Patents

Literature

1268 results about "Lithium oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium oxide (Li₂O) or lithia is an inorganic chemical compound. It is a white solid. Although not specifically important, many materials are assessed on the basis of their Li₂O content. For example, the Li₂O content of the principal lithium mineral spodumene (LiAlSi₂O₆) is 8.03%.

Nonaqueous electrolyte battery, battery pack and positive electrode active material

InactiveUS20060134520A1Improve storage characteristicsOrganic electrolyte cellsPositive electrodesLithium oxideLithium hydroxide

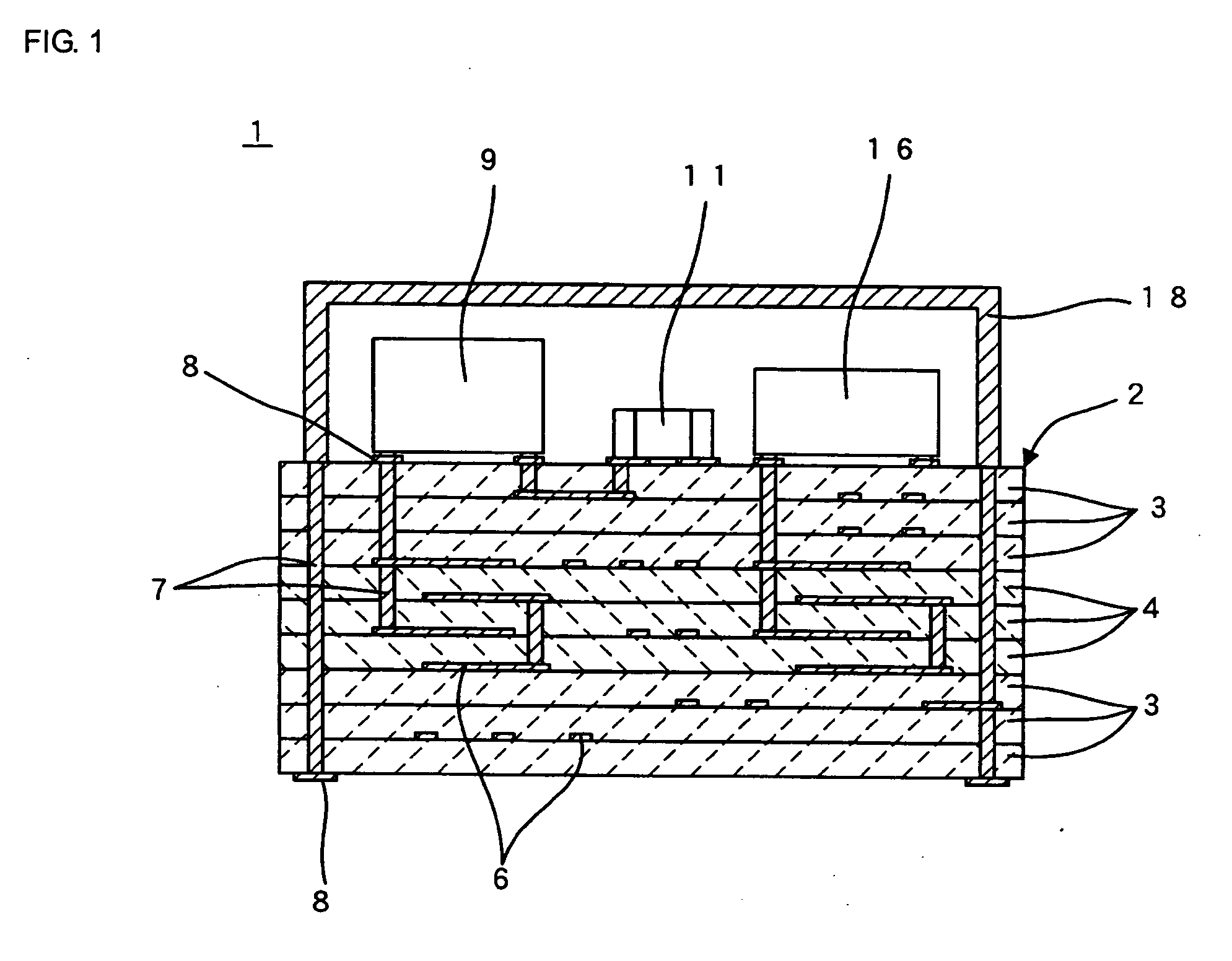

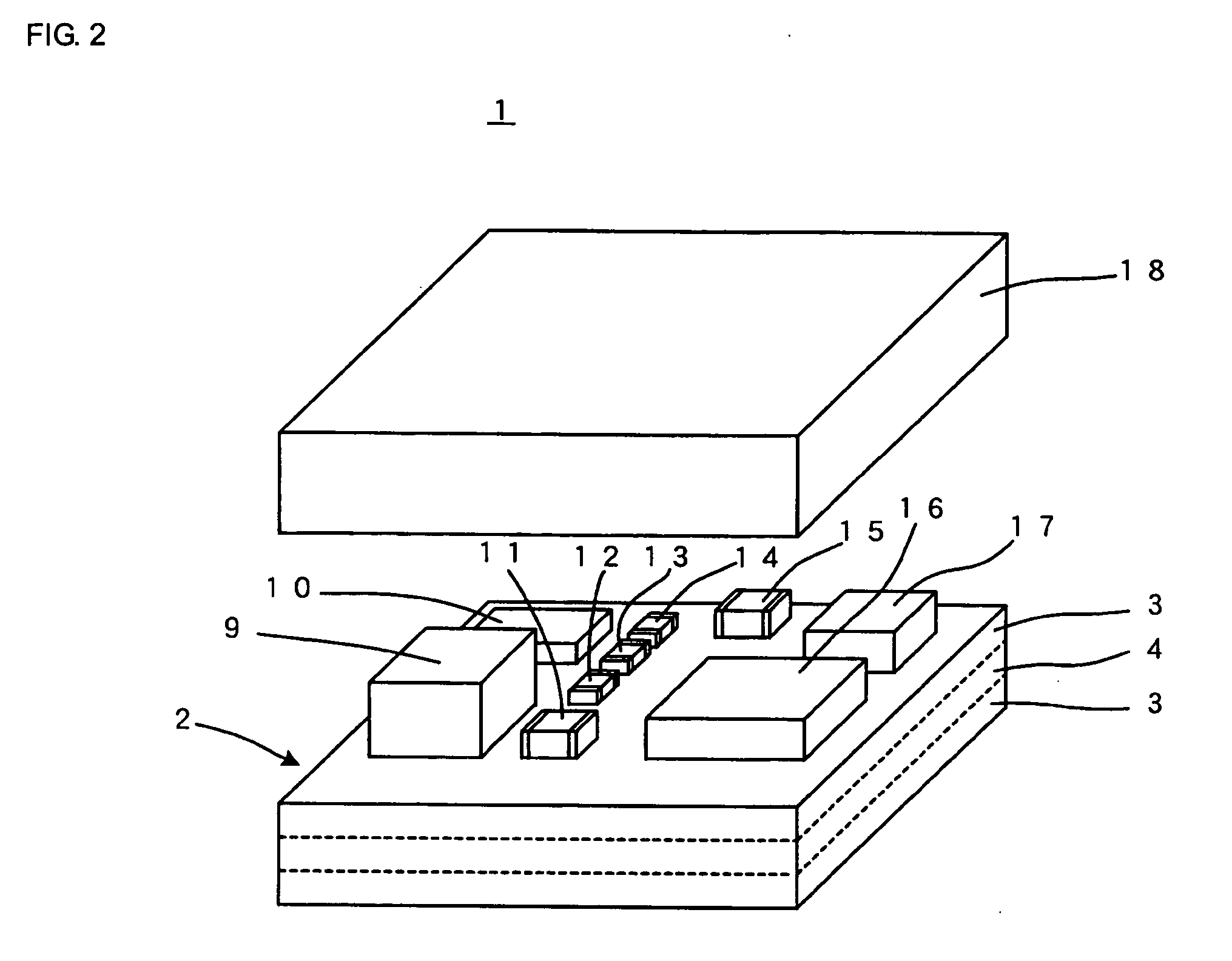

A nonaqueous electrolyte battery includes a case, a positive electrode housed in the case and including a positive electrode active material containing a lithium-nickel composite oxide and at least one of lithium hydroxide and lithium oxide, the sum of lithium hydroxide and lithium oxide falling within not less than 0.1% to not more than 0.5% by weight based on the total amount of the positive electrode active material, a negative electrode housed in the case and capable of lithium intercalation-deintercalation, and a separator sandwiched between the positive electrode and the negative electrode and impregnated with a nonaqueous electrolyte containing γ-butyrolactone.

Owner:KK TOSHIBA

Lithium ion battery positive pole material cobalt nickel oxide manganses lithium and method for making same

ActiveCN101202343AHigh specific capacityExcellent cycle characteristicsElectrode manufacturing processesLithium compoundsLithium oxideAntioxidant

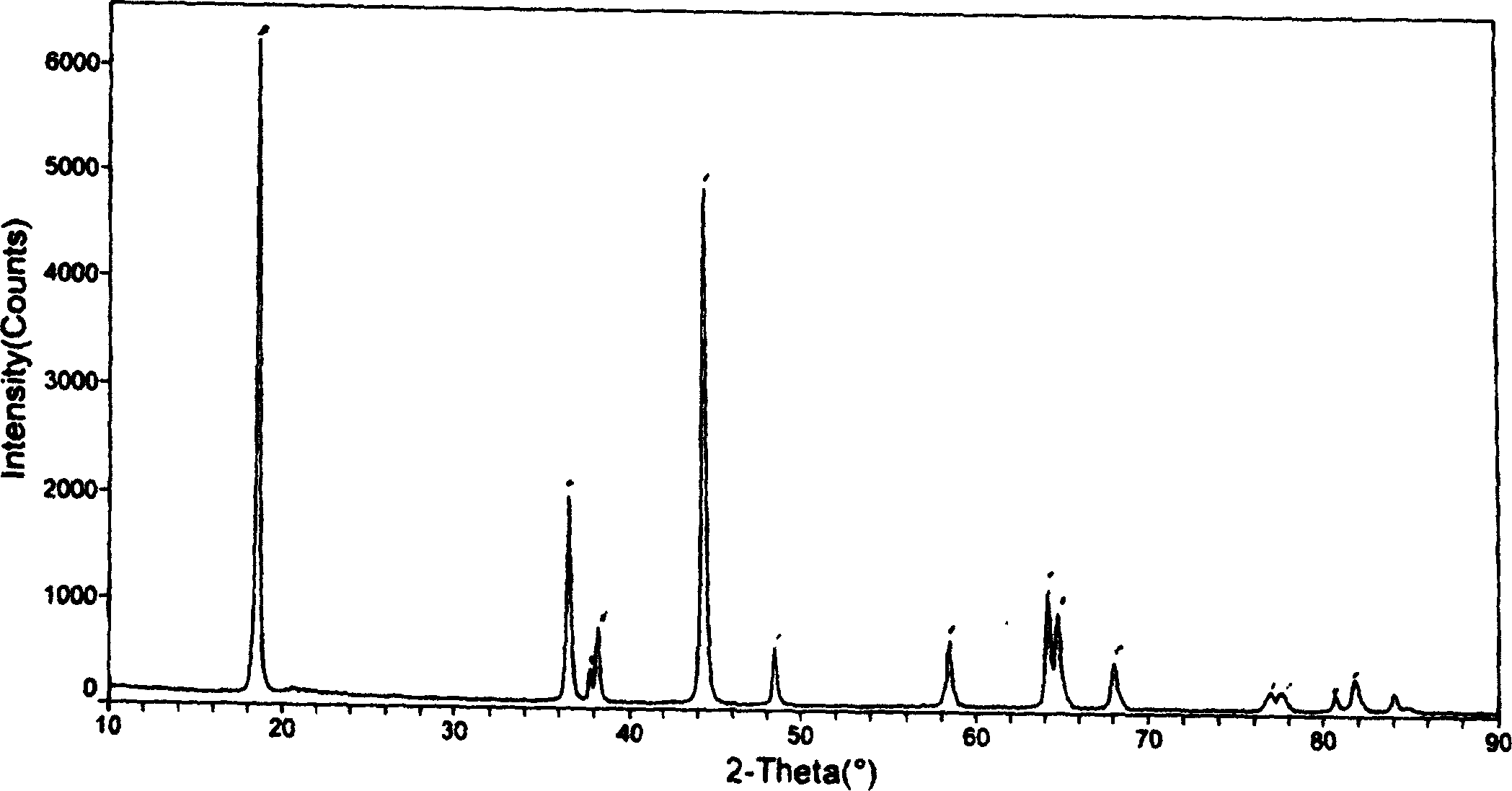

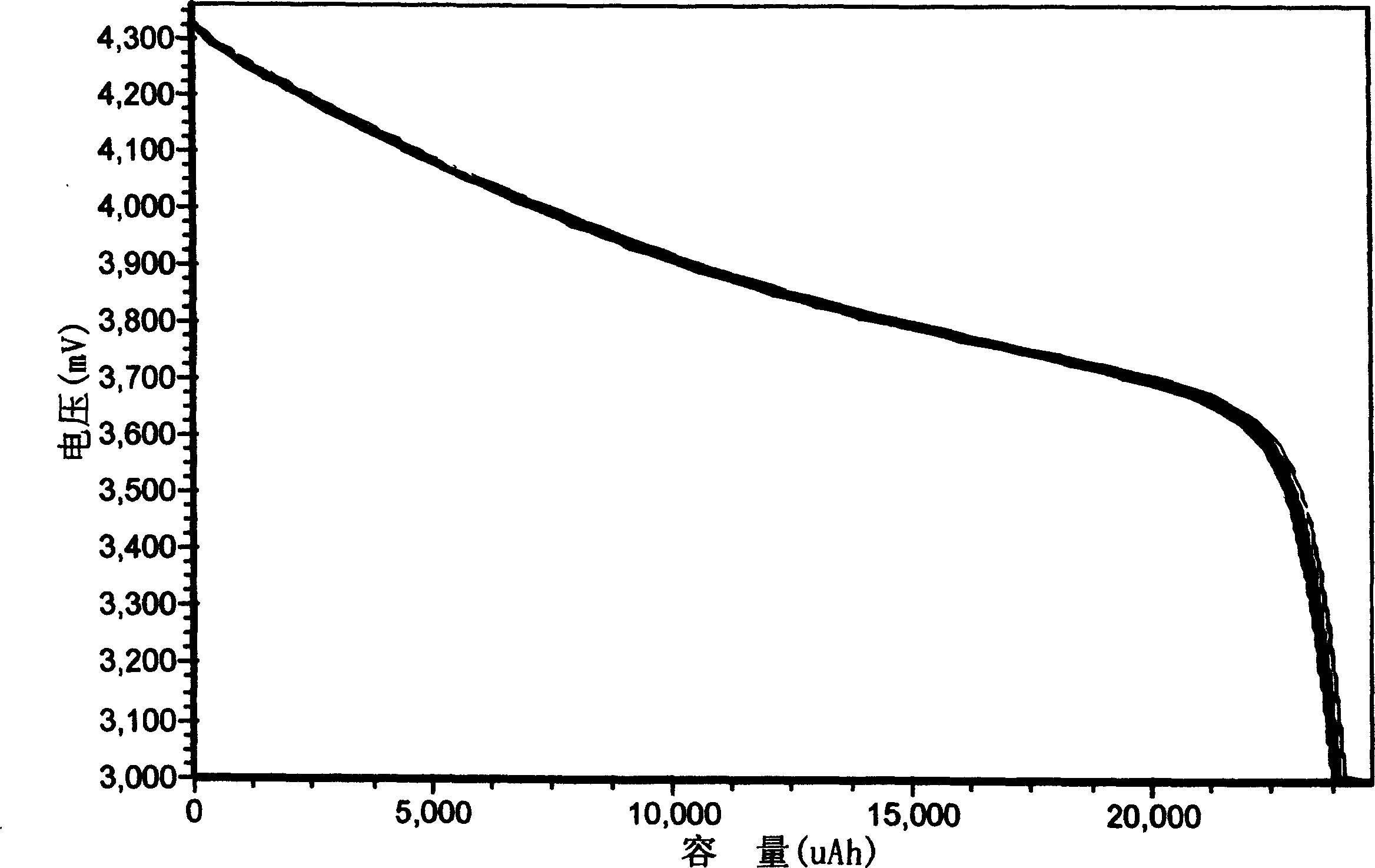

The invention relates to a nickel cobalt manganese lithium oxide material used for an anode of a li-ion battery and a preparation method. The invention belongs to the li-ion battery technical field. The nickel cobalt manganese lithium oxide material used for the anode of the li-ion battery is a li-rich laminated structure with the chemical component of Li1+zM1-x-yNixCoyO2; wherein, z is less than or equal to 0.2 and more than or equal to 0.05, x is less than or equal to 0.8 and more than 0.1, and y is less than or equal to 0.5 and more than 0.1. The preparation method of the invention is that dissoluble salt of the nickel, cobalt and manganese is taken as the raw material; ammonia or ammonium salt is taken as complexing agent; sodium hydroxide is taken as precipitator; water-dissoluble dispersant and water-dissoluble antioxidant or inert gas are added for control and protection; in a cocurrent flow type the solution is added to a reaction vessel for reaction; after alkalescence disposal, aging procedure, solid-liquid separation and washing and drying, the nickel cobalt manganese oxide is uniformly mixed with the lithium raw material; the nickel cobalt manganese lithium oxide powder is obtained by sintering the mixed powder which is divided into three temperature areas. The invention has the advantages of high specific capacity, good circulation performance, ideal crystal texture, short production period, low power loss, and being suitable for industrial production, etc.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST +1

