Patents

Literature

689 results about "CHROMIC OXIDE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of chromic oxide. : an oxide Cr2O3 obtained as a green powder by thermal decomposition of most chromium compounds or by reduction of sodium dichromate or sodium chromate and used as the very permanent pigment chrome oxide green, as a coloring agent for glass and ceramic ware, and as a catalyst — compare chromic hydroxide.

Nanometer grade low carbon paraffin dehydrogen catalyst

InactiveCN1911502ALarge specific surface areaHigh catalytic activityMetal/metal-oxides/metal-hydroxide catalystsAlkaneCarbon nanotube

The present invention relates to one kind of nanometer level low carbon alkane dehydrogenating catalyst, and features that the C3-C5 low carbon alkane dehydrogenating catalyst comprises carrier of single wall or multiple wall carbon nanotube and two active components selected from chromic oxide in 2-30 wt%, alumina in 2-25 weight and nickel oxide in 2-30 wt%. The catalyst has high catalysis activity, increased active structures, long service life, low catalytic dehydrogenation reaction temperature, high conversion rate, high selectivity and other advantages.

Owner:DAQING PETROLEUM ADMINISTRATION

Process for the Preparation of 1,3,3,3-Tetrafluoropropene and/or 1,1,3,3,3-Pentafluoropropene

InactiveUS20090043138A1Preparation by dehalogenationPreparation by hydrogen halide split-offHydrogen fluoridePtru catalyst

A process for the manufacture of CF3CH═CHF and / or CF3CH═CF2 is disclosed. The process involves involves (a) reacting HF and at least one halopropene of the formula CX3CCI═CCIX (where each X is independently F or CI) to produce a product including both CF3CCI═CF2 and CF3CHCICF3; (b) reacting CF3CCI═CF2 and / or CF3CHCICF3 produced in (a) with hydrogen to produce a product including CF3CH2CHF2 and / or CF3CH2CF3; (c) dehydrofluorinating CF3CH2CHF2 and / or CF3CH2CF3 produced in (b) to produce a product comprising CF3CH═CHF and / or CF3CH═CF2; and (d) recovering CF3CH═CHF and / or CF3CH═CF2 from the product produced in (c). In (a), the CF3CCI═CF2 and CF3CHCICF3 are produced in the presence of a fluorination catalyst comprising at least one chromium-containing component selected from (i) a crystalline alpha-chromium oxide where at least 0.05 atom % of the chromium atoms in the alpha-chromium oxide lattice are replaced by divalent copper, and (ii) a chromium-containing composition of (i) which has been treated with a fluorinating agent.

