Patents

Literature

1046results about How to "Improve heat stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

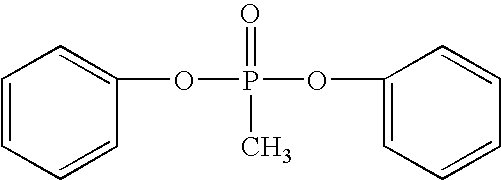

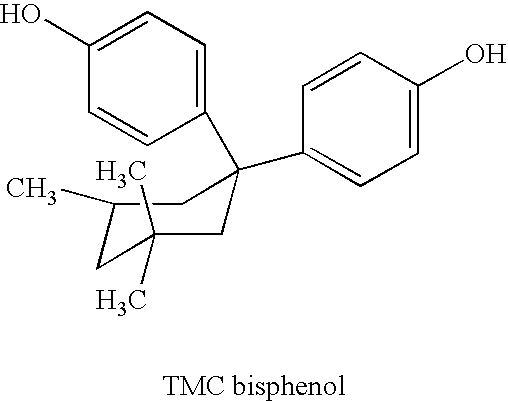

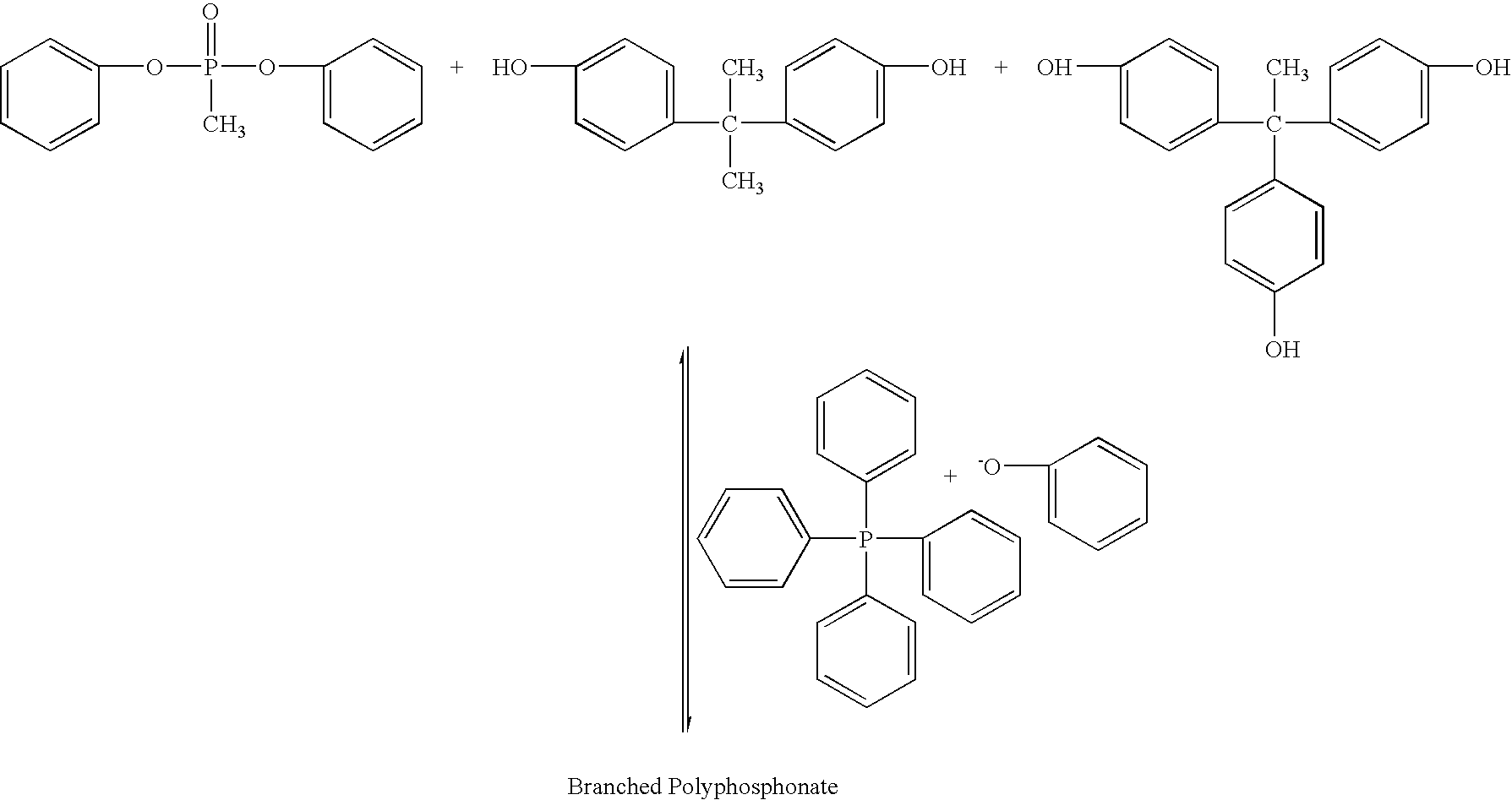

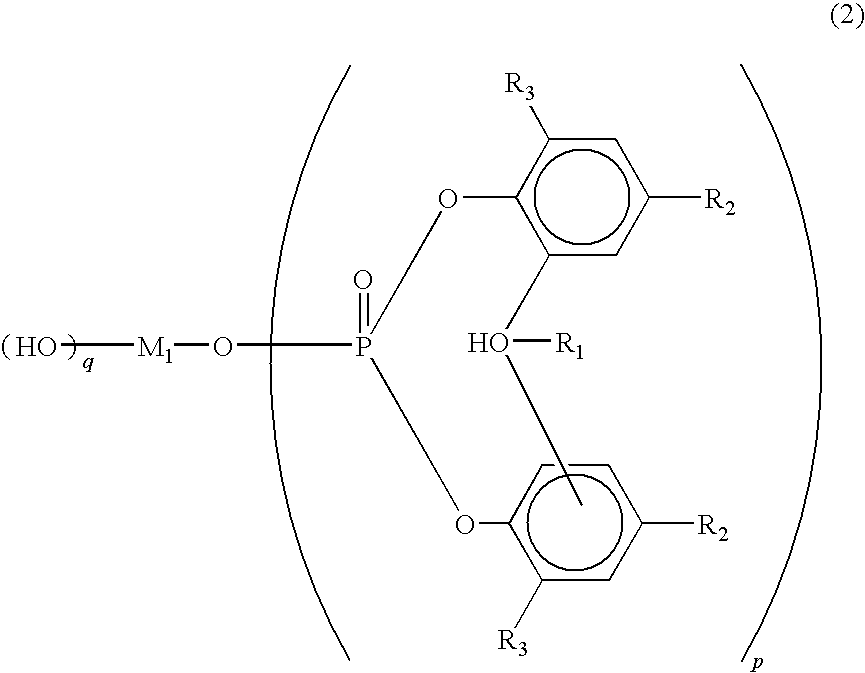

Branched polyphosphonates that exhibit an advantageous combination of properties, and methods related thereto

Disclosed are branched polyphosphonates produced via a superior transesterification process, and methods related thereto. These branched polyphosphonates exhibit a unique and advantageous combination of properties, such as outstanding fire resistance, improved heat stability, improved toughness, and superior processing characteristics. Also disclosed are polymer compositions that comprise these branched polyphosphonates and at least one other polymer, wherein the resulting polymer compositions exhibit flame retardant properties. Further disclosed are articles of manufacture produced from these polymers, such as fibers, films, coated substrates, moldings, foams, fiber-reinforced articles, or any combination thereof; these articles may be coated with a moisture barrier to enhance their moisture resistance properties.

Owner:FRX POLYMERS LLC

Method of denaturing whey protein

InactiveUS20110003975A1Improve textureGreat tastePeptide preparation methodsDepsipeptidesOrganic solventWhey protein

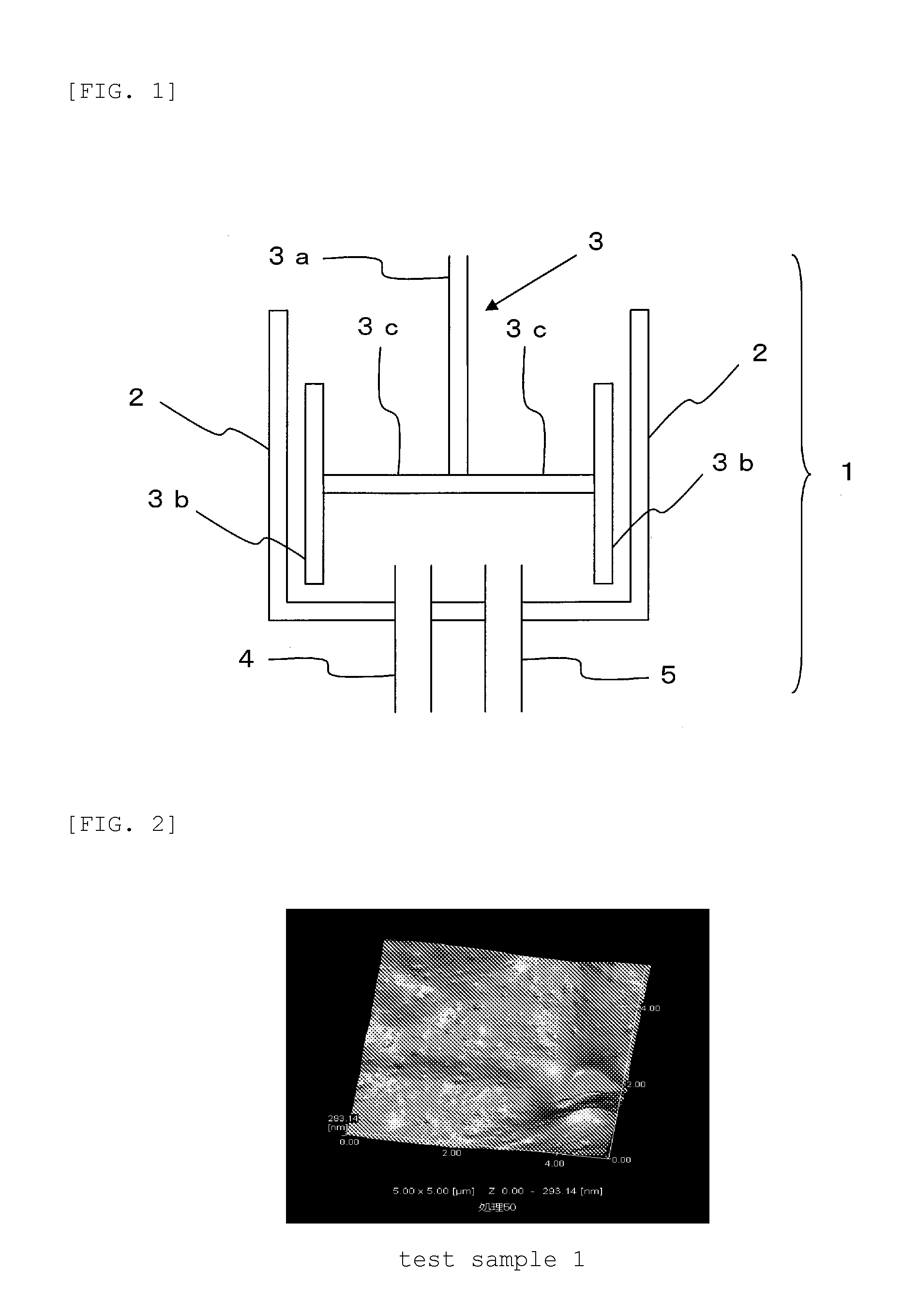

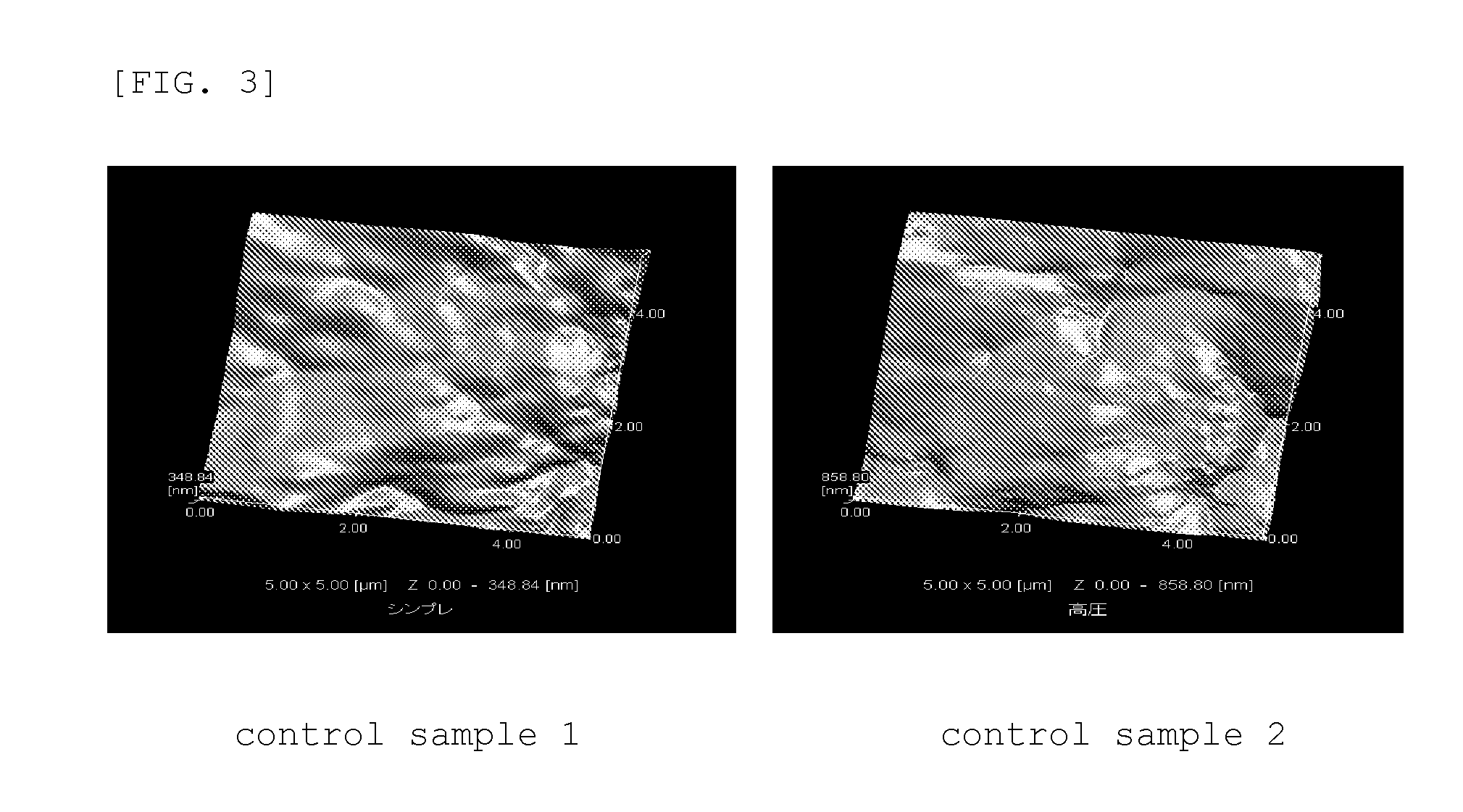

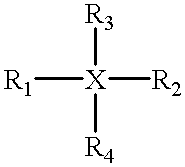

Provided is a method of producing a denatured whey protein which has an improved heat stability without using an additive such as an organic solvent. Also provided is a denatured whey protein produced by this method. A method of producing a denatured whey protein which comprises contacting and mixing a whey protein solution with a whey protein solution that is flowing as a thin film in the form of a rotating cylinder, and thus shearing the same at a temperature ranging form 76 to 120° C. at a shear speed of 5,000 s−1 to 25,000 s−1 for 8 minutes to 0.1 second; and a denatured whey protein obtained by this method.

