Patents

Literature

210 results about "Rock blasting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rock blasting is the controlled use of explosives and other methods such as gas pressure blasting pyrotechnics or plasma processes, to excavate, break down or remove rock. It is practiced most often in mining, quarrying and civil engineering such as dam or road construction. Except in mining, the result of rock blasting is often known as a rock cut. The use of explosives in mining goes back to the year 1627, when gunpowder was first used in place of mechanical tools in the Hungarian town of Banská Štiavnica. The innovation spread quickly throughout Europe and the Americas. Rock blasting currently utilizes many different varieties of explosives with different compositions and performance properties. Higher velocity explosives are used for relatively hard rock in order to shatter and break the rock, while low velocity explosives are used in soft rocks to generate more gas pressure and a greater heaving effect. For instance, an early 20th-century blasting manual compared the effects of black powder to that of a wedge, and dynamite to that of a hammer. The most commonly used explosives in mining today are ANFO based blends due to lower cost than dynamite.

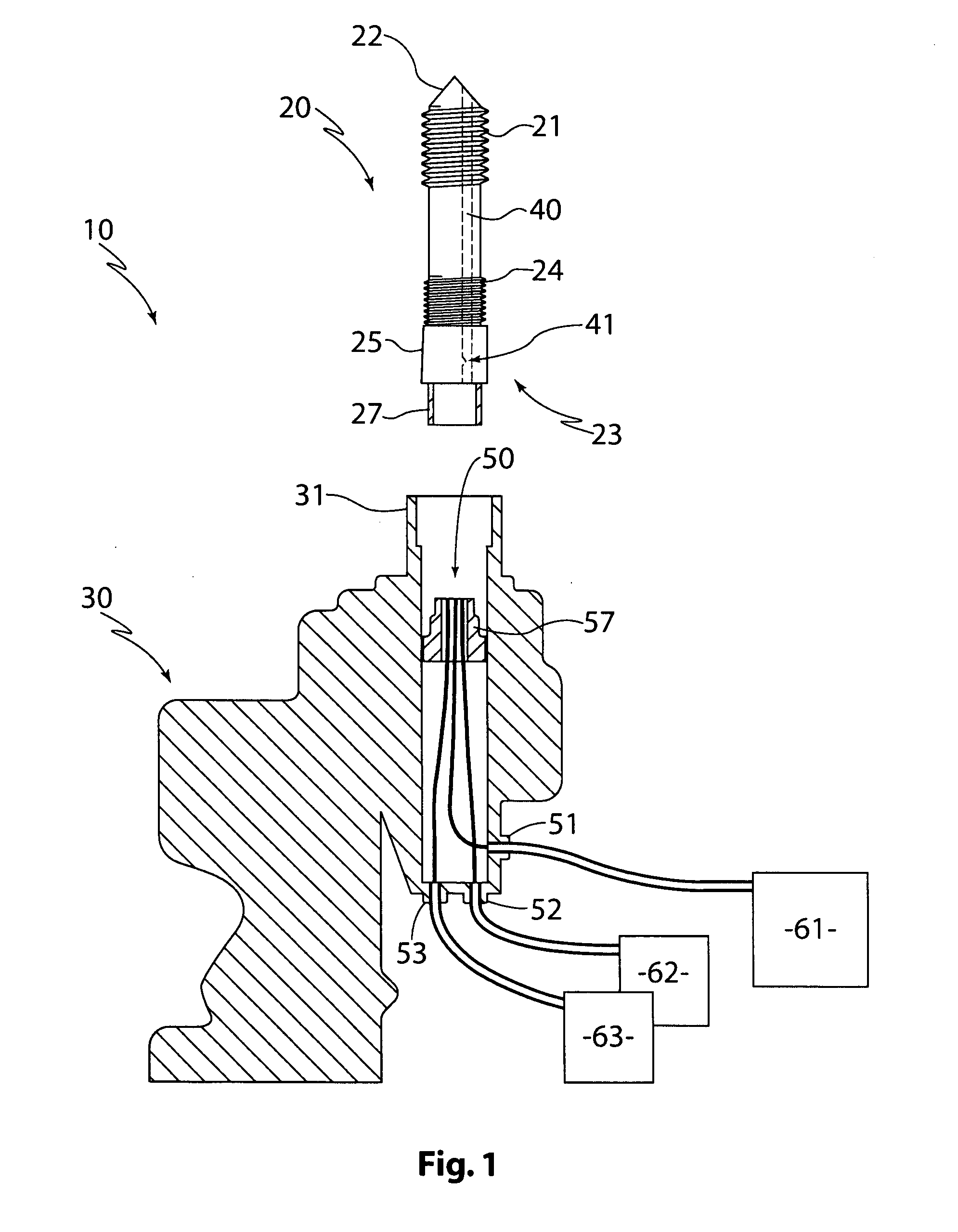

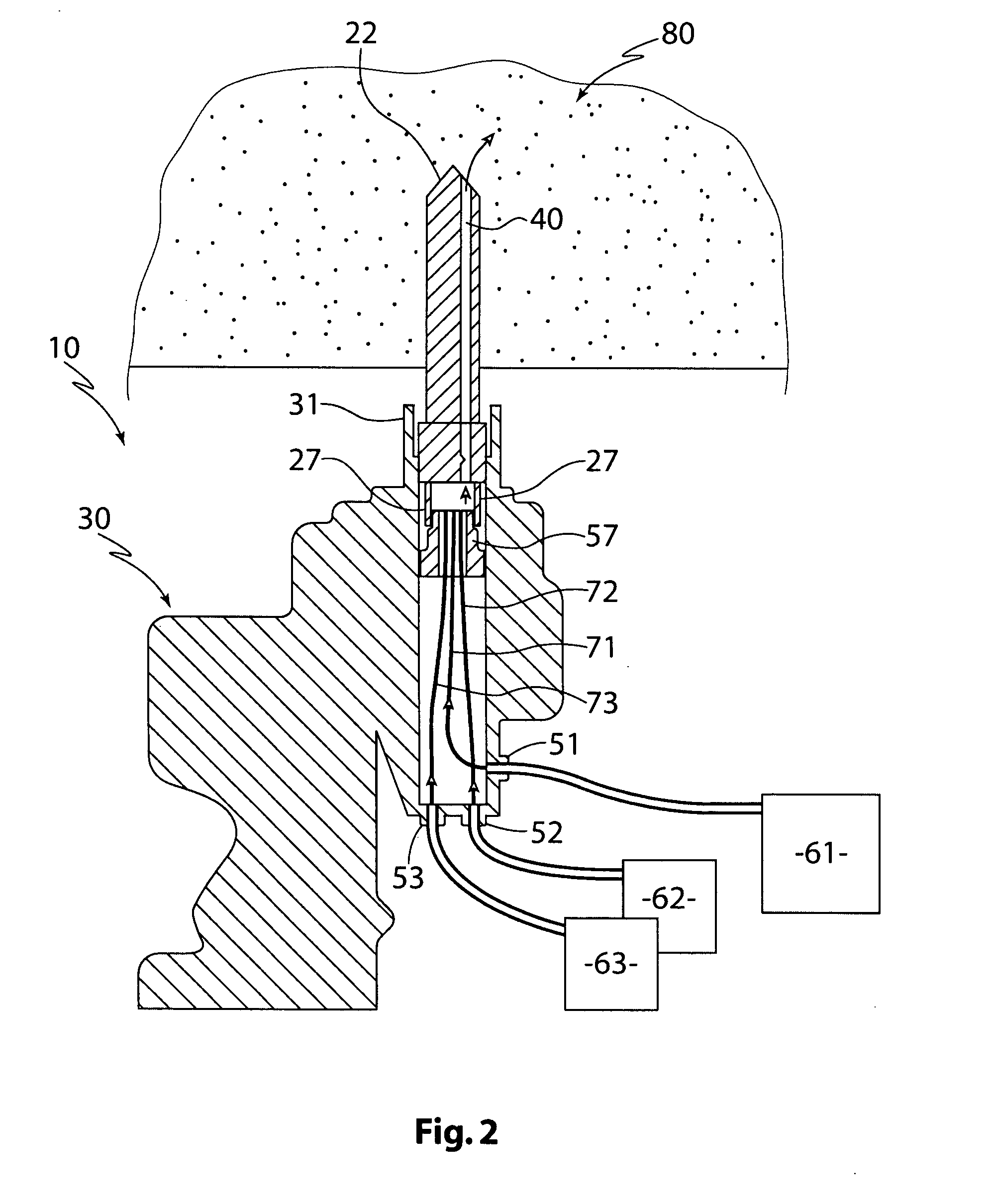

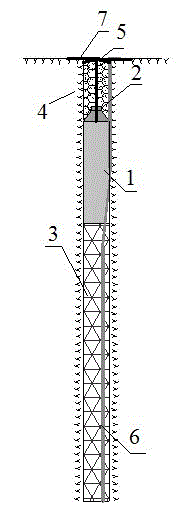

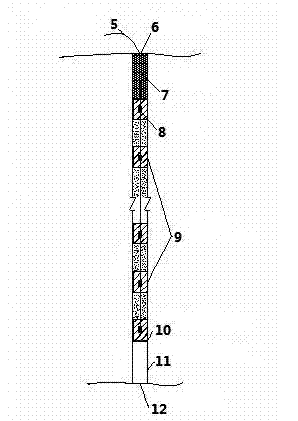

Self drilling rock bolting

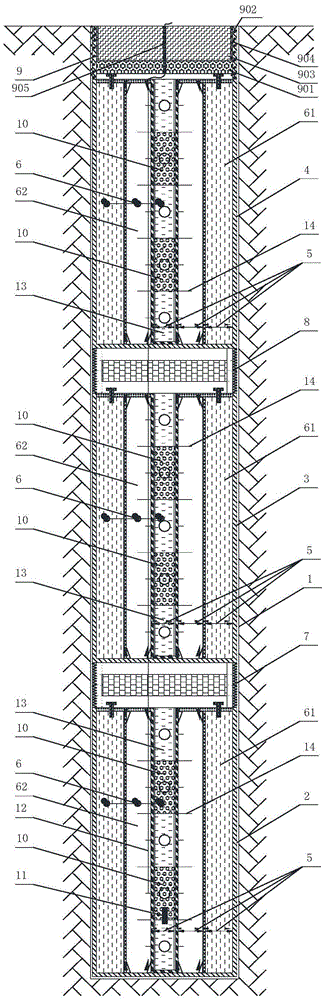

The present invention relates to self drilling rock bolting. In particular, the invention concerns both a drilling apparatus for rock bolting, and a rock bolt for use with the drilling apparatus. The drilling apparatus comprises within it a fluid injector having an upper part that mates with a self-drilling rock bolt for boring a hole. The injector includes three fluid inlets, three fluid outlets in the upper part, and three fluid conduits extending from respective inlets to respective outlets. The self drilling rock bolt comprises an elongate body having a leading end with a cutting tip, and around the tip a thread with a coarse pitch. The bolt also has a trailing end with an integral collar for fluid connection to a channel that extends axially through the body of the rock bolt to the leading end. Above the collar is a thread with a fine pitch. In other aspects the invention concerns a system comprising the drilling apparatus in combination with a rock bolt and a method for rock bolting using the system. The invention has application, but not exclusively, to rock bolting to stabilise the roof and walls of underground coal mines.

Owner:ALMINCO

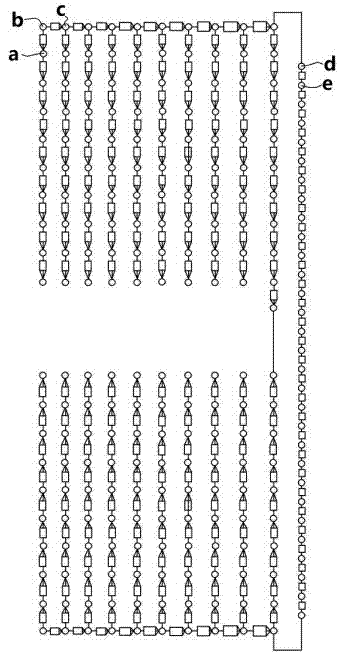

Directional rock blasting crack propagation method and device

The invention discloses a directional rock blasting crack propagation method and a directional rock blasting crack propagation device. The directional rock blasting crack propagation device consists of kerf pipes and explosive, wherein each kerf pipe is symmetrically provided with double kerfs along the longitudinal wall. During directional blasting of peripheral blast holes of a roadway or presplit blasting of an open pit slope, the kerf pipes and the explosive are filled in the blast holes to finish directional crack blasting, wherein an included angle of the kerf direction and the presplit blasting outline direction is less than 150 degrees. The energy of the explosive is preferably released along the kerf direction in a centralized way, so that a blasting fracture surface is accurately controlled, the number of blasting cracks in other directions such as a surrounding rock, a slope and the like is greatly reduced, the length for the blasting crack propagation in the direction to be protected is limited, the production efficiency is high, and the construction cost is low; the device has a simple overall structure and is convenient to use, and is particularly suitable for directional controlled blasting of a rock gangway, a tunnel and the slope.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

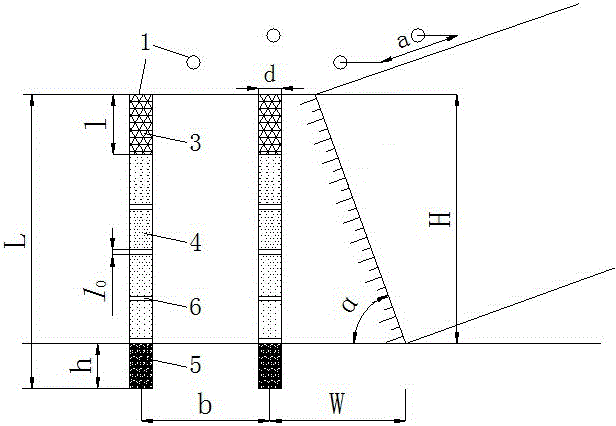

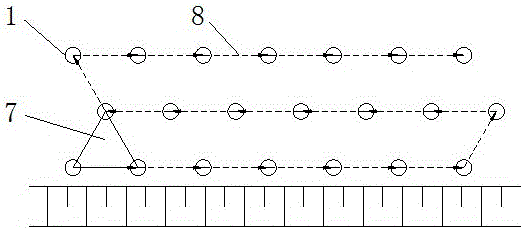

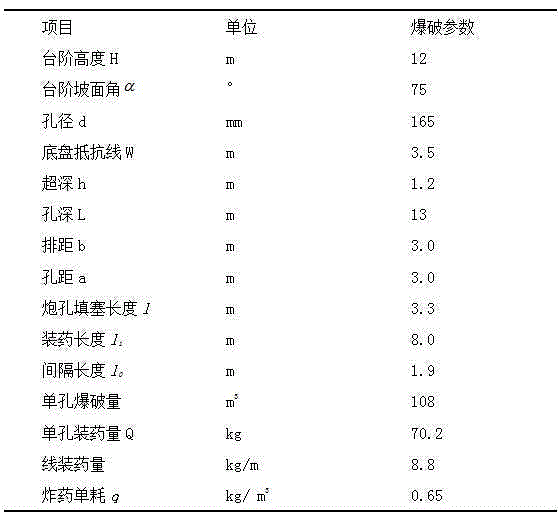

Method for improving bench blasting quality of deep-hole of super-hard rocks

The invention discloses a method for improving the bench blasting quality of a deep-hole of super-hard rocks. The method includes the following steps that blast holes are formed in a step of a blast area, hole mesh parameters are determined, and perpendicular drilling is conducted; explosive loading structures are determined, and the explosive loading structures for segmented explosive loading and mixed explosive loading are adopted in the blast holes at the same time; explosives are determined, wherein the explosives are selected according to according to matching coefficients of explosive wave impedance and rock wave impedance; blasting parameters are determined and include the length W of a resistance line of a base plate, the hole pitch a, the row distance b, the super depth h and the blast hole filling length l; and blasting is conducted, wherein the explosives are loaded, the blast holes are filled with stemming on the tops of the blast holes, reverse blasting is conducted from the bottoms of the blast holes, and blasting is conducted in an inter-hole elementary error sequence. According to the method for improving the bench blasting quality of the deep-hole of super-hard rocks, due to the fact that the hole mesh parameters, the explosive loading structures, the explosives, the blasting parameters, the blasting position and the blasting sequence are reasonably selected, multi-way comprehensive functions are achieved, the performance of the explosives is fully achieved, the sufficient reaction of the explosives is ensured, the utilization rate of the blast holes is increased, and the boulder frequency and bedrocks of rock blasting are reduced.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

