Patents

Literature

91results about How to "Simple spraying process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

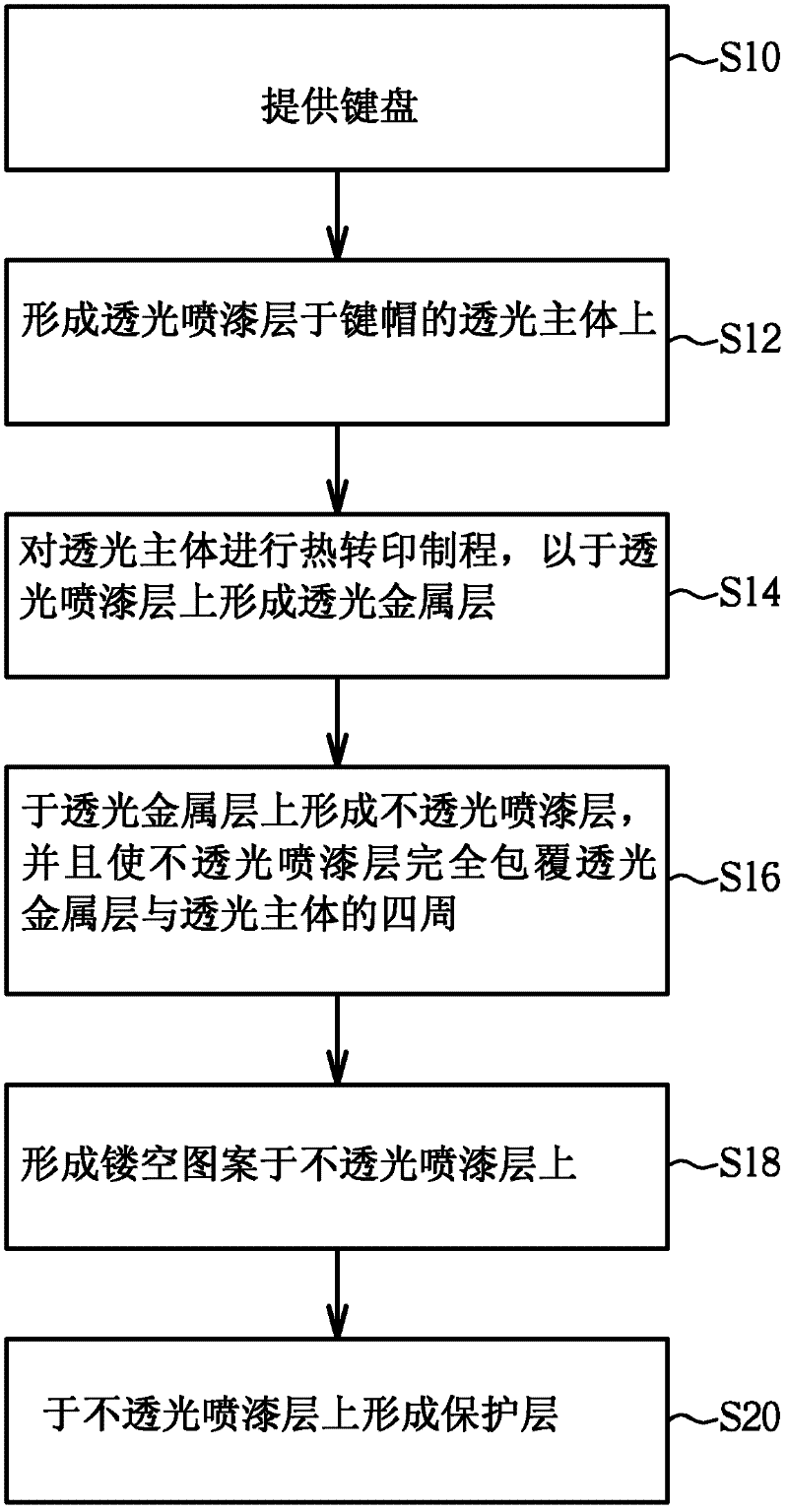

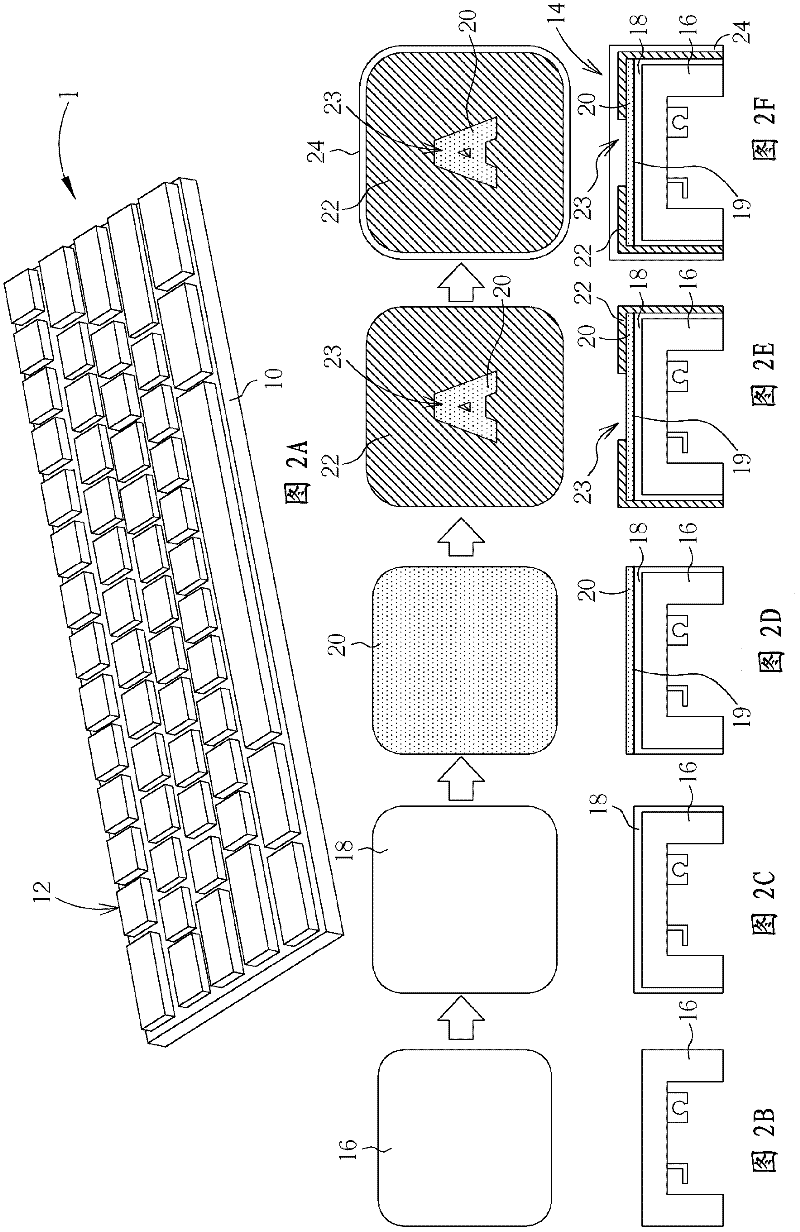

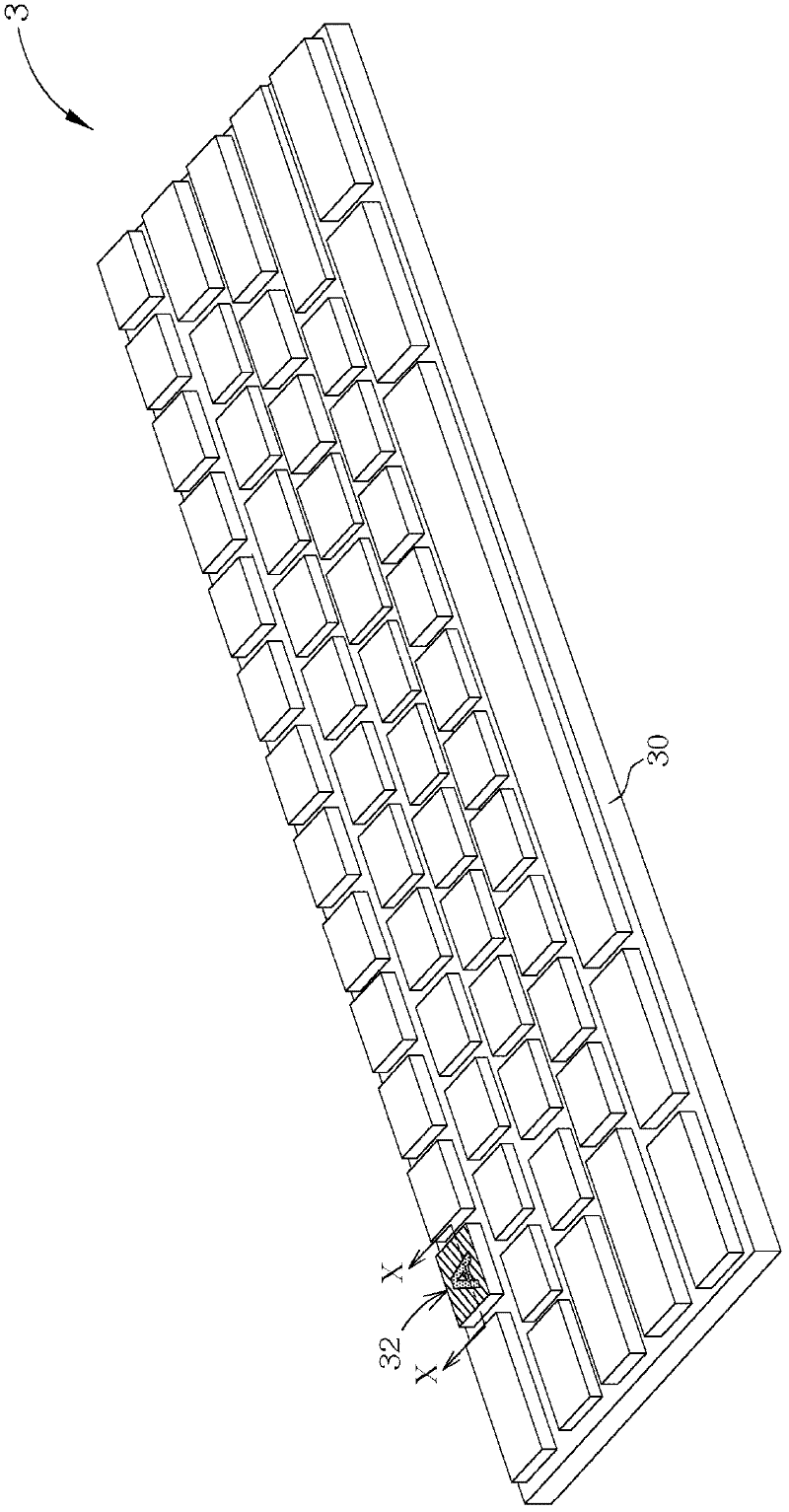

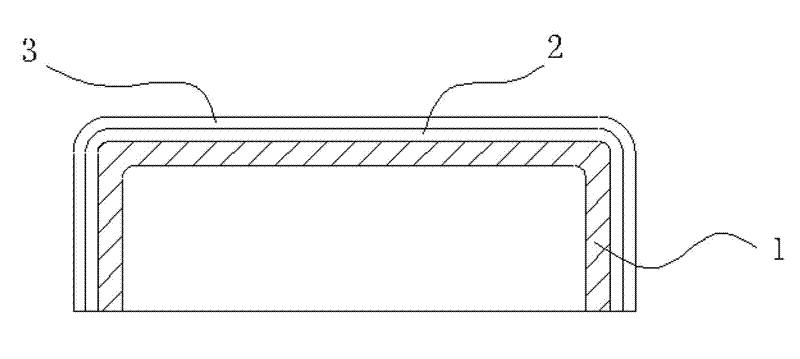

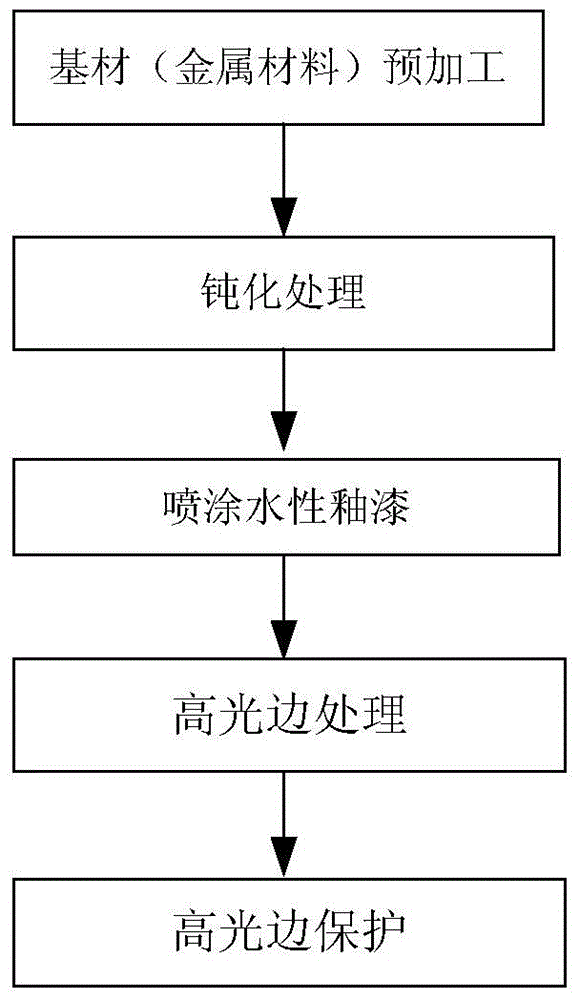

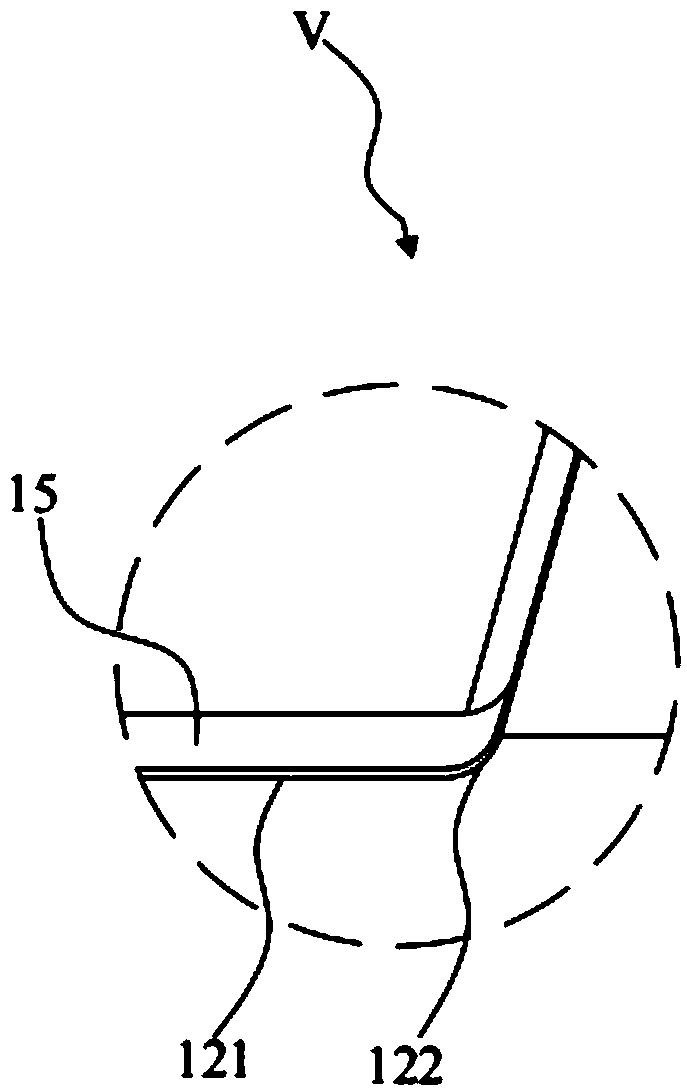

Keyboard and manufacturing method thereof

InactiveCN102496509ASimple spraying processGood metallic luster and luminous effectElectric switchesEngineeringPrinting ink

The invention discloses a keyboard and a manufacturing method thereof. The keyboard comprises: a base plate, a plurality of buttons and a backlight apparatus. A plurality of buttons are arranged on the base plate. At least one of the buttons comprises a key cap and a lifting support device. The key cap comprises a light-transmitting main body, a light-transmitting metal layer and at least one light-proof spray paint layer. The light-transmitting metal layer is formed on the light-transmitting main body. The light-proof spray paint layer is formed on the light-transmitting metal layer. The light-proof spray paint layer possesses a hollow out pattern. One part of the light-transmitting metal layer shows in the hollow out pattern. The lifting support device is arranged between the key cap and the base plate and is used to make the key cap move up and down relative to the base plate. The backlight apparatus is arranged between the base plate and a plurality of the buttons and is used to emit light to the key cap. In the invention, through using combination of the light-transmitting metal layer and the backlight apparatus, a metal luster effect which is better than the effect of learned know mirror printing ink can be generated. And a purpose of simplifying a key cap spraying flow of the keyboard can be further reached.

