Patents

Literature

91results about How to "Solve single color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

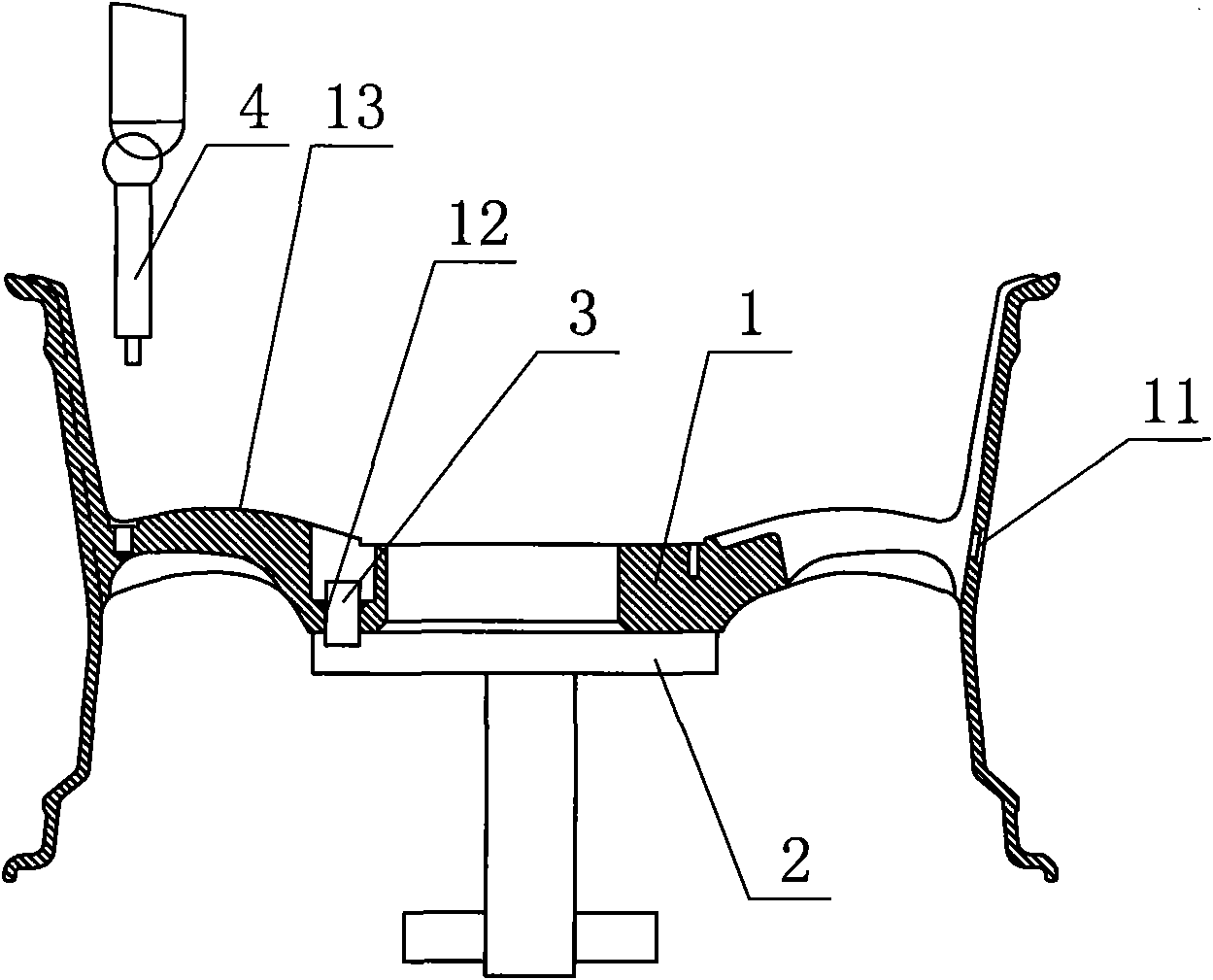

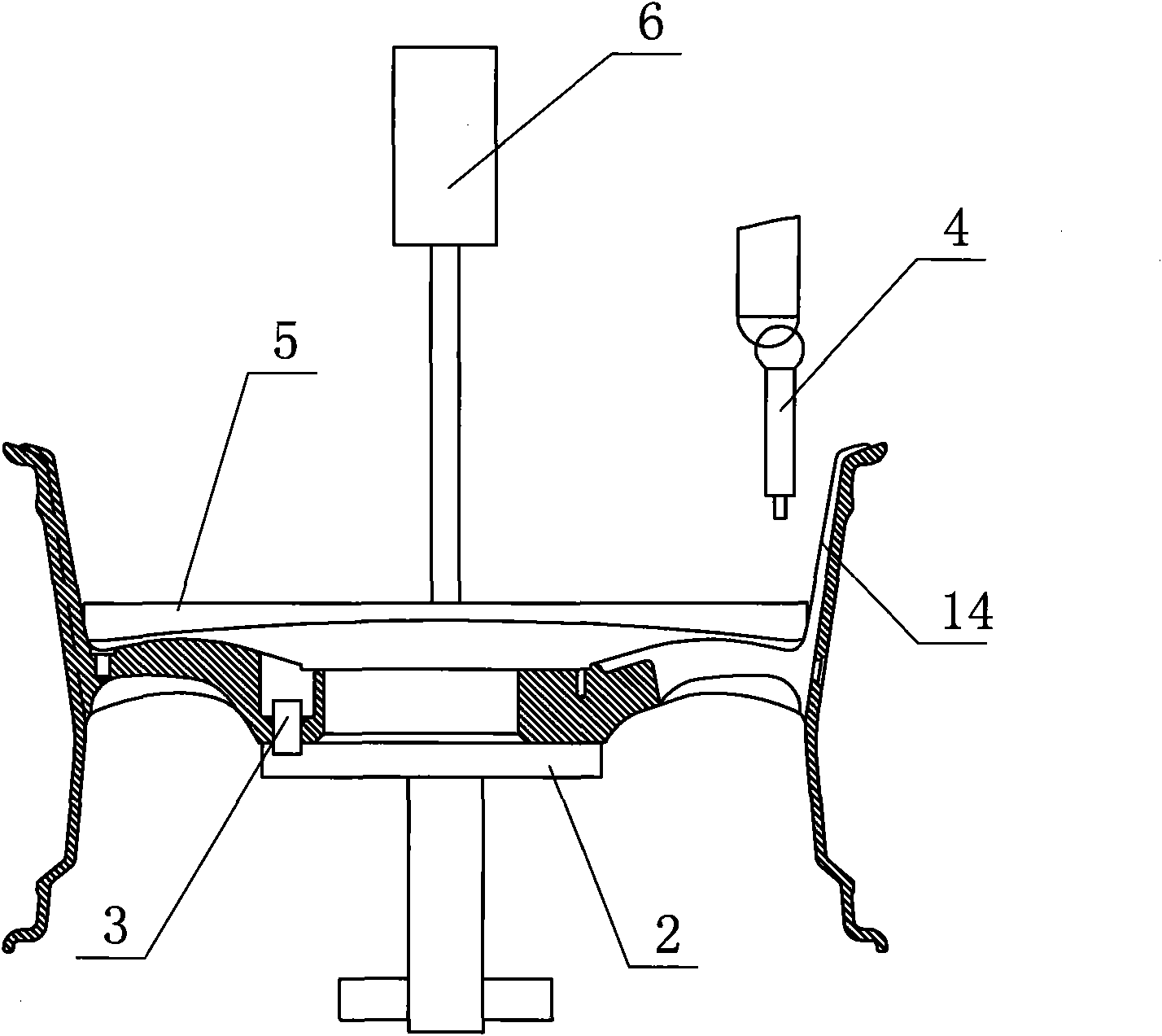

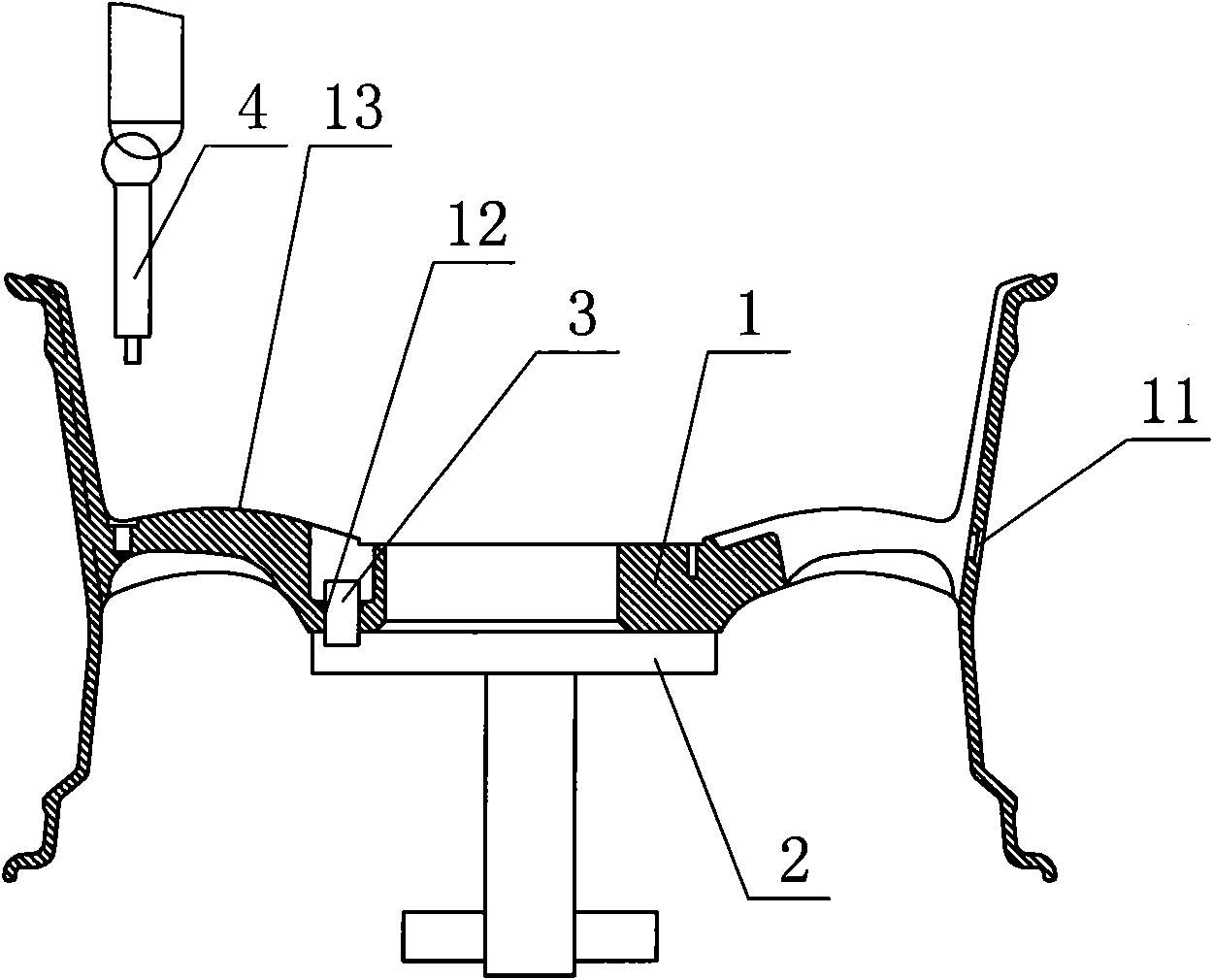

Automobile hub spraying process

ActiveCN101940993ASolve the problem of single color sprayingSolve single colorHubsSpraying apparatusEngineeringManipulator

The invention discloses a specialized automobile hub spraying process, which comprises the following steps of: 1) plugging a valve hole of an automobile hub by using a plugging tool, placing the automobile hub on a tray, then positioning the automobile hub on the tray by using the match of a positioning pin and a PCD hole of the automobile hub, finally driving the bottom of the tray to rotate by a power source, and spraying a web plate surface by adopting a spraying manipulator; 2) baking paint on the web plate surface of the automobile hub fixed on the tray; and 3) covering a pressing plate matched with the web plate surface of the automobile hub on the web plate surface, driving the bottom of the tray to rotate by the power source, and spraying an LIP surface by the spraying manipulator so as to finish secondary spraying. The spraying color of the web plate surface is different from that of the LIP surface. The spraying process solves the problem of single hub spraying color, is uniform to spray, does not produce asymmetry or discordance, and has the advantages of simple process, convenient operation and low cost.

Owner:ZHEJIANG JINFEI KAIDA WHEEL

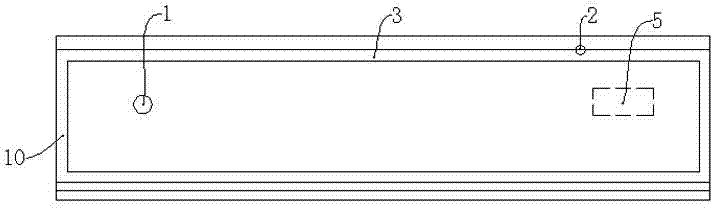

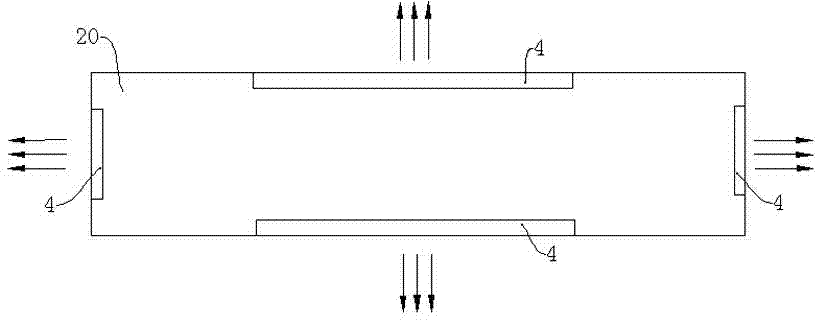

Indoor air conditioner with lamplight effect and control method thereof

InactiveCN102889642AOvercome single colorFeel goodSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringLED lamp

The invention provides an indoor air conditioner with a lamplight effect. The indoor air conditioner comprises a panel (10), a chassis, a controller (5), decorative lamps (3) at the peripheral positions of the panel, and backlight lamps (4) at the peripheral positions of the chassis, wherein the decorative lamps and the backlight lamps are a plurality of LED (Light-Emitting Diode) lamps including three colors of red, green and blue. The indoor air conditioner can be brighter and more colorful so that the problem that the color of the existing air conditioner is single is solved and the psychology feeling of a user can be scientifically optimized in a process of using the air conditioner by using the color. The invention further relates to a control method of the indoor air conditioner.

