Patents

Literature

1053 results about "Lead zinc" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lead Content of Zinc. Lead is a naturally occurring impurity in the refining of zinc. The solubility of lead in zinc is approximately 1.6% at 450oC. ASTM standard B6-00, Specification for Zinc, covers the purity of zinc bars used in the galvanizing industry and hence those used by the steel conduit industry.

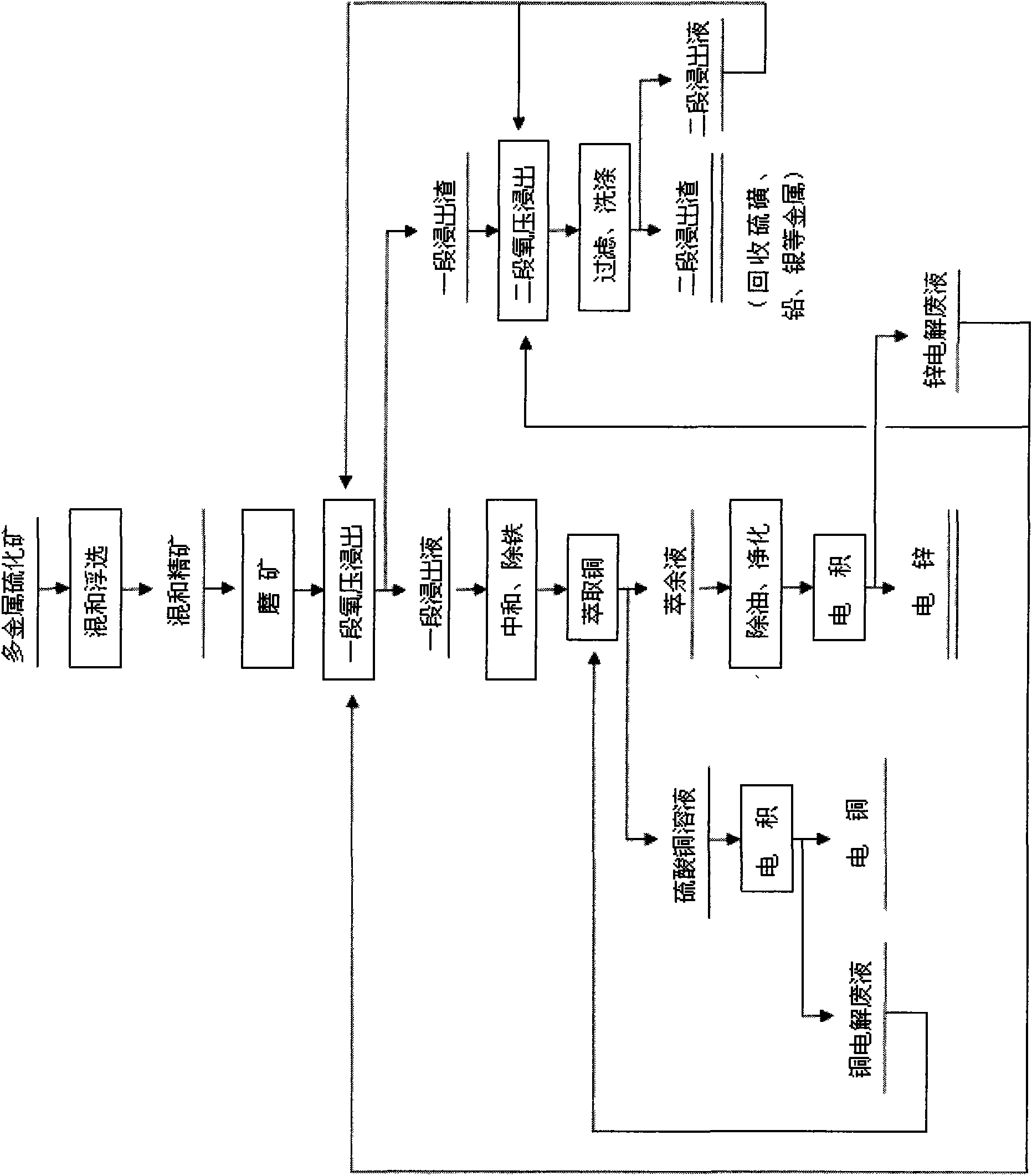

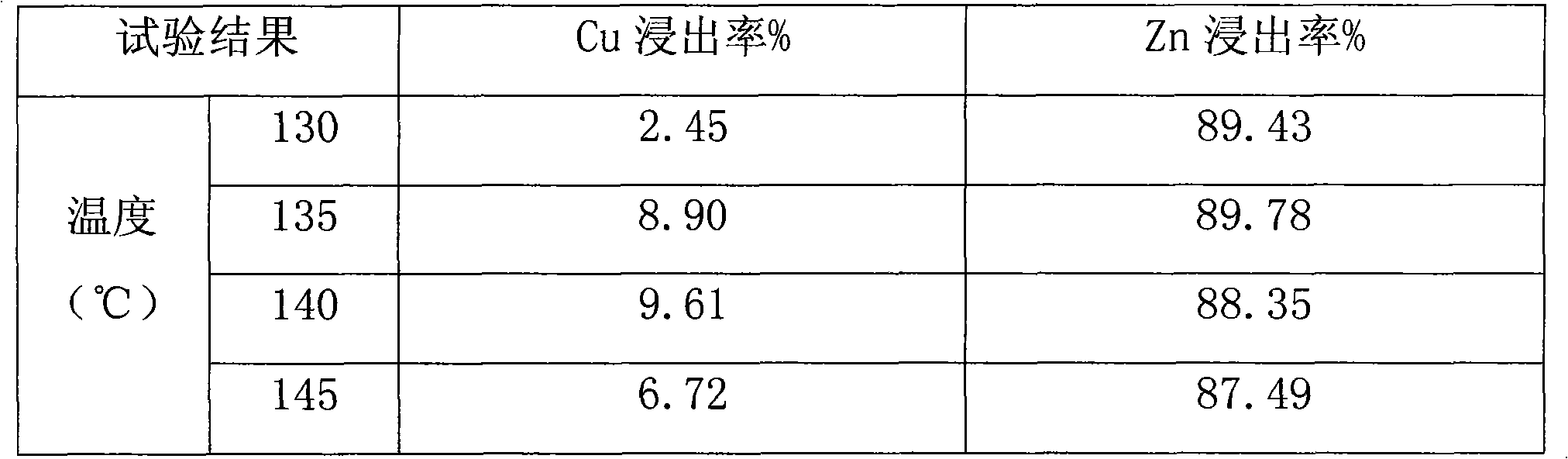

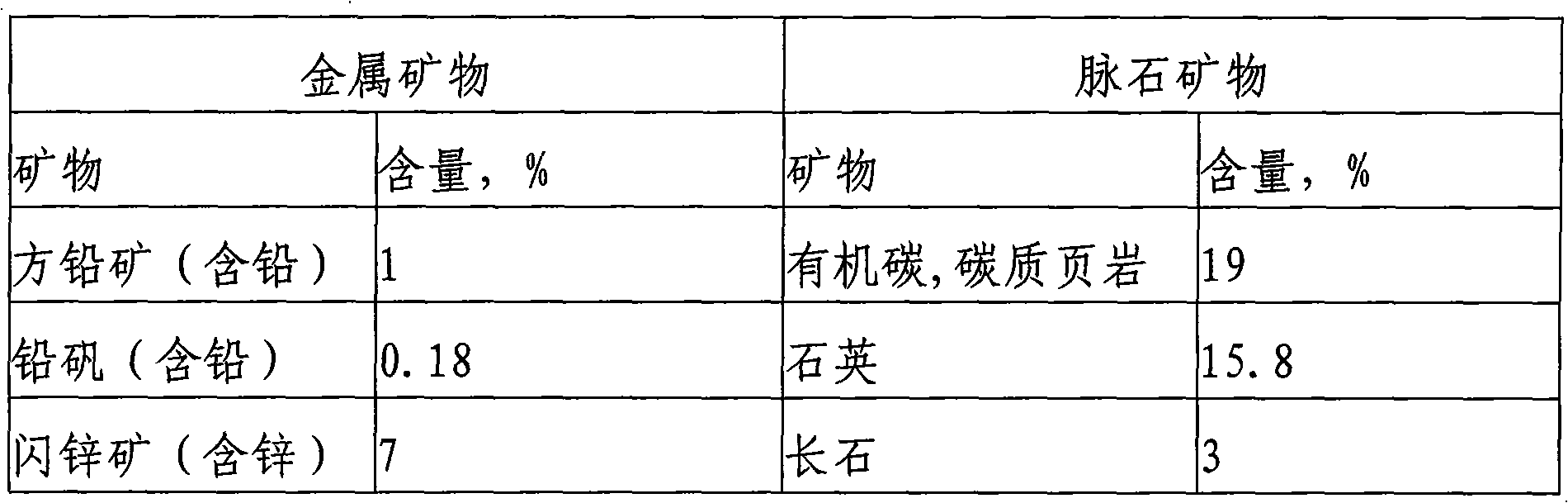

Comprehensive recovery method of complex polymetal sulphide ore containing copper, lead and zinc

InactiveCN101643857AHigh recovery rateSimple processSulfur preparation/purificationFlotationRecovery methodLead smelting

The invention discloses a comprehensive recovery method of complex polymetal sulphide ore containing copper, lead and zinc and adopts dressing-metallurgy combination method and hydrometallurgy-pyrometallurgy combination method to recover metals. The recovery method comprises the following steps: first performing bulk flotation to the complex polymetal sulphide ore, fine grinding the obtained concentrate, leaching by using two-step counter flow oxygen pressure leaching process, extracting and separating copper and zinc from the obtained leachate, electrodepositing the strip liquor of copper-loaded organic phase to obtain cathode copper, cleaning the obtained raffinate and electrodepositing to obtain cathode zinc; pressurizing leaching residue to perform flotation separation and obtain sulfur concentrate and lead silver residue, distilling sulfur concentrate to obtain sulfur; performing lead smelting process to lead silver residue to obtain electrolytic lead product and lead anodic slime; and comprehensively recovering noble metals such as gold, silver and the like from lead anodic slime. The method can greatly improve the metal recovery rate, resource utilization and the economic efficiency of mines and generate a lot of sulfur so as to obviously reduce the sulfur dioxide pollution to the atmosphere.

Owner:WESTERN MINING CO LTD

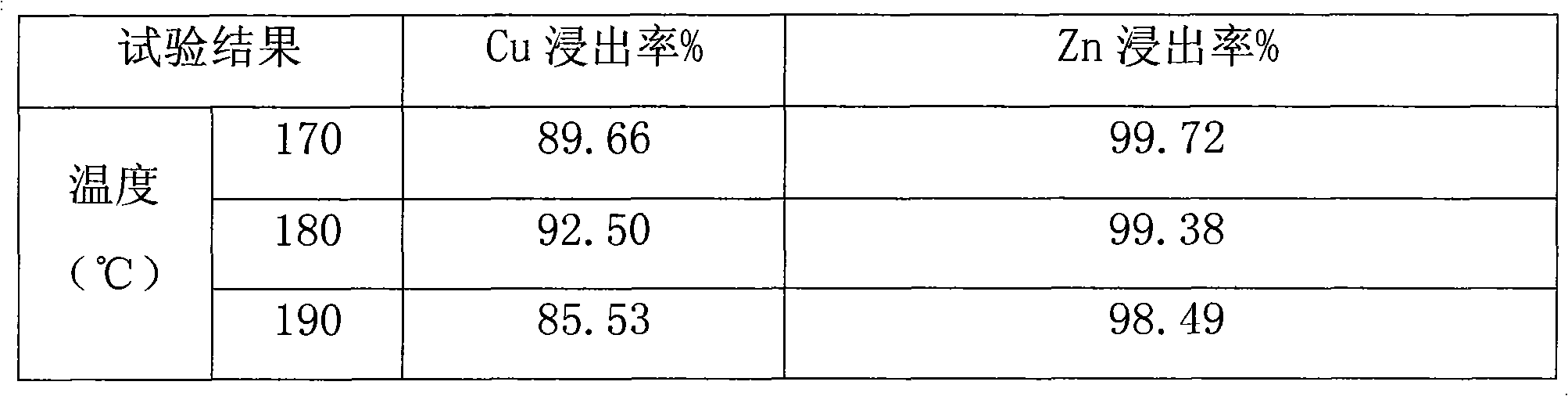

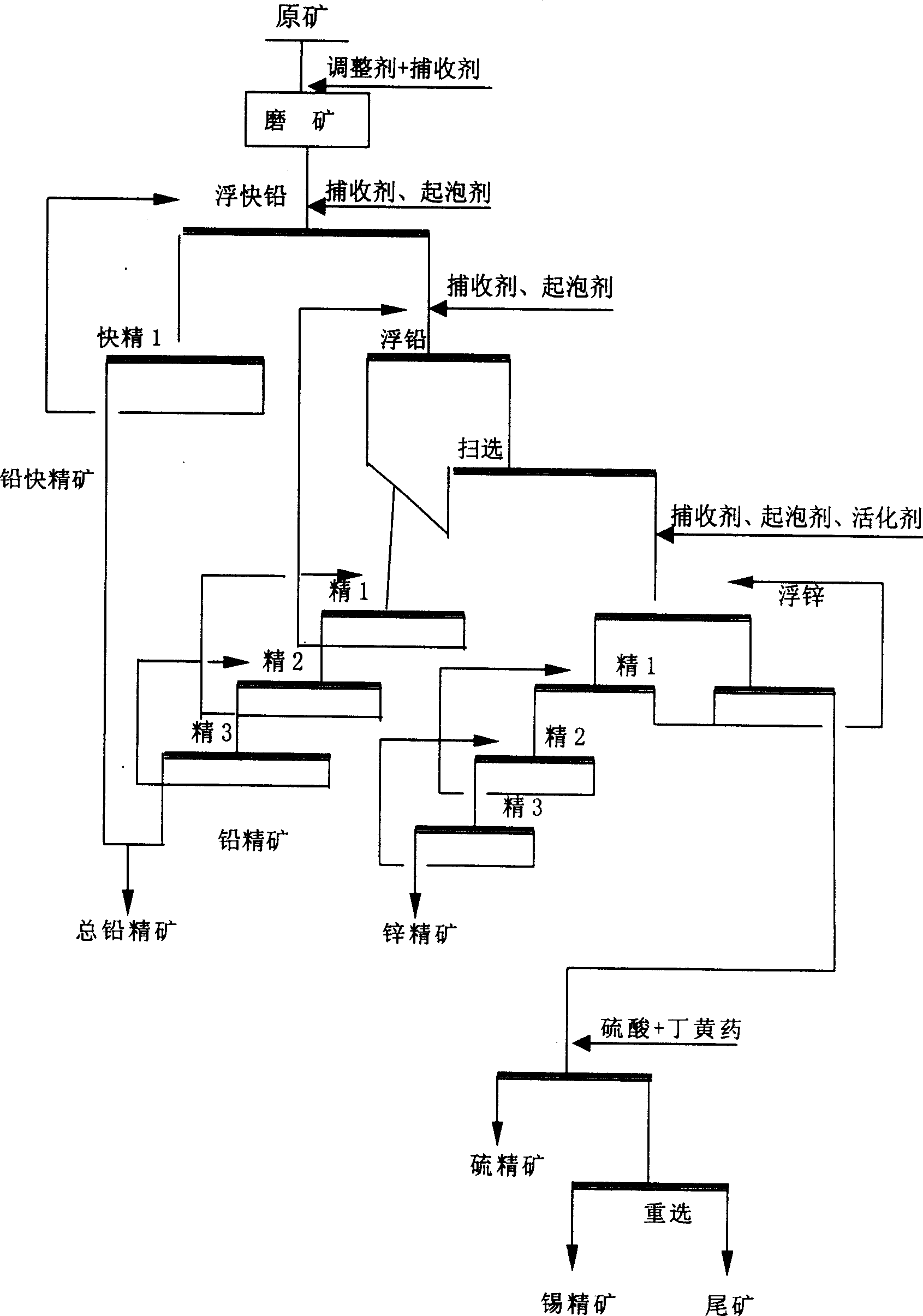

Complex plumbum, zinc, silver vulcanizing ore containing newboldite and pyrrhotite floatation method

The invention discloses a lead and zinc flotation method to ferreous blende and pyrrhotite typed complex lead zinc silver sulphide ore, mainly comprising lead ore branch flotation which controls the electrochemical conditions of the flotation and the zinc and sulfur flotation separation which controls the electrochemical conditions of the flotation. The invention has the advantages of implementing the lead-zinc sulfur separation by adopting twice branch flotation, carrying out fast flotation to the lead ore by using a novel composite catching agent to the galena and silver ore with easy floating coarse grains under the conditions of higher ore pulp potential and low pH; the normal flotation of the lead ore with difficultly floated fine grains is carried out under the conditions of lower ore pulp potential and high pH. The pH of the ore pulp is adjusted to more than 12 by lime for the gangue after the lead is floated; the iron blende is activated by bluestone; the iron blende is recovered by the catching agent with the same type of the lead sulfide floatation, thus leading the property of the lead flotation waste water to be basically consistent with that of the zinc flotation waste water and being beneficial for the circular application of floatation waste water.

