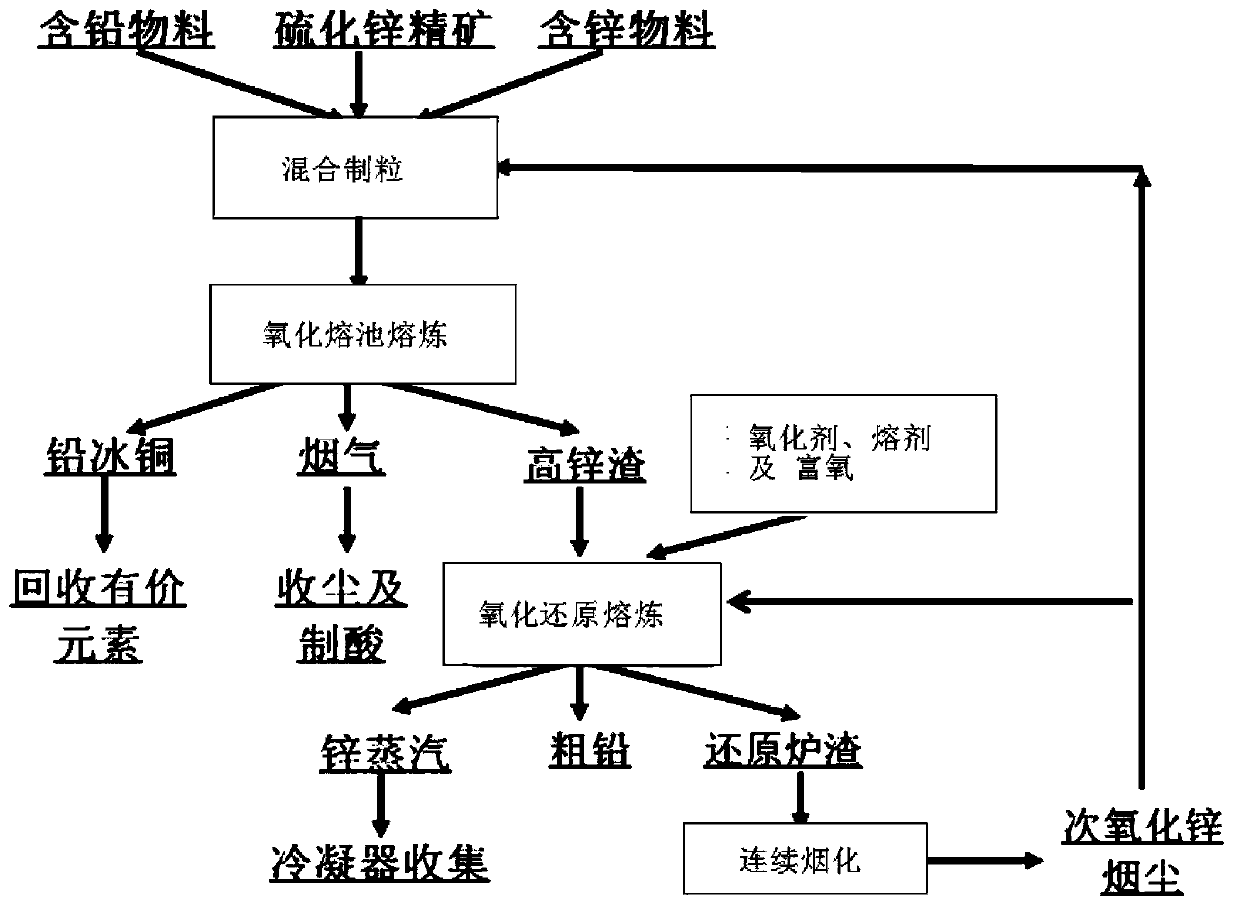

Bath smelting method and apparatus of zinc sulfide concentrate and lead-zinc containing materials

A zinc sulfide concentrate and melting pool smelting technology, applied in the field of non-ferrous metal smelting, can solve the problems of waste water and waste residue pollution, long process flow, poor comprehensive recovery, etc., achieve effective recovery, solve long-term pollution, and achieve good results in comprehensive recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