Owner:MORINAGA MILK IND CO LTD

Intercalates formed with polypropylene/maleic anhydride-modified polypropylene intercalants

InactiveUS20010033924A1Good dispersionImprove distributionThin material handlingWater-setting substance layered productPolyolefinPolymer science

A nanocomposite concentrate composition comprising about 10 weight percent to about 90 weight percent of a layered silicate material and about 10 weight percent to about 90 weight percent of a matrix polymer comprising about 90-99.8% by weight of a polyolefin and about 0.2% to about 10%, preferably about 0.2% to about 3%, more preferably about 1% to 3% by weight, of a maleic anhydride-modified polyolefin, based on the total weight of polyolefins, wherein the layered silicate material is dispersed uniformly throughout the matrix polymer. Shearing of the concentrate and later (after shear) addition of an added matrix polymer avoids thermal degradation of the added matrix polymer and optimizes the dispersion of the nanomer throughout the matrix polymer; provides increased tensile strength; and reduces degradation of the polymer by melt formation of a concentrate thereby decreasing heat degradation of added matrix polymer.

Owner:AMCOL INTERNATIONAL CORPORATION

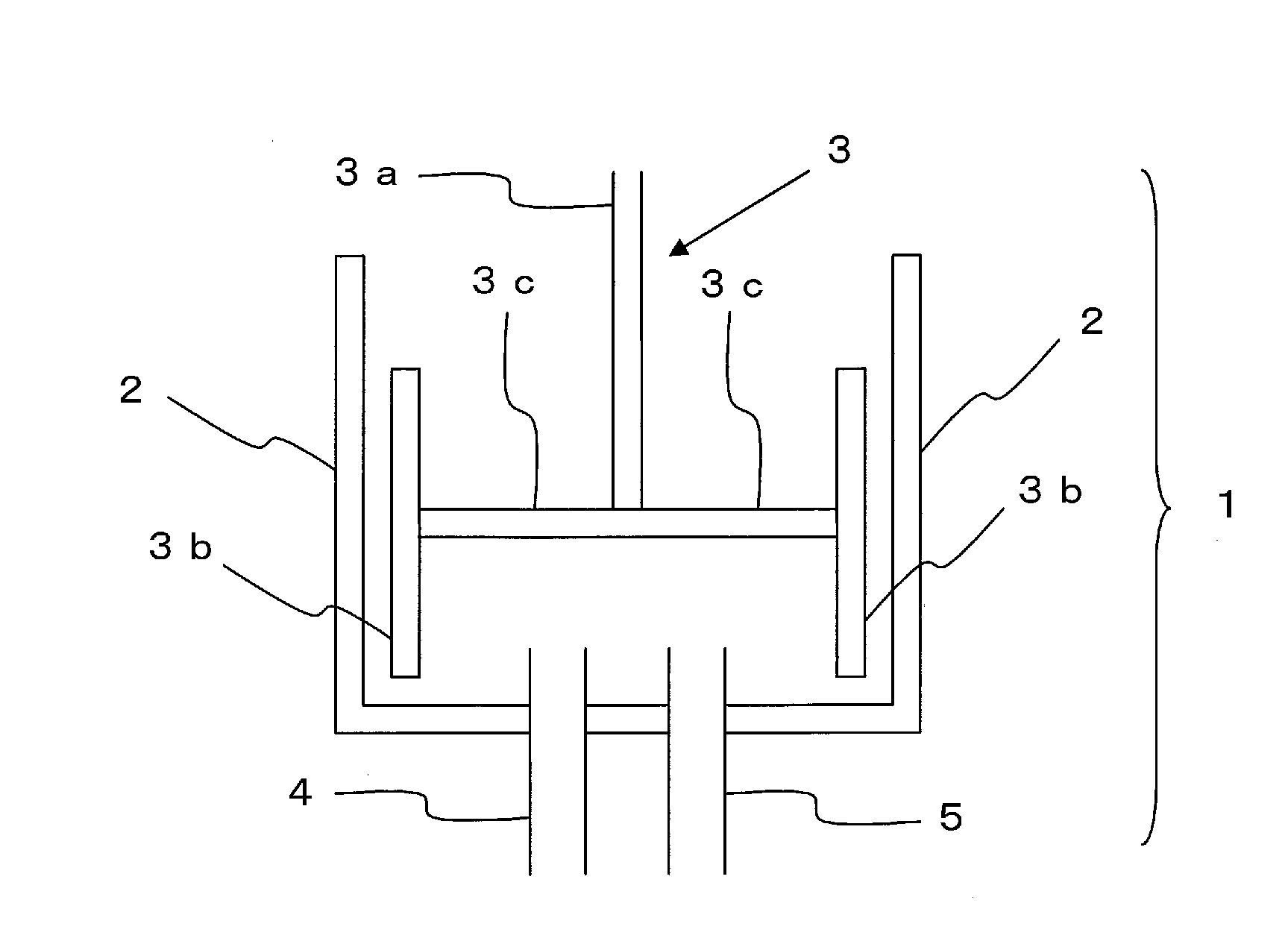

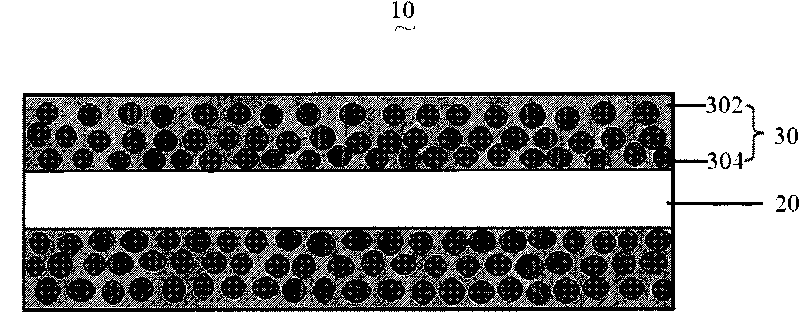

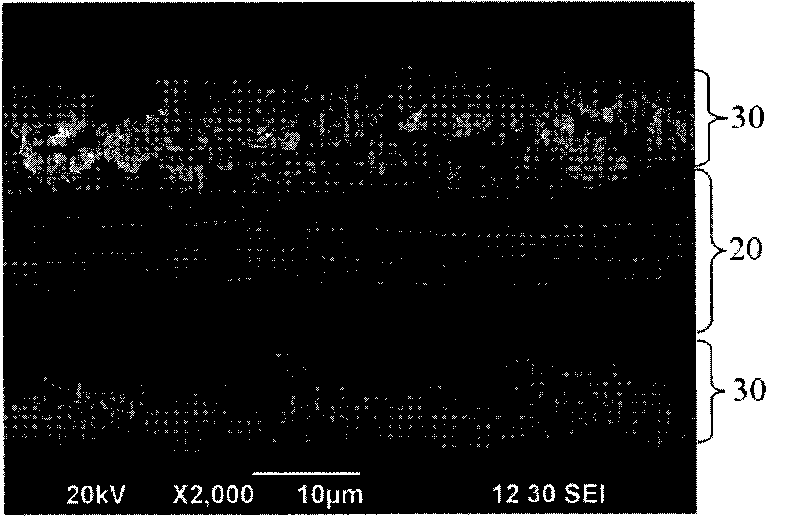

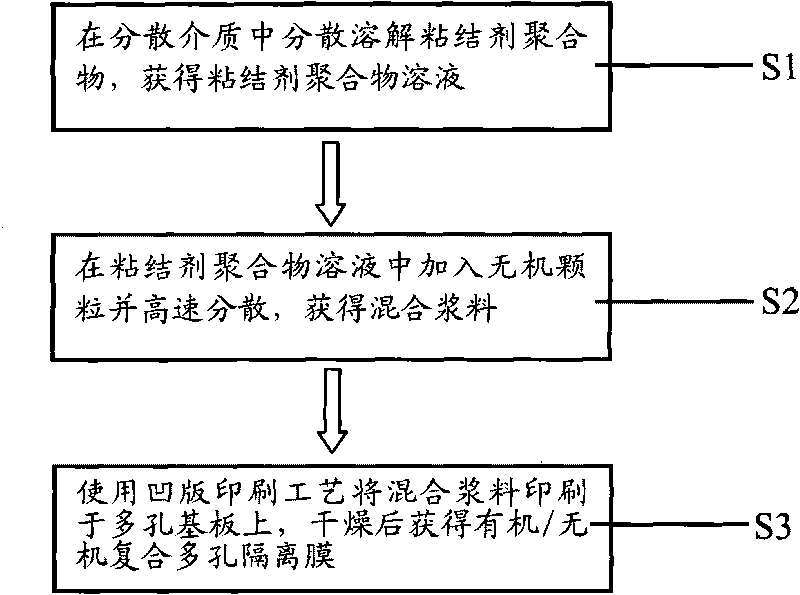

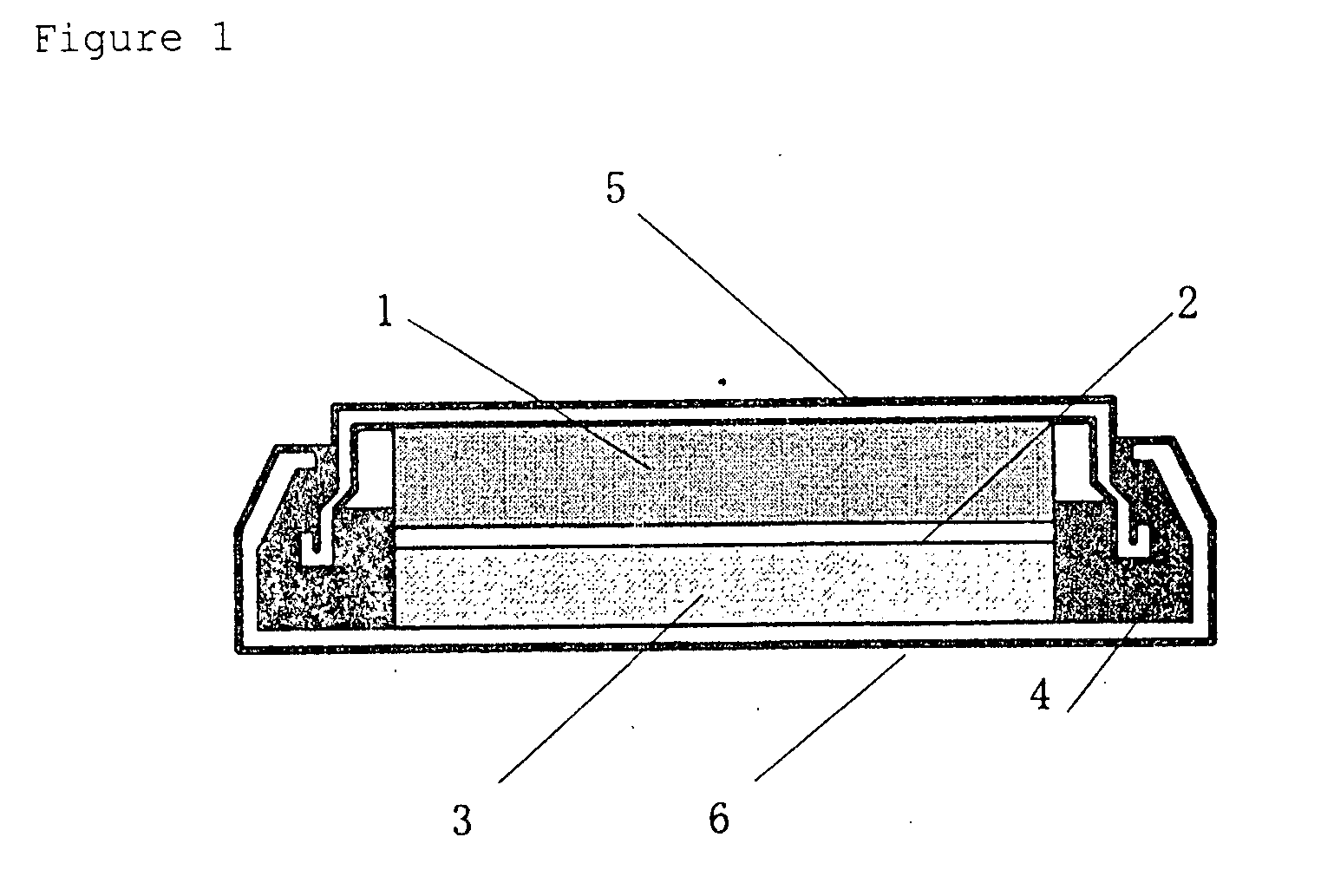

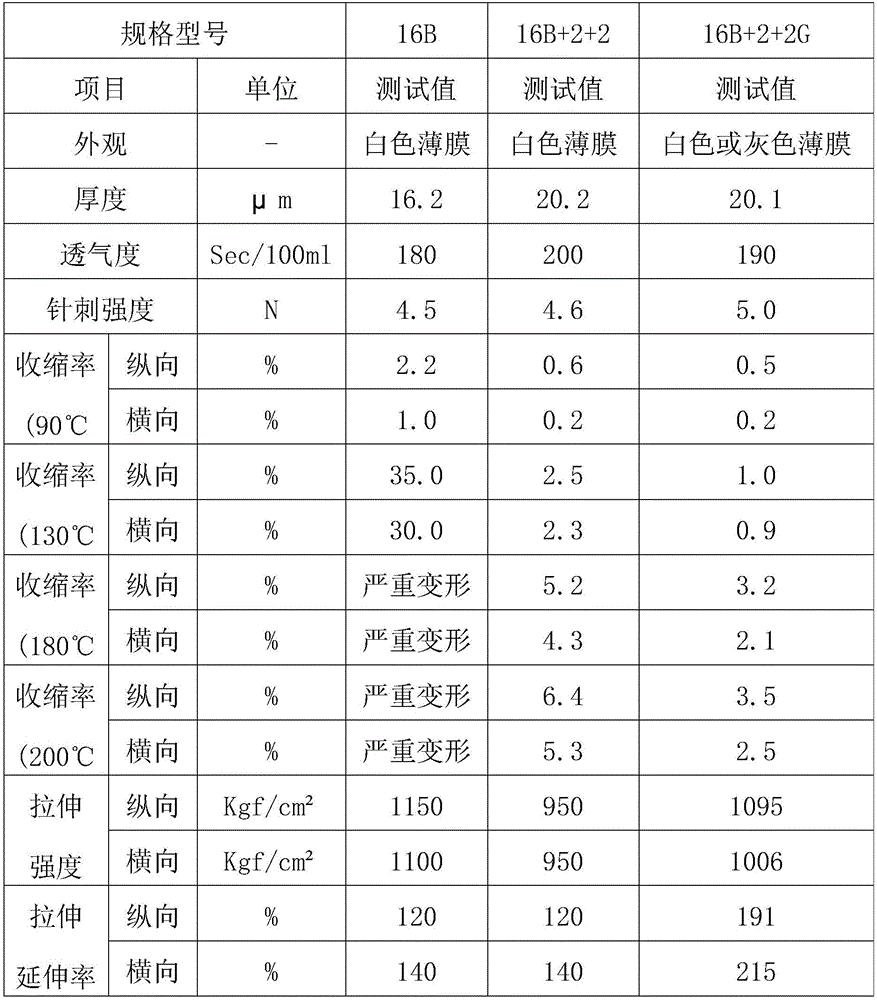

Organic/inorganic composite porous isolating membrane

InactiveCN101707242AHigh thermomechanical stabilityImprove heat stabilitySynthetic resin layered productsSecondary cellsPorous substrateInorganic particle

The invention discloses an organic / inorganic composite porous isolating membrane, which comprises a porous substrate with holes, and an organic / inorganic composite layer arranged on at least one surface or a partial surface area of the porous substrate, wherein the organic / inorganic composite layer is a layer of a mixture of inorganic particles and adhesive polymer; the inorganic particles are interconnected and are fixed through the adhesive polymer; and gaps among the inorganic particles form holes. In the organic / inorganic composite layer of the organic / inorganic composite porous isolating membrane, a weight ratio of the inorganic particles with good thermol stability to the adhesive polymer is between 80 percent: 20 percent and 99.5 percent: 0.5 percent; and the organic / inorganic composite layer has good supporting function. Therefore, the organic / inorganic composite porous isolating membrane has high thermo-mechanical stability.

