Patents

Literature

44results about How to "Comfortable aroma" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tea wine and preparation method thereof

InactiveCN103305371AHigh alcohol contentSweet and mellow tasteAlcoholic beverage preparationFlavorAlcohol

The invention provides a tea wine and a preparation method thereof. The tea wine is prepared by mixing a tea extraction solution and a grain saccharification solution and fermenting. The preparation method provided by the invention comprises the following steps of: firstly leaching tea to prepare the tea extraction solution; secondly mixing Chinese sorghum, rice and corn according to a certain proportion, crushing, steaming, boiling and saccharifying to obtain the saccharification solution, mixing with the tea extraction solution, adding koji, and forming a tea fermentation solution by liquid-state fermentation; and finally performing sterilization, blending, fining, filtering, aging and secondary filtration to obtain the tea wine. The tea wine is characterized in that a product provided by the invention has the characteristics of heavy tea fragrance, sweet and mellow taste, coordination of various flavors, long after-taste and the like; and furthermore, compared with the traditional tea wine, the tea extraction solution is adopted for performing fermentation together with the Chinese sorghum, the rice and the corn, the functional active ingredients in the tea can be retained to the greatest extent, the blending of a base wine is simultaneously performed after fermentation, the shortcomings of low alcohol degree of the fermented wine and complex process and pungent smell of the distilled wine can be overcome, the softness of the tea and the rigidity of the wine can be perfectly combined, and the species of tea and wine products are enriched.

Owner:四川省广汉市常乐春酒厂(普通合伙)

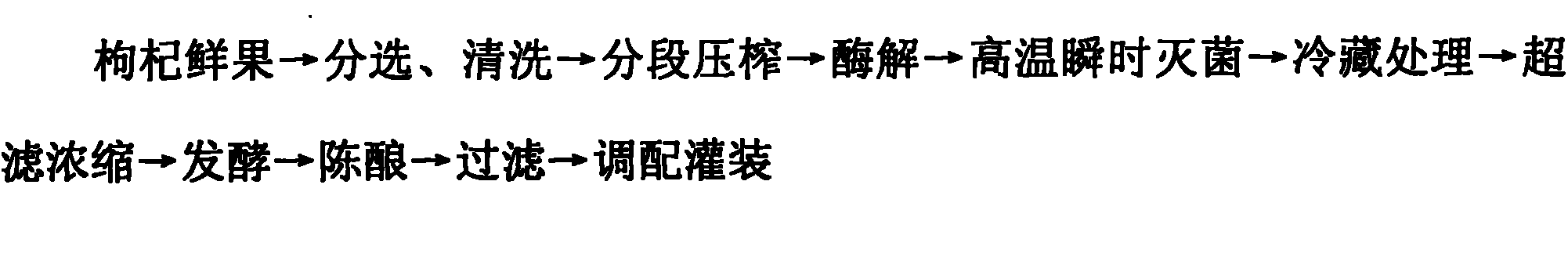

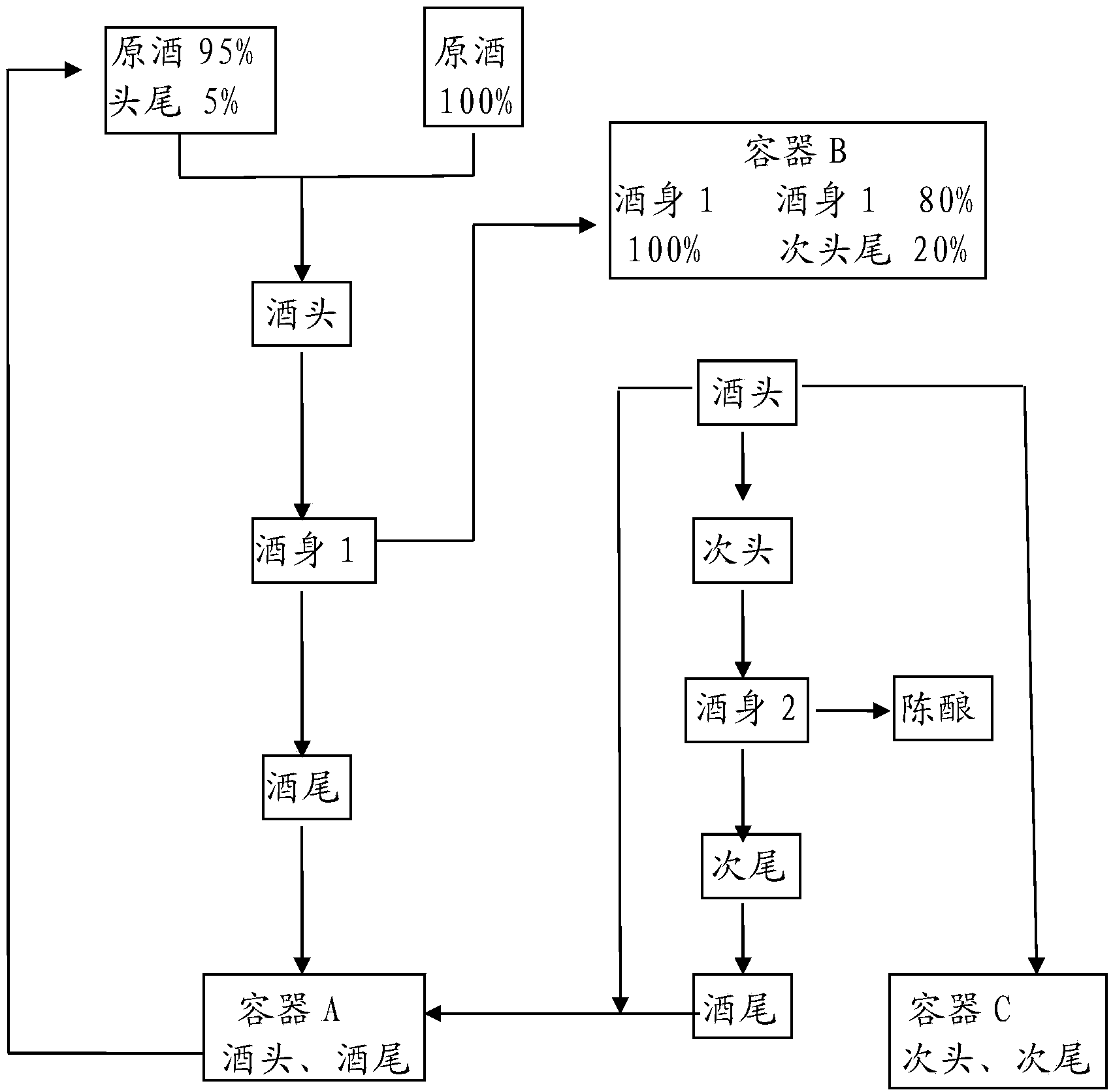

Fresh Chinese wolfberry fruit full juice fermented wine and preparation method thereof

ActiveCN103289858ASimple processLess additivesMicroorganism based processesAlcoholic beverage preparationBiotechnologyFood science

The invention relates to a fresh Chinese wolfberry fruit full juice fermented wine and a preparation method thereof. The fresh Chinese wolfberry fruit full juice fermented wine is prepared by sorting and cleaning fresh Chinese wolfberry fruit, and carrying out stage squeezing, enzymolysis, high-temperature instant sterilization, refrigeration treatment, hyperfiltration concentration, fermenting, aging, filtration and blending encapsulation. The method provided by the invention has the advantages that the process is simple, an addition agent is less, residual is not generated, and the fresh Chinese wolfberry fruit full juice fermented wine prepared by the method is golden yellow in color, clear and transparent, pure and comfortable in fragrance with mellow, has typical mature fruity flavor of Chinese wolfberry wine, is smooth, soft and full in palate, is well balanced among alcoholicity, acidity and tannin with great harmony, and has comprehensive and rich nutrient substances.

Owner:青海柴馥有机枸杞有限公司

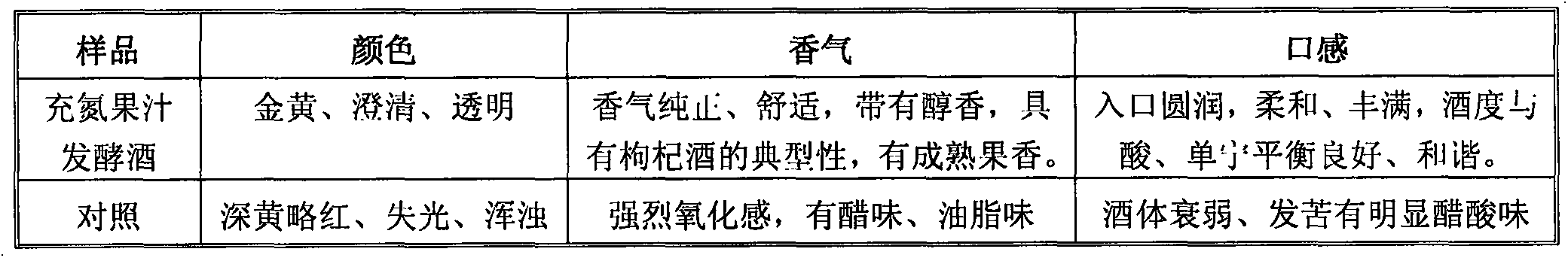

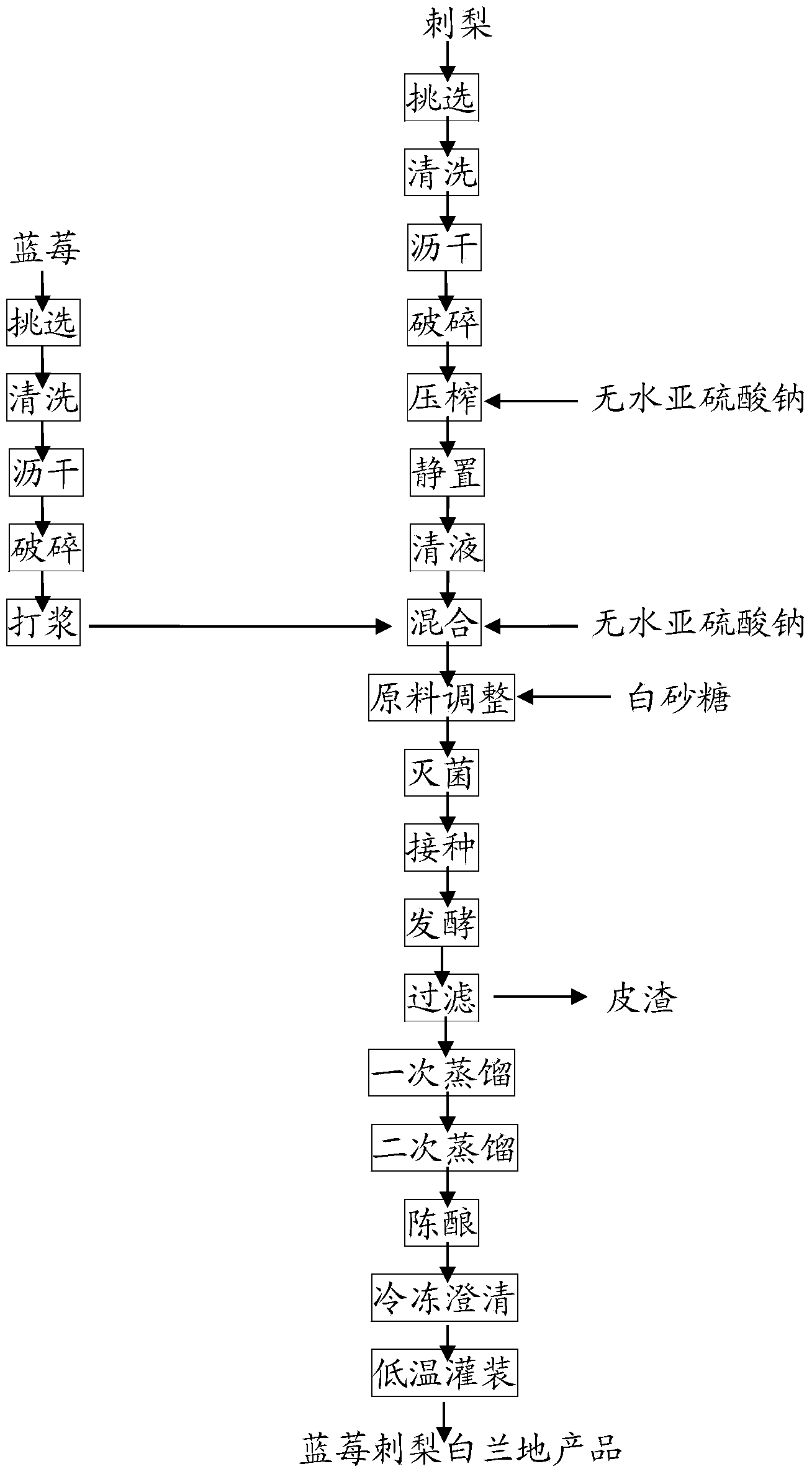

Production method of blueberry roxburgh rose brandy

ActiveCN103865733AComfortable aromaPure tasteAlcoholic beverage preparationBiotechnologyNutritive values

