Patents

Literature

142 results about "Vanilla extract" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vanilla extract is a solution made by macerating and percolating vanilla pods in a solution of ethanol and water. It is considered an essential ingredient in many Western desserts, especially baked goods like cakes, cookies, brownies, and cupcakes, as well as custards, ice creams, and puddings. Although its primary flavor compound is vanillin, pure vanilla extract contains several hundred additional flavor compounds, which are responsible for its complex, deep flavor. By contrast, artificial vanilla flavor is solely made up of artificially-derived vanillin, which is frequently made from a by-product of the wood pulp industry. Because of the way that vanilla extract is made (i.e. by macerating naturally brown vanilla beans in alcohol), there is no possible way for it to be colorless or clear. Therefore, any "clear vanilla" flavoring is artificial.

Method for the production of natural botanical extracts

InactiveUS20050074519A1Short processing timeWithout sacrificing flavorAnimal feeding stuffTeaEnzymeProcess time

Methods for producing natural botanical extracts, such as natural vanilla extracts, with low processing times and high efficiencies are provided. The methods include a high temperature extraction step and, optionally, an enzymatic treatment step. The natural vanilla extracts or other botanical extracts produced by the methods may provide the same degree of flavoring at lower concentrations than conventionally produced natural extracts.

Owner:SENSIENT FLAVORS

Top dressing flavor for harmonizing herbal fragrance with original fragrance of tobacco

The invention relates to an essence for tobacco, in particular to a top dressing flavor for harmonizing herbal fragrance with the original fragrance of the tobacco. The top dressing flavor is prepared by mixing the following raw materials in part by weight: 74 to 76 parts of alcohol, 0.2 to 0.3 part of aniseed oil, 0.05 to 0.1 part of cinnamon leaf oil, 0.3 to 0.4 part of clove oil, 0.2 to 0.4 part of Peru extractum, 0.1 to 0.2 part of tolu extractum, 0.2 to 0.4 part of vanillin, 0.1 to 0.3 part of ethyl-vanillin, 0.1 to 0.2 part of delta decalactone, 0.2 to 0.4 part of maltol, 0.05 to 0.1 part of 2,3,5- trimethylpyrazine, 0.02 to 0.05 part of methyl furfurylthio pyrazine, 0.03 to 0.05 part of 5-methyl-2-phenyl-2-hexenal, 10 parts of propylene glycol, 0.4 to 0.5 part of dill tincture, 0.5 to 0.9 part of black vanilla extract, 0.1 to 0.2 part of fenugreek tincture and 0.02 to 0.05 part of cocoa extractum. By taking spicy fragrance, cream fragrance and burnt sweet fragrance as main fragrance and milky fragrance and cocoa fragrance as auxiliary fragrance, the formula of the top dressing flavor can cover the herbal fragrance well and harmonize the herbal fragrance with the original fragrance of the tobacco.

Owner:HUBEI CHINA TOBACCO IND +1

Dog biscuit for controlling malodorous breath in dogs

InactiveUS6265011B1Pleasant tasteEasy to eatDough treatmentBaking mixturesAnimal scienceVegetable oil

A dog biscuit is disclosed for controlling malodorous breath in dogs. The dog biscuit includes about 8-12 parts by weight whole wheat flour, about 4-6 parts oat bran, about 2-3 parts non-fat dry milk, and about 2-3 parts brown rice flour. The dog biscuit also includes water, vanilla extract, parsley, alfalfa powder, vegetable oil, peppermint extract, tarragon, peppermint leaf powder, and spearmint leaf powder. The vegetable oil includes an antioxidant and is preferably sunflower oil. The parsley is preferably fresh parsley, and the ratio of parsley to whole wheat flour is about 1:4 by weight. The dog biscuit is readily eaten by dogs and effectively neutralizes malodorous breath in them. Also part of the invention is a method of making the dog biscuit.

Owner:KELLY WAYNE +1

Moist-keeping flavouring additive agent and preparation method thereof

The invention relates to a preparation method of a moistening and flavor enhancing additive agent comprising two preparation modes, wherein the mode 1 comprises the steps of firstly respectively preparing and obtaining a special tobacco extract, a seaweed extract and a vanilla extract; then mixing the special tobacco extract, the seaweed extract and the vanilla extract according to a ratio of 1:6-10:1-5, after decoloration by an activated carbon column, concentrating an effluent into a viscous fluid, thereby obtaining the moistening and flavor enhancing additive agent; and the mode 2 comprises the steps of respectively washing the seaweed and the vanilla, crushing after drying, mixing the special tobacco leaf fragment, the seaweed powder and the vanilla powder according to the ratio of 1:2-6:0.5-4, adding water, heating and reflxuing, then adding acetone, heating and refluxing, cooling, filtering, adding water or ethanol solution to a residue, continuously heating, refluxing and extracting, cooling, filtering and decoloring a concentrated solution through the activated carbon column after concentrating a filtrate, continuously concentrating the effluent into the viscous fluid, thereby obtaining the moistening and flavor enhancing additive agent. The moistening and flavor enhancing additive agent prepared by the invention not only can obviously keep the moisture of the tobacco shred, but also can enrich the flavor of the cigarette, and improve the comfortable degree of the cigarette. The cost of the invention is low, the technical process is simple, the raw material is easy to get, and the popularization and the application are convenient.

