Patents

Literature

365 results about "Thiocarbamate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thiocarbamates are a family of organosulfur compounds. As the name suggests, they are sulphur analogues of carbamates. There are two isomeric forms of thiocarbamate esters: O-thiocarbamates, ROC(=S)NR₂, and S-thiocarbamates, RSC(=O)NR₂.

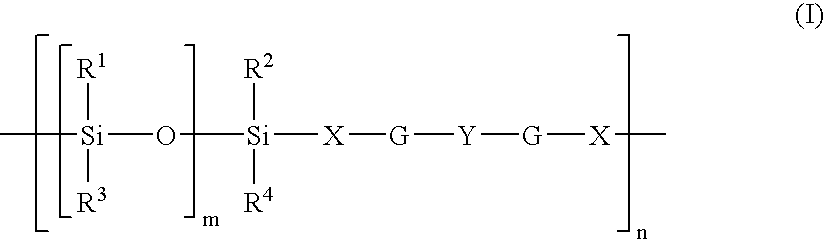

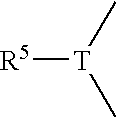

Polyorganosiloxane composition for use in unsaturated elastomer, article made therefrom, and associated method

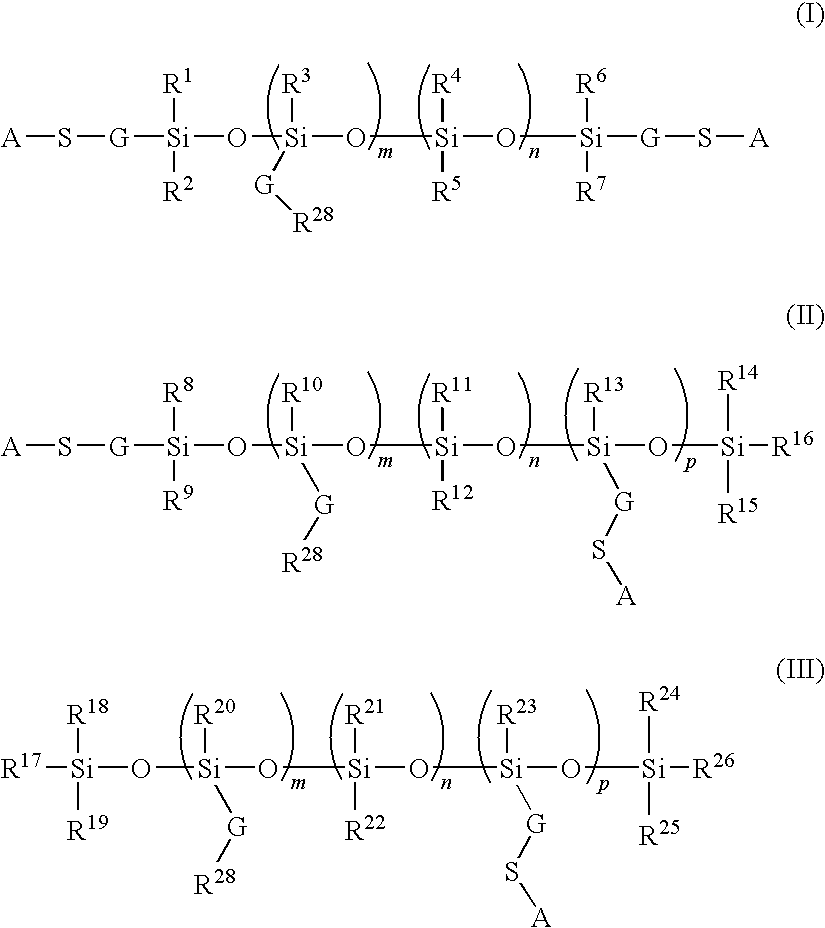

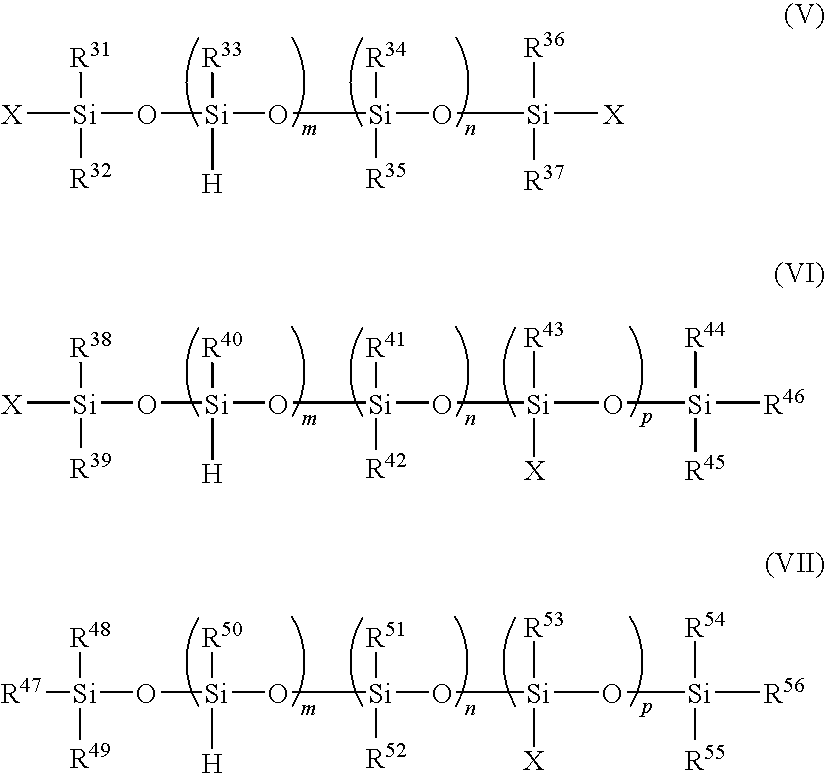

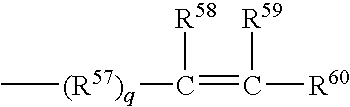

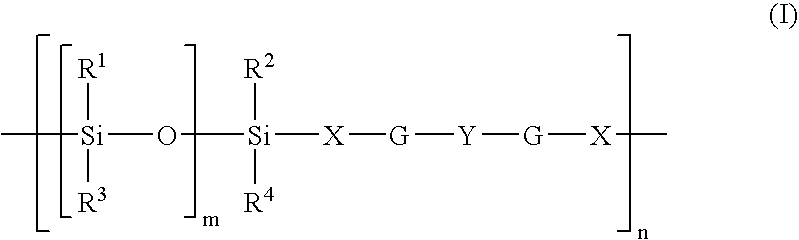

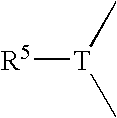

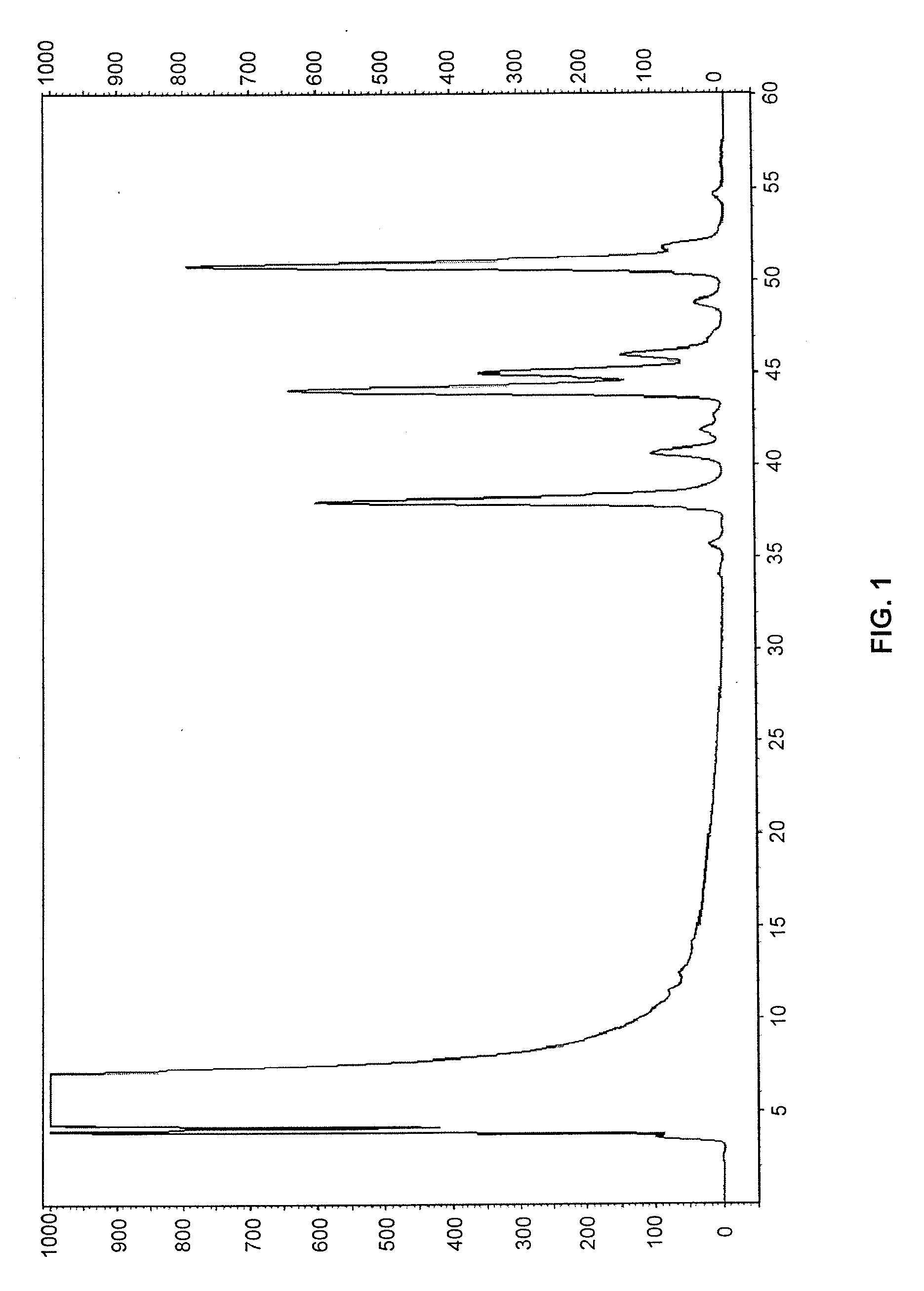

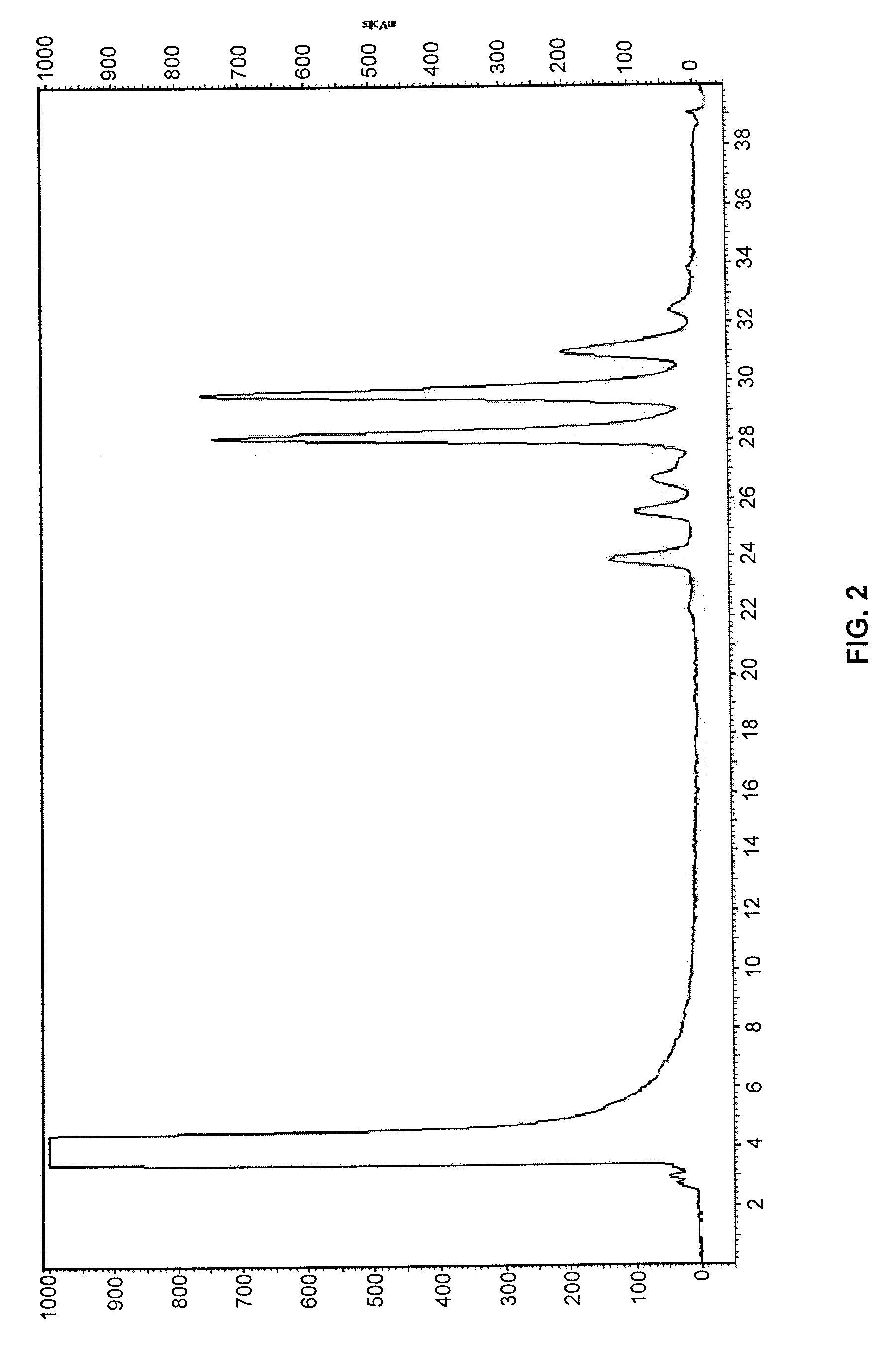

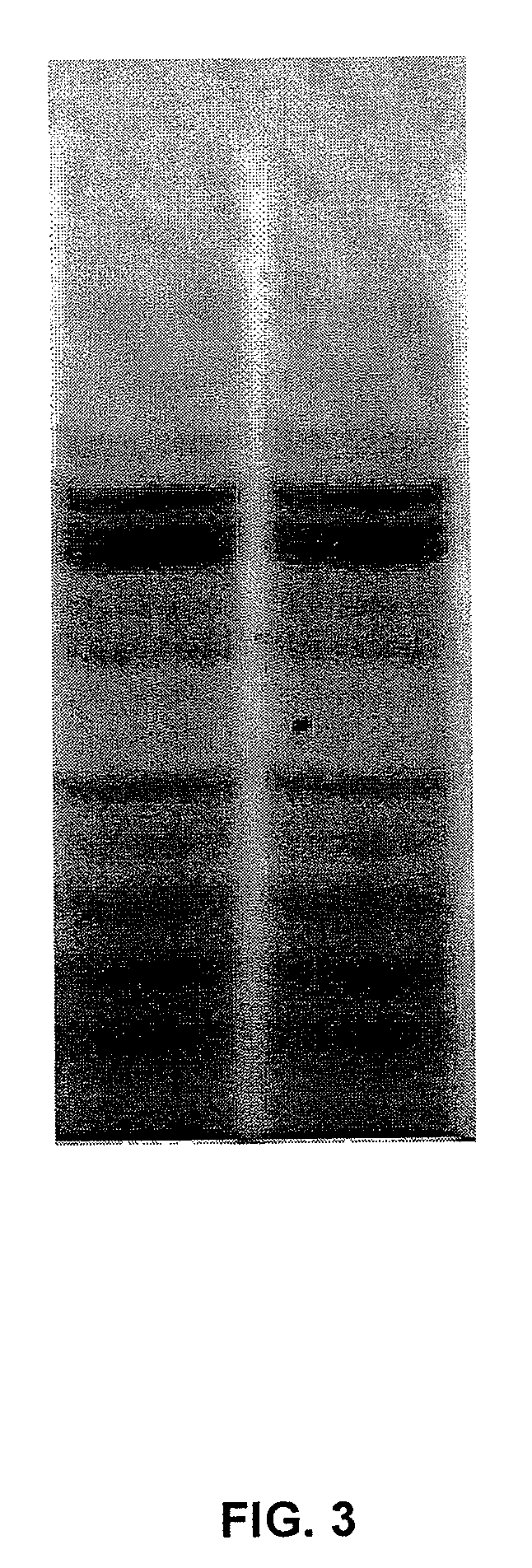

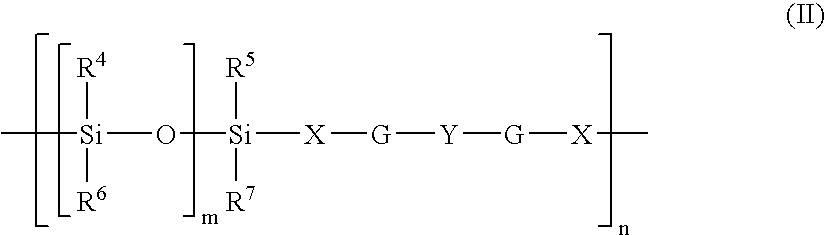

A tire composition is provided that may include a sulfur-functional linear polyorganosiloxane and an unsaturated elastomer. The sulfur-functional linear polyorganosiloxane may include a chemically protected sulfur group, which includes a thiocarbamate, a dithiocarbamate, or a derivative or analog of thiocarbamate or dithiocarbamate. Under certain conditions, the sulfur group may react with the unsaturated elastomer. The invention includes embodiments that may relate to methods of making and using the sulfur-functional linear polyorganosiloxane in tire compositions.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

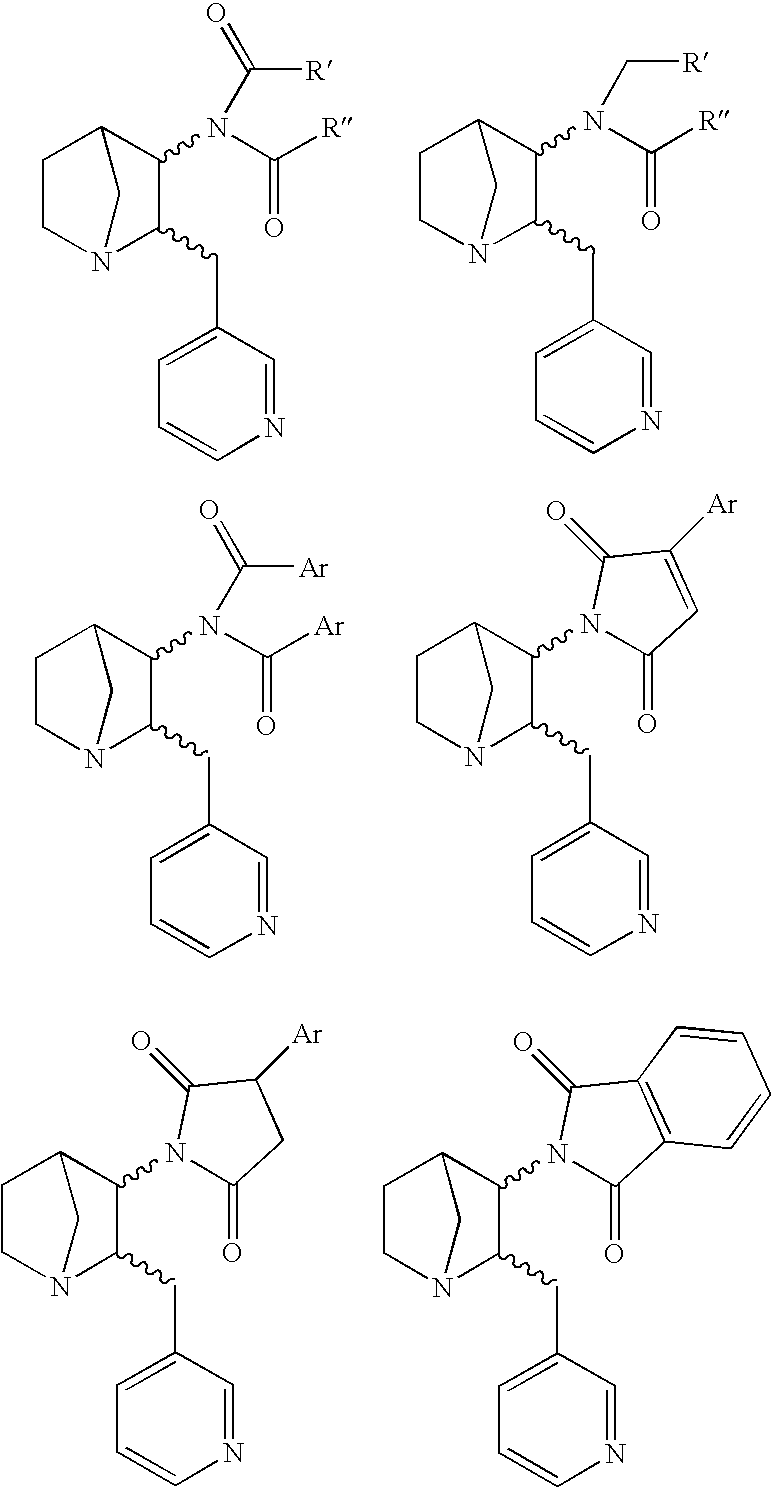

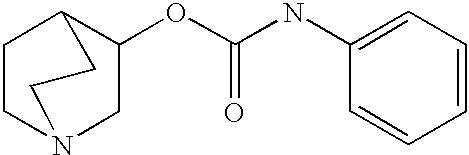

3-substituted-2(arylalkyl)-1-azabicycloalkanes and methods of use thereof

InactiveUS6953855B2Modulate activityWithout side effectAntibacterial agentsBiocideDiseaseThiocarbamate

