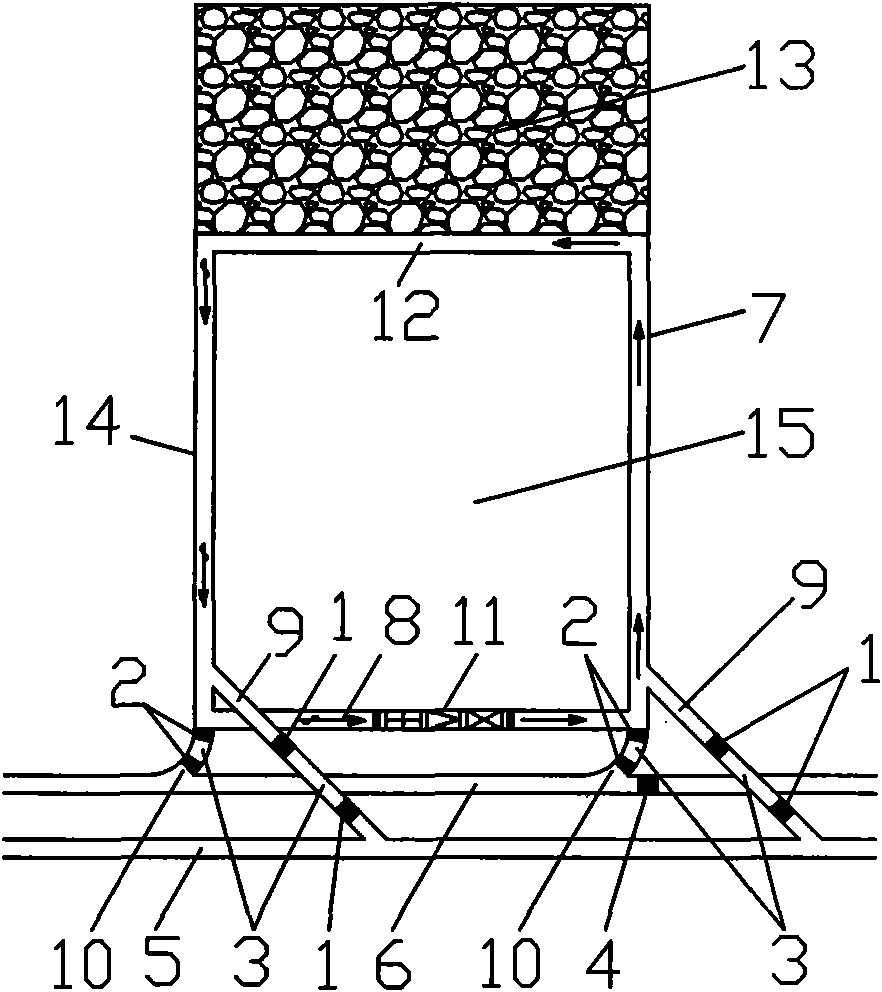

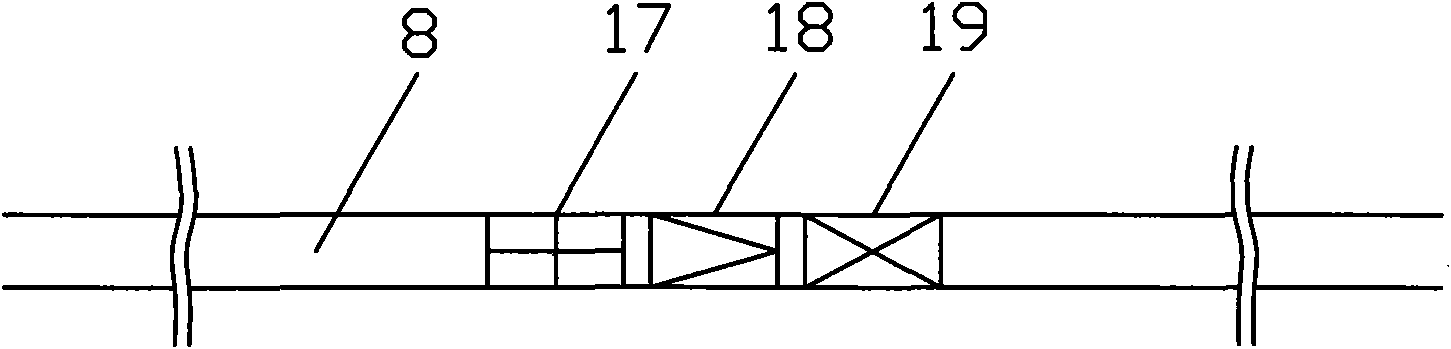

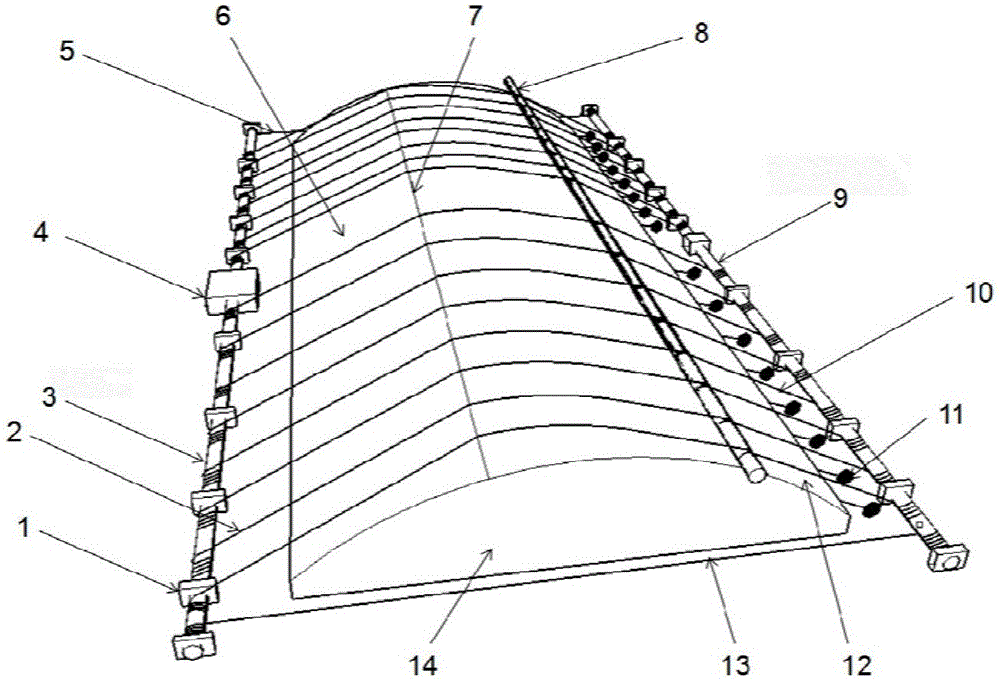

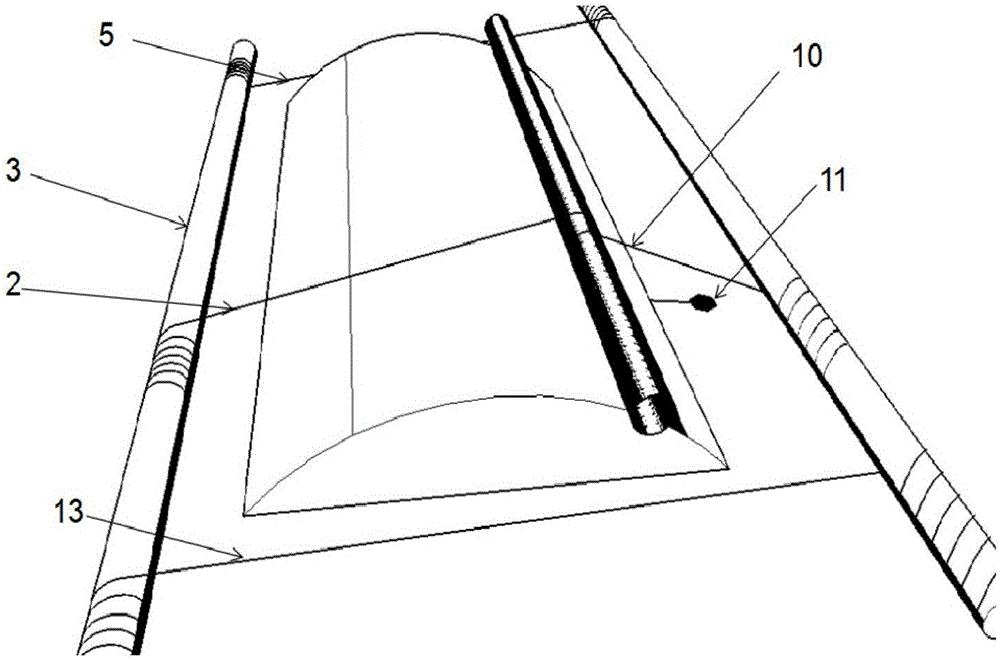

Arched shed heat-insulating quilt full-shed surface winding and unwinding device and using method thereof

InactiveCN106577037AAvoid affecting productionPrevent impact on yieldClimate change adaptationGreenhouse cultivationDevice formEngineering

The invention relates to an arched shed heat-insulating quilt full-shed surface winding and unwinding device and a using method thereof. The winding and unwinding device comprises an arched shed, a traction device, a rope system and a heat-insulating quilt. A driving screw rod and a driven screw rod in the traction device form a linkage relationship through a positive and negative rotating connecting rope which is arranged in the rope system, so that the winding and spreading work of the heat-insulating quilt can be completed by only configuring a motor; the device cost is reduced; a mounting process is simplified; the heat-insulating quilt can cross over the shed top and can be spread and wound on a full-shed surface under the driving of the winding and unwinding device; meanwhile, the heat-insulating quilt can be collected and placed on the ground by the device, and a large amount of shade in the shed caused by placing the heat-insulating quilt on the top of the arched shed can be avoided; the reduction of photosynthesis of plants caused by shading and the influence on the yield can be prevented.