Owner:YUNNAN REASCEND TOBACCO TECH GRP +1

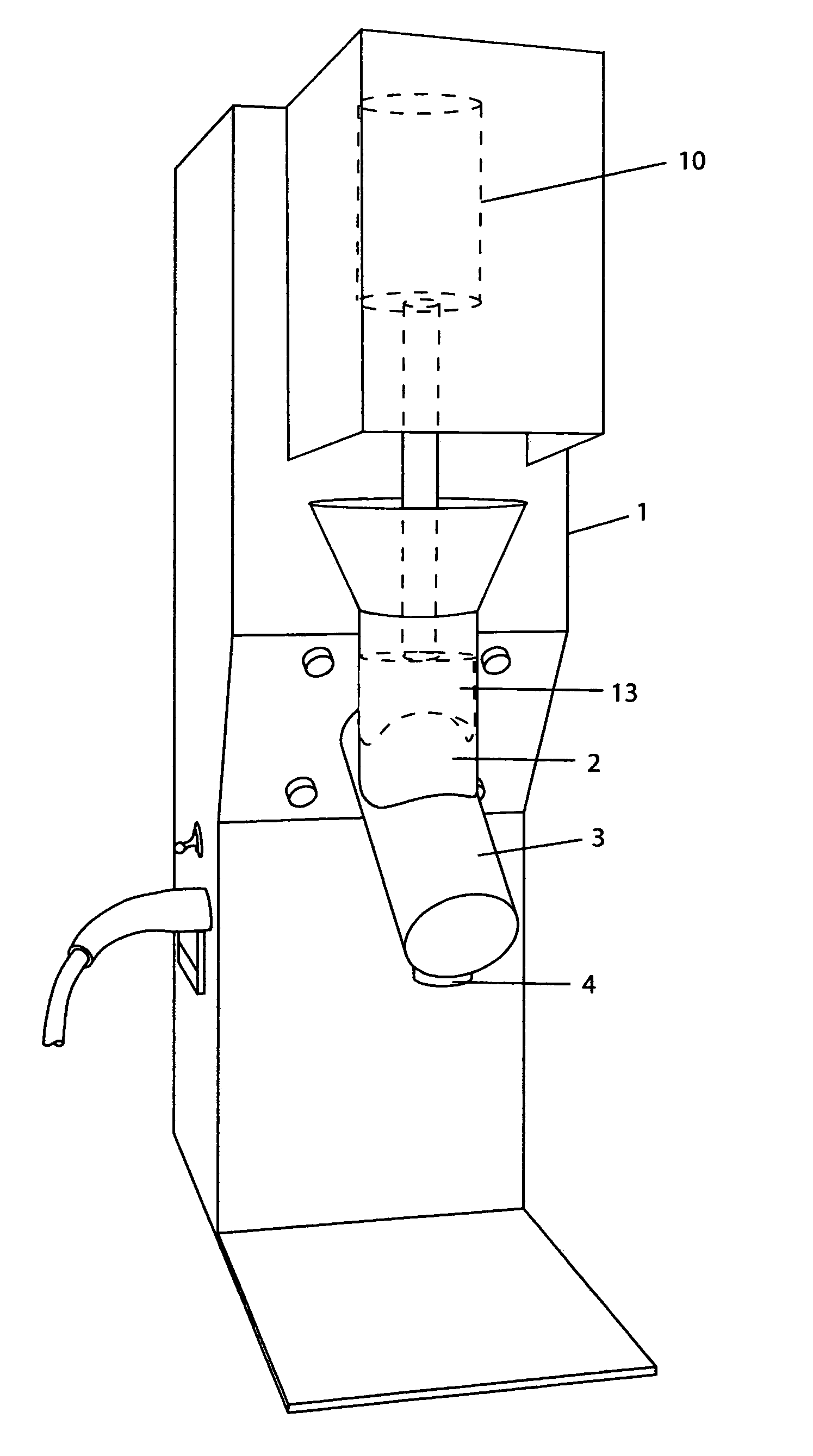

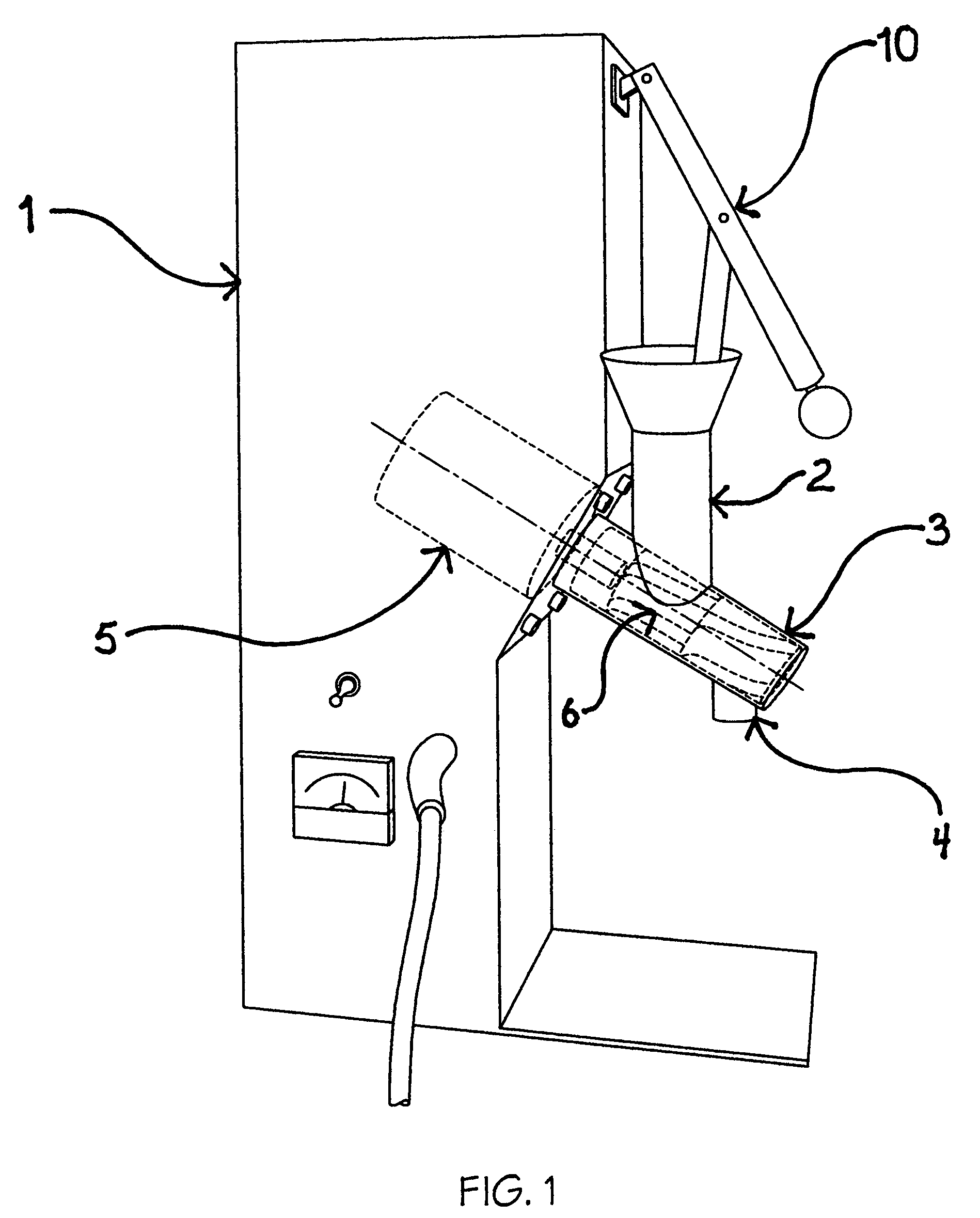

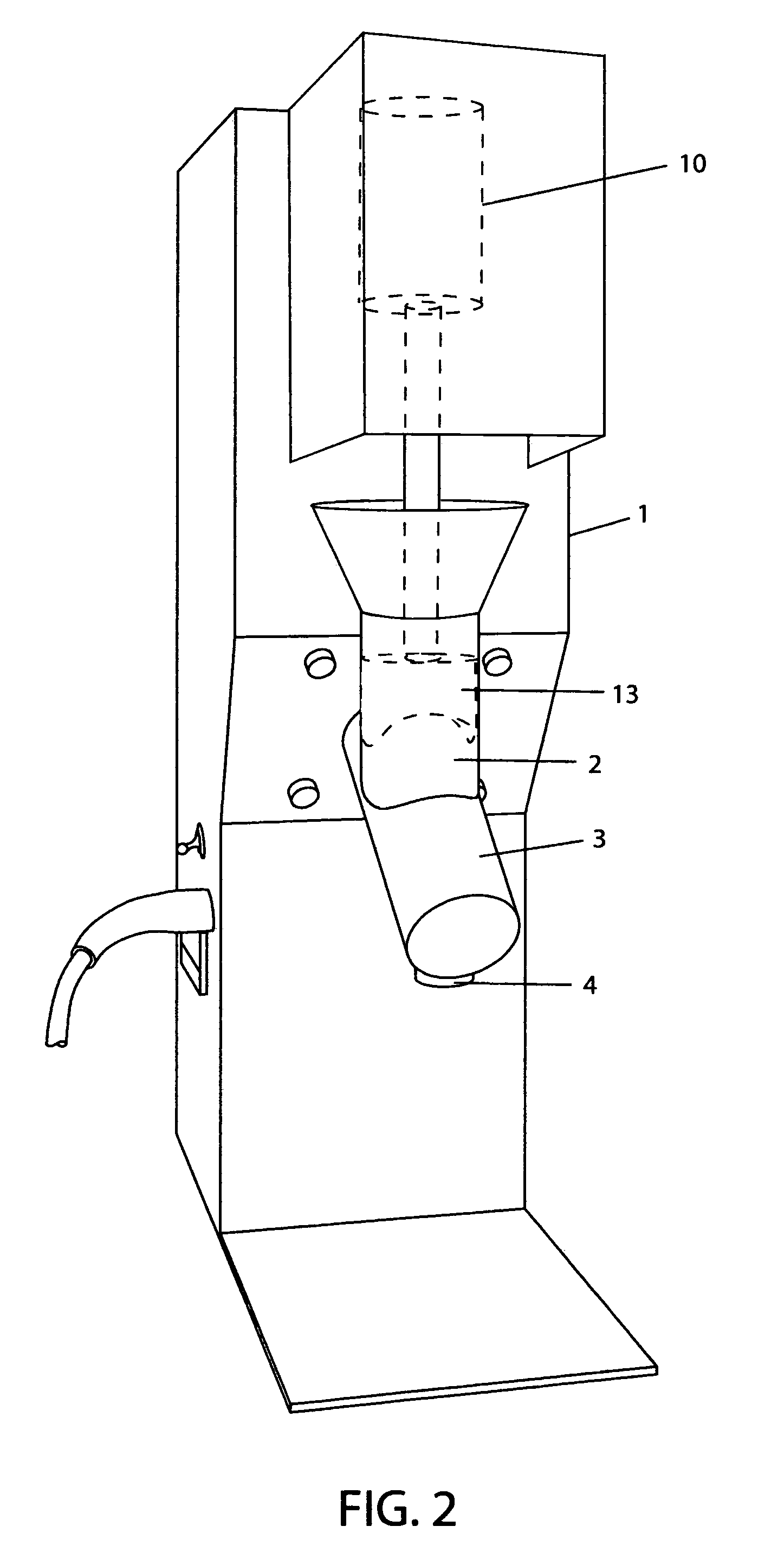

Frozen food masticating machine

A device for masticating frozen foodstuffs such device having a housing; a motor installed inside the housing; and an inlet portion for introducing foodstuffs therein connected to a masticating chamber. A plunging device is attached such that a piston is inserted into the inlet hopper to move the frozen foodstuffs into the masticating chamber. A masticating element is contained within the masticating chamber and is connected to the motor. This masticating element is formed with a threaded masticating portion with a plurality of cutting grooves having ninety degree angles of attack for masticating the frozen foodstuffs into the desired creamy texture. The masticating element also has a transferring portion with a plurality of moving shoots to move the masticated product out of the machine. The frozen fruits, vegetables, or other foodstuffs are easily loaded, masticated, and cleanly removed from the apparatus. When using frozen fruits this results in a non-dairy frozen dessert comprised of quick frozen fruit composite which has been masticated to achieve a desired creamy texture. Fruit, vegetables, or other frozen foodstuffs may be used alone or in combination with other flavoring agents such as vanilla extract, oils such as mint and powders or liquors such as chocolate and carob.

Owner:DNS FROOTZ LLC

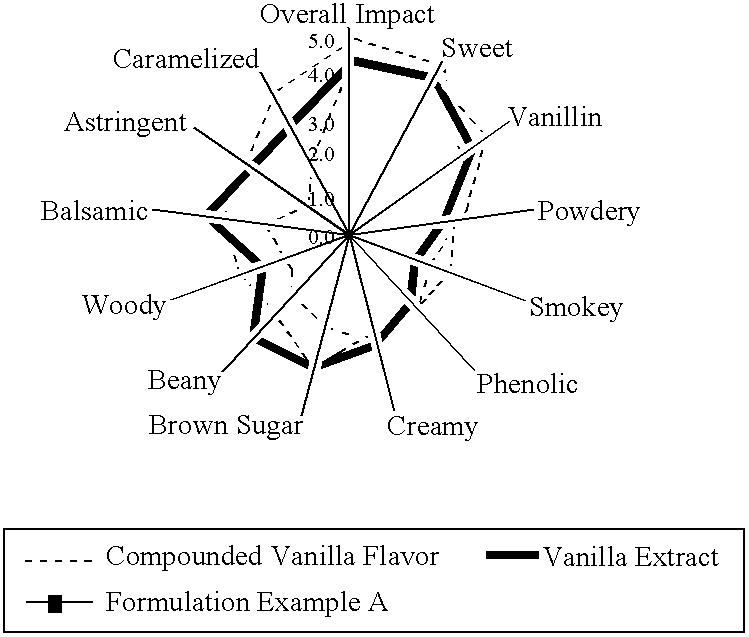

Vanilla flavoring compositions

InactiveUS20060045954A1Improve propertiesEndurance of taste impressionFood preparationBiotechnologyVanilla Flavor