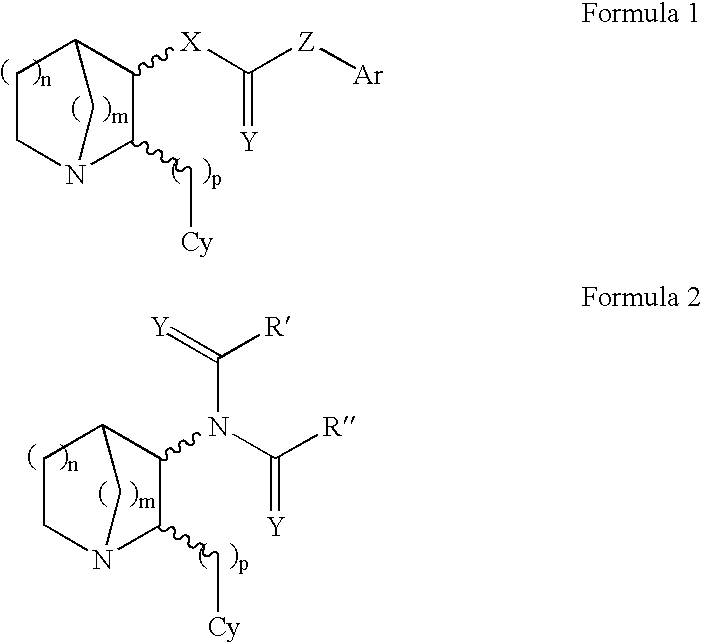

The present invention relates to 3-substituted-2-(arylalkyl)-1-azabicycloalkanes, methods of preparing the compounds and methods of treatment using the compounds. The azabicycloalkanes generally are azabicycloheptanes, azabicyclooctanes, or azabicyclononanes. The aryl group in the arylalkyl moiety is a 5- or 6-membered ring heteroaromatic, preferably 3-pyridinyl and 5-pyrimidinyl moieties, and the alkyl group is typically a C1-4 alkyl. The substituent at the 3-position of the 1-azabicycloalkane is a carbonyl group-containing moiety, such as an amide, carbamate, urea, thioamide, thiocarbamate, thiourea or similar functionality. The compounds exhibit activity at nicotinic acetylcholine receptors (nAChRs), particularly the α7 nAChR subtype, and are useful towards modulating neurotransmission and the release of ligands involved in neurotransmission. Methods for preventing or treating conditions and disorders, including central nervous system (CNS) disorders, which are characterized by an alteration in normal neurotransmission, are also disclosed. Also disclosed are methods for treating inflammation, autoimmune disorders, pain and excess neovascularization, such as that associated with tumor growth.

Owner:ATTENUA INC

Cosmetic composition for care and/or makeup, structured with silicone polymers and film-forming silicone resins

InactiveUS20030235552A1Improved deposit staying-power propertyImprove propertiesCosmetic preparationsHair cosmeticsThiocarbamateCarbamate

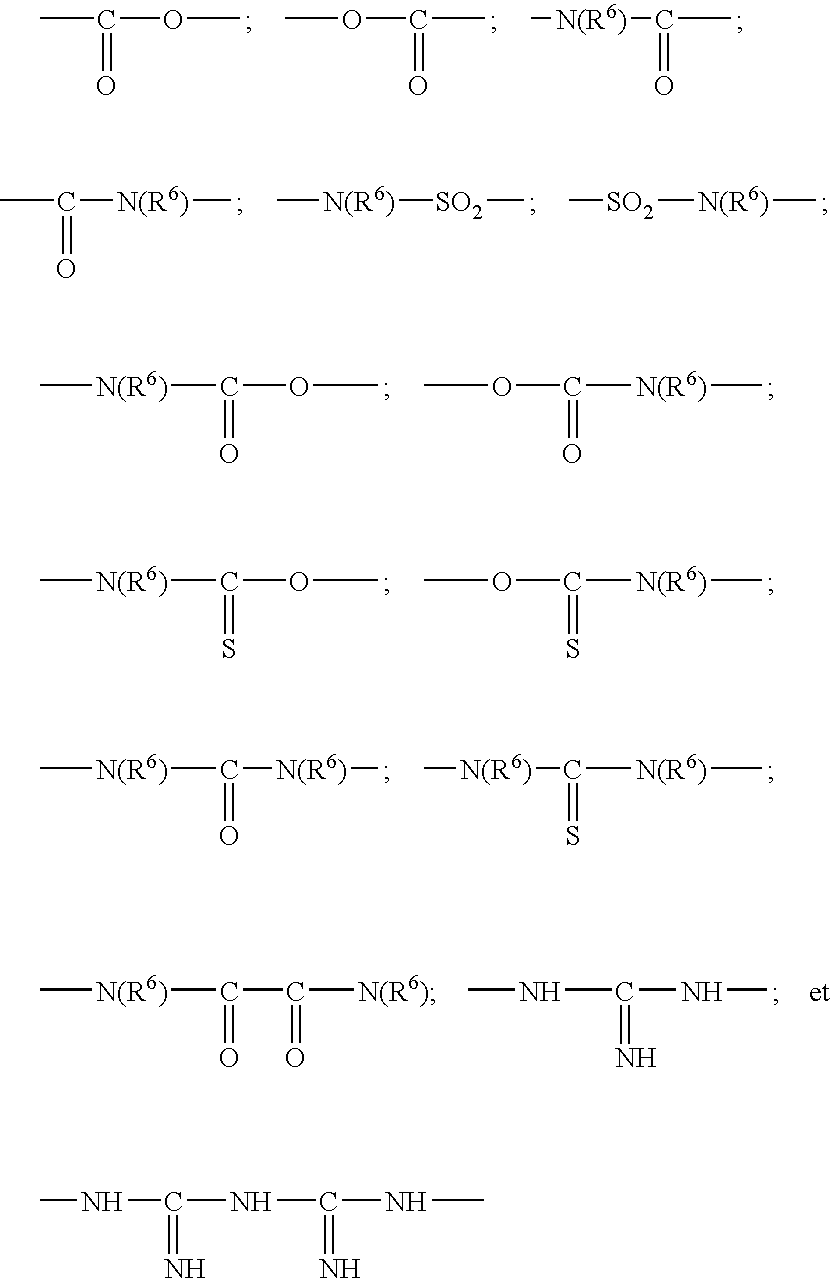

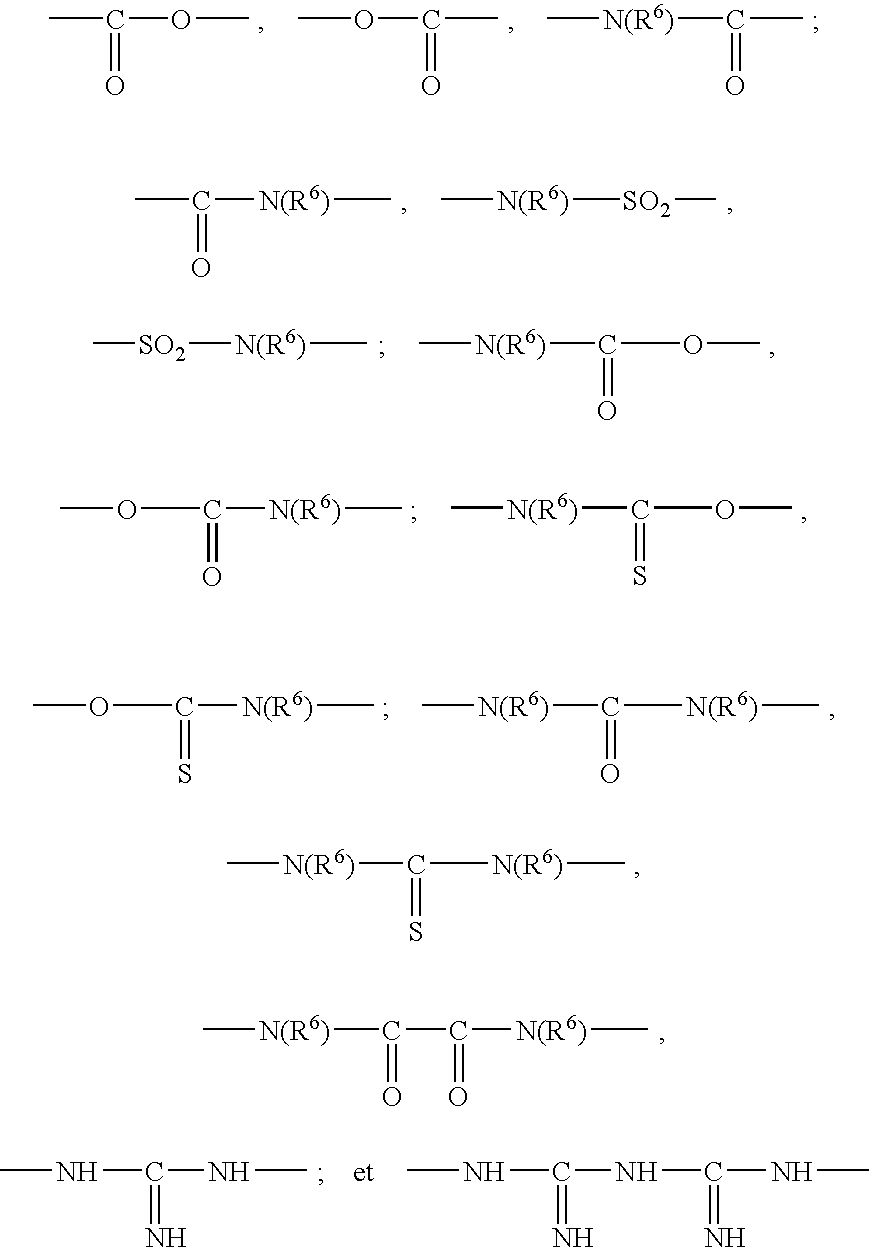

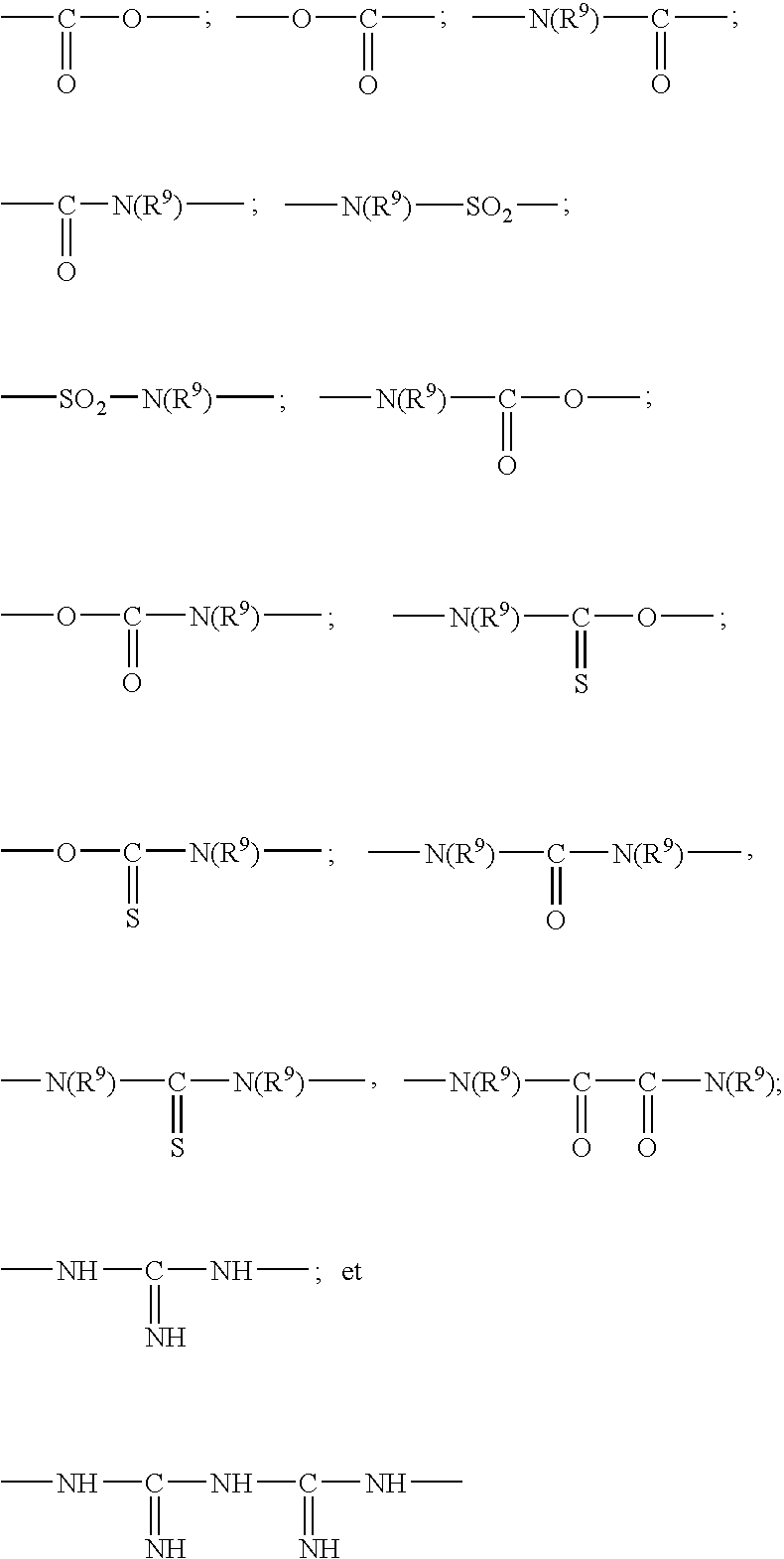

Cosmetic composition for care and / or makeup, comprising: 1) a liquid fatty phase comprising at least one silicone oil, structured with a gelling system comprising at least one polymer (homopolymer or copolymer) with a weight-average molecular mass ranging from 500 to 500,000, containing at least one moiety comprising: at least one polyorganosiloxane group, composed of 1 to 1000 organosiloxane units in the chain of the moiety or in the form of a graft, and at least two groups capable of establishing hydrogen interactions chosen from among the ester, amide, sulfonamide, carbamate, thiocarbamate, urea, thiourea, oxamido, guanidino, biguanidino groups, and combinations thereof, on condition that at least one of the groups is other than an ester group, the polymer being solid at room temperature and soluble in the liquid fatty phase at a temperature of 25 to 250° C., and 2) at least one film-forming silicone resin, the liguid fatty phase, the gelling system and the film-forming silicone resin forming a physiologically acceptable medium.

Owner:LOREAL SA

Cosmetic composition for care and/or treatment and/or makeup of the emulsion type structured with silicone polymers

InactiveUS20030235548A1Outstanding propertyIncrease flexibilityCosmetic preparationsHair cosmeticsThiocarbamatePolymer science

Cosmetic emulsion for care and / or makeup, comprising an aqueous phase and a liquid fatty phase dispersed one within the other, said liquid fatty phase comprising at least one silicone oil and being structured with at least one gelling polymer (homopolymer or copolymer) with a weight-average molecular mass ranging from 500 to 500,000, containing at least one moiety comprising: at least one polyorganosiloxane group, composed of 1 to 1000 organosiloxane units in the chain of the moiety or in the form of a graft, and at least two groups capable of establishing hydrogen interactions chosen from among the ester, amide, sulfonamide, carbamate, thiocarbamate, urea, thiourea, oxamido, guanidino, biguanidino groups, and combinations thereof, on condition that at least one of the groups is other than an ester group, the polymer being solid at room temperature and soluble in the liquid fatty phase at a temperature of 25 to 250° C., the aqueous phase, the liquid fatty phase and the gelling polymer forming a physiologically acceptable medium.