Owner:DARFON ELECTRONICS (SUZHOU) CO LTD +1

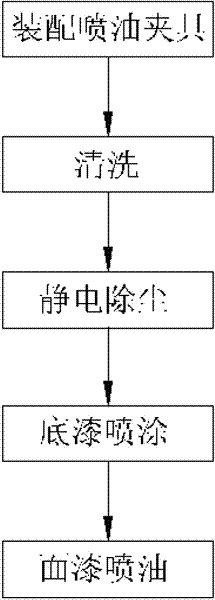

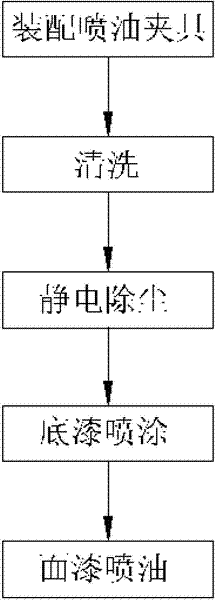

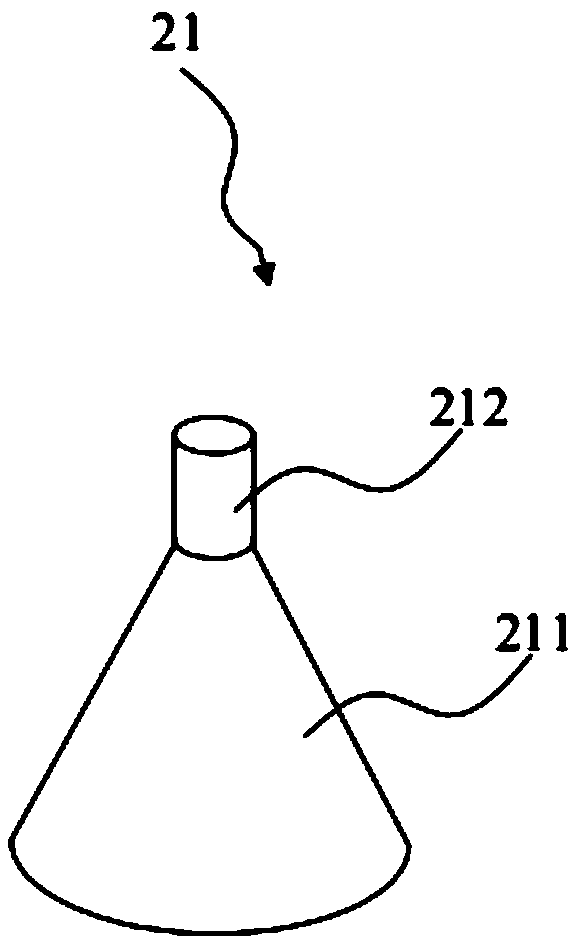

Process for spraying plastic parts of mobile phone and mobile phone shell made by adopting process

InactiveCN102671844AReduce consumptionImprove drop resistancePretreated surfacesCoatingsColor effectEngineering

The invention discloses a process for spraying plastic parts of a mobile phone. The process comprises the following steps of (1) assembly of an oil injection clamp; (2) cleaning; (3) electrostatic dust collection; (4) spraying of primer; and (5) oil injection on finishing paint. The invention also discloses a mobile phone shell made by adopting the process. The process is easy to operate, the primer of a corresponding color is selected according to the required color effect, the spraying frequency is lowered, the consumption of the pigments is reduced, and the production efficiency is improved, the production cost is lowered; and due to the adoption of the steps of cleaning and electrostatic dust collection, the adhesive force of the primer and the finishing paint is improved, the spraying effect is effectively improved, and the product quality is guaranteed. The mobile phone shell has a reasonable structure; due to the combination of the primer and the finishing paint, the primer is used for showing the required color effect, the finishing paint is used for improving the crash resistance and the wear resistance of the mobile phone shell, and the service life is prolonged. The spraying process is simple, low in cost and convenient to produce, and large-area popularization and application are facilitated.