The addition of Maillard based flavorings to volatile vanilla flavor compositions was found to significantly improve a flavorings' taste profile and increase long-lasting in-product performance (especially in dairy and baked goods). The novel flavoring composition more closely mimics the properties (taste and performance) of highly prized natural vanilla extracts.

Owner:SYMRISE GMBH & CO KG

Juice interesting biscuit

InactiveCN101536704AReasonable formulaNutritional diversityDough treatmentBakery productsFruit juiceSugar

The invention relates to a food, in particular to a juice interesting biscuit made by utilizing fresh fruit juice and vegetable juice added with flour and oat flour, belonging to the food processing technology. The juice interesting biscuit is made by raw materials according to the following parts by weight: 8-10 of flour, 1-2 of soda powders, 2-5 of oat flour, 1-2 of salad oil, 2 of granulated sugar, 2 of brown sugar, 2-4 of eggs, 1 of vanilla extract, 1 of salt, 3 of fresh juice and 3 of fresh vegetable juice. The juice interesting biscuit has reasonable formulation, rich nutrition, crisp taste and simple production; the roasted biscuits have the shapes of animals and fruits; and the juice interesting biscuit is interesting while being eaten and especially suitable for the aged and children to eat.

Owner:韩婷婷

Supplemented sesame ice cream

The invention provides a supplemented desert comprising a sweetened dairy composition containing sesame seed paste, roasted sesame seed, and an effective amount of at least one nutraceutical. Specifically, the invention provides a supplemented vanilla ice cream containing from about 850 to about 946 ml of a vanilla ice cream, from about 1 to about 3 ounces of black sesame seed paste, from about 1 to about 3 ounces of roasted sesame seed, from about 1 to about ¼ teaspoon of vanilla extract; and an effective amount of a nutraceutical.