Owner:NINGBO AOKESI ELECTRIC EQUIP FACTORY

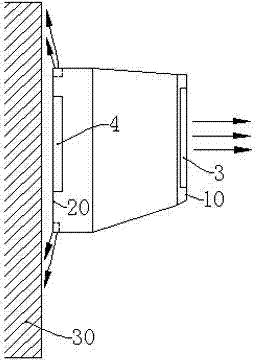

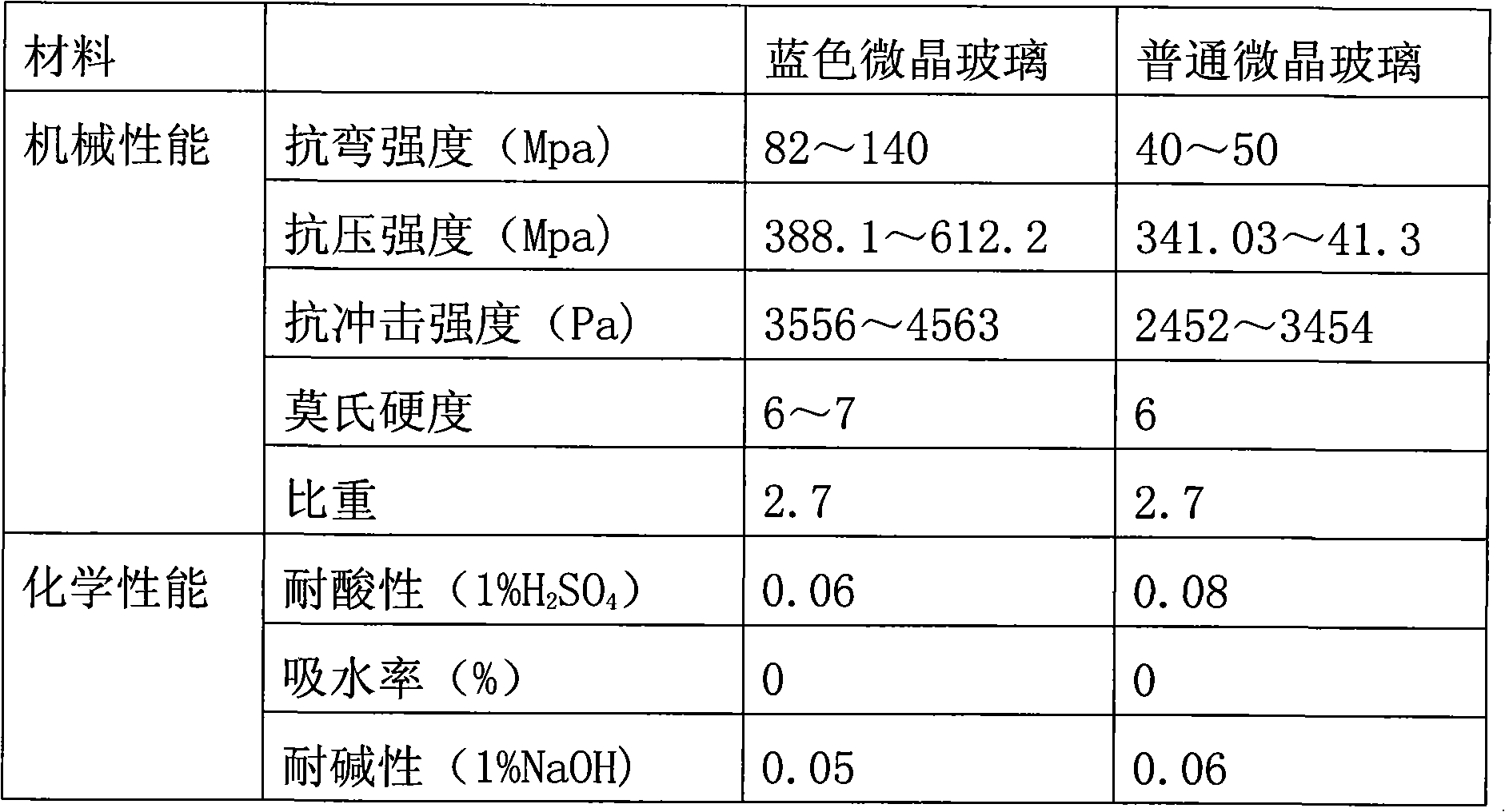

Blue glass ceramics and preparation method thereof

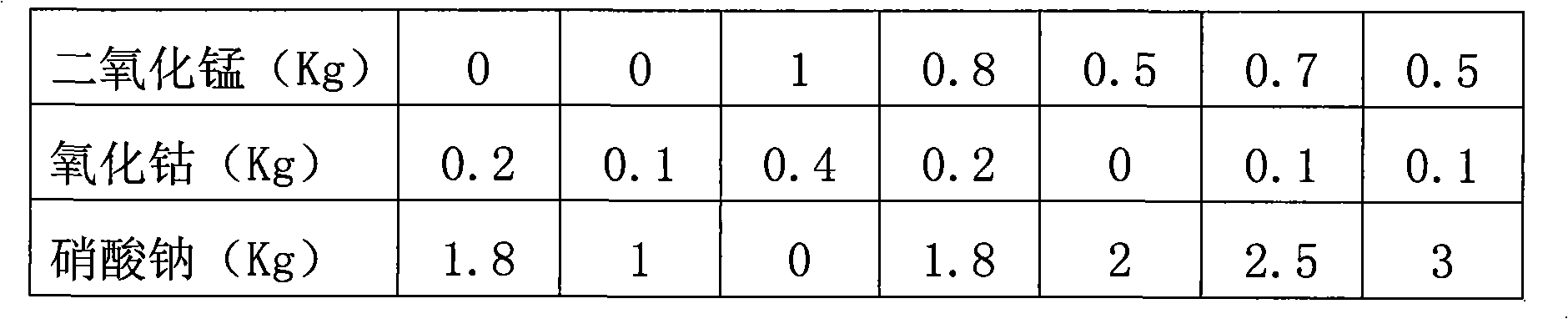

The invention discloses blue glass ceramics and a preparation method thereof, and aims to solve the problems of single color and high production process cost of the conventional glass ceramics. The blue glass ceramics are prepared from the following components in part by weight which serve as raw materials: 30 to 55 parts of iron tailings, 20 to 450 parts of quartz sand, 10 to 30 parts of lithium feldspar, 2 to 6 parts of soda ash, 2 to 6 parts of zinc oxide, 2 to 6 parts of barium carbonate, 0 to 1 part of manganese dioxide, 0 to 0.4 part of cobalt oxide and 0 to 3 parts of sodium nitrate. The invention makes waste profitable by using the iron tailings which are wastes as the raw material of the blue glass ceramics, can reduce pollution and protect environment, improve physiochemical performance of the product, solve the problem of single color of the glass ceramics, lighten corrosion of glass metal to a refractory material of a glass furnace and prolong service life of equipment. The blue glass ceramics of the invention have wide application.

Owner:浮山县晋盛新型建筑材料有限责任公司

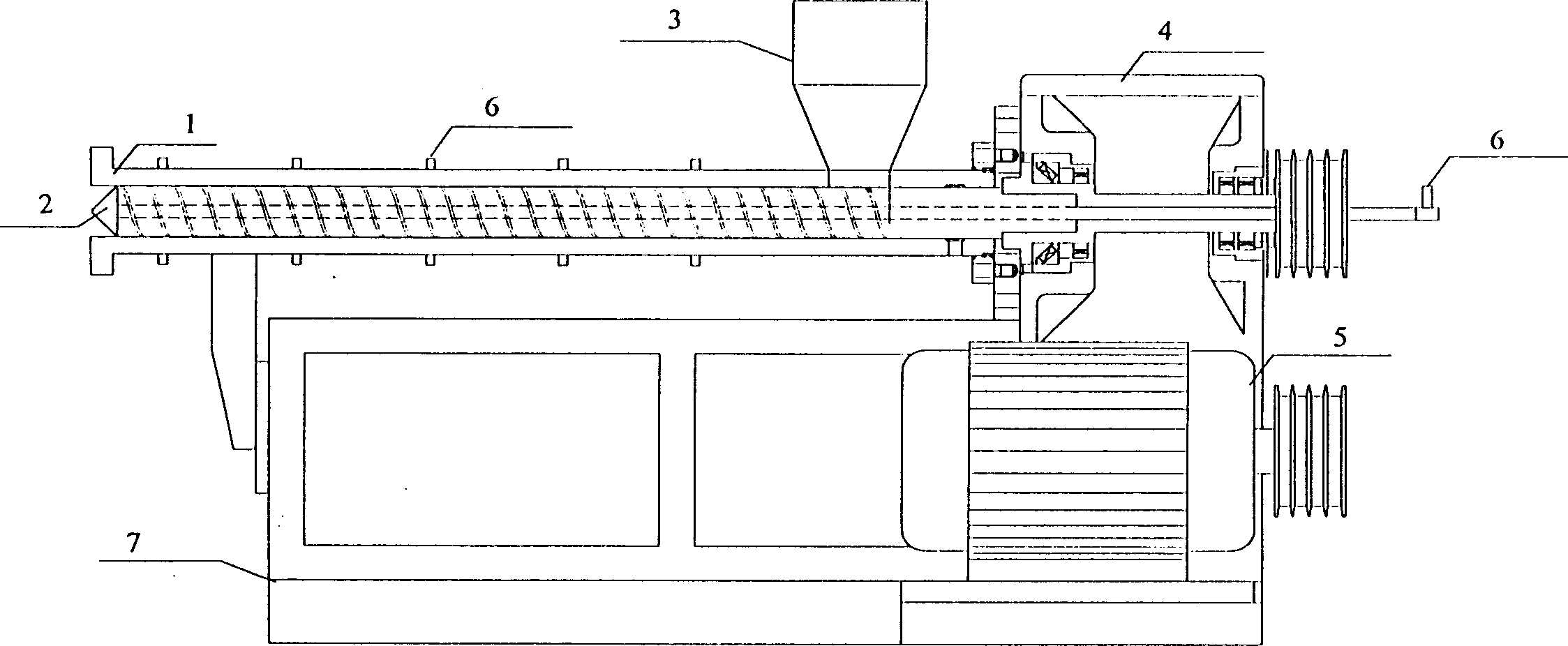

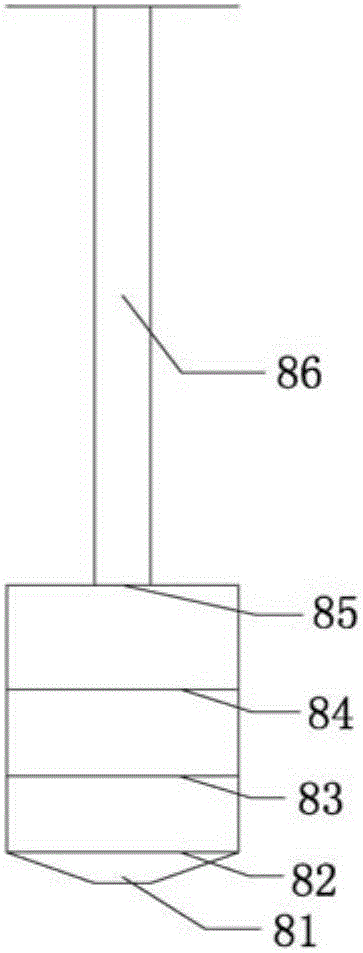

Super high-pressure single screw extruder

The invention relates to a hyper-pressure single-worm extrusion machine, comprising: a machine barrel, a screw bolt, a charging hopper, a driver, a motor, a cooling device, and an engine base. The invention is characterized in that: the cooling device is arranged on the machine barrel and the screw bolt; the geometric compression ratio of screw bolt is designed as high as 10-120; and the rotational speed of screw bolt is 30-1500 r / min. The invention has following advantages that: the cooling devices are arranged on the machine barrel and the screw bolt to eliminate the temperature over normal ones caused by the high-speed friction between chemical material and the machine barrel and screw bolt; the compression ratio of screw bolt is designed as high as 10-120 (according to the property of chemical material) to form a hyper-pressure solid transfer piston formed by extruded chemical material between the machine barrel and screw bolt; then the chemical material and the screw bolt, the chemical material and the machine barrel, the chemical material and the chemical material has friction in the hyper-pressure condition to generate heat, with which the chemical material can be melt and molded in short time, to be incised and mixed smelt; according to the friction temperature, the rotational speed of screw bolt is set at 30-1500 r / min, for controlling the amount of feeding material, the cooled amount and the friction temperature in stable balance condition.