Owner:DONGGUAN AMPEREX TECH

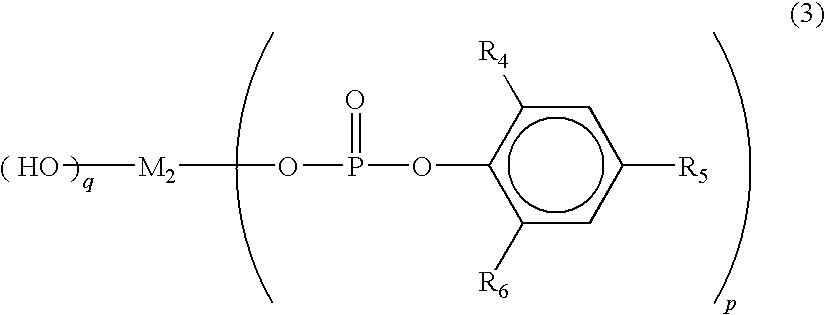

Polylactic acid composition

InactiveUS20100093888A1High crystallinityImprove heat stabilityPlastic/resin/waxes insulatorsGroup 5/15 element organic compoundsPhosphoric Acid EstersPolymer science

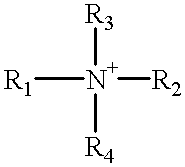

It is an object of the present invention to provide a polylactic acid composition having excellent crystallinity, wet heat stability and melt stability. It is another object of the present invention to provide a molded article which is obtained from the polylactic acid composition and excellent in appearance and color. The present invention is a composition and molded article thereof which comprises a polylactic acid (component A), a carbodiimide compound (component B) and a phosphoric acid ester metal salt (component C).

Owner:TEIJIN LTD +1

Cu-Al2O3 nano strengthened dispersion alloy and preparation method thereof

The invention relates to a Cu-Al2O3 nanometer dispersion strengthening alloy and preparation thereof. The preparation includes the steps of Cu-Al alloy vacuum smelting, pulverizing, screening, internal oxidizing, hydrogen reducing, vacuum hot pressing, canned hot extruding, etc. Comparing with oxygen-free copper, sigma of the alloy of the invention is 2 to 6 times higher that of the oxygen-free copper, the anti-annealing softening temperature is up to over 900 DEG C, the conductivity is up to 96% IACA and more. The process of the invention is simple, the prepared Cu-Al2O3 nanometer dispersion strengthening alloy has high strength, high conductivity, electrical conductivity higher than 96% IACA, and is anti-annealing and antimagnetic. The alloy can not only used for large-scale integrated circuit lead frame, manufacturing of controlled thermonuclear reaction heat sink components, and is expecially suitable for manufacturing of microwave tube grid mesh, inertial instrument sensor, particle accelerator and other high-precise parts.

Owner:CENT SOUTH UNIV

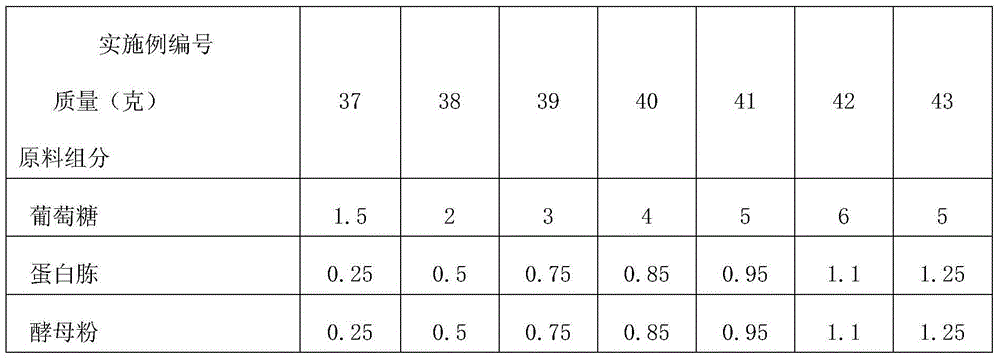

Preparation method of hypha/nanoparticle composite sphere material

InactiveCN104785216AHigh activityImprove stabilityOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsFiltrationFreeze-drying

The invention discloses a preparation method of a hypha / nanoparticle composite sphere material. The preparation method is characterized by comprising steps as follows: preparing a culture medium; adding 4-20 ml of a nanoparticle aqueous solution containing 1-10 mg of nanoparticles per milliliter to the sterilized liquid culture medium, evenly mixing the mixture, inoculating the mixture with strains, culturing the mixture for 48-96 h under conditions that the temperature is 15-35 DEG C and rotating oscillation is performed at the speed of 80-200 r / min to form a hypha / nanoparticle composite sphere material, performing filtration to remove a liquid, soaking solids, namely, hypha / nanoparticle composite spheres, with a sodium hydroxide aqueous solution for 12 h, washing the spheres with deionized water until the spheres are neutral, and then performing freeze-drying to prepare the hypha / nanoparticle composite sphere material. The composite sphere material prepared with the method is applicable to fields of industrial catalysis, wastewater treatment, biomedicine and the like and has the characteristics of low cost, high activity, easiness in recovery and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

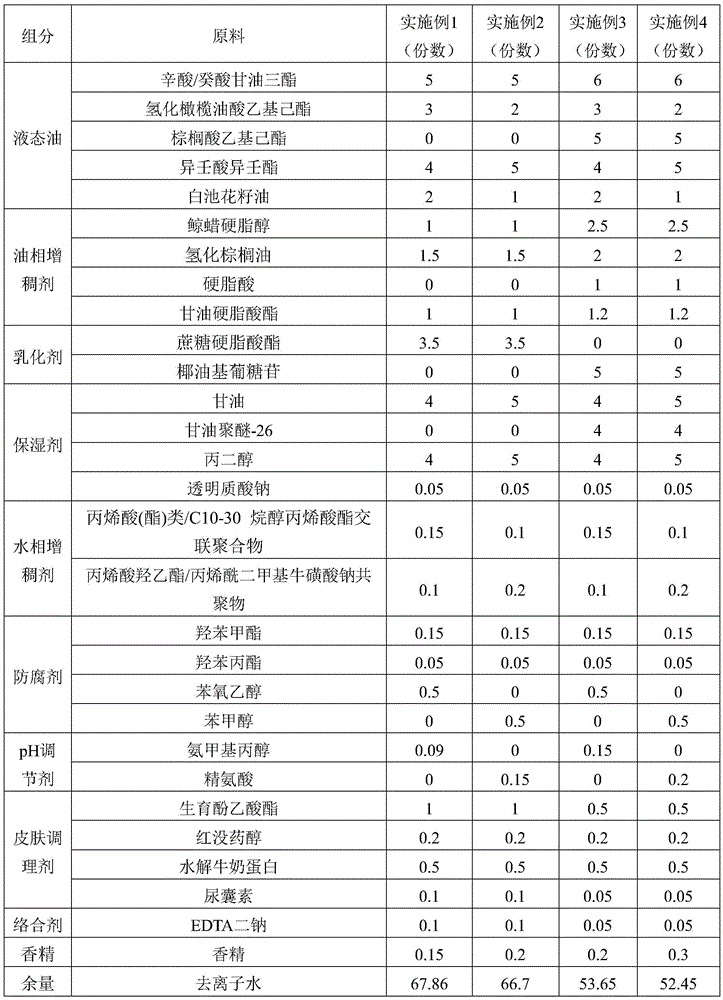

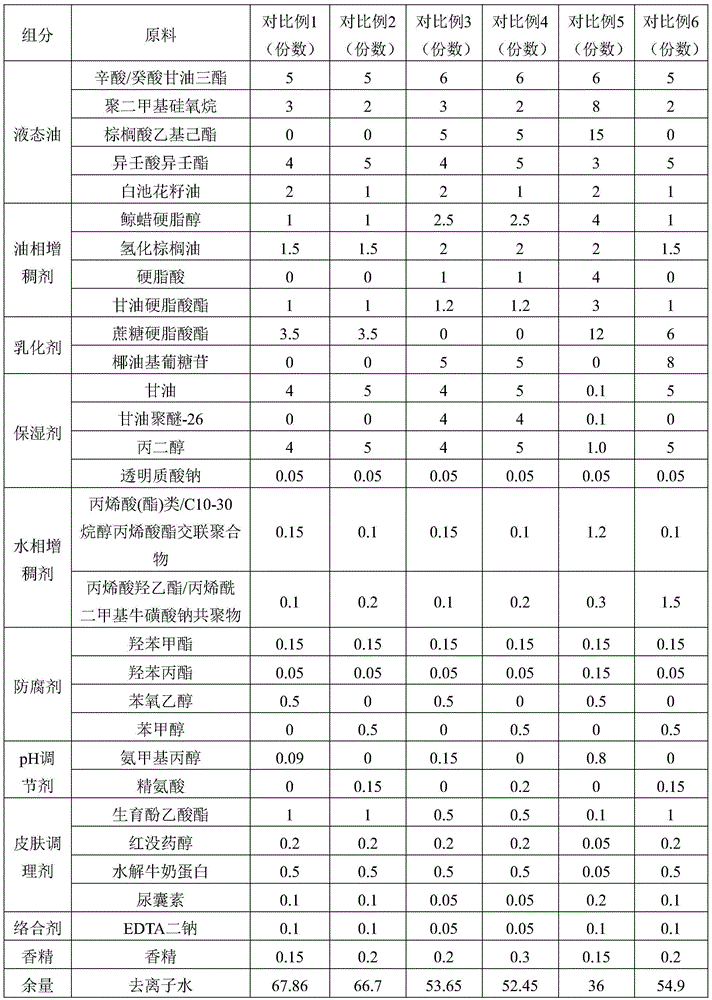

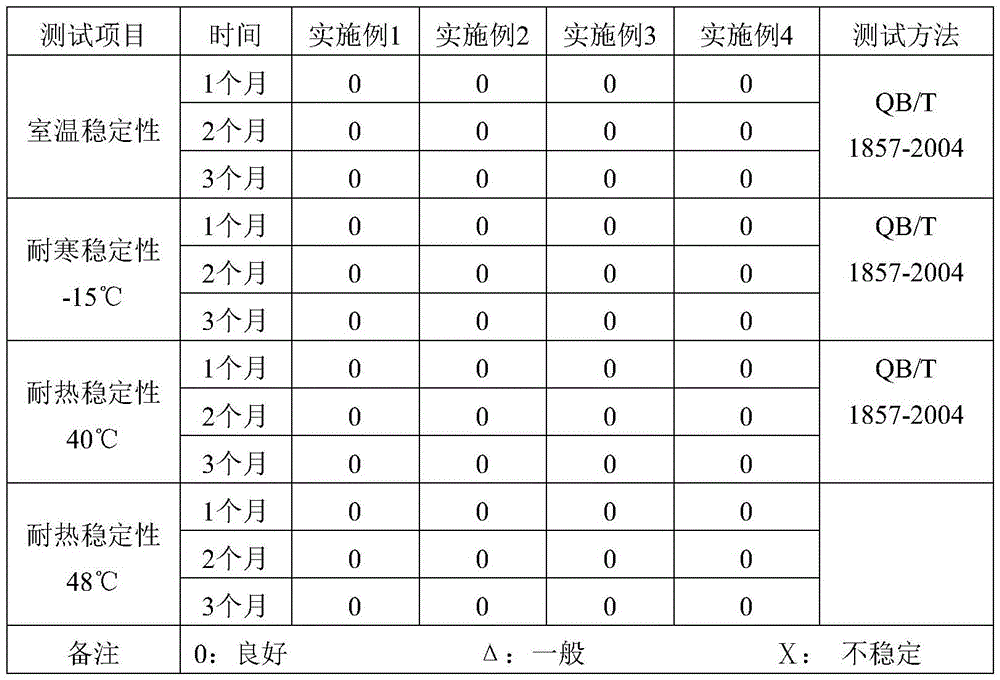

Emulsion cream and preparing method thereof

InactiveCN105456176AImprove heat stabilityExcellent stickinessCosmetic preparationsToilet preparationsOil phaseSilicone oil

The invention provides emulsion cream and a preparing method thereof. The emulsion cream is prepared from, in units of the total weight of emulsion cream, 0.1-10% of an emulsifying agent, 0.5-25% of a humectant, 0.01-1% of an aqueous-phase thickening agent, 0.1-10% of an oil-phase thickening agent, 1-30% of fluid oil, 0.01-5% of a skin conditioner and 20-85% of water, and preferably, the emulsion cream is prepared from 3-6% of the emulsifying agent, 5-15% of the humectant, 0. 1-0.5% of the aqueous-phase thickening agent, 1-6% of the oil-phase thickening agent, 10-15% of the fluid oil, 0.5-2% of the skin conditioner and 55.5-80% of the water. The emulsion cream is free of silicone oil, mild, easy to degrade in the human body, free of accumulation, environmentally friendly, nontoxic and harmless and has good emulsifying capacity and does not stimulate the skin.

Owner:GUANGZHOU KENENG COSMETICS RES CO LTD +2

Positive electrode active material for non-aqueous electrolyte-based secondary battery, production method therefor and non-aqueous electrolyte-based secondary battery using the same

ActiveUS20070231691A1Large capacityLow costNon-aqueous electrolyte accumulatorsActive material electrodesAir atmosphereHeat stability

The present invention provides a positive electrode active material for a non-aqueous electrolyte-based secondary battery, composed of a lithium / nickel composite oxide with high capacity, low cost and excellent heat stability, an industrially suitable production method therefor, and a high safety non-aqueous electrolyte-based secondary battery. A lithium / nickel composite oxide is produced by the following steps (a) to (c): (a) Nickel hydroxide or nickel oxyhydroxide having a specified component is prepared at a temperature of 600 to 1100° C., under air atmosphere. (b) Fired powders are prepared after mixing said nickel oxide and a lithium compound, and then by firing at a maximal temperature range of 650 to 850° C., under oxygen atmosphere. (c) Obtained fired powders are washed with water within a time satisfying the following equation (2) and then filtered and dried. A<B / 40 (2) wherein, A represents washing time represented by unit of minute; and B represents slurry concentration represented by unit of g / L).