Owner:LOREAL SA

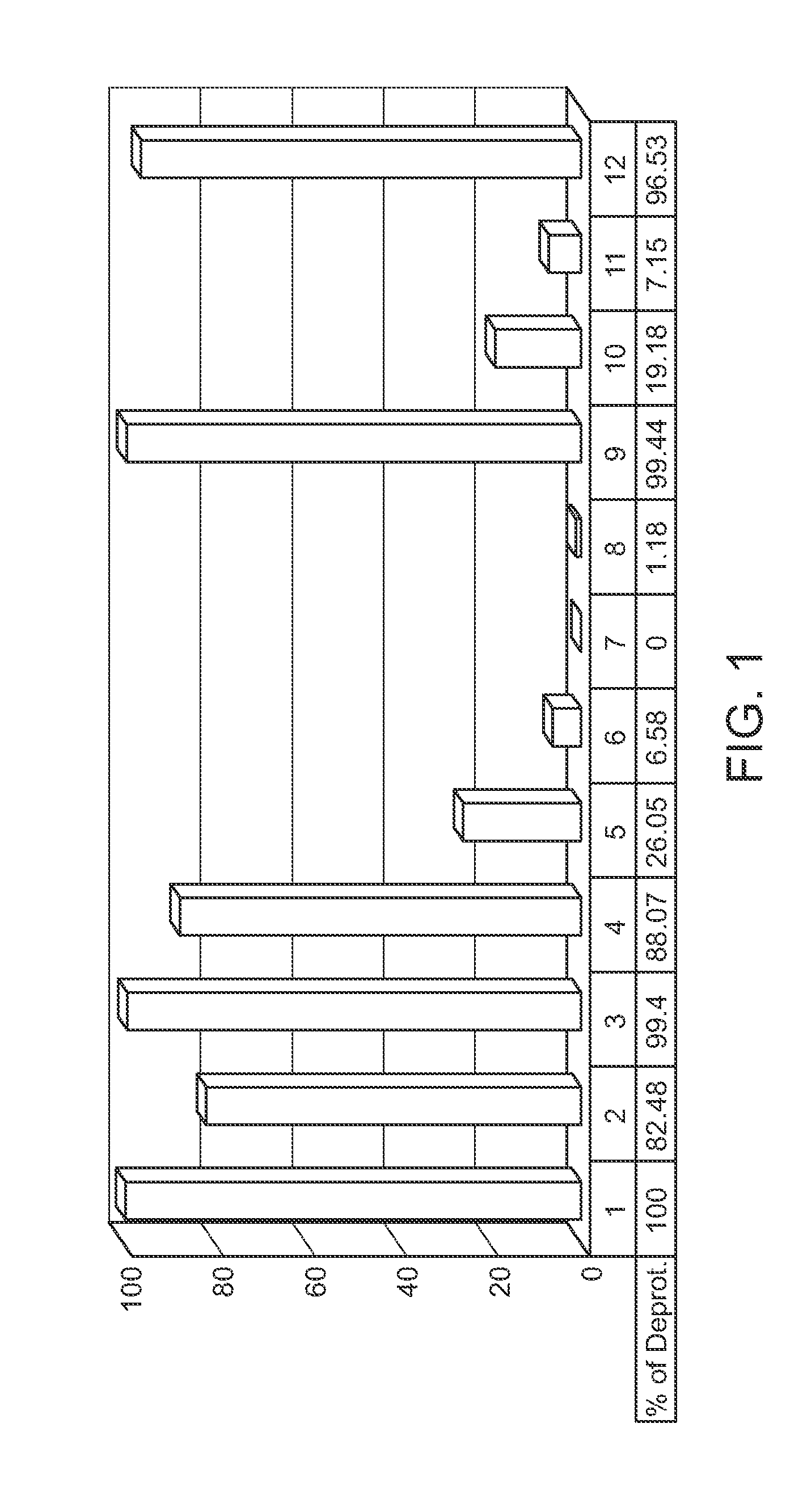

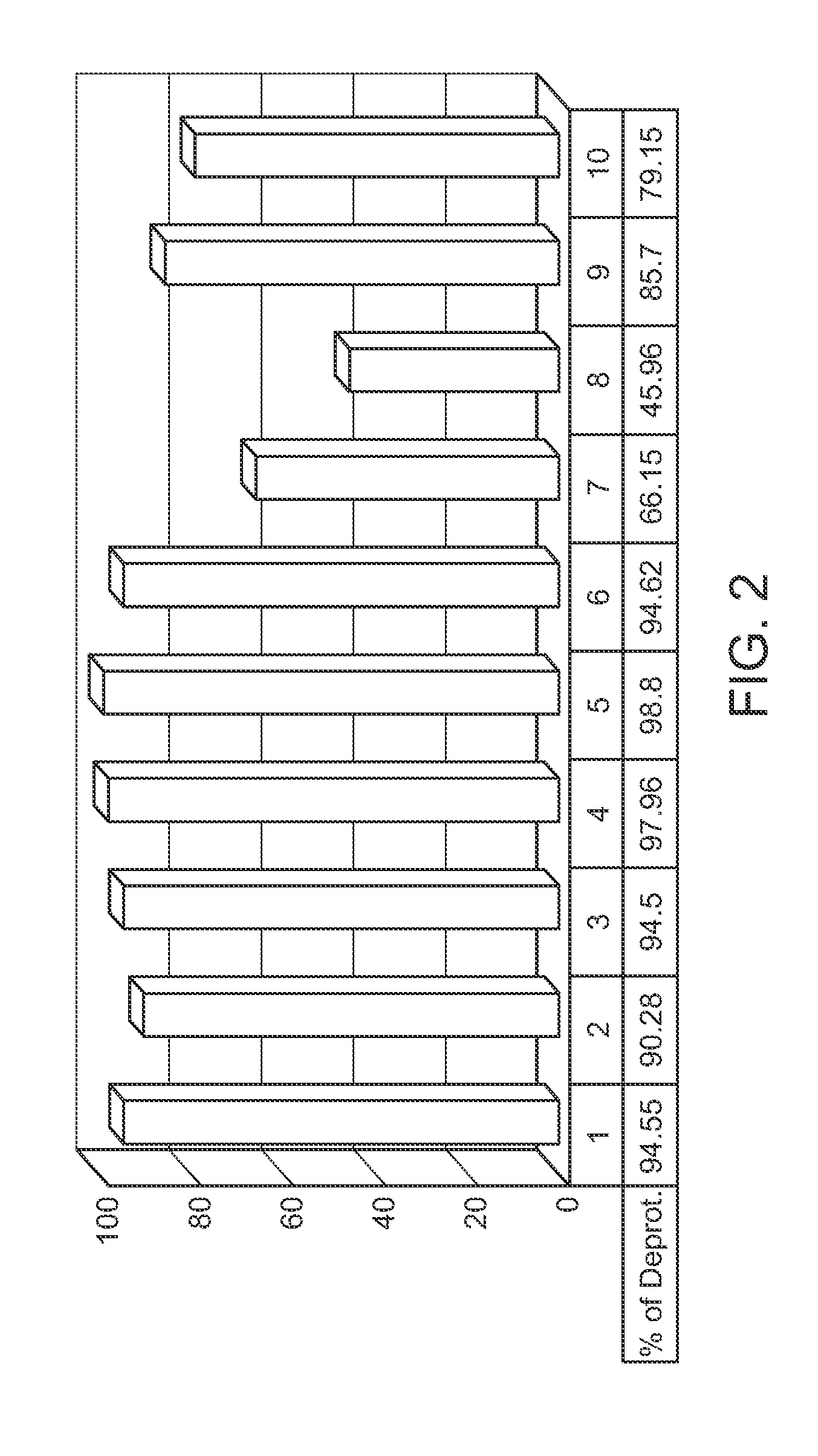

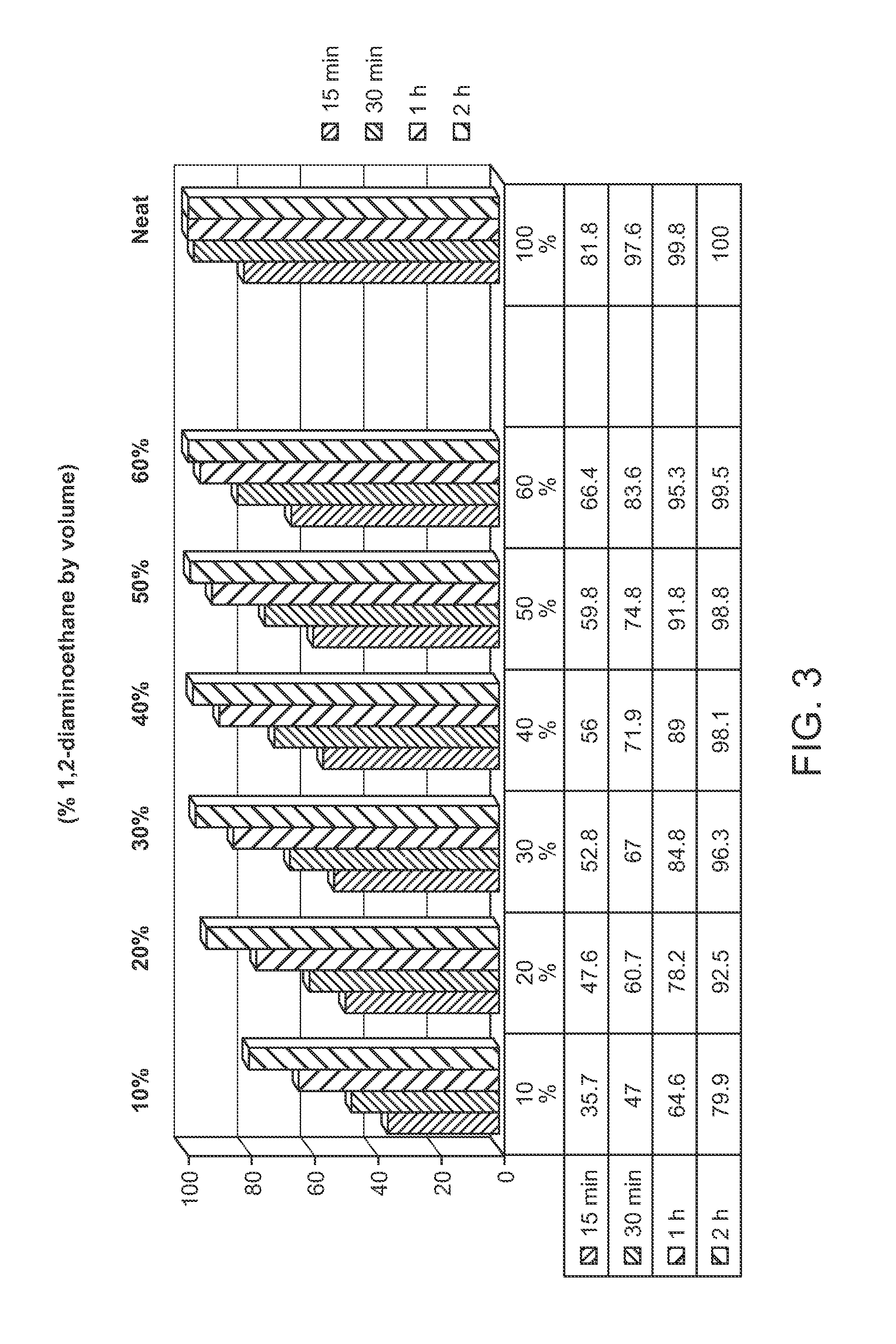

Protected monomers and methods of deprotection for RNA synthesis

InactiveUS20120184724A1High premiumsIsotope introduction to sugar derivativesSugar derivativesThiocarbamateCarbamate

A nucleoside monomer that is protected by a thionocarbamate protecting group and contains one or more 2H, 13C, or 15N isotopes in the ribose and / or base part is provided, as well as a method for making a polynucleotide that uses the same. Also provided is a polynucleotide synthesis method that employs a diamine to deprotect a protected polynucleotide.