Owner:CENT SOUTH UNIV

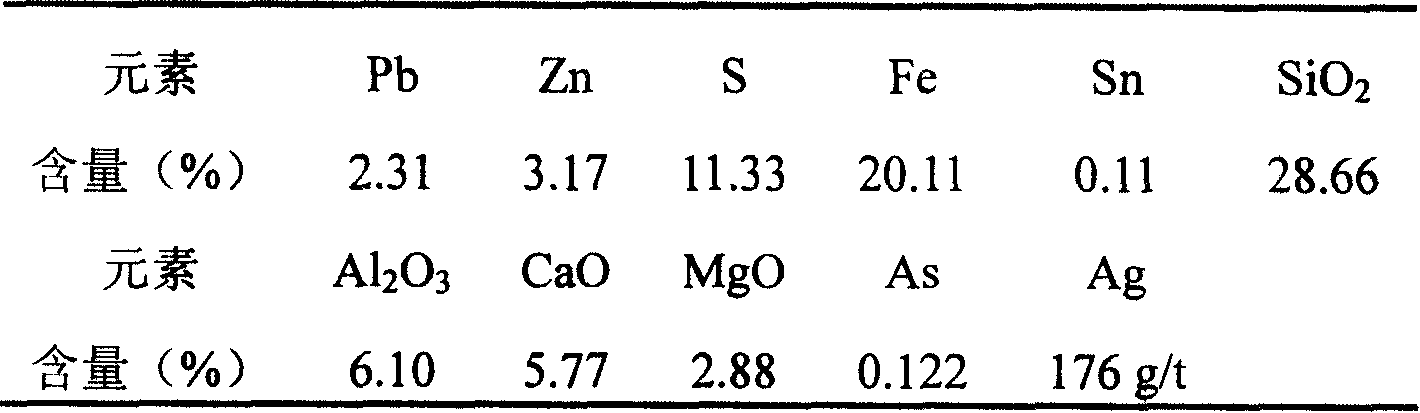

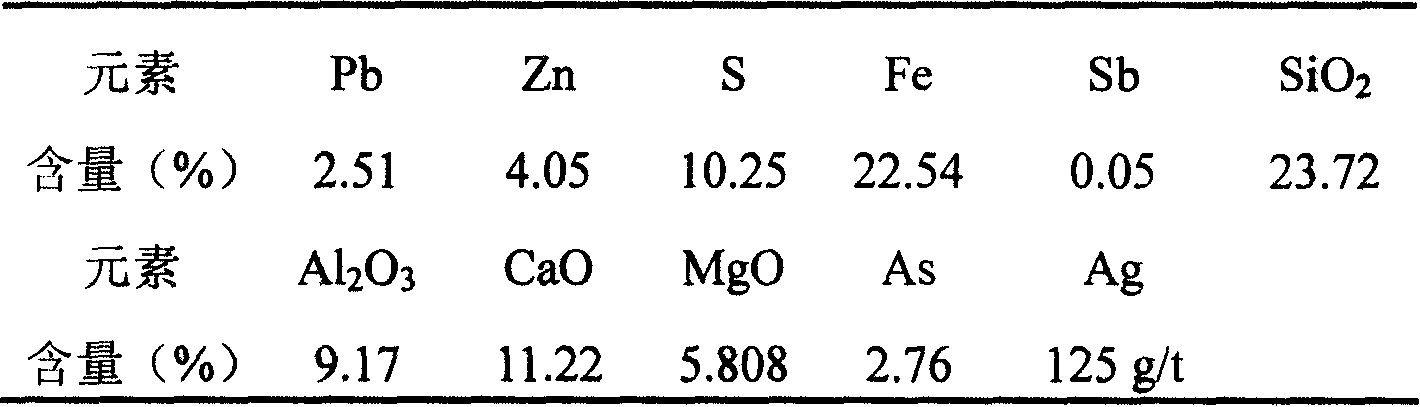

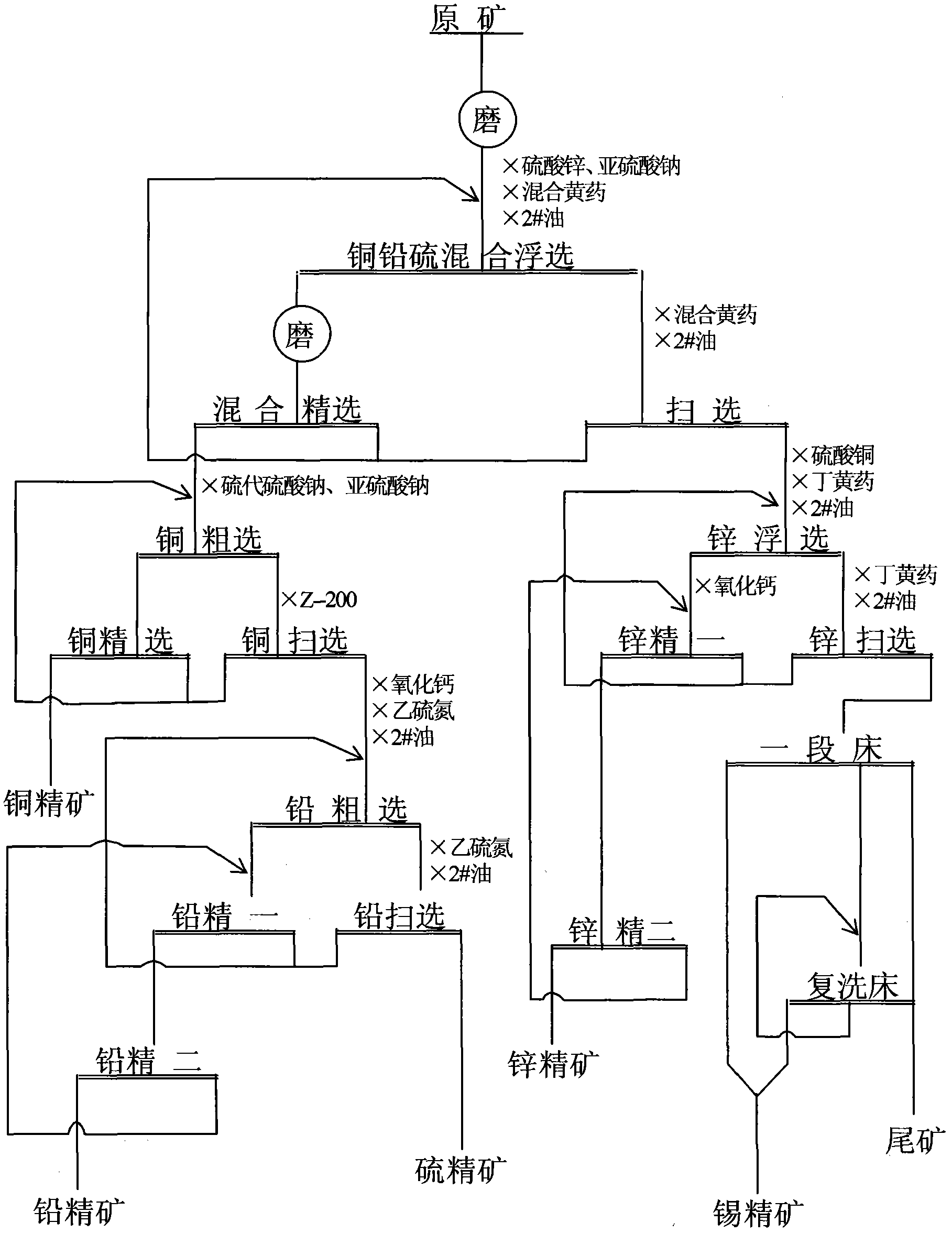

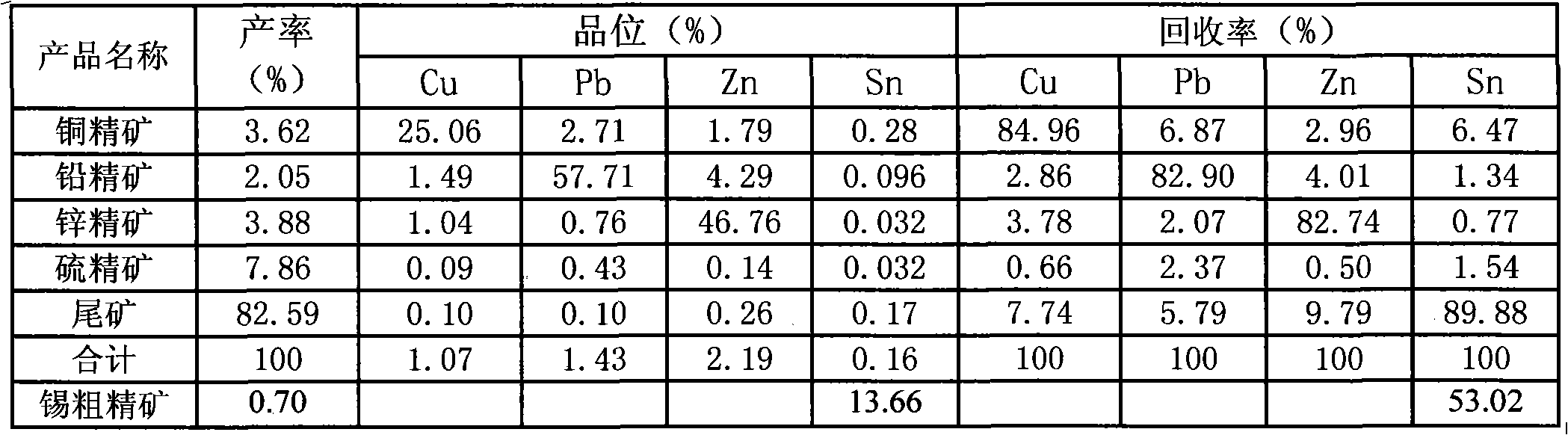

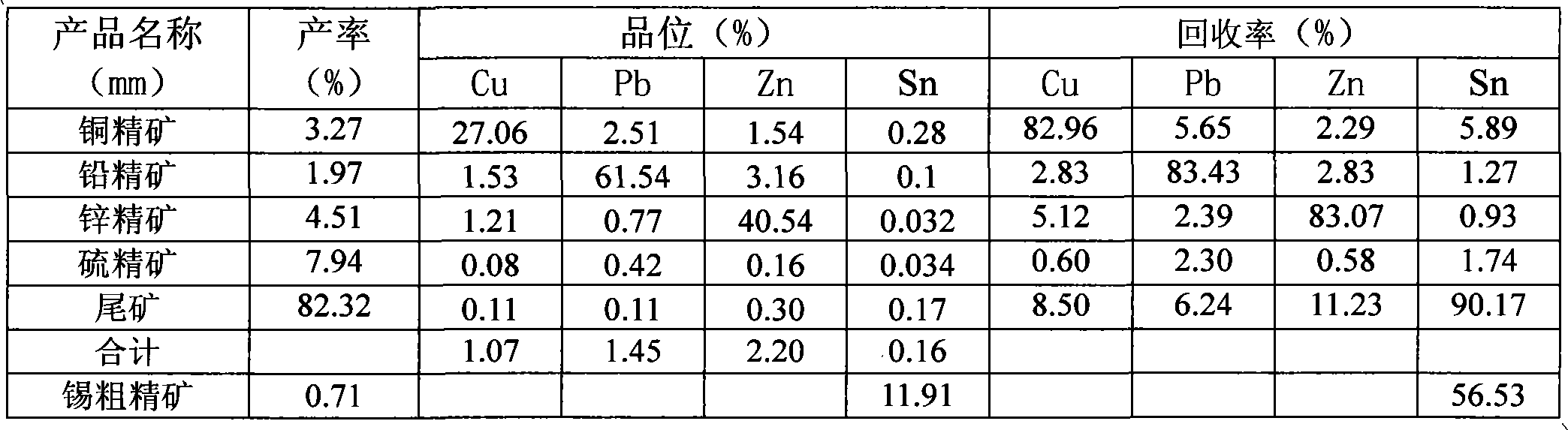

Benification combined method of polymetallic sulphide ore containing copper, lead, zinc and tin

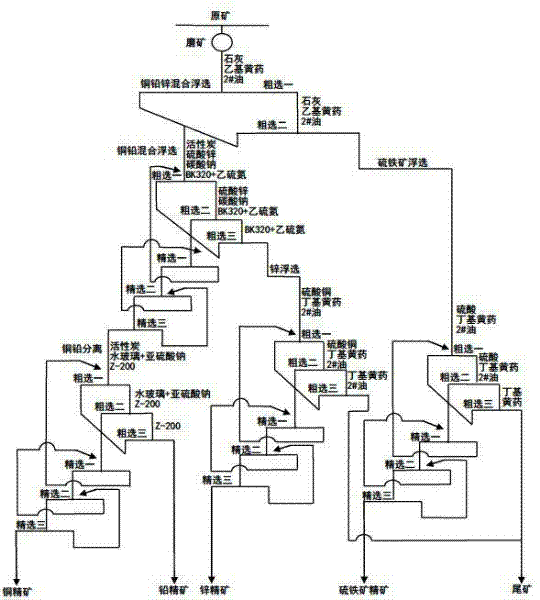

The invention relates to a beneficiation method, in particular to a beneficiation method for separating the polymetallic sulphide ore containing copper, lead, zinc and tin. The method comprises the following steps: (1) carrying out ore grinding on the raw ore before carrying out bulk flotation on copper, lead and sulphur, using diethyl mixed with xanthate as collecting agent of copper and lead mineral, using zinc sulphate and sodium sulfite as inhibitor of zinc mineral; (2) carrying out phase-2 ore grinding and selection; (3) separating copper, lead and sulphur, using sodium sulfite and sodium thiosulfate as the inhibitor of the lead and sulphur mineral, using Z-200 as collecting agent for separation and scavenging and then carrying out lead flotation after the separation and scavenging; (4) carrying out zin flotation on the bulk flotation tailings; and (5) finally, carrying out reselection on the zinc flotation tailings to recover tin. The metalliferous mineral of the invention has the advantages of good separating effect, high metal recovery rate, more complete comprehensive recovery of useful minerals, low cost of medicament, simple method, easy operation and energy conservation.

Owner:云南锡业研究院有限公司研究设计院

Municipal sludge expanded ceramsite and preparation method thereof

InactiveCN101618971ALow costSave resourcesCeramic materials productionCeramicwareSludgeExpanded clay aggregate

The invention provides municipal sludge expanded ceramsite and a preparation method thereof. The municipal sludge expanded ceramsite is prepared from the following materials by mass percentage: 20% to 45% of municipal sludge, 50% to 70% of shale, tailings or clay, 1% to 5% of organic matter and 1% to 5% of iron powder, wherein, the tailings is one of pyrite tailings, gold tailings, lead-zinc tailings and aluminum tailings; and the organic matter is sawdust. The preparation method comprises the following steps: feeding the shale, tailings or clay into a crusher, and carrying out the screening treatment; adding and mixing the municipal sludge, the organic matter and the iron powder, feeding into an ageing silo and stirring; then, feeding into a granulating machine, granulating and calcinating in a rotary kiln; and finally, cooling and stacking the calcinated ceramsite by classification. By using a great amount of municipal sludge, the invention is resource-saving and environment-friendly; compared with the original cost, the overall cost of a building is reduced by 5% to 10%; and the prepared expanded ceramsite has the advantages of light weight, fire resistance, sound absorption, good heat insulating and preserving performance, simple process and low cost, so that the invention is suitable for industrialized production.

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

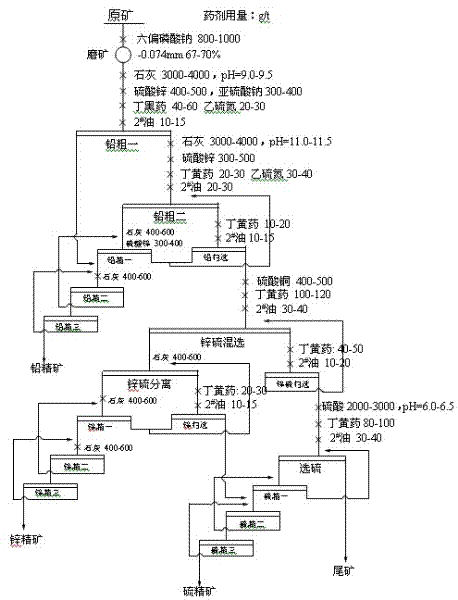

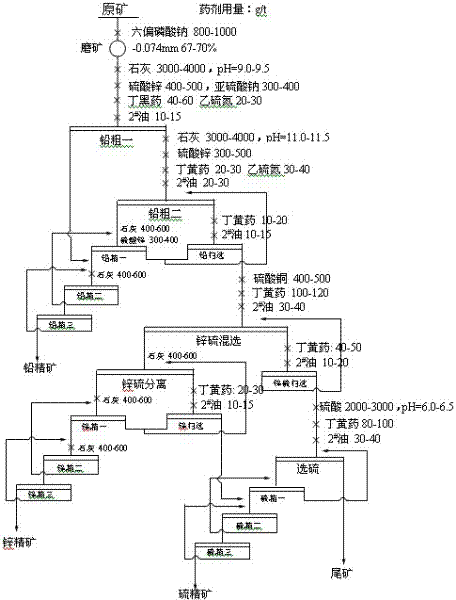

Technology of enhanced-dispersion partial selective and bulk flotation of lead and zinc sulfide ores under low and high alkalinity

The invention discloses a technology of enhanced-dispersion partial selective and bulk flotation of lead and zinc sulfide ores under low and high alkalinity. During grading of the lead and zinc sulfide ores, sodium hexametahposphate is taken as a dispersion agent and directly added into a ball mill, the ores are ground till the ores with the size of 0.074mm account for 67%-70%, lime is taken as an adjusting agent, zinc sulfate and sodium sulfite are taken as inhibitors, dithiophosphate BA and diethyldithiocarbamate are taken as collectors, and selective flotation of part of lead minerals with good floatability can be performed under low alkalinity; then xanthate and the diethyldithiocarbamate are taken as collectors, and the flotation of the lead minerals is further performed under high alkalinity; copper sulfate is added in lead flotation tailings for activation, butyl xanthate is further taken as the collector for flotation of zinc blende and part of pyrite, and zinc-sulfur separation flotation is further performed on zinc-sulfur mixed concentrate; and sulfuric acid is added in zinc flotation tailings for activation, and the xanthate is taken as the collector for flotation of the remaining pyrite. By adopting the technology, the lead-silver recovery rate can be improved, the using amount of lime and sulfuric acid can be reduced, the circulating amount of middlings can be reduced, the ore dressing cost can be reduced and the grade of the concentrate can be improved.