Owner:ESGHIPOUR MEHRDAD

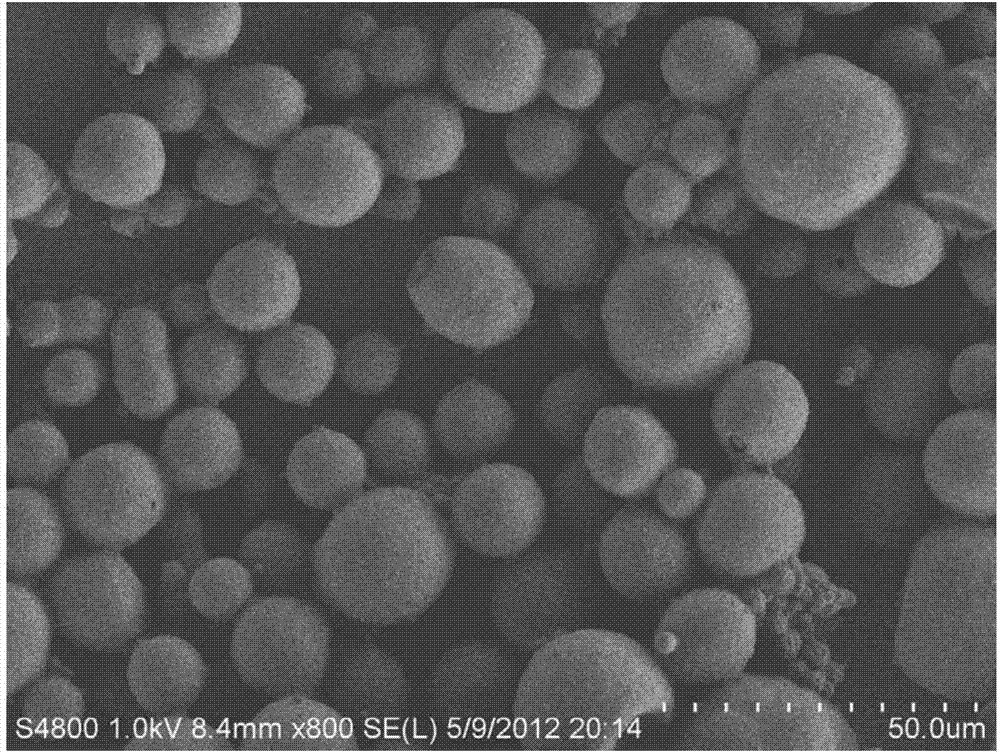

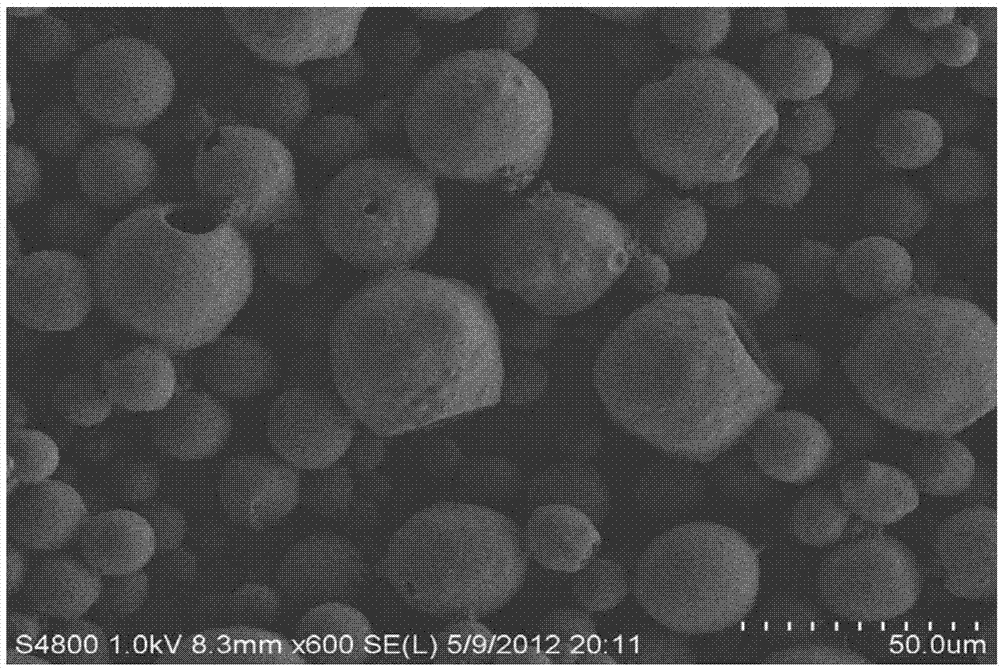

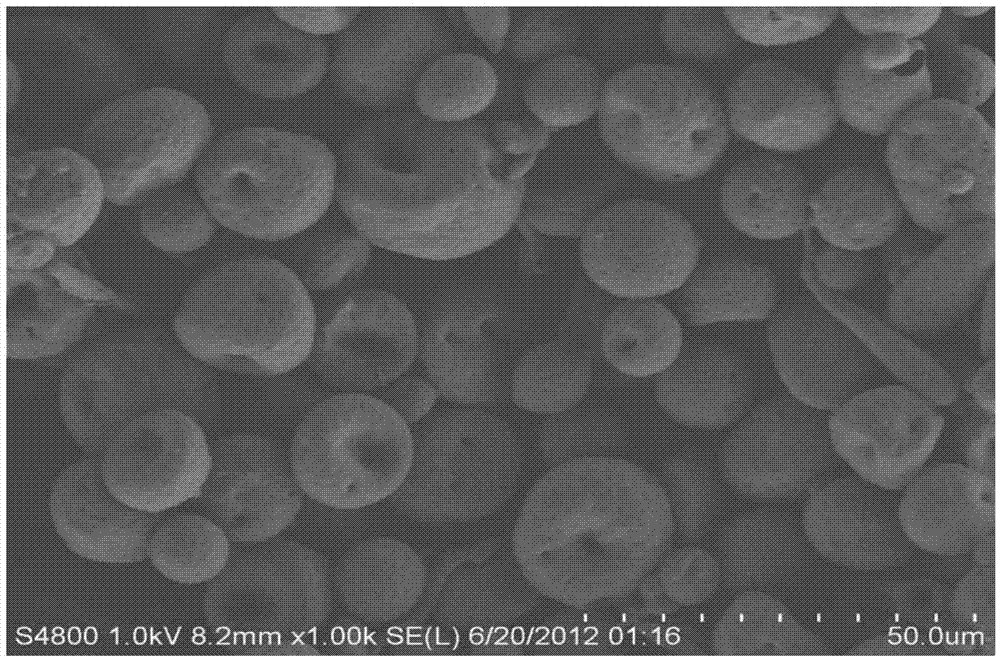

Vanilla extract microcapsule as well as preparation method and application thereof

InactiveCN103881816AReduce volatilityImprove light and heat stabilityCosmetic preparationsTobacco treatmentRetention timeHeat stability

The invention discloses a vanilla extract microcapsule. The microcapsule comprises a core material and a wall material, wherein the core material is the vanilla extract; the wall material is formed through complex coacervation of modified starch and chitosan; the core material is coated in the wall material. The invention also discloses a preparation method of the vanilla extract microcapsule and an application of the vanilla extract microcapsule to additives of food, cosmetics, skin care products and cigarettes and finishing agents of textiles. The vanilla extract microcapsule has the advantages that the light and heat stability of the vanilla extract is improved; the fragrance retention time is lengthened; the microcapsule has high embedding efficiency, is non-toxic and safe and easily achieves industrial production.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

Formula of hawthorn-extract-containing tobacco casing flavor

ActiveCN102204715AAdds natural sweet aromaSoothe the smellTobacco treatmentEssential-oils/perfumesNicotiana tabacumApple extract

The invention discloses a formula of a hawthorn-extract-containing tobacco casing flavor, wherein the hawthorn-extract-containing tobacco casing flavor comprises the following compositions in percentage by mass: 5-10% of red jujube tinctures, 5-10% of momordica grosvenori tinctures, 1-2% of Yunyan tobacco extracts, 0.1-1% of Guiyan tobacco extracts, 0.5-2% of licorice extracts, 1-5% of hawthorn extracts, 1-3% of apricot extracts, 3-8% of plum extracts, 1-2% of Hierochloe odorata extracts, 0.1-0.5% of vanilla extracts, 0.1-0.2% of lavender extracts, 1-2% of apple extracts, 0.01-0.1% of 2-ethyl-4-hydroxy-5-methyl-3(2H) furanone, 0.1-0.5% of 4-acetoxy-2,5-dimethyl-3(2H)-furanone, 0.5-1.5% of glycerin, 0.1-1% of steviol glycoside, 2-5% of licorice, 40-50% of propylene glycol, and 10-30% of pure water. The formula of a hawthorn-extract-containing tobacco casing flavor disclosed by the invention has the advantages that through adding the hawthorn extracts, the tobaccos can produce hawthorn aroma, the tobacco smell can be dispatched, the smoke flavor can be alleviated, and finally, the smoke flavor of the tobacco can be improved, and the natural sweet of the tobacco can be increased, thereby improving the dry, astringent and bitter tastes of the consumers, and satisfying the requirements of the consumers.

Owner:GUANGZHOU AOJIAN PERFUME

Water-soluble banana essence and preparation method thereof

ActiveCN103666762AIncrease the fragranceImprove freshnessEssential-oils/perfumesFood preparationEthyl butyrateGeranyl formate

The invention discloses a water-soluble banana essence and a preparation method thereof, wherein the water-soluble banana essence contains the following raw materials by weight: 40-50 parts of ethyl butyrate, 15-30 parts of pentyl butancate, 5-9 parts of clove oil, 150-200 parts of ethanol, 0.2-0.6 parts of vanilla extract, 3-8 parts of ethyl acetate, 8-15 parts of butyl acetate, 8-15 parts of sweet orange oil, 20-30 parts of glycerin, 10-20 parts of isoamyl acetate, 0.5-1 part of vanillin, 0.5-1 part of orange leaf oil, 0.2-0.5 parts of leaf alcohol, 0.2-0.6 parts of geranyl formate, and 50-60 parts of distilled water. The preparation method comprises: uniformly mixing each component, placing the mixture into a glass container, sealing the glass container at 20-30 DEG C for 8-10 days. The water-soluble banana essence provided by the invention can substantially raise freshness feeling of a beverage, can cover bad smell, simultaneously increases banana fragrance, and is easier to drink.