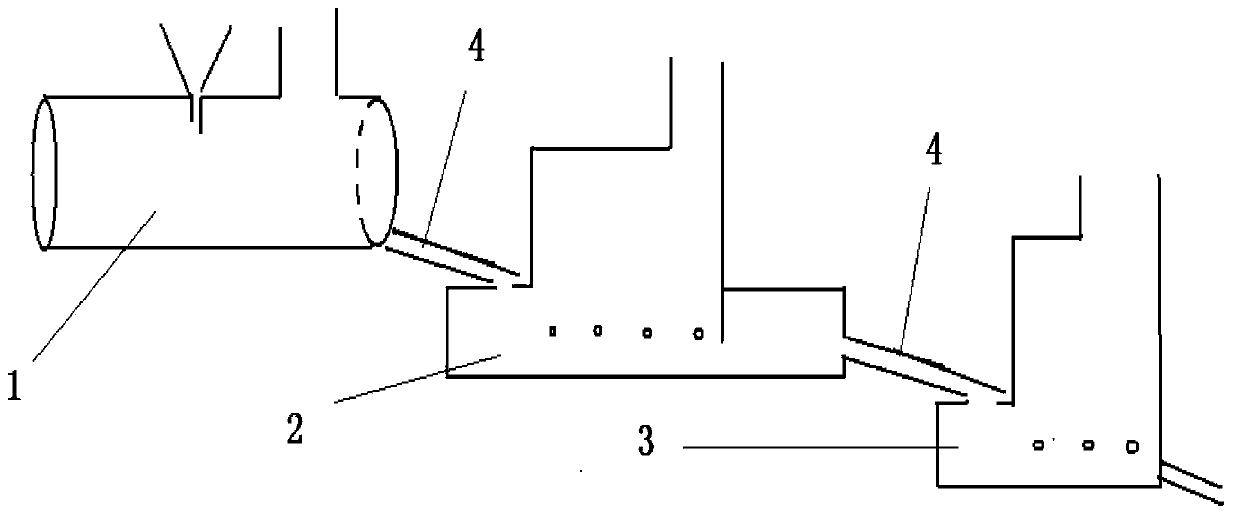

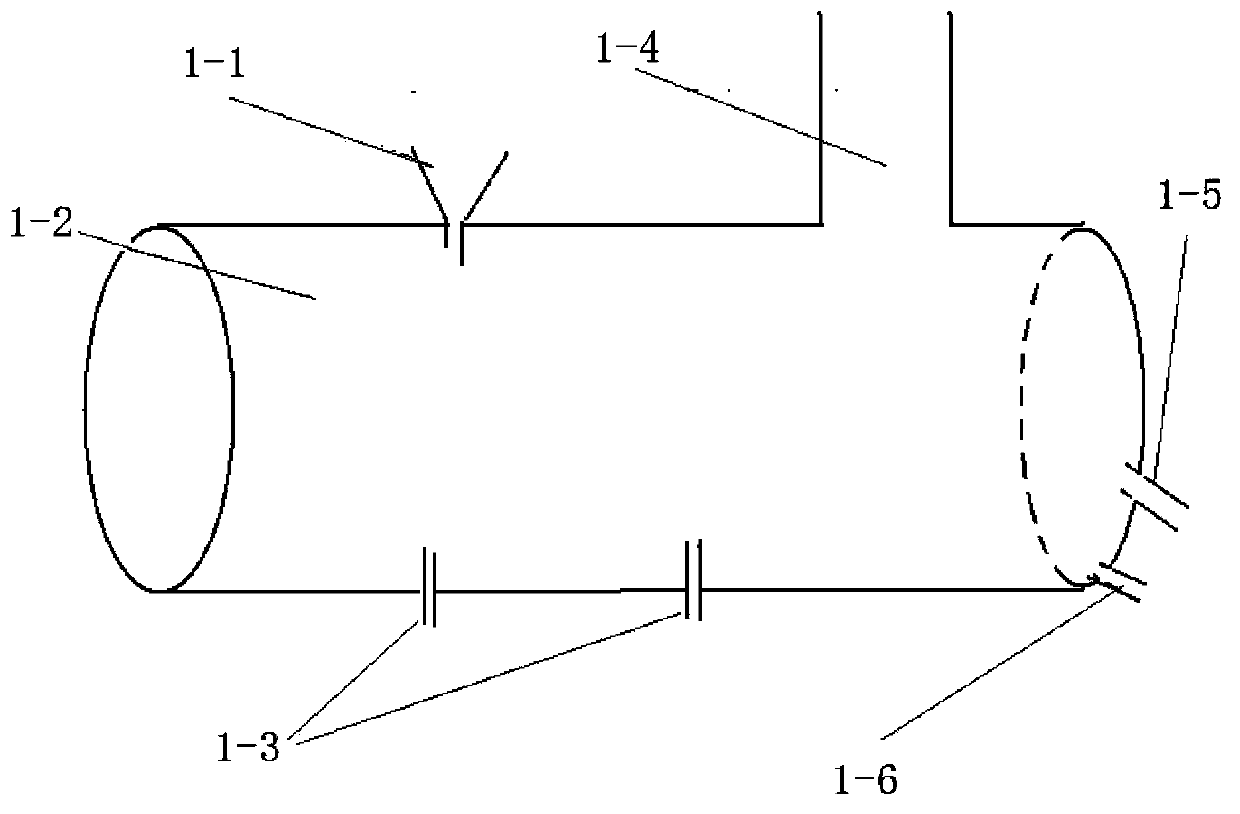

[0056] See attached figure 1 , 2 , 3, a molten pool smelting equipment for lead-zinc-containing materials, comprising an oxidation furnace 1 and a reduction furnace 2, the outlet of the oxidation furnace 1 is connected to the inlet of the reduction furnace 2 through a launder 4, and the outlet of the reduction furnace 2 It is connected to the fuming furnace 3 through the launder 4; the oxidation furnace 1 includes a furnace body 1-2 and a spray gun 1-3, and the furnace body 1-2 is a hollow cylinder, and the furnace body 1-2 is provided with a charging Port 1-1, flue gas outlet 1-4, lead-containing high-zinc slag discharge port 1-5, matte copper discharge port 1-6, spray gun socket, the spray gun 1-3 is inserted into the spray gun socket, and the rich Oxygen gas is blown into the furnace cavity; the reduction furnace 2 includes a furnace body, the furnace body is made of refractory materials, a rectangular furnace cavity is arranged in the furnace body, and a zinc vapor commun...

Embodiment 2

[0060] A molten pool smelting method for zinc sulfide concentrate and materials containing lead and zinc, comprising the following steps:

[0061] Step 1: Ingredients

[0062] The mass percentage of the composition composition is: Zn27.74%, lead 15.46%, Fe12.68%, S20.31%, SiO 2 7.32%, CaO2.46%, H 2 O ≤ 8%, the mass percent sum of each component is 100% lead-zinc-containing material, made into pellets with a particle size of 5-40mm;

