Patents

Literature

597results about How to "Lower technical barriers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Service processing method, service processing device and data sharing system

ActiveCN107124278ALower technical barriersImprove universalityKey distribution for secure communicationPublic key for secure communicationBlockchainData sharing

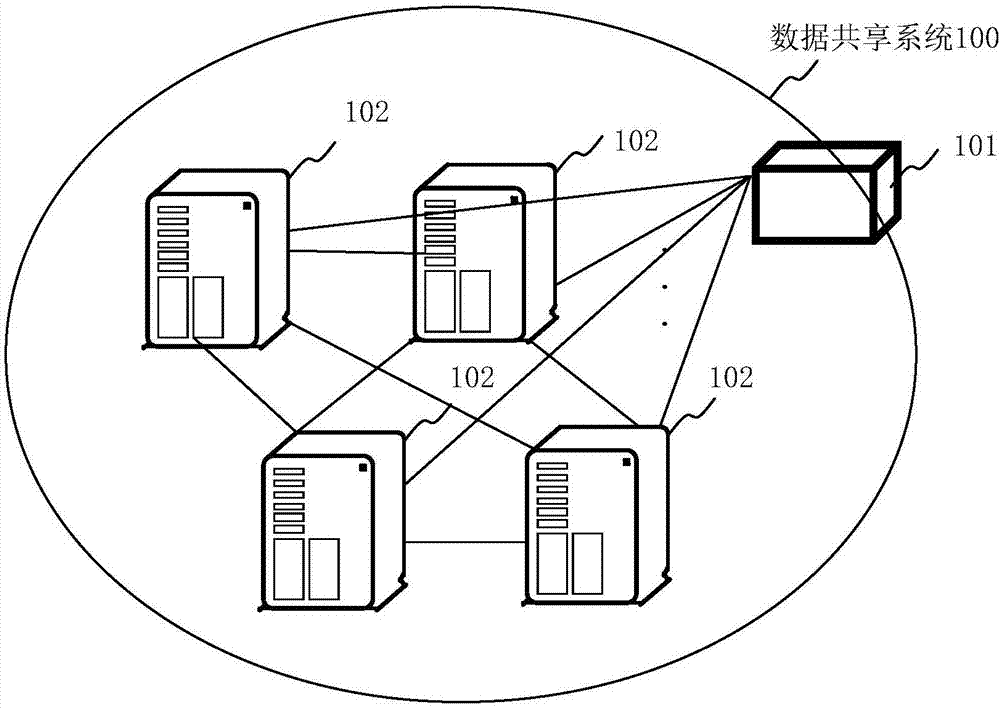

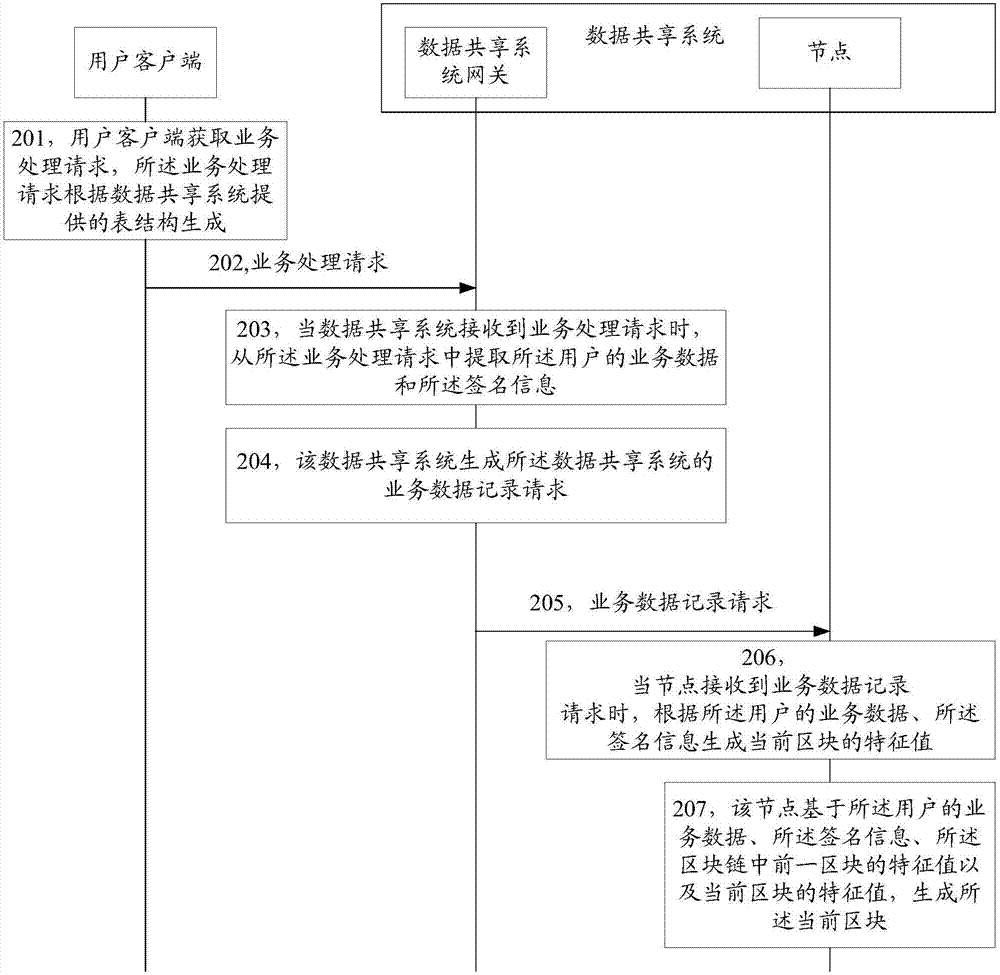

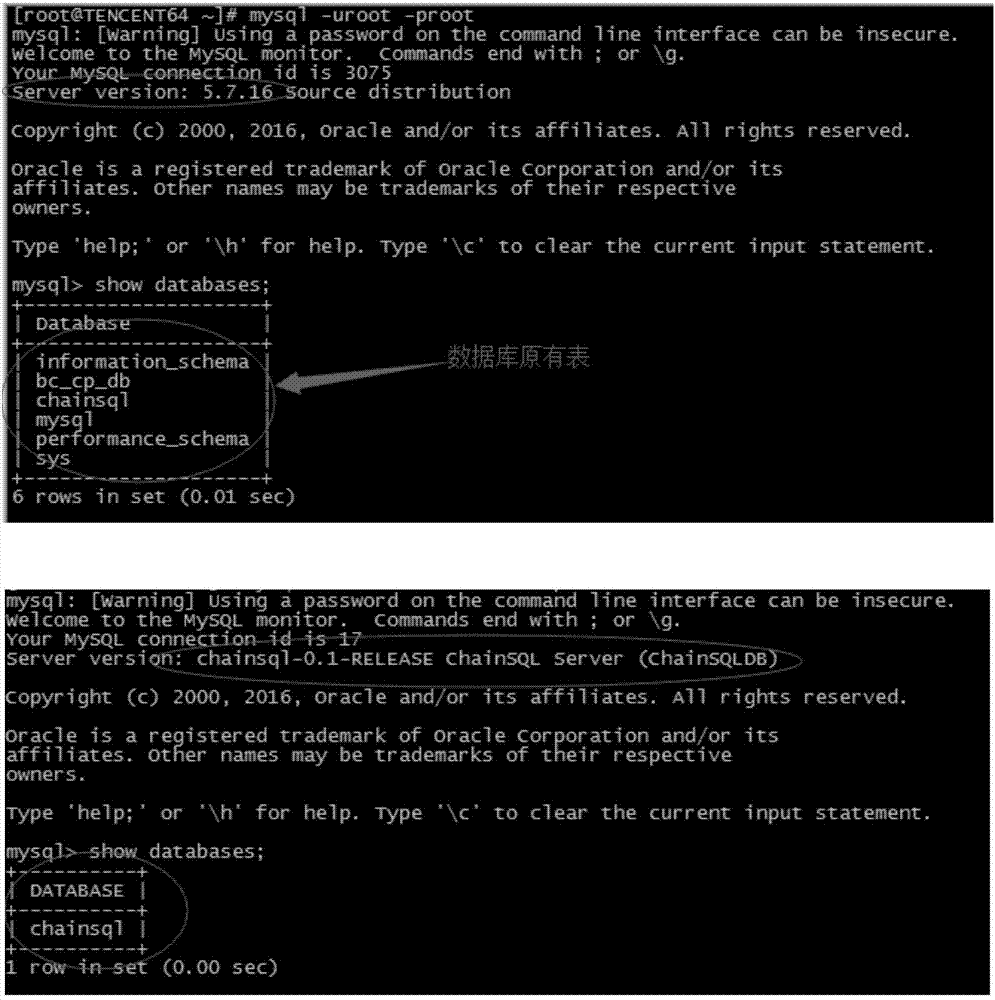

The invention discloses a service processing method, a service processing device and a data sharing system, and belongs to the technical field of networks. The method comprises the steps of: receiving a service processing request, wherein the service processing request is generated according to a table structure provided by the data sharing system; and the service processing request carries service data of a user and the signature information of the user for the service data; extracting the service data of the user and the signature information from the service processing request; generating a service data recording request of the data sharing system, wherein the service data recording request carries the service data of the user and the signature information; and sending the service data recording request to at least one node in the data sharing system. By means of the service processing method, the service processing device and the data sharing system disclosed by the invention, the technical threshold of the data sharing system is greatly reduced; multiple existing database service systems can perform seamless joint with the data sharing system; and thus, the universality of a block chain technology can be improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

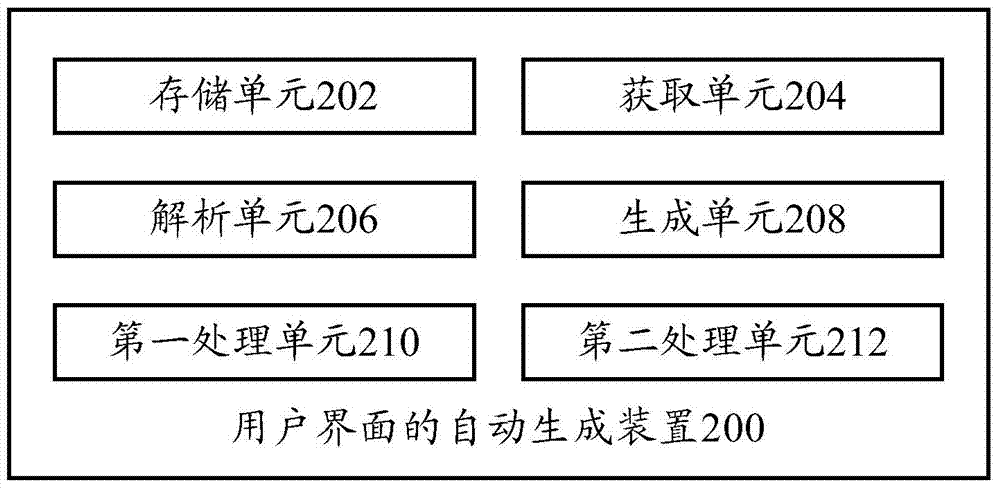

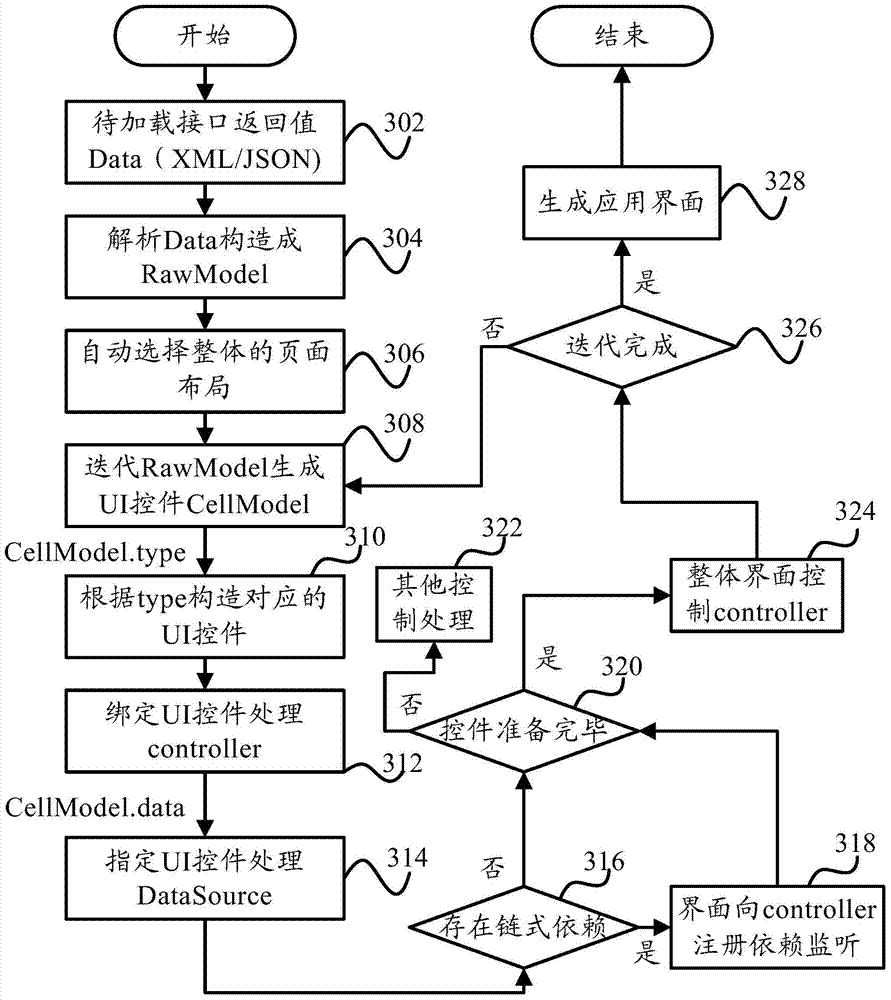

Automatic generation method and device of user interface (UI)

InactiveCN104731589AAutomatic implementation generationLower technical barriersSpecific program execution arrangementsData setSoftware engineering

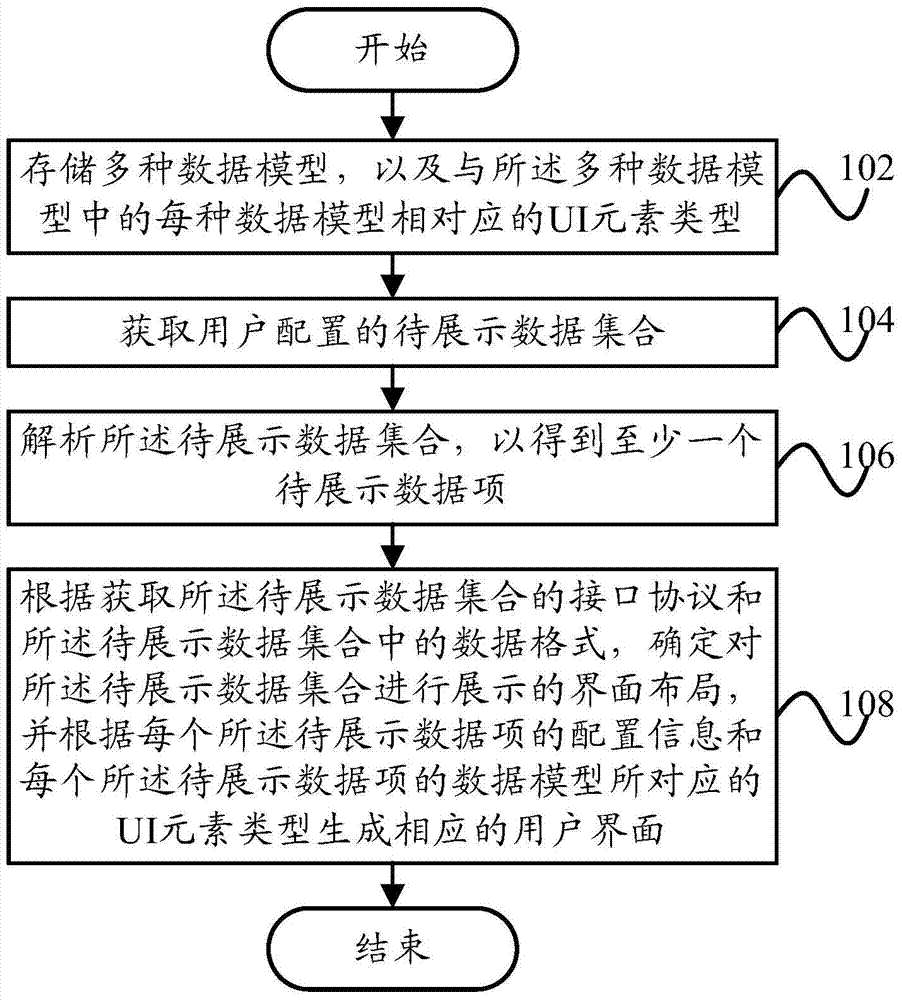

The invention provides an automatic generation method and device of a user interface (UI). The automatic generation method includes the following steps that various data models and UI element types corresponding to the data models are stored; a to-be-displayed data set configured by a user is obtained; the to-be-displayed data set is analyzed to obtain at least one to-be-displayed data item; an interface layout for displaying the to-be-displayed data set is determined according to an interface protocol for obtaining the to-be-displayed data set and the data format in the to-be-displayed data set, and the corresponding UI is generated according to the configuration information of each to-be-displayed data item and the UI element type corresponding to the data model of each to-be-displayed data item. By means of the technical scheme, generation of the UI is automatically realized according to a pre-stored description file, and the technical threshold for developing the UI and the development cost for the UI are lowered.

Owner:YONYOU NETWORK TECH

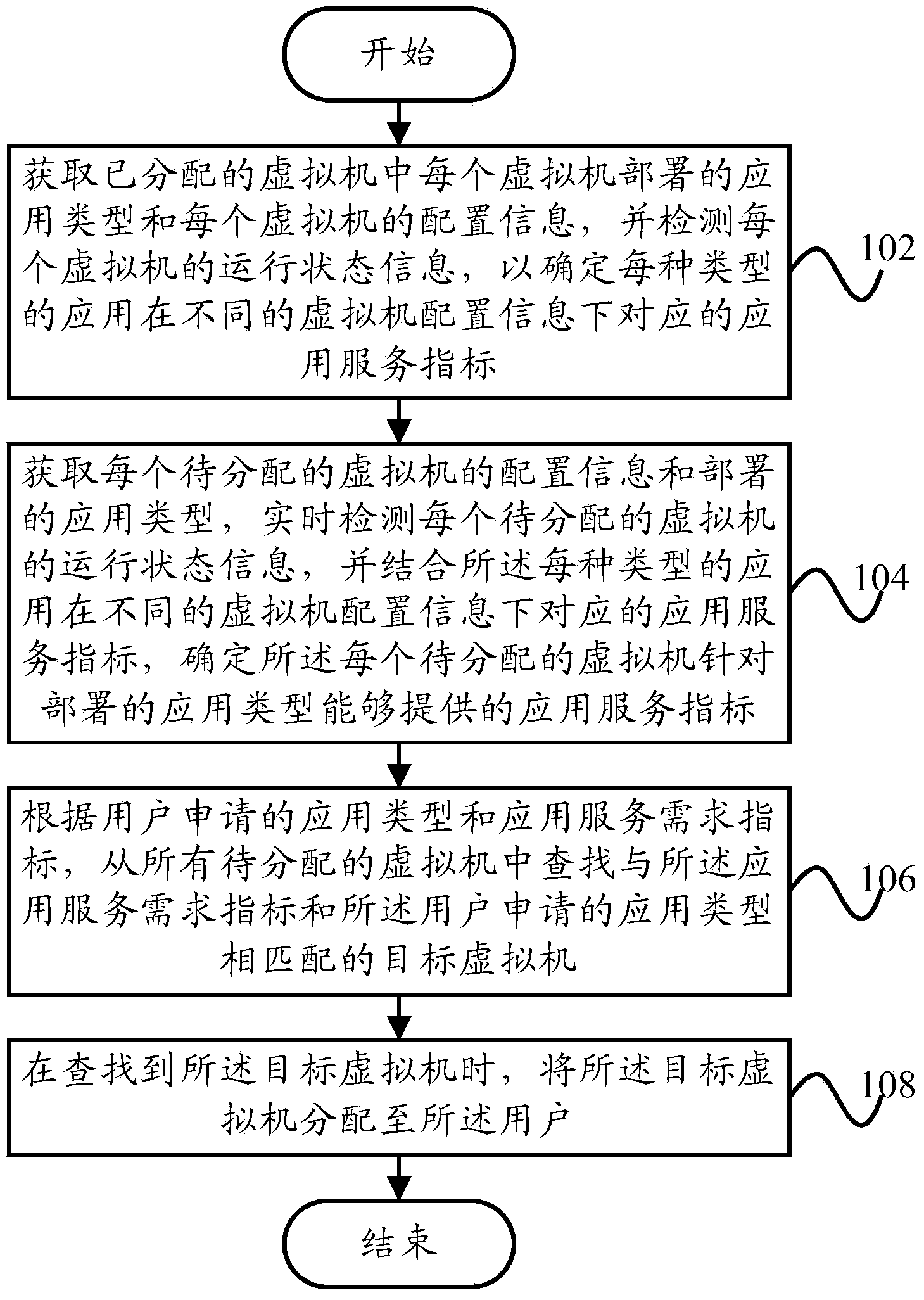

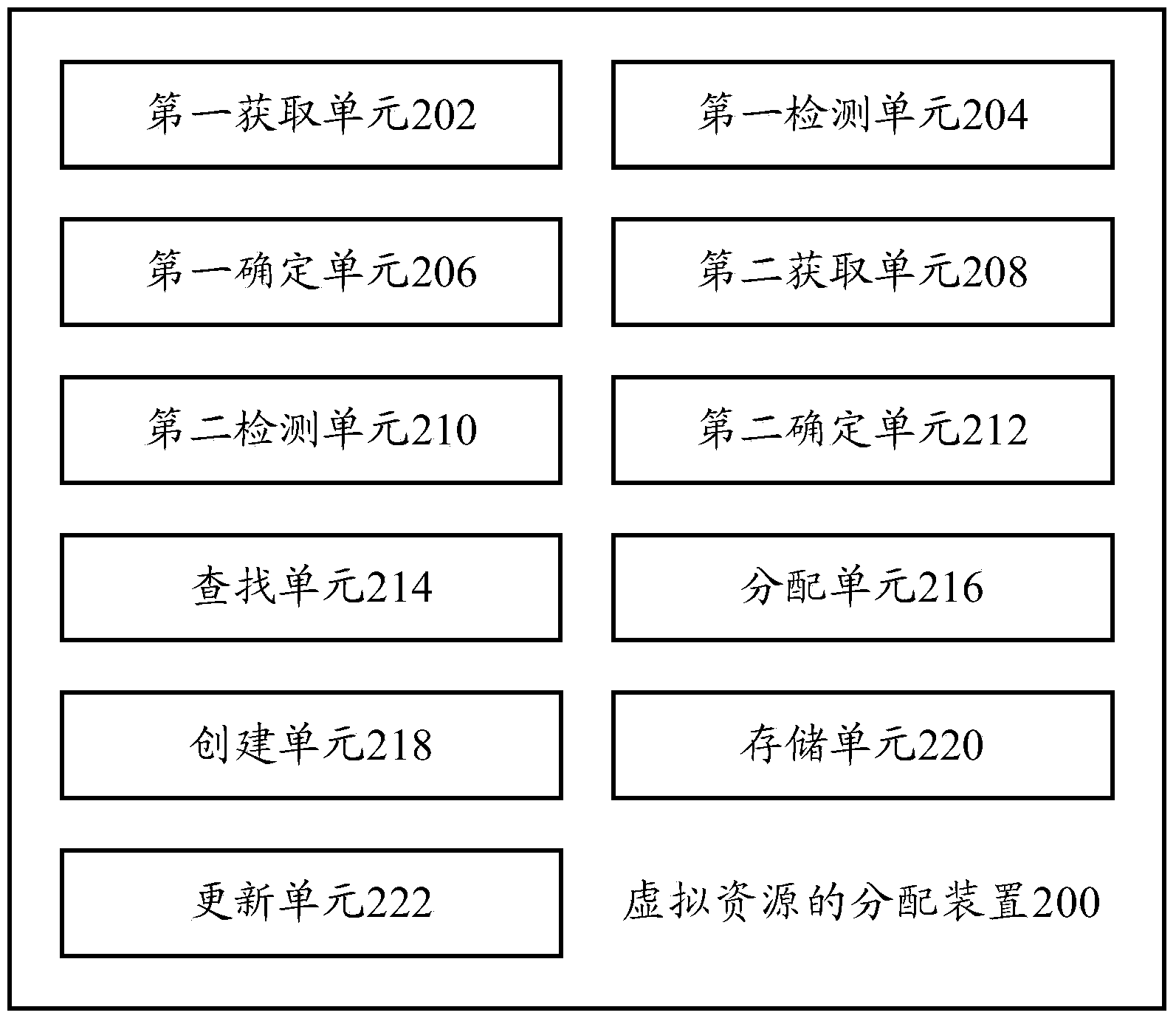

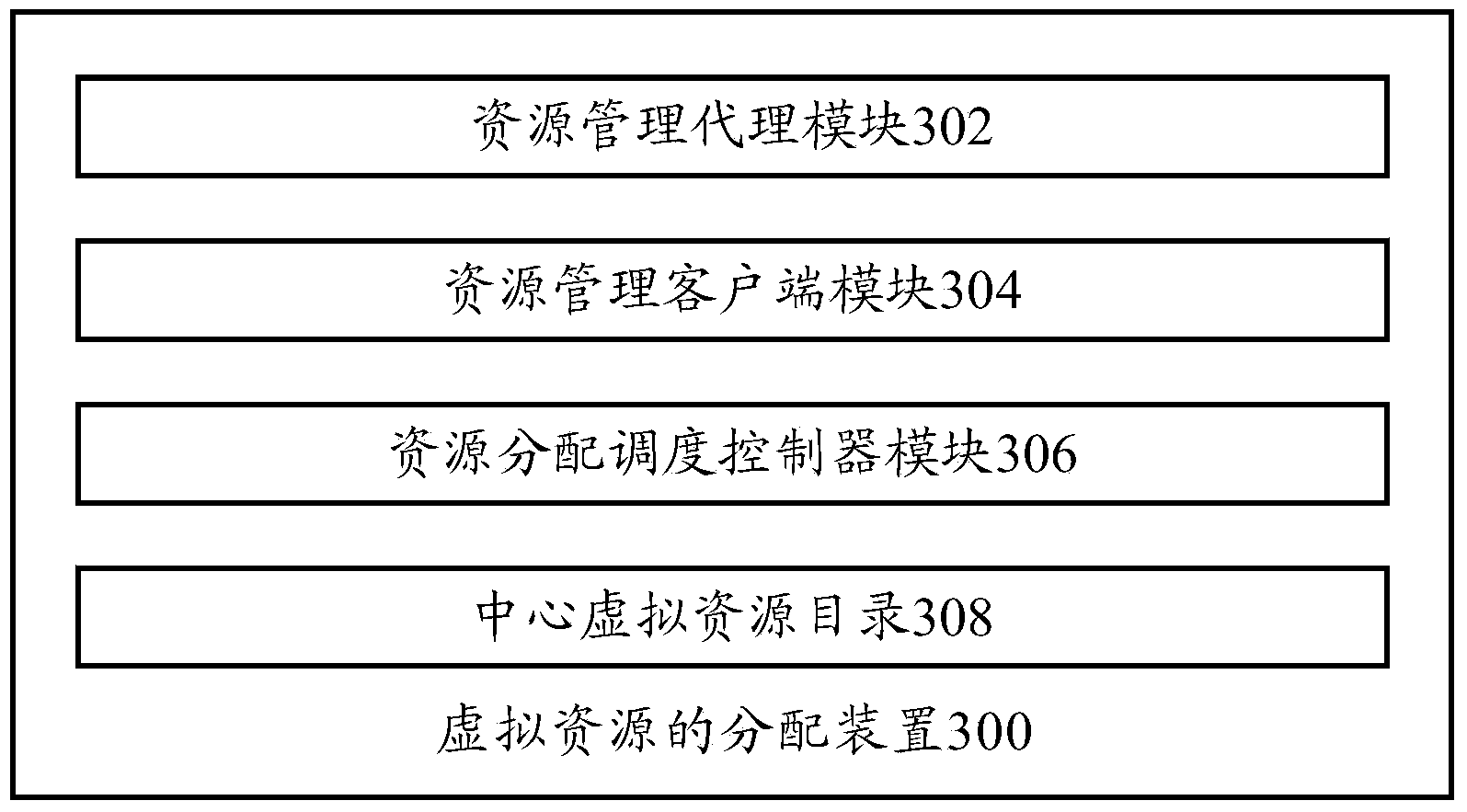

Virtual resource distribution method and virtual resource distribution device

ActiveCN104281496AAccurate estimateLower technical barriersResource allocationSoftware simulation/interpretation/emulationVirtual machineDistribution method

The invention provides a virtual resource distribution method and a virtual resource distribution device. The virtual resource distribution method comprises the following steps: obtaining an application type and configuration information of each virtual machine deployment in distributed virtual machines, detecting running state information of each virtual machine, and determining a corresponding application service index of each type of the application at the presence of different virtual machine configuration information; detecting the running state information of each to-be-distributed virtual machine, and determining the application service index which can be provided by each to-be-distributed virtual machine by combining with the corresponding application service index of each type of the application at the presence of different virtual machine configuration information; searching a target virtual machine based on the application type and the application service required index applied by a user, and distributing the target virtual machine to the user. The technical scheme of the invention reduces technical threshold of applying for virtual machine resources, and can distribute optimal virtual machine resources flexibly based on demands of the user, realizes optimization of distribution and utilization of the virtual machine resources.