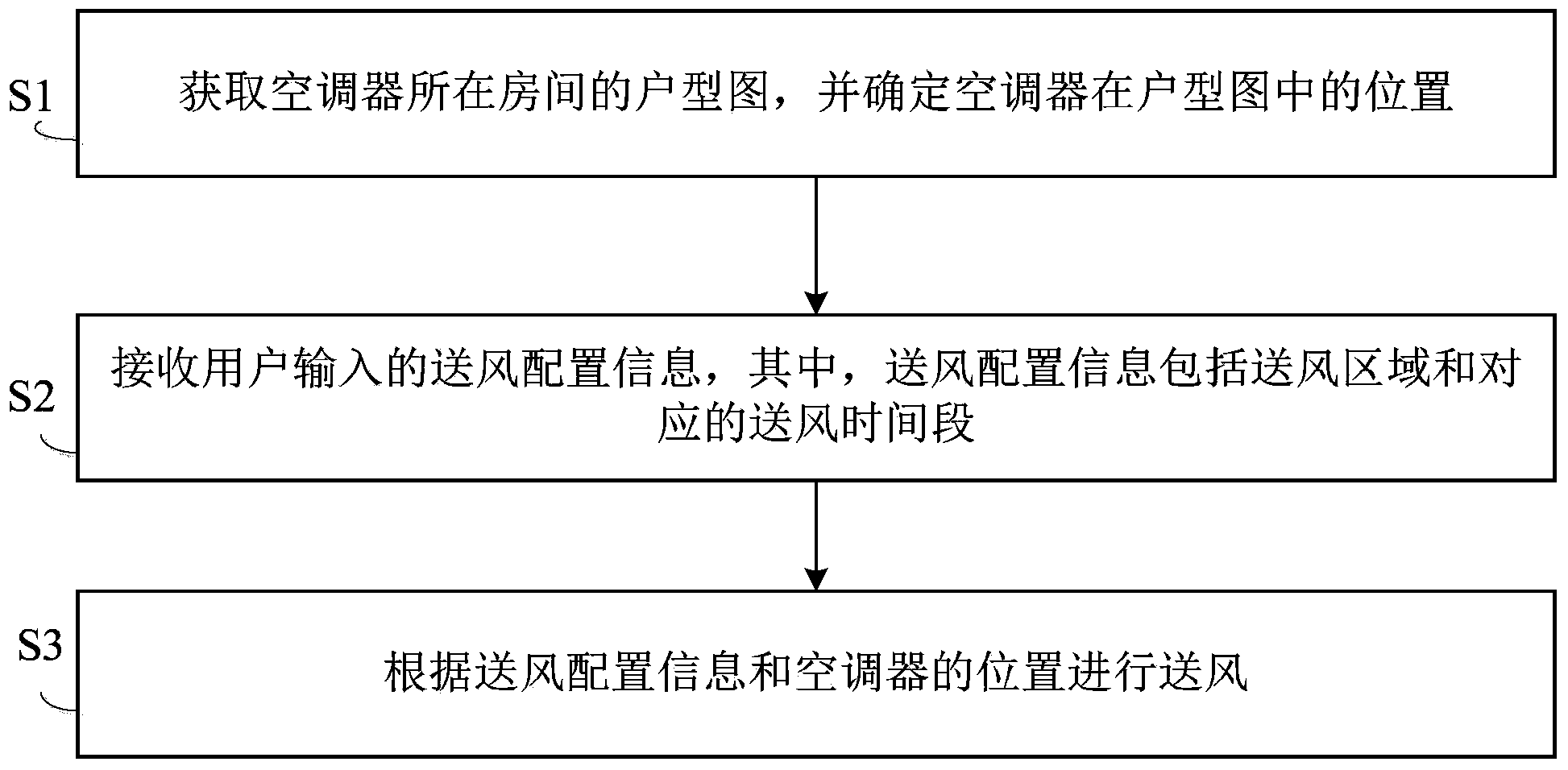

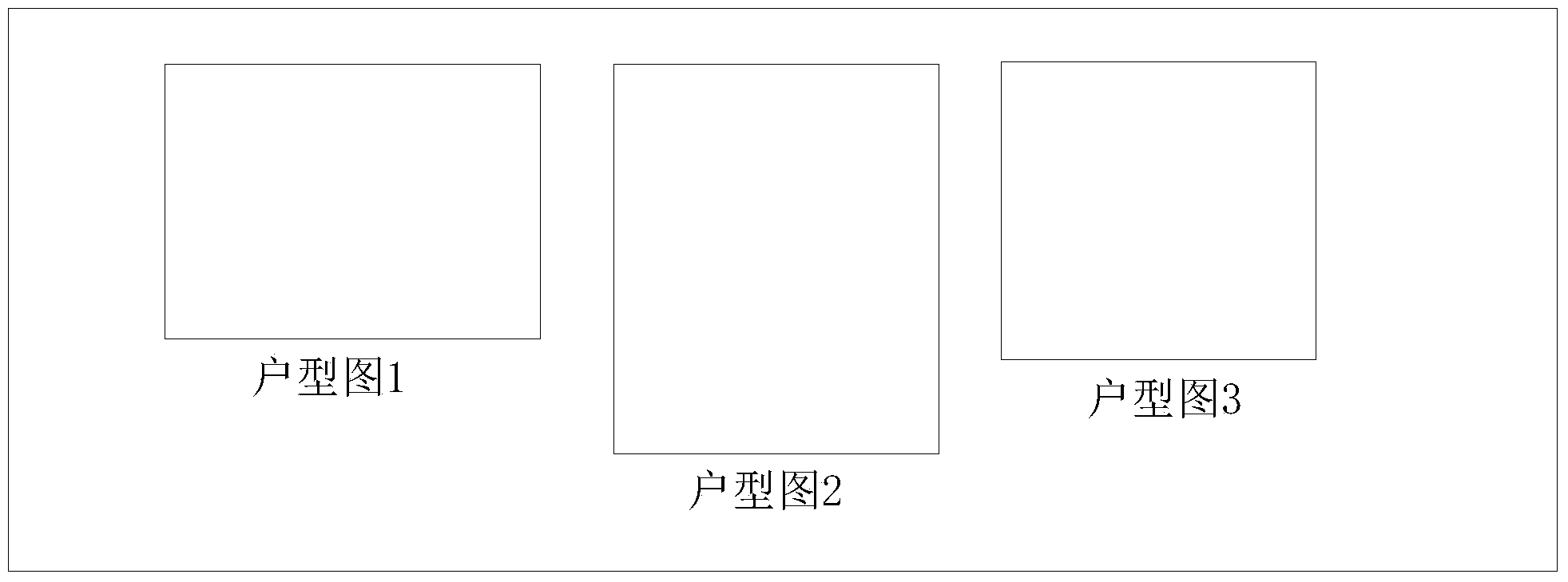

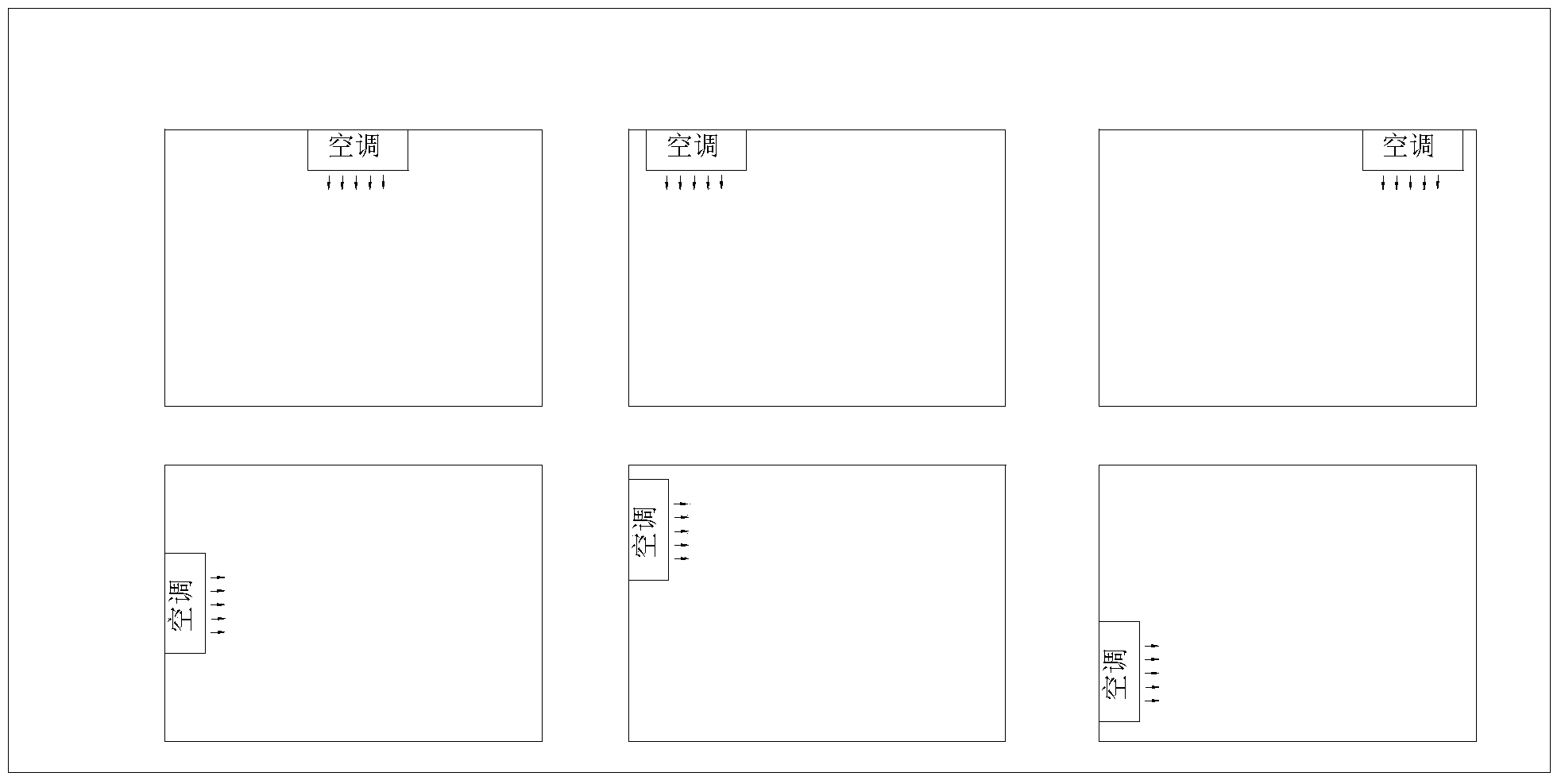

Air conditioner control method and air conditioner

InactiveCN104279712AInfluence of control accuracyLow costMechanical apparatusSpace heating and ventilation safety systemsEngineeringRock blasting

The invention discloses an air conditioner control method. The air conditioner control method comprises the following steps of acquiring a house type image of a room with the air conditioner; determining the position of the air conditioner in the house type image; receiving air blast configuration information which is inputted by a user and comprises air blast regions and corresponding air blast time frames; and performing air blasting according to the air blasting configuration information and the position of the air conditioner. By the air conditioner control method, air blasting can be performed on the air blasting regions inputted by the user at the air blasting time inputted by the user. Compared with the prior art, the air conditioner control method has the advantages that the control precision of the control method is not affected by precision of a detecting device, an air conditioner can be controlled accurately, and the cost of the air conditioner can be reduced. The invention also discloses an air conditioner.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

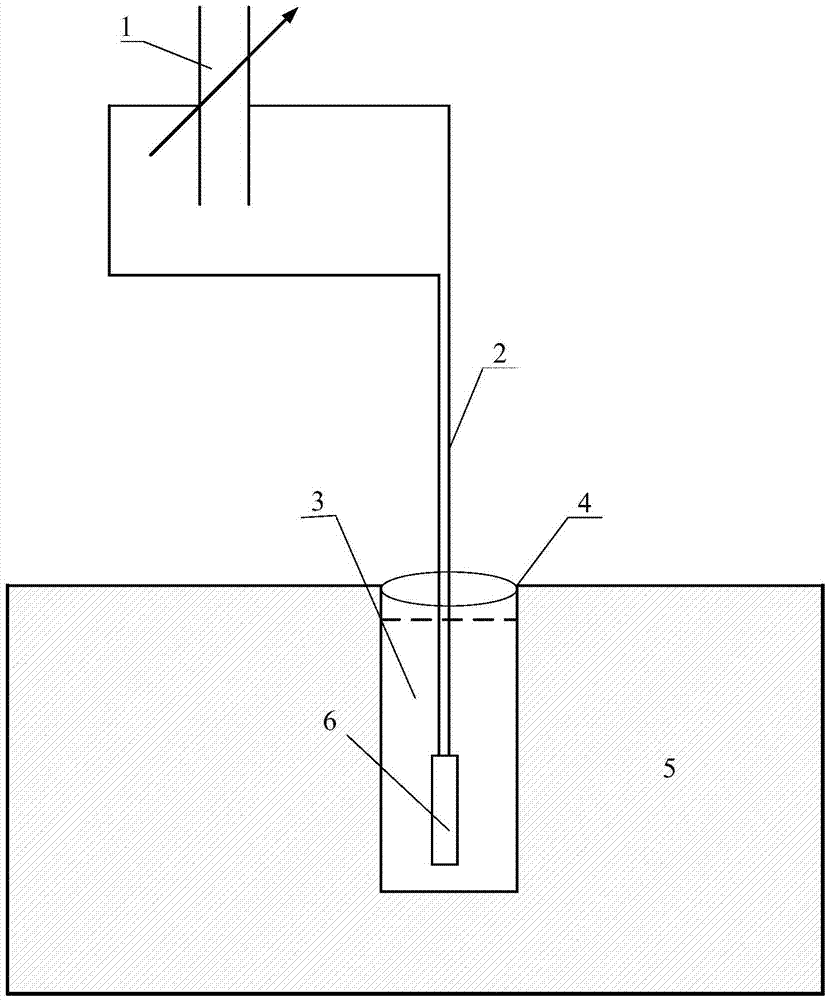

Liquid-phase plasma rock blasting method

InactiveCN105444631ATo achieve the purpose of blasting rockAchieve the desired effectBuilding repairsBlastingShock waveIon clusters

The invention discloses a liquid-phase plasma rock blasting method suitable for blasting rocks and concrete structures. According to the method, strong discharging is implemented in strong sodium chloride or potassium chloride electrolyte solutions for stimulating generation of high-density liquid-phase plasmas; in the high-density liquid-phase plasmas, due to the mutual effect of the electrical property of ion clusters, intense vibration occurs in the sections where ions exist in an instant, high temperature and high pressure are generated in the plasma sections, clustering shock waves of the ions are formed and extend outwards, and therefore the energy of ion waves is spread to the surrounding rocks, natural defects such as joints and fractures in the rocks or the concrete structures are enlarged, new cracks and weakness planes are formed until the rocks or the concrete structures are damaged, and the purpose of blasting the rocks or the concrete structures through the plasmas is realized. Compared with traditional explosive blasting methods, the liquid-phase plasma rock blasting method has the remarkable advantages that dust is avoided, fume is avoided, poisonous and harmful gas is avoided, throwing is avoided, and the noise is low.

Owner:CHINA UNIV OF MINING & TECH

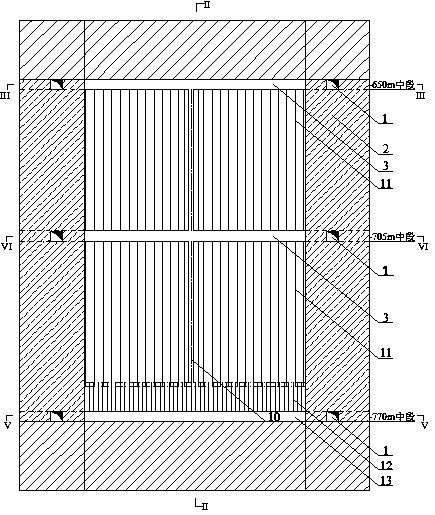

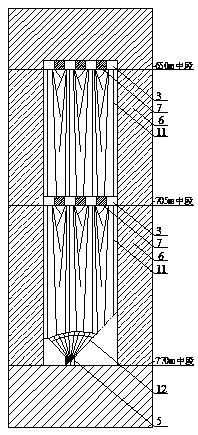

Super large-scale stope large-diameter, deep-hole and high-stage open stope subsequent backfilling mining method

InactiveCN109252862AImprove rock drilling efficiencyLarge amount of mining and cuttingUnderground miningSurface miningRock blastingMaterials science

The invention discloses a super large-scale stope large-diameter, deep-hole and high-stage open stope subsequent backfilling mining method, wherein the method comprises the following steps: (1) actualmining scheme: vertical ore body orientation of ore blocks is arranged, the ore blocks are divided into ore rooms and ore pillars, the ore rooms and the ore pillars are arranged at intervals, double-middle-section continuous actual mining is adopted to divide a stope into two middle sections, and an actual mining method of middle section drilling rock separation, double-middle section continuousore dropping, bottom ore drawing structure sharing and subsequent primary filling is adopted; (2) accurate mining; (3) patio cutting; (4) drilling rock blasting; (5) ore drawing; and (6) filling. Themethod has the beneficial effects the super-large-scale stope has the advantages of small mining and cutting engineering quantity and large stope mining quantity; the stope is divided into two middlesections, rock drilling is performed, reduction of the technical difficulty of deep-hole rock drilling in the stope is facilitated, and the rock drilling efficiency of the stope is improved; with adopting of double-middle-section continuous ore dropping and bottom mine drawing structure sharing, the method has the advantages of increasing the production capacity of a single stope, reducing the mining-cutting cost and improving the actual mining efficiency and the like.

Owner:ANHUI TONGGUAN (LUJIANG) MINING CO LTD

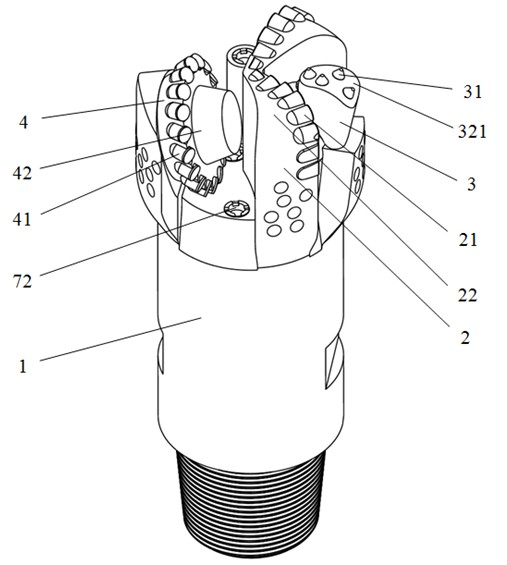

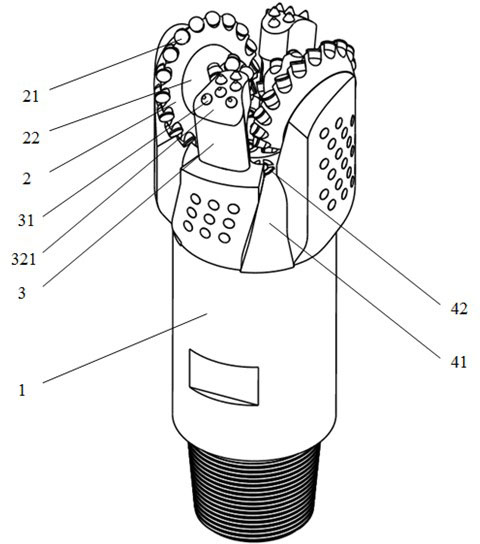

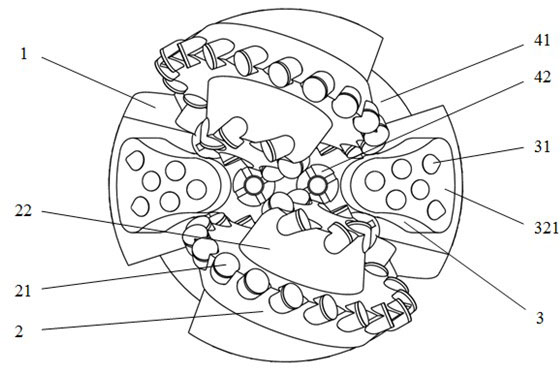

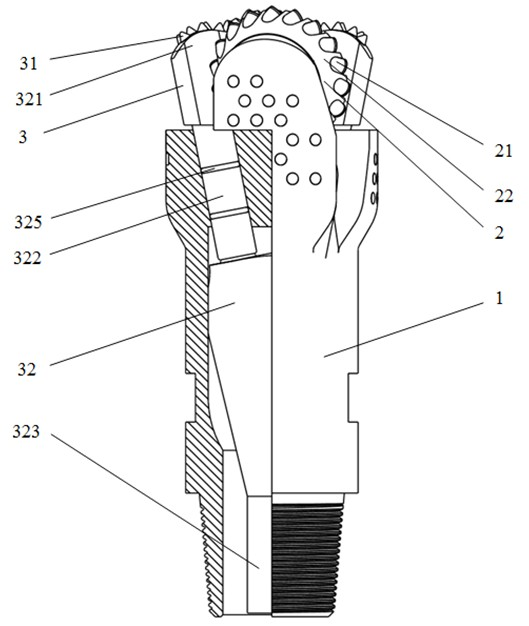

Crossed scraping-impacting composite drill bit

ActiveCN102678053AReduce difficultyReduce rock breaking energy consumptionDrill bitsConstructionsMining engineeringHydraulic structure

The invention discloses a crossed scraping-impacting composite drill bit belonging to the field of rock blasting tools for drilling equipment for oil and gas, mine engineering and building foundation engineering construction, geology, hydrology and the like. The crossed scraping-impacting composite drill bit comprises a drill bit body, a fixed cutting structure, a disc cutter cutting structure and a hydraulic structure, wherein the fixed cutting structure, the disc cutter cutting structure and the hydraulic structure are arranged on the drill bit body; the drill bit body is also provided with an impact cutting structure; and the impact cutting structure comprises a force transferring mechanism for transferring impact forces and impact cutting teeth, wherein the impact cutting teeth are solidified on a punch arranged at the tail end of the force transferring mechanism, and the punch can slide or slidingly impact relative to the drill bit body in the impact force transferring direction. Compared with a drill bit for blasting a rock in a cutting way, the crossed scraping-impacting composite drill bit is not only beneficial to the drilling of the cutting teeth of the drill bit to stratums and the increment of the rock blasting efficiency, but also beneficial to the retardance of the wear rate of the cutting teeth and particularly has remarkable technical advantages for higher-strength and stronger-abrasiveness stratums which are difficult to drill.

Owner:SOUTHWEST PETROLEUM UNIV

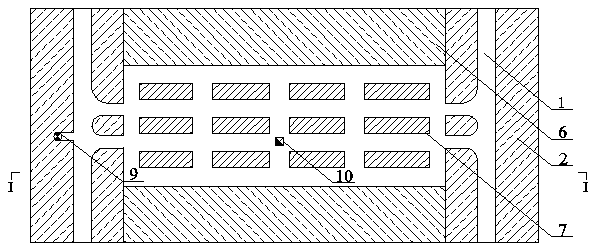

Honey comb structure consolidated fill mining method

InactiveCN101158287AHigh recovery rateFull recoveryUnderground miningSurface miningRock cuttingEngineering

The invention relates to a comb structure cementation-filling mining plan, which is suitable for the underground mining of a high-valuable, thick and broken mine. The invention is provided with a mining process: the mine is divided into a middle section along a trend of the mine, and the middle section is divided into subsections, and a stope structure of each subsection appears as combs which are mutually nested and across arranged; an upper (or lower) plate is respectively communicated with a lower (or upper) plate by cutting through a stringer along a stringer middle part, and a cutting-path is exploited along the trend in the lower (or upper) plate of the cut-stringer and a medium-length hole blasting is adopted to form a cutting groove; a vertical sector medium-length is arranged in the cut-stringer, and a rock blasting explosive is used for mine-caving; a chemical-charging device or a chemical-charging truck is used for charging chemicals, and a detonating cord and a non-conductive detonating fuse are combined for blasting; a scraper is used for taking ores out of the mine. For a first subsection, an upper half-part of the stope is mined, and partial ores are sent out after each blasting. And then a lower half-part of the stope of the first subsection is mined and the processes of cutting, rock-cutting, chemical-charging and blasting are the same as the former, and the ores of the subsection are sent out completely. And an empty stope is filled once. And after the filling, the stope of a neighboring second subsection is mined. The mining plan of the invention has the advantages of great production capability, low production cost, low loss and deficiency rate and reliable security.