Owner:包赟元

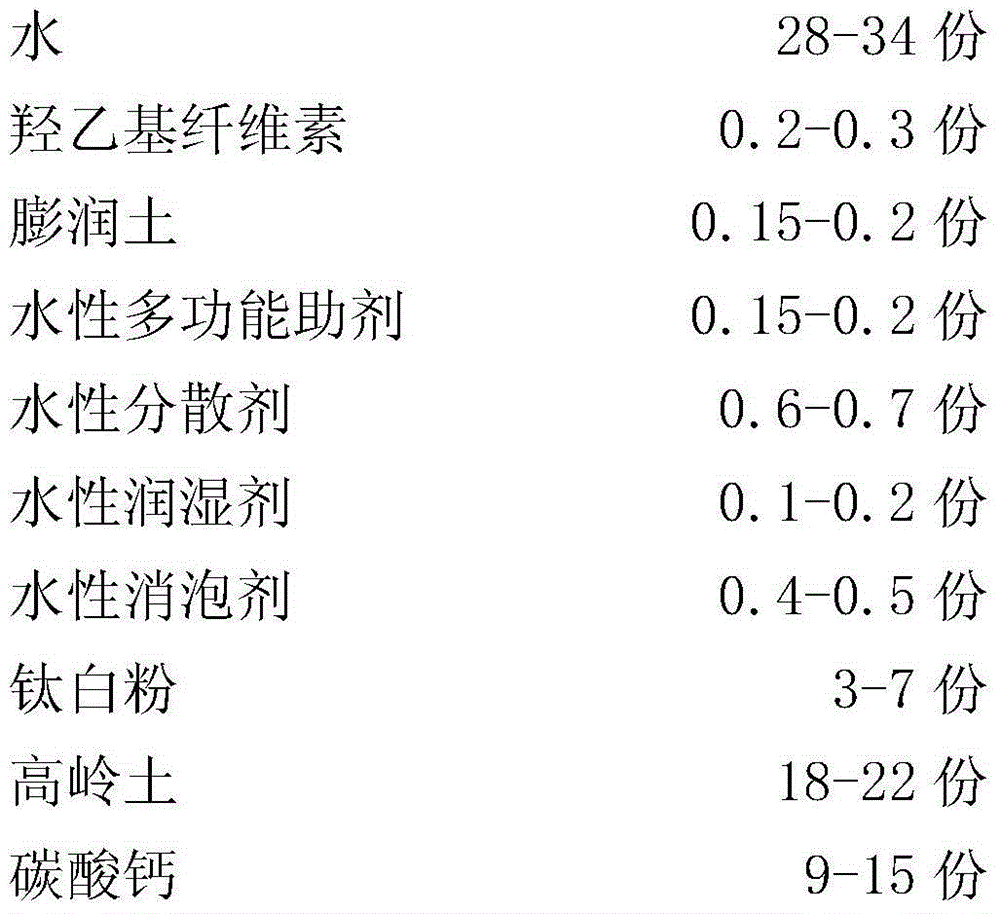

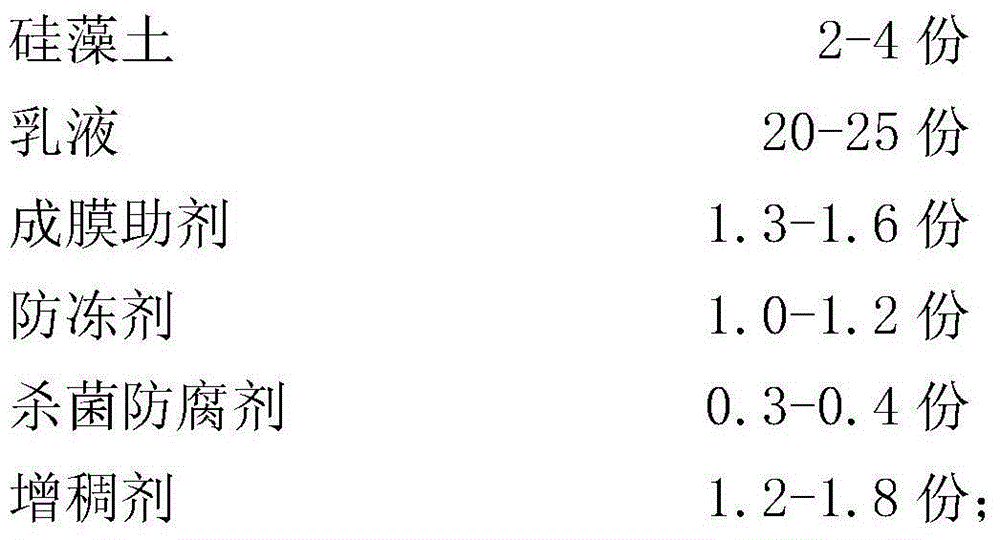

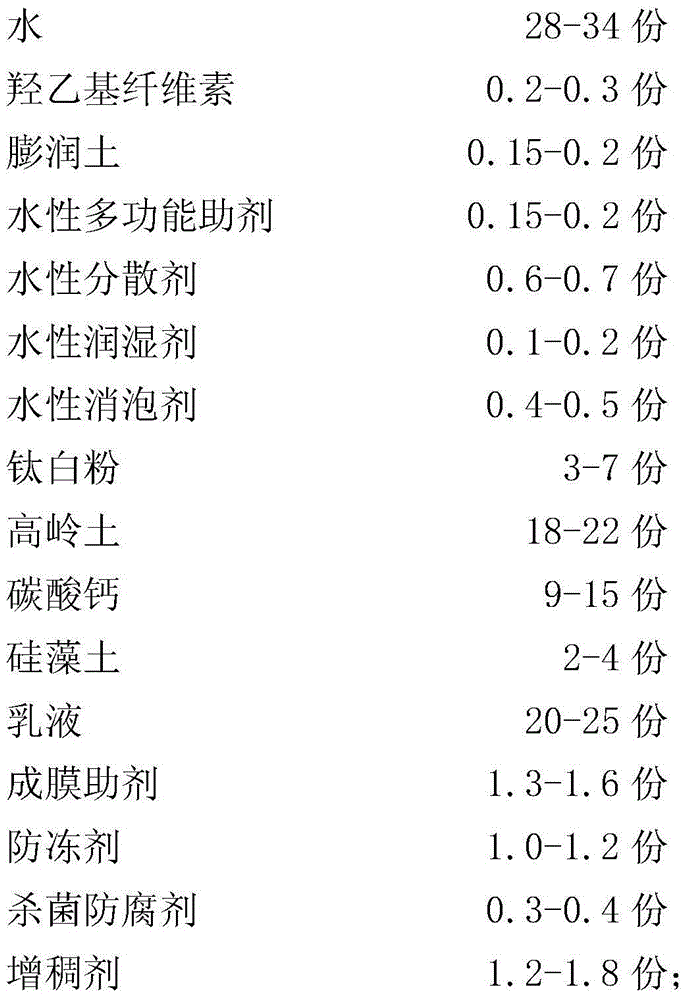

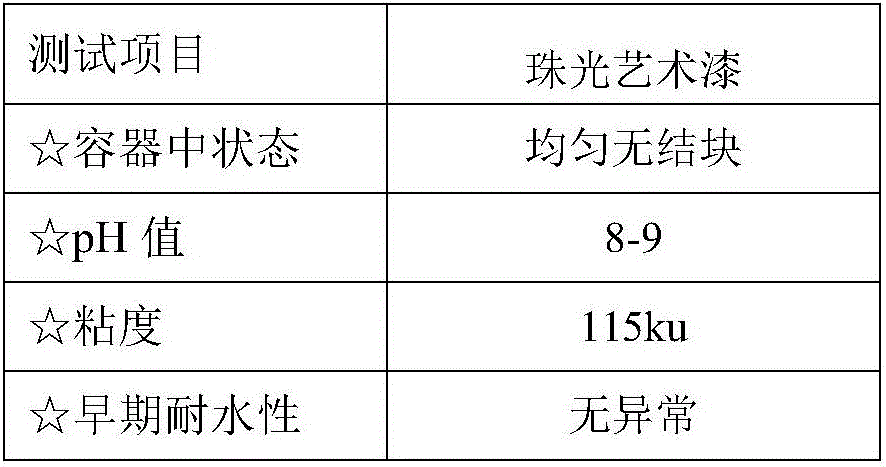

Artistic coating and preparation method thereof

The invention relates to an artistic coating and a preparation method thereof. The artistic coating is prepared from the following components in parts by weight: water, hydroxyethyl cellulose, bentonite, water-based multifunctional aids, a water-soluble dispersant, a water-based wetting agent, a water-based defoaming agent, titanium dioxide, kaolin, calcium carbonate, diatomite, emulsion, a coalescing agent, an anti-freezing agent, an antibacterial preservative and a thickening agent, wherein the emulsion refers to a water-based high polymer resin copolymerized by taking vinyl acetate and butyl acrylate as main functional monomers. When the artistic coating prepared by the method is used, only a coating is used, and different effects can be achieved according to the brushing frequency and processing technologies; and moreover, the defects that the emulsion paint is single in color and does not have sense of hierarchy and the color of wallpaper easily changes are overcome.

Owner:河北三棵树涂料有限公司

Electrolyte for micro-arc oxidation of magnesium alloys

InactiveCN104131326AChange process parametersReduce alkalinityAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention discloses an electrolyte for micro-arc oxidation of magnesium alloys to prepare ceramic layers, and a corresponding process method thereof. The electrolyte contains deionized water, sodium hexametaphosphate and additives, wherein the additives mainly include fluorides, a colorant and alkali metal hydroxides. The content of the sodium hexametaphosphate is 30-70 g / L, the content of the fluorides is 2-12 g / L, the content of the colorant is 2-10 g / L, and the pH value of the electrolyte is 7-10. The electrolyte is relatively low in system alkalinity, is a weak alkaline electrolyte for micro-arc oxidation, and can effectively reduce the process complexity of a water washing process in a micro-arc-electrophoresis production line, shorten the production line process, reduce the sewage discharge, and reduce the production cost; and once the electrolyte provided by the invention is adopted for carrying out the micro-arc oxidation of magnesium alloys, prepared ceramic layers have beautiful and decorative properties, so that a problem that ceramic layers prepared through the micro-arc oxidation of magnesium alloys are single in color is solved.

Owner:NANJING UNIV OF TECH

Coffee microcrystal glass plate and production method thereof

The invention discloses a coffee microcrystal glass plate and a production method thereof. The coffee microcrystal glass plate is prepared by the following steps of: mixing 11 to 13 parts of magnesite, 65 to 75 parts of granite, 14 to 17 parts of phosphate ore, 7 to 8 parts of heavy calcium and 2 to 4 parts of manganese ore; melting at 1,350 to 1,500 DEG C; clarifying and homogenizing at 1,400 to 1,450 DEG C; performing calendaring molding at the molding temperature of 1,150 to 1,270 DEG C to prepare a glass belt; performing annealing treatment; performing coring and crystallization; and polishing to obtain the coffee microcrystal glass plate. According to the production method of the coffee microcrystal glass plate, calcium-magnesium-aluminum-silicon serves as a main component and MnO2 serves as a coloring agent, so the problem of single color of microcrystal glass is solved; and the raw materials of the calcium-magnesium-aluminum-silicon in the formula are derived from natural minerals which are not purified and the chemical components are stable, so the raw materials are easily available and the cost is low.