Owner:EI DU PONT DE NEMOURS & CO

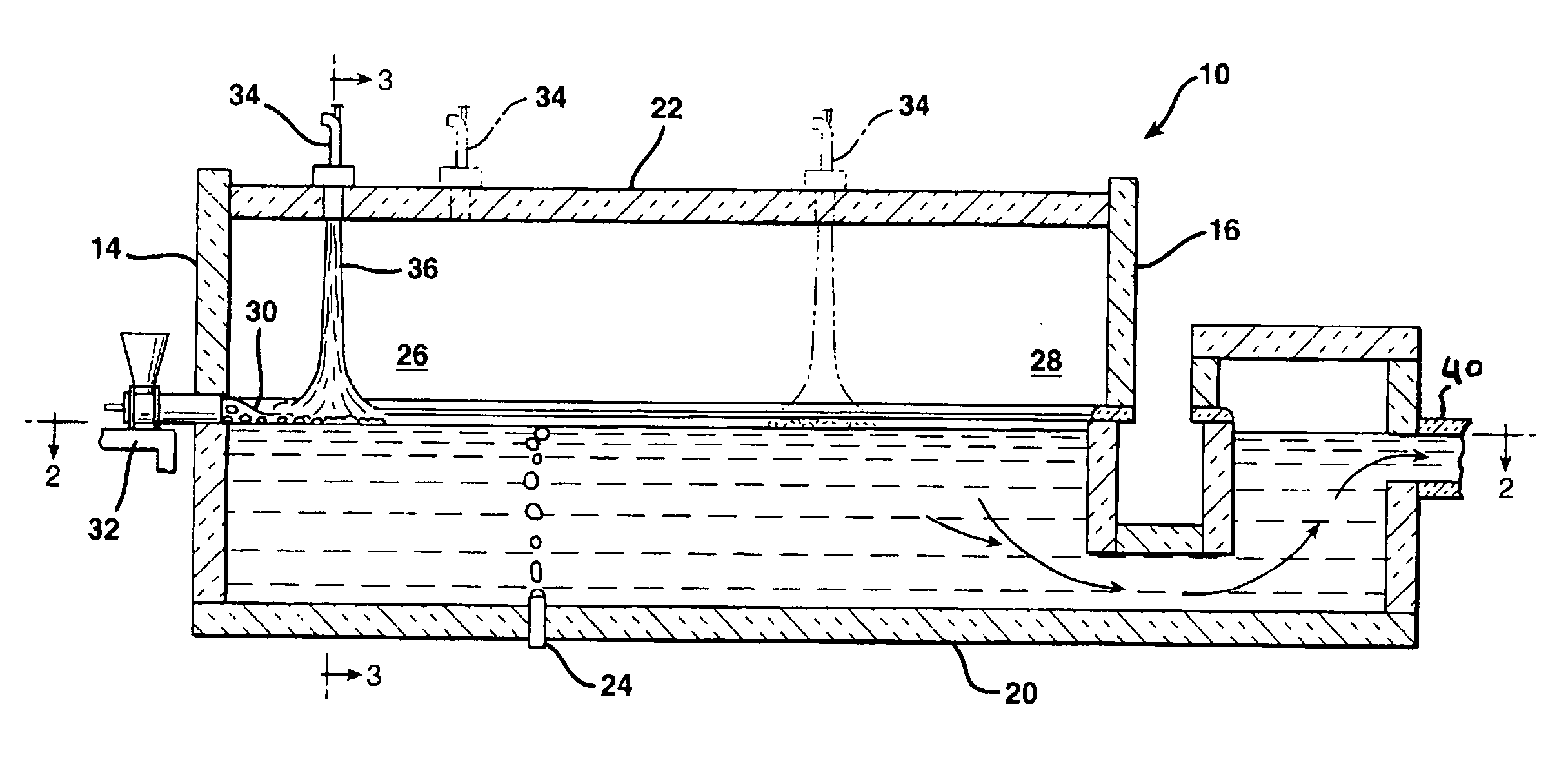

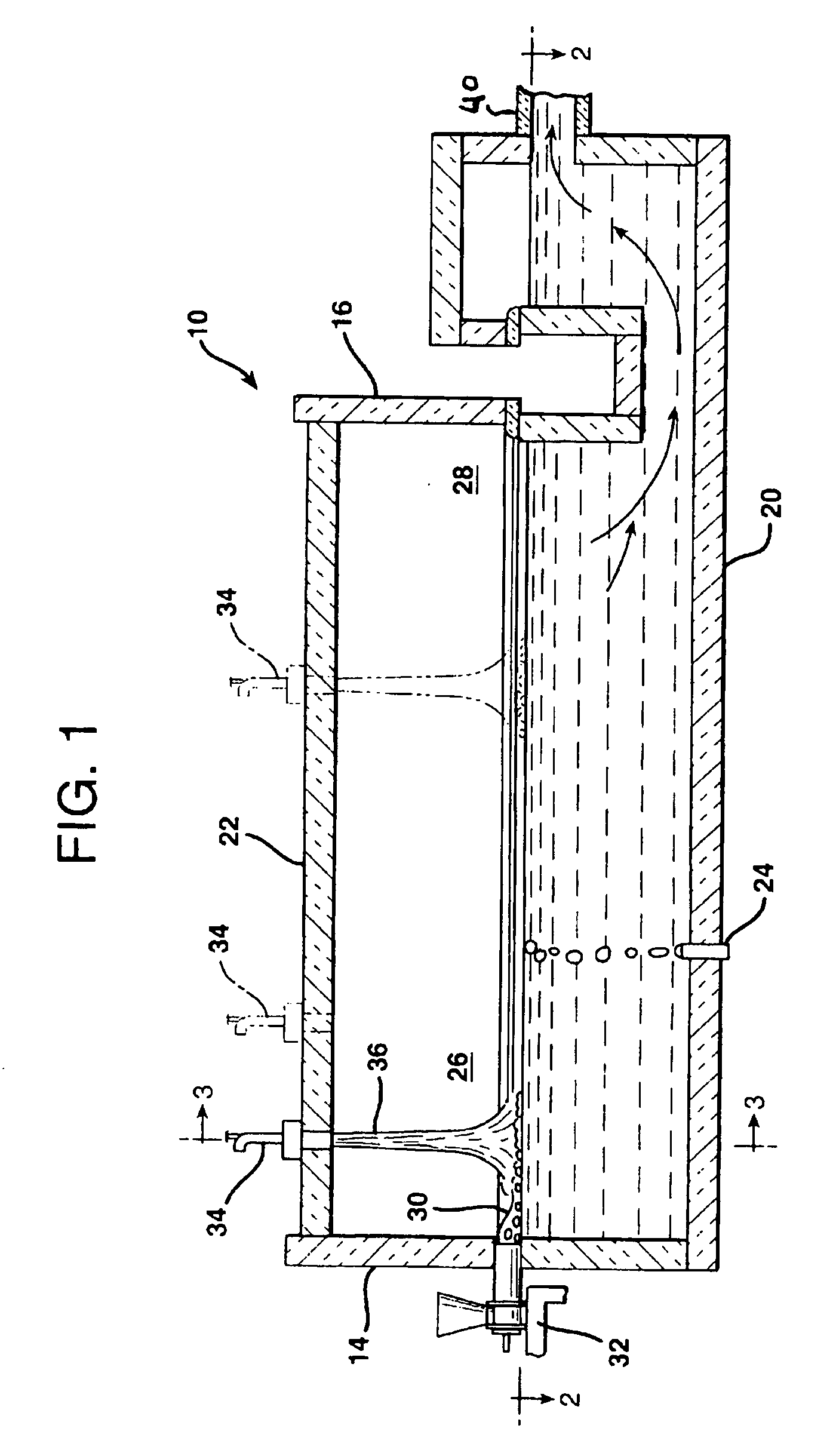

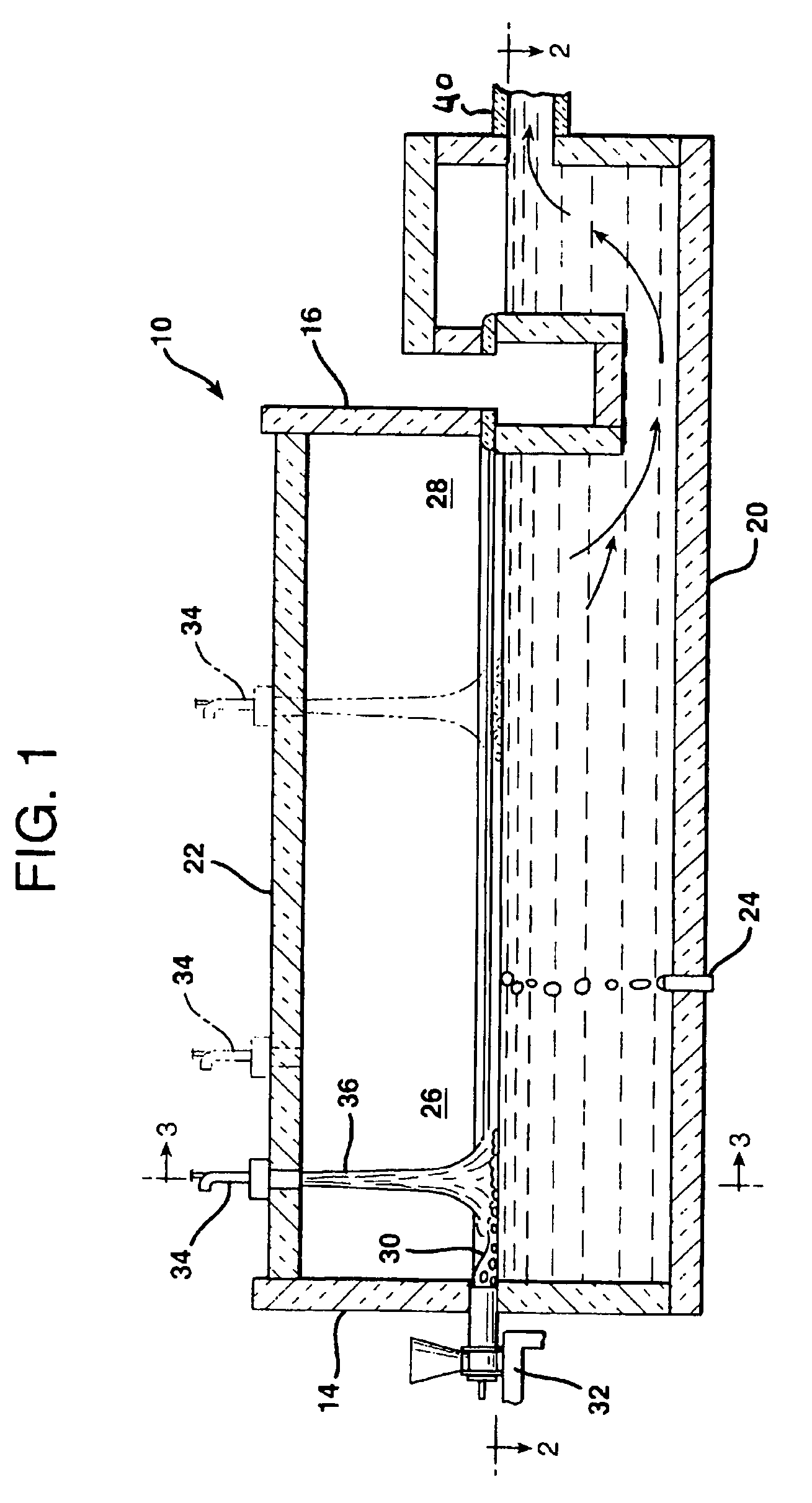

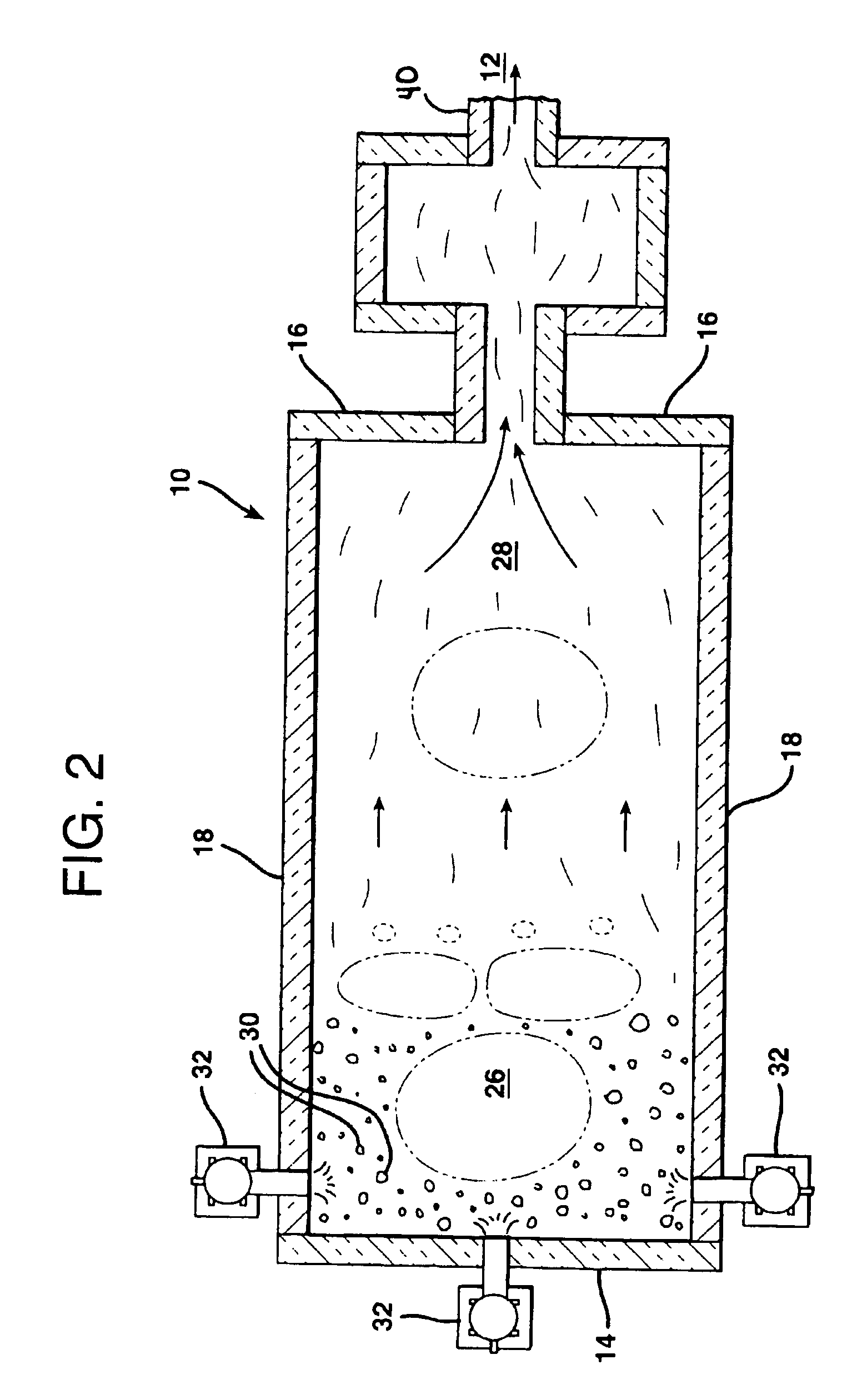

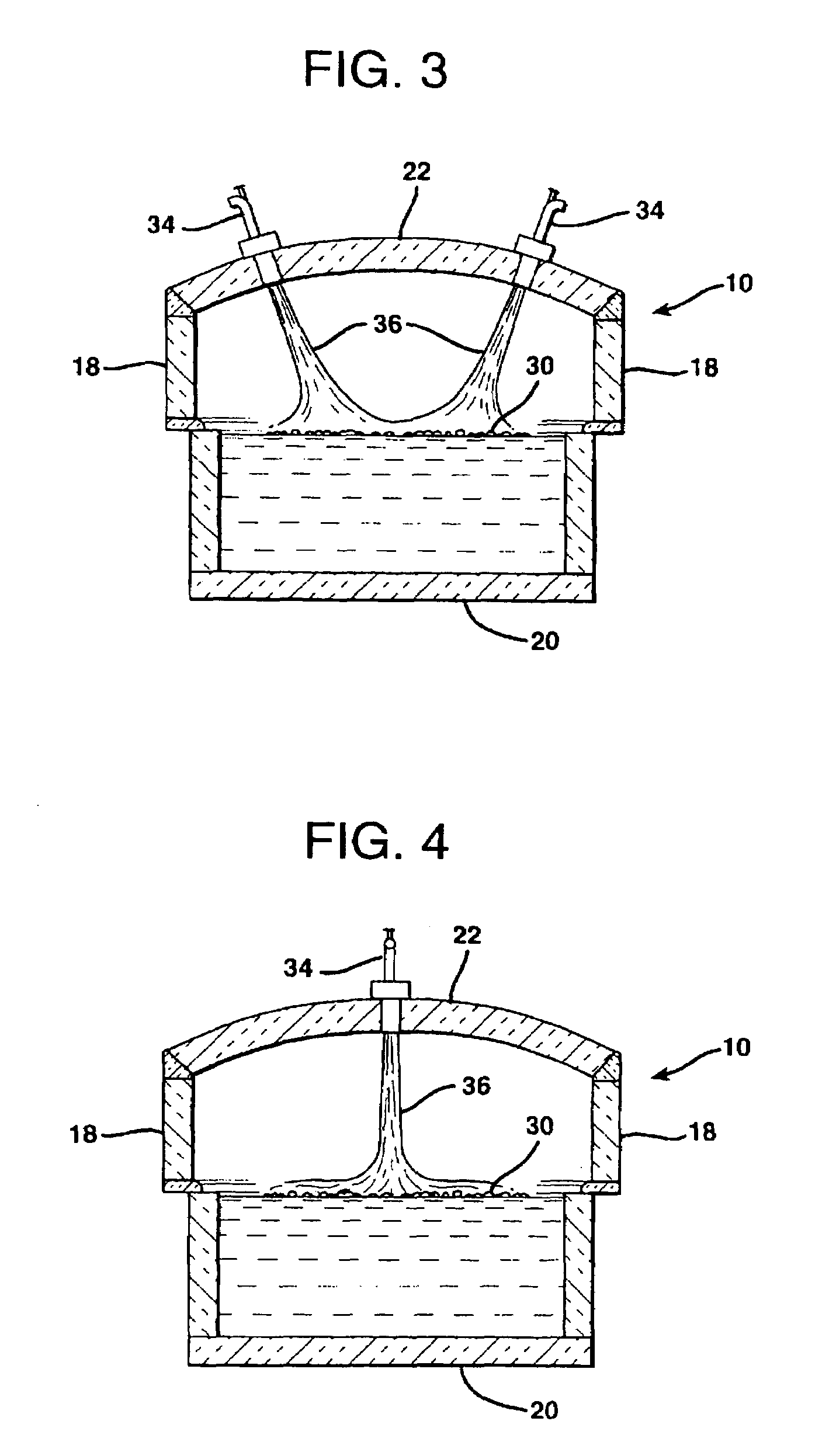

Method of manufacturing high performance glass fibers in a refractory lined melter and fiber formed thereby

ActiveUS20070105701A1Inexpensively formed into glass fiberUse in some applicationCharging furnaceGlass furnace apparatusFiberAlkali metal oxide

A method of forming high strength glass fibers in a refractory lined glass melter is disclosed. The refractory fined melter is suited to the batch compositions disclosed for the formation high modulus, and high-strength glass fibers. The glass composition for use in the method of the present invention is up to about 70.5 Weight % SiO2, 24.5 weight % Al2O3, 22 weight % alkaline earth oxides and may include small amounts of alkali metal oxides and ZrO2. Oxide based refractories included alumina, chromic oxide, silica, alumina-silica, zircon, zirconia-alumina-silica and combinations thereof. By using oxide based refractory lined furnaces the cost of production of glass fibers is substantially reduced in comparison with the cost of fibers using a platinum lined melting furnace. Fibers formed by the present invention are also disclosed.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

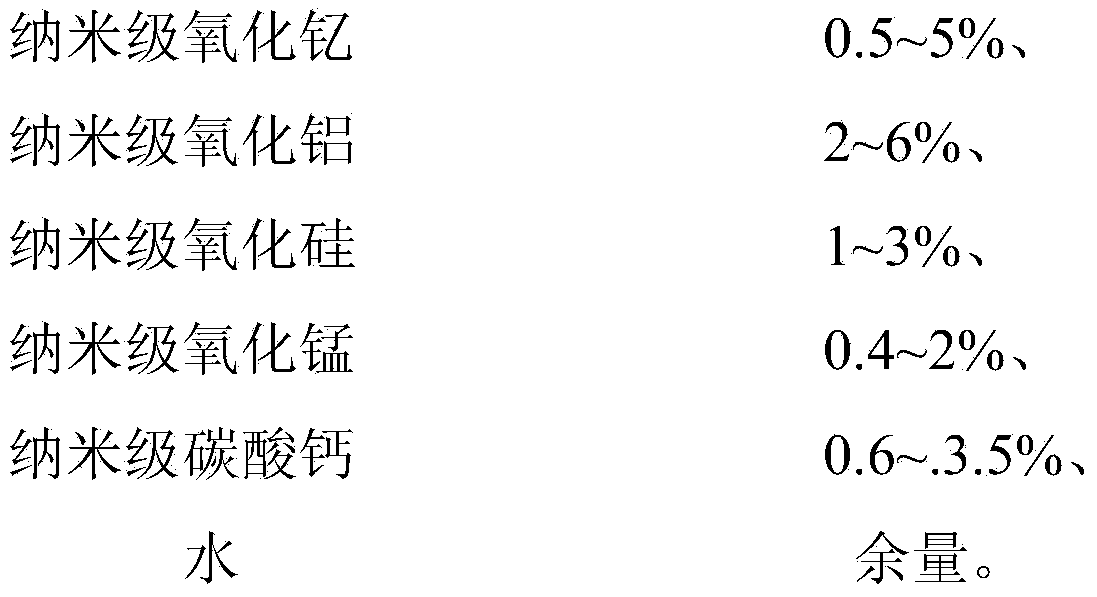

Grinding fluid for processing LED (light-emitting diode) substrate and preparation method thereof

InactiveCN102337084AReduce surface roughnessReduce surface scratchesPolishing compositions with abrasivesSemiconductor devicesSolventSilicon dioxide

The invention relates to a grinding fluid for processing an LED (light-emitting diode) substrate. The grinding fluid comprises a solvent, an additive and a grinding agent, wherein the grinding agent consists of diamond micropowder and non-diamond nano polishing material; the purity of the diamond micropowder is more than 99%, and the particle size of the diamond micropowder is W0.5-W20; and the non-diamond nano polishing material is any one or a mixture of any of alumina, silicon dioxide, cerium oxide and chromic oxide, the particle size of the non-diamond nano polishing material is 10-100nm, and the purity of the non-diamond nano polishing material is more than 99%. According to the invention, micron diamond is used as a grinding material while the non-diamond nano polishing material is also compositely added, thereby ensuring the grinding rate and well guaranteeing the processing quality of the surface of a workpiece.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD +1

Method of preparing chromium oxide powder using water heat reducing chromate

InactiveCN100999335AControl particle size distributionGood dispersionChromium trioxideSlurrySurface-active agents

This invention relates to a preparation method that prepares chromic oxide powder by using water heat to deoxidize chromate. Use chromate water solution as raw material, CO2 as acidifying agent, process by surface active agent, directly deoxidize at condition of heat water, get hydrated Cr2O3 slurry, centrifugalize, separate, dry, calcinate hydrated Cr2O3 at different temperature, prepare globular Cr2O3 micropowder. Its grade size is between submicron and nanometer. This invention utilizes surface active agent to control sexavalent chromic salt which can be directly deoxidized to get trivalence chrome crystal. It can control hydrated chromic oxide calcinating temperature to prepare globular Cr2O3 micropowder of which grade size can be controlled.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing lithium ion battery anode material doped with nanometer oxide

InactiveCN101719546AInitial reversible capacity improvement and enhancementIncreased initial reversible capacityCell electrodesCapacitanceLithium iron phosphate

The invention relates to a method for preparing a lithium ion battery anode material doped with a nanometer oxide, belonging to the technical field of manufacturing processes of lithium ion battery batteries. The method is characterized in that trace amount of nanometer oxide power is doped in the preparation process of lithium manganate, lithium cobaltoxide and lithium iron phosphate; the doping amount is 0.5-1.0 mol percent of lithium salts; and the nanometer oxide is selected from one or two of alumina, magnesia, titanium oxide, chromic oxide, nickel oxide, monox and zirconia and the nanometer oxide is subject to ball milling, drying, sieving, calcinating, crushing, grading and other processes to obtain the nanometer oxide doped or coated lithium ion battery anode material. The lithium ion battery anode material has reversible initial capacitance, and remarkably-improved attenuation property, charging-discharging properties, high-temperature circulating property and electrochemistry stability.