Owner:上海旭梅食品科技股份有限公司

Preparation method of rubber gloves containing natural vanilla extracts

A preparation method of rubber gloves containing natural vanilla extracts is provided. The preparation method comprises the following steps: uniformly adding and dispersing certain amounts of vanilla powder, Dioscorea zingiberensis powder, aloe powder and other routine ingredients to natural latex or butyronityile latex in the prevulcanization operation of raw materials of routine natural latex gloves or butyronityile latex gloves; dipping according to a routine shaping process to prepare natural latex gloves containing the natural vanilla extracts or butyronityile latex gloves containing the natural vanilla extracts; carrying out operations of overturning, chlorination, steep-washing, rinsing, and drying to obtain the finished rubber gloves. The natural latex gloves and the butyronityile latex gloves produced through the method have antibiosis and skin care functions, and can emit a fragrant smell. An effect that sweat generated on hands of a wearer is reduced can be reached by further adding acrylic acid / acrylamide copolymerization phase change energy storage microcapsules.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

Air purification composition

Owner:GUORUN BIOTECH SHENZHEN CO LTD

Sugar-free biscuits and preparation method thereof

The invention provides sugar-free biscuits, which comprise the following components: 15 to 25 parts of seedless raisins, 1 to 5 parts of egg liquid, 10 to 20 parts of flour, 10 to 20 parts of oatmeal, 10 to 15 parts of grape juice, 2 to 8 parts of strong flour, 10 to 15 parts of fig, 0.1 to 0.5 parts of vanilla extract and a proper amount of water. The invention also provides a method for preparing sugar-free biscuits. The method comprises the following steps of: 1) mixing all raw materials to obtain a dough; 2) forming, namely forming in a forming machine; 3) baking, namely baking at 177DEG C for 13 minutes; and 4) cooling and packaging. The sugar-free biscuits have the advantage that: the sugar-free biscuits do not contain sucrose, fructose or maltose, have the sugar taste but do not have the energy of sugar, and are healthy.

Owner:NANTONG GOLDEN LAND GREEN FOOD

Wet wipe for wiping heavy oil stains in kitchen

InactiveCN104263543ANo side effectsGood effectSurface-active detergent compositionsDetergent compounding agentsSide effectFatty alcohol

The invention discloses a wet wipe for wiping heavy oil stains in a kitchen and relates to the technical field of health products. The wet wipe comprises a wet wipe carrier and a wet wipe immersing solution, wherein the wet wipe immersing solution comprises the following components in parts by weight: 4-6 parts of fatty alcohol ethoxylate, 2-5 parts of sodium alkyl benzene sulfonate, 2-4 parts of sodium polyoxyethylene fatty alcohol sulfate, 1-3 parts of alkylolamide, 1-3 parts of triethanolamine, 1-3 parts of sodium toluene sulfonate, 0.4-0.5 part of sodium benzoate, 2-4 parts of ethanol, 20-25 parts of water, 8-10 parts of vanilla extract and 12-14 parts of preservative. The wet wipe disclosed by the invention has the beneficial effects that the immersing solution adopted in the wet wipe comprises strong decontamination components, so that the wet wipe has no harm to a human body, has no side effects, can be used as a health product in daily life and simultaneously has a significant effect on removing the heavy oil stains in the kitchen.

Owner:铜陵麟安生物科技股份有限公司

Preparation method of brown rice ferment

The invention provides a preparation method of brown rice ferment, and belongs to the technical field of production of foods. The method comprises the following steps of firstly cleaning brown rice, soaking the cleaned brown rice, performing culturing in a 32 DEG C constant-temperature culturing box until the brown rice sprouts, placing the sprouted brown rice in a baking box of 50-55 DEG C, performing drying, and after the water content of the sprouted brown rice is smaller than 15%, grinding the dried sprouted brown rice into powder so as to obtain the sprouted brown rice powder; and mixingthe sprouted brown rice powder with honey, white granulated sugar, table salt, a vanilla extract and water according to a certain formula proportion to obtain a culture solution, placing the culture solution at 121 DEG C, performing sterilization for 20min, after the culture solution is cooled to 40 DEG C or below, performing inoculation with lactic acid bacteria, placing the culture solution inoculated with the lactic acid bacteria in a 40-42 DEG C constant-temperature culturing box, and performing culturing for 6-10h so as to obtain the brown rice ferment. The brown rice ferment processed bythe preparation method disclosed by the invention can be directly drunk as a beverage, and has favorable mouth feel and taste, high nutrition components in rice are reserved, and the economic value of the rice is increased.

Owner:DALIAN UNIV OF TECH

Processing technique of vanilla

The invention discloses a processing technique of vanilla, which comprises the following steps: (1) adding 1 part by weight of vanilla into 2-10 parts by weight of 50-95% alcoholic solution, soaking for 5-10 days, and filtering to obtain a filtrate; (2) carrying out vacuum concentration on the filtrate in the step (1), boiling the concentrated solution, stopping heating when the volume of the filtrate is reduced to 15-20% of the original filtrate, and adjusting to normal pressure to obtain a paste liquid; (3) carrying out microwave drying on the paste liquid in the step (2) in vacuum until the weight percentage of the solvent in the paste is less than 5%; and (4) putting the paste dried in the step (3) into an extraction kettle, carrying out supercritical carbon dioxide extraction for 3-5hours, and separating the yellow oil liquid vanilla extract in the kettle, wherein the brownish black substance in the extraction kettle is vanilla oil resin. Since normal temperature and pressure extraction, vacuum concentration, microwave drying and supercritical carbon dioxide extraction are combined to extract the vanilla so as to simultaneously obtain the vanilla extract and vanilla oil resin, the extraction rate of odorous constituents in the vanilla extract can be enhanced, and the content of vanillin can also be enhanced.

Owner:海南兴科热带作物工程技术有限公司

Electric mosquito repellent tablet

The invention relates to an electrical mosquito mat with plant extracts such as lysimachia foenum-graecun hance concrete or lysimachia foenum-gracun hance oil as active insecticidal component. The electrical mosquito mat comprises paper and adding solution. Wherein, the solution comprises the following components by weight proportion: 8 to 40 portions of lysimachia foenum-graecun hance concrete or lysimachia foenum-gracun hance oil; 0.1 to 1 portion of color indicator; 0.01 to 1 portion of perfume; 60 to 92 portions of solvent. Compared with the prior art, lysimachia foenum-graecun hance extracts such as lysimachia foenum-graecun hance concrete or lysimachia foenum-gracun hance oil are used as the active component for driving off and killing mosquito, and absorbable material is used as carrier, thus reducing the adding of other material. The product has good control effect to various sanitary insect pests (such as mosquito, fly and cockroach, etc.), and is characterized by high efficiency, wide spectrum, strong contact killing effect and no residual toxicity, etc. The production and usage of the invention has no harm to human (including children under 6 years old), and the market prospect is good.

Owner:GUILIN NORMAL COLLEGE

Vegetable oatmeal cookie and preparation method thereof

The invention discloses vegetable oatmeal cookie and a preparation method thereof. The vegetable oatmeal cookie is composed of 100 to 160 parts of whole wheat flour, 100 to 140 parts of oatmeal powder, 15 to 25 parts of tomato, 10 to 20 parts of carrot, 10 to 20 parts of celery, 10 to 20 parts of spinach, 8 to 12 parts of vegetable oil, 10 to 20 parts of egg, 10 to 20 parts of honey, 1 to 2 parts of vanilla extract and 1 to 3 parts of salt by weight. The vegetable oatmeal cookie belongs to oatmeal food, and the vegetable oatmeal cookie is crispy, sweet and rich in mouth feel, is rich in vitamin and carotene, is suitable for all the people who like oatmeal taste and depend on oatmeal health care, and is the first choice of hypertension patients among all the snacks.

Owner:刘韶娜

Corn oat fiber biscuits and preparation method thereof

InactiveCN102461624AFit for consumptionFor long-term storageDough treatmentBakery productsBiotechnologySugar

The invention provides corn oat fiber biscuits, which comprise the following components: 15 to 20 parts of flour, 10 to 20 parts of oatmeal, 8 to 15 parts of corn, 3 to 5 parts of corn fiber powder, 8 to 12 parts of egg, 12 to 18 parts of brown sugar, 0.5 to 2 parts of table salt, 0.4 to 0.6 part of vanilla extract and a proper amount of water. The invention has the advantages that: 1, the corn oat fiber biscuits fully combine the nutrients of the corn and the oat, contain corn oil and a great amount of fiber, and are suitable for people with high blood pressure and high blood fat; 2, the corn oat fiber biscuits can be stored for a long term and are difficulty deteriorated; and 3, the food in the biscuit form can be produced on a large scale, can be widely circulated, and promotes people to utilize the nutrients of the corn and the oat.

Owner:NANTONG GOLDEN LAND GREEN FOOD

Chewing gum

The invention relates to chewing gum, belonging to the technical field of food. The chewing gum comprises the following components by weight: 10g of an aloe extract, 5g of a vanilla extract, 3g of pectin, 8g of a donkey-hide gelatin extract and 1g of vitamin C. The chewing gum provided by the invention has the advantages that the chewing gum is purely extracted from plants, free from chemical components, natural and safety, free from irritation and harmless to human body.