Owner:CHINA AGRI UNIV

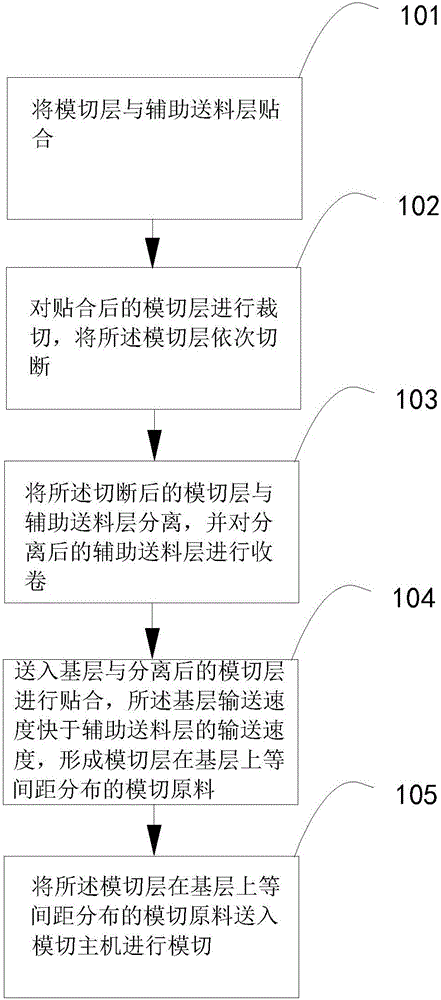

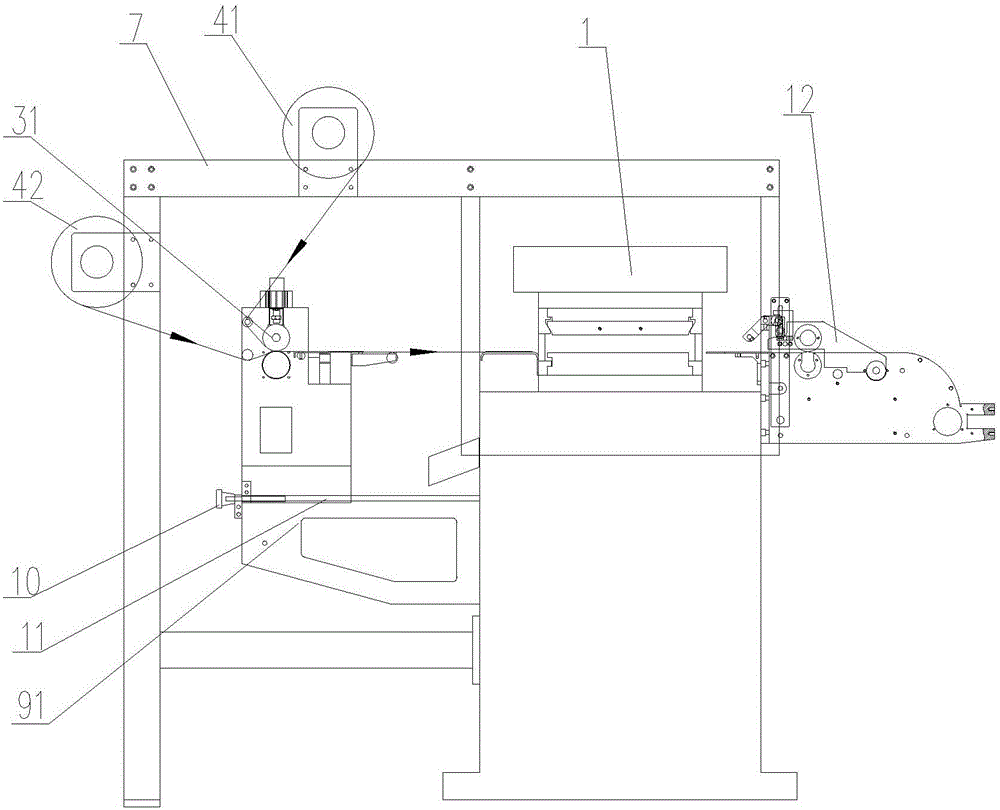

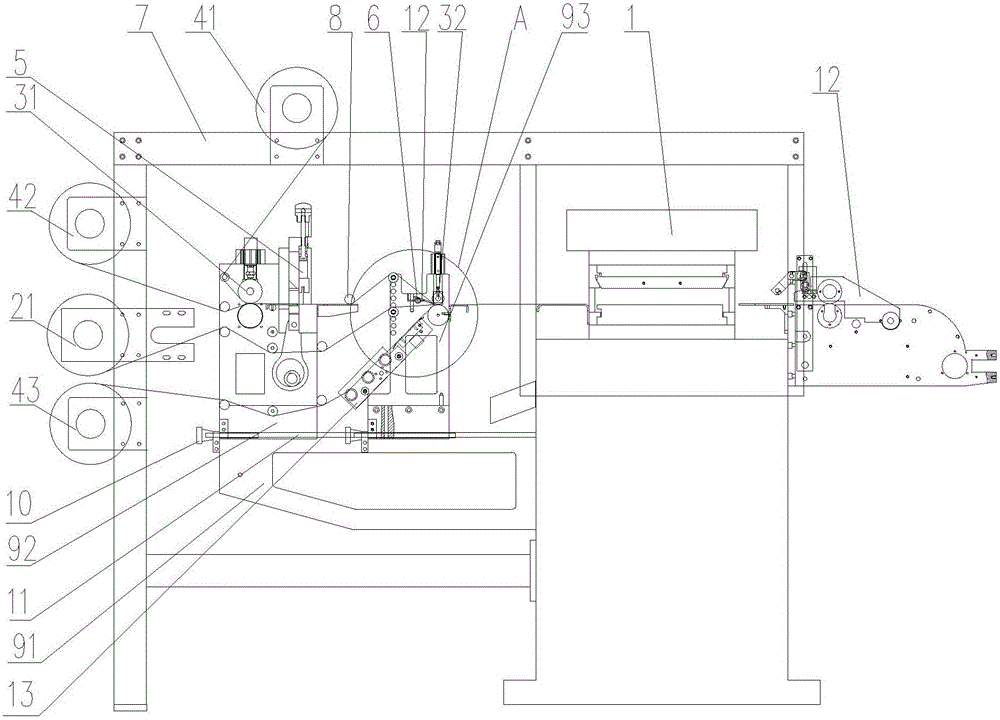

Asynchronous die cutting method and asynchronous die cutting machine for achieving method

ActiveCN106003242AInterval size controlIncrease application rateMetal working apparatusMechanical engineeringHost machine

The invention relates to an asynchronous die cutting method and an asynchronous die cutting machine for achieving the method. The asynchronous die cutting method comprises the following steps that a die cutting layer and an auxiliary feeding layer are laminated; the laminated die cutting layer is sequentially cut off; the cut die cutting layer is separated from the auxiliary feeding layer, and the separated auxiliary feeding layer is wound; a base layer is fed to be laminated with the separated die cutting layer, the conveying speed of the base layer is higher than that of the auxiliary feeding layer, and die cutting raw materials, distributed on the base layer at equal intervals, of the die cutting layer are formed; and the die cutting raw materials, distributed on the base layer at equal intervals, of the die cutting layer are fed into a die cutting main engine to be subjected to die cutting. The asynchronous die cutting machine for achieving the method comprises the die cutting main engine, a rack, discharging shafts, a laminating mechanism, a cutting mechanism for the die cutting layer, a mechanism for separating the die cutting layer from the auxiliary feeding layer and material receiving shafts. The asynchronous die cutting method and the asynchronous die cutting machine for achieving the method are efficient, rapid and capable of saving materials.

