Patents

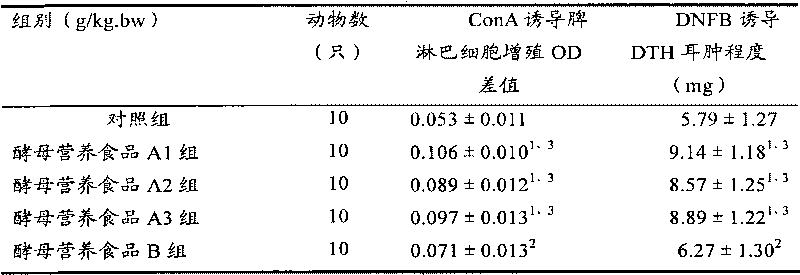

Literature

309 results about "Non dairy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-dairy. A regulatory definition does exist for the term, non-dairy. But, incredibly, the regulatory definition actually allows the presence of the milk protein, casein, in such products. Non-dairy is commonly used on coffee creamers made from caseinate, a milk protein, rather than milk or cream.

Whole grain non-dairy milk production, products and use

ActiveUS20070014892A1Increase coverageReserved functionDough treatmentWort preparationSlurryWhole milk

A method comprising selection of unbroken whole grain rice that are first washed, or whole grain corn that is first reduced in size, and then making an aqueous slurry that is subsequently wet milled to release all the protein, fat, fiber, and starch components normally held in the structure of the grain. The resulting slurry can be reacted with heat to gelatinize the starch and the subsequent product dried. Also, the heated slurry containing the liberated components can be treated to enzymatic hydrolysis via the process of liquefaction and optionally saccharification, producing whole grain rice milk products having diverse carbohydrate compositions. The whole grain milk products are characterized by a nutritional composition containing substantially all the nutritional components of the whole grain, being an opaque whole milk colloid, having smooth texture versus pulpiness, lacking in all bitterness normally associated with whole grain products, and having a variety of sweetness levels from non-sweet to very sweet.

Owner:STEUBEN FOODS

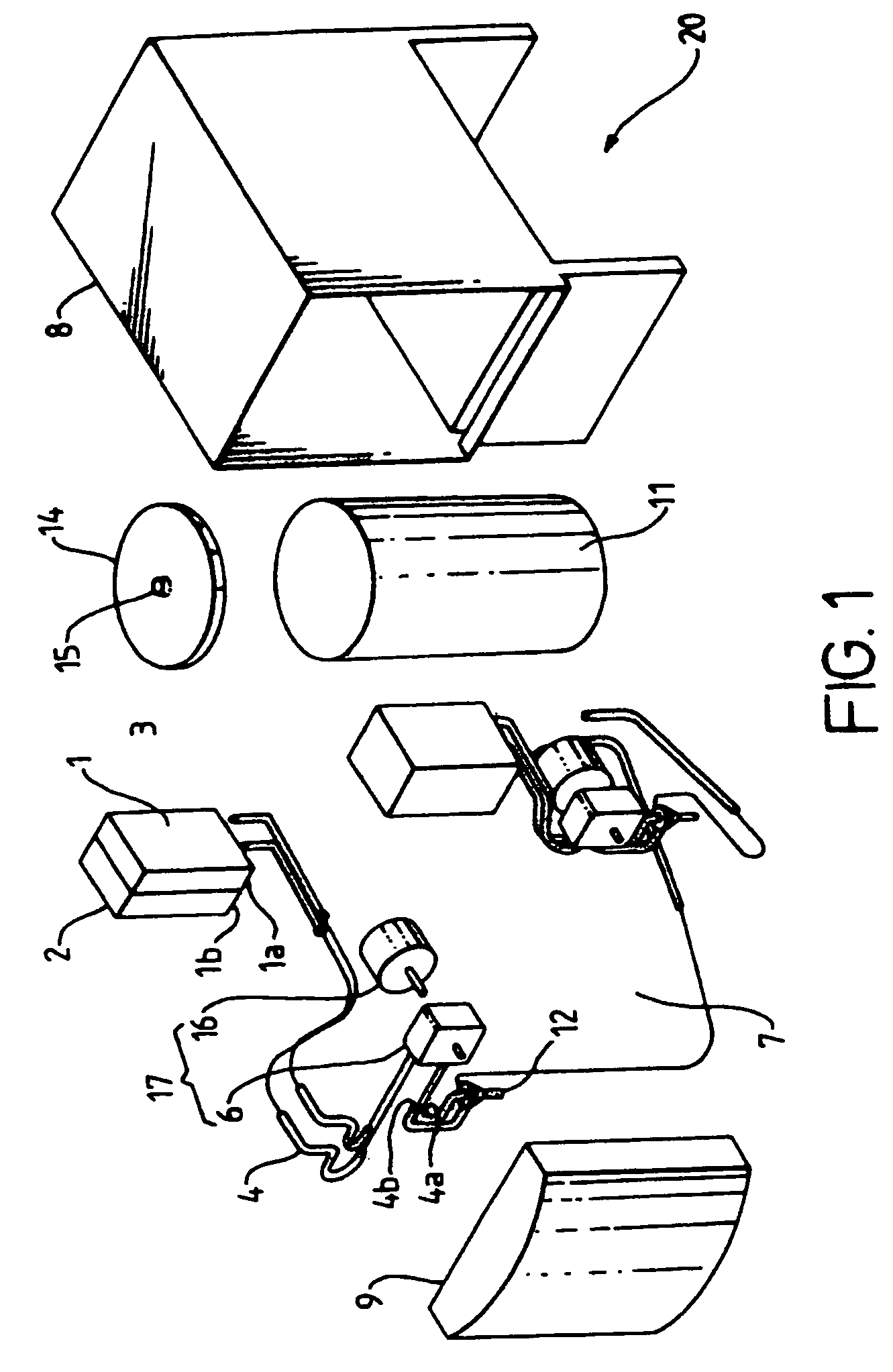

System, method and compositions for dispensing a liquid beverage concentrate

InactiveUS20050178793A1Add flavorGreat tastePower operated devicesFrozen sweetsMaillard reactionNon dairy

A beverage system for providing a beverage, methods of making the beverage and the resulting beverage are disclosed herein. The system includes a beverage-forming concentrate and an aroma or aroma-providing component separated from the concentrate; wherein the concentrate and aroma are combinable upon reconstitution for providing the beverage. One method includes delivering a fresh beverage taste to an on-premise beverage at a point of dispensation, by delivering at least one aroma or aroma-providing component in an amount sufficient to enhance the organoleptic properties of a beverage separately from a beverage concentrate prior to when the beverage is dispensed, and mixing the aroma or aroma-providing compound with a liquid and the beverage concentrate or with a mixture of a beverage concentrate and a liquid when the beverage is being dispensed. The resulting beverage may be coffee, tea, carbonation, a juice, milk, or a non-dairy creamer-based component; or a combination thereof, while the aroma or aroma-providing component is coffee aroma, tea aroma, chocolate or cocoa aroma, malt, Maillard reaction flavor, or a combination thereof.