Owner:KUNMING UNIV OF SCI & TECH

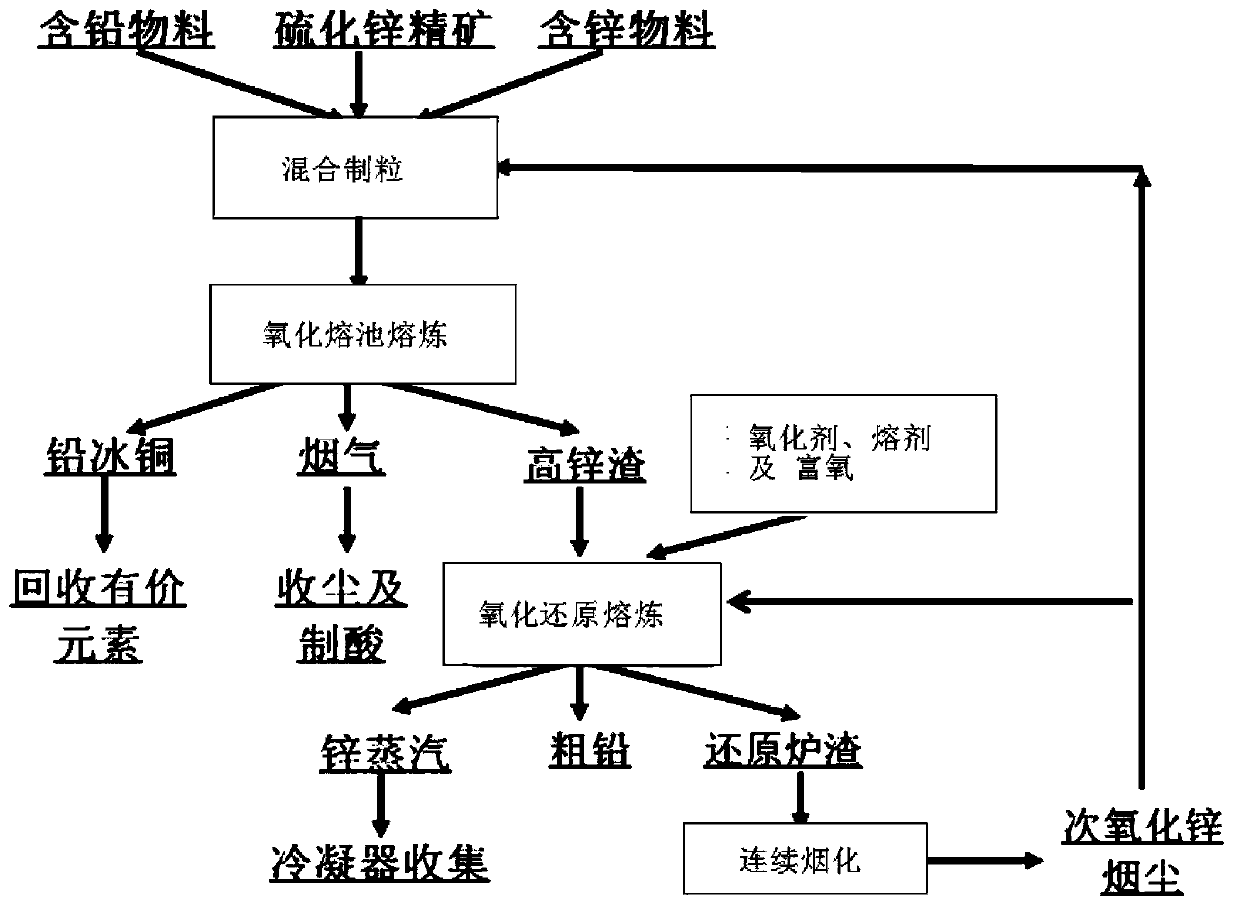

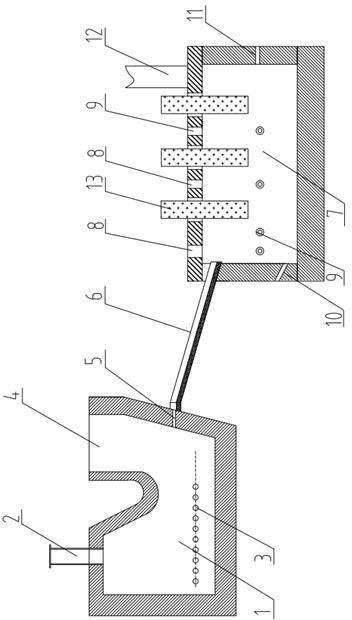

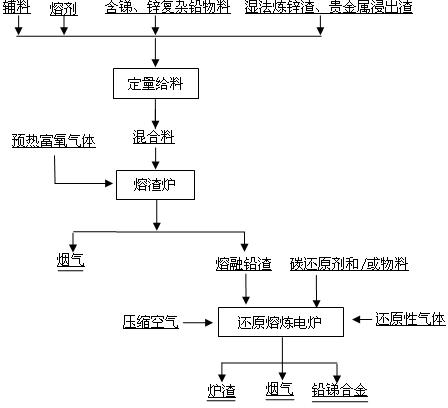

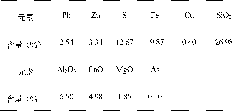

Bath smelting method and apparatus of zinc sulfide concentrate and lead-zinc containing materials

InactiveCN103388081AMeet the requirements of smeltingReduce energy consumptionMelting tankHigh concentration

The invention discloses a bath smelting method and an apparatus of zinc sulfide concentrate and lead-zinc containing materials. The smelting method comprises the following steps: mixing lead-zinc-containing mixed materials according to a certain proportion and pelletizing; and then, adding the pelletized materials into an oxidation furnace having a lead-containing high-zinc-slag bath with proper ingredients and smelting points, and blowing oxygen-enriched air into the bath for generating an oxidation reaction with the pelletizing materials to generate high-concentration SO2 flue gas and lead-containing high-zinc slag, wherein the SO2 flue gas is used for preparing acid, the lead-containing high-zinc slag is continuously discharged from the oxidation furnace into a reduction furnace bath, zinc in the lead-containing high-zinc slag is reduced into zinc vapor to be collected, and the lead is reduced into metal lead and such precious metals as gold and silver in the raw materials are captured and gathered at the bottom part of the bath to be discharged. The bath smelting method disclosed by the invention has the advantages of short flow, strong raw material adaptability, low energy consumption, environment friendliness, efficient source utilization and the like and is expected to solve the current treatment difficulty of high-iron zinc sulfide concentrate, zinc oxide ores, iron and steel plant zinc dust and gold-containing iron ores and the long-term pollution problems of zinc slag of hydrometallurgy.

Owner:CENT SOUTH UNIV

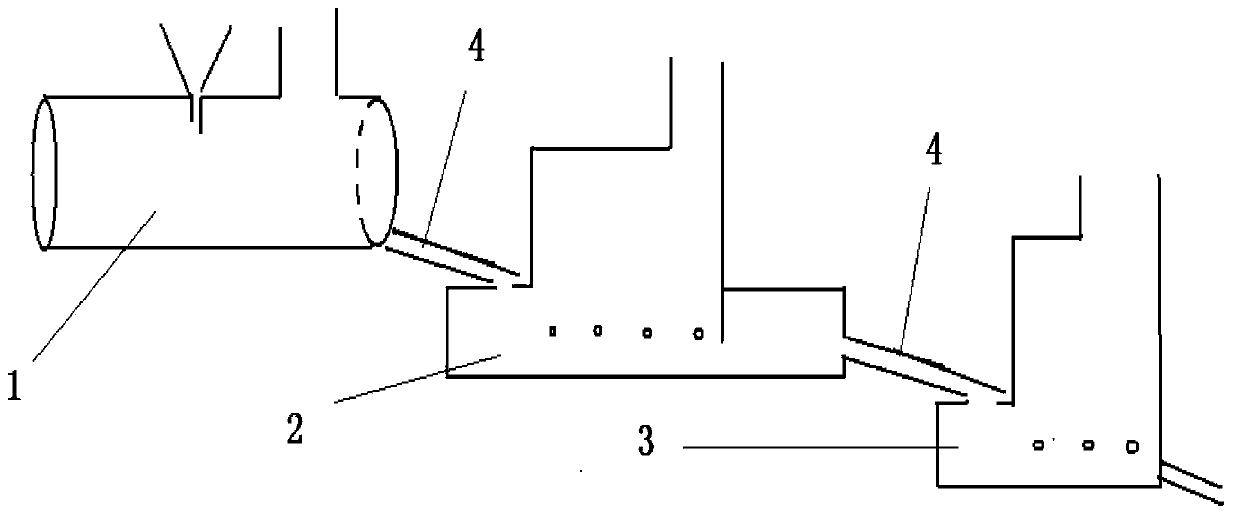

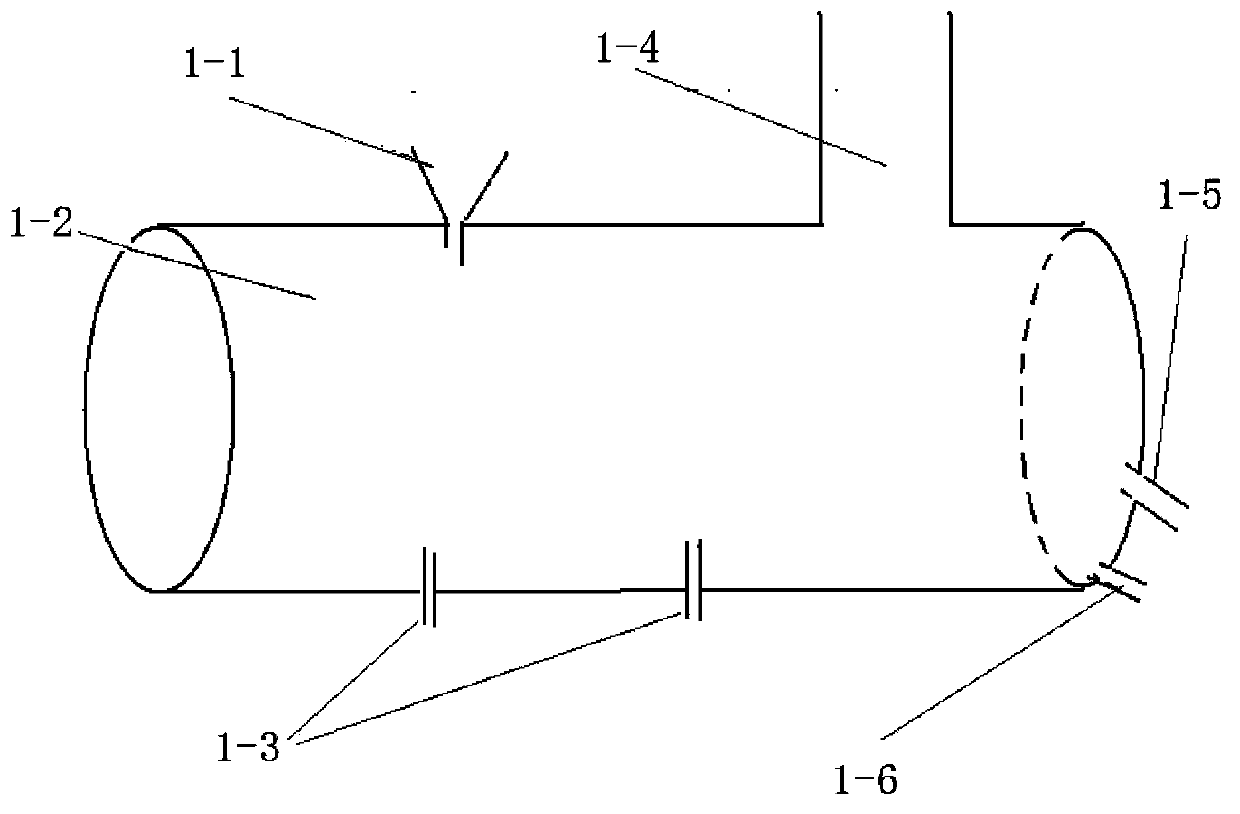

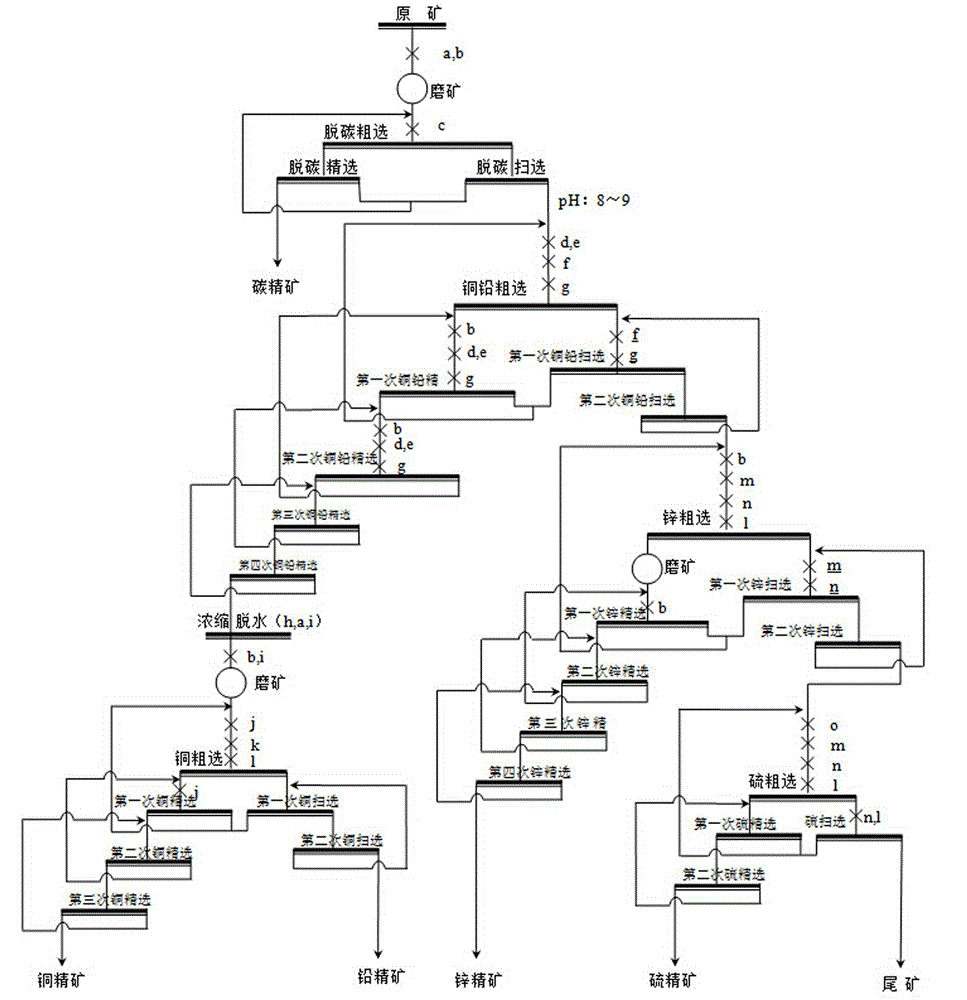

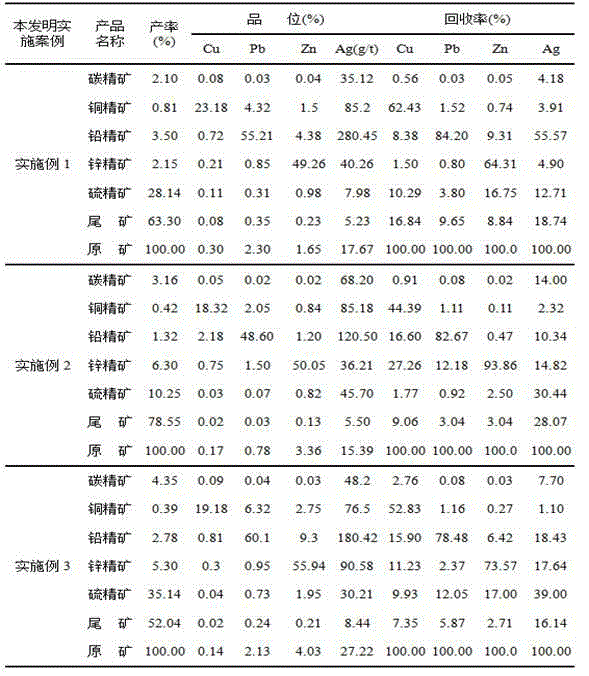

Beneficiation method for cu-pb-zn polymetallic ores

The invention discloses a beneficiation method for cu-pb-zn polymetallic ores, and belongs to the technical field of non-ferrous metal beneficiation. According to the technical scheme, the characteristic of complex cu-pb-zn-sulfur polymetallic ores with embedded fine-grained carbon level is utilized, a technological process of carbon-removing, cu-pb partial bulk flotation, cu-pb separation and zn-and-sulfur choosing in tailings is adopted, a concentration and fine grinding mode is adopted to achieve deep reagent removal, the influence of slurry on flotation is effectively eliminated, efficient collectors A8 and depressors T721 for cu-pb separation are used in the cu-pb partial bulk flotation process, separation and recovery of copper, lead, zinc and sulfur are effectively achieved, and concentrate mixing is obviously lowered.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Stepped flotation of tin, lead and zinc sulfide mine

A step floatation technology for the tin-lead-zinc sulfide ore includes such steps as high-alkali high-speed floatation and separation of lead sulfide ore, high-alkali high-Ca floatation and separation of zinc sulfide ore, and floatation of zinc tailings. Its advantages are high grade and recovering rate of lead concentrate, no loss of Ag ore, and simple apparatus.