Owner:SUMITOMO METAL MINING CO LTD +1

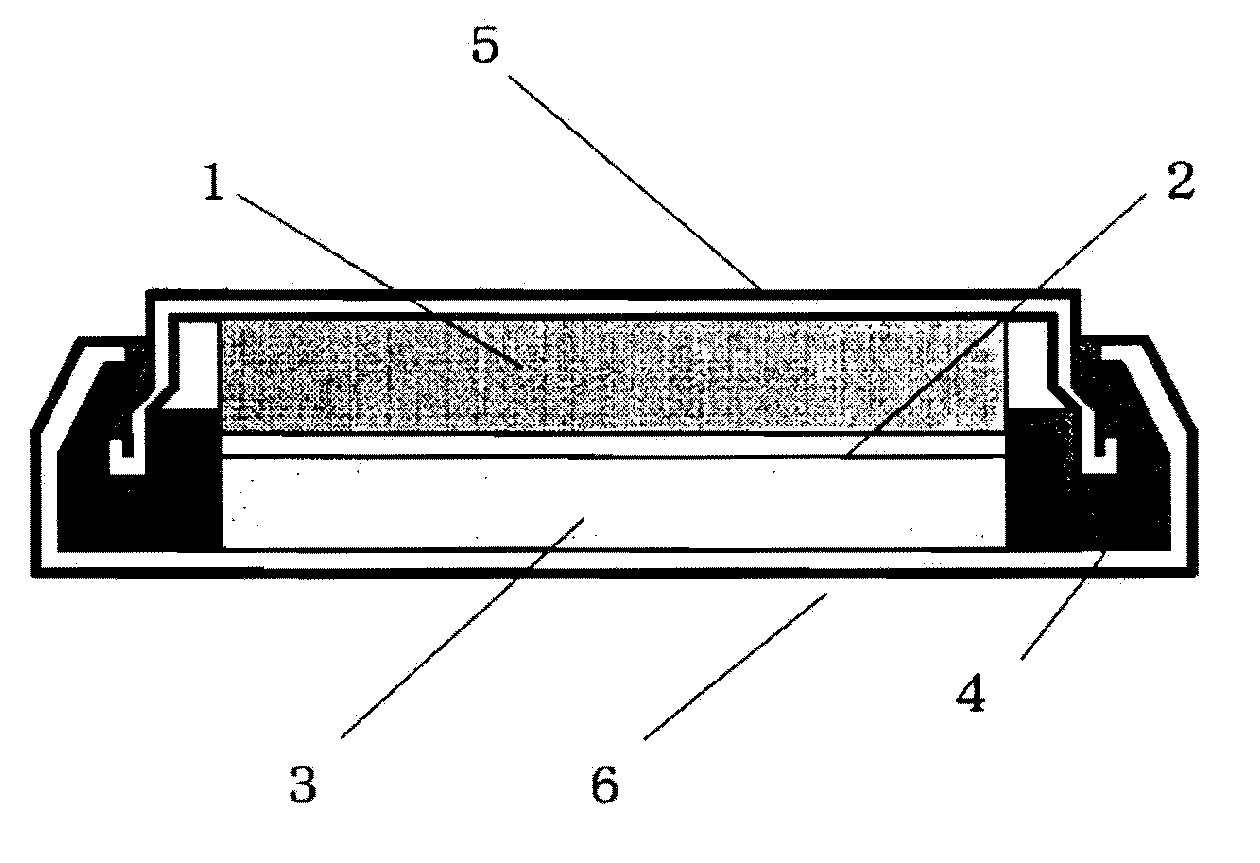

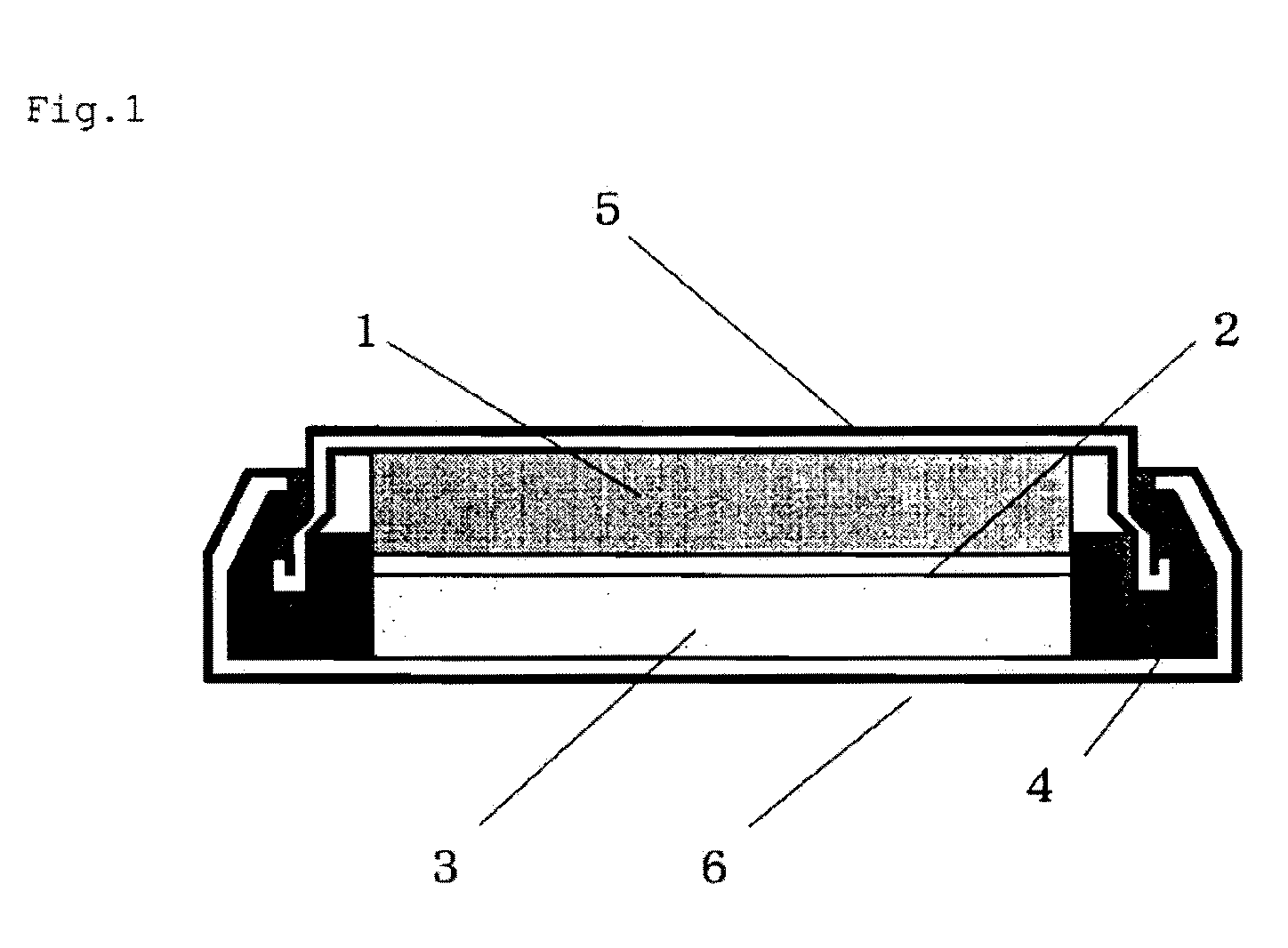

Diaphragm, preparation method of diaphragm and lithium ion battery

ActiveCN104157810AImprove heat resistanceNot easy to fall offSecondary cellsCell component detailsPolymer sciencePolymer substrate

A separator and a method for preparing the separator are provided. The separator includes a polymer substrate,a ceramic layer provided on the polymer substrate and an infiltration part formed between the polymer substrate and the ceramic layer. The polymer substrate contains a base polymer and a first curing resin. The infiltration part has at least a portion infiltrated into the polymer substrate. Each of the infiltration part and the ceramic layer independently contains ceramic particles and a second curing resin.A battery including the separator is also provided.

Owner:BYD CO LTD

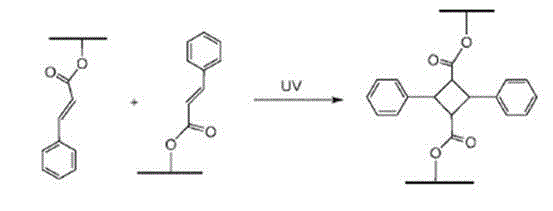

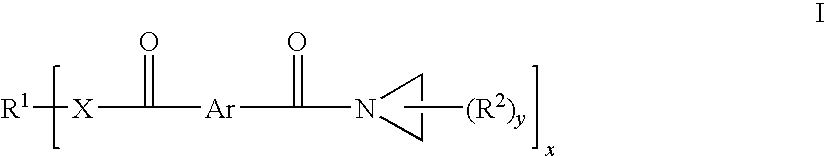

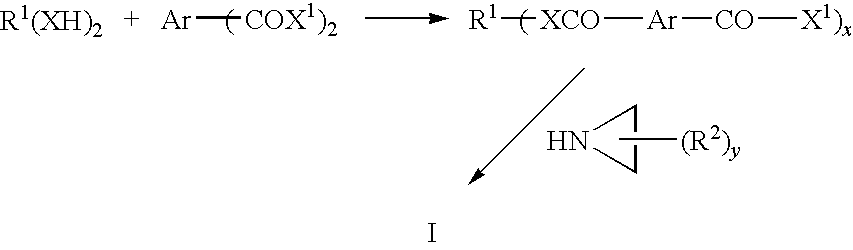

Aziridine crosslinking agents for acrylic adhesives

InactiveUS20100227969A1Reduce sensitivityGood shear propertyOrganic chemistryNon-macromolecular adhesive additivesMeth-Aziridine

Owner:3M INNOVATIVE PROPERTIES CO

Edible molded bodies, especially flat and flexible tubular films

InactiveUS6902783B1Improve heat stabilityScalding stabilitySausage casingsBakery productsPolymer scienceBiopolymer

The invention relates to edible molded bodies in the form of a flat or tubular film based on plastifiable biopolymers, the cleavage products or derivatives thereof and / or synthetic polymers from natural monomers, characterized in that they are produced according to a method comprising the following steps: a) the biopolymers, cleavage products or derivatives thereof and / or synthetic polymers are mixed with at least one edible plasticizer, at least one lubricating agent and at least one cross-linking agent, b) the mixture thus obtained is melted into a thermoplastic material, c) said material is extruded and d) the product obtained by extrusion is calendered and / or stretched or blown and deformed into the edible molded body. The molded bodies cited in the invention are suitable for use as food wrappers for sausages and boiled ham, and are particularly suitable for use as seamless sausage casings.

Owner:KALLE NALO

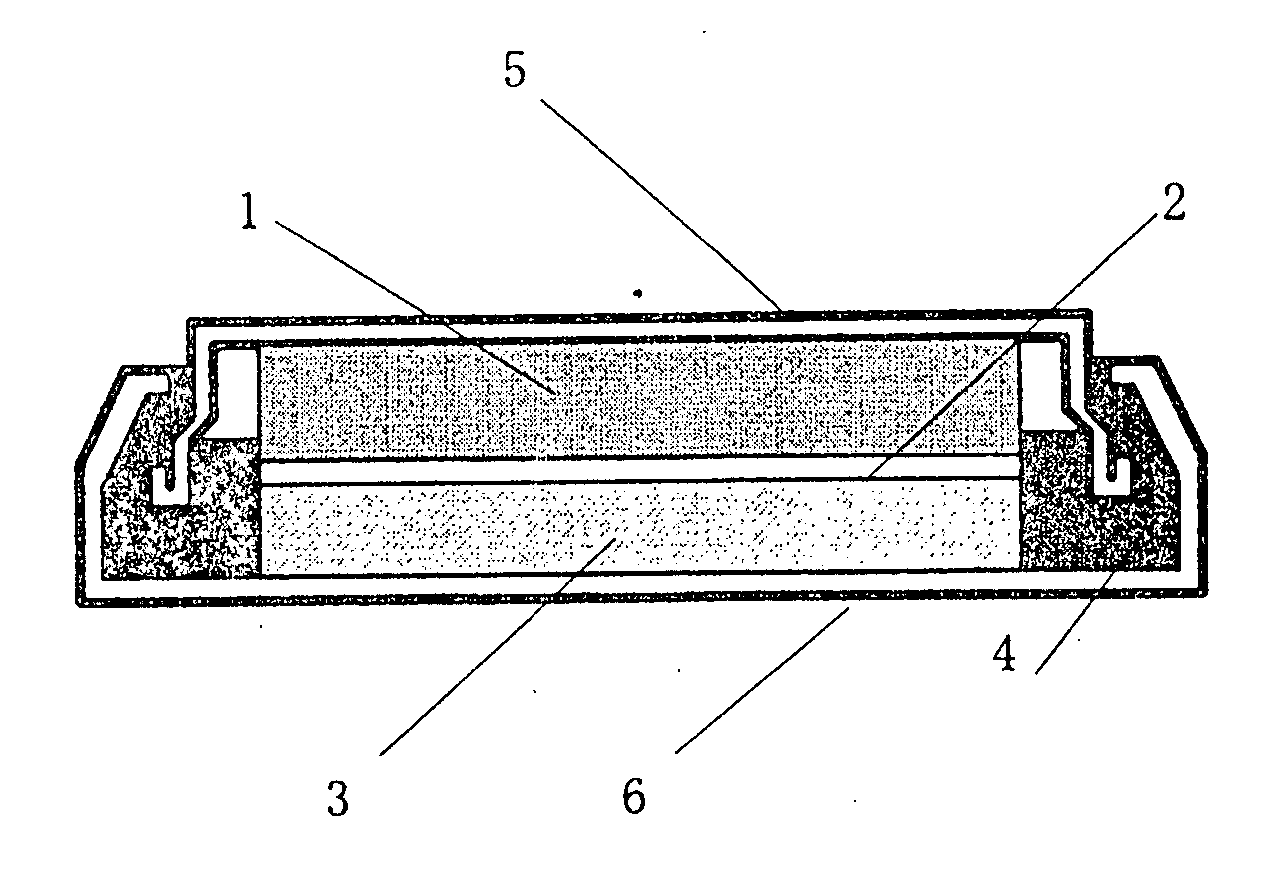

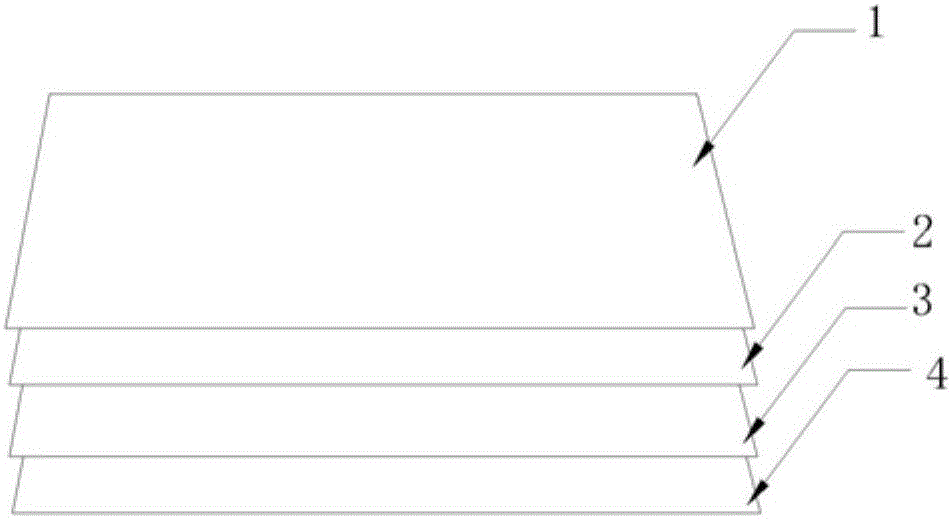

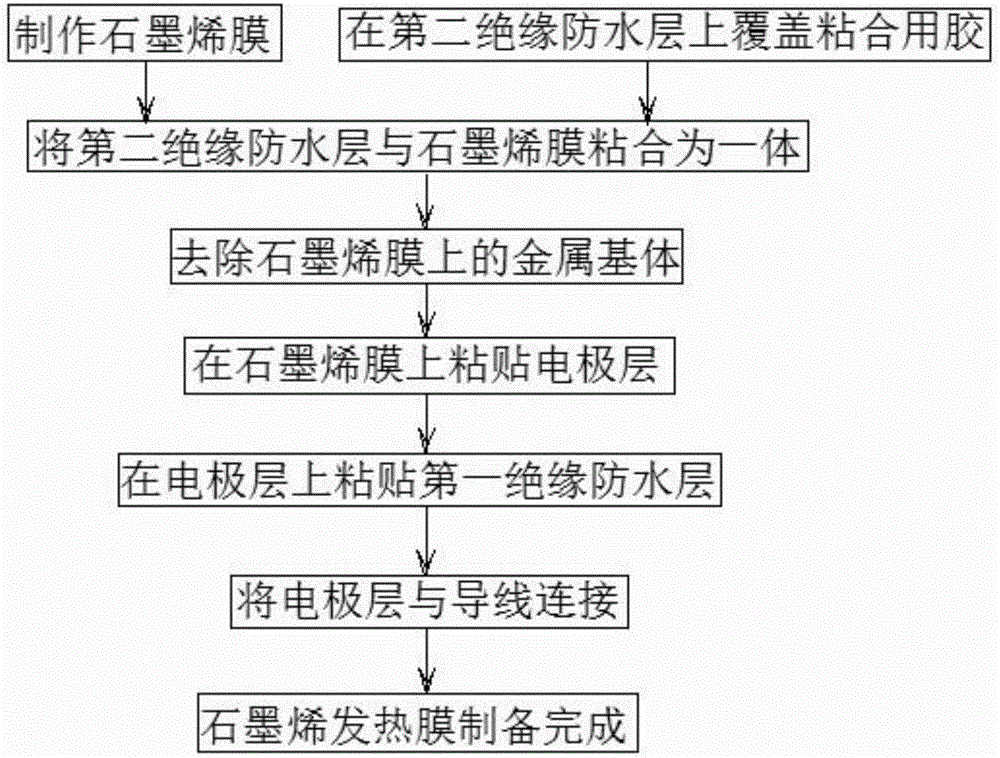

Graphene heating film and preparation method thereof

PendingCN105898907AGood heating stabilityExtended service lifeChemical industryGrapheneHeating filmCvd graphene

The invention provides a graphene heating film and a preparation method thereof. The graphene heating film is characterized by comprising a first insulated waterproof layer, an electrode layer, a heating film layer and a second insulated waterproof layer, wherein the first insulated waterproof layer, the electrode layer, the heating film layer and the second insulated waterproof layer are pasted into an integral structure; and the heating film layer is a graphene film. The preparation method of the graphene heating film comprises the following steps: (1) fabricating the graphene film; (2) covering the second insulated waterproof layer with a bonding adhesive; (3) bonding the second insulated waterproof layer and the graphene film into a whole; (4) removing a metal substrate on the graphene film; (5) pasting the electrode layer on the graphene film; (6) pasting the first insulated waterproof layer on the electrode layer; and (7) connecting the electrode layer and a lead wire. According to the graphene heating film and the preparation method thereof provided by the invention, the heating efficiency is high; large-area transferring of the graphene film can be achieved; the transfer time is short; and the transfer rate is high.