Owner:UNIV OF SCI & TECH BEIJING

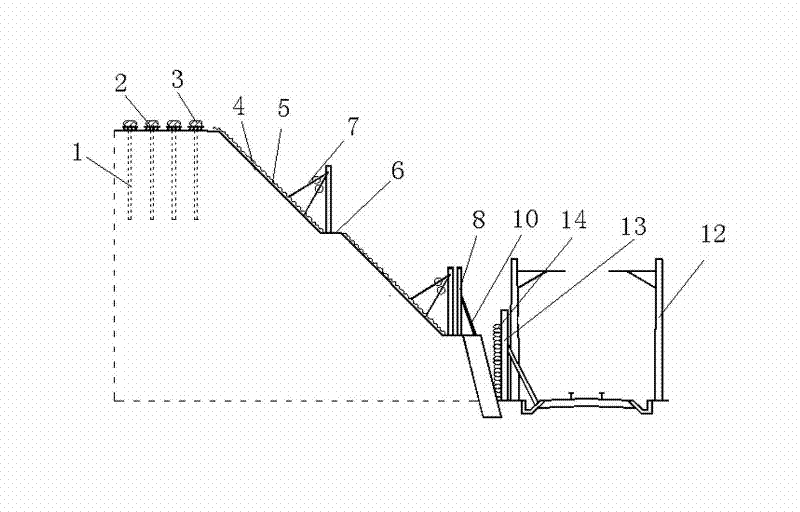

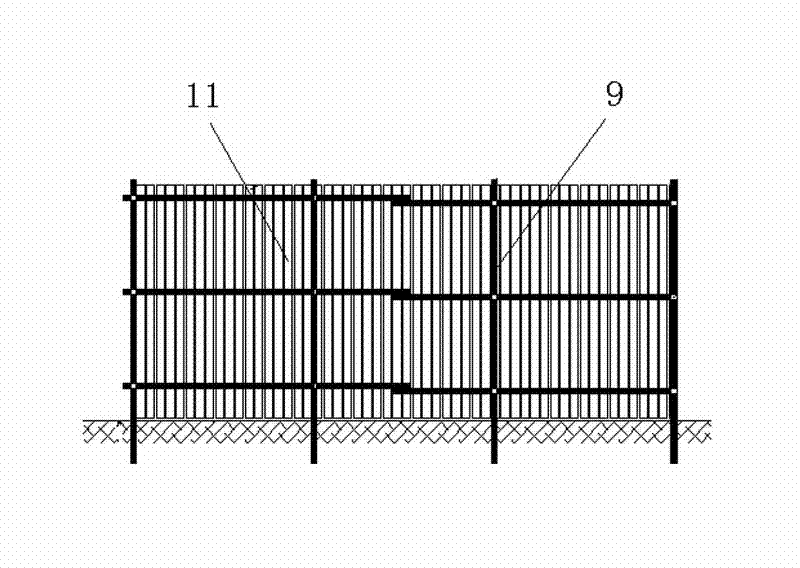

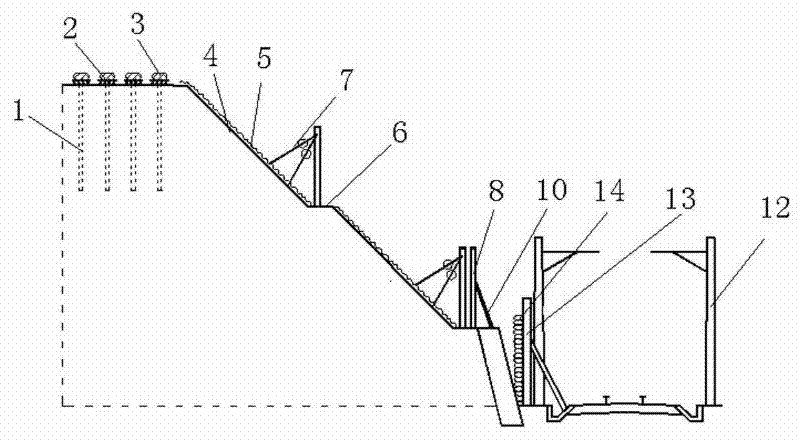

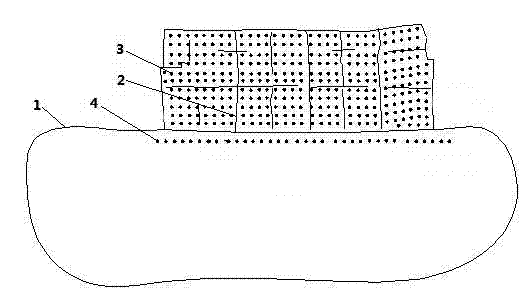

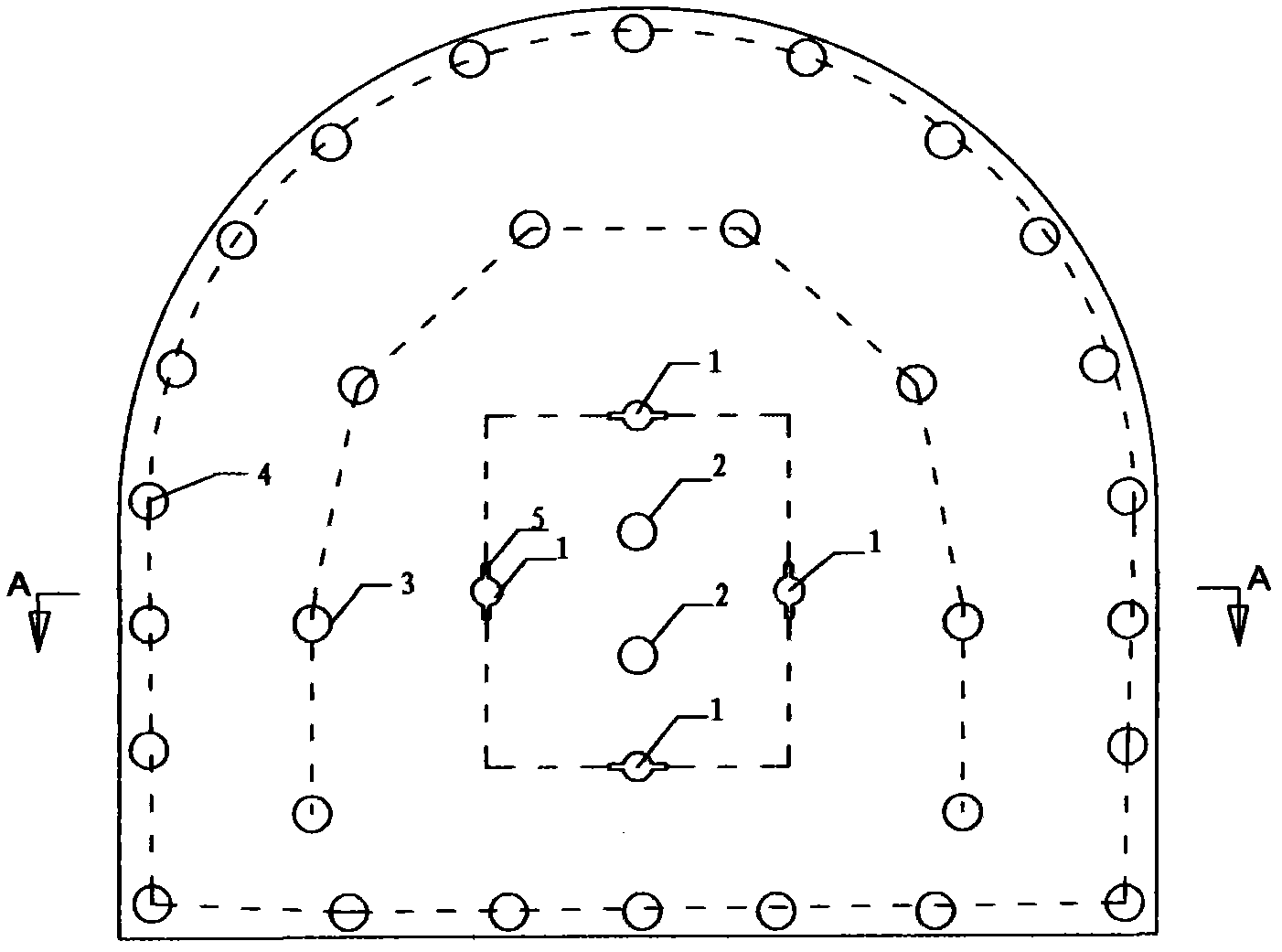

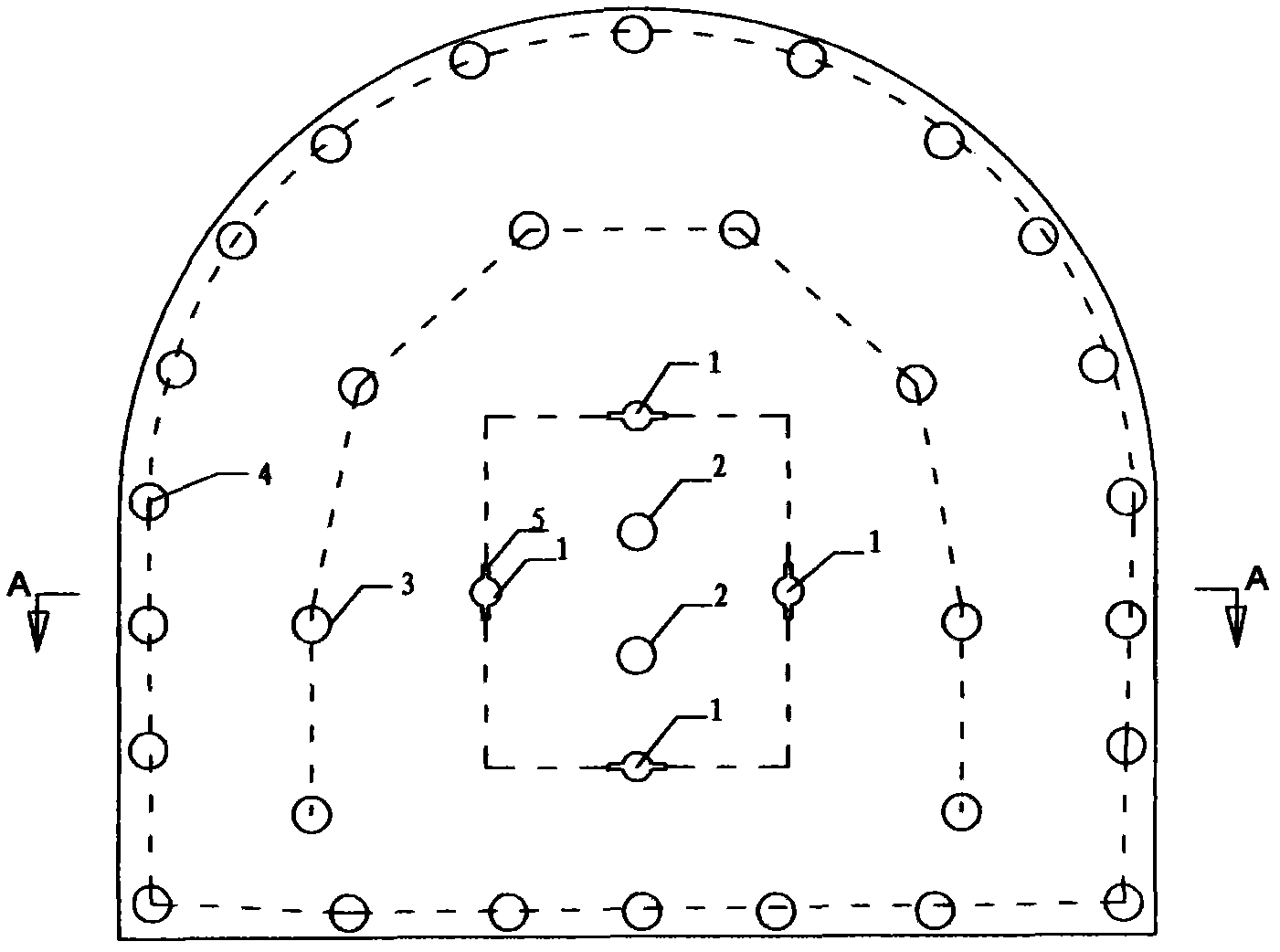

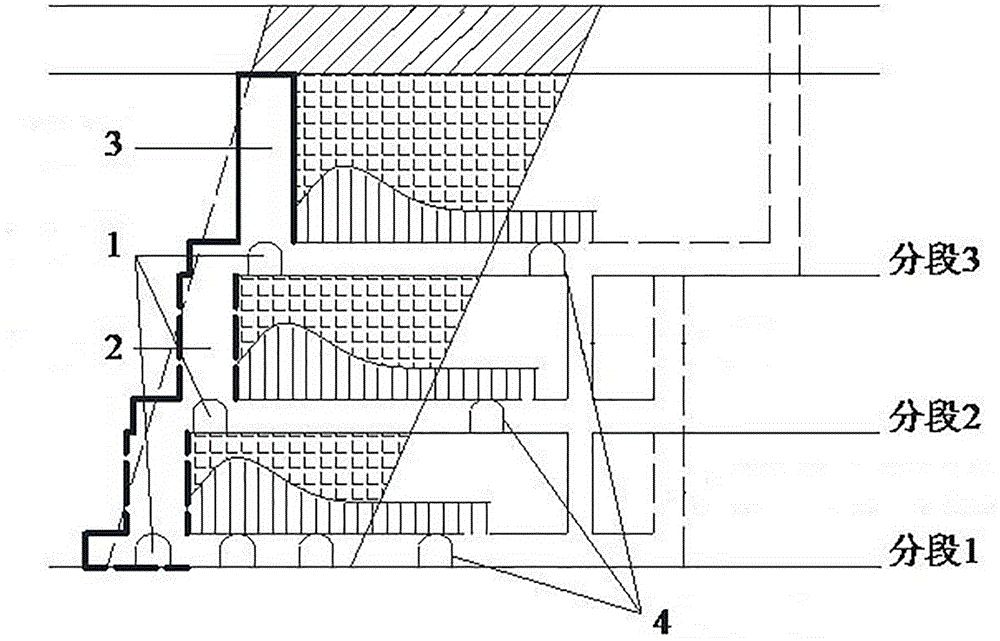

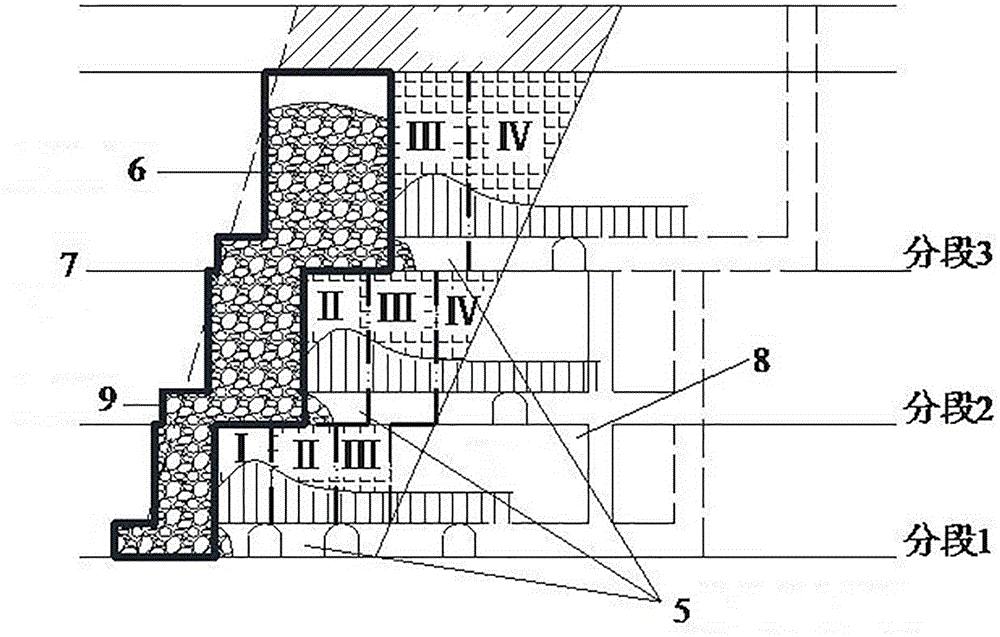

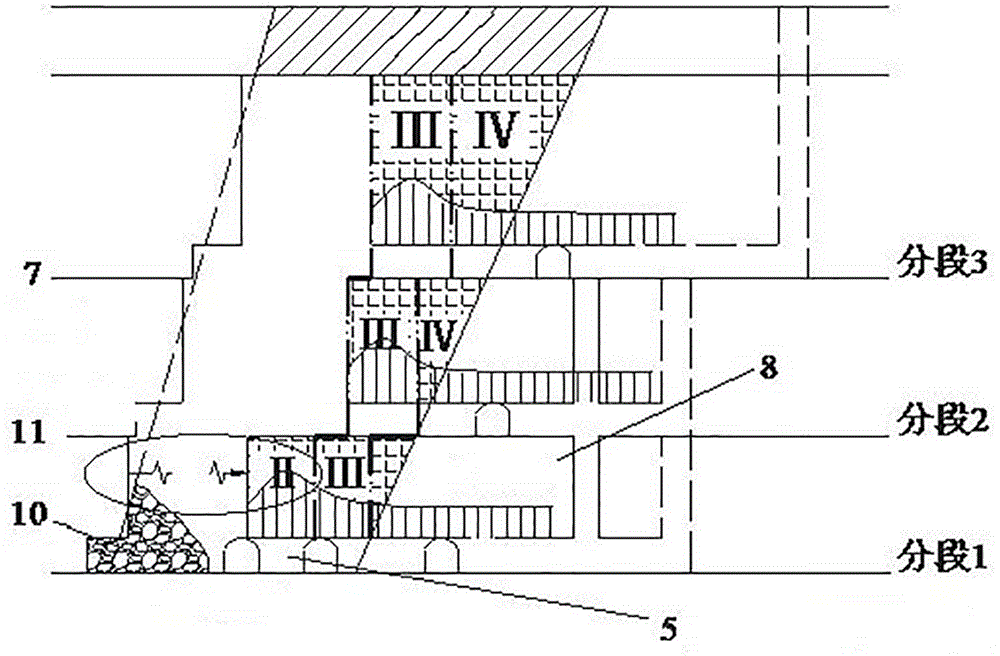

Multielement three-dimensional safety protection method

InactiveCN102419140AGuard against serious hazardsImprove the protective effectBlastingArchitectural engineeringEconomic benefits

The invention relate to a multielement three-dimensional safety protection method, which is used for rock blasting in chasm expanding and excavating in the existing railway and highway, and solves the problems that in the traditional protection method adopted by the existing rock blasting, the construction is complex, the cost is high and the protection effect is poor. The method comprises the following steps of: a, surveying a cross sectional drawing of a blasting point; b, determining chasm expansion thickness, slope height and rock orientation; c, covering a cannon quilt on each porthole, and sealing and pressing each cannon quilt by a sandbag; d, fixing an SNS (Soft Net System) active soft protective net by a side slope surface, and fixing an SNS passive soft protective net by a side slope platform; e, fixing a steel pipe bamboo raft rack on the back side of the SNS passive soft protective net, wherein the steel pipe bamboo raft rack comprises transversal steel pipes and longitudinal steel pipes which are crisscrossed and connected, the longitudinal steel pipes are buried into an underground protection layer, the back side of the protection layer is fixed with an inclined support, and the front side of the protection layer is fixed with a bamboo rack plate. The invention has the advantages that the design is reasonable and reliable, the protection units have respective pertinence and are mutually linked, so that the protection effect is greatly improved, all protection materials can be turnover for many times, and the economic benefit is outstanding.