Owner:黎东明

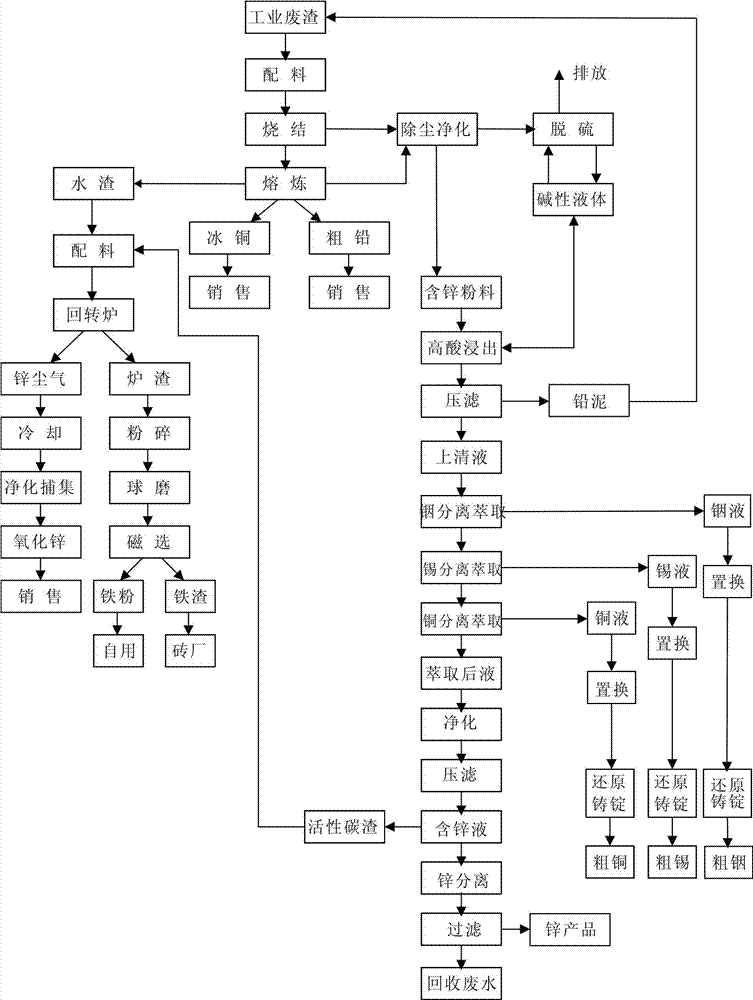

Method for recovering valuable metal from waste residue containing lead and zinc through wet-fire combination process

InactiveCN102776376AGreat tasteHigh recovery rateProcess efficiency improvementIndiumEnvironmental engineering

The invention discloses a method for recovering valuable metal from waste residue containing lead and zinc through a wet-fire combination process. The method is characterized by comprising the steps of preparation of simple-substance lead, leaching of zinc hypoxide, preparation of simple-substance copper, indium and tin, preparation of zinc and the like. By utilizing the wet-fire combination process to recover the metal, the recovery rate of the lead and the zinc is high, the leaching separation effect of the copper, the indium and the tin is good, and the waste residue is utilized cyclically. The existing resources are further recovered, and pollution of the valuable metal to the environment is avoided, so that the method is safe and environment-friendly. Besides, the method is simple in principle, reasonable in flow path, high in yield and product quality and low in cost.

Owner:四川正祥环保技术有限公司

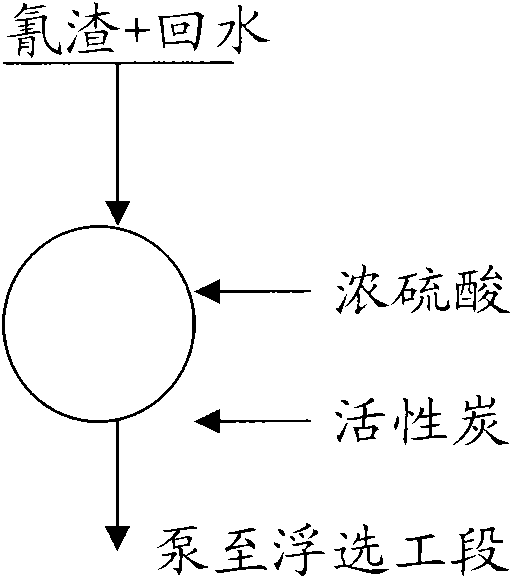

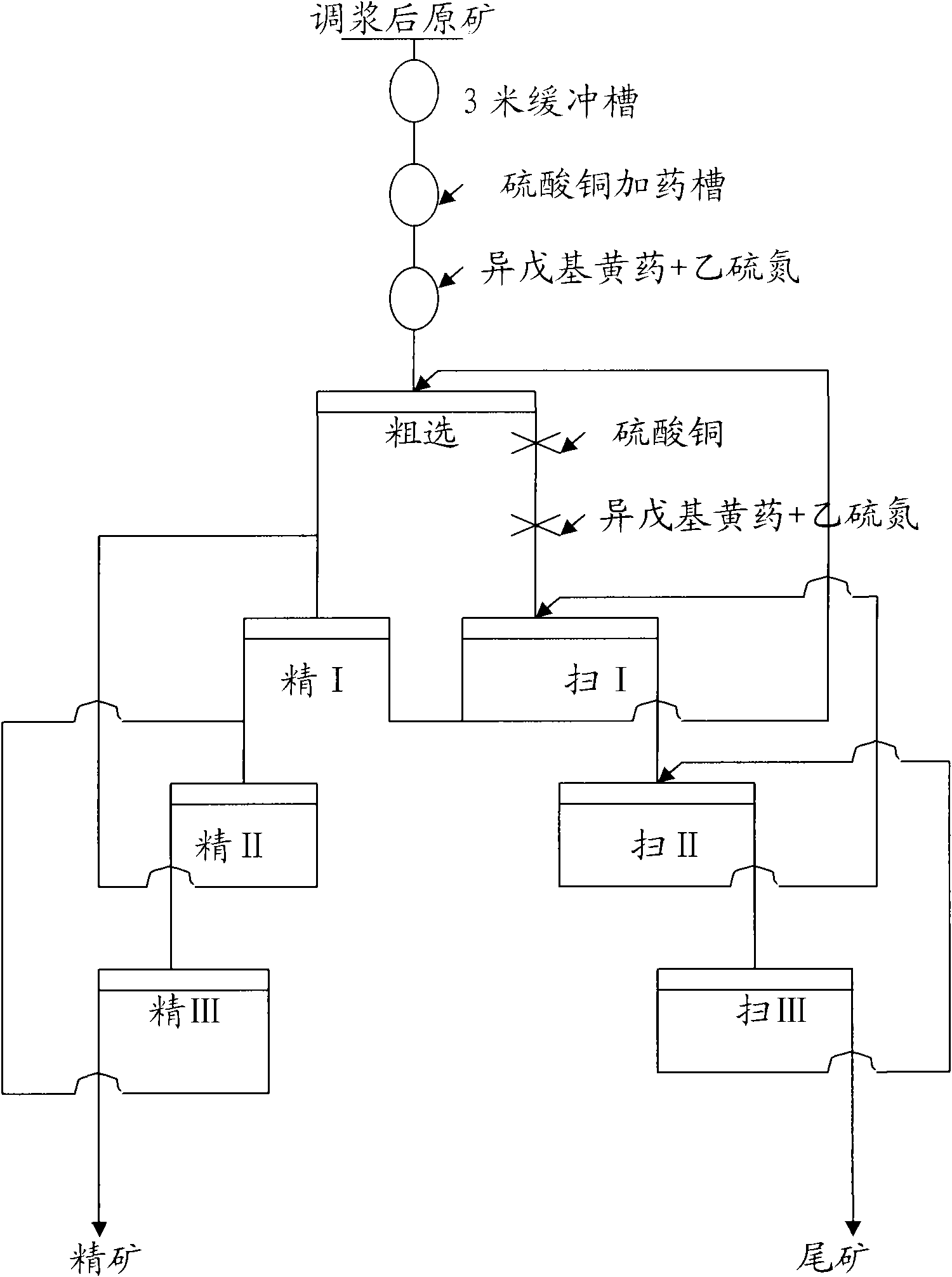

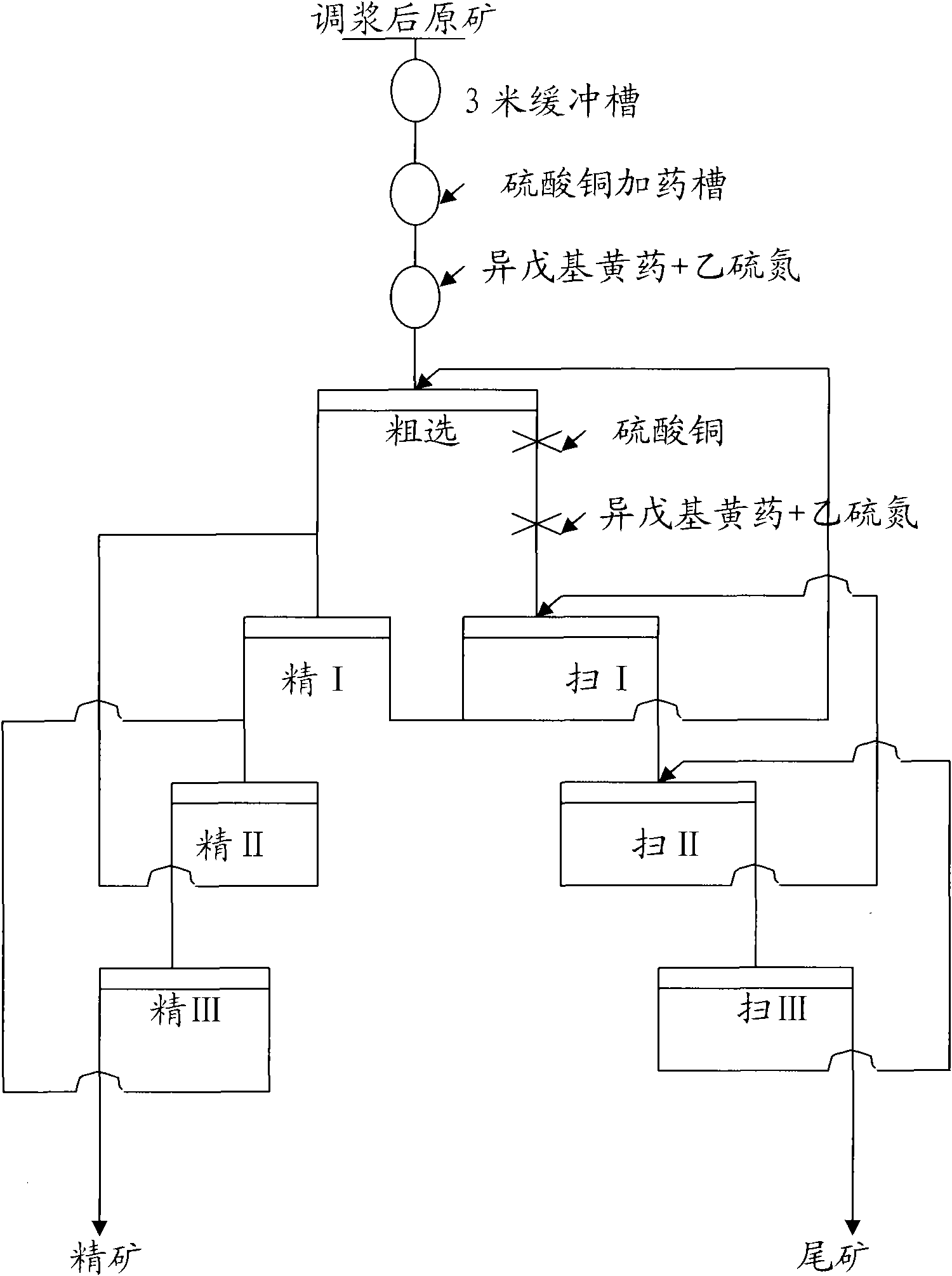

Method using mineral dressing backwater to float and to recover gold, silver, lead and zinc in cyanidation tailings of gold mine

The invention discloses a method using mineral dressing backwater to float and recover gold, silver, lead and zinc in cyanidation tailings of a gold mine. The method comprises the following working procedures: (1) pulp pre-processing stage: adding mineral dressing backwater in cyaniding tailings, adding concentrated sulfuric acid to stir for 5 minutes, reacting the concentrated sulfuric acid withthe pulp until smoke is completely generated, adding activated carbon to remove reagent for 55 minutes, and then pumping to a flotation workshop section; and (2) bulk flotation stage: pumping the pretreated pulp into a 3-meter stirring buffer slot, stirring for 30 minutes continuously, flowing into a medicine injecting slot 1 and a medicine injecting slot 2 by proper motion, sequentially adding copper sulfate and diethyldithiocarbamate, stirring fully, then entering a floatation unit to perform roughing on the pulp, further carrying out selection stage by stage on the rough concentrate obtained by roughing to obtain qualified lead and zinc bulk concentrate containing gold and silver, and further carrying out scavenging stage by stage on the roughed tailing to obtain floated tailing which is the sulphur concentrate. The invention realizes comprehensive utilization of mineral dressing tailings and zero exhaust of the tailings, thus realizing cleaner production of the mineral dressing process.

Owner:青岛黄金铅锌开发有限公司

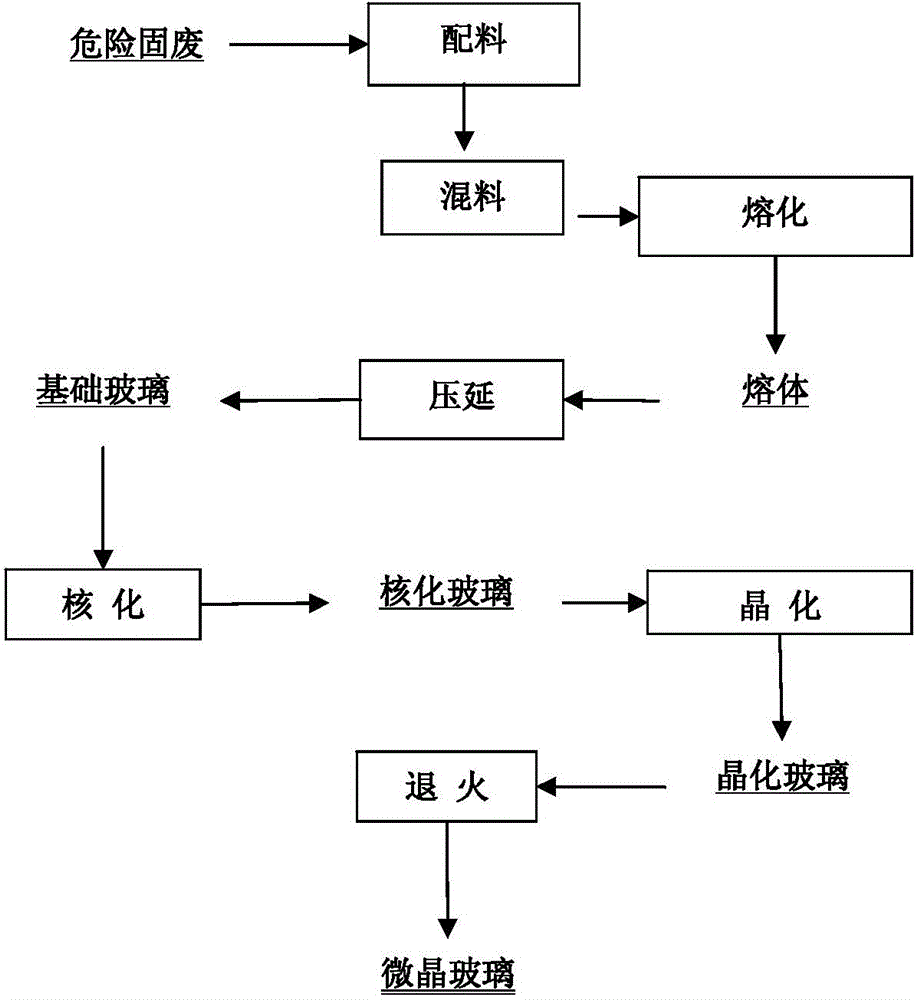

Method for preparing microcrystalline glass from hazardous solid wastes

The invention discloses a method for preparing microcrystalline glass by taking hazardous solid wastes which are hazardous solids for short. The method is characterized by taking heavy metals in the hazardous solids as nucleating agents, mixing, fusing, rolling, nucleating, crystallizing and annealing to obtain the microcrystalline glass. The method has the advantages that the heavy metal elements in waste incineration ash, stainless steel slag, stainless steel acid pickling sludge, electroplating sludge, chromium slag, lead-zinc smelting slag and coal ash can be stably solidified; the pollution is avoided; meanwhile, high-additional-value microcrystalline glass is prepared; the harmless high-value application of the hazardous solids is realized; and the method has remarkable environmental and economic benefits and wide market prospects.