Owner:HANGZHOU PAPABEAR TECH CO LTD

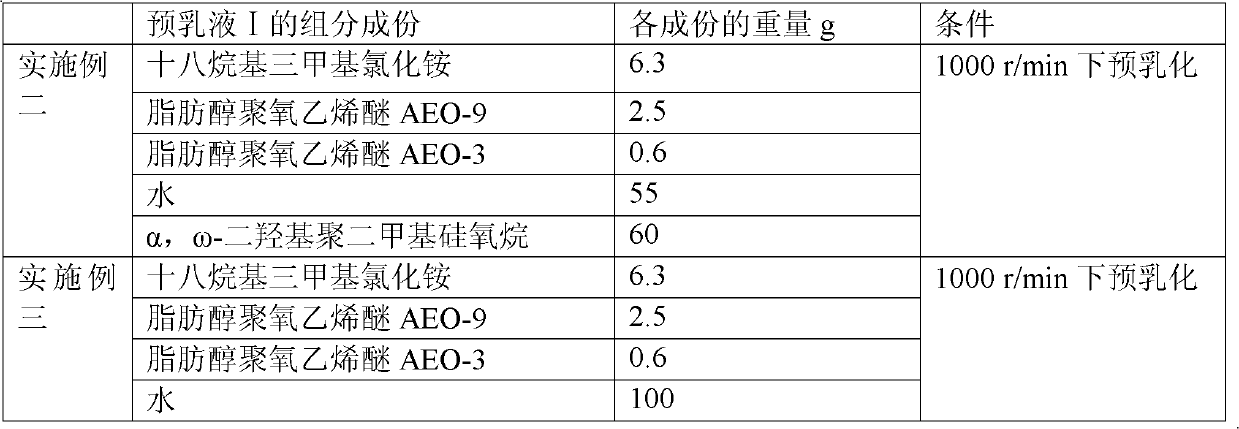

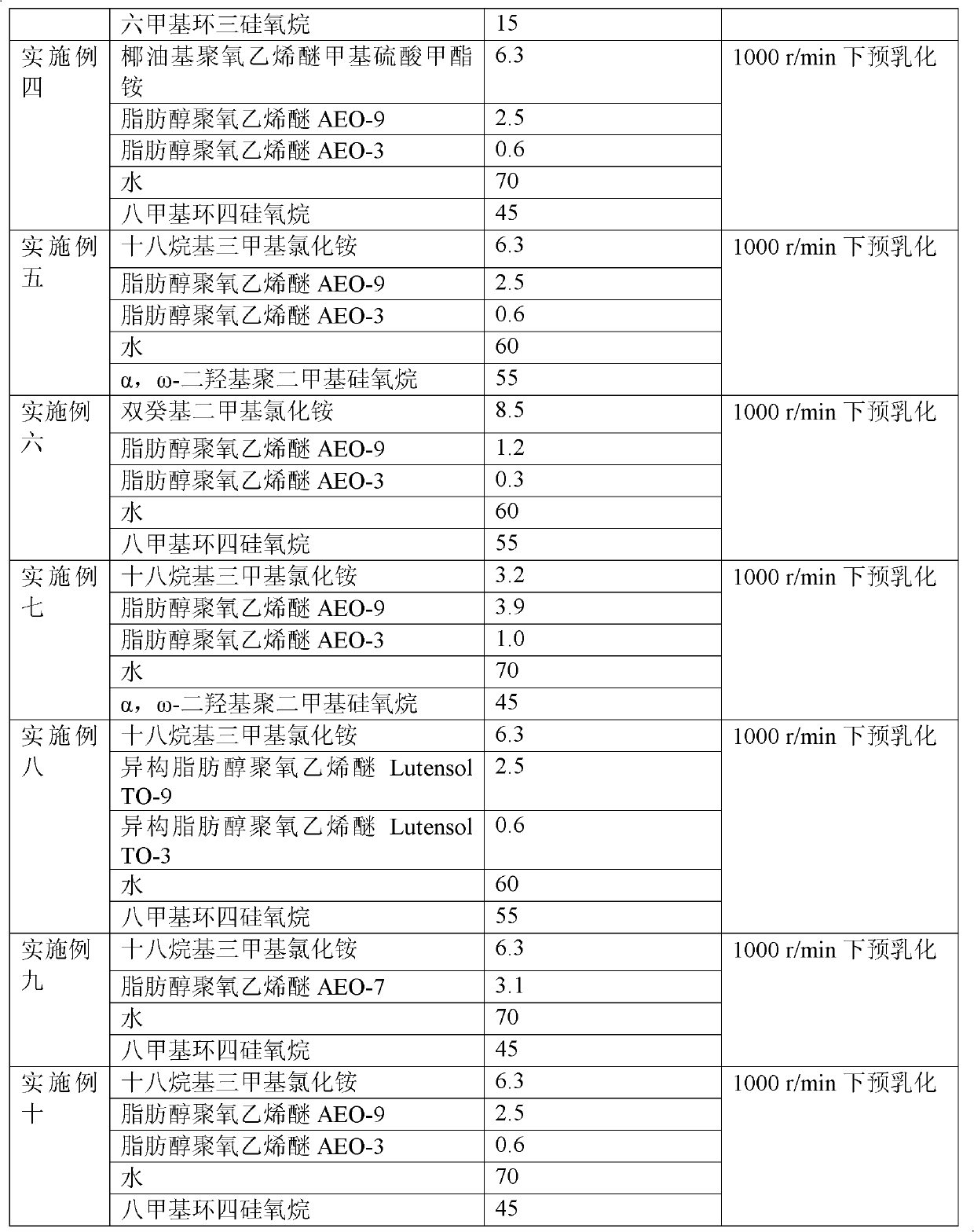

Cation amino silicone oil micro-emulsion and preparation method thereof

The invention discloses a cation amino silicone oil micro-emulsion and a preparation method thereof. The cation amino silicone oil micro-emulsion is prepared from the following components in percentage by weight: 5-30% of organo-siloxane monomer, 0.1-0.5% silane coupling agent, 3-10% of cationic emulsifier, 2-8% of nonionic emulsifier, 0.1-0.5% of basic catalyst and the balance of water, and the total weight percentage of all the components is 100%. The particle size of the cation amino silicone oil micro-emulsion prepared by using the method is 50-100nm, which is very small. The solid content of the cation amino silicone oil micro-emulsion is 10-36%. The cation amino silicone oil micro-emulsion has excellent shear stability, heat stability and storage stability, and is a favorable softener for finishing natural fibers, such as textiles made of cotton, hemp, silk, wool and the like, and synthetic fibers, such as polyester, polyamide and polypropylene ester.

Owner:WACKER DYMATIC SILICONES SHUNDE CO LTD FOSHAN

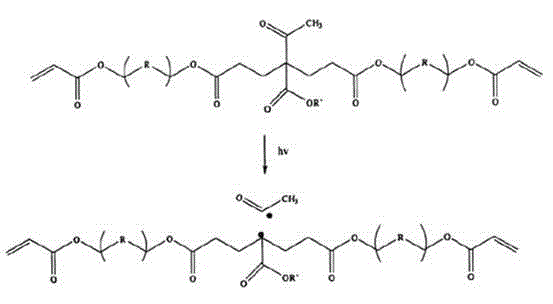

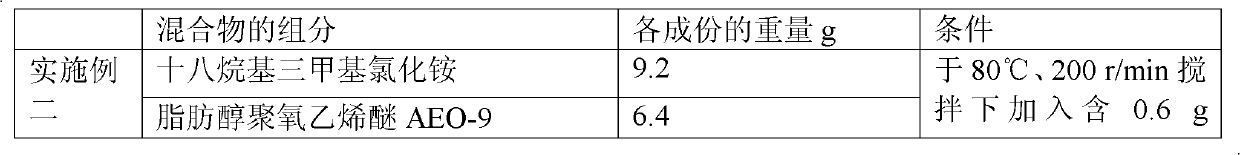

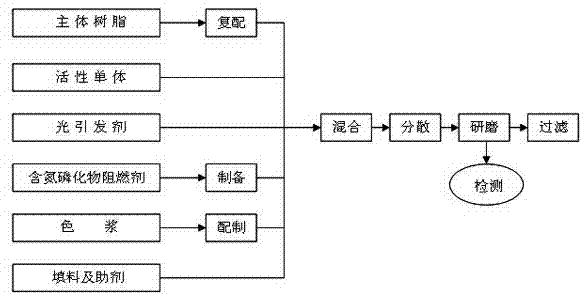

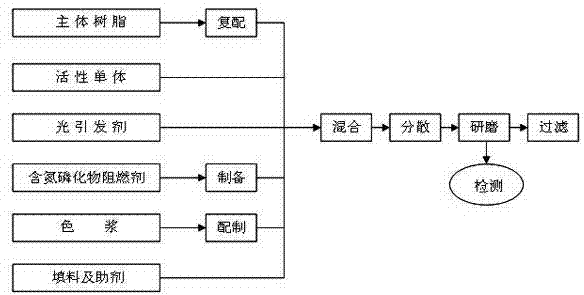

Preparation method of high temperature resistant non-halogen fire resistant ultraviolet curing solder resist ink

ActiveCN102286228AImprove heat stabilityIncrease crosslink densityPrinted circuit detailsInksResistChemistry

The invention discloses a preparation method of a high temperature resistant non-halogen fire resistant ultraviolet curing solder resist ink, belonging to the technical field of the solder resist ink for the printed circuit board. The innovation of the method is that radiation curing nitrogen-containing phosphide is introduced in the formula of the solder resist ink to be used as the non-halogen flame retardant; beta-hydroxyethyl acrylate modified melamine-formaldehyde resins and acrylate modified novolac epoxy resins are complexed to form the base resins, the base resins are mixed with a reactive monomer, a photoinitiator, a color paste, a filler and an additive, the mixture is used to perform mixing, grinding, filtration and other working procedures and prepare the high temperature resistant non-halogen fire resistant ultraviolet curing solder resist ink. The solder resist ink prepared by the method is characterized by high temperature resistance, high flame resistance, high hardness and no halogen and is mainly suitable for the lead-free soldering technology and lead-free tin blowing (hot air leveling) technology of the printed circuit board.

Owner:JIANGSU KUANGSHUN PHOTOSENSITIVITY NEW MATERIAL

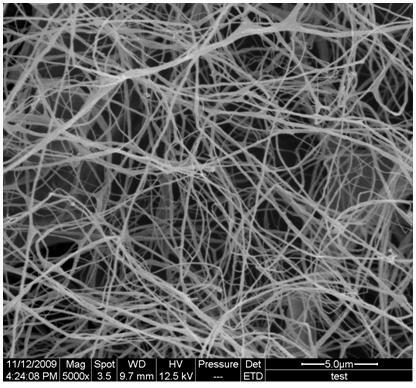

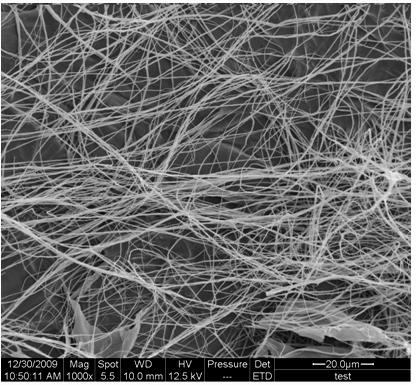

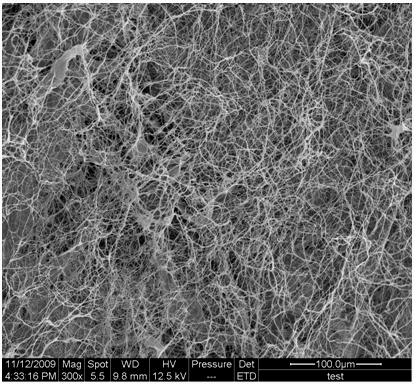

Preparation method of biomass cellulose nanofibers with high length-diameter ratio

InactiveCN101864606AHigh crystallinityBroad nanoscaleMonocomponent cellulose artificial filamentStrong acidsDiameter ratio

The invention relates to a preparation method of biomass cellulose nanofibers with a high length-diameter ratio, in particular to a preparation method of nano cellulose fibers, solving the problems that nano cellulose fibers prepared by using a traditional method for hydrolyzing biomass cellulose with strong acid have short length and small length-diameter ratio, nano cellulose fibers prepared by using a mechanical shearing method are easy to mutually aggregate, and a microbial fermentation method has high cost. The method comprises the following steps of: (1) purifying biomass cellulose with a benzyl alcohol solution; (2); treating with acidified sodium chlorite; (3) treating lye; (4) treating with the acidified sodium chlorite again; (5) treating with KOH; (6) treating with hydrochloric acid; and (7) ultrasonically treating and drying to obtain biomass cellulose nanofibers with high length-diameter ratio not less than 1500, fiber diameter from 50 nm to 300 nm, length not less than 150 um and length-diameter ratio not less than 1500. The biomass cellulose nanofibers are mutually interwoven into a tightly wound mesh structure. The invention has low cost and is suitable for preparing nano cellulose fibers from wood, bamboo, cotton, linen and crop straw.

Owner:NORTHEAST FORESTRY UNIVERSITY

Diaphragm, preparing method of diaphragm and lithium ion battery

ActiveCN104078633AGood heat resistanceImprove heat resistanceCell seperators/membranes/diaphragms/spacersSecondary cellsCeramic particlePolymer substrate

The invention provides a diaphragm, a preparing method of the diaphragm and a lithium ion battery comprising the diaphragm. The diaphragm comprises a polymer substrate and slurry layers positioned at the inside and on the surface of the substrate; each slurry layer comprises ceramic particles and curing resin; the curing resin is obtained through performing cross-linking and curing reaction on curing agents or initiating agents positioned inside the substrate and cross-linking resin positioned in the slurry layers; the high-temperature-resistant performance of the diaphragm is excellent; a heat-resistant layer cannot easily fall; and the winding, the preparation and the practical application are easier.