Owner:THE THIRD ENG OF CHINA RAILWAY 12TH BUREAU GROUP

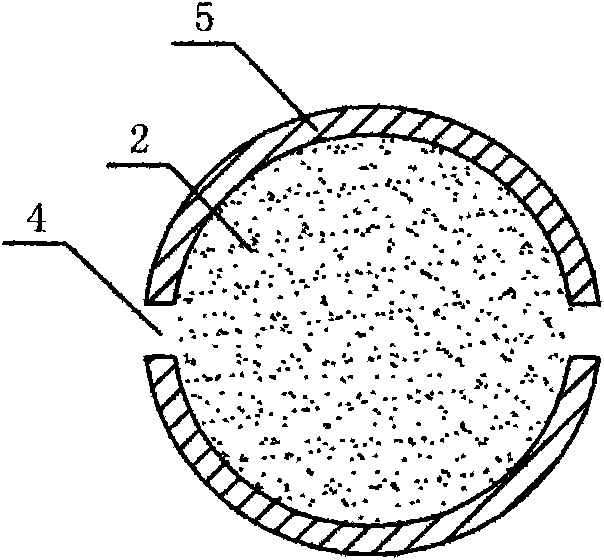

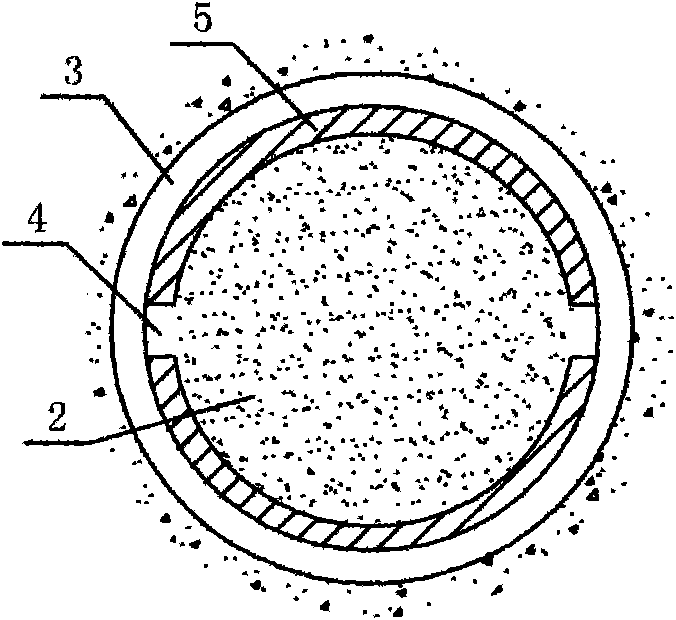

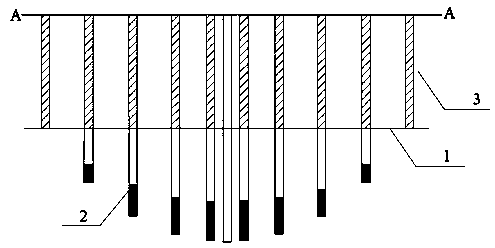

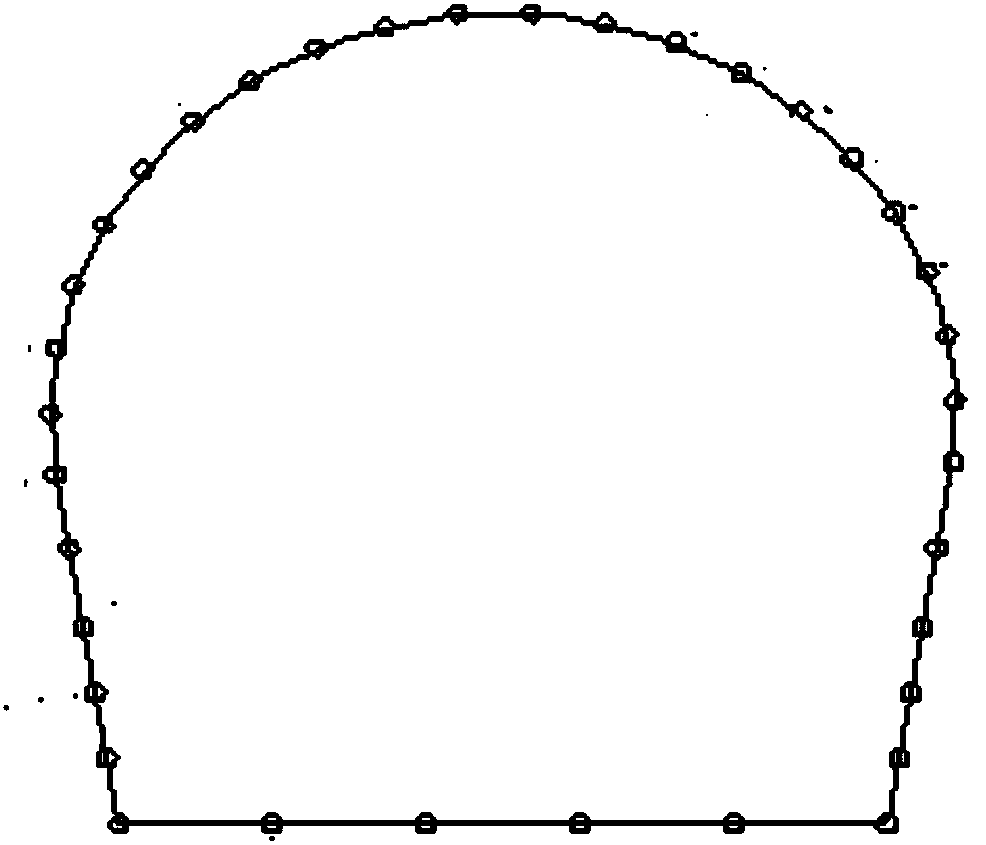

Achieving method for simulating situation that straining-type rock bursting of roadway is caused by excavating unloading effect

The invention discloses an achieving method for simulating the situation that straining-type rock bursting of a roadway is caused by the excavating unloading effect, and belongs to the field of geology simulating tests. The achieving method includes the following step that a hole is filled with a concrete column, wherein the cement-sand ratio is controlled, flocculating agents are added, the errors between the mechanical parameters and the roadway-surrounding-rock parameters of the concrete column are controlled to be lower than 10% by testing the mechanical parameters including the compressive strength, the extension strength, the poisson ratio and the elasticity modulus of the concrete column, and then the hole is filled with concrete after the concrete is evenly stirred. The achieving method has the advantages that by means of the achieving method for simulating the situation that straining-type rock bursting of the roadway is caused by the excavating unloading effect, the background of the combined effects of different self-weight stress fields and tectonic stress fields in a site can be fully considered, and the straining-type rock bursting process is generated in the roadway digging process in rock mass. In addition, other monitoring means are combined, the various physical-performance-change parameters in the rock bursting breeding process, the rock bursting occurring process and the rupturing process after rock bursting are collected, and reliability is high.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

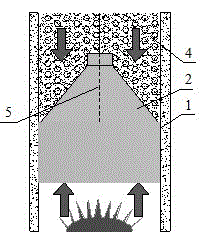

De-noising and dust removal blast hole stemming method for drilling blasting of earth and stone in urban and rural areas

The invention discloses a de-noising and dust removal blast hole stemming method for drilling blasting of earth and stone in urban and rural areas. According to the method, a stemming section comprises a bottom water bag, a middle inverted funnel and a conventional stemming material, the water bag is tied down by a traction rope and is lifted into a hole, the other end of the traction rope is tied to a bearing bar of an orifice of a blast hole, and the edge of the inverted funnel is clamped on the wall of the blast hole to be fixed. Most of shock wave energy generated by explosion can be converted into internal energy required by water vaporization and atomization and kinetic energy of water jet so as to weaken noise; meanwhile, the blasting dust can be wrapped by dispersed water mist to reduce pollution; and in addition, after the water bag is broken, the lower part of the funnel is filled with water, so that the strength of shock waves is indirectly reduced, the stemming time is prolonged, and the stemming effect is enhanced. The method provided by the invention can also be used in rock blasting construction of mines, water and electricity, traffic and other fields.

Owner:WUHAN UNIV

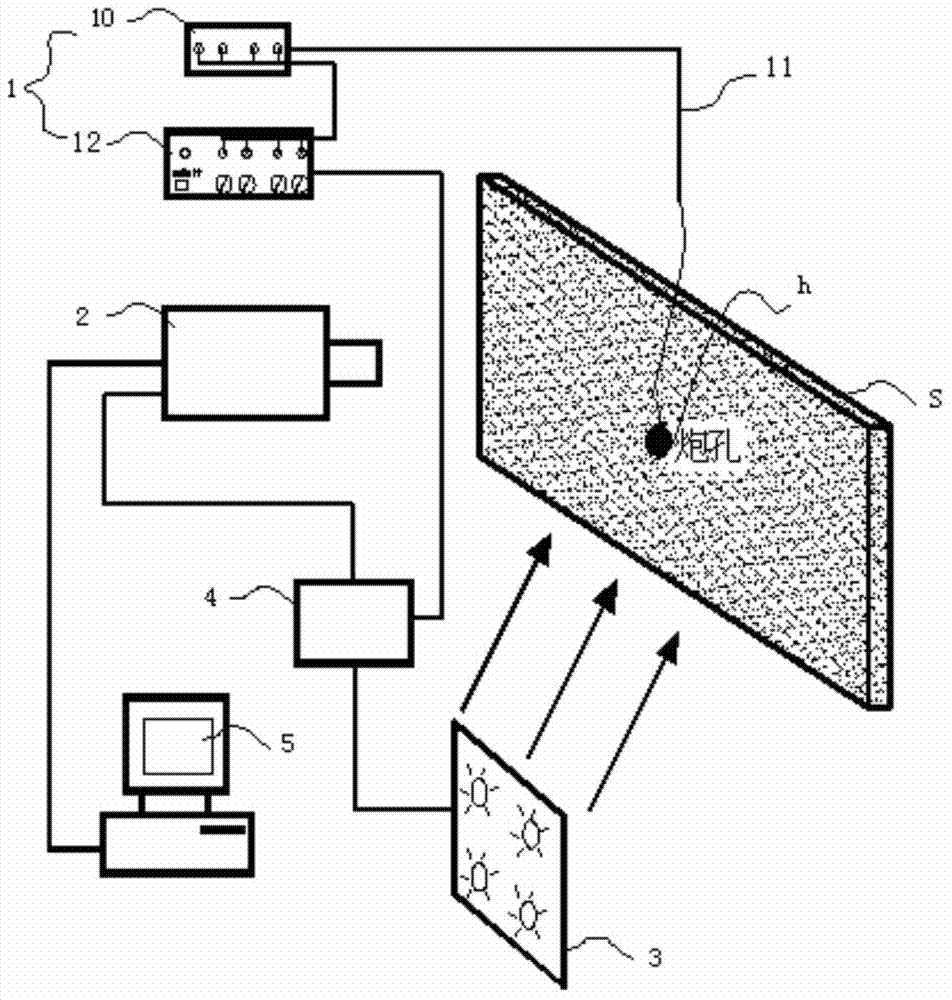

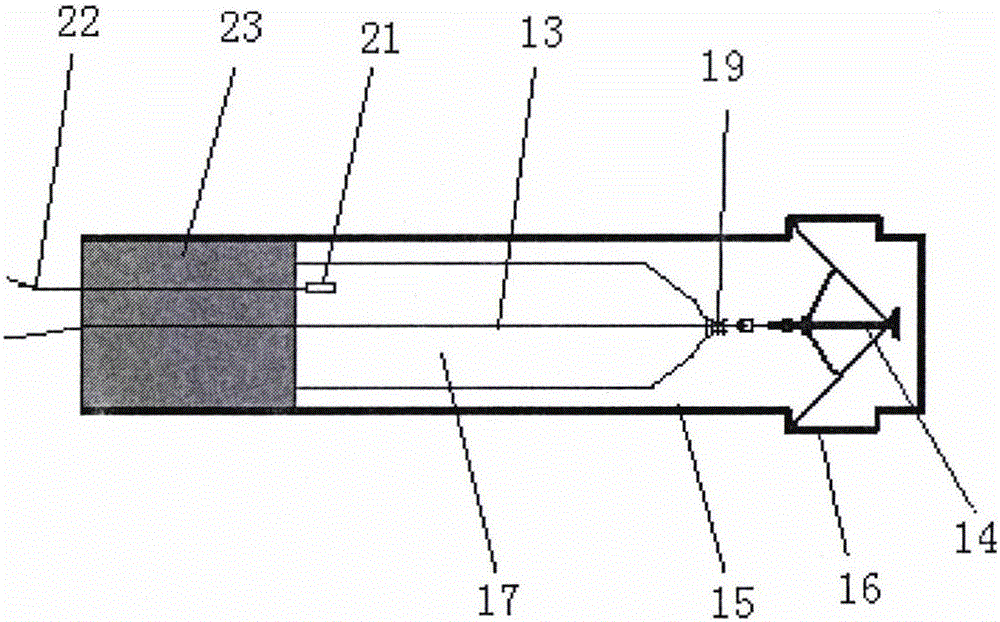

Rock blasting super dynamic strain field monitoring and analyzing system

The invention discloses a rock blasting super dynamic strain field monitoring and analyzing system which can well obtain an experiment effect of a dynamic fracture mechanics experiment under the load of blasting the natural rock. The system comprises a loading unit, a high-speed high-resolution image pickup unit, a light source unit, a synchronization unit and a digital image analysis unit, wherein the loading unit is used for carrying out blast loading on a natural rock test block and generating a super dynamic strain field in the test block; the high-speed high-resolution image pickup unit is used for carrying out alternative shooting or simultaneous shooting on the dynamic fracture process of the natural rock test block by at least two digital imaging subunits so as to obtain crack propagation images at different moments; the light source unit is used for providing illumination or reinforcing illumination light for the natural rock test block; the synchronization unit is used for carrying out synchronous control on actions of the loading unit, the high-speed high-resolution image pickup unit and the light source unit; and the digital image analysis unit is used for analyzing images shot by the image pickup unit. The system is suitable for performing the dynamic fracture mechanics experiment under the load of blasting the natural rock.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Large collapse rock blasting method under precise control of digital electronic detonators

The invention belongs to the technical field of blasting, and particular relates to a large collapse rock blasting method under precise control of digital electronic detonators. The method includes steps of designing parameters of a hole network and distributing holes; drilling holes by cutting drills; charging and blocking; and networking and detonating. The digital electronic detonators are used for precisely controlling blasting, the hole network is designed to be subjected to detonation in parallel and detonation layer by layer, powder charges on the same layer are detonated from two sides to the center obliquely hole by hole, and millisecond delay of powder charges on different layers is realized according to a sequence from bottom to top in the holes. The implementing scheme of adopting the electronic detonators to detonate during blasting of collapse rocks in complicated environments is determined. According to tests of blasting utilizing the electronic detonators to detonate, the technical method of utilizing the electronic detonators to realize precise delay detonation for improving blasting lumpiness is researched, a guarantee is provided for controlling collapse accumulation range of broken rock after blasting, shocks to surrounding rock are reduced greatly on safety blasting conditions of the collapse rock, and secondary disasters are avoided.

Owner:CHONGQING BLASTING CONSTR +1

Fireworks and crackers blasting-agent composition

The invention discloses a fireworks and crackers blasting-agent composition. Agents in the fireworks and crackers blasting-agent composition include, by weight, 40%-60% of potassium perchlorate, 15%-30% of potassium acid phthalate, 10%-20% of a metal-filled multi-walled carbon nanotube, 5%-10% of metal oxide and 3%-5% of black powder, the multi-walled carbon nanotube is filled with one or more combinations of metals of aluminum, silver, iron, nickel, potassium, magnesium, lithium, sodium and the like, and the metal oxide is one or more combinations of ferroferric oxide, iron sesquioxide, copper oxide, manganese oxide, zinc oxide, cobalt oxide and aluminum oxide. The fireworks and crackers blasting composition agents free from metal powder are obviously improved in security coefficient, the explosion dynamics of the agents is high, burning rate of bright points is high, shelf life is long and blasting effect is good.

Owner:WANZAI JIANKUN CHEM

Stone drift driving method adopting technologies of water cutting and cut blasting

The invention discloses a stone drift driving method adopting the technologies of water cutting and cut blasting. The method is guided by the idea of 'cut to drivage', and is realized through the following steps: arranging at least three blast holes on the middle part of a stone drift driving surface, wherein the partial positions of the blast holes are distributed in a circled manner; arranging one to two central holes at the central part circled by the blast holes, and also arranging breaking holes and peripheral holes; performing symmetrically distributed cut machining for two sides of a hole wall of each blast hole through the water cutting technology, so as to enable cuts to converge in the direction of an extended line; blasting cut blast holes, the central holes, the breaking holesand the peripheral holes in sequence to compete full section blast construction of the drivage drift in a cycle period. The method greatly improves the blast and drivage speed, ensures the construction quality and the construction level of the blast, achieves the safe and reliable construction process, and is especially suitable for drivage work of the stone drift with higher hardness or higher stress.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

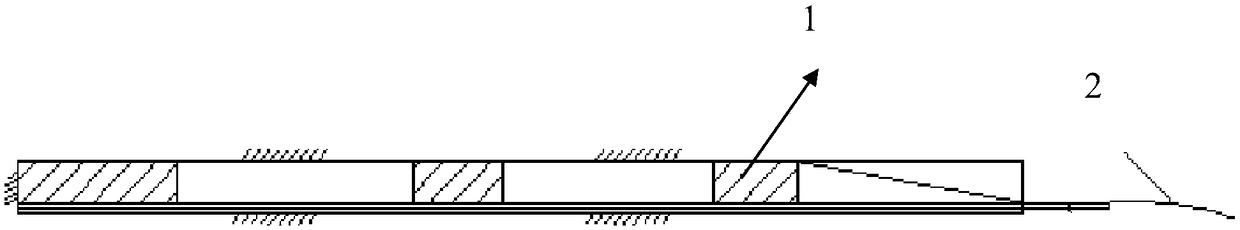

Carbon dioxide fracturing device and method for rock breaking by using carbon dioxide fracturing device

The invention discloses a carbon dioxide fracturing device and a method for rock breaking by using the carbon dioxide fracturing device, and relates to the technical field of rock breaking through carbon dioxide phase-change expansion. A first air exhausting device and a second air exhausting device are arranged on a main pipe, so that air in a cavity of the main pipe overflows from the first air exhausting device and the second air exhausting device under the double action of cooling down of thermal circulation and filling pressure, and thus filling of liquid carbon dioxide and air exhausting can be conducted synchronously and completed simultaneously. According to the main technical scheme of the carbon dioxide fracturing device, the carbon dioxide fracturing device comprises a filling valve, the main pipe and an energy releasing valve, wherein the main pipe is connected with the filling valve; the main pipe comprises a cavity for containing the liquid carbon dioxide, the first air exhausting device and the second air exhausting device, the first air exhausting device is arranged on the upper portion of the main pipe and communicates with the cavity, and the second air exhausting device is arranged on the lower portion of the main pipe and communicates with the cavity; and the energy releasing valve is connected with the main pipe, and is connected with the cavity through a constant pressure shearing sheet. The carbon dioxide fracturing device and the method for rock breaking by using the carbon dioxide fracturing device are mainly used for blasting rock mass.

Owner:赵东

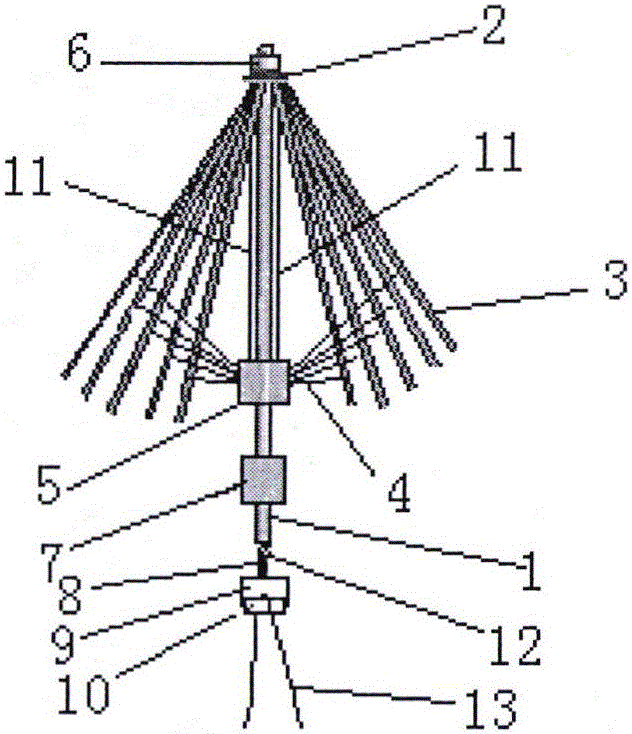

Umbrella-shaped detent hanger and method for charging blast hole through umbrella-shaped detent hanger

The invention discloses an umbrella-shaped detent hanger. An umbrella framework structure is used for reference, elastic rope yarns or springs are mounted to make surface frames have the unfolding trend, and a hanging fixed pulley is further arranged at the lower end of the structure. When the umbrella-shaped detent hanger is matched with a charging long bag for charging an upward or horizontal or downward gently inclined deep blind hole with the enlarged hole bottom, the umbrella-shaped detent hanger is clamped at the hole bottom, the charging long bag is dragged into the blast hole through a rope winds around the fixed pulley, breakage and deformation of a blasting charge can be avoided, accurate spacing charging and non-coupling charging are achieved, and the problems of charging and blockage of upward or horizontal or downward gently inclined deep blind holes are solved. The umbrella-shaped detent hanger is simple in structure and wide in available material source, and mass industrial production and usage are easy. The construction method provided by the invention is wide in application range and can be widely used for projects of demolition blasting, soil and rock blasting, controlled blasting and mine blasting, and the technical scheme with the high cost performance is provided for deep hole charging.

Owner:叶建军

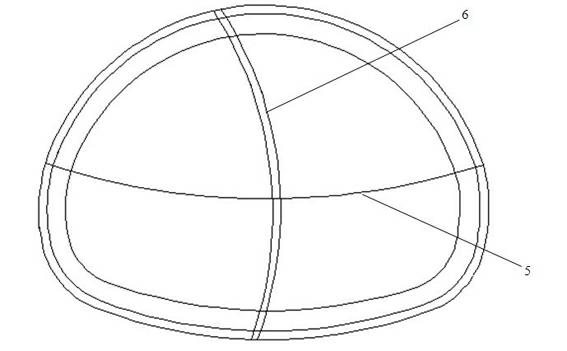

Stress relief blasting method based on tunnel face notching

ActiveCN104390538AIncreased energy release rateAchieve stress reliefBlastingStress conditionsStrain energy

The invention discloses a stress relief blasting method based on a tunnel face notching. The method has the advantages that on the basis of a traditional notching blasting method and a traditional stress relief blasting method, the single hole arrangement is not needed, original tunneling blasting holes are subject to proper re-arrangement and deepening, and a tunnel face with an elliptical surface and an arc-shaped blasting and loosening area are blasted, so a new construction technology is formed, namely that the stress relief and the tunneling excavation are synchronously performed, and strain energy stored by surrounding rock self is sufficiently utilized; the method can be widely applied to the deep tunnel excavation in the fields of mines, water conservancy and hydropower, transportation and the like under the high ground stress condition, or the active control on strong rock blasting in the deep mining process, the rock blasting control effect is effectively improved, and the application prospect is broad.