Owner:贵州蓝美食品科技有限公司

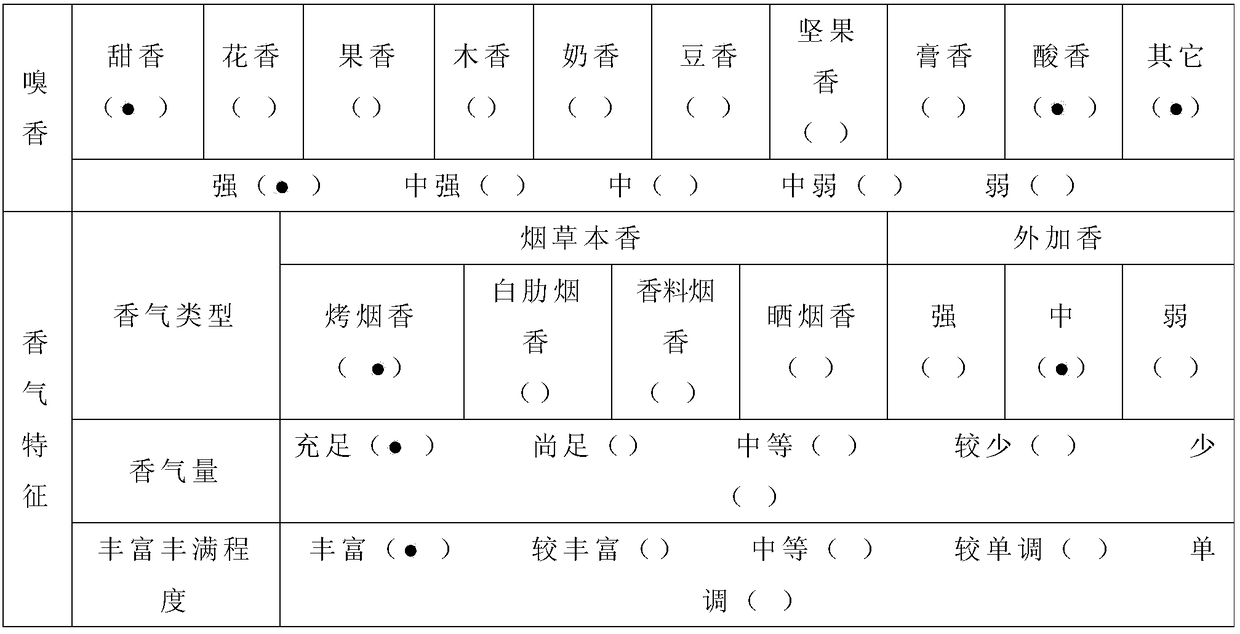

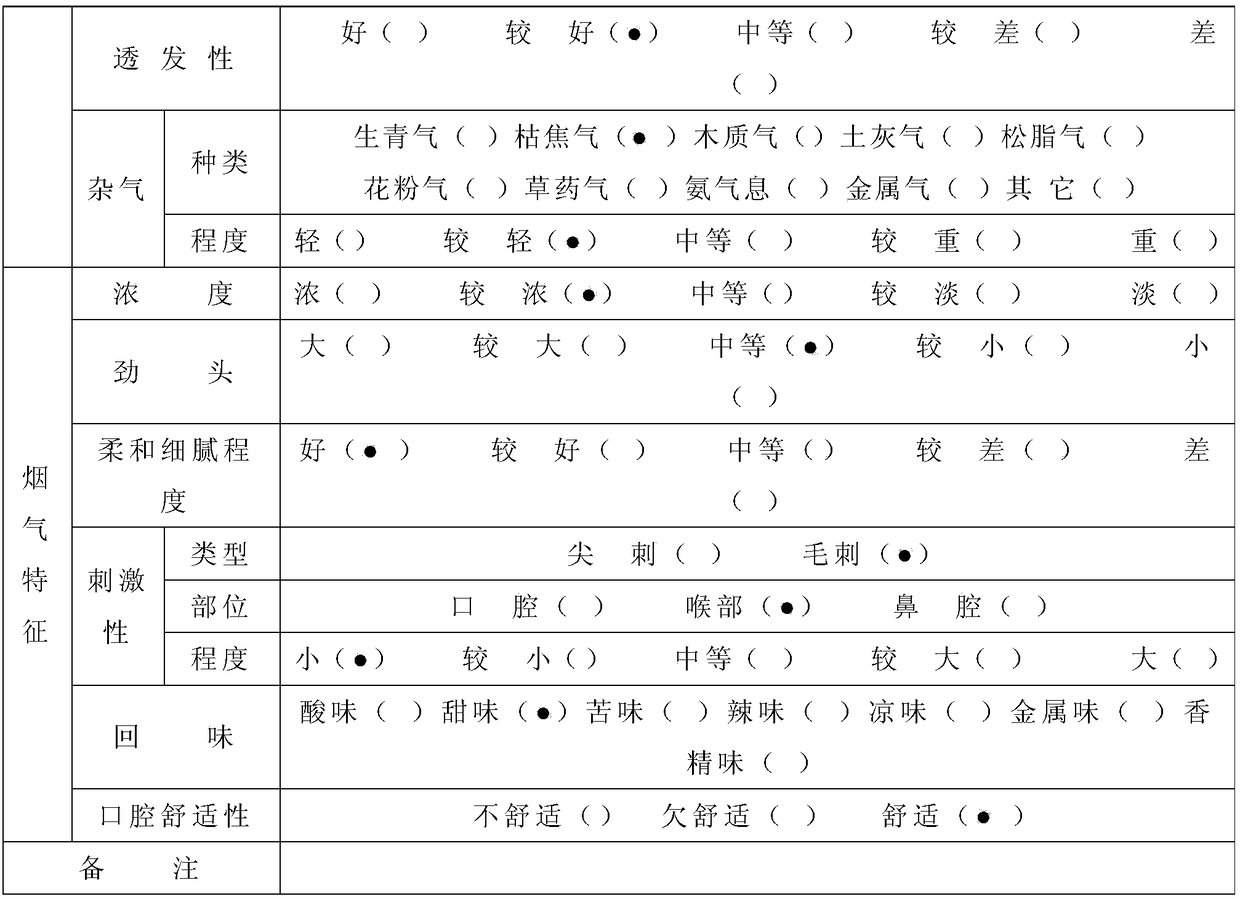

Recombinant tobacco coating chocolate and coffee flavor-mixed essence and preparation method thereof

InactiveCN106967508AComfortable aromaProminent and long-lasting scentTobacco preparationEssential-oils/perfumesCoffeaChemistry

The invention belongs to the technical field cigarette essence and particularly relates to a recombinant tobacco coating chocolate and coffee flavor-mixed essence and a preparation method thereof. The recombinant tobacco coating chocolate and coffee flavor-mixed essence is composed of, by weight part, 0.8-1.8 parts of koka aldehyde, 10-30 parts of cocoa extract, 15-30 parts of coffee extract, 2-7 parts of Zimbabwe tobacco extract and the like. The recombinant tobacco coating chocolate and coffee flavor-mixed essence provides a chocolate and coffee mixed flavor and is applicable to the field of cigarette production and particularly to adding into recombinant tobacco coating. Among the flavor components, the cocoa extract, the coffee extract and chocolate extract are relatively close to tobacco in fragrance characteristics and can enhance the flavor harmony in cigarettes. The recombinant tobacco coating chocolate and coffee flavor-mixed essence comprises the multiple flavor contents and integrates the fragrances such as burnt fragrance, bean fragrance, milk fragrance and nut fragrance, thereby being rich in layers, natural in transition and capable of well embodying the major fragrance of the cigarettes.

Owner:WUHAN HUANGHELOU FLAVOR & SPICES

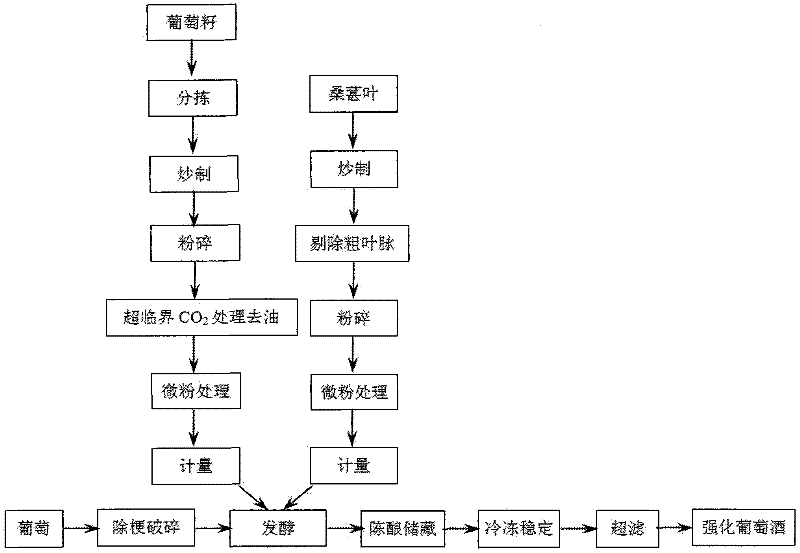

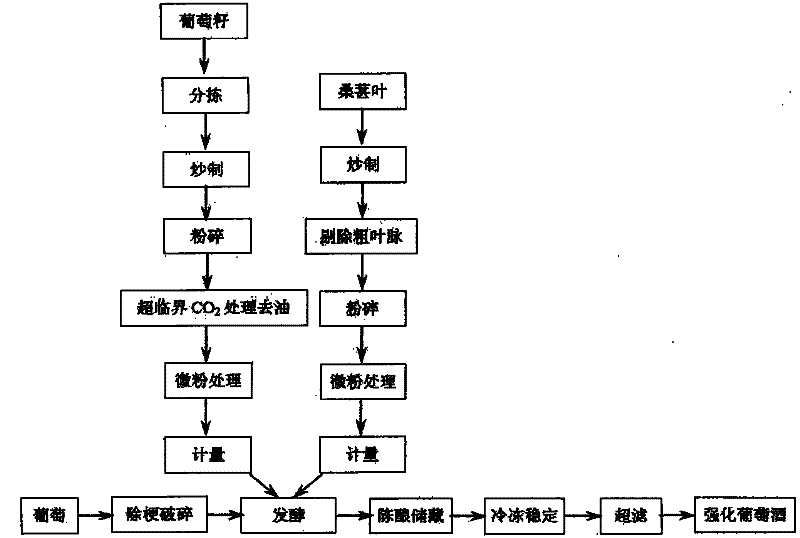

Manufacture process of fortified grape wine

The invention discloses a manufacture process of a fortified grape wine, and particularly relates to a manufacture process of a fortified grape wine containing grape seeds and mulberry leaves. The process comprises the following steps: (1) carrying out sorting, frying, pulverization and supercritical CO2 extraction on the grape seeds to remove grape seed oil, and carrying out micropowder treatment; (2) frying the mulberry leaves, pulverizing, and carrying out micropowder treatment; (3) destemming and crushing grape; and (4) separately metering the grape seeds and mulberry leaves treated in the steps (1) and (2), adding to the grape treated in the step (3), fermenting, aging and storing, freezing and stabilizing, and carrying out ultrafiltration to obtain the fortified grape wine. The process has the advantage that the grape wine with good aesthetic quality and fortified polyphenol substances, deoxynojirimycin and other components having certain functions is obtained.