Owner:BYD CO LTD

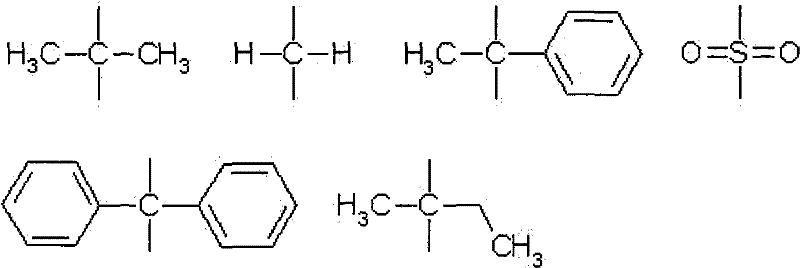

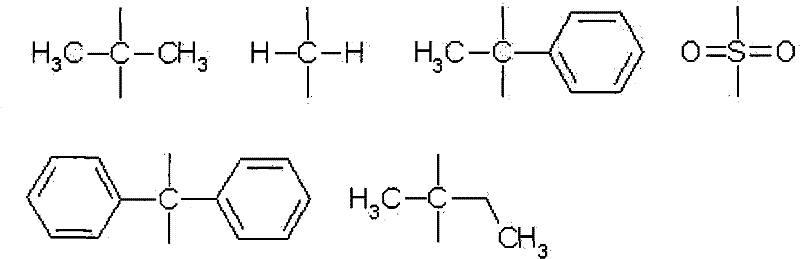

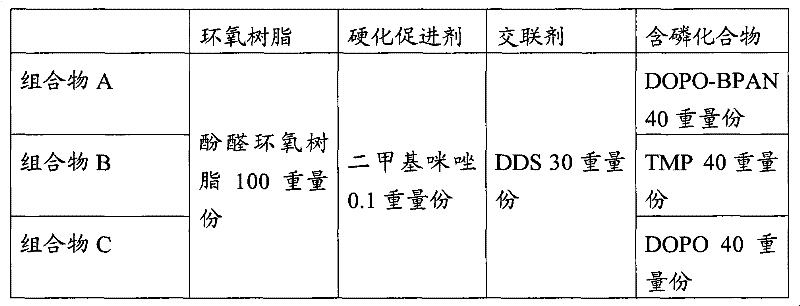

Resin composition as well as semi-solidified rubber sheet, laminating board and circuit board containing same

ActiveCN102206397AImprove flame retardant performanceImprove heat stabilitySynthetic resin layered productsGlass/slag layered productsCross-linkSheet film

The invention relates to a resin composition which mainly comprises epoxy resin, a hardening accelerator, a cross-linking agent and phosphorus-containing resin, wherein the phosphorus-containing resin is bisphenol phenolic resin or phenolic resin substituted by a 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide or derivatives thereof. The resin composition can be applied to semi-solidified rubber sheets or insulating layers of circuit boards. In addition, the invention relates to a semi-solidified rubber sheet, a laminating board and a circuit board containing the resin composition.

Owner:ELITE MATERIAL

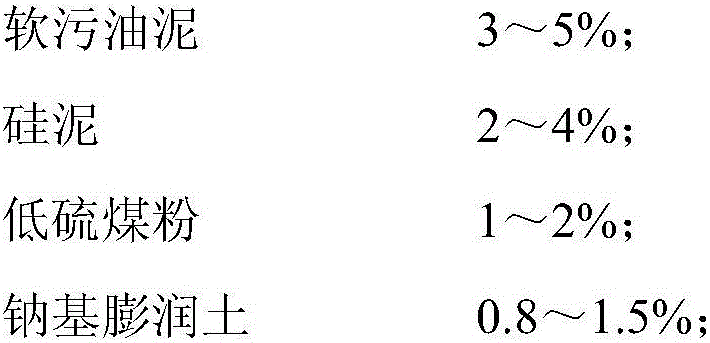

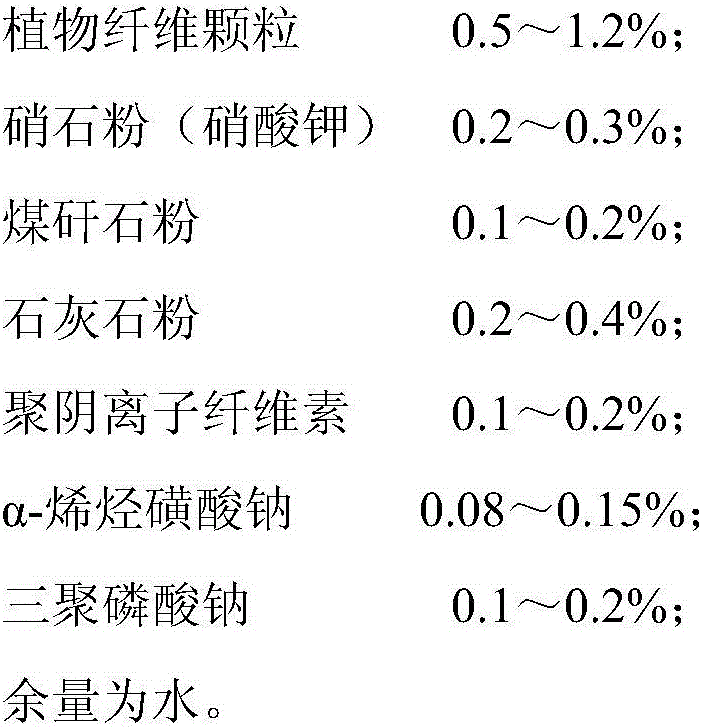

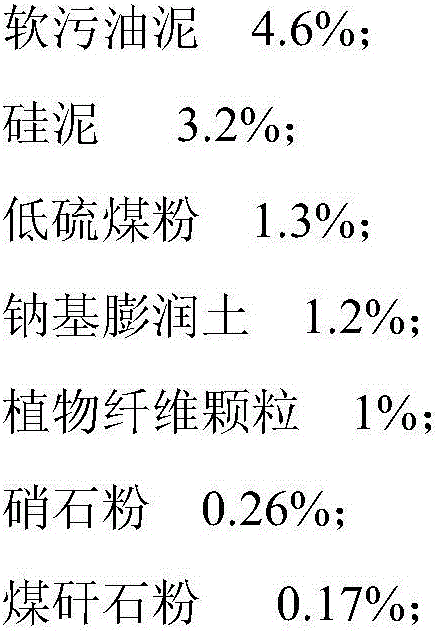

Sulfur-fixing combustion-supporting high-temperature profile control agent, and preparation method and application thereof

ActiveCN106833588AImprove temperature resistanceImprove seal strengthDrilling compositionFiberCellulose

The invention provides a sulfur-fixing combustion-supporting high-temperature profile control agent, and a preparation method and application thereof. By taking the total weight of the sulfur-fixing combustion-supporting high-temperature profile control agent as 100%, the profile control agent is prepared from the following raw materials in percentage by weight: 3-5% of soft oil sludge, 2-4% of silicon sludge, 1-2% of low sulfur coal powder, 0.8-1.5% of sodium bentonite, 0.5-1.2% of plant fiber particle, 0.2-0.3% of saltpetre powder, 0.1-0.2% of coal gangue powder, 0.2-0.4% of limestone powder, 0.1-0.2% of polyanionic cellulose, 0.08-0.15% of alpha-sodium olefinsulfonate, 0.1-0.2% of sodium tripolyphosphate and the balance of water. The profile control agent has favorable stratum compatibility, causes no damage to the oil reservoir, does not pollute the stratum, and has favorable temperature tolerance; and meanwhile, the profile control agent has sulfur-fixing and combustion-supporting functions, thereby being completely applicable to a profile control technology for a thick oil fireflood chemical profile control gas injection well.

Owner:PETROCHINA CO LTD

Double-wall sandwich structural microcapsule self-repairing rubber and preparation method thereof

ActiveCN103467791AImprove heat stabilityFully coveredMicroballoon preparationMicrocapsule preparationMolecular sieveCarbon black

The invention provides a double-wall sandwich structural microcapsule self-repairing rubber and a preparation method thereof, and relates to a rubber and a preparation method thereof. The preparation method comprises the step of sequentially mixing a rubber matrix, stearic acid, zinc oxide, an accelerant, an anti-aging agent, carbon black, paraffin, a double-wall sandwich structural self-repairing microcapsule and a nano mesoporous molecular sieve in proportion, wherein the double-wall sandwich microcapsule is utilized and adopts urea-formaldehyde resin as the wall material, so that the sealing performance is high, and the manufactured walls have moderate hardness; the nano mesoporous molecular sieve utilized as a synergist is naturally inorganic filler which can improve the mechanical performance of the rubber, and a double coating brings higher heat-resisting stability, therefore, the contact probability of a repairing agent and the catalyst is greatly increased, and the influence of excessively added repairing agents and catalysts to the mechanical performance of the rubber can be avoided. Once microcrack appears in the material, a plurality of pores act to improve the capillary siphon effect of the microcrack to the microcapsule, thus the probability of the repairing agent and the curing agent to enter the microcrack is greatly increased, and as a result, the repairing effect is greatly improved.

Owner:沈阳双骥橡塑科技有限公司

Positive electrode active material for non-aqueous electrolyte secondary battery, method for producing same and non-aqueous electrolyte secondary battery using same

InactiveUS20120292561A1Increase high capacityImprove heat stabilityPositive electrodesLi-accumulatorsComposite oxideNon aqueous electrolytes

A positive electrode active material for non-aqueous electrolyte secondary battery composed of a lithium nickel composite oxide having high capacity and superior heat stability, a production method that is suitable for its industrial production, and a non-aqueous electrolyte secondary battery having high safety. The positive electrode active material for non-aqueous electrolyte secondary battery includes a lithium nickel composite oxide having by the following general formula (1):LibNi1-aM1aO2 (1)(wherein M1 represents at least one kind of element selected from transition metal elements other than Ni, the second group elements and the thirteenth group elements; a satisfies 0.01≦a≦0.5; and b satisfies 0.85≦b≦1.05). The amount of lithium at the surface of the lithium nickel composite oxide is 0.10% by mass or lower. The positive electrode active material is obtained by water washing fired powder at a temperature range of 10 to 40° C., and then filtering and drying the same.