Owner:DONGGUAN XUTONGDA MOLD PLASTIC +2

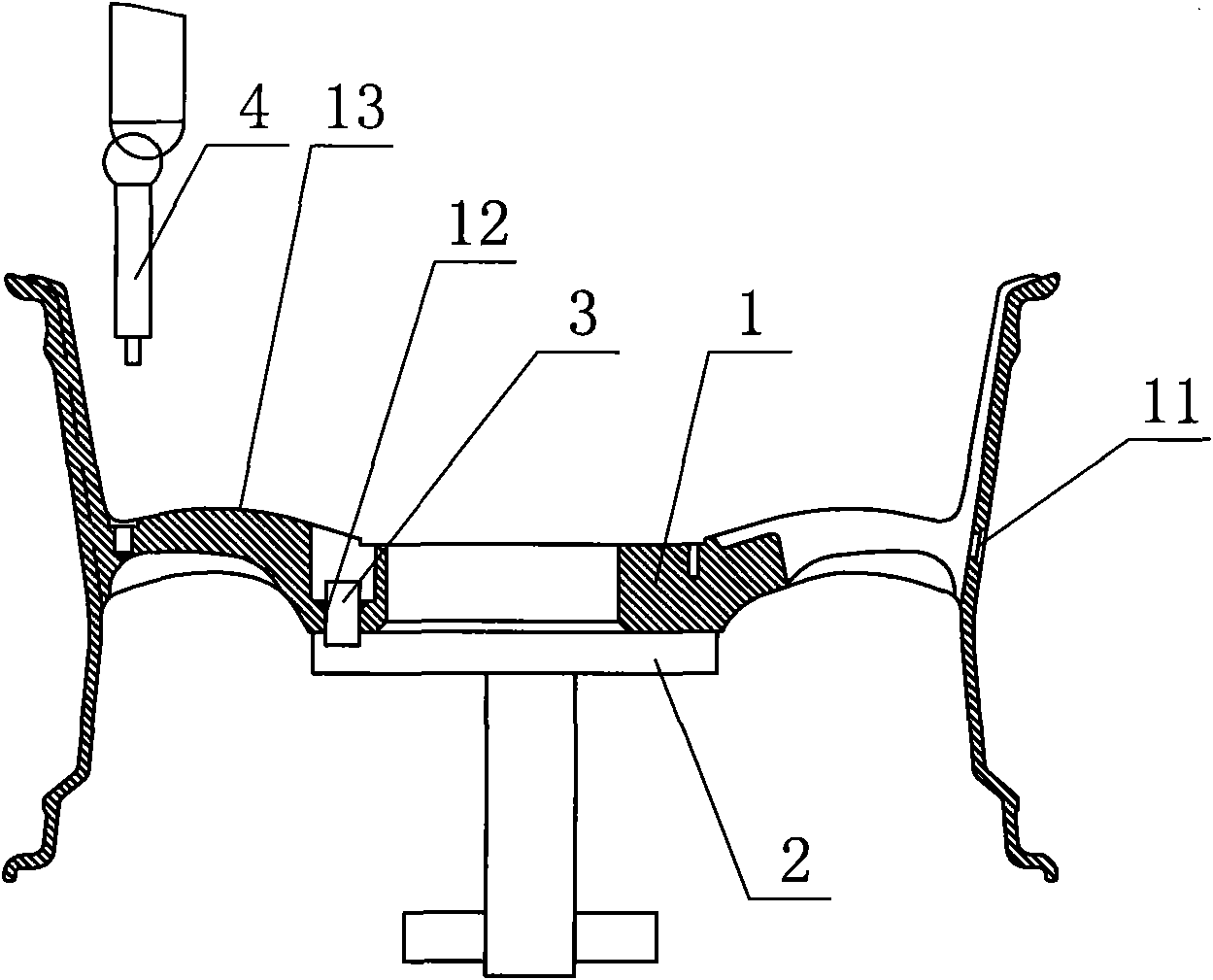

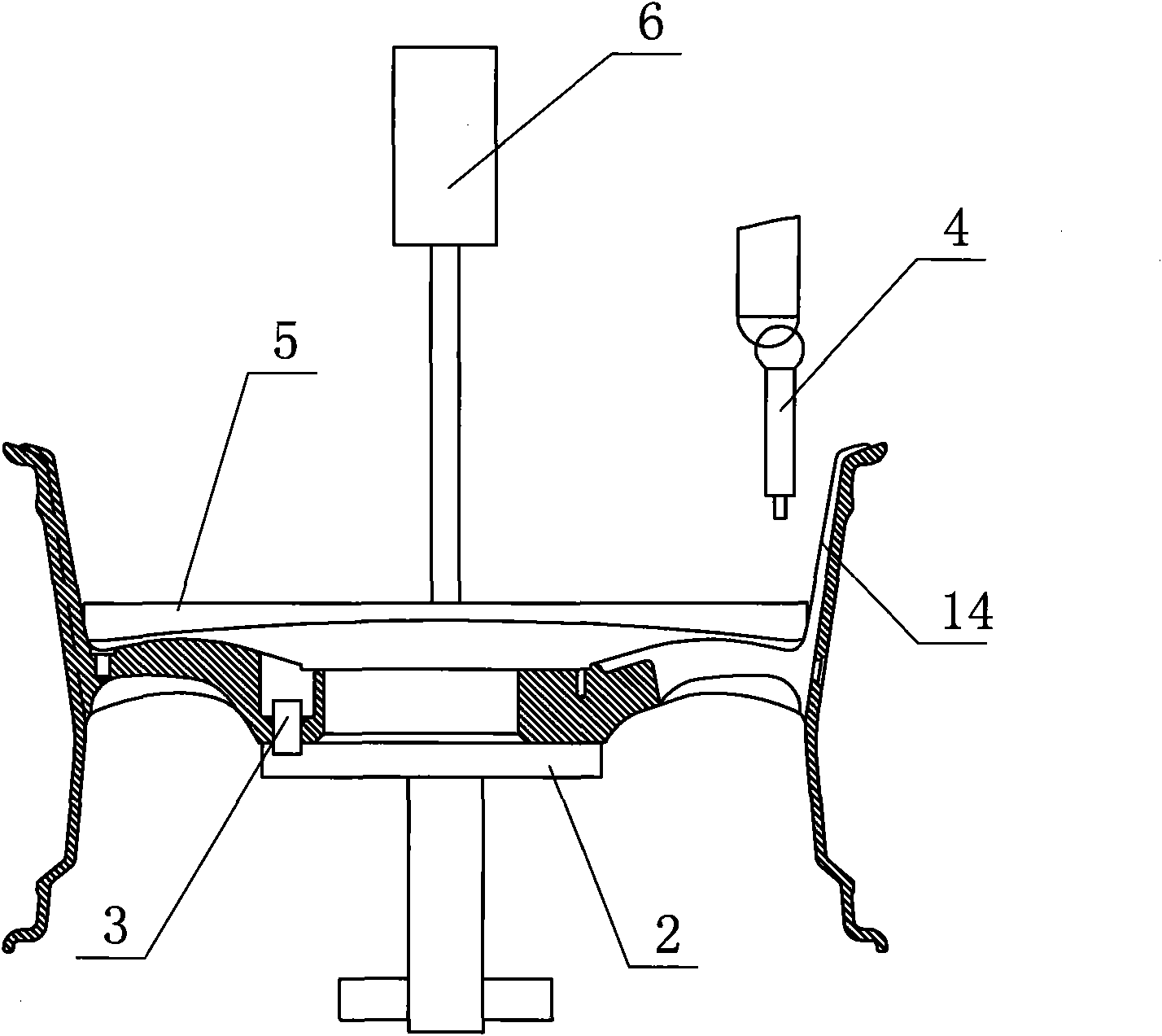

Automobile hub spraying process

ActiveCN101940993ASolve the problem of single color sprayingSolve single colorHubsSpraying apparatusEngineeringManipulator

The invention discloses a specialized automobile hub spraying process, which comprises the following steps of: 1) plugging a valve hole of an automobile hub by using a plugging tool, placing the automobile hub on a tray, then positioning the automobile hub on the tray by using the match of a positioning pin and a PCD hole of the automobile hub, finally driving the bottom of the tray to rotate by a power source, and spraying a web plate surface by adopting a spraying manipulator; 2) baking paint on the web plate surface of the automobile hub fixed on the tray; and 3) covering a pressing plate matched with the web plate surface of the automobile hub on the web plate surface, driving the bottom of the tray to rotate by the power source, and spraying an LIP surface by the spraying manipulator so as to finish secondary spraying. The spraying color of the web plate surface is different from that of the LIP surface. The spraying process solves the problem of single hub spraying color, is uniform to spray, does not produce asymmetry or discordance, and has the advantages of simple process, convenient operation and low cost.

Owner:ZHEJIANG JINFEI KAIDA WHEEL

Polyurethane paint for disposable spray finishing and application

InactiveCN101358102ASimple spraying processReduce energy consumption and costsPolyurea/polyurethane coatingsButyl acetateSolid content

The present invention relates to a polyurethane coating sprayed for one time and an application thereof. The weight percentages of the ingredients of the coating are as follows: 20 to 30 percent of hydroxylated acrylic resin; 20 to 30 percent of thermoplastic acrylic resin; 30 to 40 percent of butyl acetate, 0.2 to 1 percent of leveling agent; 0.2 to 1 percent of defoamer; 5 to 10 percent of solvent. In addition, 1 to 25 percent of color sizing can be added into the formula. The solid content of the hydroxylated acrylic resin and the thermoplastic acrylic resin is equal to or larger than 40 percent; the leveling agent is acrylic ester; the defoamer is organic silicon; the solvent is propylene glycol monomethyl ether acetate; the color sizing is mixture composed of inorganic or organic pigment, dispersant, acrylic resin and solvent. The coating of the present invention can be sprayed on the plastic shells of electronic products and electric appliances. The coating is characterized by simple spraying technique, low energy consumption, low cost, relatively low pollution, more environment-friendliness, etc.