Owner:NESTEC SA

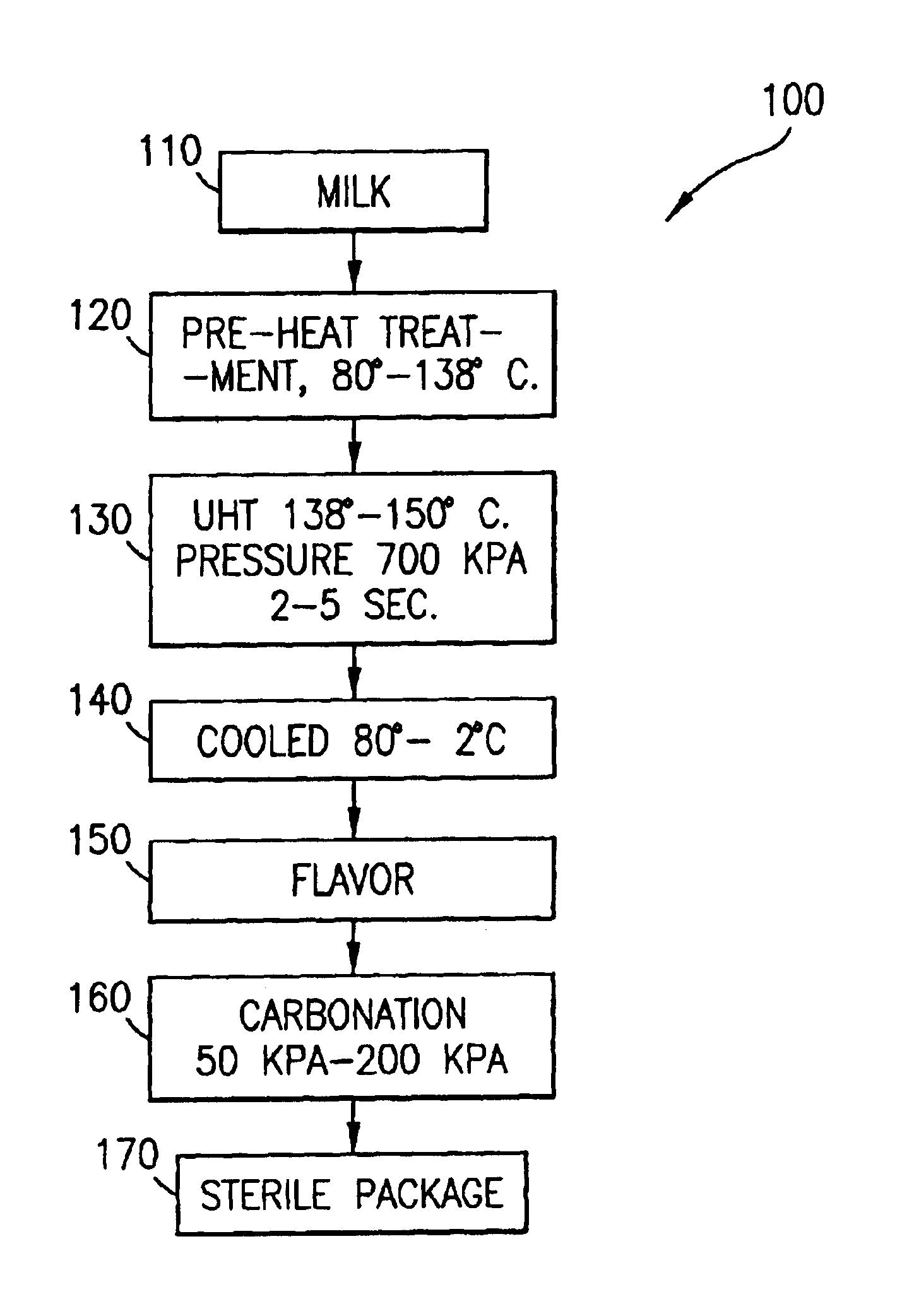

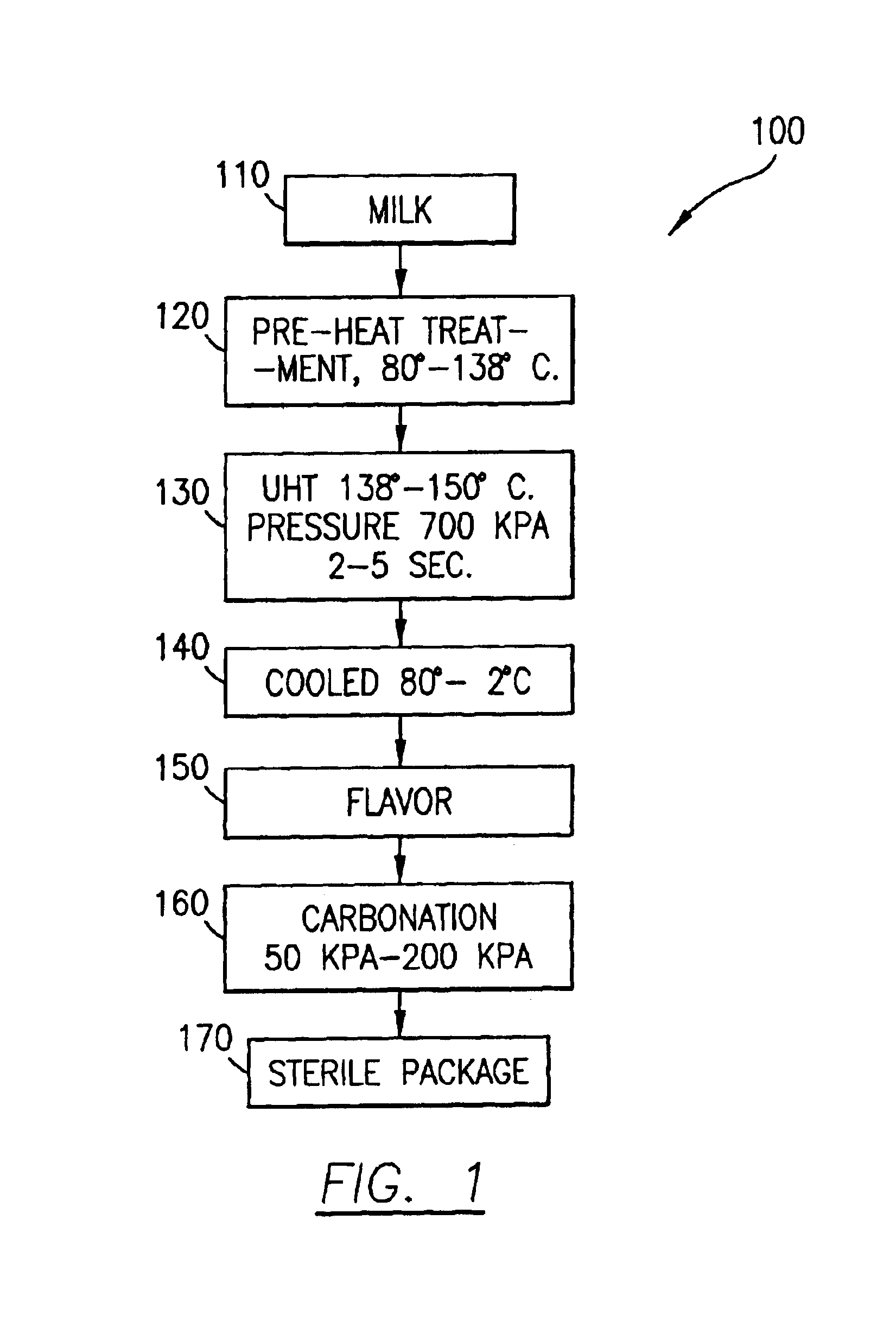

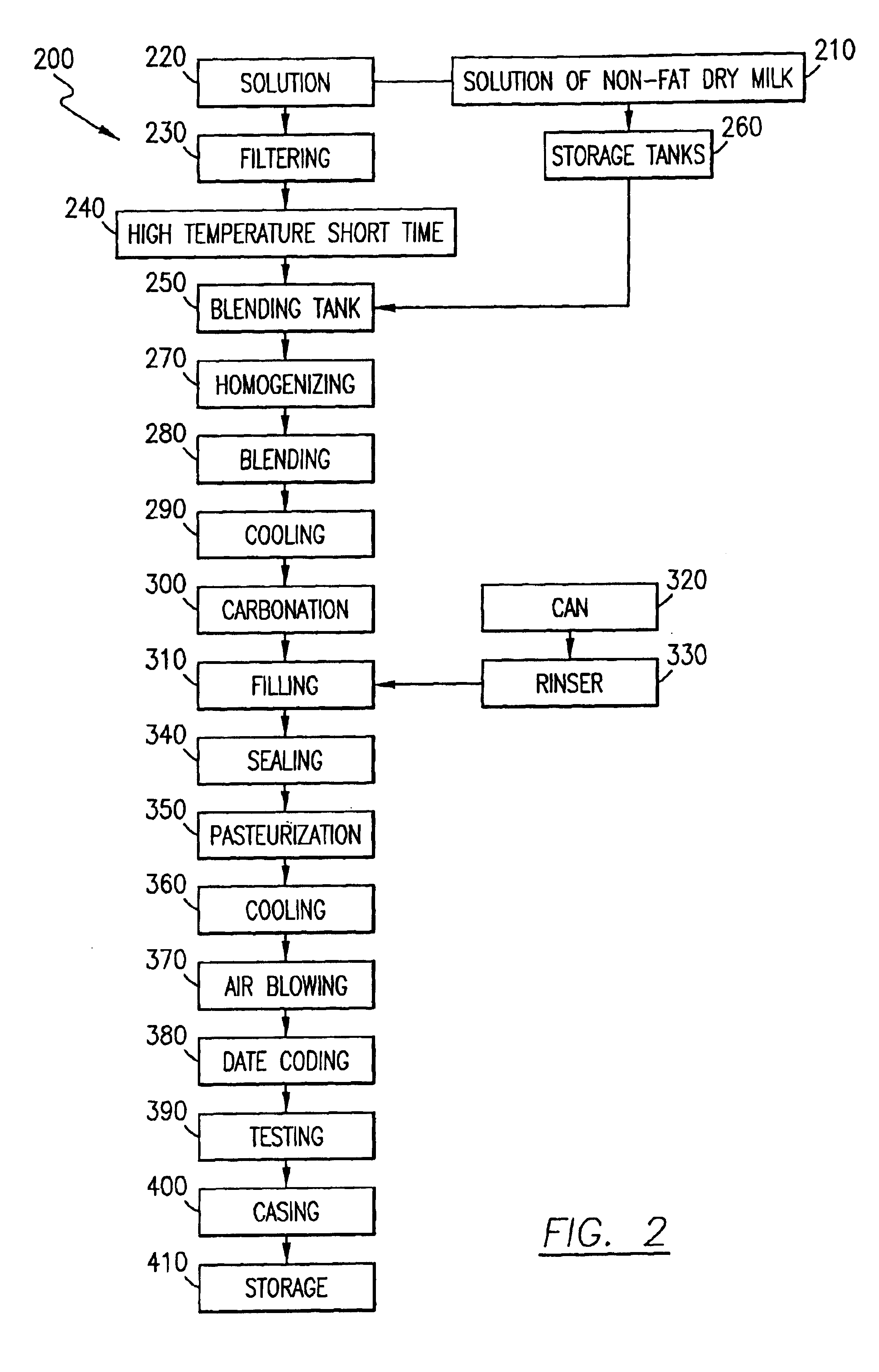

Process for making shelf-stable carbonated milk beverage

An aerated or carbonated milk product drink having a shelf stable pre-heated and pressurized ultra-heat treated milk product which has been carbonated with a gas or gases under pressure and packaged into a container. The milk product may be natural or artificial milk product including dairy products and non-dairy milk products and includes combinations of milk products with other beverages such as fruit juices. The method of producing the shelf-stable carbonated milk product of the present invention comprises injecting under pressure carbon dioxide gas or a mixture of gases into the milk product at low temperature of less than 10 degrees centigrade and high pressure of from 50 kpa to 200 kpa. The carbonated milk product remains carbonated and shelf stable in the package until opened.

Owner:KROLL DIANE +1

Process of making cold-water dispersible cellulose ethers and uses thereof

InactiveUS20070175361A1Good dispersionReduce molecular weightCellulose adhesivesCoatingsCellulosePersonal care

The present invention relates to an improved process for preparing cold water dispersible water-soluble polymers particles which readily disperse in aqueous systems. These particles are suitable for use in such end use compositions including personal care, household care, construction, paint, oilfield, pharmaceutical food including dairy and non-diary products, and antifouling products

Owner:HERCULES INC

System for dispensing a liquid beverage concentrate

InactiveUS7597922B2Add flavorGreat tastePower operated devicesFrozen sweetsMaillard reactionFruit juice

A beverage system for providing a beverage, methods of making the beverage and the resulting beverage are shown herein. The system includes a beverage-forming concentrate and an aroma or aroma-providing component separated from the concentrate; wherein the concentrate and aroma are combinable upon reconstitution for providing the beverage. The resulting beverage may be coffee, tea, carbonation, a juice, milk, or a non-dairy creamer-based component; or a combination thereof, while the aroma or aroma-providing component is coffee aroma, tea aroma, chocolate or cocoa aroma, malt, Maillard reaction flavor, or a combination thereof.

Owner:NESTEC SA

Acid-resistant non-dairy creamer and preparation method thereof

ActiveCN101919454ARaw materials are simpleSolve the problem of acid intoleranceEdible oils/fatsMonoglycerideVegetable oil

The invention discloses acid-resistant non-dairy creamer and a preparation method thereof, and the acid-resistant non-dairy creamer comprises the following components by weight percent: 20-35% of partially hydrogenated vegetable oil, 5-15% of starch sodium octenylsuccinate, 0.3-0.7% of monoglyceride, 0.3-0.7% of sodium stearoyl lactylate, 0.2-0.4% of silicon dioxide and the balance of glucose syrup. A product can solve the difficult problem that the non-dairy creamer in the prior art has no acid resistance, simplify the application method of the non-dairy creamer in the prior art, reduce the uncertainty of the process, reduce auxiliary supplementary materials required during applications and expand the range of the applications.

Owner:JIAHE FOODS IND CO LTD

Leechee ice cream and making method thereof

The invention discloses a leechee ice cream which is made from the following components in percent by weight of 30-35 percent of non-dairy cream, 10-15 percent of milk powder, 8-12 percent of white granulated sugar, 0.2-0.3 percent of sucrose fatty acid ester, 0.1-0.2 percent of xanthan gum, 0.1-0.15 percent of leechee essence and the balance of water. A making method of the leechee ice cream comprises the steps of: mixing the white granulated sugar, the sucrose fatty acid ester and the xanthan gum uniformly, slowly adding water with a temperature of 30-35 DEG C under the stirring condition, adding the milk powder after complete dissolution, dissolving and uniformly stirring, heating to 80 DEG C+ / -2DEG C, insulating for 15min, cooling to a room temperature, adding the leechee essence, and uniformly stirring; stirring the non-dairy cream at a temperature of 10-15 DEG C until the cream expands to 3.0-3.5 times, then slowly adding the mixture into the stirred non-dairy cream under the condition of slow stirring, uniformly stirring, freezing in an environment with a temperature of minus 18 DEG C-minus 22DEG C for more than 12h to obtain the leechee ice cream. The leechee ice cream is especially suitable for baking shops such as a cake shop and a bakery, and the making method can be used for developing new varieties and further increasing economic benefit.

Owner:HARBIN PATERNA BIOTECH DEV

Cold cut type non-dairy creamer and preparation method thereof

ActiveCN101919455AReduce manufacturing costSolve the characteristicsEdible oils/fatsGlucose-Fructose SyrupVegetable oil

The invention discloses a cold cut type non-dairy creamer and a preparation method thereof. The cold cut type non-dairy creamer comprises the following components by weight percent: 20-35% of low melting point vegetable oil and fat, 2.0-4.0% of sodium caseinate, 0.5-2.0% of Datem, 1.0-1.99% of dipotassium phosphate, 0.2-0.4% of silica and the balance of glucose syrup. The invention solves the problem that the non-dairy creamer is difficult to dissolve in cooling water, and expands the application filed in the low-temperature environment.

Owner:JIAHE FOODS IND CO LTD

Medlar coffee

InactiveCN101878845AImprove immunityAntioxidantCoffee extractionCoffee flavouringLife qualityNon dairy

The invention relates to medlar coffee, which is prepared by mixing the following raw materials by weight ratio: 5-25 percent of medlar extract, 20-30 percent of instant coffee powder, 5-15 percent of white sugar and 40-50 percent of non-dairy creamer. The medlar coffee has the characteristics of delicate mouthfeel, smoothness, mellowness and rich and balancing nutrition and can effectively improve the life quality of people.