Owner:SHANDONG YANTAI AGRI SCHOOL

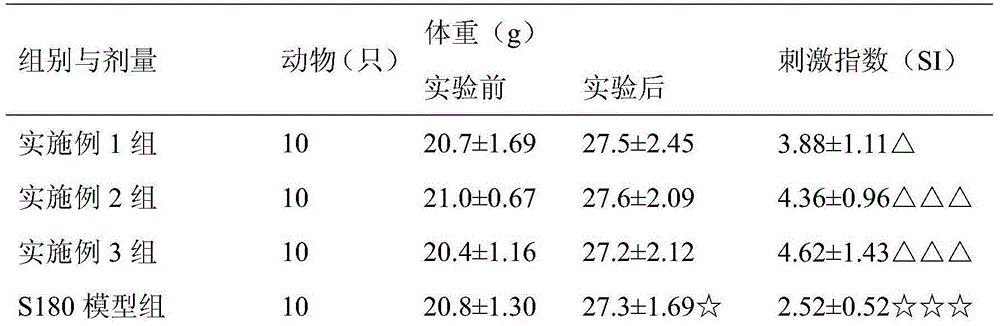

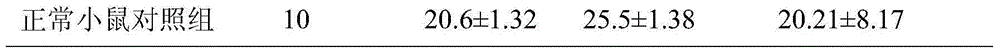

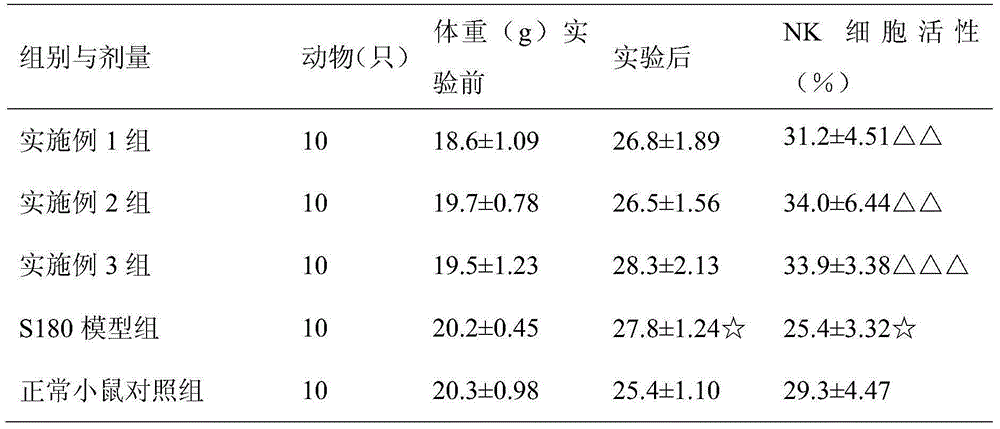

Chewable tablet for improving immunity and preparation method of chewable tablet

InactiveCN105125606AImprove food safetyImprove use valueUnknown materialsPill deliverySucroseMANNITOL/SORBITOL

The invention discloses a chewable tablet for improving immunity and a preparation method of the chewable tablet, wherein the chewable tablet consists of the following components in parts by weight: 20-50 parts of hydropotes inermis, 5-25 parts of an American ginseng extract, 20-31 parts of sucrose, 10-20 parts of mannitol, 2-6 parts of citric acid, 15-25 parts of microcrystalline cellulose, 0.1-0.5 parts of calyx canthus essence and 1-5 parts of magnesium stearate. The chewable tablet disclosed by the invention is stable in quality, good in taste, rapid to be absorbed and significant in curative effect of improving immunity.

Owner:ZHEJIANG UNIV

Cigarette filter tip comprising natural Chinese herbal medicine antibacterial agent and manufacturing method

The invention discloses a preparation method of a cigarette filter tip comprising a natural Chinese herbal medicine antibacterial agent. The cigarette filter tip comprises the natural Chinese herbal medicine antibacterial agent, wherein the weight of the natural Chinese herbal medicine antibacterial agent is 0.004-0.01 percent of that of the cigarette filter tip. The natural Chinese herbal medicine antibacterial agent comprises, by weight, 0.5-1 part of eucalyptus oil, 2-3 parts of lavender oil, 1.2-1.5 parts of mastic oil, 80-120 parts of licorice tincture, 1.2-1.8 parts of jasmine essential oil, 1.5-2 parts of lemon oil, 0.2-0.5 part of spearmint oil, 20-25 parts of mint oil, and 845-905 parts of edible alcohol. The natural Chinese herbal medicine antibacterial agent used in the cigarette filter tip has the broad-spectrum antibacterial effect, can protect the mouth cavity and the throat mucous membrane and reduces stimulation on the throat by the cigarette. During appreciation smoking of the cigarette, the taste is fresh, the fragrance is coordinated and comfortable, and the process of a manufacturing method is simple.

Owner:HUBEI CHINA TOBACCO IND +1

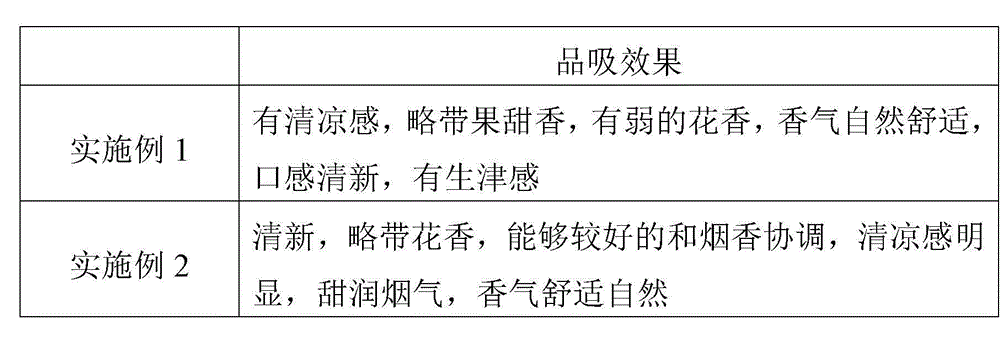

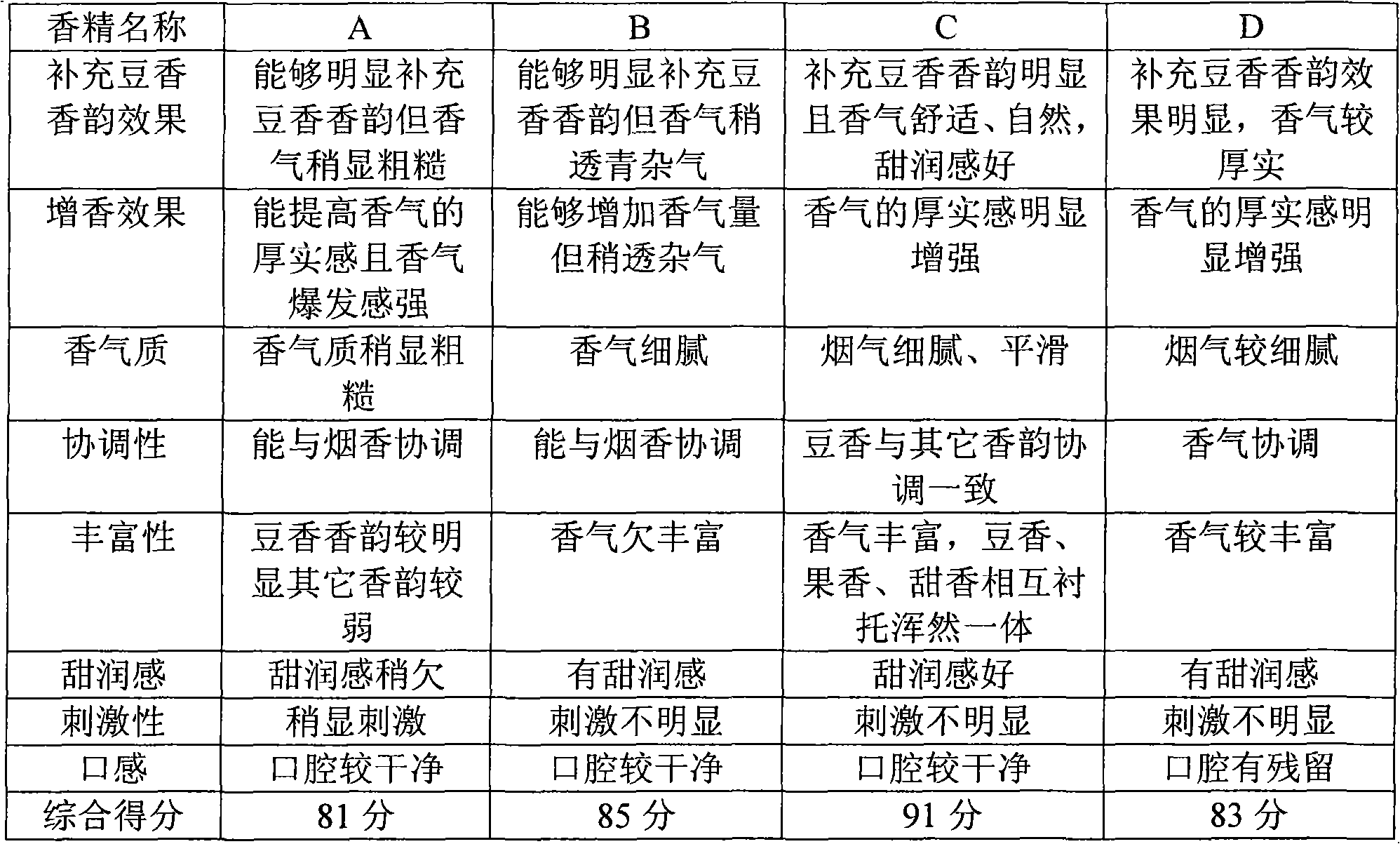

Tobacco feeding essence for replenishing bean-flavor

InactiveCN102031198AObvious fragranceComfortable aromaTobacco treatmentEssential-oils/perfumesFlavorNicotiana tabacum

The invention relates to a tobacco feeding essence, in particular to a tobacco feeding essence for replenishing bean-flavor note, which is formed by mixing the following raw materials in part by weight: 16-18 parts of black vanilla bean derivatives, 1.5-2 parts of cocoa extractives, 6-8 parts of almond derivatives, 2-3 parts of white hyacinth bean extractives, 2-2.5 parts of daidzein, 5-7 parts of fig extracts, 2.5-3 parts of plum extracts, 10-12 parts of Tsaoko Amomum fruit derivatives, 4-5 parts of balsamroot extractives, 1-1.5 parts of graecum extracts and 38-50 parts of propylene glycol water solutions. The tobacco feeding essence obviously replenishes the bean-flavor note and has comfortable and natural fragrance and good sweet feel, obviously enhances the concentration of the fragrance in tobaccos and also improves fragrance quality and smoking comfortableness when improving the concentration of the fragrance in tobaccos.

Owner:HUBEI CHINA TOBACCO IND +1

Liquid production method of Luzhou-flavor liquor

ActiveCN106010873AHas a strong flavorAchieve productionMicroorganism based processesAlcoholic beverage preparationFlavorSorghum

The invention belongs to the technical field of liquor brewing, and particularly relates to a liquid production method of Luzhou-flavor liquor. The method comprises the following steps of crushing of sorghum, liquid gelatinization, saccharifying and fermenting, esterification, and distilling. The method has the advantages that the saccharifying, fermenting and esterification are respectively performed in a fermenting tank, so that the Luzhou-flavor liquor can be produced under the liquid condition; the method is different from thetraditionalproduction method using saccharifying and fermenting to produce liquor in the Luzhou-flavor liquor pit mud under the solid condition, the whole brewing process is mechanical and automatic, thecharging and discharging of fermented mash can be avoided in the tank, the labor intensity is decreased, and the production efficiency is greatly improved.