Owner:SHANGHAI UNIV

Black zirconia ceramic and preparation method thereof

The invention discloses black zirconia ceramic material composition which comprises the following components in percentage by mass: 0-5% of ferric oxide, 0-5% of cobaltous oxide, 0-5% of chromic oxide, 0-5% of aluminum oxide, 0-5% of nickel oxide, 0-5% of manganese oxide, 0-5% of zinc oxide, 2-6% of yttrium oxide, 0-5% of titanium oxide, 0-5% of silicon dioxide, 0-5% of cerium oxide and the balance of zirconium oxide containing hafnium oxide. The black zirconia ceramic material composition disclosed by the invention is small in powder granularity and uniform in distribution, and black zirconia ceramic containing the black zirconia ceramic material composition is relatively good in covering power, high in blackness and relatively low in transmittance of light. Meanwhile the invention further discloses black zirconia ceramic prepared from the black zirconia ceramic material composition and a preparation method of the black zirconia ceramic.

Owner:CHAOZHOU THREE CIRCLE GRP

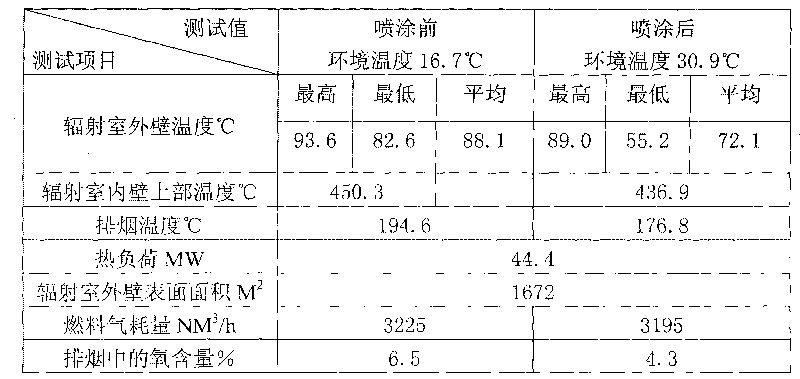

High-emissivity infrared energy-saving radiation paint and preparation method thereof

The invention discloses high-emissivity infrared energy-saving radiation paint which is prepared by a raw mixture, and the average particle size of the paint is less than 2 nanometers. The raw mixture comprises the following components in parts by weight: 100-250 parts of main body ingredient, 6-15 parts of agglutinant and 360-600 parts of binding agent, wherein the main body ingredient comprises the following components in parts by weight: 10-15 parts of yttrium oxide, 15-25 parts of chromic oxide, 4-8 parts of cobaltous oxide, 20-36 parts of zirconium oxide, 8-20 parts of manganese oxide, 30-50 parts of silicon carbide, 5-16 parts of titanium oxide, 10-28 parts of aluminum oxide and 10-25 parts of iron powder. Experiments prove that the high-emissivity infrared energy-saving radiation paint is higher in emissivity, good in fire resistance, high in viscosity, energy-saving and long in service life.

Owner:北京恩吉赛威节能科技有限公司

Preparation method of furnace transmutation sorghum red-flower glaze

The invention relates to the technical field of ceramic glaze and particularly relates to a preparation method of furnace transmutation sorghum red-flower glaze. A ground coat is prepared from feldspar, quartz, Soochow soil, calcite, glass dust, dolomite, chromic oxide, cobaltous oxide, ferric oxide and vanadium pentoxide; overglaze is prepared from feldspar, quartz, zinc oxide, Soochow soil, boron frits, cadmium-selenium haematochrome, silicon carbide and copper oxide. The preparation method comprises the following steps: firstly applying the ground coat on a green body after biscuiting; then applying the overglaze; and firing by adopting oxidizing flames of a roller kiln. By adopting formulae of the ground coat which is matte black with metallic luster and the bright-red overglaze as well as a special firing process, particularly control of the temperature-raising rate, the ground coat which is matte black with metallic luster is low in initial melting point, the green body and the glaze are compactly combined, the glaze is level and smooth, and the product is smooth, flexible, vigorous and decent in surface.

Owner:江苏省宜兴彩陶工艺厂

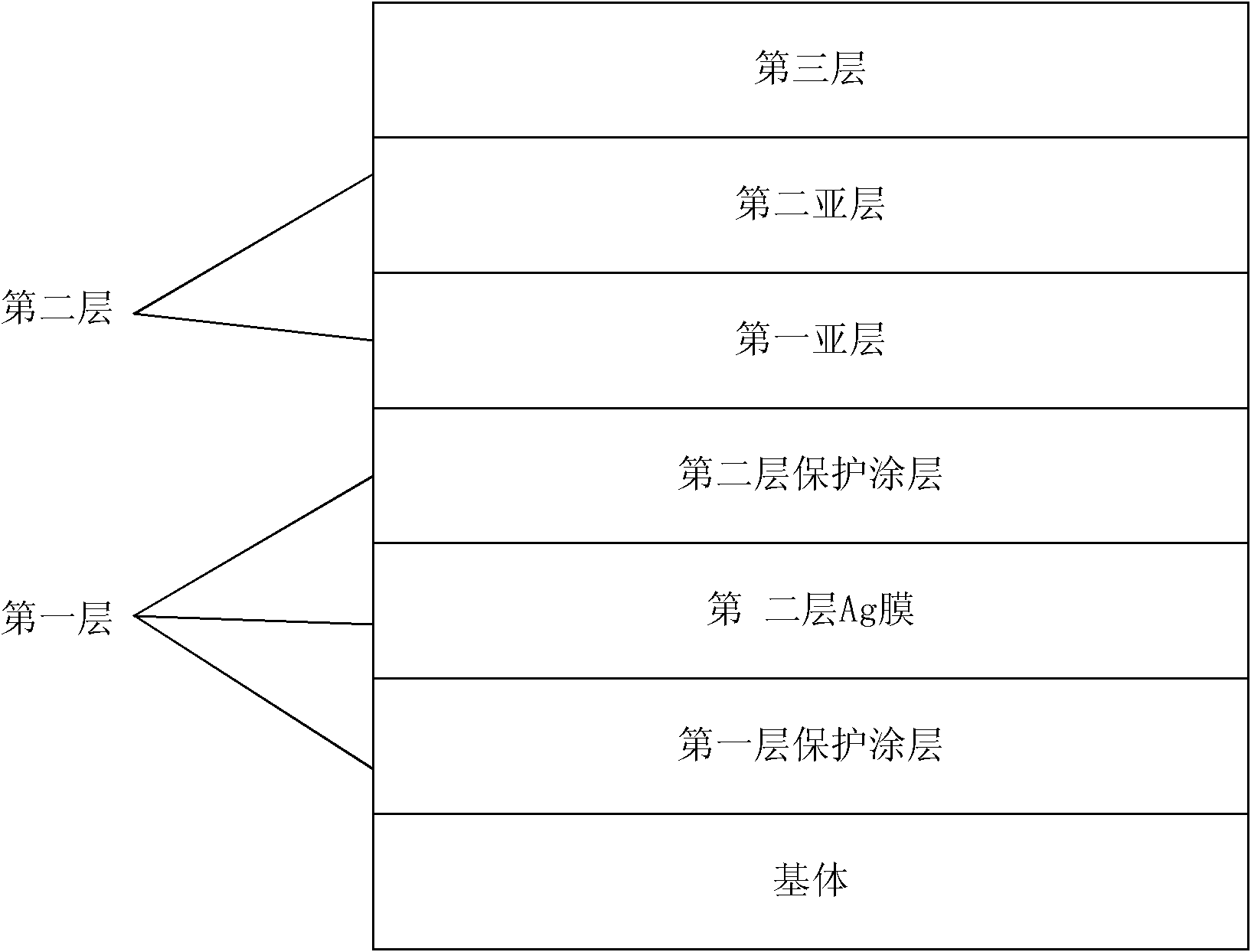

Cr series high-temperature solar selective absorbing coating and preparation method thereof

ActiveCN102102918ALow absorption rateSimple preparation processSolar heat devicesVacuum evaporation coatingMiddle infraredTectorial membrane

The invention discloses a Cr series high-temperature solar selective absorbing coating and a preparation method thereof. The coating consists of an infrared reflection layer, an absorption layer and an antireflection layer in turn from the bottom to the surface, wherein the first infrared reflection layer consists of three membranes; the middle infrared reflection layer is a Ag membrane of which the upside and downside are plated with a protective film that is any one of a chromic oxide (Cr2O3) film and an aluminum oxide (Al2O3) film respectively; the second absorption layer has two sub-layer structures both of the which are AlCrN+AlCr films, the volume percentage of the first sub-layer AlCr is greater than that of the second sub-layer AlCr; and the third antireflection layer is any one of Cr2O3 film and Al2O3 film. The preparation method comprises the steps of: preparing the infrared emission layer on the substrate surface by adopting a pure metal target magnetron sputtering process; preparing the second absorption layer on the first layer by adopting a Cr target and Al target middle-frequency magnetron sputtering process; and preparing the third antireflection layer on the second layer by adopting a metal target middle-frequency magnetron sputtering process.

Owner:北京天瑞星光热技术有限公司

Monolithic catalyst for catalyzing combustion of volatile organic compounds and preparation method of catalyst

InactiveCN105964254AEasy to manufactureImprove production efficiencyIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsCordieriteManganese oxide

The invention belongs to the technical field of catalysis, and particularly discloses a monolithic catalyst for catalyzing combustion of volatile organic compounds and a preparation method of the catalyst. According to the catalyst, cordierite honeycomb ceramic serves as a carrier, and the carrier is coated with a coating containing a metal active component and an auxiliary, wherein the catalyst active component is selected from any one or a combination of noble metals of Pt and Pd, and the catalyst auxiliary is selected from one or a combination of metal oxides such as aluminum oxide, titanium oxide, chromic oxide, cobaltous oxide and manganese oxide. The preparation method of the catalyst is simple, and the catalyst has the advantages that the coating is not prone to disengagement, the initiation temperature is low, the activity is good, the high-temperature-resistant property is good, and the noble metal content is low; the catalyst can be widely used for purification treatment of organic waste gas.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Aluminum chrome refractory material

The invention belongs to the technical field of refractory materials, in particular to an aluminum chrome refractory material, which takes white fused corundum as a body and is formed by adding scraps (the scraps are collected and crushed into the synthetic size) generated in the cold processing process of a dense chromic oxide product, Alpha-Al2O3 powder or chrome oxide green or white fused corundum powder and sintering at a high temperature in combination with an inorganic binding agent or an organic binding agent. A product obtained in the invention can be widely applied to a coal water slurry gasification furnace back lining, a hard carbon black reaction furnace inner lining, a residual oil gasification furnace inner lining in the petrochemical industry, a glass wool molten pool inner lining and the like, fully and effectively makes use of the scraps generated in the cold processing process of the dense chromic oxide product and has the characteristics of low impurity content, high refractoriness, excellent physical performance, good thermal shock resistance and strong erosion resistance.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Diamond resin grinder

The invention relates to a diamond resin grinding tool in the field of grinding tool technology. The working layer is formed by diamond grinding material, catalyst, and filler; the diamond grinding material adopts self-sharpening diamond grinding material which has working layer volume rate 12.5-31.25úÑ.The working layer also comprises: hardening carbonizable substance with volume rate 5-15úÑ and admixture formed by carbite 0-3úÑ.The hardening carbonizable substance comprises: one or two combines of silicon carbide, boron carbide, titanium carbide, and tungsten carbide; the hardening oxide substance comprises: aluminum oxide or / and silicon oxide. The catalyst chooses phenol resin or polyimide resin which has working layer volume rate 40-50úÑ; the filler chooses copper, chromic oxide, zinc oxide and iron oxide which have working layer volume rate 8-15úÑ, 5-15úÑ, 0-8úÑ, 0-8úÑ.

Owner:ZHENGZHOU ARTIFICIAL DIAMOND & PROD ENG TECH RES CENT

Process for preparing chromic oxide by hydrothermal reducing sodium chromate or sodium acid chromate

InactiveCN101456588AHigh reduction conversion rateAchieve recyclingChromium oxides/hydratesSlurryHigh pressure

The invention relates to technology for preparing chromium oxide through hydrothermal reduction of sodium chromate or sodium dichromate, which comprises: preparing the sodium chromate or the sodium dichromate into an aqueous solution, placing the aqueous solution and starch or starch derivatives into a high-pressure reaction kettle for hydrothermal reduction, and obtaining chromic hydroxide slurry; filtering and separating the chromic hydroxide slurry to obtain chromic hydroxide filter cakes and a chromic hydroxide mother solution; and performing high-temperature roasting on the filter cakes to obtain chromium oxide products. The technology has short technological flow, simple operation, low cost and mild reaction conditions, and does not have overhigh requirements on equipment; not only the product quality is better than that of the prior method but also the reduction and conversion rate of sexavalent chromium reaches more than 98 percent; and the whole technology forms a closed cycle, realizes recycling of mixed alkali, the mother solution and a washing liquid, does not discharge pollutant in any form during the whole process, and fundamentally avoids pollution.