Owner:WUHAN UNIV

Sublevel-open-stoping-method pressure-relief stoping method for high-dipping medium-thick ore body

InactiveCN107178367AExtend recovery timeAccelerate recovery cycleDisloding machinesUnderground miningDetonationRock blasting

The invention belongs to the technical field of mining, and particularly relates to a sublevel-open-stoping-method pressure-relief stoping method for a high-dipping medium-thick ore body. The method achieves pressure-relief type stoping by means of the steps that a cut parvis is formed through blasting in groups, and then the ore body is divided into three subsections in the vertical direction of the ore body; the ore body is divided into a plurality of stopes in each subsection, and each stope is divided into I-VI rows of grouped concentrated blasting subareas to conduct blasting in groups; broken ores are formed after blasting is conducted, a route for transmitting hanging wall stress to heading wall through the ore body is cut off, and pressure-relief grooves in stair shapes are formed in the vertical direction of the ore body. In addition, through multi-group concentrated blasting, a hole-by-hole millisecond blasting detonation technology is adopted, disturbance and damage to rock mass caused by multi-group blasting of traditional operation are reduced, the blasting efficiency is enhanced, the stope room stoping period is shortened, and the ore production efficiency is enhanced.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

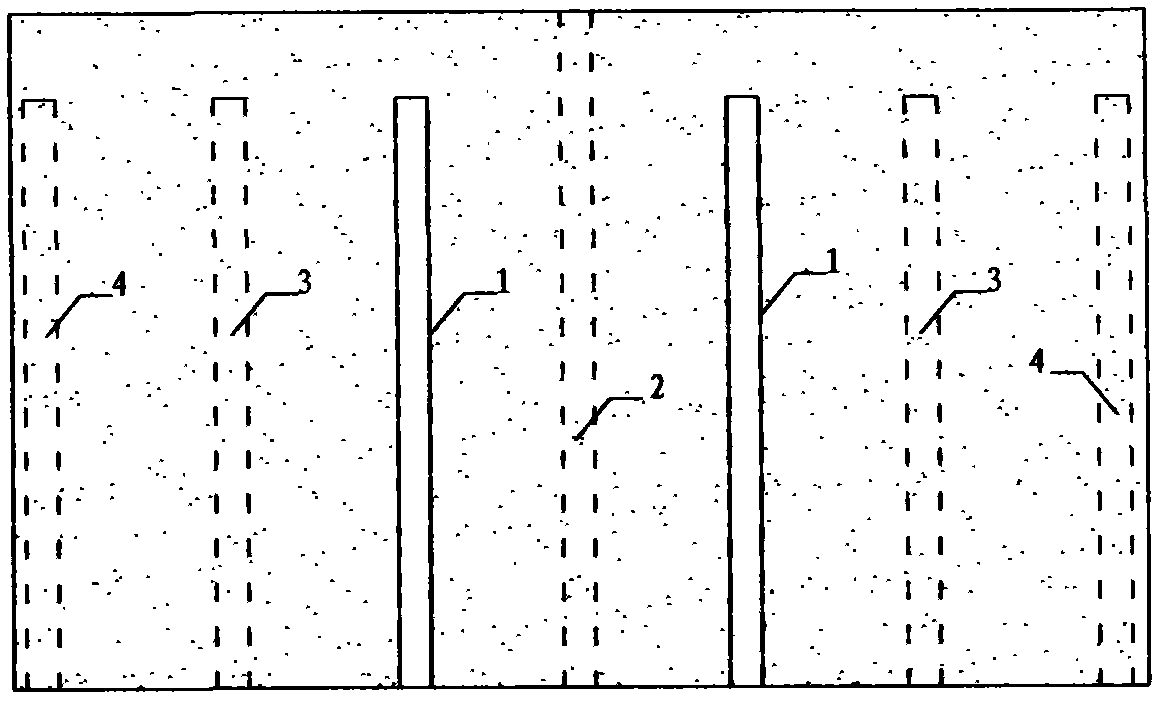

Support structure for hard rock large-section tunnel construction, and construction method for support structure

ActiveCN102305091AAvoid damageSolve complexityUnderground chambersTunnel liningSupporting systemRock blasting

The invention discloses a support structure for hard rock large-section tunnel construction, and a construction method for the support structure. The support structure comprises an initial support and a temporary support which consists of a plurality of vertical temporary supports and longitudinal temporary supports which are connected with the initial support of a tunnel arch crown, wherein the vertical temporary supports are arranged on a tunnel central line between the tunnel arch crown and a tunnel spring line and the bottoms of the vertical temporary supports are supported on unexcavatedrock on the spring line and are not needed to extend to the bottom of the tunnel section. The support structure solves the problem that support processes are complex and slow and the temporary supports are damaged seriously during blasting in the multistep blasting and excavation construction of (especially) large-section hard rock, and has the advantages of simple structure, quick construction progress, high construction safety and capacity of reducing damage of hard rock blasting to a temporary support system to the maximum extent, and the like.