Owner:深圳市美丽华科技股份有限公司

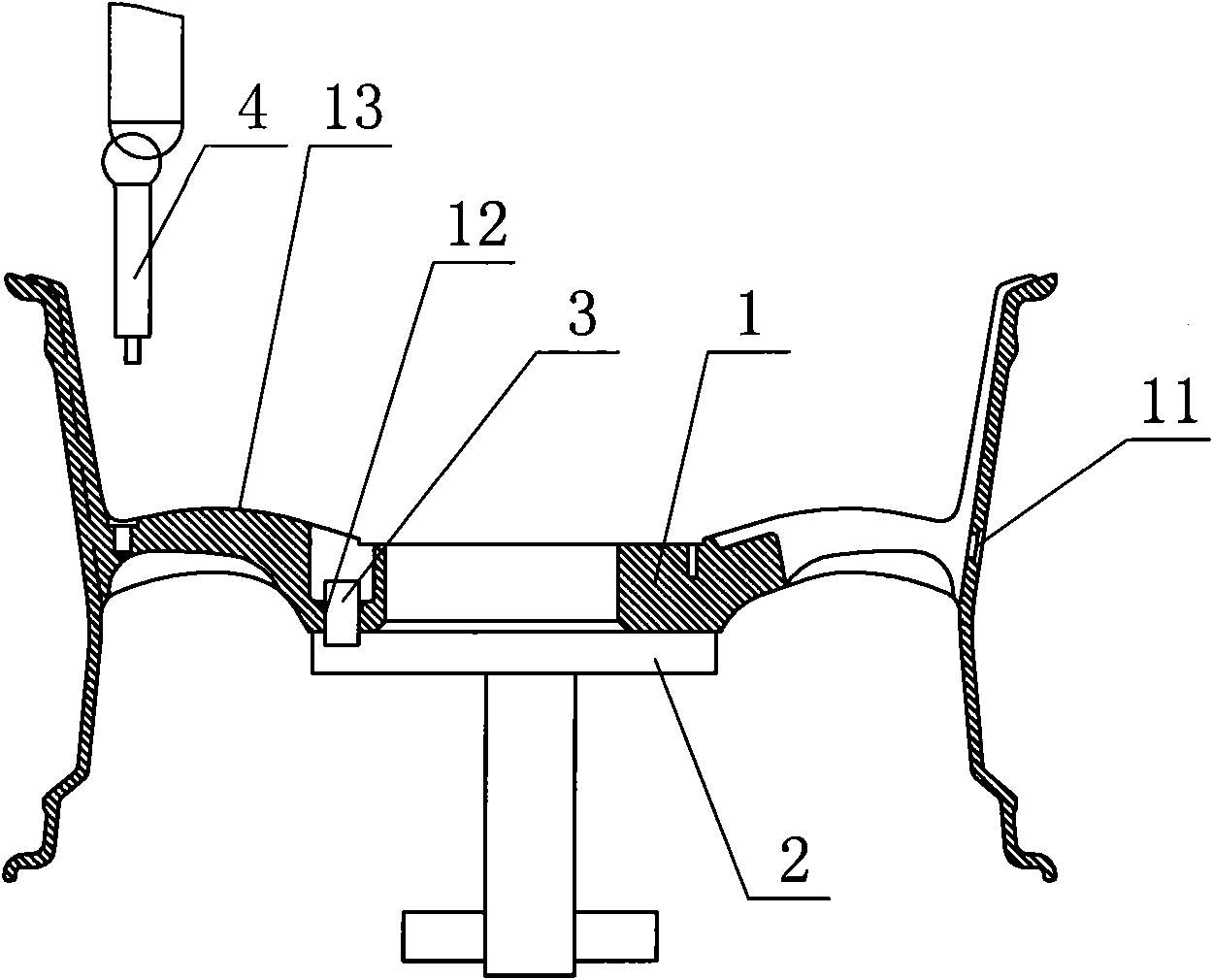

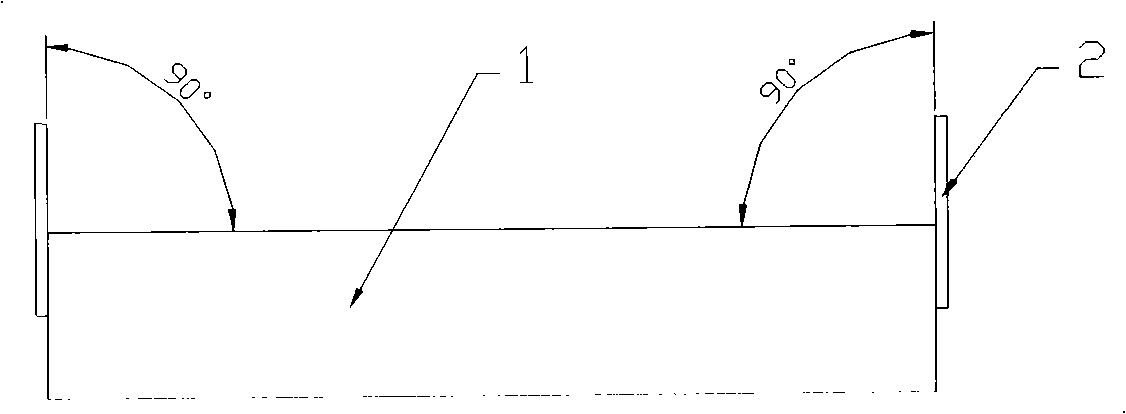

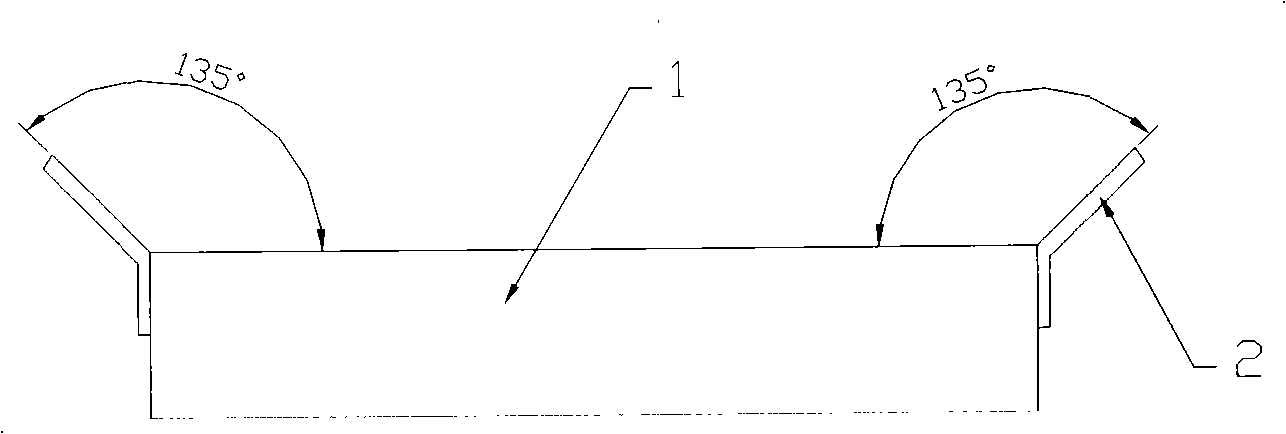

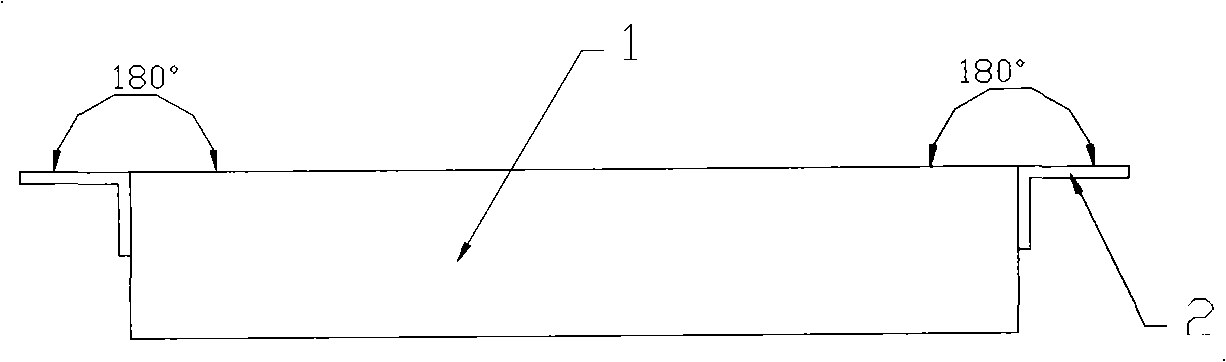

Supersonic spray coating method of crystallizer copper plate

ActiveCN101302619AImprove bindingGuarantee the quality of sprayingMolten spray coatingFurnace typesSand blastingSpray coating

The invention discloses a supersonic spraying method for crystal implement copper plates, which is characterized in that the operation of the method is carried out according to the following steps that: firstly, cleaning and sand blasting treatments are carried out to the surface of a crystal implement copper plate through a conventional cleaning process; secondly, four peripheries of thecrystal implement copper plate are provided with protective plates at an angle of between 90 and 180 degrees with a working surface of the copper plate; thirdly, nickel-base alloy powder spraying paint is put into a supersonic flame spraying device so as to spray the surface of the crystal implement copper plate through a conventional process; fourthly, after spraying, the crystal implement copper plate is insulated at a temperature of between 800 and 950 DEG C for 0.5 to 3 hours for melting-diffusing vacuum heat treatment, and then is cooled through nitrogen, argon or helium; fifthly, the cooled crystal implement copper plate is subject to aging treatment at a temperature of between 400 and 500 DEG C for 1 to 3 hours. The supersonic spraying method is simple in the whole spraying process and uniform in spraying thickness, saves spraying material, and is strong in coating binding capacity and is wearproof.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

Method for spraying surface of engineering machinery covering part

InactiveCN103894329AImprove spraying efficiencyQuality assuranceCoatingsSpecial surfacesCorrosion resistantPolishing

The invention provides a method for spraying the surface of an engineering machinery covering part. Before a complete machine is assembled, spraying of parts covering the surface of a machine body is finished, and assembling of the complete machine is then performed. The method for spraying the surface of the engineering machinery covering part includes the specific steps of surface preprocessing, primer spraying, primer drying, puttying, finish paint spraying, finish paint drying and polishing. The method is characterized in that a corrosion-resisting coating is sprayed after surface preprocessing and before primer spraying. According to the method for spraying the surface of the engineering machinery covering part, the spraying efficiency of the covering part can be improved, the spraying quality is guaranteed, the dosage of primer is reduced, and the number of times of spraying finish paint is reduced.

Owner:GANSU AGRI UNIV

Environment-friendly electro-plated silver paint and preparation method thereof

InactiveCN103319966AMake up for the defects that cannot be partially electroplatedPromote environmental protectionCoatingsButyl acetateAcrylic resin

The invention relates to the technical field of paint and in particular relates to environment-friendly electro-plated sliver paint. The environment-friendly electro-plated sliver paint consists of modified acrylic resin, aluminum sliver paste, ethyl acetate, butyl acetate, propylene glycol methyl ether acetate and a flatting agent. A stirring device with rotation speed of 500 revolutions / minute-600 revolutions / minute is used for sufficiently and uniformly stirring for at least 20 minutes; the uniformly stirred electro-plated sliver paint is sprayed and roasted for 30 minutes at 65 DEG C-80 DEG C to obtain a paint film. The environment-friendly electro-plate sliver paint is energy-saving and environment-friendly, simple in spraying process, convenient to operate and provided with a spraying effect equal to that of an electro-plated product, and therefore, the environment-friendly electro-plated sliver paint is a substitute product of the conventional electro-plating process. Besides, the environment-friendly electro-plated sliver paint can be used for the products including a television, a washing machine, an air conditioner, a bicycle, an electric bicycle, a motorcycle, a small household appliance, hardware, plastic and the like.