Owner:AGILENT TECH INC

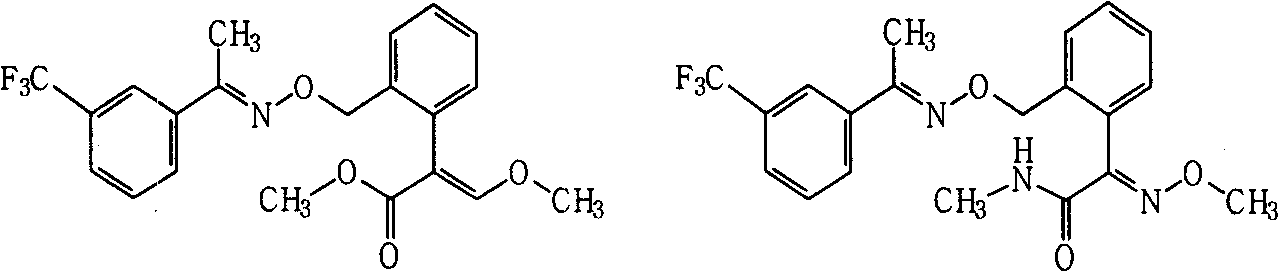

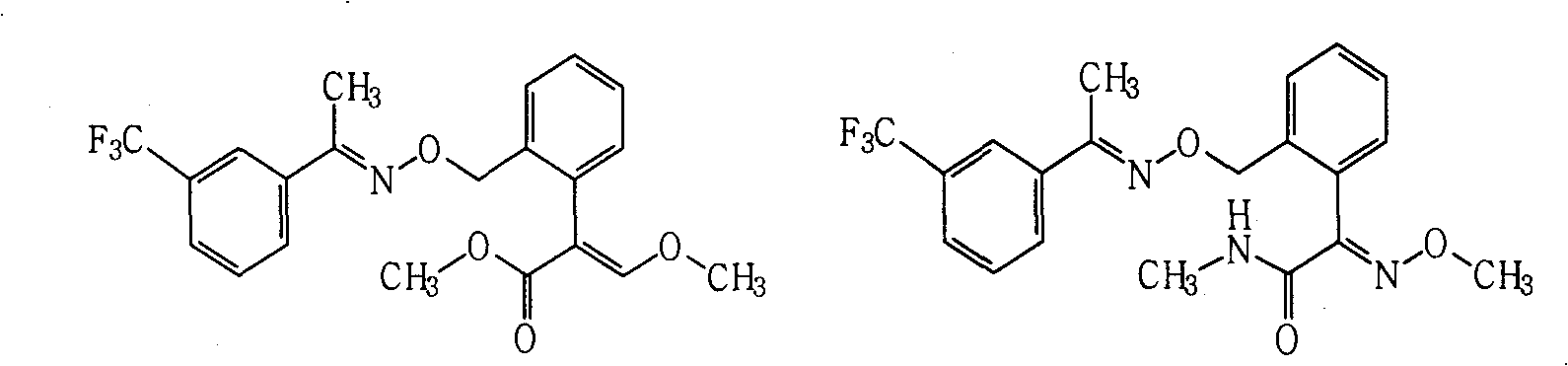

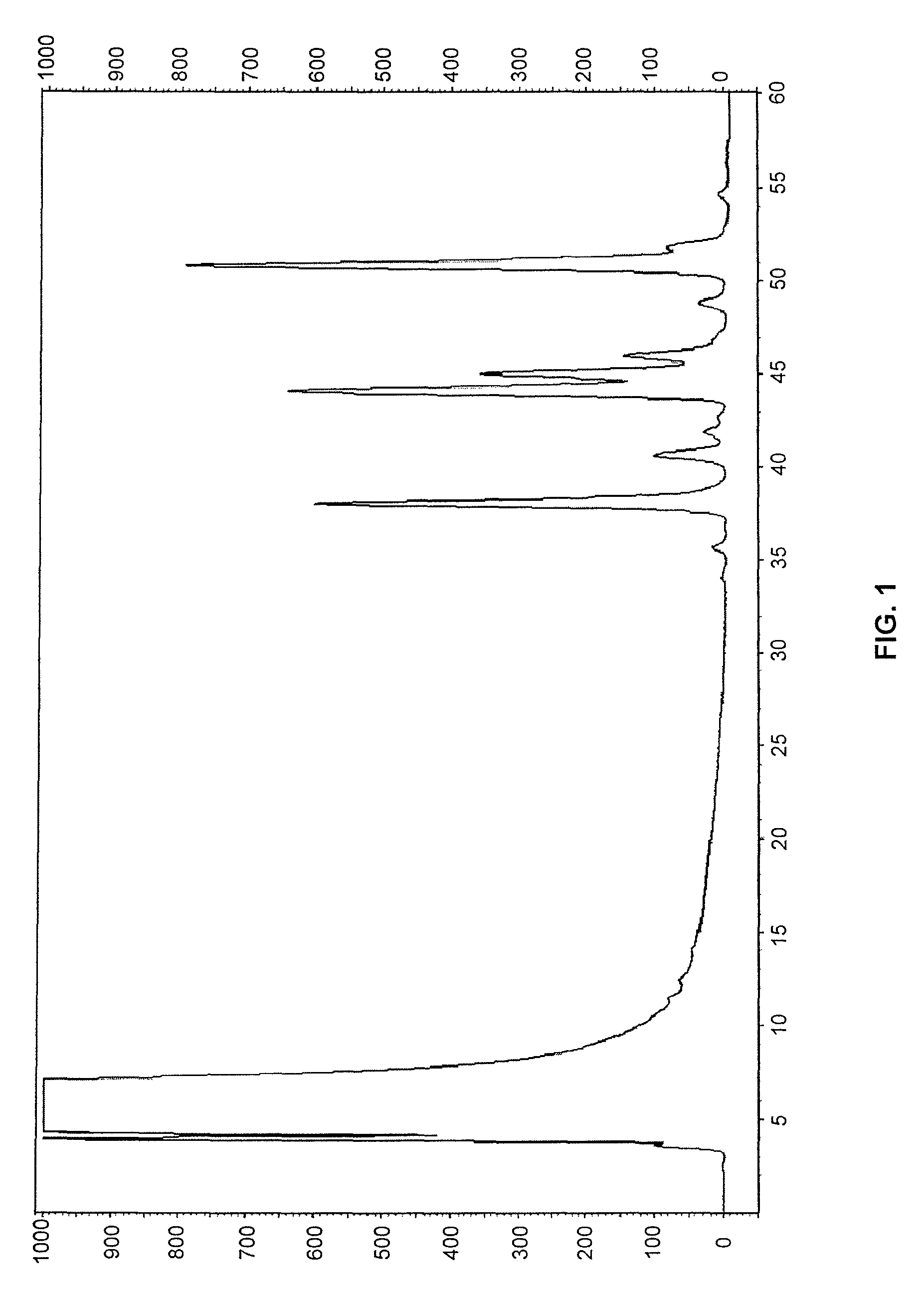

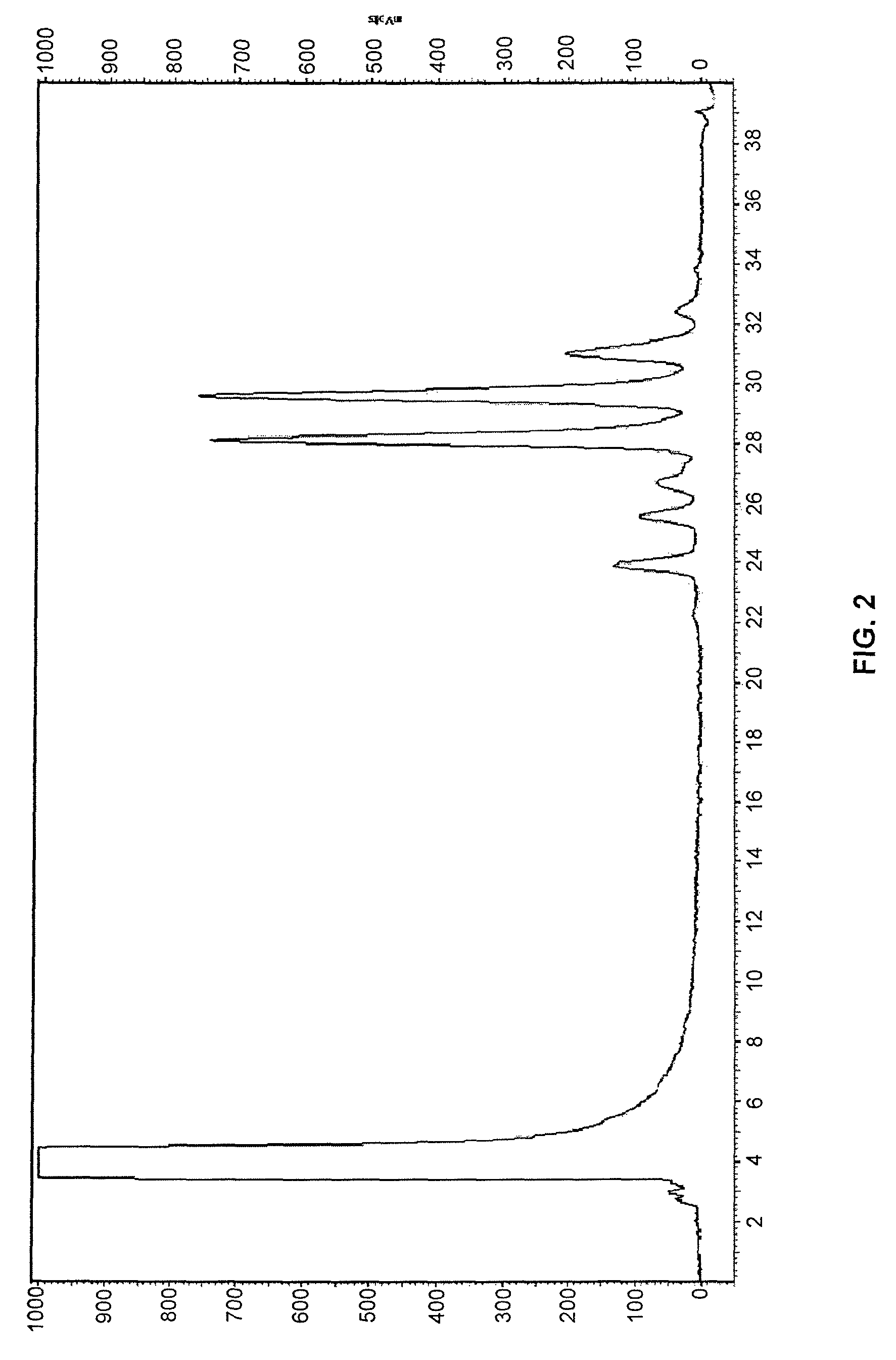

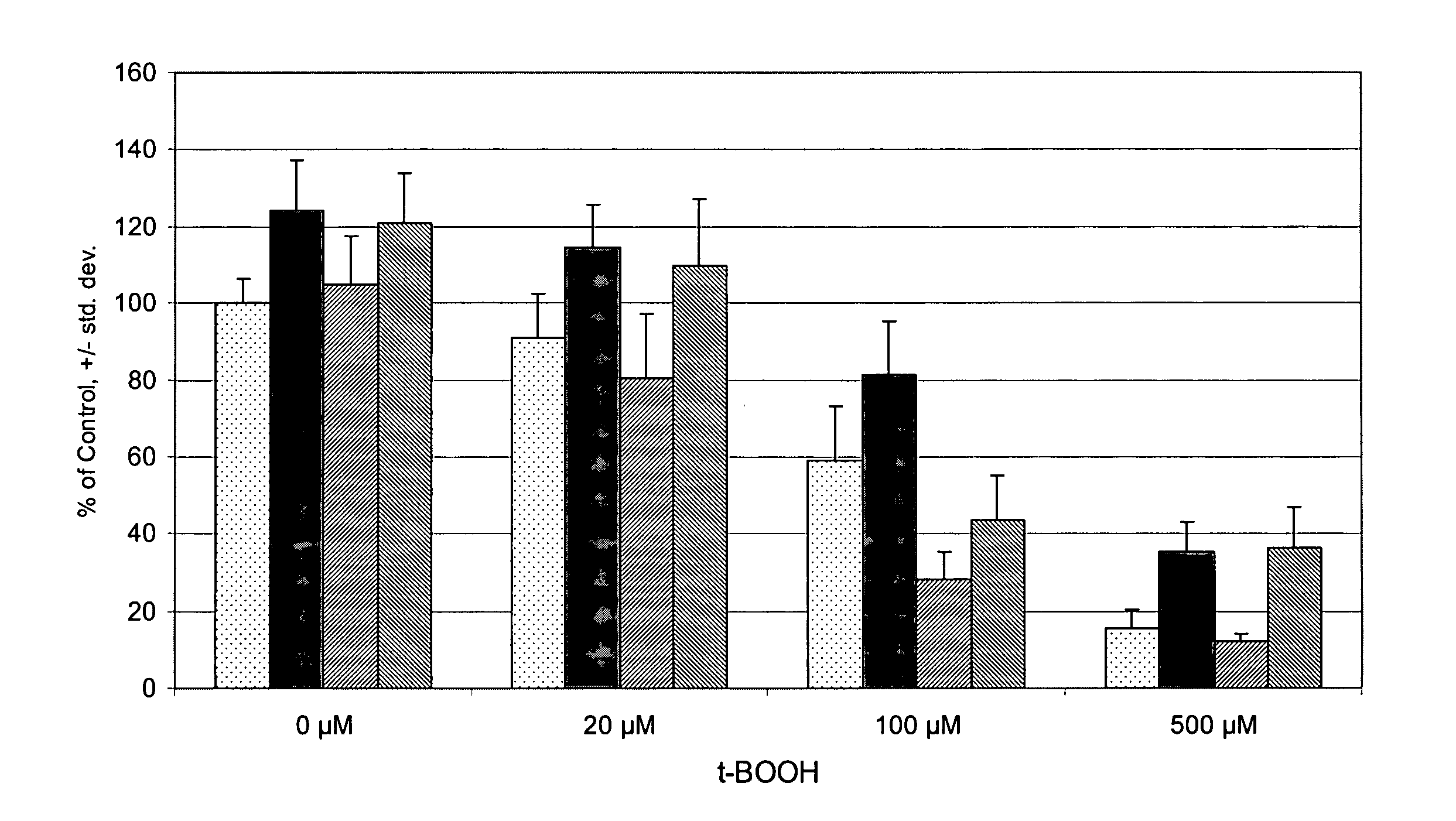

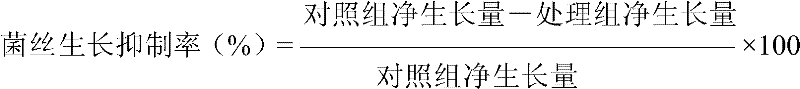

Fungicide composition

ActiveCN101637157AGood synergyImprove the effect of disease preventionBiocideFungicidesThiocarbamateCarbamate

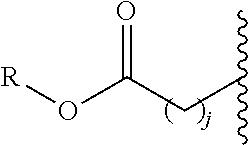

The invention provides a fungicide composition containing an active component A and an active component B, and application thereof in preventing and controlling various agricultural fungal diseases. The active component A in the composition is one of two methoxyl acrylic ester compounds; and as shown above, the active component B of the compound A1 and the compound A2 is one of the following fungicide varieties: thiocarbamate compounds or salt thereof, aliphatic compounds or salt thereof, carbamate compounds or salt thereof, oxazole compounds or salt thereof, thiazole compounds or salt thereof, amide compounds or salt thereof, organophosphorus compounds or salt thereof, imidazole compounds or salt thereof, antibiotic compounds or salt thereof, pyridine compounds or salt thereof and triazole compounds or salt thereof.

Owner:SHENYANG SINOCHEM AGROCHEMICALS R&D CO LTD

Compounds and methods for rapid labeling of N-glycans

ActiveUS8124792B2Easy to prepareRapid and facile labeling of N-glycansOrganic chemistryChemiluminescene/bioluminescenceThiocarbamateCarbamate

Owner:AGILENT TECH INC

Compounds and methods for rapid labeling of n-glycans

ActiveUS20090258437A1Easy to prepareRapid and facile labeling of N-glycansOrganic chemistryChemiluminescene/bioluminescenceThiocarbamateStereochemistry

The present invention provides compounds and methods for rapid labeling of N-glycans, for example, rapid fluorescent labeling of N-glycans. In one aspect, the present invention provides fluorescent carbamate or thiocarbamate compounds. Upon contacting with N-glycans, the compounds undergo facile reactions with N-glycans to form fluorescent-labeled N-glycans.

Owner:AGILENT TECH INC

Transparent or translucent care and/or make-up cosmetic composition structured with silicone polymers

Care and / or make-up cosmetic composition, which is transparent or translucent and / or capable of giving a transparent or translucent deposit, comprising a liquid fatty phase comprising at least one ester oil chosen from esters of monocarboxylic acids with monoalcohols and polyalcohols, structured with at least one structuring polymer (homopolymer or copolymer) having a weight-average molecular mass ranging from 500 to 500 000, containing at least one moiety comprising at least one polyorganosiloxane group consisting of 1 to 1 000 organosiloxane units in the chain of the moiety or in the form of a graft, and at least two groups capable of establishing hydrogen interactions, chosen from ester, amide, sulphonamnide, carbamate, thiocarbamate, urea, urethane, thiourea, oxamido, guanidino and biguanidino groups, and combinations thereof, the polymer being solid at room temperature and soluble in the liquid fatty phase at a temperature of 25 to 250° C., and the liquid fatty phase and the structuring polymer forming a physiologically acceptable medium.

Owner:LOREAL SA

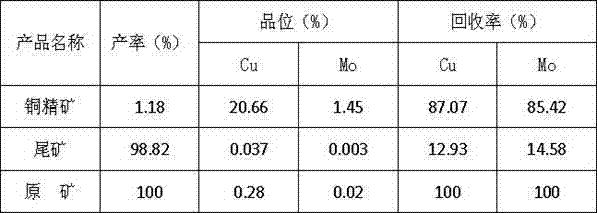

Method for using cyaniding barren solution to float, reclaim and cyaniding copper plumbum and zinc in tailings

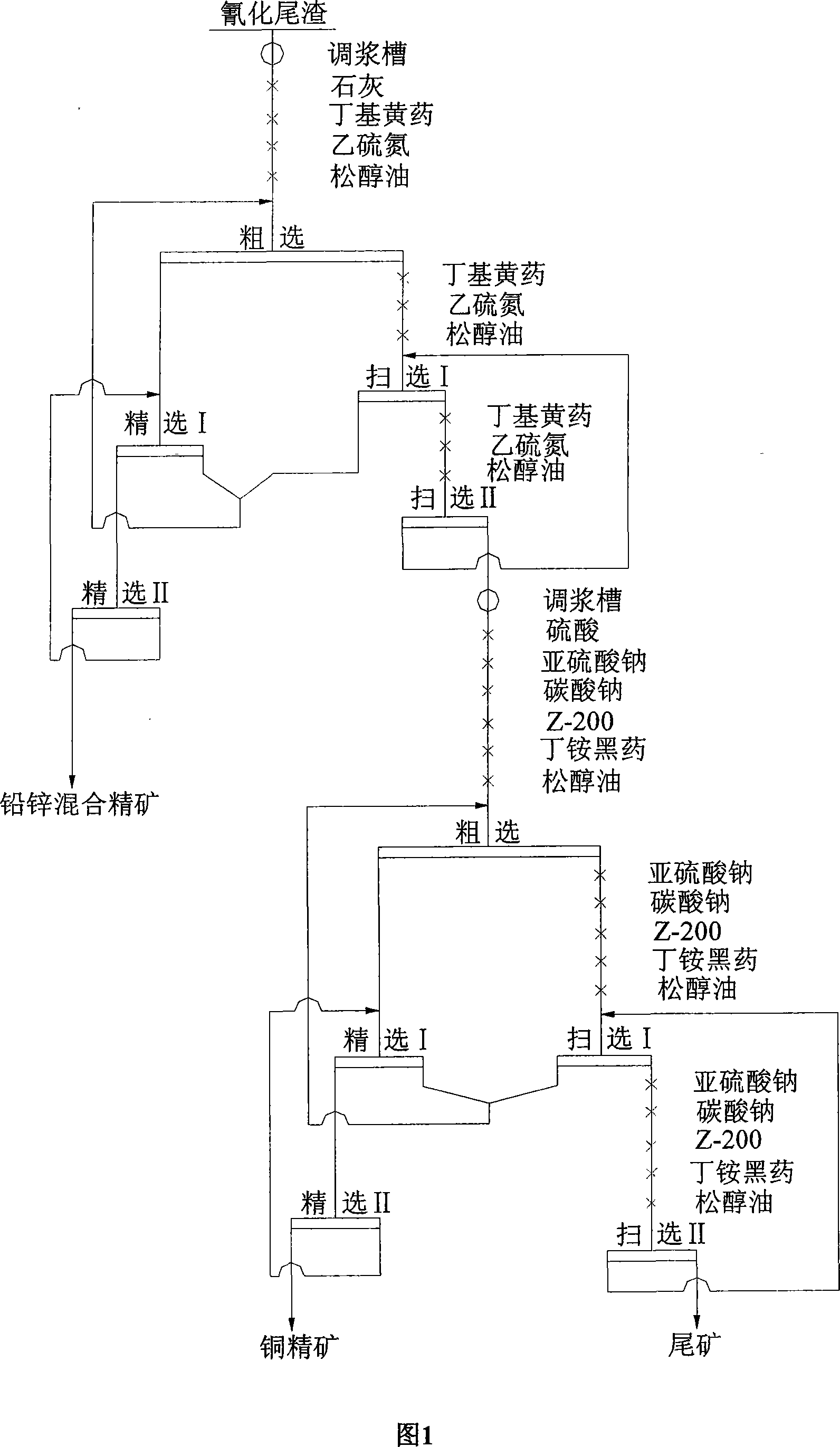

A method that cyanide barren solution is used for recovering the copper-lead-zinc from cyanide tailing by means of floatation belongs to the field of nonferrous metal separation. The processing procedures of the method are as following: (1) mashing: the cyanide barren solution is added into the cyanide tailing and stirred to ore slurry, the concentration of which is 35 to 40 per cent; (2) lead-zinc preferential flotation: after being stirred, the ore slurry is put into flotation machine and lime, Ethyl thiocarbamate and Sodium n-butyl xanthate synthetic are added in to the ore slurry. The course of once rough floatation, twice scavenging and twice concentration is processed to recover Zinc and Lead; (3) Cu-S separation: after the tailing of lead and zinc bulk flotation is concentrated, the cyanide barren solution is added into the tailing and the tailing is made into the ore slurry with the concentration of 35 to 40 per cent. And then, the ore slurry is put into the floatation machine and sulfate, sodium sulfite, Z-200 and ammonium butyl aerofloat are added into the tailing. The course of once rough floatation, twice scavenging and twice concentration is processed to recover copper. And the tailing can be for sale as sulfur concentrate; (4) Reuse of separation tailing water: the press filtrate of bulk concentrate, the overflow of thickener, the press filtrate of copper concentrate and the press filtrate of the sulfur concentrate return to the buffer slot of the cyanide barren solution to be used for replacement fluid. The invention has the advantages of good flotation effect, high recovery rate of the copper-lead-zinc and zero discharge of waste water and residue.

Owner:UNIV OF SCI & TECH BEIJING

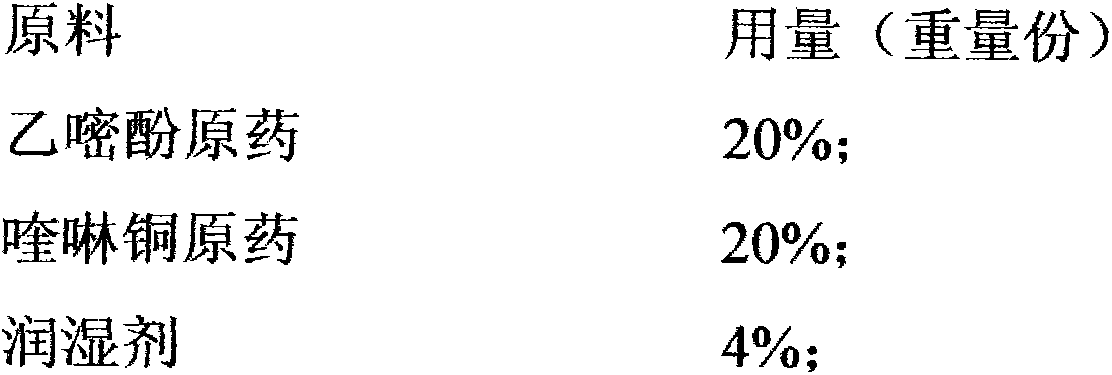

Compounded synergia sterilizing composite

InactiveCN103371149ADelay drug resistanceExpanded bactericidal spectrumBiocideFungicidesThiocarbamateCarbamate

The invention relates to a compounded synergia sterilizing composite, belonging to the technical field of pesticide. The sterilizing composite comprises an original medicine compounded by a sterilizing agent A and a sterilizing agent B, wherein the ratio of the sterilizing agent A to the sterilizing agent B is (1-90):(90-1), the sterilizing agent A is ethirimol or bupirimate, and the sterilizing agent B is any one of the following sterilizing agents: copper agent, methoxy-acrylics, triazoles, amides, pyrilamine, benzimidazole, thiocarbamate, dicarboximide, imidazole, morpholine, oxazole, ureas, pyridines, miazines, pyrroles, phthalimide, carbamates, antibiotics and others. The sterilizing composite comprises the original medicine compounded by the ethirimol or bupirimate and the sterilizing agent B, thus not only enlarging the bacteriocidal spectrum, but also slowing down the drug resistance of germs, and having obvious continuous synergia effect.

Owner:王学权

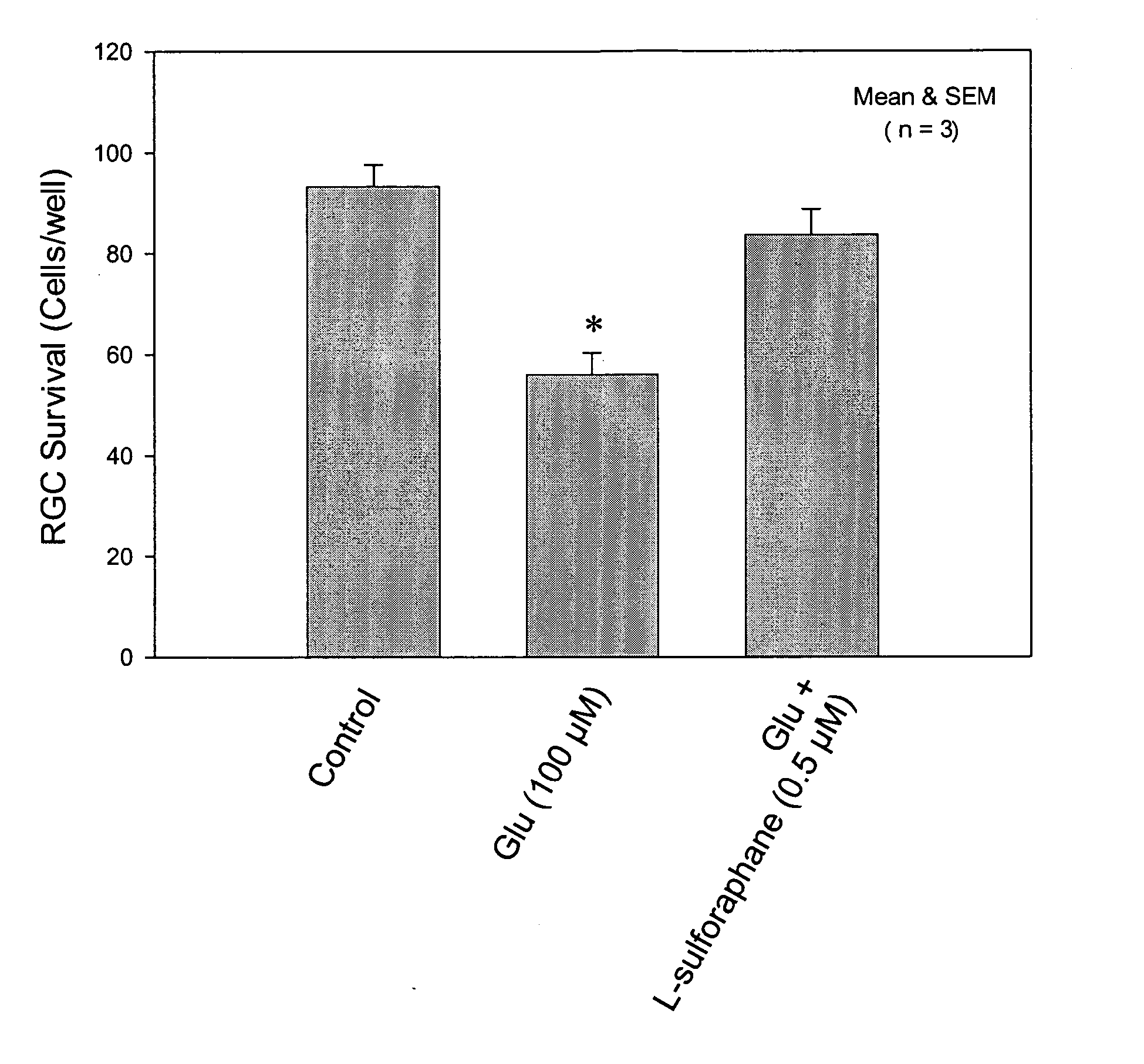

Agents for treatment of glaucomatous retinopathy and optic neuropathy

InactiveUS20050137146A1Delaying and preventing lossImprove availabilityBiocideSenses disorderQuinoneThiocarbamate

Agents that stimulate nuclear translocation of Nrf2 protein and the subsequent increases in gene products that detoxify and eliminate cytotoxic metabolites are provided in a method for treating glaucomatous retinopathy or optic neuropathy. The structurally diverse agents that act on the Nrf2 / ARE pathway induce the expression of enzymes and proteins that possess chemically versatile cytoprotective properties and are a defense against toxic metabolites and xenobiotics. Agents include certain electrophiles and oxidants such as a Michael Addition acceptor, diphenol, thiocarbamate, quinone, 1,2-dithiole-3-thione, butylated hydroxyanisole, flavonoid, an isothiocyanate, 3,5-di-tert-butyl-4-hydroxytoluene, ethoxyquin, a coumarin, combinations thereof, or a pharmacologically active derivative or analog thereof.