Owner:UNIV OF SCI & TECH BEIJING

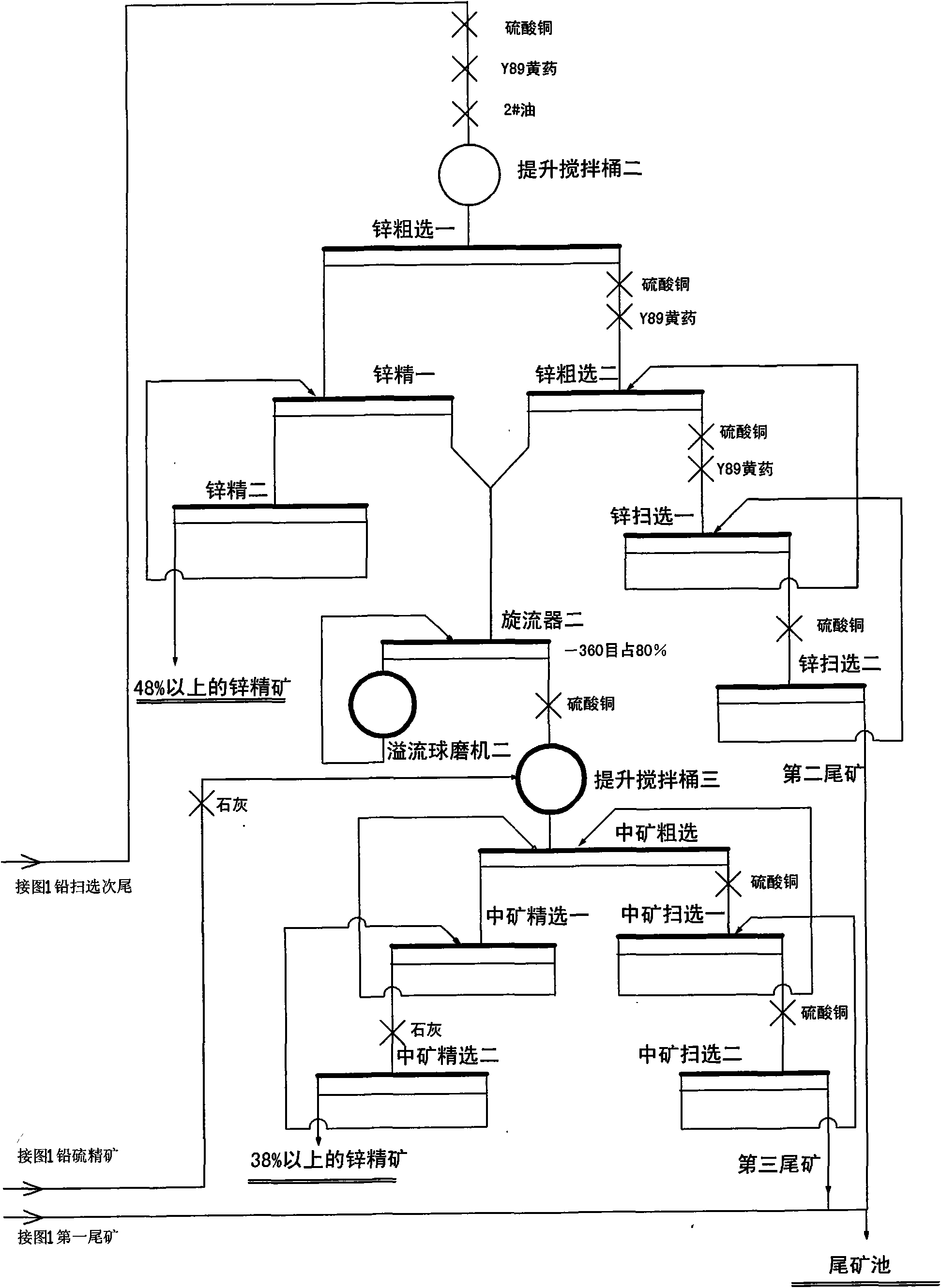

Floatation process of complex lead zinc ores

The invention relates to a floatation process of complex lead zinc ores, which uses the following process flows: ore grinding-floatation of lead in a lead flotation area-floatation of zinc in a zinc / sulfur mixed flotation area-floatation of zinc in a zinc middling re-flotation area; the invention uses floatable process like lead zinc full-opening, effectively removes carbon and iron sulfide with good floatability by means of entire processes of the lead area, reduces influence of carbon and iron sulfide with good floatability on the flotation of zinc, avoids lime from entering rougher flotation and scavenging of primary processes and enables refining of zinc to be blank refining to thereby greatly reduce vicious circle of a large amount of middling, and a collecting agent is not added to the separation of zinc from sulfur in re-flotation of zinc middling.

Owner:何任义 +2

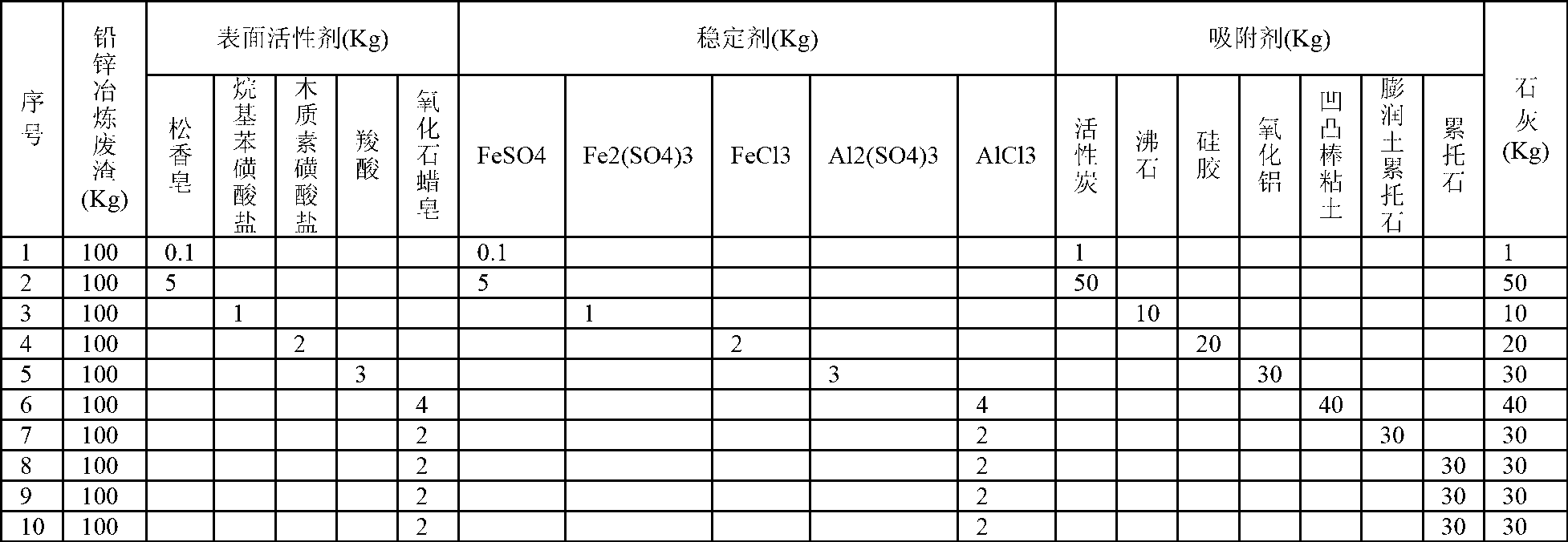

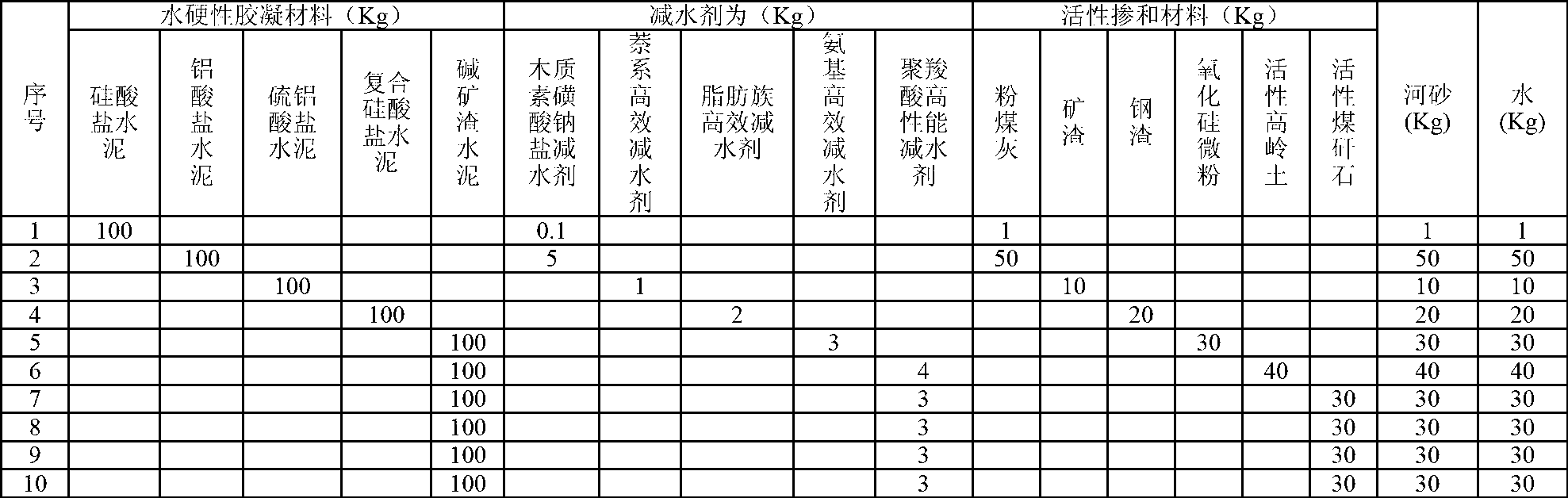

Solidification treatment process of smelting waste of lead and zinc

InactiveCN103011726AImprove workabilityImprove compactnessSolid waste managementSlagRoom temperature

The invention discloses a solidification treatment process of smelting waste of lead and zinc. The solidification treatment process is characterized in that surface active agent, stabilizing agent, adsorbent and lime are added into and mixed uniformly with the smelting waste of lead and zinc; water-reducing agent, active blending material, river sand and water are added into and mixed uniformly with the hydraulic binding material; the pretreated smelting waste of lead and zinc is added into the pretreated hydraulic binding material, placed for 24 hour under room temperature after uniformly stirred and formed, then demoulded and stored in a slag storeroom. The solidification treatment process has the characteristics of good solidification effect, simple process, low cost, easy-to-get raw material, and the like.

Owner:SHAANXI UNIV OF TECH

Method for using cyaniding barren solution to float, reclaim and cyaniding copper plumbum and zinc in tailings

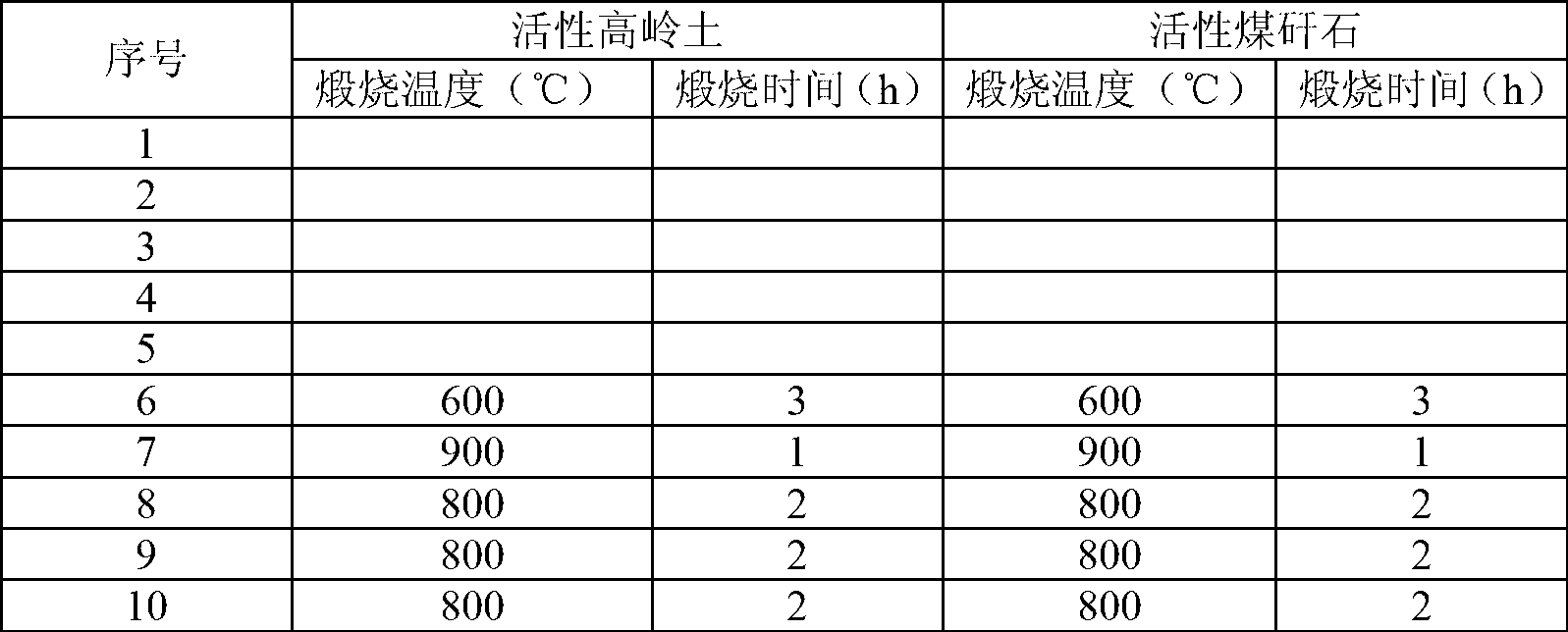

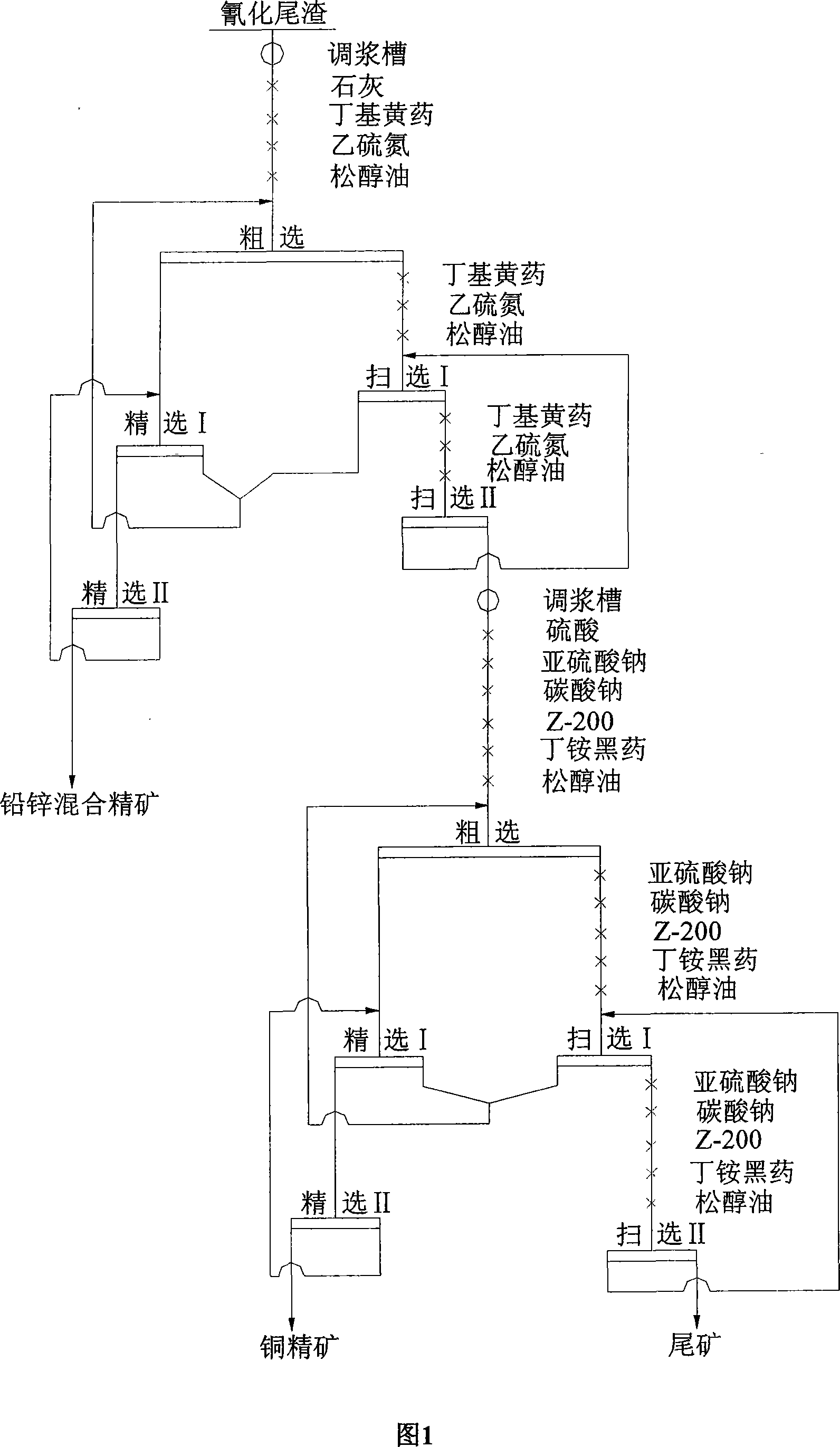

A method that cyanide barren solution is used for recovering the copper-lead-zinc from cyanide tailing by means of floatation belongs to the field of nonferrous metal separation. The processing procedures of the method are as following: (1) mashing: the cyanide barren solution is added into the cyanide tailing and stirred to ore slurry, the concentration of which is 35 to 40 per cent; (2) lead-zinc preferential flotation: after being stirred, the ore slurry is put into flotation machine and lime, Ethyl thiocarbamate and Sodium n-butyl xanthate synthetic are added in to the ore slurry. The course of once rough floatation, twice scavenging and twice concentration is processed to recover Zinc and Lead; (3) Cu-S separation: after the tailing of lead and zinc bulk flotation is concentrated, the cyanide barren solution is added into the tailing and the tailing is made into the ore slurry with the concentration of 35 to 40 per cent. And then, the ore slurry is put into the floatation machine and sulfate, sodium sulfite, Z-200 and ammonium butyl aerofloat are added into the tailing. The course of once rough floatation, twice scavenging and twice concentration is processed to recover copper. And the tailing can be for sale as sulfur concentrate; (4) Reuse of separation tailing water: the press filtrate of bulk concentrate, the overflow of thickener, the press filtrate of copper concentrate and the press filtrate of the sulfur concentrate return to the buffer slot of the cyanide barren solution to be used for replacement fluid. The invention has the advantages of good flotation effect, high recovery rate of the copper-lead-zinc and zero discharge of waste water and residue.