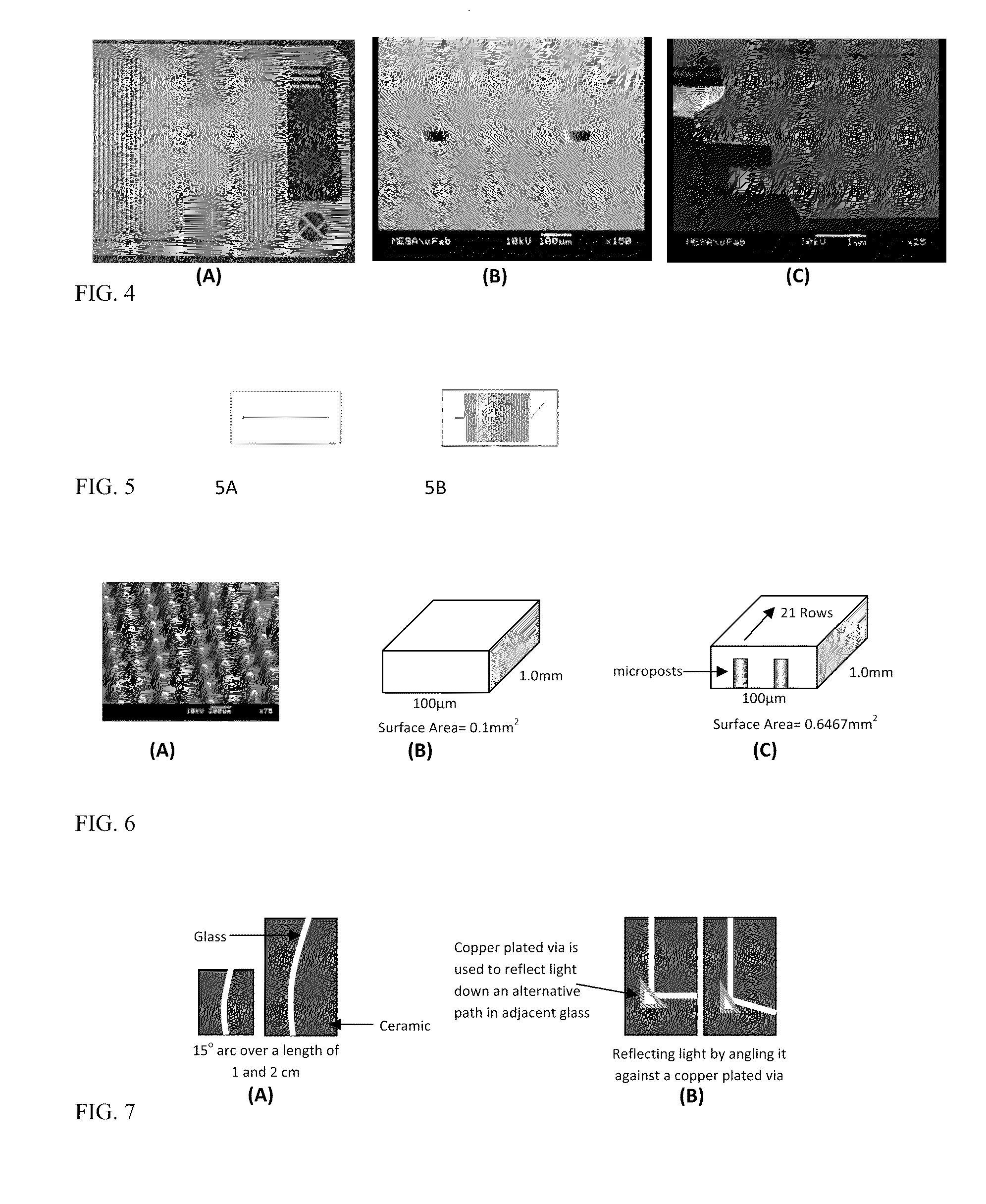

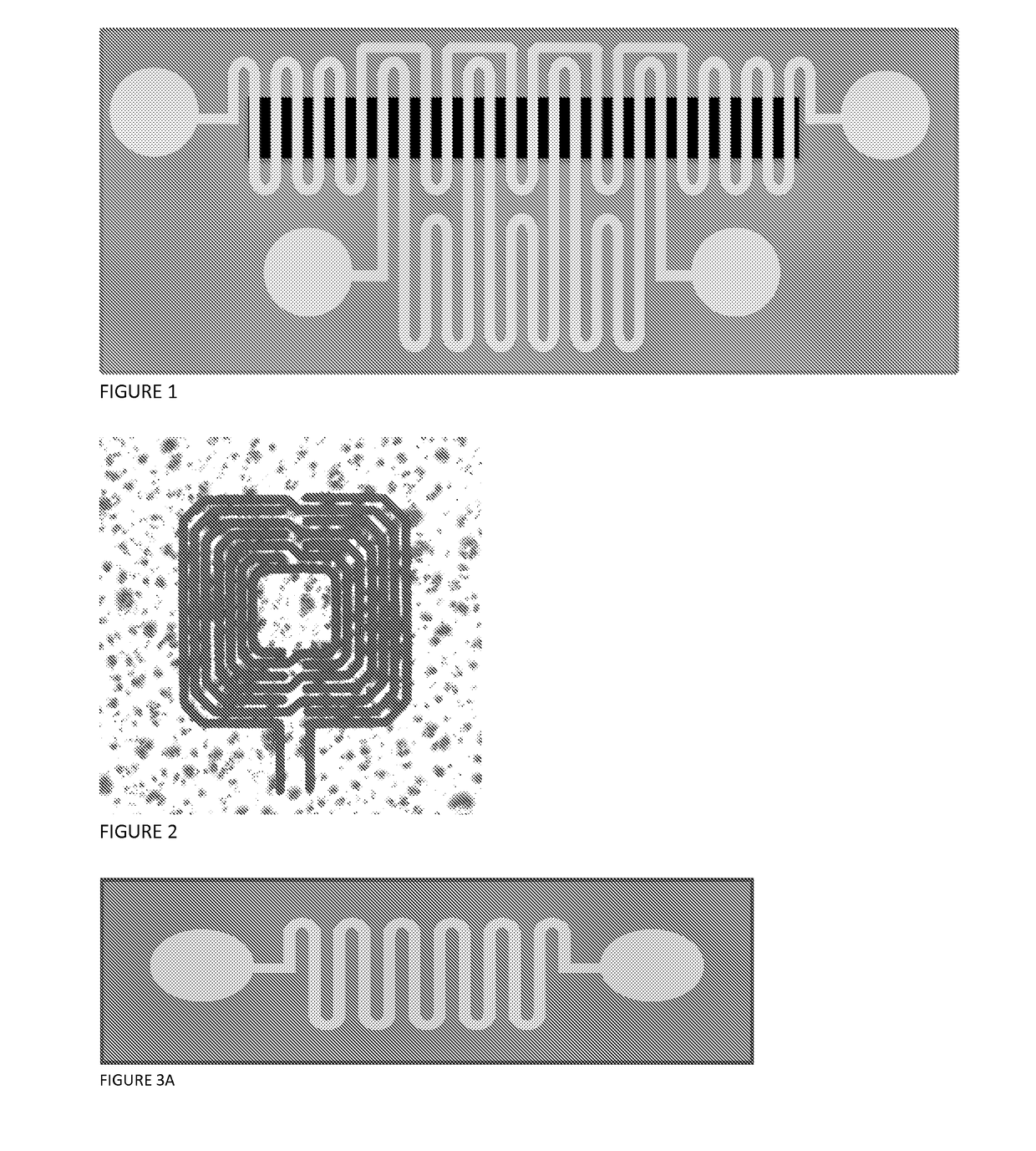

Methods to fabricate a photoactive substrate suitable for microfabrication

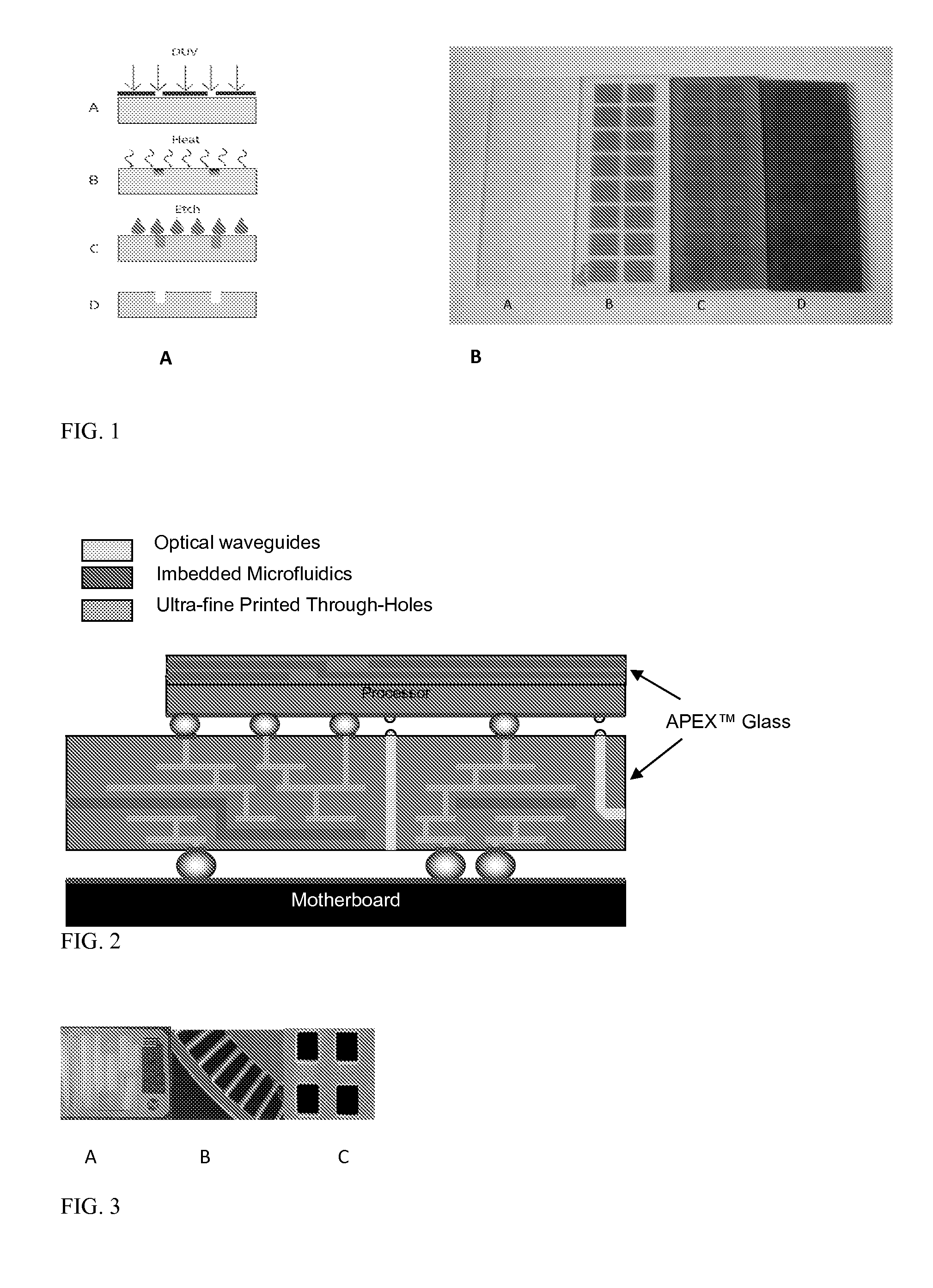

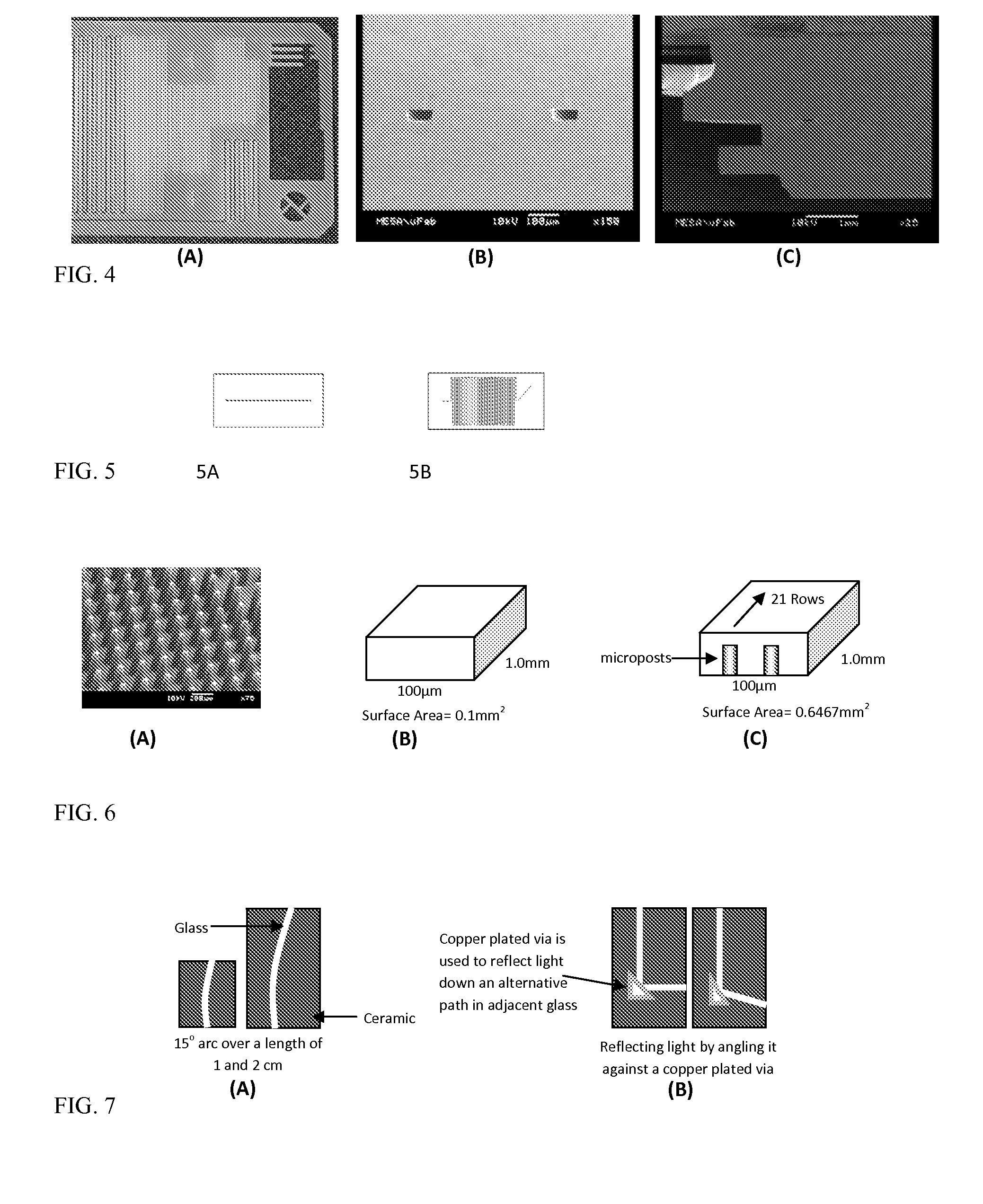

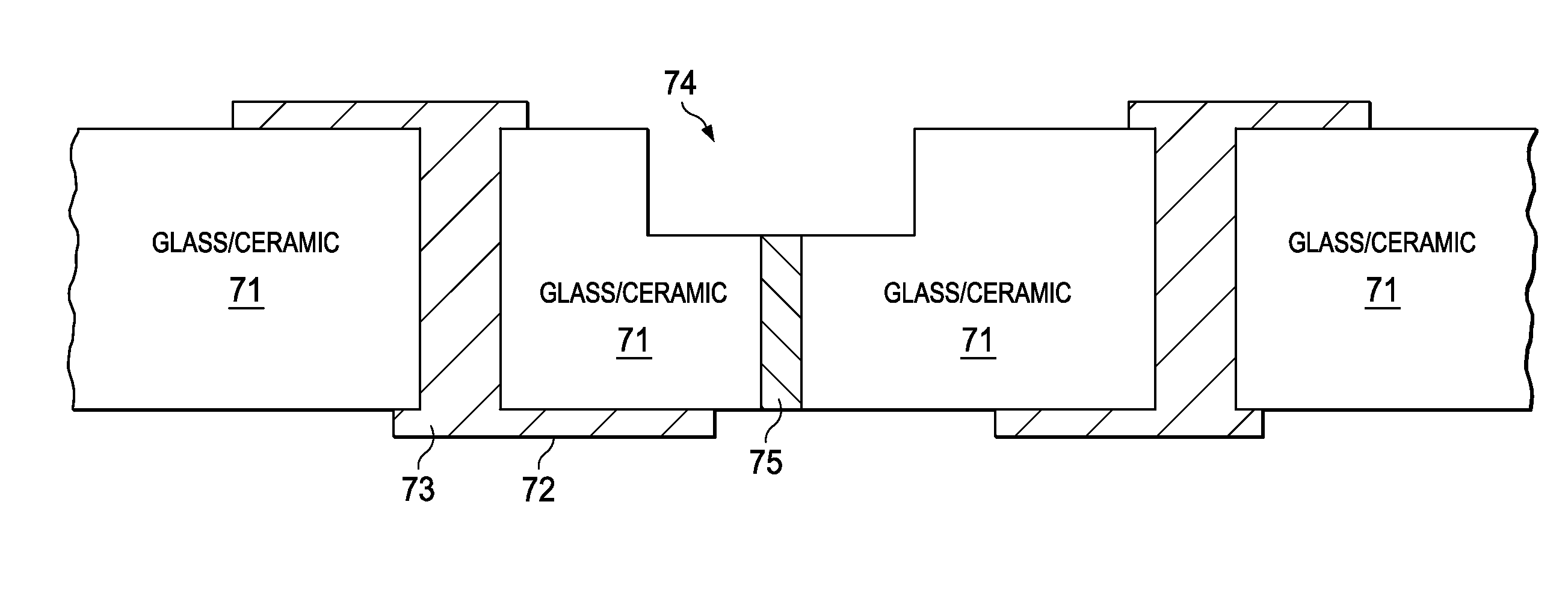

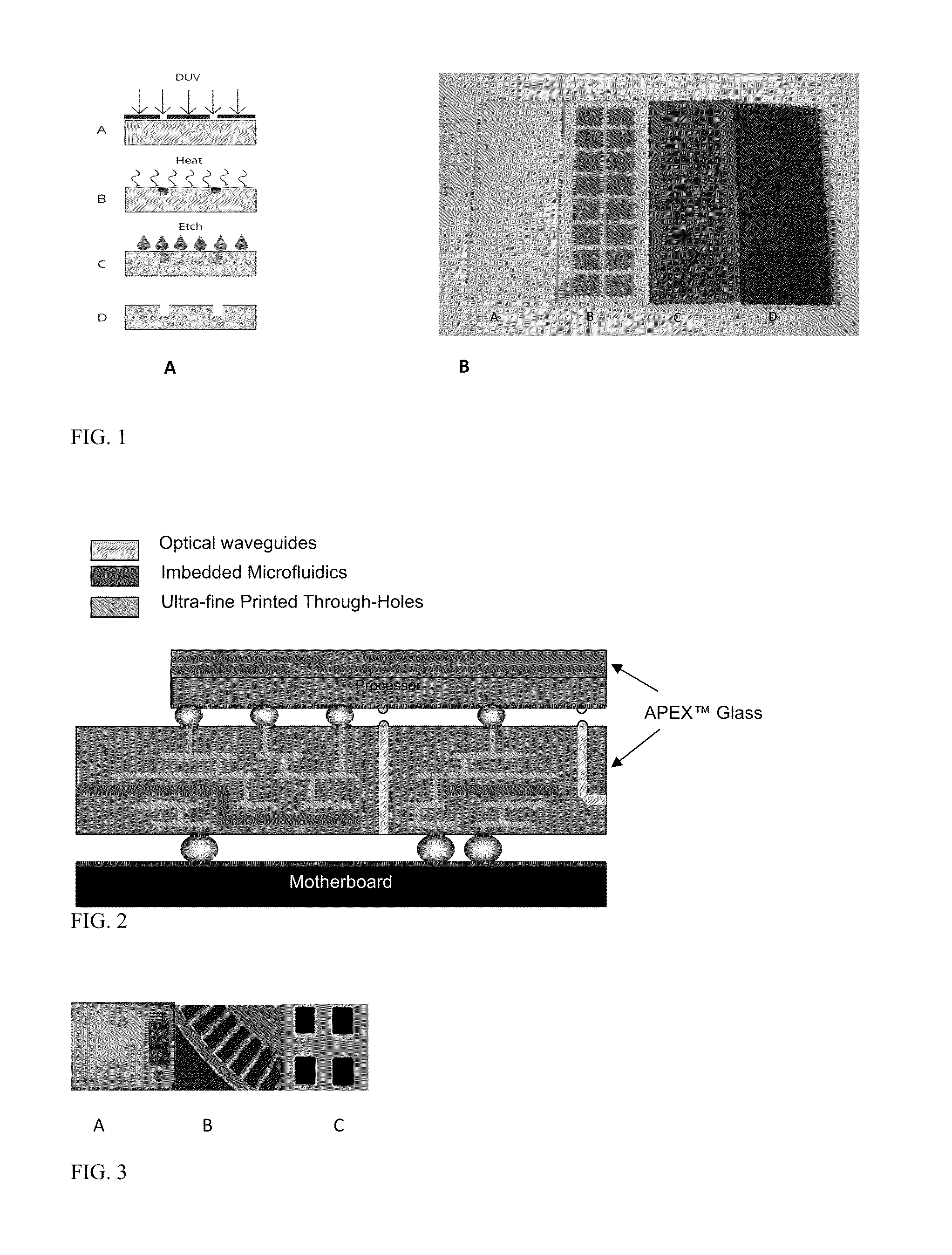

ActiveUS20110195360A1Solid-state devicesSemiconductor/solid-state device manufacturingLithium oxideGlass transition

