Hot rolled strip steel head production line and production process thereof

A hot-rolled strip and production line technology, which is applied in the direction of manufacturing tools, presses, presses using rotating pressure members, etc., can solve the problem that ordinary cutting machines cannot complete continuous cutting, it is inconvenient to replace and repair the purification machine, and it cannot meet the ideal use requirements and other problems, to achieve the effects of good hammering effect, convenient maintenance and compact layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

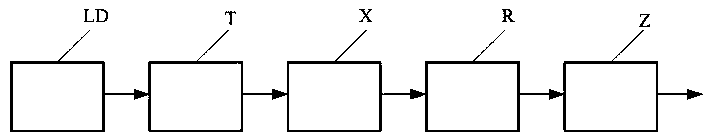

[0071] In this example, refer to the attached figure 1 , the hot-rolled strip head production line includes an upper hopper, a purifier, a sorter, a preheating furnace, a forming mill and a conveyor belt for finished products.

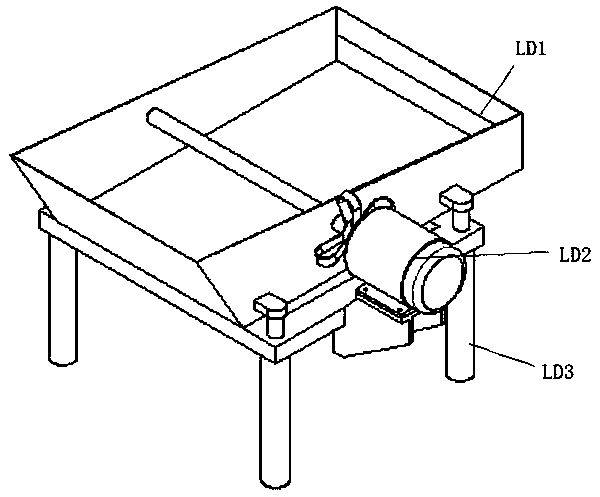

[0072] Refer to attached figure 2 , The upper hopper adopts a dustpan inclined hopper, the weight of the bucket is 5 tons to 15 tons, the angle of the bottom of the hopper LD1 is 3 degrees to 12 degrees, and the bottom of the hopper is equipped with a frequency conversion vibrator LD2.

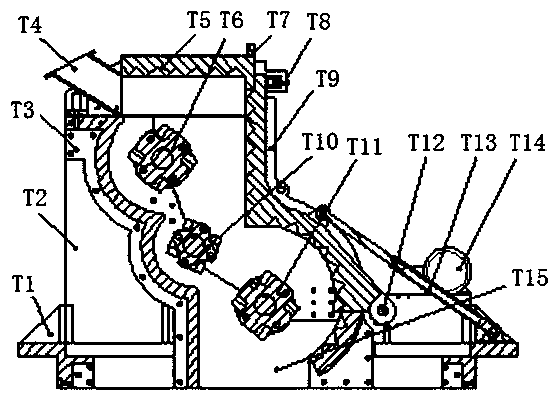

[0073] attached image 3 -8 is a schematic diagram of the specific structure of the purifier.

[0074] Refer to attached Figure 5 , The connection plate in the upper roller T6 is a cross shape matched with the ring hammer T64, which can increase the swing angle of the ring hammer T64 and improve the striking force. The connecting discs include end connecting discs T67 fixed at both ends of the upper roller shaft T62 and a plurality of intermediate connecting disc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com