Owner:CHINA RAILWAY 16TH BUREAU GRP CO LTD +1

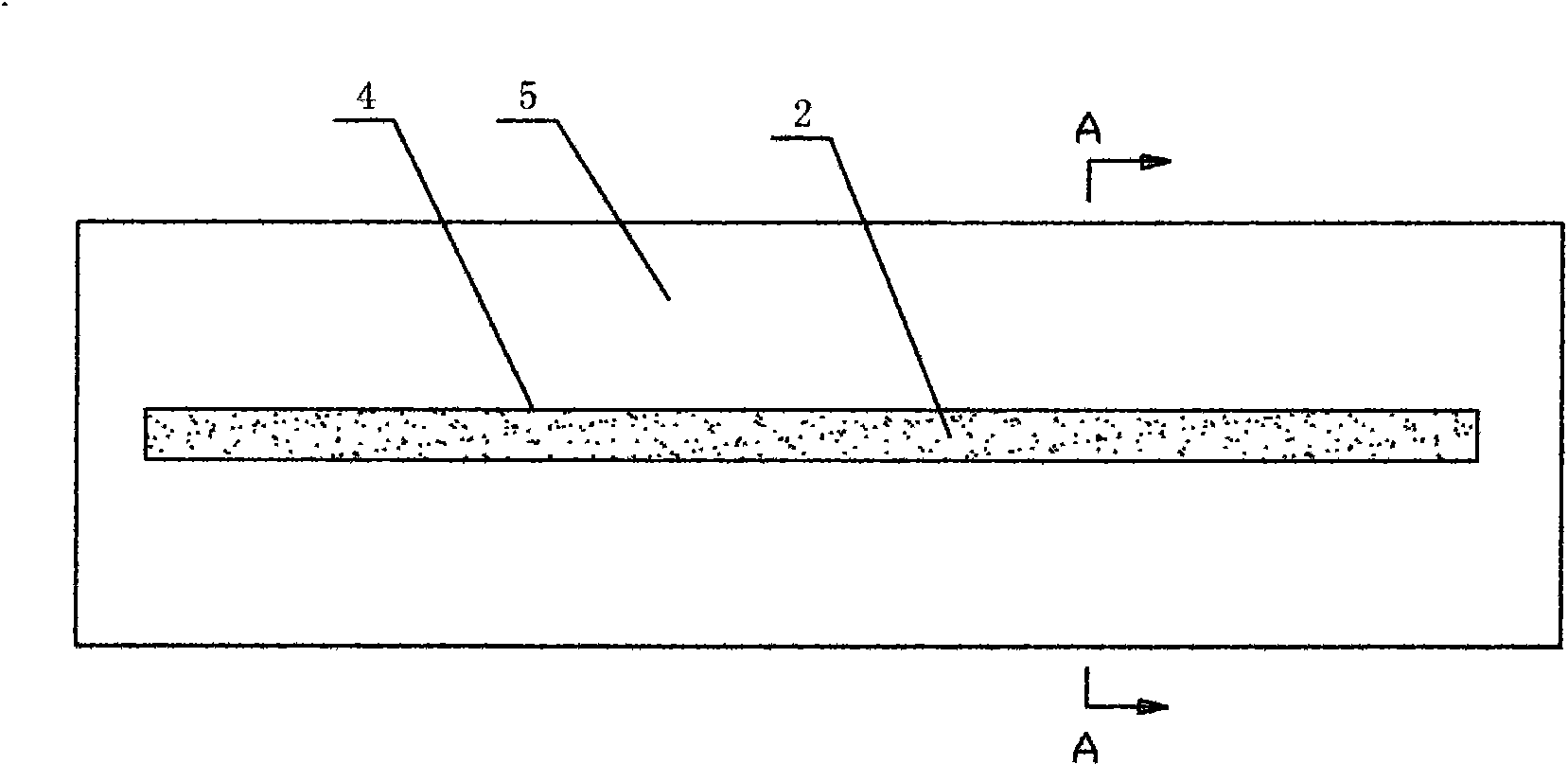

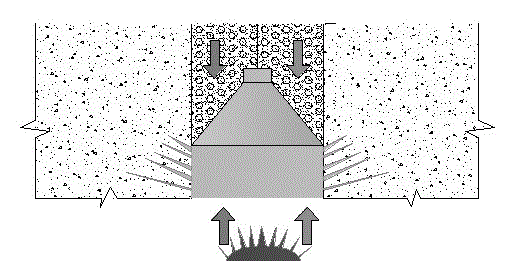

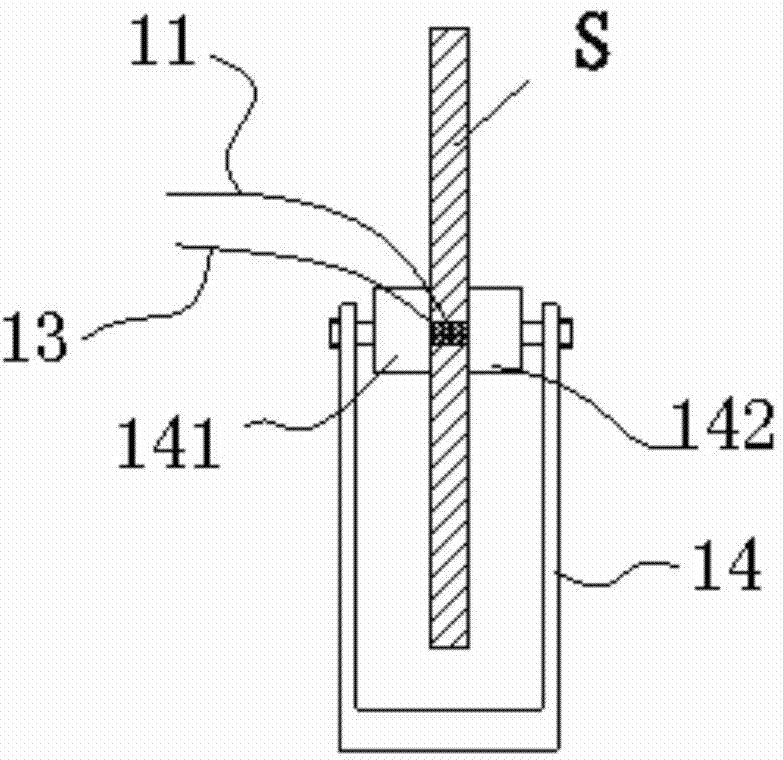

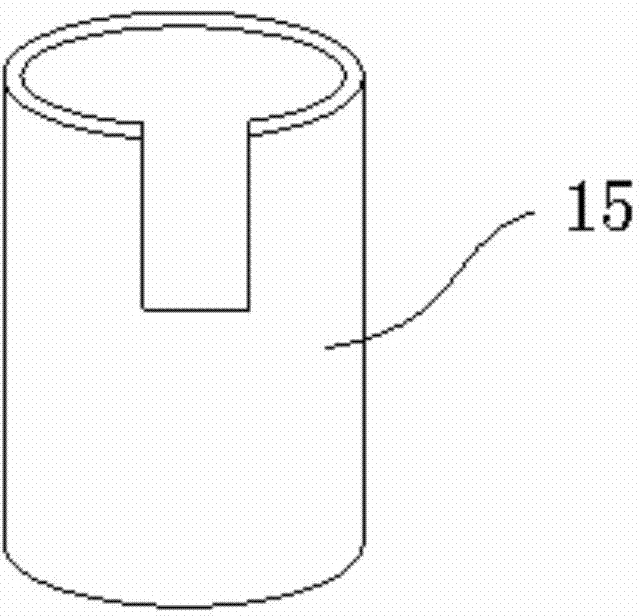

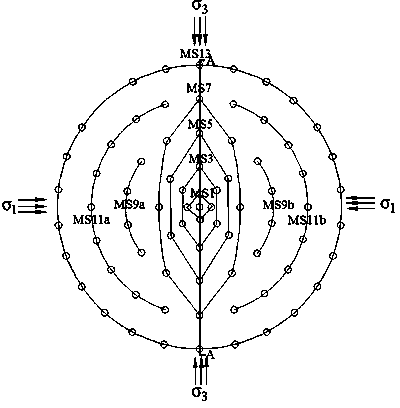

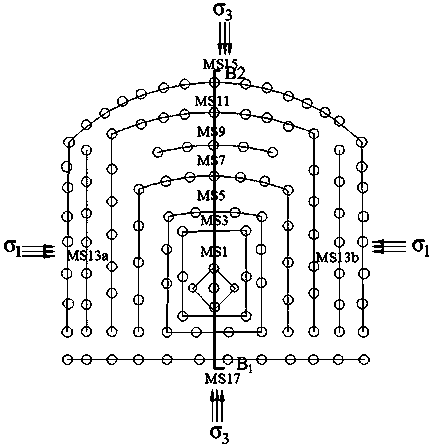

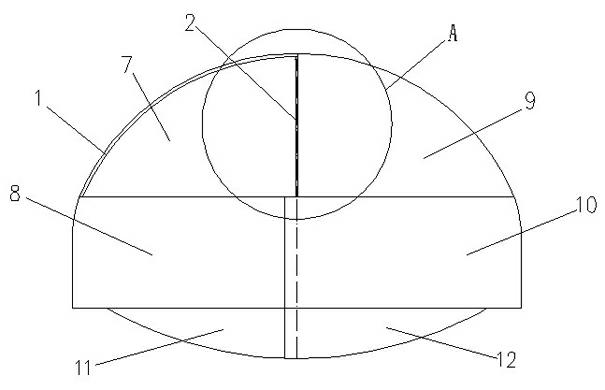

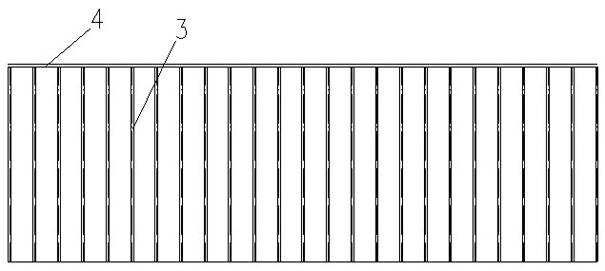

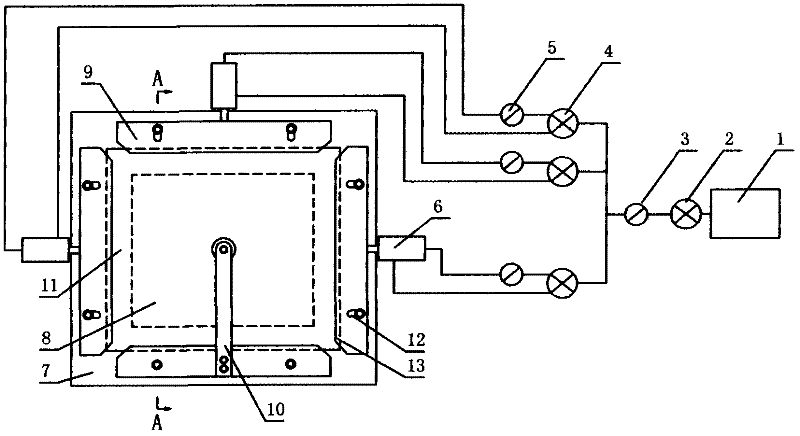

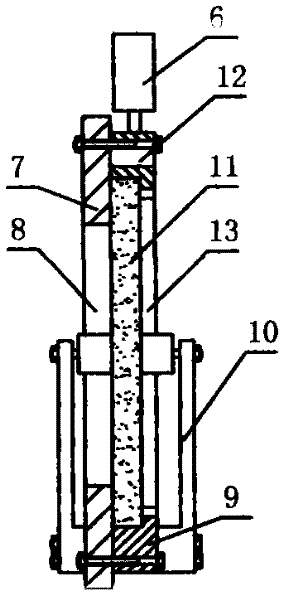

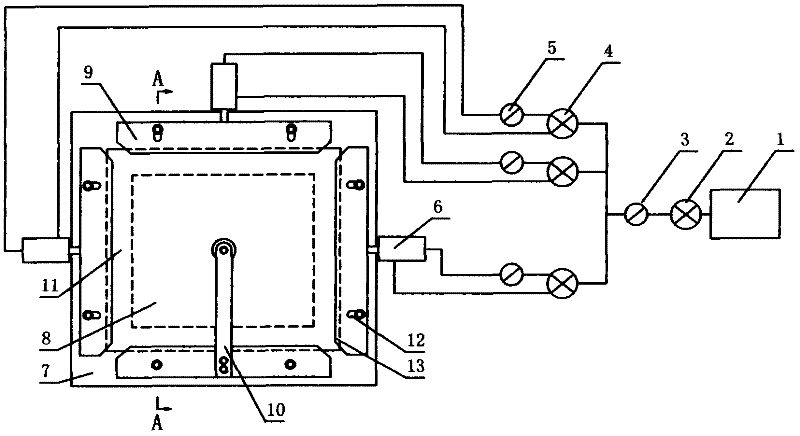

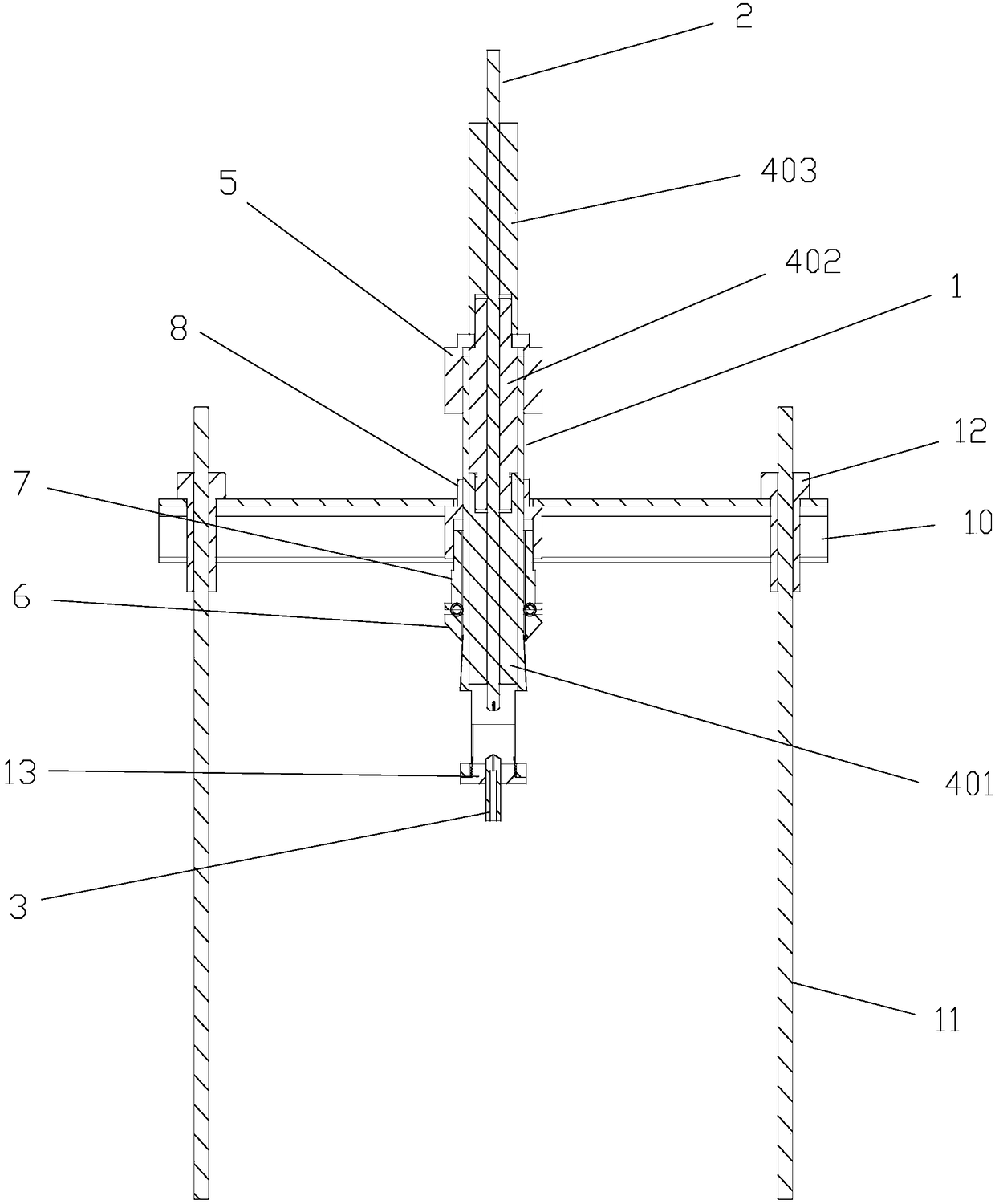

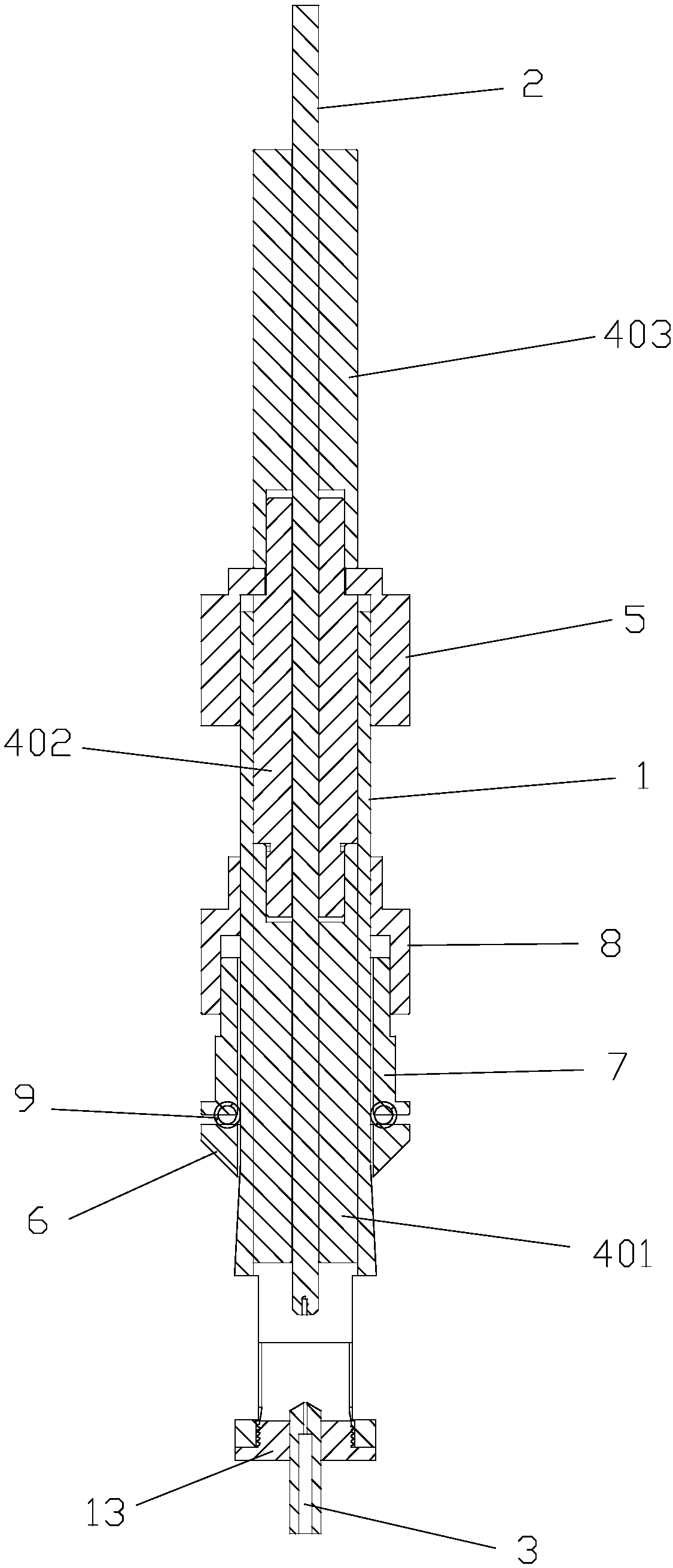

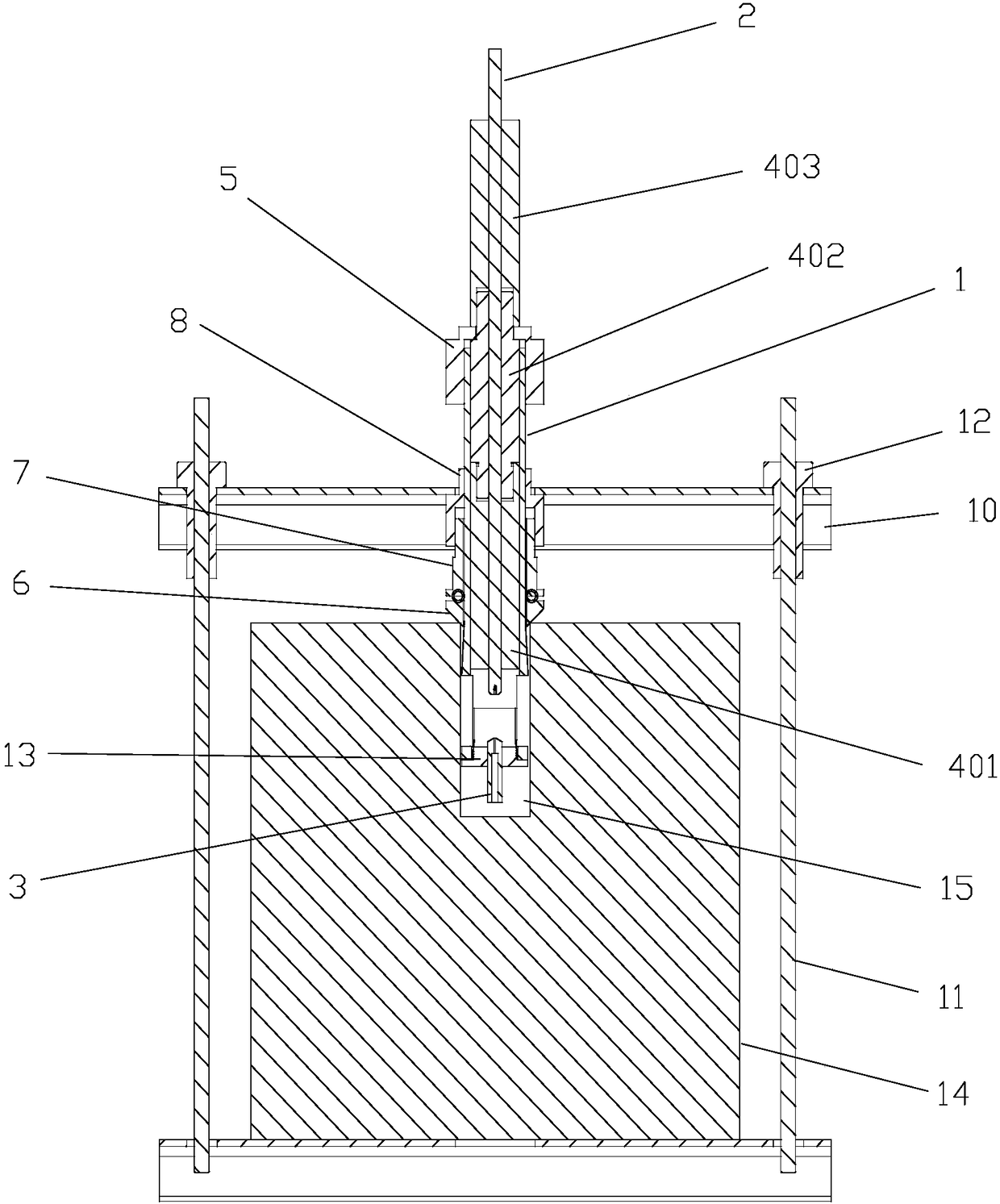

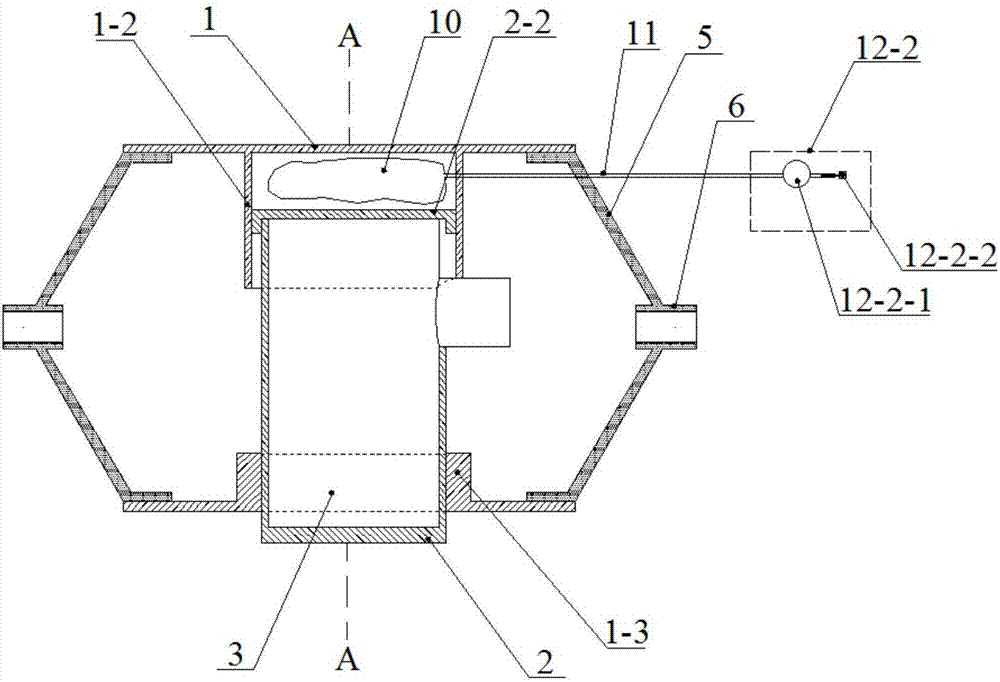

Photodetection mechanics test device for simulating deep rock explosion cracking

The invention discloses a photodetection mechanics test device for simulating deep rock explosion cracking, which comprises a static load system and an explosion load device, wherein the static load system can perform test sample stress load along the horizontal direction and the vertical direction, and the explosion load device is used for generating dynamic loads. The static load system comprises a vertically arranged base plate, four push plates and a pressure supplying system, wherein the four push plates are distributed on one side of the base plate along the upper direction, the lower direction, the left direction and the right direction, and the pressure supplying system respectively provides pressure for the push plates in the upper direction, the left direction and the right direction. The push plates tightly clamp the test sample during the moving process, the explosion load device exerts dynamic load on the test sample and really simulates an initial static stress field in a deep rock body and a dynamic stress field generated during the explosion process. With the combination of a photodetection mechanics test method, the photodetection mechanics test device achieves observation of phenomena of explosion cracking, cracking expansion and the like of the rock body under deep high land stress, and is a simple, convenient and practical device for scientific and accurate research.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

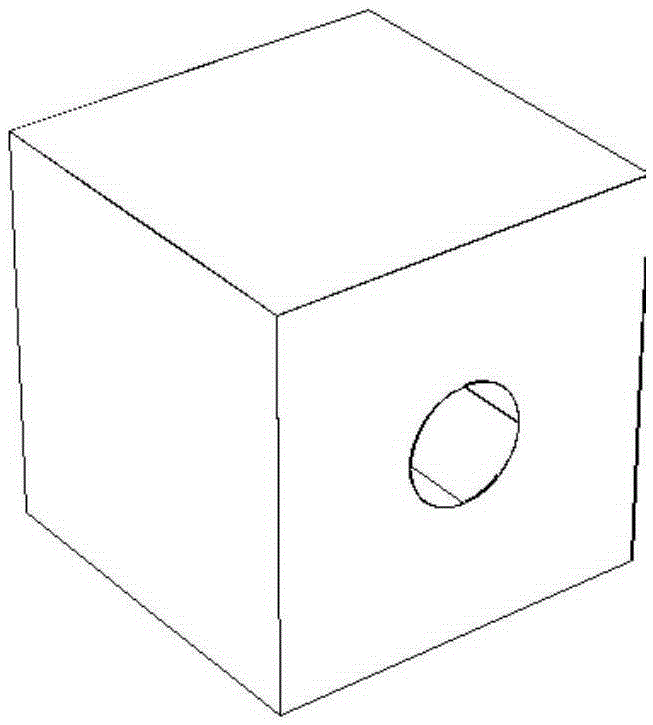

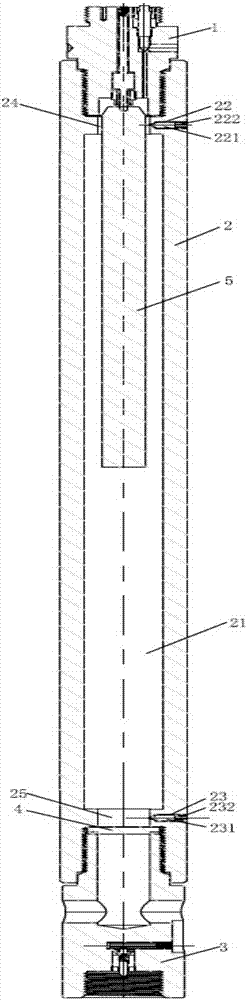

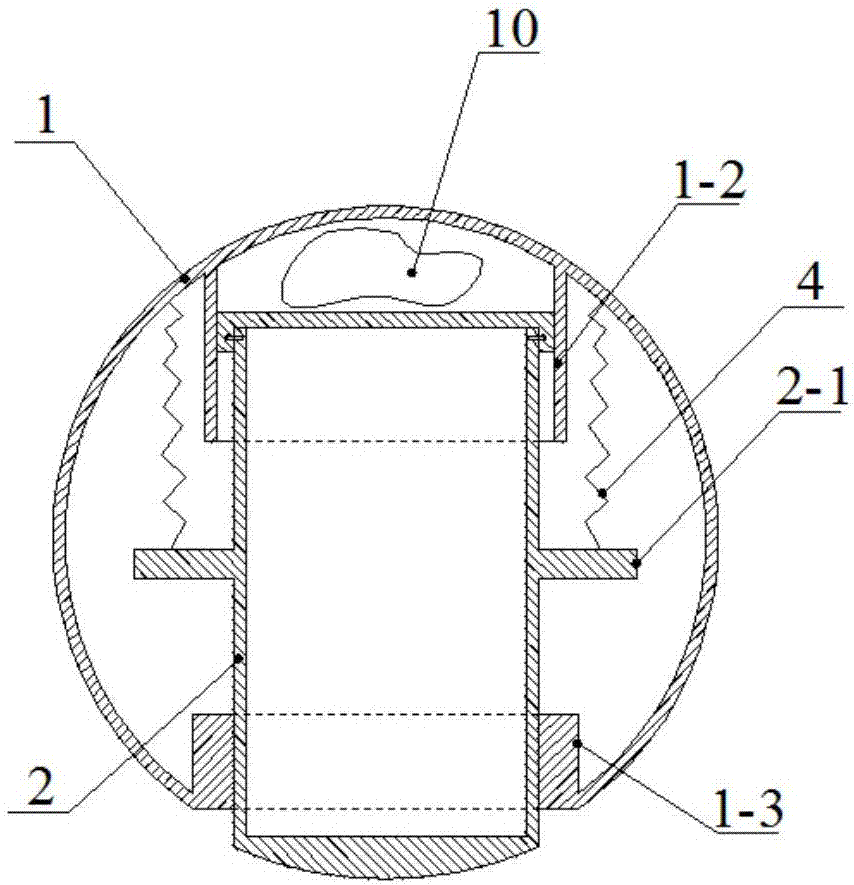

Mechanical device for generating plasma blasting rock with liquid-electric effect

The invention discloses a mechanical device for generating plasma blasting rock with a liquid-electric effect. The mechanical device comprises a device body. The device body comprises a first casing pipe, a plasma generating part and a pressing part. The first casing pipe is provided with a sealing part used for sealing a drill hole drilled in the rock blasting process. The pressing part is used for pressing the sealing part so as to make the sealing part seal the drill hole. The plasma generating part is at least partially located inside the first casing pipe. An opening allowing the plasma generating part to release energy is formed in the first casing pipe and further located in the lower end of the sealing part. According to the mechanical device, the sealing part is used for sealing the drill hole drilled in the rock blasting process, and therefore the blasting energy can be sealed into the drill hole and be further concentrated to rock blasting, and the hard rock like granite canbe blasted. By adoption of the device, a non-explosive rock blasting method can be available.

Owner:BEIJING MUNICIPAL ROAD & BRIDGE +1

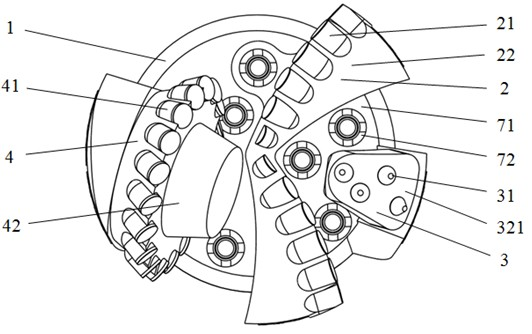

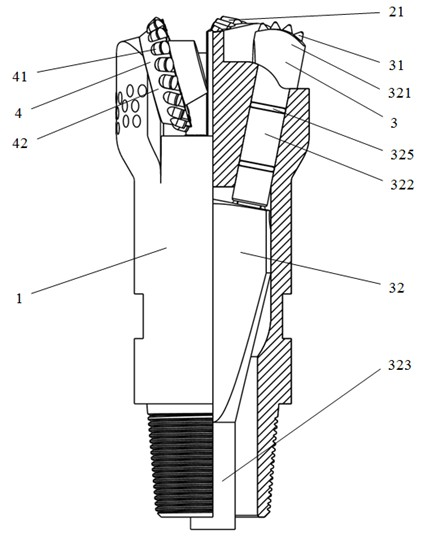

Disc cutter composite drill bit

InactiveCN102678052AReduce difficultyReduce rock breaking energy consumptionDrill bitsConstructionsMining engineeringTransfer mechanism

The invention discloses a disc cutter composite drill bit belonging to the field of rock blasting tools for drilling equipment for oil and gas, mine engineering and building foundation engineering construction, geology, hydrology and the like. The disc cutter composite drill bit comprises a drill bit body and a disc cutter cutting structure arranged on the drill bit body; the drill bit body is also provided with an impact cutting structure; and the impact cutting structure comprises a force transferring mechanism for transferring impact force and impact cutting teeth, wherein the impact cutting teeth are solidified on a punch arranged at the tail end of the force transferring mechanism, and the punch can slide or slidingly impact relative to the drill bit body in the impact force transferring direction. Compared with a drill bit (also named as wheel type drill bit) with the disc cutter cutting structure, the disc cutter composite drill bit is not only beneficial to the drilling of the cutting teeth of the drill bit to stratums and the increment of the rock blasting efficiency, but also beneficial to the retardance of the wear rate of the cutting teeth and particularly has remarkable technical advantages for higher-strength and stronger-abrasiveness stratums which are difficult to drill.