Owner:瓜州亿得生物科技有限公司

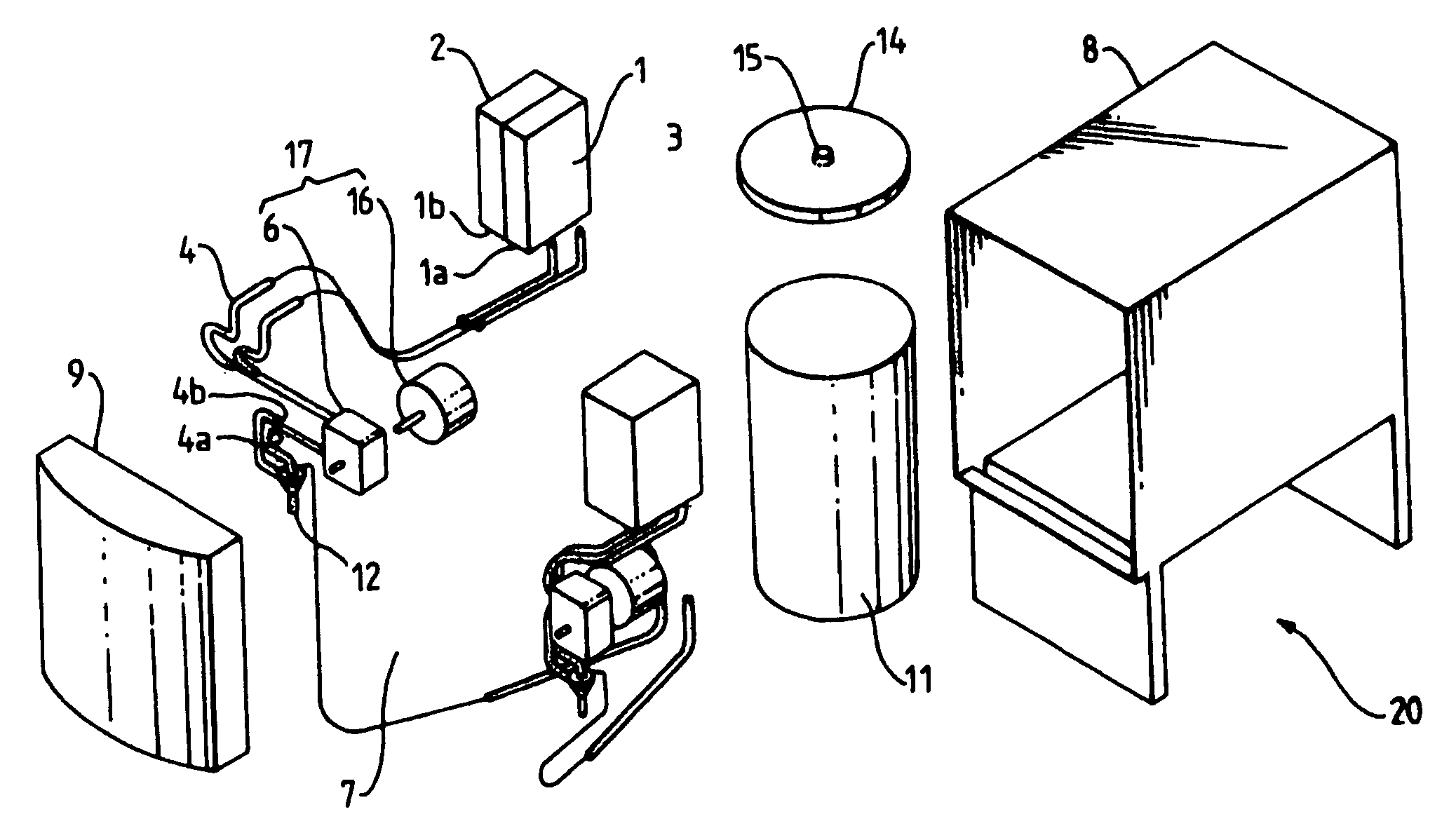

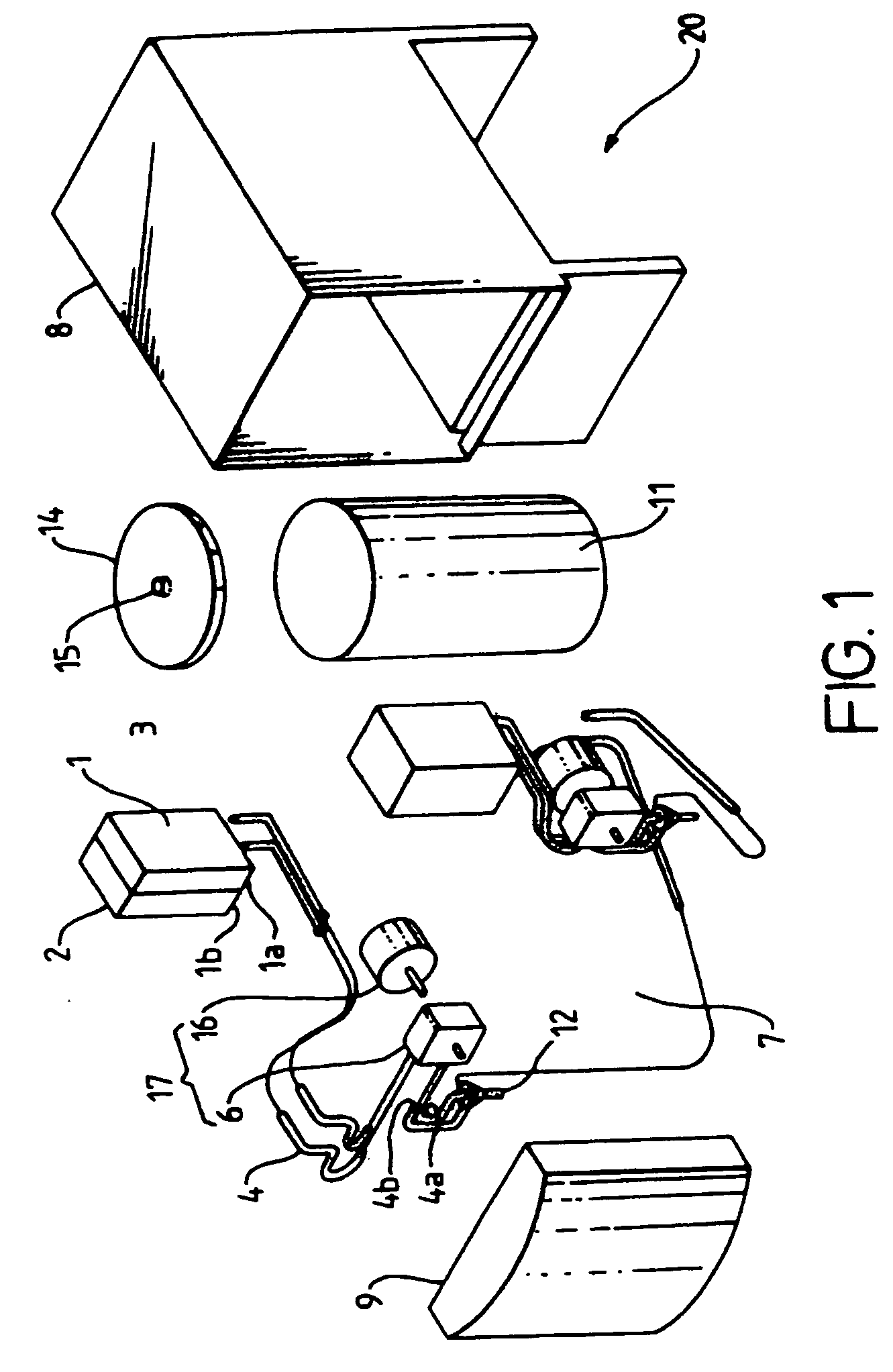

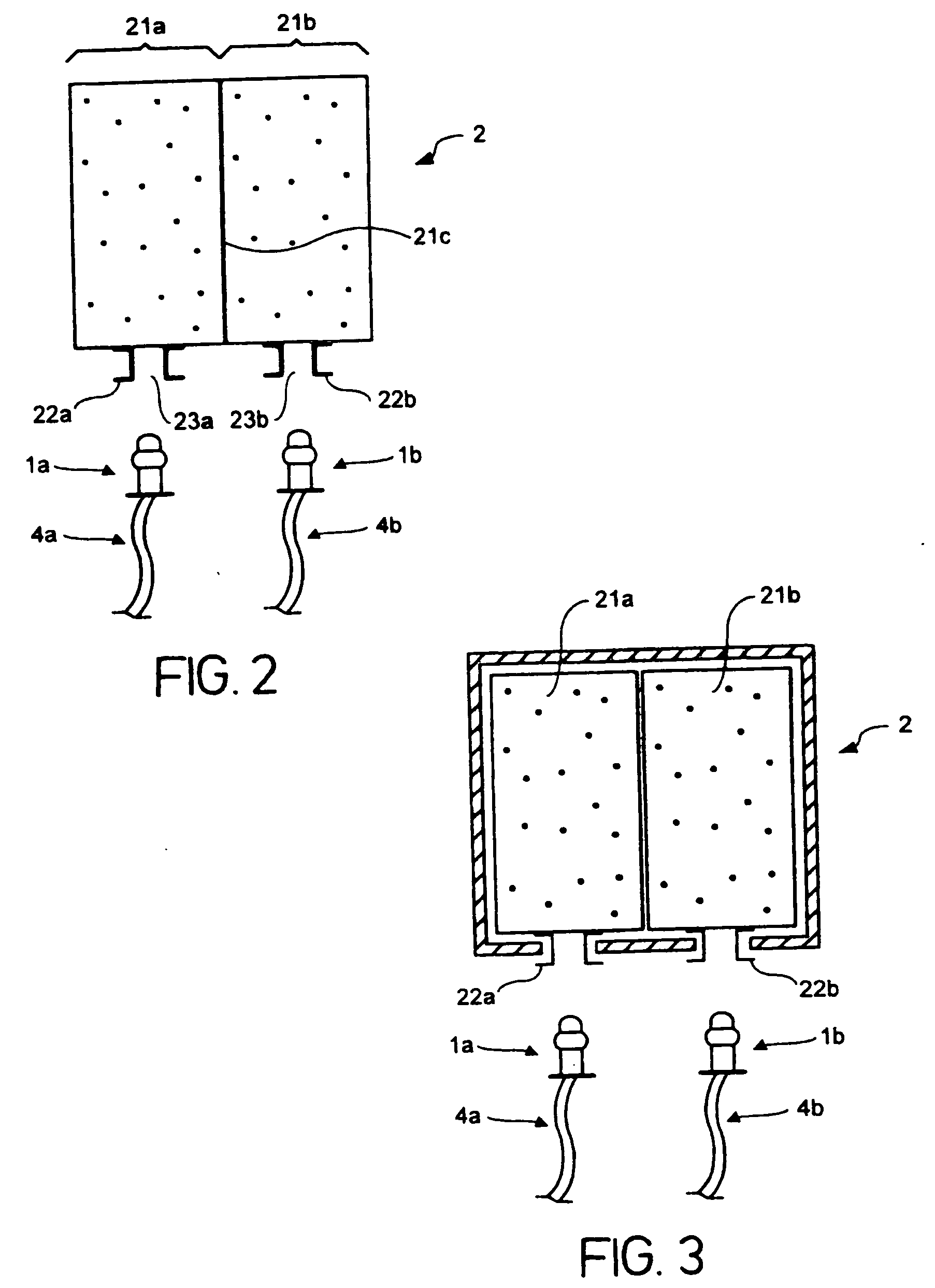

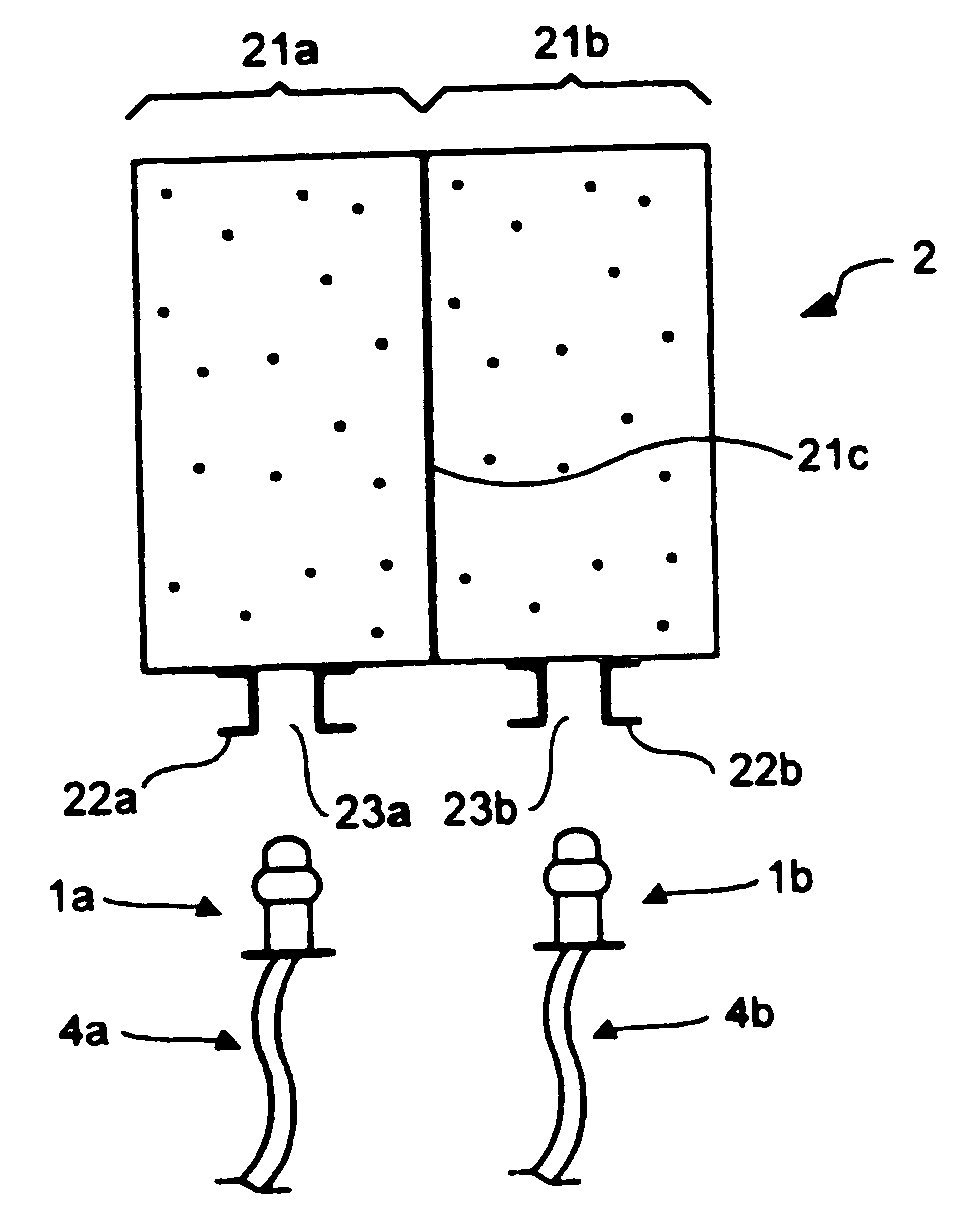

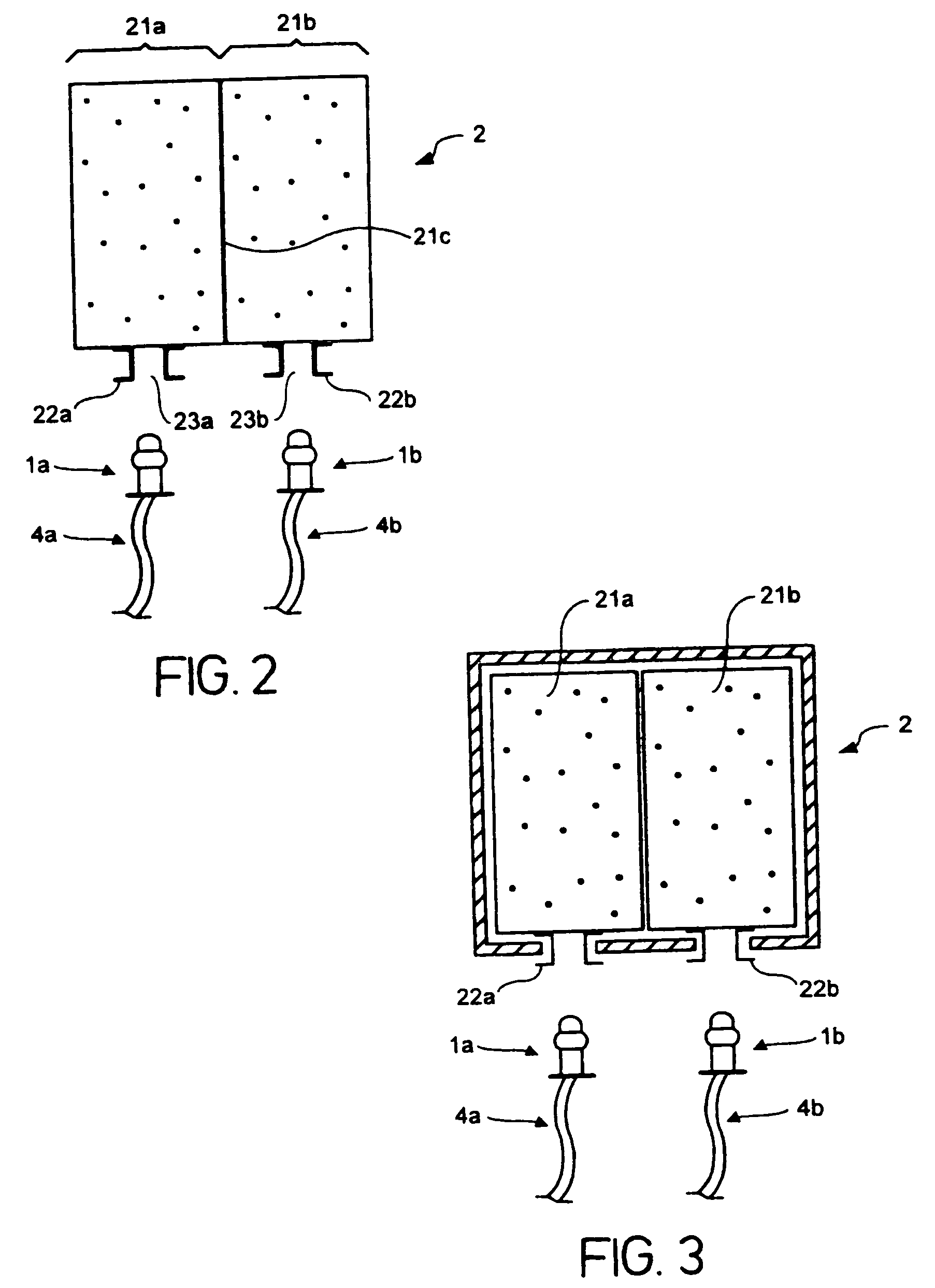

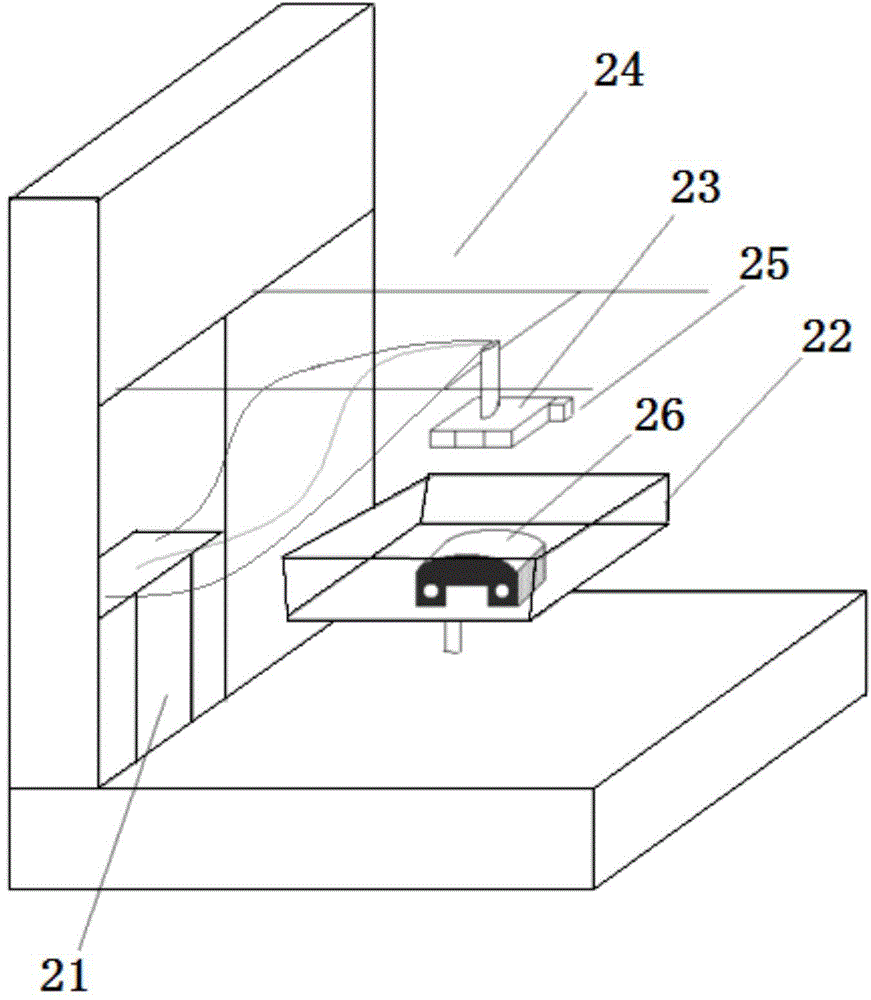

Non-dairy cream 3D printing system and process thereof

The invention relates to a 3D printing system. A non-dairy cream 3D printing system comprises three-dimensional printing equipment, the three-dimensional printing equipment comprises a material storage box for storing non-dairy cream, and a printing material box using the material storage box as the three-dimensional printing equipment; the three-dimensional printing equipment further comprises at least one printing spray head group composed of at least one printing spray head; the material storage box is communicated with the printing spray head group through a first pipeline; the three-dimensional printing equipment comprises a rack, a printing platform for loading a printed object is arranged on the rack, and the spray coating direction of the printing spray head faces to the printing platform; a cooling system for cooling the printing platform is arranged on the printing platform; the cooling system is any one of a cooling system using an air pump heat source, a cooling system using a heat exchanger and a cooling system using a compressor. According to the non-dairy cream 3D printing system provided by the invention, the cooling system is arranged on the traditional printing platform, thereby being more conducive to fix and shape the non-dairy cream and facilitating three-dimensional printing by adopting the non-dairy cream.