Owner:ALCON INC

Modified carbamate-containing prodrugs and methods of synthesizing same

InactiveUS20040152769A1Promote degradationGood drug release propertiesBiocidePhosphorous compound active ingredientsThiocarbamateCarbamate

Owner:BIOCON LTD

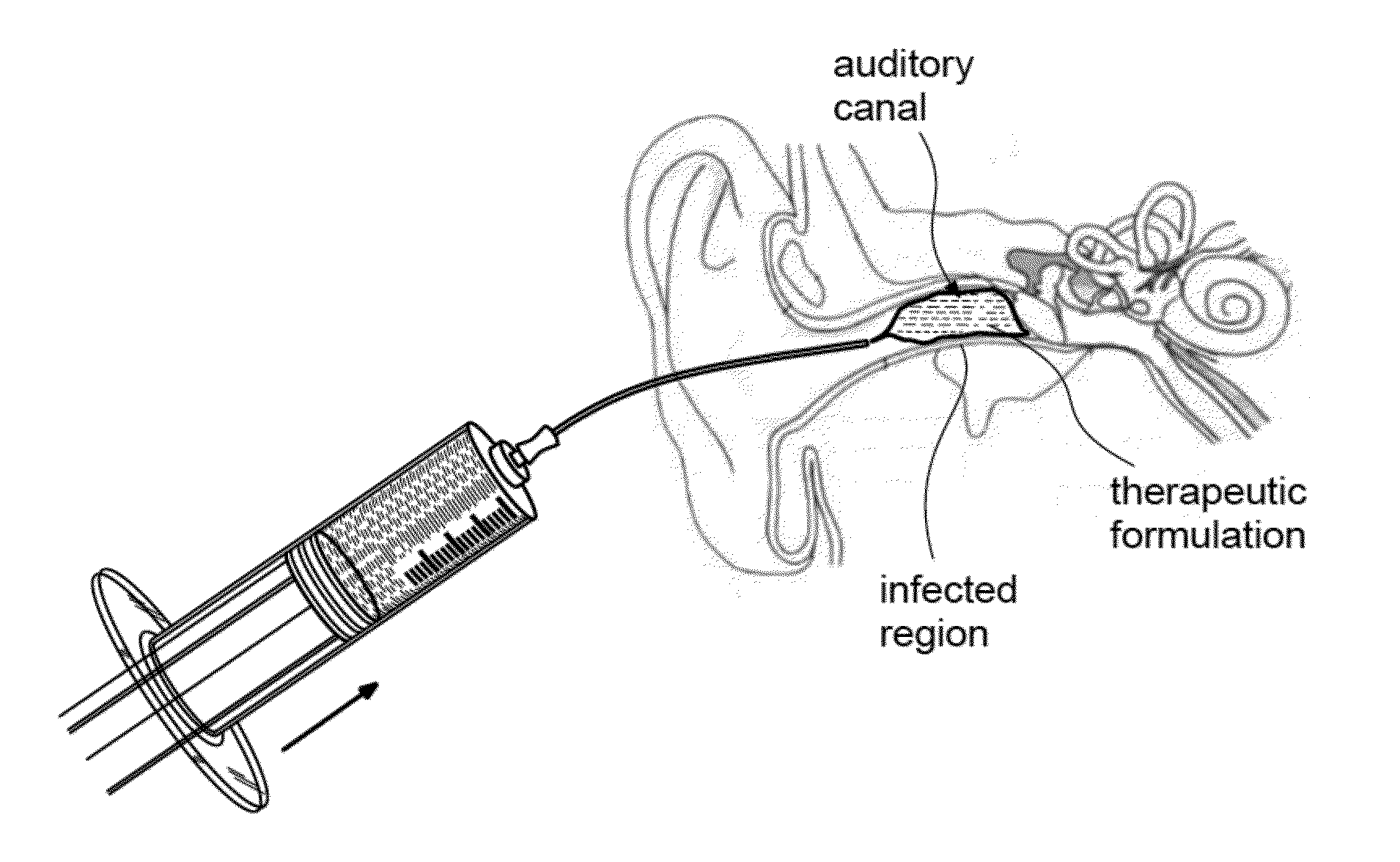

Otic formulations, methods and devices

ActiveUS20130178801A1Significant pain reliefLess bacterial community resistanceAntibacterial agentsBiocideThiocarbamateAntifungal

The present invention relates to a formulation and method for treating an ear infection, especially otomycosis and otitis externa, by administering a one-time only treatment comprising an antibiotic, and antifungal, and an anti-inflammatory in a thick, otic carrier. In one embodiment, the formulation comprises a therapeutically effective amount of active ingredients including a fluoroquinolone, a triazole antifungal, a thiocarbamate antifungal, a corticosteroid and a polyene antifungal, as well as a thickener such that the formulation, upon applying to the infected ear canal, gels and remains in the ear canal, continuously releasing the active ingredients for several days, achieving consistent complete (98-100%) clinical resolution of otomycosis and otitis externa in a single application.

Owner:METALCLAD

Rubber mixture with improved abrasion

ActiveUS20090306267A1Improve grinding effectImprove performanceSpecial tyresGranular deliveryElastomerVulcanization

A rubber mixture with improved abrasion with improved abrasion performance, in particular for pneumatic tires, has the following composition: from 30 to 100 phr of at least one diene rubber; from 0.1 to 10 phr of at least one vulcanization accelerator selected from the group consisting of: thiazole accelerators, mercapto accelerators, sulfenamide accelerators, guanidine accelerators, thiuram accelerators, dithiocarbamate accelerators, amine accelerators, thioureas, and / or other accelerators; and a vulcanization system of sulfur comprising elemental sulfur, sulfur donor and silane between 0.25 and 0.08 moles per 100 parts by weight of the rubber elastometer, whereby the free sulfur contributes in the range of 0 to 70%, the sulfur donor contributes in the range of 5 to 30%, and the silane contributes in the range of 20 to 95%.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

Premium wear resistant lubricant

Owner:EXXON RES & ENG CO

Transmission composition

InactiveUS20060264341A1Avoid corrosionMeet standardOrganic compound preparationAdditivesThiocarbamateThiazole

There is provided a transmission composition including a lead corrosion reducing effective amount of at least one lead corrosion inhibitor selected from the group consisting of sulfurized alkylphenols; phosphosulfurized hydrocarbons; substituted or unsubstituted thiocarbamates; substituted or unsubstituted thiazoles; substituted or unsubstituted triazoles; substituted or unsubstituted thiadiazoles.

Owner:AFTON CHEMICAL

Recycling of Natural and Synthetic Rubber

InactiveUS20100317752A1Efficient recyclingWide applicabilityOther chemical processesPlastic recyclingElastomerThiocarbamate

A delinking composition in the form of a combined solid dose comprising: (i) one or more elastomer delinking accelerators selected from the group consisting of zinc salts of thiocarbamates and zinc salts of dialkyl dithiophosphates; and (ii) one or more elastomer delinking accelerators selected from the group consisting of 2-mercaptobenzothiazole or derivatives thereof, thiurams, guanidines, 4,4′-dithiomorpholine and sulpenamides; and (iii) at least one elastomer delinking activator.

Owner:ELASTOMER TECH

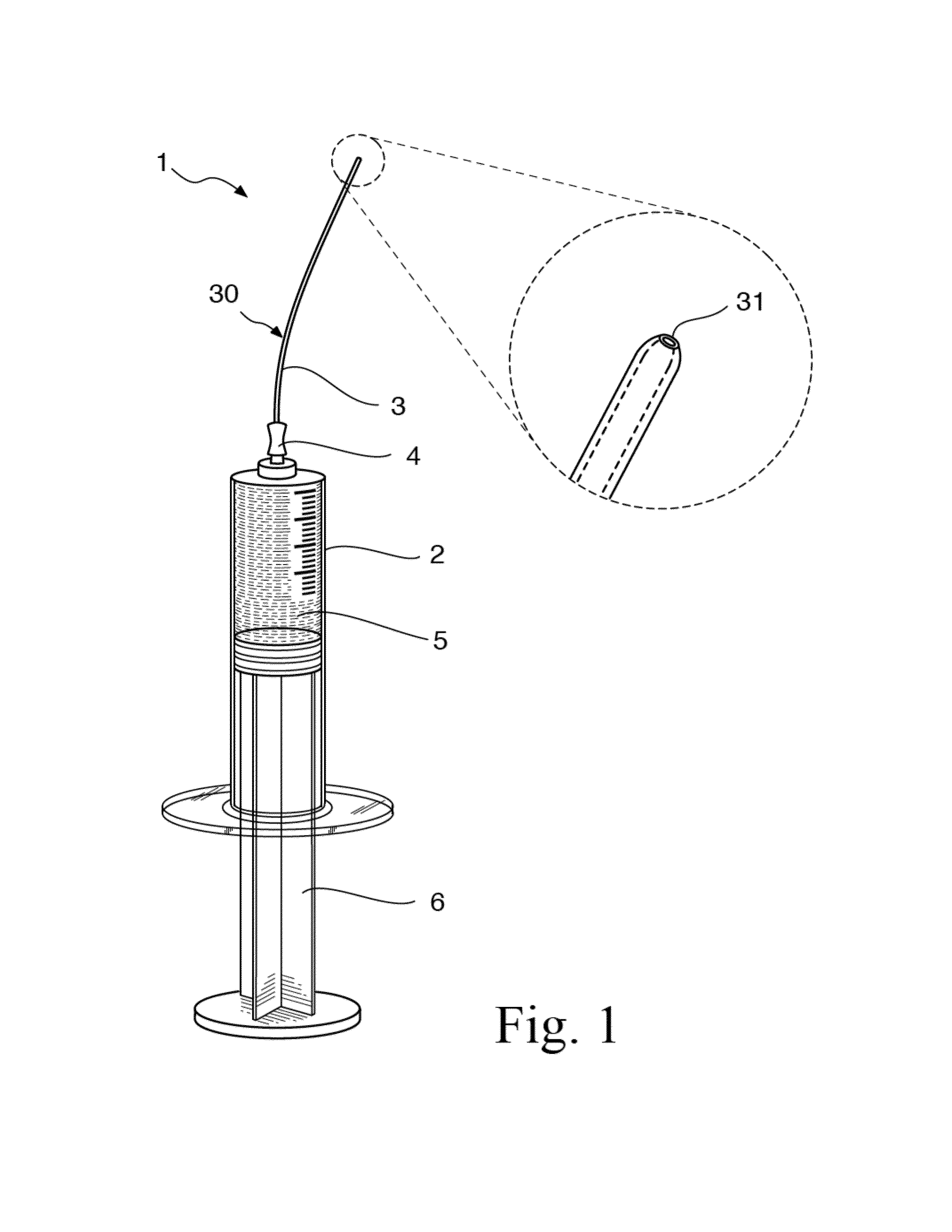

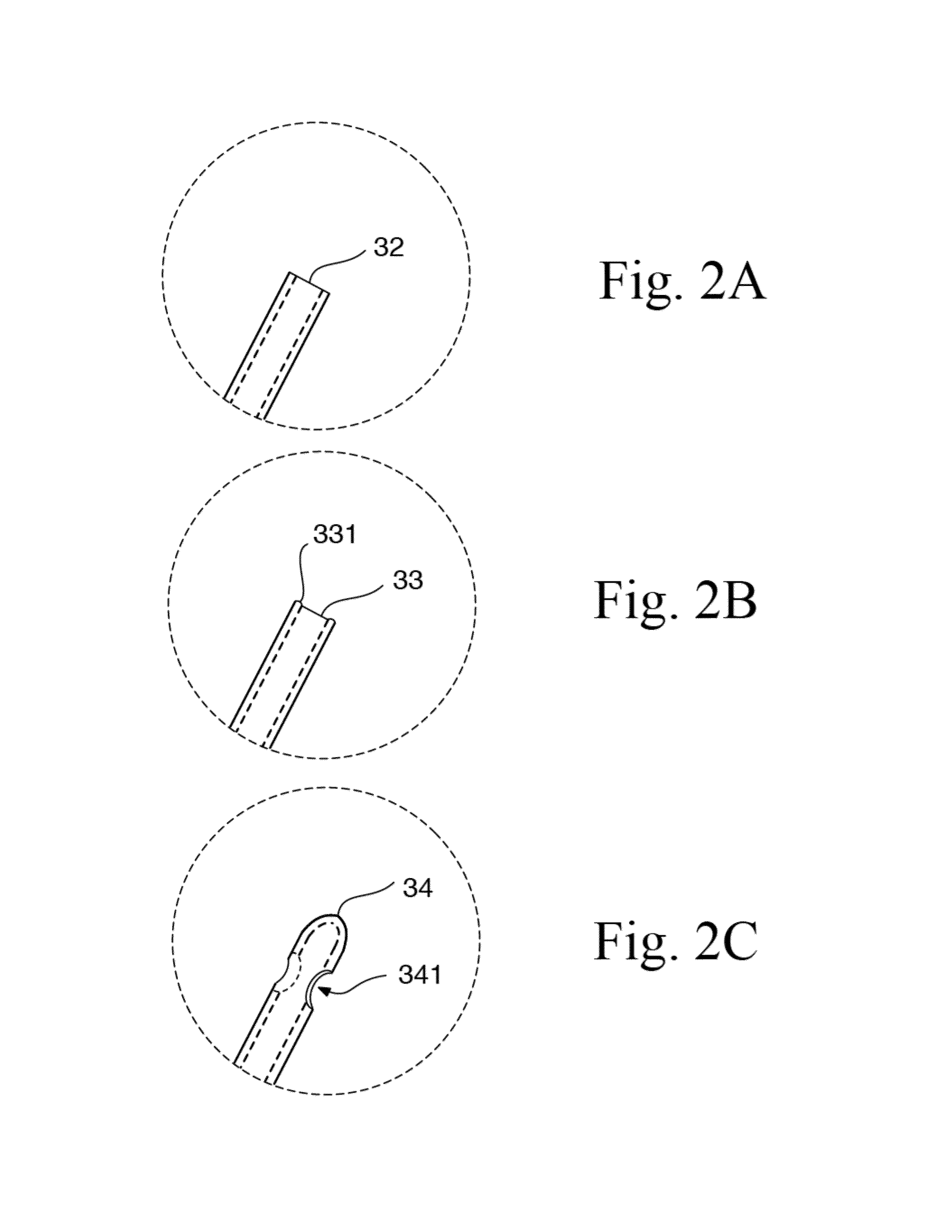

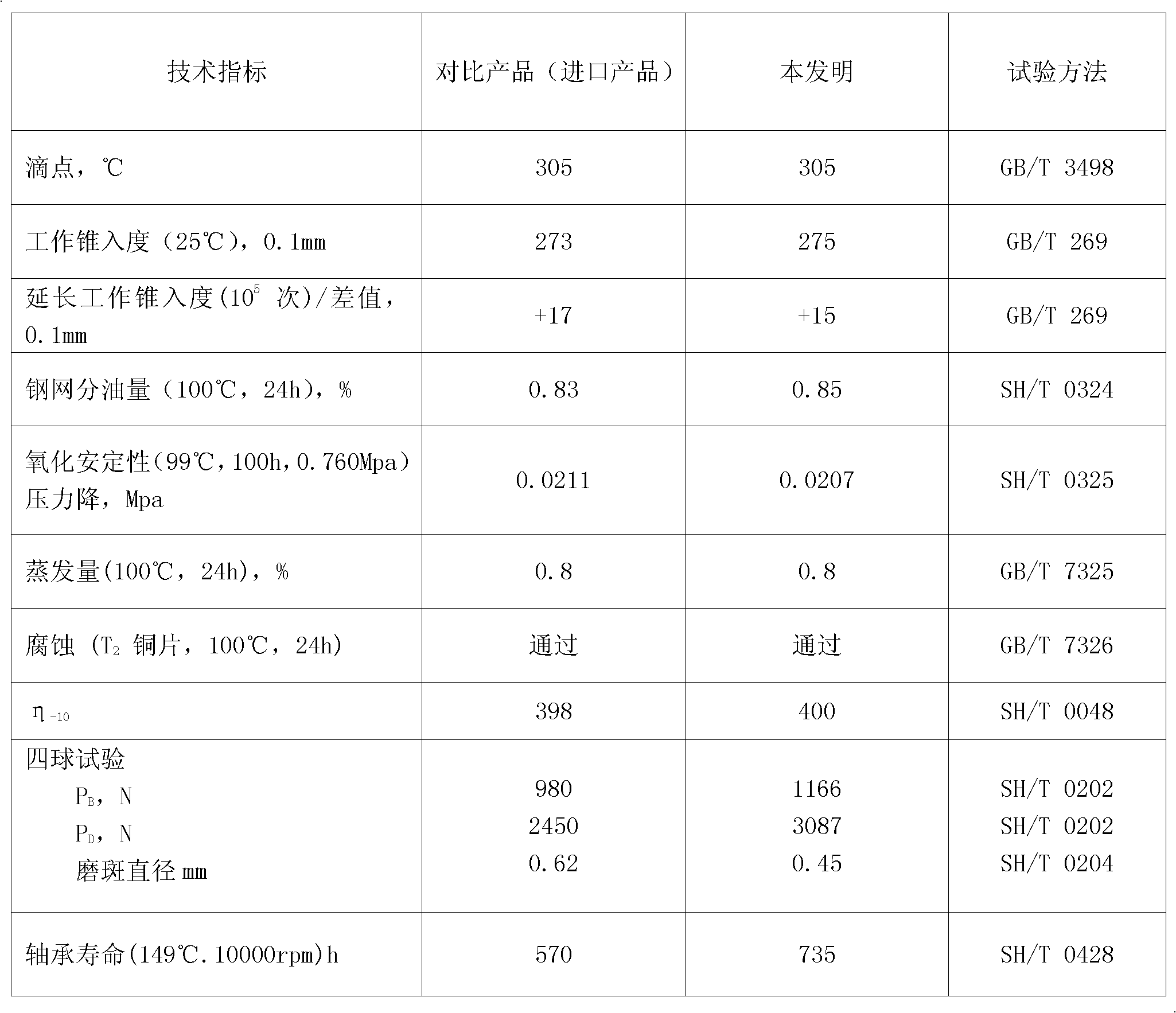

Lubricating grease for hub bearing of heavy load truck and preparation method thereof

InactiveCN103450978AEliminates tendency to overflowSlow dehydration stepThickenersThiocarbamateChemical industry

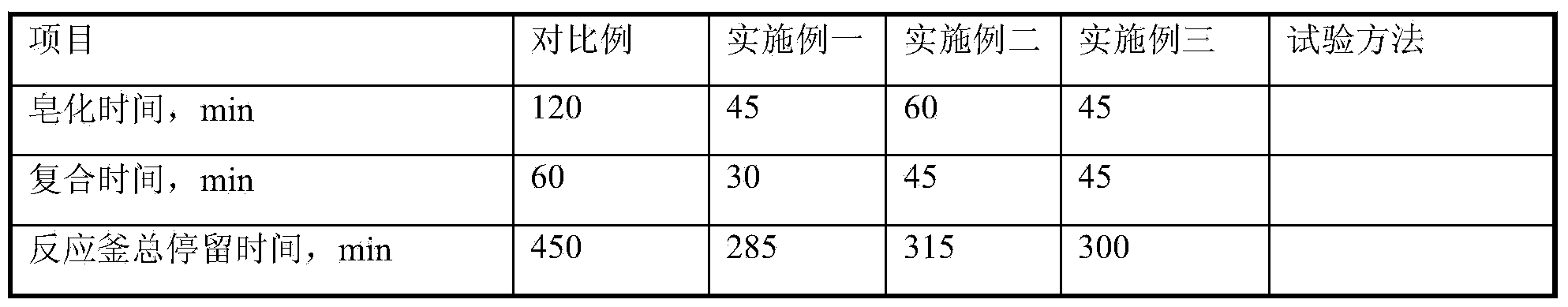

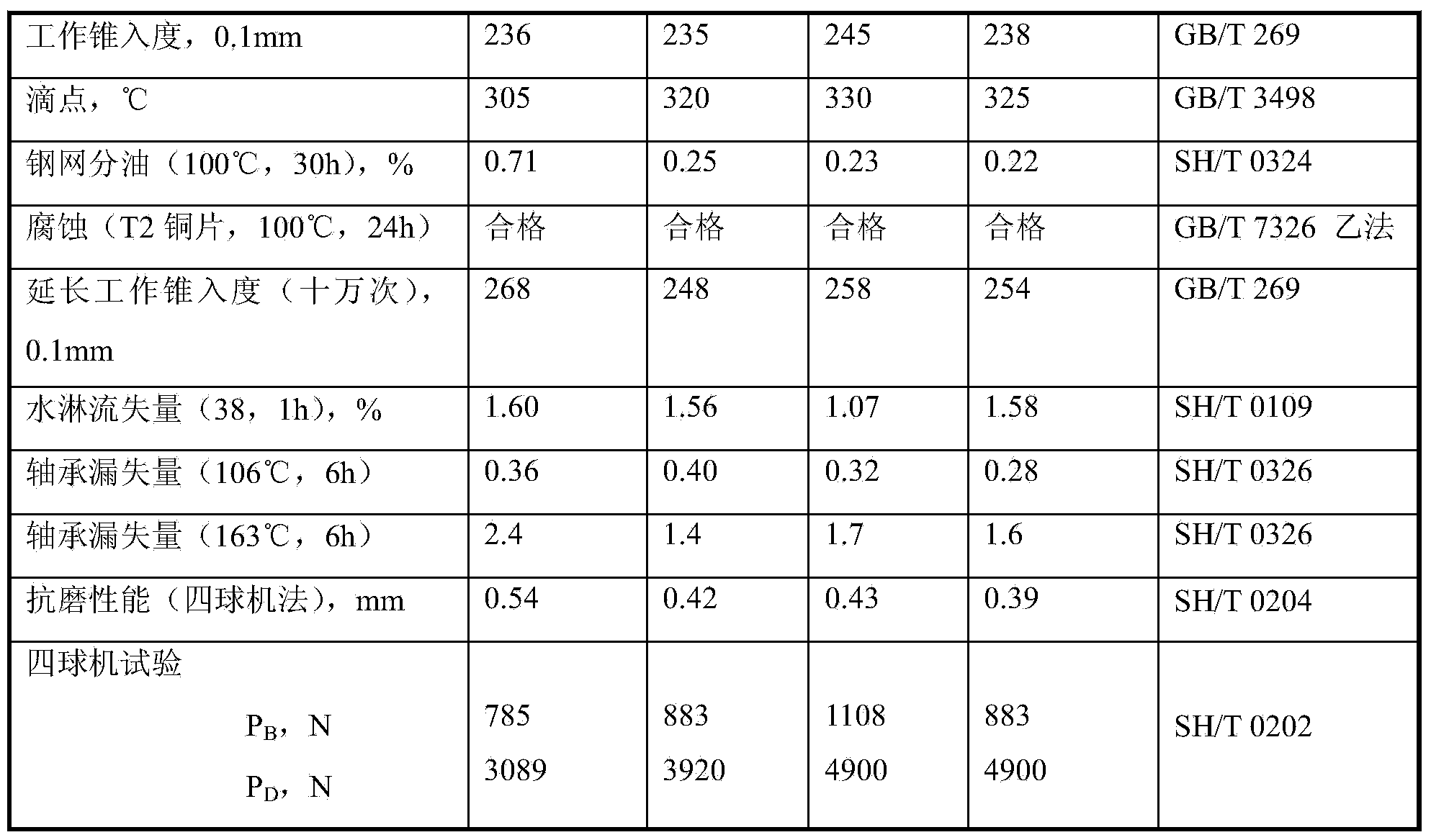

The invention relates to a lubricating grease and a preparation method thereof, particularly relates to a lubricating grease for a hub bearing of a heavy load truck and a preparation method thereof, and belongs to the technical field of a chemical industry. The lubricating grease is prepared from the following raw materials: (A) base oil which accounts for 60-85% of total weight of the lubricating grease, (B) a thickening agent, which is C12-C22 unitary organic acid which accounts for 7-12% of total weight of the lubricating grease, 0.5-3% of sebacic acid, 0.2-1% of boric acid, and 3-5% of lithium hydroxide oil solution, (C) an additive, which is thiocarbamate which accounts for 0.5-3% of total weight of the lubricating grease, 2-5% of sulfide olefin cottonseed oil, 2-4% of dialkyl dithiocarbamate salt, 0.5-2.5% of molybdenum dialkyl dithiophosphate, 0.3-2% of antirust agent and 0.3-1% of antioxidant. The lubricating grease has the beneficial effects that the production time is shortened; the lubricating grease is more controllable in process, stable in product quality, less in seepage loss of a high-temperature bearing, and prominent in extreme pressure property; lubricating protection can be better provided for hubs of the heavy load truck; the lubricating requirements of the hub bearing of the heavy load truck under various working conditions can be met; the grease exchange period of the hub bearing is prolonged.