Owner:SOUTHWEST PETROLEUM UNIV

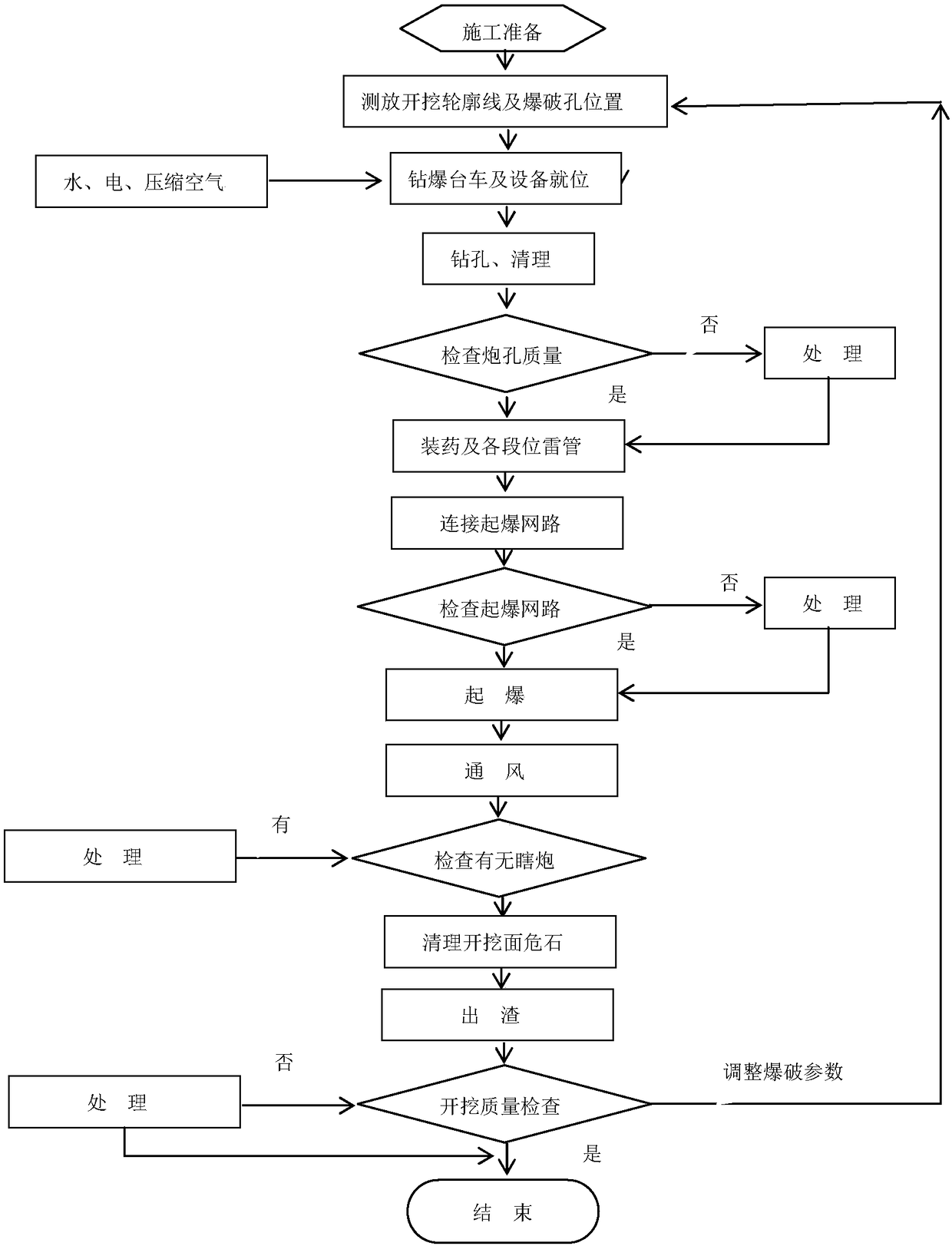

Diversion tunnel blasting excavation back break and out break controlled construction method

InactiveCN108151596AJoint fissure developmentImprove construction qualityBlastingEconomic benefitsReference function

A diversion tunnel blasting excavation back break and out break controlled construction method comprises the steps of judging geological conditions, conducting surveying and setting out; determining the interval of blast holes on the tunnel outline line and conducting marking; drilling holes; feeding explosive into the blast holes; connecting a detonating network; conducting detonating; clearing dangerous rocks, discharging broken bits and the like. By the adoption of the diversion tunnel blasting excavation back break and out break controlled construction method, the smooth control blasting technology is adopted, during blasting excavation construction of a diversion tunnel with complicated geological conditions, rapid lithologic character change, joint fissure development and soft rock occupying the main part, the construction quality can be remarkably improved, the blast hole mark preservation rate of III-type relatively complete rock is 75.8%, the blast hole mark preservation rateof IV-type relatively broken rock is 48.3%, the flatness of the excavation face reaches 90%, the back break amount is effectively controlled, the average radial back break amount of III-type surrounding rock is controlled within 5cm, the average radial back break amount of the IV-type surrounding rock is controlled within 7 cm, the construction quality standard is met, good economic benefits can be achieved, and the diversion tunnel blasting excavation back break and out break controlled construction method provides the reference function for blasting excavation back break and out break controlled construction of similar surrounding rock diversion tunnels in the future.

Owner:CHINA RAILWAY SIXTH GRP TIANJIN RAILWAY CONSTR +1

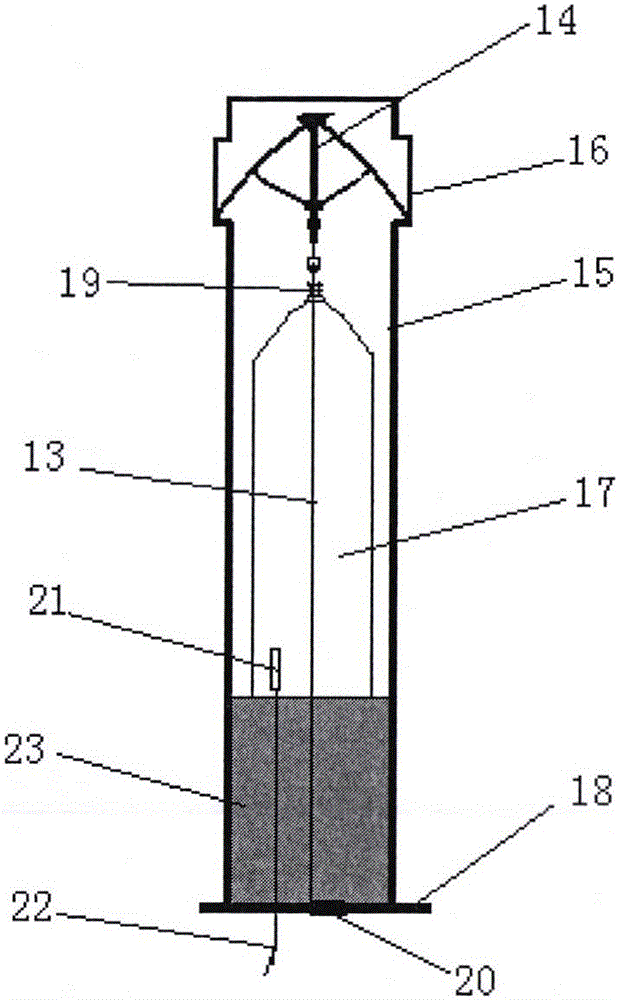

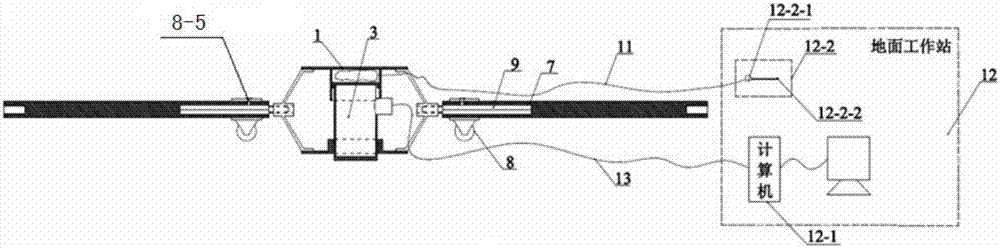

Engineering rock body sound emitting monitoring and transmission system

ActiveCN107313763AEfficient couplingMeet working conditionsSurveyMaterial analysis using acoustic emission techniquesCouplingEngineering

The invention discloses an engineering rock body sound emitting monitoring and transmission system, which comprises a sound emitting sensor and a ground work station, wherein the sound emitting sensor is arranged in a drill hole of a monitored rock body, and transmits a received monitoring signal to the ground work station through a cable; the sound emitting sensor consists of a sound emitting probe, a probe installing mechanism and a transmission mechanism; the transmission mechanism is used for transmitting the probe installing mechanism provided with the sound emitting probe to a set position in the drill hole; the probe installing mechanism comprises a casing and a probe sleeve; the casing is connected with the transmission mechanism; and the probe sleeve is used for accommodating the sound emitting probe. The probe installing mechanism in the engineering rock body sound emitting monitoring and transmission system solves the problem of effective installing and coupling difficulty of the sound emitting probe through the mutual matching of a spring and an air bag arranged between the casing and the probe sleeve; and the effective coupling of the sound emitting probe and the hole wall of the drill hole is ensured, so that the monitoring and prediction reliability on the mine rock (body) stability and rock blasting dynamic catastrophe is enhanced.

Owner:SICHUAN UNIV

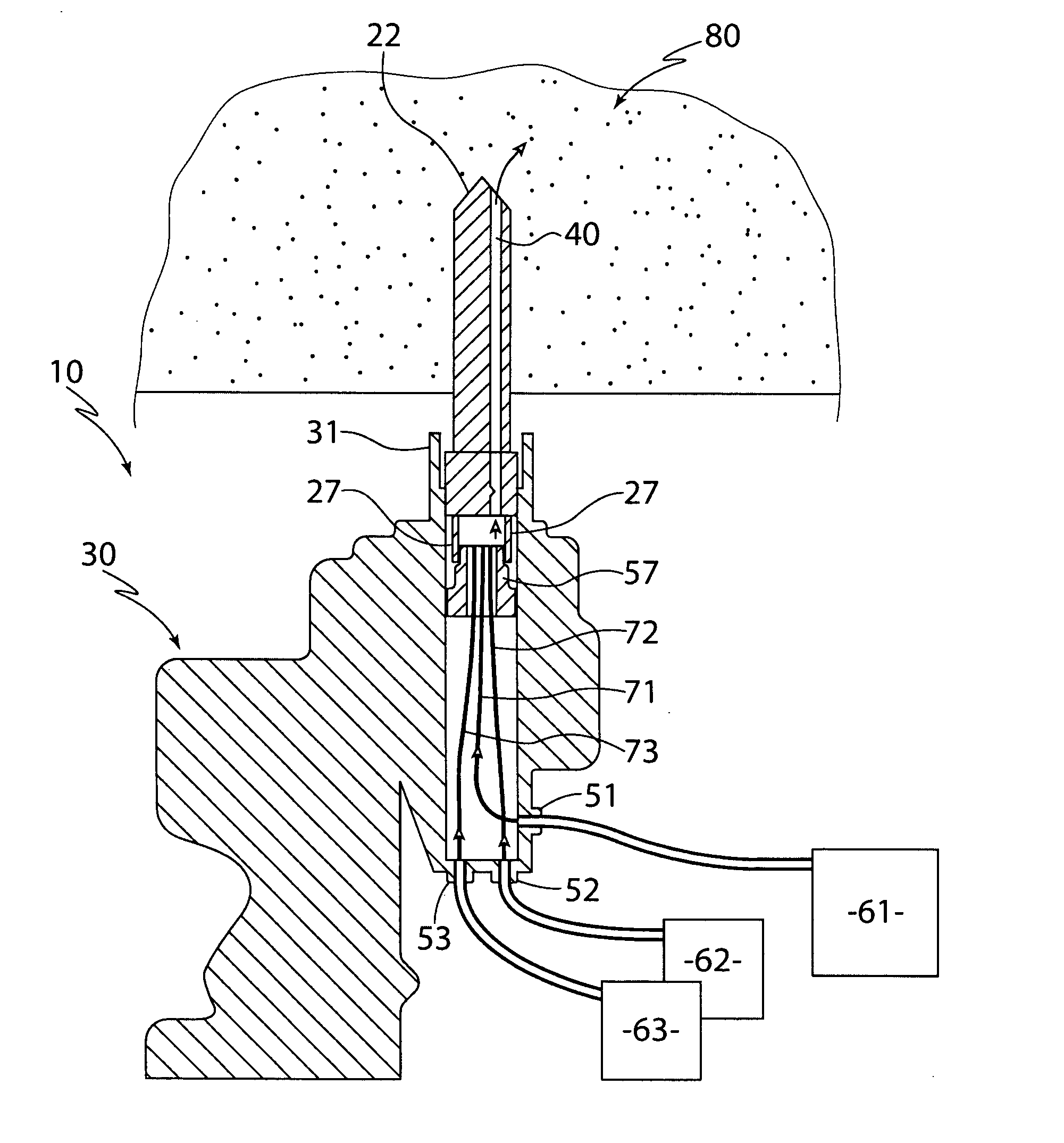

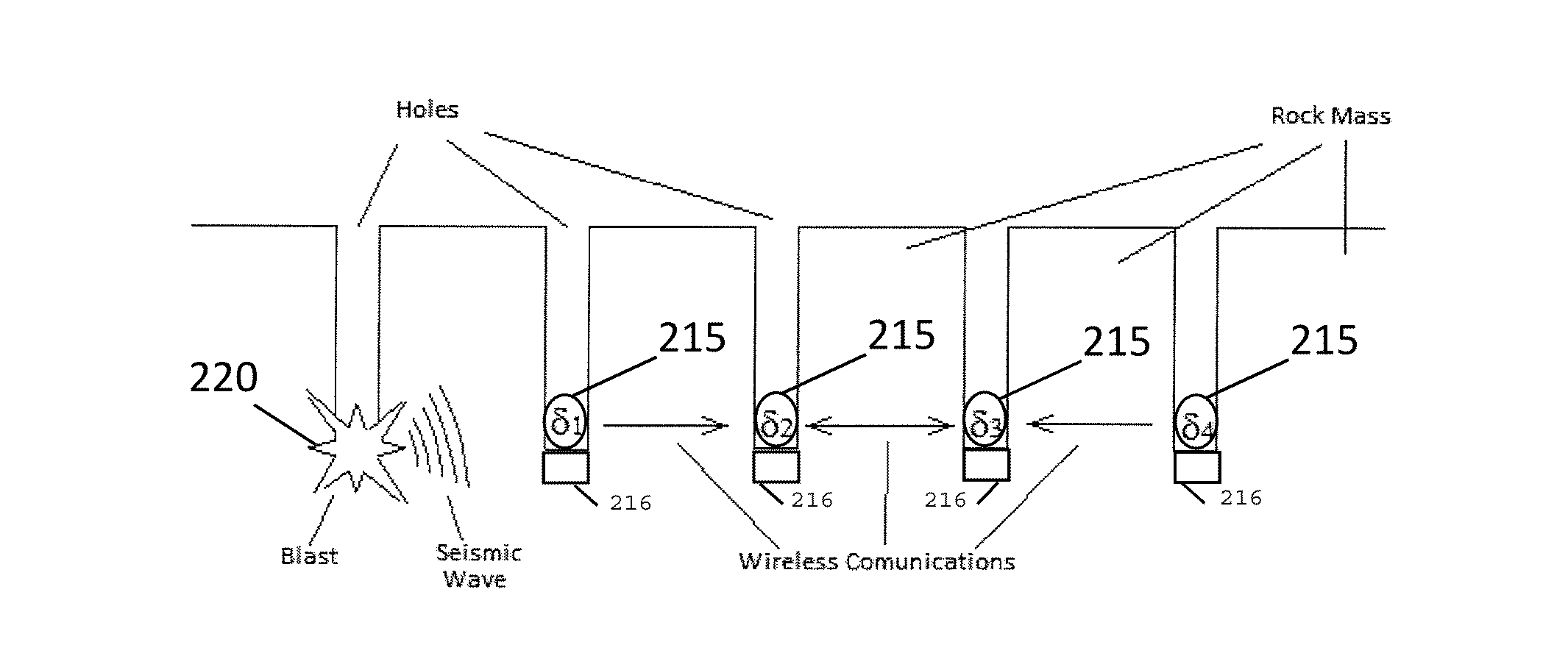

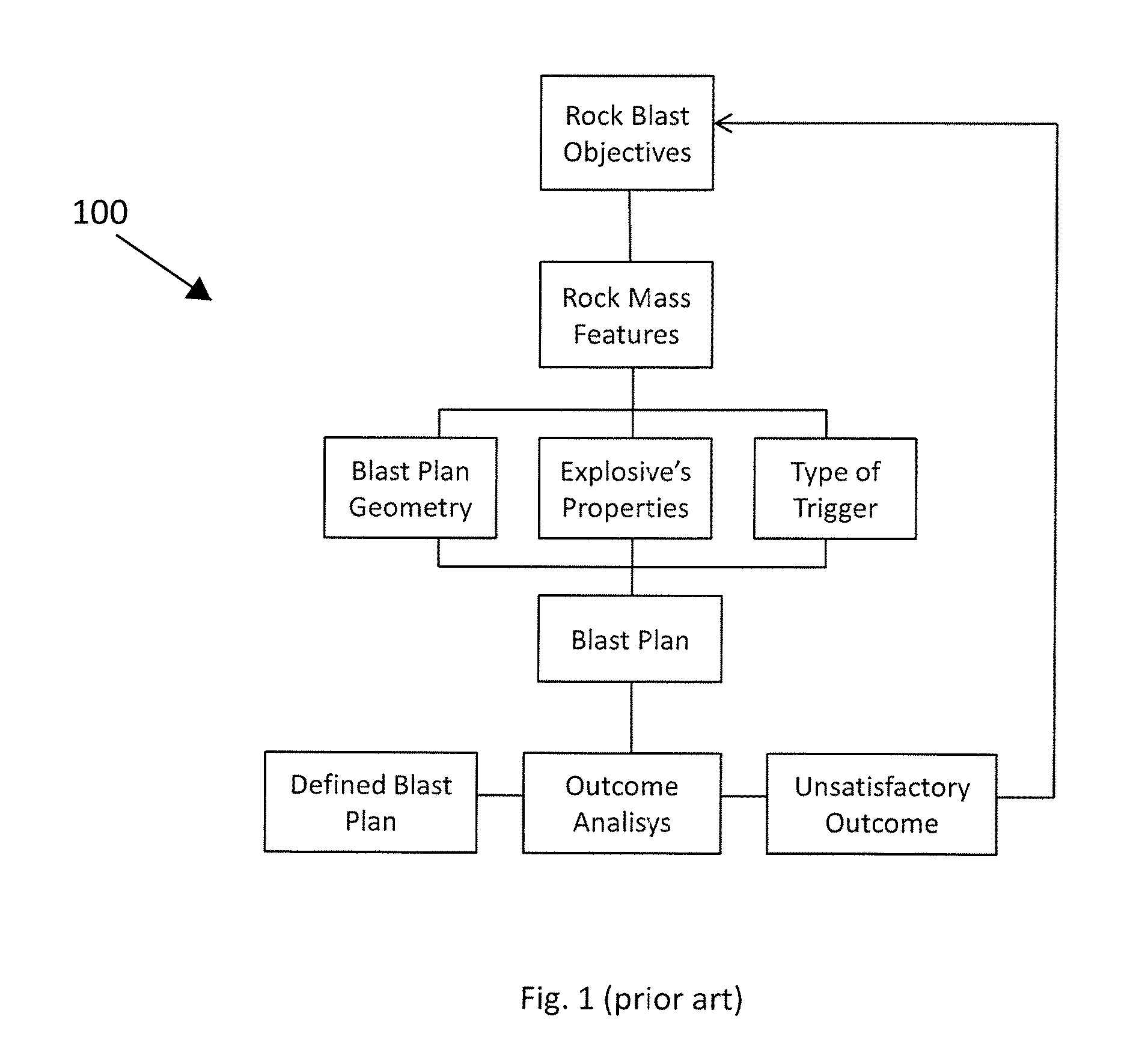

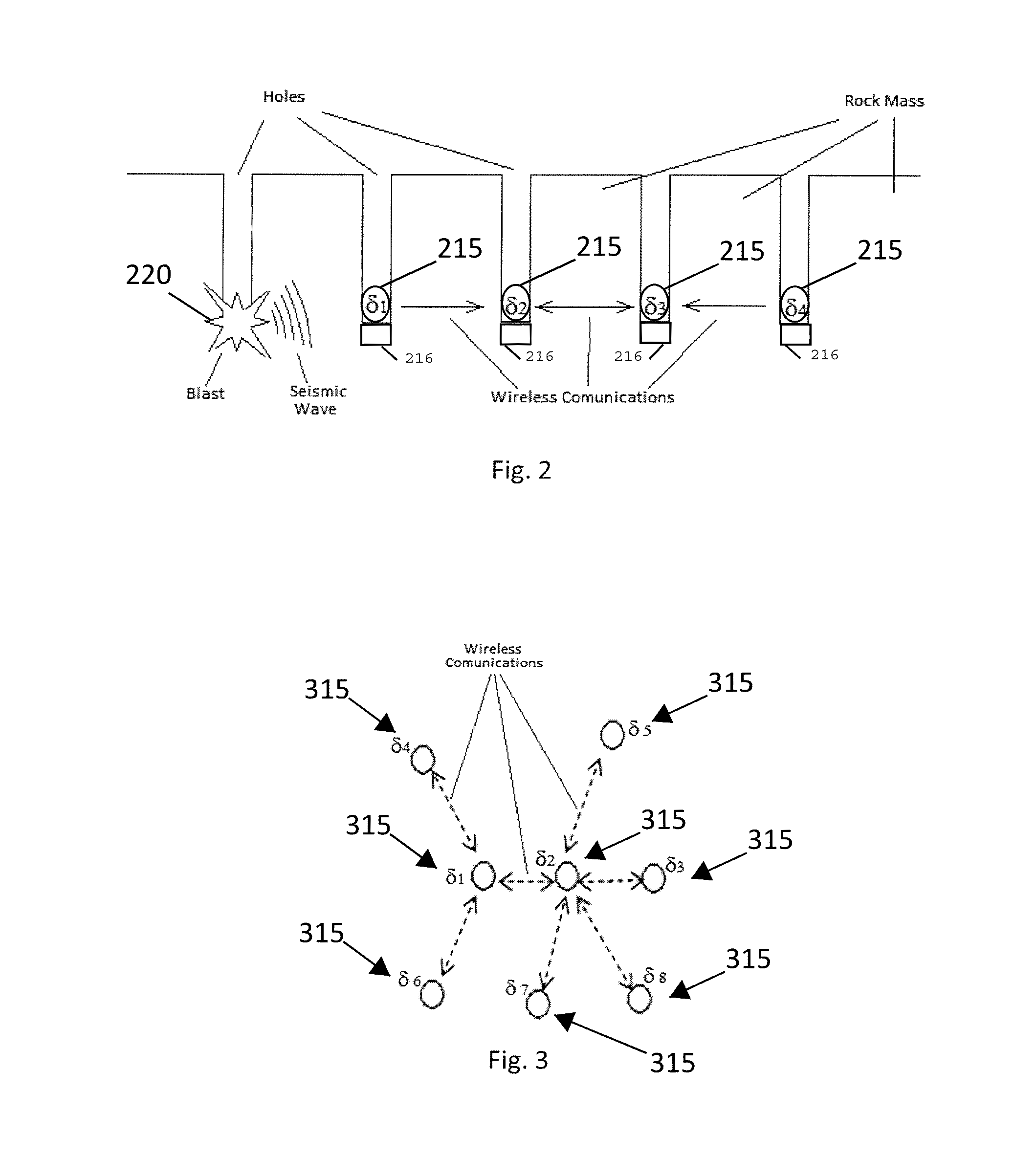

Rock blasting method and system for adjusting a blasting plan in real time

A rock blasting method and a system of rock blasting sensors and charges which form a network for use in the mining industry. The method and the system being able to self-adjust in order to maximize the extraction of raw material from a rock mass while minimizing the costs of operation and diminishing the environmental impact of the mining process.