Owner:SHANGHAI HI ROAD FOOD TECHNOLOGY CO LTD

Non-dairy cream of mixed milk fat and preparation method thereof

The invention designs non-dairy cream of mixed milk fat. The non-dairy cream is characterized by comprising the components in percentage by weight: 8-18% of vegetable fat, 0.05-0.5% of anhydrosorbitan monostearate, 0.02-0.5% of lecithin, 0.02-1% of lactic monoglycerate, 0.02-0.5% of sodium stearyl lactate, 0.05-1% of monoglycerin fatty acid ester and diglycerin fatty acid ester, 0.05-0.8% of sucrose fatty acid ester, 0.02-0.5% of polyglycerol ester, 0.01-1.5% of carrageenan, 0.05-0.8% of microcrystalline cellulose, 0.05-1% of modified cellulose, 0.1-1.5% of sodium caseinate, 0.02-0.2% of potassium dihydrogen phosphate, 2-6% of sugar, 2-12% of corn syrup, 8-18% of milk fat dairy products and 20-60% of water. The non-dairy cream provided by the invention has the advantages that the non-dairy cream is convenient to operate without cream and non-dairy cream which are mixed and whipped topped; the non-dairy cream is more convenient to condition and is not affected by original flavor of the non-dairy cream; the whipped topping rate of the product reaches over 3.6 which is greater than that of existing similar products. The non-dairy cream is more economic and applicable for client.