Owner:SUMITOMO METAL MINING CO LTD +1

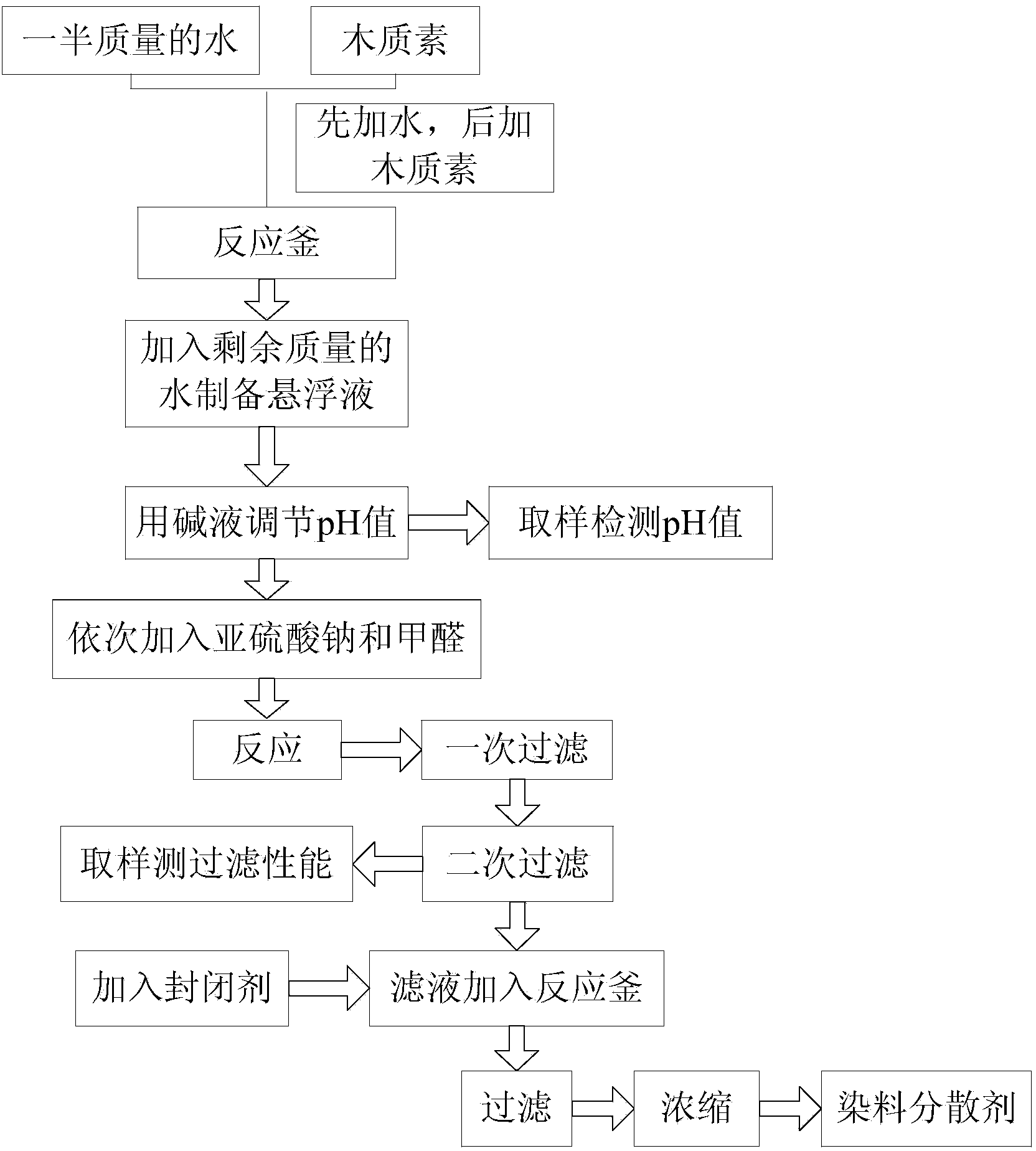

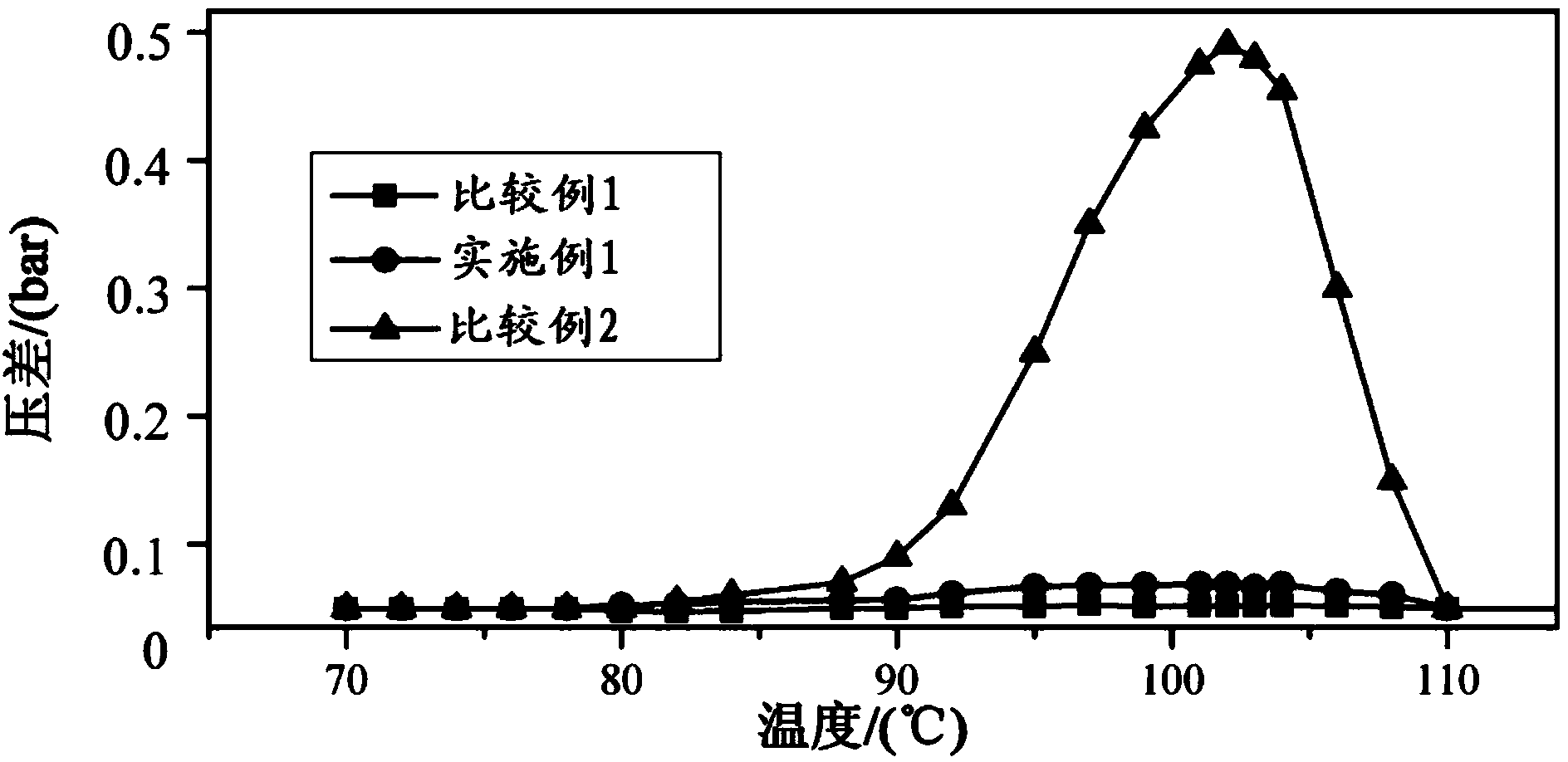

Method for preparing sodium lignosulfonate and application of sodium lignosulfonate as a dye dispersant

InactiveCN103910890AEvenly dispersedImprove heat stabilityOrganic dyesDyeing processSulfite saltSodium lignosulfonate

The invention provides a method for preparing sodium lignosulfonate. The method comprises the following steps: (A) providing a lignin suspension; (B) regulating the pH value of the suspension to 4.8-8.5; (C) sequentially adding sodium sulfite and formaldehyde to the suspension with pH value of 4.8-8.5, reacting and filtering to obtain filtrate; (D) mixing the filtrate with a sealant and reacting to obtain sodium lignosulfonate. The method provided by the invention has the advantages that the reaction between lignin and sodium sulfite and formaldehyde is controlled by controlling the adding order of sodium sulfite and formaldehyde; the filtrate obtained through filtering after reaction is reacted with the sealant to react with the free phenol hydroxyl, so that obtained sodium lignosulfonate has good dispersion property, excellent performance when used as the dye dispersant and little textile staining while having high heat stability.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

High-melting-point polyester hot melt adhesive with better fluidity

The invention discloses a synthesis method of a high-melting-point polyester hot melt adhesive with better fluidity. The synthesis method comprises the following steps of: (1) carrying out esterification reaction on p-phthalic acid, m-phthalic acid, fatty dicarboxylic acid, ethylene glycol and C3-C6 diol under the action of titanate serving as a catalyst; and (2) adding a stabilizer and a surfactant to the products obtained in the step (1), and carrying out reduced-pressure condensation polymerization reaction to obtain a product, namely the high-melting-point polyester hot melt adhesive with better fluidity. The obtained polyester hot melt adhesive has good adhesion performance, better fluidity when used at high temperature, and excellent wet leveling property.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +2

Prepolymer compositions and sealants made therefrom

ActiveUS20050075469A1Improve curing speedImprove weather stabilityOther chemical processesEndcappingAdhesive

Prepolymer compositions for preparing a one-part, moisture-curable sealant, adhesive or coating, and a method of making such prepolymer compositions are provided. The prepolymer compositions comprise a polyurethane prepolymer that is end-capped with silane groups or a combination of silane groups and end capping groups that have been derived from an alcohol and an amount, referred to hereinafter as an “excess”, of unreacted aromatic alcohol having a molecular weight of less than 2000. The excess of unreacted aromatic alcohol in the composition is from greater than 0% to 15% by mole of the level of original NCO groups in the prepolymer. From 50 to 100% of the original NCO groups are end-capped with silane groups, and from 0 to 50% of the original NCO groups are end-capped with a end-capping group that has been derived from an aromatic alcohol, an aliphatic alcohol or both. Sealant compositions and coating compositions comprising the present prepolymer composition are also provided.

Owner:TREMCO CPG INC

Clean production method of chromium-free automobile cushion leather

The clear production method for Cr-free vehicle seat cushion comprises: hair-saving, combing acid and base for expansion; ammonia-free deliming, dipping weak acid and low slat, Cr-free bating, composite batting, and adding strong-absorption fat for dyeing to treat skin from pig, cattle or sheep. The product has shrinkage temperature up to 110Deg, shows well hand feeling and resistance to thermal and age. This invention reduces material quantity and 30-50% sewage discharge, improves absorption rate, and brings a new way for Cr-free leather.

Owner:SICHUAN UNIV

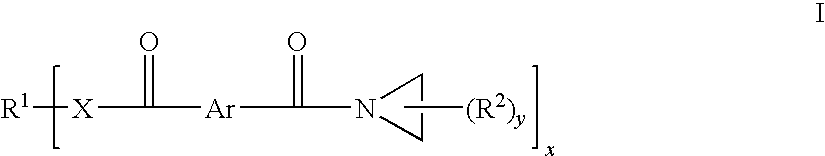

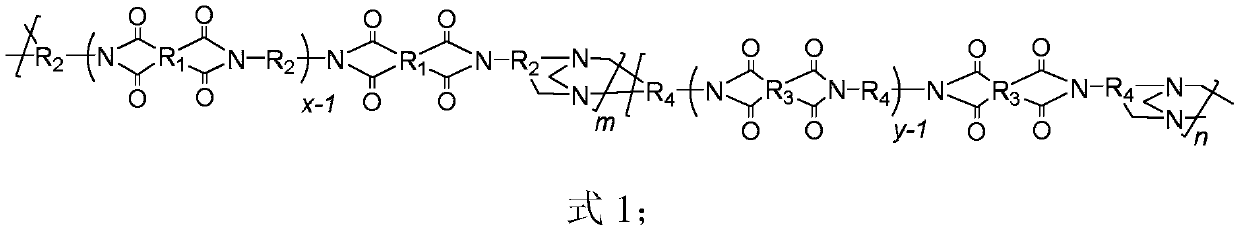

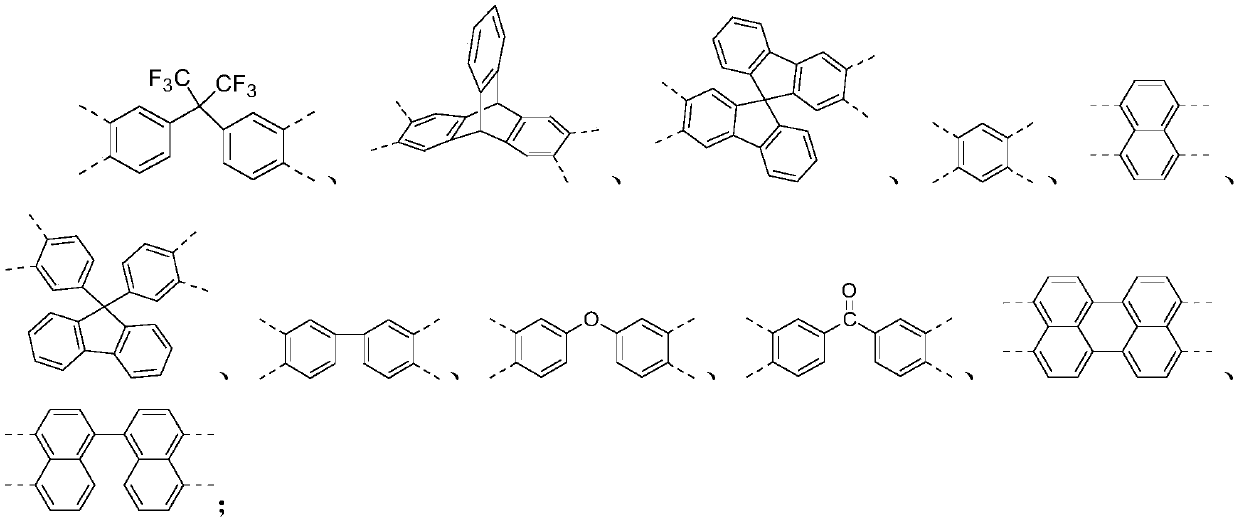

Semi-aromatic polyimide, preparation method and application thereof, and gas separation membrane containing the semi-aromatic polyimide

ActiveCN110606951AIncrease stacking distanceImprove gas permeabilityProductsMethane captureDiamineGas separation

The invention provides a semi-aromatic polyimide material, a preparation method and application thereof, and a gas separation membrane containing the semi-aromatic polyimide material. The semi-aromatic polyimide has a structure shown as a formula I, can be used as a gas separation membrane material, and is obtained by synthesizing a diamine monomer I containing an imide chain link from aromatic dianhydride and aromatic or aliphatic diamine, synthesizing a diamine monomer II containing an imide chain link from alicyclic dianhydride and aromatic or aliphatic diamine, and polymerizing the diaminemonomer I and the diamine monomer II under the action of an initiator. The semi-aromatic polyimide molecular chain provided by the invention has a Troger base structure, and the aromatic ring structure in the main chain is matched with the alicyclic structure, so that the gas separation membrane prepared from the semi-aromatic polyimide molecular chain has good mechanical properties and heat-resistant stability, and has a high permeability coefficient and good selectivity when being used for hydrogen separation and air separation.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

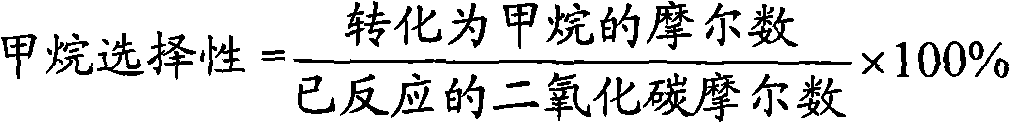

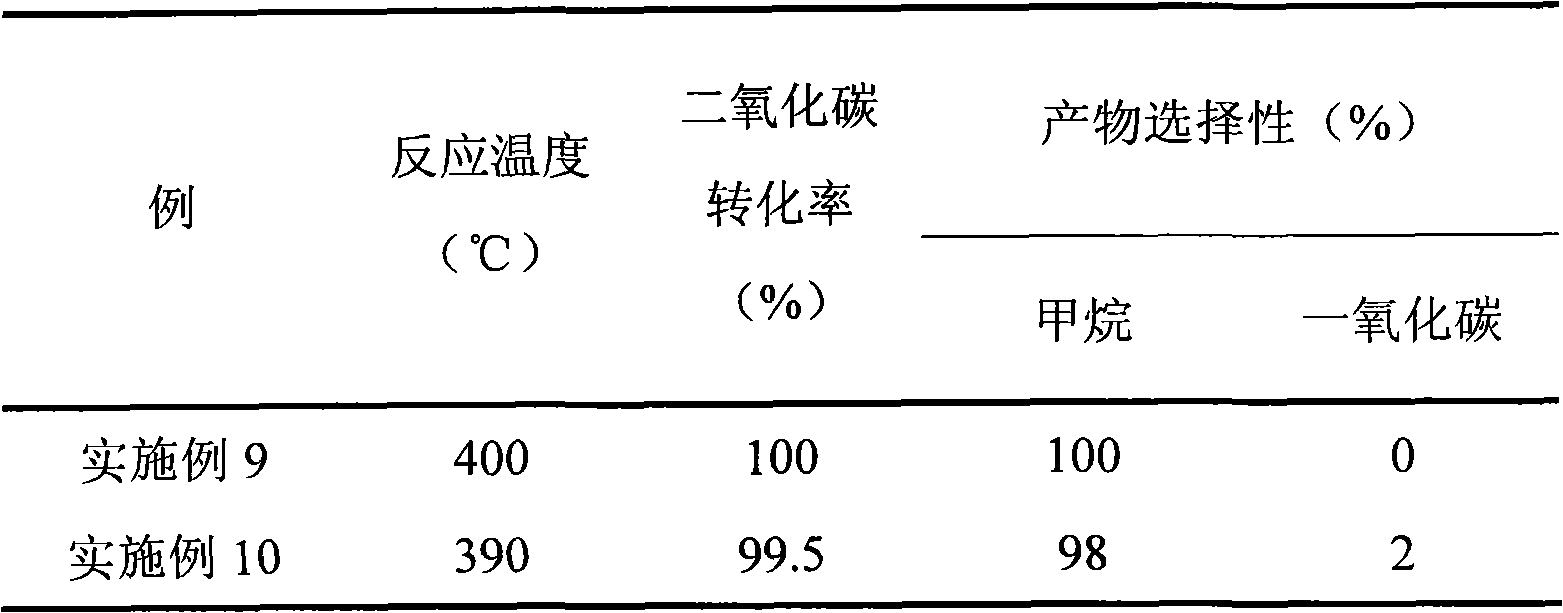

Catalyst for methanation of carbon dioxide

InactiveCN102091629AImprove structural stabilityImprove heat stabilityHydrocarbon from carbon oxidesHydrogen separation using solid contactMethanationActive component

The invention discloses a catalyst for the methanation of carbon dioxide. The carrier of the catalyst is composite oxide of rare earth and other metals, and the composition of the catalyst is represented by a general formula of AxByOz, wherein in the formula, A is a rare metal, B is one or two metals from groups IIB, IIIA, VIA, IVB, VB and VIB, x is 0 to 1, y is 0 to 2, and z is 2 to 4; and the active component of the catalyst is nickel, and the nickel loaded on the carrier accounts for 1 to 15 percent of the total weight of the catalyst. Compared with the conventional carbon dioxide methanation technique, the catalyst technique disclosed by the invention, under the similar reaction conditions, can achieve a carbon dioxide conversion rate of 100 percent, a methane selectivity of 100 percent and a methane time space yield of more than 1,000g / kg.h.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Xanthan gum graft copolymer oil displacement agent as well as preparation method and application thereof

ActiveCN102051165AImprove heat stabilityImprove biostabilityFluid removalDrilling compositionSide chainHeat resistance

The invention provides a xanthan gum graft copolymer oil displacement agent as well as a preparation method and application thereof. Based on molecular design, at least two of acrylamide (AM), 2-acrylamido-2-methylpropane sulfonic acid (AMPS), N-vinylpyrrolidone (NVP) and N,N-dimethylacrylamide (DMAM) are graft-copolymerized to xanthan gum macromolecules. Since the copolymerized side chain is introduced, the viscoelasticity, heat resistance and biological stability of the xanthan gum macromolecules can be greatly enhanced; the xanthan gum graft copolymer can be used as an oil displacement agent for tertiary oil recovery simultaneously; and the solution rate of the xanthan gum graft copolymer is obviously increased, and the xanthan gum graft copolymer can not easily generate gel in brine. When the xanthan gum graft copolymer oil displacement agent is used in a high-temperature high-salinity oil reservoir, the oil displacement effect is enhanced.