Owner:VALE LIMITED

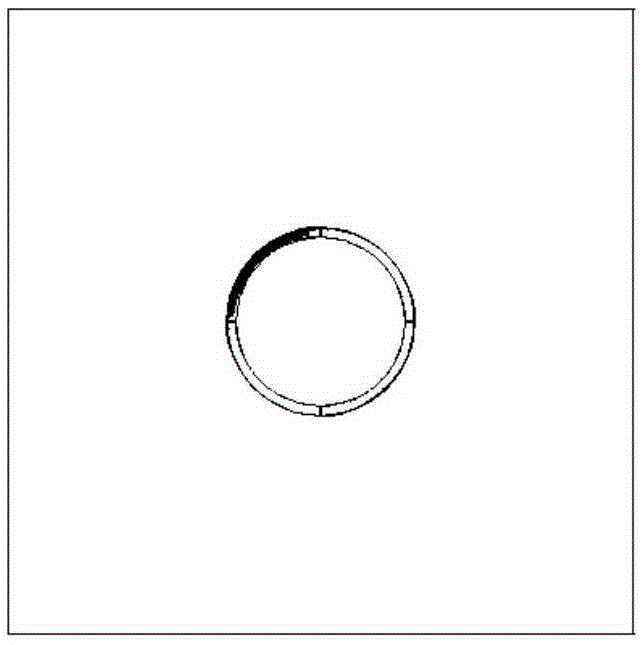

Expandable rock bolt and rock bolting system

InactiveUS7270501B2Minimize stress concentrationSimplify workMining devicesExcavationsRock boltRock blasting

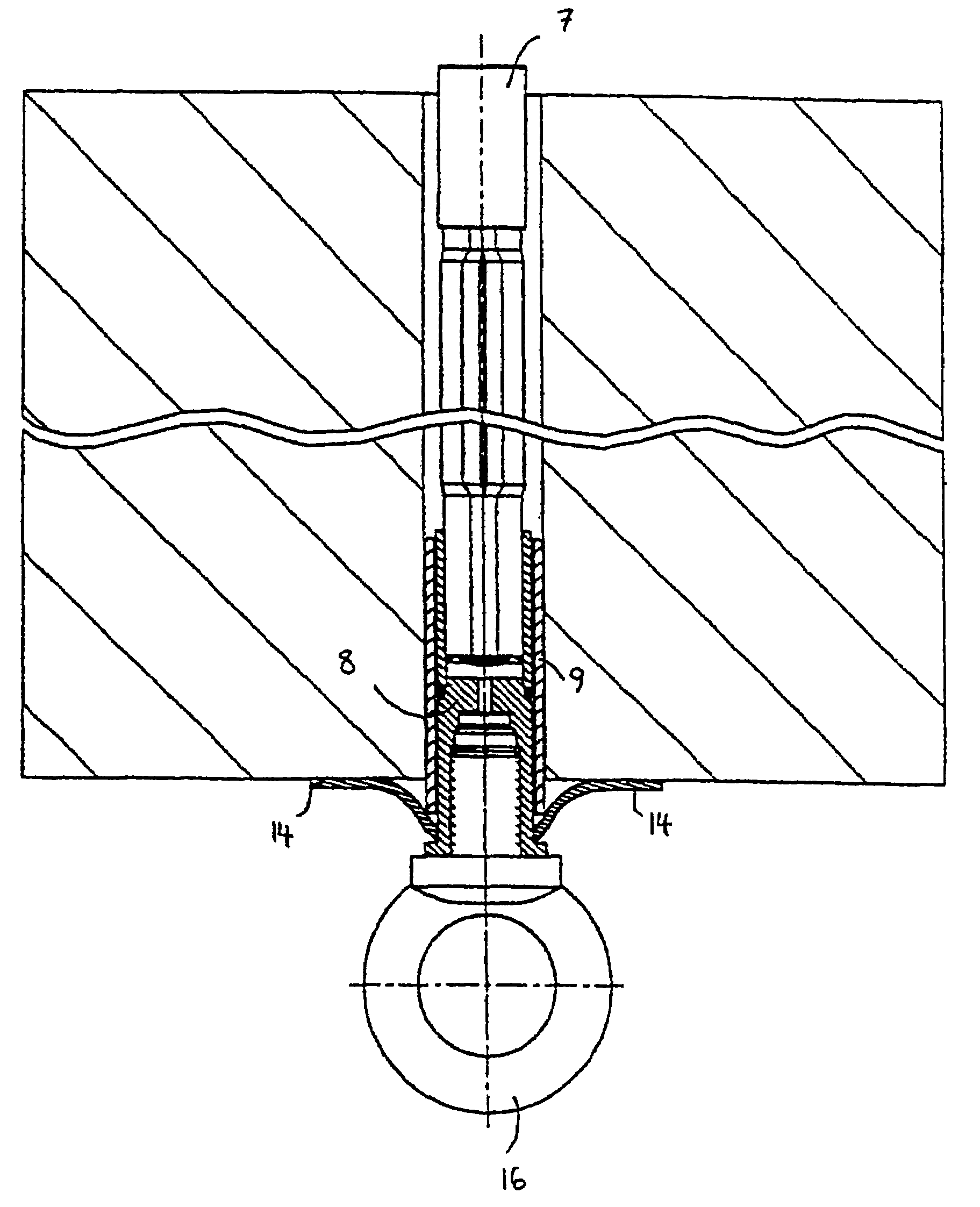

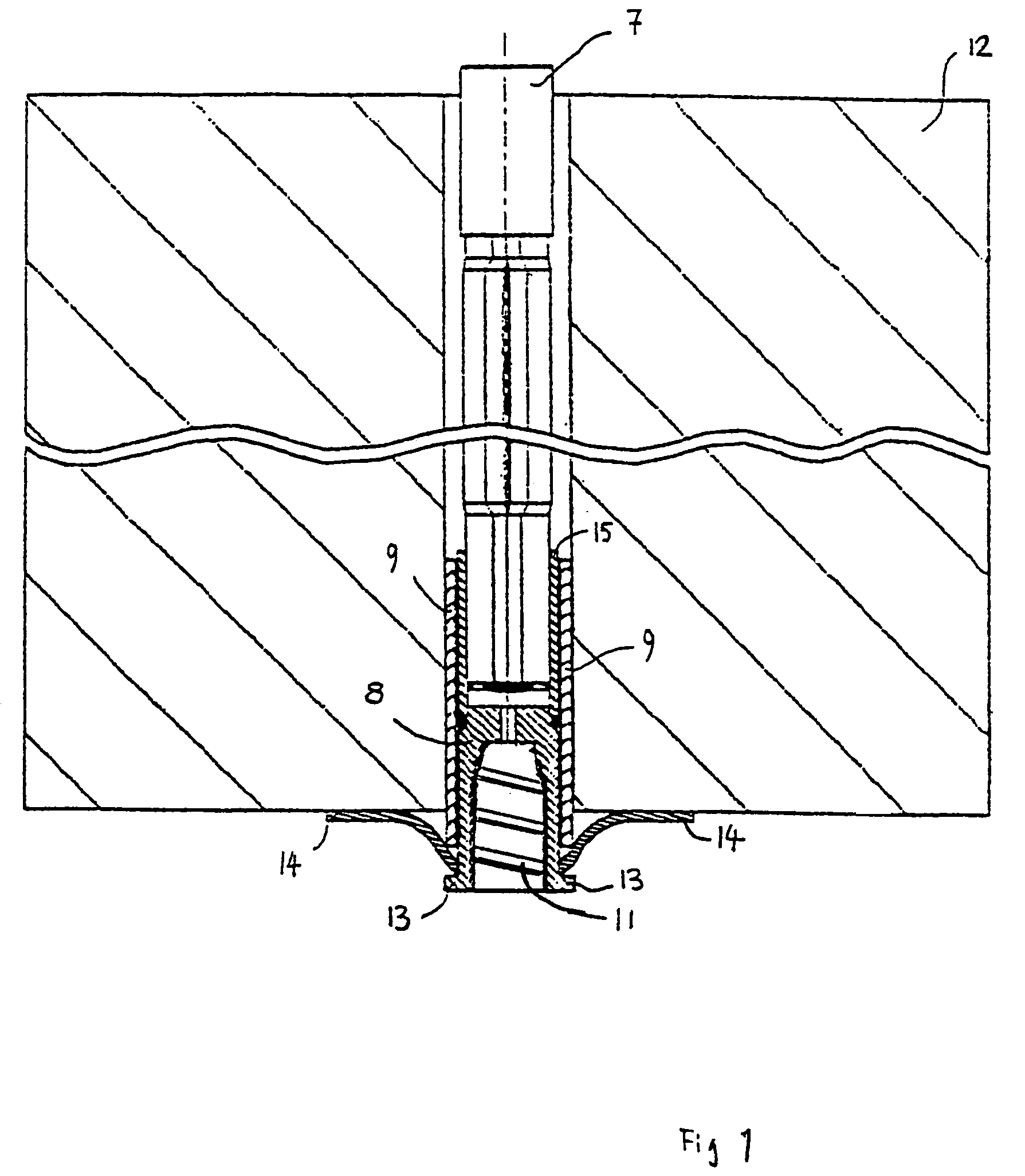

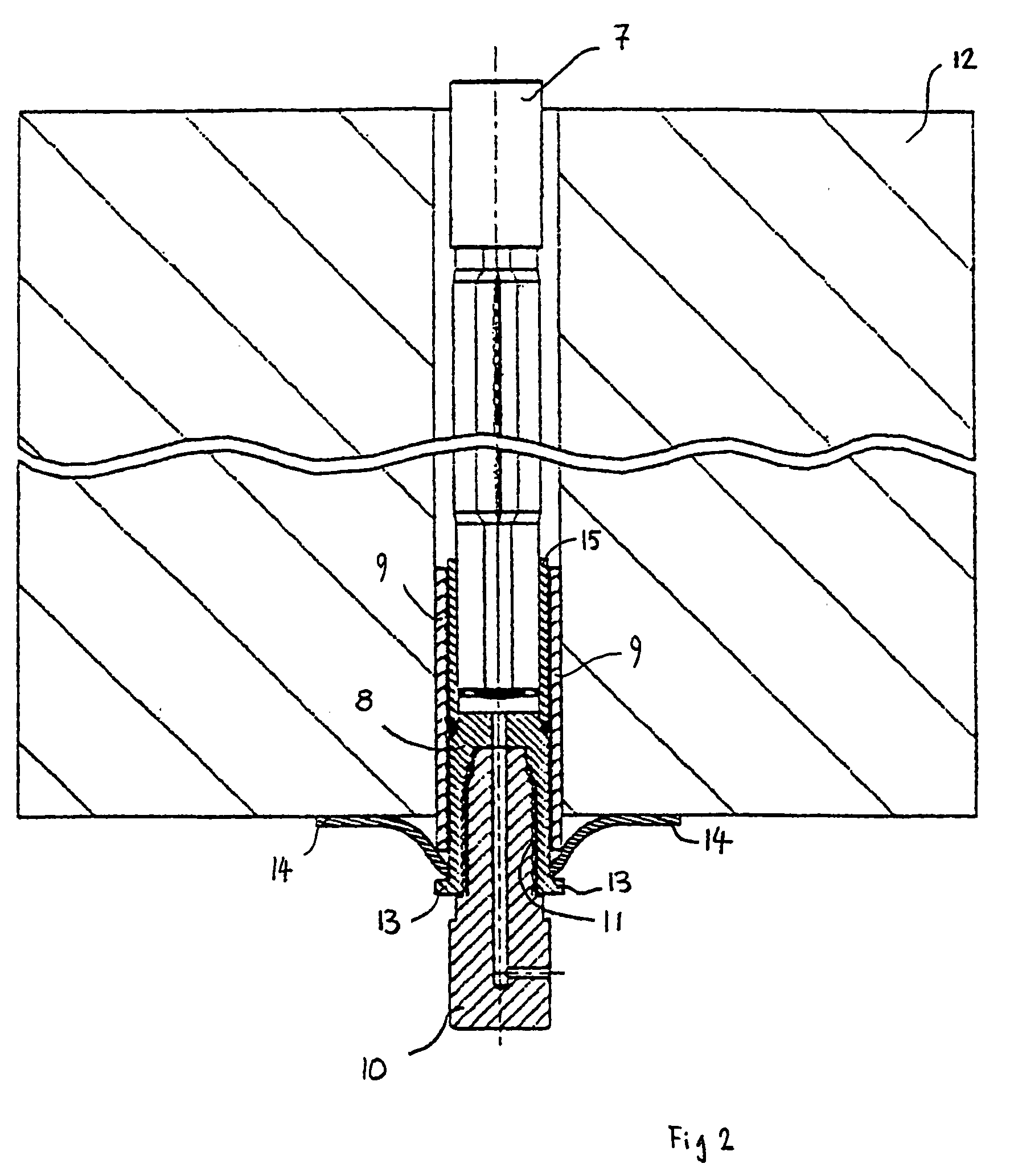

The present invention is related to a rock bolt (7), expandable by means of a pressure media, for insertion into a borehole. The expandable bolt (7) comprises a connection unit (8) with means (11) for detachable interaction with an expansion means (10) for expansion of the rock bolt (7), as well as with a suspension element (16). The connection unit is designed with such external dimensions so that it may be inserted into the bore-hole. The invention also relates to such a rock bolting system.

Owner:ATLAS COPCO ROCK DRILLS

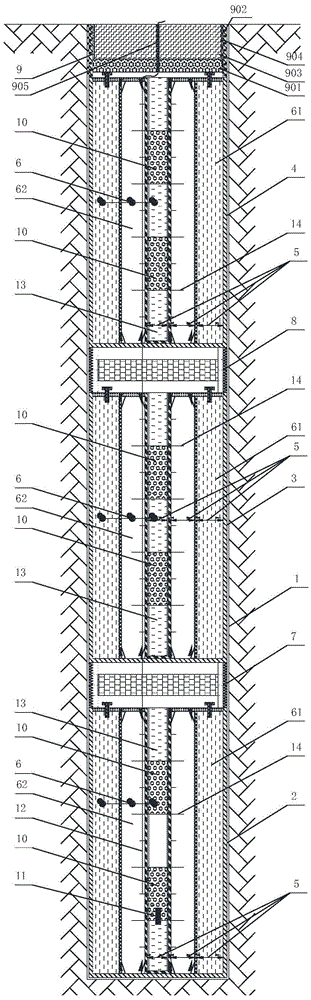

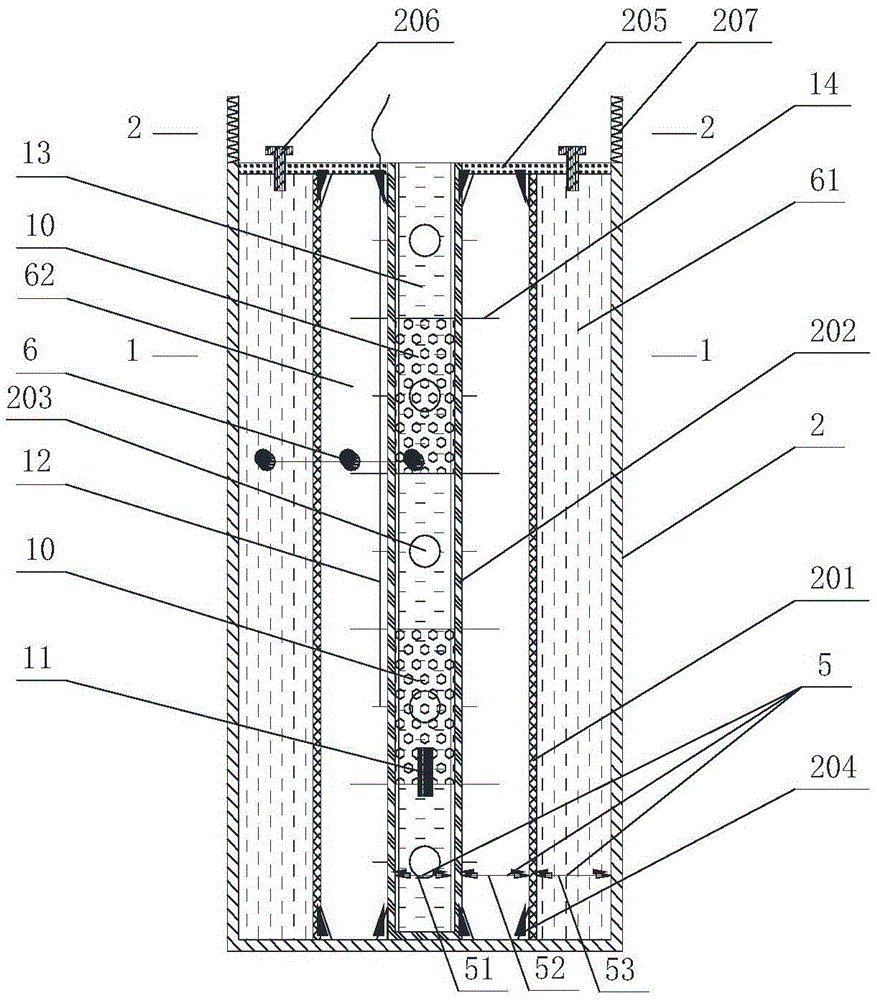

Water-air combined medium non-coupled rapid explosive charging device for tunnel extra-large cross section deep-hole rock blasting fragmentation

Disclosed is a water-air combined medium non-coupled rapid explosive charging device for tunnel extra-large cross section deep-hole rock blasting fragmentation. The device comprises a drilled hole, a first mixing explosive-charging system, a second mixing explosive-charging system, a third mixing explosive-charging system, structural cavity systems, combined medium systems, a first connecting sleeve, a second connecting sleeve, a combined blocking system, explosive, detonators and leading wires. The water-air combined medium non-coupled rapid explosive charging device for tunnel extra-large cross section deep-hole rock blasting fragmentation is provided by the invention, has the characteristics of low cost, high efficiency, reliable performance and good shock absorption and dust prevention effects and also has the following advantages that rapid explosive charging is achieved; the explosive-charging structure is accurate; the length of deep holes is accurately measured; and shock absorption, high energy utilization rate, good reliability, low cost and the like are achieved.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Rock blasting method

The invention provides a rock blasting method. An optimal rock blasting design scheme is proposed according to an optimal crushing principle of the method, that is, how to maximize the distribution uniformity degree of explosion energy in an explosion region during the blasting cartridge arrangement period and how to maximize the gradient value of comprehensive energy of adjacent blast holes during the initiation order arrangement period.

Owner:董少南

Construction method of novel artificial turf sports field

InactiveCN108914746AAvoid contactImprove protectionGround pavingsEcological environmentCrushed stone

The invention relates to a construction method of a novel artificial turf sports field and aims to provide the artificial turf sports field which facilitates the protection of the ecological environment and which conforms to national environmental protection industry development policies. The construction method comprises the following steps: (1) removing debris and leveling the field; (2) markingan elevation point in accordance with a slope of five thousandths and making the slope; (3) rolling a plain soil layer; (4) laying waterproof membranes; (5) laying a multifunctional base-layer pad; (6) laying artificial turf; (7) filling with quartz sand; (8) filling with natural granulated cork or synthetic granulated rubber. The construction method of the novel artificial turf sports field protects rainwater from contacting with soil by laying the waterproof membranes on the surface of the soil, and is capable of saving a large amount of building materials such as crushed stone, stone powder, cement and the like, greatly reducing the fundamental construction cost, saving the construction period, reducing mountain cutting and rock blasting, facilitating the protection of the ecological environment, and confirming to the national environmental industry development policies.

Owner:GUANGZHOU XIULIN SPORTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com