Method for recovering low-grade copper-zinc mineral from cyanidation tailings

A cyanide tailings, low-grade technology, applied in the metallurgical field, can solve problems such as harsh test environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

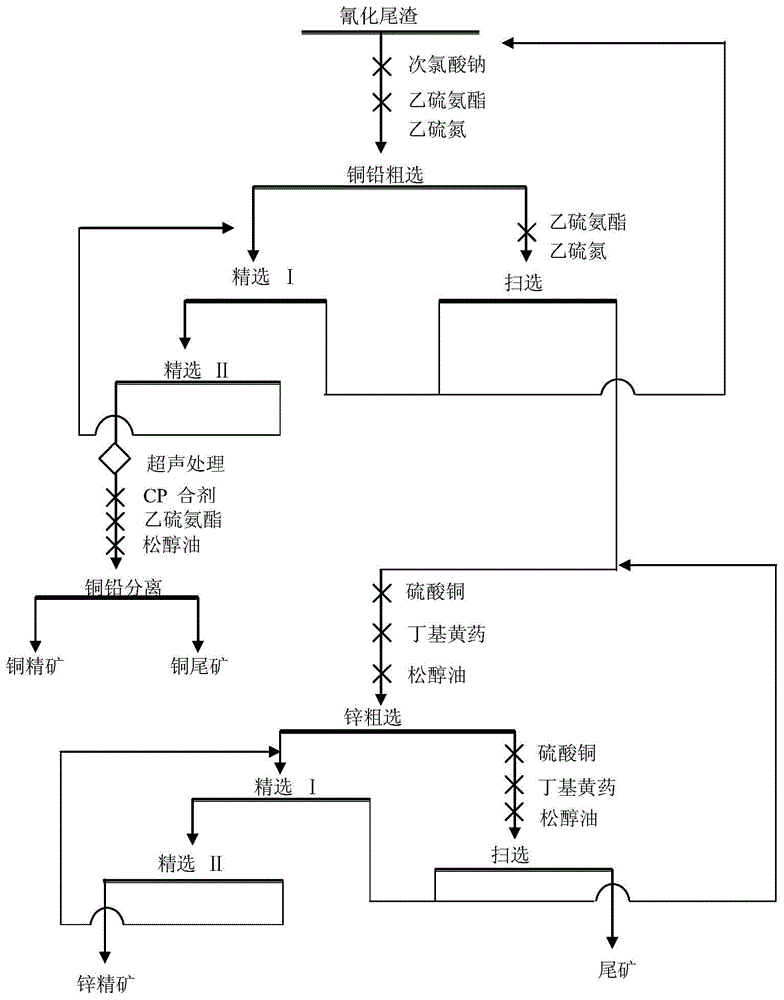

Image

Examples

Embodiment 1

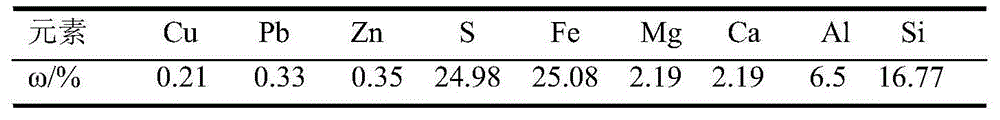

[0016] The chemical composition of a gold mine cyanide tailings filter cake is as follows:

[0017] Table 1. Element content (%) of a certain cyanide tailings filter cake

[0018]

[0019] (1) Mixing: Add water to the cyanide tailings and stir for 5 minutes to completely disperse the solid minerals. Produces a slurry with a concentration of 35%. Add 15kg / t of 8% sodium hypochlorite solution to the pulp, stir for 15min, and the pH of the pulp will increase to 12.

[0020] (2) Mixed flotation of copper-lead minerals: add ethyl thionitrogen and ethyl thiocarbamate to the above pulp as collectors, the dosages are 80g / t and 96g / t respectively, stir for 3min, through the synergy between collectors Effectively collect copper and lead minerals. Closed-circuit flotation is carried out in the flotation tank, and the roughing flotation time is 6 minutes. Sodium hypochlorite solution is not added during the sweeping, and the amount of collector is reduced by half accordingly, that ...

Embodiment 2

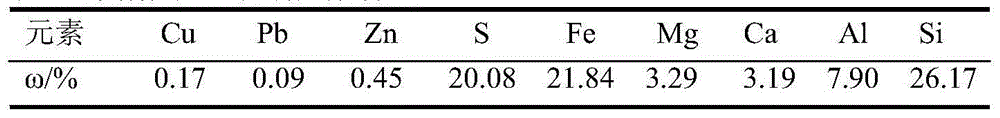

[0025] The chemical composition of a gold mine cyanide tailings filter cake is as follows:

[0026] Table 2. Element content (%) of a certain cyanide tailings filter cake

[0027]

[0028] (1) Mixing: Add water to the cyanide tailings and stir for 5 minutes to completely disperse the solid minerals. Generates a slurry with a concentration of 30%. Add 10% sodium hypochlorite solution 10kg / t to the pulp, stir for 15min, and the pH of the pulp will increase to 12.

[0029] (2) Mixed flotation of copper-lead minerals: add ethyl thionitrogen and ethyl thiocarbamate to the above pulp as collectors, the dosages are 80g / t and 96g / t respectively, stir for 3min, through the synergy between collectors Effectively collect copper and lead minerals. Closed-circuit flotation is carried out in the flotation tank, and the roughing flotation time is 6 minutes. Sodium hypochlorite solution is not added during the sweeping, and the amount of collector is reduced by half accordingly, that i...

Embodiment 3

[0034] The chemical composition of a gold mine cyanide tailings filter cake is as follows:

[0035] Table 3. Element content (%) of a certain cyanide tailings filter cake

[0036]

[0037] (1) Mixing: Add water to the cyanide tailings and stir for 5 minutes to completely disperse the solid minerals. Generates a slurry with a concentration of 30%. Add 13% sodium hypochlorite solution 8kg / t to the pulp, stir for 15min, and the pH of the pulp will increase to 12.

[0038] (2) Mixed flotation of copper-lead minerals: add ethyl thionitrogen and ethyl thiocarbamate to the above pulp as collectors, the dosages are 80g / t and 96g / t respectively, stir for 3min, through the synergy between collectors Effectively collect copper and lead minerals. Closed-circuit flotation is carried out in the flotation tank, and the roughing flotation time is 6 minutes. Sodium hypochlorite solution is not added during the sweeping, and the amount of collector is reduced by half accordingly, that is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com