Owner:CHANGZHOU HUASHI CHEM

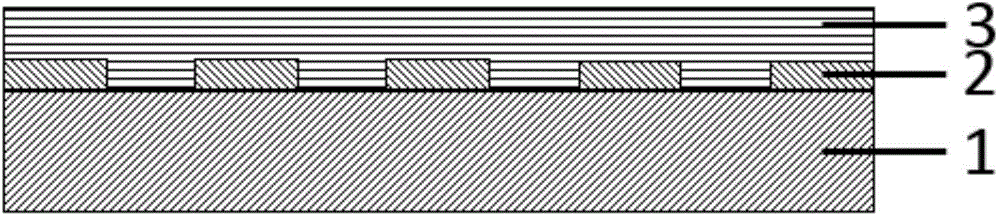

Flexible gas sensor based on three-dimensional net structured sensitive film and preparation method of flexible gas sensor

InactiveCN104865293AImprove compatibilityRapid High Sensitivity DetectionMaterial analysis by electric/magnetic meansExtensibilityEngineering

The invention discloses a flexible gas sensing device based on a three-dimensional net sensitive film and a preparation method of the flexible gas sensing device, and belongs to the fields of sensing electronics and flexible electronics. The sensing device comprises a flexible substrate layer, an interdigital electrode layer and a three-dimensional net structured sensitive film layer which are sequentially stacked according to the preparation order. The preparation method mainly comprises steps as follows: preparing a flexible interdigital electrode device, preparing a film material required by the sensing device, and preparing a three-dimensional net structured sensitive film device with a gas injection film forming technology. The flexible gas sensing device based on the three-dimensional net sensitive film and the preparation method of the flexible gas sensing device have the advantages as follows: by means of the extensibility of the flexible substrate on the three-dimensional net structured sensitive film, the response performance of the sensitive film on gas is further improved, meanwhile, the process is simple, the cost is low, and the prepared sensing device can be used in the field of gas detection.

Owner:TSINGHUA UNIV

Method for preparing strengthened coatings on the continuance casting crystallizer surface

The invention relates to a method for preparing reinforcing coating on the surface of a continuous casting crystallizer, comprising the steps as follow: preprocessing a crystallizer copper plate surface or a copper alloy plate surface, and spray painting the metal ceramic powder directly on the crystallizer copper plate surface or the copper alloy plate surface by exploding spray painting method to form surface reinforcing coating, wherein the metal ceramic powder consists of alloy and carbide, Ni-Cr alloy and Cr3C2 are preferred. The invention overcomes the drawbacks existing in the prior art, which has better integrating performance between the reinforcing coating and the copper or the copper alloy based body, and is adaptable to the work environment of the crystallizer, and avoids the preparation of middle transition coating, so as to simplify manufacture and repair method of the crystallizer and reduces the cost. The invention is widely suitable for reinforcing and repairing the copper surface or the copper alloy surface.

Owner:GUANGZHOU RUIYOU SURFACE TECH

Automobile hub spraying process

InactiveCN104998808AImprove heat resistanceImprove low temperature resistancePretreated surfacesPowdery paintsHeat resistanceEngineering

The invention discloses an automobile hub spraying process which comprises the following steps: step 1, conducting deoiling, derusting and polishing on an automobile hub; step 2, conducting alkaline etching treatment on the surface of the polished automobile hub without oil and rust, and carrying out fluorocarbon spraying according to a static liquid-phase spraying method; step 3, washing the automobile hub subjected to fluorocarbon spraying, coating the washed automobile hub with a parkerized or passivated leather film, and then drying and fixing; step 4, spraying thermoset powder coating onto the dried and fixed automobile hub with a static spraying gun; step 5, conducting high-temperature curing and baking on the automobile hub onto which the thermoset powder coating is sprayed. Therefore, the heat resistant, low-temperature resistant and chemical resistant properties can be improved, and the special non-stick and low friction properties are achieved.

Owner:ANHUI AUHER ALUMINUM TECH

Photo-thermal dual-curing plastic coating

PendingCN108929627AFully curedImprove performancePolyurea/polyurethane coatingsEpoxy resin coatingsUltravioletSolvent

The invention discloses a photo-thermal dual-curing plastic coating. The plastic coating comprises a component A and a component B, wherein the component A comprises the following components in partsby weight: 20-30 parts of dual-curing resin, 4-10 parts of a basic monomer, 2-6 parts of a multifunctional monomer, 2-6 parts of a prepolymer, 6-10 parts of a multifunctional prepolymer, 0.5-5 parts of an organic pigment, 1-4 parts of an auxiliary agent, 1-3 parts of a photoinitiator and 30-45 parts of a solvent, and the component B comprises the following components in parts by weight: 50-70 parts of a curing agent and 30-50 parts of a solvent. An ultraviolet curing system is formed by the prepolymer and the photoinitiator, a thermal curing system is formed by a plurality of similar monomersand the curing agent, so that the defects of a pure ultraviolet curing coating can be overcome in the photo-thermal dual-curing plastic coating prepared by the combination of the two systems. Particularly, during the spraying process of a dark coating, a thickened coating film and a special-shaped component, the coating can be cured completely, and various performances of the formed coating film are good. Meanwhile, a two-layer spraying mode of a bottom coating and ultraviolet curing gloss oil is replaced, the spraying process is simplified, and the production cost is reduced.

Owner:惠州市嘉淇涂料有限公司

Automobile hub spraying technology

ActiveCN103752477ASimple spraying processSimple processPretreated surfacesPolyester coatingsCooking & bakingEngineering

An automobile hub spraying technology comprises the steps of step1, performing oil removal and rust removal on automobile hubs; step2, washing the oil and rust removed automobile hubs with water, applying phosphorization or passivation coatings, and performing drying and fixation; step3, spraying thermosetting powder coatings with the average grain size being 15 microns to 25 microns on the automobile hubs through an electrostatic spray gun; step4, performing high-temperature curing baking on the sprayed automobile hubs in a bread oven or an assembly line oven, wherein the temperature is set to be in a range of 180 DEG C to 200 DEG C, and time is in a range of 25 minutes to 30 minutes; step5, checking colors, metal effects and coating adhesive forces, surface hardness, scratching resistance and the like of the automobile hubs after curing and out of the oven.

Owner:CHONGQING QICAIHONG CHEM

Ligustrun lucidum ait cutting and cultivating method

ActiveCN105475076ACause rotDisadvantages of changing a single seedbedBiocideClimate change adaptationInsect pestPlant disease

A ligustrun lucidum ait cutting and cultivating method includes the five steps of seedbed preparation, scion selection, scion processing, cutting and post-cutting management. The seedbed preparation step includes the substeps of nutrient soil preparation, disinfection and seedbed preparation. When ligustrun lucidum ait is cultivated through the method, influences of temperature and humidity on cut branches can be reduced to the maximum extent, and the requirement of the cut branches for organic nutrition is ensured; meanwhile, influences of excessive organic matter on section wounds of scions are avoided, wound surface rotting is avoided, and rooting is ensured; meanwhile, when ligustrun lucidum ait is cultivated through the method, plant diseases and insect pests are not likely to occur, and the workloads of final-period management can be greatly reduced.

Owner:YIYANG YINFENG GARDEN LANDSCAPE

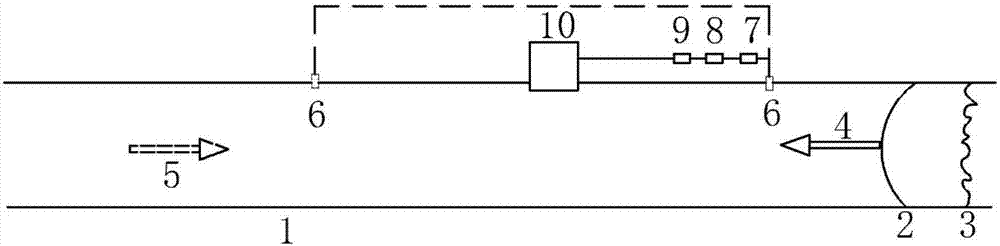

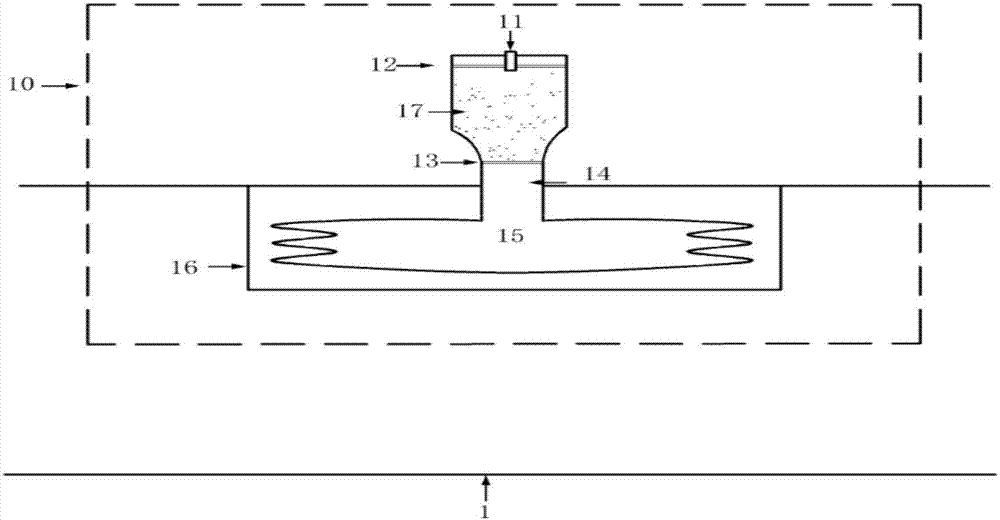

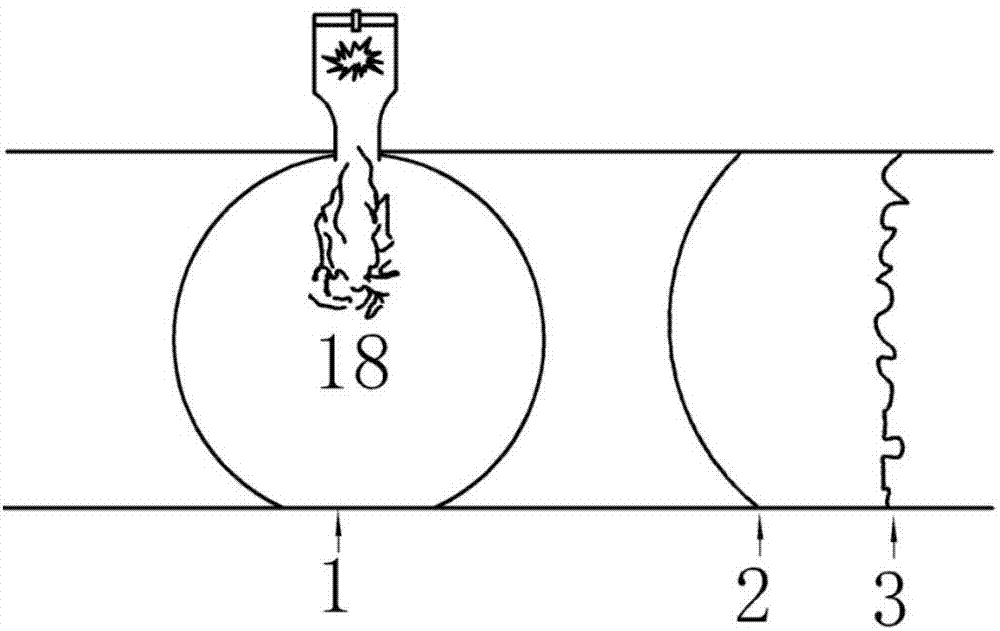

Gasbag-type active explosion suppression and isolation device and method

PendingCN107956500ASimple structureSimple spraying processDust removalFire preventionShock waveNuclear engineering

The invention provides a gasbag-type explosion suppression and isolation device and method. The gasbag-type explosion suppression and isolation device and method are applicable to explosion suppression and isolation of gas explosion in a sealed pipeline free of other decompression spaces, and are particularly applicable to explosion suppression and isolation of gas explosion of delivery pipelinesof explosive gases like gas and of coal mine shafts. Firstly, folded gasbags and folded gas generators are installed in pipelines or a roadway, and detectors are installed at the proper positions of the pipelines of the two sides of an explosion suppression and isolation unit. A power source, a control unit and a signal processing system are arranged between the explosion suppression and isolationunit and the detectors in sequence. After explosion feature signals are received by the detectors and judged by a signal processing unit, the power source is started and excites an ignition electrodeto make a gas generator exploded and generate a large amount of inert gas, the inert gas is inflated into the gasbags from diversion pipes and damages a gasbag protection box, the gasbags filled withthe inert gas are instantaneously formed in the pipelines, and propagation of gas explosive shock waves and flame waves is inhibited. By means of the gasbag-type explosion suppression and isolation device and method, the problems in the prior art that only the flame waves can be inhibited and the inhibiting effect is not ideal can be solved.