Owner:ZICT TECH CO LTD

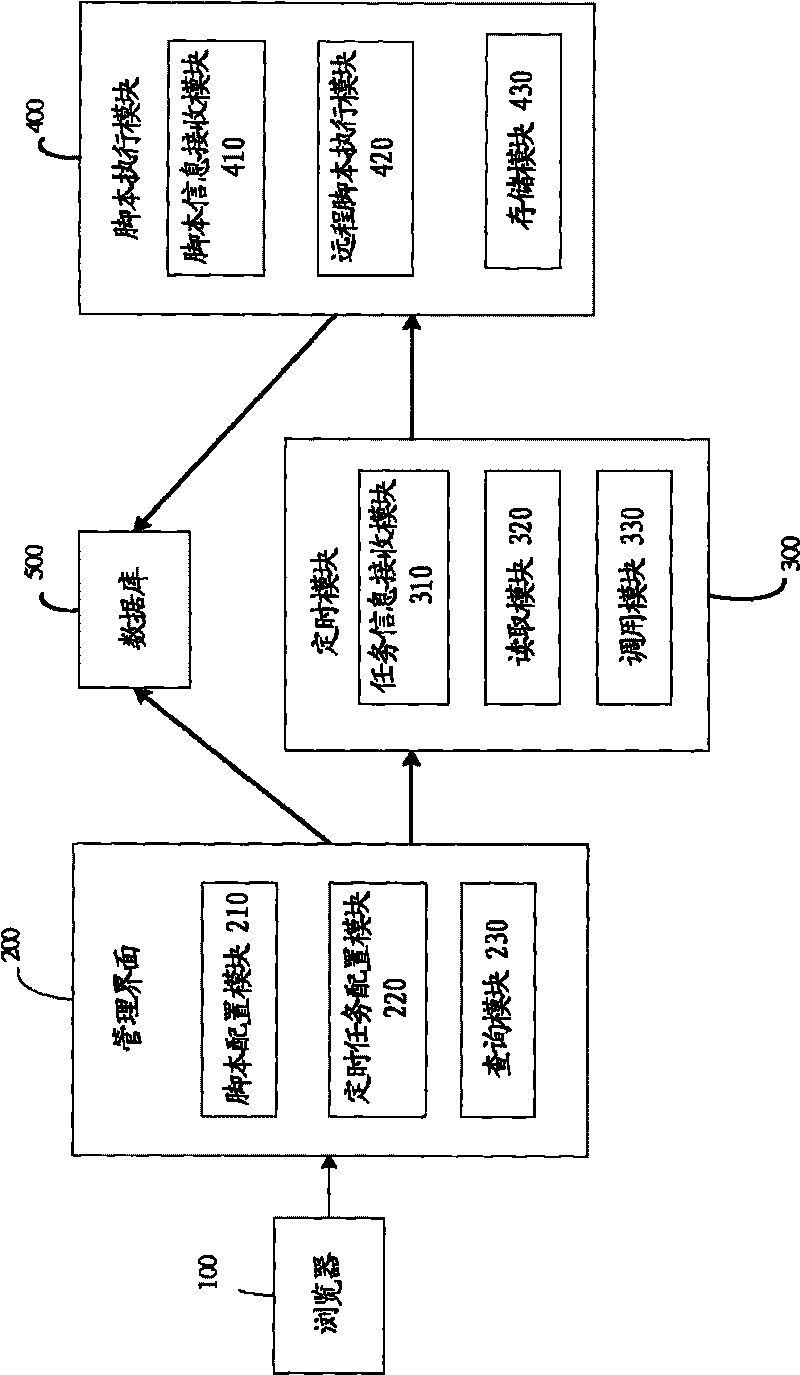

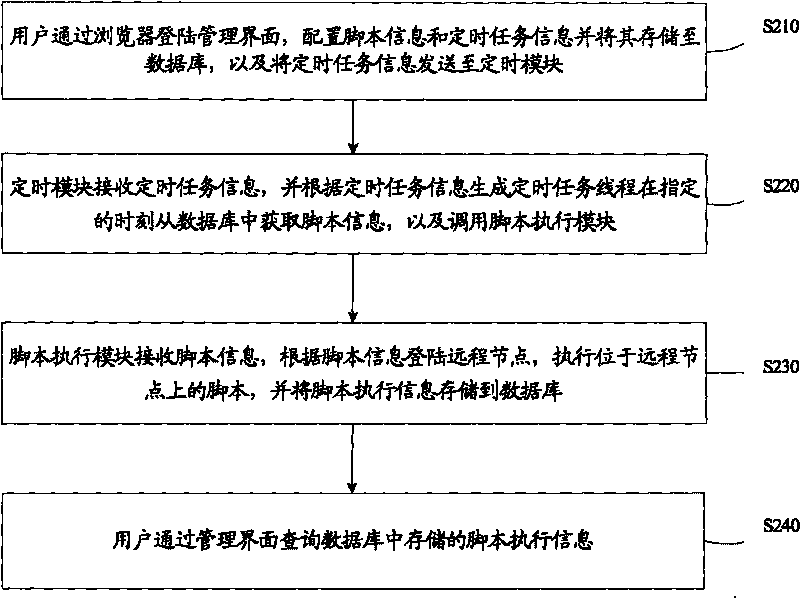

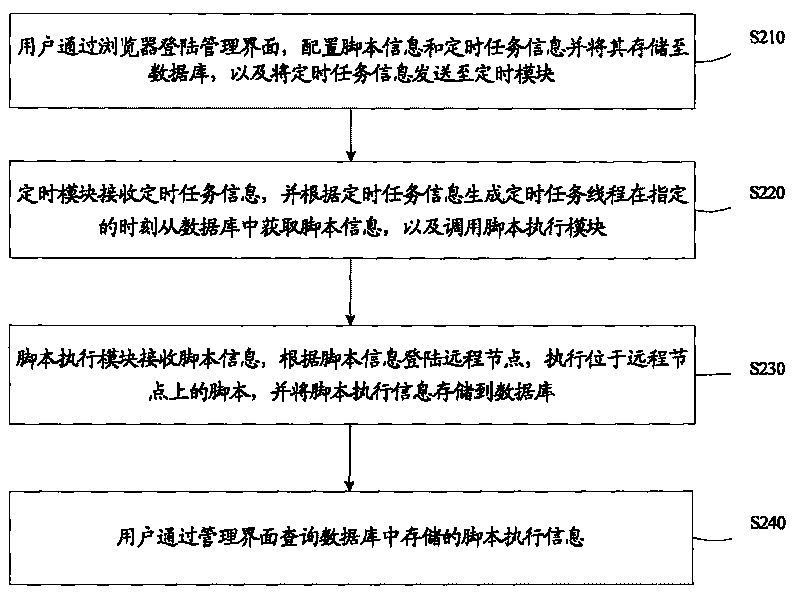

Script execution system and method

ActiveCN101694626AEasy to manageLower technical barriersProgram loading/initiatingEmbedded systemInformation storage

The invention provides a script execution system and a method. The method includes following steps that a user logins a management interface through a browser, collocates script information and timing task information, stores the same into a database and transmits the timing task information to a timing module. The timing module receives the timing task information, generates a timing task threadaccording to the timing task information, obtains script information at a specified time and invokes a script execution module. The script execution module receives the script information, logins a remote node according to the script information to execute scripts on the remote node, and stores script execution information to the database. The user inquires the script execution information storedin the database through the management interface. The script execution system and the method uniformly manage scripts in a cluster server through adding a timing task functional module, and timely automatically execute the scripts, thereby increasing efficiency of the user to execute the scripts. Simultaneously, the script execution system and the method further provide a function for the user tomanually click and execute the scripts.

Owner:中科曙光信息产业(海南)有限公司

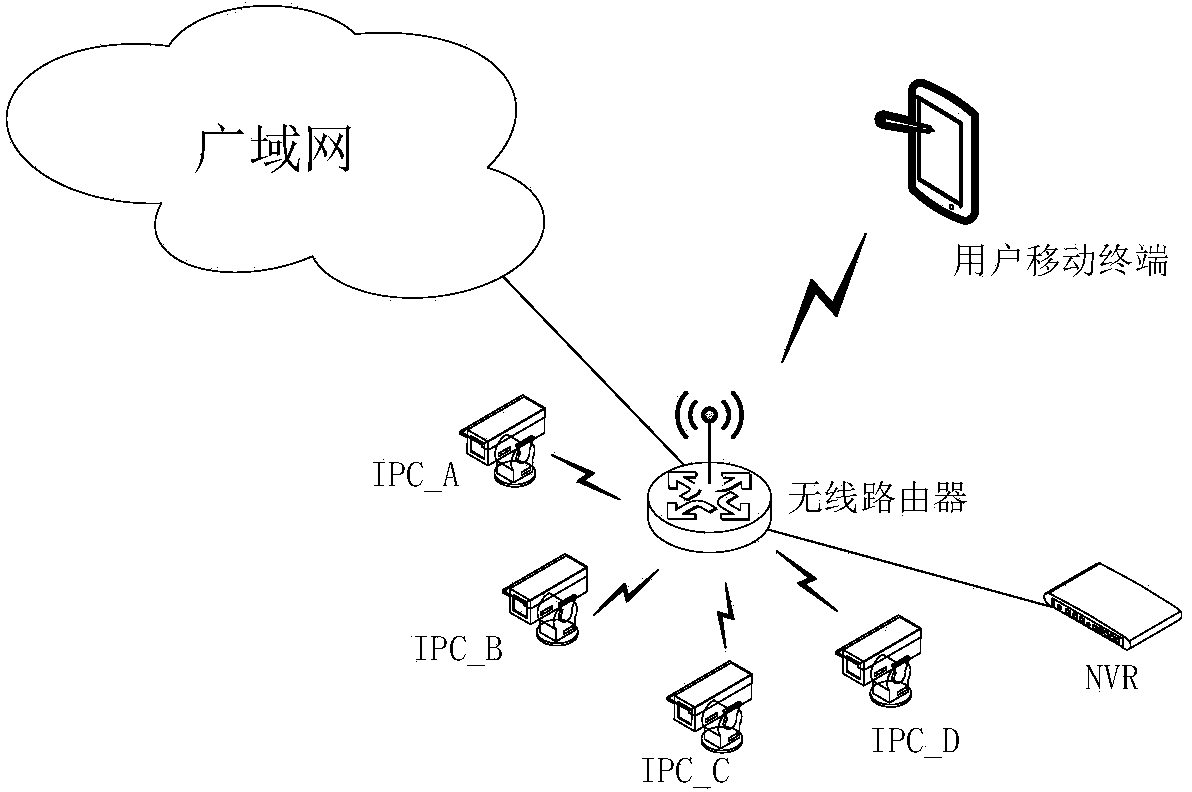

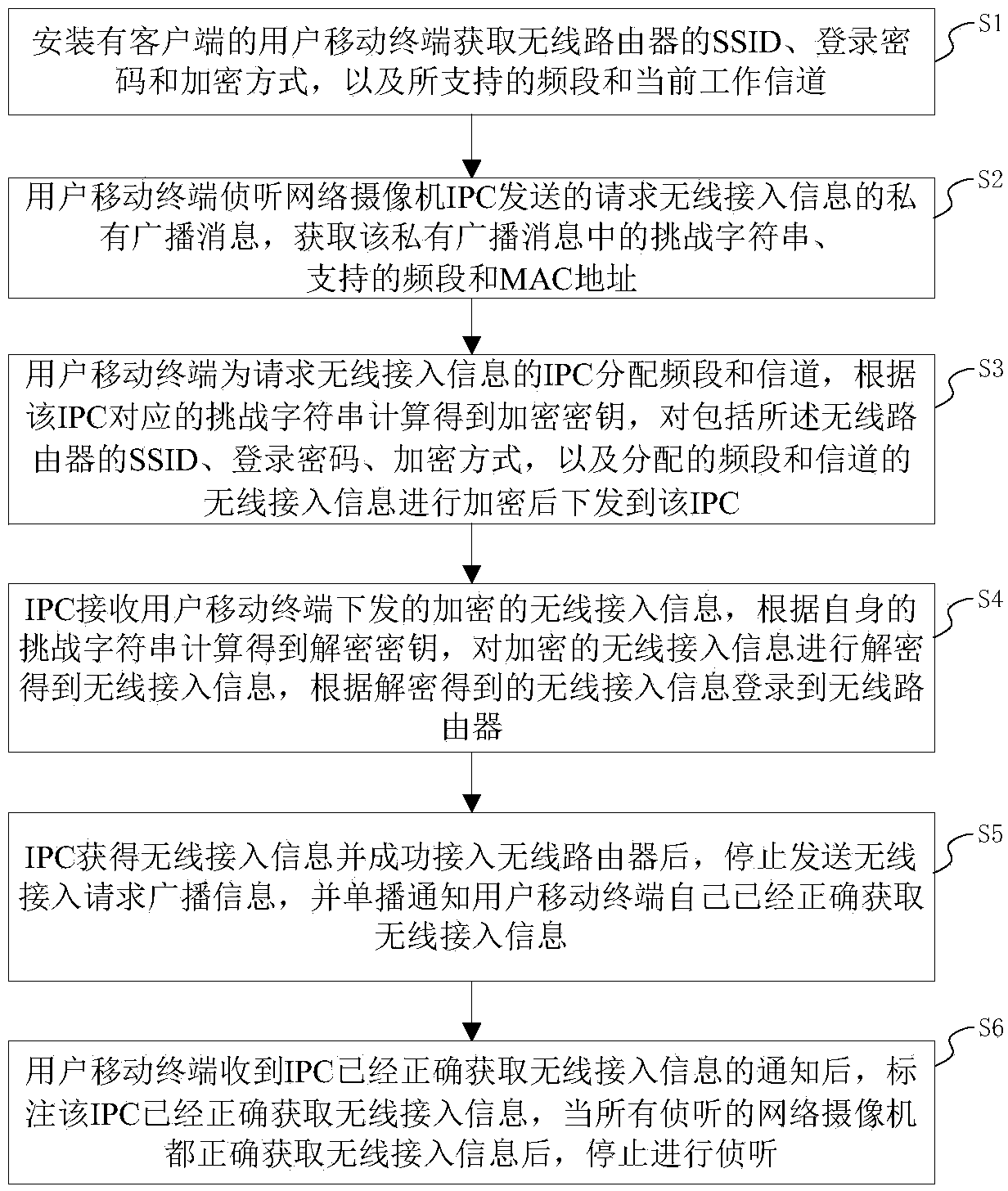

Method for configuring IP cameras to have access to wireless router

ActiveCN104301884ALower technical barriersNot cause congestionAssess restrictionClosed circuit television systemsWireless routerPassword

The invention discloses a method for configuring IP cameras to have access to a wireless router. The method comprises the steps that a user acquires the SSID, the login password and the encryption mode of the wireless router, the frequency band which the wireless router supports and the current working channel of the wireless router through a mobile terminal provided with a client-side; the mobile terminal monitors private broadcast messages sent by the IP cameras to request for wireless access information, acquires frequency bands which the IP cameras support, allocates frequency bands and channels to the IP cameras requesting for the wireless access information according to the frequency band and the current working channel of the wireless router and the frequency bands of the IP cameras, allocates the IP cameras uniformly to the frequency bands which the wireless router supports, encrypts the wireless access information and then issues the encrypted wireless access information to the IP cameras; the IP cameras have access to the wireless router after receiving the wireless access information. By means of the method, the IP cameras can automatically and equally have access to the wireless router within two frequency bands, and operation is easy and convenient.

Owner:ZHEJIANG UNIVIEW TECH CO LTD

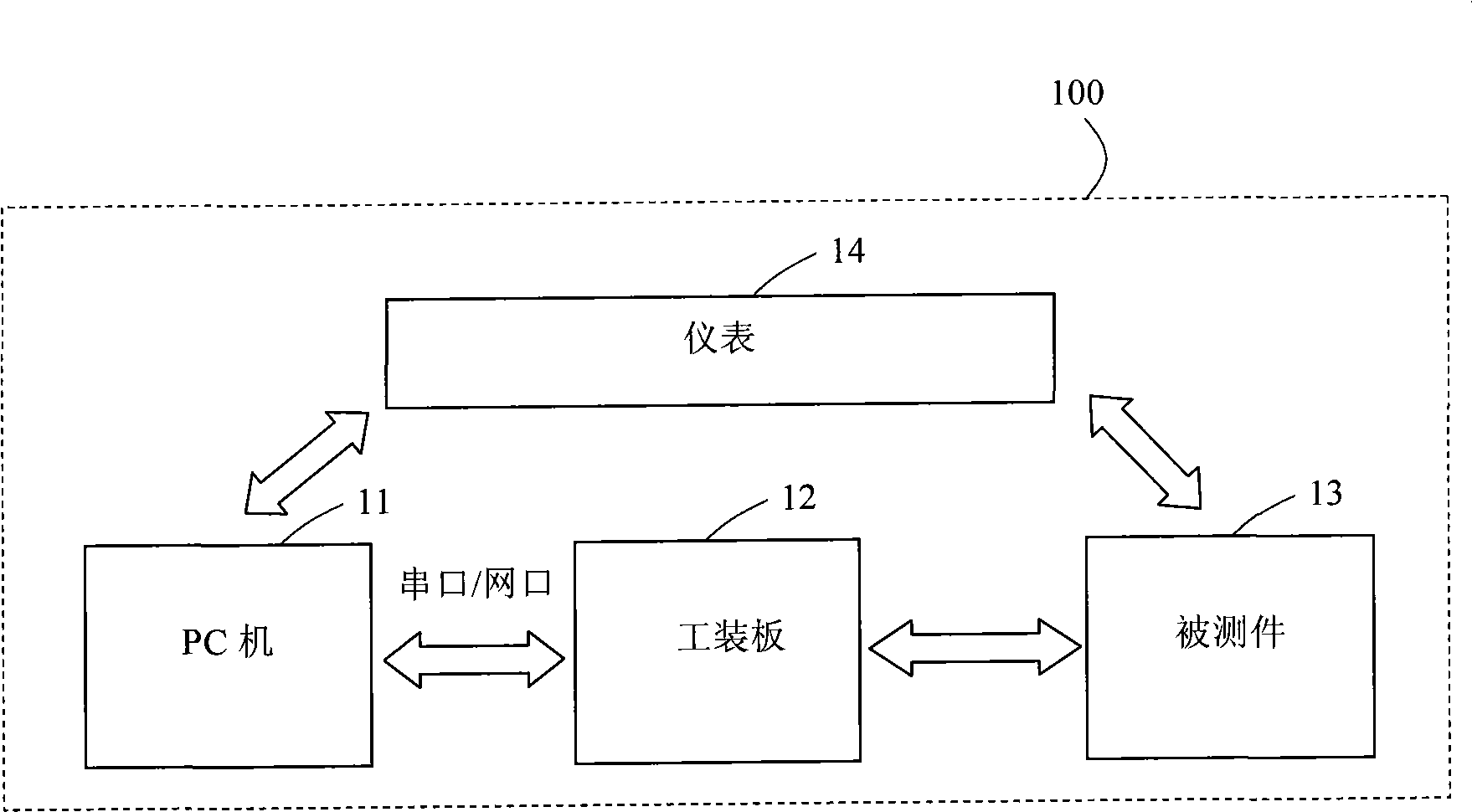

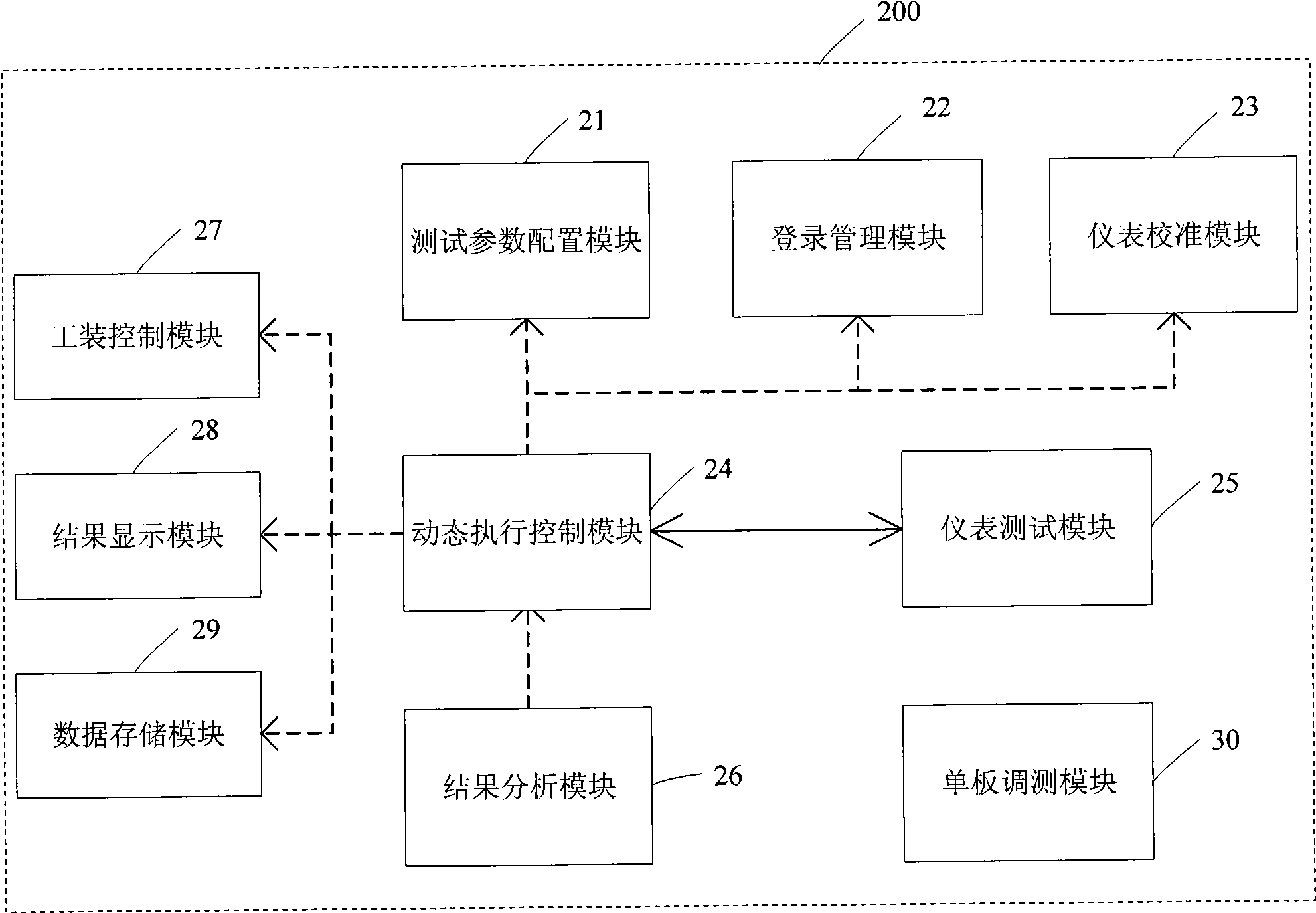

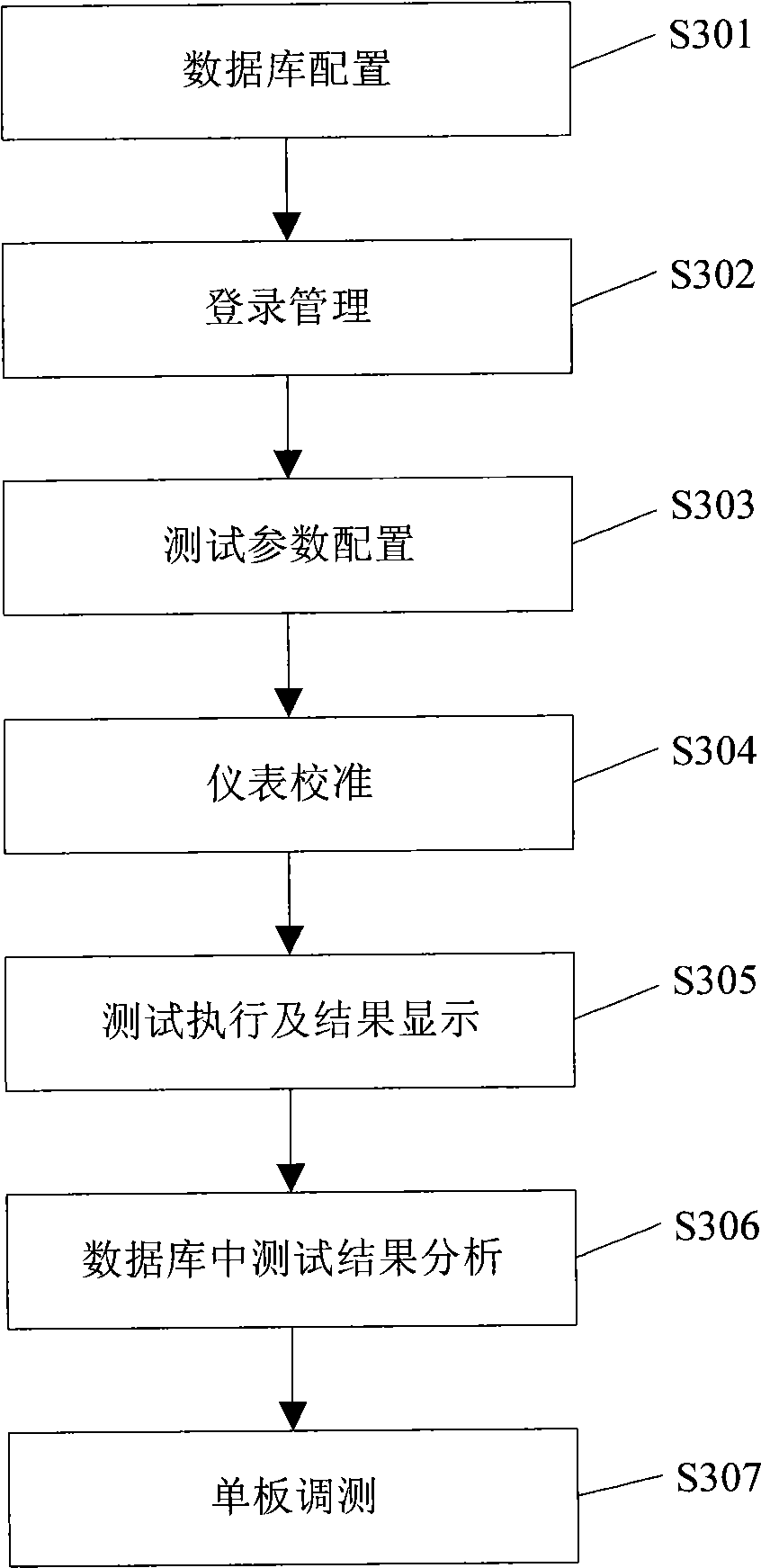

Automatic test system and method

InactiveCN101487769AImprove portabilityEnhanced tailorabilityStructural/machines measurementSoftware testing/debuggingProduction lineIndex test

The invention discloses an automatic test system and a method thereof, which are operated on a computer terminal and used for testing communication equipment through a tooling plate and a meter, wherein the system comprises a test parameter configuration module for configuring test parameters required by test, a meter calibration module for calibrating the meter to obtain a meter calibration result, a dynamic execution control module for setting working states and working modes of the communication equipment through communication with the tooling plate and controlling the meter at a normal working state according to the test parameters, and a meter test module connected with the dynamic execution control module for testing indexes of the communication equipment through the state of the control meter when the meter works in the normal working state, and returning an index test result to the dynamic execution control module for processing. The system and the method achieve efficient and automatic test for large-scale communication products of a production line.