Owner:CENT SOUTH UNIV

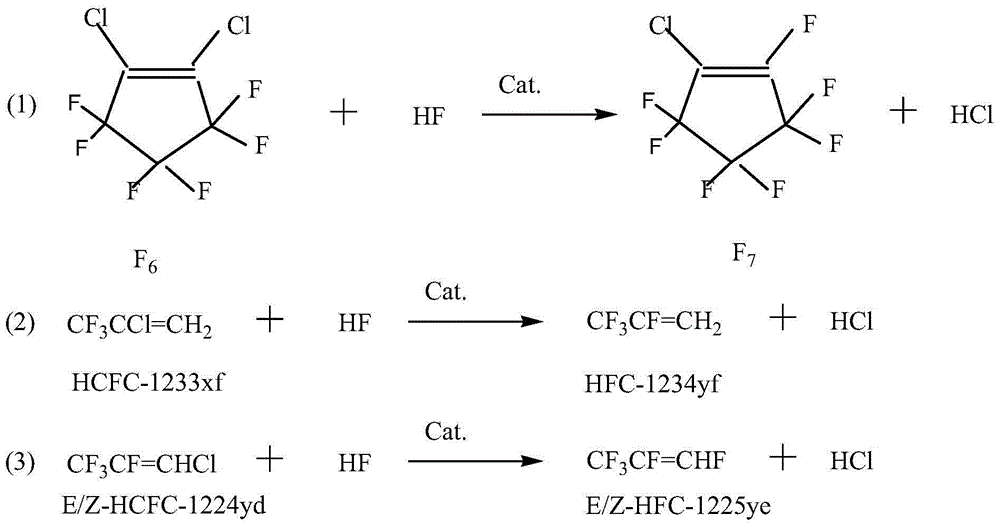

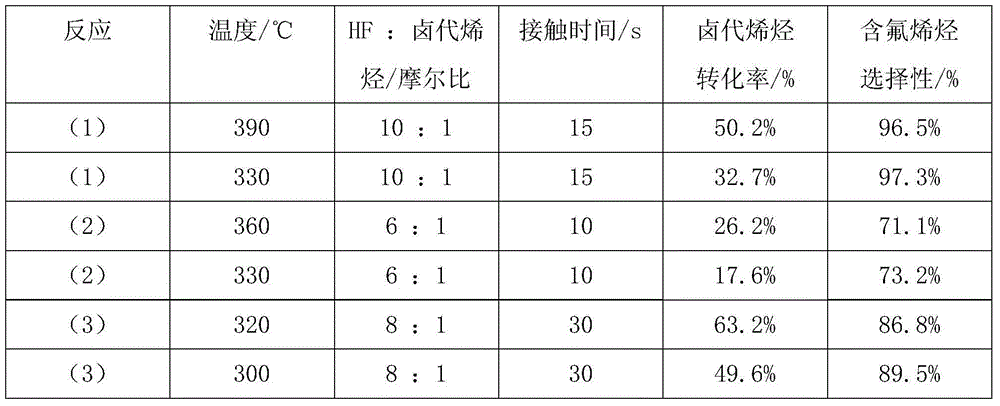

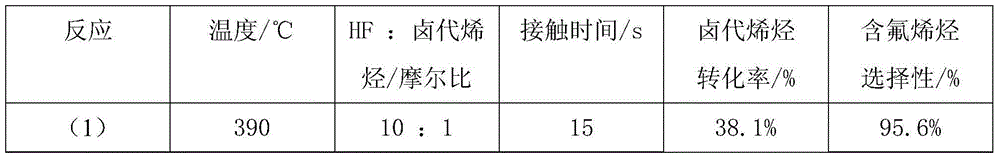

Fluorination catalyst, and preparation method and use thereof

ActiveCN104907065AIncrease the areaHigh pore volumePreparation by halogen replacementMetal/metal-oxides/metal-hydroxide catalystsChromium CompoundsChemical synthesis

The invention discloses a fluorination catalyst, and a preparation method and a use thereof, and belongs to the field of chemical synthesis. The precursor of the catalyst is formed by blending 40-95mass% of a trivalent chromium compound with 5-60mass% of tungstate, wherein the trivalent chromium compound can be chromic oxide or chromium hydroxide, and the tungstate can be zinc tungstate, nickel tungstate, magnesium tungstate, aluminum tungstate, silicotungstic acid, ammonium tungstate, ammonium paratungstate or ammonium metatungstate. The fluorination catalyst has the advantages of high use temperature, high catalysis activity and long service life, and can be mainly used in reactions for preparing fluorinated alkenes through gas phase catalysis of fluorination of alkenyl halides at a high temperature.

Owner:泉州宇极新材料科技有限公司

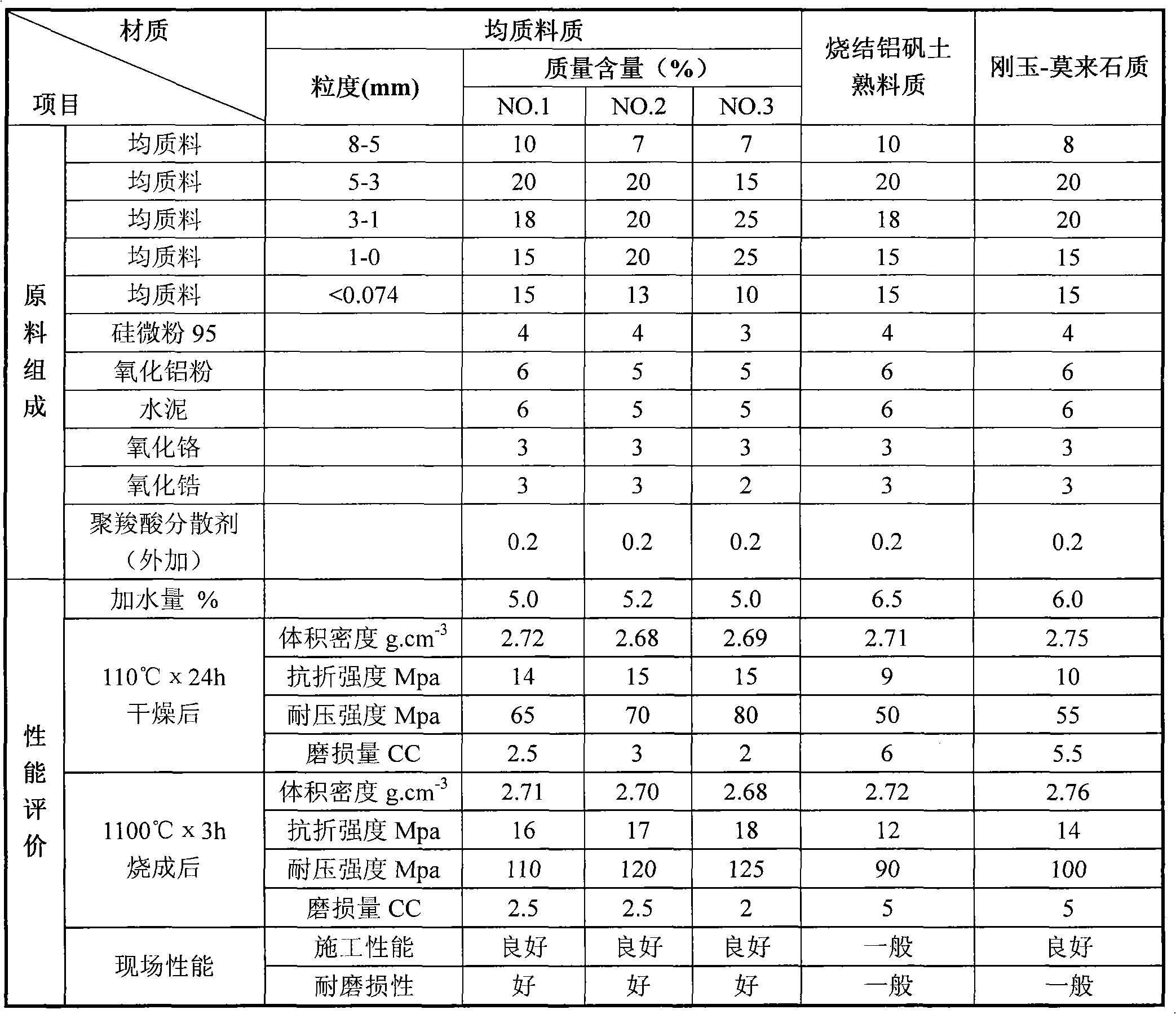

High-aluminum homogeneity-material chromic-oxide zirconium-oxide system abrasion resistant cast material

The invention provides a high-aluminum-homogeneity-material chromic-oxide zirconium-oxide system abrasion resistant cast material which belongs to the field of high-temperature abrasion resistant fireproof materials. The raw material comprises a high aluminum homogeneity material, aluminum oxide micro powder, silicon dioxide micro powder, pure calcium aluminate micro power, chromic oxide, zirconium oxide and a polycarboxylic acid dispersing agent, wherein the high aluminum homogeneity material contains 70 to 90 percent of Al2O3 with the volume density of 2.9 to 3.5 g / cm3. The invention is characterized in that: the high-aluminum-homogeneity-material chromic-oxide zirconium-oxide system abrasion resistant cast material is made of the artificially synthesized homogeneity material with low water absorption rate, low porosity and good uniformity instead of conventional sintered alumina clinker with high water absorption rate, high porosity and poor uniformity or a corundum-mullite composite system. By employing a casting construction method, the material has good construction property, high strength, high abrasion resistance and excellent on-site use effect, is favorable for prolonging the service life of a furnace lining and improving the utilization efficiency of a high temperature kiln, and is widely used in parts, which are easily abraded, penetrated and eroded, of thermal equipment, such as blast furnaces, cowper stoves, recirculating fluidized beds, garbage incinerators, catalytic cracking units and the like.

Owner:TONGDA REFRACTORY TECH CO LTD

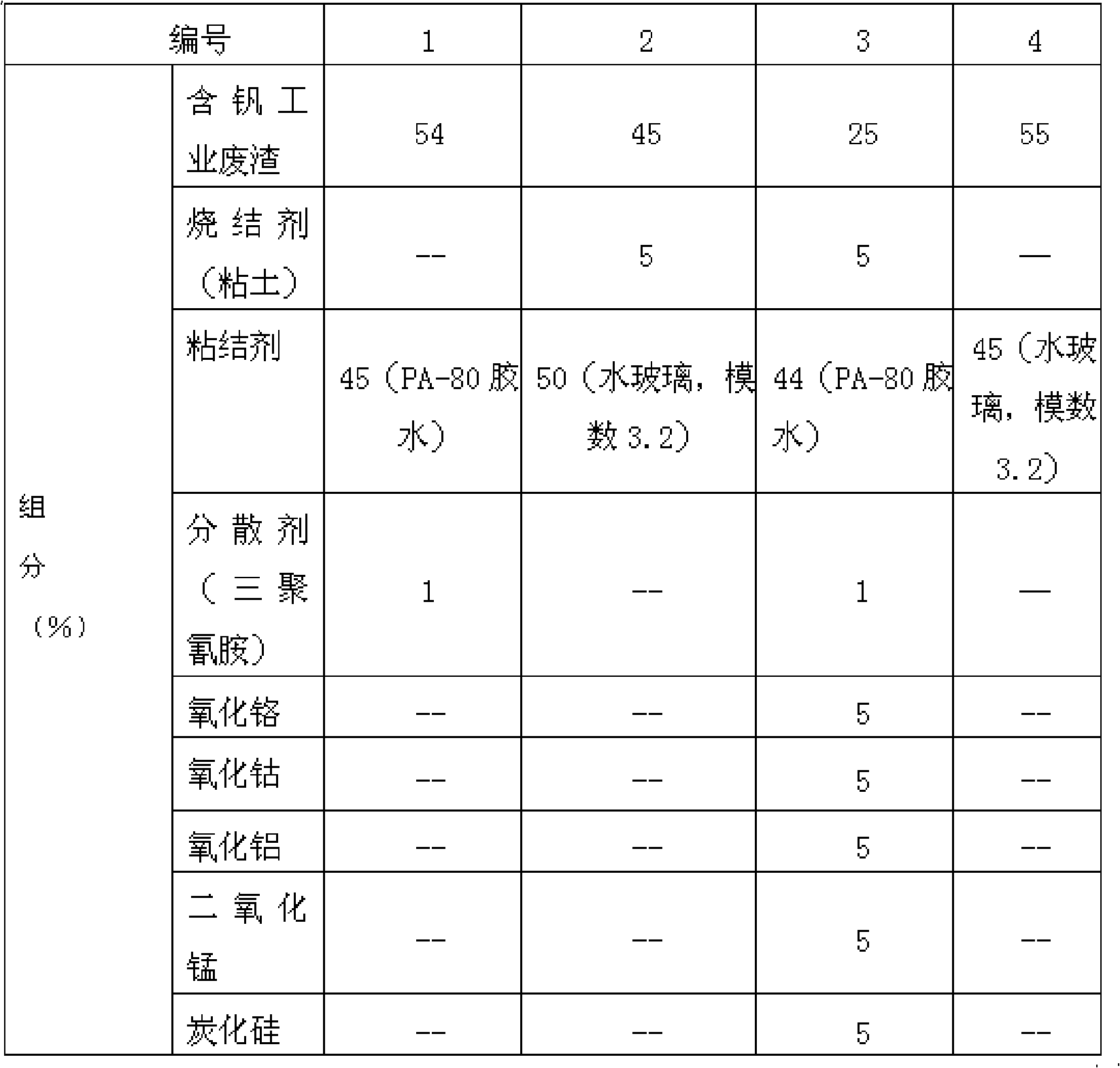

Far infrared coating and preparation thereof

InactiveCN101302365AReduce manufacturing costHigh temperature resistantCoatingsFar infraredToxic industrial waste