Owner:UNIV OF SCI & TECH BEIJING

Method for producing metallic lead and zinc by using lead-zinc containing waste slag or lead-zinc monoxide mine

ActiveCN101012514ASimplify the cleaning processImprove current efficiencyPhotography auxillary processesProcess efficiency improvementElectrolysisSlag

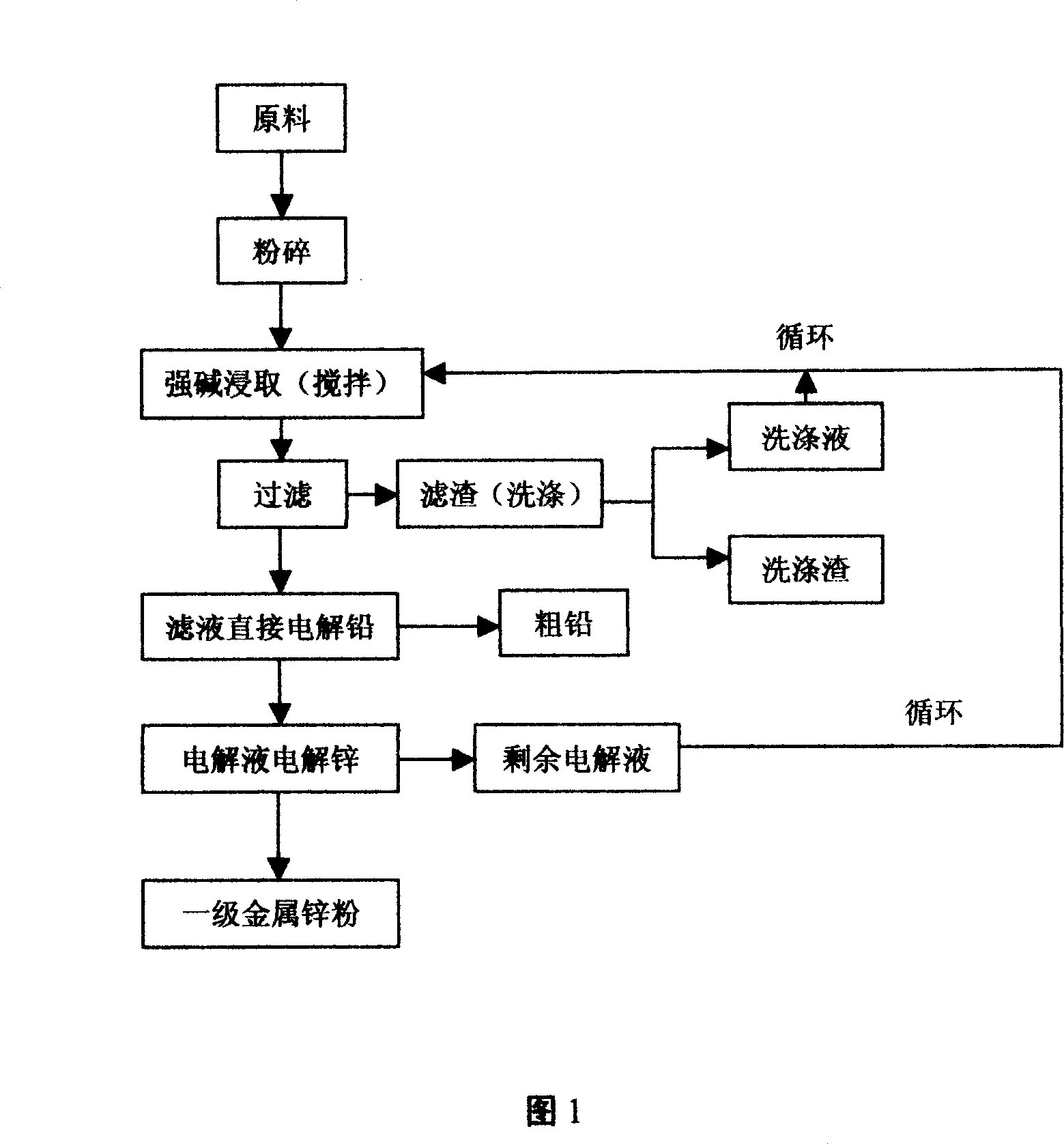

The invention discloses a manufacturing method of metal lead and zinc through waste slag with lead and zinc or low-grade lead or zinc oxide, which comprises the following steps: grinding lead zinc slag or lead zinc oxide into 0.1-1mm; stirring and leaching through strong base solution under 10-100 deg.c for 30-1000min; filtering; draining filtrate; electrolyzing filtrate directly to generate lead with current density at 100-1000A / m2 under 30-100 deg.c for 1-5h; stopping electrolyzing when tank voltage is improved to 1.8-2.5V; producing rough lead with 97-99.9% lead on the cathode; pressing; obtaining electrolytic refined lead; electrolyzing residual electrolytic liquid with zinc under 10-100 deg.c at 2.5-3.5V with current density at 500-1500A / m2 for 1-10h; drying zinc on the cathode protected by inert gas; obtaining one-grade metal zinc powder; circulating residual electrolytic solution in the alkaline leaching course directly.

Owner:昆明同越科技开发有限公司

Smelting method of lead concentrate containing antimony and zinc

InactiveCN102433448AEfficient use ofNo explosion hazardProcess efficiency improvementFlue gasSmelting process

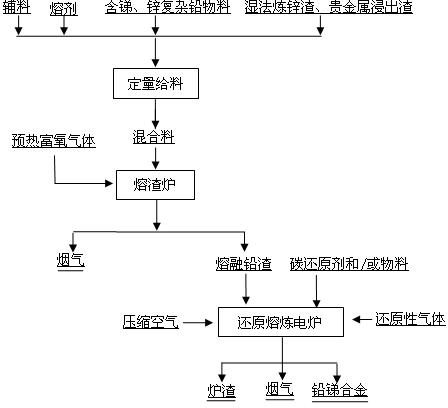

The invention relates to a nonferrous metal, and in particular relates to a smelting method of lead concentrate containing antimony and zinc. The smelting method is characterized in that in the smelting process, oxidizing smelting is performed to the lead concentrate containing antimony and zinc in a slagging furnace to generate a flue gas containing SO2, smelting dust and slagging furnace slag; then reduction smelting is performed to the slagging furnace slag in an electric furnace to generate a lead-antimony alloy, a flue gas and slag, and after the slag and the lead-antimony alloy are clarified and layered, the lead-antimony alloy is discharged from a lead discharge hole; and zinc oxide is recycled from the flue gas obtained in the reduction process and then the obtained flue gas is discharged to the outside. The method has the following advantages: the flow is short, continuous production is realized, energy is saved, the production capacity is large, resources can be efficiently utilized, the environment can be protected, the safety and labor hygiene are good, foamed slag has no explosion danger and the production is safe. The smelting method is suitable for not only the treatment of the complex lead materials containing antimony and zinc, but also the treatment of wet method zinc metallurgical slag and lead-precious metal system slag, lead, zinc and antimony are matched mutually, the lead-zinc-antimony combination enterprises are more superior and the recovery rates of lead and the associated valuable metals such as copper and antimony, and precious metals are higher.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Flotation method of brass ore-containing complex lead-zinc sulphide ore

The invention discloses a flotation method of a brass ore-containing complex lead-zinc sulphide ore, which comprises the steps of: adjusting the pH value to be 10-11 in the process of ore grinding; adding ore pulp electric potential regulating agent-sodium pyrosulfite to adjust the electric potential of the ore pulp to be at 220-260mV (relative to hydrogen standard potential); adding zinc sulfate, ethoxy-dithioformicacid ethyl formate and ethyl thio carbamate grinding ore; performing one roughing, one scavenging and two selecting to enrich copper-lead mineral by means of mixing and floating and to form into copper-lead mixed concentrate; performing reagent desorption to the copper-lead mixed concentrate by adding active carbon; adding potassium peroxydisulfate and carboxymethyl starch to restrain lead-containing mineral in the copper-lead mixed concentrate such as galena and the like; performing one roughing, one scavenging and three selecting to obtain copper concentrate; adjusting the pH value of tailings after recovering copper mineral by floating the copper-lead mixed concentrate to be 9.0; adding sodium pyrosulfite, ethyl thio carbamate and butyl ether alcohol; and performing one roughing, one scavenging and two selecting to obtain lead concentrate. The method guarantees the grade of the copper and the lead concentrate, and reduces the environmental pollution.

Owner:CENT SOUTH UNIV +1

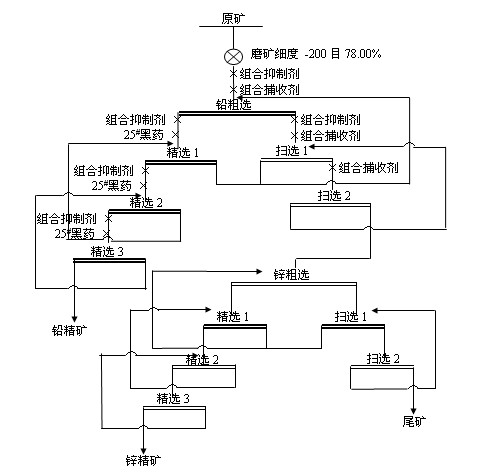

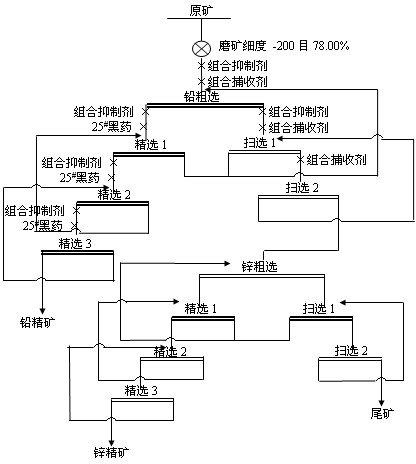

Beneficiation method for replacing sodium cyanide floating lead zinc to difficultly select ore

The invention relates to a beneficiation method for difficultly selecting lead-zinc ore, in particular to a beneficiation method for replacing sodium cyanide floating lead zinc to difficultly select ore. The beneficiation method comprises the steps of: (1) ore grinding: grinding raw ore into the ore with the material particle size being smaller than 0.074mm and being 72%-84% of the whole raw ore;(2) differential flotation of lead; and (3) differential flotation of zinc in float lead tailings. Particularly, the method adds a combined inhibitor and a combined collector in the beneficiation process to replace highly-toxic sodium cyanide selecting lead-zinc ore, so that the environmental pollution is reduced. In addition, the method is used for increasing the recovery ratio of lead-zinc concentrate, increasing the recovery ratio of precious metals including gold and silver, and increasing the economic benefit of enterprises.

Owner:HUNAN RES INST FOR NONFERROUS METALS

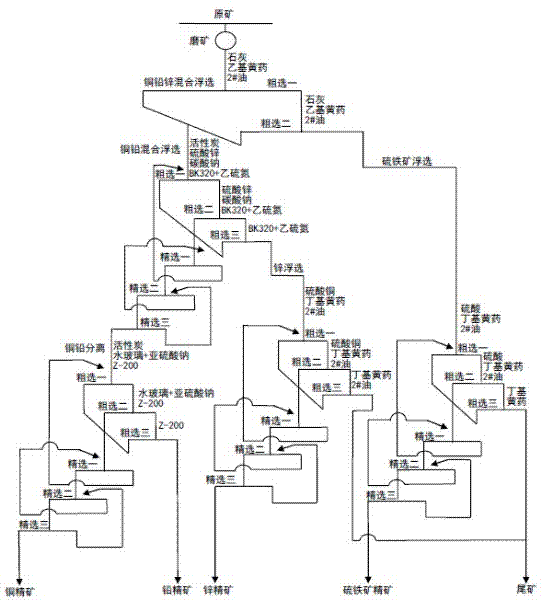

Mineral dressing method for separating Cu-Pb-Zn-Fe multi-metal sulfide mineral

The invention discloses a mineral dressing method for separating a Cu-Pb-Zn-Fe multi-metal sulfide mineral, which comprises the following steps: selecting a raw mineral, grinding the mineral, carrying out mixed flotation to Cu, Pb and Zn, carrying out mixed flotation to Cu and Pb, separating Cu and Pb, carrying out Zn flotation and pyrite flotation, and finally obtaining a Cu, Pb, Zn and pyrite concentrate. The method has the advantages of good metal sulfide mineral effect and high metal recovery rate, is simple to operate and is suitable to popularize and apply.

Owner:KUNMING UNIV OF SCI & TECH

Inhibition reelection and separation method for bulk concentrate floatation of plumbum-zincium, plumbum-zincium-copper or plumbum-copper

InactiveCN101293221AKeep natural propertiesImprove the quality of metallurgical productsWet separationEconomic benefitsCopper

An inhibition gravity treatment separation method for lead-zinc, lead-zinc-copper or lead-copper floatation collective concentrates pertains to the mineral processing technical field. In gravity treatment separation of the collective concentrates, lead sulphide inhibitor is added. The method includes the following procedures: after lead sulphide inhibitor is added, the collective concentrate is sent to a table concentrator again for gravity treatment separation; after the gravity treatment separation in the table concentrator, the concentrate belt includes lead concentrate and sub-concentrate belt and the tailing zone includes sub-concentrate and gangue containing lead-zinc, lead-zinc-copper or lead-copper; the obtained sub-concentrate and the gangue undergo the gravity treatment separation in the table concentrator again or for a plurality of times, thus finally obtaining lead concentrate, zinc concentrate, zinc-copper concentrate or copper concentrate. Due to the existence of lead sulphide inhibitor, the floatability of the lead sulphide is completely inhibited so as to highlight the high specific gravity feature of the lead sulphide; therefore, the lead sulphide is easily separated from a plurality of metallic collective concentrates by the gravity treatment separation in the table concentrator. The content of the metal elements in the obtained concentrates is mutually low and the major metal concentrate and the attaching metal concentrate can both satisfy the metallurgical standards and requirements, thus having extremely remarkable economic benefits.