Owner:SHANGHAI HI ROAD FOOD TECHNOLOGY CO LTD

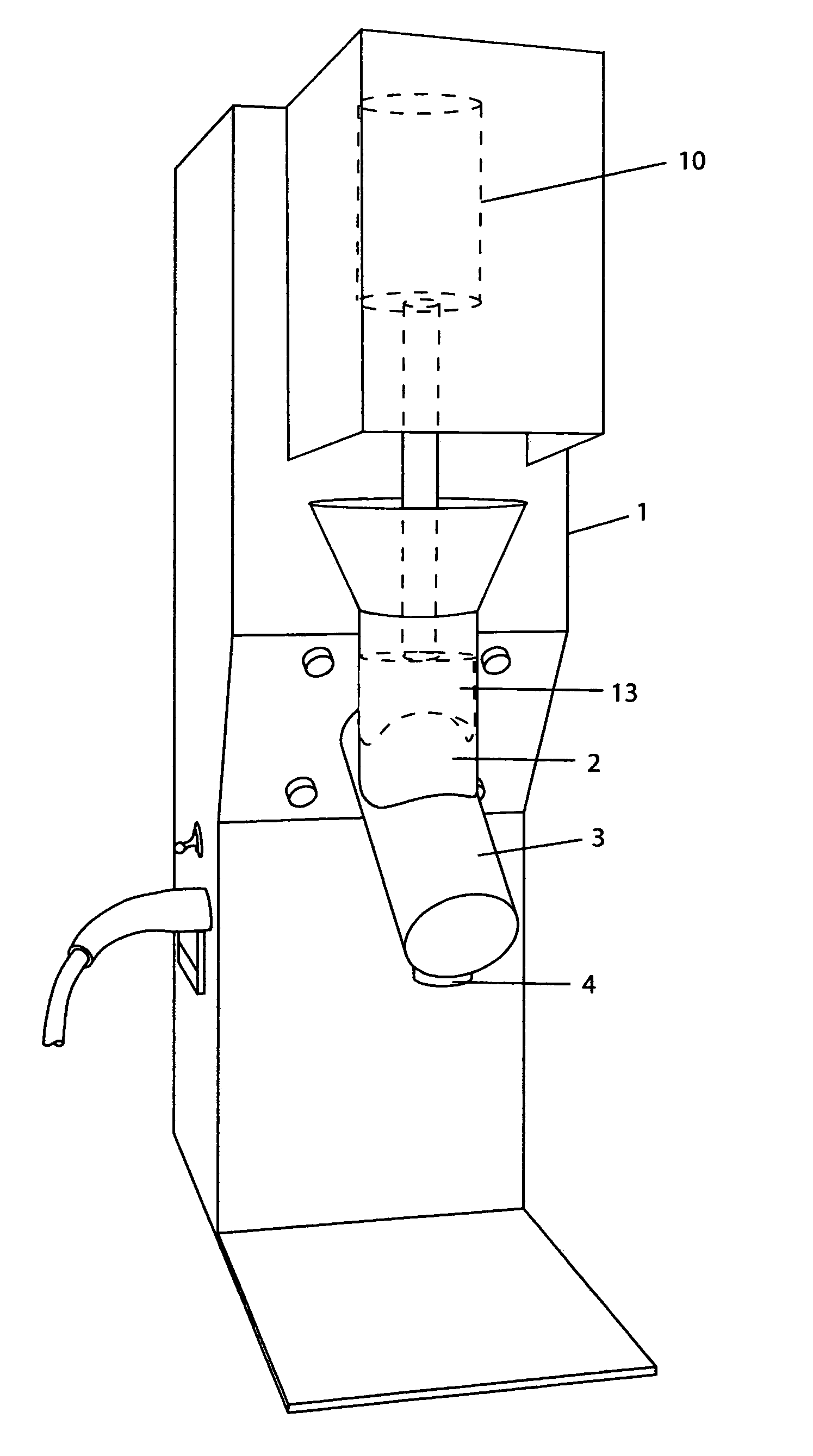

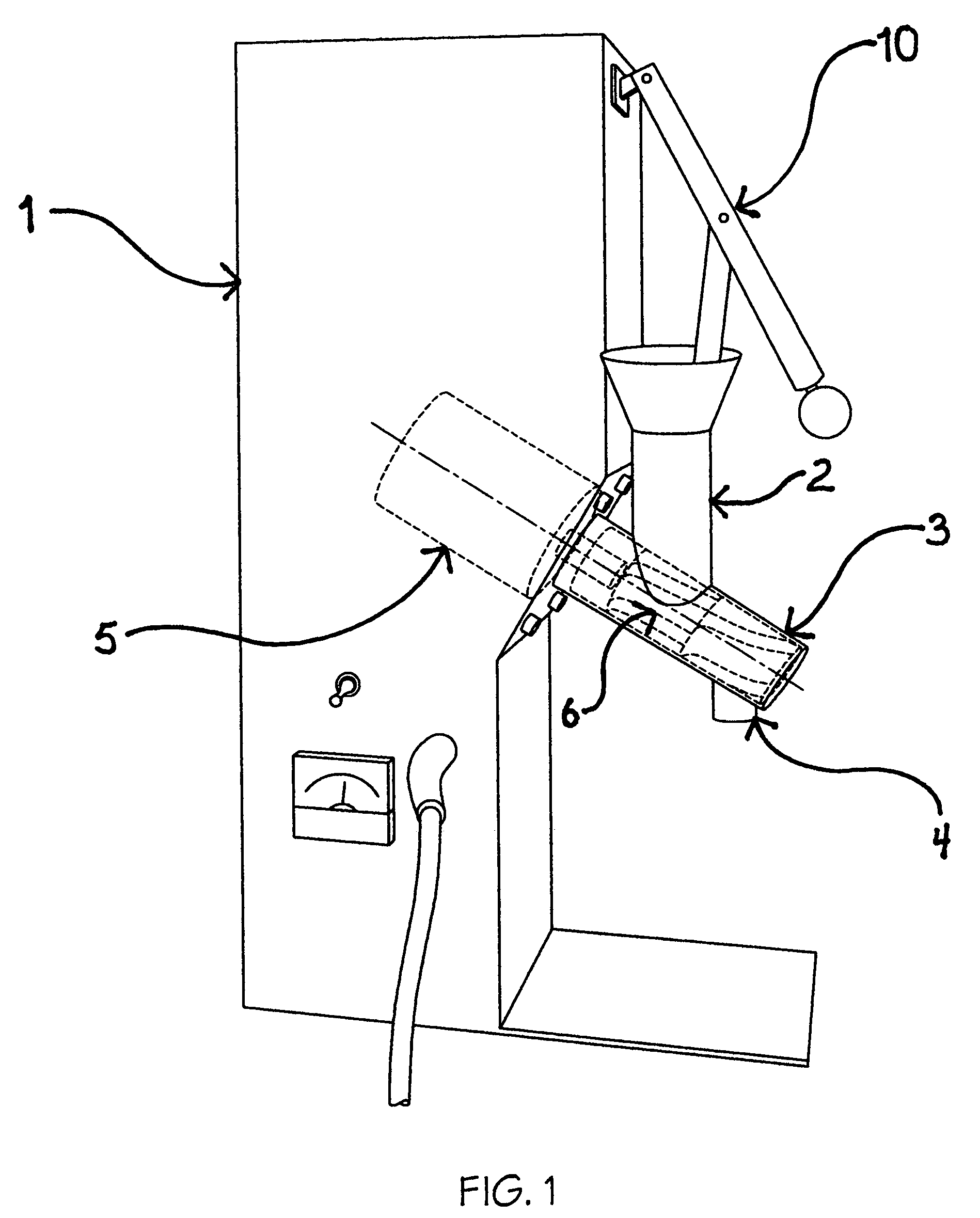

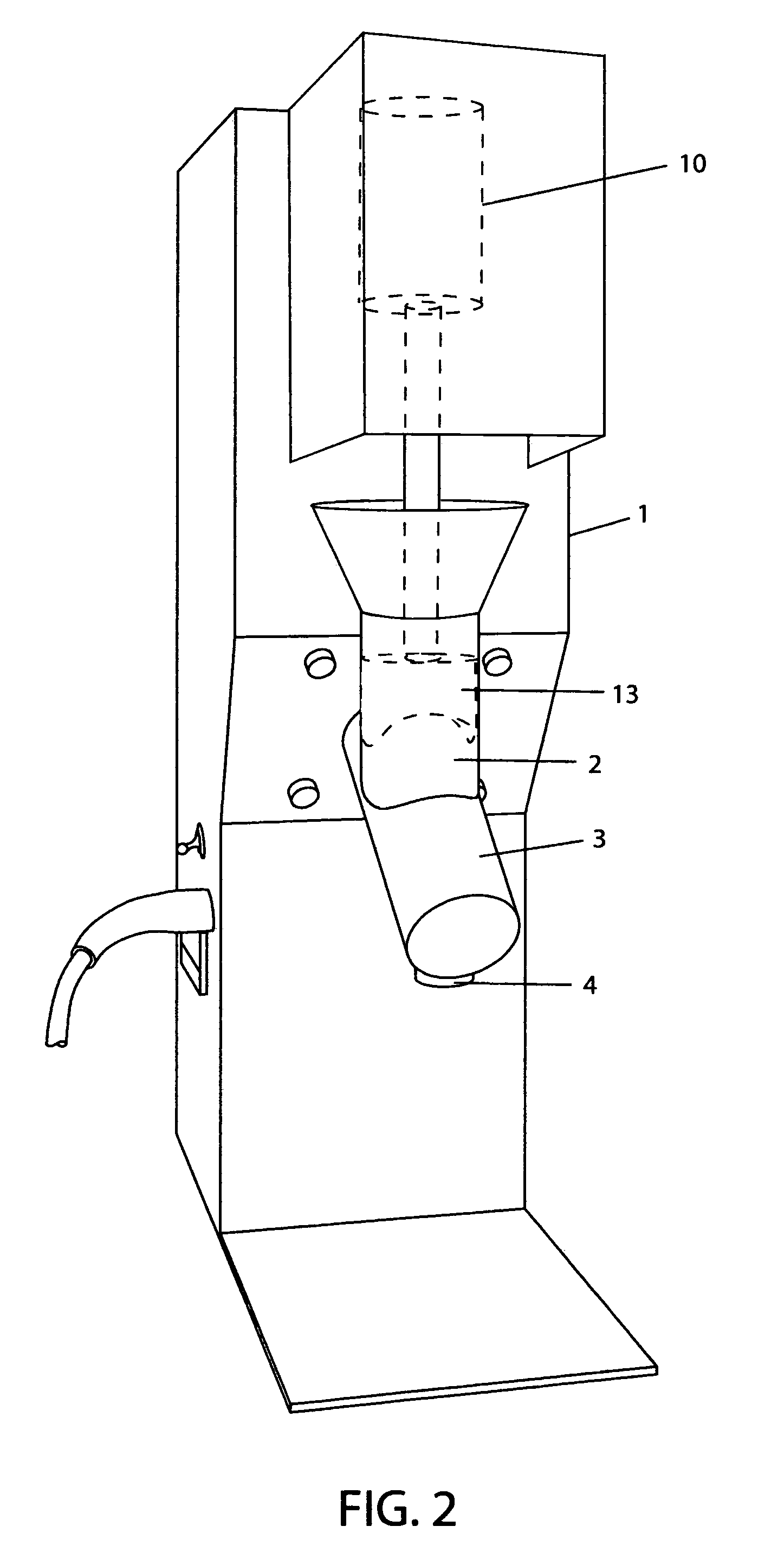

Frozen food masticating machine

A device for masticating frozen foodstuffs such device having a housing; a motor installed inside the housing; and an inlet portion for introducing foodstuffs therein connected to a masticating chamber. A plunging device is attached such that a piston is inserted into the inlet hopper to move the frozen foodstuffs into the masticating chamber. A masticating element is contained within the masticating chamber and is connected to the motor. This masticating element is formed with a threaded masticating portion with a plurality of cutting grooves having ninety degree angles of attack for masticating the frozen foodstuffs into the desired creamy texture. The masticating element also has a transferring portion with a plurality of moving shoots to move the masticated product out of the machine. The frozen fruits, vegetables, or other foodstuffs are easily loaded, masticated, and cleanly removed from the apparatus. When using frozen fruits this results in a non-dairy frozen dessert comprised of quick frozen fruit composite which has been masticated to achieve a desired creamy texture. Fruit, vegetables, or other frozen foodstuffs may be used alone or in combination with other flavoring agents such as vanilla extract, oils such as mint and powders or liquors such as chocolate and carob.

Owner:DNS FROOTZ LLC

Functional foods containing bacillus coagulans and non-dairy milk-like compositions

InactiveUS20150313951A1Confer clinical benefitFit for consumptionBiocideDispersion deliveryFunctional foodNon dairy