Owner:浙江川日机械有限公司

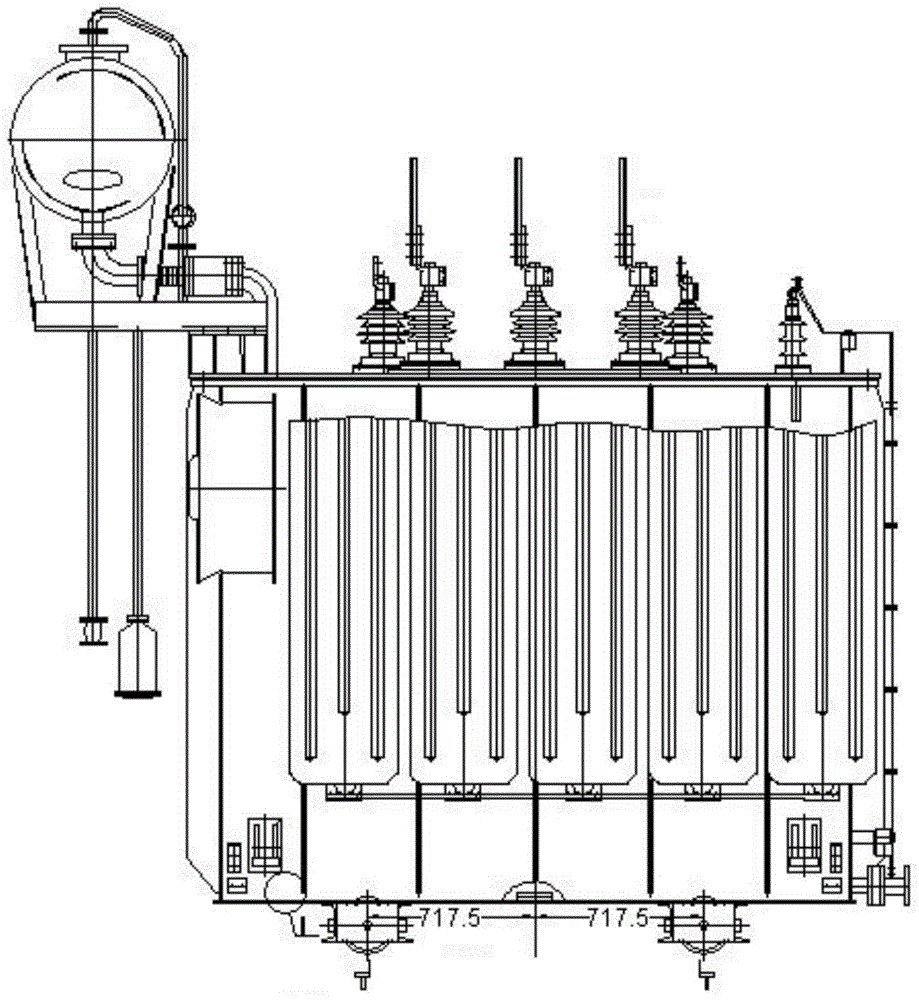

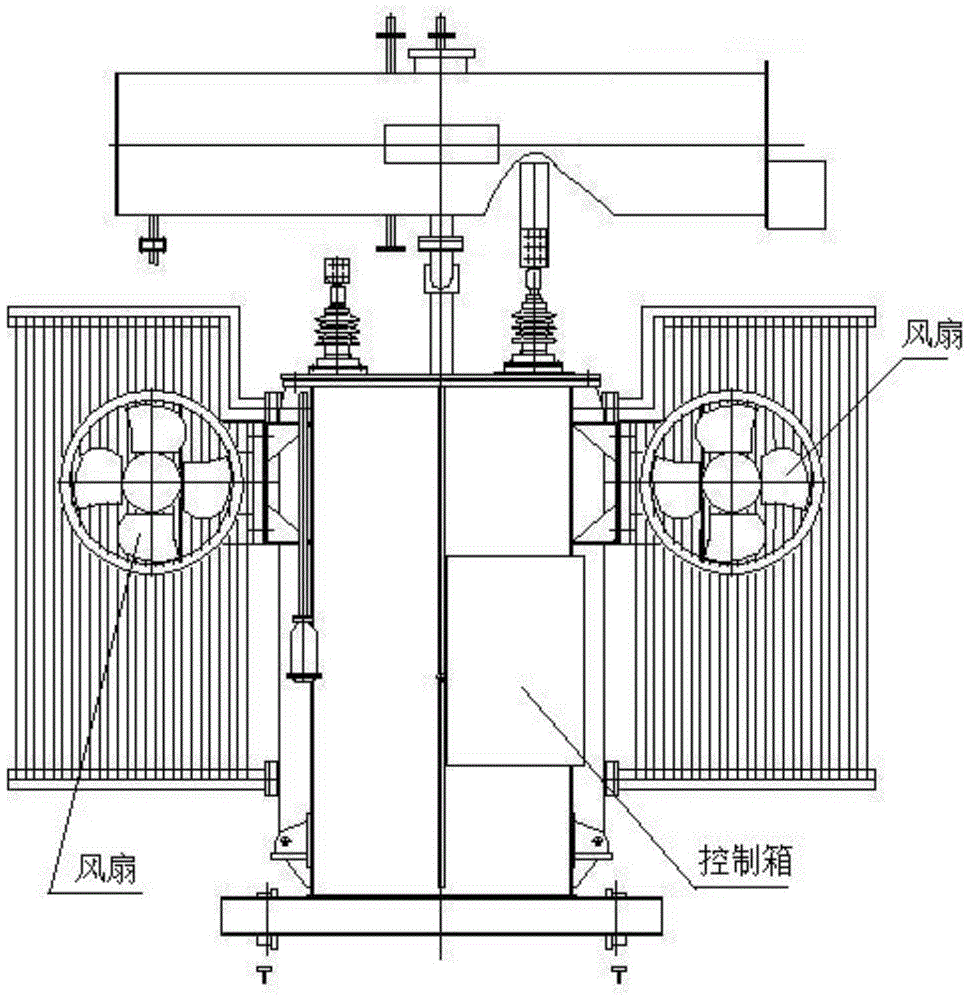

Method for cooling large oil immersed type rectifier transformer under abnormal heated condition

InactiveCN104795206AGuaranteed uptimeGuaranteed to workTransformers/inductances coolingTemperature control using electric meansTransformerLoad following power plant

The invention belongs to the field of industrial and civil large oil immersed type rectifier transformers and provides a method for cooling a large oil immersed type rectifier transformer under the abnormal heated condition. A fan is installed on a radiator of the transformer, and the fan can be started manually or automatically. When the fan is started manually, a motor of the fan is powered on to enable the fan to work. When the fan is started automatically, the temperature value of a signal thermometer arranged inside the transformer and the load value of a current relay in a user control cabinet are measured in real time. When the measured temperature value of the signal thermometer arranged inside the transformer and the measured load current value of the current relay in the user control cabinet exceed set values, the motor of the fan is controlled to be powered on so that the fan can work to ventilate and cool the transformer. By installing the fan on the radiator of the transformer, automatic starting and manual starting can be selected, circuit structure is simple and convenient to use, investment is low, adjustment is easy, and using is convenient.

Owner:WISDRI ENG & RES INC LTD

Method for cultivating morchella strains

ActiveCN110301291AMaintain stabilityAvoid morphological inconsistencies with the parentCultivating equipmentsMushroom cultivationMorchellaEdible mushroom