Owner:ZTE CORP

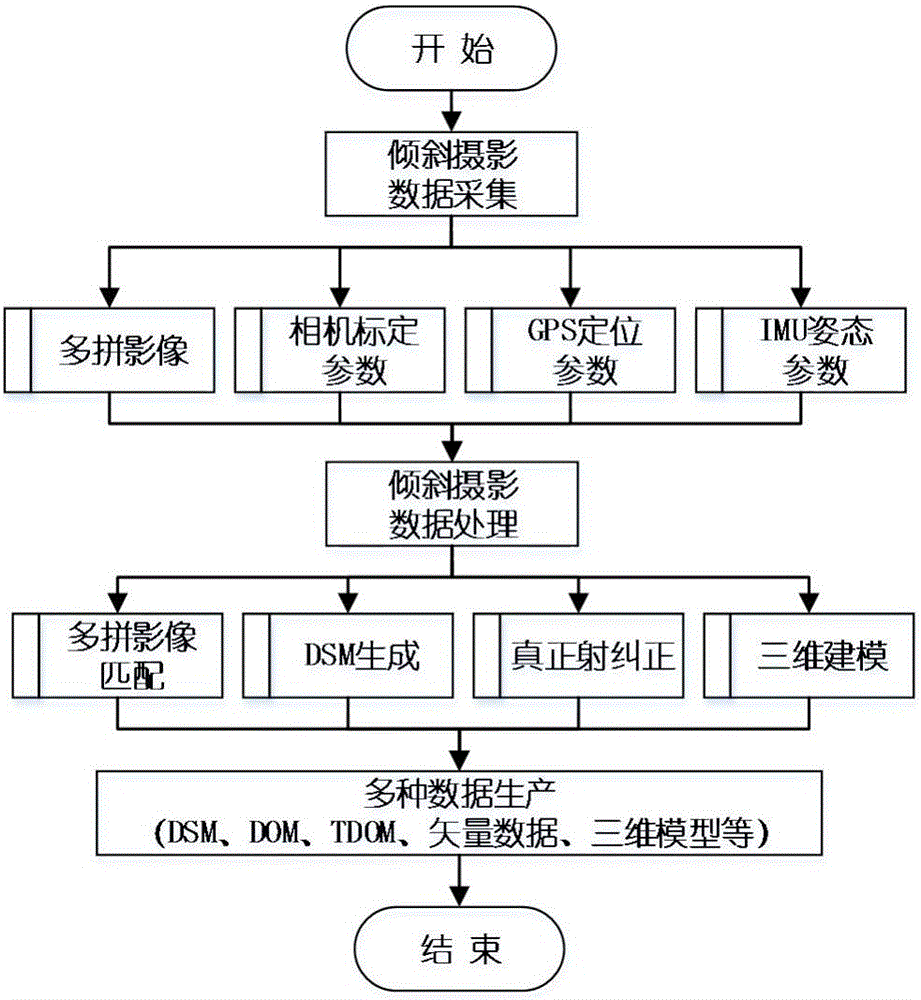

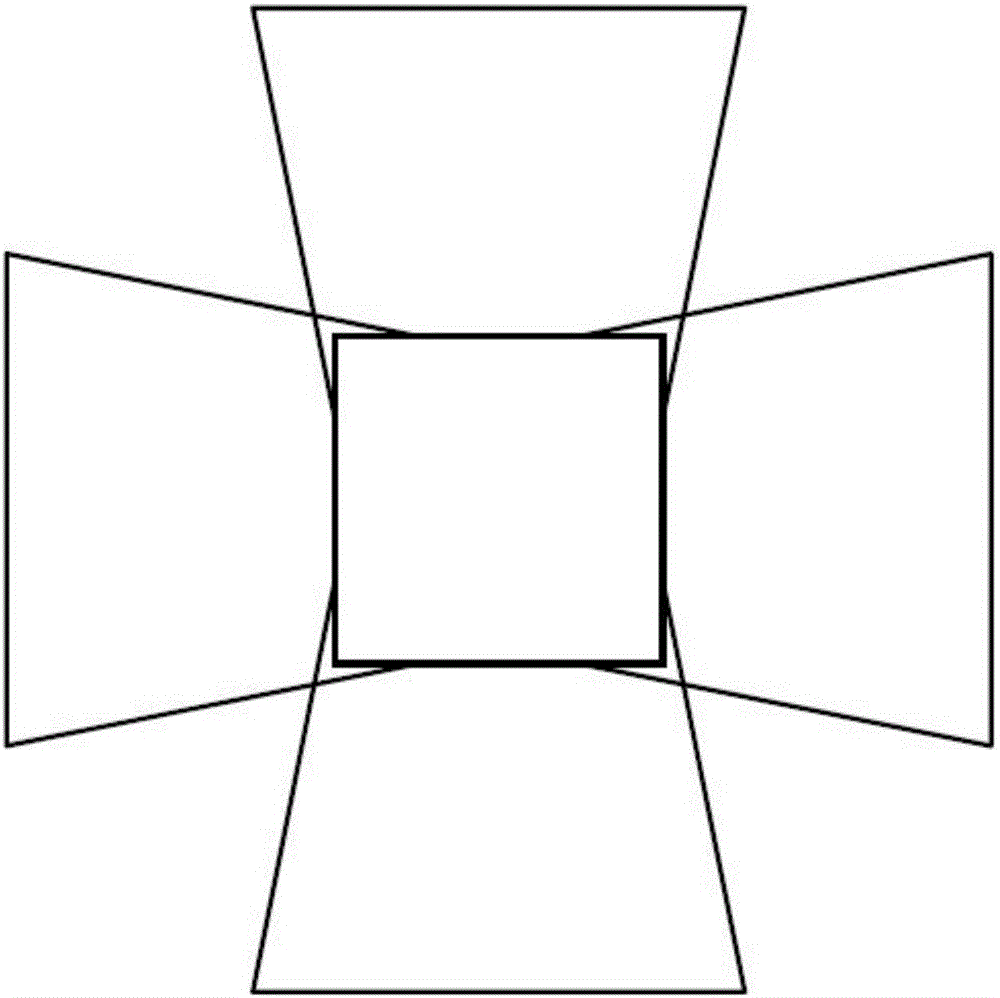

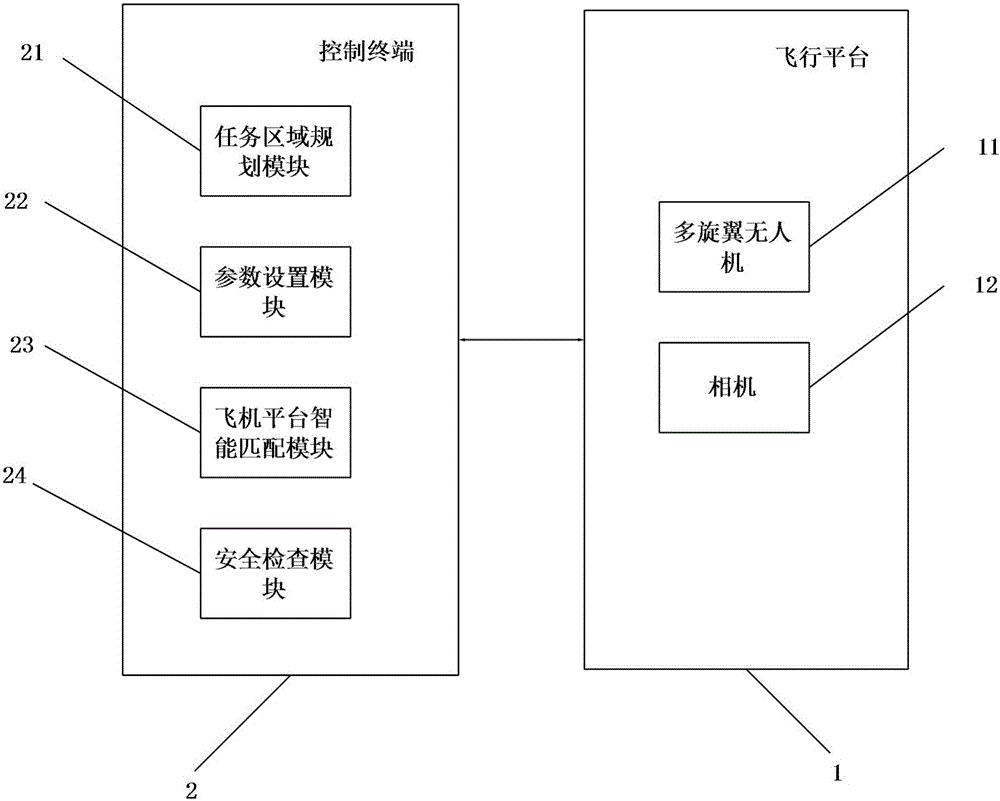

Oblique three-dimensional aerial measurement data acquisition system and acquisition method and control terminal

InactiveCN106249751ALow costExpand the range of flying platformsTelevision system detailsColor television detailsUncrewed vehicleData acquisition

The invention relates to an oblique three-dimensional aerial measurement data acquisition system, which comprises a flight platform and the control terminal. The flight platform comprises a multi-rotor unmanned aerial vehicle and a single camera arranged on the multi-rotor unmanned aerial vehicle. The control terminal comprises a task area planning module for planning the flight course; and a parameter setting module for setting flight parameters of the multi-rotor unmanned aerial vehicle, the flight parameters comprising start point position, final point position, inclination angle of a nose, airplane flying height, forward overlap degree and side overlap degree. The multi-rotor unmanned aerial vehicle flies according to the planned number of flight, the flight course and the set parameters. The camera is used for collecting data in the flying process. The invention also provides a data acquisition method and the control terminal. Compared with the prior art, the brand-new flight data acquisition method is designed to adapt to a single-lens, multi-rotor and individual oblique photograph acquisition work mode; furthermore, full-automatic flight acquisition is realized, and operation process is normalized; and achievement quality is ensured and work efficiency is improved.

Owner:广州优飞信息科技有限公司

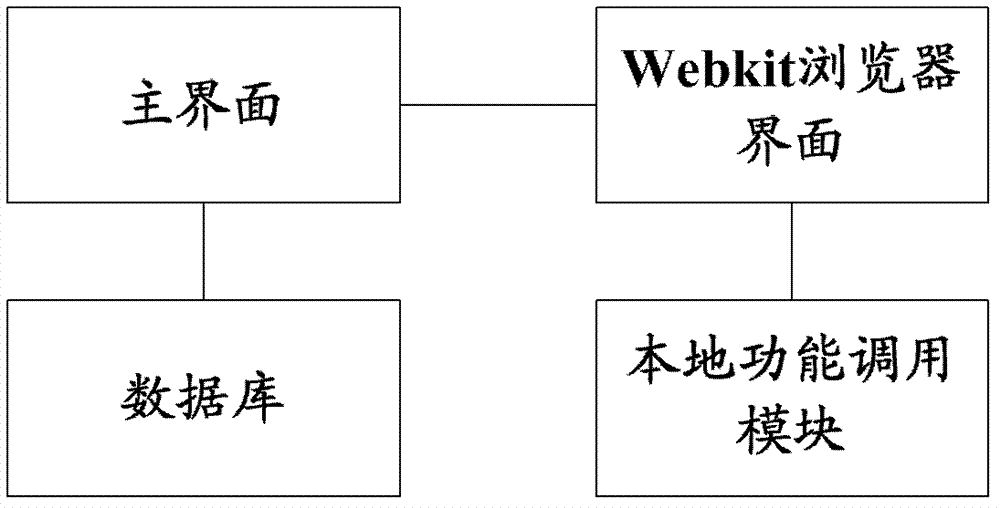

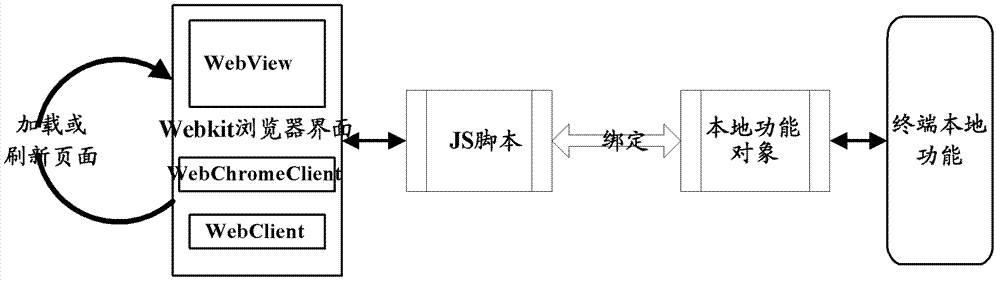

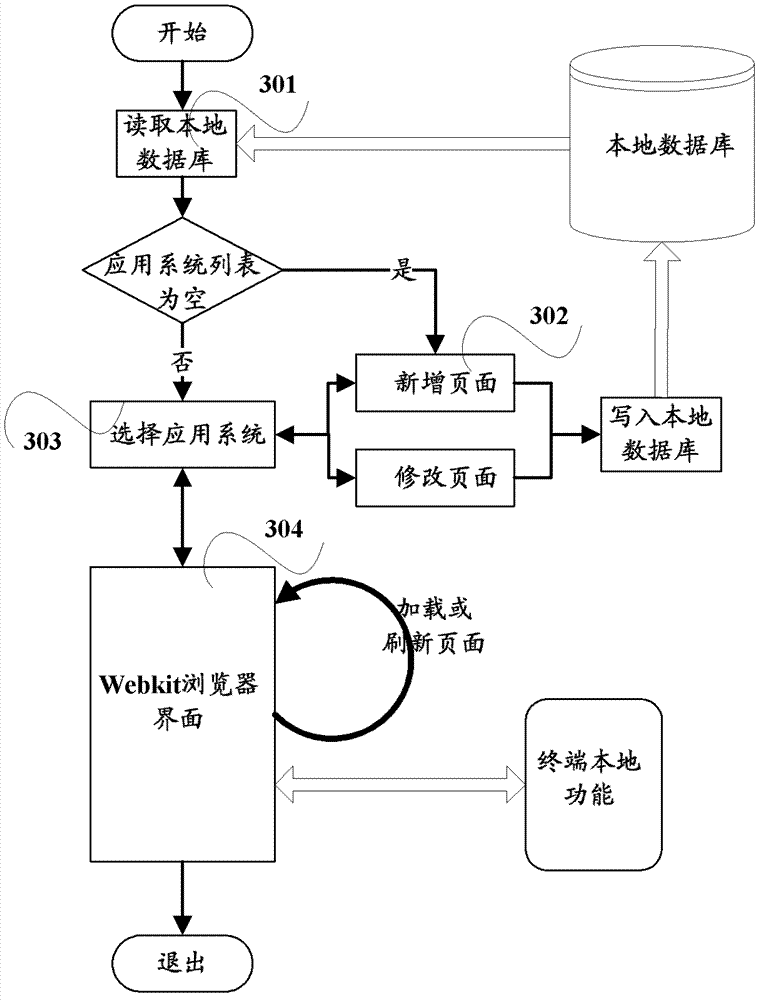

Client implementation method based on WebKit browser and client

ActiveCN102955694ASimplify the development processLower technical barriersSpecific program execution arrangementsSpecial data processing applicationsWeb browserWeb application

The invention proposes a client implementation method based on a WebKit browser and a client. The client implementation method comprises the steps of: entering a main interface in a clicking manner; reading application system data from a local database, entering an application system list interface to select an application system; loading a URL (uniform resource locator) page of the selected application system, wherein a JS (javascript) script of the application system is bounded to a local object of a terminal; and clicking a URL of the application system, transferring the local object of the terminal through the JS script to transfer the data. According to client implementation method, the development process of the client based on an Android platform is simplified; rapid development and adaptation of a single Android smart client butted with a plurality of Web application systems are adapted, and the velocity of the Android platform client butted with the Web system is improved.

Owner:CHINA TELECOM CORP LTD

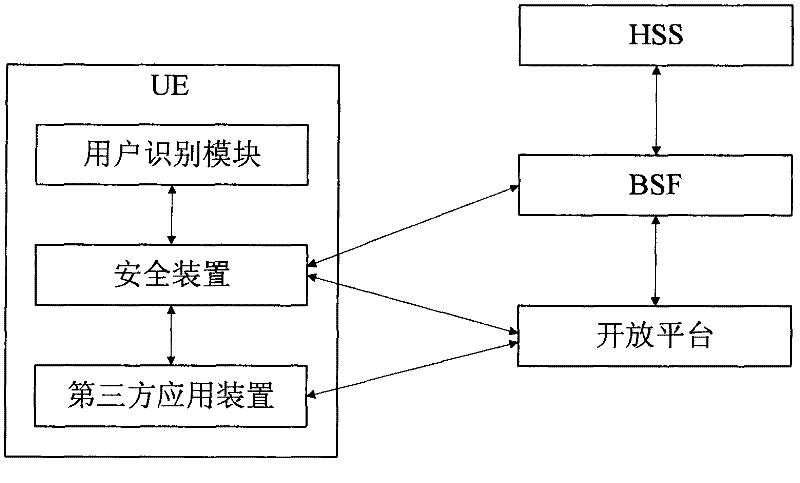

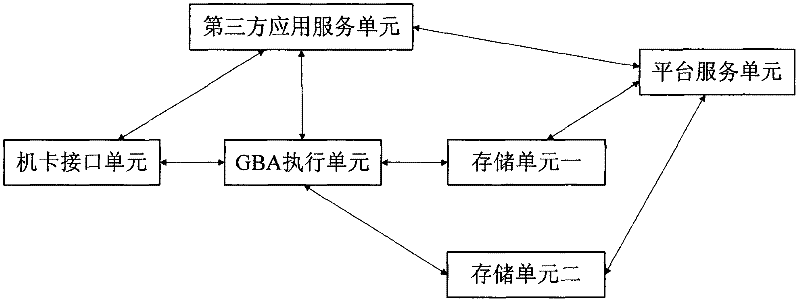

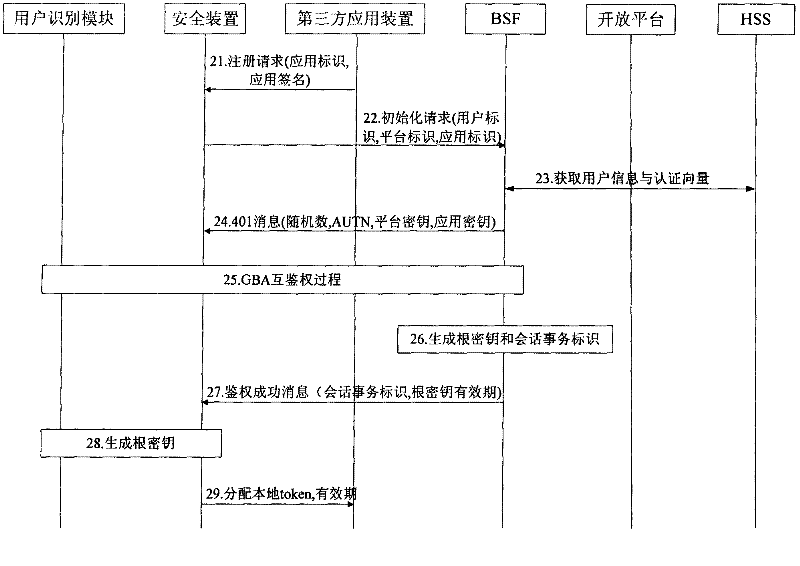

GBA (General Bootstrapping Architecture)-based secret key negotiation system and method of telecommunication capability open platform

InactiveCN102413464AImprove service efficiencyLower technical barriersSecurity arrangementThird partyOpen platform

The invention relates to a GBA(General Bootstrapping Architecture)-based secret key negotiation system and method of a telecommunication capability open platform. A safety device and a third-party application device are arranged in UE (User Equipment). The GBA-based secret key negotiation method comprises the following steps: the three-party application device sends a registration request message carrying an application identifier to the safety device; the safety device initiates an initialized request message carrying a user identifier, a platform identifier and an application identifier to a BSF (Bootstrapping Service Function); the BSF searches a platform secret key and an application secret key which are stored in local according to the platform identifier and the application identifier, informs the safety device of updating the platform secret key and the application secret key, executes an inter-authentication GBA process with the safety device and finally generates a root secret key according to the application secret key and the application secret key; and the safety device generates a root secret key Ks consistent with the BSF according to the updated platform secret key K_op and the updated application secret key K_app and returns generated local token and validity period to the third-party application device. The GBA-based secret key negotiation system and method of the telecommunication capability open platform, disclosed by the invention, belong to the technical field of mobile communication, and the open platform is capable of effectively authenticating and identifying third-party application.

Owner:EB INFORMATION TECH

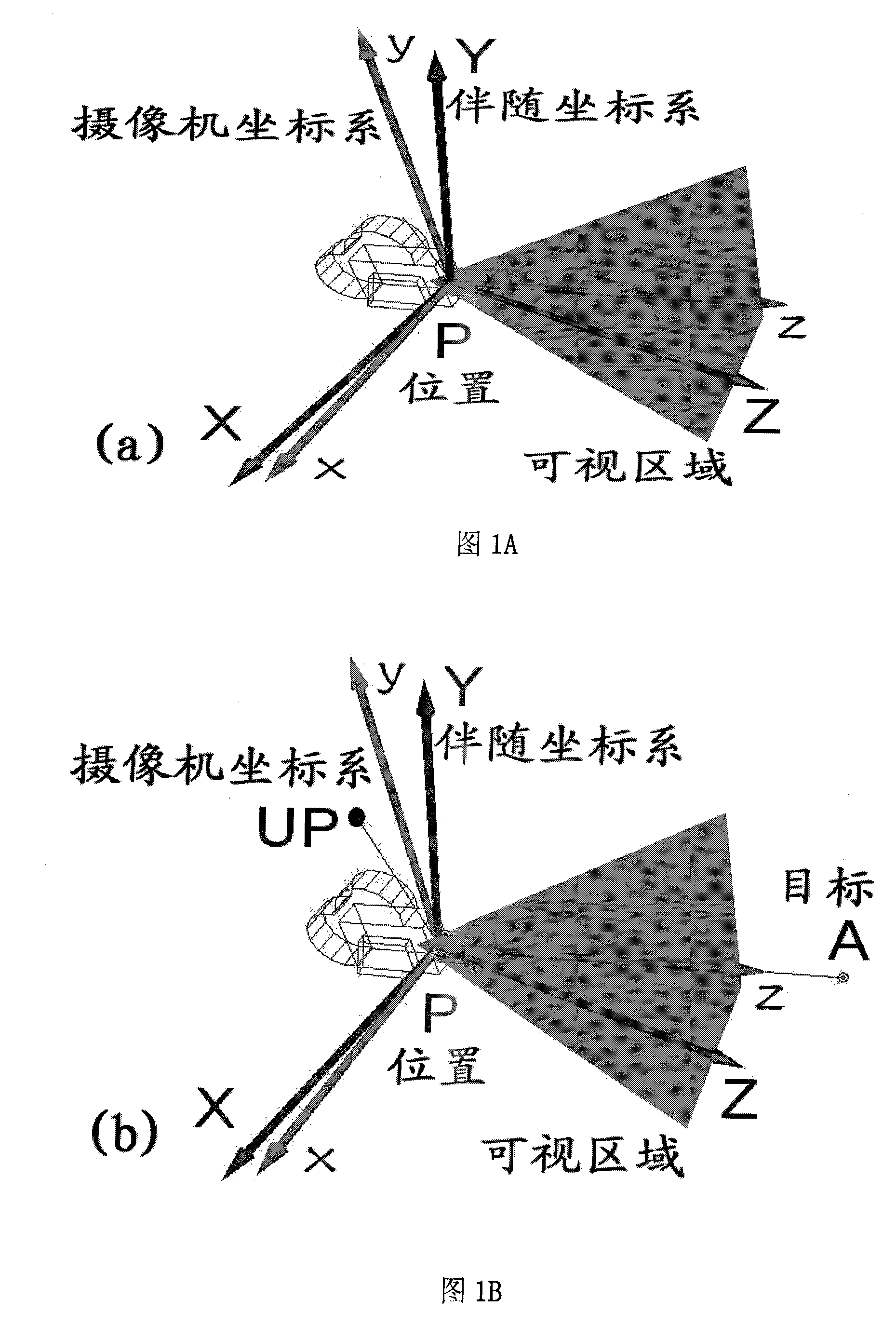

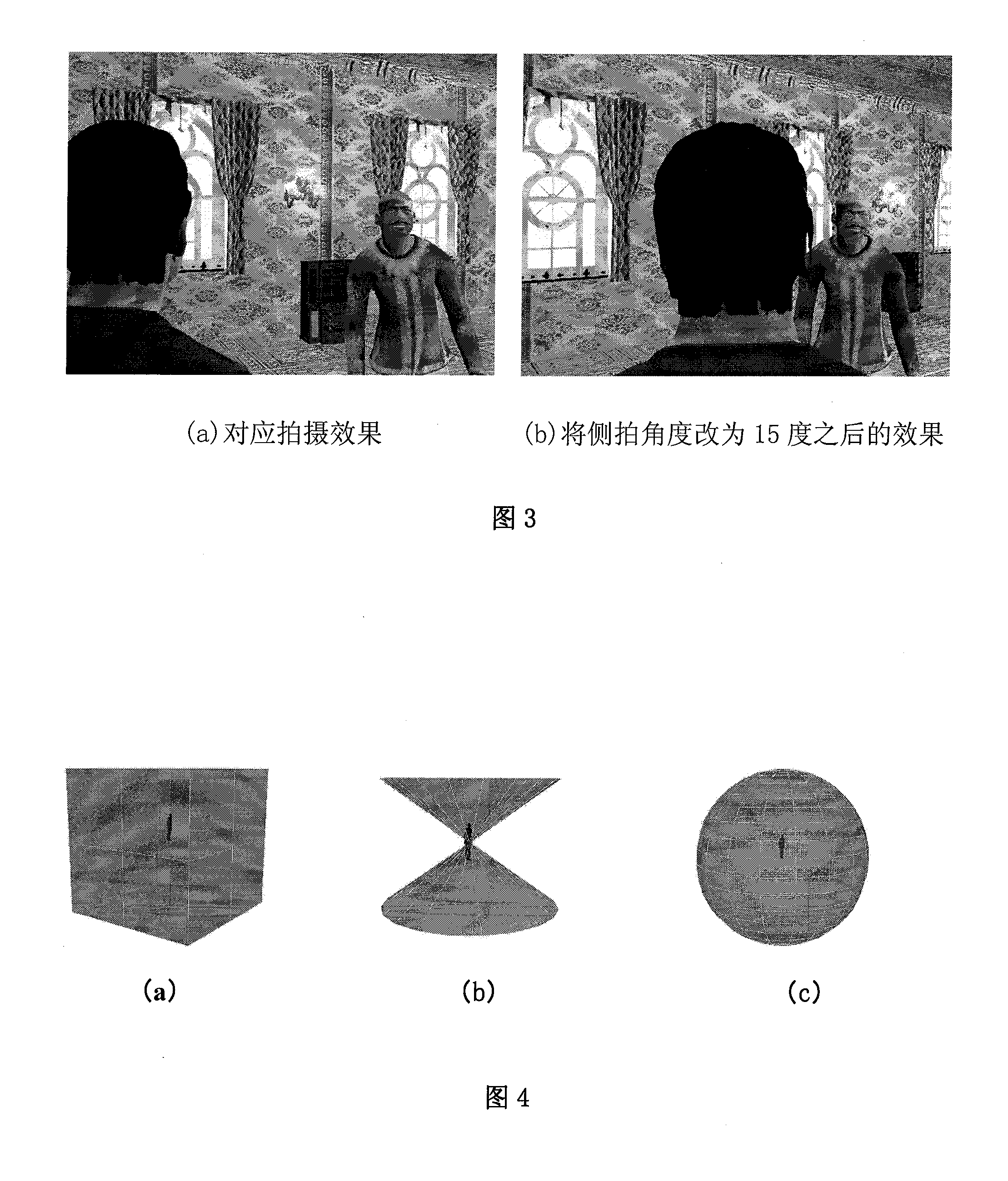

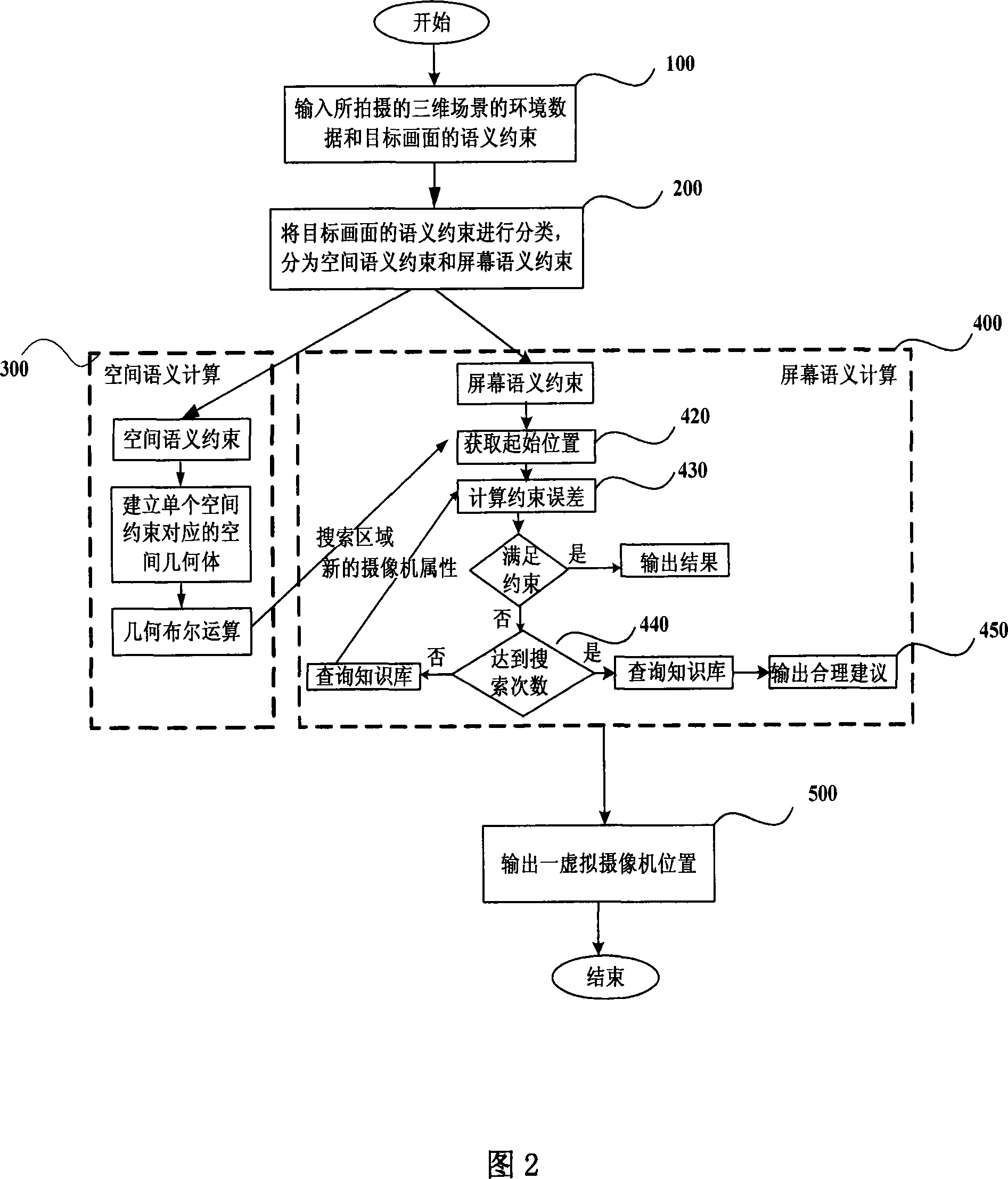

Virtual video camera planning and distributing method and system

ActiveCN101251925ALower technical barriersConvenient automatic planning layoutImage analysisKnowledge based modelsSemantic computingLocator Parameter

The invention discloses a planning layout method for a virtual camera, which comprises the following steps that: environmental data of a three-dimensional scene to be shot and semantic restraints of a target picture are input; the semantic restraints of the target picture in the step are classified into a space semantic restraint and a screen semantic restraint; the space semantic restraint is made a space semantic computation to evaluate a space area, and a predicate formula that the space semantic restraint corresponds to is true when a virtual camera or a target point is in the space area; the output result of the space semantic computation is read to make a screen semantic computation, and a group of attribute values of the virtual camera which meet all the screen semantic restraints are obtained through a method for optimized search; and the position of a virtual camera is output. The method can automatically evaluate the position parameters of the virtual camera according to the picture content which is expected to obtain and meets the different requirements.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