Owner:CHINA UNIV OF MINING & TECH

Preparation method of nickel, chromium, boron, silicon and niobium alloy abrasion-resistant coating

InactiveCN108728785AFacilitated DiffusionHigh hardnessMolten spray coatingSand blastingNiobium alloy

The invention provides a preparation method of a nickel, chromium, boron, silicon and niobium alloy abrasion-resistant coating. The method comprises the steps of 1, mixing the following powder in percentage by mass: 15-18% of Cr, 2-3% of B, 2-4% of Si, 1.5-2.5% of Mn, 4-8% of Nb, and the balance Ni, wherein the particle size of the powder is 25-50 microns; and 2: (1) hardening and tempering a substrate; (2) preprocessing the substrate surface by sand blasting; (3) performing plasma spraying on a substrate subjected to sand blasting; and (4) remelting a covered nickel, chromium, boron, siliconand niobium coating; and inductively heating through a high-frequency inductive heating device to obtain the nickel, chromium, boron, silicon and niobium alloy abrasion-resistant coating. According tothe method, the combination form of the coating and the substrate is changed, so that the combining intensity can be improved; and hard phases such as Nb2C in the coating is separated out, so that the abrasion life of the coating is prolonged.

Owner:HEBEI UNIV OF TECH

Colored polyurethane paint having elastic handfeel and used for spraying and preparation method as well as application thereof

ActiveCN103254742AGood touchImprove performancePolyurea/polyurethane coatingsPolyester coatingsAcrylic resinDefoaming Agents

The invention discloses a colored polyurethane paint having elastic handfeel and used for spraying and a preparation method as well as application thereof. The paint comprises the following components in parts by weight: 20-30 parts of saturated polyester resin, 10-20 parts of hydroxy acrylic resin, 10-20 parts of thermoplastic acrylic resin, 20-30 parts of butyl acetate, 0.2-1 part of levelling agent, 0.2-1 part of defoaming agent and 5-11 parts of solvent, wherein 1-27 parts of color paste can be added to the mixture; the levelling agent is acrylic ester; the defoaming agent is organosilicon; the solvent is a PMA (propylene glycol monomethyl acetate) solvent; and the color paste is the mixture of an inorganic or organic pigment, a dispersing agent, acrylic resin and the solvent. The paint can be sprayed on plastic shells of electronic and electrical products, and has the characteristics of simple spraying process, low energy consumption, low cost, relatively little pollution, better environment friendliness, better surface fineness, excellent elastic handfeel and the like.

Owner:深圳市美丽华科技股份有限公司

Preparation method for IC10 alloy low-pressure-turbine guide vane thermal barrier coating

InactiveCN108118278AExtended service lifeImprove corrosion resistanceMolten spray coatingAviationSuperalloy

The invention belongs to the technical field of aviation engine thermal barrier coatings and particularly relates to a preparation method for an IC10 alloy low-pressure-turbine guide vane thermal barrier coating. A matrix material is an IC10 directional solidified high temperature alloy, and the preparation process procedure comprises the steps of supplied part checking, preparing before spraying,spraying process parameter confirming, cleaning, protecting before grit blasting, grit blasting, protecting before spraying, a NiCrAlYSi metal bonding bottom layer supersonic spraying, a nano zirconium oxide coating atmospheric plasma spraying, clearing, final checking and respraying and repairing. According to the preparation method for the IC10 alloy low-pressure-turbine guide vane thermal barrier coating, the NiCrAlYSi metal bonding bottom layer supersonic spraying and the nano zirconium oxide coating atmospheric plasma spraying are adopted, so that the high temperature oxidation resistance and heat insulation capacities of the coating are improved, the preparation of low-pressure-turbine guide vane surface thermal barrier coating of an aviation engine of some type is realized, and bymeans of the preparation of coating, the service life of hot end components can be effectively prolonged.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

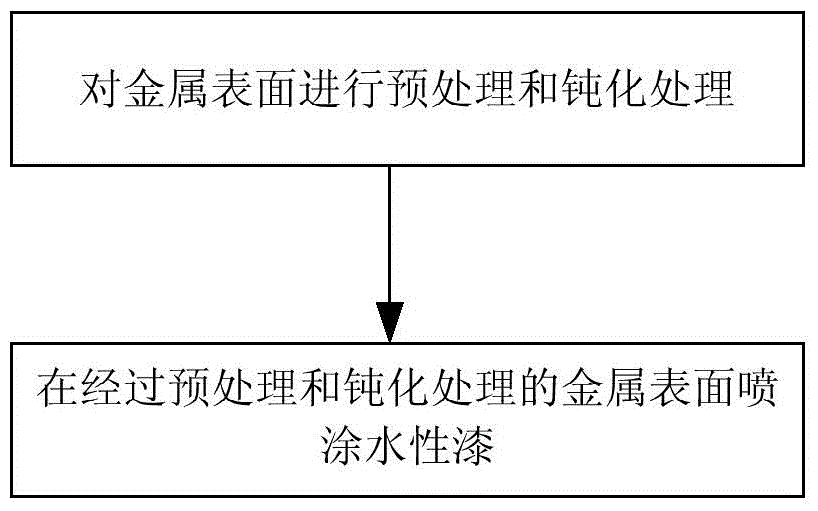

Metal spraying process and mobile phone shell

InactiveCN105149184ASimple spraying processReduce spraying costsPretreated surfacesCoatingsLacquerCommunication device

The invention relates to the technical field of communication devices, in particular to a metal spraying process and a mobile phone shell. The metal spraying process comprises pretreatment and passivating treatment of the surface of metal, and water paint is sprayed on the pretreated and passivated surface of the metal. Meanwhile, the invention further provides a mobile phone adopting the spraying process. According to the metal spraying process and the mobile phone shell, the water paint is sprayed on the pretreated and passivated surface of the metal, the spraying process is simplified, the spraying cost is lowered, and the good spraying effect and environment protection performance are achieved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Spraying coating material

InactiveCN101250356ASimple spraying processEasy to operateLiquid surface applicatorsCellulose coatingsCelluloseSpray coating

The invention discloses spray plating paint, which comprises components with percentage by weight of 10-22 wt% cellulose resin, 6-12 wt% vinyl chloride-acetate copolymer, 0.25-05 wt% micro-molecular directing auxiliary agent, 1.5-4.0 wt% silver slurry and 61.5-82.3 wt% solvent. The spray plating effect of the paint is same as electroplating products, the paint can be used on various plastic adhesive electric products such as ABS, PC, PC+ ABS and the like, and the spraying technology is simple and can be operated conveniently.

Owner:HUIZHOU CHANGRUNFA PAINT

Silver paste suitable for spraying of ceramic filter, and preparation and spraying film forming methods of silver paste

ActiveCN112071466AStable storageLow viscosityApparatus for manufacturing conducting/semi-conducting layersNon-conductive material with dispersed conductive materialSilver pasteAcrylic resin

The invention discloses a silver paste suitable for spraying of a ceramic filter. The silver paste comprises the following components in percentage by mass: 75-82% of silver powder, 0.2-3% of glass powder, 0.5-1% of an aging adhesion promoter, 8-14% of resin, 7-15% of an organic solvent and 1-3% of an assistant, wherein the resin is hydroxyl acrylic resin with a molecular weight of 1000-5000 and aviscosity of 1000-4000 mPa.S. The invention further discloses a preparation method and a spraying film forming method of the silver paste suitable for surface spraying of the ceramic filter. According to the silver paste, storage stability is enhanced, the silver paste can adapt to metallization of the surface of a special-shaped ceramic filter with a complex structure, the strength of a dried silver paste film is improved, and the adhesive force between the silver film and the ceramic surface of the filter is improved. The preparation process and the spraying process of the silver paste aresimple, the sintered silver film is firm, not prone to falling off and uniform in thickness, and the silver paste can adapt to mass production of ceramic filters.

Owner:JIANGSU HOYI TECH

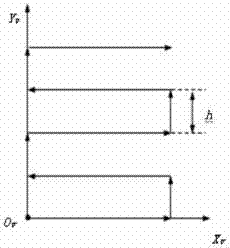

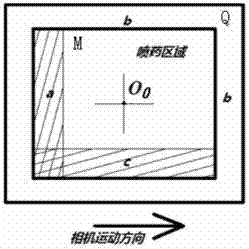

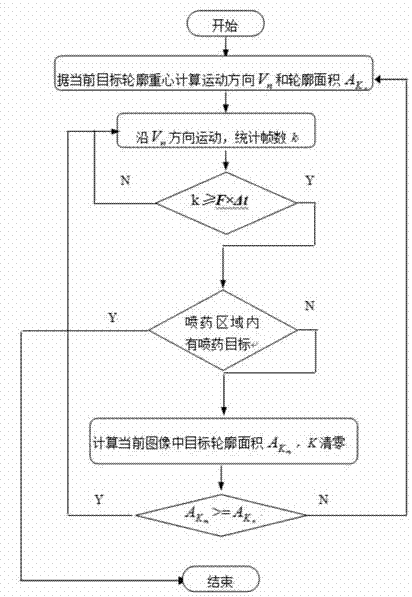

Fall webworm hyphantria cunea drury chemical spray robot local movement control method

ActiveCN104731097AGet rid of difficult constraintsImprove securityPosition/course control in two dimensionsFeature extractionImaging Feature

The invention provides a fall webworm hyphantria cunea drury chemical spray robot local movement control method. The method includes the following steps that 1, an overall movement strategy and a local movement path of a chemical spray robot are designed, and the chemical spray robot operates according to the set path and collects corresponding tree target images in real time; 2, fall webworm hyphantria cunea drury targets are extracted according to the image features, the relative distance L between the mesh curtain targets and an execution mechanism is estimated, and the image plane area S and the chemical spray covering face area S' of the position L away from the execution mechanism are determined; 3, mu is made to be equal to S' / S, the S is the image plane area, the S' is the chemical spray covering face area, and when the mu is larger than 0.5, a simple scanning control strategy is executed; when the mu is smaller than or equal to 0.5, a complex strategy of scanning, targeting and chemical spraying is executed, and finally, the optimal chemical spray position is determined.

