Organic/inorganic composite porous isolating membrane

An inorganic composite and separator technology, applied in the direction of synthetic resin layered products, structural parts, battery pack parts, etc., can solve the problems of increasing lithium ion resistance, poor performance of lithium ion batteries, and failure to obtain internal short circuit prevention effects, etc. , to achieve high thermomechanical stability and improve safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

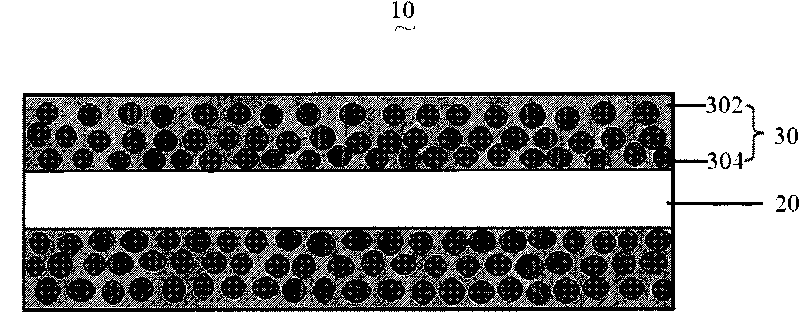

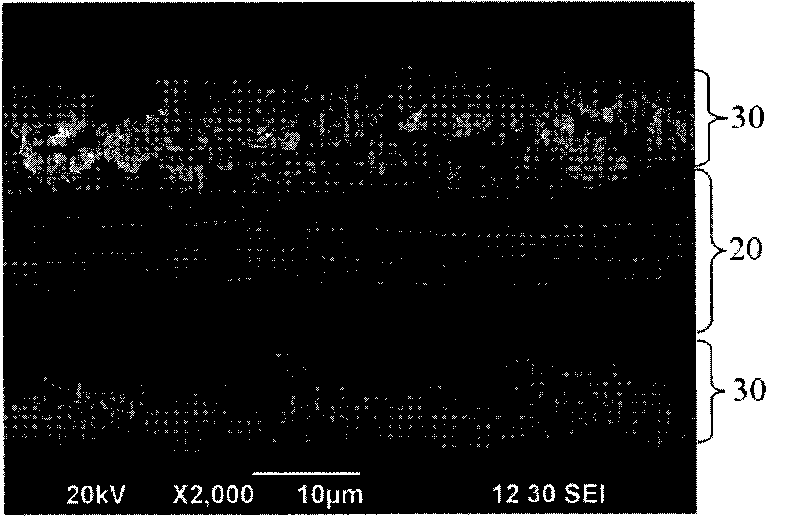

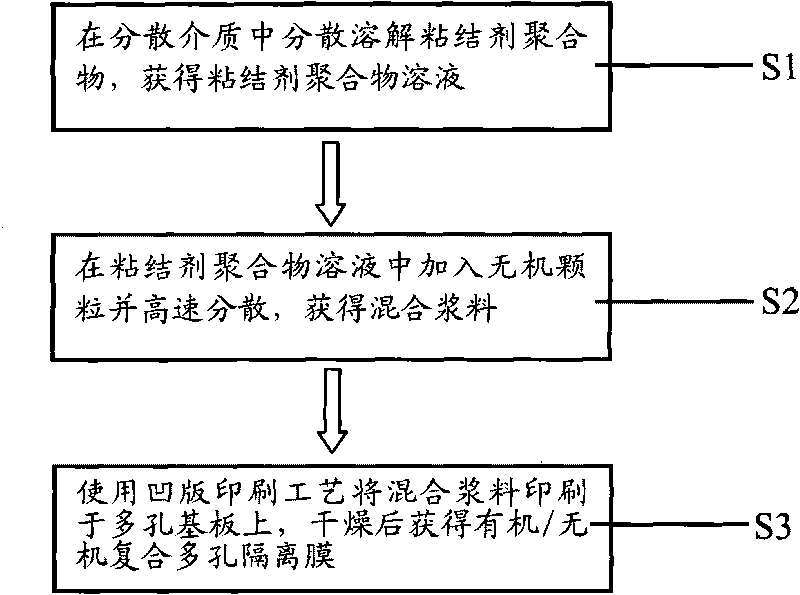

[0048] Example 1-5: Preparation of organic / inorganic composite porous membrane using gravure printing method

Embodiment 1

[0050] Add 25g of polyvinylidene fluoride (PVDF) to N-methyl-2-pyrrolidone (NMP) and dissolve at 45°C for 30 minutes or more to form a homogeneous polymer solution; add 975g to the polymer solution Inorganic Al 2 o 3 Granules and high-speed stirring to make the polymer and Al 2 o 3 The particles are uniformly dispersed, and Al 2 o 3 : PVDF is 97.5%: 2.5% slurry; then, use the gravure printing method to print the slurry to the surface of the polyethylene porous membrane, and dry to obtain the organic / inorganic composite porous diaphragm (97.5% Al 2 o 3 and 2.5% PVDF). The thickness of the organic / inorganic composite layer can be adjusted by the depth of the gravure hole and the solid content of the slurry (the weight percentage of the weight of the inorganic particles and the binder polymer in the total slurry), and the preparation process and cross-sectional structure of the organic / inorganic composite porous membrane Respectively as image 3 with figure 2 shown.

Embodiment 2

[0052] Al in embodiment 1 2 o 3 And the weight ratio of PVDF is adjusted to 98%: 2%, repeats the step in embodiment 1, obtains organic / inorganic composite porous membrane (98%Al 2 o 3 and 2% PVDF).

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com