Owner:JIANGSU LOPALTECH

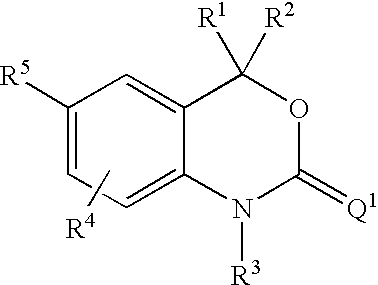

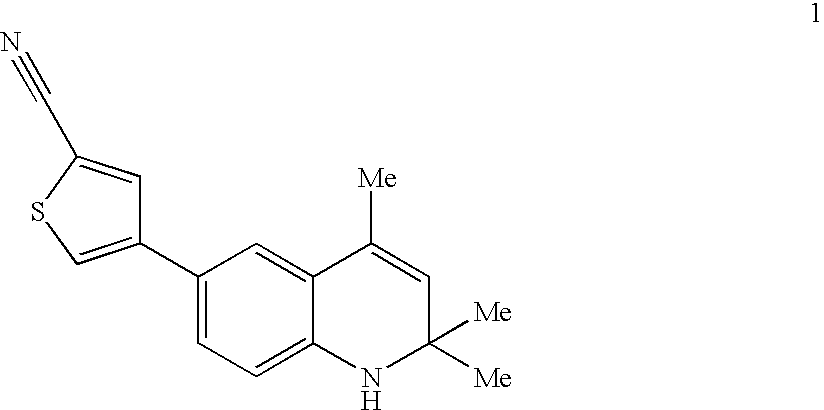

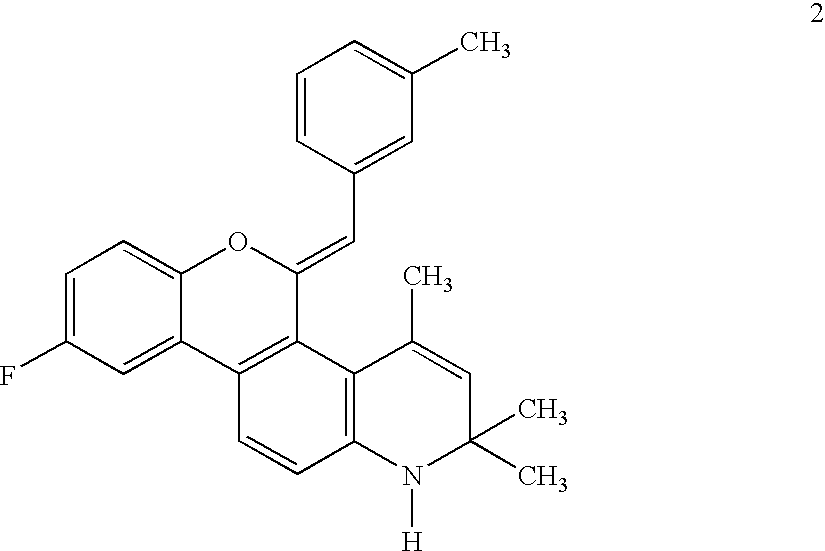

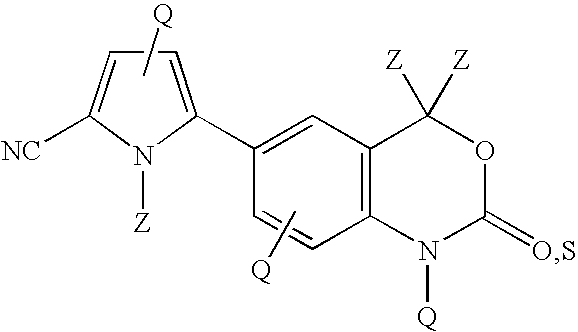

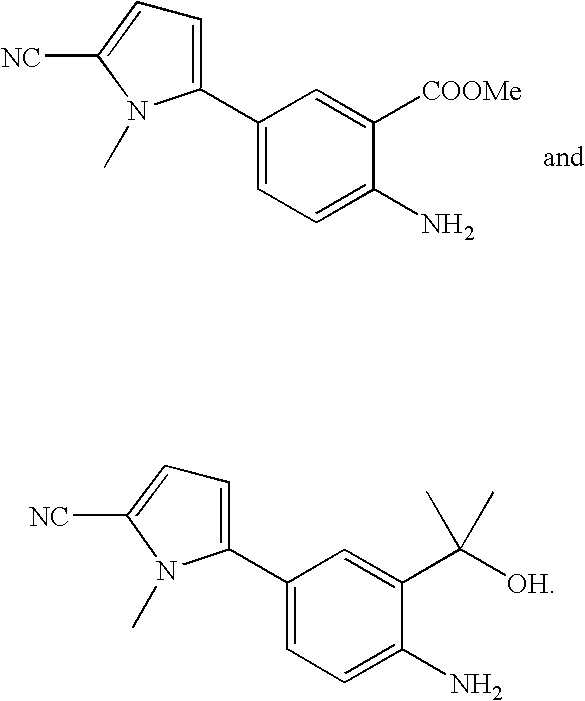

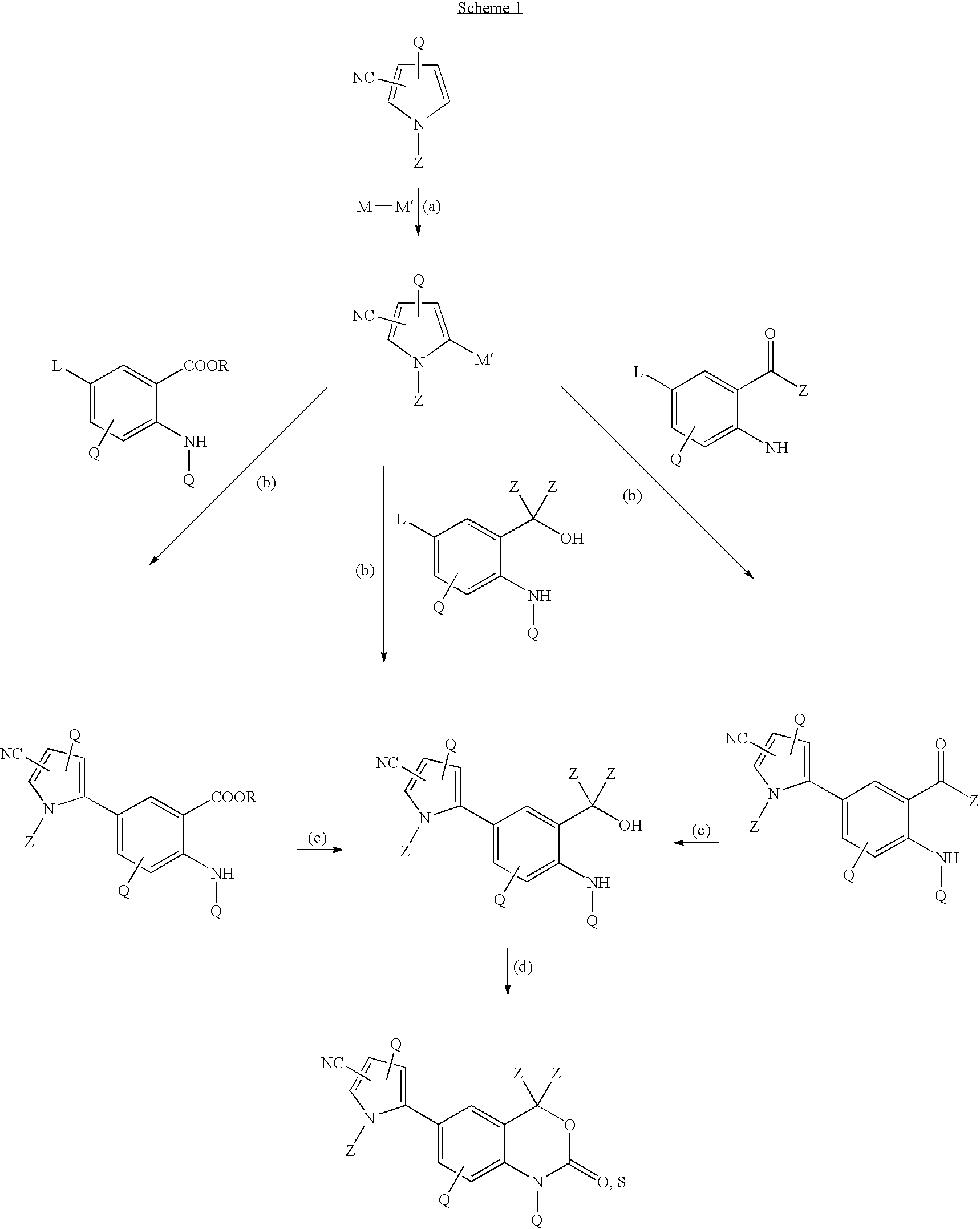

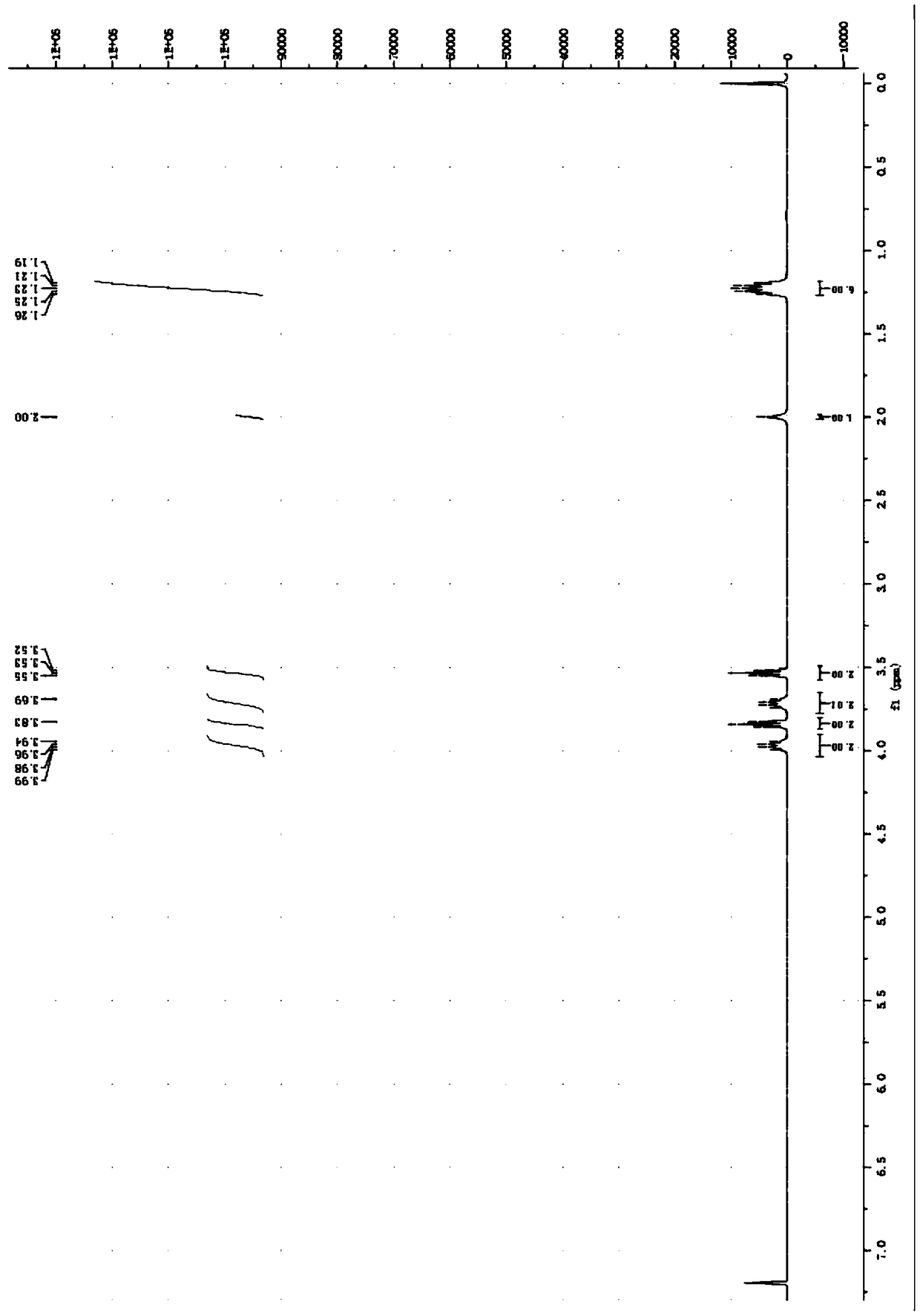

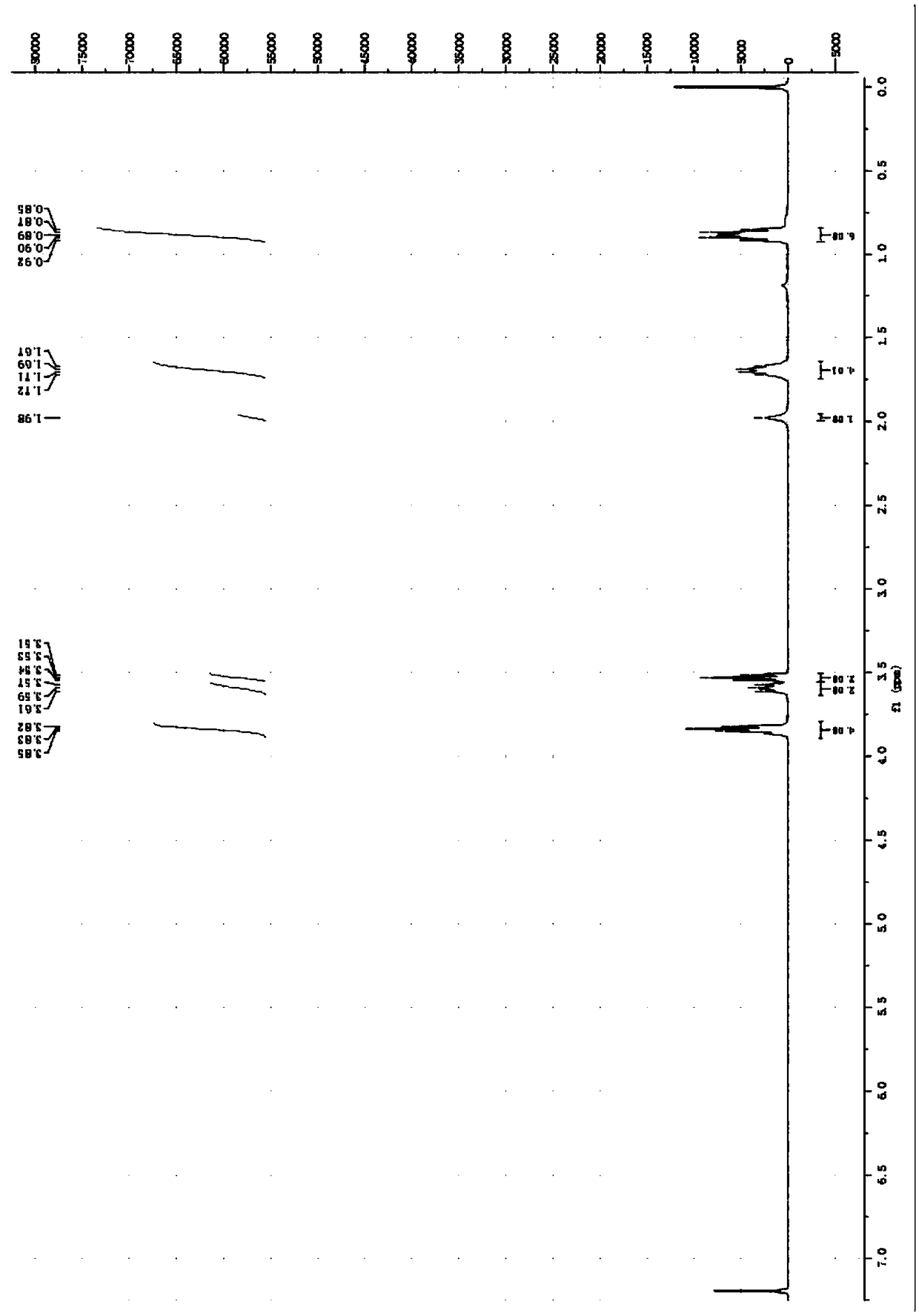

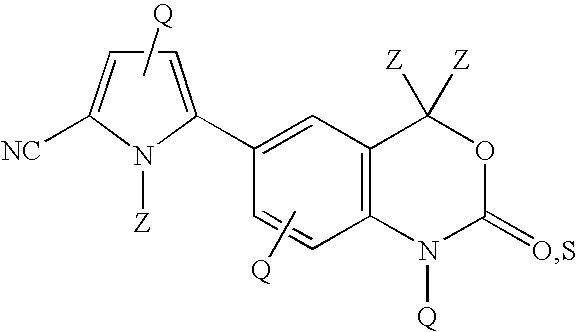

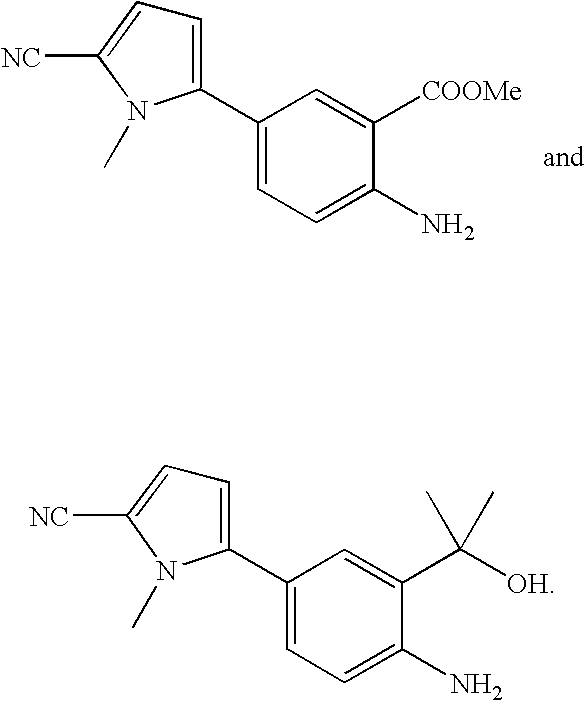

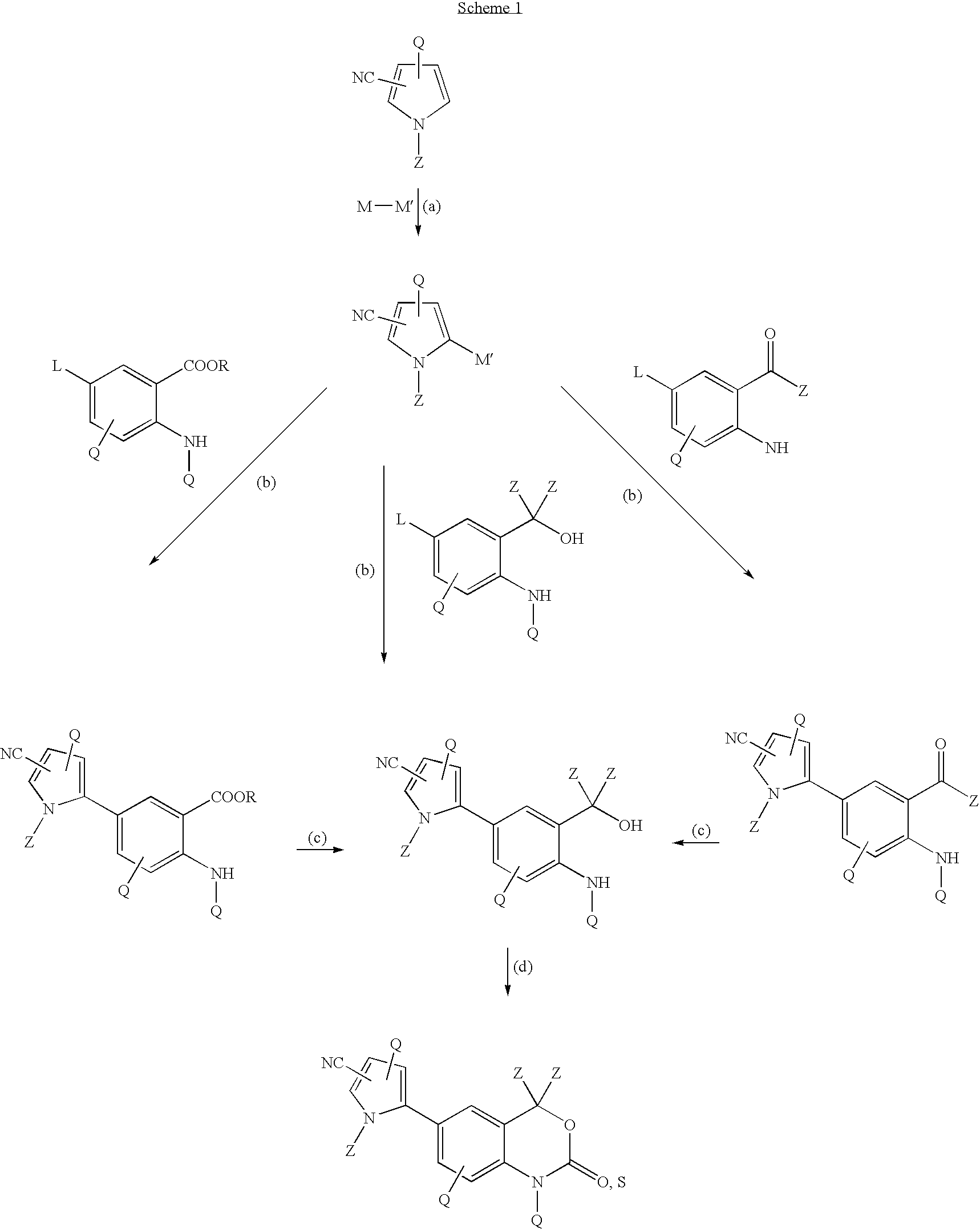

Cyanopyrrole-containing cyclic carbamate and thiocarbamate biaryls and methods for preparing the same

Methods for preparing cyclic carbamates and thiocarbamates containing cyanopyrrole moieties and of the formula are provided. Z are the same or different and are H, optionally substituted C1 to C6 alkyl, or CORA; RA is H, optionally substituted C1 to C6 alkyl, optionally substituted C1 to C6 alkoxy, or optionally substituted C1 to C6 aminoalkyl; Q are the same or different and are H, OH, NH2, CN, halogen, optionally substituted C1 to C6 alkyl, optionally substituted C2 to C6 alkenyl, optionally substituted C1 to C6 alkynyl, optionally substituted C1 to C6 alkoxy, optionally substituted C1 to C6 aminoalkyl, or CORB; and RB is H, optionally substituted C1 to C6 alkyl, optionally substituted C1 to C6 alkoxy, or optionally substituted C1 to C6 aminoalkyl. Compounds including 2-amino-5-(5-cyano-1-methyl-1H-pyrrol-2-yl) benzoic acid methyl ester, 5-[4-amino-3-(1-hydroxy-1-methyl-ethyl)-phenyl]-1-methyl-1H-pyrrole-2-carbonitrile, and 2-amino-5-(5-cyano-1-methyl-1H-pyrrol-2-yl)-phenyl-ethanone, or pharmaceutically acceptable salts thereof, and the uses thereof are also provided.

Owner:WYETH LLC

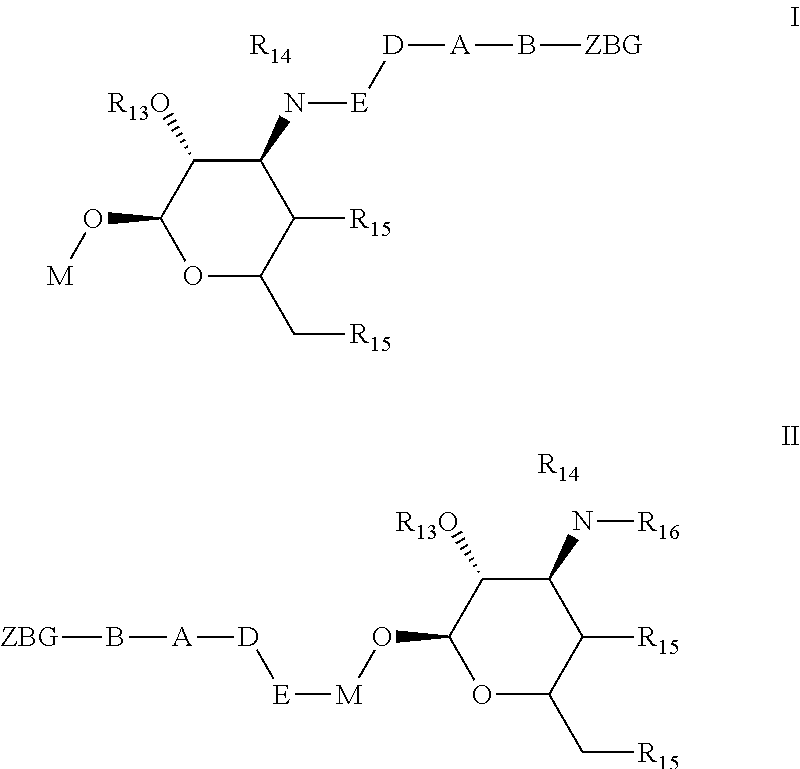

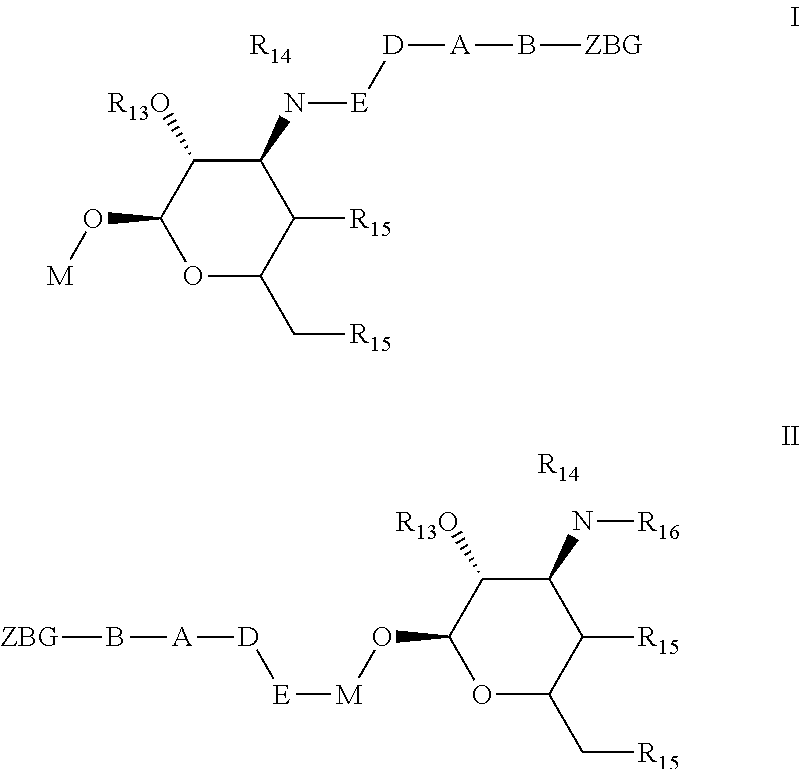

Non-peptide macrocyclic histone deacetylase (HDAC) inhibitors and methods of making and using thereof

Compounds of Formula I or II, and methods of making and using thereof, are described herein.M represents a macrolide subunit,E is a C1-6 group, optionally containing one or more heteroatoms,D is an alkyl or aryl group,A is a linking group connected to D,B is an alkyl, alkylaryl or alkylheteroaryl spacer group,ZBG is a Zinc Binding Group,R1, R2 and R4 are independently are selected from hydrogen, a C1-6 alkyl group, a C2-6 alkenyl group, a C2-6 alkynyl group, a C1-6 alkanoate group, a C2-6 carbamate group, a C2-6 carbonate group, a C2-6 carbamate group, or a C2-6 thiocarbamate group,R3 is hydrogen or —OR5,R5 is selected from a group consisting of Hydrogen, a C1-6 alkyl group, a C2-6 alkenyl group, a C2-6 alkynyl group, C1-6 alkanoate group, C2-6 carbamate group, C2-6 carbonate group, C2-6 carbamate group, or C2-6 thiocarbamate group.