Owner:3D GLASS SOLUTIONS INC

High temperature glass fiber insulation

Owner:GLASS

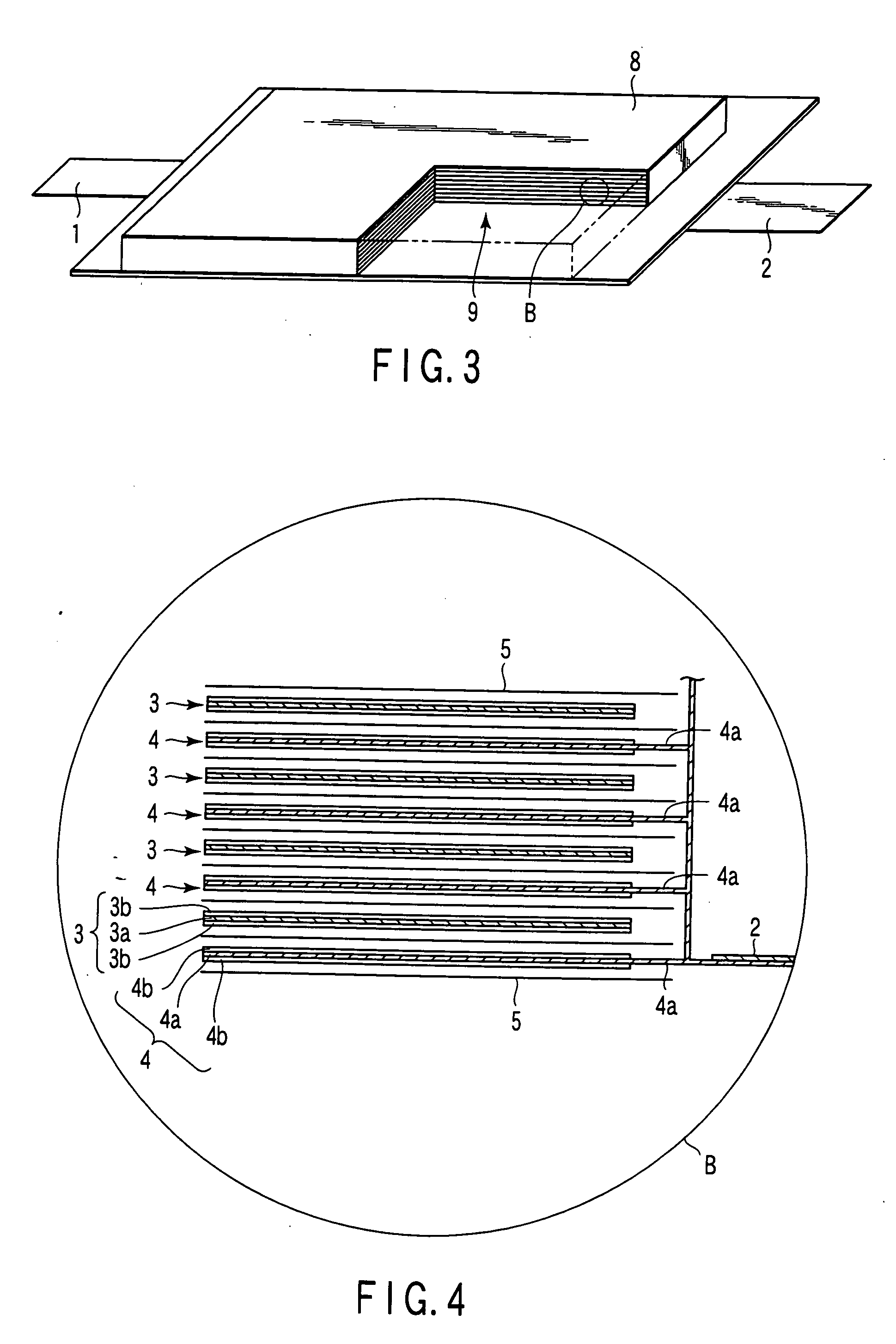

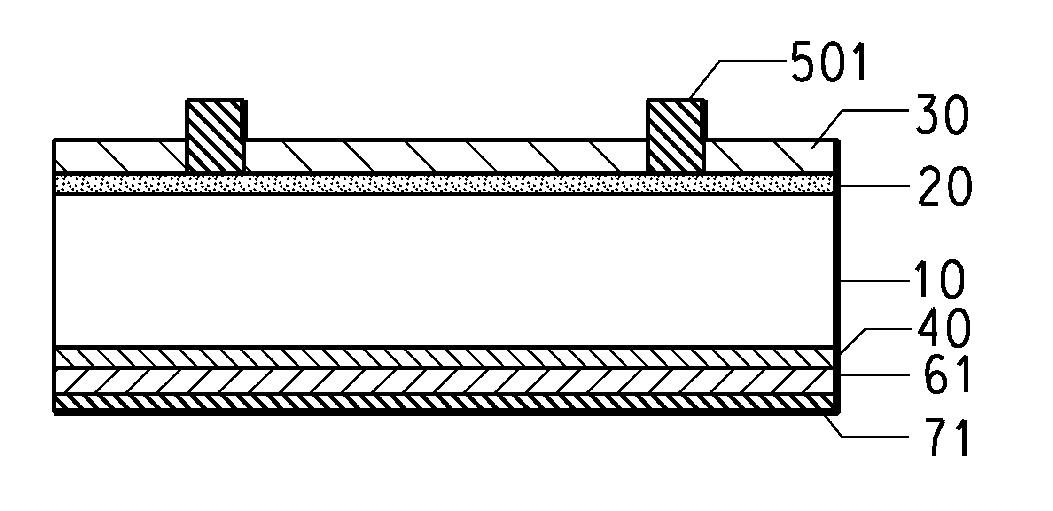

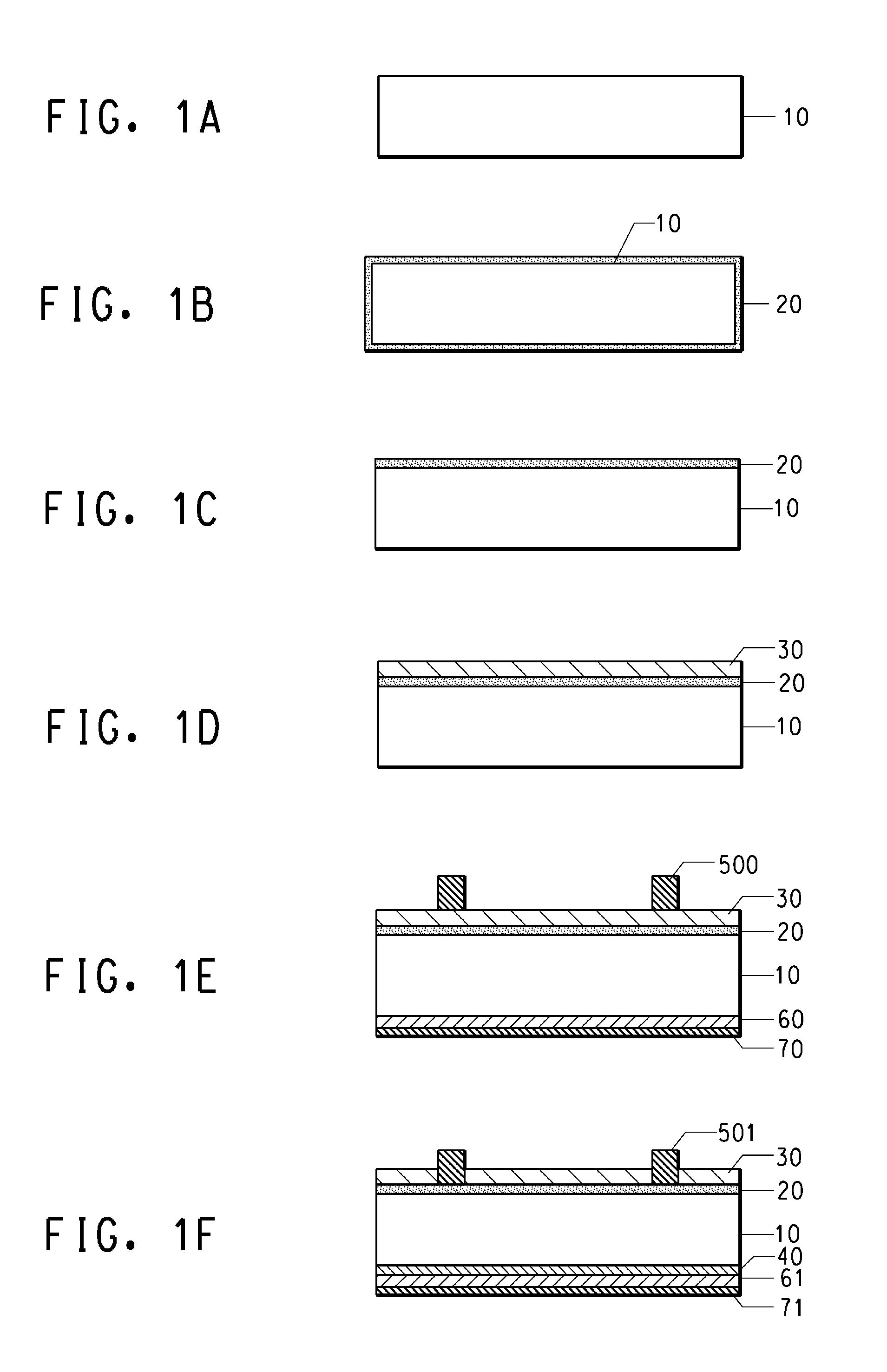

Methods to fabricate a photoactive substrate suitable for microfabrication

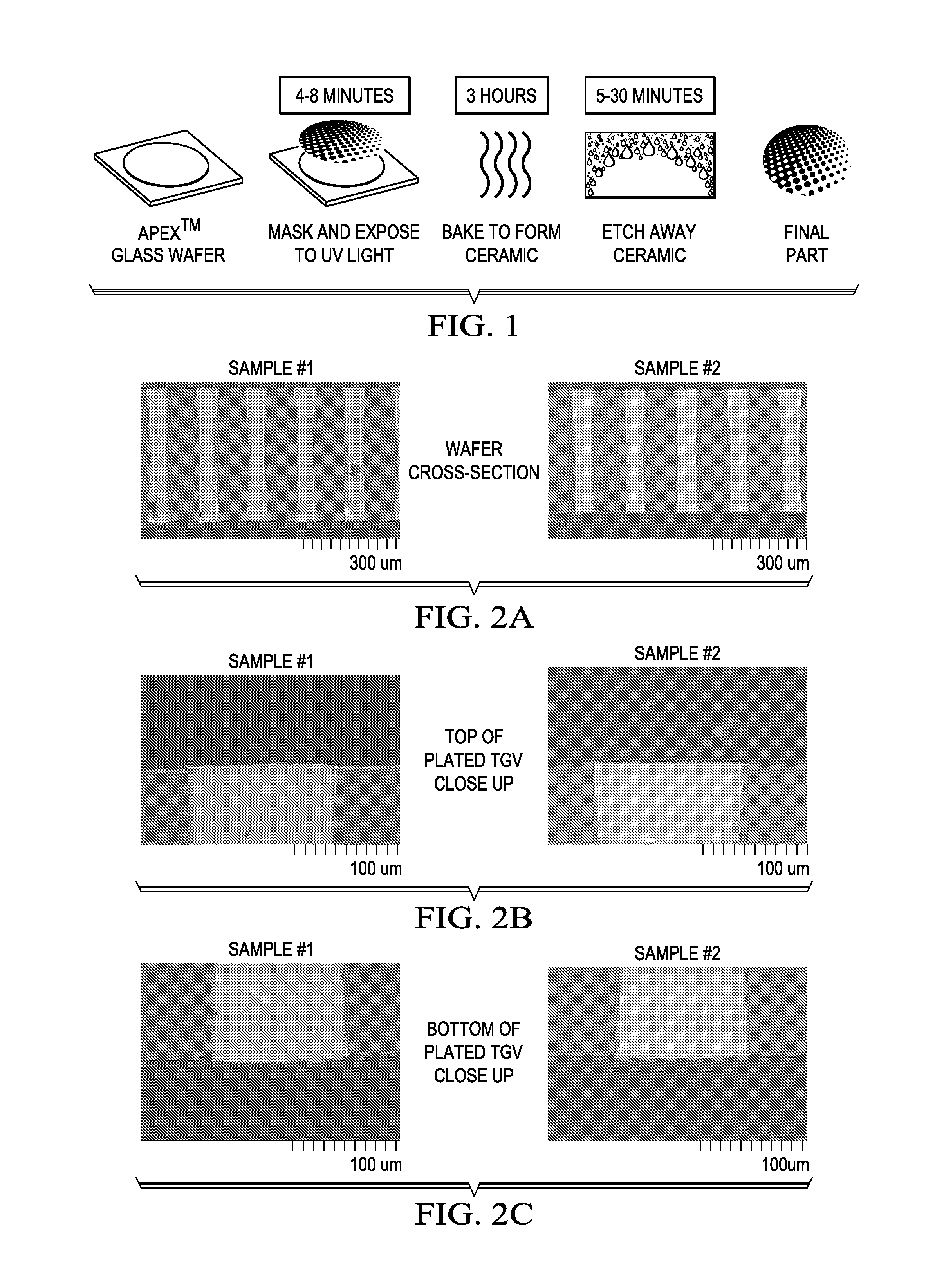

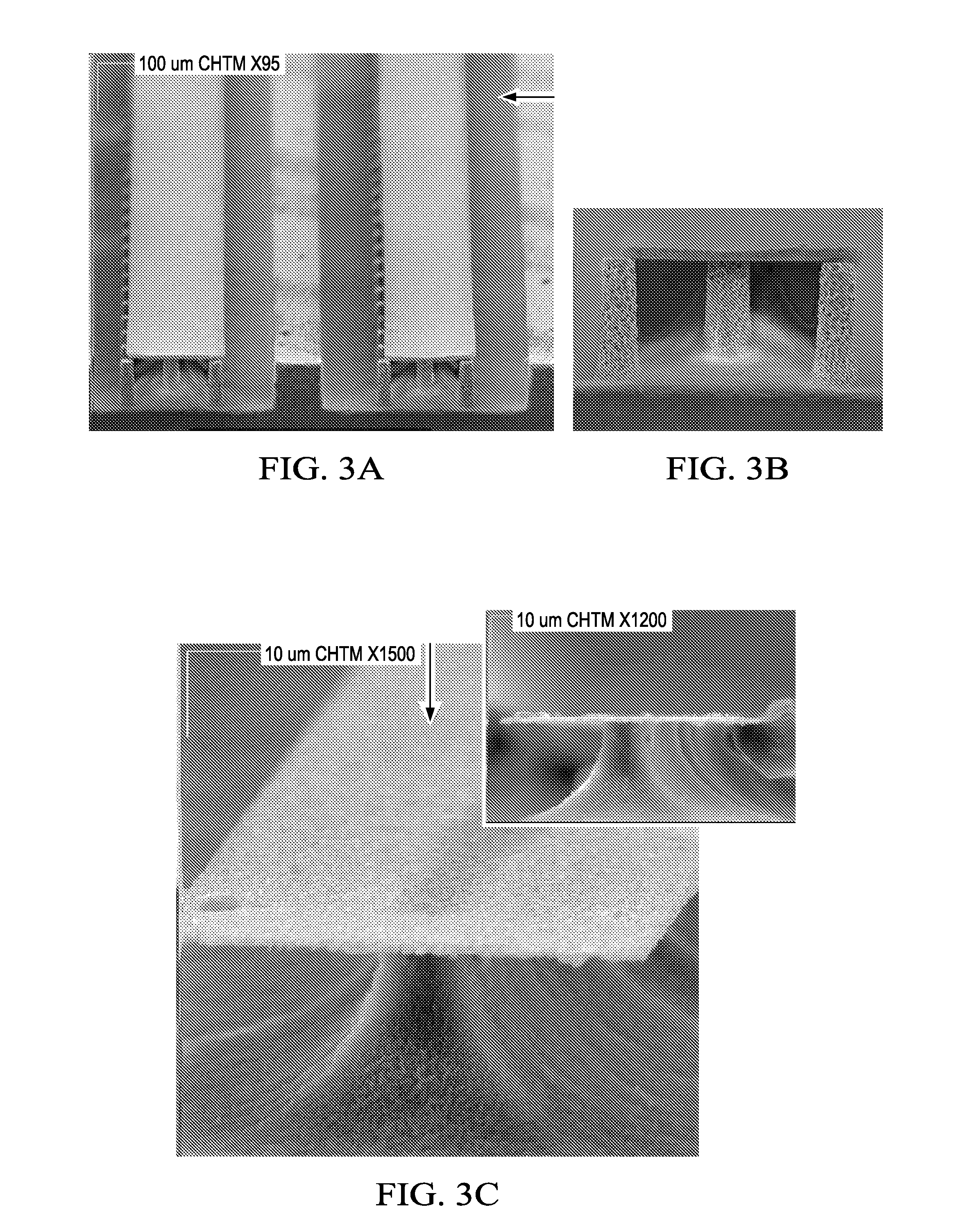

InactiveUS20110217657A1Improve performanceSmall layer thicknessContact member manufacturingPhotosensitive materialsLithium oxideSilicon dioxide

A method of fabrication and device with holes for electrical conduction made by preparing a photosensitive glass substrate comprising at least silica, lithium oxide, aluminum oxide, and cerium oxide, masking a design layout comprising one or more holes to form one or more electrical conduction paths on the photosensitive glass substrate, exposing at least one portion of the photosensitive glass substrate to an activating energy source, exposing the photosensitive glass substrate to a heating phase of at least ten minutes above its glass transition temperature, cooling the photosensitive glass substrate to transform at least part of the exposed glass to a crystalline material to form a glass-crystalline substrate and etching the glass-crystalline substrate with an etchant solution to form the one or more depressions or through holes for electrical conduction in the device.

Owner:LIFE BIOSCI

Thick-film pastes containing lead-tellurium-lithium- oxides, and their use in the manufacture of semiconductor devices

The present invention provides a thick-film paste for printing the front side of a solar cell device having one or more insulating layers. The thick-film paste comprises an electrically conductive metal, and a lead-tellurium-lithium-oxide dispersed in an organic medium.

Owner:SOLAR PASTE LLC

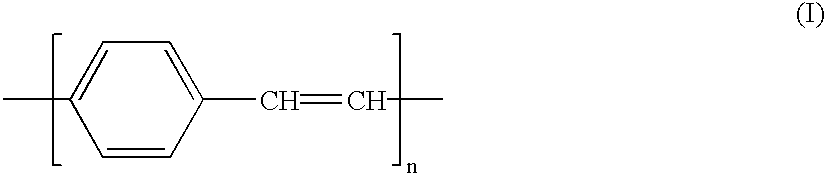

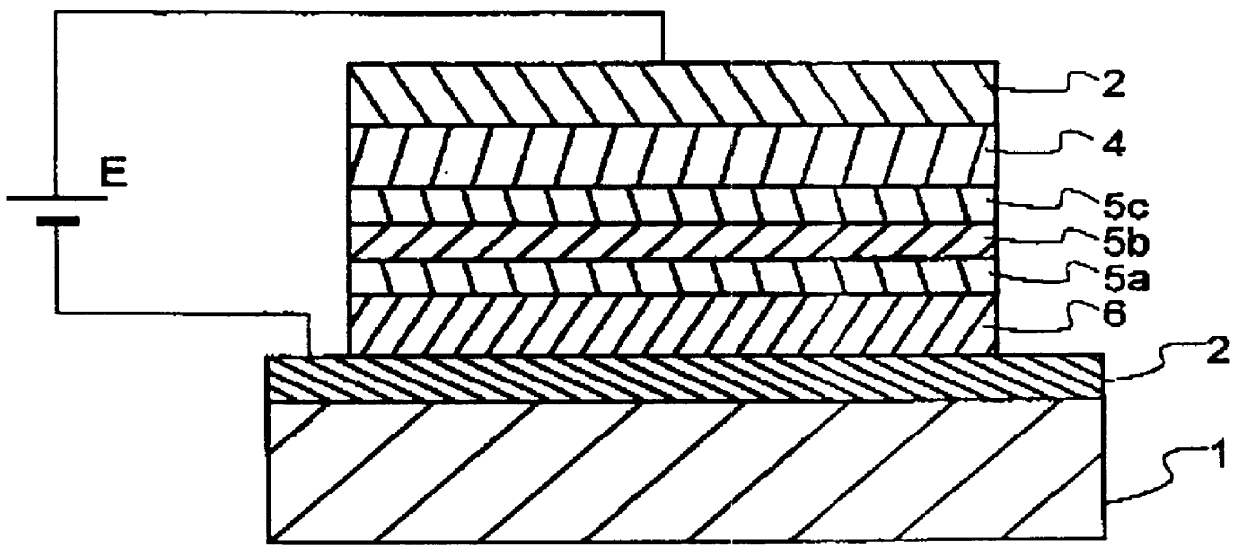

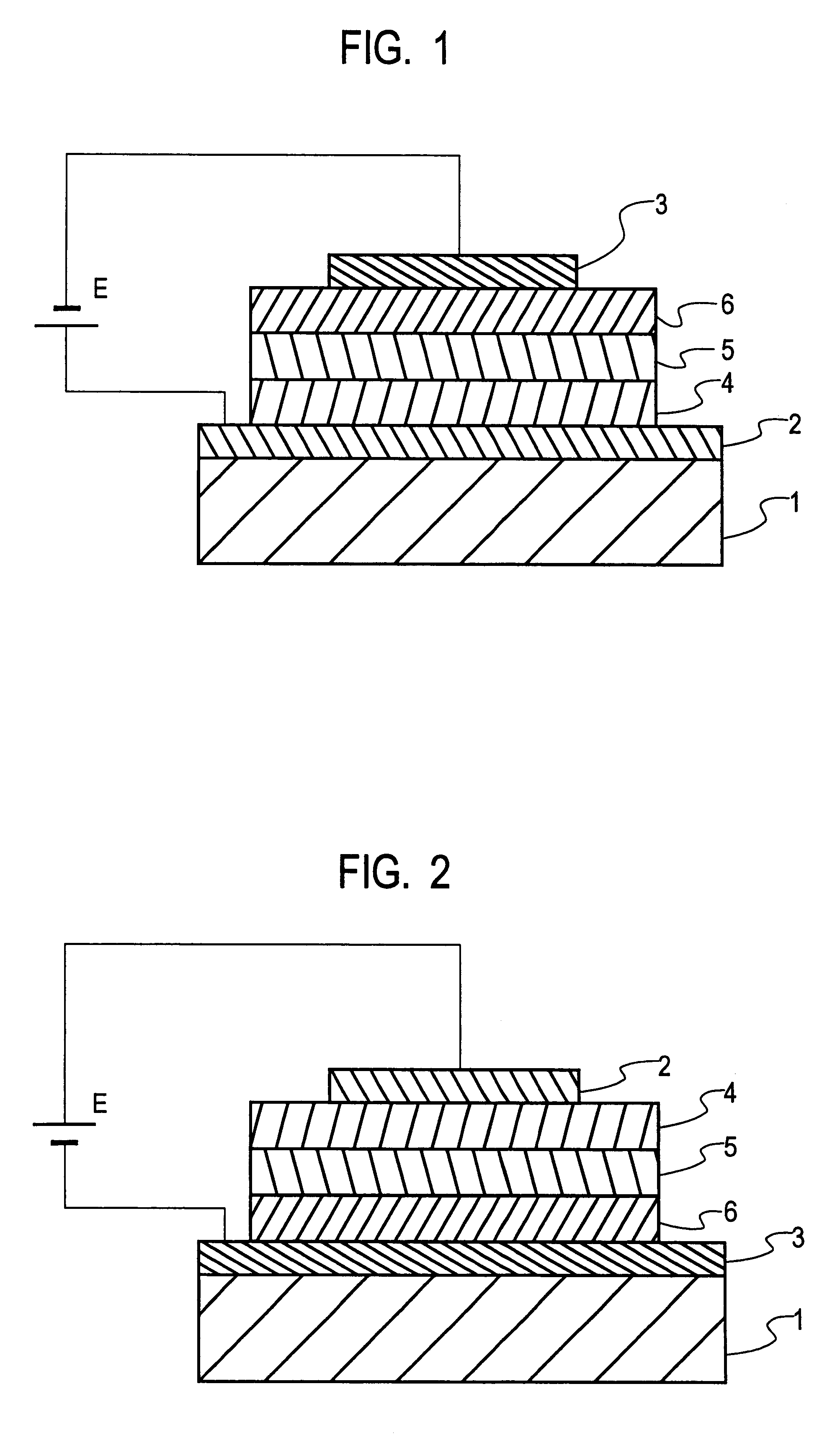

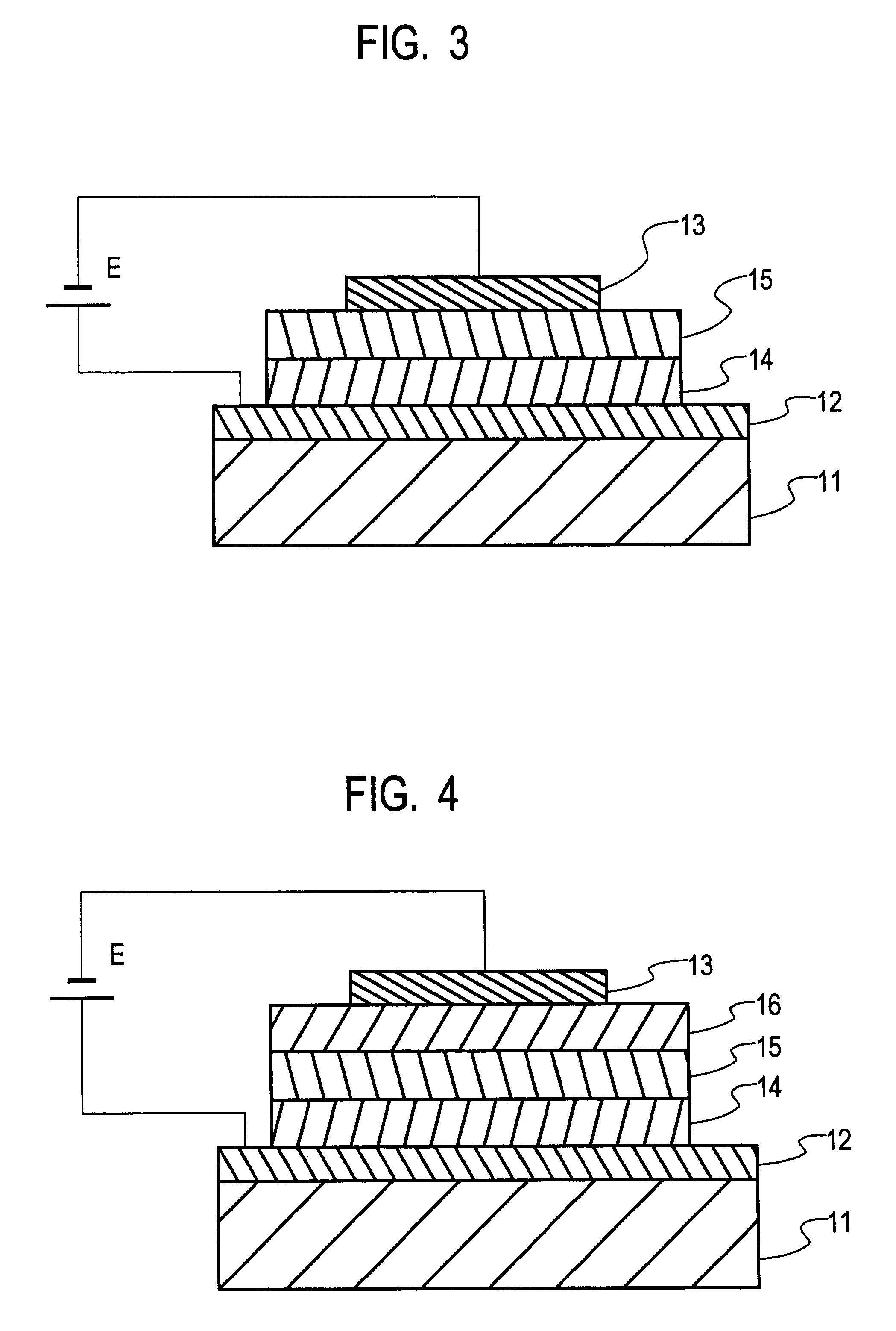

Organic electroluminescent device having a conjugated polymer and an inorganic insulative electron injecting and transporting layer

InactiveUS6404126B1Improve efficiencyLong lastingDischarge tube luminescnet screensElectroluminescent light sourcesRubidium oxideLithium oxide

An organic electroluminescent device having high efficiency, a long life time, and low cost, includes a substrate, a hole injecting electrode and an electron injecting electrode formed on the substrate, an organic material-containing organic layer between the electrodes, and an inorganic insulative electron injecting and transporting layer between the light emitting layer and the electron injecting electrode. The organic layer includes a light emitting layer containing a conjugated polymer, and the inorganic insulative electron injecting and transporting layer comprises three components. The first component is at least one oxide selected from the group consisting of lithium oxide, rubidium oxide, potassium oxide, sodium oxide, and cesium oxide. The second component is at least one of strontium oxide, magnesium oxide, and calcium oxide. The third component consists of silicon oxide, germanium oxide, or mixtures thereof.

