A method for separating and recovering chromium from vanadium-chromium waste slag

A technology for separation and recovery and waste residue, which is applied in the direction of improving process efficiency, can solve the problems of complex process and low added value, and achieve the effect of simple process, cost saving and high quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

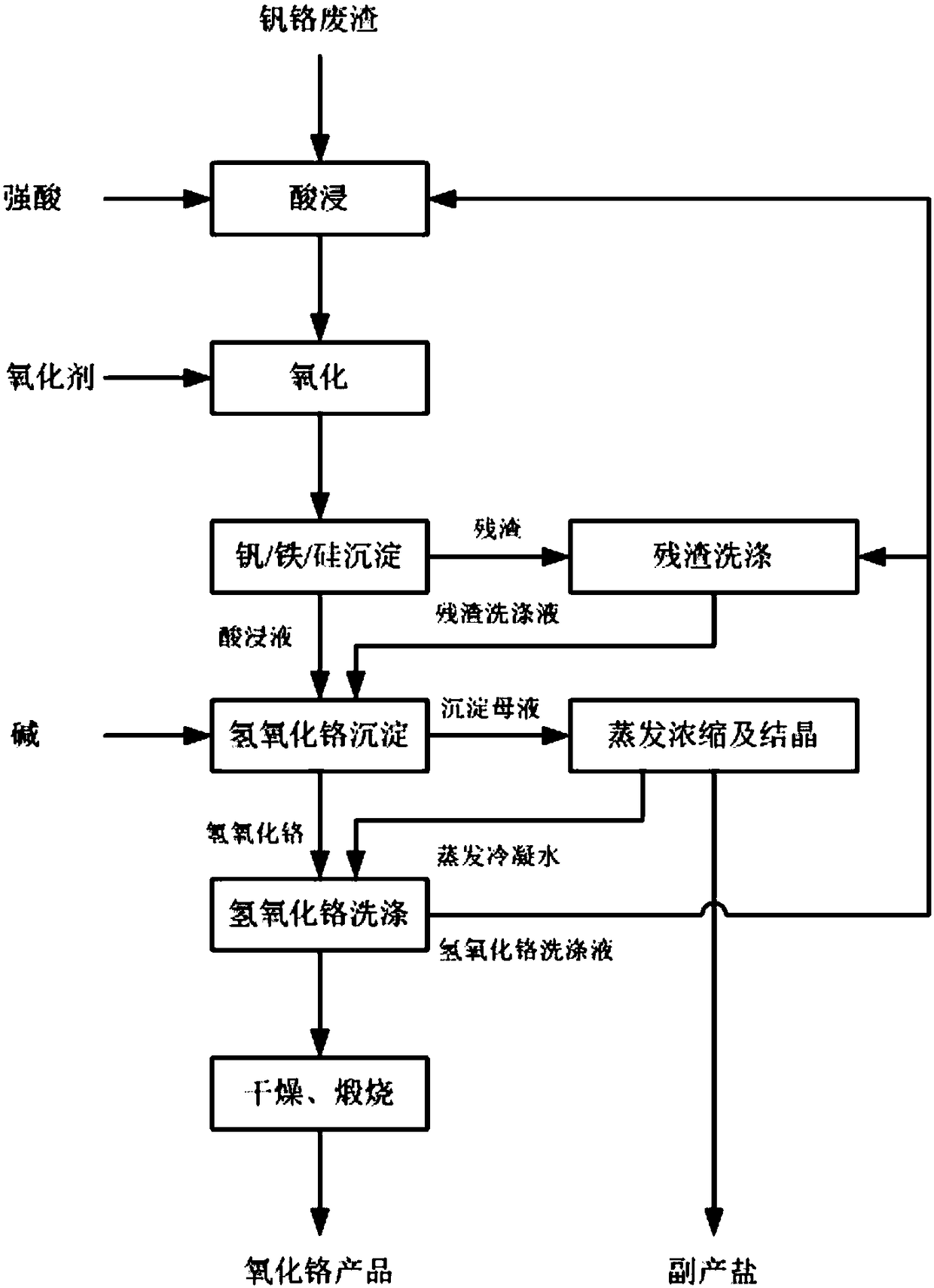

[0060] The present embodiment provides a method for separating and recovering chromium from vanadium-chromium waste slag, said method comprising the following steps:

[0061] (1) Vanadium-chromium waste residue, chromium hydroxide washing solution and sulfuric acid are placed in an acid leaching reactor for acid leaching, the leaching temperature is 70° C., and the pH of the solution after leaching is 0.5;

[0062] (2) After the leaching reaction in step (1) is completed, hydrogen peroxide is added to the reaction system, the tetravalent vanadium is oxidized to pentavalent vanadium, and the ferrous iron is oxidized to ferric iron;

[0063] (3) The material after the oxidation reaction in step (2) is sent into a high-temperature reactor to carry out synchronous precipitation and separation of vanadium, iron and silicon at 90° C., then filter and separate to obtain residue and pickling solution, and the residue obtained is treated with chromium hydroxide The washing liquid is us...

Embodiment 2

[0067] The present embodiment provides a method for separating and recovering chromium from vanadium-chromium waste slag, said method comprising the following steps:

[0068] (1) Vanadium-chromium waste residue, chromium hydroxide washing solution and sulfuric acid are placed in an acid leaching reactor for acid leaching, the leaching temperature is 70° C., and the pH of the solution after leaching is 0.5;

[0069] (2) After the leaching reaction in step (1) is completed, sodium hypochlorite is added to the reaction system, the tetravalent vanadium is oxidized to pentavalent vanadium, and the ferrous iron is oxidized to ferric iron;

[0070] (3) The material after the oxidation reaction in step (2) is sent into a high-temperature reactor to carry out synchronous precipitation and separation of vanadium, iron and silicon at 120° C., then filter and separate to obtain residue and pickling solution, and the residue obtained is treated with chromium hydroxide The washing liquid is...

Embodiment 3

[0074] The present embodiment provides a method for separating and recovering chromium from vanadium-chromium waste slag, said method comprising the following steps:

[0075] (1) Vanadium-chromium waste residue, chromium hydroxide washing solution and hydrochloric acid are placed in an acid leaching reactor for acid leaching, the leaching temperature is 70° C., and the pH of the solution after leaching is 0.5;

[0076] (2) After the leaching reaction in the step (1) is completed, sodium chlorate is added to the reaction system, the tetravalent vanadium is oxidized to pentavalent vanadium, and the ferrous iron is oxidized to ferric iron;

[0077] (3) The material after the oxidation reaction in step (2) is sent into a high-temperature reactor to carry out synchronous precipitation and separation of vanadium, iron and silicon at 140° C., then filter and separate to obtain residue and pickling solution, and the residue obtained is treated with chromium hydroxide The washing liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com