Owner:HUBEI ZHIJIANG LIQUOR INDUSTRY CO LTD

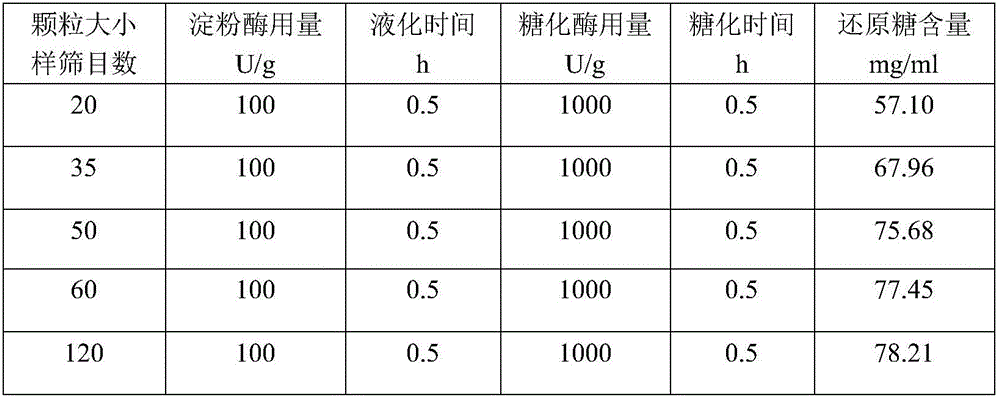

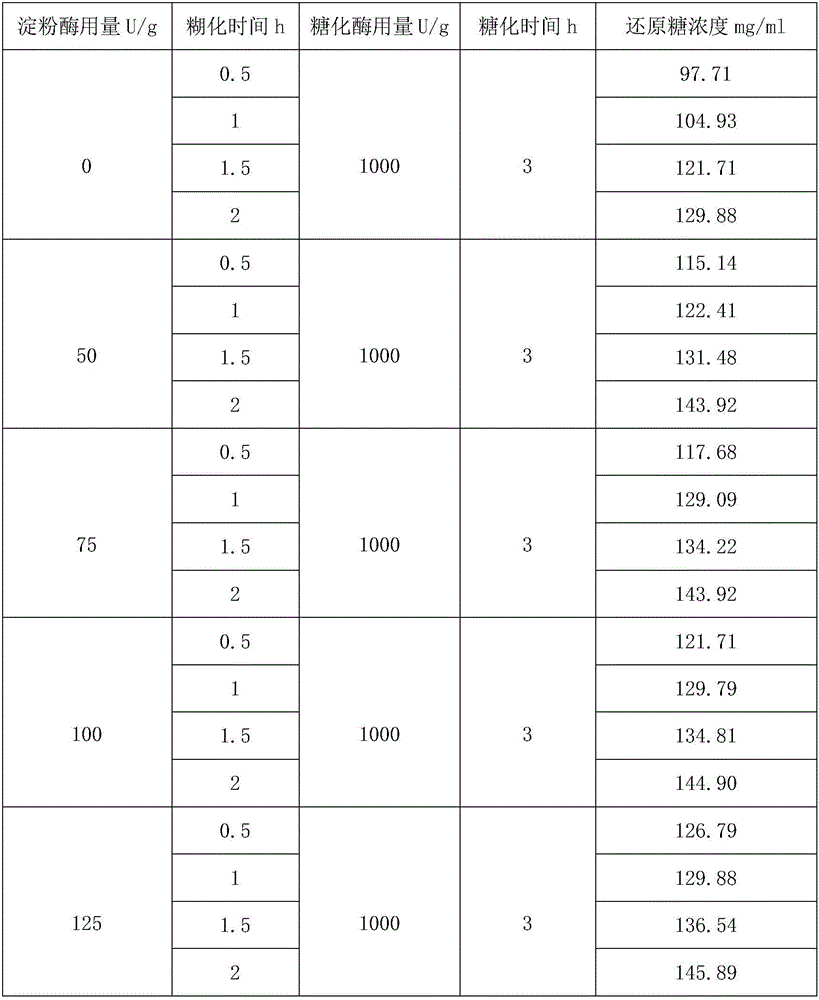

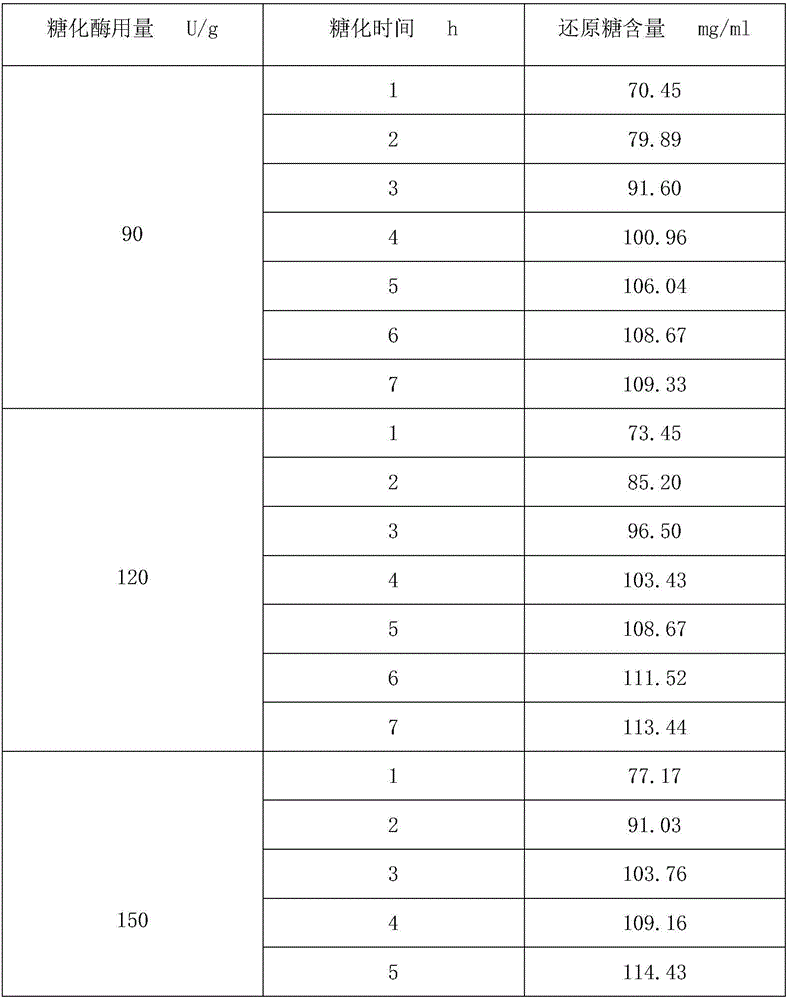

Homemade lepidium meyenii, jujube, and sorghum co-fermented white liquor with enhanced yeast

InactiveCN106434170AImprove glycationImprove liquefactionMicroorganism based processesAlcoholic beverage preparationPectinaseTriticeae

The invention discloses homemade lepidium meyenii, jujube and sorghum co-fermented white liquor. The liquor is prepared by the following raw materials in parts by weight: the balance of distilled water, the balance of monascus strain, the balance of aspergillus niger, the balance of yeast strain, 0.06-0.0.07 part of sterile water, 2500-2600 parts of sorghum, 9-10 parts of wheat, 1-1.2 parts of barley, 1-2 parts of banana, polygonum hydropiper, 200-220 parts of lepidium meyenii, 150-160 parts of Xinjiang Ruoqiang jujube, 0.7-0.8 part of cellulase, and 0.7-0.8 part of pectinase. The base of the homemade lepidium meyenii, jujube and sorghum co-fermented white liquor is made of enhanced yeast, has the advantages of pure scent, refreshing aftertaste, and long taste. The healthcare effects of lepidium meyenii and jujube are integrated. Compared with conventional grain liquor, the homemade lepidium meyenii, jujube and sorghum co-fermented white liquor better conforms to the concept of health drinking, and is worthy of popularization.

Owner:马鞍山市太白酒厂

Japanese sake and processing method thereof

InactiveCN106381258AElegant aromaComfortable aromaMicroorganism based processesAlcoholic beverage preparationTrace elementFood flavor

The invention discloses Japanese sake which comprises the following components in parts by volume: 26-95 parts of Xiaoqu fragrant liquor, 5-35 parts of rice wine and 1.8-6.2 parts of seasoning wine, wherein the Xiaoqu fragrant liquor consists of the following components in parts by volume: 5-30 parts of corn wine, 20-60 parts of kaoliang spirit and 1-5 parts of buckwheat wine; the seasoning wine consists of the following components in parts by volume: 0.1-1 part of first wine, 1.5.5 parts of last wine, 0.01-0.1 part of high-acidity seasoning wine and 0.01-0.1 part of high-ester seasoning wine. On the other hand, the invention further provides a processing method of the Japanese sake. The processing method comprises the following steps of: brewing the Xiaoqu fragrant liquor, brewing the rice wine, combining the wine and finely adjusting the wine. With the combination of the Xiaoqu fragrant liquor which is mellow and clean and the rice wine which is soft and sweet and fresh and clean, the advantage that the rice wine is high in wine yield is taken, and a proper amount of mixed-flavoring white spirit which is rich in trace elements and a trace amount of maotai-flavor white spirit are added, the Japanese sake is quietly elegant in fragrance, comfortable, fresh and clear in taste, mellow and good in taste, and people do not feel dizzy or thirsty after drinking the Japanese sake.