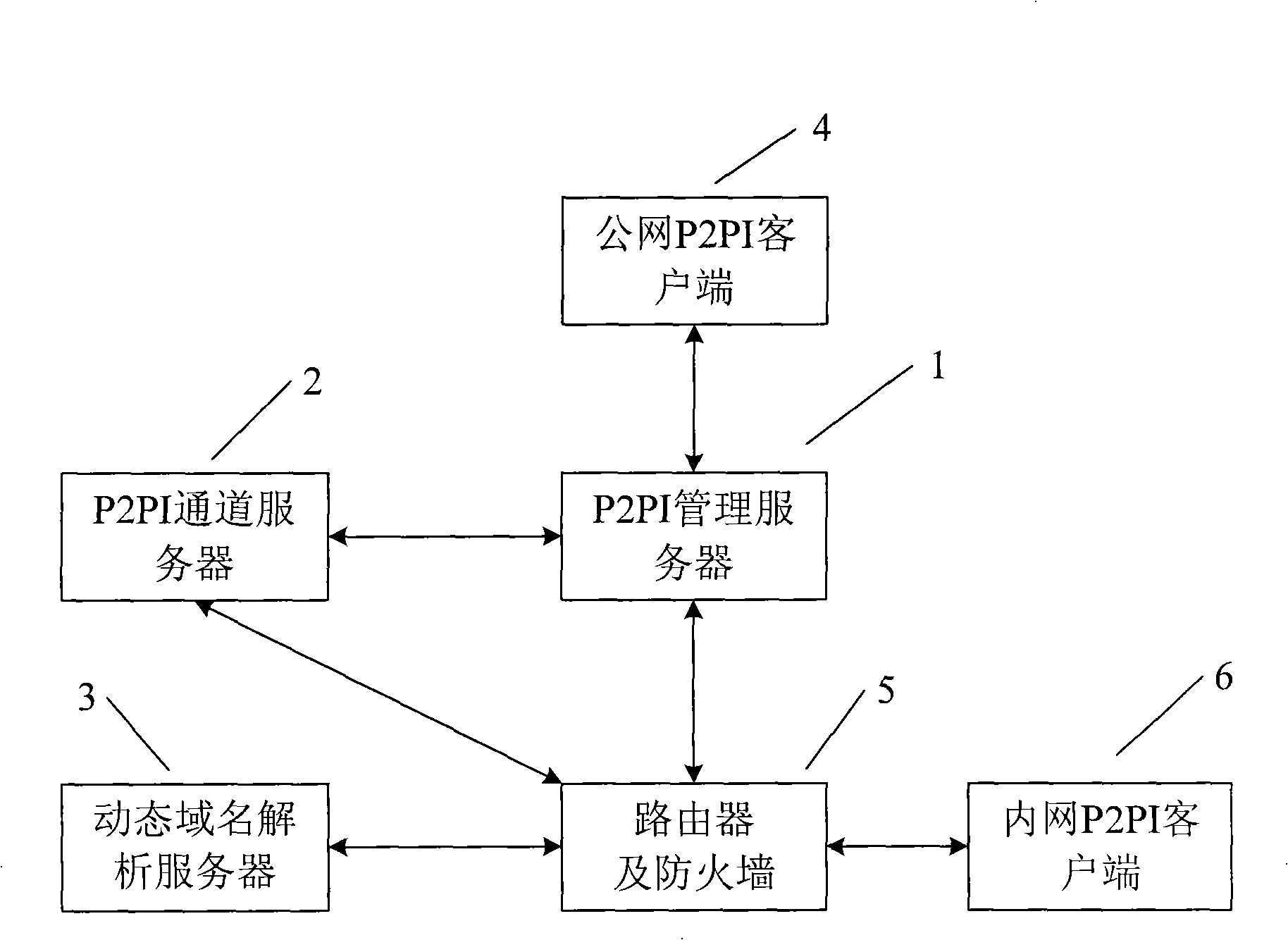

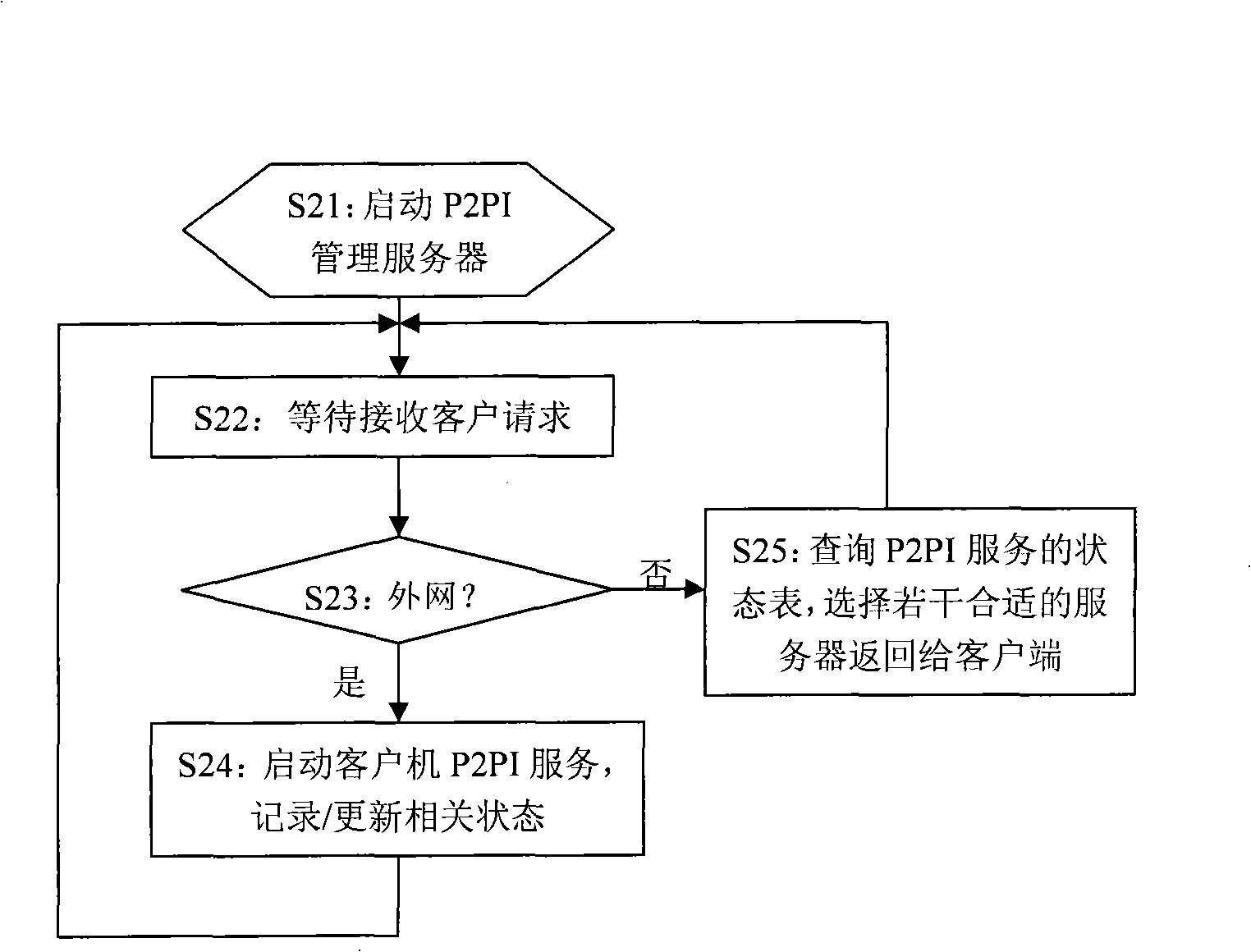

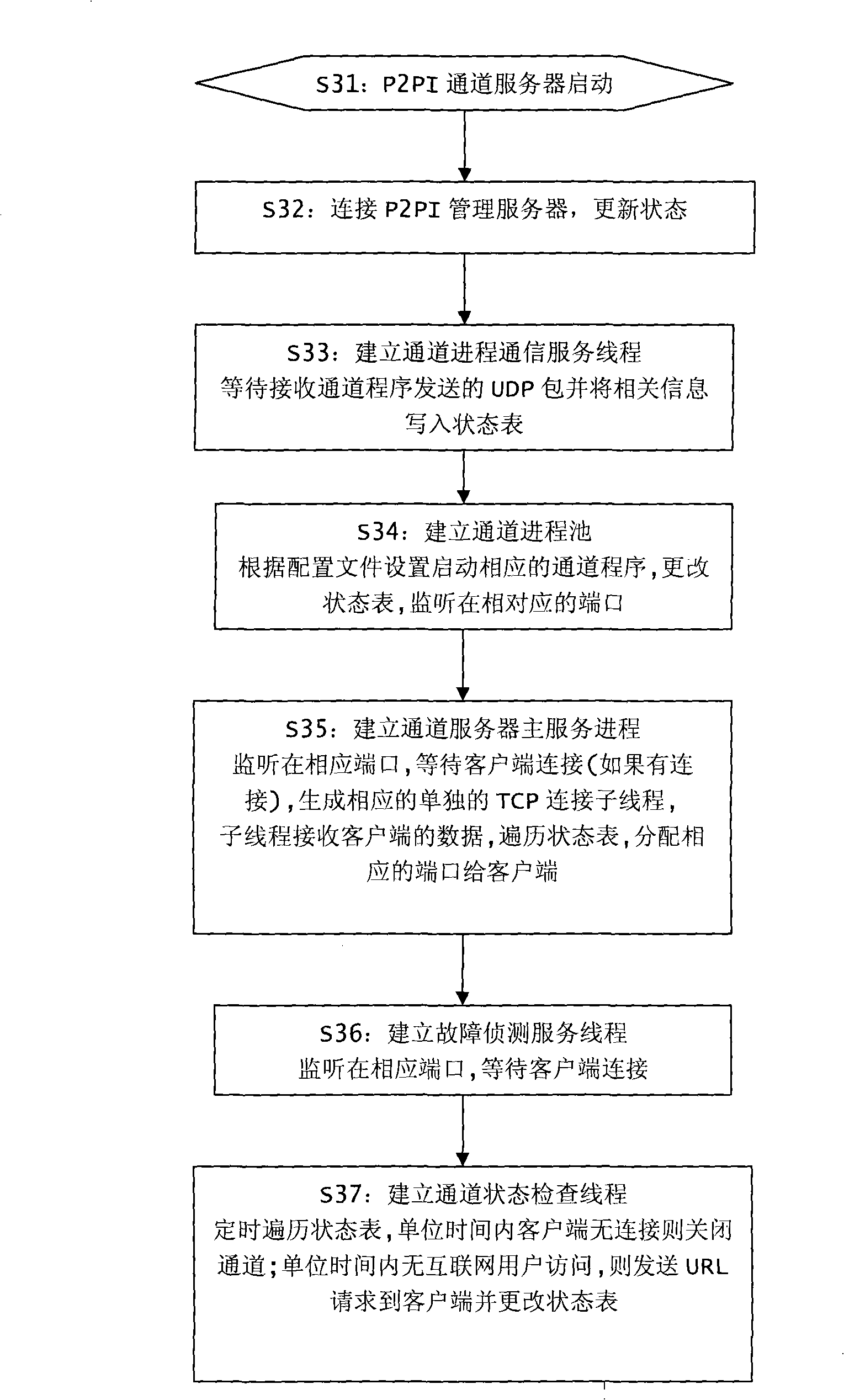

Method for accessing internet inner-network Web service

InactiveCN101282328ASolve Bandwidth BottlenecksLower technical barriersData switching networksSpecial data processing applicationsDomain nameAccess method

The present invention discloses an access method of Internet internal network Web service comprising the steps of setting one or more hardware servers in the Internet as channel server, dynamic domain name server and management server; the management server receives the request of establishing channel of client for providing Web service through the Internet, and judges whether the client has external network IP address; if the client has external network IP address, starts the channel server, and continues receiving the requests of other clients; if the client is internal network computer, the client chooses one channel server and establishes data channel with the channel server; synchronously , the dynamic domain name server updates the IP address information. The internal network Web service access method of the invention is able to effectively penetrate each Middle-boxes limitation in Internet, and break port locking.

Owner:BEIJING XIAWUCHA TECH

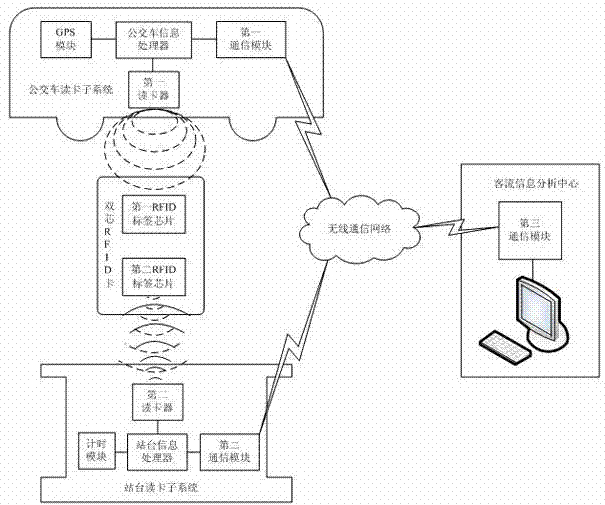

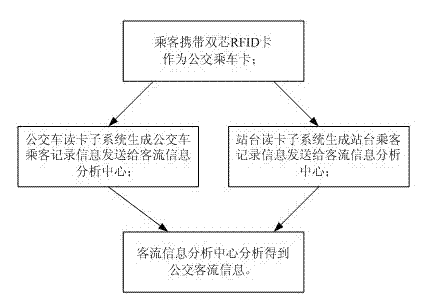

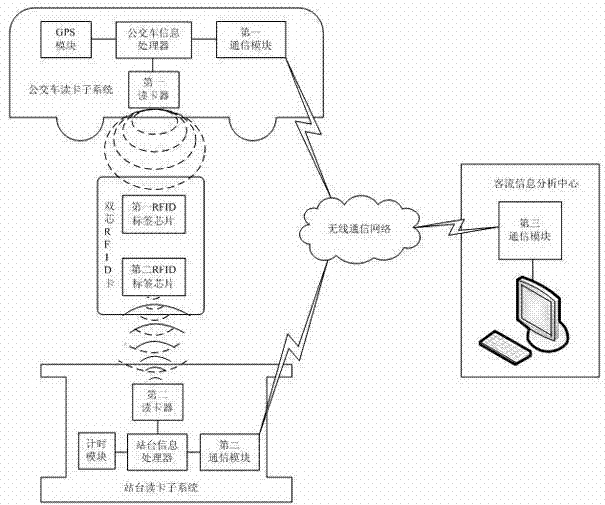

Radio frequency identification (RFID) technology-based public transport passenger flow information acquisition system and method

InactiveCN102339488ARealize automatic collectionSolve the cumbersome collectionIndividual entry/exit registersTelecommunicationsInformation analysis

The invention provides a radio frequency identification (RFID) technology-based public transport passenger flow information acquisition system and a method. The RFID technology-based public transport passenger flow information acquisition system comprises a twin-core RFID card, a bus card-reading subsystem, a station card-reading subsystem and a passenger flow information analysis center. The method for RFID technology-based public transport passenger flow information acquisition comprises the following steps that when a passenger uses the twin-core RFID card as a bus ride card, bus passengerrecorded information is produced by the bus card-reading subsystem and is transmitted to the passenger flow information analysis center and station passenger recorded information is produced by the station card-reading subsystem and is transmitted to the passenger flow information analysis center; and the bus passenger recorded information and the station passenger recorded information are analyzed by the passenger flow information analysis center to form public transport passenger flow information. The RFID technology-based public transport passenger flow information acquisition system and the method can realize automatic acquisition of public transport passenger flow information, and solves the problem of complex processes of public transport passenger flow information acquisition, and long acquisition time. In addition, the RFID technology-based public transport passenger flow information acquisition method depends on a twin-core RFID technology, avoids the influences of man-made or ambient interference on counting, and improves reliability of public transport passenger flow information acquisition.

Owner:CHONGQING ACADEMY OF SCI & TECH

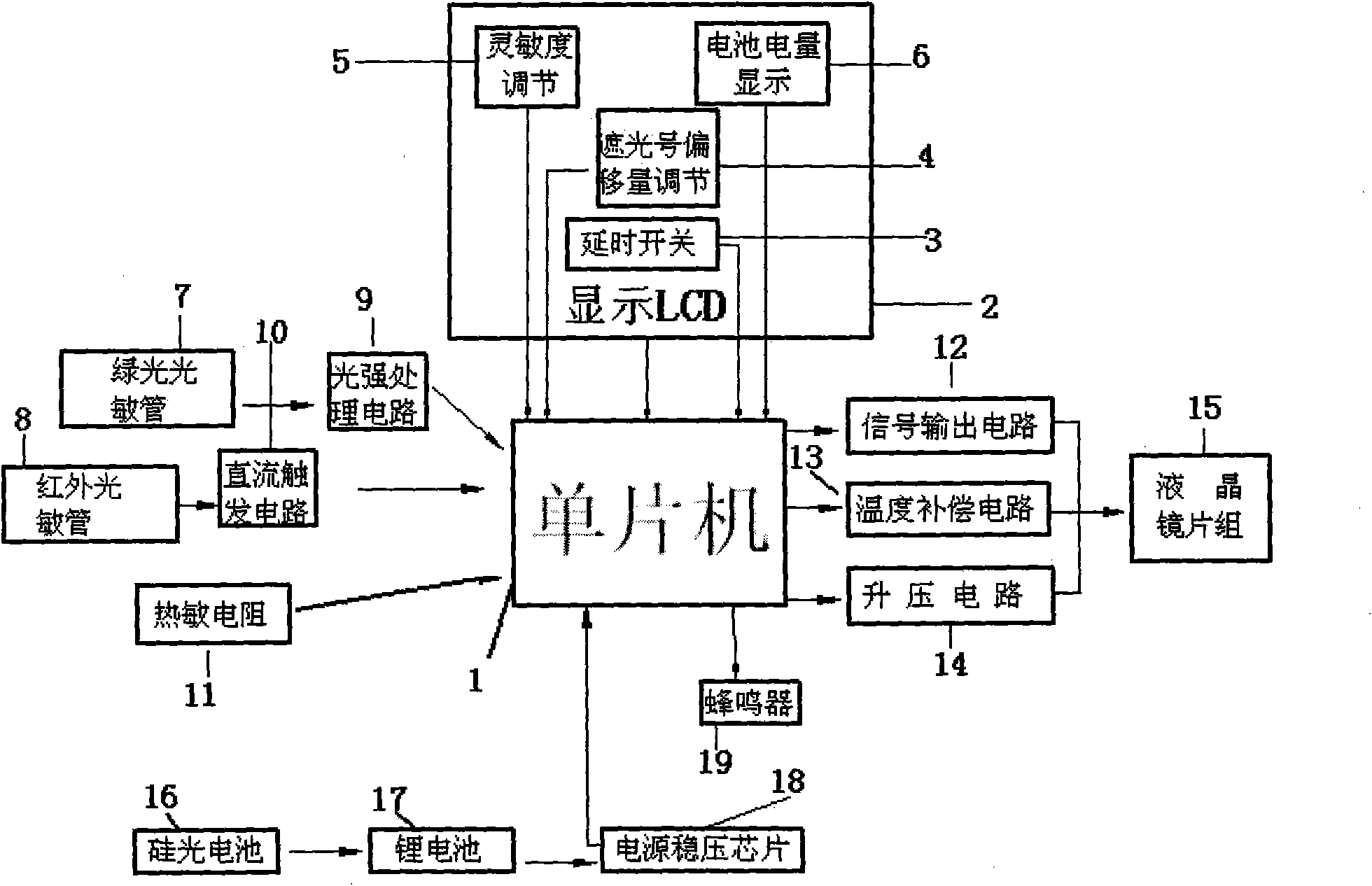

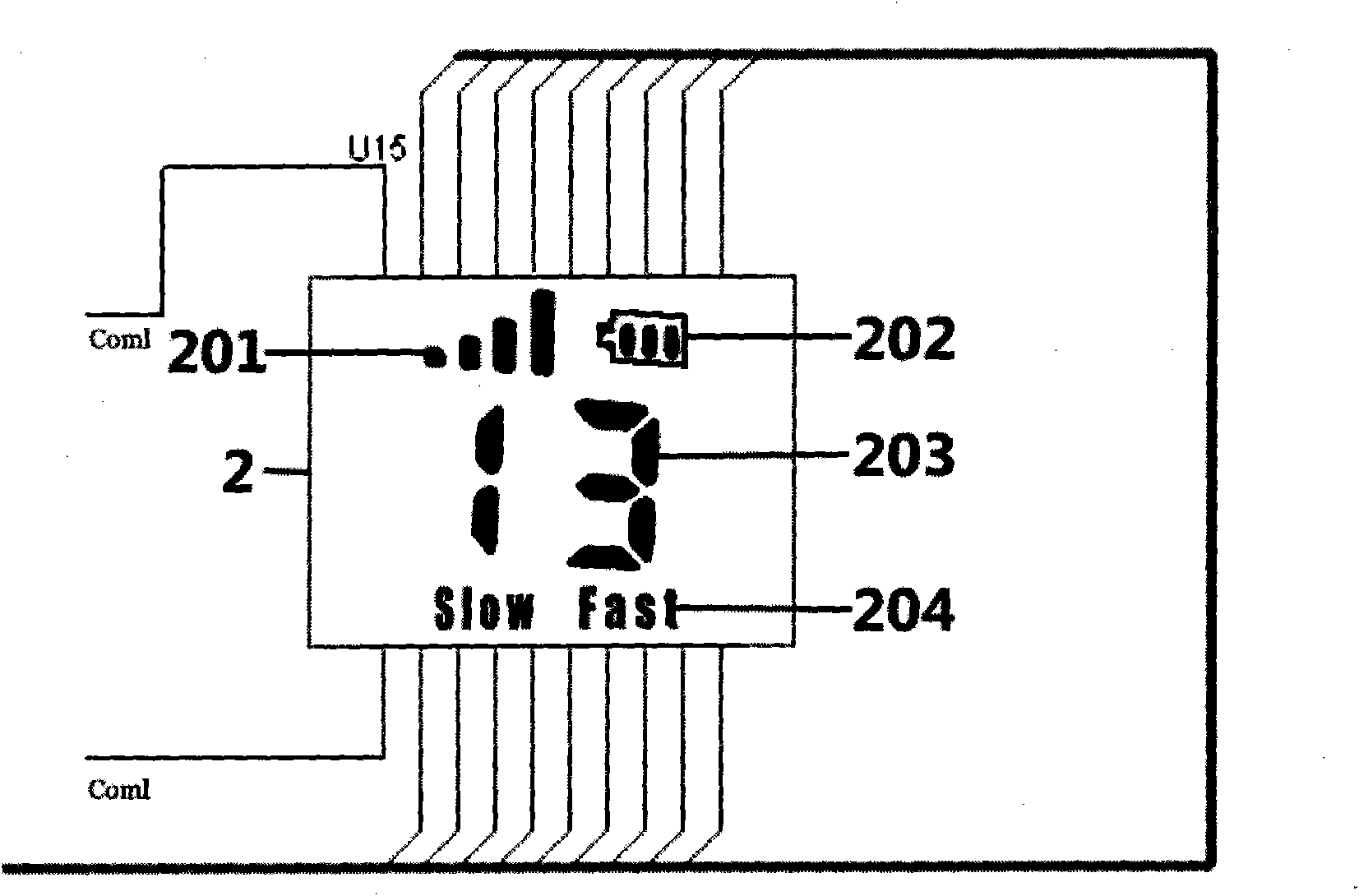

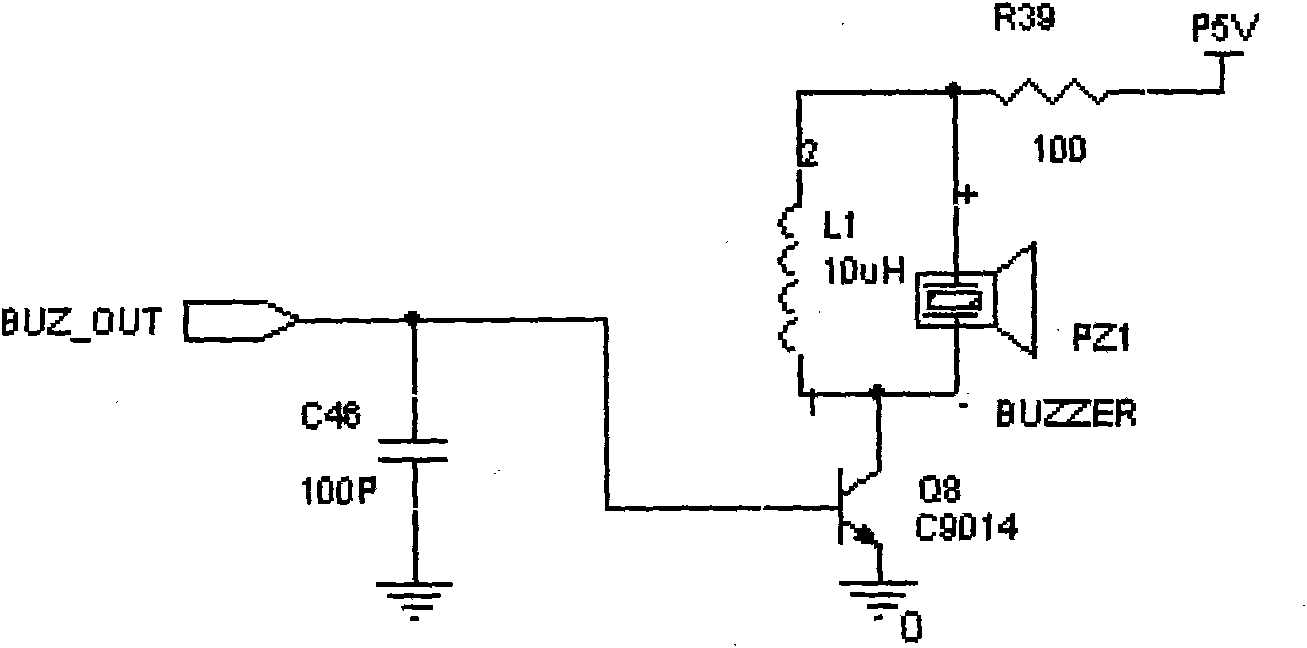

Auto-darkening welding filter capable of automatically setting shade number

ActiveCN101785725AReduce inconvenienceLower technical barriersGogglesEye-masksMicrocontrollerAutomatic control

The invention discloses an auto-darkening welding filter capable of automatically setting a shade number, comprising a liquid crystal lens group, light sensitive tubes, a trigger circuit and a singlechip. Two groups of light sensitive tubes are provided, one group includes infrared light sensitive tubes and the other group includes green light sensitive tubes, wherein, the infrared light sensitive tubes are used for detecting welding arc light and controlling the work of the singlechip through the trigger circuit; the green light sensitive tubes are used for detecting green light signals in the welding arc light and transmitting the detected signal to a matched light intensity processing circuit; the detected signal is processed into a light intensity signal by the light intensity processing circuit and is then transmitted to the singlechip; and the singlechip automatically controls the darkening of the liquid crystal lens group according to the green light intensity value. The filterovercomes the problem of damage to the users by the existing darkening welding filter owning to using complexity and easy misoperation.

Owner:DAHENG NEW EPOCH TECH

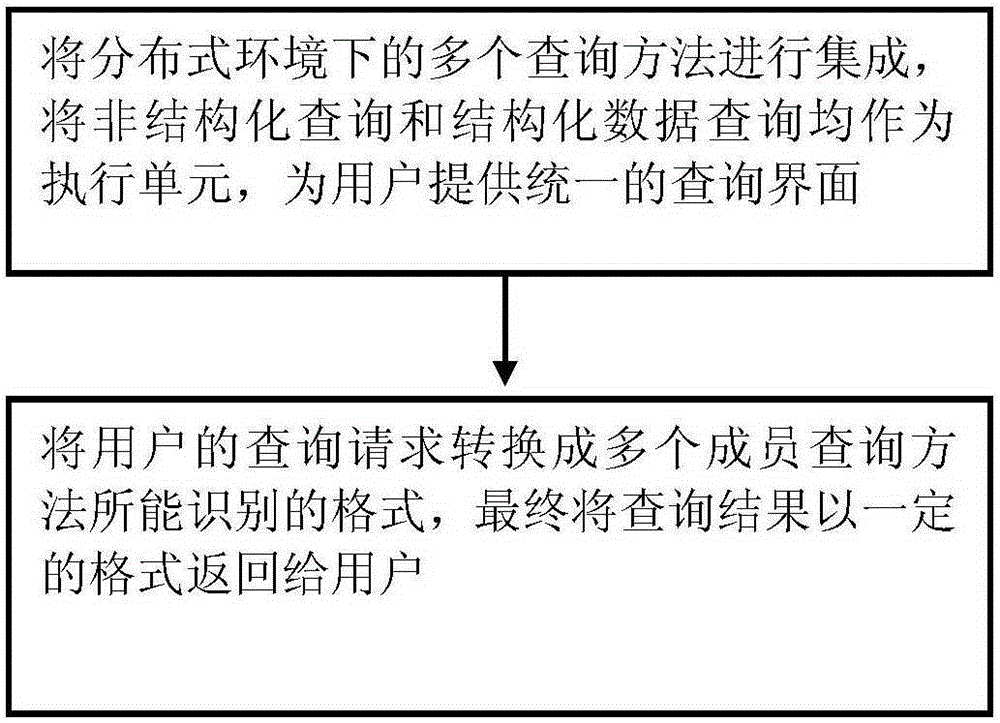

Cloud platform data acquisition method

InactiveCN105205104AOvercome flexibilityLower technical barriersOther databases indexingSpecial data processing applicationsData acquisitionExecution unit

The invention provides a cloud platform data acquisition method. The method comprises the steps of integrating multiple query methods in a distributed environment, and providing a unified query interface for a user by taking non-structured query and structured data query as execution units; converting the query requests of the user into formats which can be recognized by the multiple member query methods; and finally returning the query results to the user according to a certain format. The cloud platform financial data query method provided by the invention can be used for overcoming the defects of the conventional structured data query in the aspect of flexibility and practicability, lowering the technical difficulty that non-specialized persons query a database, and can well utilize the value of business data.