Owner:兰坪县矿产三废回收厂

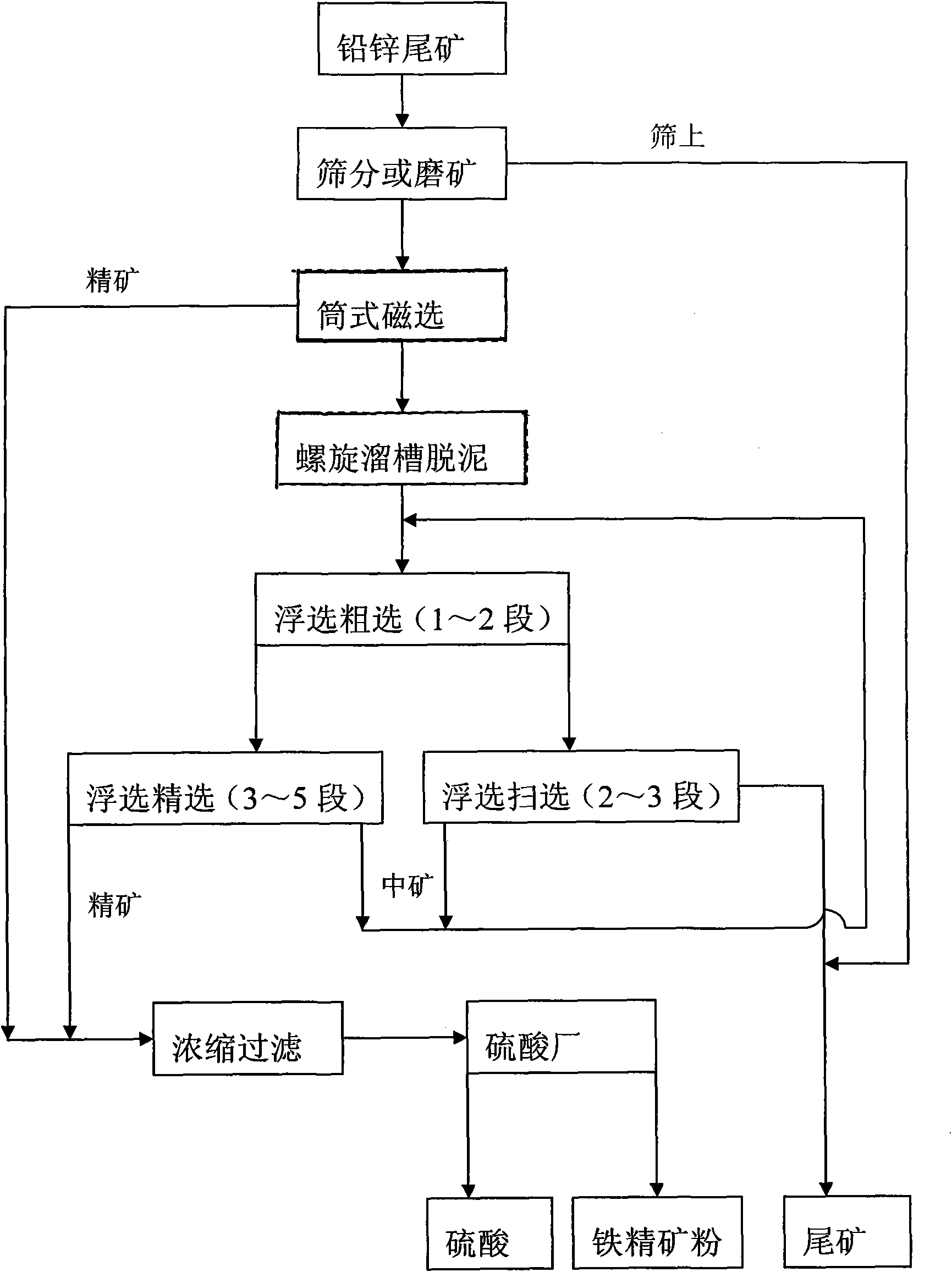

Process of using sulphur lead-zinc containing tailings to prepare sulphur iron ore concentrate

InactiveCN101549322ATake advantage ofStable in natureSulfur-trioxide/sulfuric-acidFlotationNational standardSulfur containing

The objective of the invention is to provide a process of using sulphur lead-zinc containing tailings to prepare sulphur iron ore concentrate, using magnet-floating combination process or magnet-gravity-floating combination process to produce sulphur iron ore concentrate containing more than 90% sulphur and iron, using the sulphur iron ore concentrate to produce sulphuric acid, getting 98% sulphuric acid of national standard while getting iron ore concentrate power containing more than 60% iron, and sulphur in the tailings is reduced to less than 2%, recovery rate of sulphur iron in ore concentrate is more than 86%. The invention make comprehensive recovery and use of sulphur iron in the lead-zinc tailings.

Owner:KUNMING UNIV OF SCI & TECH +1

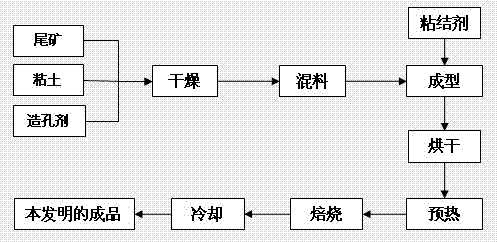

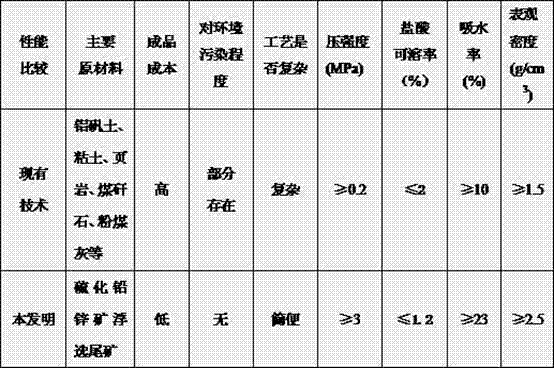

Biological ceramisite filter material made of vulcanized lead zinc ore flotation tailings, and preparation method thereof

InactiveCN103086741AImprove performance qualityLow costSolid waste disposalCeramicwareMining engineeringSulfidation

The invention relates to a biological ceramisite filter material made of vulcanized lead zinc ore flotation tailings. The material is characterized by being prepared from 80-90wt% of vulcanized lead zinc ore flotation tailings, 8-18wt% of clay, 1.5-2.5wt% of pore former and an additional bonder, wherein the pore former is sawdust, bamboo scraps or straws, the bonder is lignin calcium xanthate, sodium carbonate or sodium silicate liquid, and the solid-to-liquid ratio of materials used by the biological ceramisite filter material is (8-12):1. The preparation method comprises the following steps of: weighing based on proportion of main and auxiliary materials; drying; mixing; forming; drying; preheating; roasting; and cooling to prepare a biological ceramisite filter material product made of the vulcanized lead zinc ore flotation tailings. The preparation method is simple and convenient to implement, free from secondary pollution, practical and reliable. The biological ceramisite filter material made of the vulcanized lead zinc ore flotation tailings provided by the invention has the advantages of turning ore waste residue into wealth and greatly lowering the cost of materials, so that the biological ceramisite filter material is a high-quality water treatment agent.

Owner:HOHAI UNIV

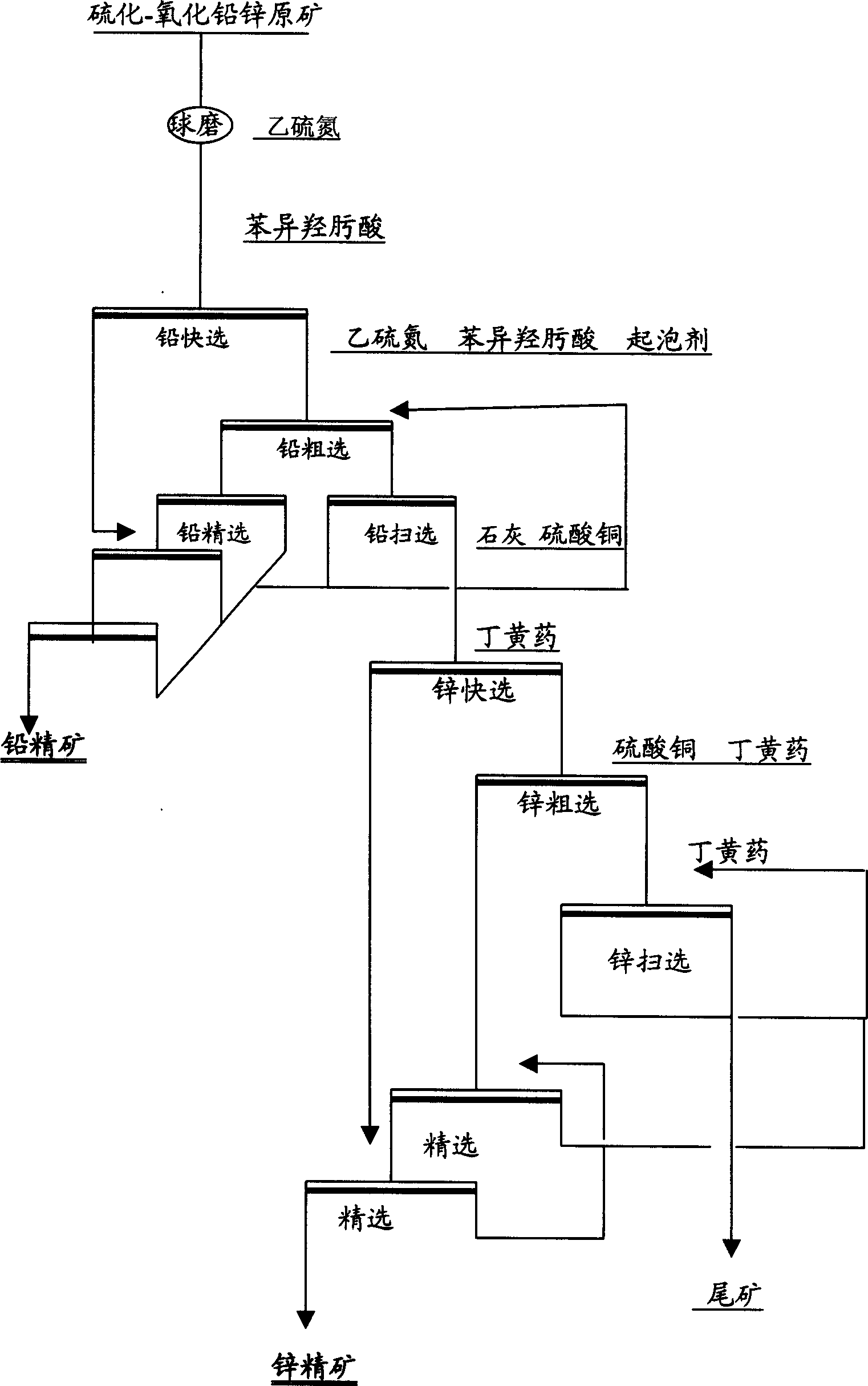

Flotation method for sulfidization-oxidization mixed lead-zinc ore

InactiveCN1704170AHigh recovery rateImprove concentrate qualityFlotationGrain treatmentsLead zincChemistry

The invention relates to a floating method of sulfide-oxide mixing Pb-Zn mine. The lead floating method adopts the flow process of one fast separation, one roughing separation, one sweeping separation and three classifications so that the mine grouting acidity of the full floating process can keep at pHú¥11. The zinc floating method adopts the flow process of one fast separation, one roughing separation, one sweeping separation and two classifications so that the mine grouting acidity of the full floating process can keep at pHú¥12. It can increase the recovery ratio of PbíóZn over 10% when Pb-Zn mine has oxide ratio over 30%.

Owner:黎东明

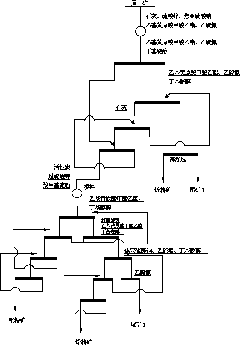

Technological method for comprehensively recovering valued metal such as indium and germanium from lead-zinc smoke

A technological method for comprehensively recovering valued metal such as indium and germanium from lead-zinc smoke. The present invention relates to the technical field of wet-process metallurgy, specifically a technological method for recovering valued metal such as lead, zinc, germanium, indium and silver from smoke volatilizing from a rotary kiln containing lead, zinc, germanium, indium and silver. The method of the present invention includes the separation and recovery of lead and silver, the extraction, separation and recover of indium, the distillation, separation and recover of germanium, and the recovery of zinc. The method of the present invention has too much comprehensive recovery rate, too much resource utilization rate and a relatively low recovery cost.

Owner:YUNNAN DONGCHANG METAL PROCESSING

Method for recovering valuable metal mineral in zinc tailing

ActiveCN101797531AImprove sorting efficiencyEffective development and utilizationMagnetic separationWet separationMaterials scienceTin

The invention relates to a method for comprehensively recovering a valuable metal in a zinc tailing and belongs to the technical field of metal beneficiation. The process procedure comprises the following steps: roughing the prepared zinc tailing under the magnetic field strength of 8,000 to 12,000 OE by taking an attractive mineral in the zinc tailing as a carrier; performing ore grinding on the magnetic material until the magnetic material which can pass through 200 meshes screen accounts for 60 to 70 percent for dissociating lead-zinc combination; selecting the ground magnetic mineral under the magnetic field strength of 2,500 to 4,000 OE to obtain an iron ore concentrate finished product with the grade of iron over 60 percent; and sorting a nonmagnetic material through a multi-section table to obtain a tin-rich middling product with the grade of tin over 3 percent. The method has the advantages of increasing recovery rate of a tin metal, recovering ferrous metal and manganese metal in the zinc tailing, and effectively utilizing the tailing resource, along with simple beneficiation process flow, low production cost, environmental-friendliness and good application and popularizing prospect; and the fruit can be spread and applied to the development and exploiting of high-ferric and low-tin resources.

Owner:YUNNAN TIN GROUP HLDG

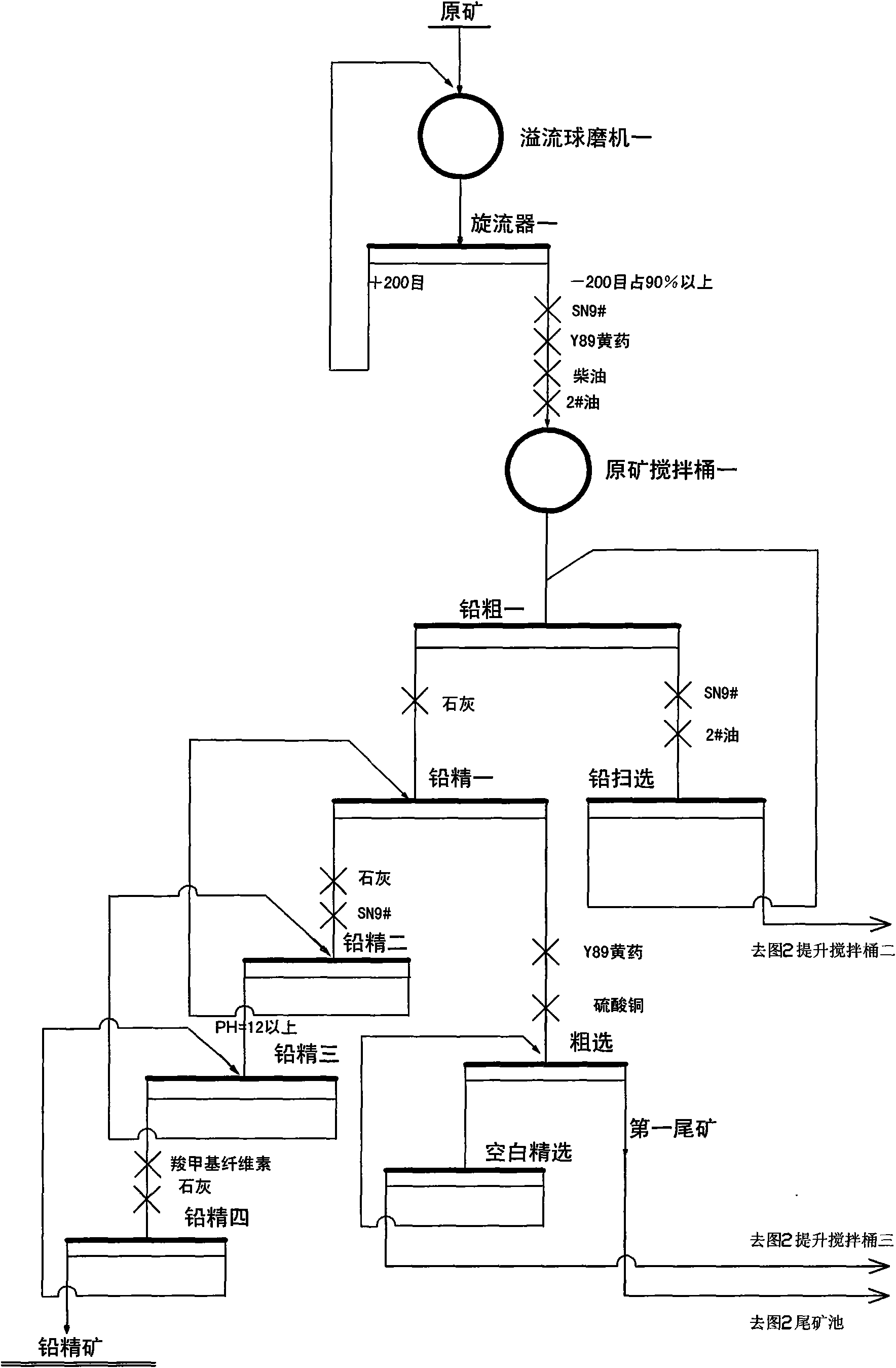

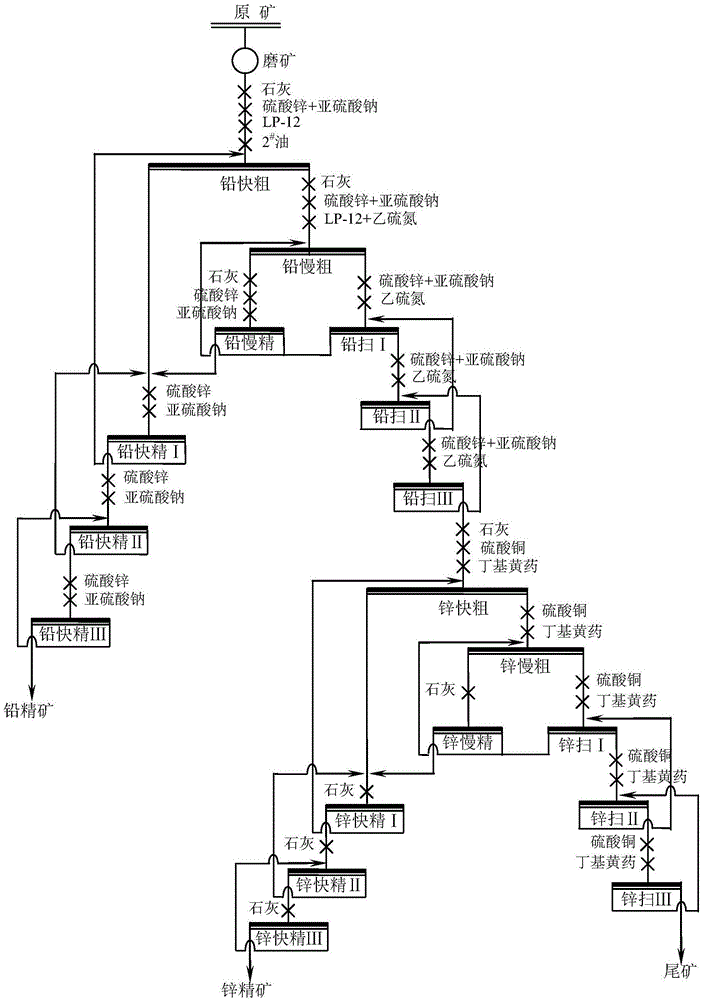

Ore dressing method for lead-zinc-silver poly-metallic ores

The invention provides an ore dressing method for lead-zinc-silver poly-metallic ores. Lead-silver concentrates and zinc concentrates are finally obtained through the steps of raw ore grinding, lead fast roughing, lead slow roughing, lead scavenging, lead fast concentration, lead slow concentration, zinc fast roughing, zinc slow roughing, zinc scavenging, zinc fast concentration and zinc slow concentration. The lead-zinc-silver poly-metallic ores sorted by the ore dressing method provided by the invention are good in sorting index and high in separation efficiency; the ore dressing method is a lead-zinc-silver ore dressing method which is stable, efficient, strong in adaptive capacity, good in sorting effect, high in comprehensive recovery index and low in production cost and is suitable for popularization and application.