Owner:王爽

Chinese chestnut pastry and manufacturing method thereof

The invention discloses a Chinese chestnut pastry and a manufacturing method thereof. Chinese chestnut pastry stuffing of the Chinese chestnut pastry is made of chestnut kernels roasted with sugar, sliced chestnut kernels, white kidney bean paste, malt syrup, white granulated sugar, peanut oil, sucrose fatty acid ester, monostearin, sodium dehydroacetate, vanilla extract and gardenia yellow. Chinese chestnut pastry skin of the Chinese chestnut pastry is made of self-raising flour, plain flour, Chinese chestnut flour, butter, white granulated sugar, dehydrated butter, egg yolk, milk powder and salt. Not only is the Chinese chestnut pastry attractive in color, crisp in taste, sweet, delicious and agreeable in sweetness, but also the fragrance of Chinese chestnut is given to the product by adding the Chinese chestnut powder, the nutrition is richer, and the Chinese chestnut pastry is suitable for all ages and better meets people's requirements for nutritional healthy foods.

Owner:SHANDONG HUIFA FOODS

Cordyceps-militaris-ingredient contained eye cream and preparing method of cordyceps-militaris-ingredient contained eye cream

InactiveCN104306323AImprove wrinkle resistanceRaw materials are easy to getCosmetic preparationsToilet preparationsTricholoma matsutakePurslane extract

The invention discloses cordyceps-militaris-ingredient contained eye cream. The cordyceps-militaris-ingredient contained eye cream contains twenty-one kinds of active ingredients including hydrolyzed avenin, aloe fermentation objects, cordyceps militaris extract, purslane extract, persimmon leaf extract, orange peel extract, scutellaria root extract, phellinus igniarius extract, white willow bark extract, vanilla extract, cold-resistant fragrant rose extract, green bean extract, green tea extract, tricholoma matsutake extract, ginseng extract, astragalus membranaceus root extract, rhodiola rosea root extract, lithospermum extract, chamomile extract, tree moss extract and honeysuckle extract, and further contains asiaticoside. The cordyceps-militaris-ingredient contained eye cream has the advantages of being safe, nontoxic and resistant to wrinkles. The invention further provides a preparing method of the cordyceps-militaris-ingredient contained eye cream. The preparing method is simple, and the production cost is effectively reduced.

Owner:沈阳园康天然生物科技有限公司

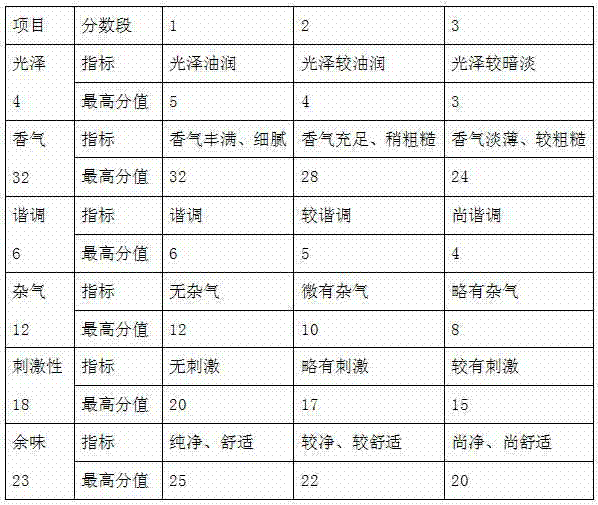

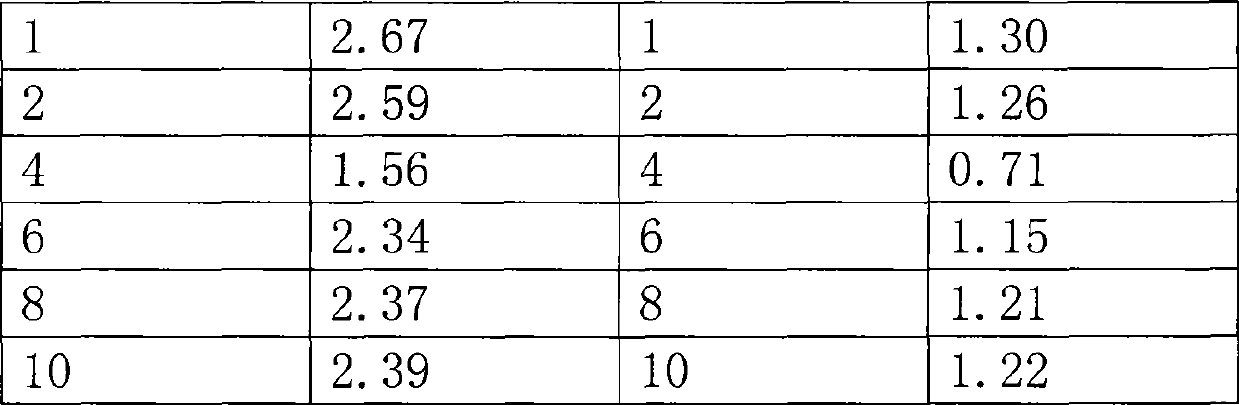

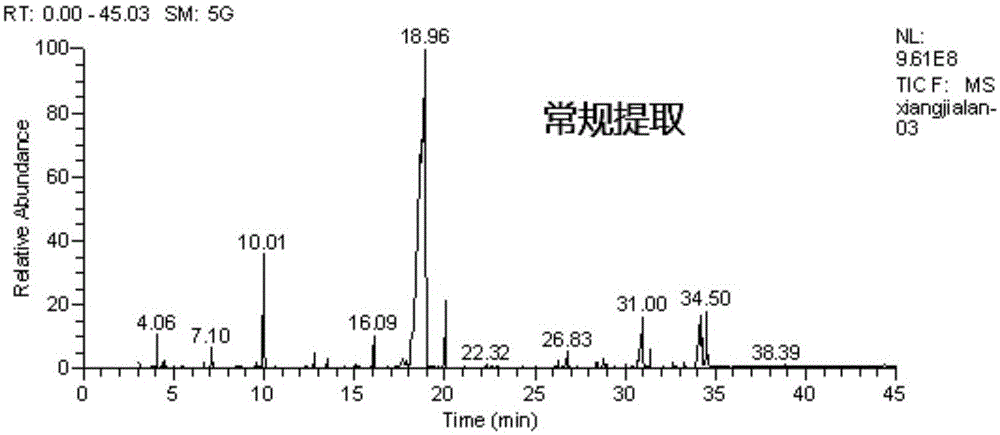

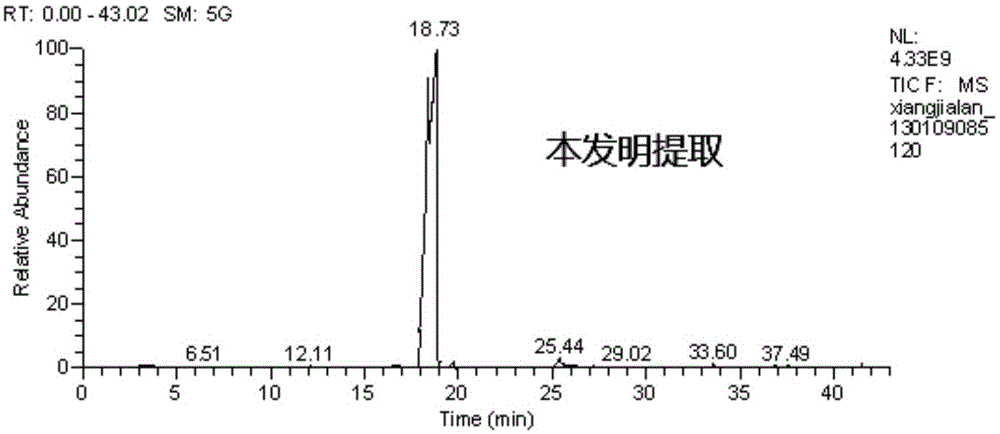

Preparation method of vanilla extracts for cigarettes

InactiveCN105146743AImprove efficiencyIncrease aromaTobacco preparationTobacco treatmentHigh pressureUltrasonic technology

The invention discloses a preparation method of vanilla extracts for cigarettes. The method includes the following steps that vanilla pods are shredded, vanilla pod particles are placed into a pressure vessel to be subjected to high-pressure puffing, and the vanilla pod particles are made to be fluffy; ethanol is added into the fluffy vanilla pod particles so that a mixed solution can be obtained, and then ultrasonic treatment is performed on the mixed solution; the mixed solution obtained after ultrasonic processing is subjected to centrifugal treatment so that supernatant liquid can be obtained; the supernatant liquid is filtered after being refrigerated so that filter liquor can be obtained; the filter liquor is concentrated so that the vanilla extracts can be obtained. The efficiency of the extracts is improved through the high-pressure puffing technology and the ultrasonic technology, and therefore the vanilla extracts high in vanillin content can be obtained. The vanilla extracts are applied in the cigarettes and have the effects of increasing cigarette aroma and improving smoke texture.