The invention belongs to the technical field of edible mushrooms and particularly relates to a method for cultivating morchella strains. The method includes production and cultivation of female species, original species and cultured species. With the method, each culture medium is adjusted in the cultivation process of the morchella strains, the preparation method of each culture medium is adjusted, and potassium dihydrogen phosphate, magnesium sulfate and corn flour are added to the culture medium, so that the female species can absorb more nutrient substances from the culture medium, and thesituation that the morphology of the strains is inconsistent with the female parent in the later breeding process to affect the yield is avoided.

Owner:南京金色种业科技有限公司

Laser cutting module for pole piece forming

PendingCN107175412ALow costIncrease productivityMetal working apparatusLaser beam welding apparatusEngineeringLaser light

The invention relates to the field of automation equipment and discloses a laser cutting module for pole piece forming. The laser cutting module comprises a rack, multiple sections of cutting rolls and a laser light source. The cutting rolls and the laser light source are arranged on the rack. The multiple sections of cutting rolls comprise two or more rotary rolls and two or more static rolls. The rotary rolls and the static rolls are coaxial, are equal in diameter and are distributed at intervals in the axial direction. The static rolls are provided with grooves. The rotary rolls can rotate relative to the static rolls. The laser light source can emit laser beams toward the grooves. According to the laser cutting module, through matching of the multiple sections of cutting rolls and the laser light source, forming of a plurality of pole pieces can be conducted simultaneously, forming of the pole pieces does not need involve a plurality of stations, the cost of operation, management and intermediate storage is reduced, and production efficiency is improved.

Owner:SHENZHEN HYMSON LASER INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com