Owner:GEORGIA TECH RES CORP

Grease for motor bearings of wind generators and production method thereof

ActiveCN102433194AInhibition of catalysisInhibit high temperature corrosionLubricant compositionThiocarbamateCarbamate

The invention relates to the field of lubricating grease, in particular to grease for motor bearings of wind generators and a production method thereof. The grease is characterized by being prepared by blending the following components in part by weight: 9 to 13.5 parts of 12-hydroxystearic acid, 3 to 4.5 parts of sebacic acid, 2.6 to 3.9 parts of lithium hydroxide, 70 to 80.7 parts of base oil, 1 to 5 parts of extreme pressure additive, 0.5 to 2 parts of antioxygen, 0.5 to 2 parts of antirust additive, and 0.3 to 0.5 part of metal passivating agent. The base oil is mixed oil of hexane diacidisotridecyl alcohol ester, polyalphaolefin10 (PAO10), PAO40 and alkyl naphthalene. The extreme pressure additive is a mixture of thiocarbamate, triphenyl thiophosphate, molybdenum oxothioxo carbamates, and nano calcium carbonate. Compared with the prior art, the grease has the advantages of wide use temperature range, high waterproof and anticorrosion performance, high loading capacity, high wear-reducing and noise-reducing performance, very high low-temperature startability and very high lubricating performance.

Owner:辽宁海华科技股份有限公司

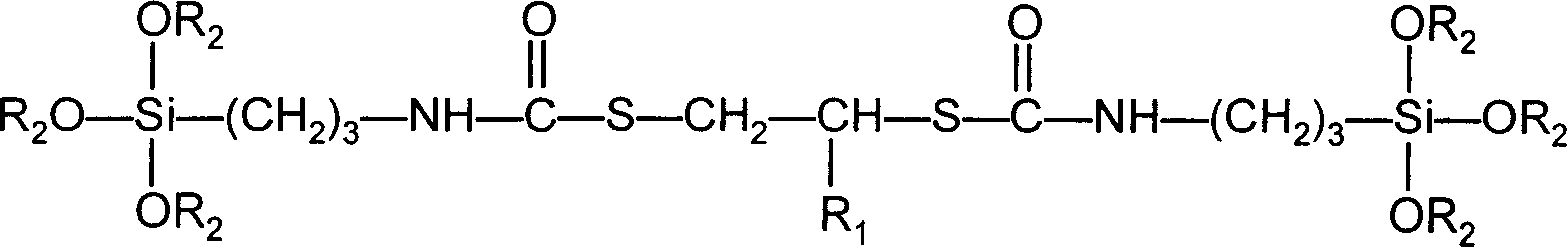

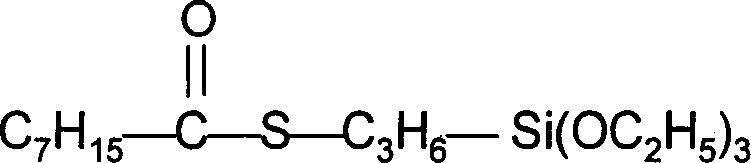

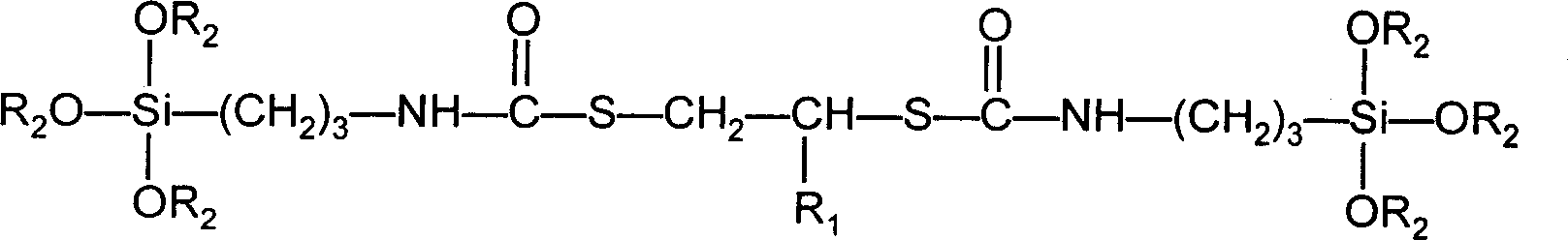

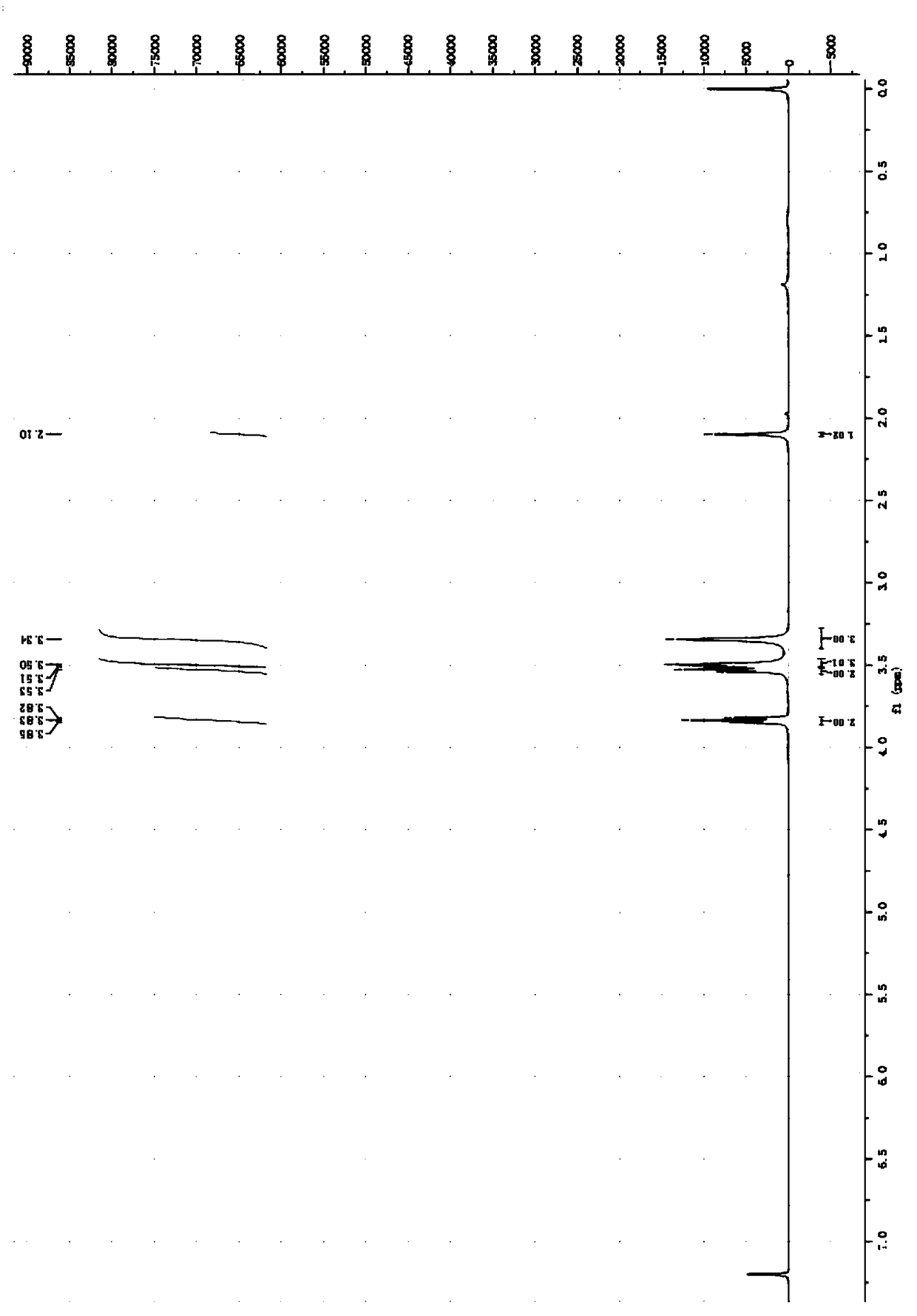

Bisilane coupler contg. sulfur and nitrogen element and prepn. thereof

InactiveCN1834100AEasy to separateSimple production processGroup 4/14 element organic compoundsThiocarbamateOrganocatalysis

This invention discloses a kind of sulphur- and nitrogen-containing silicone coupling reagent and its preparation method, that is, gamma-isocyanate propyl trialkoxyl silicane and dithiol compound react with each other at a mole ratio of 2:1 in organic solvent with the existence of organic catalyst. The mixture is then vacuum distilled to obtain a silicone coupling reagent that has two thiocarbamate units and six alkoxyls. This method has the advantages of simple technique flow, high yield and high practicability. The silicone coupling reagent based on this invention has good thermo stability and considerable coupling effect. It is a good substitution of conventional silicone coupling reagent and can be used in fumed silica-containing rubber so as to promote the comprehensive properties of vulcanized rubber.