Owner:CHINA PETROLEUM & CHEM CORP +1

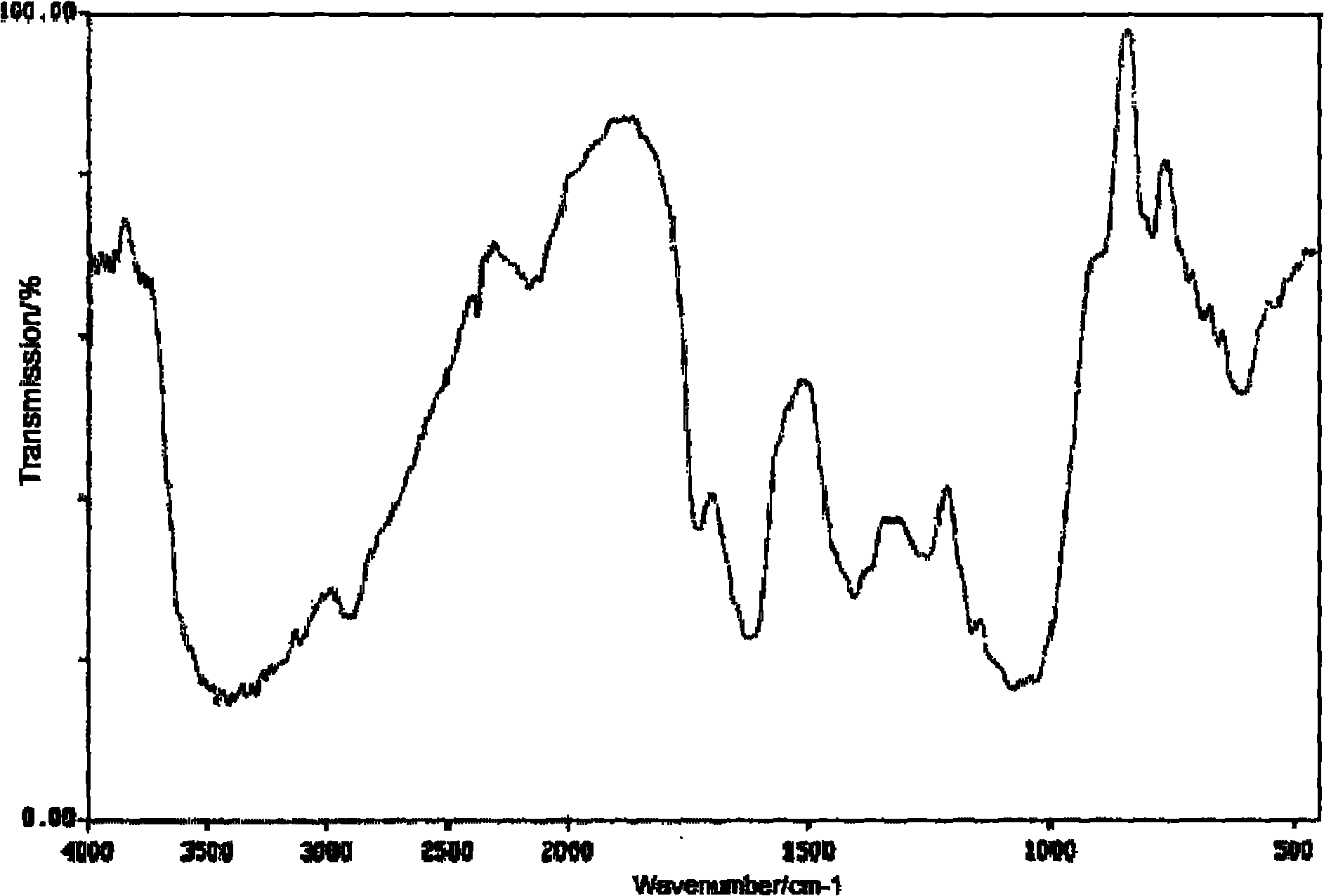

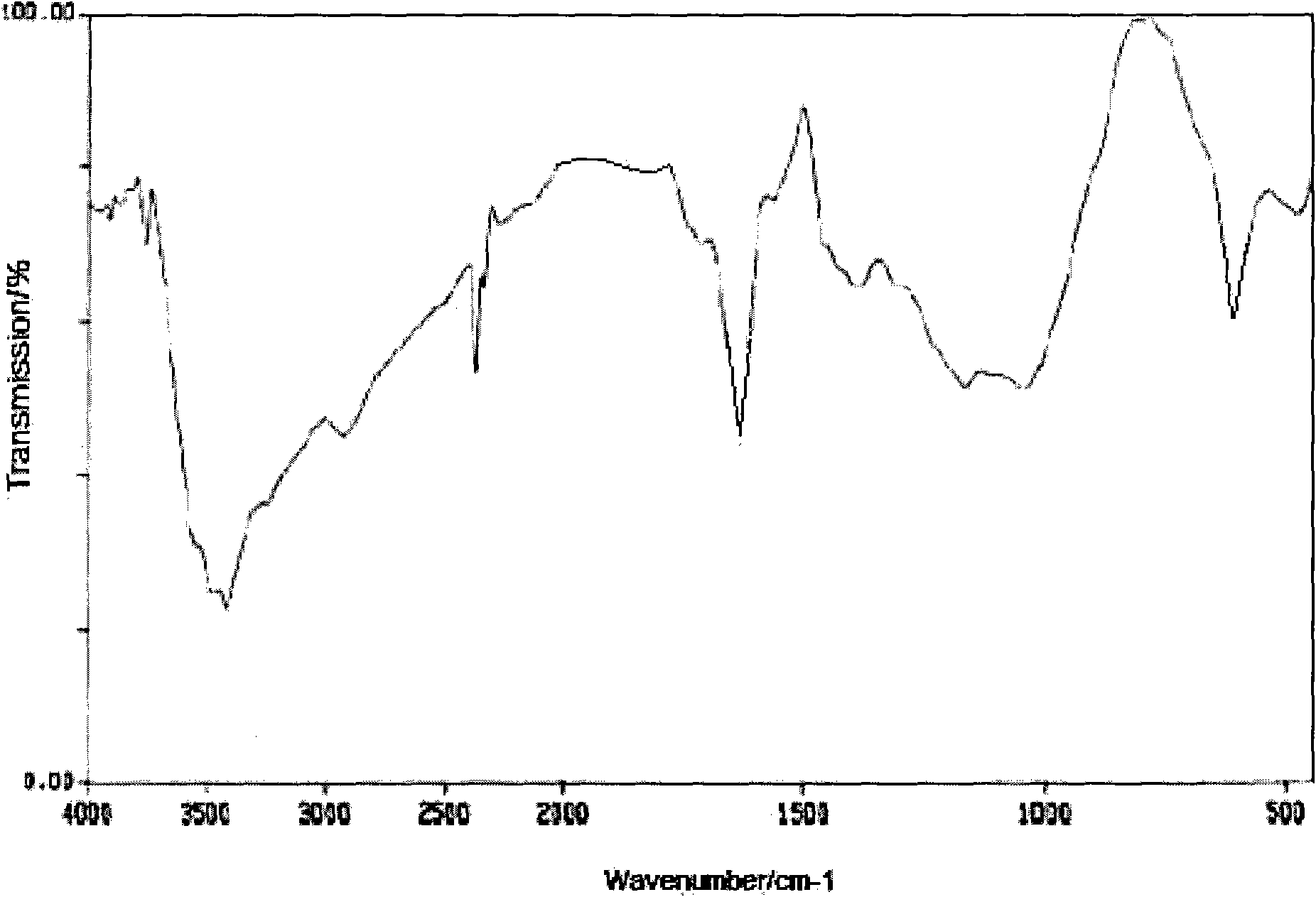

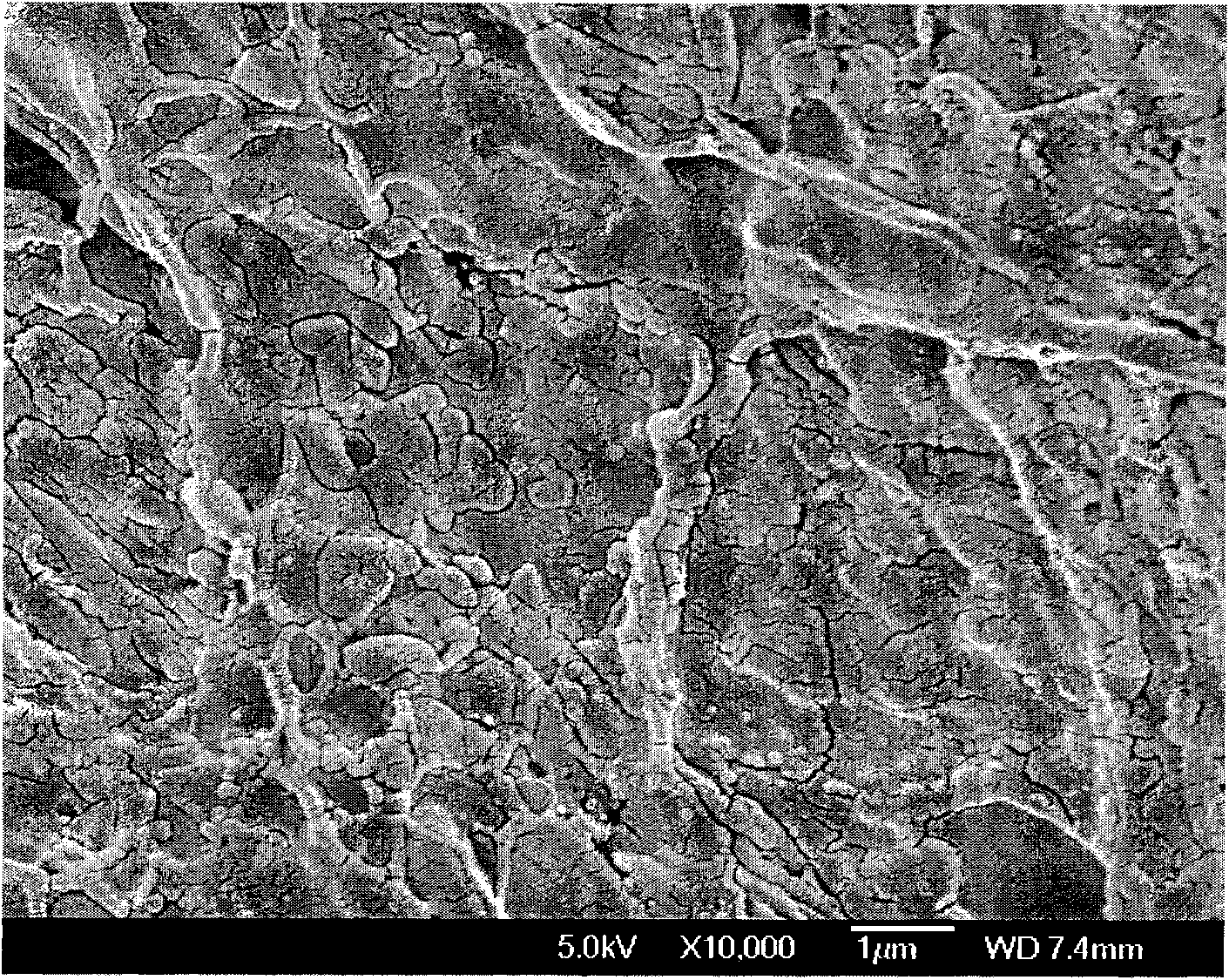

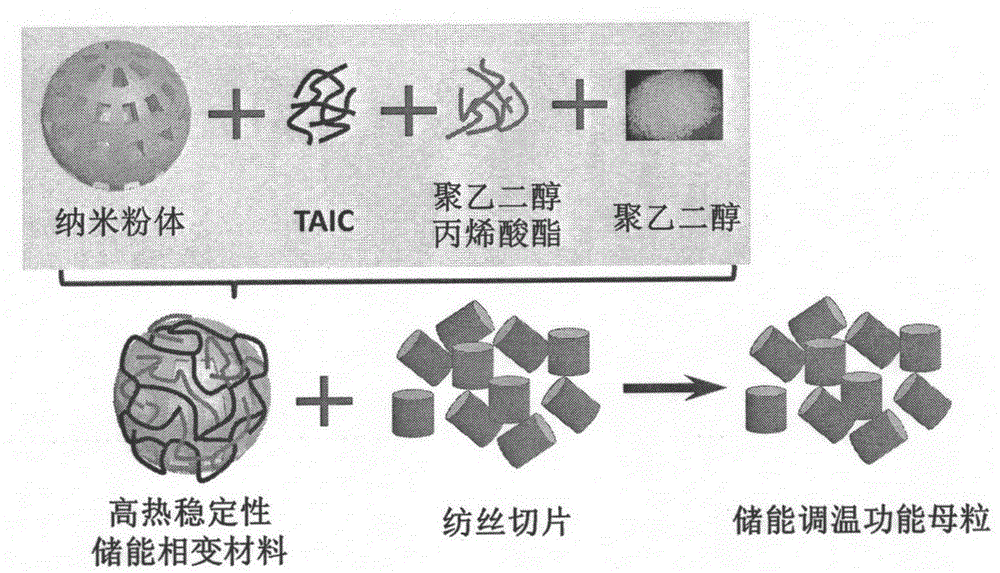

Preparation method for energy-storing and temperature-adjusting phase-change material and fibres thereof

ActiveCN104910334AStrong energy storage and temperature control abilityReduce manufacturing costHeat-exchange elementsArtifical filament manufacturePolymer scienceHigh energy

The invention provides a preparation method for an energy-storing and temperature-adjusting phase-change material and fibres thereof. The preparation method for the energy-storing and temperature-adjusting phase-change material is characterized by comprising the following specific steps: placing porous nano-powder, triallyl isocyanurate, polyethylene glycol acrylate, polyethylene glycol and an initiator in solvent water, reacting for 2-5 hours at 65-75 DEG C by means of reduced pressure ultrasonic dispersion, and finally centrifugally dewatering to obtain the energy-storing and temperature-adjusting phase-change material. The energy-storing and temperature-adjusting phase-change material is subjected to drying treatment, then sliced with polymers and blended and granulated through a double-screw extruder, and then subjected to melt-spinning to obtain the energy-storing and temperature-adjusting fibres. The phase-change energy-storing material prepared by the preparation method provided by the invention has the characteristic of high energy-storing and temperature-controlling capacity, and has the advantages of low preparation cost, good heat-resistant stability and simple operation.

Owner:DONGHUA UNIV

Preparation method of high-temperature-resistant low-resistivity lithium ion battery diaphragm

ActiveCN106299208AImprove securityFast chargingSecondary cellsCell component detailsSlurryLithium-ion battery

The invention relates to a preparation method of a high-temperature-resistant low-resistivity lithium ion battery diaphragm and belongs to the technical field of battery diaphragms. The high-temperature-resistant low-resistivity lithium ion battery diaphragm comprises a base film and a coating slurry layer applied to one lateral end surface or two lateral end surfaces of the base film, the coating slurry layer is made of ceramic slurry or graphene-modified ceramic slurry, and the coating slurry layer on at least one of the two lateral end surfaces of the base film is made from graphene-modified ceramic slurry; the preparation of the diaphragm comprises the steps of preparing graphene-modified ceramic slurry, pretreating a base film and coating and drying; sodium polyacrylate, ammonia water, alcohol, graphene and waterborne acrylic emulsion as well as sodium carboxymethyl cellulose solution are added in sequence during preparation of the graphene-modified ceramic slurry, the slurry that is obtained has stable properties and is as advantageous as the ceramic slurry and graphene material, a battery diaphragm with the base film coated with the slurry has low shrinkage and high safety, battery charging speed is high, and the diaphragm is suitable the industries requiring high-temperature operation and quick-charge batteries, such as electric vehicles.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com