The invention relates to a far infrared paint and a method for preparing the same, belonging to the paint field. To solve the technical problem, the invention provides the far infrared paint with low cost and good performance. The far infrared paint is prepared by the following raw materials in percentage by weight: 20 to 60 percent of industrial waste residue containing vanadium, 0 to 10 percent of agglutinant, 30 to 60 percent of caking agent, 0 to 2 percent of dispersant, 0 to 10 percent of chromic oxide, 0 to 10 percent of cobalt oxide, 0 to 10 percent of alumina, 0 to 10 percent of manganese dioxide and 0 to 10 percent of carborundum. The far infrared paint can be used in an industrial boiler and an industrial kiln furnace, has the advantages of high temperature resistance (over 1250 DEG C), good high-temperature conglutination performance, easy porcelain forming, energy economization, etc., and has wide application prospect.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +1

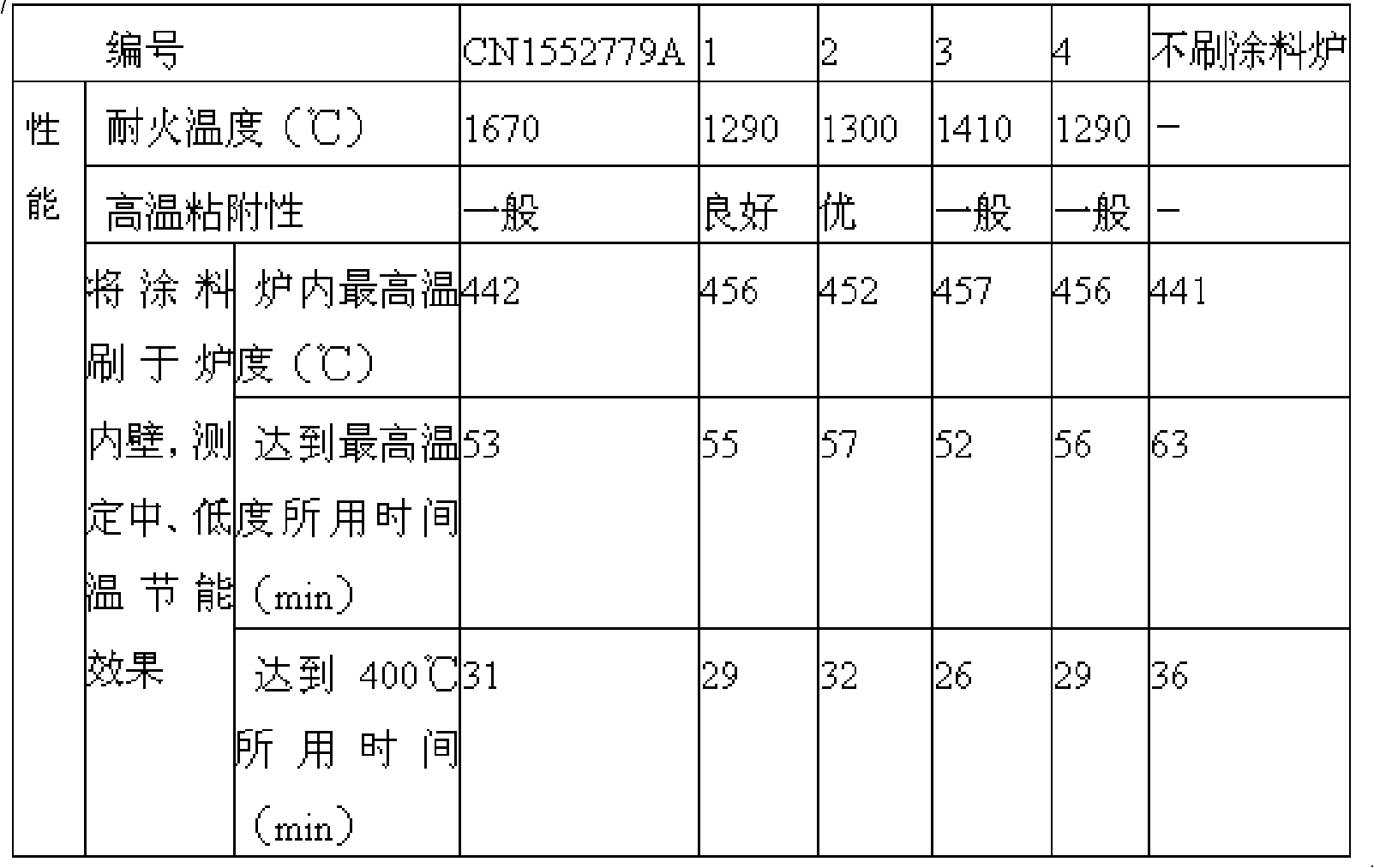

Anti-oxidation coating for heat treatment of iron and preparation method thereof

ActiveCN102585568AImprove performanceWide variety of sourcesSpecial surfacesCoatingsBoron nitrideOxidation resistant

The invention belongs to the technical field of the preparation of high-temperature anti-oxidation coatings, in particular to an anti-oxidation coating used in a long-time heat treatment process of iron, and the like at high temperature. The coating comprises solid powder and liquid, and is characterized in that the solid powder comprises following components by weight part: 30 to 50 parts of glass powder, 10 to 50 parts of boron nitride, 2 to 5 parts of chromic oxide and 3 to 10 parts of metal aluminum powder; and the liquid comprises following components by weight part: 0.1 to 5 parts of modified magnesium aluminosilicate, 20 to 35 parts of organic silicone resin and 100 parts of xylene. Through the adoption of the coating, oxydic weight gain of carbon steel or alloy steel can be guaranteed to be reduced by more than 80 percent in the heat treatment process for a long time (larger than 30 hours) at temperature of 1200 DEG C and above.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

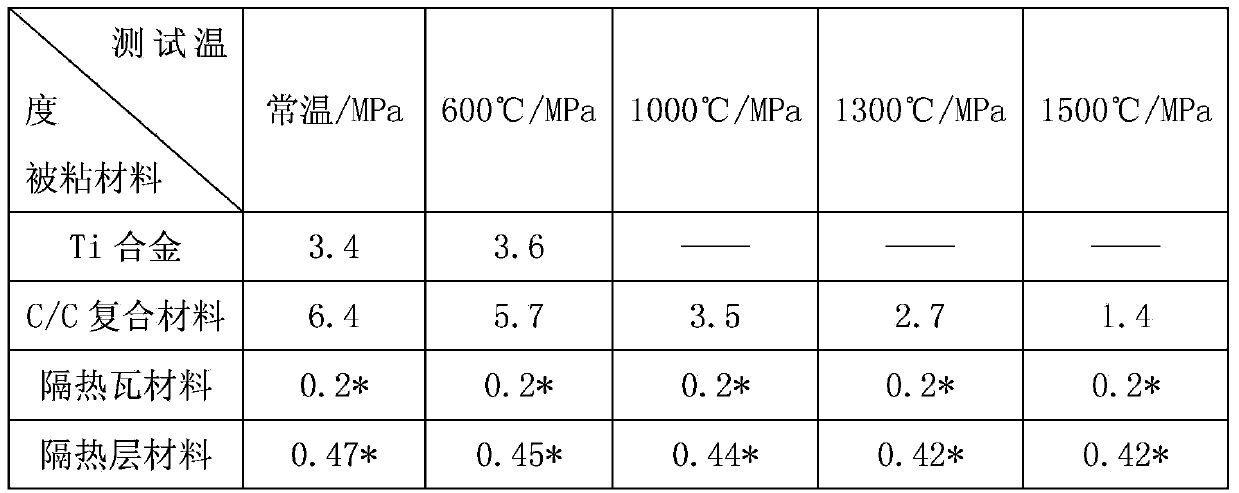

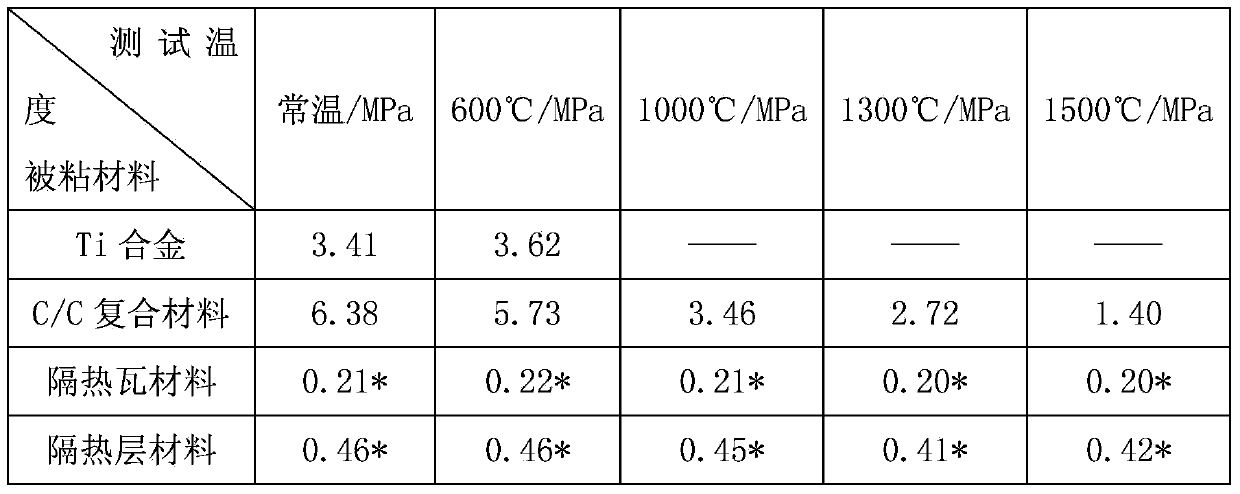

High-temperature-resistant room temperature curing phosphate adhesive and preparation method thereof

InactiveCN103468154AImprove mechanical propertiesGood mechanical propertiesNon-macromolecular adhesive additivesInorganic adhesivesAdhesivePhosphate

The invention discloses a high-temperature-resistant room temperature curing phosphate adhesive and a preparation method thereof, and relates to an adhesive and a preparation method thereof. The adhesive and the preparation method aim at solving the problems that the high-temperature-resistant adhesive prepared by the existing method cannot be cured easily at a room temperature, or the mechanical property and the heat resistance at a high temperature are poor after room temperature curing, and the preparation method is complicated. The high-temperature-resistant room temperature curing phosphate adhesive is prepared by modified aluminium dihydrogen phosphate and a curing agent. The preparation method comprises the steps that 1, aluminium hydroxide powder is added to a phosphoric acid solution; reaction is performed at 90-100 DEG C; chromic oxide is added; the reaction is continued at 90-100 DEG C; a modified aluminium dihydrogen phosphate solution is obtained; 2, aluminium nitride, yttrium oxide, calcium fluoride, boron nitride and zinc oxide are added to aluminium oxide, and mixed uniformly; the curing agent is obtained; and 3, the prepared modified aluminium dihydrogen phosphate solution and the curing agent are mixed uniformly, and stand at the room temperature; and the high-temperature-resistant room temperature curing phosphate adhesive is obtained. The adhesive is used for the fields of high-temperature-resistant ceramic material bonding and wood fire prevention coating.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

High-performance cerium zirconium oxide and production method of high-performance cerium zirconium oxide

ActiveCN104190438AOvercome doping defectsImprove thermal stabilityMetal/metal-oxides/metal-hydroxide catalystsCeriumCopper oxide

The invention relates to a solid liquid supported catalyst and in particular relates to high-performance cerium zirconium oxide. The high-performance cerium zirconium oxide is prepared from the following chemical ingredients in parts by weight: cerium oxide, zirconium oxide, aluminum oxide, praseodymium oxide, lanthanum oxide, neodymium oxide, yttrium oxide, samarium oxide, vanadium oxide, chromic oxide, manganese oxide, iron oxide, cobalt oxide, copper oxide, manganese oxide, nickel oxide and the like. The invention also provides a preparation method of the high-performance cerium zirconium oxide. The preparation method comprises the steps of mixing all raw materials, adding surface active agents, regulating pH value to be 8-10 to obtain gelatinous precipitates, and calcinating to obtain the cerium zirconium oxide. The solid liquid supported catalyst can overcome the doping defect caused by doping in the cerium zirconium carrier and can improve the thermal stability, the aged specific surface area and the oxygen storage capacity of the supported catalyst; and the preparation method is simple, the technological process is simple and the method facilitates large-scale industrial production.