[0063] A lead-containing high-zinc slag molten pool placed in an oxidation furnace, the temperature of the lead-containing high-zinc slag molten pool is 1250°C-1300°C; oxygen-enriched air (pressure 5 atmospheres, oxygen volume concentration 100%) is introduced, Oxidation reaction occurs in the granulated material, producing a high concentration of SO with a concentration of 21% by volume 2 Flue gas, lead-containing high-zinc slag and lead matte, high concentration SO 2 The flue gas is sent to make acid, the lead matte is released intermittentl...

Embodiment 3

[0068] The mass percentage of the preparation is: Zn24.14, lead 10.29, Fe27.81, S20, SiO 2 7.19, CaO0.86, H 2 O≤5% lead-zinc-containing materials, mixed and granulated to obtain 2000g of granulated material;

[0069] The lead-zinc material has a mass of 950.66g and a chemical composition (%): Zn50.00, Pb0.75, Cu0.085, Fe13.30, S30.65, SiO 2 2.30, Cd0.36, As0.029, In0.011 high-iron zinc sulfide concentrate; mass 230.79g, composition (%): S46.18, Fe30.16, Au42.42g / t, As0.28, SiO 2 6.90, CaO0.31 gold-bearing pyrite concentrate; and a mass of 818.56g, the composition (%) is: Pb24.26, Zn0.92, Fe42.18, S0.25, SiO 2 12.96,CaO2.00 ferric lead oxide ore composition.

[0070] First, put 1000g of mass percentage composition (%) into the molten pool smelting equipment containing lead and zinc materials: Zn28.45, Pb12.12, Fe31.91, S1.00, SiO 2 8.48, lead-containing high-zinc slag with CaO1.00, in a sealed state, heat up to 1250°C to melt it to form a superheated molten pool; use O 2 O...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com