Owner:四川一名微晶科技股份有限公司

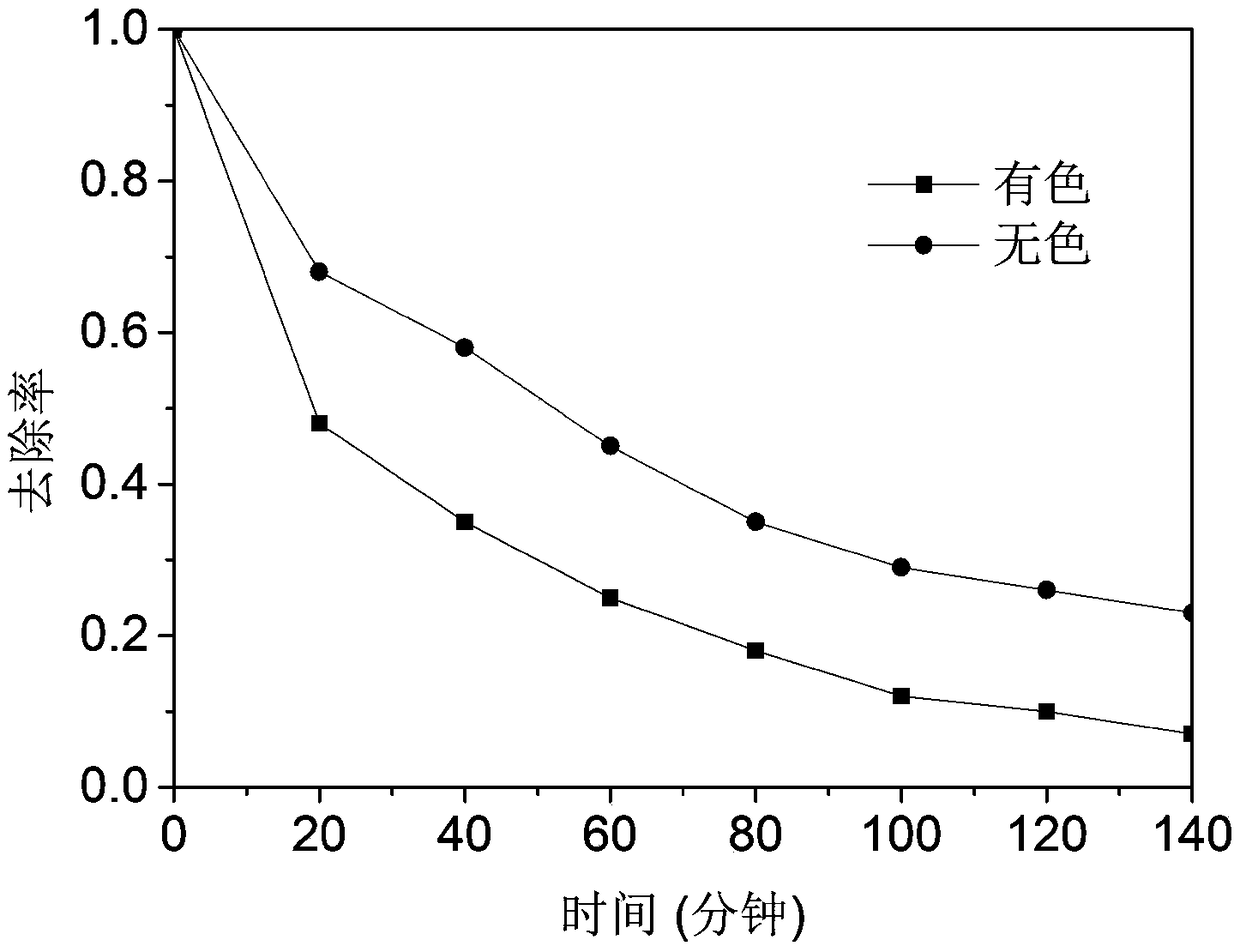

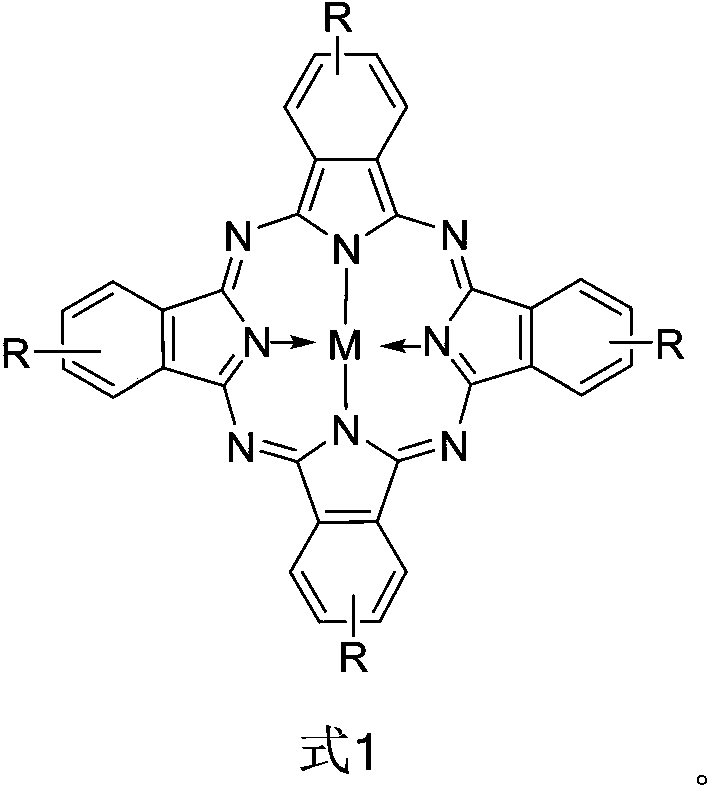

Colored photocatalysis fibers and preparation method thereof

InactiveCN108823672APhotocatalytically activeImprove photocatalytic degradation performanceMonocomponent polyesters artificial filamentSynthetic polymer filament chemical after-treatmentPhotocatalytic degradationPolyester

The invention provides colored photocatalysis fibers and a preparation method thereof. According to the invention, a polyester polymer and a composite photocatalyst are used as raw materials, and after the raw materials are spun into colored fiber protofilaments, the composite photocatalyst in the protofilaments is exposed by naking processing, so that the obtained colored photocatalysis fibers have the photocatalytic activity. Moreover, according to the invention, by adding a color master batch, when the colored photocatalysis fibers are guaranteed to have excellent photocatalytic degradationperformance, a problem of a single color of a catalytic functional textile is solved. An experiment result shows that the colored photocatalysis fibers provided by the invention have a very high degradation rate for methylene blue, and can enable the degradation rate for the methylene blue to reach 90% or higher within 140min.

Owner:ZHEJIANG SCI-TECH UNIV

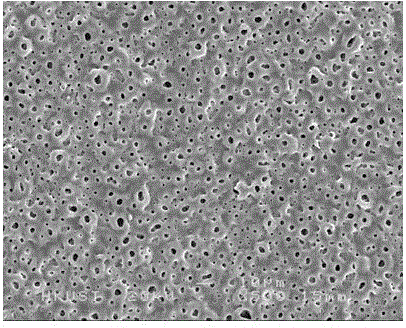

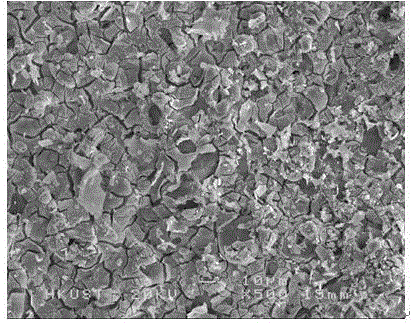

Micro-arc oxidation ceramic membrane and preparation method thereof

InactiveCN106119926AChange ingredientsImprove corrosion resistanceAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention provides a micro-arc oxidation ceramic membrane and a preparation method thereof. The preparation method comprises the steps of micro-arc oxidation treatment and hole sealing treatment. After a magnesium alloy is subjected to micro-arc oxidation treatment, the ceramic membrane with high corrosion resistance and heat radiation performance is generated on the surface, hole sealing treatment is carried out through hole sealing liquid, the compactness of the ceramic membrane is enhanced, and the corrosion resistance of the ceramic membrane is further enhanced. The micro-arc oxidation ceramic membrane and the preparation method have the following beneficial effects that after the magnesium alloy is subjected to micro-arc oxidation treatment, and the ceramic membrane with high heat radiation performance is formed on the surface, so that the heat radiation efficiency of the magnesium alloy is improved; an additive containing glycerine and tungstate is added into a micro-arc oxidation electrolyte, components of the ceramic membrane are changed, the corrosion resistance of the ceramic membrane is enhanced, and therefore the corrosion resistance of the magnesium alloy is increased, and the service life is prolonged; and hole sealing treatment is carried out through the hole sealing liquid, the compactness of the ceramic membrane is improved, the corrosion resistance of the magnesium alloy is further improved, and meanwhile the problem that the colors of micro-arc oxidation ceramic membranes in the current market are not abundant is solved.

Owner:KA SHUI TECH HUIZHOU CO LTD

ETD high-shrinkage type elastic double-color fiber and preparation method thereof

InactiveCN107829165AIncrease elasticityImprove shrinkageArtificial filament heat treatmentConjugated synthetic polymer artificial filamentsFiberMaterials science

The invention discloses an ETD high-shrinkage type elastic double-color fiber and a preparation method thereof, and is characterized in that the ETD high-shrinkage type elastic double-color fiber is formed by compositing a first filament body and a second filament body, the ratio of the first filament body to the second filament body is 3:7-7:3, the first filament body is a cationic POY filament,the second filament body is prepared by compositing a component A and a component B, the component A is one of PET, PA and PBT, the component B is one of PET, PA and PBT, and the component A is different from the component B; the preparation method comprises the steps: 1, heating and texturing the first filament body; and 2, stranding the first filament body and the second filament body, to obtainthe high-elasticity double-color fiber. The elastic double-color fiber can be produced, and the production cost can be reduced.