Owner:淄博加华新材料有限公司

Raw material proportion of bice glaze and firing method thereof

The invention relates to a mixture ratio of raw materials of a grey blue glaze. The grey blue glaze comprises the following compositions by weight percentage: 30 to 35 percent of quartz, 32 to 38 percent of feldspar, 8 to 11 percent of talcum, 2 to 5 percent of clay, 6 to 9 percent of limestone, 3 to 5 percent of aluminum oxide, 7 to 9 percent of zirconium silicate, 0.01 to 0.05 percent of manganese oxide, 0.1 to 0.4 percent of ferric oxide, 0.01 to 0.05 percent of chromic oxide, 0 to 0.3 percent of cobalt oxide, 0 to 1 percent of dispersant and 0 to 1 percent of carboxymethyl cellulose sodium. The grey blue glaze is prepared by steps of drying, grinding, screening, iron removal, aging, glaze spraying and firing according to the mixture ratio of the grey blue glaze. The mixture ratio of raw materials of the grey blue glaze and the method for firing the grey blue glaze can improve the appearance quality of ceramic pieces and the performance of glaze layers and can meet requirements for batch production and ensure high qualification rate of products and good economic benefits due to the adoption of the prior equipment in the firing process.

Owner:CHINA XD ELECTRIC CO LTD +1

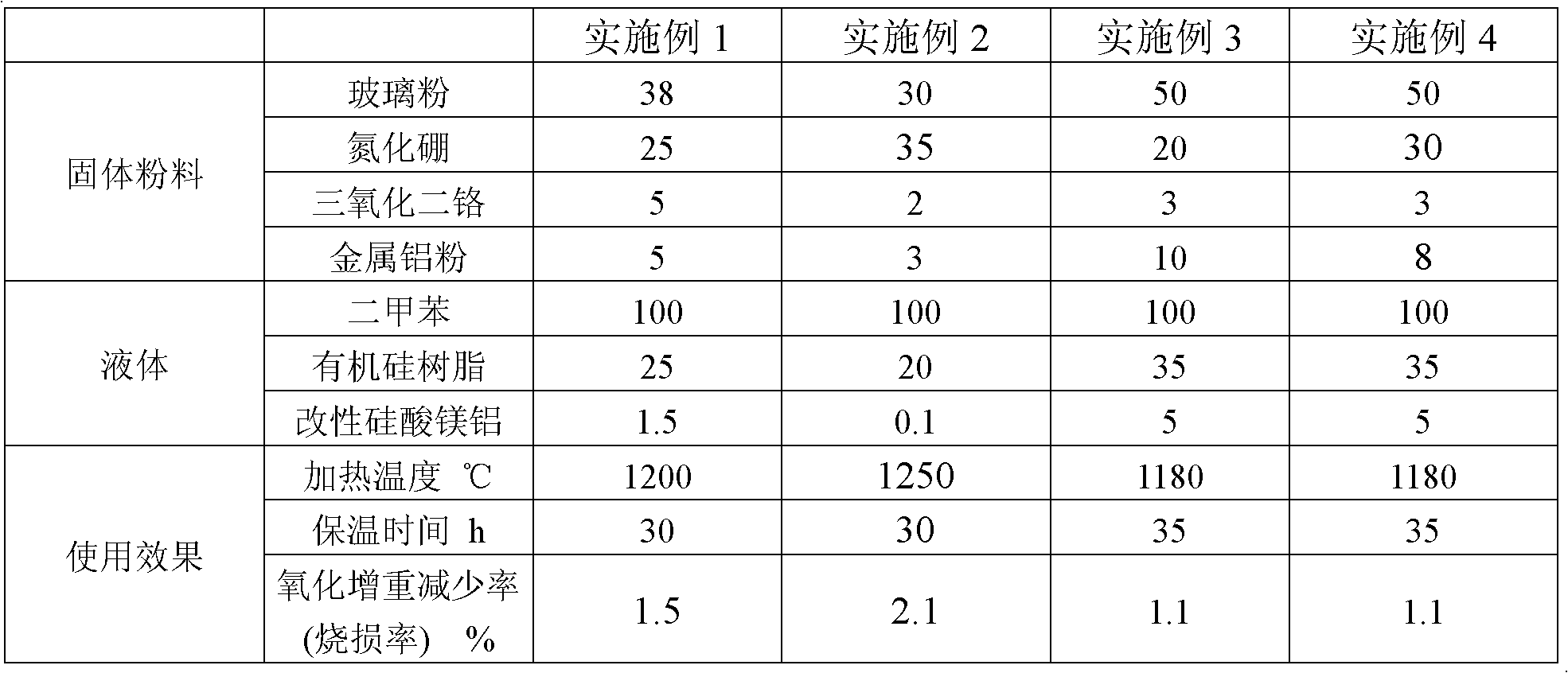

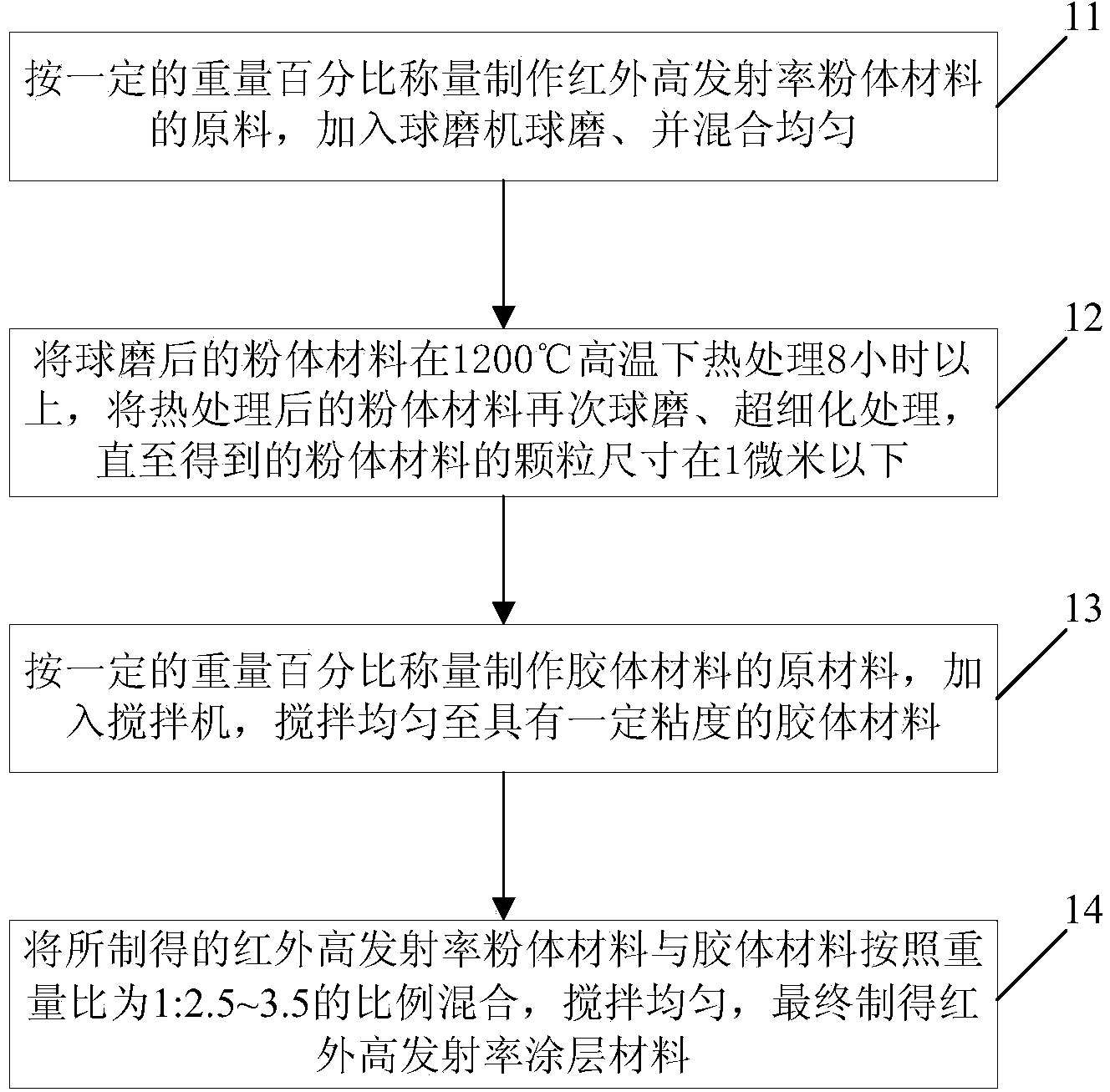

Infrared high-emissivity coating material and preparation method thereof

InactiveCN103613962AHigh and stable infrared emissivityNot easy to ageAlkali metal silicate coatingsSlagManganese oxide

The embodiment of the invention discloses an infrared high-emissivity coating material which is prepared by mixing an infrared high-emissivity powder material and a colloid material, wherein the infrared high-emissivity powder material is prepared from iron-ore slag, iron oxide, manganese oxide, zirconium oxide, chromic oxide and silicon carbide through a treatment process of ball milling, mixing, high-temperature roasting and superfining; the colloid material is prepared by mixing water, sodium silicate, carboxymethyl cellulose and superfine silicon dioxide according to a certain weight ratio. The coating material has the advantages of high infrared emitting ability, stability, difficulty in aging, high binding ability of the coating with a substrate, long service life, low price and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

High-temperature counter radiation resistant inorganic coating and preparation method thereof

InactiveCN101760058AImprove thermal shock resistanceImprove thermal efficiencyFireproof paintsAlkali metal silicate coatingsPhosphateOxidation resistant

The invention relates to an energy-saving high-temperature counter radiation resistant inorganic coating for coating the liner of a kiln and a preparation method thereof. The coating mainly comprises oxides, such as cobalt oxide, zirconium oxide powder, aluminum oxide and chromic oxide, and silicon powder, silicon carbide, sodium silicate, aluminium dihydrogen phosphate, silica flour, graphite powder, boron oxide and other components and is prepared by grinding, soaking, heating reaction, stirring and mixing. The coating has high thermal shock resistance, high radiation utilization rate, high corrosion resistance, high cracking resistance, high oxidization resistance and high thermal stability. The inorganic coating of the invention has the advantages of allowing for normal construction without making special modification of the basal body of the kiln, along with small investment, quick response, no toxicity, no corrosion and desirable social and economic benefits.