Owner:HUBEI CHINA TOBACCO IND +1

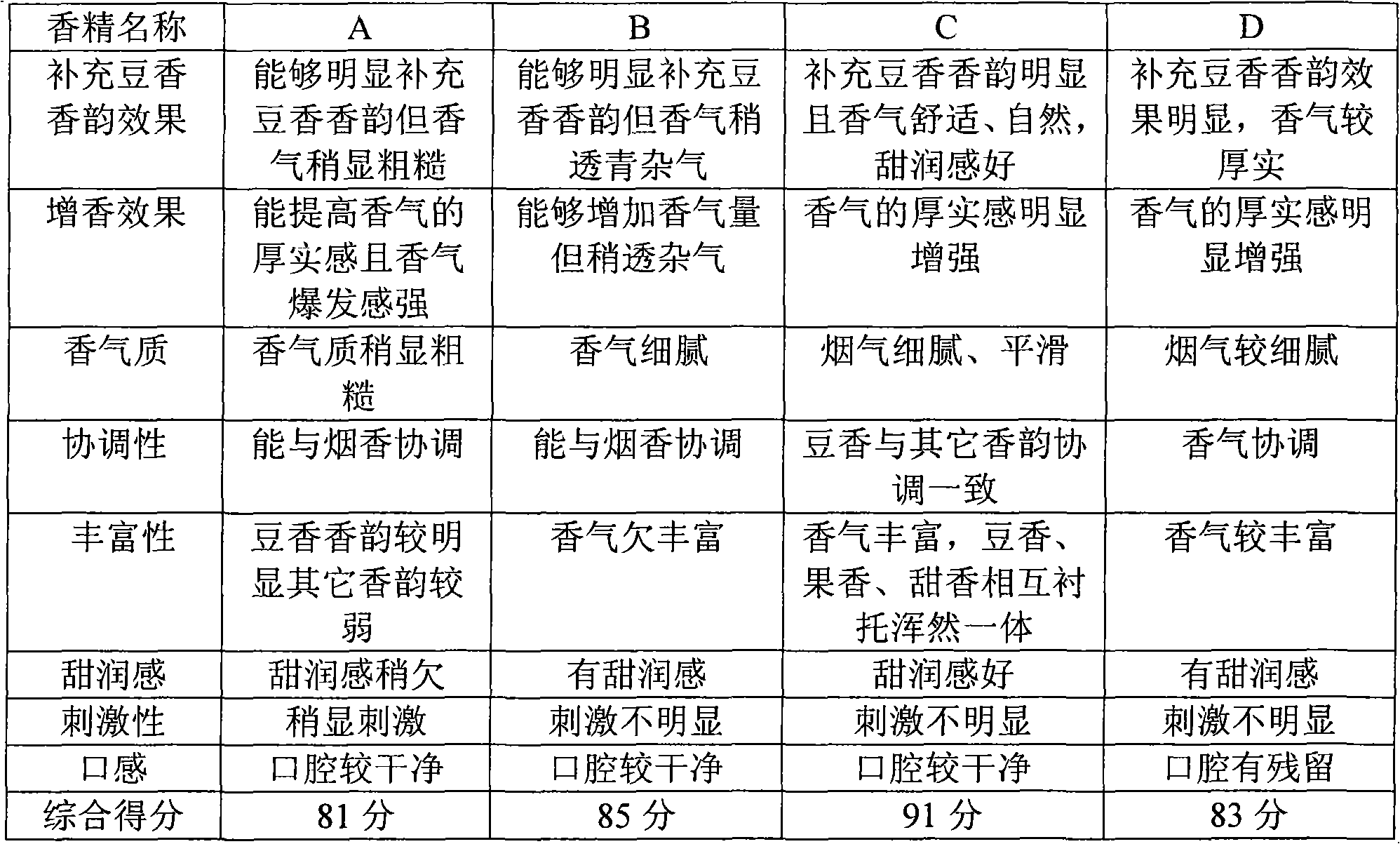

Tobacco feeding essence for replenishing bean-flavor

InactiveCN102031198AObvious fragranceComfortable aromaTobacco treatmentEssential-oils/perfumesFlavorNicotiana tabacum

The invention relates to a tobacco feeding essence, in particular to a tobacco feeding essence for replenishing bean-flavor note, which is formed by mixing the following raw materials in part by weight: 16-18 parts of black vanilla bean derivatives, 1.5-2 parts of cocoa extractives, 6-8 parts of almond derivatives, 2-3 parts of white hyacinth bean extractives, 2-2.5 parts of daidzein, 5-7 parts of fig extracts, 2.5-3 parts of plum extracts, 10-12 parts of Tsaoko Amomum fruit derivatives, 4-5 parts of balsamroot extractives, 1-1.5 parts of graecum extracts and 38-50 parts of propylene glycol water solutions. The tobacco feeding essence obviously replenishes the bean-flavor note and has comfortable and natural fragrance and good sweet feel, obviously enhances the concentration of the fragrance in tobaccos and also improves fragrance quality and smoking comfortableness when improving the concentration of the fragrance in tobaccos.

Owner:HUBEI CHINA TOBACCO IND +1

Keratolytic composition with anti-allergic anti-inflammatory properties

InactiveUS20060241190A1Improve securityAvoid loweringBiocideCosmetic preparationsAdjuvantAmmonium compounds

A product with an enhanced medicinal and cosmetic composition with a specific utility of “Psoriasis, Eczema and like skin disorders application” is characterized by the fact that it comprises active agents and ingredients as vanilla extract, ammonium chloride, potassium chloride and quaternary ammonium compound having formulated at a specific pH value with other specially selected adjuvants and fillers.

Owner:MUNISEKHAR MEDASANI

Parasite-expelling conditioner for pets and preparation method thereof

InactiveCN104288052AEasy to viewEffective careCosmetic preparationsHair cosmeticsVitamin E AcetateSide effect

The invention relates to a parasite-expelling conditioner for pets and a preparation method thereof, belonging to the field of pet products. The parasite-expelling conditioner for pets is prepared from the following raw materials in parts by weight: 40-65 parts of distilled water, 2-5 parts of olive oil, 3-8 parts of squalane, 2-8 parts of glycerin monostearate, 13-25 parts of propylene glycol, 4-9 parts of citric acid, 3-6 parts of disodium cocoyl glutamate, 2-5 parts of sodium chloride, 2-6 parts of sodium laureth sulfate, 2-4 parts of vitamin e acetate, 3-7 parts of essence, 2-4 parts of lysimachia foenum-graecum extract and 3-6 parts of radix stemonae grass extract. According to the parasite-expelling conditioner for pets disclosed by the invention, one part of Chinese herbal medicines with the parasite expelling effect are added, and the parasite-expelling conditioner is daubed on hair after the pets are washed, so that intrusion of parasites such as louses and fleas can be effectively prevented, and the conditioner does not have any toxic or side effect and can effectively care the hair. Therefore, the hair is smooth and straight, so that the ornamental value of the pets is further improved.