Owner:墨江地道酒业有限公司

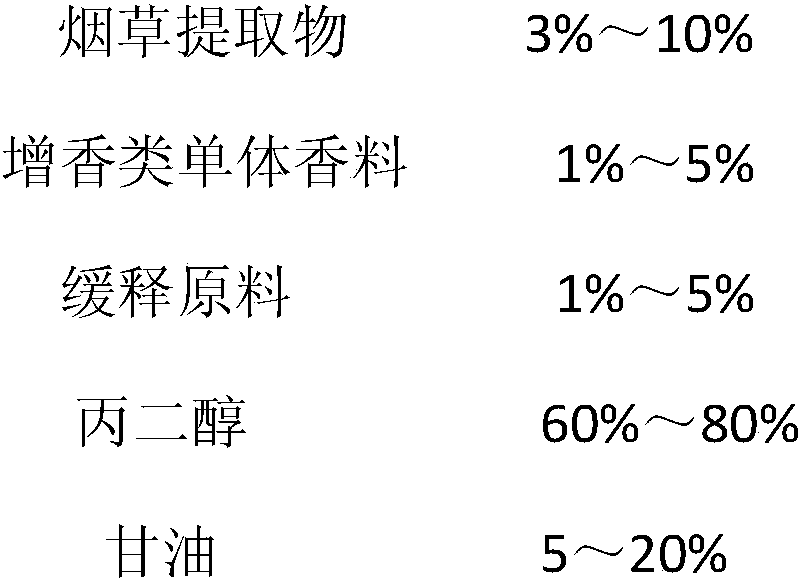

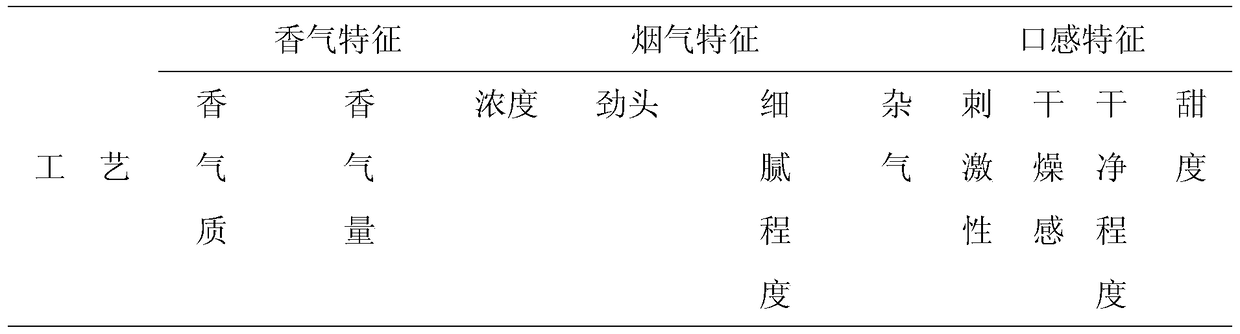

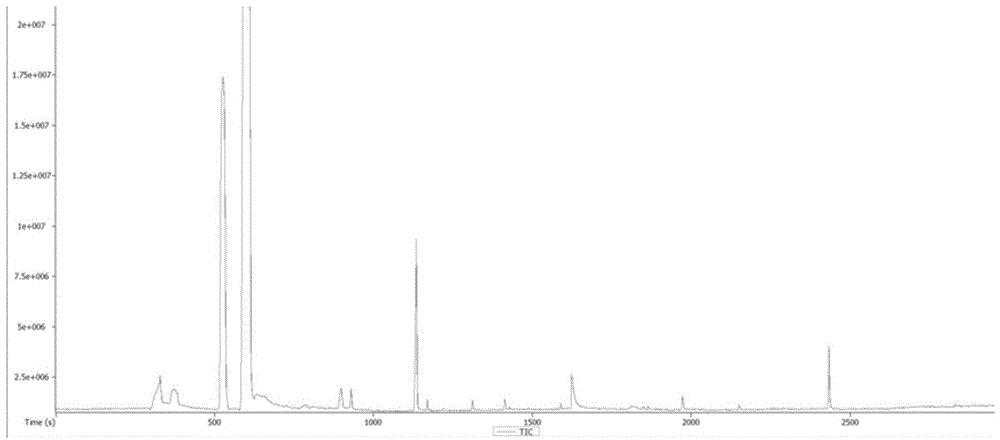

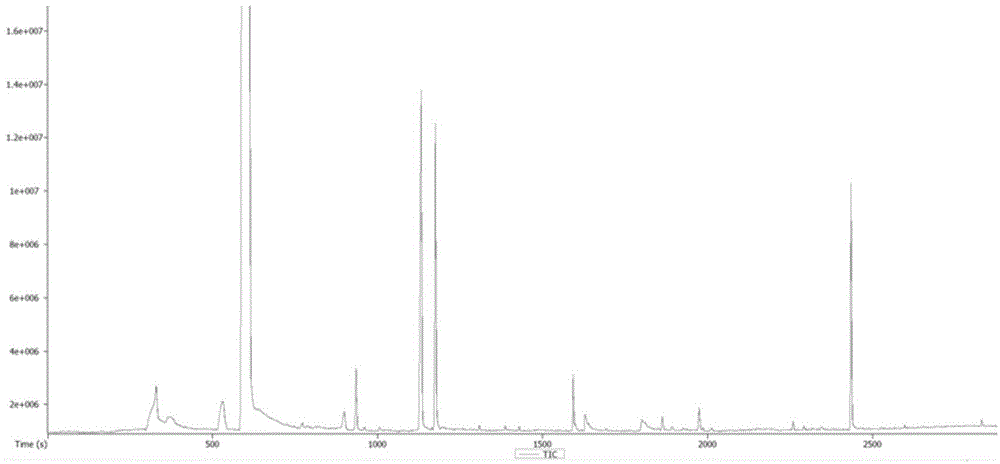

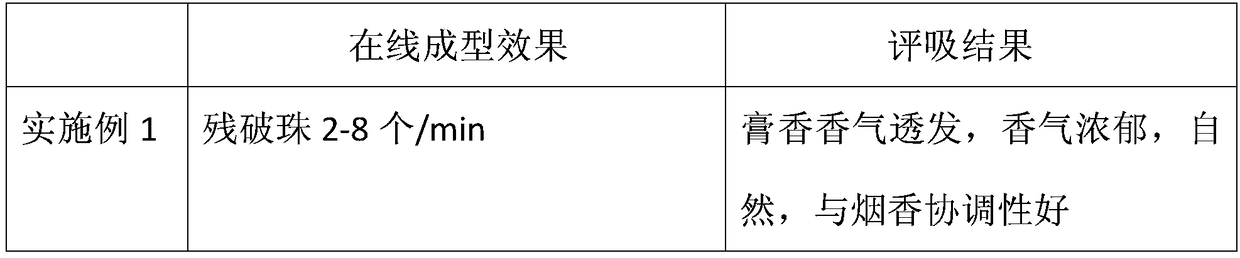

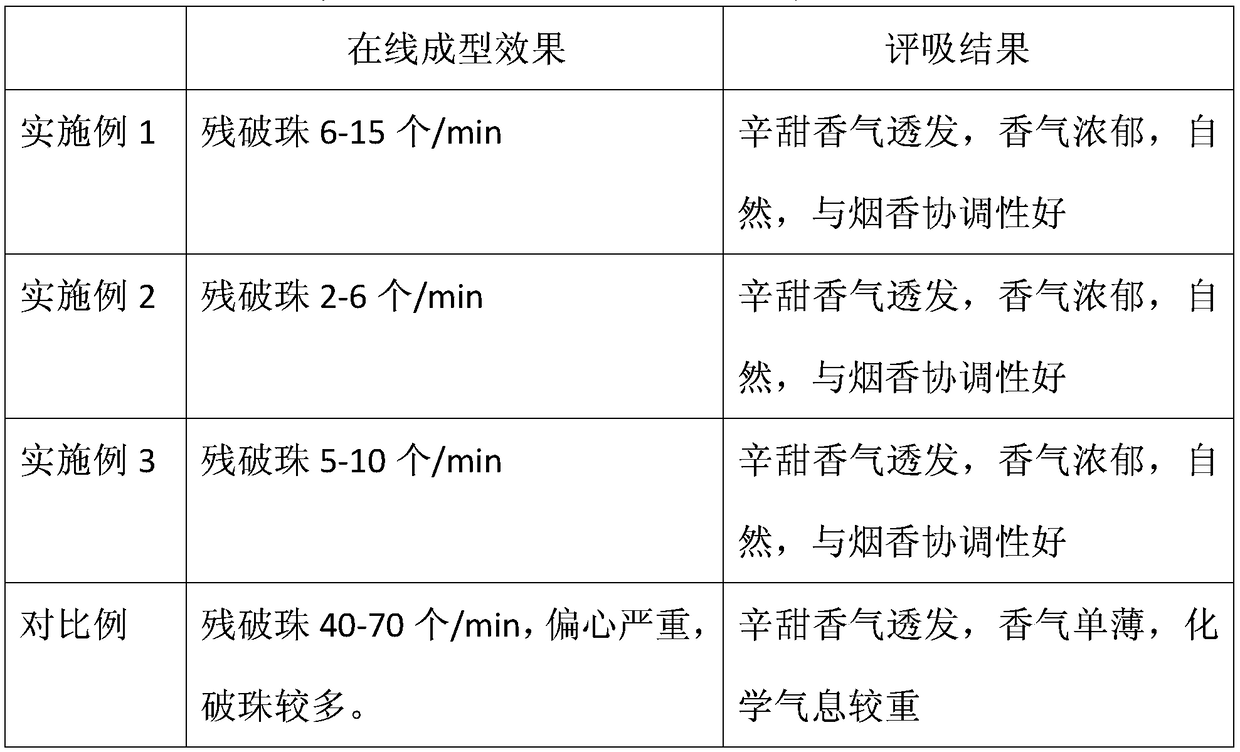

Tobacco flavor enhancing fragrance essence for heat-not-burn cigarettes as well as preparation method and application thereof

InactiveCN109337761AComfortable aromaIncrease concentrationTobacco treatmentEssential-oils/perfumesFlavorChemistry

The invention provides a tobacco flavor enhancing fragrance essence for heat-not-burn cigarettes as well as a preparation method and application thereof. The fragrance essence is in form of clear liquor obtained by mixing and filtering a tobacco extract, a flavor enhancing monomer fragrance, a slow-release raw material, propylene glycol and glycerol, wherein the tobacco extract comprises an aromatic tobacco extract and a molecular distillate thereof; and the raw materials of tobacco comprises one or more than one of aromatic tobacco, Zimbabwe tobacco, burley tobacco, sun-cured tobacco and Virginia tobacco at will. The use comprises the following steps: tobacco threads are prepared into powder; carboxymethylcellulose sodium, microcrystalline cellulose, purified water and the glycerol are added into the powder; the obtained mixture is fully mixed with the tobacco flavor enhancing fragrance essence for the heat-not-burn cigarettes and shaped into a dough; the dough is sliced into the tobacco threads after being pressed into a flat shape in a rolling manner; and the tobacco threads are manually rolled into cigarettes after water balance. Proved by evaluation, the tobacco flavor enhancing fragrance essence can well enhance the flavor of the tobacco, enables the flavor to be more comfortable and more natural, increases the concentration, prompts the satisfaction degree and conceals offensive odors, thereby improving the experience and the enjoyment of a smoker.

Owner:HUBEI CHINA TOBACCO IND

Method of promoting aging of Chinese liquor

InactiveCN108998337ALess impuritiesAccelerated agingAlcoholic beverage preparationAge methodMedicine

The invention discloses a method of promoting aging of Chinese liquor, which includes: (1) sealing to-be-aged Chinese liquor in a liquor storage pot; (2) placing the liquor storage pot, filled with the Chinese liquor, in a temperature-controllable sealed liquor storeroom for preserving the Chinese liquor for 12 h; (3) vibrating the Chinese liquor in the pot by means of an ultrasonic vibration device in regular or random time; (4) then controlling the temperature in the liquor storeroom in a stepwise temperature-controlling method, wherein in the first three days, the temperature is controlledat 35-40 DEG C, and clean air is uniformly fed into the Chinese liquor via a gas distributor, in the middle five days, the temperature is controlled at 33-34 DEG C, and then temperature is controlledat 25-30 DEG C, finally preserving the Chinese liquor for 6-8 months to produce aged liquor. The aging method is low in cost, is simple and high-effective in process, is easy to carry out and is gentle in test conditions, is free of addition of any catalytic materials, and can be applied to large-scale production.

Owner:山东恒糅酒业有限公司

Method for improving the content of characteristic aroma component ethyl propionate of special-flavor Chinese spirits

InactiveCN103266034AConducive to "Increasing C and Decreasing Milk"Conducive to increasing blood pressure and reducing milk”Microorganism based processesAlcoholic beverage preparationFlavorPropanoic acid

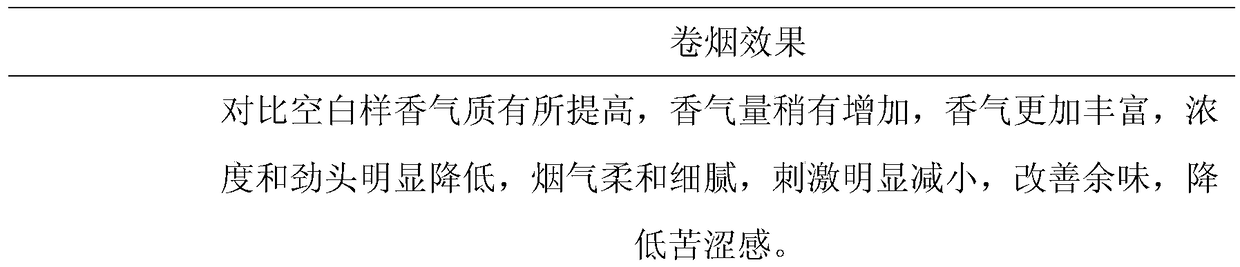

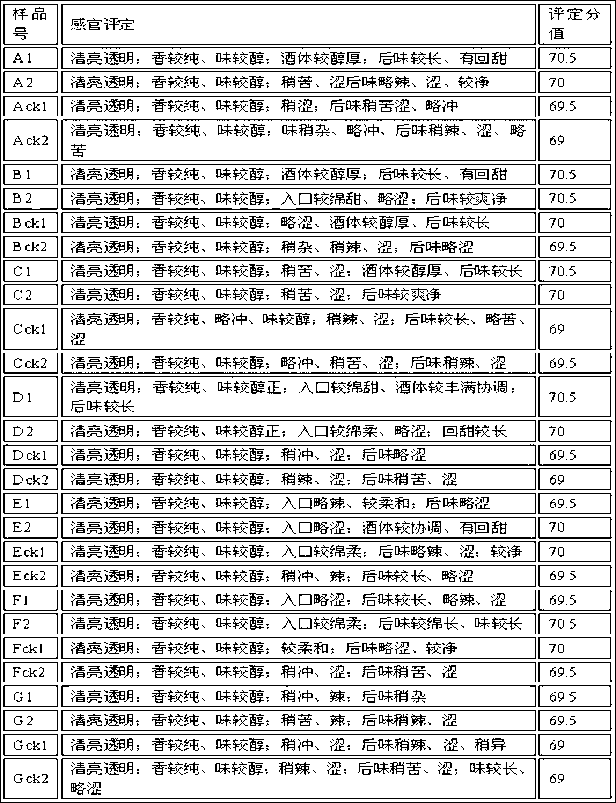

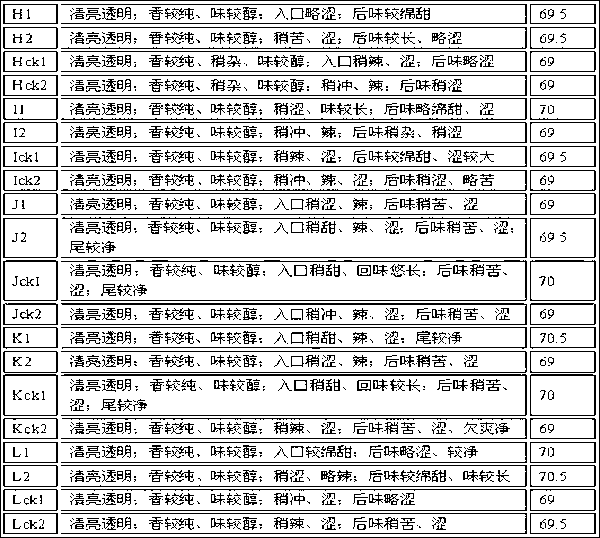

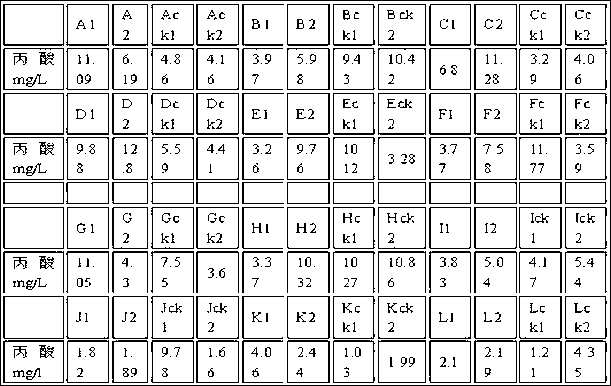

A method for improving the content of a characteristic aroma component ethyl propionate of Te-flavor Chinese spirits. Acid-proof propionibacterium with high yield of propionic acid is applied. After the amplification culture, propionibacterium liquid of volume 0.33%-1% is injected into a pit. The time for pit injection is controlled in the main fermentation period, namely the 15th day after pit opening of spirits sediment and the depth of pit injection is from 20 cm to 30 cm, the diameter of pit injection is 2.5 cm. Seed culture solution of propionibacterium is obtained through culture expansion in the invention. After the main fermentation, propionibacterium liquid is injected into the pit. Results show that the effect is obvious in the increase of content of ethyl propionate in spirit base generated in a pit with added propionibacterium liquid. The content of generated ethyl propionate is more than 2 times that of a blank pit. After tasting and evaluation, the increase in content of ethyl propionate creates a sweeter and softer taste and a more comfortable aroma of spirit base. Not only the quality of Te-flavor Chinese spirits can be improved, but also influences on yield are controlled in a reasonable scope after the pit injection time and the bacteria liquid amount are well controlled.