Owner:LIAOCHENG UNIV

Method for spraying common paint to achieve orange line beautifying effect

The invention belongs to the field of paint spraying and particularly relates to a method for spraying common paint to achieve the orange line beautifying effect. The method comprises the steps of substrate treating, plane paint spraying and orange line forming. The method is characterized in that the paint used in the orange line forming step is common paint, the granularity of orange lines is controlled by controlling the paint spraying viscosity, selecting the size of the caliber of a spray gun used in the paint spraying process, controlling the air pressure in the spraying process and selecting the gun moving mode in the spraying process, and then the orange line beautifying effect is achieved. The spraying method is simple, operation is convenient, and the cost of auxiliary materials used in the spraying process is low; it can be guaranteed that the paint is uniformly spayed on the surfaces of parts in the spraying process, needle holes and other serious defects can be prevented from appearing in a coating, the percent of pass of the parts with the sprayed orange lines is increased, and the beautifying effect is improved.

Owner:SICHUAN JIUZHOU ELECTRIC GROUP

Preparation method of composite ceramic coating

The invention discloses a preparation method of a composite ceramic coating. The preparation method comprises the following steps: a, grinding and mixing: uniformly grinding and mixing 100 parts of silicon carbide micro-powder, 3 to 7 parts of nano tungsten powder, 3 to 7 parts of ultrafine graphite powder and 5 to 10 parts of a binding agent to prepare a mixture; b, carrying out wet-process ballmilling: adding de-ionized water which accounts for 80 to 120 percent of the mass of the mixture in step a and a dispersant which accounts for 1 to 3 percent of the mass of the mixture in step a intoa planetary ball mill; carrying out the wet-process ball milling for 18 to 20h according to a rotary speed of 1500 to 1800r / min to obtain a uniform suspension solution. According to the preparation method disclosed by the invention, the silicon carbide micro-powder, the nano tungsten powder, the ultrafine graphite powder and the binding agent are subjected to the wet-process ball milling and dispersion according to a certain ratio to obtain the uniform suspension solution. Then a nano hot spray-coating technology is adopted to obtain the composite ceramic coating. The preparation method disclosed by the invention has the advantages of green and environment-friendly materials and simple spray-coating technology; the obtained composite ceramic coating has the advantages of high temperature resistance, wear resistance, corrosion resistance and the like of a ceramic material, but also has the strength and toughness of a metal material; the composite ceramic coating is a novel composite ceramic coating material.

Owner:曹志欢

Tchnology of internal for tubing of drilling well

ActiveCN1560421AImprove adhesionImprove anti-corrosion performanceDrilling rodsDrilling casingsEpoxyCooking & baking

The invention relates to inner coating process for drilling pipes. The process includes preceding threaded rinsing, heat eliminating and sand-spraying process to surface; the process is operated according to following steps: 1. the preceding processed pipe uses epoxy phenol resin paint TC2000 series to spray primer, then carries on bake to it, the temperature is 120-150deg.C, the time is 50-70 minutes; 2. uses epoxy phenol resin paint TC2000 series to carry on finishing coat to the pipe after the pipe is cooled, then carries on bake, the baking temperature is 120-150deg.C, the time is 50-70 minutes; 3. solidification process, the pipe is put into the continuous furnace to be solidified, the solidification temperature is 200-240deg.C, the time is 60 minutes. The invention simplifies the painting device, and it increases the corrosion and friction resisting performance.

Owner:SHANGHAI TUBE COTE PETROLEUM PIPE COATING

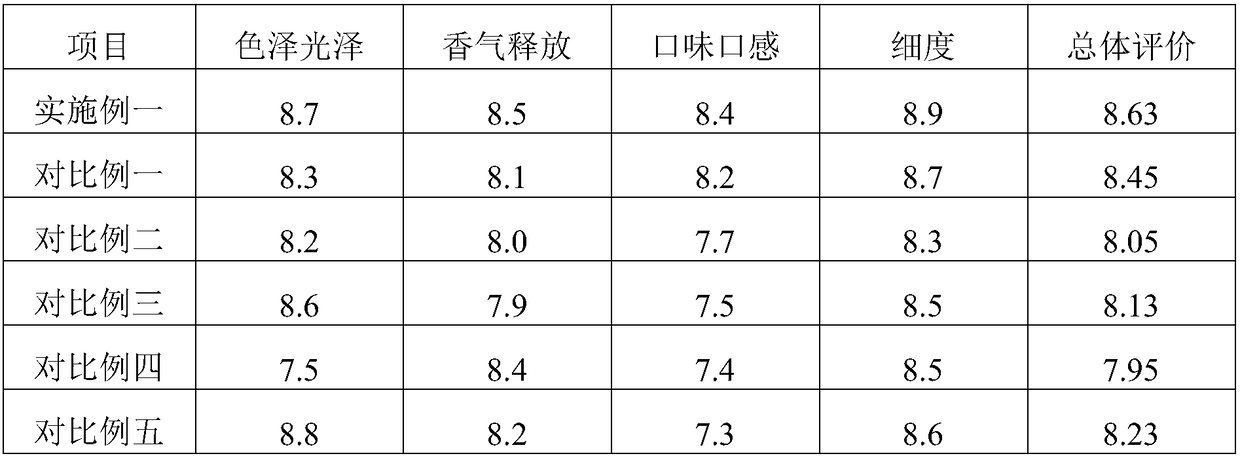

Spraying-use chocolate in crisp cones and application thereof

The present invention discloses a spraying-use chocolate in crisp cones and an application thereof. The spraying-use chocolate in the crisp cones comprises the following raw materials: 35-50 parts byweight of white granulated sugar, 40-55 parts by weight of edible oil, 5-15 parts by weight cocoa powder, 0.2-1.0 part by weight of an emulsifier and 0.1 part by weight of an edible essence and spice,wherein the edible oil is non-dairy product oil. The spraying-use chocolate in the crisp cones is stable in characters, excellent in mouthfeel, good in mouth meltability, good in spraying effects, uniform and comprehensive in coverage on the inner surfaces of the crisp cones, and good in water blocking effects. Prepared crisp-cone ice cream is good in mouthfeel and excellent in quality.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Disposable paint for spraying and its uses

InactiveCN100543096CReduce energy consumptionLow costPolyurea/polyurethane coatingsAcrylic resinPolymer chemistry

A paint for one-time spraying and its use. The weight percent of the paint is composed of: 20-30 hydroxy acrylic resin, 20-30 thermoplastic acrylic resin, 30-40 butyl acetate, 0.2-1 leveling agent, and 0.20 defoaming agent ~1, solvent 5~10. Color paste 1-25 can also be added to the above ratio. The solid content of hydroxyacrylic resin and thermoplastic acrylic resin is equal to or greater than 40%, the leveling agent is acrylate, the defoamer is silicone, the solvent is propylene glycol methyl ether acetate, and the color paste is inorganic or organic pigment, dispersant, acrylic acid A mixture of resins and solvents. The paint of the present invention can be used as a paint for spraying on the plastic casing of electronic and electrical appliances. It has the characteristics of simple spraying process, low energy consumption, low cost, relatively less pollution, and more environmental protection.

Owner:深圳市美丽华科技股份有限公司

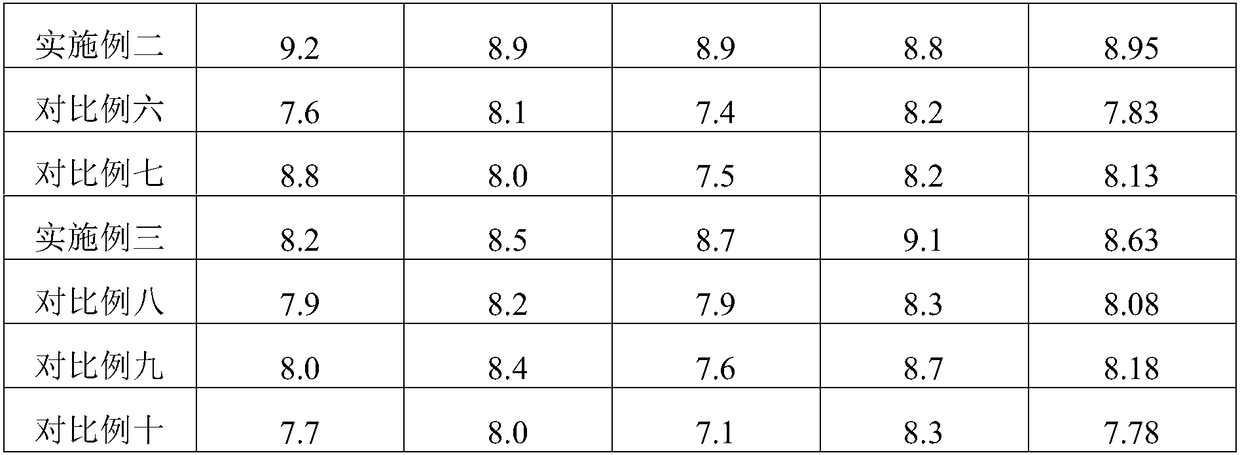

Efficient Fenton-like technology beneficial to repeated reaction

ActiveCN106111102AGuaranteed complete mixingHigh catalytic activityWater treatment parameter controlWater treatment compoundsThermal sprayingWastewater

The invention discloses an efficient Fenton-like technology beneficial to repeated reaction. Composite oxide particles are used as the catalyst, the catalyst particles are sprayed on the surface of a turbine through the thermal spraying method, the catalyst on the surface of the turbine can make full contact with hydrogen peroxide in wastewater under the stirring function of the turbine, flowing of water flow in a container is promoted, accordingly efficiency of the Fenton-like technology can be greatly improved, and separation of the catalyst and a system is convenient. The technology greatly improves utilization efficiency of hydrogen peroxide, and accordingly efficiency of the Fenton-like technology can be remarkably improved. Besides, the catalyst is loaded on the surface of the turbine, separation of the catalyst is convenient after reaction, friction between the turbine and the catalyst is avoided, efficiency of the Fenton-like technology is guaranteed, separation of the reaction system and the catalyst is convenient, and because friction is avoided, the service life of the catalyst and a device is prolonged.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Steel piston composite hear insulation coating and spraying technology thereof

InactiveCN109954643AImprove high temperature oxidation resistanceImprove bindingLiquid surface applicatorsVacuum evaporation coatingSurface engineeringInsulation layer

The invention relates to a steel piston composite hear insulation coating and a spraying technology thereof, and belongs to the technical field of material surface engineering. The steel piston composite hear insulation coating is a solid-state compound coating and includes a high-temperature anti-oxidation layer, a low heat conductivity coefficient heat insulation layer, and a high-temperature anti-corrosion layer, wherein the high-temperature anti-oxidation layer is a nano ceramics coating, the heat insulation coating is a solid polymer coating doped with zirconia low thermal conductivity nano powder, and the high-temperature anti-corrosion layer is an anti-corrosion solid polymer coating. According to the steel piston composite hear insulation coating and the spraying technology thereof, the high-temperature anti-oxidation coating is prepared by magnetic control sputtering, the obtained steel piston composite heat insulation coating can effectively prevent combustion heat in a cylinder from outward diffusing from a piston to an engine, the hear loss is reduced remarkably, the overall heat efficiency of the engine is improved, and the service life of the piston is prolonged.

