Electric furnace smelting method for low-carbon low-silicon steel

An electric furnace smelting, low-carbon and low-silicon technology, applied in the direction of electric furnaces, furnaces, furnace types, etc., can solve the problems that cannot be used to produce low-carbon and low-silicon steel, and achieve the goal of expanding smelting and processing capacity, highlighting economic benefits, and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

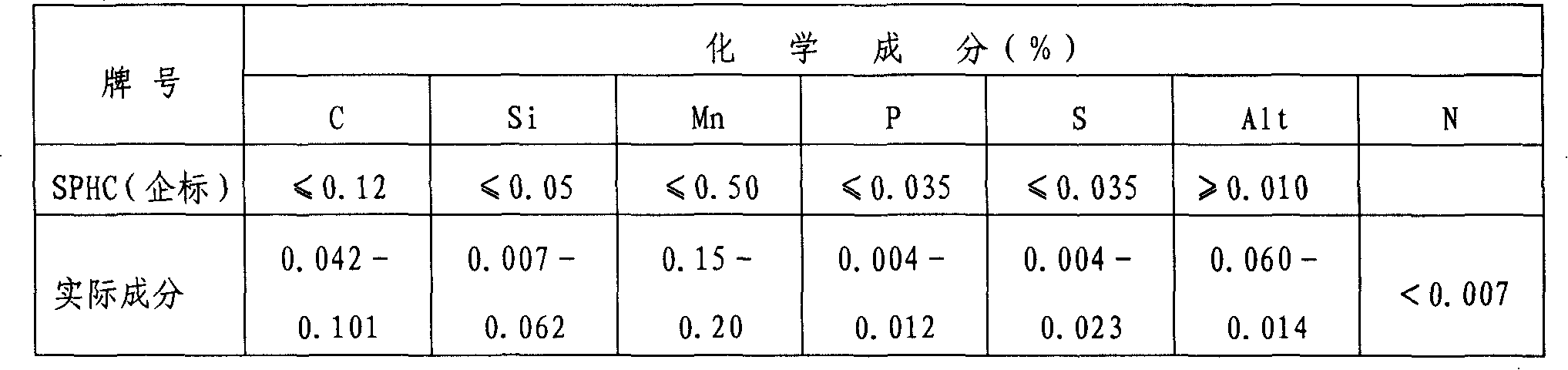

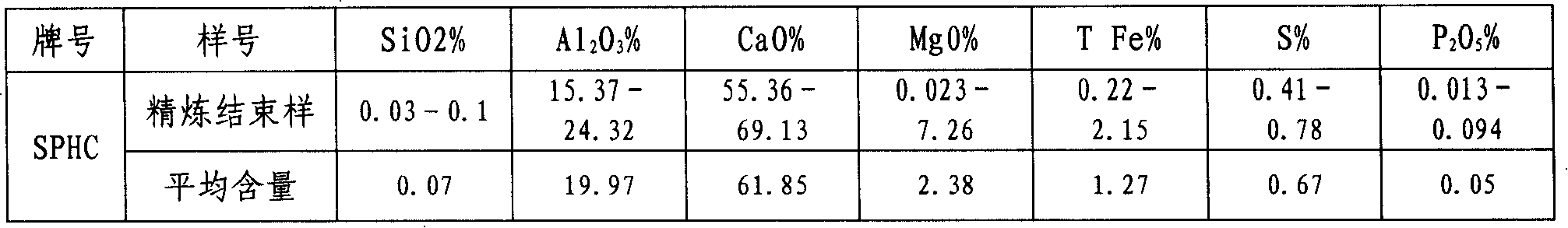

[0032] An electric furnace smelting method for low-carbon and low-silicon steel comprises the following smelting processes in sequence: an electric furnace smelting process, an LF ladle furnace refining process and a continuous casting process.

[0033] Electric furnace process: take a 110-ton AC electric arc furnace as an example to illustrate. In the electric furnace smelting process, molten iron or iron nuggets should be added to the electric furnace ingredients added. The amount of molten iron or iron nuggets accounted for 35% of the total amount of ingredients loaded. If conditions permit, add 15% of direct reduced iron. The total load is controlled at around 115 tons. The amount of lime to be added is 6500kg per furnace, and dolomite is added to 1800kg per furnace, which is added to the first blue material.

[0034] In the early stage of smelting, high-grade power transmission is adopted, and the current intensity is kept at 70-90kA, so as to shorten the melting time of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com