Owner:廖昶 +3

Spring liquor brewed for nine times and preparation method of spring liquor

ActiveCN104862182AUnique tasteSweet tasteAlcoholic beverage preparationMicroorganism based processesEvery Three DaysYeast

The invention discloses spring liquor brewed for nine times and a preparation method of the spring liquor. The preparation method comprises the following steps: taking high quality rice and sticky rice as raw materials, and smaller lumped koji and a composite yeast bacterium solution as leavening agents, and performing semi-solid state fermentation or liquid state fermentation to prepare the spring liquor brewed for nine times. The spring liquor brewed for nine times is characterized in that raw materials are cooked at high temperature, smaller lumped koji and the composite yeast bacterium solution, which are rich in rhizopus, are added after the cooked mixture is naturally cooled, a multi-strain multi-enzyme semi-solid state or liquid state fermentation technology is adopted, the fermented mixture is brewed once every three days, the brewing is performed for nine times or ten times, the fermentation time is 27 or 30 days, and the obtained liquor is filtered to remove rice dregs to obtain the spring liquor which is clear, transparent, alcohol sweet and crisp, and mellow, soft and delicious in taste.

Owner:ANHUI GUJING DISTILLERY +1

Production method for multiple-grains type Baijiu

InactiveCN108949418AStrong fragranceHigh nutritional valueMicroorganism based processesAlcoholic beverage preparationBiotechnologyFiltration

The invention discloses a production method for multiple-grains type Baijiu. The production method comprises the following steps: mixing, by weight, 30-45 parts of sorghum rice, 3-8 parts of corn, 10-20 parts of wheat, 8-15 parts of buckwheat and 10-15 parts of polished round-grained rice, adding the mixture to water for immersing, then performing primary steaming and boiling, and mixing the mixture with 5-10 parts of rice husk, 2-5 parts of bran, 2-7 parts of compound fruits and 2-9 parts of common yam rhizome; performing secondary steaming and boiling after urease-producing bacteria liquid moistening material is added, adding 3-8 parts of water and taking out from a resort, cooling, add 5-8 parts of daqu, 8-12 parts of aspergillus candidus, 2-5 parts of aroma-producing yeast and uniformly stirring, performing stacking fermentation after a urease-producing bacteria liquid is added, and fermenting in a pool to obtain fermented grains materials; and adding activated carbon after distillation and performing adsorption, storing after freezing and filtration, and preparing the multiple-grains type Baijiu by blending. The production method for the multiple-grains type Baijiu has the advantages of simple process, high production efficiency and high liquor yield; and the obtained Baijiu is clear and transparent, is pure in taste, is high in quality, and is stable.

Owner:安徽省碧绿春生物科技有限公司

Combined processing method of tea wine

InactiveCN108315145AAppearance bright red and transparentBright colorAlcoholic beverage preparationChemistryCo-fermentation

The invention provides a combined processing method of tea wine. The tea wine is prepared by carrying out mixed fermentation on a tea leaf extracting solution and a grain saccharification solution. The combined processing method comprises the following steps: firstly, extracting tea leaves, thus preparing the tea leaf extracting solution; secondly, mixing sorghum, rice and corn according to a certain proportion, smashing, cooking, saccharifying, mixing the obtained grain saccharification solution with the tea leaf extracting solution, adding koji, and forming a tea leaf fermenting solution through liquid fermentation; finally, sterilizing, blending, fining, filtering, ageing and carrying out secondary filtration, thus obtaining the tea wine. The tea wine prepared by the method provided bythe invention has the characteristics that a product has strong tea fragrance, soft-sweet and mellow taste, coordinated smell, long after taste and the like; compared with traditional tea wine, the tea wine adopts the tea leaf extracting solution and the grain saccharification solution of the sorghum, the rice and the corn for common fermentation, so that functional activity components in the tealeaves are retained to the maximum; meanwhile, base wine blending is carried out after fermentation, the disadvantages that fermented wine is low in alcohol degree and distilled wine is complicated intechnology and spicy in taste are overcome, softness of tea and rigidity of wine are completely combined, and the varieties of tea leaf and wine products are enriched.

Owner:SHANYANG COUNTY JINQIAO TEA IND CO LTD

Flavor for improving taste of heated non-burning tobacco and preparation method and application thereof

InactiveCN108991588ANo precipitationFeasibility and reliable guaranteeTobacco preparationTobacco treatmentBENZYL ALCOHOL/WATERImpurity

The invention provides a flavor for improving the taste of heated non-burning tobacco and a preparation method and application thereof. The flavor is prepared by mixing the following raw materials, byweight percentage, 2-5% of fresh fruit extracts of Siraitia grosvenorii, 3-8% of Armeniaca mume extracts, 0.02-0.08% of menthol, 0.03-0.07 of menthyl acetate, 0.2-0.8% of acetic acid, 0.5-0.9% of lactic acid, 0.5-0.8% of benzyl alcohol, 2-6% of invert sugar, and the balance being propylene glycol. The flavor and a coating liquid are mutually soluble, and no impurities are precipitated. Accordingto the prepared heated non-burning tobacco made of a tobacco core material, the aroma is comfortable and natural during the smoking process, the smoke is soft and delicate, the mouth is clean, and thecomfort feeling is improved.

Owner:HUBEI CHINA TOBACCO IND

Sweet and fragrant compound feed flavoring agent and preparation method thereof

InactiveCN107279930AImprove bad smellHas a comprehensive tasteAnimal feeding stuffFood scienceEthyl phenylacetatePhenylacetic acid

The present invention discloses a sweet and fragrant compound feed flavoring agent and belongs to the technical field of animal feeds. The sweet and fragrant compound feed flavoring agent is prepared from the following raw materials in parts by mass: 1.0-50.0 parts of anhydrous sodium saccharin, 0.1-10.0 parts of neotame, 1.0-10.0 parts of a sweetness enhancement, 2.0-10.0 parts of citric acids, 5.0-10.0 parts of disodium nucleotide, 1.0-15.0 parts of a fragrance agent, 10.0-60.0 parts of silicon dioxide and 1.0-5.0 parts of maltodextrin. The fragrance agent is prepared from the following raw materials in parts by mass: 0.01-0.5 part of phenylacetic acid, 0.01-0.5 part of ethyl phenylacetate, 1.0-10.0 parts of ethyl vanillin, 1.0-5.0 parts of ethyl maltol, 0.1-0.5 part of furanone, 0.1-1 part of ethyl butyrate, 5.0-70.0 parts of propylene glycol and 10.0-20.0 parts of ethanol. At the same time, the present invention also discloses a preparation method of the feed flavoring agent. The flavoring agent prepared from the raw materials has a combination of fragrance and sweetness, and a comprehensive taste, can effectively correct a bad smell of the feeds, and can promote animal food intake.