Owner:彭尚元

Facial cream containing ingredient of cordyceps militaris and preparation method thereof

InactiveCN104434760AImprove wrinkle resistanceRaw materials are easy to getCosmetic preparationsToilet preparationsIllicium verumAdditive ingredient

The invention relates to facial cream containing an ingredient of cordyceps militaris. The facial cream comprises the following 21 kinds of active ingredients: hydrolyzed oat protein, an aloe yeast, a cordyceps sinensis extractive, a purslane extractive, a scutellaria root extractive, a persimmon leaf extractive, an orange peel extractive, a phellinus igniarius extractive, a white willow bark extractive, a vanilla extractive, a cool-fragrance rose extractive, a green bean extractive, a green tea extractive, an illicium verum extractive, an astragalus membranceus root extractive, a ginseng root extractive, a tricholoma matsutake extractive, a radices lithospermi extractive, a chamomile extractive, a tree moss extractive and a honeysuckle extractive. The facial cream has the characteristics of being safe and non-toxic. The invention further provides a preparation method for the facial cream containing the ingredient of cordyceps militaris. The preparation method is simple, and can effectively reduce the preparation cost.

Owner:沈阳园康天然生物科技有限公司

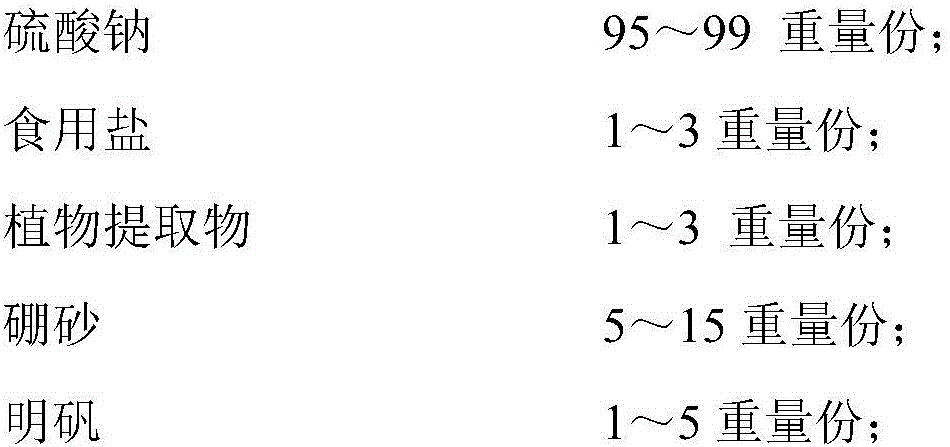

Bath crystal composition and preparation method thereof

The invention relates to the bath appliance field, and specifically discloses a bath crystal composition, wherein the bath crystal composition comprises sodium sulfate, edible salt, plant extract, borax and alum; the plant extract includes 5 to 18 parts by weight of sophora flower / rose / Calendula officinalis / honeysuckle mixed extract; 1 to 5 parts by weight of lily extract; 0.1 to 2 parts by weight of Saussurea involucrata extract; 0.1 to 3 parts by weight of Rhodiola extract; 1 to 5 parts by weight of pomelo peel extract; 0.1 to 1 part by weight of grape seed extract; 0.01 to 0.1 part by weight of Roselle extract; 1 to 13 parts by weight of raw ginger extract; 1 to 10 parts by weight of wormwood extract; 1 to 5 parts by weight of Camellia extract; 1 to 10 parts by weight of aloe extract; 1 to 3 parts by weight of eucalyptus extract, 1 to 8 parts by weight of wolfberry extract, 0.01 to 0.5 part by weight of pseudo-ginseng flower extract and 0.05 part by weight of vanilla extract.

Owner:内蒙古修远科技发展有限公司

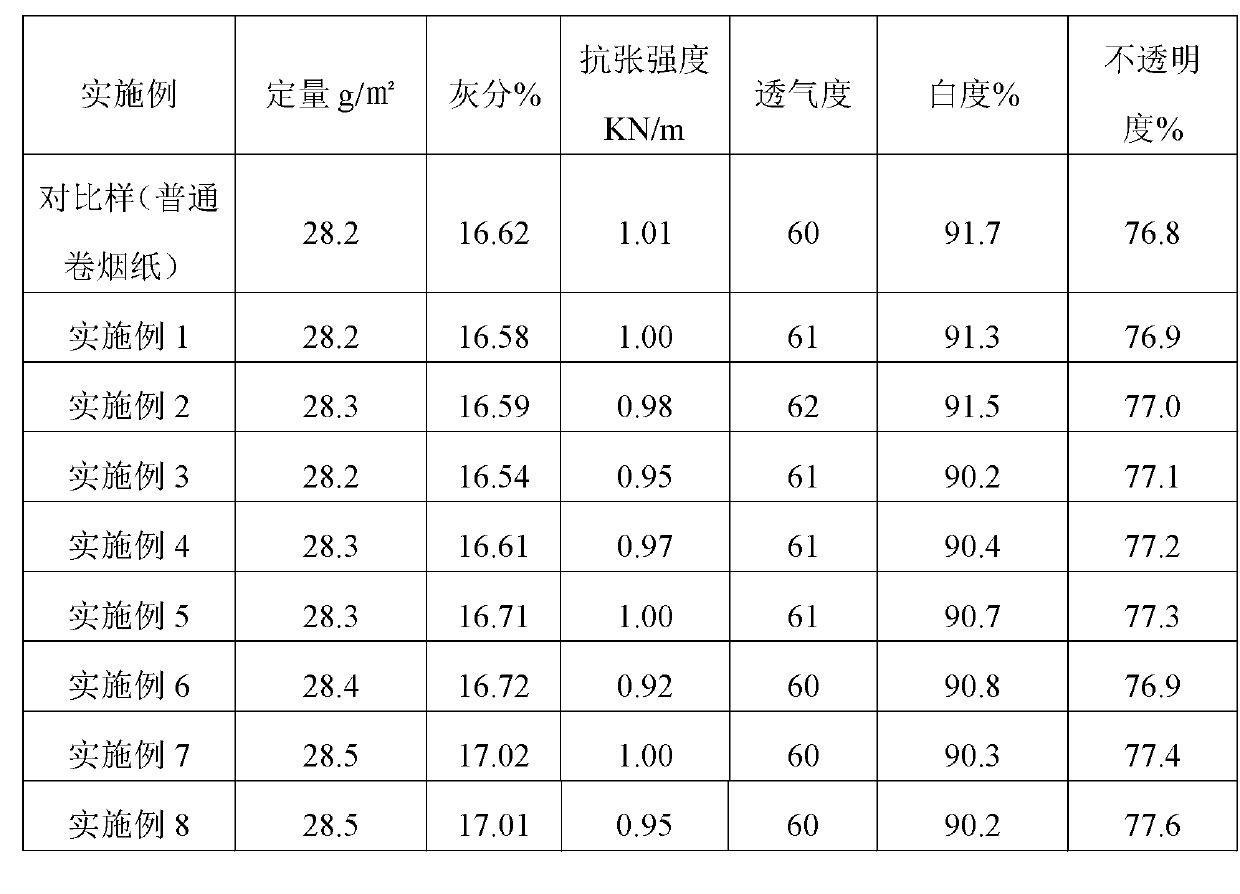

High-end cigarette paper containing black vanilla extract and preparation method thereof

ActiveCN103343487ASimple preparation processMask woodinessSpecial paperVegetable material additionCooking & bakingReflux extraction

The invention discloses a preparation method of cigarette paper containing a black vanilla extract. The method comprises the following steps of: uniformly cutting black vanilla and diluting vanillin and ethyl vanillin into 5wt%-15wt% of solutions by propanediol respectively; uniformly mixing the vanillin solution with the ethyl vanillin according to a volume ratio of (1-3) to 1; uniformly spraying the mixed solution to the surface of the black vanilla and baking for 1-3 hours at the temperature of 30+ / -2 DEG C; performing heating reflux extraction by ethanol; performing low-temperature concentration to obtain the black vanilla extract; adding the black vanilla extract into a coating solution, and stirring by a high-speed dispersing machine for uniformly mixing to finally prepare the high-end cigarette paper containing the black vanilla extract. The prepared cigarette paper can be used for effectively covering wood gas of the cigarette paper, supplementing fresh and sweet paste fragrance, sweet fragrance and soybean fragrance, enhancing cigarette fragrance and improving the useful value and the smoking quality of the cigarette paper.

Owner:HUBEI CHINA TOBACCO IND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com