Owner:成都布林特信息技术有限公司

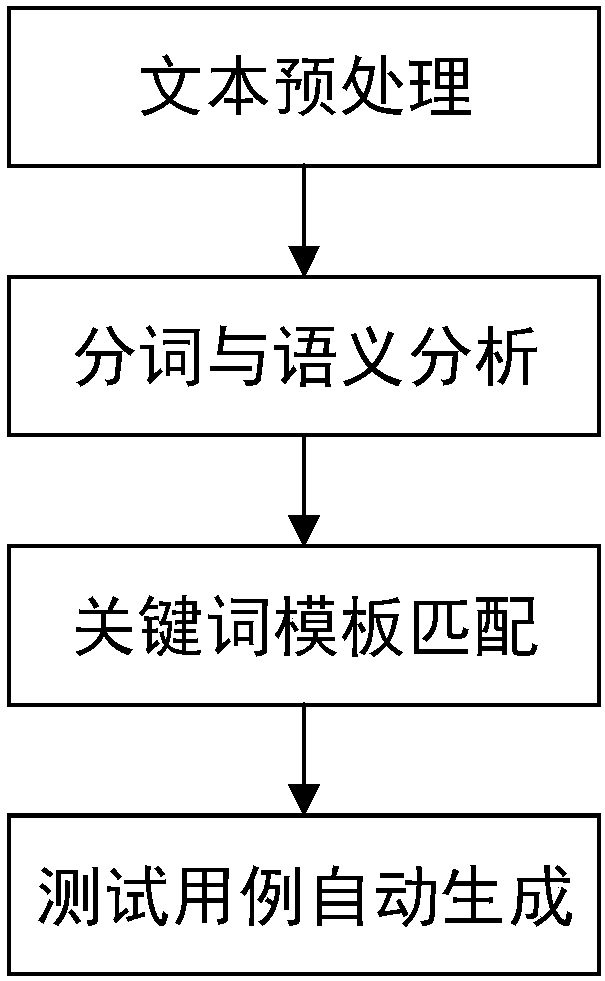

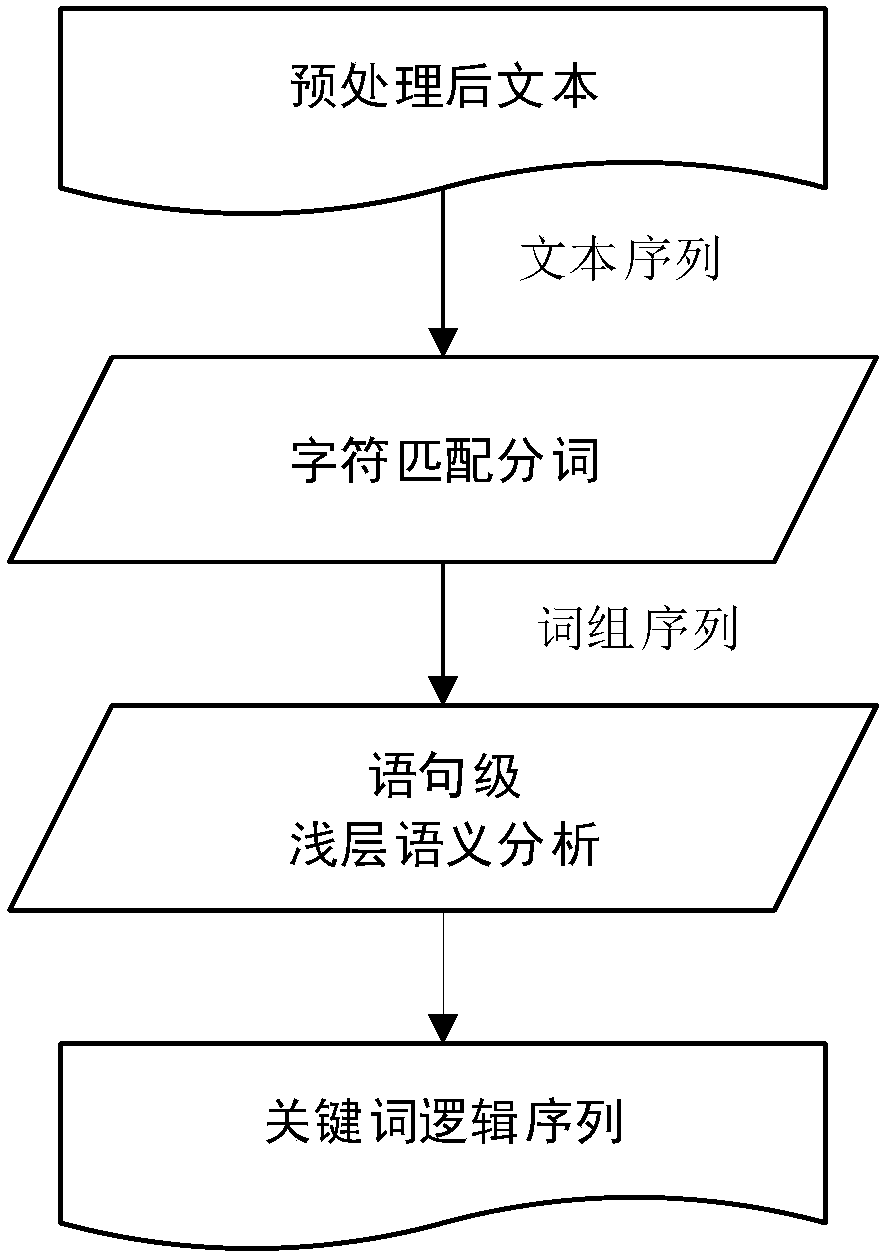

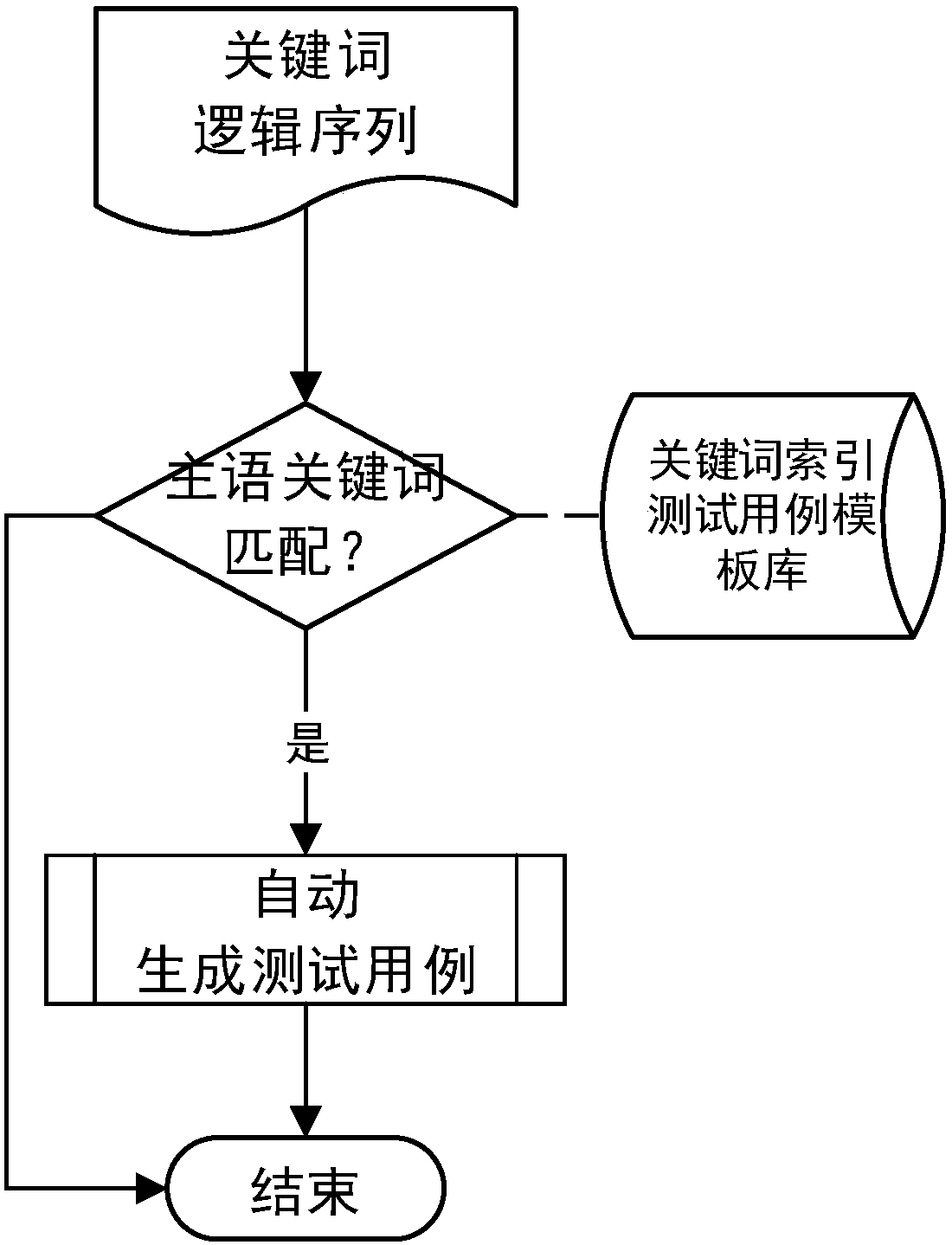

NLP-based system test case automatic generation method

ActiveCN107832229AImprove test efficiencyImprove normativeSemantic analysisSoftware testing/debuggingTest efficiencySystem testing

The invention relates to the software test field, in particular to an NLP-based system test case automatic generation method. The method comprises the steps that a software requirement document is preprocessed; the NLP technology is utilized to perform word segmentation and semantic analysis on information obtained after preprocessing; a test case template containing a specific keyword is constructed, and the analysis result is matched with the keyword template; and according to a keyword logic sequence and the test case template obtained through matching, system test cases are automatically generated through keyword substitution. Through the NLP-based system test case automatic generation method, the software requirement document can be automatically processed to obtain a software requirement with semantic logic, and the technical threshold is low; the system test cases of a specific template can be automatically generated according to software project knowledge accumulation, and thestandardability of test case design is improved; the system test cases can be automatically generated according to the software requirement document, software test efficiency is improved, and the working intensity of testers is lowered.

Owner:CHINA HELICOPTER RES & DEV INST

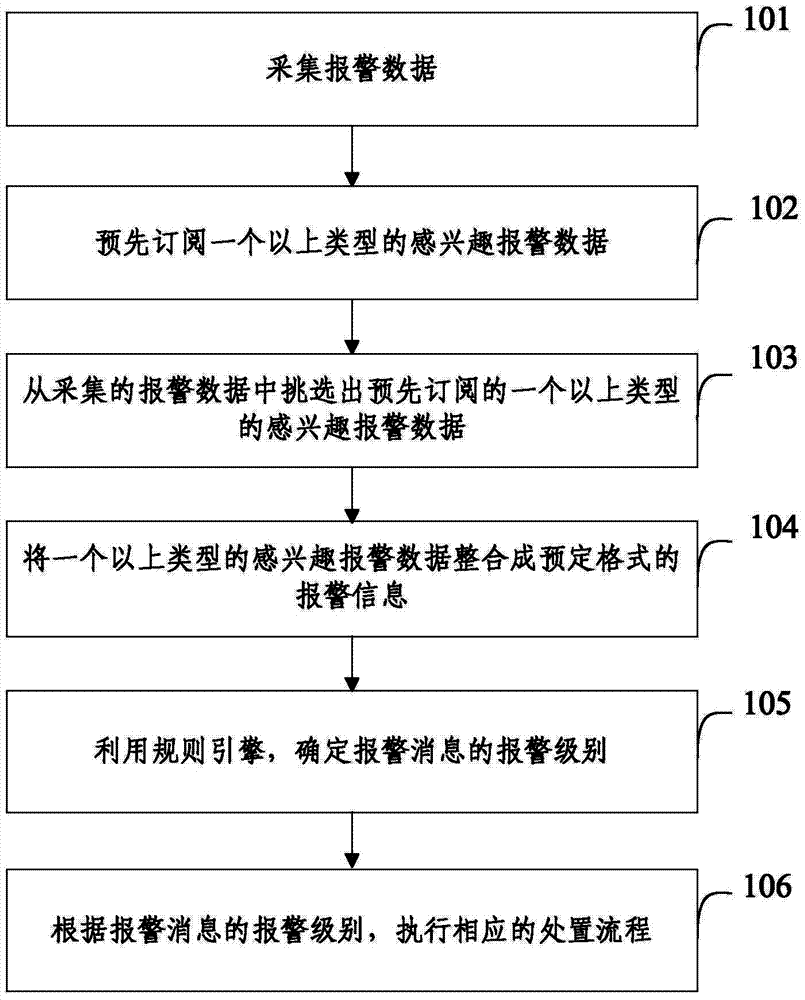

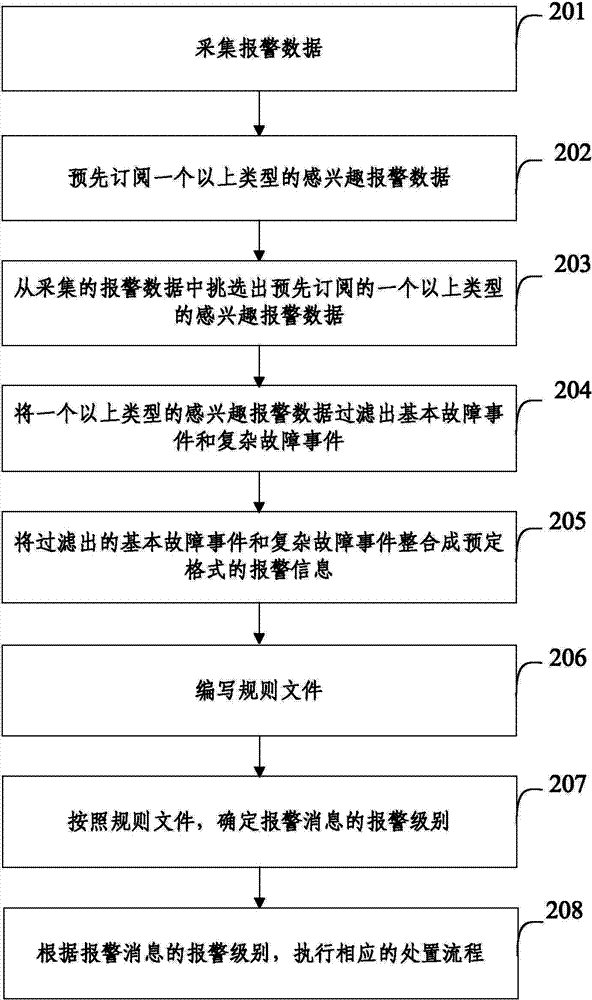

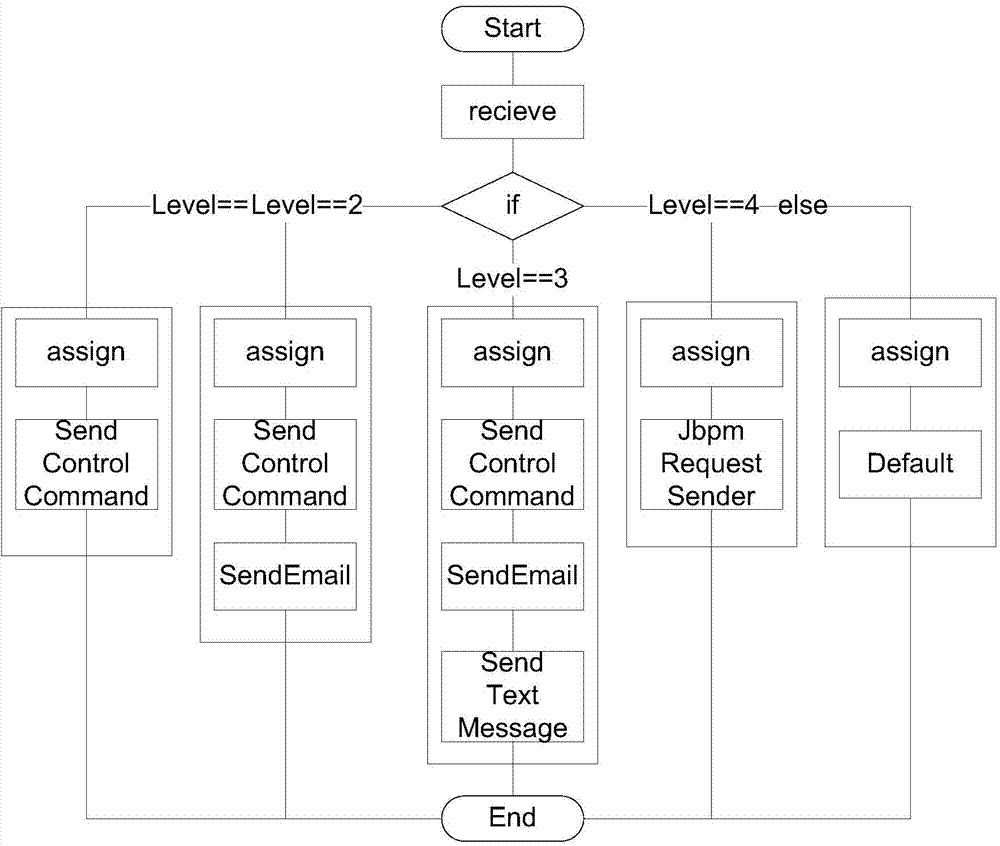

Rule-based method and system for alarming of Internet of things

The invention provides a rule-based method for alarming of Internet of things. The method comprises the following steps: collecting alarm data; subscribing for more than one type of interesting alarm data in advance; choosing the more than one type of interesting alarm data subscribed in advance from the collected alarm data; integrating the more than one type of interesting alarm data into the alarm information of predetermined format; determining the alarm level of an alarm message by using a rule engine; executing a corresponding disposal flow according to the alarm level of the alarm message. By adopting the method and the system, complicated business logic can be achieved on the basis of the rule engine, and flexible disposal measures are conveniently adopted to solve alarming of the Internet of things.

Owner:BEIJING UNIV OF POSTS & TELECOMM

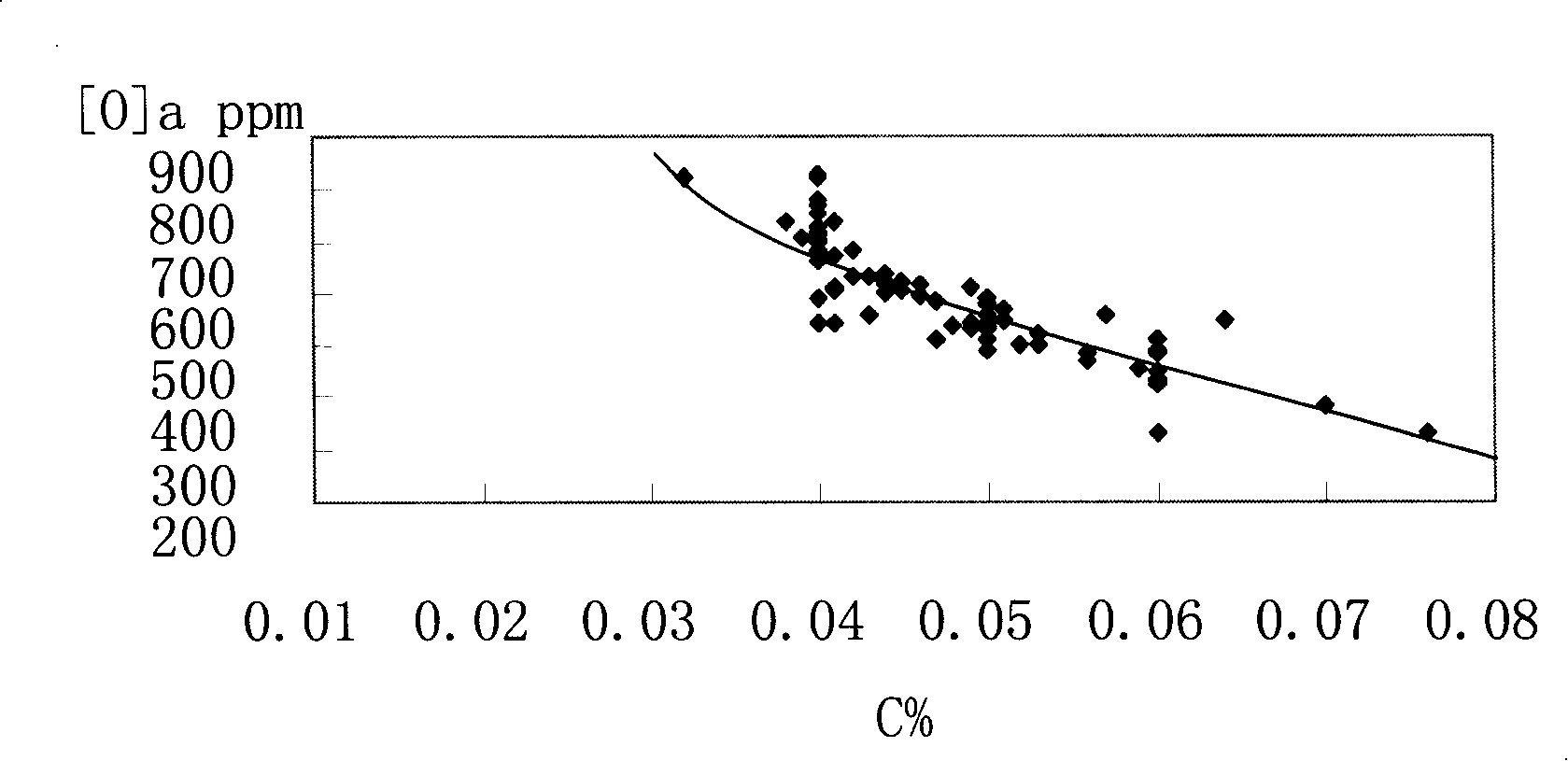

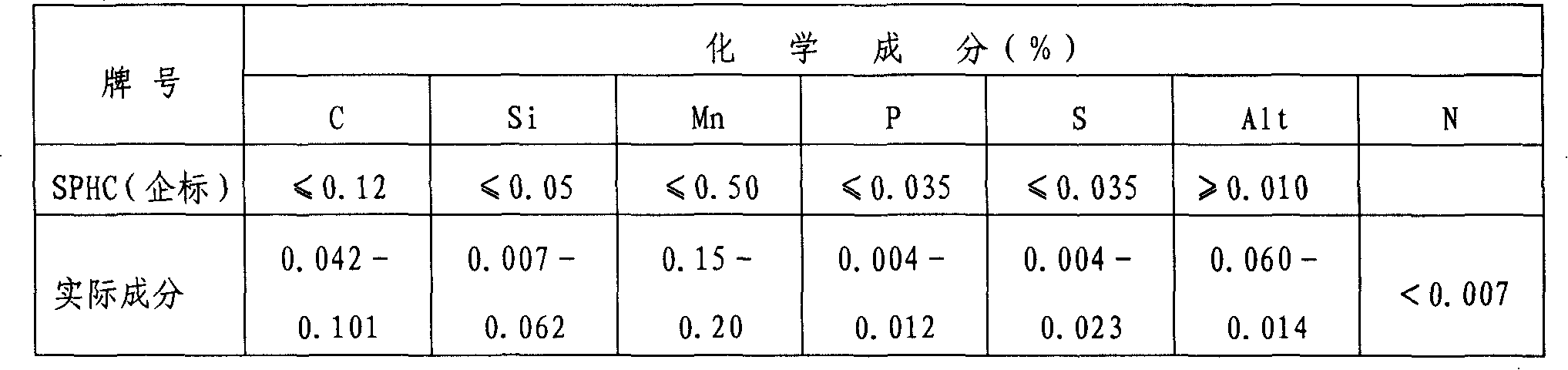

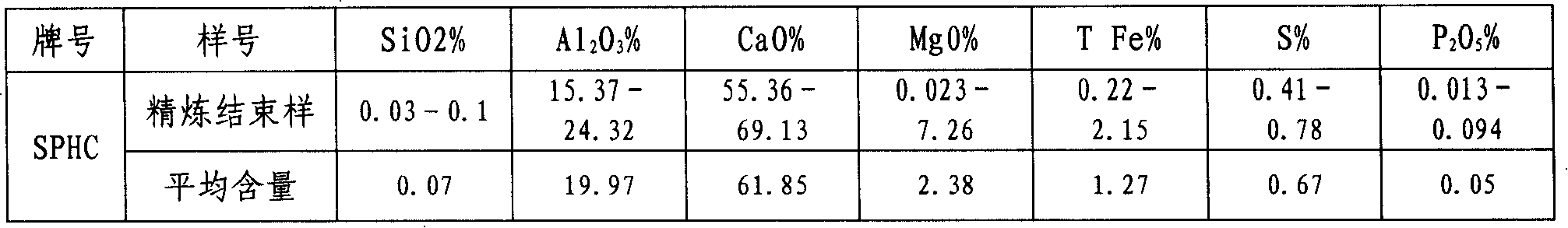

Electric furnace smelting method for low-carbon low-silicon steel

InactiveCN101225453AExpansion of smelting and processing capacityEasy to understandProcess efficiency improvementElectric furnaceFiberAlkalinity

The invention relates to an electric furnace smelting process for low carbon and low silicon steel, which comprises in series a electric furnace smelting process, a LF ladle furnace refining working procedure and a continuous casting working procedure; wherein, the refining slag adopted in the refining working procedure is CaO-Al2O3-CaF2 in which the content of CaO is 55 percent to 60 percent, the content of Al2O3 is 15 percent to 20 percent and the content of CaF2 is 1 percent to 5 percent, the content ratio of CaO and SiO2 is larger than 100; 50 percent to 60 percent Al2O3 complex slagging medium is added into the ladle at the prophase the refining, the addition of the slagging medium is 3 to 4 kg per ton steel, and the alkalinity of the slag in the ladle is adjusted; before the refining working procedure is over, the feed quantity of the wire feeding is less than 3m pre ton steel, and then the soft blowing procedure lasts 10 minutes after the wire feeding and the sedation lasts 5 to 10 minutes, the white slat in the furnace is kept for 10 minutes before tapping; in the continuous casting working procedure, the long nozzle of the ladle utilizes shielding argon gas and is sealed by aluminum silicate fiber felt sealing gasket, the overheat of the furnace shift and the first furnace in continuous casting is less than 50 degrees C and the overheat of the other continuous casting furnace is less that 30 degrees C. The electric furnace smelting process for low carbon and low silicon steel has the advantages of concise craft and low cost and can be used to produce low carbon low silicon steel.

Owner:XINJIANG BAYI IRON & STEEL

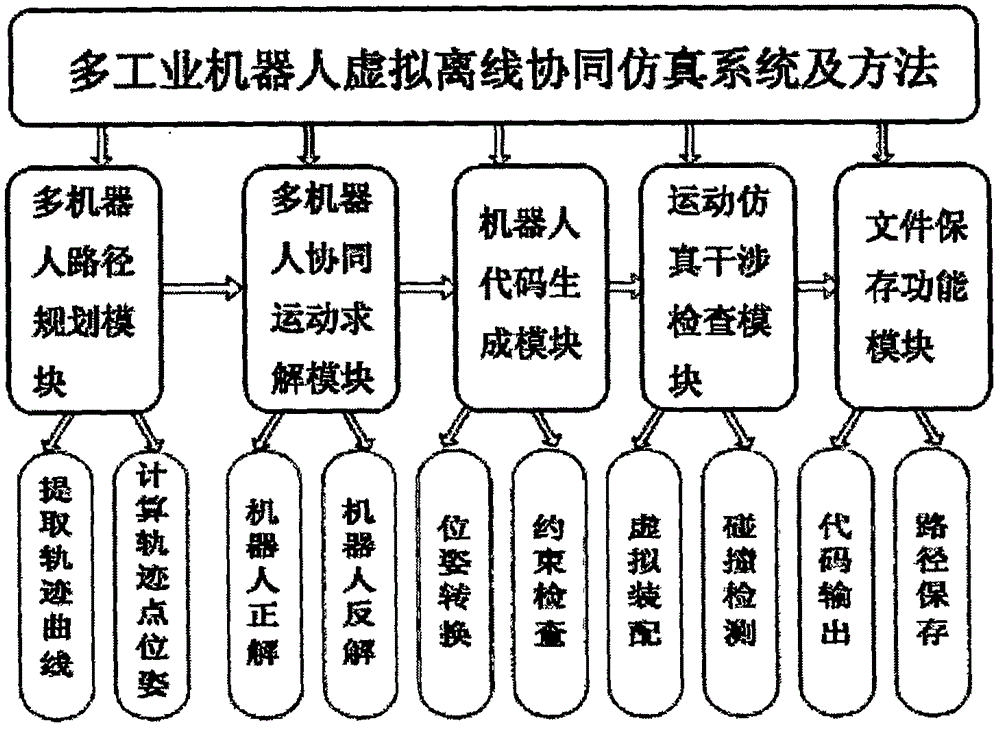

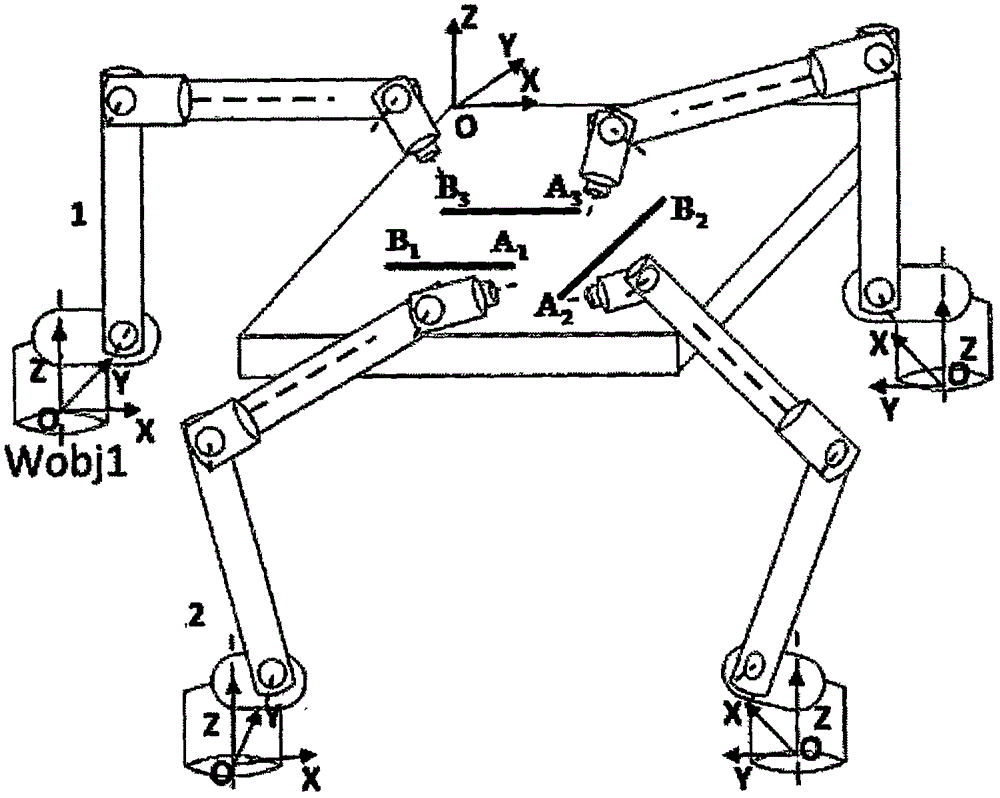

Multi-industrial-robot virtual offline co-simulation system and method

InactiveCN106444739AImprove development efficiencyIncrease productivityPosition/course control in two dimensionsVehiclesKinematicsRobot kinematics

The invention discloses a multi-industrial-robot virtual offline co-simulation system and method. The system comprises a multi-robot path planning module, a multi-robot co-movement solving module, a robot code generating module, a movement simulation interference checking module and a file saving functional module. The method comprises the steps of: 1, constructing a multi-robot virtual workstation; 2, extracting an actual machining path of robots by using workpiece numerical simulation; 3, performing robot kinematics analysis; 4, performing discrete processing on the whole path, and simulating the movement in three-dimensional software by virtual assembly; 5, outputting movement control programs of the robots in the whole movement process according to code formats of different robots; 6, repeating step 4, performing interference checking, and if interference and collision occur, performing safety prompt; and 7, saving necessary information required in the whole co-movement process. The system and the method improve the development efficiency, reduce the technical threshold, and improve the production efficiency of enterprises.