Owner:成都大帝汉克生物科技有限公司

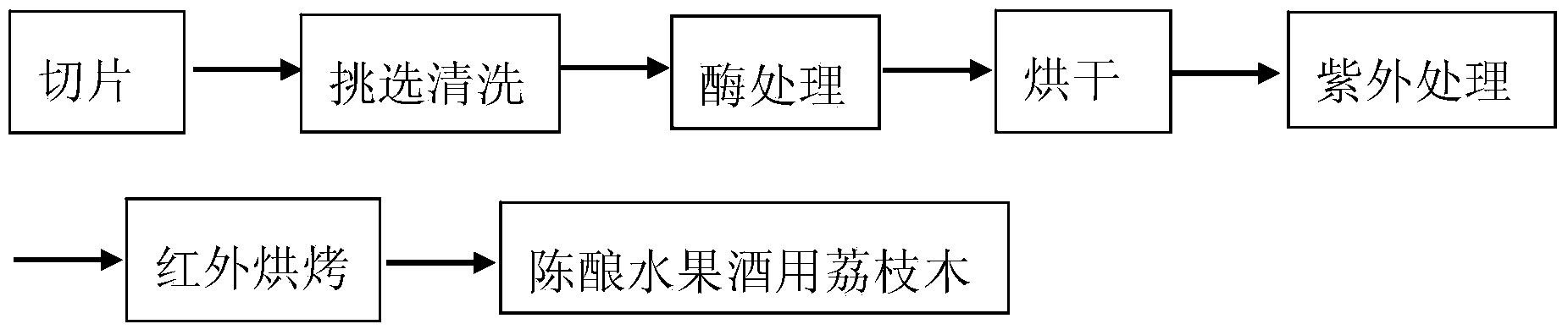

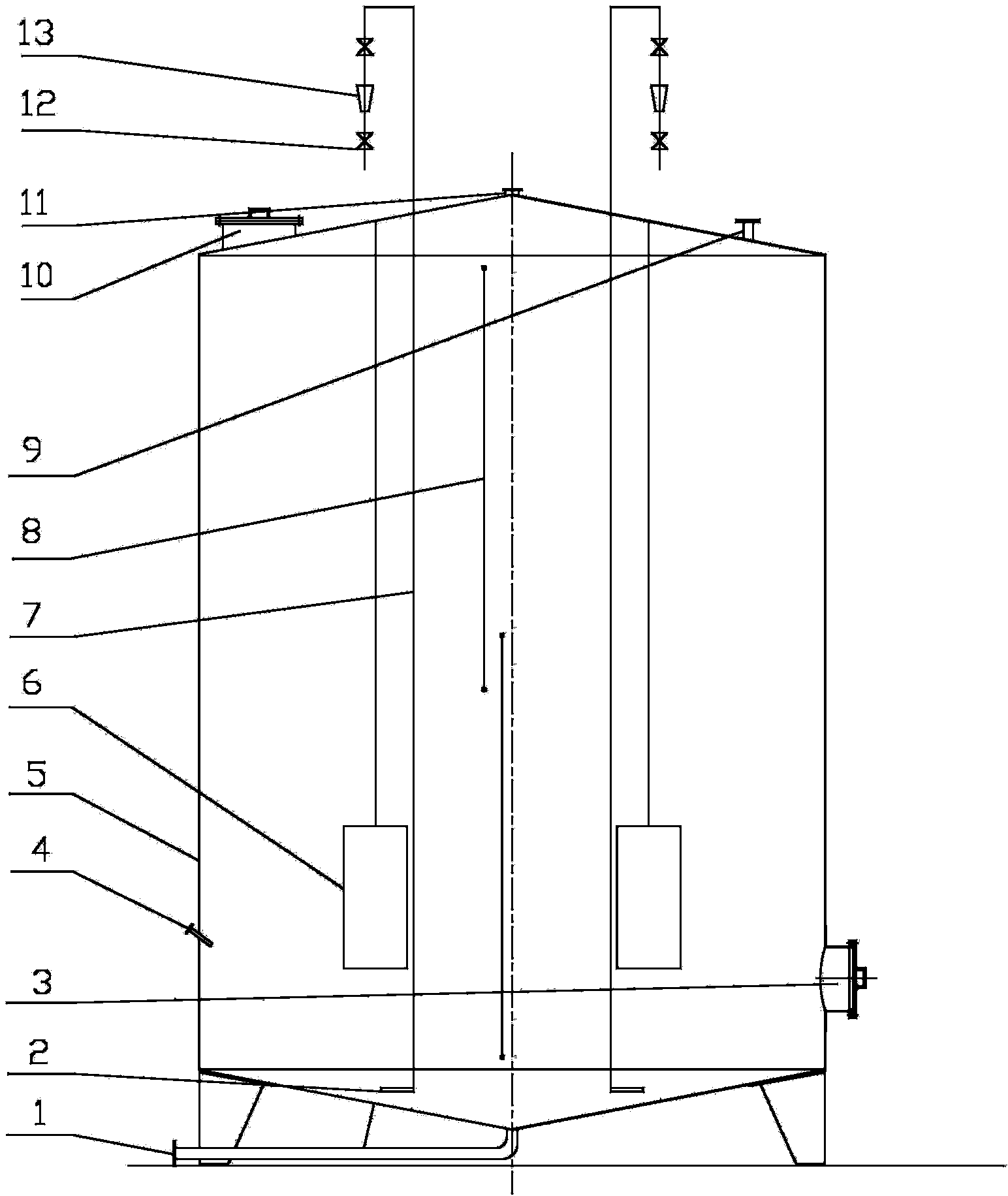

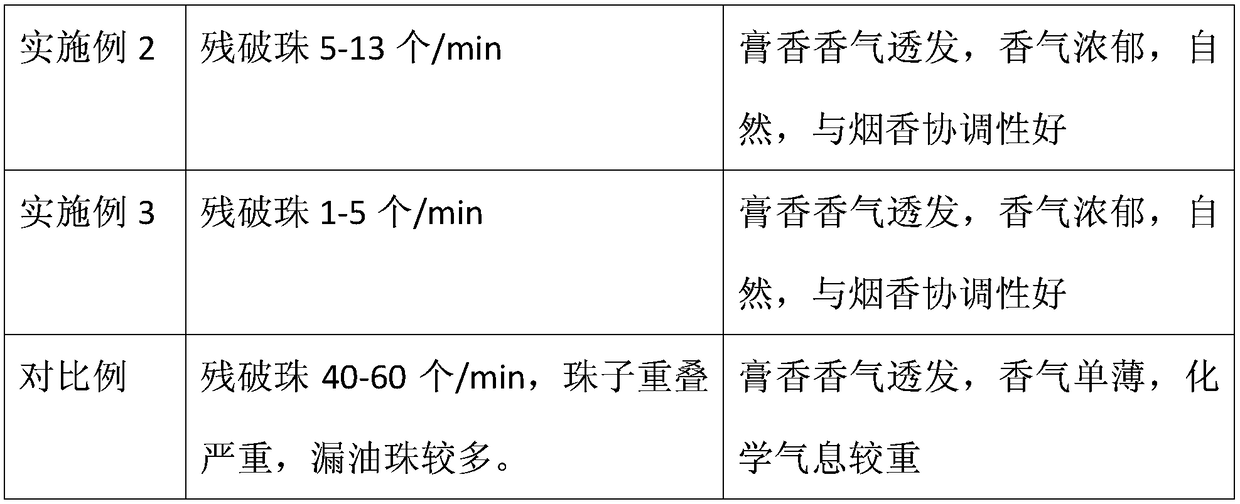

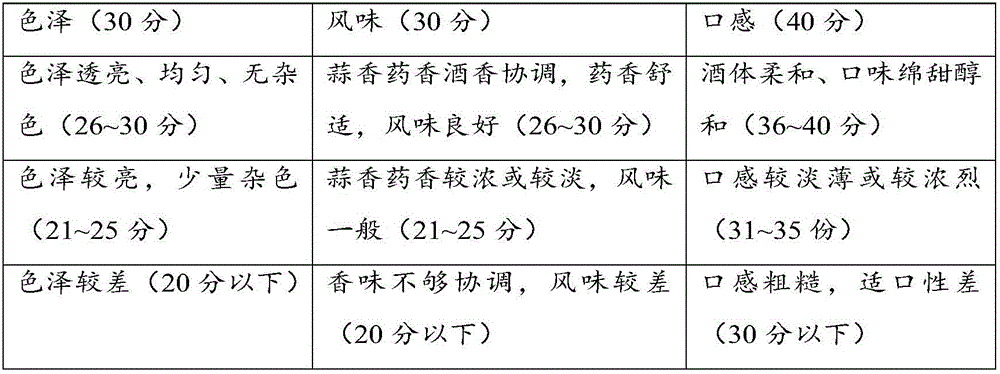

Litchi wood chip for ageing fruit wine, preparation and application process of litchi wood chip

ActiveCN103659975AUnique aromaHighlight featuresWood treatment detailsAlcoholic beverage preparationFruit wineAge method

The invention discloses a litchi wood chip for ageing fruit wine, preparation and application process of the litchi wood chip, and belongs to the field of fruit wine ageing technology. The invention further provides a preparation method of the litchi wood chip for ageing fruit wine, wherein novel ageing wood (accelerant) litchi wood is prepared to litchi wood chip for ageing fruit wine. The invention also provides the application process of the litchi wood chip for ageing fruit wine. According to the invention, the novel litchi wood chip for ageing fruit wine is adopted, the micro-oxygenation technology is utilized, and the litchi wood chip and litchi wood products are combined to enable fruit wine to mature within relatively short period, and endow the fruit wine with elegant and comfortable fragrance and soft and rich taste, and the litchi wood chip can be used for ageing various fruit wines. With adoption of the application process of the litchi wood in ageing fruit wine, the problems that the existing fruit wine ageing method consumes longer time, uses a large amount of containers, and is large in labor intensity and great in fruit wine loss, are solved.

Owner:广东省九江酒厂有限公司

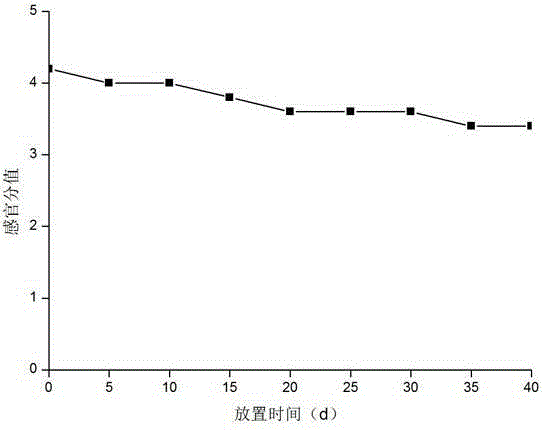

Lavender essence for aromatic leather, and preparation method and application thereof

InactiveCN105219529AComfortable aromaAroma harmonyEssential-oils/perfumesLeather surface finishingPolymer scienceOligosaccharide

The invention discloses a lavender essence for aromatic leather. The lavender essence is prepared from the raw materials of, by weight, 1-30% of lavender essence, 5-55% of composite modified oligosaccharide and the balance of deionized water. The invention also provides a preparation method of the above lavender essence for aromatic leather. According to the invention, lavender essence is mixed into composite modified oligosaccharide, such that essence molecules are cladded by the composite modified oligosaccharide, and the lavender nano-capsule sustained-release essence which can be applied in a leather finishing agent is prepared. The invention also provides the leather finishing agent comprising the lavender essence for aromatic leather. The lavender essence for aromatic leather is applied in leather finishing. With the finish, the aromatic leather has an ideal perfuming effect, and has a natural and harmonious aroma. When the leather is placed for 40 days, the aromatic leather has a good lavender aroma, and leather quality and grade can be substantially improved. The essence has a good market prospect.

Owner:SHANGHAI INST OF TECH

Method for making white spirit

InactiveCN101082019AHigh in acidHigh fat contentAlcoholic beverage preparationAlcohol contentHigh fat

The present invention relates to food producing technology, and is especially spirit producing liquid process and semi-liquid process. The spirit producing process includes the following steps: fermenting to obtain liquid fermented product, heating to sterilize, storing in a container for certain time, and distilling to obtain spirit. The spirit producing process is superior to available spirit producing liquid process and semi-liquid process in that the produced spirit has the advantages of high acid content, high fat content, low higher alcohol content, unique flavor and unique taste.

Owner:朱乙彬

Selenium-rich yeast wine and preparing method thereof

InactiveCN1233814CIncrease selenium contentHigh biological potencyAlcoholic beverage preparationFood additiveAlcohol

The invention relates to a selenium-enriched yeast wine and a process method thereof, which is prepared by the following components in weight ratio: 70-90 parts of white wine, 0.005-0.5 part of seasoning wine, and 10-30 parts of selenium source extract of selenium-enriched yeast part, 0.03-0.07 part of food additive for wine, and the content of water is added in an appropriate amount according to the alcohol content of original wine and finished wine. The selenium source extract of selenium-enriched yeast adopts alcohol extraction method. 1. Take 1 portion of selenium-enriched yeast, add 20-80 portions of ethanol at 25-60 degrees, extract at room temperature for 3-7 days, and separate solid and liquid to obtain Selenium source of selenium-enriched yeast; 2. Add 10-30 parts of selenium-enriched yeast extract to the original wine after blending, seasoning, and filtration to remove turbidity. Stir evenly and store for aging. After passing the inspection, filter and fill. Compared with the existing technology It has strong wine characteristics, basically maintains the style and characteristics of liquor, and is rich in selenium nutrients; the aroma of the liquor is elegant and comfortable, the taste is mellow and sweet, the aftertaste is refreshing, and the style is outstanding. It is a kind of rich nutrition and health. Selenium yeast wine.

Owner:太原酒厂有限责任公司

Litchi wood chips for aging fruit wine and its preparation and application technology

ActiveCN103659975BUnique aromaHighlight featuresWood treatment detailsAlcoholic beverage preparationFruit wineLychee fruit

The invention discloses a litchi wood chip for ageing fruit wine, preparation and application process of the litchi wood chip, and belongs to the field of fruit wine ageing technology. The invention further provides a preparation method of the litchi wood chip for ageing fruit wine, wherein novel ageing wood (accelerant) litchi wood is prepared to litchi wood chip for ageing fruit wine. The invention also provides the application process of the litchi wood chip for ageing fruit wine. According to the invention, the novel litchi wood chip for ageing fruit wine is adopted, the micro-oxygenation technology is utilized, and the litchi wood chip and litchi wood products are combined to enable fruit wine to mature within relatively short period, and endow the fruit wine with elegant and comfortable fragrance and soft and rich taste, and the litchi wood chip can be used for ageing various fruit wines. With adoption of the application process of the litchi wood in ageing fruit wine, the problems that the existing fruit wine ageing method consumes longer time, uses a large amount of containers, and is large in labor intensity and great in fruit wine loss, are solved.

