Method for using cyaniding barren solution to float, reclaim and cyaniding copper plumbum and zinc in tailings

A technology of cyanidation tailings and cyanidation lean liquid is applied in the field of copper, lead and zinc to achieve the effects of protecting the ecological environment, large economic benefits and saving treatment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

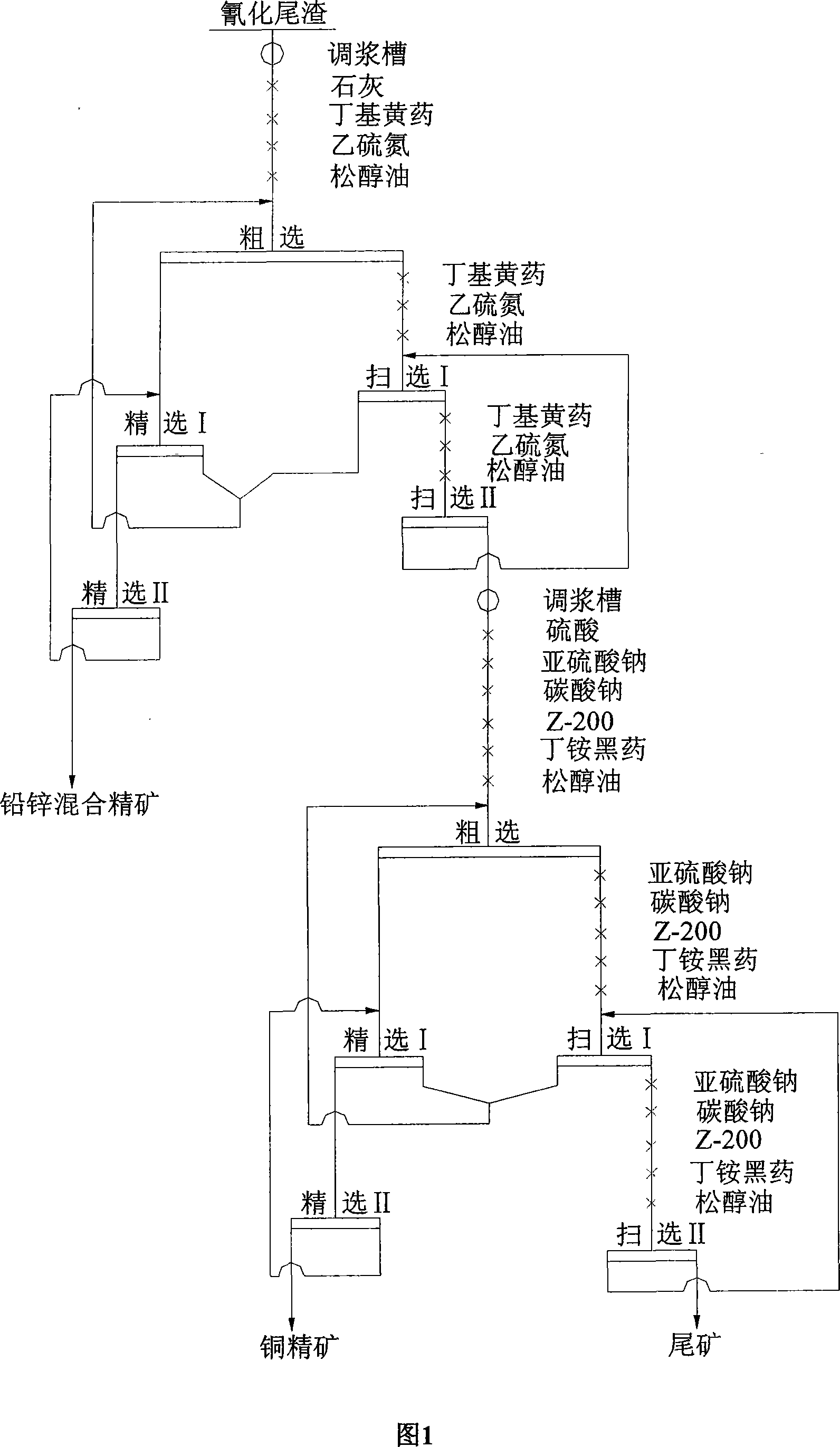

Image

Examples

Embodiment

[0037] (1) Slurry: Add cyanidation barren solution to cyanidation tailings, and stir to form a slurry.

[0038] The process conditions of pulping:

[0039] Pulp concentration: 38%; stirring time: 25min.

[0040] (2) Priority flotation of lead and zinc: Send the adjusted ore pulp to the flotation unit, add lime, ethion and butyl xanthate, and recover lead and zinc.

[0041] Process conditions for a rough selection:

[0042] Pulp pH value: 12 (adjusted with lime); ethyl disulfide: 125g / t; butyl xanthate: 125g / t;

[0043] Pinitol oil: 50g / t; flotation time: 6min.

[0044] Process conditions for one sweep:

[0045] Ethiazide: 60g / t; Butyl xanthate: 60g / t; Pinitol oil: 25g / t; Flotation time: 5min.

[0046] The process conditions of the second sweep:

[0047] Ethiazide: 30g / t; Butyl xanthate: 30g / t; Pinitol oil: 10g / t; Flotation time: 5min.

[0048] After two rounds of beneficiation, the lead-zinc mixed concentrate with a lead grade of 34.75% and a zinc grade of 32.28% was o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com