Owner:TDK CORPARATION

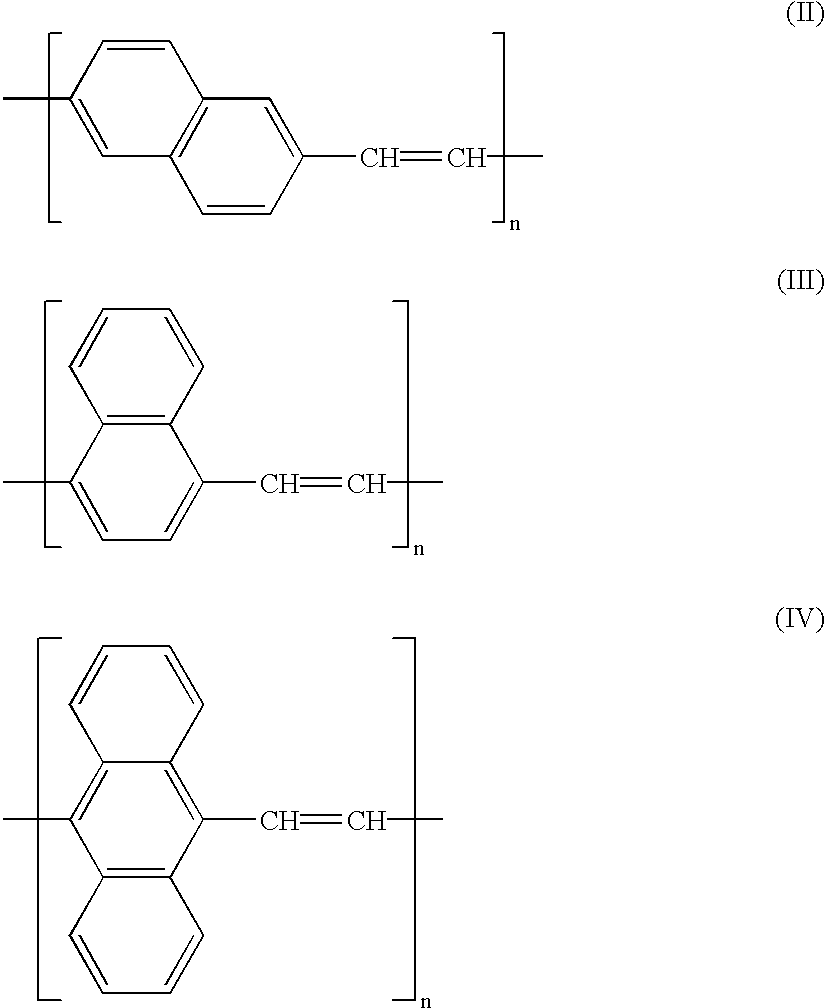

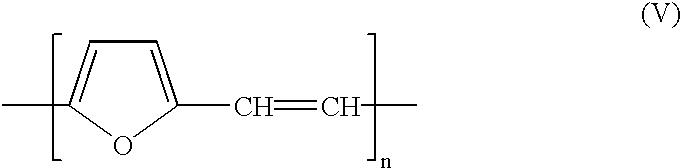

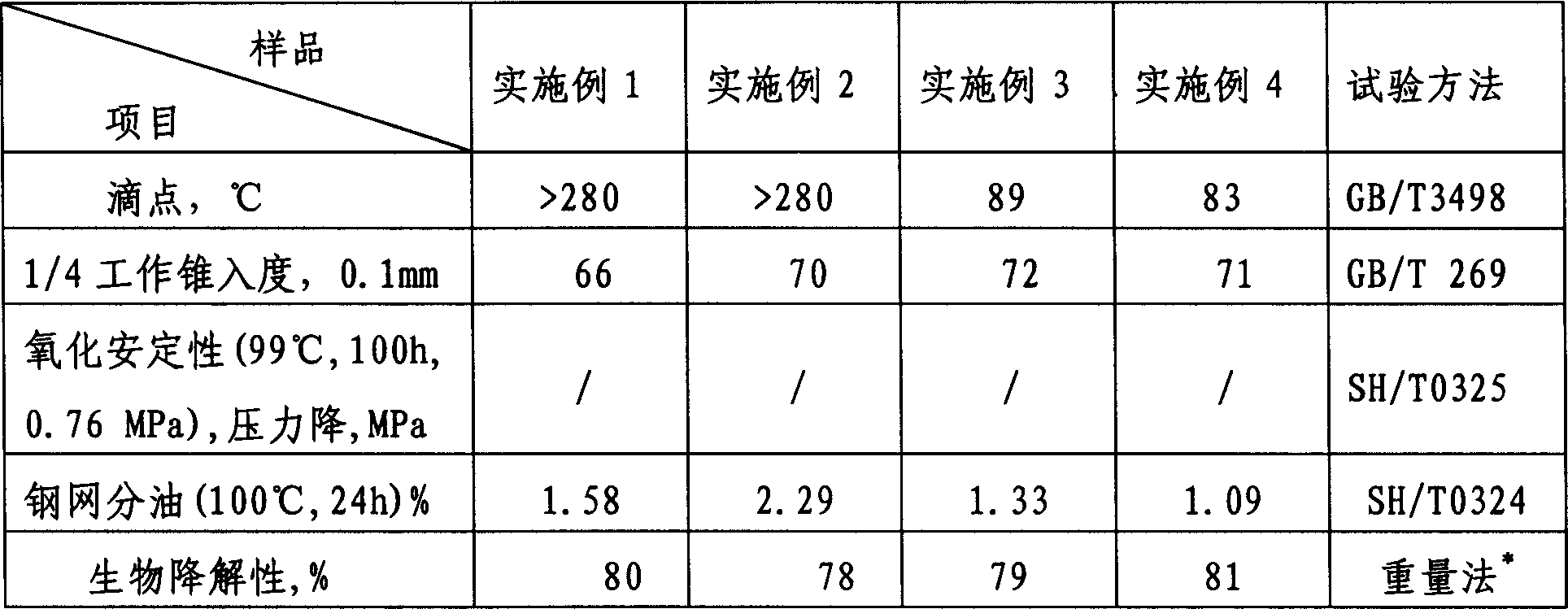

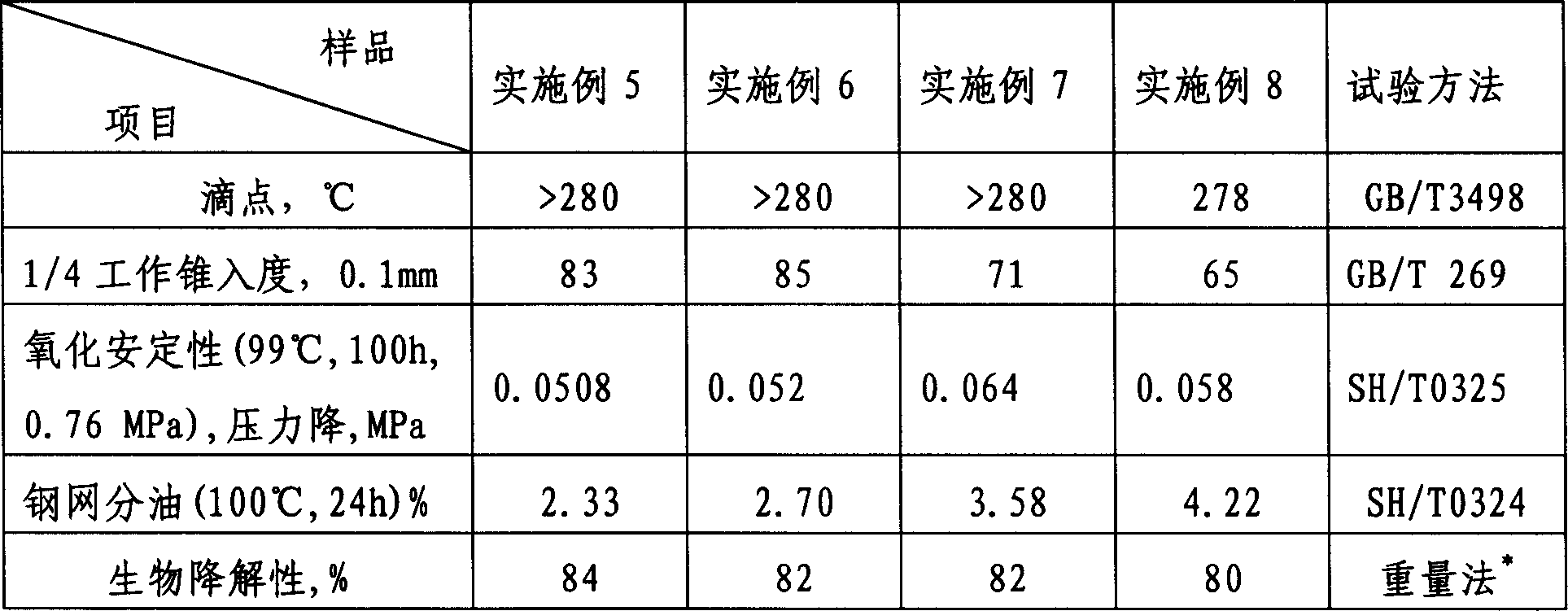

Biodegradable lubricating grease

InactiveCN1504552AExcellent conventional physical and chemical propertiesWill not polluteLubricant compositionLithium oxideVegetable oil

A biodegradable lubricating grease comprises (overall composition weight as benchmark) (1) 70-94% vegetable oil whose kinetic viscosity is 100-250 square mm per second, (2) 6-30% thickening agent, wherein the thickening agent is alta-mud, or single saponin or composite saponin produced through the reaction of C1-C20 organic acid with calcium hydroxide, calcium oxide, lithium hydroxide or lithium oxide, (3) 0-2% amine antioxidant or phenol and amine mixed anti-oxidant. The lubricating grease possesses both fine normal physical chemical properties and good bio-ecological characteristics.

Owner:CHINA PETROLEUM & CHEM CORP +1

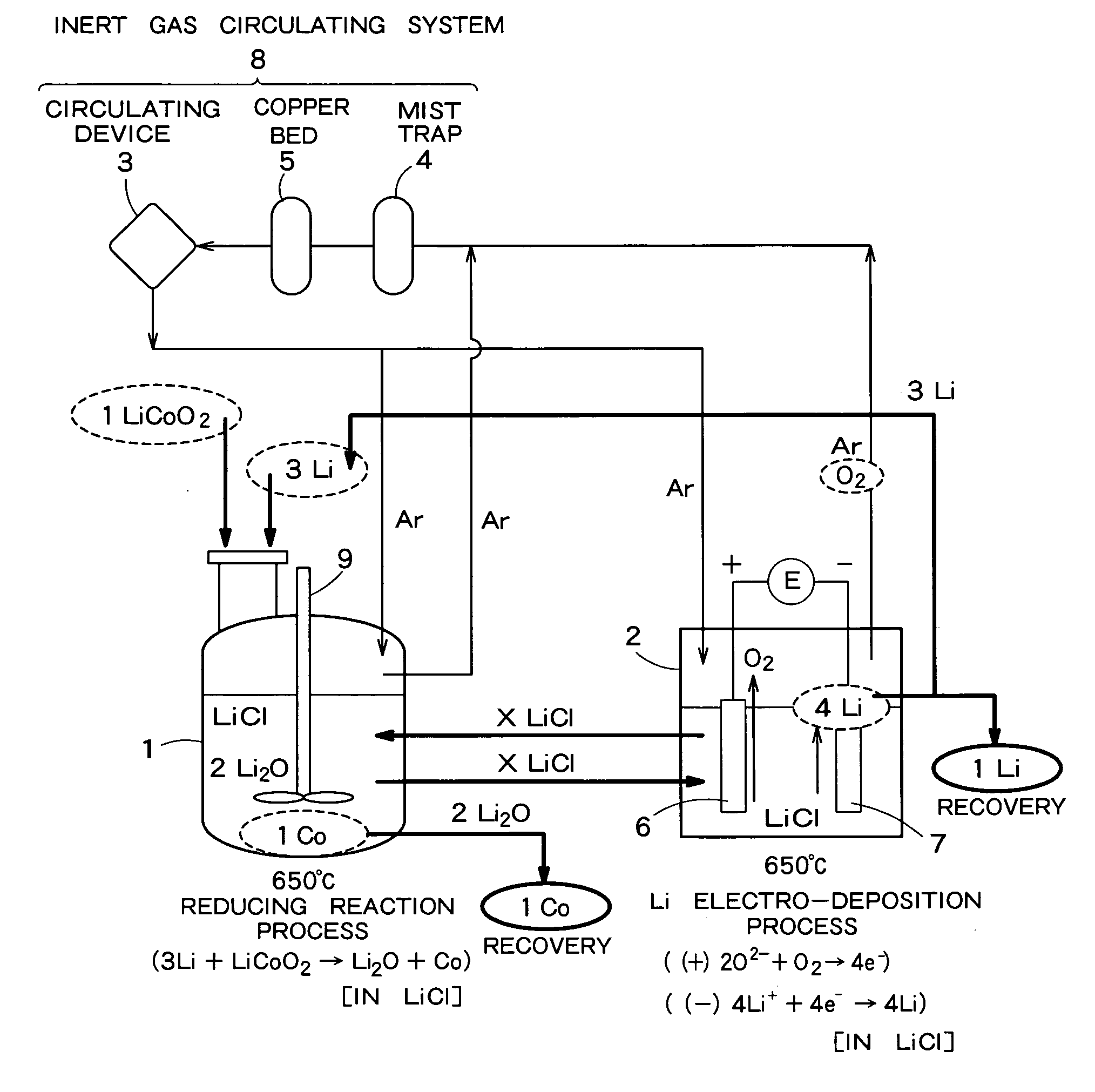

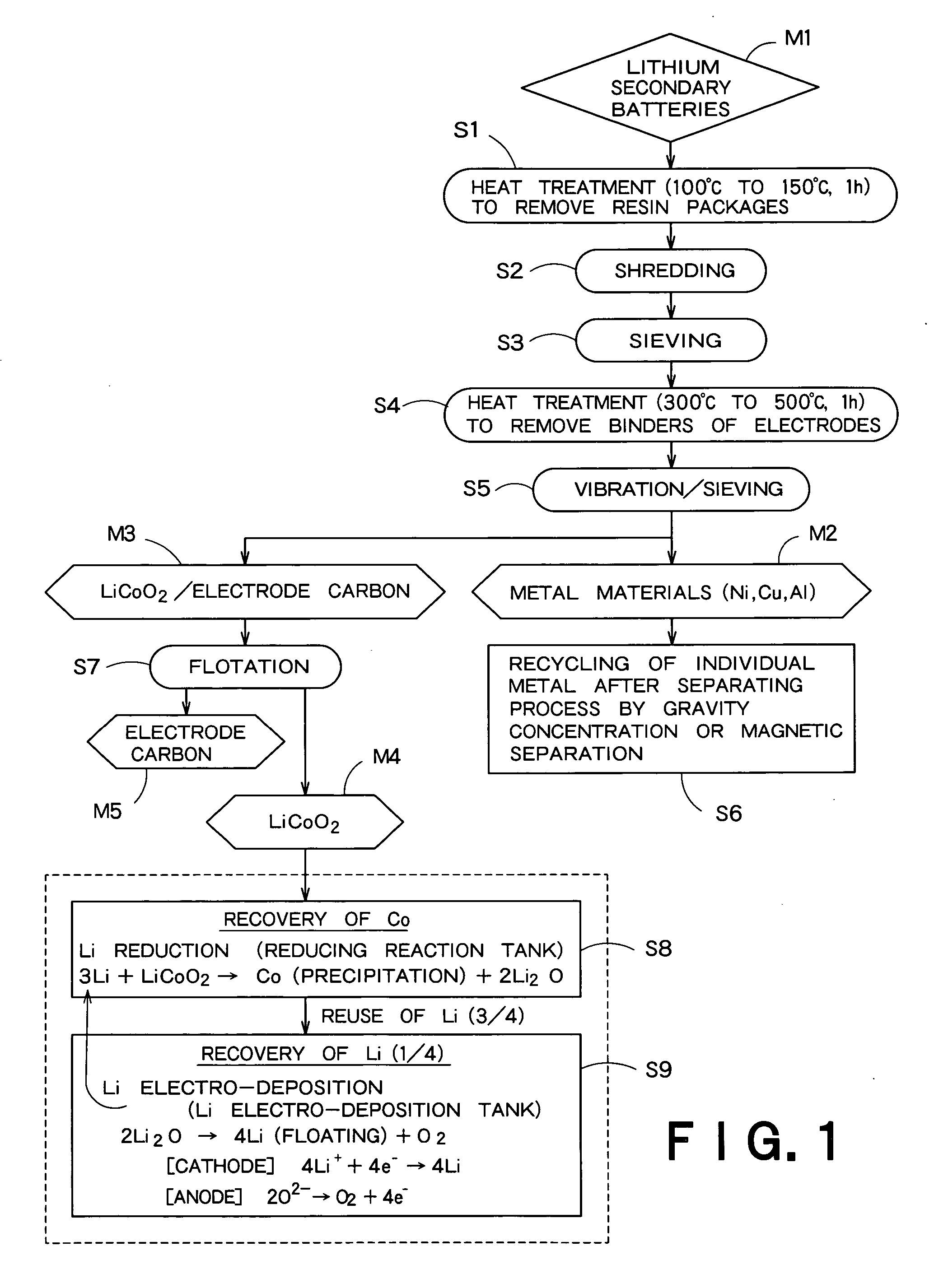

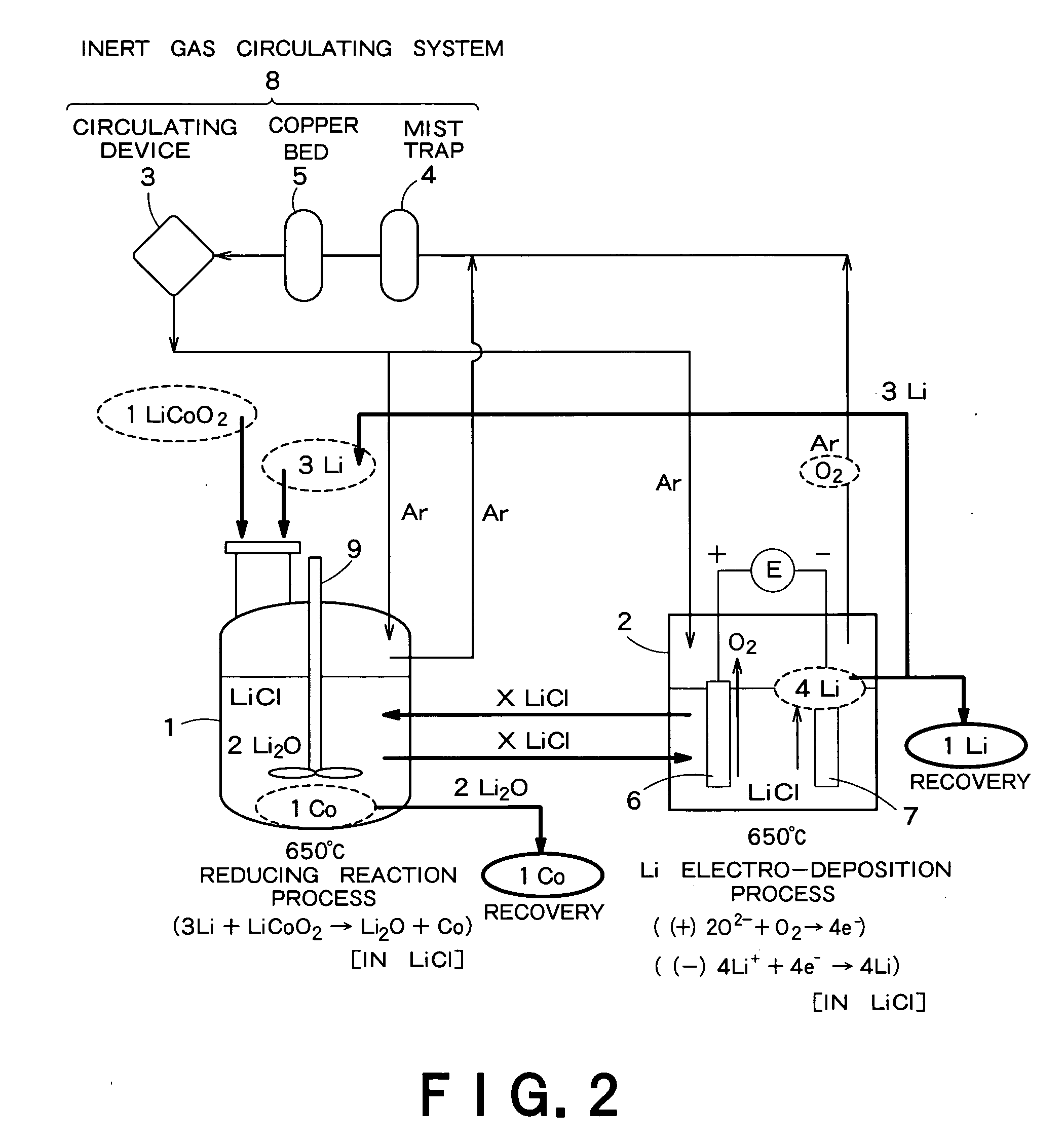

Method and apparatus for recycling electrode material of lithium secondary battery

ActiveUS20050241943A1Reduce equipment costsReduce operating costsCellsPhotography auxillary processesLithium oxideLithium chloride

Lithium cobaltate forming the positive electrode of a lithium secondary battery is subjected together with lithium metal to reducing reaction in molten lithium chloride to produce lithium oxide and to precipitate and separate cobalt or cobalt oxide. The lithium oxide is subjected to electro-deposition in molten lithium chloride contained in a lithium electro-deposition tank provided with an anode and a cathode to recover lithium metal deposited on the cathode.