Owner:广东省九江酒厂有限公司

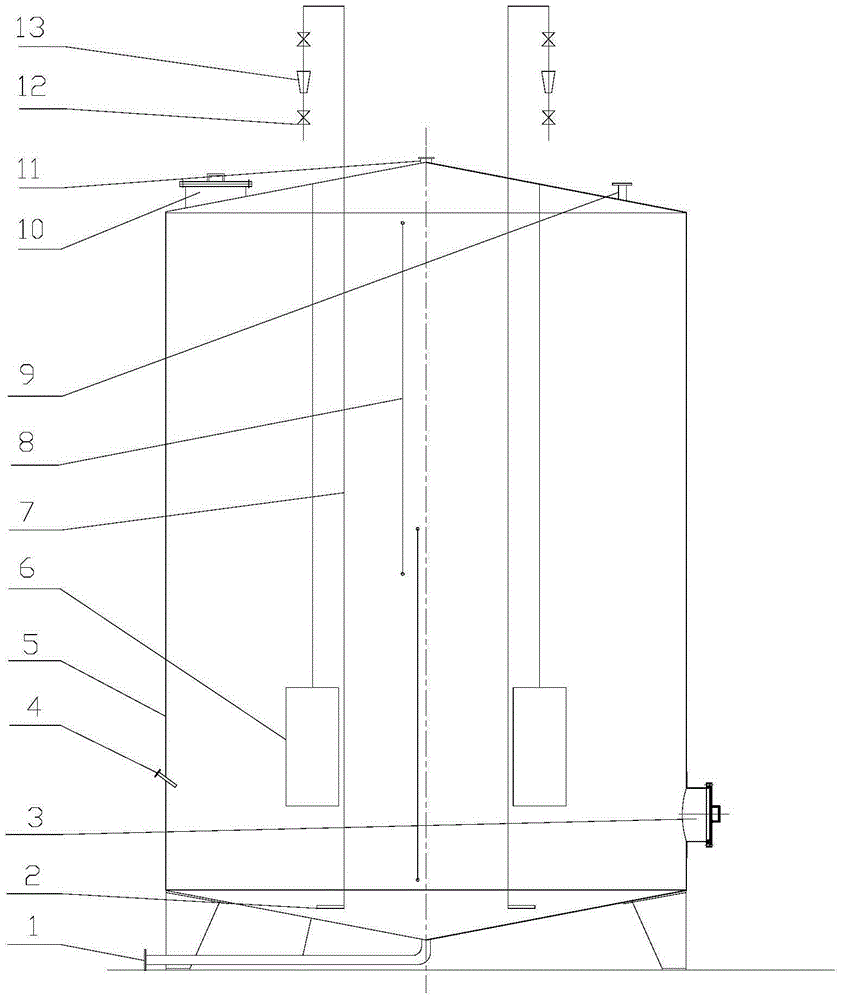

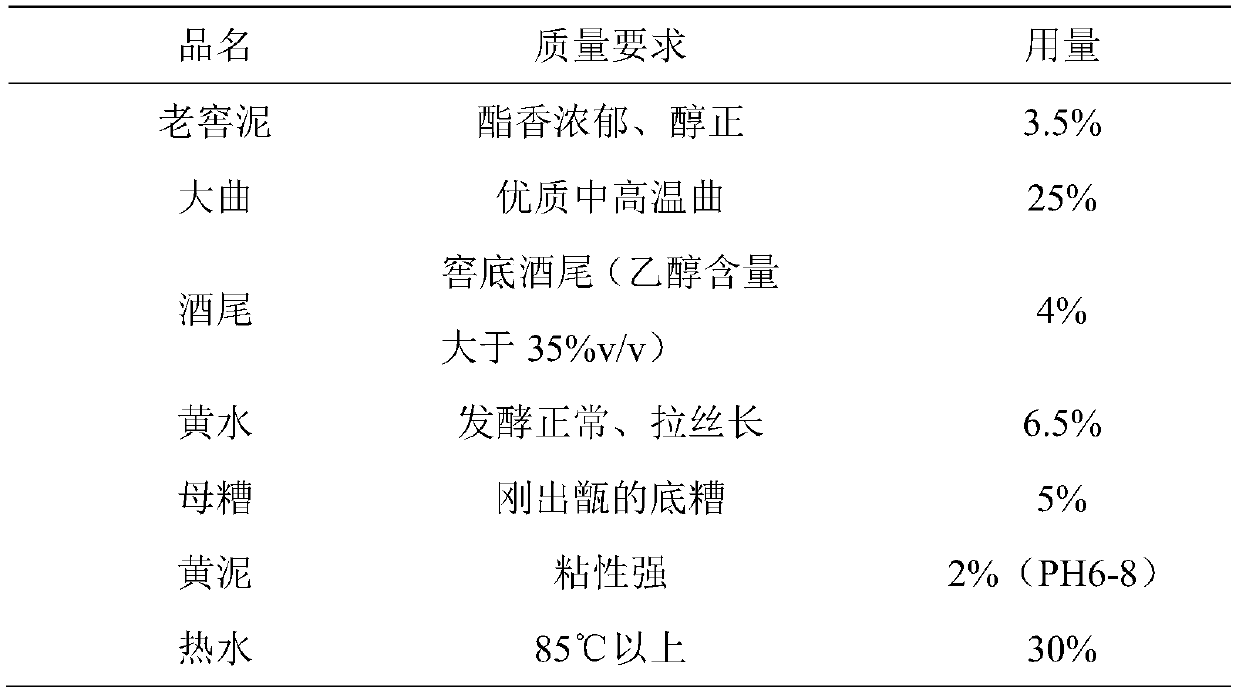

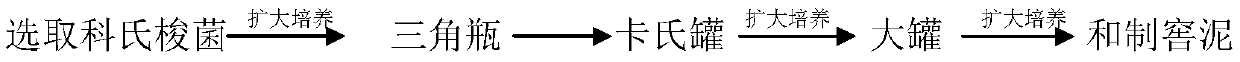

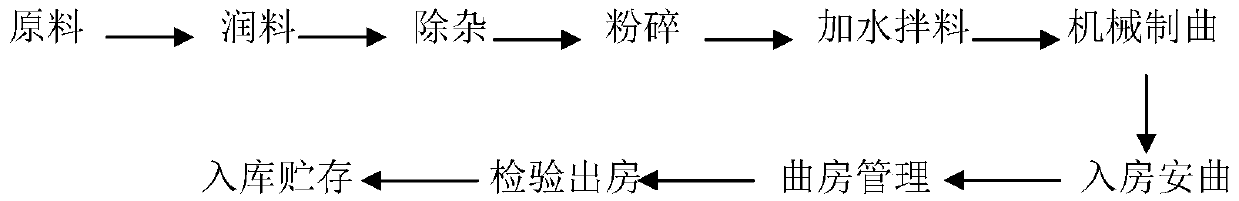

Organic pit mud for liquor brewing use and preparation technology thereof

PendingCN110669606AElegant aromaComfortable aromaAlcoholic beverage preparationBiotechnologyMicroorganism

The invention discloses organic pit mud for liquor brewing use and a preparation technology thereof. The organic pit mud for liquor brewing use is prepared from selected microorganism strain suitablefor pit mud culture isolated from high-quality old pit mud, and is prepared by the following steps: culturing the microorganism strain; carrying out amplification; carrying out mixing with pit mud; and adding organic matters (such as apples, pears, sesame seeds, soybeans and the like) as nourishments so as to carry out culturing to obtain the organic pit mud. The organic pit mud can be used for improving compound aroma mainly composed of ethyl hexanoate in Luzhou-flavor baijiu, so that high-quality liquor rate can be increased by 40-60% so as to have liquor quality effectively improved; and moreover, the defect that inorganic pit mud must be replacing every year due to liable function decline, as well as liable hardening and aging, of the inorganic pit mud in long-time usage.

Owner:山东百脉泉酒业股份有限公司

Bead-blasting base oil with natural cream fragrance and preparation method of base oil

InactiveCN109468173AEasy to integrateAdd lessTobacco preparationTobacco treatmentFlavorGlyceryl Caprate

The invention provides bead-blasting base oil with natural cream fragrance and a preparation method of the base oil. The specific preparation method of the bead-blasting base oil with natural cream fragrance comprises the following steps: taking storax and benzoin raw materials according to a weight ratio of 1-3 to 1-3, grinding into a powder, and uniformly mixing to prepare natural perfume mixedmaterials; adding caprylic / capric glycerides in an amount of 50-300 times that of the mixed raw materials, soaking at a normal temperature for 8-24 hours, performing ultrasonic treatment under the condition of a temperature of 50-60 DEG C for 1-4 hours, and filtering to remove impurities and insoluble substances, so as to obtain the bead-blasting base oil with natural cream fragrance. According tothe method disclosed by the invention, two traditional Chinese herbal medicines enriched in cream fragrance, namely the storax and benzoin, are applied to cigarette blasting beads, the addition amount is extremely small, but obvious cream fragrance can be brought, and the aroma is strong, comfortable and natural. The prepared base oil is stable in property, is not reacted with a wall material, and well solves the problems that aroma brought by adding synthetic perfume into bead-blasting base oil is slight and formation is unstable.

Owner:HUBEI CHINA TOBACCO IND

Garlic healthcare wine and production method thereof

InactiveCN106754136AEffective dissolutionShorten the production cycleDigestive systemAlcoholic beverage preparationLiquid ratioAdditive ingredient

The invention provides garlic healthcare wine and a production method thereof and relates to the technical field of compound wine. The production method includes: soaking traditional Chinese medicine materials into Baijiu with alcoholic strength being 30-45%Vol according to material-liquid ratio of 45-75g / L in a sealed manner for 7-14 days, wherein the traditional Chinese medicine materials comprise fructus crataegi, rhizoma polygonati, radix pueraiae, fructus lycii and semen cassiae; soaking garlic into Baijiu with alcoholic strength being 30-45%Vol according to material-liquid ratio of 85-115g / L in a sealed manner for 7-14 days; mixing two wine liquid to obtain the garlic healthcare wine. The garlic healthcare wine and the production method thereof have the advantages that the garlic healthcare wine is low in alcoholic strength, harmless and nonirritant to human bodies, rich in effective components of garlic and various traditional Chinese medicine materials and good in healthcare effect; the production method is simple in process, convenient to operate and suitable for large-scale production, and the produced garlic healthcare wine is gentle, good in taste and is a good daily healthcare product.

Owner:GANSU BINHE FOOD IND GRP

Grape essence for aromatic leather, and preparation method and application thereof

InactiveCN105219528AComfortable aromaAroma harmonyEssential-oils/perfumesCoatingsPolymer scienceOligosaccharide

The invention discloses a grape essence for aromatic leather. The grape essence is prepared from the raw materials of, by weight, 1-40% of grape essence, 3-50% of composite modified oligosaccharide and the balance of deionized water. The invention also provides a preparation method of the above grape essence for aromatic leather. According to the invention, grape essence is mixed into composite modified oligosaccharide, such that essence molecules are cladded by the composite modified oligosaccharide, and the grape nano-capsule sustained-release essence which can be applied in a leather finishing agent is prepared. The invention also provides the leather finishing agent comprising the grape essence for aromatic leather. The grape essence for aromatic leather is applied in leather finishing. With the finish, the aromatic leather has a natural and harmonious aroma. When the leather is placed for 40 days, the aromatic leather has a good and long-lasting grape aroma.

Owner:SHANGHAI INST OF TECH

Litchi wood chips for aging brandy and its preparation and application technology

ActiveCN103659974BUnique aromaHighlight featuresWood treatment detailsAlcoholic beverage preparationBiotechnologyFruit wine

Owner:广东省九江酒厂有限公司

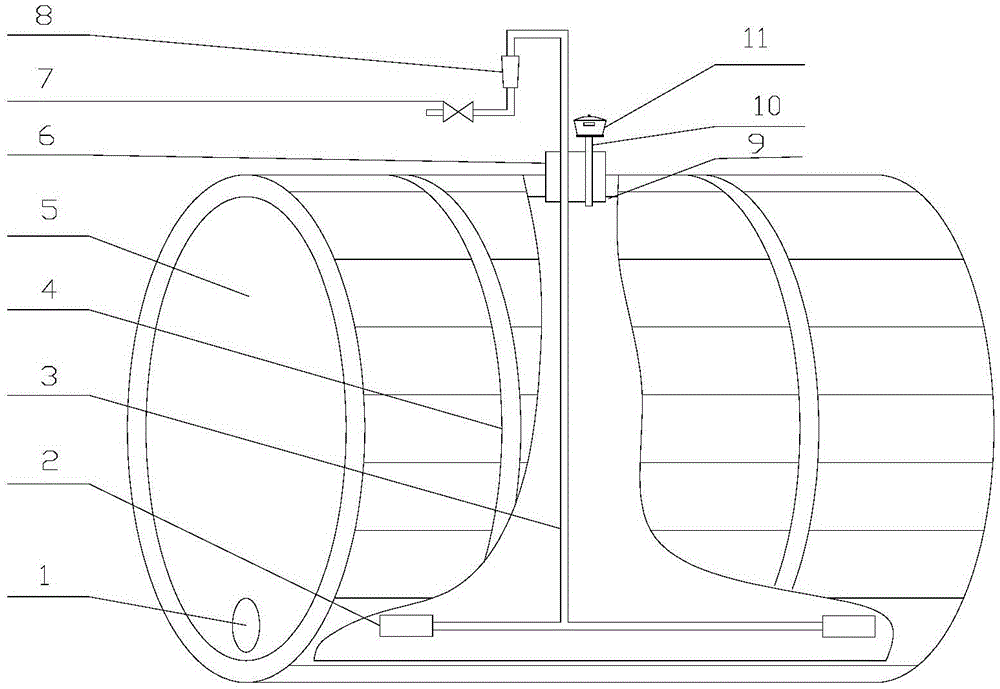

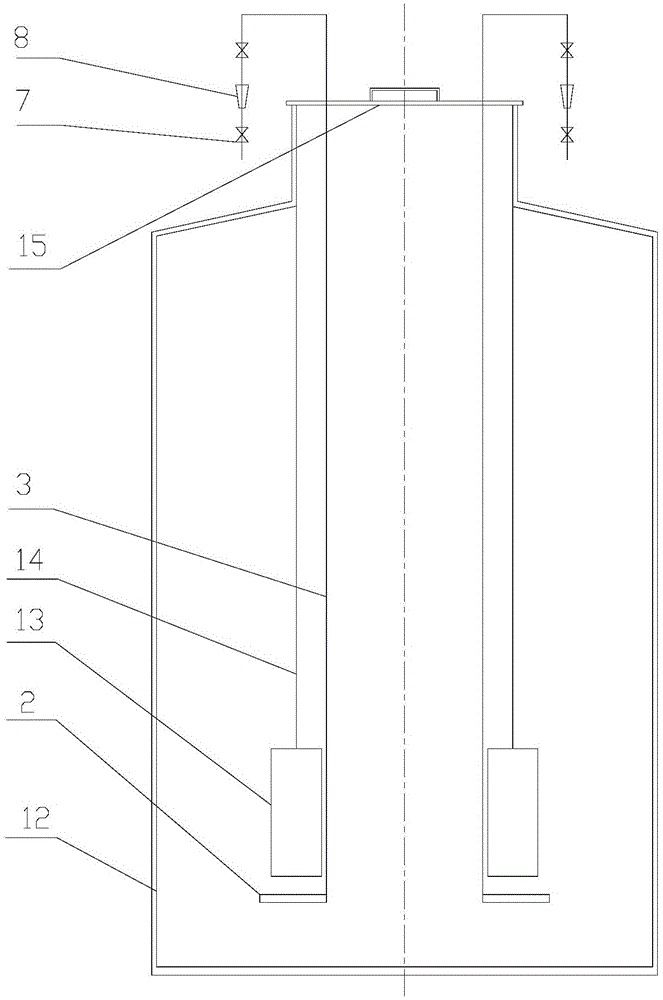

Preparation method of ice blast base oil with natural pungent and sweet note

InactiveCN109468175AIntense Spicy and Sweet AromaImprove heat stabilityTobacco preparationTobacco treatmentFlavorRoom temperature

The invention provides a preparation method of ice blast base oil with natural pungent and sweet note. The preparation method of the ice blast base oil comprises the following specific preparation steps: mixing raw materials of radix saposhnikoviae and ramulus cinnamomi and adding tap water, soaking at room temperature for 8 to 24 hours, heating, refluxing and extracting at normal pressure for 1 to 5 hours, collecting distillate by using a condenser, carrying out oil and water separation to obtain volatile oil, then dissolving the volatile oil into polyglycerol fatty acid ester of which the weight is 1000 to 10000 times that of the volatile oil, adding Tween 60 of which the weight accounts for 0.1 to 1 per mill that of the mixture into the mixture, filtering to remove impurities and insolubles, collecting filtrate, and carrying out ultrasonic treatment at 20 to 60 DEG C or below to obtain the ice blast base oil with the natural pungent and sweet note. The ice blast base oil disclosed by the invention can bring obvious pungent and sweet note, strong aroma, as well as comfortable and nature property by using extremely-low dosage of the radix saposhnikoviae and the ramulus cinnamomi in cigarette ice blast; in addition, the prepared ice blast base oil has good compatibility with a wall material, so that the problems of thin aroma and unstable molding caused by the addition of synthetic spices into the ice blast base oil can be well solved.

Owner:HUBEI CHINA TOBACCO IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com