Owner:GANEDEN BIOTECH

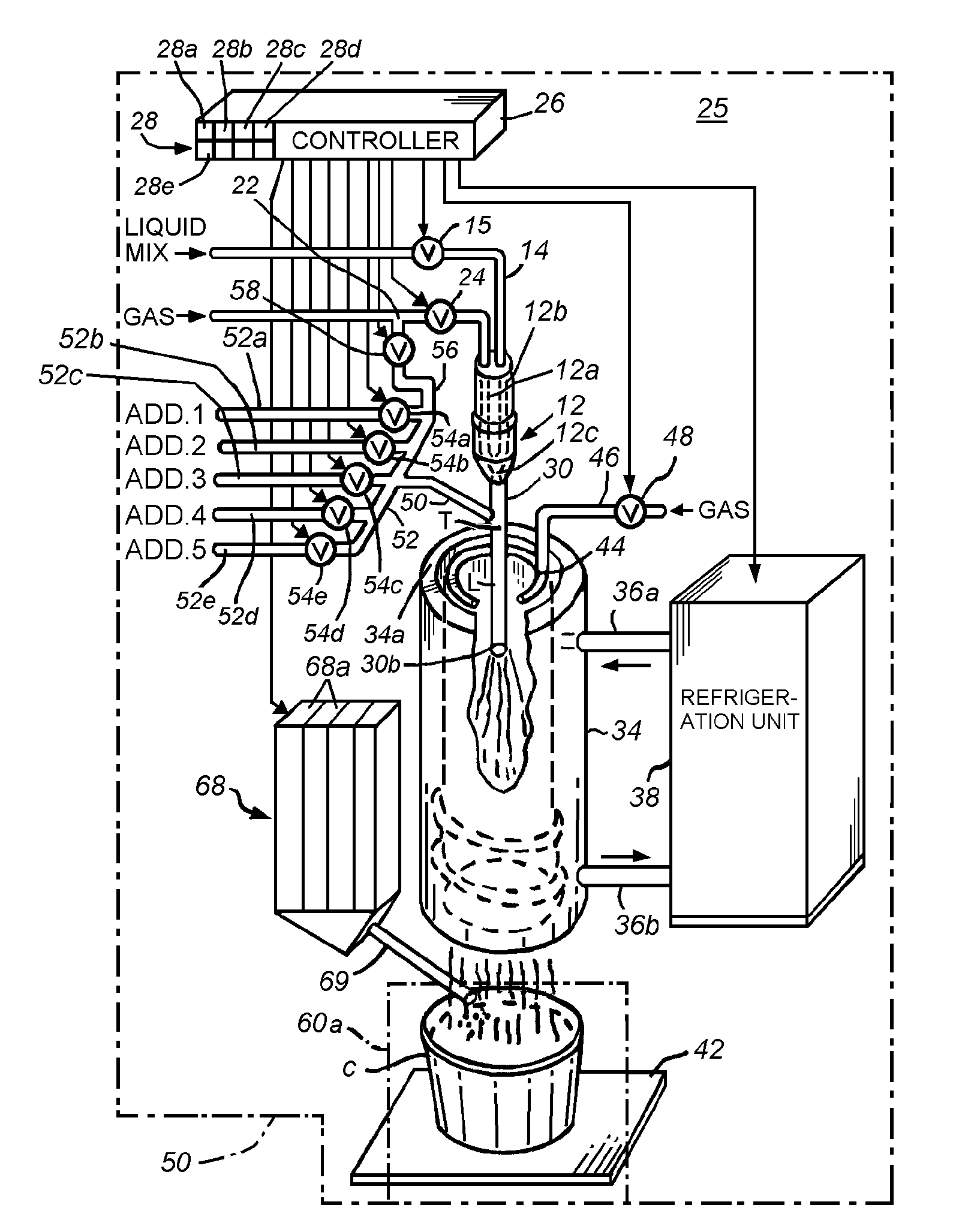

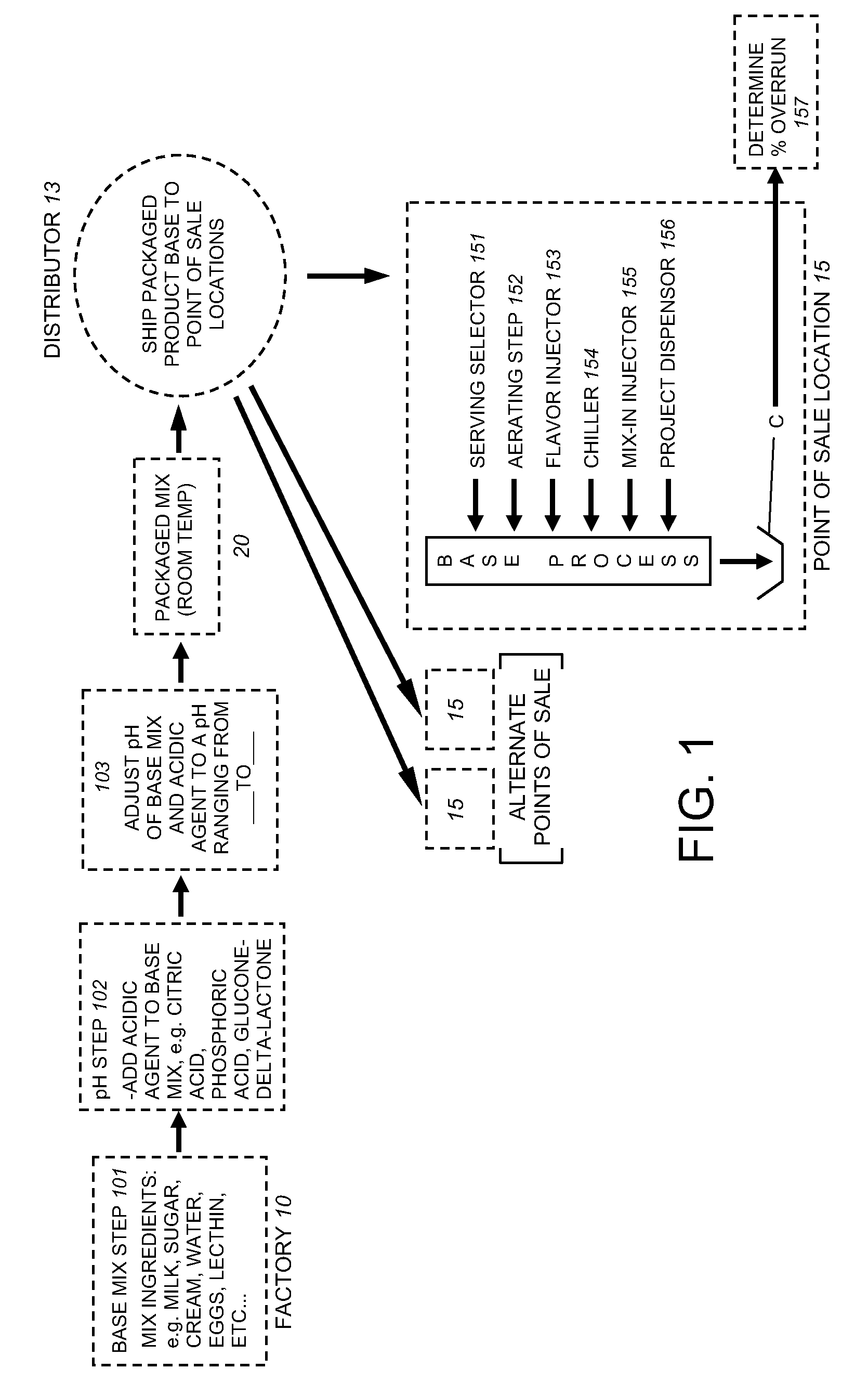

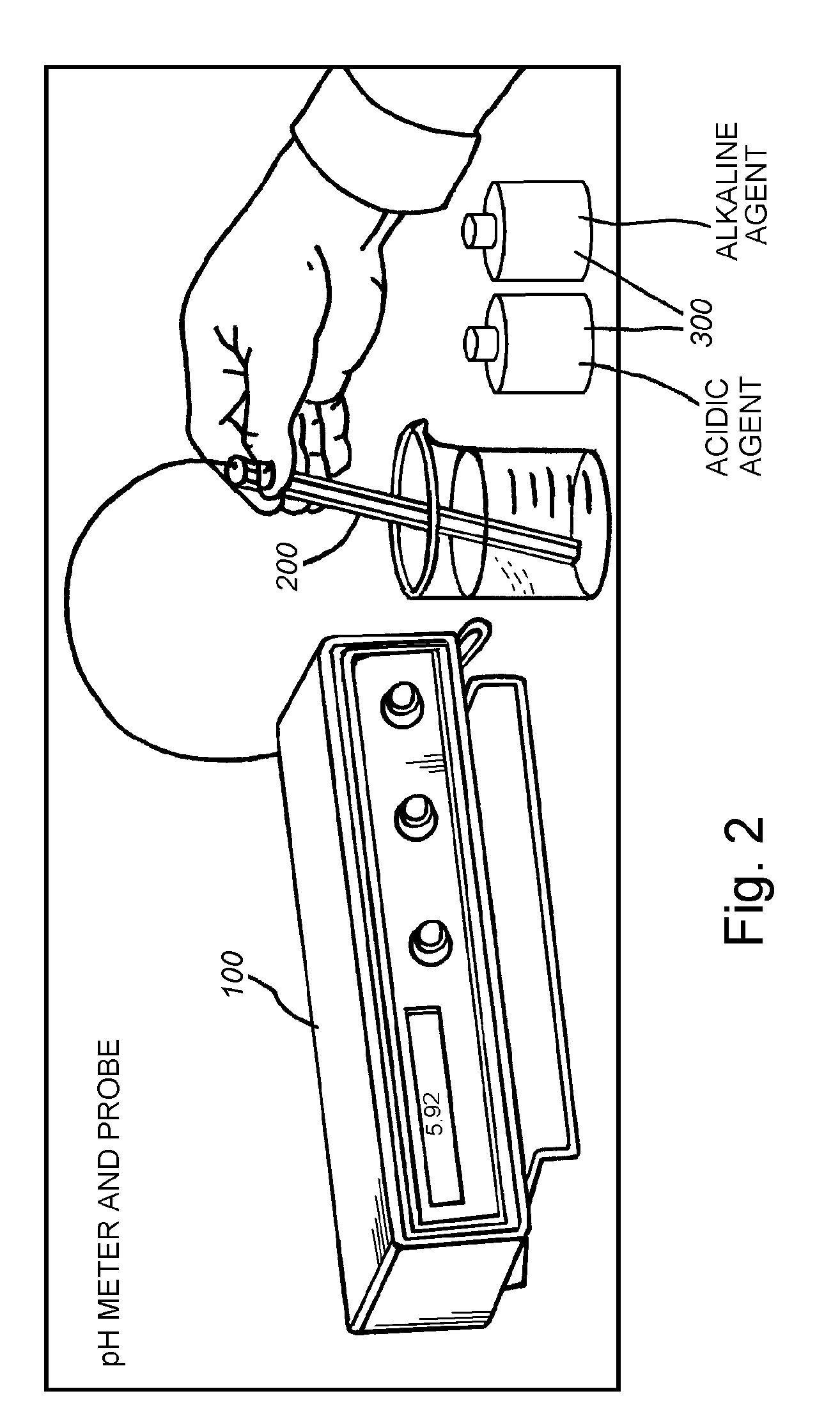

Frozen dessert compositions having increased overrun percentage

InactiveUS20100247723A1Lower pHDesirable consistencyMilk preservationFrozen sweetsNon dairyFood flavor

The present invention utilizes a base mix formulated with an acidic agent so that when processed, into a frozen dessert product, the base mix provides an increased overrun percentage without increased costs of production. The base mix component may include any suitable food component, such as one or more dairy components (e.g., a milk or cream), a sugar and / or corn syrup component, an egg component, water, a stabilizer, a thickener, and / or the like. In illustrative embodiment of the present invention, the base mix may alternatively include a non-dairy component, such as soy milk and / or soy protein. Additionally, the base mix may also include an acidic agent to lower the pH to a level that results in an increase in the overrun percentage of the resulting frozen dessert product, while maintaining a desirable consistency and flavor of the frozen dessert product.

Owner:MOOBELLA LLC

Milky tea powder and preparing method thereof

InactiveCN101248818AAbundant resourcesLow costMilk preparationPre-extraction tea treatmentBrickPlate heat exchanger

The invention discloses milk-tea powder as well as a preparation method thereof, which is prepared by fresh milk, white sugar, non-dairy creamer, green brick tea, and solid essence powder according to a certain proportion. The preparation method comprises the following steps: A. comminution: the brick tea is comminuted into superfine tea powder; B. mixture: a proper amount of the fresh milk is taken and heated by a plate heat exchanger, via a water-powder mixer, the tea powder, the white sugar, the non-dairy creamer, and the solid essence powder are added and stirred circularly, and the rest raw milk is added; C. sterilization; D. concentration: the material is sterilized and concentrated by a double effect falling film vacuum evaporator to obtain the concentrated material; E. spray drying: the concentrated material is sprayed and dried by a high pressure pump; F. redrying by a fluidized bed to obtain the milk-tea powder. The milk-tea powder has reasonable formula, convenient drinking, easy method and simple technique, thereby minimizing the energy consumption in the milk-tea processing technique, shortening the productive time with enhanced stability of the milk-tea quality, and increasing the utility ratio of the tea in the milk-tea manufacturing process without waste and pollution.

Owner:NEW HOPE DAIRY HLDG

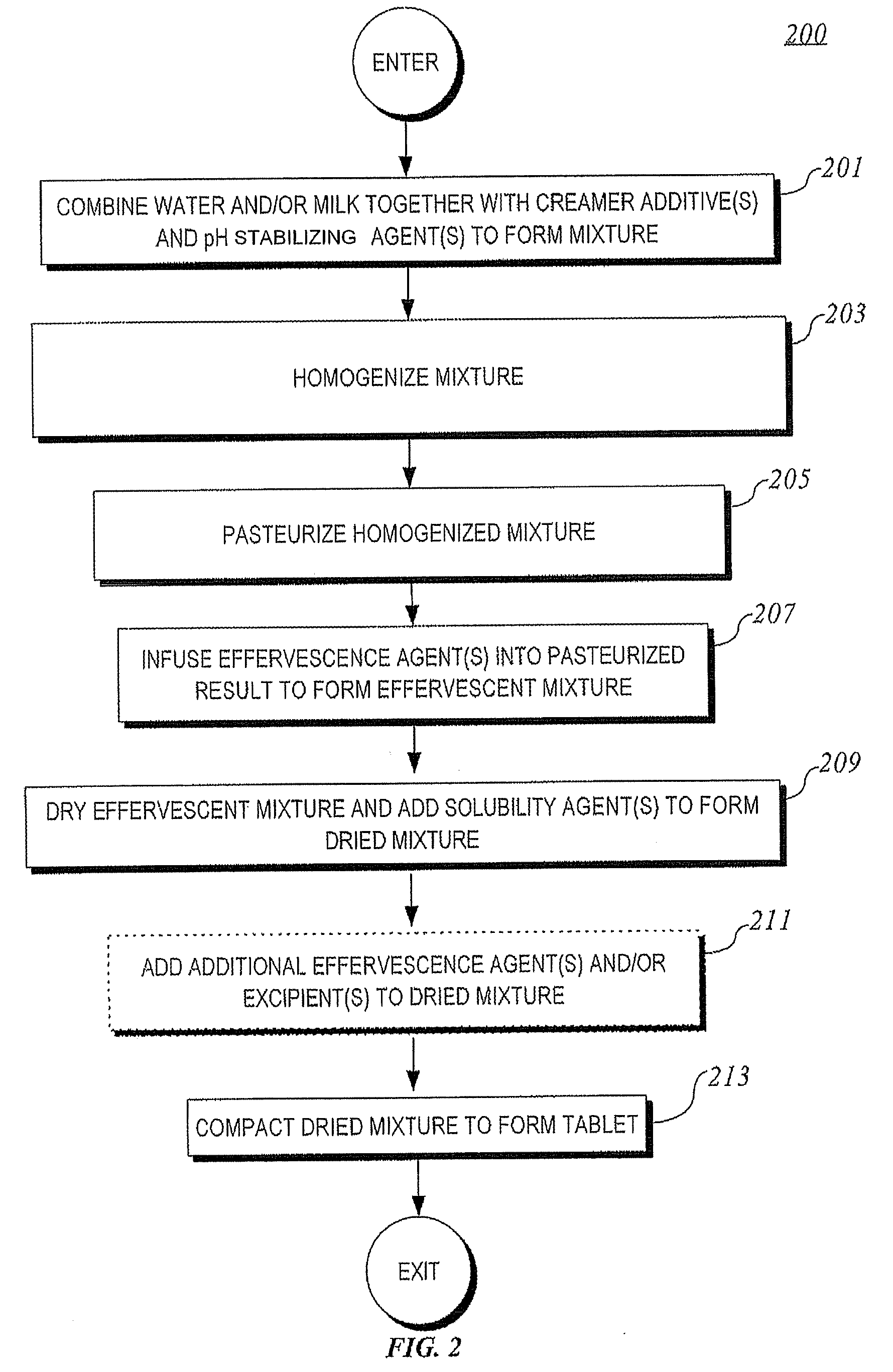

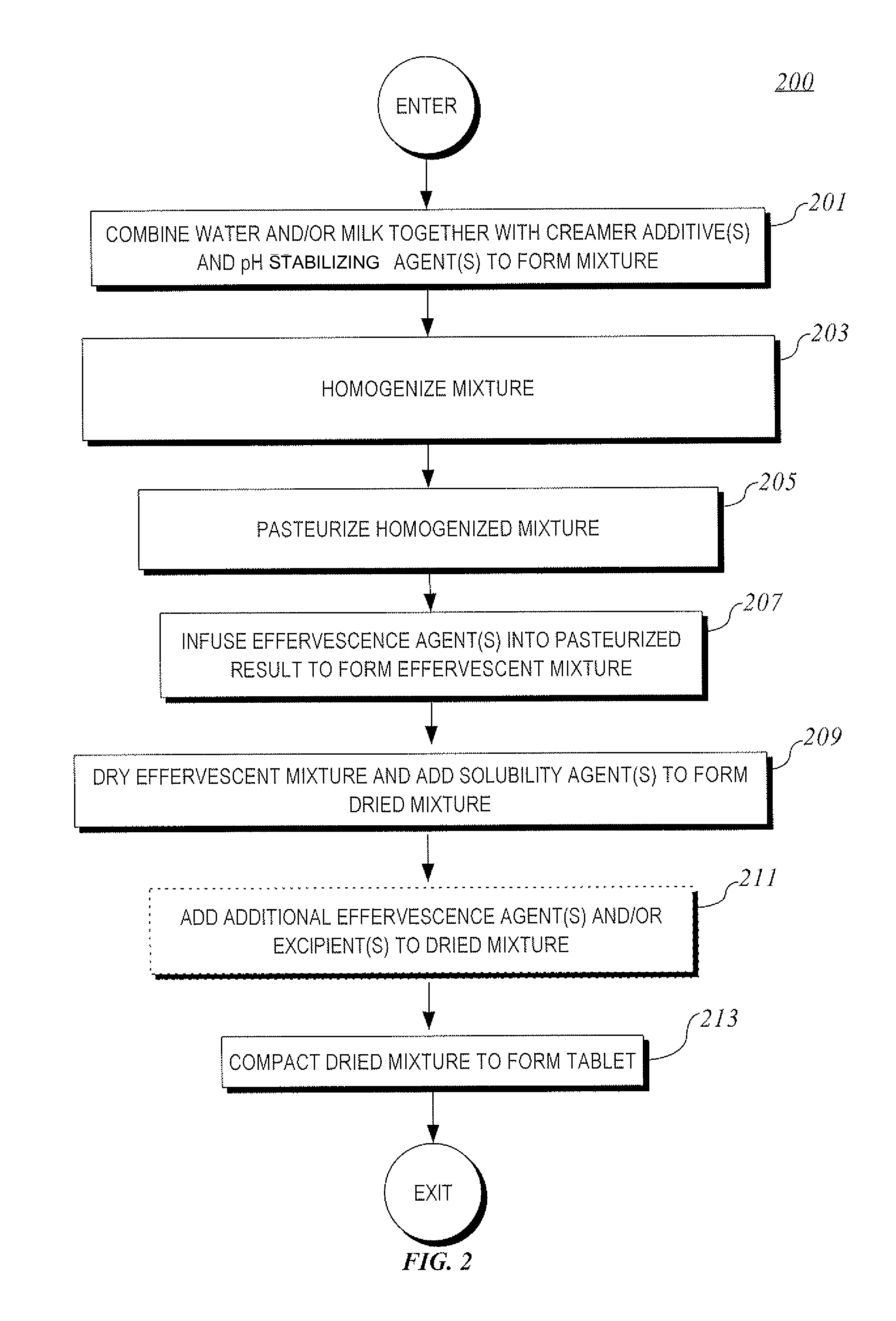

Effervescent tablet for use as an additive in hot coffee or hot water and method of making same

An effervescent tablet for direct use as an additive in hot coffee or hot water includes one or more creamer additives, pH stabilizing agents, effervescence agents, and solubility agents. In one embodiment, the tablet includes dry coffee and, in another embodiment, the tablet excludes it. The creamer additive(s) may be dairy and / or non-dairy. The effervescence agent(s) includes sufficient effervescence to separate the tablet upon placement of the tablet in the hot coffee or water and, in one embodiment, to further create foam on the surface of the coffee so as to yield an instant frothy latte or cappuccino. The pH stabilizing agent(s) stabilizes a pH of the coffee and the solubility agent(s) facilitates expeditious dissolution of the tablet in the coffee or water. Various other ingredients and agents may be included in the tablet to enhance flavor, improve mouth feel, enhance foam production, or achieve other desired characteristics or results.