Owner:鹿龙 +1

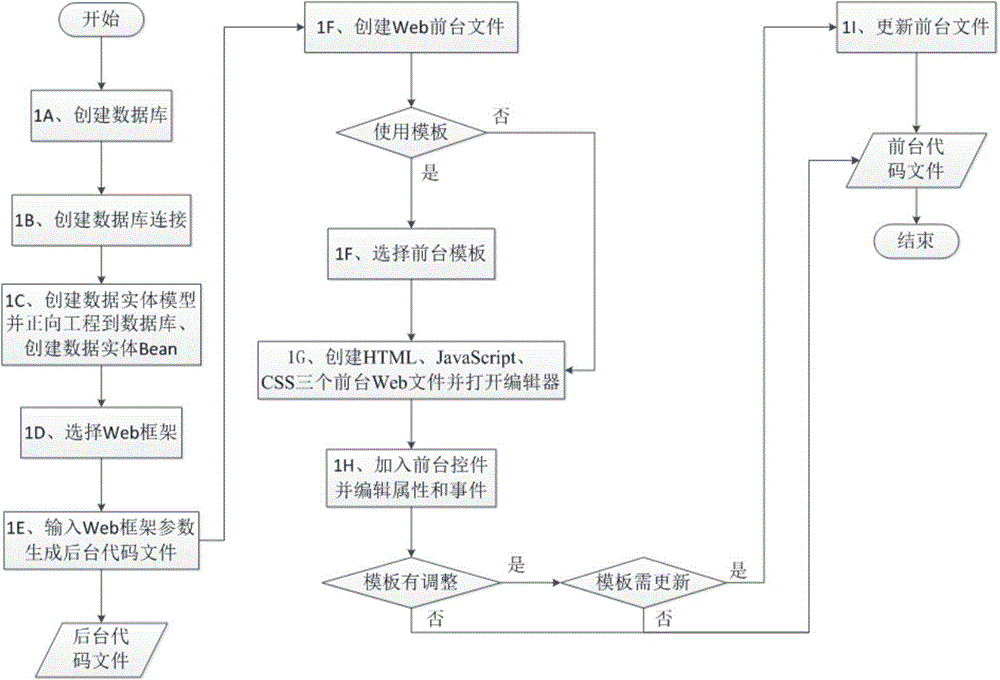

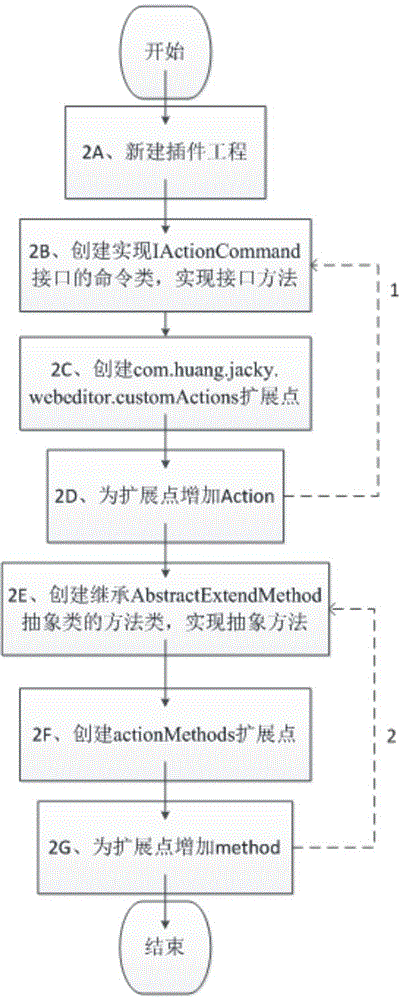

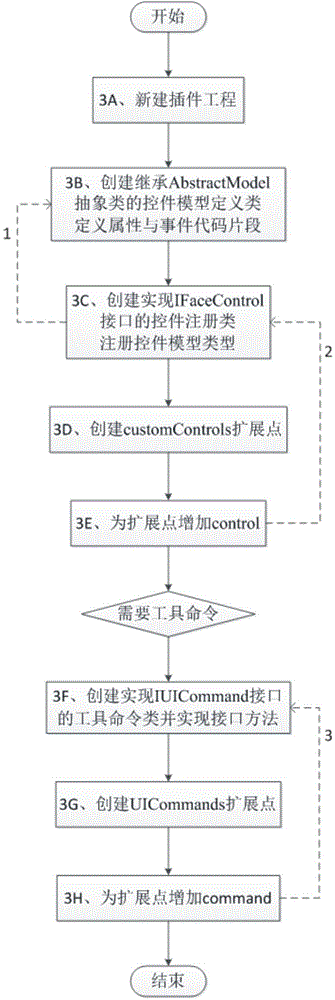

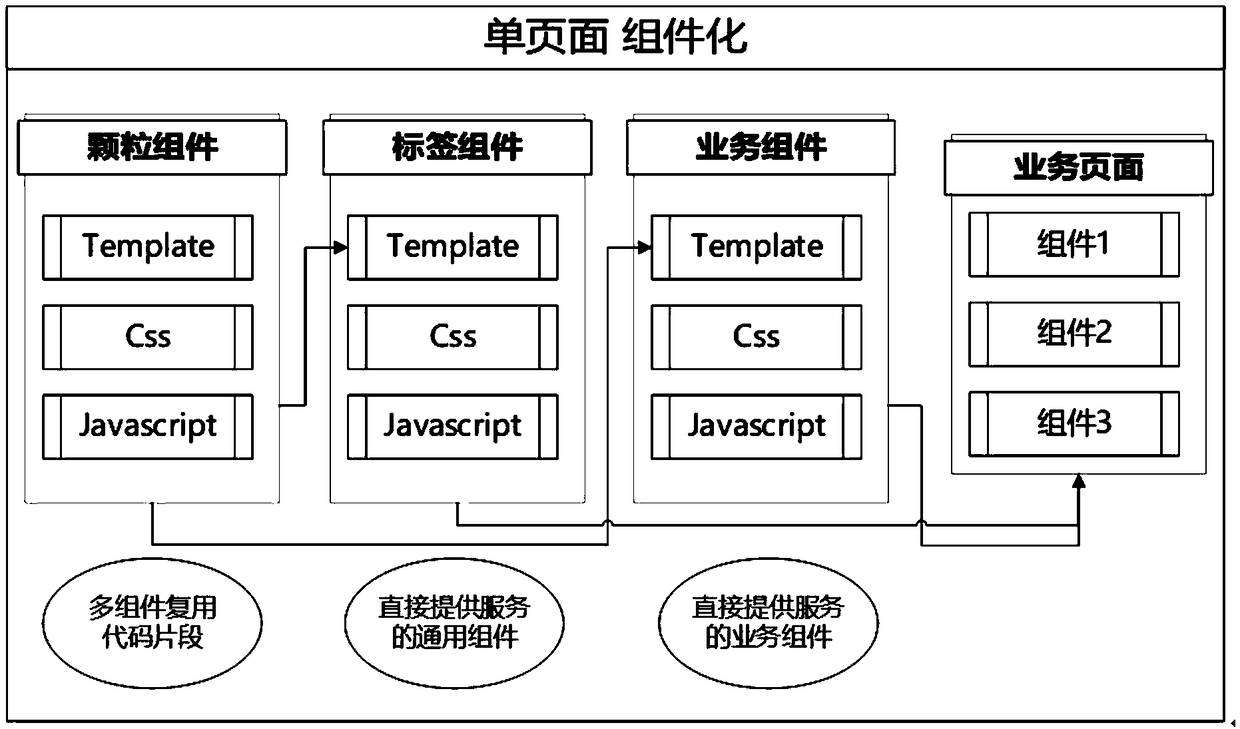

Quick JavaWeb development method and system using native Web codes

InactiveCN104793961AImprove development speed and efficiencyImprove usability and stabilitySpecific program execution arrangementsVisulationData entity

The invention provides a quick JavaWeb development method and system using native Web codes. The quick JavaWeb development method comprises the following steps that (1A) a database is created; (1B) a standard Java dynamic Web project is newly constructed, and connection with the database is created; (1C) a data entity model definition file is created, a corresponding data sheet and data entity Bean codes of the data sheet are generated through connection; (1D) a Web frame is selected; (1E) parameters of the Web frame are selected and background codes are automatically generated according to the parameters, wherein a data entity Bean is operated by utilizing interactive codes in the database; (1F) a Web foreground file is created; (1G) three foreground Web files including HTML, JavaScript and CSS and an XML configuration file are automatically created; (1H) required foreground Web controls are added into a visual designer, attributes and events of the controls are set, and relevant codes are automatically generated.

Owner:黄伟

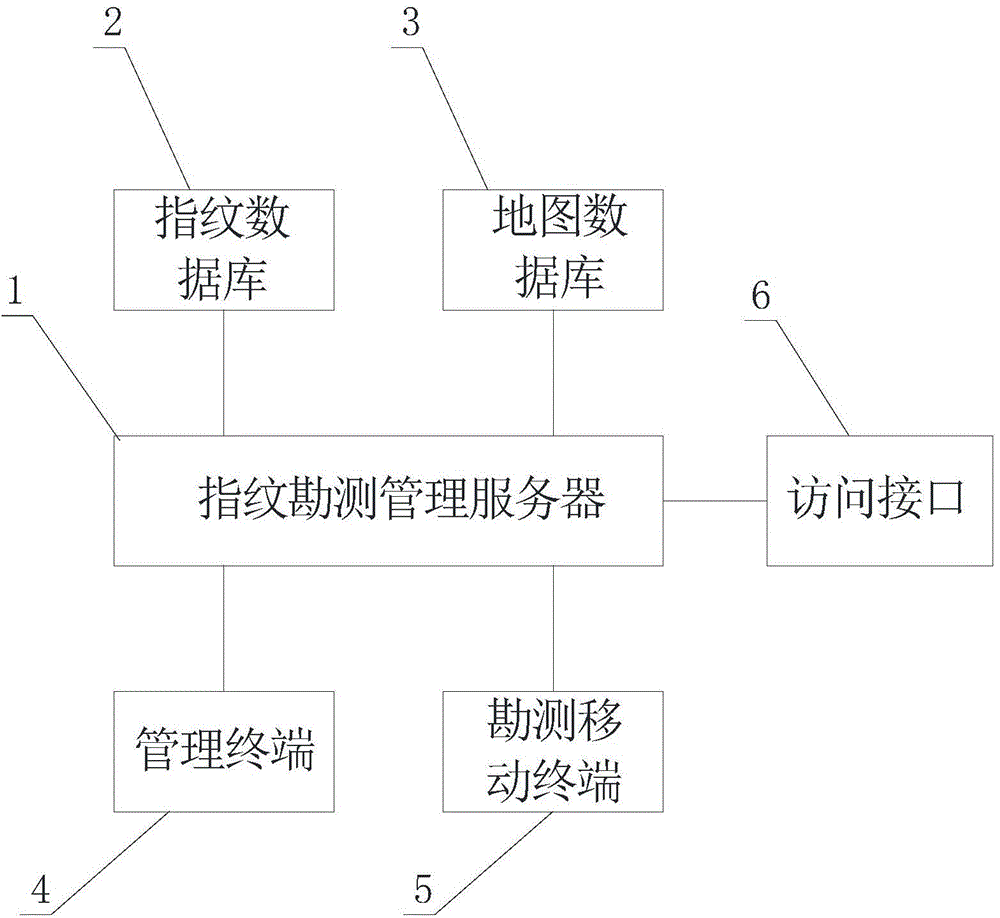

Distributed type parallel surveying system for fingerprint positioning

InactiveCN104462281AAvoid confictLower technical barriersSpecial data processing applicationsDatabase design/maintainanceData accessData acquisition

The invention relates to a distributed type parallel surveying system for fingerprint positioning. The distributed type parallel surveying system comprises a fingerprint surveying management server which is used for fingerprint surveying task distribution and surveying data storage, analysis and processing, a fingerprint data base, a map data base, a management terminal, a surveying mobile terminal and an access interface. The distributed type parallel surveying system has the advantages that the fingerprint surveying management server conducts fingerprint surveying task distribution, surveying data storage, analysis and processing and fingerprint data access service providing; the management terminal conducts fingerprint surveying task planning and fingerprint data base and map data base management, mending and updating; the surveying mobile terminal is used for executing a fingerprint surveying task and collecting and uploading surveying data; the access interface is used for conducting fingerprint and map data exchange between the fingerprint surveying management server and other systems, the distributed type parallel surveying system can be suitable for engineering surveying parts of any fingerprint positioning system supported by an intelligent mobile terminal, the technical threshold of surveying work is greatly reduced, the manual cost for surveying is reduced, and the surveying data collision can be avoided.

Owner:HANGZHOU UTEAMTEC

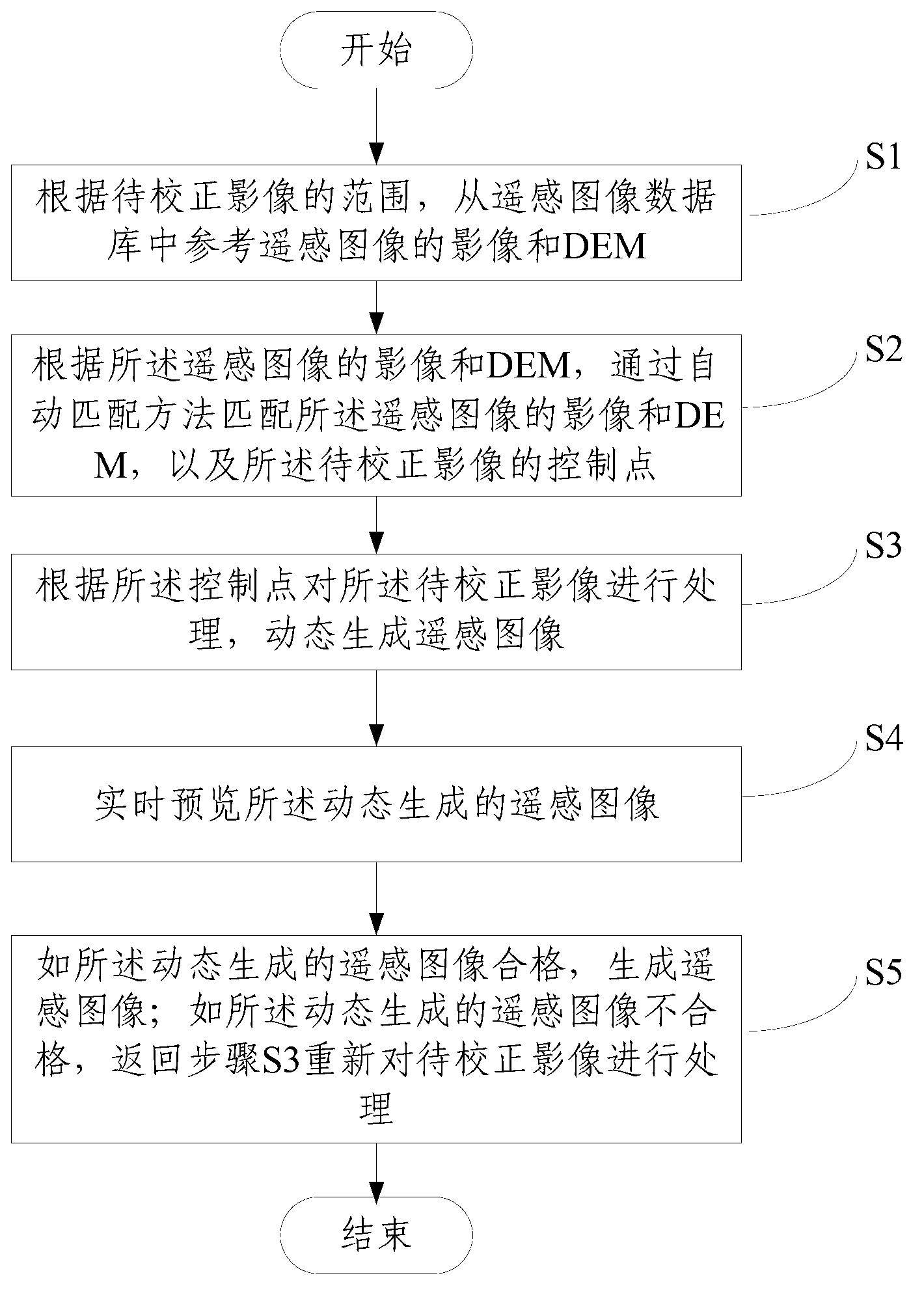

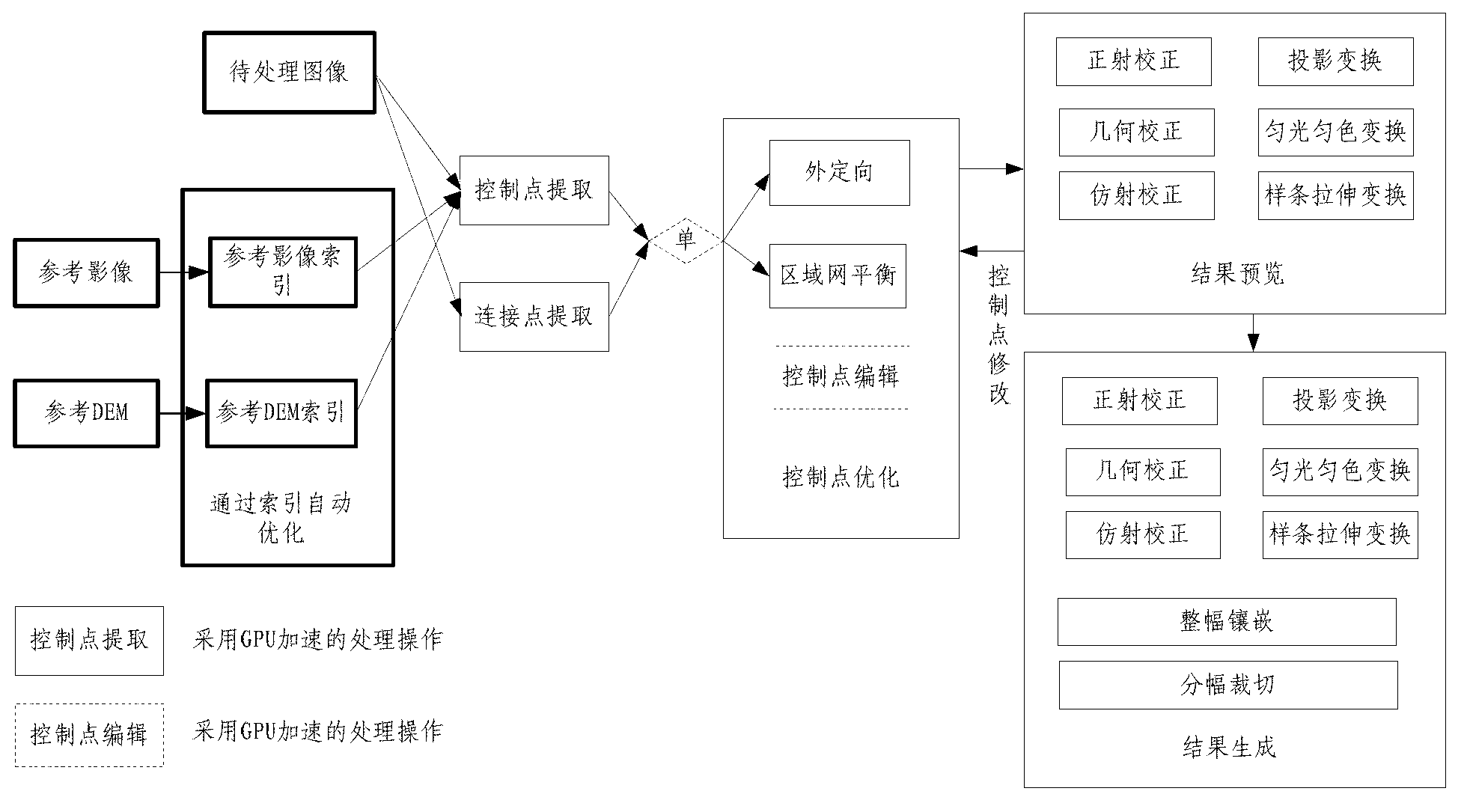

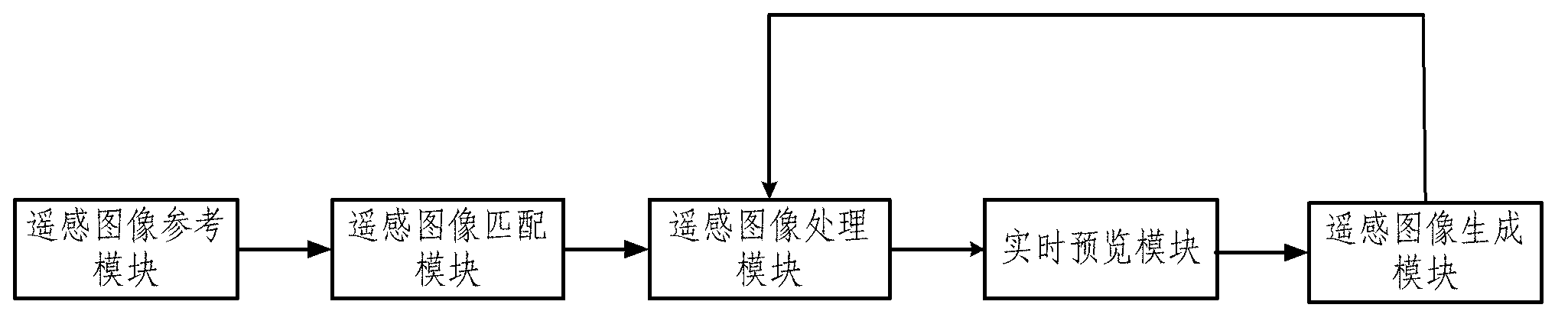

Quick processing method and system for high-resolution remote sensing image

ActiveCN103310443ASolve processingDrive application integrationImage analysisSensing dataImaging processing

The invention provides a quick processing method and a quick processing system for a high-resolution remote sensing image and relates to the field of sensing image processing. The quick processing method comprises the steps that S1, an image and a DEM (digital elevation model) are referred to from a remote sensing image database according to the range of a to-be-corrected image; S2, a control point is matched through an automatic matching method according to the image and the DEM of the remote sensing image; S3, the to-be-corrected image is processed according to the control point, and the remote sensing image is dynamically generated; S4, the dynamically-generated remote sensing image is previewed in real time; S5, if the generated remote sensing image is qualified, the remote sensing image is generated; and if the generated remote sensing is not qualified, the to-be-corrected image is processed again in the step S3. The invention also provides a quick processing system for the high-resolution remote sensing image. The quick processing method and the quick processing system for the high-resolution remote sensing image solve the problems of mass processing and high-efficiency processing of information of a remote sensing satellite, promote the application integration of remote sensing data result products, lower the technical difficulty and play an important role in applying remote sensing image data in various industries and the overall building of a digital city.

Owner:SINOVINE BEIJING TECH CO LTD

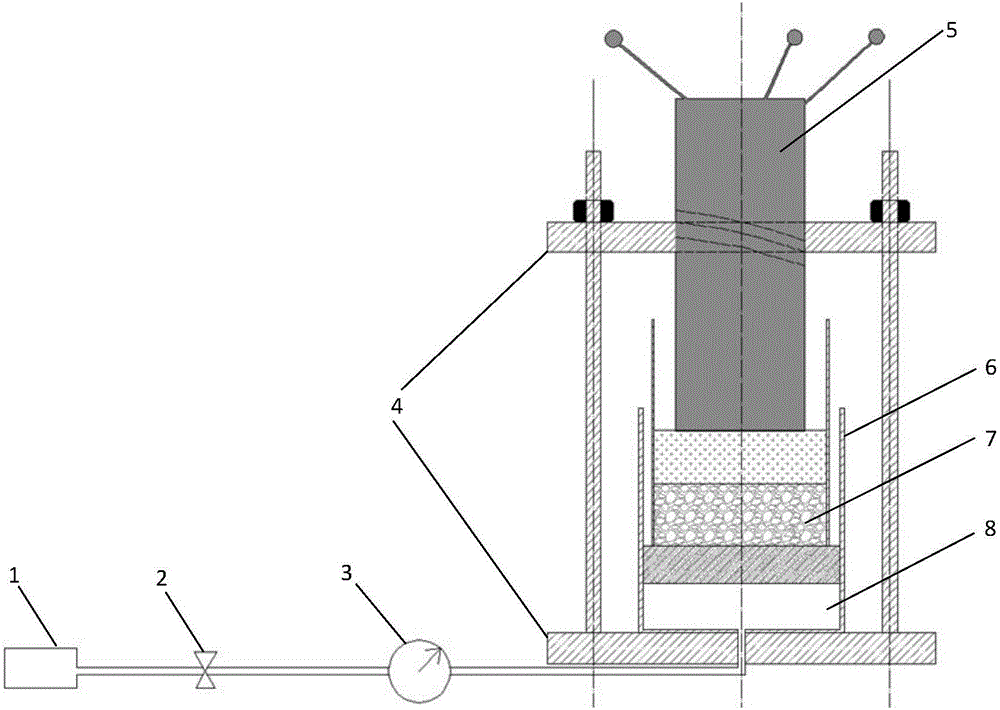

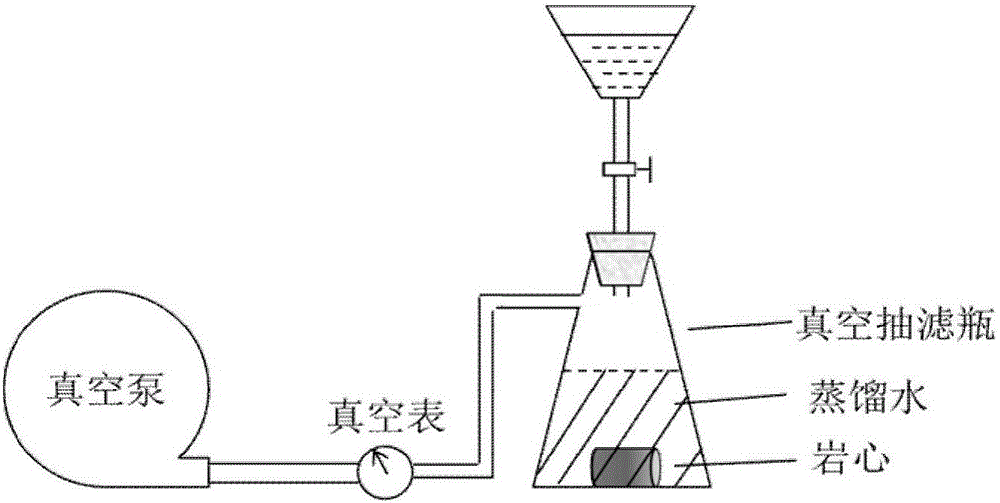

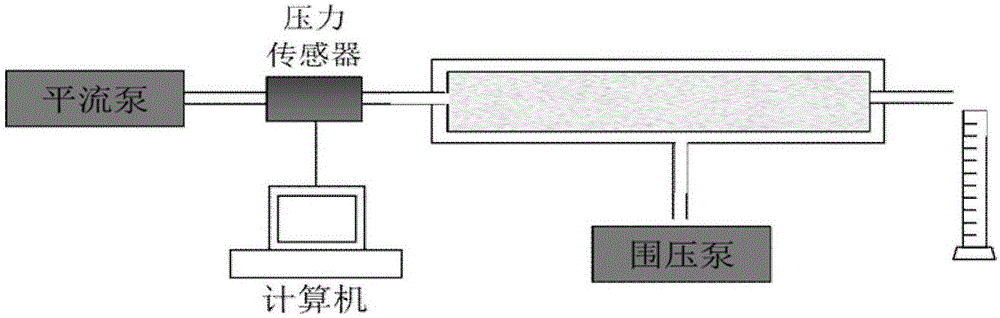

Semi-cemented artificial rock core model, and sand filling device and method thereof

ActiveCN106769751AAvoid squeezingAvoid dischargePreparing sample for investigationPermeability/surface area analysisRock coreOrganic glass

The invention relates to a semi-cemented artificial rock core model. The semi-cemented artificial rock core model is formed by a transparent organic glass tube, a quartz sand filling area at the middle portion, and sand grain cementing areas at two ends. A filling device of the semi-cemented artificial rock core model comprises a manual hydraulic pressure pump, a pressure release valve, a pressure meter, a fixed support, a solid threaded iron rod and a middle container with a stopper and an open end. The invention further provides a filling method of the semi-cemented artificial rock core model. The device and the method have the following advantages: 1, the making cost of the rock core is reduced, the technical threshold of making of the rock core is reduced, and the making efficiency of the rock core is improved; and 2, the aperture structure of the rock core is protected by the organic glass tube, so destroys of high confining pressure to the rock core and the change of the aperture structure are effectively avoided. The device has the advantages of simple structure, convenience in operation, high practicality and high simulation credibility, and the method is a novel rock core model making technology suitable for being promoted.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