Owner:上海乐恒石油化工集团有限公司

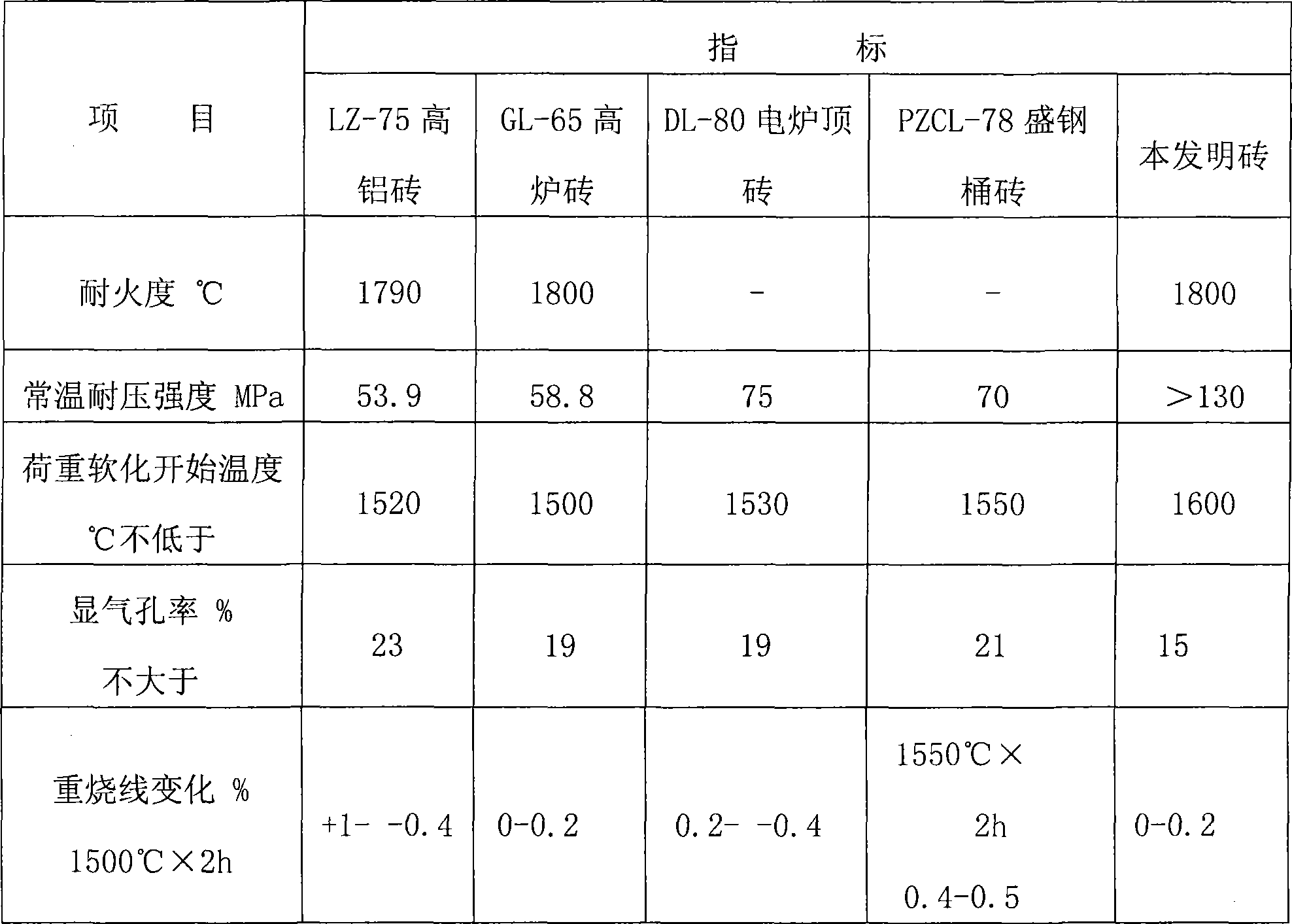

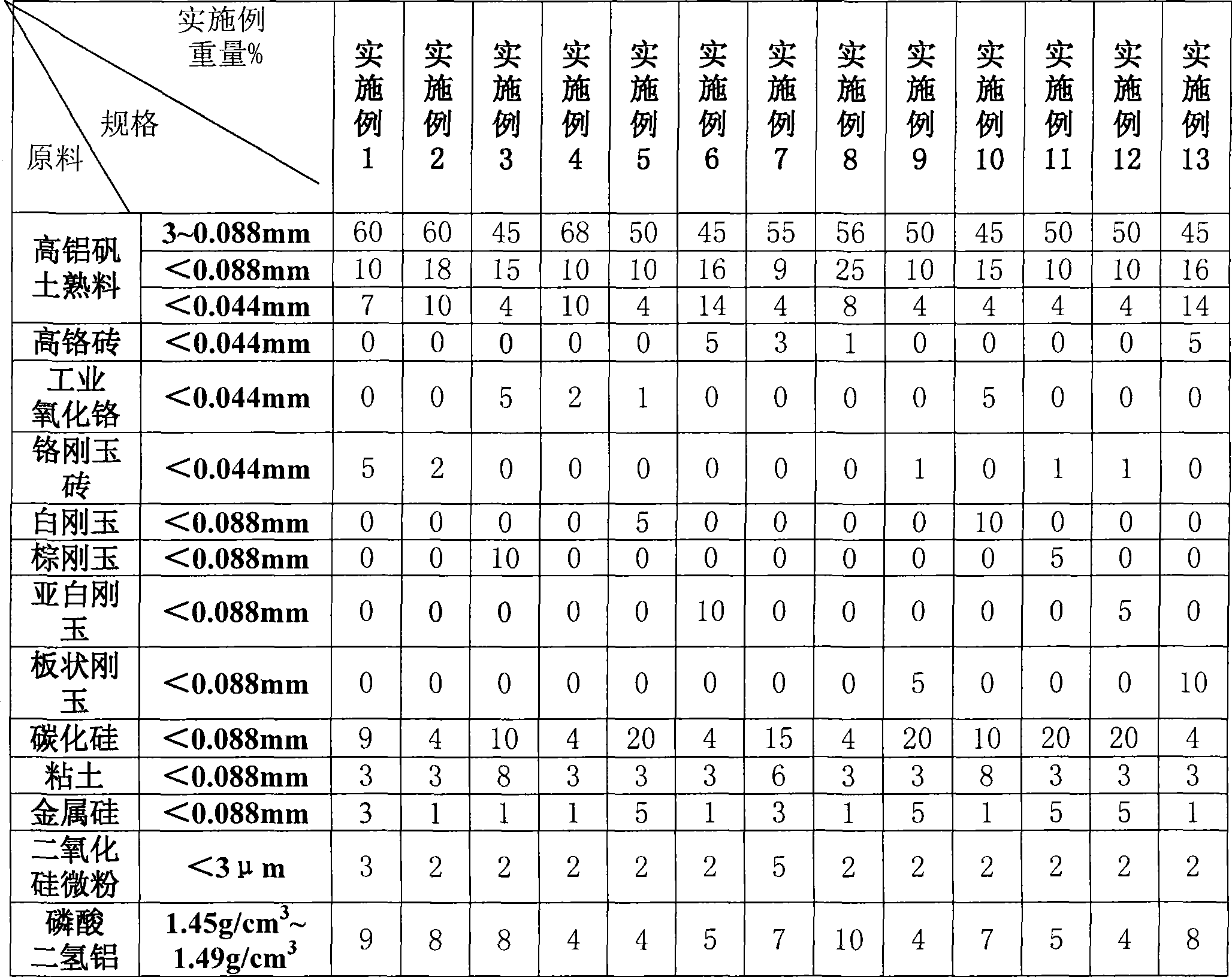

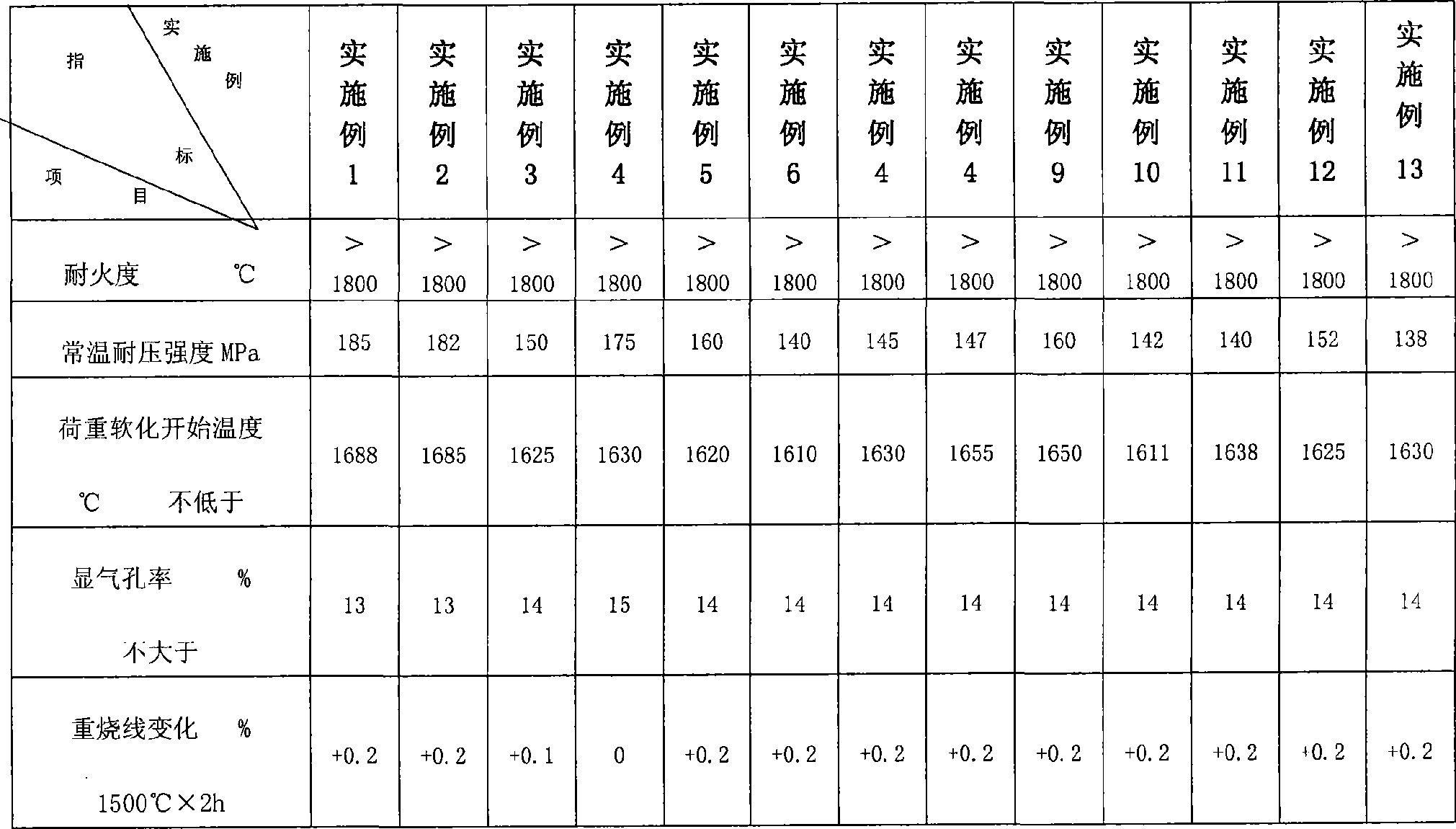

Phosphate-bonded aluminum silicon carbide brick and preparation method thereof

The invention discloses a phosphate-bonded aluminum silicon carbide brick, which is characterized by comprising main ingredients and a phosphate binder, wherein the main ingredients comprise the following raw materials by weight percentage: 45 to 68 percent of bauxite chamotte with a granularity of 3 to 0.088 mm, 10 to 25 percent of bauxite chamotte with a granularity of less than 0.088 mm, 4 to 14 percent of bauxite chamotte with a granularity of less than 0.044 mm, 0 to 10 percent of corundum, 1 to 5 percent of a chromic oxide-containing material, 4 to 20 percent of silicon carbide, 3 to 8 percent of clay, 2 to 5 percent of silicon dioxide micro powder, and 1 to 5 percent of metallic silicon; and the phosphate binder is added in an amount which is 4 to 10 percent of the weight of the main ingredients. The aluminum silicon carbide brick is made into high quality aluminum silicon carbide brick which has an apparent porosity of less than 15 percent, a cold crushing strength of more than 130MPa, a starting refractoriness under load of more than 1,600 DEG C and high inoxidability by ageing mixture, back rolling, forming, drying and baking.

Owner:巩义市金岭耐火材料有限公司

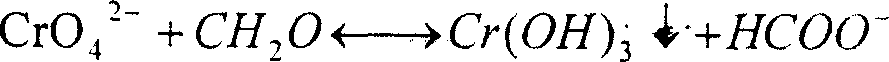

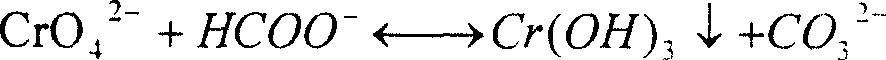

Method for separating vanadium and chromium solution and recycling vanadium and chromium

ActiveCN105861829AAchieve restorationAchieve reduction of vanadiumProcess efficiency improvementVanadium dioxideVanadyl sulfate

The invention discloses a method for separating a vanadium and chromium solution and recycling vanadium and chromium. A reducing agent is added to the vanadium and chromium solution under the condition that the pH value ranges from 8 to 14, and the temperature ranges from 20 DEG C to 100 DEG C, and pentavalent vanadium and hexavalent chromium are reduced into tetravalent vanadium and trivalent chromium; the trivalent chromium forms chromic hydroxide precipitate in situ, and a chromic hydroxide filter cake and vanadium-containing filtrate are obtained through filtering; the chromic hydroxide filter cake is used for preparing chromic oxide; and the vanadium-containing filtrate is used for preparing hydration vanadium dioxide or vanadyl sulfate or vanadium pentoxide. By means of the method, efficient separation and recovery of vanadium and chromium are achieved, the vanadium recovery rate reaches 96% or higher, the chromium recovery rate reaches 98% or higher, and the purity of vanadium and chromium products reaches 98% or higher. The method has the beneficial effects that the technological processes are short, the separation efficiency is high, the cost of raw materials and auxiliary materials is low, operation is easy and convenient, and the method can be used for large-scale industrial production.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Ceramsite sand for casting and preparation method thereof

ActiveCN107298584AImprove thermal conductivityHigh thermal expansionFoundry mouldsFoundry coresExpanded clay aggregateSilicon dioxide

The invention relates to a ceramsite sand for casting and a preparation method thereof. The ceramsite sand comprises the following chemical components in parts by weight: 35-65 parts of silicon dioxide, 30-50 parts of aluminum oxide, 1-10 parts of iron oxide, 1-4 parts of manganese dioxide and 2-8 parts of chromic oxide. The method comprises the following steps: performing grinding, and detecting the chemical composition and contents of the raw materials; and sequentially performing proportioning, ball making, screening, sintering and grading to obtain the finished product. The ceramsite sand prepared by the invention is high in thermal conductivity and refractoriness, conforms to the requirements for casting sand, can be used for casting and casting mold production instead of silica sand, chromite sand and the like, reduces the discharge amount of solid waste in the casting industry, and improves the quality of cast products.

Owner:NINGXIA KOCEL MOLD

Method of manufacturing high performance glass fibers in a refractory lined melter and fiber formed thereby

ActiveUS7823417B2Inexpensively formed into glass fiberUse in some applicationCharging furnaceGlass furnace apparatusFiberAlkali metal oxide

A method of forming high strength glass fibers in a refractory lined glass melter is disclosed. The refractory lined melter is suited to the batch compositions disclosed for the formation high modulus, and high-strength glass fibers. The glass composition for use in the method of the present invention is up to about 70.5 Weight % SiO2, 24.5 weight % Al2O3, 22 weight % alkaline earth oxides and may include small amounts of alkali metal oxides and ZrO2. Oxide based refractories included alumina, chromic oxide, silica, alumina-silica, zircon, zirconia-alumina-silica and combinations thereof. By using oxide based refractory lined furnaces the cost of production of glass fibers is substantially reduced in comparison with the cost of fibers using a platinum lined melting furnace. Fibers formed by the present invention are also disclosed.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Method for producing high-purity metal chromium by using carbon reduction method

InactiveCN102965526AHigh speedIncrease productivityProcess efficiency improvementImpurityMaterials science

The invention relates to a method for producing high-purity metal chromium by using a carbon reduction method. The method comprises the following steps of: uniformly mixing chromic oxide powder and carbon black powder, adding deionized water or alcohol to form a wet mixed material, carrying out press forming, and drying, thereby obtaining a mixed material block; putting the mixed material block in a vacuum furnace, and enabling chromic oxide to be reduced by carbon black under high-temperature vacuum conditions, thereby obtaining crude chromium; introducing gaseous carbon monoxide, and carrying out heat preservation for 3-8 hours at the temperature of 1,300-1,500 DEG C; introducing gaseous carbon dioxide, and carrying out heat preservation for 3-8 hours at the temperature of 800-1,000 DEG C; and cooling down, and discharging, thereby obtaining a high-purity metal chromium block. According to the method, a gas-solid reduction manner is adopted to remove residual raw materials and non-metallic impurities, so that the production cost is reduced, and the reduction time is shortened; and the produced high-purity metal chromium has the purity of 99.96-99.98%, the oxygen content less than 0.03%, the sulfur content less than 0.01% and the carbon content less than 0.01%, thereby meeting the standards of the high-purity metal chromium.