Owner:FAW JIEFANG AUTOMOTIVE CO

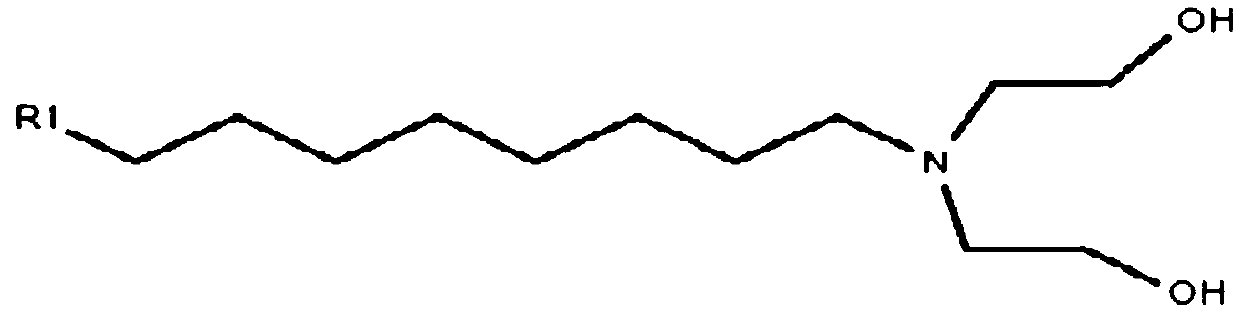

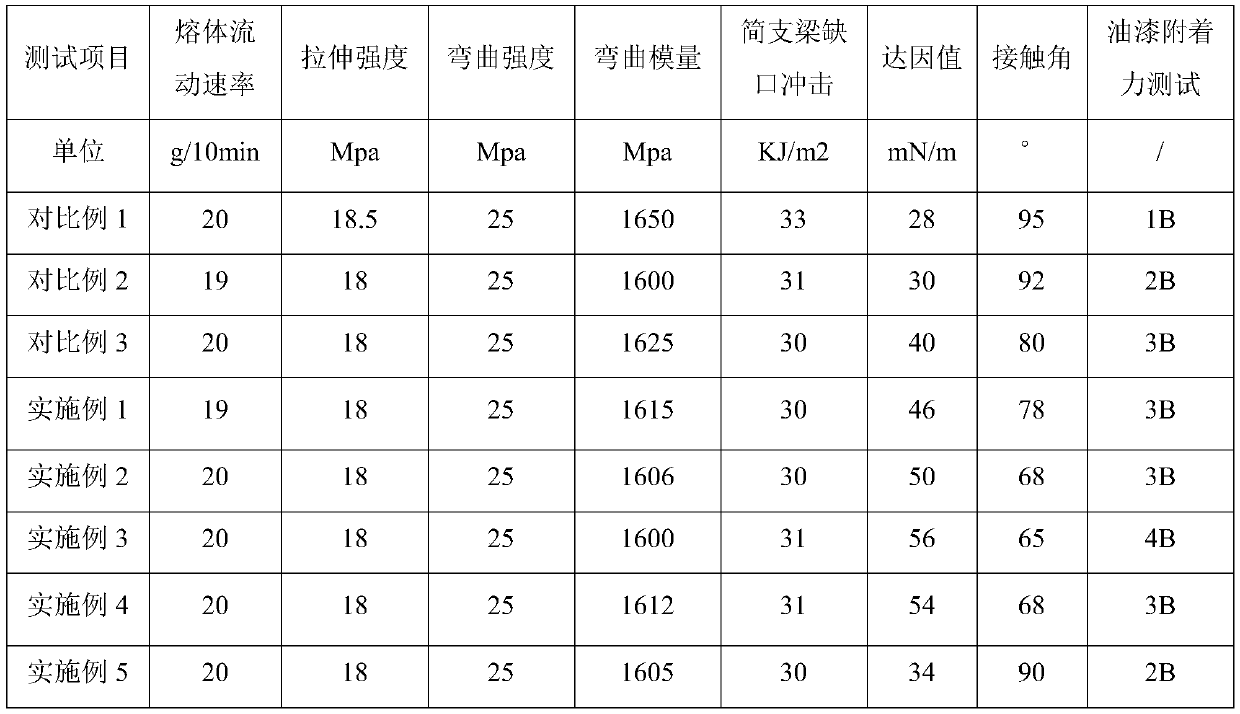

Polypropylene composition with high surface tension and preparation method thereof

The invention discloses a polypropylene composition with high surface tension and a preparation method thereof. The polypropylene composition is prepared from a polypropylene mixture, a polar modifierwith a polar group, a polar modification auxiliary aid, a filler, a flexibilizer and a functional aid, wherein the polar modifier with the polar group is diethanol amine with a long-chain alkyl group, and the polar modification auxiliary agent is at least one of maleic anhydride modified polypropylene, acrylic acid modified polypropylene and polyvinyl alcohol. The polypropylene composition disclosed by the invention has high surface tension and wettability, can obviously improve the spraying property of a polypropylene injection molding part, simplify the spraying process and reduce the spraying cost, can meet the performance requirements of automobile part manufacturers at home and abroad, and has a wide application prospect.

Owner:ORINKO NEW MATERIAL CO LTD

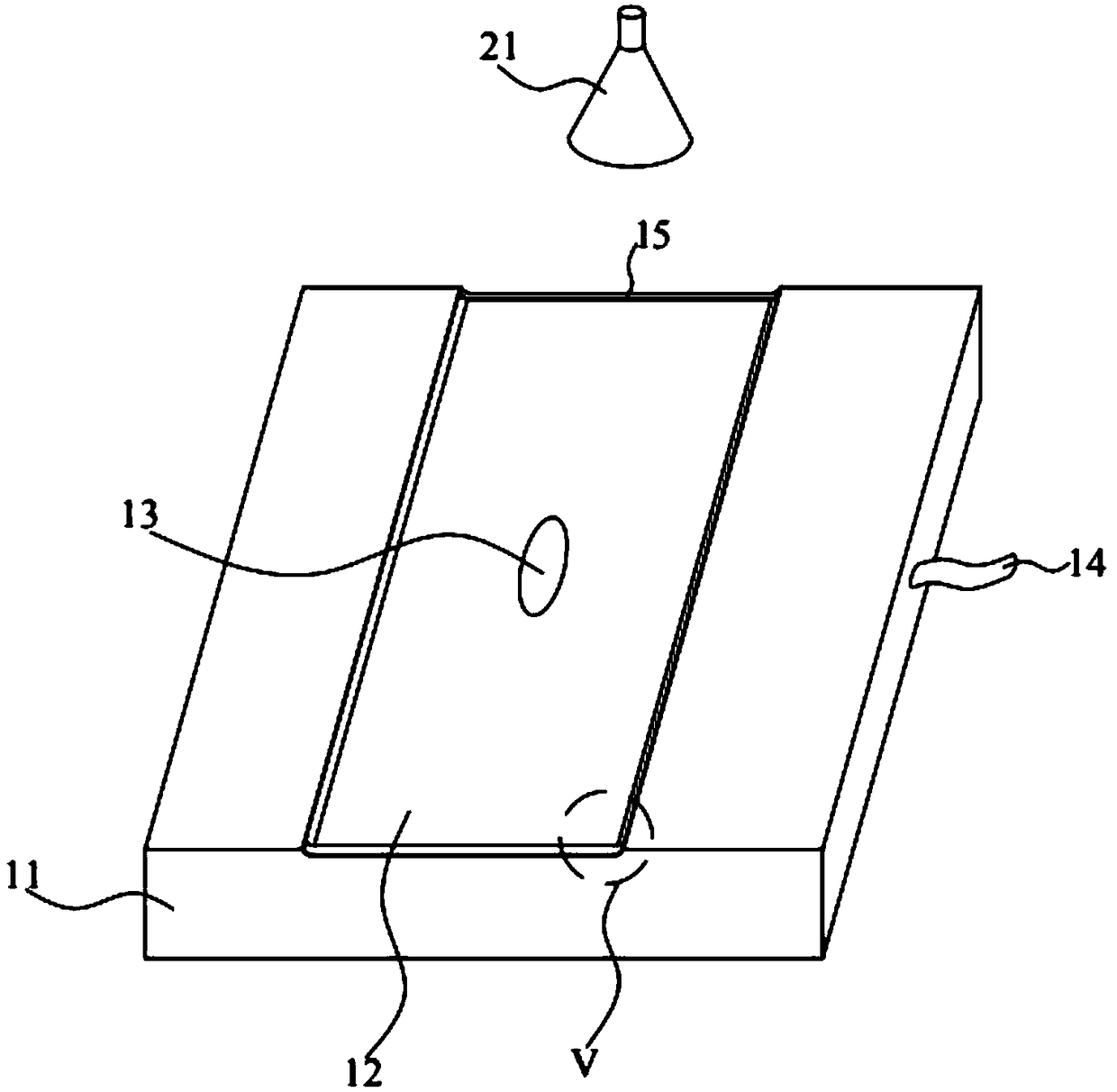

3D glass ink spraying device and spraying method

ActiveCN109020255ASimple spraying processImprove spraying efficiencyCoatingsMechanical engineeringSpray method

The invention discloses a 3D glass ink spraying device and a spraying method. The spraying device comprises a hollow box and a suction cup. The top part of the hollow box is provided with a receivinggroove for fixedly placing the 3D glass. The top surface of the hollow box is provided with a negative pressure through hole. The negative pressure through hole is provided in the area wherein which the receiving groove is located. The hollow box is connected to the negative pressure guide pipethrough hole. The negative pressure though holeguide pipe is used for forming a negative pressure in thehollow box, so as to suckadsorb the 3D glass on the receiving groove. The suction cup is used for suckingadsorbing the 3D glass up after completing a spraying operation. A to-be-sprayed area of the 3Dglass is located at the outside of the receiving groove.While the 3D glass ink spraying device provided by the invention actually sprays, no film sticking process is required, spray technology is simplified, and the spraying efficiency is improved.

Owner:抚州联创恒泰光电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com