Owner:KAWASAKI HEAVY IND LTD +1

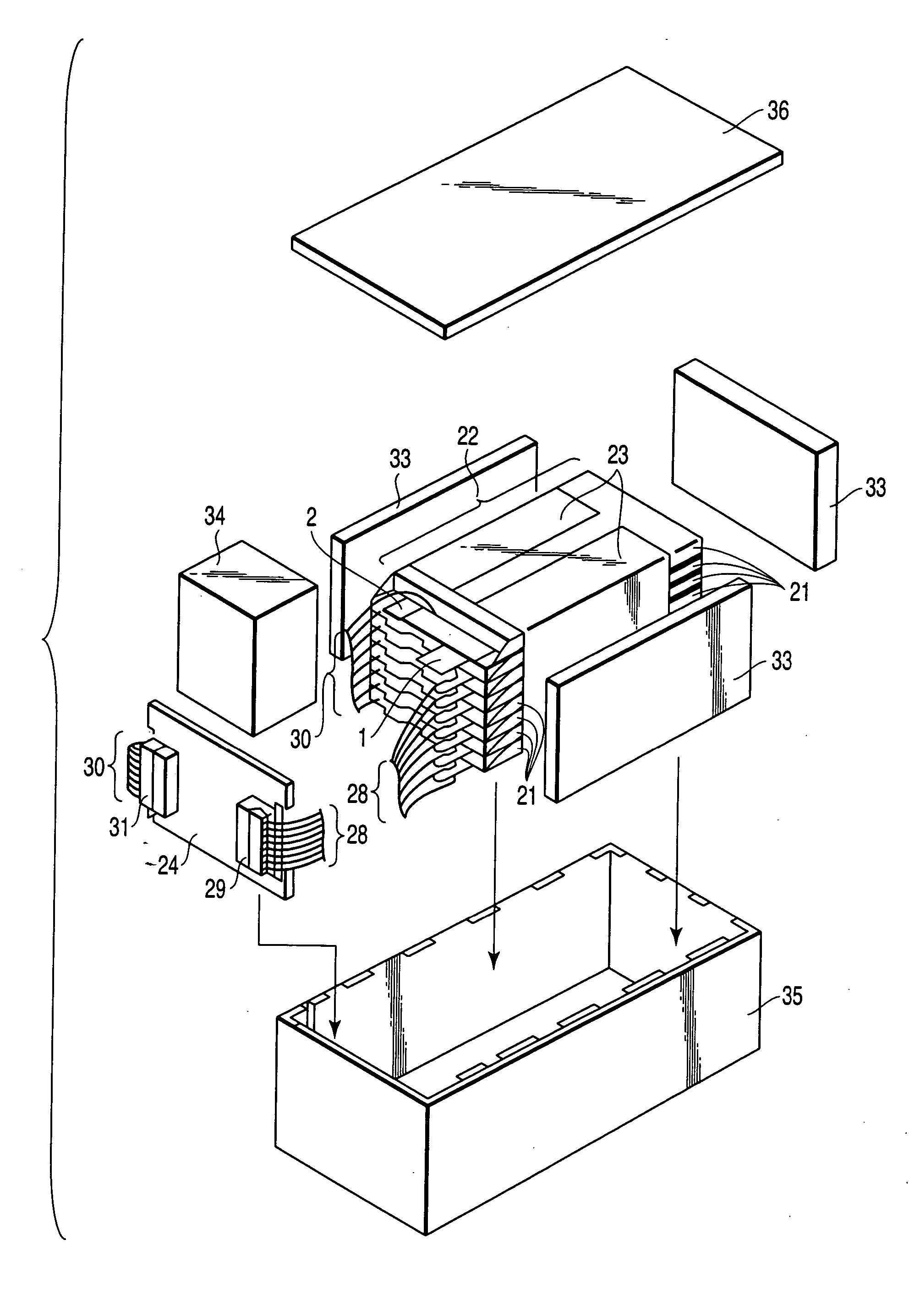

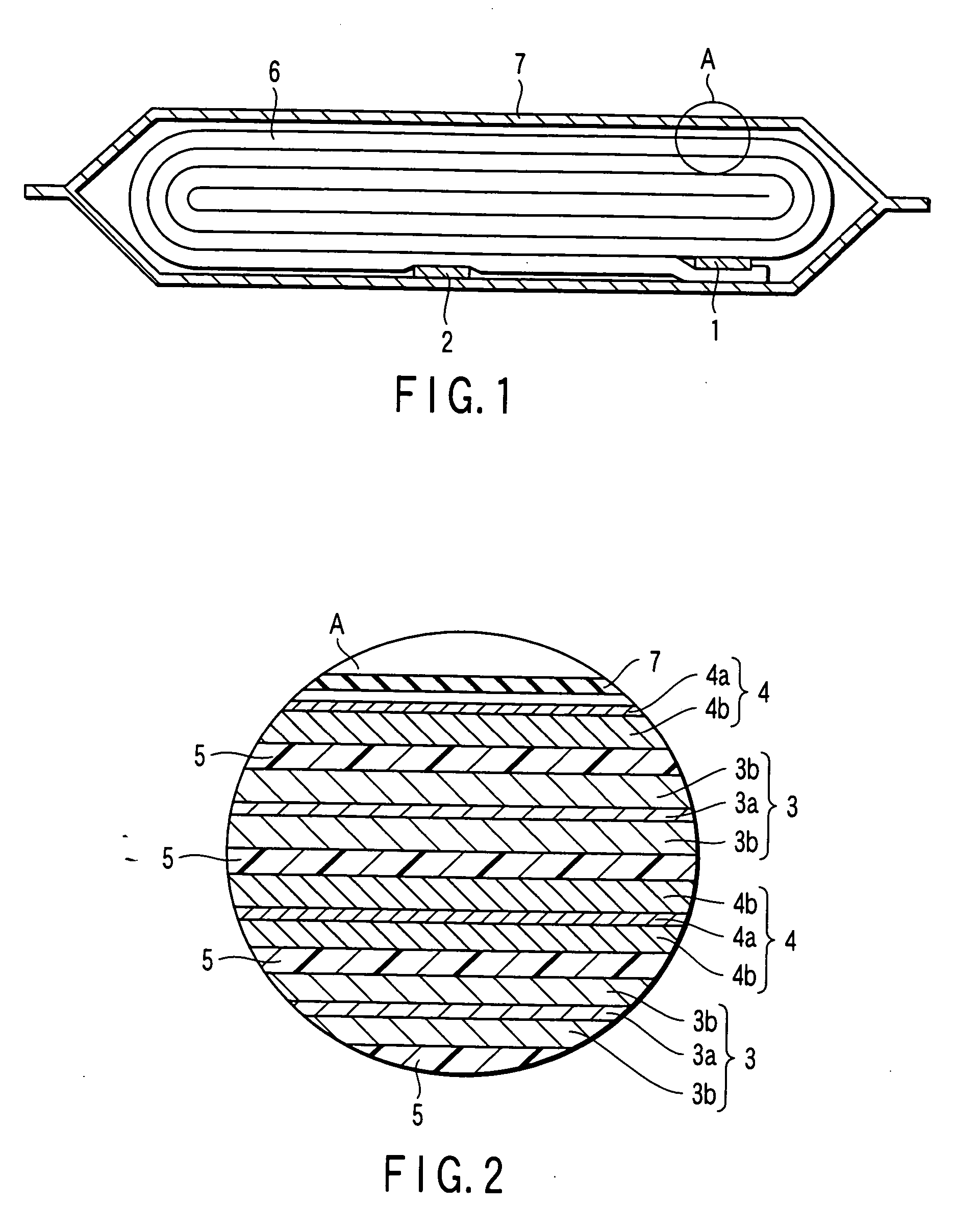

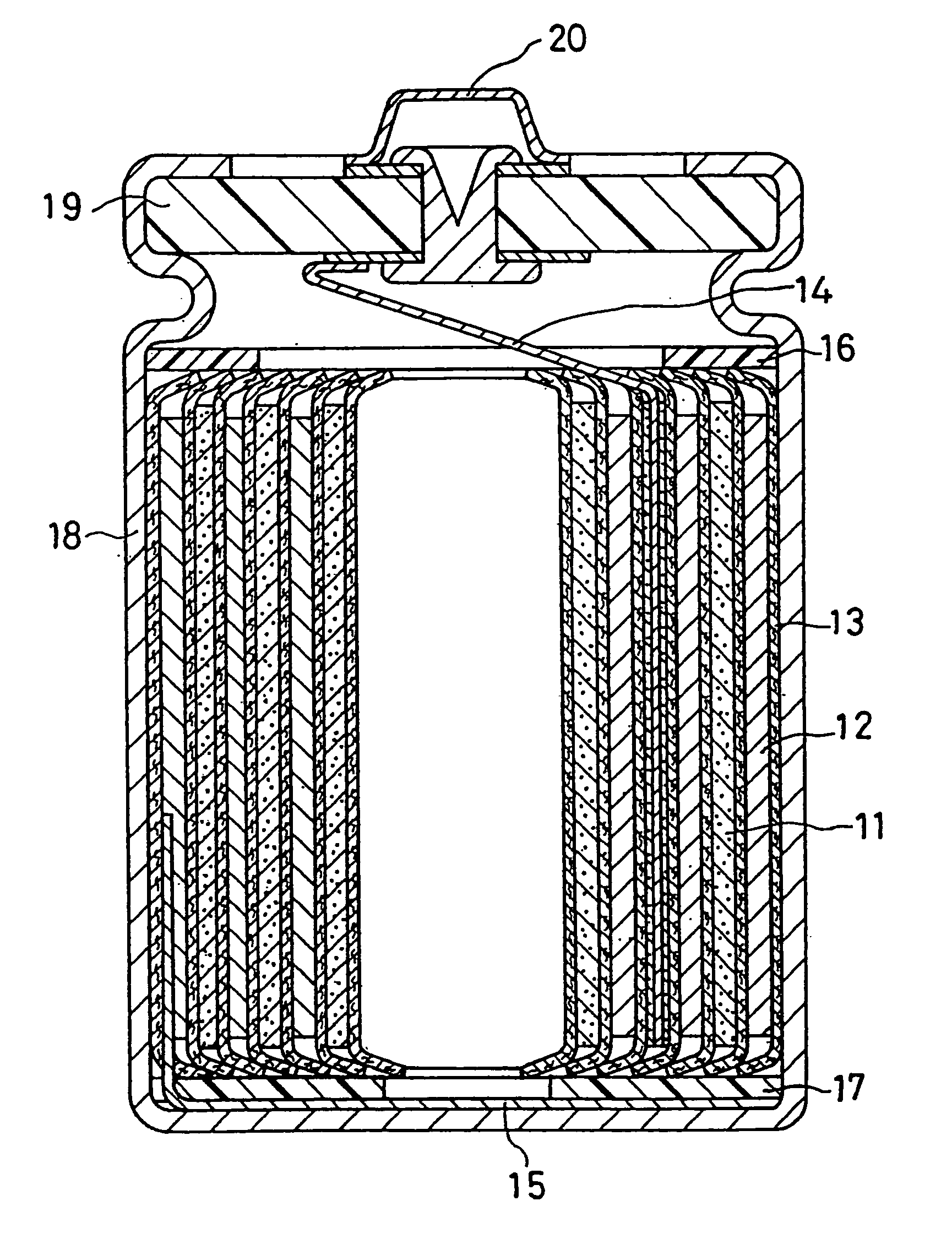

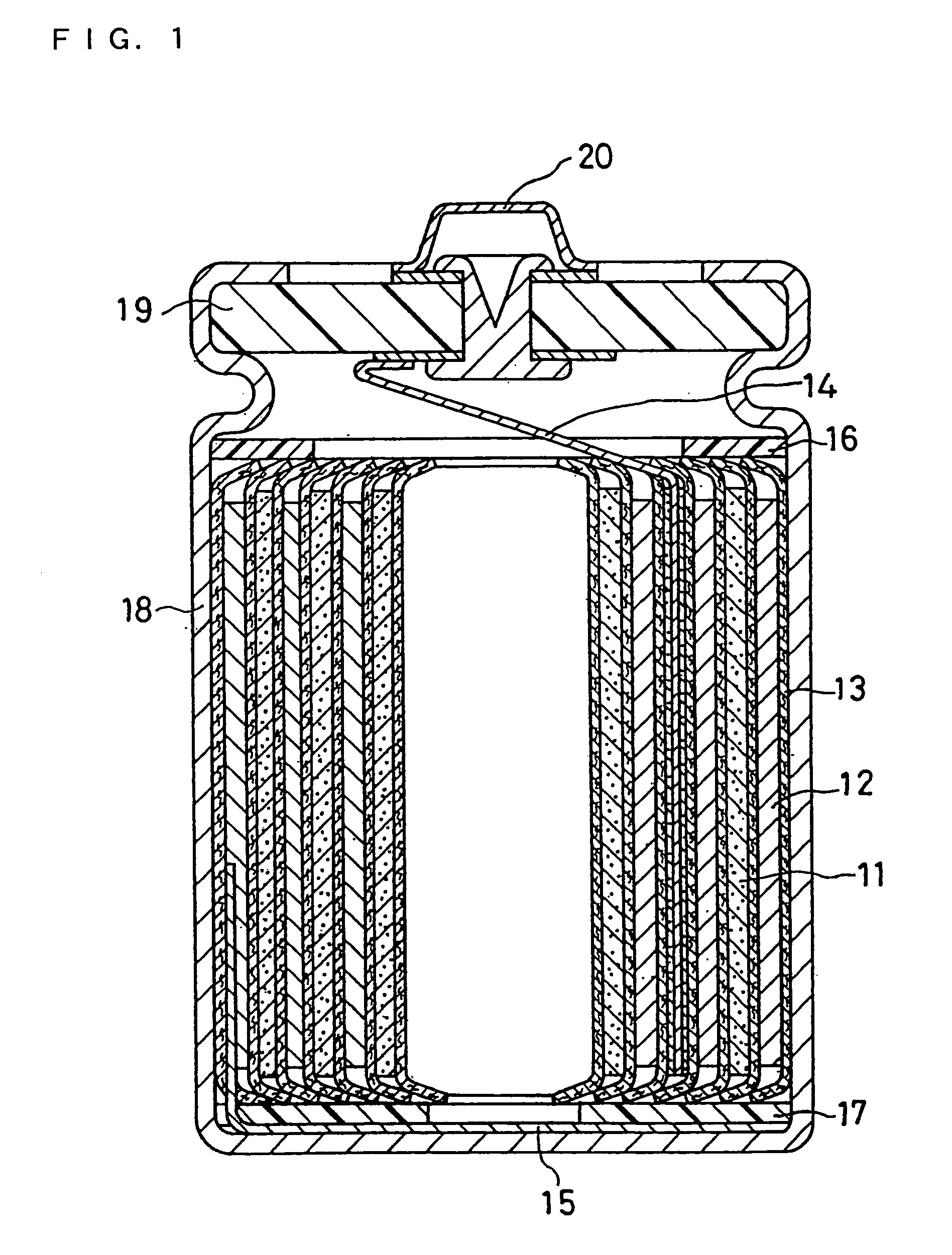

Lithium Ion Secondary Battery

InactiveUS20080038631A1Improve reliabilityImprove securityFinal product manufactureNegative electrodesLithium oxidePhysical chemistry

A lithium ion secondary battery includes a positive electrode comprising a composite lithium oxide; a negative electrode capable of charge and discharge; a separator; and a non-aqueous electrolyte including a non-aqueous solvent and a solute dissolved therein. The separator includes at least one heat-resistant porous film and at least one shut-down layer. A porous membrane is bonded to a surface of at least one selected from the positive electrode and the negative electrode, and the porous membrane comprises an inorganic oxide filler and a binder.

Owner:PANASONIC CORP

Optical glass

InactiveCN1450010AHigh coefficient of thermal expansionPrecise without migrationOptical elementsLithium oxideSilicic acid

The present invention relates to an optical glass using silicic acid group as main body, said optic glass has high expansion coefficient, high Young modulus, excellent weatherability and high transmissivity in the infrared wave zone. Said glass composition contains (mole%) 36-66% of silicon dioxide, 0-12% of aluminium oxide, 0-6% of boric oxide, 0-10% of magnesium oxide, 0-16% of calcium oxide, 0-16% of strontium oxide, 0-16% of baria, 0-8% of zinc oxide, 0-32% of lithium oxide, 0-25% of sodium oxide, 0-25% of potassium oxide, 0-20% of cesium oxide, 0-6% of phosphorus pentoxide, 0-8% of scandium oxide and others.

Owner:PICVUE OPTOELECTRONICS INT

High-toughness enamel glaze

InactiveCN108658462AImprove toughnessOvercome the defect of porcelain crackLithium oxideSilicon dioxide

The invention discloses high-toughness enamel glaze. The enamel glaze is prepared from the following components in parts by weight: 40-50 parts of silicon dioxide, 15-25 parts of titanium dioxide, 5-15 parts of potassium oxide, 10-20 parts of sodium oxide, 1-5 parts of lithium oxide, 2-4 parts of calcium fluoride, 6-12 parts of vanadium pentoxide, 1-3 parts of tungsten carbide and 5-10 parts of aluminum oxide and zirconium dioxide. According to the enamel glaze, by means of the composition, the toughness of the enamel glaze can be greatly improved, meanwhile, the defect that ceramic cracks arecaused due to collision can be overcome, and therefore, the enamel glaze has a wide application prospect.