Owner:JINZHOU NEWROUTE HYPERPURE MATERIAL CO LTD

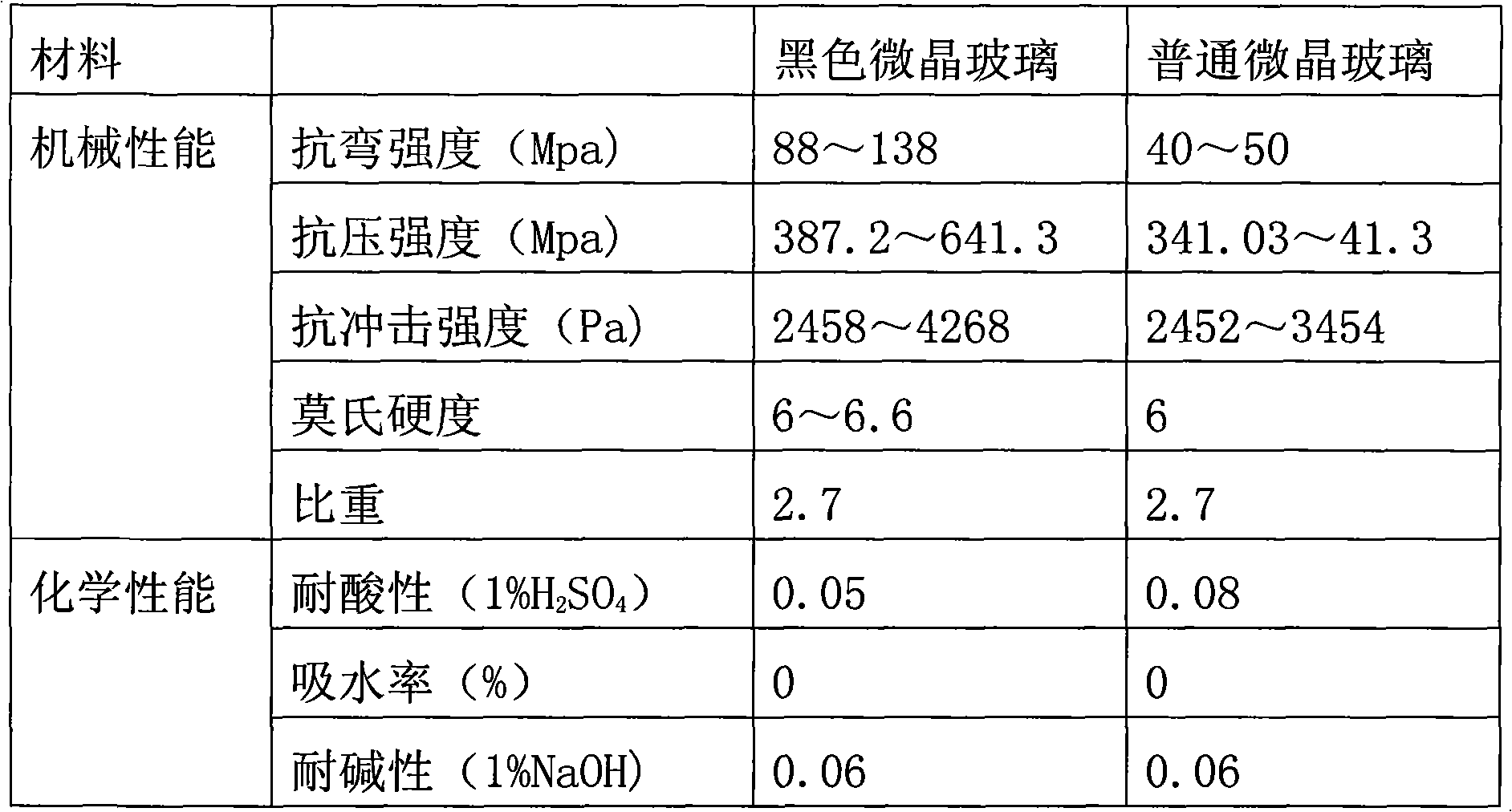

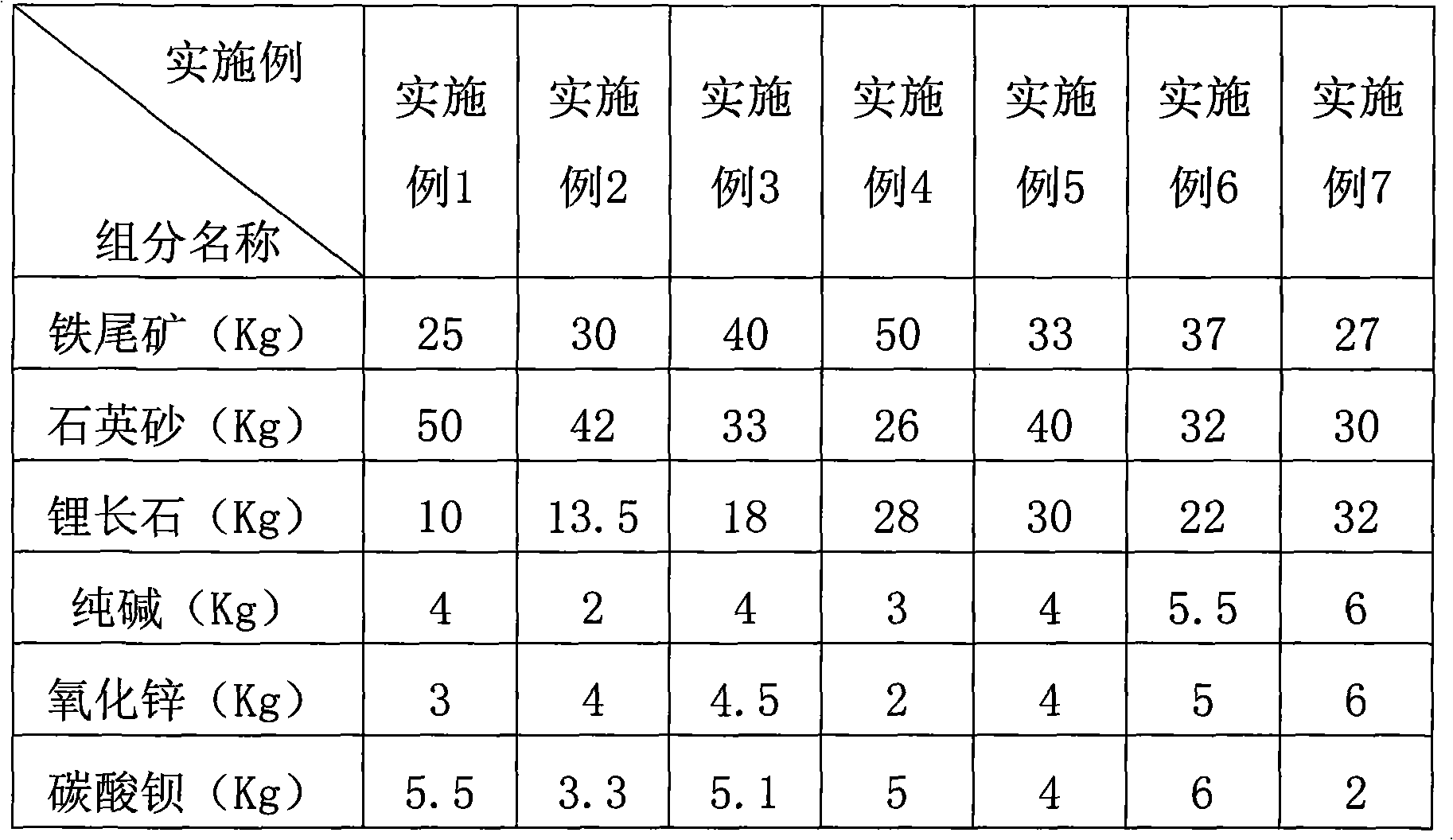

Black glass ceramic and production method thereof

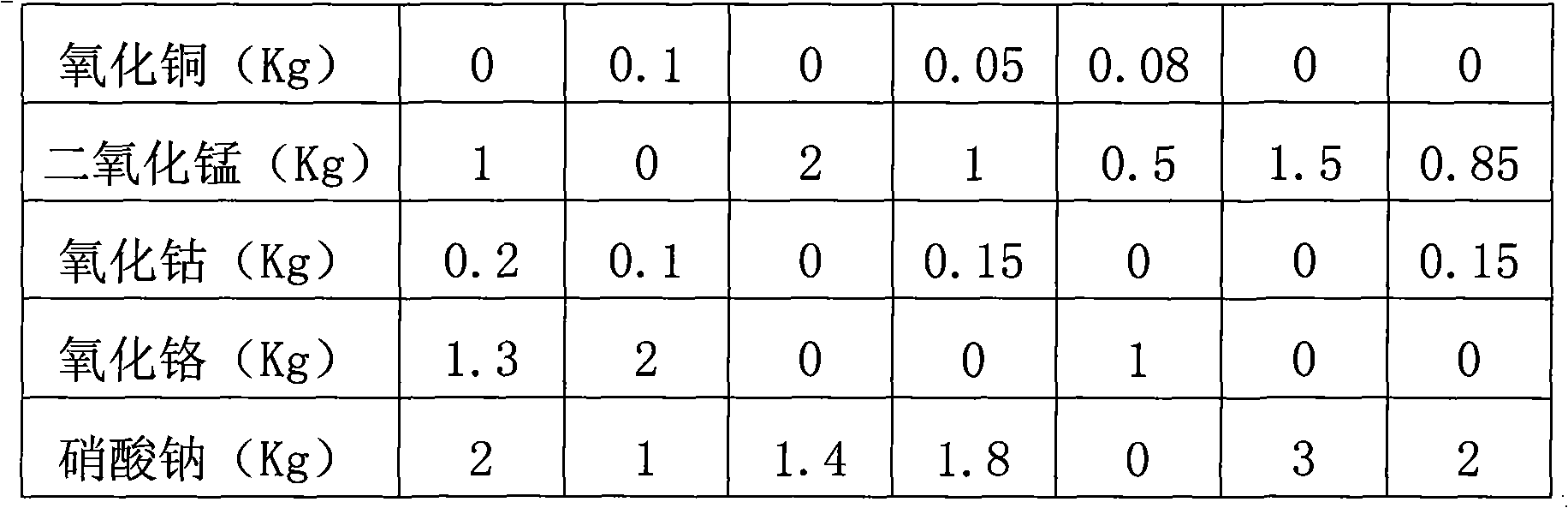

The invention discloses a black glass ceramic and a production method thereof in order to solve the problems of the conventional glass ceramic, i.e. single color and high production technique cost. The black glass ceramic is produced with the following components in part by weight: 25 to 50 parts of iron tailings, 20 to 50 parts of quartz sand, 10 to 32 parts of petalite, 2 to 6 parts of sodium carbonate, 2 to 6 parts of zinc oxide, 2 to 6 parts of barium carbonate, 0 to 0.1 part of copper oxide, 0 to 2 parts of manganese dioxide, 0 to 0.2 part of cobalt oxide, 0 to 2 parts of chromic oxide and 0 to 3 parts of sodium nitrate. Since the invention utilizes the discarded iron tailings as the material of the black glass ceramic, the waste is made profitable, pollution is reduced, the environment is protected, moreover, the physicochemical performance of the product can be enhanced, and the single-color problem of the black glass ceramic is solved; the corrosion of the refractory material of a glass furnace by molten glass is reduced, and thereby the service life of the equipment is prolonged; and the application range of the black glass ceramic is wide.

Owner:浮山县晋盛新型建筑材料有限责任公司

Fluorinated chrome base fluorination catalyst and application thereof

ActiveCN102513136AExtended service lifeHigh catalytic activityPreparation by dehalogenationPreparation by hydrogen halide split-offHydrogen fluorideHydrogen

The invention discloses a fluorinated chrome base fluorination catalyst and application thereof. The weight percentage composition of a precursor of the catalyst is that chromic oxide 80.0%-99.0% and rare-earth metal oxide 1.0%-20.0%, wherein the rare-earth metal oxide is selected from one or more of CeO2, La2O3, Nd2O3, Y2O3, ZrO2 and Yb2O3. The precursor of the catalyst is roasted at 300 DEG C-400 DEG C, and the fluorinated chrome base fluorination catalyst is obtained by fluorating the precursor of the catalyst by utilizing hydrogen fluoride gas at 350-450 centidegree. The obtained fluorination catalyst has the advantages of being good in carbon deposit resistance performance and activation and the like. The catalyst is mainly used for preparation of hydrofluoroolefin and hydrogen fluorine chlorine olefins.

Owner:XIAN MODERN CHEM RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com