Owner:WUJIANG JIALI ADVANCED FIBER CO LTD

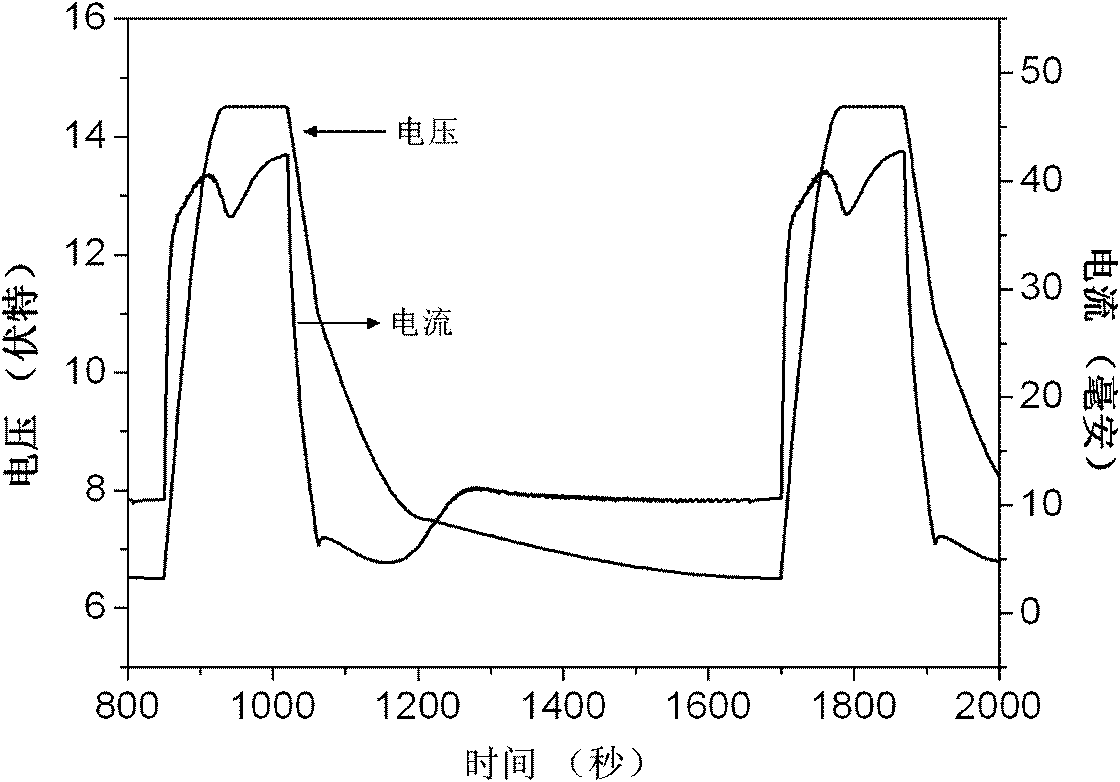

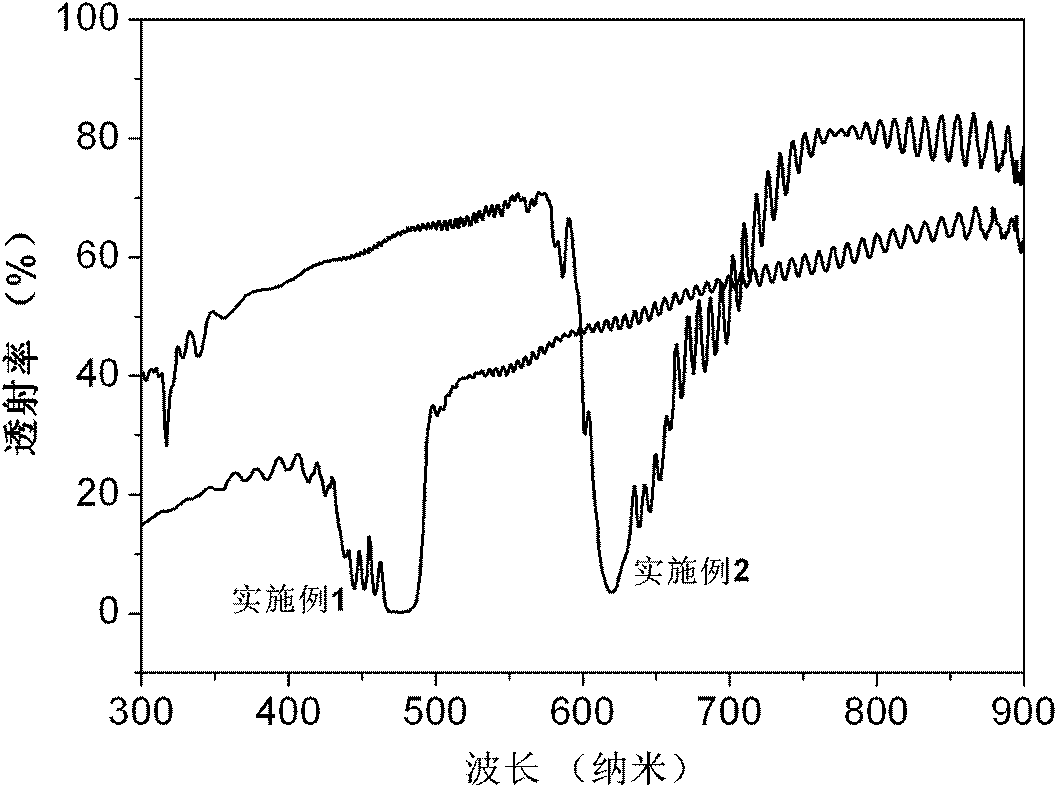

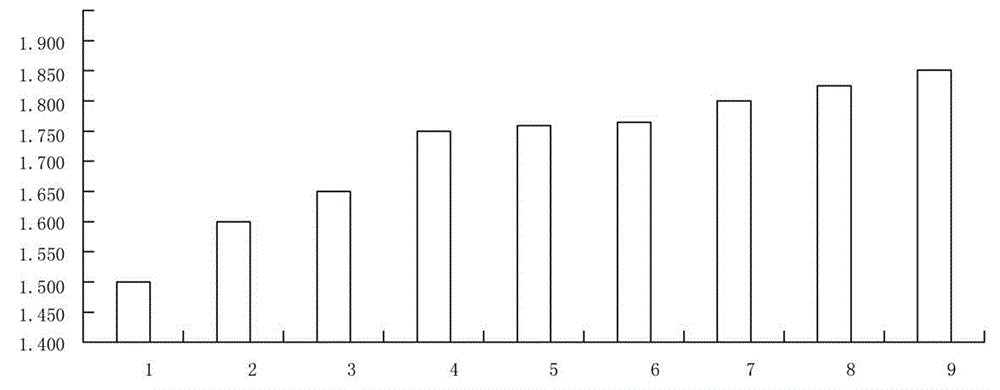

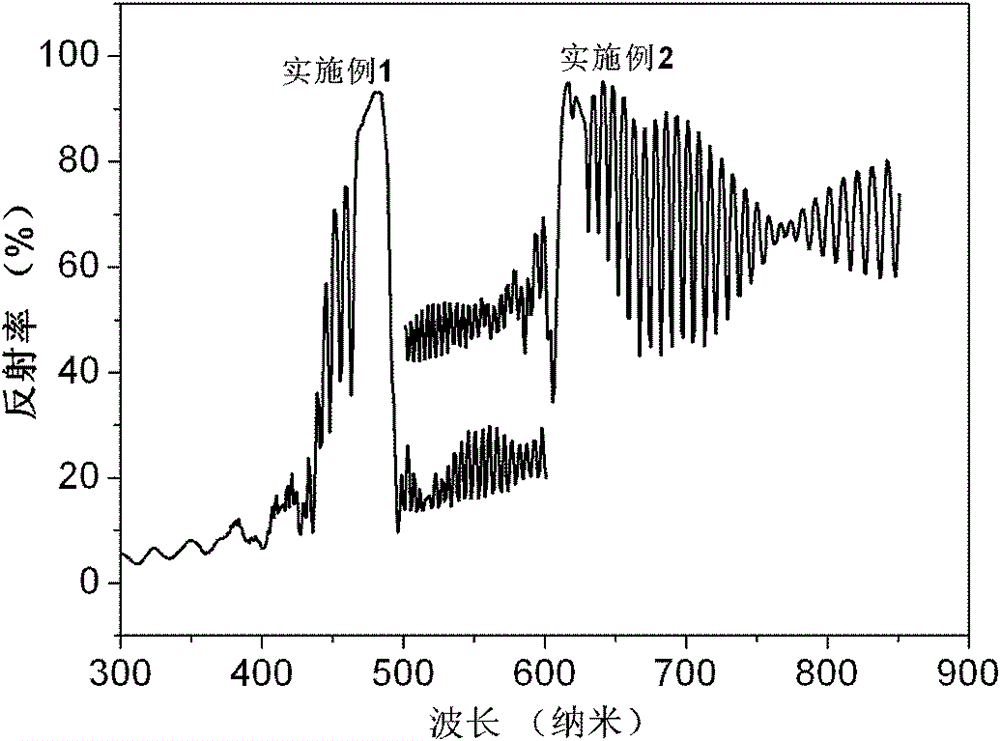

Method for coloring aluminum and alloy surface thereof

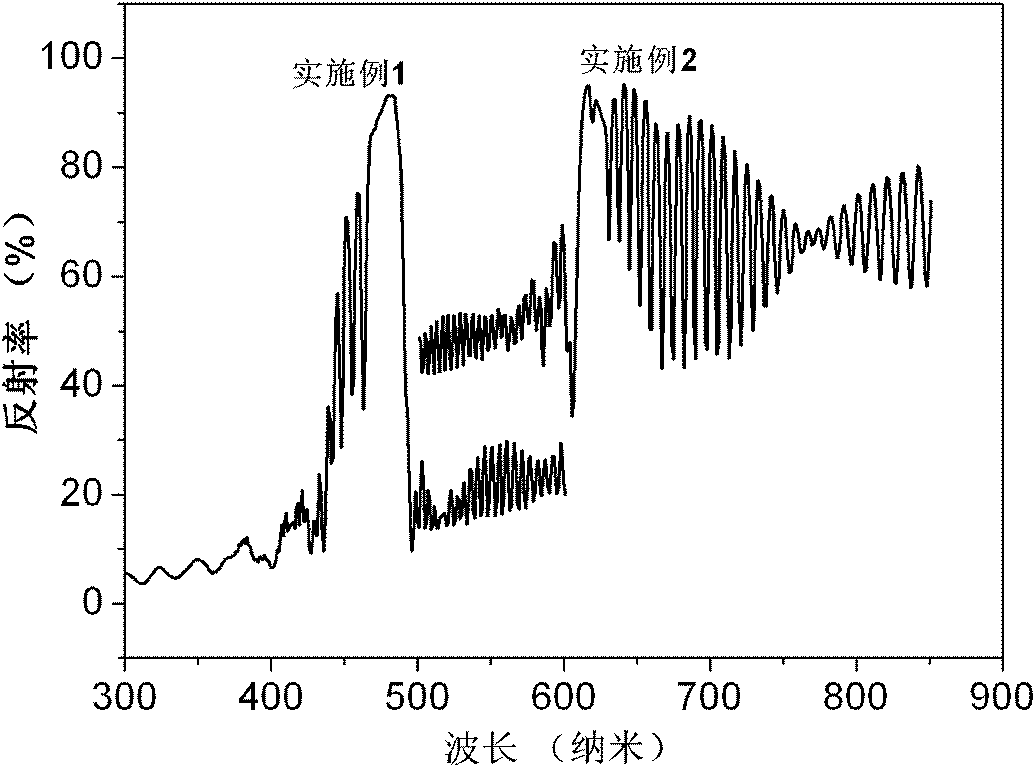

InactiveCN102181902ASimple processWide color adjustment rangeSurface reaction electrolytic coatingElectrolyteLamellar structure

The invention discloses a method for coloring aluminum and an alloy surface thereof, which comprises the following steps of: at first, cleaning and polishing the aluminum or the aluminum alloy surface; carrying out constant-pressure anode preoxidization for 20 minutes to 3 hours under the preoxidization voltage of 10 to 20 volts by using sulfuric acid electrolyte with the concentration of 0.1 to 3mol / liter under the conditions that the well-processed aluminum or aluminum alloy is used as an anode and graphite is used as a cathode; and then oxidizing the aluminum or the aluminum alloy by utilizing a voltage which varies periodically based on time to obtain a structurally laminar alumina photonic crystal, and coloring the aluminum or the aluminum alloy surface by the structural color of an optical forbidden band of the alumina photonic crystal, so that different colors can be adjusted within a scope of visible lights by maintaining constant time and changing the voltage only or maintaining constant voltage and changing time only. The coloration method of the invention has the advantages of no need of depositing metal ions, simple process and low cost, wide adjustment scope of colorsand less pollution.

Owner:SOUTH CHINA UNIV OF TECH

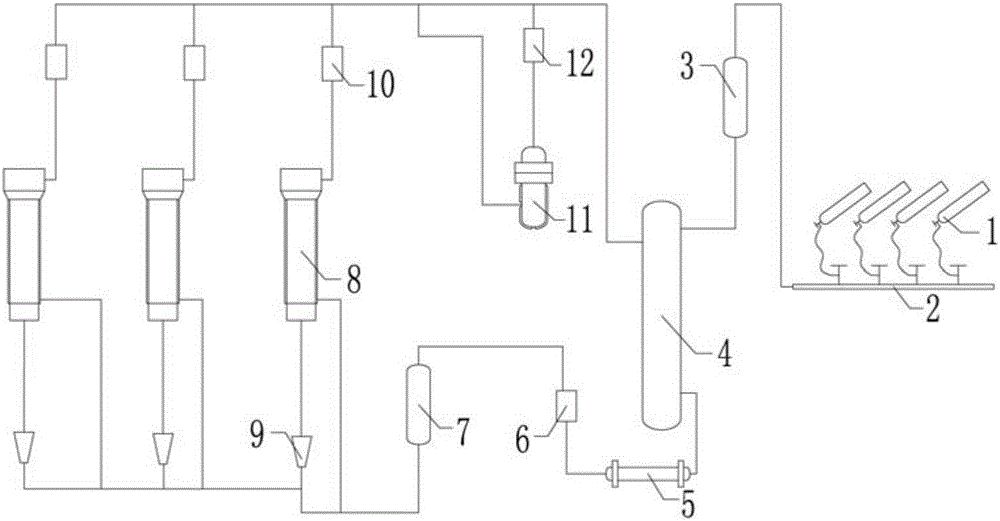

System for color-changeable engineered supercritical carbon dioxide fluid anhydrous dyeing and finishing and method thereof

ActiveCN106757918ASolve single colorGuaranteed uniformitySolvent treatment with solvent recoveryTextile/flexible product manufactureChemistryDyeing

The invention relates to a system for color-changeable engineered supercritical carbon dioxide fluid anhydrous dyeing and finishing and a method thereof and belongs to the technical field of dyeing and finishing. The system comprises a dyeing and finishing unit, a separation kettle and a particle on-line detector. The dyeing and finishing unit comprises at least one group of dyeing and finishing kettles, pumps and adsorption kettles. An outlet I of each group of dyeing and finishing kettles is connected with an inlet I thereof through the respective pump, an outlet II of each group of dyeing and finishing kettles is connected with the separation kettle through the respective adsorption kettle, an outlet of the separation kettle is connected with a three-way valve inlet through the particle on-line detector, and a three-way valve outlet I is connected with the separation kettle. Multi-color multifunctional dyeing production of textiles is implemented through the plurality of dyeing and finishing kettles, and color change in supercritical carbon dioxide fluid anhydrous dyeing production is implemented.

Owner:晋江国盛新材料科技有限公司

Colorful garden stuff fresh rice-flour noodles

The invention discloses color fruit and vegetable fresh rice noodle, which belongs to preliminarily cooked noodle. The rice noodle is prepared by the following steps: rice slurry is mixed with self-colored fruit and vegetable slurry; the slurry is sequentially spaced on a tray into stripes and is sprayed uniformly; the slurry is cured into color-spaced rice noodle pieces; the rice noodle pieces are cut lengthways or broadways to prepare the color fruit and vegetable fresh rice noodle; wherein the mixed weight proportion of the rice slurry and the self-colored fruit and vegetable slurry is 1: 0.15-0.25. The rice noodle designed by the invention solves the problem of single color of edible rice noodle and provides the colorful and appetitive color fruit and vegetable fresh rice noodle. Being rich in cellulose of fruits and vegetables, a variety of vitamins and pure natural fruit and vegetable pigment, the rice noodle is harmless to human body and is more suitable for being eaten as salad.

Owner:TIANJIN ZHONGYING HEALTH FOOD

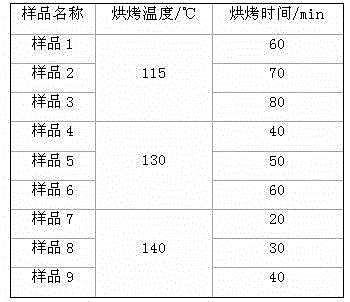

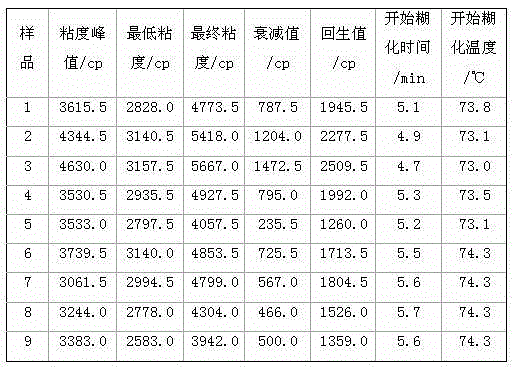

Brewing instant pea meal

InactiveCN103141777ASolve the taste problemSolve single colorFood preparationBiotechnologyLotus root

The invention provides a brewing instant pea meal which is prepared by adopting the following steps of: baking peas at a baking temperature of 130 DEG C for 50 minutes, soaking by using alkali liquor until the peas fully absorb water to expand, then peeling, and grinding to obtain pea slurry; spraying the pea slurry for drying, crushing, sieving with a sieve to obtain pea meal to be used; and weighing the pea meal to be used, lotus root powder and green gram starch according to proportion, and uniformly mixing to obtain the brewing instant pea meal, wherein the weight of the lotus root powder accounts for 20 percent that of the brewing instant pea meal, and the weight of the green gram starch accounts for 10 percent that of the brewing instant pea meal. According to the brewing instant pea meal, on the basis of the prior art, through improving a preparation process of the pea meal and increasing a certain amount of lotus root powder and green gram starch according to the proportion, the problem of single mouth-feel and color of the existing brewing instant pea meal is solved.