Owner:沙冰娟

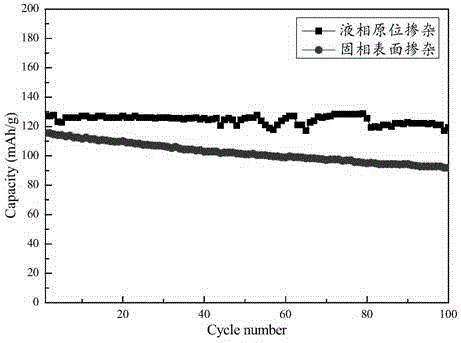

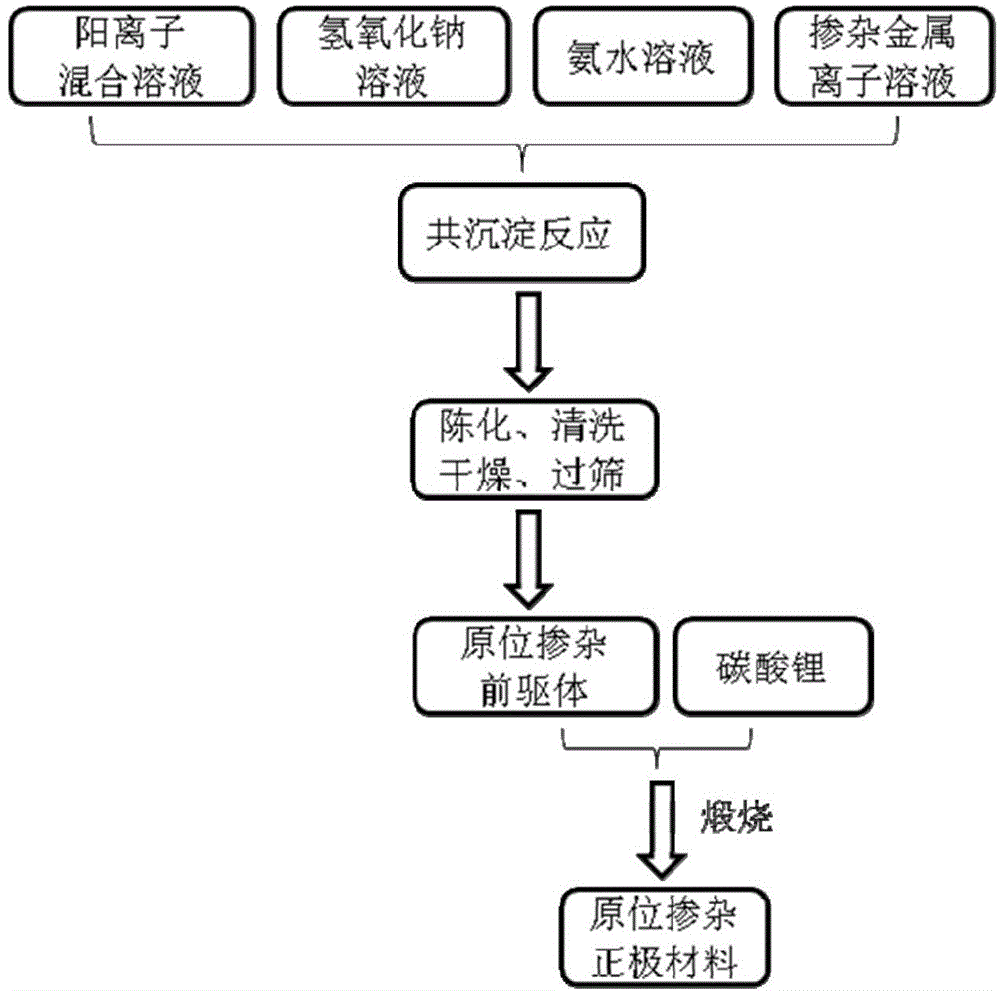

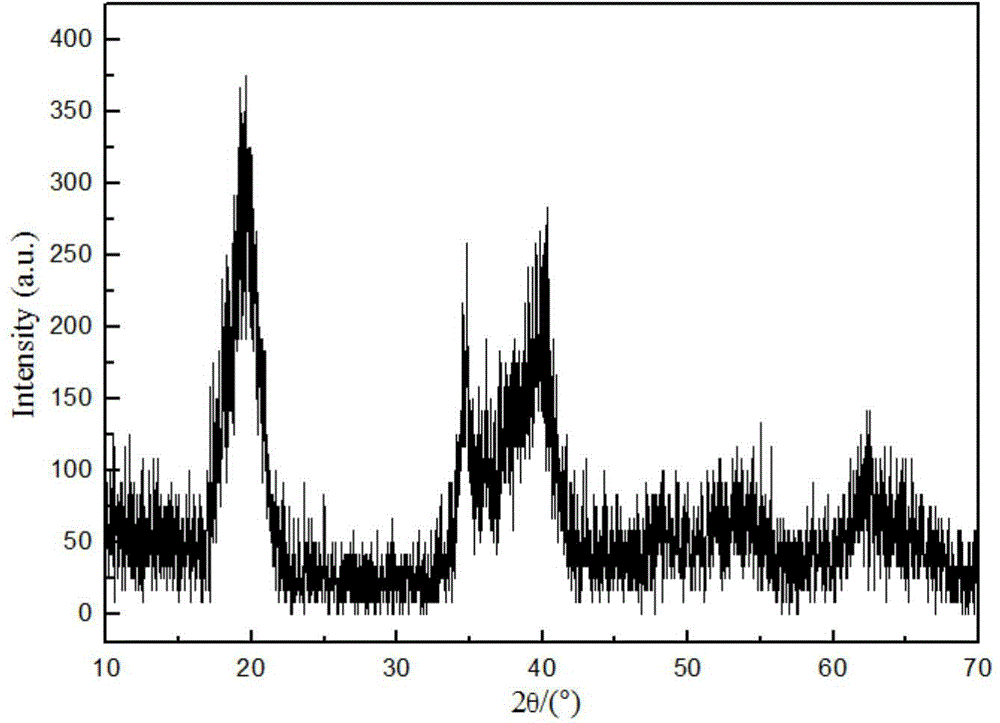

Preparation method of in-situ doped and modified nickel cobalt manganese lithium oxide positive material

InactiveCN104701530AStable structureImprove stabilitySecondary cellsPositive electrodesLithium oxideManganese

The invention discloses a preparation method of an in-situ doped and modified nickel cobalt manganese lithium oxide positive material. The preparation method of the in-situ doped and modified nickel cobalt manganese lithium oxide positive material is characterized by introducing metal elements in the process of preparing a nickel cobalt manganese precursor to stabilize the structure and implementing atom-scale mixing of doped elements and main elements in the process of preparing the precursor. Compared with the solid phase surface doping, the method can be used for stabilizing the material structure as a whole, so that the sintered positive material is relatively high in stability under the high voltage, thereby working under the relatively high voltage; the battery capacity is greatly improved; meanwhile, the cycle performance is greatly improved; by virtue of the preparation method of the positive material, a process of producing the precursor and a process of doping in the later period are integrated, so that the preparation process is simplified; the cost is saved; the raw materials are bulk chemical products; the industrialization is liable to implement.

Owner:TIANJIN B&M SCI & TECH

Glass compositions

Improved glass fibers compositions, typically useful for fire resistant blankets or containers to provide high burn-through resistance at high temperatures of 2,400° F. and higher, and typically comprising silica, sodium oxide, potassium oxide, calcium oxide, magnesium oxide, ferrous+ferric oxide, and titanium oxide; the improved glass compositions may further include alumina, lithium oxide, and boron oxide.

Owner:GLASS

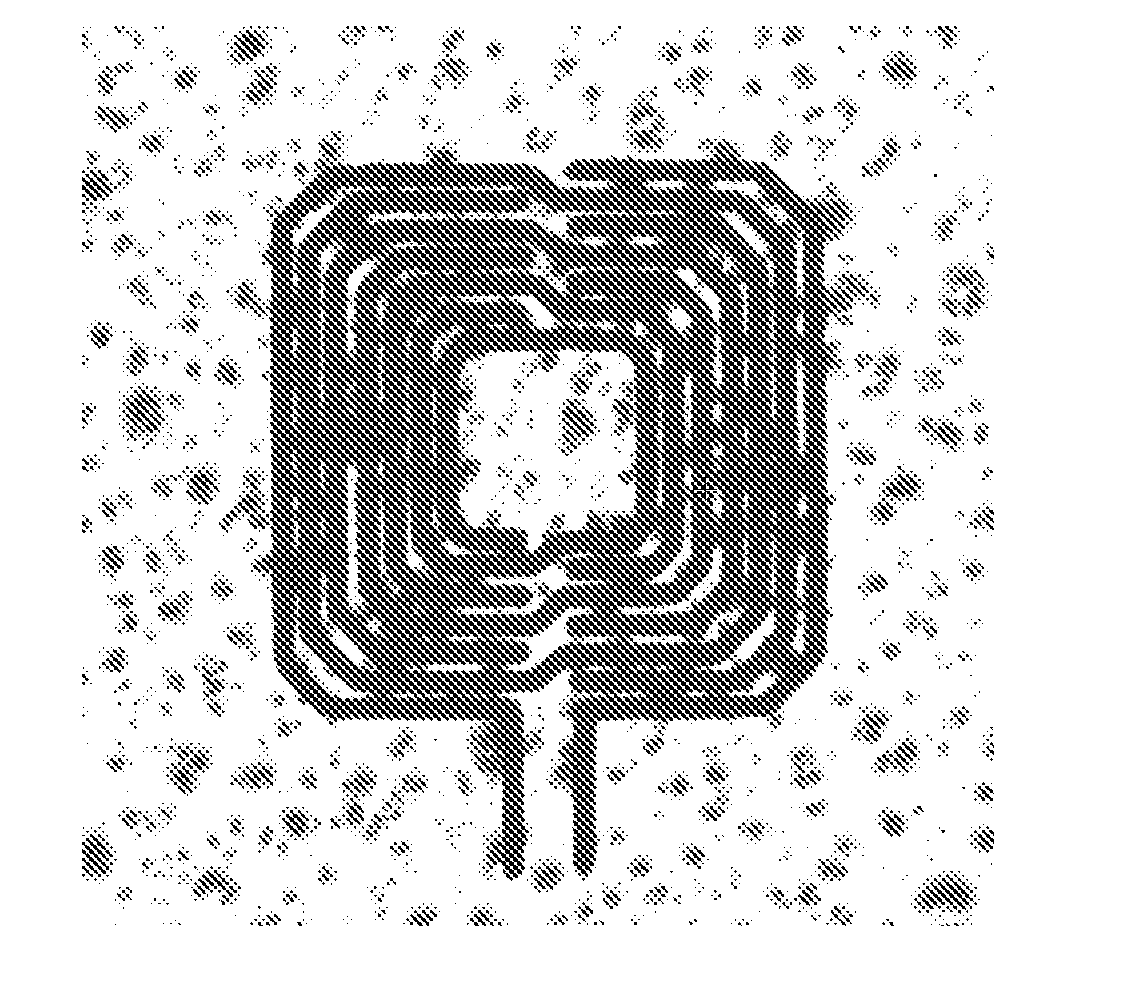

2D and 3D inductors antenna and trausformers fabricating photoactive substrates

ActiveUS20170098501A1Semiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsLithium oxideCrystalline materials

A method of fabrication and device made by preparing a photosensitive glass substrate comprising at least silica, lithium oxide, aluminum oxide, and cerium oxide, masking a design layout comprising one or more holes to form one or more electrical conduction paths on the photosensitive glass substrate, exposing at least one portion of the photosensitive glass substrate to an activating energy source, exposing the photosensitive glass substrate to a heating phase of at least ten minutes above its glass transition temperature, cooling the photosensitive glass substrate to transform at least part of the exposed glass to a crystalline material to form a glass-crystalline substrate and etching the glass-crystalline substrate with an etchant solution to form one or more angled channels that are then coated.

Owner:3D GLASS SOLUTIONS INC

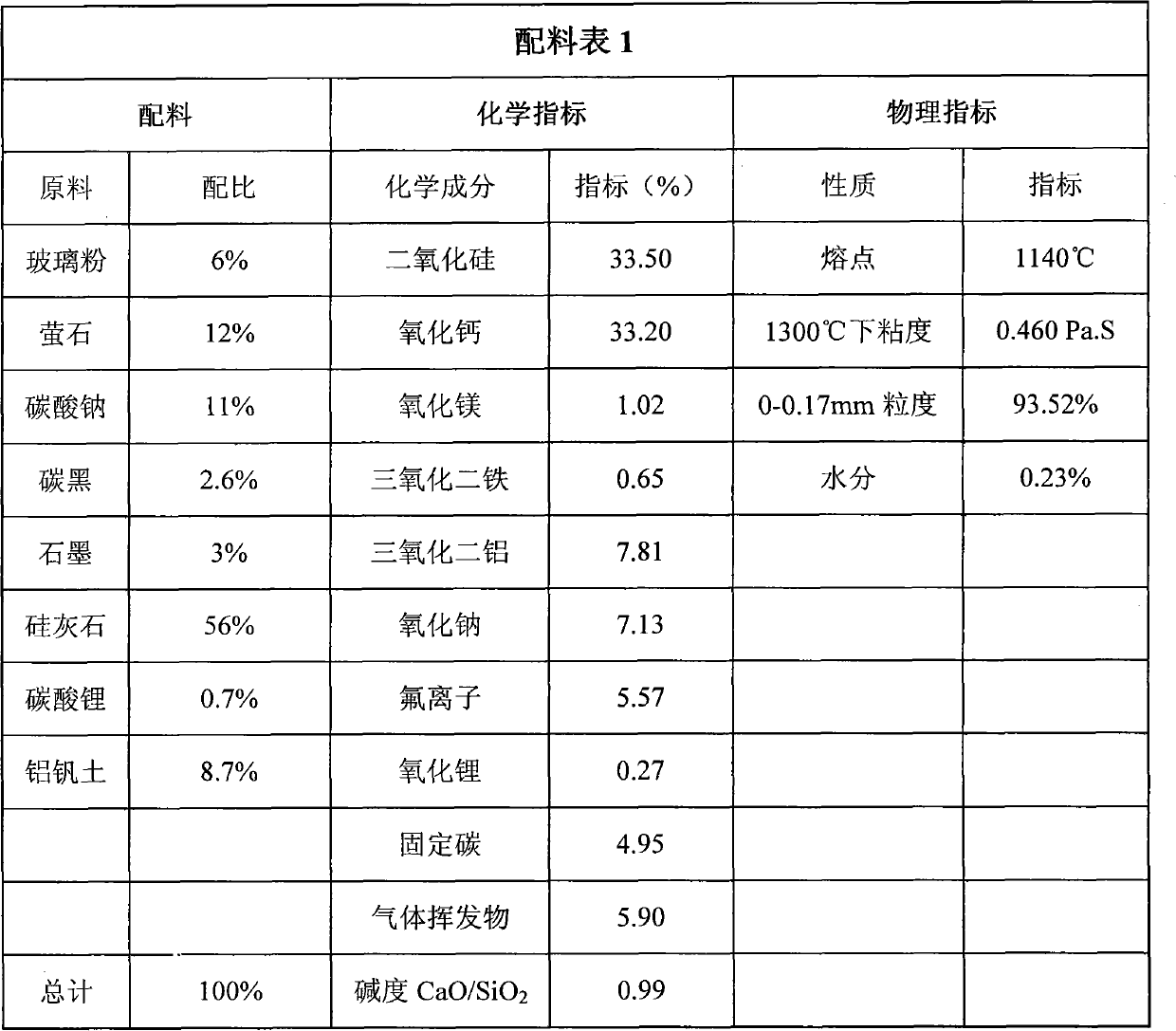

High-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting crystallizer covering slag and preparation method thereof

The invention discloses high-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting crystallizer covering slag which comprises the following components in percentage by weight: 54-57% of wollastonite, 9-13% of fluorite, 9-13% of sodium carbonate, 0-1% of lithium carbonate, 5-7% of glass dust, 8-12% of vanadine soil, 2.5-2.7% of soot carbon and 3-3.5% of graphite, and comprises the chemical components in percentage by weight: 31.9-34.9% of calcium oxide, 32.1-35.1% of silicon dioxide, 7.3-8.3% of aluminium oxide, 0.5-1.5% of magnesium oxide, 0.5-1.4% of iron sesquioxide, 4.4-6.4% of fluorion, 6.5-7.5% of sodium oxide, 0-0.39% of lithium oxide, 4.5-6.0% of fixed carbon and 4-7% of gas volatile matters. The alkalinity of the covering slag, namely the ratio of CaO to SiO2, is 0.91 to 1.00, the melting point of the covering slag is 1100 DEG C to 1160 DEG C, and the viscosity of the covering slag is 0.3 to 0.6 Pa.s at 1300 DEG C. The invention can solve the problems of easy crusting, slag entrainment, slag inclusion, slag sticking on casting blank surfaces, bubbles under skins, cracks, deep chatter mark, felting, bleed-out, and the like of the covering slag in the crystallizer during high-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting, and has the advantages of uniform and stable slagging in the crystallizer, good casting blank quality, difficult felting and bleed-out, and the like.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

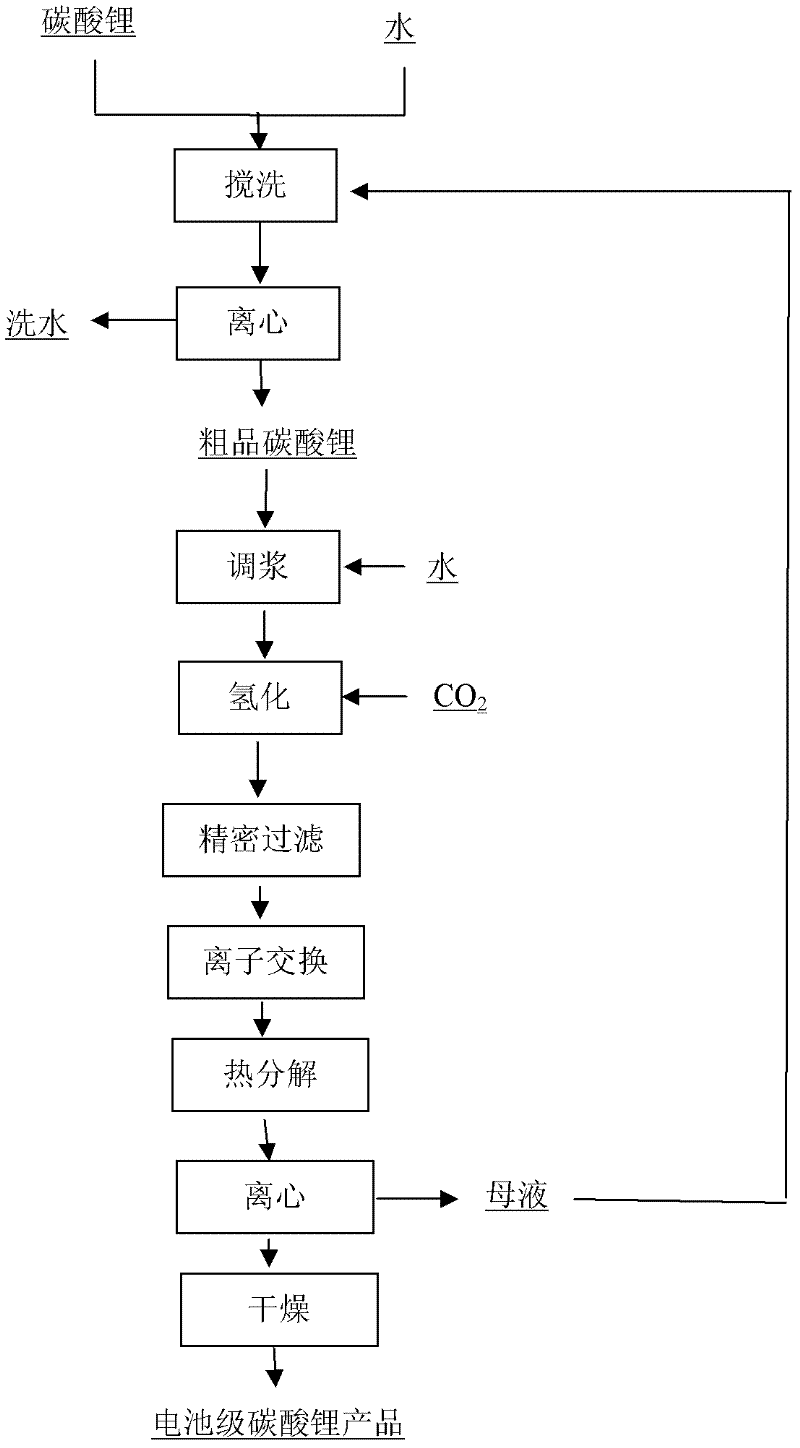

Method for purifying lithium carbonate

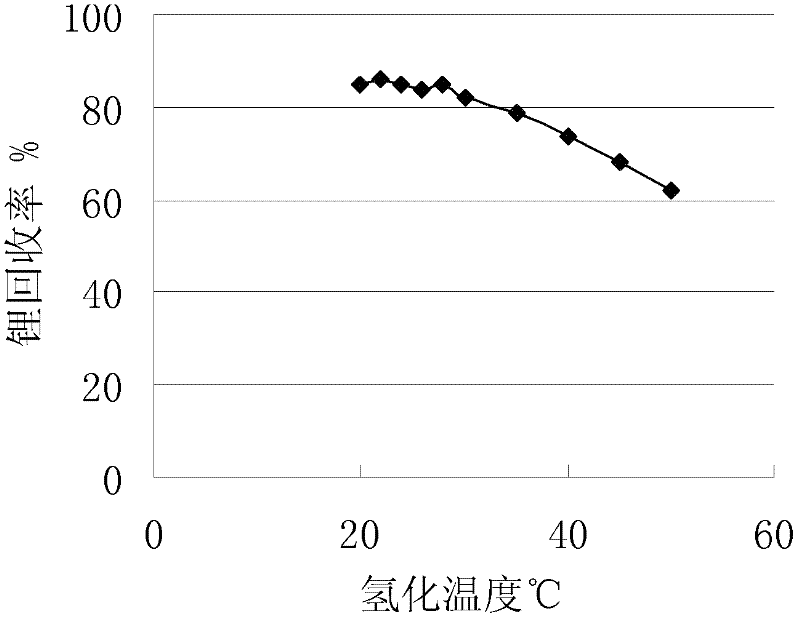

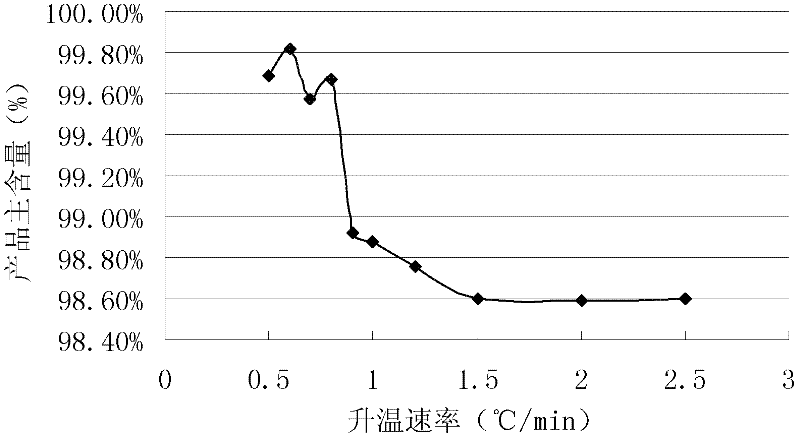

ActiveCN102531002ALow impurity contentImprove qualityLithium carbonates/bicarbonatesLithium oxideHydrogenation reaction

The invention relates to a method for purifying lithium carbonate, belonging to the technical field of the preparation of high-purity lithium carbonate. The method is characterized by safe production process and high lithium yield. The method comprises the following specific steps: (1) washing lithium carbonate to be purified to remove impurities, and adding water to prepare lithium carbonate slurry; (2) introducing CO2 into the lithium carbonate slurry prepared in the step (1) to carry out hydrogenation reaction, stopping introducing CO2 when the concentration of lithium oxide concentration in a solution is 10-30g / L, and filtering the solution to obtain a hydrogenated solution, wherein the hydrogenation reaction is carried out at the pressure of 0.2-0.6Mpa and the temperature of 20-30 DEG C; (3) subjecting the hydrogenated solution obtained in the step (2) to an ion exchange resin to remove impurity ions in the hydrogenated solution; and (4) heating the hydrogenated solution in which the impurity ions are removed in the step (3) to 70-90 DEG C to carry out decomposition reaction, separating solid from liquid to obtain the wet lithium carbonate, and drying the wet lithium carbonate. The produced battery-level lithium carbonate has high main content, excellent quality and stable performance.