Owner:SINGH HARJIT

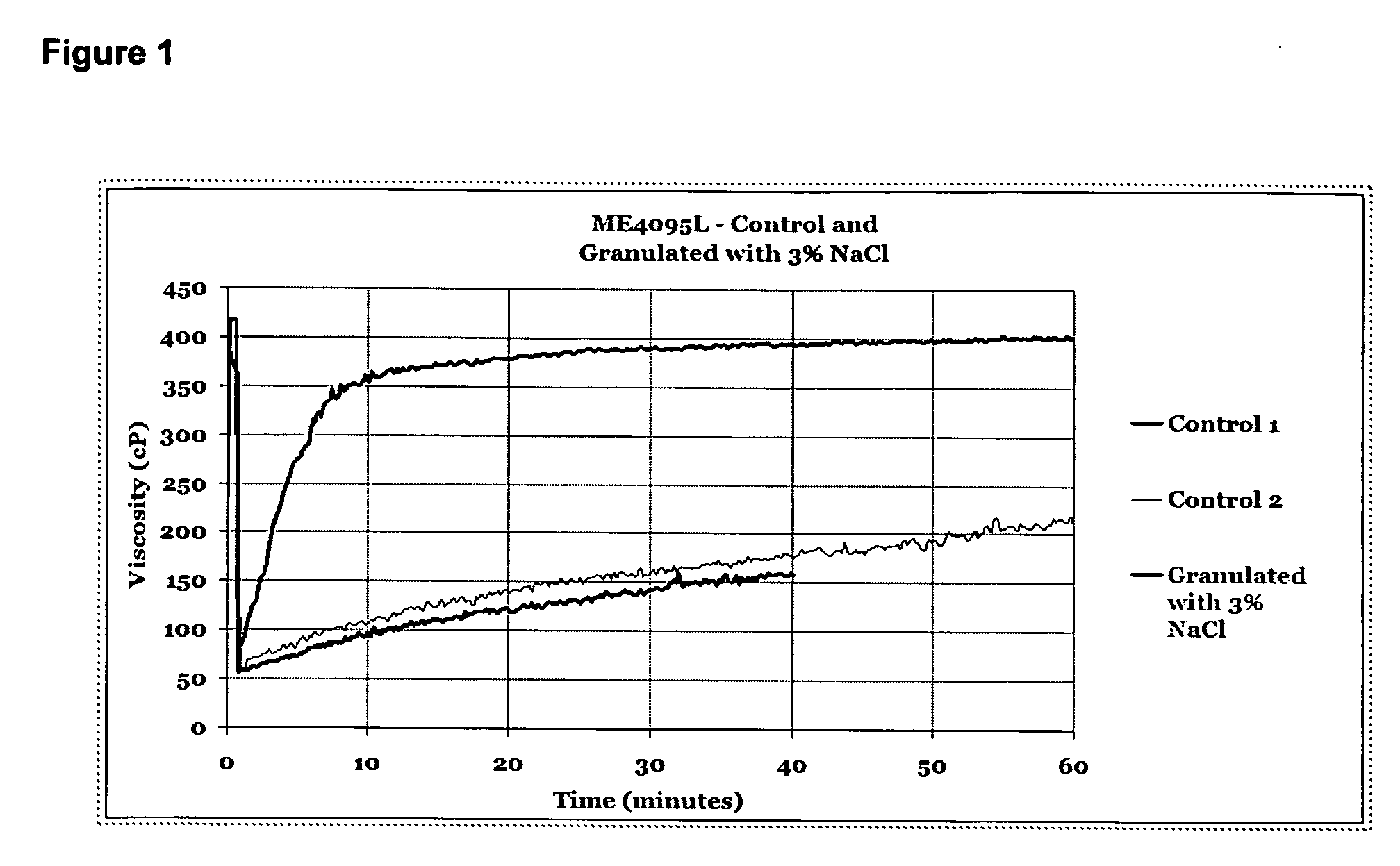

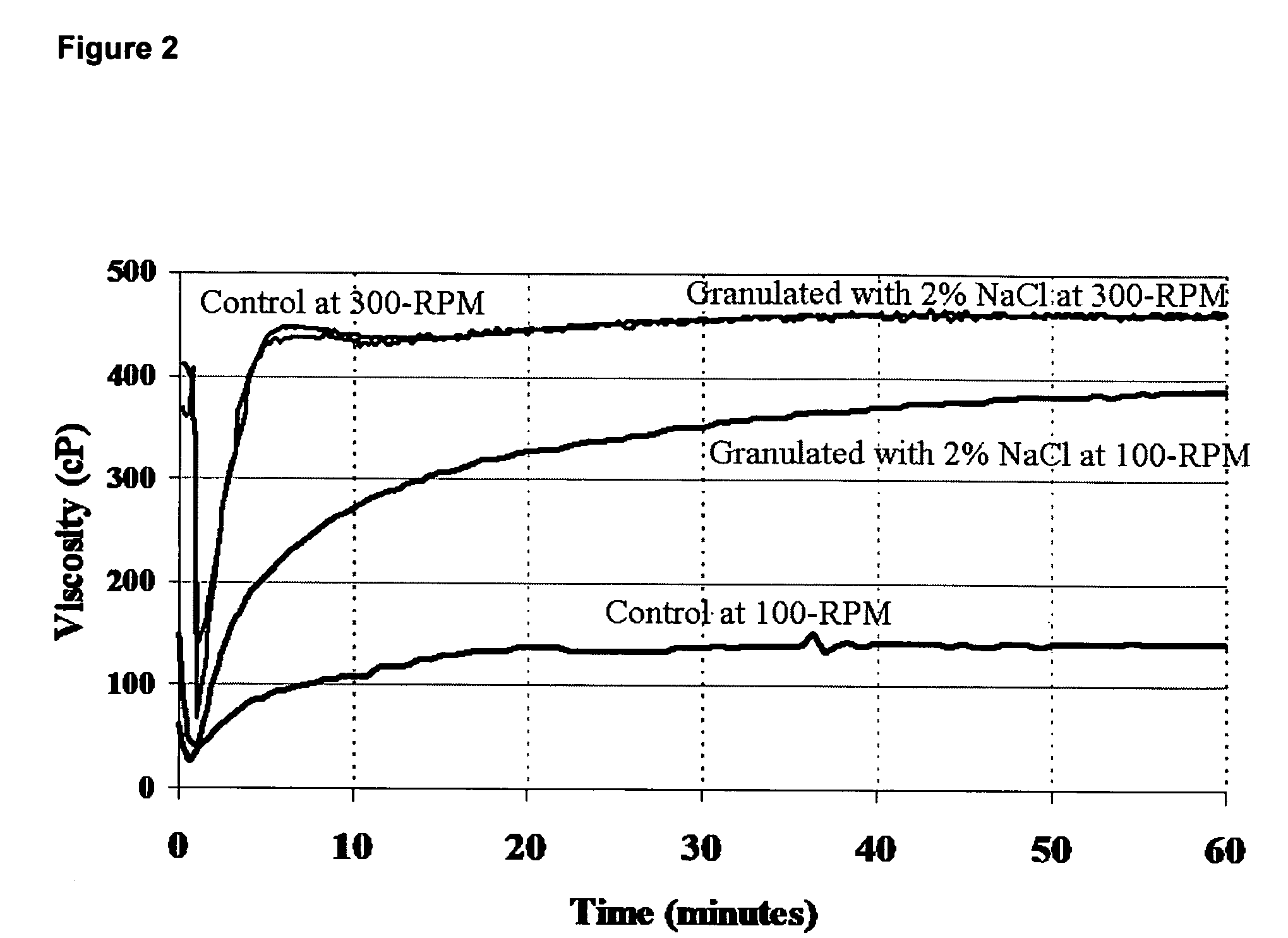

Process of making a homogeneous cheese

A process of making cheese, e.g., a mozzarella variety cheese, is disclosed. It comprises the following steps: a) preparing a cheese curd; b) grinding the curd while in admixture with (i) an aqueous solution of at least one cheese emulsifying salt and (ii) at least one GRAS food additive in the form of a comminuted solid, to obtain an emulsifier / additive-impregnated ground curd; and c) converting the emulsifier / additive-impregnated curd into cheese either by (i) heating, kneading, and stretching the emulsifier / additive-impregnated ground curd to obtain a homogeneous mass of cheese, or (ii) pressing the emulsifier / additive-impregnated ground curd to obtain a homogeneous mass of cheese. Examples of suitable GRAS food additives include gums, stabilizers, dairy solids (e.g., non-fat dry milk or whey protein concentrate), cheese powders, non-dairy protein isolates, sodium chloride, native or modified food starches, colorants, and flavorants. The process is particularly useful when a proteinaceous GRAS food additive is used.

Owner:LEPRINO FOODS

Nutritional compositions directed to subjects having cow's milk protein allergies

InactiveUS20150305359A1Shorten the timeMilk preparationVitamin food ingredientsCow's milk proteinMilk allergy

A method for supporting and promoting nutrition in a pediatric subject having allergies to cow's milk, the method involving administering to the pediatric subject a nutritional composition which includes up to about 7 g / 100 kcal of a source of non-dairy proteins; about 1×104 to about 1.5×1012 cfu of probiotic(s) per 100 kcal; about 5 g and about 25 g / 100 kcal of a carbohydrate source; up to about 7 g / 100 kcal of a fat or lipid source; and at least about 5 mg / 100 kcal of a long chain polyunsaturated fatty acid.

Owner:MEAD JOHNSON NUTRITION

Health fruit-flavored tea and making method thereof

ActiveCN102669328AHas health functionAnti-cariesPre-extraction tea treatmentBanana powderFreeze-drying

The invention provides health fruit-flavored tea and a making method thereof. The health fruit-flavored tea comprises, by weight, 30-40 parts of non-dairy creamer, 15-25 parts of maltodextrin, 8-12 parts of white sugar, 8-12 parts of milk powder, 4-6 parts of freeze-dried strawberry powder, 4-5 parts of freeze-dried black tea powder, 4-6 parts of freeze-dried pineapple powder, 4-6 parts of freeze-dried banana powder, 4-6 parts of freeze-dried apple powder, and 0.09-0.11 part of food preservative. The making method includes: firstly, freeze-drying various fruits to obtain freeze-dried fruit powders; and secondly, adding other components according to a formula ratio, and mixing well to obtain the health fruit-flavored tea. The health fruit-flavored tea has the effects of lowering blood pressure, lowering blood sugar, lowering blood lipid, preventing cancer, supplementing various vitamins and minerals. Drinking the health fruit-flavored tea often can prolong life.

Owner:ANHUI LOVE ON YOUR FOOD

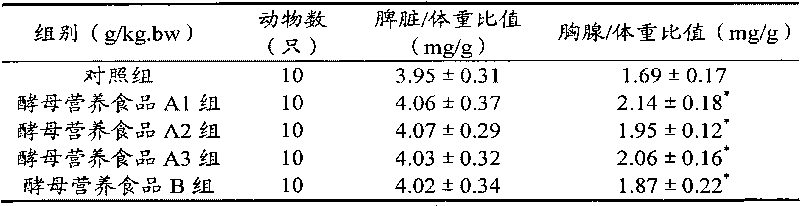

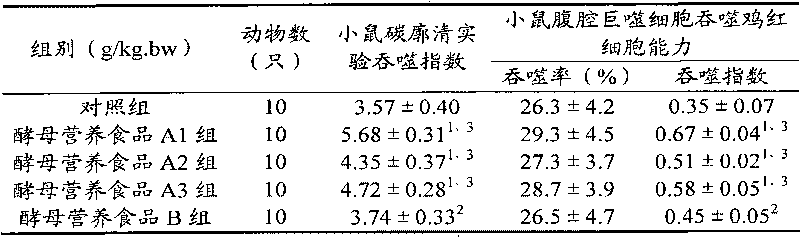

Yeast nutritious food and preparation method thereof

ActiveCN101756216AIncrease nutritionAppropriate tasteImmunological disordersFood preparationVitamin CNutritious food

The invention discloses yeast nutritious food and a preparation method thereof. The yeast nutritious food adopts yeasts as a main raw material, comprises milk powder, maltodextrin , lactose, non-dairy creamer, calcium carbonate, starch, white granulated sugar, flavoring agent and essence and also comprises folic acid, B vitamins, vitamin A, vitamin C, selenium-rich yeast, zinc-rich yeast, chromium-rich yeast, iron-rich yeast, other trace elements-rich yeast, calcium carbonate, dehydrated onion slice, microcrystalline cellulose, starch, cocoa powder, fruit and vegetable powder, sesame, milk tea powder, soy-bean milk powder and oat flakes. The invention adopts multiple raw auxiliary materials, and can be used for preparing yeast nutritious food in such forms as powder, flakes and tablets through various preparation processes, so as to develop nutritious food with tastes applicable to various groups. Moreover, multiple raw auxiliary materials can be added. Compared with the existing yeast nutritious food, the yeast nutritious food of the invention has the function of significantly improving the immunity of the user.

Owner:ANGEL NUTRITECH CO LTD

Milky tea powder and preparing method thereof

InactiveCN101248817AAbundant resourcesLow costMilk preparationPre-extraction tea treatmentBrickNon dairy

The invention discloses milk-tea powder as well as a preparation method thereof, which is prepared by sweetened whole milk powder, green brick tea, non-dairy creamer, and solid essence powder according to a certain proportion. The preparation method comprises the following steps: A. comminution: the brick tea is comminuted into superfine tea powder; B. mixture: the tea powder obtained in step A, the non-dairy creamer, the solid essence powder and the sweetened whole milk powder are added into a V-shaped stirring mill to stir; C. powder sifting: the product is sifted with a suspending powder sifter to remove block masses and sundries in the milk-tea powder; D. split charging in pouch. The milk-tea powder has reasonable formula, convenient drinking, easy method and simple technique, thereby minimizing the energy consumption in the milk-tea processing technique, shortening the productive time with enhanced stability of the milk-tea quality, and increasing the utility ratio of the tea in the milk-tea manufacturing process without waste and pollution.