Owner:HENAN HUANGGUO GRAIN COMPANY

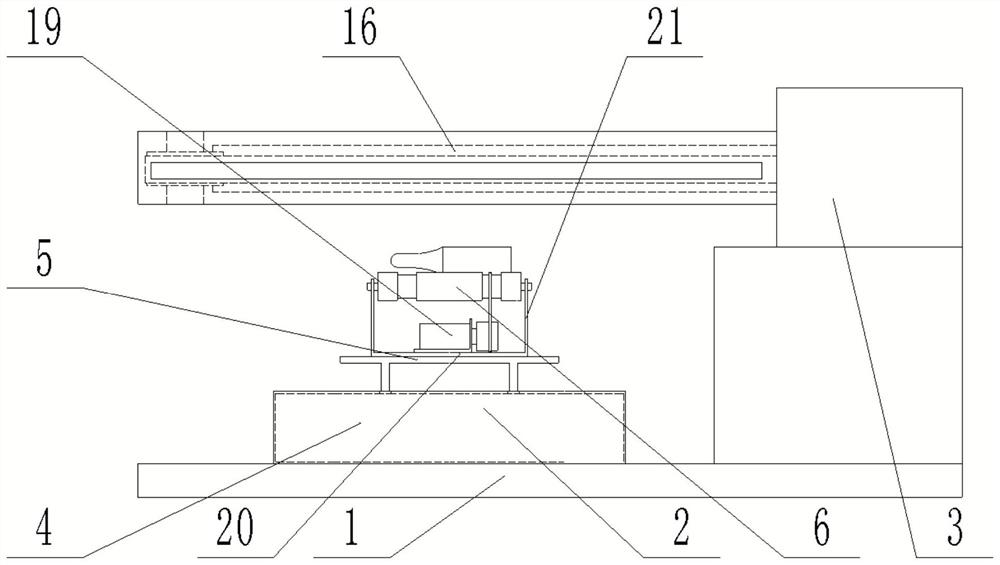

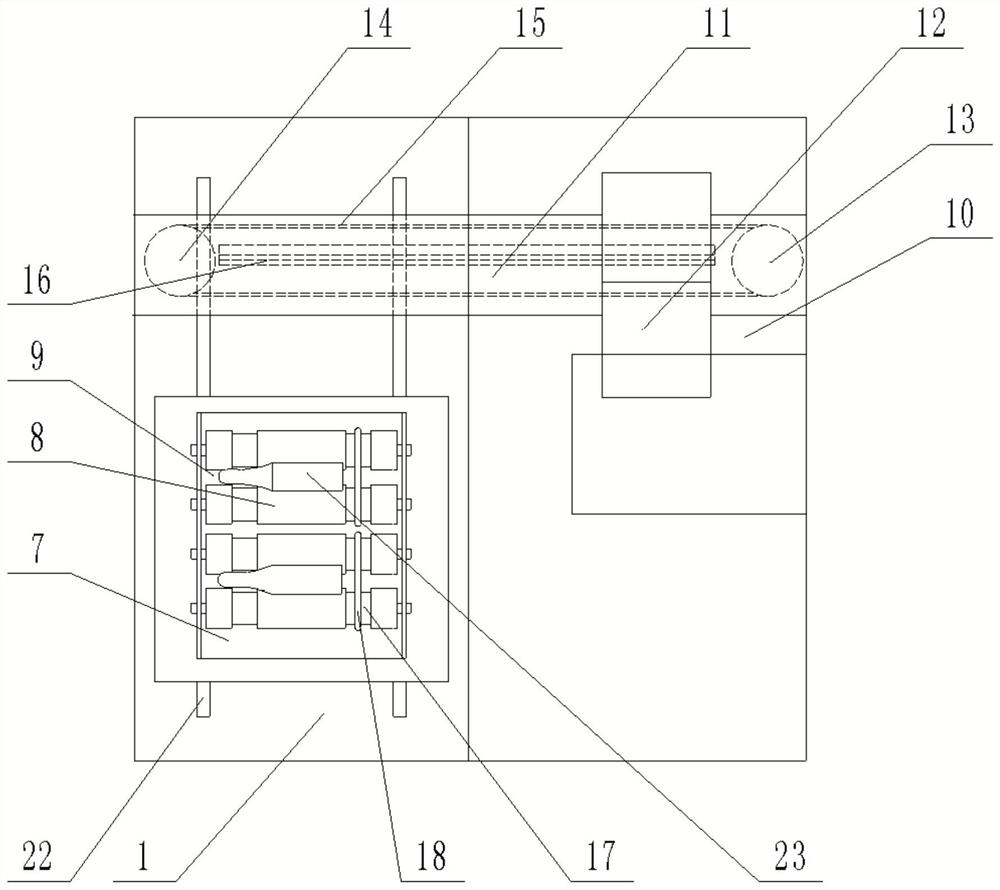

Ampoule bottle embossed printer

PendingCN112373199AGuaranteed accuracyGuaranteed clarityTypewritersOther printing apparatusComputer printingEngineering

The invention discloses an ampoule bottle embossed printer, and relates to the field of ampoule bottle processing equipment. The ampoule bottle embossed printer comprises a rack; a rotary translationprocessing mechanism and a reciprocating translation printing mechanism are arranged on the rack; the rotary translation processing mechanism comprises a fixed seat; a processing platform is movably arranged on the fixed seat; an ampoule bottle supporting mechanism for placing ampoules is arranged on the processing platform and comprises a fixed frame; two supporting rollers are rotatably arrangedon the fixed frame in parallel; a bottle placing groove is formed between the upper end faces of the two supporting rollers; the supporting rollers are connected with a servo motor; the reciprocatingtranslation printing mechanism comprises a mounting frame; a cantilever is arranged on the mounting frame and over the processing platform; a printer body used for printing on ampoule bottle bodies is movably arranged on the cantilever along the length direction; and a driving mechanism used for driving the printer body to reciprocate along the length direction of the cantilever is arranged on the cantilever. According to the ampoule bottle embossed printer, the spray printing is carried out by the printer body, and the ampoule bottle embossed printer has the advantages of good printing effect and prominent and clear handwriting.

Owner:ZHENGZHOU SHUNYI TECH CO LTD

Environmental protection type mixed multi-color wall decoration art paint and preparation method thereof

InactiveCN106833230ASolve single colorBrilliant artistic effectFireproof paintsAntifouling/underwater paintsEnvironmental resistanceLow speed

The invention relates to environmental protection type mixed multi-color wall decoration art paint and a preparation method thereof. The art paint comprises the following components in parts by weight: 170 to 200 parts of a basic paint A, 170 to 200 parts of a basic paint B, 350 to 400 parts of a 7.5 percent GTS solution and 300 to 320 parts of a continuous phase. During preparation, the environmental protection type mixed multi-color wall decoration art paint is prepared by the steps of preparing the basic paint A and the basic paint B firstly, mixing the basic paint A and the basic paint B, adding the 7.5 percent GTS solution, mixing uniformly at a low speed of 400 to 500 rpm, adding the continuous phase, mixing uniformly at the speed of 800 to 1000 rpm, and pelleting. Compared with the prior art, the art paint provided by the invention is environmentally-friendly, low in manufacturing cost, simple in production process, prominent in artistic effect, high in glossiness, not liable to peeling off, peeling and cracking, prominent in wear resistance and water resistance and favorable for popularization and use, and has a good application prospect.

Owner:BNSA NEW MATERIAL SHANGHAI CO LTD

Method for producing color bamboo sheet

InactiveCN1616199ASolve single colorChange stressWood treatment detailsCork mechanical workingWood veneerCarbonization

The present invention relates to decorative material, and is especially the production process of surface decorating color bamboo sheet. Colored bamboo sheets are matched and pressed into bulk material, which is then turned, planed or sawed and dried to form color bamboo sheet. The colored bamboo sheet is produced with thin bamboo sheet and through high temperature steaming, bleaching, drying, and pressure coloring inside one pressure container, vapor carbonization coloring, soaking coloring or printing coloring. The present invention provides various kinds of colorful decorating bamboo sheets.

Owner:胡波

Environment-friendly dyeing method for jacquard denim

InactiveCN105803800ASolve single colorSolve the problem of dull, lack of visual impactCarbon fibresBiochemical treatment with enzymes/microorganismsEngineeringCellulase

The invention discloses an environment-friendly dyeing method for jacquard denim.The process comprises the following specific steps of weaving, desizing, cellulase finishing, roasting, dyeing, softening agent application, roasting, noniron finishing and packaging.A sizing agent on clothes is removed by means of desizing, biopolishing finishing and noniron finishing are adopted, the jacquard denim meeting requirements can be made, the problems that traditional denim has a single color, the cloth cover style is depressing, and the visual impact is lacked are solved, the jacquard denim adapts to the trend of the times, and a jacquard layer reflects fashionable elements.

Owner:TAICANG QIANJING CHEM FIBER FACTORY

Colorful rice cake

Owner:樊世菊

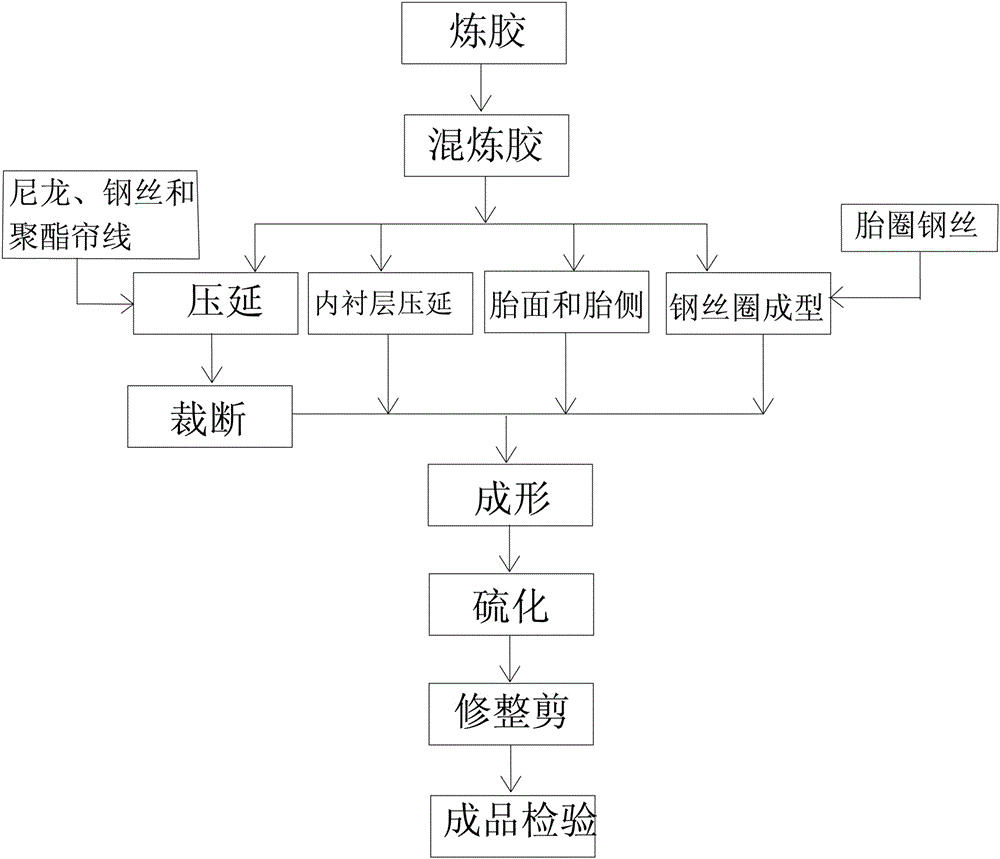

Manufacturing method for car tire with side wall colored patterns

The invention relates to a manufacturing method for a car tire with side wall colored patterns. Before a tire forming procedure, the colored patterns are printed on side wall rubber through a color printer. According to the manufacturing method for the car tire with the side wall colored patterns, the production processes of other procedures are not changed during tire production; in the tire forming link and before tread combination, as the side wall rubber of the tire is basically a plane, the colored patterns are printed on the tire side wall with the printer connected with a computer through the side wall rubber to be used; and after tire production, the tire side wall is provided with the colored patterns. By means of the manufacturing method for the car tire with the side wall colored patterns, the problem that the color of a tire is simplex and not rich enough can be solved, and various patterns and images can be printed according to the design with the computer. The manufacturing method for the car tire with the side wall colored patterns has the advantages of being simple in process, low in cost, remarkable in printing effect of the tire and the like, and can attract the eyes of customers, thereby improving the sales volume.

Owner:HEBEI XIEMEI RUBBER PROD CO LTD

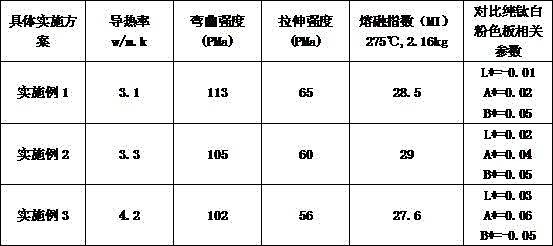

High-flowability and high-brightness heat conduction nylon composite material and preparation method thereof

The invention discloses a high-flowability and high-brightness heat conduction nylon composite material which is prepared from the following raw materials in parts by mass: 100 parts of nylon, 0.3 to 0.8 part of a nano functional material, 50 to 95 parts of a nitride heat conduction filler, 0.3 to 0.8 part of an antioxidant, 2.0 to 4.5 parts of a surfactant, 3 to 5 parts of a lubricant and 28 to 60 parts of a solvent, and provides a preparation method suitable for industrial production. According to the high-flowability and high-brightness heat conduction nylon composite material, the flowability of highly filled heat conduction nylon is improved, the dispersivity of the crystallization and heat conduction filler is improved, and the problem of color singleness is further solved.

Owner:SHENZHEN SAPAC IND

Preparation method of colored nanofiber membrane with composite structure

InactiveCN110983456AIncrease added valueImprove filtration efficiencyMembranesSemi-permeable membranesFiberPolymer science

The invention discloses a preparation method of a colored nanofiber membrane with a composite structure. The preparation method comprises the following specific preparation processes of (1) combiningfine emulsification and electrostatic spinning processes, coating dyes with different chemical structures in a polymer nanoparticle matrix through the high-speed shearing action of fine emulsificationultrasound, removing a volatile solvent under a sealed and pressure-reduced condition, and uniformly dispersing the solvent type dyes in a water phase by virtue of a polymer carrier with uniformly distributed particles; (2) adjusting different parameters of the prepared dye / polymer composite nano dispersion liquid under the action of high-voltage static electricity, and directly obtaining nanofibers with different colors by virtue of an electrostatic spinning method; and (3) receiving the nanofibers with different colors in base material manufacturers with different structures and materials to obtain the uniform colored nanofiber membrane. The colored nanofiber membrane has very wide application space in the application fields of functional masks, air filtering products, screen window products for decoration, even photosensitive sensing and the like in the future.