Owner:天齐锂业(射洪)有限公司

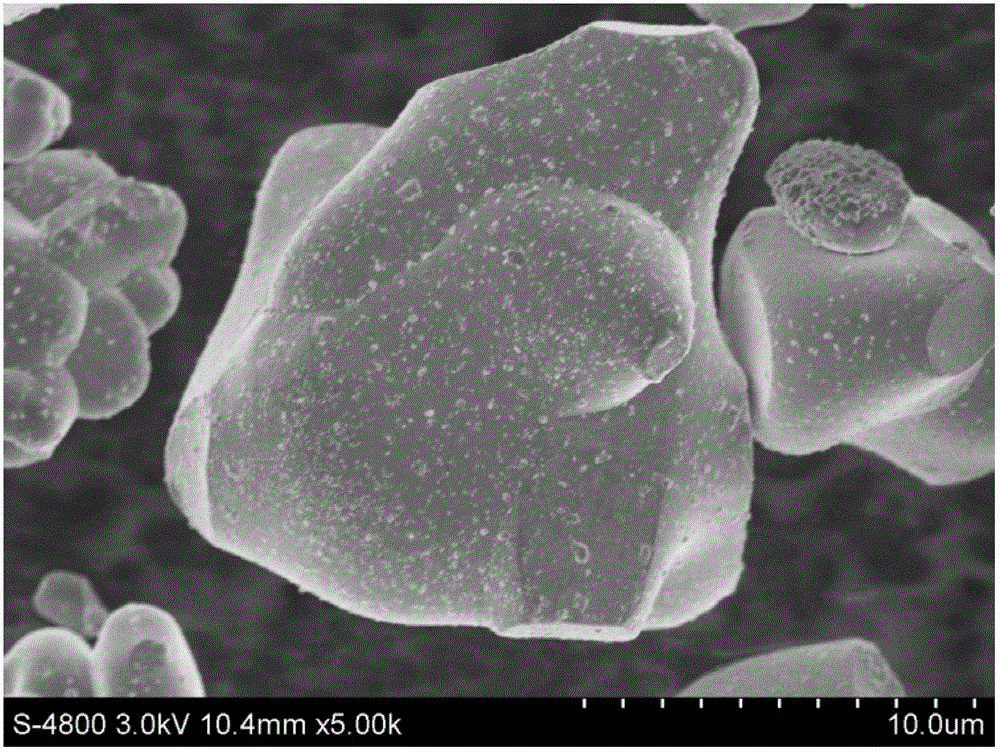

Preparation method of composite cathode material for lithium ion battery

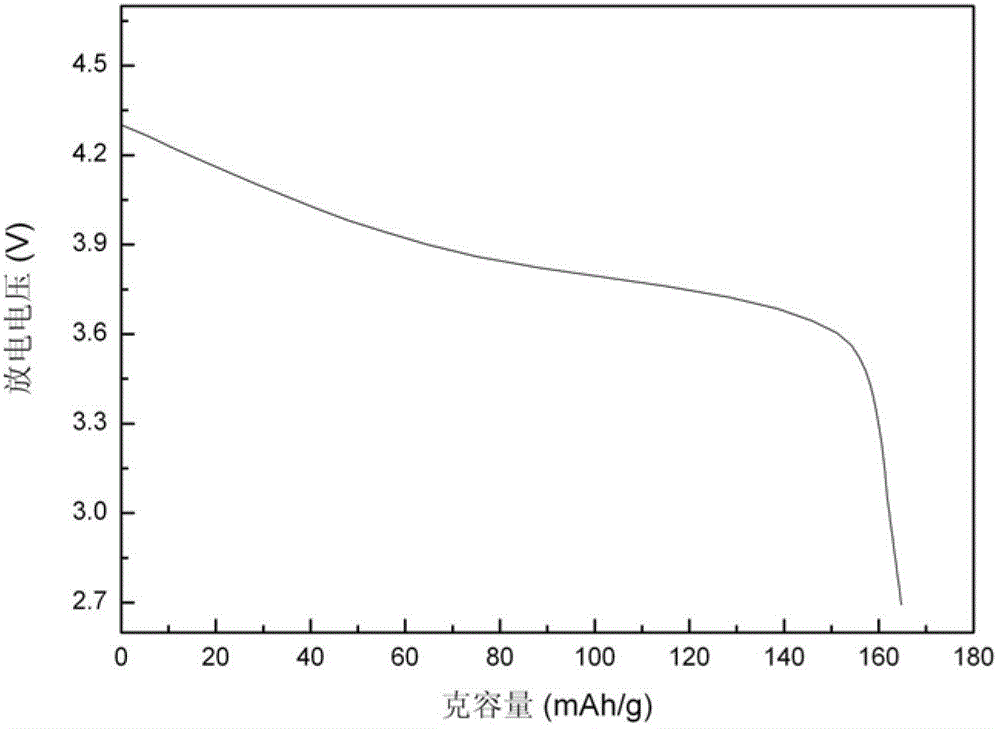

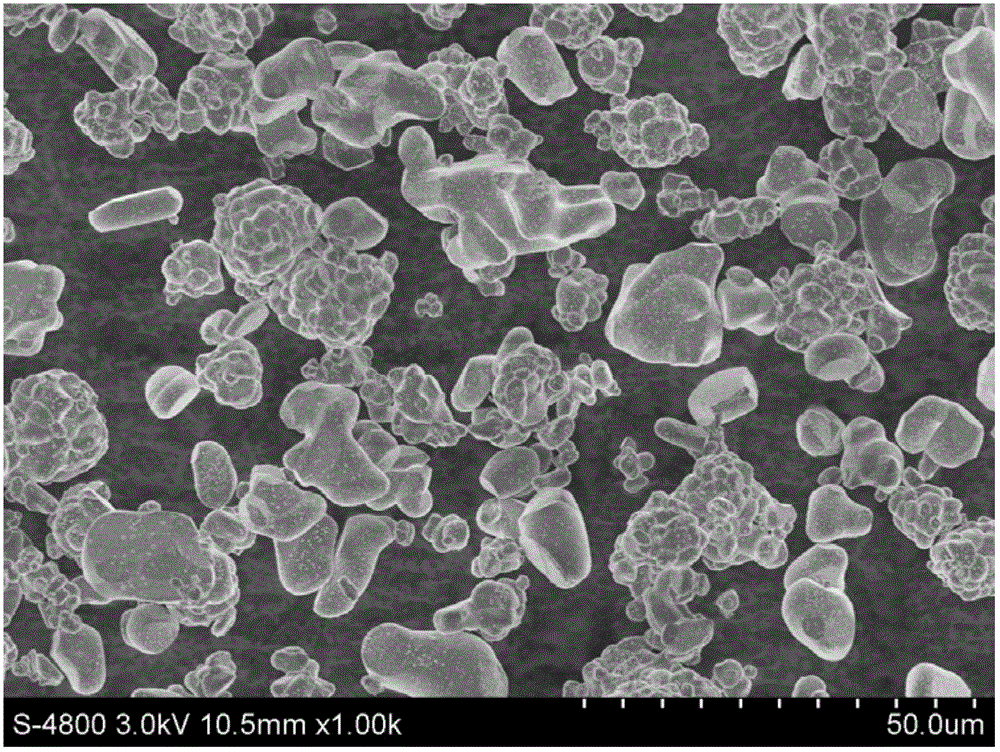

ActiveCN102751485AIncrease compaction densityIncrease energy densityCell electrodesLithium oxideElectrical battery

The invention relates to a preparation method of a composite cathode material for a lithium ion battery. The preparation method is characterized by comprising two steps of: preparing a nickel cobalt manganese oxide precursor, and preparing monocrystal layered cobalt lithium oxide grains and polycrystal layered nickel cobalt manganese oxide grains by high-temperature sintering, so that a whole composite cathode material can be grown in a fusing way. Due to the high-temperature sintering, the monocrystal layered cobalt lithium oxide and the polycrystal layered nickel cobalt manganese oxide can be grown into the whole composite cathode material in the fusing way, and the monocrystal layered cobalt lithium oxide grains play a part in supporting, so that the breaking of the material due to rolling of the polycrystal layered nickel cobalt manganese oxide grains can be avoided, and the compacted density of the material can be improved; due to the polycrystal layered nickel cobalt manganese oxide grains, the material is guaranteed to be high in discharge specific capacity and discharge voltage, and the composite cathode material is guaranteed to have the characteristics of being high in energy density, high in discharge voltage and high in compacted density; and by adopting the preparation method, the content of the cobalt element in the cathode material can be reduced, the material cost can be reduced, the preparation method is simple in process, and the preparation method is suitable for large-scale production.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST +1

Electrode active material for secondary battery and method for preparing the same

ActiveUS20110311875A1Minimizing dead volumeHigh-capacity batteryMaterial nanotechnologyGallium/indium/thallium compoundsParticulatesLithium oxide

The disclosure relates to an electrode active material including: (a) first particulate of a metal (or metalloid) oxide alloyable with lithium; and (b) second particulate of an oxide containing lithium and the same metal (or metalloid) as that of the metal (or metalloid) oxide, and to a secondary battery including the electrode active material. When the electrode active material is used as an anode active material, reduced amounts of an irreversible phase such as a lithium oxide or a lithium metal oxide are produced during initial charge-discharge of a battery since lithium is already contained in the second particulate before the initial charge-discharge, and thus a dead volume on the side of the cathode can be minimized and a high-capacity battery can be fabricated.

Owner:LG ENERGY SOLUTION LTD

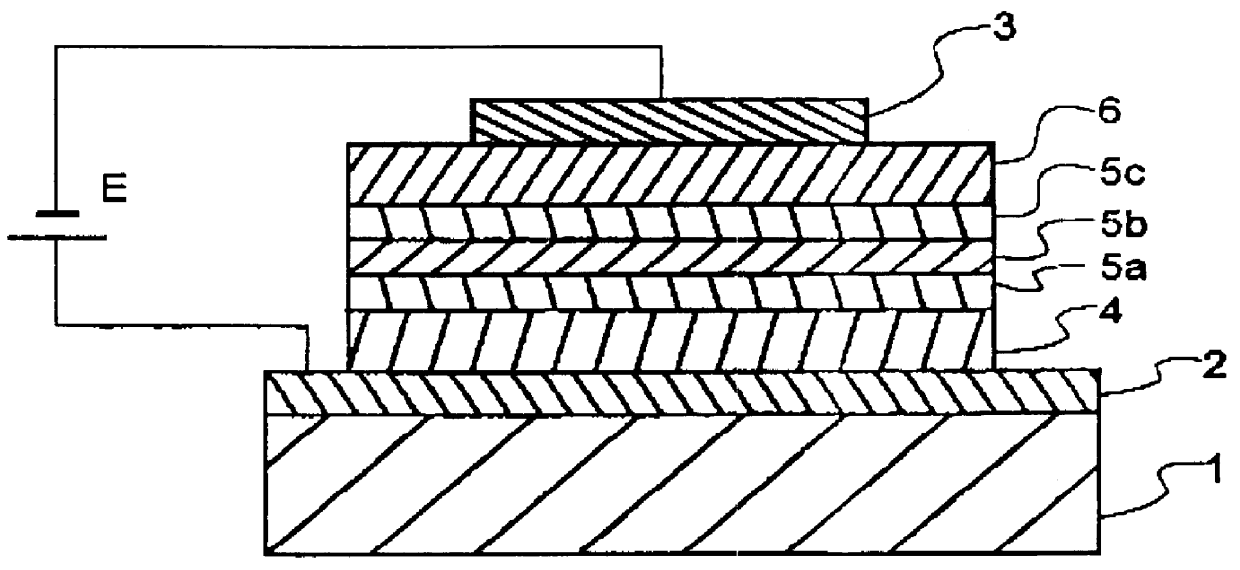

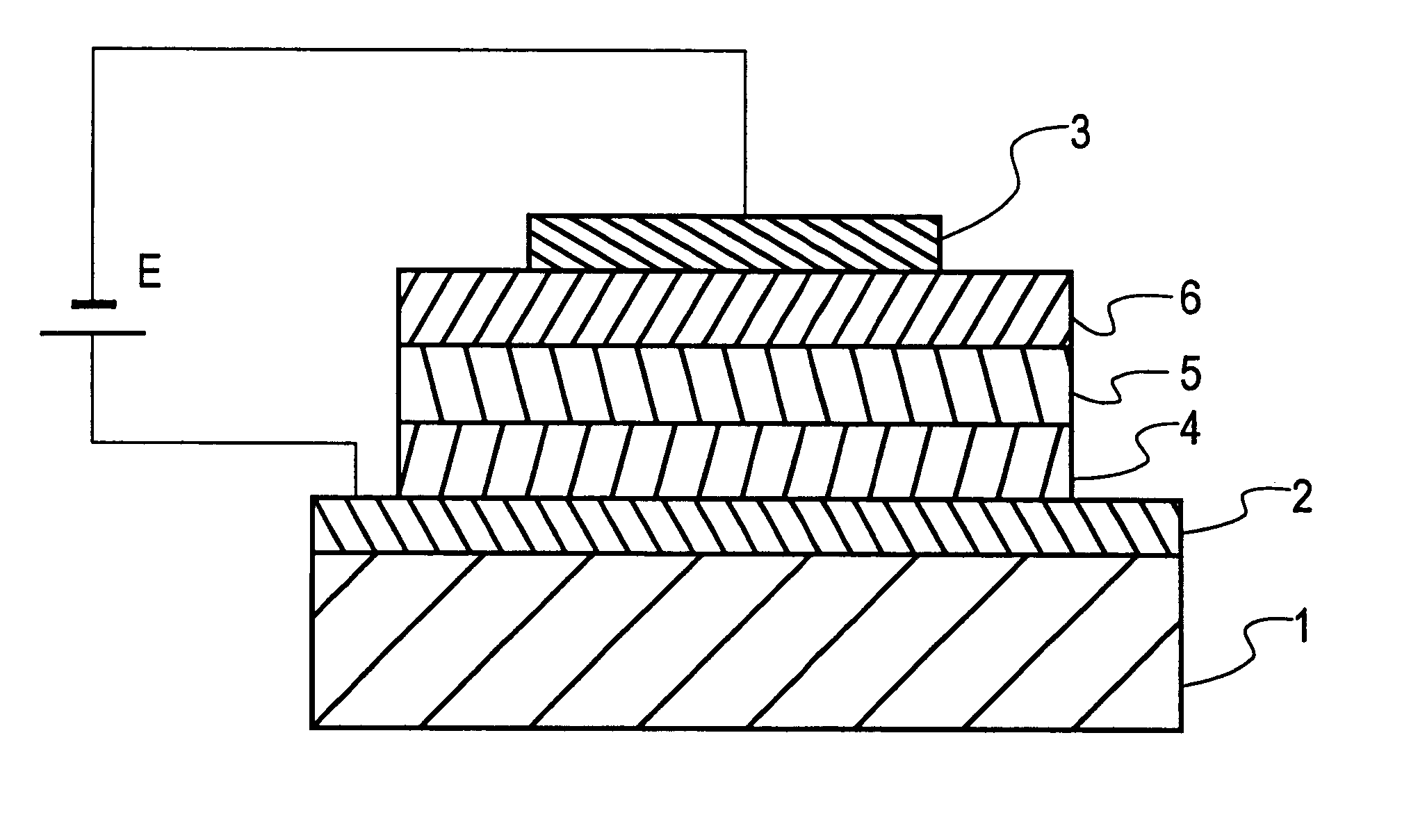

Organic electroluminescent device

InactiveUS6166488AImprove stabilityProlong lifeDischarge tube luminescnet screensElectroluminescent light sourcesRubidium oxideLithium oxide

An object of the invention is to achieve an organic EL device which is resistant to a deterioration of an inorganic-organic interface, has performance equivalent or superior to that of a prior art device comprising hole and electron injecting and transporting layers using an organic substance, possesses an extended life, weather resistance and high stability, and is inexpensive. This object is accomplished by the provision of an organic EL device which comprises a substrate, a hole injecting electrode and a cathode formed on the substrate, and an organic substance-containing light emitting layer located at least between these electrodes, wherein an inorganic insulating electron injecting and transporting layer is located between the light emitting layer and the cathode, and an inorganic insulating hole injecting and transporting layer is located between the light emitting layer and the hole injecting electrode. The inorganic insulating electron injecting and transporting layer comprises as a main component one or two or more oxides selected from the group consisting of strontium oxide, magnesium oxide, calcium oxide, lithium oxide, rubidium oxide, potassium oxide, sodium oxide and cesium oxide, and the inorganic insulating hole injecting and transporting layer comprises as a main component an oxide of silicon and / or an oxide of germanium. The main component has an average composition represented by (Si1-xGex) Oy where 0< / =x< / =1, and 1.7< / =y< / =1.99. The light emitting layer comprises a layer made up of a host substance on a side thereof contiguous to the inorganic insulating electron injecting and transporting layer and / or the inorganic insulating hole injecting and transporting layer. A layer containing a dopant in addition to the host substance is located on the side of the light emitting layer that faces away from the layer made up of the host substance or between them.

Owner:TDK CORPARATION

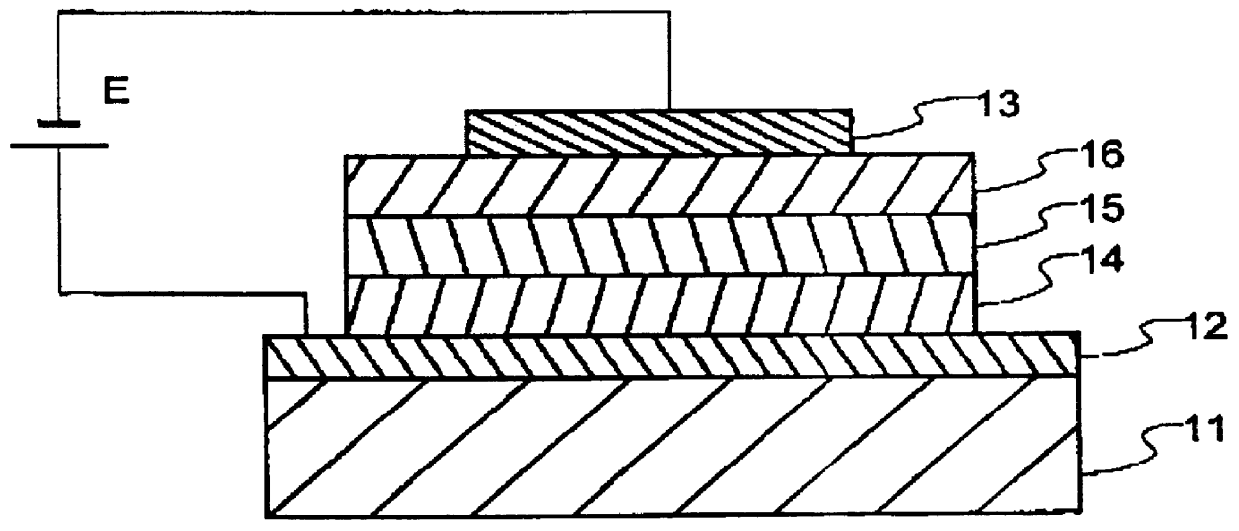

Non-aqueous electrolyte secondary battery

ActiveUS20060141341A1Improve security levelIncrease energy densityCell temperature controlNon-aqueous electrolyte accumulator electrodesLithium oxidePolyolefin