Owner:ZHEJIANG UNIV +1

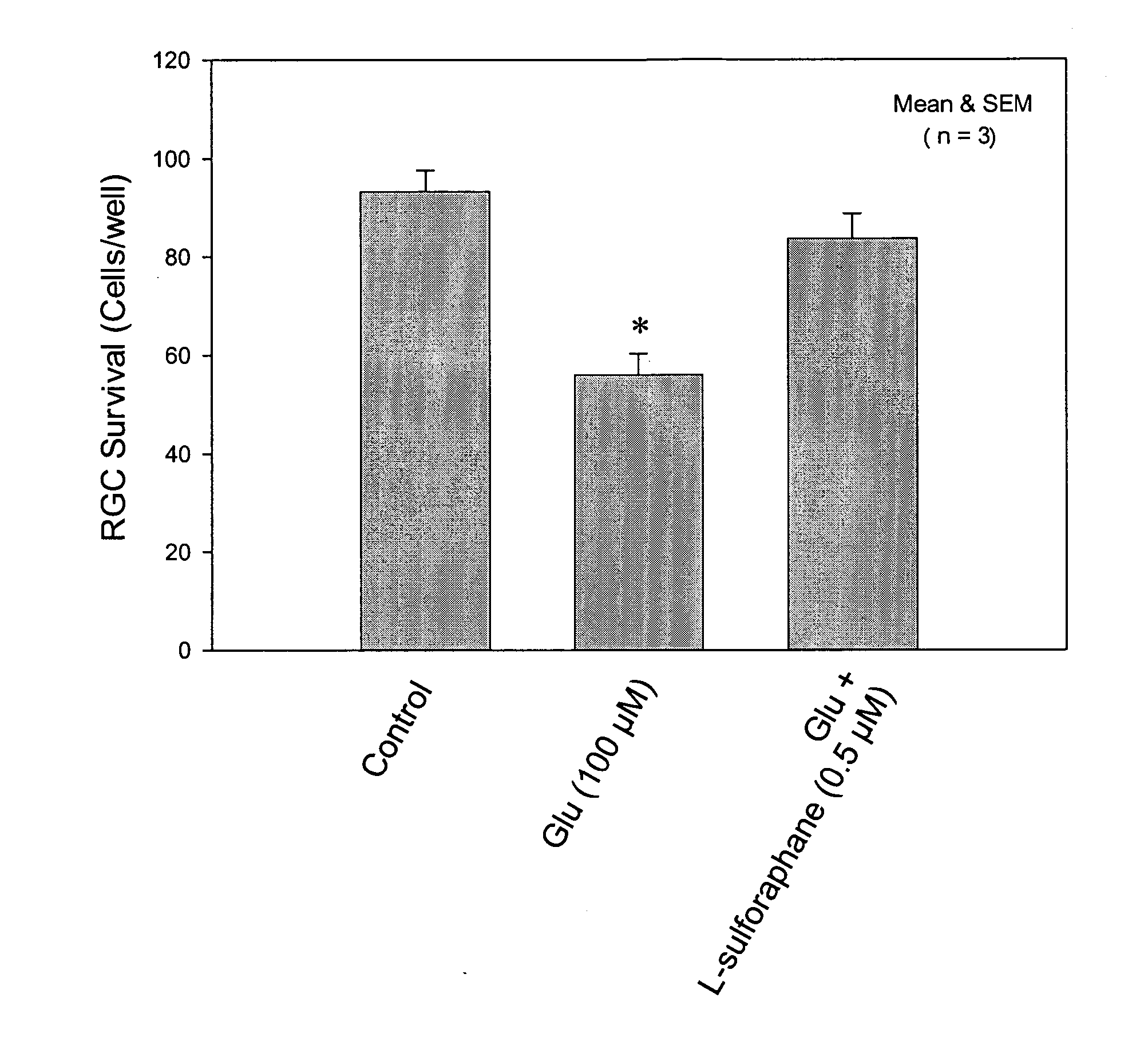

Agents for treatment of diabetic retinopathy and drusen formation in macular degeneration

InactiveUS20050137147A1Enhances availability and transportAvoid damageBiocideSenses disorderThiocarbamateQuinone

Agents that stimulate nuclear translocation of Nrf2 protein and the subsequent increases in gene products that detoxify and eliminate cytotoxic metabolites are provided in a method for treating diabetic retinopathy or drusen formation in age-related macular degeneration. The structurally diverse agents that act on the Nrf2 / ARE pathway induce the expression of enzymes and proteins that possess chemically versatile cytoprotective properties and are a defense against toxic metabolites and xenobiotics. Agents include certain electrophiles and oxidants such as a Michael Addition acceptor, diphenol, thiocarbamate, quinone, 1,2-dithiole-3-thione, butylated hydroxyanisole, flavonoid other than genistein, an isothiocyanate, 3,5-di-tert-butyl-4-hydroxytoluene, ethoxyquin, a coumarin, combinations thereof, or a pharmacologically active derivative or analog thereof.

Owner:ALCON INC

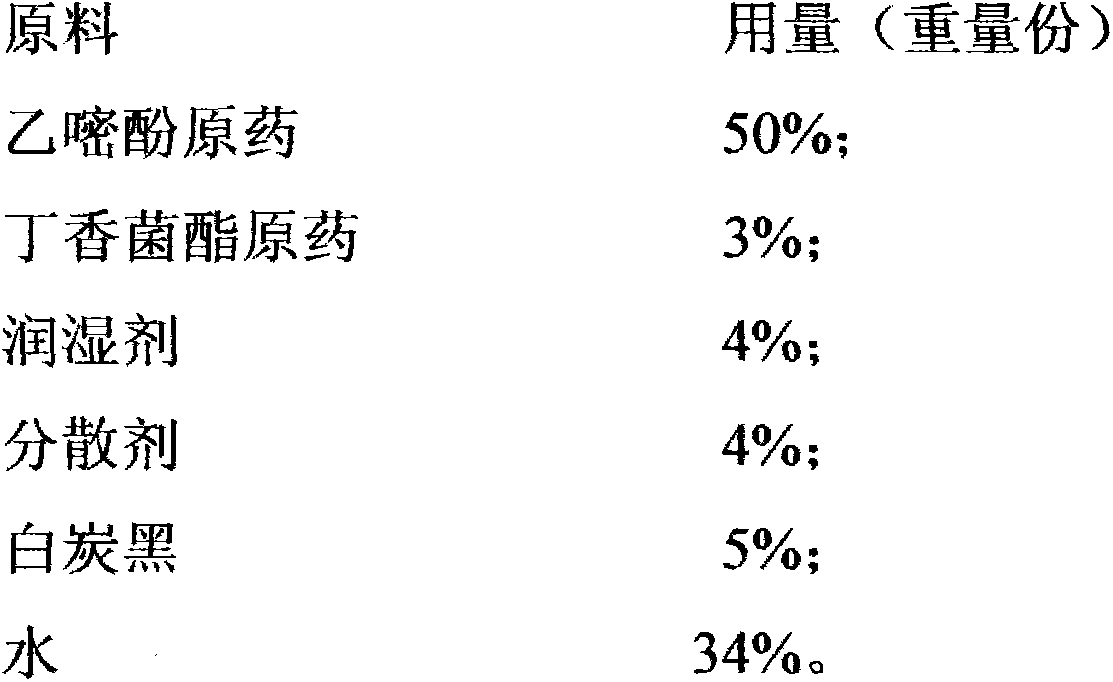

Bactericidal composition containing pyraclostrobin and thiocarbamate

The invention relates to a bactericidal composition containing pyraclostrobin and thiocarbamate. The bactericidal composition contains an active ingredient A, namely pyraclostrobin, and an active ingredient B, namely one of propineb, zineb and mancozeb, wherein the weight ratio of the active ingredient A to the active ingredient B is 1:1-1:8; aids and excipients are added into the active ingredients to prepare water dispersible granules, a suspending agent and the like; and the bactericidal composition is mainly used for preventing and controlling powdery mildew, anthracnose, downy mildew, apple scab, ring spot, spot leaf drop and the like.

Owner:陕西汤普森生物科技有限公司

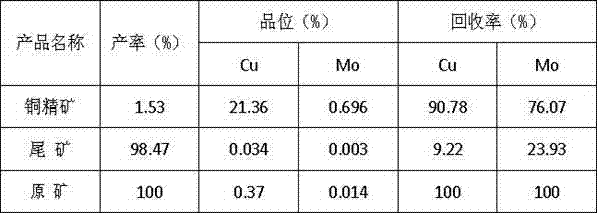

Composite collecting agent for bulk floatation of copper sulfide molybdenum ores

The invention discloses a composite collecting agent for bulk floatation of copper sulfide molybdenum ores. The collecting agent is a stable oily product which is formed by mixing 50%-70% of thiocarbamic acid ester, 2%-10% of thiophosphoric acid ester, 10%-30% of mixed non-polar hydrocarbon oil and 10%-20% of terpene alcohol. The collecting agent has the advantages that the thiocarbamic acid ester has the selective chelation on the exposing active points, such as copper and molybdenum, on the surfaces of minerals, the thiophosphoric acid ester has the selective adsorption function on the copper-containing minerals, the non-polar hydrocarbon oil can be adsorbed on the surface of the copper sulfide molybdenum ores through the Van der Waals force, and the terpene alcohol is a solution medium and has good air bubble property, so under the synergistic effect of the thiocarbamic acid ester, the thiophosphoric acid ester, the mixed non-polar hydrocarbon oil and the terpene alcohol, a good ore selection index can be obtained, and the agent mechanism is simplified; the collecting agent is used at the ore slurry temperature of 5-35 DEG C, and the usage amount is between 80-160g / t according to the change of the contents of usable minerals in the ores.

Owner:KUNMING METALLURGY INST

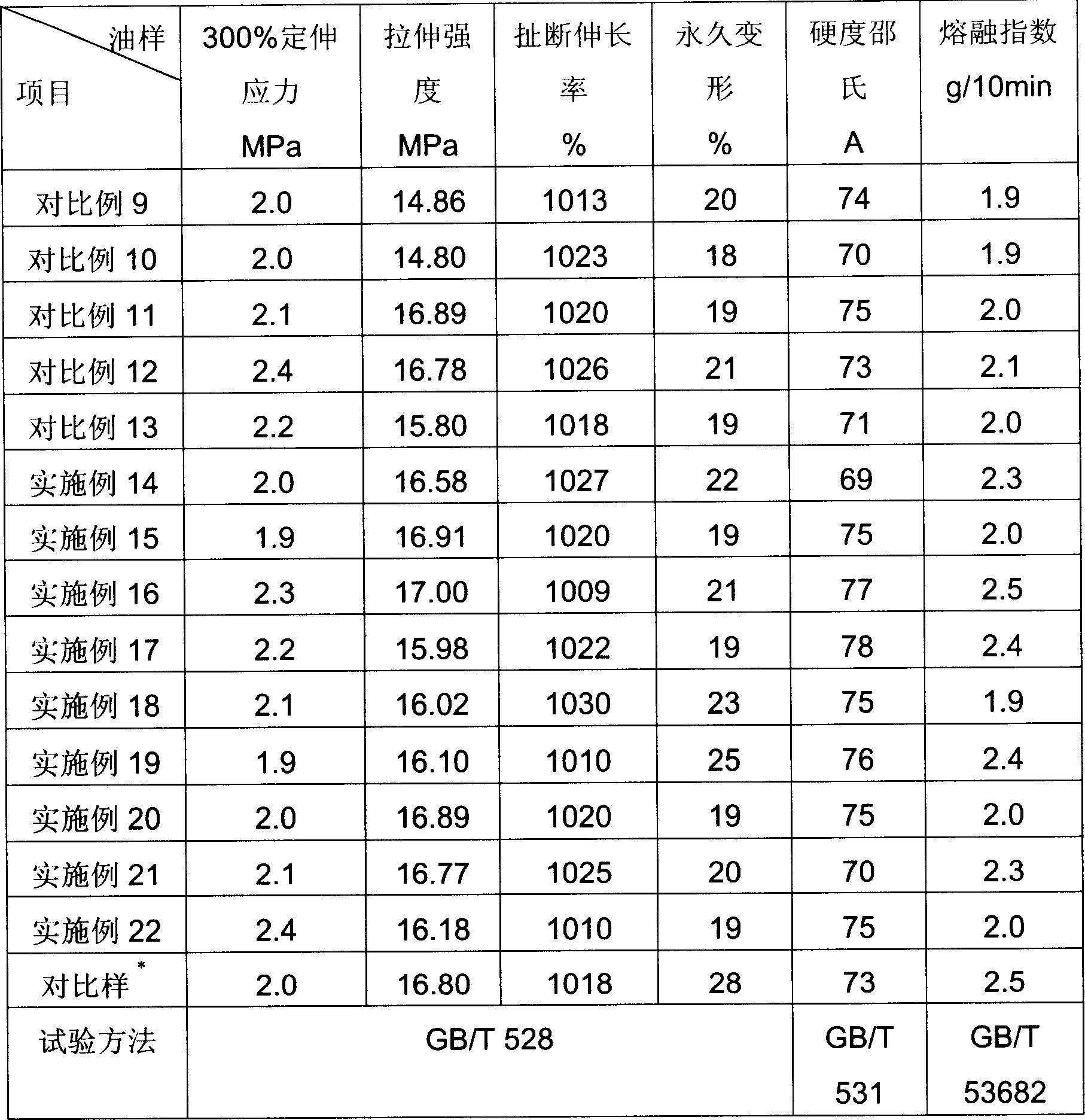

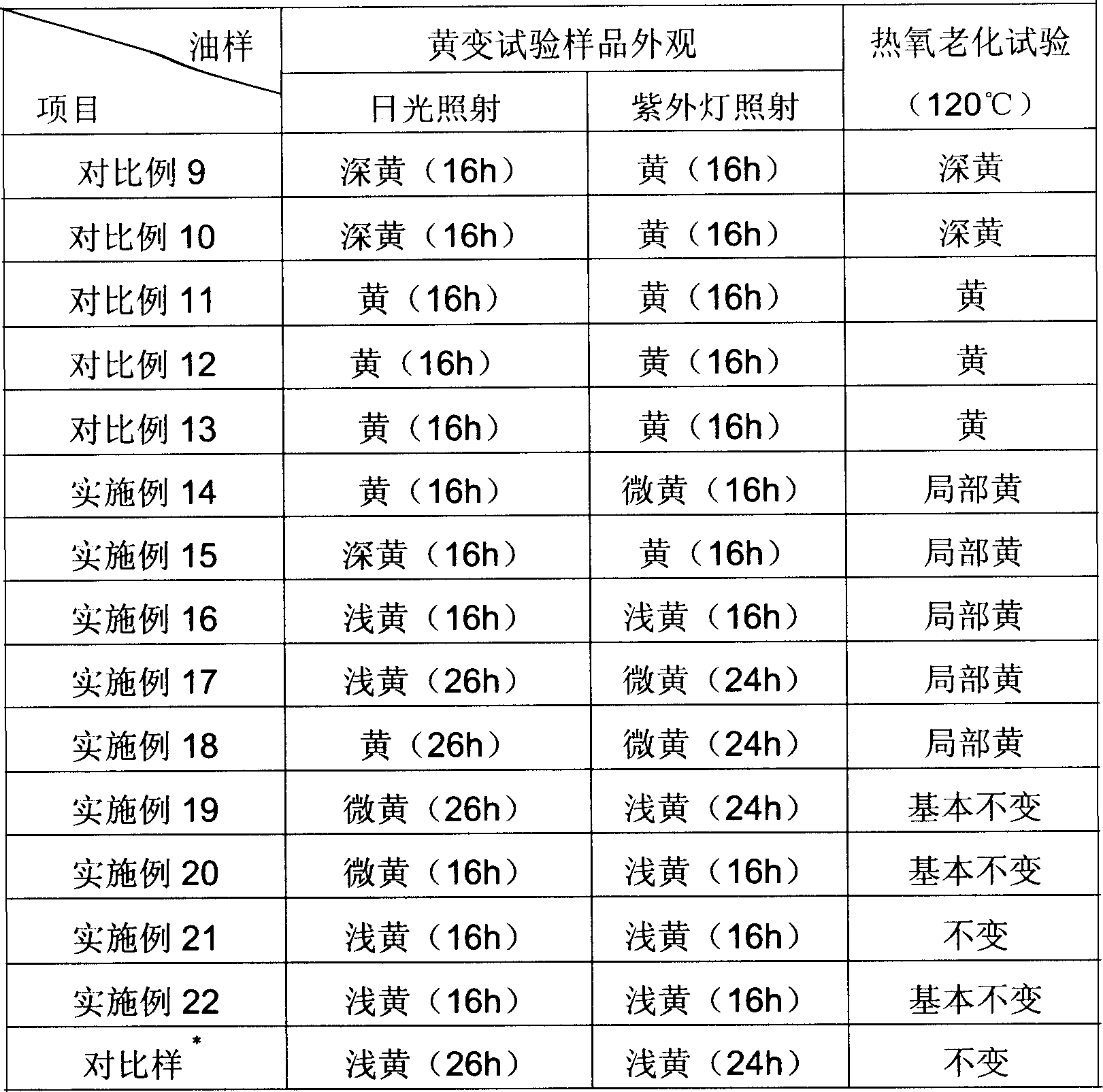

Composite stabilizer and stable oil-extended rubber composition

This invention provides a compound stabilizing agent. Using the gross weight of the compound stabilizing agent as reference, it includes the components as following: (I) the UV-absorbents and amine-impeding light stabilizers mixed according to the weight ratio of 1:1~4:1, account 30~75% of the compound stabilizing agent; (II) the antioxidants selected from shielding phenols, amines, phenol esters, thiocarbamates, account 15~45% of the compound stabilizing agent; (III) the chelating agents of sub-phosphoric acid benzene ester, account 3~18% of the compound stabilizing agent; (IV) the metal deactivators with nitrogen heterocyclic ring, account 5~15% of the compound stabilizing agent. This invention also provides an oil-extended rubber contained the above compound stabilizing agent. Utilizing the co-effects in many kinds of additions, the compound stabilizing agent in this invention improves the light invariability and the thermal stability, decreases its total dosages in rubbers, and enhances the economical efficiency and the practicability of the oil-extended rubber.

Owner:CHINA PETROLEUM & CHEM CORP +1

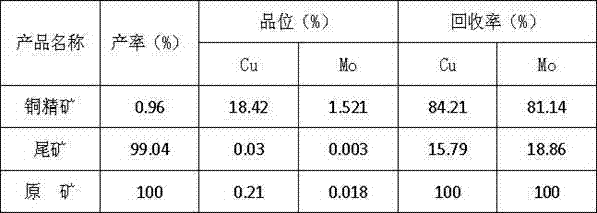

N,N-dialkyl-S-hydroxyalkyl-dithiocarbamate collecting agent and preparation method and application thereof

The invention discloses a N,N-dialkyl-S-hydroxyalkyl-dithiocarbamate collecting agent and a preparation method and an application thereof. The collecting agent is N,N-dialkyl-S-hydroxyalkyl-dithiocarbamate which is synthesized by a one-pot process by taking carbon disulfide and water as a solvent, and diamine, carbon disulfide, sodium hydroxide and haloalkyl alcohol as raw materials. The preparation method is simple to operate and mild in reaction condition. The floating collecting agent has a good collecting property, and the action of the collecting agent with metal ions on the surfaces of minerals can be improved well. The prepared collecting agent has a relatively good collecting ability and selectivity to sulphide ores such as copper sulphide ores, copper-molybdenum cores and lead zinc ores, and shows a relatively good floating index.

Owner:CENT SOUTH UNIV

Cyanopyrrole-containing cyclic carbamate and thiocarbamate biaryls and methods for preparing the same

Methods for preparing cyclic carbamates and thiocarbamates containing cyanopyrrole moieties and of the formula are provided.Z are the same or different and are H, optionally substituted C1 to C6 alkyl, or CORA; RA is H, optionally substituted C1 to C6 alkyl, optionally substituted C1 to C6 alkoxy, or optionally substituted C1 to C6 aminoalkyl; Q are the same or different and are H, OH, NH2, CN, halogen, optionally substituted C1 to C6 alkyl, optionally substituted C2 to C6 alkenyl, optionally substituted C1 to C6 alkynyl, optionally substituted C1 to C6 alkoxy, optionally substituted C1 to C6 aminoalkyl, or CORB; and RB is H, optionally substituted C1 to C6 alkyl, optionally substituted C1 to C6 alkoxy, or optionally substituted C1 to C6 aminoalkyl.Compounds including 2-amino-5-(5-cyano-1-methyl-1H-pyrrol-2-yl) benzoic acid methyl ester, 5-[4-amino-3-(1-hydroxy-1-methyl-ethyl)-phenyl]-1-methyl-1H-pyrrole-2-carbonitrile, and 2-amino-5-(5-cyano-1-methyl-1H-pyrrol-2-yl)-phenyl-ethanone, or pharmaceutically acceptable salts thereof, and the uses thereof are also provided.

Owner:WYETH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com