Owner:NEW HOPE DAIRY HLDG

Cup milky tea containing fruit and vegetable juice bag

InactiveCN103960367AFull of nutritionGreat market potentialMilk preparationPre-extraction tea treatmentFood additiveAdditive ingredient

The invention discloses cup milky tea containing a fruit and vegetable juice bag. The cup milky tea is characterized by containing a milky tea powder bag and the fruit and vegetable juice bag. The invention relates to the field of production of food beverages and particularly relates to the cup milky tea containing the fruit and vegetable juice bag. The milky tea powder bag contains one or more than one milk powder or a milk product, non-dairy creamer or acid-resisting non-dairy creamer. Ingredients, a condiment, a food additive and the like are added in a step of preparing materials; the milky tea powder bag is prepared by the procedures of blending, mixing, filling, sterilizing and the like; when a product is packaged, the fruit and vegetable juice bags with different flavors are selected and added according to requirements of the product and secondary packaging is carried out so that the disadvantages that the milky tea has no nutrition and the taste is single are overcome and multiple types of cup milky tea with different flavors can be formed.

Owner:宋信宇

Method for preparing pre-whipped non-dairy cream without trans-fatty acids

ActiveCN103907695AHigh pass multipleIncrease the payout ratioFood preparationEdible oils/fats production/working-upVegetable oilColloid

The invention discloses a method for preparing pre-whipped non-dairy cream without trans-fatty acids and belongs to the technical field of cream products. The method comprises the steps: mixing extremely hydrogenated vegetable oil, water, sugar, protein, a colloid stabilizer, an emulgator and a humectant according to a certain proportion to form an oil-in-water emulsification system, sterilizing, secondarily homogenizing, rapidly cooling, aging, freezing, unfreezing, stirring and inflating, and thus obtaining the preparing pre-whipped non-dairy cream without trans-fatty acids. Products obtained by using the method provided by the invention are high in whipping multiple, long in shelf life, safe and health, convenient to eat and good in stability and operability.

Owner:JIANGNAN UNIV +1

Lactobacillus acidophilus composite freeze-drying protective agent and preparation method and usage method thereof

InactiveCN102757922AImprove survival rateImprove stabilityBacteriaMicroorganism based processesFreeze-dryingSodium ascorbate

The invention discloses a lactobacillus acidophilus composite freeze-drying protective agent and a preparation method and a usage method thereof. The protective agent comprises lactose, galactose, trehalose, Na2HPO4, sodium ascorbate and MgSO4. Compared with the prior art, the protective agent don not contain glycerol, so that the livability (above 85%) and the stability of freeze drying preservation of the lactobacillus acidophilus, the storage period (the period is 1 year, mycelia powder viable count is more than 1011cfu / g) of the lactobacillus acidophilus is prolonged, and no milk composition is included, and the agent can be used widely in non-dairy products. The preparation method and the usage method are simple, easy to operate and low in cost.

Owner:ENZYME ENG INST SHAANXI PROVINCE ACAD OF SCI

Chicory coffee beverage and method for producing chicory extract

InactiveCN101524107AGreat tasteReduce blood viscosityFood preparationCoffee extractionCichoriumAscophyllum nodosum extract

The invention relates to a beverage taking chicory extract and coffee as main raw materials, and a method for producing chicory extract. The beverage is invented mainly for solving the problem that the prior coffee beverage is not good in taste and easy to cause calcium deficiency for human bodies after long-term drinking. The chicory extract is first made by washing chicory roots, cutting up the chicory roots, adding water 2 to 20 times of the weight of the chicory roots to the chicory roots, heating the obtained product to between 80 and 100 DEG C, preserving heat for 30 minutes, filtering the obtained product, obtaining a filtrate, repeating previous operation again to obtain another filtrate, combining two filtrates and performing spray drying or using a dryer for drying. And then the chicory coffee beverage is made, wherein the weight percentages of the raw materials in a formulation are: 20 to 50 percent of instant coffee, 10 to 70 percent of the chicory extract and 10 to 30 percent of non-dairy creamer; an appropriate amount of sweetener is added in addition; and ethyl maltol and vanillin which account for 0.001 to 0.1 percent of the total weight of the formulation respectively can be added. The beverage has the advantage of reducing calcium loss of the human bodies, along with better taste than simple coffee beverages.

Owner:马俊

Method for preparing carotene-rich sweet potato nutrition soup

The invention discloses a method for preparing carotene-rich sweet potato nutrition soup. The method comprises the following steps: selecting sweet potato raw materials, cleaning, peeling, protecting the color, cutting or shredding, blanching, cooling, drying, smashing, mixing ingredients and packing into a finished product, wherein the ingredients comprise the following components by weight percent: 40-60% of sweet potato powder, 15-35% of kudzuvine root starch, 13-18% of powdered sugar, 4-6% of non-dairy creamer and 4-6% of soybean flour, wherein the category of the sweet potato is Yanshu No.5. The method has the beneficial effects that the product retains the original nutrients and the health care efficacy of the sweet potato, kudzuvine root, the soybean flour and other single components, and is instant and easy to use; the product is rich in carotene and other bioactive ingredients, the nutritional value is higher; and the preparation technology is simple.

Owner:福建省龙岩市农业科学研究所

Whipped powdery non-dairy cream and preparation method thereof

InactiveCN102870895AEasy to storeEasy to transportEdible oils/fats production/working-upVegetable oilNon dairy

The invention relates to the field of food, in particular to a whipped powdery non-dairy cream and a preparation method thereof. The whipped powdery non-dairy cream is characterized in that the whipped powdery non-dairy cream consists of the following materials according to part by weight: 45 to 55 parts of hydrogenated vegetable oil, 20 to 40 parts of syrup, 15 to 30 parts of white sugar, 0.1 to 0.2 parts of stabilizer, 1 to 2 parts of emulsifier, 5 to 20 parts of milk powder, 0.1 to 0.2 parts of salt and 2 to 10 parts of casein sodium. With the syrup and the like as wrapping wall materials, the whipped powdery non-dairy cream is formed into powder which is tens of microns to a hundred microns, and is extremely convenient to store, transport and use, energy consumption and cost are low, moreover, the product has good flowability, dissolubility and preservability, and can be whipped to be fluffy under less than 18 DEG C, and the application range is wide.

Owner:菏泽大树生物工程科技有限公司

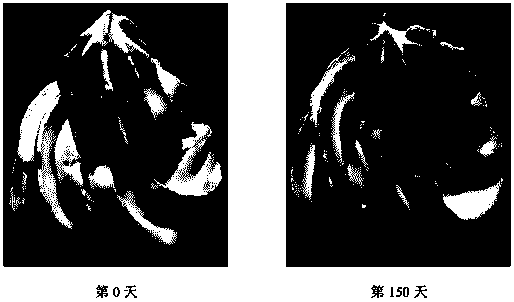

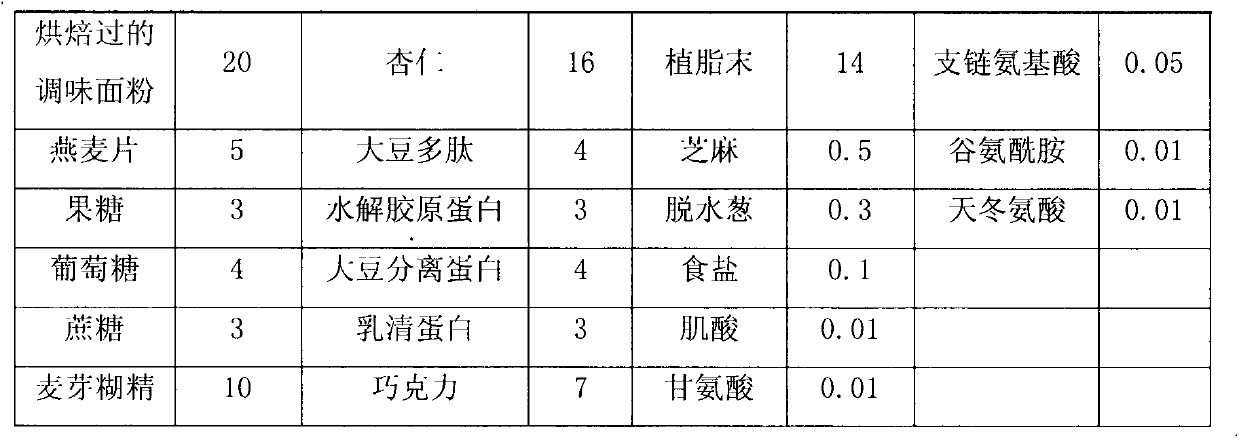

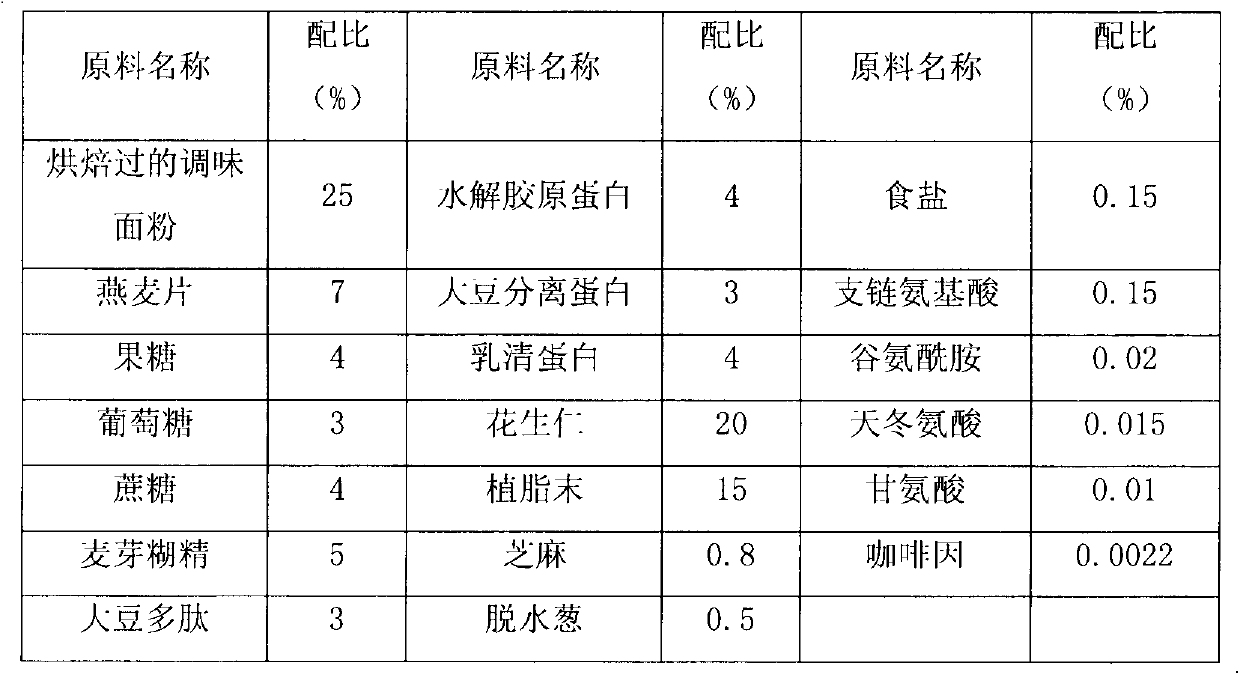

Space station spacefarer space high-energy concentrated food and preparation method thereof

The invention relates to a space station spacefarer space high-energy concentrated food and a preparation method thereof. The formula of the concentrated food is characterized in that the formula is composed of baked seasoned flour, oatmeal, fructose, glucose, sucrose, maltodextrin, soybean polypeptides, hydrolyzed collagen, whey proteins, soybean protein isolate, non-dairy creamer, nuts, chocolate, sesames, dehydrated shallot, and functional components comprising creatine, branched chain amino acids, glutamine, aspartic acid, glycine and caffeine. The preparation method of the concentrated food is characterized in that the method comprises the following steps: crushing the baked seasoned flour, the oatmeal, the nuts and chocolate to obtain powder, mixing the powder with other raw materials and auxiliary materials according to proportions in the formula, uniformly mixing, carrying out press molding, carrying out vacuum baking, and carrying out vacuum packaging.

Owner:陕西神舟太空食品有限公司

Effervescent tablet for use as an additive in hot coffee or hot water and method of making same

An effervescent tablet for direct use as an additive in hot coffee or hot water includes one or more creamer additives, pH stabilizing agents, effervescence agents, and solubility agents. In one embodiment, the tablet includes dry coffee and, in another embodiment, the tablet excludes it. The creamer additive(s) may be dairy and / or non-dairy. The effervescence agent(s) includes sufficient effervescence to separate the tablet upon placement of the tablet in the hot coffee or water and, in one embodiment, to further create foam on the surface of the coffee so as to yield an instant frothy latte or cappuccino. The pH stabilizing agent(s) stabilizes a pH of the coffee and the solubility agent(s) facilitates expeditious dissolution of the tablet in the coffee or water. Various other ingredients and agents may be included in the tablet to enhance flavor, improve mouth feel, enhance foam production, or achieve other desired characteristics or results.

Owner:SINGH HARJIT

Low fat creamer compositions

InactiveUS7018668B2No fatImproved mouth feelProtein composition from fishMilk preparationMean diameterReady to use

A non-fat creamer composition that contains from about 10% to about 90%, of a microparticulated protein component and from about 10% to about 90%, of a insoluble microcrystalline cellulose component. In the hydrated state the microparticulated protein component particles have a mean diameter particle size distribution ranging from about 0.1 microns to about 10.0 microns, and preferably less than about 5 percent of the total number of particles exceed about 10.0 microns in diameter. Further, the creamer composition contains less than about 2% of fat and oil. These non-fat creamer compositions can be powdered and liquid, dairy and non-dairy, and can be prepared in both concentrated and ready-to-use forms. The powdered creamer compositions are well suited for use in instant and / or dry food and beverage compositions that require the addition of water or other suitable fluids prior to use.

Owner:THE PROCTER & GAMBLE COMPANY +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com