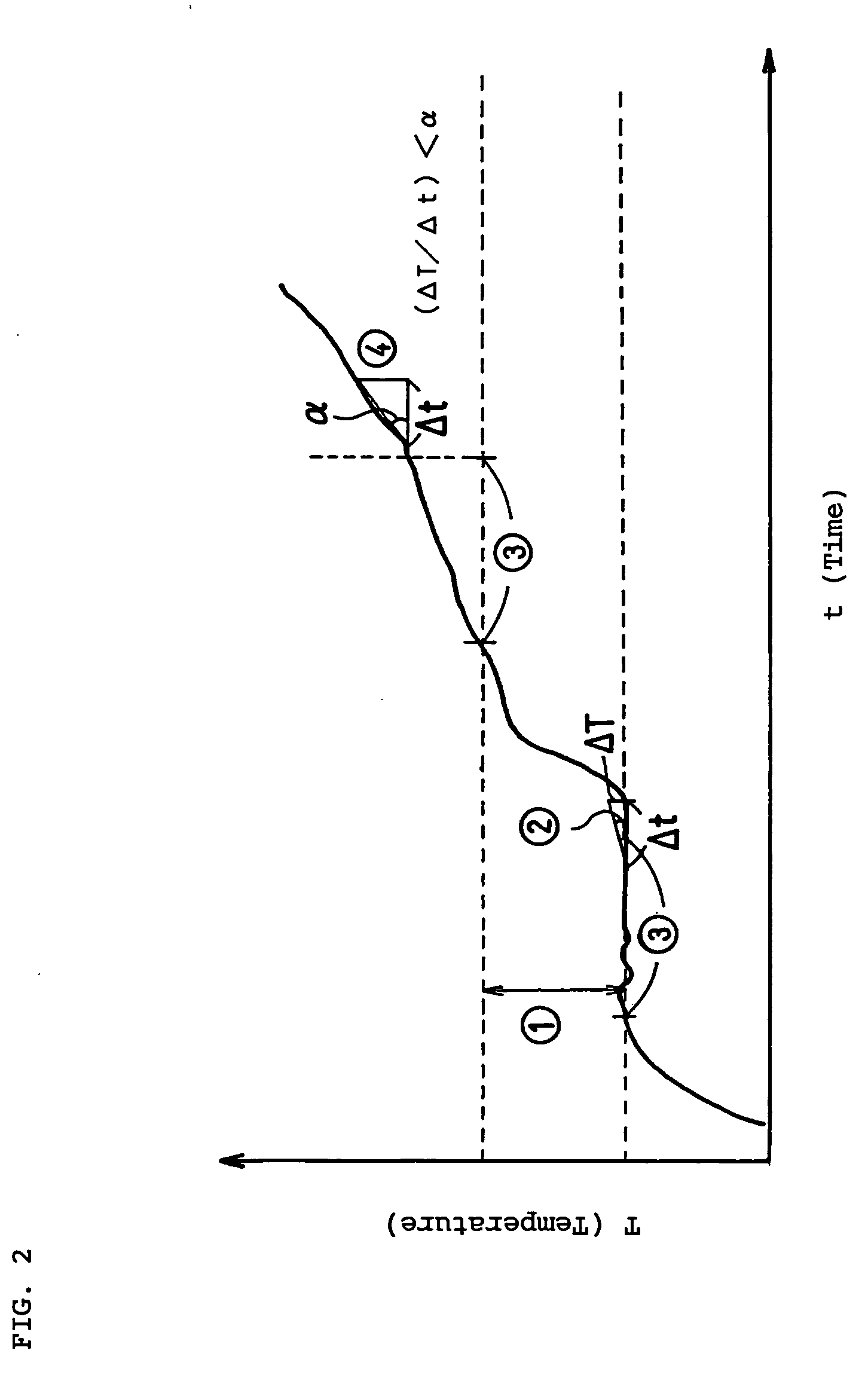

A non-aqueous electrolyte secondary battery including: a positive electrode having a positive electrode material mixture containing a composite lithium oxide; a negative electrode; a polyolefin separator; a non-aqueous electrolyte; and a heat-resistant insulating layer interposed between the positive and negative electrodes. The positive electrode active material mixture has an estimated heat generation rate at 200° C. of not greater than 50 W / kg. The estimated heat generation rate is determined by obtaining a relation between absolute temperature T and heat generation rate V of the positive electrode material mixture using an accelerating rate calorimeter; plotting a relation between the inverse of absolute temperature T and the logarithm of heat generation rate V according to the Arrhenius law; obtaining a straight line fitted to the plotted points in a heat generation temperature range of T<200° C.; and extrapolating the straight line to the temperature of 200° C.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Methods of fabricating photoactive substrates suitable for electromagnetic transmission and filtering applications

InactiveUS20150277047A1Solid-state devicesPhotomechanical apparatusLithium oxideCrystalline materials

A method of fabrication and device made by preparing a photosensitive glass substrate comprising at least silica, lithium oxide, aluminum oxide, and cerium oxide, masking a design layout comprising one or more holes to form one or more electrical conduction paths on the photosensitive glass substrate, exposing at least one portion of the photosensitive glass substrate to an activating energy source, exposing the photosensitive glass substrate to a heating phase of at least ten minutes above its glass transition temperature, cooling the photosensitive glass substrate to transform at least part of the exposed glass to a crystalline material to form a glass-crystalline substrate and etching the glass-crystalline substrate with an etchant solution to form one or more angled channels that are then coated.

Owner:3D GLASS SOLUTIONS INC

Paraffin dehydrogenation catalyst

ActiveUS7012038B2High activityRobust hydrothermal stabilityHydrocarbon by dehydrogenationCatalystsLithium oxideDehydrogenation

One aspect of the invention relates to a dehydrogenation catalyst composite containing alumina, chromium oxide, lithium oxide, and sodium oxide. The invention also relates to methods of making the dehydrogenation catalyst composite. Another aspect of the invention relates to method of dehydrogenating a dehydrogenatable hydrocarbon involving contacting the dehydrogenatable hydrocarbon with a dehydrogenation catalyst composite containing alumina, chromium oxide, lithium oxide, and sodium oxide to provide a dehydrogenated hydrocarbon, such as an olefin.

Owner:TEXAS PETROCHEM +1

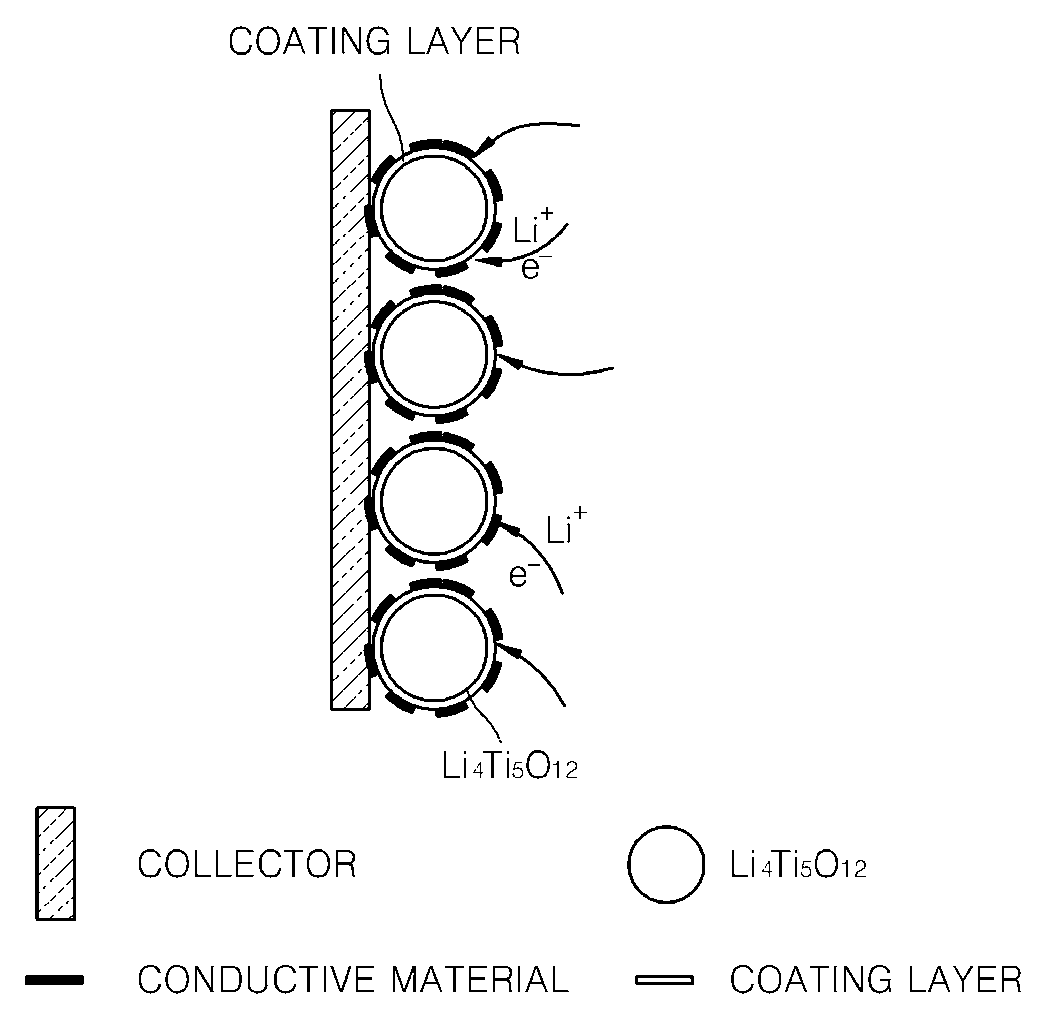

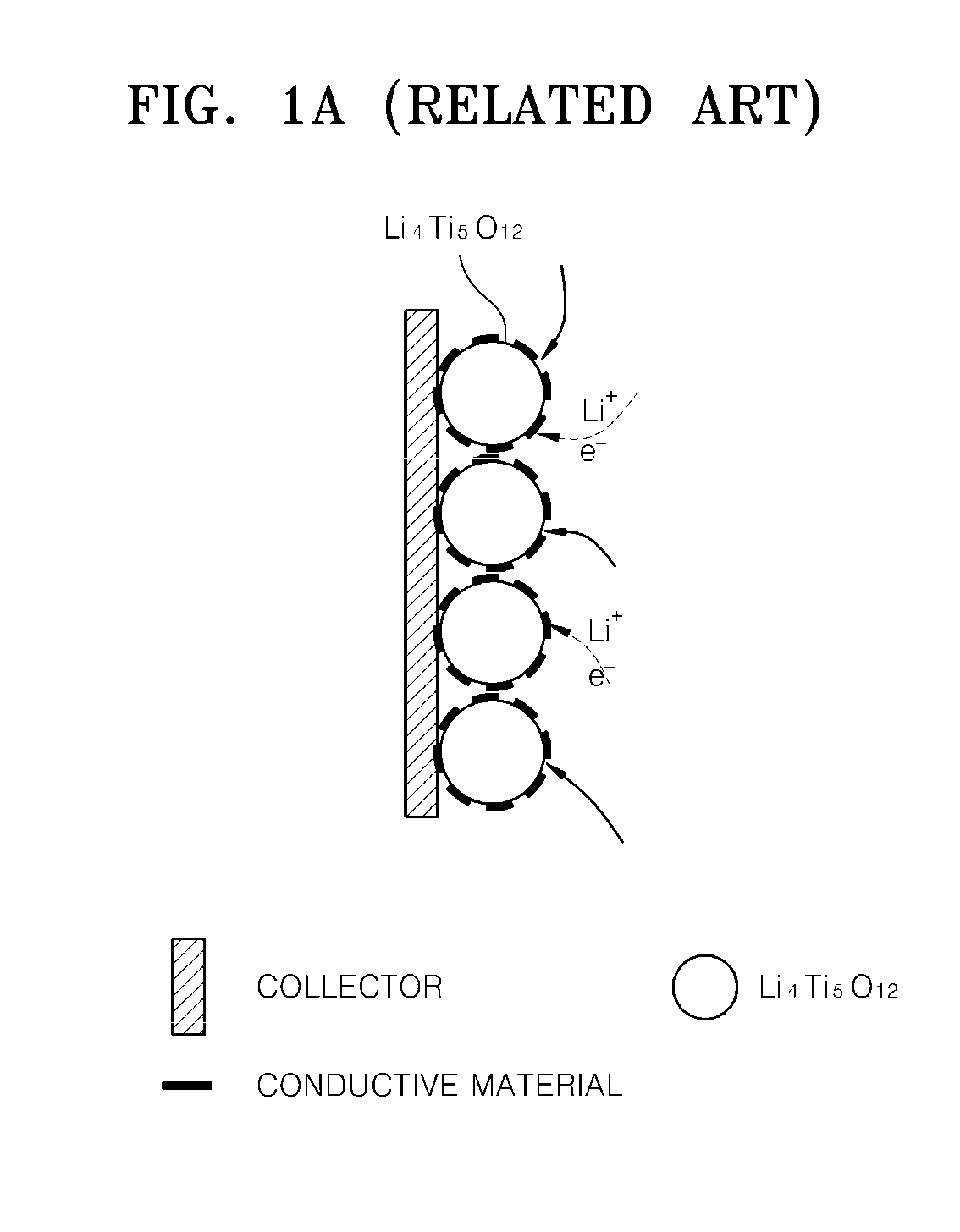

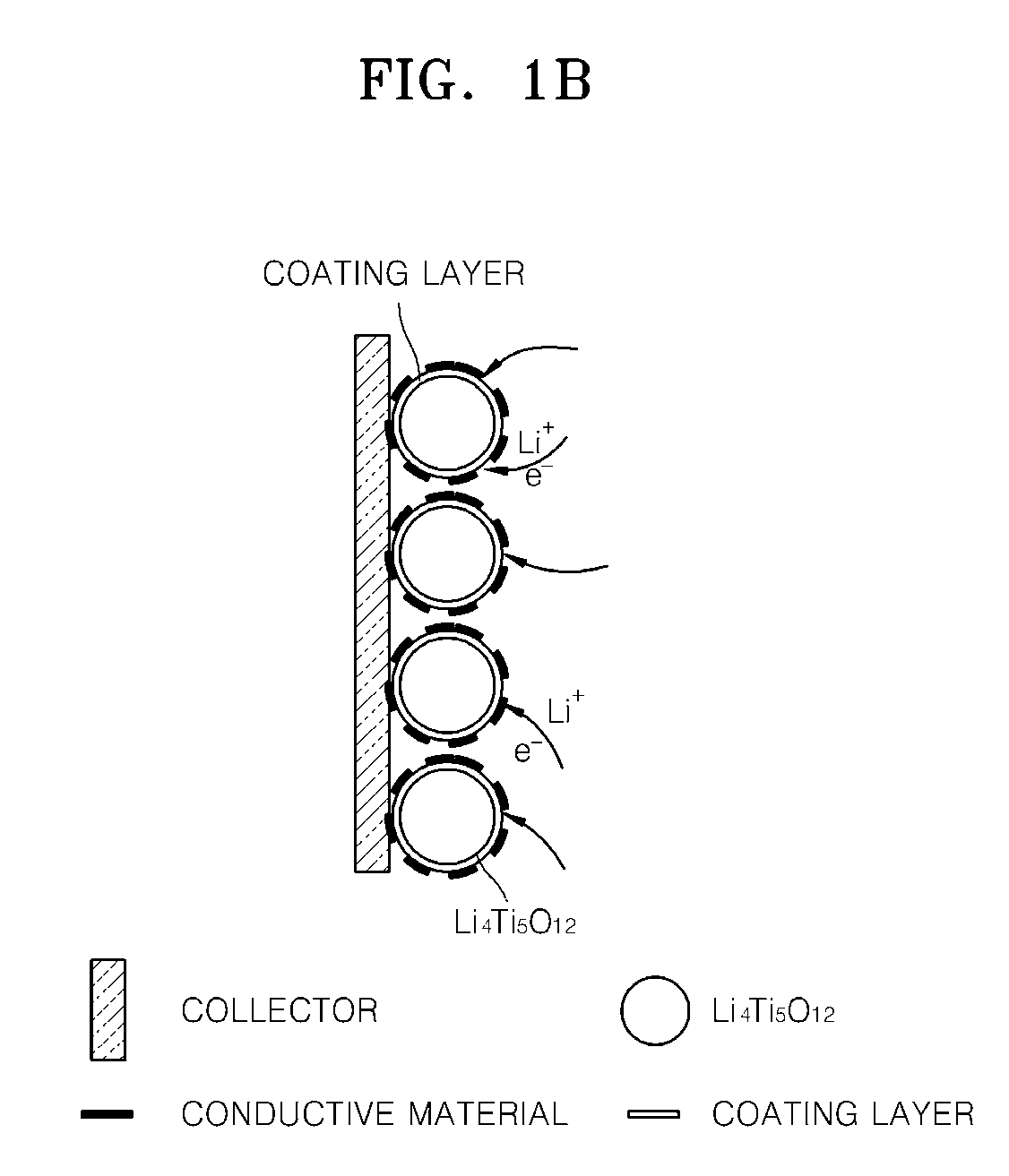

Surface treated anode active material and method of making the same, anode including the same, and lithium battery including the same

ActiveUS20090155692A1Improve efficiencyImprove cycle performanceAlkali titanatesActive material electrodesLithium oxideHigh rate

An anode includes a collector; and an anode active material layer disposed on the collector comprises an anode active material, which is lithium oxide coated Li4Ti5O12, a conductive material, and a binder, wherein the lithium oxide intercalates and / or deintercalates lithium ions into and from the lattice structure of Li4Ti5O12. By coating the surface of the anode active material with lithium oxide, an anode including the surface-treated anode active material has a high capacity, high-rate properties, and a high initial efficiency.

Owner:SAMSUNG SDI CO LTD

Organic electroluminescent device

InactiveUS6303239B1Improve stabilityImprove efficiencyDischarge tube luminescnet screensElectroluminescent light sourcesRubidium oxideLithium oxide

An object of the invention is to achieve an organic EL device which has an extended life, weather resistance, high stability, and high efficiency, and is inexpensive as well. This object is accomplished by the provision of an organic EL device comprising a substrate, a pair of a hole injecting electrode and a cathode formed on the substrate, and an organic layer located between these electrodes and taking part in at least a light emission function, wherein between the organic layer and the cathode there is provided an inorganic insulating electron injecting and transporting layer comprising a first component comprising at least one oxide selected from the group consisting of lithium oxide, rubidium oxide, potassium oxide, sodium oxide and cesium oxide, a second component comprising at least one oxide selected from the group consisting of strontium oxide, magnesium oxide and calcium oxide, and a third component comprising silicon oxide and / or germanium oxide.

Owner:TDK CORPARATION

Amorphous polyamide resin composition and molded product

Provided are an amorphous polyamide resin composition having high transparency, and is excellent in heat resistance and stiffness, and a molded product thereof. The glass filler contains, expressed in terms of oxides by mass %, 68 to 74% of silicon dioxide (SiO2), to 5% of aluminum oxide (Al2O3), 2 to 5% of boron oxide (B2O3), 2 to 10% of calcium oxide (CaO), 0 to 5% of zinc oxide (ZnO), 0 to 5% of strontium oxide (SrO), 0 to 1% of barium oxide (BaO), 1 to 5% of magnesium oxide (MgO), 0 to 5% of lithium oxide (Li2O), 5 to 12% of sodium oxide (Na2O), and 0 to 10% of potassium oxide (K2O), where a total amount of lithium oxide (Li2O), sodium oxide (Na2O), and potassium oxide (K2O) is 8 to 12%.

Owner:ASAHI FIBER GLASS CO LTD

Lithium ion secondary battery and charging method therefor, and charge or charge/discharge control system for lithium ion secondary battery

ActiveUS20050221172A1Capacity decrease can be suppressedIncrease elasticityBatteries circuit arrangementsCell seperators/membranes/diaphragms/spacersLithium oxideControl system

A lithium ion secondary battery includes a positive electrode containing a composite lithium oxide, a negative electrode capable of absorbing and desorbing lithium ions, a sheet-like separator interposed between the positive electrode and the negative electrode, a non-aqueous electrolyte and a porous electron-insulating film attached to the surface of the negative electrode. The sheet-like separator is a monolayer film made of polypropylene resin or a multilayer film whose layer to be in contact with the positive electrode is made of polypropylene resin. The porous electron-insulating film includes an inorganic oxide filler and a binder. The sheet-like separator has a thickness not less than 1.5 times the thickness of the porous electron-insulating film.

Owner:PANASONIC CORP

Manganese nickel cobalt composite lithium-inserting oxide and manufacturing method thereof

InactiveCN1547277AImprove cycle stabilityIncrease capacityElectrode thermal treatmentActive material electrodesLithium oxideManganese

The invention is lithium ion cell positive material and the manganese-nickel-cobalt compound embedded lithium oxide and the manufacturing method, the chemical formula is: Li0.7-1.0MnxNiyCozO2, x+y+z=1, x=0.2-0.5, x / y=0.8-1.2, z / x=0.1-1, the crystal structure is hexagonal system, the manufacturing method is: the mol proportion is Mn:Ni:Co=1:0.8-1.2:0.1-1, the compound liquid of the Mn2+, Ni2+, and Co2+ is confected, then they are heated, adds in excess alkali, the compound hydroxide is deposited and separated; the compound oxide can be acquired through baking and decomposition; the lithium material and the manganese-nickel-cobalt compound oxide is pressed after blended according to proportion of Li:(Mn+Ni+Co)=0.7-1.0:1, they are baked in oxide atmosphere under temperature of 700-1000oC for 6-36 hours, then they are cooled and crushed into the product. The process is simple, the capacity of the lithium ion cell positive material is large, the circular performance is good, and the cost is low.

Owner:HUNAN JINGXIN TECH

Positive pole material of lithium ion battery with nanometer structure and preparation method thereof

The invention discloses a positive pole material of a lithium ion battery with a nanometer structure and a preparation method thereof. The positive pole material is in a particle type core-shell structure, a core material consists of nanometer lithium iron phosphate, lithium vanadium phosphate or cobalt lithium oxide and graphene, and a shell material is porous carbon. The preparation method comprises the following steps of: taking lithium acetate, lithium oxalate, ammonium dihydrogen phosphate, ammonia metavanadate, phosphoric acid, lithium nitrate, cobalt nitrate and graphite oxide as raw materials, adopting a sol-gel method or a ball milling method to prepare a mixture, presintering the mixture in vacuum to obtain the core material, and mixing, grinding and calcining the core material with an organic carbon source to obtain the positive pole material with the particle type core-shell structure. The positive pole material has the advantages of good conductivity, good circulating performance, high capacity, small and uniform particle size, and simple preparation process and is easy for industrialized production.

Owner:深圳清研紫光科技有限公司

Glass-ceramic composition, glass-ceramic sintered body, and monolithic ceramic electronic component

InactiveUS20060287184A1Improve electrical insulation reliabilityReduced insulation performanceCeramic layered productsPrinted circuit manufactureStrontium titanateLithium oxide

A glass-ceramic composition contains first ceramic particles principally containing forsterite; second ceramic particles principally containing at least one selected from the group consisting of calcium titanate, strontium titanate, and titanium oxide; and borosilicate glass particles containing about 3% to 15% lithium oxide, about 20% to 50% magnesium oxide, about 15% to 30% boron oxide, about 10% to 45% silicon oxide, about 6% to 20% zinc oxide, 0% to about 15% aluminum oxide, and at least one additive selected from the group consisting of calcium oxide, barium oxide, and strontium oxide on a weight basis. The content of the borosilicate glass particles is about 3% or more; the lower limit of the content of the additive is about 2%; and the upper limit of the additive content is about 15%, about 25%, or about 25% when the additive is calcium oxide, barium oxide, or strontium oxide, respectively, on a weight basis.

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com