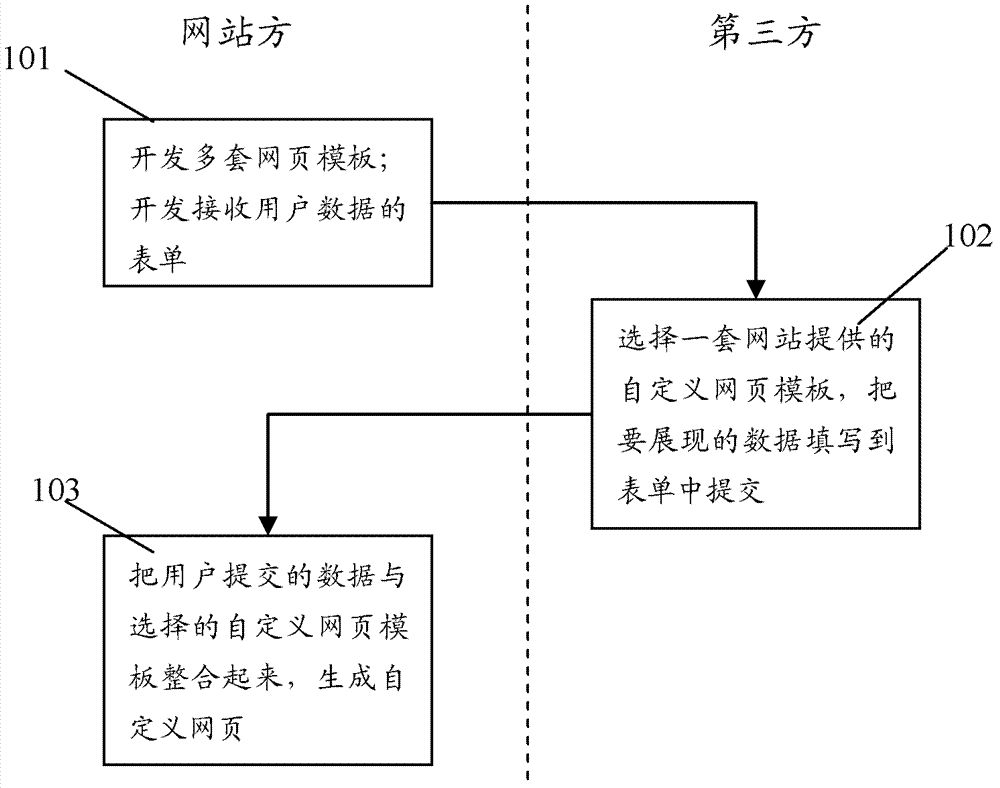

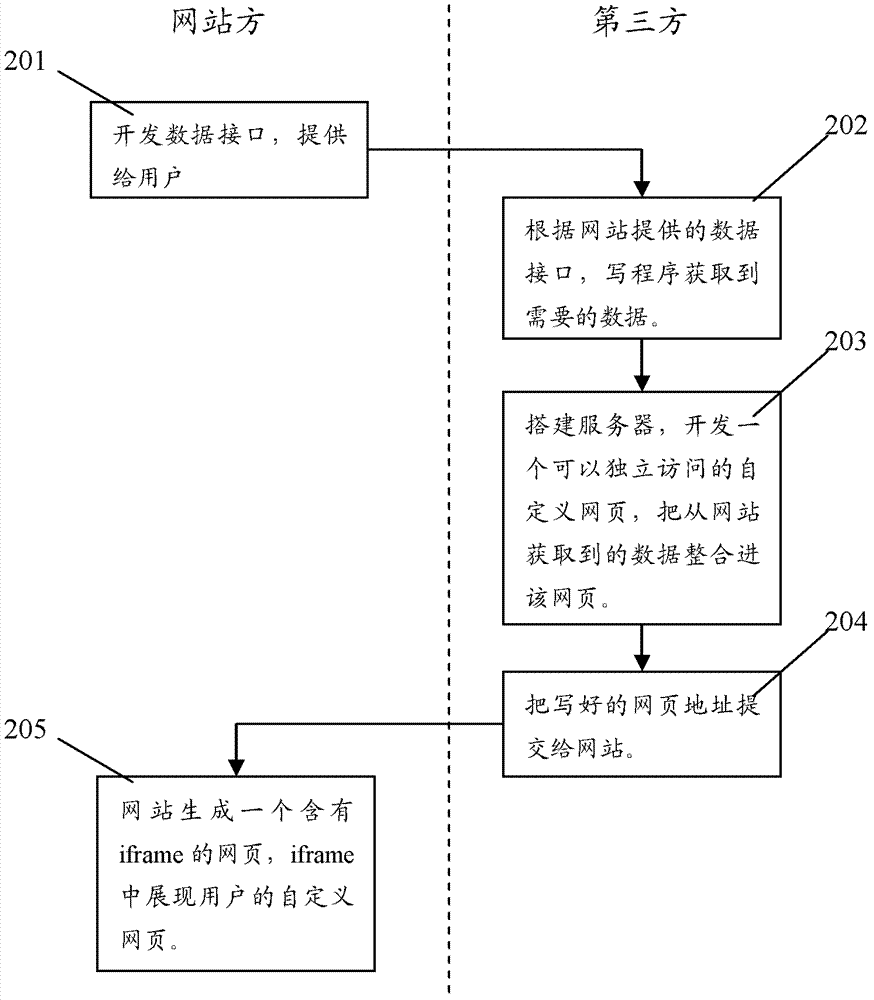

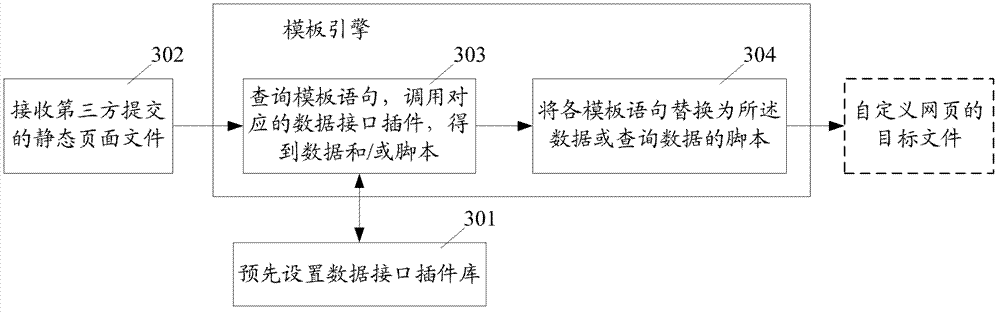

Generation method and device for user-defined webpage file

ActiveCN103365847AStrong flexibilityLower technical barriersSpecific program execution arrangementsSpecial data processing applicationsTechnology developmentWeb page

The invention discloses a generation method and device for a user-defined webpage file. The generation method includes that data interface plug-ins of a template engine are set, and each data interface plug-in corresponds to corresponding template statement; a receiving module receives a static page file from a user-defined webpage, seeks the template statements of the static page file by the aid of a template engine, the data interface plug-ins corresponding to the template statements are called to query data and / or provide a script for inquiring the data, and the template statements of the static page file are replaced with the data inquired in the data interface plug-ins corresponding to the template statements or the script for inquiring the data by the aid of the template engine so as to generate a destination file in the user-defined webpage file. By the generation method, construction cost and technology development threshold of the user-defined webpage can be reduced.

Owner:SHENZHEN TENCENT COMP SYST CO LTD

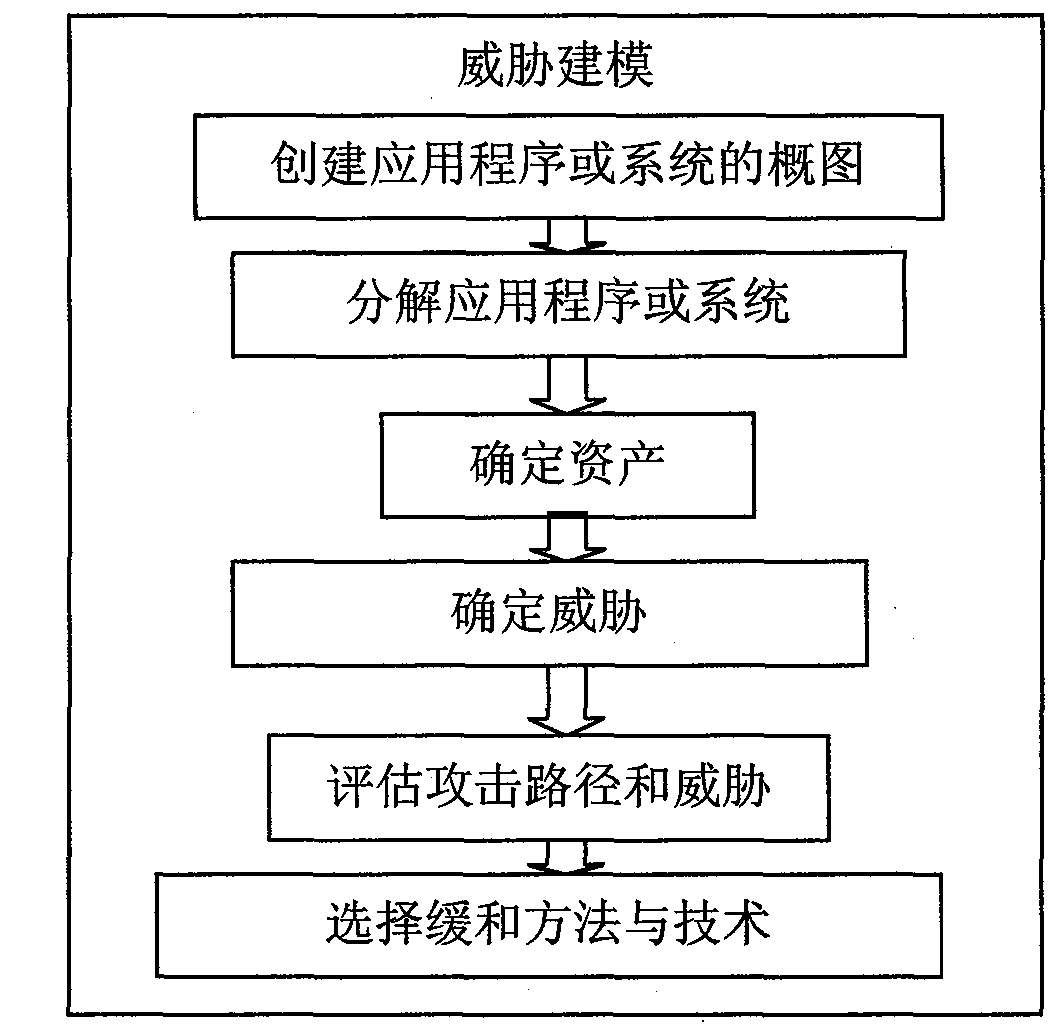

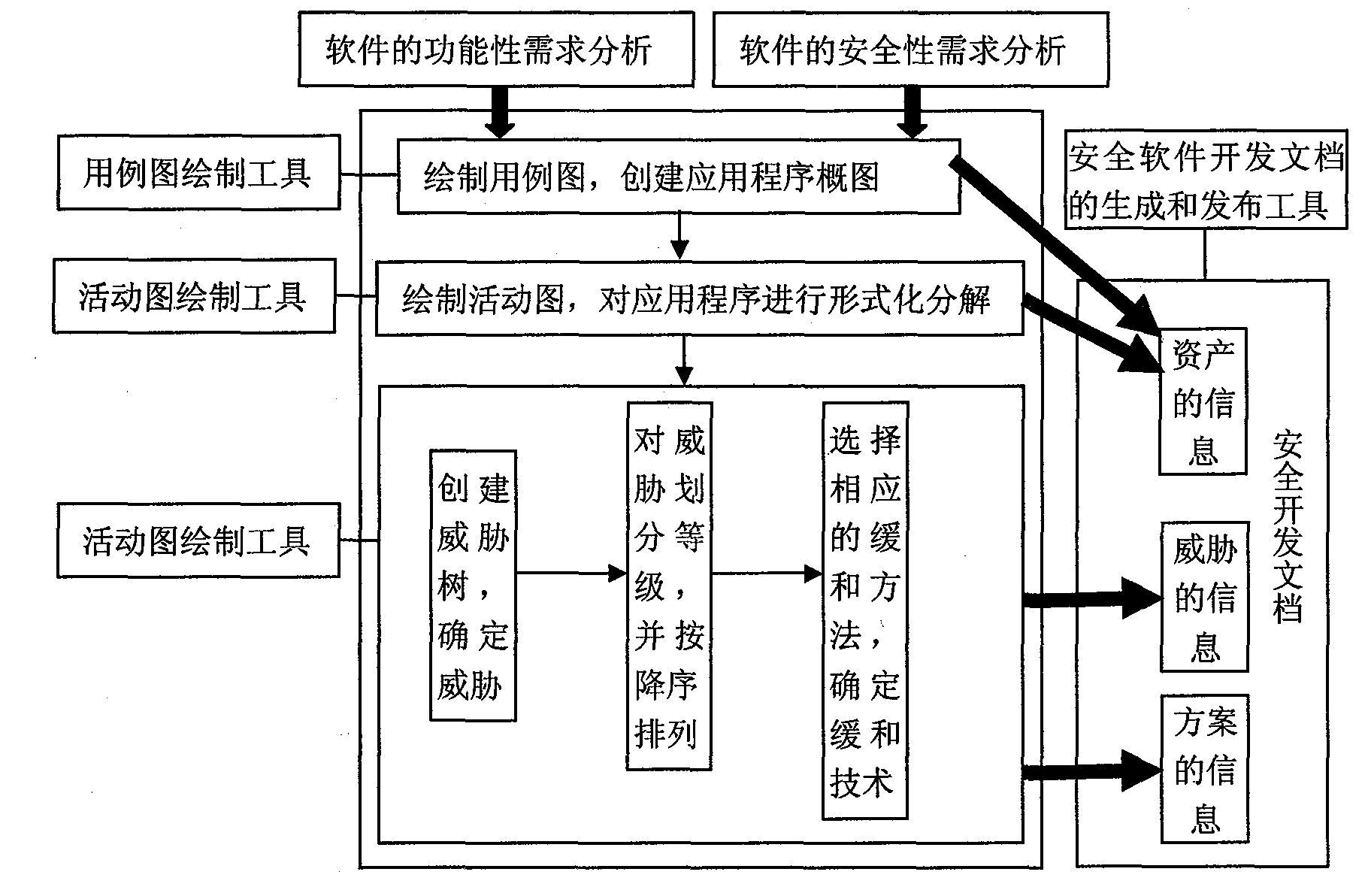

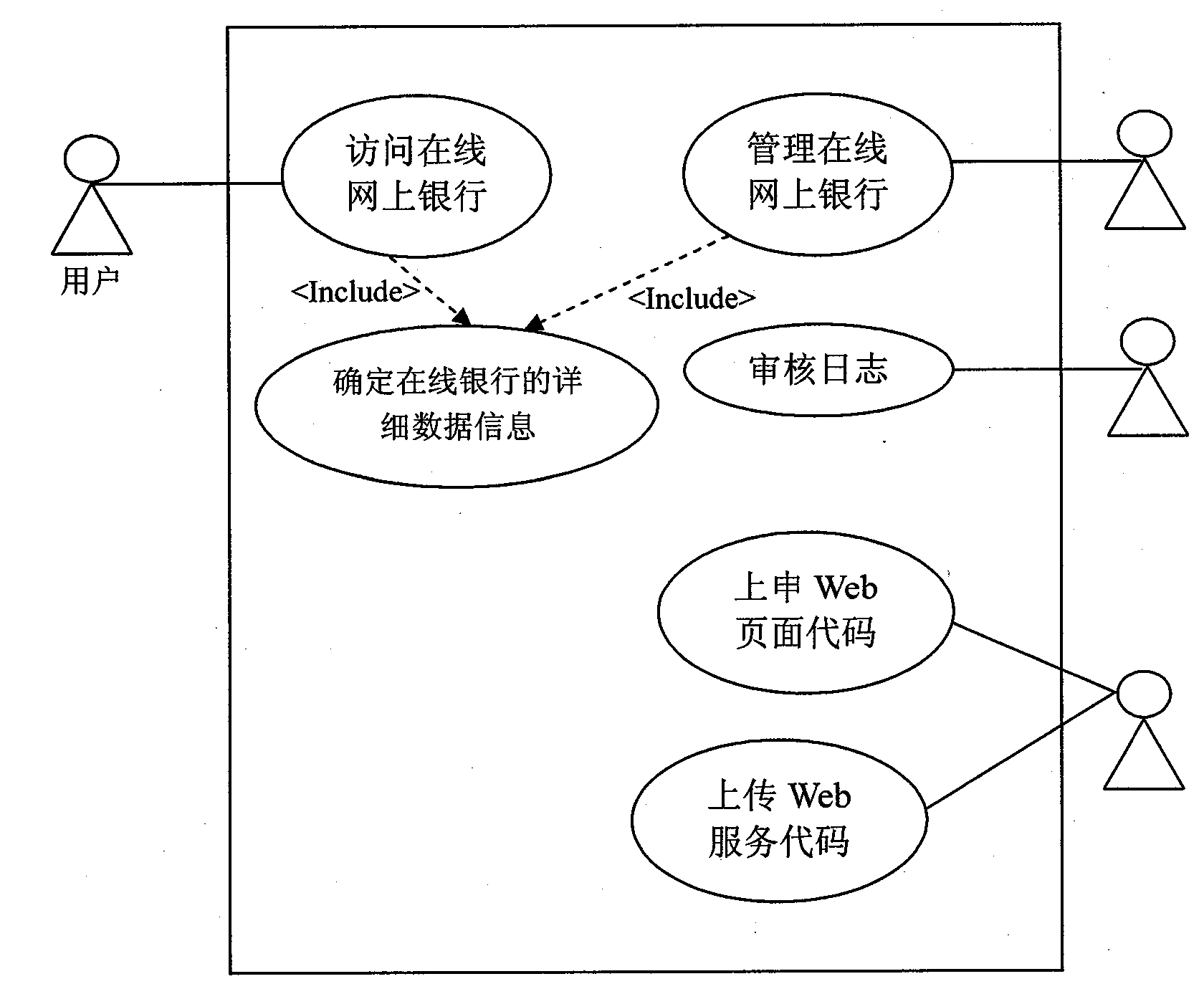

Threat modeling method added with attack path formalization analysis

InactiveCN101655787AReduce security flawsQuality improvementComputer security arrangementsSpecific program execution arrangementsApplicability domainSoftware design pattern

The invention discloses a threat modeling method added with attack path formalization analysis. In software design stage, software defect information is extracted by UML active graph decomposition application or system and threat modeling is carried out. The method includes the following steps: creating and modeling use case; creating silhouette of application or system; decomposing the application or system by using the active graph; using the acquired key asset information as threat object, creating a threat tree by taking the threat object as root node and assigning value to all nodes in the threat tree including value assignment on root nodes and leaf nodes; classifying and evaluating the threat object; and calculating the attack path of the threat tree. Compared with the prior art, the invention can reduce software product safety defect and improve software quality, improves application range of threat modeling, obtains more comprehensive and accurate threat relaxation scheme, realizes threat modeling automation and greatly reduces technical threshold, cost and development period of trusted software development.

Owner:TIANJIN UNIV

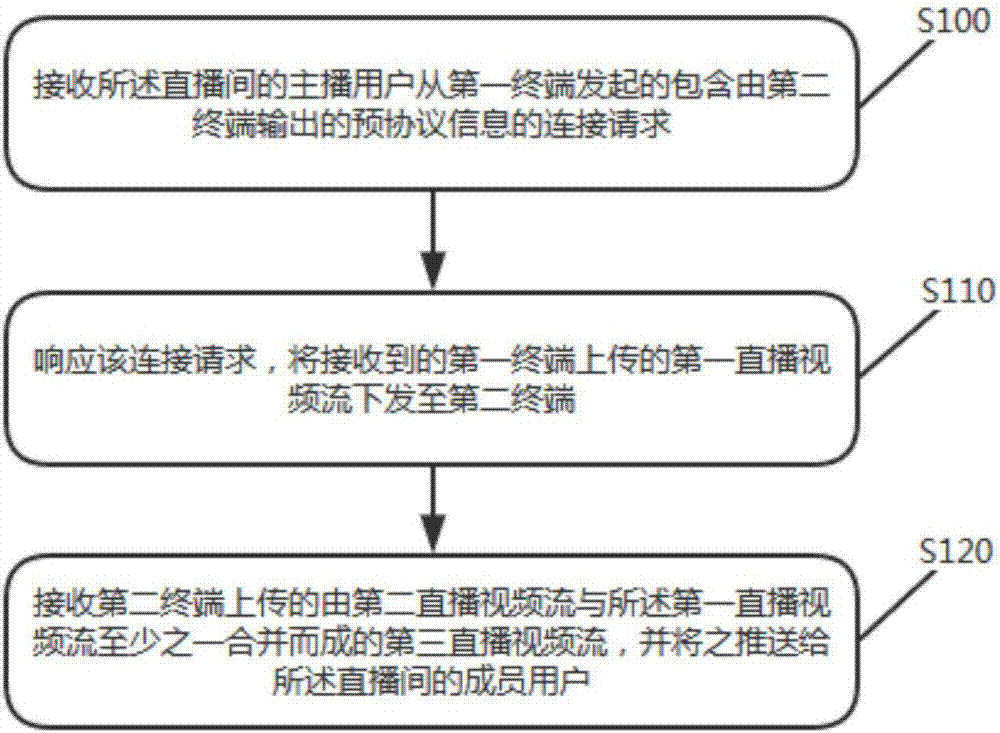

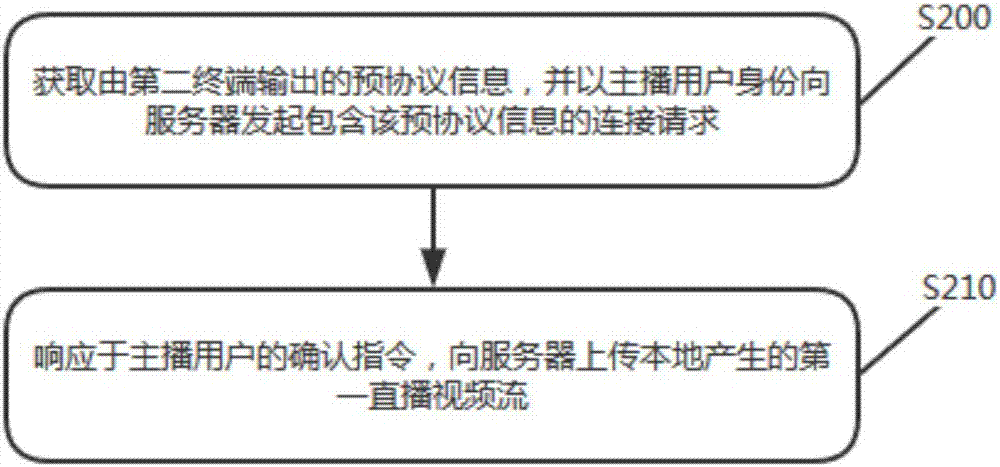

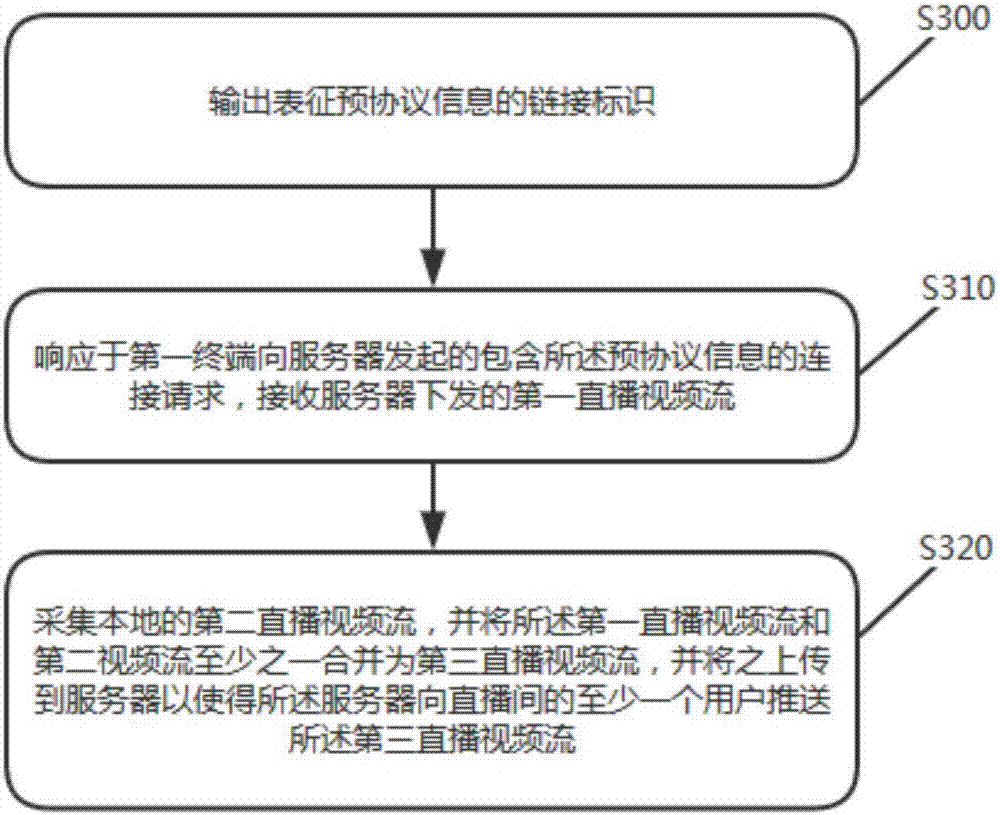

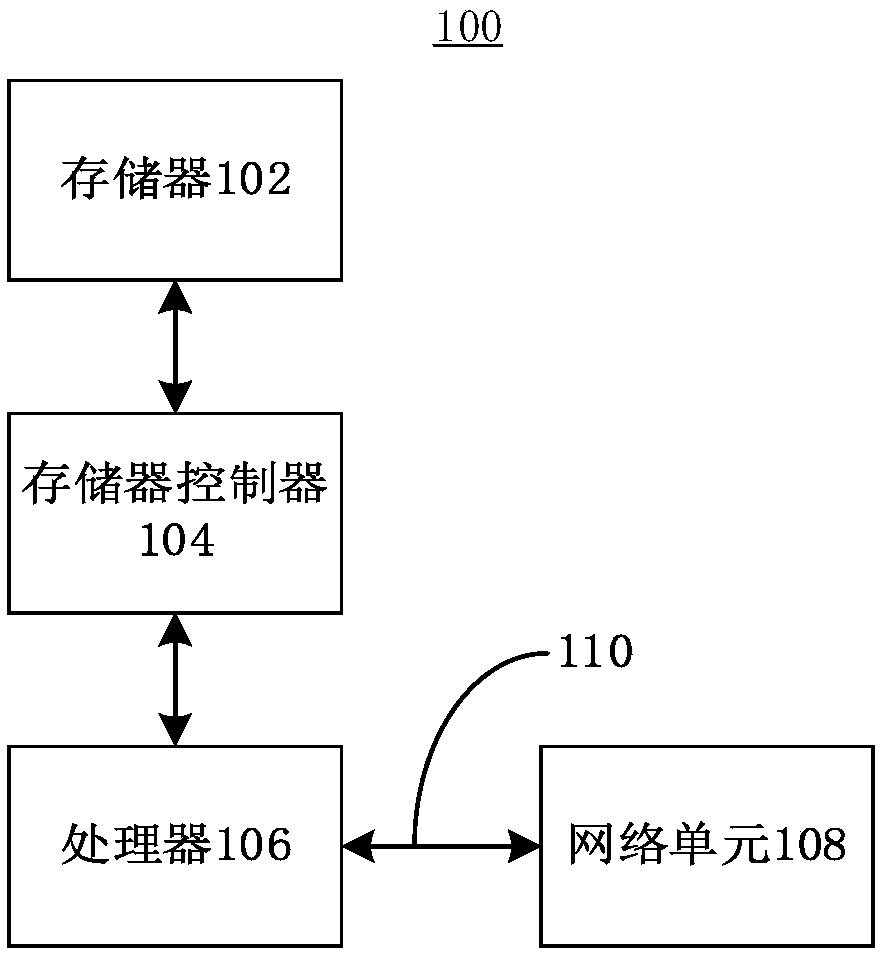

Direct broadcasting room video stream pushing control method and corresponding server and mobile terminal

ActiveCN107005721ASave resourcesLower the threshold for broadcastingTransmissionSelective content distributionMulti platformBroadcasting technology

The invention relates to a network direct broadcasting technology, in particularly to a direct broadcasting room video stream pushing control method and a corresponding server and a mobile terminal. The method includes the following steps: receiving a connection request including pre-protocol information output by a second terminal, issued by a host user in a direct broadcasting room from a first terminal; responding to the connection request, sending a received first direct broadcasting video stream uploaded by the first terminal to the second terminal; and receiving a third direct broadcasting video stream combined by at least one of a second direct broadcasting video stream uploaded by the second terminal and the first direct broadcasting video stream, and pushing the third direct broadcasting video stream to a member user in the direct broadcasting room. The method can achieve multi-platform synchronous direct broadcasting on the basis of separation and combination of video streams, can achieve sharing and flexible combination of the video streams, makes multi-platform direct broadcasting more convenient and fast, can improve the direct broadcasting efficiency, the direct broadcasting content, and can improve the user experience.