Owner:上海纷然科技有限公司

Colored polyarylester and preparation method thereof

PendingCN110184669ASolve single colorSolve the problem of not easy to dyeMonocomponent polyesters artificial filamentArtifical filament manufactureFiberSlurry

The invention discloses colored polyarylester and a preparation method thereof. The method comprises the following steps that S1, organic pigment is added into a dispersion medium mixed with a stabilizer to be uniform to obtain colored slurry; S2, the colored slurry in S1 is input into fused polyarylester, and mixing, filtering and spinning are performed to obtain the colored polyarylester; according to the preparation method of the colored polyarylester, the problem that polyarylester has single color and cannot be dyed easily is effectively solved, and the fiber application field is expanded. The colored polyarylester is obtained in the mode of dyeing and spinning in success, the dye is evenly distributed inside a polymer, the color fastness is high, the color luster is uniform, and theappearance effect is good; the colored polyarylester has no color difference between batches and inside batches, and the polyarylester is suitable for large-batch continuous production.

Owner:上海舟汉纤维材料科技股份有限公司

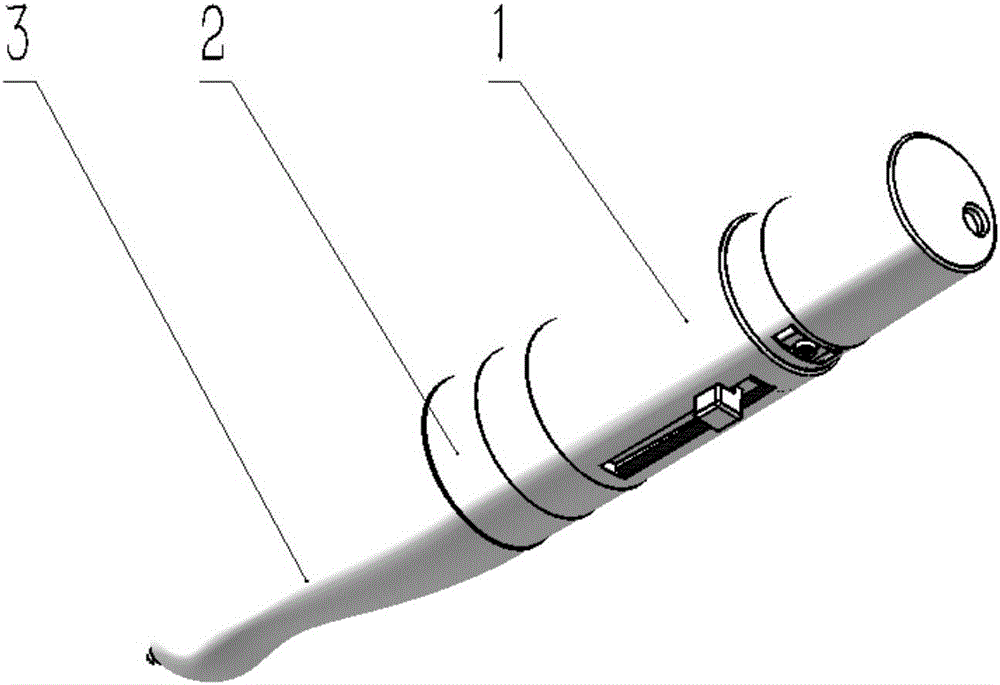

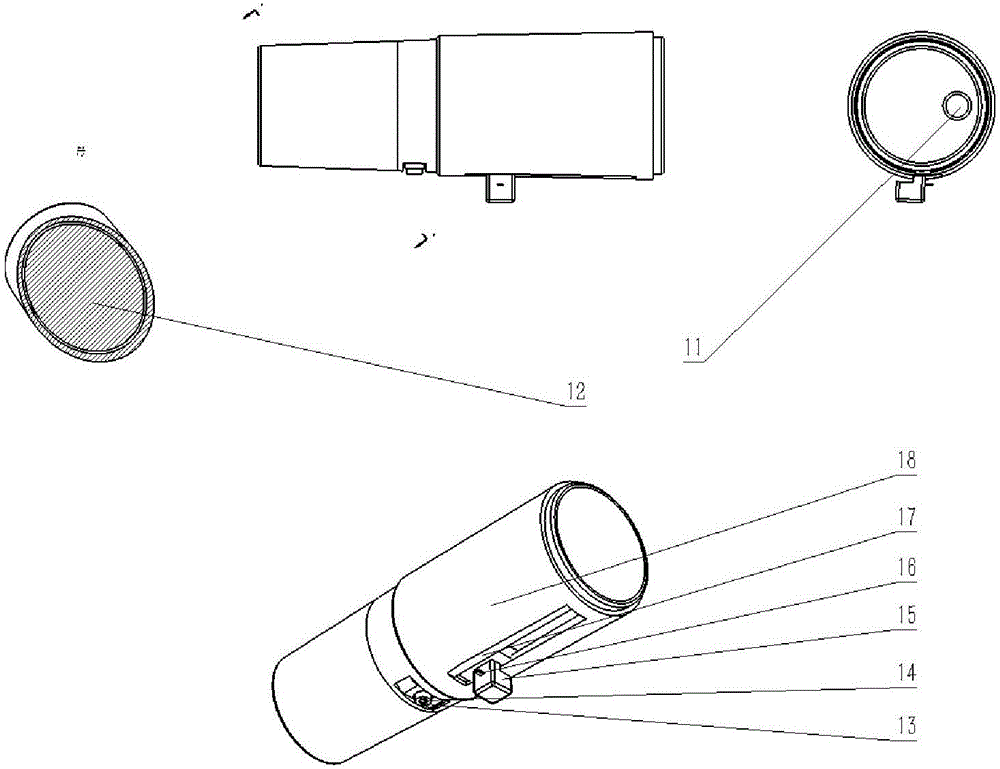

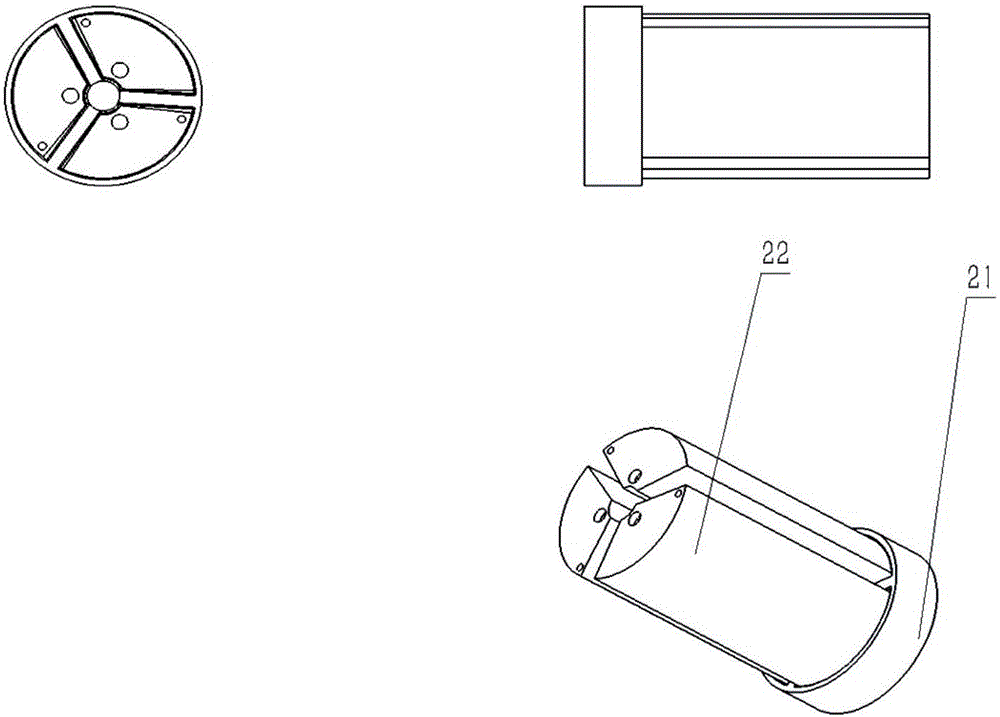

Intelligent color pen

ActiveCN106515266AMeet the needs of colorSolve single colorMultiple-point writing implementsPattern recognitionReuse rate

The embodiment of the invention discloses an intelligent color pent. The intelligent color pen aims at solving the problems that an existing pen is singular in color, although a multi-color pen exits, the color selection is still limited, meanwhile the structure of the pen is more complex, the reuse rate is not high, and some color pens cannot be reused; and although a ball-point pen with a replaceable refill exits, refill replacing is more economical relative to ink replacing, meanwhile under the condition that many colors are required, a lot of pens are needed, the color needs to be mixed by a user, and sometimes the operation that the user mixes the colors for obtaining the required color is very difficult and complicated. By means of the intelligent color pen, the technical problems that common pens are neither economic nor time-saving are solved.

Owner:GUANGDONG UNIV OF TECH

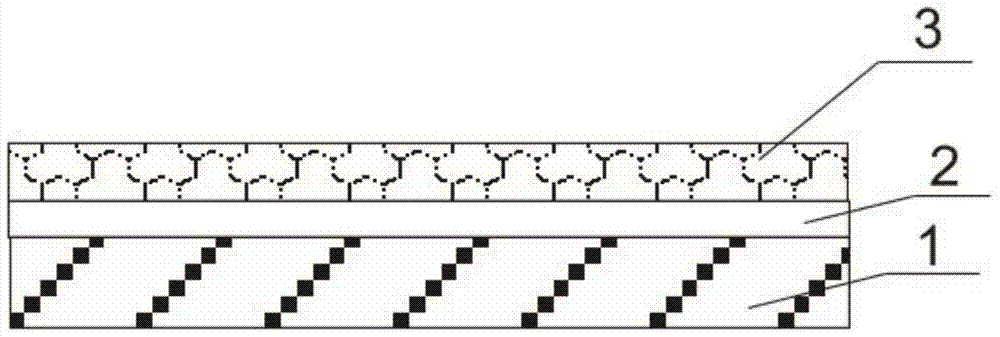

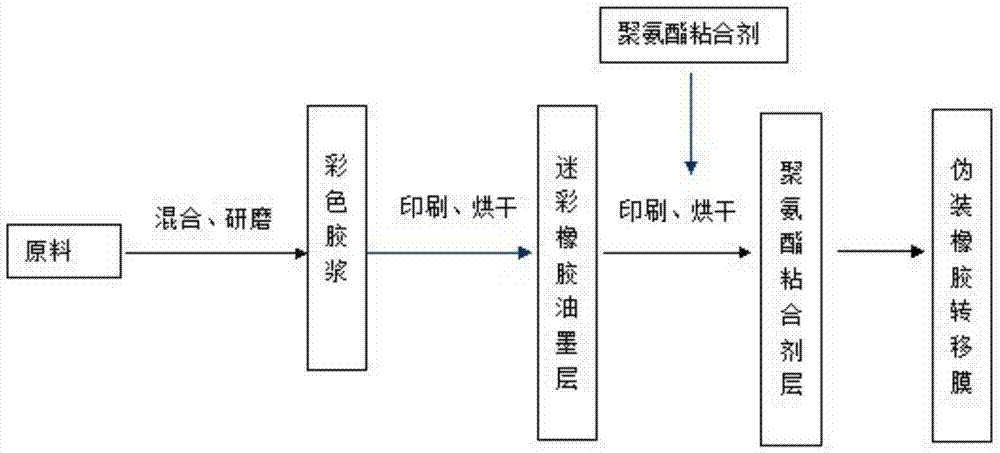

Simulated rubber transfer film and preparation method thereof

ActiveCN104723713AGood chemical resistanceHigh pigment densityDigger harvestersInksTotal solid contentPolyurethane adhesive

The invention relates to a simulated rubber transfer film and a preparation method thereof. The simulated rubber transfer film comprises a polyurethane adhesive layer, a simulated rubber printing ink layer which is printed with a simulated pattern and a two-way stretching polypropylene film layer, wherein the simulated rubber printing ink layer is printed on the two-way stretching polypropylene film layer through intaglio printing, and the polyurethane adhesive layer is printed on the simulated rubber printing ink layer through intaglio printing. The simulated rubber transfer film is characterized in that the simulated rubber printing ink layer is prepared from the following raw materials in parts by weight: 10-15 parts of pigments, 100 parts of neoprene latex, 1-2 parts of an anti-ageing agent and 1-1.5 parts of an ultraviolet light absorber, wherein the total solid content in the neoprene latex is 50%-61%; the grain size of the neoprene latex is 50-70 nm; the anti-ageing agent is di-tert-butyl p-cresol, an anti-ageing agent 4010NA or an anti-ageing agent 4020; the ultraviolet light absorber is UV-531, UV-326 or UV-327.