Owner:DONGSHENGMIAO MINING LLC +2

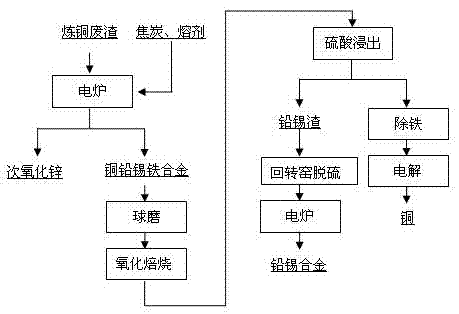

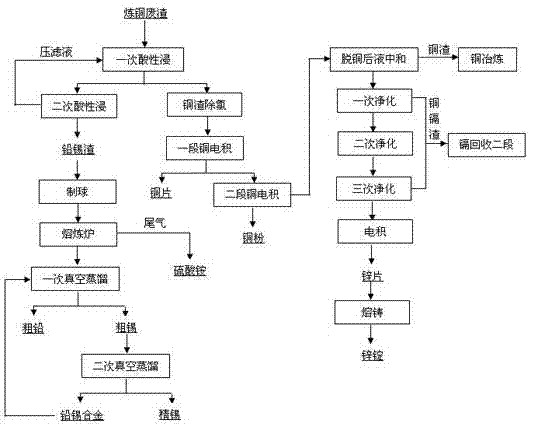

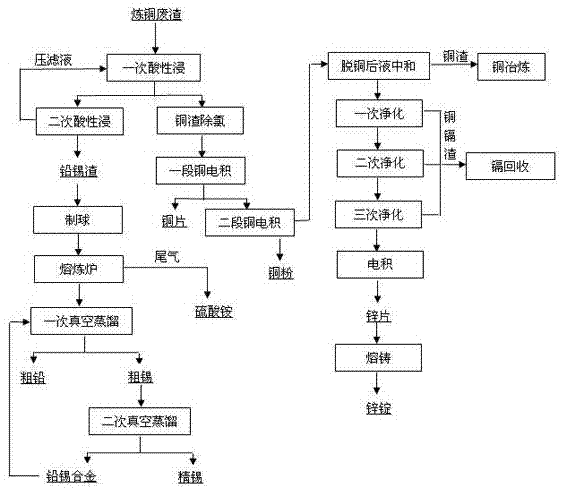

Metallurgical process for recovering metal copper, lead, zinc and tin from copper refining waste slag

ActiveCN102409180APhotography auxillary processesProcess efficiency improvementSulfate zincElectrolysis

The invention discloses a metallurgical process for recovering metal copper, lead, zinc and tin from copper refining waste slag, which uses waste liquid of zinc electrolysis with sulfuric acid or waste liquid of zinc electrolysis to perform the acid leaching; more than 95% of the zinc and copper are in the solution, the Fe 2+ in the solution is less than or equal to 1.5g / L; then the copper slag is used for removing chlorine; when the Cl- in the solution is less than or equal to 1.0g / L, the solution is sent to a copper electro-deposition; the electro-deposition decopperization can produce copper piece or copper powder; the decopperization neutralization is to add calcine or zinc oxide for neutralizing acid when the Cu2+ in the solution is less than or equal to 1.0g / L; lime is used for adjusting the pH value to 5.2-5.4; after purifying and removing residue of the zinc sulfate solution, the solution is sent to the zinc electro-deposition for producing zinc piece; the lean and tin pyrometallurgical purification is that, after more than 98% of lead and tin is sent to the acid leaching residue, the material of the acid leaching residue is balled and sent to a smelting furnace, so as to produce lead-tin alloy; the lead-tin alloy is directly sent to a vacuum fractionation furnace for purifying the lead and tin product; sulfur dioxide in the tail gas is absorbed by ammonia, so as to obtain ammonium sulphate product. The process is to extract copper and zinc joint wet process and to purify lead and tin by pyrometallurgical method; the process flow is effectively shortened, the metalrecovery rate and the resource utilization rate are both largely increased, and there is no secondary pollution in the process.

Owner:CHENZHOU FENGYUE ENVIRONMENTAL PROTECTION TECH

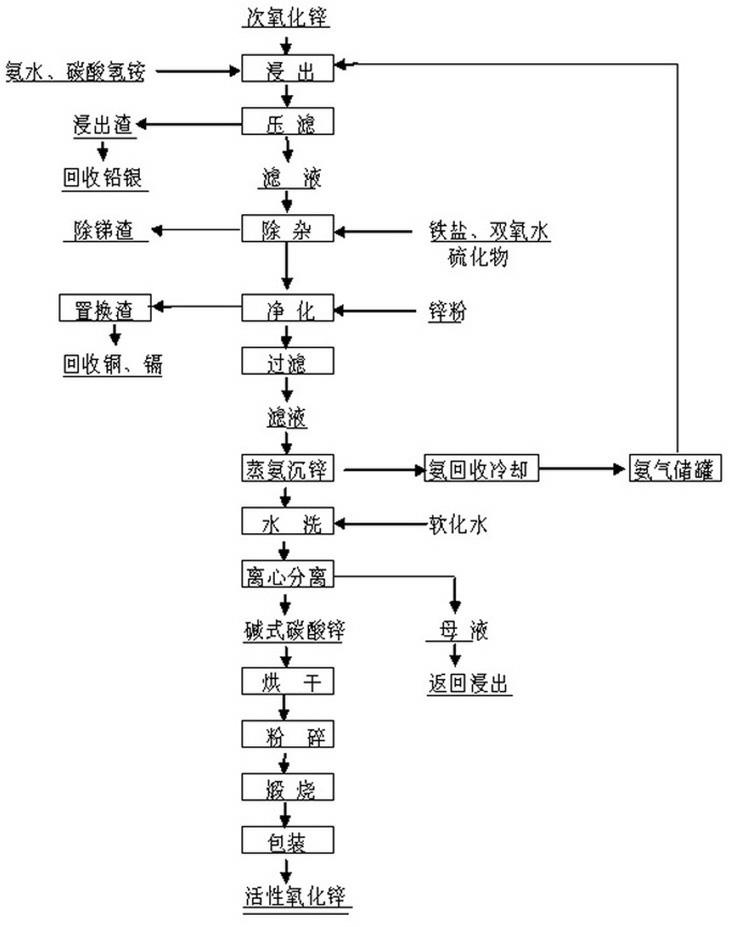

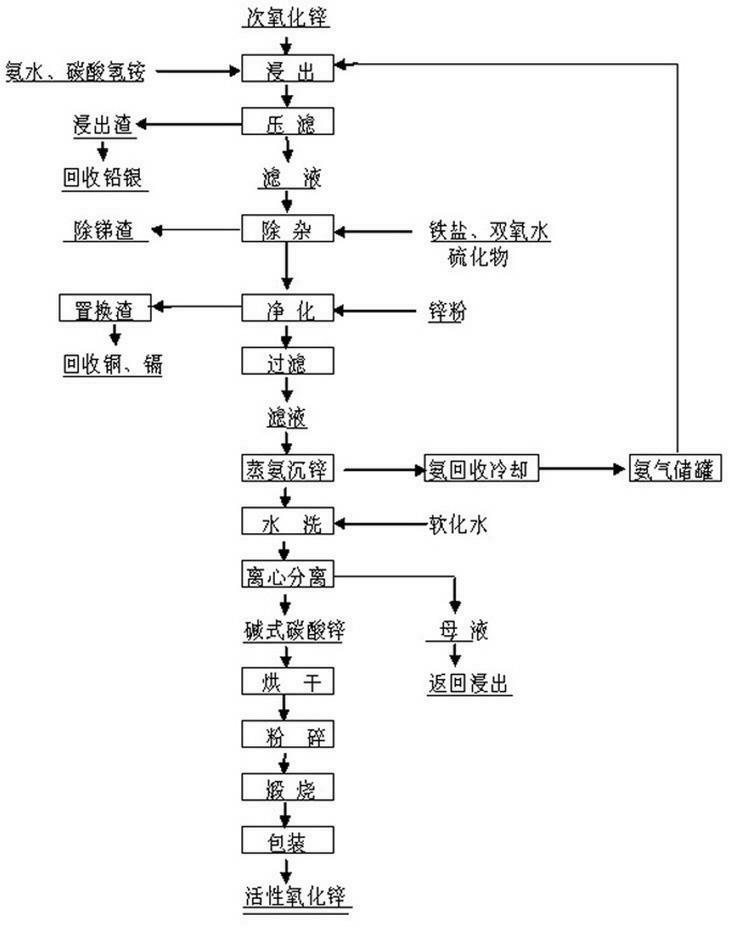

Method for preparing activated zinc oxide by utilizing high-arsenic secondary zinc oxide resource ammonia-ammonium process

The invention relates to a method for preparing activated zinc oxide by utilizing a high-arsenic secondary zinc oxide resource ammonia-ammonium process, which belongs to the field of inorganic chemical industry and secondary resource recovery. The method comprises the following technical processes in sequence as follows: leaching, purifying, ammonia distillation, washing, dry crushing, calcining and the like. According to the method for preparing the activated zinc oxide by utilizing the high-arsenic secondary zinc oxide resource ammonia-ammonium process, by taking high-arsenic-antimony secondary zinc oxide generated in a lead and zinc smelting process as a raw material, selective leaching is performed by adding ammonia water and ammonium bicarbonate; then, two-stage purification and deeppurification are performed by ferrous salt, hydrogen peroxide, sulfide and zinc powder; and the ammonia water is recycled and valued metal waste residues are comprehensively recovered. The method forpreparing the activated zinc oxide by utilizing the high-arsenic secondary zinc oxide resource ammonia-ammonium process has strong adaptability on zinc-contained materials and is capable of treating various complicated zinc-contained resources. The method for preparing the activated zinc oxide by utilizing the high-arsenic secondary zinc oxide resource ammonia-ammonium process has the advantages of short flow, production process closed cycle, convenience in operation, low energy consumption, excellent product quality, high economic benefits, low pollution, high comprehensive recovery capacityand the like, and is suitable for industrial production and popularization.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

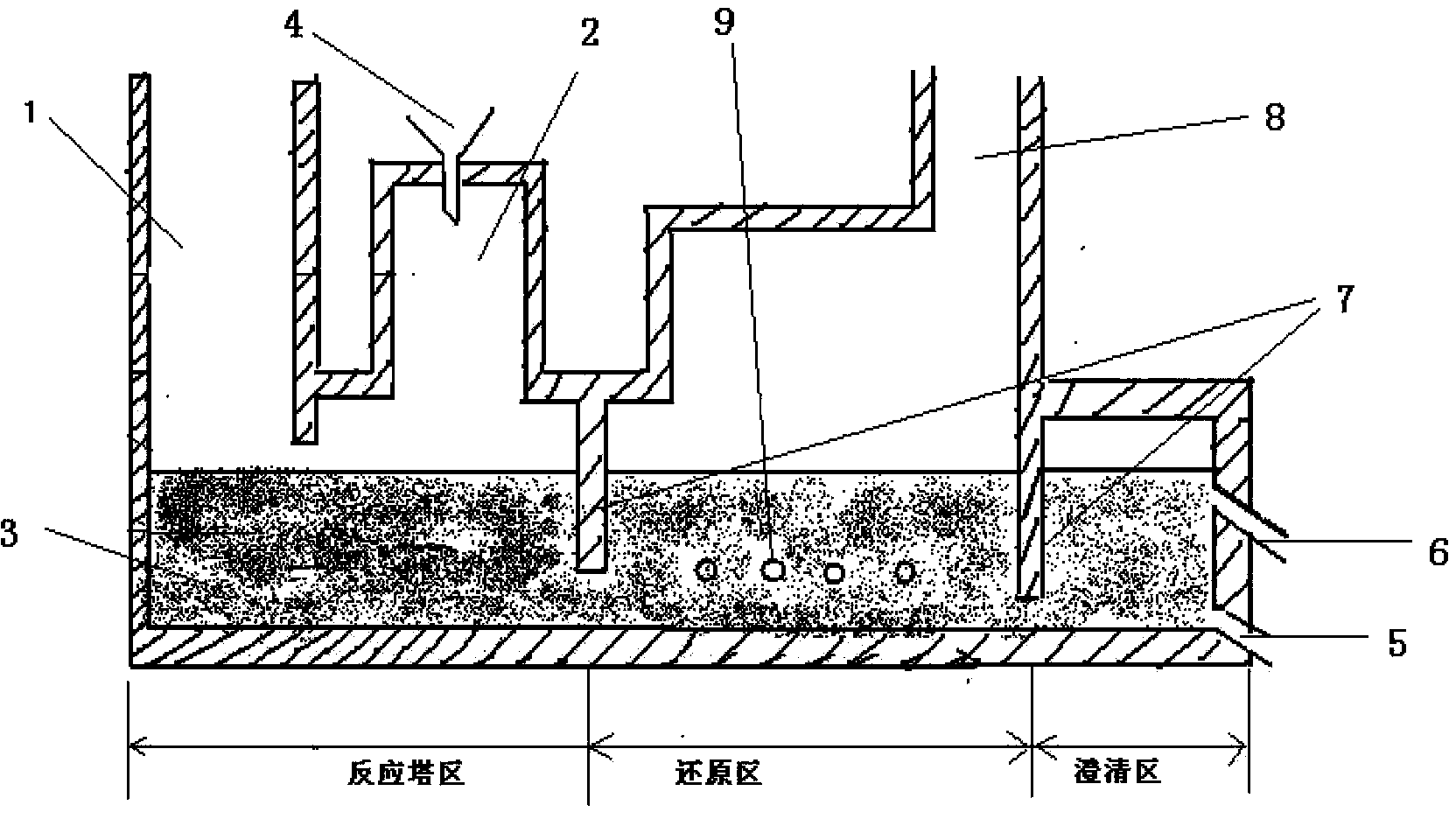

Flash smelting method and device for zinc sulfide concentrates and materials containing lead and zinc

InactiveCN103382527AMeet the requirements of smeltingTo meet the heat required for reductionEnvironmental resistanceResource utilization

The invention discloses a flash smelting method and a device for zinc sulfide concentrates and materials containing lead and zinc. The flash smelting method for the zinc sulfide concentrates and the materials containing the lead and the zinc comprises mixing the dry powder materials containing lead and zinc in proportion and spraying the mixed materials and oxygen into a smelting device from the top of a reaction tower; the smelting device is formed by three portions namely a reaction tower area, a reducing area and a clarification area which are provided with communicated bottoms; materials containing zinc achieve a oxidation sweetening reaction in the air above the reaction tower to generate into high zinc slag melt with an appropriate melting point of minus 1200 DEG C and fall into the reaction tower area; the liquid form high zinc slag melt enters into the reducing area; zinc in the high zinc slag melt is performed reduction to generate zinc steam to be collected; lead is performed reduction to be metallic lead; precious metal such as golden, silver and the like of raw materials are gathered to be precipitated at the bottom of a melt pond and discharged through a lead discharging opening. Slags which are performed reduction are discharged through a slag discharging opening, fuming processing is abandoned or further performed according to the content of the lead and the zinc. The flash smelting method and the device for the zinc sulfide concentrates and the materials containing the lead and the zinc have the advantages of being short in process, strong in material adaptability, low in energy consumption, environmentally friendly, high in resource utilization efficiency, significant for technology progress of a lead and zinc smelting industry and the like.

Owner:CENT SOUTH UNIV

Method for extracting metal indium from waste residues generated from lead and zinc smelting

InactiveCN101660054AHigh recovery rateHigh purityPhotography auxillary processesProcess efficiency improvementIndiumWastewater

The invention provides a method for extracting metal indium from waste residues generated from lead and zinc smelting. The method is implemented by the following steps: carrying out low-temperature and low-acid leaching on the waste residues generated from the lead and zinc smelting, and removing acid-soluble metals from the waste residues; then carrying out high-temperature and high-acid leachingto obtain indium; and obtaining the metal indium after extraction, re-extraction, reduction and refining. The method has relatively short process flow and low production cost, generates a great amount of byproducts, can comprehensively recover and recycle waste water and the waste residues, is not only good for environmental protection, but also realizes cyclic and comprehensive resource use. Thetotal recovery rate of the metal indium is 70-80%, and the recovery rate of high-purity metal indium is up to 99.995%.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com