Owner:BIGO TECH PTE LTD

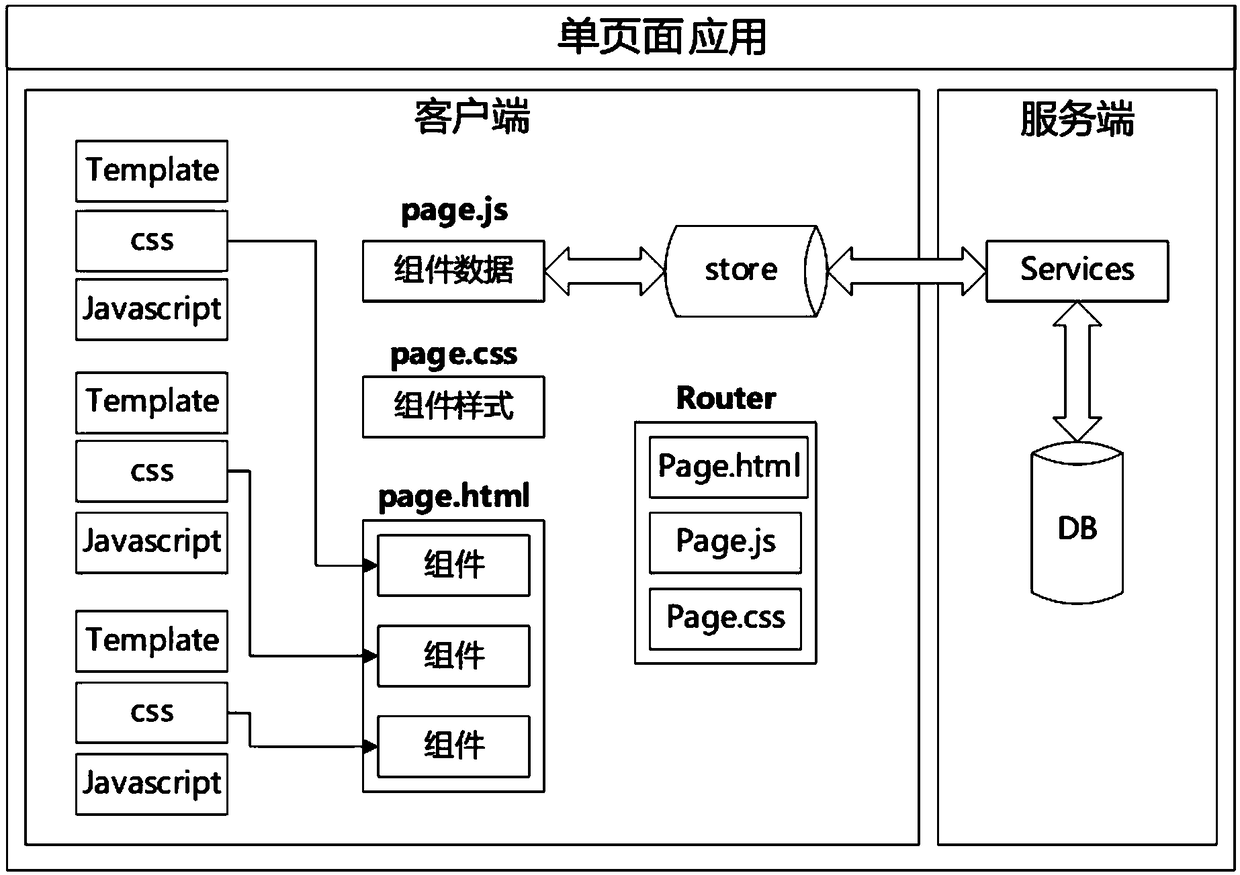

Front-end page development framework

InactiveCN108874389AEnsure consistencyImprove data synchronization issuesSoftware reuseWorkloadComputer science

The invention relates to the technical field of front-end development, and provides a front-end page development framework. The front-end page development framework includes multiple page components,data caches, and framework programs. Each of the multiple page components is configured to present data obtained from the backend on the page. The framework programs are configured to save common dataused for at least two of the multiple page components from the data obtained from the backend to the data cache, so that at least two page components need to read from the data cache when getting theshared data. In the front-end page development framework, since a copy of the shared data is not saved locally at the page components, it is possible to ensure that the shared data is consistent among the page components. Developers no longer need to pay too much attention to the synchronization of shared data across components, and reduce the workload of developers significantly.

Owner:CHINA CONSTRUCTION BANK

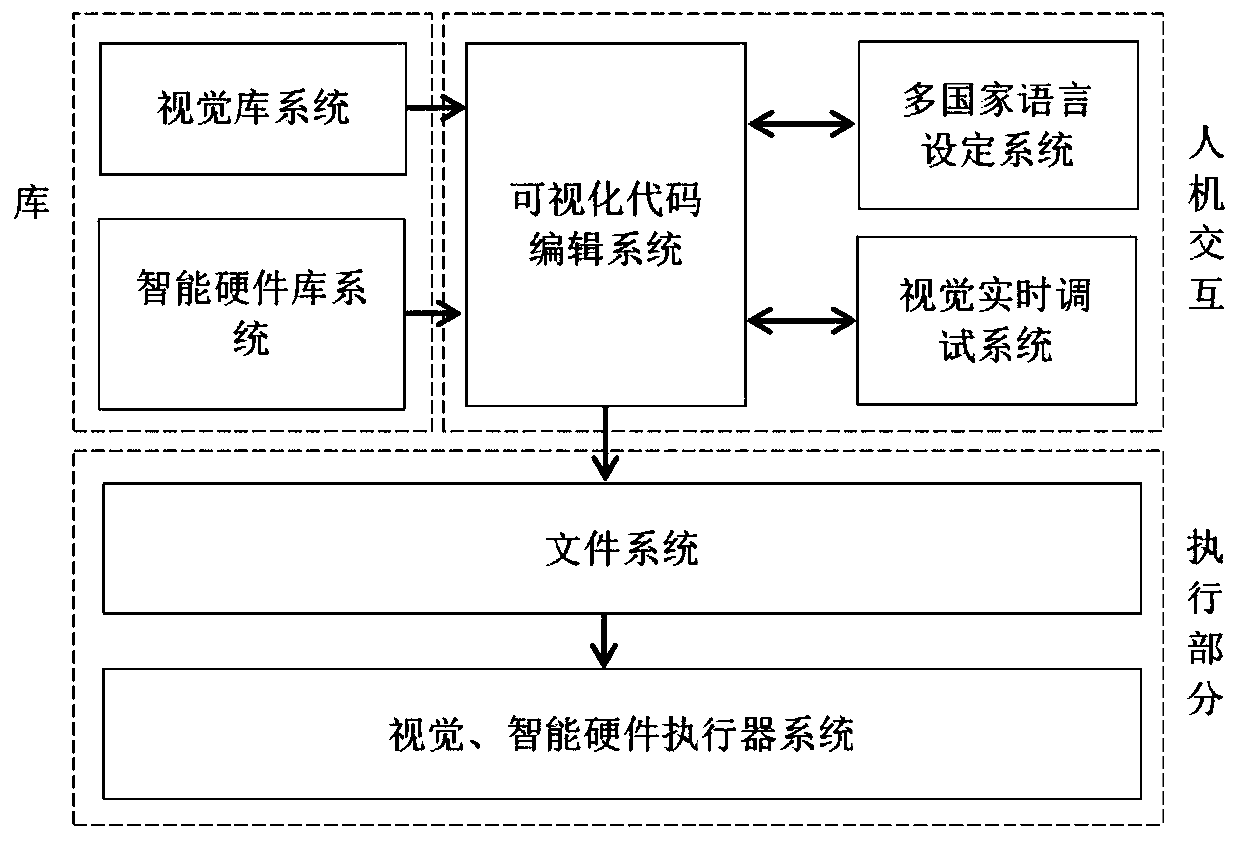

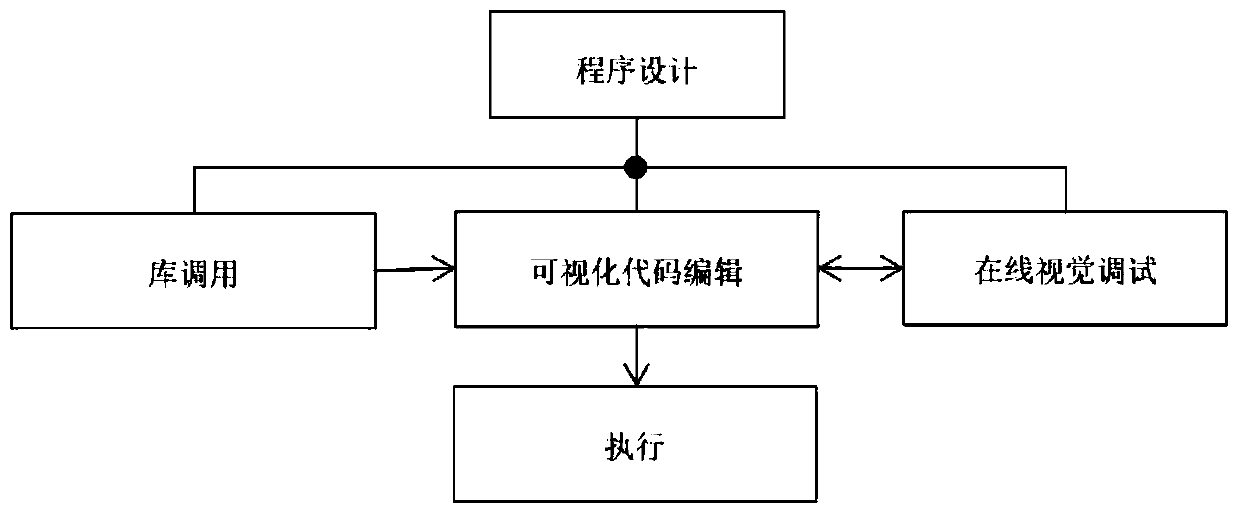

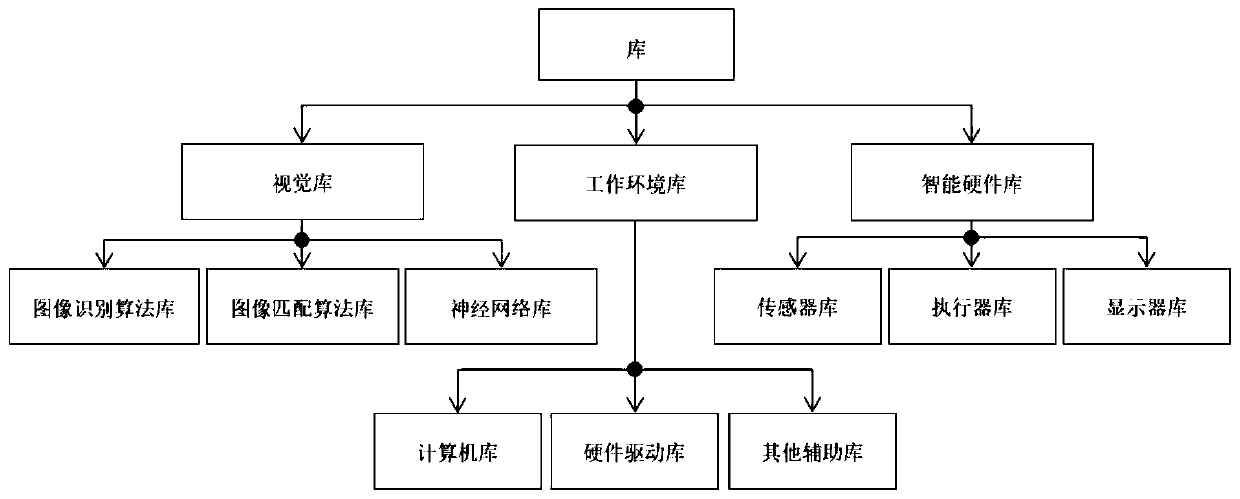

Character visualization visual programming integration device, processing device and storage medium

ActiveCN109871204ALower technical barriersEasy to learnIntelligent editorsCode compilationFile systemWorking environment

The invention provides a character visualization visual programming integration device, processing device and a storage medium. The integrated device comprises a man-machine interaction system, a library file system and an execution system, The man-machine interaction system comprises a visual man-machine interaction editing system, a multi-country language setting system and a visual real-time debugging system; The library file system comprises a visual library system, a working environment library and an intelligent hardware library system; The execution system comprises a file system and avisual and intelligent hardware actuator system; A visual man-machine interaction editing system of the integrated device is designed according to a program of a user and calls a library file to generate an executable program; The compiled program is sent to the execution system by the visual man-machine interaction editing system, the execution system runs the file system, codes sent by the visual man-machine interaction editing system are compiled into machine driving codes, and the visual and intelligent hardware actuator system is driven. The problem that an existing graphical programmingenvironment cannot process a visual module, artificial intelligence and other algorithm modules is solved.

Owner:智能佳(北京)机器人有限公司

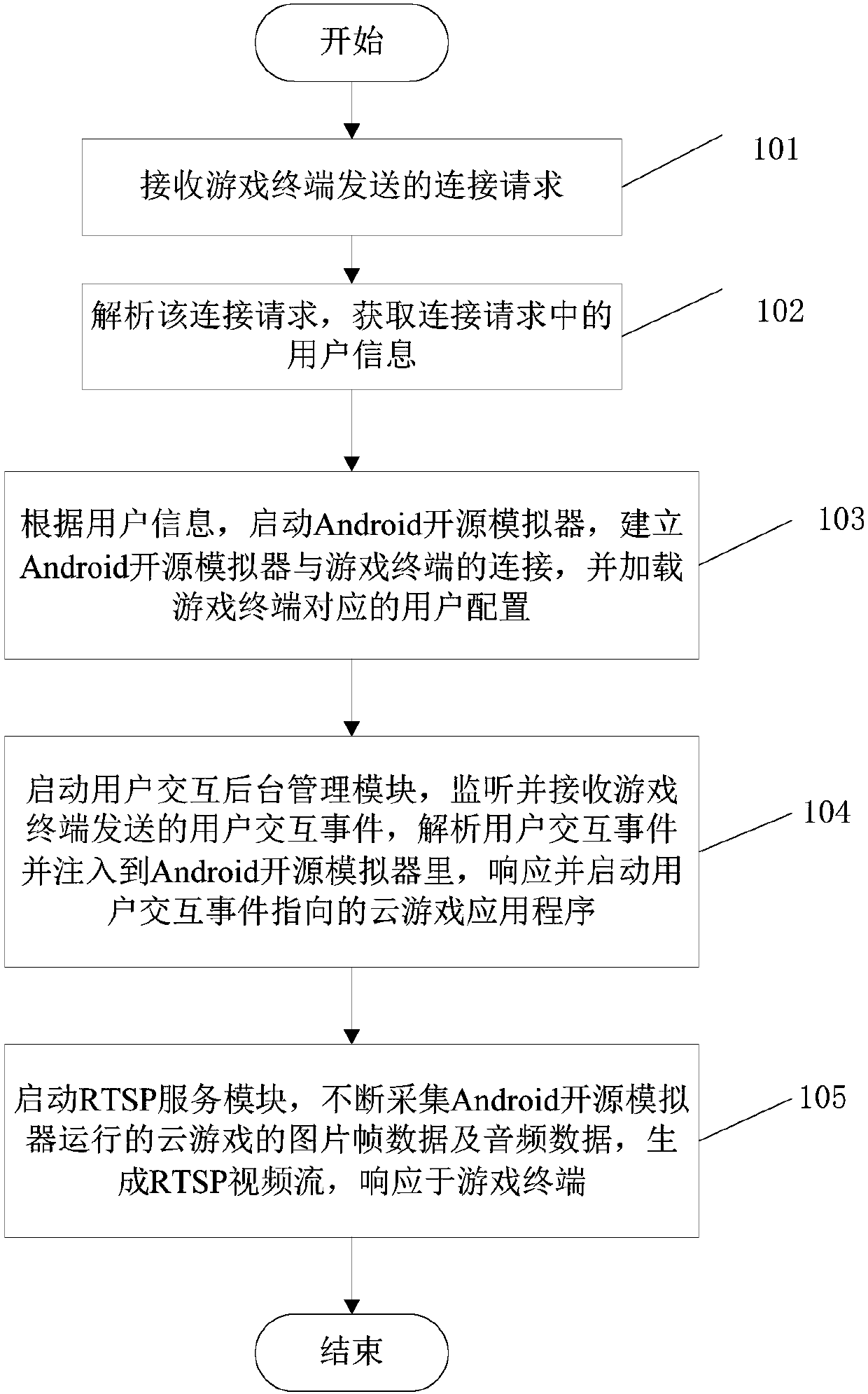

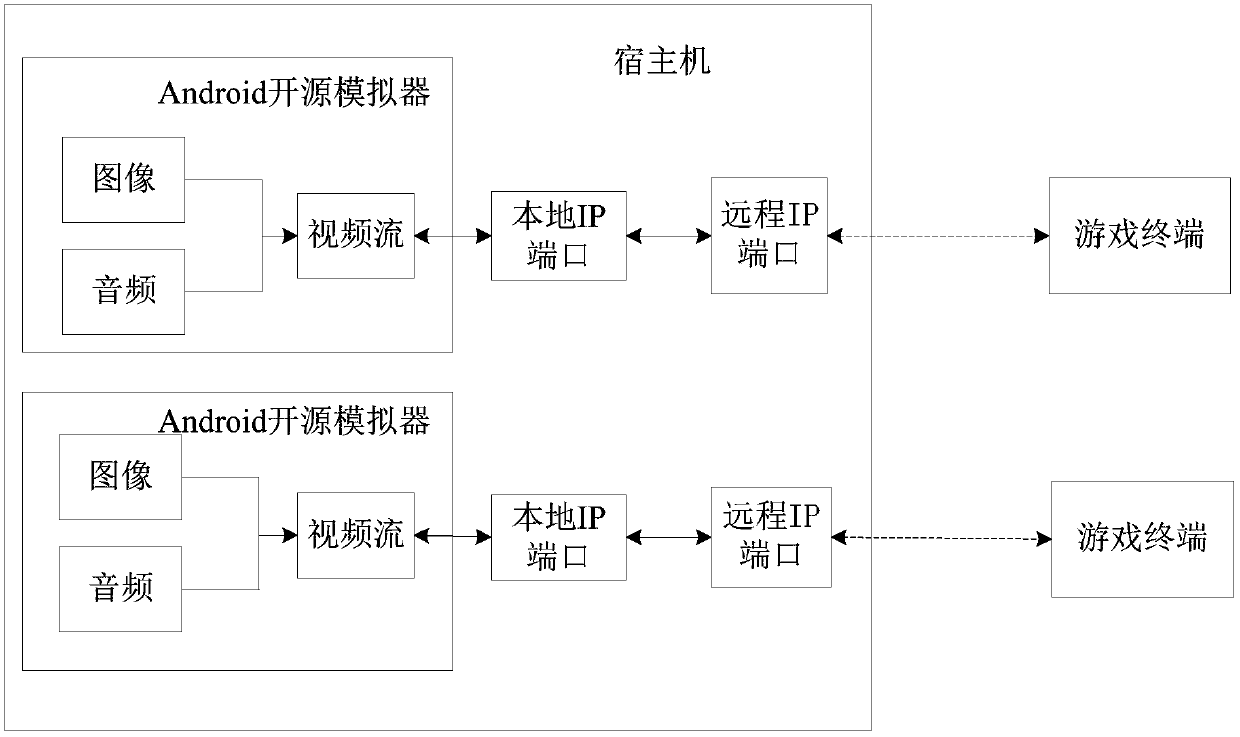

Android system-based cloud game operating method and android system-based cloud game server

ActiveCN110115835APrevent malfunctionAvoid problems when updating to new versions of AndroidVideo gamesTransmissionOpen sourceComputer compatibility

An embodiment of the invention relates to the technical field of cloud games and discloses an android system-based cloud game operating method and an android system-based cloud game server. The android system-based cloud game server starts an android open source simulator to load user configurations; starts a user interaction background management module to receive user interaction events, parse and inject them into the android open source simulator in order to respond to and start a cloud game application corresponding to a user operation; and also starts a RTSP (real time streaming protocol)service module to continuously acquire game images and audio data, thereby forming RTSP video streams that are sent to a game terminal. The android system-based cloud game server is achieved herein through the android open source simulator; the technical threshold is lowered, and the cost is reduced. In addition, the android open source simulator has a complete supporting version at each updatedandroid version and has best compatibility; therefore, the problem is avoided that the cloud game server is unable to update a new android version in time.

Owner:CHINANETCENT TECH

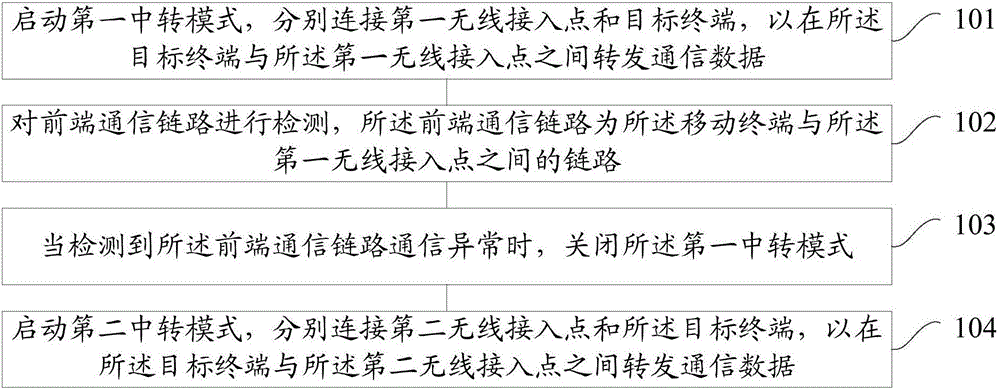

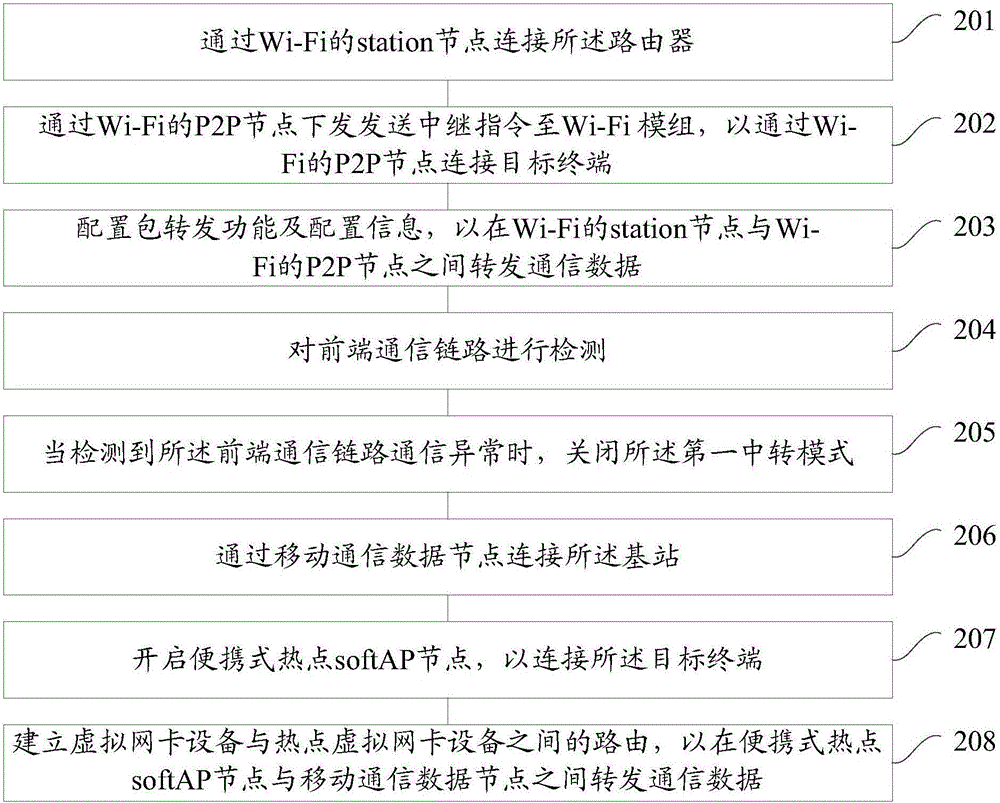

Link switching method and device

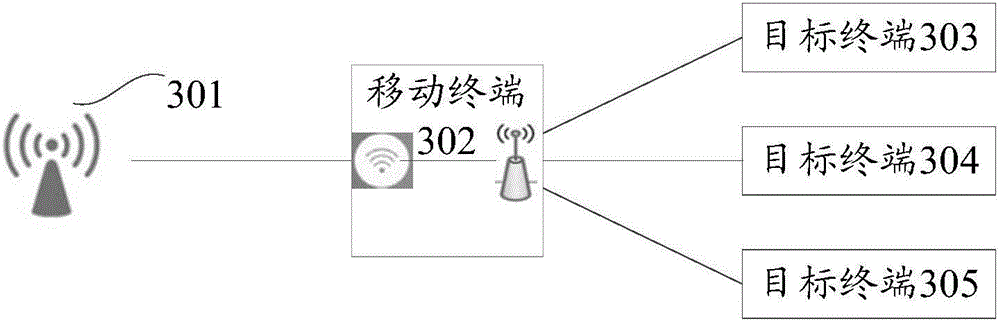

ActiveCN106535238AAvoid checkingLower technical barriersWireless communicationTelecommunicationsTelecommunications link

Embodiments of the present invention provide a link switching method and a device, wherein the method and the device are applied to a mobile terminal. The method comprises the steps of turning on a first transfer mode, and respectively connecting a first wireless access point with a target terminal so as to transmit communication data between the target terminal and the first wireless access point; detecting a front-end communication link, wherein the front-end communication link is a link between the mobile terminal and the first wireless access point; upon detecting the abnormal communication state of the front-end communication link, turning off the first transfer mode; turning on a second transfer mode, and respectively connecting a second wireless access point with the target terminal so as to transmit communication data between the target terminal and the second wireless access point. According to the embodiments of the invention, the anomaly detection and repair is automatically realized. Therefore, a user is prevented from manually checking the mobile terminal of a transfer node. The technical threshold is reduced and the convenience of operation is improved.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

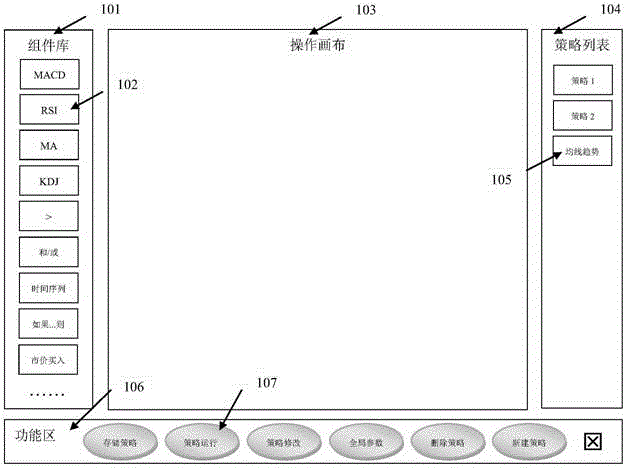

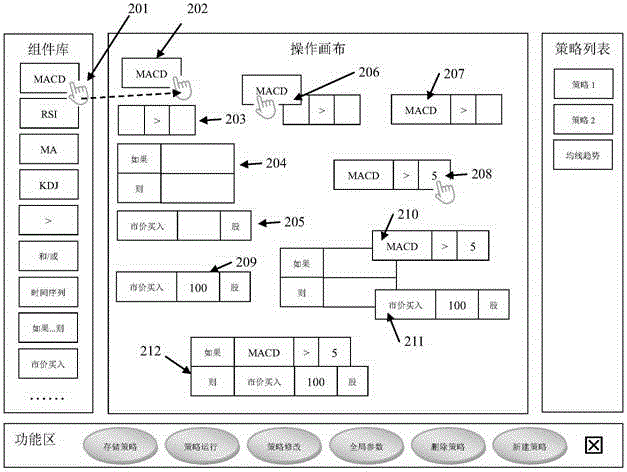

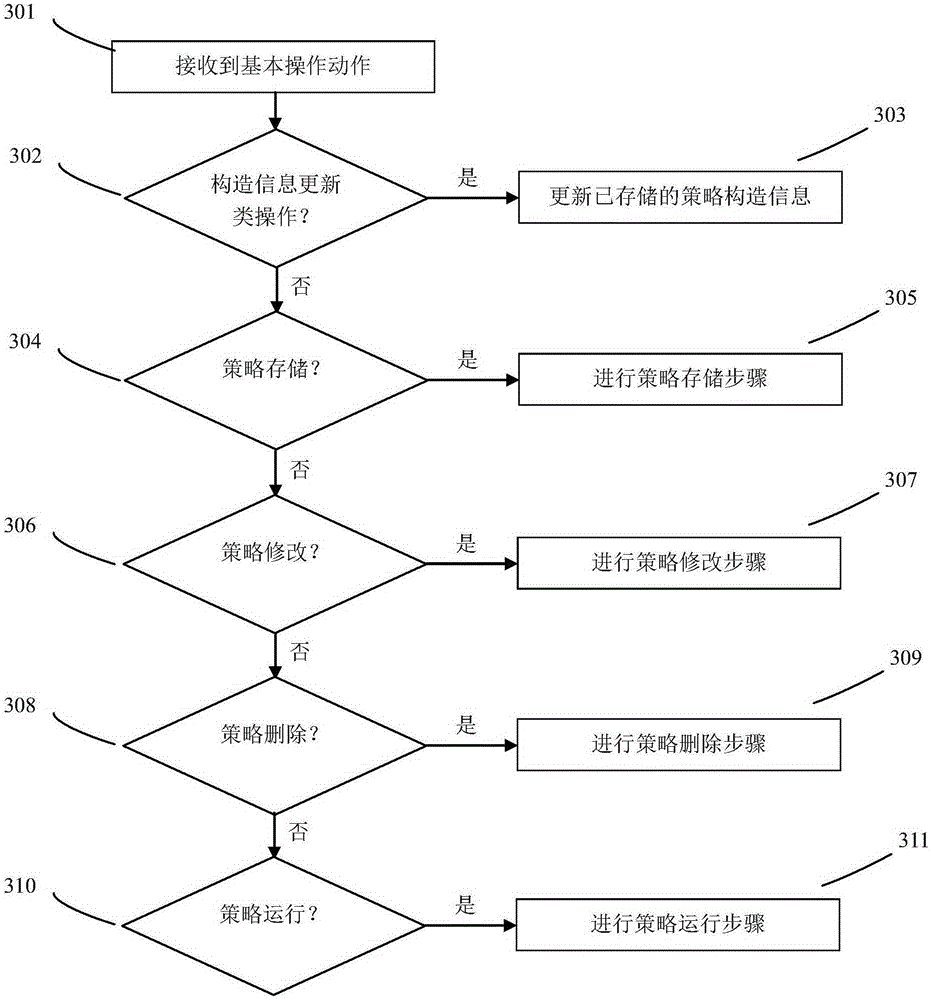

Method and system for realizing quantitative trading in mobile computing device

InactiveCN106504088AReduce computing pressureReduce energy consumptionFinanceInformation processingEnergy expenditure

The invention discloses a method and a system for realizing quantitative trading in a mobile computing device, which relate to the field of information processing related to quantitative trading and solve the problems that the quantitative trading process through the mobile computing device in the prior art occupies too many system resources and a strategy input method is complicated. Through separating functions such as strategy construction and management from functions such as strategy compilation and execution with intensive computation, the computation pressure and the energy consumption of the mobile computing device can be effectively reduced, and the quantitative trading system can be deployed in the mobile computing device efficiently; besides, operation such as strategy module selection, parameter modification and combination connection is used for replacing complicated program code input, the technical threshold of a quantitative trading system user and rely on an input keyboard are reduced, and the user can convert a trading logic to a trading strategy without mastering a programming language; and the security of the trading strategy is enhanced, and the purpose of protecting an investor is achieved.

Owner:高庆文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com