Owner:北京邦维高科新材料科技股份有限公司

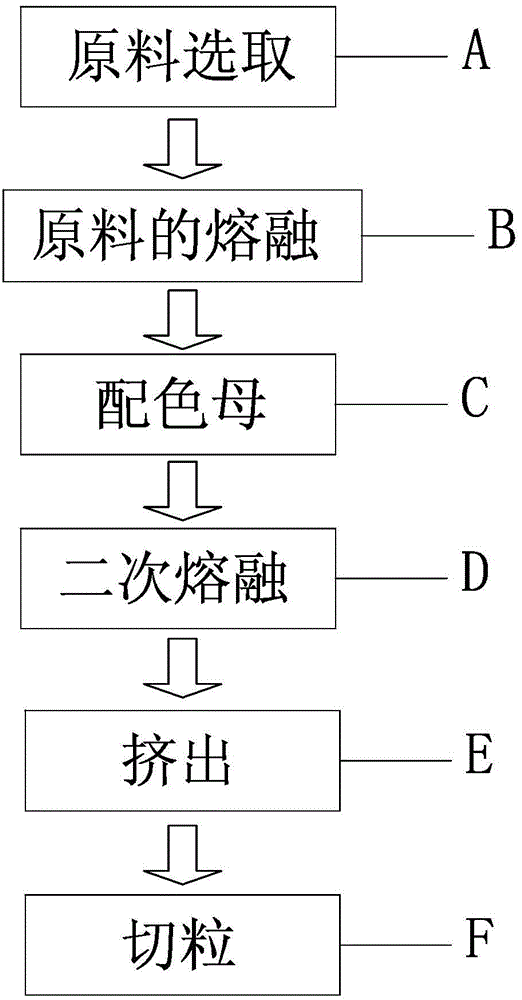

Method for producing variable color wire rod

The invention discloses a method for producing a variable color wire rod, which relates to the technical field of wire rod production. The method comprises the following steps: a)selecting a raw material; b)fusing the material; c)configuring color masterbatch; d)performing secondary fusing; e)extruding; and f) granulating. According to the production method, the color of the produced wire rod can be changed by following with illumination and temperature, the wire rod can be used for producing power lines, data lines and earphone cords, problem of signal color of the integral wire rod in prior art can be solved, individual characteristic can be added, various color of a derivative product prepared by the wire rod in practical usage can fill the disadvantage of single color of the original wire rod.

Owner:任彰淳

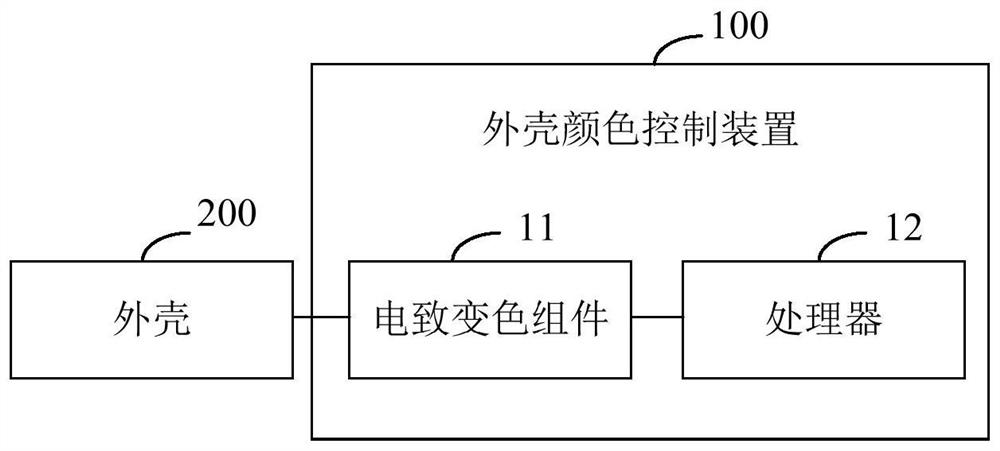

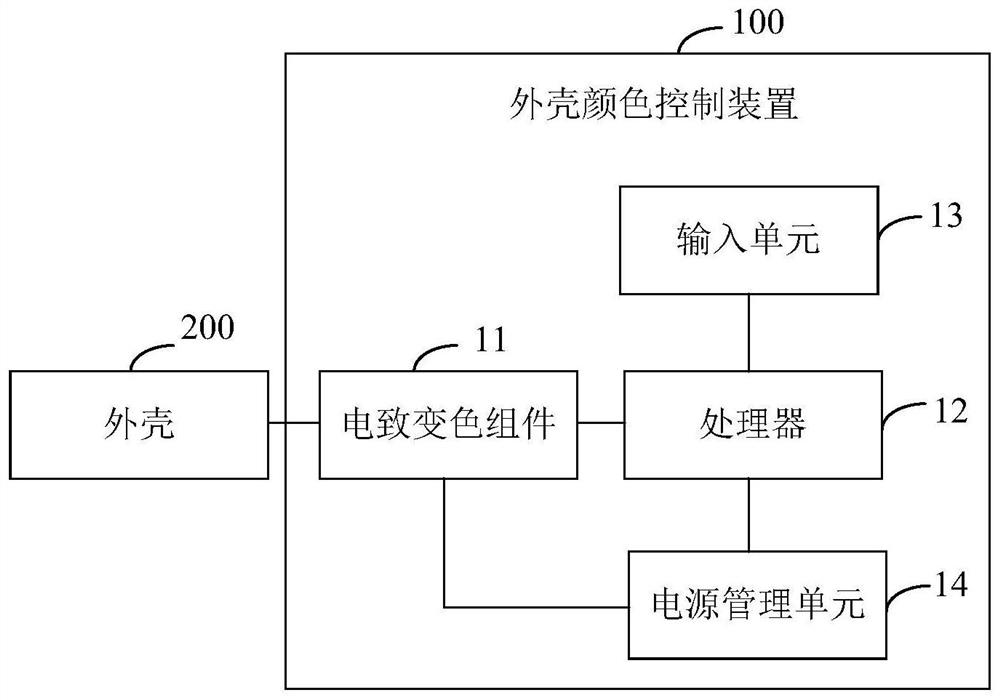

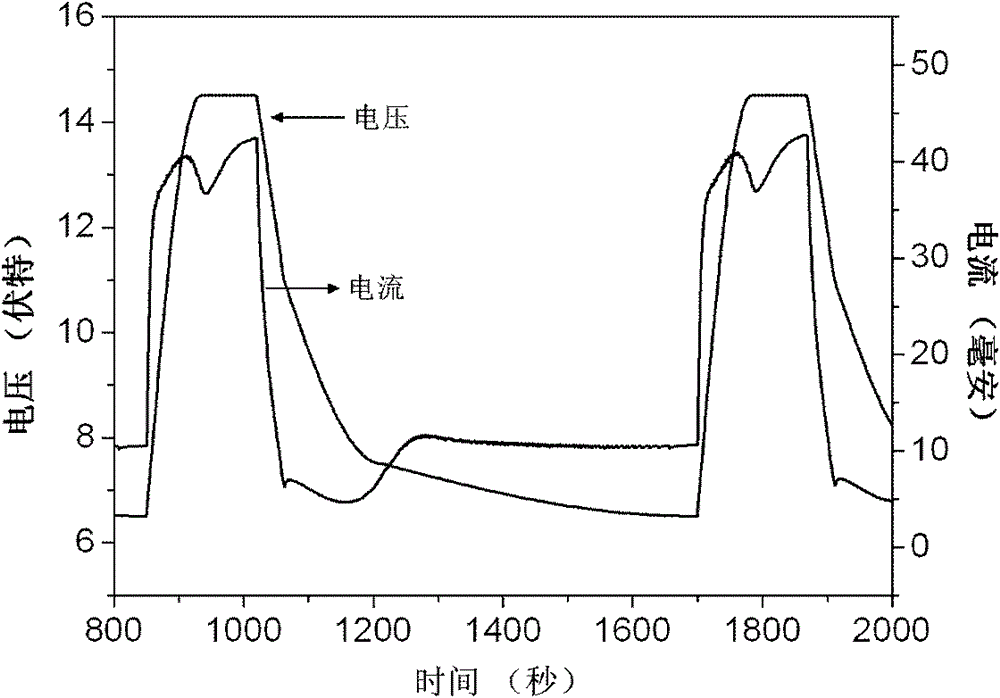

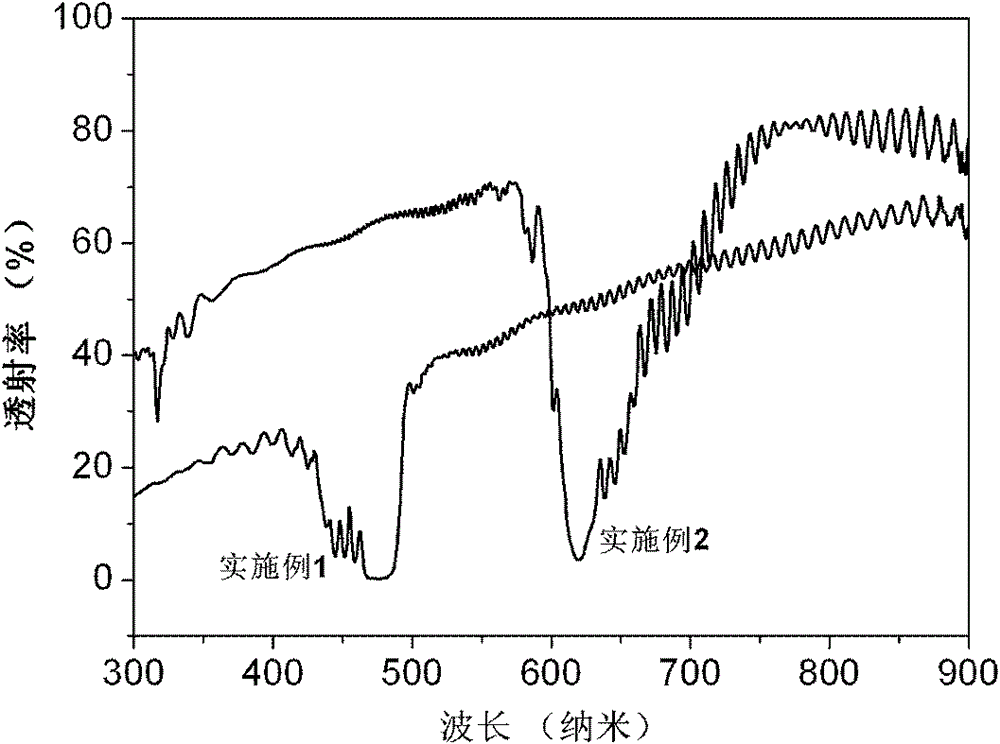

Shell color control device and mobile terminal

InactiveCN112087536AChange display colorSolve single colorTelephone set constructionsInformation controlEngineering

The invention relates to a shell color control device and a mobile terminal. The shell color control device comprises an electrochromic assembly and a processor, the electrochromic assembly is connected with the shell, and the electrochromic assembly is used for enabling the shell to display different colors; wherein the processor is electrically connected with the electrochromic assembly, the processor is used for controlling voltage values input into the electrochromic assembly according to color indication information, and the electrochromic assembly is used for displaying different colorsaccording to different voltage values. The invention provides a shell color control device and a mobile terminal, and aims to solve the problem of single shell color of the mobile terminal.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

Preparation method of coloring composite adhesive

InactiveCN109868105APlay a coloring rolePlay a bonding effectNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesComposite filmOrganic solvent

The invention discloses a preparation method of a coloring composite adhesive. The method comprises the following steps: (a) taking a connecting resin, a dispersing agent, an organic pigment and an organic solvent A, performing mixing according to a mass ratio of the connecting resin to the dispersing agent to the organic pigment to the organic solvent A of (5-10):(0.5-2):(5-15):(60-90) to obtaina mixture A; (b) putting the uniformly-dispersed mixture A into a sand mill, and performing grinding until the particle size D90 of the ground mixture A is 500 nm or less to obtain a highly-dispersible pigment; and (c) taking matrix resin, a crosslinking agent, the highly-dispersible pigment and an organic solvent B, performing mixing according to a mass ratio of the matrix resin to the crosslinking agent to the highly-dispersible pigment to the organic solvent B of (40-60):(5-20):(40-60):(0-250) to obtain a mixture B to prepare the coloring composite adhesive, wherein the solid content of themixture B is 15-60%. According to the preparation method provided by the invention, the coloring composite adhesive obtained by the method can make the obtained aluminum-plastic composite film have arequired color, shortens a technological process of the colored aluminum-plastic composite film after bonding with an outer protective layer and a middle layer, and greatly reduces the production costs, thereby meeting requirements of mass production.

Owner:ZHEJIANG DAOMING OPTOELECTRONICS TECH

Method for coloring aluminum and alloy surface thereof

InactiveCN102181902BAddress controllabilityLow costSurface reaction electrolytic coatingPollutionElectrolyte

The invention discloses a method for coloring aluminum and an alloy surface thereof, which comprises the following steps of: at first, cleaning and polishing the aluminum or the aluminum alloy surface; carrying out constant-pressure anode preoxidization for 20 minutes to 3 hours under the preoxidization voltage of 10 to 20 volts by using sulfuric acid electrolyte with the concentration of 0.1 to 3mol / liter under the conditions that the well-processed aluminum or aluminum alloy is used as an anode and graphite is used as a cathode; and then oxidizing the aluminum or the aluminum alloy by utilizing a voltage which varies periodically based on time to obtain a structurally laminar alumina photonic crystal, and coloring the aluminum or the aluminum alloy surface by the structural color of an optical forbidden band of the alumina photonic crystal, so that different colors can be adjusted within a scope of visible lights by maintaining constant time and changing the voltage only or maintaining constant voltage and changing time only. The coloration method of the invention has the advantages of no need of depositing metal ions, simple process and low cost, wide adjustment scope of colorsand less pollution.

Owner:SOUTH CHINA UNIV OF TECH

Color pavement label, processing process and construction process

ActiveCN106928614AHigh bonding strengthNot easy to fall offOrganic non-macromolecular adhesiveTraffic signalsAdhesiveRoad surface

The invention relates to a color pavement label, a processing process and a construction process. The color pavement label is prepared from, by weight, 60-70 parts of methyl methacrylate resin, 0.4-0.8 part of dispersant, 3-7 parts of color pigment, 0.5-1.5 parts of curing agent, 30-38 parts of fine silica sand and 0.3-0.7 part of lubricating grease blender. During construction, a methyl methacrylate adhesive is smeared on the back face of the color pavement label; the color pavement label is attached to a pavement base face, and a roller is used for rolling the surface of the color pavement label. The color pavement label is resistant to abrasion and oxidation, long in service life, high in anti-fouling capacity, bright in color and capable of being rapidly cured.

Owner:安徽省沥美道路新型材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com