Liquid-phase plasma rock blasting method

A liquid-phase plasma and rock blasting technology, which is applied in the field of blasting demolition of concrete structures, can solve the problems of adverse impact on the surrounding environment of the blasting area and endanger the safety of the surrounding area of the operation area, and achieve the effect of cheap price and wide source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

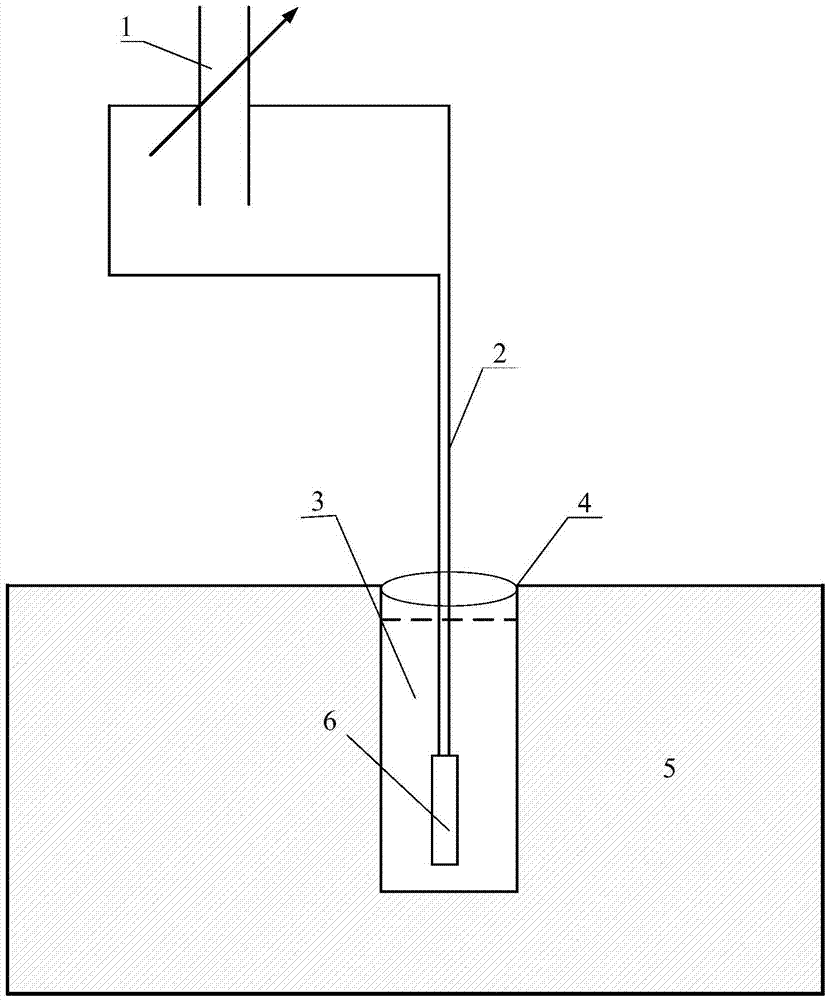

[0023] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0024] Liquid phase plasma rock blasting method of the present invention, concrete steps are as follows:

[0025] 1) Carry out actual investigation on the rock mass or concrete structure 5 to be blasted, arrange plasma blasting blast holes 4 holes in the rock mass or concrete structure 5, and carry out drilling operations, requiring the blast holes to be vertically downward, so as to Make sure that the electrolyte liquid injected later cannot flow out by itself;

[0026] 2) Configure sodium chloride electrolyte solution in a plastic bucket with a concentration of 0.1mol.L -1 , and add copper sulfate according to the ratio of 0.05% to 1% by weight of the sodium chloride solution, and fully stir to form a strong electrolyte solution 3;

[0027] 3) Charge the capacitor 1 through the charging equipment, and make the peak voltage of the capacitor reach the des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com